OKIDATA ML1120 Maintenance Manual

6

5

4

No.01

Oki Data CONFIDENTIAL

ML1120 PRINTER

Maintenance Manual

3

Related drawings

Drawing No. Name

43471801TL ML1120 Disassembly for Maintenance

2

43471801TR ML1120 RSPL

43516901TM ML1190 Troubleshooting Manual

[Rev. 1]

BOM Use for Certification Body

Rev Date DCO No. Contents Design Approval

1 2004-05-21 HP9-0009 Change format Tomoyo Sugiyama Akio Kikuchi

1

Approval

.....................................................................................................

Check

.....................................................................................................

Date

Yoshifumi Igari Yoshifumi Igari

Yoshifumi Igari

2006-10-10

Design

Name

ML1120

Maintenance Manual

Drawing No.

43471801TH

1

83

Document Revision History

Oki Data CONFIDENTIAL

Rev.No. Date

No.

1 2006-10-10 ISSUE ODS Y. Igari

Corrected items

Page Description of change

Person in

charge

43471801TH Rev.1 2 /

Oki Data CONFIDENTIAL

PREFACE

This maintenance manual describes how to maintain the ML1120 printer in the field.

This manual is for customer engineers.

For further information, refer to the Users Manual for handling or operating the equipment.

43471801TH Rev.1 3 /

Oki Data CONFIDENTIAL

Contents

1. CONFIGURATION .............................................................................................. 6

1.1 Standard Printer Configuration ............................................................................................ 6

2. OPERATION ........................................................................................................7

2.1 Summary.............................................................................................................................. 7

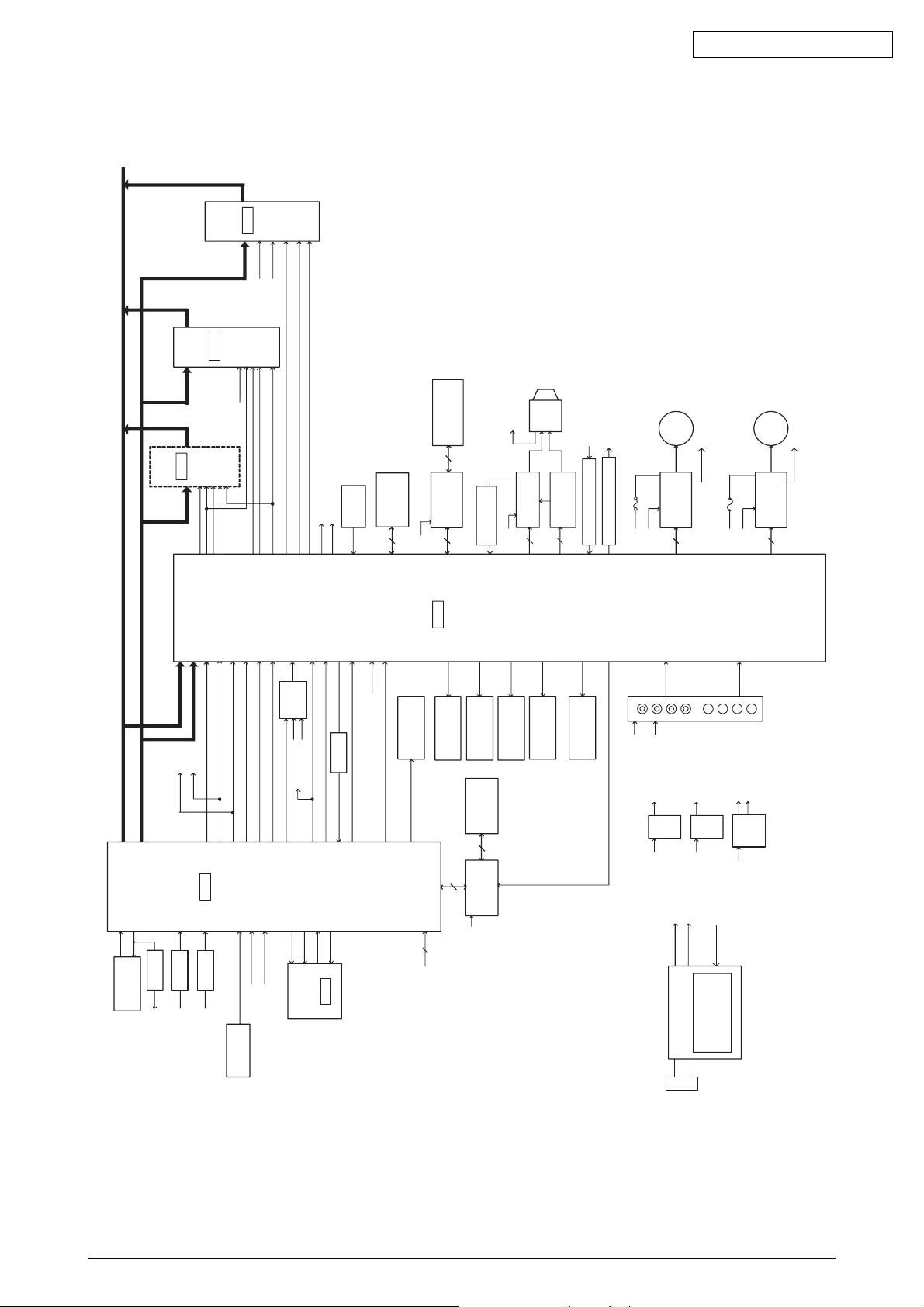

2.2 Circuit Operation (See Figure 1) .......................................................................................... 8

2.2.1 CPU and peripheral circuits .................................................................................... 8

2.2.2 Initializing operation .............................................................................................. 10

2.2.3 Controlling the interface ........................................................................................ 10

2.2.4 Print head control drive circuit .............................................................................. 10

2.2.5 Spacing ................................................................................................................. 11

2.2.6 Line feed ............................................................................................................... 11

2.2.7 Alarm circuit .......................................................................................................... 11

2.2.8 Paper-end detect circuit ........................................................................................ 11

2.2.9 Power source unit ................................................................................................. 11

2.3 Mechanical Operation ........................................................................................................ 12

2.3.1 The Printhead Mechanism and Its Operation (see figure 2) ................................. 12

2.3.2 Mechanism and operation of space (see figure 3) ................................................ 13

2.3.3 Mechanism for adjusting the head gap (see figure 4) ........................................... 14

2.3.4 Mechanism and operation of ribbon feed (See figure 5) ....................................... 15

2.3.5 Paper Feed Operation .......................................................................................... 16

2.3.6 Paper Detection Mechanism ................................................................................ 23

2.3.7 Automatic Sheet Feed (See Figure 14.) ............................................................... 25

2.3.8 Paper Park Function (Continuous paper) ............................................................. 27

3. ASSEMBLY/DISASSEMBLY ..............................................................................28

3.1 Precaution for Parts Replacement ..................................................................................... 28

3.2 Service Tools29

3.3 Disassembly/Reassembly Procedure ................................................................................ 30

3.3.1 Ribbon Protector ................................................................................................... 32

3.3.2 Printhead ............................................................................................................... 33

3.3.3 Pull-up Roller Assy ................................................................................................ 34

3.3.4 Upper Cover Assy, Access Cover Assy and Sheet Guide Assy ........................... 35

3.3.5 Platen Assy ........................................................................................................... 36

3.3.6 Printer unit ............................................................................................................. 37

3.3.7 Carriage Cable, Homing sensor ............................................................................ 38

3.3.8 Idle-pulley .............................................................................................................. 39

3.3.9 Ribbon Feed Assy. ................................................................................................ 40

3.3.10 Stepping Motor (Space) ........................................................................................ 41

3.3.11 LF Motor................................................................................................................ 42

3.3.12 Gap Sensor Cable, Gap SW and continuous-form/cut-sheet SW ........................ 43

3.3.13 Slider Pice-Slider .................................................................................................. 44

3.3.14 Mini Pitch Belt ......................................................................................................... 45

3.3.15 Paper Pan Assy, Roller Assy ................................................................................ 46

3.3.16 Bottom sensor, photo interrupter and sensor cord (6P) ........................................ 47

3.3.17 Operation Panel Board and Operation Panel cord ............................................... 48

3.3.18 Control Board Assy. ................................................................................................ 49

3.3.19 Power supply Assy................................................................................................ 50

43471801TH Rev.1 4 /

Oki Data CONFIDENTIAL

4. ADJUSTMENT ................................................................................................... 51

4.1Gap between platen and print head ....................................................................................... 52

4.2Paper top positioning distance check ..................................................................................... 53

4.3Correcting cut-sheet 40-line feed height ................................................................................. 55

4.4Correcting both-direction print registration ............................................................................. 56

4.5Paper cut position check ........................................................................................................ 57

5. CLEANING AND LUBRICATION ....................................................................... 59

5.1 Cleaning ............................................................................................................................. 59

5.2 Lubrication ......................................................................................................................... 60

6. TROUBLESHOOTING AND REPAIR ................................................................66

6.1 Items to Check Before Repair ............................................................................................ 66

7. PROGRAM UPDATE76

7.1 Prepare to amount the ROM76

7.2 Creating EPROM for rewriting flash memory and installing it. ........................................... 76

7.3 Operation to start flash download. ..................................................................................... 77

7.3.1 Execution of the rewite operation .......................................................................... 77

7.3.2 Operation Check ................................................................................................... 78

7.4 Initial condition ................................................................................................................... 78

