Page 1

INSTRUCTIONS

EVIS EXERA II ULTRASOUND GASTROVIDEOSCOPE

OLYMPUS GF TYPE UCT180

CAUTION : Balloons Used with This Product Contain Natural Rubber Latex, Which May Cause

Allergic Reactions.

USA: CAUTION: Federal law restricts this device to sale by or on the order of a

physician.

Page 2

Page 3

Contents

Contents

Symbols......................................................................................... 1

Important Information — Please Read Before Use.................... 3

Intended use ............................................................................................ 3

Applicability of endoscopy and endoscopic treatment ............................. 3

Instruction manual..................................................................................... 4

User qualifications .................................................................................... 4

Instrument compatibility ............................................................................ 5

Reprocessing before the first use/reprocessing and storage after use .... 5

Spare equipment ...................................................................................... 5

Maintenance management........................................................................ 6

Prohibition of improper repair and modification ........................................ 6

Signal words ............................................................................................. 6

Warnings and cautions.............................................................................. 7

Examples of inappropriate handling ......................................................... 11

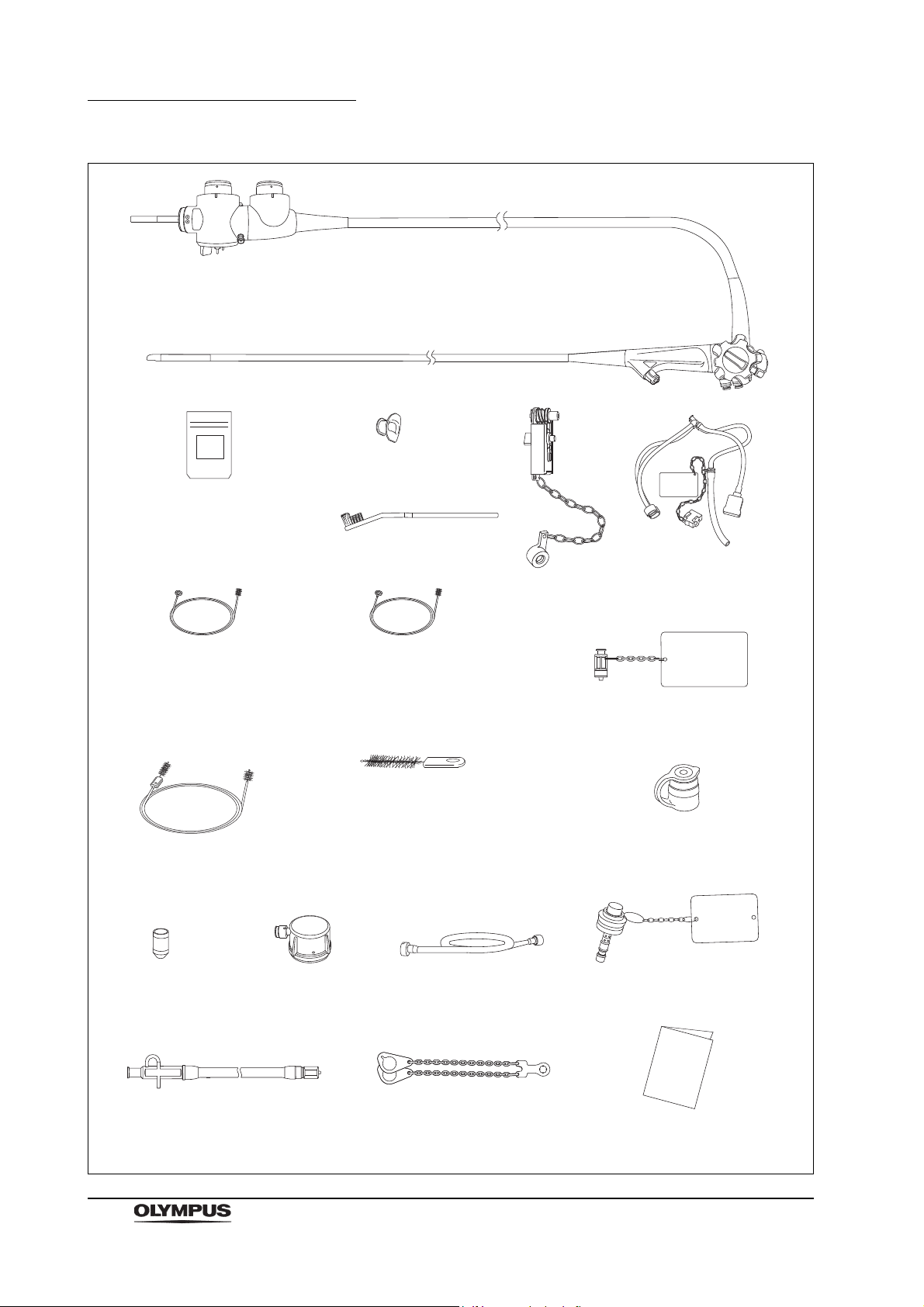

Chapter 1 Checking the Package Contents............................ 13

1.1 Standard components..................................................................... 13

1.2 Ultrasonic cable .............................................................................. 15

1.3 Optional components ...................................................................... 15

Chapter 2 Instrument Nomenclature and Specifications ...... 16

2.1 Nomenclature.................................................................................. 16

2.2 Endoscope functions....................................................................... 18

2.3 Specifications.................................................................................. 21

2.4 Attaching the chain for water-resistant cap (MAJ-1739) ................. 25

Chapter 3 Preparation and Inspection .................................... 28

3.1 Preparation of the equipment.......................................................... 29

3.2 Inspection of the endoscope ........................................................... 30

3.3 Preparation and inspection of accessories ..................................... 34

3.4 Attaching accessories to the endoscope ........................................ 38

3.5 Inspection and connection of ancillary equipment .......................... 40

3.6 Inspection of the endoscopic system .............................................. 46

3.7 Preparation and inspection of the balloon....................................... 52

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

i

Page 4

Contents

Chapter 4 Operation.................................................................. 57

4.1 Insertion .......................................................................................... 59

4.2 Observation of the ultrasound image .............................................. 64

4.3 Using EndoTherapy accessories .................................................... 66

4.4 Withdrawal of the endoscope.......................................................... 73

4.5 Removal of the balloon ................................................................... 74

4.6 Transportation of the endoscope .................................................... 75

Chapter 5 Reprocessing: General Policy................................ 76

5.1 Instructions...................................................................................... 76

5.2 Importance of cleaning, disinfection, and sterilization..................... 76

5.3 Precautions ..................................................................................... 77

5.4 Reprocessing before the first use/reprocessing

and storage after use ...................................................................... 80

Chapter 6 Compatible Reprocessing Methods and

Chemical Agents ..................................................... 81

6.1 Compatibility summary.................................................................... 81

6.2 Detergent solution........................................................................... 83

6.3 Disinfectant solution ........................................................................ 84

6.4 Rinse water ..................................................................................... 84

6.5 Ethylene oxide gas sterilization....................................................... 85

6.6 Steam sterilization (autoclaving) of accessories ............................. 87

Chapter 7 Cleaning, Disinfection, and Sterilization

Procedures .............................................................. 88

7.1 Required reprocessing equipment .................................................. 88

7.2 Cleaning, disinfection, and sterilization

procedures for the endoscope ........................................................ 102

7.3 Precleaning ..................................................................................... 103

7.4 Leakage testing............................................................................... 108

7.5 Manual cleaning .............................................................................. 113

7.6 High-level disinfection ..................................................................... 132

7.7 Rinsing after high-level disinfection................................................. 135

7.8 Sterilization ..................................................................................... 138

7.9 Cleaning, disinfection, and sterilization procedures for reusable

parts and reprocessing equipment.................................................. 139

7.10 Care of the ultrasonic cable (MAJ-1597)......................................... 147

ii

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 5

Contents

Chapter 8 Cleaning and Disinfection Equipment................... 148

Chapter 9 Storage and Disposal.............................................. 151

9.1 Storage of the endoscope............................................................... 152

9.2 Storage of the balloon..................................................................... 152

9.3 Storage of reusable parts and reprocessing equipment ................. 152

9.4 Storage of the ultrasonic cable ....................................................... 153

9.5 Disposal .......................................................................................... 153

Chapter 10 Troubleshooting ...................................................... 154

10.1 Troubleshooting guide .................................................................... 154

10.2 Withdrawal of the endoscope with an irregularity ........................... 159

10.3 Returning the endoscope for repair ................................................ 161

Appendix A: System Chart .......................................................... 163

Appendix B: Inspection of the endoscope after cleaning,

disinfection or sterilization in accordance with

IEC 60601-2-37 ......................................................... 170

Appendix C: EMC Information..................................................... 172

Appendix D: Acoustic Output Information in Accordance

with the FDA Guidance:

“Information for Manufacturers Seeking

Marketing Clearance of Diagnostic Ultrasound

Systems and Transducers” .................................... 177

Symbol key ............................................................................................... 177

Acoustic output table with ALOKA diagnostic ultrasound system ............. 179

Acoustic output table when combined with Olympus universal

endoscopic ultrasound center EU-ME1 .................................................... 182

Clinical measurement accuracy with ALOKA diagnostic

ultrasound system ..................................................................................... 183

Clinical measurement accuracy when combined with Olympus

universal endoscopic ultrasound center EU-ME1 .................................... 183

Appendix E: Acoustic Output Information Accordance with

IEC 60601-2-37 ......................................................... 184

Acoustic output table with ALOKA diagnostic ultrasound system ............ 184

Acoustic output table with Olympus universal endoscopic ultrasound

center EU-ME1 ......................................................................................... 195

