Page 1

OKIPOS 425D

okilogo.jpg

global logo.jpg

o425_72.jpg

Developer’s Guide

59336301

Page 2

Document Title and Part Number

OKIPOS 425D Developer’s Guide

P/N 59336301

Disclaimer

Every effort has been made to ensure that the information in this document is complete, accurate, and up-to-date. Oki Data

assumes no responsibility for the results of errors or omissions beyond its control. Oki Data also cannot guarantee that changes

in software and equipment made by other manufacturers and referred to in this document will not affect the applicability of the

information in it. Mention of software products manufactured by other companies does not necessarily constitute endorsement

by Oki Data.

Copyright Information

Copyright 2001 by Oki Data. All Rights Reserved

First Edition: August, 2001

Written and produced by the Oki Data Training and Publications Department.

Contact Information

Please address any comments on this publication to:

Mailing Address

Oki Data Americas

Training and Publications Department

2000 Bishops Gate Boulevard

Mount Laurel, NJ 08054-4620

e-Mail Address

pubs@okidata.com

Web Site

Please visit Oki Data’s multilingual web site at:

http://www.okidata.com

Page 3

Contents

1. Setting Up the Printer ....................................................................................................................................... 6

1.1. Select a Location ...................................................................................................................................................................6

1.2 Where to install your printer .................................................................................................................................................6

1.3 Unpacking .............................................................................................................................................................................7

Getting Started ...........................................................................................................................................................................7

1.4 Installing the Printer ..............................................................................................................................................................8

Getting to Know the OKIPOS 425D ..........................................................................................................................................8

1.4.1 Remove the Shipping Restraints ..................................................................................................................................... 9

1.4.2 Setting the Interface Board Assembly............................................................................................................................10

1.4.2.1 Setting the DIP Switches (RS-232C) ........................................................................................................................10

1.4.2.2 Installing the Interface Board Assembly ..................................................................................................................11

1.4.3 Connecting the Computer ............................................................................................................................................. 1 2

1.4.4 Connecting the Cash Drawer .........................................................................................................................................12

1.4.5 Connecting the Customer Display.................................................................................................................................12

1.4.6 Connecting the Power....................................................................................................................................................12

1.4.7 Installing the Ribbon Cartridge.....................................................................................................................................1 3

1.5 Installing the Paper..............................................................................................................................................................16

1.5.1 Roll paper.......................................................................................................................................................................17

1.5.1.1 Adjusting the Roll Paper Guide (Receipt)................................................................................................................17

1.5.1.2 Loading the Roll Paper (Receipt).............................................................................................................................18

1.5.1.3 Adjusting the Roll Paper Guide (Journal) ................................................................................................................2 0

1.5.1.4 Loading the Roll Paper (Journal) .............................................................................................................................21

1.5.1.5 Adjusting the Roll Paper Near End Sensing Position ..............................................................................................2 3

1.5.2 Cut-Sheet Paper (Slip)....................................................................................................................................................24

1.5.2.1 Loading the Cut-Sheet Paper (Slip)...........................................................................................................................24

1.5.3 Cut-Sheet Paper (Validation/Stub).................................................................................................................................25

1.5.3.1 Loading the Cut-Sheet Paper (Validation/Stub) ......................................................................................................25

1.5.4 Sprocket Paper (Tractor)................................................................................................................................................28

1.5.4.1 Loading the Sprocket Paper (Tractor) .......................................................................................................................28

2. Using the Printer ............................................................................................................................................. 32

2.1 Operation Panel Functions ..................................................................................................................................................32

2.1.1 Switching Functions ......................................................................................................................................................33

2.1.2 LED Function.................................................................................................................................................................34

2.2 Local Functions...................................................................................................................................................................35

2.2.1 Types ..............................................................................................................................................................................3 5

2.2.2 Starting ........................................................................................................................................................................... 36

2.3 Menu Function (Receipt) ....................................................................................................................................................37

2.3.1 OEM — Standard Model ...............................................................................................................................................37

2.3.2 OKI — Standard Model .................................................................................................................................................38

2.3.3 How to Operate...............................................................................................................................................................39

2.4 Hex Dump Function (Receipt) ............................................................................................................................................40

2.4.1 Print Format....................................................................................................................................................................40

2.4.2 How to Print ...................................................................................................................................................................40

2.5 Using the MICR Reader ......................................................................................................................................................41

2.6 MICR Read Test (Receipt) ..................................................................................................................................................43

2.7 Rewinder Winding Evaluation Continuous Print Test (Journal) ........................................................................................45

2.8 Using the Auto Cutter..........................................................................................................................................................46

3. Maintenance ..................................................................................................................................................... 4 7

3.1 Replacing the Ribbon Cartridge ......................................................................................................................................... 4 7

3.2 Replacing the Roll Paper .................................................................................................................................................... 5 0

3.2.1 Roll Paper (Receipt).......................................................................................................................................................50

3.2.2 Roll Paper (Journal) .......................................................................................................................................................51

3.3 Clearing Paper Jams ............................................................................................................................................................53

Developer’s Guide: English 3

|

Page 4

4. Troubleshooting and Repair .......................................................................................................................... 5 8

4.1 Alarm Indication for a Failure .............................................................................................................................................58

4.1.1 Details of Alarm Indications ..........................................................................................................................................59

4.1.2 LED Indication...............................................................................................................................................................60

5. Specifications ................................................................................................................................................... 6 1

5.1 Introduction.........................................................................................................................................................................61

5.1.1 Scope of Application ......................................................................................................................................................6 1

5.1.2 Characteristics................................................................................................................................................................6 1

5.1.3 Configuration................................................................................................................................................................. 6 3

5.2 General Specifications.........................................................................................................................................................64

5.2.1 Power Requirements ......................................................................................................................................................64

5.2.2 Environmental Conditions............................................................................................................................................. 6 4

5.2.3 Agency Approvals ..........................................................................................................................................................64

5.3 Communication Interface Specifications.................................................................................... ........................................65

5.3.1 Parallel Interface (OKI/OEM Standard T ype) ................................................................................................................65

5.3.2 RS-232C Interface (OKI Standard T ype)........................................................................................................................66

5.3.3 Cash Drawer connector (OKI Standard T ype) ................................................................................................................67

5.3.4 Customer Display connector (OKI Standard RS-232C Interface T ype) ........................................................................68

5.4 Physical Characteristics ......................................................................................................................................................69

5.4.1 Printhead ........................................................................................................................................................................69

5.4.2 Printer .............................................................................................................................................................................69

5.5 Logical Characteristics........................................................................................................................................................70

5.5.1 Print Direction................................................................................................................................................................70

5.5.2 Selectable Character Pitches ..........................................................................................................................................70

5.5.3 Maximum Number of Characters per Line.....................................................................................................................70

5.5.4 Font Size/Cell Size.........................................................................................................................................................71

5.5.5 Line Feed Pitches ...........................................................................................................................................................71

5.6 Printer Performance .............................................................................................................................................................71

5.6.1 Print Speed .....................................................................................................................................................................71

5.6.2 Line Feed Speed.............................................................................................................................................................71

5.7 Media Specifications...........................................................................................................................................................72

5.7.1 Cut-Sheet Paper (Slip/Validation) .................................................................................................................................72

5.7.2 Cut-Sheet Paper (Counterfoil/Stub)...................................................................................... .........................................7 2

5.7.3 Roll Paper (Receipt/Journal)..........................................................................................................................................72

5.7.4 Sprocket Paper (Tractor) ................................................................................................................................................72

5.7.5 Appendix: Media Specifications ..................................................................................................................................7 3

5.7.5.1. Cut-Sheet Paper (Slip/Validation) .................................................................................... .......................................73

5.7.5.2. Roll paper (Receipt/Journal) ...................................................................................................................................80

5.7.5.3. Sprocket Paper (Tractor) ..........................................................................................................................................82

5.7.5.4. MICR (only with MICR Type) ................................................................................................................................91

5.8 Paper Feed Specifications ...................................................................................................................................................92

5.8.1 Paper feed methods/Paths ..............................................................................................................................................92

5.8.2 Paper Positioning Restrictions.......................................................................................................................................92

5.8.3 Paper T ear-of f .................................................................................................................................................................92

5.8.4 Paper End Detection ......................................................................................................................................................92

5.9 MICR Specifications (Only with MICR type) ....................................................................................................................93

5.9.1 A vailable Fonts ...............................................................................................................................................................93

5.9.2 Scanning Speed............................................................................................................................................................... 9 3

5.9.3 Recognition Rating ........................................................................................................................................................ 93

5.9.4 Reliability .......................................................................................................................................................................9 3

5.9.5 Readable Area .................................................................................................................................................................93

5.9.6 Media Specifications ......................................................................................................................................................9 3

5.9.7 Other Relevant Standards ...............................................................................................................................................93

5.10 Auto Cutter Specifications ................................................................................................................................................94

5.11 Ribbon Specifications.......................................................................................................................................................9 4

5.12 Reliability ......................................................................................................................................................................... 94

4

|

OKIPOS 425D

Page 5

6. Command Description .................................................................................................................................... 95

6.1 Control Code List................................................................................................................................................................95

6.1.1 OEM — Standard Model ...............................................................................................................................................95

6.1.1.1 Function Code ..........................................................................................................................................................95

6.1.1.2 ESC Sequence...........................................................................................................................................................96

6.1.1.3 GS sequence..............................................................................................................................................................97

6.1.1.4 US Sequence .............................................................................................................................................................97

6.1.2 OKI Standard Model ......................................................................................................................................................98

6.1.2.1 Function Code ..........................................................................................................................................................98

6.1.2.2 ESC Sequence...........................................................................................................................................................99

6.1.2.3 FS Sequence........................................................................................................................................................... 101

6.1.2.4 GS Sequence .......................................................................................................................................................... 101

6.2 Character Set..................................................................................................................................................................... 102

6.2.1 Code table (OEM — Standard Type) .......................................................................................................................... 102

6.2.1.1 USA ........................................................................................................................................................................ 102

6.2.1.2 Canada-French....................................................................................................................................................... 103

6.2.1.3 Multilingual .......................................................................................................................................................... 104

6.2.1.4 Portugal.................................................................................................................................................................. 105

6.2.1.5 Norway................................................................................................................................................................... 106

6.2.1.6 BRASCII ................................................................................................................................................................ 107

6.2.1.7 Abicomp................................................................................................................................................................. 108

6.2.1.8 Multilingual 858 ................................................................................................................................................... 1 09

6.2.1.9 ISO 8859/15........................................................................................................................................................... 110

6.2.1.10 International character set table ......................................................................................................................... 111

6.2.2 Code table (OKI — Standard Type) ............................................................................................................................ 112

6.2.2.1 USA ........................................................................................................................................................................ 112

6.2.2.2 Canada-French....................................................................................................................................................... 113

6.2.2.3 Multilingual .......................................................................................................................................................... 114

6.2.2.4 Portugal.................................................................................................................................................................. 115

6.2.2.5 Norway................................................................................................................................................................... 116

6.2.2.6 BRASCII ................................................................................................................................................................ 117

6.2.2.7 Abicomp................................................................................................................................................................. 118

6.2.2.8 Multilingual 858 .................................................................................................................................................. 1 1 9

6.2.2.9 ISO 8859/15........................................................................................................................................................... 120

6.2.2.10 International character set table .......................................................................................................................... 121

7. Using the Unitool Printer Driver................................................................................................................ 1 2 2

7.1 Setting Slip Paper in the Paper Tray................................................................................................................................. 122

7.1.1 Using Registered Paper Icons ..................................................................................................................................... 123

7.1.2 Using Custom Size ...................................................................................................................................................... 126

7.1.2.1 Using Paper Size that is less than 187.96 mm (7.4") in Width .............................................................................. 126

7.1.2.2 Using Paper Size that is 187.96 mm (7.4") or more and less than 215.9 mm (8.5") in width................................ 131

7.2 About the Validation Printing Area .................................................................................................................................. 132

7.3 Setting Tractor Paper in the Tractor Unit ......................................................................................................................... 135

7.4 Orientation........................................................................................................................................................................ 135

7.5 Special functions of the Windows 95/98 Version Printer Driver...................................................................................... 136

Developer’s Guide: English 5

|

Page 6

1. Setting Up the Printer

1.1. Select a Location

· Firm, level surface capable of supporting approximately 7kg (15.4 lbs).

· Clearance to open cover

· At least 100mm (4 inches) additional clearance on both sides for adequate ventilation

· Nearby power source

· Room temperature: 5° to 40° C (41° to 104° F)

· Relative humidity: 20 to 80%

· Away from direct sunlight

· Do not place the printer near a heater.

· Do not place it in a location with abrupt temperature changes.

