Okidata C5300, C5100 Service Manual

C5300/C5100

Color LED Page Printer

SERVICE MANUAL

2003-3-28 Rev.1

C5100/5300 Service Manual 1 / 148

Document Revision History

Rev.No. Date

0.5

2002-12-26 ISSUE NC1 Maekawa

No.

Corrected items

Page Description of change

Person in

charge

1 2003-03-28 All Add C5300 NC1 Maekawa

C5100/5300 Service Manual 2 /

PREFACE

This manual describes the procedures of the maintenance of the C5300/C5100 printers.

The document is produced for maintenance personnel use. For details on the procedures for handling the

C5300/C5100 of printers, see its user documentation.

Note! • The descriptions in this manual are subject to change without prior notice.

• In preparing the document, efforts have been made to ensure that the information in it is accurate.

However, errors may be crept into the document. Oki Data assumes no responsibility for any

damage resulting from, or claimed to be the results of, those repairs, adjustments or modifications to the printers which are made by users using the manual.

• The parts used for the printers are sensitive and, if handled improperly, may be damaged. It is

strongly recommended that the products are maintained by maintenance men registered with

Oki Data.

C5100/5300 Service Manual 3 /

CONTENTS

1. SPECIFICATIONS ............................................................................................ 6

1.1 System Configuration....................................................................................................... 6

1.2 Printer Configuration ........................................................................................................8

1.3 Option Configuration ...................................................................................................... 10

1.4 Specifications ................................................................................................................. 11

2. PARTS REPLACEMENT ................................................................................ 13

2.1 Precautions in Replacing Parts ...................................................................................... 13

2.2 Part Replacement Procedures ....................................................................................... 15

2.2.1 Top Cover ......................................................................................................... 15

2.2.2 Left Side Cover ................................................................................................. 16

2.2.3 Right Side Cover .............................................................................................. 17

2.2.4 Face-Up Tray.................................................................................................... 18

2.2.5 Rear Cover ....................................................................................................... 19

2.2.6 LED Assy / LED Assy Springs .......................................................................... 20

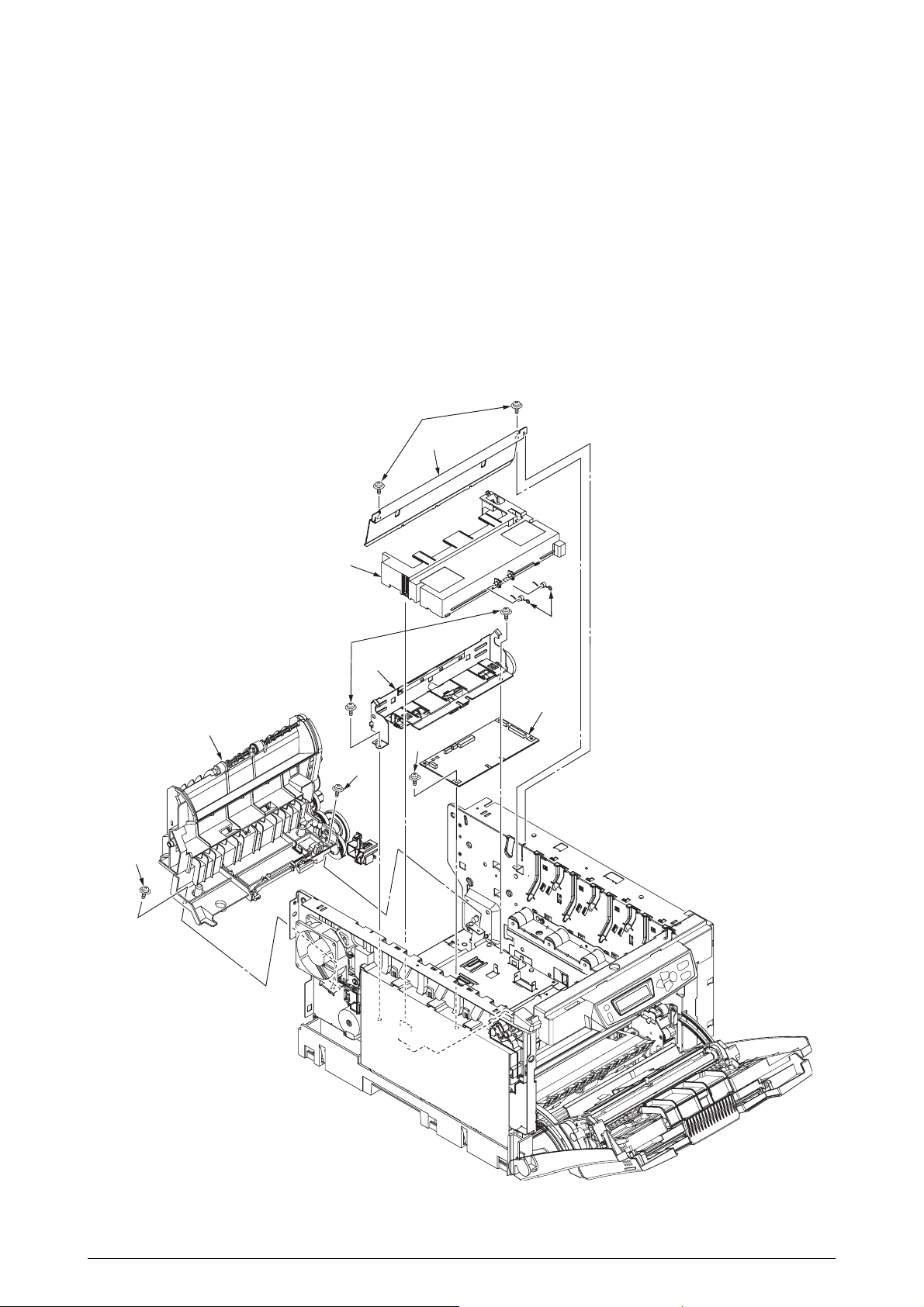

2.2.7 Controller PWB ................................................................................................. 21

2.2.8 Print Engine Controller PWB ............................................................................ 23

2.2.9 Top Cover Unit. ................................................................................................ 25

2.2.10 Controller Panel Assy ....................................................................................... 26

2.2.11 Board RSP / Environment Sensor / Top Cover Handle .................................... 27

2.2.13 Board-PRD ....................................................................................................... 29

2.2.14 Guide - Eject Assy / Color Registration Assy / Board-RSM .............................. 30

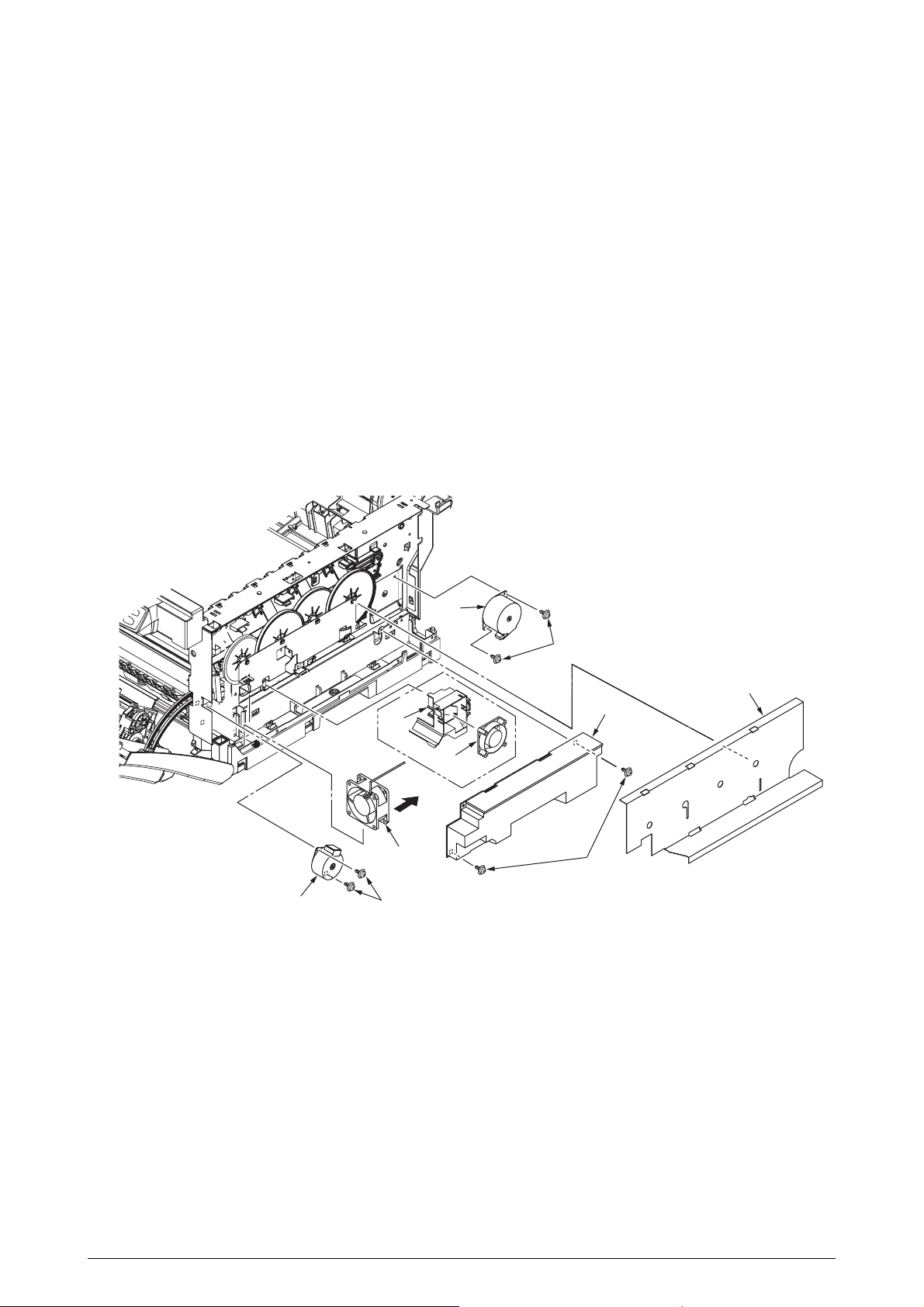

2.2.15 FAN (Fuser) / Belt Motor / High Voltage Power Supply Board / Cover Open Switch /

Image Drum Up/Down Sensor ....................................................................................... 31

2.2.16 Multipurpose Tray (MPT) Assy ......................................................................... 32

2.2.17 Feeder Unit / Board-RSF / Multipurpose Tray (MPT) Hopping Roller / Multipurpose

Tray (MPT) Frame Separator / Cover-Front .................................................................. 33

2.2.18 Main Motors / Solenoid / Paper-End Sensor .................................................... 34

2.2.19 Feed Roller ....................................................................................................... 36

