Page 1

HSMT-Compact

Manual Weld Scanner

User’s Manual

DMTA017-01EN — Rev. F

August 2016

This instruction manual contains essential information on how to use this Olympus product safely and effectively.

Before using this product, thoroughly review this instruction manual. Use the product as instructed.

Keep this instruction manual in a safe, accessible location.

Page 2

Olympus Scientific Solutions Americas, 48 Woerd Avenue, Waltham, MA 02453, USA

Copyright © 2007, 2012, 2013, 2014, 2016 by Olympus. All rights reserved. No part of this

publication may be reproduced, translated, or distributed without the express written

permission of Olympus.

This document was prepared with particular attention to usage to ensure the accuracy of the

information contained therein, and corresponds to the version of the product manufactured

prior to the date appearing on the title page. There could, however, be some differences

between the manual and the product if the product was modified thereafter.

The information contained in this document is subject to change without notice.

Part number: DMTA017-01EN

Rev. F

August 2016

Printed in Canada

All brands are trademarks or registered trademarks of their respective owners and third

party entities.

Page 3

DMTA017-01EN, Rev. F, August 2016

Table of Contents

List of Abbreviations ........................................................................................ v

Labels and Symbols ........................................................................................... 1

Important Information — Please Read Before Use ..................................... 3

Intended Use .......................................................................................................................... 3

Instruction Manual ................................................................................................................ 3

Equipment Compatibility ..................................................................................................... 4

Presence of Visual Interferences or Phantom Spots ......................................................... 5

Repair and Modification ....................................................................................................... 5

Safety Symbols ....................................................................................................................... 5

Safety Signal Words ............................................................................................................... 6

Note Signal Words ................................................................................................................. 7

Safety ....................................................................................................................................... 7

Warnings ................................................................................................................................. 8

Equipment Disposal .............................................................................................................. 8

CE (European Community) ................................................................................................. 8

WEEE Directive ...................................................................................................................... 9

Warranty Information ........................................................................................................... 9

Technical Support ................................................................................................................ 10

Introduction ...................................................................................................... 11

1. Overview ..................................................................................................... 13

2. Scanner Assembly and Setup .................................................................. 19

2.1 Changing the Frame Configuration ....................................................................... 19

2.2 Attaching the Umbilical Cable ................................................................................ 23

2.3 Setting Up the Scanner ............................................................................................. 25

Table of Contents iii

Page 4

DMTA017-01EN, Rev. F, August 2016

3. Operating the Scanner .............................................................................. 27

4. Maintenance ................................................................................................ 29

4.1 Replacing Wheels ...................................................................................................... 29

4.2 Replacing a Conventional Ultrasonic Probe ......................................................... 30

4.3 Replacing a Phased Array Probe ............................................................................ 33

4.4 Unit Cleaning ............................................................................................................. 35

5. Specifications .............................................................................................. 37

6. Accessories and Spare Parts ..................................................................... 41

6.1 Umbilical Cables ....................................................................................................... 41

6.2 Yokes ........................................................................................................................... 42

6.3 Couplant-Feed Units ................................................................................................ 43

6.4 Connector Reference ................................................................................................. 44

6.5 Spare Parts .................................................................................................................. 44

List of Figures ................................................................................................... 49

List of Tables ..................................................................................................... 51

Index ................................................................................................................... 53

Table of Contents

iv

Page 5

List of Abbreviations

hex hexagonal

ID inside diameter

PA phased array

SLA spring-loaded arm

TOFD time-of-flight diffraction

DMTA017-01EN, Rev. F, August 2016

List of Abbreviations

v

Page 6

DMTA017-01EN, Rev. F, August 2016

List of Abbreviations

vi

Page 7

DMTA017-01EN, Rev. F, August 2016

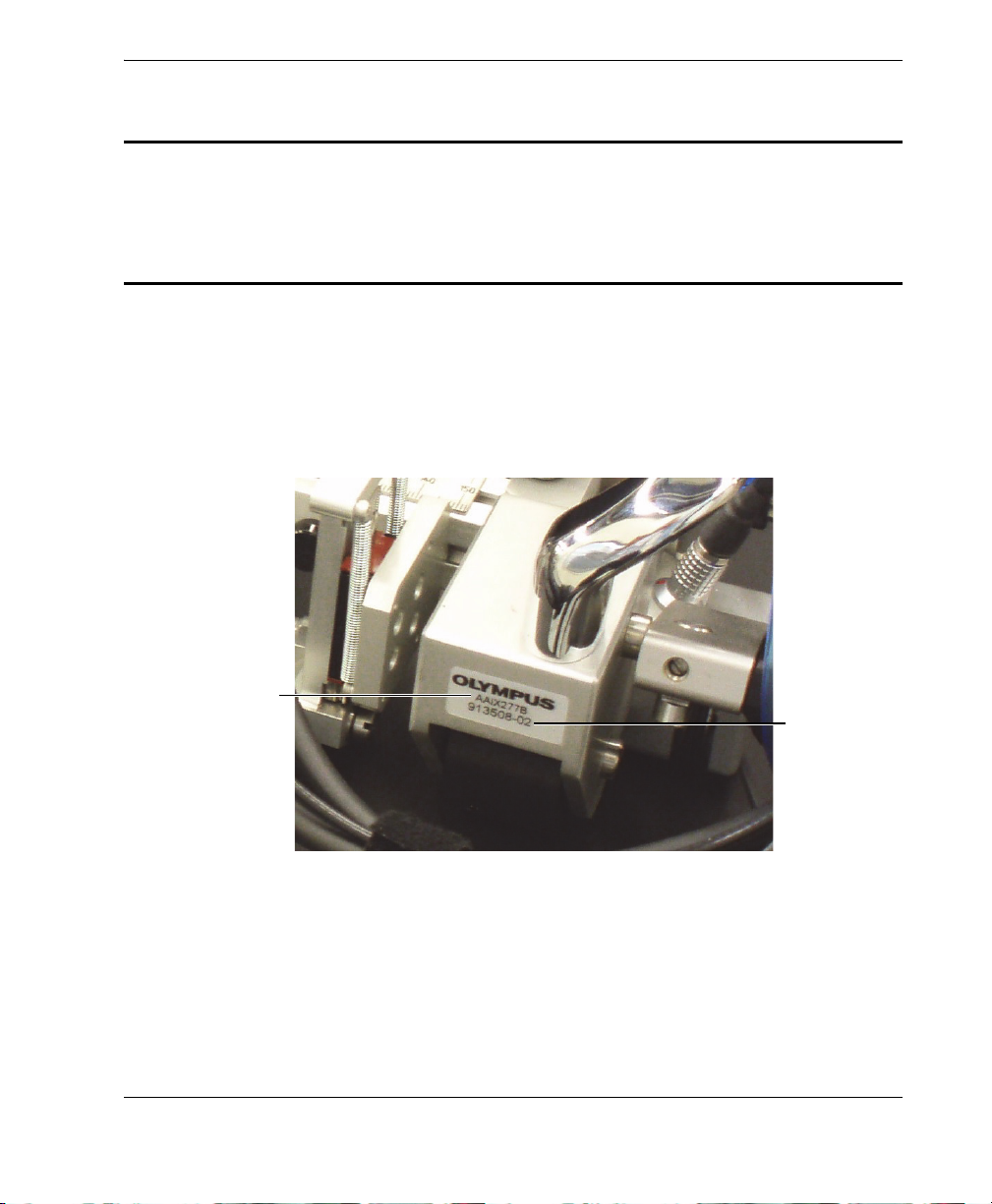

Model number

Serial number

Labels and Symbols

Product information and safety-related labels (with symbols) are attached to the

HSMT-Compact scanner at the locations shown in Figure i-1 on page 1 and Figure i-2

on page 2. Label details are provided in Table 1 on page 2. If any or all of the labels or

symbols are missing or illegible, please contact Olympus.

