Olivetti SD-505, d-Color MF450, d-Color MF201Plus, d-Color MF350, d-Color MF250 Service Manual

Page 1

SD-505

Option Printer

SERVICE MANUAL

Code Y108482-2

d-Color MF201Plus - MF250 - MF350

d-Color MF450

Page 2

PUBLICATION ISSUED BY:

Olivetti S.p.A.

77, Via Jervis - 10015 Ivrea (TO)

Italy

Copyright © 2008, Olivetti

All rights reserved

Page 3

SD-505GeneralMaintenanceAdjustment / Setting

Troubleshooting

Field Service Ver. 2.0 Jan. 2008

i

CONTENTS

SD-505

Outline

1. Product specification ............................................................................................... 1

Maintenance

2. Service tool ............................................................................................................. 3

2.1 CE tool list............................................................................................................. 3

3. Other ....................................................................................................................... 4

3.1 Disassembly/adjustment prohibited items ............................................................ 4

3.2 Disassembly/Assembly/Cleaning list (other parts)................................................ 5

3.2.1 Disassembly/Assembly parts list................................................................... 5

3.2.2 Cleaning parts list ......................................................................................... 5

3.3 Disassembly/Assembly procedure........................................................................ 5

3.3.1 Paper output tray/front cover ......................................................................... 5

3.3.2 Rear cover..................................................................................................... 6

3.3.3 Upper cover................................................................................................... 6

3.3.4 Saddle unit .................................................................................................... 7

3.3.5 Crease unit.................................................................................................... 9

3.3.6 Stapler unit .................................................................................................. 11

3.3.7 In & out guide motor.................................................................................... 15

3.3.8 Crease roller ............................................................................................... 17

3.4 Cleaning procedure ............................................................................................ 24

3.4.1 Cleaning of the rollers and rolls .................................................................. 24

Adjustment/Setting

4. How to use the adjustment section ....................................................................... 25

5. Sensor check......................................................................................................... 26

5.1 Check procedure ................................................................................................ 26

5.1.1 Sensor check screen................................................................................... 26

5.1.2 Sensor check list ......................................................................................... 27

6. Finisher operations................................................................................................ 28

6.1 Entering Finisher Check ..................................................................................... 28

6.2 Finisher Check modes ........................................................................................ 29

6.3 Fold & Staple Pos. Adjustment ........................................................................... 30

6.4 Center Staple Position Adjustment ..................................................................... 32

Page 4

SD-505

GeneralMaintenanceAdjustment / Setting

Troubleshooting

Field Service Ver. 2.0 Jan. 2008

ii

7. Mechanical adjustment ......................................................................................... 34

7.1 Fold Angle Adjustment ....................................................................................... 34

7.2 Center Staple Angle Adjustment ........................................................................ 35

Troubleshooting

8.Jam display for d-Color MF350 / MF250 / MF201Plus .........................................37

8.1 Misfeed display................................................................................................... 37

8.2 Sensor layout...................................................................................................... 37

8.3 Solution .............................................................................................................. 38

8.3.1 Initial check items ....................................................................................... 38

8.3.2 Solution when paper curl occurs................................................................. 38

8.3.3 Paper bundle exit misfeed........................................................................... 39

8.3.4 Staple unit 1 misfeed/Staple unit 2 misfeed................................................ 40

8.3.5 Creasing section misfeed............................................................................ 41

9

.Jam display for d-Color MF450 ............................................................................43

9

.1Misfeed display...................................................................................................43

9

.2Sensor layout......................................................................................................43

9

.3Solution..............................................................................................................44

9

.3.1Initial check items.......................................................................................44

9.3.2Paper bundle exit misfeed...........................................................................45

9.3.3Staple unit 1 misfeed/Staple unit 2 misfeed................................................46

9.3.4Creasing section misfeed............................................................................47

10.Malfunction code.................................................................................................48

10.1Trouble code.....................................................................................................48

10.2Solution............................................................................................................49

10.2.1C11A2: Saddle exit roller pressure/retraction failure................................49

10.2.2C11A4: Saddle exit motor failure..............................................................49

10.2.3C11A5: Saddle in & out guide motor failure..............................................50

10.2.4C11A6: Saddle layable guide drive failure................................................50

10.2.5C11B5: Side staple 1 drive failure.............................................................51

10.2.6C11B6: Side staple 2 drive failure.............................................................51

10.2.7C11D0: Crease motor drive failure...........................................................51

Page 5

Field Service Ver. 2.0 Jan. 2008 1. Product specification

1

SD-505General

Outline

1. Product specification

A. Type

B. Paper

C. Machine specifications

*1: Size when the paper output tray is pulled out

D. Operating environment

• Conforms to the operating environment of the main body.

E. Consumables

• Staples 2000 (MS-2C) x 2

NOTE

• These specifications are subject to change without notice.

Name Saddle sticher SD-505

Type Built into the finisher

Installation Screwed to the finisher

Document alignment Center

Stapling function

Center parallel two points

No. of sheets to be stapled together: 2 to 15

Ty pe

Plain paper

60 g/m

2

to 90 g/m

2

16 to 24 lb

Recycled paper

Thick paper

91 g/m

2

to 209 g/m

2

24.25 to 55.5 lb

Size

B5S to A3

8-

1

/2 x 11S to 11 x 17

Capacity 200 sheets or 20 copies

Power requirements

DC 24 V (supplied from the finisher)

DC 5 V

Max. power consumption 9.5 W or less

Dimensions

Crease unit

48 mm (W) x 399 mm (D) x 121 mm (H)

2 inch (W) x 15.75 inch (D) x 4.75 inch (H)

Saddle unit

445 mm (W) x 478 mm (D) x 203 mm (H)

17.5 inch (W) x 18.75 inch (D) x 8 inch (H)

576 mm (W) x 478 mm (D) x 281 mm (H) *1

22.75 inch (W) x 18.75 inch (D) x 11 inch (H) *1

Weight

Crease unit 1.9 kg (0.5 lb)

Saddle unit 7.4 kg (2.0 lb)

Y108482-2 Service Manual

Page 6

1. Product specification Field Service Ver. 2.0 Jan. 2008

2

SD-505

General

Blank Page

Service Manual Y108482-2

Page 7

Field Service Ver. 2.0 Jan. 2008 2. Service tool

3

SD-505Maintenance

Maintenance

2. Service tool

2.1 CE tool list

Tool name Shape Personnel Parts No. Remarks

Stapler unit positioning jig1

Y108482-2 Service Manual

AVGR08550Z

Page 8

3. Other Field Service Ver. 2.0 Jan. 2008

4

SD-505

Maintenance

3. Other

3.1 Disassembly/adjustment prohibited items

A. Paint-locked screws

NOTE

• To prevent loose screws, a screw lock in blue or green series color is applied to

the screws.

• The screw lock is applied to the screws that may get loose due to the vibrations

and loads created by the use of machine or due to the vibrations created during

transportation.

• If the screw lock coated screws are loosened or removed, be sure to apply a screw

lock after the screws are tightened.

B. Red-painted screws

NOTE

• The screws which are difficult to be adjusted in the field are painted in red in order

to prevent them from being removed by mistake.

• Do not remove or loosen any of the red-painted screws in the field. It should also

be noted that, when two or more screws are used for a single part, only one representative screw may be marked with the red paint.

