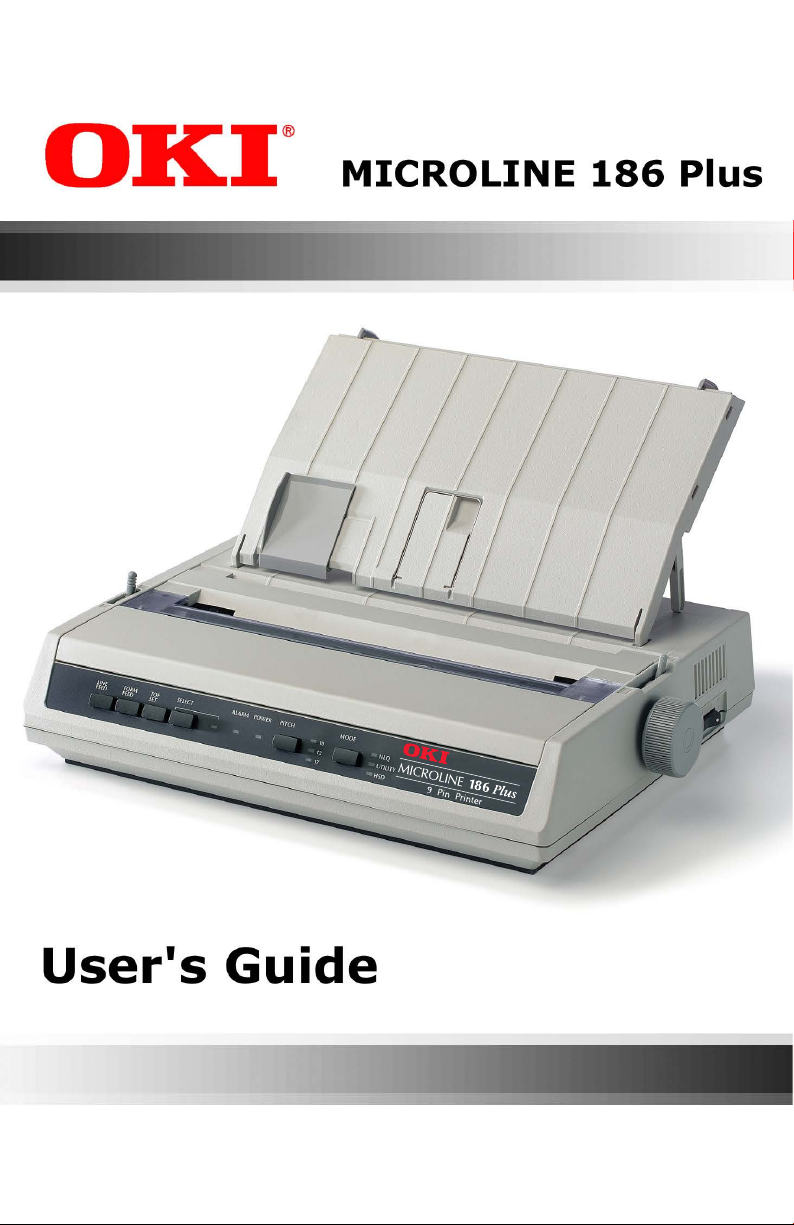

Page 1

Page 2

Every effort has been made to ensure that the information in this

document is complete, accurate, and up-to-date. Oki Data

assumes no responsibility for the results of errors or omissions

beyond its control. Oki Data also cannot guarantee that changes in

software and equipment made by other manufacturers and

referred to in this document will not affect the applicability of the

information in it. Mention of software products manufactured by

other companies does not necessarily constitute endorsement by

Oki Data.

Copyright 2017 by Oki Data. All Rights Reserved

Document: MICROLINE ML186 Plus User’s Guide

First Edition: May, 2017

We invite you to visit OKI Data global web site at:

http://www.oki.com/printing/.

OKI and MICROLINE are registered trademarks of Oki Electric

Industry Company, Ltd. Epson is a registered trademark of Seiko

Epson Corporation (SEC), registered in the U.S. and other countries.

IBM is a registered trademark of IBM Corporation. LINUX is a

registered trademark of Linus Torvalds. Microsoft, MS-DOS,

Windows, Windows NT and DOS are either registered trademarks or

trademarks of Microsoft Corporation in the United States and/or other

countries. Word Perfect is a registered trademark of Corel

Corporation.

Page 3

Contents

Notes, Cautions, etc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Contents and Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Removing the Shipping Restraint . . . . . . . . . . . . . . . . . . . . . . .6

Installing/Replacing the Ribbon Cartridge . . . . . . . . . . . . . . . .7

Installing the Platen Knob . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Adjusting the Head Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Installing the Paper Separator . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting Up Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Loading Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Testing Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Computer Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Setting up the Printer to Work with Your Computer . . . . . . . . 36

Operating Your Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Front Panel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Setting Printer Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Using the Pull Tractor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Using the Roll Paper Stand . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Replacing the Ribbon Cartridge . . . . . . . . . . . . . . . . . . . . . . . 58

Testing Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Cleaning the Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Clearing Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Parts & Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Oki contact details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

3

Page 4

Notes, Cautions, etc.

Note

A note appears like this. It provides additional

information which helps you to use and understand

the product.

Important

An important message appears like this. It provides

supplemental information which can prevent potential

problems.

CAUTION!

A caution message appears like this. It provides

information which, if ignored, can result in equipment

malfunction or damage.

WARNING!

A warning message appears like this. It provides

information which, if ignored, can result in the risk of

personal injury.

4 • Notes, Cautions, etc.

Page 5

Getting Started

Location

• Select a firm, solid surface for your printer.

• Allow enough space around the printer to easily access the

platen knob and the various paper feed paths.

• Make sure a suitable grounded power outlet is available nearby.

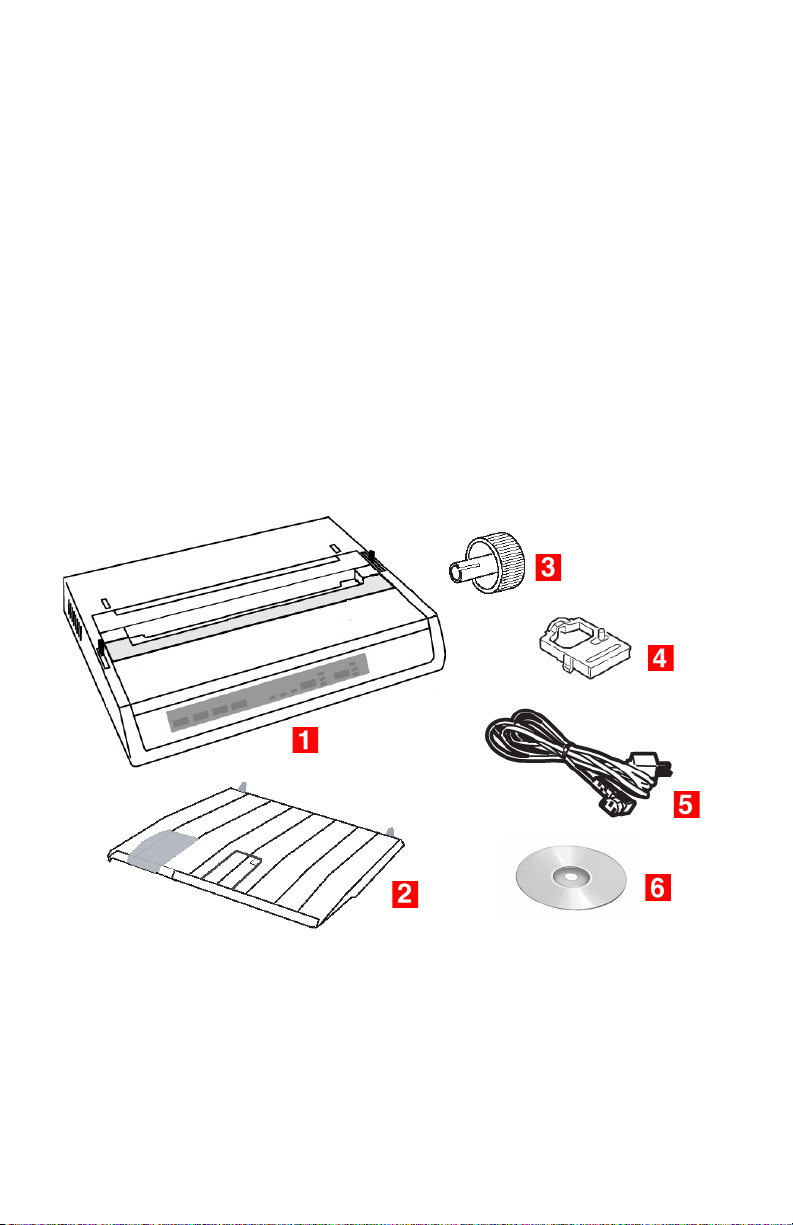

Contents and Unpacking

• If any items are missing, contact your dealer immediately.

• Keep your packing materials and carton in case you ever need

to ship or transport the printer.

• Interface cables and paper are sold separately.

.

