Oliver 10040 Owner's Manual

10040 10” Hybrid Table Saw

Owner’s Manual

Oliver Machinery M-10040 08/2017

Seattle, WA Copyright 2003-2017

info@olivermachinery.net www.olivermachinery.net

1

Table of contents

READ CAREFULLY BEFORE OPERATING THE MACHINE ........................................................... 2

General Power Tool Safety Warnings ............................................................................................... 3

10” TABLE SAW ............................................................................................................................... 7

GROUNDING INSTRUCTIONS ........................................................................................................ 9

MOVEABLE CASTER & MACHINE LEVELING .............................................................................. 10

RESET PROTECTOR .................................................................................................................... 10

MAGNETIC SWITCH ...................................................................................................................... 11

UNPACKING .................................................................................................................................. 11

CLEAR UP ...................................................................................................................................... 11

PLACEMENT THE TABLW SAW .................................................................................................... 11

ASSEMBLY TABLE SAW ............................................................................................................... 12

INSTALL BLADE GUARD ............................................................................................................... 14

RIVING KNIFE ................................................................................................................................ 15

TABLE INSERT .............................................................................................................................. 15

SAW BLADE ................................................................................................................................... 16

FENCE ASSEMBLY ....................................................................................................................... 17

MITER GAUGE ............................................................................................................................... 19

STORAGE BOX .............................................................................................................................. 19

PERIODIC MAINTENANCE ............................................................................................................ 20

LUBRICATION & CLEAN ................................................................................................................ 20

MAINTENANCE & ADJUSTMENTS ............................................................................................... 21

BELT TENSION .............................................................................................................................. 23

BELT REPLACEMNET ................................................................................................................... 23

TYPE OF CUT ................................................................................................................................ 24

WIRING DIAGRAMS ...................................................................................................................... 26

PARTS DIAGRAMS ........................................................................................................................ 28

PARTS LIST ................................................................................................................................... 32

2

READ CAREFULLY BEFORE OPERATING THE MACHINE

WARNING – To reduce the risk of injury, user must read instruction manual

a) DANGER – Never place your hands in the vicinity or in line with the saw blade.

b) WARNING – Wear eye protection² or the sign M004 of ISO 7010.

c) WARNING – Always use a properly functioning saw-blade guard, riving knife and

anti-kickback device for every operation for which it can be used, including all through sawing.

d) WARNING – Use a push-stick or push-block when required.

e) WARNING – Do not perform any operation freehand.

f) WARNING – Pay particular attention to instructions on reducing risk of kickback. (or “Know

how to reduce risk of kickback.”)

g) WARNING – Never reach around or over saw blade. (or “Never reach in back of or over saw

blade.”)

h) WARNING – Turn off tool and wait for saw blade to stop before moving workpiece or changing

settings.

i) WARNING – Never stand 5428markdirectly in line with the saw blade. Always position your body

on the same side of the saw blade as the fence.

j) Keep hands out of the line of saw blade.

k) DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tools in damp or wet locations,

or expose them to rain. Keep work area well lighted.

m) MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter keys.

n) USE RIGHT TOOL. Don't force tool or attachment to do a job for which it was not designed.

o) WEAR PROPER APPAREL Do not wear loose clothing, gloves, neckties, rings, bracelets, or

other jewelry which may get caught in moving parts. Nonslip footwear is recommended. Wear

protective hair covering to contain long hair.

p) ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

q) CHECK DAMAGED PARTS. Before further use of the too., a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function - check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

8.8 Except for TYPE Z ATTACHMENT, terminals shall be indicated as follows:

– Terminals intended exclusively for the neutral conductor shall be indicated by the letter N.

– Earthing terminals shall be indicated by the symbol IEC 60417-5019 (2006-08).

3

General Power Tool Safety Warnings

WARNING Read all safety warnings, instructions, illustrations and specifications provided with this

power tool. Failure to follow all instructions listed below may result in electric shock, fire and/or

serious injury.

Save all warnings and instructions for future reference.

