OKIDATA ML390 TURBO, ML391 TURBO Service Manual

Thank You for purchasing this

Click Here for more Factory Service

Manuals for other Computer and

Printer / Copier Manufacturers

from PCTECHINFO!

Page: 1

Service Guide ML390/ML391Turbo

Chapter 0 About This Manual

ML390 Turbo // ML391 Turbo

Dot Matrix Printers

Adobe Acrobat printable reference

copy of the OKIDATA Service Training Manual.

09/17/97

Note: This Adobe Acrobat version of the Okidata Service Training Manual was built with the

pictures rendered at 300 dpi, which is ideal for printing, but does not view on most

displays well.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Table of Contents Page

Service Guide ML390/ML391Turbo

0 About This Manual

Front Cover 1

Copyright / About Information 2

1 Configuration

1.1. Standard Printer Configuration 3

1.2 Options 4

2 Theory of Operation

....2.1.01 Summary 5

....2.1.02 Microprocessor and the Peripheral Circuit 6

........Printer Block Diagram (Figure 2-1) 7

........Program ROM 8

........RAM (MSM51C464A-80RS) 9

........EEPROM 10

........Large Scale Integrated Chip (LSI) 11

....2.1.03 Initialization 12

....2.1.04 Parallel Interface Control 13

....2.1.05 Print Control 14

........Print Compensation Control 15

....2.1.06 Space Motor / Line Feed Motor Control 16

....2.1.07 Operation Panel 17

....2.1.08 Alarm Circuit 18

....2.1.09 Power Supply Circuit 19

2.2.01 Printhead Mechanism and Operation 20

....2.2.02 Spacing Operation 21

....2.2.03 Head Gap Adjusting 22

....2.2.04 Ribbon Drive 23

....2.2.05 Paper Feed Operation 24

........(1) Cut Sheet and Continuous Forms Switching

Mechanism

........(2) Cut-sheet feeder operation 26

........(3) Continuous Forms Operation (Rear) 27

........(4) Push and pull tractor mechanism (Option) 28

........(5) Pull tractor mechanism (option) 29

........(6) Bottom Push Feed Operation (Option) 30

........(7) Paper Clamp Mechanism 31

....2.2.06 Paper Detection Mechanism 32

....2.2.07 Automatic Sheet Feed 33

....2.2.08 Paper Park Function (Continuous Forms) 34

3 Assembly/Disassembly

ASSEMBLY/DISASSEMBLY 35

....3.1 Precaution for Parts Replacement 36

....3.2 Service Tools 37

25

Table of Contents Page

....3.3 Disassembly/Reassembly Procedure 38

............How to Change Parts 39

........3.3.01 Printhead 40

........3.3.02 Ribbon Protector 41

........3.3.03 Pull-up Roller Assy 42

........3.3.04 Upper Cover Assy, Access Cover Assy and Sheet

Guide Assy

........3.3.05 Gear Case Assy 44

........3.3.06 PC Connector 45

........3.3.07 Space Motor, Guide Roller Assy 46

........3.3.08 Space Rack 47

........3.3.09 Carriage Cable 48

........3.3.10 Backup Roller Holder Assy 49

........3.3.11 Platen Assy 50

........3.3.12 Driver Board (SRXD) 51

........3.3.13 LF Motor 52

........3.3.14 Operation Panel PCB (LEOP) 53

........3.3.15 Control/Power Supply Board (SRXC) 54

........3.3.16 Transformer Assy 55

........3.3.17 Change Lever and Gears 56

........3.3.18 Carriage Shaft 57

........3.3.19 Paper Pan 58

........3.3.20 Rear Tractor Assy 59

........3.3.21 Rear Pressure Assy 60

........3.3.22 Switch Lever 61

4 Adjustments

4. ADJUSTMENT 62

....4-1-1 Gap between the platen and the printhead 63

....4-1-2 Measure variation of gap when range is changed. 64

4-2 Gap between the platen and the paper pan 65

4-3 Gap between the platen and the pressure roller 66

....4-4-1 Rotation of the push tractor 67

....4-4-2 Backlash between gears 68

....4-5-1 Ribbon feed 69

....4-5-2 Running load to spacing mechanism 70

....4-6 Engagement of the double gear and the LF motor idle

gear of the Platen

5 Cleaning and Lubrication

5.1 Cleaning 72

5.2 Lubrication 73

....(1) Cleaning time 74

....(2) Lubricant 75

....(3) Amount of lubricant 76

....(4) Areas to Avoid 77

43

71

Table of Contents Page

........(5) Lubrication points -- 1. Ribbon feed gear Assy. 78

........2. Space rack 79

........3. Platen Assy. 80

........4. Tractor driving mechanism 81

........5. Tractor drive shaft 82

........6. Pressure roller 83

........7. Pull up roller Assy. 84

........8. Main chassis Assy. 85

........9. Carriage Assy. 86

6 Troubleshooting and Repair

6.1 Items to Check Before Repair 87

6.2 Troubleshooting Table 88

6.3 Lamp Display 89

6.4 Connection Circuit Check for Printhead and SP/LF Motor 90

........(2) Line Feed Motor 91

........(3) Space Motor 92

6.5 Troubleshooting Flow Charts 93

........2 No Spacing Operation (The Alarm LED Blinks) 94

........3 Homing does not end normally 95

........4 Paper jam while paper insertion 96

........5 Smearing/Missing Dots 97

........6 Faint or dark print 98

........7 Ribbon feed trouble 99

........8 Line feed trouble 100

........9 Malfunction of switch on operation panel 101

........10 Data receiving failure 102

A PCB Layout

APPENDIX A: PCB LAYOUT 103

B Parts Listing

SPARE PARTS LIST 104

....Upper Cover Assembly (Figure 11-1) 105

....Printer General Assembly (Figure 11-2) 106

....Printer Unit (Figure 11-3 ) [1 of 2] 107

....Printer Unit (Figure 11-3 ) [2 of 2] 108

....Carriage Option Assembly (Figure 11-4) 109

....Option Spare Parts (Figure 11-5) 110

C RS-232C Serial Interface Board

APPENDIX C: RS-232C SERIAL INTERFACE BOARD 111

C2. Operation Description 112

........C2.2.01 Operation at Power On 113

........C2.2.02 RS-232C Interface 114

....C2.3 Communication Procedure Flowchart 115

........C2.3.02 Mode B (Figure C-2-3) 116

C3. Troubleshooting Flowcharts 117

Table of Contents Page

....C3.3 Local Test 118

........C3.3.1.2 Function 119

Service Guide ML390/ML391Turbo

Chapter 0 About This Manual

Disclaimer

This document may not be reproduced without the written permission of Okidata Training and

Publications. Every effort has been made to ensure the accuracy of the information contained in this

training course. Okidata is not responsible for errors beyond its control.

Copyright / About Information

1996 by Okidata. All rights reserved.

First Release P/N 59274601 November, 1996

Written by:

OKI Data Corporation

11-22, Shibaura 4-chome, Minato-ku, Tokyo 108, Japan

Tel: +81 (Japan)-3 (Tokyo)-5445-6159 Fax: +81-3-5445-6188

Revised by Okidata Training and Publications

Contact

Please address any comments on this publication to:

OKIDATA

Training and Publications

532 Fellowship Road

Mount Laurel, NJ 08054-3499

Page: 2

Okilink Login Name: Technical Training

Internet Web Site: okidata.com

Copyright Listing

OKIDATA is a registered trademark of Oki America, Inc.

OKIDATA est une marque déposée de Oki America, Inc.

Centronics is a registered trademark of Centronics Data Corporation.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

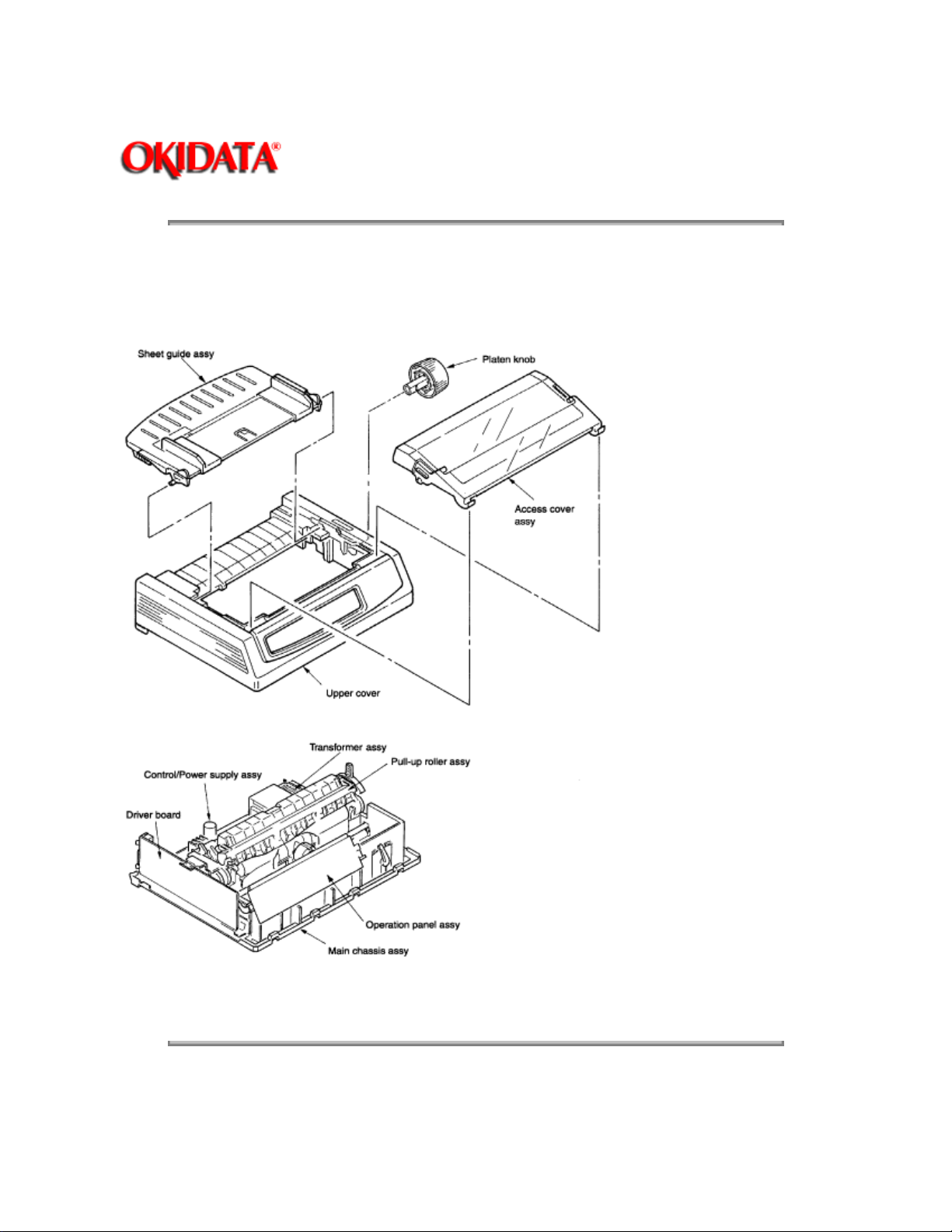

Service Guide ML390/ML391Turbo

1.1. Standard Printer Configuration

This printer consists of the following assemblies:

