Page 1

PS-900

Soldering System

PS-900 系统用户指南

7000-2250_1a

PS-900 系統使用者指南

PS-900 取扱説明書

PS-900 시스템 사용자 설명서

Page 2

PS-900 Soldering System

Operations Manual & User Guide

Congratulations on your purchase of the PS-900 Soldering Station. It utilizes SmartHeat

technology to ensure unsurpassed performance without the need for system calibration. It

has been designed and manufactured to the highest quality standards to provide

consistent good performance and reliability.

This document has been prepared to guide you with the setup, operation, and user

maintenance of your station. We recommend that you review it to optimize performance

and operational consistency.

Table of Contents

1. Packing / Spares Lists .............................................1

2. Initial Setup..............................................................2

3. Smartheat

4. Selecting Heater Tips...............................................3

5. Replacing Heater Tips .............................................3

6. Replacing the Coil Assembly...................................4

7. Troubleshooting.......................................................4

8. Specifications...........................................................5

9. Warranty ..................................................................6

10. Safety Information..................................................7

®

..............................................................2

1-a. PACKING LIST

a. PS-900 Power Supply (Part Number: PS-PW900)

b. PS-900 Auto-sleep Workstand - Black (Part Number: WS2)

c. Sponge (Part Number: AC-YS4)

d. PS-900 Soldering Handle / Coil Assembly (Part Number: PS-HC3)

e. Cartridge Removal Pad (Part Number: AC-CP2 )

f. Power Cord

g. Instruction Manual

(with part numbers for re-ordering):

1-b. ADDITIONAL SPARE PART / CONSUMABLE ITEMS:

a. Coil assembly, PS-900 system (Part Number: PS-CA3)

b. Handpiece / power cord. (NO Coil Assembly) (Part Number: PS-H3)

c. PS-900 Auto-sleep Workstand - Green (Part Number: WS2G)

d. Heater Tips (See section 4)

e. Net Power Meter for PS-900 system (part Number: PS-PM900)

2. INITIAL SETUP

®

The PS-900 Soldering System consists of a Power Supply, Workstand with Cradle and

Sponge, and a Soldering Handle. The soldering handle also houses a replaceable Coil

Assembly and replaceable heater tip. Both of these consumables are available from your

authorized OK International distributor as needed. The power supply features a Power Switch,

green “Power On” indicator light, power cord, and a connecting port for the solder handle cord.

1. Mount the power supply in a convenient location in your workspace, such as on the

workbench.

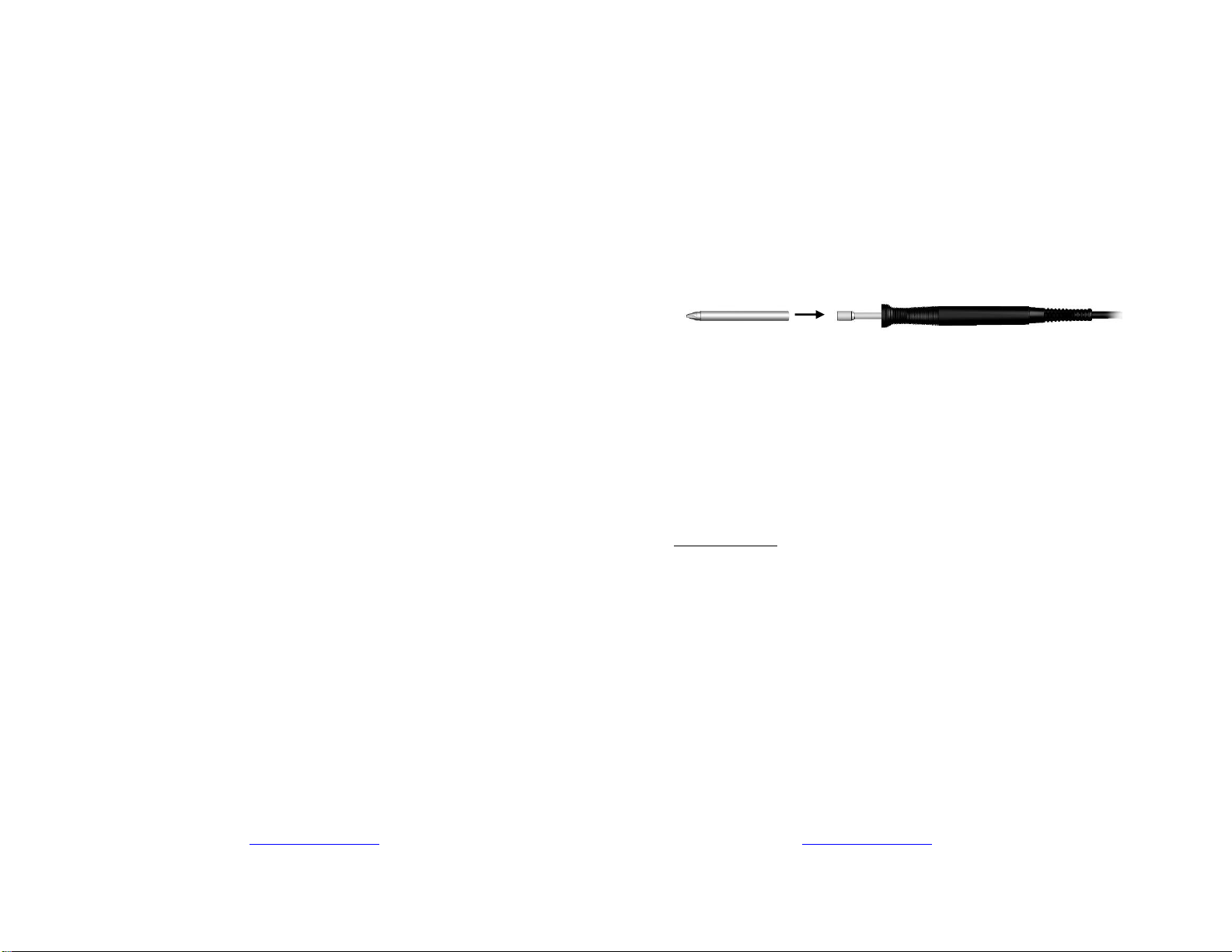

2. Insert a heater tip onto the Coil Assembly and simply push the Heater Tip all the way

until it seats. You should feel a slight “click” as it locks into place.

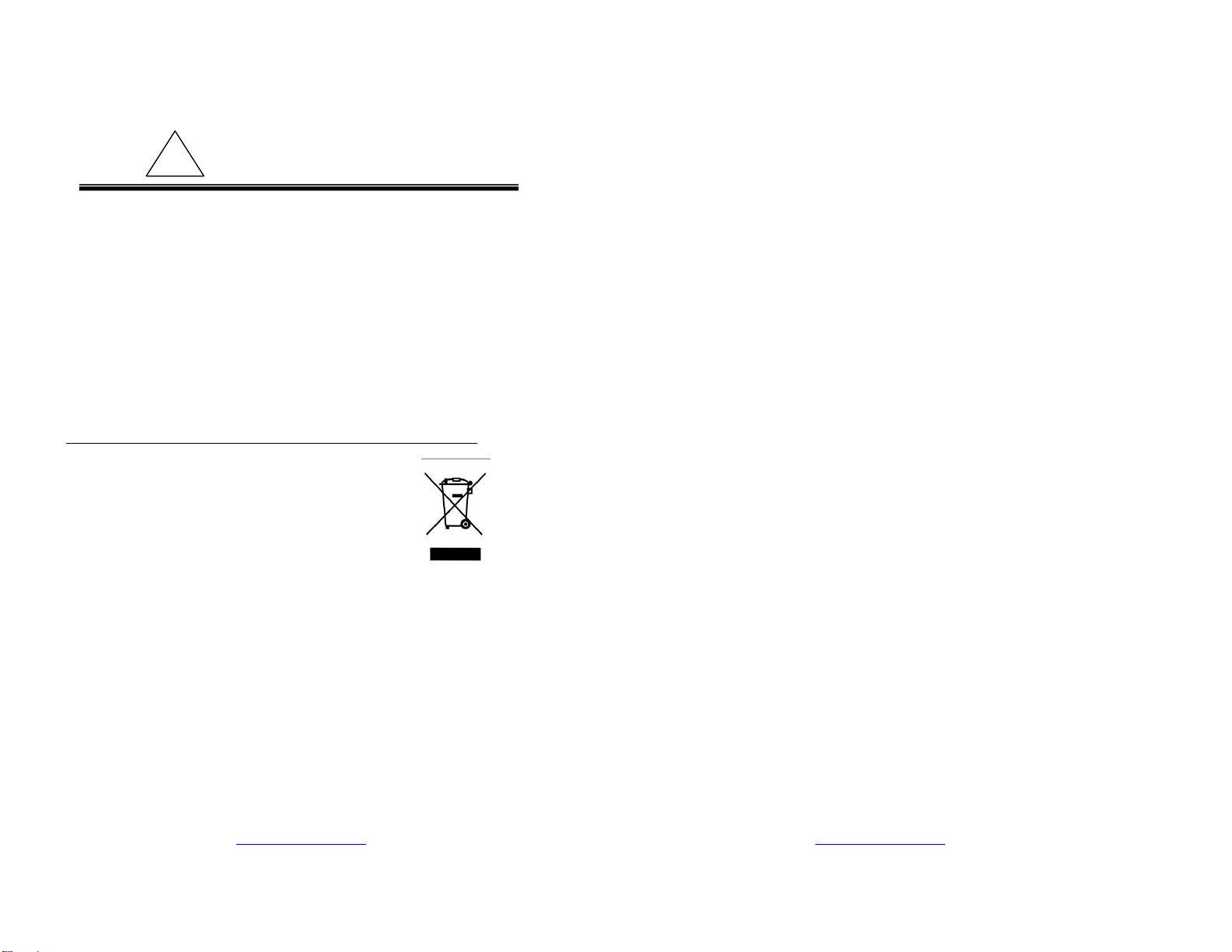

Insert Tip onto Coil Assembly

3. With the power “Off”, attach the solder handle cord to the power supply by inserting

the cord connector into the power supply connecting port. To align the 3 pins, position

CAUTION: To provide continued protection against the risk of electric shock, connect

only to properly grounded

the flat side of the cable connector toward the 9 o'clock position of the power supply.

