OKIDATA 520, 521 Service Manual

Chapter 0

Manual Front Cover

Microline 520/521

Service Handbook

P/N 59257803

Part of the Microline 520/521Service Training Kit

P/N 58229403

ML520/521 ( 96-02-04 )

Chapter 1

1.1.01 General Information

1.1.01 General Information

The Microline 520 and Microline 521 are letter quality, nine-pin, dot-matrix printers which utilize

OKISMART

adjustment. The printer actually reads and learns the print medium being used, then automatically adjusts

the head gap to the optimum distance. This autogapping process leads to longer printhead life.

Options include the Bottom Feed Push Tractor, Cut-Sheet Feeder, Pull Tractor and Serial Interface

Board.

The Microline 520 is an 80 column printer.

The Microline 521 is a 132 column printer.

Okidatas one year limited warranty covers the parts, labor and printhead on both printers.

The following items are available for the printer.

OKISMART Typer

typewriter on checks, labels and envelopes.

OKISMART Panel

computer.

Scalable Fonts - 14 scalable fonts, available on diskette.

NOTE:

The OkiSmart software includes three programs.

1. OkiSmart Control

2. OkiSmart Panel Emulator

3. OkiSmart Setup

Refer to the Printer Handbook for more information.

paper handling. Patented Okidata technology does away with the manual head gap

- software which provides the flexibility for the Microline 590/521 to function like a

- a utility program that lets you control selected printer functions from your personal

ML520/521 ( 96-02-04 )

%1.2 Physical Specifications

1.2 PHYSICAL SPECIFICATIONS

1.2.01 Dimensions

NOTE:

Dimensions INCLUDE the platen knob, acoustic cover, and paper separator.

Microline 520

Width: 16.9 inches (43 centimeters)

Depth: 14.9 inches (37.8 centimeters)

Height: 6.5 inches (16.5 centimeters)

Microline 521

Width: 23 inches (58.4 centimeters)

Depth: 14.9 inches (37.8 centimeters)

Height: 6.5 inches (16.5 centimeters)

1.2.02 Printer Weight

Microline 520

17.6 pounds (8.0 kilograms)

Microline 521

23.1 pounds (10.5 kilograms)

ML520/521 ( 96-02-04 )

%1.3 Power Requirements

1.3 POWER REQUIREMENTS

1.3.01 Input Power

120 VAC: +5.5 / -15%

230/240 VAC: +10 / -14%

1.3.02 Power Consumption

Operating: 110 VA

Idle: 40 VA

Local Test: 70 VA

1.3.03 Power Frequency

120 VAC: 60 Hz +/- 2%

230/240 VAC: 50/60 Hz +/- 2%

ML520/521 ( 96-02-04 )

%1.4 Environmental Conditions

1.4 ENVIRONMENTAL CONDITIONS

1.4.01 Acoustic Rating

Near Letter Quality Mode

Microline 520 54.9 dBA

Microline 521 54.4 dBA

Utility Mode

Microline 520 57.2 dBA

Microline 521 56.9 dBA

Quiet Mode

Microline 520 52.5 dBA

Microline 521 52.3 dBA

1.4.01 Altitude

10,000 feet (3,050 meters)

1.4.03 Ambient Temperature and Relative Humidity (RH)

While operating: 41 to 104 degrees Fahrenheit (5 to 40 degrees Celsius)

Operating humidity: 20% to 80% RH

While in storage: 14 to 122 degrees Fahrenheit ( - 10 to 50 degrees Celsius)

Storage humidity: 5% to 95% RH

ML520/521 ( 96-02-04 )

%1.6 Operational Specifications

1.6 OPERATIONAL SPECIFICATIONS

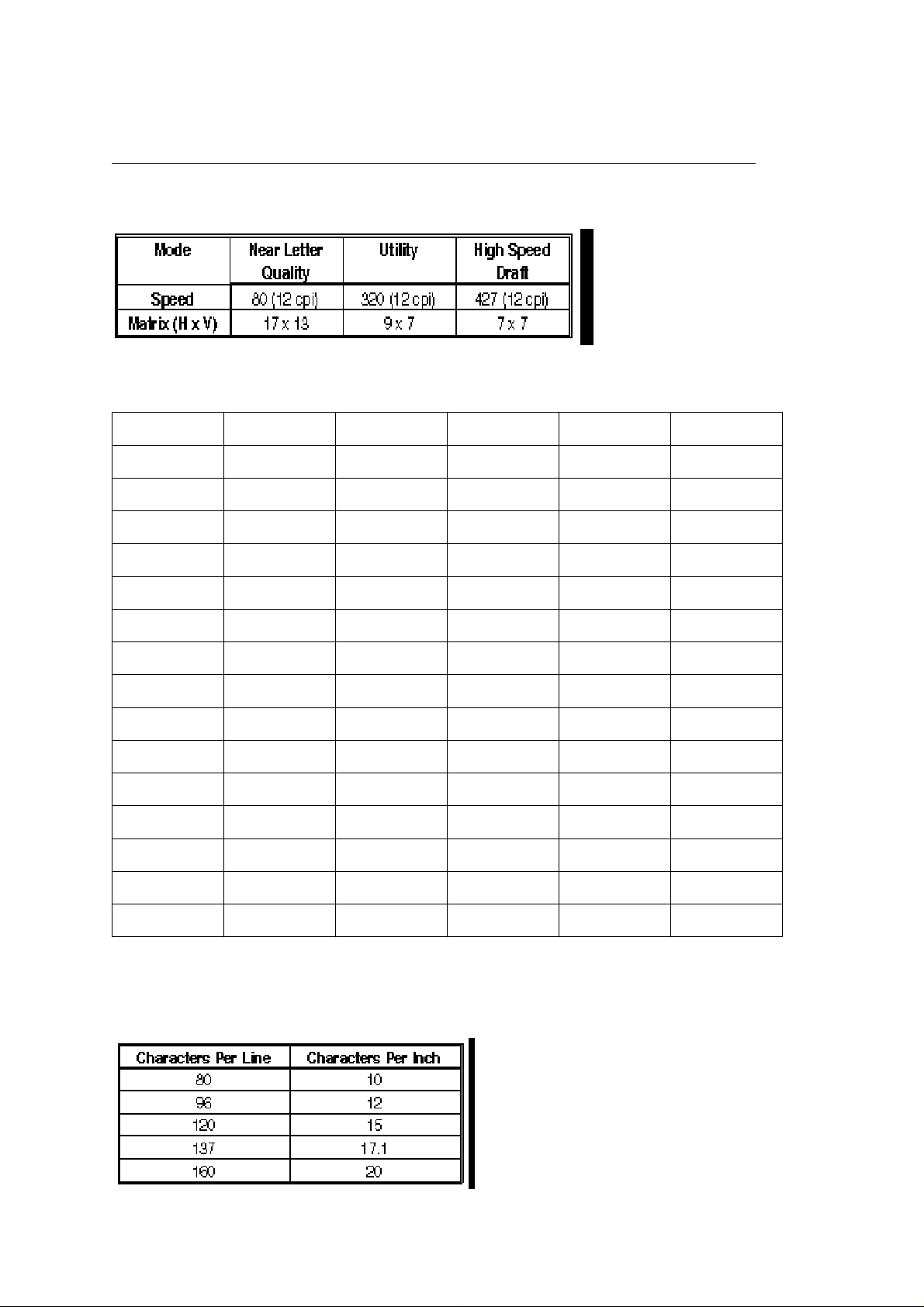

1.6.01 Character Matrix Sizes

Table of Print Speed and Character Matrix

Print Speed at Different CPI for the ML 520/521

Mode CPI CPS Horiz. DPI Vert DPI IPS

HSD 10 427 90 72 42.7

12 427 108 72 35.6

15 427 135 72 28.5

17.1 427 154 72 25.0

20 427 180 72 21.4

Utility 10 320 120 72 32

12 320 144 72 26.7

15 320 180 72 21.3

17.1 320 206 72 18.6

20 320 240 72 16.0

LQ 10 80 240 144 16.0

12 80 288 144 13.3

15 80 360 144 13.3

17.1 80 412 144 9.32

20 80 480 144 8.0

1.6.02 Characters Per Line

Microline 520

ML520/521 ( 96-02-04 )

Microline 521

1.6.03 Character Pitches

5, 6, 8.5, 10, 12, 15, 17.1, 20

1.6.04 Character Sets

Standard ASCII

EPSON Character Set I & II

IBM Character Set I, II & All Characters

Foreign Character Substitution

International Character Sets

Code Page 850, 860, 863, 865 and 437

Line Graphics

Bar Code

Code 39

UPC A

UPC E

EAN 8

EAN 13

Interleaved 2 of 5

Code 128 (A, B, C)