Page: 3

Chapter 1 Configuration

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

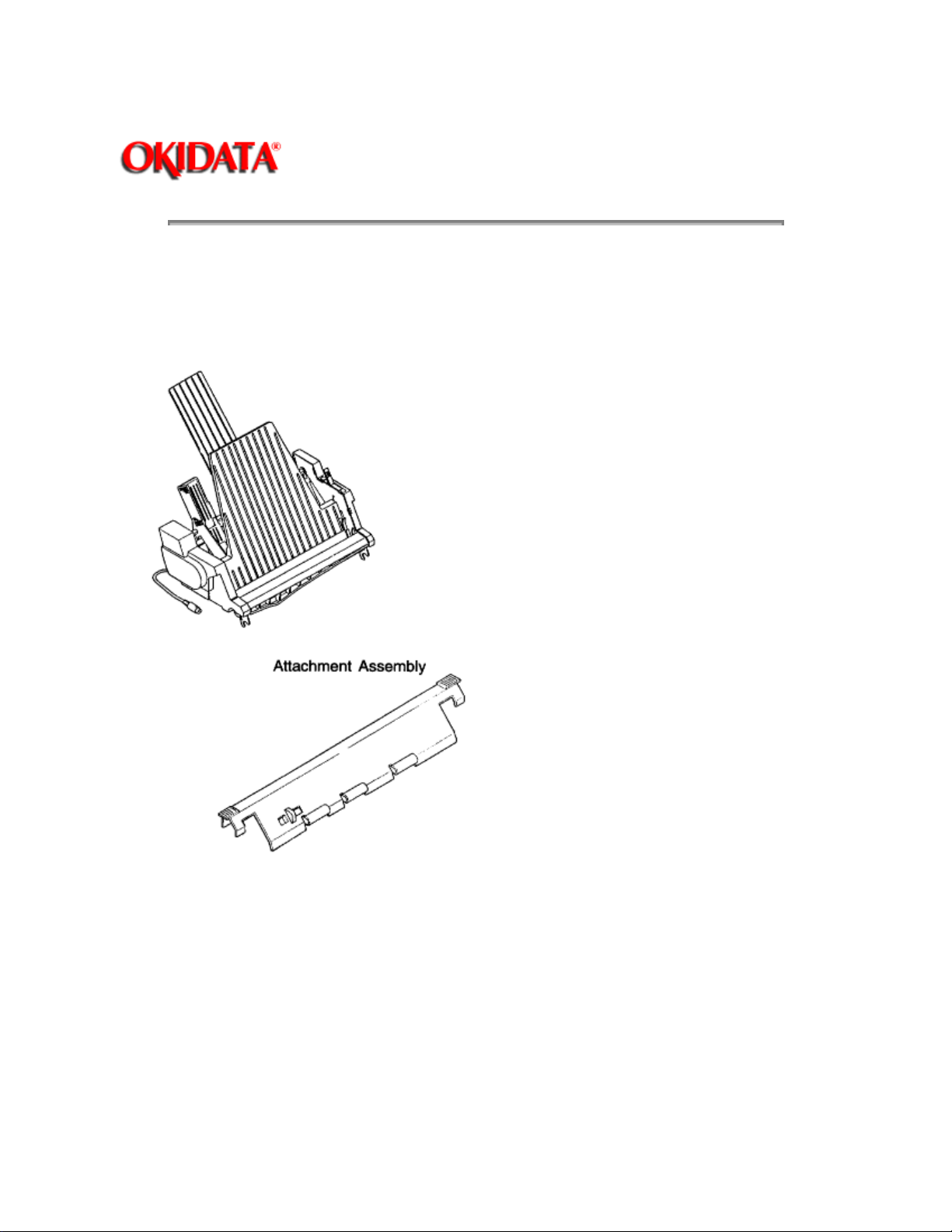

1.2 Options

(1) Cut Sheet Feeder Unit (CSF)

Single-Bin Cut Sheet Feeder

Page: 4

Service Guide ML390/ML391Turbo

Chapter 1 Configuration

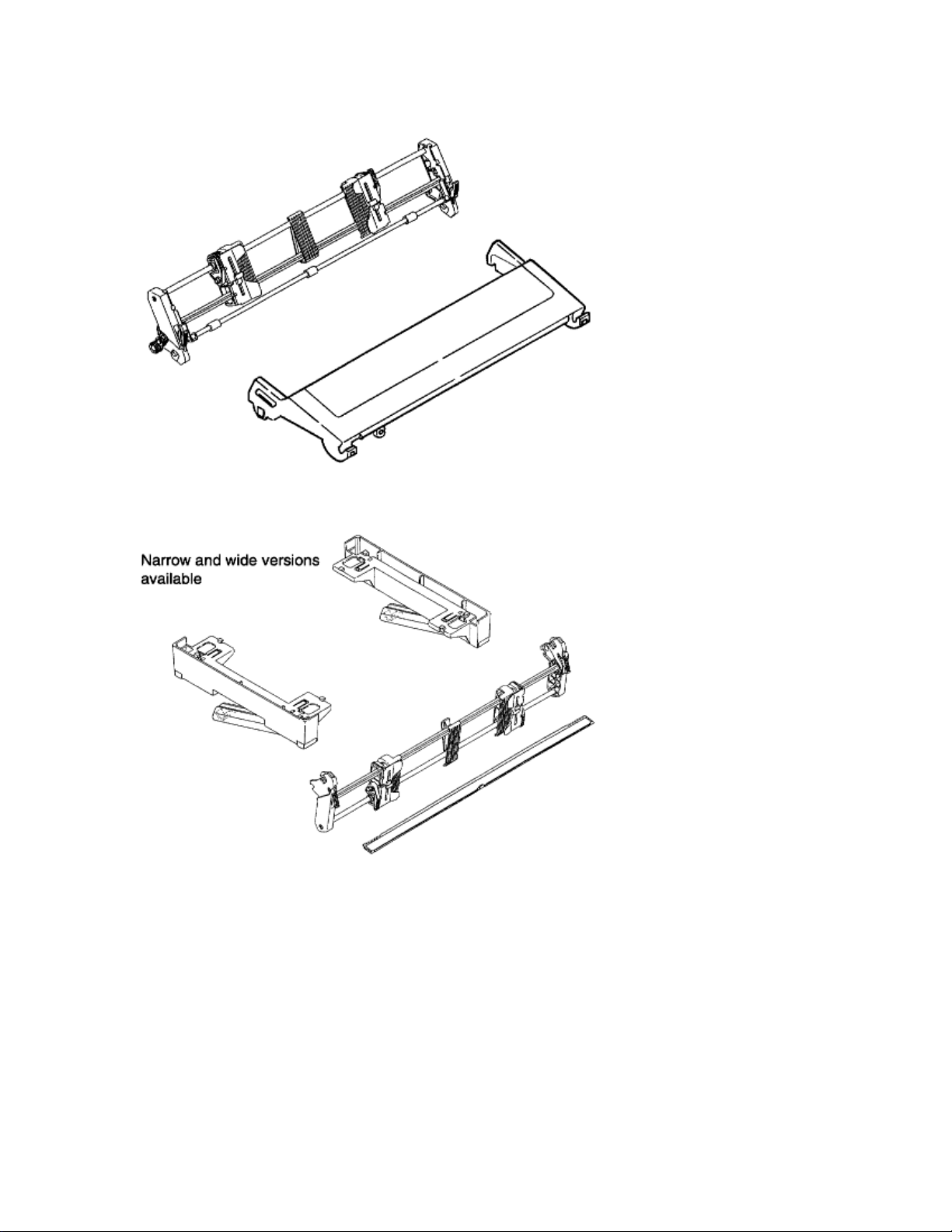

(2) Pull-tractor Assembly

(3) Bottom Push Tractor Unit

(4) Roll Paper Stand (Narrow only)

(5) Serial Interface

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page: 5

Service Guide ML390/ML391Turbo

Chapter 2 Theory of Operation

2.1.01 Summary

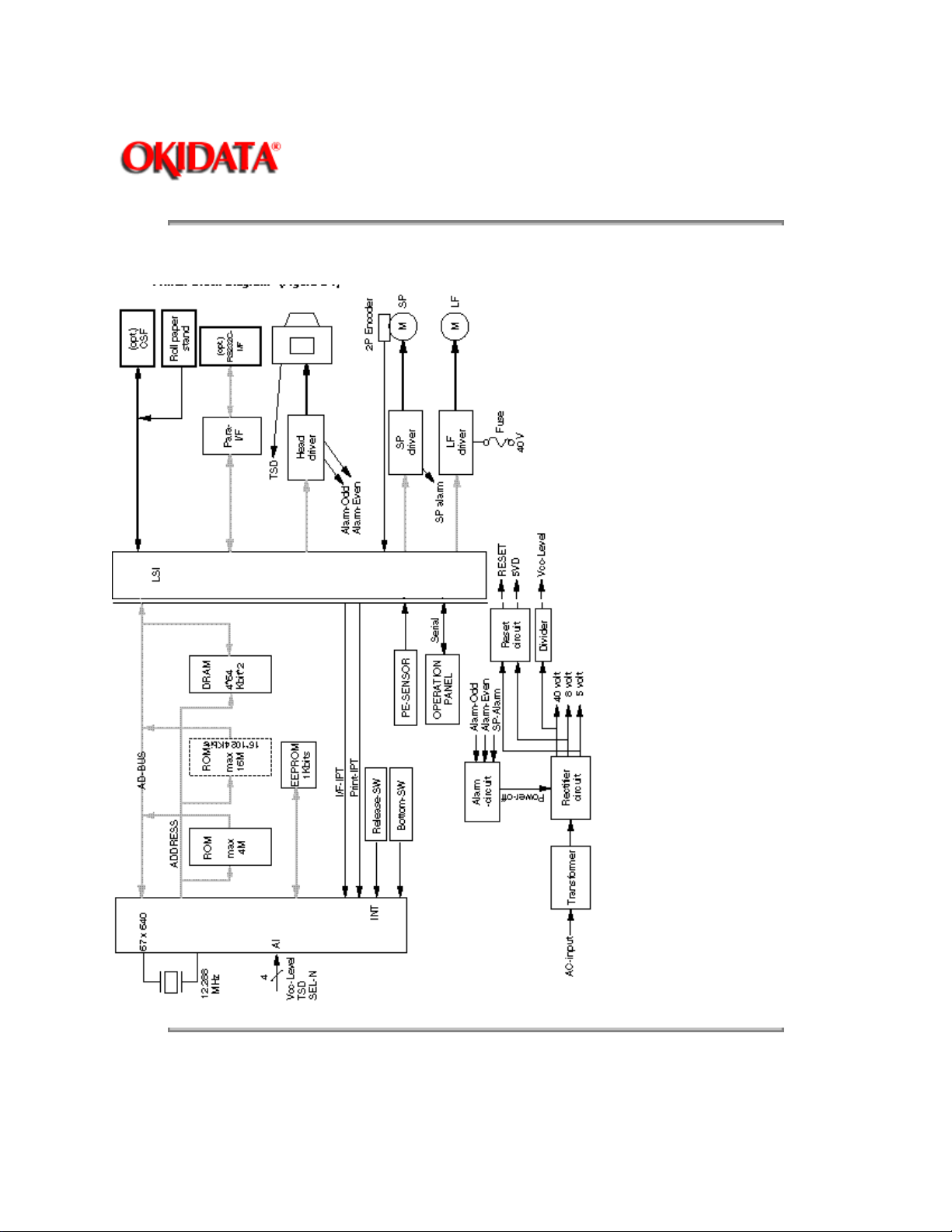

Figure 2-1 shows the block diagram of the printer.