4. Wet the sponge with de-ionized water until it is moist but not soaked. Then place it in

the workstand tray.

5. Plug the power cord into a grounded wall socket of the appropriately rated input line

voltage. To turn the unit on, push the switch (located on the front of the power supply)

until it latches. The green indicator light should light up. If it does not, see the

“Troubleshooting Guide” in this manual.

outlets.

3. SMARTHEAT

®

: NO CALIBRATION REQUIRED

The PS-900 System is comprised of an induction coil assembly and a heater tip. Each heater tip

is equipped with a self-regulating heater which ‘senses’ its own temperature and tightly

maintains its pre-set idle temperature for the life of the heater-tip; all controlled by OK

International’s proprietary SmartHeat

inherent metallurgical properties of the heater; no external adjustment or equipment is required.

The power delivered to the tip automatically varies in direct response to the thermal load. This

eliminates spikes and transients associated with electrically switched elements found in

conventional soldering irons. Please feel free to contact your OK International representative

with any questions.

®

technology. The tip temperature is determined by the

www.okinternational.com

1

7000-2250 修订版 1

www.okinternational.com

2

7000-2250 修订版 1

Page 3

4. SELECTING HEATER TIPS

y

OK International’s Heater Tips come in a wide variety of tip geometries and temperature ranges

(contact your local OK International Representative or visit our website for more information).

These tip geometries cover a broad range of tasks from delicate precision work to heavy ground

plane soldering.

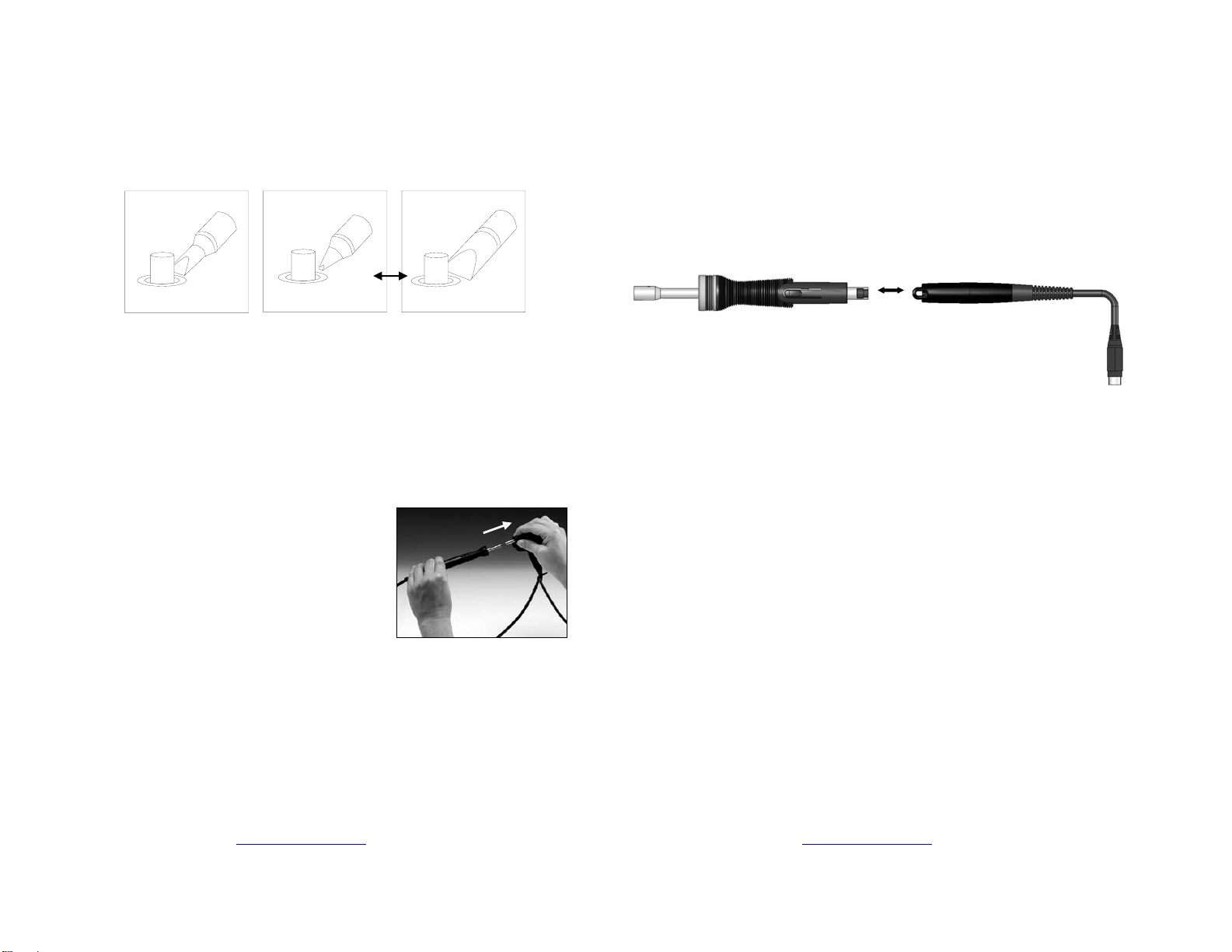

6. REPLACING COIL ASSEMBLIES

1. Push the Power Switch “Off.” Wait for the heater tip to reach room temperature.

2. Remove the heater tip from the handle assembly. DO NOT USE METAL TOOLS (SUCH

AS PLIERS) TO REMOVE HEATER TIPS.

3. To disconnect the Coil Assembly from the Soldering Handle depress the button on the Coil

Assembly and pull it away from the Soldering Handle assembly.

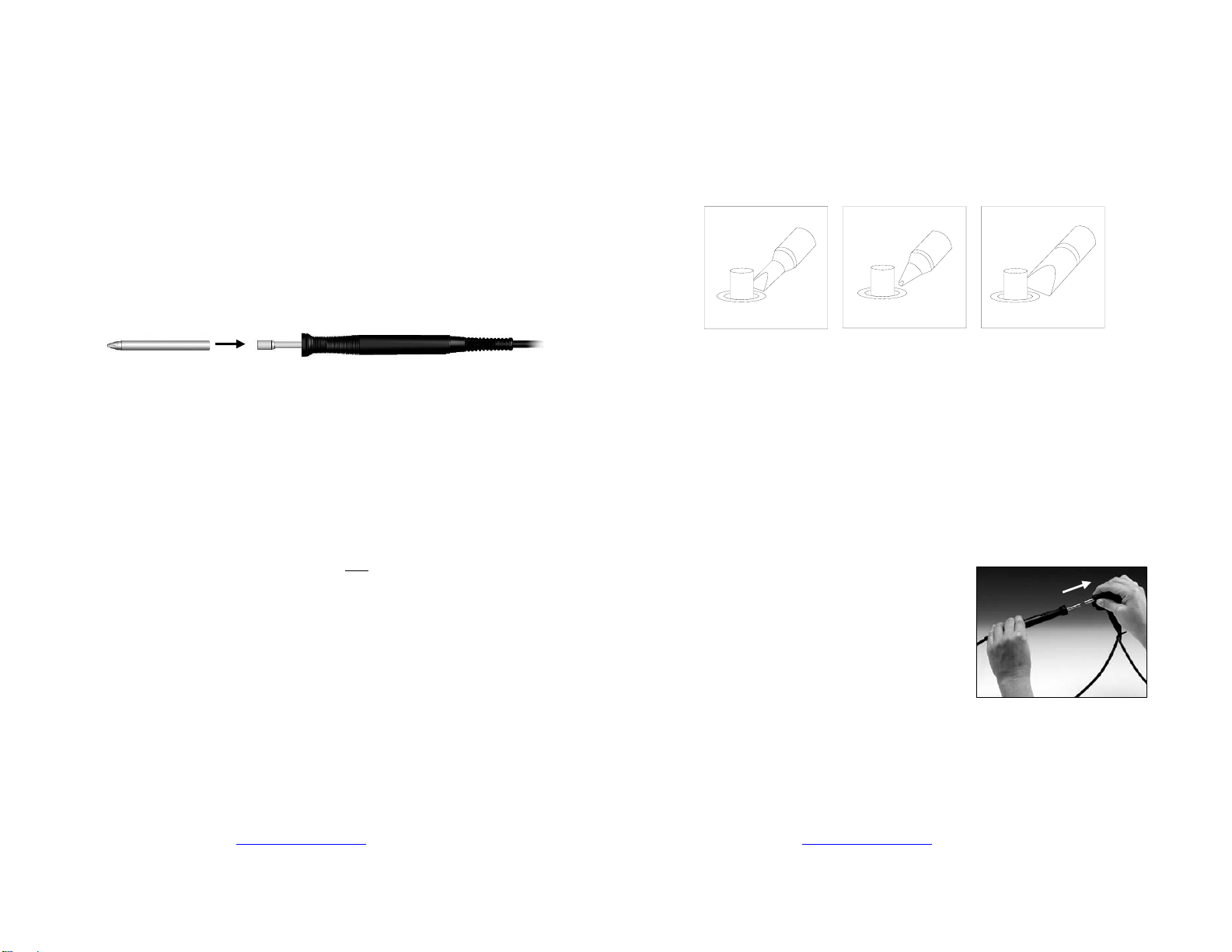

Correct

1. Pick a tip that maximizes contact area between the tip and solder joint. Maximizing contact

area gives the most efficient heat transfer, producing high quality solder joints quickly.

