Page 1

OKIPLATE 904PSIII

OKIPROOF 905PSIII

Maintenance Manual

1999. 3. 4 Rev. 2

40801701TH Rev.2 1 / 122

Page 2

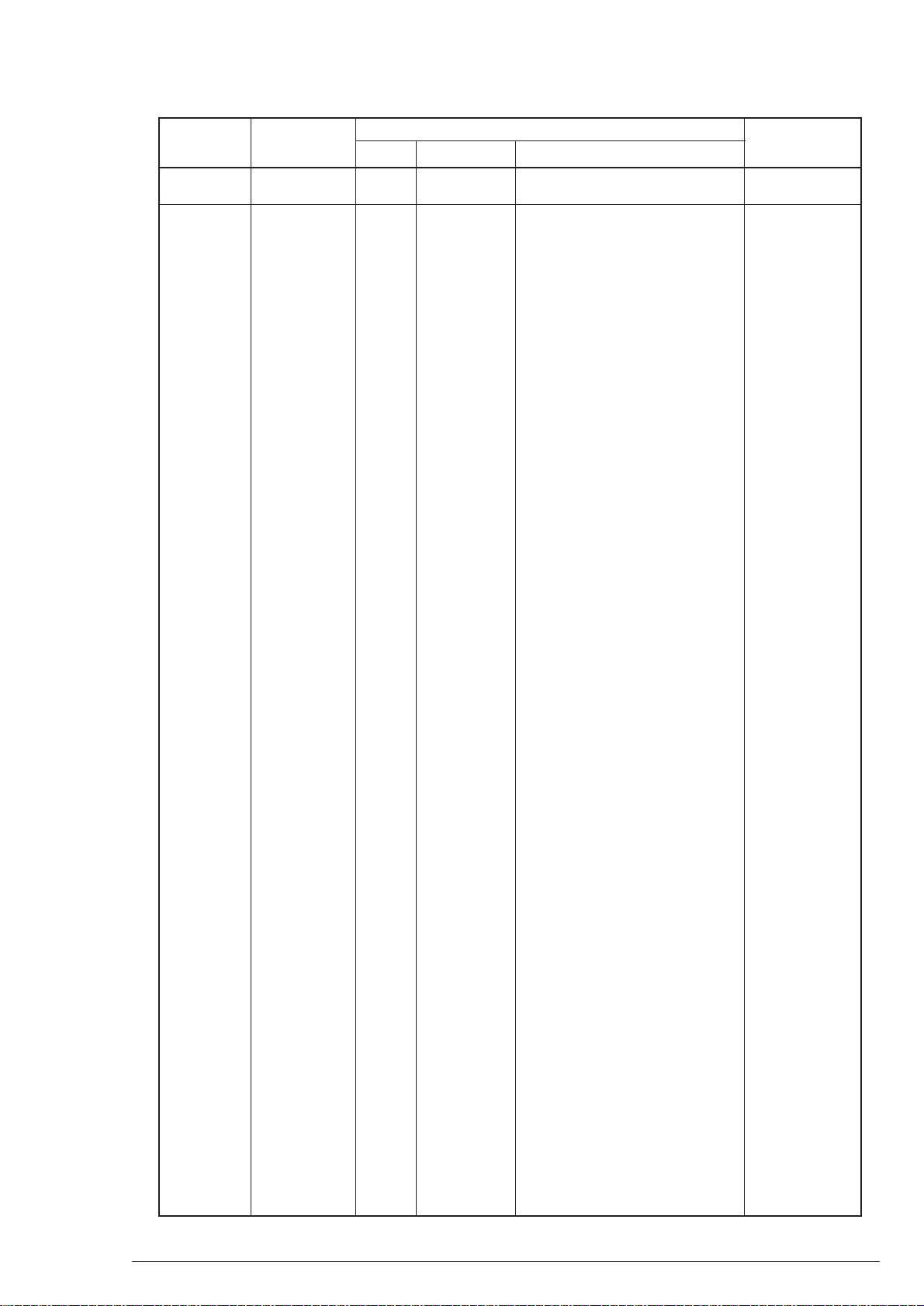

Rev.No. Date Corrected items Person in

No. Page Description of change change

2 1999.3.4 4.1.2 67 Revision of Table E1 Miyazaki

40801701TH Rev.2 2 / 122

2 /

Page 3

Introduction

Introduction

This manual, intended for maintenance personnel, describes the machine maintenance methods in its field.

For handling and operating, see the “Users Manual”. The unit names are referred to as follows.

OKIPLATE 904PSIII .........................OP904

OKIPROOF905PSIII .........................OP905

*Difference of OP904 from OP905 is in

Controller Board (Board Same, only RAM Capacity Different);

LED Head, Mechanism Control Board (Board and ROM Different),

and their print engine blocks are the same.

Note:

40801701TH Rev.2 3 /

• All or any part of the contents is not allowed to be reproduced without permission from the

owner of copyright.

• The contents are subject to change due to improvements in the machine or the description in

the manual itself without notice.

Page 4

Contents

Contents

1. Configuration................................................................................................................... 7

1.1 System Configuration............................................................................................................................7

1.2 Printer Configuration .............................................................................................................................8

1.3 Specification..........................................................................................................................................9

1.4 Printer Indication .................................................................................................................................11

1.4.1 TÜF, CE Label ..............................................................................................................................11

1.4.2 Warning Label ...............................................................................................................................11

2. Operation Description ...................................................................................................12

2.1 Circuit Operation Description ..............................................................................................................14

2.1.1 Controller ......................................................................................................................................14

2.1.1.1 Hardware Configuration ..........................................................................................................14

2.1.1.2 Circuit Operation Description ..................................................................................................15

2.2 Power/Sensor Board ...........................................................................................................................16

2.3 Electrophotographic Process Mechanism...........................................................................................17

2.3.1 Operation Description of Each Process ........................................................................................19

2.4 Paper Jam Sensing.............................................................................................................................26

2.5 Cover Open State ...............................................................................................................................26

2.6 “Toner-low” Detection .........................................................................................................................27

2.7 Paper Size Sensing ............................................................................................................................27

3. Parts Replacement........................................................................................................28

3.1 Parts Replacing Precautions...............................................................................................................28

3.2 Parts layout .........................................................................................................................................30

3.3 Parts Replacing Methods ....................................................................................................................35

3.3.1 Face-up Stacker Assy...................................................................................................................36

3.3.2 Contact Assy.................................................................................................................................37

3.3.3 DC Fan Motor ...............................................................................................................................38

3.3.4 Operator Panel Assy.....................................................................................................................39

3.3.5 SRA-PCB .....................................................................................................................................40

3.3.6 Stacker Cover Assy, DC12V Fan Motor, Damper Arm .................................................................41

3.3.7 Damper .........................................................................................................................................43

3.3.8 Eject Roller Assy ...........................................................................................................................44

3.3.9 Separation Piece (Sticky)..............................................................................................................45

3.3.10 FF Roller Assy, Bearing F ...........................................................................................................48

3.3.11 Paper Feed Motor .......................................................................................................................49

3.3.12 Resister Roller Assy....................................................................................................................50

3.3.13 Main Motor, Resister Motor.........................................................................................................51

3.3.14 Fuser Assy ..................................................................................................................................53

3.3.15 Fusing guide ...............................................................................................................................54

3.3.16 Back-up Roller ............................................................................................................................55

3.3.17 Hopping Roller Assy ...................................................................................................................56

3.3.18 Power Supply..............................................................................................................................57

3.3.19 Paper End Lever .........................................................................................................................58

3.3.20 Detector Spring, LLSW-PCB (First Tray) ....................................................................................59

3.3.21 LED Head ...................................................................................................................................60

40801701TH Rev.2 4 /

Page 5

Contents

3.3.22 Paper Cassette ...........................................................................................................................61

3.3.23 Transfer Roller, TR Gear, TR Bearing ........................................................................................62

3.3.24 Feeding Roller.............................................................................................................................63

3.3.25 Detector Spring, LLSW-PCB (Second Tray)...............................................................................64

4. Adjustment ....................................................................................................................65

4.1 LED Head Driving Time Set-up...........................................................................................................65

4.1.1 Outline of Set-up Procedure .........................................................................................................66

4.1.2 Driving Time Set-up ......................................................................................................................67

4.2 Fuser Counter Reset (only OP905) ....................................................................................................69

5. Routine Maintenance ....................................................................................................70

5.1 Routine Replacement Parts ................................................................................................................70

5.2 Cleaning..............................................................................................................................................70

5.2.1 LED Lens Array Clearning ...........................................................................................................70

6. Troubleshooting Produre...............................................................................................72

6.1 Prior to Repairing ................................................................................................................................72

6.2 Check Points prior to Handling Imperfect Image ................................................................................72

6.3 Precautions on Handling Imperfect Image..........................................................................................72

6.4 Preparation for Troubleshooting .........................................................................................................73

6.5 Troubleshooting Methods ...................................................................................................................73

6.5.1 LCD Status Message List .............................................................................................................73

6.5.2 LCD Message Troubleshooting ....................................................................................................77

6.5.3 Imperfect Image Troubleshooting .................................................................................................85

6.5.4 Manual Feed Hopper Assy Opening/Closing Troubleshooting .....................................................94

7. Connection Diagram .....................................................................................................95

7.1 Connection Diagram ...........................................................................................................................95

7.2 Board Layout.......................................................................................................................................99

8. Interface Specification.................................................................................................104

8.1 Interface Specification.......................................................................................................................104

8.1.1 Centronics Interface Specification ..............................................................................................104

8.1.2 Centronics Interface Connector and Cable.................................................................................104

8.1.3 Centronics Interface Level ..........................................................................................................104

8.1.4 Centronics Interface Circuit.........................................................................................................105

8.2 RS232C Interface Specification ........................................................................................................107

8.2.1 RS232C Interface General..........................................................................................................107

8.2.2 RS232C Interface Connector and Cable ....................................................................................107

8.2.3 RS232C Interface Level..............................................................................................................107

8.2.4 RS232C Interface Circuit ............................................................................................................108

8.2.5 RS232 Interface Signal ...............................................................................................................108

8.3 RS422A Interface Specification ........................................................................................................109

8.3.1 RS422A Interface General..........................................................................................................109

8.3.2 RS422A Interface Connector and Cable.....................................................................................109

8.3.3 RS422A Interface Signal.............................................................................................................110

8.4 AppleTalk® Interface Specification ....................................................................................................111

8.4.1 AppleTalk® Interface General.....................................................................................................111

8.4.2 AppleTalk® Interface and Connector...........................................................................................111

8.4.3 AppleTalk® Interface Level ..........................................................................................................111

40801701TH Rev.2 5 /

Page 6

Contents

8.4.4 AppleTalk® Interface Circuit ........................................................................................................111

8.4.5 AppleTalk® Interface Signal ........................................................................................................112

8.5 Parallel Interface Specification..........................................................................................................113

8.5.1 Electrical Conditions ...................................................................................................................113

8.5.2 Timing Chart ...............................................................................................................................114

9. Component Parts List..................................................................................................115

40801701TH Rev.2 6 /

Page 7

1. Configuration

Controller Block

Centronics

RS232C

Appletalk

RS422A

Ethertalk

Main Control Board

1750MB HDD

Expansion RAM

Board

16MB

Operator

Panel

Engine Block

136 Roman Fonts

EtherTalk

Board

100/10

Base-TX

Engine Control Board

OP905 : Engine

(A3/1200dpi/10ppm)

OP904 : Engine

(A3/600dpi/12ppm)

First Tray

Front Feeder

Second Tray

Power Supply

AC IN

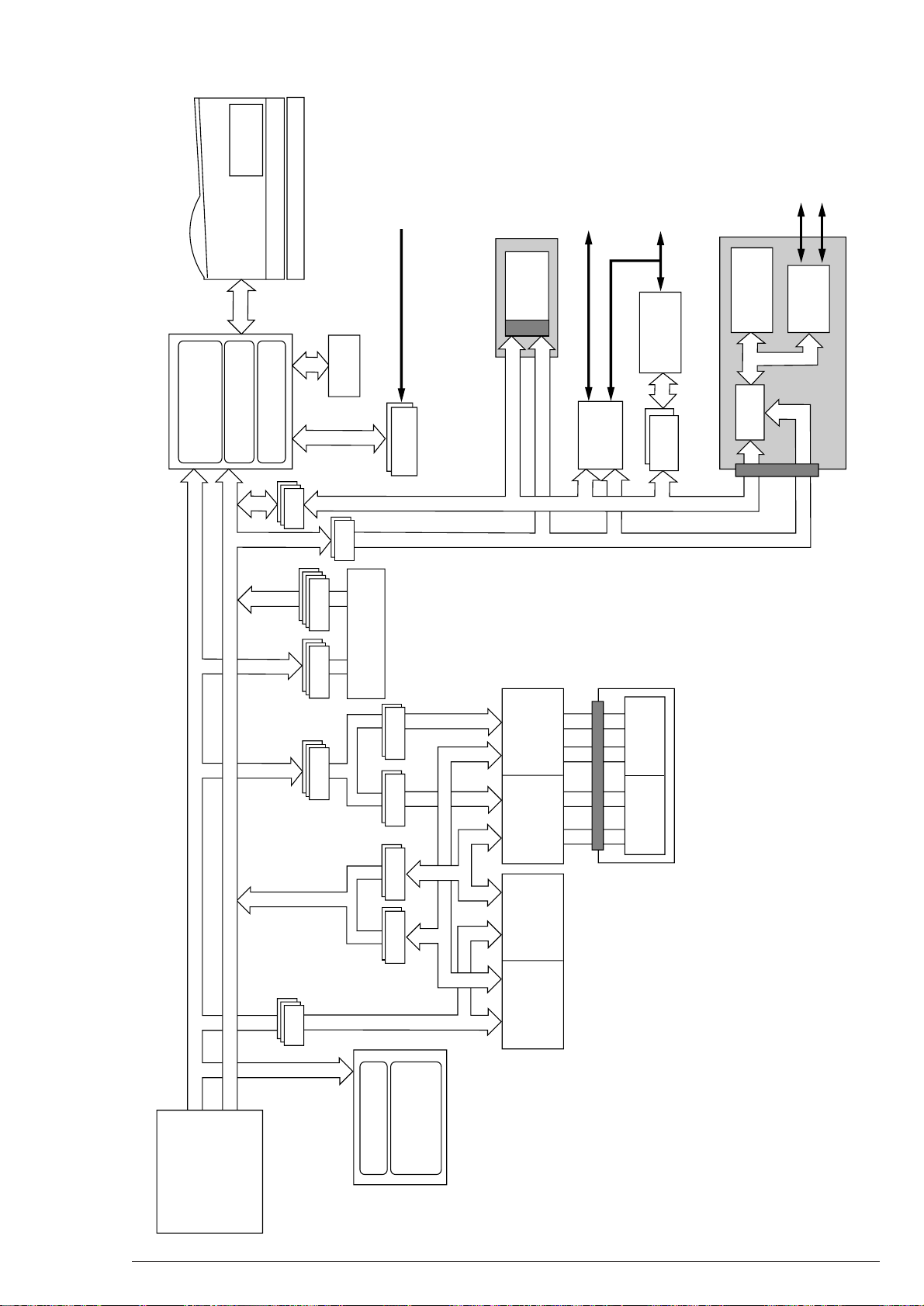

1.1 System Configuration

This unit consists of a control block and an engine block as standard. (See Figure 1-1.)

