Page 1

OKIPOS 425S/D

(OKI Standard Version)

POS-PRINTER

Product Specifications

(Software edition)

2001-05-10 Rev.3

41049421PS Rev.3 1 / 221

Page 2

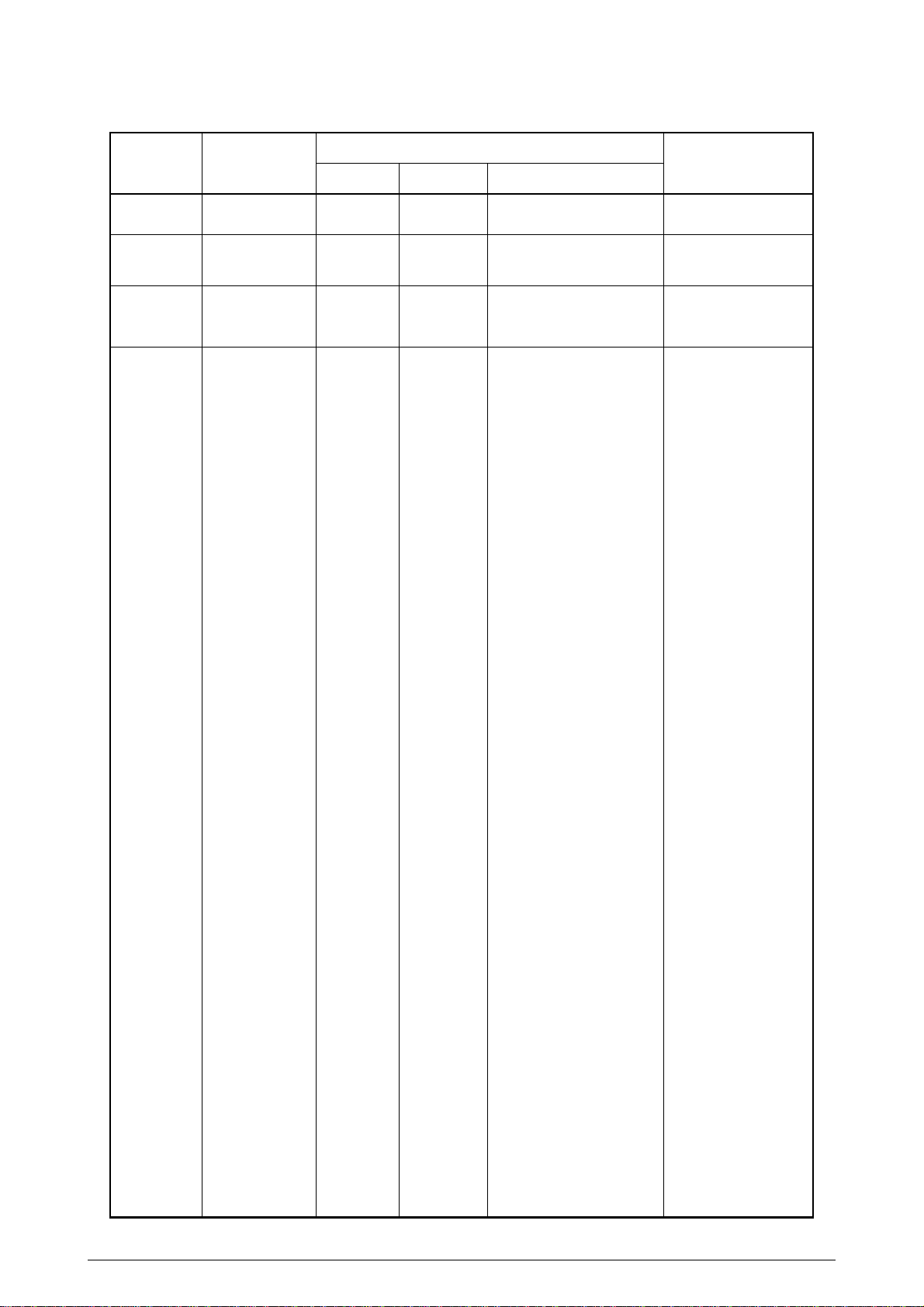

Document Revision History

Rev.No. Date

Corrected items

No.

Page Description of change

1 2001-01-17 ISSUE ODS Kanno

2 2001-02-28 ALL Review in entirely and ODS Kanno

update

3 2001-05-10 ALL Addition of Bar Code ODS Kanno

Command and update

Person in

charge

41049421PS Rev.3 2 /

Page 3

CONTENTS

1. OVERVIEW ......................................................................................................... 7

2. OPERATOR CONTROL ..................................................................................... 8

2.1 Operator Panel Functions................................................................................................... 8

2.1.1 Operator Panel Specifications................................................................................ 8

2.2 LOCAL FUNCTIONS ........................................................................................................ 12

2.2.1 Kinds of Local Functions and How to Start........................................................... 12

2.3 LOCAL TEST.................................................................................................................... 13

2.3.1 Printer Status in Local Test Mode ........................................................................ 13

2.3.2 Details of Local Test Prints................................................................................... 13

2.3.2.1 All Letter and Rolling ASCII Continuous Print Test (Receipt) ............... 13

2.3.2.2 All Letter and Rolling ASCII Continuous Print Test (Journal)................ 14

2.3.2.3 All Letter and Rolling ASCII Continuous Print Test (Receipt + Journal) 14

2.3.2.4 All Letter and Rolling ASCII Continuous Print Test (Slip/Sprocket) ...... 15

2.3.2.5 Sample Data Continuous Print Test (Validation)................................... 15

2.3.2.6 MICR Read Test (Receipt).................................................................... 16

2.3.2.7 Rewinder Winding Evaluation Continuous Print Test (Journal) ............ 17

2.3.3 Local Test Header ................................................................................................ 18

2.4 MENU FUNCTION (Receipt) ............................................................................................ 19

2.4.1 Overview............................................................................................................... 19

2.4.2 Menu Items........................................................................................................... 19

2.4.3 How to Operate .................................................................................................... 21

2.4.3.1 Start....................................................................................................... 21

2.4.3.2 Operation .............................................................................................. 21

2.5 HEX DUMP FUNCTION (Receipt).................................................................................... 22

2.5.1 Print Format.......................................................................................................... 22

2.5.2 How to Print.......................................................................................................... 22

2.6 PLATEN MAINTENANCE MODE..................................................................................... 23

3. COMMAND DESCRIPTION.............................................................................. 24

3.1 Control Code..................................................................................................................... 24

3.1.1 Control Code List.................................................................................................. 24

3.1.1.1 Function Code....................................................................................... 24

3.1.1.2 DLE Sequence ...................................................................................... 24

3.1.1.3 ESC Sequence...................................................................................... 25

3.1.1.4 FS Sequence ........................................................................................ 27

3.1.1.5 GS Sequence........................................................................................ 27

3.2 Control Operations............................................................................................................ 28

3.2.1 Print Operation Control......................................................................................... 28

3.2.1.1 Print/Carriage Return ............................................................................ 28

3.2.2 Space Control....................................................................................................... 29

3.2.2.1 Left Margin Set...................................................................................... 29

3.2.2.2 Absolute Position Designate ................................................................. 30

3.2.2.3 Relative Position Designate .................................................................. 31

3.2.2.4 Position Align ........................................................................................ 33

3.2.2.5 Journal Tab ........................................................................................... 33

3.2.3 Line Feed Control................................................................................................. 34

3.2.3.1 Print/Line Feed...................................................................................... 34

3.2.3.2 1/8-inch Line Feed Set .......................................................................... 35

3.2.3.3 7/72-inch Line Feed Set ........................................................................ 35

3.2.3.4 1/6-inch Line Feed Set .......................................................................... 36

3.2.3.5 n/144-inch Line Feed Pitch Set ............................................................. 36

3.2.3.6 n/72-inch Line Feed Pitch Set ............................................................... 37

3.2.3.7 Cut Sheet Paper Print and Eject or Sprocket Paper Form Feed........... 37

3.2.3.8 Sprocket Paper Page Length Set.......................................................... 38

3.2.3.9 Sprocket Paper Perforation Skip Set .................................................... 39

41049421PS Rev.3 3 /

Page 4

3.2.3.10 Sprocket Paper Perforation Skip Reset ................................................ 40

3.2.3.11 n/144-inch Paper Feed.......................................................................... 40

3.2.3.12 n-line Paper Feed.................................................................................. 41

3.2.3.13 n/144-inch Paper Feed.......................................................................... 41

3.2.3.14 n/144-inch Line Feed Pitch Set ............................................................. 42

3.2.4 Character Control ................................................................................................. 43

3.2.4.1 International Character Set Select ........................................................ 43

3.2.4.2 Character Code Table Select................................................................ 44

3.2.5 Print Mode Control................................................................................................ 45

3.2.5.1 Character Right-side Space Set............................................................ 45

3.2.5.2 Underline Designate/Clear .................................................................... 46

3.2.5.3 Double Height Print Set/Reset .............................................................. 46

3.2.5.4 Double Width Print Set/Reset ............................................................... 47

3.2.5.5 Italic Mode Set ...................................................................................... 47

3.2.5.6 Italic Mode Reset .................................................................................. 48

3.2.5.7 Emphasized Print Designate/Clear ....................................................... 48

3.2.5.8 Double Strike Print Designate/Clear ..................................................... 49

3.2.5.9 Blanket Print Mode Designate............................................................... 49

3.2.5.10 Condense Designate............................................................................. 50

3.2.5.11 Condense Designate............................................................................. 50

3.2.5.12 Condense Clear .................................................................................... 50

3.2.6 Image Control....................................................................................................... 51

3.2.6.1 Bit Image Mode Designate.................................................................... 51

3.2.6.2 9-Pin Bit Image Mode Designate .......................................................... 53

3.2.7 Print Sheet Control ............................................................................................... 56

3.2.7.1 Print Sheet Select ................................................................................. 56

3.2.7.2 Set Sheet Select ................................................................................... 57

3.2.7.3 Paper Sensor Select Enabling Paper End Signal ................................. 58

3.2.7.4 Print Stop Sensor Select ....................................................................... 59

3.2.7.5 Cut Form Wait Time Set........................................................................ 60

3.2.7.6 Full Cut.................................................................................................. 61

3.2.7.7 Partial Cut (one point left intact)............................................................ 61

3.2.7.8 Receipt+Journal Same Data Print Designate/Clear.............................. 61

3.2.7.9 Print Sheet Select ................................................................................. 62

3.2.7.10 Set Sheet Select ................................................................................... 64

3.2.8 Printer Hardware Control...................................................................................... 65

3.2.8.1 Peripheral Device Select....................................................................... 65

3.2.8.2 Peripheral Device Status Send ............................................................. 67

3.2.8.3 Panel Switch Enable/Disable ................................................................ 68

3.2.8.4 Print Data Cancel .................................................................................. 69

3.2.8.5 Printer Initialize...................................................................................... 69

3.2.8.6 Unidirectional Print Designate/Clear ..................................................... 70

3.2.8.7 One Line Unidirectional Print ................................................................ 70

3.2.8.8 Paper Sensor Status Send.................................................................... 71

3.2.8.9 Menu Item Set....................................................................................... 73

3.2.8.10 Print Speed and Head Currerent Run Time Set.................................... 75

3.2.8.11 Desiganted Pulse Generate (Open Cash Drawer)................................ 76

3.2.8.12 Auto Status Send Enable/Disable ......................................................... 77

3.2.8.13 Printer Status Real-time Send............................................................... 82

3.2.8.14 Printer ID Send...................................................................................... 84

3.2.8.15 Status Send........................................................................................... 86

3.2.8.16 Status Real-time Sent ........................................................................... 89

3.2.8.17 Real-time Request to Printer................................................................. 93

3.2.8.18 Real-time MICR Status Send ................................................................ 95

3.2.8.19 Check Paper Read (MICR Mode Select) .............................................. 96

3.2.8.20 Paper Load to Print Start Position....................................................... 100

3.2.8.21 Check Paper Eject .............................................................................. 100

3.2.8.22 Check Paper Read Result Re-send Request...................................... 101

3.2.8.23 Validation Insert Position Select.......................................................... 102

3.2.8.24 Auto Status Send Enable/Disable ....................................................... 103

3.2.8.25 Status Real-time Send ........................................................................ 105

41049421PS Rev.3 4 /

Page 5

3.2.9 Bar Code Control................................................................................................ 106

3.2.9.1 Bar Code Style Select and Size Set.................................................... 106

3.2.9.2 Print Bar Code Data ............................................................................ 116

3.3 Character set .................................................................................................................. 129

3.3.1 Code table .......................................................................................................... 129

3.3.1.1 USA..................................................................................................... 129

3.3.1.2 Canada-French ................................................................................... 130

3.3.1.3 Multilingual .......................................................................................... 131

3.3.1.4 Portugal............................................................................................... 132

3.3.1.5 Norway ................................................................................................ 133

3.3.1.6 BRASCII.............................................................................................. 134

3.3.1.7 Abicomp .............................................................................................. 135

3.3.1.8 Multilingual 858 ................................................................................... 136

3.3.1.9 ISO 8859/15 ........................................................................................ 137

3.3.1.10 International character set table.......................................................... 138

3.3.2 Spec ................................................................................................................... 139

3.3.3 Character development ...................................................................................... 140

3.4 Operation ........................................................................................................................ 142

3.4.1 Default ................................................................................................................ 142

3.4.2 Print Start............................................................................................................ 145

3.4.2.1 Conditions for Print Start ..................................................................... 145

3.4.3 Right Margin Process ......................................................................................... 146

3.4.4 Combination of print mode ................................................................................. 149

3.4.5 Print Pass Position Control................................................................................. 151

4. IEEE1284 SPECIFICATIONS ......................................................................... 152

4.1 Terminology .................................................................................................................... 152

4.2 I EEE1284....................................................................................................................... 153

4.3 Compatible Mode............................................................................................................ 154

4.3.1 Compatible Mode Handshake ............................................................................ 155

4.3.1.1 Compatible mode handshake timing chart.......................................... 155

4.3.1.1.1 Data receive (forward data transfer phase) ....................... 155

4.3.1.1.2 Initialization by POWER ON .............................................. 155

4.3.1.1.3 Initialization by I-PRIME (nlnit) signal ................................ 155

4.3.1.1.4 Paper end .......................................................................... 156

4.3.1.1.5 Recoverable alarm............................................................. 156

4.3.1.1.6 Fatal alarm......................................................................... 157

4.3.1.1.7 Feed SW hold down .......................................................... 157

4.3.1.2 Negotiation phase start ....................................................................... 157

4.4 Negotiation...................................................................................................................... 158

4.4.1 Details of Negotiation ......................................................................................... 158

4.4.1.1 Negotiation and handshake ................................................................ 159

4.4.1.2 Negotiation timing chart ...................................................................... 160

4.5 Nibble Mode.................................................................................................................... 164

4.5.1 Nibble Mode Handshake .................................................................................... 165

4.5.1.1 Nibble mode handshake timing charts ................................................ 166

4.6 Interface Errors ............................................................................................................... 177

