Page 1

CNC 501

Programming and Operation of Lathes

York Technical College

452 South Anderson Road

Rock Hill, SC 29730

Page 2

Page 3

TABLE OF CONTENTS

I. General Safety and Standard Operating Procedures

II. OSP Control Functions

• Primary and Secondary Modes

• Parameters; Soft Limits vs. Stroke End Limits

• Function of all keys on Machine Operation Panel

III. Manual Machine Control

• Door Interlock restrictions

IV. Coordinate System and Program Zero Point

• Coordinate System

• Absolute Position Encoder Advantages

V. Program Codes

• G Codes

• Additional G Codes

• M Codes

VI. Program Format and Data Word/Address

• Refer to LB25-T min Program at Front

• Begin with Simple Examples; T-Command will be covered in detail later

• Discuss comments inside Parentheses

• Tool Offset relationship to zero set

VII. Angle Command

VIII. Circular Interpolation

• Write Simplie Program on Board Part DR202-3

1. Eliminate speed and gear range

2. Write program with zero at front and back

• Write Program on Board for DR201-3

1. Have a student key in the program on simulator as you write

2. Add graphics commands to program, without explanation to students

• Call Up and Test Program

• Review

IX. Machining Guidelines

• Surface Footage, Feed rate and Depth of Cut

• Cutter Radius Compensation

1. What CRC is; how it works; and it’s advantages

2. CRC Cancellation

Page 4

X. Auto Chamfer and Automatic Radius

Xl. LAP Cycles

• LAP Cycle Concept

• Types of LAP Cycles

• Write new program for DR201-3 and modify to use LAP cycles

Xll. Miscellaneous Cycles

• Drilling Cycles

• Grooving Cycles

• Tapping Cycles

XIII. Threading Fixed Cycles

XIV. Subprograms, Schedule Programs, and Additional File Types

• Schedule Program – Explanation

• Common Variables

• Local Variables; use variable jaw-boring program as an example

XV. Graphic Commands

XVI. Appendix

Page 5

Programming and Operation

of 2 Axis Lathe

Course Objectives - Upon completion, the individual will be procient in all basic skills necessary to

allow the functional/productive operation of the machine tool and associated safety practices.

The course is designed to provide the knowledge and skills required to “translate” the part drawing

into a nished product. The individual will be capable of dening the list of required processes, their

logical/optimum sequence, create the complete CNC part program, install the appropriate tools correctly, establish the program zero point, and perform corresponding tool offsets.

Course emphasis is a blend of classroom instruction, time spent on the machine tool, and individually

displayed skills.

Mastery of the topics is measured by actual demonstration and examples.

Page 6

Page 7

GENERAL SAFETY

AND

STANDARD OPERATING

PROCEDURES

Page 8

General Safety and Standard Operating Procedures

SAFETY PRECAUTIONS/STANDARD OPERATING PROCEDURES..................................

PRE-POWER UP CHECKLIST...............................................................................................

CHUCK PRECAUTIONS........................................................................................................

PRECAUTIONS FOR MACHINE OPERATION......................................................................

SETUP....................................................................................................................................

WORK PIECE LOADING AND UNLOADING.........................................................................

END-OF-DAY CHECKLIST.....................................................................................................

WHEN A PROBLEM OCCURS..............................................................................................

OTHER GENERAL PRECAUTIONS......................................................................................

Page 9

SAFETY PRECAUTIONS

Okuma machines are fully equipped with various safety devices to prevent operators and the

machine itself from accidents. However, operators are urged to operate the machine with safety in

mind. Strict observance of all safety guidelines indicated in the documentation provided with the machine is essential. The following are some points to observe when working with any machine tool.

PRE-POWER UP CHECKS

1) Close the doors of the electric control cabinet and the operation panel.

2) Never place obstacles around the machine.

3) Turn on power to the machine in the following sequence:

a) Depress the Emergency stop button

b) Turn on the Main power disconnect.

c) CONTROL ON button on the operation panel. (POWER ON button on the control

cabinet on machining centers.)

4) Once the control ‘boots up’, release E-stop and press the Control On button.

CHUCK PRECAUTIONS

1) Before starting the spindle or cutting operations, close the front door.

2) Strictly observe the allowable spindle speed for the chuck installed. Never exceed the maxi

mum allow able spindle speed.

3) When a chuck or xture unique to the user’s applications is used, check the allowable maxi

mum spindle speed and run the spindle within the allowable range. Pay due attention to work

piece gripping force and balance.

4) The maximum spindle speed can be limited by inputting the spindle speed with G50. To

ensure safety in operation, input this spindle speed limiting command in the program

(G50S****).

5) If the spindle is operated at a speed close to the allowable maximum speed:

Avoid imbalance in the work piece clamped in the chuck. Apply the maximum allowable

pressure to grip the work piece since increased centrifugal force reduces the chuck’s gripping

force.

Page 10

The maximum allowable spindle speed and applicable pressure for the chuck are indicated on

the name plate attached to the front door as well as on the chuck body. The maximum allow

able speed and the applicable pressure ensure a chucking force larger than one-third the

original chuck gripping force with the standard soft-to[ jaw set in line with chuck body’s outer

periphery.

6) When special jaw larger than standard soft-top jaws are used:

Lower the spindle speed because the chuck’s gripping force is reduced due to increased

centrifugal force and lowered efciency.

If the jaw-clamping nut (jaw nut) is outside the chuck’s outer periphery, only one clamping bolt

holds the jaws in place, causing very dangerous conditions. Jaw nuts must always be located

within the chuck body’s outer periphery

Machine the jaws to the shape of the work piece.

7) Tighten the bolts on the chuck body, jaws, and block securely. Clamping force should be

greater than 40 to 50 kg.

DAILY CHECKS

1) Before starting daily operations, always check the lubrication oil levels.

2) Always use the specied brand or grade of lubrication oil.

3) For cutting uid (coolant), use Okuma’s recommendation whenever possible.

4) Change and replenish lubrication oil for each reservoir at the predetermined schedule as

explained in the operation & maintenance manual.

5) Clean the lters periodically according to the schedule explained in the operation &

maintenance manual.

6) Check the pressure gauges of the air and hydraulic lines to make sure they all read the correct

values as specied in the operation & maintenance manual.

7) For any work required inside the machine door, turn off power and ensure safety before hand.

For work done at the back of the machine that requires the operator to enter the machine operating zone, do not forget to turn off power before attempting any work.

PRECAUTIONS FOR MACHINE OPERATION

1) Always follow the instructions given in the operation manuals.

2) Never run the machine without protective covers and doors, such as the front door and chuck

cover.

Page 11

3) Close the front door rst before starting the machine.

4) With a new program, never attempt to start actual cutting operations. First run the program

without setting a work piece in the machine to check machine operations and interference;

after making sure that the program is completely free of bugs, cut a work piece in the single

block mode operation. Only after making sure that the work piece can be cut without problems

in the single block mode operation should the automatic mode operation be started.

5) Before attempting the following, always make sure that untended operation can be

accomplished safely:

Spindle rotation

Turret indexing

Axes movements

6) While the spindle is revolving, never touch chips or the work piece.

7) Never try to stop a revolving object with hands or tools.

8) Conrm the jaw installation conditions, hydraulic pressure, and allowable maximum speed for

the power chuck.

9) Check the installed conditions and arrangement of the tools.

10) Conrm the tool and zero offset settings.

11) Set the spindle speed and feed rate override dials to 10%.

12) Before feeding the turret, conrm the soft-limit settings and the emergency limit switch settings

for both X and Z-axes.

13) Conrm the position where the turret index or rotation is allowed.

14) Conrm the tail stock position.

15) Make sure that cutting is conducted within the allowable transmission power and torque

ranges.

16) Clamp the work piece in the chuck or xture securely.

17) Check the cutting uid nozzle positions. Set them at positions to supply cutting uid correctly

to the cutting point.

SETUP

1) Always make sure that the setup is complete

2) After changing the setup, operate the machine step by step to make sure the cutting can be

conducted without problems.

Page 12

3) Before replacing the chuck and/or chuck jaws, make sure that the new set is for the job

intended.

4) When two or more workers work as a group, establish the necessary safety signs, for example,

when lifting or setting heavy objects conrm with other workers whether or not it’s ‘okay’ to

start the next process.

5) When handling heavy objects, use a crane or equivalent tool.

6) When attempting unfamiliar setups, check the setup again before going on to the next step.

WORK PIECE LOADING AND UNLOADING

1) Load and unload work pieces securely.

2) Retract the turret before loading and unloading a work piece to a position where the cutting

tools on the turret will not injure the operator’s hands.

3) Before attempting to load or unload a work piece, make sure the spindle has come to a

complete stop.

4) Before running a new program, rst rotate only the spindle to make sure the work piece is

securely clamped in the chuck.

5) To machine irregularly shaped work pieces, make sure the work piece is clamped in the chuck

securely without imbalance.

6) When handling heavy work pieces, use a crane, hoist, or other tool.

7) Before setting a work piece in the machine, make sure the work piece has portions that can he

used for proper chucking.

AT THE END OF THE DAY

1) Clean the machine.

2) Locate the turret at the predetermined retraction position.

3) Before leaving the machine, turn off all power switches.

4) Turn off power to the machine in the following sequence:

CONTROL OFF button on the operation panel. The main power disconnects.

Page 13

WHEN A PROBLEM OCCURS

1) Stop all spindle(s) and axis movement by pushing the closest EMERGENCY STOP switch.

2) Contact the maintenance person to determine what action to take.

3) Use only the fuses and other replacement parts of the specied rating.

4) Be extra careful when handling the following high-voltage units:

Main Breaker

Servo Drive unit (BL-11D)

VAC drive unit

Power cables

OTHER GENERAL PRECAUTIONS

1) Wear suitable safety clothes.

2) Keep work areas clean as well as the machine.

3) Do not touch controls with wet hands.

Page 14

Page 15

OSP CONTROL FUNCTIONS

Primary/Secondary Modes

Parameters - Limits

Function of all keys on Machine Operation Panel

Page 16

Turning the Power ON and OFF

Turning the Power ON

< Procedure >

(1) Turn ON the main switch at the control box.

(2) Press the [CONTROL ON] button on the NC operation panel.

(3) The NC control software is loaded from the data storage memory to the operation

memory and the NC starts running. File names are displayed on the screen, as they are

loaded to the operation memory.

(4) SBP 6-A V*.**-*(???)

MEMORY TEST :0000

BOOTDEV FROA:

LOAD:SYS

OPERATING SYSTEM PROGRAM V*.**-*(???)

OKUMA 1997.**.**

File names of NC application software to be loaded

PBU FILE ON LOADING

FIRMWARE FILE ON LOADING

GRAPHIC DATA ON INITIAL PROCESSOR

Turning the Power OFF

< Procedure >

(1) Make sure that all machine operating commands are completed.

(2) If a peripheral (printer, punch, etc.) is connected to the NC, switch off the peripheral.

(3) Press the [CONTROL OFF] button on the NC operation panel.

(4) Turn OFF the main switch at the control box.

Notice: NC control data and mode information are backed up to the data

storage memory at preset intervals. Therefore, the data may not be

backed up if the power is turned OFF immediately after changing the

data. Back up the data, press the function key (BACK UP) before

turning the power off.

Page 17

Emergency Stop

(1) Emergency Stop

Press the [EMERGENCY STOP] button to stop the machine in an emergency. The

machine stops immediately if the [EMERGENCY STOP] button is pressed.

(2) Recovery from the Emergency Stop State

The [EMERGENCY STOP] button is a push-to-lock type switch and it is locked in the

pressed state. To unlock the button, turn the button in the direction indicated by an

arrow on the button.

After unlocking the [EMERGENCY STOP] button, press the [CONTROL ON] button on

the NC operation panel, so that the NC can recover from the emergency stop state.