1. Configuration

Figure 1-1

40801701TH Rev.2 7 /

Page 8

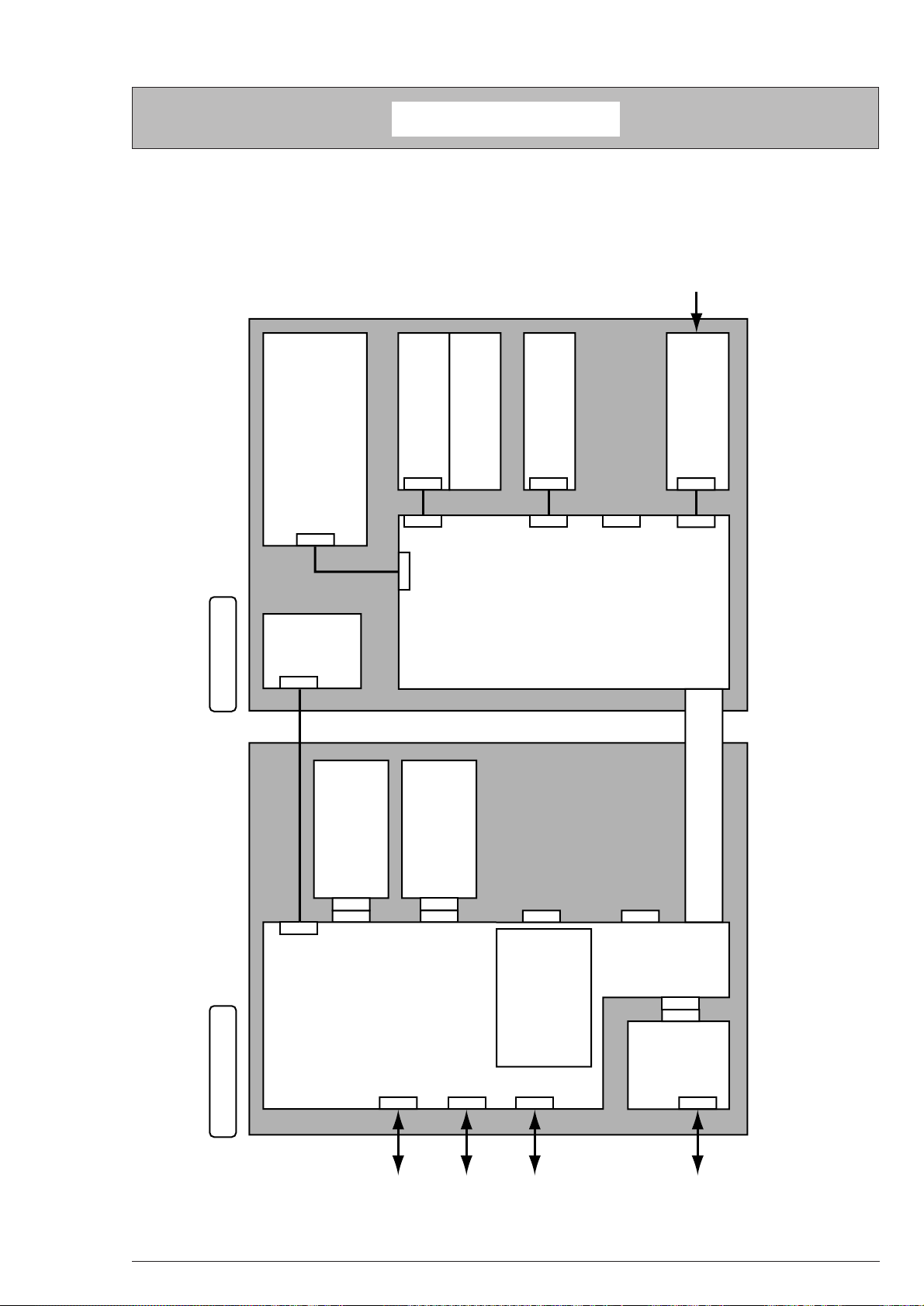

1.2 Printer Configuration

The internal part of the printer consists of the following parts.

• Electrophotographic Processor

• Paper Feeder

• Control Block

• Operator Panel

• Power-supply Unit

Figure 1-2 shows the printer unit configuration.

Only in ML905, the LED head and the circled cover parts differ from those of others.

OP905

1. Configuration

OP905

Figure 1-2

40801701TH Rev.2 8 /

Page 9

1.3 Specification

(1) Type Desk Top Type

(2) External Dimensions Height 317mm

(Excluding protrusion) Width 498mm

Depth 430

(3) Weight 30kg (OP904), 28kg (OP905)

(4) Development Method Dry Electrophotography

Exposure Method LED Head Method

(5) Paper

1. Configuration

Type Size Thickness Texture

Plain

Paper

Thick

Paper

Special

Paper

105 x 148mm

to 328 x 453mm

148 x 210mm

to 328 x 453mm

148 x 210mm

to 328 x 453mm

105 x 148mm

to 328 x 453mm

297 x 488mm

to 340 x 505mm

20lb to 28lb

28lb to 32lb

Appointment paper Vertical

Vertical

Vertical

Vertical

Paper Feed Method

First

Tray

Second

Tray

Front

Feeder

Remark

Use Face-up

Stacker.

Use Face-up

Stacker.

(6) Printing Speed First Printing 16 sec

Consecutive Printing 12 copies/min. (A4 Horizontal)

Warm-up Time 2 min

(AC230V, Ambient Temperature 25°C)

(7) Paper Feed Method Automatic Paper Feed Method, Manual Feed Method

(8) Paper Delivery Method Face-down, Face-up

(9) Resolution 600 x 600 dot/inch (OKIPLATE 904PSIII)

1200 x 1200 dot/inch (OKIPLATE 904PSIII)

(10) Power Input AC230V

(11) Power Consumption Maximum Average

During operation 1100W or less Approx. 400W

Heater off 45W

40801701TH Rev.2 9 /

Page 10

(12) Temperature, Humidity

Temperature Humidity

During

operation

10 to 32°C 20 to 80%RH (Relative Humidity)

In storage -23 to 43°C 10 to 90%RH (Relative Humidity)

No condensation detected.

1. Configuration

Note:

In storage, a packaged condition is required and the period shall

not exceed one year.

(13) Noise During operation 53dB(A) or less

In standby time 45dB(A) or less

(14) Consumables Life Toner Cartridge Approx. 5,000 copies

(A4 5% duty consecutive printing. Except

for the life of the first toner cartridge to be set

to a new drum.)

Drum Cartridge Approx. 10,000 copies

(A4 consecutive printing)

40801701TH Rev.2 10 /

Page 11

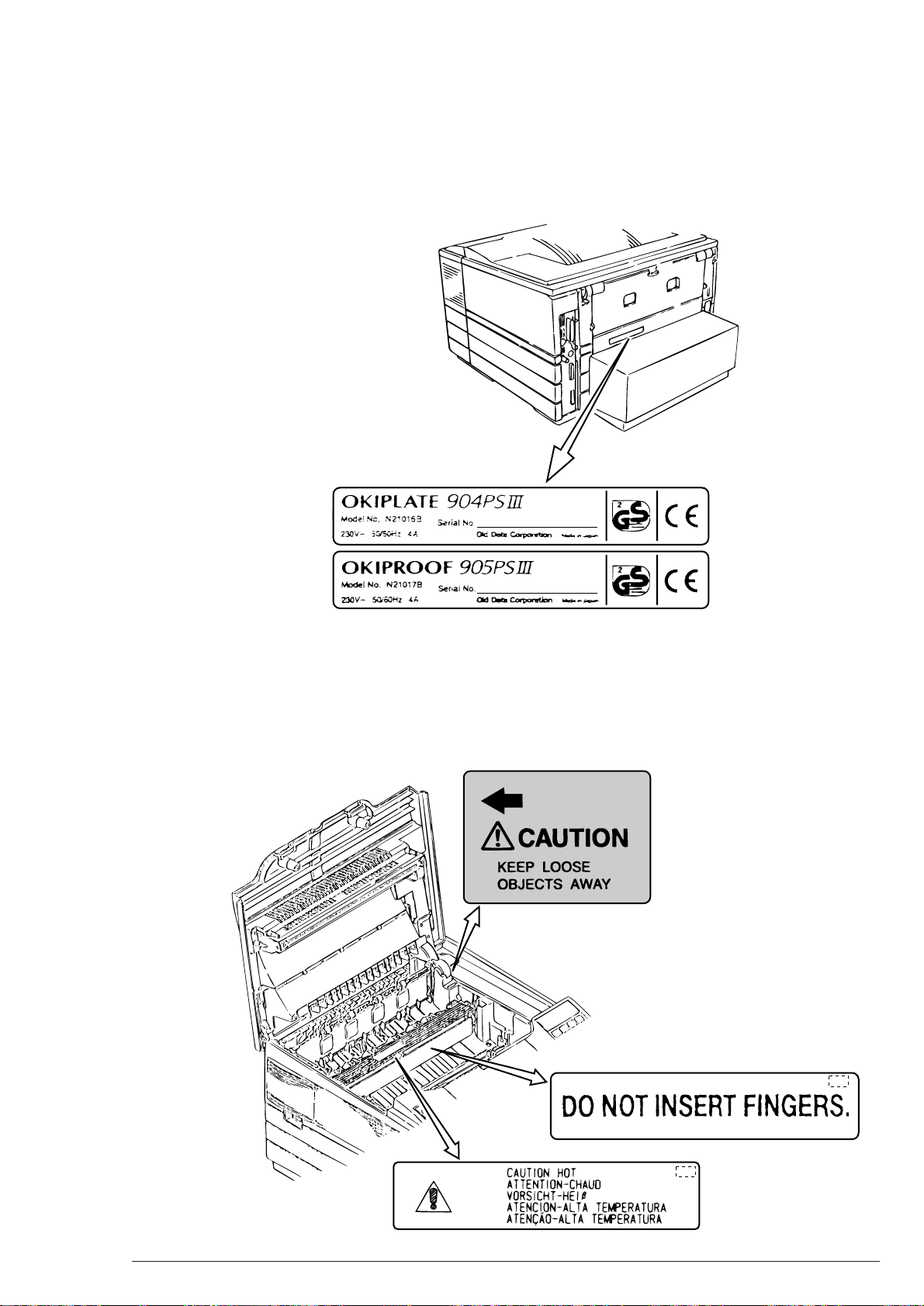

1.4 Printer Indication

1.4.1 TÜF, CE Label

The following parts of the printer are labeled TÜF, CE.

Such as

1. Configuration

1.4.2 Warning Label

Warning indications are given at the places hazardous to human bodies.

Pay attention to the warnings and take precautions carefully while at work.

MN

40801701TH Rev.2 11 /

Page 12

2. Operation Description

2. Operation Description

This unit consists of a control board, a power/sensor board, an operator panel, and an electrophotographic

process mechanism. Print data is received from the host interface. They are decrypted and edited before

sequential storing in memory. When editing one page of data is finished, font memory referring is performed

and bit images are generated in the same memory. Concurrently, the bit images are from time to time transferred

to the LED head by dot line and printed on paper by the electrophotographic process mechanism.

The operator panel operates the device and displays the status.

Figure 2-1 shows the block diagram of the device.

40801701TH Rev.2 12 /

Page 13

SIMM SIMM

ABT373x2 ABT373x2

(Even) (Odd)

Regident DRAM

(16Mbitx8)

(904/905)

(Even) (Odd)

CODE ROM

512K word x 16

x 2

CODE ROM

512K word x 16

x 2

F244x3

F158x3

FCT16543

x2

FCT16543

x2

F245x3

F373x3

F244x2

F244x4

FONT ROM

ATC1284x2

EEPROM

3.5" HDD

(EIDE)

RS232C I/F

Centro I/F

12PPM PRINT UNIT

A3 / 600dpi :OP904

A3 / 1200dpi :OP905

AppleTalk/RS422I/F

100Base-TX

10Base-TX

Address BUS

Data BUS

Command ROM

Address Generation

DRAM Controller,

Refresh, Access

Sequencer

NEC G/A 240pin

uPD65806GN-136-LMU

LS374

85C30

SCSI

NEC G/A 240pin

uPD68806GN-136-LMU

I/O Access Controller

Engine I/F(VIDEOI/F)

Operator Panel,

Command I/F

Operator Panel

Mechanism

Control

POWER UNIT

First Tray 250 sheets

Second Tray 250 sheets

Peripheral Data BUS

NIC Controller

MPD70236

ROM 1MByte

RAM 512KByte

Dualport

RAM

Z80181

ROM 512Kbit

RAM 256Kbit

Am29040-50KC

(Clock 50MHz)

Redident SIMM

16M Byte x 2 (905)

8M Byte x 2

2. Operation Description

Figure 2-1 Block Diagram

40801701TH Rev.2 13 /

Page 14

2. Operation Description

2.1 Circuit Operation Description

2.1.1 Controller

The main control board of the OP900’s controller is a printer controller designed for a postscript. The controller

has a high-performance RISC processor Am29040, 32-megabyte RAM (64 megabytes for OP905), ROM, a

RS-232C port, an AppleTalk TM port, a parallel transmission port, a printer unit interface port, and 512-byte

EEPROM.

This controller is designed so as to connect to an OKI A3 engine and has an OKI standard printer interface.

In this controller, PostScript is used to print images read in a “Text,” a “Graphics,” and a scanner. All the print

files which the controller handles are generated by PostScript programs. PostScript enables graphics image

processes, general program flow control, and data structures.

2.1.1.1 Hardware Configuration

The OP904 and OP905 controllers consist of the following circuit blocks in rough.

(1) RISC Processor

(2) RAM

(3) Program ROM

(4) Font ROM

(5) Printer Interface

(6) Communication Interface

(7) Operator Panel Interface

40801701TH Rev.2 14 /

Page 15

2.1.1.2 Circuit Operation Description

(1) CPU Peripherals

Element Used : AMD-made Am29040-50KC

CPU Operation Clock : 50MHz

Timer : Timer with built-in CPU is used.

(2) Memory Peripherals

(a) RAM

Element Used : Equivalent to HM514400ZP-8

Access : Operation in “High Speed Page” Mode

RAS Inactive only in performing Miss Hit or Refresh.

Refresh Control : CAS before RAS

1024 Refresh/Approx. 10.49mS

Controlling by G/A #1

3 wait (in Miss Hit)

0 wait (in Burust Access)

2. Operation Description

OP905 and OP904 have eight banks of tatal 64-megabyte storage and four banks of total 32megabyte storage, at eight megabytes per bank unit, respectively.

(b) Program ROM

Element Used : Equivalent to 27C852-12

Access time 120nS or less is required.

0 wait (in Burust Access)

0 wait or 1+1 wait (except for Burust)

A 32-bit width or one word is generated with two units because the program ROM is 16-bit wide.

(c) Font ROM

Element Used OP904 : 32M-MASK x 2 + 8M-MASK x 2

OP905 : 32M-MASK x 2 + 8M-MASK x 2

(d) Resident EEPROM

Element Used : Equivalent to X2404(Xicor)

Capacity : 8bit x 256word x 2page

EEPROM is used for data memorizing as fixed memory. Batteries are not required.

Menu set-up values and other data are borne in memory.

40801701TH Rev.2 15 /

Page 16

2. Operation Description

Sensor

Inlet Sensor 1

Inlet Sensor 2

Inlet Sensor 3

Paper Sensor

Outlet Sensor

Paper End Sensor

Toner Sensor

Functions

When paper is loaded, the leading part of paper is detected to

obtain a supervision timing for switching from a hopping operation to a feeding operation. Also paper feeding and its size

are monitored accordong to paper arrival and running time.

Paper Width Check

Paper Width Check

The leading part of paper is detected.

Paper feeding is monitored.

Paper feeding and its size are monitored based on paper

arrival and running time.

The paper end is detected.

Toner-low is detected.

Sensing State

ON : Paper exists.

OFF : No paper exists.

ON : A4 size or larger

OFF : A4 size or smaller

ON : B4 size or larger

OFF : B4 size or smaller

ON : Paper exists.

OFF : No paper exists.

ON : Paper exists.

OFF : No paper exists.

ON : Paper exists.

OFF : No paper exists.

ON LONG : Toner is low.

ON SHORT : Toner exists.

