OKIDATA 4410 Service Manual

P ACEMARK 4410/

MICROLINE 4410

PRINTER

MAINTENANCE MANUAL

ODA/OEL/INT

1999. 3. 26 Rev.1

40496501TH Rev.1 1 / 214

Rev.No. Date Corrected items Person in

No. Page Description of change change

40496501TH Rev.1 2 /

PREFACE

This maintenance manual describes how to maintain the Pacemark 4410/Microline 4410 printer

in the field.

This manual is for customer engineers.

For further information, refer to the Users Manual for handling or operating the equipment.

40496501TH Rev.1 3 /

CONTENTS

1. CONFIGURATION..................................................................................... 6

1.1 Basic System Configuration............................................................... 6

1.2 Printer Specifications......................................................................... 7

1.3 Option Specifications......................................................................... 8

1.4 Basic Specifications........................................................................... 9

2. THEORY OF OPERATION........................................................................ 12

2.1 Electrical Operation ........................................................................... 12

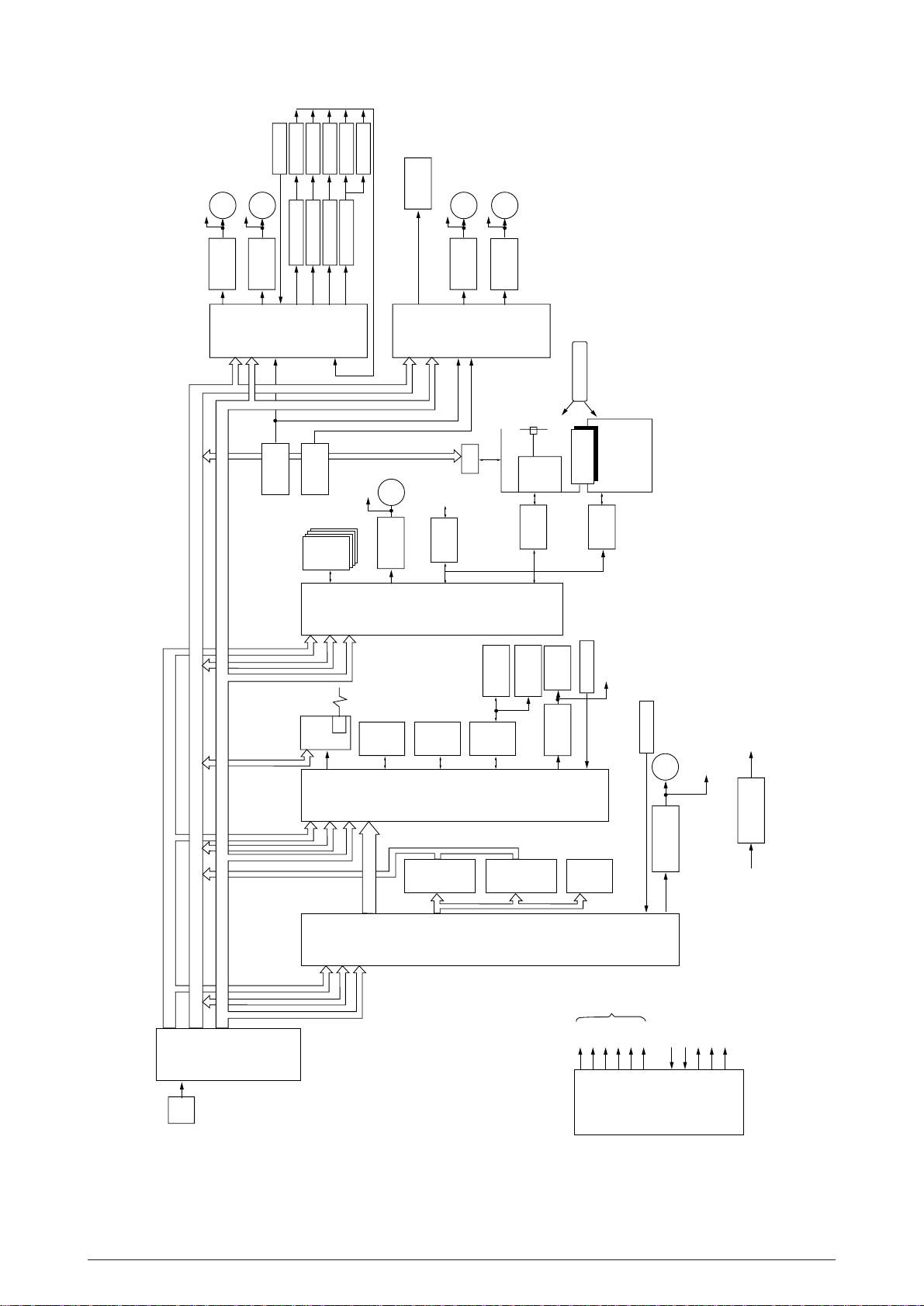

2.1.1 Summary ................................................................................................. 12

2.1.2 Microprocessor and the peripheral circuit ............................................... 12

2.1.3 Initialization.............................................................................................. 21

2.1.4 Interface control....................................................................................... 22

2.1.5 Parallel Interface Control ......................................................................... 22

2.1.6 Serial Interface ........................................................................................ 23

2.1.7 Printing operation .................................................................................... 24

2.1.8 Printhead control ..................................................................................... 25

2.1.9 Print Compensation Control .................................................................... 27

2.1.10 Space motor control ................................................................................ 27

2.1.11 Line feed..................................................................................................28

2.1.12 Bail, tractor switching, AG, ribbon motor control ..................................... 29

2.1.13 Operation Panel ...................................................................................... 30

2.1.14 Alarm circuits ........................................................................................... 32

2.1.15 Power supply circuit ................................................................................ 34

2.2 Mechanical Operation........................................................................ 35

2.2.1 Printhead mechanism and operation (See Figure 2-13) ......................... 35

2.2.2 Spacing operation (See Figure.2-15) ...................................................... 37

2.2.3 Head gap adjusting ................................................................................. 38

2.2.4 Ribbon drive (See Figure) ....................................................................... 41

2.2.5 Paper Feed Mechanism .......................................................................... 42

2.2.6 Bail Feed Mechanism (See Figure ) ........................................................ 46

2.2.7 Paper End Detection Mechanism (See Figure ) ..................................... 48

3. PARTS REPLACEMENT........................................................................... 50

3.1 Precautions for Parts Replacement................................................... 50

3.2 Parts Layout....................................................................................... 53

3.3 How to Change Parts......................................................................... 54

3.3.1 Cover-Assy-Access / Cover-Assy-Side (R) / Cover-Assy-Side (L)

/Cover-Assy-Front / Frame-Assy-Rear / Plate-Front (stuck) .................. 55

3.3.2 Printer Unit .............................................................................................. 56

3.3.3 Control Block [Control Board (PMA Printed Board),

Driver Board (PDA Printed Board)] ......................................................... 57

3.3.4 Power Supply Assy ................................................................................. 58

3.3.5 PG Cooling Fan ....................................................................................... 59

3.3.6 I/F Board (PHA Printed Board) ................................................................ 60

3.3.7 AG Board (PGA Printed Board) / Connector Cord .................................. 61

3.3.8 AG Motor Assy ........................................................................................ 62

3.3.9 Mini Pitch Belt.......................................................................................... 63

3.3.10 Tractor Change Motor Assy .................................................................... 64

3.3.11 Bail Motor Assy ....................................................................................... 65

3.3.12 LF Motor Assy ......................................................................................... 66

3.3.13 Head Cooling Fan 1 ................................................................................ 67

3.3.14 Head Cooling Fan 2 ................................................................................ 68

3.3.15 Space Motor ............................................................................................ 69

40496501TH Rev.1 4 /

3.3.16 Operator Board (POA Printed Board) ...................................................... 70

3.3.17 Ribbon Feed Assy ................................................................................... 71

3.3.18 Printing Head........................................................................................... 72

3.3.19 Head Cable ............................................................................................. 73

3.3.20 Ribbon Protector ..................................................................................... 74

3.3.21 Space Motor Fan ..................................................................................... 75

3.3.22 Junction Board ........................................................................................ 76

3.3.23 Cover Open Switch Assy / Ribbon Rotation Sensor ............................... 77

3.3.24 Interlock Switch / Interlock Switch Cord Assy ......................................... 78

3.3.25 Knob Bracket Assy .................................................................................. 79

3.3.26 Space Belt ............................................................................................... 80

3.3.27 AG Sensor Frame / Start Searching Sensor ........................................... 81

3.3.28 Paper Jam Sensor Assy / Bail PE Sensor Assy ...................................... 82

3.3.29 Sprocket Assy (L) (R) (Front Tractor) ...................................................... 83

3.3.30 Sheet Feeder Assy (L) Rear / Sheet Feeder Assy (R) Rear ................... 84

3.3.31 Bail Assy.................................................................................................. 87

4. ADJUSTMENTS ........................................................................................ 88

5. CLEANIG AND LUBRICATION ................................................................ 95

5.1 Cleaning............................................................................................. 95

5.2 Lubrication ......................................................................................... 96

6. TROUBLESHOOTING AND REPAIR ....................................................... 104

6.1 Items to Check Before Repair............................................................ 104

6.2 Troubleshooting Table....................................................................... 104

6.3 Lamp and LCD Display...................................................................... 105

6.4 Part Layout ........................................................................................ 110

6.5 Connection......................................................................................... 113

6.6 Troubleshooting Flow Chart............................................................... 130

7. PARTS LIST .............................................................................................. 161

APPENDIX A PCB LAYOUT.......................................................................... 202

APPENDIX B RS-232C SERIAL INTERFACE BOARD (OPTION) ............... 205

1. GENERAL.......................................................................................... 205

2. OPERATION DESCRIPTION............................................................ 206

2.1 Element Description ................................................................................ 206

2.2 Circuit Description ................................................................................... 206

2.3 Local Test................................................................................................ 209

APPENDIX C MAINTENANCE-SUPPORT FUNCTION ................................ 211

1. Normal mode ..................................................................................... 211

2. Maintenance mode 1 ......................................................................... 212

3. Maintenance mode 2 ......................................................................... 213

40496501TH Rev.1 5 /

1. CONFIGURATION

1.1 Basic System Configuration

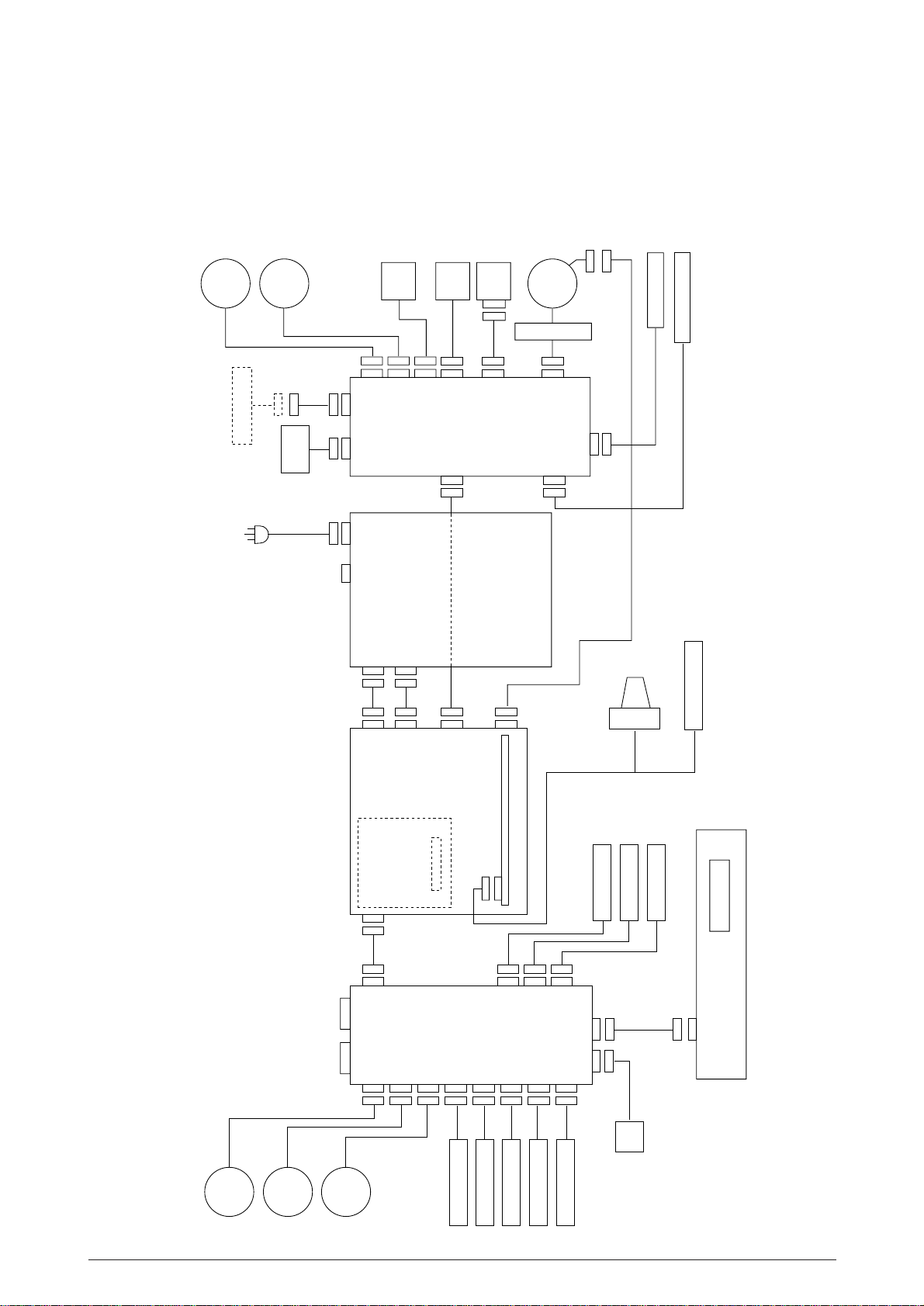

The basic system configuration of Pacemark 4410/ Microline 4410 is illustrated in Figure 1.1.

