Page 1

Page: 1

Service Guide ML590/ML591

Chapter 0 About This Manual

ML590 // ML591

Dot Matrix Printers

Adobe Acrobat printable reference

copy of the OKIDATA Service Training Manual.

09/17/97

Note: This Adobe Acrobat version of the Okidata Service Training Manual was built with the

pictures rendered at 300 dpi, which is ideal for printing, but does not view on most

displays well.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 2

Table of Contents Page

Service Guide ML590/ML591

0 About This Manual

Front Cover 1

Copyright 2

Part Number & Manual Revision 3

1 Product Specifications

1.1 General Information 4

1.2 Physical Specifications 5

1.3 Power Requirements 6

1.4 Environmental Conditions 7

1.5 Agency Approvals 8

1.6 Operation Spec's - Print Speed and Character Matrix 9

....1.6.02 Characters Per Line 10

....1.6.03 Character Pitches 11

....1.6.04 Character Sets 12

....1.6.05 Printer Emulations 13

1.6.06 Fonts 14

1.6.07 Front Panel Switches 15

1.6.08 Graphics Resolution 16

1.6.09 Interface 17

....1.6.10 Line Feed Increments 18

....1.6.11 Line Feed Time 19

1.6.12 Menu Mode 20

....1.6.13 Paper Feed Methods 21

....1.6.14 Paper Feed Paths 22

....1.6.15 Paper Loading 23

....1.6.16 Paper Out Detection 24

....1.6.17 Paper Tear Capabilities 25

....1.6.18 Print Method 26

........Printhead Gap Information 27

....1.6.19 Print Modes 28

....1.6.20 Print Speed 29

1.7 Paper Specifications 30

1.8 Memory Specifications 31

1.9 Consumables 32

1.10 Options 33

....1.10.01 Cut Sheet Feeders 34

....1.10.02 Pull Tractor Kit 35

....1.10.03 Color Ribbon Kit 36

....1.10.04 Bottom Push Tractor Kit 37

....1.10.05 Serial Interface 38

....1.10.06 Roll Paper Stand 39

....1.10.07 Bitstream Facelift 2.0 40

Page 3

Table of Contents Page

....1.10.08 OKISmart Typer Utility 41

....1.10.09 OKISmart Panel Utility 42

1.11 Reliability 43

2 Principles of Operation

2.1 Electrical Operation 44

....2.1.02 Main Control Board 45

........Block Diagram 46

........Program ROM 47

........RAM 48

........Character Generator ROM (CG ROM) 49

........Electrically Erasable Programmable ROM (EEPROM) 50

........LSI 51

....2.1.03 Initialization 52

....2.1.04 Parallel Interface Control 53

....2.1.05 Print Control 54

........LSI/Printhead Interface 55

........Gap Adjust Control 56

........Print Compensation Control 57

....2.1.06 Space and Line Feed (SP/LF) Motor Control 58

........Line Feed Motor Control 59

........Space Motor Control 60

........Encoder Disk 61

....2.1.07 Operation Panel 62

....2.1.08 Alarm Circuit 63

........Head Drive Time 64

........Print Speed 65

........Head Overheat Alarm Processing 66

....2.1.09 Power Supply Circuit 67

2.2 Mechanical Operation 68

....2.2.01 Printhead Mechanism 69

........Interconnect Diagram: Control Board to Printhead 70

........Line Feed Motor Resistance 71

........Space Motor Resistance 72

........Printhead Operation 73

....2.2.02 Spacing Mechanism 74

....2.2.03 Head Gap Mechanism 75

....2.2.04 Ribbon Drive Mechanism 76

........Color Ribbon Shift Mechanism 77

....2.2.05 Line Feed Mechanism 78

........Cut Sheet/Continuous Sheet Switching Mechanism 79

........Cut Sheet Paper Feed Operation 80

........Continuous Paper Feed (Rear Tractor Mechanism) 81

........Continuous Paper Feed (Pull Tractor Mechanism) 82

........Continuous Paper Feed (Bottom Tractor Feed

Mechanism)