4.6.1 Interface Error Timing Charts ............................................................................. 178

4.7 DEVICE ID...................................................................................................................... 184

4.7.1 Device ID Format................................................................................................ 184

4.7.2 Device ID Data ................................................................................................... 185

4.7.3 Error control during device ID data transfer........................................................ 185

4.8 NIBBLE MODE REVERSE CHANNEL TRANSFER ...................................................... 186

4.8.1 Reverse channel transfer data ........................................................................... 186

4.8.1.1 Transfer priority of reverse channel transfer data ............................... 186

4.8.2 Error control while reverse channel transfer data is being transferred............... 187

4.8.2.1 Control when status other than ASB is being transferred ................... 187

4.8.2.2 Control when ASB is being transferred ............................................... 187

4.8.2.3 Control while MICR read data is being transferred ............................. 188

4.8.2.4 Control while ASB/non-ASB mixed data is being transferred ............ 189

41049421PS Rev.3 5 /

Page 6

4.9 Interface Iinitialization ..................................................................................................... 190

4.9.1 I/F Signals During Initialization .......................................................................... 190

4.10 Status Transition Diagram .............................................................................................. 192

4.11 ASB performance ........................................................................................................... 193

5. RS-232C SPECIFICATIONS........................................................................... 195

5.1 Receive Buffer ................................................................................................................ 195

5.1.1 Receive Buffer Size............................................................................................ 195

5.1.2 Receive buffer structure ..................................................................................... 195

5.2 Serial Interface................................................................................................................ 196

5.2.1 Explanation of Interface Signal and Pins............................................................ 196

5.2.2 Interface Cable Wiring Diagram ......................................................................... 197

5.2.2.1 Wiring diagram when the host side serial board connector is D-SUB 9-pin.. 197

5.2.2.2 Wiring diagram when the host side serial board connector is D-SUB 25-pin 197

5.2.3 Overview............................................................................................................. 198

5.2.4 RS-232C Interface.............................................................................................. 199

5.2.4.1 Signal level.......................................................................................... 199

5.2.4.2 Character structure on transmission circuit......................................... 199

5.2.4.3 BUSY signal timing chart .................................................................... 200

5.2.5 Receiving Margin................................................................................................ 200

5.3 Selecting a Function ....................................................................................................... 201

5.3.1 DIP switch structure............................................................................................ 201

5.3.1.1 Details of DIP switch functions............................................................ 202

5.3.2 Factory default.................................................................................................... 203

5.3.3 Receive data error check.................................................................................... 204

5.3.3.1 Parity check......................................................................................... 204

5.3.3.2 Framing error check ............................................................................ 205

5.3.3.3 Overrun error check ............................................................................ 206

5.3.4 DSR signal control.............................................................................................. 207

5.3.4.1 DSR signal when data is being received............................................. 207

5.3.4.2 DSR signal when data is being sent ................................................... 207

5.3.4.3 Printer status request command that monitors status of DSR signal.. 208

5.3.4.4 Printer status request command when DSR signal is in MARK status 209

5.3.5 Protocol .............................................................................................................. 210

5.3.5.1 Ready / Busy protocols ....................................................................... 210

5.3.5.2 X-ON / X-OFF protocol........................................................................ 211

5.3.6 Busy On timeout receive control......................................................................... 212

5.3.6.1 Behavior .............................................................................................. 212

5.3.6.2 BUSY ON timeout receive time chart.................................................. 213

5.3.7 Local test function............................................................................................... 215

5.3.7.1 Circuit test mode ................................................................................. 215

5.3.8 Custmer display.................................................................................................. 218

5.3.8.1 Customer display connection and RTS signal .................................... 218

5.3.8.2 Customer display connection/non-connection and RTS signal status 218

5.3.9 Printer reset signal.............................................................................................. 219

5.3.9.1 Printer Busy control when reset signal is received.............................. 219

5.3.9.2 Busy control in X-ON/X-OFF protocol ................................................. 220

5.3.9.2.1 H/W reset........................................................................... 220

5.3.9.2.2 F/W reset ........................................................................... 221

41049421PS Rev.3 6 /

Page 7

1. OVERVIEW

This specification defines the following that are realized by the firmware, for the OKIPOS 425S/D

(POS Printer) OKI Standard Version.

• OKIPOS 425S : OKI Single Standard Version

• OKIPOS 425D : OKI Dual Standard Version

<Conventions in this specification document>

This printer comes in two models, 1-Roll Model and 2-Roll Model. The 2-Roll Model printer has three

roll paper modes, Receipt, Journal, and Receipt+Journal. The 1-Roll Mode printer has only the Roll

paper mode.

In this specification document, if the 1-Roll Model is not specifically mentioned when the 1-Roll

Model is involved, for “Receipt (mode)”, read “Roll Paper (mode)”, and ignore the descriptions for

“Journal (mode)” or “Receipt+Journal (mode)”.

<Definitions of Off-line>

This printer is not equipped with the On-line/Off-line switch. It becomes Off-line under the following

conditions:

(1) During the period from POW ON or initialization of the mechanism prompted by the reset from

the interface, to the time communications become available.

(2) During execution of local test.

(3) When the cover is opened (“Cover Open Alarm” on the menu is set to “Yes”)

(4) During paper feed by the switch.

(5) Printing has stopped due to Paper End.

(Paper End of Receipt, Journal, or Receipt+Journal selected by ESC c4.)

(6) Recoverable Error has occurred.

(Except Head Thermal Alarm, SP Thermal Alarm or LF Thermal Alarm)

(7) Unrecoverable Error has occurred.

At Off-line, an On-line/Off-line status that is sent by GS a n, ESC DLE a Pno n, GS ENQ, DLE EOT

n, and ESC DLE r Pno n becomes off-line, and the I/F becomes Busy. In the case of (3) through

(6), the I/F becomes Busy only if “Off-line Busy Control” on the menu is set to “Yes”

* Each I/F becomes Busy in the following manner.

• With the Parallel model (Centronics I/F), the Busy signal becomes High at Off-line.

• With the Serial model (RS232C I/F), the following Busy control is performed at Off-line.

If handshake is DTR/DSR, the DTR signal will change to MARK.

If handshake is XON/XOFF, DC3 will be sent.

41049421PS Rev.3 7 /

Page 8

2. OPERATOR CONTROL

This specification document describes the details of the operator panel and the local functions that

are realized by the firmware.

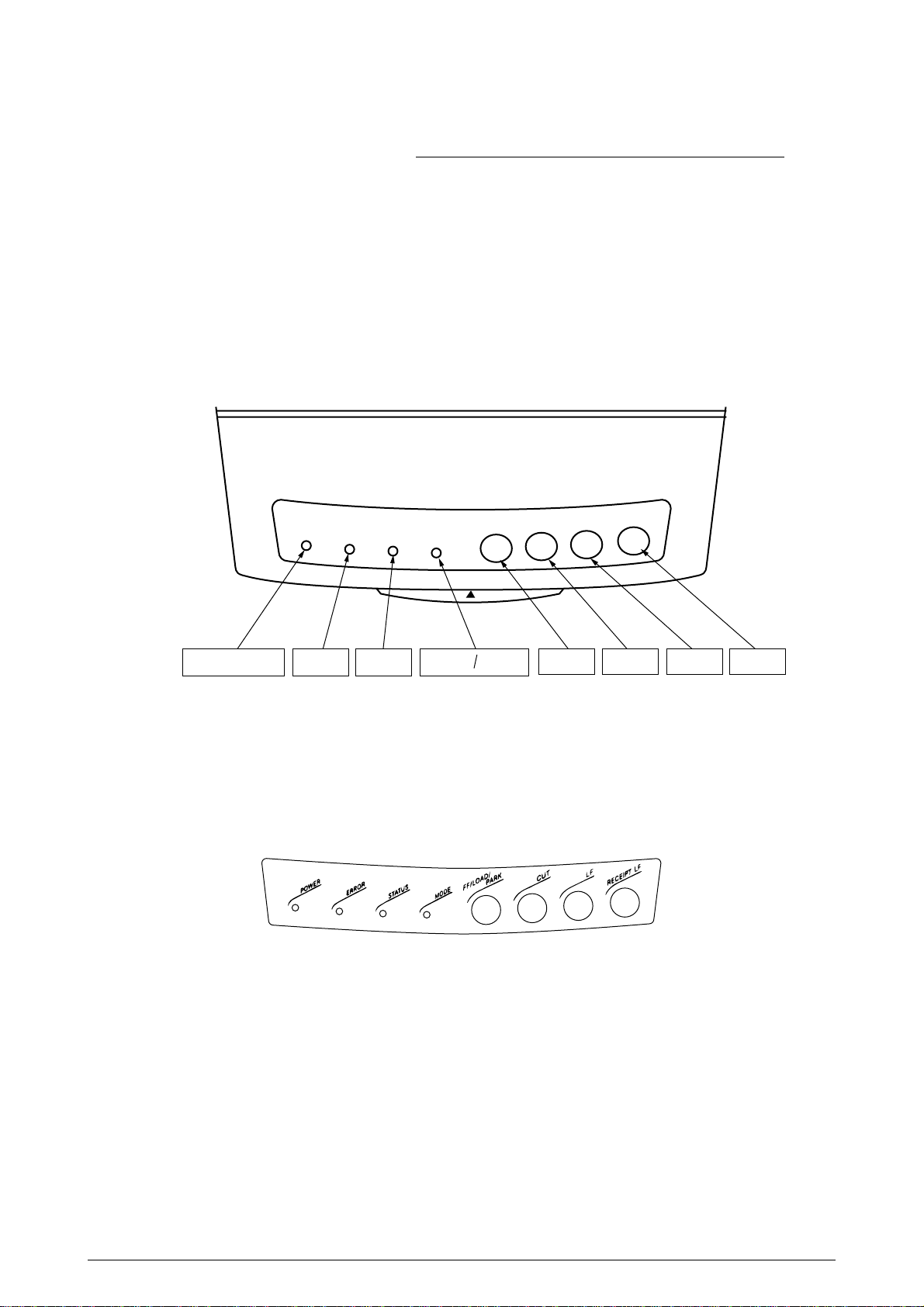

2.1 Operator Panel Functions

This chapter describes the operator panel functions.

2.1.1 Operator Panel Specifications

(Operator Panel layout)

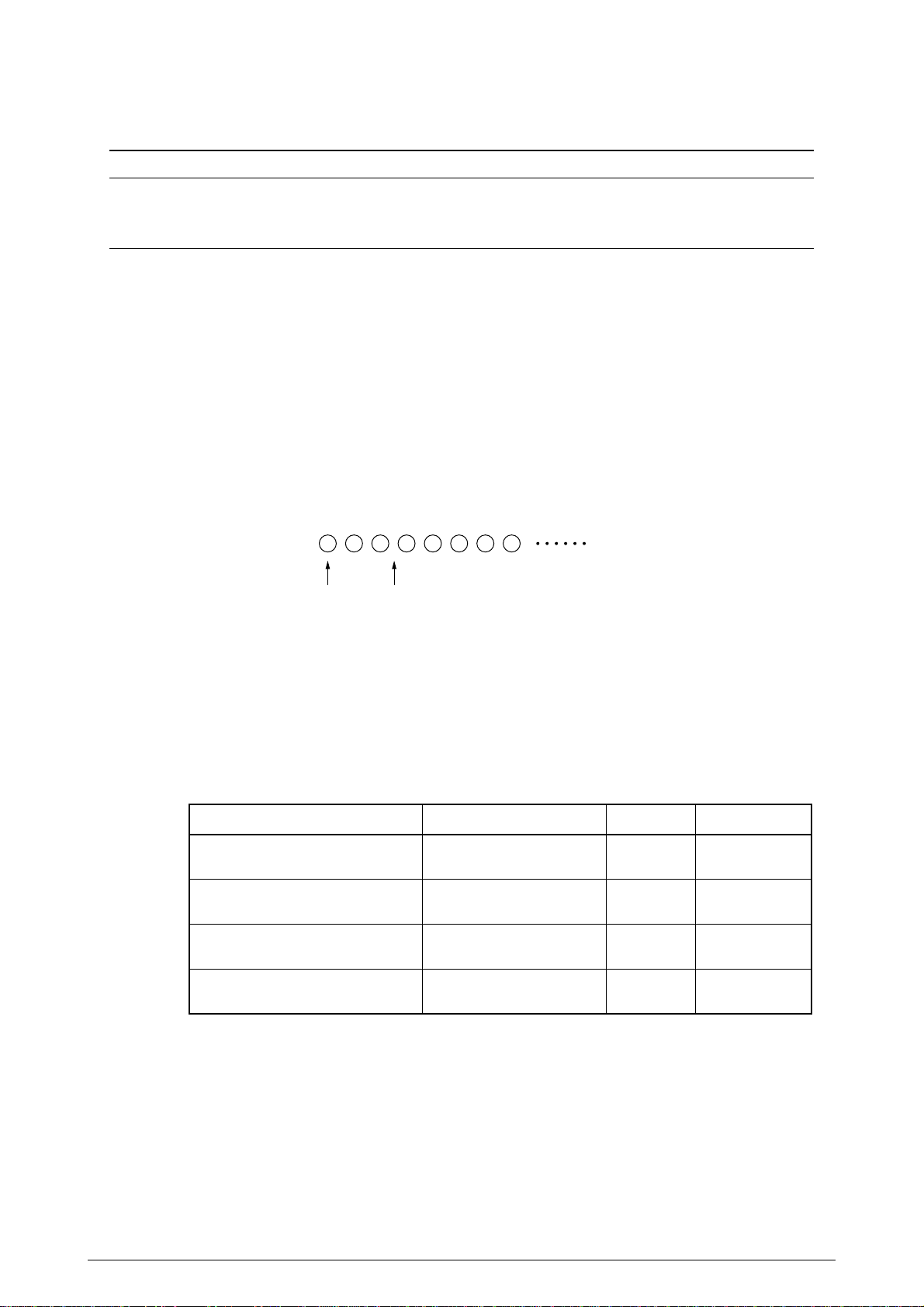

POWER LED LED1 LED2 SW2 SW3 SW1 SW4LED3 LED4

* The SW names in the above layout are tentative. They have been assigned to make their

explanations easy.