feed

motorAGmotor

Ribbon

FAN

HEAD

SP

FAN

AG

PCB

sensor

SP

motor

AC source

FAN

Power supply

Motor/Sensor PCB

FUSE holder

Power supply unit

Inter lock SW

Print head

Cover open SW

Ribbon jam sensor

Paper width sensor

Figure 1.1

Bail

motor

RS232C

IEEE 1284

motorLFmotor

Tractor

change

Main control/

I/F

I/F

Interface/Motor

Motor driver PCB

(Option)

Interface board

/Sensor PCB

Head driver PCB

Bail position SW

Front PE SW

Tractor change SW

Rear PE SW

Paper jam sensor

Bail PE sensor

AG sensor coil

Paper top sensor

FAN

Head

LCD

Operation panel PCB

40496501TH Rev.1 6

1.2 Printer Specifications

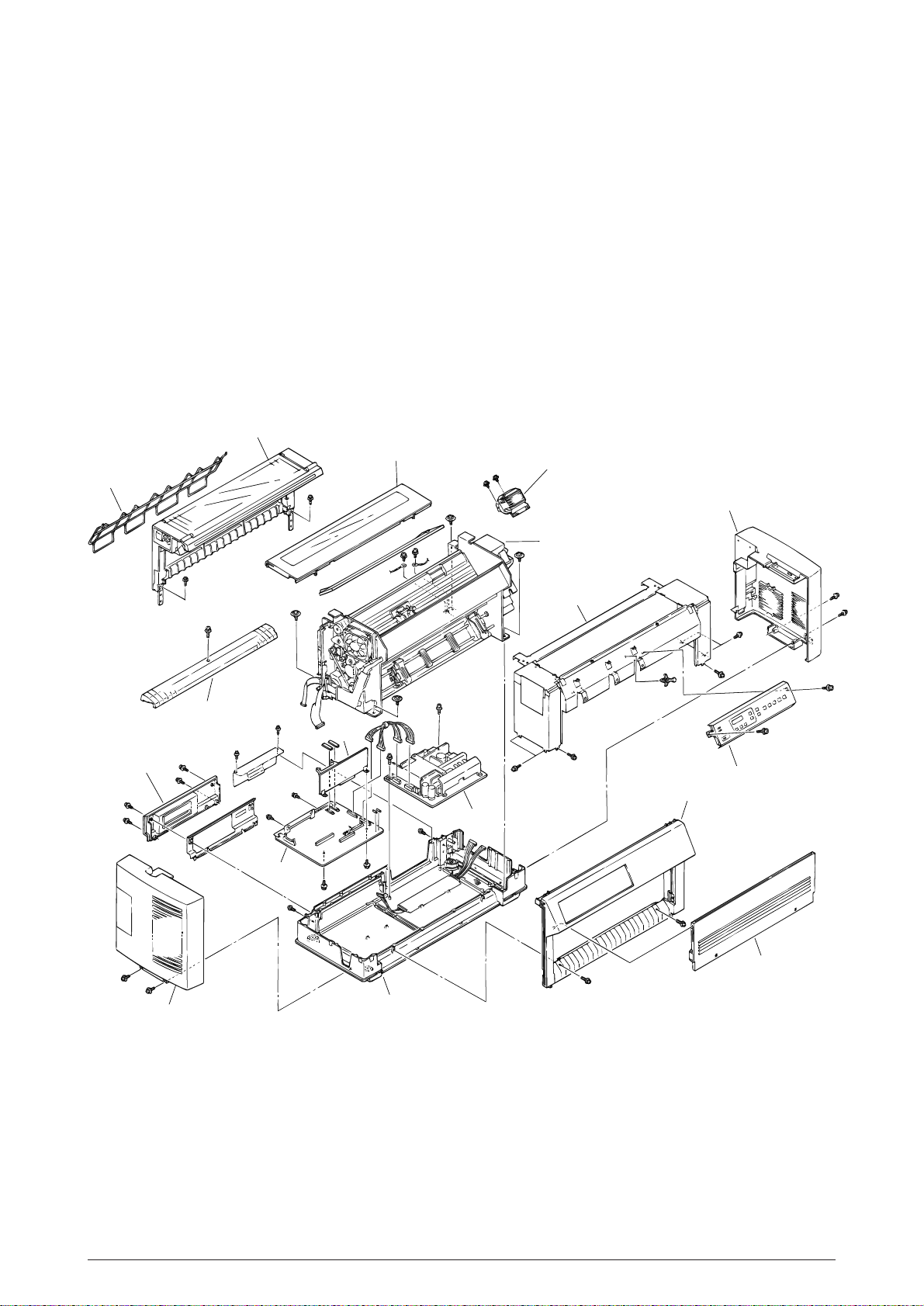

Sheet guide

Cover Assy Rear

Cover Assy Access

Print head

Printer Unit

Cover-Assy-Side(R)

Operation panel Assy

Cover Assy Front

Door Assy Front

Cover Assy Lower

Cover Assy Side(L)

Control Board

Cover Rear B

Guide Paper B

Driver Board

Power Supply Assy

Plate Front

(stuk)

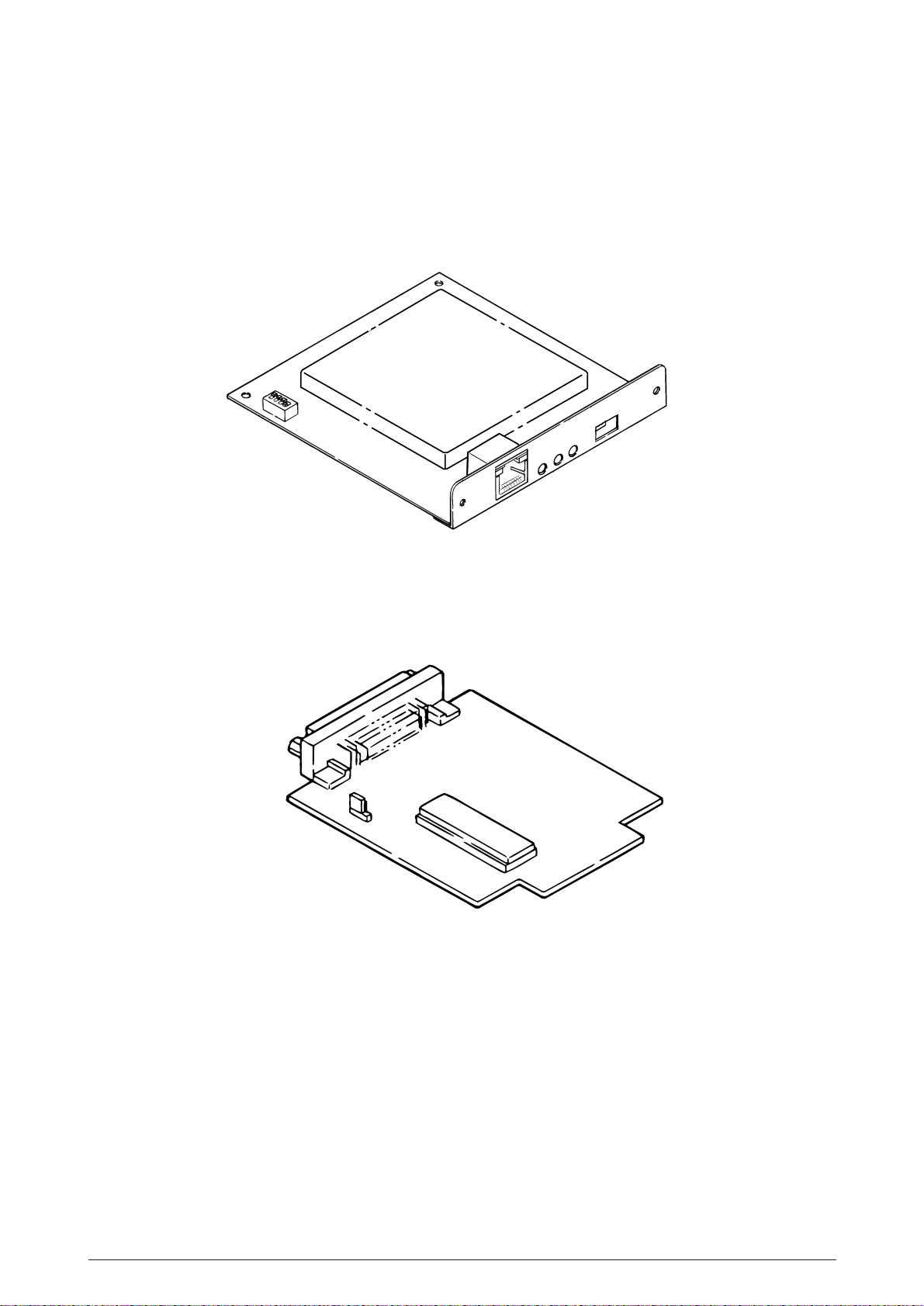

This printer unit is composed with the following hardware.

• Printer mechanism

• Main control/Motor driver board

• Head driver board

• Interface/Motor/Sensor board (including IEEE 1284 bidirectional parallel interface and RS232C serial interface)

• Motor/Sensor and AG sensor boards

• Operation panel board

• Power supply unit

• Covers

Figure 1-2 show the printer unit configuration.