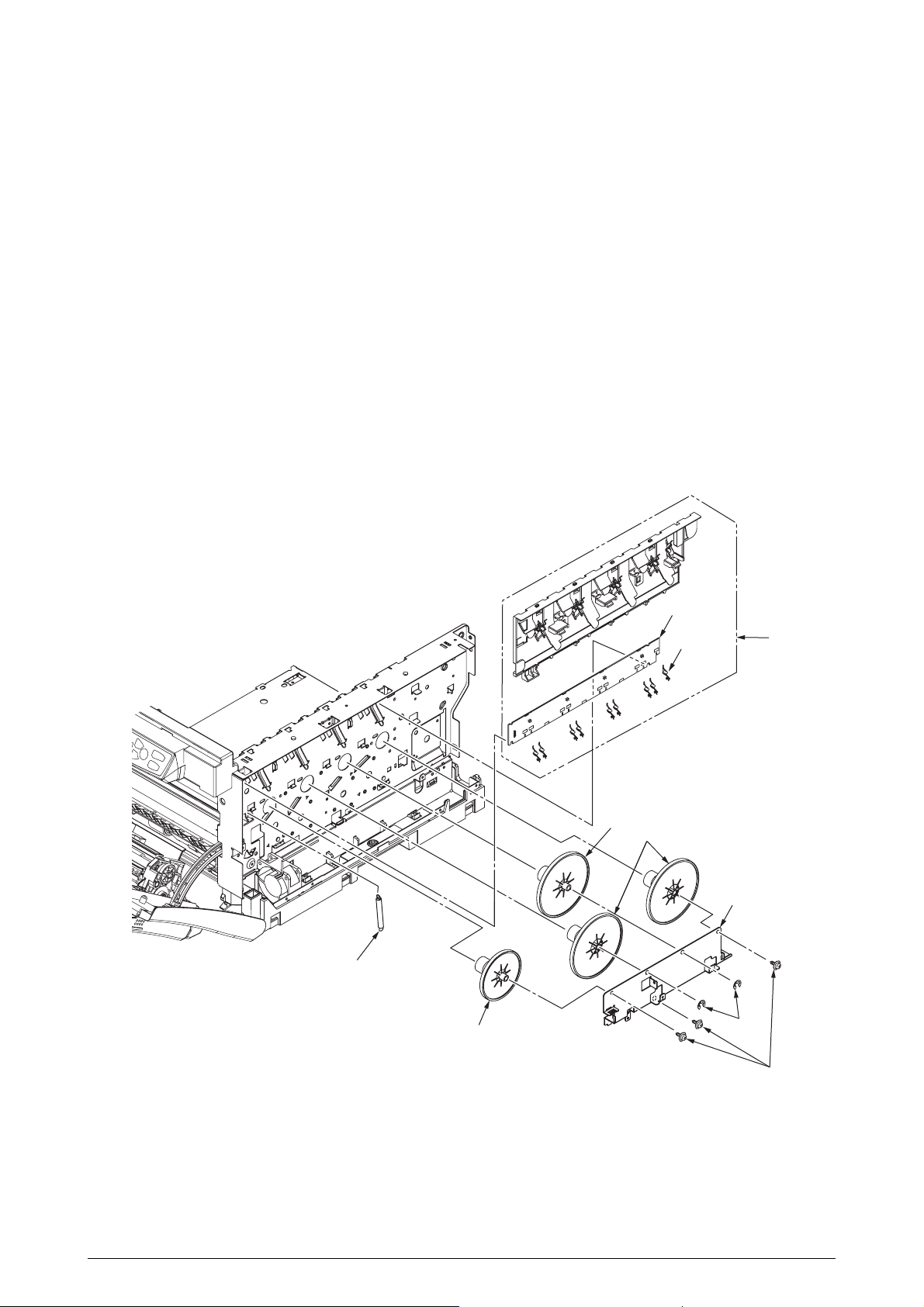

2.2.20 Shaft Eject Assy (FU) / Shaft Eject Assy (FD) / Eject Sensor .......................... 37

2.2.21 Fuser Unit ......................................................................................................... 38

2.2.22 Belt Unit ............................................................................................................ 39

3. ADJUSTMENTS ............................................................................................. 40

3.0 System Maintenance Menu ........................................................................................... 40

3.1 Maintenance Modes and Their Functions ...................................................................... 41

3.1.1 Maintenance Menu ........................................................................................... 41

3.1.2 Engine Maintenance Mode ............................................................................... 42

3.1.2.1 Operator panel.................................................................................................. 42

3.1.2.2 Normal self-diagnostic mode (level 1) .............................................................. 42

3.1.2.2.1 Entering self-diagnostic mode (level 1).......................................................... 43

3.1.2.2.2 Exiting self-diagnostic mode .......................................................................... 43

3.1.2.3 Switch scan test................................................................................................ 43

3.1.2.4 Motor and clutch test ........................................................................................ 46

3.1.2.5 Test printing ...................................................................................................... 48

3.1.2.6 Consumable counter display ............................................................................ 53

3.1.2.7 Consumable counter display - continuous ....................................................... 53

3.1.2.8 Operator panel display ..................................................................................... 54

3.1.3 Printing on Printer Equipped with Controller..................................................... 59

3.2 Adjustments after Parts Replacement ........................................................................... 60

3.2.1 Notes on Engine Controller Board Replacement ............................................. 60

3.2.3 Destination Setting (Check Method: Printing demo page)............................... 61

3.3 Print Density Adjustment................................................................................................ 62

3.4 Print Density Adjustment (Calibration Chip)................................................................... 63

C5100/5300 Service Manual 4 /

4. REGULAR MAINTENANCE ........................................................................... 64

4.1 Parts Replaced Regularly .............................................................................................. 64

4.2 Cleaning ......................................................................................................................... 64

4.3 Cleaning the LED Lens Array ........................................................................................ 64

4.4 Cleaning the Pick-up Roller ........................................................................................... 64

5. TROUBLESHOOTING PROCEDURES ......................................................... 65

5.1 Precautions before troubleshooting ............................................................................... 65

5.2 Precautions before handling an abnormal image .......................................................... 65

5.3 Precautions upon handling an abnormal image............................................................. 65

5.4 Preparing for Troubleshooting ....................................................................................... 66

5.5 Troubleshooting Procedure............................................................................................ 66

5.5.1 LCD message list ............................................................................................. 67

5.5.2 Preparing for troubleshooting ........................................................................... 72

5.5.3 Image Problem Troubleshooting ...................................................................... 83

5.6 Fuse Checking ............................................................................................................... 97

6. CONNECTION DIAGRAM .............................................................................. 98

6.1 Resistance Checks ........................................................................................................ 98

6.2 Program/Font ROM Layouts ........................................................................................ 102

7. PARTS LIST ................................................................................................. 108

APPENDIX A INTERFACE SPECIFICATIONS ................................................. 134

1. Parallel Interface Specifications (C5300) ..................................................................... 134

1.1 Parallel Interface...................................................................................................

134

1.2 Parallel Interface Connector and Cable.......................................................... 134

134

1.3 Parallel Interface Level ................................................................................... 134

134

1.4 Timing Charts ................................................................................................. 135

1.5 Parallel I/F Signals.......................................................................................... 136

136

2. Universal Serial Bus (USB) Interface Specifications.................................................... 137

2.1 USB Interface ................................................................................................. 137

137

2.2 USB Interface Connector and Cable .............................................................. 137

137

2.3 USB Interface Signals .................................................................................... 137

3 Network Interface Specifications.................................................................................. 138

3.1 Network Interface ........................................................................................... 138

3.2 Network Interface Connector and Cable ........................................................ 138

3.3 Network Interface Signals............................................................................... 138

APPENDIX B 2ND TRAY MAINTENANCE....................................................... 139

1. Parts Replacement ...................................................................................................... 139

1.1 PCB ................................................................................................................ 139

1.2 Frame Assy- Hopping ..................................................................................... 140

2. PARTS LIST ................................................................................................................ 141

APPENDIX C DUPLEX UNIT MAINTENANCE................................................. 143

1. Parts Replacement ...................................................................................................... 143

1.1 Duplex Unit ..................................................................................................... 143

1.2 Upper Assy / Rear Assy ................................................................................. 144

1.3 Duplex Transport Assy ................................................................................... 145

C5100/5300 Service Manual 5 /

1. SPECIFICATIONS

1.1 System Configuration

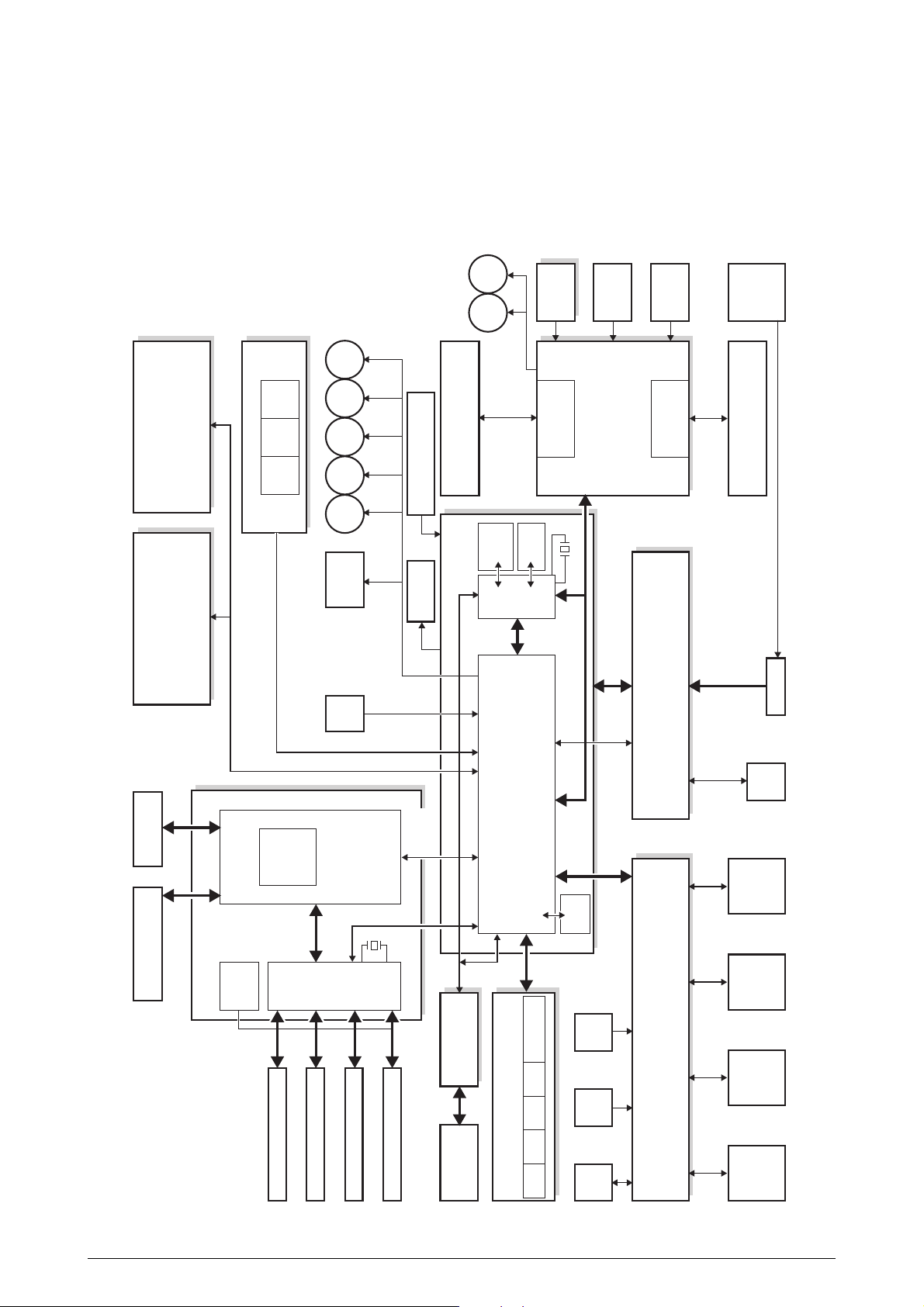

C5300

Figure 1-1-1 shows the system configuration of C5300.

IN1 IN2 WR

Front Sensor Board

M

HOP

M

CID

M

MID

M

YID

M

KID

Solenoid

Paperfeed

M

M

Belt Unit

Belt Thermistor

PU-Board

FAN

HEAT

BELT

8M or

FLASH

4Mbit

Color

Belt Unit Fuse

SRAM

256Kbit

Registration

Cut-Out/

Recognition

28MHz

Density

EXIT

Thermistor

Recognition/

Fuser Fuse Cut-Out/

Driver Relay Board

Inlet

Fuser

Duplex Board 2nd Tray Board

HDD

LAN, USB, Centro I/F

LVDS

CU Board

Driver

LEISUS Video

CU-FAN

Interface

(data8bit × 4,

fsync × 4,

Isync, wclk)