83

Page 4

Table of Contents Page

........Continuous Paper Feed (Push/Pull Tractor Mechanism) 84

....2.2.06 Paper Detection Mechanism 85

....2.2.07 Support Protector Mechanism 86

....2.2.08 Automatic Paper Load 87

....2.2.09 Paper Park 88

3 Maintenance & Disassembly

....3.1.01 General Information 89

....3.1.02 Maintenance Tools 90

....3.1.03 Maintenance Precautions 91

3.2 Disassembly/Assembly Procedures 92

....3.2.01 Preliminary Items 93

....3.2.02 Printhead Assembly 94

....3.2.03 Ribbon Protector 95

....3.2.04 Gear Case Assembly 96

....3.2.05 Pull-up Roller Assembly 97

....3.2.06 Upper Cover, Access Cover, and Sheet Guide

Assemblies

....3.2.07 Control Board (AKGI) 99

....3.2.08 Power Supply Assembly 100

....3.2.09 Operator Panel PCB (LEOP) 101

....3.2.10 PC Connector 102

....3.2.11 Space Motor and Roller Guide Assemblies 103

....3.2.12 Carriage Cable 104

....3.2.13 Space Rack 105

....3.2.14 Roller/Holder Backup Assembly 106

....3.2.15 Guide Rail and Adjust Cam 107

....3.2.16 Left Ground Plate 108

....3.2.17 Right Ground Plate 109

....3.2.18 Rear and Cut Sheet Paper Feed Sensor Levers 110

....3.2.19 Platen Assembly 111

....3.2.20 Paper Chute Assembly 112

....3.2.21 Line Feed Motor Assembly 113

....3.2.22 Reset Spring 114

....3.2.23 Idle Gear and Change Lever 115

....3.2.24 Pressure Spring 116

....3.2.25 Carriage Shaft 117

....3.2.26 Leaf Spring 118

....3.2.27 Bottom Paper Sensor Levers 119

....3.2.28 Front Pressure Roller Assembly 120

....3.2.29 Tractor Assembly 121

....3.2.30 Main Frame 122

3.3 Printer Adjustments 123

....3.3.02 Printhead Gap Adjustment 124

....3.3.03 Key Combinations 125

98

Page 5

Table of Contents Page

....3.3.04 Menu Operation 126

........Printing the Menu 127

........Reset Menu to Factory Defaults 128

........Limited Operation 129

........Procedure 130

........Menu Settings 131

....3.3.05 Top of Form 132

....3.3.06 Paper Park 133

....3.3.07 Tear Feature 134

....3.3.08 Forms Tear Off 135

3.4 Cleaning 136

....3.4.02 Cleaning Schedule 137

....3.4.03 Cleaning Tools 138

....3.4.04 Areas to be Cleaned 139

3.5 Lubrication 140

3.6 Shipping Instructions 141

4 Failure & Repair Analysis

4.1 Introduction 142

....4.1.02 Printer Serial Number Identification 143

4.2 Reporting Problems 144

4.3 Troubleshooting Updates 145

4.4 Troubleshooting Tips - Preliminary Checks 146

....4.4.02 Problem Categories 147

....4.4.03 Start Here Flowchart 148

....4.4.04 Tips for Preventing Image Problems 149

....4.4.05 Common Problems 150

4.5 Abnormal Output & Output Samples 151

........Left Margin Drifting Problem 152

4.6 Fault Alarms 153

....4.6.02 Alarm/LED Display Troubleshooting Table Index 154

....4.6.03 Alarm/LED Display Troubleshooting Tables 155

4.7 Repair Analysis Procedures (RAPs) 156

....4.7.01 Using the RAPs 157

....4.7.02 RAP Index 158

........RAP 01 No Power Supplied to Printer 159

........RAP 02 No Spacing Operation 160

........RAP 03 Printhead Homing Error 161

........RAP 04 Paper Jam During Paper Loading 162

........RAP 05 Printhead Pins Not Firing 163

........RAP 06 Poor Print Quality 164

........RAP 07 Ribbon Feed Problem 165

........RAP 08 Line Feed Problem 166

........RAP 09 Operation Panel Malfunction 167

........RAP 10 Parallel Interface Problem 168

Page 6

Table of Contents Page

........RAP 11 Serial Interface Problem 169

4.8 Printer Tests 170

....4.8.02 Rolling ASCII Test 171

....4.8.03 Font Test 172

....4.8.04 Serial Interface Loopback Test 173

........Serial Cable Information 174

........Commonly Used Serial Cable Configurations 175

....4.8.05 Hexadecimal Dump Mode 176

4.9 Resistance Checks 177

....4.9.02 Printhead Interconnect Diagram: Control Board to

Printhead

....4.9.03 Line Feed Motor Resistance 179

....4.9.04 Space Motor Resistance 180

A Reference Charts

General Information 181

A.2 Index To Charts 182

....Interconnect Diagram 183

....A.2.01 Main Controller Board (AKGI) 184

....A.2.02 Operator Panel Board (LEOP) 185

....A.2.03 Power Supply Assembly 186

....A.2.04 Space Motor Board 187

....A.2.05 RS232-C Serial Interface Board (LXHI) Option 188

B Illustrated Parts Listing

General Information 189

....B.1.02 Definition of Terms 190

....B.1.03 Parts Ordering Information 191

B.2 Charts 192

....Board Overview 193

....B.2.01 Printer 194

....B.2.02 Upper Cover Assembly 195

....B.2.03 Printer General Assembly 196

....B.2.04 Printer Unit (1 of 3) 197

....B.2.05 Printer Unit (2 of 3) 198

....B.2.06 Printer Unit (3 of 3) 199

....B.2.07 Carriage Assembly 200

....B.2.08 Options 201

....B.2.09 Option Parts 202

....B.2.10 Consumables 203

....B.2.11 Packing Materials 204

....B.2.12 Documentation 205

....B.2.13 Service Training Kit Revision List 206

178

Page 7

Service Guide ML590/ML591

Chapter 0 About This Manual

This document may not be reproduced without the written permission of the Okidata Technical

Training Group. Every effort has been made to ensure the accuracy of the information contained

in this training course. Okidata is not responsible for errors beyond its control.

Written and produced by the Okidata Technical Training Group

Please address any comments on this publication to:

Technical Training Group

Okidata

532 Fellowship Road

Mount Laurel, NJ 08054-3499

Fax Number: (609) 235-2600, ext. 7034

Page: 2

Okilink Login Name: Technical Training

OKIDATA is a registered trademark of Oki Electric Industry Company, Ltd.; marques deposee de

Oki Electric Industry Company, Ltd.; marca registrada, Oki Electric Industry Company, Ltd.

MICROLINE is a registered trademark of Oki Electric Industry Company, Ltd.; marque depose de

Oki Electric Industry Company, Ltd.

OkiSmart Paper Handling is a trademark of Oki Electric Industry Company, Inc.

PLUG 'n PRINT is a registered trademark of Oki America, Inc.; marque deposee de Oki America,

Inc.

Bitstream is a registered trademark of Bitstream Incorporated.

Epson is a registered trademark of Seiko Epson Corporation.

IBM is a registered trademark of International Business Machine Corporation.

MS-DOS is a registered trademark of Microsoft Corporation.

PC is a registered trademark of International Business Machine Corporation.

Proprinter is a registered trademark of International Business Machine Corporation.

Windows is a trademark of Microsoft Corporation.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 8

Page: 3

Service Guide ML590/ML591

Chapter 0 About This Manual

© 1994 by Okidata All rights reserved.

First Edition October, 1992 P/N 59256301

Second Revision March, 1993

Third Revision August, 1993

Second Edition April, 1994 P/N 59256302

Fourth Revision April, 1994

Third Edition November, 1994 P/N 59256303

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 9

Page: 4

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.1.01 General Information

The Microline 590 and Microline 591 are letter quality dot-matrix printers which utilize OKISMART paper

handling. Patented Okidata technology does away with the manual head gap adjustment. The Microline

590/591 actually "reads and learns" the media you feed in, then automatically adjusts the head gap to the

optimum distance. This auto-gapping process leads to longer printhead life.

An optional, user-installable Color Kit (coupled with a customer-provided color software package) allows

the printers to add impact to graphics, charts, transparencies and text presentations.

Additional options include the Bottom Feed Push Tractor, Cut-Sheet Feeder, Pull Tractor and Serial

Interface Board.

The Microline 590 is an 80 column printer.

The Microline 591 is a 132 column printer.

Okidata's extended two year limited warranty covers the parts, labor and printhead on both printers.

The following items are included with the printer:

OKISMART Typer - software which provides the flexibility for the Microline 590/591 to function like a

typewriter on checks, labels and envelopes.

OKISMART Panel - a utility program that lets you control selected printer functions from your personal

computer.

Scalable Fonts - 14 scalable fonts, available on diskette.

Note:

The OkiSmart software includes three programs:

1. OkiSmart Control

2. OkiSmart Panel Emulator

3. OkiSmart Setup

Refer to the Printer Handbook for more information.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 10

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.2 PHYSICAL SPECIFICATIONS

1.2.01 Dimensions

Note:

Dimensions INCLUDE the platen knob, acoustic cover, and paper separator.

Microline 590

Width: 18.35 inches (466 millimeters)

Depth: 17.24 inches (438 millimeters)

Height: 6.52 inches (165 millimeters)

Microline 591

Width: 24.41 inches (620 millimeters)

Depth: 17.24 inches (438 millimeters)

Height: 6.52 inches (165 millimeters)

1.2.02 Printer Weight

Page: 5

Microline 590

16.5 pounds (6.5 kilograms)

Microline 591

19.8 pounds (8.9 kilograms)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 11

Page: 6

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.3 POWER REQUIREMENTS

1.3.01 Input Power

120 VAC: +5.5 / -15%

230/240 VAC: +10 / -14%

1.3.02 Power Consumption

Operating: 110 VA

Idle: 40 VA

1.3.03 Power Frequency

120 VAC: 60 Hz +/- 2%

230/240 VAC: 50/60 Hz +/- 2%

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 12

Page: 7

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.4 ENVIRONMENTAL CONDITIONS

1.4.01 Acoustic Rating

Letter Quality Mode: 53 dBA

Quiet Mode: 50 dBA

1.4.01 Altitude

10,000 feet (3,050 meters)

1.4.03 Ambient Temperature and Relative Humidity (RH)

While operating: 41° to 104° F (5° to 40° C)

Operating humidity: 20% to 80% RH

While in storage: 14° to 122° F (-10° to 50° C)