Page 18

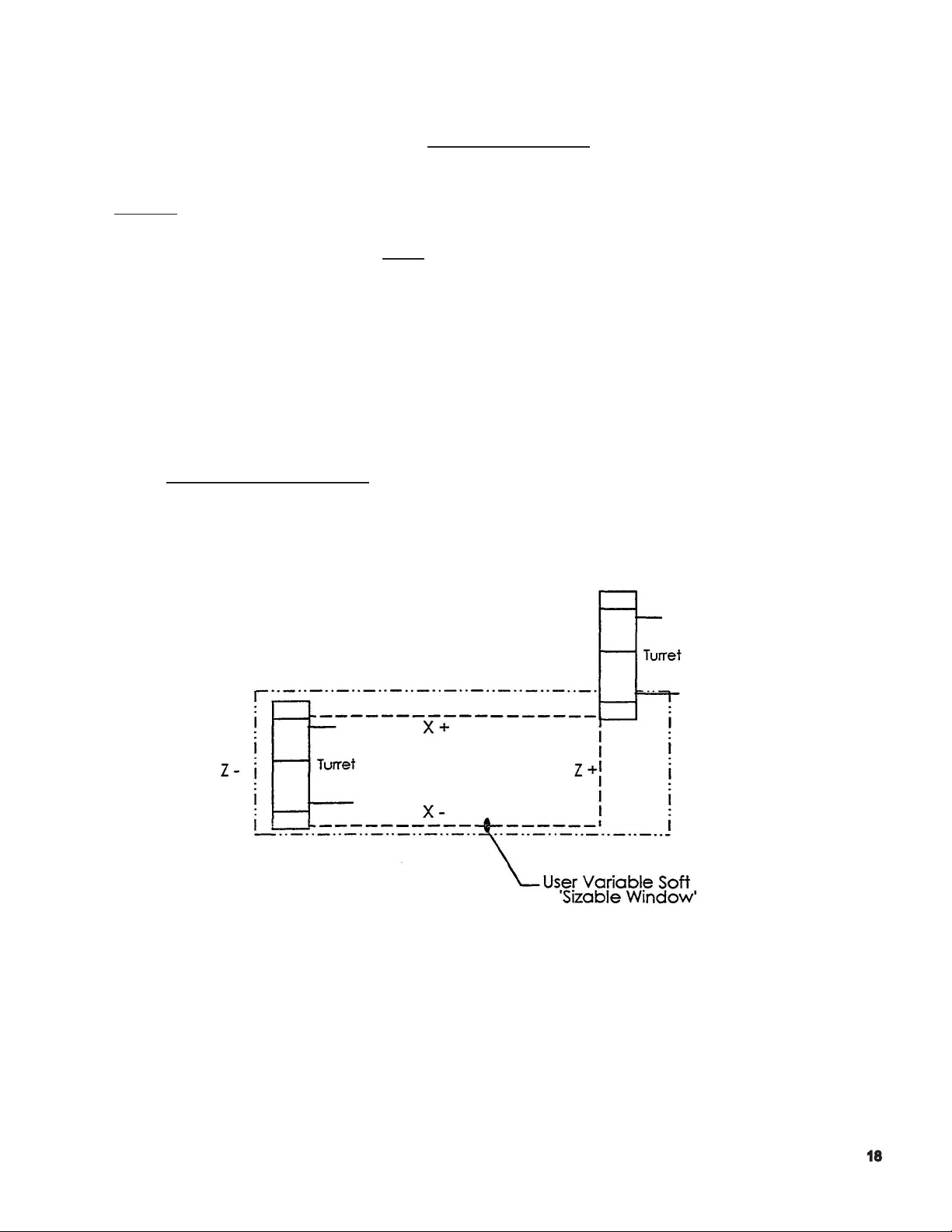

Turret Home Position - this refers to the position to which the turret must move to

before the turret can index a commanded tool into the cutting position. The

turret home position is also called the turret index position.

For the turret to be able to index, it must be positioned on either the

positive X, or Z axis limits .

Whenever the turret slide is at a ‘limit’, the OSP panel light illuminates,

indicating a valid position to index the turret.

For obvious reasons, the position for turret indexing should always allow

for the longest tool in the turret to safely clear the chuck, etc. . Given the

rapid axis speeds moving an additional 3 or 4 inches from the work piece will improve

overall safety and cause little if any increase in net cycle time.

The turret indexing position can be placed anywhere within the

machine working range. To index the furthest distance from the chuck, the turret should move

to the positive stroke end limits - in X and Z.

Page 19

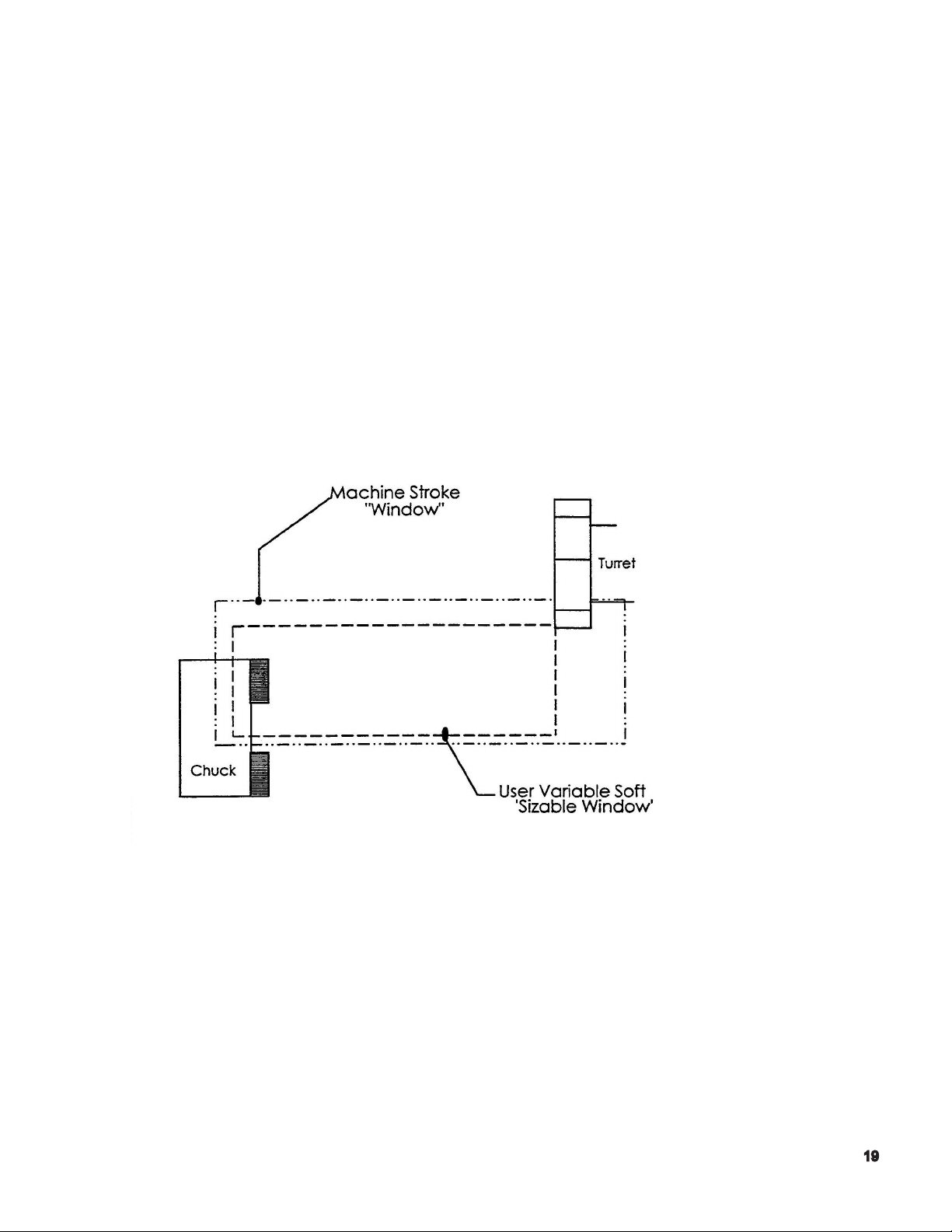

User Soft Limit / Variable Soft Limit - within the machine’s stroke end limits, it is possible to

establish/dene a smaller ‘window’ used to dene a smaller working range. The boundaries of

this smaller window are called user soft limits.

The primary reason to establish a ‘soft limit’ is to reduce the distance the turret has to travel

in order to ‘be at a limit’ and receive the conrmation signal, so that a turret index command

may be executed.

The machine’s turret will not index until either the ‘X’ positive, or ‘Z’ positive

limit condition is satised .

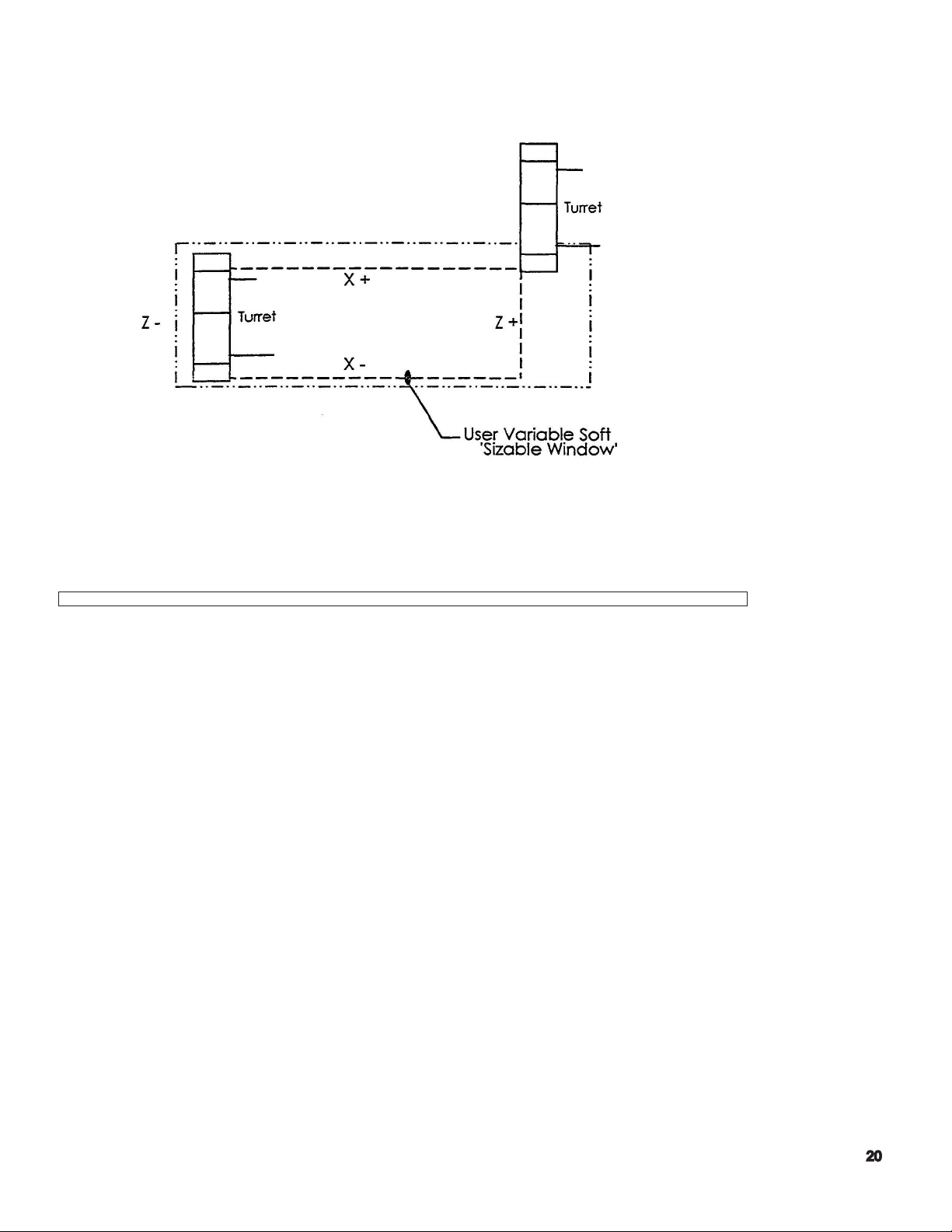

Page 20

The following illustration depicts the ‘working range’ within which the turret can travel, based on those ‘soft

limits’ that have been dened in the OSP control.

Note: In the above illustration, the ‘chuck’ is not shown for reasons of clarity.

To make the turret travel to its [X+, Z+} limit, the user should use the following command:

G00 X50 Z50

This command will position the turret to the current soft limits, which may or may not

be representative of the machine’s maximum stroke end travel.

Notes:

1. Positioning the turret to the “limits” cannot be performed by using a G01

command.

2. The user must select a ‘X’ and ‘Z’ value that will always exceed the machine’s working range.

A general rule of thumb is to double the actual axis stroke amounts. Using X50, Z50 will

sufce for the majority of instances, except for those machines with considerable bed length.