1st

P. E

DCON

LEISUS

Command

CU Area

33MHz

DCON I/F, LSYNC

Humidity Signals

Environment Temperature

Interface

Operator Panel

Board

MCON CPU

Image drum fuse

cut-out/recognition

sensor

C toner

Signals

Color Registration,

Density, Thermistor

Motor Control

Fuse Cut-Out/

Recognition, Exit,

EEPROM

Open

Cover-

0VL, 0VP

3.3V, 5V, 24V,

Control, etc

Fan, Heater

High Voltage Interface,

Fan Control, Cover-Open

High Voltage Board Low Voltage Board

AC-SW

FAN

Down

ID UP/

FAN

K-ID Y-ID M-ID C-ID

Y LED HEAD

K LED HEAD

C LED HEAD

M LED HEAD

Sensor

Environment

sensor

M toner

Toner Sensor Board

sensor

Y toner

sensor

K toner

Figure 1-1-1

C5100/5300 Service Manual 6 /148

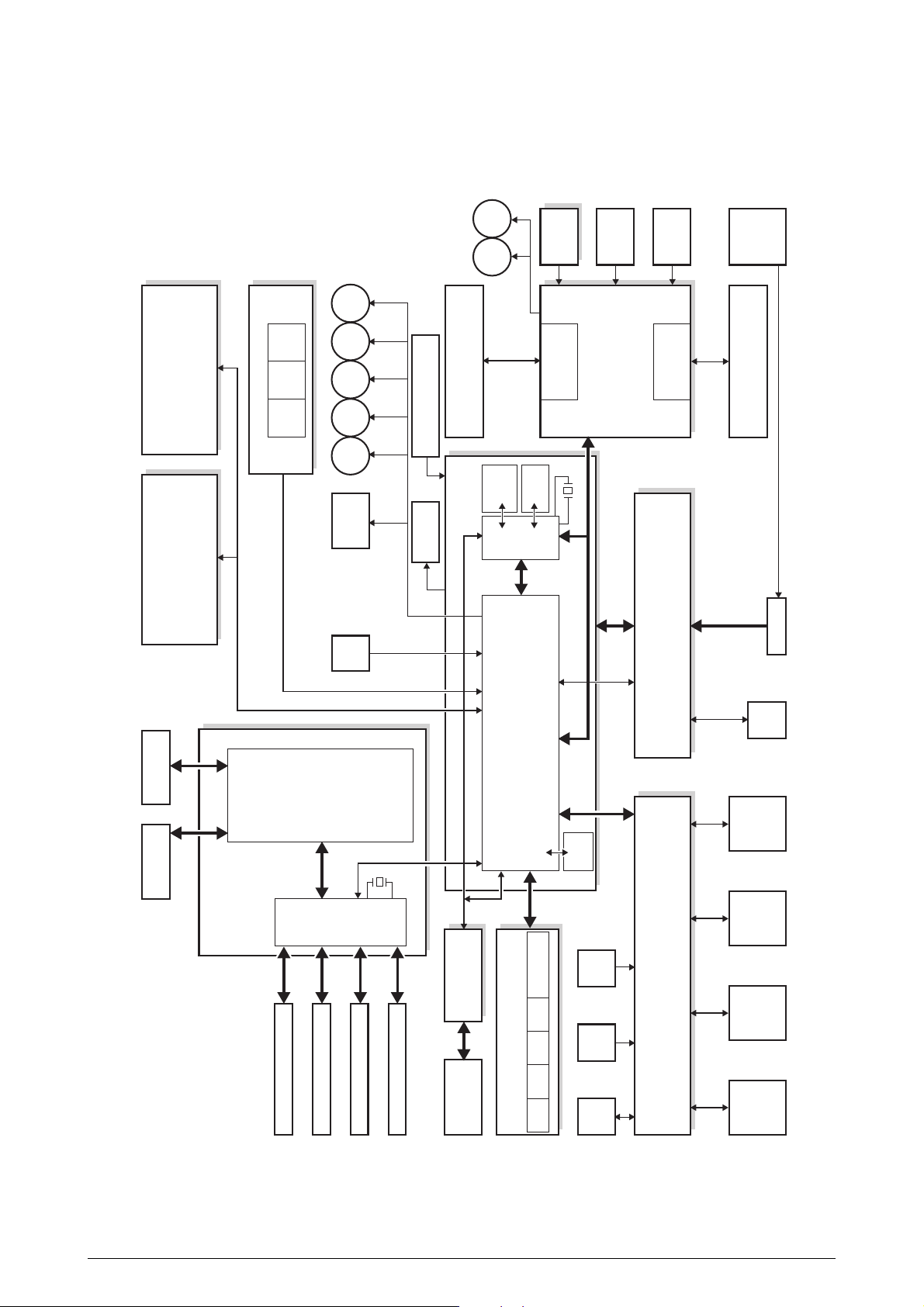

C5100

Figure 1-1-2 shows the system configuration of C5100.

IN1 IN2 WR

Front Sensor Board

M

HOP

M

CID

M

MID

M

YID

M

KID

Solenoid

Paperfeed

M

M

Belt Unit

Belt Thermistor

PU-Board

FAN

HEAT

BELT

8M or

FLASH

4Mbit

Color

Belt Unit Fuse

SRAM

256Kbit

Registration

Cut-Out/

Recognition

28MHz

Density

EXIT

Thermistor

Recognition/

Fuser Fuse Cut-Out/

Driver Relay Board

Inlet

Fuser

USB I/F LAN I/F

Duplex Board 2nd Tray Board

CU Board

LEISUS Video

Interface

(data8bit × 4,

CPU

fsync × 4,

Isync, wclk)

1st

ASIC

(ARBOKS)

Humidity Signals

Environment Temperature

Signals

Color Registration,

Density, Thermistor

0VL, 0VP

3.3V, 5V, 24V,

AC-SW

P. E

Control, etc

Fan, Heater

FAN

MCON CPU

Motor Control

Fuse Cut-Out/

Image drum fuse

cut-out/recognition

sensor

C toner

Recognition, Exit,

EEPROM

High Voltage Interface,

Fan Control, Cover-Open

Open

Cover-

High Voltage Board Low Voltage Board

CU Area

66MHz

DCON I/F, LSYNC

Board

Operator Panel

Down

ID UP/

FAN

K-ID Y-ID M-ID C-ID

Y LED HEAD

K LED HEAD

C LED HEAD

M LED HEAD

Sensor

Environment

sensor

M toner

Toner Sensor Board

sensor

Y toner

sensor

K toner

Figure 1-1-2

C5100/5300 Service Manual 7 /148

1.2 Printer Configuration

The inside of C5300 printers is composed of the following:

• Electrophotographic Processor

• Paper Paths

• Controller Block (CU and PU)

• Operator Panel

• Power Units (High Voltage Unit and Low Voltage Unit)

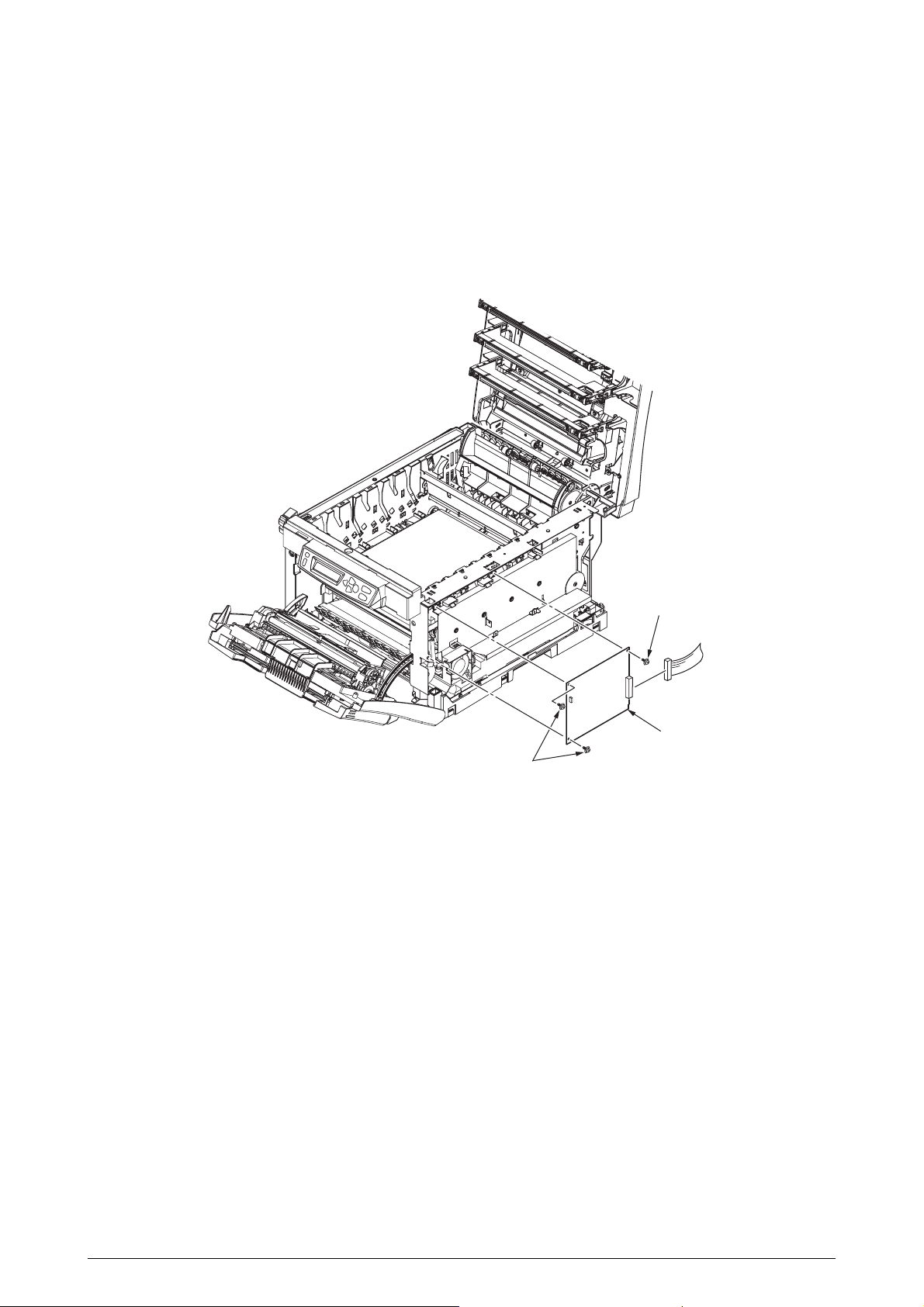

Figure 1-2-1 shows the configuration of each printer.

Figure 1-2-1

C5100/5300 Service Manual 8 /148

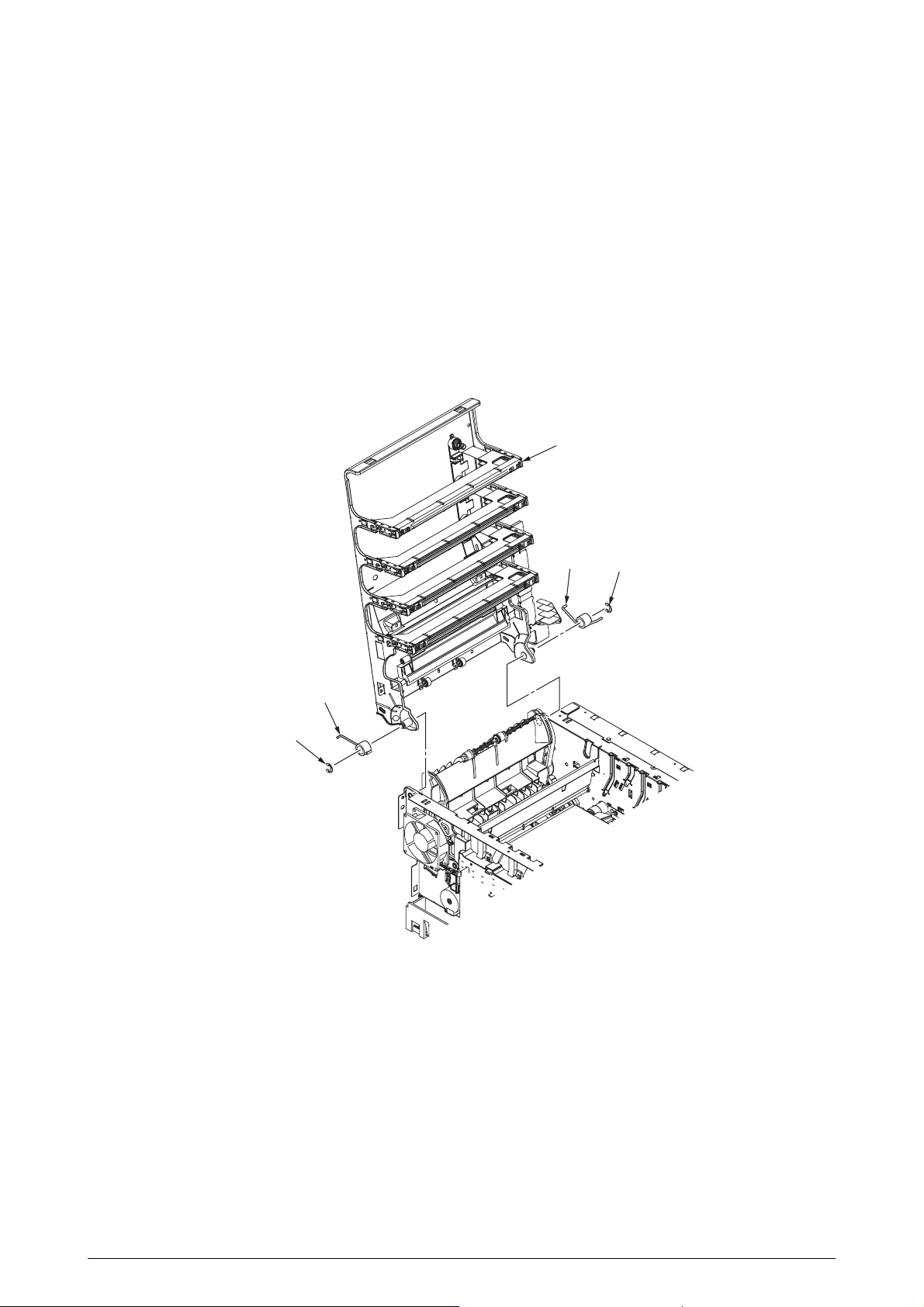

The inside of C5100 printers is composed of the following:

• Electrophotographic Processor

• Paper Paths

• Controller Block (CU and PU)

• Operator Panel

• Power Units (High Voltage Unit and Low Voltage Unit)

Figure 1-2-2 shows the configuration of each printer.