2. Pick a tip that allows good access to the solder joint. Shorter tip lengths allow more precise

control. Longer or angled tips may be needed for soldering densely populated boards.

3. Pick the lowest temperature tip cartridge that will accomplish the task. This minimizes the

potential for thermal damage. The temperature series is marked on the shaft of the Heater

Tip.

Too Light

Too Heav

5. REPLACING HEATER TIPS

1. Push the Power Switch “Off.” Removal of the

2. Pull out the heater tip using the supplied AC-CP2

1. Push a new heater tip into the solder handle with the supplied AC-CP2 Cartridge Pad.

2. Push the Power Switch “On.” The new heater tip will heat up to temperature in less

Heater Tip with the power On will result in damage

to the coil assembly.

Cartridge Removal Pad. DO NOT USE METAL

TOOLS (SUCH AS PLIERS) TO REMOVE

HEATER TIPS, AS THIS CAN DAMAGE THE

HEATER.

CAUTION: THE HEATER TIP MAY BE HOT!

than 20 seconds.

4. Insert the new Coil assembly into the handle assembly, you will feel a ‘click’ as it seats.

7. TROUBLESHOOTING

a. Power LED Not ON

• Check the power cord

• Check to see that you have mains voltage

• Check to see if the power switch is in the ON position

b. Tip Does Not Heat

• Is the LED Illuminated?

• Is the Hand-Piece Connected to the Power Supply?

• Is the PS-CA3 Coil assembly firmly inserted into the PS-H3 Soldering

Handle assembly?

• Is the Tip Firmly Inserted onto the PS-CA3 Coil Assembly?

• Has a replacement PS-CA3 been tried?

If you cannot resolve the problem after conformation of the above, please contact your local OK

International representative.

www.okinternational.com

3

7000-2250 修订版 1

www.okinternational.com

4

7000-2250 修订版 1

Page 4

8. SPECIFICATIONS

Power Supply

Ambient Operating Temperature 10 - 40°C

Maximum Enclosure Temperature 65°C

Input Line Voltage 100 - 240 VAC

Input Line Frequency 50/60 Hz

Power Consumption 90 Watts max.

Output Power 60 Watts max. at 22°C ambient temperature

Output Frequency 470 KHz

Power Cord (3-wire) 183 cm 18/3 SJT

Dimensions (approx.) W = 80 mm (3.1"), D = 160 mm (6.3"),

Soldering Handle and Coil Assembly

Tip-to-Ground Potential < 2 mV True RMS, 50-500 Hz

Tip-to-Ground Resistance < 2 ohms DC, unit on

Idle Temperature Stability ± 1.1°C in still air

Handle Cord Assembly Length 122 cm – burn proof, ESD safe

Connector 3-pin power connector

Dimensions (approx.)

Overall length (with tip) 230 mm (9.06") with standard tips

Grip diameter 13 mm (0.51")

Tip to grip 58 mm (2.28")

Tip shaft diameter 8.0 mm (0.31")

Tip length 82 mm (3.23") to 93mm (3.66") (typical)

Workstand

Dimensions W = 105 mm (4.1"), D = 175 mm (6.9"),

H = 115 mm (4.5")

H = 90 mm (3.5")

9. WARRANTY

Please visit OK International's products web page (www.okinternational.com) where you will

find available infor mation on systems, tips, acc essories, technical notes, and m ore. You may

also contact your local OK International representative for pricing and availability.

OK International warrants the PS-900 power supply and Handle cord assembly against any

defects in materia ls or workman ship for one (1) year from t he date of pur chase by the o riginal

owner. This Warranty excludes normal maintenance and shall not apply to any opened,

misused, abused, altered or damaged items. If the product should become defective within the

warranty period, OK International will repair or replace it free of charge at its sole option. The

replacement item(s) will be shipped, freight prepaid, to the original purchaser. The warranty

period will start from the date of purchase. If the date of purchase cannot be substantiated the

date of manufacture will be used as the start of the warranty period.

SERVICE AFTER WARRANTY

OK International will repair or replace (at OK International's sole option) a PS-900 Power Supply

that fails in normal use within one year (1) year after the expiration of the one-year warranty at

the then current repair or exchange rate. To return a failed Power Supply for repair or

replacement, follow the steps outlined below. This repair/replace offer does not apply to any

previously opened, modified, repaired, altered, misused or damaged Power Supply.

REPLACEABLE PS-CA3 HEATER COIL ASSEMBLY WARRANTY

OK International warra nts the coil assembly against material and wor kmanship defects for a

period of 30 days.

REPLACEABLE TIP WARRANTY

OK International warrants that the heater-tip will operate according to specifications for the

lifetime of the tip plating. A heater tip that fails to heat during the lifetime of the plating will be

replaced at no charge. For replacement contact your local retail supplier. Because tip plating is

mainly dependent upon the user’s application and practices, tips are not warranted for plating

wear. Heater-tips are warranted against any defects in materials or workmanship. Misused,

abused, altered or damaged tips are not warranted. All heater-tips that fail to heat will be

repaired or replaced at OK International’s option. For returns follow the steps outlined below.

RETURN PROCEDURE

Please contact your local OK International Representative for return procedures and policies.

www.okinternational.com

5

7000-2250 修订版 1

www.okinternational.com

6

7000-2250 修订版 1

Page 5

10. SAFETY INFORMATION

With power applied, the tip temperature can be > 300°C. Failure to observe the following

precautions may lead to injury to users or damage the equipment:

• Do not touch any metallic parts of the hand-piece

• Do not use ne ar flammable items

• Do not use unit for any function other than described in this manual

• Use only genuine PS replacement parts

• Use in a well ventilated area

• Do not use the equipment with wet hands

• Connect only to properly grounded outlets to prevent risk of electric shock.

• Always place hand-piece back into the workstand to prevent accidental

burning of oneself or surrounding objects.

Although the systems offer superior EOS (Electrical Overstress) protection, periodic checks of

the instrument cord should be incorporated into standard operator maintenance procedures.

Waste Electrical and Electronic Equipment Directive - WEEE (2002/96/EC).

When this product is no longer required, if it cannot be re-used,

we ask our customers not to dispose of it as unsorted municipal

waste but to appropriately recycle the product. In Europe, please

contact your OK International distributor who can advise the

recycling options available (www.okinternational.com).

WARNING

!

www.okinternational.com

7

7000-2250 修订版 1

PS-900 焊接系统

操作手册和用户指南

祝贺您购买了 PS-900 焊接系统。它利用 SmartHeat® 技术确保其卓越的性能,且无需系统校

准。它的设计和制造过程均符合最高质量标准,可提供始终如一的卓越性能和可靠性。

本文用来指导您安装、操作和自行维护焊接台。我们建议您熟读本文,以便优化性能和操作

连贯性。

目录

1. 包装/备件清单 ..........................................................1

2. 首次安装...................................................................2

3. Smartheat

4. 选择加热烙铁头........................................................3

5. 更换加热烙铁头........................................................3

6. 更换加热体组件........................................................4

7. 故障排除...................................................................4

8. 规格说明...................................................................5

9. 保修..........................................................................6

10. 安全信息.................................................................7

1-a. 包装清单

a. PS-900 主机 (零件号:PS-PW900)

b. PS-900 自动休眠烙铁支架- 黑色 (零件号:WS2)

c. 海绵 (零件号:AC-YS4)

d. PS-900 焊接手柄(含加热体组件) (零件号:PS-HC3)

e. 烙铁头拆卸垫 (零件号:AC-CP2)

f. 说明手册

g. 说明手册

®

..............................................................2

(提供重新订货的零件号):