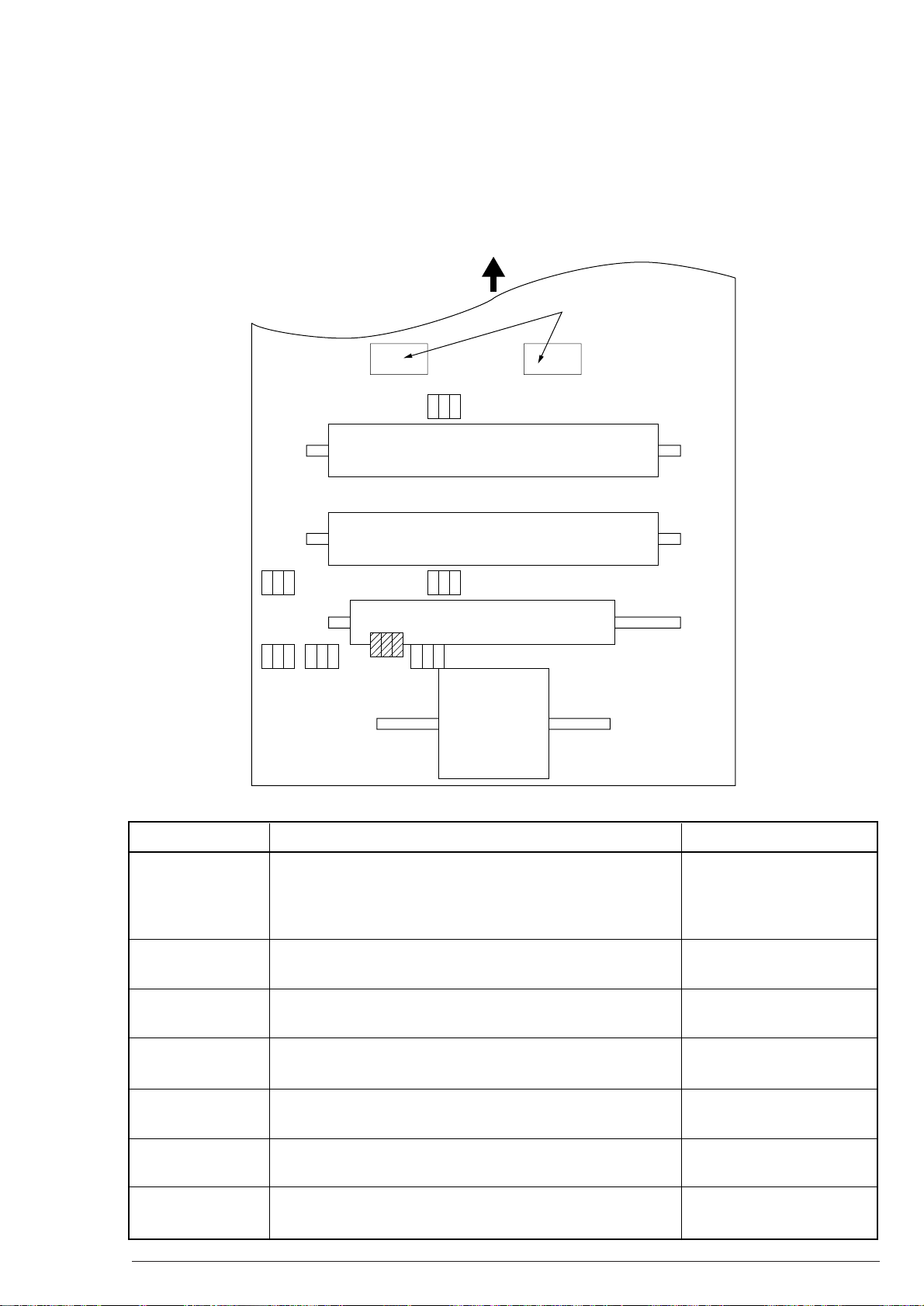

2.2 Power/Sensor Board

This board consists of an AC filter circuit, a low voltage power supply circuit which supplies power to the control

system, a high voltage power supply circuit which supplies power to the electrophotographic process system, a

heater driver circuit, and a photosensor for the paper feed system and toner detection use.

Figure 2-2 shows the sensor layout.

Paper Feeding Direction

Eject Roller

Outlet Sensor

Heat Roller

Transfer Roller

Paper Sensor

Toner

Sensor

Inlet

Sensor 3

Paper End

Sensor

Inlet

Sensor 2

Resist Roller

Inlet Sensor 1

Hopping Roller

Figure 2-2 Sensor Layout

40801701TH Rev.2 16 /

Page 17

2.3 Electrophotographic Process Mechanism

(1) Electrophotographic Process

The following is the outline of the electrophotographic process.

1 Charging

Applying DC voltage to the CH roller charges the surface of the OPC drum evenly in negative.

2 Exposure

Light from the LED head is directed onto the surface of the negatively charged OPC drum. The

emitted parts of the drum surface attenuates in the surface potential and electrostatic latent images

are generated according to image signals.

3 Development and Recovery of Residual Toner

Negatively charged toner contacts the OPC drum. With static, the toner is fixed on the electrostatic

latent images on the drum and changed into its visible images.

At the same time, residual toner on the drum is drawn to the developing roller with static.

2. Operation Description

4 Transfer

The toner is drawn on paper with static by laying the paper on the OPC drum surface and applying

a positive charge opposite to the toner polarity to the back of the paper by the transfer roller.

5 Cleaning

The cleaning roller draws the residual toner on the OPC drum with static after the transfer and then

returns it to the drum.

6 Fusing

Applying heat and pressure fuses post-transfer unfixed toner images on the paper.

40801701TH Rev.2 17 /

Page 18

2. Operation Description

(2) Paper Feeding Motor

48-step/rotation pulse motor. Two-phase excited driving is made based on signals from the control

board.

The hopping roller for the first tray and the front feed roller are driven via two one-way clutches

according to each motor rotating direction.

(3) Resister Roller

48-step/rotation pulse motor. Two-phase excited driving based on signals from the control board

drives the resister roller.

(4) Drum Motor

96-step/rotation pulse motor. Two-phase excited driving based on signals from the cotrol board

changes into motive power of the mechanism.

(5) LED Head

The shift/latch resister receives images by dot line from the control board and 76,800 (600dpi Head),

15,360 (1200dpi Head) of LEDs are driven to emit onto the image drum.

(6) Fuser

A heater, a heat roller, a thermistor, and a thermostat constitute the fuser.

The power/sensor board supplies AC voltage to the heater based on signals (HRATON) from the

control board to heat the heat roller, while the control board supervises the heat roller temperature via

the thermistor and sets on/off the heater AC voltage supply to keep the even temperature.

An extraordinary rise in temperature of the heat roller causes the thermostat in the heater voltage

supply circuit on and cuts off the AC voltage supply by force.

40801701TH Rev.2 18 /

Page 19

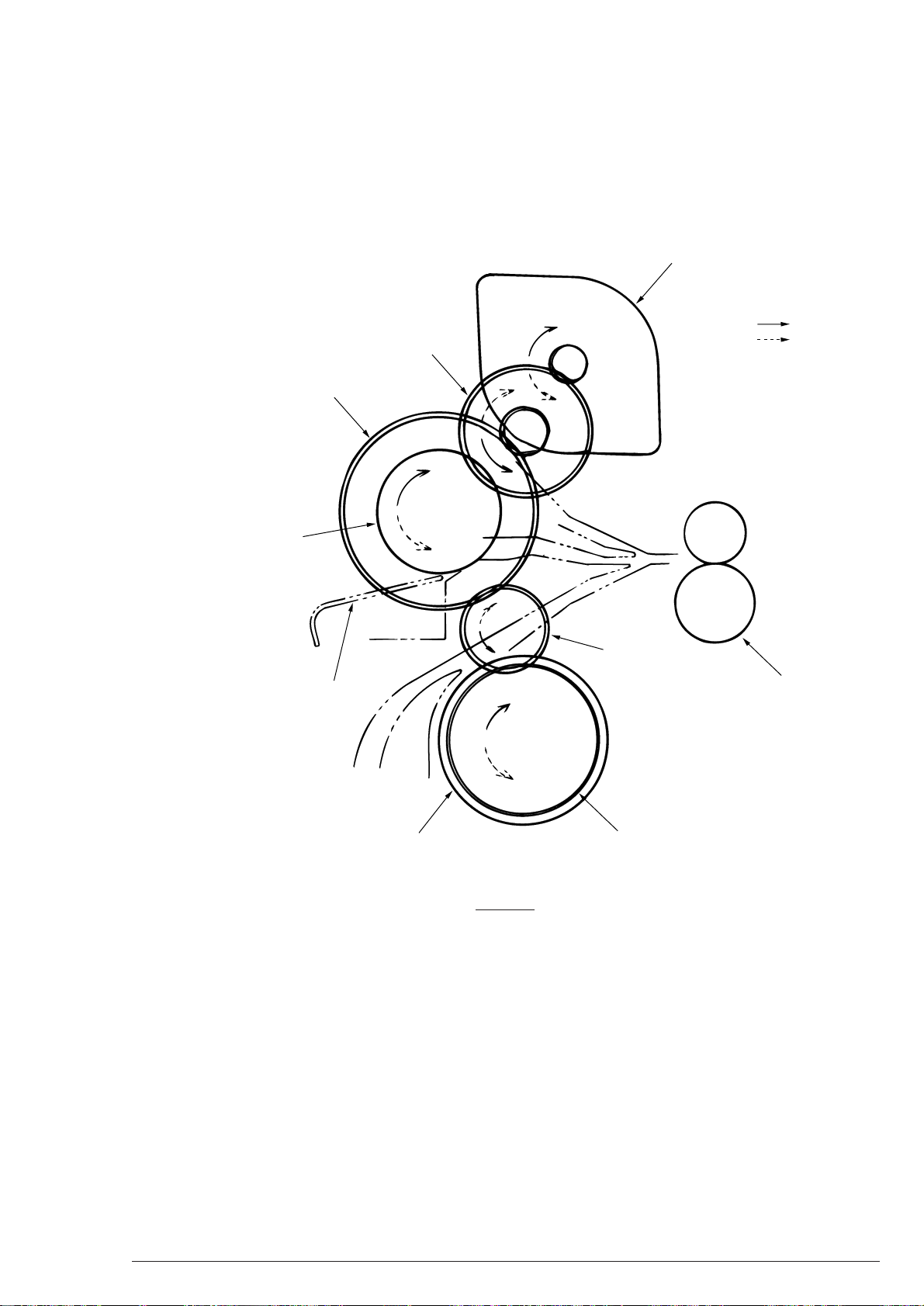

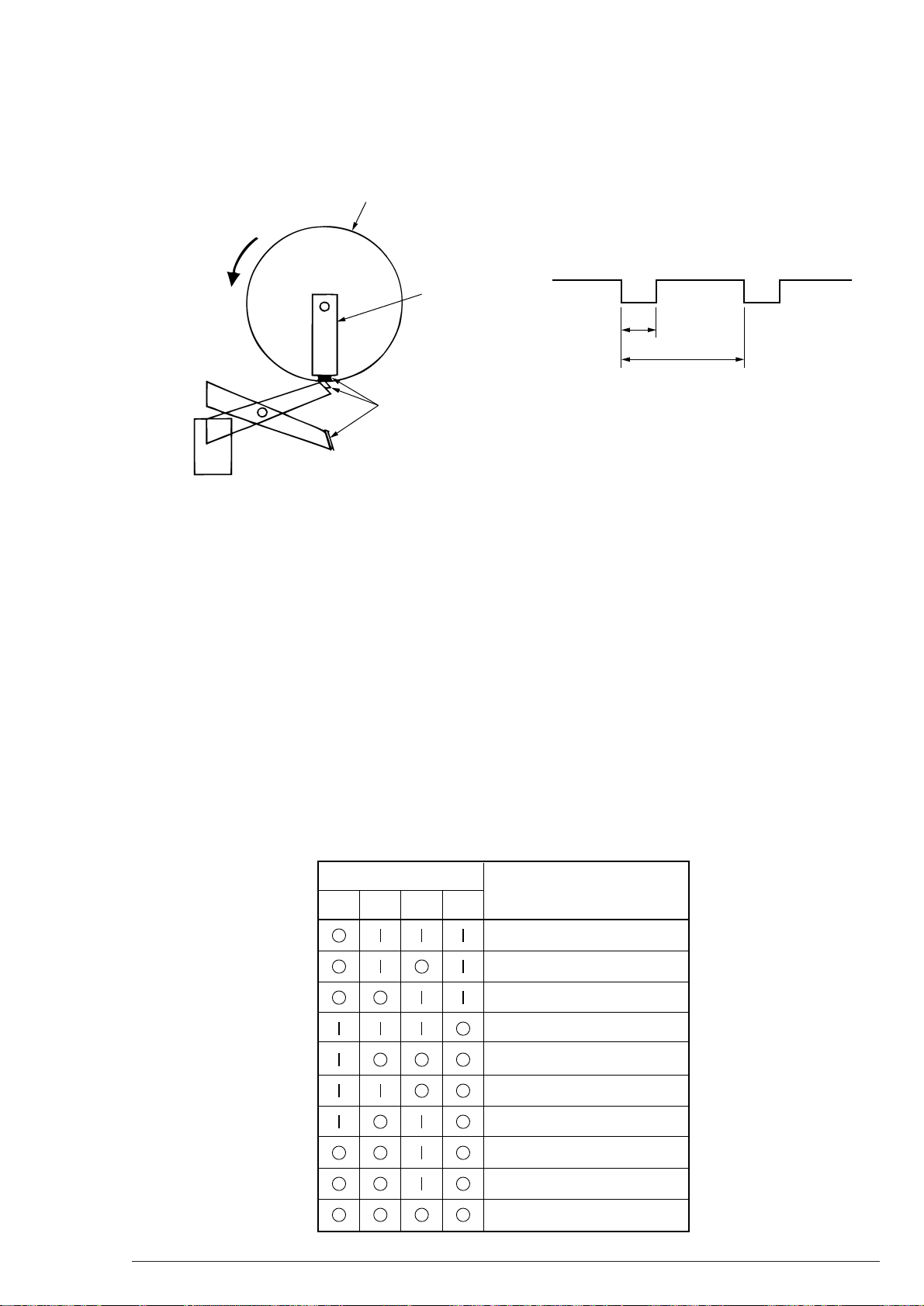

2.3.1 Operation Description of Each Process

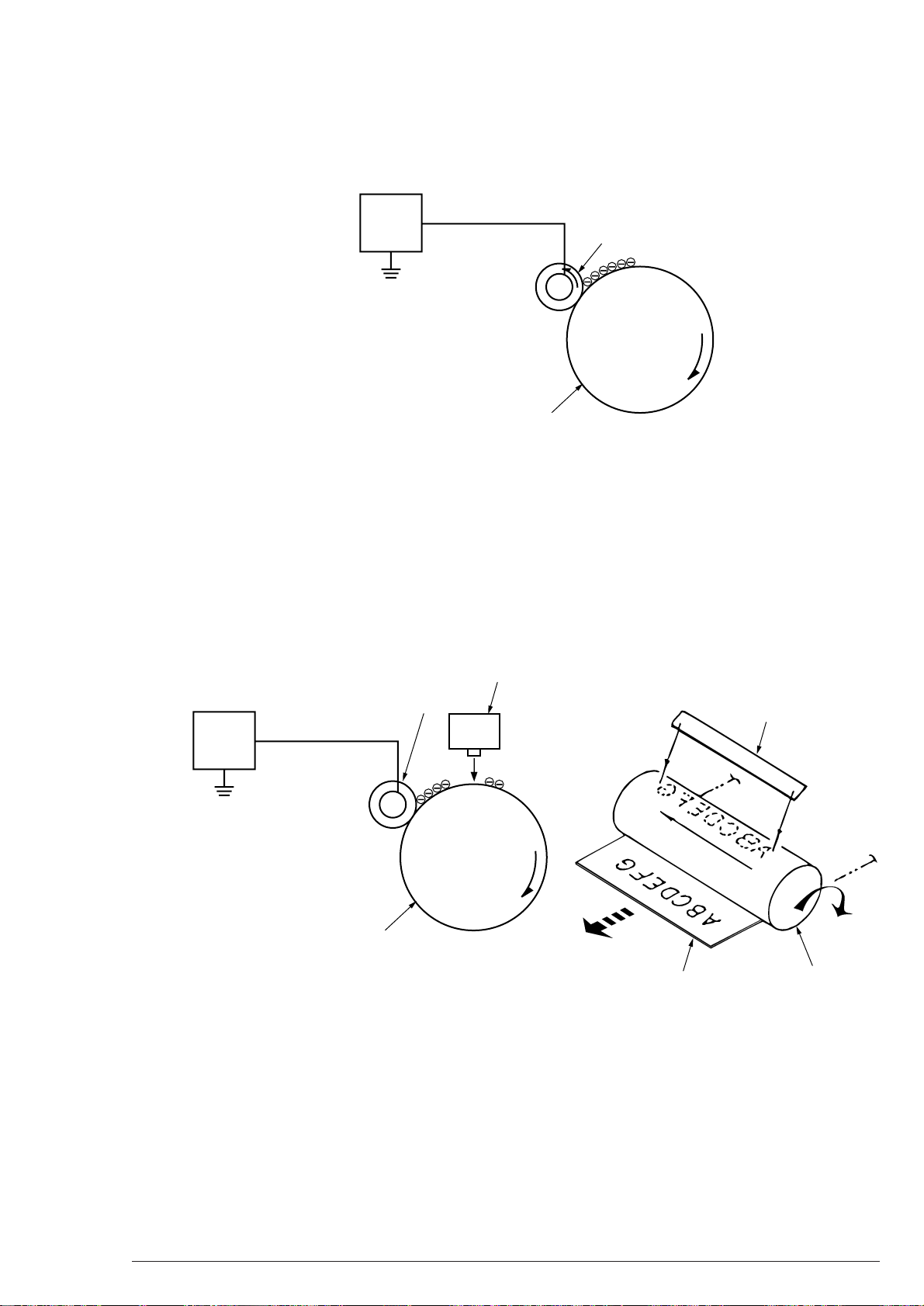

• Hopping

Hopping switches between the first tray and the front feeder paper feeding by the following mechanism:

Idle Gear A

One-way Clutch Gear B

2. Operation Description

Paper Feed Motor

(Pulse Motor)

a

b

Hopping Roller

(Front Feeder)

FF Plate

Hopping Roller

(First Tray)

(1) Paper Feeding from First Tray

Idle Gear B

Resister Roller

One-way Clutch Gear A

Figure A

1 Figure A shows that the paper feed motor rotates in the “a” direction (CW direction) to drive the

hopping roller and paper is fed until the inlet sensor is on.

