Okidata B4350 Service Manual

Oki Data CONFIDENTIAL

B4350/B4350n

Service Manual

060125A

Document Revision History

Oki Data CONFIDENTIAL

Rev.No. Date

Corrected items

No.

Page Description of change

1 2004-04-01 ISSUE ME5 Ono

Person in

charge

42641101TH Rev.1 2 /

Oki Data CONFIDENTIAL

PREFACE

This Maintenance Manual describes the field maintenance methods for B4350 Monochrome LED Page

Printers.

This manual is written for use by service persons. Please note that you should refer to the Printer Handbook

for the handling and operating methods of the equipment.

42641101TH Rev.1 3 /

Oki Data CONFIDENTIAL

CONTENTS

1. CONFIGURATION.................................................................................................... 7

1.1 System Configuration ....................................................................................... 7

1.2 Printer Configuration ......................................................................................... 8

1.3 Optional Configuration ...................................................................................... 9

1.4 Specification ................................................................................................... 11

1.5 Safety Standards ............................................................................................ 13

1.5.1 Certification Label ...................................................................................................... 13

1.5.2 Warning Label ........................................................................................................... 13

1.5.3 Warning/Caution Marking .......................................................................................... 14

2. PARTS REPLACEMENT........................................................................................ 15

2.1 Precautions for Parts Replacement ................................................................ 15

2.2 Parts Layout.................................................................................................... 17

2.3 How to Change Parts...................................................................................... 20

2.3.1 Upper Cover Assy ..................................................................................................... 21

2.3.2 LED Head .................................................................................................................. 22

2.3.3 Operator Panel Assy ................................................................................................. 23

2.3.4 Lower Base Unit ........................................................................................................ 24

2.3.5 Pulse Motor (Main/Drum) .......................................................................................... 25

2.3.6 Pulse Motor (Registration) ......................................................................................... 26

2.3.7 Pulse Motor (Hopping)............................................................................................... 27

2.3.8 Face Up Stacker Assy ............................................................................................... 28

2.3.9 Eject Roller Assy ....................................................................................................... 29

2.3.10 Motor Assy ................................................................................................................. 30

2.3.11 Hopping Roller Shaft Assy ......................................................................................... 31

2.3.12 Stacker Cover Assy ................................................................................................... 32

2.3.13 Registration Roller ..................................................................................................... 33

2.3.14 Roller Transfer Assy .................................................................................................. 34

2.3.15 Fusing Unit ................................................................................................................ 35

2.3.16 Back-up Roller ........................................................................................................... 36

2.3.17 Sensor Plate (Inlet) .................................................................................................... 37

2.3.18 Sensor Plate (Outlet), Sensor Wire Assy .................................................................. 38

2.3.19 Manual Feed Guide Assy .......................................................................................... 39

2.3.20 Sensor Plate (Paper Supply) ..................................................................................... 40

2.3.21 GRV-2 PCB ............................................................................................................... 41

2.3.22 Power Supply Board and High Voltage/Sensor Board .............................................. 42

2.3.23 Cassette Guide L Assy .............................................................................................. 43

2.3.24 Cassette Guide R Assy ............................................................................................. 44

3. ADJUSTMENT........................................................................................................ 45

3.1 Maintenance Modes and Functions ................................................................ 45

3.1.1 User Maintenance Mode (Administrator Menu) ......................................................... 45

3.1.2 System Maintenance Mode (System Maintenance Menu) ........................................ 46

3.1.3 EEPROM Initial Setting Range for Events................................................................. 48

3.2 Adjustment When Replacing a Part ................................................................ 49

3.2.1 Uploading/Downloading EEPROM data .................................................................... 49

4. PERIODICAL MAINTENANCE .............................................................................. 50

4.1 Periodical Replacement Parts ........................................................................ 50

42641101TH Rev.1 4 /

Oki Data CONFIDENTIAL

4.2 Cleaning.......................................................................................................... 50

4.2.1 Cleaning of LED Lens Array ...................................................................................... 50

4.2.2 Cleaning Page Function ............................................................................................ 51

5. TROUBLESHOOTING PROCEDURES ................................................................. 52

5.1 Troubleshooting Tips ...................................................................................... 52

5.2 Points to Check before Correcting Image Problems....................................... 52

5.3 Tips for Correcting Image Problems ............................................................... 52

5.4 Preparation for Troubleshooting ..................................................................... 53

5.5 Troubleshooting Flow ..................................................................................... 53

5.5.1 LCD Status Message/Problem List............................................................................ 53

5.5.2 LCD Message Troubleshooting ................................................................................. 59

5.5.3 Image Troubleshooting .............................................................................................. 67

6. WIRING DIAGRAM................................................................................................ 76

6.1 Interconnect Signal Diagram .......................................................................... 76

6.2 PCB Layout and Connector Signal List .......................................................... 77

6.3 Resistance Check ........................................................................................... 89

APPENDIX A RS-232C SERIAL INTERFACE (OPTION) ......................................... 91

APPENDIX B CENTRONICS PARALLEL INTERFACE............................................ 96

APPENDIX C UNIVERSAL SERIAL BUS (USB)..................................................... 105

APPENDIX D LOOP TEST (RS-232C INTERFACE) ............................................... 111

APPENDIX E DIAGNOSTICS TEST ........................................................................ 112

42641101TH Rev.1 5 /

Oki Data CONFIDENTIAL

APPENDIX G HIGH CAPACITY SECOND PAPER FEEDER ................................. 138

1. OUTLINE ...................................................................................................... 138

1.1 Functions ................................................................................................................. 138

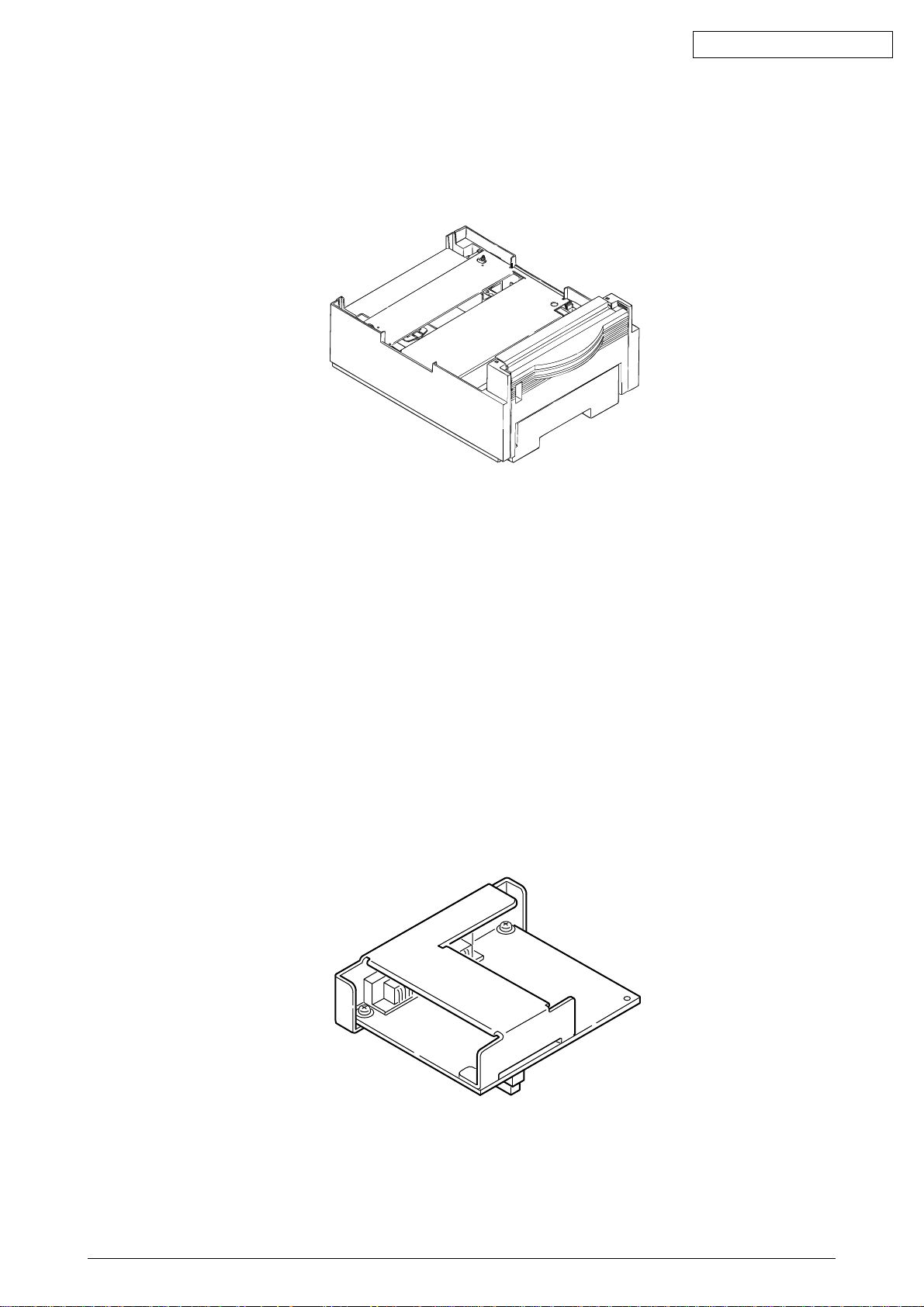

1.2 External View and Component Names ................................................................... 138

2. MECHANISM DESCRIPTION ...................................................................... 139

2.1 General Mechanism ................................................................................................ 139

2.2 Hopper Mechanism ................................................................................................. 139

3. PARTS REPLACEMENT .............................................................................. 140

3.1 Precautions Concerning Parts Replacement .......................................................... 140

3.2 Parts Layout ............................................................................................................ 141

3.3 Parts Replacement Methods ................................................................................... 142

3.3.1 Stepping Motor (Hopping) ......................................................................... 143

3.3.2 TQSB-2 PCB ............................................................................................. 145

3.3.3 Hopping Roller Shaft Assy and One-way Clutch Gear .............................. 145

4. TROUBLESHOOTING.................................................................................. 146

4.1 Precautions Prior to the Troubleshooting ................................................................ 146

4.2 Preparations for the Troubleshooting ...................................................................... 146

4.3 Troubleshooting Method .......................................................................................... 147

4.3.1 LCD Status Message List .......................................................................... 147

5. CONNECTION DIAGRAM ............................................................................ 149

5.1 Interconnection Diagram ......................................................................................... 149

5.2 PCB Layout ............................................................................................................. 149