The term ²power tool in the warnings refers to your mains-operated (corded) power tool or

BATTERY operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can cause you to

lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk

of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the

risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use a power tool while you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment such as

dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power

source and/or BATTERY pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energizing power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure these

are connected and properly used. Use of dust collection can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore

tool safety principles. A careless action can cause severe injury within a fraction of a second.

4

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or remove the BATTERY pack, if detachable, from

the power tool before making any adjustments, changing accessories, or storing power tools Such

preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools and accessories. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s operation. If damaged,

have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into

account the working conditions and the work to be performed. Use of the power tool for operations

different from those intended could result in a hazardous situation.

h) Keep handles and grasping surfaces dry, clean and free from oil and grease.

Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in

unexpected situations.

5) Service

a) Have your power tool serviced by a qualified repair person using only identical replacement parts.

This will ensure that the safety of the power tool is maintained.

WARNING Read all safety warnings designated by the symbol and all instructions.

1) Guarding related warnings

a) Keep guards in place. Guards must be in working order and be properly mounted. A guard that is

loose, damaged, or is not functioning correctly must be repaired or replaced.

b) Always use saw blade guard, riving knife and anti-kickback device for every through-cutting

operation. For through-cutting operations where the saw blade cuts completely through the

thickness of the workpiece, the guard and other safety devices help reduce the risk of injury.

c) Immediately reattach the guarding system after completing an operation (such as rabbeting,

dadoing or resawing cuts) which requires removal of the guard, riving knife and/or anti-kickback

device. The guard, riving knife, and anti-kickback device help to reduce the risk of injury.

d) Make sure the saw blade is not contacting the guard, riving knife or the workpiece before the

switch is turned on. Inadvertent contact of these items with the saw blade could cause a

hazardous condition.

e) Adjust the riving knife as described in this instruction manual. Incorrect spacing, positioning and

alignment can make the riving knife ineffective in reducing the likelihood of kickback.

f) For the riving knife and anti-kickback device to work, they must be engaged in the workpiece.

5

The riving knife and anti-kickback device are ineffective when cutting workpieces that are too short

to be engaged with the riving knife and anti-kickback device. Under these conditions a kickback

cannot be prevented by the riving knife and anti-kickback device.

g) Use the appropriate saw blade for the riving knife. For the riving knife to function properly, the saw

blade diameter must match the appropriate riving knife and the body of the saw blade must be

thinner than the thickness of the riving knife and the cutting width of the saw blade must be wider

than the thickness of the riving knife.

2) Cutting procedures warnings

a) DANGER: Never place your fingers or hands in the vicinity or in line with the saw blade. A

moment of inattention or a slip could direct your hand towards the saw blade and result in serious

personal injury.

b) Feed the workpiece into the saw blade or cutter only against the direction of rotation. Feeding the

workpiece in the same direction that the saw blade is rotating above the table may result in the

workpiece, and your hand, being pulled into the saw blade.

c) Never use the mitre gauge to feed the workpiece when ripping and do not use the rip fence as a

length stop when cross cutting with the mitre gauge. Guiding the workpiece with the rip fence and

the mitre gauge at the same time increases the likelihood of saw blade binding and kickback.

d) When ripping, always apply the workpiece feeding force between the fence and the saw blade.

Use a push stick when the distance between the fence and the saw blade is less than 150 mm,

and use a push block when this distance is less than 50 mm. ²Work helping devices will keep

your hand at a safe distance from the saw blade.

e) Use only the push stick provided by the manufacturer or constructed in accordance with the

instructions. This push stick provides sufficient distance of the hand from the saw blade.

f) Never use a damaged or cut push stick. A damaged push stick may break causing your hand to slip

into the saw blade.

g) Do not perform any operation ²freehand². Always use either the rip fence or the mitre gauge to

position and guide the workpiece. ²Freehand means using your hands to support or guide the

workpiece, in lieu of a rip fence or mitre gauge. Freehand sawing leads to misalignment, binding

and kickback.

h) Never reach around or over a rotating saw blade. Reaching for a workpiece may lead to accidental

contact with the moving saw blade.

i) Provide auxiliary workpiece support to the rear and/or sides of the saw table for long and/or wide

workpieces to keep them level. A long and/or wide workpiece has a tendency to pivot on the

table’s edge, causing loss of control, saw blade binding and kickback.