C. Variable resistors on board

NOTE

• Do not turn the variable resistors on boards for which no adjusting instructions

are given in Adjustment/Setting.

D. Removal of PWBs

CAUTION

• When removing a circuit board or other electrical component, refer to “Handling of

PWBs” and follow the corresponding removal procedures.

• The removal procedures given in the following omit the removal of connectors and

screws securing the circuit board support or circuit board.

• Where it is absolutely necessary to touch the ICs and other electrical components

on the board, be sure to ground your body.

Service Manual Y108482-2

Page 9

Field Service Ver. 2.0 Jan. 2008 3. Other

5

SD-505Maintenance

3.2 Disassembly/Assembly/Cleaning list (other parts)

3.2.1 Disassembly/Assembly parts list

3.2.2 Cleaning parts list

3.3 Disassembly/Assembly procedure

3.3.1 Paper output tray/front cover

1. Align the cutout and remove the paper output tray [1].

2. Remove two screws [2], and remove the front cover [3].

No. Section Part name Ref. page

1

Exterior parts

Paper output tray P. 5

2 Front cover P. 5

3 Upper cover P. 6

4Rear cover P. 6

5

Units

Saddle unit P. 7

6 Crease unit P. 9

7 Stapler unit P. 1 1

8

Others

In & out guide drive motor P. 1 5

9 Crease roller P. 1 7

No. Section Part name Ref. page

1

Exit section

Transport section

Rollers and rolls P. 2 4

4511F2C500DA

[1]

[3]

[2]

Y108482-2 Service Manual

Page 10

3. Other Field Service Ver. 2.0 Jan. 2008

6

SD-505

Maintenance

3.3.2 Rear cover

1. Remove two screws [1], and remove the rear cover [2].

3.3.3 Upper cover

1. Remove the front cover.

See P.5

2. Remove the rear cover.

See P.6

3. Remove four screws [1], and remove

the upper cover [2].

4511F2C501DA

[1]

[2]

4511F2C514DA

[1]

[1]

[2]

Service Manual Y108482-2

Page 11

Field Service Ver. 2.0 Jan. 2008 3. Other

7

SD-505Maintenance

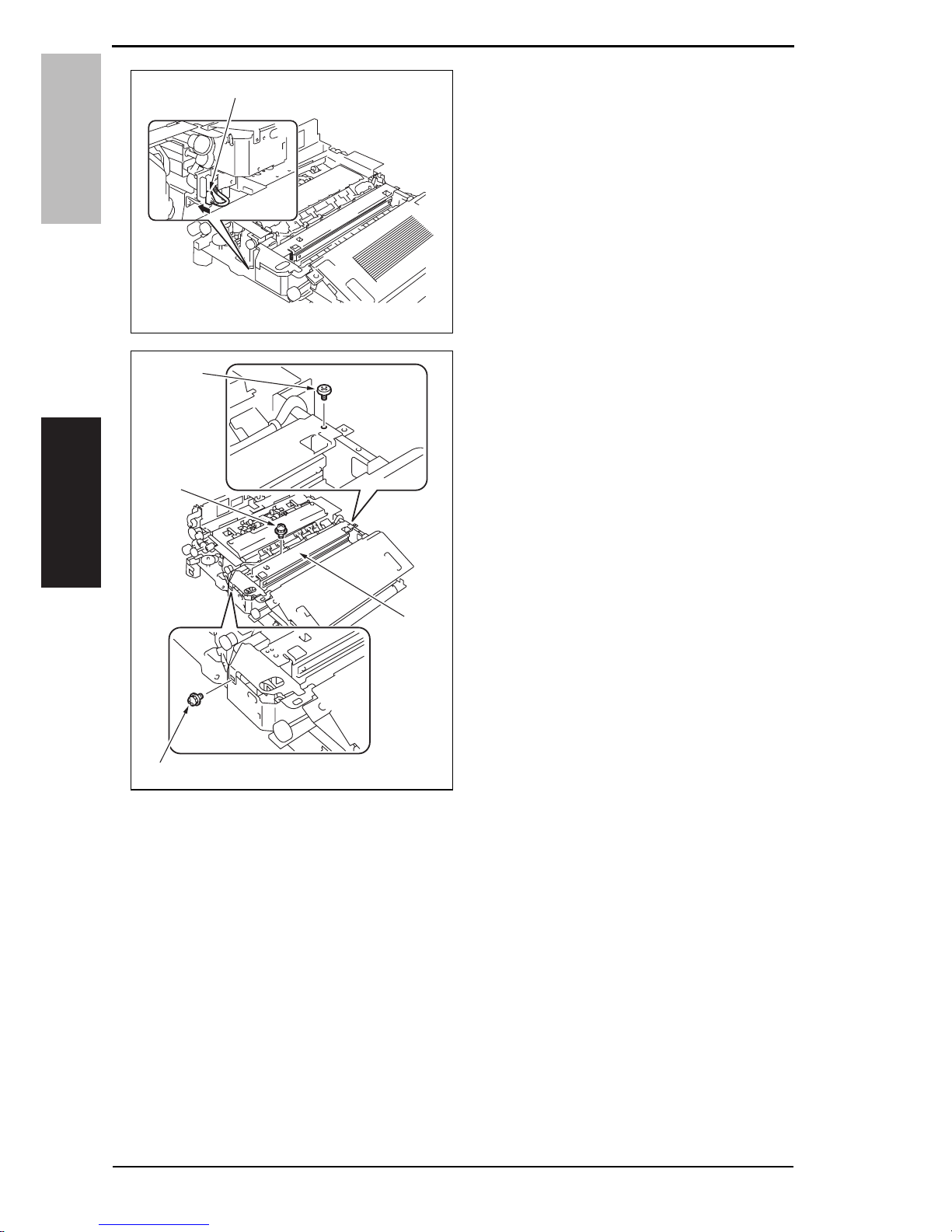

3.3.4 Saddle unit

1. Remove the screw [1], and remove

the connector cover [2].

2. Remove the screw [1], and remove

the ground wire [2].

3. Disconnect two connectors [3].

4. Remove the snap band [4].

5. Remove the screw [1], and remove

the mounting bracket [2].

4511F2C555DA

[2]

[1]

4511F2C556DA

[1]

[2]

[3] [4]

4511F2C557DA

[1]

[2]