Figure 1-2-2

C5100/5300 Service Manual 9 /148

1.3 Option Configuration

The following options are available for C5300/C5100.

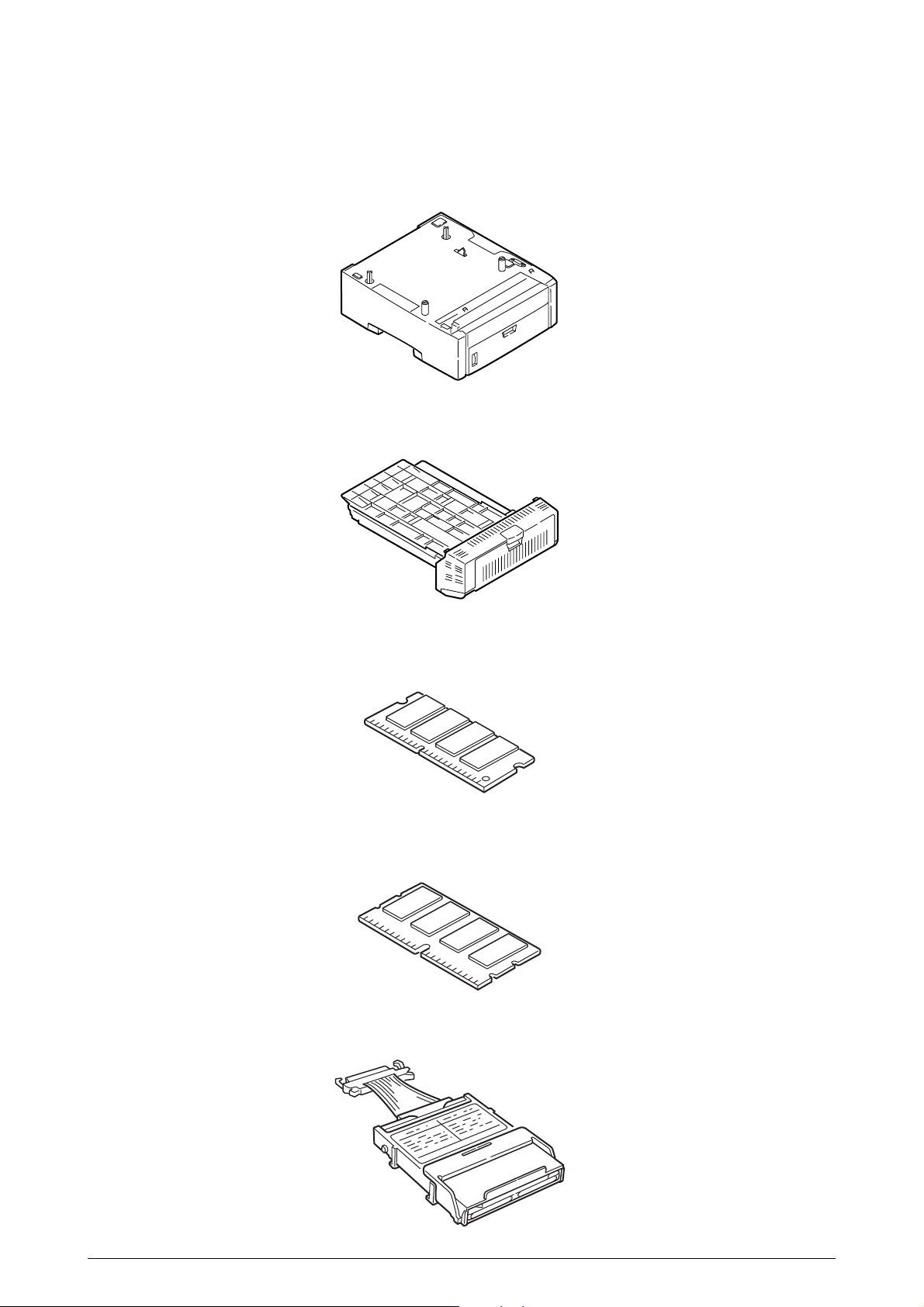

(1) 2nd Tray

(2) Duplex Unit

(3) Expansion Memory (ML5300) 64 MB

(4) Expansion Memory (ML5100) 64/256 MB

(5) Hard Disk (ML5300)

C5100/5300 Service Manual 10 /148

1.4 Specifications

(1) External Dimensions

Height: 345 mm. Width: 422 mm. Length: 561 mm.

(2) Weight

Approx. 20 kg (except consumables)

(3) Paper

Type: Plain paper, Transparencies (Recommended: MLOHP01)

Size: Postal card, Legal 13" or 14", Executive, A4, A5, B5, A6 (A6 held in and fed from

only 1st tray and front feeder)

Weight: 1st tray 55 kg to 103 kg (64 to 120 g/m2)

Front feeder 55 kg to 172 kg (64 to 203 g/ m2)

(4) Print Speed

Color: 12 pages per minute (Transparencies: 6 pages per minute)

Monochrome: 20 pages per minute (Transparencies: 12 pages per minute)

Postal Cards, Labels, Thick Paper: 8 pages per minute

(5) Resolution

600 × 1200 dots per inch

(6) Power Input

100 VAC ±10%

(7) Power Consumption

Peak: 850W

Normal Operating: 400W (5% duty)

Idle: 80W

Power Save Mode: 18W or less

(8) Frequency

50Hz or 60Hz ± 2 Hz

(9) Noise

Operating: 54 dB (Without duplex unit and 2nd tray)

Standby: 40 dB

Power Saving: Background noise

(10) Consumable Life

Toner Cartridges: 5,000 pages (images) (5% duty, Each of Y, M, C and K)

Image Drums: 22,000 pages (images) (5% duty, Continuous printing, Each of Y, M, C

and K)

(11) Parts Replaced Periodically

Fuser Unit: Every 45,000 pages (prints)

Belt Unit: Equivalent of 50,000 pages (images) (3 pages/job)

C5100/5300 Service Manual 11 /148

(12) Temperature and Relative Humidity

Temperatures

Temperature condition

Operating

Non-Operating

Storage (Max. One Year)

Delivery (Max. One Month)

Delivery (Max. One Month)

Humidities

Operating

Non-Operating

Storage

Delivery

Relative

Humidity (%)

20 to 80

10 to 90

10 to 90

10 to 90

Celsius

10 to 32

0 to 43

-10 to 43

-29 to 50

-29 to 50

17 to 27 Celsius (Temperatures to assure full color

print quality)

Power off

With drum and toner

With drum and without toner

With drum and toner

Humidity condition

Max. Wet-Bulb

Temperature (Celsius)

25

26.8

35

40

Remarks

Remarks

50 to 70% (for assurance of full color

print quality)

Power off

(13) Printer Life

420,000 pages (on a A4-size basis) or five years

C5100/5300 Service Manual 12 /148

2. PARTS REPLACEMENT

This section describes the procedure for replacing the parts, assemblies and units in the field. The

replacing procedure is given for detachment. To attach, use the reverse procedure.

2.1 Precautions in Replacing Parts

(1) Before replacing the parts, be sure to remove the AC cable and the interface cable.

(a) To remove the AC cable, always use the following procedure.

i) Flip the power switch of the printer off (to “O”).

ii) Pull the AC inlet plug of the AC cable out of the AC receptable.

iii) Remove the AC cable and the interface cable from the printer.

(b) To connect the printer again, always use the following procedure.

i) Connect the AC cable and the interface cable to the printer.

ii) Insert the AC inlet plug into the AC receptacle.

iii) Flip the power switch of the printer on (to “I”).

Disconnect

Disconnect

(2) Do not disassemble the printer so long as it operates properly.

(3) Minimize the disassembly. Do not detach parts other than those shown in the replacing procedure.

(4) For maintenance, use designated tools.

(5) Follow the order instructed to disassemble the printer. Incorrect order may damage the parts.

(6) Small parts such as screws and collars tend to get lost, so temporarily place and fix them in

(7) When handling ICs and circuit boards such as microprocessors, ROMs and RAMs, do not use

(8) Do not place the printed circuit boards directly on the printer or the floor.

their original positions.

gloves that are likely to have static.

Connect

Connect

C5100/5300 Service Manual 13/148

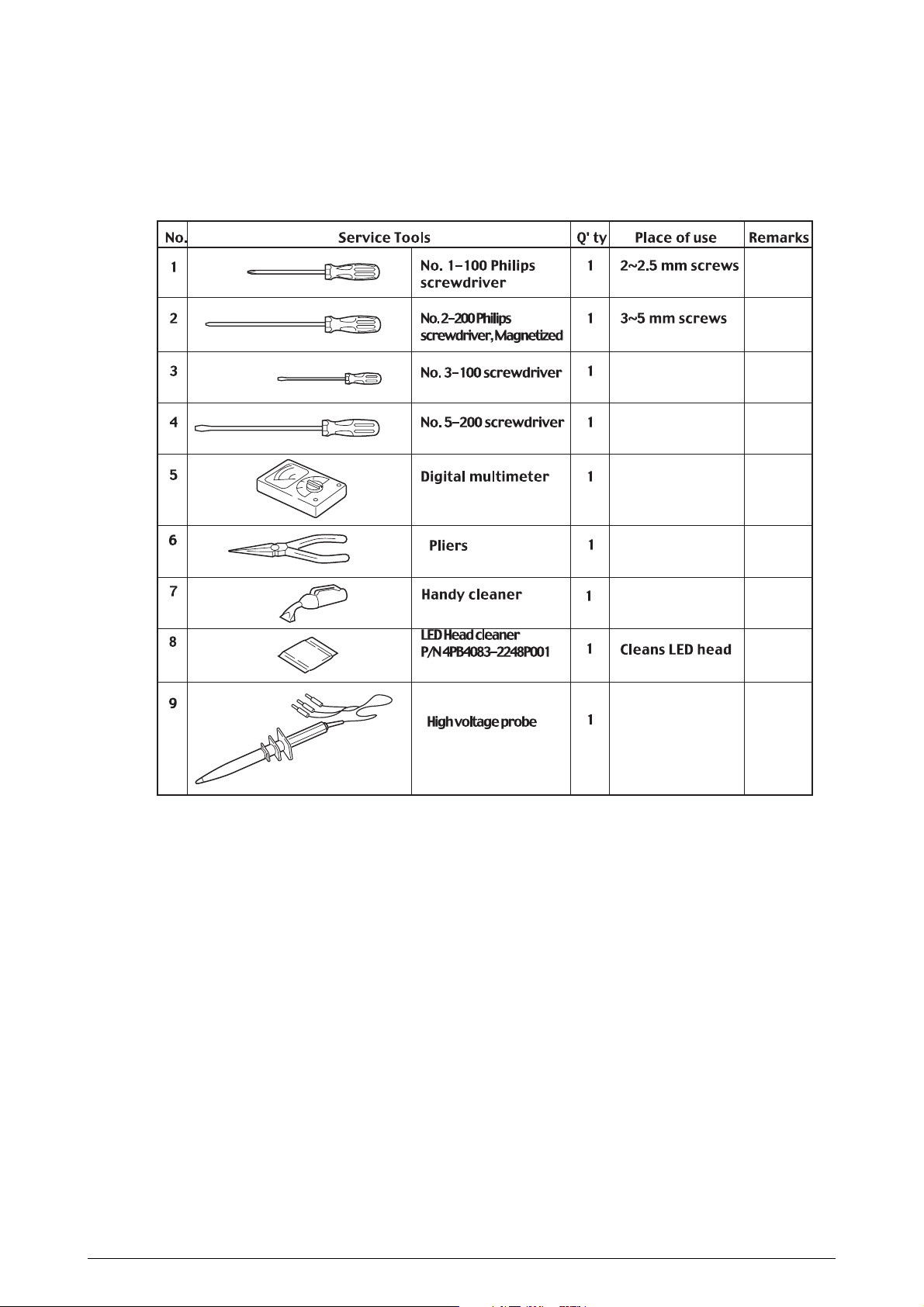

[Maintenance Tools]

Table 2-1 lists tools necessary to replace the printed circuit boards and the units.