Figure 1.2

40496501TH Rev.1 7

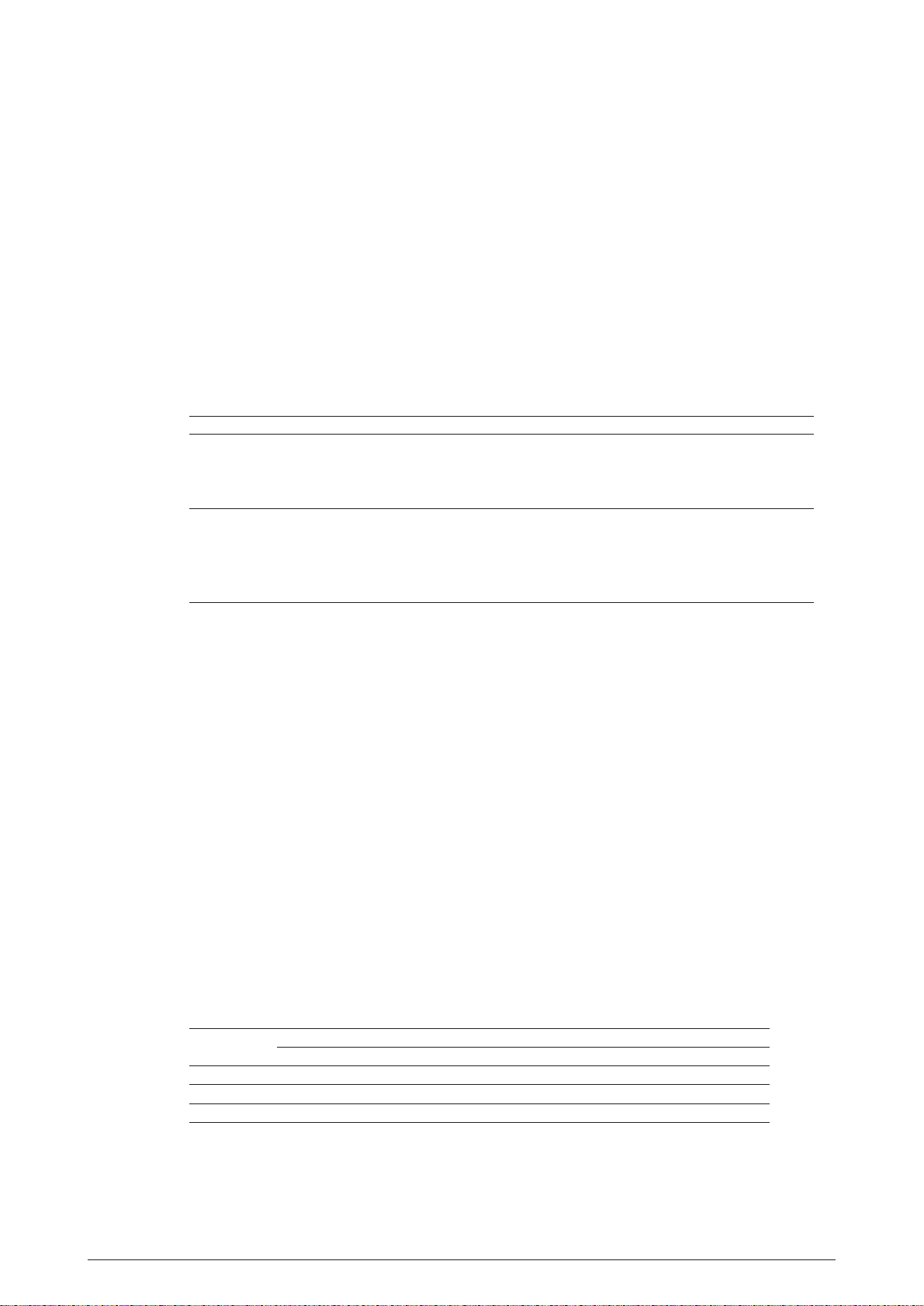

1.3 Option Specifications

Options available for Pacemark 4410/ Microline 4410 are as follows.

(1) Interface boards

(a) Oki-HSP (MUPIS) Network card

(b) 300/500 Series Serial/ HSP Adapter

• RS232C

• RS422A

• Current Loop

40496501TH Rev.1 8

1.4 Basic Specifications

(1) Dimensions

Width: 768mm(30.24inches) Length: 385mm(15.16inches) Height: 358mm(14.09inches)

(2) Weight

Approx. 42kg (92.6lbs)

(3) Form

Continous Paper

One-part paper

Ream weight: 45 to 90g/m2 (12 to 24 lb)

Multiple-part paper Max.0.79mm(0.031inches)total thickness(with front feed)

Paper type Ream weight Number of sheet

Carbon-lined paper Ten sheet maximum including original

Pressure-senstive (9 to 11 lbs) Six sheet maximum including original

paper (with rear feed)

Interleaf paper (9 to 14 lbs) (with front feed)

Max.0.36mm(0.014inches)total thickness(with rear feed)

35 to 40 g/m

2

(with front feed)

Paper

35 to 52 g/m

2

Seven sheet maximum including original

Corbon paper Four sheet maximum including original

34 g/m2 (9 lbs) (with rear feed)

When 7p or more papers are used for the front tractor, "High Impact Copy" should be

selected in the menu mode to print these papers.

Continuous Envelope

Weight : Max. 90 g/m2 (24lb)

Thickness : Max. 0.36mm (0.014 inch)

Width : 76.2 - 254mm (3 - 10 inches)

Media supply :Front paper feed only

Card

Weight : Max. 375 g/m2 (100lb)

Thickness : Max. 0.20mm (0.008 inch)

Size : 5 x 8 inches (separated)

Media supply :Front paper feed only

Label

Thickness : Max 0.28mm (0.011 inch)

Size : Max. 381 x 83mm (15 x 3.25 inches)

Media supply :Front paper feed only

(4) Print speed

Print Mode Character Pitch

10 CPI 12 CPI 15 CPI 17.1 CPI 20 CPI

HSD 1066 CPS 1066 CPS 1066 CPS 1066 CPS 1066 CPS

NLQ 200 CPS 200 CPS 200 CPS 200 CPS 200 CPS

UTILITY 800 CPS 800 CPS 800 CPS 800 CPS 800 CPS

40496501TH Rev.1 9

(5) Maximum Number of Dot Columns per Line

a) Graphics

Single Density Double Density Quadruple Density

816 1,632 3,264

b) Text

Print Mode Character Pitch (CP)

10 CPI 12 CPI 15 CPI 17.1 CPI 20 CPI

ML, EPSON, IBM UTILITY 1,632 1,958 2,448 2,798 3,264

ML, EPSON, IBM NLQ 3,264 3,917 4,896 5,596 6,528

ML, EPSON, IBM HSD 1,224 1,468 1,836 2,098 2,448

(6) Maximun Number of Character per Line

Character Pitch (CPI) 5 6 7.5 8.5 10 12 15 17.1 20

ML EPSON IBM 68 81 102 116 136 163 204 233 272

(7) Printhead

Print method: Impact dot matrix

Number of dot wires: 9 wires x 2 rows

Dot wire diameter: 0.36mm(0.014inch)

(8) Line feed Speed

6 LPI spacing, one LF = 60 ms

8 LPI spacing, one LF = 52 ms

Continuous paper feed rate is 15 inches per second. (at head gap 1, 2)

(9) Line Feed Pitches

6 LPI 0.167 inch (4.23mm)

8 LPI 0.125 inch (3.175mm)

A variable line feed pitch of n/216 inch (integer n: 0 ≤ n ≤ 255) can also be specified. Also,

7/72 inch and n/72 inch can be specified.

PROPRINTER n : 1 ≤ n ≤ 255

EPSON n : 1 ≤ n ≤ 255 (Cannot specify MSB : 1≤ n ≤ 127)

(10) Power Requirements

a) Input power

Single-phase AC

Voltage : 120VAC +5.5%, -15%

230 VAC ±15%

Frequency : 50/60Hz ±2%

b) Power consumption

Local Test : Max. 295 W (Rolling ASCII, Utility)

Idle : Max. 15W (Energy Star compliant)

c) AC power cable

Length : Approximately 5.9 It (1.8 m)

Cable conforms to the UL, CSA, and European Standards.

40496501TH Rev.1 10

(11) Ambient temperature and relative humidity

Operating Non-operating Storage Transportation Unit

Temperature 41 to 95 32 to 109.4 14 to 122 -40 to 158 °F

(5 to 35) (0 to 43) (-10 to 50) (-40 to 70) (°C)

Relative 20 to 80 10 to 90 5 to 95 5 to 95 %RH

Humidity

Avoid condensation at all times.

(12) Vibration

Operating : Max. 0.3G (5 to 150 Hz) (except at resonant frequency)

Non-operating : Max. 1G (5 to 150 Hz) (except at resonant frequency)

(13) Impact (Drop Test)

Packing : 12" Drop

(14) Noise

The 8-second average noise is Max. 55 dBA in quiet utility mode. (ISO 7779)

(15) Ribbon

Genuine OKI cartridge ribbon

Ink color : Black

Ribbon life : Approximately 15 million characters (Characters in Utility mode)

(16) Reliability

a) MTBF (mean time between failures)

12,000 hours of power-on time at 25% duty cycle and 35% page density.

b) Printhead life

400 million characters (average) in 10 CPI Utility print mode at 25% duty cycle and 35%

page density.

c) Printer life

12,000 hours of power-on time at 25% duty cycle and 35% page density, or 5 years.

d) MTTR

30 minutes, major Sub-assembly level.

Definition of terms

• Duty cycle : Actual operation rate

• Page density : The proportion in area of characters and spaces within print head

PPmovable area.

• Power on Time : 8H/day, 25days/month and 12 months/year.

40496501TH Rev.1 11

2. THEORY OF OPERATION

2.1 Electrical Operation

The electrical operation of the printer circuit is described in this section.