Page 21

Problems

1) If your part has a program zero at the front of the part, explain why the Zs in the program have

a negative sign in front of the numbers?

2) What is meant by soft limits?

3) Where is the turret home position?

4) How do you know if the turret slide is at a slide limit?

5) What is meant by the positive stroke end limit?

6) Also, what can you do with the turret when it reaches that limit?

7) What is the line code that will allow you to index the turret?

Page 22

OPERATION

Basic Construction of Operation Panels

For operating the machine, the following four kinds of man-machine interfaces are provided:

(1) NC Operation Panel

It is used for le operation and data setting.

(2) Machine Operation Panel

These switches and keys used mainly for manual operation. They are located in the

controls operation panel.

(3) Option Panel

An option panel is provided, which contains switches and indicating lamps required for

user specied options. Arrangements of the switches and indicating lamps differ

depending on the selected optional specication.

(4) Foot Pedal (Foot Switch)

A foot pedal is provided to control chuck open/close and tail stock spindle advance/

retract.

Various types of operator panels are included, depending on the shape of

the panel and the arrangement of the controls. External views of the operator panels

are provided in the Appendix of this manual.

Page 23

Outline of Controls on Operation Panel

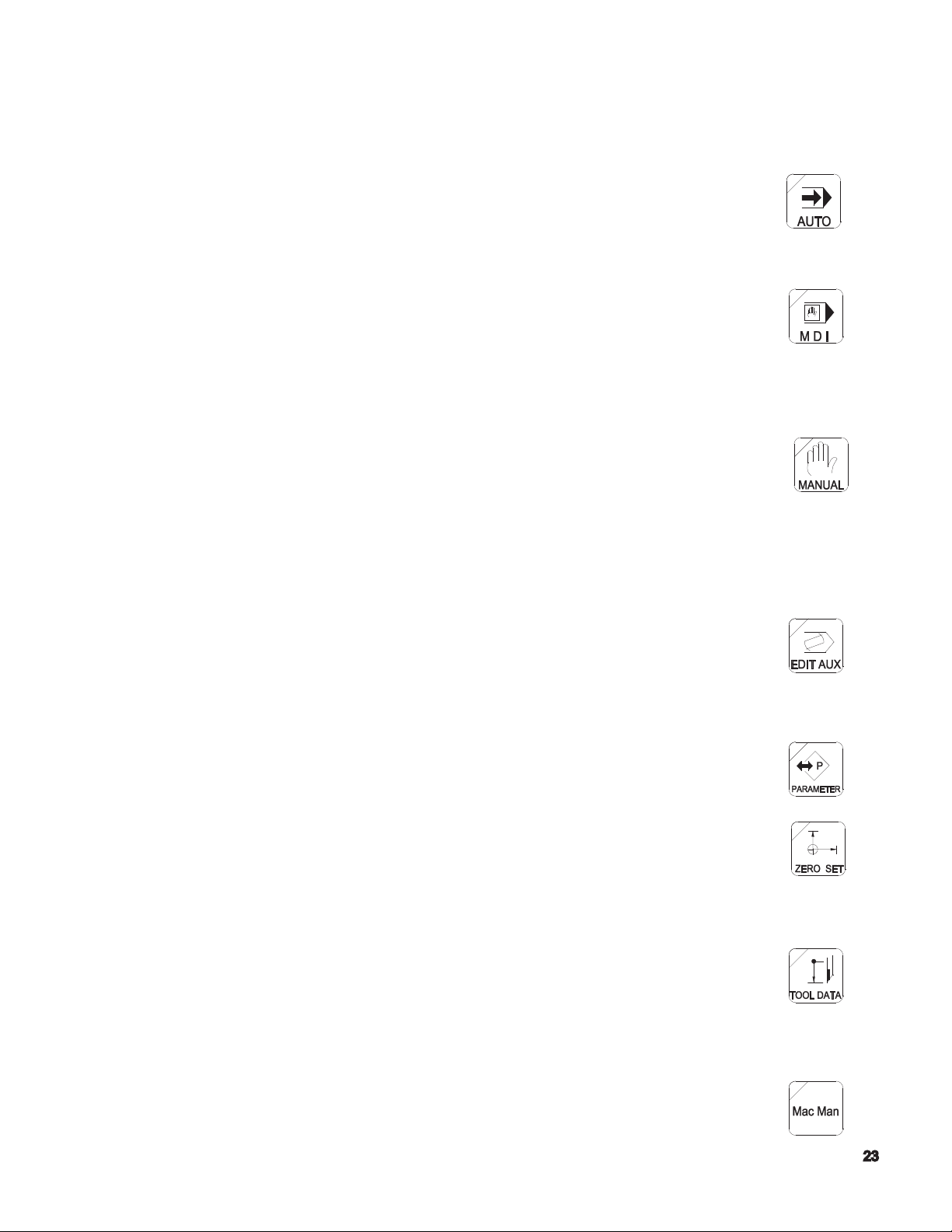

Operation Mode Selection Keys

(1) AUTO Key

Select the automatic mode when operating the machine using

a stored part program.

(2) MDI Key

Select the MDI mode for block operation, permitting input of the data

necessary for operation by the keyboard in the NC operation

panel.

(3) MANUAL Key

Selects the manual mode for operator by the switches on the machine

operation panel.

Data Setting Mode Selection Keys

(1) EDIT AUX. Key

Selects the program operation mode for operating program les and

data les. In this program operation mode, it is possilbe to edit input/

output, display or delete a program le.

(2) PARAMETER Key

Selects the parameter mode for setting, changing or displaying

parameter data necessary for NC control.

(3) ZERO SET Key

Selects the zero set mode for setting, changing, or checking the

zero offset data and zero shift data which dene a program coordinate system.

(4) TOOL DATA

Selects the tool data mode for setting, changing, or displaying the

tool offset data, nose R compensation data, tool shape data, and load monitor data.

(5) MacMan

Selects the MacMan (machining management function).

Page 24

NC Status Indicating lamps

(1) RUN Lamp

The RUN lamp 15 on when the machine is operation in the

automatic or MDI mode.

(2) S.T.M Lamp

The S.T.M. indicating lamp is on while auxiliary function operation

such as spindle gear range change, tool change, and spindle rotation, is executed.

When an axis movement command is designated with an S, T, and /or M command,

the axis movement command is executed after the completion of the S, T, and /or M

command designated in the same block.

If a spindle gear range command, spindle speed command, or tool number command

is changed using the manual intervention function (called out by pressing the [MID

AUTO MANUAL] key), the S.T.M. indicating lamp blinks.

(3) SLIDE HOLD Lamp

The SLIDE HOLD indicating lamp is on when the [SLIDE HOLD]

button is pressed in the automatic or MDI mode.

For the two-saddle option, it also goes on if the operation of either of

the two saddles enters the slide hold state with the other saddle having

completed single block mode operation in the automatic mode.

(4) PROGRAM STOP Lamp

The PROGRAM STOP indicating lamp is on during the execution of

a program stop (M00) or optional stop (M01) function in the automatic

or MDI mode.

The indication lamp blinks during the execution of a dwell (G04) function.

(5) LIMIT Lamp

The LIMIT indicating lamp is on when either X- or Z - axis reaches

its limit position.

For the two-saddle option, the indicating lamp is on if any of XA, ZA-,

XB-, and ZB - axis reaches the limit.

The indicating lamp blinks if the actual spindle speed reaches the maximum or

minimum speed of the selected gear range, or when it reaches the spindle speed

specied using the maximum spindle speed specication function.

Page 25

(6) ALARM Lamp

The ALARM indicating lamp is on when the machine malfunctions or

an incorrect program is input. It is also on if the computer

fails to function correctly.

Page 26

Status Indicating

Lamp

RUN - The machine is normally running in

S.T.M -The machine is waiting for the

Condition for ON Condition for Blinking

the AUTO or MDI mode

(except for during the SLIDE HOLD

and PROGRAM STOP mode).

operation completion of an M code

command. (Spindle rotation command, gear command, etc.).

- A spindle speed command is given

(S command).

- A turret rotation command is given

(T command).

Only for the multi-machinig options:

-The program selection command is a

schedule program is being executed.

-The following items have been

changed during manual intervention.

Tool number

Spindle rotation/gear command

Only for the multi-machining specication

-The machine is waiting for the

operation completion of a multi-machining M code command.

(C-axis joint command , M-tool

spindle rotation command, etc.).

-An M-tool spindle speed command

is given (SB command).

-The C-axis brake pressure is

switched between high and low.

Only for the ATC specication

- The machine is waiting for the operation completion of the MG, MT or

TN command.

SLIDE HOLD -The SLIDE HOLD button has been

pressed in the AUTO or MDI mode.

C- axis joint state

C-axis clamp

M-tool spindle ratation/gear

command

Does not blink.

-A block of program commands

has been executed on one saddle

while the other saddle is placed in

the slide hold mode with the single

block function activated in the AUTO

mode.

PROGRAM STOP -M00 OR M01 is designated in the

AUTO or MDI mode.

-The dwell command (G04) is executed.

Page 27

Status In dicating

Lamp

LIMIT -Either X- or Z -axis has reached

ALARM -Any erroneous operation is at-

Condition for ON Condition for Blinking

the variable soft-limit position.

tempted (An alarm of level A, B,

C, or D).

-The spindle speed has reached the limit in

the selected gear range.

-The spindle speed has reached the limit

specied by the maximum spindle speed

designation function.

-The spindle position is controlled after the

completion of spindle orientation (DIFF

control).

-The M-tool spindle position is controlled

after the completion of spindle orientation.

Does not blink.

Page 28

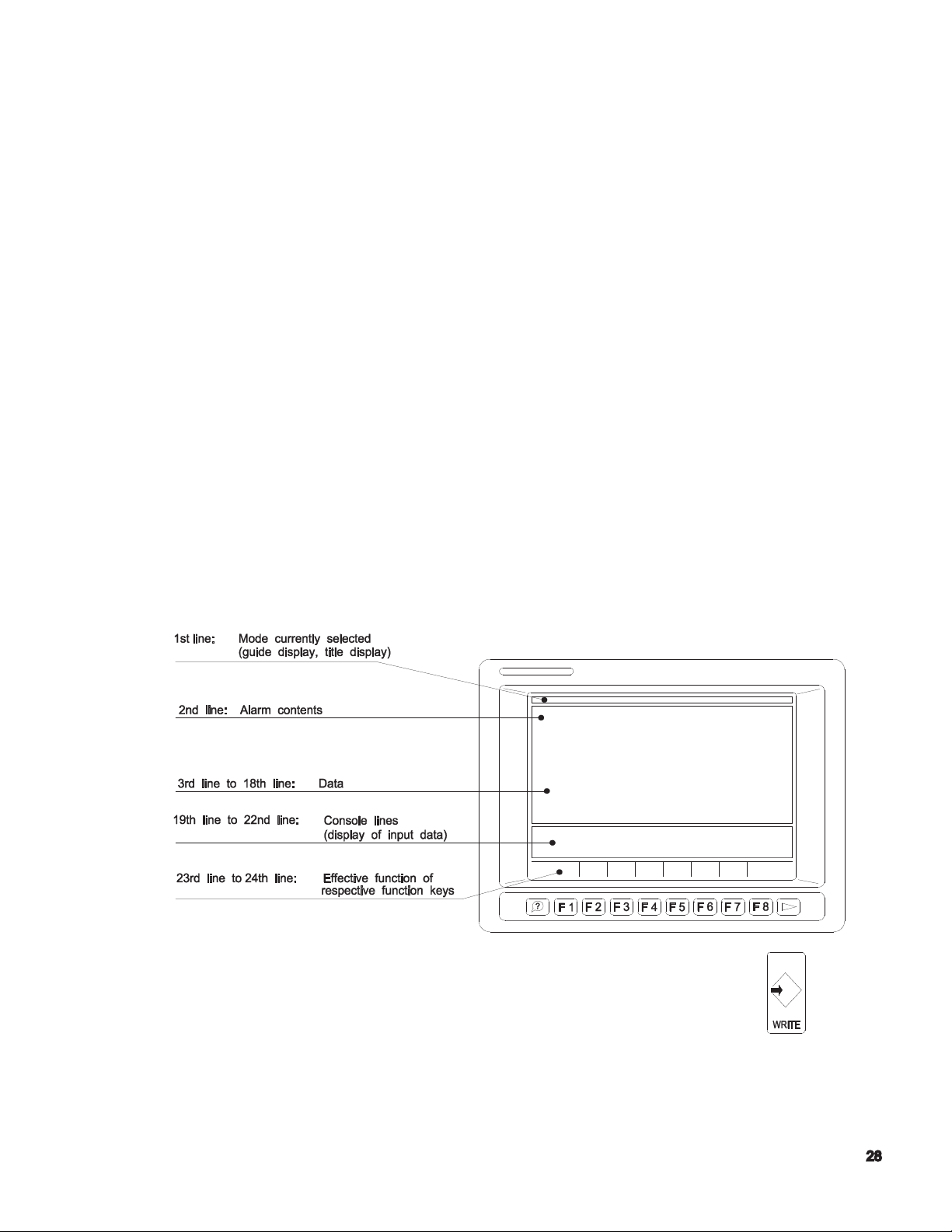

Other Controls on NC Operation Panel

(1) Function Keys: F1 to F8

There are eight function keys on the NC operation panel.