j) Feed workpiece at an even pace. Do not bend or twist the workpiece. If jamming occurs, turn the

tool off immediately, unplug the tool then clear the jam. Jamming the saw blade by the workpiece

can cause kickback or stall the motor.

k) Do not remove pieces of cut-off material while the saw is running. The material may become

trapped between the fence or inside the saw blade guard and the saw blade pulling your fingers

into the saw blade. Turn the saw off and wait until the saw blade stops before removing material.

l) Use an auxiliary fence in contact with the table top when ripping workpieces less than 2 mm thick. A

thin workpiece may wedge under the rip fence and create a kickback.

3) Kickback causes and related warnings

Kickback is a sudden reaction of the workpiece due to a pinched, jammed saw blade or misaligned

6

line of cut in the workpiece with respect to the saw blade or when a part of the workpiece binds

between the saw blade and the rip fence or other fixed object.

Most frequently during kickback, the workpiece is lifted from the table by the rear portion of the saw

blade and is propelled towards the operator. Kickback is the result of saw misuse and/or incorrect

operating procedures or conditions and can be avoided by taking proper precautions as given below.

a) Never stand directly in line with the saw blade. Always position your body on the same side of the

saw blade as the fence. Kickback may propel the workpiece at high velocity towards anyone

standing in front and in line with the saw blade.

b) Never reach over or in back of the saw blade to pull or to support the workpiece. Accidental contact

with the saw blade may occur or kickback may drag your fingers into the saw blade.

c) Never hold and press the workpiece that is being cut off against the rotating saw blade. Pressing

the workpiece being cut off against the saw blade will create a binding condition and kickback.

d) Align the fence to be parallel with the saw blade. A misaligned fence will pinch the workpiece

against the saw blade and create kickback.

e) Use a featherboard to guide the workpiece against the table and fence when making non-through

cuts such as rabbeting, dadoing or resawing cuts. A featherboard helps to control the workpiece in

the event of a kickback.

f) Use extra caution when making a cut into blind areas of assembled workpieces. The protruding

saw blade may cut objects that can cause kickback.

g) Support large panels to minimise the risk of saw blade pinching and kickback. Large panels tend to

sag under their own weight. Support(s) must be placed under all portions of the panel overhanging

the table top.

h) Use extra caution when cutting a workpiece that is twisted, knotted, warped or does not have a

straight edge to guide it with a mitre gauge or along the fence. A warped, knotted, or twisted

workpiece is unstable and causes misalignment of the kerf with the saw blade, binding and

kickback.

i) Never cut more than one workpiece, stacked vertically or horizontally. The saw blade could pick up

one or more pieces and cause kickback.

j) When restarting the saw with the saw blade in the workpiece, centre the saw blade in the kerf so

that the saw teeth are not engaged in the material. If the saw blade binds, it may lift up the

workpiece and cause kickback when the saw is restarted.

k) Keep saw blades clean, sharp, and with sufficient set. Never use warped saw blades or saw

blades with cracked or broken teeth. Sharp and properly set saw blades minimize binding, stalling

and kickback.

4) Table saw operating procedure warnings

a) Turn off the table saw and disconnect the power cord when removing the table insert, changing the

saw blade or making adjustments to the riving knife, ant kickback device or saw blade guard, and

when the machine is left unattended. Precautionary measures will avoid accidents.

b) Never leave the table saw running unattended. Turn it off and don’t leave the tool until it comes to

a complete stop. An unattended running saw is an uncontrolled hazard.

c) Locate the table saw in a well-lit and level area where you can maintain good footing and balance.

It should be installed in an area that provides enough room to easily handle the size of your

workpiece. Cramped, dark areas, and uneven slippery floors invite accidents.

d) Frequently clean and remove sawdust from under the saw table and/or the dust collection device.

Accumulated sawdust is combustible and may self-ignite.

7

e) The table saw must be secured. A table saw that is not properly secured may move or tip over.

f) Remove tools, wood scraps, etc. from the table before the table saw is turned on. Distraction or a

potential jam can be dangerous.

g) Always use saw blades with correct size and shape (diamond versus round) of arbor holes.