6. PARTS LIST ................................................................................................. 150

APPENDIX H NETWORK INTERFACE (OPTION).................................................. 156

42641101TH Rev.1 6 /

1. CONFIGURATION

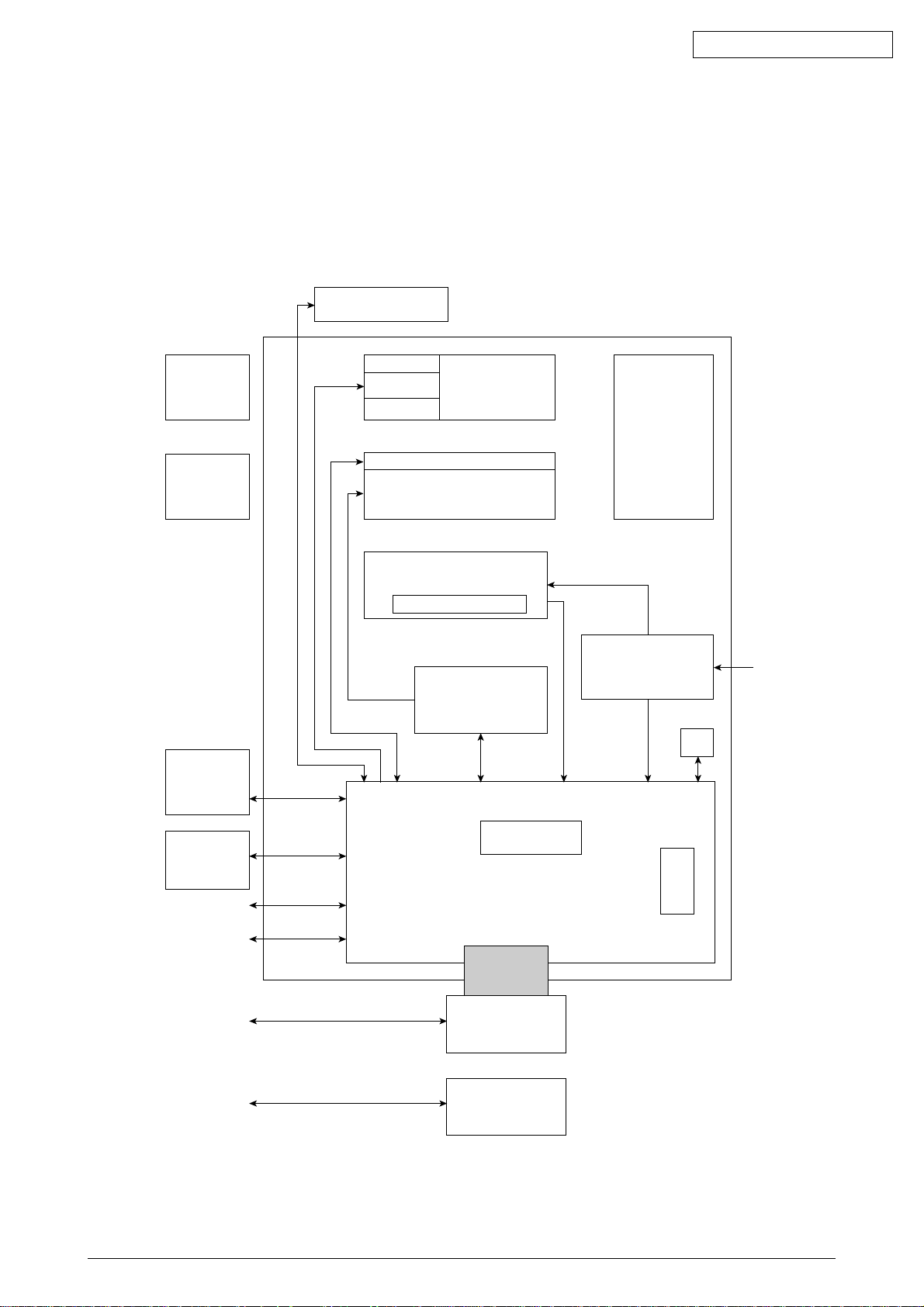

1.1 System Configuration

B4350 consists of control and engine blocks in the standard configuration, as shown in Figure 1-1.

In addition, the options marked with asterisk(*) are available.

Operator Panel

Oki Data CONFIDENTIAL

LCD : 1

LED : 1

SW : 8

Paper

Cassette

ID

Unit

*

High Capacity

Second Paper

Feeder

Drum Motor

Registration

Motor

Hopping Motor

Electrophotogarphic

Processing Unit

Halogen-Lamp

Paper Feeding

Mechanism

(First Tray Unit)

LED Head

Fuser Unit

High Voltage /

Sensor Board

Face Down

Stacker

Power Supply

Board

AC

INPUT

FAN

*

*

*

ROM DIMM

*

RAM

DIMM

Network

Board

OR

* : Optional

RS232C

Board

*

Multi Purpose

Feeder

IEEE1284

USB

Network

RS232C

Main Control Board

Figure 1-1

42641101TH Rev.1 7 /

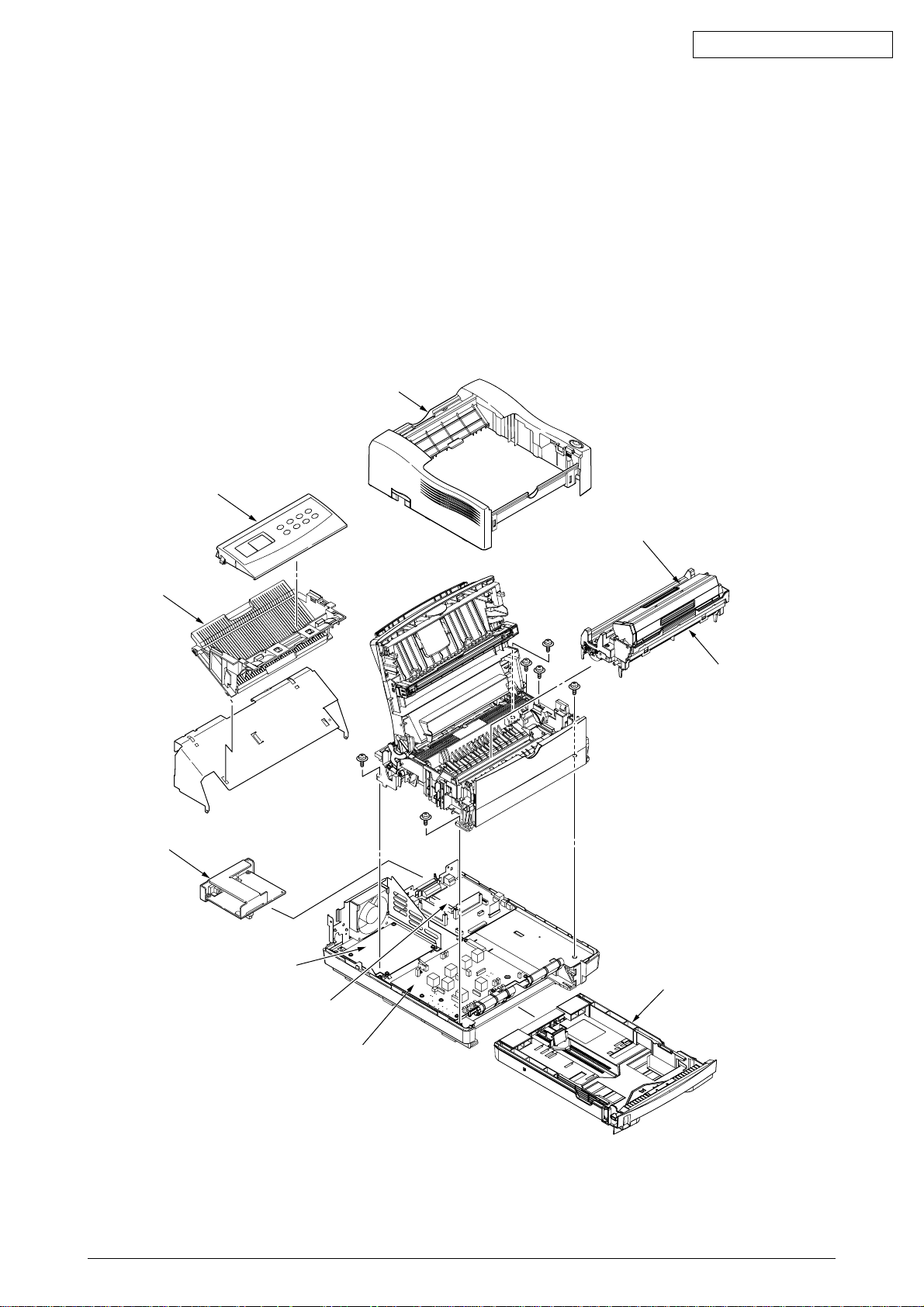

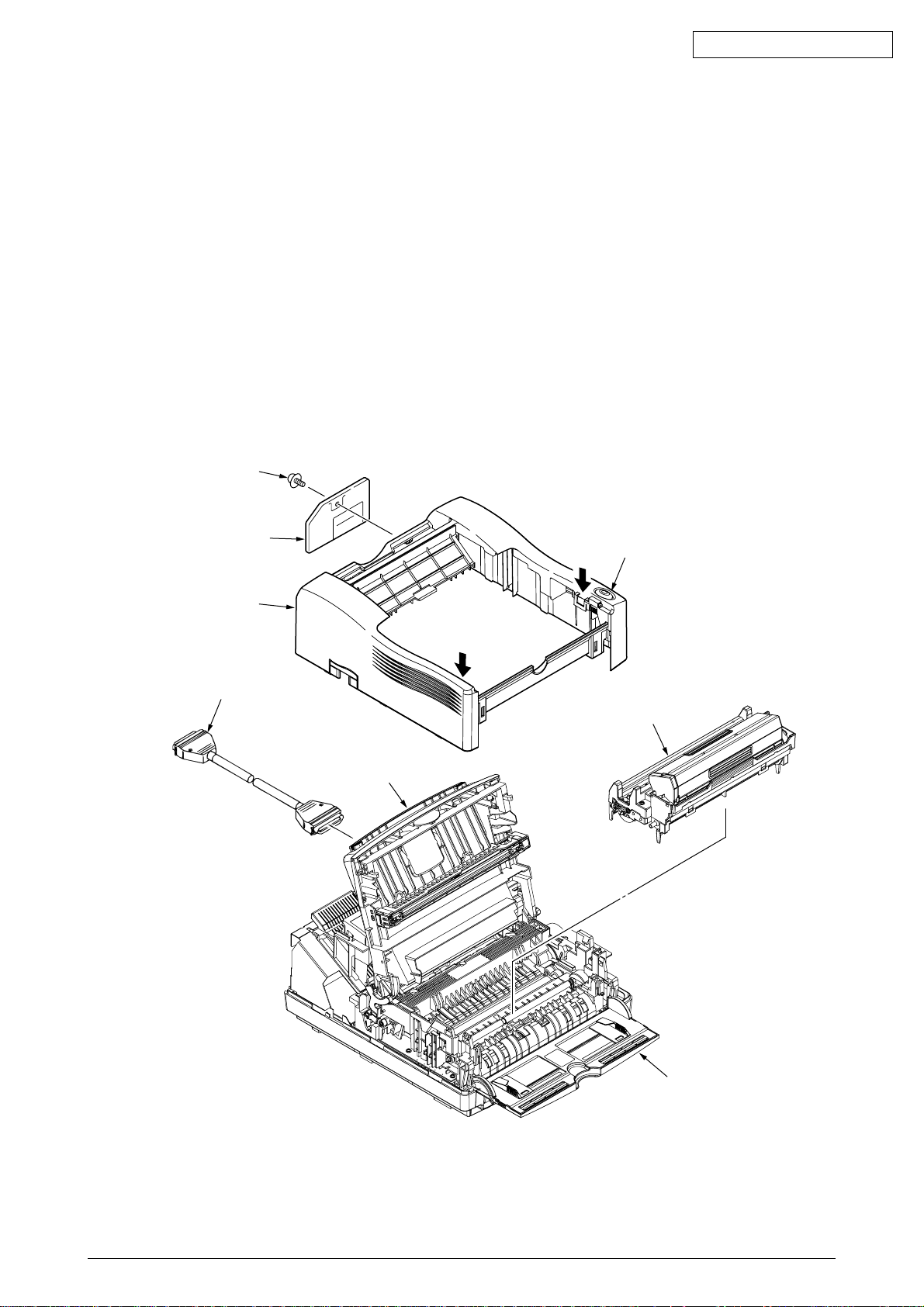

1.2 Printer Configuration

The printer unit consists of the following hardware components:

• Electrophotographic Processor

• Paper Feeder

• Controller

• Operator Panel

• Power Supply Unit

The printer unit configuration is shown in Figure 1-2.

Operator panel assy

Oki Data CONFIDENTIAL

Upper cover

Stacker assy

Optional board

Toner-cartridge(Type 9)

(consumable)

Image drum unit(Type 9)

(consumable)

Power supply

Main control board

High Voltage / Sensor board

Legal/universal paper cassette

Figure 1-2

42641101TH Rev.1 8 /

1.3 Optional Configuration

The options shown below are available for use with B4350. These are available separately from the

printer unit.

(1) High Capacity Second Paper Feeder

Oki Data CONFIDENTIAL

(3) RS-232C Serial Interface Board

42641101TH Rev.1 9 /

(4) Network Interface Board(Soft NIC CARD)

(5) SDRAM DIMM

Oki Data CONFIDENTIAL

(i) 16MB (ii) 32MB (iii) 64MB

(6) Flash DIMM

(iv) 128MB (v) 256MB

(i) 1MB (ii) 8MB (iii) 16MB

(7) Postscript 3 Emulation DIMM

42641101TH Rev.1 10 /

1.4 Specification

(1) Type Desktop

(2) External dimensions Height 8.5” (215 mm)

(3) Weight Approx. 9 kg

(4) Developing method Dry electrophotography

Exposing method LED stationary head

(5) Paper used <Type>

Oki Data CONFIDENTIAL

Width 14.0” (355 mm)

Depth 15.7” (400 mm)

• Standard paper

– Xerox 4200 (20 lbs)

• Application paper (manual face-up feed)

– Label

– Envelope

– OHP paper (transparency)

<Size>

• Standard sizes

– Letter

– Legal* [* Without Multi Purpose Feeder (Option)]

– Legal-13*

– Executive

– COM-9 **

– COM-10** [** manual feed and Multi Purpose Feeder

– Monarch** (option) only]

– DL**

– C5**

– A4

– A5

– B5 (JIS)

– A6

• Applicable sizes

– Width : 3.5” to 8.5” (90 to 216 mm)

– Length : 5.8” to 14” (148 to 355.6 mm)

<Thickness>

– Automatic feed : 16 to 28 lbs (60 to 105 g/m2)

– Manual feed : Label, OHP paper (transparency)

Envelope (24 to 28 lbs)

(6) Printing speed Continuous printing : 23 pages per minute with Letter size paper.

