Page 1

Page: 1

Service Guide OJ2010

Chapter 0 About This Manual

OKIJET 2010

InkJet Printers

Adobe Acrobat printable reference

copy of the OKIDATA Service Training Manual.

09/17/97

Note: This Adobe Acrobat version of the Okidata Service Training Manual was built with the

pictures rendered at 300 dpi, which is ideal for printing, but does not view on most

displays well.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 2

Table of Contents Page

Service Guide OJ2010

0 About This Manual

Front Cover 1

Copyright 2

1 Product Specifications

1.1 Overview 3

1.2 Physical Specifications 4

1.3 Power Requirements 5

1.4 Environmental Conditions 6

1.5 Agency Approvals 7

1.6 Operational Specifications 8

....1.6.06 Paper Loading 9

........Auto Feed 10

........Manual Feed 11

....1.6.07 Print Method 12

....1.6.08 Print Modes And Print Resolution 13

....1.6.10 Print Speed 14

1.7 Print Media (Paper) Specifications 15

....1.7.02 Length 16

....1.7.05 Weight 17

....1.7.06 Width 18

........Card Stock (Index Cards) 19

........Cut Sheet 20

........Envelopes 21

........Auto Feed 22

........Manual Feed 23

........Orientation 24

........Labels 25

........Transparency 26

1.8 Memory Specifications 27

1.9 Consumables 28

1.10 Options 29

1.11 Reliability 30

2 Principles of Operation

2.1 Electrical Operation 31

....2.1.02 Emulations 32

....2.1.03 Interface 33

....2.1.04 Memory 34

....2.1.05 Operator Panel 35

....2.1.06 Parallel Port 36

....2.1.07 Power On Self Test (Post) Sequence 37

....2.1.08 Power Supply 38

....2.1.09 System Board 39

Page 3

Table of Contents Page

2.2 Mechanical Operation - Paper Feed 40

....2.2.02 Paper Feed Methods 41

....2.2.03 Paper Feed Path 42

....2.2.04 Paper Loading 43

........Envelope Orientation 44

........Auto Feed 45

........Manual Feed 46

....2.2.05 Printhead Mechanism 47

....2.2.06 Print Modes 48

....2.2.07 Print Resolution 49

....2.2.08 Print Speed 50

....2.2.09 Print Quality Enhancement Technique (PQET) [Edge

Smoothing]

....2.2.10 Spacing 52

....2.2.11 Maintenance Station 53

3 Maintenance and Disassembly

3.1 Overview 54

....3.1.02 Maintenance Items 55

....3.1.03 Maintenance Precautions 56

3.2 Disassembly/Assembly Procedures 57

....3.2.01 Preliminary Items 58

....3.2.02 Base Assembly 59

....3.2.03 Carrier Belt 60

....3.2.04 Carrier Frame Assembly 61

....3.2.05 Carrier Transport Motor 62

....3.2.06 Code Module / EPROM 63

....3.2.07 Edge Guide Assemblies And Paper Load Shaft 64

....3.2.08 Ejectors 65

....3.2.09 Encoder Card 66

....3.2.10 Encoder Strip 67

....3.2.11 Feed Arm Assembly 68

....3.2.12 Front Cover 69

....3.2.13 Gutter Pad 70

....3.2.14 Inside Idler Gears 71

....3.2.15 Large Feed Roller 72

....3.2.16 Large Outside Gear 73

....3.2.17 Left Side Frame Assembly 74

....3.2.18 Maintenance Station Assembly 75

....3.2.19 Maintenance Wipers And Caps 76

....3.2.20 Manual Insert Tray 77

....3.2.21 Mid Frame Assembly 78

....3.2.22 Paper Feed Motor 79

....3.2.23 Paper Guide And End Of Form (Eof) Flag Assembly 80

....3.2.24 Paper Load Door 81

51

Page 4

Table of Contents Page

....3.2.25 Pick Roll Hub, Shaft, And Envelope Bucklers 82

....3.2.26 Power Supply 83

....3.2.27 Printhead Cable And Paper Deflector 84

....3.2.28 Printhead Carrier Assembly 85

....3.2.29 Printhead Rubber Backer 86

....3.2.30 Rear Cover 87

....3.2.31 Right Side Frame Assembly 88

....3.2.32 Small Feed Roll Shaft, Rollers, And Flap 89

....3.2.33 System Board 90

3.3 Adjustments 91

....3.3.02 Printhead Alignment 92

....3.3.10 Resets 93

3.4 Cleaning 94

....3.4.02 Cleaning Schedule 95

....3.4.03 Cleaning Tools 96

....3.4.04 Areas To Be Cleaned 97

....3.4.04 Nozzle Test 98

........Procedure 99

............Wipe The Nozzles And Contacts 100

............Clean The Carrier Contacts 101

3.5 Lubrication 102

....3.5.02 Lubrication Schedule 103

....3.5.03 Lubrication Types And Amounts 104

....3.5.04 Areas Not Lubricated 105

3.6 Shipping Instructions 106

3.7 Print Cartridge Maintenance 107

....3.7.02 Installation 108

....3.7.03 Replacement 109

....3.7.04 Disposal 110

4 Failure and Repair Analysis

4.1 Overview 111

....4.1.02 Printer Serial Number Identification 112

....4.1.03 Code Level Identification 113

4.2 Reporting Problems 114

....4.2.02 Problem Lists 115

....4.2.03 Reporting Methods 116

4.3 Troubleshooting Updates 117

4.4 Troubleshooting Tips 118

....4.4.02 Problem Categories 119

....4.4.03 Start Here Flowchart 120

....4.4.04 Tips For Preventing Image Problems 121

....4.4.05 Common Problems 122

4.5 Abnormal Output 123

4.6 Fault Alarms 124

Page 5

Table of Contents Page

....4.6.02 Power On Self Test (Post) Sequence 125

....4.6.03 Symptom Lists 126

4.7 Repair Analysis Procedures (Raps) - Using The Raps 127

....4.7.02 Rap Index 128

........RAP 01: Envelope Feed Service Check 129

........RAP 02: First Print Line Service Check 130

........RAP 03: Maintenance Service Check 131

........RAP 04: Paper Feed Service Check 132

........RAP 05: Paper Path Service Check 133

........RAP 06: Parallel Port Service Check 134

........RAP 07: Power Service Check 135

........RAP 08: Print Quality Service Check 136

........RAP 09: Transport Service Check 137

4.8 Tests 138

....4.8.02 Test Page 139

....4.8.03 Parallel Port Test 140

....4.8.04 Encoder Sensor Test 141

....4.8.05 End Of Forms Sensor Test 142

....4.8.06 Initialize Error Log 143

....4.8.07 Printer Error Log Recovery 144

4.9 Resistance Checks 145

....4.9.02 Checkpoint Locations 146

A Board Diagrams

A.1 Board Diagrams And General Information 147

A.2 Index To Charts 148

....A.2.01 System Board 149

....A.2.02 Power Supply 150

....A.2.03 Encoder Card 151

A.3 Resistance Checkpoints 152

....A.3.02 Checkpoint Locations 153

B Illustrated Parts Listing

B.1 Illustrated Parts Listing - General Information 154

........Format 155

........Current Part Numbers 156

....B.1.02 Definition Of Terms 157

....B.1.03 Parts Ordering Information 158

B.2 Charts 159

....B.2.01 Printer 160

....B.2.02 Covers 161

....B.2.03 Frames 162

....B.2.04 Paper Feed 163

....B.2.05 Electronics 164

....B.2.06 Carrier 165

....B.2.07 Carrier Transport 166

Page 6

Table of Contents Page

....B.2.08 Sheet Feeder 167

....B.2.09 Maintenance Station 168

....B.2.10 Packing Materials 169

....B.2.11 Consumables 170

....B.2.12 Documentation 171

....B.2.13 Service Training Kit Revision List 172

Page 7

Page: 2

Service Guide OJ2010

Chapter 0 About This Manual

Copyright

This document may not be reproduced without the written permission of Okidata Sales and Product

Training. Every effort has been made to ensure the accuracy of the information contained in this training

course. Okidata is not responsible for errors beyond its control.

© 1995 by Okidata All rights reserved.

First Release P/N 59269701 June, 1995

Second Release P/N 59269702 July, 1995

Written by Okidata Sales and Product Training

Please address any comments on this publication to:

Okidata

Sales and Product Training

532 Fellowship Road

Mount Laurel, NJ 08054-3499

Okilink Login Name: Technical Training

OKIDATA is a registered trademark of Oki Electric Industry Company, Ltd.; marques deposee de Oki

Electric Industry Company, Ltd.; marca registrada, Oki Electric Industry Company, Ltd.

Faxable Facts is a trademark, all rights reserved, 1993

OkiJet is a trademark of Oki Electric Industry Company, Ltd.

Okilink II is a trademark of Oki Electric Industry Company, Ltd.

ZIP Code is a registered trademark of the United States Postal Service.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 8

Page: 3

Service Guide OJ2010

Chapter 1 Product Specifications

1.1 OVERVIEW

1.1.01 General Information

The OkiJet 2010 is the first thermal inkjet product to wear the Okidata name badge.