Storage humidity: 5% to 95% RH

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 13

Page: 8

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.5 AGENCY APPROVALS

1.5.01 Listings

UL No: UL Standard No. 1950

CSA No: CSA Standard 22.2-950

FCC: FCC Certified per Part 15, Subject J, Class B

IEC: IEC 950

VDE: VDE 0805 VDE 0875 Class B

BS: BS 7002

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 14

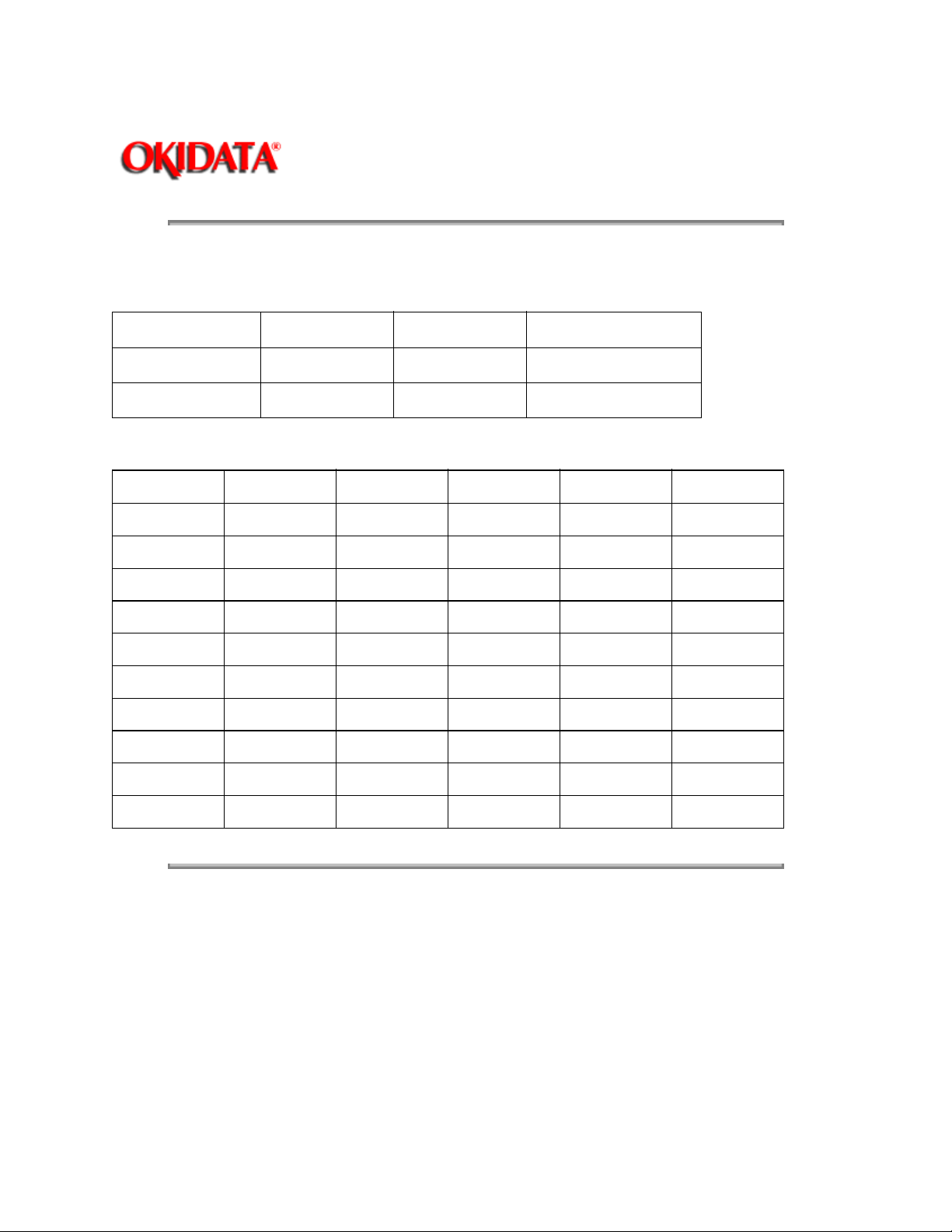

1.6.01 Character Matrix Sizes

Table of Print Speed and Character Matrix

Page: 9

Service Guide ML590/ML591

Chapter 1 Product Specifications

Mode

Speed 120 (12 cpi) 360 (12 cpi) 450 (15 cpi)

Matrix (H x V) 29 x 18 9 x 17 7 x 17

Print Speed at Different CPI for the ML 590

Mode

Utility 10 300 120 180 30

LQ 10 100 360 180 10

LQ Utility High Speed Draft

CPI CPS Horiz. DPI Vert DPI IPS

12 360 120 180 30

15 450 120 180 30

17.1 257 240 180 15

20 300 240 180 15

12 120 360 180 10

15 150 360 180 10

17.1 171 360 180 10

20 200 360 180 10

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 15

1.6.02 Characters Per Line

Microline 590

Page: 10

Service Guide ML590/ML591

Chapter 1 Product Specifications

Characters Per

Line

80 10 164 65

96 12 161 65

120 15 148 65

136 17.1 96 65

160 20 95 65

Microline 591

Characters

Per Line

136 10 105 40

Characters Per

Inch

Characters

Per Inch

Utility Letter Quality

Utility Letter Quality

163 12 96 40

204 15 88 40

233 17.1 59 40

272 20 59 40

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 16

Page: 11

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.03 Character Pitches

5, 6, 8.5, 10, 12, 15, 17.1, 20

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 17

1.6.04 Character Sets

Standard ASCII

EPSON Character Set I & II

IBM Character Set I, II & All Characters

Foreign Character Substitution

International Character Sets

Code Page 850, 860, 863 and 865

Bar Code:

Code 39

UPC A

UPC E

EAN 8

EAN 13

Interleaved 2 of 5

Code 128

POSTNET

Page: 12

Service Guide ML590/ML591

Chapter 1 Product Specifications

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 18

Page: 13

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.05 Printer Emulations

Note:

The emulations are co-resident

Epson LQ

IBM XL 24E (AGM)

IBM Proprinter

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 19

1.6.06 Fonts

Letter Quality

Courier

Letter Gothic

Prestige

Orator

Roman

Swiss

Draft

Utility

High Speed Draft (15 cpi)

Bar Code

Code 39

UPC A

UPC E

EAN 8

EAN 13

Interleaved 2 of 5

Code 128

POSTNET

Page: 14

Service Guide ML590/ML591

Chapter 1 Product Specifications

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 20

Page: 15

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.07 Front Panel Switches

Select Micro Feed Up / Down

Menu Mode Paper Park

Line Feed Pitch Selection

Form Feed Print Quality Selection

Top of Form Tear

Quiet

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 21

Page: 16

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.08 Graphics Resolution

Graphics Resolution: 360 x 360 DPI maximum

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 22

Page: 17

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.09 Interface

Standard

Parallel

Optional

RS232C Serial

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 23

Page: 18

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.10 Line Feed Increments

Fixed

(6 lines per inch lpi) [0.167 inch (4.23 millimeters)]

(8 lines per inch lpi) [0.125 inch (3.175 millimeters)]

Variable

n/60 inch

n/72 inch

n/180 inch

n/216 inch

n/360 inch

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 24

Page: 19

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.11 Line Feed Time

65 milliseconds 6 lines per inch (lpi)

6 milliseconds 8 lines per inch (lpi)

1 second 5.0 inches (Continuous paper feed rate)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 25

Page: 20

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.12 Menu Mode

Print: Prints the entire menu.