Saw blades that do not match the mounting hardware of the saw will run off-center, causing loss of

control.

h) Never use damaged or incorrect saw blade mounting means such as flanges, saw blade washers,

bolts or nuts. These mounting means were specially designed for your saw, for safe operation and

optimum performance.

i) Never stand on the table saw, do not use it as a stepping stool. Serious injury could occur if the tool

is tipped or if the cutting tool is accidentally contacted.

j) Make sure that the saw blade is installed to rotate in the proper direction. Do not use grinding

wheels, wire brushes, or abrasive wheels on a table saw. Improper saw blade installation or use of

accessories not recommended may cause serious injury.

WARNING Read all safety warnings, instructions, illustrations and specifications provided

with this power tool. Failure to follow all instructions listed below may result in electric shock,

fire and/or serious injury.

CAUTION: This means that if precautions are not heeded, it may result in minor or moderate injury and/or

possible machine damage

WARNING: This means that if precautions are not heeded, it could result in serious injury or possibly even

death.

WARNING: The operation of any power tool can result in foreign objects being thrown into your eyes, which can

result in severe eye damage. Before beginning power tool operation, always wear safety goggles

or safety glasses with side shields and a full face shield when needed. We recommend Wide Vision

Safety Mask for use over eyeglasses or standard safety glasses with side shields. Always use eye

protection which is marked to comply with ANSI Z87.1.

WARNING: If the replacement of the SUPPLY CORD is necessary, this has to be done by the

manufacturer or his agent in order to avoid a safety hazard.