The control board is made up of the microprocessors, peripheral circuits, drive circuits,

sensors and interface connectors.

The power to the control board is supplied by the power board through the connector cord.

The power to other electrical parts is also distributed through the connectors within the

control board.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide ML390/ML391Turbo

Chapter 2 Theory of Operation

2.1.02 Microprocessor and the Peripheral Circuit

Microprocessor (Q7: 67X640)

This processor is a CMOS single-chip computer with integrated peripheral device

functions and a 16 bit MPU core, all OKI original architecture.

The processor has a 20 bit address bus and a 16 bit data bus.

It is capable of accessing up to 1M word program memory and 1M bytes of data

memory.

The following characteristics are also provided:

Built-in type data memory of 512 bytes

8-bit 4-channel A/D converter ¥ 1

Page: 6

16-bit automatic reload timer ¥ 2

8-bit serial port ¥ 2

8-bit parallel port ¥ 3 (bitwise I/O specification available)

And others.

The function of this microprocessor is to provide a central mechanism for the entire

printer by executing the control program through the LSI and driver circuits.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

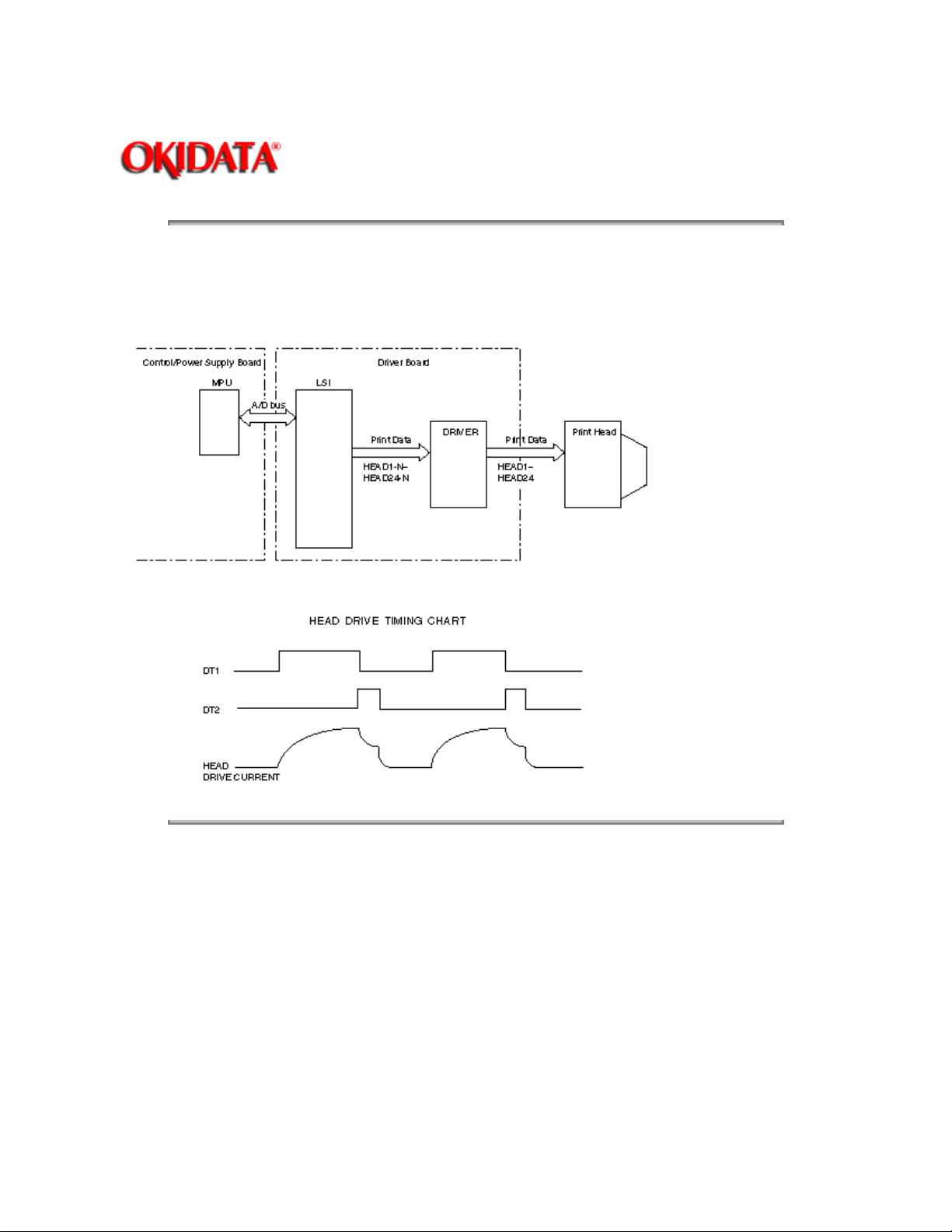

Printer Block Diagram (Figure 2-1)

Page: 7

Service Guide ML390/ML391Turbo

Chapter 2 Theory of Operation

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide ML390/ML391Turbo

Chapter 2 Theory of Operation

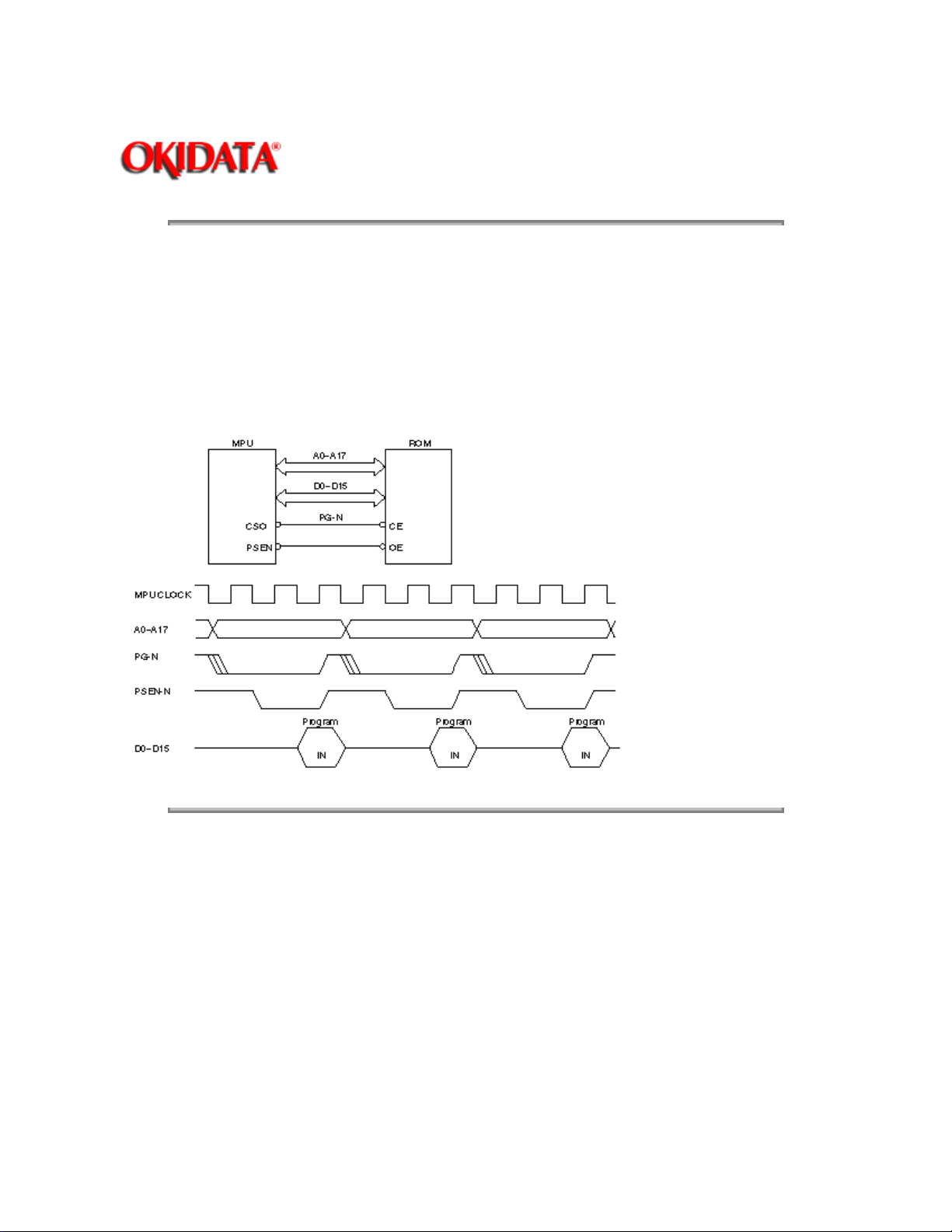

Program ROM

This is a 256 ¥ 16 bits (4M bit) [MAX] EPROM with the control program for the printer

stored. The MPU executes instructions under this program.

The program ROM is assigned to the program memory area of the MPU and is

fetched by the PSEN signal of the MPU.

The following shows the operation of the memory access.

