Page 1

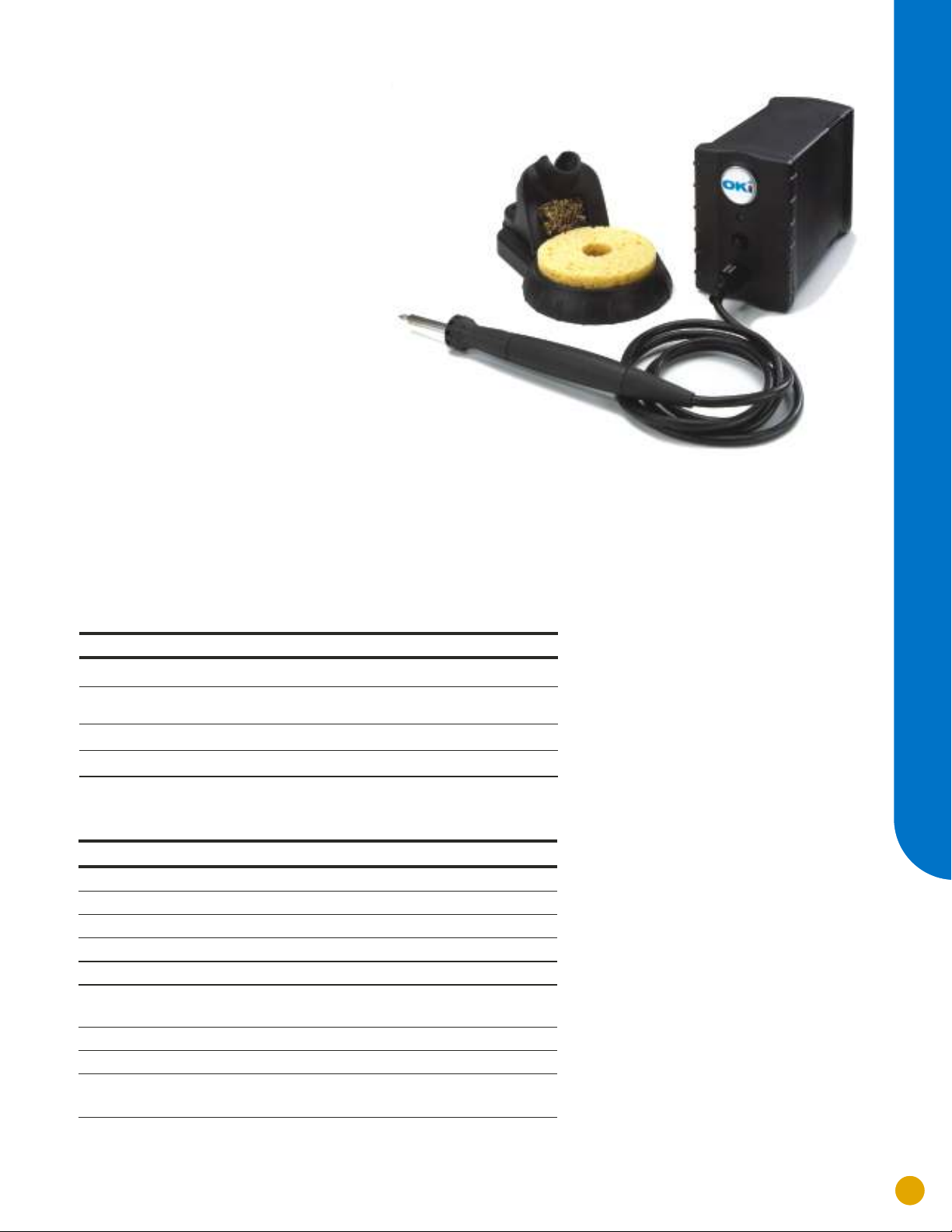

P S - 8 0 0 S o l d e r i n g S y s t e m

PS-800 Soldering System

Compact Production Soldering System

Designed to be the perfect, compact system for repetitive manual soldering and touch-up. The PS-800 Soldering System

features an innovative, compact power supply with a small footprint which is ideal for production environments. The

system combines the power and superior process control advantages of SmartHeat , with the system quality and

innovative design of OK International irons. In addition, the PS-800 Soldering System utilizing SmartHeat Technology

requires no calibration

®

®

Minimal Cost of Ownership

The PS-800 Soldering System uses replaceable heater tips rather than cartridges, with the cost being comparable to

that of conventional tips, making cost of ownership competitive. The unique two-piece design separates the induction coil

from the heater tip. The long-life induction coil remains in the handle, while replaceable heater tips are easily removed

and replaced.