1 ML186 Printer

2 Paper Separator

3 Platen Knob

4 Ribbon Cartridge

5 Power Cord

6 CD

5 • Getting Started

Page 6

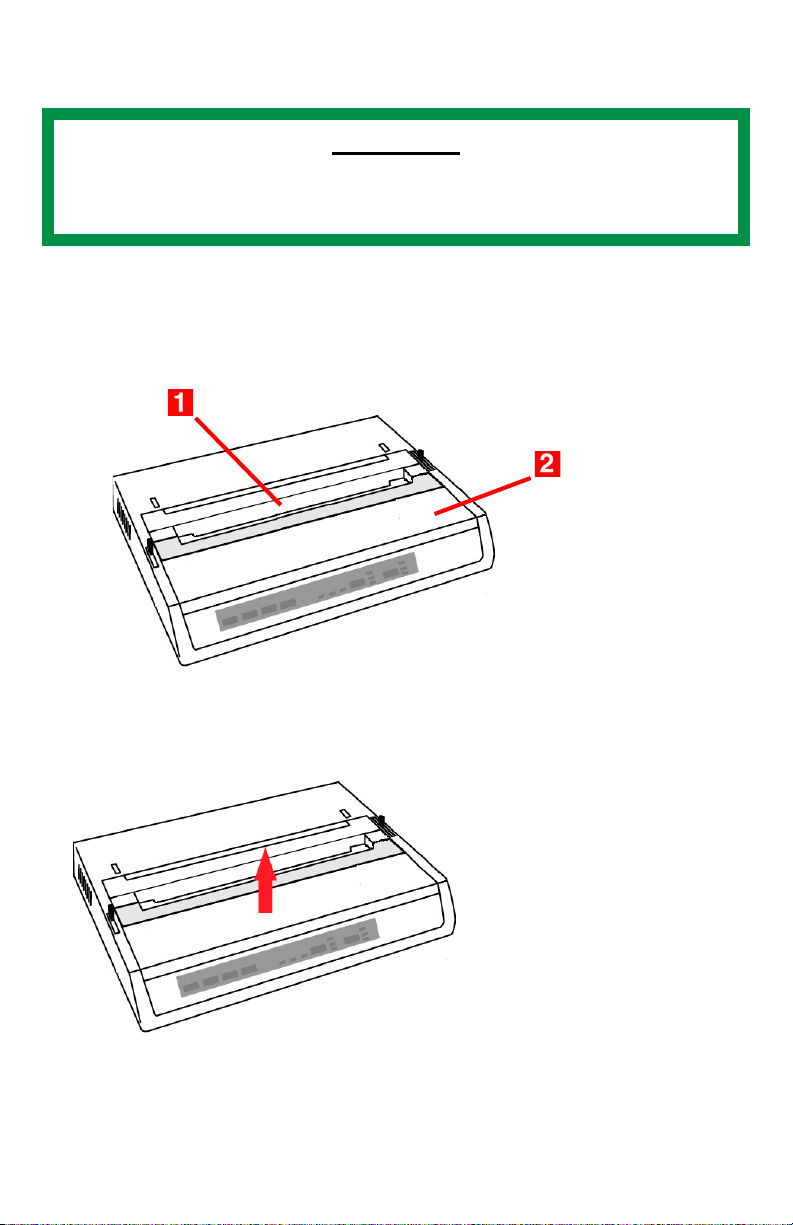

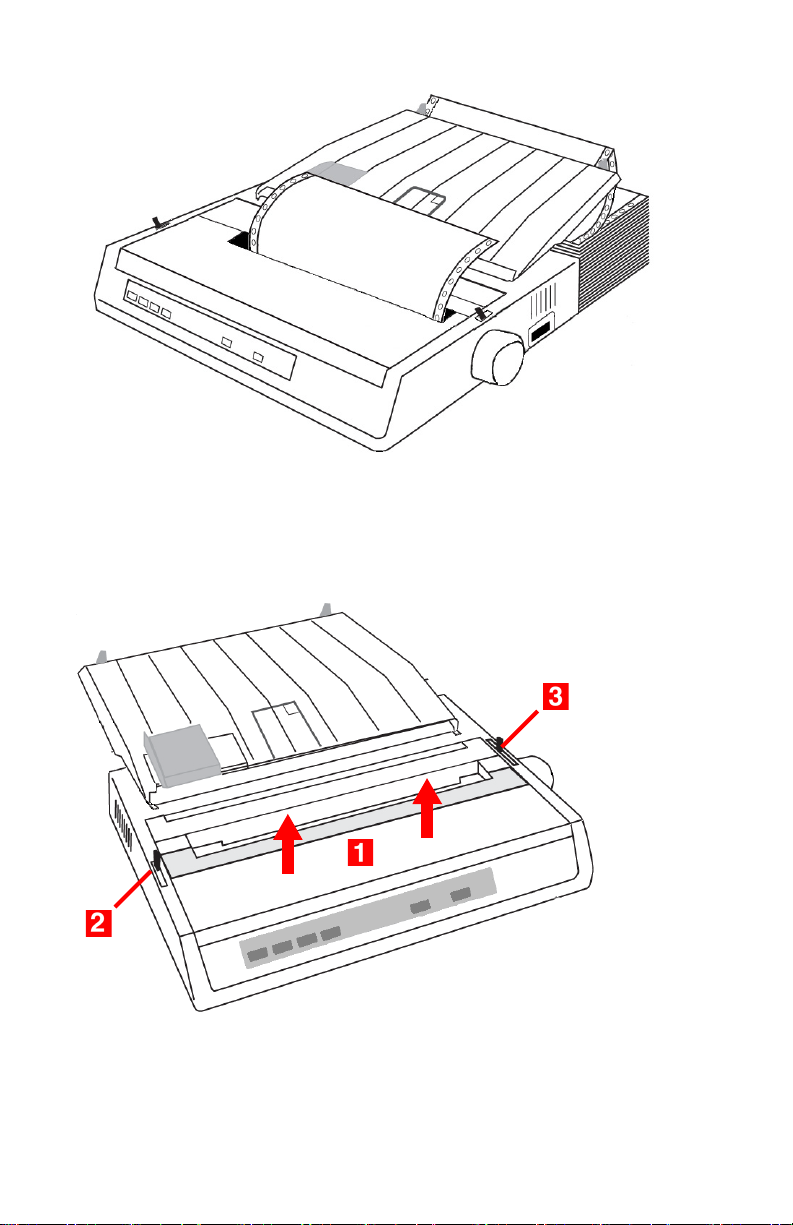

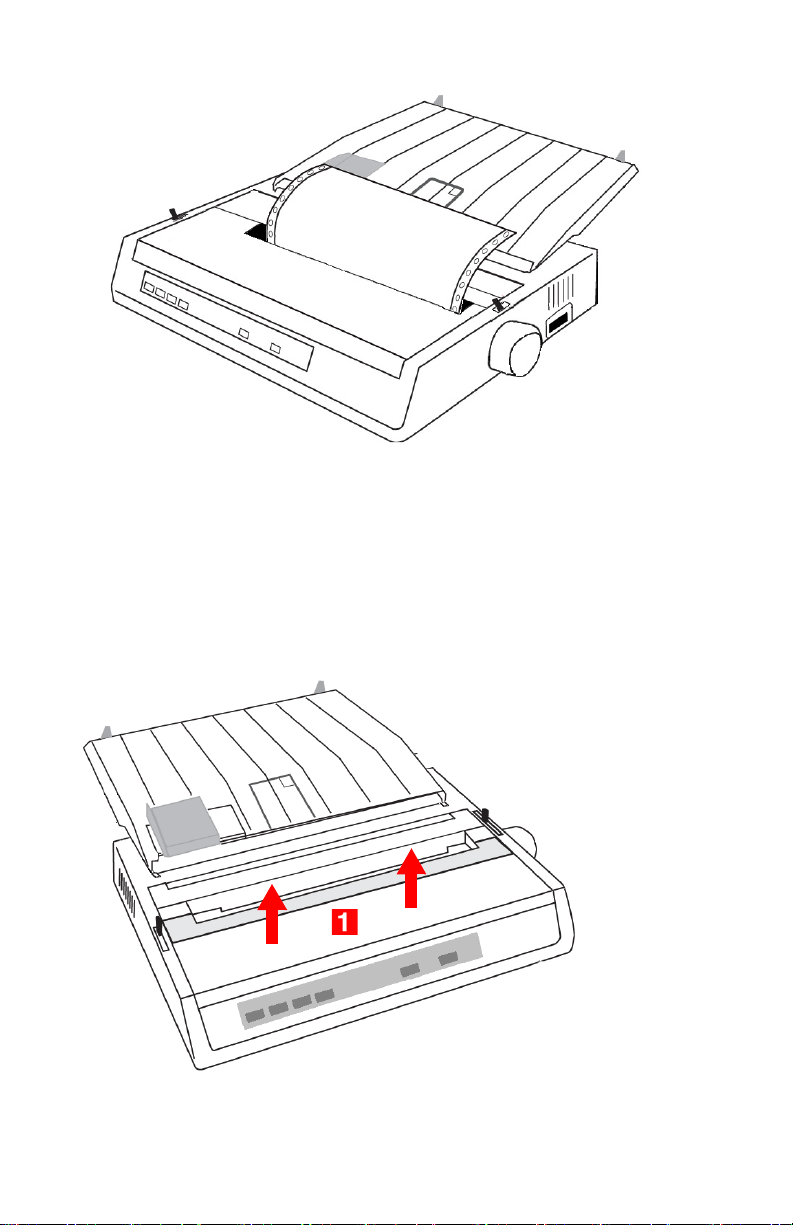

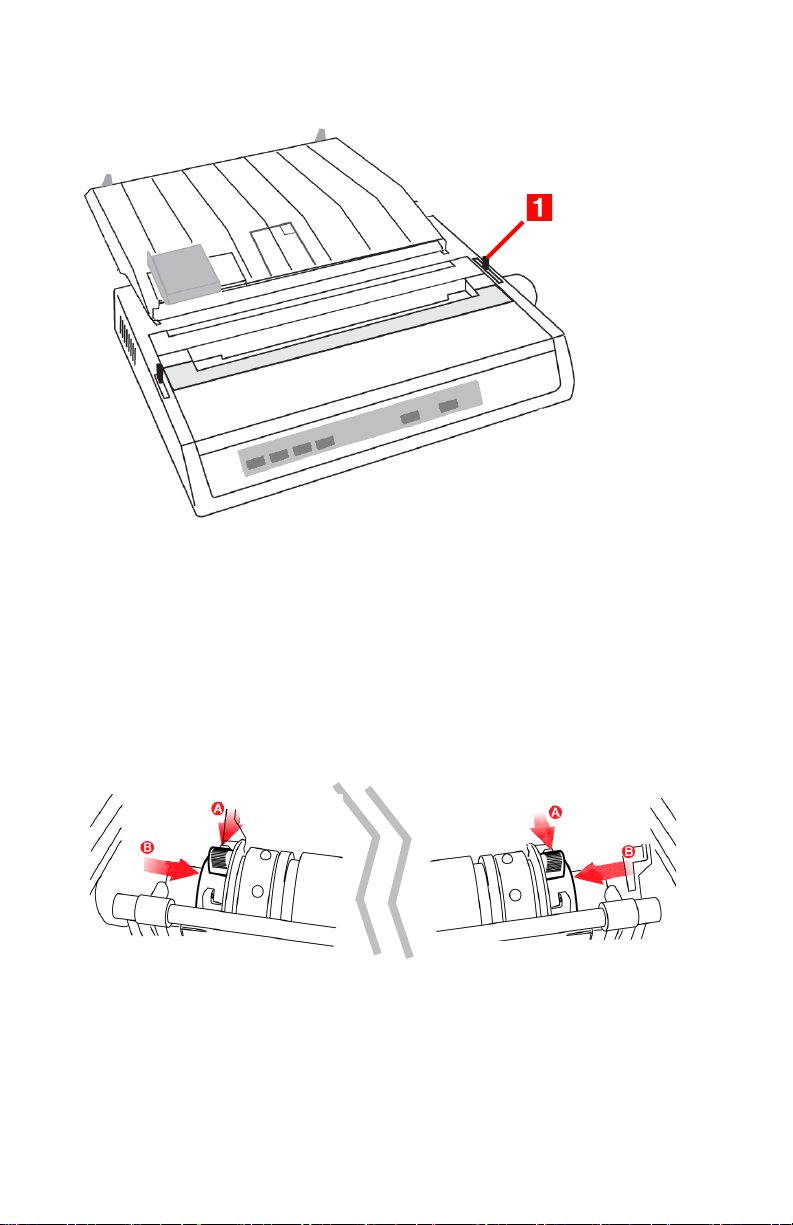

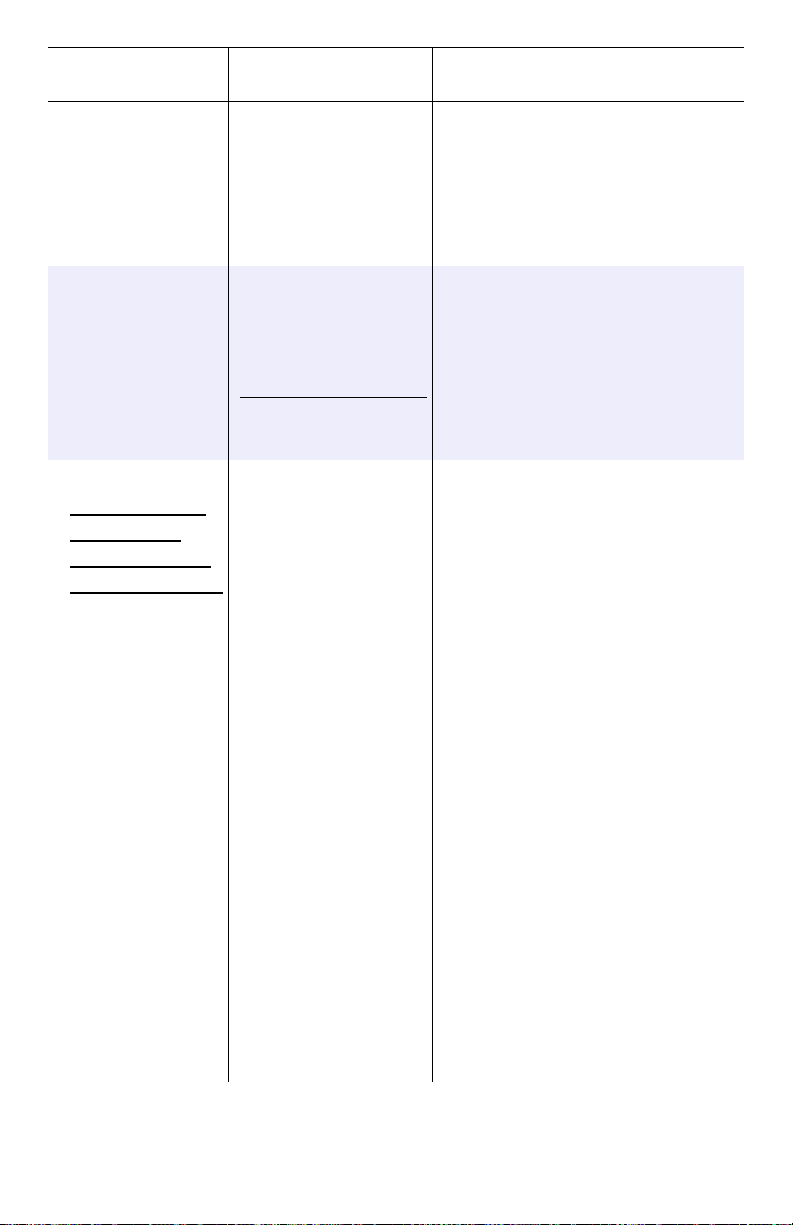

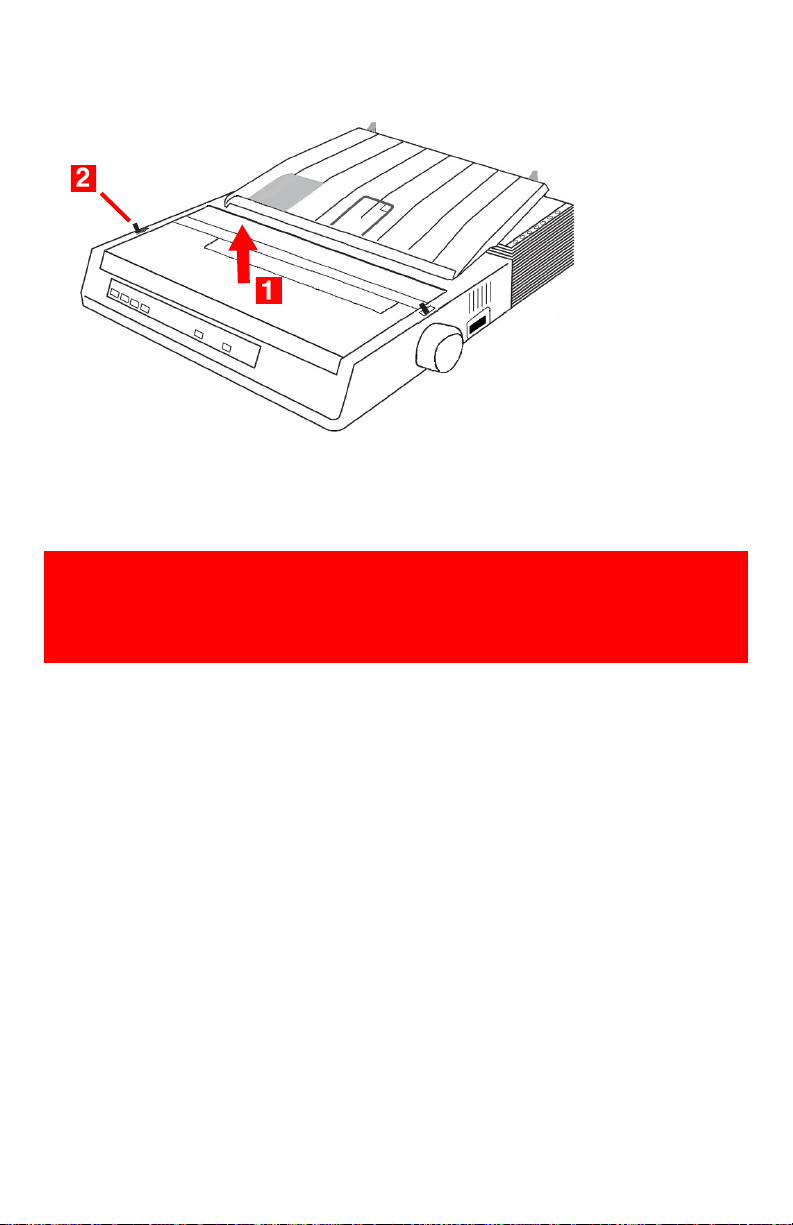

Removing the Shipping Restraint

Important

Do not plug the printer into the power outlet until the following

steps have been completed.

1. Remove any packing tape.

2. Reach into the top cover slot (1) and remove the access cover

(2) by lifting it.

3. Remove the printhead shipping restraint. Keep the shipping

restraint for future use.

4. Reinstall the access cover.

6 • Getting Started

Page 7

Installing/Replacing the Ribbon

Cartridge

Use only genuine Oki Data ribbon cartridges.

When replacing a ribbon cartridge, make sure you have the correct

replacement ribbon for your printer. The wrong ribbon will not print

when installed in your printer.

Important

• Leave unused ribbon cartridges in their packaging until you

are ready to install them.

• Careful! The ribbon ink can cause permanent stains.

• Ribbon ink on skin or clothing can usually be removed with

soap and water.

1. Make sure the printer is turned off!

WARNING!

If the printer has been recently used, the printhead may be

HOT!

7 • Getting Started

Page 8

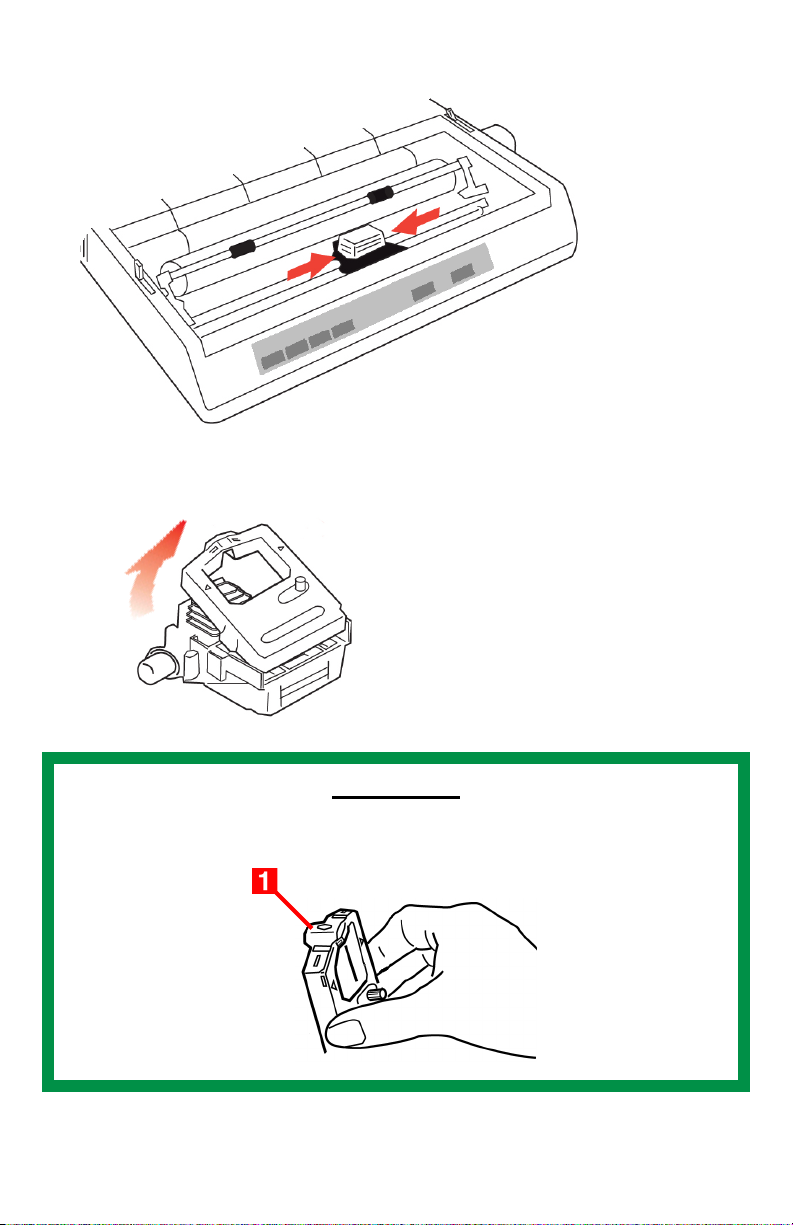

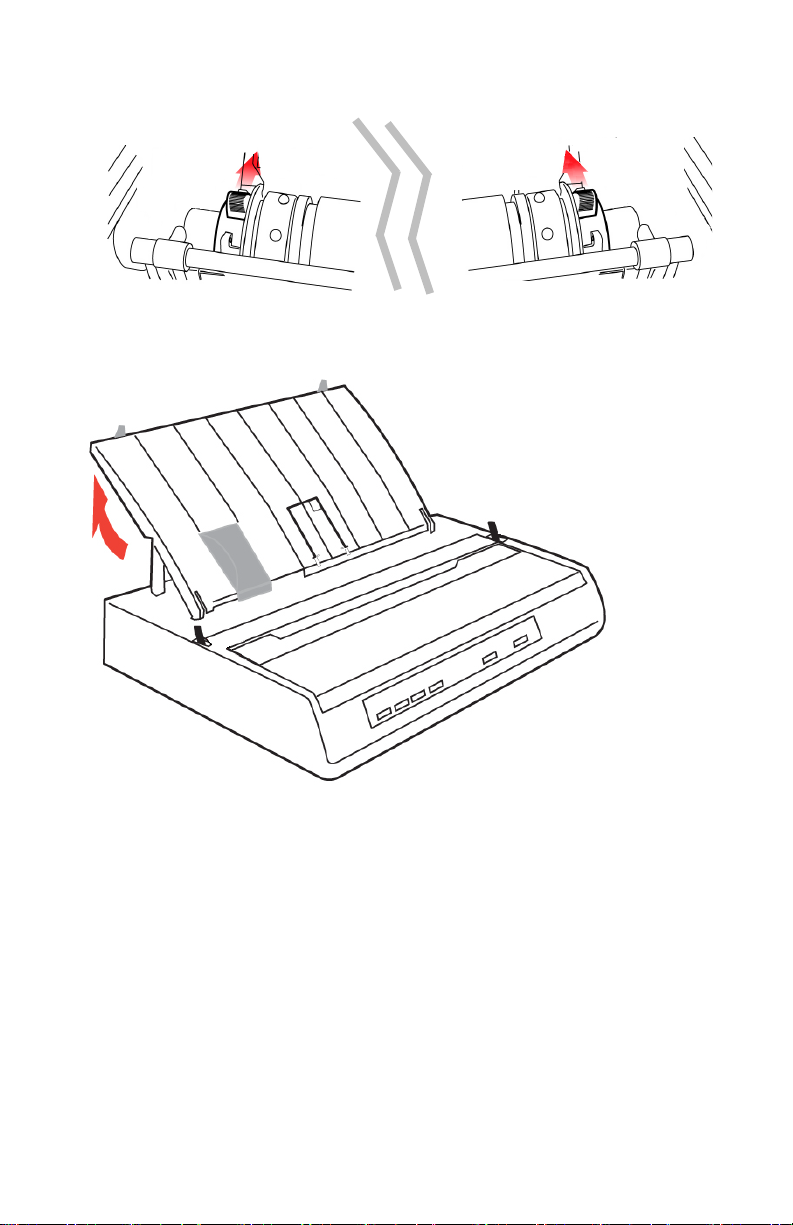

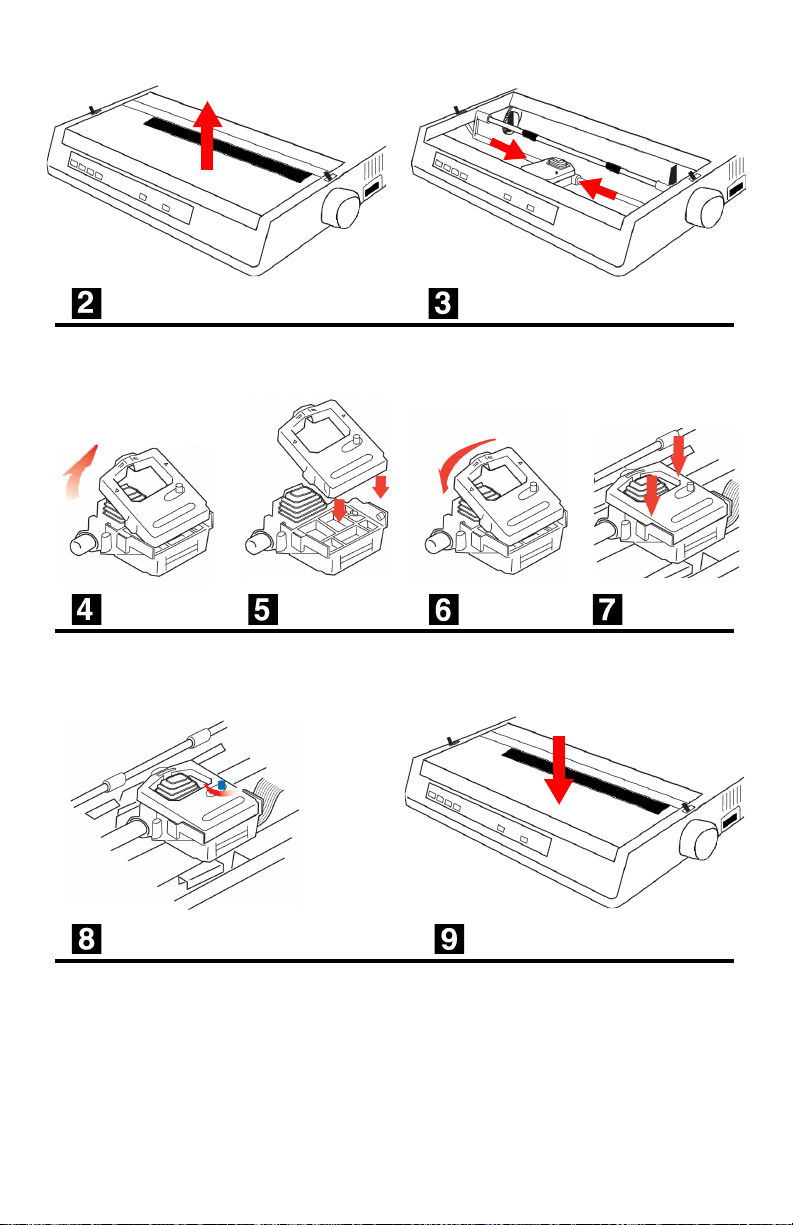

2. Remove the access cover and center the printhead.

3. If you are replacing the ribbon cartridge, remove the used one:

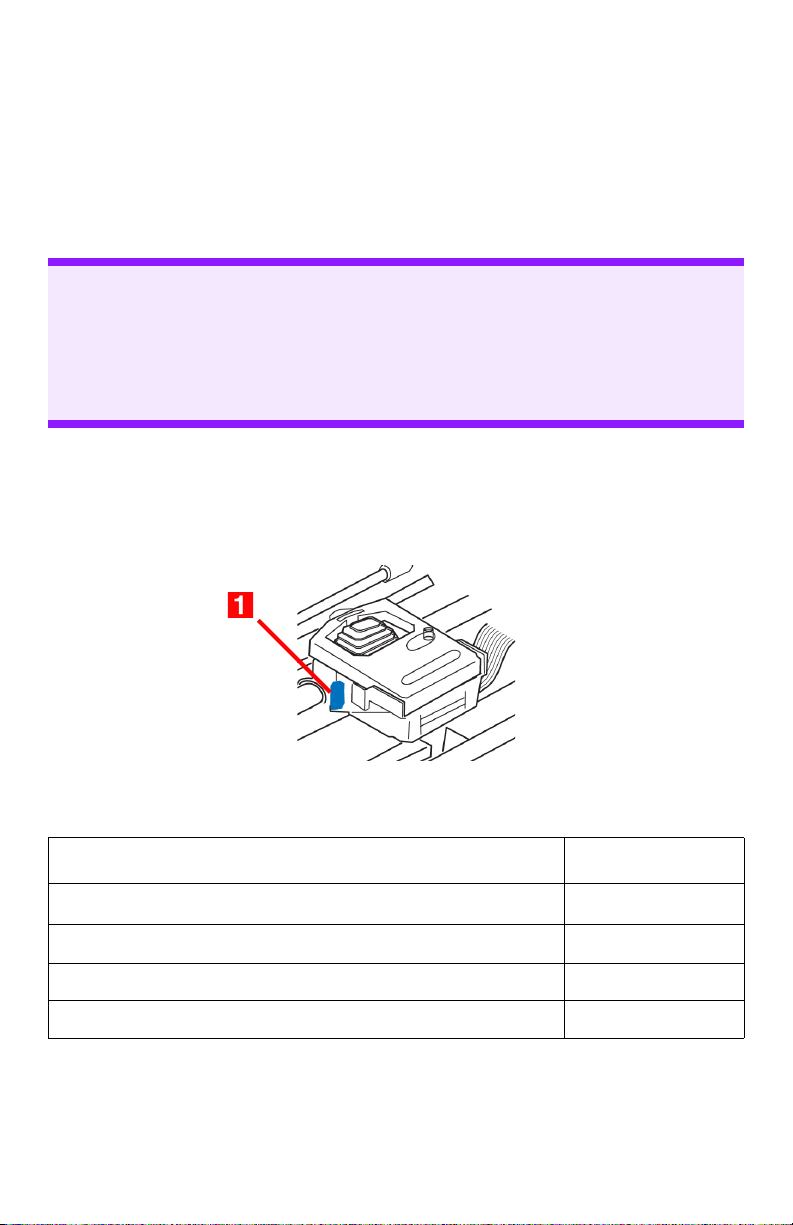

Important

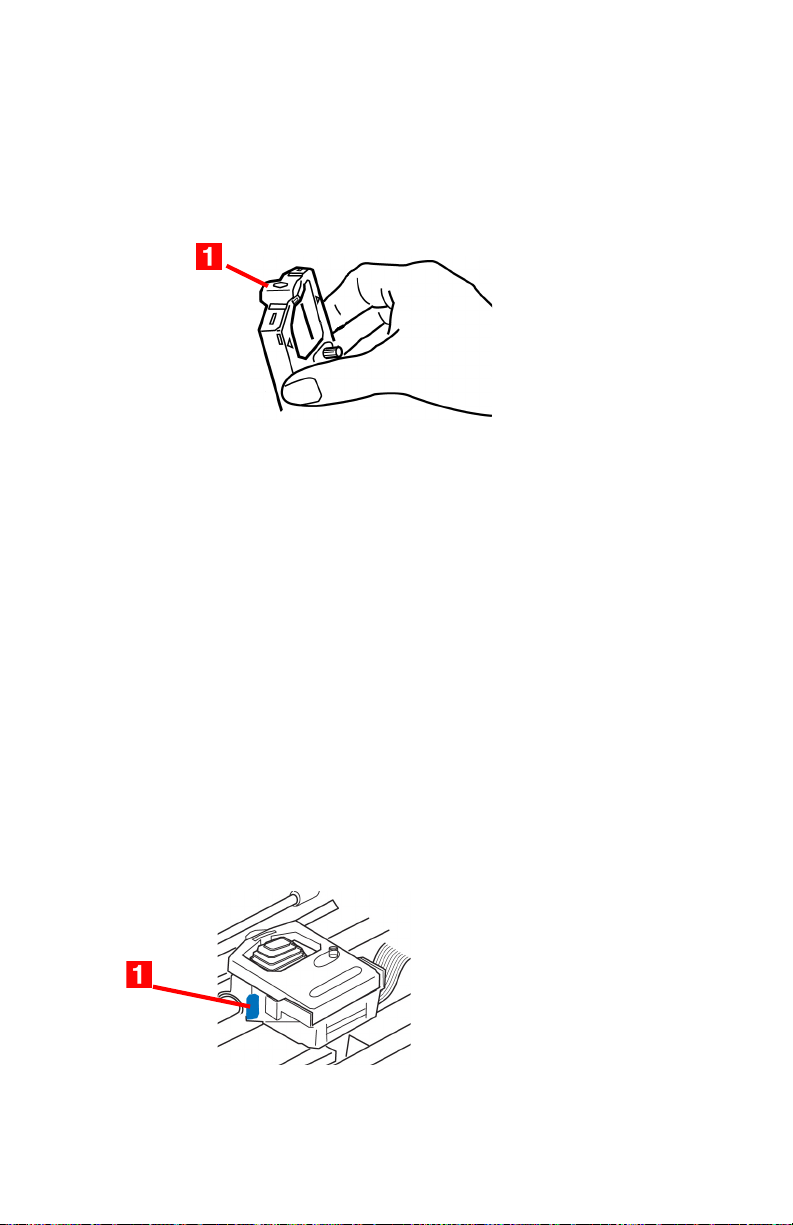

Do not remove the ribbon shield (1) from the new ribbon!