Figure i‑1 Identification label location

Labels and Symbols

1

Page 8

DMTA017-01EN, Rev. F, August 2016

Rating label (see

Table 1 on page 2)

Figure i‑2 Rating label location

Table 1 Rating label content

Content

Labels and Symbols

2

S/N

The serial number is an eight (8) digit number

The CE marking is a declaration that this product conforms to

all the applicable directives of the European Community. See

the Declaration of Conformity for details. Contact your Olympus

representative for more information.

The regulatory compliance mark (RCM) label indicates that

the product complies with all applicable standards, and has

been registered with the Australian Communications and

Media Authority (ACMA) for placement on the Australian

market.

The WEEE symbol indicates that the product must not be

disposed of as unsorted municipal waste, but should be

collected separately.

The direct current symbol.

Page 9

DMTA017-01EN, Rev. F, August 2016

WARNING

Important Information — Please Read Before Use

Intended Use

The HSMT-Compact scanner is designed to perform nondestructive inspections on

industrial and commercial materials.

Do not use the HSMT-Compact scanner for any purpose other than its intended use. It

must never be used to inspect or examine human or animal body parts.

Instruction Manual

This instruction manual contains essential information on how to use this Olympus

product safely and effectively. Before using this product, thoroughly review this

instruction manual. Use the product as instructed.

Keep this instruction manual in a safe, accessible location.

Important Information — Please Read Before Use

3

Page 10

DMTA017-01EN, Rev. F, August 2016

IMPORTANT

CAUTION

Some of the details of components and/or software images in this manual may differ

from your instrument’s components or software display. However, the principles

remain the same.

Equipment Compatibility

The HSMT-Compact scanner is compatible with the Olympus ancillary equipment

listed in Table 2 on page 4.

Always use equipment and accessories that meet Olympus specifications. Using

incompatible equipment could cause equipment malfunction and/or damage, or

human injury.

Important Information — Please Read Before Use

4

Table 2 Ancillary equipment

Equipment Description

OmniScan PA and FOCUS Several types of phased array instrument

model can be used (may require one of the

encoder cable adaptors listed below).

Phased array probe and wedge Several models used. See Table 7 on page 42

for optional holder models required according

to wedge models.

P/N: U8775201 Scanner interface adaptor to connect scanner

encoder cables with DE15 connector to

OmniScan MX2, SX or FOCUS PX with LEMO

connector scanner interface.

P/N: U8780329 Scanner interface adaptor to connect scanner

encoder cables with LEMO connector to

OmniScan MX with DE15 connector scanner

interface.

Page 11

DMTA017-01EN, Rev. F, August 2016

CAUTION

Table 2 Ancillary equipment (continued)

Equipment Description

P/N: U8769010 0.3 m long adaptor LEMO female to Bendix

male linking LEMO encoder cable to Focus LT

P/N: U8767107 0.3 m long adaptor DE15 female to Bendix

male linking DE15 encoder cable to Focus LT

Presence of Visual Interferences or Phantom Spots

In a situation of physical proximity to powerful electromagnetic radiators, visual

interferences or phantom spots may be present. These interferences are temporary

and their persistence is not permanent in comparison with physical features of the

inspected part.

Repair and Modification

The HSMT-Compact scanner does not contain any user-serviceable parts. Opening

the instrument might void the warranty.

In order to prevent human injury and/or equipment damage, do not disassemble,

modify, or attempt to repair the instrument.

Safety Symbols

The following safety symbols might appear on the instrument and in the instruction

manual:

Important Information — Please Read Before Use

5

Page 12

DMTA017-01EN, Rev. F, August 2016

DANGER

WARNING

General warning symbol

This symbol is used to alert the user to potential hazards. All safety messages that

follow this symbol shall be obeyed to avoid possible harm or material damage.

Shock hazard caution symbol

This symbol is used to alert the user to potential electric shock hazards. All safety

messages that follow this symbol shall be obeyed to avoid possible harm.

Magnetic field warning symbol

This symbol is used to alert the user to potentially strong magnetic fields. All

safety messages that follow this symbol shall be obeyed to avoid possible harm.

Safety Signal Words

The following safety symbols might appear in the documentation of the instrument:

The DANGER signal word indicates an imminently hazardous situation. It calls

attention to a procedure, practice, or the like that if not correctly performed or

adhered to will result in death or serious personal injury. Do not proceed beyond a

DANGER signal word until the indicated conditions are fully understood and met.

The WARNING signal word indicates a potentially hazardous situation. It calls

attention to a procedure, practice, or the like that if not correctly performed or

adhered to could result in death or serious personal injury. Do not proceed beyond a

WARNING signal word until the indicated conditions are fully understood and met.

Important Information — Please Read Before Use

6

Page 13

DMTA017-01EN, Rev. F, August 2016

CAUTION

IMPORTANT

NOTE

TIP

The CAUTION signal word indicates a potentially hazardous situation. It calls

attention to a procedure, practice, or the like that if not correctly performed or

adhered to may result in minor or moderate personal injury, material damage,

particularly to the product, destruction of part or all of the product, or loss of data. Do

not proceed beyond a CAUTION signal word until the indicated conditions are fully

understood and met.

Note Signal Words

The following safety symbols could appear in the documentation of the instrument:

The IMPORTANT signal word calls attention to a note that provides important

information, or information essential to the completion of a task.

The NOTE signal word calls attention to an operating procedure, practice, or the like,

which requires special attention. A note also denotes related parenthetical

information that is useful, but not imperative.

The TIP signal word calls attention to a type of note that helps you apply the

techniques and procedures described in the manual to your specific needs, or

provides hints on how to effectively use the capabilities of the product.

Safety

Before turning on the instrument, verify that the correct safety precautions have been

taken (see the following warnings). In addition, note the external markings on the

instrument, which are described under “Safety Symbols” on page 5.