Group: Selects Group Function

Item: Selects Item

Set: Selects Item Value

Exit: Exits Menu Mode, Enters Select

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 26

Page: 21

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.13 Paper Feed Methods

Standard

Friction Feed (Top)

Rear Push Tractor (Rear)

Optional

Pull Tractor (Bottom)

Bottom Push Tractor (Bottom)

Single-Bin Cut Sheet Feeder (Top)

CSF 5000 - Narrow

CSF 5001 - Wide

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 27

Page: 22

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.14 Paper Feed Paths

Top Feed (Standard)

Rear Feed (Standard)

Bottom Feed (by using an Optional feed mechanism)

Special Features

Paper Park

Automatic Paper Loading

Forms Tear Off

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 28

Page: 23

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.15 Paper Loading

Auto Loading (Top Feed)

LOAD

Press

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

switch for Bottom/Rear Feed

Page 29

Page: 24

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.16 Paper Out Detection

Distance from end of paper

Rear Feed: 0.5 inches (12.7 mm)

Bottom Feed: 0.5 inches (12.7 mm)

Top Feed: 0.5 inches (12.7 mm)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 30

Page: 25

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.17 Paper Tear Capabilities

Forms Tear-0ff (sharp edge on access cover)

Metal Tear Bar (with optional bottom tractor unit)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 31

Service Guide ML590/ML591

1.6.18 Print Method

Printhead Type

General Information

Impact: Dot Matrix

24 pin printhead

.0079 inch (.20 millimeter) diameter pins

Overheat Protection

When printhead temperature exceeds 110 degrees Celsius, the printer stops

bi-directional printing. Uni-directional printing begins.

If the temperature exceeds 115 degrees Celsius, printing stops.

Printing will resume when the printhead temperature drops below 115 degrees Celsius.

Note:

Refer to Section Two for more information on printhead operation.

Page: 26

Chapter 1 Product Specifications

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 32

Printhead Gap Information

Three items factor into printhead gap information.

1. Printhead Gap Adjustment

This is a

It is covered in Section 3.3 of this Service Handbook.

The Adjustment measures 0.014, +/- 0.001 inches (0.35, +/- 0.03 mm).

2. Printhead Gap Adjust

This is a

It fine tunes the automatic setting of the printhead gap.

The settings are 0, 1, and -1.

0 is the factory default.

Use 1 to darken print (if output is consistently light).

Use - 1 to lighten print (if output is consistently dark).

3. Gap Control

This is a

The Groups are

Gap Control determines how the printhead gap is set.

The settings are listed below.

An explanation of each setting follows.

SERVICE ADJUSTMENT

MENU ITEM

MENU ITEM

REAR FEED, BOTTOM FEED,

Auto Gap, Semi Auto Gap, 1, 2, 3, 4, 5, 6, 7, 8, 9

Auto Gap

This is the factory default.

Automatically determines paper thickness of the first page.

During single-sheet feed, each page's thickness is checked while

a job is printing.

Semi Auto Gap

Similar to Auto Gap.

Automatically determines paper thickness of the first page.

During single-sheet feed, each page's thickness IS NOT checked

"while" a job is printing

1, 2, 3, 4, 5, 6, 7, 8, 9

Used when the same paper is used ALL of the time.

Bypasses the automatic head gap adjustment.

1 is the narrowest gap setting.

9 is the widest gap setting.

SET-UP

in the

in each [Paper Feed] Group.

Service Guide ML590/ML591

Chapter 1 Product Specifications

made by a technician.

Group.

TOP FEED

and

.

Page: 27

Page 33

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 34

Page: 28

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.6.19 Print Modes

Letter Quality

Utility

High Speed Draft

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 35

1.6.20 Print Speed

Table of Print Speed and Character Matrix

Page: 29

Service Guide ML590/ML591

Chapter 1 Product Specifications

Mode

Speed 120 (12 cpi) 360 (12 cpi) 450 (15 cpi)

Matrix (H x V) 29 x 18 9 x 17 7 x 17

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

LQ Utility High Speed Draft

Page 36

1.7 PAPER SPECIFICATIONS

Page: 30

Service Guide ML590/ML591

Chapter 1 Product Specifications

CAUTION:

1.7.01 Types

Card Stock

Weight: 120 lbs. (450 g/m2) Maximum

Width: Microline 590 5 to 8 inches (12.7 to 20.3 centimeters)

Length: 3 to 17 inches (7.62 to 43.18 centimeters)

Thickness: .017 inches (0.44 millimeters)

Paper Feed Path: Bottom

Printhead Gap

Information:

Continuous Form

Weight:

Single Part 12 - 24 lb. (45 to 90 g/m2)

Multi-Part

Carbonless 9 - 11 lb. (35 to 40 g/m2)

Multi-Part,

Interleaf

Paper 10 - 12 lb. (38 to 45 g/m2) Carbon 9 lb. (35 g/m2)

Width: Microline 590 3.5 to 10.5 inches (8.8 to 26.6 centimeters)

Length: 3 to 17 inches (7.62 to 43.18 centimeters)

Thickness: 0.014 inches (0.36 millimeters) Rear Feed

Use Bottom Feed and/or optional Pull Tractor for card stock and labels.

Microline 591 5 to 14 inches (12.7 to 35.6 centimeters)

Refer to the Printhead Gap Information, Section 1.6

Microline 591 3.5 to 16.5 inches (8.8 to 41.9 centimeters)

0.017 inches (0.44 millimeters) Bottom Feed

.

Paper Feed Path: Rear or Bottom

Printhead Gap

Information:

Cut Sheet

Weight: 12 to 24 lbs. (45 to 90 g/m2)

Width: 7.2 to 14.3 inches (18.3 to 36.3 centimeters)

Width: Microline 590 7.2 to 8.5 inches (18.2 to 21.5 centimeters)

Length: 3 to 17 inches (7.62 to 43.18 centimeters)

Thickness: 0.014 inches (0.325 millimeters) Maximum

Paper Feed Path: Top

Printhead Gap

Information:

Envelopes

Weight: 24 lbs. (90 g/m2) Maximum

Size:

Refer to the Printhead Gap Information, Section 1.6

Microline 591 7.2 to 14.3 inches (18.2 to 36.3 centimeters)

Refer to the Printhead Gap Information, Section 1.6.

.

Page 37

Single Feed

Continuous

Thickness: .014 inches (.325 millimeters) Maximum

Paper Feed Path: Bottom

Printhead Gap

Information: Refer to the Printhead Gap Information, Section 1.6. .

Labels

Weight: N/A

Width: Microline 590 3.5 to 10.5 inches (8.8 to 26.6 centimeters)

Length: 3 to 17 inches (7.62 to 43.18 centimeters)

Thickness: .011 inches (0.28 mm) Maximum (including backing)

Paper Feed Path: Bottom

Printhead Gap

Information: Refer to the Printhead Gap Information, Section 1.6. .

CAUTION: Use Bottom Feed and/or optional Pull Tractor for card stock and labels.

Transparency

Note: Roller marks may mar the transparency under high temperature/

Weight: 12 to 24 lbs. (45 to 90 g/m2)

Width: Microline 590 7.2 to 8.5 inches (18.2 to 21.5 centimeters)

Length: 3 to 17 inches (7.62 to 43.18 centimeters)

Thickness: 0.14 inches (0.36 millimeters)

Paper Feed Path: Top

Printhead Gap

Information: Refer to the Printhead Gap Information, Section 1.6. .

Minimum: 6.5 x 3.6 inches (16.5 x 9.1 centimeters)

Maximum: 9.5 x 4.1 inches (24.1 x 10.4 centimeters)

Non-overlap type

Microline 591 3.5 to 16.5 inches (8.8 to 41.9 centimeters)

high humidity conditions.

Microline 591 7.2 to 14.3 inches (18.2 to 36.3 centimeters)

1.7.02 Length

Note: The recommended length is specific to paper type.