22 pages per minute with A4 size paper.

[Except, Multi purpose Feeder (14ppm) with

Letter size paper]

Warm-up time : 35 seconds typical at room temperature

[68 F (20 C), AC 120/230 V].

First page print time : 6.0 seconds typical for the Letter size paper

(6.2 seconds for the A4 size) after warm-up.

(7) Paper feeding method Automatic feed or manual feed

(8) Paper delivery method Face down/face up

(9) Resolution 600 × 600 dots/inch

600 × 1200 dots/inch

42641101TH Rev.1 11 /

Oki Data CONFIDENTIAL

(10) Power input 110~127 VAC ± 10%

220~240 VAC ± 10%

(11) Power consumption 120VAC 230VAC

Peak : Approx. 700W Approx. 700W

Typical operation : Approx. 360W Approx. 360W

Idle : Approx. 68W Approx. 66W

Power save mode : Approx. 9W Approx. 10W

(Without option)

Power save mode : Approx. 13W Approx. 14W

(With full option)

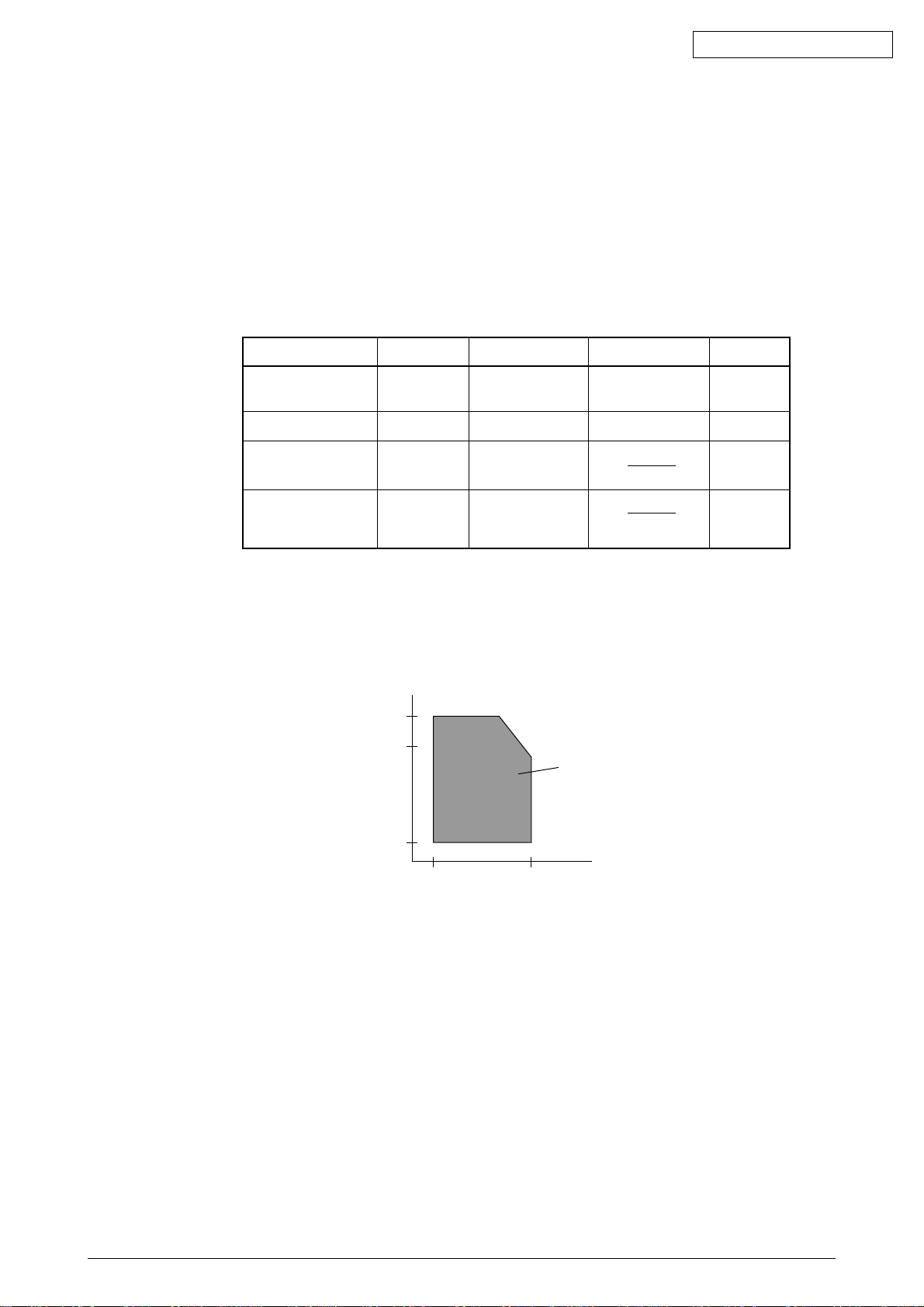

(12) Temperature and humidity

In operation Power off mode During Storage Unit

Temperature

Humidity

Maximum wet bulb

temperature

Minimum diference

between wet and dry

50-90

(10-32)

20-80

77

(25)

35.6

(2)

32-110

(0-43)

10-90

80.4

(26.8)

35.6

(2)

14-110

(–10-43)

10-90

°F

(°C)

%RH

°F

(°C)

°F

(°C)

bulb temperatures

1. Storage conditions specified above apply to printers in packed condition.

2. Temperature and humidity must be in the range where no condensation occurs.

Temperature

(

°

C)

32

28

Operation range

10

20 80

Humidity (%)

(13) Noise During operation : 53 dB (A) or less

Standby : 38 dB (A) or less

Quiet mode : Back ground level

(14) Consumables Toner cartridge kit 2,500 (5% duty) 6,000 (Optional 6K Toner 5%

duty)

Image drum cartridge 25,000 (at continuouts printing)

17,000 (3 page/job) without Power Save

11,000 (1 page/job) without Power Save

7,000 (1 page/job) with Power Save

(Minimum)

42641101TH Rev.1 12 /

1.5 Safety Standards

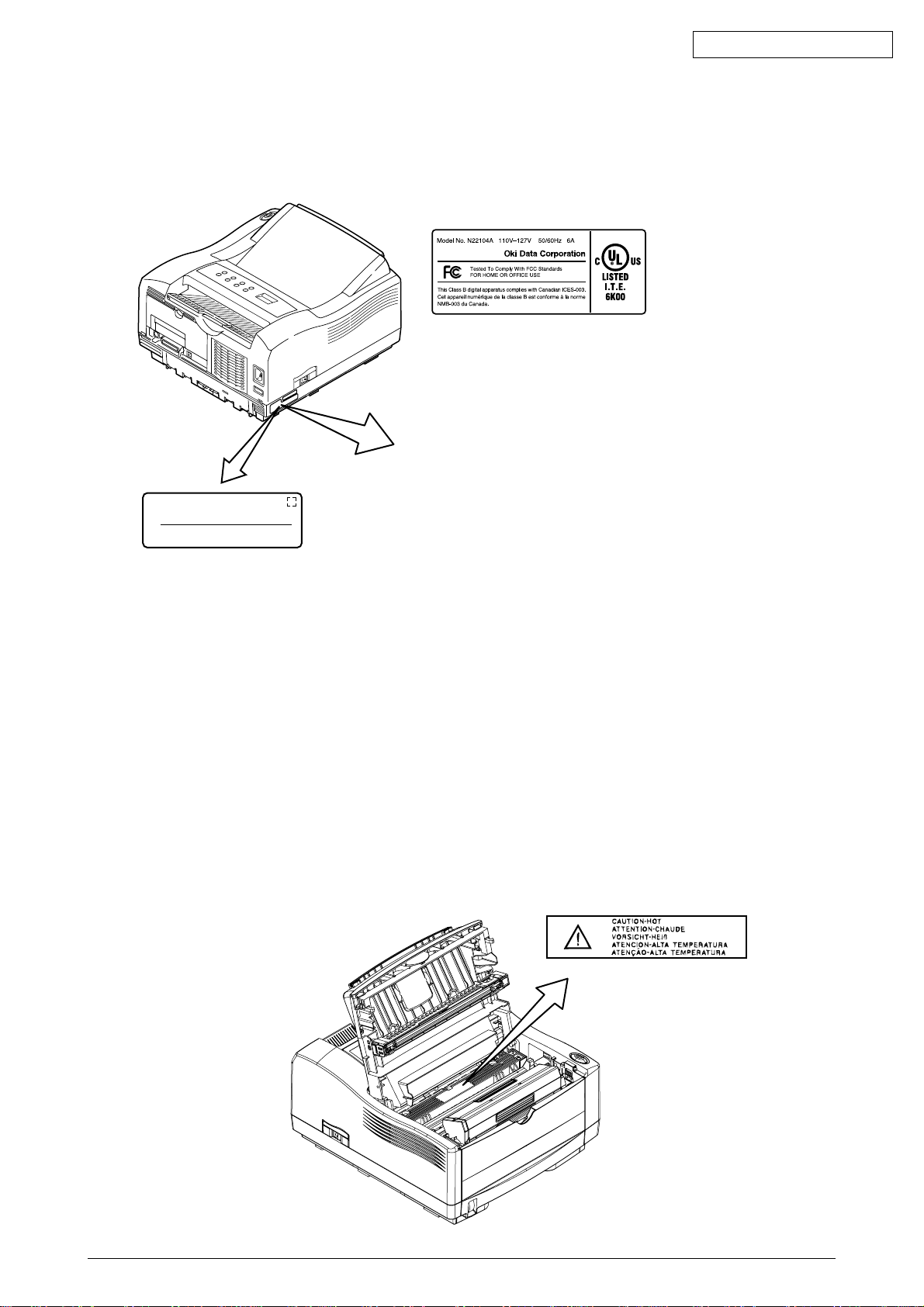

1.5.1 Certification Label

The safety certification label is affixed to the printer in the position described below.

Oki Data CONFIDENTIAL

ODA AC : 120V model

Serial No.

1.5.2 Warning Label

The warning labels are affixed to the sections which may cause bodily injury.

Follow the instructions on warning labels during maintenance.