Important Information — Please Read Before Use

7

Page 14

DMTA017-01EN, Rev. F, August 2016

WARNING

Warnings

General Warnings

• Carefully read the instructions contained in this instruction manual prior to

turning on the instrument.

• Keep this instruction manual in a safe place for further reference.

• Follow the installation and operation procedures.

• It is imperative to respect the safety warnings on the instrument and in this

instruction manual.

• If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment could be impaired.

• Do not install substitute parts or perform any unauthorized modification to the

instrument.

• Service instructions, when applicable, are for trained service personnel. To avoid

the risk of electric shock, do not perform any work on the instrument unless

qualified to do so. For any problem or question regarding this instrument, contact

Olympus or an authorized Olympus representative.

• Do not allow metallic or foreign objects to enter the device through connectors or

any other openings. Otherwise, a malfunction or electric shock may result.

Equipment Disposal

Before disposing of the HSMT-Compact scanner, check your local laws, rules, and

regulations, and follow them accordingly.

CE (European Community)

This device complies with the requirements of both directive

2014/30/EU concerning electromagnetic compatibility and directive

2014/35/EC concerning low voltage. The CE marking indicates

compliance with the above directives.

Important Information — Please Read Before Use

8

Page 15

DMTA017-01EN, Rev. F, August 2016

WEEE Directive

In accordance with European Directive 2012/19/EU on Waste Electrical

and Electronic Equipment (WEEE), this symbol indicates that the

product must not be disposed of as unsorted municipal waste, but

should be collected separately. Refer to your local Olympus distributor

for return and/or collection systems available in your country.

Warranty Information

Olympus guarantees your Olympus product to be free from defects in materials and

workmanship for a specific period, and in accordance with conditions specified in the

Olympus Scientific Solutions Americas Inc. Terms and Conditions available at

http://www.olympus-ims.com/en/terms/.

The Olympus warranty only covers equipment that has been used in a proper

manner, as described in this instruction manual, and that has not been subjected to

excessive abuse, attempted unauthorized repair, or modification.

Inspect materials thoroughly on receipt for evidence of external or internal damage

that might have occurred during shipment. Immediately notify the carrier making the

delivery of any damage, because the carrier is normally liable for damage during

shipment. Retain packing materials, waybills, and other shipping documentation

needed in order to file a damage claim. After notifying the carrier, contact Olympus

for assistance with the damage claim and equipment replacement, if necessary.

This instruction manual explains the proper operation of your Olympus product. The

information contained herein is intended solely as a teaching aid, and shall not be

used in any particular application without independent testing and/or verification by

the operator or the supervisor. Such independent verification of procedures becomes

increasingly important as the criticality of the application increases. For this reason,

Olympus makes no warranty, expressed or implied, that the techniques, examples, or

procedures described herein are consistent with industry standards, nor that they

meet the requirements of any particular application.

Olympus reserves the right to modify any product without incurring the

responsibility for modifying previously manufactured products.

Important Information — Please Read Before Use

9

Page 16

DMTA017-01EN, Rev. F, August 2016

Technical Support

Olympus is firmly committed to providing the highest level of customer service and

product support. If you experience any difficulties when using our product, or if it

fails to operate as described in the documentation, first consult the user’s manual, and

then, if you are still in need of assistance, contact our After-Sales Service. To locate the

nearest service center, visit the Service Centers page at: http://www.olympusims.com.

Important Information — Please Read Before Use

10

Page 17

DMTA017-01EN, Rev. F, August 2016

Introduction

This manual provides instructions for assembling, installing, and operating the

HSMT-Compact scanner. The HSMT-Compact scanner is a versatile pipe and plate

scanner that can be used to inspect pipes of 4 in. schedule or greater (with minimum

outside diameters of 114 mm [or 4.5 in.]), as well as flat surfaces.

To help users understand the HSMT-Compact scanner’s operation and configuration,

this manual provides the following subject matter:

• The scanner’s main components

• Assembly and setup

• Scanner operation

•Maintenance

• Technical specifications, including system connectors

• Accessories and spare parts, with exploded view diagram and descriptions

Introduction 11

Page 18

DMTA017-01EN, Rev. F, August 2016

12

Introduction

Page 19

DMTA017-01EN, Rev. F, August 2016

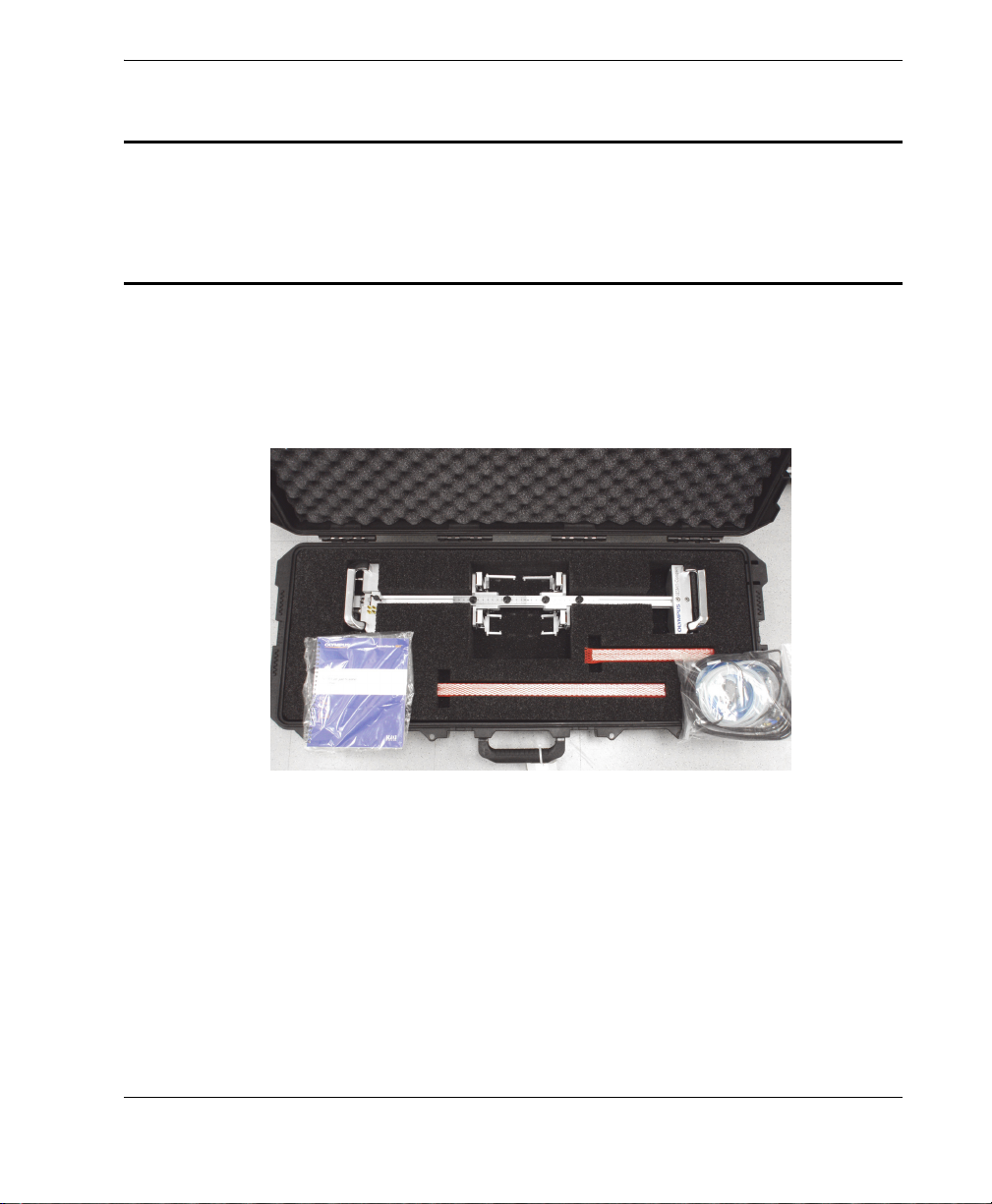

1. Overview

This chapter provides an overview of the main HSMT-Compact scanner components.

The contents of a standard case are shown in Figure 1-1 on page 13.

Figure 1‑1 Case contents

The main HSMT-Compact scanner components are the frame (with four wheels and

two handles), the probe holders, the water-couplant distribution system, and the

encoder (see Figure 1-2 on page 14).

Overview 13

Page 20

DMTA017-01EN, Rev. F, August 2016

Water manifold

Handle for moving the

scanner (2)

Magnetic wheels

Safety

attachment ring

or umbilical

bracket

Encoder Frame

Water feed

Probe holder (2)

14

Figure 1‑2 The HSMT‑Compact scanner

Frame

The frame provides a base for up to four conventional ultrasonic probes or

phased array ultrasonic probes. It is supported at both ends by subassemblies that

hold the wheels and handles used to move the unit across the surface being

inspected. If necessary, the handles can be removed to reduce the height of the

scanner.

Magnetic wheels

The magnetic wheels help hold the unit against a ferromagnetic inspection

surface. The wheels are covered with a plastic layer for smooth motion during

inspection (see Figure 1-2 on page 14).

Chapter 1

Page 21

DMTA017-01EN, Rev. F, August 2016

WARNING

To avoid injury, use caution when handling the magnetic wheels; the magnetic pull of

the wheels is strong and could cause bodily harm—for example, a finger pinched

between two wheels, or between a wheel and a steel surface.

Probe holders

The probe holders are used to secure the probes. The probe-holder position is

adjustable. The probe holders are also spring-loaded to ensure a proper contact

between the probes and the surface to be inspected.

Wat e r manifold

Four tubes branch out from one main water-entry point to supply the wedges

with water couplant.

Encoder

A wheel encoder measures the scanner displacement to determine the position on

the scan axis.

The encoder is waterproof and compatible with the OmniScan unit. The encoder

is also spring-loaded to ensure that it remains in contact with the inspection

surface, with adequate pressure for different pipe diameters.

Safety attachment ring

This ring can be used to secure the scanner with a safety hook (see Figure 1-3 on

page 16). If the scanner is equipped with an umbilical cable, this cable can be

attached to the ring to prevent overtensioning of the probe cables.

Umbilical bracket

An umbilical bracket is supplied with the scanner for quick attachment of a cable

bundle wrapped with a divisible shell (see “Attaching the Umbilical Cable” on

page 23).

Overview 15

Page 22

DMTA017-01EN, Rev. F, August 2016

Main water-supply

tube

Safety attachment

ring or umbilical

bracket

Encoder-cable

connection

Water distribution

to wedges

Probe cables

Wheel encoder

Positioning a probe holder

Two removable rulers are provided on the top of the scanner frame to help

accurately position a probe holder. The edges of the probe-holder brackets can be

used to position the exit points of the ST1 and ST2 TOFD wedges, which are

designed to align with each other (see Figure 1-4 on page 17).

Figure 1‑3 Detail of connections

16

Chapter 1

Page 23

DMTA017-01EN, Rev. F, August 2016

Two removable rulers

The edges on the probe-holder brackets

Figure 1‑4 Removable rulers

Alternative frame configuration

The frame can hold both conventional ultrasonic probes and phased array

ultrasonic probes.

The frame section between the wheels can be changed to vary the scanner length

(see Figure 1-5 on page 17).

Figure 1‑5 Changing the scanner length

Overview 17

Page 24

DMTA017-01EN, Rev. F, August 2016

Preamplifier (optional)

Sliding the wheel assembly to change the frame

configuration

When loosened, the wheel assembly slides freely on the frame, and can be

temporarily removed and reinstalled in a different configuration. For example,

the frame can be positioned to extend outside the limits of the wheels, which is

well-suited to hard-to-reach areas, such as pipe-to-component welds (see

Figure 1-6 on page 18).

Preamplifier

If necessary, a preamplifier (often required for TOFD inspections) can be mounted

on the frame. In the example shown in Figure 1-6 on page 18, an Olympus

TRPP 5810 pulser/preamplifier is used. A bracket is required to mount the

TRPP 5810 on HSMT scanners. This bracket is included with some TRPP 5810

packages, and can also be ordered separately (part number: HSMT-A-BRK5810

[U8779088]).

Chapter 1

18

Figure 1‑6 Alternative scanner configuration

Page 25

DMTA017-01EN, Rev. F, August 2016

2. Scanner Assembly and Setup

This chapter explains how to adjust parts on the HSMT-Compact scanner (for

example, the wheel-assembly position on the frame), and how to set up the scanner

for inspection.

2.1 Changing the Frame Configuration

The frame configuration can be changed as follows:

• The frame section between the wheels can be changed to increase or decrease the

distance between the wheels. This is accomplished using frame sections of

different lengths.

OR

• The wheel-assembly position can be adjusted on the frame; it can be loosened and

moved along the frame section. As such, the wheel assembly can be temporarily

removed, and then reinstalled so that the frame and the probe extend outside the

limits of the wheels, which is ideal for hard-to-reach areas, such as pipe-tocomponent welds (see Figure 1-6 on page 18).

To change the frame section between the wheels

1. On the end of the scanner displaying the company name, perform the following

steps:

a) Using a hexagonal key, remove the two screws that attach the frame section to

the wheel assembly (see Figure 2-1 on page 20).

b) Remove the wheel assembly from the frame.

c) To facilitate reassembly, remove the T-nut, and then install it onto the new

frame section.

