Page 1

MB460/470/480

Maintenance Manual

011409B

Oki Data CONFIDENTIAL

Page 2

Document Revision History

Oki Data CONFIDENTIAL

Corrected items

Rev.No. Date

No. Page Description of change

1 2009-08-14 Issue PED14 M. Yamazaki

2 2009-10-13 P70

P125

P177

Change of P70 /P125

/P177

Person in

charge

PED25 H. Ishizuka

44306601TH Rev. 2

2 /

Page 3

Oki Data CONFIDENTIAL

Preface

This manual explains the maintenance methods of MB460/MB470/MB480.

This manual is prepared for the maintenance person. In regard to the handling methods of MB460/

MB470/MB480, please refer to the User’s Manual.

Note! • Contents of

• While all reasonable efforts have been made to make this document as accurate and helpful as possible, we make no warranty of any kind, expressed

or implied, as to the accuracy of the information contained herein. Oki Data

assumes no responsibility to the damages caused or claimed to have been

caused by the user as a result of repair, adjustment and/or change using this

manual.

• Parts of this product are delicate and can be damaged unless properly handled.

We strongly recommend the user to maintain the product at the hand of the

registered maintenance person of our company

• Before

this manual is subject to change without notice.

starting the maintenance work, please neutralize the static electricity.

44306601TH Rev. 2

3 /

Page 4

Oki Data CONFIDENTIAL

Table of contents

1. ConfiguRaTion ................................................................................................7

1.1 System Configuration ...........................................................................................................7

1.2 Structure of MFP ...................................................................................................................9

Offer of Options ...................................................................................................................10

1.3

Specifications ......................................................................................................................11

1.4

Interface Specification .........................................................................................................13

1.5

.1 USB Interface Specification ...................................................................................13

1.5

.1.1 Outline of USB Interface .........................................................................13

1.5

.1.2 USB Interface Connector and Cable ......................................................13

1.5

.1.3 UBS Interface Signal ..............................................................................13

1.5

.2 Network Interface Specification .............................................................................14

1.5

.2.1 Outline of Network Interface ...................................................................14

1.5

.2.2 Network Interface Connector and Cable ................................................14

1.5

.2.3 Network Interface Signal ........................................................................14

1.5

.3 Telephone Line Interface Specification (Only MB470/MB480) ............................15

1.5

.3.1 Outline of telephone Line Interface ........................................................15

1.5

.3.2 Telephone Line Interface Connector and Cable .....................................15

1.5

.3.3 Telephone Line Interface signal .............................................................15

1.5

.4 Parallel Interface Specifications ...........................................................................16

1.5

.4.1 Parallel Interface Overview ....................................................................16

1.5

.4.2 Parallel Interface Connector and Cable .................................................16

1.5

.4.3 Parallel Interface Level ..........................................................................16

1.5

2. oPeRaTional exPlanaTion ........................................................................17

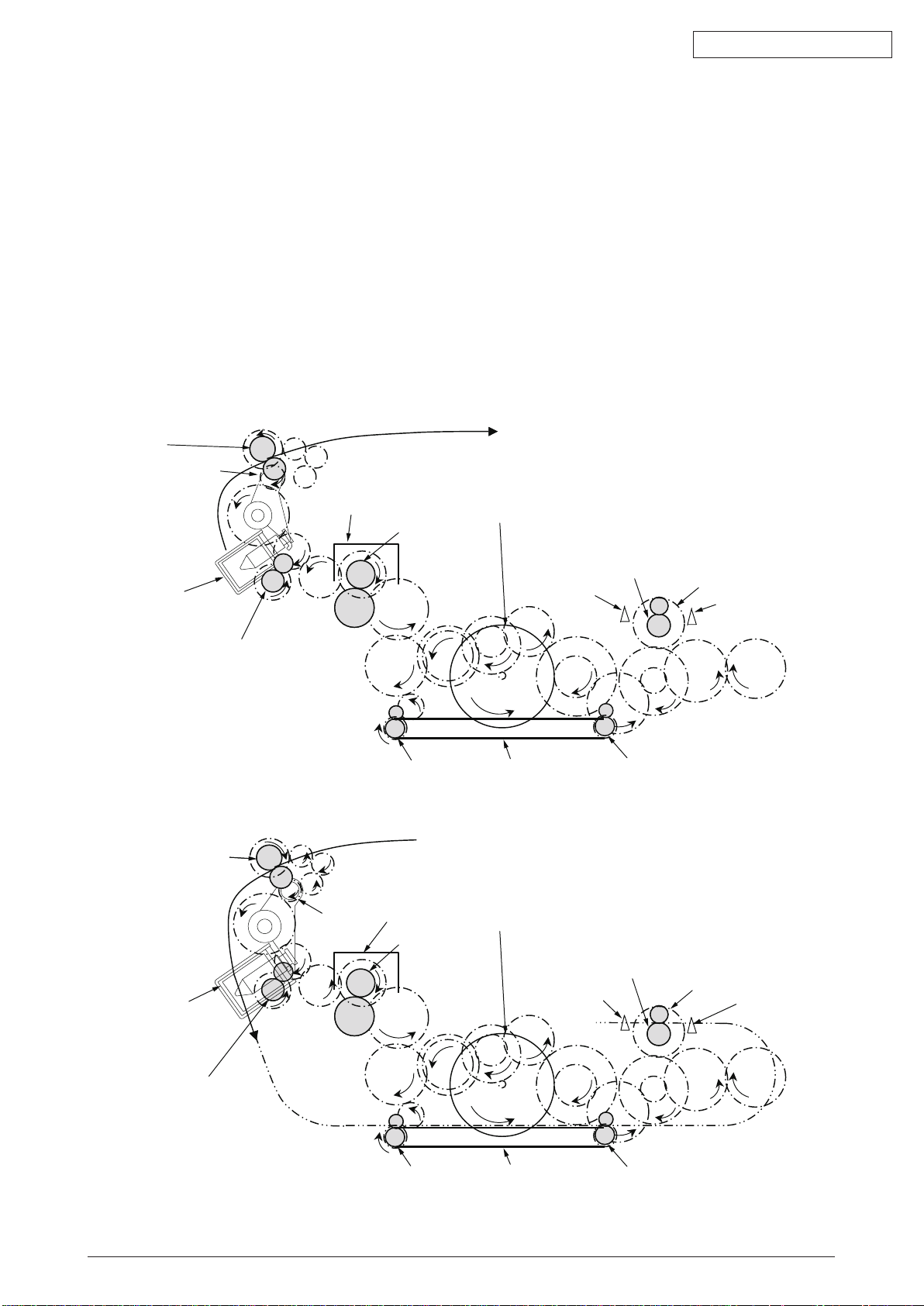

2.1 Electrophotographic process mechanism ..........................................................................17

2.2 Printing process ..................................................................................................................24

Toner entrance detection ....................................................................................................28

2.3

3. MfP insTallaTion ..........................................................................................30

3.1 Precautions and Prohibition ................................................................................................30

3.2 MFP Unpacking Procedure .................................................................................................32

MFP Installation Instructions ...............................................................................................33

3.3

Packed Units and Attachments ...........................................................................................34

3.4

Assembly Procedure ...........................................................................................................35

3.5

.1 MFP Main Body .....................................................................................................35

3.5

.2 Power Cable Connection .......................................................................................44

3.5

.3 Installation of Optional Components .....................................................................46

3.5

.4 Confirm the Recognition of Option ........................................................................50

3.5

Configuration Page Print .....................................................................................................51

3.6

Network Information Print ....................................................................................................54

3.7

Connection Procedures.......................................................................................................55

3.8

Checking of User Paper ......................................................................................................59

3.9

4. RePlaCeMenT of PaRTs ..............................................................................60

4.1 Precautions on the replacement of parts ............................................................................60

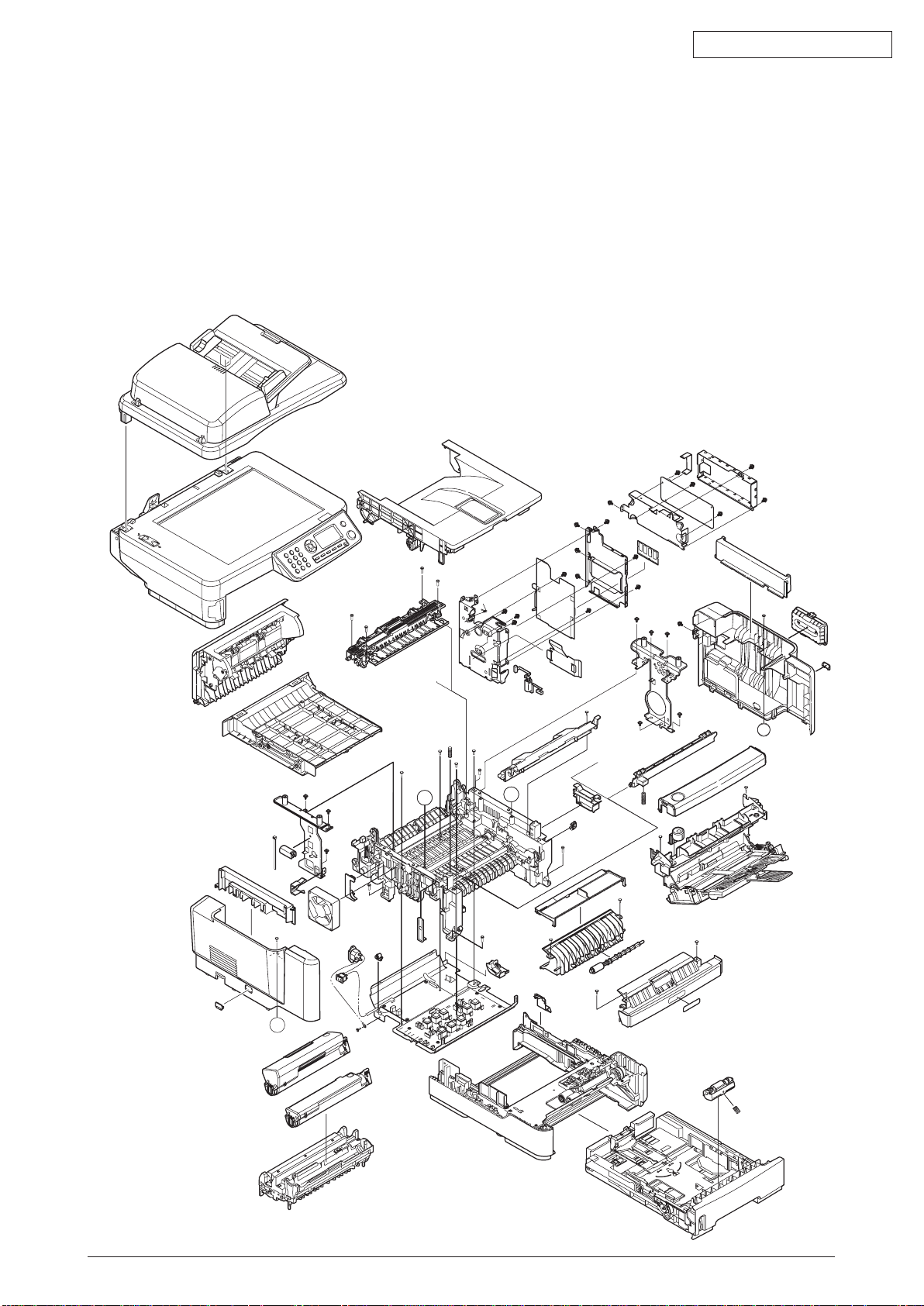

4.2 Parts layout .........................................................................................................................62