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

iii

Page 6

Contents

iv

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 7

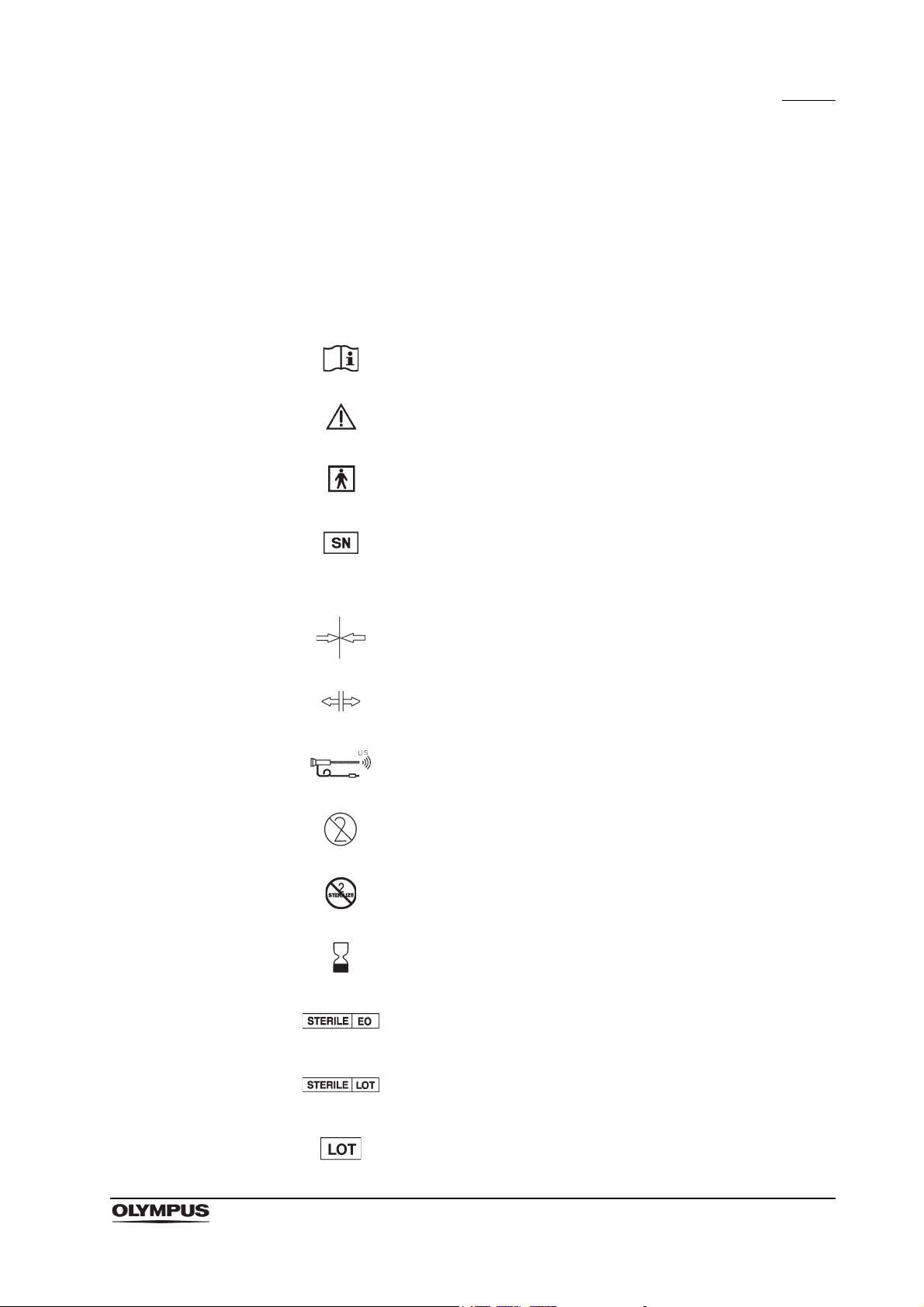

Symbols

Symbols

The meaning(s) of the symbol(s) shown on the package, the back cover of this

instruction manual and/or this instrument are as follows:

Refer to instructions.

Caution

TYPE BF applied part

Serial number

IPX7 Ingress protection rating (except for connectors)

Lock the ultrasound connector

Release the ultrasound connector

Ultrasonic endoscope

Single use only

Do not resterilize

Use by (expiration date)

Sterilized using ethylene oxide

Sterilization lot number

Lot number

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

1

Page 8

Symbols

Nonsterile

Keep away from sunlight

Keep dry

Do not use if package is damaged

Contains or Presence of Natural Rubber Latex

Date of manufacture

Manufacturer

Authorized representative in the European Community

2

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 9

Important Information — Please Read Before Use

Important Information — Please Read

Before Use

Intended use

This instrument has been designed to be used with an Olympus universal

endoscopic ultrasound center or a diagnostic ultrasound system (ALOKA CO.,

LTD), video system center, light source, documentation equipment, monitor,

EndoTherapy accessories and other ancillary equipment.

This instrument is designed for endoscopic real-time ultrasound imaging,

ultrasound guided needle aspiration and other endoscopic procedures within the

upper gastrointestinal tract and surrounding organs.

Do not use this instrument for any purpose other than its intended use.

Applicability of endoscopy and endoscopic treatment

If there is an official standard on the applicability of endoscopy and endoscopic

treatment that is defined by the hospital’s administration or other official

institutions such as academic societies on endoscopy, follow that standard.

Before starting endoscopy and endoscopic treatment, thoroughly evaluate its

properties, purposes, effects, and possible risks (their nature, extent, and

probability). Perform endoscopy and endoscopic treatment only when its

potential benefits are greater than its risks.

Fully explain to the patient the potential benefits and risks of the endoscopy and

endoscopic treatment as well as any examination/treatment methods that can be

performed in its place, and perform the endoscopy and endoscopic treatment

only after obtaining the consent of the patient.

Even after starting the endoscopy and endoscopic treatment, continue to

evaluate the potential benefits and risks, and immediately stop the

endoscopy/treatment and take proper measures if the risks to the patient

become greater than the potential benefits.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

3

Page 10

Important Information — Please Read Before Use

Instruction manual

This instruction manual contains essential information for using this instrument

safely and effectively. Before use, thoroughly review this manual and the

manuals of all equipment that will be used during the procedure. Then use the

equipment as instructed.

Keep this and all related instruction manuals in a safe and accessible location. If

you have any questions or comments about any information in this manual,

please contact Olympus.

Terms used in this manual

NBI (Narrow Band Imaging) observation mode:

This is an observation mode using narrow band observation light.

Normal light observation (or WLI (White Light Imaging) observation

mode):

This is an observation mode using the standard white light illumination.

Elastography:

Mode for displaying the relative elasticity information of a tissue using

color images.

For more details, refer to the instruction manual for the ultrasound

instrument for which elastography is available.

User qualifications

If there are official standards for user qualifications for performing endoscopy

and endoscopic treatment that are defined by the hospital’s medical

administrators or other official institutions, such as academic societies on

endoscopy, follow those standards. If there are no official qualification standards,

the operator of this instrument must be a physician approved by the medical

safety manager of the hospital or person in charge of the department

(department of internal medicine, etc.).

The physician should be capable of safely performing the planned endoscopy

and endoscopic treatment following guidelines set by the academic societies on

endoscopy, etc., and considering the difficulty of endoscopy and endoscopic

treatment. This manual does not explain or discuss endoscopic procedures.

4

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 11

Important Information — Please Read Before Use

Instrument compatibility

Refer to the “System chart” in the Appendix to confirm that this instrument is

compatible with the ancillary equipment being used. Using incompatible

equipment can result in patient or operator injury and/or equipment damage.

This instrument complies with EMC standard for medical electrical equipment,

edition 3 (IEC 60601-1-2: 2007). However, when connected with an instrument

that complies with EMC standard for medical electrical equipment, edition 1

(IEC 60601-1-2: 1993), the whole system complies with edition 1.

Reprocessing before the first use/reprocessing and storage after use

This instrument was not cleaned, disinfected, or sterilized before shipment.

Before using this instrument for the first time, reprocess it according to the

instructions given in Chapter 7, “Cleaning, Disinfection, and Sterilization

Procedures”.

After using this instrument, reprocess and store it according to the instructions

given in the endoscope’s companion reprocessing manual. Improper and/or

incomplete reprocessing or storage can present an infection control risk, cause

equipment damage, or reduce performance.

The balloons are disposable, and are intended for a single use only; a new one

must be used for each patient. Do not attempt to reuse or resterilize a balloon.

Spare equipment

Be sure to prepare another endoscope to avoid interruption of the examination

due to equipment failure or malfunction.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

5

Page 12

Important Information — Please Read Before Use

Maintenance management

The probability of failure of the endoscope and ancillary equipment increases as

the number of procedures performed and/or the total operating hours increase.

In addition to the inspection before each procedure, the person in charge of

medical equipment maintenance in each hospital should inspect the items

specified in this manual periodically. An endoscope with an observed irregularity

should not be used, but should be inspected by following Section 10.1,

“Troubleshooting guide” on page 154. If the irregularity is still observed after

inspection, contact Olympus.

Prohibition of improper repair and modification

This instrument does not contain any user-serviceable parts. Do not

disassemble, modify, or attempt to repair it; patient or operator injury and/or

equipment damage can result. Equipment that has been disassembled,

repaired, altered, changed, or modified by persons other than Olympus’ own

authorized service personnel is excluded from Olympus’ limited warranty and is

not warranted by Olympus in any manner.

Signal words

The following signal words are used throughout this manual:

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also

be used to alert against unsafe practices or potential

equipment damage.

Indicates additional helpful information.

6

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 13

Warnings and cautions

Follow the warnings and cautions given below when handling this instrument.

This information is to be supplemented by the warnings and cautions given in

each chapter.

• After using this instrument, reprocess and store it according

• Before endoscopy, remove any metallic objects (watch,

Important Information — Please Read Before Use

to the instructions given in Chapter 7, “Cleaning, Disinfection,

and Sterilization Procedures”. Using improperly or

incompletely reprocessed or stored instruments may cause

patient cross-contamination and/or infection.

glasses, necklace, etc.) from the patient. Performing

high-frequency cauterization treatment while the patient is

wearing metallic objects may cause burns on the patient in

areas around the metallic objects.

• Move the elevator control lever slowly in the opposite

direction of the “ U” direction until it stops and visually

confirm that the portion of the elevator wire extending from

the distal end of the insertion section is not broken or bent. If

the elevator wire is broken or bent, patient injury, bleeding,

and/or perforation could result.

• Do not strike, hit, or drop the endoscope’s distal end,

insertion tube, bending section, control section, universal

cord, or endoscope connector. Also, do not bend, pull, or

twist the endoscope’s distal end, insertion tube, bending

section, control section, universal cord, or endoscope

connector with excessive force. The endoscope may be

damaged and could cause patient injury, burns, bleeding,

and/or perforations. It could also cause parts of the

endoscope to fall off inside the patient.

• Never perform angulation control forcibly or abruptly. Never

forcefully pull, twist, or rotate the angulated bending section.

Patient injury, bleeding, and/or perforation may result. It may

also become impossible to straighten the bending section

during an examination.

• Never insert or withdraw the endoscope’s insertion section

while the bending section is locked in position. Patient injury,

bleeding, and/or perforation may result.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

7

Page 14

Important Information — Please Read Before Use

• Never operate the bending section, feed air, perform suction,

• Never operate the bending section, feed air, perform suction,

• Never insert or withdraw the insertion section abruptly or with

• Do not touch the light guide of the endoscope connector

• That before each use or after a change of viewing

insert or withdraw the endoscope’s insertion section, or use

EndoTherapy accessories without viewing the endoscopic

image. Patient injury, bleeding, and/or perforation may result.

insert or withdraw the endoscope’s insertion section, or use

EndoTherapy accessories while the image is frozen. Patient

injury, bleeding, and/or perforation may result.

excessive force. Patient injury, bleeding, and/or perforation

may result.

immediately after removing it from the light source because it

is extremely hot. Operator or patient burns can result.

modes/settings, check to ensure the view observed through

the endoscope provides a live image (rather than a stored

one) and has the correct image orientation. Patient injury,

bleeding, and/or perforation could result.