Postnet

1.6.05 Emulations

NOTE:

The emulations are co-resident

Epson FX

IBM Proprinter

Microline Standard

1.6.06 Fonts

Near Letter Quality

Courier

Utility

Gothic

High Speed Draft

Gothic

Bar Code

Code 39

UPC A

UPC E

EAN 8

EAN 13

Interleaved 2 of 5

Code 128 (A, B, C)

Postnet

1.6.07 Front Panel Switches

SELECT / Menu Micro Feed Up / Down

Shift Paper Park

Line Feed Pitch Selection

FORM FEED / Load Print Quality Selection

ML520/521 ( 96-02-04 )

Top of Form Tear

Quiet Reset

1.6.08 Graphics Resolution

Graphics Resolution: 288 (horizontal) x 144 (vertical) dots per inch (DPI) maximum

1.6.09 Interface

Standard

Centronics Parallel

Optional

RS232C Serial

1.6.10 Line Feed Increments

Fixed

6 lines per inch (lpi) [0.167 inch (4.23 millimeters)]

8 lines per inch (lpi) [0.125 inch (3.175 millimeters)]

Variable

n/60 inch

n/72 inch

n/144 inch

n/216 inch

1.6.11 Line Feed Time

65 milliseconds 6 lines per inch (lpi)

6 milliseconds 8 lines per inch (lpi)

1 second 5.0 inches (Continuous paper feed rate)

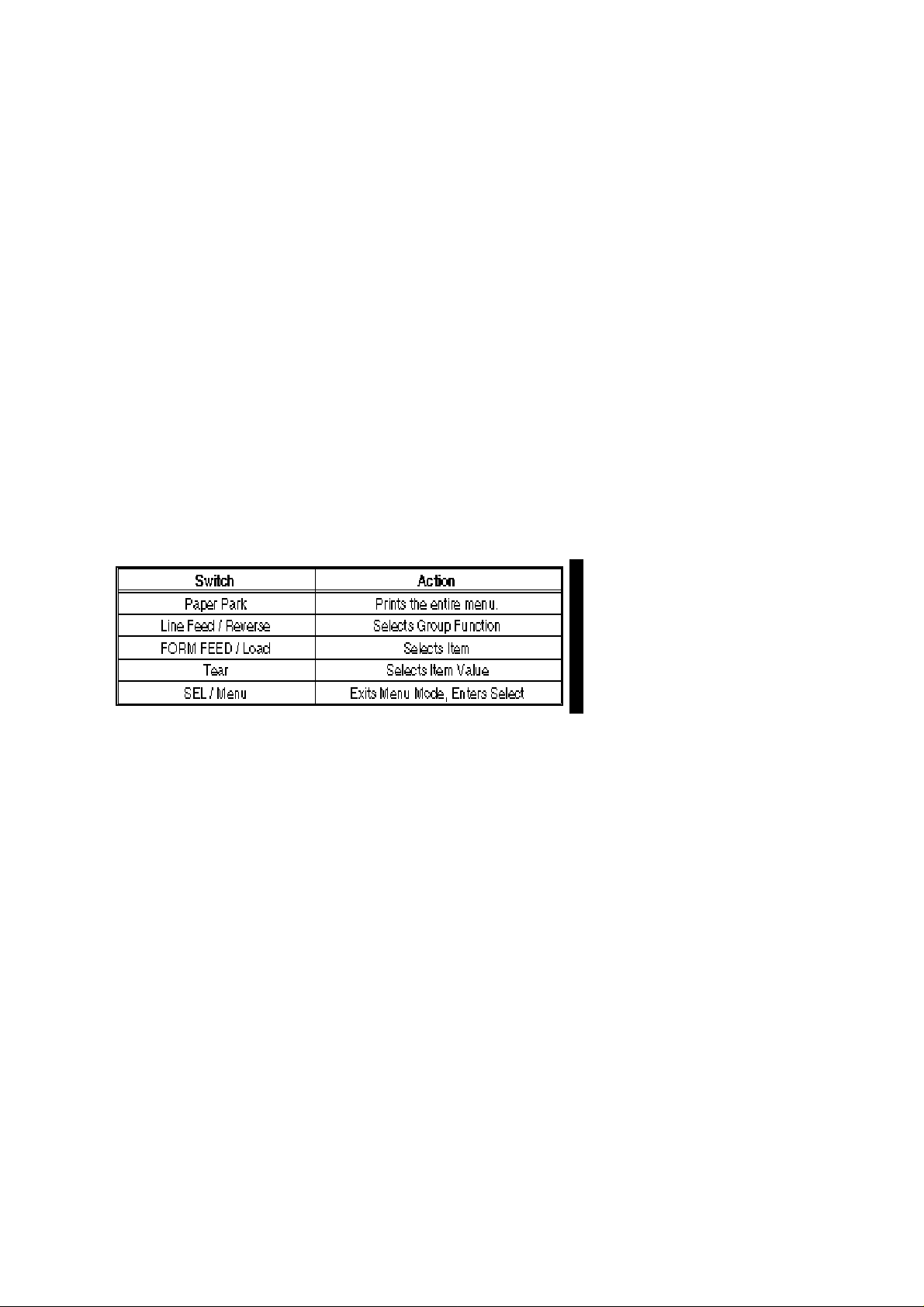

1.6.12 Menu Mode

1.6.13 Paper Feed Methods

Standard

Friction Feed (Top)

Rear Push Tractor (Rear)

Optional

Pull Tractor (Bottom)

Bottom Push Tractor Feed (Bottom)

Single-Bin Cut Sheet Feeder (Top)

CSF 5000 - Narrow

CSF 5001 - Wide

1.6.14 Paper Feed Paths

Top Feed (Standard)

Rear Feed (Standard)

Bottom Feed (by using an Optional feed mechanism)

Special Features

Paper Park

Automatic Paper Loading

Forms Tear Off

1.6.15 Paper Loading

Auto Loading (Top Feed)

Press FORM FEED / Load switch to feed paper to default position

1.6.16 Paper Out Detection

Distance from end of paper

Rear Feed: 0.5 inches (12.7 mm)

ML520/521 ( 96-02-04 )

Bottom Feed: 0.5 inches (12.7 mm)

Top Feed: 0.5 inches (12.7 mm)

1.6.17 Paper Tear Capabilities

Forms Tear-0ff (sharp edge on access cover)

Metal Tear Bar (with optional bottom feed tractor unit)

1.6.18 Print Method

Printhead Type

General Information

Impact: Dot Matrix

9 pin printhead

.0134 inch (0.34 millimeter) diameter pins

Overheat Protection

When printhead temperature exceeds 110 degrees Celsius, the printer stops bi-directional printing.

Uni-directional printing begins.

If the temperature exceeds 118 degrees Celsius, printing stops.

Printing will resume when the printhead temperature drops below 118 degrees Celsius.

NOTE:

Refer to Section Two for more information on printhead operation.

1.6.19 Print Modes

Near Letter Quality

Utility

High Speed Draft

1.6.20 Print Speed

Table of Print Speed and Character Matrix

ML520/521 ( 96-02-04 )

%1.7 Paper Specifications

1.7 PAPER SPECIFICATIONS

CAUTION:

Use Bottom Feed and/or optional Pull Tractor for card stock and labels.

1.7.01 Types

Card Stock

Weight: 120 lbs. (450 g/m 2 ) Maximum

Width: Microline 520 5 to 8 inches (12.7 to 20.3 centimeters)

Microline 521 5 to 14 inches (12.7 to 35.6 centimeters)

Length: 3 to 17 inches (7.62 to 43.18 centimeters)

Thickness: .017 inches (0.44 millimeters)

Paper Feed Path: Bottom

Printhead Gap Information: Refer to the Printhead Gap Information, Section 1.6

Continuous Form

Weight:

Single Part 12 - 24 lb. (45 to 90 g/m 2 )

Multi-Part, Carbonless 9 - 11 lb. (35 to 40 g/m 2 )

Multi-Part, Interleaf Paper 10 - 12 lb. (38 to 45 g/m 2 ) Carbon 9 lb. (35 g/m 2 )

Width: Microline 520 3.5 to 10.5 inches (8.8 to 26.6 centimeters)

Microline 521 3.5 to 16.5 inches (8.8 to 41.9 centimeters)

Length: 3 to 17 inches (7.62 to 43.18 centimeters)

Thickness: 0.014 inches (0.36 millimeters) Rear Feed 0.017 inches (0.44 millimeters) Bottom Feed

Paper Feed Path: Rear or Bottom

Printhead Gap Information: Refer to the Printhead Gap Information, Section 1.6

Cut Sheet

Weight: 12 to 24 lbs. (45 to 90 g/m 2 )

Width: 7.2 to 14.3 inches (18.3 to 36.3 centimeters)

Width: Microline 520 7.2 to 8.5 inches (18.2 to 21.5 centimeters)

Microline 521 7.2 to 14.3 inches (18.2 to 36.3 centimeters)

Length: 3 to 17 inches (7.62 to 43.18 centimeters)

Thickness: 0.014 inches (0.325 millimeters) Maximum

Paper Feed Path: Top

Printhead Gap Information: Refer to the Printhead Gap Information, Section 1.6.