Table 2-1 Maintenance Tools

C5100/5300 Service Manual 14/148

2.2 Part Replacement Procedures

1

1

1

3

2

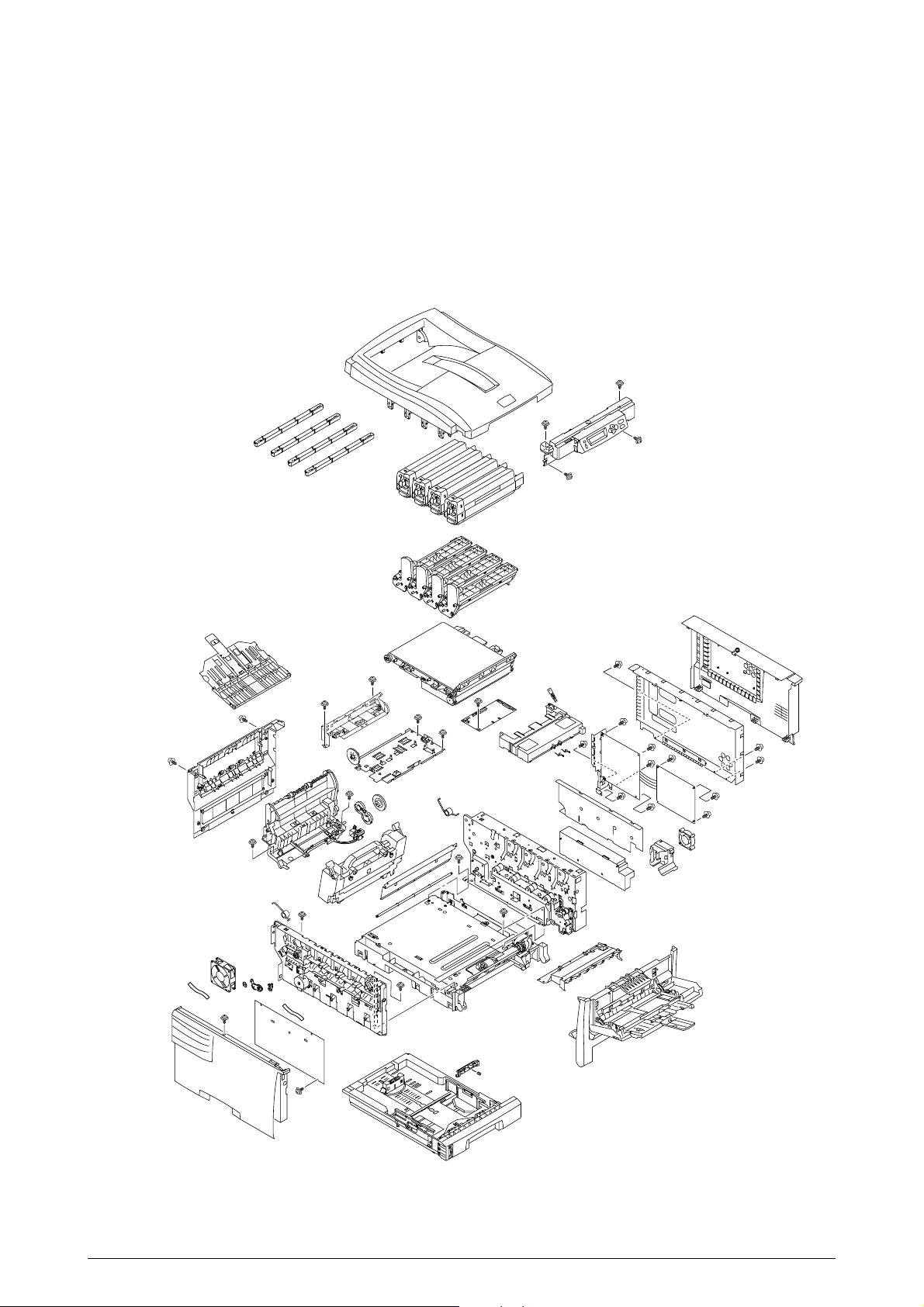

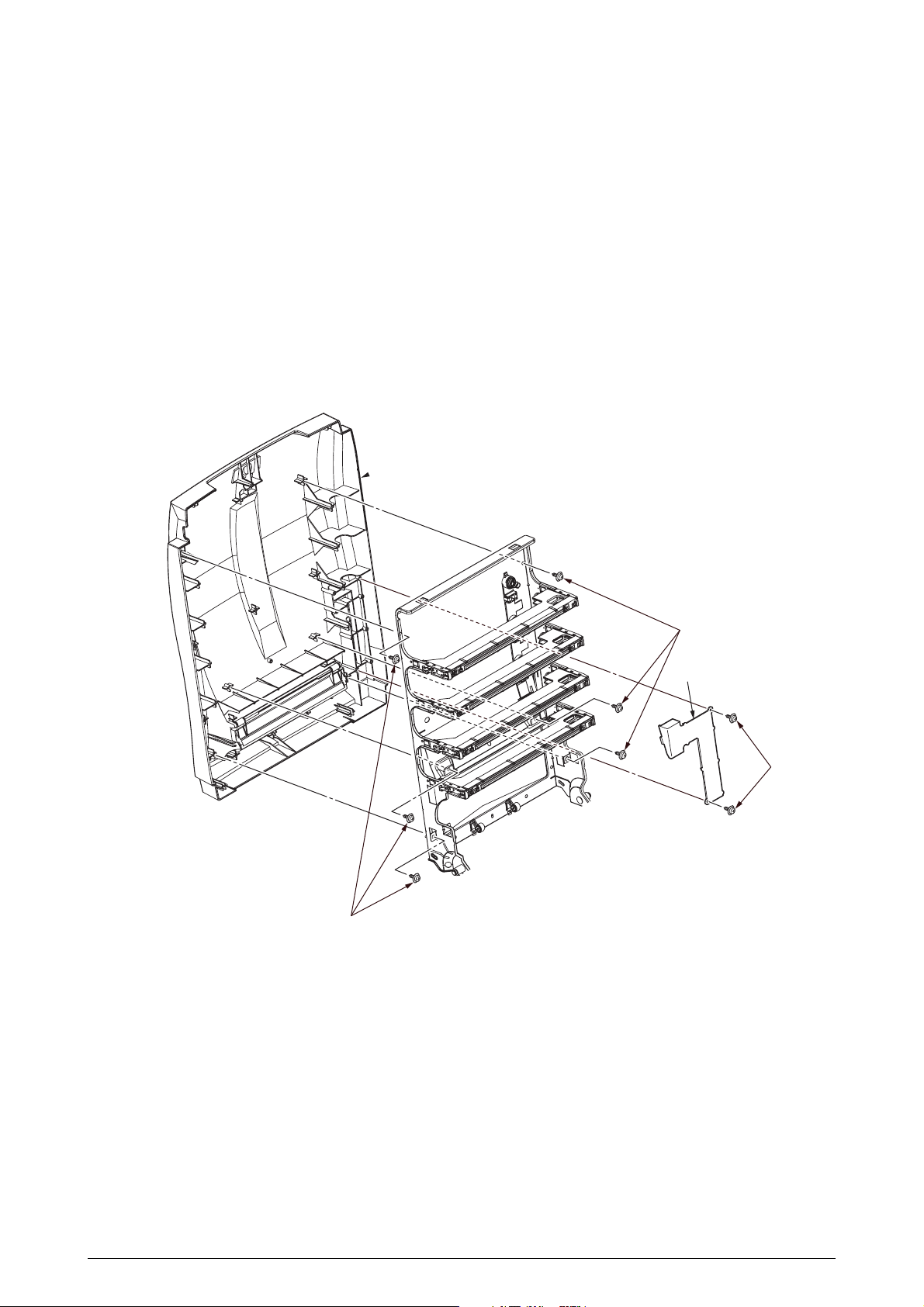

This section describes the procedures for replacing the parts and assemblies shown in the

following disassembly chart:

2.2.1 Top Cover

(1) Open the top cover assy.

(2) Remove the eight screws 1 to detach the cable cover 2 and the top cover 3.

Figure 2-2-1 Top Cover

C5100/5300 Service Manual 15/148

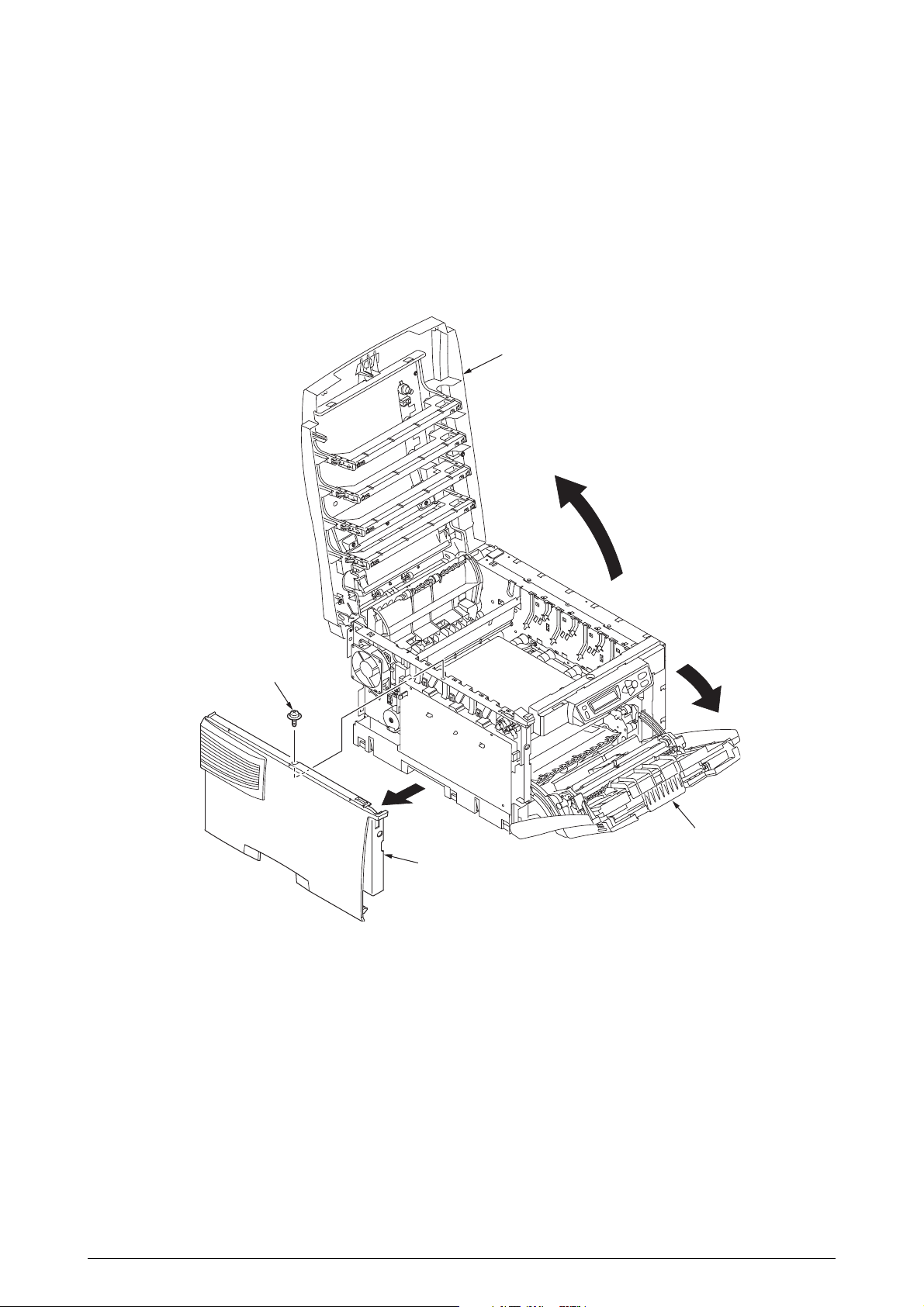

2.2.2 Left Side Cover

(1) Open the top cover 1.

(2) Open the feeder unit 2.

(3) Remove the screw 3 to detach the left side cover 4.

