Page 1

MAINTENANCE MANUAL

UES-40

ISSUE4

2008/01

Page 2

Page 3

UES-40

INTRODUCTION

Repair and maintenance of this product requires highly specialized knowledge and techniques.

We recommend that you contact an Olympus service center in your area if a problem develops with the

product.

If repairs or modifications are made by personnel not authorized by Olympus, the warranty is void, and

Olympus shall not be liable for damage that occurs to or as a result of use of the modified product.

Applicable Unit

• ELECTROSURGICAL UNIT UES-40 120 V

• ELECTROSURGICAL UNIT UES-40 220 V

Copyright

© 2004 Olympus Medical Systems Corp. All rights reserved.

Unauthorized reproduction or distribution in part or in whole is prohibited.

Trademarks

OLYMPUS is a registered trademark of the Olympus Corporation.

The company names, product names, and proprietary technical terms in this document are the trade-

marks or registered trademarks of their respective owners.

ISSUE4 INTRODUCTION

Page 4

UES-40

CONTENTS

Chapter 1: Product Specification..........................................1-1

1 Outline ...................................................................................................... 1-2

2 Specifications............................................................................................1-2

2-1 High-frequency output.................................................................................1-2

2-2 Safety functions.................................................... .......................................1-5

2-3 Additional features.......................................................................................1-6

2-4 Safety ..........................................................................................................1-7

2-5 Laws, regulations, and standards................................................................1-7

2-6 Others..........................................................................................................1-7

3 Operating Requirements...........................................................................1-8

4 Name and Function of Each Part............................................................1-10

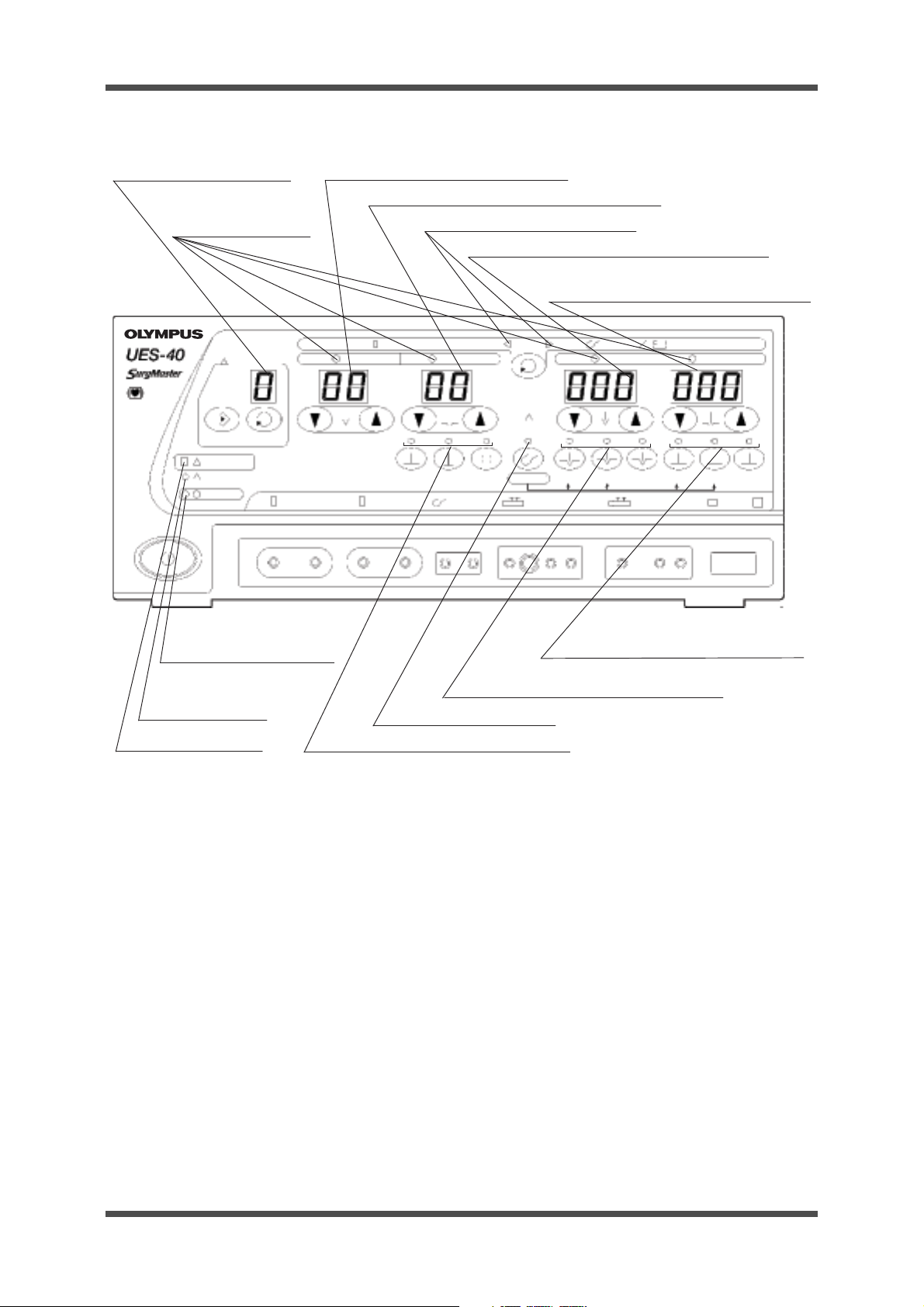

4-1 Front panel (for 120 V and 220 V).............................................................1-10

4-2 Rear panel.................................................................................................1-13

5 Ports ....................................................................................................... 1-14

5-1 Foot switch port for MAJ-1258 ..................................................................1-14

5-2 Bipoler foot switch port for MAJ-1259........................................................1-14

5-3 System port ...............................................................................................1-15

6 System Diagram.....................................................................................1-16

6-1 Endoscopic Treatment with UES-40 - System Diagram............................1-16

6-2 Electrosurgical Treatment with UES-40 - System Diagram.......................1-18

Chapter 2: Troubleshooting...................................................2-1

1 Troubleshooting........................................................................................2-2

1-1 Troubleshooting list .....................................................................................2-3

2 Error Codes .............................................................................................. 2-7

2-1 Error-code list.......... ....................................................................................2-7

Chapter 3: Disassembly and Reassembly Procedure.........3-1

1 Precautions for disassembly and reassembly .......................................... 3-2

2 Disassembly procedure............................................................................3-3

2-1 Tools............................................................................................................3-3

2-2 Disassembly procedure...............................................................................3-4

3 Reassembly procedure...........................................................................3-16

3-1 Tools..........................................................................................................3-16

3-2 Reassembly procedure..............................................................................3-16

CONTENTS 1 ISSUE4

Page 5

UES-40

Chapter 4: Inspection.............................................................4-1

1 Preparation...............................................................................................4-2

2 Inspection Procedure................................................................................4-2

Chapter 5: Parts List...............................................................5-1

1 Exploded Parts Diagram...........................................................................5-2

2 Parts List...................................................................................................5-6

ISSUE4 2 CONTENTS

Page 6

Page 7

Chapter 1: Product Specification

Chapter 1:Product Specification

1 Outline .....................................................................1-2

2 Specifications...........................................................1-2

3 Operating Requirements..........................................1-8

4 Name and Function of Each Part...........................1-10

5 Ports.......................................................................1-14

6 System Diagram .................................................... 1-16

ISSUE4 1-1 Product Specification

Page 8

UES-40

1. Outline

The ELECTROSURGICAL UNIT UES-40 (UES-40) is designed for use in medical facilities

under doctor supervision in combination with designated reusable high-frequency instruments, endoscopes, and light sources in surgical procedures and treatment using endoscopes (fiber scopes, videoscopes, and rigid scopes) for the cutting and coagulation of living

tissue.

(1) Expanding the functions available with the UES-30

The UES-40 also offers an output system for use in physiological saline (TURis). TURis

frees surgeons from the need for a patient plate, and offers improved safety over conventional TUR is.

TURis (TUR in saline): A technique for cutting and ablation in physiological saline

TUR: Transurethral resection of the prostate

(2) Supports the use of multiple electrodes

(Separate settings can be used for each system: bipolar, monopolar, and saline.)

(3) The UES-40 features exclusive specifications and is compatible with EndoALPHA.

(4) For easier use, the front panel is designed at a 20° vertical orientation.

(5) The design of the UES-40 is coordinated with the VISERA Video System.

2. Specifications

2-1 High-frequency output

2-1-1 Output methods

• Bipolar system

• Monopolar system

• Saline system

2-1-2 Options

• Bipolar system

Cutting Mode: 1 option (Cut)

Coagulation Mode: 3 options (Soft 1, Soft 2, Hard)

• Monopolar system

Cutting Mode: 3 options (Pure, Blend, Uro)

Coagulation Mode: 3 options (Coag 1, Coag 2, Spray)