Made In China

42641101TH Rev.1 13 /

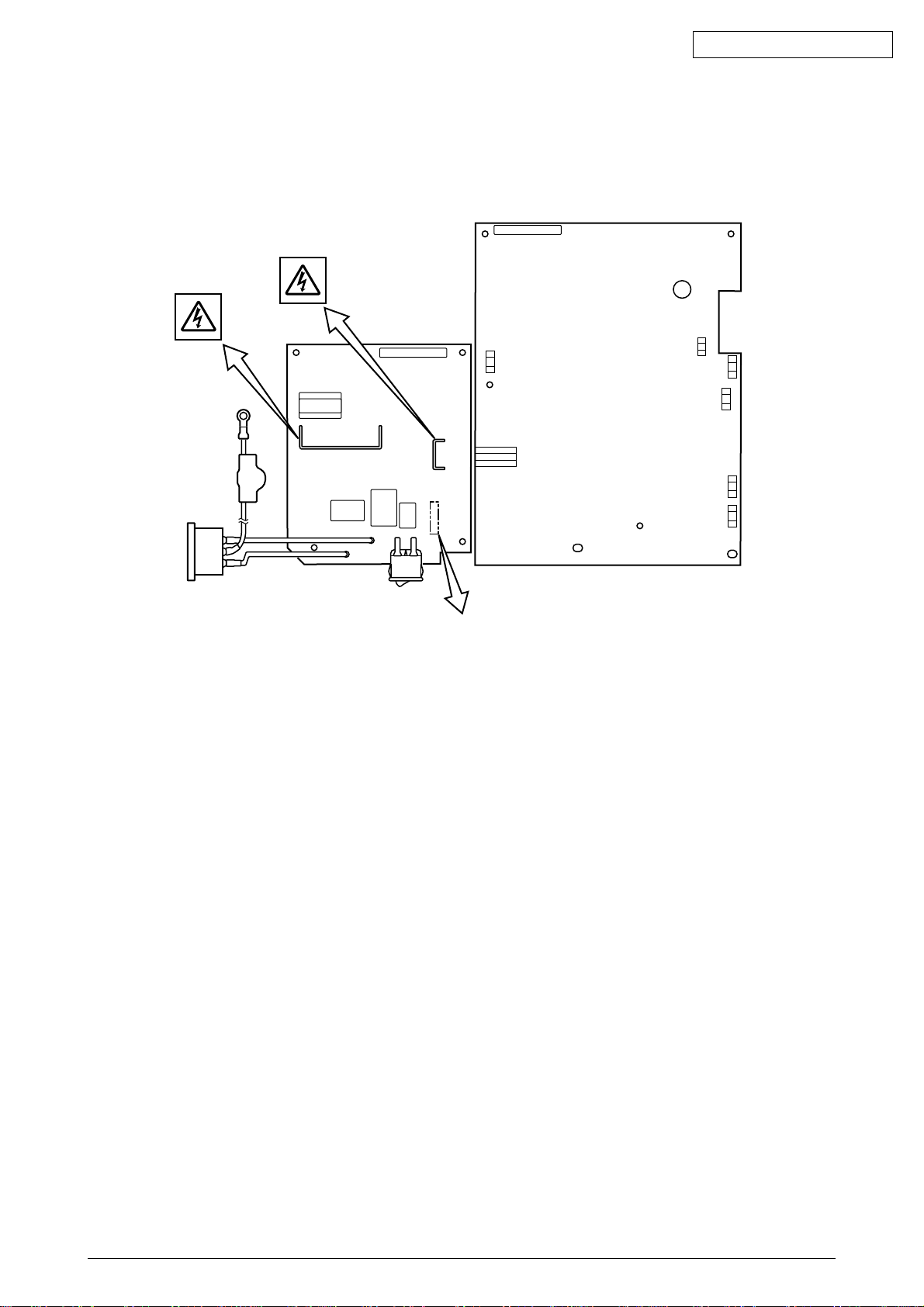

1.5.3 Warning/Caution Marking

The following warning and caution markings are made on the power supply/sensor board.

Oki Data CONFIDENTIAL

CAUTION

ENGLISH

Heatsink and transformer core present risk of electric shock. Test before touching.

42641101TH Rev.1 14 /

2. PARTS REPLACEMENT

The section explains the procedures for replacement of parts, assemblies, and units in the field. Only

the disassembly procedures are explained here. For reassembly, reverse the disassembly procedure.

2.1 Precautions for Parts Replacement

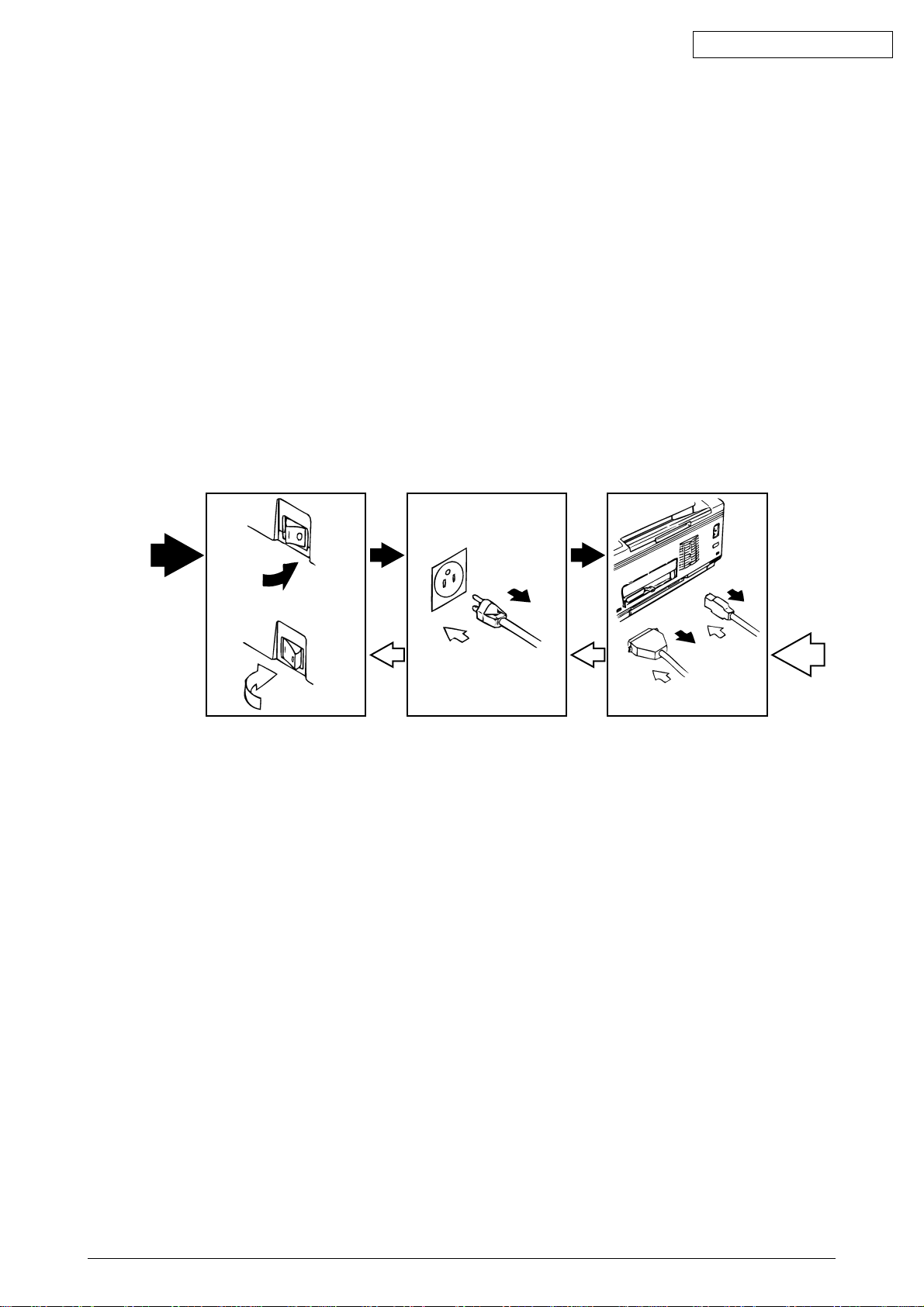

(1) Before starting to replace parts, remove the AC cord and interface cable.

(a) Remove the AC cord in the following sequence:

i) Turn off (“o”) the power switch of the printer

ii) Disconnect the AC inlet plug of the AC cord from the AC receptacle.

iii) Disconnect the AC cord and interface cable from the printer.

(b) Reconnect the printer in the following procedure.

i) Connect the AC cord and interface cable to the printer.

ii) Connect the AC inlet plug to the AC receptacle.

iii) Turn on (“l”) the power switch of the printer.

Oki Data CONFIDENTIAL

Disconnect

OFF

ON

(2) Do not disassemble the printer as long as it is operating normally.

(3) Do not remove parts which do not have to be touched; try to keep the disassembly to a minimum.

(4) Use specified service tools.

(5) When disassembling, follow the laid out sequences. Parts may be damaged if these sequences are

not followed.

(6) Since screws, collars and other small parts are likely to be lost, they should temporarily be attached

to the original positions during disassembly.

Reconnect

(7) When handling IC’s such as microprocessors, ROMs and RAMs, or circuit boards, do not wear

gloves that are likely to generate static electricity.

(8) Do not place printed circuit boards directly on the equipment or floor.

42641101TH Rev.1 15 /

Oki Data CONFIDENTIAL

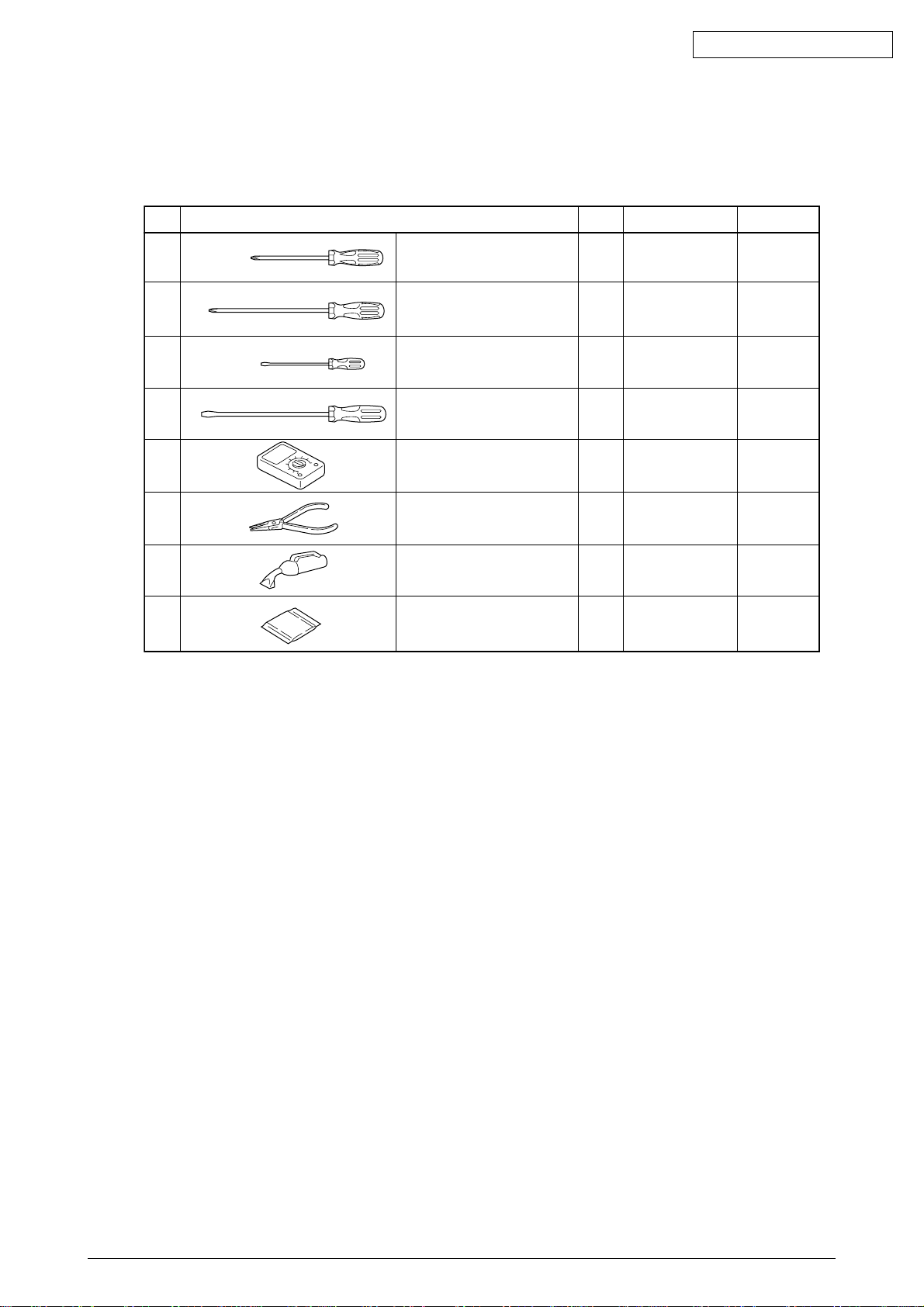

[Service Tools]

The tools required for field replacement of printed circuit boards, assemblies and units are listed in Table

2-1.

Table 2-1 Service Tools

No. Q’ ty Application RemarksService Tools

1

2

3

4

5

6

7

8

No. 1-100 Philips screwdriver

No. 2-100 Philips screwdriver

No. 3-100 screwdriver

No. 5-200 screwdriver

Digital multimeter

Pliers

Handy cleaner

LED Head cleaner

1

2~2.5 mm screws

1

3~5 mm screws

1

1

1

1

1

1

Cleans LED head

42641101TH Rev.1 16 /

2.2 Parts Layout

This section explains the layout of main components of the equipment.