1

3

2

4

Figure 2-2-2 Left Side Cover

C5100/5300 Service Manual 16/148

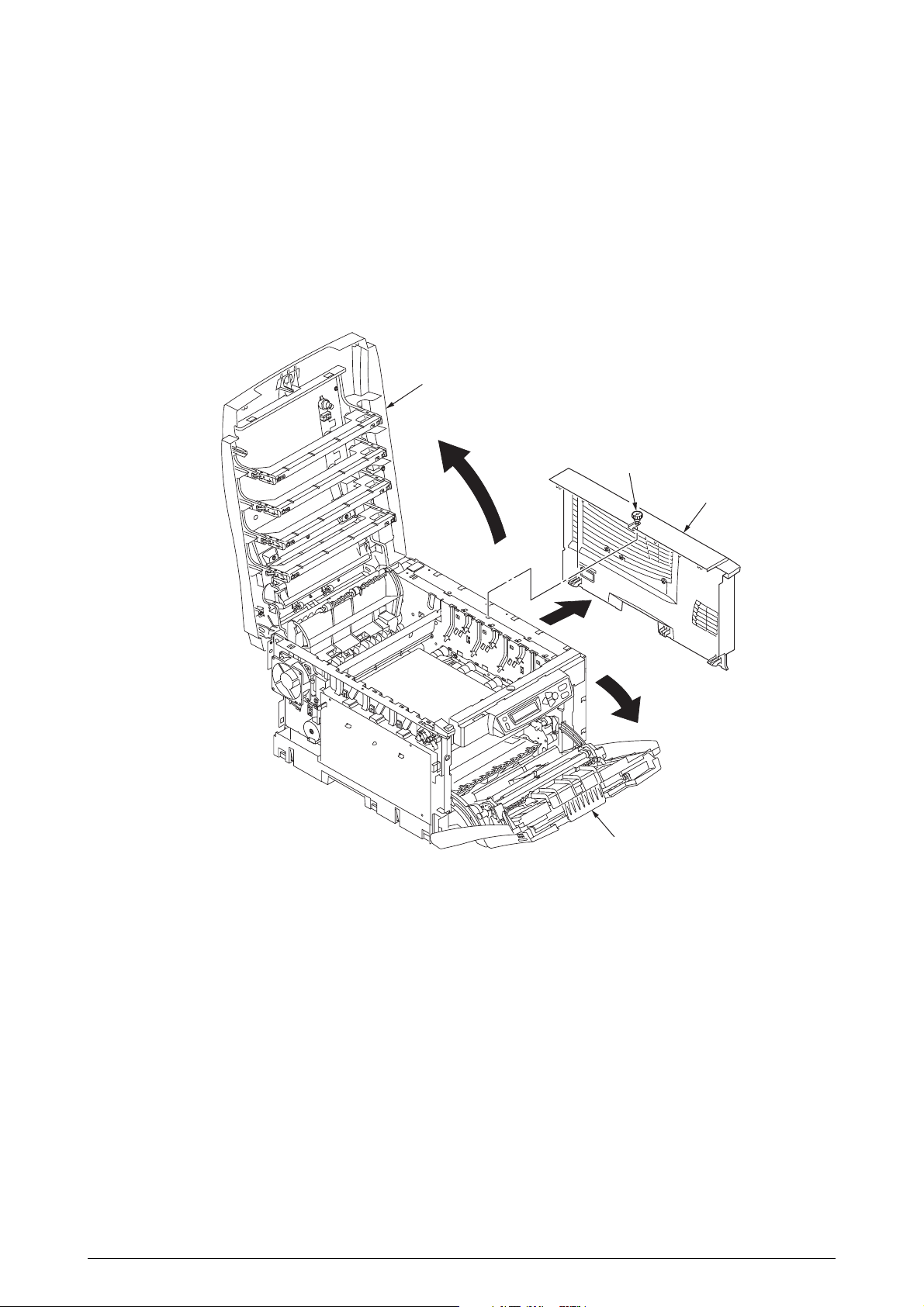

2.2.3 Right Side Cover

(1) Open the top cover 1.

(2) Open the feeder unit 2.

(3) Loosen the screw 3 to detach the right side cover 4.

1

3

(loosen)

4

2

Figure 2-2-3 Right Side Cover

C5100/5300 Service Manual 17/148

1

2.2.4 Face-Up Tray

(1) Open the face-up tray 1 in the direction of the arrow, and disengage it at its two places to

detach it.

Figure 2-2-4 Face-Up Tray

C5100/5300 Service Manual 18/148

2.2.5 Rear Cover

(1) Remove the two screws 1 to detach the rear cover 2.

Figure 2-2-5 Rear Cover

C5100/5300 Service Manual 19/148

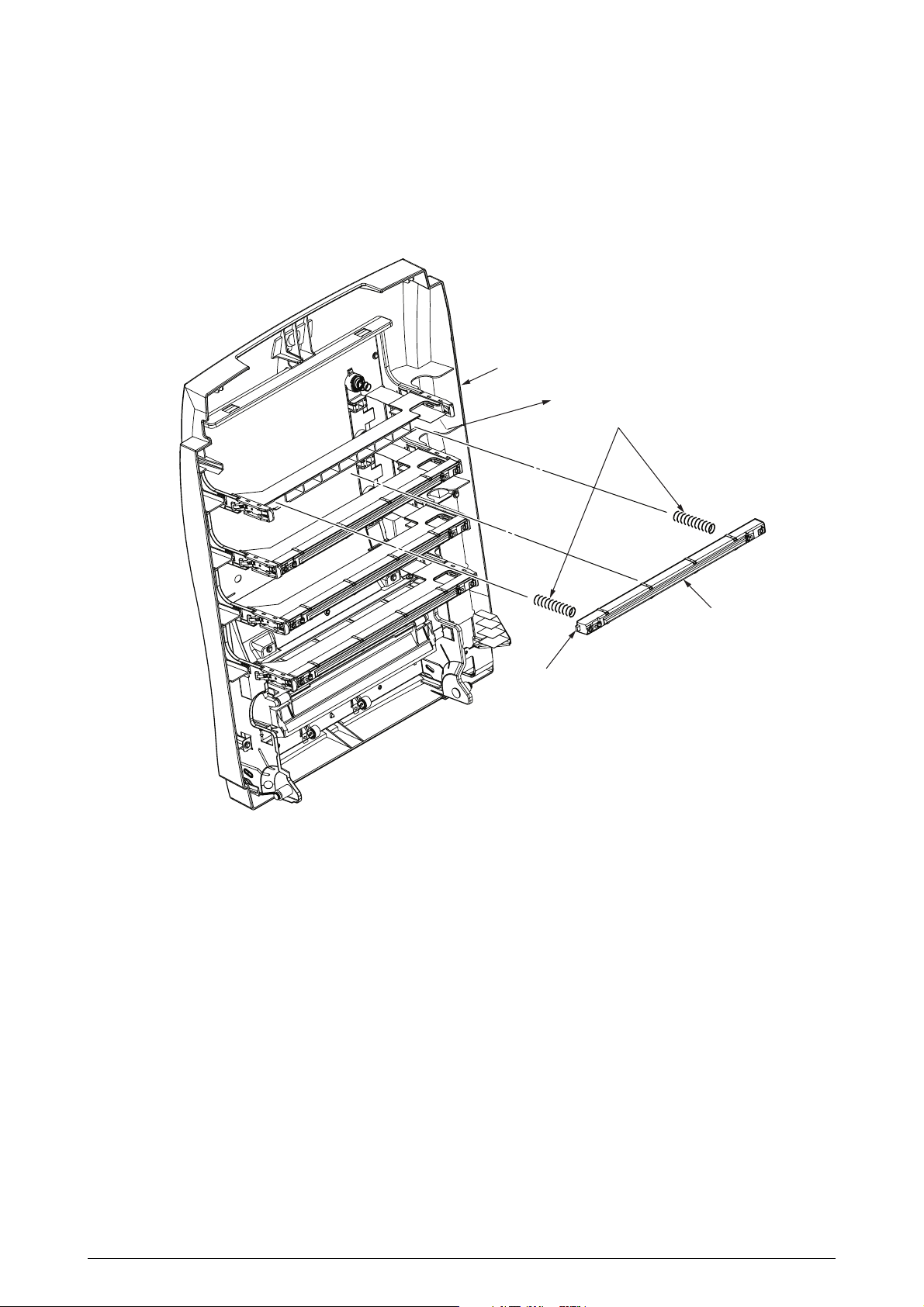

2.2.6 LED Assy / LED Assy Springs

(1) Open the top cover 1.

(2) Remove the LED assy cable connection 4, and disengage the two hooks of the LED assy 2

to detach the assy (the two springs 3 are detached together with the LED assy 2).

1

4

3

Hook (each side)

Figure 2-2-6 LED Assy / LED Assy Springs

2

C5100/5300 Service Manual 20/148

2.2.7 Controller PWB

1

2

4

C5300

(1) Remove the Print Engine Controller PWB (see section 2.2.8).

(3) Remove the screw 1 and then the head cable 2.

(4) Remove the eight screws 3, then detach the controller PWB 4.

Figure 2-2-7-1 Controller PWB (C5300)

×

8

3

C5100/5300 Service Manual 21/148

C5100

1

2

6

3

4

7

(1) Open the top cover.

(2) Remove the right side cover (see section 2.2.3).

(3) Unscrew the three screws 1 to remove the plate-shield assy (GDI) 2.

(4) Remove the screw 3 and then the head cable 4.

(5) Remove the six screws 5 and the connector 6, then detach the controller PWB 7.

Figure 2-2-7-2 Controller PWB (C5100)