8. PARTS REPLACED PERIODICALLY ................................................................79

APPENDIX A PCB LAYOUT ....................................................................................80

APPENDIX B CIRCUIT SYMBOLS..........................................................................82

43471801TH Rev.1 5 /

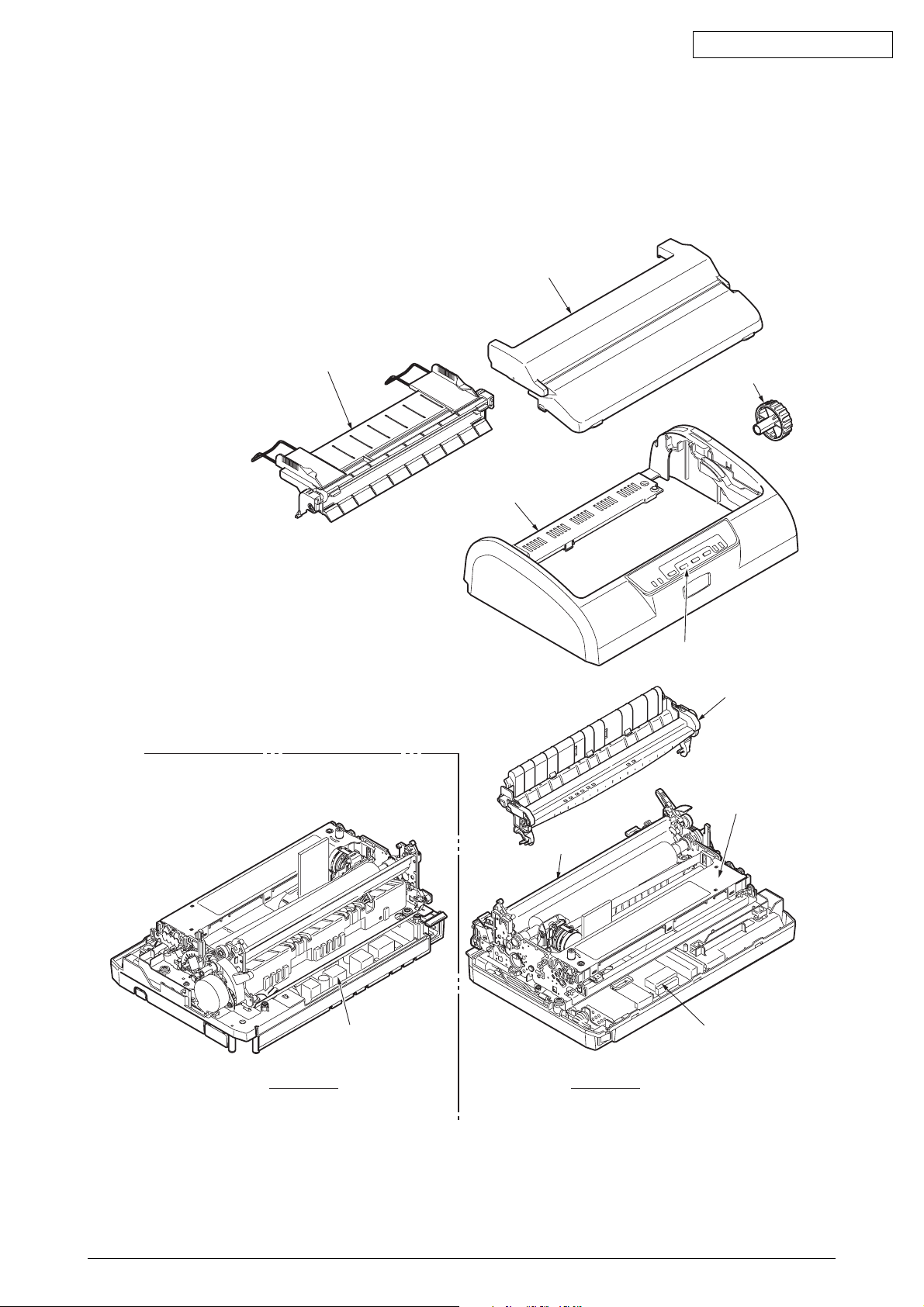

1. CONFIGURATION

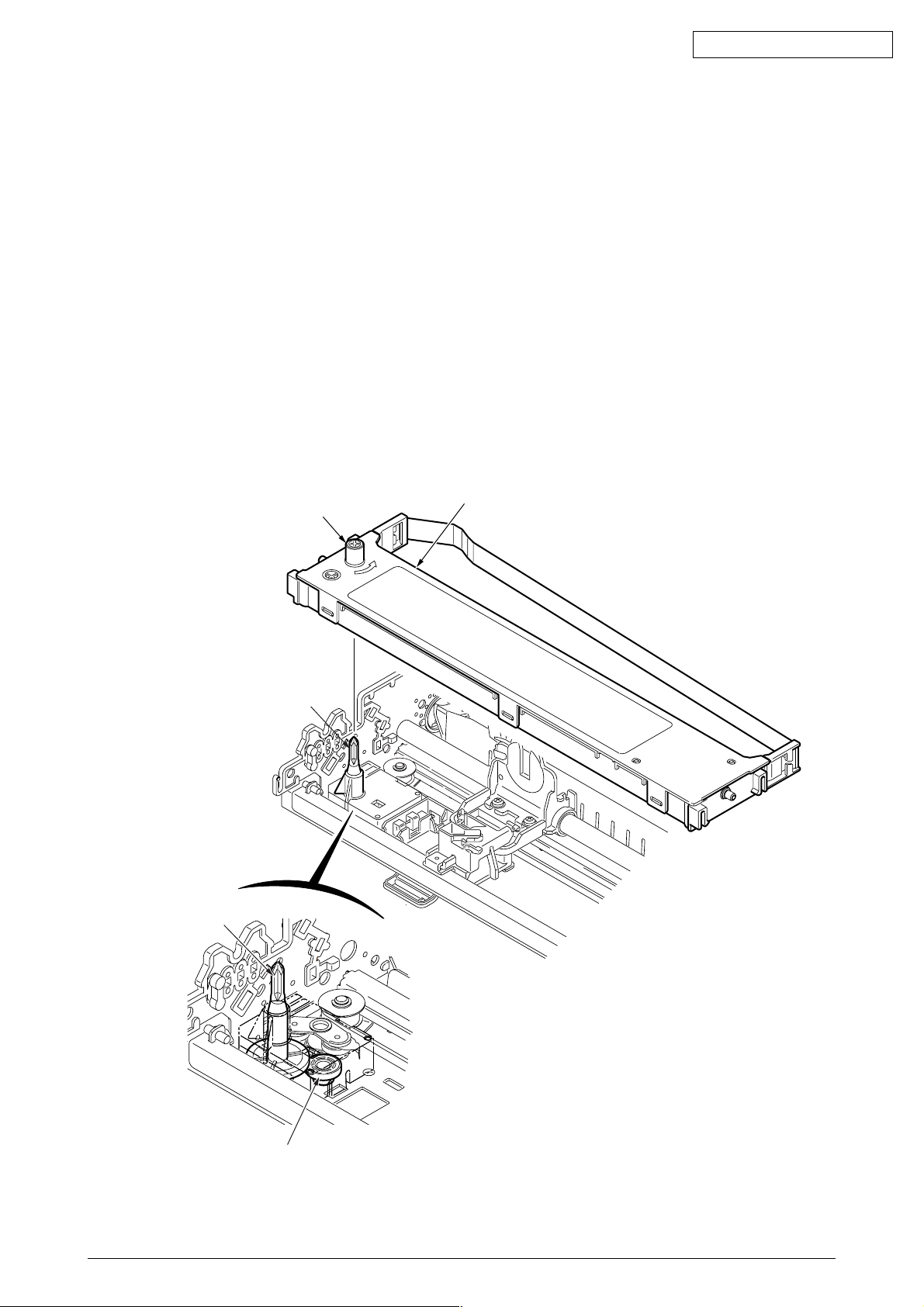

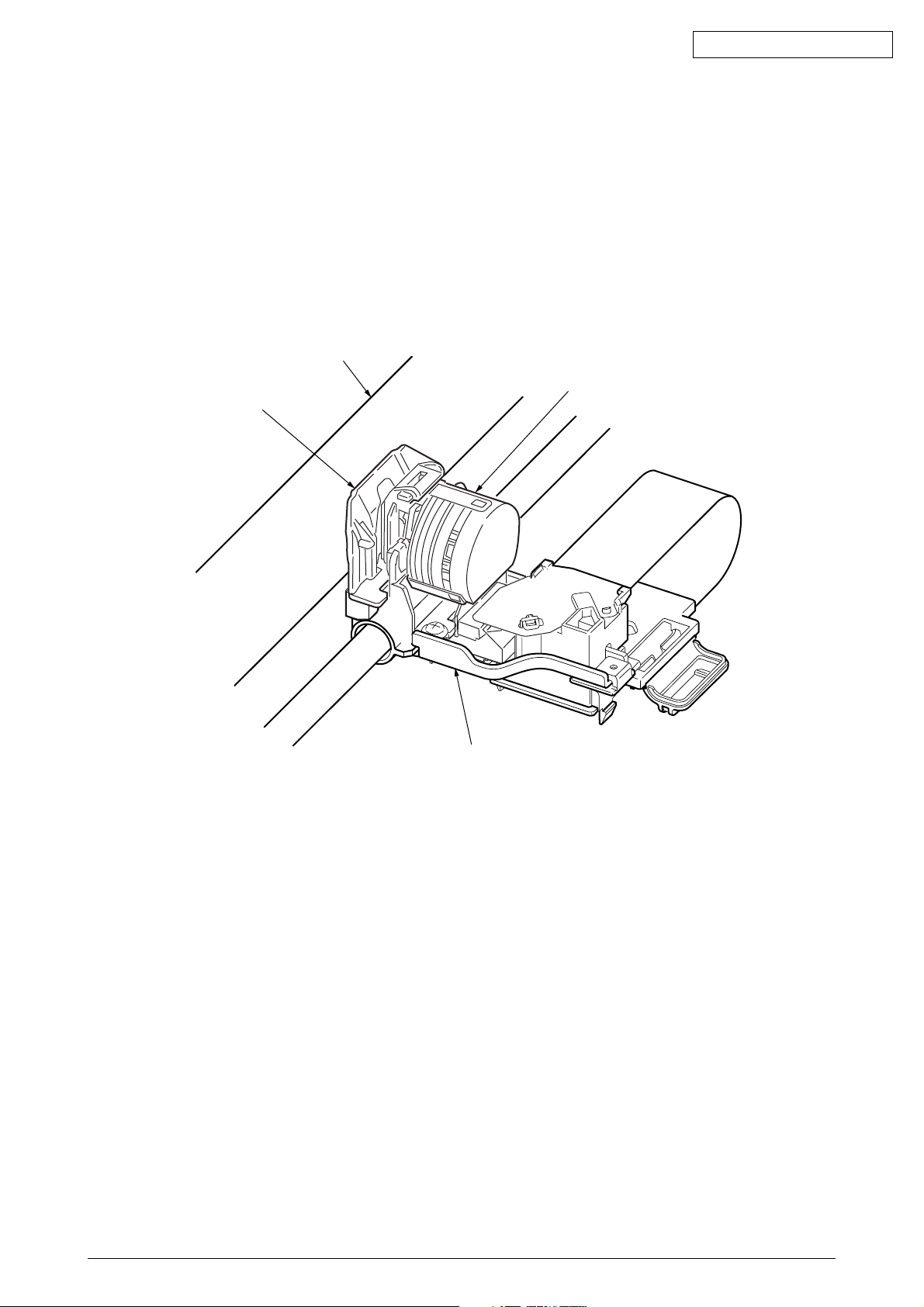

1.1 Standard Printer Configuration

The standard configuration of the ML1120 is as follows:

Oki Data CONFIDENTIAL

Access cover assy

Sheet guide assy

Platen Knob

Upper cover

Operation panel assy

Pull-up roller assy

Ribbon cartridge

Print unit

Rear View

Power Supply board

Fuont View

Control board

Figure 1-1. Printer Configuration

43471801TH Rev.1 6 /

Oki Data CONFIDENTIAL

2. OPERATION

2.1 Summary

The main configuration of this printer is the print mechanism unit and print control unit.

The print mechanism unit can be divided broadly into the print head, space system, paper-feed system,

and ribbon-feed system. The operation of each item is listed below.

(1) Print head ........................... Prints with the 9 wire-dot magnet. The dot patterns are configured

in the print control unit.

(2) Space system ..................... The stepping motor moves the carriage and performs spacing,

tab, and carriage return.

(3) Paper-feed system.............. Paper is feed by the stepping motor.

(4) Ribbon-feed system ............ Ribbon is feed by obtaining drive force from the stepping motor

just as in the space system.