• When the endoscopic image does not appear on the monitor,

the CCD may have been damaged. Turn the video system

center OFF immediately. Continued power supply in such a

case will cause the distal end to become hot and could cause

operator and/or patient burns.

• Turn ON the diagnostic ultrasound system only when the

ultrasonic cable is connected to both the diagnostic

ultrasound system and the ultrasonic cable connector on the

endoscope. In particular, confirm that the diagnostic

ultrasound system is OFF before connecting or

disconnecting the ultrasonic cable from the ultrasonic cable

connector on the endoscope. Operator injury may result

and/or equipment damage may result.

• Do not rely on the NBI observation mode alone for primary

detection of lesions or to make a decision regarding any

potential diagnostic or therapeutic intervention.

• Never withdraw the endoscope while the balloon is still

inflated. Otherwise, the balloon may burst or detach from the

distal end of the endoscope. If the balloon cannot be

deflated, insert the channel cleaning brush (BW-7L) into the

balloon channel. Using slow, short strokes, carefully feed the

brush to remove debris.

8

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 15

Important Information — Please Read Before Use

• When withdrawing the endoscope, make sure that the

balloon is completely deflated, using the ultrasound image

and endoscopic field of view. Withdrawing the endoscope

while the balloon is inflated could result in patient injury.

• If it is difficult to insert the endoscope, do not forcibly insert

the endoscope; stop the endoscopy. Forcible insertion can

result in patient injury, bleeding, and/or perforation.

• If any irregularity in the ultrasound image is observed, turn

the ultrasound center OFF immediately. Continued

ultrasound radiation will cause the distal end to become hot

and could cause operator and/or patient burns.

• Elastography

*1

uses the pulsation of a living body.

Intentional pressurization is not necessary. Compression

onto the tissue by operating the bending section, inserting or

withdrawing the endoscope may cause tissue damage,

bleeding or perforation.

1 Elastography is not available with the diagnostic

ultrasound system (Hitachi Aloka Medical, Ltd.) in

Canada.

• After using the endoscope reprocess it according to the

instructions given in Chapter 7, “Cleaning, Disinfection, and

Sterilization Procedures”. Using improperly or incompletely

reprocessed, the endoscope’s distal end damage may result.

• Do not pull the universal cord during an examination. The

endoscope connector will be pulled out from the output

socket of the light source and the endoscopic image will not

be visible.

• Do not coil the insertion tube or universal cord with a

diameter of less than 12 cm. Equipment damage can result.

• Do not attempt to bend the endoscope’s insertion section

with excessive force. Otherwise, the insertion section may be

damaged.

• Do not touch the electrical contacts inside the videoscope

cable connector. CCD damage may result.

• Do not apply shock to the distal end of the insertion section,

particularly the ultrasound transducer and the objective lens

surface at the distal end. Visual abnormalities may result.

• Do not hold the ultrasonic transducer when holding the

insertion tube. The ultrasonic transducer damage can result

and/or the ultrasonic image will be abnormal.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

9

Page 16

Important Information — Please Read Before Use

• Do not twist or bend the bending section with your hands.

• Do not squeeze the bending section forcefully. The covering

• Turn the video system center ON only when the videoscope

• The endoscope’s remote switches cannot be removed from

Equipment damage may result.

of the bending section may stretch or break and cause water

leaks.

cable is connected to both the video system center and the

videoscope cable connector on the endoscope. In particular,

confirm that the video system center is OFF before

connecting or disconnecting the videoscope cable from the

electrical connector on the endoscope. Failure to do so can

result in equipment damage, including destruction of the

CCD.

the control section. Pressing, pulling, or twisting them with

excessive force can break the switches and/or cause water

leaks.

• If remote switch 1 does not return to the OFF position after

being pressed strongly from the side, gently pull the switch

upwards to return it to the OFF position.

• Do not hit or bend the electrical contacts on the endoscope

connector. The connection to the light source may be

impaired and faulty contact can result.

• Do not touch the electrical contacts in the ultrasonic cable

connector. Equipment damage can result.

• Do not pull, twist or tightly coil the ultrasonic cable. Noise can

develop in the ultrasound image.

• Electromagnetic interference may occur on this instrument

near equipment marked with the following symbol or other

portable and mobile RF (radio frequency) communications

equipment such as cellular phones. If electromagnetic

interference occurs, mitigation measures may be necessary,

such as reorienting or relocating this instrument, or shielding

the location.

10

• To check the electromagnetic interference from other

equipment (any equipment other than this instrument or the

components that constitute this system), the system should

be observed to verify its normal operation in the configuration

in which it will be used.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 17

Important Information — Please Read Before Use

• To prevent unnecessary patient exposure to ultrasound

radiation, follow the ‘as-low-as-reasonably achievable’

(ALARA) principle when using ultrasound equipment. Freeze

the image whenever you are not actively viewing the “live”

ultrasound image. When the equipment is in the FREEZE

mode, no ultrasound energy is emitted.

• It is highly recommended that a backup ultrasonic cable be

available to continue clinical procedures in case of a

malfunction.

• This endoscope contains a memory chip that stores

information about the endoscope and communicates this

information to the video system center CV-160 and CV-180.

Examples of inappropriate handling

Details on clinical endoscopic technique are the responsibility of trained

specialists. Patient safety in endoscopic examinations and endoscopic treatment

can be ensured through appropriate handling by the physician and the medical

facility. Examples of inappropriate handling are described below.

• Over-insufflating the lumen may cause patient pain, injury, bleeding,

and/or perforation.

• Applying suction with the distal end in prolonged contact with the

mucosal surface, with higher suction pressure than required, or with

prolonged suction time may cause bleeding and/or lesions.

• The endoscope has not been designed for use in retroflexed

observation in parts of the body other than the stomach. Performing

retroflexed observation in a narrow lumen may make it impossible to

straighten the angle of the bending section and/or withdraw the

endoscope from the patient. Retroflexed observation in parts of the body

other than the stomach should be performed only when the usefulness

of doing so is determined to be greater than the risk that is posed to the

patient.

• Inserting, withdrawing, and using EndoTherapy accessories without a

clear endoscopic image may cause patient injury, burns, bleeding,

and/or perforation.

• Inserting or withdrawing the endoscope, feeding air, applying suction, or

operating the bending section without a clear endoscopic image may

cause patient injury, bleeding, and/or perforation.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

11

Page 18

Important Information — Please Read Before Use

• For reasons described below, do not rely on the NBI

alone for primary detection of lesions or to make a decision regarding

any potential diagnostic or therapeutic intervention.

NBI has not been demonstrated to increase the yield or

sensitivity of finding any specific mucosal lesion including

colonic polyps or Barrett’s esophagus.

NBI has not been demonstrated to aid in differentiating

establishing the presence or absence of dysplasia or

neoplastic changes within mucosa or mucosal lesions.

1 NBI stands for Narrow Band Imaging. For more details,

refer to the instruction manual for the video system

center CV-180.

Natural rubber latex medical alert

Balloons used with this instrument contain natural rubber

latex that may cause allergic reactions.

Do not use the balloon on a latex-sensitive patient. Instead,

perform the procedure using “The sterile deaerated water

immersion method” described in Section 4.2, “Observation of

the ultrasound image” on page 64, in Chapter 4, “Operation”.

1

observation mode

12

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 19

Chapter 1 Checking the Package Contents

Chapter 1 Checking the Package

Contents

1.1 Standard components

Match all items in the package with the components shown below. Inspect each

item for damage. If the instrument is damaged, a component is missing, or you

have any questions, do not use the instrument; immediately contact Olympus.

This instrument was not disinfected or sterilized before shipment. Before using

this instrument for the first time, reprocess it according to the instructions given

in Chapter 7, “Cleaning, Disinfection, and Sterilization Procedures”.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

13

Page 20

Chapter 1 Checking the Package Contents

Ultrasound endoscope

Balloon 3 for the USA

(MAJ-249 sterile, 20 pcs.)

Balloon for countries other

than the USA (MAJ-213,

nonsterile, 20 pcs.)

Mouthpiece

(MB-142, 2 pcs.)

Single use channel cleaning

brush for the USA

(BW-201T, 3 pcs.

1

)

Channel cleaning brush for

countries other than the USA

(BW-20T, 1 pcs.)

Channel cleaning brush

(BW-7L, 2 pcs.

1

)

Single use single-ended

cleaning brush

(BW-400L, 3 pcs.

1

)

Water-resistant cap

(MH-553, 2 pcs.)

Washing tube

(MH-974)

Chain for water-resistant cap

(MAJ-1739)

Air/water channel cleaning adapter

(MAJ-629)

Instruction manual

Suction cleaning adapter

(MH-856)

Single use channel-opening cleaning

brush for the USA

(MAJ-1339, 3 pcs.

1

)

Channel-opening cleaning brush for

countries other than the USA

(MH-507, 1 pcs.)

Balloon applicator

(MAJ-675)

Biopsy valve

(MAJ-853, nonsterile, 10 pcs.)

Cleaning adapter for instrument

channel port (MAJ-350)

Injection tube

(MH-946)

Channel plug

(MAJ-621)

Cleaning brush

(MAJ-1534)

1 These products may not be available in some areas.

Single use combination

cleaning brush

(BW-412T, 3 pcs.