[Lower base unit]

Eject roller assy

Oki Data CONFIDENTIAL

Stacker cover assy

Back-up roller

Diselectrification bar

Lower base unit

View A

Transfer roller

Registration

roller Assy

Pulse motor

(main/drum)

Pulse motor

(registration)

Pulse motor

(hopping)

Manual feed guide assy

Toner cartridge (Type 9)

(consumable)

Stacker cover assy

Hopping roller rubber

LED head

Hopping roller shaft

Image drum unit (Type 9)

(consumable)

View A

Figure 2-1

42641101TH Rev.1 17 /

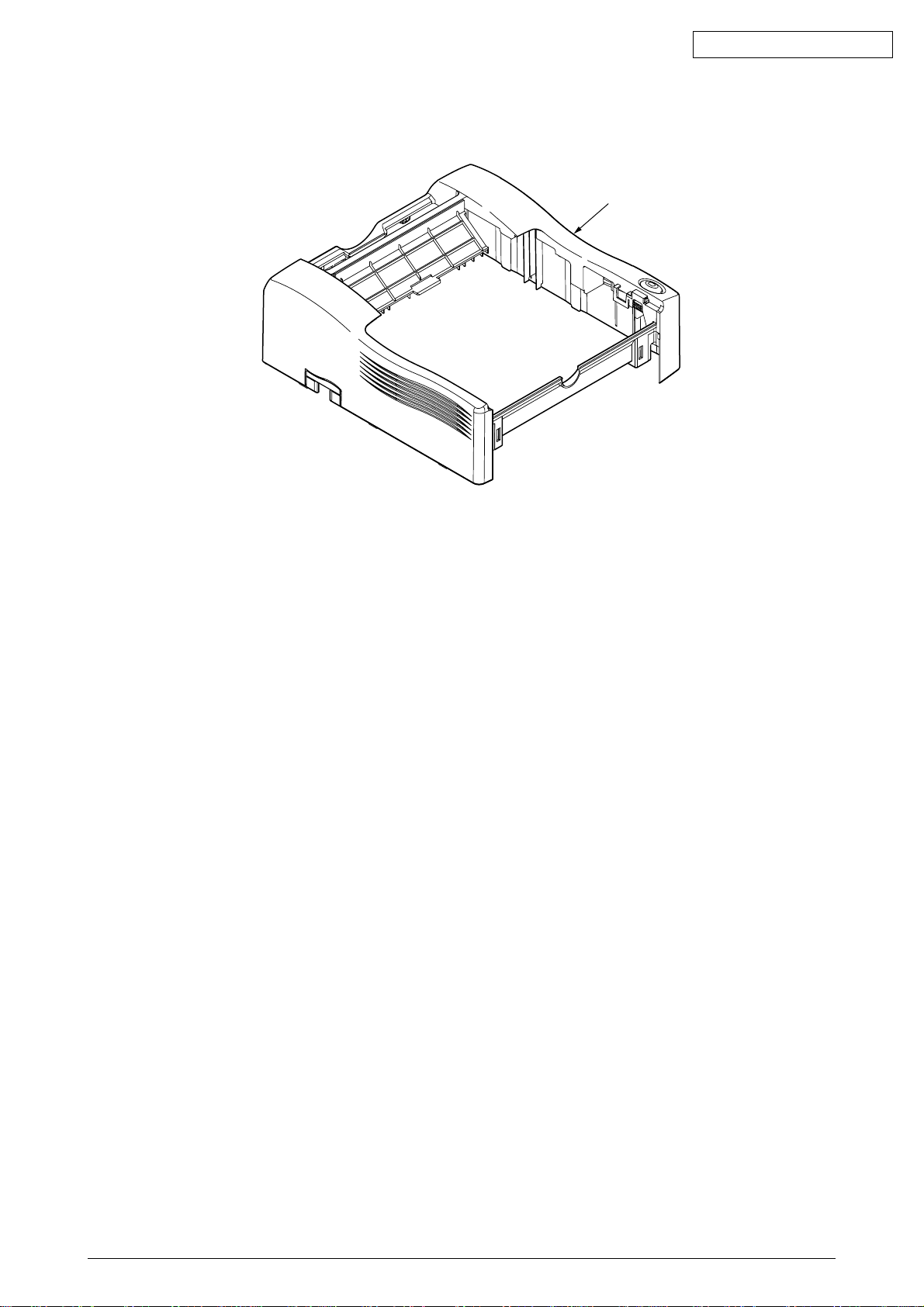

[Upper cover unit]

Oki Data CONFIDENTIAL

Upper cover

Figure 2-2

42641101TH Rev.1 18 /

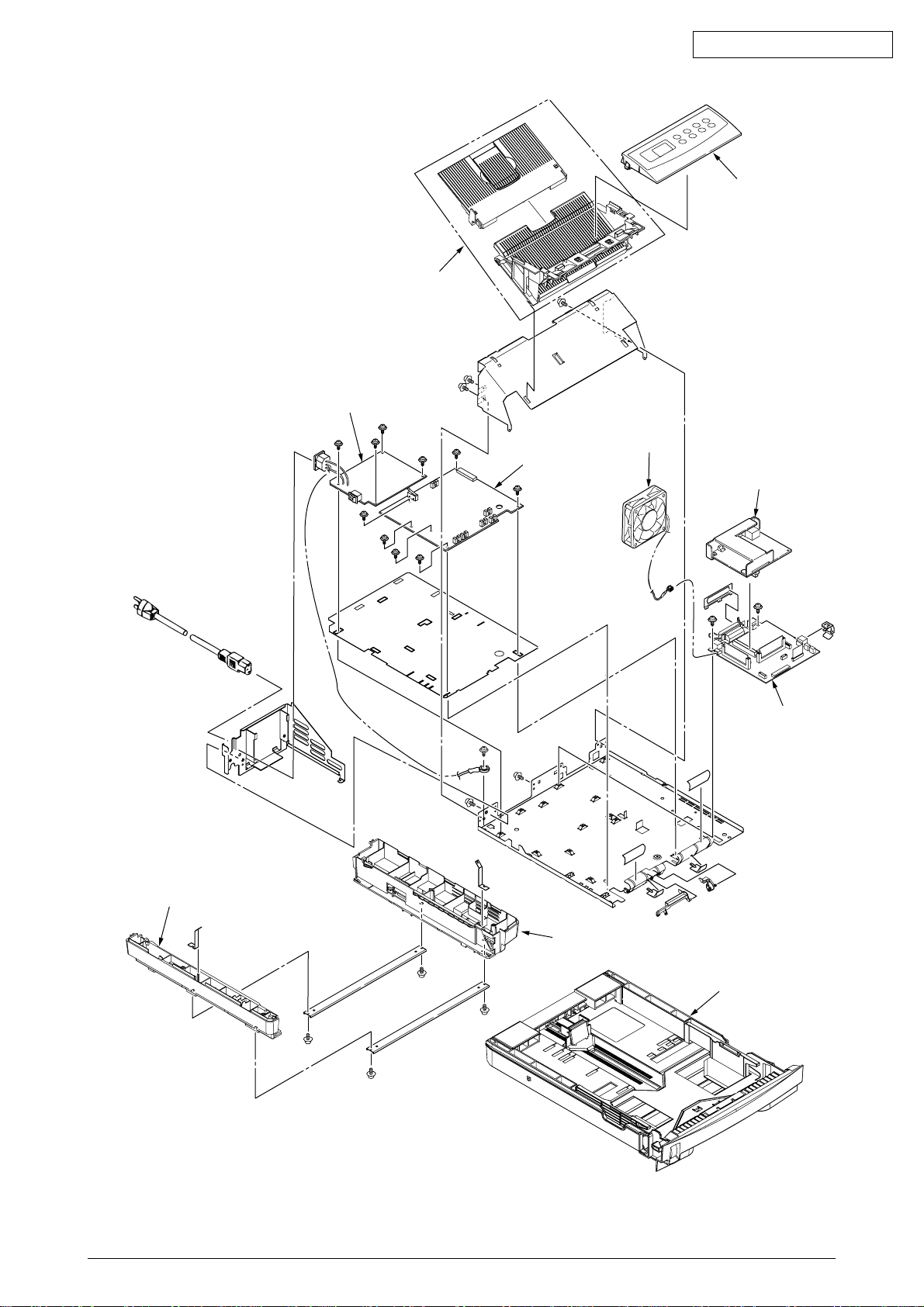

[Base unit]

Oki Data CONFIDENTIAL

Operator panel assy

Face up stacker assy

Power supply/sensor board

(Low voltage)

High voltage /

sensor board

DC fan assy

Network Interface board

Main control board

Cassette guide (L) Assy

Cassette guide (R) Assy

Paper cassette

Figure 2-3

42641101TH Rev.1 19 /

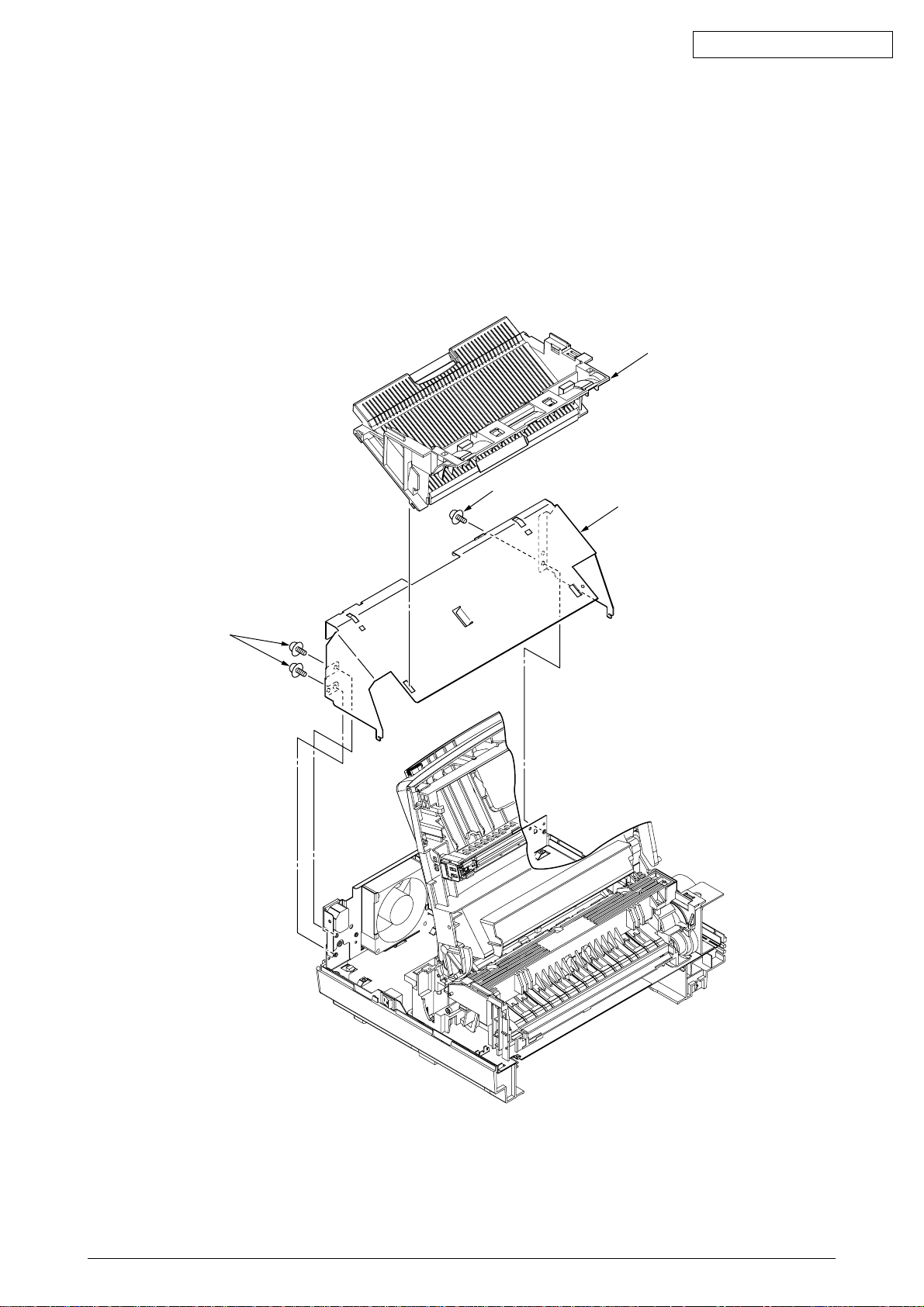

2.3 How to Change Parts

This section explains how to change parts and assemblies listed in the disassembly diagram below.