2.1.1 Summary

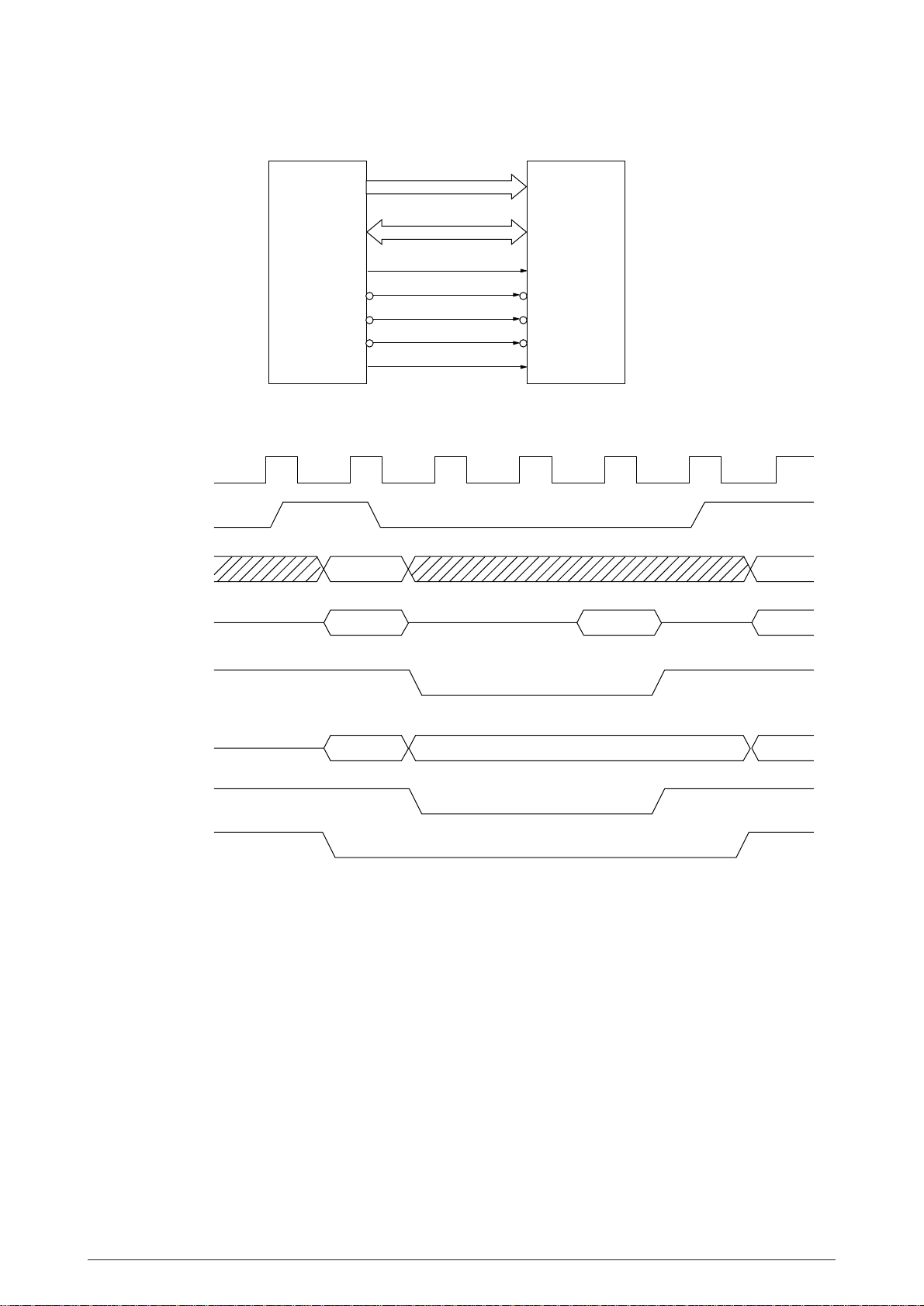

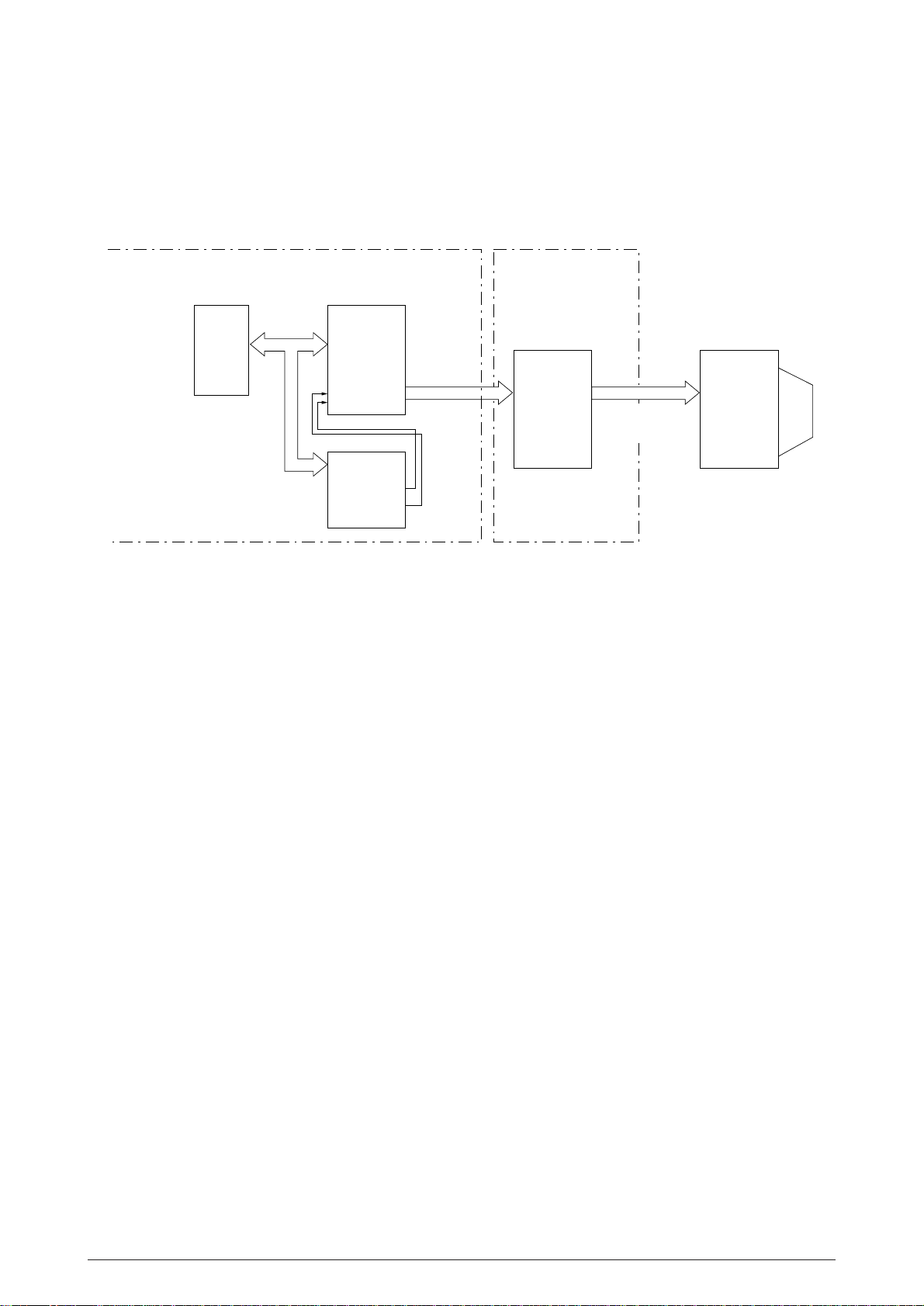

Fig. 2-1 shows the block diagram of the printer.

The control board is made up of the microprocessors, peripheral circuits, drive circuits, sensors and

interface connectors.

The power to the control board is supplied by the power board through the connector cord.

The pwer to other electrical parts is also distributed through the connectors within the control board.

2.1.2 Microprocessor and the peripheral circuit

(1) Microprocessor (IC24: 80C186-16)

This processor is a CMOS single-chip computer with integrated peripheral device functions

and a 16 bit MPU core.

The processor has a 20 bit address bus and a 16 bit data bus.

It is capable of accessing up to 4M bit program memory and 4M bit of data memory.

The following characteristics are also provided:

• High-Speed DMA Channel x 2

• Programmable Interrupt Controller

• Programmable 16-bit Timer x 3

• Programmable Memory and Peripheral Chip-Select Logic

• Programmable Wait State Generator

• Local Bus Controller

And others.

The function of this microprocessor is to provide a central mechanism for the entire printer

by executing the control program through the LSI and driver circuits.

40496501TH Rev.1 12

to ALM circuit

PM

LF motor

driver

Sub LSI #1

72V017

AG slit sensor

to ALM circuit

PM

AG motor

driver

P/S FANP/S FAN DV.

HD FAN 1

HD FAN 2

HD FAN DV.1

HD FAN DV.2

SP FAN

CB FAN

SP FAN DV.

FAN ALM

Continuous

paper cutter

(option)

Sub LSI #2

72V017

to ALM circuit

PM

Bail motor

driver

to ALM circuit

PM

Paper path

switching

motor driver

Either of them

LAN

Sensor, SW

DIP SW

SRAM

(1M)

2/2

NHDC LSI

RS232

LSI

1/2

NHDC LSI

D/R

to ALM

circuit

PM

Ribbon motor

driver

DRAM

(4M)

TFA. TFD.720S

PRG,

EEPROM

ROM

(4M)

IEEE1284

BUF

BUF

OPpanel

OPpanel

LSI

CG,

ROM

MUPIS

LCD

(4M)

card

BUF

(x1)

HEAD

Head driver

Extended slot

<OPTION>

ML300's/ 500's

BUF

to ALM circuit

AG sensor

FL ROM

(8M)

OPTION

RS232C, TWINAX,

COAX, etc

Slit sensor

to ALM circuit

SP motor

DC

SP motor driver

ALM circuit

Head/ motor driver POWEROFF-P

Main LSI

Each part

ALE/ RD/ WR/ CS/ CLK

AD0~AD15

A16~A19/ BHE

+44V

+12V

+ 5V

CPU

80C186

32

MHz

-12V0VEP

Unit

Power Supply

POWOFF-P

POWDOWN-P

AC DOWN-P

POW ONRST-N

POWALM-P

Figure 2.1

40496501TH Rev.1 13

(2) PG ROM (IC46)

This is a 256 x16 bits (4M bit) EPROM with the control program for the printer stored. The MPU

executes instructions under this program.

The program ROM is assigned to the program memory area of the MPU and is fetched by the

RD signal of the MPU.

The following shows the operation of the memory access.

MPU

ALE

RD

WR

CS

CLK

A16~BHE

AD0~AD15

Main LSI PG ROM

A17

A16

A1~A16

NHDC LSI

BANK0

BANKS

CS

A0~A15

OE

CE

MPU CLOCK

ALE

A16~BHE

AD0~AD15

RD

CS

A16-BHE

A0–A15 D0–D15

Figure 2.2

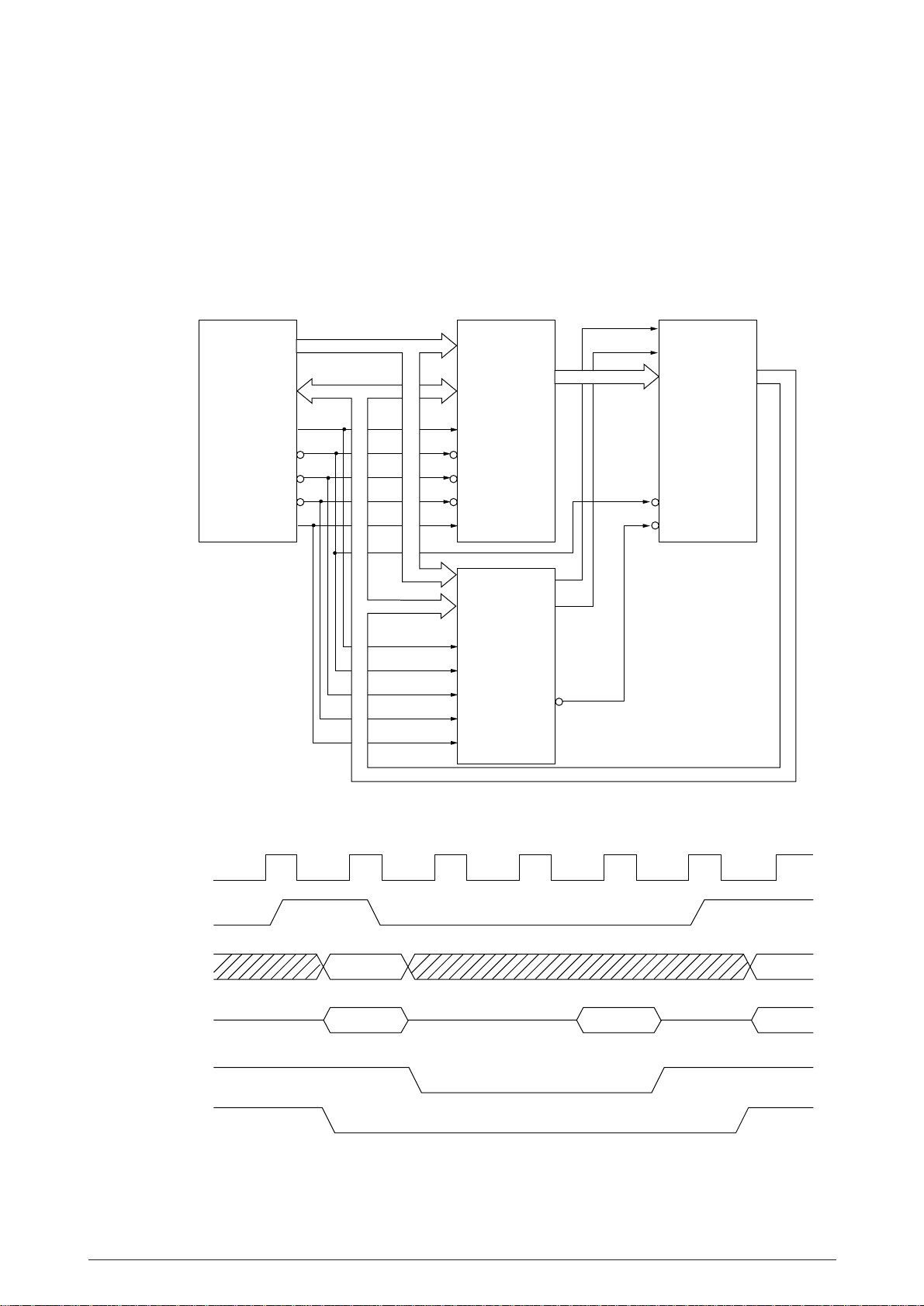

40496501TH Rev.1 14

(3) DRAM(IC28)

The RAM is CMOS dynamic RAM with (256K x 16 bit) configuration, and used as buffers (such

as receiving buffer, printing buffer, DLL buffer and working buffer).

The following shows the examples of the memory access operation.

MPU CLOCK

ALE

A16~BHE

MPU NHDC LSI

A16~BHE

AD0~AD15

ALE

RD

WR

CS

CLK

A16~BHE

RAS

CASU

CASL

WR

DRAM

DRAMA0~A9

DRAMD0~D15

RD

AD0~AD15

RD

AD0~AD15

WR

CS

A0–A15 D0–D15

A0–A15 D0–D15

Figure 2.3

40496501TH Rev.1 15

(4) CG ROM (IC48)

This is a 256K x 16 bits (4M bits) EPROM with the font data for the characters stored.

CG ROM is assigned to the program memory area of the MPU and is fetched by the RD signal

of the MPU.

The following shows the memory access operation.