When an operator selects a desired operation mode, the screen displays the T

operation functions at the bottom line. Each function corresponds to a function key

(F1 through F8). Select the function to execute and press the corresponding function key.

If all functions called out by the selection of a mode cannot all be displayed

simultaneously, the ([EXTEND]) message is displayed for function key [F8]. In this case,

press [F8] to display the rest of functions.

[F1] [F2] [F3] [F4] [F5] [F6] [F7] [F8]

(2) ? (Help) Key

This key is used to display the description of the alarm which occurred during machine

operation and also the alarm history.

It shows actual position data, part program data, block data, zero offset values, tool

offset values, parameter data, alarm description, etc.

The basic format of display on the scree

(3) WRITE Key

n is shown below.

The [WRITE} key to select an operation and also conrms

input data.

Page 29

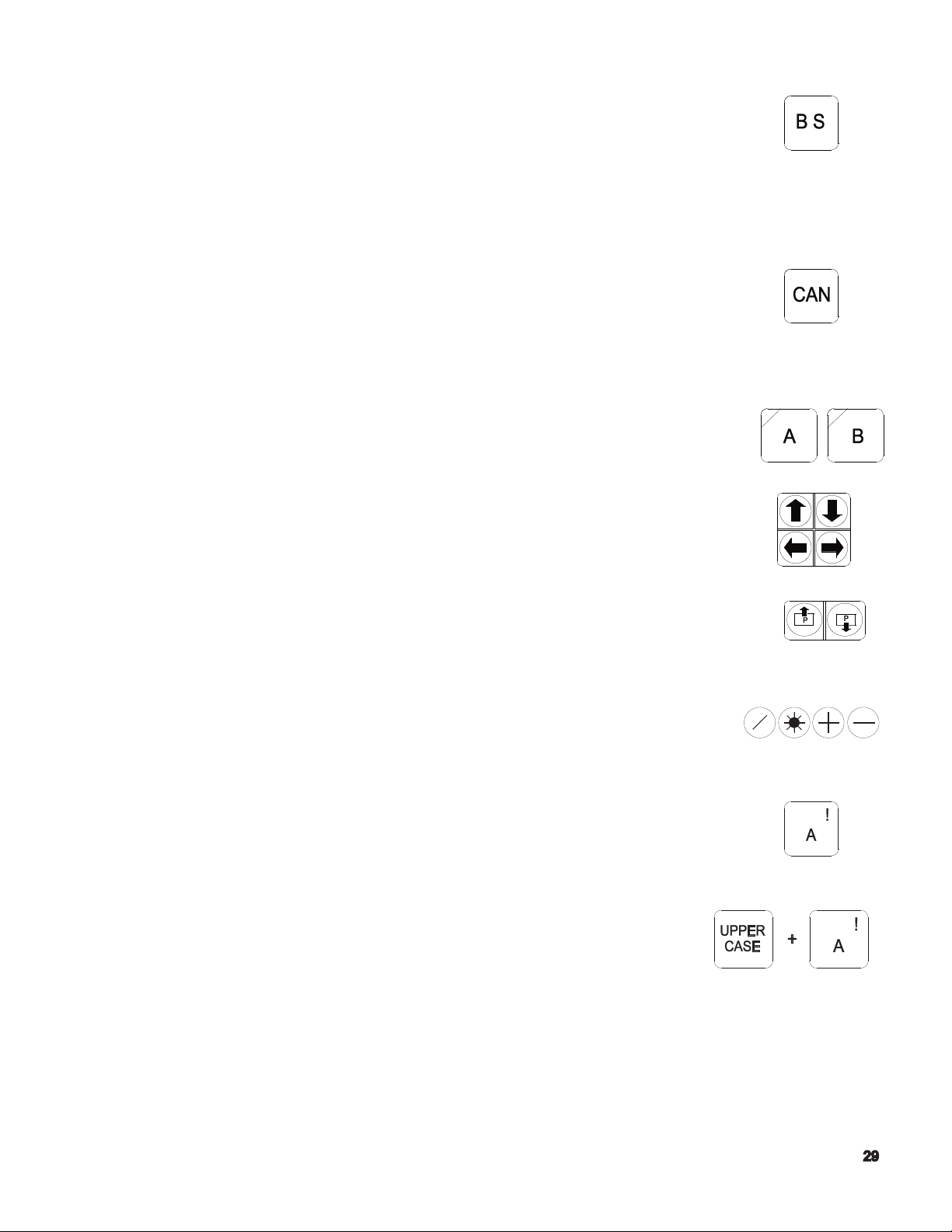

(4) BS (Backspace) Key

The [BS] key is used when erroneous data has been input.

Each time this key is pressed, the character input last is erased.

For the display of le index and list, this key is used to display the next

page.

(5) CAN Key

The [CAN] key is used when erroneous data has been input.

Each time this key is pressed, one line of the data is erased.

(6) Turret Selection (AB) Keys

These keys are used to select the appropriate turret or saddle

(A saddle side, B saddle side) for NC control of the two-saddle

or two-turret models.

(7) Cursor Keys

Four cursor keys are used to move the cursor displayed

on the screen.

(8) Page keys

If the information called out is displayed in more than one

page, the page keys are used to change the display page.

(9) Operator Keys

These keys are used when an operator edits a program or enters data.

(10) Character Keys

Character keys are used for inputting a character for data

input, program operation, and le edit operation.

(a) To input a character shown at the upper right

corner of a key top, use the [UPPER CASE] key.

Page 30

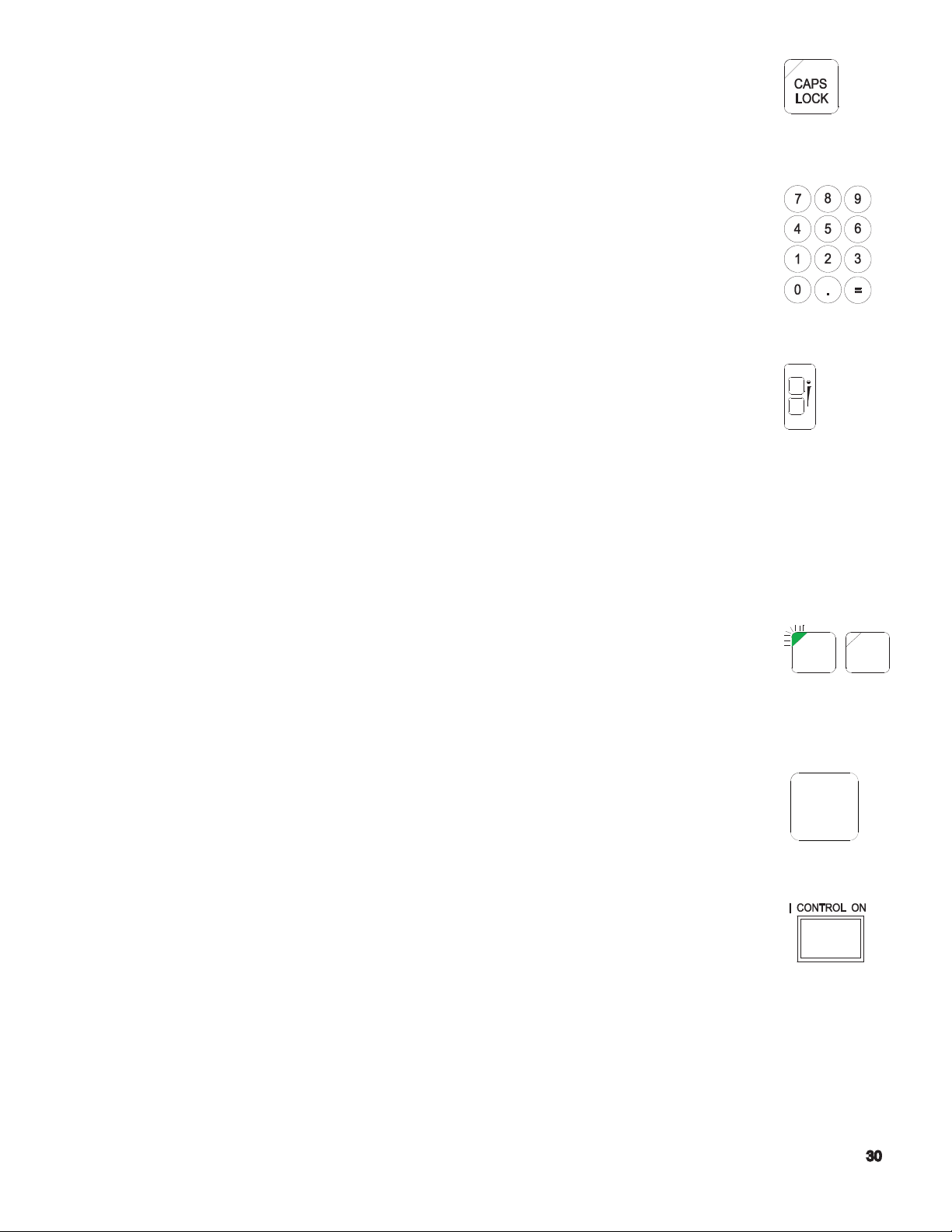

(b) When the [CAPS LOCK] key is pressed

(indicating lamp at the upper left corner lit), upper

case alphabetic letters A to Z are input. When the [CAPS LOCK]

key is not pressed, lower case alphabetic letters a to z are input.

(11) Numerical Key Pad.

These keys are used for inputting numbers for data input,

program operation, and le edit operation.

(12) Contrast Adjusting Keys

(only for Operation Panel with Monochrome STN Screen)

These keys are used to adjust the contrast for the display.

Controls on Machine Operation Panel

Flat keys used on the machine operation panel have features as indicated

below depending on whether or not they have an indicator lamp.

< Flat keys with an indicating lamp >

The indicating lamp in a key indicates if the function of the key

is valid or not.

- Indicating lamp lit . . . . . . . . . Key function is valid.

- Indicating lamp unlit . . . . . . Key function is invalid.

< Flat keys without an indicating lamp >

The function of the key is valid only while the key is

held down. If the key is not pressed, the function is invalid.

(1) CONTROL ON Switch

The [CONTROL ON] switch is used to turn on the

control power of the NC unit after turning on the main switch of the machine.

The pilot lamp in this switch lights when the control power is turned on.

If the [EMERGENCY STOP] button is pressed, the pilot lamp in this

switch goes off. To leave the emergency stop state, press the

[CONTROL ON] switch.

Page 31

(2) CONTROL OFF Switch

The [CONTROL OFF] switch is used to turn off the control

power of the NC unit.

When shutting off the power, turn off the control power rst by pressing the [CONTROL

OFF] switch before turning off the main switch of the machine.

(3) RESET Key

The NC unit is reset when the [RESET) key is pressed.

The key is used to reset an alarm.

(4) NC PANEL Switch

(a) UNLOCK position

Enables all controls on the NC and machine operation panels.

(b) EDIT LOCK position

Operations in the program operation (EDIT AUX) mode and parameter

setting mode are displayed.

(c) LOCK position

All controls on the NC operation panel are disabled.

(5) CYCLE START Button

The [CYCLE START] button is used to start the execution of

the program.

The CYCLE START signal is output when the button is pressed and released.

(6) SLIDE HOLD Button

Axis movements of X-, Z-, and C-axis stop immediately

when the [SLIDE HOLD] button is pressed. To resume axis movements,

press the [CYCLE START] button .