<Panel sheet design>

41049421PS Rev.3 8 /

Page 9

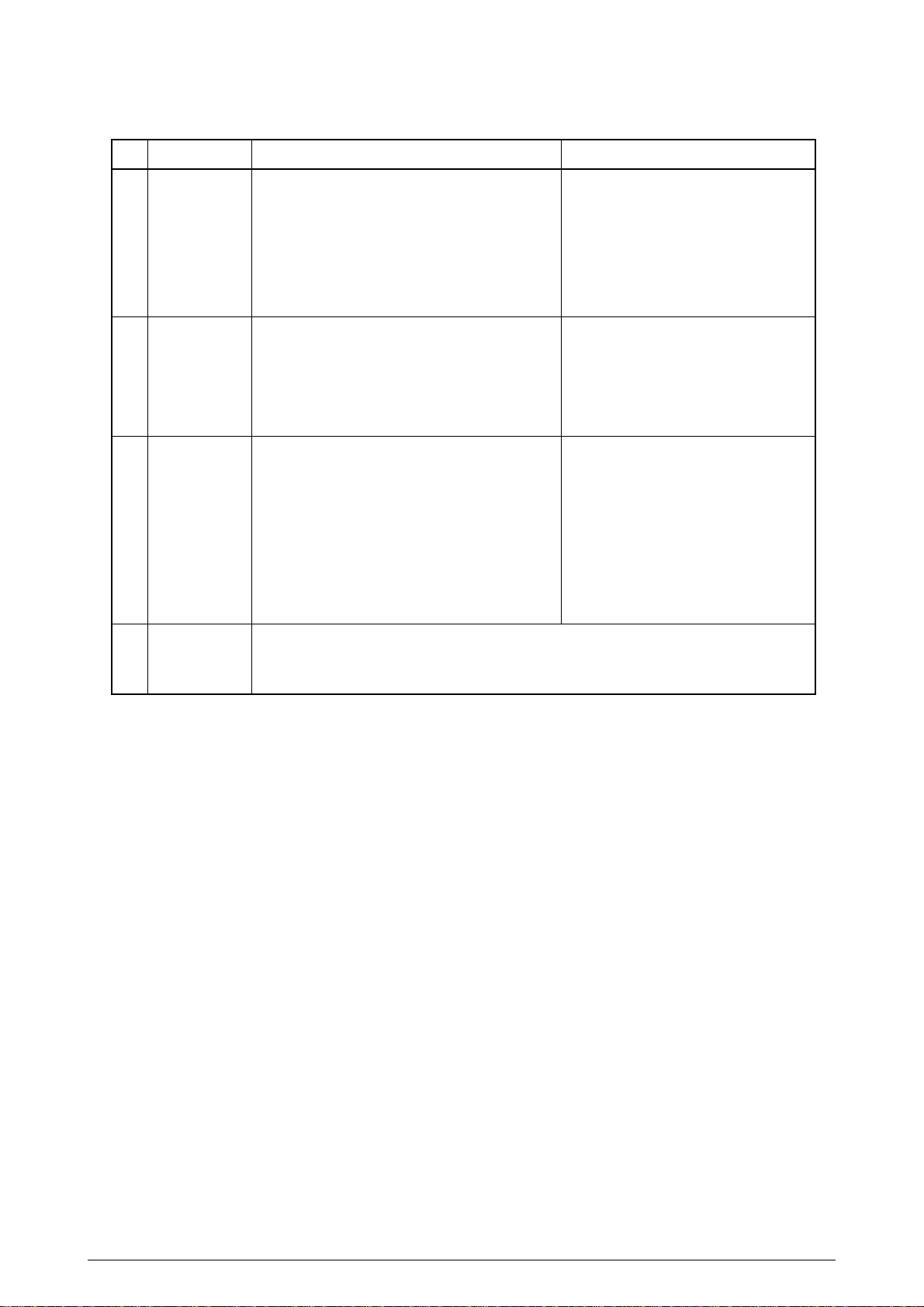

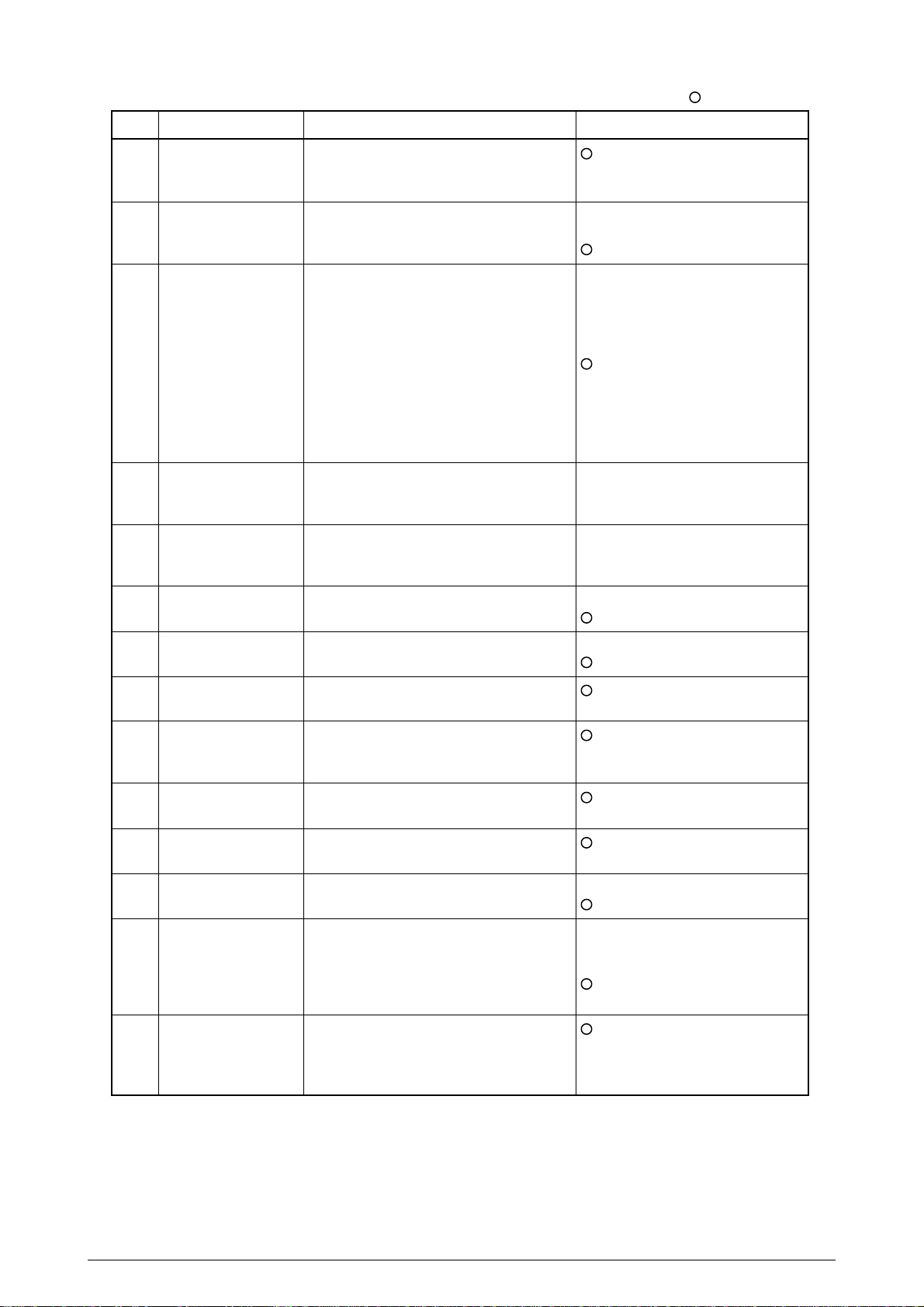

(Switch functions)

No.

1

2

3

Switch

SW2

(FF/LOAD/

PARK)

SW3

(CUT)

SW1

(LF)

Function in Modes other than Tractor Mode

In Receipt mode: Line-feeds receipts for a

fixed amount (10/6")

In Receipt+Journal mode: Same as above.

In Journal mode: Invalid.

In Slip mode: Ejects when paper is already

set.

In Validation mode: Invalid

* Does not cause printing to start.

Auto Cut (partial cut) Note 1)

* Valid regardless of print sheet mode or

print sheet status.

In Slip mode: Line-feeds the slip already set

by 1-line .

In Receipt mode: Line-feeds a jour nal by 1

line. Note 2)

In Validation mode: Invalid.

In Journal mode: Line-feeds a journal by 1line.

In Receipt+Journal mode: Line-feeds a

journal by 1-line.

* None of the above cause printing to start.

Function in Tractor Mode

Paper not loaded: Auto Load

Paper already loaded: Auto Park

* When No Paper is sensed by Slip

Sensor, Auto Park is invalid.

Cut position: Reverse-feeds to print

position.

Print position: Feeds to cut position.

Paper not loaded: Above does not

occur when pressed.

Single Press: Feeds Sprocket paper by 1-line.

Continuous Press: Form-feeds.

* Line-feeds 1-line immediately af-

ter the SW is pressed. Formfeeds after the SW is held down

continuously at least for 500ms.

* Does not cause printing to start.

4

SW4

(RECEIPT

Line-feeds a receipt by 1-line.

* Valid regardless of the print sheet mode or print sheet status.

LF)

Note 1)

Invalid when “Auto Cutter Unit = No” is set in the menu.

In the 1-Roll Model, Auto Cut function is invalid since this model does not have the auto

cutter unit.

Note 2)

In the 1-Roll Model, a receipt is line-fed by 1-line.

* When panel SW is set to invalid by Panel SW enable/disable command (ESC c5), the SW is

invalid.

* During the time between MICR read start and check paper eject, SW is invalid.

41049421PS Rev.3 9 /

Page 10

(LED display)

No.

1

2

3

4

LED ON

POWER

LED1

(ERROR)

LED2

(STATUS)

LED3/

LED4

(MODE)

Green

Red

Orange

Orange

Green

Powered on

Recoverable alarms

• Slip Load/Eject Alarm

• Auto loading Alarm

• Auto parking Alarm

• Media Does Not

Match Alarm (1)

• Media Does Not

Match Alarm (2)

• Cover Open Alarm

Note 1)

Paper not loaded (waiting for paper to be loaded) state

Slip Mode

Receipt+Journal Mode

Roll Paper Mode (1-Roll

Model)

OFF

Powered off

Normal state

Paper loaded

(ready for print)

state

Tractor Mode

BLINK

• Fatal alarms

(Alarm type is differentiated

by the number of times the

light blinks)

* Refer to the table on next

page.

• SP thermal alarm

(Blinks simultaneously with

LED2.)

• LF thermal alarm

• Waiting for removal

• SP thermal alarm

(Blinks simultaneously with

LED1.)

Validation mode

* Fast blinking

Receipt mode

* Fast blinking

MICR mode

* Slow blinking

Journal mode

* Slow blinking

Note 1)

When “Cover Open Alarm” is set to No in Menu, Cover Open Alarm does not happen

(Printing does not stop.)

* Media Does Not Match Alarm (1) is detected by monitoring the lever of the option tractor. Media

Does Not Match Alarm (2) is detected by the Validation sensor monitoring (media manually

inserted to the validation opening).