×

6

5

C5100/5300 Service Manual 22/148

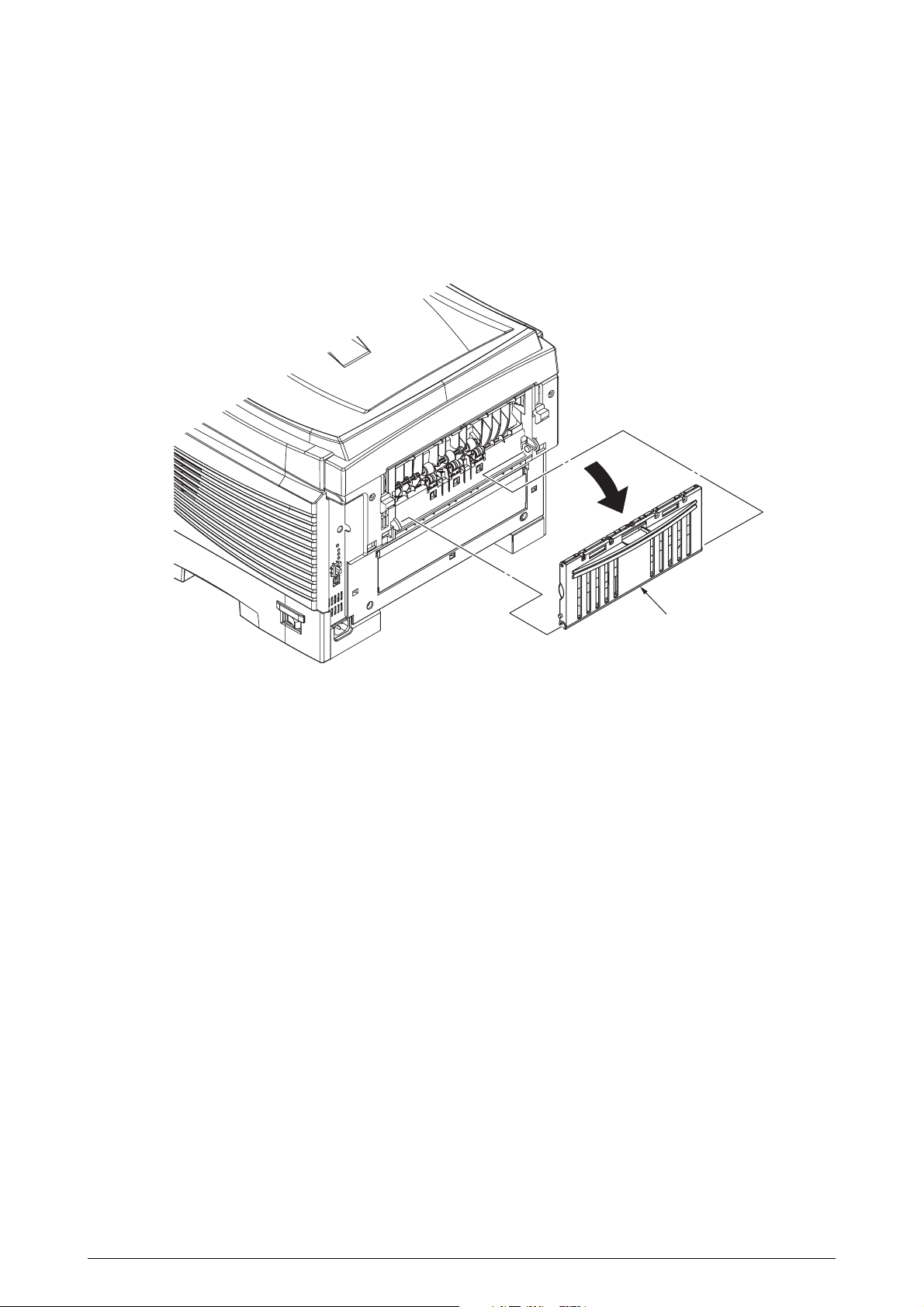

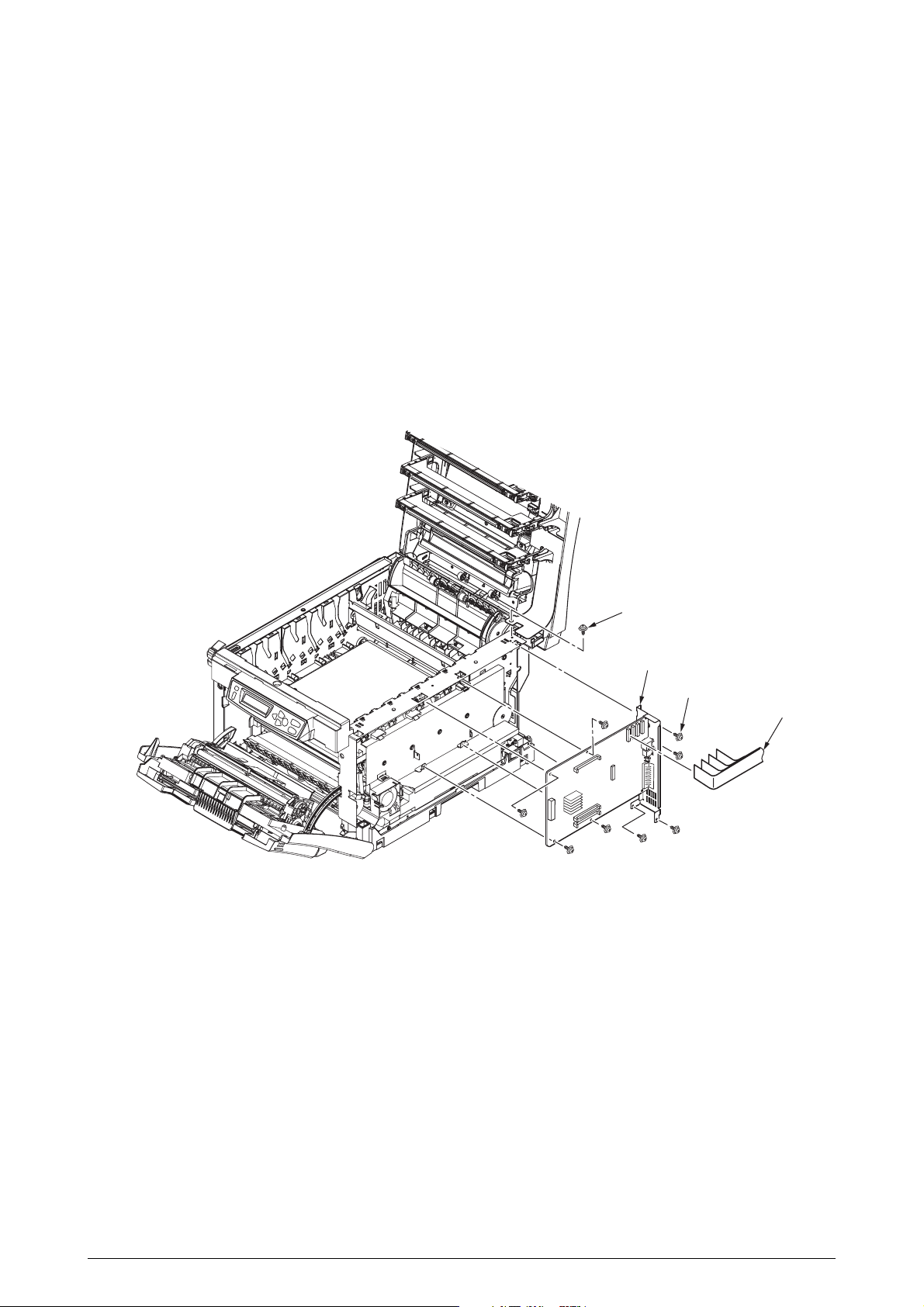

2.2.8 Print Engine Controller PWB

7

6

6

4

4

2

5

3

1

C5300

(1) Open the top cover.

(2) Remove the right side cover (see section 2.2.3).

(3) Remove the connector 1, and disengage the two hooks 2 of to detach the FAN (CU) 3.

(4) Remove the three screws 4 to detach the plate shield assy (PCL) 5.

(5) Remove the three screws 6 and all the connectors to detach the print engine controller PWB

7.

Figure 2-2-8-1 Print Engine Controller PWB (C5300)

C5100/5300 Service Manual 23/148

C5100

2

1

1

(1) Remove the plate shield assy (GDI) [see section 2.2.7, steps (1) to (3)].

(2) Remove the three screws 1 and all the connectors to detach the print engine controller PWB

2.

Figure 2-2-8-2 Print Engine Controller PWB (C5100)

C5100/5300 Service Manual 24/148

2.2.9 Top Cover Unit.

3

2

1

2

1

(1) Remove the top cover (see section 2.2.1).

(2) Remove the left side cover (see section 2.2.2).

(3) Remove the right side cover (see section 2.2.3).

(4) Remove the rear side cover (see section 2.2.5).

(5) Remove the plate-shield assy (GDI) [see section 2.2.7, step (2)].

(6) Remove the two E-shaped rings 1 and the two springs - torsion 2, then detach the top cover

unit 3.

Figure 2-2-9 Top Cover Unit

C5100/5300 Service Manual 25/148

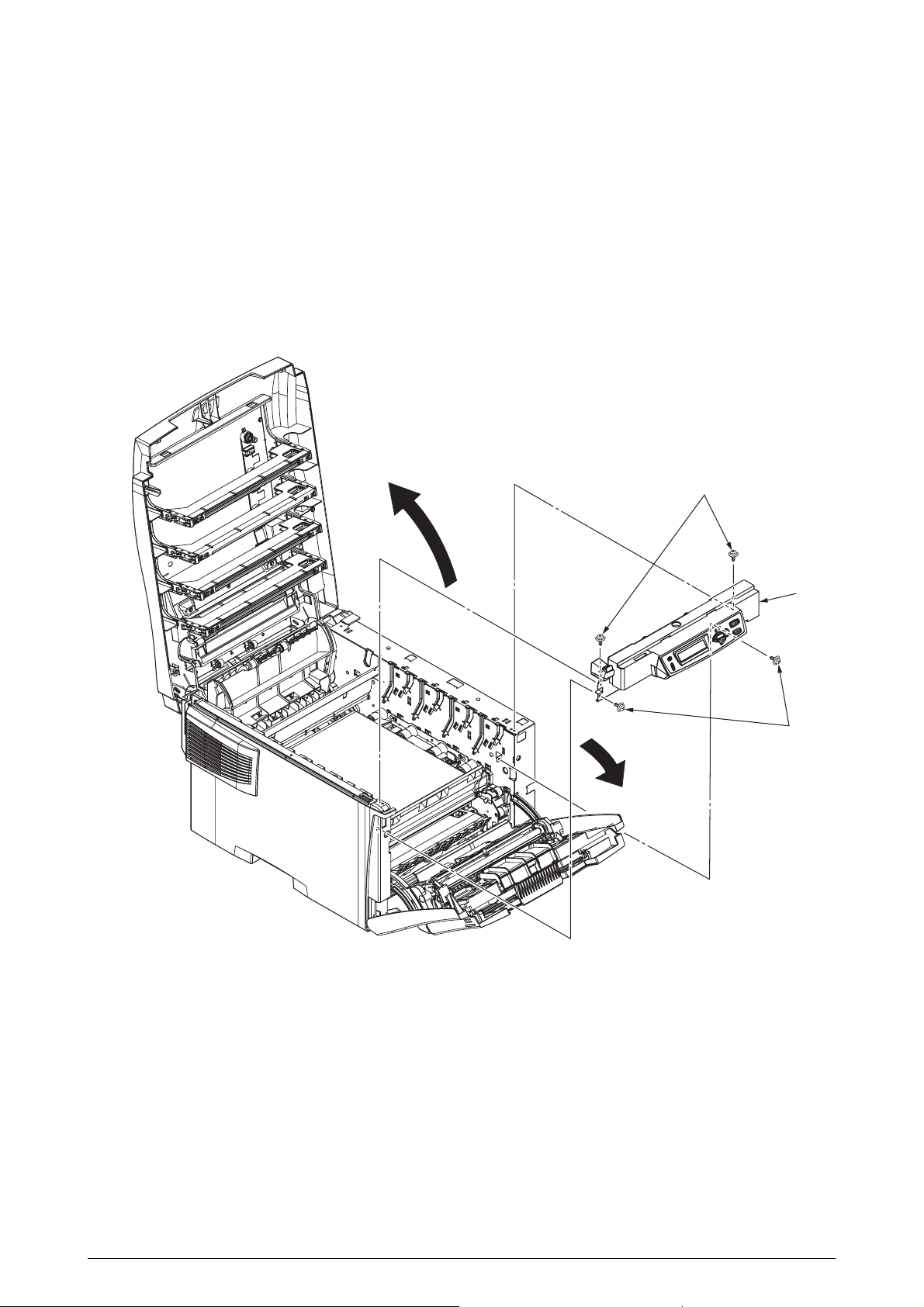

2.2.10 Controller Panel Assy

(1) Open the top cover.

(2) Open the feeder unit.

(3) Remove the right side cover (see section 2.2.3).

(4) Remove the plate-shield assy (GDI) [see section 2.2.7, step (2)].

(5) Make control panel assy connector removal (see section 2.2.10).

(6) Remove the four screws 1, then detach the control panel assy 2.

1

Figure 2-2-10 Control Panel Assy

2

1

C5100/5300 Service Manual 26/148

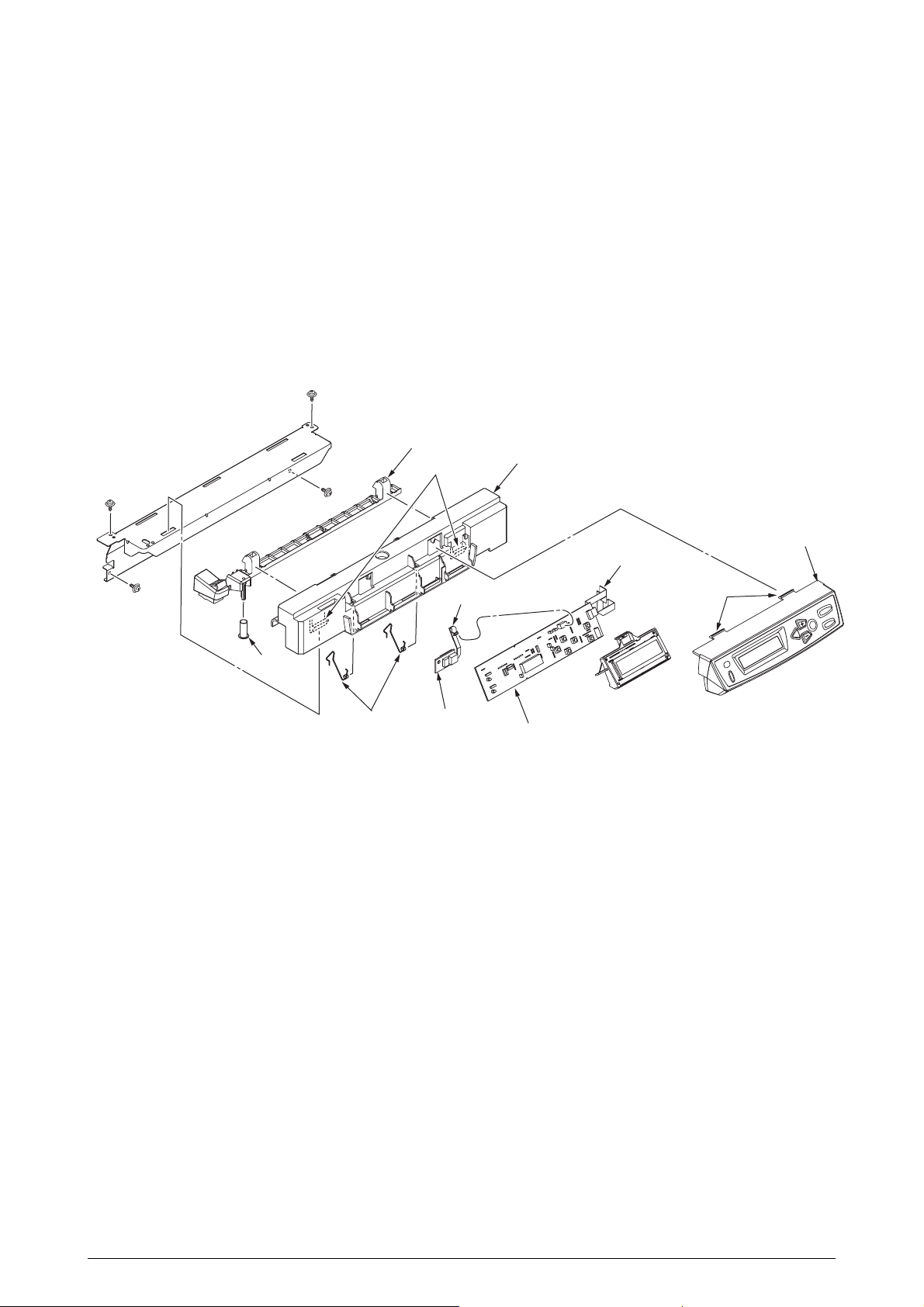

2.2.11 Board RSP / Environment Sensor / Top Cover Handle

(1) Remove the control panel assy (see section 2.2.10).