Y108482-2 Service Manual

Page 12

3. Other Field Service Ver. 2.0 Jan. 2008

8

SD-505

Maintenance

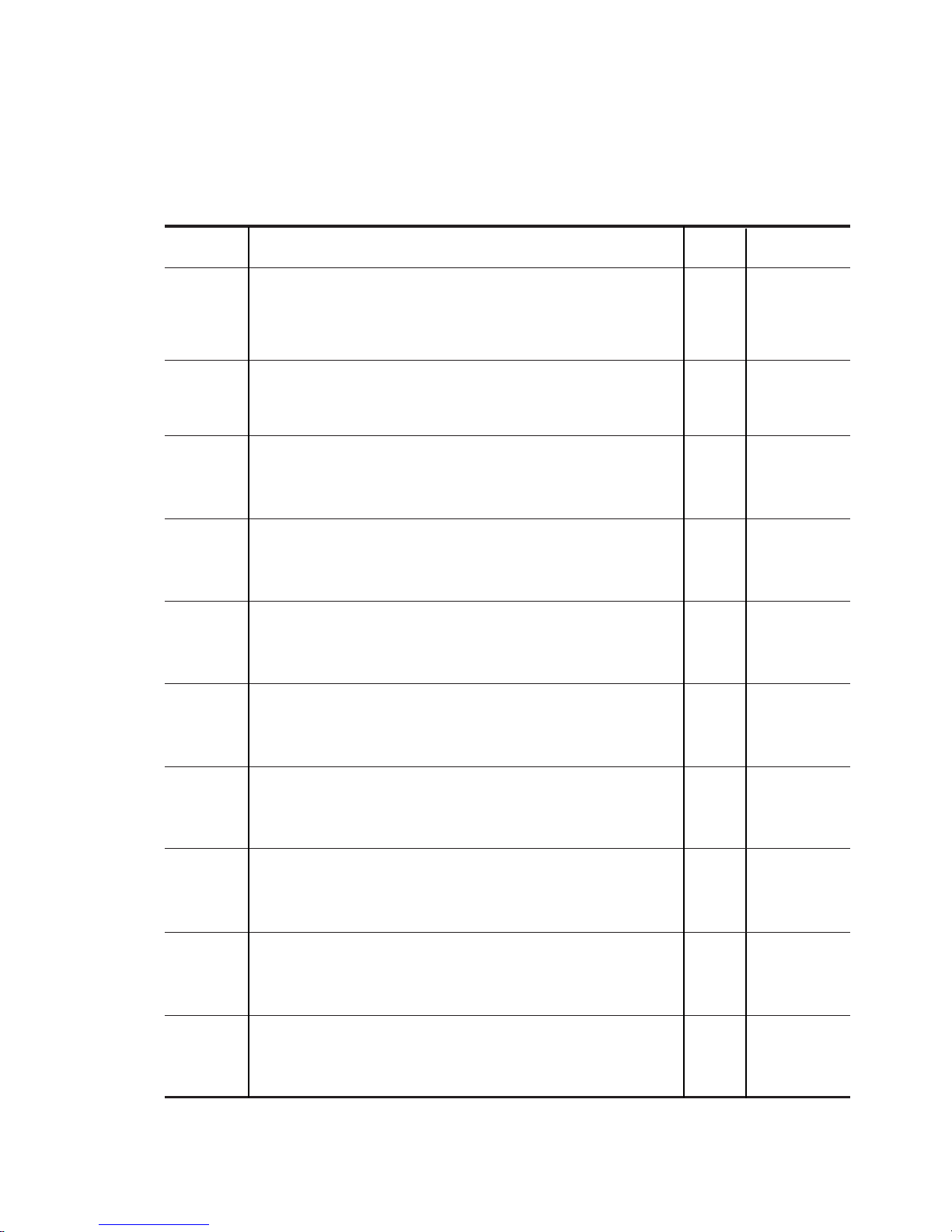

6. Pull the lock release lever [1], and

open the saddle unit.

7. Remove the screw [2].

8. Remove two screws [1], and remove

the saddle unit [2].

4511F2C558DA

[2]

[1]

4511F2C559DA

[1]

[2]

Service Manual Y108482-2

Page 13

Field Service Ver. 2.0 Jan. 2008 3. Other

9

SD-505Maintenance

3.3.5 Crease unit

1. Remove the saddle unit.

See P.7

2. Remove the finisher unit.

See P.34 of the FS-519/PK-515/OT-602 service manual.

3. Remove four screws [1] and remove

the finisher unit rear cover [2].

4. Disconnect the connector [3].

5. Remove three screws [1] and

remove the finisher unit upper cover

[2].

6. Remove two screws [1] and remove

the finisher unit right front cover [2].

NOTE

• At reinstallation, first fit the tab [3]

into position.

4511F2C560DA

[3]

[1]

[2]

[1]

4511F2C561DA

[1]

[1]

[2]

4511F2C562DA

[2]

[3]

[1]

Y108482-2 Service Manual

Page 14

3. Other Field Service Ver. 2.0 Jan. 2008

10

SD-505

Maintenance

7. Disconnect the connector [1].

8. Remove three screws [1], and

remove the crease unit [2].

NOTE

• When the punch kit is mounted,

remove the punch kit first.

4511F2C563DA

[1]

4511F2C564DA

[1]

[1]

[1]

[2]

Service Manual Y108482-2

Page 15

Field Service Ver. 2.0 Jan. 2008 3. Other

11

SD-505Maintenance

3.3.6 Stapler unit

1. Remove the saddle unit.

See P.7

2. Remove the paper output tray.

See P.5

3. Remove the front cover.

See P.5

4. Remove the rear cover.

See P.6

5. Remove the upper cover.

See P.6

6. Remove the screw [1], and remove

the ground wire [2].

7. Remove two screws [3], and remove

the holder [4].

8. Release the lock release lever [1],

and slide the saddle unit mounting

plate [2].

9. Remove the shoulder screw [3] and

the washer [4], and remove the saddle unit mounting plate [2].

10. Remove the harness clamp [1] from

the metal bracket.

11. Remove the harness from the

wire

saddle.

12. Disconnect four connectors [1].

13. Remove the C-ring [2], and remove

the bearing [3].

14. Remove five screws [4], and remove

the drive unit [5].

4511F2C513DA

[1]

[2]

[3]

[3]

[4]

4511F2C515DA

[3]

[4]

[1]

[2]

4511F2C516DA

[1]

4511F2C517DA

[5]

[1]

[1]

[2]

[3]

[4]

[4]

Y108482-2 Service Manual

Page 16

3. Other Field Service Ver. 2.0 Jan. 2008

12

SD-505

Maintenance

15. Remove the wire saddle [1], and disconnect the connector [2].

16. Remove two screws [1] and two

shoulder screws [2].

17. Remove the processing tray [1].

18. Disconnect all the connectors on the

SD control board.

19. Remove the board support, and then

remove the SD control board [1].

20. Remove the screw [1], and remove

the lock release lever [2].

4511F2C518DA

[2]

[1]

4511F2C519DA

[1]

[2]

4511F2C520DA

[1]

4511F2C521DA

[1]

4511F2C522DA

[1]

[2]

Service Manual Y108482-2

Page 17

Field Service Ver. 2.0 Jan. 2008 3. Other

13

SD-505Maintenance

21. Remove eight screws [1], and

remove the lower cover [2].

22. Remove the wire saddle and disconnect the connector.

23. Remove three screws [1], and

remove the clincher 1 [2].

24. Remove the staple cartridge 1 [1].

25. Remove four screws [1], and remove

the stapler 1 [2].

NOTE

• To replace clincher 2 and stapler 2,

repeat steps 22 to 25.

4511F2C523DA

[2]

[1]

[1]

[1]

[1]

4511F2C524DA

[2]

[1]

4511F2C525DA

[1]

4511F2C526DA

[1]

[2]

Y108482-2 Service Manual

Page 18

3. Other Field Service Ver. 2.0 Jan. 2008

14

SD-505

Maintenance

Precaution for clincher reinstallation

• When the clincher is installed, the position of the stapler and the clincher will be

misaligned. Be sure to perform the following adjustment.

1. Use three screws [1] to temporary fix

the clincher [2].

2. Loosen the screw [1] of the stopper.

3. Loosen three screws [2] of the

clincher.