Envelopes

Weight: 24 lbs. (90 g/m 2 ) Maximum

Size:

Single Feed

Minimum: 6.5 x 3.6 inches (16.5 x 9.1 centimeters)

Maximum: 9.5 x 4.1 inches (24.1 x 10.4 centimeters)

Continuous

Non-overlap type

Thickness: .014 inches (.325 millimeters)Maximum

Paper Feed Path: Bottom

Printhead Gap Information: Refer to the Printhead Gap Information, Section 1.6.

Labels

Weight: N/A

Width: Microline 520 3.5 to 10.5 inches (8.8 to 26.6 centimeters)

Microline 521 3.5 to 16.5 inches (8.8 to 41.9 centimeters)

Length: 3 to 17 inches (7.62 to 43.18 centimeters)

Thickness: .011 inches (0.28 mm) Maximum (including backing)

Paper Feed Path: Bottom

Printhead Gap Information: Refer to the Printhead Gap Information, Section 1.6.

CAUTION:

Use Bottom Feed and/or optional Pull Tractor for card stock and labels.

Transparency

ML520/521 ( 96-02-04 )

NOTE:

Roller marks may mar the transparency under high temperature / high humidity conditions.

Weight: 12 to 24 lbs. (45 to 90 g/m 2 )

Width: Microline 520 7.2 to 8.5 inches (18.2 to 21.5 centimeters)

Microline 521 7.2 to 14.3 inches (18.2 to 36.3 centimeters)

Length: 3 to 17 inches (7.62 to 43.18 centimeters)

Thickness: 0.14 inches (0.36 millimeters)

Paper Feed Path: Top

Printhead Gap Information: Refer to the Printhead Gap Information, Section 1.6.

1.7.02 Length

NOTE:

The recommended length is specific to paper type.

Rear Feed

Minimum 3 inches (7.62 centimeters)

Maximum 17 inches (43.18 centimeters)

Bottom Feed

Minimum 3 inches (7.62 centimeters)

Maximum 17 inches (43.18 centimeters)

Top Feed

Minimum 3 inches (7.62 centimeters)

Maximum 17 inches (43.18 centimeters)

1.7.03 Number of Copies

Original + 4 Interleaf

Original + 4 Carbonless

Original Cut Sheet

1.7.04 Thickness

0.014 inches / 0.36 mm Maximum Thickness, Rear Feed

0.017 inches / 0.44 mm Maximum Thickness, Bottom Feed

1.7.05 Weight

NOTE:

The recommended weight is specific to paper type.

Minimum: 9 lb. (35 g/m 2 )

Maximum: 120 lb. (90 g/m 2 )

1.7.06 Width

NOTE:

The recommended width is specific to paper type.

Paper

Microline 520

Minimum: 3.5 inches ( 8.8 centimeters)

Maximum: 10.5 inches (26.6 centimeters)

Microline 521

Minimum: 3.5 inches ( 8.8 centimeters)

Maximum: 16.5 inches (41.9 centimeters)

Printing Area

Microline 520 8 inches Maximum

Microline 521 13.6 inches Maximum

ML520/521 ( 96-02-04 )

%1.8 Memory Specifications

1.8 MEMORY SPECIFICATIONS

1.8.01 EEPROM

1 Kbit serial EEPROM (used to store Menu data)

1.8.02 EPROM

1 MBit EPROM (Printer Control Program - Fonts)

1.8.03 RAM

128 Kbyte Total Resident RAM

Used as

Receive Buffer

Receive Buffer Size is selected through the Menu.

Settings are: 64 K, 32 K, 1 line

Print Buffer

DLL Buffer

Scratch Pad

ML520/521 ( 96-02-04 )

%1.9 Consumables

1.9 CONSUMABLES

1.9.01 Ribbon

CAUTION:

Using a non-Okidata ribbon may damage the printhead and void any warranties.

Material

Nylon fabric, cartridge type, re-inking

Type

Black Ribbon

Life (On average, at 10 characters per inch, Utility Mode)

4 million characters

ML520/521 ( 96-02-04 )

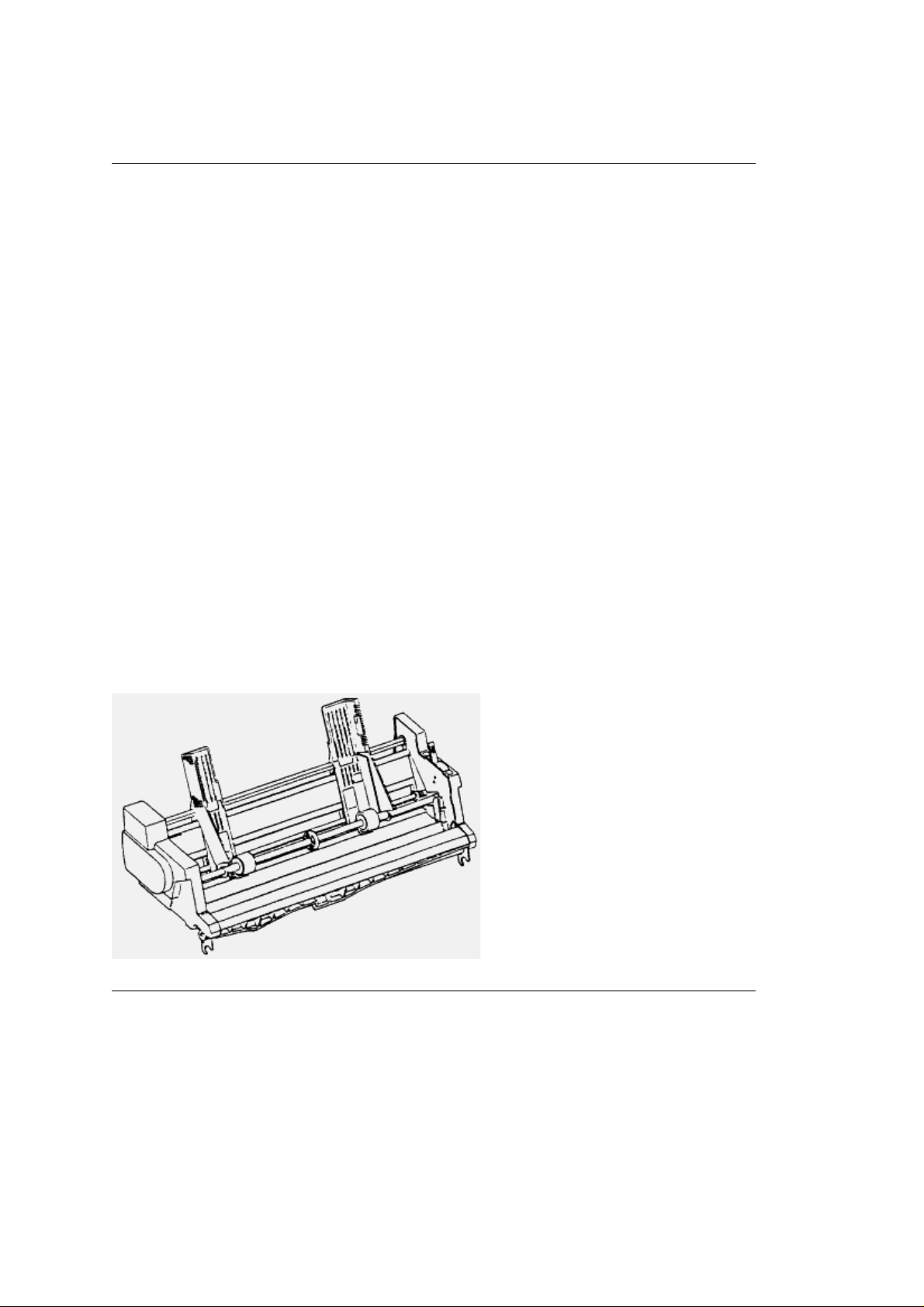

%1.10 Options - Cut Sheet Feeders

1.10 OPTIONS - Cut Sheet Feeders

1.10.01 Cut Sheet Feeders

Single Bin

The CSF-5000 is a narrow feeder for the Microline 520.