· Do not let condensation develop on the printer.

· Do not place it in a dirty location.

· Do not place it near a device with abrupt consumption power fluctuations.

· Do not place it near a device producing any noise.

· Do not place it near an object discharging static electricity (i.e., on a carpet).

· Do not place it near a location where it is subjected to any impacts or vibrations.

· Do not place it near a strong magnetic field or source of corrosive gas.

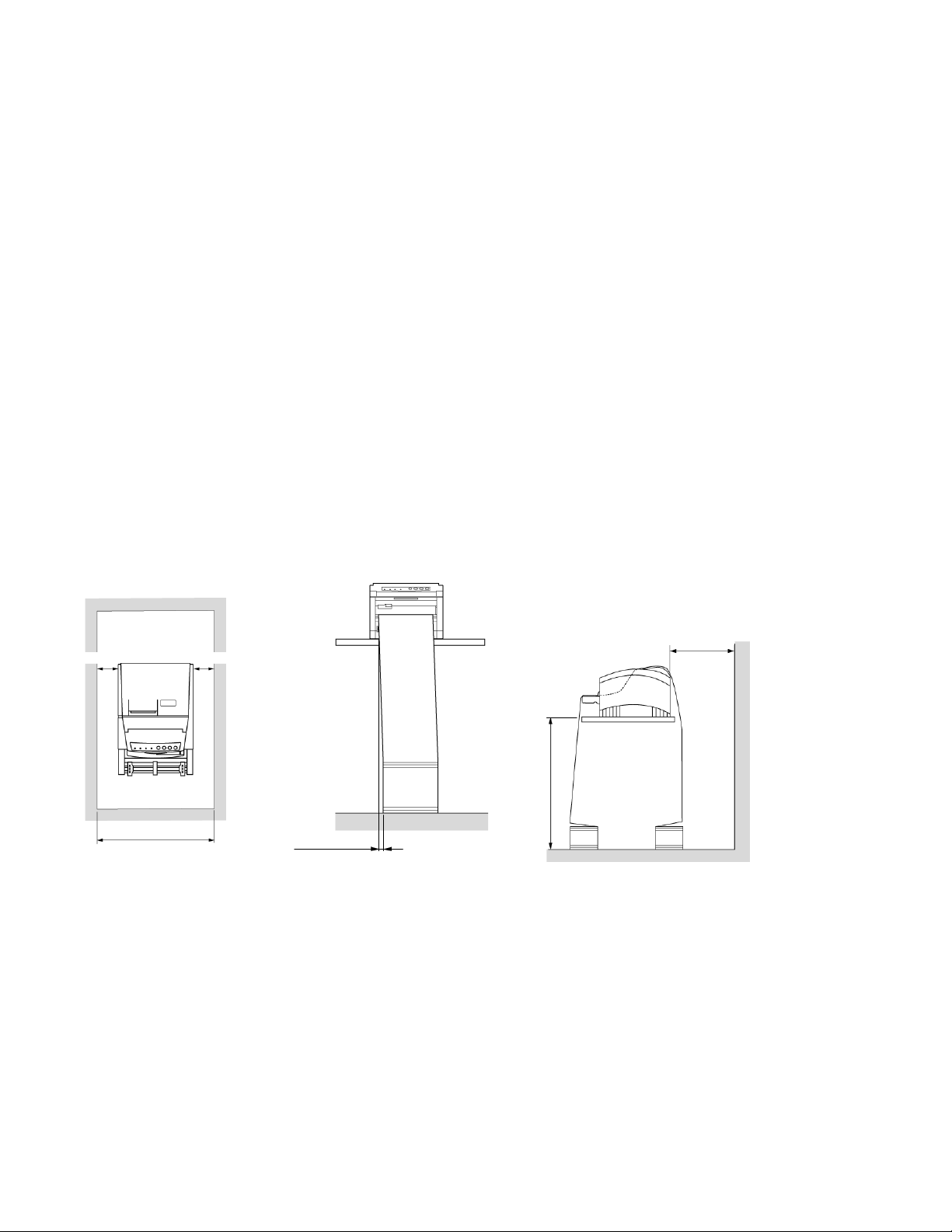

1.2 Where to install your printer

Install your printer on as flat and stable a desk as possible. Also, make sure that the following installation space is reserved for

services such as operation, daily check and replacement of supplies to maintain the performance of your printer.

F-002.eps, F-003.eps and F-004.eps

11

1 Approximately 100mm

2 50mm or less

3 750mm

4 600mm or more

4

3

2

6

|

OKIPOS 425D

Page 7

1.3 Unpacking

Getting Started

Check the contents:

1 Printer

2 Ribbon Cartridge

If anything is missing or damaged, contact your dealer immediately.

o425_72.jpg and o425_07.jpg

1

2

Developer’s Guide: English 7

|

Page 8

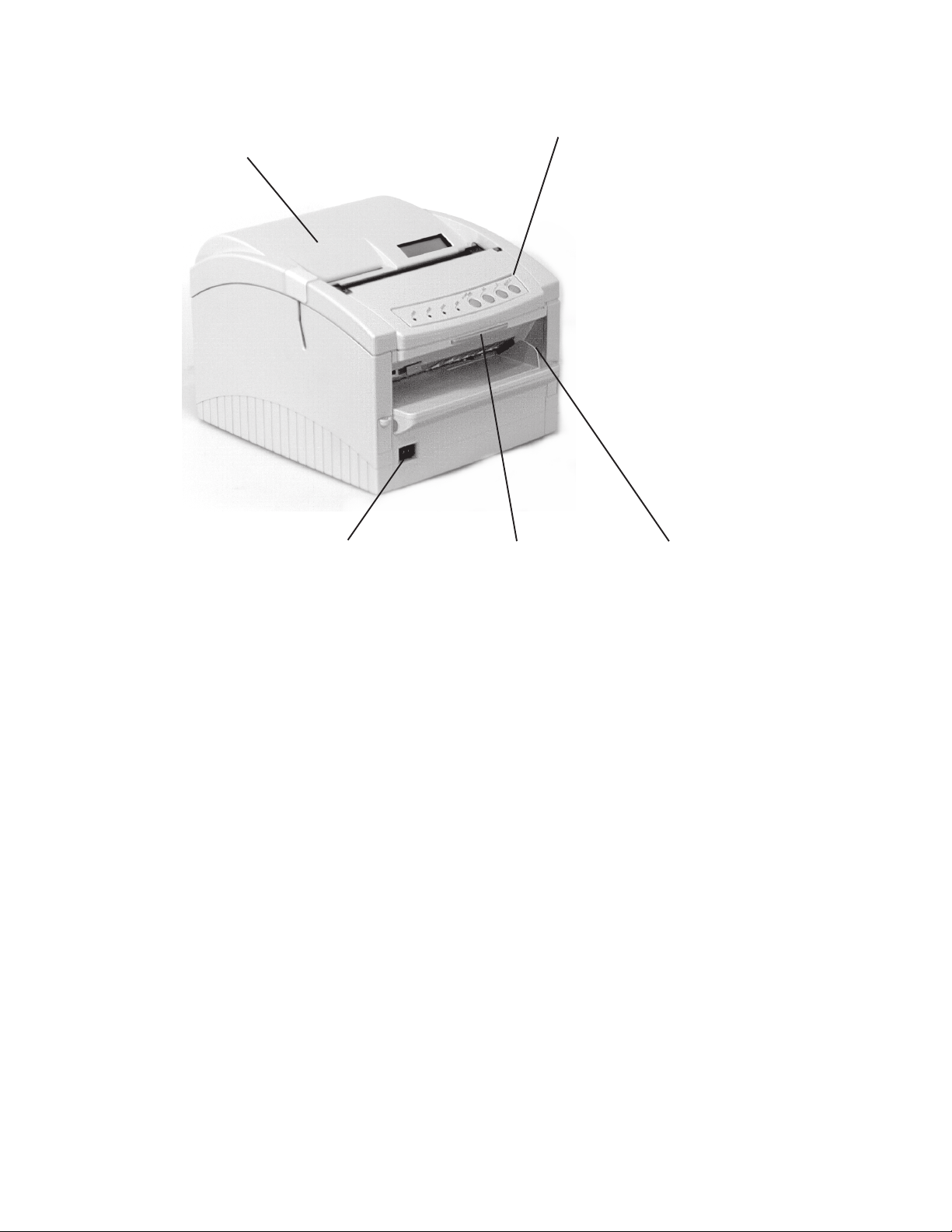

1.4 Installing the Printer

Getting to Know the OKIPOS 425D

o425_72.jpg

1

1 Printer Cover

2 Control Panel

3 Paper Guide

4 Cover Open Bar

5 ON/OFF Switch

5

2

4

3

8

|

OKIPOS 425D

Page 9

1.4.1 Remove the Shipping Restraints

Important! Save the shipping restraints and packing materials in case you ever need to ship the printer.

