Oliver 0006 Owner's Manual

Model 0006

6” Jointer

Owner’s Manual

Oliver Machinery M-0006HS 08/2015

Seattle, WA Copyright 2003-2015

info@olivermachinery.net www.olivermachinery.net

Table of contents

SAFETY INSTRUCTIONS ....................................................................................................... 2

Receiving Jointer ...................................................................................................................... 4

Installation Stand Assembly ..................................................................................................... 4

Safety Switch ........................................................................................................................... 7

Grounding Instructions ............................................................................................................. 8

Adjustments ............................................................................................................................. 9

Fence Adjustments: Tilt ......................................................................................................... 10

Helical Cutterhead .................................................................................................................. 12

Cutterhead Removal .............................................................................................................. 12

Depth of Cut ........................................................................................................................... 13

Jointing Knives ....................................................................................................................... 13

Basic Operations .................................................................................................................... 14

Push Blocks ........................................................................................................................... 17

Wiring Diagrams ..................................................................................................................... 18

Parts Diagrams ...................................................................................................................... 19

Parts List ................................................................................................................................ 22

1

SAFETY INSTRUCTIONS

For Your Safety Read Instruction Manual Before Operating Jointer

As with all machines, there is a certain amount of hazard involved with the use of this jointer. Use the machine with

the respect and caution demanded where safety precautions are concerned. When normal safety precautions are

overlooked or ignored, personal injury to the operator can result.

Wear eye protection.

Always keep cutter head and drive guards in place and in proper operating condition. Do not remove guard for

rabbeting operations.

Never make jointing , planning, or rabbeting cut deeper than 1/8 in.

Always use hold-down/push blocks for jointing material narrower than 3 inches, or planning material thinner

than 3inches.

Never perform jointing. Planning, or rabbeting cuts (with jointers provided with a rabbeting guard) on pieces

shorter than 8 inches (203 mm) in length.

Keep guards in place and in working order.

Remove adjusting keys and wrenches. Form habit of checking to see that keys and adjusting wrenches are

removed from tool before turning it on .

Keep work area clean. Cluttered areas and benches invite accidents.

Don’t use in dangerous environment. Don’t use power tools in damp or wet locations, or expose them to rain.

Keep work area well lighted.

Keep children away. All visitors should be kept safe distance from work area.

Make workshop kid proof with padlocks, master switches, or by removing starter keys.

.

Don’t force tool. It will do the job better and safer at the rate for which it was designed.

Use right tool. Don’t force tool or attachment to do a job for which it was not designed.

Use proper extension cord. Make sure your extension cord is in good condition. When using an extension

cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power and overheating Table (see Figure 9) shows the correct

size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The

smaller the gage number, the heavier the cord.

Wear proper apparel. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry which

may get caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering to contain

long hair.

Always use safety glasses. Also use face or dust mask if cutting operation is dusty. Everyday eyeglasses

only have impact resistant lenses, they are NOT safety glasses.

Secure work. Use clamps or a vise to hold work when practical. It’s safer than using your hand and it frees

both hands to operate tool.

Don’t overreach. Keep proper footing and balance at all times.

Maintain tools with care. Keep tools sharp and clean for best and safest performance. Follow instructions for

lubricating and changing accessories.

Disconnect tools before servicing; when changing accessories, such as blades, bits, cutters, and the like.

Reduce the risk of unintentional starting. Make sure switch is in off position before plugging in.

2

Use recommended accessories. Consult the owner’s manual for recommended accessories. The use of

!

!

improper accessories may cause risk of injury to persons.

Never stand on tool. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally

contacted.

Check damaged parts. Before further use of the tools, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function – check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting , and any other conditions

that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

Direction of feed. Feed work into a blade or cutter against the direction of rotation of the blade or cutter only.

Never leave tool running unattended. Turn power off. Don’t leave tool until it comes to a complete stop.

Do not perform jointing operation on material shorter than 8 in , narrower than 3/4 in, or less than 1/4 in thick.

Do not perform planing operation on material shorter than 8 in , narrower than 3/4 in, or wider than 6” in or

thinner than 1/2 in.

Maintain the proper relationships of infeed and outfeed table surfaces and cutter head knife path.

Support the work piece adequately at all times during operation; mqintain control of the work at all times.

Do not back the work toword the infeed table.