4. Aligning the protrusions of the jig [2]

with the recesses in the stapler [1], fit

the jig to the stapler.

NOTE

• Make sure that the protrusions of

the jig properly rest in the recesses.

5. Turn the gear [1] of the clincher and

then slide the clincher assy so that

the protrusion of the clincher [3] fits

into the recess in the jig [2].

4511F2C550DA

[2]

[1]

4511F2C551DA

[1]

[2]

4511F2C552DA

[2]

[1]

4511F2C553DA

[1]

[3]

[2]

Service Manual Y108482-2

Page 19

Field Service Ver. 2.0 Jan. 2008 3. Other

15

SD-505Maintenance

6. Tighten six screws [1].

NOTE

• Turn the gear again and check to

see that the protrusion of the

clincher smoothly fits into the

recess in the jig.

7. Turn the gear and remove the jig.

3.3.7 In & out guide motor

1. Remove the saddle unit.

See P.7

2. Remove the paper output tray.

See P.5

3. Remove the front cover.

See P.5

4. Remove the rear cover.

See P.6

5. Remove the upper cover.

See P.6

6. Remove the screw [1], and remove

the ground wire [2].

7. Remove two screws [3], and remove

the holder [4].

8. Release the lock release lever [1],

and slide the saddle unit mounting

plate [2].

9. Remove the shoulder screw [3] and

the washer [4], and remove the saddle unit mounting plate [2].

10. Remove the screw [1], and remove

the lock release lever [2].

4511F2C554DA

[1]

[1]

4511F2C513DA

[1]

[2]

[3]

[3]

[4]

4511F2C515DA

[3]

[4]

[1]

[2]

4511F2C522DA

[1]

[2]

Y108482-2 Service Manual

Page 20

3. Other Field Service Ver. 2.0 Jan. 2008

16

SD-505

Maintenance

11. Remove eight screws [1], and

remove the lower cover [2].

12. Remove the wire saddle [1], and disconnect two connectors [2].

13. Remove the screw [1], and remove

the in & out guide motor assy [2].

14. Remove two C-rings [1].

15. Remove two bushings [2], and

remove the clutch gear assy [3].

16. Remove two screws [1], and remove

the in & out guide motor [2].

4511F2C523DA

[2]

[1]

[1]

[1]

[1]

4511F2C529DA

[1]

[2]

4511F2C530DA

[1]

[2]

4511F2C531DA

[3]

[2]

[1]

4511F2C532DA

[1]

[1]

[2]

Service Manual Y108482-2

Page 21

Field Service Ver. 2.0 Jan. 2008 3. Other

17

SD-505Maintenance

Precaution for in & out guide motor reinstallation

1. Press the two in & out guides [1] in and check that they touch the stopper [2] simultaneously.

2. Check that pins [4] can be inserted through the positioning holes [3] (3 holes) of the in

& out guide sensor assy.

3. Use two screws to secure the in & out guide motor.

3.3.8 Crease roller

1. Remove the crease unit.

See P.9

2. Remove two springs [1] and four

screws [2], and remove the upper

plate [3].

4511F2C533DA

[1]

[2]

[3]

[4]

4511F2C565DA

[1]

[1]

[2]

[2]

[3]

Y108482-2 Service Manual

Page 22

3. Other Field Service Ver. 2.0 Jan. 2008

18

SD-505

Maintenance

3. Remove two screws [1], and remove

the guide plate [2].

4. Remove two screws [1], and remove

the chopper assy [2].

NOTE

• Install the chopper assy in the

direction shown in the left figure.

4511F2C566DA

[2]

[1]

4511F2C567DA

[1]

[1]

[2]

4511F2C583DA

Front Rear

Service Manual Y108482-2

Page 23

Field Service Ver. 2.0 Jan. 2008 3. Other

19

SD-505Maintenance

5. Remove three C-rings [1] and three

pins [2], and remove three gears [3].

NOTE

• Use care not to lose the pin.

NOTE

• Install the gear so that the mark [1]

is aligned to the position shown in

the left figure.

6. Remove two C-rings [1], and remove

two bearings [2].

7. Remove the bushing [3].

4511F2C568DA

[1]

[2]

[3]

[3]

4511F2C569DA

[1]

4511F2C570DA

[1]

[2]

[3]

Y108482-2 Service Manual

Page 24

3. Other Field Service Ver. 2.0 Jan. 2008

20

SD-505

Maintenance

8. Remove two screws [1], and remove

the rear holder [2].

9. Remove the C-ring [1] and the pin

[2], and remove the gear [3].

NOTE

• Use care not to lose the pin.

NOTE

• Install the gear so that the mark [1]

is aligned to the position shown in

the left figure.

4511F2C571DA

[1]

[2]

4511F2C572DA

[1]

[3]

[2]

4511F2C573DA

[1]

Service Manual Y108482-2

Page 25

Field Service Ver. 2.0 Jan. 2008 3. Other

21

SD-505Maintenance

10. Remove two C-rings [1], two bearings [2] and two washers [3].

NOTE

• Use care not to lose the washer.

11. Remove two gears [1] of crease

roller 1 assy, and remove the guide

plate [2].

NOTE

• When installing the gear [1] to the

guide plate [2], insert the gear [1] at

an angle and use care not to break

the tabs [3].

• Install the guide plate as shown on

the left.

4511F2C574DA

[1]

[2]

[3]

4511F2C581DA

[1]

[2]

4511F2C575DA

[1]

[2]

[3]

Long one

Y108482-2 Service Manual

Page 26

3. Other Field Service Ver. 2.0 Jan. 2008

22

SD-505

Maintenance

NOTE

• When mounting the crease roller 1

assy [1], mount it so that the tally

mark on the gear [2] for the crease

roller 1 and the tally mark on the

gear below will be next to each

other with the one on the gear [2]

being outer side.

12. Remove the screw [1].

13. Remove two C-rings [2] and remove

the crease roller A [3], B [4] and C

[5].

14. Remove two gears [1] of crease

roller 2 assy, and remove the guide

plate [2].

4511F2C576DA

[2]

[1]

4511F2C577DA

[1]

[2]

[2]

[5]

[4]

[3]

4511F2C582DB

[1]

[2]

Service Manual Y108482-2

Page 27

Field Service Ver. 2.0 Jan. 2008 3. Other

23

SD-505Maintenance

NOTE

• When installing the gear [1] to the

guide plate [2], insert the gear [1] at

an angle and use care not to break

the tabs [3].

• Install the gear and guide plate as

shown on the left.

15. Remove the screw [1].

16. Remove two C-rings [2] and remove

the crease roller A [3], B [4] and C

[5].

NOTE

• When mounting the crease roller

assy 2, mount it so that the gear [1]

for the crease roller 2 assy will be

over the gear for the cease roller 1

by one tooth.

4511F2C578DA

[1]

[3] [2]

D cutting

4511F2C577DA

[1]

[2]

[2]

[5]

[4]

[3]

4511F2C579DA

[1]

Y108482-2 Service Manual

Page 28

3. Other Field Service Ver. 2.0 Jan. 2008

24

SD-505

Maintenance

NOTE

• Use care to mount the crease roller

assy 1 [1] and 2 [2] in the proper

directions.

3.4 Cleaning procedure

NOTE

• The alcohol described in the cleaning procedure of maintenance represents the

isopropyl alcohol.