In the parts replacement procedure, those parts marked with the part number inside ● with white letters

are RSPL parts.

Oki Data CONFIDENTIAL

Printer unit Upper cover assy

(2.3.1)

LED head

(2.3.2)

Transfer roller

(2.3.14)

1

Hopping roller shaft assy

(2.3.11)

Stacker cover assy

(2.3.12)

Registration roller

(2.3.13)

Operator panel assy

(2.3.3)

Manual feed guide assy

(2.3.19)

Fusing unit

(2.3.15)

Back up roller

(2.3.16)

Face up stacker assy

(2.3.8)

Lower base unit

(2.3.4)

Pulse motor (main/drum)

(2.3.5)

Pulse motor (registration)

(2.3.6)

Pulse motor (hopping)

(2.3.7)

Eject roller assy

(2.3.9)

Motor assy

(2.3.10)

Sensor plate (inlet)

(2.3.17)

Sensor plate (outlet),

sensor wire assy

(2.3.18)

Sensor plate (paper supply)

(2.3.20)

To

1

2

Power supply board, high voltage / sensor board

(2.3.22)

Cassette guide (L)

(2.3.23)

Cassette guide (R)

(2.3.24)

GRV-2 PCB

(2.3.21)

To

2

42641101TH Rev.1 20 /

2.3.1 Upper Cover Assy

(1) With the power switch turned off, unplug the AC power cord from the outlet.

(2) Disconnect the interface cable 1.

(3) Press the button 2 on right side of the Upper cover and open the stacker cover assy 3.

(4) Take out the image drum unit 4.

(5) Remove one screw 5, and remove the I/F cover 6 from the back side of the printer.

(6) Open the manual feed guide assy 7. Unlock the latches at two locations on the front side. Lift the

front side of the upper cover 8 up and unlock the latches at two locations on the back side. Lift and

remove the upper cover assy 8.

Oki Data CONFIDENTIAL

Note :

When removing or reinstalling the upper cover, be careful not to get the motor cables tangled

or caught.

5

6

LATCH

2

8

LATCH

1

4

3

7

42641101TH Rev.1 21 /

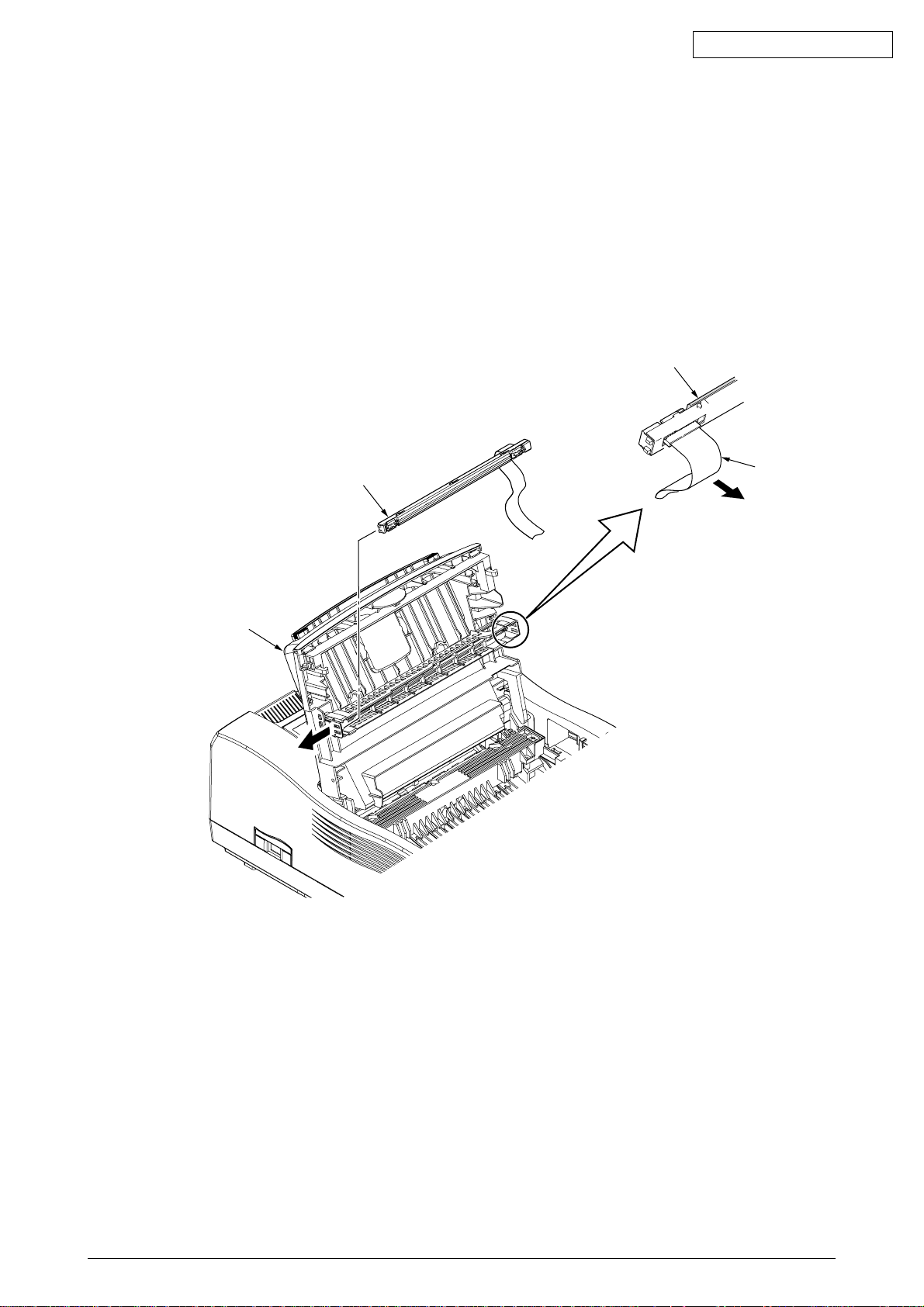

2.3.2 LED Head

SLA

(Seltoc Lens Array)

1

2

3

(1) Press the button on right side of the upper cover and open the stacker cover assy 1.

(2) Open the hook section on the left side of the head holder and remove the LED head 2.

(3) Remove the head cable 3 from the head connector.

Oki Data CONFIDENTIAL

Note:

Be sure not to touch directly or push on the SLA part of the LED head.

42641101TH Rev.1 22 /

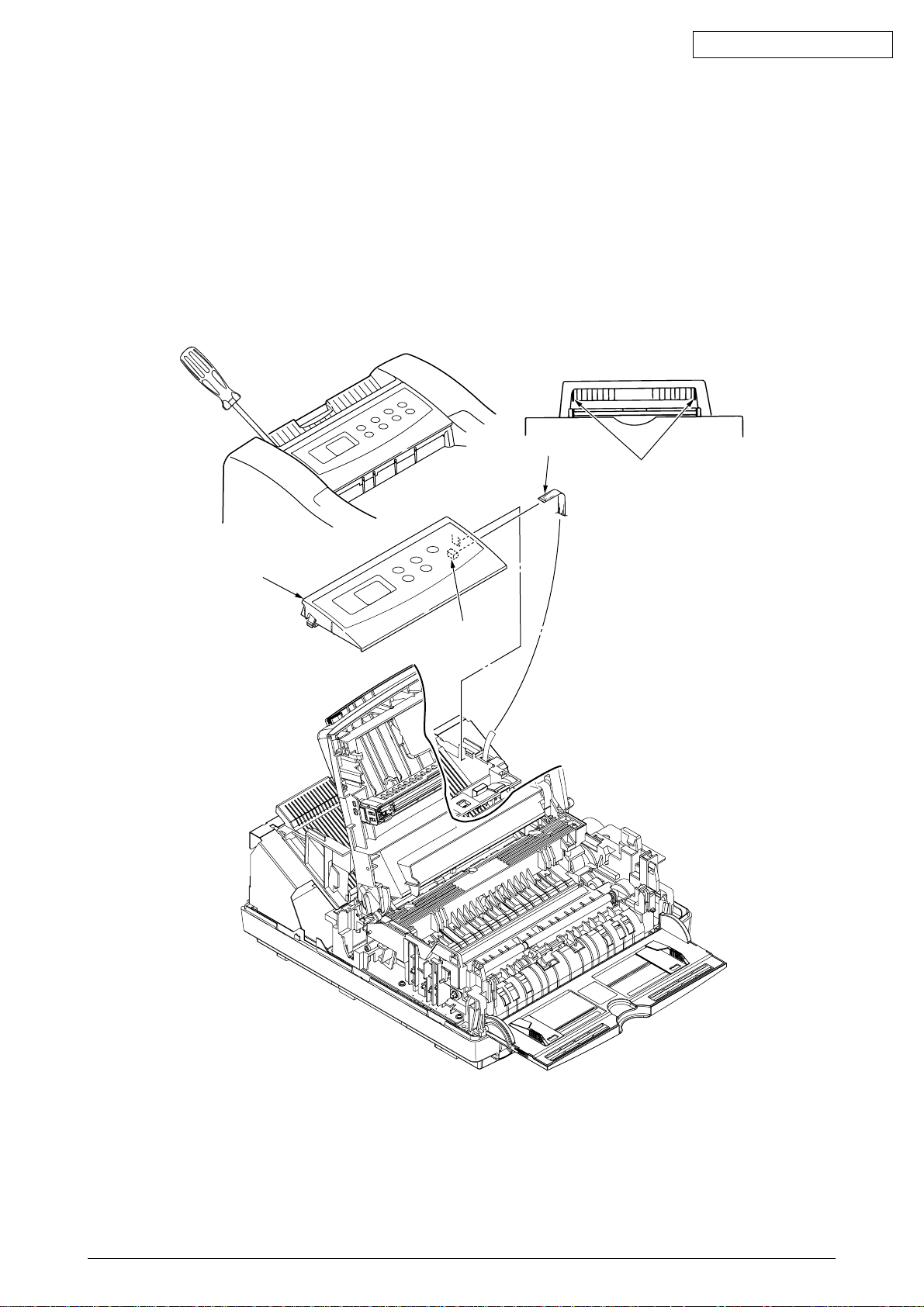

2.3.3 Operator Panel Assy

(1) Unlock two latches on the upper cover from the rear side, lift the operator panel assy 1 from the

back and remove it.

(2) Remove the Sumi card (operator panel) 2 from the connector (CN1) 3.

Oki Data CONFIDENTIAL

Note :

You can remove the operator panel assy while the upper cover installed on the unit. However,

it is much easier to remove the panel assy after removal of upper cover.

Rear view

2

Unlock two latches with a tip of

screw driver. For the purpose,

insert a driver through faceup

paper outlet as shown.