1

)

14

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 21

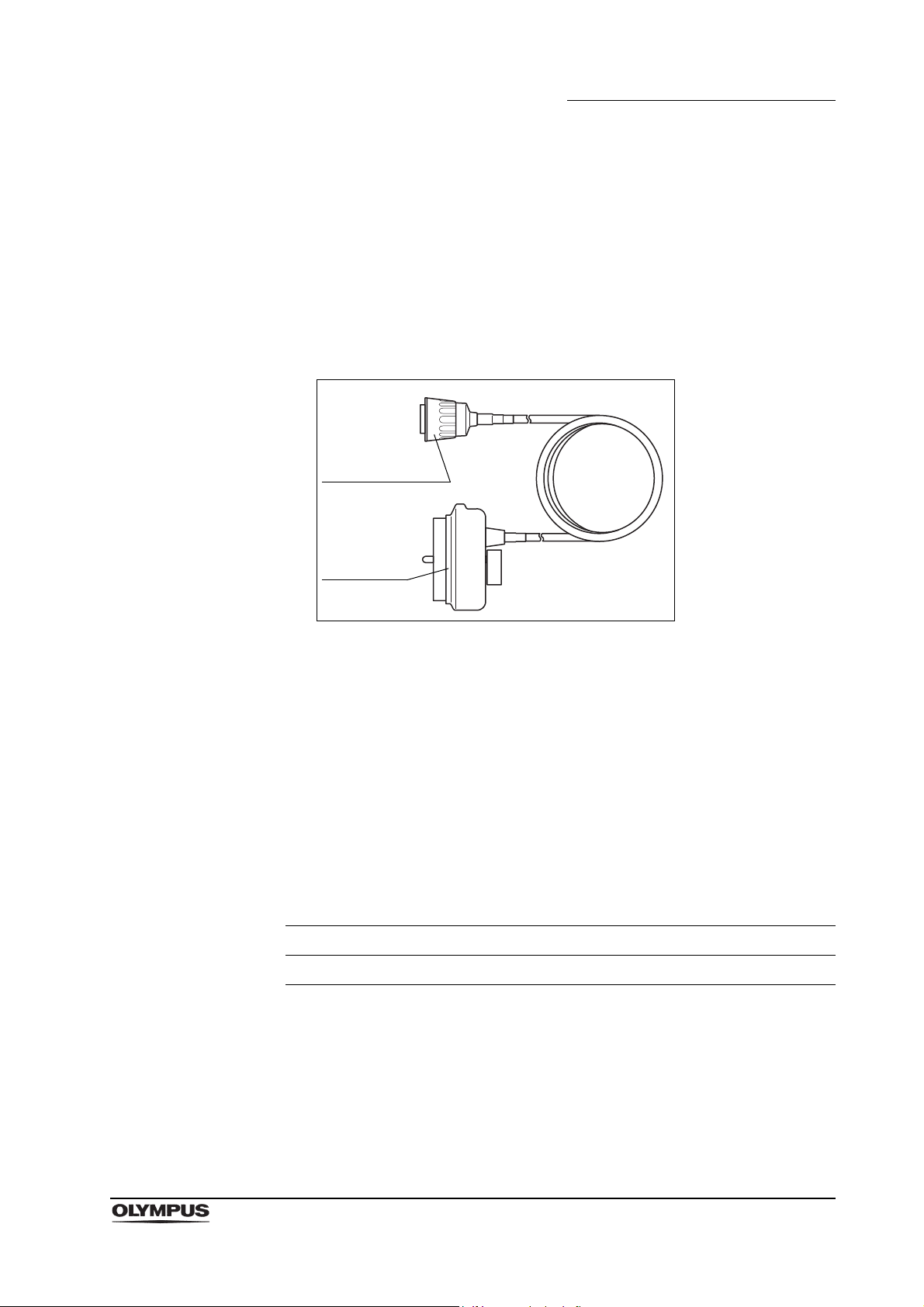

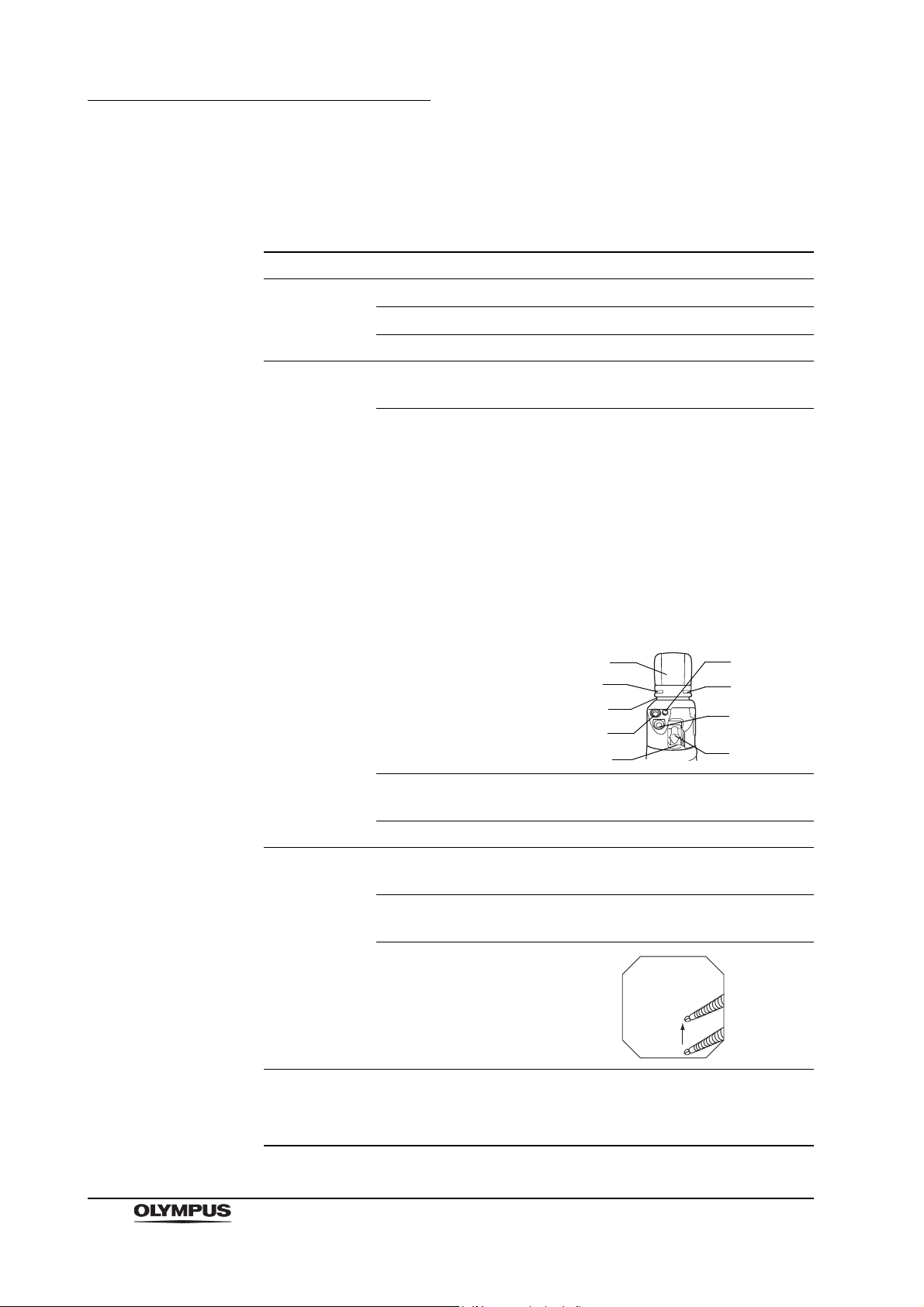

1.2 Ultrasonic cable

Ultrasonic cable

(MAJ-1597)

Endoscope-side

connector

Ultrasound

connector

The ultrasonic cable (MAJ-1597) is necessary to use this endoscope

(GF-UCT180), but it must be purchased separately (optional) from Olympus.

For Olympus universal endoscopic ultrasound center

EU-ME1 and the diagnostic ultrasound system (ALOKA

CO., LTD)

Chapter 1 Checking the Package Contents

1.3 Optional components

The item listed below is optional for countries other than the USA, and may be

purchased from Olympus.

Balloon 3

Balloon 3 is shipped sterile in sets of 20 pieces, enclosed in a resealable

package. The correct model to be used with this endoscope is listed in Table 1.1

below.