MPU

ALE

RD

WR

CS

CLK

A16~BHE

AD0~AD15

Main LSI CG ROM

A17

A16

A1~A16

NHDC LSI

BANK0

BANKS

CS

A0~A15

OE

CE

MPU CLOCK

ALE

A16~BHE

AD0~AD15

RD

CS

A16-BHE

A0–A15 D0–D15

Figure 2.4

40496501TH Rev.1 16

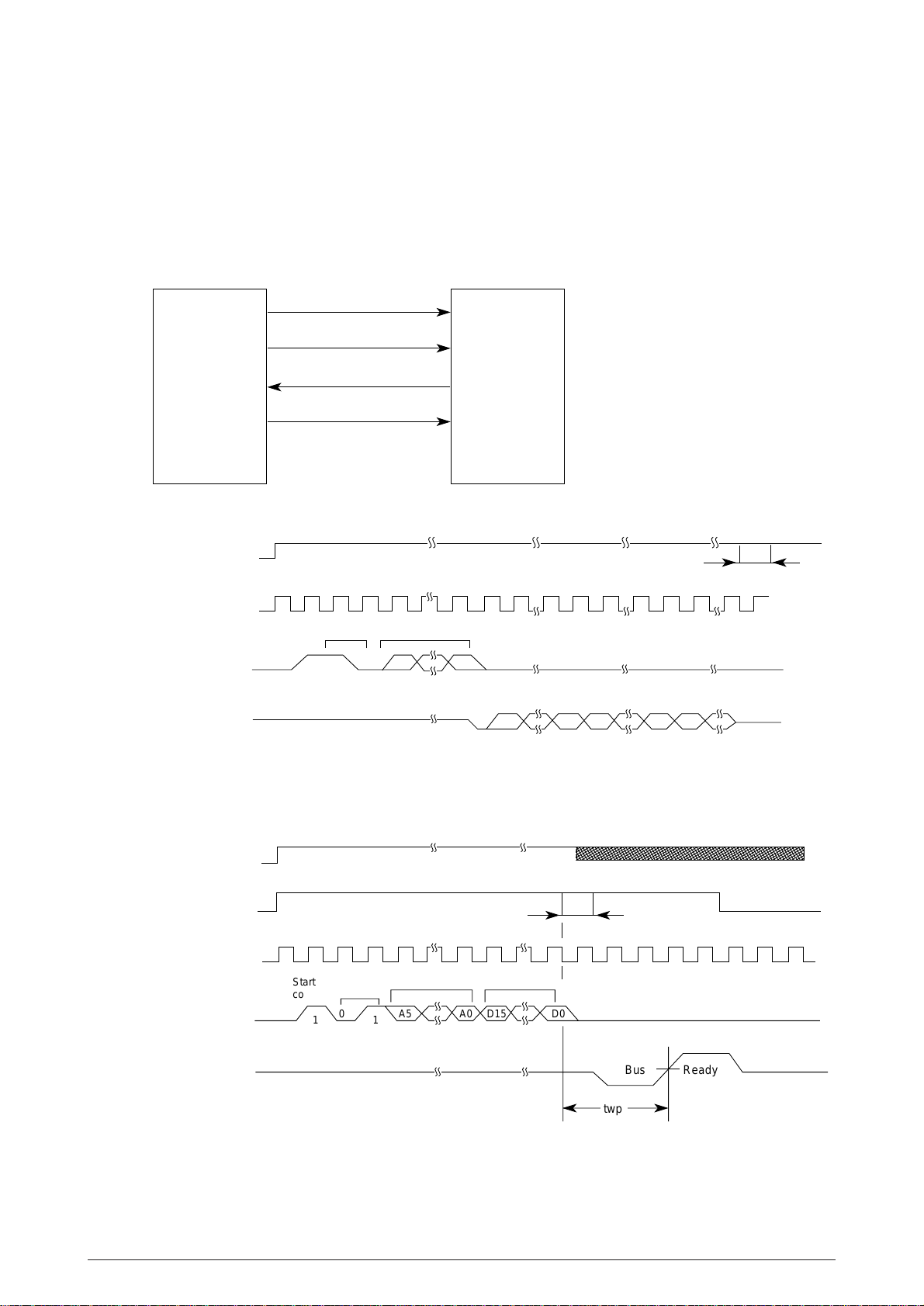

(5) EEPROM(IC40)

,

The EEPROM is a CMOS serial I/O type memory which is capable of electrically erasing and

writing 1,024 bits.

The EEPROM contains menu data.

The following shows the memory access operation.

NHDC LSI EEPROM

EEPROMWR-P

DI

EEPROMCS-P

CS

EEPROMRD-P

DO

EEPROMCLK-P

SK

PRE = O

PE = X

EEPROMCS-P

EEPROMCLK-P

EEPROMWR-P

EEPROMRD-P

PRE = O

PE

EEPROMCS-P

EEPROMCLK-P

EEPROMWR-P

Read cycle timing (READ)

Operation

Start

code

code

0

11

Write cycle timing (WRITE)

Operation

Start

code

code

0

11

Address

A0A5

0

D15 D0 D15 D0 D15

Address Data

t

CS

t

CS

D0D15A0A5

EEPROMRD-P

twp

ReadyBus

Figure 2.5

40496501TH Rev.1 17

(6) Main LSI (IC38: MSM91U036)

MSM91U036 is control LSI for head data, DC motor and modification of print data, which has

the following functions.

(a) Head data control

It distributes print data stored in the DRAM over wire arrangements of the print head and

outputs it as dot data in synchronism with print timing. In this time, the distribution

complies with each print mode which is specified by the MPU.

(b) Print timing control

It outputs the signals which control the print timing of ODD and EVEN pins on the print

head.

(c) Space motor speed control function

It controls the space motor with micro-programs to accelerate/decelerate it.

This LSI also controls the speed of the space motor in agreement with each print mode.

(d) I/O port

This printer has 8-bit output port which is used for controlling the SRAM.

(e) Head position count

It counts the outputs from slit sensors (SPPHASE A, B) located on the space motor to

keep monitoring the current position of the print head.

(f) Print data modifying function

It modifies the print data stored in the DRAM with command inputs from the MPU.

(h) DMA control function

It outputs a DMA request to the MPU, simultaneously controlling the DMA.

This LSI is connected in multiplex to the MPU.

40496501TH Rev.1 18

MPU CLOCK

ALE

MPU Main LSI

A16~BHE

AD0~AD15

ALE

RD

WR

CS

CLK

A16~BHE

AD0~AD15

RD

AD0~AD15

WR

CS

A16~BHE

A0–A15 D0–D15

A0–A15 D0–D15

Figure 2.6

40496501TH Rev.1 19

(7) NHDC LSI(IC27: TC190G08CF-7036)

This LSI controls timer, interruption, memories, printing, external interface, motor drive

interface.

(a) Timer control

It controls the watchdog timer for detecting any out-of-control program, baud rate

generator for setting the baud rate of the serial interface, and pulse generation timer for

AG plus count.

(b) Interruption control

It controls LSI inside interruptions, external interruptions and interruptions from an

external interface as outputs for the MPU.

(c) Memory control

DRAM and SRAM control, chip select output control of ROM, flash memory and MUPIS,

and bank switch control for expanding their memory spaces.

(d) Print control

It creates a print timing corresponding to the print DPI to control the possition and print

correction for pins.

This also controls the print Mask and DMAC which reads print data from the memory and

transmits it to the print output buffer.

(e) External interface

It controls various interfaces for main LSI, IEEE1284, serial, MUPIS, OpePaneLSI,

EEPROM.

(f) Motor drive interface

Each control of OVDV pulse generation for AG motor, generation of pulse for switching

ribbon motor phase, and OVDV pulse generation for LF motor.

(8) Sub LSI (IC17, IC18: MSM72V017)

This LSI is the I/O port LSI which controls the input/output of various controlling signals with

command inputs from the MPU.

(a) Sub LSI #1 (IC17: MSM72V017)

Input/output control for controlling signals to various sensors, FAN controlling signals,

sensor slice level controlling signals, AG motor controlling signals, and LF motor

controlling signals.

(b) Sub LSI #2 (IC18: MSM72V017)

Input/output control for controlling signals to various sensors, SP motor current controlling signals, external interface controlling signals, TR motor controlling signals, bail motor

controlling signals, cutter motor (for optional connection) controlling signals.

(9) Serial I/F LSI (IC35: 85L30)

This LSI is the serial I/F LSI which controls the input/output of serial I/F controlling signals with

command inputs from the MPU.

40496501TH Rev.1 20

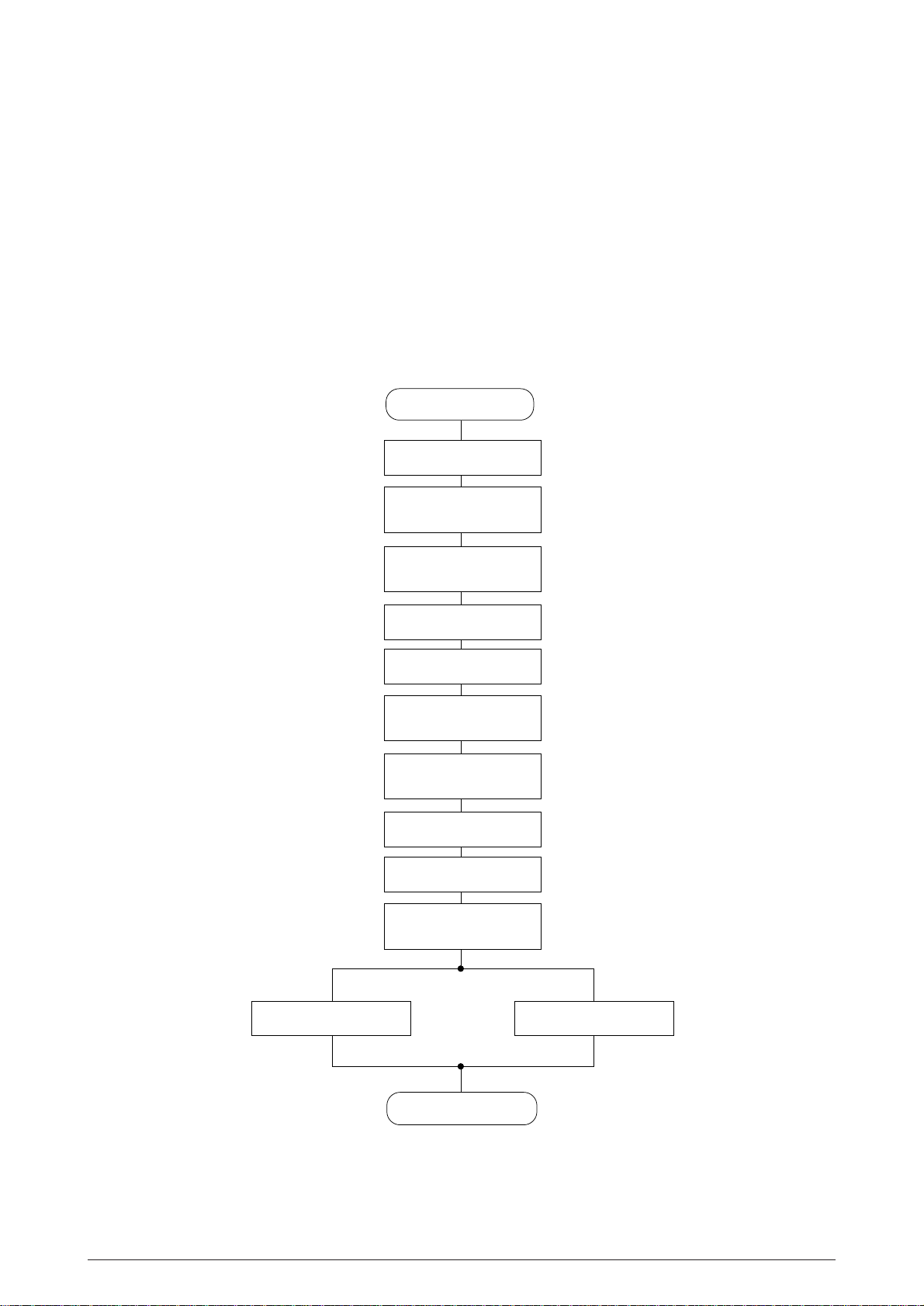

2.1.3 Initialization

This printer is initialized when the power is tumed on or when the I-PRIME-N signal is input from

the host side via the parallel interface.

For the initialize operation, the RESET-N signal is first output from the reset circuit to reset the MPU

and LSIs. When resetting ends, the program starts and the LSIs are reset by NHDC LSI via

LRESET-N. Reset operation by I-PRIME starts program to initialize, but does not reset the MPU.

The program here sets the mode of the LSI including the MPU, checks the memories (ROMs and

RAMs), then carries out carriage homing, and determines the LF motor phase.

Finally, the program establishes the interface signals (P-I/F: ACK-P signal sending, and S-I/F:

BUSY-N signal off) and lights the SELECT lamp to inform the ready state for receiving to the host

side and ends the initialize operation.

Start

MPU RESET

MPU

Initial Setting

Internal RAM

CHECK

Serial

I/F

I/F BUSY OFF

ROM CHECK

LSI RESET

External RAM

CHECK

LSI Initial Setting

and I/F Busy ON

RAM Clear

Carriage Homing

LF Motor Phase

Initialization

Parallel

I/F

I/F ACK Send

End

Figure 2.7

40496501TH Rev.1 21

2.1.4 Interface control

The PM4410 is provided with the centronics parallel interface and RS-232C serial interface as

standard features.Also, it can be connected to option OKI HSP or Opt. Card. The interface cable

can be connected simultaneously with these interfaces.

These interfaces can be switched with the menu switch on the operation panel, in addition, you can

designate auto-select for them. The MPU communicates with hosts through the NHDC according

to the selected interface mode. The selected interface is stored to the EEPROM and can maintain

even after powering the printer off.