While the front feeder gear is also revolving then, the FF roller is not turned by the one-way bearing.

2 After the paper turns the inlet sensor on, feeding a certain quantity of further paper runs the paper

against the resister roller. (This corrects a skew of paper.)

40801701TH Rev.2 19 /

Page 20

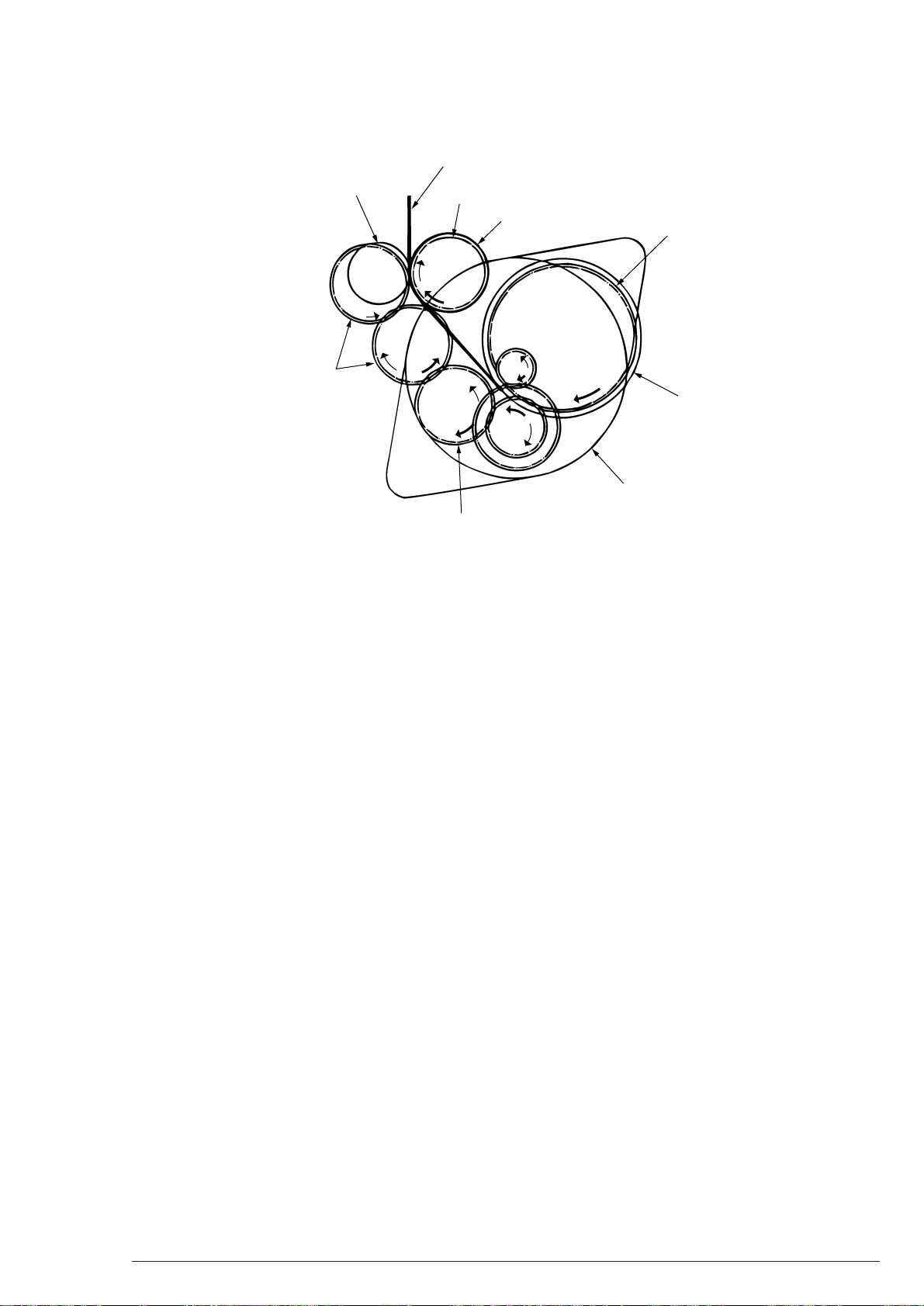

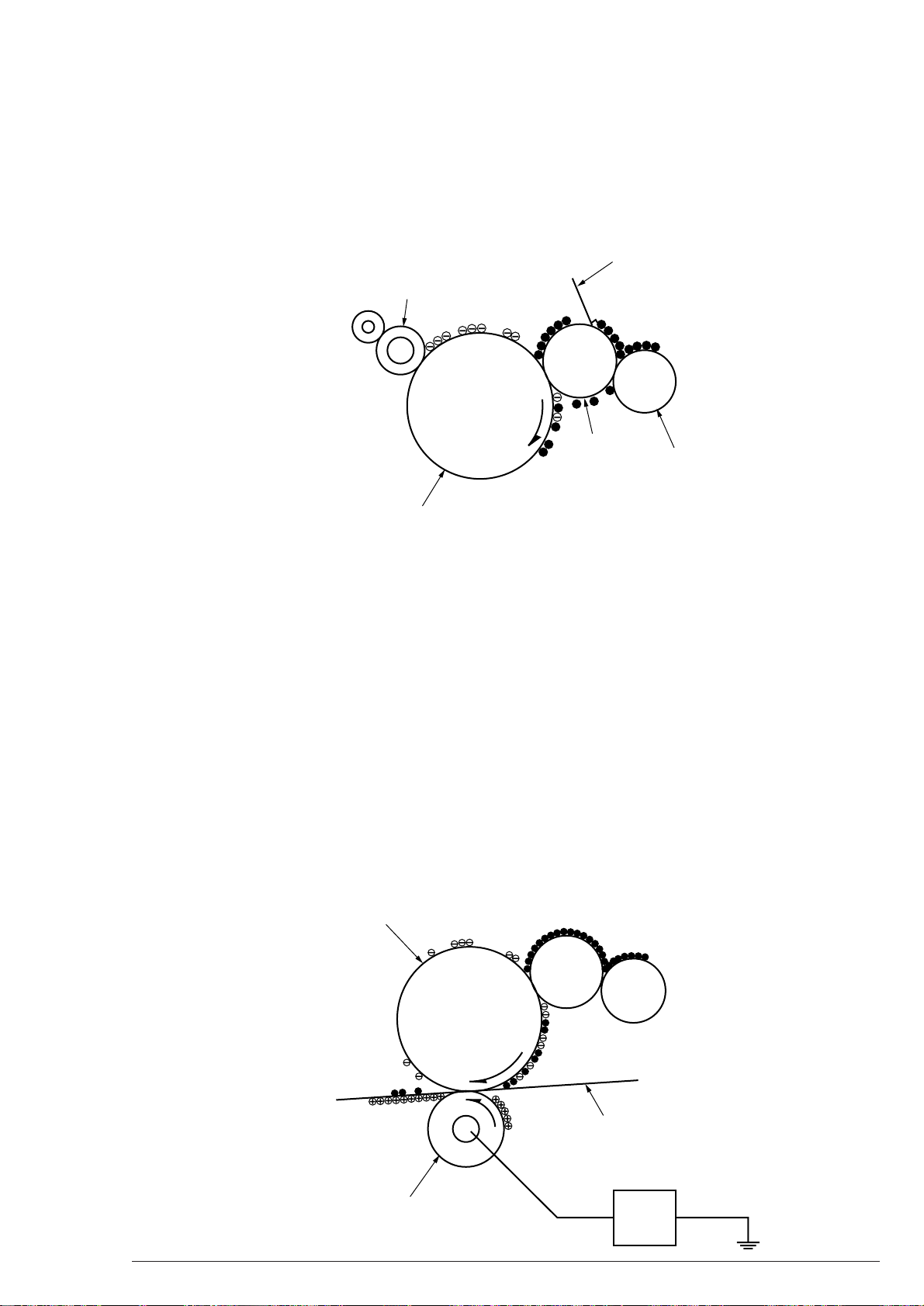

(2) Paper Feeding from Second Tray

Idle Roller

Planet Gear

Paper

Feeding Gear

(One-way Clutch Gear)

Feeding Roller

Hopping Gear

(One-way Clutch Gear)

Hopping Roller

Paper Feed Motor

Idle Gear

b"

a"

a'

b

a

2. Operation Description

1 Hopping

The pulse motor rotates in the “a” direction (CW direction) to drive the hopping roller and feeding

roller.

2 Feeding

When hopping is finished, the pulse motor rotates in the “b” direction (CCW direction) to drive the

feeding roller. While the hopping gear is also revolving then, the hopping roller is not being turned

by the one-way bearing.

40801701TH Rev.2 20 /

Page 21

2. Operation Description

(3) Paper Feeding from Front Feeder

1 When the printer is turned on, the front feeder takes up a position to lower the FF plate.

(its home position).

2 Figure A shows that the one-way clutch gear B revolves via the idle gear to turn the FF roller and FF

cam when the paper feed motor rotates in the “b” direction (CCW direction).

3 Turning the FF cam releases the FF plate from the FF plate pressing release lever, then the FF

plate is raised by the spring. Paper on the FF plate is pressed against the FF roller. The FF roller

feeds out the paper pressed. It continues until the inlet sensor is on, and a certain further quantity

is moved forward to run the paper against the resister roller. (This corrects a skew of paper.)

4 While the FF roller feeds the paper, the FF cam turns and presses down the FF plate. When the FF

plate lowers in its full, the release lever lies on the FF plate to keep the plate uchanged even if the

plate is disconnected from the FF cam.

5 Feeding the paper by the resister roller turns the FF roller by rubbing against the paper. This

turning power drives the shaft and it continues until the FF cam touches the release lever to obtain

a standby state for the next hopping.

The one-way bearing is built into the FF roller boss. After the cam touches the release lever, the

one-way bearing runs idle so as not to turn the shaft.

40801701TH Rev.2 21 /

Page 22

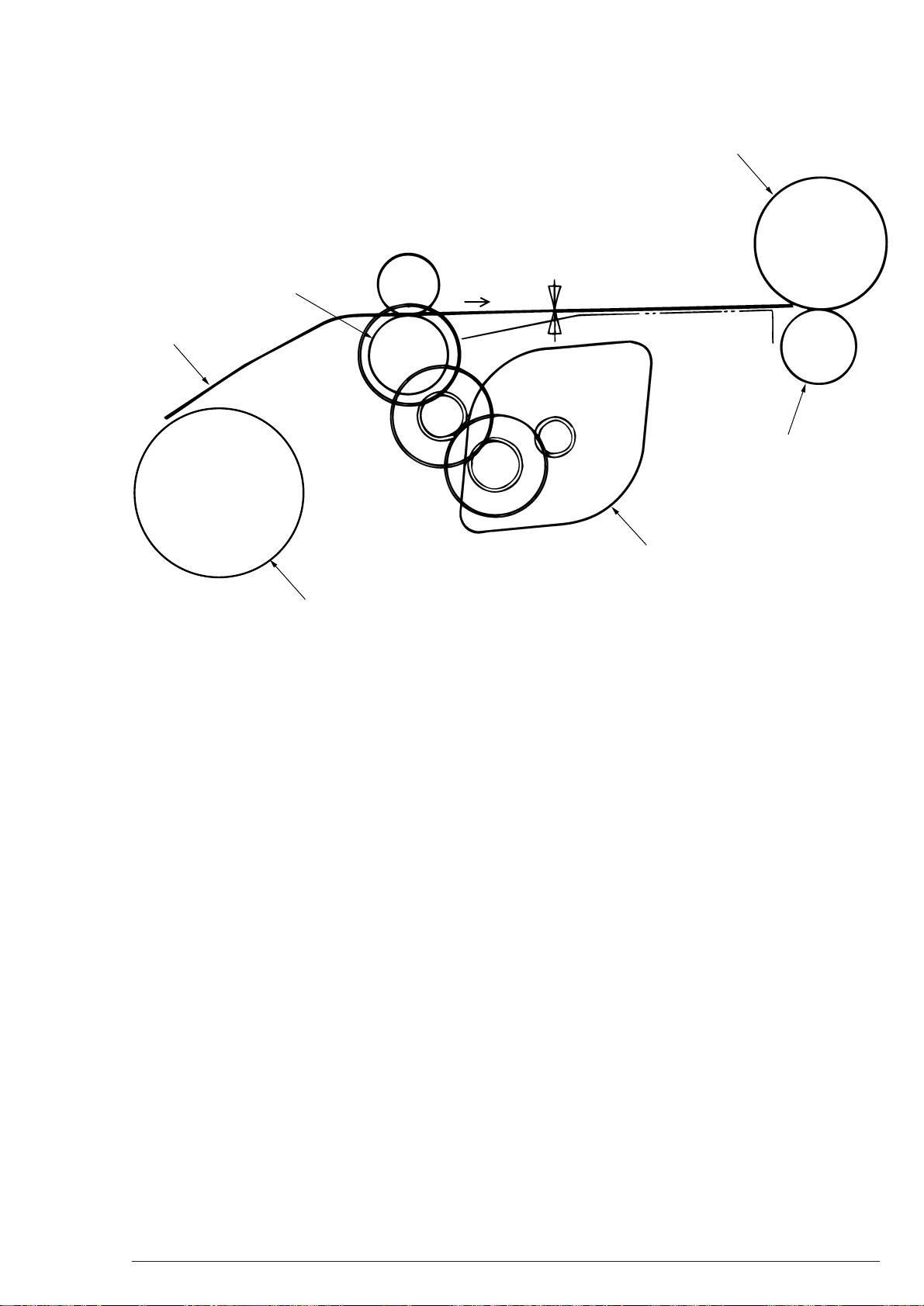

• Feeding

g

2. Operation Description

OPC Drum

Paper Sensor

Transfer Roller

Pulse Motor

Paper

Resister Roller

Hoppin

Roller

1 After the hopping is finished, the resister motor rotates to drive the resister roller and paper is fed

until the paper sensor is on.