3.4.1 Cleaning of the rollers and rolls

1. Using a cleaning pad dampened with

alcohol, wipe the roller [1] and roll

[2].

2. Remove the crease unit.

See P.9

3. Using a cleaning pad dampened with

alcohol, wipe the roller [1].

4511F2C580DA

[1]

[2]

4511F2C502DA

[1]

[1]

[1]

[2]

[2]

[2]

4511F2C011DA

[1]

Service Manual Y108482-2

Page 29

Field Service Ver. 2.0 Jan. 2008 4. How to use the adjustment section

25

SD-505Adjustment / Setting

Adjustment/Setting

4. How to use the adjustment section

• “Adjustment/Setting” contains detailed information on the adjustment items and procedures for this machine.

• Throughout this “Adjustment/Setting,” the default settings are indicated by “ ”.

Advance checks

Before attempting to solve the customer problem, the following advance checks must be

made. Check to see if:

• The power supply voltage meets the specifications.

• The power supply is properly grounded.

• The machine shares the power supply with any other machine that draws large current

intermittently (e.g., elevator and air conditioner that generate electric noise).

• The installation site is environmentally appropriate: high temperature, high humidity,

direct sunlight, ventilation, etc.; levelness of the installation site.

• The original has a problem that may cause a defective image.

• The density is properly selected.

• The original glass, slit glass, or related part is dirty.

• Correct paper is being used for printing.

• The units, parts, and supplies used for printing (developer, PC drum, etc.) are properly

replenished and replaced when they reach the end of their useful serv

ice life.

• Toner is not running out.

CAUTION

• To unplug the power cord of the machine before starting the service job procedures.

• If it is unavoidably necessary to service the machine with its power turned ON, use

utmost care not to be caught in the scanner cables or gears of the exposure unit.

• Special care should be used when handling the fusing unit which can be

extremely hot.

• The developing unit has a strong magnetic field. Keep watches and measuring

instruments away from it.

• Take care not to damage the PC drum with a tool or similar device.

• Do not touch IC pins with bare hands.

Y108482-2 Service Manual

Page 30

5. Sensor check Field Service Ver. 2.0 Jan. 2008

26

SD-505

Adjustment / Setting

5. Sensor check

5.1 Check procedure

A. Procedure

1. Display the Service Mode screen.

See P.338 of the main body service manual.

2. Touch [State Confirmation].

3. Touch [Sensor Check].

4. Touch three times [z].

5.1.1 Sensor check screen

•This is only typical screen which may be different from what are shown on each individ-

ual main body.

4511F3E541DA

Service Manual Y108482-2

d-Color MF350 / d-Color MF250 / d-Color MF201Plus

d-Color MF450

4510F3E515DA

Page 31

Field Service Ver. 2.0 Jan. 2008 5. Sensor check

27

SD-505Adjustment / Setting

5.1.2 Sensor check list

A. Sensors 4

Symbol Panel display Part/Signal name

Operation characteris-

tics/Panel display

10

PS20

Sensors monitor4

Saddle exit Saddle exit sensor

Paper

present

Paper not

present

PS22 Folding R home Crease roller home position sensor

Paper

present

Paper not

present

SW5 Middle guide Middle guide switch Open Closed

PS24 Saddle guide Layable guide home sensor Blocked Unblocked

— Saddle stapler 1

— Home Staple Home Position Sensor 1 Blocked Unblocked

— Staple empty Staple Empty Detection Sensor 1 Blocked Unblocked

— Self priming Self-Priming Sensor 1 Blocked Unblocked

— Saddle stapler 2

— Home Staple Home Position Sensor 2 Blocked Unblocked

— Staple empty Staple Empty Detection Sensor 2 Blocked Unblocked

— Self priming Self-Priming Sensor 2 Blocked Unblocked

SW4 Saddle Saddle opening switch Open Closed

PS21 Saddle empty Saddle tray empty sensor

Paper

present

Paper not

present

PS18 Home (Saddle exit) Saddle exit roller home position sensor

Paper

present

Paper not

present

Y108482-2 Service Manual

Page 32

6. Finisher operations Field Service Ver. 2.0 Jan. 2008

28

SD-505

Adjustment / Setting

6. Finisher operations

6.1 Entering Finisher Check

1. Display the Service Mode screen.

See P.338 of the main body service manual.

2. Touch [Finisher].

3. Touch [CB-FN adjustment].

4. Touch [Finisher Check].

5. Touch the item one wants.

4511F3E533DA

Service Manual Y108482-2

Page 33

Field Service Ver. 2.0 Jan. 2008 6. Finisher operations

29

SD-505Adjustment / Setting

6.2 Finisher Check modes

A. Fold Drive

• Performs the creasing drive once.

o Raises the layable guide.

o Stops after the predetermined time.

o Lowers the layable guide.

o The operation is finished.

B. Saddle Outlet Open&Close

• Opens the saddle exit after the saddle exit is opened and closed.

o Stops after the predetermined time.

o The saddle exit closes.

o The saddle in & out guide advances.

o Stops after the predetermined time.

o The saddle in & out guide retracts.

o The operation is finished.

C. Conveyance Drive

• Transport drive is performed for the predetermined time. (Performs the same transport

drive as the pre-drive with the high speed of the connected copier.)

o Drives the entrance motor (M1).

o Drives the transport motor/1 (M2).

o Drives the transport motor/2 (M3).

o Drives the exit motor (M4).

o The operation is finished.

• If the mail bin kit MT-502 is installed, the mail bins are also driven.

• If the saddle kit SD-505 is also installed, the saddle transport motor (M8) is also driven.

Y108482-2 Service Manual

Page 34

6. Finisher operations Field Service Ver. 2.0 Jan. 2008

30

SD-505

Adjustment / Setting

6.3 Fold & Staple Pos. Adjustment

NOTE

Make this adjustment after any of the following procedures has been performed.

• When the crease unit has been replaced.

• When a deviation occurs in the crease.

• When fold angle adjustment has been made.

1. Make a copy in the crease mode. (A3 size)

2. Fold the copy fed out along the

crease.

3. Check the crease for deviation (Measure width A).

Specification: 0 ± 1.5 mm

4. When the width A does not fall within

the specified value, conduct the following adjustment.

5. Display the Service Mode screen.

See P.338 of the main body service manual.

6. Touch [Finisher].

7. Touch [CB-FN adjustment].

8. Touch [Fold & Staple Pos.Adjustment].

9. Touch [Fold Position Adjustment].

10. Touch [A3] and then touch [Normal Paper].

4511F3C505DA

A

Exit direction

4511F3E539DA

Service Manual Y108482-2

Page 35

Field Service Ver. 2.0 Jan. 2008 6. Finisher operations

31

SD-505Adjustment / Setting

• If the fold is offset as shown on the left.

11. Touch [-] and set the appropriate

numeric value.

Adjustment range: 0 to -10

(1 increment 0.5 mm)

• If the fold is offset as shown on the left.

12. Touch [+] and set the appropriate

numeric value.

Adjustment range: 0 to +10

(1 increment 0.5 mm)

13. Touch [END].

14. Make another copy, and check the deviation.

15. Touch [Exit] on the Service Mode screen.

16. Turn OFF the main power switch, wait for 10 sec., then turn the switch ON.

4511F3C505DA

A

Exit direction

4511F3C506DA

A

Exit direction

Y108482-2 Service Manual

Page 36

6. Finisher operations Field Service Ver. 2.0 Jan. 2008

32

SD-505

Adjustment / Setting

6.4 Center Staple Position Adjustment

NOTE

Make this adjustment after any of the following procedures has been performed.