(2) Disengage the two claws of the lever-lock 2 to remove the frame OP 1, and remove the lever-

lock 2 and the spring-compression 3.

(3) Disengage the two claws of the cover assy OP 4 to remove it, and remove the springs torsion

5.

(4) Detach the board RSP 6, the environment sensor 7, the cable 8 and the harness 9.

2

Claws

1

8

9

3

5

Figure 2-2-11 Board RSP / Environment Sensor / Top Cover Handle

7

6

4

Claws

C5100/5300 Service Manual 27/148

2.2.12 Low Voltage Power Unit / FAN (ID) / FAN (PowL) / Hopping Motor / Fuser Motor

6

8

7

9

5

1

3

10

2

4

Air

(1) Remove the print controller PWB (see section 2.2.8).

(2) Remove the controller PWB (see section 2.2.7).

(3) Remove the film 1 and the frame duct 2 to remove the FAN (ID) 3.

(4) Remove the two screws 4 and the four connectors to remove the POW unit 5.

(5) Demount the FAN (PowL) 6 by releasing claw engagement.

(6) Remove the two screws 7 and the connector to detach the hopping motor 8.

(7) Remove the two screws 9 and the connector to detach the fuser motor 10.

Note! When reassembling the FAN (PowL) 6, check the attachment direction.

Figure 2-2-12 Low voltage Power Unit / FAN (ID) / FAN (PowL) / Hopping Motor / Fuser Motor

C5100/5300 Service Manual 28/148

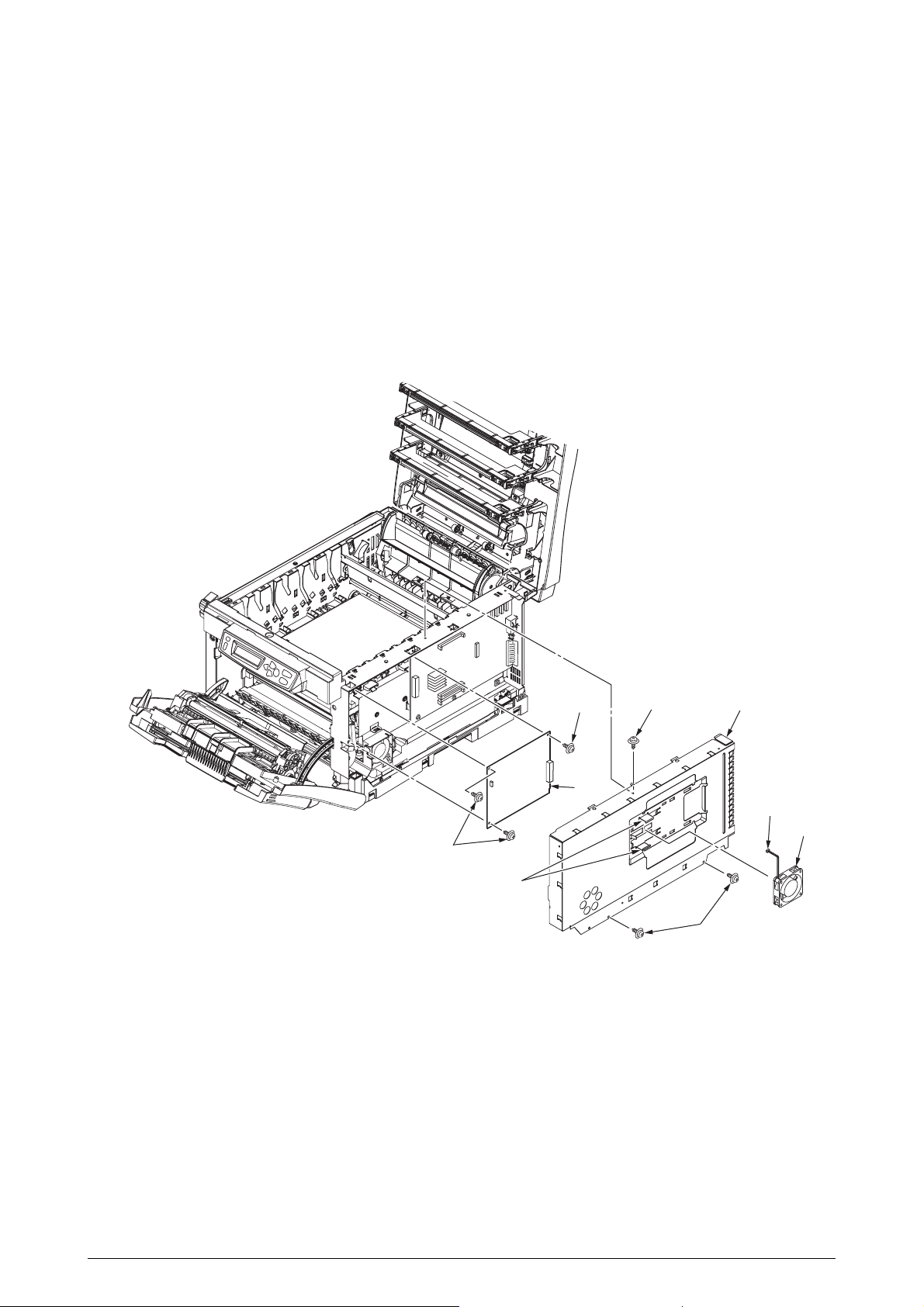

2.2.13 Board-PRD

7

1

2

4

9

8

10

3

× 9

6

5

(1) Remove the right side cover (see section 2.2.3).

(2) Remove the print engine controller PWB and the controller PWB (see sections 2.2.7 and

2.2.8).

(3) Remove the film and the low voltage power unit (see section 2.2.12).

(4) Remove the three screws 1 and the two E-shaped snaps 2 to remove the plate-outer 3.

(5) Remove the gear-idle-ID - K 4, Y and C 5, each in one piece, and M 6, and the spring 7 of the

solenoid.

(6) Unlatch, and remove by sliding the guide assy - side R 8, the assy and detach the board-PRD

9 and the nine springs 10.

Note! When reassembling the board-PRD, do not forget to attach the spring of the solenoid 7.

Figure 2-2-13 Board-PRD

C5100/5300 Service Manual 29/148

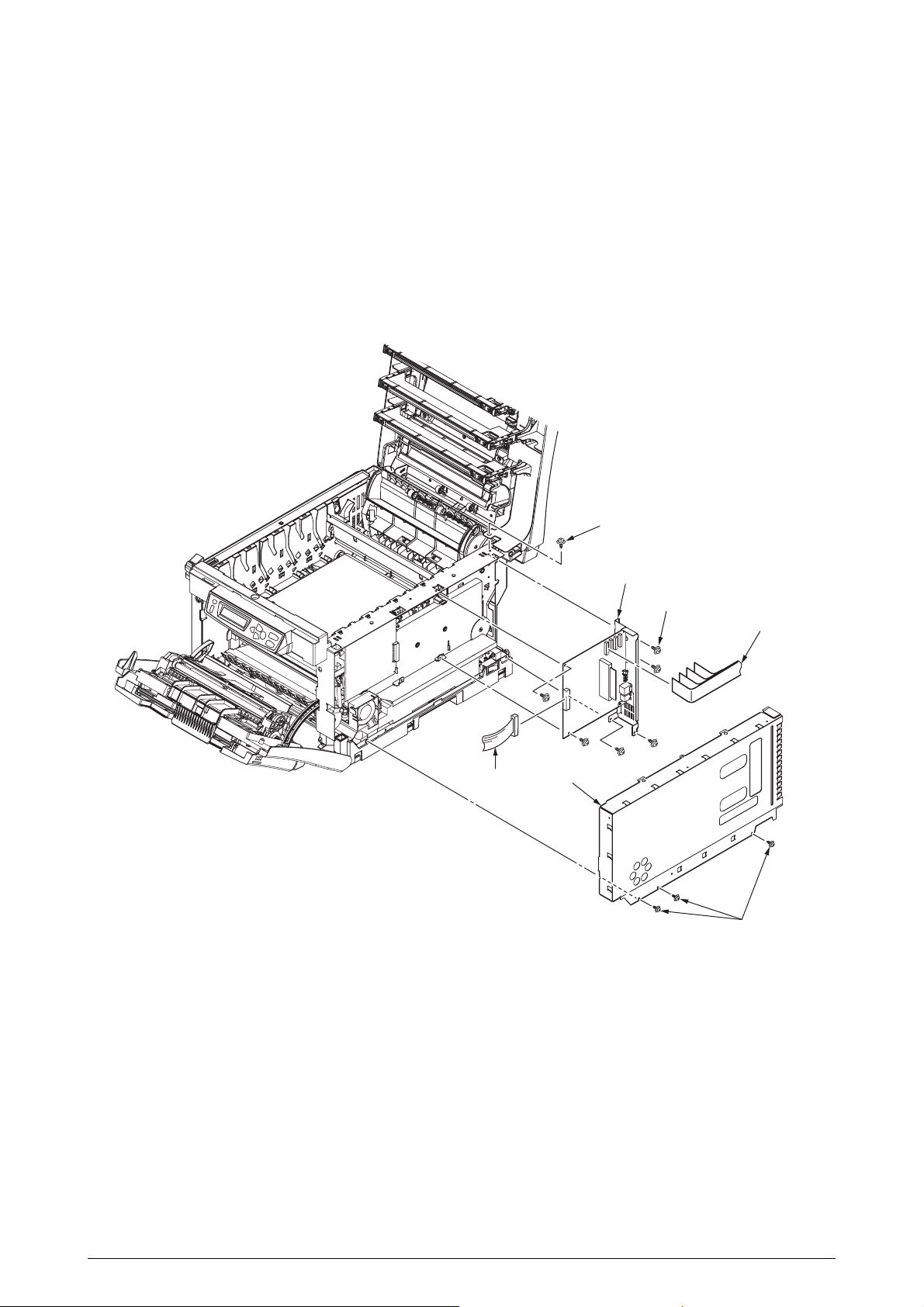

2.2.14 Guide - Eject Assy / Color Registration Assy / Board-RSM

(1) Remove the left side cover, the write side cover, the rear cover and the top cover unit (see

sections 2.2.2, 2.2.3, 2.2.5 and 2.2.9).

(2) Remove the engine controller PWB, the controller PWB and the film [see sections 2.2.7 and

2.2.8, and step (3) of section 2.2.12].

(3) Unscrew the two screws 1 to remove the plate-heat 2.

(4) Remove the two springs - torsion 3 and disengage the latches to remove the cover-driver 4.

(5) Remove two-screw 5 and connector removal to detach the color registration assy 6.

(6) Remove two-screw 7 and connector removal to detach the guide eject assy 8.

(7) Remove screw 9 and connector removal to detach the board-RSM 10.

1

2

4

5

3

6

10

8

9

7

7

Figure 2-2-14 Guide - Eject Assy / Color Registration Assy / Board-RSM

C5100/5300 Service Manual 30/148

Loading...

Loading...