The unit is a fully featured Windows-based, inkjet printer.

This product is a Graphics Device Interface (GDI) printer. Data leaving the computer is "preformatted" for

the printer. Very little printer circuitry is required for data handling. The received data is already formatted

for the GDI printer. RAM in the printer is minimized.

There is NO operator panel. The unit is controlled via software in the computer.

The units print resolution is 600 by 300 dots per inch. Dual printhead design allows the unit to print color

and true black without changing printheads.

The unit utilizes an edge smoothing technique called Print Quality Enhancement Technique (PQET). This

technique reduces the "jaggies" seen in slanted (italics) character set printouts.

The OkiJet 2010 printer is a "Windows Based Host Printer". The printer can print from a DOS based

program running in a Windows "DOS-based session", but it is not the best possible configuration. DOS is

a very non-graphical based operating system. The OkiJet 2010 is a GDI printer.

A parallel interface cable IS NOT shipped with the unit. The end user must purchase the interface cable

separately. It must be capable of supporting bi-directional communications to connect the printer to the

computer. This cable CANNOT be more than six (6) feet long.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 9

Page: 4

Service Guide OJ2010

Chapter 1 Product Specifications

1.2 PHYSICAL SPECIFICATIONS

1.2.01 Dimensions

Width: 17.2 inches (43.6 centimeters)

Depth: 23.3 inches (59.1 centimeters)

Height: 13.5 inches (34.3 centimeters)

1.2.02 Printer Weight

9.4 pounds (4.3 kilograms) with no ink cartridges installed

9.75 pounds (4.42 kilograms) with two ink cartridges installed

UPS Shippable

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 10

1.3 POWER REQUIREMENTS

1.3.01 Input Power

90 to 259 volts, AC

1.3.02 Power Consumption

Voltage Range: 120/220/240

The numbers listed below are estimates.

less than 2 W - Power OFF

7.5 W - Idle Mode

12 W - Printing Mode Average

25 W - Printing Mode Peak

1.3.03 Power Frequency

50/60 Hz

Page: 5

Service Guide OJ2010

Chapter 1 Product Specifications

1.3.04 Energy Star Rating

The product qualifies for the Environmental Protection Agency (EPA) Energy Star Program, a cooperative

effort between the EPA and computer and peripheral manufacturers to promote energy efficient

equipment and to reduce air pollution caused by power generation.

The Energy Star emblem does not represent EPA endorsement of any product or service.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 11

Service Guide OJ2010

Chapter 1 Product Specifications

1.4 ENVIRONMENTAL CONDITIONS

1.4.01 Acoustic Rating

Printing - 45 dBA

Idle - not measurable

1.4.02 Altitude

10,000 feet (3,048 meters)

1.4.03 Ambient Temperature and Relative Humidity (RH)

Operation

Temperature: 65 to 80 degrees Fahrenheit (18 to 26.7 degrees Celsius)

Relative Humidity: 30% to 60%

Storage

Temperature: 50 to 110 degrees Fahrenheit (10 to 43 degrees Celsius)

Relative Humidity: 8% to 80%

Page: 6

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 12

1.5 AGENCY APPROVALS

1.5.01 Listings

Canadian ICES Class B

CE

CSA No: CSA Standard C22.2 (220)

DEMCO

FCC: FCC Class B, Part 15

FEI

GS

Page: 7

Service Guide OJ2010

Chapter 1 Product Specifications

SEMCO

UL no: UL Standard No. 478

VCCI

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 13

Service Guide OJ2010

Chapter 1 Product Specifications

1.6 OPERATIONAL SPECIFICATIONS

1.6.01 Emulations

Graphics Device Interface (GDI) for Windows

HP PCL3 for DOS via Windows MS-DOS prompt

1.6.02 Graphics Resolution

300 (horizontal) x 600 (vertical) dots per inch (DPI) in Black and Color Modes

1.6.03 Interface

Bi-Directional Centronics Parallel

Recommended cable IEEE 1284 compliant, No more than six (6) feet long.

Page: 8

Purchased separately

1.6.04 Paper Feed Methods

Auto

Holds up to 150 sheets (depending on thickness) in the Automatic Sheet Feeder

Holds up to 15 envelopes (depending on thickness) in the standard feeder

Manual

1.6.05 Paper Feed Path

Lazy "L"

Auto

Manual

The paper bends approximately 75 degrees. The gentle bend allows the OkiJet 2010 to have fewer paper

jams. The unit also handles a wide variety of size and weight print media.

Page 14

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 15

Page: 9

Service Guide OJ2010

Chapter 1 Product Specifications

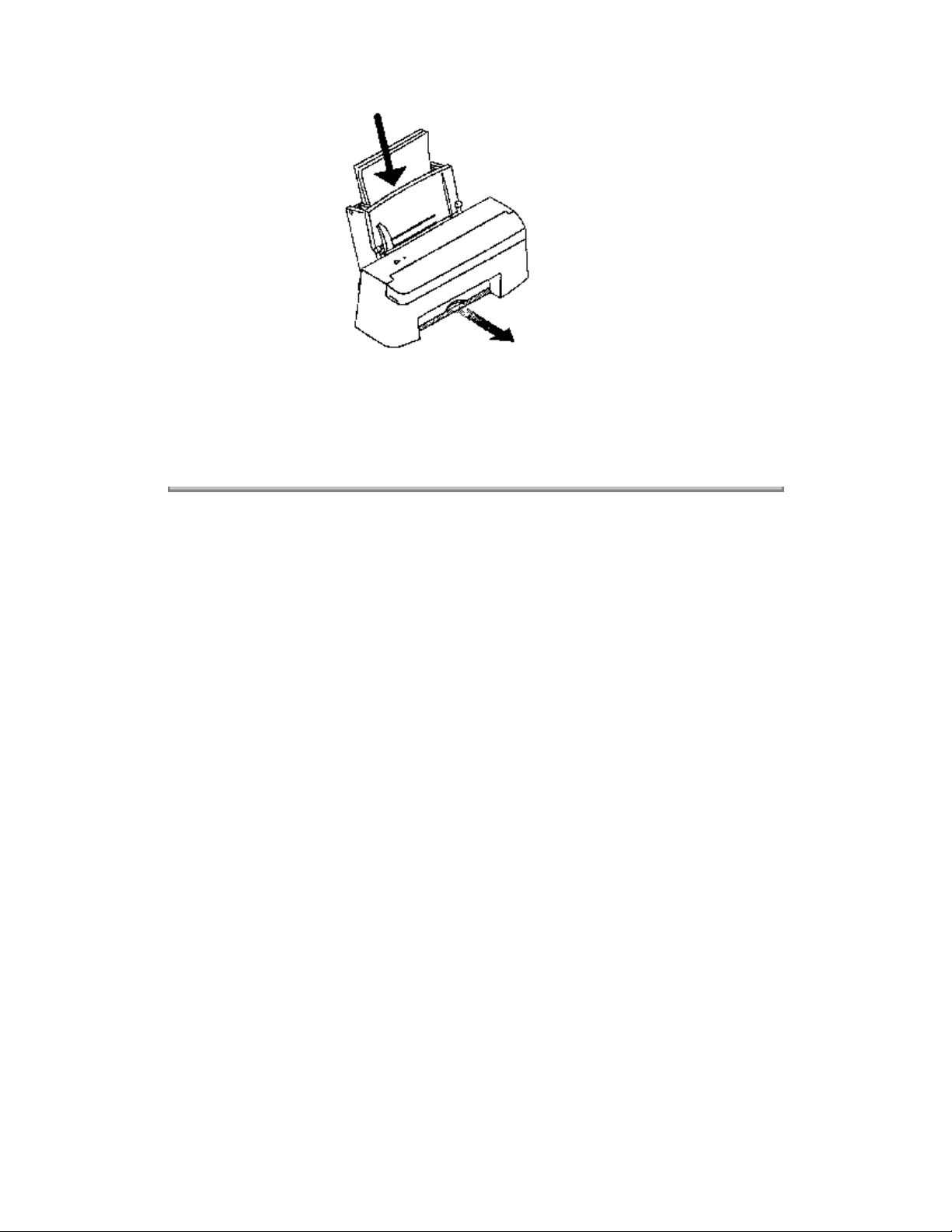

1.6.06 Paper Loading

Paper is installed face up.

The leading edge (top of form) faces down into the printer.

The aligned edge of the paper is to the right side of the printer (when the operator is facing the front of the

unit.

Also refer to the Users Guide for information on paper loading

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

.

Page 16

Service Guide OJ2010

Chapter 1 Product Specifications

Auto Feed

Step Number

1. Fold down the automatic sheet feeder access cover.

2. Adjust the paper guides to the width of the paper.

3. Once the paper guides are adjusted, slide the paper into the automatic sheet feeder.

IMPORTANT:

Page: 10

The side of the paper to be printed on

The leading edge (top of form) of the sheet faces

4. Fold the access cover up and the printer is ready to print

MUST

face the front of the printer.

DOWN

into the printer.

Page 17

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 18

Page: 11

Service Guide OJ2010

Chapter 1 Product Specifications

Manual Feed

Step Number

1. Paper to be loaded into the manual slot is placed against the Automatic Sheet Feed Access cover,

shown in gray.