8 • Getting Started

Page 9

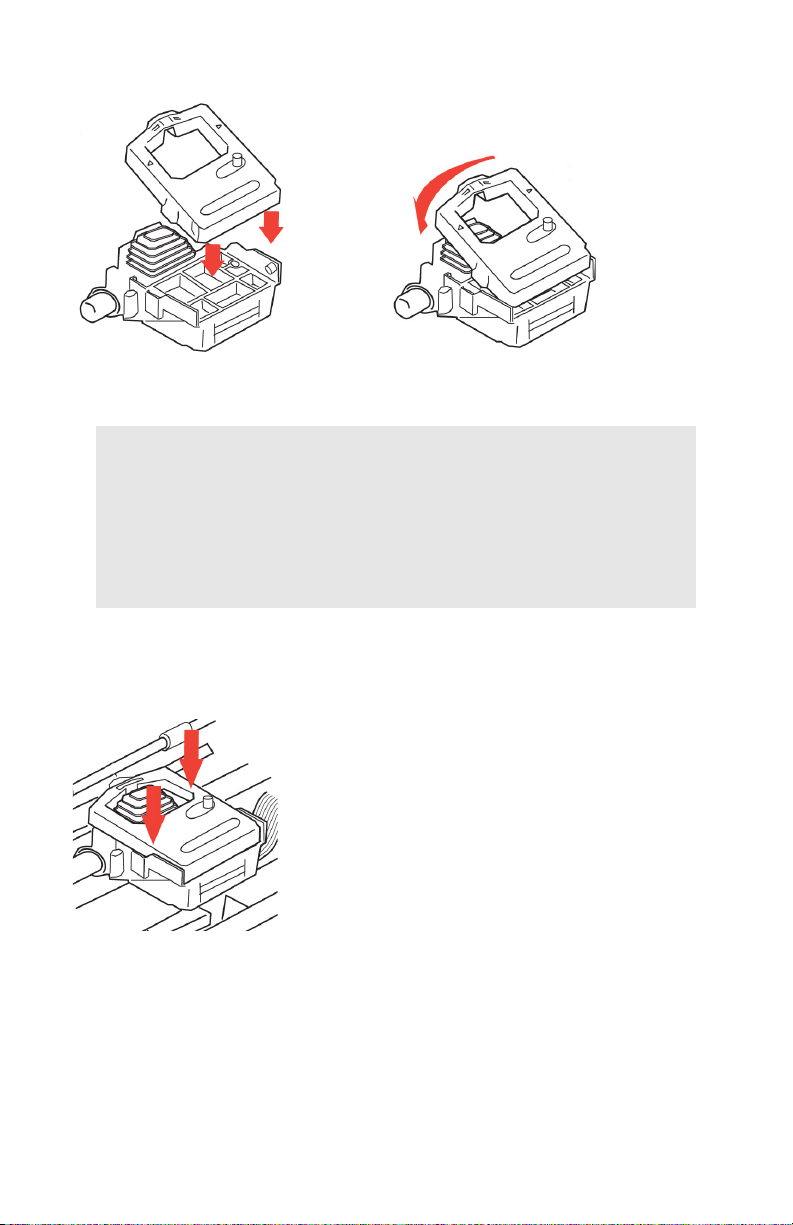

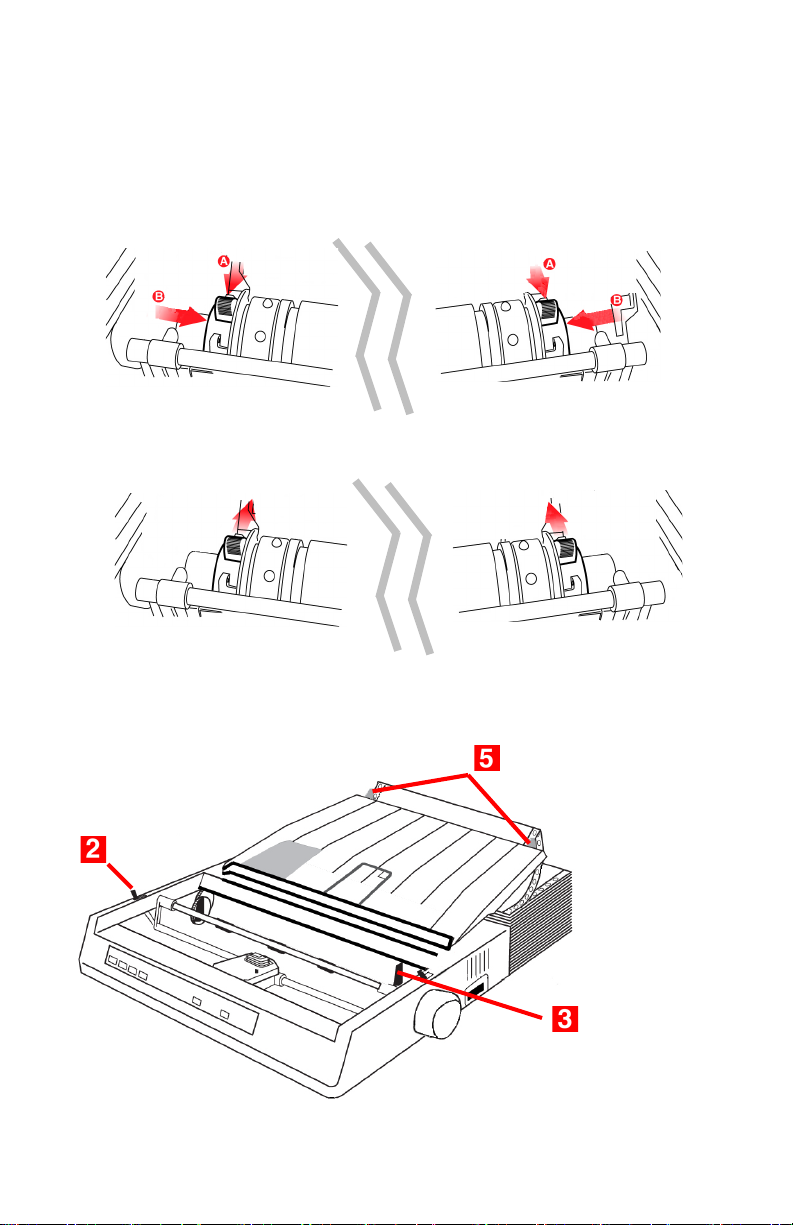

4. Unpack the ribbon cartridge and install it on the printhead.

Note

If the ribbon won’t load easily, turn the take- up knob

slightly until the x-shaped notch on the bottom of the

ribbon cartridge aligns with the x-shaped insert on

the ribbon plate.

5. Press gently on the ribbon cartridge until you feel it click into

place.

9 • Getting Started

Page 10

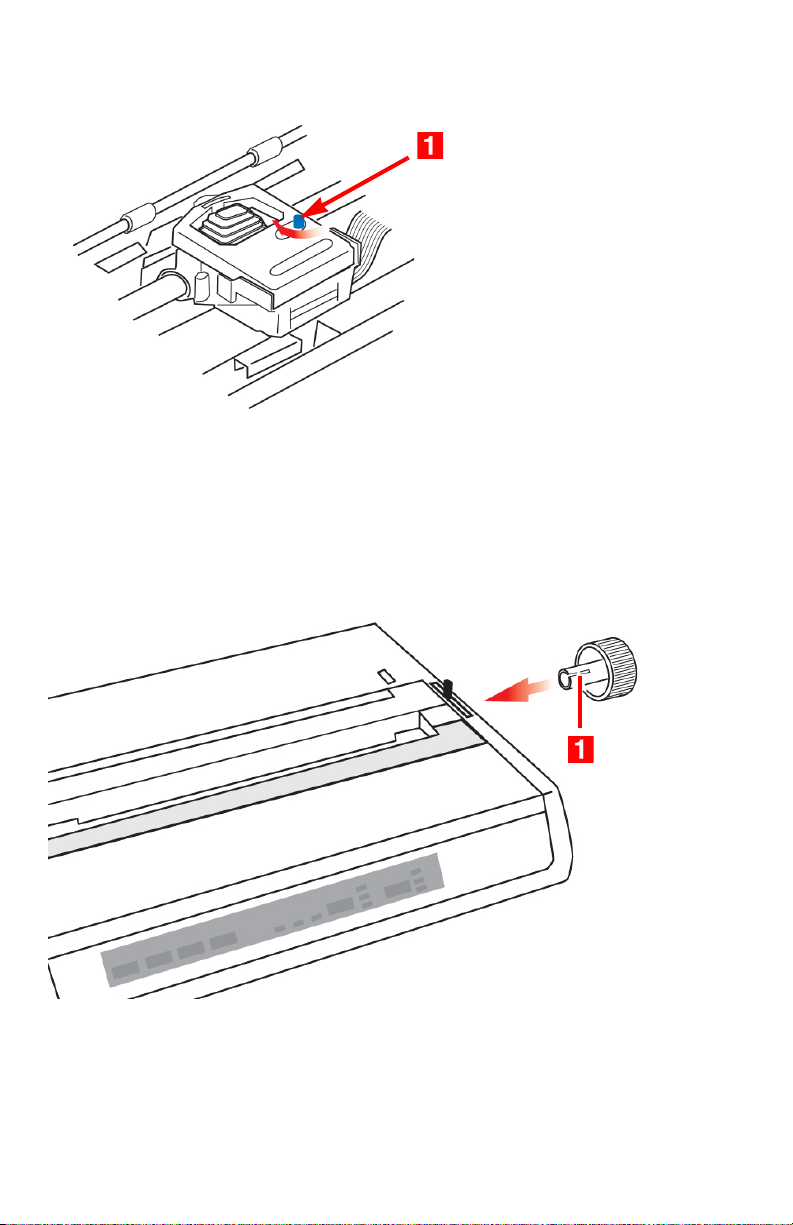

6. Turn the take-up knob (1) in the direction of the molded arrow to

take up any ribbon slack.

7. Replace the access cover.

Installing the Platen Knob

Align the notch (1) with the pin on the platen shaft and push it firmly

into place.

10 • Getting Started

Page 11

Adjusting the Head Gap

The head gap is the distance between the printhead and the platen

roller. When you use envelopes or multipart forms, you need to

have a larger gap than when using plain paper. Use the

recommended head gap to ensure the best print quality and easy

paper feed

CAUTION!

Incorrect setting of the head gap can cause printhead

damage or ribbon jams. To avoid these problems set the

head gap for the type of media being used.

To adjust the head gap, move the colored lever (1) located to the

left of the ribbon cartridge to the correct position for the type of

media being used …

…as detailed in the following table:

Paper Type Lever Position

2

Single Sheets, up to 20 lb. (75 g/m

Forms, 2-part [maximum thickness 0.28 mm] 2 or 3

Forms, 3-part [maximum thickness 0.28 mm] 3

Forms, 4-part [maximum thickness 0.28 mm] 3

)

1 or 2

11 • Getting Started

Page 12

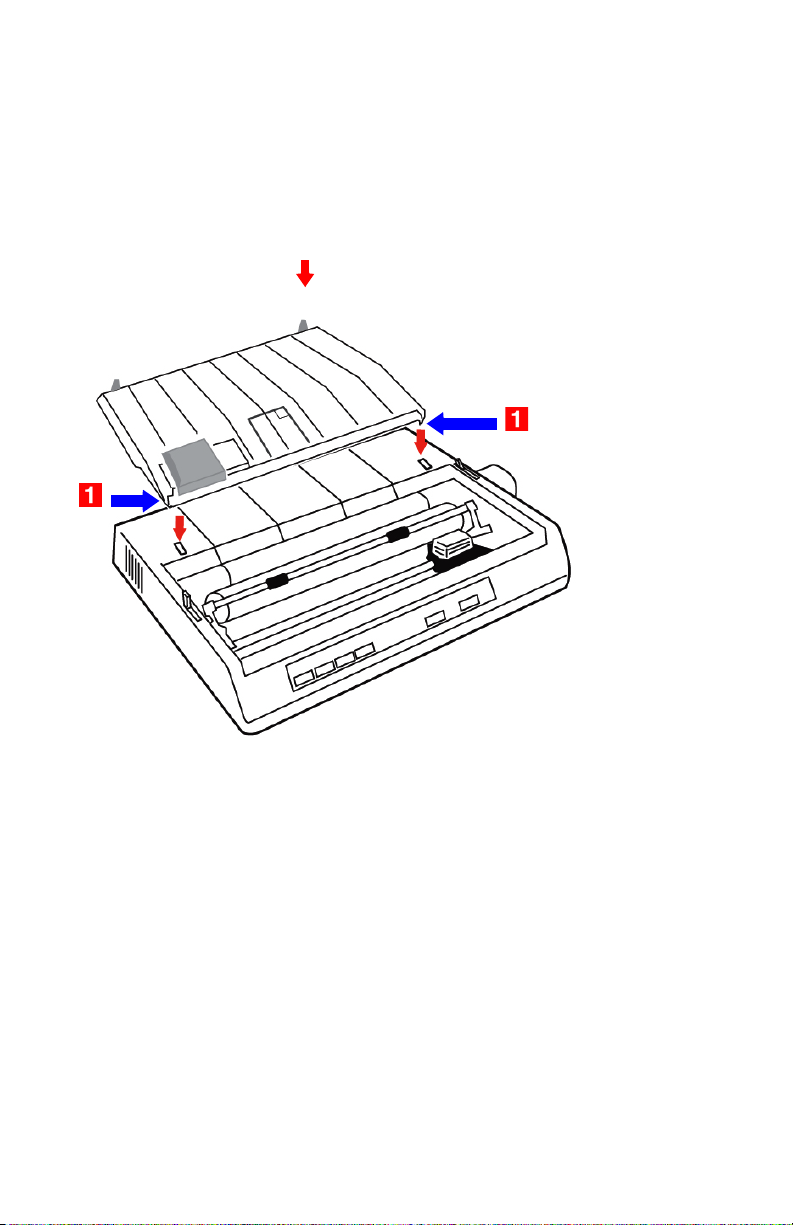

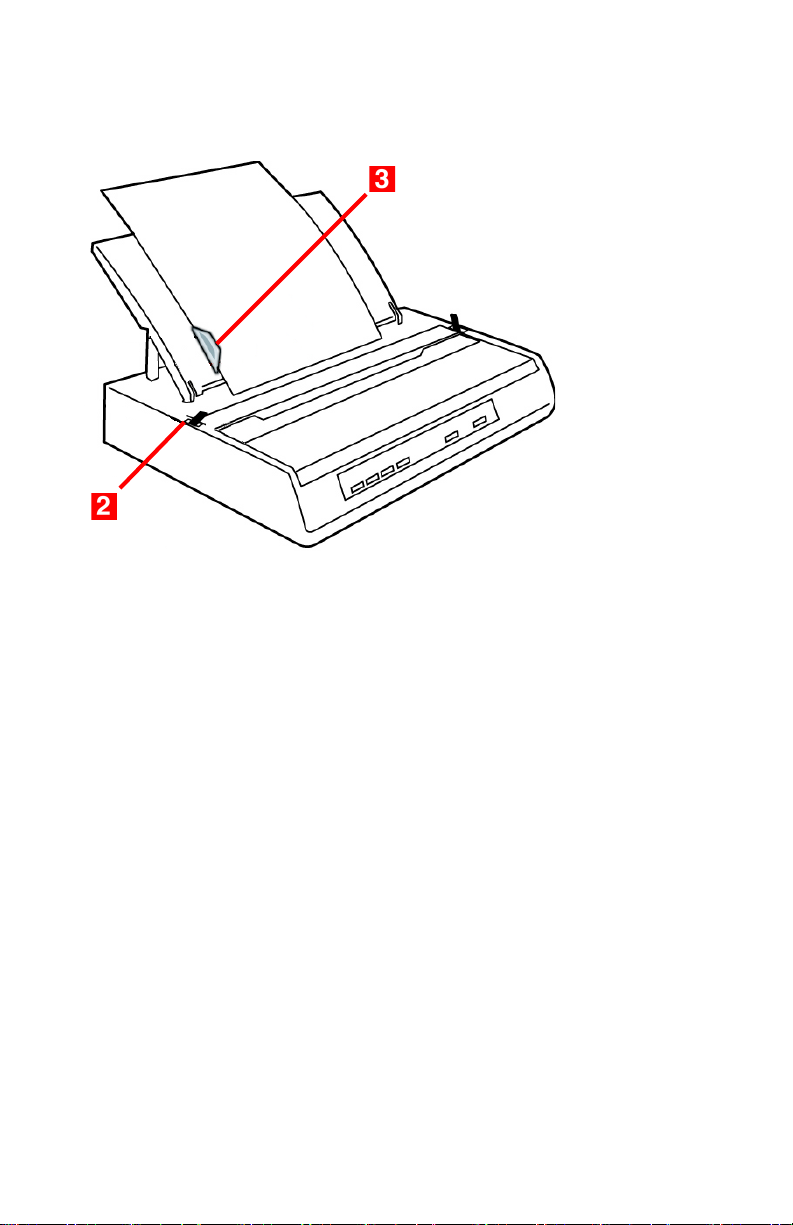

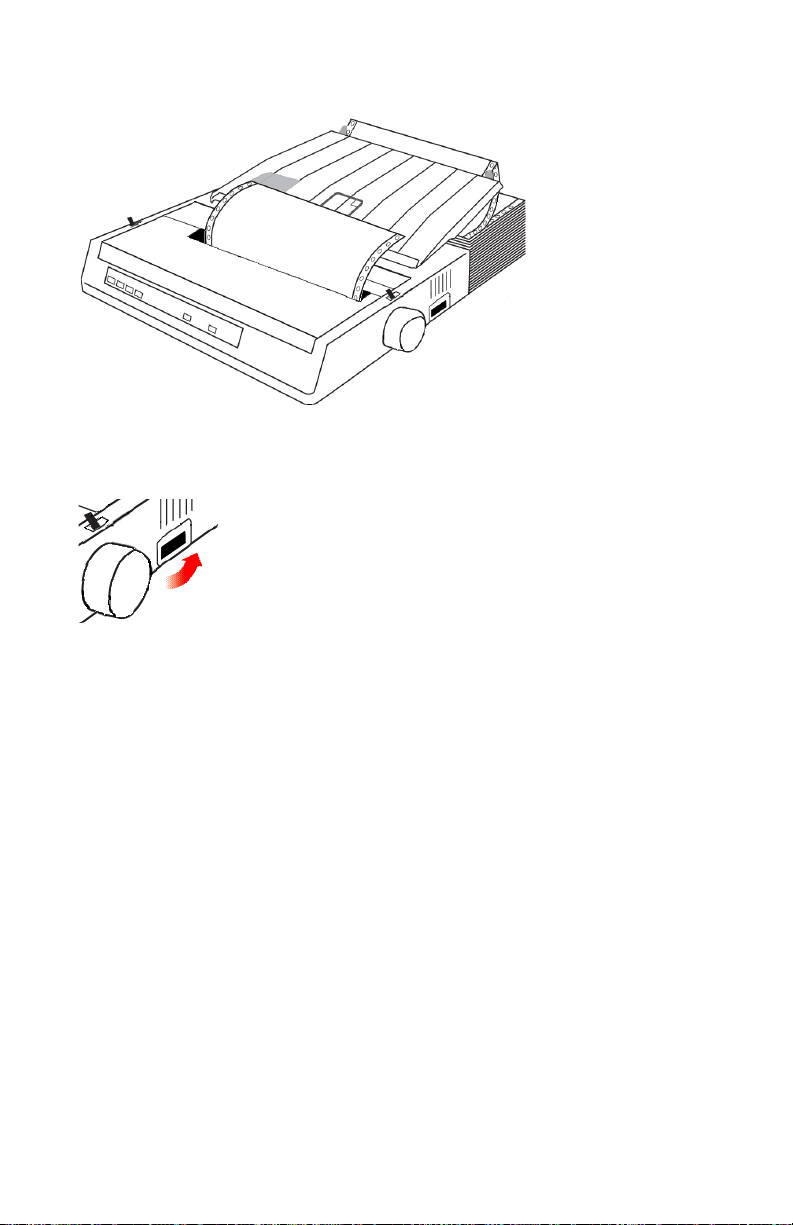

Installing the Paper Separator

The paper separator is used for printing on single sheets (no

carbons). With continuous forms paper, it is used to separate the

ingoing/outgoing paper to prevent paper jams.