44306601TH Rev. 2

4 /

Page 5

Oki Data CONFIDENTIAL

4.3 Parts replacement method ..................................................................................................67

4.3.1 Detachment methods of the scanner and printer ..................................................68

.1.1 Cover-Side-R ..........................................................................................68

4.3

.1.2 Cover-Side-L ..........................................................................................69

4.3

.1.3 FAX Board (In case of MB470/480 ) ....................................................70

4.3

.1.4 Detachment methods of the scanner and printer ...................................71

4.3

.2 Scanner .................................................................................................................73

4.3

.2.1 Detachment of the paper tray .................................................................73

4.3

.2.2 Detachment of Pad .................................................................................74

4.3

.2.3 Removing ADF PCBA ............................................................................75

4.3

.2.4 Removing operation panel .....................................................................76

4.3

.2.5 Removing the MPCBA ............................................................................77

4.3

.2.6 Removing ADF Assembly ......................................................................79

4.3

.2.7 Removing the Window-ADF ...................................................................81

4.3

.3 Printer ....................................................................................................................82

4.3

.3.1 LED Head ...............................................................................................82

4.3

.3.2 Roller-Transfer ........................................................................................83

4.3

.3.3 CU Board ................................................................................................84

4.3

.3.4 OP Cover Assy .......................................................................................85

4.3

.3.5 MPT-Assy (In case of MB460, it is Manual-Assy) ..................................86

4.3

.3.6 Front-Guide-Assy ...................................................................................87

4.3

.3.7 Roller-Assy-Feed ....................................................................................88

4.3

.3.8 Guide-Paper-Duplex ...............................................................................89

4.3

.3.9 Stacker-Cover-Assy ................................................................................90

4.3

.3.10 Motor-DC-Main .......................................................................................91

4.3

.3.11 Fuser-Assy ..............................................................................................92

4.3

.3.12 Rear-Cover-Assy ....................................................................................94

4.3

.3.13 Frame-Assy-Lower .................................................................................95

4.3

.3.14 High voltage / Low voltage power board ................................................97

4.3

.3.15 Plate-Bracket-Motor................................................................................99

4.3

.3.16 Roller-Back up ......................................................................................100

4.3

.3.17 Roller-Resist .........................................................................................101

4.3

.3.18 Lever-In-Sensor ....................................................................................102

4.3

.3.19 Lever-Eject-Sensor/Photo-Interrupter ..................................................103

4.3

.3.20 Lever-End/Lever-Duplex/Lever-Cassette/Gear-Assy-Clatch ...............104

4.3

.3.21 Paper feeding roller

4.3

(Roller-Pick-Up, Roller-Feed-NOW, Roller-Assy-MPT) ........................106

5. MainTenanCe Menu ....................................................................................108

5.1 Maintenance Menu ............................................................................................................108

5.1.1 Boot Menu ...........................................................................................................108

.2 System Maintenance Menu ................................................................................. 111

5.1

.3 Fax Maintenance Menu .......................................................................................115

5.1

.4 Print Statistics Menu ............................................................................................ 117

5.1

Maintenance Utility ............................................................................................................119

5.2

Variou s printing of the MFP unit with controller ................................................................121

5.3

Switch pressing function when power supply is turned on ...............................................121

5.4

Settings after Parts Replacement .....................................................................................122

5.5

.1 Notes when exchanging the main circuit board and EEPROM setting after the

5.5

exchange of 86M circuit board .................................................................................122

44306601TH Rev. 2

5 /

Page 6

Oki Data CONFIDENTIAL

6. PeRioDiC MainTenanCe..............................................................................126

6.1 Periodic Replacement Parts ..............................................................................................126

6.2 Cleaning ............................................................................................................................126

Cleaning of LED lens array ...............................................................................................126

6.3

Cleaning the pick-up roller ...............................................................................................128

6.4

Cleaning the inside of the MFP .........................................................................................129

6.5

Cleaning the papaer path in the ADF ...............................................................................130

6.6

Cleaning the underside of the ADF ...................................................................................132

6.7

Cleaning the Flatbed glass................................................................................................132

6.8

7. TRouBlesHooTing PRoCeDuRes ............................................................133

7.1 Precautions prior to repair .................................................................................................133

7.2 Items to be checked prior to taking action on abnormal images .......................................133

Precautions when taking action on abnormal images ......................................................133

7.3

Preparations for troubleshooting .......................................................................................133

7.4

Troubleshooting method ....................................................................................................133

7.5

.1 LCD Message List ...............................................................................................134

7.5

.2 LCD Message Troubleshooting ...........................................................................183

7.5

.3 Print Troubleshooting ...........................................................................................199

7.5

.4 Response after Flash compulsive initialization ....................................................207

7.5

.5 Network Troubleshooting .....................................................................................208

7.5

.5.1 Connection error occurs with the Web browser ...................................209

7.5

.5.2 Print operation is not possible ..............................................................215

7.5

.5.3 Cannot create Certificate ......................................................................216

7.5

.5.4 Installation of Certificate is not possible ...............................................216

7.5

.5.5 Other questionnaires ............................................................................219

7.5

.5.6 Restrictions when using Internet Explore 7 ..........................................222

7.5

.6 Fax Error Code List ..............................................................................................223

7.5

Fuse Checking ..................................................................................................................225

7.6

8. ConneCTion DiagRaMs ..............................................................................226

8.1 Resistance value ...............................................................................................................226

8.2 Component layout .............................................................................................................228

aPPenDix C MainTenanCe Manual foR seConD TRay uniT ..................234

1 Overview ...........................................................................................................................234

1.1 Function ......................................................................................................................234

Exterior and Parts Name ............................................................................................234

1.2

2. D

3. P

4. C

escription for Operation of Second Tray unit ..................................................................235

art Replacement .............................................................................................................236

Precautions on replacing parts ...................................................................................236

3.1

Arrangement of Parts ..................................................................................................237

3.2

How to Replace Parts .................................................................................................238

3.3

.1 Roller-Pick-Up, Roller-Feed-Now .........................................................239

3.3

.2 Guard-Connector, Connector (9715S-08Z02-G4C) .............................240

3.3

.3 Roller-Feed ...........................................................................................241

3.3

.4 Board-OT7 ............................................................................................242

3.3

.5 CONN Cord-AMP8P-AMP8P ...............................................................243

3.3

.6 Gear-Assy-Clatch .................................................................................244

3.3

.7 Frame-Assy-Retard, Spring-Retard ......................................................246

3.3

leaning of Paper Feed Roller and Separation Roller ......................................................247

44306601TH Rev. 2

6 /

Page 7

1. ConfiguRaTion

DM

PE

RCLT

THERM

HCLT

MCLT

SON

HVIF

EXRCO

Fax IF

PW

HEAD

PNLUSB

LAN

USB

CENT

DC Motor

Assy.

JST2

2

JST2

2

JST2

2

clutch

clutch

AMP8

8

USB IF

Centronics IF

JST24

24

JST24

Panel PCB

LCD

FB

Moter

CCD UNIT

20

JST20

JST20

Scanner Unit

JST9

9

28 JST28

FAN

2nd

Tray

6

JST7

Board-TT1

cover open switch

JST10

3

Cover open sensor

EXIT sensor

6

3

2

JST2

Temperature sensor

IP100

ALF

UPD7

202

AMP6

JST28

CN1

CN2

CN3

High Volt PCB

3

3

5

2

FUSER UNIT

2

2

AC Inlet

AC SW

2

2

86M

SPILYTAS 2

8051

I2C

16C550

UART

LC98500B

PU LSI

DDR

I/F

10

JST10

Nor

Nand

DIMM

I2C

ROM

64

Kbit

74LVC

161284

3

3

Paper end

duplex

JST9

SCANNER

PCB

L629

SOLENOID

ພ

ROM IF

PCI

ROM IF

PCI

2NDTRAY

LED HEAD UNIT

TXD/

RXD

DP/

DM

DP/DM

HEAD IF

HEAD Clock

RS232C

DP/

DM

RS232C

PUIF

DDR-

SDRAM

64

MB

I2C

DDR IF

IEEE1284

IEEE1284

Cable

FFC

Sensor

BUS

5V

24V

5V

24V

5V

24V

JST2

2

clutch

AFD

Moter

AFD PCB

LAN IF

Power Supply PCB

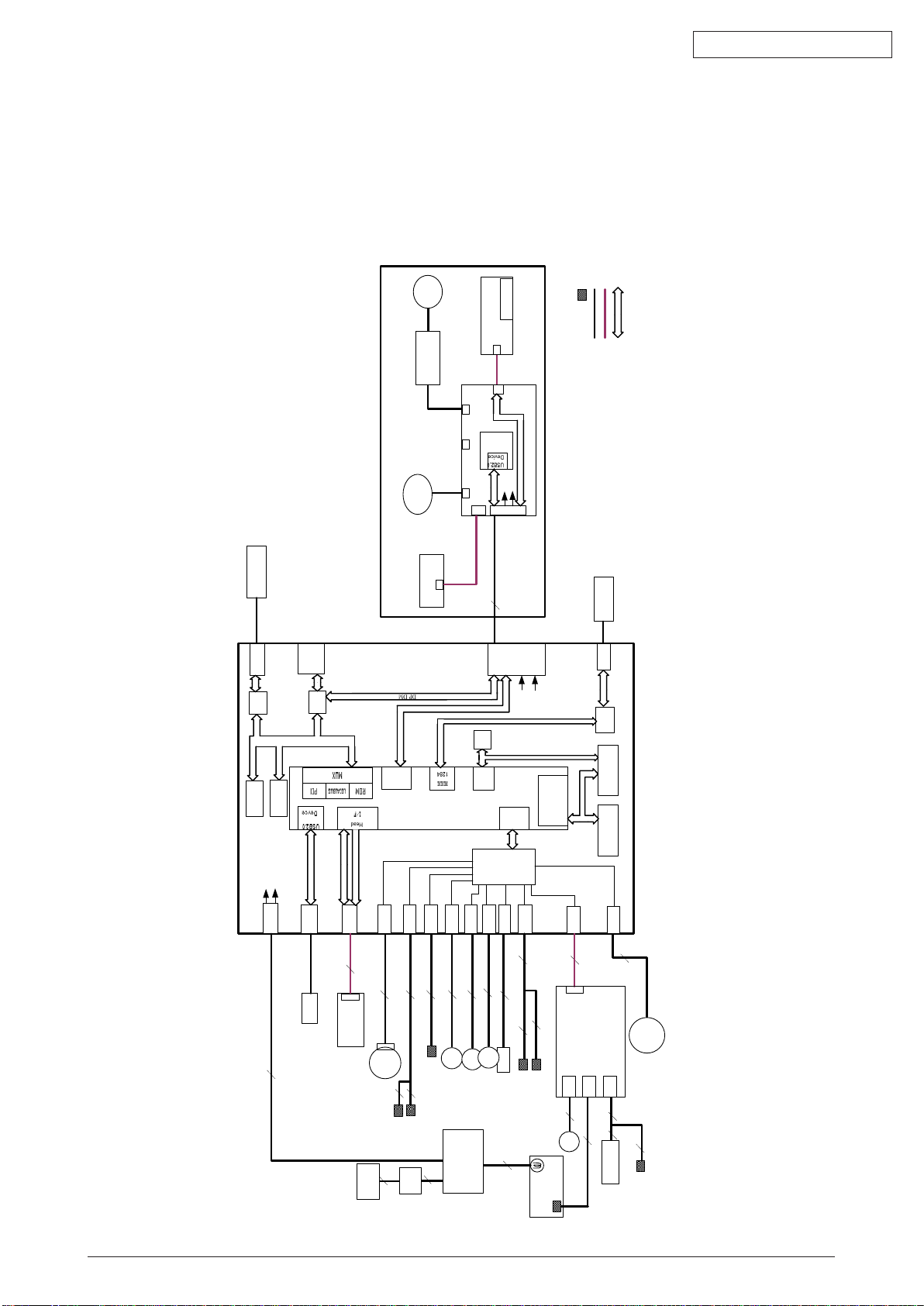

1.1 System Configuration

MB460

The system configuration of this product is shown in Figure 1-1-1.