2. Slide the manual feed support lever to the right, to the approximate width of the page / envelope being

inserted.

The RIGHT SIDE of the document is aligned against the static feed support.

The LEFT SIDE of the document is aligned against the movable feed support.

3. Insert the page / envelope.

IMPORTANT:

The side of the paper to be printed on

The leading edge (top of form) of the sheet faces

Envelopes

Orientation is landscape left (90 degree clockwise rotation).

Envelopes feed lengthwise.

Envelopes feed face-up.

Close envelope flaps before feeding

4. Make the final width adjustments.

MUST

face the front of the printer.

DOWN

into the printer.

Page 19

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 20

Service Guide OJ2010

Chapter 1 Product Specifications

1.6.07 Print Method

Thermal InkJet

InkJet printers work by spraying liquid ink onto the print media.

The inkjet printhead-to-media gap is very small.

A crease or sharp edge on the paper may damage the inkjet head.

Paper dust or other contaminants can clog the inkjet nozzles on the printhead.

Page: 12

Perform the nozzle test to clean the inkjet nozzles.

printheads are delicate and easily damaged .

NOTE:

The printhead is part of the print cartridge.

The printhead is replaced when the print cartridge is replaced.

Black Print Cartridge: Average Life (Ink Saver OFF): 1000 pages at 5% coverage

Color Print Cartridge: Average Life (Ink Saver OFF): 200 pages at 15% coverage of seven color graphics.

CAUTION:

Using a non-Okidata ink cartridge may damage the unit and void any warranties.

Always perform the printhead alignment procedure when a print cartridge is replaced.

Guide or Section 3.3 for further information .

WARNING:

NEVER

Refilling empty print cartridges with unapproved ink will invalidate the warranty.

Incompatible inks can cause damage to the printhead or printer.

refill or use refilled print cartridges.

Refer to Section 3.4 for further information. Inkjet

Refer to the Users

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 21

Page: 13

Service Guide OJ2010

Chapter 1 Product Specifications

1.6.08 Print Modes

Black Draft

Black Letter Quality

Full Color

1.6.09 Print Resolution

300 (horizontal) x 600 (vertical) dots per inch (DPI) in Black and Color Modes

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 22

Page: 14

Service Guide OJ2010

Chapter 1 Product Specifications

1.6.10 Print Speed

3 pages per minute in Black Draft Mode.

2 pages per minute in Black Letter Quality Mode.

2 to 4 pages per minute in Full Color Mode.

Graphics Device Interface (GDI)

When working with a GDI printer, data leaves the computer "pre-formatted" for the printer. Very little

printer circuitry is required for data handling. The received data is already formatted for the printer. RAM in

the printer is minimized. Because the printer is controlled via software in the computer, the operator panel

is minimized.

Printer Speed versus System Speed

As a general rule, the faster the computer, the faster the printout from a GDI printer.

Example:

Two identical GDI printers are connected to two different systems.

One system is a 25 MHz. 80386 based computer with 4 MB of RAM.

One system is a 66 MHz. 80486 based computer with 8 MB of RAM.

Question

If both systems being printing the same file at the exact same time, which system will finish first?

Answer

The 66 MHz. 80486 based computer with 8 MB of RAM.

Reason

All of the pre-print data processing is being done in a system with greater "system resources" (more RAM,

high level processor at a higher speed). Data is sent to the printer faster.

Windows Printing versus DOS Based Printing

The OkiJet 2010 printer is a "Windows Based Host Printer". The printer can print from a DOS based

program running in a Windows "DOS-based session". However, this is not the best configuration. DOS is

a very non-graphical based operating system. The OkiJet 2010 is a "Graphics Device Interface" printer. It

is better to run the OkiJet 2010 with a Windows system.

Page 23

Improving Performance

A GDI printer is the only type of printer that improves (up to the printers maximum rated performance) with

the host computers improvement.

In the example, a 25 MHz. 80386 system was compared to a 66 MHz 80486 system.

Performance gains come from improving the computer, not by adding extras to the printer.

Upgrades will improve the customers computer system and the performance of the OkiJet 2010.

Upgrading to Pentium will allow software speeds and print speeds to increase (up to the maximum rated

performance).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 24

Page: 15

Service Guide OJ2010

Chapter 1 Product Specifications

1.7 PRINT MEDIA (PAPER) SPECIFICATIONS

CAUTION:

For best results when printing with color, use coated paper.

Paper types that work well with the color print cartridge may not work well with the black print cartridge.

Since the quality of plain paper varies widely, test the print quality before buying large quantities of paper.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 25

Service Guide OJ2010

Chapter 1 Product Specifications

1.7.02 Length

Note:

The recommended length is specific to paper type.

Auto

Minimum 5 inches (127 millimeters)

Maximum 14.33 inches (364 millimeters)

Manual

Minimum 5 inches (127 millimeters)

Maximum 14.33 inches (364 millimeters)

1.7.03 Number of Copies

Original (One)

1.7.04 Thickness

Paper

Manual 0.0028 to 0.0075 inches (0.071 to 0.191 millimeters)

Auto 0.0028 to 0.0075 inches (0.071 to 0.191 millimeters)

Page: 16

Envelopes

Manual 0.0028 to 0.024 inches (0.071 to 0.60 millimeters)

Auto 0.0028 to 0.020 inches (0.071 to 0.50 millimeters)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 26

Page: 17

Service Guide OJ2010

Chapter 1 Product Specifications

1.7.05 Weight

Note:

The recommended weight is specific to paper type and paper feed path.

Auto

16 to 24 lb. (60 to 90 g/m 2 )

Manual

16 to 32 lb. (60 to 120 g/m 2 )

Recommended

20 lb. (75 g/m 2 )

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 27

Page: 18

Service Guide OJ2010

Chapter 1 Product Specifications

1.7.06 Width

Note:

The recommended width is specific to paper type and paper feed path.

Auto

Normal

3.5 to 8.5 (88.9 to 215.9 millimeters)

Heavy weight / stiff

3 to 8 inches (76.2 to 215.9 millimeters)

Manual

3 to 9 inches (76.2 to 228.6 millimeters)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 28

Page: 19

Service Guide OJ2010

Chapter 1 Product Specifications

Card Stock (Index Cards)

Weight: 16 to 24 lbs. (60 to 90 g/m 2 )

Width: 3 to 8 inches (76.2 to 215.9 millimeters)

Length: 5 to 14.33 inches (127 to 364 millimeters)

Thickness: .0028 to 0.020 inches (0.071 to 0.50 millimeters)

Paper Feed Path: Auto Manual

Up to 15 cards (depending on thickness) may be loaded into the sheet feeder

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 29

Page: 20

Service Guide OJ2010

Chapter 1 Product Specifications

Cut Sheet

Weight: 16 to 32 lbs. (60 to 120 g/m 2 )

Width: 3 to 9 inches (76.2 to 228.6 millimeters)

Length: 5 to 14.33 inches (127 to 364 millimeters)

Thickness: 0.0028 to .0075 inches (0.071 to 0.191 millimeters)

Paper Feed Path: Manual

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 30

Page: 21

Service Guide OJ2010

Chapter 1 Product Specifications

Envelopes

Notes:

Envelopes are ONLY printed in landscape mode

Envelopes are ONLY printed in landscape left (90 degree clockwise rotation).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 31

Auto Feed

Weight: 20 to 24 lbs. (75 to 90 g/m 2 )

Width: 3 to 8 inches (76.2 to 215.9 millimeters)

Length: 5 to 14.33 inches (190.5 to 364 millimeters)

Size:

Page: 22

Service Guide OJ2010

Chapter 1 Product Specifications

Thickness: .003 to .024 inches (0.071 to 0.60 millimeters)

Paper Feed Path: Auto

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 32

Manual Feed

Weight: 20 to 28 lbs. (75 to 105 g/m 2 )

Width: 3 to 9 inches (76.2 to 228.6 millimeters)

Length: 7.5 to 14.33 inches (190.5 to 364 millimeters)

Size:

Page: 23

Service Guide OJ2010

Chapter 1 Product Specifications

Thickness: .003 to .024 inches (0.071 to 0.60 millimeters)

Paper Feed Path: Manual

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 33

Service Guide OJ2010

Chapter 1 Product Specifications

Orientation

Orientation is landscape left (90 degree clockwise rotation)

Envelopes feed lengthwise.

Envelopes feed face-up.

Close envelope flaps before feeding

When using the manual tray, line up the envelope with its right edge to the edge location symbol.

Page: 24

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 34

Labels

Notes:

Page: 25

Service Guide OJ2010

Chapter 1 Product Specifications

The page size for labels is limited to letter and A4.

For best results, DO NOT use labels with a slick backing material.

For best results, DO NOT print within 0.04 inches (1 millimeter) of the die cut.

Acrylic-based labels are preferred.

Adhesive

the die cuts of the labels, or come in contact with any part of the printer. Labels that do not meet these

guidelines may damage the printer.

Use full label sheets. Partial sheets (with areas exposed by missing labels) may allow labels to peel off

during printing, causing a paper jam.

