OLYMPUS POLARIZING MICROSCOPE

[

INSTRUCTION

MANUAL

I

MODEL

BHSP

This instruction manual has been written for the use of the Olympus Polarizing Microscope Model

BHSP.

It

is

recommended to read the manual carefully in order to familiar-

ize yourself fully with the use of the microscope, so that you can obtain optimum per-

formance from it.

VL.__n_NWW___---x--

IMPORTANT

Observe the following points carefully:

Operation

1. Always handle the microscope with the care it deserves, and avoid abrupt motions.

2.

Avoid exposure of the microscope to direct sunlight, high temperature* and humidity,

dust and vibration.

If the microscope is used in an ambient temperature higher than 40°c (104"F), it

may cause a trouble to the microscope.

3.

Only use the tension adjustment ring for altering the tension of the coarse adjustment.

Do not twist the two coarse adjustment knobs in the opposite directions simultane-

ously, which might cause damage.

4. Ascertain that the line voltage selector switch on the base plate is set to conform with

the local mains voltage.

Maintenance

1. Lenses must always be kept clean.

Fine dust on lens surfaces should be blown or

wiped off by means of an air blower or a clean brush. Carefully wipe'off oil or fingerprints deposited on the lens surfaces with gause moistened with a small amount of

xylene, alcohol or ether.

2.

Do not use organic solutions to wipe the surfaces of various components. Plastic

parts, especially, should be cleaned with a neutral detergent.

3.

Never disassemble the microscope for repair. Only authorized Olympus service per-

sonnel should make repairs.

4.

The microscope should

be

stored in its container immediately after use. If this is not

possible, it should be covered with'a vinyl dust cover.