Oki Data CONFIDENTIAL

44306601TH Rev. 2

Fig 1.1.1

7 /

Page 8

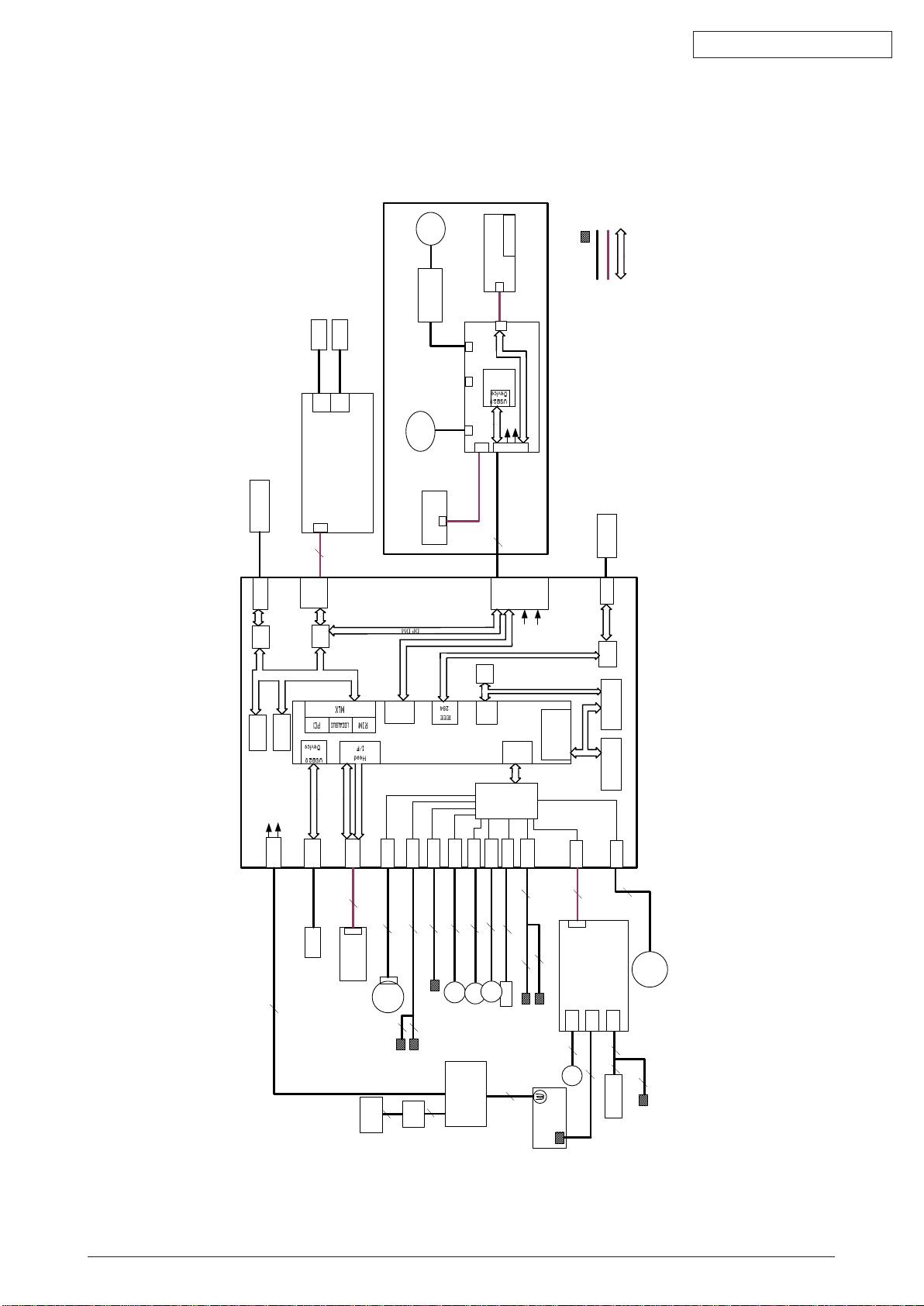

MB470/MB480

DM

PE

RCLT

THERM

HCLT

MCLT

SON

HVIF

EXRCO

Fax IF

PW

HEAD

PNLUSB

LAN

USB

CENT

DC Motor

Assy.

JST2

2

JST2

2

JST2

2

clutch

clutch

AMP8

8

USB IF

Centronics IF

JST24

24

JST24

FAX PCB

Panel PCB

LCD

FB

Moter

CCD UNIT

20

JST20

JST20

Scanner Unit

JST9

9

28 JST28

FAN

2nd

Tray

6

JST7

Board-TT1

cover open switch

JST12

JST10

3

Cover open sensor

EXIT sensor

6

3

2

JST2

Temperature sensor

IP100

ALF

UPD7

202

AMP6

JST28

CN1

CN2

CN3

High Volt PCB

3

3

5

2

FUSER UNIT

2

2

AC Inlet

AC SW

2

2

86M

SPILYTAS 2

8051

I2C

16C550

UART

LC98500B

PU LSI

DDR

I/F

10

JST10

Nor

Nand

JST12

12

DIMM

Line

Tel

I2C

ROM

64

Kbit

74LVC

161284

3

3

Paper end

duplex

JST9

SCANNER

PCB

L629

SOLENOID

ພ

ROM IF

PCI

ROM IF

PCI

2NDTRAY

LED HEAD UNIT

TXD/

RXD

DP/

DM

DP/DM

HEAD IF

HEAD Clock

RS232C

DP/

DM

RS232C

PUIF

DDR-

SDRAM

64

MB

I2C

DDR IF

IEEE1284

IEEE1284

Cable

FFC

Sensor

BUS

5V

24V

5V

24V

5V

24V

JST2

2

clutch

AFD

Moter

AFD PCB

LAN IF

Power Supply PCB

Line

Tel

The system configuration of this product is shown in Figure 1-1-2.

Oki Data CONFIDENTIAL

44306601TH Rev. 2

Fig 1.1.2

8 /

Page 9

1.2 Structure of MFP

A

A

A’

A’

The insides of MB460/MB470/MB480 printers are composed of the following parts.

• Scanner part

• Electronic photography process part

• Paper path

• Control part (CU part/PU part)

• Power supply parts (high voltage part/low voltage part)

Figure 1-2 shows the composition of the MFP.

Oki Data CONFIDENTIAL

Fig 1.2.1

44306601TH Rev. 2

9 /

Page 10

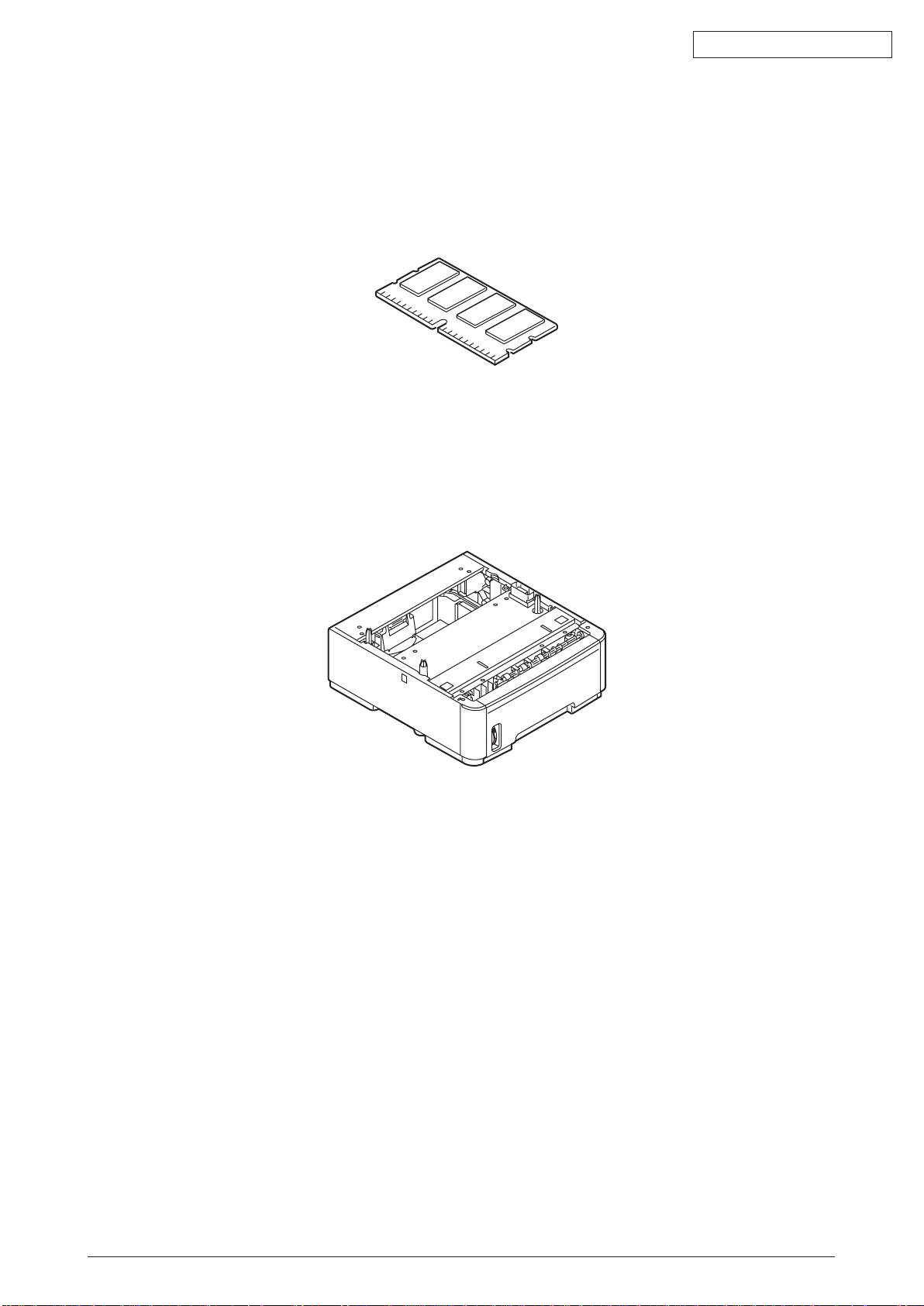

1.3 Offer of Options

This product can be installed with the following option.