8

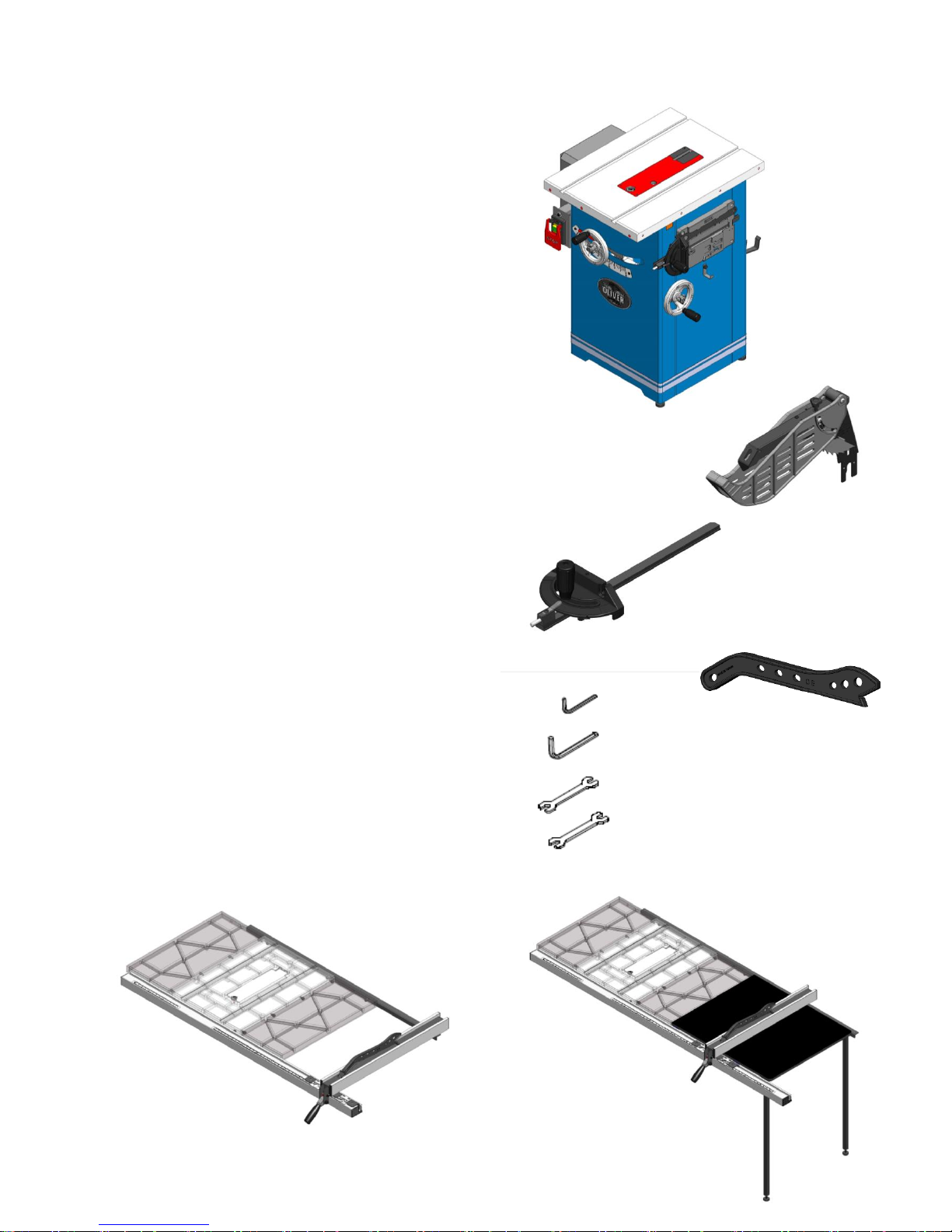

Miter Gauge Assembly

Blade Guard Assembly

Fence & 36” Rail Assembly

Option: 52” Rail & Right Table

10” TABLE SAW

Thank you for choosing this table saw.

This unit is carefully tested and inspected

before shipment and if properly used.

To ensure optimum performance and trouble

free operation a reasonable amount of care and

attention is required.

To get the most from your new table saw,

please take the time to read this manual before

assembling, installing and operating the unit.

The table saw features a circular blade

underneath that can be raised and lowered to

control the depth of cut.

The rail-mounted fence, which slides freely

toward or away from the blade, is used as the

main cutting guide for the workpiece.

The miter gauge is used to guide and support

the workpiece during the cut when the

workpiece cannot slide against the fence in a

stable manner that miter gauge body can be

rotated to allow a wide range of cutting angles.

The blade guard assembly is equipped

with a spreader . anti-kickback pawls and riving

knife, which work to prevent kickback and stop

or slow kickback if it happens. the riving knife is

used when the guard is removed for certain non

through cuts.

The push Stick is used to support the workpiece

during the cut and reduces the risk of injury by

keeping hands away from the blade while

cutting.

Cutting Capacities

Maximum depth of cut at 90° ···················· 3-1/8in.

Maximum depth of cut at 45° ···················· 2-1/4in.

Maximum rip to right of blade ······················ 36in.