Single Bin with envelope capability

Paper Width: 7.2" to 8.5" (18.3 cm to 36.3 cm)

Paper Length: 10.1" to 14" (25.6 cm to 35.6 cm)

Capacity: 170 sheets (16 lb.), 100 sheets (20 lb.)

The CSF-5001 is a wide feeder for the Microline 521.

Single Bin with envelope capability

Paper Width: 7.2" to 14.3" (18.3 cm to 36.3 cm)

Paper Length: 10.1" to 14" (25.6 cm to 35.6 cm)

Capacity: 170 sheets (16 lb.), 100 sheets (20 lb.)

Dual Bin

P/N 70022601 is a narrow feeder for the Microline 520.

Dual Bin with envelope capability

Paper Width: 7.2" to 8.5" (18.3 cm to 36.3 cm)

Paper Length: 10.1" to 14" (25.6 cm to 35.6 cm)

Capacity: 170 sheets (16 lb.), 100 sheets (20 lb.)

P/N 70022801 is a wide feeder for the Microline 521.

Dual Bin with envelope capability

Paper Width: 7.2" to 14.3" (18.3 cm to 36.3 cm)

Paper Length: 10.1" to 14" (25.6 cm to 35.6 cm)

Capacity: 170 sheets (16 lb.), 100 sheets (20 lb.)1-1-01.pcx

ML520/521 ( 96-02-04 )

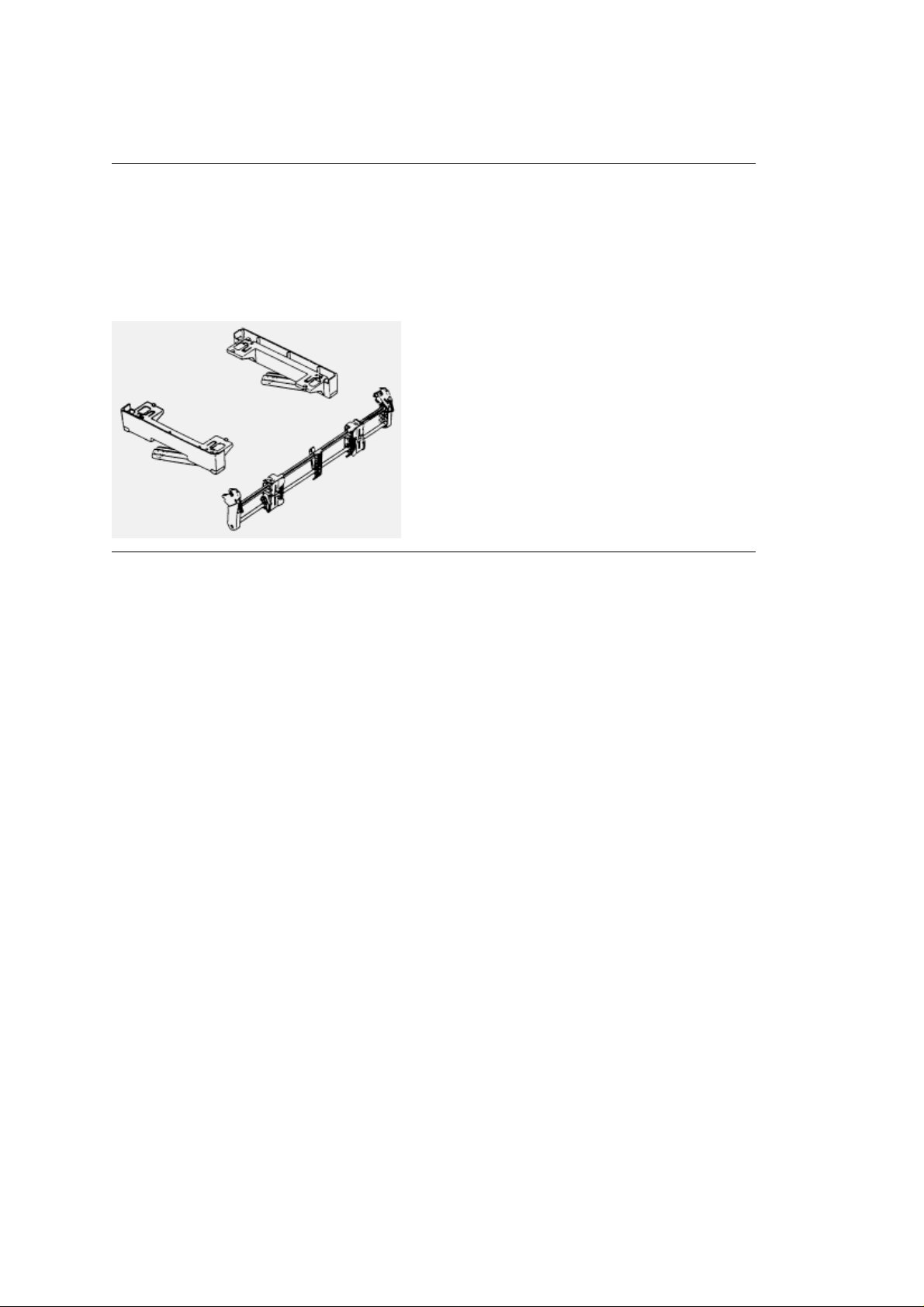

%1.10.02 Pull Tractor Kit

1.10.02 Pull Tractor Kit

NOTE:

The Pull Tractor Kit (P/N 70023001) is a narrow feeder for the Microline 520.

The Pull Tractor Kit (P/N 70023201) is a wide feeder for the Microline 521.

Bottom Feed

Rear Feed (For Push/Pull Operation)

Paper Types: Continuous Feed and Labels

ML520/521 ( 96-02-04 )

%1.10.04 Bottom Push Tractor Kit

1.10.04 Bottom Push Tractor Kit

NOTE:

The Bottom Push Tractor Kit (P/N 70022901) is a narrow feeder for the Microline 520.

The Bottom Push Tractor Kit (P/N 70023101) is a wide feeder for the Microline 521.

Bottom Feed

Paper Type: Continuous Feed

Includes: Stand and Metal Tear Bar

ML520/521 ( 96-02-04 )

%1.10.05 Serial Interface

1.10.05 Serial Interface

Super-Speed 19.2K RS-232C

Ready/Busy/X-On/X-Off Protocols

Can be configured through the Menu or OKISmart Utility Program

ML520/521 ( 96-02-04 )

%1.10.06 Roll Paper Stand

1.10.06 Roll Paper Stand

Adapts printer for use with roll-type paper (Model 520 only)

Includes: Stand, Support, Cord and DIN plug for connection to printer

ML520/521 ( 96-02-04 )

%1.11 Reliability

1.11 RELIABILITY

1.11.01 Mean Time Before Failure (MTBF)

Approximately 6,000 hours: 25% duty cycle / 35% page density

1.11.02 Mean Time To Repair (MTTR)

Approximately 15 minutes to major sub-assembly level

1.11.03 Printer Life

Approximately 16,000 hours of power-on time: 25% duty cycle / 35% page density

1.11.04 Printhead Life

Average 200 million characters in 10 cpi utility mode @ normal 25% duty, 35% page density

1.11.05 Ribbon Life

Approximately 4 million characters

1.11.06 Warranty (Limited)

One year, parts and labor

1.11.07 Service

Authorized OKIdata Service Centers

ML520/521 ( 96-02-04 )