Product Specification 1-2 ISSUE4

Page 9

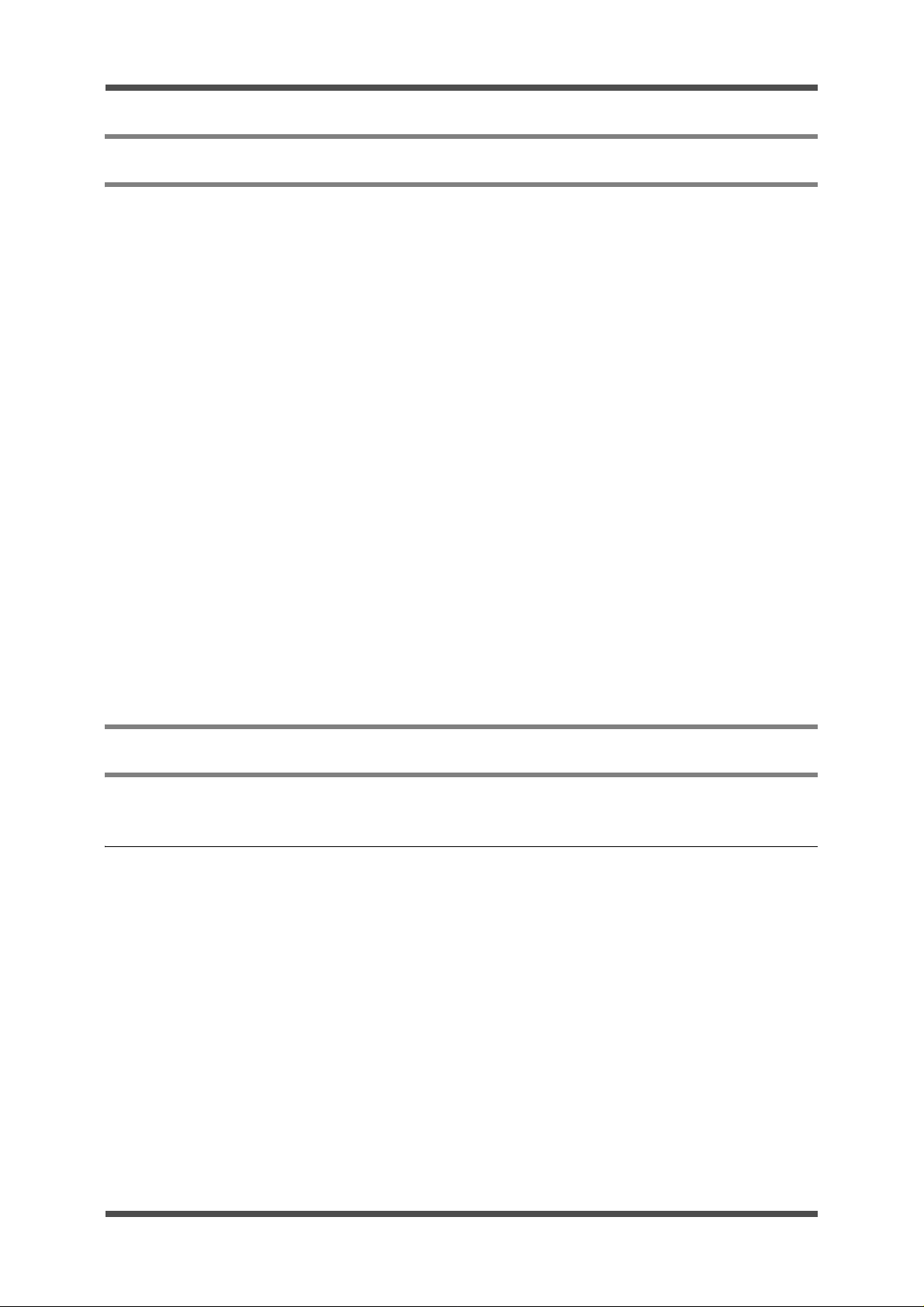

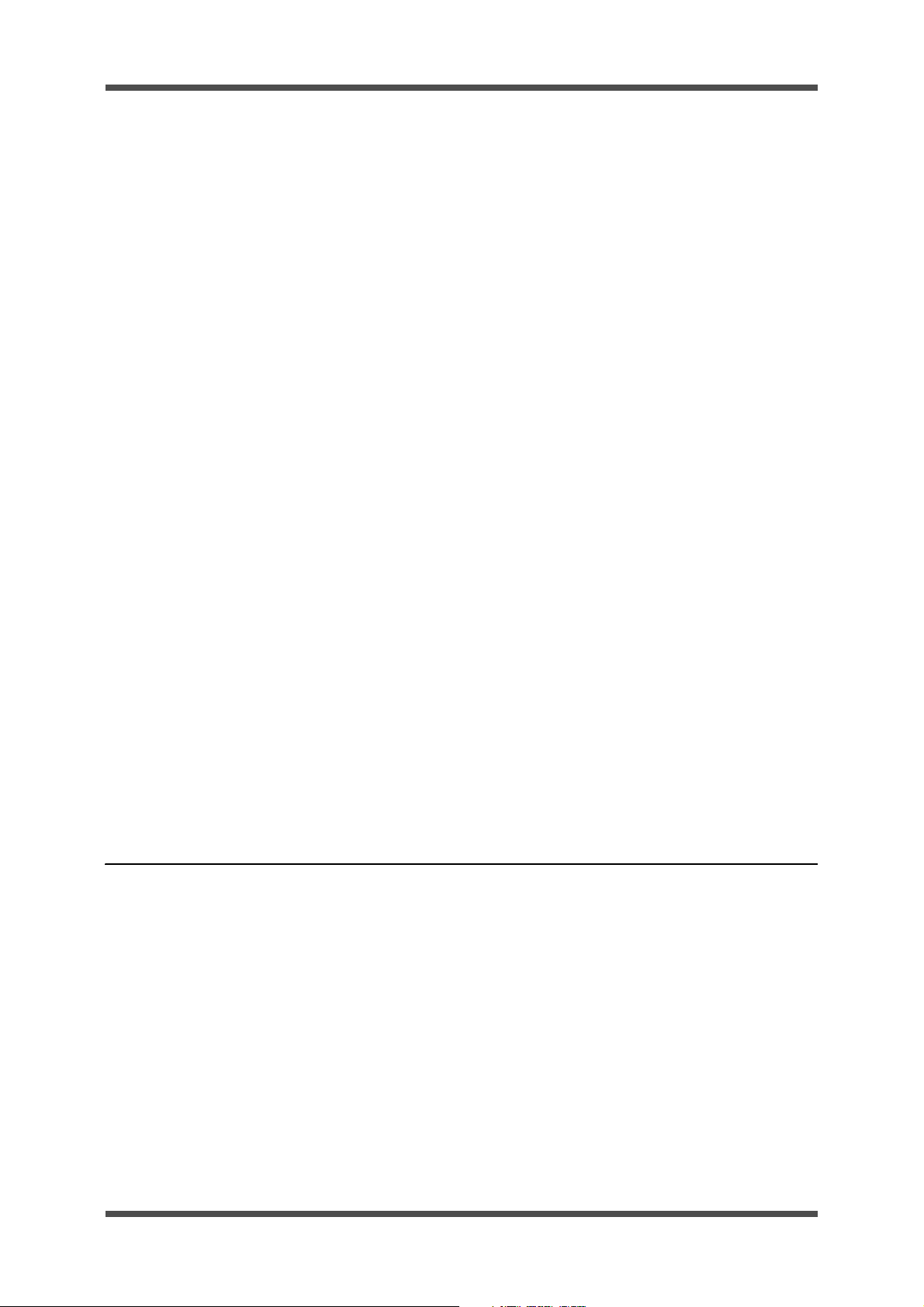

• Saline system

Pure

Soft 1, Soft 2

140

120

100

80

60

40

20

0

0 500 1000 1500 2000 2500

Load resistance ( )

Power (W)

Bipolar: Maximum setting

Cutting Mode: 2 options (Pure, Blend)

Coagulation Mode: 2 options (Coag 1, Coag 2)

2-1-3 Basic frequencies

350 kHz, 1 MHz (when using Spray)

2-1-4 Output characteristics

• Bipolar system

UES-40

250

200

150

100

Power (W)

50

0

0

Bipolar: Maximum setting (Hard)

500 1000 1500 2000 2500

• Monopolar system

400

350

300

250

200

Power (W)

150

100

50

0

0 500 1000

Monopolar: Maximum setting

Load resistance ( )

1500

Load resistance ( )

2000 2500

L1

L2

L3

Pure/Urology

Blend

Coag 1

Coag 2

Spray

ISSUE4 1-3 Product Specification

Page 10

UES-40

0 500 1000

1500

2000 2500

400

350

300

250

200

150

100

0

50

Pure

Blend

Coag 1

Coag 2

Saline output: Maximum setting

Load resistance ( )

Power (W)

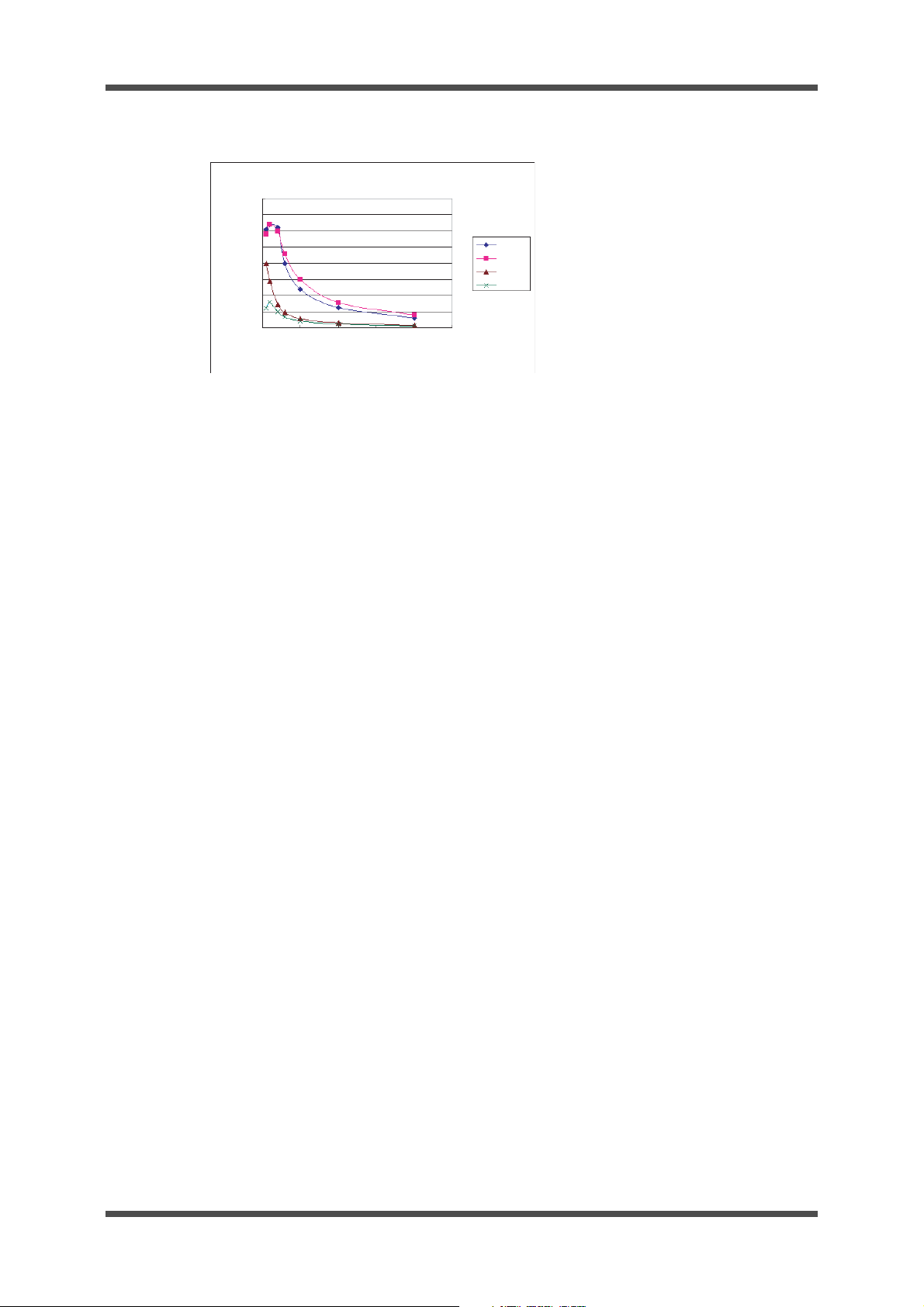

• Saline system

2-1-5 Maximum values

• Bipolar system

Cut: 90 W; Soft 1: 90 W; Soft 2: 90 W; Hard: L3

• Monopolar system

Pure: 300 W; Blend: 250 W; Uro: 300 W; Coag 1: 120 W; Coag 2: 120 W;

Spray: 120 W

• Saline system

Pure: 320 W; Blend: 320 W; Coag 1: 200 W; Coag 2: 80 W

2-1-6 Adjustment increments

• Bipolar system

0 to 20 W: 1-W increments; 20 W to 30 W: 2-W increments; 30 W and over: 5-W increments

(Hard is adjustable in 1-level increments.)

• Monopolar system

5-W increments

• Saline system

5-W increments

2-1-7 Control switches

l Foot switch for UES-40 (MAJ-1258)

Controls the high-frequency output of monopolar and bipolar instruments (ON/OFF)

l Bipolar foot switch for UES-40 (MAJ-1259)

Controls the high-frequency output of bipolar instruments (ON/OFF)

l Handpiece output switch

Controls the high-frequency output of the handpiece (ON/OFF)

Product Specification 1-4 ISSUE4

Page 11

2-1-8 Output terminals

• Bipolar system

Bipolar cord port 2 ports

• Monopolar system

Active port 1 port

Handpiece port 2 ports

• Saline system

Dedicated cord port 1 port

Different control systems are available, depending on the output terminal. The output terminals and their corresponding controls are listed below.

UES-40

System Output terminal

Bipolar 1 port Coag, Cut

Bipolar

Bipolar 2 port Coag only

Saline Saline port Coag, Cut MAJ-1258

Handpiece 1 port Coag, Cut

Monopolar

Active port

Handpiece 2 port Coag, Cut Handpiece

Output

option

Coag, Cut MAJ-1258

Control system Remarks

Foot switch for UES-40

(MAJ-1258)

Bipolar foot switch for

UES-40 (MAJ-1259)

MAJ-1258

handpiece

2-1-9 Recommended timing

Output (ON) timing: within 10 seconds; output stop (OFF): 30 seconds or more

Bipolar output can be

selected using the

switch select switch

The saline port detects the

saline cable to be connected

and the output terminal is

automatically selected.

Monopolar output can be

selected using the Footswitch select switch (except

during control using the

handpiece)

Foot.

2-2 Safety functions

2-2-1 Patient-plate monitor (for monopolar systems only)

Detects connection problems or disconnection of the single type patient plate, as well as

loosening of split type patient plates. If problems are detected, the following operations are

performed.

• Warning indicator is lit.

• Error code is displayed on output indicator.

• Audible warning is issued.

• High-frequency output is stopped.

ISSUE4 1-5 Product Specification

Page 12

UES-40

2-2-2 High-frequency-output monitor

Detects whether the output value is correct for the output setting value. If problems are

detected, the following operations are performed.

• Error code is displayed on output indicator.

• Audible warning is issued.

• High-frequency output is stopped.

2-2-3 Output timing monitor (for monopolar or saline systems only)

Detects the high-frequency output timing. If output continues for more than 60 seconds, the

following operations are performed.

• Error code is displayed on output indicator.

• Audible warning is issued.

• High-frequency output is stopped.

2-2-4 Self-check monitor

Verifies the correct operation of all safety functions. If problems are detected, the following

operations are performed.

• Error code is displayed on output indicator.

• Audible warning is issued.

• Various settings are disabled.

• High-frequency output is stopped.

2-2-5 Control switch monitor

Detects short-circuits of each switch (foot switch and handpiece). If problems are detected,

the following operations are performed.

• Error code is displayed on output indicator.

• Audible warning is issued.

• Various settings are disabled.

• High-frequency output is stopped.

2-3 Additional features

2-3-1 Preset function

Use of the preset function enables the most-recently used output setting, as well as up to

five configurations of preset user settings, to be stored for future use.

2-3-2 CQM function

When split type patient plates are attached, the CQM indicator lights up when there is a

good connection with the patient.

Product Specification 1-6 ISSUE4

Page 13

2-4 Safety

2-4-1 Medical electrical-equipment classifications

l Protection against electrical shock

Class-I equipment (three-prong plug for power supply)

l Level of electrical-shock protection

CF-type (low-frequency leakage current of 10µþA or less)

l Level of explosion protection

Never use the UES-40 where flammable vapors occur.

l Others

Defibrillator protection

2-5 Laws, regulations, and standards

UES-40

Region / country Applicable laws and regulations / external standards

EU/EFTA

U.S. UL mark

Other areas None

2-6 Others

l Dimensions

350 mm (W) ¥ 400 mm (D) ¥ 150 mm (H)

l Weight

12 kg

MDD

Classification: IIb

CE marking: CE0197

ISSUE4 1-7 Product Specification

Page 14

UES-40

3. Operating Requirements

(1) The operating conditions must be as follows.

Ambient temperature: 10°C to 40°C

Relative humidity: 30% to 85%

Atmospheric pressure: 700 hPa to 1060 hPa

Never use the UES-40 where flammable vapors occur.

(2) The power requirements are as follows.

Rated input voltage 120 V 220 V

Rated input current 12A 6A

Frequency 50/60 Hz

Permissible voltage fluctuation ±10%

(3) Do not use in combination with products not designated by Olympus.

(4) Before using the UES-40 for the treatment of patient s weari ng pacemakers, consult the

pacemaker manufacturer.

(5) Do not attach the patient plate for use near metallic implants.

(6) Do not wind UES-40 cords into loops or allow them to touch the patient or metall ic p art s

of the surgical table.

(7) Do not bundle UES-40 cords with cords of other medical equipment during use.

(8) Keep the UES-40 and its cords adequately separated from other medical equipment

and cords.

(9) If non-CF products are used in combination with the UES-40, do not use directly on the

heart.