Rear Feed

Minimum 3 inches (7.62 centimeters)

Maximum 17 inches (43.18 centimeters)

Bottom Feed

Minimum 3 inches (7.62 centimeters)

Maximum 17 inches (43.18 centimeters)

Top Feed

Minimum 3 inches (7.62 centimeters)

Maximum 17 inches (43.18 centimeters)

1.7.03 Number of Copies

Original + 4 Interleaf

Original + 4 Carbonless

Original Cut Sheet

1.7.04 Thickness

0.014 inches / 0.36 mm Maximum Thickness, Rear Feed

0.017 inches / 0.44 mm Maximum Thickness, Bottom Feed

1.7.05 Weight

Page 38

Note: The recommended weight is specific to paper type.

Minimum: 9 lb. (35 g/m2)

Maximum: 24 lb. (90 g/m2)

1.7.06 Width

Note: The recommended width is specific to paper type.

Paper

Microline 590

Minimum: 3.5 inches (8.8 centimeters)

Maximum: 10.5 inches (26.6 centimeters)

Microline 591

Minimum: 3.5 inches (8.8 centimeters)

Maximum: 16.5 inches (41.9 centimeters)

Printing Area

Microline 590 8 inches Maximum

Microline 591 13.6 inches Maximum

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 39

1.8 MEMORY SPECIFICATIONS

1.8.01 EEPROM

1 Kbit serial EEPROM (used to store Menu data)

1.8.02 ROM

"Older" Configuration

1 Mbit, Character Generator ROM (located on main control board, 05C)

1 Mbit, Printer Control EPROM (located on main control board, 05D)

"New" Configuration

4 Mbit (located on main control board, 05D)

1.8.03 RAM

Receive Buffer Size is selected through the Menu.

Settings are: 64 K, 32 K, 1 line

Page: 31

Service Guide ML590/ML591

Chapter 1 Product Specifications

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 40

1.9 CONSUMABLES

1.9.01 Ribbon

Page: 32

Service Guide ML590/ML591

Chapter 1 Product Specifications

CAUTION:

warranties.

Material

Types

Life (On average, at 10 characters per inch, Utility Mode)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Using a non-Okidata ribbon may damage the printhead and void any

Cartridge Fabric

Black Ribbon

Color Ribbon

Magenta

Yellow

Cyan

Black

Black Ribbon 4 million characters

Color Ribbon

Magenta 1.5 million characters

Yellow 0.8 million characters

Cyan 1.5 million characters

Black 1.5 million characters

Page 41

1.10 OPTIONS

Page: 33

Service Guide ML590/ML591

Chapter 1 Product Specifications

Cut Sheet Feeders ...... (

Pull Tractor Kit ............ (

Color Ribbon Kit .......... (

Bottom Push Tractor .... (

Serial Interface ............ (

Roll Paper Stand ......... (

Bitstream Facelift 2.0 ...(

OKIsmart Typer Utility .. (

OKIsmart Panel Utility .. (

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

)

)

)

)

)

)

)

)

)

Page 42

Page: 34

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.10.01 Cut Sheet Feeders

The CSF-5000 is a narrow feeder for the Microline 590.

Single Bin with envelope capability

Paper Width: 7.2" to 8.5" (18.3 cm to 36.3 cm)

Paper Length: 10.1" to 14" (25.6 cm to 35.6 cm)

Capacity: 170 sheets (16 lb.), 100 sheets (20 lb.)

The CSF-5001 is a wide feeder for the Microline 591.

Single Bin with envelope capability

Paper Width: 7.2" to 14.3" (18.3 cm to 36.3 cm)

Paper Length: 10.1" to 14" (25.6 cm to 35.6 cm)

Capacity: 170 sheets (16 lb.), 100 sheets (20 lb.)

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 43

Page: 35

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.10.02 Pull Tractor Kit

Note:

The Pull Tractor Kit (P/N 70023001) is a narrow feeder for the Microline 590.

The Pull Tractor Kit (P/N 70023201) is a wide feeder for the Microline 591.

Bottom Feed

Rear Feed (For Push/Pull Operation)

Paper Types: Continuous Feed and Labels

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 44

Page: 36

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.10.03 Color Ribbon Kit

Includes:

Color mechanism

Color Ribbon

End user installable

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 45

Page: 37

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.10.04 Bottom Push Tractor Kit

Note:

The Bottom Push Tractor Kit (P/N 70022901) is a narrow feeder for the Microline

590. The Bottom Push Tractor Kit (P/N 70023101) is a wide feeder for the

Microline 591.

Bottom Feed

Paper Type: Continuous Feed

Includes: Stand and Metal Tear B

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 46

Page: 38

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.10.05 Serial Interface

Super-Speed 19.2K RS-232C

Ready/Busy/X-On/X-Off Protocols

Can be configured through the Menu or OKISmart Utility Program

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 47

Page: 39

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.10.06 Roll Paper Stand

Adapts printer for use with roll-type paper (Model 590 only)

Includes: Stand, Support, Cord and DIN plug for connection to printer

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 48

Page: 40

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.10.07 Bitstream Facelift 2.0

For Windows 3.0 and 3.1

Includes: 14 scalable fonts

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 49

Page: 41

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.10.08 OKISmart Typer Utility

Packaged with printer

Includes: Typewriter Mode, Form Creation Utility and Barcode Utility

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 50

Page: 42

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.10.09 OKISmart Panel Utility

Packaged with printer

Includes: Front Panel Control Utility and Drivers for Windows 3.0 & 3.1

Note:

The OkiSmart software includes three programs.

1. OkiSmart Control

2. OkiSmart Panel Emulator

3. OkiSmart Setup

Refer to the Printer Handbook for more information.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 51

1.11 RELIABILITY

1.11.01 Mean Time Before Failure (MTBF)

Approximately 6,000 hours: 25% duty cycle / 35% page density

1.11.02 Mean Time To Repair (MTTR)

Approximately 15 minutes to major sub-assembly level

1.11.03 Printer Life

Approximately 16,000 hours of power-on time: 25% duty cycle / 35% page density

1.11.04 Printhead Life

Average 200 million characters in 10 cpi utility mode @ normal 25% duty, 35% page

density

Page: 43

Service Guide ML590/ML591

Chapter 1 Product Specifications

1.11.05 Ribbon Life

Black: Approximately 4 million characters

Color:

1.11.06 Warranty (Limited)

Two years, parts and labor

1.11.07 Service

Authorized Okidata Service Centers

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Black: Approximately 1.5 million characters

Cyan: Approximately 1.5 million characters

Magenta: Approximately 1.5 million characters

Yellow: Approximately 0.8 million characters

Page 52

Page: 44

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.1 ELECTRICAL OPERATION

2.1.01 General Information

The printers is made of the following electrical components.

Main Control Board

Power Supply Assembly

Operator Panel

Space Motor / Line Feed Motor

Printhead

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 53

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.1.02 Main Control Board

The main control board is made up of the microprocessor, peripheral circuits, drive circuits,

sensors and interface connectors.

The power to the main control board is supplied by the power supply assembly through a wire

harness. The power to other electrical parts, such as the line feed motor, space motor and

printhead, is supplied by the power supply assembly through the connectors on the main control

board.

Microprocessor (MPU)

Location 04D: 67X640

16 bit MPU, using CMOS technology.

The MPU contains a 20 bit address bus, a 16 bit data bus.

The MPU can access 1 Mbyte of program memory space and 1 Mbyte of data

memory space.

The microprocessor controls the entire printer by executing the control program

through the LSI and the driver circuit.

Page: 45

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 54

Page: 46

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 55

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Program ROM

Location 05D: 27C1024

This 64k x 16 bit (Mbit) EPROM contains the control program for the printer. The MPU executes

the instructions contained in this program.

The Program ROM is assigned to the program memory area of the MPU and instructions are

fetched by the PSEN signal of the MPU.

Page: 47

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 56

Service Guide ML590/ML591

Chapter 2 Principles of Operation

RAM

Location 05E: 511664Z.