1. Hold the paper separator with the spring-loaded feet down.

2. Place the tabs (1) on the paper separator in the two

corresponding slots ( ) on the printer.

3. Press down to release the paper separator onto the printer.

12 • Getting Started

Page 13

Setting Up Your Printer

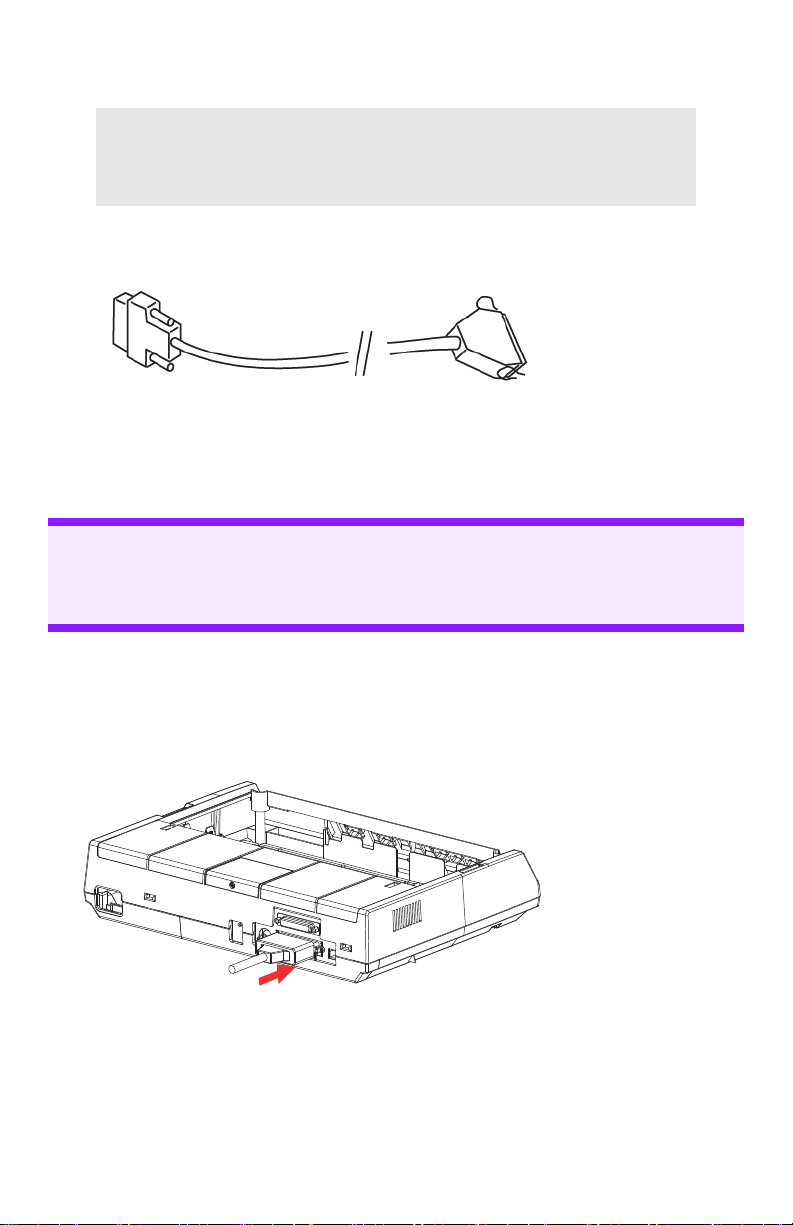

Power Connection

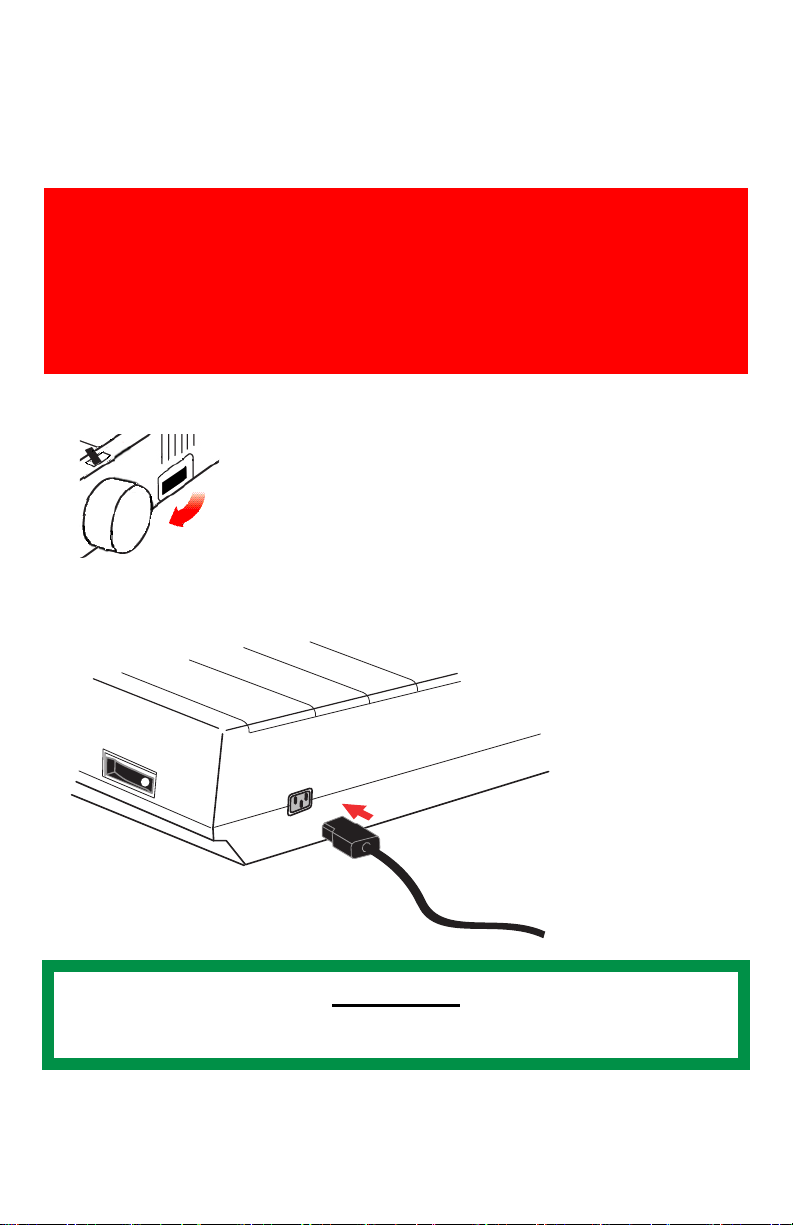

WARNING!

Operations of this equipment are not warranted when the

equipment is connected to UPS (Uninterruptible Power

Supply) and/or inverter. Doing so may result in damage of

this equipment. Do not use an UPS and/or inverter.

1. Make sure the printer is turned off.

2. Plug the power cord supplied with your printer into the back of

the printer.

Important

The outlet voltage must match the voltage marked on the printer label.

3. Plug the other end of the power cord into an appropriate grounded outlet.

13 • Setting Up Your Printer

Page 14

Loading Paper

Three types of paper can be used with your printer:

• Continuous Forms Paper

(with or without the optional Pull Tractor)

• Single Sheets

• Roll Paper, using the optional Roll Paper Stand

Before You Start

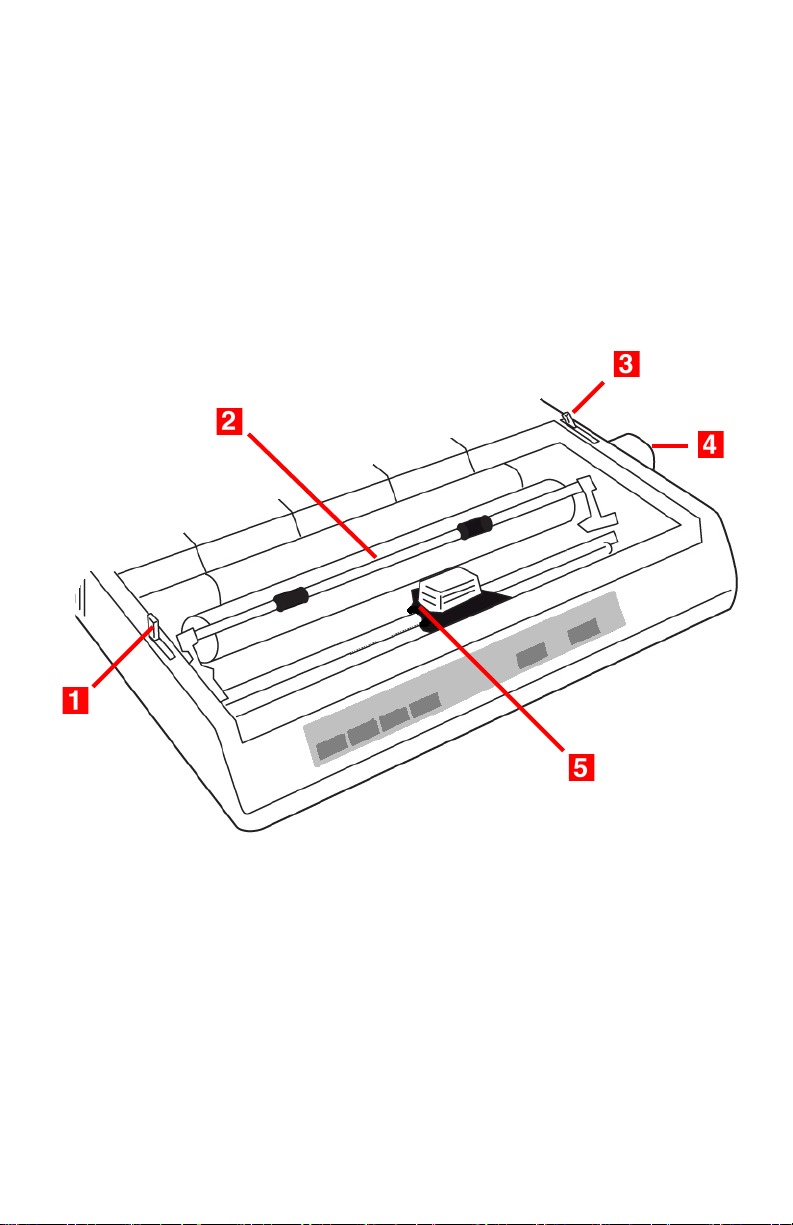

1 Bail Arm Lever

2 Bail Arm

3 Paper Lever

4 Platen Knob

5 Head Gap Lever

14 • Setting Up Your Printer

Page 15

Paper Lever Positions

= Single Sheet Feed

= Continuous Forms

Setting the Head Gap

Before you load paper, be sure to check the head gap lever setting

(see page 11).

Important

Do not plug the printer into the power outlet until the following

steps have been completed.

15 • Setting Up Your Printer

Page 16

Loading Continuous Forms, Rear Feed

1. Make sure the printer is turned off.

2. Place the stack of continuous forms paper behind the printer.

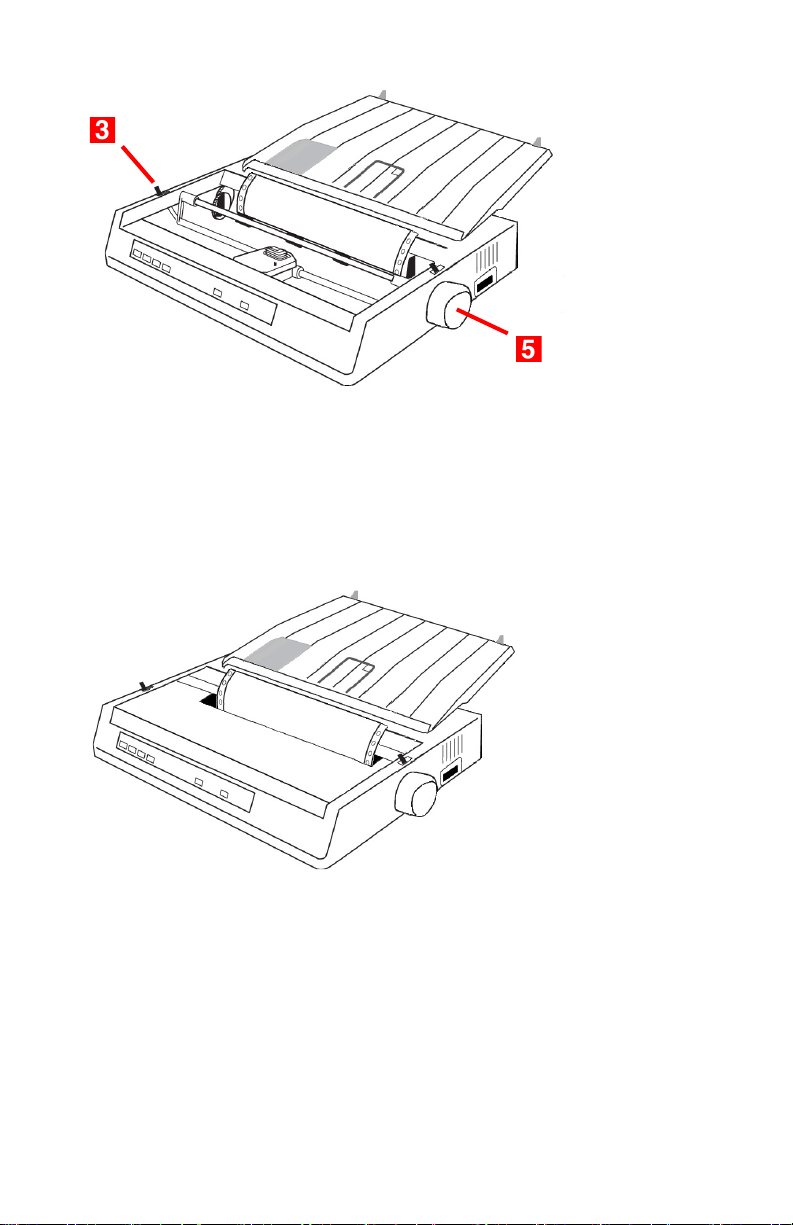

3. Remove the access cover (1).

4. Pull the bail arm lever (2) — on the left side of the printer —

toward the front of the printer to lift the bail arm.

16 • Setting Up Your Printer

Page 17

5. Move the paper lever (3) — on the right side of the printer —

toward the front of the printer to the continuous forms symbol.

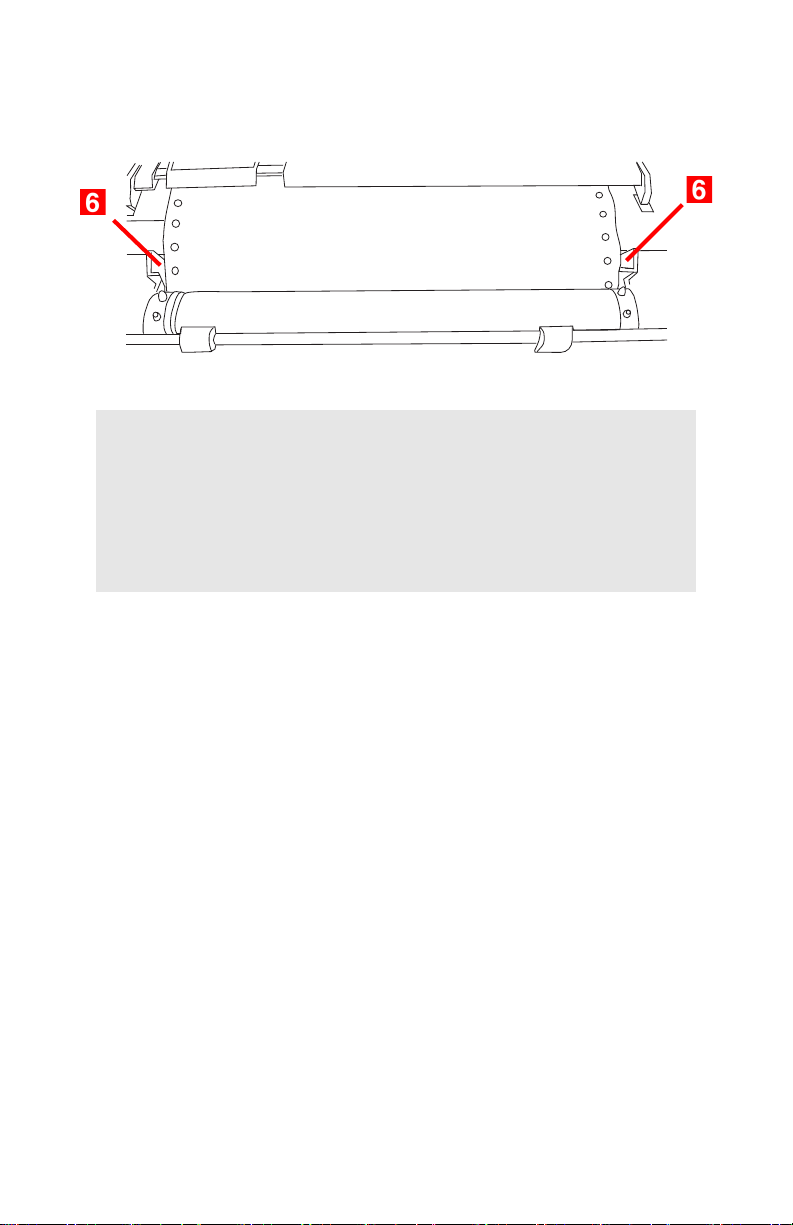

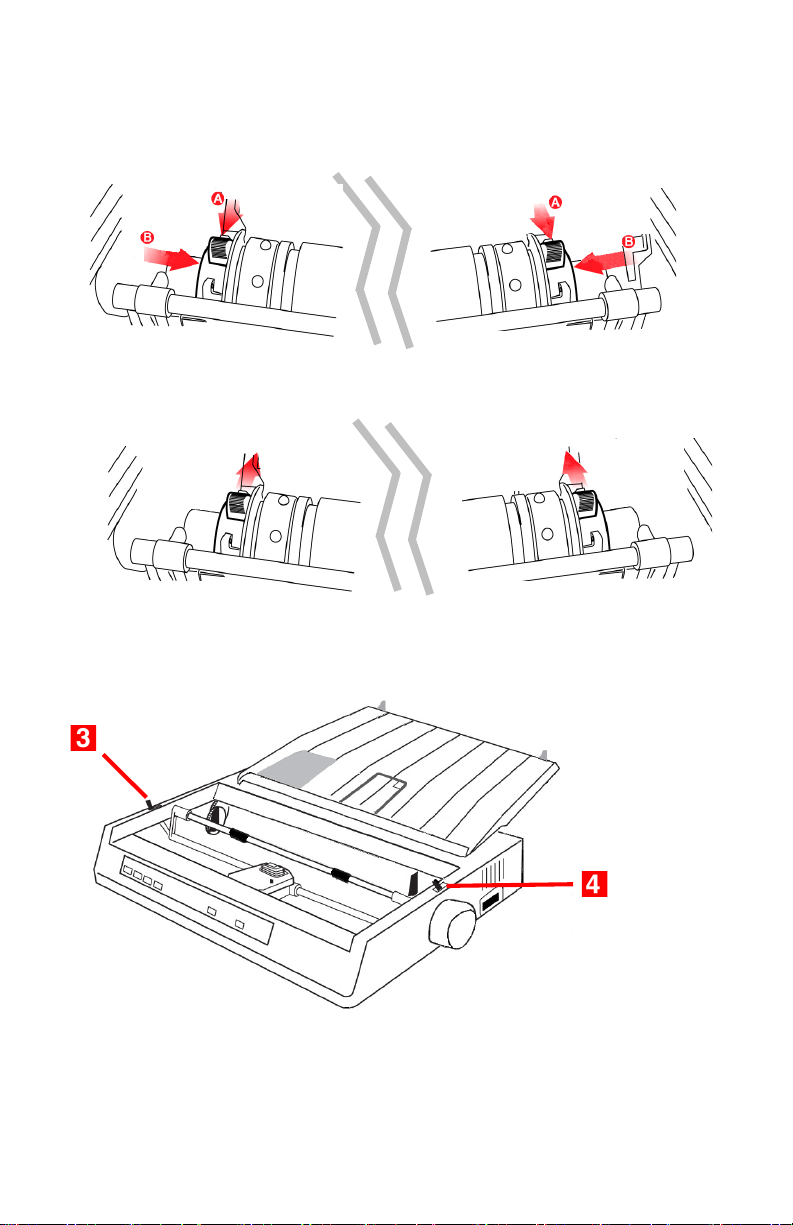

6. Pull the lock levers (A) on the sprocket wheels at either end of

the platen forward, then adjust the sprocket wheels (B) so that

the sprockets align with the holes in the continuous forms you

are using.