(5) Print control unit .................. Controls the interface and mechanism with one MSM67 × 640

microprocessor (µCPU).

43471801TH Rev.1 7 /

Oki Data CONFIDENTIAL

2.2 Circuit Operation (See Figure 1)

The circuit of this printer consists of the control board and carriage board.

Circuits such as µCPU and its peripheral circuits, drive circuits, and the external interface circuit are set

on the control board.

The switches and LED are set on the control board.

With the control board being the main board, the boards are connected by cables.

2.2.1 CPU and peripheral circuits

(1) CPU (MSM67 × 640)

The CPU is a 16-bit one-chip CPU which operates the peripheral circuits. Each I/O port is set

as ADDRESS - BUS, DATA - BUS, and various control lines. It is capable of 4-channel A/D

converter input and has five timers.

(2) Program ROM (Flash ROM)

The control program of the printer is stored. µCPU operates according to the contents and

various controls are performed.

(3) Printer Butter etc (D-RAM)

This is used to store various data for data received in 4Mbit RAM or print buffer, etc.

(4) LSI (MG74Q514-131)

This is an LSI exclusively for the print head controller, external interface, and motor control. It

has the following functions.

(a) Print head data control

Print data is unarchived to the print timing of a disperse allocation head and controls 24-pin

worth of impact data drive time.

(b) Dot timing generating function

Dot timing (IPT) in sync with the print speed is generated and notifies the information to

CPU.

(c) Speed control function of the space motor

The speed of the space motor is controlled and input command from CPU. Furthermore,

the space motor speed in various print modes are also controlled.

(d) Parallel interface function

IFD 1-8 are used as input/output data of parallel data. Parallel data sent from the interface

connector is latched by strobe signal STB-N and is read into CPU by a RD signal.

Furthermore, control signals such as BSY-N, ACK, PE-N, and SEL-N are output to the

interface connector by WR signals.

(e) I/O port

The I/O port has 14-bit input/output ports and controls various signals by input command

from CPU.

(5) Download ROM (EPROM)

Use when update the Flash-ROM program. Usually nonimplement.

43471801TH Rev.1 8 /

CPU

MSM67X6

40

LSI

2

18

20

14

SP Driver

+35V

7

LF Driver

5

8

Switching Power

Supply

Overvoltage/

overcurrent

Detector circuit

+5V

+35V

AC IN

REG

IC

+3.3V

RESET

IC

4

1

RESET

EP-ROM

(16Mbit)

20MHz

OSC

XTL1

XTL2

Power

Contror

+5VH

5.0V

5.0V

3.3V

RX

D

IPT-N

CLKP10

ADI1

ADI0

PSEN

PSEN

PSEN

A19

CS1

P01

LSICS(CS3)

P04

LSICSN

RSTN

CAS

D-RAM

(4Mbit)

5.0V

IR1

IR0

IPT

9

9

STN1

AFN1

IPN1

SIN1

BSY1

AKN1

SLP1

FTN1

PEP1

IFDIR

SPAPH

SPENB-AS

SPDCYA

SPBPH

SPENB-BS

SPDCYB

SPREF1

SPREF2

LFENBA0

LFENBA1

LF-PHA

LFENBB0

LFENBB1

LF-PHB

LFREF1

SW

EEPROM

(4kbit)

P1

7

P1

4

P1

2

EEDIN

P1

3

5.0V

RDN

CLK

CS0

FL2C

P03

RAS

5VH

5V

+35V

Buffer

Buffer

FLASH-

ROM

(8Mbit)

5.0V

P11

P05

P06

4

FL1BYT

FLAM-1

Buffer

ALMIN2,3

ALMIN1

1

FG

ADI3

ADI2

RAS

3

(ALMIN4,5,6)

Home Position

Sensor

SWI4

SWI1

SWI5

SWI3

SWI2

RAS

Buffer

Temperature

sensor

CS0

P00

CS2

CS2

ALM

ALM

ALM

P02

Buffer

WR

D00

‘

D15

WE

OE

BYTE

CE RAS

OE

UCAS

LCAS

RAS

BYTE

CE

OE

A19

MG74Q514-131

Alarm Circuit (IN)

Alarm Circuit (Out)

Operator Board

Program ROM

CLK

A00

‘

A19

3.3V

¤

5.0V

3.3V

¤

5.0V

HTEMP-N

DCLOW

RD

EECS

EEDOUT

EECLK

P16

P17

A00

‘

D00

‘

D15

DRL

RD

LWR

RAS

LSIRST

BREQ

BACK

WRH

RD

WRL

LPG

WR

3.3V

¤

5.0V

TXD/RXD/DSR/CTS/CD

Serial I/F

Driver

Serial I/F

Connector

Bottom PE

Sensor

Paper SelectPE

Sensor

Head Gap 2

Sensor

Head Gap 1

Sensor

Paper Select

Micro SW

LED

+5V

D15ZA-1

D15ZA-1

WRL

RD

Print Buffer etc

ALMOUT

+5V

+5V

+5V

RESET

+5VD

SP

Motor

LF

Motor

5VH

USB

Connector

OSC

48MHz

Pararel I/F

Connector

Alarm Circuit

(IN

j

Head Driver

(DT1)

Head Driver

(DT2)

9pin

Head

HTEMP

Pararel I/F

Driver IC

RXD

CASH

CASL

5V

IF11

‘

IF18

5VH

ALMOUT

ALMOUT

FLRS

DFL2BY

FLA19TE

FL1CSE

DRAMWR

CASH

CASL

SPENB-A0

‘

SPENBA2

SPENB-B0

‘

SPENB-B2

SWC1

‘

4

LED1

‘

4

RTS/SSD/DTR

WRN

DCASN

BACKP

BREQP

DWRHN

Oki Data CONFIDENTIAL

43471801TH Rev.1 9 /

Figure 1

Oki Data CONFIDENTIAL

2.2.2 Initializing operation

The initializing operation is performed for this printer when the power is turned ON and when I-PRIME for

the parallel interface is input from the Host.

In the initializing operation, the RST-N signal is first output from the reset IC (RST-1 pin) to reset CPU.

The program start after CPU is reset.

The program sets the LSI mode including CPU, checks the memory (ROM/RAM), and initializes the

RAM. Then it determines the phase of the LF motor and performs homing for the carriage. Finally, it

determines the interface signal (outputs ACK signal and BUSY signal), illuminates the A lamp, notifies

the Host that it is in a mode that can receive data (data standby mode), and completes initialization.

(Paper-end mode when using continuous form is excluded.)

2.2.3 Controlling the interface

1) Parallel interface

Data from the interface is input from the connector (CENT) and is read in the timing of the

STB-N signal by the interface, print head, and LSI for motor control (MG74Q514-131).

When this signal is being process, the BUSY signal goes ON. When the process is completed,

the BUSY signal goes OFF, sends an ACK-N signal, and waits to receive the next data.

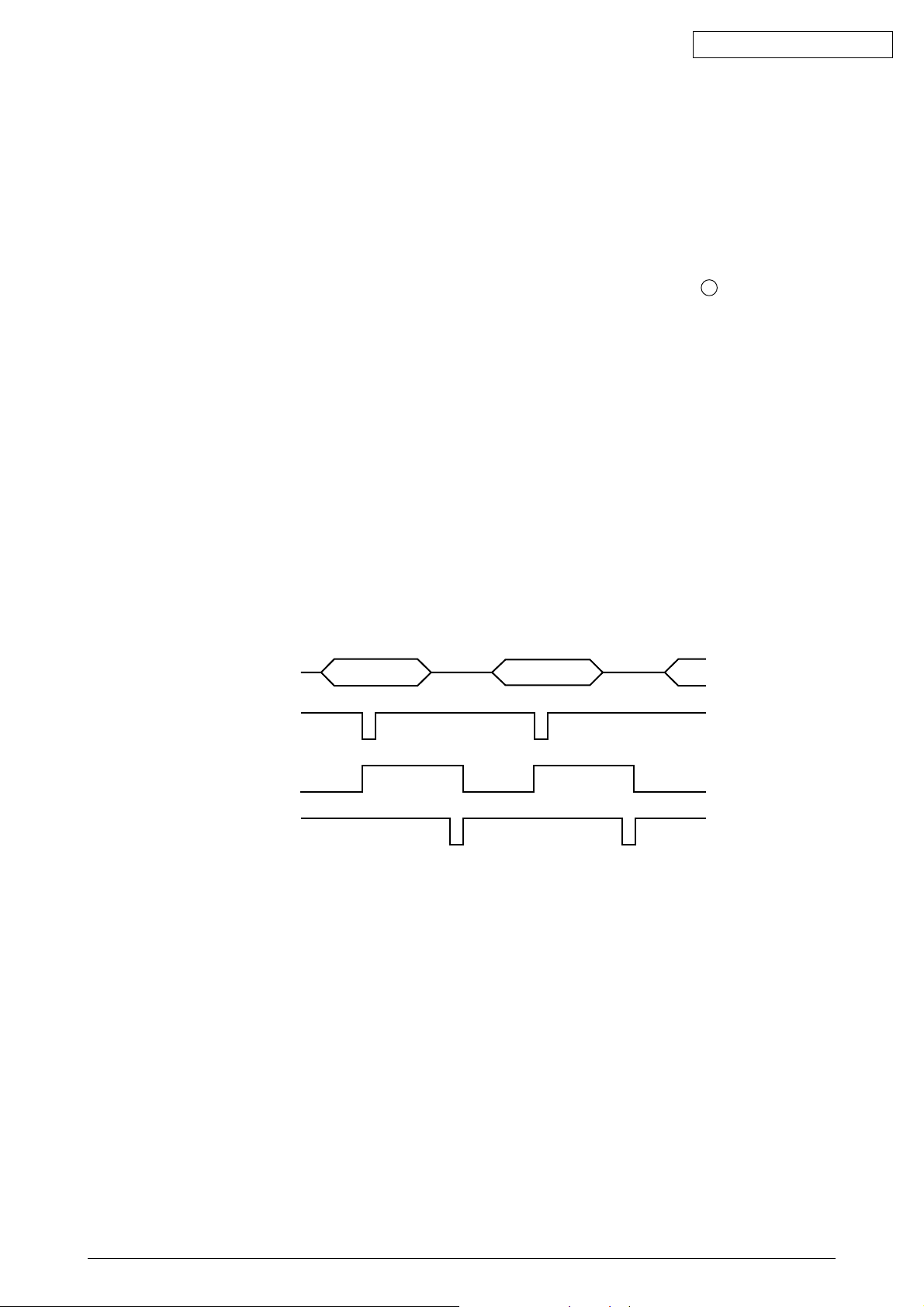

(E.g.) When [I/F timing] is set to [A-B] in an English menu.

DATA1~8

STROBE-N

BUSY

ACK-N

2.2.4 Print head control drive circuit

This circuit produces the print timing and drive time from LSI, drives the head magnet that corresponds to

HEAD 1~9 with HD01-09-P signal and HDCOM1~9 - P signal and prints.

As the print head is dispersed and allocated in each group, the nine groups are controlled individually.