• When staple unit has been replaced.

• When center staple position is misaligned.

• When center staple angle adjustment has been made.

1. Load a five-page A4 document in the

document feed tray.

2. Select the center staple mode and

make a copy. (A3 Size)

3. Check the staple position for deviation from the crease (Measure width

A).

Specification: 0 ± 1.5 mm

4. When the width A does not fall within

the specified value, conduct the following adjustment.

5. Display the Service Mode screen.

See P.338 of the main body service manual.

6. Touch [Finisher].

7. Touch [CB-FN adjustment].

8. Touch [Fold & Staple Pos.Adjustment].

9. Touch [Center Staple Position].

10. Touch [A3] and then touch [Normal Paper].

4511F3C510DA

A

Exit direction

4511F3E540DA

Service Manual Y108482-2

Page 37

Field Service Ver. 2.0 Jan. 2008 6. Finisher operations

33

SD-505Adjustment / Setting

• If the fold is offset as shown on the left.

11. Touch [-] and set the appropriate

numeric value.

Adjustment range: 0 to -10

(1 increment 0.5 mm)

• If the fold is offset as shown on the left.

12. Touch [+] and set the appropriate

numeric value.

Adjustment range: 0 to +10

(1 increment 0.5 mm)

13. Touch [END].

14. Make another copy, and check the deviation.

15. Touch [Exit] on the Service Mode screen.

16. Turn OFF the main power switch, wait for 10 sec., then turn the switch ON.

4511F3C510DA

A

Exit direction

4511F3C511DA

A

Exit direction

Y108482-2 Service Manual

Page 38

7. Mechanical adjustment Field Service Ver. 2.0 Jan. 2008

34

SD-505

Adjustment / Setting

7. Mechanical adjustment

7.1 Fold Angle Adjustment

NOTE

Make this adjustment after any of the following procedures has been performed.

• When the crease unit has been replaced.

• When a slant occurs in the crease.

1. Make a copy in the crease mode. (A3 size)

2. Fold the output paper along the

crease [1].

3. Fold the output paper and half and

measure the width A of the paper.

Specification: 0 ± 1.5 mm

4. If the fold position is slanted as

shown on the left, make the following

adjustment.

5. Open the front door, loosen the

adjustment screw [1], and move the

crease unit to the left to make the

adjustment.

Graduated in 1-mm divisions

• If the fold position is slanted opposite

to the figure of step 4, move the

crease unit to the right to make the

adjustment.

6. Make another copy and check the

fold position.

4511F3C501DA

[1]

A

Exit direction

Center

4511F3C532DA

[1]

Service Manual Y108482-2

Page 39

Field Service Ver. 2.0 Jan. 2008 7. Mechanical adjustment

35

SD-505Adjustment / Setting

7.2 Center Staple Angle Adjustment

NOTE

Make this adjustment after any of the following procedures has been performed.

• When staple unit has been replaced.

• When a slant occurs in the position of the center staple.

1. Load a five-page A4 document in the

document feed tray.

2. Select the center staple mode and

make a copy. (A3 Size)

3. Check the staple position for deviation from the crease (Measure width

A).

Specification: 0 ± 1.5 mm

4. If the staple position is slanted as

shown on the left, make the following

adjustment.

5. Release the lock release lever [1] of

the saddle unit.

6. Loosen the adjustment screw [2] and

move the lock lever to the left to

make the adjustment.

• If the staple position is slanted oppo-

site to the figure of step 2, move the

lock lever to the right to make the

adjustment.

7. Make another copy and check the staple position.

4511F3C507DA

Exit direction

A

4511F3C508DA

[2]

[1]

Y108482-2 Service Manual

Page 40

7. Mechanical adjustment Field Service Ver. 2.0 Jan. 2008

36

SD-505

Adjustment / Setting

Blank Page

Service Manual Y108482-2

Page 41

Field Service Ver. 2.0 Jan. 2008 8. Jam display

37

SD-505

Troubleshooting

Troubleshooting

8.Jam display for d-Color MF350 / MF250 / MF201Plus

8.1 Misfeed display

• When misfeed occurs, message, misfeed location “Blinking” and paper location “Lighting” are displayed on the touch panel of the main body.

8.2 Sensor layout

Display Code Misfeed location Misfeed processing location Action

[1]

7221 Paper bundle exit misfeed Front door P. 3 9

7285 Staple unit 1 misfeed Saddle cover

P. 4 0

7284 Staple unit 2 misfeed Saddle cover

7225 Creasing section misfeed Front door P. 4 1

4511F4C505DA

[1]

[1] Saddle exit sensor PS20

[2] Entrance sensor PS1

[3] Storage tray detect sensor PS3

4511F4C501DA

[1]

[3]

[2]

Y108482-2 Service Manual

Page 42

8. Jam display Field Service Ver. 2.0 Jan. 2008

38

SD-505

Troubleshooting

8.3 Solution

8.3.1 Initial check items

• When a paper misfeed occurs, first perform the following initial check items.

8.3.2 Solution when paper curl occurs

Check Item Action

Does the paper meet product specifications? Change the paper.

Is paper curled, wavy, or damp? See “Solution when paper curl occurs” on P.38.

Is a foreign object present along the paper path, or is

the paper path deformed or worn?

Clean or change the paper path.

Are the rolls/rollers dirty, deformed, or worn? Clean or change the defective roll/roller.

Are the edge guide and trailing edge stop at the correct position to accommodate the paper?

Set as necessary.

Are the actuators found operational when checked for

correct operation?

Correct or change the defective actuator.

Step Check items/actions

1 Turn over the stacked paper in the paper tray.

OK —

NG Go to step 2.

2

Does paper curl occur just after a warm-up has been completed or

the sleep mode has been turned OFF?

YES Go to step 3.

Does paper curl occur under normal conditions (under conditions

other than those mentioned above)?

YES Go to step 5.

3

1. Call the Service Mode to the screen.

2. Select [System 1] → [Change Warm Up Time].

3. Change the setting to [Mode3].

See P.394 of the main body service manual.

OK —

NG Go to step 4.

4

1. Call the Service Mode to the screen.

2. Select [System 1] → [Change Warm Up Time].

3. Change the setting to [Mode4].

See P.394 of the main body service manual.

——

5

1. Call the Service Mode to the screen.

2. Select [Machine] → [Fusing Temperature].

3. Select a paper type.

4. Change the temperature of Heater Roller to [-10 °C].

See P.346 of the main body service manual.

OK —

NG Go to step 6

6

1. Call the Ser

vice Mode to the screen.

2. Select [Machine] → [Fusing Temperature].

3. Select a paper type.

4. Change the temperature of Heater Roller to [-20 °C].

See P.346 of the main body service manual.

——

Service Manual Y108482-2

Page 43

Field Service Ver. 2.0 Jan. 2008 8. Jam display

39

SD-505

Troubleshooting

8.3.3 Paper bundle exit misfeed

A. Detection timing

B. Action

Type Description

Paper bundle misfeed

detection

The storage tray detecting sensor (PS3) is not turned OFF even after the

set period of time has elapsed after the exit motor (M4) is energized.