1. Remove the five pieces of shipping tape.

o425_30.jpg

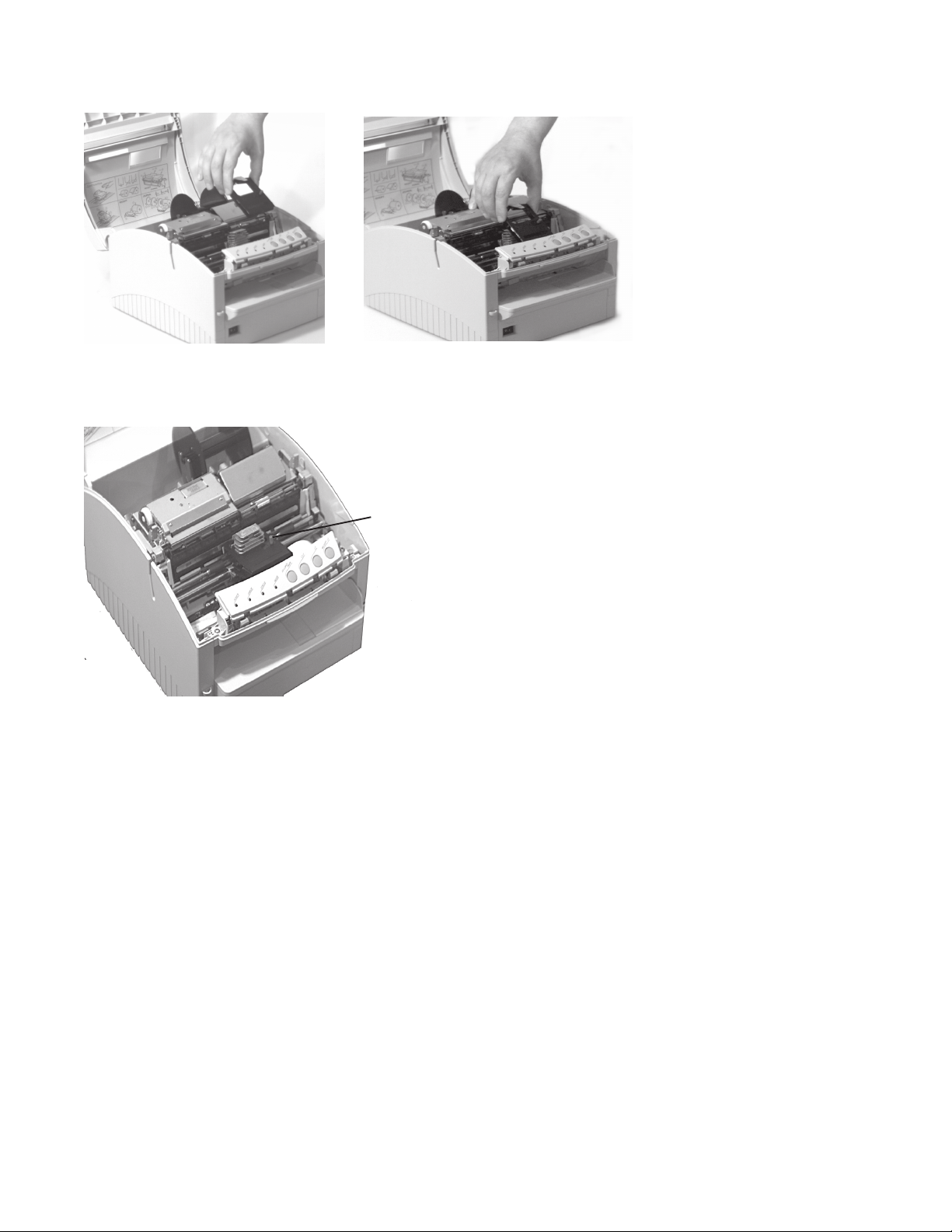

2. Press the Cover open bar and open the printer cover.

o425_31.jpg and o425_32.jpg

3. Remove the two printhead shipping restraints and red rubber, and detach the two pieces of tape.

o425_33.jpg

2

1

4

1 Printer Cover

2 Shipping Restraint

3 Control Panel

4 Red Rubber

3

Developer’s Guide: English 9

|

Page 10

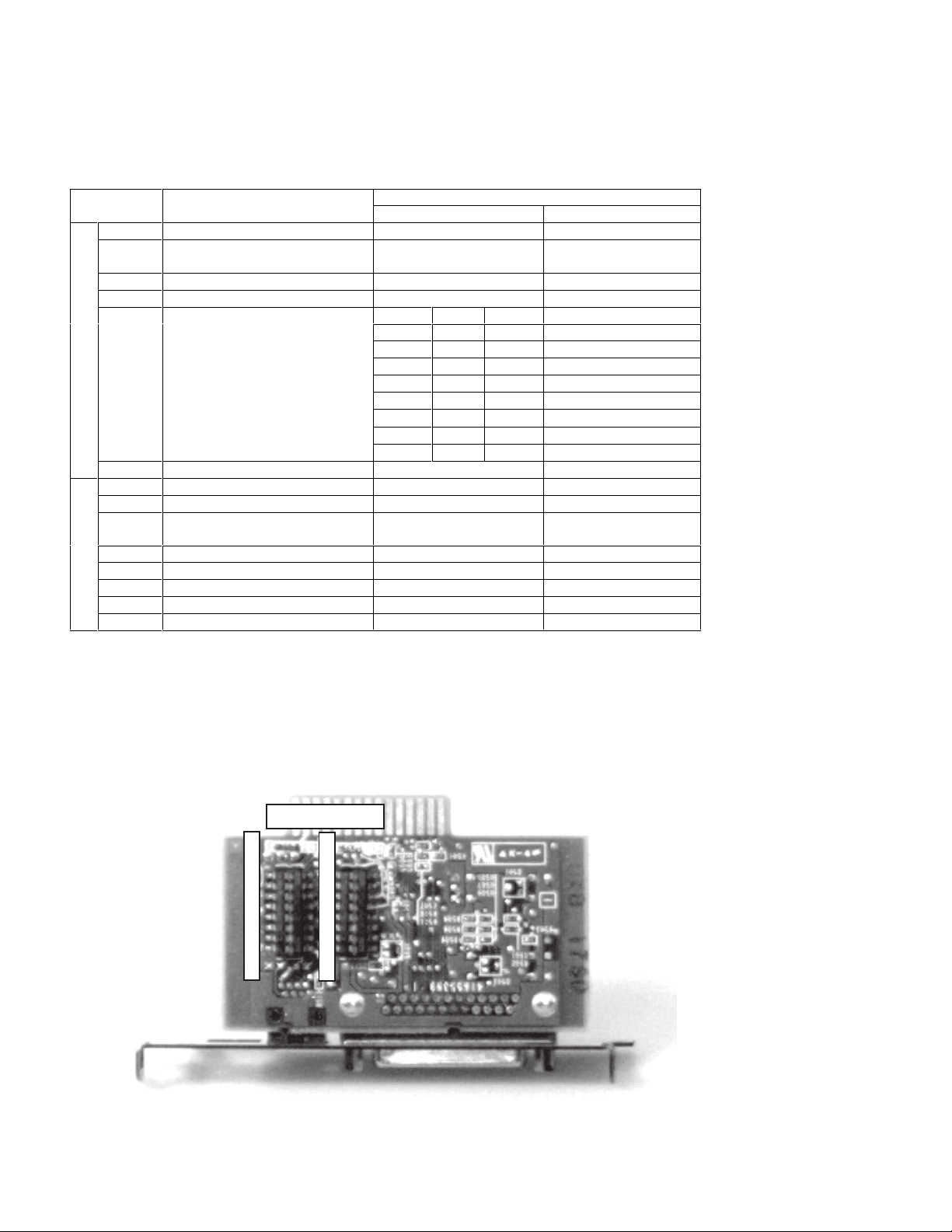

1.4.2 Setting the Interface Board Assembly

1.4.2.1 Setting the DIP Switches (RS-232C)

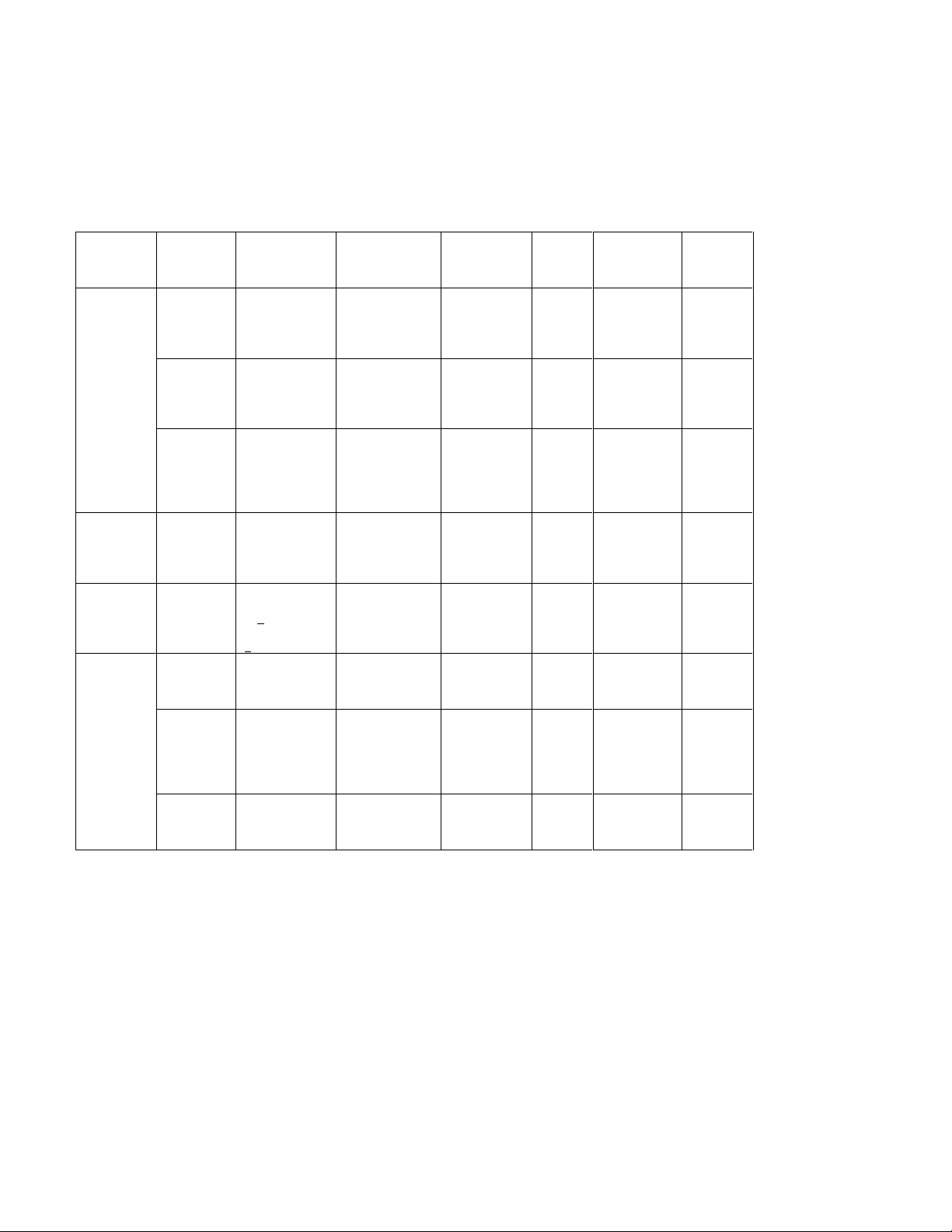

A25001.doc

Switch Setting

DIP SW Function

1 Selects the data bit length 7 bits 8 bits

2 Selects between the presence and

absence of parity bits.

3 Selects the parity Even Parity Odd parity

4 Selects the protocol XON / XOFF Ready / Busy

D

I

P

5 –

S

W

7

1

8 Selects the customer display Connect Disconnect

1 Selects the #6 pin reset signal Enable Disable

D

2 Selects the #25 pin reset signal Enable Disable

I

3 Selects the display of received

P

4 Selects the mode of circuit test Select Deselect

S

5 Selects the hard reset signal Enable Disable

W

6 Selects the software reset signal Enable Disable

2

7N/A - 8N/A - -

Selects the signaling speed

data errors

ON OFF

Present Absent

5 6 7 Signal ing Speed (BPS)

OFF OFF OFF 1200

OFF OFF ON 2400

OFF ON OFF 4800

OFF ON ON 9600

ON OFF OFF 19200

ON OFF ON Reserved

ON ON OFF Reserved

ON ON ON Reserved

Ignore (error conversion

is not performed)

Convert to receive error

characters

* There are three types of errors: the parity error, the framing error, and the overrun error.

o425_83.jpg

DIPSW1 DIPSW2

10 11 10 11

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

10

10 = OFF; 11 = ON

OKIPOS 425D

|

Page 11

1.4.2.2 Installing the Interface Board Assembly

(1) Insert the Interface Board Assembly in the direction of the arrow.

o425_84.jpg

(2) Secure the Interface Board Assembly with 2 screws.

o425_28.jpg

Developer’s Guide: English 11

|

Page 12

1.4.3 Connecting the Computer

This printer supports either Parallel Interface or RS232C when the interface board is installed in the printer. To install the

interface board, refer to Section 1.4.2.2.

1. Check to be sure that the printer’s power is OFF.

2. Connect the interface cable to the connector shown below.

A ) Parallel Interface

B) Serial Interface

o425_24.jpg and o425_82.jpg

A

3. Secure the connector by its latches or screws.

B

1.4.4 Connecting the Cash Drawer

1. Check to be sure that the printer’s power is OFF.

2. Insert the cable connector from the Cash Drawer to the area indicated by DM above until you hear a clicking sound.

1.4.5 Connecting the Customer Display

With the RS232C interface option board installed, Customer Display can be supported.

1. Check to be sure that the printer’s power is OFF.

2. Insert the cable connector from the Customer Display into the area indicated by C Dis above until you hear a clicking

sound.