43471801TH Rev.1 10 /

Oki Data CONFIDENTIAL

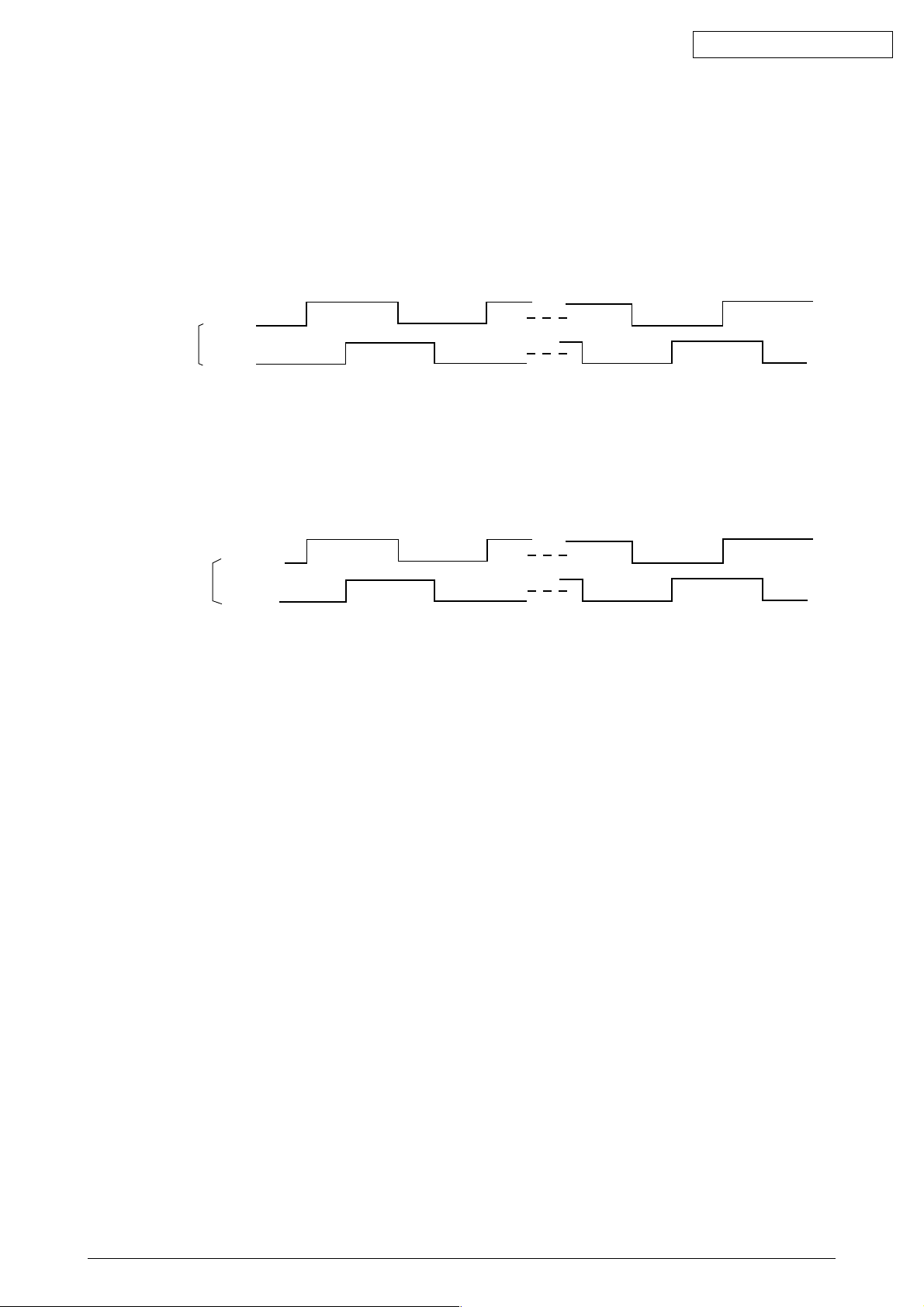

2.2.5 Spacing

The LSI (MG74Q514-131) outputs space motor phase signals (SP_PHA,SP_PHB) when it receives a

spacing command from µCPU. It outputs IPT signals as the dot timing and carriage position detection

timing in sync with these phase signals.

The space motor phase signals (SP_PHA,SP_PHB) are input to the motor driver, which drives the space

motor.

SH_PHA

Motor driver input

SP_PHB

2.2.6 Line feed

The LF motor phase signals (LF_PHA, LF_PHB) from LSI (MG74Q514-131) are input to the motor driver,

which drives the LF motor.

LF_PHA

Motor driver input

LF_PHB

2.2.7 Alarm circuit

(1) High-temperature head alarm

The temperature of the head is monitored by a thermistor embedded in the head to protect the

head coil.

The head temperature will rise after continuous heavy-duty print jobs. Therefore, when the

head rises beyond a specified temperature, a thermal alarm mode will be entered, and after the

current line is printed, the speed for printing the following lines will be decreased. Furthermore,

if the head temperature does not fall, the following lines will be divided into two depending on

the temperature, and printed by single-direction print.

The alarm is detected when the resistance of the thermistor decreases from the rise in the

head temperature and CPU is input in the A/D converter.

2.2.8 Paper-end detect circuit

When paper runs out, the photosensor (PE) goes Hight level and the paper-end signal becomes 1. This

signal is input in CPU which goes on the B lamp.

2.2.9 Power source unit

The power source unit supplies DC+35V and +5V to each section by switching power.

43471801TH Rev.1 11 /

2.3 Mechanical Operation

2.3.1 The Printhead Mechanism and Its Operation (see figure 2)

The print head is spring-loaded, utilizing a permanent magnet, and can be easily removed or

installed. The print head is mounted on a carriage that runs parallel to the platen and is

connected with the control circuit via the head board.

The print head consists of:

(a) Wire guide

(b) Print wires

(c) Armature assembly

(d) Yoke

(e) Springs

(f) Spacer

(g) Magnet assembly

(h) Thermistor

(i) Printed-circuit board

(1) Print head operation

Oki Data CONFIDENTIAL

When the print head is in the non-printing state, each armature is attracted by the

permanent magnet, and the springs holding the armatures are compressed by the thickness of the spacer, The print wires, which are fastened to the individual armatures, are

therefore held retracted within the wire guide.

When signals corresponding to a character to be printed are detected by the control circuit,

currents flow through the corresponding coils to nullify the magnetic flux generated by the

permanent magnet between the armatures corresponding to those coils and the permanent

magnet pole. As a result, those armatures are driven toward the platen by the force of

the armature springs, and the print wires fastened to those armatures eject from the tip

of the wire guide and strike the paper through the ribbon to print dots on the paper.

After the character is printed, the magnetic flux of the permanent magnet attracts the

armatures again so that the print wires retract into the wire guide.

The print head has a built-in thermistor to prevent the coils from overheating and burning

due to continuous bi-directional printing over a long period. If the coil temperature exceeds

the limit (approximately 100 degrees C), the control circuit detects the thermistor signal

and stops the printing operation until the coil temperature drops below the limit.