If this button is pressed while an axis is not moving, the slide hold becomes valid after

the completion of the sequence having been executed at the time the [SLIDE HOLD]

button was pressed or when the next axis movement is executed.

Page 32

(7) EMERGENCY STOP Button

Press the [EMERGENCY STOP] button when an emergency

occurs.

The power supply to the NC is shut off when the [EMERGENCY STOP]

button is pressed.

To release the emergency stop state, unlock the [EMERGENCY STOP]

button and press the [CONTROL ON] button.

(8) SLIDE JOG Buttons

These are used to jog an axis in the manual mode.

The button is valid only while it is pressed and

the setting of the FEED RATE override dial is appropriate for jog

feed operation.

For the two-saddle option, the saddle selected by the turret selection keys moves.

Notice Feed rates differ depending on the machine models and options.

With some special order machines, the feed patterns will differ from

those illustrated below.

(a) Other than at-bed machines

(b) Flat-bed machines

(9) FEED RATE

The FEED RATE override dial overrides the

specied feed rate in the range 0 to 200% in 15 steps.

Page 33

Notice In single block OFF operation in automatic mode, override is not valid

for a rapid feed command (G00).

Override is not valid for thread cutting operation.

(10) PULSE HANDLE X Key

Select this key to operate the X-axis using the pulse handle.

(11) PULSE HANDLE Z Key

Select this key to operate the Z-axis using the pulse handle.

(12) PULSE HANDLE 1/1 Key

Select this key to move an axis using the pulse handle at the

rate of unit distance per pulse.

(13) PULSE HANDLE 10/1 Key

Select this key to extend axis movement per pulse

to 10 times the unit distance.

(14) PULSE HANDLE 50/1 Key

Select this key to extend axis movement per pulse

to 50 times the unit distance

(15) Pulse Handle

The pulse handle is used to move a selected axis by

pulse signals which are generated as the pulse handle is turned.

(16) TOOL INDEX Button

The [TOOL INDEX] button is used to rotate the turret

turret manually. The turret will rotate continuously if the button is

held pressed.

(17) SPINDLE STOP Button

Use the [SPINDLE STOP] button to stop the spindle

manually.

For the multiple-machining models, the button is also used to start the M-tool

spindle.

Page 34

(18) SPINDLE CW Button

Used to start the spindle in the forward (CW) direction.

For multiple-machining models, the button is also used to start the M-tool spindle

in the forward (CW) direction.

(19) SPINDLE CCW Button

Used to start the spindle in the reverse (CCW) direction.

For multiple-machining models, the button is also used to start the M-tool spindle

in the reverse (CCW) direction.

(20) SPINDLE JOG Button

The [SPINDLE JOG] button is used to jog the spindle at

the speed set for a parameter.

For multiple-machining models, the button is also used to jog the M-tool spindle.

(21) SPINDLE GEAR ENGAGE Key

For machines with a transmission, press this key to engage

the spindle drive gears.

The indicator lamp at the upper left corner of the key lights when the output

of the gear range and the input pattern of the gear engage conrmation limit

switches agree with each other. It blinks if they do not agree.

(22) SPINDLE GEAR NEUTRAL Key

For equipped with a transmission, press this key to put the spindle drive gears in

neutral.

(23) SPINDLE OVERRIDE Dial

Override the specied spindle speed in 10 steps

from 50 to 200% .

If the spindle speed reaches the maximum allowable speed or the spindle speed

limit set by G50 when it is overridden, the actual spindle speed is limited to the

maximum allowable speed or the spindle speed limit.

(24) COOLANT-MANUAL Key

When the [COOLANT - MANUAL] key is pressed (indicating

lamp at the upper left corner lit), coolant can be supplied

independent. of the operation mode.

Page 35

This key cannot be turned ON if the [COOLANT -AUTO] key is ON.

(25) COOLANT-AUTO Key

When the [COOLANT-AUTO] key is pressed (indicating lamp at the upper

left corner lit), coolant is supplied according to the coolant command

given in the automatic or MDI mode.

This key cannot be turned ON if the [COOLANT -MANUAL] key is ON.

(26) LIGHTING Key

The [LIGHTING] key is used to turn on and off the machine’s

work light of the machine.

(27) DISPLAY OFF Key

Turn off the display on the screen, make this key valid

(indicating lamp at the upper left corner lit) .

(28) LOAD MONITOR -MONITOR/AUTO SET Keys

Use these keys for machines equipped with load option.

(29) AIR BLOW Key

Air blow is supplied while the key is held pressed for

machines equipped with the air blow option.

(30) DOOR -OPEN/CLOSE Keys

Use these keys for machines equipped with the

automatic door open/close option.

(31) DOOR INTERLOCK - ON/OFF Switch

The switch is used to select whether or not the door

interlock function is operating.

For details of the door interlock function, refer to the Door Interlock

Function Manual.

Page 36

Mode Selection Keys

To operate the machine using a program, a variety of operation modes are provided.

(1) SINGLE BLOCK Key

(a) When the [SINGLE BLOCK] key is on (indicating

lamp at the upper left corner lit), a program is executed in units of blocks. To

execute each block, press the [CYCLE START] button.

(b) When the [SINGLE BLOCK] key off (indicating lamp at the upper left corner

unlit), program blocks are executed continuously.

(2) BLOCK DELETE Key

(a) When the [BLOCK DELETE] key is on (indicating lamp

at the upper left corner lit), commands between a slash (/) code

and “ER” code are ignored.

Notice A slash code (/) must be placed at the start of a program block or

immediately after the sequence number (or sequence name) of a block.

(b) When the [BLOCK DELETE] key is off (indicating lamp at the upper left

corner unlit), commands entered following a slash code (/) are executed.

(3) OPTIONAL Stop Key

(a) When the [OPTIONAL STOP] key is on valid (indicating lamp

the upper left corner lit), operation stops after the execution of an

M01 block in a program. Spindle rotation and coolant supply also stop.

When the [CYCLE START] button is pressed, the previous state is recovered

and the program is continuously executed .

(b) When the [OPTIONAL STOP] key is off (indicating lamp at the upper left

corner unlit), program is continuously executed even after the execution of

an M01 block.

(4) DRY RUN Key

(a) When the [DRY RUN] key is on (indicating lamp at the upper

left corner lit), axis feed is executed at the feed unit amount set

by parameter with exceptions of G00 feed and manual axis feed .

(b) When the [DRY RUN] key is off (indicating lamp at the upper left corner

unlit), axis feed is executed at the specied feed rate .

Page 37

Note: To change the dry run mode on/off state, it is necessary

to press the [DRY RUN] key while holding down the

[INTERLOCK] key

(5) MACHINE LOCK Key

(a) When the [MACHINE LOCK] key is on

(indicating lamp at the upper left corner lit), all commands in

a program are executed without actual machine operation.

However, the actual position data and block data display are updated as the

program is executed. The data display returns to the previous state when the

NC is reset.

(b) When the [MACHINE LOCK] key is off (indicating lamp at the upper left

corner unlit), all commands in a part program are executed normally.

Note: To change the machine lock mode on/off state, it is necessary to press

the [MACHINE LOCK] key while holding down the [INTERLOCK] key.

(6) INDIVIDUAL MODE -TURRET A/TURRET B Keys

The individual turret operation function is valid only for the two-

saddle option.

The two-saddle option allows cutting to be performed by

controlling the four axes simultaneously . By using these keys, the

following operation modes can be selected.

(a) Independent turret A operation mode

In the automatic or MDl mode of operation, only turret A side operates.

[UPPER A] key: On (indicating lamp at the upper left corner lit)

[LOWER B] key: Off (indicating lamp at the upper left corner unlit)

(b) Independent turret B operation mode

In the automatic or MDl mode of operation, only turret B side operates.

[UPPER A] key: Off (indicating lamp at the upper left corner unlit)

[LOWER B] key: On (indicating lamp at the upper left corner lit)

(c) Independent turret A/turret B operation mode

In the automatic or MDI mode of operation, turret A and turret B operate

alternately according to the synchronization codes entered in a part program.

Page 38

[UPPER A] key: On (indicating lamp at the upper left corner lit)

[LOWER B] key: On (indicating lamp at the upper left corner lit)

(d) Normal operation mode

Simultaneous 4-axis operation is executed according to a part program.

[UPPER A] key: Off (indicating lamp at the upper left corner unlit)

[LOWER B] key: Off (indicating lamp at the upper left corner unlit)

Note: To change the independent turret A/turret B operation mode on/off state, it is

necessary to press the [UPPER A] or [LOWER B] key while holding down the

[INTERLOCK] key.

(7) SEQUENCE RESTART Key

The [SEQUENCE RESTART] key is used to restart a part program

from a specic block.

(8) MID AUTO MANUAL Key

To perform manual operation during automatic or MDI mode operation,

press the [MID AUTO MANUAL] key.

(9) INTERLOCK Key

To change the on/off state of the dry run mode, machine lock mode

machine lock mode and independent turret A/turret B operation mode, it is

necessary to press the [INTERLOCK] key at the same time the corresponding

mode key is pressed.

Controls on Additional Panel (C-axis Panel)

An additional panel is provided only for machines equipped with the multiple machining

function .

(1) MILLING SPINDLE Key

When the [MILLING SPINDLE] key is turned on (indicating lamp at the upper

left corner lit), the [SPINDLE - START], [SPINDLE - CCW], [SPINDLE - CW],

and [SPINDLE - JOG] buttons and the [SPINDLE OVERRIDE] dial become

valid for the M-tool spindle.

Page 39

(2) C-AXIS Key

Turn this key on to operate the C-axis manually

using the pulse handle. The key functions only in the C-axis control mode.

(3) C-AXIS CLAMP Key

The [C-AXIS CLAMP] key is used to clamp the C-axis manually. The key

functions only in the C-axis control mode.

The indicating lamp at the upper left comer is turned on when the C-axis

is in the clamped state.

(4) C-AXIS UNCLAMP Key

The [C-AXIS UNCLAMP] key is used to unclamp the C-axis manually.

The key functions only in the C-axis control mode.

The indicating lamp at the upper left corner is turned on when the C-axis

is in the unclamped state.

(5) C-AXIS JOG - +/- Keys

The C-axis jog feed keys used in manual operation. Jog feed occurs

when a key is held down. The setting of the FEED RATE override dial

on the machine operation panel is valid for jog feed of C-axis. These keys function only

in the C-axis control mode.

8. Foot Pedal

In addition to the operation panels, foot pedals are used to operate the machine.

(1) Check Open/Close Foot Pedal

There are two types of foot pedals used for opening and closing a chuck. One type is

the standard pedal in which the same pedal is used for opening and closing a chuck,

and the other type is the dual-pedal type foot pedal in which the independent pedal is

used for opening and closing a chuck.

(2) Tail stock Spindle Advance/Retract Foot Pedal

The foot pedal used for tail stock operation can advance, retract, and inch the tail stock

spindle.

Page 40

Page 41

MANUAL MACHINE CONTROL

Door Interlock Restriction

Page 42

Spindle Related Operation

Preparing for Spindle Rotation

(1) Setting the allowable Chuck Speed

Set the allowable speed of the chuck which is mounted to the machine with a

parameter. (machine parameter)

(2) Inputting the Maxium Spindle Speed

Input the maximum spindle in the MDI operation mode.

=IN G50 S_[WRITE] [CYCLE START]

(3) Inputting the Spindle Speed

In the MDI operation mode, input the spindle speed at which the spindle should be

operated.

=IN S_[WRITE] [CYCLE START]

(4) Inputting the Gear Range

For the machine equipped with a transmission, input the gear range that meets the

input spindle speed. Select the MDI mode also for this operation.

=IN M_[WRITE] [CYCLE START]

Starting the Spindle CW/CCW

<Procedure>

(1) Select the manual operation mode by pressing the [MANUAL] key on the NC

operation panel.

(2) Press the [SPINDLE - CW] or [SPINDLE - CCW] button on the machine

operation panel.

[Supplement] A The setting of the SPINDLE OVERRIDE dial is valid for the

specied spindle speed.

B The [SPINDLE - CW] OR [SPINDLE - CCW] button may be

released after pressing it once. The spindle keeps

rotating even if the button is released.

C To start the spindle, the chuck must be in the closed state.

Page 43

D An alarm occurs if the actual spindle speed exceeds 120% of

the allowable speed of the chuck.