Scanner Assembly and Setup 19

Page 26

DMTA017-01EN, Rev. F, August 2016

Frame section

Wheel

assembly

Encoder

assembly

Thumb screw

Figure 2‑1 Sliding the wheel assembly off

2. On the water-manifold end of the scanner:

a) Remove the cable from the encoder assembly.

b) Remove the thumb screw that holds the encoder assembly, and then pull this

assembly away from the scanner (see Figure 2-2 on page 20).

The remaining frame screws are now easy to access.

20

Chapter 2

Figure 2‑2 Thumb screw for the encoder assembly

Page 27

DMTA017-01EN, Rev. F, August 2016

Frame section

Wheel

assembly

3. Using a hexagonal key, remove all five of the frame screws, and then pull out the

frame section (see Figure 2-3 on page 21).

Figure 2‑3 Removal of the frame screws behind the encoder assembly

4. Reinstall the new frame section and scanner parts in the reverse order from the

preceding steps.

To adjust the wheel-assembly position on the frame

1. Using a hexagonal key, loosen the two screws that hold the wheel assembly onto

the frame section (see Figure 2-4 on page 21).

Figure 2‑4 Loosening the wheel assembly

Scanner Assembly and Setup 21

Page 28

DMTA017-01EN, Rev. F, August 2016

NOTE

2. Slide the wheel assembly to the desired new location (see Figure 2-5 on page 22).

Figure 2‑5 Sliding the wheel assembly onto the frame

If necessary, you can temporarily remove the entire wheel assembly, and probe

holders from the frame section in order to reassemble them in the desired new

configuration.

3. Attach the remaining scanner components in the desired configuration. An

example inspection setup with the frame extended beyond the wheel limits is

shown in Figure 2-6 on page 23.

Chapter 2

22

Page 29

Figure 2‑6 Scanner with frame extended beyond wheel limits

2.2 Attaching the Umbilical Cable

DMTA017-01EN, Rev. F, August 2016

The umbilical cable can be attached to the HSMT-Compact scanner using the

umbilical bracket (see Figure 2-7 on page 24).

Scanner Assembly and Setup 23

Page 30

DMTA017-01EN, Rev. F, August 2016

Attachment

Umbilical bracket

Locking pin

Mounting hole

Figure 2‑7 Umbilical‑cable attachment and bracket

To attach the umbilical cable

1. Press the locking pin on the umbilical bracket, slide the mounting hole over the

attachment on the HSMT-Compact scanner, and then release the pin (see

Figure 2-8 on page 24).

24

2. Loosen the strap, wrap it around the umbilical cable, then reinsert the strap into

the buckle and tighten it (see Figure 2-9 on page 25).

Chapter 2

Figure 2‑8 AEIX378 umbilical‑cable attachment

Page 31

DMTA017-01EN, Rev. F, August 2016

Water-

manifold

intake

Encoder

connector

Short section of

tube between the

two unused watermanifold outlets

Water-manifold

outlets

Figure 2‑9 Loosened strap (left) and tightened strap (right)

2.3 Setting Up the Scanner

This section describes the procedure for preparing the HSMT-Compact scanner for

inspection.

To set up the scanner

1. Connect the probes and any other equipment (a preamplifier, for example) to the

acquisition unit.

2. Connect the encoder cable to the side of the scanner (carefully align the marks on

the connector), and then connect the other end of the encoder cable to the

instrument (see Figure 2-10 on page 25).

Figure 2‑10 Scanner connections

Scanner Assembly and Setup 25

Page 32

DMTA017-01EN, Rev. F, August 2016

Thumb screw

Bracket edge

TIP

NOTE

3. Connect the water-manifold intake to the feed system (see Figure 2-10 on

page 25).

4. Connect the water-manifold outlet to the wedge-couplant intake.

If only two out of the four water-manifold outlets are used, connect a tube

between the two unused outlets (see Figure 2-10 on page 25).

5. Adjust the probe position as follows:

a) Loosen the thumb screw that secures the probe-holder bracket to the scanner

frame (see Figure 2-11 on page 26).

26

Figure 2‑11 Adjusting the probe position

b) Slide the probe holder to the desired position, and then tighten the thumb

screw.

For the TOFD ST1 and ST2 models exclusively, the edges of the probe-holder brackets

are in line with the beam exit point of the wedge to facilitate probe positioning.

Equipment connections and probe positions vary according to the application. To

mount the components, you might have to add or correctly position T-nuts in the

frame slots.

Chapter 2

Page 33

DMTA017-01EN, Rev. F, August 2016

3. Operating the Scanner

The HSMT-Compact scanner is designed for manual use, and is straightforward to

operate.

To operate the scanner

1. Hold the scanner above the inspection surface, and then align the scanner so that

the inspection area is centered between the probes.

2. With the inspection area centered between the probes, bring the scanner’s

magnetic wheels into contact with the inspection surface.

3. Next, push or pull the scanner in the desired inspection direction.

If the inspection surface is made of a ferromagnetic material, the scanner does not

need to be pushed down to prevent liftoff.

Operating the Scanner 27

Page 34

DMTA017-01EN, Rev. F, August 2016

28

Chapter 3

Page 35

DMTA017-01EN, Rev. F, August 2016

WARNING

4. Maintenance

This chapter contains procedures for replacing wheels, probes, and wedges for both

conventional ultrasonic and phased array ultrasonic technologies. The probes may

need to be replaced if they malfunction, or if the inspection application has changed.

Depending on operating conditions, the HSMT-Compact scanner parts might need

periodic cleaning.

4.1 Replacing Wheels

This section contains the procedure for changing the wheels once they are too worn.

To replace wheels

To avoid injury, use caution when handling the magnetic wheels; the magnetic pull of

the wheels is strong and could cause bodily harm—for example, a finger pinched

between two wheels, or between a wheel and a steel surface.

1. Using a flathead screwdriver, remove the screw that secures the wheel to the

frame (see Figure 4-1 on page 30).

Maintenance 29

Page 36

DMTA017-01EN, Rev. F, August 2016

WARNING

Figure 4‑1 Removing the wheel screw

2. Lift the scanner and pull the wheel down and outward.

3. Insert the new wheel in the frame and secure it with the screw.

Make sure the bearings are placed in the correct position.

4. Repeat the procedure for the other wheels.

To avoid the risk of injury from magnetic attraction forces between wheels, only

remove and replace one wheel at a time (always reinstall the magnetic wheel on the

scanner before removing the next one).

4.2 Replacing a Conventional Ultrasonic Probe

This section describes the procedure for removing a conventional ultrasonic probe

and wedge from the holder on the scanner.

Chapter 4

30

Page 37

DMTA017-01EN, Rev. F, August 2016

To replace a conventional ultrasonic probe

1. Turn off the couplant flow.

2. Disconnect the couplant tubes from the couplant source, or from the wedge.

3. Disconnect the probe cable.

4. Remove the scanner from the inspection surface.

5. Using a flathead screwdriver, loosen the screw at the back of the spring-loaded

arm (SLA), just enough to free the yoke from the arm (see Figure 4-2 on page 31).