The label sheet and adhesive must not melt, release hazardous gases, or allow the cover sheet to come

off when the label sheet is exposed to the internal operating temperature or the ink of the unit.

If the unit is powered

using the paper release lever, before the unit is powered ON. This will prevent labels from peeling off of

the carrier (backing) and sticking to the inside of the unit.

Determine the suitability of labels before ordering or printing large quantities.

Item

Letter Size Auto 8.5 x 11 inches (216 x 279

MUST NOT

extend to within 0.04 inches (1 millimeter) of the edge of the label, come between

OFF

or disconnected while labels are being printed, remove the labels manually,

Feed Method Type Specifications

millimeters)

Manual 8.5 x 11 inches (216 x 279

millimeters)

A4 Size Auto 8.3 x 11.7 inches (210 x 297

millimeters)

Manual 8.3 x 11.7 inches (210 x 297

millimeters)

Basic Weight Auto Paper 32 to 40 lb. (120 to 150 g/m2)

(Substance) Polyester 59 lb. (220 g/m2)

Vinyl 53 lb. (200 g/m2)

Page 35

Manual Paper 32 to 49 lb. (120 to 185 g/m2)

Polyester 59 lb. (220 g/m2)

Vinyl 80 lb. (300 g/m2)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 36

Page: 26

Service Guide OJ2010

Chapter 1 Product Specifications

Transparency

NOTES:

In general, only specially coated transparencies are recommended for use in inkjet printers. Select

transparencies specifically designed for inkjet printers.

The time required for the ink to dry on a transparency may be very long. Special precautions may be

required. The printed surface of the transparency should not be touched when removing the page from the

printer.

Multi-sheet transparencies

When printing multiple sheet jobs, remove each printed sheet from the output tray before the next sheet

enters.

It may be necessary to limit the amount of graphic heavy fill areas used in transparency printing.

Sometimes heavy fill areas cause the printed image to contract as it dries. The contraction causes poor

print quality.

Determine the suitability of transparencies before ordering or printing large quantities.

Size: Letter 8.5 x 11 inches (216 x 279 millimeters)

A4 8.3 x 11.7 inches (210 x 297 millimeters)

Weight: 36.8 to 39 lbs. (138 to 146 g/m 2 )

Width: 8.3 to 8.5 inches (210 to 216 millimeters)

Length: 11 to 11.7 inches (279 to 297 millimeters)

Thickness: 0.0039 to 0.0043 inches (0.100 to 0.110 millimeters)

Paper Feed Path: Auto Manual

ARE NOT

recommended.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 37

Service Guide OJ2010

Chapter 1 Product Specifications

1.8 MEMORY SPECIFICATIONS

1.8.01 General Information

The unit uses the resources of the personal computer (PC) for most functions.

Okidata recommends the configuration listed below.

386 or faster IBM PC

Windows 3.1 (or higher)

Windows Applications Software

Four Megabytes Random Access Memory (RAM)

Five Megabytes Hard Disk Space

Page: 27

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 38

Service Guide OJ2010

Chapter 1 Product Specifications

1.9 CONSUMABLES

1.9.01 Black Print Cartridge

56 Nozzles

Black ink

Average Life (Ink Saver OFF): 1000 pages at 5% coverage

1.9.02 Color Print Cartridge

48 Nozzles

16 each Cyan, Magenta, and Yellow

Color Ink

Average Life (Ink Saver OFF): 200 pages at 15% coverage of seven colors

Page: 28

NOTE:

CAUTION:

Using a non-Okidata ink cartridge may damage the unit and void any warranties.

Always perform the printhead alignment procedure when a print cartridge is replaced.

Refer to the Users Guide or Section 3.3 for further information

WARNING:

NEVER

Refilling empty print cartridges with unapproved ink will invalidate the warranty.

Incompatible inks can cause damage to the printhead or printer.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

The printhead is part of the print cartridge. It is replaced when the print cartridge is replaced.

.

refill or use refilled print cartridges.

Page 39

Page: 29

Service Guide OJ2010

Chapter 1 Product Specifications

1.10 OPTIONS

1.10.01 General Information

At this time, no options are available for the unit.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 40

Service Guide OJ2010

Chapter 1 Product Specifications

1.11 RELIABILITY

1.11.01 Mean Time Before Failure (MTBF)

Approximately 25,000 hours

Approximate maximum usage: 1,000 pages / month

1.11.02 Mean Time To Repair (MTTR)

Approximately 36 minutes to major sub-assembly level

1.11.03 Print Cartridge Life

Black Print Cartridge

Average Life (Ink Saver OFF): 1000 pages at 5% coverage

Page: 30

Color Print Cartridge

Average Life (Ink Saver OFF): 200 pages at 15% coverage of seven colors

1.11.04 Printhead Life

The printhead is part of the print cartridge. It is replaced when the print cartridge is replaced.

1.11.05 Warranty (Limited)

Two years, parts and labor

Overnight exchange

1.11.06 Service

Authorized Okidata Service Centers

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 41

Page: 31

Service Guide OJ2010

Chapter 2 Principles of Operation

2.1 ELECTRICAL OPERATION

2.1.01 General Information

The OkiJet 2010 is a fully featured Windows-based, inkjet printer.

This product is a Graphics Device Interface (GDI) printer. Data leaving the computer is "pre-formatted" for

the printer. Very little printer circuitry is required for data handling. The received data is already formatted

for the GDI printer. RAM in the printer is minimized.

The OkiJet 2010 printer is a "Windows Based Host Printer". The printer can print from a DOS based

program running in a Windows "DOS-based session", but it is not the best possible configuration. DOS is

a very non-graphical based operating system. The OkiJet 2010 is a GDI printer.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 42

Page: 32

Service Guide OJ2010

Chapter 2 Principles of Operation

2.1.02 Emulations

The unit is capable of the emulations listed below.

Graphics Device Interface (GDI) for Windows

HP PCL3 for DOS via Windows MS-DOS prompt

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 43

Page: 33

Service Guide OJ2010

Chapter 2 Principles of Operation

2.1.03 Interface

Bi-Directional Centronics Parallel

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 44

Page: 34

Service Guide OJ2010

Chapter 2 Principles of Operation

2.1.04 Memory

The unit uses the resources of the personal computer (PC) for most functions.

Okidata recommends the configuration listed below.

386 or faster IBM PC

Windows 3.1 (or higher)

Windows Applications Software

Four Megabytes Random Access Memory (RAM)

Five Megabytes Hard Disk Space

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 45

Page: 35

Service Guide OJ2010

Chapter 2 Principles of Operation

2.1.05 Operator Panel

There is a minimal operator panel. The unit is controlled via software in the computer.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 46

2.1.06 Parallel Port

Page: 36

Service Guide OJ2010

Chapter 2 Principles of Operation

The parallel port may be checked by running the Parallel Port Test.

Service Handbook for further information.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Refer to Section 3.3

of this

Page 47

Page: 37

Service Guide OJ2010

Chapter 2 Principles of Operation

2.1.07 Power On Self Test (POST) Sequence

When the printer is powered ON, the Power On Self Test (POST) Sequence occurs.

Correct POST

The correct POST sequence is listed below.

1. The power light comes on.

2. The carrier moves over the maintenance station and seals the printheads.

3. The paper feed gears turn.

4. All motors stop and the power light stays on.

If the unit DOES NOT complete POST, refer to the POST Symptom Table in Section Four of this Service

Handbook and perform the indicated action.

If you are troubleshooting, and the unit completes the POST with no errors, refer to the Symptom Tables,

Section Four of this Service Handbook.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 48

Page: 38

Service Guide OJ2010

Chapter 2 Principles of Operation

2.1.08 Power Supply

The power supply board is a universal switching power supply. Incoming ac voltage is converted to dc

voltage, which is then supplied to the system board.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 49

Page: 39

Service Guide OJ2010

Chapter 2 Principles of Operation

2.1.09 System Board

The system board controls all printer functions not controlled by the computer.

U56 on the system board is the code module (EPROM). When replacing the system board, be sure to

remove the EPROM. Replacement boards are shipped without the EPROM.

Removing the system board resets the head to head and bi-directional printing alignments to factory

defaults. The end user performs these alignments through the User Software Utility. Refer to the Users

Guide for details.

Power to the system board is supplied by the power supply unit. The power to the other electrical parts is

distributed via the connectors on the system board.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 50

Page: 40

Service Guide OJ2010

Chapter 2 Principles of Operation

2.2 MECHANICAL OPERATION

2.2.01 Paper Feed

Paper feeding is performed by the large and small feed roll assemblies, which are driven by the paper

feed motor assembly and the pick roll assembly.

At the beginning of the paper feed operation, the paper feed motor reverses momentarily to allow the feed

arm pawl to drop off the home position notch in the left side frame.

If the pawl fails to drop off the notch, check the feed arm assembly for binds, worn parts, and or broken

parts.

After the paper exits from the feed rollers, the paper feed motor reverses.

This causes the paper ejectors to move the last sheet of paper into the exit tray.

If the ejectors do not move or restore, check them for worn, loose, or broken parts.

Be sure that the ejectors are connected to the large feed roller shaft.