1.4.6 Connecting the Power

1. Attach the power cord to the back of the printer.

o425_29.jpg

2. Plug the opposite end into a suitable grounded outlet.

12

OKIPOS 425D

|

Page 13

1.4.7 Installing the Ribbon Cartridge

1. Make sure the printer is turned OFF.

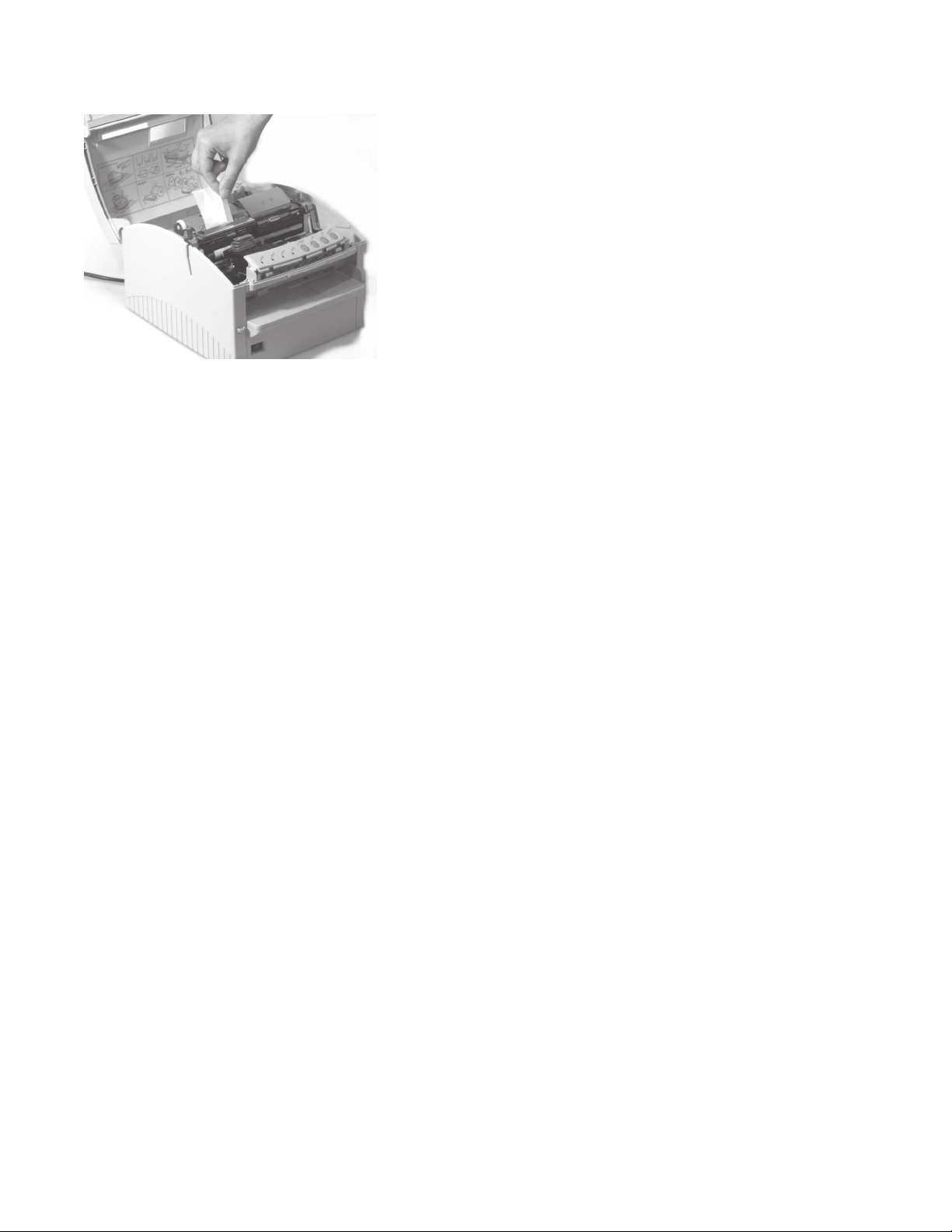

2. Press the Cover open bar and open the printer cover.

o425_31.jpg and o425_32.jpg

3. Center the printhead.

o425_86.jpg

Developer’s Guide: English 13

|

Page 14

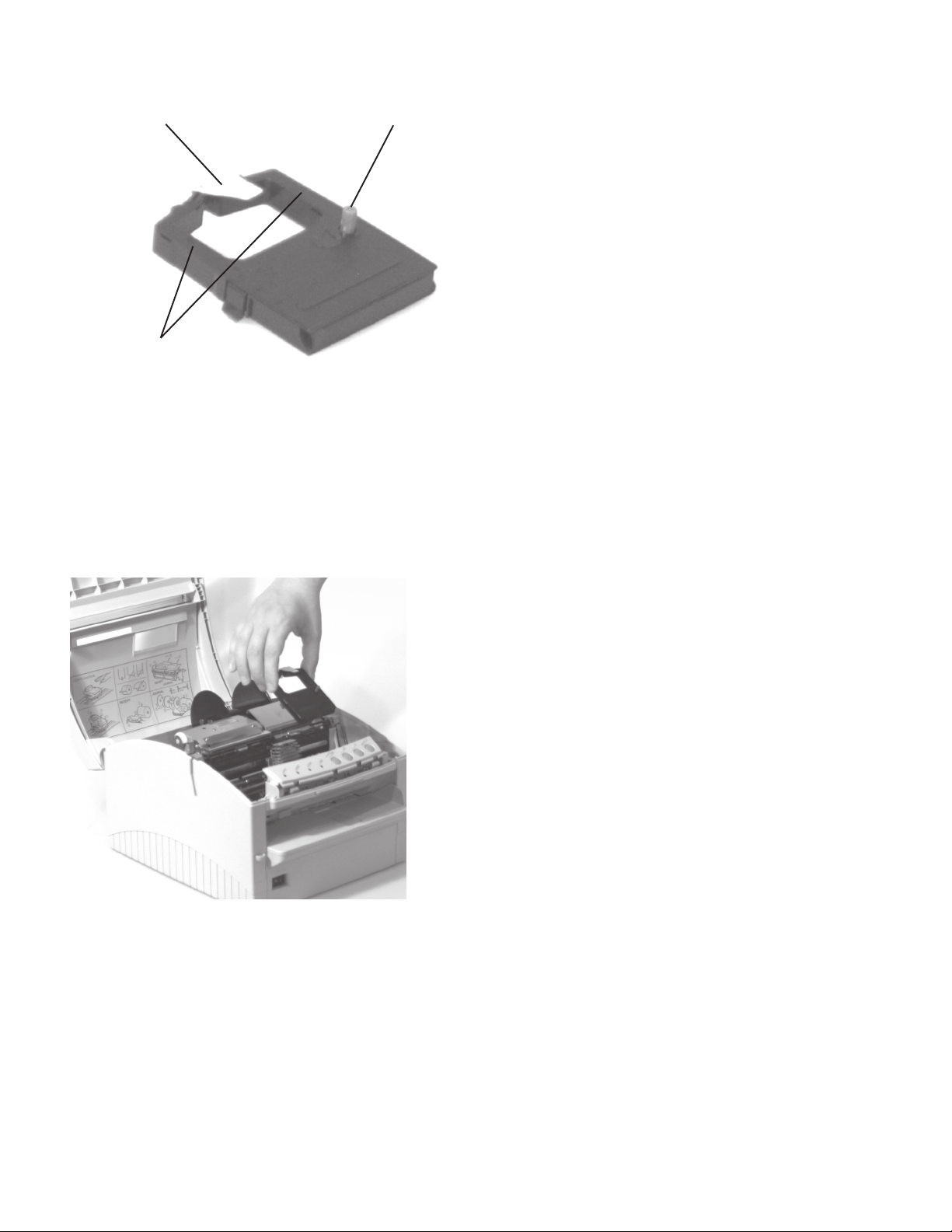

4. Unpack the ribbon cartridge.

Important! Do NOT remove the ribbon shield from the ribbon!

o425_07.jpg

1 Ribbon Shield

2 Take-up Knob

3 Grip Points

5. Install the new ribbon cartridge.

1) Hold the ribbon cartridge as shown below.

o425_87.jpg

1

3

2

14

2) Fit the grooves in the flat end of the cartridge over the posts on the ribbon plate.

OKIPOS 425D

|

Page 15

3) Lower the front of the cartridge over the printhead until it snaps into place.

o425_87.jpg and o425_88.jpg

4) Turn the knob (1) in the direction of the arrow on the cartridge to take up the ribbon slack.

o425_86.jpg

1

Developer’s Guide: English 15

|

Page 16

1.5 Installing the Paper

A25002.doc

Paper Specifications

Maximum thickness: 0.3 mm (0.012 inches)

Media Type Width Length Weight Number

of

copies

2

Cut-Sheet

Paper

Single part

(slip)

105 to 215.9mm

(4.13” to 8.5”)

70 to 297mm

(2.76” to 11.7”)

52 to 105 g/m

(14 to 28lb)

- 0.065 to 0.13

(Sip/

Validation)

Note 1

Single part

(validation)

Multi part

carbon lined

or pressure

105 to 215.9mm

(4.13” to 8.5”)

105 to 215.9mm

(4.13” to 8.5”)

70 to 297mm

(2.76” to 11.7”)

70 to 297mm

(2.76” to 11.7”)

65 to 81 g/m

(17 to 21lb)

34 to 40 g/m

(9 to 11lb)

2

- 0 .08 to

2

Original

plus 4

copies

sensitive

(slip)

2

Cut-Sheet

paper

(counterfoil/

Single part

only

70mm or more

(2.76” or more )

40mm or more

(1.57” or more)

65 to 81 g/m

(17 to 21lb)

- 0.08 to 0.1

stub)

2

Roll paper

Note 2

Single part 69.5mm/76.2m

m + 0.5mm

- 52 to 81g/m

(14 to 21lb)

- 0.065 to

(2.73”/3”

Sprocket

Paper

Single part

+ 0.02”)

76.2 to

215.9mm

(3” to 8.5”)

76.2 to 355.6mm

(3” to 14”)

52 to 81 g/m

(14 to 21lb)

2

- 0.065 to

(Tractor)

Note 3

Multi part

carbon

lined or

76.2 to

215.9mm

(3” to 8.5”)

76.2 to 355.6mm

(3” to 14”)

34 to 40 g/m

(9 to 11lb)

2

Original

plus 3

copies

pressure

sensitive

2

Multi part

interleaf

76.2 to

215.9mm

(3” to 8.5”)

76.2 to 355.6mm

(3” to 14”)

38 to 45 g/m

(10 to 12lb)

Original

plus 2

copies

Thickness Diameter

-

mm

(0.0026” to

0.005”)

-

0.1mm

(0.0031” to

0.0039”)

0.3mm max.

(0.012” max) -

mm

-

(0.0031” to

0.0039”)

83mm

0.1mm

(0.0026 to

0.039”)

max.

(3.27”

max)

-

0.1mm

(0.0026” to

0.0039”)

0.27mm max.

-

(0.0l” max)

-

0.27mm max.

(0.01” max)

Note 1: All part must be glued at the top. Multipart is slip only.

Note 2: The standard paper weight is 57g/m2 (15lb).

Note 3: Multiple part paper should be fastened by spot-pasting or crimpling on both sides and should be free of wrinkles.

16

OKIPOS 425D

|

Page 17

1.5.1 Roll paper

1.5.1.1 Adjusting the Roll Paper Guide (Receipt)

1. Adjust paper guide A (1) to the paper width.

Paper width: 2.75 inches (69.5 mm) or 3.00 inches (76.2 mm)

Adjustment must be made for both Receipt and Journal.

1) When the printer is shipped, the paper width is set for wide roll paper (3 inch or 76.2 mm width)

o425_89.jpg

2) To use narrow roll paper (2.73 inch or 69.5 mm width), hold up the roll paper guide and move it to the left to insert

o425_89.jpg

1

into the hole (1) at the lower frame.

1

3) The figure below shows the proper guide position for narrow roll paper (2.73 inch or 69.5mm width).

(To return the guide to the position for wide roll paper, reverse step 2).

o425_90.jpg

Developer’s Guide: English 17

|

Page 18

1.5.1.2 Loading the Roll Paper (Receipt)

Use roll paper that matches the specifications.

Note: The printer must be turned on before installing the roll paper.