Page: 8

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide ML390/ML391Turbo

Chapter 2 Theory of Operation

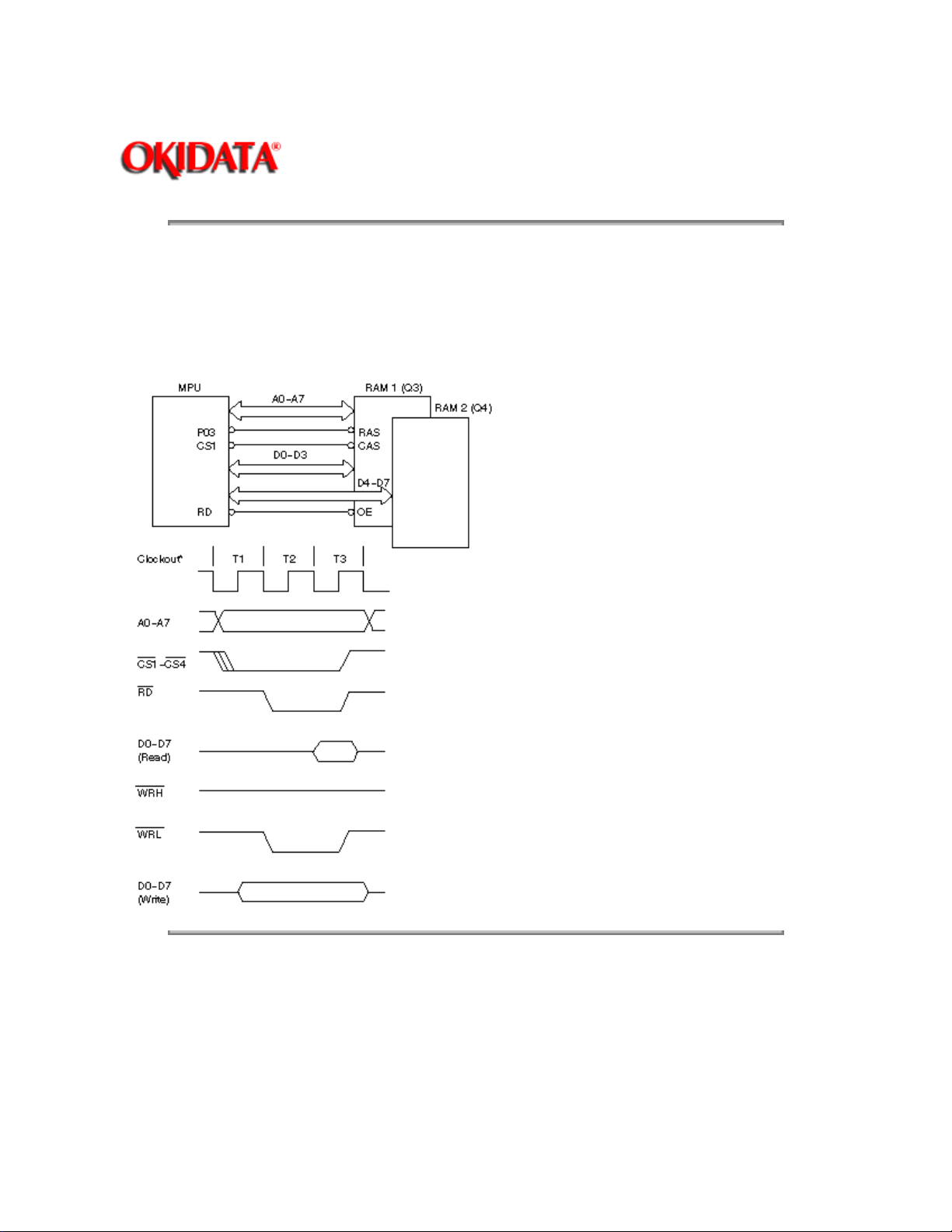

RAM (MSM51C464A-80RS)

The RAM is CMOS dynamic RAM with (64K ¥ 4-bit) ¥ 2 configuration, and used as

buffers (such as receiving buffer, printing buffer, DLL buffer and working buffer).

The following shows the examples of the memory access operation.

Page: 9

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide ML390/ML391Turbo

Chapter 2 Theory of Operation

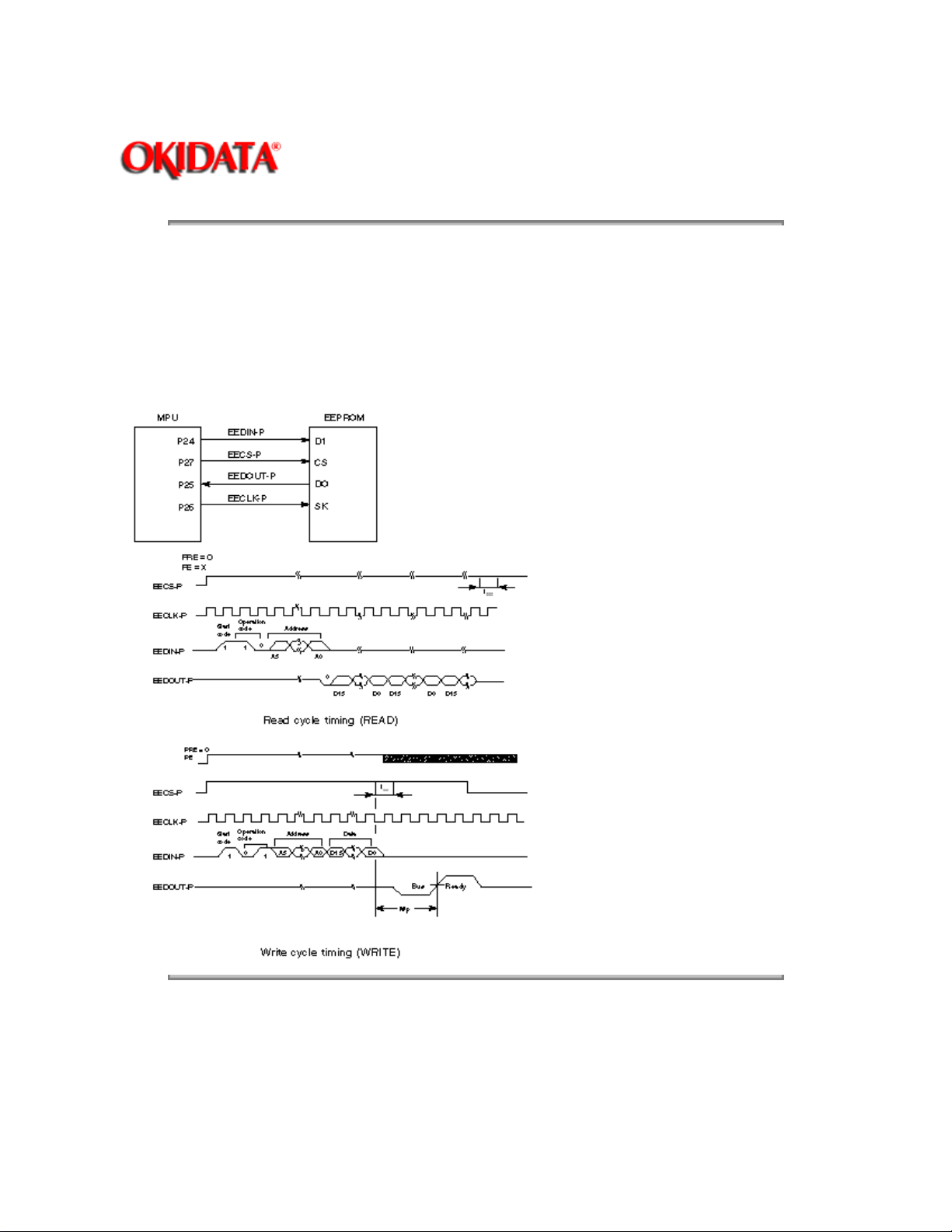

EEPROM

The EEPROM is a CMOS serial I/O type memory which is capable of electrically

erasing and writing 1,024 bits.

The EEPROM contains menu data.

The following shows the memory access operation.

Page: 10

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide ML390/ML391Turbo

Chapter 2 Theory of Operation

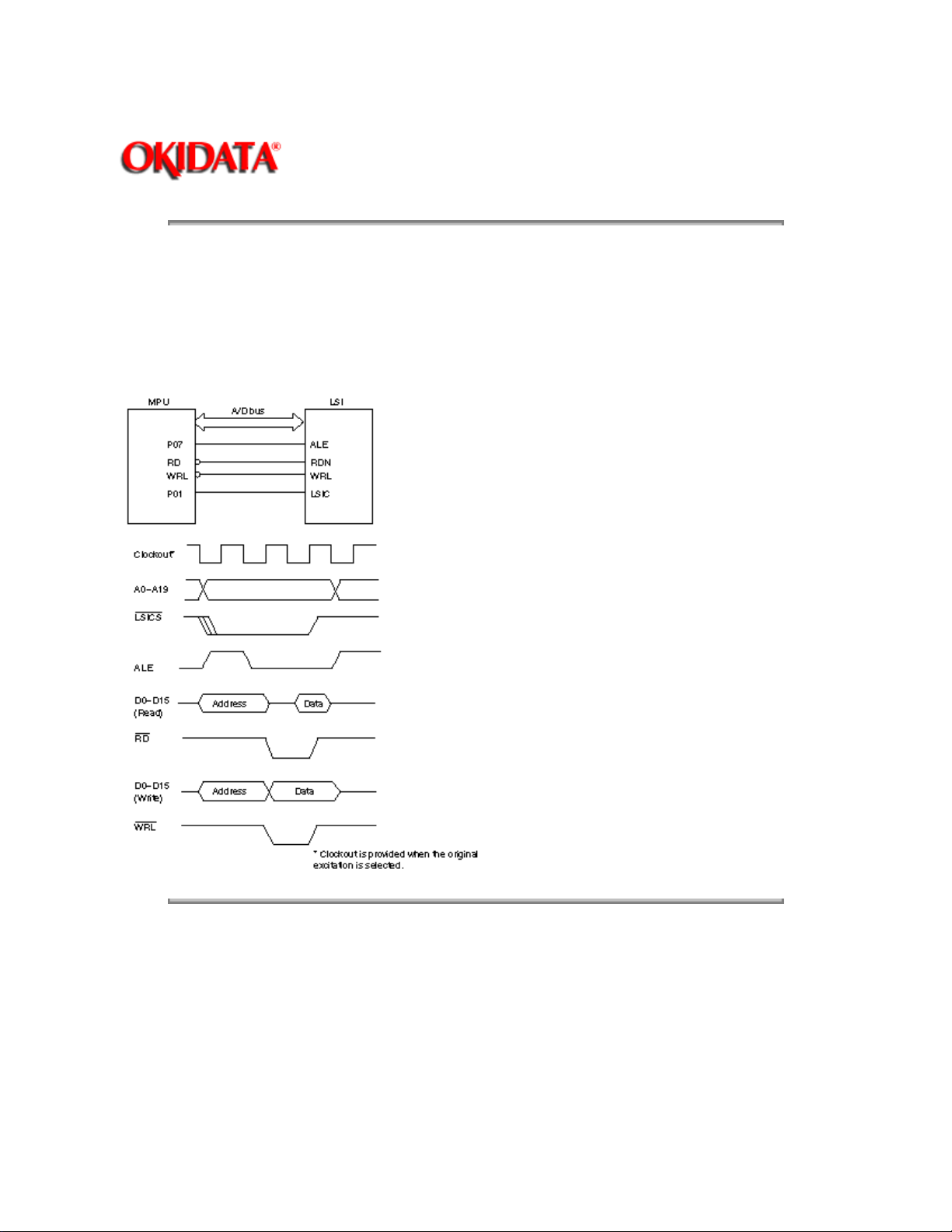

Large Scale Integrated Chip (LSI)

This LSI detects and controls the SP motor speeds by monitoring the two phase

sensor signals obtained from the DC motors and modifying the excitation phases as

appropriate.