The saddle exit sensor (PS20) is not turned ON even after the set period of

time has elapsed after the exit motor (M4) is energized.

The saddle exit sensor (PS20) is not turned OFF even after the set period

of time has elapsed after the saddle exit sensor (PS20) is turned ON.

Relevant electrical parts

Storage tray detect sensor (PS3)

Saddle exit sensor (PS20)

Exit motor (M4)

Saddle exit motor (M8)

SD control board (SDCB)

Step Action

WIRING DIAGRAM

Control signal

Location

(Electrical

component)

1 Initial check items — —

2 PS3 I/O check, sensor check FSCB PJ14-8 (ON) FS-519 C-12

3 PS20 I/O check, sensor check SDCB PJ19-8 (ON) SD-505 B-2

4 M4 operation check FSCB PJ10-5 to 8 FS-519 C-3

5 M8 operation check SDCB PJ4-1 to 2 SD-505 G-6

6 Change SDCB — —

Y108482-2 Service Manual

Page 44

8. Jam display Field Service Ver. 2.0 Jan. 2008

40

SD-505

Troubleshooting

8.3.4 Staple unit 1 misfeed/Staple unit 2 misfeed

A. Detection timing

B. Action

Type Description

Staple unit misfeed

detection

The staple home position sensor in the staple unit is not turned ON even

after the set period of time has elapsed after the staple motor rotates forward, and then the staple motor rotates backward, and the staple home

position sensor in the staple unit is turned ON within the set period of time.

Relevant electrical parts

Staple unit 1

Staple unit 2

SD control board (SDCB)

Step Action

WIRING DIAGRAM

Control signal

Location

(Electrical

component)

1 Initial check items — —

2 Drive coupling section check — —

3 Sensor check — —

4 Change staple unit 1 — —

5 Change staple unit 2 — —

6 Change SDCB — —

Service Manual Y108482-2

Page 45

Field Service Ver. 2.0 Jan. 2008 8. Jam display

41

SD-505

Troubleshooting

8.3.5 Creasing section misfeed

A. Detection timing

B. Action

Type Description

Creasing section

misfeed detection

The entrance sensor (PS1) is not turned ON even after the set period of

time has elapsed after the entrance motor (M1) is energized (beginning of

backward rotation operation).

The entrance sensor (PS1) is not turned OFF even after the set period of

time has elapsed after the entrance motor (M1) is energized (beginning of

forward rotation operation).

Relevant electrical parts

Entrance sensor (PS1)

Entrance motor (M1)

SD control board (SDCB)

Step Action

WIRING DIAGRAM

Control signal

Location

(Electrical

component)

1 Initial check items — —

2 PS1 I/O check, sensor check FSCB PJ19-11 (ON) FS-519 C-7

3 M1 operation check FSCB PJ9-1 to 4 FS-519 C-6 to 7

4 Change SDCB — —

Y108482-2 Service Manual

Page 46

1. Product specification Field Service Ver. 2.0 Jan. 2008

42

SD-505

Blank Page

Service Manual Y108482-2

Troubleshooting

Page 47

Field Service Ver. 2.0 Jan. 20089. Jam display

43

SD-505

Troubleshooting

Troubleshooting

9.Jam display for d-Color MF450

9.1 Misfeed display

• When misfeed occurs, message, misfeed location “Blinking” and paper location “Lighting” are displayed on the touch panel of the main unit.

9.2 Sensor layout

Display Code Misfeed location Misfeed processing location Action

[1]

7221

Paper bundle exit misfeedFront doorP.45

7285

Staple unit 1 misfeed Saddle cover

P.46

7284

Staple unit 2 misfeed Saddle cover

7225

Creasing section misfeedFront doorP.47

4511F4C504DA

[1]

[1] Saddle exit sensor PS20

[2] Entrance sensor PS1

[3] Storage tray detect sensor PS3

4511F4C501DA

[1]

[3]

[2]

Y108482-2 Service Manual

Page 48

9. Jam displayField Service Ver. 2.0 Jan. 2008

44

SD-505

Troubleshooting

9.3 Solution

9.3.1 Initial check items

• When a paper misfeed occurs, first perform the following initial check items.

Check Item Action

Does the paper meet product specifications? Change the paper.

Is paper curled, wavy, or damp?

Change the paper.

Instruct the user in correct paper storage.

Is a foreign object present along the paper path, or is the

paper path deformed or worn?

Clean or change the paper path.

Are the rolls/rollers dirty, deformed, or worn? Clean or change the defective roll/roller.

Are the edge guide and trailing edge stop at the correct

position to accommodate the paper?

Set as necessary.

Are the actuators found operational when checked for

correct operation?

Correct or change the defective actuator.

Service Manual Y108482-2

Page 49

Field Service Ver. 2.0 Jan. 20089. Jam display

45

SD-505

Troubleshooting

9.3.2 Paper bundle exit misfeed

A. Detection timing

B. Action

Type Description

Paper bundle misfeed

detection

The storage tray detecting sensor (PS3) is not turned OFF even after the

set period of time has elapsed after the exit motor (M4) is energized.

The saddle exit sensor (PS20) is not turned ON even after the set period of

time has elapsed after the exit motor (M4) is energized.

The saddle exit sensor (PS20) is not turned OFF even after the set period

of time has elapsed after the saddle exit sensor (PS20) is turned ON.

Relevant electrical parts

Storage tray detect sensor (PS3)

Saddle exit sensor (PS20)

Exit motor (M4)

Saddle exit motor (M8)

SD control board (SDCB)

Step Action

WIRING DIAGRAM

Control signal

Location

(Electrical

component)

1 Initial check items — —

2 PS3 sensor check FSCB PJ14FSCB-8 (ON) FS-519 C-12

3 PS20 sensor check SDCB PJ19SDCB-8 (ON) SD-505 B-2

4 M4 operation check FSCB PJ10FSCB-5 to 8 FS-519 C-3

5 M8 operation check SDCB PJ4SDCB-1 to 2 SD-505 G-6

6 Change SDCB — —

Y108482-2 Service Manual

Page 50

9. Jam displayField Service Ver. 2.0 Jan. 2008

46

SD-505

Troubleshooting

9.3.3 Staple unit 1 misfeed/Staple unit 2 misfeed

A. Detection timing

B. Action

Type Description

Staple unit misfeed

detection

The staple home position sensor in the staple unit is not turned ON even

after the set period of time has elapsed after the staple motor rotates forward, and then the staple motor rotates backward, and the staple home

position sensor in the staple unit is turned ON within the set period of time.

Relevant electrical parts

Staple unit 1

Staple unit 2

SD control board (SDCB)

Step Action

WIRING DIAGRAM

Control signal

Location

(Electrical

component)

1 Initial check items — —

2 Drive coupling section check — —

3 Sensor check — —

4 Change staple unit 1 — —

5 Change staple unit 2 — —

6 Change SDCB — —

Service Manual Y108482-2

Page 51

Field Service Ver. 2.0 Jan. 20089. Jam display

47

SD-505

Troubleshooting

9.3.4 Creasing section misfeed

A. Detection timing

B. Action

Type Description

Creasing section

misfeed detection

The entrance sensor (PS1) is not turned ON even after the set period of

time has elapsed after the entrance motor (M1) is energized (beginning of

backward rotation operation).