The RAM is CMOS dynamic RAM with 65,536 words x 16-bit configuration, and is used as a

receive buffer, print buffer and work buffer.

Page: 48

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 57

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Character Generator ROM (CG ROM)

Location 05C: 27C4096.

This 256k x 16 bits (4 Mbit) masked EPROM contains the character data for the various fonts.

The CG ROM is assigned to the program memory area of the MPU. The data is accessed by the

PSEN signal of the MPU.

Page: 49

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 58

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Electrically Erasable Programmable ROM (EEPROM)

Location 03C: 93CS46.

The EEPROM is a CMOS serial I/O type memory which is capable of electrically erasing and

writing 1,024 bits

The EEPROM contains the menu data and the head drive time correction data.

Page: 50

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 59

Service Guide ML590/ML591

Chapter 2 Principles of Operation

LSI

Location 02D: MSM(79V035).

Detects the output of the two-phase sensor on the DC space motor to control the motor drive

phase.

Transmits and receives serial data to and from the printhead based on the dot timing (which is

derived from the space motor speed).

Controls the external interface. The LSI is connected to the MPU.

Page: 51

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 60

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.1.03 Initialization

This printer is initialized when the printer is powered on or when the I-PRIME-N signal is input

from the host via the parallel interface.

Printer Initialization occurs as listed below.

The RST-N signal is output from the Reset circuit to reset the MPU and LSIs.

The program is executed and the LSIs are reset by the MPU via IORST-N.

Page: 52

Note:

The program sets the LSI (02D) mode, checks the memory (ROM/RAM), then executes carriage

homing and determines the phase of the line feed motor.

Finally, the program establishes the interface signals (P-I/F: ACK-P signal sending, and S-I/F:

BUSY-N signal off) and lights the SELECT lamp to indicate that the printer is in the ON-LINE

state.

A Reset operation initiated by I-PRIME does not reset the MPU.

Page 61

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 62

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.1.04 Parallel Interface Control

The parallel data input from the host to the interface LSI is latched to the internal register by the

falling edge of the STROBE-N signal.

The LSI sets the BUSY-N signal to inform the host that the data is being processed. The LSI also

outputs the RXD-N signal to inform the MPU of data reception. The data is read upon receiving

the RD-N signal from the MPU.

When the data processing is complete, the BUSY-N signal is disabled and the ACK-N signal is

sent to request the next data. When the buffer is full and reception is not desired, the BUSY signal

is sent to request data transmission be stopped.

Page: 53

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 63

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.1.05 Print Control

The print data is transmitted as serial data from the LSI to the control circuit and the driver

contained in the printhead.

After the data is printed, the sensor analog circuit controlling each pin returns the pin stroke data

to the MPU. The MPU will make an automatic head gap adjustment. This feedback system sets

the optimum drive time for each pin in order to maintain high print quality.

Page: 54

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 64

Service Guide ML590/ML591

Chapter 2 Principles of Operation

LSI/Printhead Interface

The connection between the LSI and the printhead is made with the bi-directional serial data bus.

The LSI transmits the print data as serial data to the logic circuit of the printhead. The printhead

returns serial data from the printhead sensor analog circuit to the LSI. This information is used to

determine the optimum drive time for the next print request.

The logic circuit of the printhead signals the LSI if a parity error is detected in the print data.

Page: 55

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 65

Service Guide ML590/ML591

Chapter 2 Principles of Operation

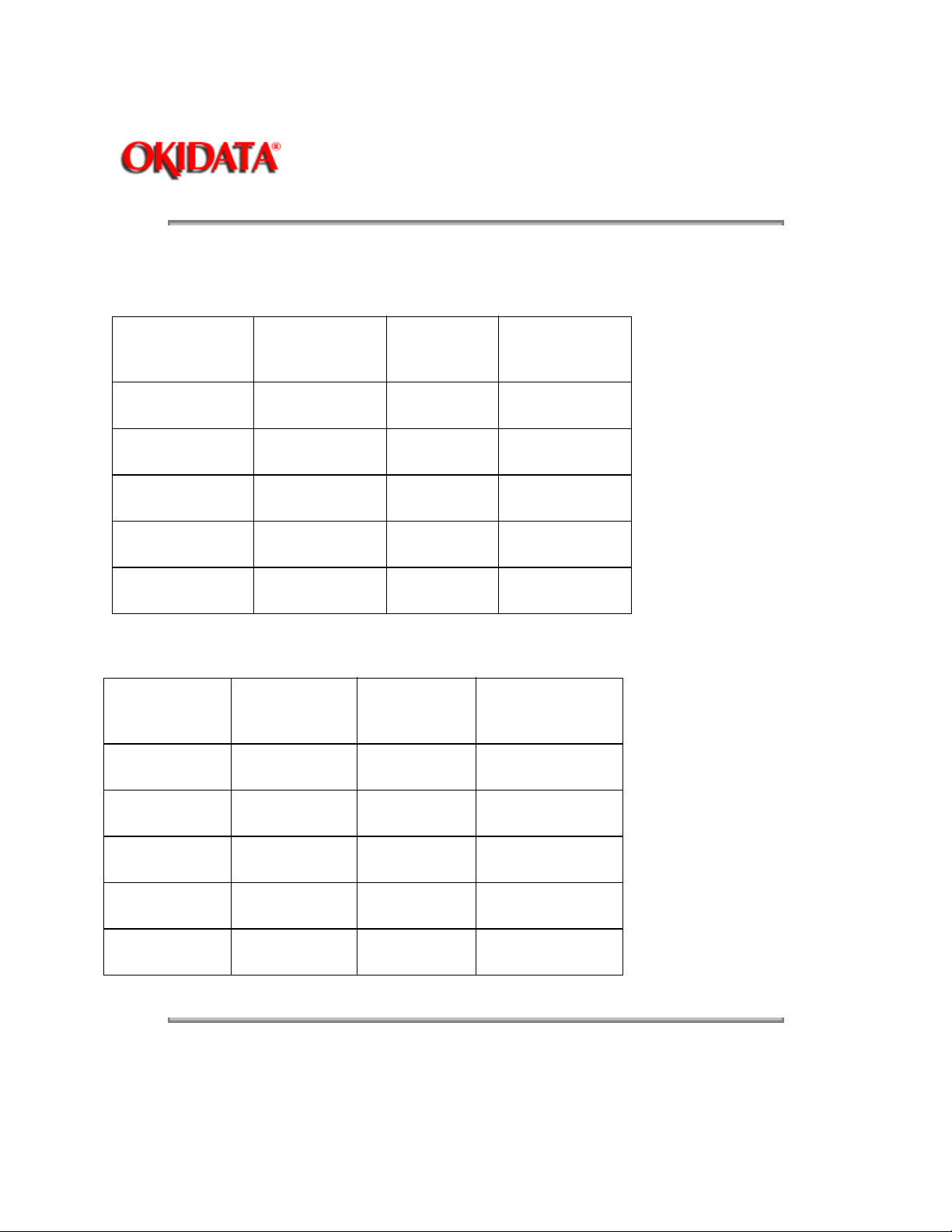

Gap Adjust Control

The Gap Adjust LSI receives stroke length information for all of the printhead pins from the sensor

analog circuit. The Gap Adjust LSI then sets the optimum printhead gap for the printing medium.

Page: 56

Note: Refer to Section 2.2.03

All values in the chart are in millimeters

for a description of the mechanical process.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 66

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Print Compensation Control

The printhead compensates for the shape of the platen as shown below.