2 Further feeding is synchronized with printing data.

40801701TH Rev.2 22 /

Page 23

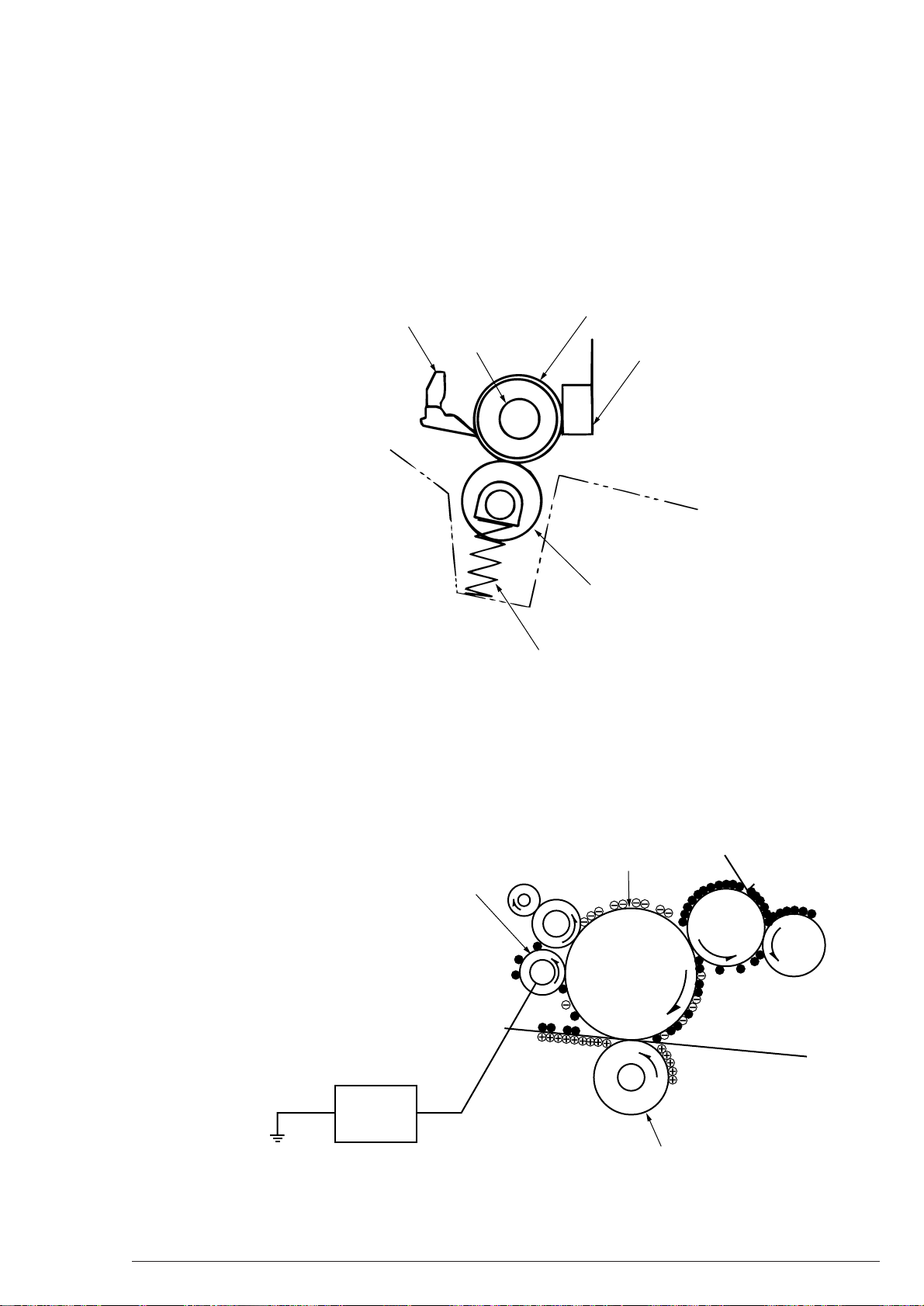

2. Operation Description

Power

Supply

OPC Drum

Charging Roller

Power

Supply

OPC Drum

Charging Roller

OPC Drum

LED Head

LED Head

Paper

(1) Charging

Charging is processed by applying DC voltage to the charging roller contacting the OPC drum surface.

(2) Exposure

Light from the LED head is directed onto the surface of the negatively charged OPC drum. The

potential of the emitted parts of the OPC drum attenuates and electrostatic latent images are generated

according to image signals.

40801701TH Rev.2 23 /

Page 24

2. Operation Description

OPC Drum

Transfer Roller

Paper

Power

Supply

(3) Development

Fixing toner on electrostatic latent images on the OPC drum surface changes the toner to its visible

images. Development is processed in the contact parts between the OPC drum and the developing

roller.

1 The sponge roller fixes toner on the developing roller. The toner is charged negatively then.

Developing Blade

Charging Roller

Developing

Roller

OPC Drum

Sponge Roller

2 The toner on the developing roller is shaven by the developing blade to make a thin layer of the

toner on the surface of the developing roller.

3 Fixing the toner to the exposed parts of the OPC drum makes electrostatic latent images visible in

the contact parts between the OPC drum and the developing roller.

(4) Transfer

The transfer roller is made of a conductive sponge material and arranged so that paper and the OPC

drum surface are well close together.

A positive charge opposite to the toner polarity (negative) is applied to the back of paper by the

transfer roller, laying the paper on the OPC drum surface.

Applying high voltage from the power supply (positive) to the transfer roller moves a positive charge

induced on the roller surface to the paper side in the contact parts of the transfer roller.

A positive charge on the back of the paper moves the negative toner on the OPC drum surface to the

upside of the paper. Transfering to the paper is performed by this.

40801701TH Rev.2 24 /

Page 25

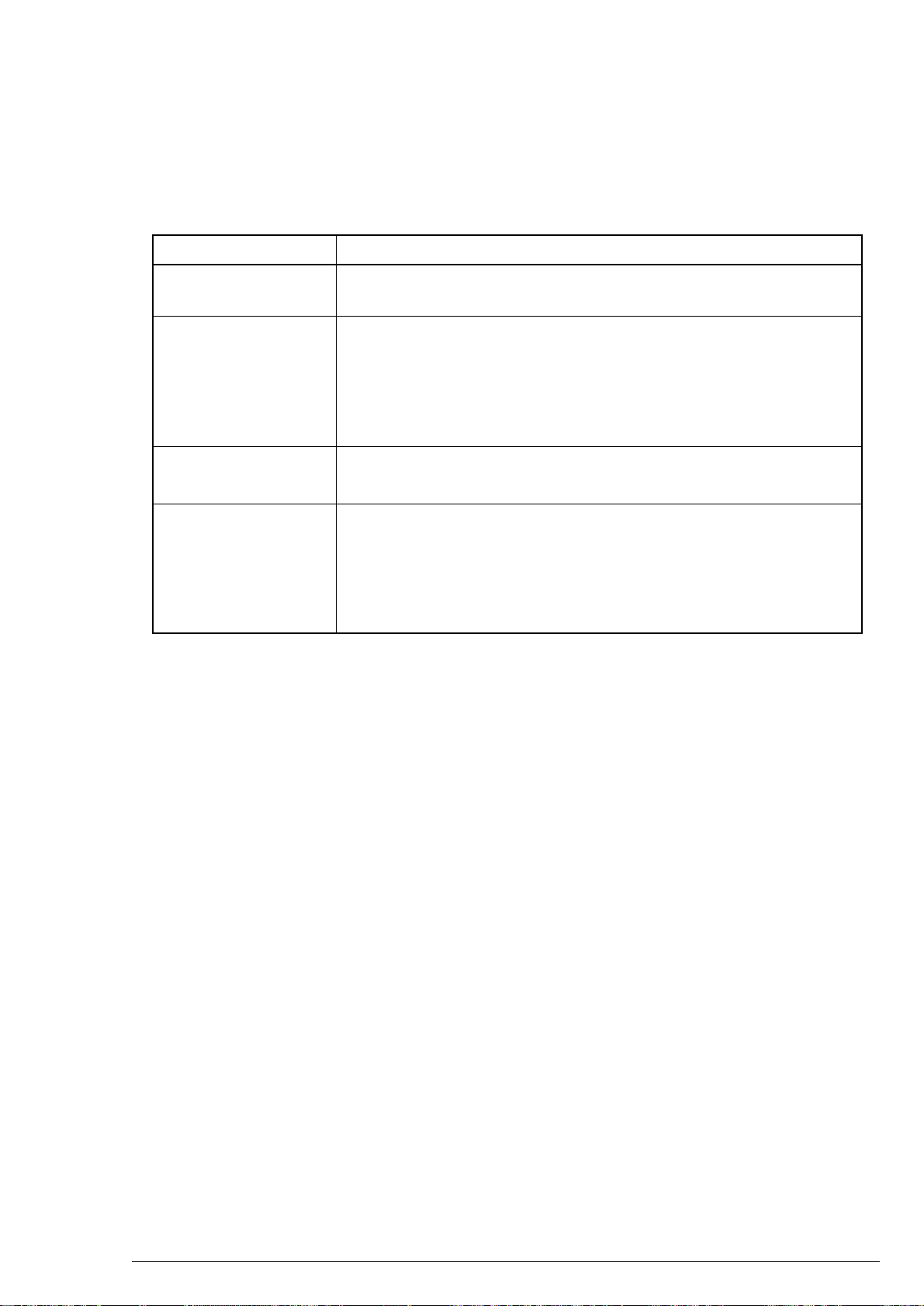

2. Operation Description

(5) Fusing

When passing between the heat roller and back-up roller, post-transfer unfixed toner images fuse on

the paper with heat and pressure.

A 800W of heater (halogen lamp) is inserted into the internal part of the teflon-coated heat roller to

heat the heat roller. Also a thermistor moves over the surface of the heat roller and controls the

temperature to keep it constant. In addition, thermostat, which is open for the duration of a temperature

rise to break voltage supply to the heater, is attached for safety.

The pressure springs on both sides press the back-up roller.

Separation claw

Heater

Pressure Spring

Heater roller

Thermistor

Back-up roller

(6) Cleaning

After the transfer, the cleaning roller draws the non-transferred residual toner on the OPC drum with

static and then returns it to the OPC drum.

Also the CH cleaner negatively charges positive toner on the charging roller to return the toner from

the charging roller to the OPC drum.

OPC Drum

Cleaning Roller

Power

supply

40801701TH Rev.2 25 /

+DC

Transfer Roller

Page 26

2. Operation Description

2.4 Paper Jam Sensing

Paper states are monitored when power is turned on and while printing. If any one of the following events

occurs, the print processing is suspended as a paper jam. Removing the jammed paper (Cover open/Remove/

Cover close) processes recovery printing.

Error Error Condition

Paper Input Jam

"PAPER LOAD JAM"

Paper Feed Jam

"PAPER FEED JAM"

Paper Outlet Jam

"EJECTION JAM"

Paper Size Error

"PAPER SIZE ERROR"

•

The leading part of paper does not reach Inlet Sensor after three times of

hopping at paper loading.

•

Paper exists on Inlet Sensor or Paper Sensor when power is turned on.

•

The leading part of paper does not reach Paper Sensor within a certain

time after passing Inlet Sensor.

•

The leading part of paper does not reach Ejection Sensor within a certain time after passing Paper Sensor.

•

Paper does not pass Inlet Sensor within the specified time.

•

Paper exists on Outlet Sensor when power is turned on.

•

Paper does not pass Outlet Sensor within the specified time.

•

Inlet Sensor and Outlet Sensor monitor the paper running time each and

detect a size difference of 45mm or more between paper used and the

tray-set paper.

•

A paper width detected by Paper Width Sensor is different from the trayset one. (Paper Width Sensor detection is applicable to the paper size

B4 or larger, and A4 or smaller.)

2.5 Cover Open State

Opening the stacker cover turns the cover opening microswitch on the power/sensor board off and cuts off 38V

supply to a high voltage supply to stop all high voltage lines output.

Concurrently, CVOPN signals inform the control board of the switching state and cover open processing is

performed.

40801701TH Rev.2 26 /

Page 27

2. Operation Description

2.6 “Toner-low” Detection

When toner is low, the lever reaches the magnet position of the toner sensor soon. In a tonerful state, the lever

moves almost as fast as the stirring roller turns.

Internal Stirring Roller of EP

Lever

Magnet

Toner Sensor

TNRSNS

On Off

t

T

Toner-low State : t>T/4

Tonerful State : t<T/4

Toner Replacing Alarm and Toner Life Alarm Detection Sequence

(1) Two consecutive toner-low states give a toner replacing alarm.

(2) Processing 100 pages of printing at toner replacing alarming gives a toner life alarm.

(3) Two consecutive tonerful states in toner replacing alarming cancel a toner replacing alarm.

Note:

If the drum motor is not rotating, the toner sensor monitoring is not executed.

2.7 Paper Size Sensing

T=6.1 sec

Four tab pieces are driven according to setting positions of the paper guide, through the cam linked with the

paper guide of the paper cassette.

When the paper cassette is attached to the printer, the microswitch detects a state of tab pieces to recognize a

paper size.

Microswitchin Prosess

Paper Size

SW1 SW2 SW3 SW4

Letter

Executive

A4

Legal 14

B5 Y

A5

B4

A3

A3 Nobi

A4 Y

40801701TH Rev.2 27 /

Page 28

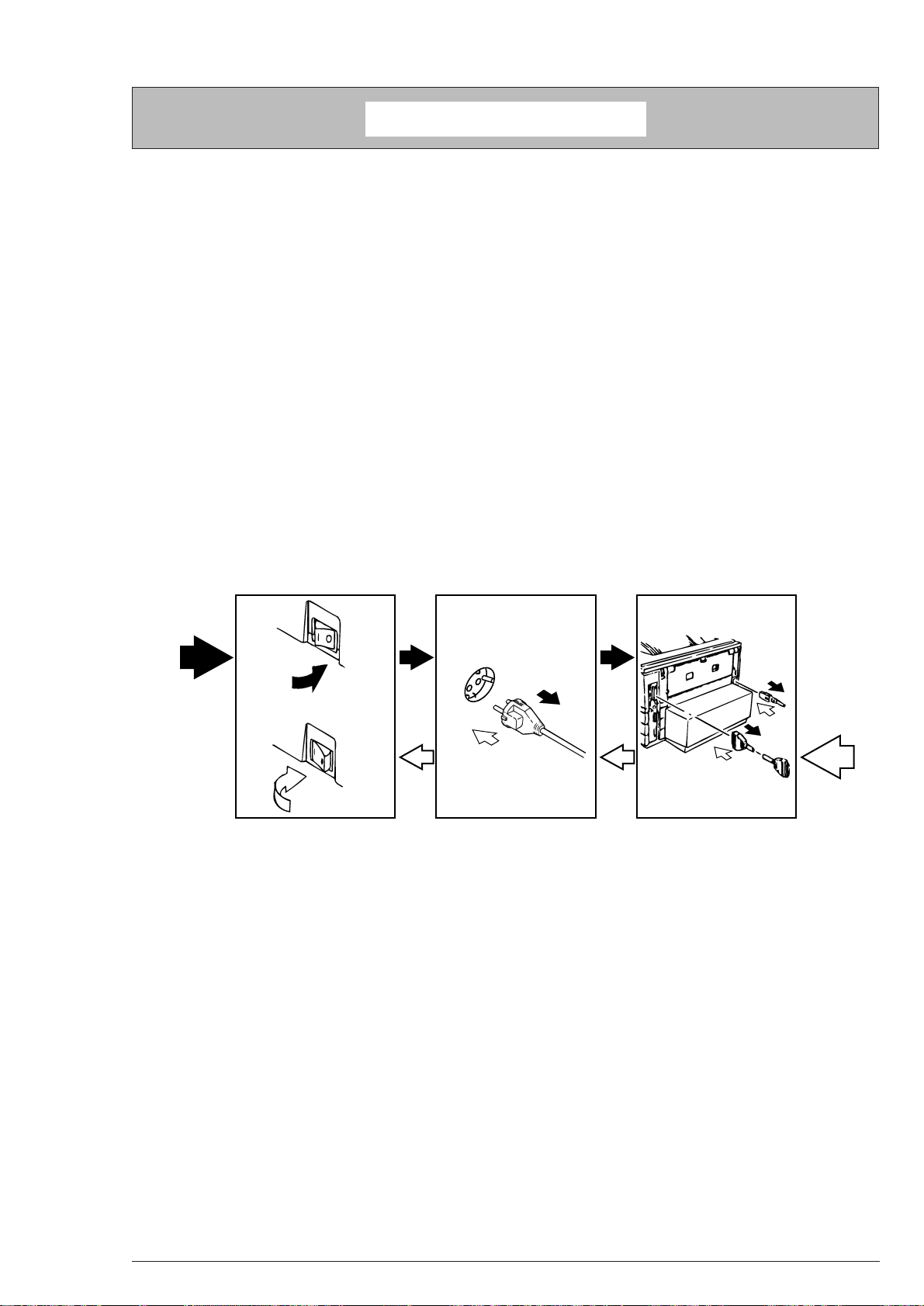

3. Parts Replacement

Disconnect

Reconnect

OFF

ON

3. Parts Replacement

This section describes the procedure for replacing the parts, assemblies, and units in the field. Although the

replacing procedure is for detaching, the reverse procedure must be used for attaching them.

3.1 Parts Replacing Precautions

(1) Never fail to disconnect the AC cable and the interface cable before replacing the parts.

(a) Detach the AC cable by using the following procedure.

1 Switch the POWER of the printer off to “O”.

2 Pull the AC inlet plug of the AC cable out of the AC receptacle.

3 Pull the AC cable and the interface cable out of the printer.

(b) To re-connect to the printer, use the following procedure.

1 Connect the AC cable and the interface cable to the printer.

2 Connect the AC inlet plug to the AC receptacle.

3 Switch the POWER of the printer on to “I”.

(2) Do not disassemble as long as the printer operates normally.

(3) Disassemble at a minimum if necessary. (Any parts except the parts described in the replacing

procedure are not allowed to be detached.)

(4) Use the designated maintenance tools.

(5) To disassemble, follow the procedure instructed. Disassembling in an incorrect order may damage

the parts.

(6) Small parts such as screws and collars likely to be lost shall be fixed to the original positions temporarily.

(7) In handling ICs and boards such as microprocessors, ROM, RAM, do not use gloves apt to get static.

(8) The print board shall not be put on any device and directly on the floor.