Push Stick

Hex. Wrench 2.5mm * 1

Hex. Wrench 6mm * 1

Open Wench 8*10

Open Wrench 11*13

9

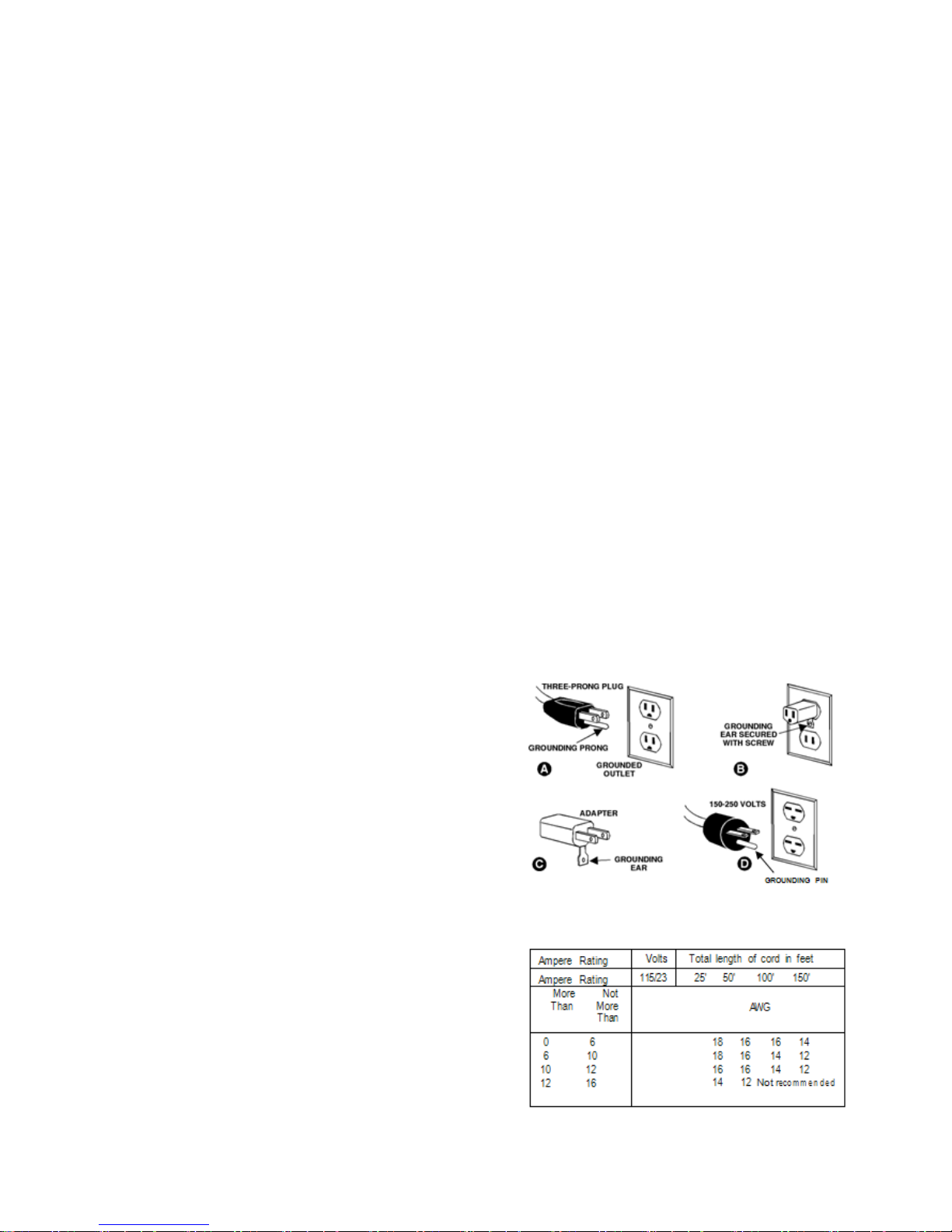

GROUNDING INSTRUCTIONS

1. All grounded, cord connected tools:

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce the risk of electric

shock. This tool is equipped with an electric

cord having an equipment- grounding

conductor and a grounding plug. The plug

must be plugged into a matching outlet that is

properly installed and grounded in accordance

with all local codes and ordinances. Do not

modify the plug provided - if it will not fit the

outlet, have the proper outlet installed by a

qualified electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

The conductor with insulation having an outer

surface that is green, with or without yellow

stripes, is the equipment-grounding conductor.

If repair or replacement of the electric cord or

plug is necessary , do not connect the

equipment- grounding conductor to a live

terminal. Check with a qualified electrician or

service personnel if the grounding instructions

are not completely understood, or if in doubt

as to whether the tool is properly grounded.

Use only 3-wire extension cords that have

3-prong grounding plugs and 3-pole

receptacles that accept the tool’s plug.

Repair or replace damaged or worn cord

immediately.

2. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

less than

150 volts:

This tool is intended for use on a circuit that

has an outlet that looks like the one illustrated

in Sketch A, Fig. A. The tool has a grounding

plug that looks like the plug illustrated in

Sketch A.

A temporary adapter, which looks like the

adapter illustrated in Sketches B and C in Fig.

A, may be used to connect this plug to a

2-pole receptacle as shown in Sketch B if a

properly grounded outlet is not available. The

temporary adapter should be used only until a

properly grounded outlet can be installed by a

qualified electrician. The green-colored rigid

ear, lug, and the like, extending from the adapter

must be connected to a permanent ground

such as a properly grounded outlet box.