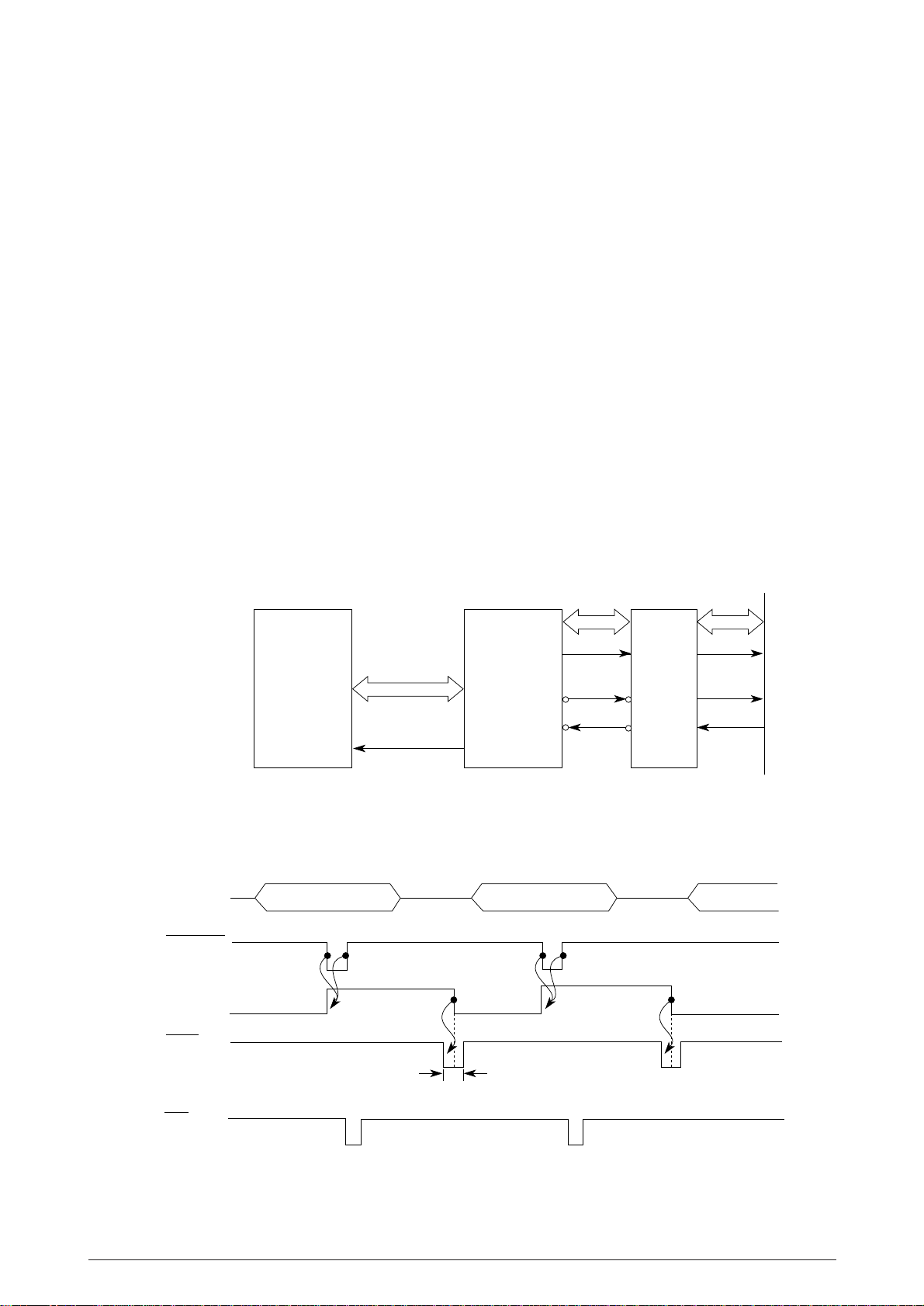

2.1.5 Parallel Interface Control

The Parallel data input from the host to the NHDC LSI is latched to its internal register at the falling

or rising edge of the STROBE-N signal.

At the same time, the LSI sets the BUSY signal to the high level to inform the host that the data

is being processed, and outputs the INT-P signal to inform the MPU of data reception. The data

is read upon receiving the RD-N signal from the MPU.

When the data processing ends, the BUSY signal is set to off and the ACK-N signal in sent to

request the next data. When reception is impossible because the buffer is full, the BUSY signal is

sent to request stopping of data transmission.

Data

1 to 8

STROBE

BUSY

MPU NHDC LSI

BSYP

A/D bus

ACKN

PSBN

INT-P

INT INT

or or

500ns max.

Line

driver

receiver

Parallel I/F

BUSY

ACK-N

STB-N

ACK

2~8µs

INT

Figure 2.8

40496501TH Rev.1 22

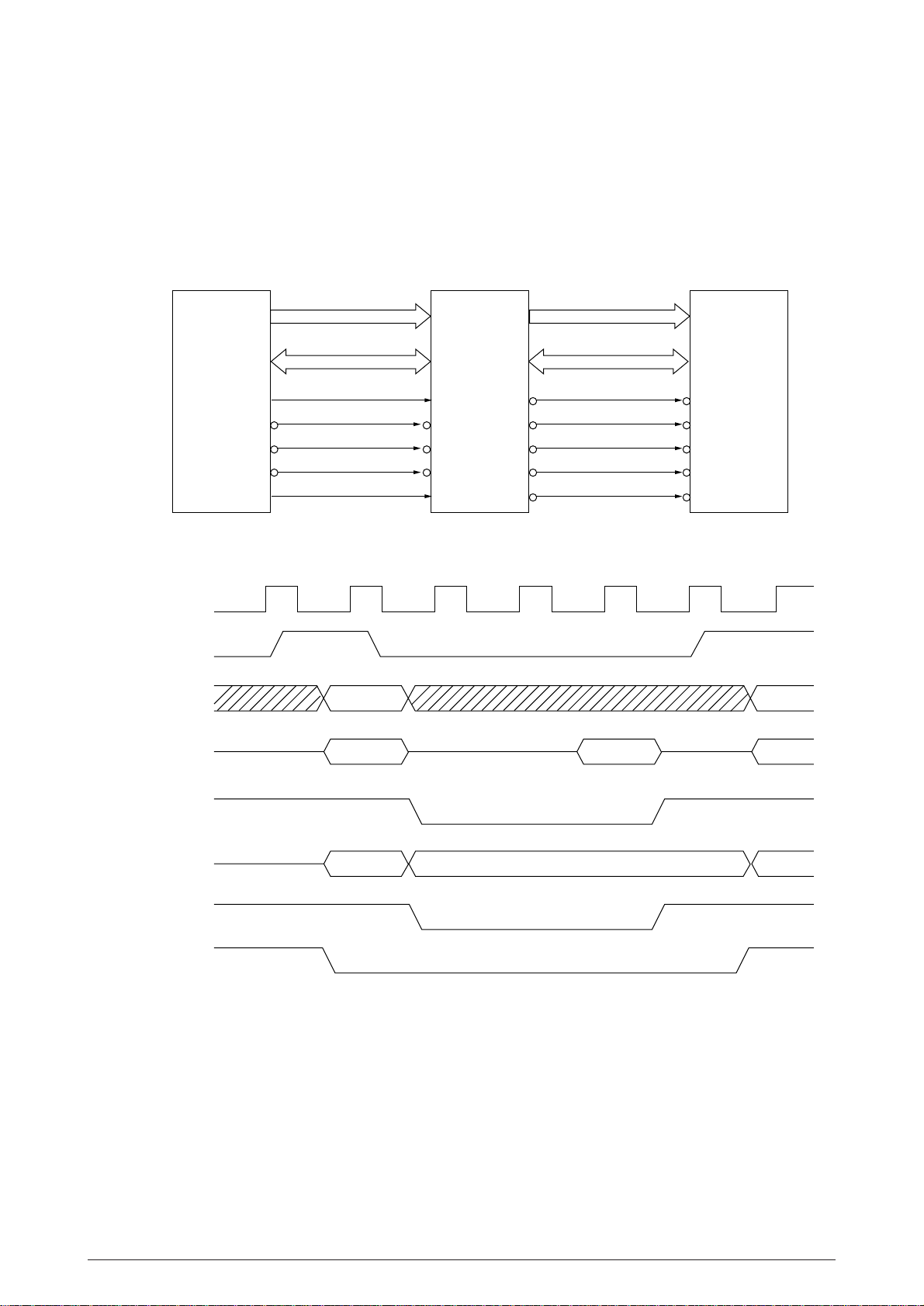

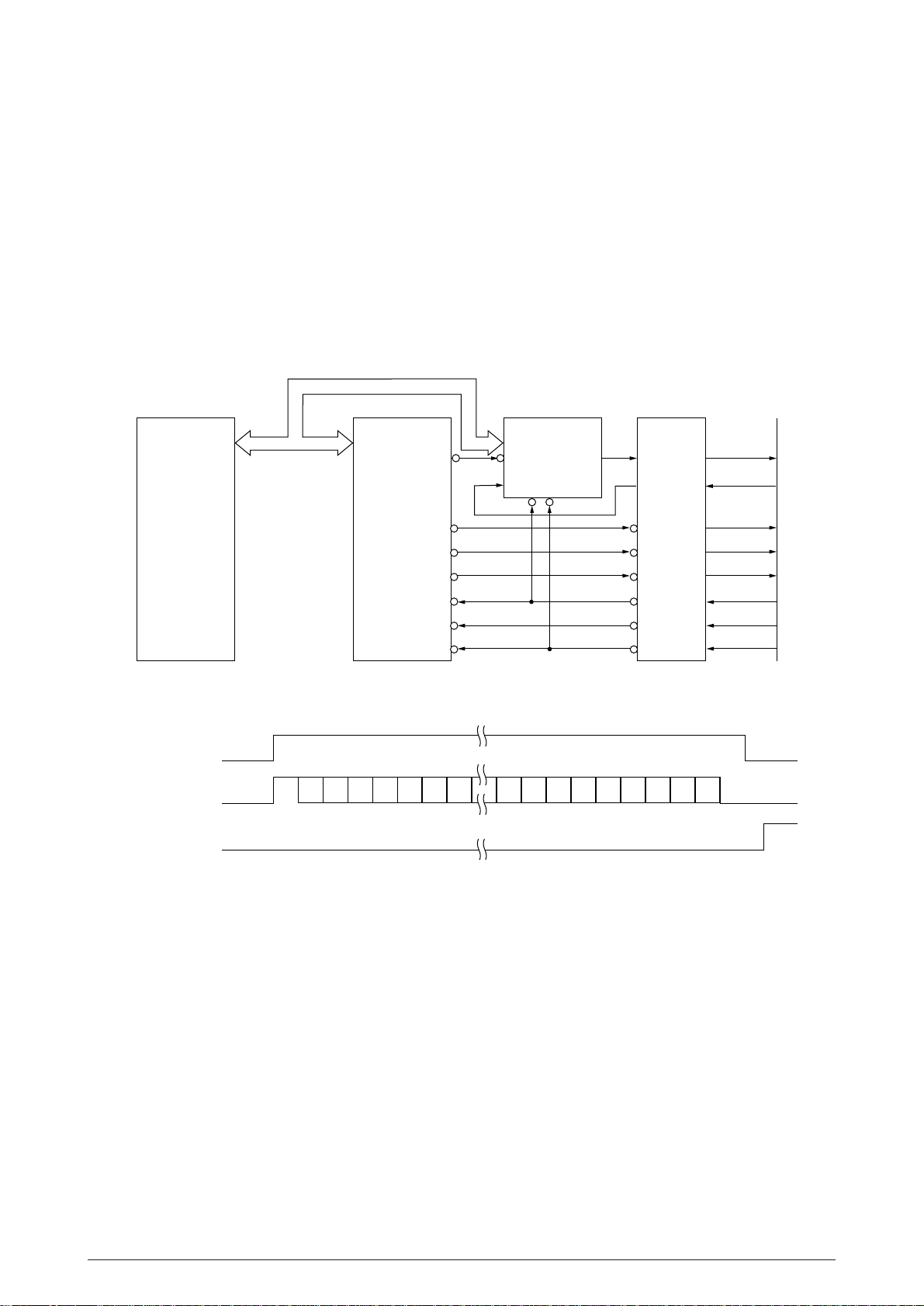

2.1.6 Serial Interface

The MPU sets the baud rate which is selected with the menu switch for the NHDC LSI and have

the serial I/F LSI to output the clock frequency of the baud rate.

Input signals from the serial I/F (DSR, CTS, CD and RD) are converted into TTL level ones by the

Line driver/receiver and input to the serial I/F LSI and NHDC LSI. The serial I/F LSI converts serial

data into parallel data to output it to the MPU.