(10) To ensure electrical safety, use of the following electronic medical equipment in combi-

nation with the UES-40 is prohibited:

a) Equipment not yet proven safe when used with the UES-40

b) Equipment not yet proven safe due to certain aspects of operation (such as the

leakage current)

(11) If the UES-40 is used in combination with endoscopic instruments for which the rated

voltage is listed in each instrument user manual, compare the open outpu t-volt age char-

acteristics of the instruments with those of the UES-40 and adjust the output within the

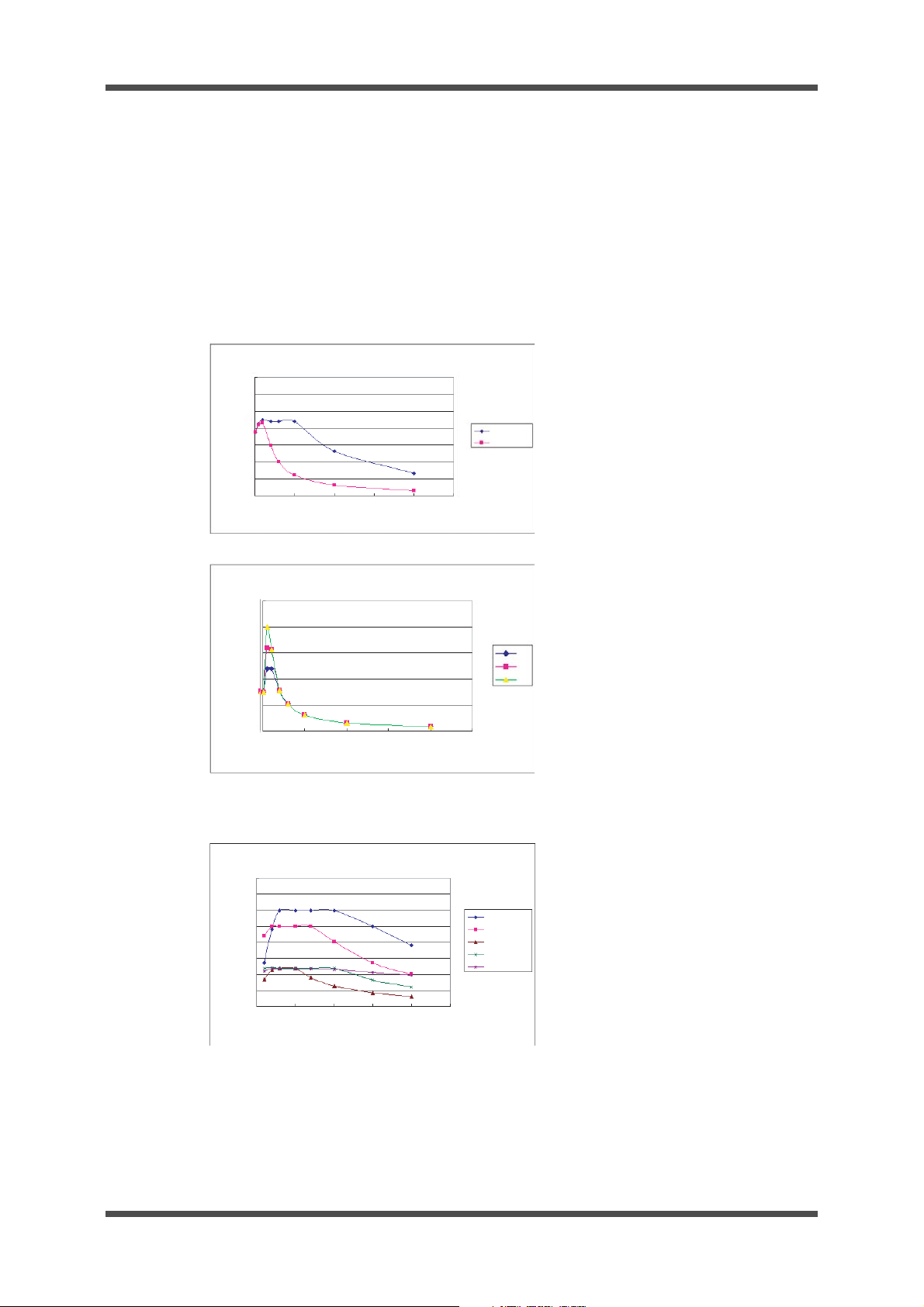

USE-40’s rated voltage values. Refer to Fig. 1-1 to 1-4 for the open voltage characteris-

tics. If the user’s manuals for these instruments do not list the rated voltage, set the out-

put low initially and then gradually increase the output level.

Product Specification 1-8 ISSUE4

Page 15

UES-40

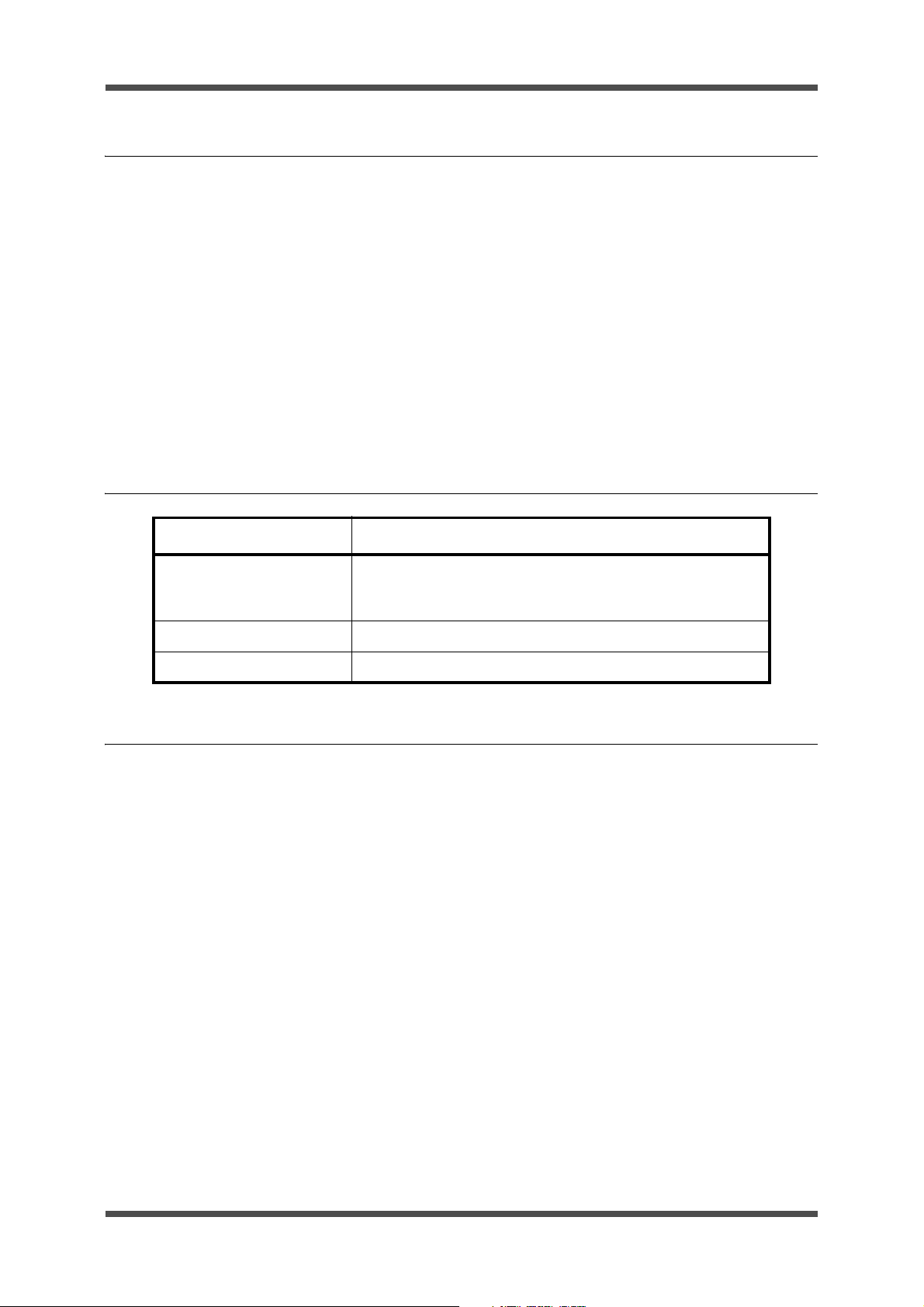

L1 L2 L3

Hard

Bipolar: Hard

Maximum output voltage (Vp)

Output setting (W)

250

200

100

50

0

150

3500

3000

2500

2000

1500

1000

500

0

0 100 200 300 400

Pure/Urology

Blend

Coag 1

Coag 2

Spray

Monopolar

Maximum output voltage (Vp)

Output setting (W)

800

600

400

0

200

0 100 200 300 400

Pure/Urology

Blend

Coag 1

Coag 2

Maximum output voltage (Vp)

Output setting (W)

1000

Saline

500

400

300

200

100

Maximum output voltage (Vp)

0

0

Bipolar: Cut, Soft 1, Soft 2

20 40 60 80 100

Output setting (W)

Cut

Soft1, Soft2

Figure 1-1 Open voltage characteristics (Bipolar: Pure, Soft 1, Soft 2)

Figure 1-2 Open voltage characteristics (Bipolar: Hard)

Figure 1-3 Open voltage characteristics (Monopolar)

ISSUE4 1-9 Product Specification

Figure 1-4 Open voltage characteristics (Saline)