Do not attempt to perform an abnormal or a little-used operation without study and the use of adequate hold-

down/push blocks, jigs, fixtures, stops and the like.

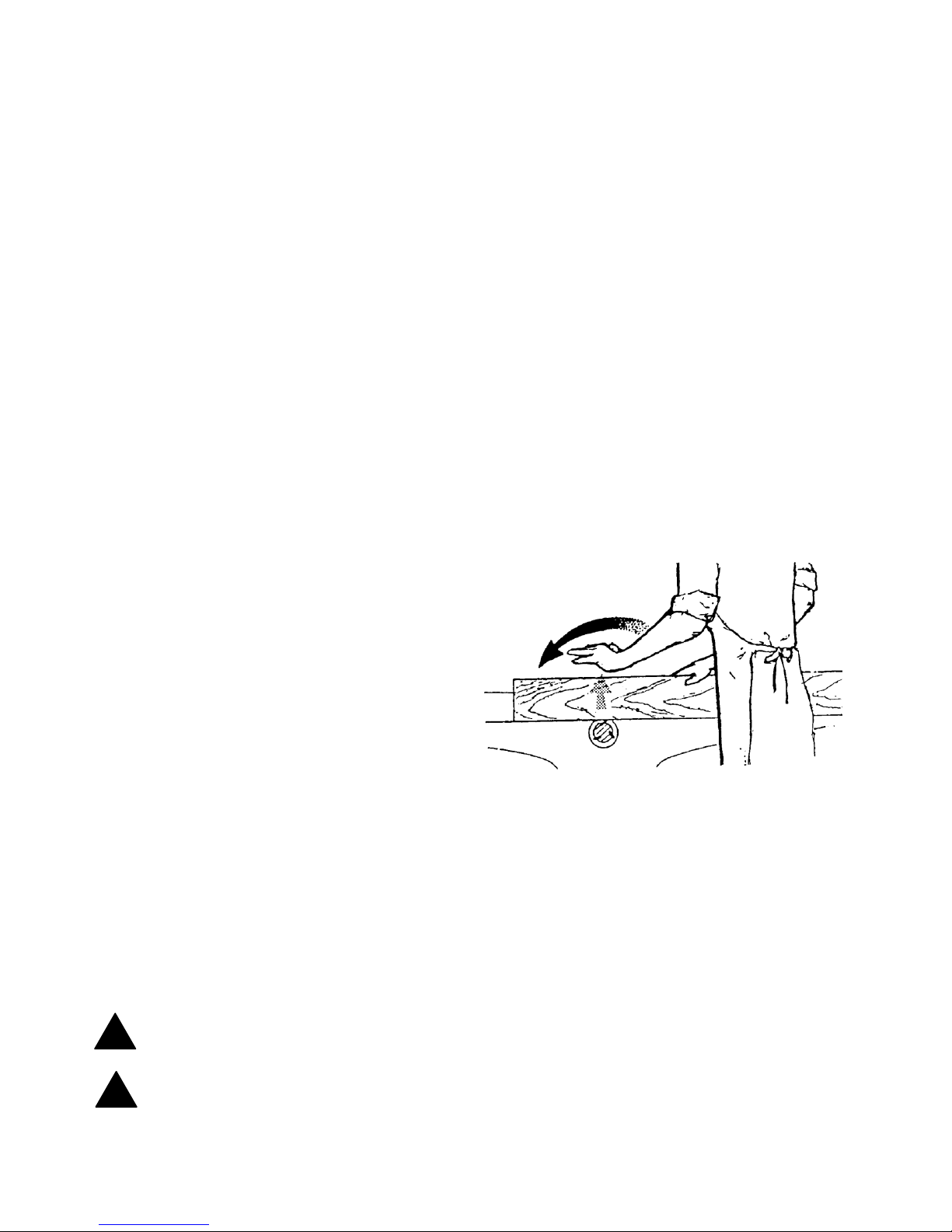

Hand safety. It is good practice to move the hands

in an alternate motion from back to front as the work

continues through the cut. Never pass the hands

directly over the cutter knife. As one hand approaches

the knives remove it from the stock in an arc motion

and place it back on the stock in a position beyond

the cutterknife.

Three inch rule. When working a piece of wood on

the jointer, follow the 3 inch radius rule. The hands

must never be closer than 3 inches to the cutter head.