The pick roll assembly performs the manual feed process.

The large and small feed roll assemblies perform the auto feed process.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 51

Page: 41

Service Guide OJ2010

Chapter 2 Principles of Operation

2.2.02 Paper Feed Methods

The unit can feed the print media two ways: auto and manual.

Auto

Holds up to 150 sheets (depending on thickness) in the Automatic Sheet Feeder

Holds up to 15 envelopes (depending on thickness) in the standard feeder

Manual

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 52

Page: 42

Service Guide OJ2010

Chapter 2 Principles of Operation

2.2.03 Paper Feed Path

The unit feeds the printer media (paper) in a Lazy "L" path. The paper bends approximately 75 degrees.

The gentle bend allows the OkiJet 2010 to have fewer paper jams. The unit also handles a wide variety of

size and weight print media.

The path is the same for both the auto and manual feed.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 53

Page: 43

Service Guide OJ2010

Chapter 2 Principles of Operation

2.2.04 Paper Loading

Paper is installed face up.

The leading edge (top of form) faces down into the printer.

The aligned edge of the paper is to the right side of the printer (when the operator is facing the front of the

unit.

Also refer to the Users Guide for information on paper loading.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 54

Service Guide OJ2010

Chapter 2 Principles of Operation

Envelope Orientation

Orientation is landscape left (90 degree clockwise rotation)

Envelopes feed lengthwise.

Envelopes feed face-up.

Close envelope flaps before feeding

When using the manual tray, line up the envelope with its right edge to the edge location symbol.

Page: 44

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 55

Service Guide OJ2010

Chapter 2 Principles of Operation

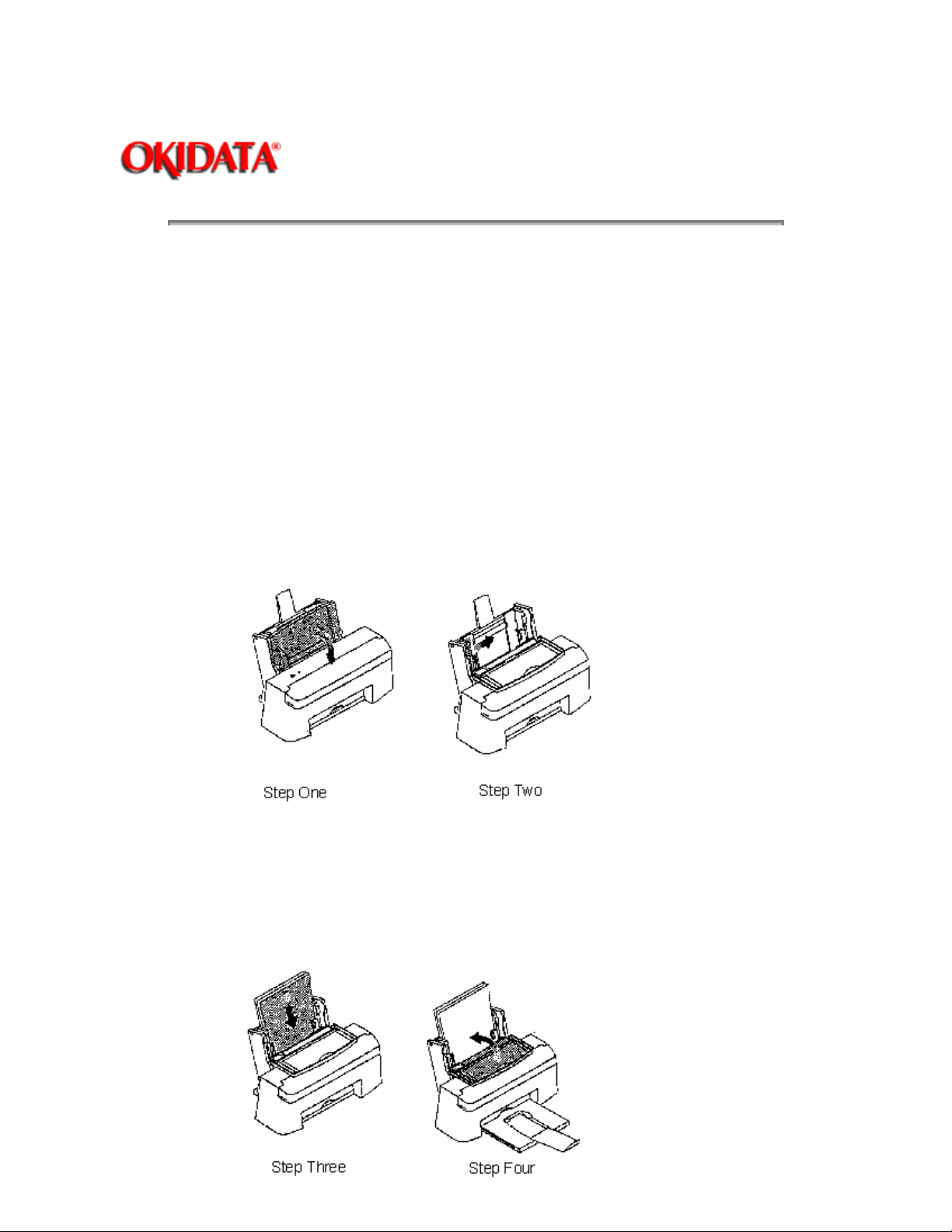

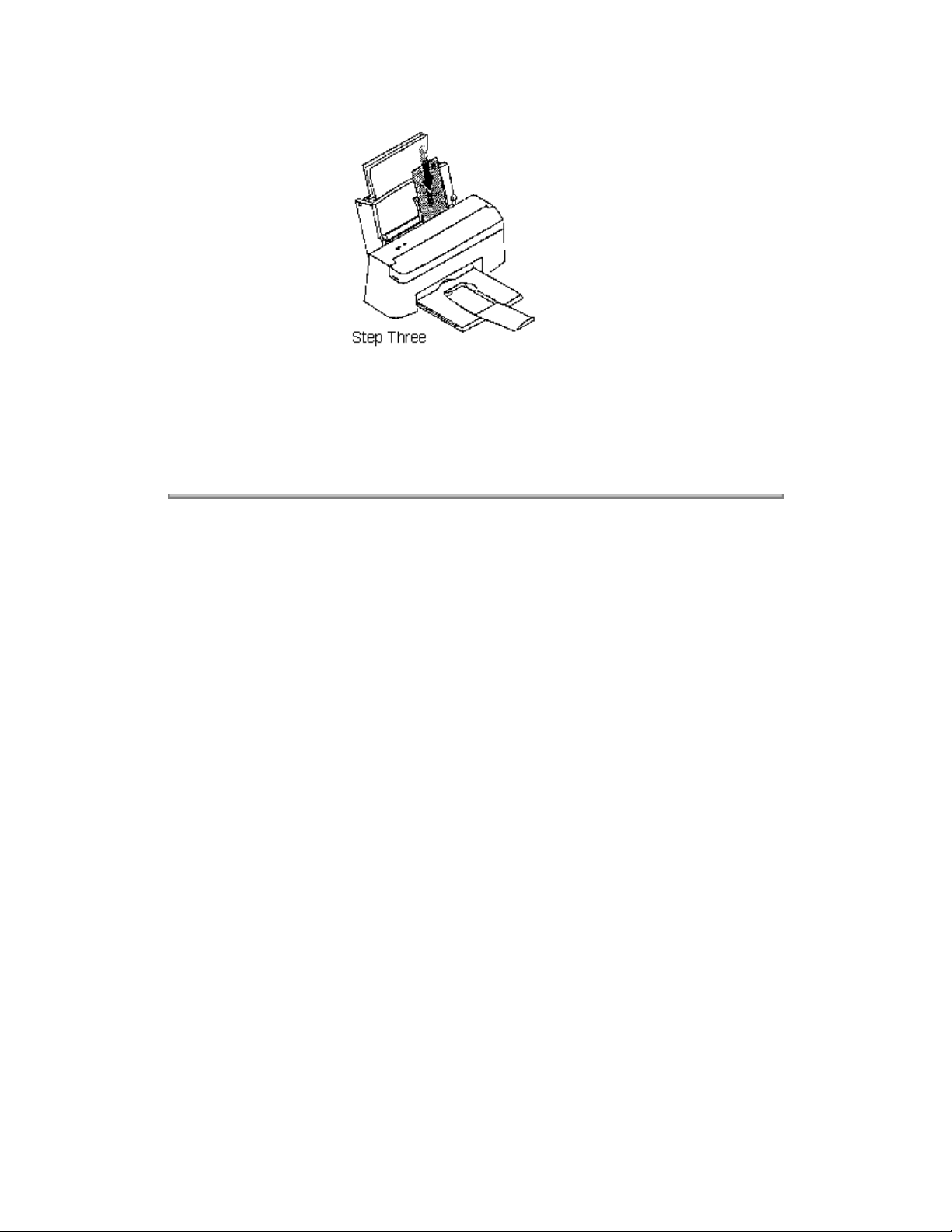

Auto Feed

Step Number

1. Fold down the automatic sheet feeder access cover.

2. Adjust the paper guides to the width of the paper.

3. Once the paper guides are adjusted, slide the paper into the automatic sheet feeder.

IMPORTANT: The side of the paper to be printed on MUST face the front of the printer.