Page 16

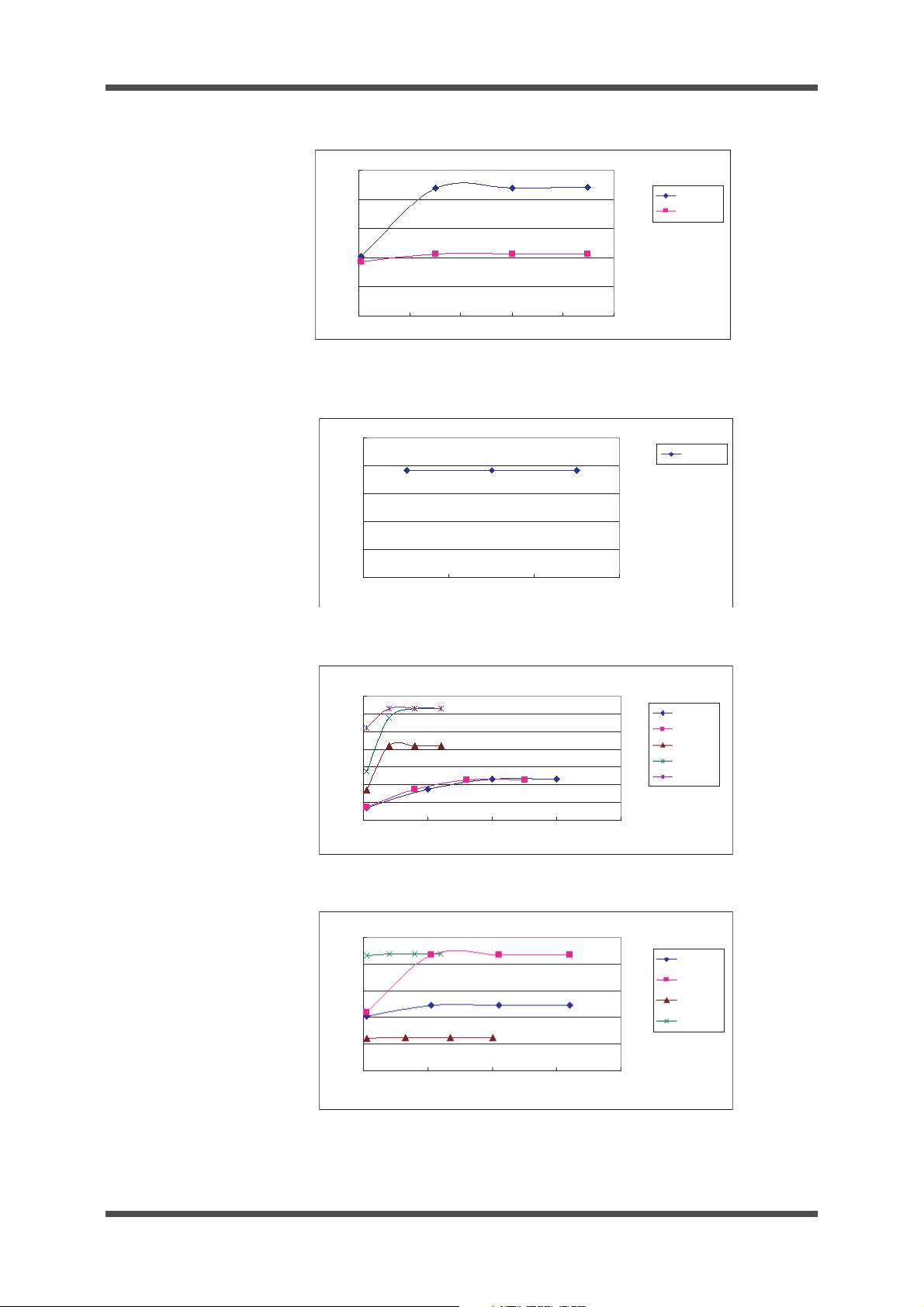

UES-40

WW W W

BIPOLAR

CUT

PRESET

MEMORY

WARNING

COM

POWER

BIPOLAR1 HAND PIECE1 HAND PIECE2

PATIENT

F

BIPOLAR2

SOFT1 SOFT2 HARD

SALINE

SALINE PURE

COAG.1 COAG.2

BLEND URO SPRAY

SELECT

COAG

FOOT

SWITCH

SELECT

CUT COAG

SALINE MONOPOLAR

(1) Memory switch

(16) Power switch

(15) Bipolar port 1

(14) Bipolar port 2

(12) Active port

(11) Hand piece

port 1

(9) Patient plate port

(10) Hand piece port 2

(13) Saline port

(2) Select switch

(3) Output control

switch

(4) Bipolar coagulation mode

select switch

(7) Monopolar/saline cut mode select switch

(8) Monopolar/saline coagulation

mode select switch

(5) Saline switch

(6) Foot switch

select switch

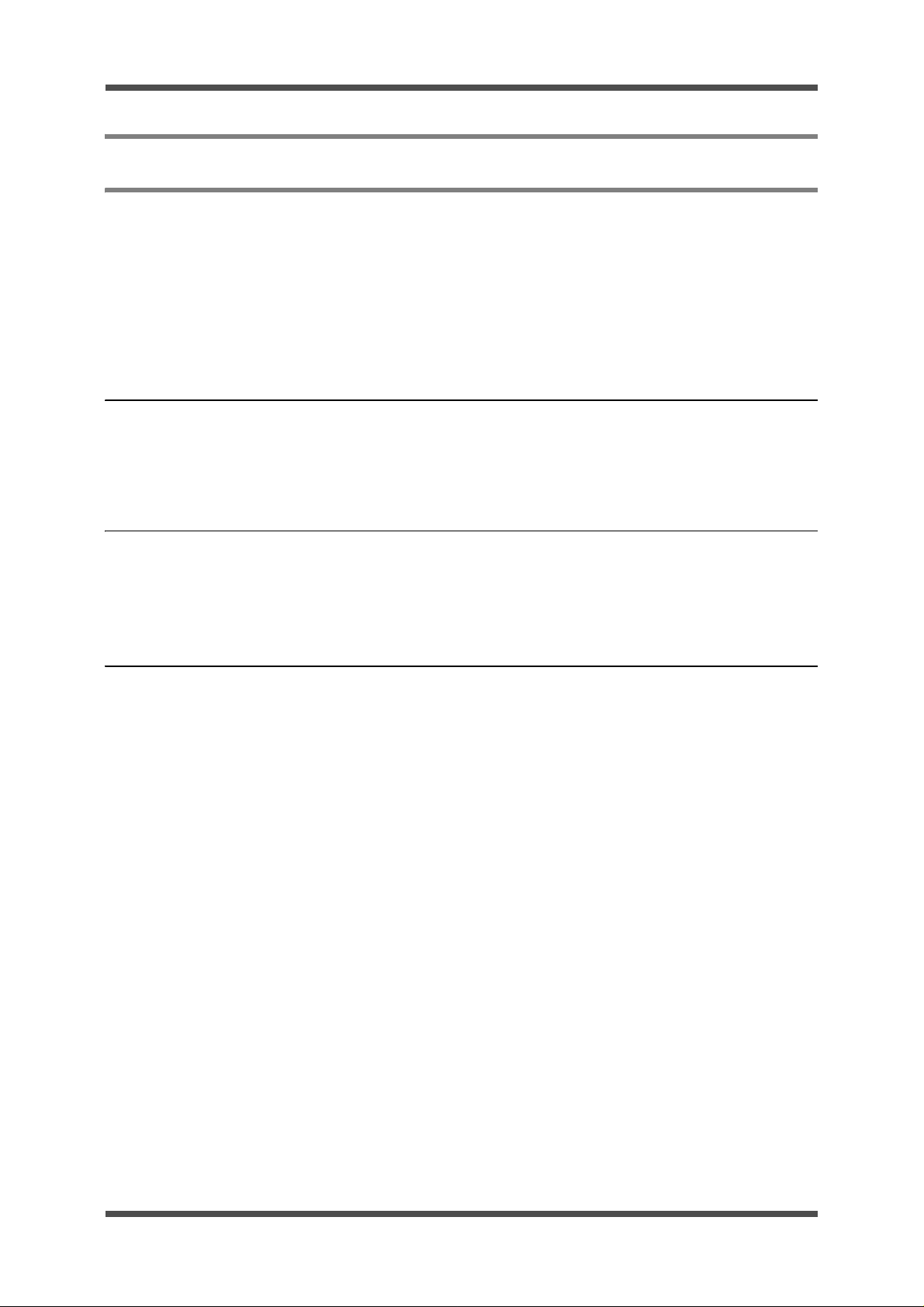

4. Name and Function of Each Part

4-1 Front panel (for 120 V and 220 V)

4-1-1 Switches and ports

(1) Memory switch

This switch is used to store output settings and modes that have been previously set.

(2) Select switch

This switch is used to recall stored output settings and modes.

(3) Output control switches

To increase the displayed setting value, press s. To decrease it, press t.

(4) Bipolar coagulation mode select switches

These switches are used to select bipolar coagulation modes.

(5) Saline switch

This switch is used to select the saline mode.

Product Specification 1-10 ISSUE4

Page 17

(6) Foot-switch select switch

This switch is used to switch between the saline/monopolar mode and the bipolar output mode.

(7) Monopolar/saline cut mode select switches

These switches are used to select the monopolar and saline cut mode

(8) Monopolar/saline coagulation mode select switches

These switches are used to select the monopolar and saline coagulation mode.

(9) Patient-plate port

This port is used for connection of the patient-plate plug.

(10) Handpiece port 2

This port is used for connection of a monopolar handpiece plug.

(11) Handpiece port 1

This port is used for connection of a monopolar handpiece plug.

(12) Active port

This port is used for the connection of the active electrode of the Active cord.

(13) Saline port

This port is used for connection of the saline code.

(14) Bipolar port 2

This port is used for connection of bipolar electrodes.

UES-40

(15) Bipolar port 1

This port is used for connection of bipolar electrodes.

(16) Power switch

For turning the power on. When the power is turned on, the power switch indicator lights up.

ISSUE4 1-11 Product Specification

Page 18

UES-40

WW W W

BIPOLAR

CUT

PRESET

MEMORY

WARNING

COM

POWER

BIPOLAR1 HAND PIECE1 HAND PIECE2

PATIENT

F

BIPOLAR2

SOFT1 SOFT2 HARD

SALINE

SALINE PURE

COAG.1 COAG.2

BLEND URO SPRAY

SELECT

COAG

FOOT

SWITCH

SELECT

CUT COAG

SALINE MONOPOLAR

(18) Preset number indicator

(21) Foot switch setting indicators

(17) Output indicators

(22) Monopolar/saline cut output setting indicator

(19) Bipolar cut output setting indicator

(20) Bipolar coagulation output setting indicator

(30) Warning indicator

(29) CQM indicator

(28) Power switch indicator

(27) Bipolar coagulation mode indicators

(26) Saline mode indicator

(25) Monopolar/saline cut mode indicators

(24) Monopolar/saline coagulation

mode indicators

(23) Monopolar/saline coagulation

output setting indicator

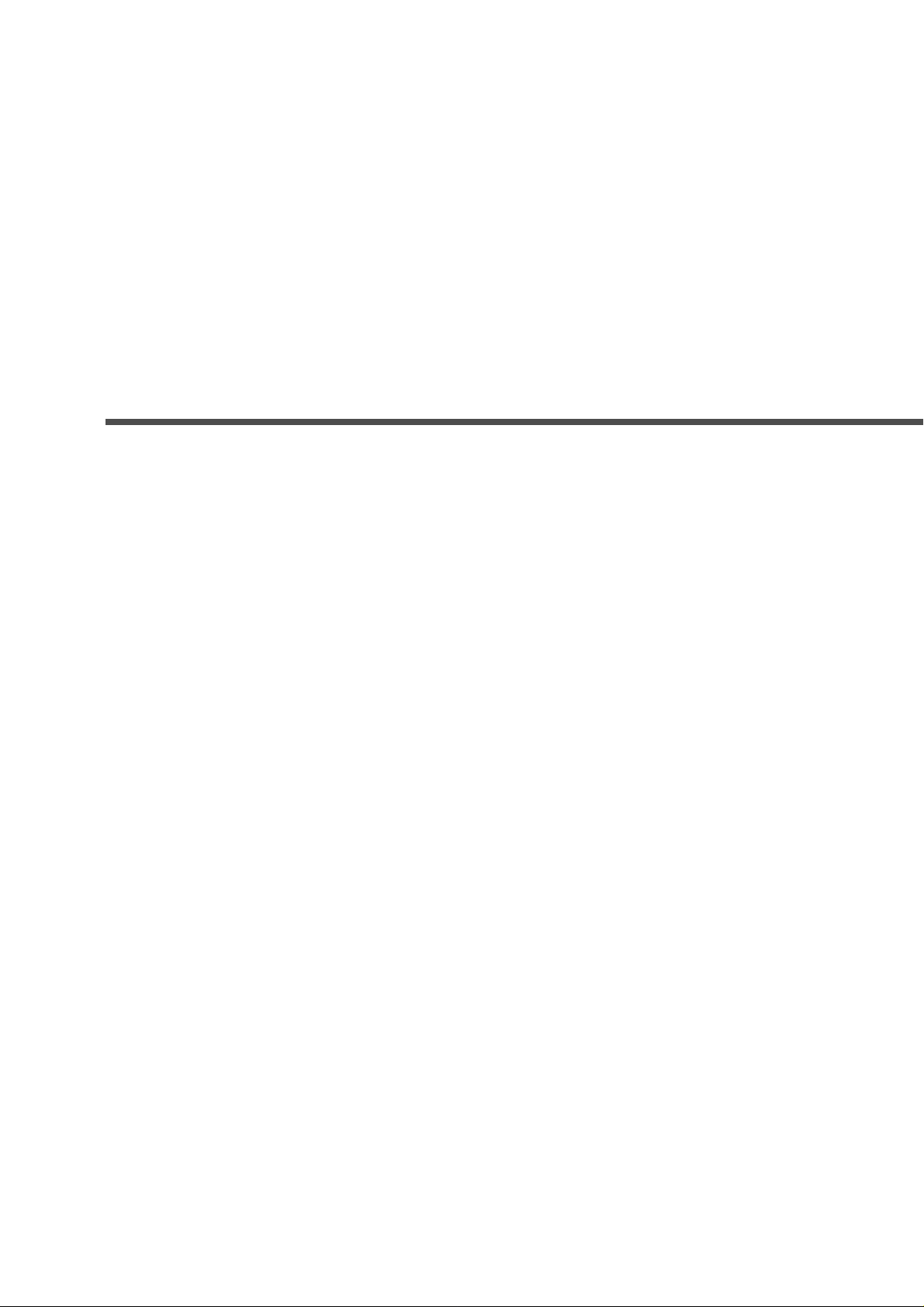

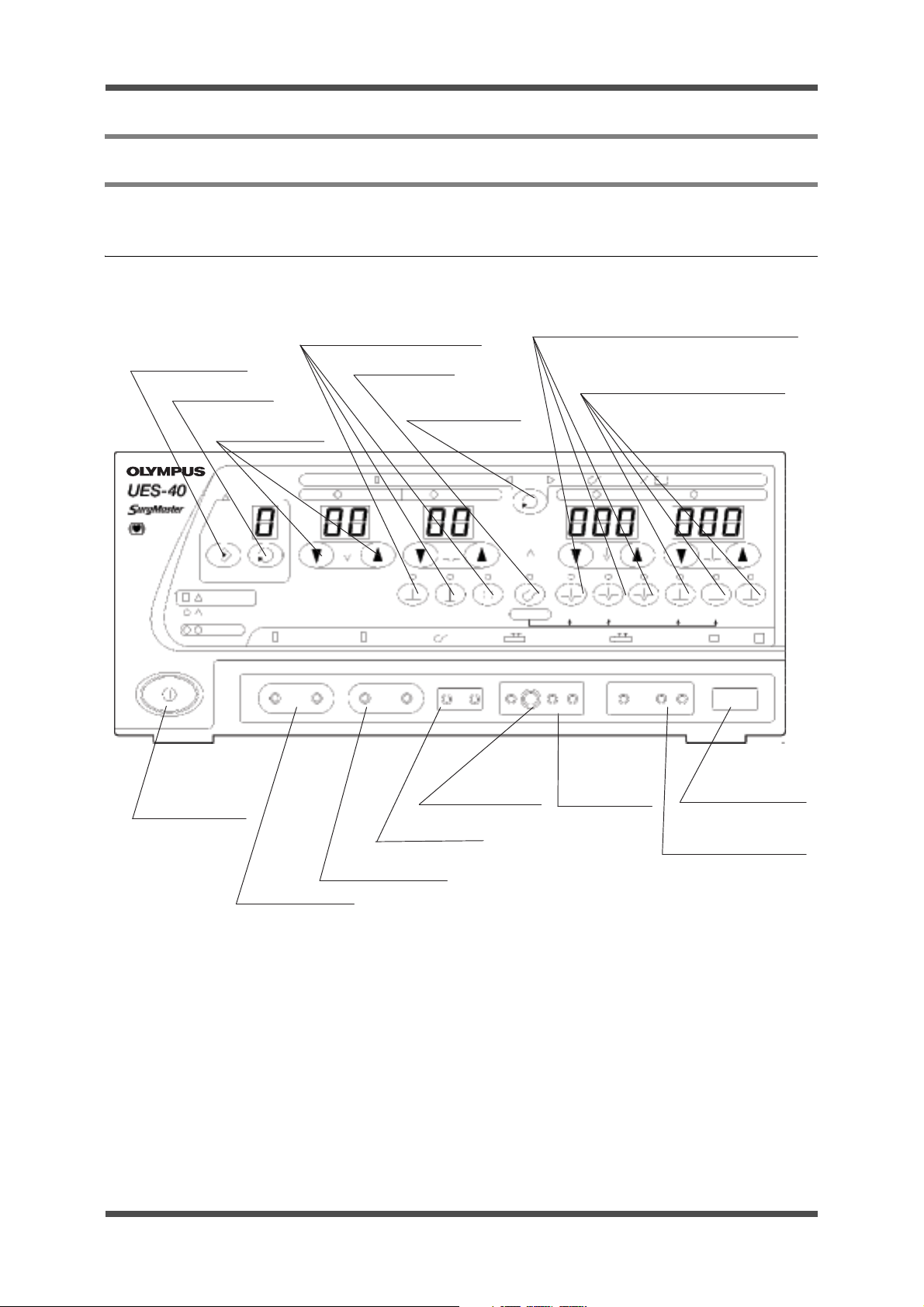

4-1-2 Indicators

(17) Output indicators

During high-frequency output, the indicator corresponding to the selected output mode (Cut or

Coag) lights up.

(18) Preset number indicator

During the use of preset functions, this indicator displays digits from 1 to 5 or P.

(19) Bipolar cut output setting indicator

This indicator displays the value specified using the output control switches.

(20) Bipolar coagulation output setting indicator

This indicator displays the value specified using the output control switches.

(21) Foot-switch setting indicator

This indicator displays the available output from the foot switch for the UES-40 (MAJ-1258).

(22) Monopolar/saline cut output setting indicator

This indicator displays the value specified using the output control switches.

(23) Monopolar/saline coagulation output setting indicator

This indicator displays the value specified using the output control switches.