Chapter 2

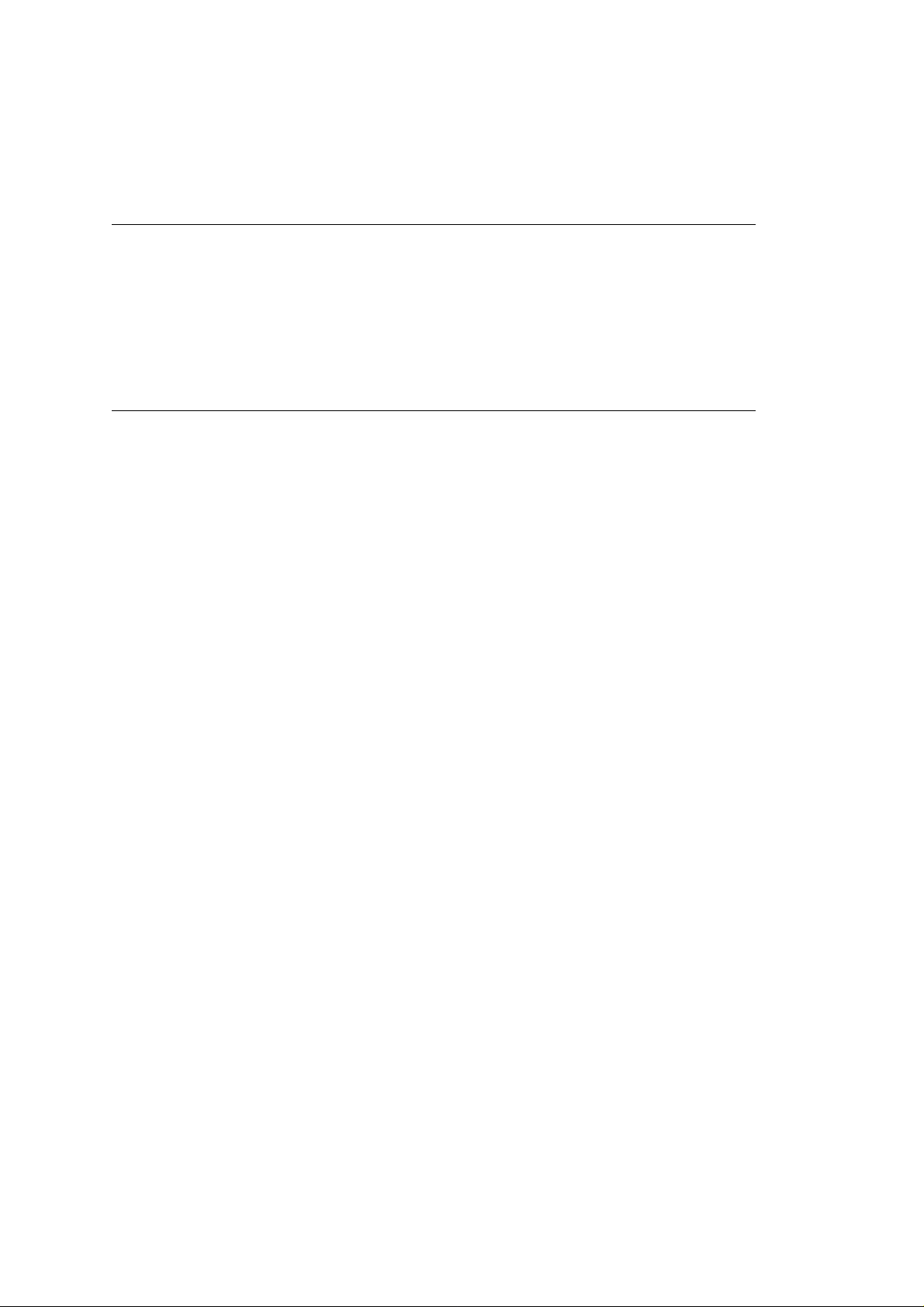

2.1 Electrical Operation

2.1 ELECTRICAL OPERATION

The printer is comprised of the electrical components listed below.

Main Control Board

Power Supply Assembly

Transformer

Filter Board

Operator Panel

Space Motor / Line Feed Motor

Printhead

ML520/521 ( 96-02-04 )

%2.1.01 Main Control Board

2.1.01 Main Control Board

The main control board is made up of the microprocessor, peripheral circuits, drive circuits, sensors and

interface connectors.

The power to the main control board is supplied by the transformer assembly through a wire harness.

The power to other electrical parts (line feed motor, space motor and printhead) is provided by the power

supply circuitry through connectors on the main control board.

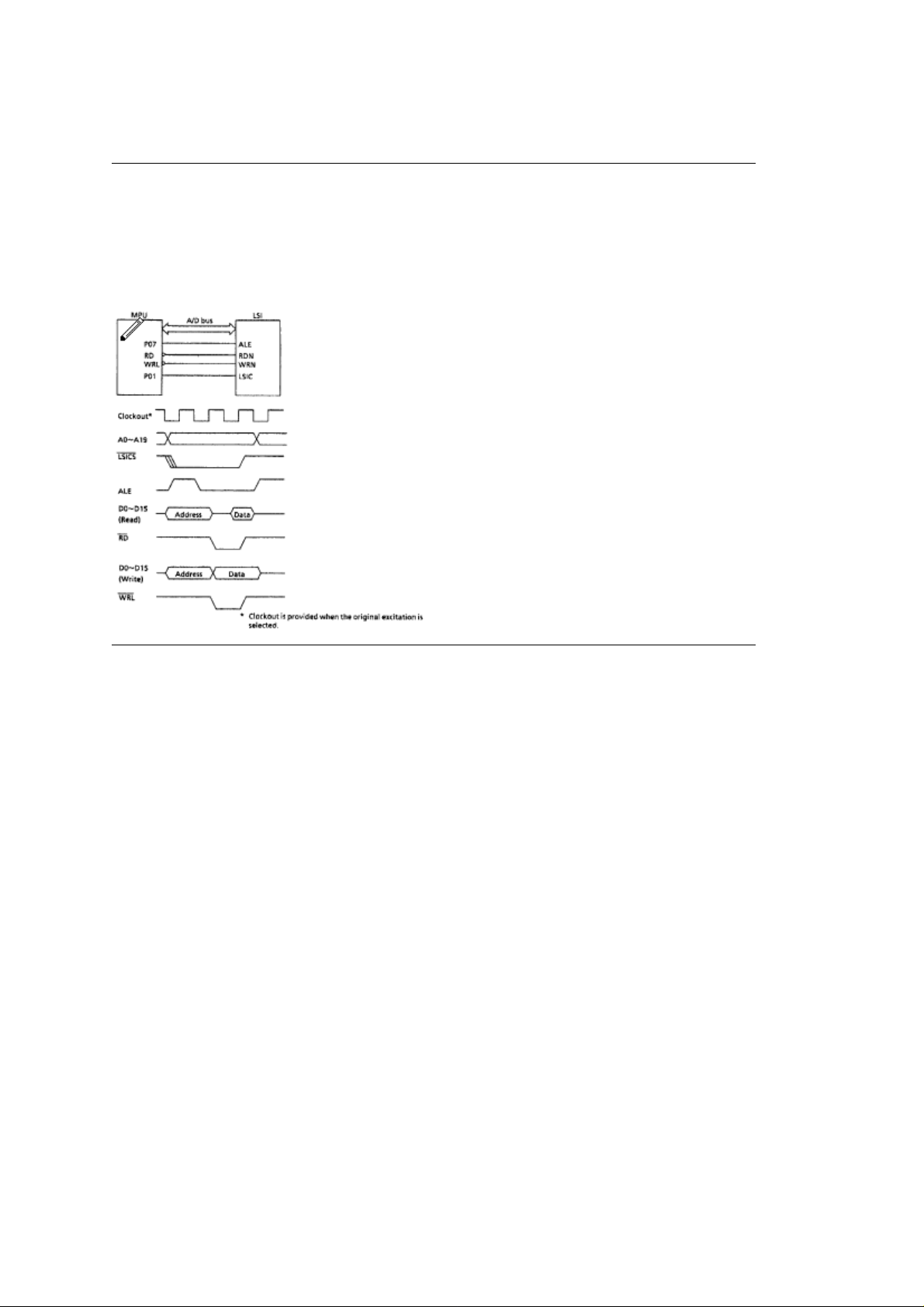

Microprocessor (MPU) (Location 04C: 67X640)

16 bit MPU, using CMOS technology.

The MPU contains a 20 bit address bus, a 16 bit data bus.

The MPU can access 1 Mbyte of program memory and 1 Mbyte of data memory space.

The microprocessor controls the entire printer by executing the control program through the LSIs

and the driver circuits.