Paper

Ribbon

Print wire

Amature assembly

Thermistor

Core

Wire guide

Yoke Magnet coil

Figure 2

43471801TH Rev.1 12 /

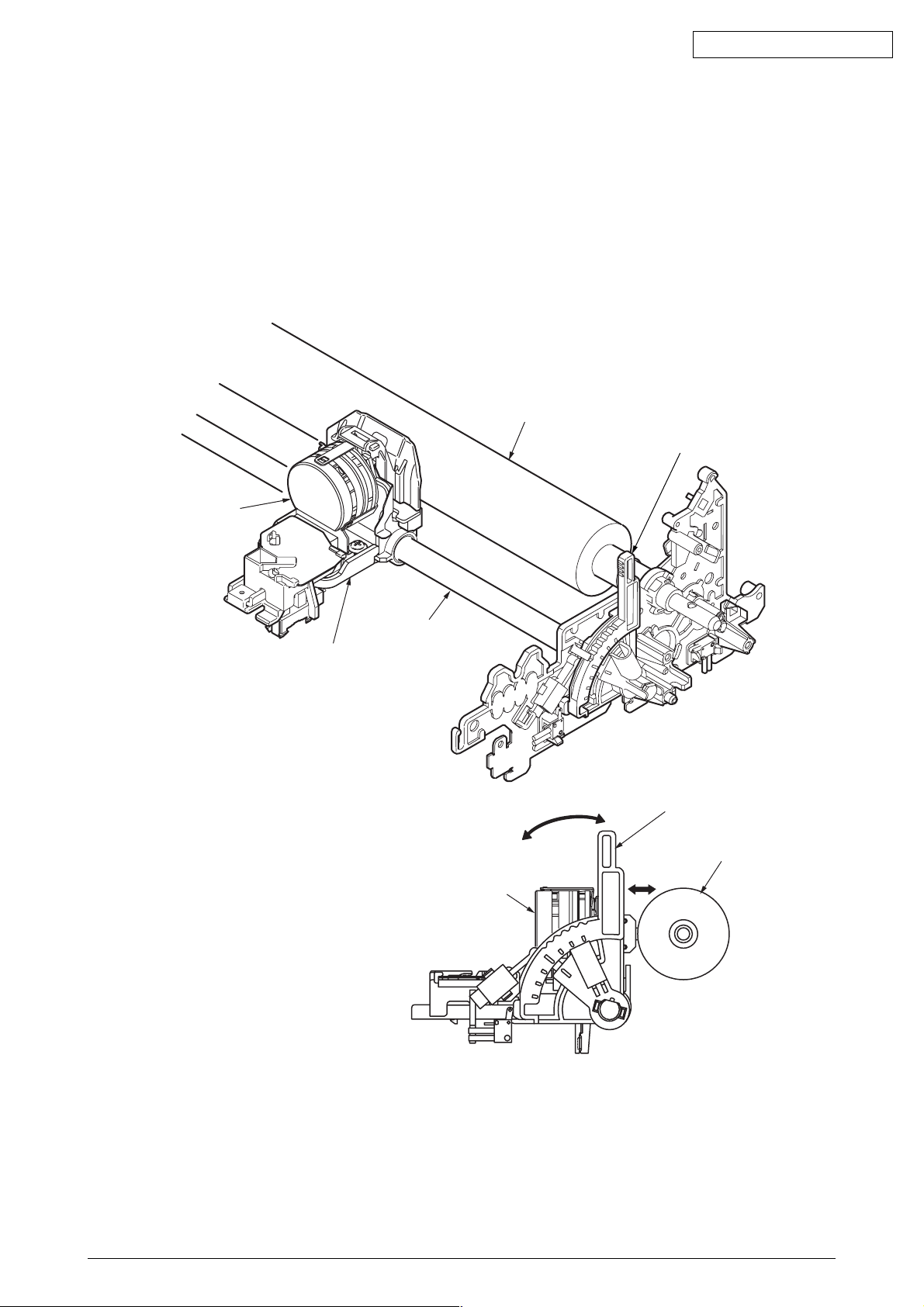

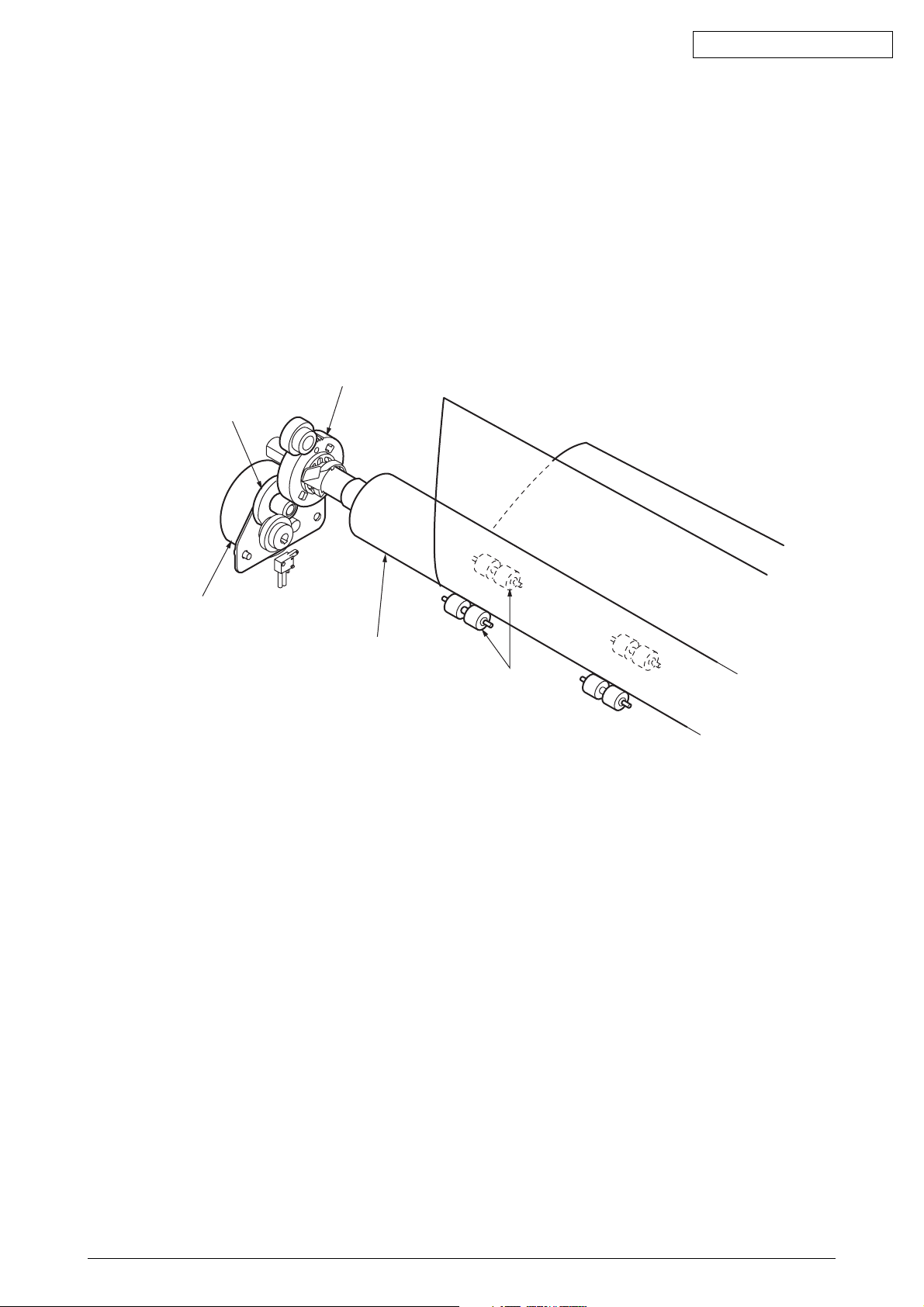

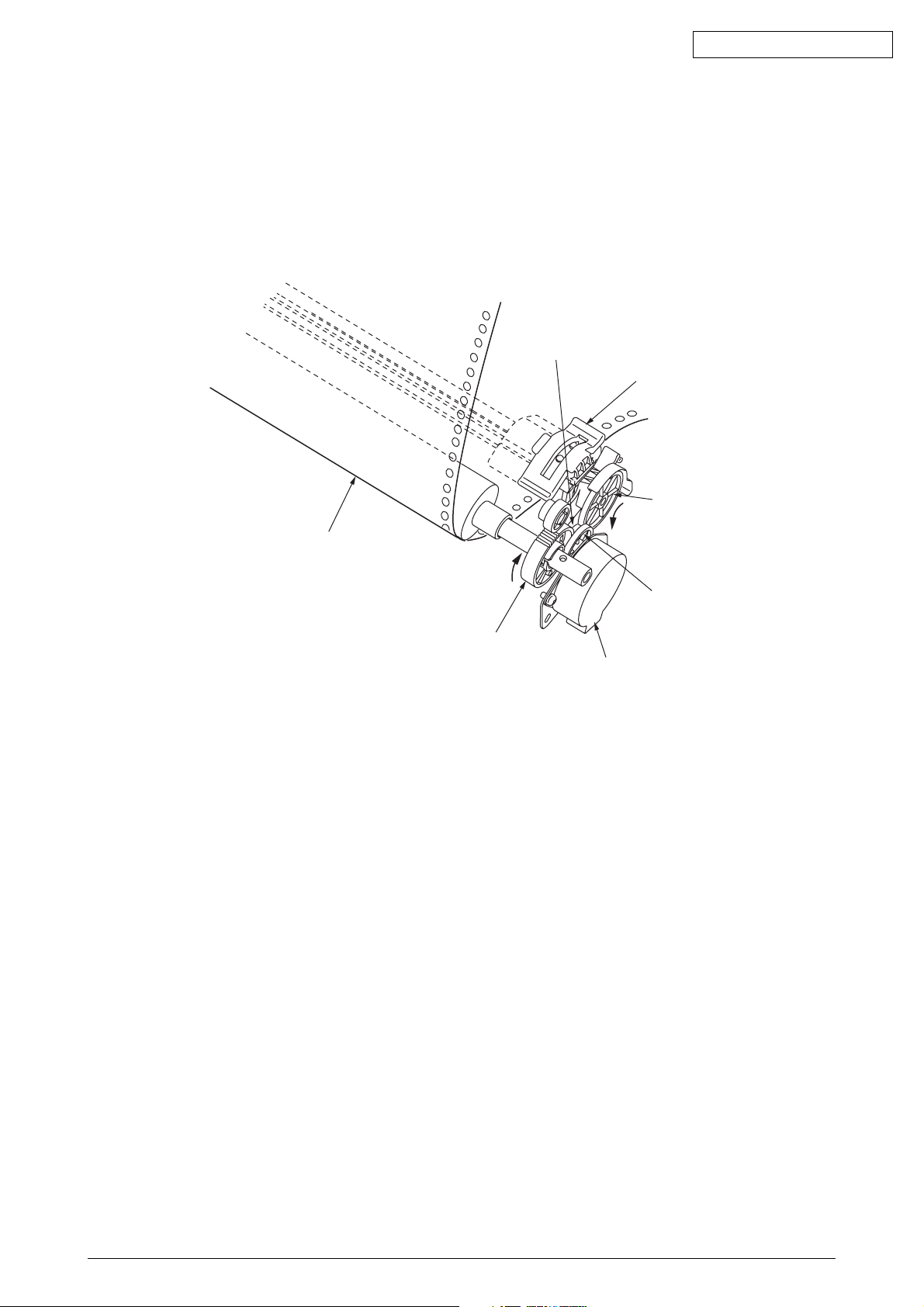

2.3.2 Mechanism and operation of space (see figure 3)

The space mechanism of printers consists of several parts, including a carriage shaft placed

parallel to a platen and a carriage frame that moves along the carriage shaft. The space

mechanism is driven by a space motor located behind the carriage frame.

The space mechanism consists of:

(a) Stepping motor with motor gear

(b) Carriage frame

(c) Carriage shaft

(d) Carriage position sensor

(e) Slide rail

(1) Spacing operation

A carriage carrying a print head moves on its shaft parallel to a platen. As a space motor

revolves, the power of the space motor is transferred to a mini pitch belt. This completely

moves the carriage. The position of the carriage frame is detected by the left-hand carriage

position sensor.

Oki Data CONFIDENTIAL

Print head

Platen

Carriage shaft

Slide rail

Space motor

Mini pitch belt

Carriage frame

Carriage frame

Carriage position

sensor

Figure 3

43471801TH Rev.1 13 /

2.3.3 Mechanism for adjusting the head gap (see figure 4)

The head gap adjustment is a mechanism to correct the gap between the print head and platen

by moving the adjust lever vertically and rotating and moving the carriage shaft toward and away.

The movement of the adjust lever rotates the carriage shaft that is connected directly to the

adjust lever.The carriage shaft is decentered against the fulcrum of the adjust lever (section fit

with the carriage shaft), therefore, the carriage shaft moves towaed and away when the adjust

lever rotates. The print head then moves towaed and away the platen.