1

3

42641101TH Rev.1 23 /

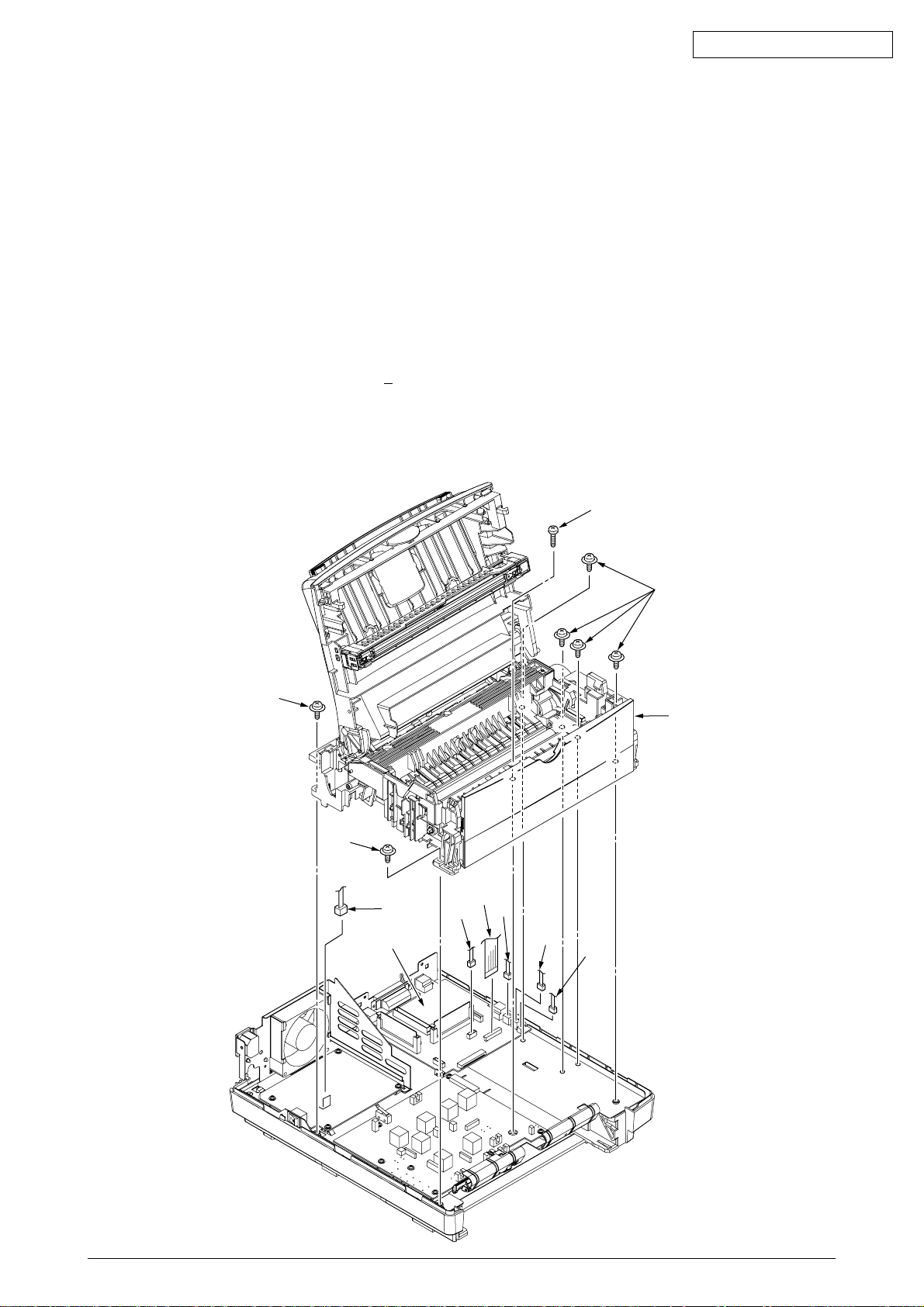

2.3.4 Lower Base Unit

(1) Remove the upper cover assy (see 2.3.1).

(2) Remove the operator panel assy (see 2.3.3).

(3) Remove the face up stacker assy (see 2.3.7).

(4) Remove the transfer roller assy (see 2.3.14).

(5) Remove the connecting cables 1, 2 and 3 of the pulse motors from the connectors (DM, RM, HM)

of the GRV-2 PCB 1.

(6) Remove the LED head cables 4 from the connector (HEAD).

(7) Remove the Thermistor cable 5 from the connector (THERM).

(8) Remove the connecting cable 8 of the heater from the connector (CN2).

(9) Open the manual feed guide assy, remove seven screws 7, then remove the lower base unit 6.

Oki Data CONFIDENTIAL

7

7

8

1

5

4

7

7

6

2

3

1

42641101TH Rev.1 24 /

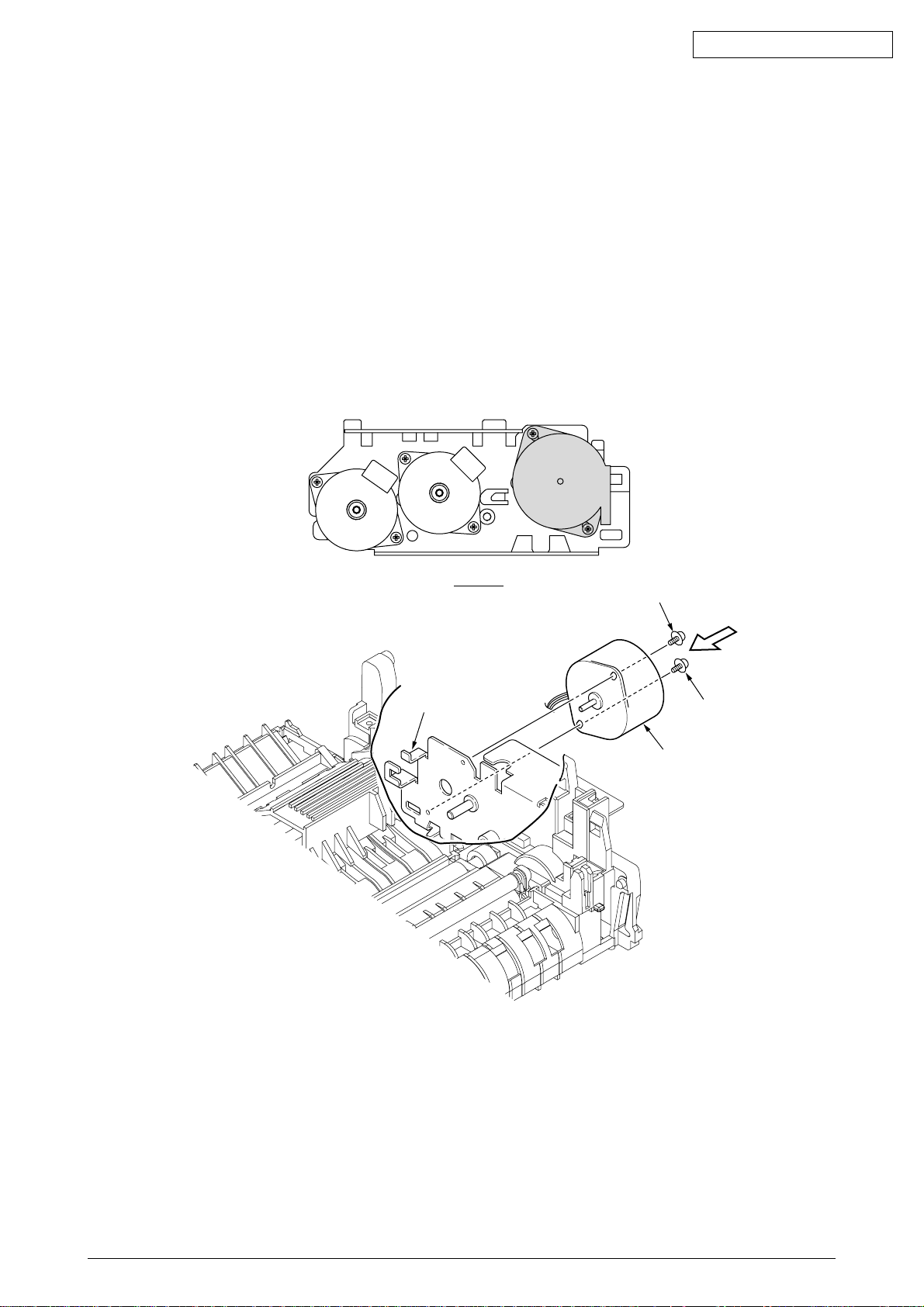

2.3.5 Pulse Motor (Main/Drum)

3

1

2

1

View A

(1) Remove the upper cover assy (see 2.3.1).

(2) Remove the lower base unit (see 2.3.4).

(3) Remove two screws 1 and remove the pulse motor (main/drum) 2 from the motor bracket 3.

Oki Data CONFIDENTIAL

View A

42641101TH Rev.1 25 /

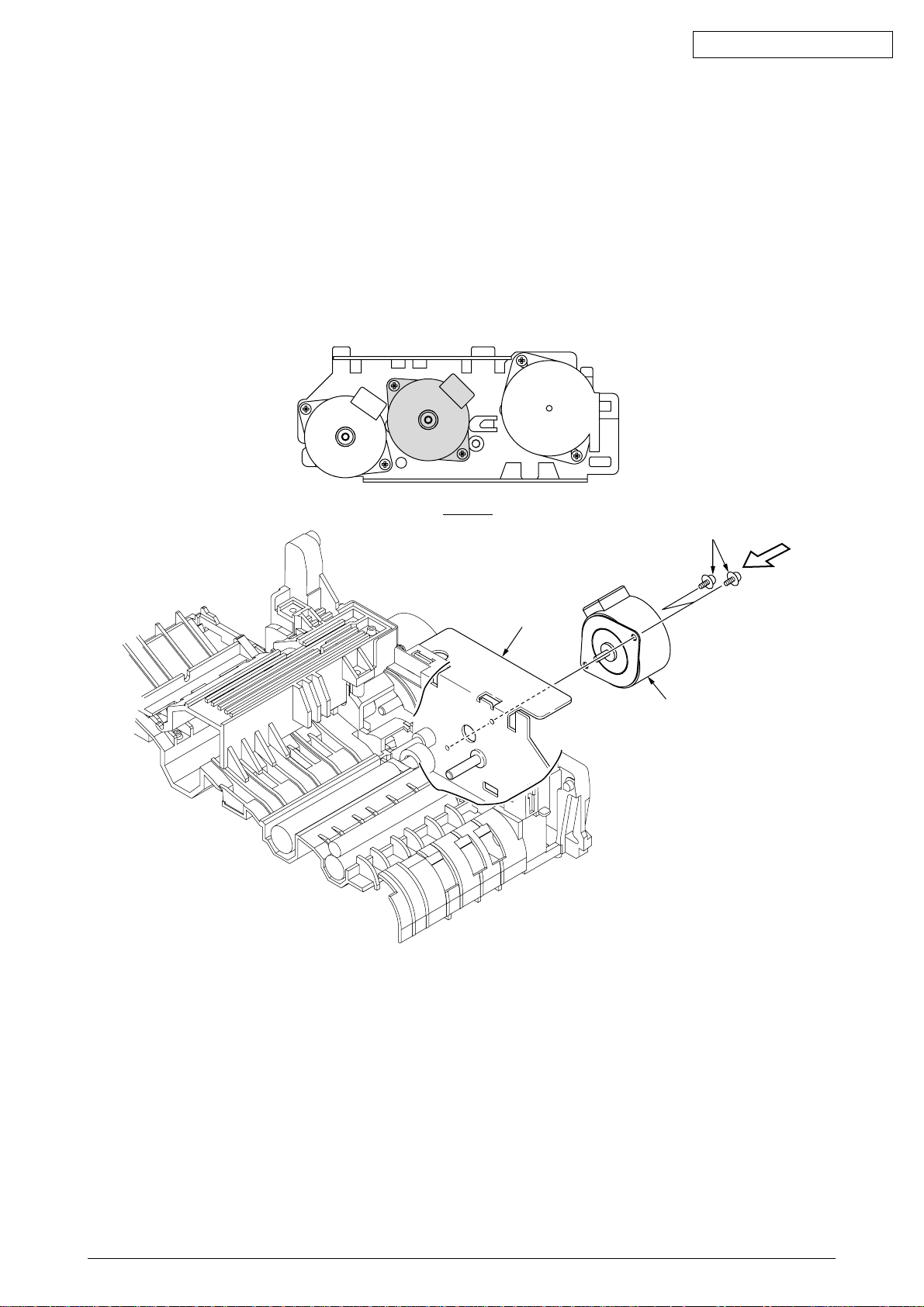

2.3.6 Pulse Motor (Registration)

(1) Remove the upper cover assy (see 2.3.1).

(2) Remove the lower base unit (see 2.3.4).

(3) Remove two screws 1 and remove the pulse motor (registration) 2 from the motor bracket 3.