Page: 57

Note:

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Refer to Section 2.1.08 - Head Drive Time

Page 67

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.1.06 Space and Line Feed (SP/LF) Motor Control

The LSI (Location 02D: MSM79V035) generates the space motor and the line feed motor control

signals according to commands received from the MPU. These signals are sent to the SP/LF

motor driver.

Page: 58

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 68

Page: 59

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Line Feed Motor Control

The SP/LF motor driver (Location 5A: MHM2025) drives the line feed motor in two-phase bipolar,

based on the phase changeover data output from the LSI.

The serial data from the LSI (02D:MSM79V035) is processed by a register contained in the SP/LF

motor driver to measure the overdrive time and to change the phase.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 69

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Space Motor Control

The SP/LF motor driver (Location 5A: MHM2025) drives the three-phase brushless motor. Motor

movement is based on the phase signal (SPU,SPV and SPW) and the speed instruction data

from the LSI. The MPU can identify the current speed of the space motor by measuring the pulse

width of the output (Phase A, Phase B) of the encoder disk sensor.

After comparing the target speed for each print mode with the actual speed, the motor is

accelerated or decelerated to maintain the desired speed for each print mode.

Page: 60

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 70

Page: 61

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Encoder Disk

As the space motor operates, the encoder disk spins. When the encoder disk interrupts the photo

sensors, the signals Phase A and Phase B are generated. The LSI (Location 02D: MSM79V035)

divides these edge pulse signals (the frequency division is based on the selected print pitch) to

generate the signal IPT. The IPT signal provides dot-on timing and carriage position detection

timing.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 71

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.1.07 Operation Panel

The Serial I/O Port (Ports 20 - 23) of the MPU reads the operation panel switch data from the

operation panel control LSI (Location IC1: BUS148S). The Serial I/O Port also outputs LED data

to the operation panel control LSI.

A two byte (15 bits +1 parity bit (even parity)) command (OPTXD) is transmitted from the MPU to

the operation panel LSI in synchronization with the OPCLK signal. Once the LSI decodes the

command, the command must pass a command code check and have no parity errors. Then, the

specified I/O control will return the two byte command response to the MPU.

Page: 62

Page 72

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 73

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.1.08 Alarm Circuit

Driver Circuit Alarm Processing

The printhead driver output, the head gap magnet output and the color ribbon magnet drive signal

are monitored at R670 and C15, and the POWER OFF-P signal is output by the comparator

(Location 01A: IC2901) when driven for more than the specified time. This signal becomes the

ALM signal. The ALM signal is sent to the power supply board and causes the DC voltages to be

turned off.

Page: 63

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 74

Page: 64

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Head Drive Time

The head drive time is modified to compensate for the amount of the voltage drop of the

POWLEV signal. By monitoring the voltage drop every 500 microseconds, the MPU is able to

control and maintain the impact necessary for each printhead pin.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 75

Print Speed

Page: 65

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Actual Voltage (+40 vdc)

+34 vdc or greater 1 100%

+32 vdc to +34 vdc 1 Approximately 85%

+30 vdc to +32 vdc 1 Approximately 50%

+30 vdc or less 2 Less than 50%

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Passes

Required

Relative Print Speed

Page 76

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Head Overheat Alarm Processing

Two thermistors are used to monitor the printhead temperature. One is contained in the printhead

and the other in the printhead driver. The voltage of the TSD signal is monitored at the MPU A/D

port to control the pass number and print method (unidirectional / bi-directional) at each of seven

levels. If the printhead temperature exceeds 110 degrees Celsius, the printer will switch to

unidirectional print. If the temperature exceeds 115 degrees Celsius, printing will stop. Once the

printhead cools, printing will resume.

Page: 66

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 77

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.1.09 Power Supply Circuit

The switching type power supply circuit supplies the +5 vdc, +/-8 vdc, +12 vdc and +40 vdc.

Page: 67

Table of Output Voltages

Voltage / Signal

+5 vdc IC logic levels LED drive voltages

+8 vdc Serial interface line voltage comparator IC

-8 vdc Serial interface line voltage

+12 vdc Printhead analog circuit

+40 vdc Printhead space motor and line feed motor drive voltage

ALM Output from the main control board upon detection of an

Purpose

abnormality in the printhead head gap or color ribbon drive circuits.

This signal will cause all DC voltages to be turned off.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 78

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.2 MECHANICAL OPERATION

The following section explains the mechanical operation of the printer.

Page: 68

Spacing Mechanism .................................... (

Head Gap Mechanism .............................. (

Ribbon Drive Mechanism .......................... (

Line Feed Mechanism ................................ (

Paper Detect Mechanism ......................... (

Support Protector Mechanism ................. (

Automatic Paper Load ............................... (

Paper Park .................................................. (

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

)

)

)

)

)

)

)

)

Page 79

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.2.01 Printhead Mechanism

The printhead is a spring charged 24-pin printhead. It is attached to the carriage, which moves

parallel to the platen. Electrically, the printhead is controlled by the main control board via the

carriage cable and the space motor.

Page: 69

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 80

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Interconnect Diagram: Control Board to Printhead

Note:

The printhead coil resistance values ARE NOT LISTED.

The individual print wire control lines CANNOT be accessed on this printhead.

Page: 70

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 81

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Line Feed Motor Resistance

The resistance of each coil should be approximately 13 ohms.

Page: 71

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 82

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Space Motor Resistance

The resistance of each coil should be approximately 5 ohms.

Page: 72

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 83

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Printhead Operation

When the printhead is idle, the armature is attracted to the permanent magnet. The print wires,

which are attached to each armature, are then concealed inside the wire guide.

When a signal to print a character is received, current flows through a coil. The magnetic field

generated by the coil opposes the magnetic field between the armature and the permanent

magnet. The armature is then driven in the direction of the platen by the force of the armature

spring. The print wire, which is attached to the armature, protrudes from the tip of the wire guide,

strikes the paper through the ribbon and prints a dot on the paper.

As the armature gets closer to the electrode of the analog sensor, the capacitance between them

increases and a small amount of current flows. This current is amplified and sent to the logic

control LSI to indicate armature activity. In order to attain optimum drive time, this information is

transferred to the MPU. The MPU continually modifies the head gap to maintain the optimum

drive time condition.

The analog sensor element monitors all of the pins. The difference in pin stroke due to the

curvature of the platen is compensated for at the logic control section of the printhead and is not

transferred to the MPU.

Page: 73

After the character has been printed, the permanent magnet attracts the armature and the print

wires are retracted into the wire guide.

Two thermistors are used to monitor the printhead temperature.

A thermistor in the printhead prevents over-heating of the coil during periods of continuous

bi-directional printing. If the printhead temperature exceeds 110 degrees Celsius, the printer will

switch to unidirectional print. If the temperature exceeds 115 degrees Celsius, printing will stop.

Once the printhead cools, printing will resume. When the temperature of the coil exceeds the

pre-determined limits, the control circuit detects the thermistor signal (TSD).

A thermistor in the printhead driver monitors the temperature of the driver. If the temperature of

the driver exceeds the pre-determined limits (110 degrees Celsius - unidirectional printing / 115

degrees Celsius - printing stops) the control circuit detects the thermistor signal (TSD). The

voltage of the TSD signal is monitored at the MPU A/D port to control the pass number and print

method (unidirectional / bi-directional) at each of seven levels.

Page 84

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 85

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.2.02 Spacing Mechanism

The spacing mechanism consists of a carriage shaft (mounted parallel to the platen), and a

carriage frame which moves along the shaft. The carriage frame is driven by a DC servo motor

mounted on the carriage frame. Items included in the spacing mechanism are listed below.