Figure 4‑2 The screw that secures the yoke to the SLA

6. Remove the yoke.

7. Using a hex socket-head screwdriver, remove the screw (on the side of the yoke)

that holds the parts together (see Figure 4-3 on page 32).

Maintenance 31

Page 38

DMTA017-01EN, Rev. F, August 2016

Figure 4‑3 The screw that secures the yoke assembly

8. Ensure that the probe cable is disconnected, and then unscrew the probe from the

wedge (see Figure 4-4 on page 32).

In certain equipment configurations, it may be possible to unscrew the probe

without removing the wedge from the yoke (and the yoke from the SLA).

32

Figure 4‑4 Unscrewing the probe

Chapter 4

Page 39

DMTA017-01EN, Rev. F, August 2016

NOTE

CAUTION

CAUTION

9. Install the new probe.

Before installing the new probe into the probe holder, ensure that there is enough

couplant between the probe and the wedge.

10. Tighten the probe inside the holder.

Do not overtighten the screws; doing so could crack the wedge.

11. Reinstall the yoke onto the holder.

12. Reinstall the yoke, probe holder, and probe assembly onto the spring-loaded arm.

This concludes the procedure for replacing a conventional ultrasonic probe.

4.3 Replacing a Phased Array Probe

This section describes the procedures for removing a phased array ultrasonic probe

from the scanner, and for removing the probe and wedge from the holder.

To replace a phased array probe

1. Turn off the couplant flow.

2. Disconnect the couplant tubes from the couplant source.

3. Disconnect the probe cable from the instrument.

To prevent any damage to the pins, always place the protective cover over the phased

array probe’s Hypertronics connector when it is disconnected.

4. Remove the scanner from the inspection surface.

Maintenance 33

Page 40

DMTA017-01EN, Rev. F, August 2016

5. Using a flathead screwdriver, remove the screw (at the back of the SLA) that

secures the yoke to the spring-loaded arm.

6. Remove the yoke, probe holder, and probe assembly from the scanner.

7. Using a hexagonal key, remove the screw (on the side of the yoke) that holds the

parts together (see Figure 4-5 on page 34).

Figure 4‑5 The screw that secures the yoke assembly

8. Using a cross-head screwdriver, loosen the four screws (see Figure 4-6 on

page 34), and then remove the probe from the wedge.

Figure 4‑6 The probe holder

9. Install the new probe.

Chapter 4

34

Page 41

DMTA017-01EN, Rev. F, August 2016

NOTE

CAUTION

Before installing the new probe into the probe holder, ensure that there is enough

couplant between the probe and the wedge.

10. Install and tighten the screws to secure the probe within the holder.

Do not overtighten the screws; doing so could crack the wedge.

11. Reinstall the yoke onto the holder.

12. Reinstall the yoke, probe holder, and probe assembly onto the spring-loaded arm.

This concludes the procedure for replacing a phased array probe.

4.4 Unit Cleaning

To clean the unit

The HSMT-Compact scanner’s external surfaces can be cleaned when needed.

The magnetic wheels can be strongly attracted to any ferromagnetic materials or

surfaces, which potentially can cause injuries (for example, pinched fingers) or

equipment damage.

1. Ensure the unit is turned off by removing the source of power.

2. Disconnect all cables.

3. To bring the unit back to its original finish, clean the housing with a soft cloth.

4. To remove persistent stains, use a damp cloth with a soft, soapy solution. Do not

use abrasive products or powerful solvents that could damage the finish.

Maintenance 35

Page 42

DMTA017-01EN, Rev. F, August 2016

5. Wait until the unit dries completely before reconnecting the cables.

36

Chapter 4

Page 43

DMTA017-01EN, Rev. F, August 2016

Case

White

Green

Red

Black

Shield + drain wire

Case

5. Specifications

This chapter contains the general specifications for the HSMT-Compact scanner (see

Table 3 on page 37 to Table 5 on page 38).

Table 3 General specifications

Parameter Va l ue

Dimensions See Table 4 on page 38 and Figure 5-2 on page 38.

Encoder Type: Quadrature

Resolution: 12 steps/mm ± 0.15 steps/mm (encoder

calibration is recommended for every setup)

Waterproof

Pinout: See Figure 5-1 on page 37.

Power rating 5 VDC, 25 mA max.

Frequency: 0 kHz to 1.5 kHz (for a maximum

displacement velocity per second of 10 cm or 4 in.)

Figure 5‑1 Encoder pinout for EWIX1418 cable

Specifications 37

Page 44

DMTA017-01EN, Rev. F, August 2016

Length

Width

Height

Table 4 Dimensions (overall)

Bar length

(mm)

250 152 5.98 344 13.54 102 4.02

450 152 5.98 544 21.42 102 4.02

650 152 5.98 744 29.29 102 4.02

Width Length Height

(mm) (in.) (mm) (in.) (mm) (in.)

38

Figure 5‑2 Scanner dimensions

Table 5 Environmental conditions

Parameter Va l ue

Operating temperature –10 °C to 55 °C

Storage temperature –30 °C to 60 °C

Chapter 5

Page 45

DMTA017-01EN, Rev. F, August 2016

Table 5 Environmental conditions (continued)

Parameter Va l ue

Relative humidity (RH) Max. 85 % RH noncondensing

Altitude Up to 2000 m

Outdoor use Yes

Wet locations Yes

IP rating Waterproof (designed for IP67)

Pollution level 1

Specifications 39

Page 46

DMTA017-01EN, Rev. F, August 2016

40

Chapter 5

Page 47

DMTA017-01EN, Rev. F, August 2016

6. Accessories and Spare Parts

This chapter contains lists of accessories (such as cables, yokes, and pumps) and spare

parts for the HSMT-Compact scanner.

6.1 Umbilical Cables

Umbilical cables are available as either a closed type or a divisible type. The closed

type incorporates a protective conduit that is waterproof and dust proof, and comes

with safety hooks on both ends (for order details, contact Olympus). The divisible

type makes it possible to change cables, without the need of connection boxes (for

order details, see Table 6 on page 41).

Table 6 Umbilical cables (divisible‑conduit type)

Part Number Description

U8779093 One 0.3 m divisible cable conduit with a 16 mm ID. Well-suited to

2 × PA, irrigation tube, and the encoder cable.

U8779094 One 0.3 m divisible cable conduit with a 19.2 mm ID. Well-suited to

2 × PA, 2 × conventional UT, irrigation tube, and the encoder cable.

U8775093 One 0.3 m divisible cable conduit with a 24.2 mm ID. Well-suited to

2 × PA, 4 × conventional UT, irrigation tube, encoder, and

preamplifier power supply cables.

U8779095 One 5 m divisible cable conduit with 24.2 mm ID. Well-suited to

2 × PA, 4 × conventional UT, irrigation tube, encoder, and

preamplifier power supply cables.