Output signals (DTR, RTS, SSD and TD) to the serial I/F are output from the MPU to the NHDC

LSI and serial I/F LSI, and then converted through the Line driver/receiver into line voltage which

is output to the serial I/F.

AD0-AD7

MPU NHDC LSI

DSR

RD

ST SP

TCK0

RTSN

SSDN

DTRN

CTSN

DSRN

DCDN

Serial I/F LSI

CLK

RXDA

TXDA

Line

driver

receiver

Serial I/F

TD

RD

RTS

SSD

DTR

CTS

DSR

CD

SSD

Figure 2.9

40496501TH Rev.1 23

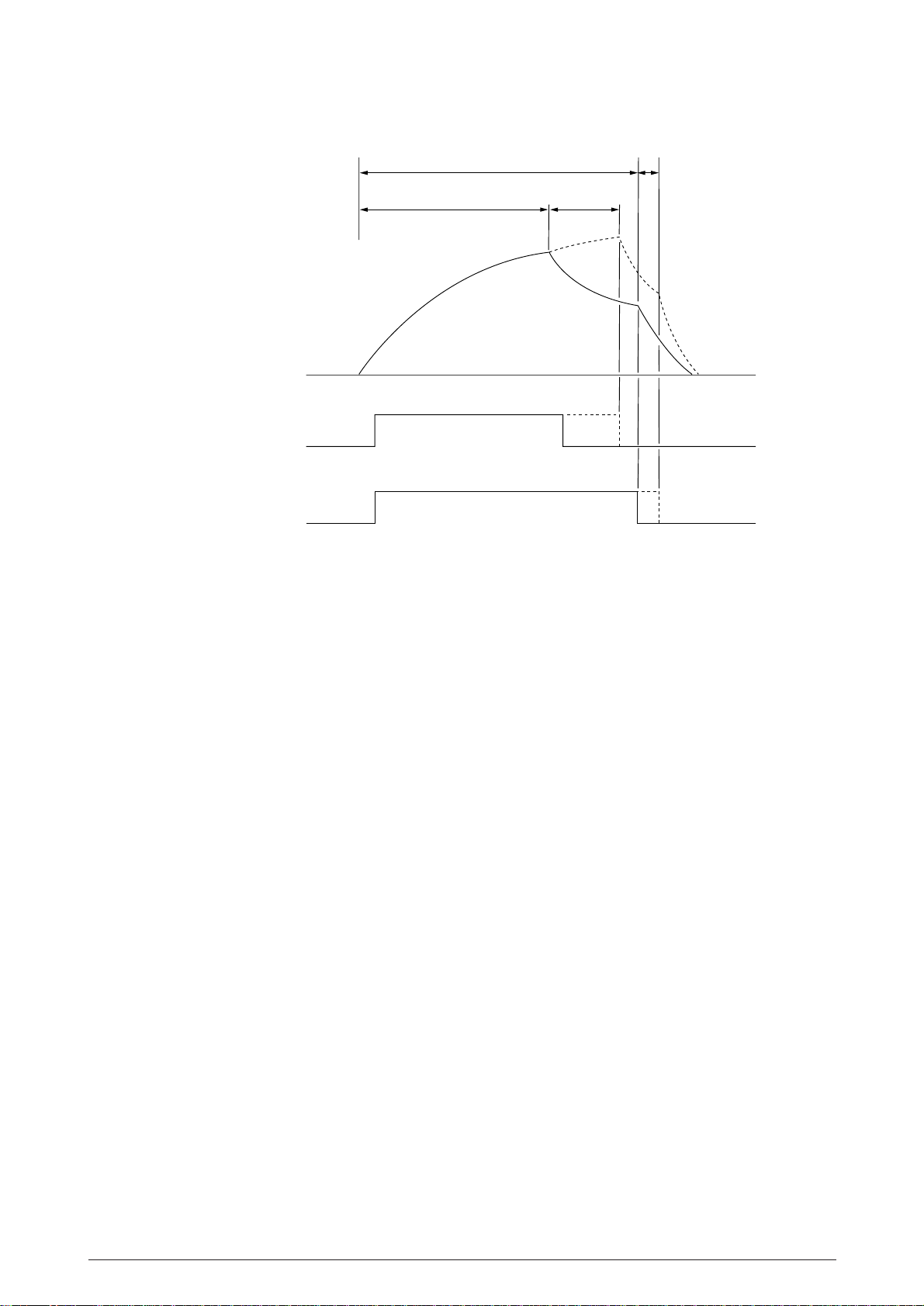

2.1.7 Printing operation

The time chart for the spacing and printing, line feed operations are as shown below.

The spacing, printing and line feed operations are controlled by the MPU. The MPU also controls

the entire timing of these operations.

Acceleration

Constant speed

Deceleration

SP Motor

Operation

Printing

Print

Line Feed

LF

Figure 2.10

When starting the printing operation, the MPU specifies the distance moved, print start position,

printing speed, etc. to the LSI, and activates the spacing motor. The MPU, when the carriage

arrives at the print position specified, activates the printer to start printing, and when printing

terminates, the MPU activates the line feed motor for line feed operation. During the line feed

operation, the MPU causes the carriage to decelerate. Upon termination of line feed operation, the

spacing operation is performed.

40496501TH Rev.1 24

2.1.8 Printhead control

The printhead is controlled by the Main LSI and NHDC LSI.

Printing is synchronized with the ITOUT signal from the NHDC LSI.

Control Board

The NHDC LSI outputs the dot timing1 signals (DT1:1~18) and the dot timing2 signals (DT2:1~18),

and the driver IC drives each dot magnet. These signals are output from the NHDC LSI after the

following corrections for final driving time determination inside the LSI:

(1) Correction for the number of pins driven

MPU NHDC LSI

A/D bus

Main LSI

TFA-N

TFD-N

Print Data

HEAD1-P~

HEAD18-P

Figure 2.11

Driver Board

DRIVER

Print Data

HEAD1~

HEAD18

Print Head

The driving time is corrected according to the number of pins driven at the same time out of

18 pins.

(2) Correction according to adjacent pin drive timing

The driving time is adjusted by checking whether the pin adjacent to the pin to be driven is

driven on the previous timing.

(3) Correction for head gap

The driving time is corrected according to the head gap.

40496501TH Rev.1 25

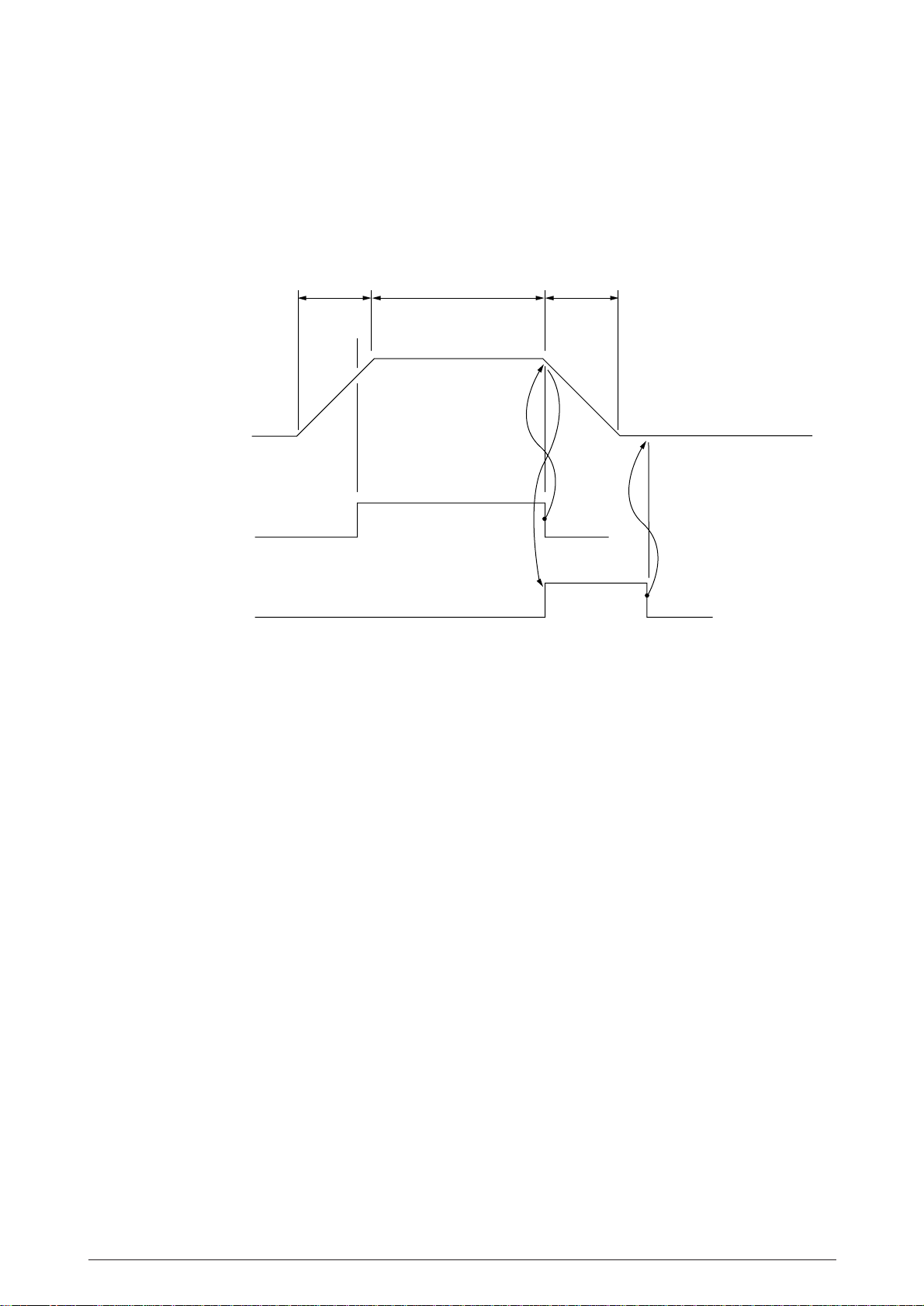

DT2 Basic drive time

(3)

Dot magnet drive

coil current

signals

DT

1

(D1–D18)

signals

DT

2

(D1–D18)

Basic drive time

DT

1

Figure 2.12

(1)+(2)+(3)

40496501TH Rev.1 26

2.1.9 Print Compensation Control

The print compensation can be made as shown below:

(a) Simultaneous Compensation of the number of impact pins

The NHDC LSI is provided with the compensation table for each pin to make necessary

compensation.

Number of impact pins Few Many

Drive time Short Long

(b) Duty control

1. If the number of the lines which exceeds 60% printing duty is continuous 8 lines, the printer

starts 2-path printing at the 8th line.

2. If the printer can activate 12 pins simultaneously in a line, it 2-path prints the line.

(c) Temperature compensation (See2.1.14 "Alarm Circuit.")

(d) Print mode compensation

According to the thickness of the printing medium, the print mode is compensated as shown

in the table below:

Head Gap Range 1 2 3 4 5

Print speed 100% 97% 95% 90% 89%

Drive time Short Long

(Drive time lengthens at each step.)

2.1.10 Space motor control

(1) The Main LSI generates the SPDV-P signal upon receiving the spacing command from the

MPU. This is a fixed cycle pulse signal.

The Main LSI varies the pulse duty according to the speed data from the MPU to control the

motor speed.

The SPFOW-P or SPREV-P signal from the Main LSI changes the current direction in the DC

motor to run the motor in the forward or reverse direction.