41049421PS Rev.3 10 /

Page 11

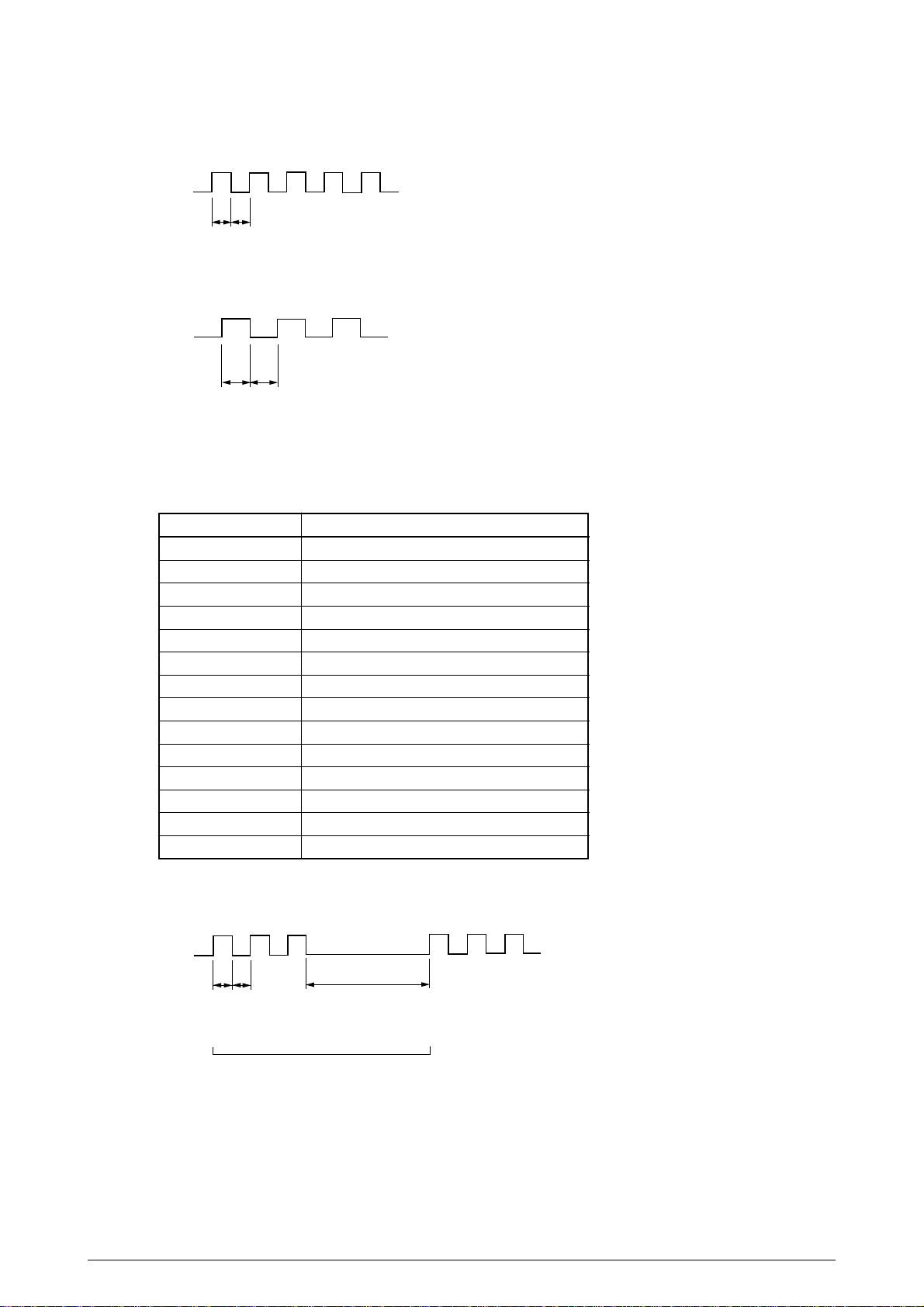

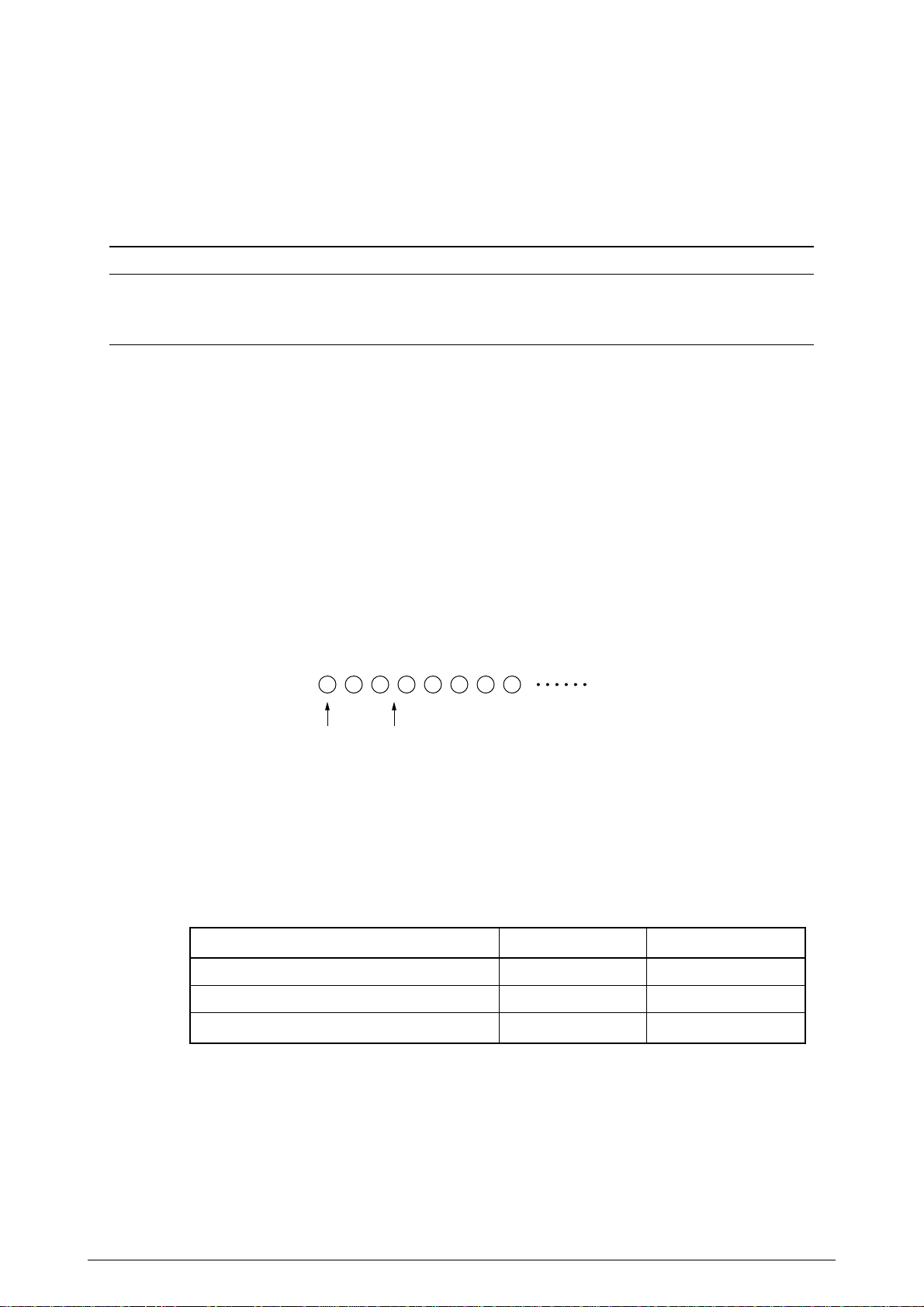

(Timing charts for LED1 and LED2 display for Waiting for removal and SP/LF thermal alarm state

and LED3 display for Validation mode and Receipt mode.)

LED

T1 T2

T1=T2=500msec

(LED3 display timing chart for MICR mode and Journal mode)

LED

T2T1

T1=T2=1sec

(Number of times LED1 blinks when fatal alarms have occurred)

Number of times Fatal alarm

1 Program ROM

2 EEPROM

3 Internal RAM

4 External RAM

5 Homing

6 Spacing

7 Auto Cutter

8 Platen Switch

9 Head A/D Error

10 WDT (F/W Control)

11 NMI (F/W Control)

12 BRK command (F/W Control)

13 MICR Unit Error

14 I/F board

(LED1 display timing chart when a fatal alarm has occurred)

LED1

T1 T2

1cycle

41049421PS Rev.3 11 /

T3

T1=T2=250msec

T3=1500msec

Page 12

2.2 LOCAL FUNCTIONS

The local and maintenance functions are described next.

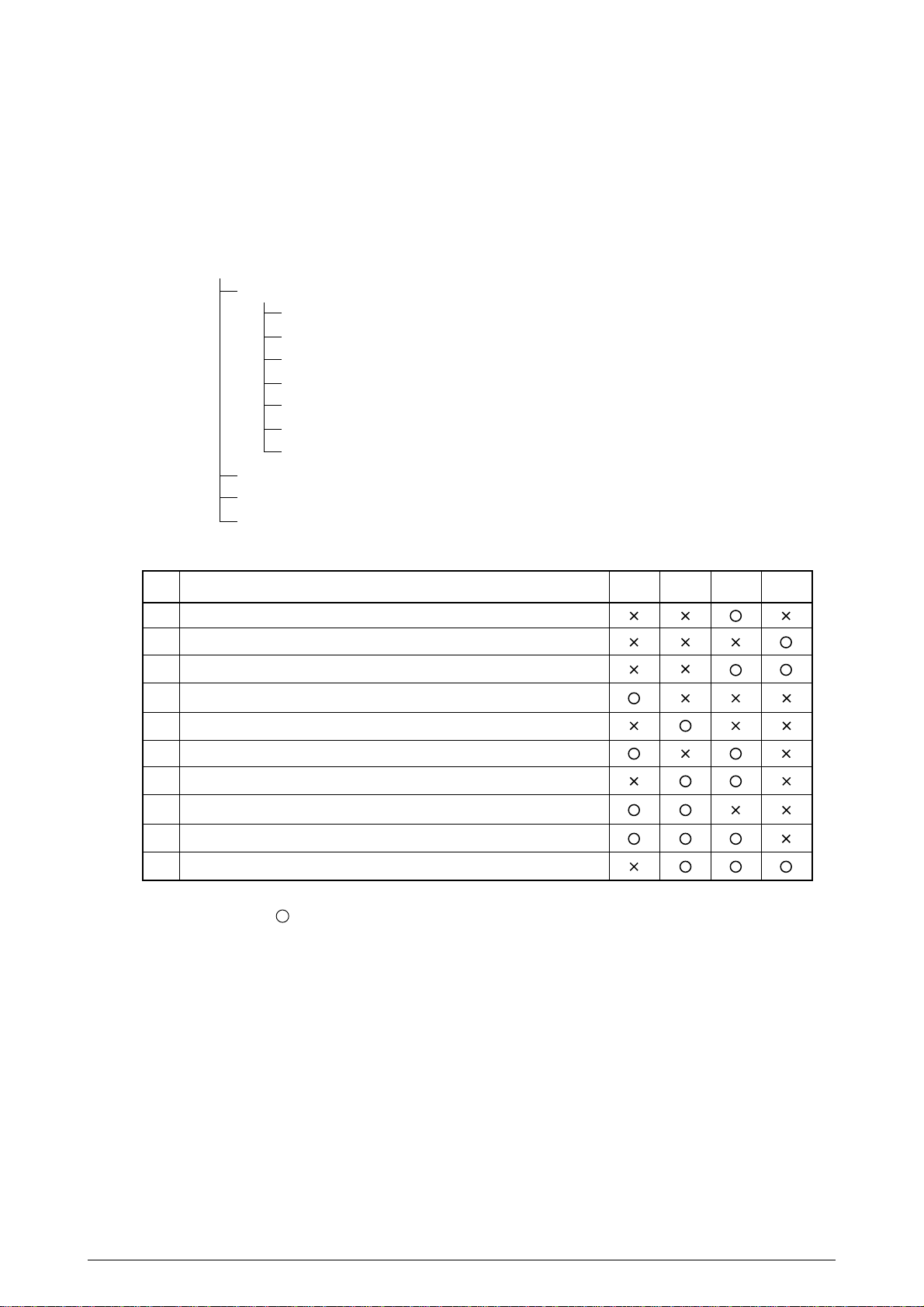

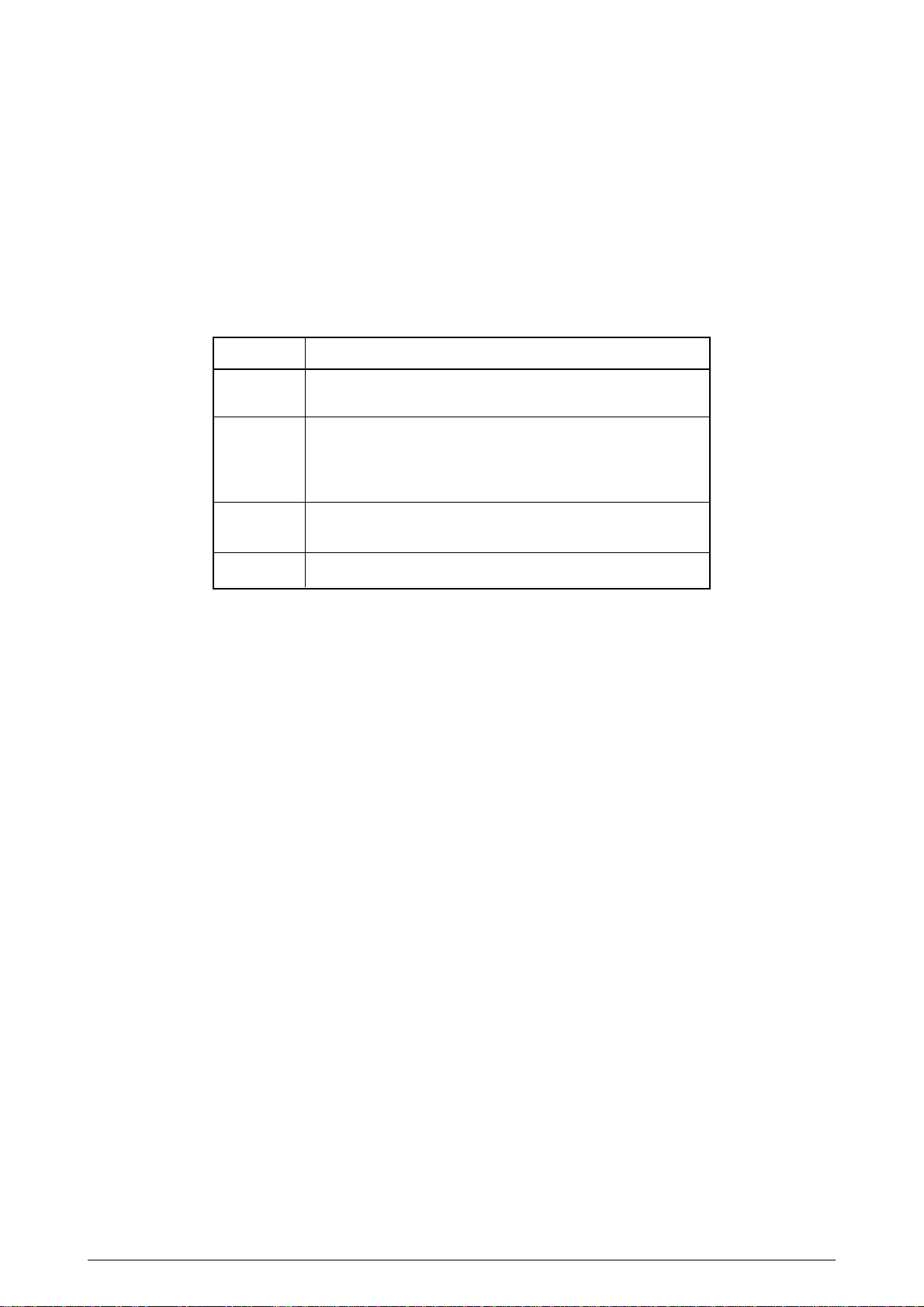

2.2.1 Kinds of Local Functions and How to Start

(1) Kinds

Local functions

Local tests

All Letter and Rolling ASCII Continuous Print Test (Receipt)

All Letter and Rolling ASCII Continuous Print Test (Journal)

All Letter and Rolling ASCII Continuous Print Test (Receipt + Journal)

All Letter and Rolling ASCII Continuous Print Test (Slip/Sprocket)

Sample Data Continuous Print Test (Validataion)

MICR Read Test (Receipt)

Rewinder Rewind Evaluation Continuous Print Test (Journal)

Menu (Receipt)

HEX Dump (Receipt)