This LSI is connected in multiplex to the MPU.

Page: 11

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide ML390/ML391Turbo

Chapter 2 Theory of Operation

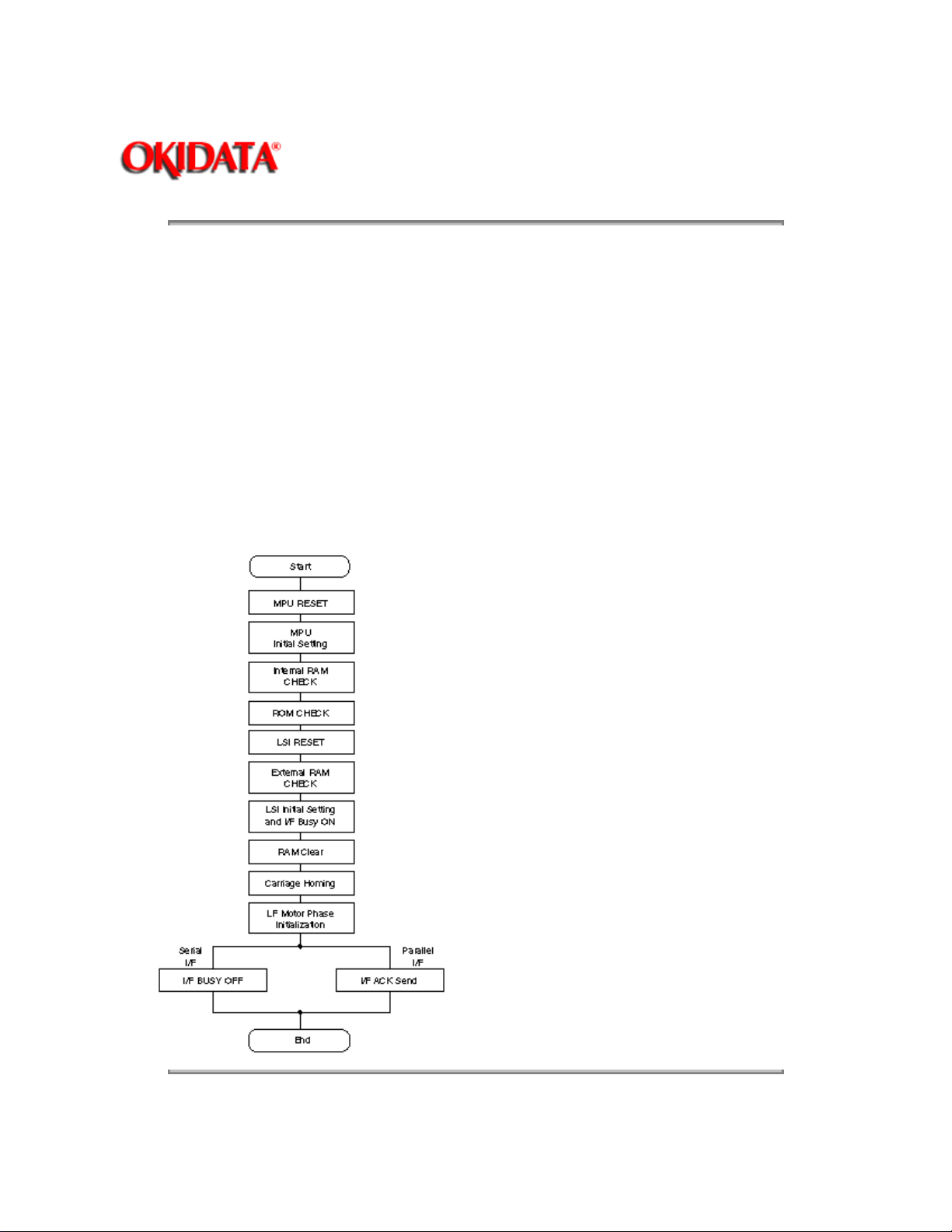

2.1.03 Initialization

This printer is initialized when the power is turned on or when the I-PRIME-N signal is input

from the host side via the parallel interface.

For the initialize operation, the RST-N signal is first output from the reset circuit to reset the

MPUs and LSIs. When resetting ends, the program starts and the LSIs are reset by MPU via

LSIRST-N. Reset operation by I-PRIME starts program to initialize, but does not reset the

MPU.

The program here sets the mode of the LSI including the MPU, checks the memories (ROMs

and RAMs), then carries out carriage homing, and determines the LF motor phase.

Finally, the program establishes the interface signals (P-I/F: ACK-P signal sending, and S-I/F:

BUSY-N signal off) and lights the SELECT lamp to inform the ready state for receiving to the

host side and ends the initialize operation.

Page: 12

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide ML390/ML391Turbo

Chapter 2 Theory of Operation

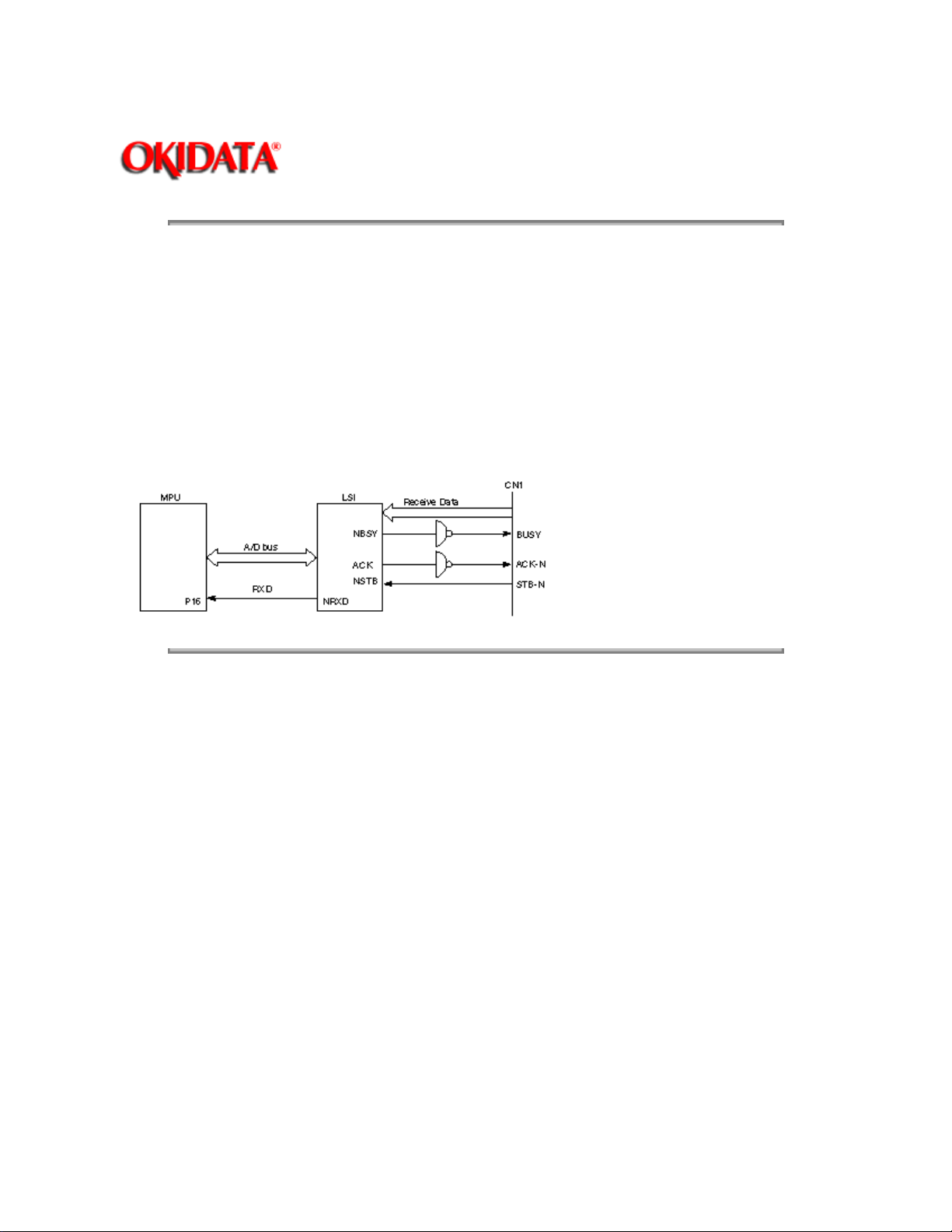

2.1.04 Parallel Interface Control

The parallel data input from the host to the interfaced LSI is latched to its internal register at

the falling edge of the STROBE-N signal.

At the same time, the LSI sets the BUSY signal to the high level to inform the host that the

data is being processed, and outputs the RXD signal to inform the MPU of data reception. The

data is read upon receiving the RD-N signal from the MPU.

When the data processing ends, the BUSY signal is set to off and the ACK-N signal in sent to

request the next data. When reception is impossible because the buffer is full, the BUSY

signal is sent to request stopping of data transmission.

Page: 13

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide ML390/ML391Turbo

Chapter 2 Theory of Operation

2.1.05 Print Control

Print data is transmitted as parallel data (HEAD1~HEAD24) from LSI to print head. LSI

generates print timing and drive time.