The leading edge (top of form) of the sheet faces DOWN into the printer.

4. Fold the access cover up and the printer is ready to print.

Page: 45

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 56

Page: 46

Service Guide OJ2010

Chapter 2 Principles of Operation

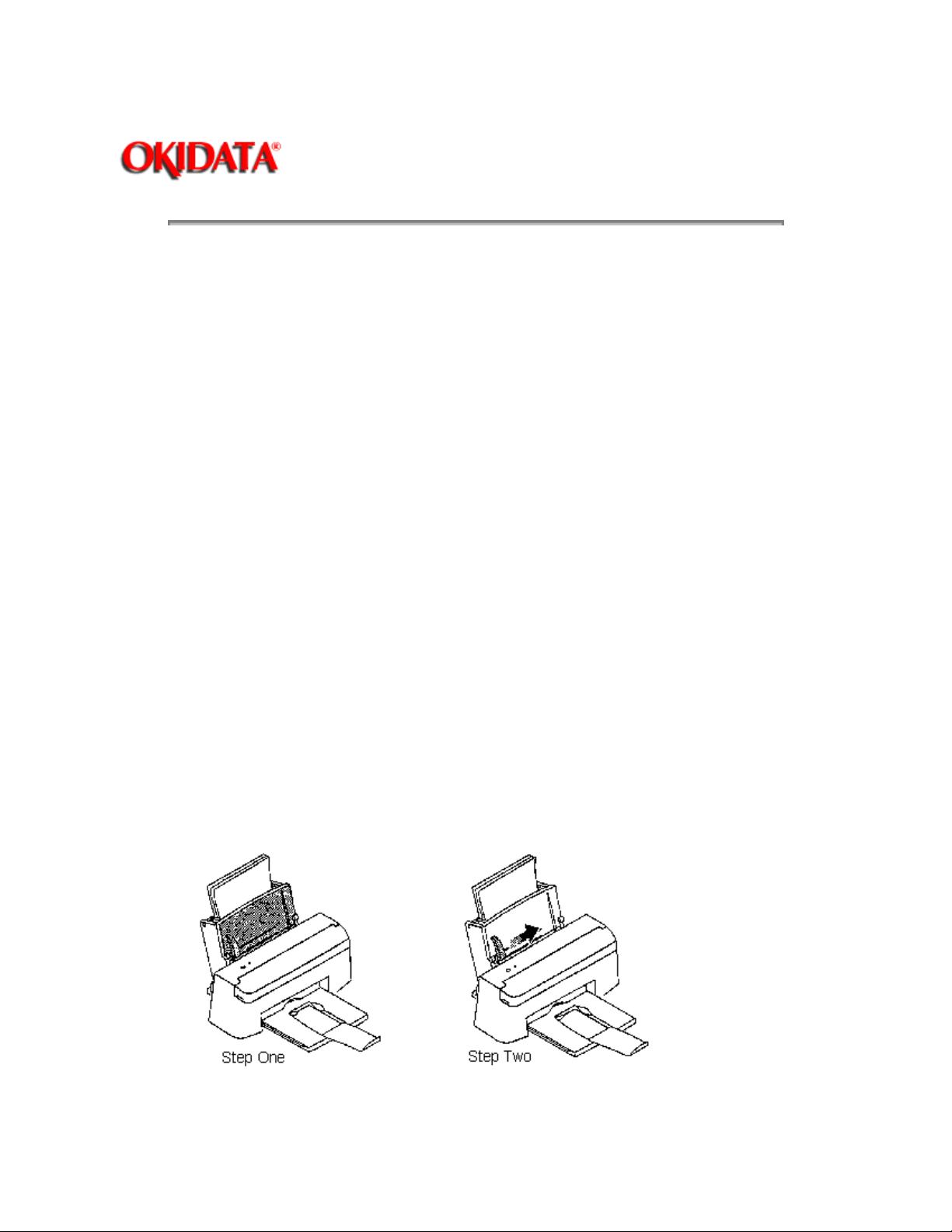

Manual Feed

Step Number

1. Paper to be loaded into the manual slot is placed against the Automatic Sheet Feed Access cover,

shown in gray.

2. Slide the manual feed support lever to the right, to the approximate width of the page / envelope being

inserted.

The RIGHT SIDE of the document is aligned against the static feed support.

The LEFT SIDE of the document is aligned against the movable feed support.

3. Insert the page / envelope.

IMPORTANT:

The side of the paper to be printed on MUST face the front of the printer.

The leading edge (top of form) of the sheet faces DOWN into the printer.

Envelopes

Orientation is landscape left (90 degree clockwise rotation).

Envelopes feed lengthwise.

Envelopes feed face-up.

Close envelope flaps before feeding

4. Make the final width adjustments.

Page 57

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 58

Page: 47

Service Guide OJ2010

Chapter 2 Principles of Operation

2.2.05 Printhead Mechanism

The printhead is part of the print cartridge. It is replaced when the print cartridge is replaced.

The OkiJet 2010 is a thermal inkjet printer. It sprays liquid ink onto the print media.

The inkjet printhead-to-media gap is very small. A crease or sharp edge on the paper may damage the

inkjet head. Paper dust or other contaminants can clog the inkjet nozzles on the printhead.

Perform the nozzle test to clean the inkjet nozzles. Refer to Section 3.3 for further information.

Inkjet printheads are delicate and easily damaged.

NOTES:

Refer to Section One of this Service Handbook for the print media (paper) specifications.

The printhead is part of the print cartridge.

The printhead is replaced when the print cartridge is replaced.

Black Print Cartridge

56 Nozzles

Black ink

Average Life (Ink Saver OFF): 1000 pages at 5% coverage

Color Print Cartridge

48 Nozzles

16 each Cyan, Magenta, and Yellow

Color Ink

Average Life (Ink Saver OFF): 200 pages at 15% coverage of seven colors

CAUTION:

Using a non-Okidata ink cartridge may damage the unit and void any warranties.

Always perform the printhead alignment procedure when a print cartridge is replaced. Refer to the Users

Guide or Section 3.3 for further information.

WARNING:

Page 59

NEVER refill or use refilled print cartridges.

Refilling empty print cartridges with unapproved ink will invalidate the warranty.

Incompatible inks can cause damage to the printhead or printer.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 60

Page: 48

Service Guide OJ2010

Chapter 2 Principles of Operation

2.2.06 Print Modes

The unit is capable of the print modes listed below.

Black Draft

Black Letter Quality

Full Color

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 61

Page: 49

Service Guide OJ2010

Chapter 2 Principles of Operation

2.2.07 Print Resolution

The units print resolution is 600 by 300 dots per inch. Dual printhead design allows the unit to print color

and true black without changing printheads.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 62

Service Guide OJ2010

Chapter 2 Principles of Operation

2.2.08 Print Speed

The unit is capable of the print speeds listed below.

3 pages per minute in Black Draft Mode.

2 pages per minute in Black Letter Quality Mode.

2 to 4 pages per minute in Full Color Mode.

Graphics Device Interface (GDI)

When working with a GDI printer, data leaves the computer "pre-formatted" for the printer. Very little

printer circuitry is required for data handling. The received data is already formatted for the printer.

RAM in the printer is minimized. Because the printer is controlled via software in the computer, the

operator panel is minimized.

Page: 50

Printer Speed versus System Speed

As a general rule, the faster the computer, the faster the printout from a GDI printer.

Example:

Two identical GDI printers are connected to two different systems.

One system is a 25 MHz. 80386 based computer with 4 MB of RAM.

One system is a 66 MHz. 80486 based computer with 8 MB of RAM.

Question

If both systems being printing the same file at the exact same time, which system will finish first?

Answer

The 66 MHz. 80486 based computer with 8 MB of RAM.

Reason

All of the pre-print data processing is being done in a system with greater "system resources" (more

RAM, high level processor at a higher speed). Data is sent to the printer faster.

Windows Printing versus DOS Based Printing

The OkiJet 2010 printer is a "Windows Based Host Printer". The printer can print from a DOS based

program running in a Windows "DOS-based session". However, this is not the best configuration.

DOS is a very non-graphical based operating system. The OkiJet 2010 is a "Graphics Device

Interface" printer. It is better to run the OkiJet 2010 with a Windows system.

Improving Performance

A GDI printer is the only type of printer that improves (up to the printers maximum rated performance)

with the host computers improvement.

Page 63

In the example, a 25 MHz. 80386 system was compared to a 66 MHz 80486 system.

Performance gains come from improving the computer, not by adding extras to the printer.

Upgrades will improve the customers computer system and the performance of the OkiJet 2010.

Upgrading to Pentium will allow software speeds and print speeds to increase (up to the maximum

rated performance).

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 64

Page: 51

Service Guide OJ2010

Chapter 2 Principles of Operation

2.2.09 Print Quality Enhancement Technique (PQET) [Edge Smoothing]

The unit utilizes an edge smoothing technique called Print Quality Enhancement Technique (PQET).