7. Push the levers back to lock the sprocket wheels in position.

8. Insert the first sheet of paper between the paper separator

guides (5) and push it through the paper separator.

17 • Setting Up Your Printer

Page 18

9. Place the paper between the sprocket feed guides (6) and feed

it behind the platen, gently positioning it so that its holes

engage the sprockets on the ends of the platen.

Note

Make sure you keep the lead edge of the paper

straight so that the sprockets engage the matching

pins on either side. Otherwise the paper will feed in

skewed and paper jams will occur.

18 • Setting Up Your Printer

Page 19

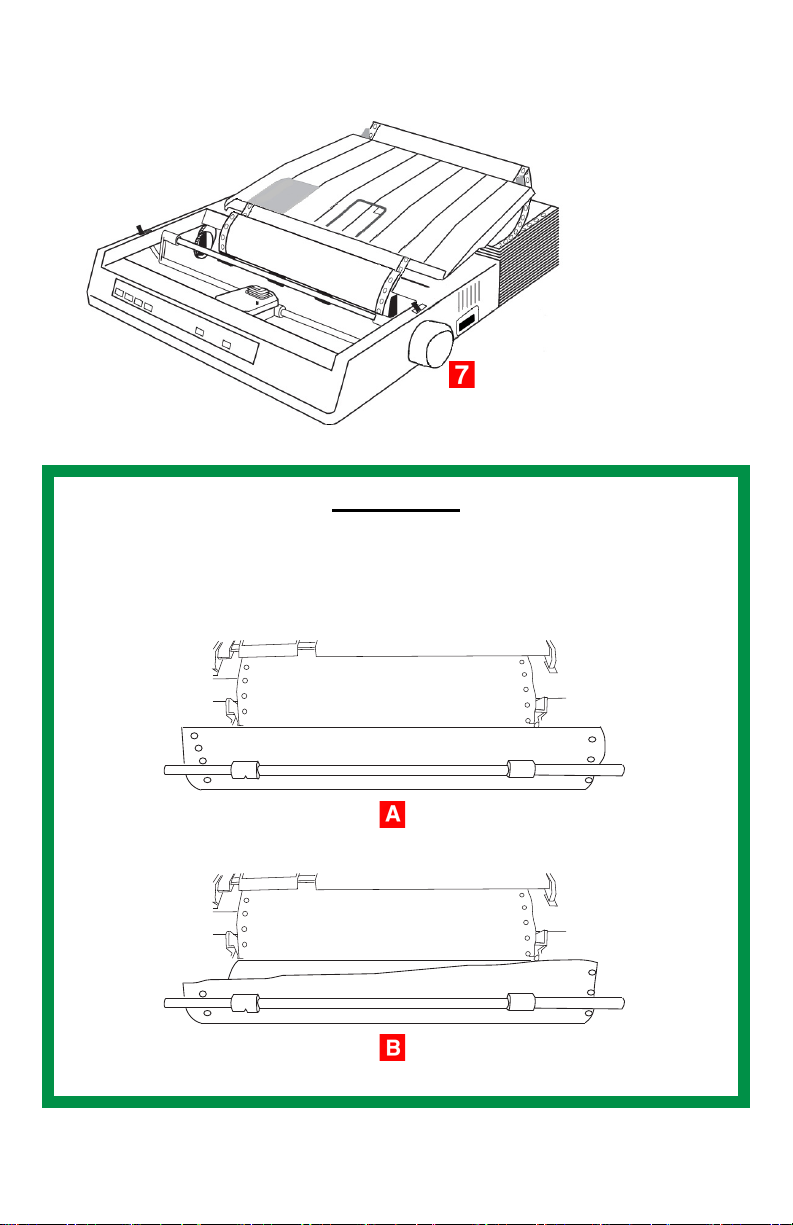

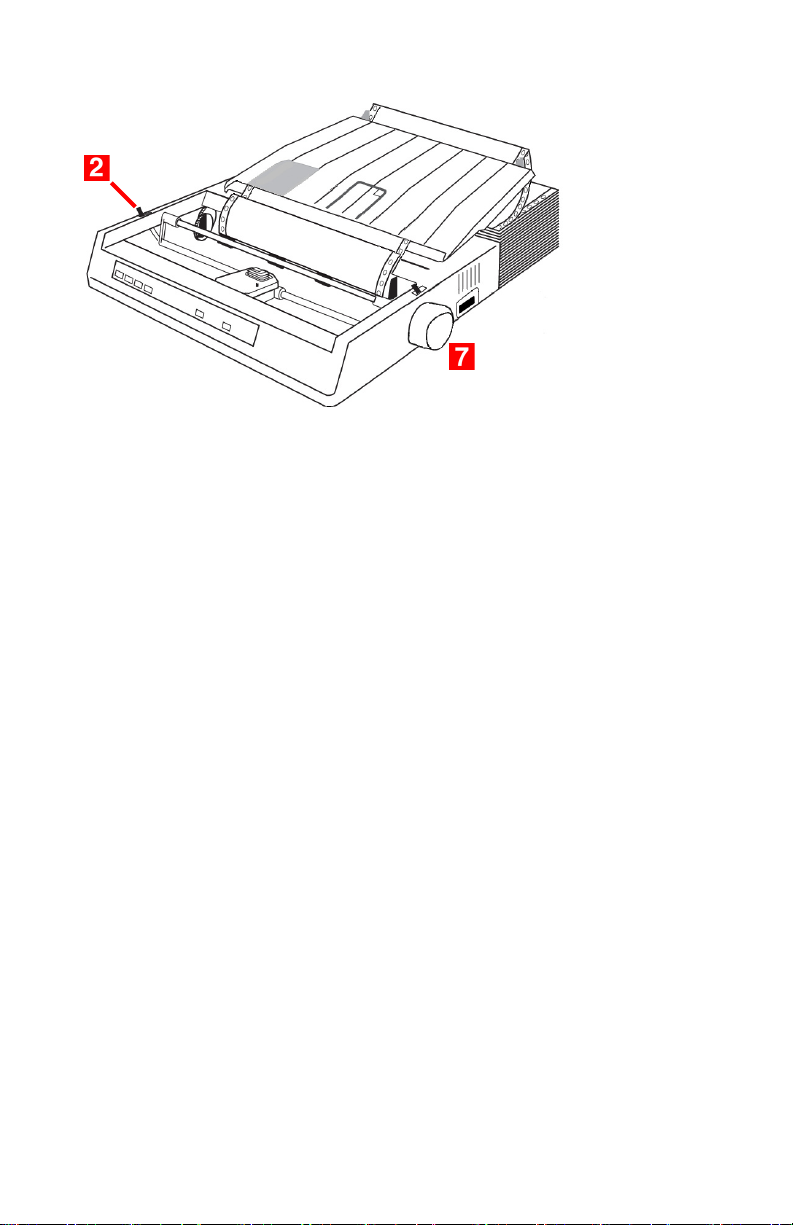

10.Turn the platen knob (7) to advance the paper until it appears

in front of the platen, behind the bail arm.

Important

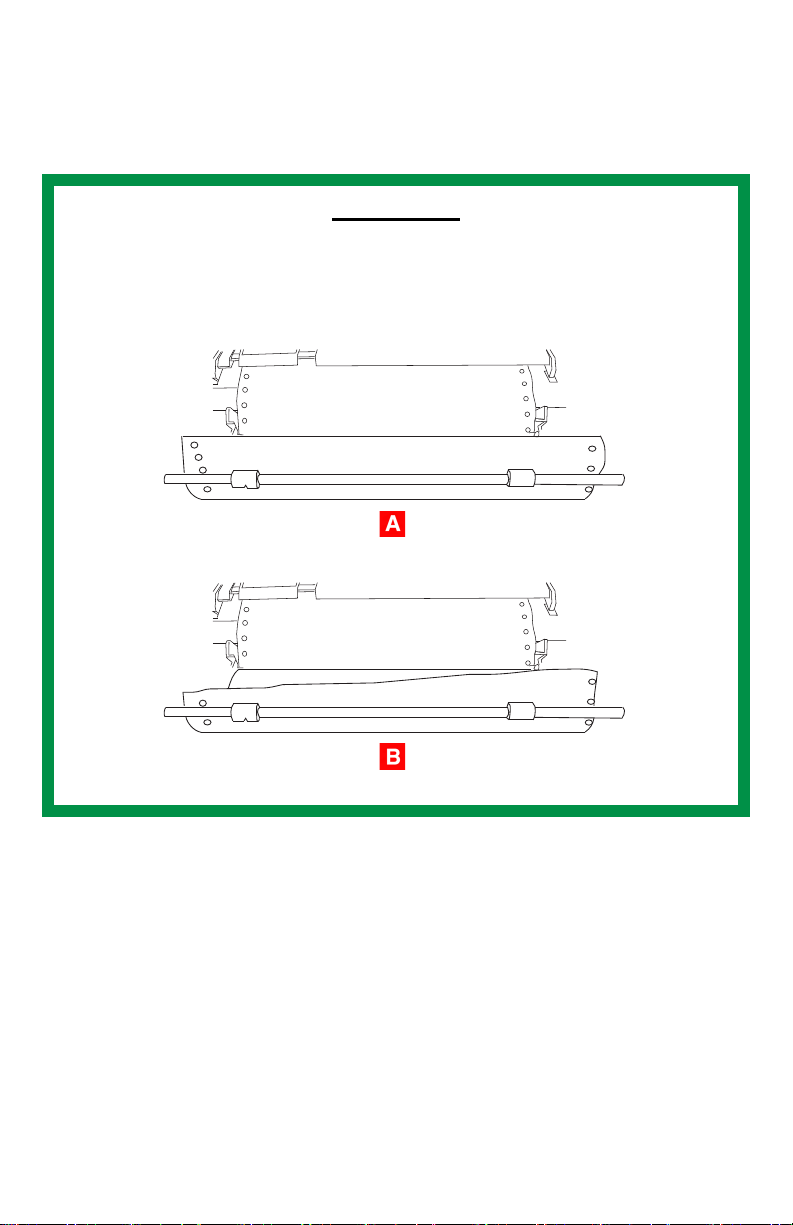

Check to be sure that the matching holes on either side are

engaging the sprockets (A). If they are not evenly matched

and the paper is skewed (B), back the paper out and try again!

19 • Setting Up Your Printer

Page 20

11. Push back on the bail arm lever (2) to lower the bail arm.

12. Use the platen knob (7) to set the position of the paper to the

first printing line.

13.Replace the access cover, being sure to feed the edge of the

paper through the slot in the cover.

14.Turn the printer on.

20 • Setting Up Your Printer

Page 21

Loading Continuous Forms, Bottom Feed

1. Make sure the printer is turned off.

2. Place the printer on a slotted printer stand, carefully aligning the

slot in the stand with the slot in the base of the printer.

3. Place a box of continuous forms paper on the stand, under the

printer.

4. Remove the access cover (1).

21 • Setting Up Your Printer

Page 22

5. Pull the lock levers (A) on the sprocket wheels at either end of

the platen forward, then adjust the sprocket wheels (B) so that

the sprockets align with the holes in the continuous forms you

are using.

6. Push the levers back to lock the sprocket wheels in position.

7. Pull the bail arm lever (3) — on the left side of the printer —

toward the front of the printer to lift the bail arm.

8. Move the paper lever (4) — on the right side of the printer —

toward the front of the printer to the continuous forms symbol.

22 • Setting Up Your Printer

Page 23

9. Insert the first sheet of continuous forms paper through the

opening in the printer stand and into the bottom of the printer,

gently feeding it into the printer until it appears in front of the

platen, and above the bail arm.

Important

Check to be sure that the matching holes on either side are

engaging the sprockets (A). If they are not evenly matched

and the paper is skewed (B), back the paper out and try again!

23 • Setting Up Your Printer

Page 24

10. Move the bail arm lever (3) back to lower the bail arm.

11. Use the platen knob (5) to advance the paper to the first

printing line.

12.Replace the access cover, being sure to feed the edge of the

paper through the slot in the cover.

13.Turn the printer on.

24 • Setting Up Your Printer

Page 25

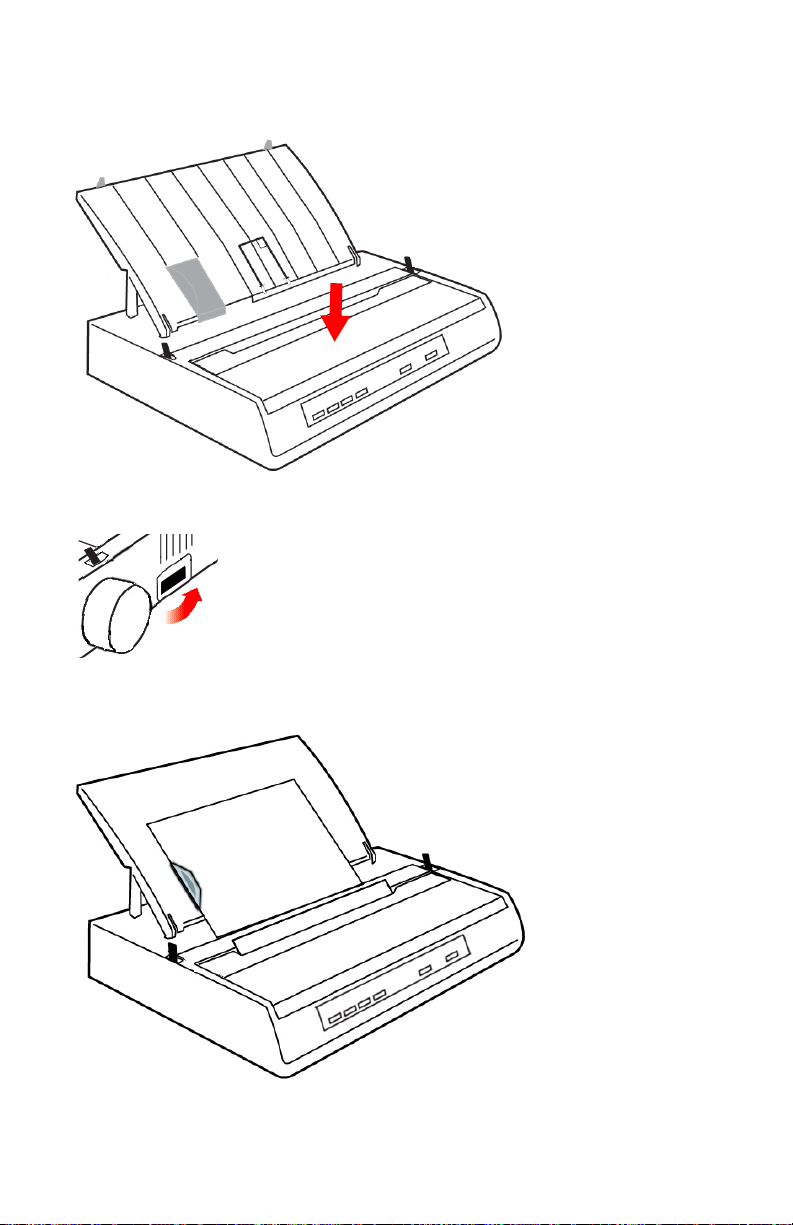

Loading Single Sheets

Note

Before printing single sheets, you must remove the

Pull Tractor or Roll Paper Stand, if installed.

Your printer can accommodate single sheets up to 9.5 inches

(241 mm) wide.

Note

In order to use paper wider than traditional letter size,

you must move the sprocket wheels to their

outermost positions so that the paper does not tear

on the sprockets. See the directions below.

1. Turn the printer on.

25 • Setting Up Your Printer

Page 26

2. Move the paper lever (1) — on the right side of the printer —

toward the rear of the printer, to the single sheet symbol.

3. Ensure that the printer is off-line (SELECT light off): press

SELECT if necessary.

4. If you are using paper wider than 8.5 inches (216 mm), move

the sprocket wheels to their outermost position:

a. Remove the access cover.

b. Pull the lock levers (A) at either end forward and move the

sprocket wheels (B) as needed.

26 • Setting Up Your Printer

Page 27

c. Push back on the levers to lock the sprocket wheels in

position.

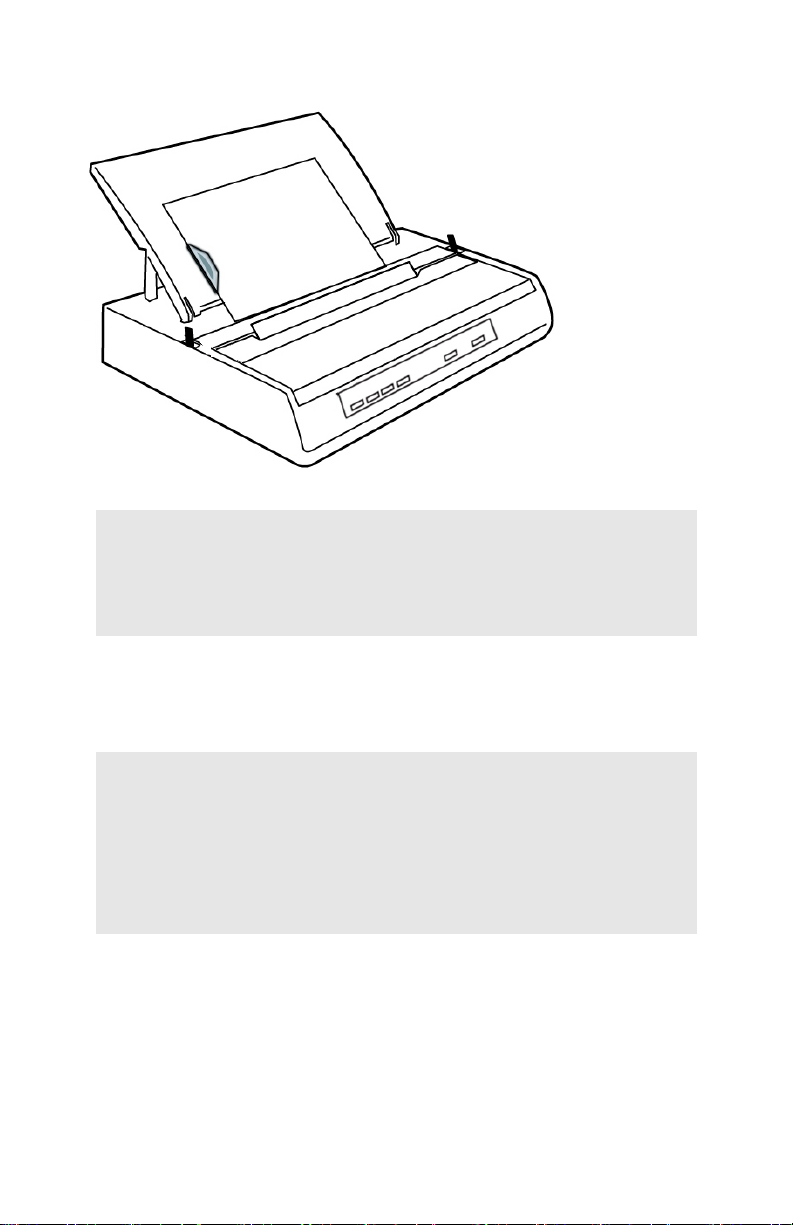

5. Raise the paper separator.

27 • Setting Up Your Printer

Page 28

6. Adjust the sheet guide (3) on the paper separator to position the

left edge of the sheet, then insert a single sheet along the

guide until it reaches the pinch roller.