40801701TH Rev.2 28 /

Page 29

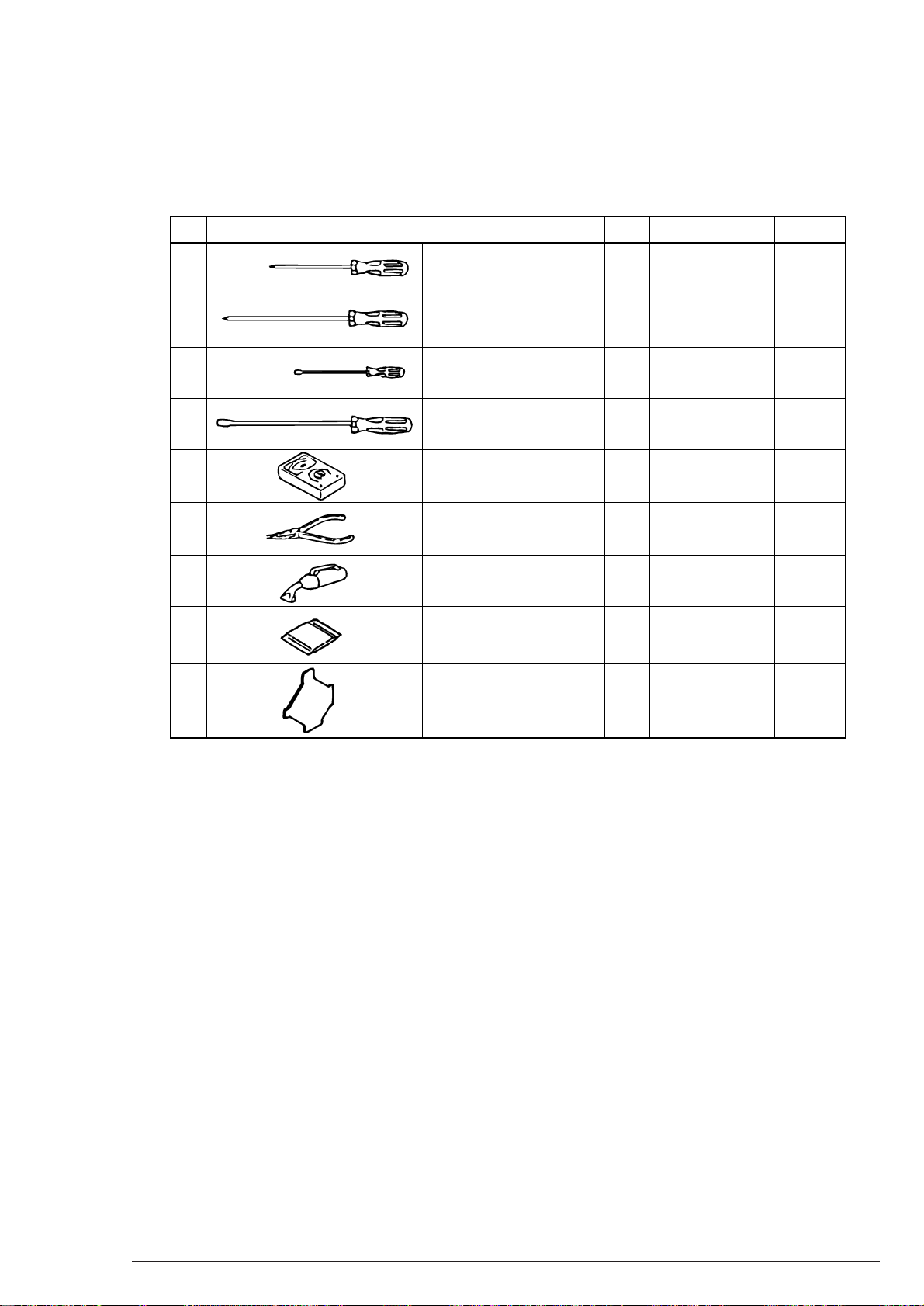

[Maintenance Tools]

Table 3-1 shows tools necessary to replace the parts.

Table 3-1 Tools for Maintenance

No. Q' ty Use for RemarkService Tools

3. Parts Replacement

1

2

3

4

5

6

7

8

9

Driver No.1-100

Driver No.2-200

Driver No.3-300

+

+

+

Driver No. 5-200

Digital multimeter

Pliers

Handy Cleaner

LED Head cleaner

Drawing No: 4PB4083-2248P1

Jack-in Connector Pulling

Tools

Drawing No: 4PP4076-5395P1

1

2~2.5 mm screws

1

3~5 mm screws

1

1

1

1

1

1

LED Head Cleaning

1

Jac-in Connector

Pulling

40801701TH Rev.2 29 /

Page 30

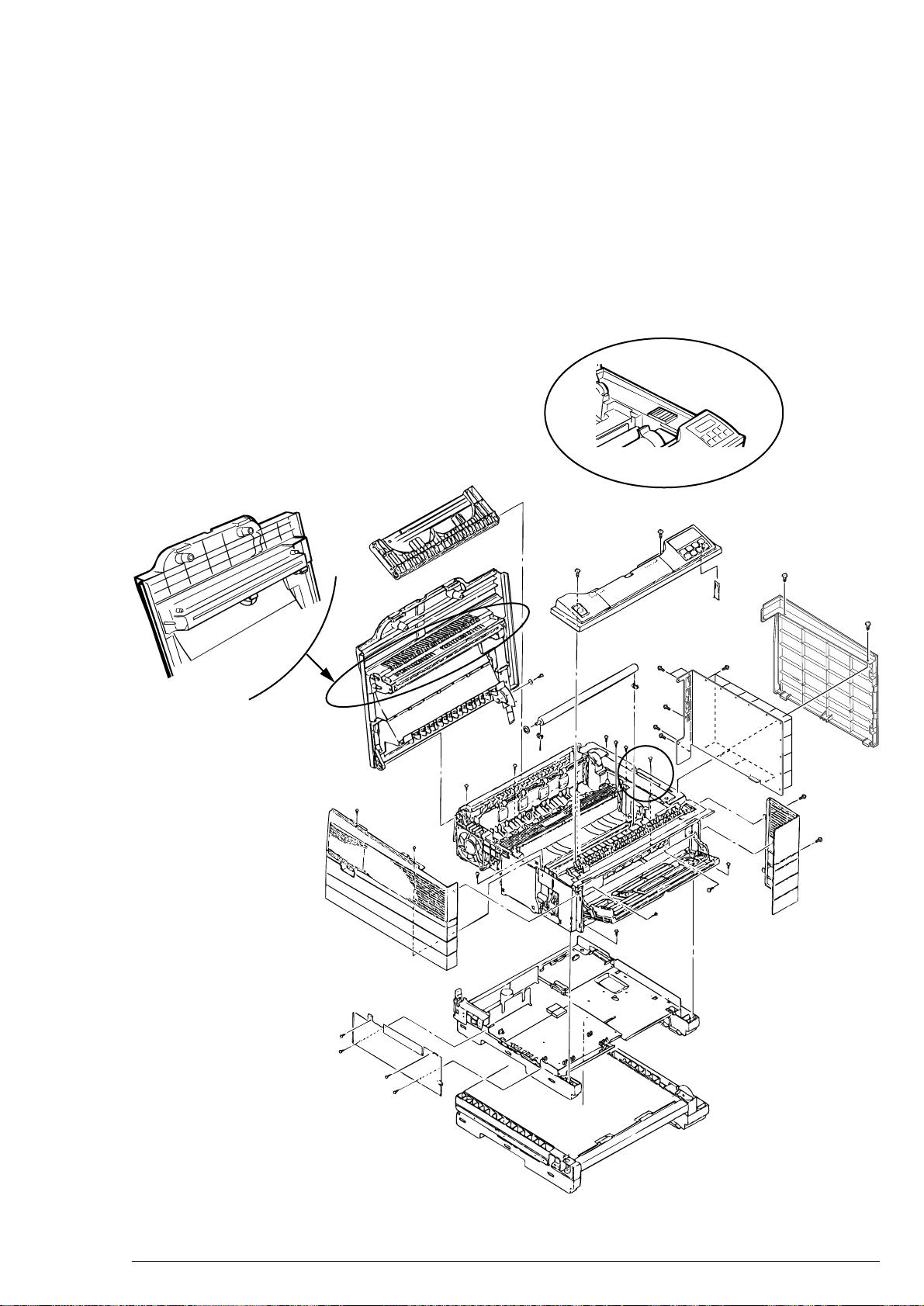

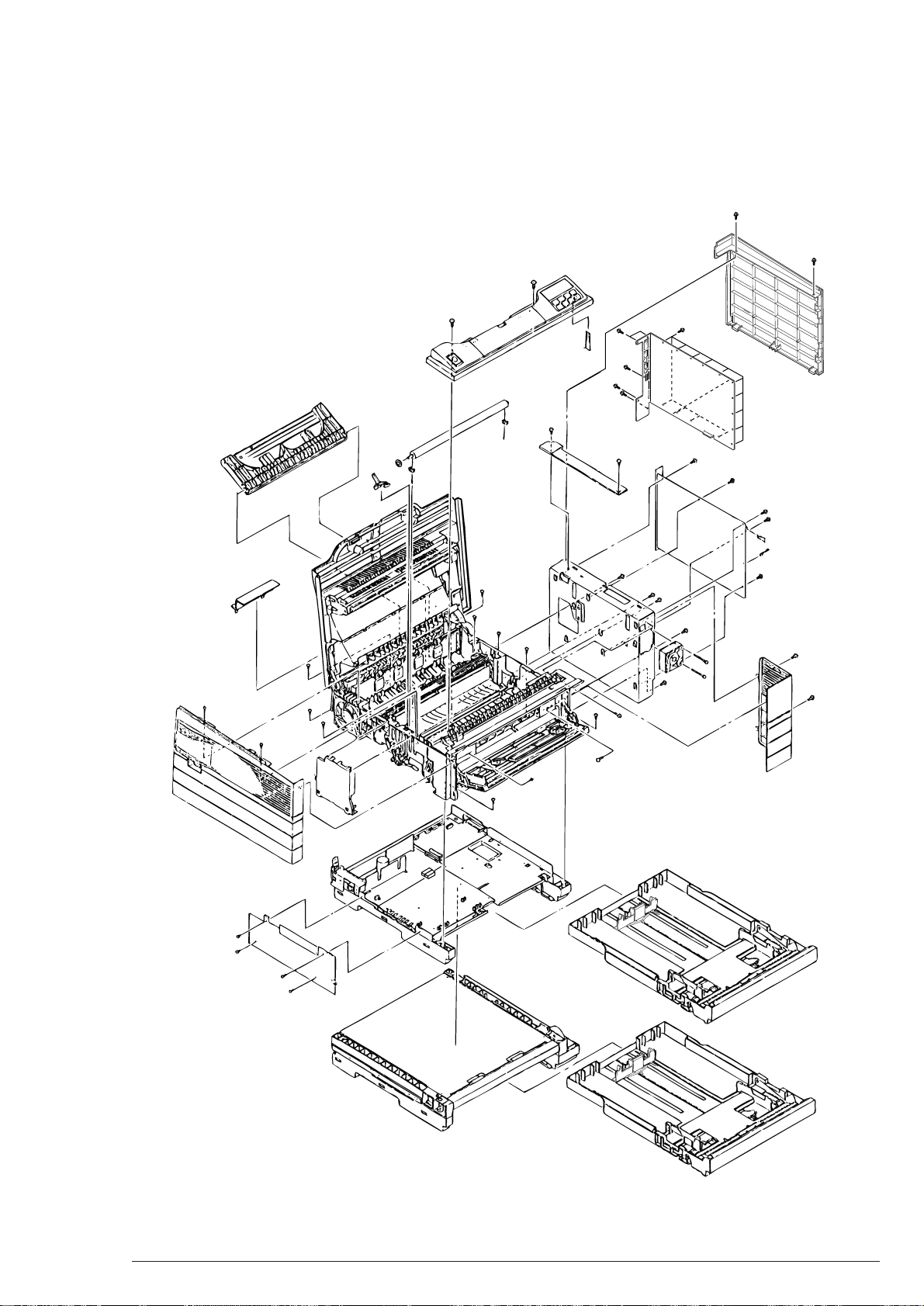

3.2 Parts layout

This section describes the layout of the main parts.

3. Parts Replacement

Figure 3-1

40801701TH Rev.2 30 /

Page 31

[Main Chassis Unit]

3. Parts Replacement

Figure 3-2

40801701TH Rev.2 31 /

Page 32

[Front Feeder Assy]

3. Parts Replacement

Figure 3-3

40801701TH Rev.2 32 /

Page 33

[Base Unit]

3. Parts Replacement

Figure 3-4

40801701TH Rev.2 33 /

Page 34

[Second Tray Unit]

3. Parts Replacement

Figure 3-5

40801701TH Rev.2 34 /

Page 35

3. Parts Replacement

Printer Unit Face-up Stacker Assy

(3.3.1)

Contact Assy

(3.3.2)

DC Fan Motot

(3.3.3)

Stacker Cover Assy,

DC12V Fan Motor,

Damper Arm

(3.3.6)

Fuser Assy

(3.3.14)

Damper

(3.3.7)

Eject Roller Assy

(3.3.8)

Fusing Guide

(3.3.15)

Back-up Roller

(3.3.16)

Operater Panel

Assy

(3.3.4)

SRA-PCB

(3.3.5)

Separation

Piece (Sticky)

(3.3.9)

FF Roller,

Bearing F

(3.3.10)

Paper Feed Motor

(3.3.11)

LED Head

(3.3.21)

Paper Cassette

(3.3.22)

Transfer Roller, TR Gear, TR Beaing

(3.3.23)

Resister Roller

Assy

(3.3.12)

Motor Assy

(3.3.13)

Hopping Roller Assy

(3.3.17)

Power

Supply

(3.3.18)

Paper End

Lever

(3.3.19)

Detector

Spring,

LLSW-PCB

(First Tray)

(3.3.20)

Feeding

Roller

(3.3.24)

Detector

Spring,

LLSW-PCB

(Second Tray)

(3.3.25)

3.3 Parts Replacing Methods

This section describes the methods for replacing the parts and assemblies shown in the following disassembing

system diagram.

40801701TH Rev.2 35 /

Page 36

3. Parts Replacement

3.3.1 Face-up Stacker Assy

(1) Turn off the AC power switch and pull the AC power cord out of the outlet.

(2) Disconnect the interface cable 1.

(3) After opening the face-up stacker Assy 2 and removing the right and left protrusions, detach the

face-up stacker Assy 2.

2

1

40801701TH Rev.2 36 /

Page 37

3. Parts Replacement

3.3.2 Contact Assy

(1) Open the stacker cover 1 and the manual feed hopper Assy 2, remove the three screws 3, and

detach the side cover (L) Assy 4.

(2) After removing the four screws 5, detach the plate (contact) 6 and the contact Assy 7.

Note:

4

Take care not to deform the electrode plate of the contact Assy 7.

3

1

3

5

7

2

5

6

40801701TH Rev.2 37 /

Page 38

3. Parts Replacement

3.3.3 DC Fan Motor

(1) Detach the side cover (L) Assy. [See 3.3.2 (1).]

(2) The connector of the DC fan motor 1 must be detached before demounting the DC fan motor 1.

1

40801701TH Rev.2 38 /

Page 39

3. Parts Replacement

3.3.4 Operator Panel Assy

(1) Disconnect the interface cable 1.

(2) Open the stacker cover 2 and remove the two screws 3 to detach the I/F cover 4.

(3) By removing the two screws 5 and the corner card 6, the operator panel Assy 7 is released.

5

7

1

6

3

4

2

40801701TH Rev.2 39 /

Page 40

3. Parts Replacement

8

9

3

3

7

A

B

C

C

5

3

0

D

4

3

2

6

1

1

3.3.5 SRA-PCB

(1) Demount the operator panel Assy. (See 3.3.4.)

(2) Remove the nineteen screws C and detach the Shield plate D.

(3) Remove the three screws 9 and detach the connector panel 8.

(4) Remove the screw 7, then demount the hard disk unit 6.

(5) Remove the three screws A to detach the Ethernet board B.

(6) Remove the three screws 1 to detach the side cover R 2.

(7) After releasing the SRA-PCB 5 from the six screws 3 and the two connectors 4, detach it with

moving backward.

40801701TH Rev.2 40 /

Page 41

3. Parts Replacement

3.3.6 Stacker Cover Assy, DC12V Fan Motor, Damper Arm

(1) Detach the face-up stacker. (See 3.3.1.)