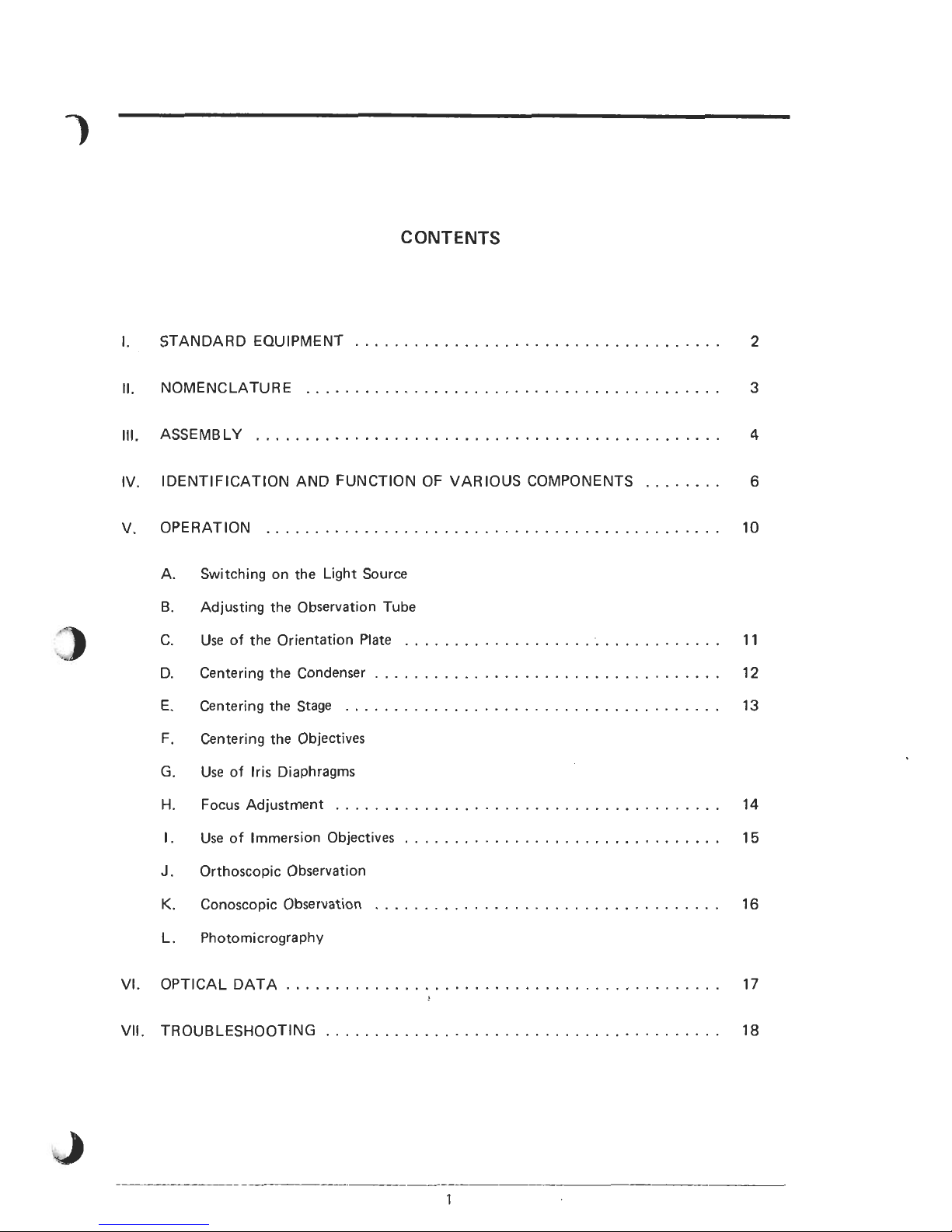

CONTENTS

I . STANDARD EQUIPMENT

.....................................

2

..........................................

.

II

NOMENCLATURE

3

...............................................

.

Ill

ASSEMBLY 4

........

IV . IDENTIFICATION AND FUNCTION OF VARIOUS COMPONENTS 6

V

. OPERATION

..............................................

10

Switching on the Light Source

Adjusting the Observation Tube

Use of the Orientation Plate

................................

11

Centering the Condenser

...................................

12

Centering the Stage

......................................

13

Centering the Objectives

Use of Iris Diaphragms

.......................................

Focus Adjustment 14

Use of Immersion Objectives

................................

15

Orthoscopic Observation

Conoscopic Observation

...................................

16

Photomicrography

VI . OPTICAL DATA

............................................