(24) Monopolar/saline coagulation mode indicators

The lighted indicator corresponds to the coagulation mode selected using the switches.

Product Specification 1-12 ISSUE4

Page 19

(25) Monopolar/saline cut mode indicators

SYSTEM

SN

MAJ-1259

MAJ-1258

12A

AC IN

BREAKERS

Foot Switch

VOLUME

12A

Foot Switch

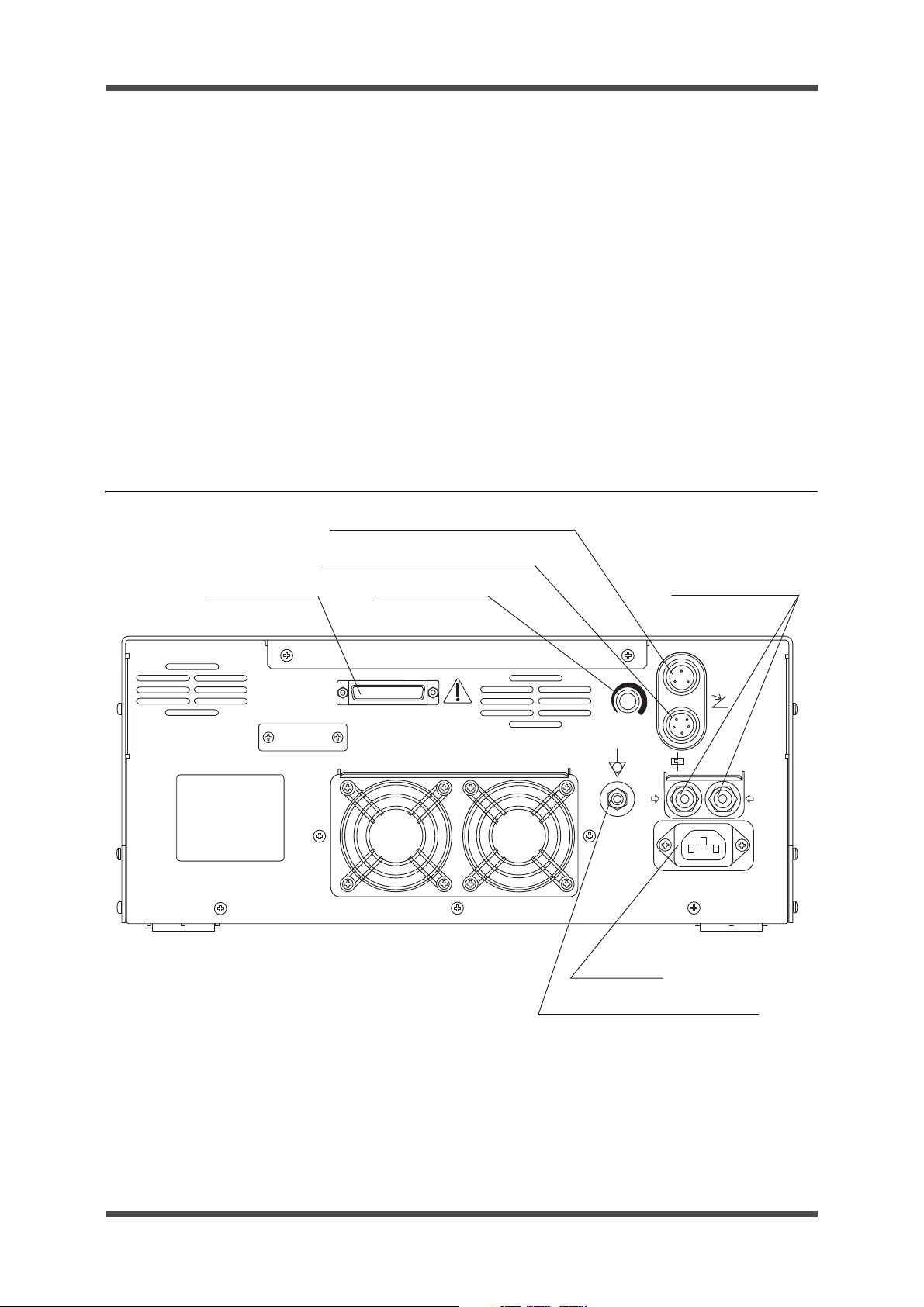

(7) Potential equalization terminal

(1) System port

(5) Circuit breakers

(2) Volume knob

(3) Foot switch port for MAJ-1258

(4) Foot switch connector for MAJ-1259

(6) AC inlet

The lighted indicator corresponds to the cutting mode selected using the switches.

(26) Saline mode indicator

This indicator lights up when saline mode is selected using the switch.

(27) Bipolar coagulation mode indicators

The lighted indicator corresponds to the coagulation mode selected using the switches.

(28) Power switch indicator

This indicator shows that the power is on after the power switch is activated.

(29) CQM indicator

When split type patient plates are attached, the CQM indicator lights up when there is a good

connection with the patient.

(30) Warning indicator

This indicator lights up if equipment problems occur.

4-2 Rear panel

UES-40

(1) System port

This system port is for connecting products to expand the functionality of the unit. Connect only

Olympus products.

(2) Vo lume knob

This knob is for adjustment of the sound output.

ISSUE4 1-13 Product Specification

Page 20

UES-40

As viewed from the connection side

As viewed from the connection side

(3) Foot switch port for MAJ-1258

This port is for connecting the standard accessory foot switch for UES-40.

(4) Foot switch port for MAJ-1259

This port is for connecting an optional bipolar foot switch for UES-40.

(5) Circuit breakers

These breakers are used in the event of mechanical problems to prevent electrical surges

within the UES-40.

(6) AC inlet

This inlet is for connecting the power cord.

(7) Potential-equalization terminal

This terminal is connected for potential equalization.

5. Ports

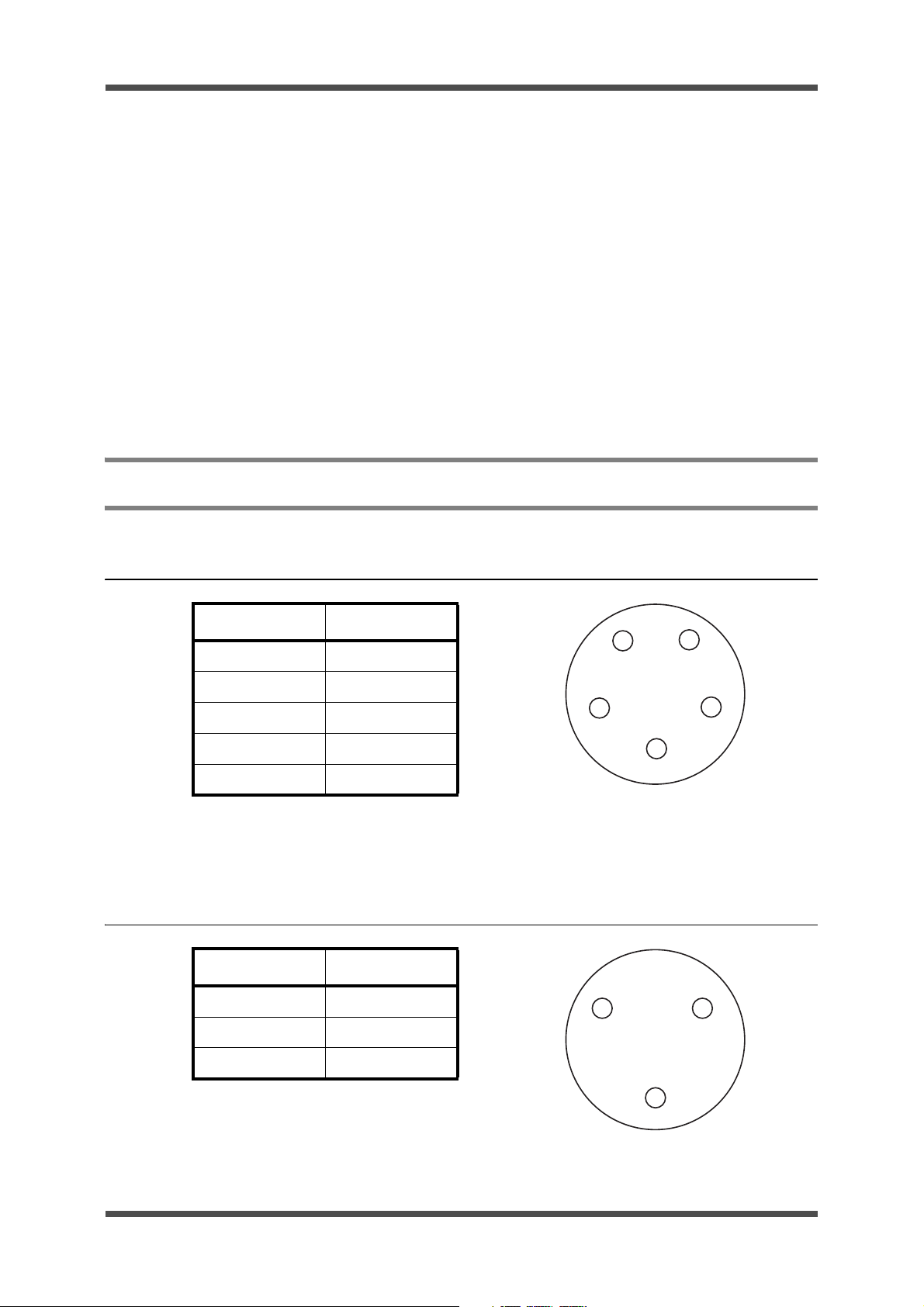

5-1 Foot switch port for MAJ-1258

Pin No. Signal

AFS1CUT1

B TS1COAG1

CFS1PA1

DGND

EFS/MODE

5-2 Bipoler foot switch port for MAJ-1259

Pin No. Signal

A FS3COAG1

BGND

A

B

A

E

D

C

C

CNC

Product Specification 1-14 ISSUE4

B

Page 21

5-3 System port

As viewed from the connection side

Pin No. Signal Pin No. Signal

1NC14SG1

2TxD115NC

3RxD116 NC

4RTS117 NC

5CTS118 NC

6DSR119 NC

7 SG1 20 DTR1

8NC21NC

9NC22NC

10 NC 23 NC

UES-40

11 NC 24 NC

12 NC 25 NC

13 SMKEVAC1

13 12 11 10 9 8 7 6 5 4 3 2 1

25 24 23 22 21 20 19 18 17 16 15 14

ISSUE4 1-15 Product Specification

Page 22

UES-40

A adapter 2

(MAJ-619)

A adapter 3

(MAJ-620)

Interactive cable

(MAJ-877)

High flow insufflation unit (UHI-3)

High flow insufflation unit (UHI-2)

A cord

(A02915A (MAJ-860))

(A02916A (MAJ-861)*)

(A8406 (MH-969)**)

(MA-255**)

UES-40

Disposable

P-cord

(MAJ-814)

High frequency accessory

Bipolar foot switch for

UES-40 (MAJ-1259)

Videoscope

without the S-cord

connector mount

Fiberscope without the

S-cord connector mount

Foot switch

(MAJ-1258)

Some products may not be available in some regions. Please contact the nearest Olympus office for details

Specifications, design and accessories are subject to change without any notice or obligation on the part of the

manufacturer.

6. System Diagram

6-1 Endoscopic Treatment with UES-40 - System Diagram

l 120 V specification

Product Specification 1-16 ISSUE4

Page 23

l 220 V specification

A adapter 2

(MAJ-619)

A adapter 3

(MAJ-620)

Interactive cable

(MAJ-877)

High flow insufflation unit (UHI-3)

High flow insufflation unit (UHI-2)

A cord

(A02915A (MAJ-860))

(A02916A (MAJ-861)*)

(A8406 (MH-969)**)

(MA-255**)

UES-40

Disposable

P-cord

(MAJ-814)

P-plate

(MAJ-897)

High frequency accessory

Bipolar foot switch for

UES-40 (MAJ-1259)

Videoscope

without the S-cord

connector mount

Fiberscope without the

S-cord connector mount

Foot switch

(MAJ-1258)

UES-40

ISSUE4 1-17 Product Specification

Page 24

Working elements

(A2749), (A2750)

(A2751), (A2752)

(A2753), (A2754)

(A2755), (A2757)

(A3752), (A4512)

Sheath

Sheath

Trocar tube

Laparoscopic instrument

(4 mm connector)

4ψ3 mm adapter

(A0101)

3ψ4 mm adapter

(A0100)

Laparoscopic instrument

(3 mm connector)

Bipolar forceps

Bipolar forceps

(A5380), (A5382)

(A5384), (A5386)

(A5388), (A5390)

(A5392), (A5394)

Bipolar forceps

(O5119)

Saline electrodes

(WA22301D), (WA22302D)

(WA22305D), (WA22306D)

(WA22331D), (WA22332D)

(WA22351A), (WA22351C)

(WA22355A), (WA22355C)

Electrode

Saline working elements

(WA22060B)

(WA22061B)

Working elements

(A22060A), (A22061A)

(A20063A)

Working elements

(A2760), (A2761)

Resectoscope for saline

(and other cystourethroscopes)

A

B

C

D

E

F

G

H

I

J

UES-40

6-2 Electrosurgical Treatment with UES-40 - System Diagram

l 120 V specification

Product Specification 1-18 ISSUE4

Page 25

A adapter (MAJ-1) is not available in some countries.

**: A adapter 2 (MAJ-619) is required when the A-Cord marked (**) is used.

*: A adapter 3 (MAJ-620) is required when the A-Cord marked (*) is used.