Platen

Oki Data CONFIDENTIAL

Adjusting lever

Print head

Carriage frame

Carriage shaft

Print head

2

1

2

Adjusting lever

Platen

1

Figure 4

43471801TH Rev.1 14 /

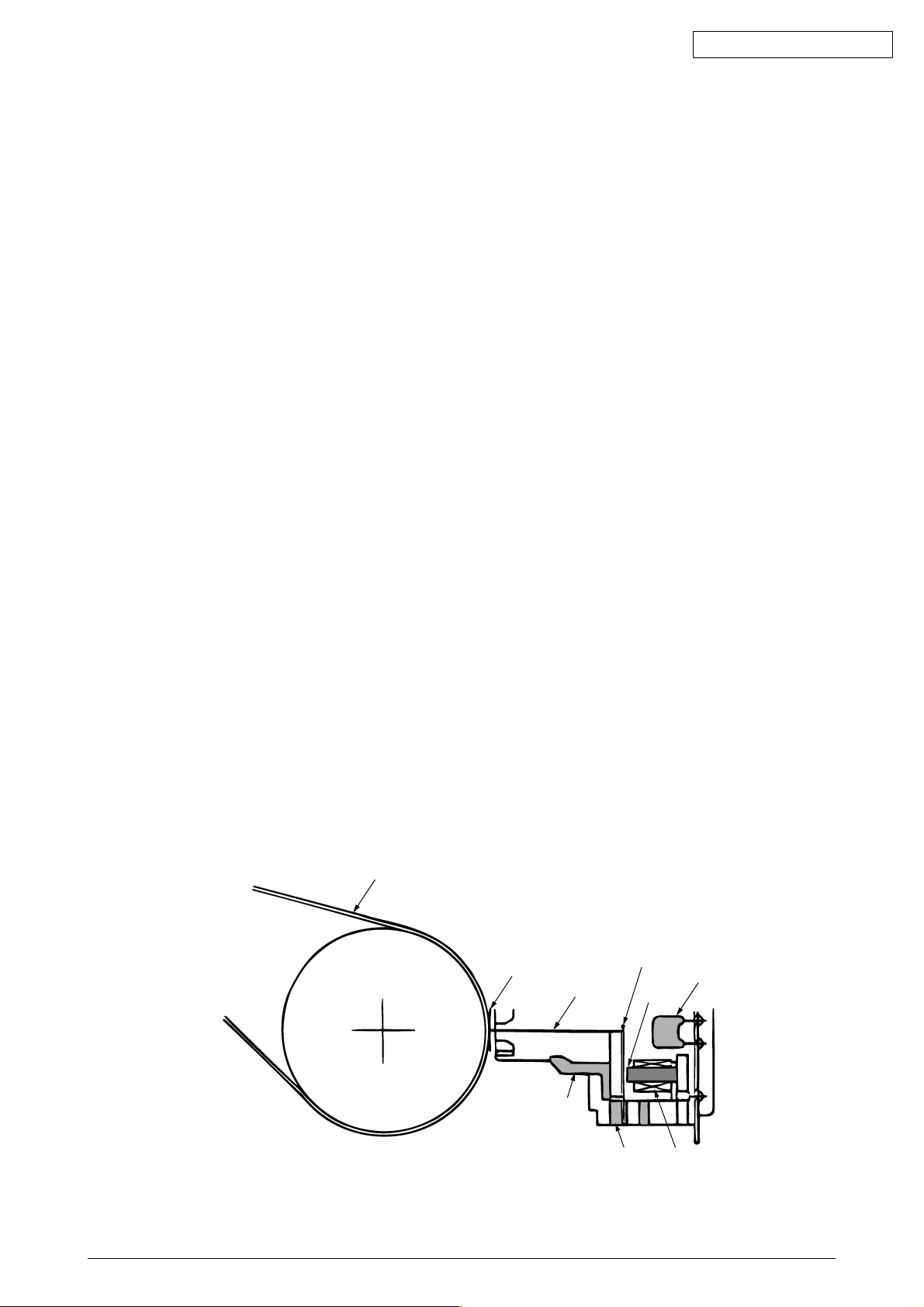

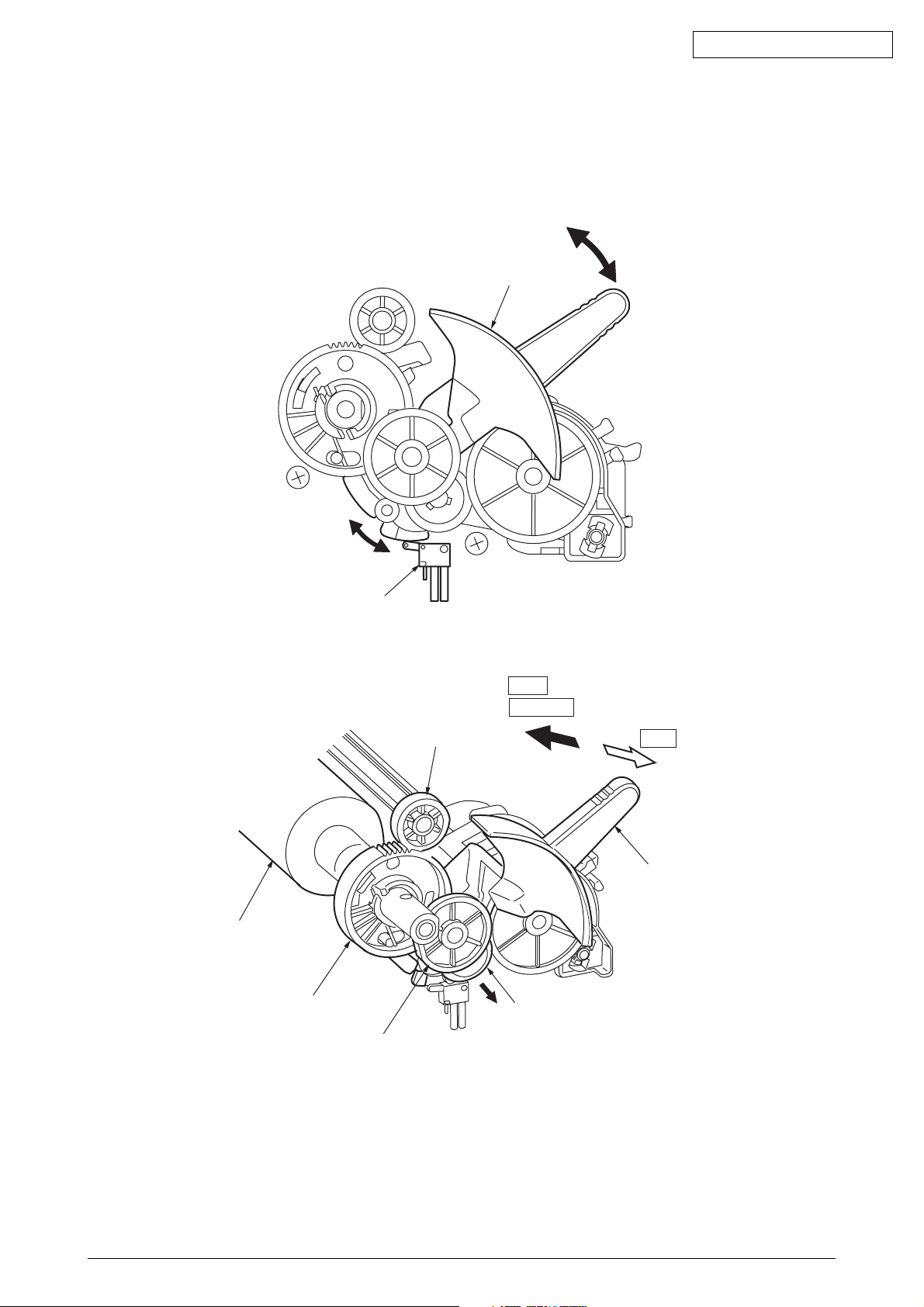

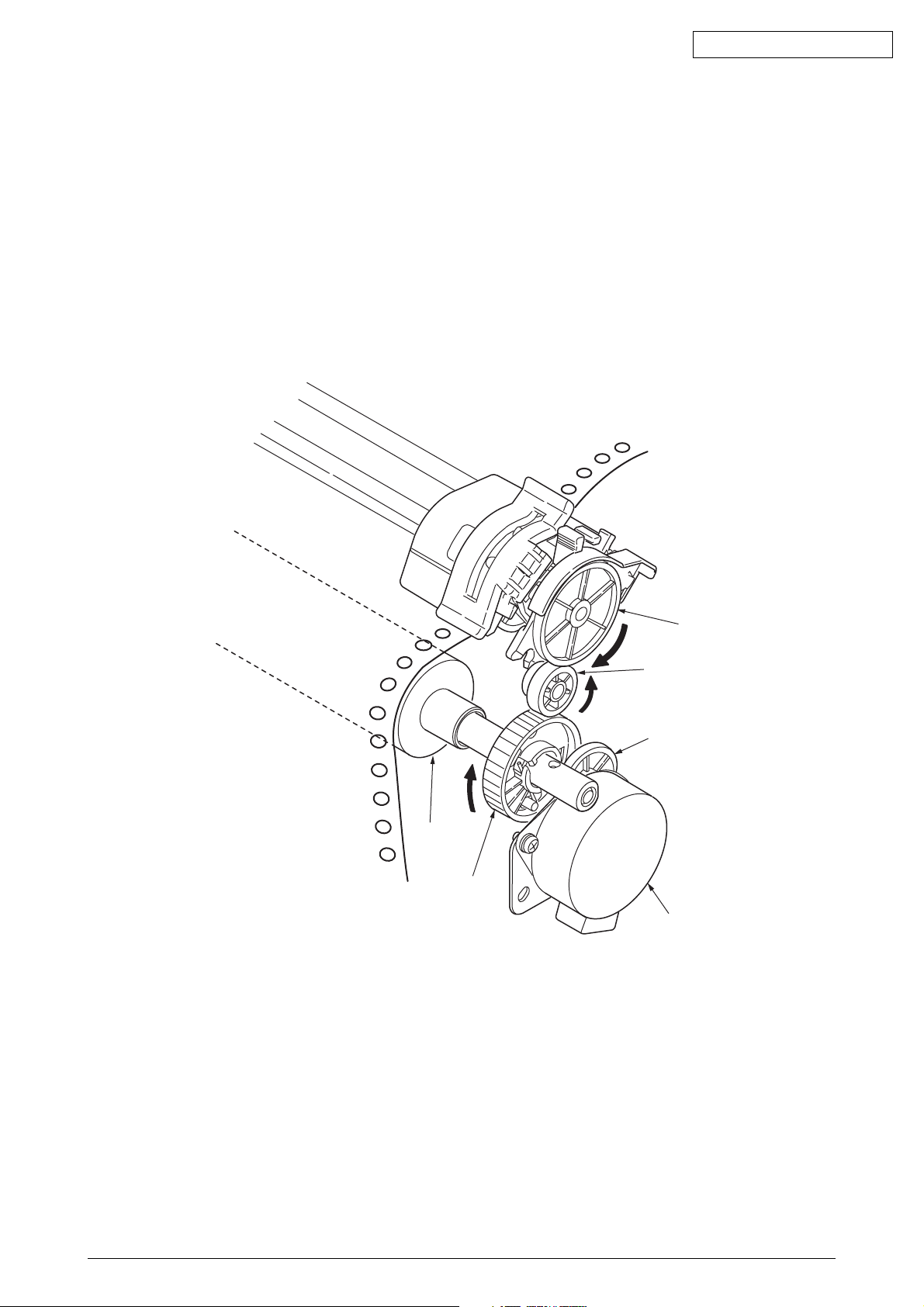

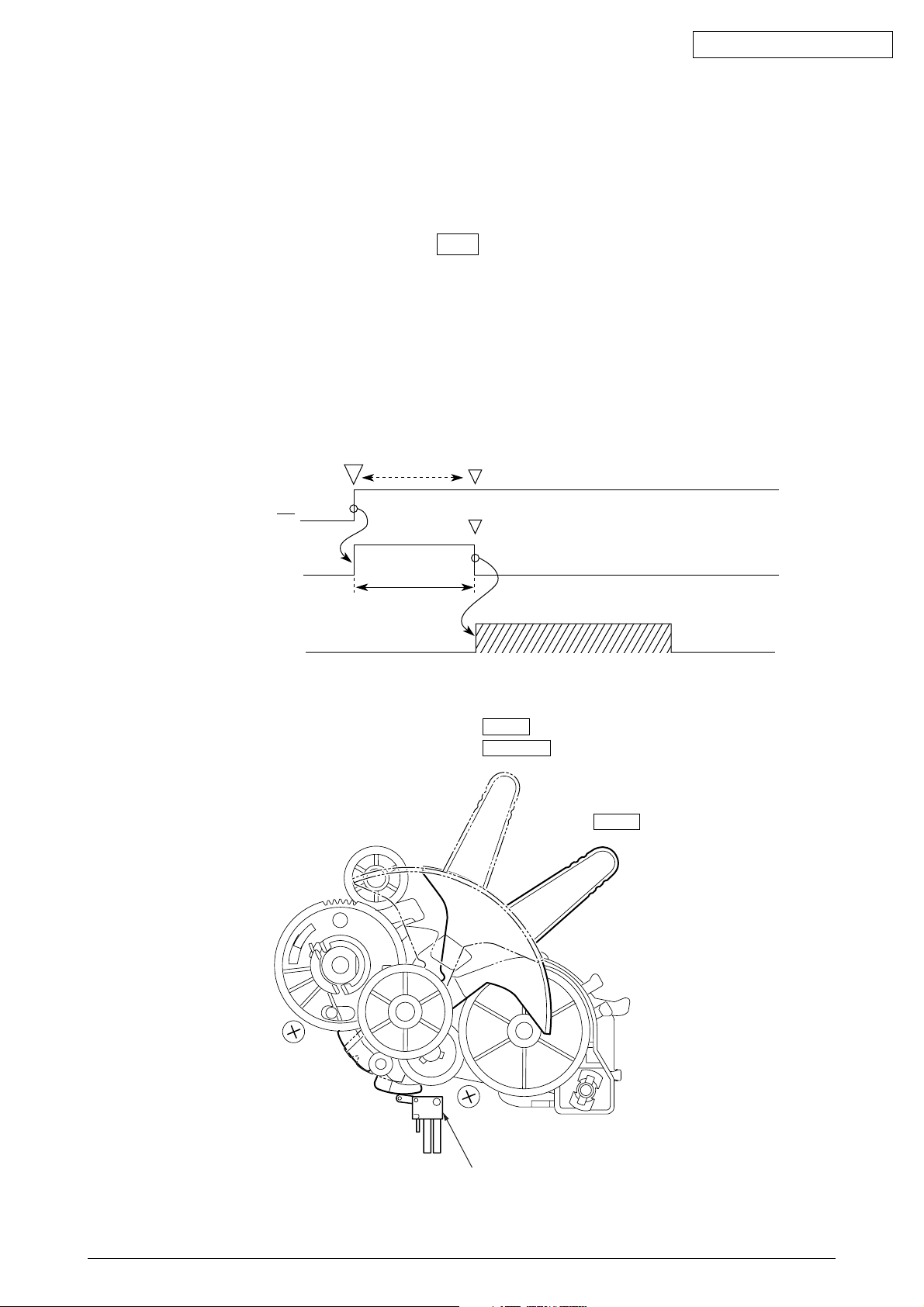

2.3.4 Mechanism and operation of ribbon feed (See figure 5)

Ribbon feed is a mechanism to feed the ribbon which is driven by the stepping motor.

The ribbon feed mechanism consists of:

(a) Ribbon feed gear assembly

(b) Ribbon cartridge

1) Ribbon cartridge

The use of a one-way feed endless ribbon provides clear print results.

(2) Feed operation

Ribbon feed is initiated at the same time the spacing operation is initiated regardless of the

mode, and stops when the spacing operation is ceased.