(1) Additional memory board 64MB/256MB

Fig 1.3.1

Oki Data CONFIDENTIAL

(2) Option Tray

Fig 1.3.2

44306601TH Rev. 2

10 /

Page 11

Oki Data CONFIDENTIAL

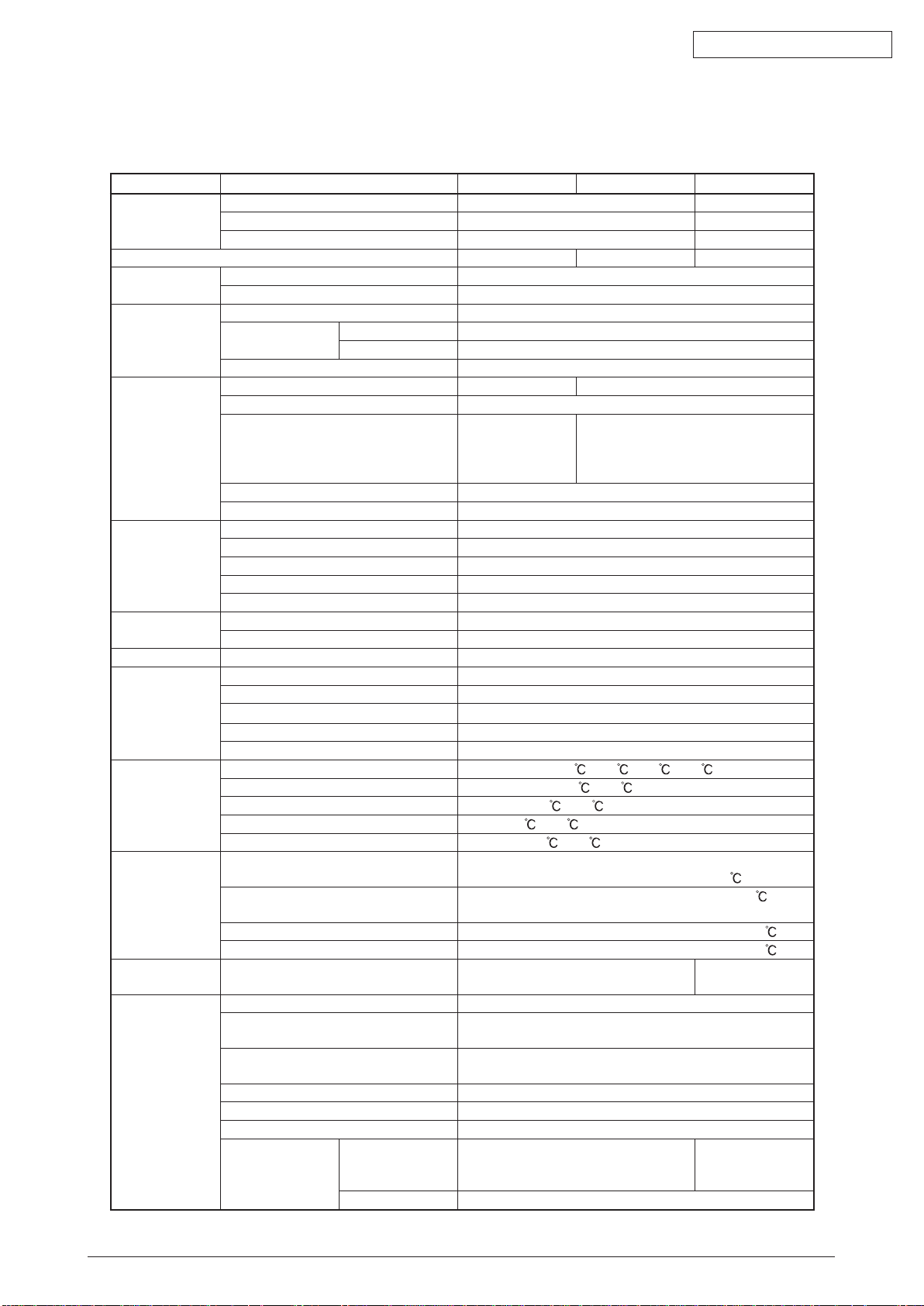

1.4 Specifications

Table 1.4.1

Category Item MB460 MB470 MB480

Exterior

Dimensions

Weight 17Kg 18.5Kg 19Kg

printer Engine Engine speed (A4/Letter) 28/30 PPM

Fast print time

(A4)

Resolution LED Head 600dpi 1200dpi

CPU Core PowerPC405

RAM Standard 64MB

ROM Program NOR-Flash 2MB + NAND-Flash 64MB

Power

Consumption

Operation

Environment

(temperature)

Operation

Environment

(humidity)

Duty Cycle Maximum 50,000 pages per month 70,000 pages per

Life Printer 180,000 pages or 5 years

Width 447mm 447mm

Depth 432mm 432mm

Height 500mm 529mm

Auto Duplex Standard

First Print Out Time Less than 5.5 seconds

Warm-up Time from Power On 60 seconds

from Power Save 25 seconds

Low noise mode Unavailable

Maximum input resolution F/B:1200 x 600dpi / ADF:1200 x 300dpi

Output resolution 600x600dpi

1200x600dpi

2400x600dpi(half

speed)

step 4 step 600 x 600dpi

Economic mode toner saving by lowering light

I-Cache 16KB

D-Cache 16KB

Clock 297MHz

Bus width 32bit

Option 64MB/256MB available (SO-DIMMx1)

Max. 800W

Normal Operation 500W

Stand-by 100W

Power Saver Mode 10W or less

Energy Star Application Yes

In operation 10

At stand-by 0 - 43 , power off

In storage (1 year max.) -10

At transport (1 month max.) -29

At transport (1 month max.) -29

In operation 20%-80%, 50%-70%

At stand-by 10%-90%, Max. wet bulb temperature : 26.8 with

In storage 10%-90%, Max. wet bulb temperature : 35

At transport 10%-90%, Max. wet bulb temperature : 40

Scanner Flatbed:50,000pages or 5years / ADF:240,000 pages

Duty cycle (M=L/12, A=L/12/5) 35,000 pages per month max.

MTBF (2.3% duty) 6,000 hours

MPBF 24,000 pages

MTTR 30 minutes

Toner

life@ISO19752

consumption 3,500

Starter 1500

- 50 , with drum and without toner

Max. wet bulb temperature : 25

5,000 pages per month average

- 32 , 17 - 27

- 43 , with drum and toner

- 50 , with drum and toner

7,000

1200x1200dpi

600x600dpi

power off

month

or 5years

3,500

7,000

12,000

44306601TH Rev. 2

11 /

Page 12

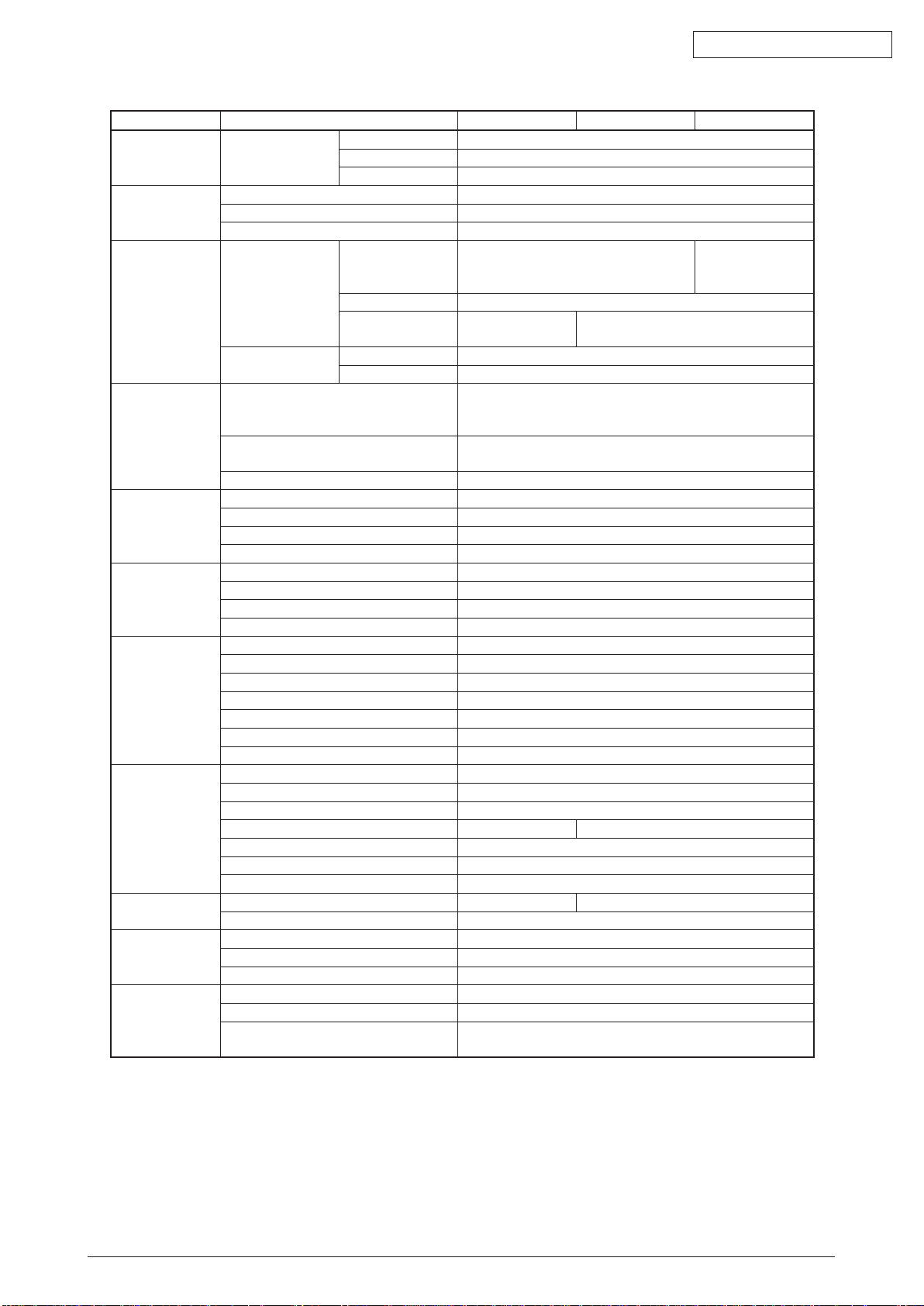

Oki Data CONFIDENTIAL

Category Item MB460 MB470 MB480

Life Image drum life

(w/o power save)

Operation noise Operating 56dB

Standby 32dB

Power save mode Back ground level

Paper handling Paper Input

Capacity

Paper Output

Capacity

Paper Size Legal/universal or A4 cassette/

Universal cassette

MP Tray 13,13.5,14Legal,Letter,Executive,A4,A5,B5,A6,C5,C6,DL

Duplex Letter,A4,up to Legal14"