Platen Maintenance Mode

(2) How to start

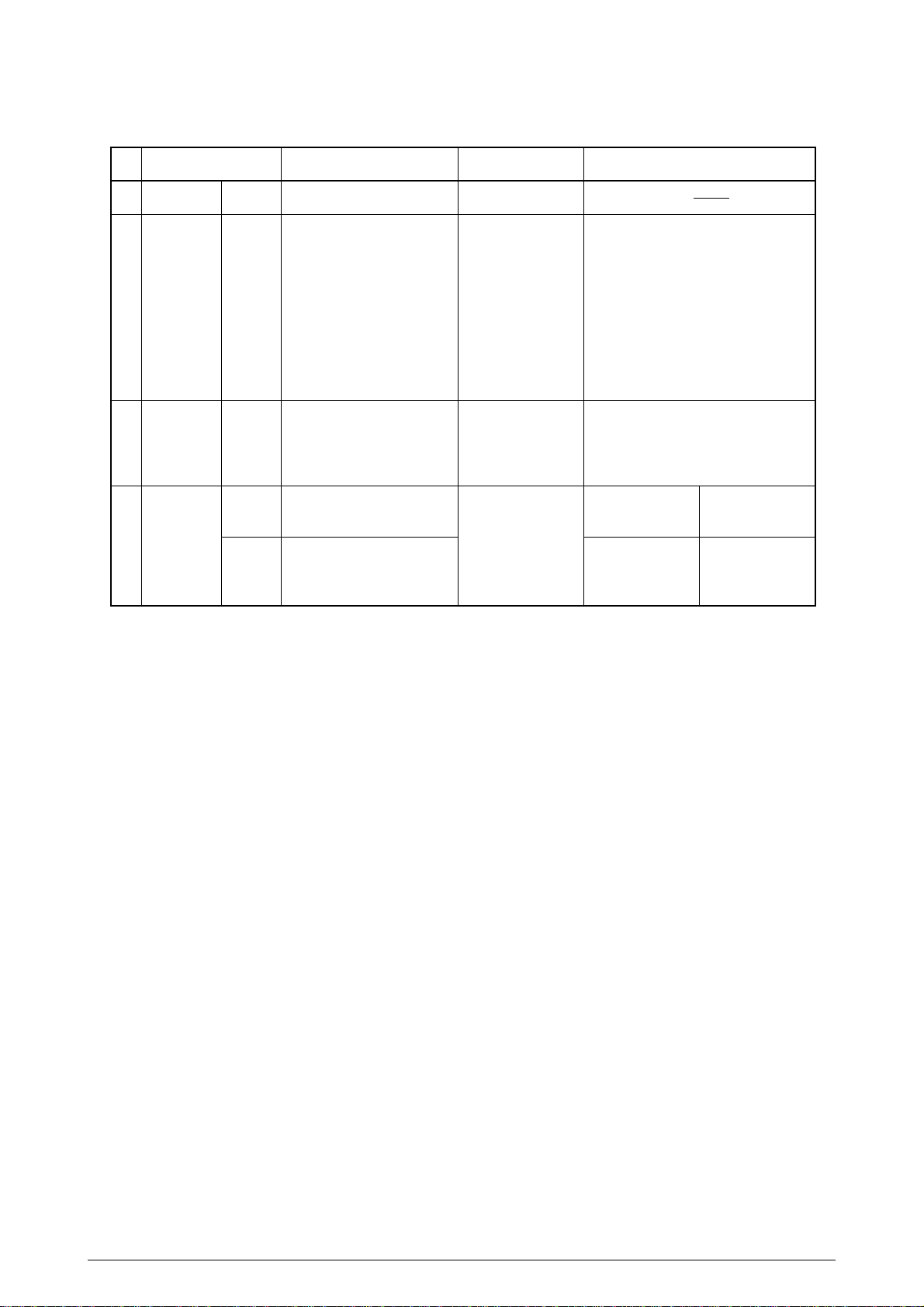

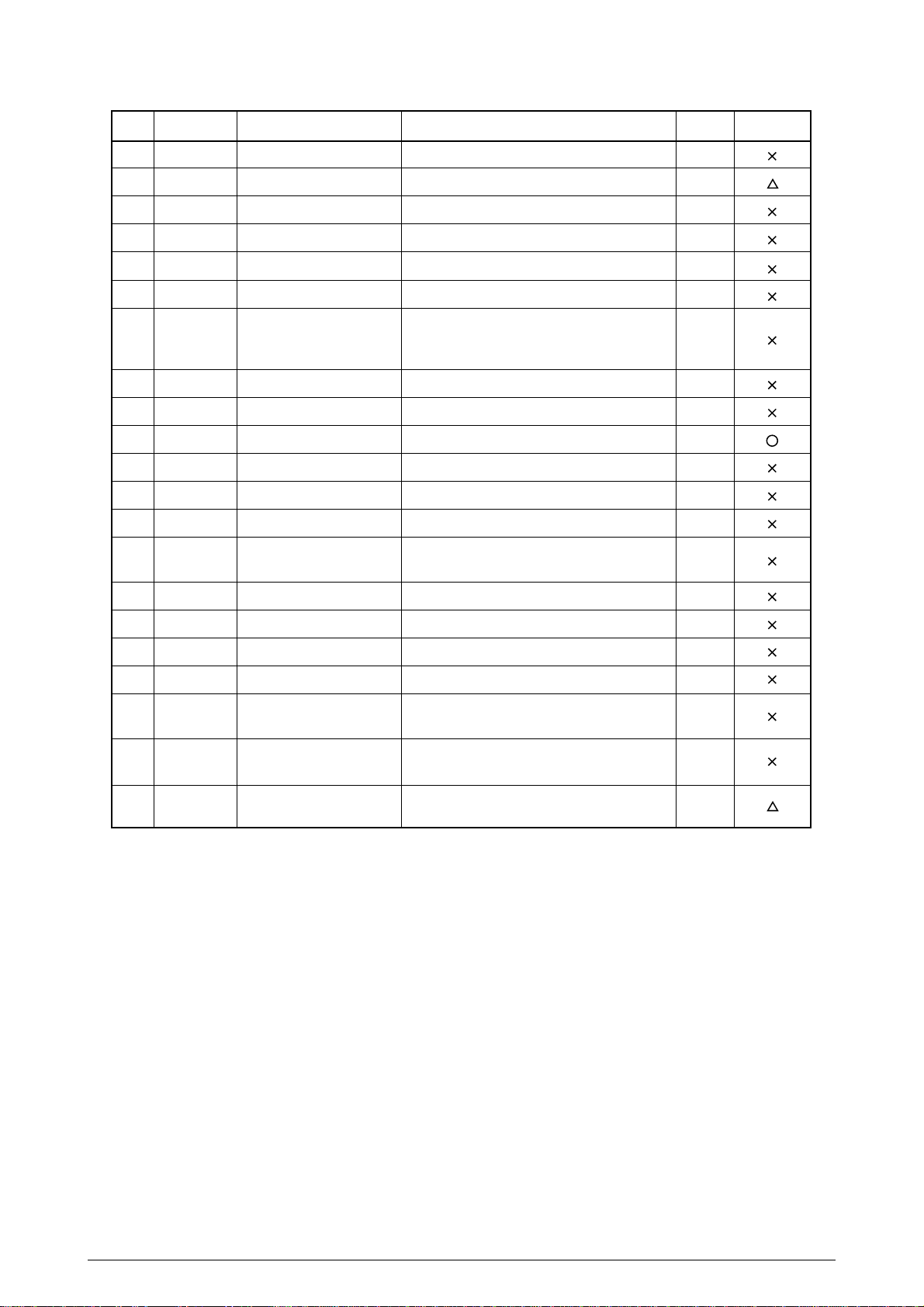

NO.

1

All Letter & Rolling ASCII Continuous Print Test (Receipt)

2

All Letter & Rolling ASCII Continuous Print Test (Journal)

3

All Letter & Rolling ASCII Continuous Print Test (Receipt+Journal)

4

All Letter & Rolling ASCII Continuous Print Test (Slip)/(Sprocket)

5

Sample Data Continuous Print Test (Validation)

6

Menu (Receipt)

7

HEX Dump (Receipt)

8

MICR Read Test (Receipt)

9

Platen Maintenance Mode

10

Rewinder Rewind Evaluation Continuous Print Test (Journal)

Note 1

Note 2

Note 3

Note 4

Note 5

Note 6

Note 7

To enter the above modes, turn the power on while holding down the switches marked with

a circle ( ).

In No.4, if the lever is on the tractor side, the Sprocket Print Test becomes effective. If the

lever is not on the tractor side, the Slip Print Test becomes effective.

In Nos. 5, 8 and 10, if the lever is on the tractor side, these local functions become invalid,

and the printer starts in normal mode.

Nos.1 ~ 3, 6, 7 and 9 become effective regardless of the lever state.

In Nos.1~ 3, the print widths will be those set in the menu “Width of Roll Paper”.

In Nos.1 ~ 4 and 10, if SW1 is pressed, printing suspends. When the SW1 is pressed again,

the printing resumes.

In No.1 ~ 5, 8 and 10, if the cover is opened, printing suspends. When the cover is closed,

printing resumes.

(This is limited to only with the setting of Menu "Cover Open Alarm = YES", suspend in the

cases of No.6 and 7.)

In each local function, if the tractor lever is switched, Media Does Not Match Alarm (1) will

result. When the tractor is returned to the original position, the alarm is cleared and test

printing resumes.

Local Functions

SW 2 SW 3 SW 1 SW 4

41049421PS Rev.3 12 /

Page 13

2.3 LOCAL TEST

This function creates test data internally as if the printer received the data from the host, and prints

the test pattern.

2.3.1 Printer Status in Local Test Mode

When the local test begins, the printer cannot receive data (*1).

Even when a recoverable alarm occurs, the test mode is not cleared, and the test print resumes

when the alarm element is cleared.

The condition to end the local test is to turn the power off, but the local test is terminated when

I- PRIME signal (Parallel model) /Reset signal (Serial model) is received or a fatal alarm occurs.

(*1) When the printer cannot receive data, each I/F presents Busy as follows.

* Parallel model (Centronics interface): Busy signal → High

* Serial model (RS232C I/F): Busy control as follows.

When handshake is DTR/DSR: DTR signal → MARK status

When handshake is XON/XOFF: Sends DC3

2.3.2 Details of Local Test Prints

2.3.2.1 All Letter and Rolling ASCII Continuous Print Test (Receipt)

This function performs All Letter Print and Rolling ASCII Continuous Print in Receive mode.

It can test Auto Cutter Unit as well, and executes Auto Cut operations. It executes Auto Cut operation

only when “Auto Cutter Unit = Yes” is sent in the menu, however.

* In case of 1-Roll Model, since this model does not come with Auto Cutter Unit, the Auto Cut

function is invalid.

(1) How to start

Turn the power on while holding down the SW1.

(2) How to exit this mode

Turn the power off.

* During test printing, if you press SW1, printing suspends. If you press the SW1 again,

printing resumes.

(3) Printed contents and operations

(a) Auto Cut (Full Cut) operation

(b) Horizontal line (bit image print) printing

(c) Pattern (“ ”) printing to check breakage of the head pins

(d) Local test header printing

(e) UTL and HSD characters (20H~FFH) All Letter Print

(f) Auto Cut (Partial Cut) operation

(g) UTL characters (20H~7EH) Rolling ASCII Continuous Print

41049421PS Rev.3 13 /

Page 14

2.3.2.2 All Letter and Rolling ASCII Continuous Print Test (Journal)

This function performs All Letter Print and Rolling ASCII Continuous Print in Journal mode.

* In case of 1-Roll Model, this function is invalid.

(1) How to start

Turn the power on while holding down the SW4.

(2) How to exit this mode

Turn the power off.

* During test printing, if you press SW1, printing suspends. If you press the SW1 again,

printing resumes.

(3) Printed contents

(a) Horizontal lines (bit image print) printing

(b) Pattern (“ ”) printing to check breakage of the head pins

(c) Local test header printing

(d) UTL and HSD characters (20H~FFH) All Letter Print

(e) UTL characters (20H~7EH) Rolling ASCII Continuous Print

2.3.2.3 All Letter and Rolling ASCII Continuous Print Test (Receipt + Journal)

This function performs All Letter Print and Rolling ASCII Continuous Print in the Receipt+Journal

mode.

Prints the same data on both receipt and journal.

This function can test the auto cutter unit as well, and executes Auto Cut operation of receipts only

when “Auto Cutter Unit = Yes” is set in the menu, however.

* In case of 1-Roll Model, this function is invalid.

(1) How to start

Turn the power on while holding down SW1 + SW4.

(2) How to exit this mode

Turn the power off.

* During test printing, if you press SW1, printing suspends. If you press the SW1 again,

printing resumes.

(3) Print contents and operations

(a) Auto Cut (Full Cut) operation

(b) Horizontal line (bit image print) printing

(c) Pattern (“ ”) printing to check breakage of the head pins

(d) Local test header printing

(e) UTL and HSD characters (20H~FFH) All Letter Print

(f) Auto Cut (Partial Cut) operation

(g) UTL characters (20H~7EH) Rolling ASCII Continuous Print

41049421PS Rev.3 14 /

Page 15

2.3.2.4 All Letter and Rolling ASCII Continuous Print Test (Slip/Sprocket)

This function performs Rolling ASCII Continuous Print after All Letter Print.

(1) How to start

Turn the power on while holding down the SW2. If the lever is on the tractor side, the Sprocket

paper print test takes place. Otherwise, Slip paper print test takes place.

(2) How to exit

Turn the power off.

* During test printing, if you press SW1, printing suspends. If you press the SW1 again,

printing resumes.

(3) Print contents

(a) Horizontal line (bit image print) printing

(b) Pattern (“ ”) printing to check breakage of the head pins

(c) Local test header printing

(d) UTL and HSD characters (20H~FFH) All Letter Print

(e) UTL and HSD characters (20H~FFH) All Letter Print in Compressed Mode.

(f) UTL characters (20H~7EH) Rolling ASCII Continuous Print

2.3.2.5 Sample Data Continuous Print Test (Validation)

This function performs the test print on the Validation paper.

(1) How to start

Turn the power on while holding down the SW3.

(2) How to exit

Turn the power off.

(3) Print contents

(a) UTL character (20H~86H) printing (prints only one-line)

* Prints one-line when Validation is inserted, then enters Waiting for Removal state. After

the validation is removed, the printer enters the Waiting for Insertion state. Repeat the

sequence : Set paper → Print → Remove.

41049421PS Rev.3 15 /

Page 16

2.3.2.6 MICR Read Test (Receipt)

This function performs MICR read and prints that result on the receipt paper.

Effective only when the MICR unit is installed and “MICR Unit = Yes(CMC-7)” or “MICR Unit = Yes(E13B)” is set in the menu.

(1) How to start

Turn the power on while holding down SW2 + SW3.

(2) How to exit

Turn the power off.

(3) Contents of the test

(a) When this mode is started, the printer enters Wait for MICR Insertion state.

(b) Insert MICR card and perform MICR read.

(c) The printer prints MICR read results on the Receipt paper, and enters Wait for MICR

Insertion state.

(b) and (c) above are repeated.

(4) Contents printed

<When Read is OK:>

(a) Prints “Read OK”.

(b) Prints the MICR read results in HEX dump.

(“XX XX ...... XX” + ASCII: 1 line contains 8 byte information)

<When Read is NG:>

(a) Prints “Read NG”.

(b) Prints the MICR read results (Return Code (1 byte) and read data) in HEX dump.

(“XX XX ...... XX” + ASCII: 1 line contains 8 byte information)

* Regarding MICR Read result, Return Code (1 byte) and Read Data are printed.

When the Return Code is 30H (“No errors”), it is assumed as “Read OK” Otherwise, it

is assumed as “Read NG”

* Return codes are shown below:

Return code Status

30H (0) No errors.

33H (3) Error: Read/Decode error.

34H (4) Error: No magnetic ink detected.

36H (6) Error: Document jam or document is too long.