Page: 14

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

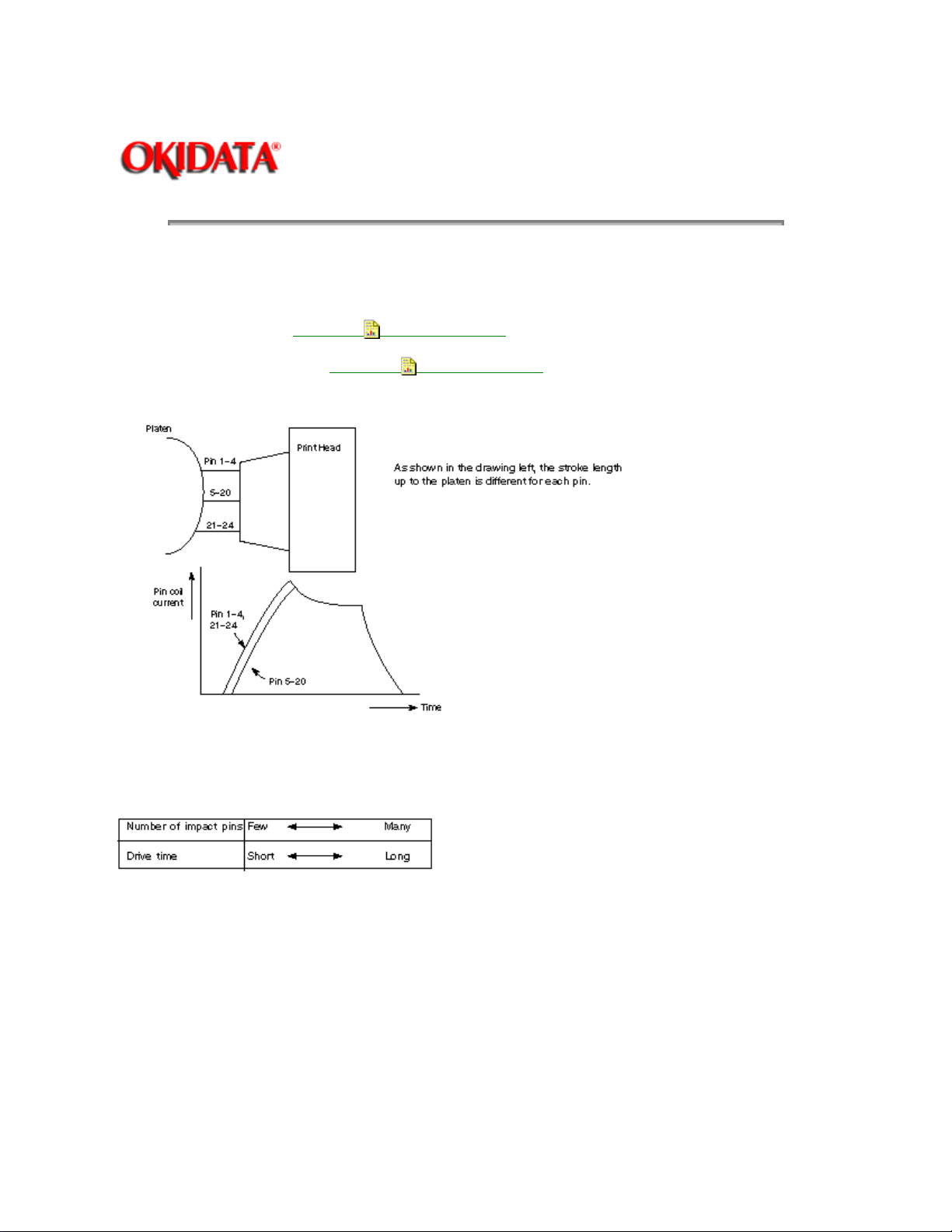

Service Guide ML390/ML391Turbo

Print Compensation Control

The print compensation can be made as shown below:

Page: 15

Chapter 2 Theory of Operation

(a) Voltage compensation

(b) Temperature compensation

(c) Pin stroke compensation

(d) Simultaneous Compensation of the number of impact pins

The LSI is provided with the compensation table for each pin to make

necessary compensation.

(See 2.1.8

(See 2.1.8

“Alarm Circuit.”)

“Alarm Circuit.”)

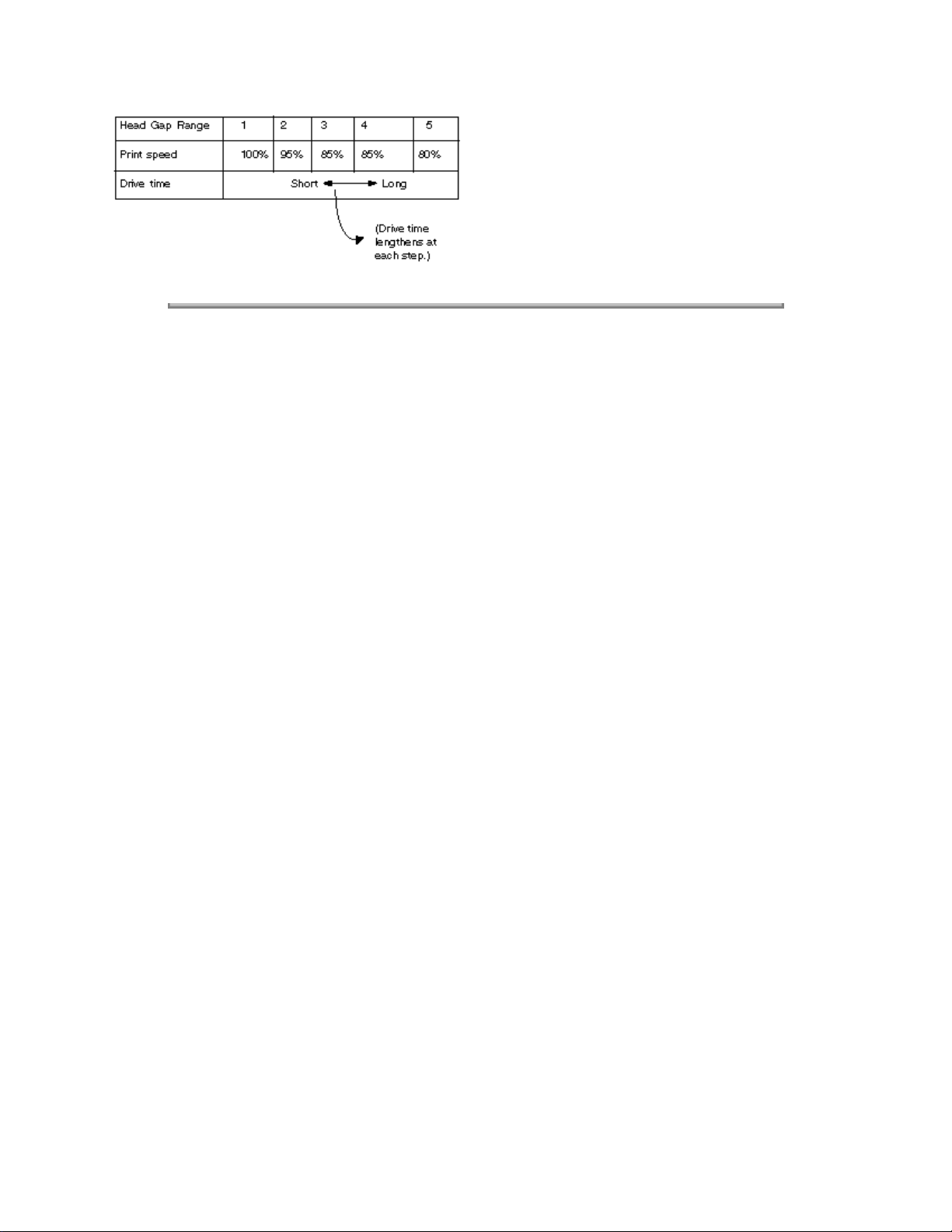

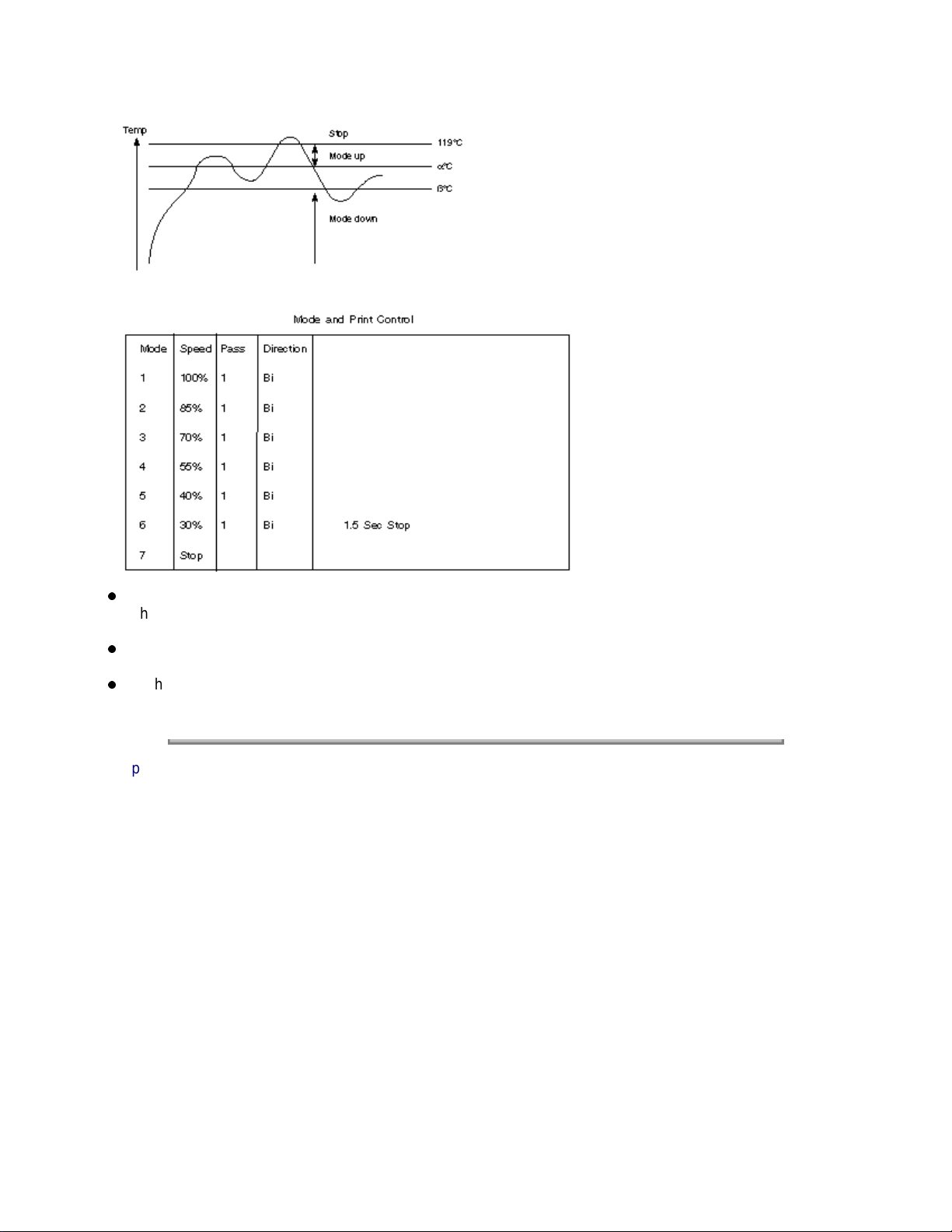

Print Mode Compensation

According to the thickness of the printing medium, the print mode is compensated as shown in the table

below:

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide ML390/ML391Turbo

Chapter 2 Theory of Operation

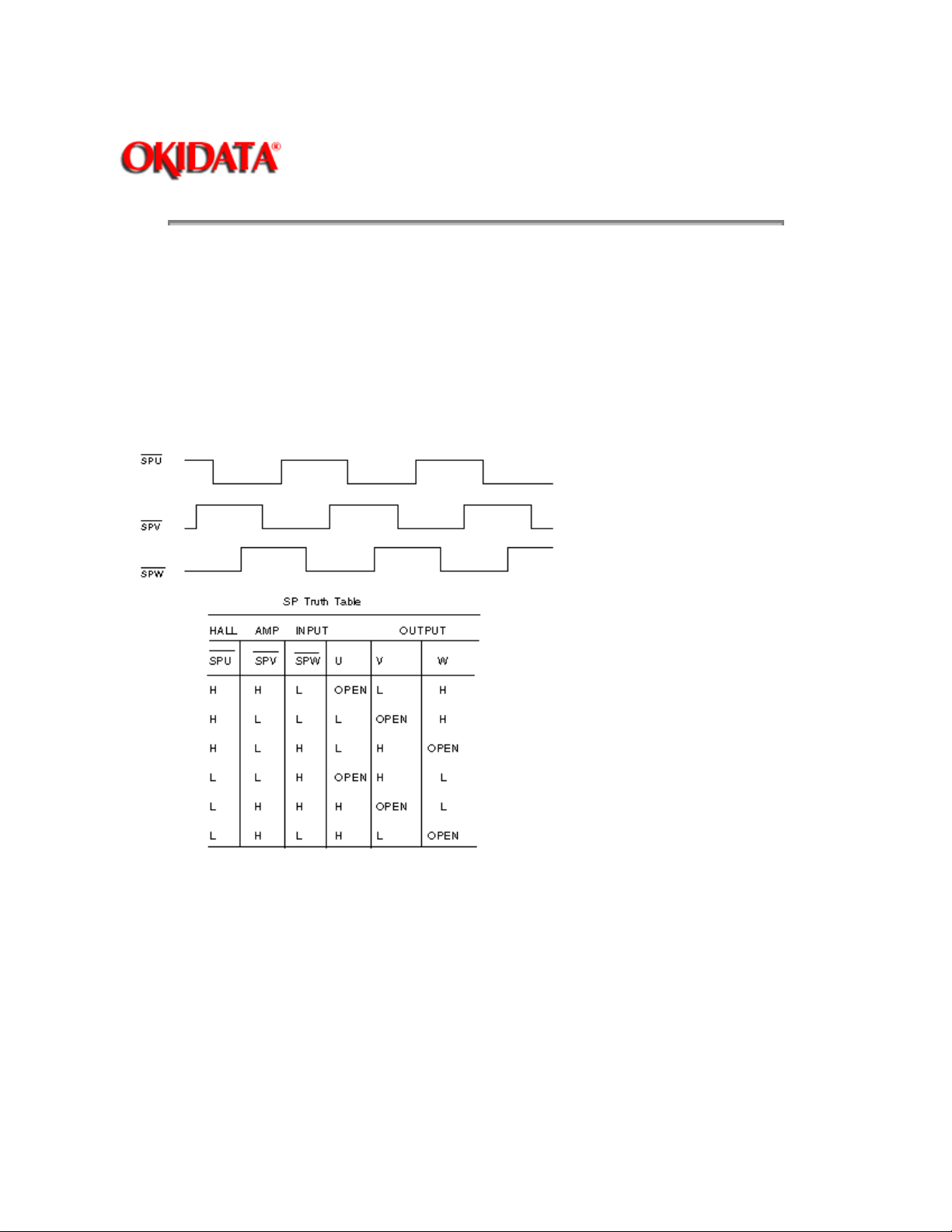

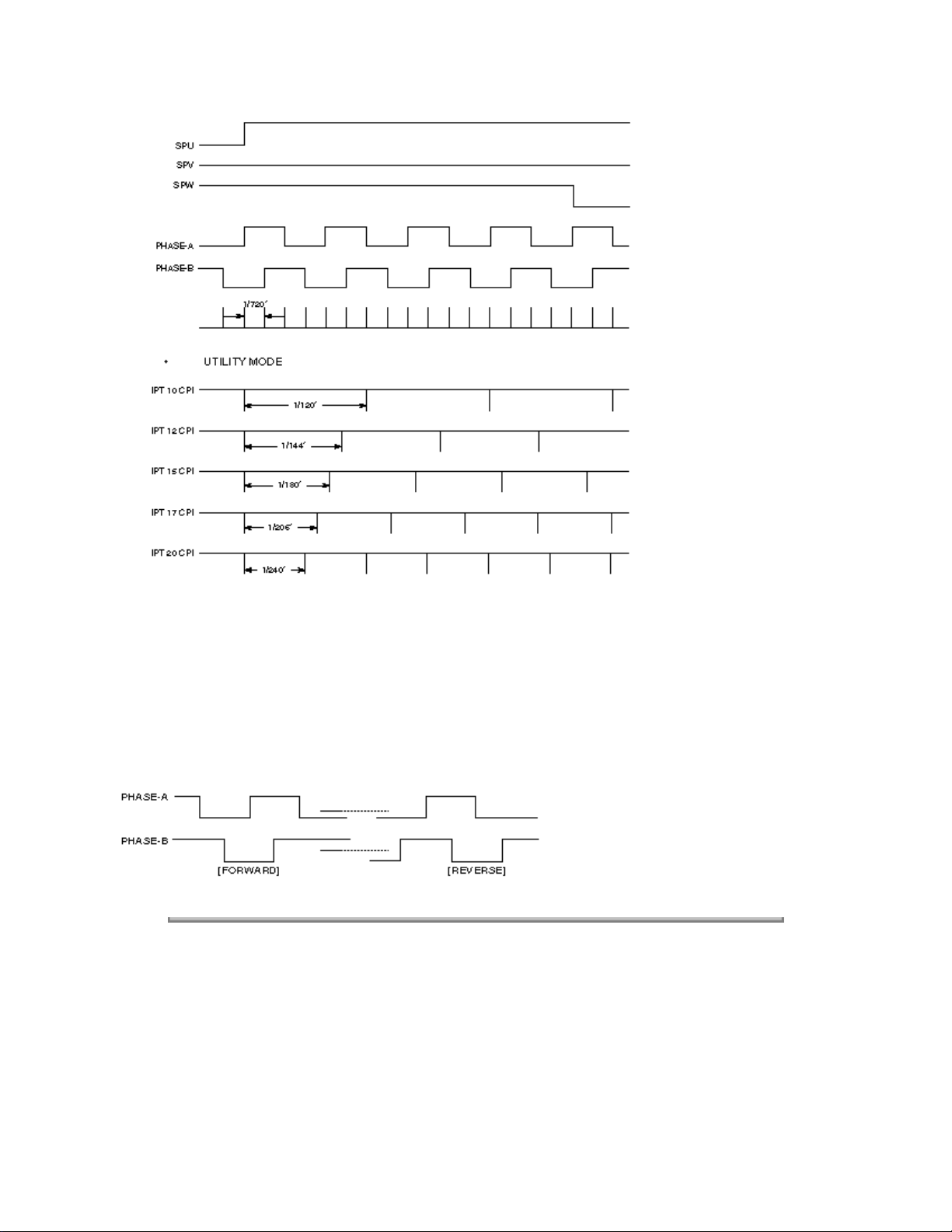

2.1.06 Space Motor / Line Feed Motor Control

Space Motor Control

The SP motor driver (HA13412) drives the three-phase brushless motor based on the

phase signal (SPU, SPV and SPW) and the speed instruction data from the LSI. The

MPU can identify the current speed of the space motor by measuring through the LSI

the pulse length of the output (øA, øB) of the slit encoder included in the space motor.

By comparing the target speed for each print mode with the actual current speed to

change the speed instruction data, the motor speed is accelerated or decelerated to

maintain the specified speed for each print mode.

Page: 16

Encoder Disk

In the operation of the spacing motor, the PHASE-A and PHASE-B signals are

generated when the encoder disk interrupts the photo sensor.

The LSI divides these edge pulse signals in accordance with the print pitch, and

sends the IPT signal to provide dot-on timing and carriage position detection timing.

Line Feed Motor Control

The Line Feed motor driver (MTD2005F) drives the Line Feed motor in two-phase or

1-2 phase bipolar, based on the phase changeover data and the output current data

from the LSI.

The data from the LSI is processed by a specific register contained in the LF motor

driver to measure the overdrive time and to change the phase.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide ML390/ML391Turbo