1-b. 其他备件/耗材:

a. 加热体组件 (PS-900 系统) (零件号:PS-CA3)

b. 手柄线/(无加热体组件) (零件号:PS-H3)

c. PS-900 自动休眠烙铁支架 - 绿色 (零件号:WS2G)

d. 加热烙铁头 (参见第 4 部分)

e. PS-900 功率表 (零件号:PS-PM900)

www.okinternational.com

1

7000-2250 修订版 1

Page 6

2. 首次安装

PS-900 焊接系统由“主机”、带有“海绵”的“烙铁支架”以及“焊接手柄”组成。焊接手柄中还可装入

一个可更换的加热体组件和一个可更换的加热烙铁头。可以根据需要从已授权的 OK

International 经销商那里获得这两种耗材。主机包括“电源开关”、绿色“通电”指示灯、以及焊接

手柄电线的连接端口。

1. 将电源固定在工作区内的适当位置上,例如工作台上。

2. 将烙铁头插入到“加热体组件”中,仅需用力推动“烙铁头”直到卡入到位。“烙铁头”插入

到位时会发出一声轻微的“卡嗒”声。

烙铁头插入到加热体组件中

3. “关闭”主机电源,将电线插头插入主机连接端口中,从而将焊接手柄电线连接到主机

上。要校准 3 个插脚,请将电线插头扁平面置于主机上(处于主机的 9 点钟位置)。

4. 用脱离子水将海绵弄湿,但不要浸透。然后将其置于烙铁支架的托盘上。

5. 将主机电源线插入具有相应额定输入线电压的接地壁装插座中。要开启设备,请按下

(位于主机前面的)开关直到卡定到位。绿色指示灯变亮。如果没有变亮,请参阅本

手册的“故障排除指南”。

注意:为了长期预防触电危险和正常使用,必须连接正确接地

的电源插座。

3. SMARTHEAT

®

:不需要校准

PS-900 加热系统主要由一个感应线圈组和一个加热烙铁头组成。每个加热烙铁头都装有一个温

度自适应加热体,用来感知自身温度并严格保持其预置的闲置温度,以延长加热烙铁头的使用寿

命,这一切均可由 OK International 的专利 SmartHeat

固有金属性质所确定;不需要外部电路或外部设备来调节。输送到烙铁头的功率根据热负载的大

小自动变化,从而消除了普通焊铁中采用电子开关元件作为控制电路而产生的峰值脉冲和瞬变现

象。如有任何问题,请随时联系 OK International 代表处。

®

技术控制。该烙铁头的温度由加热器的

4. 选择加热烙铁头

OK International 的加热烙铁头形状各异、温度范围很大(详细信息请联系当地 OK International 代

表处或者访问我们的网站)。这些不同形状的烙铁头能够完成从精细焊点到大接地焊盘等各种焊接

任务。

1. 挑选烙铁头和焊接点之间接触面积最大的烙铁头。最大的接触面积会使热传递效率最高,从而

得到高质量的焊接点。

2. 挑选与焊接点接触良好的烙铁头。长度较短的烙铁头会使控制更为精确。焊接焊点密集的电路

板时,可能需要使用较长或弯曲的烙铁头。

3. 挑选可完成任务的温度最低的烙铁头。这将使可能的热损坏降至最低程度。“加热烙铁头”的杆

上标有温度序列。

正确

太小

太大

5. 更换加热烙铁头

1. 应将“电源开关”置为“Off(关)”。如果在“ON(通电)”

的状态下拆卸烙铁头,将导致加热体组件的损坏。

2. 用随附的 AC-CP2“烙铁头拆卸垫”拔出烙铁头。切勿

使用金属工具(例如钳子)拔下烙铁头,因为这样

做会损坏烙铁头。

注意:加热烙铁头可能很烫!

3. 用随附的 AC-CP2“烙铁头拆卸垫”将新的烙铁头推入焊接手柄中。

4. 将“电源开关”置为“On(开)”。在 20 秒之内新烙铁头将加热至工作温度。

www.okinternational.com

2

7000-2250 修订版 1

www.okinternational.com

3

7000-2250 修订版 1

Page 7

6. 更换加热体组件

1. 将“电源开关”置为“Off(关)”。等待加热烙铁头降至室温。

2. 从手柄装置上拔下加热烙铁头。切勿使用金属工具(例如钳子)拔下烙铁头。

3. 要将加热体组件从“焊接手柄”上拆除,请按下加热体组件上的按钮,然后将加热体组件从焊

接手柄装置上拔掉。

4. 将新的加热体组件插入到焊接手柄中,当插入到位时将发出“卡嗒”声。

7. 故障排除

a. 电源指示灯不亮

• 检查电源线

• 检查是否有电源电压

• 检查电源开关是否处在“ON(开)”的位置上

b 烙铁头不热

• 指示灯亮了吗?

• “手柄”是否“连接”到“电源”上?

• PS-CA3加热体组件是否牢固地插入 PS-H3“焊接手柄”装置中?

• 烙铁头是否牢固地插入到 PS-CA3“加热体组件”中?

• 是否尝试更换 PS-CA3?

如果确认了上述情况之后仍不能解决问题,请联系当地 OK International 代表处。

8. 规格说明

主机

操作环境温度 10 - 40°C

最高内部温度 65°C

输入线电压 100 - 240 VAC

输入线频率 50/60 Hz

功率消耗 最大为 90 瓦

输出功率 在 22°C 的环境温度中最大为 60 瓦

输出频率 470 KHz

电源线(3 线) 183 cm 18/3 SJT

(大约)尺寸 宽 = 80 mm (3.1"),深 = 160 mm (6.3"), 高 = 115 mm (4.5")

焊接手柄和加热体组件

烙铁头对地的电位 < 2 mV 真 RMS,50-500 Hz

烙铁头对地的电阻 < 2 欧姆,直流电流下的数值

闲置温度稳定性 在静止空气中为 ± 1.1°C

手柄电线装置长度 122 cm - 防火,ESD 安全

插头 3 插脚电源插头

(大约)尺寸

总长度(含烙铁头) 插入标准烙铁头后为 230 mm (9.06")

手柄直径 13 mm (0.51")

烙铁头到手柄的长度 58 mm (2.28")

烙铁头杆直径 8.0 mm (0.31")

烙铁头长度 82 mm (3.23") – 93mm (3.66")(典型)

自动休眠烙铁支架

尺寸 宽 = 105 mm (4.1"),深 = 175 mm (6.9"), 高 = 90 mm (3.5")

www.okinternational.com

4

7000-2250 修订版 1

www.okinternational.com

5

7000-2250 修订版 1

Page 8

9. 保修

请访问 OK International 产品网页 (www.okinternational.com),您将获得关于系统、烙铁头、附

件、技术说明以及更多信息。还可以向当地 OK International 代表处咨询价格和供货等事宜

自第一个买主购买之日起的一年内,OK International 对 PS-900 电源和“手柄”电线装置在材料或

工艺方面的缺陷提供保修。此保修不包含正常的维护,且不保修由任何打开、误用、违规操作、

经改动或受损的零件。如果产品在保修期内出现故障,OK International 将免费地修理或更换产

品而不得推卸责任。更换件将寄送到第一个买主手中,并预付运费。保修期从购买之日开始算

起。如果无法确定购买日期,生产日期将作为保修期的起始日期。

保修期之后的服务

保修期(一年)届满之后的一年内,如果 PS-900 电源不能正常使用,OK International 将以当时

的价格进行修理或者更换(OK International 不得推卸责任)。要退还一个需要修理或更换的故

障电源,请遵循下列步骤。此项维修/更换服务不适用于任何曾打开、修改、修理、改动、误用或

受损的“电源”。

可更换 PS-CA3加热体组件保修

OK International 对加热体组件在材料和工艺方面的缺陷提供 30 天的保修期。

可更换

烙铁头保修

OK International 保证加热烙铁头在烙铁头电镀层的寿命期限内都将按照规范进行工作。如果加

热烙铁头在电镀层的寿命期限内不能正常加热,将免费更换加热烙铁头。请联系当地零售商进行

更换。由于烙铁头电镀层的状况主要取决于用户的实际应用和操作,故不对烙铁头电镀层的磨损

进行保修。对加热烙铁头在材料或工艺方面的缺陷提供保修。不保修由误用、违规操作、改动或

受损的烙铁头。由 OK International 决定是否对所有出现加热故障的烙铁头进行修理和更换。有

关退货事宜请遵循下列步骤。

退货过程

请向当地 OK International 代表处咨询退货过程和退货政策。

10. 安全信息

通电后,烙铁头温度将达到 300°C 以上。为了避免受到伤害或者损坏设备,请牢记以下注意事

项:

• 切勿接触手柄的任何金属部分

• 切勿在易燃物附近使用

• 切勿使用本手册中没有介绍的设备功能

• 只使用原装的 PS 更换件

• 在通风良好的区域中使用

• 切勿用湿手使用设备

• 为了防止触电的危险,只能连接到适当接地的电源插座中。

• 请始终将手柄放回到工作台,以防止意外烫伤自己或者烧坏周围的物品。

尽管该系统提供了可靠的 EOS(电性过压)保护,仍应将定期检查设备电线纳入标准的操作员维

护程序中

废弃电子电器设备指令 - WEEE (2002/96/EC)。

当客户不再需要某产品,且该产品无法回收利用,我们将要求客户

不要不加分类地将其作为市政垃圾丢弃,而要正确地加以回收利

用。在欧洲,请联系您的 OK International 经销商,以获取回收利

用可用选项的建议 (www.okinternational.com)。

!