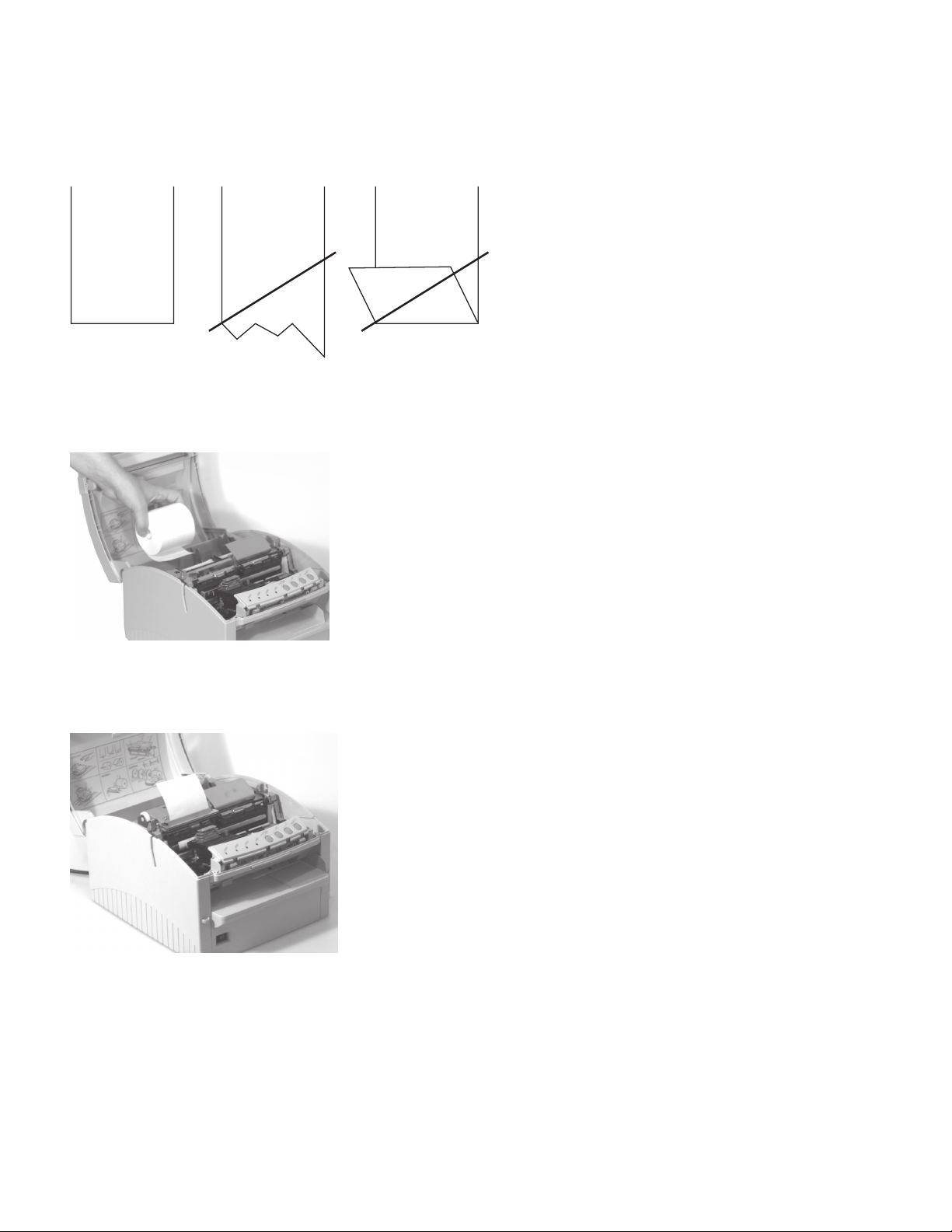

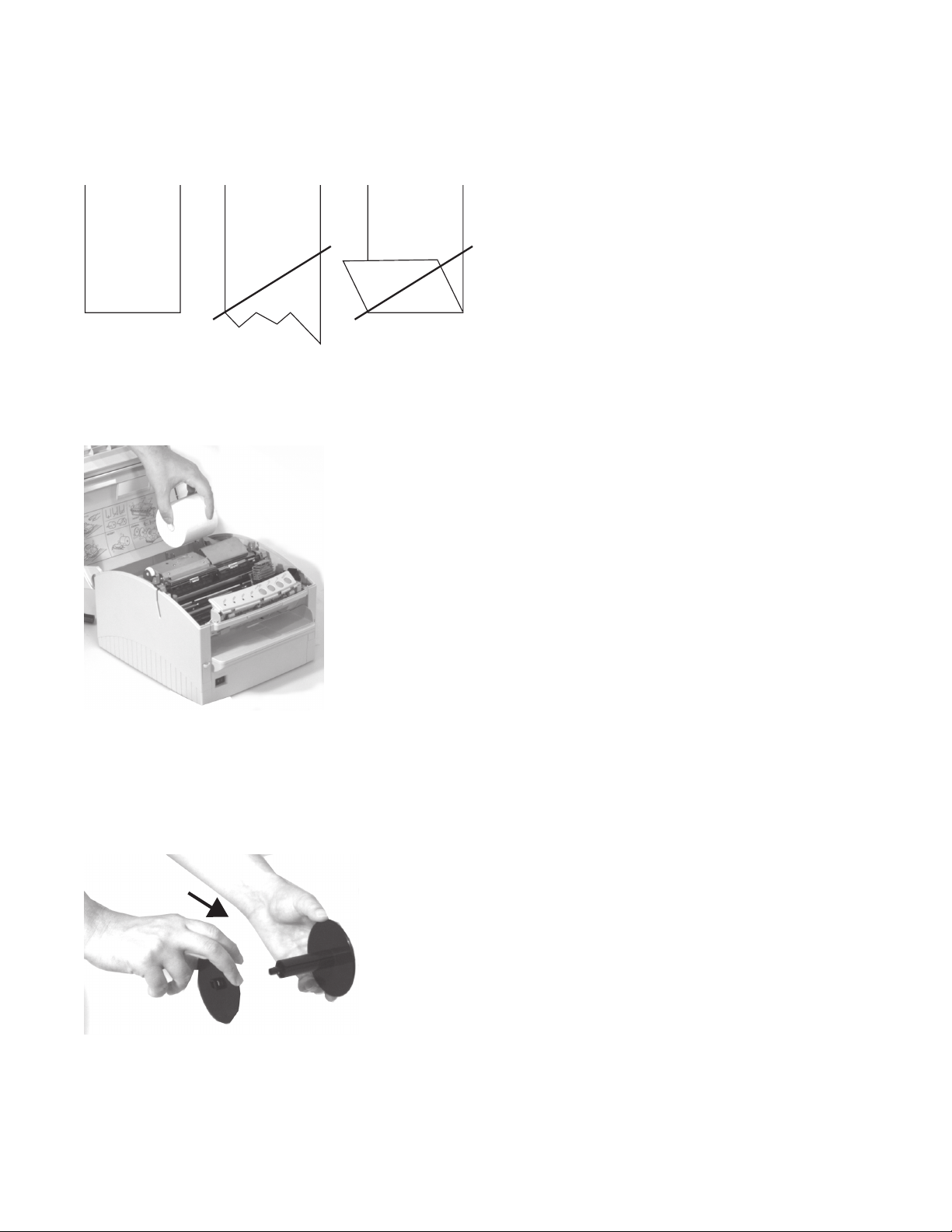

1. Fold the paper so it is exactly straight and even (1), and will not tear off jaggedly (2).

OP425_01b.eps

1

2. Turn on the printer and open the printer cover.

3. Insert the roll paper as shown below.

o425_55.jpg

2

2

4. Insert the tip of the paper into the paper inlet as far as it will go, and feed the roll paper until the paper comes out from the

top of the printer.

o425_91.jpg

18

OKIPOS 425D

|

Page 19

5. Cut the roll paper.

o425_92.jpg

6. Close the printer cover.

Developer’s Guide: English 19

|

Page 20

1.5.1.3 Adjusting the Roll Paper Guide (Journal)

1. Adjust paper guide B (1) to the paper width.

Paper width: 2.75 inches (69.5 mm) or 3.00 inches (76.2 mm)

Adjustment must be made for both Receipt and Journal.

1) When the printer is shipped, the paper width is set for wide roll paper (3 inch or 76.2 mm width)

o425_89.jpg

1

2) To use narrow roll paper (2.73 inch or 69.5 mm width), hold up the roll paper guide and move it to the right to insert

into the hole (1) at the lower frame.

o425_89.jpg

1

3) The figure below shows the proper guide position for narrow roll paper (2.73 inch or 69.5mm width).

(To return the guide to the position for wide roll paper, reverse step 2).

o425_89.jpg

20

OKIPOS 425D

|

Page 21

1.5.1.4 Loading the Roll Paper (Journal)

Use roll paper that matches the specifications.

Note: The printer must be turned on before installing the roll paper.

1. Fold the paper so it is exactly straight and even (1), and will not tear off jaggedly (2).

OP425_01b.eps

1

2. Turn on the printer, open the printer cover, and remove the rewinder.

3. Insert the roll paper as shown below.

o425_58.jpg

2

2

4. With the right side of the roll paper adjusted to the rightmost, insert the paper tip into the paper inlet as far as it goes, and

printer feed the roll paper until the paper comes out from the top of the printer.

5. When using the rewinder, follow the steps and the illustration below.

1) Turn the flange into the arrow direction and remove it.

o425_93.jpg

Developer’s Guide: English 21

|

Page 22

2) Insert the tip of roll paper into the groove of the rewinder as shown in the detail figure.

Then, turn the rewinder into the arrow direction to wind the roll paper around it 2 or 3 times.

o425_94.jpg and o425_95.jpg

3) Insert the flange into the rewinder (to the arrow direction 1) until it stops, then turn it into the arrow direction 2 to

lock.

o425_96.jpg

2

1

4) Mount the rewinder on the printer.

Note: When using narrow roll paper (69.5 mm width), turn over the flange as the arrow (e) and then mount it

following the above procedures 3) and 4).

Note that the flange can be demounted in the reverse procedures to its mounting.

Note: This printer can use two kinds of roll paper. Their widths are 69.5mm+0.5mm and 76.2mm+0.5mm.

6. Close the printer cover.

22

OKIPOS 425D

|

Page 23

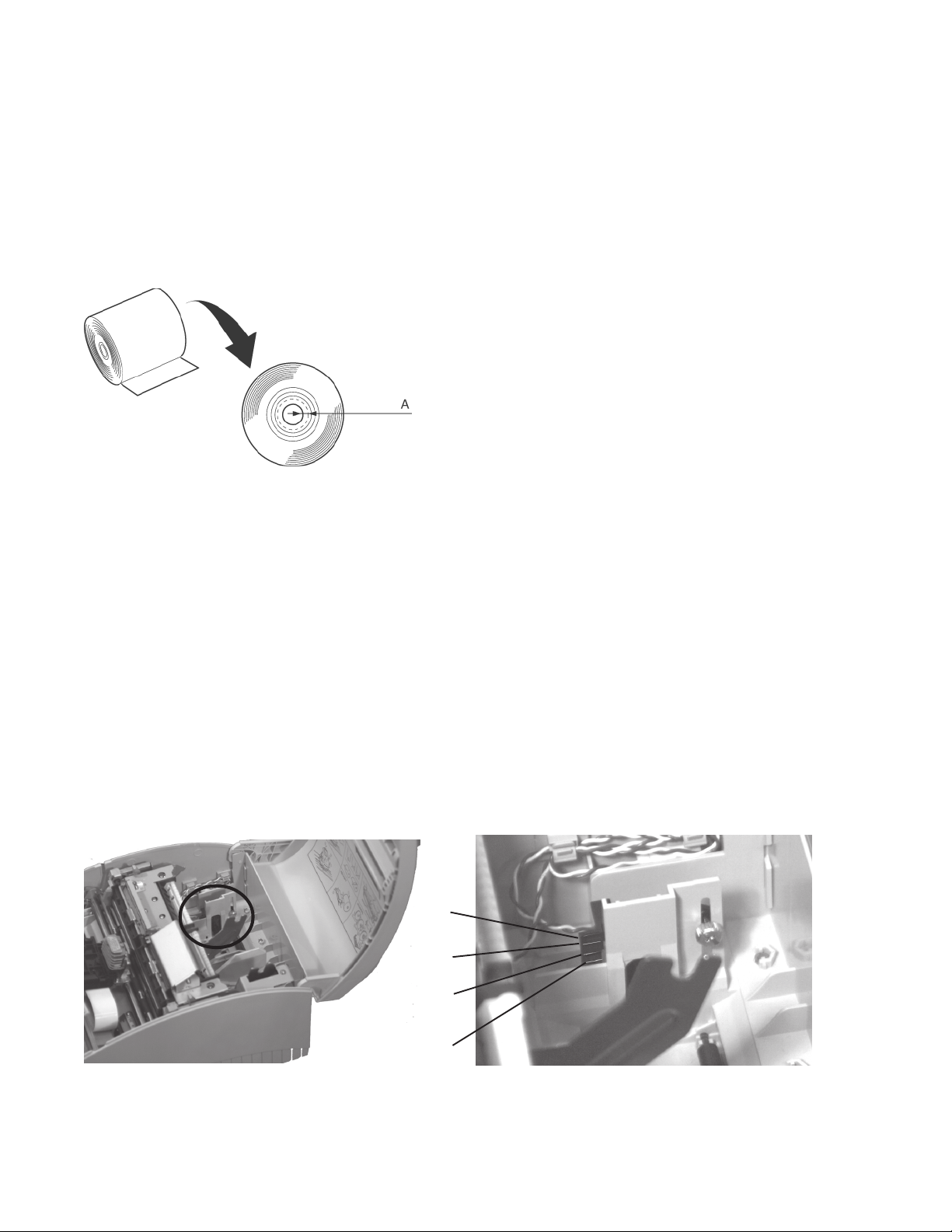

1.5.1.5 Adjusting the Roll Paper Near End Sensing Position

The paper near end detector detects when the paper is almost gone by measuring the diameter of the Roll paper.

If you want to change the amount of paper remaining when the printer stops printing, follow the steps below to adjust the

paper near end detector.

Note: If the inner diameter of the Roll paper core is more than 26mm (1.02 inch), the Roll paper near end detector may

not work properly.

1. Open the printer cover and remove the rewinder.

2 Determine the point on the Roll paper at which you want the near end detector to be triggered. Then measure the distance

A shown in the illustration.

OP425_02.eps

Note:There may be some difference between the measured distance A and the actual sensing position.

3. Find the corresponding adjustment position number from the table below.

Distance A Adjustment position number

4 mm (0.16") #1

6 mm (0.24") #2

8 mm (0.32") #3

11 mm (0.43") #4

19 mm (0.75") #5

26 mm (1.02") #6

Note:Above values are applicable when the inside diameter at the core of the Roll paper is 10 mm.