17

VII . TROUBLESHOOTING ........................................ 18

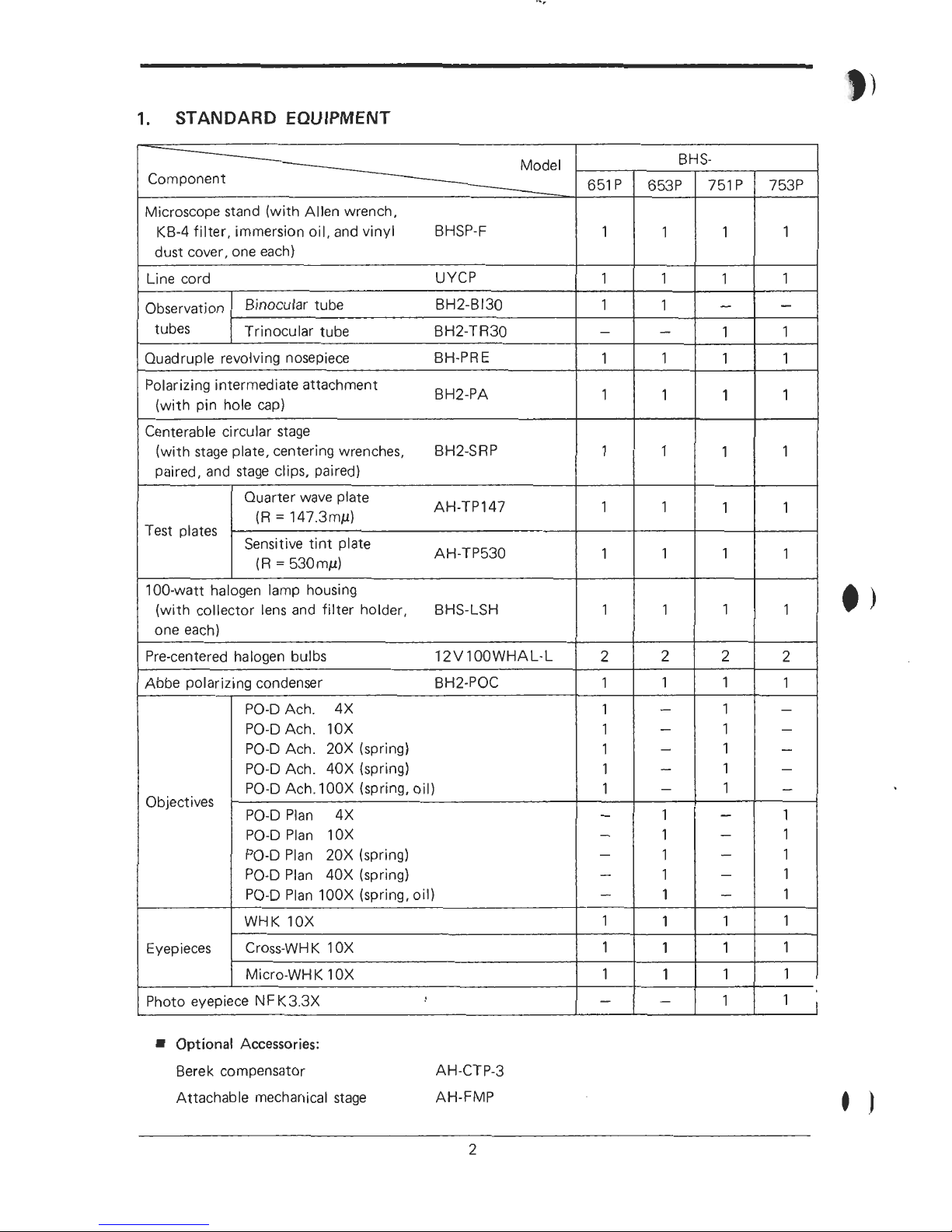

1.

STANDARD EQUIPMENT

Optional Accessories:

Berek compensator AH-CT P-3

Attachable mechanical stage AH-FMP

-

Model

Component

-------__-

Microscope stand (with Allen wrench,

KB-4 filter, immersion oil, and vinyl

BHSP-F

dust cover, one each)

Line cord UYCP

651P

1

1

1

-

1

1

1

1

1

1

2

1

1

1

1

1

1

-

-

-

-

-

1

1

1

-

Observation

tubes

Binocular tube BH2-B130

Trinocular tube

BH2-TR30

653P

1

1

1

-

1

1

1

1

1

1

2

1

-

-

-

-

1

1

1

1

1

1

1

1

-

Quadruple revolving nosepiece BH-PRE

Polarizing intermediate attachment

BH2-PA

(with pin hole cap)

Centerable circular stage

(with stage plate, centering wrenches,

BH2-SRP

paired, and stage clips, paired)

BHS-

751P

1

1

-

1

1

1

1

1

1

1

2

1

1

1

1

1

1

-

-

-

-

-

1

1

1

1

Test plates

753P

1

1

-

1

1

1

1

1

1

1

2

1

-

-

-

-

-

1

1

1

1

1

1

1

1

1

Quarter wave plate

(R

=

147.3my)

AH-TP147

-

Sensitive tint plate

(R

=

530my)

AH-TP530

100-watt halogen lamp housing

(with collector lens and filter holder,

BHS-LSH

one each)

Pre-centered halogen bulbs 12VlOOWHAL-L

Abbe polarizing condenser BH2-POC

Objectives

Eyepieces

PO-D Ach. 4X

PO-D Ach. 10X

PO-D Ach. 20X (spring)

PO-D Ach. 40X (spring)

PO-D Ach. 100X (spring, oil)

PO-D Plan 4X

PO-D Plan 10X

PO-D Plan 20X (spring)

PO-D Plan 40X (spring)

PO-D Plan 100X (spring, oil)

WHK 10X

Cross-WH

K

1 OX

Micro-WH

K

1 OX

Photo eyepiece NF K3.3X

11.