The rotation of a driven stepping motor is transferred to the drive roller in the ribbon cartridge

via the ribbon gear which feeds the ink ribbon.

Ribbon cartridge

Drive roller

Oki Data CONFIDENTIAL

Ribbon drive gear

Ribbon drive gear

Idie gear

Figure 5

43471801TH Rev.1 15 /

2.3.5 Paper Feed Operation

Feeding of the paper is performed by turning the platen and the pin tractor, which is driven by

the LF stepping motor.

Item of the paper feed mechanism are as follows:

(a) Stepping motor with gears

(b) Decelerating gear

(c) Platen

(d) Tractor feed unit

(e) Pressure roller

Oki Data CONFIDENTIAL

43471801TH Rev.1 16 /

Oki Data CONFIDENTIAL

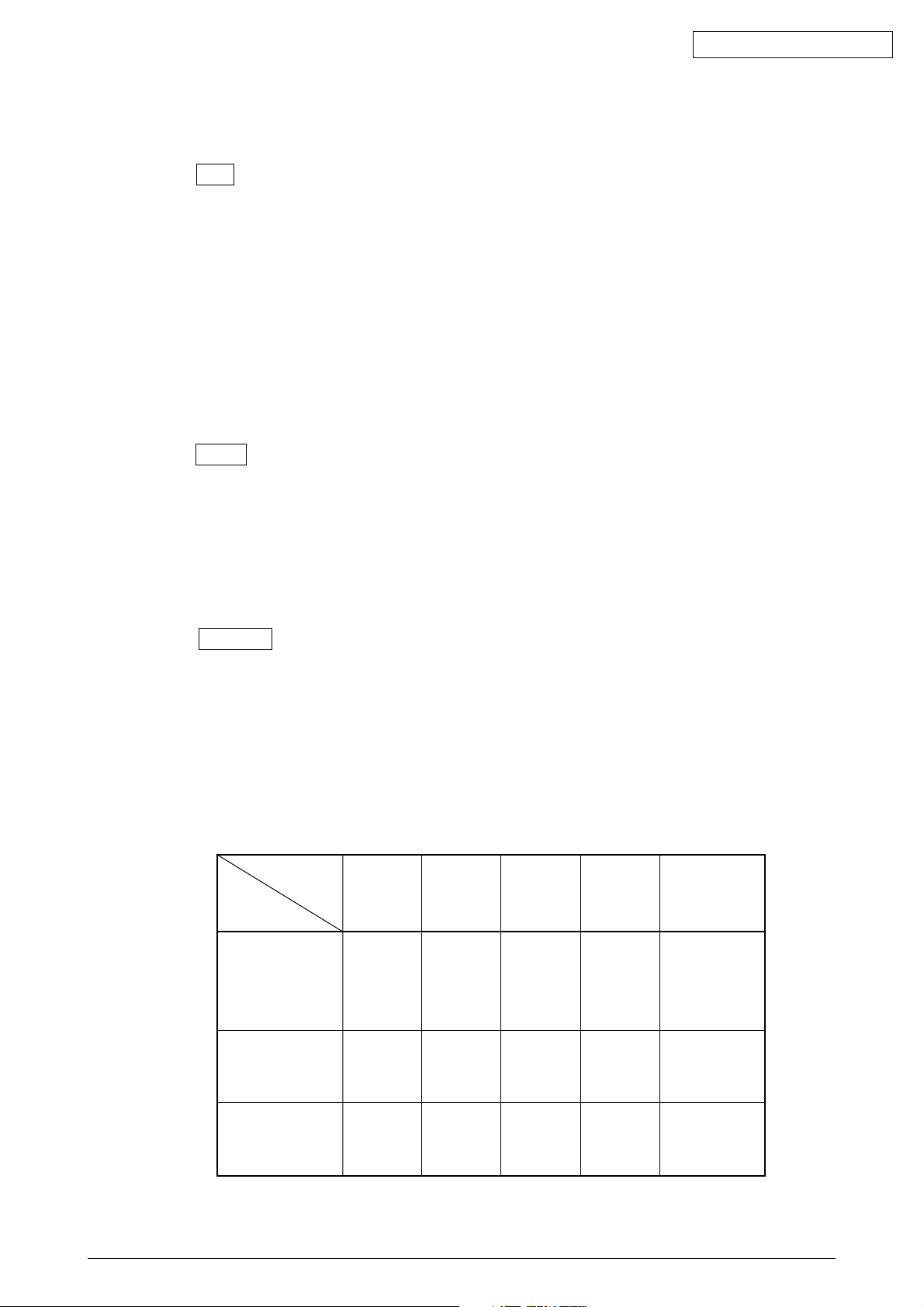

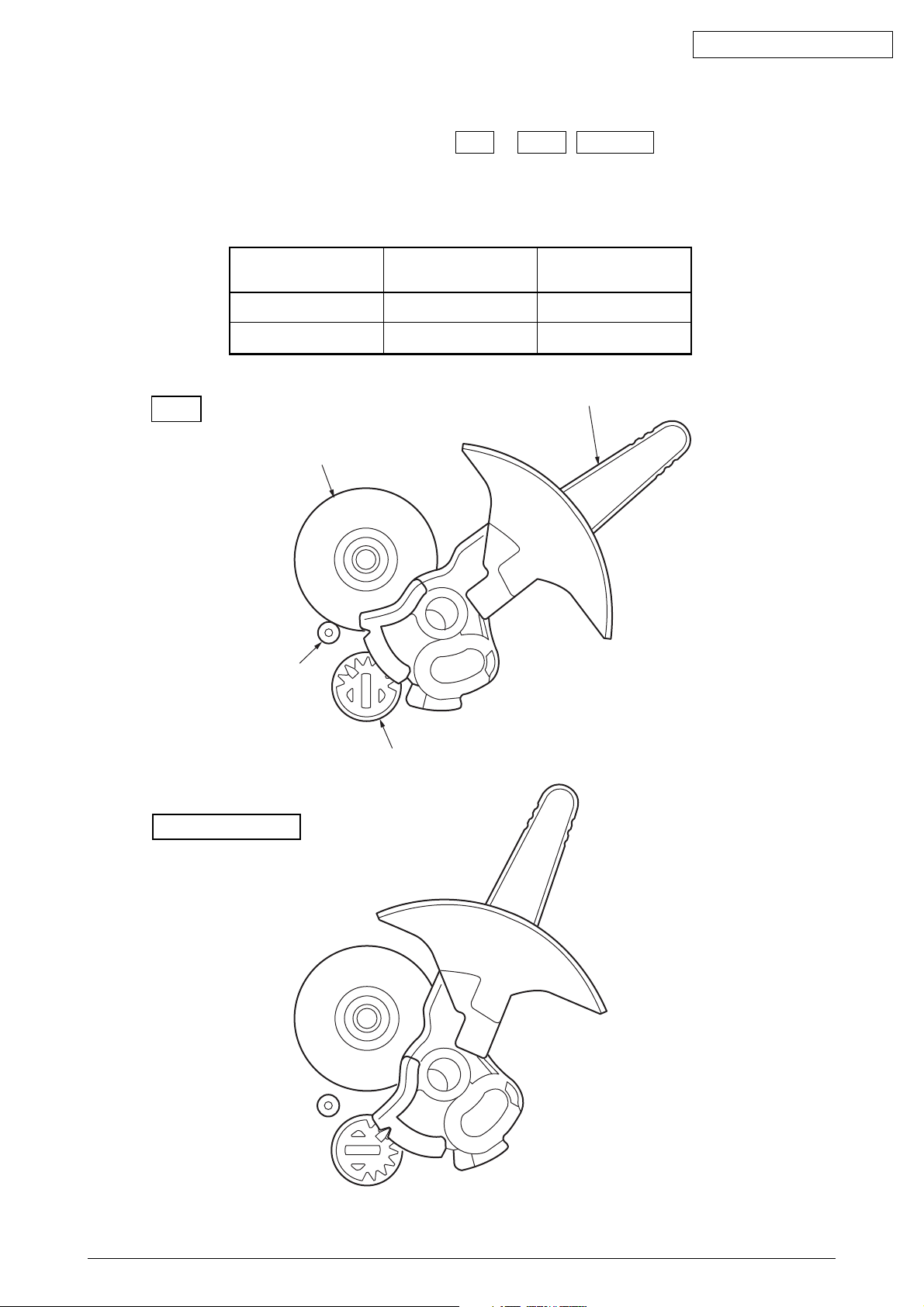

(1) Cut sheet and continuous sheet switching mechanism (See Figure 6.)