Endoscope Balloon 3

GF-UCT180 MAJ-249

Table 1.1

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

15

Page 22

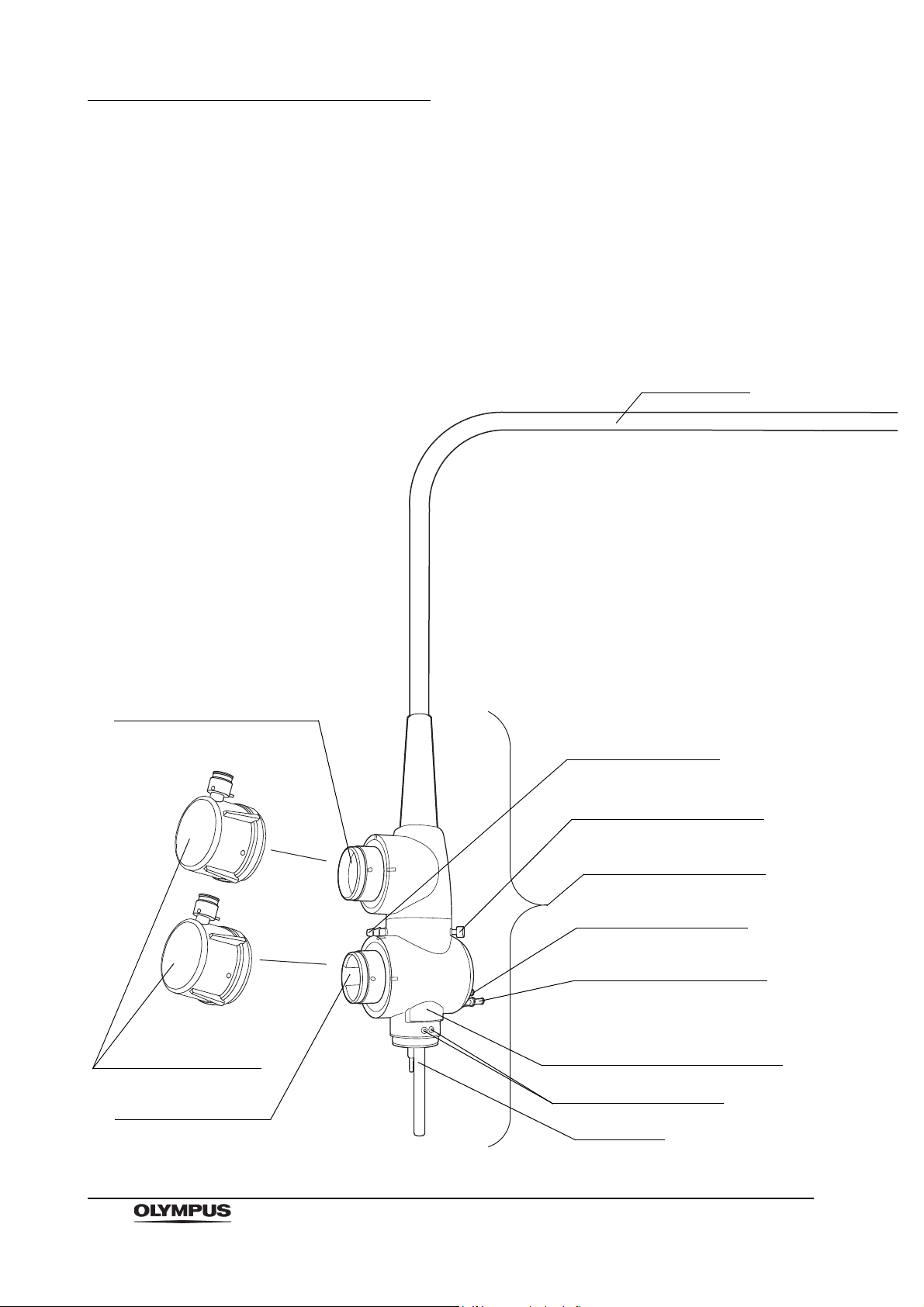

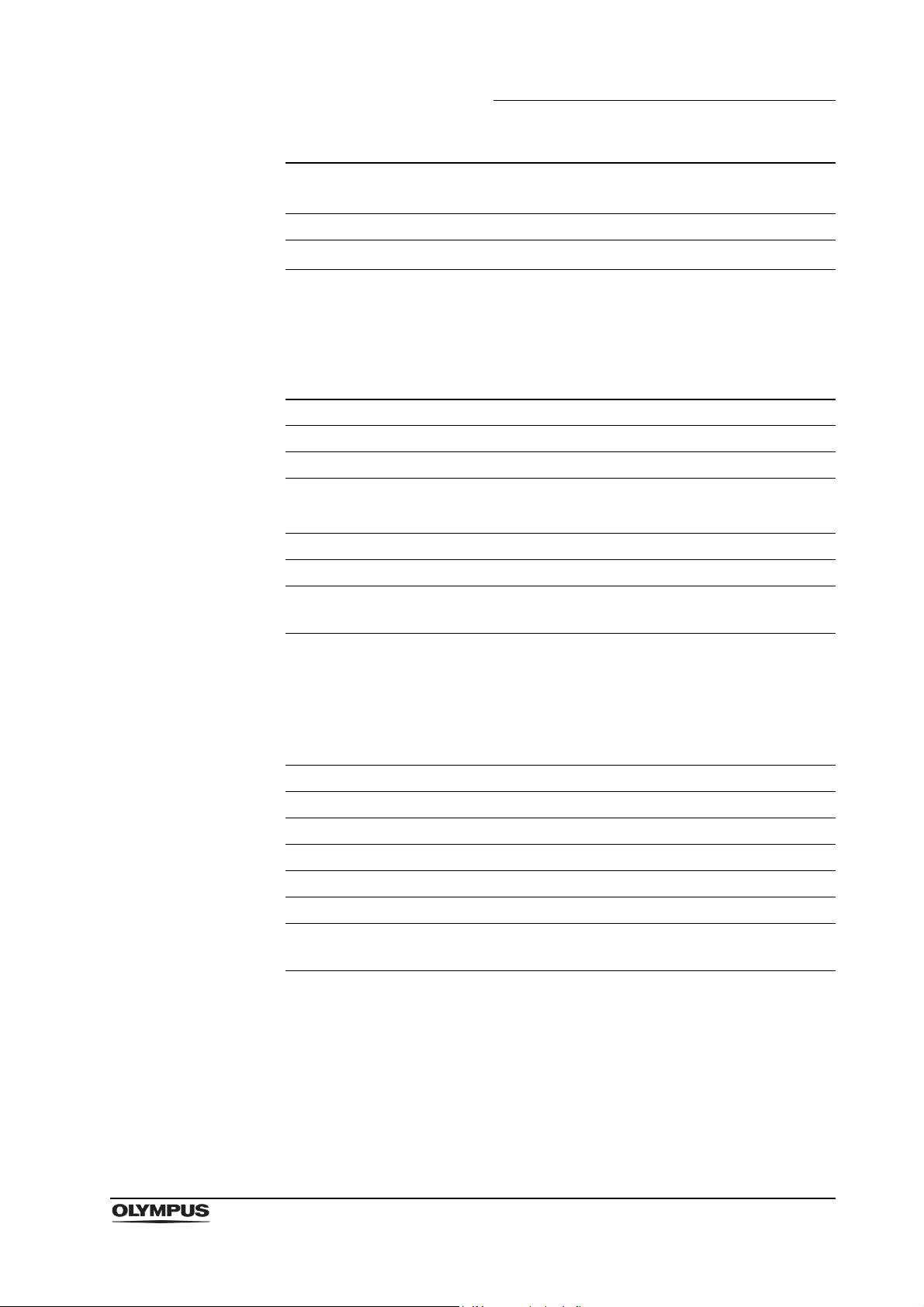

Chapter 2 Instrument Nomenclature and Specifications

Universal cord

Product number and serial number

Electrical contact points

4. Endoscope connector

Light guide

1. Ultrasonic cable connector

6. Videoscope cable

connector

Water-resistant cap

(MH-553)

2. Suction connector

3. S-cord connector mount

5. Air supply connector

5. Water supply connector

Chapter 2 Instrument Nomenclature

and Specifications

2.1 Nomenclature

16

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 23

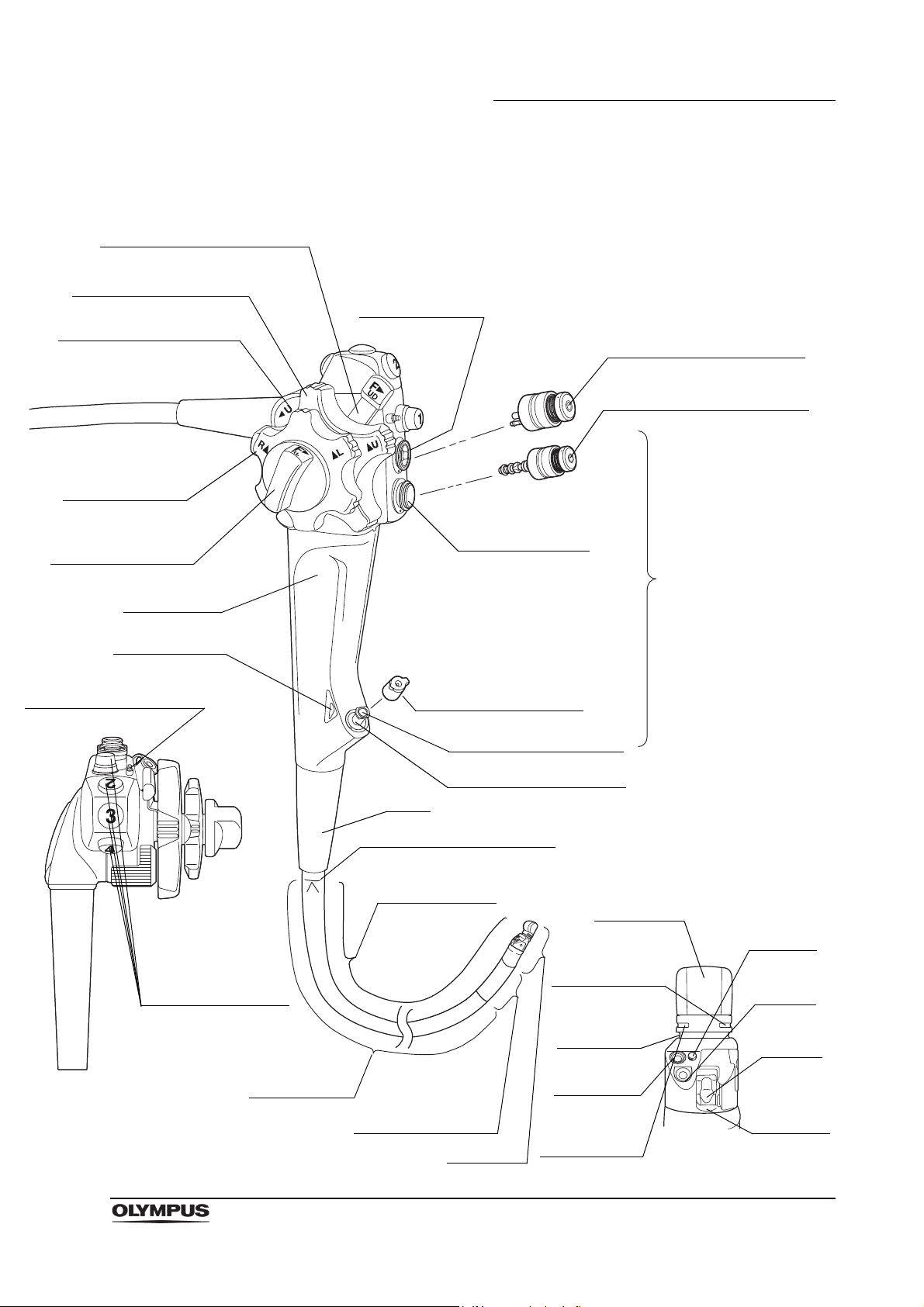

Control

section

Top view

Suction cylinder

11. Air/water valve (MAJ-1444)

9. UP/DOWN angulation lock

7. Elevator control lever

8. UP/DOWN angulation

control knob

18. Color code

17. Elevator channel plug

20. RIGHT/LEFT

angulation

control knob

19. RIGHT/LEFT

angulation lock

Grip section

Boot

Insertion section

Insertion tube

Distal end

14. Bending section

Instrument channel port

12. Instrument channel

Air/water cylinder

Biopsy valve (MAJ-853)

Insertion section limit mark

16. Remote

switches 1 to 4

10. Suction valve (MAJ-1443)

Air/water

nozzle

Detail of distal end

Objective

lens

Forceps

elevator

Instrument

channel

outlet

Light guide

lens

Balloon

attachment

groove

Balloon water

supply port is in

this groove

Ultrasound

transducer

Balloon water

suction port is

in this groove

Chapter 2 Instrument Nomenclature and Specifications

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

17

Page 24

Chapter 2 Instrument Nomenclature and Specifications

2.2 Endoscope functions

1. Ultrasonic cable connector

Connects the ultrasonic cable of the ultrasound diagnostic equipment to the

endoscope.

2. Suction connector

Connects the endoscope to the suction tube of the suction pump.

3. S-cord connector mount

Connects the endoscope with the Olympus electrosurgical unit via the

S-cord. The S-cord conducts leakage current from the endoscope to the

electrosurgical unit. To connect the S-cord, refer to the instruction manual

for the electrosurgical unit. Connect the fitting part of the chain for

water-resistant cap to this mount, as required (see Section 2.4, “Attaching

the chain for water-resistant cap (MAJ-1739)” on page 25).

4. Endoscope connector

Connects the endoscope to the output socket of the light source and

transmits light from the light source to the endoscope.

5. Water supply connector and air supply connector

Connects the endoscope to the water container via the water container tube

to supply water to the distal end of the endoscope.