41049421PS Rev.3 16 /

Page 17

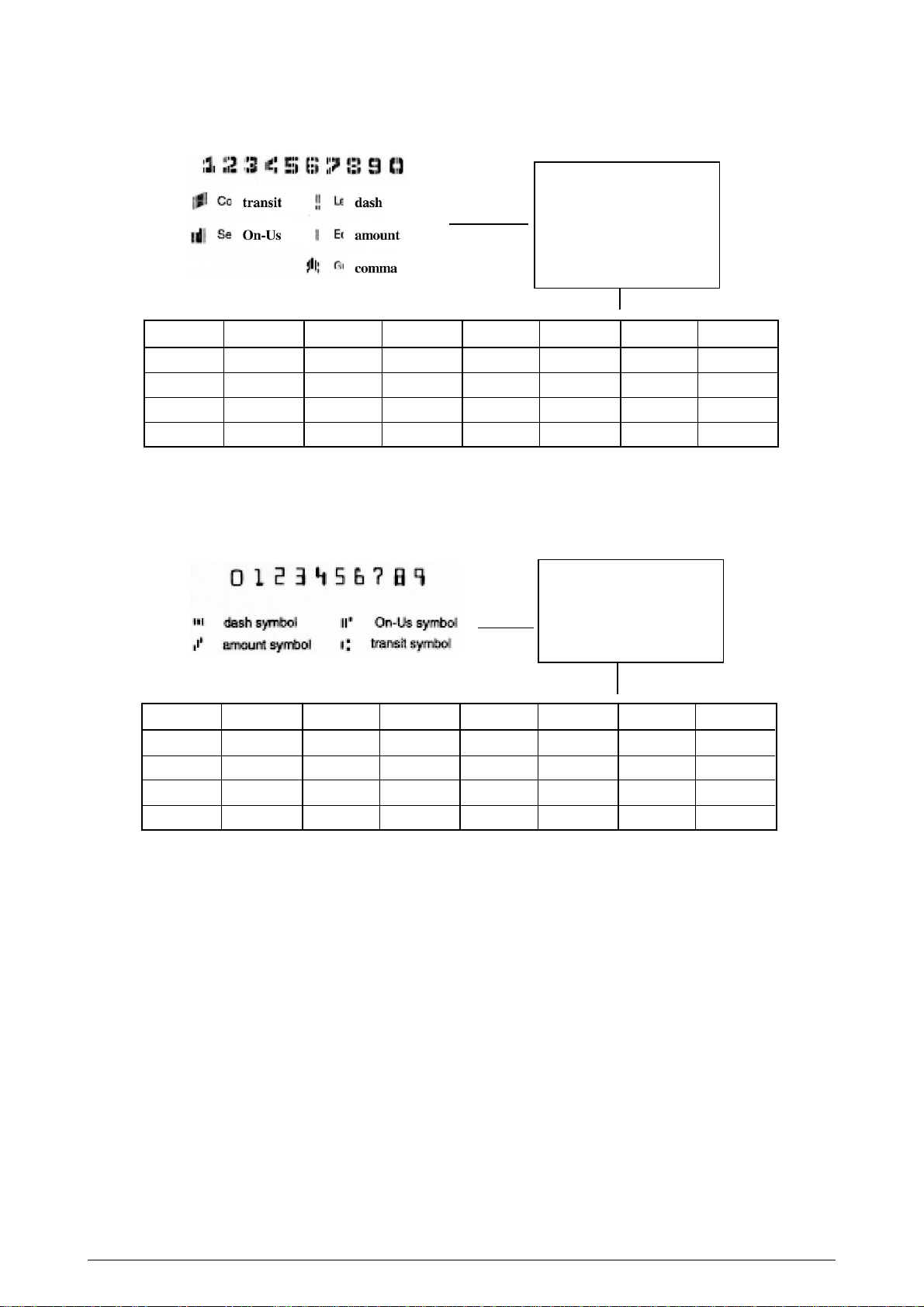

* When character set is CMC-7, the below codes are returned.

A: dash symbol

B: amount symbol

C: transit symbol

D: On-Us symbol

E: comma symbol

Character Code Character Code Character Code Character Code

1 31H 2 32H 3 33H 4 34H

5 35H 6 36H 7 37H 8 38H

9 39H 0 30H (space) 20H A 41H

B 42H C 43H D 44H E 45H

* Unknown:3FH(?)

* When character set is E-13B, the below codes are returned.

A: dash symbol

B: amount symbol

C: transit symbol

D: On-Us symbol

Character Code Character Code Character Code Character Code

1 31H 2 32H 3 33H 4 34H

5 35H 6 36H 7 37H 8 38H

9 39H 0 30H (space) 20H - -

A 41H B 42H C 43H D 44H

* Unknown:3FH(?)

(Note)

In both cases of CMC-7 and E-13B, special character codes are different from those sent

to host by a check paper read command.

2.3.2.7 Rewinder Winding Evaluation Continuous Print Test (Journal)

This function performs print/platen switch continuous test to evaluate the rewinder winding

performance.

* In case of 1-Roll Model, this function will be in Roll Paper mode.

(1) How to start

Turn the power on while holding down SW3 + SW1 + SW4.

(2) How to exit

Turn the power off.

* During test printing, if you press the SW1, printing suspends. If you press the SW1 again,

printing resumes.

(3) Contents printed

(a) Prints “HHH”+ Space + “HHH” (UTL characters)

(b) Print Sheet Mode switching (Journal → Slip → Journal)

41049421PS Rev.3 17 /

Page 18

2.3.3 Local Test Header

Prints Model Name, Design Drawing Number, Version and F/W Revision.

OKIPOS 425D 41783801YR *1

VER 01 F/W REV 01.00

*1 1-Roll model: OKIPOS 425S 41783701YR

2-Roll model: OKIPOS 425D 41783801YR

The device names are not finalized yet.

The above names are tentative.

41049421PS Rev.3 18 /

Page 19

2.4 MENU FUNCTION (Receipt)

2.4.1 Overview

The menu function is the local function that sets each mode to control the printer and adjusts it. This

mode has the following items, saved in the E2P-ROM. This information is printed only when the

menu mode is activated at Power On, and the information can be written over from the operator

panel.

Menu Print is printed in Receipt Mode.

For the printer’s initialization state, each mode is set according to the information of this area.

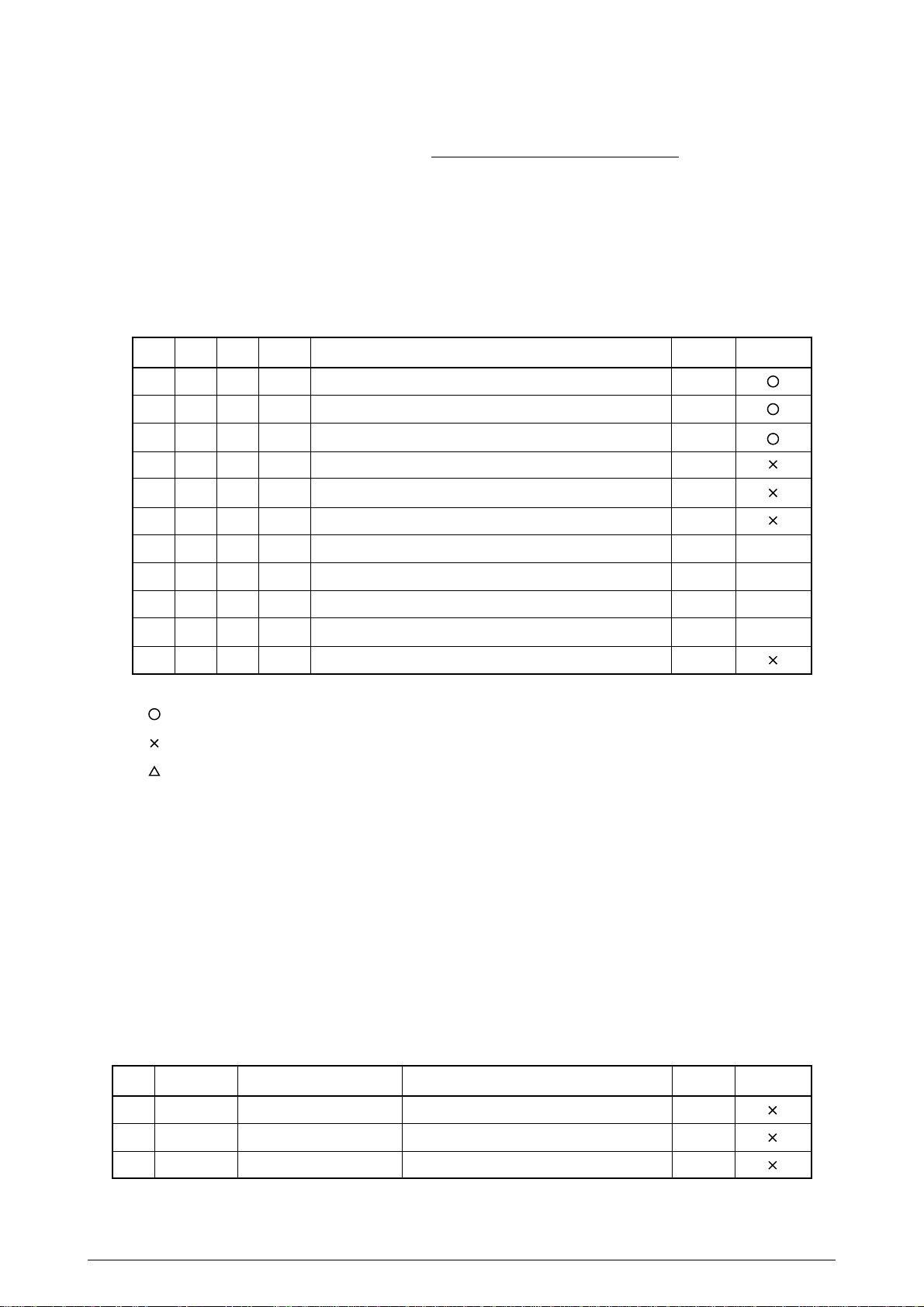

2.4.2 Menu Items

(1) Auto Cutter Unit

(2) MICR Unit

(3) Print Registration

(4) Top Adjust

(5) Cut Adjust

(6) Auto LF (Auto line feed)

(7) Receive Buffer Size

(8) Print Mode

(9) Off-line Busy Control

(10) Cover Open Alarm

(11) Width of Roll Paper

(12) Zero Character

(13) Page Lengths

(14) Page End Signal

41049421PS Rev.3 19 /

Page 20

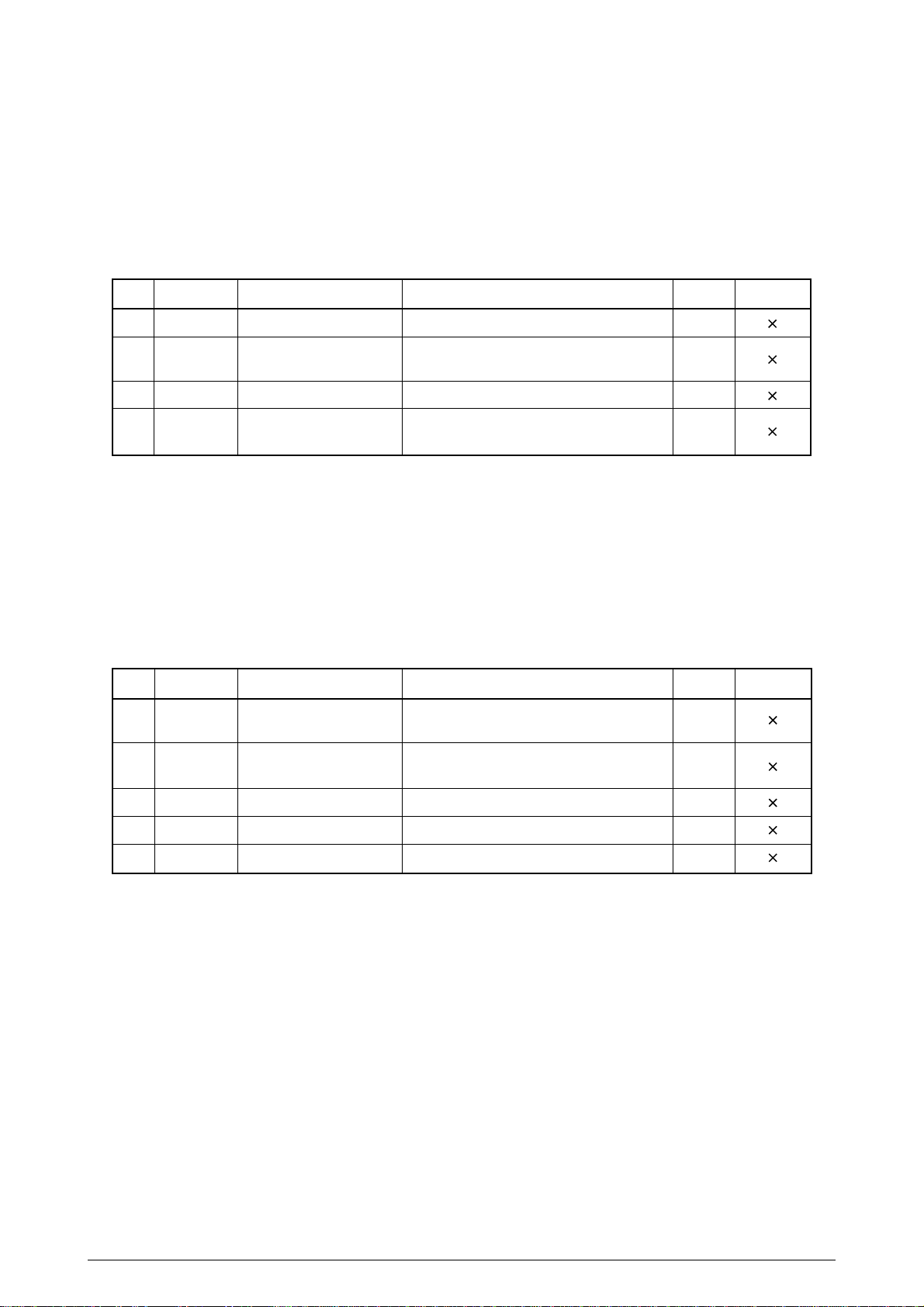

Default Value

NO.

1

Auto Cutter Unit

2

MICR Unit

3

Print Registration

4

Top Adjust

5

Cut Adjust

Item

Function

Selects Auto Cutter Unit Installed/Not

Installed.

Selects MICR Unit Installed/Not Installed.

Adjusts the print position if it shifts in

Forward printing and Reverse printing.

Adjusts Top Of Form position when

Slip/Sprocket are used.

Adjusts Cut Position when cutting

Sprocket paper.

Sets

Yes

No

*Default of 1-Roll Model is No.

Yes(CMC-7)

Yes(E-13B)

No

0.25mm Right

0.20mm Right

0.15mm Right

0.10mm Right

0.05mm Right

0

0.05mm Left

0.10mm Left

0.15mm Left

0.20mm Left

0.25mm Left

-1.75mm ~ +1.75mm

* Can be set in the 0.35mm unit.

* Default value : 0 mm

-1.75mm ~ +1.75mm

* Can be set in the 0.35mm unit.

* Default value : 0 mm

6

Auto LF

(Auto line feed)

7

Receive Buffer Size

8

Print Mode

9

Off-line Busy Control

10

Cover Open Alarm

11

Width of Roll Paper

12

Zero Character

13

Page Length

14

Paper End Signal

Selects auto line feed.

(Selects auto line feed by CR Code)

Selects Receive Buffer Size

Selects font

Selects conditions of BUSY

Selects enable/disable of print stop in

Cover Open

Selects the paper width of Roll paper

(Changes the print area.)

Selects a zero font

Selects the paper length of Sprocket

paper.

Selects the paper sensor that enables

Paper End signal.

* RNE :

Receipt/Journal Near End Sensor

* RE : Receipt/Journal End Sensor

Yes

No

2K

16K

Utility

HSD

Yes * Off-line or Receive buff-

er-full

No * Receive buffer-full

Yes

No

76.2mm

69.5mm

Slashed

Unslashed

88.9mm

139.7mm

215.9mm

279.4mm

304.8mm

Yes (RNE or RE)

Yes (RE)

No

Note 1)

Note 2)

In the 1-Roll Model, an auto cutter unit cannot be installed.

I/F control information (baud rate and etc.) and customer display connection/disconnec-

tion of serial model are set by DIP-SW of the I/F board.

Note 3)

MICR Unit selection has the following two types for MICR Read test (Refer to Section

2.3.2.6.): “Yes (CMC-7),” and “Yes (E-13B)” Normally, either selection is recognized as

an actual installation status of MICR Unit, and MICR type is selected by designation of the

command.