A

UES-40

B

C

D

A cord

(A0139.1**)

(A0139.2**)

(A0336.1)

E

F

(WA00013A)

A cord

(A00010A**)

(A00011A*)

(A00012A)

A cord

(A0391**)

(A0392*)

(A0393)

A cord

(3 mm type)

(A0130.1**), (A0130.2**)

(A0335.1)

A adapter 2

(MAJ-619)

A adapter 3

(MAJ-620)

Foot switch

(MAJ-1259)

Foot switch

(MAJ-1258)

UES-40

G

A cord

(4 mm type)

(A0355**), (A0357*), (A0358)

(A00506A)

Hand piece

H

Bipolar cord

(A5121.1)

I

Bipolar cord

(A5377)

J

Bipolar cord

Disposable

P-plate

ISSUE4 1-19 Product Specification

Page 26

Working elements

(A2749), (A2750)

(A2751), (A2752)

(A2753), (A2754)

(A2755), (A2757)

(A3752), (A4512)

Sheath

Sheath

Trocar tube

Laparoscopic instrument

(4 mm connector)

4ψ3 mm adapter

(A0101)

3ψ4 mm adapter

(A0100)

Laparoscopic instrument

(3 mm connector)

Bipolar forceps

Bipolar forceps

(A5380), (A5382)

(A5384), (A5386)

(A5388), (A5390)

(A5392), (A5394)

Bipolar forceps

(O5119)

Saline electrodes

(WA22200D)

(WA22232D)

(WA22208D)

(WA22209D)

(WA22233D)

Electrode

Saline working elements

(WA22060B)

(WA22061B)

Working elements

(A22060A), (A22061A)

(A20063A)

Working elements

(A2760), (A2761)

Resectoscope for saline

(and other cystourethroscopes)

K

L

M

N

O

P

Q

R

S

T

UES-40

l 220 V specification

Product Specification 1-20 ISSUE4

Page 27

A adapter 2

(MAJ-619)

A cord

(A00010A**)

(A00011A*)

(A00012A)

(WA00013A)

A cord

(3 mm type)

(A0130.1**), (A0130.2**)

(A0335.1)

A cord

(A0139.1**)

(A0139.2**)

(A0336.1)

A cord

(A0391**)

(A0392*)

(A0393)

A cord

(4 mm type)

(A0355**), (A0357*), (A0358)

(A00506A)

Bipolar cord

(A5121.1)

Bipolar cord

(A5377)

Bipolar cord

A adapter 3

(MAJ-620)

UES-40

Hand piece

P-cord

(MAJ-814)

P-plate

(MAJ-897)

Foot switch

(MAJ-1259)

Foot switch

(MAJ-1258)

A adapter (MAJ-1) is not available in some countries.

**: A adapter 2 (MAJ-619) is required when the A-Cord marked (**) is used.

*: A adapter 3 (MAJ-620) is required when the A-Cord marked (*) is used.

K

L

M

N

O

P

Q

R

S

T

UES-40

ISSUE4 1-21 Product Specification

Page 28

Page 29

Chapter 2: Troubleshooting

Chapter 2:Troubleshooting

1 Troubleshooting.......................................................2-2

2 Error Codes .............................................................2-7

ISSUE4 2-1 Troubleshooting

Page 30

UES-40

UPHF40SS00U

(monitor board)

UPHF40CR00U

(control board)

UPHF40OT00U

(oscillation board)

CONVERTER

UPHF40EX00U

(relay board)

1. Troubleshooting

Configuration of the main unit

Troubleshooting 2-2 ISSUE4

Page 31

ISSUE4 2-3 Troubleshooting

*

1

Problem

Power-on

problem

No response

even when the

output

switches

pressed

*1 The numbers indicate the relative likelihood that this is the affected unit. These numbered units may be damaged.

*2 Foot-switch cutting or coagulation pedal and handpiece output switch

Converter fan unresponsive — — — — — 1 Converter – Power switch Power switch —

Power-switch LED remains unlit. — — — 3 2 1 Converter – Oscillation board (J2) Power switch —

No startup sound — 2 — 1 — 3 Oscillation board (J3) – Monitor board (J5) — —

All panel lights remain unlit. — — — 1 2 — Control board (J2) – Panel sheet — —

All panel lights remain lit. — — — 1 2 — — — —

All output switches

including the handpiece and foot

2

switch are unre-

are

*

sponsive.

Handpiece switch

unresponsive (but

foot switch works)

Foot switch unresponsive (but

handpiece switch

works)

Switch unresponsive when using

handpiece connector 1

Switch unresponsive when using

handpiece connector 2

Foot switch (MAJ-

1258) unresponsive

Bipolar foot switch

(MAJ-1259) unresponsive

No sound — 2 — 1 — — — — —

LEDs remain unlit. — — — 1 2 — — — —

No sound, LEDs

remain unlit.

No sound — 1 — 2 — — — — —

LEDs remain unlit. — — — 1 2 — — — —

No sound, LEDs

remain unlit.

No sound — 1 — 2 — — — — —

LEDs remain unlit. — — — 1 2 — — — —

No sound, LEDs

remain unlit.

No sound — 1 — 2 — — — — —

LEDs remain unlit. — — — 1 2 — — — —

No sound, LEDs

remain unlit.

No sound — 1 — 2 — — — — —

LEDs remain unlit. — — — 1 2 — — — —

No sound, LEDs

remain unlit.

No sound — 1 — 2 — — — — —

LEDs remain unlit. — — — 1 2 — — — —

No sound, LEDs

remain unlit.

No sound — 1 — 2 — — — — —

LEDs remain unlit. — — — 1 2 — — — —

No sound, LEDs

remain unlit.

Oscillation

Monitor

Relay

Control

Panel

board

board

board

board

—2—1—— — — —

—132—— — — —

—1—2—— — — —

— 1 3 2 — — — Front port

— 1 3 2 — — — Front port

— 1 3 2 — — Monitor board (J1) – Foot switch (MAJ-1258) Foot switch

— 1 3 2 — — Monitor board (J1) – Foot switch (MAJ-1259) Foot switch

Converter Harnesses Other Other than main unit

sheet

Parts That Might Have Caused the Problem

Oscillation board (J4) – Control board (J5)

Control board (J2) – Panel sheet

Monitor board (J2) – Speaker

Monitor board (J16) – Control board (J1)

part

part

(MAJ-1258)

port part

(MAJ-1259)

port part

Handpiece switch damage

Handpiece switch damage

Foot-switch

damage

Foot-switch

damage

(Continued next page)

ëÊ2èÕ Troubleshooting

1-1 Troubleshooting list

UES-40

Page 32

Troubleshooting 2-4 ISSUE4

Problem

There is a

response when

the output

switch is

pressed, but it

cannot be

treated.

Cannot be set upPanel-switch prob-

No output

Low output

High output

All normal

lem

Active cord

(for saline) is

not detected.

*

1

Oscillation

7-segment LED

problem (cannot

display correctly)

Switch unresponsive

LEDs remain unlit. — — — 2 1 — Control board (J2) – Panel sheet — —

Pressing the

switch once gives

a prolonged

response

No sound — 1 — 2 — —

Even with the cord

attached, saline

mode is unavailable.

Cord is not

attached, but unit

is in saline mode.

Removing the cord

does not restore

the mode.

Monitor

Relay

Control

Panel

board

board

board

board

1243—5

2143—5

2143—5

—————— — —

— — — 2 1 — Control board (J2) – Panel sheet — —

— — — 2 1 — Control board (J2) – Panel shee — —

— — — 2 1 — Control board (J2) – Panel sheet — —

—132——

—132—— —

—132—— —

Converter Harnesses Other Other than main unit

sheet

Parts That Might Have Caused the Problem

Converter – Oscillation board (J1)

Monitor board (J3) – Oscillation board (J7)

Monitor board (J3) – Oscillation board (J3)

Oscillation board (J4) – Control board (J5)

Monitor board (J7) – Relay board (J2)

Monitor board (J5) – Relay board (J1)

Monitor board (J16) – Control board (J1)

Converter – Oscillation board (J5)

Monitor board (J16) – Control board (J1)

Oscillation board (J4) – Control board (J5)

Monitor board (J16) – Control board (J1)

Monitor board (J2) – Speaker

Monitor board (J16) – Control board (J1)

Monitor board (J5) – Relay board (J1)

Monitor board (J16) – Control board (J1)

Front port

part

Front port

part

——

• Active cord disconnected

• Incorrect use

Speaker —

Front port

part

Front port

part

Front port

part

Active cord (for saline) connector is

defined.

UES-40

—

—Oscillation board (J4) – Control board (J5)

—

—

(Continued next page)

Page 33

ISSUE4 2-5 Troubleshooting

When used with

the UHI, does

not control

smoke and cannot be linked

No communication with

EndoALPHA

Error code displayed

*

1

Problem

Does not function in a ganged manner

Ganged when not switched ON

No communication

Communication interruptions

Patient-plate problem (Coag. 01)

Solution detection problem (Coag. 02)

Output timing problem (Coag. 04)

Output-switch problem (Coag. 08) — 1 3 2 — — — — One of the output switches is broken.

Output-switch ON problem (Coag. 10) — 1 3 2 — — — — One of the output switches is broken.

Short circuit of setting-switch

(Coag. 20)

Oscillation

Monitor

Relay

Control

Panel

board

board

board

board

— — — 1 — — Control board (J6) – System port System port part

— — — 1 — — Control board (J6) – System port System port part

— — — 1 — — Control board (J6) – System port System port part

— — — 1 — — Control board (J6) – System port System port part

4132——

4132——

—231—— —

— — — 2 1 — Control board (J2) – Panel sheet

Converter Harnesses Other Other than main unit

sheet

Parts That Might Have Caused the Problem

Monitor board (J5) – Relay board (J1)

Monitor board (J16) – Control board (J1)

Converter – Oscillation board (J1)

Converter – Oscillation board (J5)

Monitor board (J3) – Oscillation board (J7)

Monitor board (J6) – Oscillation board (J3)

Oscillation board (J4) – Control board (J5)

Monitor board (J7) – Relay board (J2)

Monitor board (J5) – Relay board (J1)

Monitor board (J16) – Control board (J1)

Front connector

part

Front connector

part

Foot switch

(MAJ-1258)

connector part

• Smoke-controlling cable disconnected

• Using an EndoALPHA communication cable

• UHI not ready for smoke control

• UHI main-unit damage

• Use a cable other than the smokecontrol cable or EndoALPHA communication cable

• UHI main-unit damage

• EndoALPHA communication cable

disconnected

• Using smoke-control cable

• UCES damage

• EndoALPHA communication cable

disconnected

• UCES damage

• Patient-plate cord disconnected

• Patient plate coming loose

• Using a liquid other than saline (uromatic or the like)

• Output in air

Monopolar output for more than 60

sec

(Continued next page)

UES-40

Page 34

Troubleshooting 2-6 ISSUE4

(From previous

page)

Error code displayed

Problem

High-frequency current monitor damage (Cut 01)

*

1

Oscillation

Monitor

Relay

Control

Panel

board

board

board

board

—132——

Converter Harnesses Other Other than main unit

sheet

Parts That Might Have Caused the Problem

Monitor board (J7) – Relay board (J2)

Monitor board (J16) – Control board (J1)

Used where the high-frequency current is prone to leakage. (Touching

metal parts of patient’s bed or objects

such as external devices that have

fallen to the ground; used simultaneously with high-frequency grounded

—

electric scalpels [semi-floating], etc.)

UES-40

High-frequency voltage-monitor damage (Cut 02)

2143—5

Waveform-circuit damage (Cut 04) — — — 1 — — — — —

Converter (Power-supply) 1 damage

(Cut 08)

Converter (Power-supply) 2 damage

(Cut 10)

Converter (Power-supply) 3 damage

(Cut 20)

Patient-plate-circuit damage (Cut 40)

3——1—2

3——1—2

3——1—2

—132——

Converter – Oscillation board (J1)

Converter – Oscillation board (J5)

Monitor board (J3) – Oscillation board (J7)

Monitor board (J6) – Oscillation board (J3)

Oscillation board (J4) – Control board (J5)

Monitor board (J7) – Relay board (J2)

Monitor board (J16) – Control board (J1)

Oscillation board (J4) – Control board (J5)

Oscillation board (J5) – Converter

Oscillation board (J4) – Control board (J5)

Oscillation board (J5) – Converter

Oscillation board (J4) – Control board (J5)

Monitor board (J5) – Relay board (J1)

Monitor board (J16) – Control board (J1)

——

——

——

——

——

Page 35

ëÊ2èÕ Troubleshooting

2-1 Error-code list

Display location and error codes

UES-40

2. Error Codes

Monopolar cut

output-setting

indicator

— 01 Patient-plate problem

—02

—04

—08

—10

—20

01 —

02 —

04 —

08 —

10 —

20 —

40 —

Monopolar

coagulation output-

setting indicator

Error Identification Remarks

Solution detection

problem

Output timing problem

Output-switch problem

Output-switch ON

problem

Short-circuit of

setting switch

High-frequency

current-monitor damage

High-frequency voltage-monitor damage

Waveform-circuit

damage

Converter (power

supply)-1 damage

Converter (power

supply)-2 damage

Converter (power

supply)-3 damage

Patient-plate circuit

damage

• Patient-plate cord is disconnected.

• Improper patient-plate connection

•

Patient plate

• Output occurred without the use

of saline

• Output occurred when the electrode was not immersed in sa line .

• Active cord (for saline) is disconnected.

• Active cord (for saline) is broken.

Output for more than 60 sec

(Only during monopolar or saline

mode)

• Output level set to 0 W

• Output switch damaged

• Power was supplied while the

output switch was pressed.

Multiple switches of the foot switch

or handpiece were simultaneously

pressed.

• Power was supplied while the

front-panel switches were

pressed.

• A front-panel switch is damaged.

Overcurrent signal (converter)

Overvoltage signal (converter)

Temperature problem signal (con-

verter)

is disconnected.

ISSUE4 2-7 Troubleshooting

Page 36

Page 37

Chapter 3: Disassembly and Reassembly Procedure

Chapter 3:Disassembly and Reassem-

bly Procedure

1 Precautions for disassembly and reassembly..........3-2

2 Disassembly procedure ........................................... 3-3

3 Reassembly procedure..........................................3-16

ISSUE4 3-1 Disassembly and Reassembly Procedure

Page 38

UES-40

1. Precautions for disassembly and reassembly

(1) Keep all components safe, since you will need to reattach them at their original positions and reroute

the cables as originally routed.