OK International has developed a comprehensive line of soldering tip geometries for the PS-800 Soldering System.

Plus, enhancements to SmartHeat Technology have allowed for an increase to the plating thickness of the tips. The

result is extended tip life without reducing thermal performance.

®

18

Contents of this brochure subject to change without notice

Page 2

Perfect For Lead-Free Hand Soldering

The most important technical challenge of lead-

free hand soldering is being able to solder heat

sensitive components at 215-220°C, without

causing damage. This requires a soldering iron that

can respond to the thermal energy demands of the

application and deliver the correct amount of

energy to the joint without overshoot that can

cause damage.

OK International's PS-800 Soldering System is

perfect for lead-free hand soldering. SmartHeat

Technology allows the higher thermal performance

requirements of lead-free alloys to be met without

increasing the tip temperature. Thus, the risk of

thermal damage is eliminated.

The PS-800 Soldering System allows operators to produce high quality product quickly, easily and safely. It is a reliable, hassle-

free production tool that can be used to solder lead-free PCBs immediately without needing to be continually re-calibrated to meet

the higher temperature requirements like traditional technologies.

®

Shown with optional

PS-WSAS Workstand

PS-800 Soldering System

Part No.

PS-800

Includes

PS-PW1

PS-WSK1

PS-HC1

Description

PS-800 Soldering System

PS-800 Power Supply

PS-800 Workstand with Sponge

PS-800 Soldering Handle with Coil Assembly

Specifications

Power Supply

Ambient Operating Temperature 10 - 40°C

Maximum Enclosure Temperature 65°C

Input Line Voltage 90 - 240 VAC

Input Line Frequency 50/60 Hz

Power Consumption 50 Watts max.

Output Power 35 Watts max. at

22°C ambient temperature

Output Frequency 470 KHz

Power Cord (3-wire) 183cm (72”)

Dimensions (W x D x H) 70mm x 161mm x 100mm

(2.76" x 6.34" x 3.94")

P S - 8 0 0 S o l d e r i n g S y s t e m

19

Page 3

P S - 8 0 0 A c c e s s o r i e s

Lead-Free Process Identification

For factories that are transitioning to lead-free, it is important to identify which

processes are using lead-free to avoid accidental cross-contamination of solder

materials. To easily identify the lead-free processes, we have designed visual

indicators that fit on the system parts where cross-contamination can occur, such

as tips & workstand sponges.

Part No.

PS-WSAS-G

AC-CK1

Description

Auto Sleep Workstand with Green Cradle

Green cartridge identification ring for

PHT Consumables (Pack of 50)

Accessories & Spare Parts

Part No.

PS-PW1

PS-WSK1

PS-WSC1

PS-WSAS

AC-YS4

PS-HC1

PS-CA1

AC-CP2

AC-PM

Description

PS-800 Power Supply

PS-800 Workstand with Sponge

PS-800 Cradle

PS-800 Auto Sleep Workstand with Sponge

Sponge 3.12" ø x 1" (pack of 10)

PS-800 Soldering Handle with Coil Assembly

PS-800 Coil Assembly

Heater Tip Removal Pad

Power Meter – AC

PS-800 Heater Tips

.394"

10mm

.472"

12.0mm

3.0mm

.12"

1.78mm

2.5mm

.04"

.07"

.10"

.197"

5.0mm

1.0mm

.06"

1.5mm

10.0mm

10.0mm

.65"

16.5mm

.06"

1.5mm

.394"

10.0mm

.394"

.394"

.315"

8.0mm

PHT- 0315 PHT- 2017

Chisel Fine 30° 1.0mm (.04") Conical 60° 0.25mm (.01")

PHT- 0326 PHT- 2035

Chisel Fine/Bent 30° 1.5mm (.06") Conical Fine 0.5mm (.02")

PHT- 0335 PHT- 2057

Chisel Fine 30° 1.78mm (.07") Conical Fine 1.0mm (.04")

PHT- 1355 PHT- 2327

Chisel 30° 2.5mm (.10") Conical Fine/Bent 0.4mm (.016")

PHT- 0325 PHT- 2335

Chisel 60° 1.5mm (.06") Conical Fine 30° 0.5mm (.02")