警告

www.okinternational.com

6

7000-2250 修订版 1

www.okinternational.com

7

7000-2250 修订版 1

Page 9

PS-900 焊接系統

操作手冊和使用者指南

恭喜您購買了「PS-900 焊接系統」。它使用的是 SmartHeat® 技術,可確保其卓越的性能

而且無需考慮系統校準。它的設計和製造過程均符合最高品質標準,並能提供穩定的性能和

可靠性。

本手冊將會指導您安裝、操作和自行維護焊接系統。我們建議您熟讀本手冊,以便讓性能和

操作的連貫性達到最佳化。

目錄

1. 包裝清單 / 備件清單 .......................................................1

2. 首次安裝 ...........................................................................2

3. Smartheat

4. 選取加熱烙鐵頭...............................................................3

5. 更換加熱烙鐵頭...............................................................3

6. 更換線圈組.......................................................................4

7. 疑難排解 ...........................................................................4

8. 規格 ...................................................................................5

9. 保固 ...................................................................................6

10. 安全資訊.........................................................................7

®

......................................................................2

1-a. 包裝清單

a. PS-900 電源 (零件編號:PS-PW900)

b. PS-900 自動休眠工作台– 黑色 (零件編號:WS2)

c. 海綿 (零件編號:AC-YS4)

d. PS-900 焊接手柄 / 線圈組 (零件編號:PS-HC3)

e. 烙鐵頭拆卸墊 (零件編號:AC-CP2)

f. 電源線

g. 說明手冊

(含零件編號以便重新訂購):

1-b. 其他備用零件 / 消耗零件:

a. 加熱線圈組,PS-900 系統 (零件編號:PS-CA3)

b. 握把 / 電源線(無線圈組) (零件編號:PS-H3)

c. PS-900 自動休眠工作台 - 綠色 (零件編號:WS2G)

d. 加熱烙鐵頭 (請參閱第 4 節)

e. PS-900 功率表 (零件編號:PS-PM900)

www.okinternational.com

1

7000-2250 修訂版 1

2. 首次安裝

「PS-900 焊接系統」由「主機」、帶有「支架」和「海綿」的「工作台」以及「焊接手柄」

組成。焊接手柄中還可裝入一個可更換的線圈組和一個可更換的加熱烙鐵頭。可根據需要向授

權的 OK International 經銷商購買這些消耗零件。主機包括「電源開關」、綠色「通電」指示

燈、電源線以及焊接手柄電線的連接埠。

1. 將主機固定在工作區內的適當位置上,例如工作台上面。

2. 將烙鐵頭插入「加熱體組件」,然後將其完全推入直到卡入定位為止。烙鐵頭插入到

定位時會發出一聲輕微的「卡嗒」聲。

將落鐵頭插入加熱體組件中

3. 「關閉」主機電源,將電線插頭插入主機連接埠中,然後將焊接手柄電線連接到主機

上。要校準 3 個插腳,請將電線插頭的扁平面朝向主機的 9 點鐘方向。

4. 用去離子水將海綿弄濕,但不要浸透。然後將其置於烙鐵支架的托盤上。

5. 將主機電源線插入具有相應額定輸入線電壓的接地壁裝插座中。要開啟設備,請按下

(位於主機前面的)開關直到閂上為止。綠色指示燈亮起。如果沒有亮起,請參閱本

手冊的「疑難排解指南」。

注意:為了長期預防觸電危險和正常使用,必須連接正確接地

3. SMARTHEAT

®

:不需要校準

PS-900 加熱系統主要由主機和一個感應線圈組及一個加熱烙鐵頭組成。每個加熱烙鐵頭都裝有

一個自調加熱器,用來感知自身溫度並嚴格保持其預設的閒置溫度,以延長加熱烙鐵頭的使用壽

命;這一切皆由 OK International 的專利 SmartHeat

金屬性質所確定;不需要外部電路或使用外部設備來調節。輸送到烙鐵頭的功率根據熱負載的大

小自動變化。這將消除了普通焊鐵中採用電子開關元件作為控制電路而產生的峰值脈衝和瞬變現

象。如有任何問題,請隨時聯絡 OK International 代表處。

®

技術所控制。烙鐵頭溫度由加熱器的固有

www.okinternational.com

2

的電源插座。

7000-2250 修訂版 1

Page 10

4. 選取加熱烙鐵頭

確

OK International 的「加熱烙鐵頭」形狀各異、溫度範圍很大(如需詳細資訊,請聯絡當地

OK International 代表處或造訪我們的網站)。這些不同形狀的烙鐵頭能夠完成從精細焊點到大

型接地焊盤等各種焊接任務

正

太大

1. 挑選烙鐵頭和焊接點之間接觸面積最大的烙鐵頭。最大的接觸面積會使熱傳遞效率最高,進而

產生高品質的焊接點。

2. 挑選與焊接點接觸良好的烙鐵頭。長度較短的烙鐵頭會使控制更為精確。焊接焊點密集的電路

板時,可能需要使用較長或彎曲的烙鐵頭。

3. 挑選可完成任務的溫度最低的烙鐵頭。這將使可能的熱損壞降至最低程度。「加熱烙鐵頭」的

手柄上標有溫度序列。

太小

5. 更換加熱烙鐵頭

1. 將「電源開關」推至「Off(關)」。如果在電源「On

(開)」的狀態下拆卸烙鐵頭,將會導致加熱體組件損壞。

2. 用提供的 AC-CP2「烙鐵頭拆卸墊」拔出加熱烙鐵

頭。切勿使用金屬工具(例如鉗子)拔下加熱烙鐵

頭,因為這樣做會損壞加熱器。

注意:加熱烙鐵頭可能很燙!

3. 用提供的 AC-CP2「烙鐵頭拆卸墊」將新的加熱烙鐵頭推入焊接手柄中。

4. 將「電源開關」推至「On(開)」。在 20 秒之內新加熱烙鐵頭將加熱至工作溫度。

6. 更換加熱體組件

1. 將「電源開關」推至「Off(關)」。等待加熱烙鐵頭降至室溫。

2. 從手柄裝置上拔下加熱烙鐵頭。切勿使用金屬工具(例如鉗子)拔下加熱烙鐵頭。

3. 要將「加熱體組件」從「焊接手柄」上拆除,只要按下加熱體組件上的按鈕,然後將加熱體

組件從「焊接手柄」裝置上拔掉即可。

4. 將新的「加熱體組件」插入手柄裝置,插入定位後會發出「卡嗒」聲。

按鈕

7. 疑難排解

a. 電源指示燈不亮

• 檢查電源線

• 檢查是否有電源電壓

• 檢查電源開關是否處在「ON(開)」的位置上

b. 烙鐵頭不熱

• 指示燈亮了嗎?

• 「手柄」是否「連接」到「電源」上?

• PS-CA3 加熱體組件是否牢固地插入「PS-H3 焊接手柄」裝置中?

• 「烙鐵頭」是否牢固地插入「PS-CA3 加熱體組件」中?

• 是否嘗試更換 PS-CA3?

如果確認了上述情況之後仍不能解決問題,請聯絡當地 OK International 代表處。

www.okinternational.com

3

7000-2250 修訂版 1

www.okinternational.com

4

7000-2250 修訂版 1

Page 11

8. 規格說明

主機

操作環境溫度 10 - 40°C

最高內部溫度 65°C

輸入線電壓 100 - 240 VAC

輸入線頻率 50/60 Hz

功率消耗 最大為 90 瓦

輸出功率 在 22°C 的環境溫度中最大為 60 瓦

輸出頻率 470 KHz

電源線(3 線) 183 cm 18/3 SJT

尺寸(大約) 寬 = 80 mm (3.1"),深 = 160 mm (6.3"),高 = 115 mm (4. 5")

焊接手柄與加熱體組件

烙鐵頭對地的電位 < 2 mV 真 RMS,50-500 Hz

烙鐵頭接地的電阻 < 2 歐姆,直流電流下的數值

閒置溫度穩定性 在靜止空氣中為 ± 1. 1°C

手柄電線裝置長度 122 cm - 防火,ESD 安全

插頭 3 插腳電源插頭

尺寸(大約)

總長度(含烙鐵頭) 插入標準烙鐵頭後為 230 mm (9.06")

手柄直徑 13 mm (0.51")

烙鐵頭到手柄的長度 58 mm (2.28")

烙鐵頭杆直徑 8.0 mm (0.31")

烙鐵頭長度 82 mm (3.23") – 93mm (3.66")

自動休眠烙鐵支架

尺寸 寬 = 105 mm (4.1"),深 = 175 mm (6.9"),高 = 90 mm (3.5")

5

www.okinternational.com

(典型)