(2) Exercise extreme caution to prevent possible injuries during disassembly.

Be especially careful to avoid injuring yourself on the sharp edges of metal parts.

(3) Remove the cable housing carefully. Never detach cables by pulling on them.

(4) To ensure electrical safety in accordance with the governing electrical standards, attach the following

in their original configurations when reassembling:

a) Insulators, such as insulating tubes and mylar sheets

b) Cables tied with binder to keep them from touching heat-generating and high-voltage compo-

nents

c) Cover screws with toothed washers to reduce noise radiation

(5) Always use specified components.

The product is comprised of components designed to withstand anticipated vibration, heat, and volt-

age. When replacing any component, make sure that the replacement component has the same

characteristics as the original component.

(6) Be sure to use the specified tightening torque and components of specified dimensions.

(7) Clean the components.

When reusing components, first remove any sealing tape and sealing compound, then clean them.

Note that you must clean the surfaces of any O-rings and packings that will come in contact with

components before use. Failure to do so may result in water leak against moisture or other problems.

(8) Check that all screws and nuts are properly tightened.

Failure to do so will result in water leak or other problems.

Disassembly and Reassembly Procedure 3-2 ISSUE4

Page 39

2-1 Tools

No. N ame Specifications Remarks

1 Box screwdriver 5 mm between opposite sides

2 Box screwdriver 5.5 mm between opposite sides

3 Box screwdriver 8 mm between opposite sides

4 Wrench 19 mm between opposite sides

5 Neji-lock 1401C Red

6 Phillips screwdriver No.1

7 Phillips screwdriver No.2

UES-40

2. Disassembly procedure

ISSUE4 3-3 Disassembly and Reassembly Procedure

Page 40

UES-40

TOP COVER

CBK3x6SA

1 SCREW

HCBK3x6SA

12 SCREWS (6 on the opposite side)

HCBK3x6SA

2 SCREWS

E45F CABLE

J5

UPHF40CR00U

(control board)

UPHF40SS00U

(monitor board)

J5

E23F CABLE

2-2 Disassembly procedure

2-2-1 UES-40 main-unit disassembly

(1) Remove the 15 SCREWS holding the TOP

COVER (HCBK3x6SA: 14 SCREWS;

CBK3x6SA: 1 SCREW) and remove the TOP

COVER.

Phillips screwdriver (No. 2)

Note: During reassembly, make sure no

CABLES are caught under the

COVER.

(2) Detach the E45F CABLE from J5 of

UPHF40CR00U (control board).

(3) Detach the E23F CABLE from J5 of

UPHF40SS00U (monitor board).

Disassembly and Reassembly Procedure 3-4 ISSUE4

Page 41

UES-40

J7

E23 HARNESS

UPHF40SS00U

(monitor board)

FRONT PANEL UNIT

C6N3SZ

3 NUTS

CABLE

FRONT PANEL UNIT

POWER SWITCH

Green tube, black wire

Blue tube, black wire

Green tube, white wire

Blue tube,

white wire

(4) Detach the E23 HARNESS from J7 of

UPHF40SS00U (monitor board).

(5) Remove the 3 NUTS holding the FRONT

PANEL UNIT (C6N3SZ) and detach the

FRONT PANEL UNIT.

Box screwdriver (5.5 mm between opposite sides)

ISSUE4 3-5 Disassembly and Reassembly Procedure

(6) Detach the CABLE from the POWER

SWITCH, and then remove the FRONT

PANEL UNIT.

Note: During reassembly, pay attention to

the following items:

• Fully reinsert the CABLE into the

POWER SWITCH.

• If the binder is removed during disassembly, bind the root of the CABLE

for reassembly.

Page 42

UES-40

UPHF40CR00U

(control board)

J16

E12 HARNESS

E24F CABLE

UPHF40SS00U

(monitor board)

UPHF40OT00U

(oscillation board)

J1

J3

J7

SYSTEM HARNESS

E14F CABLE

UPHF40CR00U

(control board)

UPHF40OT00U

(oscillation board)

J5

J6

J4

UPHF40CR00U (control board)

CCUK3x6SZ

4 SCREWS

(7) Detach the E12 HARNESS from J3 of

UPHF40SS00U (monitor board) and J7 of

UPHF40OT00U (oscillation board).

(8) Detach the E24F CABLE from J1 of

UPHF40CR00U (control board) and J16 of

UPHF40SS00U (monitor board).

(9) Detach the E14F CABLE from J5 of

UPHF40CR00U (control board) and J4 of

UPHF40OT00U (oscillation board).

(10) Detach the SYSTEM HARNESS from J6 of

UPHF40CR00U (control board).

(11) Remove the 4 SCREWS (CCUK3x6SZ) hold-

ing UPHF40CR00U (control board), and

detach UPHF40CR00U (control board).

Phillips screwdriver (No. 2)

Disassembly and Reassembly Procedure 3-6 ISSUE4

Page 43

UES-40

E12 HARNESS 2

UPHF40OT00U (oscillation board)

J6

J3

UPHF40SS00U

(monitor board)

SPEAKER HARNESS

UPHF40SS00U

(monitor board)

J9

J2

VOLUME HARNESS

UPHF40SS00U

(monitor board)

J1

J17

FSW MONO HARNESS

FSW BI HARNESS

(12) Detach the E12 HARNESS 2 from J6 of

UPHF40SS00U (monitor board) and J3 of

UPHF40OT00U (oscillation board).

(13) Detach the VOLUME HARNESS from J9 of

UPHF40SS00U (monitor board), and detach

the SPEAKER HARNESS from J2 of

UPHF40SS00U (monitor board).

ISSUE4 3-7 Disassembly and Reassembly Procedure

(14) Detach the bottom FSW MONO HARNESS

from J1 of UPHF40SS00U (monitor board)

and the top FSW BI HARNESS from J17 of

UPHF40SS00U (monitor board).

Page 44

UES-40

UPHF40SS00U

(monitor board)

4 SPACERS

CCUK3x6SZ

2 SCREWS

J2

CONVERTER

J5

J1

(15) Remove the 4 SPACERS between

UPHF40CR00U (control board) and

UPHF40SS00U (monitor board).

Box screwdriver (5.5 mm between opposite sides)

(16) Remove the 2 SCREWS (CCUK3x6SZ) hold-

ing UPHF40SS00U (monitor board), and

remove UPHF40SS00U (monitor board).

Phillips screwdriver (No. 2)

(17) Detach the CONVERTER HARNESS from

UPHF40OT00U (oscillation board).

(Pin 3: J1; pin 6: J2; pin 9: J5)

Note: During reassembly, ensure that the

HARNESS will not obstruct with the

fan vent. In addition, make sure the

CABLE is affixed to the clamp

attached to the CONVERTER.

Disassembly and Reassembly Procedure 3-8 ISSUE4

Page 45

UES-40

CONVERTER

CCUK3x6SZ

6 SCREWS

UPHF40OT00U

(oscillation board)

CONVERTER

C6N3SZ

4 NUTS

REAR PANEL UNIT

HCBK3x6SA

5 SCREWS

CONVERTER

(18) Remove the 6 SCREWS (CCUK3x6SZ) hold-

ing UPHF40OT00U (oscillation board), and

detach UPHF40OT00U (oscillation board).

Phillips screwdriver (No. 2)

(19) Remove the 4 NUTS (C6N3SZ) holding the

CONVERTER.

Box screwdriver (5.5 mm between opposite sides)

(20) Remove the 5 SCREWS (HCBK3x6SA) hold-

ing the REAR PANEL UNIT.

Phillips screwdriver (No. 2)

Note: During reassembly, ensure that the

CONVERTER is in close contact with

the REAR PANEL, with no gaps.

(21) Remove the CONVERTER and REAR

PANEL UNIT.

Note: During reassembly, attach the REAR

PANEL UNIT and CONVERTER

before attaching the CHASSIS and

CONVERTER.

ISSUE4 3-9 Disassembly and Reassembly Procedure

Page 46

UES-40

CAP

KNOB

PEAR PANEL

Attached

SCREW

Apply Neji-lock to

the center of the

shaft

Thinnest part of the

volume-level mark

REAR PANEL

White line on KNOB

KNOB

Indicator Indicator

2-2-2 REAR PANEL UNIT disassembly

(1) Remove the CAP.

(2) Remove the single attached SCREW (for the

VOLUME HARNESS) and remove the

KNOB.

Phillips screwdriver (No. 1)

Neji-lock (during reassembly)

Note: During reassembly, pay attention to the

following items.

• Turn the shaft counterclockwise until

it stops.

• Visually identify the center of the

shaft, and apply Neji-lock.

• Align the white line on the KNOB with

the thinnest part of the volume-level

mark printed on the REAR PANEL,

and affix it using the SCREW.

• Ensure that when the KNOB is

turned, the CAP and KNOB indicator

move to the positions shown below.

Disassembly and Reassembly Procedure 3-10 ISSUE4

Page 47

UES-40

REAR PANEL

EARTH CABLE

HWB3SA

2 NUTS

C6N3SZ

2 NUTS

REAR PANEL

C6N3SZ

4 NUTS

SYSTEM HARNESS

METAL FIT

TING

ISOLATION

PLATE

METAL

FITTING

Coat with

Neji-lock

REAR PANEL

[Cross-sectional view]

(3) Remove the 2 NUTS (C6N3SZ) and 2

WASHERS (HWB3SA) holding the EARTH

CABLE, and remove the EARTH CABLE.

Box screwdriver (5.5 mm between opposite sides)

(4) Remove the 2 METAL FITTINGS hol ding the

SYSTEM HARNESS, and remove the SYSTEM HARNESS.

Box screwdriver (5 mm between opposite sides)

Neji-lock (during reassembly)

Note: During reassembly, apply Neji-lock to

the 2 METAL FITTINGS as shown in

the figure.

(5) Remove the 4 NUTS (C6N3SZ) holding the

ISOLATION PLATE, and remove the ISOLATION PLATE.

Box screwdriver (5.5 mm between opposite sides)

ISSUE4 3-11 Disassembly and Reassembly Procedure

Page 48

UES-40

Attached

WASHER

Attached

NUT

VOLUME

HARNESS

SPEAKER

HARNESS

CUTB3x8SZ

4 SCREWS

Center position

FSW BI HARNESS

FSW MONO HARNESS

EARTH PLATE

ISOLATION

PLATE

Attached

2 NUTS

(6) Remove the attached NUT and 2 WASHERS

holding the VOLUME HARNESS, and

remove the VOLUME HARNESS.

Box screwdriver (8 mm between opposite sides)

Neji-lock (during reassembly)

Note: During reassembly, apply Neji-lock to

the HARNESS threads. When viewed

from the position shown below, affix it

so that the three harnesses attached

to the VOLUME HARNESS faces up

from the center position.

(7) Remove the 4 SCREWS (CUTB3x8SZ) hold-

ing the SPEAKER HARNESS.

Phillips screwdriver (No. 2)

Note: During reassembly, attach the har-

nesses attached to the SPEAKER

HARNESS in the orientation shown in

the figure to the left.

(8) Remove the 2 attached NUTS holding the

FSW MONO HARNESS, FSW BI HARNESS,

and EARTH PLATE, and remove the FSW

MONO HARNESS and FSW BI HARNESS.

Wrench (19 mm between opposite sides)

Note: During reassembly, pay attention to

the following items.

• Align the D cut of the foot-switch

connector with the D cut of the ISOLATION PLATE, and attach them.

• Attach the FSW MONO HARNESS

and FSW BI HARNESS in the proper

position.

FSW BI HARNESS: Pin 3 (top)

FSW MONO HARNESS: Pin 5 (bottom)

Disassembly and Reassembly Procedure 3-12 ISSUE4

Page 49

2-2-3 FRONT PANEL UNIT disassembly

FRONT PANEL

UNIT

FRONT CHASSIS

CUKSK3x6SZ

7 SCREWS

Pushbutton

switch

FRONT CHASSIS

UPHF40EX00U

(relay board)

E23 HARNESS

E23F CABLE

J2

J1

CORE

UES-40

(1) Remove the 7 SCREWS (CUKSK3x6SZ)

holding the FRONT CHASSIS, and remove

the FRONT CHASSIS.

Phillips screwdriver (No. 2)

Note: During reassembly, thread each of the

3 HARNESSES through the FRONT

CHASSIS holes.

(2) Remove the pushbutton switch from the

FRONT CHASSIS.

Note: During reassembly, insert the pushbut-

ton switch until you feel a click.

(3) Detach the E23 HARNESS from the J2 con-

nector of UPHF40EX00U (relay board), and

the E23F CABLE from the J1 connector.

ISSUE4 3-13 Disassembly and Reassembly Procedure

Page 50

UES-40

NN2.5SA 2 NUTS

UPHF40EX00U

(relay board)

SW2.5SA 2 WASHERS

KNW2.5SA 2 WASHERS

CUKSK3x6SZ

17 SCREWS

UPHF40EX00U

(relay board)

CUKSK3x6SZ

1 SCREW

A PLATE

(4) Remove the 2 NUTS (NN2.5SA) and 4

WASHERS (2 WASHERS each of SW2.5SA

and KNW2.5SA) holding UPHF40EX00U

(relay board).

Box screwdriver (5 mm between opposite sides)

(5) Remove the 17 SCREWS (CUKSK3x6SZ)

holding UPHF40EX00U (relay board), and

remove the UPHF40EX00U (relay board).

Phillips screwdriver (No. 2)

(6) Remove the single SCREW (CUKSK3x6SZ)

holding the A PLATE, and remove the A

PLATE.

Phillips screwdriver (No. 2)

Disassembly and Reassembly Procedure 3-14 ISSUE4

Page 51

UES-40

SPACER 23.7

CUKSK3x6SZ

CONTACT SPRING

[CONTACT, top view]

SPACER 23.7

FRONT PANEL

CONTACT

PLATE

SPACER 25

SWITCH

side

CONTACT

SPRING

SPACER 25

CUKSK3x6SZ

CONTACT PLATE

FRONT PANEL

SWITCH SPRING

SWITCH COLLAR

MAIN SWITCH

(7) Remove the 2 SCREWS (CUKSK3x6SZ),

and then remove the SPACER 23.7, CONT ACT SPRING, SPACER 25, and CONTACT

PLATE (in that order).