6. Videoscope cable connector

Connects the endoscope to the video system center via the videoscope

cable. The endoscope contains a memory chip that stores information about

the endoscope and communicates this information to the video system

center CV-160, CV-180. For more details, refer to the instruction manual for

the CV-160, CV-180.

7. Elevator control lever

When this lever is moved in the “ U” direction, the forceps elevator is

raised; when the lever is moved in the opposite direction, the forceps

elevator is lowered.

8. UP/DOWN angulation control knob

When this knob is turned in the “ U” direction, the bending section moves

UP; when the knob is turned in the “D ” direction, the bending section

moves DOWN.

9. UP/DOWN angulation lock

Moving this lock in the “F ” direction frees angulation. Moving the lock in

the opposite direction locks the bending section at any desired position.

18

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 25

Chapter 2 Instrument Nomenclature and Specifications

10. Suction valve (MAJ-1443)

The suction valve is depressed to the first stage to activate suction. The

valve is also used to remove any fluid or debris adhering to the objective

lens.

The suction valve is depressed completely to activate suction of sterile

water from the balloon through the balloon channel.

11. Air/water valve (MAJ-1444)

The hole in the air/water valve is covered to insufflate air and the valve is

depressed to the first stage to feed water for lens washing. It also can be

used to feed air to remove any fluid or debris adhering to the objective lens.

The valve is depressed completely to fill the balloon with sterile water

through the balloon channel.

12. Instrument channel

The instrument channel functions as:

channel for the insertion of EndoTherapy accessories

suction channel

Fluid feed channel (from a syringe via the biopsy valve)

13. Insertion section limit mark

This mark shows the maximum point to which the endoscope may be

inserted into the patient’s body.

14. Bending section

This section moves the distal end of the endoscope when the UP/DOWN

and RIGHT/LEFT angulation control knobs are operated.

15. Forceps elevator

The elevator moves EndoTherapy accessories when the elevator control

lever is operated.

16. Remote switches 1 to 4

The functions of remote switches 1 to 4 can be selected on the video system

center. Refer to the instruction manual for the video system center when

setting these functions.

17. Elevator channel plug

This plug is used for connection of the washing tube to clean and disinfect

the elevator channel.

18. Color code (orange)

This code is used to quickly determine the compatibility of EndoTherapy

accessories. The endoscope can be used with EndoTherapy accessories

that have the same color code. For more information on combining the

endoscope with particular EndoTherapy accessories, refer to the “System

chart” in the Appendix and the instruction manuals for the compatible

accessories.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

19

Page 26

Chapter 2 Instrument Nomenclature and Specifications

19. RIGHT/LEFT angulation lock

Turning this lock in the “F ” direction frees angulation. Turning the lock in

the opposite direction locks the bending section at any desired position.

20. RIGHT/LEFT angulation control knob

When this knob is turned in the “R ” direction, the bending section moves

RIGHT; when the knob is turned in the “ L” direction, the bending section

moves LEFT.

20

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 27

2.3 Specifications

Environment

Chapter 2 Instrument Nomenclature and Specifications

Operating

environment

Transportation

and storage

environment

Ambient temperature 10 – 40C (50 – 104F)

Relative humidity 30 – 85%

Atmospheric

pressure

Ambient temperature –47 to 70C (–52.6 to 158F)

Relative humidity 10 – 95%

Atmospheric

pressure

700 – 1060 hPa

(0.7 – 1.1 kgf/cm

(10.2 – 15.4 psia)

700 – 1060 hPa

(0.7 – 1.1 kgf/cm

(10.2 – 15.4 psia)

2

)

2

)

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

21

Page 28

Chapter 2 Instrument Nomenclature and Specifications

6.

7.

9.

3.

2.

4.

5.

1.

8.

Specifications

Endoscope functions

Model GF-UCT180

Optical system Field of view

100

Direction of view

Depth of field 3 – 100 mm

Insertion tube Distal end outer

diameter

Distal end enlarged 1. Air/water nozzle

55

forward oblique

ø 14.6 mm

2. Objective lens

3. Light guide lens

4. Forceps elevator

5. Instrument channel outlet

6. Ultrasonic transducer

7. Balloon water supply port

8. Balloon suction port

9. Balloon attachment groove

Insertion tube outer

diameter

Working length 1250 mm

Instrument

channel

Airflow rate

22

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Channel inner

diameter

Minimum visible

distance

Direction from which

EndoTherapy

accessories enter

and exit the

endoscopic image

6 mm from the objective lens

Note: Standard when CLV-180 (high air

pressure) is used.

ø 12.6 mm

ø3.7mm

3

20 cm

/s

Page 29

Chapter 2 Instrument Nomenclature and Specifications

Bending

section

Total l e ngth 1555 mm

NBI observation mode

Angulation range

1

UP 130

, DOWN 90,

RIGHT 90

Available

, LEFT 90

1 For more details, refer to the instruction manual for the CV-180.

Ultrasound function with ALOKA diagnostic ultrasound

system SSD-10/ProSound 71/ProSound F75

Operation mode B-mode, M-mode, D-mode, Bflow mode, Powerflow mode

Scanning method Electronic curved linear array

Scanning direction Parallel to the insertion direction

Receiving frequency

Scanning range 180

Contacting method Balloon method, Direct contact method

Transducer surface

max. temperature

5, 6, 7.5, 10 MHz (SSD-10/ProSound F75

4, 6.67, 10, 13.3 MHz (ProSound 7)

43C >

1

1

)

1

1 These products may not be available in some areas.

Ultrasound function with Olympus universal endoscopic

ultrasound center EU-ME1

Operation mode B mode, color flow mode, power flow mode

Scanning method Electronic curved linear array

Scanning direction Parallel to the insertion direction

Receiving frequency 5, 6, 7.5, 10, 12 MHz

Scanning range 180

Contacting method Balloon method, Direct contact method

Transducer surface

max. temperature

43C >

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

23

Page 30

Chapter 2 Instrument Nomenclature and Specifications

1912345

General safety

standard for medical

electrical equipment

Medical Devices

Directive

EMC Applied standards;

Year of manufacture

IEC 60601-1: 2005 Whole of this instrument is possible

IEC 60601-1-2: 2007

IEC 60601-2-37: 2007

to contact live bodies of operators or

patients.

This device complies with the

requirements of Directive 93/42/EEC

concerning medical devices.

Classification: Class II a

This instrument complies with the

standards listed in the left column.

CISPR 11 of emission:

Group 1, Class B

This instrument complies with the

EMC standard for medical electrical

equipment, edition 3 (IEC 60601-1-2:

2007). However, when connecting to

an instrument that complies with the

EMC standard for medical electrical

equipment, edition 1 (IEC 60601-1-2:

1993), the whole system complies

with edition 1.

The last digit of the year of

manufacture is given in the second

digit of the serial number.

24

Degree of protection

against electric

shock

Ingress protection

rating

IPX7 This instrument complies with the

TYPE BF applied part

standards for medical electrical

equipment: IEC 60601-1: 2005

IEC 60601-2-37: 2007.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 31

Chapter 2 Instrument Nomenclature and Specifications

2.4 Attaching the chain for water-resistant cap (MAJ-1739)

• Do not lift the endoscope by the chain for water-resistant cap.

Doing so may result in the fitting part of the chain detaching

from the S-cord connector mount, causing the endoscope to

fall. This could cause operator or patient injury and/or

equipment damage.

• Connect the fitting part only to the S-cord connector mount.

Connecting the fitting part to the suction connector may

impair the connection of the suction tube to the suction

connector. It may also cause the suction tube to become

disconnected from the endoscope and allow patient debris to

spray.

• The chain for water-resistant cap and water-resistant cap

itself cannot be ultrasonically cleaned; doing so could

damage them. The water-resistant cap with the chain can

only be ultrasonically cleaned if connected to endoscopes

that are being cleaned in an endoscope reprocessor (such as

1

OER

• Connecting the fitting part to the suction connector may

impair the connection of the suction tube to the suction

connector. It may also cause the suction tube to become

disconnected from the endoscope and allow patient debris to

spray.

• When attaching the water-resistant cap to the connector of

the endoscope, do not pinch the chain for water-resistant cap

between the connector of the endoscope and the

water-resistant cap. Otherwise, equipment damage may

result.

• The chain for water-resistant cap and water-resistant cap

cannot be steam sterilized (autoclaved); doing so can

damage them severely.

, OER-A1) with an ultrasonic cleaning phase.

1 These products may not be available in some areas.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

25

Page 32

Chapter 2 Instrument Nomenclature and Specifications

Notch

Chain part

Fitting part

Connecting plate

Hole

Connecting plate

Notch

Pin

Venting connector

Water-resistant cap

Figure 2.1

To ensure that you do not forget to attach the water-resistant

cap, it is recommended that you connect the chain for

water-resistant cap to the endoscope’s S-cord connector

mount.

1. Confirm that the chain for water-resistant cap is free from cracks, flaws,

wear, deformation, or other damages (see Figure 2.1).

2. Align the notch on the connecting plate with the pin on the venting connector

of the water-resistant cap (MH-553, see Figure 2.2).

3. Place the connecting plate over the venting connector (see Figure 2.2).

4. Confirm that the connecting plate is securely attached to the foot of the

venting connector and can be smoothly rotated.

5. Place the hole on the fitting part over the endoscope’s S-cord connector

mount.

26

Figure 2.2

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 33

Chapter 2 Instrument Nomenclature and Specifications

The instructions on the remaining pages of this manual are

given under the assumption that the chain for water-resistant

cap is detached from the endoscope.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

27

Page 34

Chapter 3 Preparation and Inspection

Chapter 3 Preparation and Inspection

Before each procedure, prepare and inspect this instrument as instructed below.

Inspect other equipment to be used with this instrument as described in their

respective instruction manuals. If this instrument malfunctions, do not use it.

Return it to Olympus for repair as described in Section 10.3, “Returning the

endoscope for repair” on page 161. If any irregularities are suspected after

inspection, follow the instructions given in Chapter 10, “Troubleshooting”.

• This instrument was not cleaned, disinfected, or sterilized

before shipment. Before using this instrument for the first

time, reprocess it according to the instructions given in

Chapter 7, “Cleaning, Disinfection, and Sterilization

Procedures”.

• Using an instrument that is not functioning properly may

compromise patient or operator safety and may result in

more severe equipment damage.

Do not pull the universal cord or the ultrasonic cable with

excessive force when the endoscope is connected to the

other equipment. Doing so could cause equipment damage.