Minimum paper

size

Paper Weight 1st Tray 16~32 lb. (60.16~120.32gsm)

Status switch/

Sensor

Communication

Interface

Emulation Standard PCL6/5e , SIDM PCL6/5e , SIDM , PS3

Option RAM RAM DIMM 1slot (64MB or 256MB)

Others USB-IF logo Available

1st Tray 3.94"x8.3" (210mm)

2nd Tray 5.8"x8.3"(210mm,A5)

MP Tray 3.4"x5.5"(140mm)

Duplex Auto Duplex Letter,A4;Manual Duplex 3.4"x5.5"

2nd Tray 16~32 lb. (60.16~120.32gsm)

MP Tray 16~43 lb. (60~160gsm) (Enve. : N/A)

Duplex Print 16~28 lb. (60.16~105.28gsm)

Paper tray empty Available

Paper low N/A

Toner Empty Available

Cover open Available

Fuser temp Available

Paper size N/A

Stacker full N/A

USB Host IF N/A

USB Device IF USB connector Type B (2.0 Hi-Speed)

Ethernet I/F RJ-45 (10/100 Base TX)

Tel/Line I/F N/A RJ-11x2 (PSTN/PBX , Ext-TEL)

Parallel I/F CEN36 (IEEE1284)

Wireless LAN N/A

Card Slots N/A

Option N/A

2nd tray 530 sheet tray

Emulation N/A

Windows logo Available

Operation by UPS Operation by UPS (outage free power supply) is not

Continuous 25,000 pages (at simplex)

3 pages per job 20,000 pages (at simplex)

1 page per job 12,000 pages (at simplex)

1st Tray Legal/universal cassette

250 sheets

2nd Tray (optional) Legal/universal cassette 530 sheets

MP Tray Single sheet

manual feed slot

Face up N/A

Face down 150 sheets

13,13.5,14Legal,Letter,Executive,A4,A5,B5

statement(first cassette only)

,Com-9,Com-10,Monarch,statement,Free

guaranteed. (Do not use UPS)

50 sheets Multi Purpose Tray

Free

Legal/universal

cassette

530 sheets

44306601TH Rev. 2

12 /

Page 13

2

3 4

1

1.5 Interface Specification

1.5.1 USB Interface Specification

1.5.1.1 Outline of USB Interface

(1) Basic Specification

USB

(2) Transmission Mode

Hi speed (480Mbps±0.05% max.)

(3) Power Control

Self power device

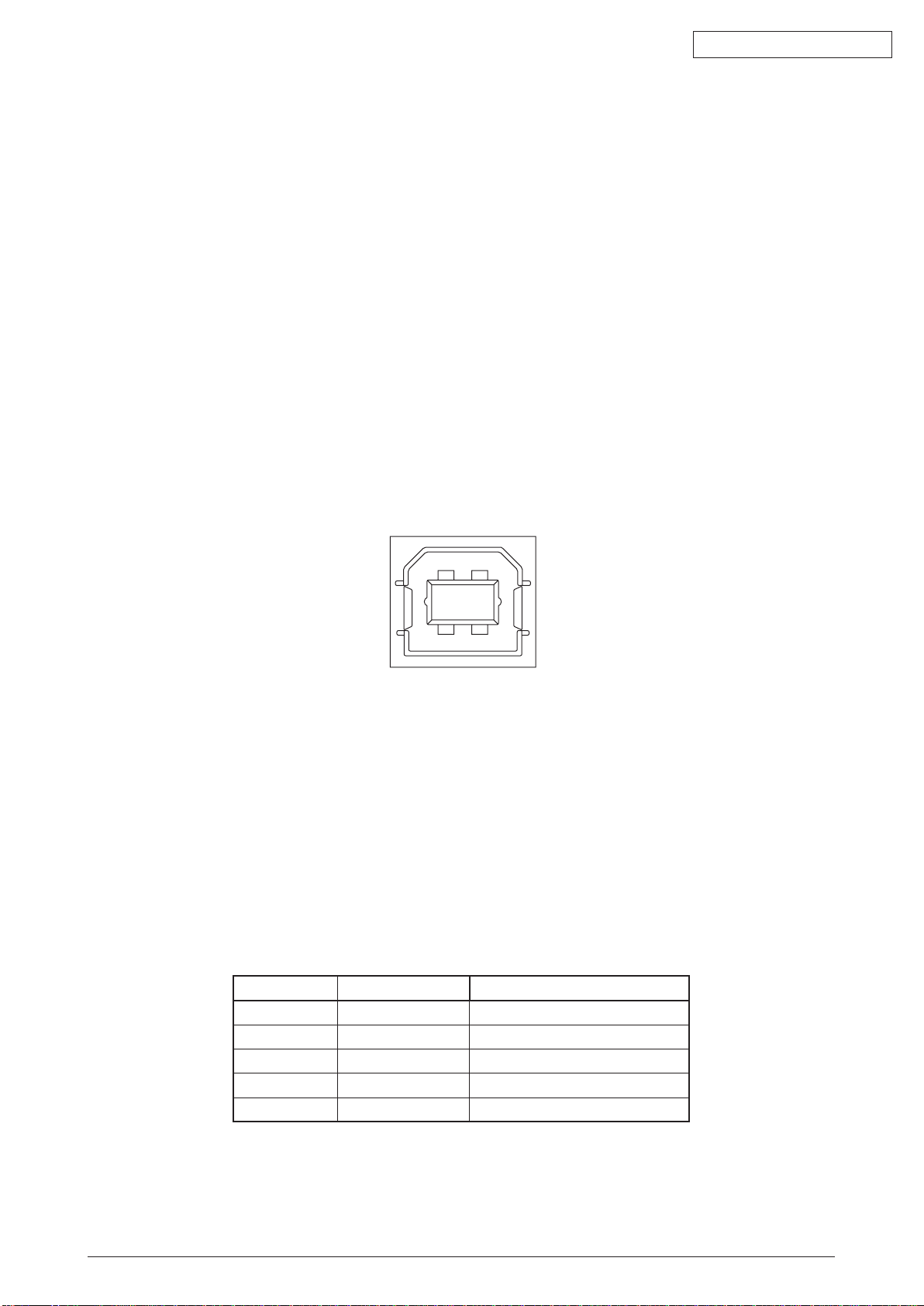

1.5.1.2 USB Interface Connector and Cable

(1) Connector

• Printer side: B receptacle

Upstream port

Equivalent of UBR24-4K5C00 (made by ACON)

Oki Data CONFIDENTIAL

Connector pin arrangement

Fig 1.5.1

• Cab

le side: B plug (off)

(2) Cable

Cable length: Specification Cable of USB2.0 spec. of less than 5m.(less than 2m is

recommended)

(

Shielded cable is used here.)

1.5.1.3 UBS Interface Signal

Table 1.5.1

Name of Single Function

1 Vbus Power Supply (+5V)(red)

2 D - Data transmission (white)

3 D + Data transmission (green)

4 GND Single ground (black)

Shell Shield

44306601TH Rev. 2

13 /

Page 14

1 8

1.5.2 Network Interface Specification

1.5.2.1 Outline of Network Interface

Table 1.5.2 Basic Specification of Network Interface

Protocol Family Network Protocol Application

TCP/IP ARP,IP,ICMP,IPv6,TCP,UDP LPR,Port9100,FTP,HTTP,HTTPS,IPP,

SNMPv1/v3,TELNET,DHCP/BOOTP,DNS,

DDNS,WINS,UPnP,Bonjour,SNTP,SMTP,

POP3,Windows Rally(WSD Print,LLTD),

ODNSP,SSL/TLS,LDAP,Kerberos

NBT/NetBEUI SMB,NetBIOS,NetBIOS over TCP

EtherTalk ELAP,AARP,DDP,AEP,NBP,ZIP,R

TMP,ATP,PAP

IEEE802.1X EAP-TLS,PEAP

Oki Data CONFIDENTIAL

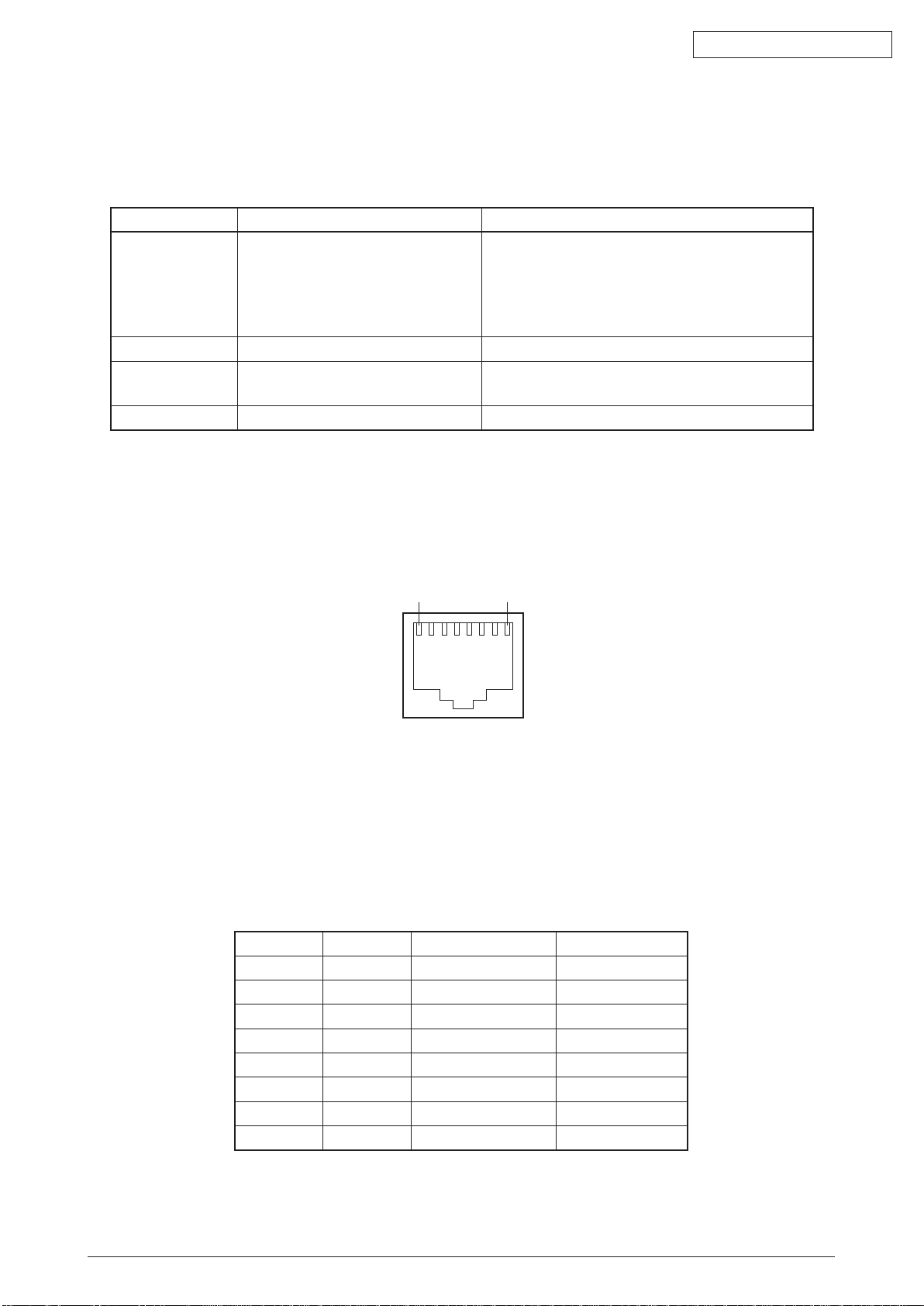

1.5.2.2 Network Interface Connector and Cable

(1) Connector

100 BASE-TX/10 BASE-T (automatic switch, no simultaneous use)

Connector pin arrangement

Fig 1.5.2

(2)

Cable

Unshielded twist pair cable with RJ-45 connector (Category 5 is recommended.)