7. Pull the bail arm lever (2) toward the front of the printer.

28 • Setting Up Your Printer

Page 29

8. Use the platen knob to wind the paper through to the front of the

printer and adjust the top of form. Press the

the printer is deselected (

SELECT

light offf) to set top of form.

TOF SET

button while

9. Push back the bail arm lever, ensuring that the paper has been

positioned correctly.

10.Press SELECT to place the printer on line.

29 • Setting Up Your Printer

Page 30

Testing Your Printer

Your printer has a built-in test (self test) to make sure that it is set

up and working correctly.

1. Load continuous forms paper into the printer (see page 14, ff.).

2. Make sure the printer is turned off, then press and hold LINE

while turning the printer on.

FEED

The test print begins.

3. To stop the test, press SELECT or turn the printer off.

Important

The top of each test printout contains information about your

printer. Be sure to have a copy of the printout handy if you

have to call for service.

30 • Setting Up Your Printer

Page 31

Computer Connections

USB Connection

Notes

• The operation of a printer is not assured if a USB

compatible device is connected concurrently with

other USB-compatible machines.

• When connecting multiple printers of the same

type. they appear as *****, *****(2), *****(3), etc.

These numbers depend on the order of

connecting or turning on of each printer.

• USB is a "hot-pluggable" protocol. This means

that the printer and computer do not necessarily

have to be switched OFF.

• Interface cables are not supplied with your printer.

USB Cable Requirements

• USB 1.1 or higher

• Max. length 19.7 ft. (5 m)

• USB "B" series connector

31 • Setting Up Your Printer

Page 32

1. Attach a suitable USB cable to the USB series "B" port on the

back of the printer.

2. Connect the other end of the cable to the computer.

3. If you turned the computer and printer off, turn them back on.

32 • Setting Up Your Printer

Page 33

Parallel (LPT) Connection, IEEE-1284

Note

Interface cables are not supplied with your printer.

Parallel Cable Requirements

• bi-directional

• max. length 6 ft. (1.8 m)

• 36-pin Centronics type connector

CAUTION!

Make sure the printer and computer are both turned OFF.

1. Turn both the computer and the printer OFF.

2. Attach a suitable bi-directional cable to the parallel connector

on the back of the printer and secure it with the wire loops.

33 • Setting Up Your Printer

Page 34

3. Attach and secure the cable to your computer.

4. Turn the printer and computer back on.

Serial (COM) Connection, RS-232C

Serial Model Only

Note

Interface cables are not supplied with your printer.

Serial Cable Requirements:

• Shielded RS-232C cable, UL and CSA approved

• Max. length 50 ft. (15 m)

• 25-pin serial connector.

CAUTION!

Make sure the printer and computer are both turned OFF.

34 • Setting Up Your Printer

Page 35

1. Switch both the computer and the printer OFF.

2. Plug the cable into the serial port on the back of the printer and

tighten the screws.

3. Plug the cable into the computer and tighten the thumbscrews.

4. Turn the printer and computer back on.

35 • Setting Up Your Printer

Page 36

Setting up the Printer to Work with

Your Computer

Notes

• Settings made in your software application

normally override settings made in your printer

driver.

• Settings made in the printer driver normally

override settings made in the printer menu or via

the front panel.

Install the Windows Printer Driver

To print from a Windows-based system, install the printer driver

located in the Drivers folder on the CD supplied with your printer.

This driver incorporates commands which use the full capability of

the printer and automatically switches the printer to the correct

emulation regardless of which emulation is selected in the printer

menu.

1. Place the CD in your CD-ROM drive.

2. Follow the on-screen instructions to install the driver to be used

with your printer.

36 • Setting Up Your Printer

Page 37

Non-Windows Systems:

Set the Emulation in the Printer Menu

Your printer has three emulations:

•IBM® 2480 — the factory default

• Epson® ESC/P2

• Oki Data® MICROLINE® Standard

If you are using a non-Windows system such as LINUX®, a

non-Windows application such as a DOS® program, or an older

application such as Word Perfect® 5.1, you need to make sure you

have the correct emulation selected in the printer menu (see

"Changing the Emulation Default in the Printer Menu" below). If

you have the wrong emulation selected, you will see strange

characters, incorrect fonts, etc.

Important

See your software documentation for information on how to

select an emulation in that application.

If you are directly replacing a MICROLINE ML184 Turbo or ML184

printer with the ML186 Plus, you must make sure that the printer

menu on your new ML186 Plus is set to match the emulation being

used for the existing printer (see "Changing the Emulation Default

in the Printer Menu" below).

For Non-Windows Applications

Your printer is compatible with the emulations listed in the table

below and will function properly with software developed for them.

To make full use of the ML186 Plus printer’s features, use the top

entry for the applicable emulation (e.g., IBM 2480). Entries further

down (e.g., IBM Graphics Printer Plus, IBM Graphics Printer) work

well with the printer, but do not provide full use of the printer’s

capabilities.

37 • Setting Up Your Printer

Page 38

ML186 Plus Emulation Mode Compatible Printers/Drivers

IBM IBM 2480

IBM Graphics Printer Plus

IBM Graphics Printer

Epson Epson ESC/P2

Epson LX Plus

Epson LX

ML Okidata MICROLINE Standard

Changing the Emulation Default in the

Printer Menu

The default for the emulation in the printer menu is IBM. If you wish

to change the menu default to another emulation:

1. Make sure continuous forms paper is loaded.

2. Turn the printer off.

3. Press and hold SELECT while turning the printer back on.

The printer enters the menu mode.

4. Press FORM FEED.

The first line of the menu prints, showing the emulation

engaged. For example:

Printer Control Emulation Mode IBM

5. Press TOF SET once or twice until the emulation you wish to

engage appears in the right-hand column.

Each time you press TOF SET, a new line prints and the setting

which appears in the last column changes. For example:

Printer Control Emulation Mode Epson

Printer Control Emulation Mode ML

6. Press PITCH and MODE together to save your setting and exit

the printer menu.

38 • Setting Up Your Printer

Page 39

Operating Your Printer

Front Panel Operation

Front Panel Lights

LED Status, Function

On = Printer is on line.

Off = Printer is off line.

Flashing = flashes with

has been detected.

ALARM light to indicate a fault

SELECT light off = paper out.

On,

On,

SELECT light flashing = auto diagnostics have

detected an error.

Flashing,

Normal print operation will resume only after a

cooling period.

On = printer is turned on.

Off = printer is turned off.

The one lit indicates which character pitch —in

characters per inch (cpi)— is engaged.

39 • Operating Your Printer

SELECT light on = printer has overheated.

Page 40

LED Status, Function

The one lit indicates which print mode is engaged:

NLQ = Near Letter Quality

UTILITY = Draft mode

HSD = High Speed Draft mode, or SSD (Super Speed

Draft) if 12 cpi is selected.

40 • Operating Your Printer

Page 41

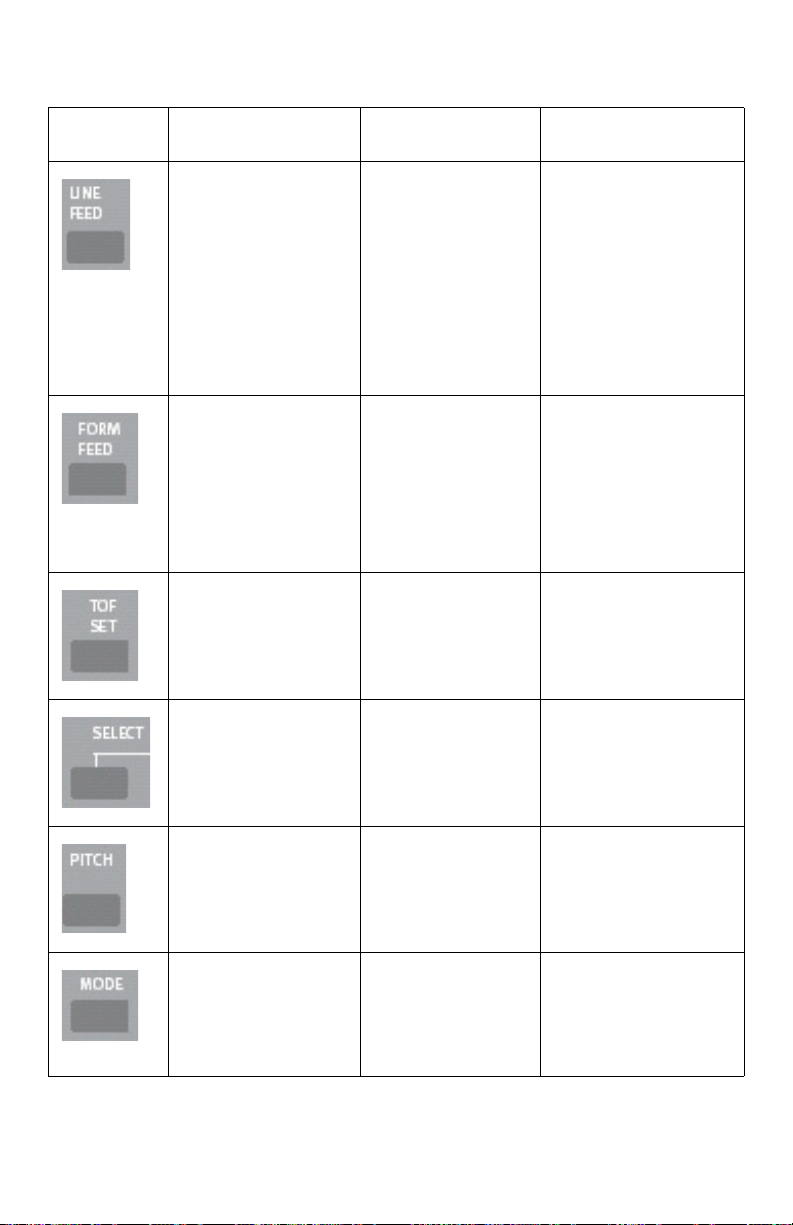

Front Panel Buttons

Button Print Mode Menu Mode Held at Power Up

Advances the

paper one line

Advances the

paper to the

next top of form

or ejects single

sheet from the

printer.

Sets a new top of

form (TOF)

position.

Toggles the

printer on and

off line.

Scrolls through

the printer

menu groups.

Scrolls through

the items for

each menu

group.

Scrolls through

the settings for

each item

within a group.

Prints list of

current menu

settings.

Initiates printer

Self Test (see

page 60).

LINE FEED +

SELECT =

Initiates Rolling

ASCII test (see

page 61).

FORM FEED +

SELECT = Places

printer in hex

dump mode (see

page 60).

Sets printer to 17

cpi.

Places printer in

Menu Mode.

Selects the

character pitch

setting (cpi).

Sets print mode

(NLQ, Utility,

HSD).

41 • Operating Your Printer

PITCH + MODE

= save settings

and exit to print

mode.

PITCH + MODE

= save settings

and exit to print

mode.

Not applicable.

Not applicable.

Page 42

Setting Printer Defaults

The printer has an internal menu containing a number of default

parameters which can be set to enable your printer to match the

parameters required by your computer.

Using the Menu Mode

Entering the Menu Mode

To enter the Menu Mode, press SELECT while turning on the

printer.

The 12 and UTILITY LEDs flash.

Printing a List of Current Menu Settings

With the printer in the Menu Mode, press SELECT to print the

complete menu.

The current default settings print out.

42 • Operating Your Printer

Page 43

Sample Default Menu Printout

Printer Control Emulation Mode IBM

Font Print Mode Utility

Font DRAFT Mode SSD

Font Pitch 10 CPI

Font Proportional Spacing No

Font Style Normal

Font Size Single

Symbol Sets Character Set Set I

Symbol Sets Language Set American

Symbol Sets Zero Character Slashed

Symbol Sets Code Page USA

Vertical Control Line Spacing 6 LPI

Vertical Control Skip Over Perforation No

Vertical Control Page Length 11"

Set-Up Graphics Uni-directional

Set-Up Receive Buffer Size 64K

Set-Up Paper Out Override No

Set-Up Print Registration 0

||||||||||||||||||||| <----- | | | | | | --------> |||||||||||||||||||

Set-Up Operator Panel Function Full Operation

Set-Up Reset Inhibit No

Set-Up Print Suppress Effective Yes

Set-Up Auto LF No

Set-Up Auto CR Yes

Set-Up SI Select Pitch (10 CPI) 17.1 CPI

Set-Up SI Select Pitch (12 CPI) 12 CPI

Set-Up Time Out Print Invalid

Set-Up Auto Select No

Set-Up ESC SI Pitch 17.1 CPI

Set-Up Impact Mode Normal

Set-Up Power Saving Enable

Set-Up Power Save Time 5 min

43 • Operating Your Printer

Page 44

Parallel I/F I-Prime Buffer Print

Parallel I/F Bi-Direction Enable

Serial I/F Parity None

Serial I/F Serial Data 7/8 Bits 8 bits

Serial I/F Protocol Ready/Busy

Serial I/F Diagnostic Test No

Serial I/F Busy Line SSDSerial I/F Baud Rate 9600 bps

Serial I/F DSR Signal Valid

Serial I/F DTR Signal Ready on Power UP

Serial I/F Busy Time 200 ms

(*1) Serial I/F Group only appear for printers equipped with Serial Interface.

44 • Operating Your Printer

Page 45

Changing Menu Settings

1. Press SELECT while turning on the printer.

2. Change settings:

a. Press LINE FEED to select the relevant group that needs to be

changed (the group is the left-hand column on the Menu

printout).

b. Press FORM FEED to select the relevant item within the

selected group (the Item is the center column on the Menu

printout).

c. Press TOF SET to cycle through the settings available for the

item you want to change (the settings are the right-hand

column on the Menu printout).

d. To continue making changes:

• press LINE FEED for the next group

or

• press FORM FEED for the next item.

3. Repeat the previous step until you are finished changing

settings.

4. Press PITCH and MODE together to save the changes you have

made and exit the Menu Mode.

Important

Exiting the Menu Mode by turning off the printer will

cancel any changes you have made.

45 • Operating Your Printer

Page 46

For Example

The default setting for the zero character is slashed. To change the

setting to unslashed:

1. Press and hold SELECT while turning the printer on.

The following line prints:

Printer Control Emulation Mode IBM

2. Press LINE FEED several times until the Symbol Sets group line

appears:

Symbol Sets Character Set SetI

3. Press FORM FEED repetitively until the Zero Character item line

appears:

Symbol Sets Zero Character Slashed

4. Press TOF SET once.

The following line prints:

Symbol Sets Zero Character Unslashed

5. Press PITCH and MODE together to save the setting and exit the

Menu Mode.

46 • Operating Your Printer

Page 47

Default Menu Selections

Default settings are indicated in bold italic.

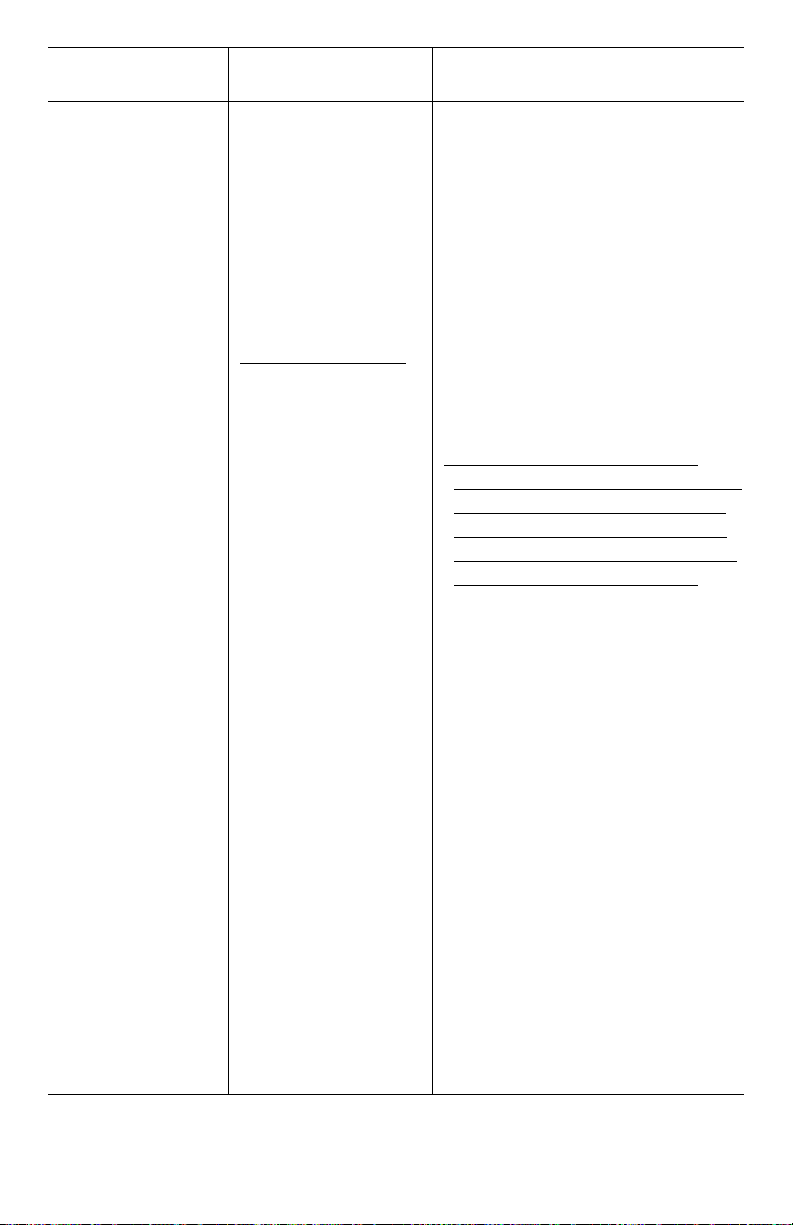

Group Item Setting

Printer Control Emulation Mode IBM, Epson, ML

Font Print Mode Utility, NLQ Courier, NLQ

Gothic, Draft

(Font) DRAFT Mode HSD, SSD

(Font) Pitch 10 CPI, 12 CPI, 15 CPI, 17.1

CPI, 20 CPI

(Font) Proportional

Spacing

(Font) Style Normal, Italics

(Font) Size Single, Double

No, Yes

Selects both double width and

double height characters or

single width and single height

characters.

47 • Operating Your Printer

Page 48

Group Item Setting

Symbol Sets Character Set Set I, Set II, Standard, Line

Graphics, Block Graphics (ML

mode only)

(Symbol Sets) Language Set American, French, German,

British, Danish I, Swedish,

Italian, Spanish I, Japanese,

Norwegian, Danish II,

Spanish II, Latin American,

French Canadian, Dutch,

Publisher

(Symbol Sets) Zero Character Slashed, Unslashed

(Symbol Sets) Code Page USA, Canada French,

Multilingual, Portugal,

Norway, BRASCII, Abicomp,

Multilingual 858, ISO8859-15

Vertical Control Line Spacing 6 LPI, 8 LPI

(Vertical Control) Skip Over

No, Yes

Perforation

(Vertical Control) Page Length 11 ", 11-2/3", 12", 14", 17", 5",

3", 3.25", 3.5", 4", 5.5", 6", 7",

8", 8.5"

Set-Up Graphics Bi-directional, Uni-directional

(Set-Up) 7 or 8 Bits Graphics

ML emulation only.

8, 7

(Set-Up) Receive Buffer Size 1 Line*, 32K, 64K, 128K

* When 1 Line is selected, the

receive buffer size is 2K bytes.