28

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 35

3.1 Preparation of the equipment

mouthpiece

Monitor

Video system center

Light source

Water container

Suction pump

Ultrasound endoscope

Olympus universal endoscopic

ultrasound center EU-ME1 or

ALOKA diagnostic ultrasound

system

Ultrasonic cable

EndoTherapy accessories

Prepare the equipment shown in Figure 3.1 (for compatibility, see the “System

chart” in the Appendix) and personal protective equipment, such as eyewear,

face mask, moisture-resistant clothing, and chemical-resistant gloves that fit

properly and are long enough so that your skin is not exposed. Refer to the

respective instruction manuals for each piece of equipment.

Chapter 3 Preparation and Inspection

• Paper towels • Trays • Lint-free cloths • Personal protective equipment

• 3-way stopcock • Syringe • Extension tube • Sterile deaerated water

• Medical-grade, water-soluble lubricant

Figure 3.1

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

29

Page 36

Chapter 3 Preparation and Inspection

3.2 Inspection of the endoscope

Clean and disinfect or sterilize the endoscope as described in Chapter 7,

“Cleaning, Disinfection, and Sterilization Procedures” and Chapter 8, “Cleaning

and Disinfection Equipment” of this manual. Then remove the water-resistant

cap from the endoscope connector.

Inspection of the endoscope

1.

Inspect the control section and the endoscope connector for excessive

scratching, deformation, loose parts, or other irregularities.

2. Inspect the boot and the insertion section near the boot for bends, twists, or

other irregularities.

3. Inspect the external surface of the entire insertion section including the

bending section and the distal end for dents, bulges, swelling, scratches,

holes, sagging, transformation, bends, adhesion of foreign bodies, missing

parts, protruding objects, or other irregularities.

4. Gently holding the insertion section with one hand, carefully run your other

hand back and forth over the entire length of the insertion section (see

Figure 3.2). Confirm that no objects or metallic wire protrude from the

insertion section. Also, confirm that the insertion tube is not abnormally rigid.

Figure 3.2

30

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 37

Chapter 3 Preparation and Inspection

5. Using both hands, bend the insertion tube of the endoscope into a

semicircle. Then, moving your hands as shown by the arrows in Figure 3.3,

confirm that the entire insertion tube can be smoothly bent to form a

semicircle and that the insertion tube is pliable.

Figure 3.3

6. Gently hold the midpoint of the bending section and a point 20 cm from the

distal end. Push and pull gently to confirm that the junction between the

bending section and the insertion tube is not loose.

7. Inspect the objective lens and light guide lens at the distal end of the

endoscope’s insertion section for scratches, cracks, stains, or other

irregularities.

8. Inspect the air/water nozzle at the distal end of the endoscope’s insertion

section for abnormal swelling, bulges, dents, or other irregularities.

9. Inspect the ultrasound transducer surface at the distal end of the

endoscope’s insertion tube for scratching, cracks, bulges, dents or other

irregularities.

Inspection of the bending mechanisms

Perform the following inspections while the bending section is straight.

If the movement of the UP/DOWN angulation lock,

RIGHT/LEFT angulation lock, and the angulation control

knobs are loose and/or not smooth, or the bending section

does not angulate smoothly, the bending mechanism may be

abnormal. In this case, do not use the endoscope because it

may be impossible to straighten the bending section during

an examination.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

31

Page 38

Chapter 3 Preparation and Inspection

Inspection for smooth operation

1. Confirm that both the UP/DOWN and RIGHT/LEFT angulation locks move

all the way in the “F ” direction.

2. Turn the UP/DOWN and RIGHT/LEFT angulation control knobs slowly in

each direction until they stop, and return them to their respective neutral

positions. Confirm that the bending section angulates smoothly and

correctly, that maximum angulation can be achieved, and that the bending

section returns to its neutral position.

3. When the UP/DOWN and RIGHT/LEFT angulation control knobs are turned

to their respective neutral positions as shown in Figure 3.4, confirm that the

bending section returns smoothly to an approximately straight condition.

Figure 3.4

Inspection of the UP/DOWN angulation mechanism

1. Move the UP/DOWN angulation lock all the way in the opposite direction of

the “F ” mark. Then turn the UP/DOWN angulation control knob in the

“ U” or the “D ” direction until it stops.

2. Confirm that the angle of the bending section is roughly stabilized when the

UP/DOWN angulation control knob is released.

3. Confirm that the bending section straightens out when the UP/DOWN

angulation lock is moved all the way in the “F ” direction and the

UP/DOWN angulation control knob is released.

32

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 39

Chapter 3 Preparation and Inspection

Inspection of the RIGHT/LEFT angulation mechanism

1. Turn the RIGHT/LEFT angulation lock all the way in the opposite direction of

the “F ” mark. Then turn the RIGHT/LEFT angulation control knob in the

“R ” or the “ L” direction until it stops.

2. Confirm that the angle of the bending section is roughly stabilized when the

RIGHT/LEFT angulation control knob is released.

3. Confirm that the bending section straightens out when the RIGHT/LEFT

angulation lock is turned in the “F ” direction and the RIGHT/LEFT

angulation control knob is released.

Inspection of the forceps elevator mechanism

Perform the following inspections while the bending section is straight.

Move the elevator control lever slowly in the opposite

direction of the “ U” direction until it stops and visually

confirm that the portion of the elevator wire extending from

the distal end of the insertion section is not broken or bent. If

the elevator wire is broken or bent, patient injury, bleeding,

and/or perforation could result.

Inspection for smooth operation

1. Move the elevator control lever slowly all the way in the opposite direction of

the “ U” direction. Visually confirm that the portion of the elevator wire

extending from the distal end of the insertion section is not broken or bent

(see Figure 3.5).

2. While observing the forceps elevator at the distal end of the insertion

section, slowly move the elevator control lever all the way in the “ U”

direction. Confirm that the lever can be operated smoothly and that the

forceps elevator is raised smoothly. Also confirm that the forceps elevator

remains stationary when pushed from behind while holding the elevator

control lever stationary (see Figure 3.5).

3. Move the elevator control lever slowly all the way in the opposite direction of

the “ U” direction. Confirm that the lever can be operated smoothly and

that the forceps elevator is lowered smoothly (see Figure 3.5).

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

33

Page 40

Chapter 3 Preparation and Inspection

Forceps elevator

Elevator control lever

Figure 3.5

3.3 Preparation and inspection of accessories

Clean and disinfect or sterilize the air/water valve, suction valve, biopsy valve as

described in Chapter 7, “Cleaning, Disinfection, and Sterilization Procedures”.

Inspection of the air/water and suction valves

Confirm that the top hole of the air/water valve is not blocked

(see Figure 3.6). If the hole is blocked, air is fed continuously

and patient pain, bleeding, and/or perforation can result.

1. Confirm that the holes of the valves are not blocked (see Figures 3.6 and

3.7).

2. Confirm that the valves are not deformed or cracked (see Figures 3.6 and

3.7).

3. Check for excessive scratching or tears in the air/water valve’s seals (see

Figure 3.6).

34

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 41

Figure 3.6

Air/water valve (MAJ-1444)

Skirt

Seal

Packings

Spring

Cap

Top view

Hole

Suction valve (MAJ-1443)

Skirt

Packing

Hole

Spring

Cap

Chapter 3 Preparation and Inspection

Figure 3.7

The air/water and suction valves are consumables. If the

inspection of the air/water or suction valve reveals any

irregularity, use new valves.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

35

Page 42

Chapter 3 Preparation and Inspection

Normal Abnormal

Slit

Hole

Main body

Cap

Splits, cracks

Discoloration

Slit

Main body

Cap

Inspection of the biopsy valve

1. Confirm that the slit and hole on the biopsy valve have no splits, cracks,

deformations, discoloration, or other damage (see Figure 3.8).

The biopsy valve is a consumable that should be inspected

as follows before each use. Replace it with a new one if any

irregularity is observed during the inspection. An irregular,

abnormal, or damaged valve can reduce the efficacy of the

endoscope’s suction system, and may leak or spray patient

debris or fluids, posing an infection control risk.

Figure 3.8

2. Attach the cap to the main body (see Figure 3.9).

Figure 3.9

36

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 43

Inspection of the mouthpiece

Opening

Outer flange

Main body

Do not use a mouthpiece that is damaged, deformed, or

reveals other irregularities. Doing so may cause patient injury

and/or equipment damage.

Placing the mouthpiece in the patient’s mouth before the

procedure prevents the patient from biting and/or damaging

the endoscope’s insertion section.

1. Confirm that the mouthpiece is free from cracks, deformations, or

discoloration (see Figure 3.10).

2. Using your fingers, check all surfaces of the mouthpiece for scratches,

cracks, or other irregularities (see Figure 3.10).

Chapter 3 Preparation and Inspection

Figure 3.10

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

37

Page 44

Chapter 3 Preparation and Inspection

Suction valve

Suction cylinder

Skirt

Moving surface

3.4 Attaching accessories to the endoscope

The air/water valve and the suction valve do not require

lubrication. Lubricants can cause swelling of the valves’

seals, which will impair valve function.

Attaching the suction valve

Attach the suction valve (MAJ-1443) to the suction cylinder of the endoscope

(see Figure 3.11). Confirm that valve is fitted properly without any bulging of the

skirt.

Figure 3.11

The suction valve will make a whistling noise when it is dry;

this does not indicate a malfunction.

38

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 45

Attaching the air/water valve

Skirt

Air/water cylinder

Air/water valve

Biopsy valve

Instrument

channel port

Attach the air/water valve (MAJ-1444) to the air/water cylinder of the endoscope

(see Figure 3.12). Confirm that valve is fitted properly without any bulging of the

skirt.

Chapter 3 Preparation and Inspection

Figure 3.12

The air/water valve may stick at first, but it should operate

smoothly after it is depressed a few times.

Attaching the biopsy valve

If a biopsy valve is not properly connected to the instrument

channel port, it can reduce the efficacy of the endoscope’s

suction system, and leak or spray patient debris, posing an

infection control risk.

Attach the biopsy valve to the instrument channel port of the endoscope (see

Figure 3.13). Confirm that the biopsy valve fits properly.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Figure 3.13

39

Page 46

Chapter 3 Preparation and Inspection

3.5 Inspection and connection of ancillary equipment

Inspection of ancillary equipment

• Attach the water container to the specified receptacle on the

trolley (cart) or the light source. If the water container is

attached anywhere else, water may drip from the water

container’s water supply tube, and equipment malfunction

can result.

• Take care not to spill water from the water container’s

connection adapter when detaching the connection adapter

from the endoscope. Spilled water could splash on the

equipment, and may cause equipment malfunction.

1. Prepare and inspect the light source, video system center, ultrasound

diagnostic equipment, monitor, water container, suction pump, and

EndoTherapy accessories as described in their respective instruction

manuals.

2. Confirm that there are no scratches, cracks, excessive wear, or deformation

of the ultrasonic cable.