Health hazards. Some dust created by power

sanding, sawing, grinding, drilling and other construction activities contains chemicals known to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

* Lead from lead-based paint.

* Crystalline silica from bricks and cement and other masonry products.

* Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area, and work with approved safety equipment, such

as those dust masks that are specifically designed to filter out microscopic particles.

Familiarize yourself with the following safety notices used in this manual:

3

CAUTION: (This means that if precautions are not heeded, it may result in minor or moderate injury

WARNING: (This means that if precautions are not heeded, it could result in serious injury or

!

and/or possible machine damage)

possibly even death).

Receiving Jointer

Upon delivery, open shipping containers and check

that

all parts are in good condition. Any damage

should be reported to your distributor and

shipping agent immediately. Before proceeding

further, read your manual and familiarize yourself

thoroughly with assembly, maintenance and

safety procedures.

Warning: This machine is very heavy.

Please don’t move or assembly this machine

alone. Ask someone to help for safety required.

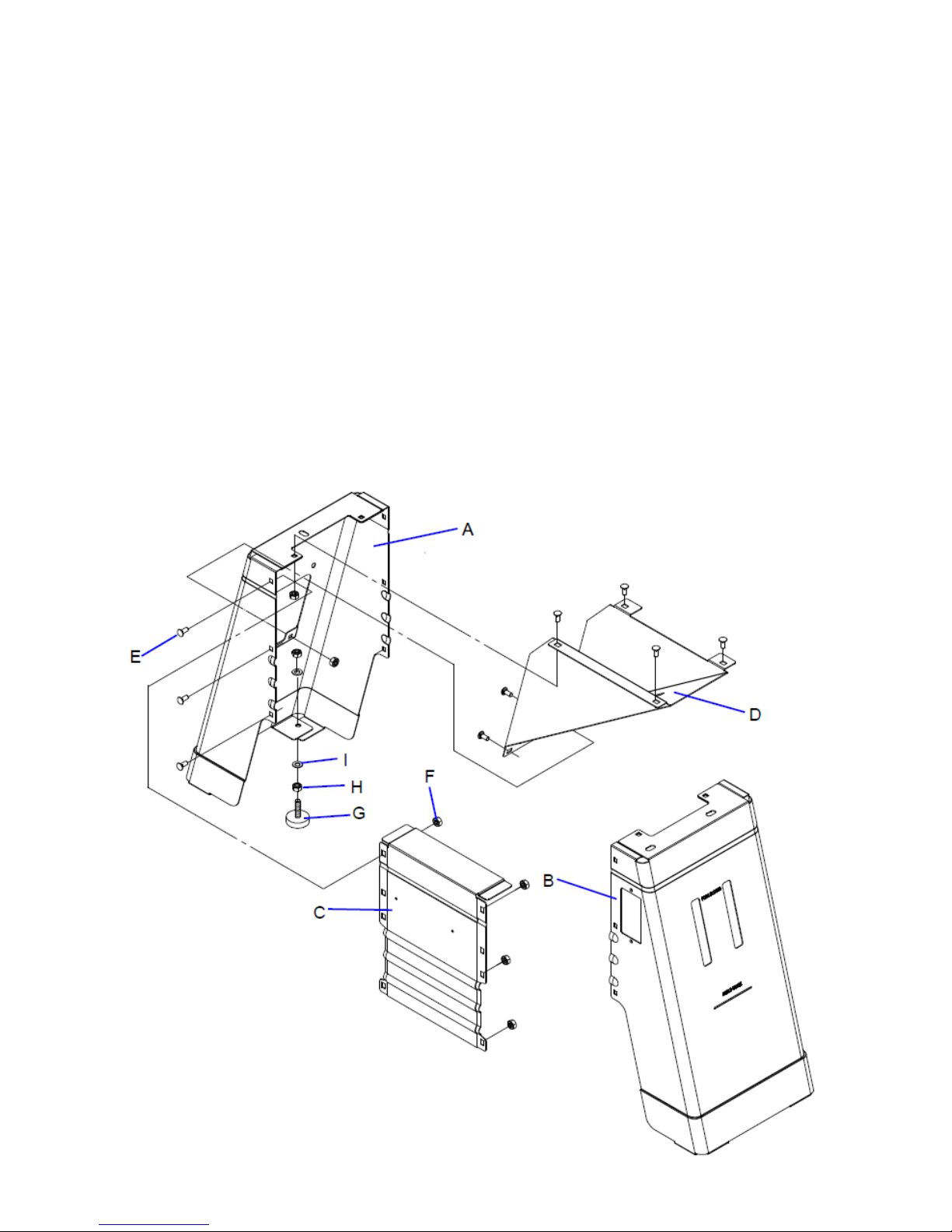

Installation Stand Assembly

Showing as below:

Prepare following parts for stand install

A: Stand- Left ................................ 1

B: Stand- Right .............................. 1

C: Front Panel ............................... 1

D: Motor Bracket ........................... 1

E: Shoulder Screw 5/16”x1/2” ........ 12

F: Hex. Nut 5/16”-18NC ................. 12

H: Foot Leveling ............................ 4

I; Hex. Nut 3/8”-16NC ................... 8

J: Flat Washer 10.5x27x2t ............. 8

K: Hex. Screw w/washer ............... 3

Step 1: Assembly Stand- Left (A) . Stand- Right (B) &

Front Pane (C) with Shoulder Screw (F)*6 & G Hex.

Nut*6 but not tighten all screws.

Step 2: Put Motor bracket (E) on the stand (step 1)

lock by Shoulder Screw (F)*6 & Hex. Nut (G)*6 but

not tighten all screws.

Step 3: Turn over the stand assembly upside down

then locate Foot (H) . Hex (I). Nut & Flat Washer (J)

on four corners.

4

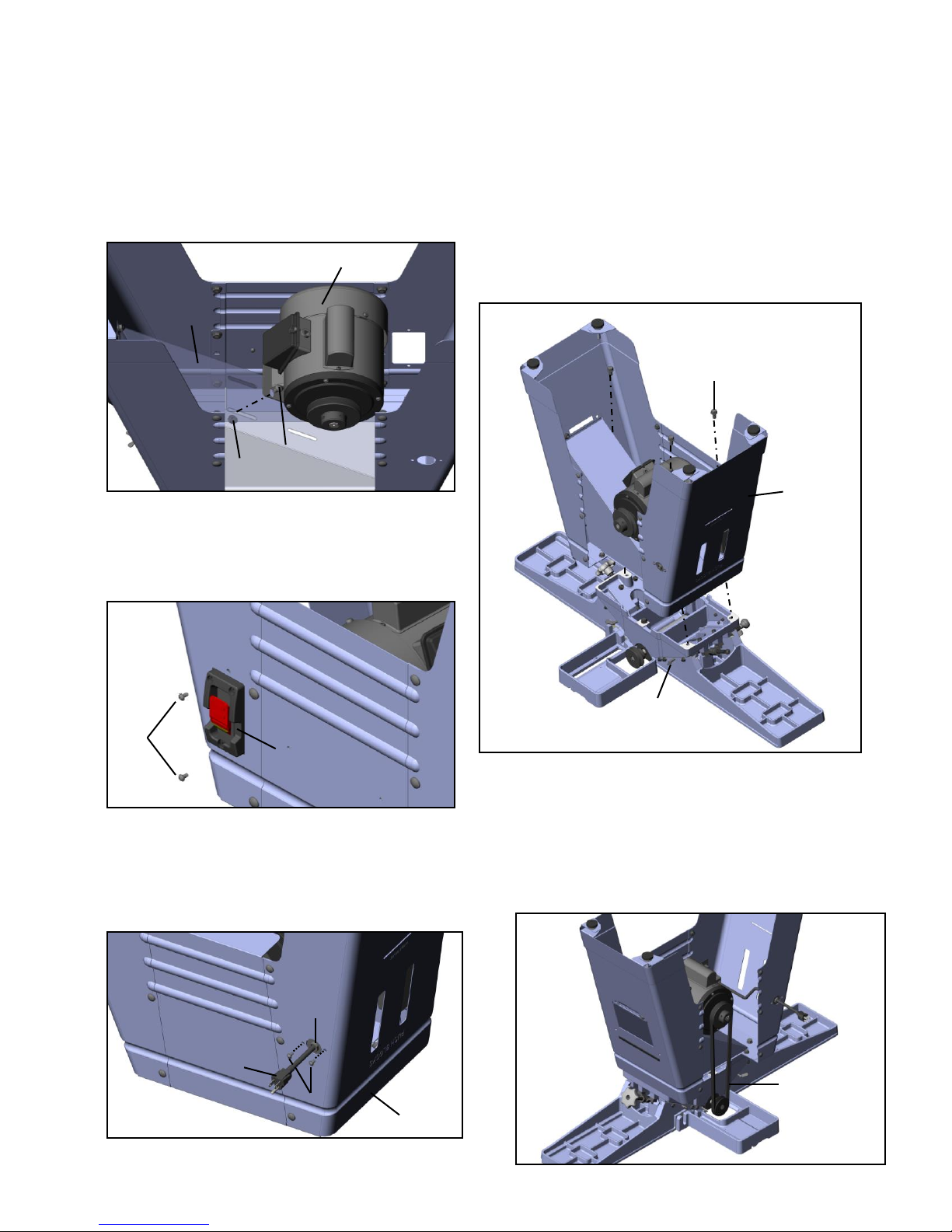

Installation Motor & Switch

Stand-Right

Switch

L

Stand-Right

M

O

N

Motor

E

F

D

Jointer Body

Stand

V-Belt

Step 4: Put the motor & switch assembly on the

Motor Bracket (D) and lock by Shoulder Screw

(E)*4 & Hex. Nut (F)*4 but not tighten all screws.

Warning: The motor & switch assembly is

heavy. Do not assemble motor by yourself; ask

someone to help is required.

Step 5: Place to switch into the rectangle hole

on stand-right and tighten by 2 Round Head

phillips screw w/teeth washer (L)

Step 6: The plug (M) need to pass through the

round hole on the stand-right and fix the power

Fixing plate (O) by Round Head phillips screw

w/flat washer (N)* 2

Installation Jointer Body & Stand

Step 7: Put a large clean carton board or plastic paper

on the floor to protect the jointer table top surface.

Step 8: Turn over the jointer Body then put the stand

of step 6 to the jointer base by 3 Hex. Screw

w/washer 3/8” x16NCx3/4” (P) but not tighten all

screws

Warning: The jointer body & stand are heavy.

Be careful and asking help when needed.

Installation V-Belt

Step 9: To attach the V-belt over cutterhead pulley

and motor pulley.