(Set-Up) Paper Out Override No, Yes

48 • Operating Your Printer

Page 49

Group Item Setting

(Set-Up) Print Registration 0.25 mm Right, 0.20 mm

Right, 0.15 mm Right, 0.10

mm Right, 0.05 mm Right, 0,

0.05 mm Left, 0.10 mm Left,

0.15 mm Left, 0.20 mm LEft,

0.25 mm Left

(Set-Up) 7 or 8 Bits Data

8, 7

Word

ML emulation only.

(Set-Up) Operator Panel

Function

FULL OPERATION, Semi

Operation*, Limited Operation

* When Limited Operation is

selected, after exiting the Menu,

only the SEL, LINE FEED and

FORM FEED buttons operate.

The PRINT QUALITY, TOF and

PITCH buttons are inactive.

(Set-Up) Reset Inhibit No, Yes

(Set-Up) Print Suppress

No, Yes

Effective

(Set-Up) Auto LF No, Yes

(Set-Up) Auto CR No, Yes

(Set-Up) SI Select Pitch (10

15 CPI, 17.1 CPI

CPI)

(Set-Up) SI Select Pitch (12

12 CPI, 20 CPI

CPI)

(Set-Up) TIme Out Print Valid , Invalid

(Set-Up) Auto Select No, Yes

(Set-Up) ESC SI Pitch 17.1 CPI, 20CPI

49 • Operating Your Printer

Page 50

Group Item Setting

(Set-Up) Impact Mode Normal, Quiet

(Set-Up) Power Saving Enable, Disable

(Set-Up) Power Save Time 5 min, 10 min, 15 min, 30 min,

60 min

Parallel I/F I-Prime Invalid, Buffer Print, Buffer

Clear

(Parallel I/F) Auto Feed XT

EPSON emulation only.

(Parallel I/F) Bi-Direction Enable, Disable

Serial I/F

Only appears

for printers

equipped with

Serial Interface.

(Serial I/F) Serial Data 7 or 8

(Serial I/F) Protocol Ready/Busy, X-ON/X-OFF

(Serial I/F) Diagnostic Test No, Yes

(Serial I/F) Busy Line SSD-, SSD+, DTR, RTS

(Serial I/F) Baud Rate 19,200 bps, 9600 bps,

Parity None, Odd, Even

Bits

Valid , Invalid

8 bits, 7 bits

4800 bps, 2400 bps, 1200 bps,

600 bps, 300 bps

(Serial I/F) DSR Signal Valid, Invalid

(Serial I/F) DTR Signal Ready on Power Up, Ready

on Select

(Serial I/F) Busy Time 200 ms, 1 sec

50 • Operating Your Printer

Page 51

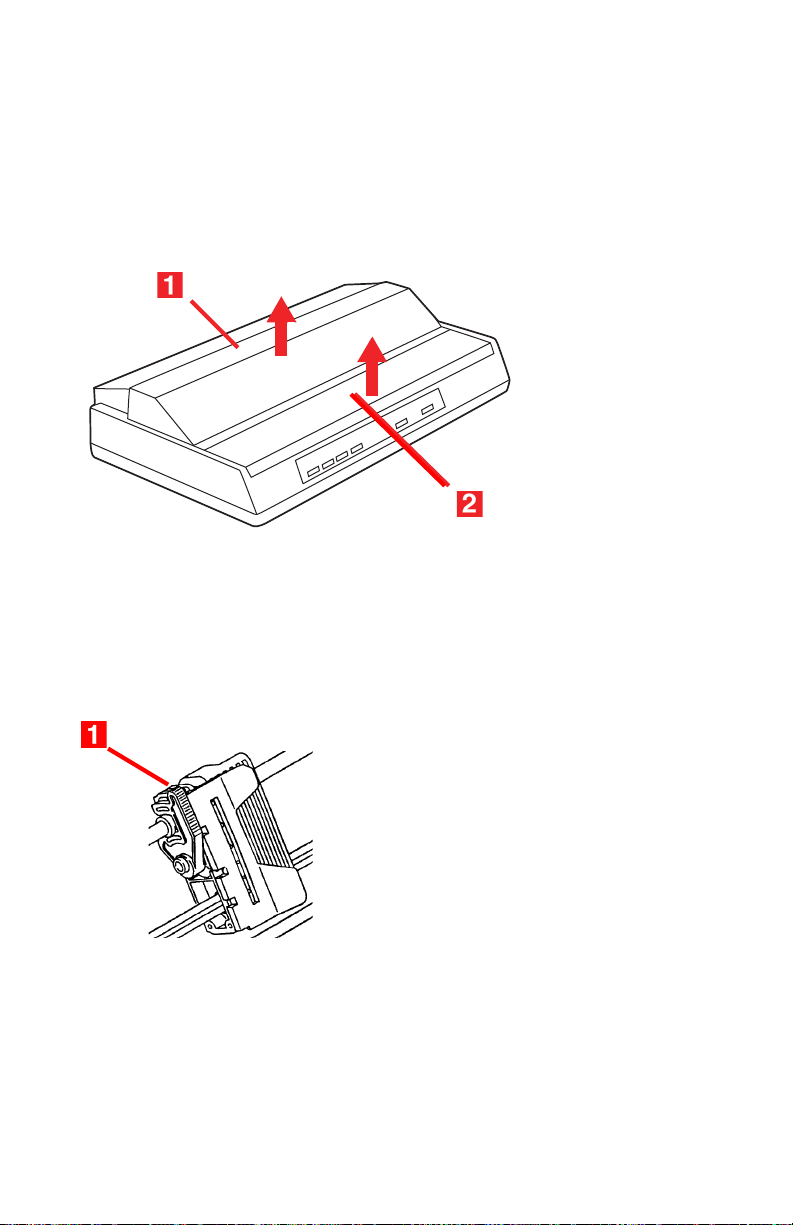

Using the Pull Tractor Unit

(if installed)

Paper can be loaded from the rear of the printer or, if you have a

slotted printer stand, it can be loaded from the bottom.

1. Remove the acoustic cover (1) and access cover (2).

2. Adjust the left tractor if necessary, making sure that it is not

more than ½-inch (12.7 mm) from the left end of the tractor unit.

To move the tractor, pull the lock lever (1) forward, slide the

tractor to the desired position, then push the lever back to lock it

in place.

51 • Operating Your Printer

Page 52

3. Adjust the right tractor to the paper width by pulling its lock lever

(1) forward, sliding the tractor to the desired position, then

pushing the lever back to lock it in place.

4. Pull the paper under the bail arm and up to the level of the

tractor unit.

5. Open the sprocket covers (A) at either end of the pull tractor.

6. Pull the paper lever (on the right side of the printer) forward to

the continuous forms position.

52 • Operating Your Printer

Page 53

7. Place the holes in the paper over the sprockets on the pull

tractor unit and close both sprocket covers.

Note

Be careful to align the paper properly so that an

equal number of holes are engaged on the sprockets

at either end of the pull tractor. Misalignment will

cause paper jams and/or ripping.

8. Replace the access cover and acoustic cover.

53 • Operating Your Printer

Page 54

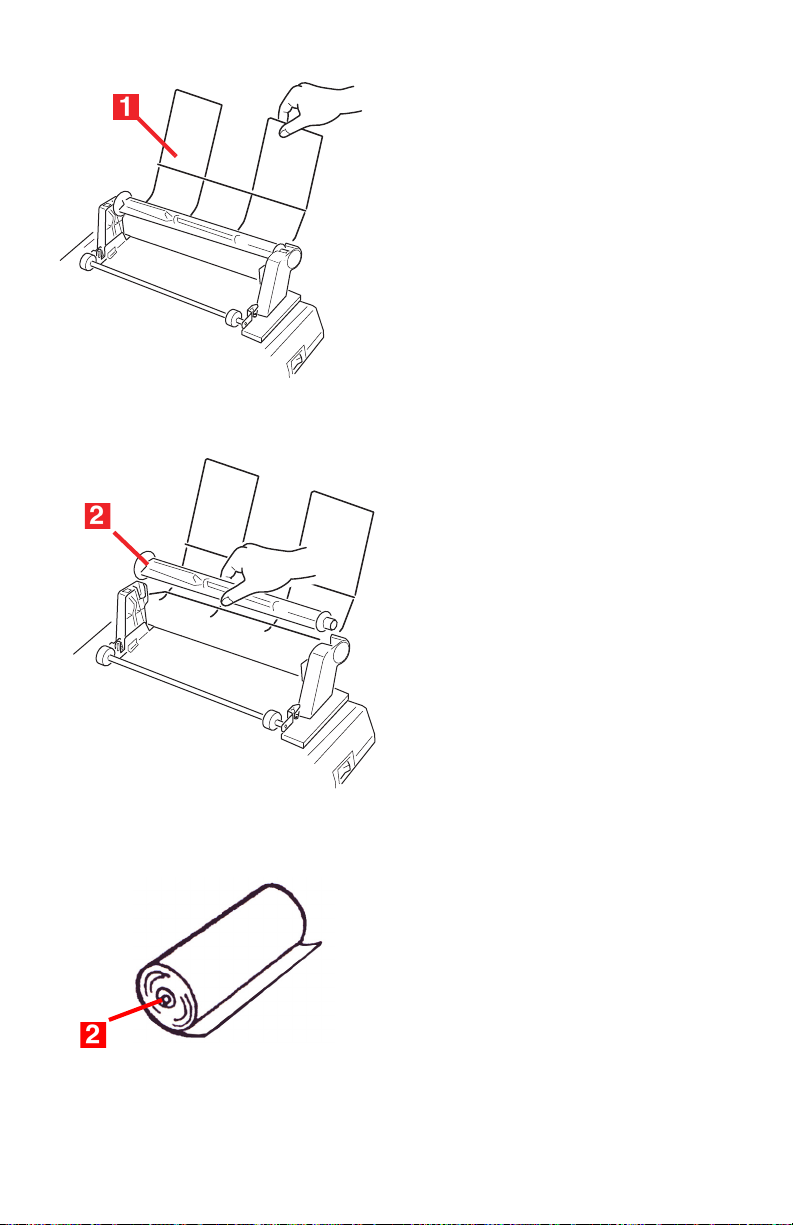

Using the Roll Paper Stand

(if installed)

Loading the Paper

Correct Paper Path

1 Paper Roll

2 Roll Paper Stand

3 Paper Guide

4 Platen

5 Paper Separator

1. Remove the access cover from the printer.

2. Place the paper lever (right side of printer) in the single sheet

position (back) and the bail arm lever (left side of printer) toward

the front of the printer (bail arm raised away from platen).

54 • Operating Your Printer

Page 55

3. Open the paper separator (1).

4. Remove the paper roller. Note that there is a disk (2) on the left

end of the roller.

5. Slide the roller into a roll of paper, making sure that the disk (2)

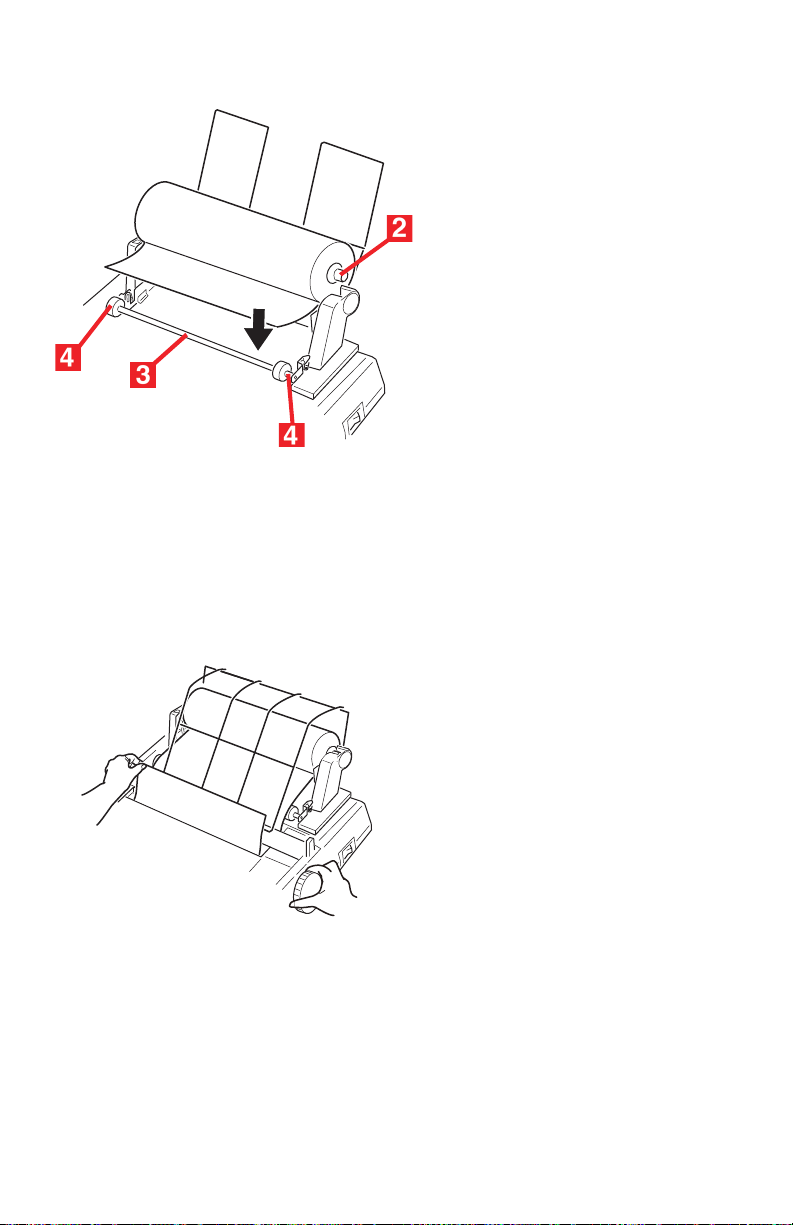

is on the left side and that the paper rolls up from the bottom.

55 • Operating Your Printer

Page 56

6. Put the paper roller back into the stand, with the disc (2) on the

left side.

7. Feed the paper over (not under!) the roller (3) on the stand,

adjusting the round paper guides on either end (4) to the paper

width.

8. Feed the paper down behind the platen and use the platen

knob to bring the paper through the printer. Feed the paper in

as straight as possible.

9. Continue to feed the paper through for approximately 4 inches

(102 mm).

56 • Operating Your Printer

Page 57

10.Pull the paper lever (right side of printer) toward the front of the

printer—to the continuous forms position—and make sure the

paper is straight by adjusting it to align the left and right sides

behind the platen with the sides in front of the platen.

Important

Be sure that the paper covers the groove in the left end of the

platen so that it clears the paper out detector.

11. Push the paper lever back to the single sheet position to

reapply pressure on the platen.

12.Push the bail arm lever (left side of printer) back to close the

bail arm.

13.Replace the access cover:

a. Fit the cover tabs into the slots at the printer front.

b. Lower the cover carefully, making sure the paper fits through

the front slot in the access cover.

14. Lower the paper separator so that paper enters the printer

from under the separator and exits the printer going over the

separator (see "Correct Paper Path" diagram on page 54).

15. Turn the platen knob to move the paper to the point where you

want printing to start. (Many word processing packages

automatically allow for a top margin of 1 inch [25 mm]).

Note

To save this position as the permanent Top of Form,

press the TOF button.

57 • Operating Your Printer

Page 58

Maintenance

Replacing the Ribbon Cartridge

For more details, see page 7.

WARNING!

If the printer has been recently used, the printhead may be

HOT!

Turn the printer off !

58 • Maintenance

Page 59

59 • Maintenance

Page 60

Testing Your Printer

Self Test (Font Samples)

Your printer has a built-in test (self test) to make sure that it is set

up and working correctly.

1. Load continuous forms paper into the printer (see page 14, ff.).

2. Make sure the printer is turned off, then press and hold LINE

while turning the printer on.

FEED

The test print begins.

3. To stop the test, press SELECT or turn the printer off.

Note

The top of each test printout contains information

about your printer. Be sure to have a copy of the

printout handy if you have to call for service.

60 • Maintenance

Page 61

Rolling ASCII Test

The Rolling ASCII Test produces a continuous sampling of ASCII

characters using the default type style. To run the test:

1. Make sure continuous forms paper is loaded.

2. With the printer turned off, press and hold SELECT and LINE

while turning the printer on.

FEED

The Rolling ASCII Test begins.

3. To stop the test, press SELECT or turn the printer off.

Hex Dump Mode

In Hex Dump Mode, all data sent to the printer, including text and

printer commands, prints in both hexadecimal and ASCII format.

• To place the printer in the Hex Dump Mode, press and hold

SELECT and FORM FEED while turning the printer on.

• To disengage the Hex Dump Mode, turn the printer off, then on

again.

61 • Maintenance

Page 62

Cleaning the Housing

CAUTION!

Never use solvents or strong detergents on the cabinet:

they could damage the housing.

You should clean the printer every six months (or after about 300

hours of operation).

1. Turn the printer off.

2. Remove any paper from the path.

3. Remove the access cover (1).

4. Pull the bail arm lever (2) forward to lift the bail arm.

5. Use a clean, dry cloth to dust around the carriage shaft and

platen.

6. Remove any loose bits of paper.

62 • Maintenance

Page 63

7. Push the bail arm lever back and reinstall the access cover.

8. Reload paper.

9. Turn the printer on.

63 • Maintenance

Page 64

Troubleshooting

General Information

Here are some general things to check before proceeding with detailed

troubleshooting.

• Is the printer plugged in and turned on?

• Are the connections (power and interface) secure?

• Is the printer being operated under the proper ambient conditions (see page 82)?

• Does the paper being used meet the specifications for this

printer (see page 81)?

• Is the paper properly installed (see pages 14, ff.)?

• Is the ribbon properly installed (see pages 7, ff.)?

• Is an Oki ribbon being used?

• Is the head gap correctly set (see page 11)?

• Are the correct printer drivers being used for the printer (see

page 36)?

Notes

• Settings made in your software application

normally override settings made in your printer

driver.

• Settings made in the printer driver normally

override settings made in the printer menu or via

the front panel.

64 • Troubleshooting

Page 65

General Problems/Solutions

Problem 1 __________________________________________

My word processor files do not print the way I have the menu and

front panel set.

Solution

1. Check your software application and/or printer driver settings:

these override the menu and front panel settings (see Note

above).

2. Before sending a file to the printer, many word processors

send either an "initialization string" or an I-Prime signal to the

printer.

The initialization string contains codes that override the panel

and menu settings. To change your printer to ignore the reset

code, enter the Menu Mode, go to the Set-Up group and change

the setting for Reset Inhibit to Yes.

The I-Prime signal will automatically override any front panel

settings you have made. To eliminate this problem, enter the

Menu Mode, go to the Parallel Interface group and change the

setting for I-Prime to Invalid.

For more information on changing menu settings, see page 42.

Problem 2 __________________________________________

Nothing happens when I turn on the printer.

Solution

1. Check the power cord connection to the outlet and to the

printer.

2. If you are using a power strip, make sure it is turned ON, and

that the fuse hasn’t blown or that the circuit breaker hasn’t

tripped.

3. If the solution is not obvious — call for service.

65 • Troubleshooting

Page 66

Problem 3 __________________________________________

The printer does not print when the computer sends data.

Solutions

1. Is the SELECT light on? If not, press SELECT.

2. Check that the interface cable is securely connected to both

the printer and the computer.

Problem 4 __________________________________________

I'm getting strange symbols, incorrect fonts, etc., when I try to print

a document.

Solutions

1. Check to be sure that the printer driver you have selected in

your software matches the printer emulation: see "Changing

Menu Settings" on page 45.

2. If you have embedded any printer commands in your

software, check to be sure that you entered them correctly.

Problem 5 __________________________________________

Ink smears on the paper when I print narrow columns.

Solutions

The head gap could be too close. Check that the Head Gap Lever (1) is set

correctly (see "Adjusting the Head Gap" on page 11).

66 • Troubleshooting

Page 67

Problem 6 __________________________________________

I've installed a new ribbon and the printing is smeared and streaked.

Solution

The ribbon shield (1) is either loose or missing.

1. Remove the ribbon cartridge and check the ribbon shield.

2. If it is loose, secure it.

3. If it is missing, find it and install it. If you cannot find it, see if

you have an old ribbon cartridge with the shield still on it. If

so, remove the shield from it and put in on the current ribbon

cartridge. If not, replace the ribbon cartridge.

Problem 7 __________________________________________

There are dots missing in my printouts (typically, tops and /or

bottom of characters missing).

Solution

The head gap may not be set correctly. Try moving the Head Gap Lever (1)

to a lower setting.

If that doesn’t help, the printhead may be damaged; call for service.