Oki Data CONFIDENTIAL

View A

3

2

1

View A

42641101TH Rev.1 26 /

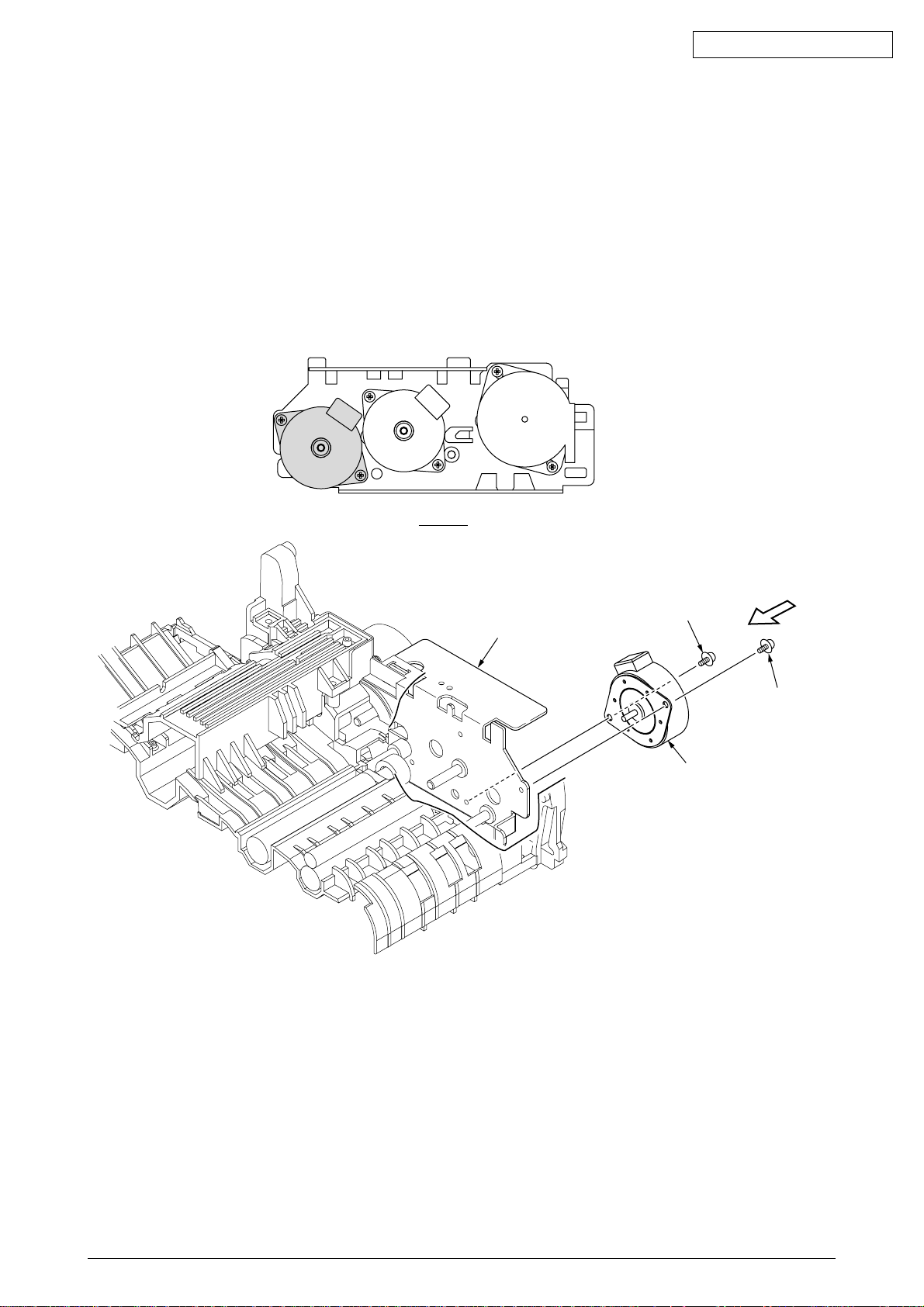

2.3.7 Pulse Motor (Hopping)

(1) Remove the upper cover assy (see 2.3.1).

(2) Remove the lower base unit (see 2.3.4).

(3) Remove two screws 1 and remove the pulse motor (hopping) 2 from the motor bracket 3.

Oki Data CONFIDENTIAL

View A

View A

1

3

1

2

42641101TH Rev.1 27 /

2.3.8 Face Up Stacker Assy

(1) Remove the upper cover assy (see 2.3.1).

(2) Remove the operator panel assy (see 2.3.3).

(3) Remove three screws 1 and remove both the shield plate 2 and face up stacker 3 together.

(4) Unlock the latches at two locations, and remove the face up stacker 3.

Oki Data CONFIDENTIAL

3

1

1

2

42641101TH Rev.1 28 /

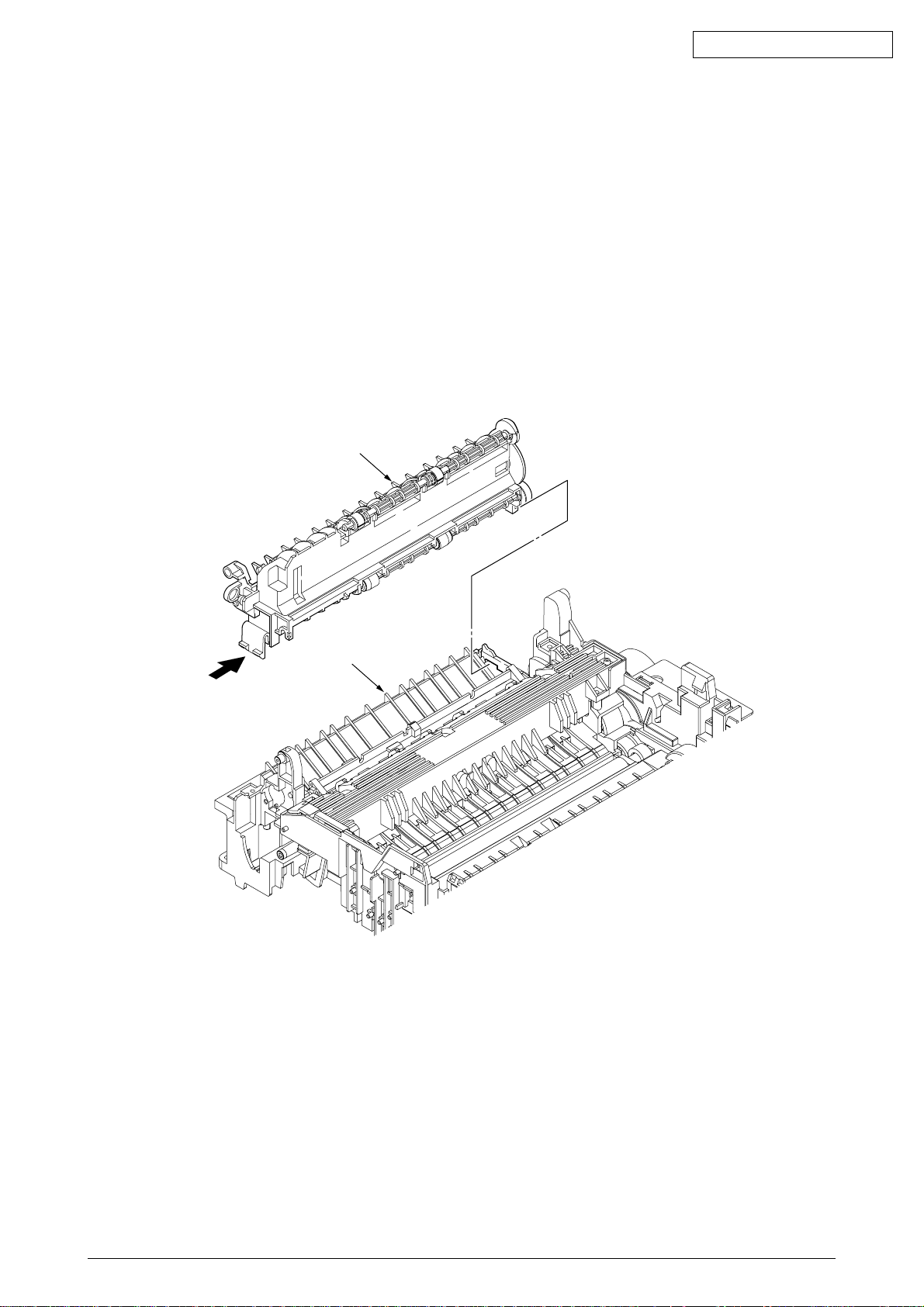

2.3.9 Eject Roller Assy

(1) Remove the upper cover assy (see 2.3.1).

(2) Remove the operator panel assy (see 2.3.3).

(3) Remove the face up stacker assy (see 2.3.8).

(4) Remove the stacker cover assy (see 2.3.12).

(5) Disengage the eject roller assy 1 from the lower base 2 by pressing the latch section of the eject

roller assy 1 in the direction of the arrow shown below, and remove the eject roller assy 1.

Oki Data CONFIDENTIAL

1

LATCH

2

42641101TH Rev.1 29 /

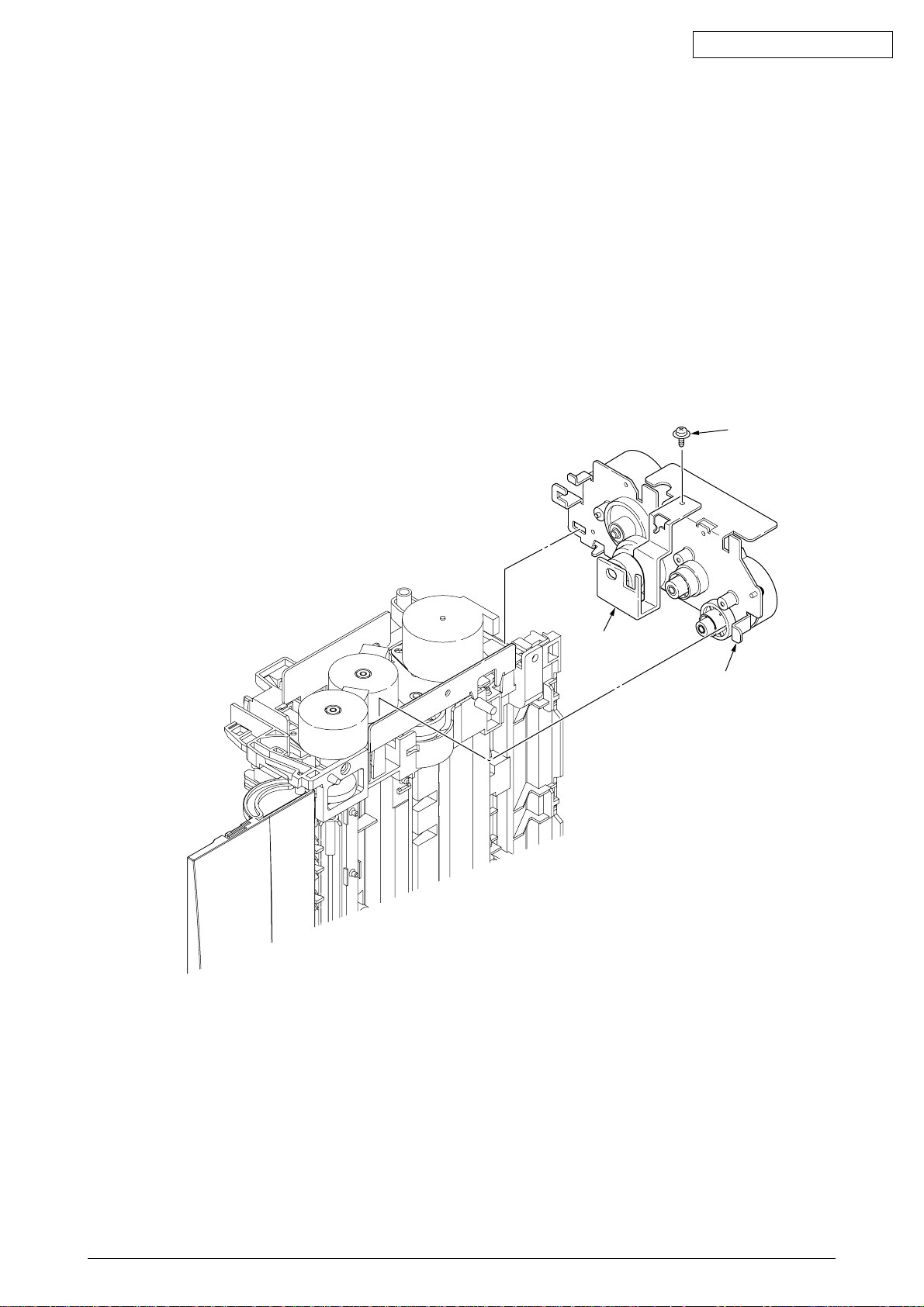

2.3.10 Motor Assy

(1) Remove the upper cover assy (see 2.3.1).

(2) Remove the operator panel assy (see 2.3.3).

(3) Remove the face up stacker assy (see 2.3.8).

(4) Remove the lower base unit (see 2.3.4).

(5) Stand the lower base unit on its side as shown, and unlock two latches, then remove the motor assy

1.

(6) Remove screw 2 and remove the bracket-Motor-Sub 3 from the Motor bracket.

Oki Data CONFIDENTIAL

2

3

1

42641101TH Rev.1 30 /

Loading...

Loading...