Accessories and Spare Parts 41

Page 48

DMTA017-01EN, Rev. F, August 2016

Button

6.2 Yokes

Figure 6-1 on page 42 and Table 7 on page 42 provide ordering information for yokes.

Yoke dimensions depend on the wedge model used.

Figure 6‑1 Yoke geometry

Table 7 Replacement yokes

42

Part

number

Standard yokes

a

U8775048

U8775047

U8775046 SA10, SA11, SA31, and SA32 8 40 38

Other yokes

U8775187 SPWZ1 and SA14 (in reverse position) 8 40 46

U8780194 SPWZ1, SA14, RexoFORM, and SNW3-

U8775055 SA1-L (lateral) 8 45 60

U8779096 SA3 8 50 55

U8775084 SA4, SA5, and HydroFORM-A-LiteHolder 8 55 55

U8779097 Water wedge 8 50 65

U8775132 SNW1 8 31.75 55

ST1, ST2, SPE1, SPE2, SPE3, SA0 5 31.75 23.5

b

SA1, SA2, SA10, SA11, SA12, SA31, SA32,

SI1, SPWZ3, SNW1-AQ25 (WR), and

SNW3-AQ25

AQ25-WR

Wedge compliance

Button

OD

(mm)

(mm)B (mm)

84055

84065

Chapter 6

A

Page 49

DMTA017-01EN, Rev. F, August 2016

Table 7 Replacement yokes (continued)

Part

number

U8775165 SNW2 8 31.75 23.5

U8775164 SNW3 8 31.75 65

Q7750014 SA17-DN 5 50 38

Q7750015 SA17-N 5 31.75 38

U8775056 SA27-DN and Creeping wave probe

holder (U8775080)

a. Standard yoke for TOFD-P/E probe mounting

b. Standard yoke for phased array probe mounting

Wedge compliance

Button

OD

(mm)

54023

A

(mm)B (mm)

6.3 Couplant-Feed Units

Couplant can be supplied to wedges by either an electric or a manual pump (see

Table 8 on page 43).

Table 8 Couplant‑feed units

Part number Description

U8780008 Electric couplant-feed unit

3.78 l/min at 414 kPa (1 GPM at 60 psi)

100 VAC/240 VAC

U8780009 Electric couplant-feed unit with suction capability

Same operating specification as CFU03

U8775153 4 L manual water pump with irrigation tubes and

fittings

U8775001 8 L manual water pump with irrigation tubes and

fittings

Accessories and Spare Parts 43

Page 50

DMTA017-01EN, Rev. F, August 2016

6.4 Connector Reference

HSMT-Compact scanner models sold after July 2013 come standard with the LEMO

connector, which is compatible with the OmniScan MX2 and SX instruments. For use

with a different instrument, an optional adaptor is required (see Table 9 on page 44).

Table 9 Required encoder cable adaptor

Scanner

Connector

LEMO

(from July

2013 onward)

DE15

(Prior to July

2013)

OmniScan MX

P/N: U8780329 — P/N: U8769010

— P/N: U8775201 P/N: U8767107

Instrument

OmniScan MX2, SX

and FOCUS PX

To mo Sc a n

FOCUS LT

6.5 Spare Parts

An exploded view of the scanner is shown in Figure 6-2 on page 45. A list of standard

spare parts is provided in Table 10 on page 45.

44

Chapter 6

Page 51

DMTA017-01EN, Rev. F, August 2016

Figure 6‑2 Exploded view

Table 10 Spare parts

Drawing

item

b

1

a

Qty

Part number Description

1 U8775097 Spring-loaded encoder and bracket

2 1 U8775235 M5 × 25 mm hex flat

3 4 U8908261 M3 × 16 mm hex socket

4 4 U8905961 Spring washer M3

5 1 Q8300237 Thumb screw assembly 10 mm

6 4 U8902678 10-32 to T-1/8 in. ID short-barb brass fitting

7 8 U8900310 Dovetail M5 nut

8 2 Q8300422 Ruler

Accessories and Spare Parts 45

Page 52

DMTA017-01EN, Rev. F, August 2016

Table 10 Spare parts (continued)

Drawing

item

9 4 U8909791 Thumb screw assembly 6 mm

10 1 U8830333 Double dovetail M5 nut

11 11 U8900327 Spring washer M5

12 1 Q8300899 Locking umbilical pin

13 2 U8900317 M5 × 12 mm hex socket

14 1 Q1500599 Push-in fitting

15 4 U8902414 Wheel shaft

16 4 U8750050 Kit of one magnetic wheel and two bearings

17 16 Q8300893 M3 × 5 mm hex screw

18 16 U8905961 Lock washer M3

19 4 U8767270 90° probe-holder bracket for serial numbers

20 4 U8775070 Thumb screw assembly 12 mm

21 4 U8775041 Shoulder screw for yoke

22 8 U8775110 Yoke bearing

23 4 U8830739 Spring-loaded arm (SLA)

24 8 U8900337 Spring for SLA

25 16 Q8300929 M2.5 × 6 mm hex socket

26 2 U8775047 PA yoke 5°, 40 mm wide × 55 mm long

27 4 U8775048 TOFD yoke 10°, 31.75 mm × 23.5 mm

28 2 U8779086 Pair of SLA mounted on brackets (left and

29 1 U8775229 Profile 250 mm

a

Qty

1 U8775104 Profile 450 mm

1 U8775103 Profile 650 mm

Part number Description

below 872542-nn

U8775204 90° probe-holder bracket for serial numbers

872542-nn and above

U8775046 PA yoke 5°, 40 mm wide × 38 mm long

right)

46

Chapter 6

Page 53

DMTA017-01EN, Rev. F, August 2016

Table 10 Spare parts (continued)

Drawing

item

Qty

a

Part number Description

30 4 U8770529 M4 × 10 mm hexagonal head stainless steel

screw

31 4 U8831534 PA probe yoke arm 55 mm

Q8300930 PA probe yoke arm 38 mm

32 4 U8906398 M3 × 8 mm Phillips flathead stainless steel

screw

33 4 U8721914 PA 8 mm yoke button

34 8 Q8300931 UT probe yoke arm

35 8 U8770531 0.040 in. yoke button spacer

36 8 U8770530 UT 5 mm yoke button

37 1 U8831178 M8 × 13 mm bolt with stainless steel ring

38 1 Q8300895 Umbilical bracket

Not

Shown

1 U8775313 5 m encoder cable with LEMO connector

(for direct connection to OmniScan MX2

and SX models)

Not

1 U8775040 Metric hexagonal key kit

Shown

Not

5 U8902320 4 mm ID irrigation tube (unit: ft)

Shown

Not

4 U8900341 0.125 in. ID irrigation tube (unit: ft)

Shown

Not

1 U8902317 Irrigation valve

Shown

Not

4 U8902321 “Y” irrigation splitter

Shown

Not

1 Q8300932 Velcro tape (unit: ft)

Shown

a. This number represents the typical quantity initially included with your scanner package.

b. For serial number 872542-nn and below, the encoder part number is ADIX1584 [U8780200]

(former part number ADIX847).