Note: In Canada, the use of a

temporary adapter is not permitted

by the Canadian Electrical Code.

WARNING:If the replacement of the SUPPLY

CORD is necessary, this has to be done

by the manufacturer or his agent in order

to avoid a safety hazard

3. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

between

150-250 volts, inclusive:

This tool is intended for use on a circuit that

has an outlet that looks like the one illustrated

in Sketch D Fig. A. The tool has a grounding

plug that looks like the plug illustrated in

Sketch D.

Make sure the tool is connected to an outlet

having the same configuration as the plug.

No adapter is available or should be used with

this tool. If the tool must be reconnected for

use on a different type of electric circuit, the

reconnection should be made by qualified

service personnel and after reconnection, the

tool should comply with all local codes and

ordinances.

EXTENSION CORDS

Use proper extension cord. Make sure your

extension cord is in good condition. When

using an extension cord, be sure to use one

heavy enough to carry the current your product

will draw. An undersized cord will cause a drop

in line voltage resulting in loss of power and

overheating. Fig. B shows the correct size to

use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number, the

heavier the cord.

Fig. A

Fig. B

10

MOVEABLE CASTER & MACHINE

LEVELING

The moveable caster on this saw with (2)

casters (2) leveling screws and (2) feet that will

easier to move this saw and to place this saw as

you want.

The machine leveling adjustment, using a open

wrench to turn the (2) leveling screws located.

RESET PROTECTOR

Your saw comes equipped with a manual-reset

thermal-overload protector designed to open

the power line circuit when the motor

temperature exceeds a safe level, when motor

is overloaded, or when a low voltage condition

exists.

NOTE: This motor should be blown out or

vacuumed frequently to prevent sawdust buildup

which can interfere with normal motor ventilation.

Once the

motor

is

cooled to a safe

operating

temperature, reset

the thermal overload

protector

by

pushing the red

button

on the

front of

the

junction

box. An

audible

click

will indicate the

thermal overload

protector

is reset. Once the

switch button is reset, the saw may be started

and operated as normal.

NOTE :

If the reset button won't

click into p

lace

immediately,

the

motor

is still

too hot

and must be allowed to

cool.

Fr

equent

“blowing”

of fuses or T

ripping of

circuit br

eakers may result if:

Motor is overloaded. Overloading can occur

if a workpiece is fed too rapidly or if the saw

is misaligned.

Motor circuit is fused differently from

recommendations. Always follow

instructions for the proper fuse/breaker.

Do not use a fuse/breaker of greater

capacity without consulting a qualified

electrician.

Low voltage. Although the moto

r is designed

for operatio

n on the voltage and frequency

specified on the

motor

, normal loads will be

handled

safely

on voltage no more

than ten

percent above or below

that

figure.

Heavy

loads, however, require

that

voltage at

motor

terminals

equal

the voltage specified on the

motor

.

NOTE :