1.5.2.3 Network Interface Signal

Table 1.5.3

Pin No. Singles Single Direction Functions

1 TXD+ FROM PRINTER Send Data +

2 TXD- FROM PRINTER Send Data 3 RXD+ TO PRINTER Received Data +

4 - - Unassigned

5 - - Unassigned

6 RXD- TO PRINTER Received Data 7 - - Unassigned

8 - - Unassigned

44306601TH Rev. 2

14 /

Page 15

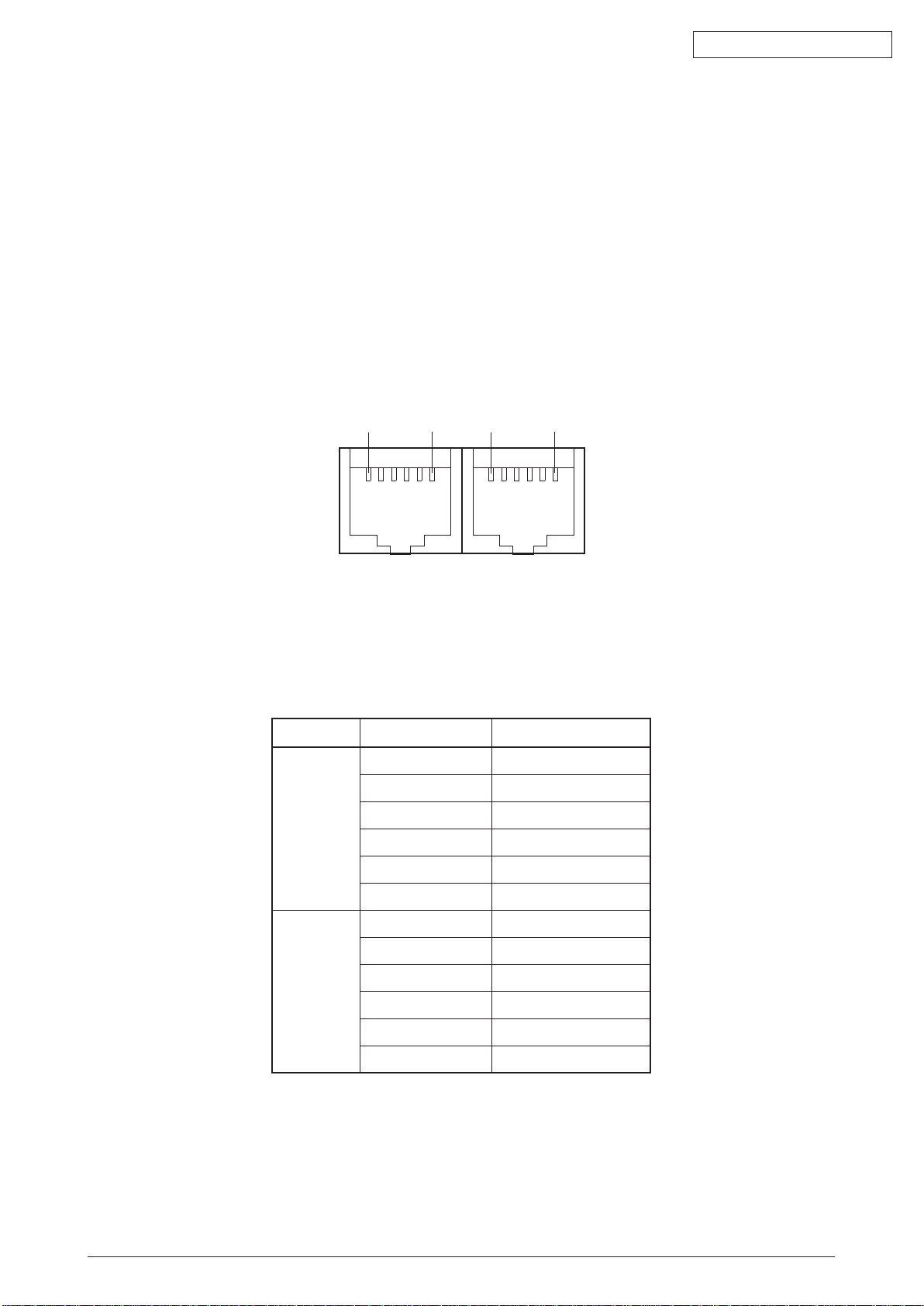

1.5.3 Telephone Line Interface Specification (Only MB470/MB480)

A1 A6

B1 B6

TEL

LINE

1.5.3.1 Outline of telephone Line Interface

The machine will reliably communicate with distant stations over voice-level telephone line.

1.5.3.2 Telephone Line Interface Connector and Cable

Printer side : RJ-11

Cable side : TEL Cable (Cable with plug)

Connector contact arrengement

Oki Data CONFIDENTIAL

1.5.3.3 Telephone Line Interface signal

Contact No. Functions

TEL A1 Unspecified

A2 Unspecified

A3 TCP

A4 TCP

A5 Unspecified

A6 Unspecified

LINE B1 Unspecified

B2 Unspecified

B3 TCP

B4 TCP

B5 Unspecified

Fig 1.5.3

Tabel 1.5.4

TCP : Terminal Connection Point

44306601TH Rev. 2

B6 Unspecified

15 /

Page 16

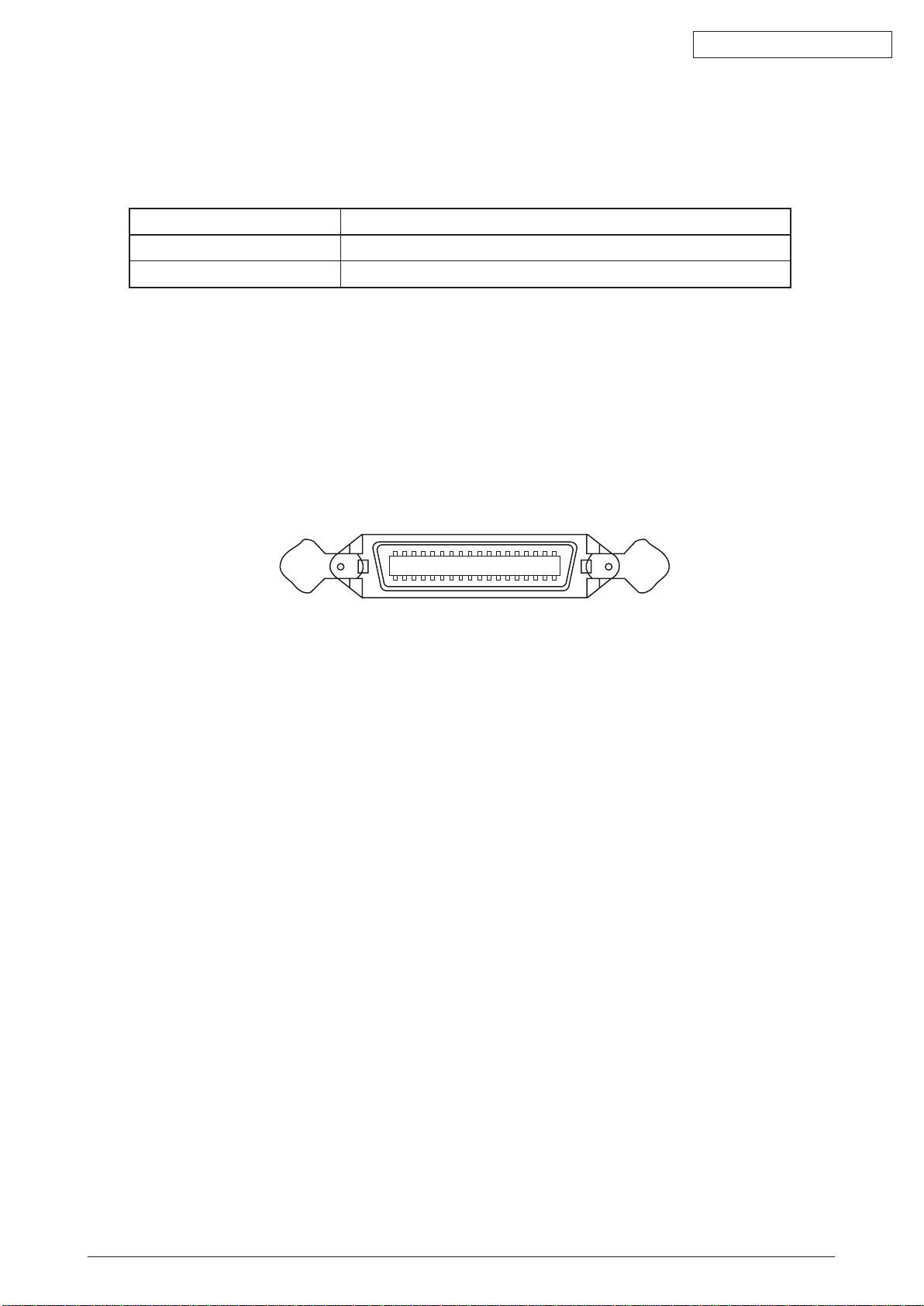

1.5.4 Parallel Interface Specifications

118

1936

1.5.4.1 Parallel Interface Overview

Table 1.5.5

Item Details

Corresponding mode Comatible mode, nibble mode, ECP mode

Data bit length Compatible: 8, Nibble: 4, ECP: 9 bit

1.5.4.2 Parallel Interface Connector and Cable

(1) Connector

Printer: 36pConnector (Female)

57LE-40360-12 (D56) (DDK Ltd.) equivalent product

Cable: 36pConnector (Male)

57FE-30360-20N (D8) (DDK Ltd.) equivalent product

Oki Data CONFIDENTIAL

Pin arrangement from interface cable side

Fig 1.5.4

Cable

(2)

Use a cable shorter than 1.8m.

(Use a cable with a shielded twisted-pair wire for to prevent noise interference.)

1.5.4.3 Parallel Interface Level

Low Level : 0.0V to +0.8V

High Level : +2.4V to +5.0V

44306601TH Rev. 2

16 /

Page 17

2. oPeRaTional exPlanaTion

2.1 Electrophotographic process mechanism

(1) Electrophotographic process

The following describes the overview of electrophotographic process.