Accessories and Spare Parts 47

Page 54

DMTA017-01EN, Rev. F, August 2016

48

Chapter 6

Page 55

DMTA017-01EN, Rev. F, August 2016

List of Figures

Figure i-1 Identification label location ................................................................................ 1

Figure i-2 Rating label location ............................................................................................ 2

Figure 1-1 Case contents ...................................................................................................... 13

Figure 1-2 The HSMT-Compact scanner ........................................................................... 14

Figure 1-3 Detail of connections ......................................................................................... 16

Figure 1-4 Removable rulers ............................................................................................... 17

Figure 1-5 Changing the scanner length ........................................................................... 17

Figure 1-6 Alternative scanner configuration .................................................................. 18

Figure 2-1 Sliding the wheel assembly off ........................................................................ 20

Figure 2-2 Thumb screw for the encoder assembly ......................................................... 20

Figure 2-3 Removal of the frame screws behind the encoder assembly ....................... 21

Figure 2-4 Loosening the wheel assembly ........................................................................ 21

Figure 2-5 Sliding the wheel assembly onto the frame ................................................... 22

Figure 2-6 Scanner with frame extended beyond wheel limits ..................................... 23

Figure 2-7 Umbilical-cable attachment and bracket ........................................................ 24

Figure 2-8 AEIX378 umbilical-cable attachment .............................................................. 24

Figure 2-9 Loosened strap (left) and tightened strap (right) ........................................... 25

Figure 2-10 Scanner connections .......................................................................................... 25

Figure 2-11 Adjusting the probe position ........................................................................... 26

Figure 4-1 Removing the wheel screw .............................................................................. 30

Figure 4-2 The screw that secures the yoke to the SLA .................................................. 31

Figure 4-3 The screw that secures the yoke assembly ..................................................... 32

Figure 4-4 Unscrewing the probe ....................................................................................... 32

Figure 4-5 The screw that secures the yoke assembly ..................................................... 34

Figure 4-6 The probe holder ............................................................................................... 34

Figure 5-1 Encoder pinout for EWIX1418 cable ............................................................... 37

Figure 5-2 Scanner dimensions ........................................................................................... 38

Figure 6-1 Yoke geometry .................................................................................................... 42

Figure 6-2 Exploded view ................................................................................................... 45

List of Figures 49

Page 56

DMTA017-01EN, Rev. F, August 2016

List of Figures

50

Page 57

DMTA017-01EN, Rev. F, August 2016

List of Tables

Table 1 Rating label content ................................................................................................ 2

Table 2 Ancillary equipment ............................................................................................... 4

Table 3 General specifications ........................................................................................... 37

Table 4 Dimensions (overall) ............................................................................................. 38

Table 5 Environmental conditions .................................................................................... 38

Table 6 Umbilical cables (divisible-conduit type) .......................................................... 41

Table 7 Replacement yokes ................................................................................................ 42

Table 8 Couplant-feed units .............................................................................................. 43

Table 9 Required encoder cable adaptor ......................................................................... 44

Table 10 Spare parts .............................................................................................................. 45

List of Tables 51

Page 58

DMTA017-01EN, Rev. F, August 2016

52

List of Tables

Page 59

Index

DMTA017-01EN, Rev. F, August 2016

A

accessories

pumps 43

umbilical cables 41

yokes 42

assembling the scanner 19

attachment ring, safety 15

Australia, RCM compliance 2

C

cable, umbilical 23

CAUTION signal word 7

cautions

instrument compatibility 4

modification prohibited 5

CE (European Community) 8

CE marking 2

cleaning, system components 35

compatibility, instrument 4

compliance

RCM (Australia) 2

components

changing the frame configuration 17

encoder 15

frame 14

overview 13

positioning rulers 16

preamplifier 18

safety attachment ring 15

water manifold 15

wheels 14

configuration, frame 17, 19

connector reference (specifications) 44

D

DANGER signal word 6

dimensions, scanner 37

direct current symbol 2

disposal, equipment 8

E

encoder 15, 37

equipment disposal 8

European Community (CE) 8

exploded view, scanner 44

F

frame

configuration, changing 17, 19

scanner 14

H

holders, probe 15

I

important information 3

IMPORTANT signal word 7

inspection (operating the scanner) 27

instruction manual 3

instrument compatibility 4

introduction 11

L

labels 1

list, spare parts 44

M

magnetic wheels, warning 15, 29, 30, 35

Index 53

Page 60

DMTA017-01EN, Rev. F, August 2016

maintenance

cleaning of components 35

conventional probe replacement 30

phased array probe replacement 33

wheel replacement 29

manifold, water 15

manual

organization 11

purpose 11

manual, instruction 3

modification, instrument 5

N

NOTE signal word 7

notes, information

signal words 7

O

Olympus technical support 10

operating the scanner 27

organization, manual 11

overview, scanner components 13

P

parts, spare 44

positioning rulers, probe 16

preamplifier 18

precautions, safety 7

probe holders 15

probe replacement

conventional ultrasonic 30

phased array 33

procedures

assembly, scanner 19

changing the frame configuration 19

replacing a conventional ultrasonic probe 30

replacing a phased array probe 33

replacing wheels 29

scanner operation 27

setting up the scanner 25

pumps 43

purpose, manual 11

R

rating label location 2

RCM mark 2

repair, instrument 5

replacement

conventional ultrasonic probe 30

phased array probe 33

wheels 29

ring, safety attachment 15

ruler, probe position 16

S

safety

instrument compatibility 4

misuse of instrument 3

precautions 7

signal words 6

symbols 5

warnings

magnetic wheels 15, 29, 30, 35

serial number format 2

setting up the scanner 25

signal words

information notes 7

IMPORTANT 7

NOTE 7

TIP 7

safety 6

CAUTION 7

DANGER 6

WARN I N G 6

spare parts 44

specifications

connector 44

general 37

umbilical cables 41

yokes 42

support information, technical 10

symbols 1

CE 2

direct current 2

RCM (Australia) 2

safety 5

WEEE 2

T

technical support 10

TIP signal word 7

54

Index

Page 61

DMTA017-01EN, Rev. F, August 2016

U

umbilical cable 23

use, intended 3

W

WARNING signal word 6

warning symbols

general 6

shock hazard 6

warnings

general 8

magnetic wheels 15, 29, 30, 35

misuse of instrument 3

warranty information 9

waste electrical and electronic equipment 9

water manifold 15

WEEE directive 9

symbol 2

wheels 14

replacement 29

safety (magnetic wheels) 15, 29, 30, 35

Y

yokes 42

Index 55

Page 62

DMTA017-01EN, Rev. F, August 2016

56

Index

Loading...

Loading...