5

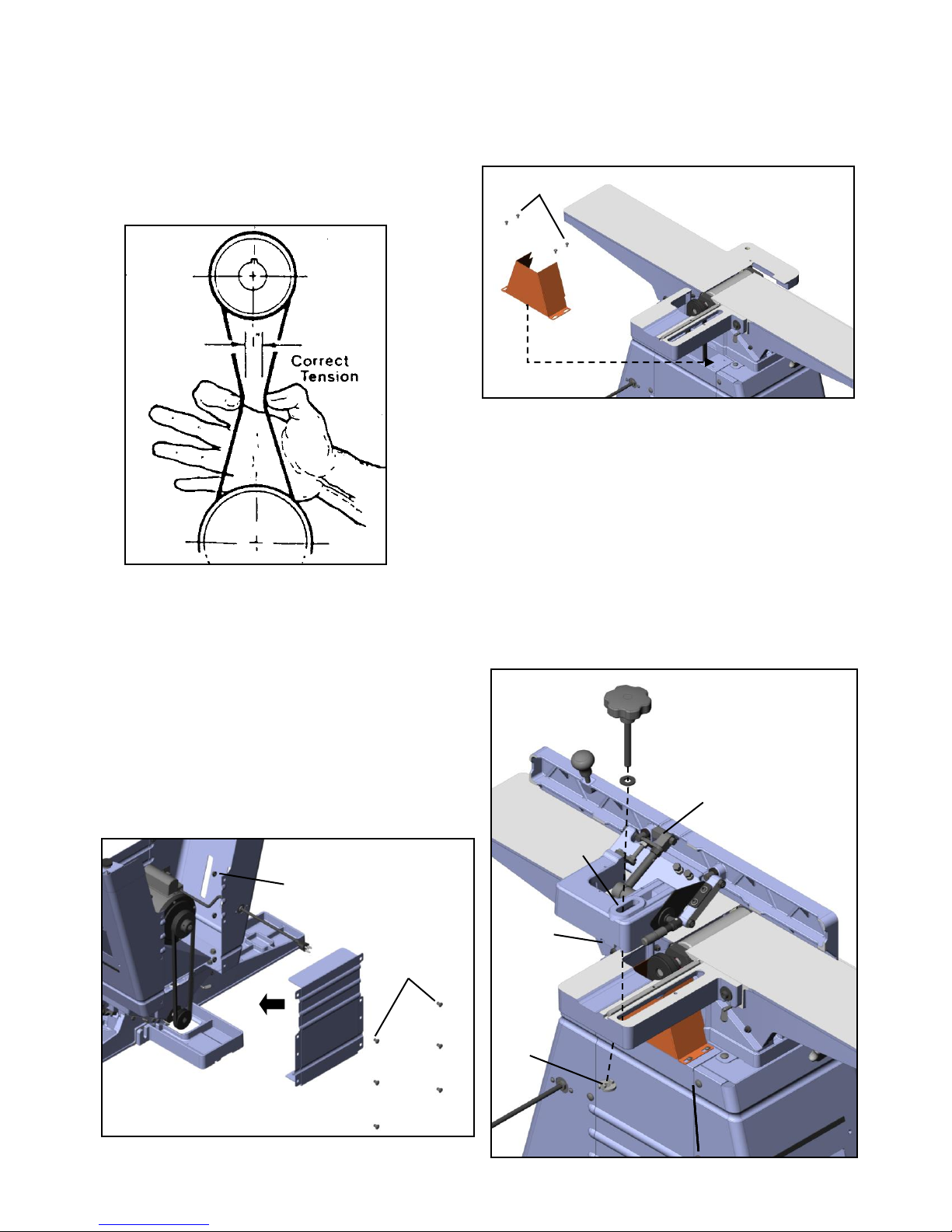

Checking Belt Tension

R

S

U

T

Fence Assembly

W

V L E

F

Step 10: Pull down on the motor to achieve the

desired belt tension (the correct belt tension is

achieved when the belt can be deflected

approximately one inch at the center belt span

using light finger pressure) Snug tight the 4

Shoulder Screw (E) & Hex. Nut (F).

Installation Rear Panel

Step 11: Assembly the rear panel after the Vbelt adjustment with 3 Shoulder Screw (E) &

Hex. Nut (F) then tighten all of screws on the

stand assembly.

Then Turn over the jointer .

Warning: The jointer with stand is heavy.

Be careful and asking help is required.

6

Installation Pulley Cover

The pulley cover is mounted with 2 Round Head

phillips screw w/teeth washer (L) to the threaded

holes in the Stand.

Installation Fence

1. Take the lock Knob (R), flat washer (S), and lock

nut (T) from the hardware bag..

2. Place the Key (U) on the Fence bracket slot then

put the fence assembly onto the table (B) Be sure

the key stock (U) on the bed lines up with the

channel (V) in the fence casting.

3. Place the flat washer (S) on slot (W); insert the

lock Knob (R) through the fence casting and the

table casting.

4. Thread the lock nut (T) onto the lock Knob

(R). Make sure the tab on the nut faces up and

engages the slot in the table casting.

Installation Blade Guard & Removal

A

Y Z X

B C D

Lock Key

Switch Assembly

WARNING: Use the jointer guard for all

operations. Do not connect the plug to power

source

1. Loosen the Round Head phillips screw

(A)from guard post (Z)

2. Turn knob (Y) counterclockwise to create

tension on spring, and hold it there.

3. Insert guard post (Z) down through hole in

front of ledge.

4. Slightly turn knob (Y), if necessary, until

the guard seats itself, and the spring

engages the slot at the end of the guard

post.

5. Check the guard for proper tension. If

guard does not spring back into place

when pulled back from cutterhead, remove

guard and adjust spring tension by repeating

steps 1-3 until correct tension is achieved.

NEVER run the jointer without the guard

being in place and in perfect working order.