7000-2250 修訂版 1

9. 保固

請造訪 OK International 的產品網頁 (www.okinternational.com),您將獲得關於系統、烙鐵頭、

附件、技術說明以及更多資訊。還可以向當地 OK International 代表處諮詢價格和供貨等事宜。

自第一個買主購買之日起的一年內,OK Intern atio nal 對 PS-900 電源和「手柄」電線裝置在材料

或製成品方面的缺陷提供保固。此保固不包含正常的維護,且不保固由任何開啟、誤用、違規操

作、經改動或受損的零件。如果產品在保修期內出現故障,OK International 將免費地修理或更

換產品而不得推卸責任。更換件將寄送到第一個買主手中,並預付運費。保固期從購買之日開始

算起。如果無法確定購買日期,生產日期將作為保固開始日期。

保固期之後的服務

保固期(一年)屆滿之後的一年內,如果 PS-900 電源不能正常使用,OK International 將以當時

的價格進行修理或者更換(OK International 不得推卸責任)。如果要退還需要修理或更換的故

障電源,請遵循下列步驟。此項維修/更換服務不適用於由任何上述開啟、修改、修理、改動、誤

用或損壞的「電源」。

可更換 PS-CA3 加熱體組件保固

OK International 對加熱體組件在材料或製程方面的缺陷提供為期 30 天的保固。

可更換烙鐵頭保固

OK International 保證加熱烙鐵頭在烙鐵頭電鍍層的壽命期限內都將按照規範進行工作。如果加

熱烙鐵頭在電鍍層的壽命期限內不能正常加熱,將免費更換加熱烙鐵頭。請聯絡當地零售商進行

更換。由於烙鐵頭電鍍層的狀況主要取決於使用者的實際應用和操作,故不對烙鐵頭電鍍層的磨

損提供保固。對加熱烙鐵頭在材料或製成品方面的缺陷提供保固。不保修由誤用、違規操作、改

動或受損的烙鐵頭。由 OK International 決定是否對所有出現加熱故障的烙鐵頭進行修理和更

換。有關退貨事宜,請遵循下列步驟。

退貨程序

請向當地的 OK International 代表處諮詢退貨程序與政策。

www.okinternational.com

6

7000-2250 修訂版 1

Page 12

10. 安全資訊

通電後,烙鐵頭溫度可能會達到 300°C 以上。請牢記以下注意事項以免受到傷害或損壞設備:

• 切勿接觸手柄的任何金屬部分

• 切勿在易燃物附近使用

• 切勿使用本手冊中沒有介紹的設備功能

• 只使用原廠的 PS 更換零件

• 在通風良好的區域中使用

• 切勿在手潮濕的情況下使用設備

• 為預防觸電危險,只能連接適當接地的電源插座。

• 始終將手柄放回工作台內,避免意外燒傷自己或燒到周圍的物件。

儘管系統提供了可靠的 EOS(電性過壓)保護,仍應將定期檢查設備電線納入標準的操作員維護

程序中。

廢棄電子電機設備管制指令 - WEEE (2002/96/EC)。

當顧客不再需要此產品,且如果無法再次利用,我們將要求顧客不

要將產品當作未分類的都市廢棄物處理,而是應當將產品適當的回

收再利用。在歐洲,請與您的 OK International 經銷商連絡,您將

可獲得可用之回收選項的建議 (www.okinternational.com)。

!

警告

PS-900 操作マニュアル

このたびはPS-900をご購入いただきありがとうございます。本機は、SmartHeat

テクノロジーを利用することで、システム較正が必要なく、最適な性能を実現できます。

本機は、最適性能基準に従って設計製造されており、一貫した性能と信頼性を提供してい

ます。

本書は、設定、操作、お客様の作業場所での保守作業の目的で作成されています。最適性

能と安定した操作を実現するため、本書をご一読ください。

目次

1. 梱包内容 / スペアパーツ リスト ..............................1

2. 初期設定...................................................................2

3. Smartheat

4. チップの選定 ...........................................................3

5. チップの交換 ...........................................................3

6. コイルホルダーの交換.... .........................................4

7. トラブルシューティング .........................................4

8. 仕様..........................................................................5

9. 保証..........................................................................6

10. 安全情報.................................................................7

®

..............................................................2

1-a. 梱包内容

a. PS-900 電源ユニット (部品番号:PS-PW900)

b. PS-900 Auto-sleep コテ台 – 黒 (部品番号:WS2)

c. スポンジ (部品番号:AC-YS4)

d. PS-900 コテホルダーセット (部品番号:PS-HC3)

e. 耐熱パッド (部品番号:AC-CP2)

f. 電源ケーブル

g. 取扱説明書

®

www.okinternational.com

7

7000-2250 修訂版 1

www.okinternational.com

1

7000-2250 JAP1

Page 13

1-b. スペアパーツ / 消耗アイテム:

a. コイルホルダー (部品番号:PS-CA3)

b. コテホルダー(コイルホルダー無) (部品番号:PS-H 3)

c. PS-900 Auto-sleep コテ台 – 黒 (部品番号:WS2)

d. チップ (第 4 項を参照)

2. 初期設定

PS‐900は、電源ユニット、コテ台 (コテ先クリーナーとスポンジ付き)、およびコテホル

ダーセットで構成されています。

コテホルダーセットは、コテホルダーとコイルホルダーで構成されています。

チップは、必要に応じて弊社代理店から入手できます。

1. 電源ユニットを適当な作業場所、たとえば作業台などに設置します。

2. チップをコイルホルダーに取り付け、完全に止まるまで、チップを押し込みます。

チップをコイルホルダーに取り付けます

3. 電源ユニットを「OFF」の状態で、電源ケーブルを電源ユニットに接続します。次

にコテホルダーのケーブルを電源ユニットに接続してください。ケーブルコネクタ

の平らな面が電源ユニットの上面側を向くように接続してください。

4. きれいな水でスポンジを水が染み出さない程度に湿らせます。スポンジをコテ台の

トレイに入れてください。

5. 電源ケーブルを、アース付き3端子コンセントに接続してください。電源を ON に

するには、電源ユニットの前面にある Power スイッチを押してください。緑色の表

示灯が点灯します。この表示灯が点灯しない場合、本取扱説明書内の「トラブルシ

ューティング」の項をご覧ください。

注意:感電事故を確実に防止するため、必ず適切に接地された

い。

2

www.okinternational.com

コンセントに接続してくださ

7000-2250 Rev1

3. SMARTHEAT®:較正不要

PS‐900 システムには、誘導コイルアセンブリとチップが含まれます。各チップには自己

調整型ヒータが内臓されています。自己調整型ヒータは、ヒータ自身の温度を検知しチップの

耐用期間中、前もって設定されたヒータアイドリング温度を厳密に維持します。これらは、す

べて弊社独自の SmartHeat

金属物性により規定されるため、外部からの温度調節または外部温度調節装置は不要です。チ

ップに供給される電力は、熱負荷に直接対応して自動的に変化します。そのため、従来型のハ

ンダゴテのように、電力供給の ON/OFF で制御される発熱エレメント特有のスパイクおよびオ

ーバーシュートがありません。詳しくは、オーケー・インターナショナルまでお気軽にお問い

合わせください。

®

テクノロジーにより制御されます。チップ温度は、ヒータ素材の

4. チップの選定

多様な形状および温度帯のチップをご用意しております (より詳細な情報については、最寄り

の オーケー・インターナショナル 代理店にお問い合わせいただくか、弊社 Web サイトをご覧

ください)。多様なこて先形状が提供されているため、繊細な小面積はんだ付けから大面積で

の厚盛りまで、多彩な作業に対応できます。

1. チップ先端とハンダ接合面の接触面積が最大となるようなチップを選定してください。接触

面積を最大にすることで、最適な熱伝達が生じ、高品質なはんだ作業を迅速に行うことがで

きます。

2. はんだ接合面に接触させやすいチップを選定してください。短いチップは精密な位置決めを

容易にできます。長いチップや曲がった形状のチップは、狭い間隔で配置されたボードでの

はんだ付け時に最適です。

3. チップ選択の際は、なるべく低い温度帯のチップから選定して下さい。必要以上の高い温度

で作業を行うと基板や部品に熱ダメージを与える危険があります。

www.okinternational.com

3

7000-2250 Rev1

Page 14

5. チップの交換

1. Power スイッチを押し OFF にします。電源を ON

にしたままチップを取り外すと、コイルシャフト

が損傷する恐れがあります。

2. 付属の耐熱パッドを使用してチップを抜き出しま

す。チップを取り外す際に金属製工具 (たとえばプ

ライヤなど) を使ってはいけません。チップやヒー

タを破損することがあります。

注意:チップは高温になっている可能性があります!

3. 付属の耐熱パッドを使用して、新しいチップを挿入します。

4. Power スイッチを押し ON にします。取り付けたチップは急速に設定温度まで上昇

します。

6. コイルシャフトの交換

1. Power スイッチを OFF にします。チップを室温まで冷ましてください。

2. コイルシャフトからチップを取り外します。チップを取り外す際に金属製工具 (たとえば

プライヤなど) を使ってはいけません。

3. コテホルダーからコイルシャフトを分離するには、コイルシャフトを引っ張って、コテホ

ルダーからコイルシャフトを抜き取ります。

7. トラブルシューティング

a. Power LED が点灯しない。

• 電源ケーブルが確実に接続されているかを確認する。

• 電源電圧が正しいか確認する。

• Power スイッチが ON 位置になっていることを確認する。

b. チップが熱くならない。

• LED が点灯しているか?

• コテホルダーが電源ユニットに確実に接続されているか?

• コイルシャフトがコテホルダーに確実に挿入されているか?

• チップがコイルシャフトに確実に挿入されているか?