41049421PS Rev.3 20 /

Page 21

2.4.3 How to Operate

2.4.3.1 Start

To start the Menu Mode, turn the printer on while holding down SW2 + SW1. When the printer’s

initialization ends correctly, the printer prints the title “Menu Print” and all the menu items and set

values. Then, the printer line-feeds until the print result goes beyond the Manual Cutter position,

prints the item/set value immediately after “Menu Print”, then, waits for a switch to be pressed.

2.4.3.2 Operation

The switch functions during the menu mode are as follows:

Switch

SW2

SW3

SW1

SW4

Function

Advances the set values of the Menu Item, one at a time.

From the last set value, returns to the first set value.

Ends Menu Mode.

Registers the set values in EEPROM, then, prints the end

message “Menu End” and returns to the same initialized

state as at power on.

Advances the Menu Items, one at a time.

From the last Menu Item, returns to the first Menu Item.

Feeds the receipt, by one line.

41049421PS Rev.3 21 /

Page 22

2.5 HEX DUMP FUNCTION (Receipt)

This function converts received data, as it is, to character codes, and prints it in the Receipt mode.

The printed contents are as follows: Upon receiving one byte, the printer divides it into three

characters, High-nibble, Low-nibble and a space. Regarding these as 1 block, the printer prints 8

blocks in one line, then, prints the same data in the character format.

Upon entering the HEX dump mode, the printer prints “Hex Data Dump”. (Title printing)

2.5.1 Print Format

Hex Data Dump

0000 XX XX XX XX XX XX XX XX : ........

0008 XX XX XX XX XX XX XX XX : ........

.

.

.

.

FFF8 XX XX XX XX XX XX XX XX : ........

0000 XX XX XX XX XX XX XX XX : ........

.

.

.

.

Hex dataLine No. ASCII data

2.5.2 How to Print

(1) If it does not receive data after 150ms have passed since receiving last data, the printer starts

printing (CR) if it has some data.

(If there is not enough data to form 8 blocks, spaces will be used.)

If it subsequently receives data, the printer prints from a position next to the position at which

the printing started.

(2) If it receives the I-PRIME signal (Parallel model)/Reset signal (Serial model), the printer starts

printing if it has some data, then, feeds one line. Then, the printer is initialized. (If it does not

have any data, the printer feeds one line and then, is initialized.) After the initialization, the

printer starts up in dump mode again and prints. The line number is reset, however, and

counting begins from “0000”.

* When I-PRIME signal (Parallel model)/Reset signal (Serial model) is hard reset (setting by

Short Plug with Parallel I/F board and by DIP SW with Serial I/F board), it immediately starts

initialization and does not continue hex dump.

(3) One line-feed is added for every 16 lines.

(4) The count begins from “0000” when the line number exceeds “FFF8”.

41049421PS Rev.3 22 /

Page 23

2.6 PLATEN MAINTENANCE MODE

This function is for switching the platen position when the print head gap is adjusted in the production

line.

(1) How to start the mode

Turn the power on while holding down SW2 + SW3 + SW1.

*1 This mode can be executed even when the print head is not installed.

*2 When this mode is being started, the initial platen position should be on the Receipt side.

If the paper is already loaded in the Tractor mode, the platen should be on the Slip side.

(2) How to operate

Switch

SW2

SW3

SW1

SW4

(3) How to exit the maintenance mode

Turn the power off.

Moves the platen to the Receipt side.

Moves the platen to the Slip side.

Invalid

Function

41049421PS Rev.3 23 /

Page 24

3. COMMAND DESCRIPTION

The intent of this document is to describe the details of the command functions that are effectuated

by the firmware.

3.1 Control Code

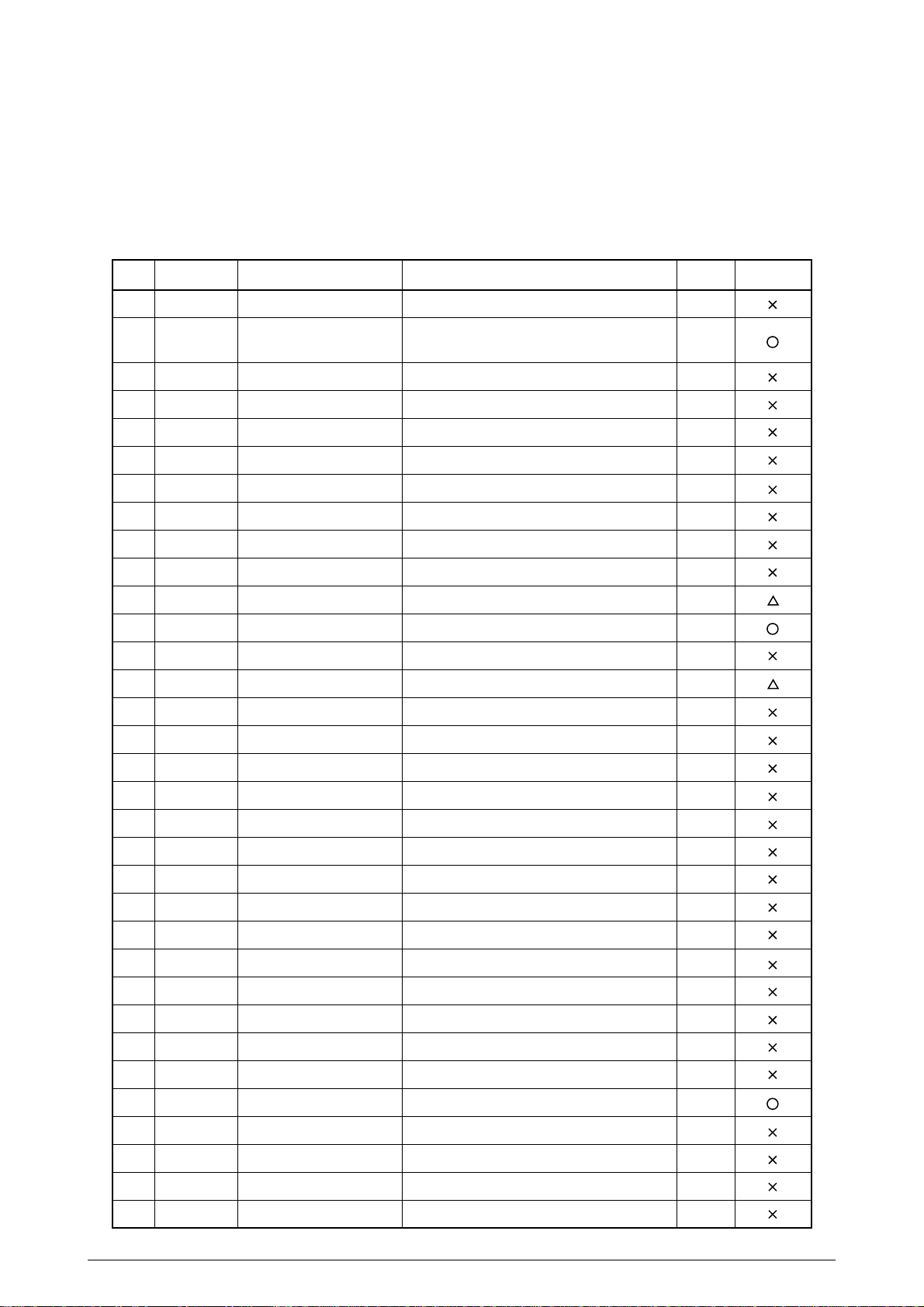

3.1.1 Control Code List

3.1.1.1 Function Code

(1) List of Function Codes

No.

HEX

DEC

CODE

1

0A

10

LF

Print/line feed

2

0C

12

FF

Eject Cut Sheet paper or form-feed sprocket paper

3

0D

13

CR

Print/carriage return

4

0F

15

5

12

18

6

18

24

7

10

16

SI

Condense Designate

DC2

Condense Clear

CAN

Cancel print data

DLE

Start DLE sequence

Remarks

Section

3.2.3.1

3.2.3.7

3.2.1.1

3.2.5.10

3.2.5.12

3.2.8.4

3.1.1.2

Print Start

–

8

1B

27

9

1C

28

10

1D

29

11

1E

30

* Print Start Column

: Command that invokes print start

: Command that does not invoke print start

: Command that sometimes invokes print start

(This applies hereafter.)

3.1.1.2 DLE Sequence

(1) Command recognition

A code that follows a DLE code is treated as a 7-bit code. (MSB=0)

For the parameters, which vary among the commands, see each command’s functions.

If a function code follows a DLE code, it is is treated as a stand-alone function code.

If DLE codes come in succession, they are treated as a DLE code.

Example: DLE DLE EOT n is treated as command DLE EOT n.

ESC

Start ESC sequence

FS

Start FS sequence

GS

Start GS sequence

RS

Journal T ab

3.1.1.3

3.1.1.4

3.1.1.5

3.2.2.5

–

–

–

(2) DLE sequences

No.

1

2

3

41049421PS Rev.3 24 /

HEX

10 04

10 04 08

10 05

Command Sequence

DLE EOT n

DLE EOT BS n

DLE ENQ n

Functions

Real-time status sending

Real-time MICR status sending

Real-time request to Printer

Print StartSection

3.2.8.16

3.2.8.18

3.2.8.17

Page 25

3.1.1.3 ESC Sequence

(1) Command recognition

For the handling of codes that follow the ESC Code, when the ESC codes come in succession,

and their relationship with the functional codes, the way the DLE sequence is handled applies.

(2) ESC sequence list

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

HEX

1B 0F

1B 10 44

1B 10 61

1B 10 63

1B 10 63

1B 10 6C

1B 10 72

1B 10 76

1B 20

1B 21

1B 24

1B 25 35

1B 25 39

1B 2A

1B 2D

Command Sequence

ESC SI

ESC DLE D

Pno Pa1 Pb1...Pan Pbn

ESC DLE a Pno n

ESC DLE c Pno 0 n

ESC DLE c Pno 1 n

ESC DLE l Pno n1 n2

ESC DLE r Pno n

ESC DLE v Pno n

ESC SP n

ESC ! n

ESC $ n1 n2

ESC % 5 n

ESC % 9 n

ESC * m n1 n2 data

ESC - n

Functions

Condense Designate

Sets up menu items

Enables/disables auto status send

Selects print sheet

Selects set sheet

Sets Left Margin

Real-time status sending

Selects Validation insert position

Sets chracter right-side space

Designates Print Mode all at once

Designates absolute position

Feeds paper in inrements of n/144"

Sets n/144" line feed

Designates Bit Image Mode

Designates/clears Underline

Print StartSection

3.2.5.11

3.2.8.9

3.2.8.24

3.2.7.9

3.2.7.10

3.2.2.1

3.2.8.25

3.2.8.23

3.2.5.1

3.2.5.9

3.2.2.2

3.2.3.13

3.2.3.14

3.2.6.1

3.2.5.2

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

1B 30

1B 31

1B 32

1B 33

1B 34

1B 35

1B 3C

1B 3D

1B 40

1B 41

1B 43

1B 45

1B 47

1B 4A

1B 4E

1B 4F

1B 52

ESC 0

ESC 1

ESC 2

ESC 3 n

ESC 4

ESC 5

ESC <

ESC = n

ESC @

ESC A n

ESC C n

ESC E n

ESC G n

ESC J n

ESC N n

ESC O

ESC R n

Sets 1/8" line feed

Sets 7/72" line feed

Sets 1/6" line feed

Sets n/144" line feed

Sets Italic Mode

Resets Italic Mode

Designates one-line uni-directional print

Selects peripheral device

Initializes printer

Sets n/72" line feed pitch

Sets page length for Sprocket paper

Designates/cancels Emphaize print

Designates/cancels Double Strike print

Feeds paper in increments of n/144"

Sets Sprocket paper performation skip

Resets Sprocket paper perforation skip

Selects international character set

3.2.3.2

3.2.3.3

3.2.3.4

3.2.3.5

3.2.5.5

3.2.5.6

3.2.8.7

3.2.8.1

3.2.8.5

3.2.3.6

3.2.3.8

3.2.5.7

3.2.5.8

3.2.3.11

3.2.3.9

3.2.3.10

3.2.4.1

33

1B 55

41049421PS Rev.3 25 /

ESC U n

Designates/cancels uni-directional print

3.2.8.6

Page 26

No.

HEX

Command Sequence

Functions

Print StartSection

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

1B 57

1B 5C

1B 5E

1B 61

1B 63 30

1B 63 31

1B 63 32

1B 63 34

1B 63 35

1B 64

1B 66

1B 69

1B 6D

1B 70

1B 74

ESC w n

ESC \ n1 n2

ESC ^ m n1 n2

ESC a n

ESC c 0 n

ESC c 1 n

ESC c 3 n

ESC c 4 n

ESC c 5 n

ESC d n

ESC f t1 t2

ESC i

ESC m

ESC p m t1 t2

ESC t n

Designates/cancels double width print

Desigantes relative position

Desigantes 9-pin Bit Image Mode

Aligns positions

Selects print sheet

Selects set sheet

Selects paper sensor that enables the

paper end signal; valid only with Parallel I/F

Selects print stop sensor

Enables/disables panel switch

Feeds paper for n lines

Sets Cut paper wait time

Full cut

Partial cut (keeping one point uncut)

Generaes designated pulse (Open

Cash Drawer)

Selects character code table

3.2.5.4

3.2.2.3

3.2.6.2

3.2.2.4

3.2.7.1

3.2.7.2

3.2.7.3

3.2.7.4

3.2.8.3

3.2.3.12

3.2.7.5

3.2.7.6

3.2.7.7

3.2.8.11

3.2.4.2

49

50

51

52

53

54

1B 75

1B 76

1B 77

1B 7A

ESC u n

ESC v

ESC w n

ESC z n

Sends perupheral device status

Sends paper sensor status

Sets/resets Double Height print

Designates/cancels Receipt+Journal

3.2.8.2

3.2.8.8

3.2.5.3

3.2.7.8

same data print

1B 10 41

ESC DLE A Pno N1...N8

Selects and sets the barcode type and

3.2.9.1

size

1B 10 42

ESC DLE B Pno Pm

Prints barcode data

3.2.9.2

DATA

* The ESC DLE sequence other than No. 2~8, 53, 54 will be ignored by the sequence.

(The data that follows “Pno” will be ignored as many bytes as set by Pno.)

41049421PS Rev.3 26 /

Page 27

3.1.1.4 FS Sequence

(1) Command recognition

For the handling of subsequent codes that follow the FS code, when the FS codes come in

succession, and their relationship with the functional codes, the way the DLE sequence is

handled applies.

(2) FS Sequence table

No.

1

2

3

4

HEX

1C 61 30

1C 61 31

1C 61 32

1C 62

Command Sequence

FS a 0 n

FS a 1

FS a 2

FS b

3.1.1.5 GS Sequence

(1) Command recognition

For the handling of subsequent codes that follow the GS code, when the GS codes come in

succession, and their relationship with the functional codes, the way the DLE sequence is

handled applies.

(2) GS Sequence table

No.