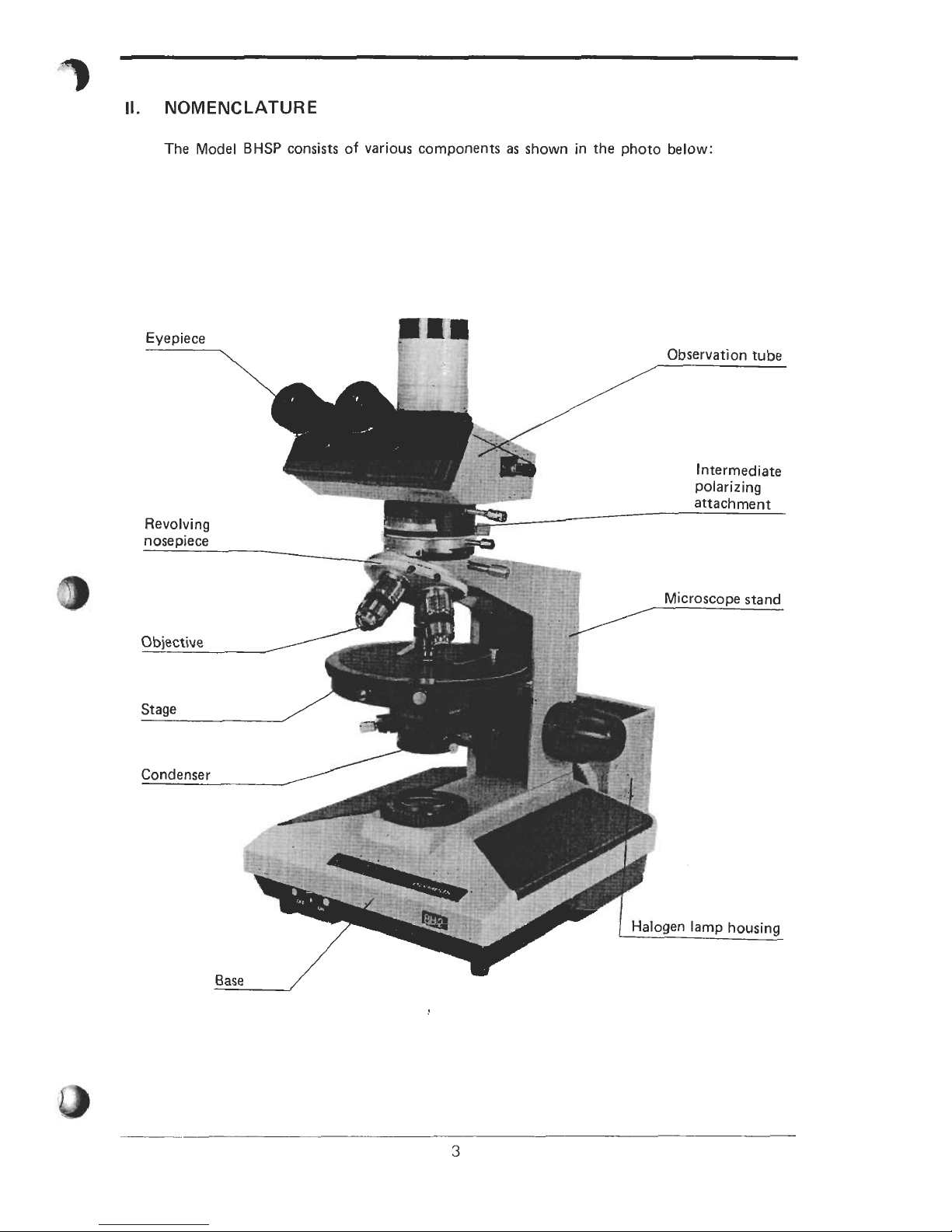

NOMENCLATURE

The Model

BHSP

consists of various components as shown in the photo below:

Revolving

nosepiece

Objective

Stage

Condenser

Base

Observation tube

,

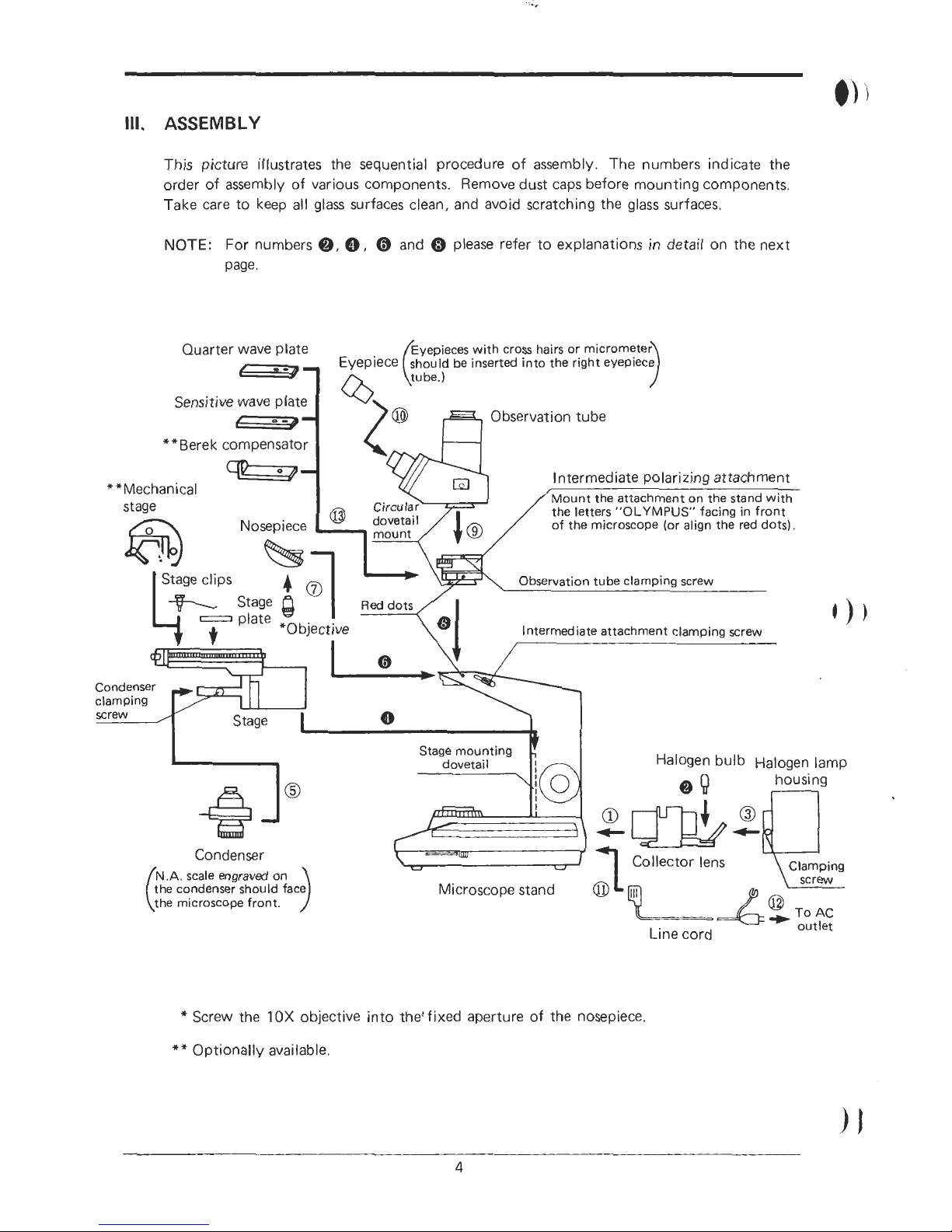

Ill.

ASSEMBLY

This picture illustrates the sequential procedure of assembly. The numbers indicate the

order of assembly

of

various components. Remove dust caps before mounting components.

Take care to keep all glass surfaces clean, and avoid scratching the glass surfaces.

NOTE:

For numbers

0,

0,

0

and 0 please refer to explanations in detail on the next

page.

Quarter wave plate

Sensitive wave plate

Observation tube

**Berek compensator

**Mechanical

Condenser

Collector lens

Microscope stand

*

Screw the

10X

objective into theJfixed aperture of the nosepiece.

**

Optionally available.