E For center-work operation, the tailstock spindle must be set in

the correct position.

F The door must be closed.

Stopping the Spindle

<Procedure>

1. Select the manual operaiton mode by pressing the [MANUAL] key on the

NC operation panel.

2. Press the [SPINDLE - STOP] button on the machine operation panel.

Jogging the Spindle

<Procedure>

1. Press the [SPINDLE - JOG] button on the machine operation panel.

[Supplement] A Spindle jog speed is set with a parameter (machine

parameter).

B The spindle jogs only while the [SPINDLE - JOG] button is

being pressed.

C The setting of the SPINDLE OVERRIDE dial is not valid for

spindle jog operation.

Page 44

Axis Feed Operaiton ( X-, Z-, and C-axis)

An axis (X-, Z-, or C-axis) can be moved in either of the following methods.

(1) Using SLIDE JOG buttons.

(2) Using the pulse handle.

SLIDE JOG Buttons

<Procedure>

(1) Select the manual operation mode by pressing the [MANUAL] key on the NC operation

panel.

(2) For the two-saddle specication, select the saddle to be operated by the turret

selection keys.

(3) Press the [SLIDE JOG] button corresponding to the required axis feed direction.

Note that the arrow symbol in a button indicates the direction of saddle movements

and it is not related to the positive and negative directions in the program coordinate

system. The [C-AXIS JOG] keys do not have the arrow symbol in them, but they have

the “+” and “-” signs which indicate the positive and negative directions in the program

coordinate system.

[Supplement] A An axis moves only while a [SLIDE JOG] button is held down.

B The saddle can move within the range dened by the variable

limits which are set with parameters.

C Jog feedrate can be changed by the setting of the FEED RATE

override dial on the machine operation panel.

D The illustration below shows the saddle movement directions.

Page 45

-Note that the direction of axis movement differs for the following models:

LH35, LH55, LS30

Pulse Handle

<Procedure>

(1) Select the manual operation mode by pressing the [MANUAL] key on the NC

operation panel.

(2) For the two-saddle specication, select the saddle to be operated by the turret

selection keys.

(3) Select the axis to move by pressing the [PULSE - X] or [PULSE - Z] key on the

machine operation panel.

(4) Select the distance to move an axis per pulse by selecting the [PULSE - 1/1],

[PULSE - 10/1], or [PULSE - 50/1] key on the machine operation panel.

Linear axis Rotary axis

mm Unit System inch Unit System degree Unit System

1/1 .001 mm/pulse 0.0001 inch/pulse 0.001 deg/pulse

10/1 .010 mm/pulse 0.0010 inch/pulse 0.010 deg/pulse

50/1 .050 mm/pulse 0.0050 inch/pulse 0.050 deg/pulse

(5) Turn the pulse handle.

The axis moves in the positive direction in the program coordinate system if

the pulse handle is turned clockwise. It moves in the negative direction if the

pulse handle is turned counterclockwise.

[Supplement] A When operating an axis by the pulse handle, it is not possible to

select more than one axis at a time.

B To operate the C-axis by the pulse handle, set the C-axis in the

engaged state beforehand in the MDI operation mode.

C =N M110 [WRITE] [CYCLE START]

Page 46

Turret Rotation

<Procedure>

(1) Move the saddle to the position where turret rotation is possible. The turret rotation

enabled position differs depending on the machine model.

(2) For the two-saddle specication and the two-turret specication, select the turret to be

operated by the turret selection keys.

(3) Press the [TURRET INDEX] button on the machine operation panel.

[Supplement] A The turret keeps rotating if the [TURRET INDEX] button is held

down.

B The turret rotation direction should be set in the MDI operation

mode before indexing the turret.

If the turret is rotated without setting the rotation detection, the

turret rotates in the direction the station numbers increase. For

the at-bed construction machines (LH series), the turret can be

rotated only in the direction the station numbers increase.

C To rotate the turret, the following conditions must be satised.

LBII series LT15/25

LU series LC series

LCC series LCS series

V-turret specication of LH series/LS30N

H4 specication of LH series/LS30N LT10 The X-axis is positioned at the variable limit in

H6 specication of LH series/LS30N

H8 specication of LH series/LS30N

Two-turret specication of LH series/LS30N The saddle may be at any position.

Either the X- or Z-axis is positioned at the

variable limit in the positive direction.

(The [LIMIT] status indicating lamp must be lit.)

the positive direction.

The Z-axis is positioned at the variable limit in

the positive direction.

Page 47

Chuck Open/Close Operation

A foot pedal is provided to open and close the chuck.

(1) Procedure (Standard Foot Pedal)

(1) Step on the foot pedel to open or close the chuck. Each time the foot

pedal is stepped on, the chuck opens and closes alternately.

(2) Procedure (Dual-Pedal Foot Pedal)

(1) To close the chuck, step on the chuck close foot pedal.

(2) To open the chuck, step on the chuck open foot pedal.

Tailstock Body Positioning

With the simplied tow-along tailstock specicaiton, it is possible to move the tailstock

body using the saddle movement in the Z-axis direction after joining the tailstock body

to the saddle (A saddle for the two-saddle specication). When the tailstock body is

joined to the saddle by the joint pin, the tailstock body is unclamped from the rail.

When the saddle in not joined to the tailstock, the tailstock body is clamped against

the rail.

<Procedure>

(1) Select the manual operation mode by pressing the [MANUAL] key on

the NC operation panel.

(2) Move the saddle in the Z-axis direction to the position where the match

mark (↑) (↓) in the saddle is aligned with the match mark in the tailstock

body.

(3) Manually push the joint pin into the saddle and tailstock body joint holes

to join the saddle and the tailstock body.

(4) Move the saddle in the Z-axis direction using the Z-axis jog button or the

pulse handle to tow the tailstock body.

[Supplement] A Tailstock body movable range

The tailstock body is repositioned by moving the saddle

in the Z-axis direction after joining it to the saddle. When

tailstock body is joined to the saddle, the saddle has a Z axis movement range that is different from the saddle Z axis movement range when disconnected from the tail

stock body. Therefore, the movable range of the saddle in

the Z-axis direction with the tailstock body joined to the

saddle is set for W axis stroke end limit of the system

Page 48

parameter to restrict the saddle movable range when the

tailstock body is joined to the saddle.

If an axis movement command is specied that causes the Z-axis

to move beyond the set range, the command is disregarded.

B Feedrate

Feedrate of the Z-axis operated by pressing a SLIDE JOG button is

determined by the setting for system parameters W axis JOG

FEED and W axis ACCEL JOG FEED.

C Torque monitor

When moving the Z-axis in the state the tailstock body is joined

to the saddle, torque monitor is executed based on the value set for

the system parameter W axis TORQUE VALUE

If the torque exceeds the value determined by the setting and the

torque rating, an alarm occurs.

Tailstock Spindle Advance/Retract Operation

A foot pedal is provided to operate the tailstock spindle (advance (inching)/advance/retract).

The foot pedal used for tailstock spindle operation is of a dual-pedal type and one pedal is

used for the tailstock spindle retract operation. The other pedal has the two-position switch

and it is used for the tailstock spindle advance (inching)/advance operation.

(1) Procedure (Tailstock Spindle Advance (Inching))

(1) Step on the tailstock spindle advance side foot pedal to the rst-step switch

position

The tailstock spindle advances only while the rst-step switch is kept pressed.

(2) Release the foot pedal and the tailstock spindle stops advancing.

(2) Procedure (Tailstock Spindle Advance)

(1) Step on the tailstock spindle advance side foot pedal until he second-

step switch is actuated. Once the second-step switch is actuated, the tailstock

spindle keeps advancing even if the foot pedal is released.

(3) Procedure (Tailstock Spindle Retract)

(1) Step on the tailstock spindle retract side foot pedal. Once the switch in the

pedal is actuated, the tailstock spindle keeps retracting even if the foot pedal is

released.

Page 49

Coolant

<Procedure>

(1) Press the [COOLANT - MANUAL] key on the machine operation panel to turn

on the indicating lamp in it.

(2) Coolant stops when the [COOLANT - MANUAL] key is pressed again to turn off

the indicating lamp on it.

[Supplement] It is not possible to select the [COOLANT - MANUAL] key while the

[COOLANT - AUTO] key is selected (indicating lamp at the upper left

corner lit). If the manual coolant operation is selected, automatic

coolant operation is made invalid. Similarly, if the automatic coolant

operation is selected while the manual coolant operation is valid, the

manual coolant operation is made invalid.

Page 50

MDI Operation

1. Press MDI key in Mode Select Area.

2. Press function key (F3) (Program)

3. *Select “A” or “B” turret.

4. Press Page until MDI display appears with current/buffer.

5. *The Individual/Simultaneous switches should be in individual or simultaneous settings

6. Press function key (F1) (Data Input)

7. Enter the MDI data (G00X20,Z20,S800T101010)

8. Press Write Key - at this point the MDI data is transferred to the buffer side of the MDI

screen.

9. Before pressing cycle start, decrease the feed rate switch to minimize RAPID movements.

10. Press Cycle Start - at this point MDI data is transferred from “Buffer” to

“Current” side of MDI screen and the machine executes your command.

Starting Spindle Rotation

1. Make sure Chuck is clamped.

2. Press MDI key in Mode Select Area.

3. Press function key (F3) (Program)

4. Page until you nd MDI/Current-Buffer

5. *Select “A” or “B” turret.

6. *The Individual/Simultaneous switches should be in either individual or simultaneous setting.

7. Press function key (F1) (Input)

8. Key in M 41 S 500 M03

9. Press Write Key, at this point the MDI data is transferred to the Buffer side of the screen.

10. Press Cycle Start button

Page 51

11. The machine will now execute your command.

*For 2 turret model machine only.

Setting Z Zero Offsets

There are two methods of offsetting on the Okuma control. This rst method is used

for Z-axis.

1. *Select “A” turret.

2. Select a tool for the Zero Set Tool. (Only one tool per turret will be used for Zero

setting.)

3. In manual, face the part, then withdraw the tool in the X-axis.

4. Stop the spindle and measure overall length. Write this number down as it will

be used later.

5. Select Zero Set in the Mode Select Area.

6. With the cursor shift keys, locate the cursor to the Z-axis position.

7. Press function key (F3) (CAL), then key in dimension value.

8. Press Write Key.

9. The CRT displays the machine coordinate position.

10. Check the actual position display by pressing manual mode, then function key

(F2) (ACTUAL POSITION).

11. *Select “B” turret.

12. Select a tool for the Zero set tool.

13. *Move Zero Set Tool to touch the face of the part.

14. *Repeat steps 5 thru 8.

Page 52

Setting X Zero Offsets

This method is used for zero setting for a drill from the management data card (X-axis only).

1. Selet Zero Set Mode

2. *Select “A” turret

3. With the cursor shift keys, locate the cursor to the X-axis zero offset.

4. Press function key (F1) (SET), then key in the value from management data card. (89.1256)

(EXAMPLE)

5. Press Write Key.

6. The CRT will display this zero offset value.

7. *Select “B” turret.

8. Repeat steps 3 thru 5.

Adjusting Zero Offsets

On the control, there is also a method to adjust the zero set value. After properly zero setting and tool

offsetting, this method allows us to shift the zero set value further away from the part, thus allowing us

to run through a machine cycle without cutting any material.

1. Select Zero Set Mode.

2. Select “A” turret.

3. With the cursor shift keys, locate the cursor to the Z zero offset position.

4. Press function key (F2) (ADD) then key in amount of adjustment.

5. Press the Write Key.

6. The CRT will display the modied zero set value.

7. *Select “B” turret.

8. *Repeat steps 3 thru 5.

Page 53

Setting Tool Offsets

There are two methods of tool offsetting. The rst is used when the tool offsets are unknown. This

will be the most commonly used method.

1. Select Manual Mode.

2. Select Tool Data Mode.

3. *Select “A” turret.

4. Select a tool for offsetting.

5. Manually touch off a faced part in Z axis.

6. With the cursor shift key, locate the cursor to this tool’s offset number then select Z axis.

7. Press function key (F3) (CAL) Key in Dimension Value.

8. Press Write Key.

9. The CRT will display the offset.

10. Next, touch off a turned diameter for X-axis offset. If you do not have a diameter to work from

manually turn a diameter and measure this diameter. Write this number down.