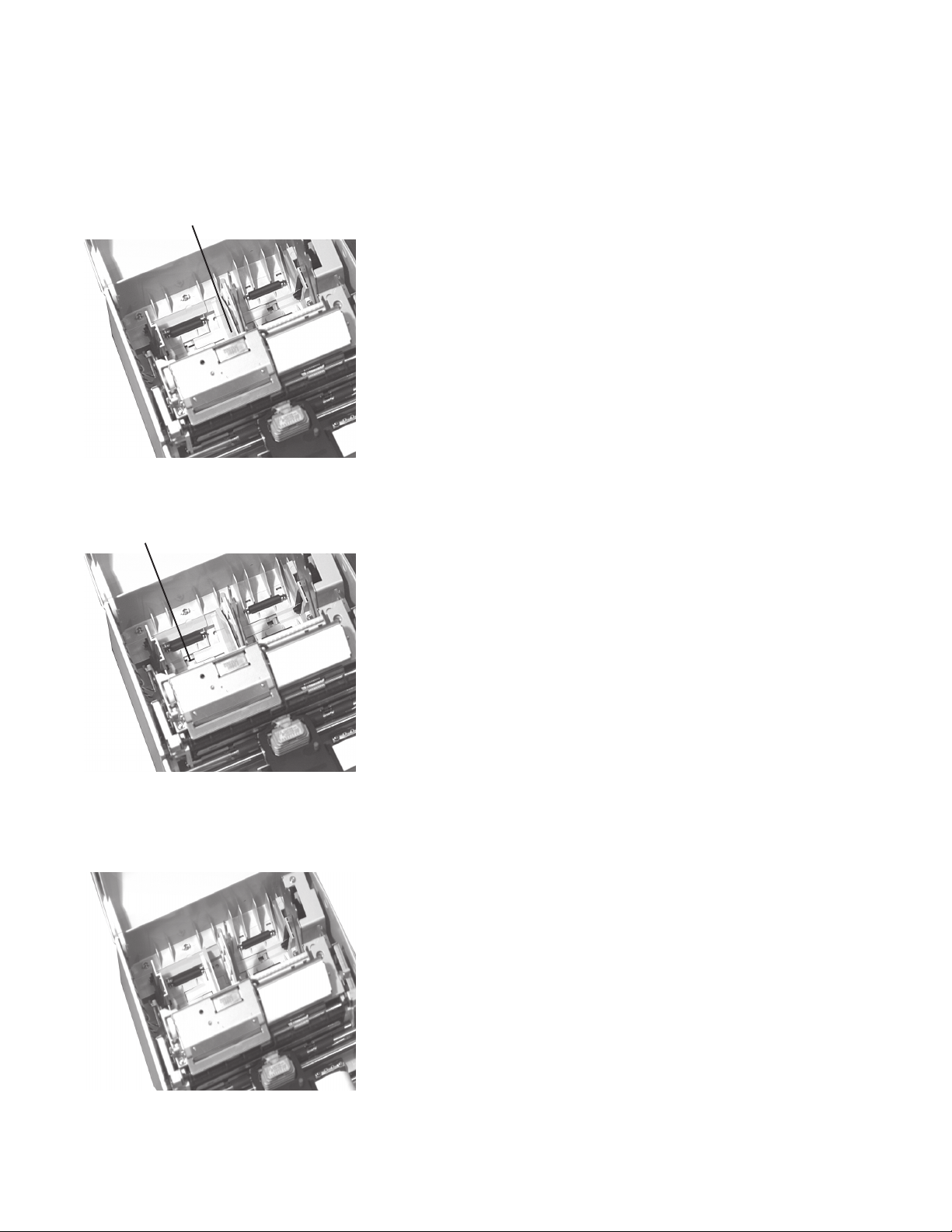

4. Loosen the detector screw with a coin or screwdriver.

5. Set the detector scale to the position you determined from the table by moving the detector screw up or down. The

numbers #1, #2, #3... are not marked on the detector scale.

o425_35.jpg and o425_97.jpg

1

2

3

4

6. Secure the detector screw; then replace the rewinder and close the printer cover.

Developer’s Guide: English 23

|

Page 24

1.5.2 Cut-Sheet Paper (Slip)

1.5.2.1 Loading the Cut-Sheet Paper (Slip)

Use the paper that matches the specifications.

Note: The printer must be turned on before loading the paper.

1. Turn on the printer.

2. Insert the paper as shown below, while butting the right edge of the paper against the paper guide.

Note: When using a MICR-version machine, align the marks “¶” and “Ä” as shown below and set the paper along the

paper guide.

o425_59.jpg

1

3. Printer feed the paper until the top of form of the paper is reached.

Note:If cut sheet paper is set askew, remove the paper following the procedure below and reset it:

1. Pull the lever (1) (marked “PULL”).

2. Pull out the paper in the direction of the arrow.

3. Reset the paper.

o425_59.jpg

24

1

OKIPOS 425D

|

Page 25

1.5.3 Cut-Sheet Paper (Validation/Stub)

1.5.3.1 Loading the Cut-Sheet Paper (Validation/Stub)

Use the paper that matches the specifications.

Note: The printer must be turned on before loading the paper.

1. Turn on the printer.

2. With the right edge of the paper positioned at the “Ä” mark on the Cover Top, insert the paper.

o425_48.jpg

Note: To feed paper along the long edge, remove the Piece (1) on the left side of the printer cover and set the paper.

o425_72.jpg

1

Developer’s Guide: English 25

|

Page 26

How to remove the Piece

1. Press the Cover Open Bar and open the Printer Cover.

CAUTION: Printhead may be very hot.

o425_31.jpg and o425_32.jpg

2. Unlock the latch (1) of the Piece Cover B (2) and remove the Piece Cover B.

o425_13.jpg

2

3. Remove Piece Cover A.

o425_14.jpg

1

26

OKIPOS 425D

|

Page 27

4. Close Printer Cover.

* Paper has been set for long-edge printing.

o425_49.jpg

* Store the removed Piece in a safe place so that you will not lose it.

Developer’s Guide: English 27

|

Page 28

1.5.4 Sprocket Paper (Tractor)

1.5.4.1 Loading the Sprocket Paper (Tractor)

Use the paper that matches the specifications.

Note: The printer must be turned off before inserting the tractor .

1. Turn off the printer. Move the Paper Guide all the way to the right. Pull the hooks (1) on the tractor cover (2) in the arrow

direction and remove the tractor cover.

o425_72.jpg

1

2

1

2. Insert the tractor as shown below, and lock the tractor lock lever (1).

o425_16.jpg

1

28

OKIPOS 425D

|

Page 29

3. Set the tractor lever (1) in the direction of the arrow.

o425_18.jpg

1

4. Turn on the printer.

5. Pull up on the lock levers (1) and open the tractor covers (2), then move the right tractor over to fit the width of the paper.

Center the support (3) between the tractors.

o425_50.jpg

2

2

1

6. Place the first two holes in the paper over the tractor pins (4) on either side and close the tractor covers.

o425_51.jpg

4

3

4

1

Developer’s Guide: English 29

|

Page 30

7. Move the left tractor to align the edge of the paper with the appropriate reference mark (!), and push back the right lock

lever (2).

o425_52.jpg

1

2

8. Fine-tune the position of the right tractor to center the holes in the paper on the pins, and push back the left lock lever (1).

o425_52.jpg

1

30

OKIPOS 425D

|

Page 31

9. Printer feeds the paper into the printer when your computer sends data.

10. Preparation

1) Position the printer at the front edge of the support (this promotes the unrestricted flow of paper into the printer), then

place a stack of Sprocket (Tractor) Paper below the printer.

2) The standard height of desks on which the printer is installed should be 75cm. Paper should be loaded in parallel with

the paper running path wherever possible. The deviation to right and left should be 5cm or less.

3) The ejected paper should be folded squarely on the floor to enable smooth paper conveyance. Inappropriate paper

setting may deteriorate print quality.

F-002.eps and F-003b.eps

3

2

1

1 50mm or less

2 750mm

3 600mm or more

Developer’s Guide: English 31

|

Page 32

2. Using the Printer

2.1 Operation Panel Functions

Note) OEM Fiscal Type:

The operation panel is under the control of the fiscal control PCB. Consequently, the fiscal control PCB should be

removed before self tests. Alternatively, disconnecting the cable from the main control PCB is acceptable.

Operation Panel Specification

o425_20.jpg

1 POWER LED Green

2 LED1 Red

3 LED2 Orange

4 LED3 Orange

LED4 Green

5 SW2

6 SW3

7 SW1

8 SW4

456123 7

Operation Panel

8

32

OKIPOS 425D

|

Page 33

2.1.1 Switching Functions

A25046.doc

No. Switch Function in Modes other than Tractor Func tion in Tractor Mode

1SW2

(FF/LOD,PAK)

2SW3

(CUT)

3SW1

(LF)

4SW4

(Receipt LF)

* The above switch operations in principle correspond to special commands for switch control.

Note 1) Disabled when the menu “Auto Cutter Unit = No” i

In Receipt Mode:

Feeds Receipt paper for the specified

length (10/6”)

In Slip Mode: Eje cts a fed slip paper

In Validation Mode: Disabled

*Printing will n ot be started.

In Receipt/Slip/Validation Modes:

Disabled

In Receipt Mode: Feed a line of

Receipt paper

In slip mode: Feed a line of a fed Slip

paper

In Validation mode: Disabled

*Printing will not be started.

Feeds a line of Receipt paper

*Enabled regardless of media mode and media state.

Without paper: Aut om a tic loading

With paper: Automatic parking

At cutting position:

Reverse – feed to the printing

position

At printing position:

Feed to the cutting position

Without paper: D isabled

With a single pus h:

One line feed of Sprocket paper

With a continuous push: Page feed

*A line is fed immediately after a

switch push, and a page after a

500ms continuous push.

*Printing will not be started

Developer’s Guide: English 33

|

Page 34

2.1.2 LED Function

A25004.doc

No. LED ON OFF Blinking

1 POWER Green Powered On Powered off 2 LED 1

(ERROR)

3 LED2

(Status)

4 LED3/

LED4

(Mode)

When “Cover Open Alarm” is set to No in Menu, Cover Open Alarm is disabled (printing does not stop).

Red Recoverable Alarms

*Slip Feed/Eject

Alarm

*Auto Loadin g Alarm

*Auto Parking Ala rm

*Media Mismatch

Alarm (1)

*Media Mismatch

Alarm (2)

*Cover Open Alarm

(Only OKI

standard type )

Orange Paper is not fed

(In sheet-insertion

wait state)

Orange In Slip Mode In Validation

In Receipt + Journal

Green

Mode

Normal state *Unrecoverable Alarms

(blinking pattern indicates

alarm type)

*See the table in section 4.1

*SP Thermal alarm

(LED2 blinks concurrently)

*LF Thermal Alarm

Paper has

been fed

(in print ready

state)

In Tractor

Mode

*In sheet-extraction wait

state

*SP Thermal Alarm

(LED1 blinks concurrently)

mode

*Quick

blinking

In Receipt

Mode

* Quick

blinking

In MICR

Mode

*Slow

blinking

In Journal

Mode

* Slow

blinking

* Media Does Not Ma tch Alarm (1) is detected by monitoring the option tractor lever. Media Does Not

Match Alarm (2) is detected by the Validation sensor monitoring (media manually inserted into the

validation openi ng) .

34

OKIPOS 425D

|

Page 35

2.2 Local Functions

Note OEM Fiscal Type :

This section describes local maintenance capabilities under the control of the printer block.

The fiscal control PCB should be removed before the functions are performed.

2.2.1 Types

Local Functions

Local test

All letters & rolling ASCII continuous printing test (Receipt)

All letters & rolling ASCII continuous printing test (Journal)

All letters & rolling ASCII continuous printing test (Receipt+Journal)

All letters & rolling ASCII continuous printing test (Slip/Sprocket)

Sample data continuous printing test (Validation)

MICR read test (Receipt) (only with MICR Type)

Rewinder winding-performance evaluation continuous printing test (Journal)

Menu function (Receipt)

Hexadecimal dump (Receipt)

Platen maintenance mode

Developer’s Guide: English 35

|

Page 36

2.2.2 Starting

No. Local Functio ns SW2 SW3 SW1 SW4

A25047.doc

1 All letters & rolling ASCII continuous printi ng

test (Receipt)

2 All letters & rolling ASCII continuous printi ng

test (Slip/Sprocket)

3 Sample data co ntinuous printing test (Validation) X O X X

4 Menu function (Receipt) O X O X

5 Hexadecimal dump (Receipt) X O O X

6 MICR read test (Receipt) (Only with MICR type) O O X X

7 Platen maintenance mode O O O X

8 Rewinder winding-performance e valuation

continuous printing test (Receipt)

Note :

1. To make the above modes are active, turn on the printer while pressing the switches marked with a circle and

releasing those with a cross.

2. No.4: Sprocket paper printing test is performed when the lever is on the Tractor side, and Slip paper printing test

when the lever is not on the Tractor side.

3. No. 5, 8 and 10: if the lever is on the Tractor side, the printer starts up for normal printing with the function disabled.