SPFOW-P

SPREV-P

SPDV-P

MotorCurrent

Figure 2.13

40496501TH Rev.1 27

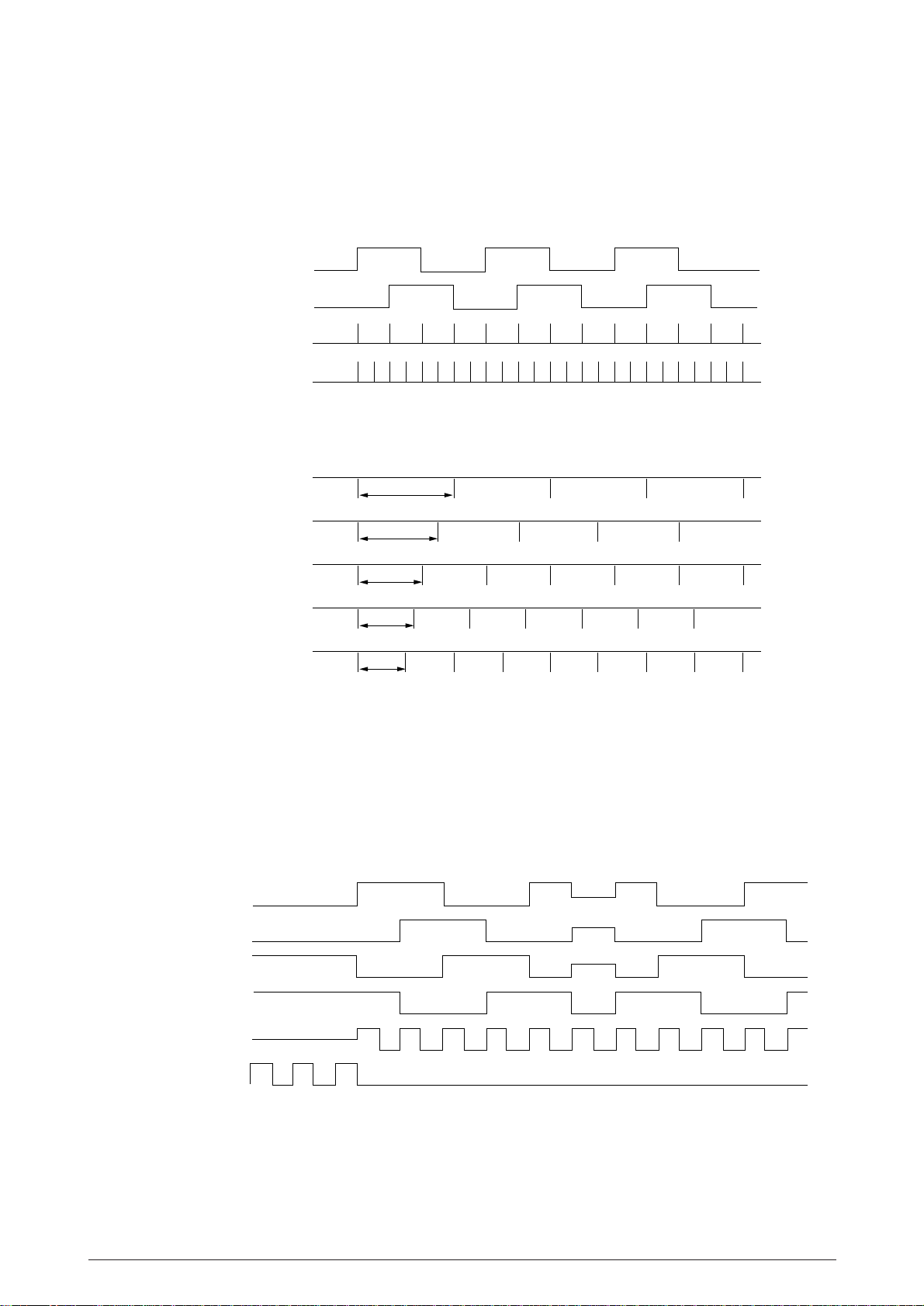

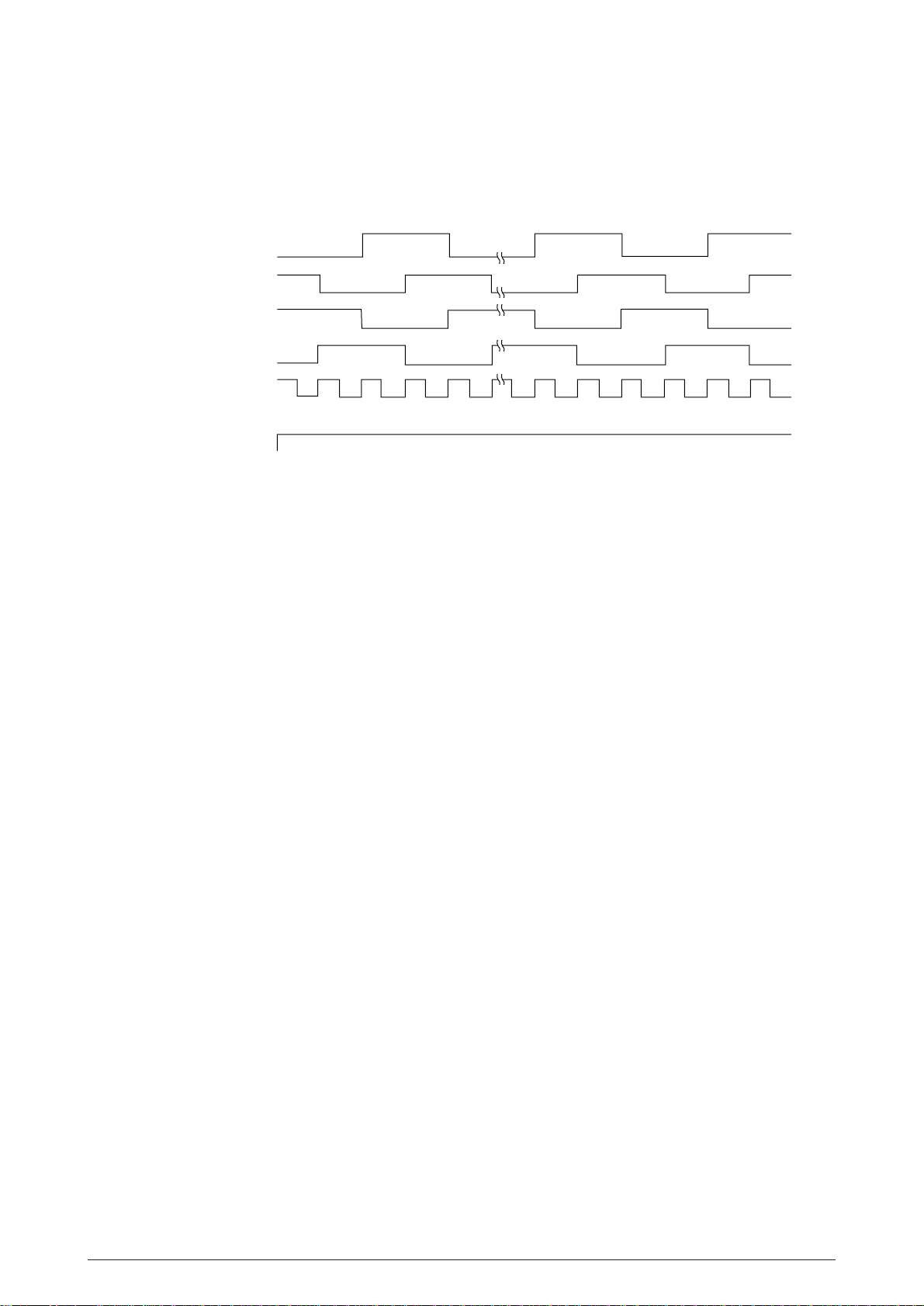

(2) Slit encoder

As the space motor rotates, it generates feedback pulse signals SPA-P and SPB-P. The Main

LSI detects the edge pulses from these signals and multiplies the frequency to output the

S720-P signals as the normalized timing to NHDC LSI to generate head drive timing.

SPA-P

SPB-P

Edge pulse

S720-P

UTILITY MODE

ITOUT 10CPI

ITOUT 12CPI

ITOUT 15CPI

ITOUT 17CPI

ITOUT 20CPI

2.1.11 Line feed

1/360"

1/120"

1/144"

1/180"

1/206"

1/240"

Figure 2.14

The LF motor is locked by the current supplied from +12V according to the pulse duty of the

LFCHOP-P signal during the stop period.

It is driven by +44V application by the LFOVDV-P signal for line feed operation.

LFø1

LFø2

LFø3

LFø4

LFOVDV-P

LFCHOP-P

Figure 2.15

40496501TH Rev.1 28

2.1.12 Bail, tractor switching, AG, ribbon motor control

Bail, tractor switching, AG and ribbon motor control is as shown below.

The AG motor is locked with AGHOLD-P.

MO ø1

MO ø2

MO ø3

MO ø4

MO OVDV

AGHOLD-P

Figure 2.16

40496501TH Rev.1 29

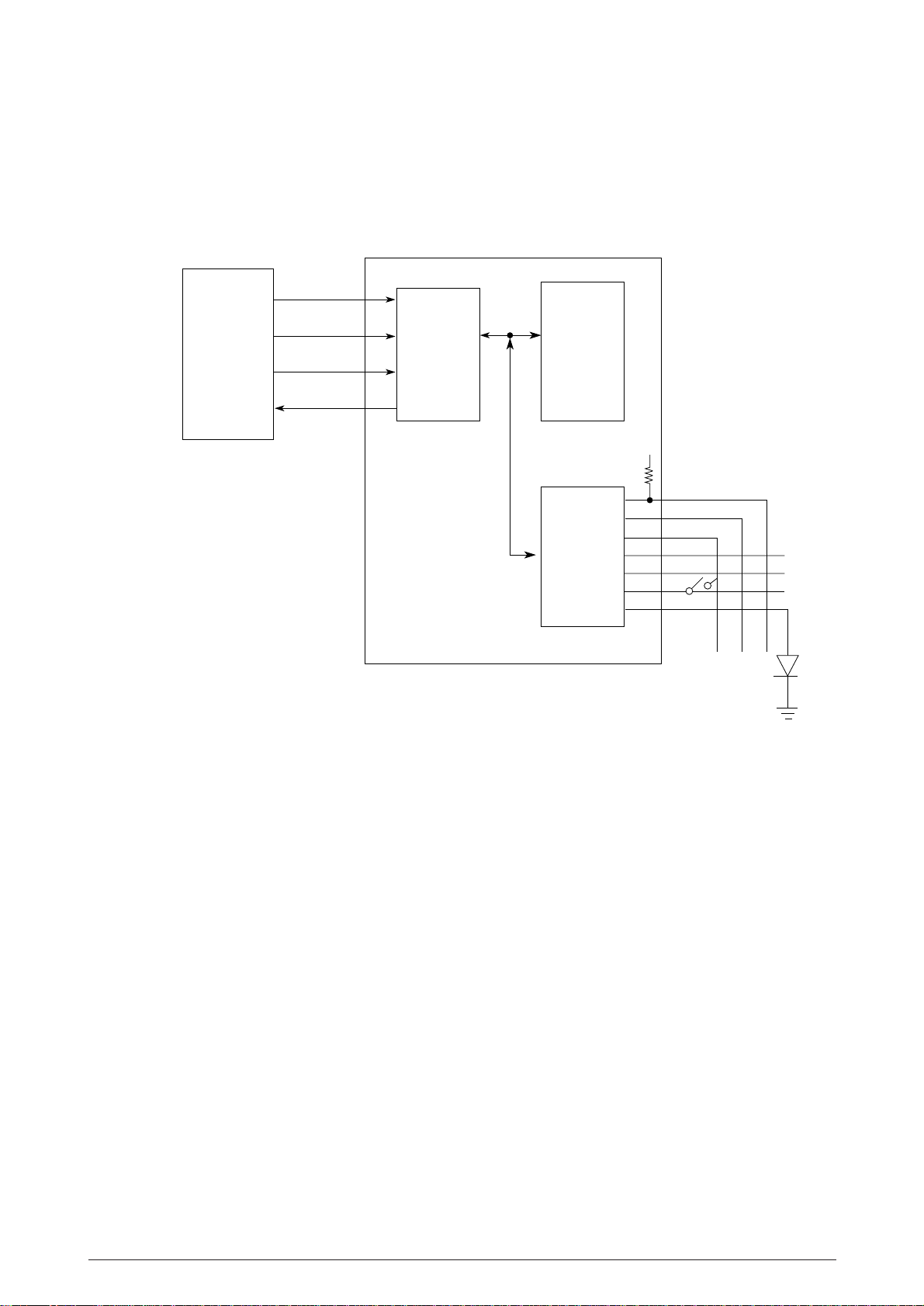

2.1.13 Operation Panel

The clock synchronization OPCLK of NHDC LSI is used to input the switch data and output the LED

data and LCD data through the operation panel control LSI (IC1: BU6152S).

NHDC LSI

SCKN

SCSN

SDO

SDI

OPDATAOUT-P

56

OPSCLK-N

59

OPSQCR-N

58

OPDATAIN-P

57

BU6152S

Command

and Data

latch

LED driver

+5V

Switch

controller

Figure 2.17

A 2-byte (15 bits + 1 even parity bit) command (OPDATAOUT-P) is transmitted to the LSI

(BU6152S) in synchronization with the OPSCLK-N signal. The LSI decodes this command and

when it is found to be legal, returns a 2-byte command response back to the NHDC LSI which

includes data on Switch information, LED status, LCD status receive command ACK/NAK and 1

odd parity bit.

Any transmission errors found cause the command to be reissued after the transmission of the

OPSQCR-N signal.

40496501TH Rev.1 30

Loading...

Loading...