67 • Troubleshooting

Page 68

Problem 8 __________________________________________

The ALARM light is flashing.

Solution

Try turning the printer off, then back on again. If the light still blinks, call for

service.

Problem 9 __________________________________________

The Print Quality and Character Pitch keys on the front panel don't

work.

Solution

The Operator Panel Function in the printer menu can be used to disable these

buttons (Limited Function). If the printer is part of a customized system or if it

is used by a number of people, the system manager may have used this

option to make sure the printer is always set properly.

Check with your system manager before changing any menu settings.

Problem 10 _________________________________________

My printer keeps indicating "Paper out" even though there is paper

installed.

Solution

The most likely cause is that the paper sensor groove at the left end of the

platen is not covered by the paper. Move the paper over to cover the sensor

groove.

Problem 11 _________________________________________

When I am using continuous feed paper, the sprocket holes are

torn, causing alignment problems.

Solution

The most likely cause is that the paper lever (right side of printer) is in the

single sheet position. Make sure the lever is in the continuous forms position

(forward).

68 • Troubleshooting

Page 69

Clearing Paper Jams

Rear Feed Jams

1. Turn the printer off.

2. Use the platen knob to back the paper all the way out of the printer.

CAUTION!

Make sure the printer is turned OFF before you remove

the access cover.

69 • Troubleshooting

Page 70

3. Remove the access cover (1).

ml186_34b_rearfeed.bmp, sq_1_red.tif, sq_2_red.tif

4. Move the bail arm lever (2) toward the front of the printer to

open the bail arm.

WARNING!

The printhead may be HOT!

5. Remove any torn paper.

6. Reload the paper (see pages 14, ff.).

70 • Troubleshooting

Page 71

7. Move the bail arm lever (2) towards the rear of the printer and

replace the access cover (1) being sure to feed the edge of the

paper through the slot in the cover.

8. Turn the printer on.

71 • Troubleshooting

Page 72

Rear Feed, Repeating Paper Jams

If the paper keeps jamming, you may have:

• defective paper

• misaligned paper

• bits of paper in the paper path

For Defective Paper

Replace the defective paper with a fresh stack.

For Misaligned Paper

1. Turn the printer off.

2. Use the platen knob to back the paper all the way out of the

printer.

3. Tear off a couple of sheets of paper, leaving a new, clean,

square-cut edge.

72 • Troubleshooting

Page 73

4. Reload the paper.

5. Turn the printer back on.

For Bits of Paper in the Paper Path

1. Turn the printer off.

2. Remove any accessories.

73 • Troubleshooting

Page 74

3. Use the platen knob to back the paper all the way out of the printer.

CAUTION!

Make sure the printer is turned OFF before you remove

the access cover.

4. Remove the access cover.

5. Remove any debris from the paper path.

6. Replace the access cover and any accessories which you removed.

74 • Troubleshooting

Page 75

7. Reload the paper.

8. Turn the printer on.

75 • Troubleshooting

Page 76

Single Sheet Paper Jams

1. Turn the printer off.

2. Use the platen knob to back the paper out.

CAUTION!

Make sure the printer is turned OFF before you remove

the access cover.

3. Remove the access cover. ML186_13a_SheetJam

WARNING!

If the printer has been recently used, the printhead may be

HOT!

76 • Troubleshooting

Page 77

4. Remove any torn pieces from around the carriage.

5. Replace the access cover.

6. Turn the printer back on.

7. Reload the paper.

77 • Troubleshooting

Page 78

Parts & Options

Replacement Parts

Ribbon Cartridge

(Oki 52102001)

Platen Knob

(Oki 53459807)

Power Cord

(Oki 56609701)

Access Cover

(Oki 53467410)

Paper Separator

(Oki 53459303)

78 • Parts & Options

Page 79

Options

Pull Tractor (Oki 70009701)

Includes Pull Tractor (1), Acoustic Cover (2) and Access Cover (3).

Roll Paper Stand (46634101)

79 • Parts & Options

Page 80

Specifications

General

Print Method

Printhead

Emulations (co-resident)

Print Speed, characters per

second (cps)

Super Speed Draft (SSD)

High Speed Draft (HSD)

Utility (UTL)

Near Letter Quality (NLQ)

Buffer size

Impact dot matrix

9 pins, 0.34 mm (0.0134") diameter,

with thermal protection

IBM 2480

Epson ESC/P2

Okidata MICROLINE Standard

375 cps (12 cpi only)

333 cps

250 cps

62.5 cps

128 Kb

80 • Specifications

Page 81

Paper

Type Feed Weight Width

Cut Sheets

Continuous, Single Part

Continuous, Multipart

• 4 sheets (orig.+3),

Carbonless

• Up to 0.11" (0.28 mm)

thick

Reliability

Ribbon Life

Top only 16 to 21 lb.

US Bond

(60 to 81

g/m²)

Rear/Bottom 14 to 20 lb.

US Bond

(53 to 75

g/m²)

Rear/Bottom 14 to 20 lb.

US Bond

(53 to 75

g/m²)

3 million characters, on average

3" to 9.5"

(76 to

241 mm)

3" to 9.9"

(76 to

251 mm)

3" to 9.9"

(76 to

251 mm)

Printhead Life

Mean Time Between

Failures (MTBF)

Mean Time to Repair

(MTTR)

200 million characters average in

10 cpi utility mode

20,000 hours at 25% duty cycle

and 35% page density

15 minutes

81 • Specifications

Page 82

Physical

Height

Width

Depth

Weight

Electrical

Voltage

Frequency

Environmental

Temperature

Operating

Storage

3.15" (80 mm)

14.17" (360 mm)

10.83" (275 mm)

8.6 lb. (3.9 Kg)

120VAC, +6%, -15%

220-240VAC, ±10%

50 or 60 Hz, ±2%

41 to 95°F (5 to 35°C)

-40 to 158°F (-40 to +70°C)

Humidity

Operating

Storage

Noise level

20 to 80% RH

5 to 95% RH

Normal: Less than 58 dBA (Utility Print)

82 • Specifications

Page 83

Interfaces

Parallel Models

Serial Models

Centronics Parallel, IEEE-1284 compliant

USB 2.0 (Full Speed)

Centronics Parallel, IEEE-1284 compliant

USB 2.0 (Full Speed)

RS-232C Serial

83 • Specifications

Page 84

Index

Emulations ................................. 80

Environmental specifications ... 82

A

Access cover

replacement #

ALARM light ............................... 39

....................... 78

B

Bail arm ...................................... 14

Bail arm lever ............................ 14

Bottom feed paper

loading

Buffer size .................................. 80

Buttons, front panel .................. 41

.............................. 21–24

C

Caution boxes ............................. 4

Cleaning the housing ................ 62

Computer connections

parallel

serial ................................. 34–35

USB ........................................ 31

Continuous forms

loading

specifications ......................... 81

Cut sheet paper ......................... 81

.............................. 33–34

bottom feed

rear feed ...................... 16–20

................. 21–24

D

Default

menu settings

Defaults ................................ 42–43

menu mode ........................... 49

Dimensions ................................ 82

Drivers, printer ........................... 36

........................ 47

E

Electrical specifications ............ 82

F

FORM FEED button ................. 41

Frequency .................................. 82

Front panel ........................... 39–41

buttons .................................... 41

lights .................................39–40

G

Gap, printhead ........................... 11

H

Head gap .................................... 11

lever ........................................ 14

Hex dump mode ........................ 61

Humidity specifications ............. 82

I

Important boxes .......................... 4

Interfaces

parallel

serial ....................................... 83

USB ........................................ 83

I-Prime ........................................ 50

.................................... 83

J

Jams, paper

rear feed

single sheet .....................76–77

...........................69–75

K

Knob, platen ............................... 10

L

LEDs, front panel ................ 39–40

Levers ......................................... 14

Lights, front panel ...............39–40

LINE FEED button .................... 41

84 • Index

Page 85

Loading

......... 14–17, 19–26, 28–29

paper

Location ........................................ 5

M

Menu

changing settings

default settings ...................... 49

defaults .................................. 43

settings ................................... 42

settings, changing ................ 45

Menu mode ............. 42–43, 45–49

MODE button ............................. 41

Mode lights ................................ 40

............ 45–46

N

Noise level specifications ........ 82

Notes ............................................ 4

O

Options

pull tractor

roll paper stand ..................... 79

.............................. 79

P

Paper jams

rear feed

single sheet ..................... 76–77

Paper lever ................................ 14

Paper loading

continuous

forms

bottom feed ................. 21–22

rear feed ......... 16–17, 19–20

single sheets ...... 25–26, 28–29

Paper separator

installing

replacement # ....................... 78

Paper specifications ................. 81

........................... 69–72

.................. 14–17, 19–24

................................. 12

Parallel

computer connection

interface menu settings ........ 50

PITCH button ............................. 41

PITCH lights ............................... 39

Platen knob ................................ 10

replacement # ....................... 78

Power connection ..................... 13

Power cord

replacement #

POWER light .............................. 39

Print speed ................................. 80

Printer

defaults

dimensions ............................ 82

drivers ..................................... 36

reliability ................................. 81

weight ..................................... 82

Printhead .................................... 78

gap .......................................... 11

life ........................................... 81

shipping restraint .................... 6

specifications ......................... 80

Pull tractor .................................. 79

using ................................. 51, 53

................................... 42

....................... 78

......33–34

R

Rear feed paper

loading

Reliability .................................... 81

Replacement parts .................... 78

Ribbon cartridge

installing

life ........................................... 81

replacement # ....................... 78

replacing ............................ 7, 58

take-up knob .......................... 10

Ribbon shield ............................... 8

................. 16–17, 19–20

................................... 7

85 • Index

Page 86

Roll paper stand ........................ 79

using ................................. 54–57

Rolling ASCII test ...................... 61

S

SELECT button ......................... 41

SELECT light ............................. 39

Self test ................................ 30, 60

Separator, paper ....................... 12

Serial interface connection

Shipping restraints ...................... 6

Single sheet paper

loading

specifications ......................... 81

Specifications ...................... 80–83

................. 25–26, 28–29

... 34–35

T

Take-up knob, ribbon ............... 10

Temperature specifications ..... 82

Testing ........................................ 30

Tests

font sample

hex dump mode .................... 61

Rolling ASCI .......................... 61

self test ................................... 60

TOF SET button ........................ 41

............................ 60

U

Unpacking .................................... 5

USB connection .................. 31–32

V

Voltage ....................................... 82

W

Warning boxes ............................ 4

Weight ........................................ 82

86 • Index

Page 87

Oki contact details

OKI Systems (UK) Ltd.

Blays House

Wick Road

Egham

Surrey

TW20 0HJ

Tel: +44 (0) 1784 274300

Website: www.oki.com/uk

OKI Systems (Ireland) Ltd

A7 Calmount Park

Ballymount

Dublin 12

D12 TX94

Ireland

Tel: +353 (0) 1 4049590

Fax: +353 (0)1 4049591

Website: www.oki.com/ie

OKI Systems (Czech and

Slovak), s.r.o.

Futurama Business Park Sokolovská 651/136D

186 00 Praha 8

Czech Republic

Tel: +420 224 890158

Fax: +420 22 232 6621

Website: www.oki.cz, www.oki.sk

Oki Systems (Deutschland)

GmbH

Hansaallee 187

40549 Düsseldorf

Tel: +49 (0) 211 / 5266-0

Fax: +49 (0) 211 59 33 45

Website: www.oki.de

Email: info@oki.de

CEE Export Group:

OKI Systems (Poland) Sp. z o.o.

Platinum Business Park 2, 3rd Floor

ul. Domaniewska 42,

02-672 Warsaw

Poland

Tel: +48 (0) 22 448 65 00

Fax: +48 (0) 22 448 65 0

Website: www.oki.pl

Albania, Bosnia, Bulgaria, Croatia,

Cyprus, Estonia, Greece, Israel,

Latvia, Lithuania, Macedonia,

Romania, Serbia, Slovenia

Oki Systèmes (France) S.A.

Zone Silic - Immeuble Osaka

21 rue du Jura

CS 90277

94633 RUNGIS Cedex

Paris

Tél: Standard 0820 200 410

(0.09€/min depuis une ligne fixe*)

Hotline 01 76 54 21 50 (n° non

surtaxé)

Website: www.oki.fr

87 • Oki contact details

Page 88

OKI Systems (Magyarország)

Kft.

H-1133 Budapest,

Váci út 76

Hungary

Telefon: +36 1 814 8000

Telefax: +36 1 814 8009

Website: www.okihu.hu

OKI Systems (Italia) S.p.A.

via Milano, 11,

20084 Lacchiarella (MI)

Tel: +39 (0) 2 900261

Fax: +39 (0) 2 70059826

Website: www.oki.it

OKI Systems (Polska) Sp. z o.o

Platinium Business Park II,

3rd Floor

ul. Domaniewska 42

02-672 Warsaw

Poland

Tel: +48 22 448 65 00

Fax: +48 22 448 65 01

Website: www.oki.pl

E-mail: oki@oki.com.pl

Hotline: 0800 120066

E-mail: tech@oki.com.pl

OKI Europe Limited, Sucursal

em Portugal

Av. Quinta Grande, nº 53

7º D - Alfragide

2610-156 Amadora

Portugal

Tel: +351 21 470 4200

Fax: +351 21 470 4201

Website: www.oki.com/pt

E-mail: oki-portugal@okieurope.com

Oki Service

Serviço de Apoio Técnico ao

Cliente

Tel: 214 727 660

E-mail: portugal@okiservice.com

OKI Systems Rus, LLC (Russia)

Sector B, 3rd Floor, Svyatogor-4

Business Center10/4,

Letnikovskaya

str.115114, Moscow

Tel: +7 495 258 6065

Fax: +7 495 258 6070

e-mail: info@oki.ru

Website: www.oki.ru

Technical support:

Tel: +7 495 564 8421

e-mail: tech@oki.ru

88 • Oki contact details

Page 89

Oki Systems (Österreich)

Campus 21

Businesszentrum Wien Sued

Liebermannstrasse A02 603

22345 Brun am Gebirge

Tel: +43 223 6677 110

Service-Hotline:

+43 (0) 2236/677 110-501

Website: www.oki.at

OKI Europe Ltd. (Ukraine)

Raisy Opkinoy Street,8

nd

Building B, 2

Floor,

Kiev 02002

Ukraine

OKI Systems (Danmark) a·s

Herstedoestervej 27

2620 Albertslund

Danmark

Adm.: +45 43 666 500

Fax: +45 43 666 590

E-mail: salg@oki.dk

Website: www.oki.dk

OKI Europe Limited, Sucursal

en España

Complejo Vega Norte. C/ Anabel

Segura, 16. Edif. 3 – 4º Plta.

28.108, Alcobendas

Madrid

Tel: +380 44 537 5288

e-mail: event@oki.ua

Website: www.oki.ua

OKI Sistem ve Yazıcı Çözümleri

Tic. Ltd. Şti.

Harman sok Duran Is Merkezi,

No:4, Kat:6,

34394, Levent

İstanbul

Tel: +90 212 279 2393

Faks: +90 212 279 2366

Web: www.oki.com.tr

Oki Systems (Belgium)

Medialaan 24

1800 Vilvoorde

Helpdesk: 02-2574620

Fax: 02 2531848

Website: www.oki.be

Tel: +34 91 343 16 20

Website: www.oki.com/es

Soporte Técnico:

Tel: (+34) 91 217 15 63

Email: espana@okiservice.com

OKI Middle East, India and Sub

Sahara Africa

Building 7W A

Office 2008,

Dubai Airport Free Zone

PO Box 54604

Dubai, UAE

Tel: +971 4 204 5810

Website: www.oki.com/me

89 • Oki contact details

Page 90

Oki Systems (Finland) Oy

Vänrikinkuja 3

02600 Espoo

Finland

Tel: +358 207 900 800

Fax: +358 207 900 809

Website: www.oki.fi

Oki Systems (Holland) b.v.

Neptunustraat 27-29

2132 JA Hoofddorp

Helpdesk: 0800 5667654

Tel: +31 (0) 23 55 63 740

Fax: +31 (0) 23 55 63 750

Website: www.oki.nl

Oki Systems (Schweiz)

Baslerstrasse 15

CH-4310 Rheinfelden

Support deutsch +41 61 827 94 81

Support français +41 61 827 94 82

Support italiano +41 61 827 94 73

Tel: +41 61 827 94 94

Email: info@oki.ch

Website: www.oki.ch

Oki Data Americas Inc.(United

States • États-Unis)

2000 Bishops Gate Blvd.

Mt. Laurel, NJ 08054

USA

Oki Systems (Norway) AS

Tevlingveien 23

1081 Oslo

Tel: +47 63 89 36 00

Telefax: +47 63 89 36 01

Website: www.oki.no

Oki Systems (Sweden) AB

Box 1193

164 26 KISTA

Stockholm

Sverige

Tel: +46 (0) 8 634 37 00

Fax: +46 (0) 8 634 37 01

Website: www.oki.se

Tel: 1-800-654-3282

Fax: 1-856-222-5247

http://WWW.OKIPRINTINGSOLUTIONS.COM

http://my.okidata.com

8505 Freeport Pkwy

Suite 100

Irving, TX 75063

http://www.okidata.com

2067 Wineridge Place

Suite C & D

Escondido, CA 92029

Phone: 760-781-5200

Toll Free: 800-264-1272

http://www.okidata.com/wide-format

90 • Oki contact details

Page 91

Oki Data Americas Inc.

(Canada • Canadá)

4140B Sladeview Crescent Unit 7 & 8

Mississauga, Ontario

Canada L5L 6A1

Tél: 1-905-608-5000

Téléc: 1-905-608-5040

http://WWW.OKIPRINTINGSOLUTIONS.COM

Oki Data Americas Inc.(América

Latina (OTRO))

2000 Bishops Gate Blvd.

Mt. Laurel, NJ 08054

USA

Tel (Español): 1-856-222-7496

1-856-222-5276

Fax: 1-856-222-5260

Email: LASatisfaction@okidata.com

Oki Data de Mexico, S.A. de C.V.

Mariano Escobedo #748, Piso 8

Col. Nueva Anzures

C.P. 11590, México, D.F.

Tel: 52-555-263-8780

Fax: 52-555-250-3501

http://WWW.OKIPRINTINGSOLUTIONS.COM

Oki Data do Brasil Informática

Ltda.

Av. Alfredo Egídio de Souza

Aranha, 100 - 5º Andar - Bloco C

Chácara Santo Antonio - São

Paulo, SP - Brasil

CEP: 04726-170

Tel: 55-11-3543-5500

Fax: 55-11-3444-3501

email: okidata@okidata.com.br

HTTP://www.okiprintingsolutions.com

Argentina/Chile/Paraguay/Perú/Uruguay

Oki Data Americas, Inc.

Sucursal Argentina

Ugarte 3610 Piso 4°(1605) Olivos

Buenos Aires, Argentina

TEL: +54 11 5288 7500

Fax: +54 11 5288 7599

Colombia/Ecuador/Venezuela/

Centroamérica y Caribe

Oki Data Americas, Inc.

Sucursal Colombia

Carrera 13 #97-51, Oficina 101

Bogotá Colombia

TEL: +57 1 704 5159

Oki Data (Singapore) Pte. Ltd.

438A Alexandra Road #02-11/12,

Lobby 3, Alexandra Technopark

Singapore (119967)

Tel: (65) 6221 3722

Fax: (65) 6594 0609

http://www.oki.com/sg/printing

91 • Oki contact details

Page 92

Oki Systems (Thailand) Ltd.

1168/32 Lumpini Tower,

16th Floor, Rama IV Road,

Tungmahamek, Sathorn

Bangkok 10120

Tel: (662) 679 9235

Fax: (662) 679 9243/245

http://www.oki.com/th/printing

Oki Data(Australia) Pty Ltd.

Level1 67 Epping Road,

Macquarie Park

NSW 2113, Australia

Tel: +61 2 8071 0000

(Support Tel: 1800 807 472)

Fax: +61 2 8071 0010

http://www.oki.com.au

OKI Data New Zealand

8 Antares Place Rosedale,

Auckland, 0632 New Zealand

Tel: (64) 9 477 0500

(Customer Support: 0800 778 800)

Fax: (64) 9 477 0549

http://www.oki.co.nz

Oki Data(S) P Ltd. Malaysia Rep

Office

Suite 21.03, 21st Floor Menara

IGB, Mid Valley City,

Lingkaran Syed Pura 59200,

Kuala Lumpur, Malaysia

Tel: (60) 3 2287 1177

Fax: (60) 3 2287 1166

92 • Oki contact details

Page 93

4-11-22 Shibaura, Minato-ku,Tokyo

108-8551, Japan

www.oki.com/printing/

May 2017

46633701EE Rev1

Loading...

Loading...