Three different paper paths can be selected and set by the change lever.

(a) TOP (Cut-sheet mode)

To use cut-sheet paper in manual mode, turn the change lever to the “TOP” position to

enter cut-sheet mode.

[Operation]

Turning the change lever to the “TOP” position moves the change gear and disengages

this component from the tractor gear.

Driven by the LF motor, the idle gear rotates and transmits this rotation to the platen gear.

The pressure rollers (front/rear) are pressed to the platen to feed the cut-sheet paper.

At the same time, the change lever activates “TOP-REAR_SW,” conveying to the control

board that the change lever is in the top position and that the cut-sheet mode is selected.

In cut-sheet mode, after paper has been set in position and the specified time stored in the

menu has elapsed, the paper is fed automatically into the start position.

(b) REAR (Continuous-form: The push tractor is placed in the rear.)

When the change lever is in the rear position, the change gear is engaged with the tractor

gear and the rotation of the LF motor is transmitted to the tractor gear via the idle gear and

the change gear.

The rotation of the tractor gear rotates the tractor shaft, which in turn feeds the continuous-

form set in the push tractor.

At the same time, the change lever turns off “TOP-REAR_SW,” conveying to the control

board that the change lever is in the rear position and that continuous-form mode is selected.

(c) BOTTOM (Continuous-form: The tractor is placed above the platen.)

The rotation of the LF motor is transmitted to the tractor gear via the idle gear, the platen

gear, and the pull-up gear.

The rotation of the tractor gear rotates the tractor shaft, which in turn feeds the continuous

form set in the pull tractor.

At the same time, the change lever turns off “TOP-REAR_SW,” conveying to the control

board that the change lever is in the rear position and that continuous-form mode is selected.

Correlation in Mechanism

Mechanism

Lever

Position

TOP

REAR

BOTTOM

43471801TH Rev.1 17 /

Top

Rear

change

Switch

OFF

ON

OFF

Idle

Gear

Rotate

Rotate

Rotate

Change

Gear

Rotate

Rotate

Rotate

Tractor

Gear

Stop

Rotate

Stop

Sheet

Insertion

Manual/

automatic

•

Operation

SW

or

•

instruction

•

Operation

SW

or

•

instruction

Change lever

Oki Data CONFIDENTIAL

Platen

Top-Rear changswitch

Platen gear

Idle gear

Pull up gear24

Rear

BOTTOM

TOP

Change lever

Change gear

Figure 6

43471801TH Rev.1 18 /

Oki Data CONFIDENTIAL

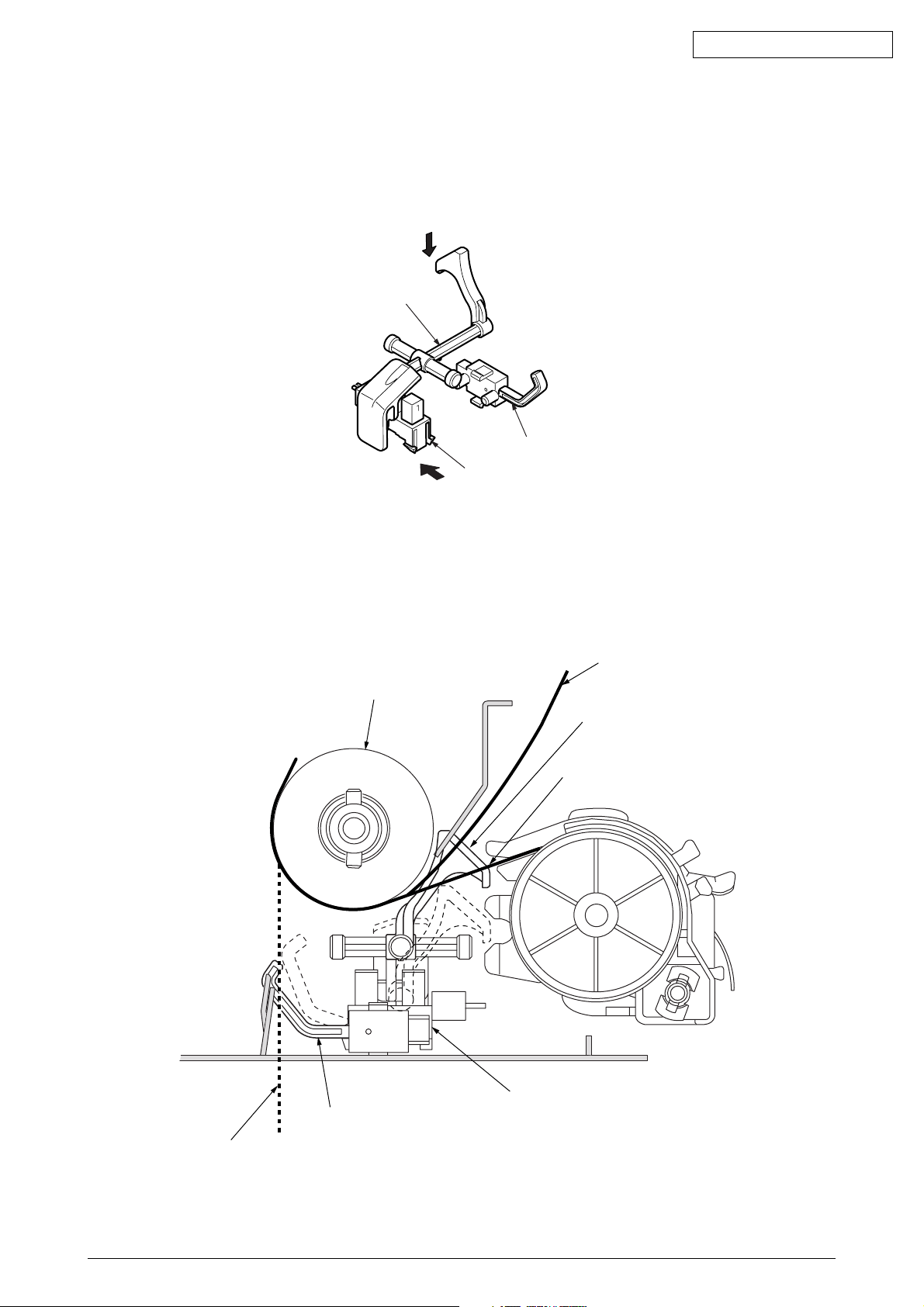

i2) Cut-sheet feeder operation (See Figure 7.)

The pulse motor used for the paper feed mechanism is mounted on the left of the frame,

and the rotation of the motor is transmitted through decelerating gears (LF idle gear, platen

gear) to the platen. When using cut-sheet paper, the change lever must be in the TOP

position to grab the paper, while disengaging the push tractor.

When the change lever is set to the TOP position, the cut sheet is automatically fed

in up to the print start position after pausing for the wait time stored in the menu.

Platen gear

Idel gear

Stepping motor

(LF motor)

Platen

Pressurp roller

Figure 7

43471801TH Rev.1 19 /

Oki Data CONFIDENTIAL

(3) Continuous paper feed operation (Rear) (See Figure 8.)

The force transmitted to the platen, rotates the tractor gear through platen gear, the idler

gear and the change gear. The rotation of the tractor gear makes the pin tractor belt rotate

through a sheet feeder shaft, feeding the continuous paper.

Change gear

Tractor

Paper

Tractor gear

Idle gear

Platen gear

LF motor

Figure 8

43471801TH Rev.1 20 /

Oki Data CONFIDENTIAL

(4) Bottom push feed operation (See Figure 9.)

Remove the pull-up assy.

By removing the tractor assy. installed in the rear and installing it above the platen, the

assy. is used for bottom pull feed.

The rotation of the LF motor is transmitted via the platen gear and the pull-up gear and

rotates the tractor gear.

The rotation of the tractor gear rotates the tractor shaft, which in turn feeds the continuous

form set in the tractor assy. into the print start position.

Platen

Platen gear

Figure 9

Tractor gear

pull gear

Idle gear

LF motor

43471801TH Rev.1 21 /

Oki Data CONFIDENTIAL

(5) Paper clamp mechanism (See Figure 10.)

When setting the change lever to the TOP or REAR , BOTTOM position, the operation

of the front release gear arm changes according to the position of the release cam. And

at the same time, the position of the cam installed to the front release gear shaft changes,

and the open and close of the pressure roller.

TOP

Position of

change lever

BOTTOM/REAR OPEN OPEN

TOP CLOSE CLOSE

Platen

Front roller

Open or close of

front pressure roller

Open or close of

rear pressure roller

Change lever

REAR/BOTTOM

Rerizu shaft

Figure 10

43471801TH Rev.1 22 /

2.3.6 Paper Detection Mechanism

(1) Cut sheet detection/Rear feed detection(See Figure 11.)

When a cut sheet is inserted or a continuous form is fed by the tractor, the sensor arm

is pushed down by the paper and rotated. This moves the end of the sensor arm away

from the paper sensor that it has blocked, and the paper sensor detects “ON.”

Sensor arm

Oki Data CONFIDENTIAL

Bottom sensor

Paper end sensor

Figure 11

(2) Bottom feed detection(See Figure 12.)

When paper is fed from the bottom, the bottom sensor lever is pushed down by the paper

and the bottom sensor detects “ON.”

When the tail end of paper has passed the bottom sensor, the sensor lever returns into

position and the bottom sensor detects “OFF.”

Paper

Platen

(Cut shwwt feed)

Sensor arm

Paper

(Rear paper feed)

Peper end sensor

Bottom sensor lever

Paper

(bottom paper feed)

Figure 12

43471801TH Rev.1 23 /

Oki Data CONFIDENTIAL

(3) Top line print mechanism (See Figure 13.)

The front edge of the sheet is protected by the ribbon protector so that it can stop at a

position just near to the print head (0 tear off position) to start printing at the front end

of the sheet, without causing the sheet to crumple or curl up.

The printing starts at the front end of the sheet, and continues uni-directionally until the

front end of the sheet gets to the inside of the pull up roller cover.

After that, that printing continues bi-directionally.

Platen

Print head

Ribbon protector

Carriage frame assy

Figure 13

43471801TH Rev.1 24 /

2.3.7 Automatic Sheet Feed (See Figure 14.)

This function is used to feed in the sheet automatically up to the print start position when the

cut sheet or the continuous sheet is used.

[Operational procedure]

(1) When using the cut sheet

1) Set the change lever to the TOP position. (See Figure 2-16.)

2) Insert a sheet of paper between the platen and the paper shoot.

3) After the lapse of time selected by the “wait time” in the menu, the LF motor starts

its operation to feed the sheet of paper up to the print position.

4) When the default is selected, the sheet of paper is feed in up to the position 0.85

inches (first dot position) from the upper end of the sheet. However, the 0 tear off

mechanism allows the printing at the front end of the sheet by changing the TOF

position.

Sheet setting

Oki Data CONFIDENTIAL

PE

Detection timer

LF action

Time out

Time selected

on the menu

REAR

BOTTOM

TOP

Top-Rear chang switch

Figure 14

43471801TH Rev.1 25 /

Loading...

Loading...