Box screwdriver (5.5 mm between opposite sides)

Phillips screwdriver (No. 2)

(8) Remove the MAIN SWITCH, SWITCH

SPRING, and SWITCH COLLAR.

ISSUE4 3-15 Disassembly and Reassembly Procedure

Page 52

UES-40

3. Reassembly procedure

3-1 Tools

Please refer to “2-1 Tools.”

3-2 Reassembly procedure

To perform reassembly, reverse the disassembly procedure, referring to “2-2 Disassembly

procedure.”

No adjustments such as positioning are required during reassembly.

Disassembly and Reassembly Procedure 3-16 ISSUE4

Page 53

Chapter 4: Inspection

Chapter 4:Inspection

1 Preparation .............................................................. 4-2

2 Inspection Procedure...............................................4-2

ISSUE4 4-1 Inspection

Page 54

UES-40

1. Preparation

Prepare the following equipment for inspection.

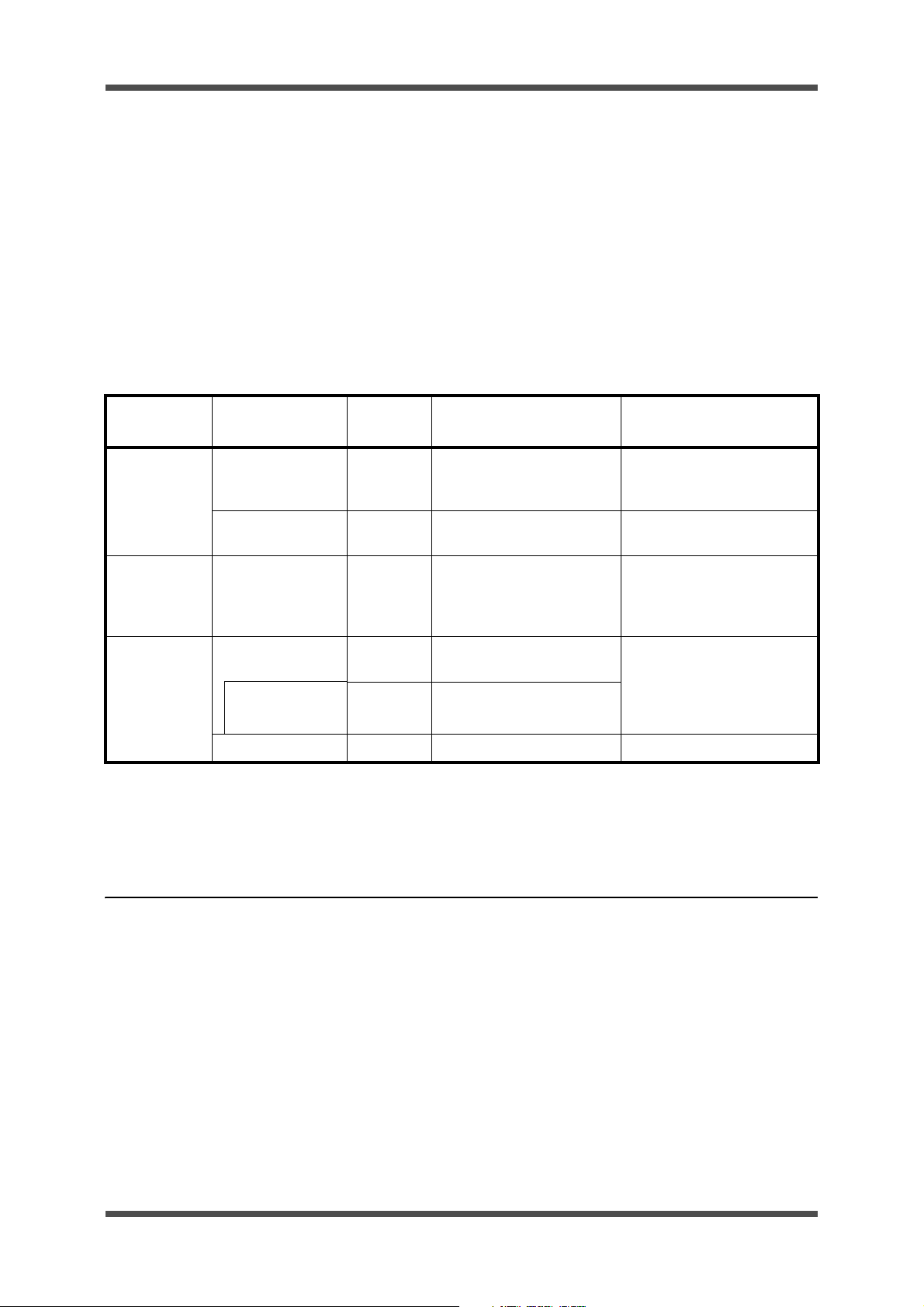

Name Model Specifications Remarks

Electrosurgical Analyzer 454A – DNI NEVADA INC.

2. Inspection Procedure

Connect the Electrosurgical Analyzer to the UES-40. (Refer to the Electrosurgical Analyzer

instruction manual for details.)

Refer to the following table to check output values:

Table 4-1 Setting and output of each mode

Output mode Load resistance [¾] UES-40 output setting [W] Standard [W]

Monopolar Spray 200 60 48-72

Monopolar Coag. 1 300 60 48-72

Monopolar Coag. 2 300 60 48-72

Monopolar Blend 300 125 100-150

Monopolar Cut 300 150 120-180

Bipolar Soft1 100 45 36-54

Saline Blend 100 160 128-192

The above listed measurement points can cover all output specifications, because there are

no difference other than the amplitude of waveform in each output mode.

Inspection 4-2 ISSUE4

Page 55

Chapter 5: Parts List

Chapter 5: Parts List

1 Exploded Parts Diagram ....................................... 5-2

2 Parts List.................................................................5-6

ISSUE4 5-1 Parts List

Page 56

UES-40

1. Exploded Parts Diagram

ABCD

1

HCBK3x6SA

HCBK3x6SA

HCBK3x6SA

CBK3x6SA

2

2

GL465300

2

HCBK3x6SA

GT011600

2

1

1

3

4

(C) 2004 Olympus Medical Systems Corporation. All rights reserved.

Parts List 5-2 ISSUE4

EXPLODED PARTS DIAGRAM

MODEL UNIT FR.1590

UES-40 TOP COVER

OLYMPUS MEDICAL SYSTEMS CORP.

FIG.1/4

Page 57

EXPLODED PARTS DIAGRAM

FIG.2/4

MODEL

UNIT

OLYMPUS MEDICAL SYSTEMS CORP.

UES-40

FRONT PANEL , CONVERTER

ABCD

1

2

3

4

FR.1590

(C) 2004 Olympus Medical Systems Corporation. All rights reserved.

1

CUKSK3x6SZ

GT012800

GC981200

A

B

A

B

1

1

GC688500

11GC688300

1 GC688400

GT012500

GT086700

CUKSK3x6SZ

CUKSK3x6SZ

GC981400

GL354700

GC475800

DY266000

CUKSK3x6SZ

CUKSK3x6SZ

GL357200

GC981500

GL357300

GT013100

C6N3SZ

KNW2.5SA

SW2.5SA

NN2.5SA

HCBK3x6SA

HCBK3x6SA

GT017300

DO078500

GC981300

GC980900

C6N3SZ

GL465700(120V, 220V)1

GT064500

CUKSK3x6SZ

GT203000(220V)

GT086600

1

UES-40

ISSUE4 5-3 Parts List

Page 58

EXPLODED PARTS DIAGRAM

FIG.3/4

MODEL UNIT

OLYMPUS MEDICAL SYSTEMS CORP.

UES-40 PCB , REAR PANEL

ABCD

1

2

3

4

FR.1590

(C) 2004 Olympus Medical Systems Corporation. All rights reserved.

GL355600

GL356300

GL355900

GL355500

GT041800

HWB2.6SA

GL355700

GC980700

GC982200

HWB3SA

GL356000

CUTB3x8SZ

C6N3SZ

GL356100

C6N3SZ

GH253300

GH253500

GL356200

GL356800

GL357200

GL357300

CCUK3x6SZ

GC981400

CUKSK3x25SZ

CCUK3x6SZ

GL357000

GL356400(Ver.1)

CCUK3x6SZ

GL357100

GL356700

GU197300(220V)

GL335500(120V)

4

4 GL356900

4

3

6

7

3

GL356600

(Ver.1)

5

5

5

6

7

5

3

GT086600

GT011800(120V)

GT011900(220V)

DZ253200

GT289900(Ver.2 120V)

GT290000(Ver.2 220V)

8

GN380100(Ver.2)

8

8 GN380200

(Ver.2)

Upgrade kit

GN380600 (English)

GN380700 (Symbol)

UES-40

Parts List 5-4 ISSUE4

Page 59

ABCD

1

2

3

4

EXPLODED PARTS DIAGRAM

FIG.4/4UES-40

MODEL UNIT

CABLE

OLYMPUS MEDICAL SYSTEMS CORP.

FR.1590

(C) 2004 Olympus Medical Systems Corporation. All rights reserved.

J1

J1

J16

GL357100

J6

J1

J2

J2

GL356900

FAN

UPHF40CR00U

UPHF40SS00U

UPHF40EX00U

HPHF40OT00U

CONVERTER

INLET

VOLUME

MAIN SW

FSW

(For MAJ-1258)

FSW

(For MAJ-1259)

SPEAKER

GL355900

GL355500

GL356000

GL355700

GL355600

SYSTEM

FRONT PANEL

J7

J7

J3

J5

J4

J6

J1

J2

J5

J5

J9

J1

J17

J2

GL357200

GL357000

GL356800

GL357300

GL356700

J3

J6

J1

UES-40

ISSUE4 5-5 Parts List

Page 60

UES-40

2. Parts List

PARTS No. INDEX PARTS NAME E. SPECIFICATION REMARK

DO078500 2-D2 BINDING WIRE

DY266000 2-C2 SWITCH

DZ253200 3-A2 FERRITE CORE

GC475800 2-A2 BUSH 4

GC688300 2-D2 SWITCH SPRING

GC688400 2-D2 SWITCH COLLAR

GC688500 2-D1 MAIN SWITCH

GC980700 3-A2 ISOLATION PLATE

GC980900 2-D4 CHASSIS

GC981200 2-D1 F PACKING

GC981300 2-D4 FOOT

GC981400 2-C1 SPACER 25

GC981500 2-A2 F CHASSIS

GC982200 3-A2 GROUND PLATE

GH253300 3-A2 KNOB

GH253500 3-A1 CAP

GL335500 3-B4 POWER CABLE OAU 120V

GL354700 2-B1 UPHF40EX00U RELAY PCB

GL355500 3-A1 SYSTEM HARNESS

GL355600 3-B2 VOLUME HARNESS

GL355700 3-A2 FSW MONO HARNESS

GL355900 3-A2 FSW BI HARNESS

GL356000 3-B2 SPEAKER HARNESS

GL356100 3-A2 GROUND CABLE

GL356200 3-D2 UPHF40OT00U

GL356300 3-B3 UPHF40SS00U MONITOR PCB

GL356400 3-B1 UES40 CONTROL U CONTROL PCB

GL356600 3-B1 UES40ROMU

GL356700 3-C1 E14F HARNESS

GL356800 3-C2 E12 HARNESS

GL356900 3-D2 FAN HARNESS

GL357000 3-D1 E12 HARNESS 2

GL357100 3-C1 E24F HARNESS

GL357200 2-A2 E23 HARNESS

GL357300 2-B2 E23F HARNESS

GL465300 1-D1 TOP COVER U

GL465700 2-D1 PANEL EU 120V, 220V

GN380100 3-B1 UES40 V2 CONTOL U Ver.2

GN380200 3-B1 UES40 V2 ROM U Ver.2

OSCILLATION

Parts List 5-6 ISSUE4

Page 61

PARTS No. INDEX PARTS NAME E. SPECIFICATION REMARK

GN380600 3-D3 VER2 SET-E Ver.2 English

GN380700 3-D3 VER2 SET-S Ver.2 Symbol

GT011600 1-C2 MYLAR T

GT011800 3-A1 REAR PANEL E 120V

GT011900 3-A1 REAR PANEL S 220V

GT012500 2-C1 CONTACT PLATE

GT012800 2-B1 A CORD PLATE

GT013100 2-A2 CABLE CLAMP

GT017300 2-C2 CONVERTER

GT041800 3-A1 METAL FITTING

GT064500 2-C1 CONTACT SPRING

GT086600 2-D1 MYLAR C

GT086700 2-C1 SPACER23.7

GT203000 2-A3 WEEE MARK 220V

GT289900 3-A1 REAR PANEL E Ver.2 120V

GT290000 3-A1 REAR PANEL S Ver.2 220V

GU197300 3-A4 POWER CABLE 2U 220V

C6N3SZ 2-A2 NUT

CBK3x6SA 1-C1 SCREW

CCUK3x6SZ 3-B3 SCREW

CUKSK3x25SZ 3-D2 SCREW

CUKSK3x6SZ 2-A1 SCREW

CUTB3x8SZ 3-B2 SCREW

HCBK3x6SA 1-A1 SCREW

HWB2.6SA 3-A1 WASHER

HWB3SA 3-A2 WASHER

KNW2.5SA 2-A1 WASHER

NN2.5SA 2-A1 NUT

SW2.5SA 2-A1 WASHER

UES-40

ISSUE4 5-7 Parts List

Page 62

Page 63

Page 64

2951 Ishikawa-cho, Hachioji- shi, Tokyo Japan

Service Engineering

Medical Service Engineering Depertment

Production and Service Division

PRINTED IN JAPAN FIRST EDITION : 05.2004 W102B

Loading...

Loading...