(2) Remove the side cover (L) Assy. [See 3.3.2 (1)]

(3) Demount the operator panel Assy. (See 3.3.4)

(4) Detach the SRA-PCB. (See 3.3.5)

(5) By removing the two screws 1, detach the cover 2.

(The cable of the LED head and the cable guide are also released then.)

(6) Remove the two clicks and detach the connector cover 3 to disconnect the LED head cable.

(7) Remove the two screws 6 to detach the DC12V fan motor 7.

(OP905 ; Remove the two screws C to detach the LED Cooling fan.)

(8) Remove the six screws 4 to detach the side plate R 5.

(9) Detach the back-up release lever 8 and disconnect the protrusion on the right surface of the gear on

the right of the stacker cover.

(10) Remove the screw 9 and the washer 0 to detach the stacker cover Assy A.

(At the same time, the damper arm B is released.)

40801701TH Rev.2 41 /

Page 42

A

9

3. Parts Replacement

C

Only OP905

D

1

2

3

Protrusion

0

4

4

4

B

8

7

6

4

5

4

40801701TH Rev.2 42 /

Page 43

3.3.7 Damper

(1) Detach the damper arm. (See 3.3.6.)

(2) Remove the two screws 1, then detach the two dampers 2.

2

3. Parts Replacement

1

40801701TH Rev.2 43 /

Page 44

3.3.8 Eject Roller Assy

(1) Detach the stacker cover Assy. (See 3.3.6.)

(2) After unlatching the right side of the eject roller 1, raise it to release.

1

3. Parts Replacement

40801701TH Rev.2 44 /

Page 45

3. Parts Replacement

3.3.9 Separation Piece (Sticky)

(1) Open the manual feed hopper Assy 1 and undo the fits in its lower part both on the right and the left.

(2) Set the manual feed hopper Assy 1 vertical, then detach the right and left levers.

(3) Demount the operator panel Assy. (See 3.3.4.)

(4) Remove the four screws 2 to detach the front feeder Assy 3.

(5) Detach the inner cover 6 after removing the four screws 4.

(At the same time, the cover lock lever 6 and the torsion spring 7 are released.)

(6) Remove the two screws 8 to detach the square connector 9.

(7) The switch code Assy 0 must be removed from the square connector 9 by using the exclusive tools.

(8) Revolve the idle gear A in the arrow A direction to raise the FF plate (sticky) B.

(9) Detach the front gear C, then remove the two springs D.

(10) Release the paper feeding guide F from the four screws E.

(The FF earth plate G is also released then.)

(11) Undo the two points of connection to detach the FF plate (sticky) B.

(12) Raise the separation piece (sticky) H to your side, then unlatch the two parts.

(Also the two springs I are released. Be careful not to lose them.)

40801701TH Rev.2 45 /

Page 46

2

3. Parts Replacement

1

2

3

40801701TH Rev.2 46 /

Page 47

6

7

4

4

9

8

C

A

0

D

I

F

B

D

G

H

E

E

E

E

5

A

3. Parts Replacement

40801701TH Rev.2 47 /

Page 48

3. Parts Replacement

3.3.10 FF Roller Assy, Bearing F

(1) Deatch the manual feed hopper Assy. [See 3.3.9 (1) and (2).]

(2) Detach the front feeder Assy. [See 3.3.9 (3) and (4).]

(3) Remove the paper feeding guide A. [See 3.3.9 (5) to (10).]

(4) Detach the idle gear 1 and then detach the FF cam on the R side, the release lever (R) 3 and the

spring 4.

(At the same time, the knock pin 5 and the bearing (F) 6 are released. Take care not to lose them.)

(5) Pull out the FF shaft 7 to the left to detach the FF roller boss 8.

(Give attention to the direction of the one-way clutch of the FF roller boss 8.)

(6) Release the FF cam 0, the release lever (L) A and the spring B from the nock pin 9.

The bearing (F) on the L side is also released then.

(7) Remove the FF roller D from the FF roller boss 8.

Note:

When assembling the FF roller to the FF roller boss, pay attention to its direction.

Also apply ethylalcohol to the inside of the FF roller boss and attach it to the FF roller boss in one

movement. Remove strain of the roller rubber by revolving the FF roller on the boss four to five

times immediately after assembling. If the applied alcohol is insufficient and the rubber does not

revolve on the boss lightly, try again. Be careful to protect the one-way clutch from alcohol.

4

1

2

3

6

5

7

9

B

C

D

8

A

0

40801701TH Rev.2 48 /

Page 49

3. Parts Replacement

3.3.11 Paper Feed Motor

(1) Detach the manual feed hopper Assy. [See 3.3.9 (1) and (2).]

(2) Demount the operater panel Assy. (See 3.3.4.)

(3) Detach the front feeder Assy. [See 3.3.9 (4).]

(4) Detacn the inner cover and the square connector. [See 3.3.9 (5) and (6).]

(5) The connector of the paper feed motor 1 must be detached from the square connector, using the

exclusive tools.

(6) Remove the paper guide A. [See 3.3.9 (6) to (10).]

(7) Detach the release lever (R). [See 3.3.10 (4).]

(8) After removing the two screws 2, detach the side plate R Assy 3.

(9) Remove the four screws 4, then detach the paper feed motor 1.

4

1

3

2

40801701TH Rev.2 49 /

Page 50

3.3.12 Resister Roller Assy

(1) Detach the front feeder Assy. [See 3.3.9 (1) to (4).]

(2) Remove the four screws 1, then raise to detach the resister roller Assy 2.

3. Parts Replacement

Note:

While the screws 1 are removed, the stacker cover must be close.

1

2

1

40801701TH Rev.2 50 /

Page 51

3. Parts Replacement

3.3.13 Main Motor, Resister Motor

(1) Detach the resister roller Assy. (See 3.3.12.)

(2) Detach the stacker cover Assy. (See 3.3.6.)

(3) Detach the front feeder Assy. [See 3.3.9 (1) to (2).]

(Detaching the manual feed hopper Assy is not required then.)

(4) Demount the second unit.

(5) Detach the earth plate (HP) 1.

(6) The TR gear 2 and the TR roller 3 are released by pressing the TR release lever and unlocking.

(ML803PSII has no TR release lever.)

(7) Remove the connector cover 5 to detach the four connectors.

(8) Removing the nine screws 6 detaches the main chassis 7.

(9) Unlatch the back-up release lever 8 and pull out on the right.

(At the same time, the idle gear is released.)

(10) Detach the springs 0, then detach the pressure release lever A.

(11) Remove the EP lock spring B and detach the EP lock lever C.

(12) By unlatching the two parts, detach the motor Assy D.

Note:

The detached TR roller is to be wrapped in paper. Do not put it directly on the floor.

40801701TH Rev.2 51 /

Page 52

5

6

2

3

6

3. Parts Replacement

8

9

A

C

6

0

B

1

4

6

7

Second Unit

6

D

40801701TH Rev.2 52 /

Page 53

3. Parts Replacement

3.3.14 Fuser Assy

(1) Detach the side cover (L) Assy. [See 3.3.2 (1).]

(2) Pull out the connector 1.

(3) Remove the four screws 3 and detach the fuser Assy 2 with holding the top of it by hands.

Note:

• The temperature of the fuser Assy 2 is high directly after the power is turned off. Work after

it cools well.

• After replacing the parts, reset the counter. (See Section 4.2.)

3

2

3

40801701TH Rev.2 53 /

Page 54

3. Parts Replacement

3.3.15 Fusing guide

(1) Detach the fuser Assy. (See 3.3.14.)

(2) Removing the two screws 1 and the three points of clicks releases the fuser guide Assy 2.

1

2

1

40801701TH Rev.2 54 /

Page 55

3.3.16 Back-up Roller

(1) Detach the fuser Assy. (See 3.3.14.)

(2) Detach the back-up release lever. [See 3.3.13 (8).]

(3) Detach the fuser guide. (See 3.3.15.)

(4) Disconnect the back-up roller 2 from the earth plate L 1 (BK) and raise it.

(At the same time, the two back-up roller bearings 3 and the two bias springs 4 are released.)

3. Parts Replacement

3

4

3

4

2

1

40801701TH Rev.2 55 /

Page 56

3. Parts Replacement

3.3.17 Hopping Roller Assy

(1) Detach the main chassis. [See 3.3.13 (1) to (8).]

(2) Unlatch and detach the hopping roller gear 1 and the bearing R 2, then detach the idle gear HF 3.

(3) Unfix the left side of the hopping roller shaft from the groove and pull out the hopping roller shaft 4

and the hopping roller Assy 5 to the left.

(4) Unlatch the bearing L 6 to detach it.

(5) Unlatch and detach the hopping roller Assy 5.

(The knock pin is also released then. Be careful not to lose it.)

7

4

3

1

2

6

40801701TH Rev.2 56 /

5

Page 57

3. Parts Replacement

3.3.18 Power Supply

(1) Unfix the main chassis. [See 3.3.13 (1) to (8).]

(2) Remove the two screws 1 to detach the inlet holder 2.

(Remove the inlet 3 from the inlet holder 2 then.)

(3) Detach the seven screws 4, the three connectors 5, the three screws 6 and three Nylon latch 0,

then detach the mechanism control board 8 together with the power supply 7.

(4) Disconnect 9 the power supply 7 from the board.

Note:

Be careful not to deform the paper end lever.

4

4

3

4

7

2

6

5

4

9

4

6

8

6

1

1

0

Paper End Lever

40801701TH Rev.2 57 /

Page 58

3.3.19 Paper End Lever

(1) Unfix the main chassis. (See 3.3.15.)

(2) Detach the power supply. (See 3.3.18.)

(3) Unlock and detach the paper end lever 1.

3. Parts Replacement

1

40801701TH Rev.2 58 /

Page 59

3.3.20 Detector Spring, LLSW-PCB (First Tray)

(1) Unfix the main chassis. [See 3.3.13 (1) to (7).]

(2) Remove the insulator 1.

(3) After removing the two screws 2, detach the base plate 3.

(4) Unscrew 4 the detecter spring 5 to detach it.

(5) Remove the screw 6 and detach the LLSW-PCB 7.

3. Parts Replacement

1

2

3

2

7

6

5

4

40801701TH Rev.2 59 /

Page 60

3. Parts Replacement

3.3.21 LED Head

(1) Open the stacker cover 1.

(2) Detach the PC connector 2 from the LED head 4.

(3) Pushing over the hook on the left of the stacker cover 1 in the arrow direction unfixes the LED head

4.

(4) Pull the head spring 5 out of the post.

4

2

2

OP905

4

2

1

3

5

5

40801701TH Rev.2 60 /

Page 61

3.3.22 Paper Cassette

1

(1) Pull the paper cassette Assy 1 out of the printer.

3. Parts Replacement

40801701TH Rev.2 61 /

Page 62

3.3.23 Transfer Roller, TR Gear, TR Bearing

3

2

4

1

6

4

5

5

Green

Green

(1) Open the stacker cover 1.

(2) Pressing the TR release lever 6 releases the TR gear 2 and the transfer roller 3.

3. Parts Replacement

Note:

(3) Unfix the two right and left TR bearings 4 from the main chassis, sliding the bearings to the inside

The detached transfer roller 3 shall not be put directly on the desk. Lay paper to put it.

with pressing it. The two transfer springs 5 are also released then.

40801701TH Rev.2 62 /

Page 63

3.3.24 Feeding Roller

(1) Demount the second unit 1. [See 3.3.13 (1) to (4).]

(2) Remove the four screws 1 and unfix the upper plate 2.

(3) Detach the front roller Assy 3.

(4) Removing three screws 4 releases the cassette guide (R) Assy 5.

(5) Unlatch the feeding gear 6 and the feeding bearing 7, then detach the feeding roller.

(The bearing 9 is also released. Take care not to lose it.)

1

2

3. Parts Replacement

1

1

8

3

4

4

4

6

9

4

7

5

40801701TH Rev.2 63 /

Page 64

3.3.25 Detector Spring, LLSW-PCB (Second Tray)

(1) Demount the second unit [See 3.3.13 (1) to (4).]

(2) Detach the cassette guide (R) Assy. [See 3.3.24 (1) to (4).]

(3) The detecter spring 1 is released by unscrewing 2.

(4) Remove the screw 3 and unfix the LLSW-PCB 4.

4

3. Parts Replacement

3

1

2

40801701TH Rev.2 64 /

Page 65

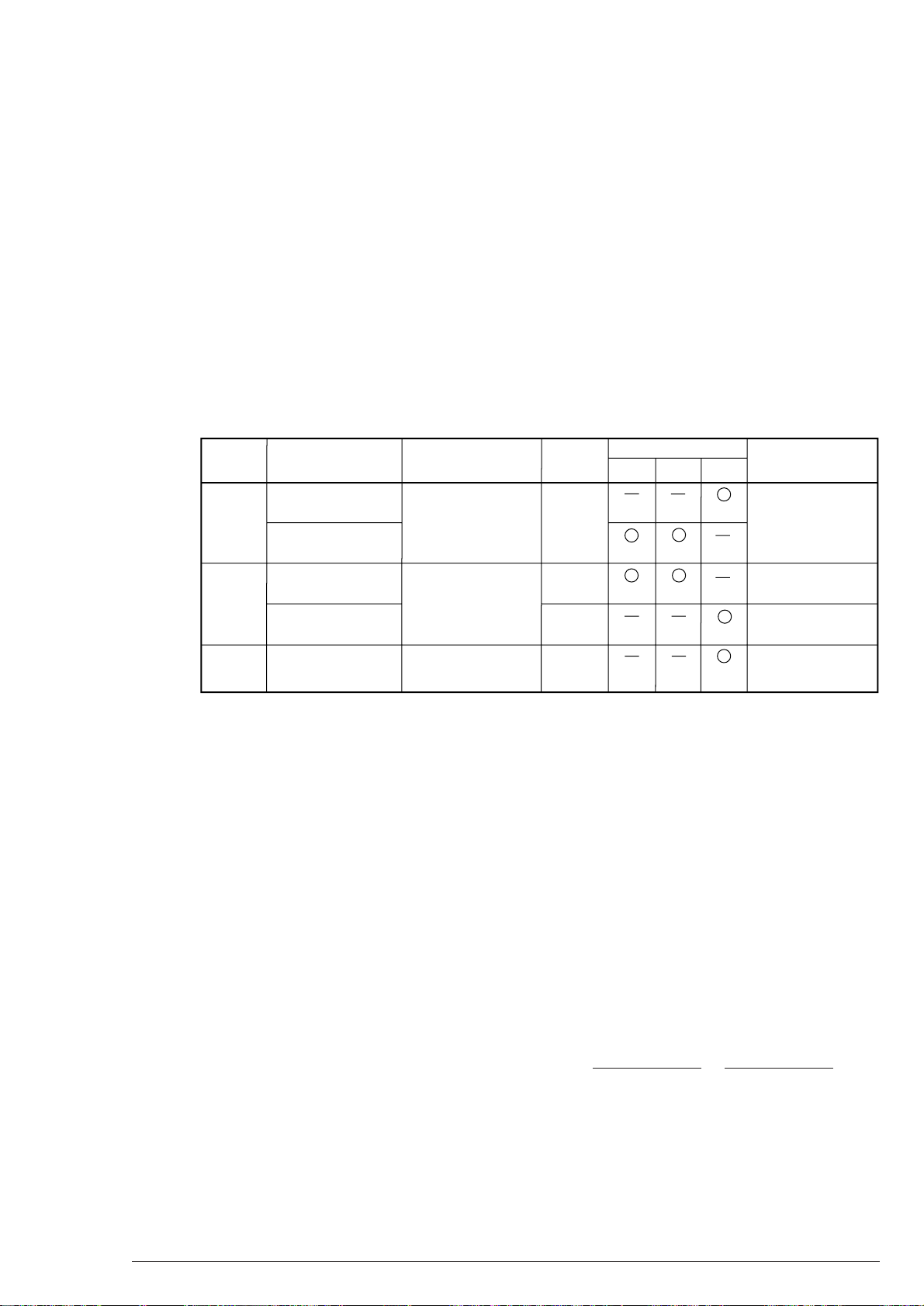

4. Adjustment

y

Model Name

OP904

OP905

Head Specification

600DPI

A3

1200DPI

A3

Nameplate

This section describes the necessary adjustments after replacing the parts.

The following shows units replaced and necessary adjustments on them.

Part Replaced Adjustment

4. Adjustment

LED Head

Fuser

Drum Cartridge

4.1 LED Head Driving Time Set-up

Note:

When a set-up indication on a replacement LED head (new one) is the same as that of an used

LED head (old one), setting its LED head driving time is not required.