ML520/521 ( 96-02-04 )

%Block Diagram

Block Diagram

ML520/521 ( 96-02-04 )

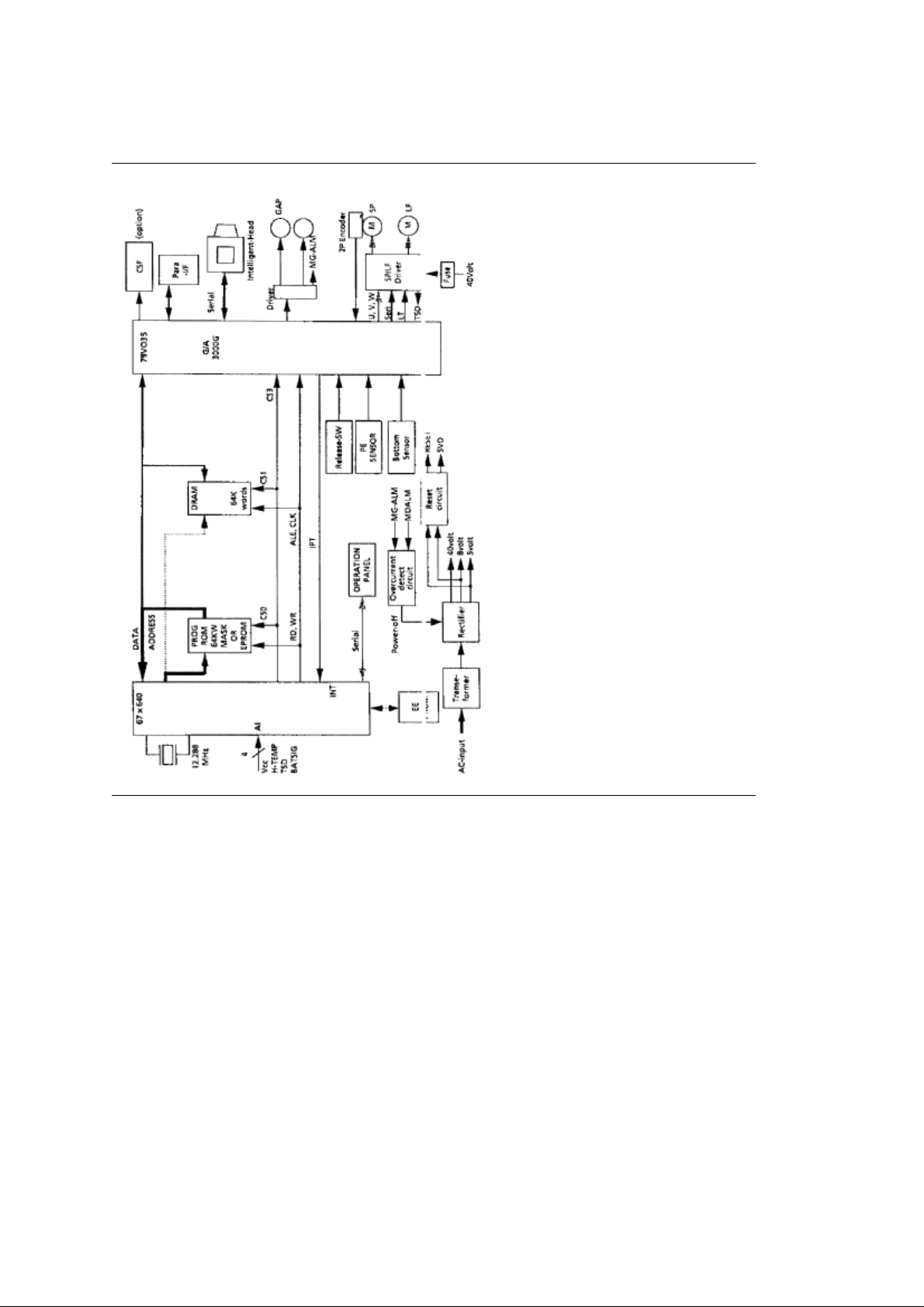

%Program ROM

Program ROM

Location 05CA: 27C1024

This 64k x 16 bit (1Mbit) EPROM contains the control program for the printer. The MPU executes the

instructions contained in this program.

The Program ROM is assigned to the program memory area of the MPU and instructions are fetched by

the PSEN signal of the MPU.

ML520/521 ( 96-02-04 )

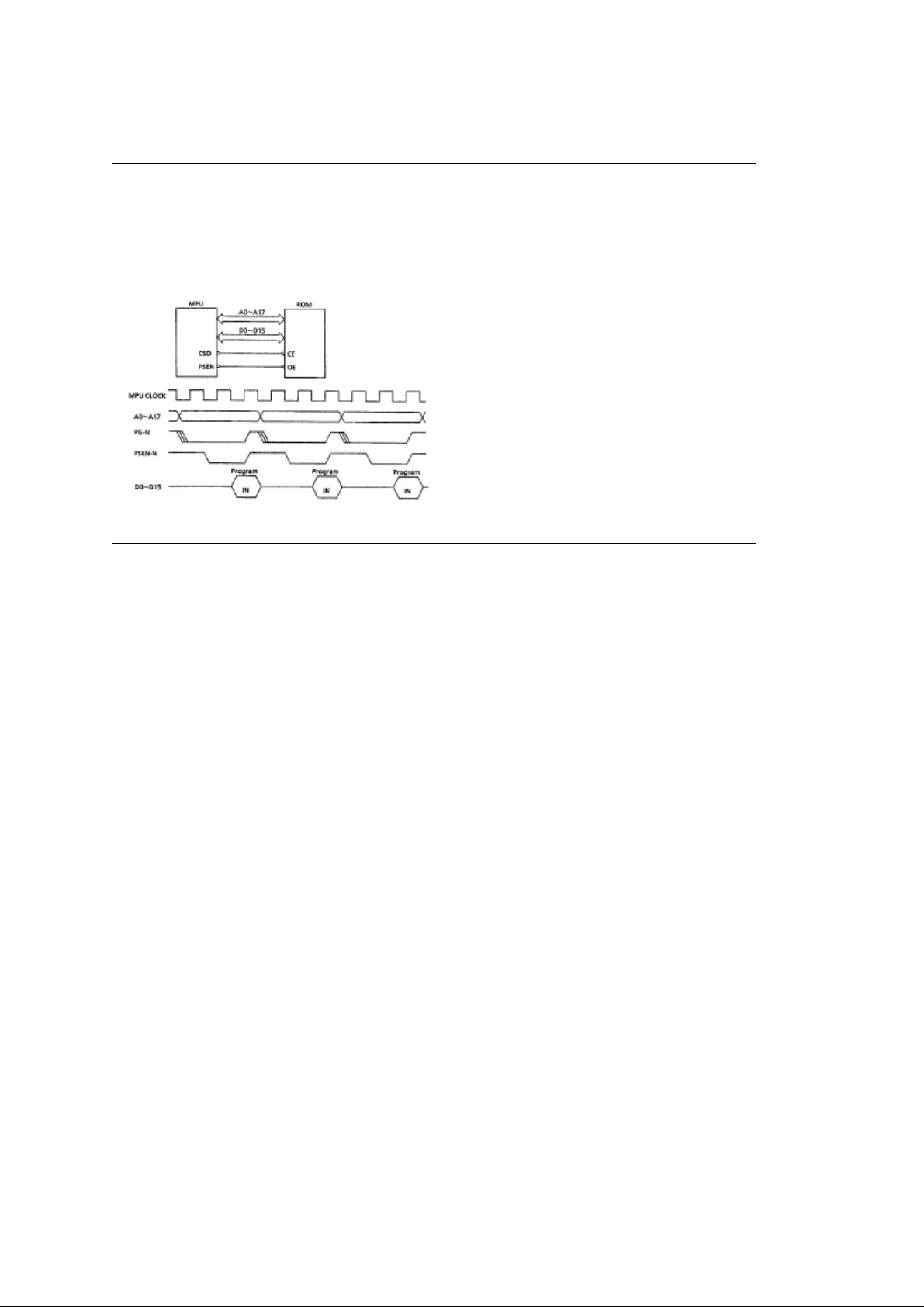

%RAM

RAM

Location 05CB: 511664Z

The RAM is CMOS dynamic RAM with 65,536 words x 16-bit configuration. It is used as a receive buffer,

print buffer and work buffer.

ML520/521 ( 96-02-04 )

%LSI

LSI

Location 04B: MSM79VO35

Detects the output of the two-phase sensor on the DC space motor to control the motor drive phase.

Transmits and receives serial data to and from the printhead based on the dot timing (which is derived

from the space motor speed).

Controls the external interface. The LSI is connected to the MPU.

ML520/521 ( 96-02-04 )

%Electrically Erasable Programmable Read Only Memory

(EEPROM)

Electrically Erasable Programmable Read Only Memory (EEPROM)

(Location 03C: 93CS46)

The EEPROM is a CMOS serial I/O type memory (EEPROM). It is capable of electrically erasing and

writing 1,024 bits.

The EEPROM contains the menu data and the head drive time correction data.