Chapter 2 Theory of Operation

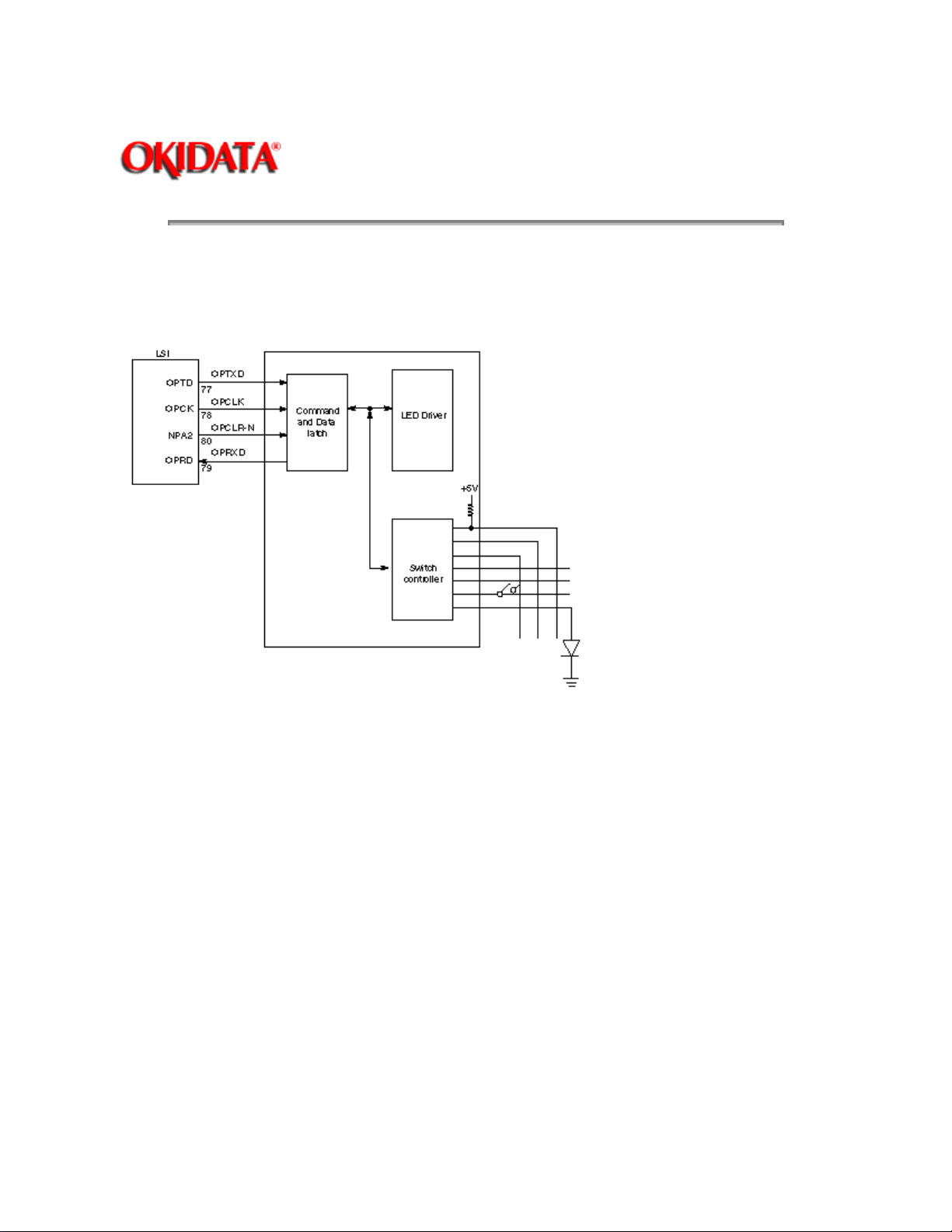

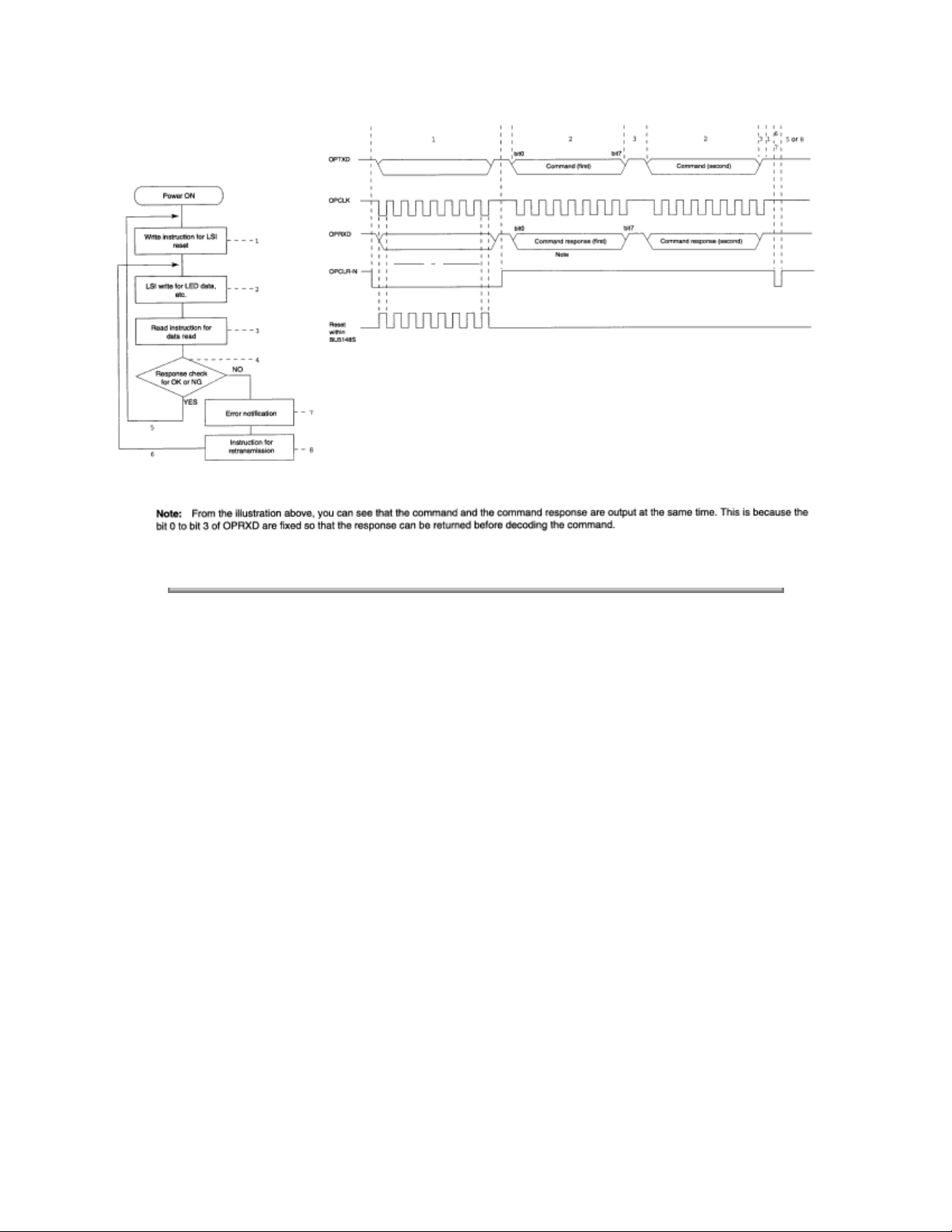

2.1.07 Operation Panel

The clock synchronization OPCLK of LSI is used to input the switch data and output the LED

data through the operation panel control LSI (IC1: BU5148S).

Page: 17

A 2-byte (15 bits + 1 even parity bit) command (OPTXD) is transmitted to the LSI (BU5148S)

in synchronization with the OPCLK signal. The LSI decodes this command and when it is

found to be legal, returns a 2-byte command response back to the LSI which includes data on

Switch information, LED status, receive command ACK/NAK and 1 odd parity bit.

Any transmission errors found cause the command to be reissued after the transmission of

the OPCLR-N signal.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Service Guide ML390/ML391Turbo

Chapter 2 Theory of Operation

2.1.08 Alarm Circuit

Head Drive Time Alarm Circuit

This circuit monitors the drive time using the HDALM signal interlocked with the

overdrive signal of each drive circuit.

If the drive time of any drive circuit exceeds the specified time, the drive fault alarm

circuit sends an ALARM-N signal to turn on the SCR (SO).

This cause the secondary coil (40V) of the transformer to be short-circuited, causing

an overcurrent to flow through the primary coil and making the AC fuse (transformer

ASS) open.

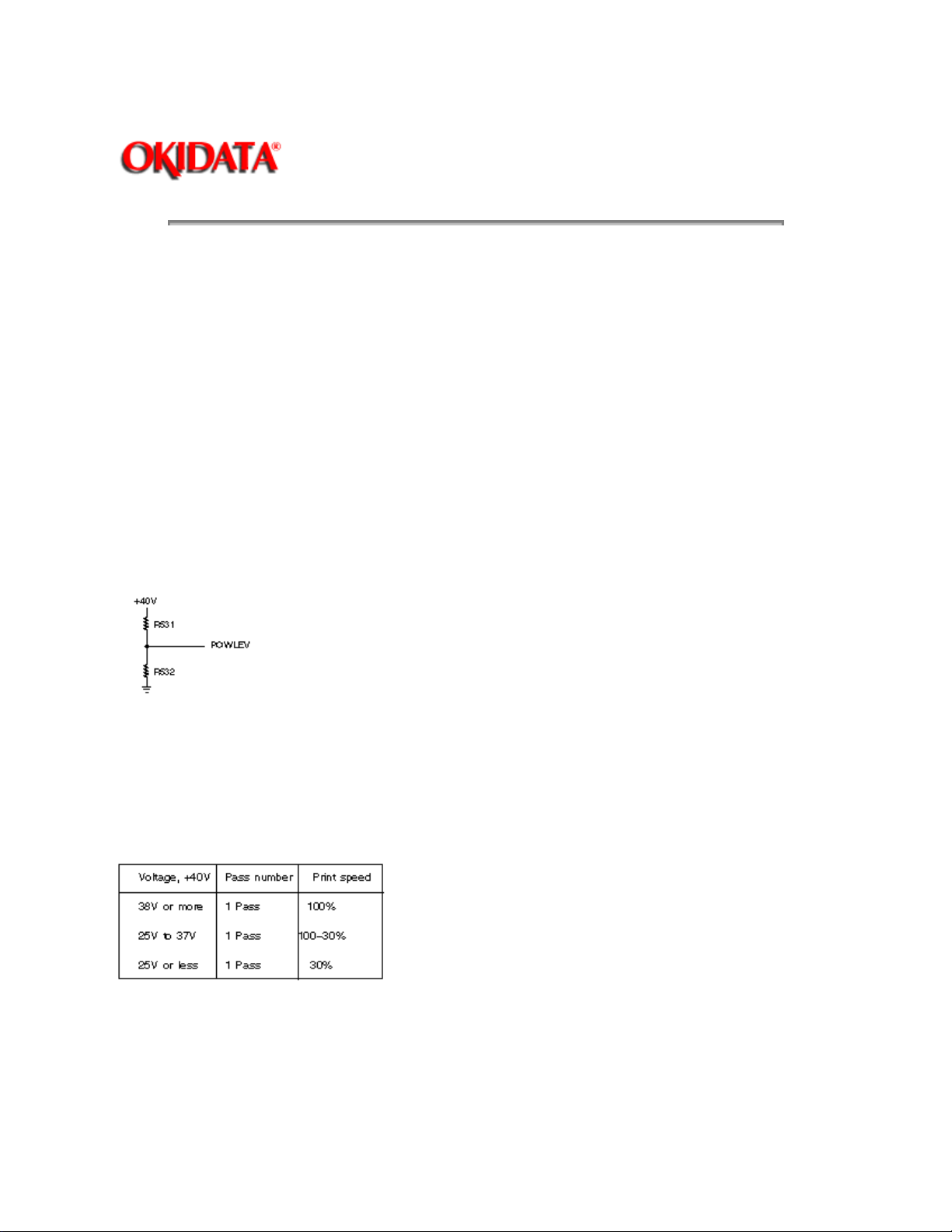

Alarm Processing When DC Power is Low

+ 40V is converted into the POWLEV signal (0V to +5V) by R531 and R532 and input

into the A/D port of the MPU to control the drive time and the print speed (pass

number) of the head.

Page: 18

Head Drive Time

The head drive time is lengthened to compensate for the amount of voltage

drop by monitoring the POWLEV signal once every 500 m sec. to control and

maintain the impact necessary for each printing pin at the fixed value.

Print Speed

Head Overheat Alarm

The voltage of the output TSD signal of the thermistors, one of which is contained in

the print head and the other in the print head driver, is monitored by the CPU/AD port

to control the voltage.

When the temperature is between a°C and 119°C, the mode switches sequentially to

higher level. When the temperature falls below ß°C, the mode switches to lower level.

When the temperature exceeds 119°C, printing will stop.

When temperature gradient is steep, higher mode shall be specified directly.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Loading...

Loading...