Always check the connectio

ns, the load

and the

supply

circuit whenever

the

11

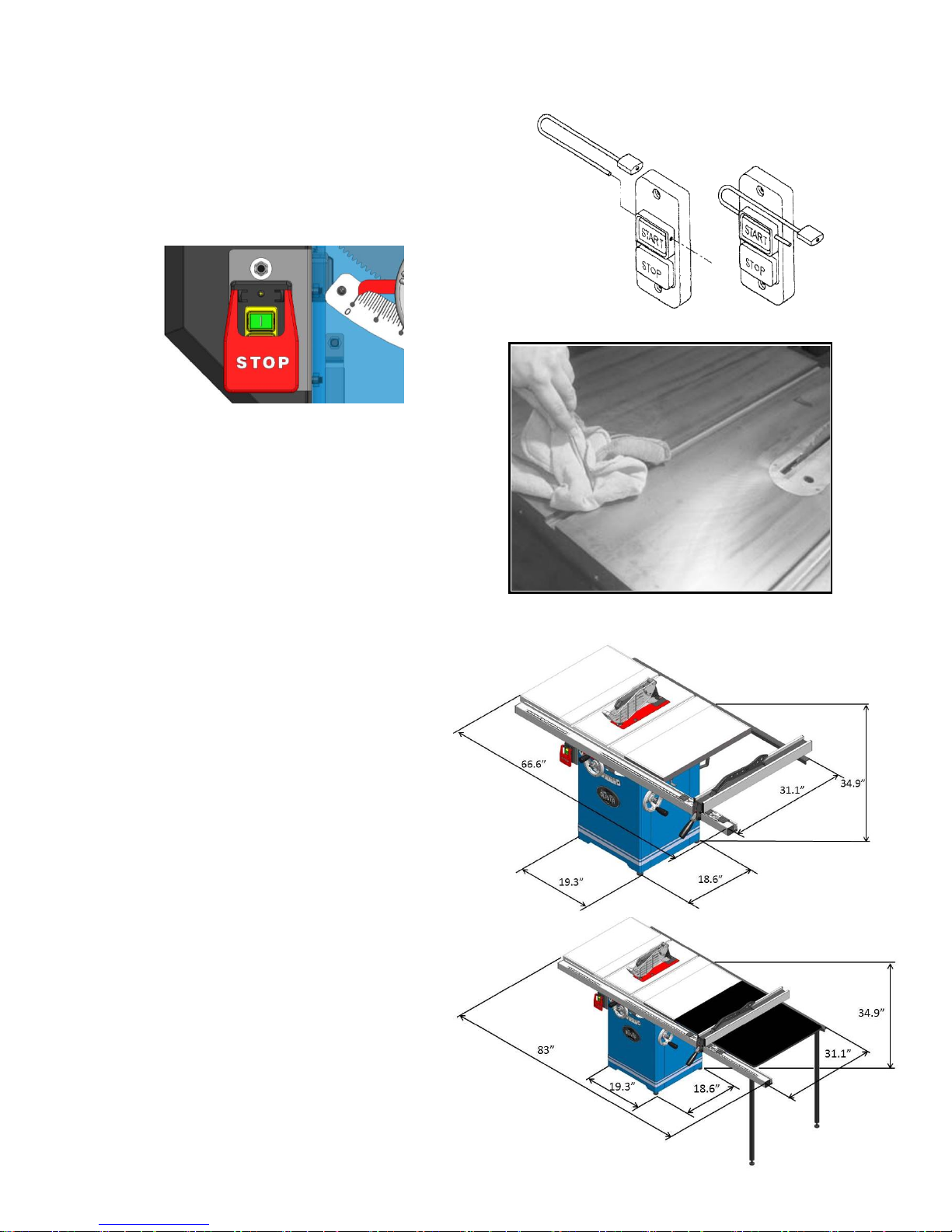

SWITCH

The table saw is equipped with a pushbutton switch that will accept a safety

padlock (not included). See Fig. 1. To

safeguard your machine from unauthorized

operation and accidental starting by young

children, the use of a padlock is required.

UNPACKING

This table saw is very heavy. Get lifting help or

use power lifting equipment such as a forklift to

move this Table Saw.

CLEAR UP

The protective coating on the saw table

prevents rust from forming during shipping

and storage. Remove it by rubbing with a

rag dipped in kerosene, mineral spirits or

paint thinner. (Dispose of potentially

flammable solvent- soaked rags according

to manufacturer’s safety

recommendations.)

A putty knife, held flat to avoid scratching

the surface, may also be used to scrape off

the coating followed by clean-up with

solvent. Avoid rubbing the saw’s painted

surfaces, as many solvent-based products

will remove paint Fig. 2.

To prevent rust, apply a light coating of

paste wax or use regular applications of any

after-market surface protected or rust

inhibitor.

PLACEMENT THE TABLW SAW

This machine should be installed and

operated only on a solid, flat and stable floor

that is able to support the weight of the

1.75HP saw (270 lbs-122 kgs) ..

Using the dimensions shown as a guideline,

plan for placement within your shop that will

allow the operator to work unencumbered

and unobstructed by foot traffic or other

tools or machinery.

Fig. 1

Fig. 2

With a screw

driver,

push a

solv

ent-sa

tura

ted

rag into

the T

-slots to

remove the grease.

Loading...

Loading...