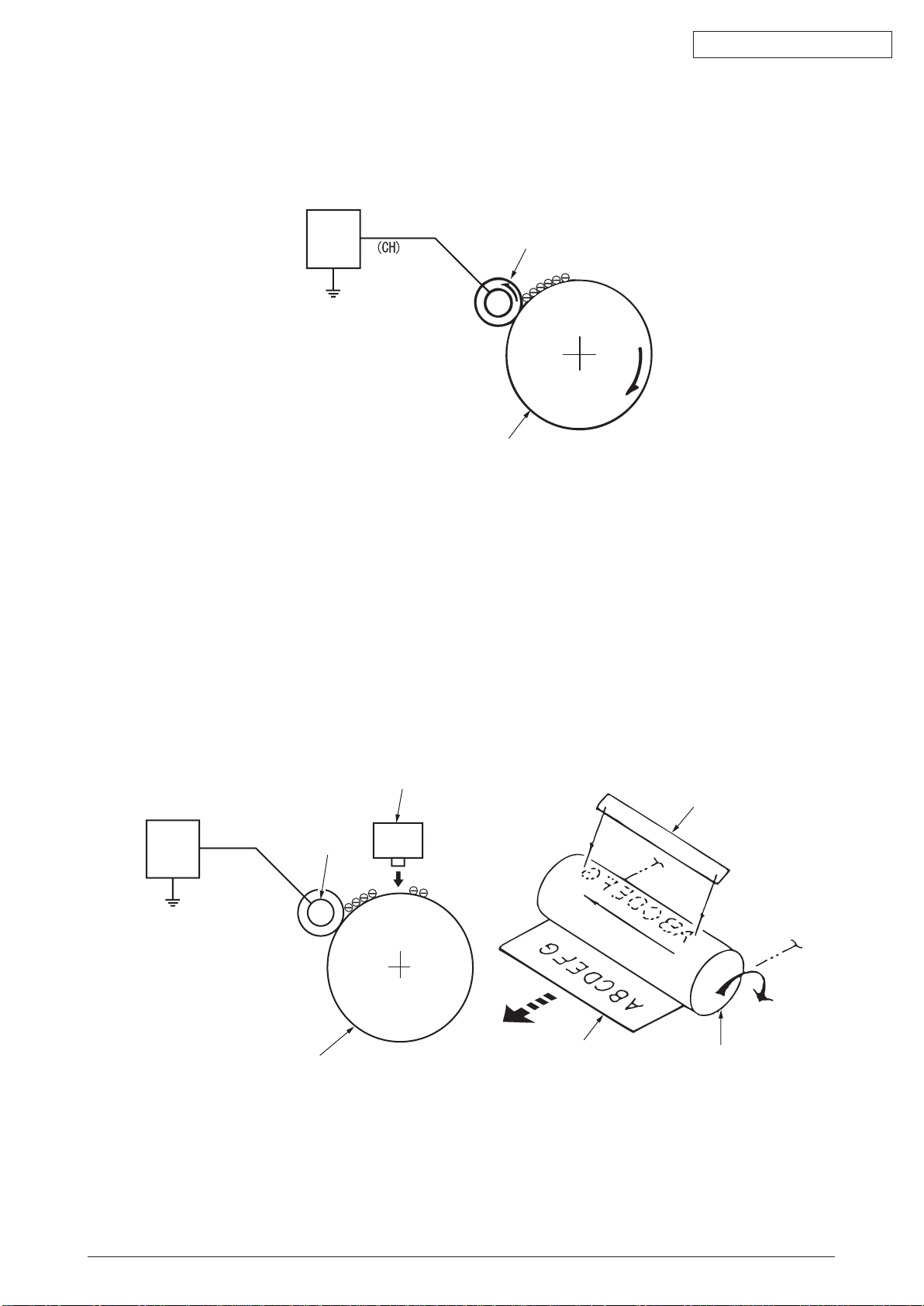

1. Charging

Equally charge the surface of image drum by implying negative voltage to the

charged roller due to negative charge.

2. Exposure

The light from LED Head is exposed on the negative-charged surface of image drum.

The surface electrical potential of the exposed part of image drum surface becomes

lower. Then forms electrostatic latent image.

3. Development

Negative-charged toner is attracted to the electrostatic latent image due to

electrostatic while touching the image drum. Then forms viewable image.

4. Transfer

Overlap paper on the surface of OPC drum, from the backside of paper transfer

toner image to the paper by applying electrical charge by transfer roller.

5. Drum cleaning

The remaining toner on the image drum that is not transferred is made to be

equable by cleaning roller. And is temporarily attracted to the cleaning roller due to

electrostatic.

6. Fusing

The toner image that is transferred to paper is fused on paper by heat and pressure.

Oki Data CONFIDENTIAL

44306601TH Rev. 2

17 /

Page 18

Oki Data CONFIDENTIAL

Image drum

Charged roller

Power

Charged roller

LED head

LED head

Image drum

Image drum

Paper

Power

1. Charging

Charge the image drum surface by implying voltage to the charged roller that contacts the image

drum surface.

Fig 2.1.1

2. Exposure

The light emitting from the LED Head will be exposed to the negative charged image drum. When

the surface electric potential of exposed part of the image drum goes to decrease, the electrostatic

latent image complying with image signal is formed.

Image drum is coated by basic layer (UL), charge generating layer (CGL), charge transferring layer

(CTL) on the basic material aluminum. The thickness of the organic light sensor (OPC) that is

consisted by CTL and CGL is approximate 20µm.