1

HEX

1D 05

Command Sequence

GS ENQ

Functions

Reads Check paper

Loads Check paper to the print start

position

Ejects Check paper

Requests for resending a result of

reading Check paper

Functions

Sends a status of the pritner status

real-time

Print StartSection

3.2.8.19

3.2.8.20

3.2.8.21

3.2.8.22

Print StartSection

3.2.8.13

2

3

4

5

1D 45

1D 49

1D 61

1D 72

GS E n

GS I n

GS a n

GS r n

Selects print speed and printhead

current flow time

Sends a prionter ID

Enables/disables auto status send

Sends a status

3.2.8.10

3.2.8.14

3.2.8.12

3.2.8.15

41049421PS Rev.3 27 /

Page 28

3.2 Control Operations

The control functions are described in the subsequent sections.

3.2.1 Print Operation Control

This section describes the print operation control functions.

3.2.1.1 Print/Carriage Return

Name: Print/Carriage Return

HEX: 0DH

Code

DEC: 13

Functions:

(1) To start printing received data and set the position to start receiving the next line’s data at the

left margin position (start of that line) after printing.

(2) To perform Carriage Return and Line Feed if Auto LF is set to Enabled on the menu.

(3) To perform Carriage Return to the start position of the line on Receipt side in Receipt+Journal

mode.

(4) To prompt the mode to shift Receipt+Journal in Validation Mode if Auto LF is set to Enabled

on the menu.

CR

41049421PS Rev.3 28 /

Page 29

3.2.2 Space Control

The space control functions are described in the subsequent sections.

3.2.2.1 Left Margin Set

ESC DLE l Pno n1 n2

Name: Setting Left Margin

HEX: 1BH 10H 6CH Pno n1 n2

Code

DEC: 27 16 108 Pno n1 n2

Function:

(1) To set Left Margin in increments of 1/60" from the home position.

n1= low-order bytes and n2=high-order bytes

(2) The DEL in the command sequence disables MSB. (“90H” is effective as well.)

(3) Valid range and definitions of parameters

(a) Pno: To designate the number of bytes (number of parameters) following ESC DLE

l Pno MSB is invalid.

Range: 00H ≤ Pno ≤ FFH

With this command, Pno=2.

(b) To designate the print position by n1 n2 on the basis of the home position.

Example) In case of ESC DLE l 02H 02H 00H:

n1=02H

n2=00H

The print position would be:

Home Position "0" Left Margin (increments of 1/60")

In this case, Left Margin is 2/60" from the home position.

(4) Range and definitions of n1,n2

0(00H) ≤ n1 ≤ 255 (FFH)

0(00H) ≤ n2 ≤ 255 (FFH)

If a value exceeding the value below is set, this command will be ignored and the previous

setting will remain valid.

The maximum value of n1, n2 would be one that does not fall below 1.25" in the distance to

the right margin.

Selected print sheet

Receipt/Journal/Receipt+Journal(76.2mm)

Receipt/Journal/Receipt+Journal(69.5mm)

Slip(/MICR Read)/Sprocket paper (option)

Range of n1, n2

0 ≤ n2 n1 ≤ 93

0 ≤ n2 n1 ≤ 77

0 ≤ n2 n1 ≤ 303

Right Margin (")

2.8

2.53

6.3

(5) Received within the line, this command will be ignored.

(6) If setting is made by this command in Receipt/Journal/Receipt+Journal Mode, that setting will

be valid for both Receipt and Journal.

It will not affect Slip/Validation/Sprocket.

(7) If setting is made by this command in Slip/Validation/Sprocket Mode, that setting will be valid

for all of Slip/Validation/Sprocket.

It will not affect Receipt or Journal.

(8) Neither the left margin position that is set in Receipt/Journal/Receipt+Journal Mode nor the left

margin position set in Slip/Validation/Sprocket Mode will change when the mode is switched.

41049421PS Rev.3 29 /

Page 30

3.2.2.2 Absolute Position Designate

ESC $ n1 n2

Name: Absolute Position Designate

HEX: 1BH 24H n1 n2

Code

DEC: 27 36 n1 n2

Function:

(1) To move a next printing position from the start position in the line to the one designated by n1

n2 in increments of 1/180" or 1/240".

Default unit of measurement is 1/180", but 1/240" if Condense is set.

n1 = low-order byte, n2 = high-order byte

(2) To designate the print position according to n1 n2, based on the left margin position (start

position of the line).

The left margin changes, the print start position, too, changes even if the setting is the same.

e.g.) ESC $ 02H 00H

n1 = 02H

n2 = 00H

The print position would be:

Left Margin Print Position (increments of 1/180 or 1/240")

In this case, subsequent data will be printed 2/180" or 2/240" from the left margin.

(3) Valid range and definitions of n1,n2

0(00H) ≤ n1 ≤ 255(FFH)

0(00H) ≤ n2 ≤ 255(FFH)

(4) Range of n1 n2 (If any value outside the range is designated, the command will be ignored in

its entirety.)

The range in the table below assumes the left margin position being 0.

If Left Margin + Absolute Position exceeds the right margin (ininches) in the table below, the

command will be ignored in its entirety.

Selected print sheet

Receipt/Journal/Receipt+Journal

(76.2mm)

Receipt/Journal/Receipt+Journal

(69.5mm)

Slip/Validation

Sprocket (option)

Range of n1 n2

0 ≤ n2 n1 ≤ 504 (1/180")

0 ≤ n2 n1 ≤ 672 (2/240")

0 ≤ n2 n1 ≤ 456 (1/180")

0 ≤ n2 n1 ≤ 608 (2/240")

0 ≤ n2 n1 ≤ 1134 (1/180")

0 ≤ n2 n1 ≤ 1512 (2/240")

0 ≤ n2 n1 ≤ 1134 (1/180")

0 ≤ n2 n1 ≤ 1512 (2/240")

Margin

504/180"

672/240"

456/180"

608/240"

1134/180"

1512/240"

1134/180"

1512/240"

Right Margin (")

2.8

2.53

6.3

6.3

(5) The amount of movement is calculated according to the following formula.

Movement (Distance from left margin) = {n1+(n2 AND 03H) × 256}/180 (inch) or

= {n1+(n2 AND 03H) × 256}/240 (inch)

0 ≤ movement < 6.3 (inch)

(6) If the parameter (n1 n2), which would set the print position to the left of the present print position,

is designated, print start is prompted.

(7) No underline is added to the movement made by this command.

(8) When Same Data Print is reset with Receipt+Journal, if the present position is located on the

Receipt side, the setting within the Receipt print position is valid, and if the present position is

located on the Journal side, the setting within the Journal print range is valid.

(On the Journal side, the left edge of the Journal print area is set as a start position of the pint line.)

41049421PS Rev.3 30 /

Page 31

3.2.2.3 Relative Position Designate

ESC \ n1 n2

Name: Relative Position Designate

HEX: 1BH 5CH n1 n2

Code

DEC: 27 92 n1 n2

Function:

(1) To move a next print position to the right or to the left, relative to the present position.

To move the print position to the position designated by n1 n2 in increments of 1/180" or 1/240".

Default unit is 1/180" but 1/240" if Condense is set.

n1 = low-order byte, n2 = high-order byte

(2) To designate the print position to left/right by the dots as designated by n1 n2, on the basis of

the present position being “0.”

Ex.) In case ESC \ 02H 00H is received:

n1=02H

n2=00H

Thus, the print position would be

1/180" or 1/240"

Present Position Print Position

(3) A pair of n1 n2 consists of 2 bytes making up a 16-bit numerical value.

Its 16th bit indicates a code. {positive = right, negative (Two’s complement)=left}

n1

LSB

15 14 13 12 11 10 9 8

MSB

0: Right

Code bit

1: Left

n2

bb

b b

7 6 5 4 3 2 1 0

41049421PS Rev.3 31 /

Page 32

(4) Range of move

Direction

Forward

Selected Print

Sheet

Receipt/Journal

(76.2mm)

Receipt/Journal

(69.5mm)

Slip/Validation

Sprocket

(option)

Reverse

Receipt/Journal

(76.2mm)

Receipt/Journal

(69.5mm)

Slip/Validation

Sprocket

(option)

(5) Maximum value of n2 n1

Range of n1 n2

0H ≤ n2 n1 ≤ 504-(present Position) (1/180")

0H ≤ n2 n1 ≤ 672-(present Position) (1/240")

0H ≤ n2 n1 ≤ 456-(present position) (1/180")

0H ≤ n2 n1 ≤ 608-(present position) (1/240")

0 ≤ n2 n1 ≤ 1134-(present position) (1/180")

0 ≤ n2 n1 ≤ 1512-(present position) (1/240")

0 ≤ n2 n1 ≤ 1134-(present position) (1/180")

0 ≤ n2 n1 ≤ 1512-(present position) (1/240")

-(present position) ≤ n2 n1<0 (1/180")

-(present position) ≤ n2 n1<0 (1/240")

-(present position) ≤ n2 n1<0 (1/180")

-(present position) ≤ n2 n1<0 (1/240")

-(present position) ≤ n2 n1<0 (1/180")

-(present position) ≤ n2 n1<0 (1/240")

-(present position) ≤ n2 n1<0 (1/180")

-(present position) ≤ n2 n1<0 (1/240")

Right Margin

504/180"

672/240"

456/180"

608/240"

1134/180"

1512/240"

1134/180"

1512/240"

504/180"

672/240"

456/180"

608/240"

1134/180"

1512/240"

1134/180"

1512/240"

Right

Margin (")

2.8

2.53

6.3

6.3

2.8

2.53

6.3

6.3

Selected Print Sheet

Receipt/Journal (76.2mm)

Receipt/Journal (69.5mm)

Slip/Validation

Sprocket(option)

Maximum value for Forward

504/180"

672/240"

456/180"

608/240"

1134/180"

1512/240"

1134/180"

1512/240"

Maximum value for Reverse

-504/180"

-672/240"

-456/180"

-608/240"

-1134/180"

-1512/240"

-1134/180"

-1512/240"

(6) A move in Reverse will prompt print start.

(7) If a move outside the printable range is designated, the command is ignored in its entire

sequence.

(8) If Underline is designated with the move made by this command, no underline will be applied

to the skipped spaces.

(9) When Same Data Print is reset with Receipt+Journal, if the present position is located on the

Receipt side, the setting within the Receipt print position is valid, and if the present position is

located on the Journal side, the setting within the Journal print range is valid. (On the Journal

side, the left edge of the Journal print area is set as a start position of the line.)

(10) In Validation Mode, if this command is received when the present position is already beyond

the right margin, the command will be ignored in its entire sequence. (See 3.4.3 Right Margin

Process.)

41049421PS Rev.3 32 /

Page 33

3.2.2.4 Position Align

Name: Position Align

HEX: 1BH 61H n

Code

DEC: 27 97 n

Function:

(1) To align the print position

(2) Valid range and definitions of n

Mode Value of n Definition

0 00H, 30H Left alignment (Default)

1 01H, 31H Center alignment

2 02H, 32H Right alignment

(a) If n is any other value than the above, this command is ignored and the previously set mode

remains effective.

(b) This command is valid only when received at the start of the line. Received some-way into

the line, the command will be ignored.

(3) Mode 0 (Left alignment)

To align the print start position relative to the left margin.

(4) Mode 1 (Center alignment)

(a) Those characters that would go beyond the right margin will be aligned relative to the

center of a next line. (This includes spaces at the start and end of the line.)

(b) Even if character pitch is changed in the middle of the line (Normal, Enlarge, and Character

right-side space), an entire text will be spread over evenly.

(5) Mode 2 (Right alignment)

To align the printer end position relative to the right margin.

(6) To align image as well.

(7) To align absolute skip and relative slip as well.

ESC a n

3.2.2.5 Journal Tab

RS

Name: Journal Tab

HEX: 1EH

Code

DEC: 30

Function:

(1) To move the print position to the top of Journal.

(2) Valid only in Receipt+Journal Mode and if Same Data Print to Receipt/Journal has been reset.

(Invalid if the present horizontal position is on the Journal side.)

41049421PS Rev.3 33 /

Page 34

3.2.3 Line Feed Control

The line feed control functions are described in the subsequent sections.

3.2.3.1 Print/Line Feed

Name: Print/Line Feed

HEX: 0AH

Code

DEC: 10

Functions:

(1) To complete receiving data for a line and start printing. To perform one line-feed after printing

has ended, according to the amount of line feed set for each type of print sheet (Receipt,

Journal, Slip, or Sprockect paper (option)).

(To perform line feed for the amount in accordance with each set value in the Receipt+Journal

mode.)

(2) To perform carriage return after printing by this command has started. The position following

carriage return is at the left margin (start of the line).

(The position is at the left margin on the Receipt side with the Same Data Print is reset in

Receipt+Journal Mode.)

(3) To perform perforation skip to the next TOF position when the selected print sheet is Sprocket

(option) if the position following line feed is within the perforation skip area.

(4) To set the line feed pitch for each type of print sheet in a combination of designation by ESC

0, ESC 1, ESC 2, ESC 3 n, ESC A n, or ESC % 9 n and Sheet selection by ESC c 1 n, ESC

DLE c Pno 1 n.

(5) Default line feed is one sixth of an inch (1/6") for all types of print sheet.

(6) To perform only carriage return following print start if the line feed pitch is “0.” (No line feed is

performed.)

(7) To perform only carriage return following print start in the Validation mode and prompt the

mode to shift to the Receipt+Journal mode when Validation media is removed.

LF

41049421PS Rev.3 34 /

Page 35

3.2.3.2 1/8-inch Line Feed Set

Name: 1/8-inch Line Feed Set

HEX: 1BH 30H

Code

DEC: 27 48

Function:

(1) To set the line feed pitch for the print sheet selected by the Set Sheet Select command (ESC

c 1 n, ESC DLE c Pno 1 n) to one eighth of an inch (1/8").

(2) To perform 1/8-inch line feed upon receiving the LF code with the type of print sheet set after

this command has been designated.

(3) For line feed by Right Margin Over and Switch, too, the 1/8-inch line feed pitch set by this

command applies.

(4) Default line feed is one sixth of an inch (1/6") for all types of print sheet.

(5) This command is effective at any point in the line.

Except in the middle of image data or a function sequence.

(6) The commands that execute line feed by the line feed pitch set by this command are LF and

CR (with Auto LF enabled).

(7) This command does not set TOF.

(8) The line feed pitch set by this command applies to the following commands.

(a) ESC d n (Printing, then feeding paper for an “n” number of lines)

(b) ESC C n (Setting the eject length for cut sheet paper and the page length for sprocket

paper)

(c) ESC N n (Setting perforation skip for sprocket paper)

ESC 0

3.2.3.3 7/72-inch Line Feed Set

Name: 7/72-inch Line Feed Set

HEX: 1BH 31H

Code

DEC: 27 49

Function:

(1) To set the line feed pitch for the print sheet selected by the Set Sheet Select command (ESC

c 1 n, ESC DLE c Pno 1 n) to seven seventy-seconds of an inch (7/72").

(2) To perform 7/72-inch line feed upon receiving the LF code with the type of print sheet set after

this command has been designated.