ML520/521 ( 96-02-04 )

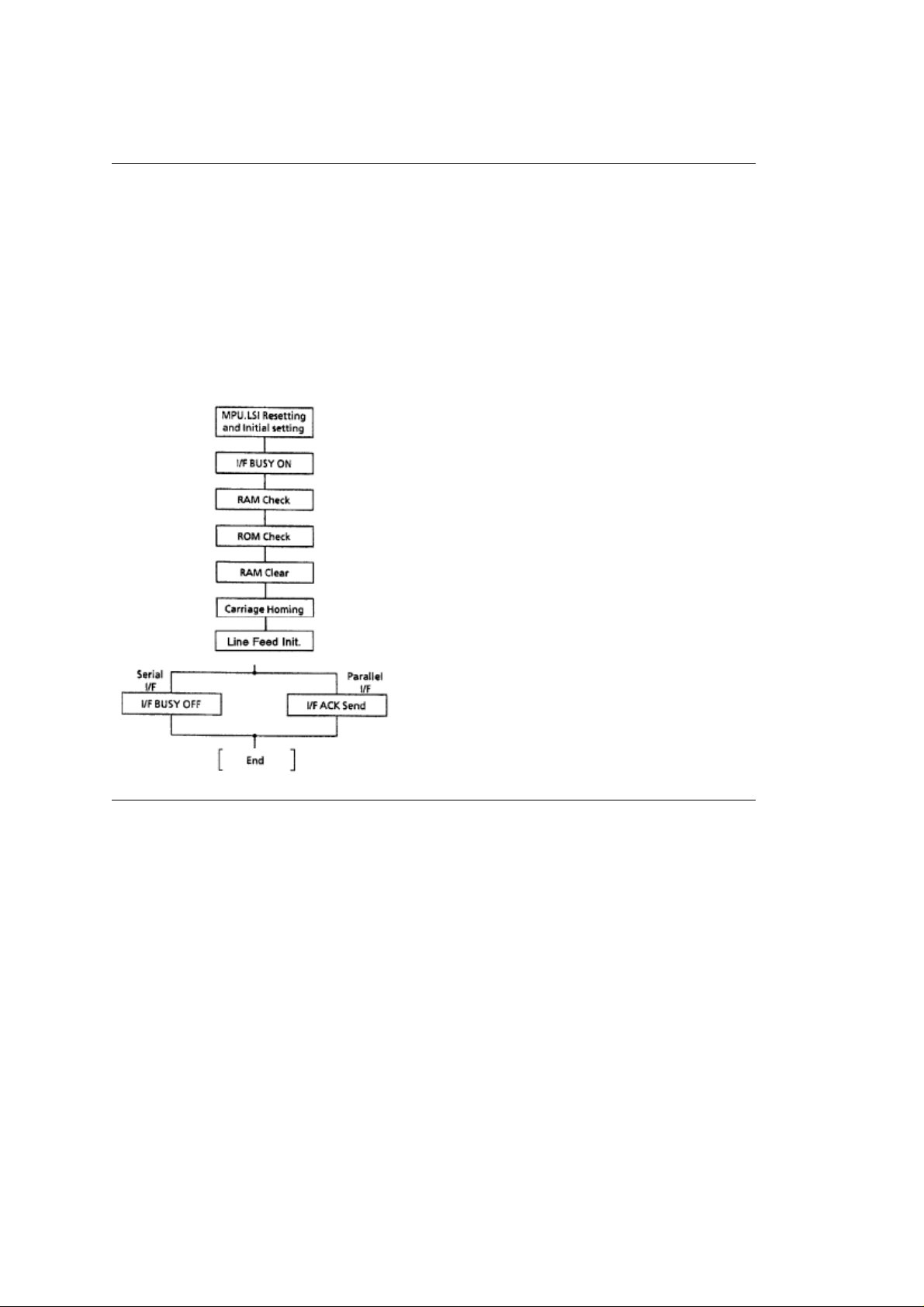

%2.1.02 Initialization

2.1.02 Initialization

This printer is initialized when the printer is powered on or when the I-PRIME-N signal is input from the

host via the parallel interface.

The steps in Printer Initialization are listed below.

The RST-N signal is output from the reset circuit to reset the MPU and LSIs.

The program is executed and the LSIs are reset by the MPU via IORST-N.

NOTE:

A reset operation initiated by I-PRIME does not reset the MPU.

The program sets the LSI (02D) mode, checks the memory (ROM/RAM), then executes carriage homing

and determines the phase of the line feed motor.

Finally, the program establishes the interface signals (P-I/F: ACK-P signal sending, and S-I/F: BUSY-N

signal off) and lights the SELECT lamp to indicate that the printer is in the ON-LINE state.

ML520/521 ( 96-02-04 )

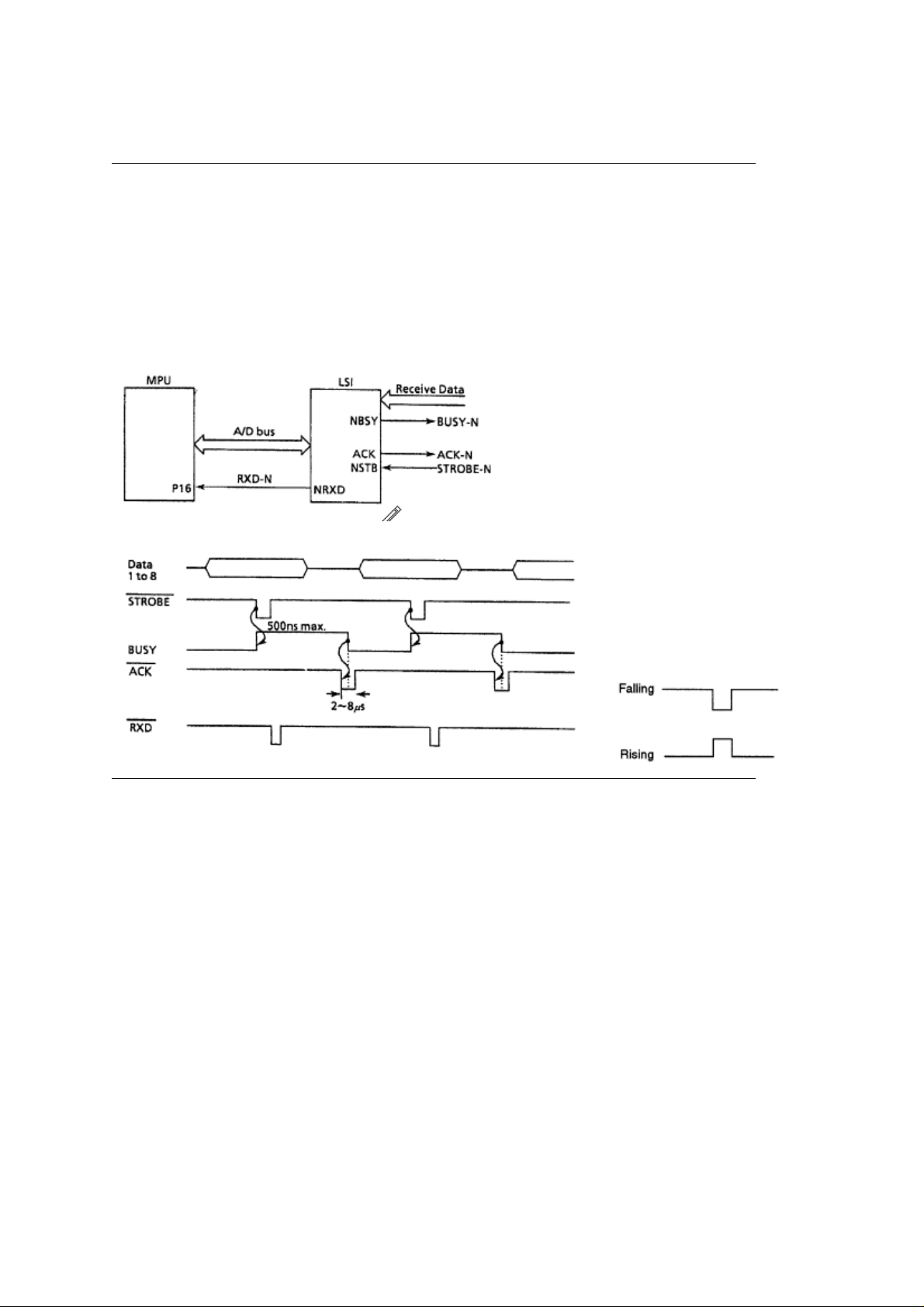

%2.1.03 Parallel Interface Control

2.1.03 Parallel Interface Control

The parallel data input from the host to the interface LSI is latched to the internal register at the falling

edge of the STROBE-N signal.

The LSI sets the BUSY-N signal to inform the host that the data is being processed. The LSI also outputs

the RXD-N signal to inform the MPU of data reception. The data is read upon receiving the RD-N signal

from the MPU.

When the data processing is complete, the BUSY-N signal is disabled and the ACK-N signal is sent to

request the next data. When the buffer is full and reception is not desired, the BUSY signal is sent to

request data transmission be stopped.