11. With the cursor shift key select X-axis.

12. Press function key (F3) (CAL) then key in the dimension value.

13. Press Write Key.

14. The CRT will display the new offset value.

15. Repeat steps 4 thru 13 until all “A” turret tools are offset.

16. *Select “B” turret.

17. Repeat steps 4 thru 13 until all “B” turrets tools are offset.

Page 54

Setting Tool Offsets

This method of setting tool offsets will be used when preset tools are placed in the turret station, that

is, the tooling has been premeasured for tool length and tool width prior to being placed in the turret

stations. This method can also be used to erase offsets.

EXAMPLE: Drill X offset = 0.000

1. Press the Tool Data key in this Mode Select area.

2. *Select “A” turret.

3. With the cursor shift key locate the cursor to the tool offset number then select X or Z axis.

4. Press function key (F8) (EXTEND)

5. Press function key (F1) (SET) key in premeasured value.

6. Press Write key.

7. Repeat steps 3 thru 6 as needed for “A” turret tools.

8. *Select “B” turret.

9. Repeat steps 3 thru 6 as needed for “B” turret tools

Adjusting Tool Offsets

This method is used to compensate for insert wear by incrementally adjusting the offset value for that

particular tool. The rule of thumb for adjusting the tool offset is: the part dimension is oversized you

must subtract (-) the oversize amount from the original offset value. If the part dimension is undersized you must add (+) the undersized amount to the original offset value.

1. Press the Tool Data Key.

2. *Select the proper turret “A” or “B”.

3. With the cursor shift keys locate the cursor to the proper tool offset position.

4. Press function key (F2) (ADD) and key in the adjustment value (oversize = -value, undersize =

+value).

5. Press Write Key.

6. The CRT will display the new offset calculation.

Page 55

7. Repeat steps 3 thru 5 as needed for additional tool offset adjustment.

Notes:

1. A constant for adjustment can be set in Optional Parameter Long Word 32.

2. To prevent accidental over adjustment of an offset, a limit can be set in Optional

Parameter Long Word 33.

3. A limit can be set in Optional Parameter Long Word 33 to prevent accidental adjust

ment of offsets.

Setting Soft Stroke End Limits

Method 1

Soft wired stroke end limit positions are used as a home position for indexing the turret. There are

two methods of setting these limits. The rst method is called the PLAYBACK METHOD. This

method allows us to physically move the turret to a safe index position and set the soft limits.

1. Manually move “A” turret to the desired “SAFE” position in X and Z axis.

2. Press the Parameter key in the Mode Select area.

3. Press function key (F6) or (F7) until the “User Parameter” display appears.

4. *Select “A” turret.

5. *With cursor shift keys locate the cursor to the X-axis data position.

6. *Press function key (F3) (CAL) (Value is not necessary).

7. *Press Write Key.

The CRT will display the new soft limits (manually check these limits).

8. Locate the cursor to the Z axis data position.

9. Repeat steps 6 and 7.

10. *Select “B” turret.

11. Manually move the “B” turret to the desired “SAFE” position in X and Z axis.

12. *Repeat steps 5 thru 9.

Page 56

Method 2

This method for setting the stroke end limits is used when it is necessary to calculate the stroke end

limits from the program zero point without having to move the turret(s) to that position.

1. Press the Parameter Key in the Mode Select area.

2. Press function key (F6) or (F7) until the “User Parameter” display appears.

3. *Select “A” turret.

4. With cursor shift keys located the cursor to the X-axis data position.

5. Press function key (F1) (SET) and then key in soft limit value.

6. Press Write Key.

7. With cursor shift keys locate the cursor to the Z-axis data position.

8. Repeat steps 5 and 6.

9. *Select “B” turret.

10. *Repeat steps 4 thru 8.

11. “The CRT will display the new soft limit positions.

CAUTION - The amount of adjustment cannot exceed the maximum stroke end limits.

Adjusting the Soft Stroke End Limits

This method is used to incrementally adjust the stroke end limits.

1. Press the Parameter Key in the Mode Select area.

2. Press function key (F6) or (F7) until the “User Parameter” display appears.

3. *Select “A” turret.

4. With the cursor shift keys locate the cursor to the Z-axis data position.

5. Press function key (F2) (ADD) and key in the amount of adjust (+ or -1).

6. Press Write Key.

7. *Select “B” turret.

8. *Repeat steps 4 thru 8.

Page 57

9. The CRT will display the new soft limit position.

CAUTION - The amount of adjustment cannot exceed the maximum stroke end limits.

Procedure to Store Programs into Memory from Tape

1. Set the N.C. part program tape in the tape reader.

2. Press the Edit Aux. key in the Mode Select area.

3. Press function key (F3) (PIP).

4. Press function key (F1) (READ).

5. Press Write Key.

6. Press function (F7) (QUIT) when tape reader is nished reading the N.C. tape.

Program Selection

Method 1

1. Press Auto in the Mode Select area.

2. Press function key (F1) (Program Select) then the * on the key pad.

3. Press Write Key.

4. Move cursor to the desired program.

5. Press Write Key.

Method 2

1. Press Auto in the Mode Select area.

2. Press function key (F1) (Program Select).

3. Key in the program name.

4. Press the Write Key

*For 2 turret mode machines only.

Page 58

Block to Block Operation

This method allows the operator to “single step” through the N.C. program one block at a time.

*Steps 1 thru 5 need only be done when you are selecting a new program.

1. Press the Auto Key in the Mode Select area.

2. Press “Single Block” switch on.

3. Place the individual/simultaneous switches to the appropriate settings.

4. Turn feed rate override to 10% to reduce rapid movements.

5. Press Cycle Start button.

NOTE: With the Single Block switch on you must depress cycle start after every block. (For

automatic continuous operation, at Step 4, press Single Block switch off) and feed rate

override to 100%.)

Sequence Re-Start

This method is used to restart the program to a specic section in the N.C. program by designating

that sequence number.

CAUTION - After pressing the Sequence Restart button the machine advances to one block be-

fore the commanded restart block

1. Press the Auto key in the Mode Select Area.

2. Press function key (F3) (Part Program)

3. Press page until program is displayed. “For 4-axis machines page until both “A” and “B”

programs are shown in a split screen.

4. “Select the “A” turret.

5. Press function key (F8) (EXTEND) to display F2/restart button.

6. Press “Single Block” switch “ON”

7. Press function key (F2) (restart).

8. Key in sequence number for upper turret program (N-).

9. Press Write Key.

NOTE: For 2-axis machines jump to procedure #14.

Page 59

10. *Select “B” turret.

11. *Press function key (F2) (RESTART)

12. *Key in sequence number for lower turret.

13. *Press Write Key

14. Wait for cursors to stop on the program.

15. Press the Sequences Restart button.

16. Press Single Block switch off, press cycle start to run.

CAUTION - Before pressing Sequence Restart button decrease the feed rate override switch to

minimize rapid movements.

Sequence Restart - Block Counter Method

This method of Sequence Restart entails using the block counter, which is located at the extreme top

right corner of the CRT next to the “N” sequence number.

CAUTION - After pressing the Sequence Restart button the machines advances to one block before

the commanded restart block.

1. Press the Auto key in the Mode Select area.

2. Press function key (F3) (Part Program)

3. Press Page until program is displayed. “For 4-axis machines page until both “A” and “B”

programs are shown in split screen.

4. *Select “A” turret.

5. Press function key (F8) (EXTEND) to display F2 restart key.

6. Press function key (F2) (RESTART)

7. Key in block counter number for upper turret program (for example 15).

8. Press Write Key.

NOTE: For 2-axis machines jump to procedure #13.

9. *Select “B” turret.

10. *Press function key (F2) (RESTART).

11. Key in block counter number for lower turret program (for example 75)

Page 60

12. *Press Write Key.

13. Wait for cursor to stop in the program.

14. Press Single Block key.

15. Decrease the feed rate override switch to minimize rapid movements

16. Press the Sequence Restart button.

*For 2 turret mode machines only.

MID-Auto Manual Mode and Restart Function

This method allows the operator to interrupt the machining cycle, manually jog away from the work

piece, stop the spindle, change inserts, and then return back to the position where the machining

cycle was interrupted.

1. Press the “Slide Hold” button.

2. Press the Mid-Auto Manual Button - (NOT THE MANUAL BUTTON)

3. Manually move the turret away from the work piece. At this time, the operator can stop the

spindle and index the turret to change inserts.

4. Return turret to original station and restart spindle to get the STM light to stop blinking.

5. Manually move the turret close to the point where the slide hold button was originally pressed.

6. Press the “Single Block” switch on and decrease the feed rate override switch.

7. Press “Sequence Restart” button.

CAUTION - After pressing the Sequence Restart button, the machine moves in rapid toward the

work piece.

8. Return feed rate override switch to 100%

9. Press the “Cycle Start” button.

The functions that are operative under this function are:

A. Manual axis feed.

B. Axis feed using the pulse handle.

C. Spindle rotation (CCW, CW, STOP, JOG)

D. Spindle gear range selection.

E. Turret Indexing

Page 61

Page 62

Page 63

COORDINATE SYSTEM AND

PROGRAM ZERO POINT

Coordinate System

Absolute Position Encoder Advantages

Page 64

COORDINATE SYSTEM

AND ZERO POINT

CNC machine tool motions must be identied carefully. Motions formerly done manually must now be

explained numerically to the machine. Cutting tool and metal must come together at the right place

and cutting conditions must be established. Points in space are specied to the machine by numerical

coordinates along specied axes. This manual explains programming for Okuma Lathes with two

perpendicular axes (common to most lathes).

Positions on the work surface are identied by X and/or Z commands. All points are determined by

their distance from a Zero point in each axis. Positions are positive or negative, depending on their

position relative to Zero.

Page 65

Program Zero Point - the program zero point denes a ‘relative’ X0 Z0 position with regards to the

machine’s center line. It denes the point along the machine’s center line, which in turn, correlates to

the part program’s origin.

The illustration below depicts at case which the user has dened the program zero to be at the face

of the chuck body. This ‘zero’ is often referred to as the part’s ‘Z’ zero. This point corresponds to the

programmers X0 Z0 point, or ‘origin’ in the programming process.

Note:

Fundamentally, there are two (2) methods of deciding the location of the Program Zero.

In the Okuma method, the program zero point is typically placed at the left end of the

work piece. The main advantage of this ‘style’ is that ALL programmed dimensions will by default - be positive. Additionally, there is the benet that the ‘zero’ point is effectively

represented by a physical surface of the work holder.

The other method places the program zero point at what is effectively the parts

right end. Therefore, part programs that use this ‘style’, have negative ‘Z’ program

dimensions. The decision of which method to use is mainly a matter of personal

preference.

Page 66

Coordinate Positions / Program Points

Often a cylindrical part is redrawn to show only one half of the basic part

prole, and the program points in a logical sequence. The following illustration

reects this basic technique for the part, shown above.

Page 67

G90 Absolute Positioning - this is most common method of programming. The

absolute method denes all the dimensions of the part based on parts origin point [X0 Z0]. It

is the preferred method because it simplies relating the part drawing dimensions to that of the

actual part program X, Z dimensions. The majority of engineering drawings today are based on

the ‘datum dimensioning’ technique, which, corresponds directly to absolute programming.

G91 Incremental Positioning - this method is only used when necessary. It describes the

program path based on the tool’s current coordinate in X and Z, and ‘incrementally’ denes

the next ‘target position’ relative to the actual current position. It is similar in concept to chain

dimensioning .