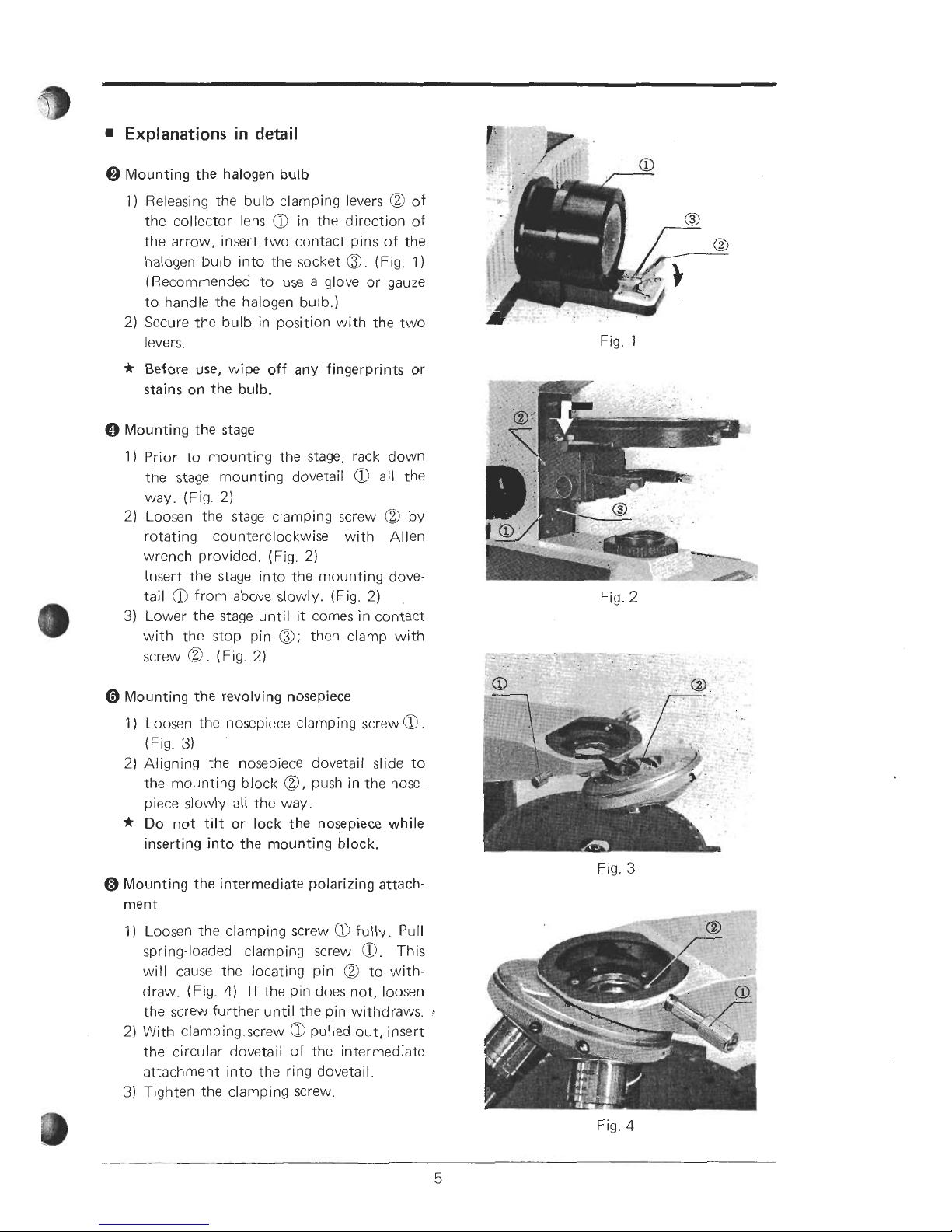

Explanations

in

detail

@

Mounting the halogen bulb

1)

Releasing the bulb clamping levers @ of

the collector lens

a

in the direction of

the arrow, insert two contact pins of the

halogen bulb into the socket

@.

(Fig.

1)

(Recommended to use a glove or gauze

to handle the halogen bulb.)

2)

Secure the bulb in position with the two

levers.

*

Before use, wipe off any fingerprints or

stains on the bulb.

0

Mounting the stage

1) Prior to mounting the stage, rack down

the stage mounting dovetail

a

all the

way. (Fig.

2)

2)

Loosen the stage clamping screw

@

by

rotating counterclockwise with Allen

wrench provided. (Fig.

2)

Insert the stage into the mounting dove-

tail

a

from above slowly. (Fig.

2)

3)

Lower the stage until it comes in contact

with the stop pin

0;

then clamp with

screw

@

.

(Fig.

2)

0

Mounting the revolving nosepiece

Fig. 1

Fig.

2

1)

Loosen the nosepiece clamping screw

a

(Fig.

3)

2)

Aligning the nosepiece dovetall slide to

the mounting block

@,

push in the nose-

piece

slowly all the way

*

Do

not

tilt

or lock the nosepiece while

inserting into the mounting block.

Mounting the intermediate polarizing attachment

1)

Loosen the clamping screw

a

fully. Pull

spring-loaded clamping screw

@.

This

will cause the locating pin

@

to with-

draw. (Fig.

4)

If the pin does not, loosen

the screw further until the pin withdraws.

!

2)

With clamping.screw 0 pulled out, insert

the circular dovetail of the intermediate

attachment into the ring dovetail.

3)

Tighten the clamping screw.

Fig.

3

Fig.

4

Loading...

Loading...