ML520/521 ( 96-02-04 )

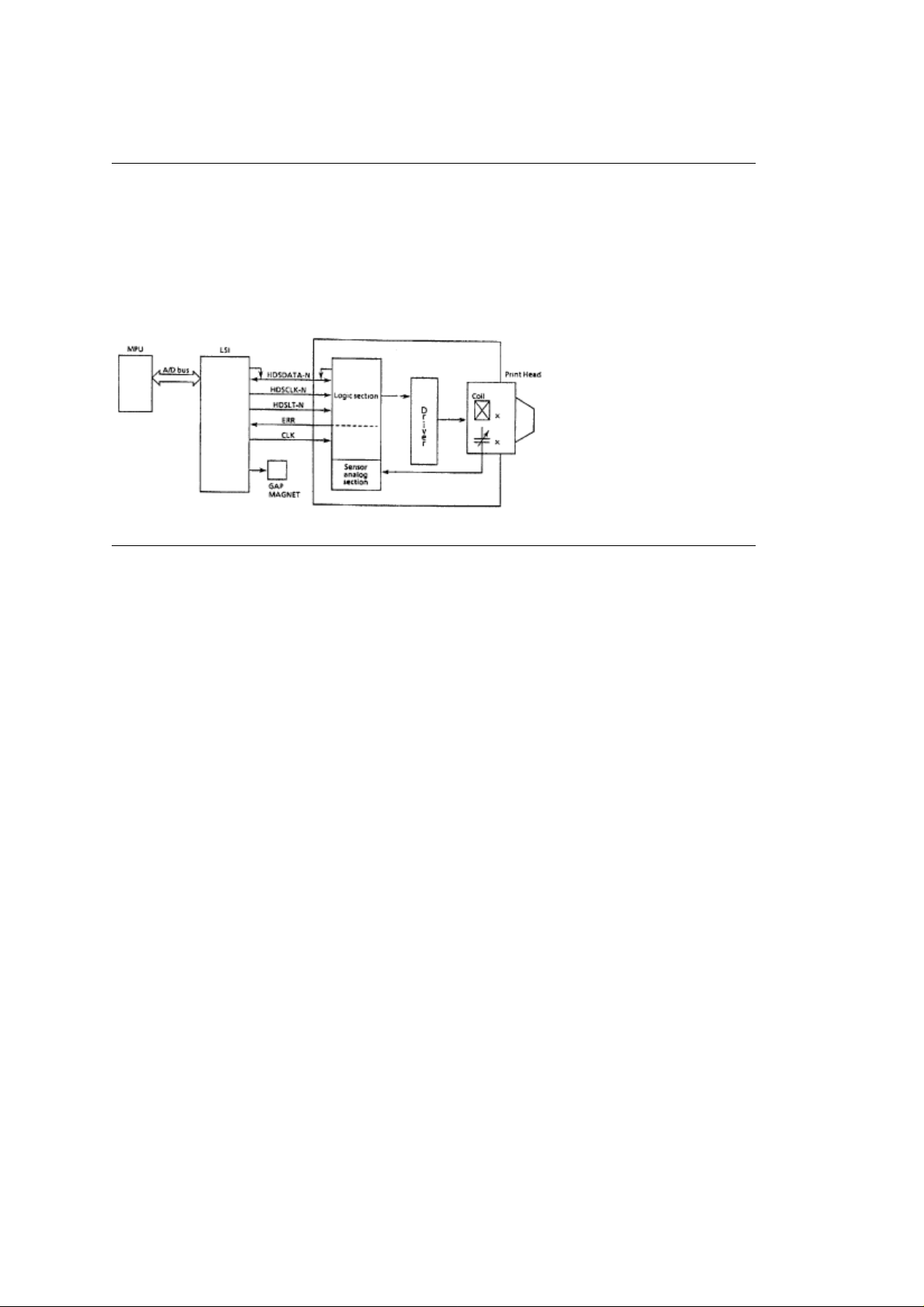

%2.1.04 Print Control

2.1.04 Print Control

The print data is transmitted as serial data from the LSI to the control circuit and the driver contained in

the printhead.

After the data is printed, the sensor analog circuit controlling each pin returns the pin stroke data to the

MPU. The MPU will make an automatic head gap adjustment. This feedback system sets the optimum

drive time for each pin in order to maintain high print quality.

In the case of envelopes, where the medium thickness varies as the printhead moves along the platen,

the strike force of the pins changes to compensate for the differences in thickness.

ML520/521 ( 96-02-04 )

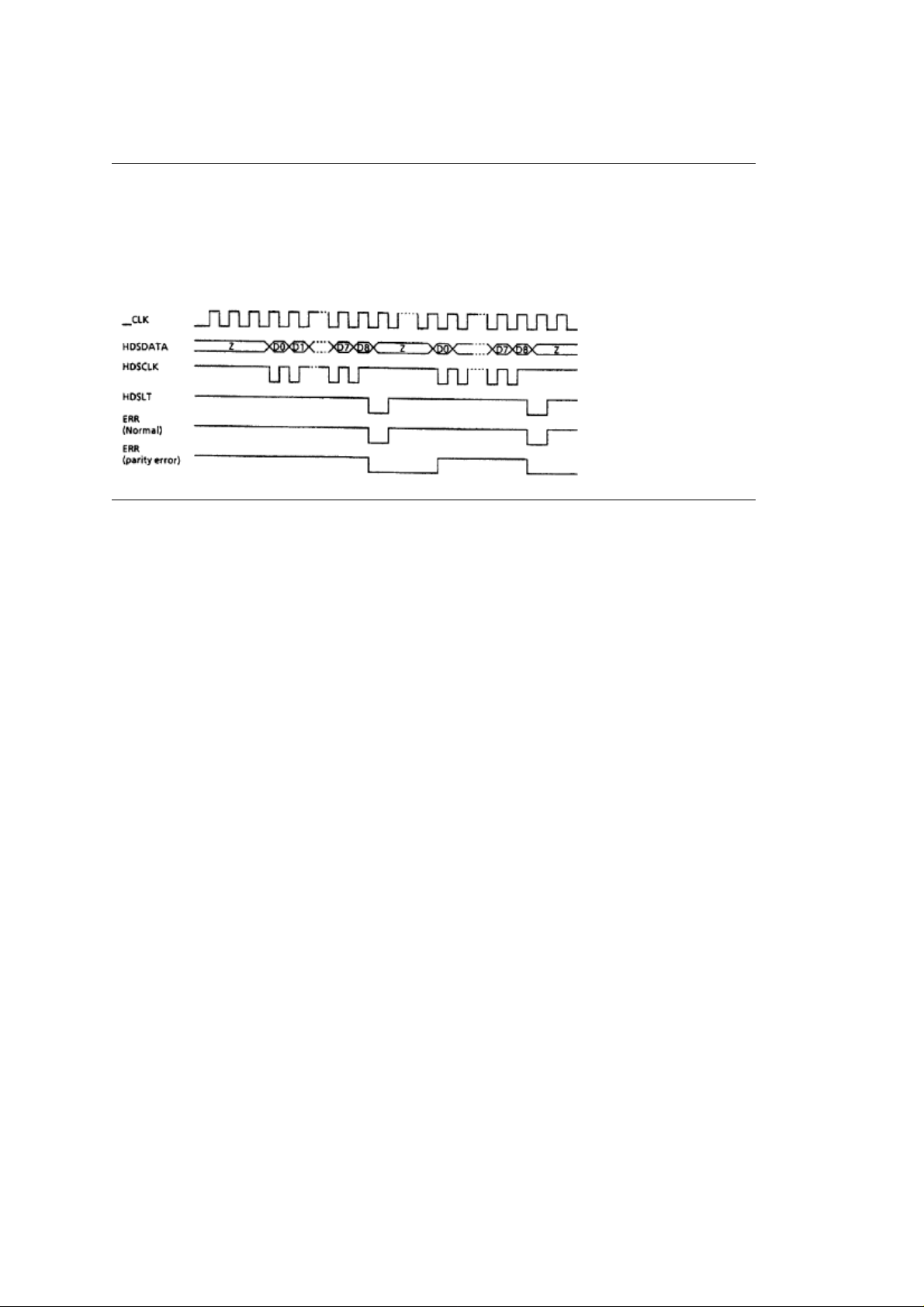

%LSI/Printhead Interface

LSI/Printhead Interface

The connection between the LSI and the printhead is made with the bi-directional serial data bus. The LSI

transmits the print data as serial data to the logic circuit of the printhead. The printhead returns serial data

from the printhead sensor analog circuit to the LSI. This information is used to determine the optimum

drive time for the next print request.

The logic circuit of the printhead signals the LSI if a parity error is detected in the print data.

ML520/521 ( 96-02-04 )

Loading...

Loading...