Set-up Indication Label

LED Head Driving Time Set-up (See Section 4.1)

Fuser Counter Reset (See Section 4.2)

Drum Counter Reset (See User's Manual)

(OP905)

(OP904)

Set-up Indication

(expressed b

40801701TH Rev.2 65 /

Last Three Digits)

Page 66

4. Adjustment

4.1.1 Outline of Set-up Procedure

The following shows the outline of the LED head driving time set-up procedure. See “4.1.2 Driving Time Setup” for details after No. 3.

1. Take off the rear cover and the connector cover.

2. Switch the POWER on to “I”, pressing the switch (SW1) of the mechanism control board (Engine

controller) by the switch bar. (to obtain the printer maintenance mode.)

3. Set LED head driving time according to the set-up indication on the LED head.

4. Switch the POWER off to “O”.

5. Switch the POWER on to “I” again and proceed with the usual printing operation.

LED

Switch(SW1)

Rear Cover

HIR-PCB , LLEH-PCB

Connector Cover

ROM

40801701TH Rev.2 66 /

Page 67

4. Adjustment

4.1.2 Driving Time Set-up

To arrange LED head driving time, set a driving time set-up address corresponding to the set-up indication on

the LED head in EEPROM, using the switch on LLEH PCB (OP904) or HIR PCB (OP905).

a. Set-up Indication - Driving Time Corresponding Table

OP904 600dpi

LED Head Set-up

Indication

011

012

013

014 ~ 015

016

017

018 ~ 019

020

021 ~ 022

023 ~ 024

025 ~ 026

027 ~ 028

029 ~ 031

032 ~ 034

035 ~ 036

037 ~ 039

Drive Time Set-up

Address

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

LED Head Set-up

Indication

040 ~ 043

044 ~ 046

047 ~ 050

051 ~ 054

055 ~ 059

060 ~ 063

064 ~ 068

069 ~ 073

074 ~ 080

081 ~ 087

088 ~ 096

097 ~ 101

102 ~ 113

114 ~ 120

121 ~ 128

129 ~ 138

Drive Time Set-up

Address

0

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

b. Set-up Indication - Driving Time Corresponding Table

OP905 1200dpi

LED Head Set-up

Indication

046 ~ 048

049 ~ 051

052 ~ 054

055 ~ 057

058 ~ 061

062 ~ 065

066 ~ 069

070 ~ 074

075 ~ 079

080 ~ 084

Drive Time Set-up

Address

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

LED Head Set-up

Indication

085 ~ 088

089 ~ 094

095 ~ 010

101 ~ 107

108 ~113

114 ~ 121

122 ~ 129

130 ~ 137

138 ~ 145

146 ~ 155

156 ~ 166

167 ~ 175

Drive Time Set-up

Address

0

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

40801701TH Rev.2 67 /

Page 68

Example: In the case of the address “0” > “14”

The LED head driving time is specified in the parameter No. 13.

Operation LED Indication Followed Remark

4. Adjustment

Switch the POWER on to "I", pressing the switch (SW1).

Press the switch (SW1) short twelve

time.

Press the switch (SW1) long one

time. (Set Address is indicated.)

Press the switch (SW1) short fourteen times.

Press the switch (SW1) long one

time.

The lamp lights short one time.

The lamp lights short thirteen times.

Thirteen times Thirteen times

The lamp lights long one time and

short ten times.

Ten times Ten times

The lamp lights long one time, short

one time, and shot four times.

The lamp lights short thirteen times.

Thirteen times Thirteen times

Printer Maintenance Mode

Selecting Parameter No.13

(Example)

Indicates Address "0".

Indicates Address "14".

Setting in EEPROM

(Indicating Parameter

No.13)

Switch the POWER off to "O".

Short Press

Long Press

: One pressing time is one sec. or less., ,

: One pressing time is one sec. or more.,

b. Adjustment after Set-up

The set address may be adjusted to the next above or before address only.

: LED Lighting Form

: Short Lighting, : Long Lighting

40801701TH Rev.2 68 /

Page 69

4.2 Fuser Counter Reset (only OP905)

After replacing the fuser, reset the fuser counter by using the following procedure.

1. Set the printer to the printer maintenance mode. (See 1 to 3 of Section 4.4.1.)

2. Reset the fuser counter.

For the fuser counter, the value is specified in the parameter No. 3.

Operation LED Indication Followed Remark

4. Adjustment

Switch the POWER on to "I", pressing the switch (SW1).

Press the switch (SW1) short twice.

Press the switch (SW1) long one time.

(Set Counter Value is indicated.)

Press the switch (SW1) long one time.

Press the switch (SW1) short one

time.

Switch the POWER off to "O".

The lamp lights short one time.

The lamp lights short three times.

The lamp lights eight cycles over, at one

long and one short lightings per cycle.

The lamp lights ten cycles over, at one

long and one short lightings per cycle.

Ten times Ten times

The lamp lights short three times.

Printer Maintenance Mode

Selecting Parameter No.3

(Example)

Indicates 14111 pages.

Resetting Value of Counter.

(Indicating Parameter

No.3)

Short Press

Long Press

3. Switch the POWER on to “I” again and proceed with the usual printing operation.

: One pressing time is one sec. or less., ,

: One pressing time is one sec. or more.,

: LED Lighting Form

: Short Lighting, : Long Lighting

40801701TH Rev.2 69 /

Page 70

5. Routine Maintenance

White Stripe, White Belt

(Void or Light Printing)

5. Routine Maintenance

5.1 Routine Replacement Parts

Routine replacement parts and units must be replaced according to the following standard.

Table 6-1 Routine Replacement Parts

Replacement Parts

Toner Cartridge

Drum Cartridge

Note:

Even when “DRUM LIFE” is displayed, the drum cartridge can be used until the toner is used

up.

Replacement Time

When "TONER LOW" is displayed.

When "DRUM LIFE" is displayed.

Check Point

LED Head

Remark

Consumable

Consumable

5.2 Cleaning

• Remove toner/foreign matters and clean with waste around and inside the printer.

• In case of frequent paper jams (PAPER FEED JAM or EJECTION JAM), see Section 3.3.14.

Detach the fuser Assy and clean the back-up roller surface with waste to clean adhering toner and paper

dust.

(Cleaning with alcohol is recommended against much dirt.)

Note:

Do not touch the OPC drum.

5.2.1 LED Lens Array Clearning

When a white stripe or a white belt (void or light printing) appears vertically on the printed surface, clean the

LED lens array or replace the toner cartridge.

Note:

Use LED head cleaners when cleaning the LED Lens array.

40801701TH Rev.2 70 /

Page 71

5. Routine Maintenance

(1) Set the LED head cleaner to the LED lens array as shown in the following figure. Clean it, moving the

cleaner horizontally several times.

Note:

Do not press the LED head cleaner towards the LED lens array.

LED Head Cleaner

LED Lens Arry

40801701TH Rev.2 71 /

Page 72

6. Troubleshooting Produre

6. Troubleshooting Produre

6.1 Prior to Repairing

(1) Be sure the basic points to be checked described in Users Manual.

(2) Obtain information from the customers concerning the situation in which the trouble occurred in details

as much as possible.

(3) Checking the printer in condition close to the trouble is required.

6.2 Check Points prior to Handling Imperfect Image

(1) Machine Operating Circumstances Proper.

(2) Consumables (toner, drum cartridge) Replaced Appropriately.

(3) Paper Normal

(4) Drum Cartridge Set Properly

6.3 Precautions on Handling Imperfect Image

(1) Do not touch the OPC drum surface with hands and foreign matters.

(2) Keeping the OPC Drum out of direct sunlight is essential.

(3) The fuser becomes very hot. Do not touch it with hands.

(4) The image drum shall not be kept in light for 5 minutes or more at room temperature.

40801701TH Rev.2 72 /

Page 73

6.4 Preparation for Troubleshooting

ON-LINESERVICE

OPERATOR

MANUAL

MENU MENU SELECT

MANUAL START

RESET TRAY SELECT ON-LINE

Trouble

Occurred

Trouble Appeared on

LCD in Message

Form

Locate a fault by using LCD

Status Messate List

See Section 6.5.1.

Locate a fault, using detailed

Troubleshooting Flowchart.

See Section 6.5.1.

Imperfect Image

Trouble (or Trouble

Not Appeared on

LCD Message)

Locate a fault, using detailed

Troubleshooting Flowchart.

See Section 6.5.1 and Section

6.5.4.

(1) Operator Panel Display

Failure statuses of the machine are appeared on the LCD (Liquid Crystal Display) of the operator

panel.

Troubleshoot according to each message on the LCD appropriately.

6. Troubleshooting Produre

6.5 Troubleshooting Methods

If any trouble occurs out of the printer, locate a fault by using the following procedure.

6.5.1 LCD Status Message List

Table 6-1 lists status and troubles to be appeared on the LCD in message form.

40801701TH Rev.2 73 /

Page 74

Table 6.1(1/3) LCD Status Message List

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Cover Open

Engine Block

Error

COVER OPEN

ERROR PU

ROM/RAM CHECK

ERROR PU

EEPROM ERROR

ERROR PU

EEPROM WRITE

ERROR PU

CONTROL

ERROR PU-OPTION

I/F TIMEOUT

ERROR PU

S-RAM ERROR

ERROR PU

FAN MOTOR

ERROR PU

FUSER UNIT

Stacker Cover Opened

Engine ROM or RAM Check

Error Occurred

No Engine EEPROM, or EEPROM Damaged

Engine EEPROM Write Error

Occurred

Engine Firmware Got Out of

Control.

PU Second Tray Communication Error Occurred

Engine S-RAM Check Error

Occurred

DC Fan Stopped, No Power

(+38V) Supplied to DC Fan

Fuser Temperature Not

Reached, or Over Specified

Temperature

• Thermistor Shortcircuit or

Disconnection

Close Stacker Cover.

In case the same message is

displayed even after closing

Stacker Cover, replace Mechanism Control Board or PU Power

Unit.

Replace Mechanism Control

Board.

Check whether EEPROOM is

built.

Replace EEPROM.

Replace Mechanism Control

Board.

- Same as the above -

Replace Mchanism Control

Board.

Check whether Second Tray is

attached properly.

Replace Second Tray or

Mechanism Control Board.

Replace Mchanism Control

Board.

Check whether there is a foreign matter in DC Fan.

Check whether DC Fan Connector is connected.

Replace DC Fan or Mechanism Control Board.

See 6.5.2 4.

Classification Message on LCD Fault Remedy

6. Troubleshooting Produre

40801701TH Rev.2 74 /

Page 75

Table 6.1(2/3) LCD Status Message List

•

•

•

•

•

•

•

Jam Error PAPER INPUT JAM

PAPER FEED JAM

PAPER EXIT JAM

REMOVE THE PAPER

ERROR PAPER SIZE

Jam Occurred in Cassette

Leading Part of Paper does

not reach inlet Sensor after

Hopping Roller works. (Retried three times)

Or Inlet Sensor is on when

power is turned on.

Jam Occurred in Paper Feeder

If Specified Time elapses after starting Resister Roller,

Leading Part of Paper does

not reach Write Sensor.

If Specified Time elapses after starting Resister Roller,

Leading Part of Paper does

not reach Outlet Sensor.

Write Sensor does not turn off

within a certain time after Paper End passed Inlet Sensor.

Write Sensor is on before Inlet Sensor turns on.

Write Sensor is off before Inlet Sensor turns off.

Inlet or Write Sensor is on

when power is turned on.

Jam Occurred in Outlet Sensor

Running Time of Paper on

Outlet Sensor does not meet

Specifiedified one, or Outlet

Sensor is on when power is

turned on.

Error Occurred in case Length

of Printing Paper is different

from that Printer recongnized (or

Tray size), or Length of Paper

used is different from that set by

Cassette or Menu.

Detection based on Running

Time of Paper on Inlet Sensor

and by Inlet Sensor.

Open Cover to remove Jammed

Paper, and close Cover.

See 6.5.2 2-1.

Open Cover to remove Jammed

Paper, and close Cover.

See 6.5.2 2-2.

Open Cover to remove Jammed

Paper, and close Cover.

See 6.5.2 2-3.

See 6.5.2 3.

Classification Message on LCD Fault Remedy

•

•

•

•

•

•

•

•

•

6. Troubleshooting Produre

40801701TH Rev.2 75 /

Page 76

Table 6.1(3/3) LCD Status Message List

Controller Error

CU-PU

Communication

Error

CU EEPROM ERROR

ERROR SERIAL

COMMUNICATION

HDD ERROR

ERROR CU-PU

I/F TIMEOUT

ERROR CU-OPTION

I/F TIMEOUT

ERROR CU-PANEL

I/F TIMEOUT

SRA EEPROM Check Error

(Unable to write)

Protocol Error Occured om Serial I/F (such as Parity Error,

Framing Error) or Receiving

Data from Deselect Serial I/F

Ports Detected.

Built-in Hard Disk Error Occurred With Unformatted Hard

Disk.

I/F Error Occurred between CU

and PU.

I/F Error Occurred between CU

and Tray 2 Paper Feed Unit.

I/F Error Occurred between CU

and Operator Panel.

Press "RESET" switch to restore

the system to the condition in

which the machine is shipped. If

this does not recover the system,

replace SRA PCB Board.

Set the contents of Menu to the

higher devices.

See 6.5.2 7.

Press "RESET" switch to restore

Disk File to the initial condition. If

the system does not resume, see

6.5.2 6.

Classification Message on LCD Fault Remedy

•

6. Troubleshooting Produre

40801701TH Rev.2 76 /

Page 77

6. Troubleshooting Produre

6.5.2 LCD Message Troubleshooting

If the printer can not be repaired after the fault locating by the LCD Status Message List, troubleshoot based on

the following Troubleshooting Flowchart.

Item Fault Flowchart No.

1. Printer does not operate properly after power is turned on. 1

2. Jam Alarm

Paper Load Jam 2-1

Paper Feed Jam 2-1

Paper Ejection Jam

3. Paper Size Error 3

4. Fusing Error 4

5. Fan Error 5

6. HDD Error 6

7. Serial I/F Error 7

40801701TH Rev.2 77 /

Page 78

1 The printer does not operate properly when power is turned on.

Turn off the power, then turn on again.

"INITIALIZING" is displayed?

NO AC input is normal?

NO Check the AC connection.

↓

YES +38V is being output?

NO Fuse in Power Supply Unit is broken?

↓

YES Check whether the circuit between +38V-0V is shorted before

replacing Fuse.

NO Power is output when AC is tuned on after detaching Mechanism Control

Board? (at Power Supply Unit)

↓

YES Check whether the circuits between +38V-0V and +5V-0V are

shorted. (on Mechanism Control Board)

6. Troubleshooting Produre

NO Replace Power Supply Unit.

YES “ “ is displayed on Operator Panel 16 seconds after power is turned on?

↓

YES Replace Control Board.

NO Connection Cord of Operator Panel is released?

↓

YES Connect Connection Cord.

NO Replace Operator Panel.

YES Alarm Indicator Lamp lights?

↓

YES Troubleshoot according to each indication.

NO Fan rotates?

↓

NO Replace Mechanism Control Board.

YES Replace Control Board.

40801701TH Rev.2 78 /

Page 79

[Jam Alarm]

2-1 Hopping JAM (PAPER INPUT JAM)

Jam Alarm lights when paper is loaded?

YES Paper is fed to the underside of Inlet Sensor Lever?

YES Inlet Sensor Signals on?

NO Replace Mechanism Control Board.

NO Replace Hopping Roller or Paper Feed Assy.

NO Hopping Roller is turning?

YES Set Tray properly.

6. Troubleshooting Produre

[Check by Tenth Pin on Mechanism Control Board 02F (74HC158).]

YES Check the Inlet Sensor Lever operation.

NO Replace Paper Feed Assy or Mechanism Control Board.

• In the case of Second Tray, replace Paper Feed Assy or Mechanism Control Board LLFL

PCB.

• Check Pulse Motor (Resister). If any trouble with Pulse Motor, replace it.

40801701TH Rev.2 79 /

Page 80

[Jam Alarm]

2-2 Paper Feeding Jam (PAPER FEED JAM)

Paper Feeding Jam occurs when power is turned on?

YES Paper exists on Paper Sensor or Inlet Sensor 1 to 3?

YES Remove Paper.

NO Signals of Paper Sensor or Inlet Sensors 1 to 3 turn on/off?

(Check Mechanism Control Board or Power Supply Unit.)

YES Check the Lever operation of Write Sensor or Inlet Sensor 1 to 3.