No. 1-3, 6, 7 and 9: the printer starts up with the function enabled regardless of the lever position.

4. No. 1-3: printing width is as set in the Width of Roll Paper menu.

XXOX

OXXX

XOOO

5. No.1-4 and 10: printing is suspended by pressing SW1. Pressing SW1 again restarts printing.

6. No. 1-5 and 10: printing is suspended by opening the cover. Close the cover to restart printing.

7. During any local function, lever operation causes media mismatch alarm (1). When the lever is returned to the

original position, the alarm is released to restart test printing.

36

OKIPOS 425D

|

Page 37

2.3 Menu Function (Receipt)

Overview

The menu function is the local function that sets each mode to control the printer and adjust it. This mode has the following

items, saved in the E2P-ROM. This information is printed only when the menu mode is activated at Power On, and the

information can be overwritten from the operator panel.

Menu Print is printed in Receipt Mode.

The menu determines the initialization state of each mode.

2.3.1 OEM — Standard Model

No. Item Function Sets

1 Auto Cutter Unit Selects Auto Cutter Unit

2 MICR Unit Selects MICR Unit Installed/Not

3 Print Registration Adjusts the print position if it

4 Top Adjust Adjusts Top of Form position

5 Cut Adjust Adjusts Cut Position when cutting

6 Width of Roll Pape r Selects the paper width of Roll

O = default value

A25006.doc

Installed/Not Installed

Installed

shifts in Forwar d printing and

Reverse printi ng

when Slip/Sprocket are used

Sprocket paper

paper.

(Changes the print area)

O Yes

No

Yes (CMC-7)

Yes (E-13B)

O No

0.25mm Righ t

0.20mm Righ t

0.15mm Righ t

0.10mm Righ t

0.05mm Righ t

0

0.05mm Left

0.10mm Left

0.15mm Left

0.20mm Left

0.25mm Left

-1.75mm ~+1.75mm

*Can be set in the 0.35mm

unit

*Default value: 0 mm

-1.75mm ~+1.75mm

*Can be set in the 0.35mm

unit

*Default value: 0 mm

O 76.2mm

69.5mm

Note For No. 3, 4, and 5, adjust to the proper values at factory shipment.

Developer’s Guide: English 37

|

Page 38

2.3.2 OKI — Standard Model

No. Item Function Sets

A25007.doc

1 Auto Cutter Unit Selects Auto Cutter Unit Installed/Not

2 MICR Unit Selects MICR Unit Installed/Not Installed Yes(CMC-7)

3 Print Registration Adjusts the print position if it shifts in

4 Top Adjust Adjusts Top Of Form position when

5 Cut Adjust Adjusts Cut Position when cutting

6Auto LF

(Auto line feed)

7 Receive Buffer Size Selects Receive Buffer Size 2K

8 Print Mode Selects font O Utility

9 Off-line Busy

Control

10 Cover Open Alarm Selects enable/disable of print stop in

11 Width of Roll Paper Selects the paper width of Roll paper

12 Zero Character Selects a zero font Slashed

13 Page Length Selects the paper length of Sprocket paper 88.9mm

14 Paper End Signal Selects the paper sensor that enables Paper

O = default value

Installed

Forward printing and Reverse printing

Slip/Sprocket are used.

sprocket paper.

Selects auto line feed.

(Selects auto line feed by CR Code)

Selects conditions of BUSY O Yes (Off-line or receive

Cover Open

(Changes the print area)

End Signal.

• RNE: Receipt/Journal Near End

Sensor

• RE: Receipt/Journal End Sensor

O Yes

No

Yes(E-13B)

O No

0.25mm Right

0.20mm Right

0.15mm Right

0.10mm Right

0.05mm Right

0

0.05mm Left

0.10mm Left

0.15mm Left

0.20mm Left

0.25mm Left

-1.75mm ~ +1.75mm

*Can be set in the 0.35mm

unit

*Default value: 0 mm

-1.75mm ~ +1.75mm

*Can be set in the 0.35mm

unit

*Default value: 0 mm

Yes

O No

O 16K

HSD

buffer-full)

No (Receive buffer-full)

O Yes

No

O 76.2mm

69.5mm

O Unslashed

139.7mm

215.9mm

O 279.4mm

304.8mm

O Yes (RNE or RE)

Yes (RE)

No

Note 1) I/F control information (baud rate, etc.) and customer display connection/disconnection of serial model are set by

DIP-SW on the I/F board.

Note 2) MICR Unit selection has the following two types for MICR Read test (Refer to Section 2.6): “Yes (CMC-7),” and

“Yes (E-13B).” Normally, either selection is recognized as an actual installation status of MICR Unit, and MICR type is

selected by designation of the command.

Note 3) For No. 3, 4, and 5, adjust to the proper values at factory shipment.

38

OKIPOS 425D

|

Page 39

2.3.3 How to Operate

Start

To start the Menu Mode, turn the printer on while holding down SW2 + SW1. When the printer’s initialization ends correctly,

the printer prints the title “Menu Print” and all the menu items and set values. Then, the printer line-feeds until the print result

goes beyond the Manual Cutter position, prints the item/set value immediately after “Menu Print,” then waits for a switch to be

pressed.

Operation

The switch functions during the menu mode are as follows:

A25008.doc

Switch Function

Advances the set values of the Menu Item, one at a time. From the last set

SW2

SW3 Ends Menu Mode.

SW1 Advances the Menu Items, one at a time.

SW4 Feeds the receipt, by one line

value, returns to the first set value.

Registers the set values in EEPROM, then prints the end message “Menu

End” and returns to the same in itialized state as at power on.

From the last Menu Item, returns to the fir st Menu Item.

Developer’s Guide: English 39

|

Page 40

2.4 Hex Dump Function (Receipt)

This function converts received data, as it is, to character codes, and prints it in the Receipt mode. The printed contents are as

follows: Upon receiving one byte, the printer divides it into three characters, High-nibble, Low-nibble and a space. Regarding

these as 1 block, the printer prints 8 blocks in one line, then, prints the same data in the character format.

Upon entering the HEX dump mode, the printer prints “Hex Data Dump”. (Title printing)

2.4.1 Print Format

OP425_03c.eps

Hex Data Dump

0000 XX XX XX XX XX XX XX XX : ........

0008 XX XX XX XX XX XX XX XX : ........

.

.

.

.

FFF8 XX XX XX XX XX XX XX XX : ........

0000 XX XX XX XX XX XX XX XX : ........

.

.

.

.

Hex dataLine No. ASCII data

2.4.2 How to Print

1 If it does not receive data after 150ms have passed since receiving last data, the printer starts printing (CR) if it has some

data.

(If there is not enough data to form 8 blocks, spaces will be used.)

If it subsequently receives data, the printer prints from a position next to the position at which the printing started.

2 If it receives the I-PRIME signal (Parallel model)/Reset signal (Serial model), the printer starts printing if it has some data,

then feeds one line. Then, the printer is initialized. (If it does not have any data, the printer feeds one line and then is

initialized.) After the initialization, the printer starts up in dump mode again and prints. The line number is reset,

however, and counting begins from “0000”.

* When I-PRIME signal (Parallel model)/Reset signal (Serial model) is hard reset (setting by Short Plug with Parallel I/F

board and by DIP SW with Serial I/F board), it immediately starts initialization and does not continue hex dump.

3 One line-feed is added for every 16 lines.

4 The count begins from “0000” when the line number exceeds “FFF8.”

40

OKIPOS 425D

|

Page 41

2.5 Using the MICR Reader

If your printer has the factory installed optional MICR (Magnetic Ink Character Recognition) reader that enables the printer to

read and process MICR characters on personal checks, read this section.

Note 1: If Cut-sheet Paper or Sprocket Paper has been loaded, eject it before you use the MICR feature. This does not apply

to the Roll Paper.

Note 2: When the Tractor (Option) (1) has been installed, remove or park the Sprocket Paper, then switch the Lever to the

Cut Sheet side (1) from the Sprocket side (3)

o425_50.jpg

2

1

3

Note 3: When using a MICR-version machine, align the marks “¶” and “Ä” as shown and set the paper along the paper

guide.

Note 4: Use a flat Check Sheet. If you use Check Sheets that are dog-eared, have wrinkles, or are wavy, they are more likely

to cause a paper jam, scan failure, or damage to the MICR Head.

o425_59.jpg

1

1 Sheet Guide

Developer’s Guide: English 41

|

Page 42

How to use the MICR Reader

1. Send the command “FS a 0 n” from the host computer. Then the printer shifts to the MICR Mode and waits for the Check

Sheet to be inserted. LED3 blinks slowly in orange (repeats 1 sec ON, 1 sec OFF).

2. Insert the Check Sheet with its magnetic ink print surface up and the magnetic ink print area to the right side of the

direction of insertion, butting it against the right side of the printer. The printer feeds the Check Sheet and reads at the same

time.

3. To print on the Check Sheet, send the command “FS a 1” which feeds the Check Sheet to the print start position, then send

the print command.

4. To eject the Check Sheet, send the command “FS a 2.”

5. T o have the Check Sheet read results sent again, send the command “FS b.”

42

OKIPOS 425D

|

Page 43

2.6 MICR Read Test (Receipt)

This function performs MICR read and prints that result on the receipt paper.

Effective only when the MICR unit is installed and “MICR Unit = Yes(CMC-7)” or “MICR Unit = Yes(E-13B)” is set in the

menu.

(1) How to start

Turn the power on while holding down SW2 + SW3.

(2) How to exit

Turn the power off.

(3) Contents of the test

(a) When this mode is started, the printer enters Wait for MICR Insertion state.

(b) Insert MICR card and perform MICR read.

(c) The printer prints MICR read results on the Receipt paper, and enters Wait for MICR Insertion state.

(b) and (c) above are repeated.

Developer’s Guide: English 43

|

Page 44

(4) Contents printed

When Read is OK:

(a) Prints “Read OK.”

(b) Prints the MICR read results in HEX dump.

(“XX XX ...... XX” + ASCII: 1 line contains 8 byte information)

When Read is NG:

(a) Prints “Read NG.”

(b) Prints the MICR read results (Return Code (1 byte) and read data) in HEX dump.

(“XX XX ...... XX” + ASCII: 1 line contains 8 byte information)

• Regarding MICR Read result, Return Code (1 byte) and Read Data are printed.

When the Return Code is 30H (“No errors”), it is assumed as “Read OK.” Otherwise, it is assumed as “Read NG.”

• Return codes are shown below:

Return code Status

30H (0) No errors.

33H (3) Error: Read/Decode error.

34H (4) Error: No magnetic ink detected.

36H (6) Error: Document jam or document is too long.

• When character set is CMC-7, the below codes are returned.

A25010a.doc and OP425_01.tif

A: dash symbol

B: amount sym bol

C: transit symbol

D: On-Us symbol

E: comma symbol

A25010.doc

Character Code Character Code Character Code Character Code

131H232H333H434H

535H636H737H838H

9 39H 0 30H (space) 20H A 41H

B 42H C 43H D 44H E 45H

• When character set is E-13B, the below codes are returned.

A25011a.doc andOP425_02.tif

A: dash symbol

B: amount symbol

C: transit symbol

D: On-Us symbol

A25011.doc

Character Code Character Code Character Code Character Code

131H232H333H434H

535H636H737H838H

9 39H 0 30H (space) 20H - A 41H B 42H C 43H D 44H

Note In both cases of CMC-7 and E-13B, special character codes are different from those sent to host by a check paper

read command.

44

OKIPOS 425D

|

Page 45

2.7 Rewinder Winding Evaluation Continuous Print Test (Journal)

This function performs print/platen switch continuous test to evaluate the rewinder winding performance.

(1) How to start

Turn the power on while holding down SW3 + SW1 + SW4.

(2) How to exit

Turn the power off.

• During test printing, if you press SW1, printing suspends. If you press SW1 again, printing resumes.

(3) Contents printed

(a) Prints “HHH”+ Space + “HHH” (UTL characters)

(b) Print Sheet Mode switching (Journal ® Slip ® Journal)

Developer’s Guide: English 45

|

Page 46

2.8 Using the Auto Cutter

This printer is equipped with an Auto Cutter. Follow the procedure below to automatically cut the Roll Paper (Receipt).

Note 1: Make sure that “Auto Cutter Unit” items in the menu are set to “Yes.” If there are any “No” items, change them to

“Yes.”

Note 2: Never touch the Auto Cutter Window part (paper route); this could cause an injury.