ABSOLUTE

Method

G50 S2000 G50 S2000

G00 X50 Z50 G00 X50 Z50

X1.25 Z3 T0101 G97S900 M03 X1.25 Z3 T0101 G97S900 M03

G01 Z2 F.015 G91 G01 Z-1 F.015

X2.5 X1.25

Z1 Z-1

X3.75 X1.25

G00 X50 Z50 G90 G00 X50 Z50

M02 M02

INCREMENTAL

Method

Page 68

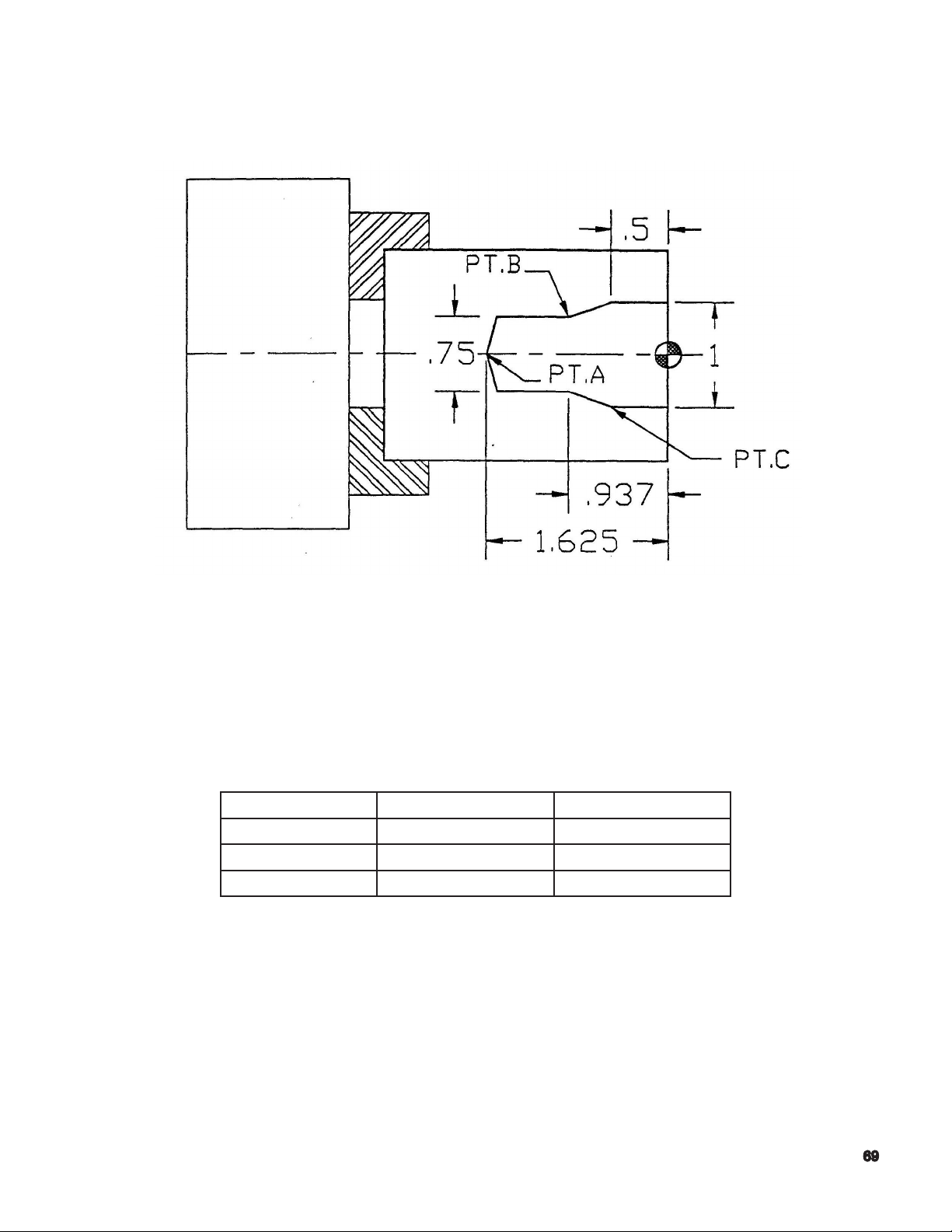

PT.A

PT.B

PT.C

IDENTIFY

COORDINATES:

X Z

Page 69

PT.A

PT.B

PT.C

IDENTIFY

COORDINATES:

X Z

Page 70

Page 71

Program Codes

G Codes

Additional G Codes

M Codes

Page 72

G Codes

Page 73

G Code Description Notes

G00 Rapid Travel Positioning

G01 Linear Interpolation

G02 Circular Interpolation (Clockwise)

G03 Circular Interpolation (Counter clockwise)

G04 Dwell, expressed as seconds (used with the “F”

format word)

G13 Designates ‘A’ Turret (upper)

G14 Designates ‘B’ Turret (lower)

G32 Fixed Threading Cycle (face)

G33 Fixed Threading Cycle (longitudinal)

G34 Increasing Lead Threading Cycle

G35 Decreasing Lead Threading Cycle

G40 Cancellation of G41 or G42 Tool Nose Radius

Compensation

G41 Tool Nose Radius Compensation (left of mate-

rial)

G42 Tool Nose Radius Compensation (right of mate-

rial)

G50 Used with ‘S’ Format Word, for Maximum spin-

dle Speed Designation

G64 Droop Control ‘OFF’

G65 Droop Control ‘ON’

G71 Longitudinal Threading Compound Cycle

G72 Transverse (end face) Thread Cutting Cycle

G73 Grooving Cycle, Feeding on the ‘X’ Axis

G74 Face Grooving/Drilling Cycle, Feeding on the ‘Z’

Axis

G75 Automatic Chamfering (45 degree corners and

llets only)

G76 Automatic Radius ( corners and llets only)

G77 Right Hand Tapping Cycle

G78 Left Hand Tapping Cycle

G80 End of Contour Denition for LAP

G81 Start of Longitudinal Contour Denition for LAP

G82 Start of Transverse Contour Denition for LAP

G83 LAP 4-High Speed Copy Turning

G84 Change of Rough Cutting Conditions in the LAP

‘G85’ Cycle

G85 Rough Cutting Cycle for LAP

G86 Copy Turning Cycle for LAP

G87 Finish Cutting Cycle for LAP

G88 Continuous Thread Cutting Program

Page 74

G Codes Description Notes

G90 Absolute Coordinate Programming

G91 Incremental Coordinate Programming

G94 Feed rate Expressed as INCHES PER MIN-

UTE

G95 Feed rate Expressed as INCHES PER REV-

OLUTION

G96 Constant Surface Footage

G97 Direct Spindle RPM Command

G110 Constant Surface Footage (cutting) - ‘A’ Tur-

ret Priority

G111 Constant Surface Footage (cutting) - ‘B’ Tur-

ret Priority

G152 Call for Programmable Tail stock

Page 75

Additional G Codes

Page 76

FREQUENTLY USED CODES

G50 Spindle Speed Limit

Power chucks are used on CNC lathes have a maximum safe RPM. This is usually stamped on the

chuck. This maximum RPM must be input on the rst line of every part program.

FORMAT:

G50 S__________

G0 Rapid Travel

Used to move the slides at full speed. Note the tool path in the G0. At rapid travel both axes move

at full speed and no linear interpolation takes place. Though the axes move simultaneously they

move individually until they reach the specied coordinate.

G0 X50 Z50: Rapid to home position for Turret Index

Set Soft Limits so that the longest tool can safely index. Also allow room for the operator to be able

to move parts from the chuck without interference with the tools in the turret. The OSP will not allow

the turret to index unless the machine is in this position

Page 77

G94 and G95 - IPR and IPM Feed

In a cutting mode, the rate by which the turret or the X-axis and Z-axis is moved, is controlled by the

“F” or feed rate word.

The mode of the “F” word is dictated by which “G” command code is chosen by the programmer.

The feedrate choices are as follows:

G94: Inches per minute

G95: Inches per revolution

The control powers up in the G95 mode, when the machine is turned on.

FEEDRATE: Fxxxx.xxx Inch per Minute

Fxxxx.xxx Inch per Revolution

Feedrate is used in conjunction with the G-codes G94 and G95 to control the rate of feed in a linear

or circular contouring mode.

Most of the programmed feedrates will be in inches per revolution; however, if inch per minute programming is needed use this formula to calculate the value:

IPM = (IPR * RPM)

ADDITIONAL USE FOR “F” WORD:

When using the G04 preparatory function the “F” word is the method used to describe dwell in

seconds

Page 78

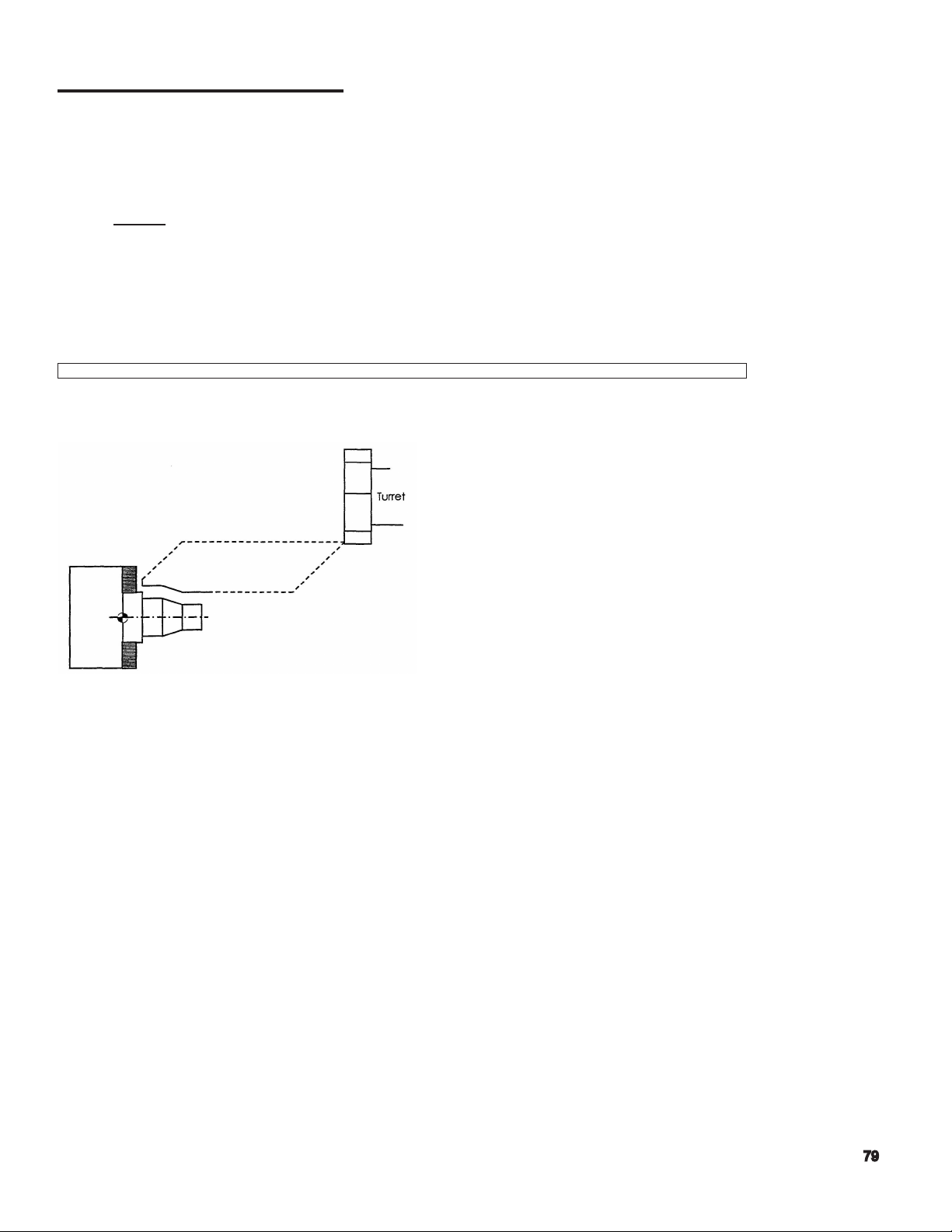

G00 Rapid Travel Positioning - this command causes all the machines axis slides to

move at ‘full speed’ to the target position.

Note that a G00 command does not always result in a ‘straight-line’ path of motion between the

current position and the target position.

Effectively, both axes move simultaneously - (45 degree) until such time where either axis has

met its target point, and any continued axis motion is done to satisfy the remaining axis.

FORMAT: G00……Z……

N1 G00 X50 Z50

N2 X10 Z5

Notes: example performed under MDI, assumes ‘inch’ mode.

Line ‘N1” positions the turret at either of the machine’s positive stroke end limits, or the current ‘soft

limit’ positions. Main spindle rotation is not required during a ‘G00’ movement. The G00 command

becomes modal following its initial occurrence. As no tool number is ‘active’ the positioning does not

include any tool offset values. Positioning is relative to the current ‘Z’ zero offset position, and the

machine’s X and Z offset origins.

Line ‘N2’ positions the axes at X10 Z5. This line can be changed to: X10 Z5 T0101 to include the

offset value for tool number 1. Note the difference in the nal position, when including the tool offset

value.

Page 79

G01 Linear Interpolation - a fundamental program command that is used whenever ‘cutting’