This technique reduces the "jaggies" seen in slanted (italics) character set printouts.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 65

Page: 52

Service Guide OJ2010

Chapter 2 Principles of Operation

2.2.10 Spacing

Spacing is performed when the encoder card drives the print cartridge along the carrier guide rod, parallel

to the print media.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 66

Service Guide OJ2010

Chapter 2 Principles of Operation

2.2.11 Maintenance Station

The maintenance station has two functions.

1. It cleans the printhead nozzles during the print operation.

2. It seals the printhead when it is not being used. This prevents the nozzles from drying.

Maintenance Station Assembly

The carrier moves to the right over the maintenance station

A slot on the bottom of the carrier engages a tab on the sled of the maintenance station.

This causes the maintenance station caps to rise and seal the printhead.

Carrier movement to the left uncaps the printheads.

Page: 53

The wipers clean the printhead nozzles as the carrier leaves the maintenance station.

The wipers clean the printheads only when the carrier is moving to the left.

No wiping action (of the printhead nozzles) should occur when the carrier is moving to the right.

After the cleaning operation is complete, a tab on the maintenance station engages a slot on the carrier.

This lowers the wipers.

Wiper

A worn wiper causes degraded print quality just after a maintenance cleaning.

Cap

A worn cap causes the printhead nozzles to dry and clog.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 67

Page: 54

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

3.1 OVERVIEW

3.1.01 General Information

This section lists the parts replacement, adjustment, cleaning, lubrication, and shipping procedures.

Disassembly should not be performed unless absolutely necessary.

malfunctioning unit until you have followed the failure analysis procedures in Section Four of this Service

Handbook.

Follow the procedures listed in Adjustments and Service Settings. Adjustments may be required when

either consumables or parts are replaced. Failure to perform these procedures could result in

unnecessary service calls.

Cleaning procedures must be performed correctly if high print quality is to be achieved.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

NEVER

perform disassembly on a

Page 68

Chapter 3 Maintenance and Disassembly

3.1.02 Maintenance Items

The following items are required to service the unit.

Disassembly / Adjustments

#1 Phillips Screwdriver (with magnetic tip)

Straight-slot Screwdriver

Needle Nose Pliers (4 inch)

Digital Multimeter

Cleaning / Lubrication

Water

Cloth (soft and lint-free)

Page: 55

Service Guide OJ2010

All-Purpose Cleaner

Contact Kleen (Okidata P/N 51802301)

Nye Nyogel 744 (lubricant)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 69

Page: 56

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

3.1.03 Maintenance Precautions

1. Do not disassemble the unit if it is operating normally.

2. Before starting disassembly and assembly, always power OFF the unit and detach the AC power

cord.

3. Detach the interface cable, if installed.

4. Do not remove parts unnecessarily. Try to keep disassembly to a minimum.

5. Use the recommended maintenance tools.

6. When disassembling, follow the listed sequence. Failure to follow the correct sequence may result in

damaged parts.

7. Since screws, collars and other small parts are easily lost, they should be temporarily attached to the

original positions.

8. Use extreme care when handling circuit boards. Integrated circuits (microprocessors, ROM, and

RAM) can be destroyed by static electricity.

9. Do not place printed circuit boards directly on conductive surfaces.

10. Follow the recommended procedures when replacing assemblies and units.

11. When replacing the system board, be sure to remove the socketed EPROM.

Replacement printed circuit boards are shipped

When removing the EPROM, you

precautions or you may damage the components.

12. When replacing the system board, be sure to perform the printhead alignment.

Refer to Section 3.3 of this Service Handbook of the Users Guide for details

13. Perform the printhead alignment when any of the following occur.

Poor Print Quality

Misaligned Print Quality

Parts are replaced

MUST

follow standard Electrostatic Sensitive Device (ESD) safety

WITHOUT

this item.

.

Print Cartridge

System Board

(Refer to 3.7

(Refer to 3.2.33

)

)

Page 70

14. Perform the Nozzle Test when any of the following occur.

Refer to Section 3.3 of this Service Handbook .

The nozzles appear to be clogged.

Characters are not printing properly.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 71

Page: 57

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

3.2 DISASSEMBLY/ASSEMBLY PROCEDURES

General Information

This section contains the printer disassembly procedures. Only the removal procedures are explained

here. Reverse the procedure for the installation.

At the bottom of each procedure is a listing of the parts covered in that procedure. The Okidata part

number, item description, comment (RSPL, Option, Consumable) and cross-reference to Appendix B is

provided for each part. Items included in the Recommended Spare Parts List are indicated by the acronym

RSPL. N/A will appear where a part number is not available.

Part Item Comment Appendix B Number Description Reference

This Service Handbook lists the disassembly procedures for major components of the unit. Okidata

NOT

recommend disassembling a unit which is operating normally. If you decide to perform disassembly

during this training, Okidata recommends that you perform only the disassembly procedures for RSPL

items. All other procedures are provided to assist you in identifying parts. It is not likely that you will

perform these procedures while servicing the unit.

Be sure to read all notes, cautions, and warnings, as they contain important information regarding

disassembly / assembly.

Here are the definitions of the notices.

NOTE:

This notice refers to supplemental information.

CAUTION:

Deviation from the listed procedures may result in damage to the product.

WARNING:

Deviation from the listed procedures may result in personal injury.

DOES

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 72

3.2.01 Preliminary Items

1. Power OFF the unit.

2. Remove any paper.

Page: 58

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

3. Detach the AC power cord, if installed.

4. Detach the parallel interface cable, if installed.

NOTE:

The AC power cord IS NOT supplied with the printer. It must be purchased separately.

The parallel interface cable IS NOT supplied with the printer. It must be purchased separately.

The parallel interface cable MUST BE capable of supporting bi-directional communications to

connect

the printer to the computer.

This cable CANNOT BE more than six (6) feet long.

P/N 56612101 Cord: Power RSPL B.2.05

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 73

3.2.02 Base Assembly

Page: 59

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items. . . . . . . .

2. Remove the front cover. . . . . . . . . . . . . .

3. Remove the rear cover. . . . . . . . . . . . . .

4. Disconnect the power supply connector at the system board. Not shown

5. Unlatch the two ejectors (1) from the large feed roll shaft (2) by pushing down on the ejectors where

they grip the large feed roll shaft.

6. Remove the two screws (3) securing the carrier frame (4) to the base cover.

7. Remove the ground straps from the carrier frame. Not shown

8. Slide the maintenance assembly (5) out of the carrier frame.

9. Slide the machine off the base assembly (6).

NOTE:

Installation

(3.2.01

(3.2.12

(3.2.30

)

)

)

Page 74

When installing the machine on the base assembly, be sure to connect the ejectors to the large

feed roll shaft.

P/N 50220101 Assembly: Base RSPL B.2.02

Includes the parts listed below.

P/N N/A Exit Tray B.2.02

P/N N/A Feet B.2.02

P/N 50516901 Gutter Pad: Base Assembly RSPL B.2.02

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 75

3.2.03 Carrier Belt

Page: 60

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items. . . . . . . . . .

2. Remove the front cover. . . . . . . . . . . . . . . .

3. Remove the carrier frame assembly. . . .

4. To release the tension on the belt, push the idler pulley tension assembly (1) to the right.

5. Remove the belt (2).

P/N 51305001 Belt: Carrier

P/N 51236101 Assembly: Idler Pulley Tension

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

(3.2.01

(3.2.12

(3.2.04

)

)

)

RSPL

RSPL

B.2.07

B.2.07

Page 76

3.2.04 Carrier Frame Assembly

Page: 61

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

Page 77

1. Remove the preliminary items. . . . . . . . . . (3.2.01 )

2. Remove the front cover. . . . . . . . . . . . . . . . (3.2.12 )

3. Remove the rear cover. . . . . . . . . . . . . . . . (3.2.30 )

4. Remove the base assembly. . . . . . . . . . . . . (3.2.02 )

5. Disconnect the paper feed motor connector from the system board. Not shown

6. Remove the four screws (1). The screws secure the carrier frame assembly (2) to the left and right

side frames.

7. Remove the carrier frame assembly.

NOTE:

Installation

Be sure that the small feed roll spring extensions (3) are in the grooves of the small feed roll

arms. Be sure that the short extensions of the two paper flap springs are caught under the

carrier frame (4).

P/N 53347601 Frame: Carrier RSPL B.2.03

P/N 58237001 Packet: Accessory Parts RSPL B.2.03

Includes the part listed below.

P/N N/A Screw: Frame Mounting (PP) B.2.03

Page 78

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 79

3.2.05 Carrier Transport Motor

Page: 62

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items. . . . . . . . . .

2. Remove the front cover. . . . . . . . . . . . . . . .

3. Disconnect the transport motor connector from the system board. Not shown

4. Remove the belt (1) from the transport motor pulley.

5. Remove the two screws (2) securing the transport motor (3) to the carrier frame.

NOTE:

Note the routing of the motor cable before performing the next step.

6. Remove the motor.

P/N 56512501 Assembly: Carrier Transport Motor RSPL

P/N 58237001 Packet: Accessory Parts RSPL

Includes the part listed below.