Connection of the ultrasonic cable (MAJ-1597) and Olympus universal endoscopic ultrasound center

Insert the ultrasonic connector properly into the transducer port of the Olympus

universal endoscopic ultrasound center. Rotate the connector’s lock handle 1/4

turn clockwise (see Figure 3.14).

40

Figure 3.14

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 47

Chapter 3 Preparation and Inspection

Connection of the ultrasonic cable (MAJ-1597) and ALOKA diagnostic ultrasound system

Insert the ultrasound connector properly into the transducer port of the

diagnostic ultrasound system. Rotate the connector’s lock handle 1/4 turn

clockwise (see Figure 3.15).

Connect the Ultrasound connector to one of the probe

connectors on the lower side (PROBE 3 or 4) of the

ProSound F75 (see Figure 3.15).

If the Ultrasound connector is connected to one of the probe

connectors on the upper side (PROBE 1 or 2) , the operation

panel of the ProSound F75 may hit the Ultrasound connector,

which may result in the equipment damage. When adjusting

the height, a horizontal and / or vertical position of the

operation panel of the ProSound F75 with the Ultrasound

connector connected to the PROBE 1 or 2, move slowly the

operation panel with visually confirming the position of the

bottom of the operation panel.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

41

Page 48

Lock handle

Ultrasound connector

Transducer port

SSD-10

ProSound 7

1

1 These products may not be available in some areas.

Lock handle

Ultrasonic connector

ProSound F75

1

PROBE 1

PROBE 2

PROBE 4

Lock handle

Ultrasound connector

PROBE 3

Chapter 3 Preparation and Inspection

Figure 3.15

42

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 49

Chapter 3 Preparation and Inspection

Connection of the endoscope and ancillary equipment

Firmly connect the suction tube from the suction pump to the

suction connector on the endoscope connector. If the suction

tube is not attached properly, debris may drip from the tube

and can pose an infection control risk, cause equipment

damage, and/or reduce suction capability.

The electrical contacts inside the ultrasound connector may

be damaged by handling. Do not touch the electrical

contacts. If electrical contacts are dirty, wipe the contacts with

a soft and lint-free cloth.

1. If any ancillary equipment is ON, turn it OFF.

2. Insert the endoscope connector completely into the output socket of the light

source.

3. Make sure that the inside of the videoscope cable connector is dry and free

of debris.

4. Place the water container’s water supply channel onto the water supply

connector on the endoscope connector at an angle of 90 and push it in until

it stops (see Figure 3.16 (1)).

5. Turn the water container’s connection adapter 90 clockwise to align the air

supply channel with the air supply connector of the endoscope connector

(see Figure 3.16 (2)).

6. Push the water container’s connection adapter again until it stops (see

Figure 3.16 (3)).

7. Confirm that the water container’s connection adapter fits properly and that

it cannot be rotated (see Figure 3.16 (4)).

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

43

Page 50

Chapter 3 Preparation and Inspection

(1) (2) (3) (4)

Water supply connector

Air supply connector

Water container’s connection adapter

Endoscope connector

Air supply channel

Water supply channel

Metal tip

Mark (gray)

Mark 1 (gray)

Mark 2 (gray)

Figure 3.16

8. Align the mark on the videoscope cable with mark 1 on the endoscope

connector and push it in until it stops (see Figure 3.17).

Figure 3.17

44

9. Turn the connector of the videoscope cable towards mark 2 until it stops

(see Figure 3.17).

10. Confirm that the mark on the videoscope cable is aligned with mark 2 on the

endoscope connector.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 51

Chapter 3 Preparation and Inspection

Suction pump

Suction connector

Suction tube

11. Connect the suction tube from the suction pump to the suction connector on

the endoscope connector (see Figure 3.18).

Figure 3.18

Connection of the endoscope and ultrasonic cable

The electrical contacts inside the ultrasound connector have

sharp tips and may be damaged by handling. Do not touch

the electrical contacts.

For more information on combining the endoscope with the

ultrasonic cable, refer to the “System chart” in the Appendix.

When connect the endoscope-side connector of the

ultrasonic cable to the ultrasonic cable connector, do not

entwine the universal cord with the ultrasonic cable.

Equipment damage can result.

1. Make sure that the inside of the ultrasonic cable connector is dry and free of

debris.

2. Align the mark on the ultrasonic cable with mark A on the ultrasound

connector and push it until it stops (see Figure 3.19).

3. Turn the endoscope-side connector of the ultrasonic cable clockwise until it

stops (see Figure 3.19).

4. Confirm that the mark on the ultrasonic cable is aligned with mark B on the

endoscope connector (see Figure 3.19).

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

45

Page 52

Chapter 3 Preparation and Inspection

Mark A (red)

Mark B (red)

Mark (red)

Mark A (red)

Mark B (red)

Mark (red)

Endoscope-side connector of the ultrasonic cable

Figure 3.19

3.6 Inspection of the endoscopic system

Inspection of the endoscopic image

Do not stare directly into the distal end of the endoscope

while the examination light is ON. Otherwise, eye injury may

result.

1. Turn the video system center, light source, and monitor ON and inspect the

WLI and NBI endoscopic image as described in their respective instruction

manuals.

2. Confirm that light is output from the endoscope’s distal end.

3. While observing the palm of your hand, confirm that the WLI and NBI

endoscopic image is free from noise, blur, fog, or other irregularities.

4. Angulate the endoscope and confirm that the WLI and NBI endoscopic

image does not momentarily disappear or display any other irregularities.

46

If the object cannot be seen clearly, wipe the objective lens

using a clean, lint-free cloth moistened with 70% ethyl or

isopropyl alcohol.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 53

Inspection of the remote switches

All remote switches should be checked prior to the

examination, even when they are not expected to be used.

The endoscopic image may freeze, or other irregularities

may occur during examination and may cause patient injury,

bleeding, and/or perforation.

Depress every remote switch and confirm that the specified functions work

normally.

Inspection of the air-feeding function

1.

Set the airflow regulator on the light source to “High”, as described in the

light source’s instruction manual.

2. Immerse the distal end of the insertion section in sterile water to a depth of

10 cm and confirm that no air bubbles are emitted when the air/water valve

is not operated.

Chapter 3 Preparation and Inspection

3. Cover the hole in the air/water valve with your finger and confirm that air

bubbles are continuously emitted from the air/water nozzle.

4. Uncover the hole in the air/water valve and confirm that no air bubbles are

emitted from the air/water nozzle.

If a stream of air bubbles is emitted from the air/water nozzle

even though the air/water valve is not being operated and the

distal end of the insertion section is 10 cm or more below the

surface of the sterile water, there may be an irregularity in the

air-feeding function. If the endoscope is used while air is

continuously fed, over-insufflation and patient injury may

result. If air bubbles are emitted from the air/water nozzle,

remove and reattach the air/water valve correctly, or replace

it with a new one. If this fails to stop air bubbles from being

emitted, do not use the endoscope because there may be a

malfunction. Contact Olympus.

When the distal end of the insertion section is immersed less

than 10 cm below the surface of the sterile water, a small

amount of air bubbles may be emitted from the air/water

nozzle even when the air/water valve is not operated. This

does not indicate a malfunction.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

47

Page 54

Chapter 3 Preparation and Inspection

Inspection of the objective lens cleaning function

1. Keep the air/water valve’s hole covered with your finger and depress the

valve to the first stage. Observe the endoscopic image and confirm that

water flows on the entire objective lens.

Use sterile water only. Nonsterile water may cause patient

cross-contamination and/or infection.

• When the air/water valve is depressed for the first time, it

may take a few seconds before water is emitted.

• If the air/water valve returns to its original position slowly after

water feeding, remove the air/water valve and moisten the

seals with sterile water.

• During the inspection, place the distal end of the endoscope

in a beaker or other container so that the floor does not get

wet.

2. Release the air/water valve. While observing the endoscopic image, confirm

that the emission of water stops and that the valve returns smoothly to its

original position.

3. While observing the endoscopic image, feed air after feeding water by

covering the hole in the air/water valve with your finger. Confirm that the

emitted air removes the remaining water from the objective lens and clears

the endoscopic image.

Inspection of the water feeding function into the balloon

Cover the air/water valve’s hole and completely depress the valve. Confirm that

water is emitted through the balloon water supply port. It may take a few seconds

until water is emitted when the air/water valve is depressed for the first time.

48

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

Page 55

Inspection of the suction function

• If the suction valve does not operate smoothly, detach it and

reattach it, or replace it with a new one. If the endoscope is

used while the suction valve is not working properly, it may

be impossible to stop suction, which could cause patient

injury. If the reattached or replaced suction valve fails to

operate smoothly, the endoscope may be malfunctioning;

stop using it and contact Olympus.

• If the biopsy valve leaks, replace it with a new one. A leaking

biopsy valve can reduce the efficacy of the endoscope’s

suction system and may leak or spray patient debris or fluids,

posing an infection control risk.

1. Place the container of sterile water and the endoscope at the same height.

For the inspection, adjust the suction pressure to the same level as it will be

during the procedure.

Chapter 3 Preparation and Inspection

2. Immerse the distal end of the insertion section in sterile water with the

endoscope’s instrument channel port at the same height as the water level

in the water container. Press the suction valve and confirm that water is

continuously aspirated into the suction bottle of the suction pump.

3. Release the suction valve. Confirm that suction stops and the valve returns

to its original position.

4. Depress the suction valve to the first stage and aspirate water for one

second. Then, release the suction valve for one second. Repeat this several

times and confirm that no water leaks from the biopsy valve.

5. Remove the distal end of the endoscope from the water. Depress the

suction valve and aspirate air for a few seconds to remove any water from

the instrument and suction channels.

Inspection of aspiration from the balloon water suction port

1.

Immerse the distal end of the insertion tube in sterile water and completely

depress the suction valve. Confirm that water is continuously aspirated.

2. Release the suction valve. Confirm that suction stops and the suction valve

returns to its original position.

3. Remove the distal end from the water.

ULTRASOUND GASTROVIDEOSCOPE GF-UCT180

49

Page 56

Chapter 3 Preparation and Inspection

Inspection of the instrument channel and forceps elevator

1. Confirm that the forceps elevator is lowered, then insert the EndoTherapy

accessory through the biopsy valve. Confirm that the EndoTherapy

accessory extends smoothly from the distal end, and that a foreign object

does not come out.

2. Extend the EndoTherapy accessory approximately 3 cm from the distal end.

Move the elevator control lever in the “ U” direction and confirm that the

forceps elevator is raised smoothly.

3. Move the elevator control lever in the opposite direction of the “ U”

direction and confirm that the forceps elevator is lowered.

Keep your eyes away from the distal end when inserting

EndoTherapy accessories. Extending the EndoTherapy

accessory from the distal end could cause eye injury.