PHT- 1367 PHT- 2337

Chisel 30° 3.0mm (.12") Conical Fine/Bent 30° 0.5mm (.02")

PHT- 1384 PHT- 3035

Chisel 30° 5.0mm (.197") Conical 30° 0.5mm (.02")

.59"

0.4mm

0.5mm

.04"

.02"

0.02"

.02"

0.5mm

1.0mm

.016"

0.5mm

15.0mm

10.0mm

.59"

15.0mm

.63"

16.0mm

0.5mm

10.0mm

.394"

15.0mm

.59"

15.0mm

0.59"

.39"

XY XY

.01"

0.25mm

XY XY

XY XY

XY XY

XY XY

XY XY

.02"

XY XY

20

650 Series = 65, 750 Series = 75

XY XY

Dimensions and artwork listed are for indication/guidance only. Numbers have been rounded up.

Please contact your local technical support if you require specific technical information.

Page 4

PS-800 Heater Tips

0.5mm

0.5mm

.59"

.04"

15.0mm

1.2mm

.59"

15.0mm

.04"

1.0mm

1.0mm

.04"

15.0mm

.590"

1.0mm

.04"

16.65mm

.656"

60°

.02"

15.0mm

.59"

45°

.02"

15.0mm

.59"

XY XY

PHT- 3047 PHT- 4497

Conical 1.2mm (.05") Hoof 45° 4.0mm (.16")

XY XY

PHT- 3057 PHT- 4697

Power Conical 1.0mm (.04") Hoof 60° 4.0mm (.16”)

XY XY

PHT- 3067 PHT- 4627F

Conical Long 1.0mm (.04") Mini Hoof 60° Face Only 1.0mm (.04")

XY XY

PHT- 3077 PHT- 4637F

Power Conical 1.0mm (.04") Mini Hoof 60° Face Only 1.5mm (.06")

XY XY

PHT- 4607 PHT- 4467F

Mini Hoof 60° 0.5mm (.02") Hoof 45° Face Only 2.0mm (.08")

XY XY

PHT- 4617 PHT- 4487F

Mini Hoof 45° 0.5mm (.02") Hoof 45° Face Only 3.0mm (.12")

4.0mm

.16"

4.0mm

.16"

1.0mm

.04"

1.5mm

.06"

2.0mm

.08"

3.0mm

.12"

45°

17.0mm

.67"

60°

17.0mm

.67"

60°

15.0mm

.59"

60°

15.0mm

.59"

45°

45°

17.0mm

.67"

17.0mm

.67"

P S - 8 0 0 H e a t e r T i p s

1.5mm

2.0mm

.08"

2.0mm

.08"

3.0mm

3.0mm

.12"

1.0mm

.04"

.06"

.12"

45°

60°

15.0mm

.59"

60°

15.0mm

.59"

45°

17.0mm

.67"

60°

17.0mm

.67"

45°

17.0mm

.67"

60°

17.0mm

.67"

XY XY

PHT- 4627 PHT- 4497F

Mini Hoof 60° 1.0mm (.04") Hoof 45°, 4.0mm (.16")

XY XY

PHT- 4637 PHT- 5437

Mini Hoof 60° 1.5mm (.06") Knife Sharp 45° 3.0mm (.12")

XY XY

PHT- 4467 PHT- 5457

Hoof 45° 2.0mm (.08") Knife Sharp 45° 4.5mm (.18")

XY XY

PHT- 4667 PHT- 5477

Hoof 60° 2.0mm (.08") Knife Bevel 45° 5.0mm (.20")

XY XY

PHT- 4487 PHT- 5487

Hoof 45° 3.0mm (.12") Knife Sharp 45° 5.0mm (.20")

XY

PHT- 4687

Hoof 60° 3.0mm (.12")

4.0mm

.16"

.12"

3.0mm

4.5mm

.18 "

5.0mm

5.0mm

0.5mm

.02"

.20"

0.43mm

.017"

.20"

45°

45°

17.0mm

.67"

15.0mm

.59 "

15.0mm

.5 9"

2.0mm

.08"

1.0mm

.04"

45°

15.0mm .59"

16.38mm

45°

4.32mm

.645"

.17"

650 Series = 65, 750 Series = 75

XY XY

Dimensions and artwork listed are for indication/guidance only. Numbers have been rounded up.

Please contact your local technical support if you require specific technical information.

21

Loading...

Loading...