Space Motor Assembly

DC Servo Motor

Motor gear

Sensor

Encoder Disk

Carriage Frame

Carriage Shaft

Space Rack

Spacing Operation

The carriage frame, which contains the printhead and space motor, moves along the carriage

shaft parallel to the platen. When the space motor rotates, the driving force is transmitted to the

motor gear. As the motor gear rotates, the carriage moves along the platen. For every revolution

of the DC servo motor, the carriage frame moves 0.8 inch (20.32 mm).

Page: 74

As the DC servo motor rotates, a slotted disk (called the encoder disk), passes between a light

source and two photosensors. The position of the carriage frame can be determined by counting

the pulses generated by the photosensors.

In the same way, the rotation of the space motor can be recognized and controlled by measuring

the phase relationship and the pulse width of the signals generated by the photosensors.

Page 86

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 87

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.2.03 Head Gap Mechanism

The head gap is automatically set for the thickness of the medium loaded in the printer. In the

case of envelopes, where the medium thickness varies as the printhead moves along the platen,

the head gap changes to compensate for the differences in thickness.

Head Gap Setting Operation

Once printing starts, the space motor rotates the ribbon gear, causing idle gear C to turn the

change gear.

When the MPU requests a change in the head gap setting, the GAP-P signal causes the armature

(which is holding the change gear) to be attracted to the pranger magnet. The gap reset spring

can now push the change gear so it contacts the gap change gear.

The rotation of the gap change gear causes idle gear D to turn the adjust gear. The adjust gear

turns the adjusting screw, resulting in a new head gap setting.

Page: 75

Note:

As the adjusting screw turns counter-clockwise, the gap narrows.

As the adjusting screw turns clockwise, the gap widens.

There is a cam at each setting of the gap change gear. When the change gear is at the top of the

cam, the change gear disengages from the gap change gear. At this time, the armature resets,

changing the head gap by one setting.

The head gap is modified in .06 mm units for each range setting.

Page 88

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 89

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.2.04 Ribbon Drive Mechanism

Black Ribbon Drive Operation

The ribbon drive mechanism feeds the ribbon in synchronization with the spacing operation. The

force required to drive the ribbon is obtained from the space motor.

The ribbon drive mechanism is composed of the following items.

Ribbon drive gear assembly

Ribbon gear (located on the space motor assembly)

Ribbon cartridge

Page: 76

A continuous loop ribbon with uni-directional feed is used. Ink is supplied from an ink tank, which

is built into the ribbon cartridge.

When the space motor turns, the ribbon gear on the spacing motor shaft rotates. The rotation is

transmitted via a combination of gears, from the ribbon drive gear assembly to the drive gear in

the ribbon cartridge.

Although the space motor moves in both the forward and reverse directions during bi-directional

printing, the gears in the ribbon drive assembly maintain uni-directional ribbon feed by switching

the rotation direction of the gears.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Page 90

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 91

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Color Ribbon Shift Mechanism

Items of the color ribbon unit option are listed below.

Color shift unit

Color ribbon (4 colors)

Four colors can be selected by sliding the color ribbon holder up or down. Here is a description of

how the ribbon holder is shifted.

Page: 77

As the space motor moves, idle gear C on the ribbon drive unit rotates. Idle gear C rotates the

color idle gear, located in the color shift unit.

When the color-P signal from the main control board activates the pranger magnet, the magnet

attracts the armature. This causes the reset spring to force the change gear downward. The color

idle gear rotates the change gear, which turns the color change gear. The color change gear turns

the color cam shaft. The rotation of the color cam shaft moves the color ribbon holder up/down to

select the desired ribbon color.

There is a cam at each setting of the color change gear. When the change gear is at the top of

the cam, the change gear disengages from the color change gear. At this time, the armature

resets, changing the color band selection by one setting.

Page 92

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 93

Service Guide ML590/ML591

Chapter 2 Principles of Operation

2.2.05 Line Feed Mechanism

The line feed operation is accomplished by activating the line feed motor which turns the platen.

The rotation of the platen is used to feed paper from the selected paper path.

Components of the paper feed mechanism are listed below.

Line Feed Motor (pulse motor) with Gears

Line Feed Idler Gear

Page: 78

Platen

Rear Tractor Feed Unit

Pressure Roller

Change Lever (Paper Path Selection Lever)

The change lever is used to select one of three different paper paths; top, rear or bottom.

Paper Clamp Mechanism

Moving the Change Lever between the Bottom, Top and Rear positions, changes the positions of

the Front Release Gear Arm and the Release Cam.

Page 94

The movement of the Front Release Gear Arm changes the position of the Front Release Gear

Shaft. This causes the Front Pressure Roller to open or close.

The movement of the Release Cam causes the Rear Pressure Roller to open or close.

Position of

Change Lever

Bottom OPEN N/A OPEN N/A

Top CLOSED 250 g CLOSED 700 g

Rear CLOSED 90 g OPEN N/A

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Status of Front

Pressure Roller

Tension of

Front Pressure

Roller

Status of

Rear

Pressure

Roller

Tension of

Rear Pressure

Roller

Page 95

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Cut Sheet/Continuous Sheet Switching Mechanism

Top Feed (for cut sheet paper)

When cut sheet paper is used, place the change lever in the Top Feed position.

As the platen turns, the platen gear causes the idle gear to rotate.

At this time, the rear and front pressure rollers press against the platen and feed the cut sheet.

The cut sheet detection lever enables the cut sheet detection switch, which is located on the main

control board. This places the printer in the cut sheet mode.

When cut sheet paper is placed between the platen and the paper chute, the printer automatically

feeds the sheet to the print start position.

Rear/Bottom Feed (for continuous feed paper)

When the continuous feed paper is used, either with the rear tractor, optional bottom tractor or

optional pull tractor, place the change lever in the Rear/Bottom Feed position.

Page: 79

When the change lever is placed in this position, the reset spring pushes the change gear. In this

position, the idle gear is engaged with the bottom tractor unit drive gear and the tractor gear. As

the platen turns, power is transferred from the platen gear - to the idle gear - to the change gear and to the push tractor shaft.

Page 96

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 97

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Cut Sheet Paper Feed Operation

As the line feed motor rotates, power is transferred through decelerating gears (line feed idler

gear, platen gear) to the platen.

Page: 80

When using cut sheet paper, the change lever must be in the

pressure rollers can feed the paper. This also disengages the push tractor.

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

TOP

position so the platen and

Page 98

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Continuous Paper Feed (Rear Tractor Mechanism)

As the platen rotates, power is transferred to the tractor gear from the platen gear, the idler gear

and the change gear. The tractor gear drives the pin tractor belts which feed the continuous

paper.

Page: 81

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 99

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Continuous Paper Feed (Pull Tractor Mechanism)

Bottom feed of continuous sheets is possible only when an optional pull tractor unit is installed.

As the platen rotates, power is transferred to the drive gear from the LF idler gear, the platen gear,

idler gear B and idler gear A. The drive gear turns the pull tractor assembly which feed the

continuous paper.

Page: 82

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Page 100

Service Guide ML590/ML591

Chapter 2 Principles of Operation

Continuous Paper Feed (Bottom Tractor Feed Mechanism)

As the platen rotates, power is transferred to the drive gear from the platen gear, the idle gear and

the tractor change gear. The drive gear turns the pin tractor belts on the bottom tractor feed unit to

feed the continuous paper.

Page: 83

Copyright 1997, Okidata, Division of OKI America, Inc. All rights reserved. See the OKIDATA Business

Partner Exchange (BPX) for any updates to this material. (http://bpx.okidata.com)

Loading...

Loading...