P/N N/A Screw: Carrier Transport Motor Mounting

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

(3.2.01

(3.2.12

)

)

B.2.07

B.2.07

B.2.07

Page 80

3.2.06 Code Module / EPROM

Page: 63

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items.

2. Remove the front cover.

3. Remove the rear cover.

(3.2.12

(3.2.30

(3.2.01

)

)

)

Page 81

4. Gently pry the code module (EPROM) from the system board.

NOTES:

Note the position of the notch in the module.

The notch is down.

Removing the system board resets the head to head and bi-directional printing alignments to factory

defaults. The end user performs these alignments through the User Software Utility. Refer to the Users

Guide for details.

When replacing the system board, be sure to remove the EPROM at U56. Replacement boards are

shipped WITHOUT the EPROM.

Check Okilink II for information updates on the EPROM.

CAUTION:

When removing the EPROM, you must follow standard electrostatic sensitive device (ESD) procedures or

you may damage the components.

P/N N/A EPROM B.2.05

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 82

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

3.2.07 Edge Guide Assemblies and Paper Load Shaft

Page: 64

1. Remove the preliminary items. . . . . . . . . .

2. Remove the front cover. . . . . . . . . . . . . . . .

3. Remove the rear cover. . . . . . . . . . . . . . . .

4. Remove the carrier frame assembly. . . .

5. Remove the manual insert tray. . . . . . .

6. Remove the pick roll hub, shaft, and envelope bucklers. . . .

7. Remove the two screws (1) from the right side frame (2).

8. Work the paper load shaft (3) out of the side frames.

9. Pull up the bottom of both the left (4) and right (5) edge guides to separate them from the top of the

back plate and remove the assembly from the frames.

NOTE:

Installation

Be sure that the left (6) and right (7) edge guide springs are turned to the INSIDE to maintain

spring tension on the guides.

P/N 51018001 Assembly: Left Edge Guide RSPL

(3.2.01

(3.2.12

(3.2.30

(3.2.04

(3.2.20

)

)

)

)

)

B.2.08

(3.2.25

)

P/N 51018201 Guide: Right Edge & Width Strip RSPL

P/N N/A Gear: Paper Load (Gears B/M)

P/N 58237001 Packet: Accessory Parts RSPL

B.2.08

B.2.08

B.2.08

Page 83

Includes

Spring: Left Paper Load (PP)

Spring: Right Paper Load (PP) B.2.08

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

B.2.08

Page 84

3.2.08 Ejectors

Page: 65

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items. . . . . . . . . .

2. Remove the front cover. . . . . . . . . . . . . . . .

3. Unlatch the ejectors (1) from the large feed roll shaft (2) by pushing down on the ejectors where they

grip the large feed roll shaft.

4. Pry the ejectors forward to unlatch them.

5. Remove the ejectors.

P/N 50929601

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Arm: Ejector RSPL B.2.04

(3.2.01

(3.2.12

)

)

Page 85

3.2.09 Encoder Card

Page: 66

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items. . . . . . . . . .

2. Remove the front cover. . . . . . . . . . . . . . . .

3. Remove the printhead carrier assembly.

4. Disconnect the printhead cable (1) from the encoder card (2).

5. Remove the screw (3) from the encoder card.

6. Remove the encoder card.

P/N 50220201 Assembly: Encoder Card

P/N 58237001 Packet: Accessory Parts

Includes

P/N N/A Screw: Encoder Card Mounting (PP)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

(3.2.01

(3.2.12

(3.2.28

RSPL

RSPL

RSPL

)

)

)

B.2.06

B.2.06

B.2.06

Page 86

3.2.10 Encoder Strip

Page: 67

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items. . . . . . . . . .

2. Remove the front cover. . . . . . . . . . . . . . . .

3. Remove the printhead carrier assembly.

4. Gently release the tension on the encoder strip (1) by flexing the encoder strip tensioner (2) and

remove the encoder strip.

NOTE:

Installation

Make sure that the ends of the strip are centered in the mounting notches.

Make sure that the strip does not bind in the encoder card on the carrier.

P/N 51017901 Strip: Encoder

P/N 58237001 Packet: Accessory Parts

Includes

P/N N/A Tensioner: Encoder Strip (PP)

P/N N/A Cuff: Tensioner (PP)

(3.2.01

(3.2.12

(3.2.28

RSPL

RSPL

RSPL

RSPL

)

)

)

B.2.07

B.2.07

B.2.07

B.2.07

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 87

3.2.11 Feed Arm Assembly

Page: 68

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items. . . . . . . . . .

2. Remove the front cover. . . . . . . . . . . . . . . .

3. Remove the rear cover. . . . . . . . . . . . . . . .

4. Remove the C-clip (1) from the feed arm (2).

5. Remove the assembly.

P/N 53075001 Assembly: Feed Arm

P/N 58237001 Packet: Accessory Parts

Includes

P/N N/A C-Clip (PP)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

(3.2.01

(3.2.12

(3.2.30

RSPL

RSPL

RSPL

)

)

)

B.2.04

B.2.04

B.2.04

Page 88

3.2.12 Front Cover

Page: 69

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items.

2. Place a straight-slot screwdriver in slot A and release the cover latches.

3. Slide the cover in the direction of Arrow B and remove the cover (1).

Installation

Slide the cover over the matching pieces on the bottom cover.

Press in both sides opposite the cover latches until they latch.

P/N 53074601

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Assembly: Front Cover RSPL B.2.02

Includes the parts listed below.

P/N N/A Access Cover B.2.02

P/N N/A Button B.2.02

P/N N/A LED Lens B.2.02

(3.2.01

)

Page 89

3.2.13 Gutter Pad

Page: 70

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items. . . . . . . . . .

2. Remove the front cover. . . . . . . . . . . . . . . .

3. Remove the rear cover. . . . . . . . . . . . . . . .

4. Remove the base assembly. . . . . . . . . . . . .

5. Scrape the gutter pad (1) off of the base.

P/N 50516901

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Gutter Pad: Base Assembly RSPL B.2.02

(3.2.01

(3.2.12

(3.2.30

(3.2.02

)

)

)

)

Page 90

3.2.14 Inside Idler Gears

Page: 71

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items. . . . . . . . . .

2. Remove the front cover. . . . . . . . . . . . . . . .

3. Remove the rear cover. . . . . . . . . . . . . . . .

4. Remove the printer from the base assembly.

5. Remove the paper feed motor. . . . . . . . . . . . .

6. Gently pry the two idler gears (1) from the left side frame. Be careful not to break the locking tabs (A).

P/N 51236201

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Gears: B/M RSPL B.2.03 , B.2.04

(3.2.01

(3.2.12

(3.2.30

(3.2.22

)

)

)

)

Page 91

3.2.15 Large Feed Roller

Page: 72

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items. . . . . . . . . .

2. Remove the front cover. . . . . . . . . . . . . . . .

3. Remove the rear cover. . . . . . . . . . . . . . . .

4. Remove the carrier frame assembly. . . .

(3.2.01

(3.2.12

(3.2.30

(3.2.04

)

)

)

)

Page 92

5. Use a small straight-slot screwdriver to break the four prongs of the small compound gear.

6. Remove the small compound gear.

7. Release the large feed roller (B/M) assembly (2) from the four mounting clips and remove the large

feed roller assembly from the mid frame.

8. Spread the right side frame (3) and remove the large feed roll.

NOTE:

Install the new small compound gear after the machine is installed in the base assembly.

P/N 50409601 Assembly: Large Feed Roller B/M RSPL B.2.04

Includes the part listed below.

P/N Gear: Small Compound RSPL B.2.04

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 93

3.2.16 Large Outside Gear

Page: 73

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items. . . . . . . . . .

2. Remove the front cover. . . . . . . . . . . . . . . .

3. Remove the rear cover. . . . . . . . . . . . . . . .

4. Remove the carrier frame assembly. . . .

5. Remove the paper load door. . . . . . . . . . .

6. Remove the C-clip (1) from the feed arm assembly (2).

7. Remove the feed arm assembly.

8. Remove the C-clip from the left side of the pick roll shaft. Not shown

9. Pull the pick roll shaft out far enough to remove the large gear (3).

10. Gently pull the feed arm guide (4) on the left side frame forward and remove the large gear.

P/N 51236201 Gears: B/M

P/N 58237001 Packet: Accessory Parts

Includes the part listed below.

(3.2.01

(3.2.12

(3.2.30

(3.2.04

(3.2.24

RSPL B.2.03

RSPL

)

)

)

)

)

,B.2.04

B.2.04

Page 94

P/N N/A C-Clip (PP)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

RSPL B.2.04

Page 95

3.2.17 Left Side Frame Assembly

Page: 74

Service Guide OJ2010

Chapter 3 Maintenance and Disassembly

1. Remove the preliminary items. . . . . . . . . . (3.2.01 ( ))

2. Remove the front cover. . . . . . . . . . . . . . . . (3.2.12 (

3. Remove the rear cover. . . . . . . . . . . . . . . . (3.2.30 (

4. Remove the carrier frame assembly. . . . (3.2.04 (

5. Remove the paper load door. . . . . . . . . . . (3.2.24 (