Note 3: Do not operate the Auto Cutter (1) when a foreign object is in the Auto Cutter Window (paper route) (2) or when

paper is jammed. Do not use Roll Paper that does not match the specifications. Using such paper may damage the

Auto Cutter or may shorten its life.

o425_85.jpg

1

How to Use

1. Manual operation

When SW 3 (2) is pressed, the cutter cuts the paper partially (1 point remains) once regardless of media mode and media

status. When “Auto Cutter Unit = No” is set in the menu, the switch does not work even if you press it down. Manual

operation does not cut the paper fully.

2. Operation from your host computer

Send Command “US*0E*02”: One full cut.

Send Command “US*0E*03”: One partial cut (1 point remains).

2

3

46

OKIPOS 425D

|

Page 47

3. Maintenance

3.1 Replacing the Ribbon Cartridge

When printing becomes light, replace the Ribbon Cartridge, following the procedure shown below:

1. Make sure the printer is turned OFF.

2. Press the Cover open bar and open the printer cover.

o425_31.jpg and o425_32.jpg

3. Center the printhead.

o425_86.jpg

Developer’s Guide: English 47

|

Page 48

4. Swing the front of the cartridge up off the printhead, then lift the cartridge out and discard it.

Caution! The printhead may be HOT!

o425_87.jpg

5. Unpack the ribbon cartridge.

Important! Do NOT remove the ribbon shield (1) from the ribbon!

o425_07.jpg

1

2

3

1 Ribbon Shield

2 Take-up Knob

3 Grip Points

6. Install the new ribbon cartridge.

1) Hold the ribbon cartridge as shown below.

o425_87.jpg

48

2) Fit the grooves in the flat end of the cartridge over the posts on the ribbon plate.

OKIPOS 425D

|

Page 49

3) Lower the front of the cartridge over the printhead until it snaps into place.

o425_87.jpg and o425_88.jpg

4) Turn the knob (1) in the direction of the arrow on the cartridge to take up the ribbon slack.

o425_86.jpg

1

Developer’s Guide: English 49

|

Page 50

3.2 Replacing the Roll Paper

When the Roll is used up, load a new one, following the procedure shown below.

3.2.1 Roll Paper (Receipt)

1. Press Form Feed switch (1) on Receipt side so that the whole Receipt Paper (2) is ejected.

o425_62.jpg

2

1

2. Press the Cover Open Bar and open the Printer Cover.

* Caution! The printhead may be HOT!

o425_31.jpg and o425_32.jpg

3. Load new paper roll.

For loading Roll Paper, refer to Section 1.5.1.2.

50

OKIPOS 425D

|

Page 51

3.2.2 Roll Paper (Journal)

1. Make sure that the media mode is set to one of the following: Receipt mode, journal mode, or Receipt + Journal mode. If

not, set to one of the above modes. For mode switching, refer to Section 2.1.

2. Press Form Feed switch on the Journal side so that the whole Journal Roll Paper is ejected.

o425_72.jpg

1

2

1 Journal Paper Form Feed Switch

2 Media Mode Display LED

• Green light on: Journal + Receipt mode

• Green light blinking (slow): Journal mode

• Green light blinking (quick): Receipt mode

3. Press the Cover Open Bar and open the printer cover.

Caution! The printhead may be HOT!

o425_31.jpg and o425_32.jpg

Developer’s Guide: English 51

|

Page 52

4. Remove the paper roll (Journal) on the rewinder following the procedure below.

(1) Remove the rewinder (1) from the printer.

(2) Rotate the flange (2) in the direction shown below and remove it from the rewinder.

Note 1: Rotation direction of the flange varies depending on the width of the Roll Paper.

Arrow 3: Wide Roll Paper (Width: 76.2 mm)

Arrow 4: Narrow Roll Paper (Width: 69.5 mm)

Note 2: When a spacer is installed, remove the spacer along with the flange.

o425_73.jpg

2

1

3

4

(3) Pull the Roll Paper (1) out from the rewinder (2). When it is tight, rotate the rewinder in the direction below, and pull

out the paper.

o425_74.jpg

1

2

5. Load new paper roll.

For loading Roll Paper, refer to Section 1.5.1.4.

52

OKIPOS 425D

|

Page 53

3.3 Clearing Paper Jams

When Roll Paper gets jammed, remove the paper, following the procedure shown below:

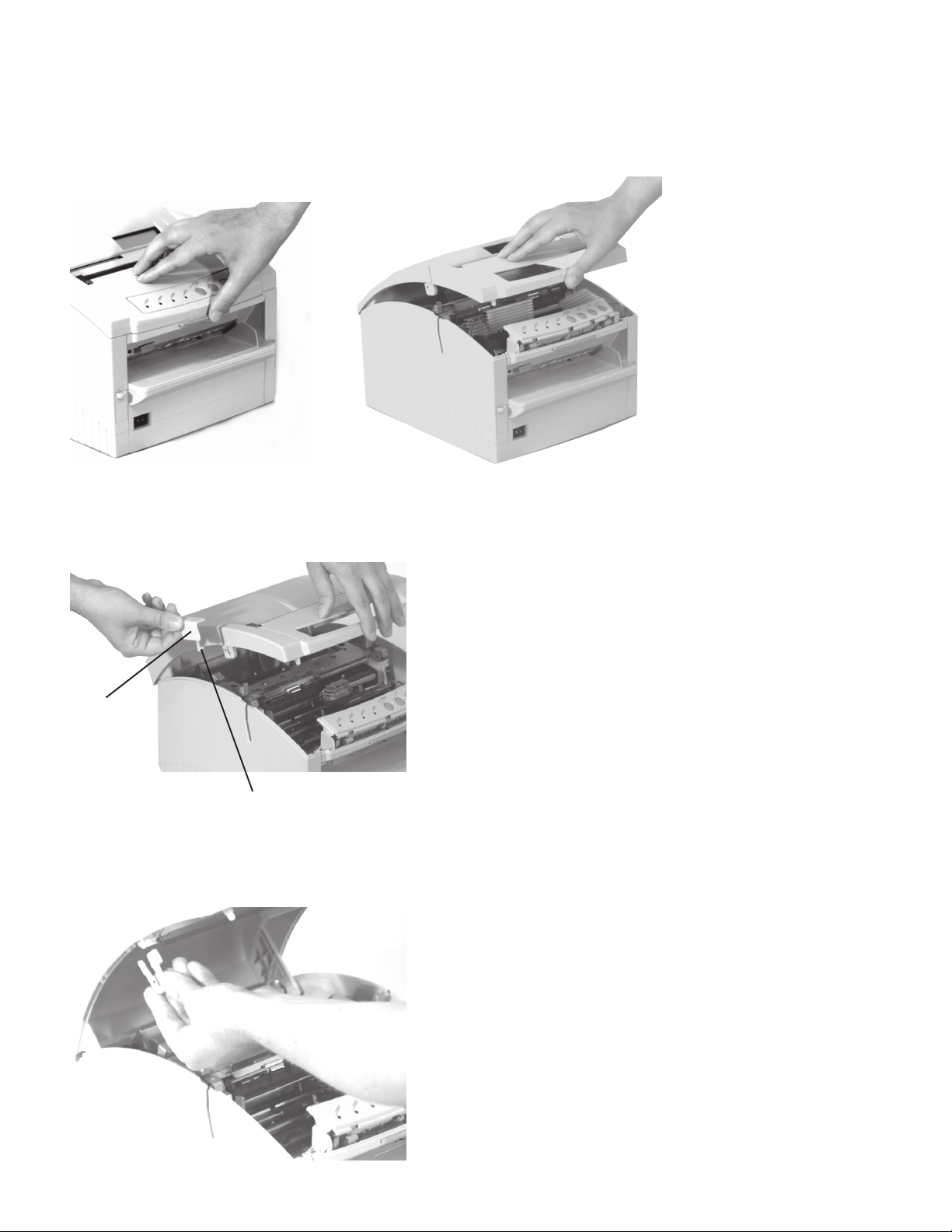

1. Press Cover Open Bar and open the printer cover.

* Print head may be very hot. Exercise caution.

o425_31.jpg and o425_32.jpg

2. Remove the rewinder and cut the Roll Paper at the location shown below.

o425_75.jpg

1

2

1 Roll Paper (Receipt) not yet printed

2 Roll Paper (Journal) not yet printed

3 Cut Positions

3

Developer’s Guide: English 53

|

Page 54

3. Press the two levers (1) on either side at the same time as shown, lift the plate assembly and gently pull out the jammed

paper in the direction of the arrow.

Note:Be careful not to leave small pieces of paper.

o425_76.jpg and o425_77.jpg

1

4. Load a new paper roll.

For the procedure to load Roll Paper, refer to Section 1.5.1.

Note: Before loading Roll Paper, press down on the two levers shown below to close the plate assembly securely.

o425_78.jpg

1

Auto Cutter

When paper gets jammed at the Auto Cutter, remove the paper following the procedure below.

1. Press the Cover Open Bar, and open the printer cover.

Caution! The printhead may be HOT!

o425_31.jpg and o425_32.jpg

54

OKIPOS 425D

|

Page 55

2. Remove the rewinder and cut the paper at the positions (1).

o425_75.jpg

1

3. Press down the two levers shown below simultaneously, lift up the plate assembly, and gently pull out the paper (Journal)

in the direction shown below.

o425_76.jpg and o425_77.jpg again

4. Cut the paper roll (Receipt) and gently pull out the paper in the direction shown below.

o425_77.jpg

Developer’s Guide: English 55

|

Page 56

5. Gently remove the paper left on the Auto Cutter.

Note: When the blade of the Auto Cutter is exposed, turn the knob (1), and manually move the blade to the original

position.

o425_79.jpg

1

Note: Turn on the power . If the Auto Cutter behaves abnormally, contact your shop or maintenance service.

Note: Do not forcibly remove a piece of paper left in the Auto Cutter . Use a vacuum cleaner, or contact maintenance

service.

Cut-Sheet Paper

When cut-sheet paper gets jammed, remove the paper, following the procedure shown below:

1. Press the Cover Open Bar and open the printer cover

* Print head may be hot. Exercise caution.

o425_31.jpg and o425_32.jpg

2. Slowly pull out the paper upward or toward you while pulling the lever (1) [marked “PULL”] toward you.

Note: Be careful not to leave small pieces of paper behind.

o425_60.jpg

56

OKIPOS 425D

|

1

Page 57

Sprocket Paper

When sprocket paper gets jammed, remove the paper, following the procedure shown below.

1. Open the Tractor Cover (1) and cut the sprocket paper at the perforation (2).

o425_57.jpg

2

1

2. Press the Cover Open Bar and open the printer cover

o425_31.jpg and o425_32.jpg

3. Slowly pull out the paper upward or toward you while pulling the lever (1) [marked “PULL”] toward you.

Note: Be careful not to leave small pieces of paper behind.

o425_80.jpg

1

Developer’s Guide: English 57

|

Page 58

4. Troubleshooting and Repair

4.1 Alarm Indication for a Failure

When a failure occurs, the printer indicates its contents with LED1 lamp on the operation panel, which blinks in different ways

depending on the failure type.

Note: OEM Fiscal Type:

The alarm indication works only when the Fiscal Control PCB is not mounted.

o425_20.jpg

1 POWER LED Green

2 LED1 Red

3 LED2 Orange

4 LED3 Orange

LED4 Green

5 SW2

6 SW3

7 SW1

8 SW4

456123 7

Operation Panel

8

58

OKIPOS 425D

|

Page 59

4.1.1 Details of Alarm Indications

Table411.doc

No. of

times

LED 1

blinks

1 Program ROM Alarm

2 EEPROM Alarm

3 Internal RAM Alarm

4 External RAM Al arm

5 Homing Alarm

6 Spacing Alar m

7 Auto Cutter Alarm Is a piece of paper jammed in the paper passage of

8 Platen Switching Alarm Is the media jammed?

9 Head A/D Error

10 WDT (F/T Control)

11 NMI (F/W Control)

12 BRK (F/W Control)

13 MICR Unit Error (only

14 Interface PCB Error (only

Malfunction contents What you should do

Contact the store where you bought the printer or

the Maintenance Service Center

Is the media jammed?

If it is, remove the jammed paper.

→

Is the ribbon snagged?

Replace the ribbon.

→

If the above do not a pply to your case, contact the

store where you bought the printer or the

Maintenance Se rvice Center

the Auto Cutter?

Caution: The Auto Cutter blade is very sharp — do

not touch it.

→ Turn off the printer, then remove the jammed

paper. Be careful not to touch the blade.

If there is no jammed paper, contact your service

department or retailer.

→ If it is, remove the jammed paper.

If this is not the case, contact the stor e where you

bought the printer or Maintenance Service Center

Contact the store where you bought the printer or

Maintenance Se rvice Center

Although the MICR Option is not installed in your

with MICR type)

OKI standard type)