上記の確認後も問題が解決しない場合、オーケー・インターナショナルにご連絡ください。

4. 新しいコイルシャフトをコテホルダーにカチリという手ごたえがあるまで押し込みます。

www.okinternational.com

4

7000-2250 Rev1

www.okinternational.com

5

7000-2250 Rev1

Page 15

8. 仕様

電源ユニット

使用環境温度 10 - 40°C

最大本体耐熱温度 65°C以下

入力電圧 AC 100 ~ 240 V(マルチ電源)

入力周波数 50/60 Hz

消費電力 90 W 以下

出力 気温 22℃ にて 60W 以下

出力周波数 470 KHz

電源ケーブル (3端子) 2100 mm 18/3 SJT

寸法 (概略値) W = 80 mm (3.1")、D = 165 mm (6.5")、H = 115 mm (4.5")

コテホルダーおよびコイルシャフト

漏れ電圧 2 mV以下 実行値, 50-500 Hz

アース間抵抗 2 ohms DC、ユニットの電源 ON 時

アイドル状態の温度安定度 静止空気内で ± 1.1°C

コテホルダ+ケーブル長さ 1360 mm – 難燃性、ESD対応

接続プラグ 3Pコネクタプラグ

寸法 (概略値)

コテホルダー本体 標準型チップ付きで175 mm (6.8")

グリップ径 15 mm (0.59")

チップ軸径 8mm (0.31")

チップ長さ 82~93 mm (3.23~3.66")

コテ台

寸法 W = 105 mm (4.1")、D = 175 mm (6.9")、H = 95 mm (3.7")

6

www.okinternational.com

7000-2250 Rev1

9. 保証

オーケー・インターナショナル社製品の Web ページ (www.okinternational.co.jp) をご覧くださ

い。この Web ページには、システム、チップ、付属品、技術解説などの情報が記載されてい

ます。価格と納期については、最寄りの オーケー・インターナショナル代理店にお問い合わせ

ください。

株式会社オーケー・インターナショナルは、PS-900 電源とコテホルダーセットに関して、購

入日から 1 年間、材料または製造上のなんらかの欠陥に対して保証を行うものとします。本保

証は、取扱説明書以外の誤操作、悪用、不注意によって生じた故障。火災、天災、地変等によ

る故障は保証の対象とはなりません。

本製品が保証期間内に故障した場合、故障した製品を無償で修理または交換かの判断は、株式

会社オーケー・インターナショナルが行います。

初期不良を除き、消耗品に関しては保証の対象とはなりません。

本保証内容は、日本国内においてのみ有効です。

保証期間は、購入日から起算されます。購入日を証明できない場合、製造日が保証期間の開始

日として用いられます。

返送処理

機器に明らかな不具合がある場合、下記内容を弊社にご連絡ください。

1. 製品シリアル番号

2. 不具合内容(出来るだけ具体的にお知らせください)

3. ご購入年月日

4. 御社名、部署名、ご担当者名

5.ご連絡先(住所、電話番号)

株式会社オーケー・インターナショナル

〒143-0006 東京都大田区平和島5-3-1

www.okinternational.com

TEL:03-5753-0085 FAX:03-3765-8855

7

7000-2250 Rev1

Page 16

10. 安全情報

電源が投入された状態では、チップの温度は 300°C 以上 まで上昇します。以下の注意に従わ

なかった場合、負傷あるいは装置の破損につながることがあります。

• ホルダーのいかなる金属部にも触れてはいけません。

• 可燃物の近くで使用してはいけません。

• ユニットを本書に記載した目的以外に使用しないでください。

• 純正交換部品のみを利用してください。

• 十分に換気されている場所で使用してください。

• 濡れた手で装置に触れてはいけません。

• 必ず適切に接地されたコンセントに接続してください。

• ホルダーまたはその周辺を誤って焼かないように、ホルダーは必ずコテ台に置いて

ください。

システムには、高度な EOS (Electrical Overstress) 保護が施されてい

ますが、保守の一環としてケーブル類の定期的点検を行ってくださ

い。

!

警告

PS-900 인두기 시스템

작동 매뉴얼 및 사용자 설명서

PS-900 인두기 장치를 구매해 주셔서 감사합니다. SmartHeat® 기술을 통하여 시스템 보정

없이 사용할 수 있을 정도의 탁월한 성능을 보장합니다. 최고의 품질 표준에 맞게 설계,

제작되어 훌륭한 성능과 신뢰성을 제공하고 있습니다.

본 설명서는 사용자가 장치를 설정, 작동 및 유지 보수할 수 있도록 제작되었습니다. 뛰어난

성능과 일관성 있는 작동을 위해서 본 설명서를 참조하시기 바랍니다.

목차

1. 포장 / 예비부품 목록 ................................................1

2. 초기 설정..................................................................2

3. Smartheat

4. 히터 팁 선택 .............................................................3

5. 히터 팁 교체 .............................................................3

6. 코일부품 교체 ..........................................................4

7. 문제 해결..................................................................4

8. 규격..........................................................................5

9. 보증..........................................................................6

10. 안전 정보................................................................7

®

..............................................................2

1-a. 포장 목록 (재주문용 부품번호 포함):

a. PS-900 전원공급기 (부품번호: PS-PW900)

b. PS-900 오토 슬립 작업대– 검은색 (부품번호: WS2)

c. 스폰지 (부품번호: AC-YS4)

d. PS-900 납땜 핸들 / 코일 부품 (부품 번호: PS-HC3)

e. 카트리지 제거 패드 (부품번호: AC-CP2)

f. 전원 코드

g. 설명서

1-b. 추가 예비부품 / 소모품 항목:

a. 히터 코일 부품, PS-900 시스템 (부품번호: PS-CA3)

b. 핸드피스 / 전원 코드. (코일 부품 없음) (부품번호

c. PS-900 오토 슬립 작업대 – 녹색 (부품번호: WS2G)

d. 히터 팁 (4장 참조)

: PS-H3)

www.okinternational.com

8

7000-2250 Rev1

www.okinternational.com

1

7000-2250 개정판 1

Page 17

2. 초기 설정

PS-900 인두 시스템은 전원공급기, 작업대(받침대, 스펀지 포함)와 인두 핸들로 구성되어

있습니다. 또한 인두 핸들에는 코일부품과 히터 팁을 교체 및 장착할 수 있습니다. 두 소모품이

모두 필요하시면 OK International 로부터 인증 받은 대리점에서 구매할 수 있습니다.

전원공급기는 전원스위치, 녹색 “전원” 표시등, 전원코드, 인두 핸들코드 연결포트로 구성되어

있습니다.

1. 작업공간(예: 작업대) 내

2. 히터 팁을 코일부품에 삽입하십시오. 그리고 제자리에 맞게 장착되도록 히터 팁을

주의: 전기 감전의

밀어주십시오. 제자리에 고정되면 “찰칵” 소리가 납니다.

팁을 코일부품에 삽입하십시오.

3. 전원이 "꺼지면” 전원공급기 연결포트에 코드커넥터를 삽입하여 전원공급기에

인두핸들 코드를 연결합니다. 3 핀을 정렬하여 케이블 커넥터의 평평한 부분을

전원공급기 위쪽으로 위치시킵니다.

4. 스폰지를 탈이온수에 가득

작업대 트레이에 갖다 놓습니다.

5. 입력전압을 적절히 조절할 수 있는 접지된 벽 소켓에 전원 코드를 연결하십시오. 본

기기를 작동하려면 걸쇠가 걸릴 때까지 스위치(전원공급기 앞면에 위치되어 있음)를

누르십시오. 초록색 표시등에 불이 들어옵니다. 작동하지 않으면 이 설명서의

문제해결 편을 참조하십시오.

위험을 지속적으로 예방하려면 완전히 접지된 콘센트에만 연결하십시오.

편리한 장소에 전원공급기를 연결하십시오.

적시지 말고 촉촉할 정도로 적십니다. 그리고 스폰지를

3. SMARTHEAT

®

: 보정이 필요 없음

PS-900 시스템은 유도 코일부품과 히터 팁으로 구성되어 있습니다. 각 히터 팁은 자가 조절

히터를 장착하여, 고유 온도를 감지하고 히터 팁의 수명기간 동안 미리 설정한 대기 온도를

완벽하게 유지합니다. OK International 의 독점적인 Smartheat

있습니다. 팁 온도는 히터의 금속 고유의 성질에 따라 결정됩니다; 외부 조정이나 장치는

필요하지 않습니다. 팁에 전달된 전력은 열량 하중에 대한 직접 반응에 따라 자동으로 변환되며

종전의 납땜 인두에서 발견되었던 전기적 교류 스파크와 과도 전류가 제거되었습니다. 질문이

있으면 OK International 판매자에게 연락하십시오.

®

기술에 의하여 모두 제어되고

4. 히터 팁 선택

OK International 의 히터 팁은 다양한 종류의 팁 모형과 온도 범위를 갖고 있습니다(더 많은

정보를 얻으려면 OK International 판매자 또는 자사 웹사이트를 방문해 주십시오). 이러한 팀

모형은 섬세한 정밀작업에서 지반 인두작업에 이르기까지 다양한 작업에 사용됩니다.