The entrance sensor (PS1) is not turned OFF even after the set period of

time has elapsed after the entrance motor (M1) is energized (beginning of

forward rotation operation).

Relevant electrical parts

Entrance sensor (PS1)

Entrance motor (M1)

SD control board (SDCB)

Step Action

WIRING DIAGRAM

Control signal

Location

(Electrical

component)

1 Initial check items — —

2 PS1 sensor check FSCB PJ19FSCB-11 (ON) FS-519 C-7

3 M1 operation check FSCB PJ9FSCB-1 to 4 FS-519 C-6 to 7

4 Change SDCB — —

Y108482-2 Service Manual

Page 52

10. Malfunction code Field ServiceVer. 2.0 Jan. 2008

48

SD-505

Troubleshooting

10.Malfunction code

10.1Trouble code

• The machine’s CPU performs a self-diagnostics function that, on detecting a malfunction,

gives the corresponding malfunction code and maintenance call mark on the touch

panel.

Code Item Description

C11A2

Saddle exit roller

pressure/retraction

failure

• The saddle exit roller home position sensor (PS18) is not

turned ON even after the set period of time has elapsed after

the saddle exit open/close motor (M9) is energized (beginning

of pressure operation).

• The saddle exit roller home position sensor (PS18) is not

turned OFF even after the set period of time has elapsed after

the saddle exit open/close motor (M9) is energized (beginning

of retraction operation).

C11A4 Saddle exit motor failure

The lock signal is detected after the set period of time has

elapsed after the saddle exit motor (M8) is energized.

C11A5

Saddle in & out guide

motor failure

• The in & out guide home sensor (PS23) is not turned OFF

even after the set period of time has elapsed after the in & out

guide motor (M13) is energized (beginning of advancing operation).

• The in & out guide home sensor (PS23) is not turned ON even

after the set period of time has elapsed after the in & out

guide motor (M13) is energized (beginning of retracting operation).

C11A6

Saddle layable guide drive

failure

• The layable guide home sensor (PS24) is not turned ON even

after the set period of time has elapsed after the layable guide

motor (M14) is energized (beginning of return operation to

predetermined position).

• The layable guide home sensor (PS24) is not turned OFF

even after the set period of time has elapsed after the layable

guide motor (M14) is energized (beginning of return operation

to predetermined position).

C11B5

Side staple 1 drive

failure

Home position sensor 1 is not turned OFF even after the set

period of time has elapsed after saddle staple motor 1 is energized (beginning of staple operation).

C11B6

Side staple 2 drive

failure

Home position sensor 2 is not turned OFF even after the set

period of time has elapsed after saddle staple motor 2 is energized (beginning of staple operation).

C11D0

Crease motor drive

failure

• The crease roller home position sensor (PS22) is not turned

OFF even after the set period of time has elapsed after the

crease motor (M10) is energized (beginning of backward rotation operation).

• The crease roller home position sensor (PS22) is not turned

ON even after the set period of time has elapsed after the

crease motor (M10) is energized (beginning of forward rotation operation).

Service Manual Y108482-2

Page 53

Field Service Ver. 2.0 Jan. 2008 10. Malfunction code

49

SD-505

Troubleshooting

10.2Solution

10.2.1C11A2: Saddle exit roller pressure/retraction failure

10.2.2C11A4: Saddle exit motor failure

Relevant electrical parts

Saddle exit open/close motor (M9)

Saddle exit roller home position sensor (PS18)

SD control board (SDCB)

Step Action

WIRING DIAGRAM

Control signal

Location

(Electrical

component)

1

Check the M9 connector for proper connection and correct as necessary.

——

2

Check M9 for proper drive coupling and

correct as necessary.

——

3 M9 operation check SDCB PJ4-6 to 7 SD-505 G-5 to 6

4 PS18 I/O check, sensor check SDCB PJ9-6 (ON) SD-505 B-2

5 Change SDCB — —

Relevant electrical parts

Saddle exit motor (M8) SD control board (SDCB)

Step Action

WIRING DIAGRAM

Control signal

Location

(Electrical

component)

1

Check the M8 connector for proper connection and correct as necessary.

——

2

Check M8 for proper drive coupling and

correct as necessary.

——

3 M8 operation check SDCB PJ4-1 to 2 SD-505 G-6

4 Change SDCB — —

Y108482-2 Service Manual

Page 54

1

50

SD-505

Troubleshooting

10.2.3C11A5: Saddle in & out guide motor failure

10.2.4C11A6: Saddle layable guide drive failure

Relevant electrical parts

In & out guide motor (M13)

In & out guide home sensor (PS23)

SD control board (SDCB)

Step Action

WIRING DIAGRAM

Control signal

Location

(Electrical

component)

1

Check the M13 connector for proper connection and correct as necessary.

——

2

Check M13 for proper drive coupling and

correct as necessary.

——

3 M13 operation check SDCB PJ4-4 to 5 SD-505 G-6

4 PS23 I/O check, sensor check SDCB PJ10-3 (ON) SD-505 B-2 to 3

5 Change SDCB — —

Relevant electrical parts

Layable guide motor (M14)

Layable guide home sensor (PS24)

SD control board (SDCB)

Step Action

WIRING DIAGRAM

Control signal

Location

(Electrical

component)

1

Check the M14 connector for proper connection and correct as necessary.

——

2

Check M14 for proper drive coupling and

correct as necessary.

——

3 M14 operation check SDCB PJ4-8 to 9 SD-505 G-5

4 PS24 I/O check, sensor check SDCB PJ10-6 (ON) SD-505 B-3

5 Change SDCB — —

Service Manual Y108482-2

10. Malfunction code Field ServiceVer. 2.0 Jan. 2008

Page 55

51

SD-505

Troubleshooting

10.2.5C11B5: Side staple 1 drive failure

10.2.6C11B6: Side staple 2 drive failure

10.2.7C11D0: Crease motor drive failure

Relevant electrical parts

Staple unit 1

Staple unit 2

SD control board (SDCB)

Step Action

WIRING DIAGRAM

Control signal

Location

(Electrical

component)

1

Check the staple units 1 and 2 connectors

for proper connection and correct as necessary.

——

2

Check staple units 1 and 2 for proper drive

coupling, and correct as necessary.

——

3 Staple units 1 and 2 operation check — —

4 Change staple units 1 and 2 — —

5 Change SDCB — —

Relevant electrical parts

Crease motor (M10)

Crease roller home position sensor (PS22)

SD control board (SDCB)

Step Action

WIRING DIAGRAM

Control signal

Location

(Electrical

component)

1

Check the M10 connector for proper connection and correct as necessary.

——

2

Check M10 for proper drive coupling and

correct as necessary.

——

3 M10 operation check SDCB PJ3-1 to 2 SD-505 C-7

4 PS22 I/O check, sensor check SDCB PJ2-3 (ON) SD-505 C-7

5 Change SDCB — —

Y108482-2 Service Manual

Field Service Ver. 2.0 Jan. 2008 10. Malfunction code

Page 56

52

SD-505

Troubleshooting

Blank Page

Service Manual Y108482-2

10. Malfunction code Field ServiceVer. 2.0 Jan. 2008

Page 57

UPDATING STATUS

DATE UPDATED PAGES PAGES CODE

10/2008 1ST EDITION 57 Y108482-2

Loading...

Loading...