6. Tighten the Round Head phillips screw

(A)from guard post (Z)

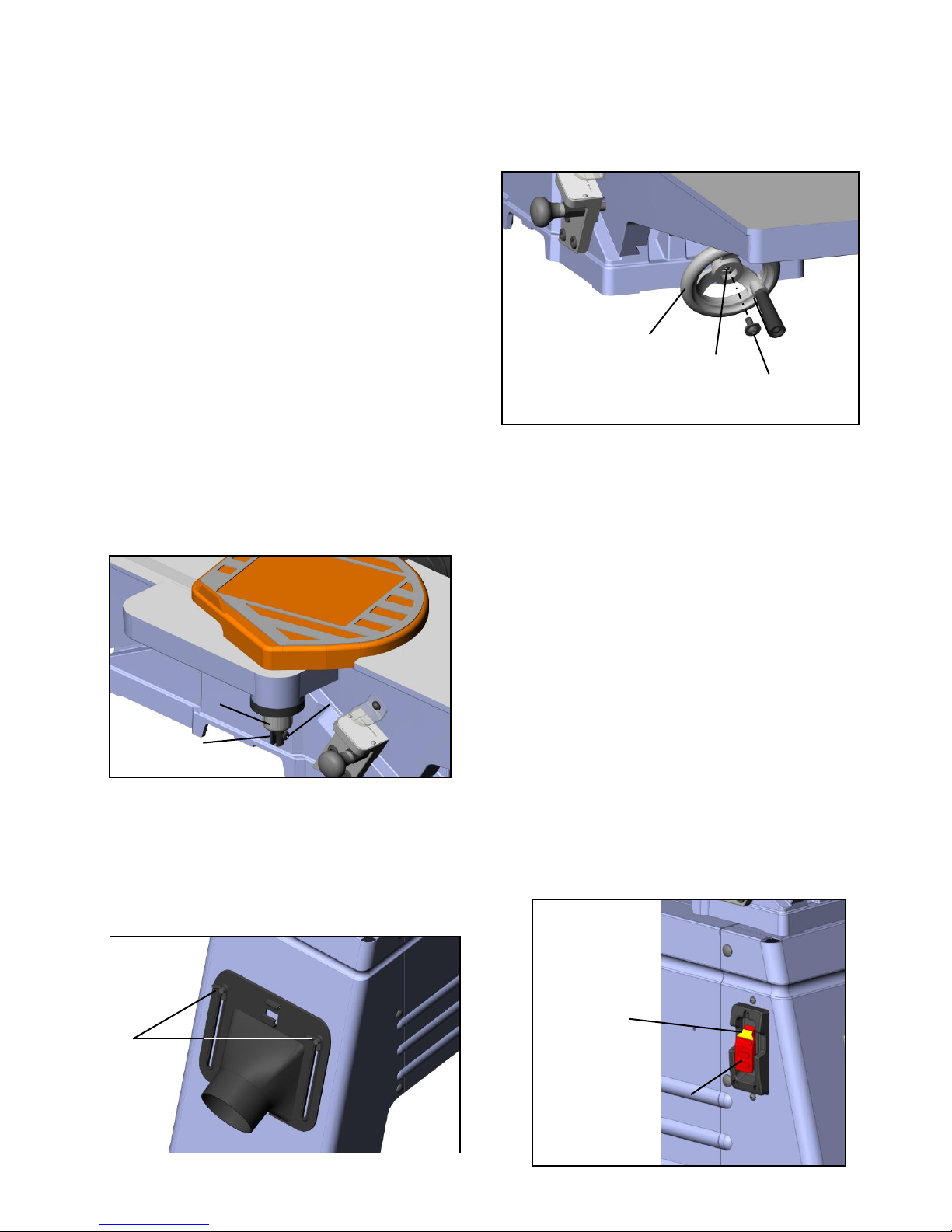

Installation Dust Chute

Mount the dust chute to the pre-tapped holes in

the side of the stand with 2 wing screws (A) .

7

Installation Handwheel

Slip the handwheel (B) onto the elevation shaft (C)

(under the infeed table) then tighten with the Round

Head phillips screw w/washers (D)

Installations are completed.

Safety Switch

This Jointer has a rocker style switch with a

removable locking key to prevent unauthorized

use. If you intend to be away from the machine for

a long period of time and there is any chance of its

use by others, especially children, Remove the

lock key with the switch in the “OFF” position.

Store it in a safe, inconspicuous place in your

workshop. To turn the planer on, insert the red

locking key and turn the switch to the ON position.

The planer will then be operable. To turn the

planer off, turn the switch to the “OFF” position.

WARNING: Always be sure the switch is in the

“OFF” position before connecting the

jointer to the power source.

Loading...

Loading...