올바름

1. 팁과 납땜 접합부 사이의 접촉면을 최대화하도록 팁을 잡으십시오. 접촉면을 최대화하는 것이

열을 가장 효율적으로 전달하여 고품질의 납땜 성능을 신속히 얻을 수 있습니다.

2. 납땜 접합부에 잘 접근할 수 있도록 팁을 잡으십시오. 팁 길이가 짧을수록 더욱 정밀한 제어를

할 수 있습니다. 팁이 길거나 각도가 있으면 실장기판을 조밀하게 납땜하는데 사용됩니다.

3. 작업을 끝마칠 경우에는 온도가 제일 낮은 팁 카트리지를 고르십시오. 이는 잠재적인 열

손상을 최소화해 줍니다. 히터 팁의 손잡이에는 일련의 온도가 표시되어 있습니다.

너무 세밀함

너무 넓음

5. 히터 팁 교체

1. 전원 스위치 “OFF”를 누르십시오. 전원이 켜진

2. 제공된 AC-CP2 카트리지 제거패드를 사용하여

3. 제공된

4. 전원 스위치 “On.”을 누르십시오. 새 히터 팁은 20초 이내에 가열됩니다.

상태에서 히터 팁을 제거하면 코일 부품에 손상을

줄 수 있습니다.

히터 팁을 빼내십시오. 히터 팁을 제거하기 위해

금속 도구(예: 펜치)를 사용하지 마십시오. 금속

도구를 사용하면 히터가 손상될 수 있습니다.

주의: 히터 팁이 뜨거울 수 있습니다!

AC-CP2 카트리지 패드를 사용하여 히터 팁을 인두 핸들 안으로 밀어

넣으십시오.

www.okinternational.com

2

7000-2250 개정판 1

www.okinternational.com

3

7000-2250 개정판 1

Page 18

6. 코일 부품 교체

1. 전원 스위치 “OFF”를 누르십시오. 히터 팁이 실내 온도에 도달할 때까지 기다려 주십시오.

2. 핸들 부품에서 히터 팁을 제거하십시오. 금속 기구(예: 펜치)를 사용하여 히터 팁을 제거하지

마십시오.

3. 인두 핸들로부터 코일 부품을 분리하려면 간단히 코일 부품을 잡아당기면 됩니다. 그리고

인두 핸들부품에서 이를 분리하십시오.

4. 새 코일 부품을 핸들부품에 삽입하십시오. 올바르게 장착되면 ‘찰칵’소리가 납니다.

5. 인두 핸들을 코일부품 뒤편의 중심점에 맞추십시오. 그리고 정확히 장착될 때까지 새 코일

부품을 인두 핸들부품에 삽입하십시오 (히터 팁도 함께 삽입).

7. 문제 해결

a. 전원 LED 에 불이 들어오지 않은 경우

b. 팁이 가열되지 않은 경우

위 증상으로도 문제를 해결하지 못했을 경우에는 OK International 판매자에게 문의하십시오.

• 전원 코드를 점검하십시오.

• 전압을 유지하는지 확인하십시오.

• 전원 스위치가 ON 위치에 있는지 확인하십시오.

• LED 에 불이 들어옵니까?

• 핸드피스가 전원공급기에 연결되었습니까?

• PS-CA3 히터 코일이 PS-H3 인두 핸들부품에 정확히 삽입되었습니까?

• 팁이 PS-CA3 히터 코일 부품에 정확히 삽입되었습니까?

• PS-CA3 대체품으로 시도해 보았습니까

?

8. 사양

전원 공급기

대기 동작 온도 10 - 40°C

최대 봉입 온도 65°C

입력선 전압 100 - 240 VAC

입력선 주파수 50/60 Hz

전력 소비 최대 90 와트.

출력 전력 22°C 대기온도에서 최대 60 와트

출력 주파수 470 KHz

전원 코드(3선) 183 cm 18/3 SJT

크기(약) W(너비) = 80 mm (3.1"), D(길이) = 160 mm (6.3"),

인두 핸들 및 코일 부품

팁 접지전압 < 2 mV True RMS, 50-500 Hz

팁 접지저항 < 2 ohms DC, unit on(장치 장착시)

정지 온도 안전성 ± 1.1°C in still air(공기 접촉시)

핸들 코드 부품 길이 122 cm – burn proof(번 프루프), ESD 세이프

커넥터 3핀 전원 커넥터

크기(약)

전체 길이(팁 포함) 표준 팁 포함 230 mm (9.06")

그립 직경 13 mm (0.51")

팁 그립 58 mm (2.28")

팁 손잡이 직경 8.0 mm (0.31")

팁 길이 82 mm (3.23")

작업대

크기 W(너비) = 105 mm (4.1"), D(길이) = 175 mm (6.9"),

H(높이) = 115 mm (4.5")

H(높이) = 90 mm (3.5")

www.okinternational.com

4

7000-2250 개정판 1

www.okinternational.com

5

7000-2250 개정판 1

Page 19

9. 보증

OK International 제품 웹페이지(www.okinternational.com)를 방문하시면 시스템, 팁, 액세서리,

기술지원에 대한 유용한 정보를 얻을 수 있습니다. 또한 가격과 구매 여부 등에 관하여

OK International 판매자와 연락할 수 있습니다.

OK International는 원 소유자가 구매한 날로부터 1년간 제품 또는 기능에 결함이 있을 경우, PS-

900 전원공급기, 핸들 코드부품을 보증합니다. 본 보증은 일반적인 유지보수일 경우에는

보증에서 제외되며, 개봉, 오용, 남용, 변형 또는 손상된 품목에 대해서는 보증되지 않습니다. 본

제품이 보증 기간 내에 결함이 있을 경우, OK International은 무상으로 수리하거나 교체해

드립니다. 교체 품목은 원

시작됩니다. 구매일을 입증할 수 없을 경우, 보증기간은 제조날짜로부터 시작됩니다.

구매자에게 운임선불로 선적되며 보증 기간은 구매일로부터

보증 후 서비스

OK International은 수리 또는 교환 가능한 1년의 보증기간 만료후 1년 이내에 PS-900

전원공급기를 정상적으로 사용하다가 고장이 난 경우 수리하거나 교체해드립니다

(OK International 독점 옵션). 결함이 있는 전원공급기를 수리 또는 교체받으려면 아래의 절차를

따라 주십시오. 수리/교체 제공은 이전에 개봉, 개조, 수리, 변경, 오용 또는 손상된

전원공급기에는 적용되지 않습니다.

교체 가능한 PS-CA3 히터 코일 부품 보증

OK International은 제품 및 기능에 결함이 있는 경우 30일동안 코일 부품을 보증합니다.

교체가능 팁 보증

OK International은 히터 팁 플레이팅 수명기간 동안 규격에 따라 올바르게 작동하고 있음을

보장합니다. 기계 수명기간 동안 결함이 있는 히터 팁은 무상으로 교체해 드립니다. 교체를

받으려면 지역 판매 대리점에 문의를 하십시오. 팁 플레이트는 주로 사용자의 기기 및 실행

방식에 따라 다르기 때문에 플레이팅 웨어에 대해서는 보증되지 않습니다. 히터 팁은 제품 또는

기능에

결함이 있는 경우 보증됩니다. 남용, 오용, 개조 또는 손상된 팁은 보증되지 않습니다.

가열되지 않은 모든 히터 팁은 OK International의 옵션정책에 따라 수리 또는 교체됩니다.

환불을 받으려면 아래에 요약된 단계를 따라 하십시오.

환불 절차

환불 절차 및 환불 정책에 대해서는 지역 OK International 판매자에게 연락을 하십시오.

10. 안전 정보

전원이 공급되면 팁 온도는 300°C 이상입니다. 다음 예방조치를 준수하지 않으면 사용자가

상해를 입거나 기계에 손상을 유발할 수 있습니다.

• 핸드피스 금속 부품을 만지지 마십시오.

• 가연성 물질 근처에서 사용하지 마십시오.

• 본 설명서에 설명된 기능 이외의 목적으로 기기를 사용하지 마십시오.

• 정품 PS 교체부품만을 사용하십시오.

• 통풍이 잘되는 지역에서 사용하십시오.

• 젖은 손으로

• 전기적 쇼크의 위험을 예방하려면 충분히 접지된 콘센트에만 연결하십시오.

• 제품 또는 주변 물질의 화재사고를 예방하려면 작업대에 핸드피스를 항상 갖다

놓으십시오.

본 시스템이 우수한 EOS (전기적 과부하) 보호를 제공하더라도, 표준 작업자 유지보수 절차에

따라 기기 코드를 주기적으로 점검해야 합니다.

전기 및 전기 기기 폐기물 지침 - WEEE (2002 / 96/EC).

본 제품이 필요없거나 재사용할 수 없는 경우, 도시 미분류

쓰레기도 처리하지 말고 제품 재활용을 권장합니다. 유럽에서

재활용 옵션에 대한 상담을 원하시면 OK International 판매자에게

연락하십시오(www.okinternational.com).

경고

!

기기를 사용하지 마십시오.

www.okinternational.com

6

7000-2250 개정판 1

www.okinternational.com

7

7000-2250 개정판 1

Page 20

www.okinternational.com

8

7000-2250 개정판 1

Loading...

Loading...