44306601TH Rev. 2

Fig 2.1.2

18 /

Page 19

Oki Data CONFIDENTIAL

Image drum

Charged roller

Image developing plate

Toner supply roller

Image

developing

roller

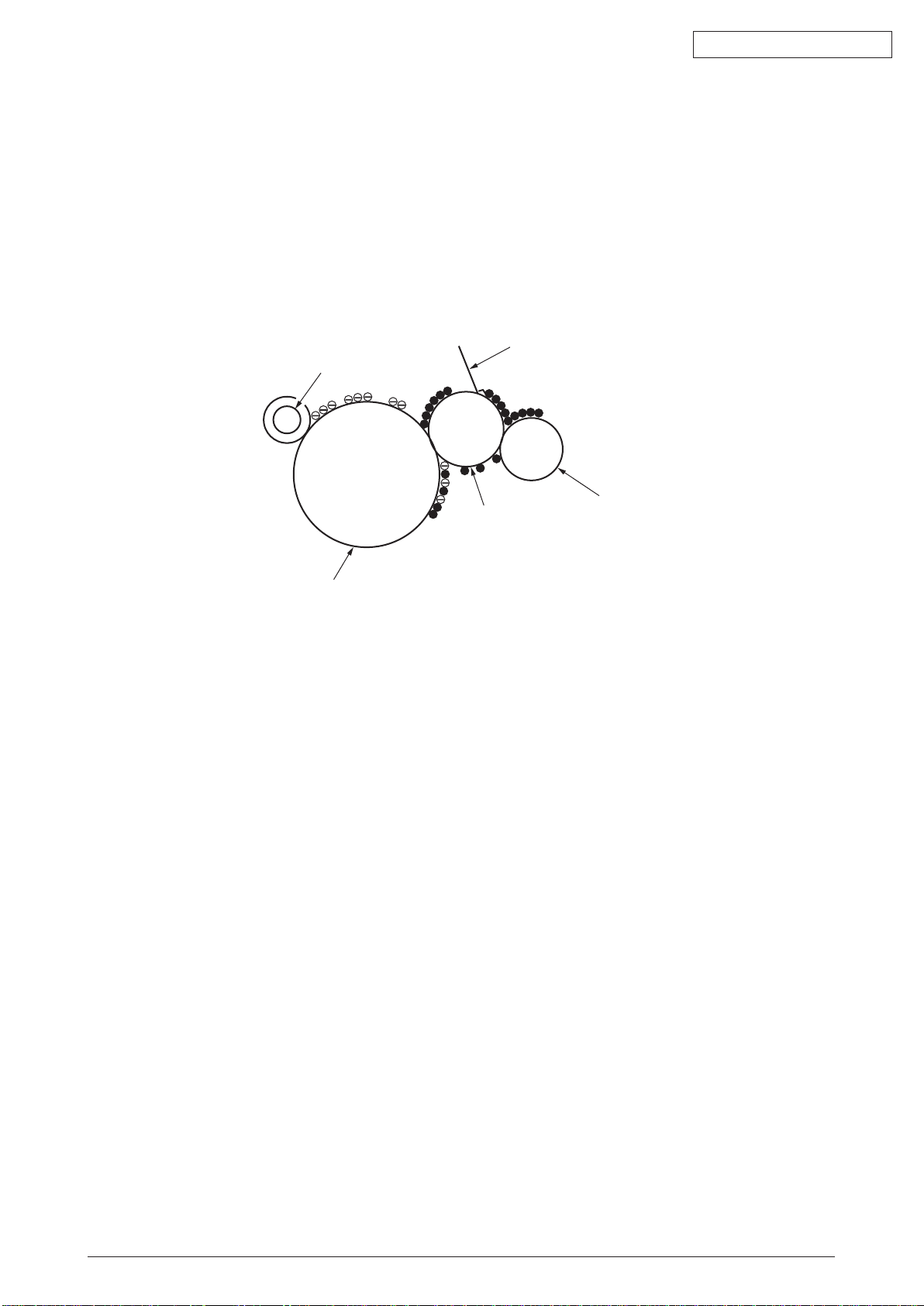

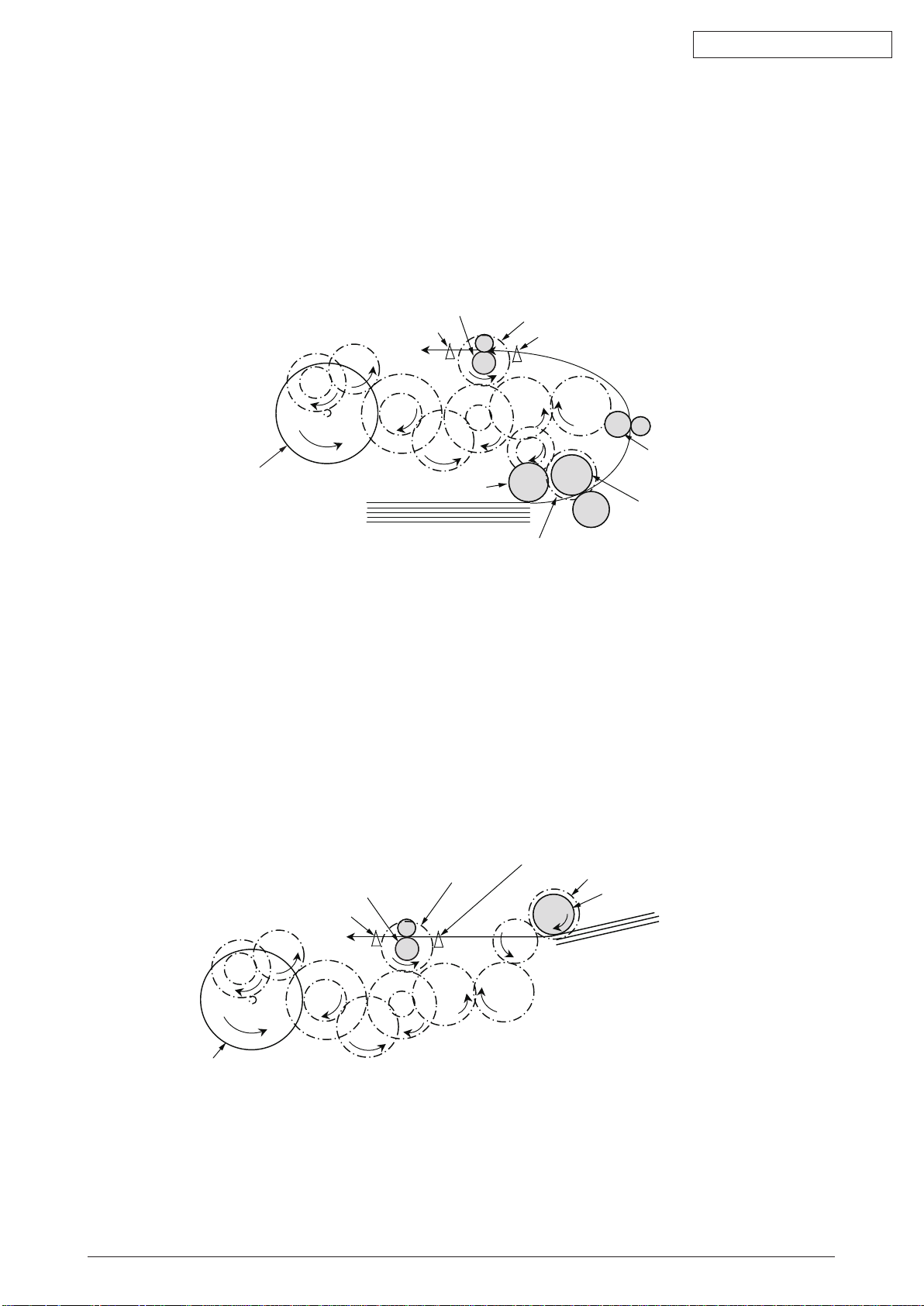

3. Image development

Toner is attracted to the electrostatic latent image on the image drum surface, then the electrostatic

latent image changes to toner image.

1 As

the roller on the supply spot of toner rotates while scrubbing the image-developing

roller, fiction electricity occurs between the image developing roller and toner; toner is

attracted to the image-developing roller.

e toner that has been attracted to the image-developing roller is dropped down to

2. Th

the developing plate to make a thin toner film on the image developing roller side.

Fig 2.1.3

3 The toner is attracted by the exposed part (Low electrical potential part) of the image

drum when the image drum contact the image developing roller, so as to see the

electrostatic latent image.

44306601TH Rev. 2

19 /

Page 20

Oki Data CONFIDENTIAL

Image drum

Basic material

Toner feeding roller

While the cover is closed it will be

connected and bias will be applied.

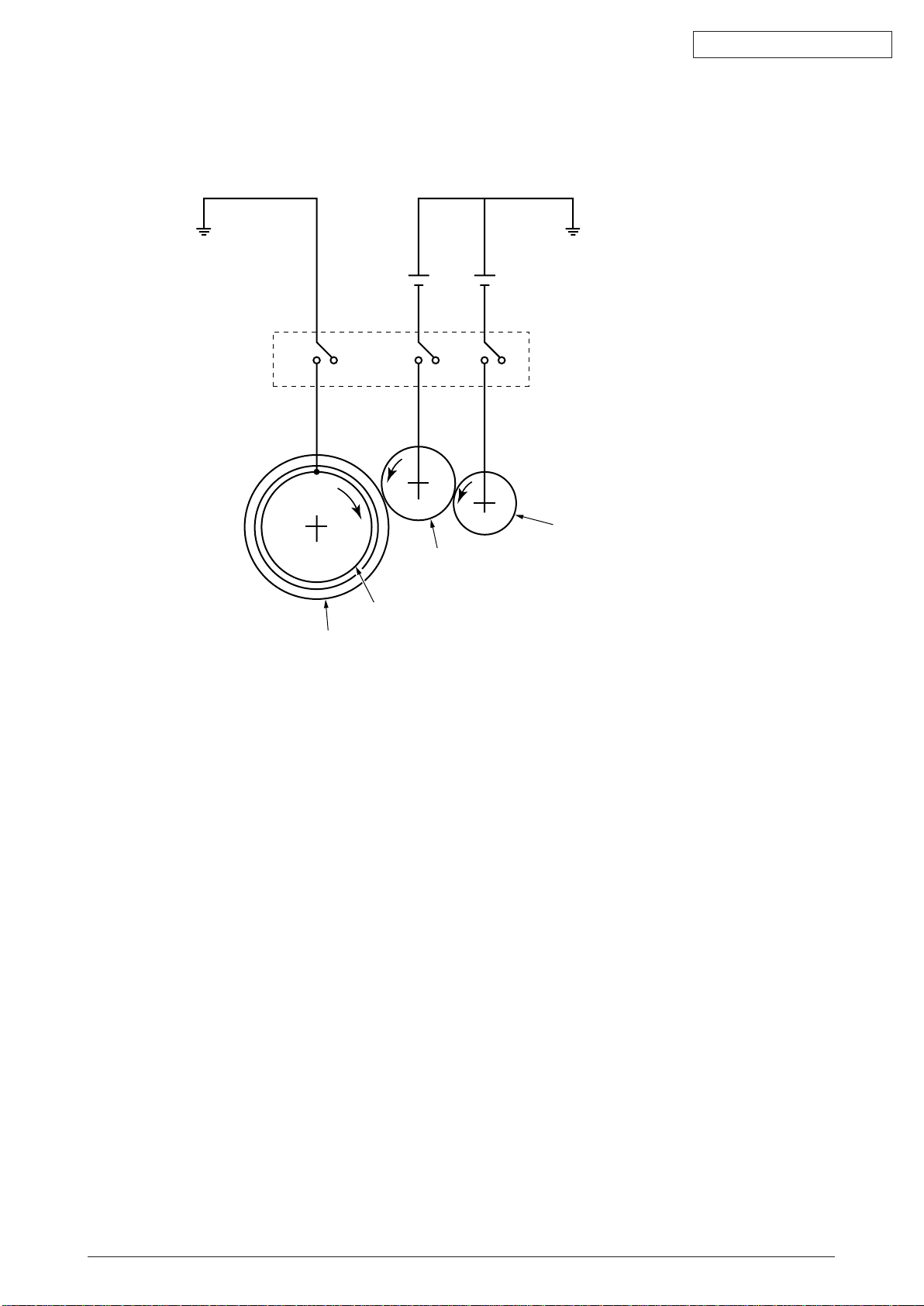

Image developing roller

Note! The necessary bypass voltage in image processing is impressed on the toner feeding

roller and image developing roller as show below.

Fig 2.1.4

44306601TH Rev. 2

20 /

Page 21

Oki Data CONFIDENTIAL

Image drum

Transfer roller

Paper

Power

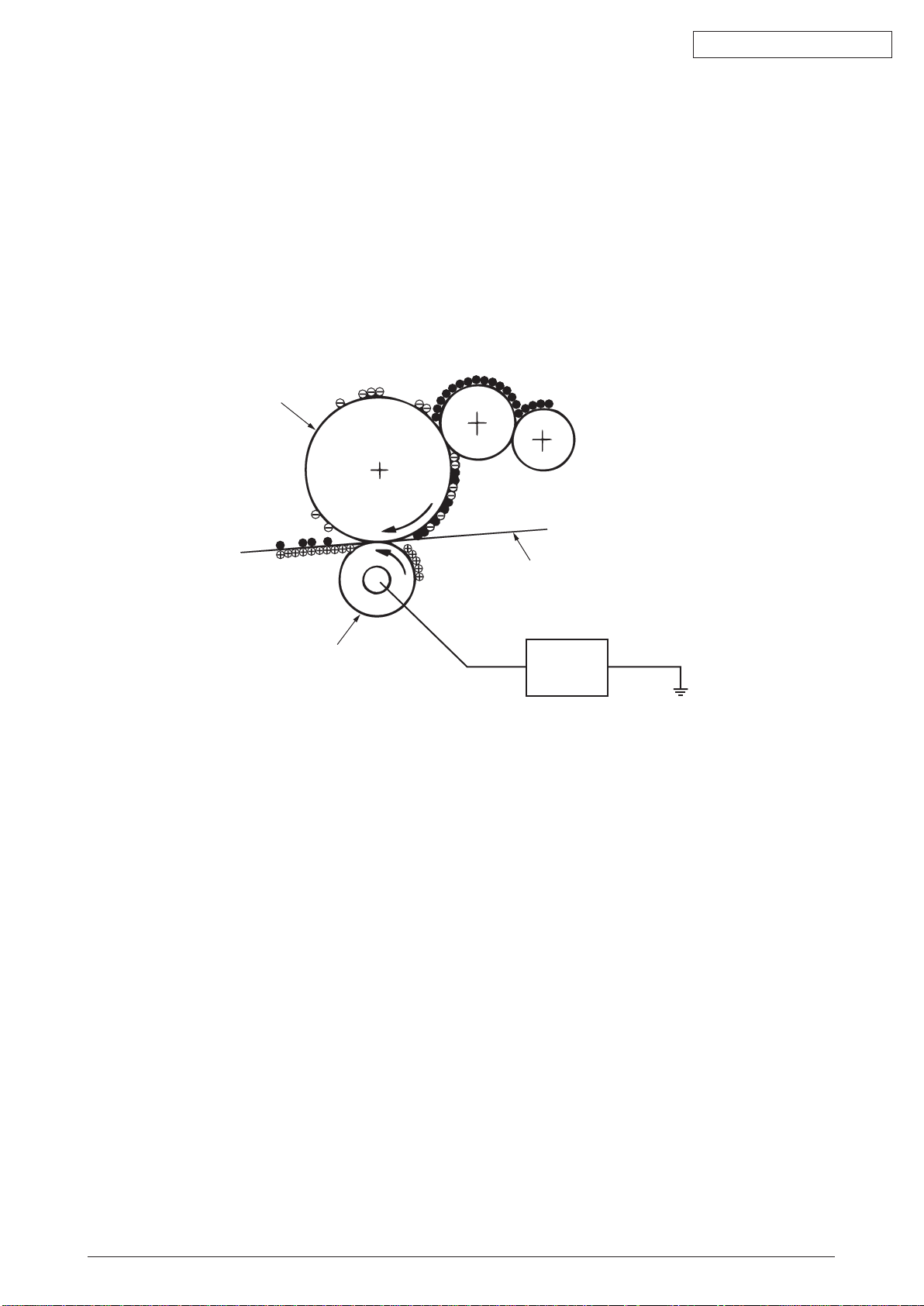

4. Transfer

The transfer roller, which is from conductive sponge material, is created to meet intimate

attachment of image drum roller surface and feeding paper. The feeding paper is set up on the

surface of image drum. Plus charge, which is the converse polarity with toner polarity, is applied

from the backside of the paper.

As high plus voltage is applied to transfer roller from the power supply, the plus charge on the

transfer roller surface is induced and transferred to the paper while the paper contact the transfer

roller. The negative charged toner, which has been attracted to the image drum surface, is

transferred to the surface of feeding paper by the plus charge of the backside of the paper.

Fig 2.1.5

44306601TH Rev. 2

21 /

Page 22

Oki Data CONFIDENTIAL

Power supply

Cleaning roller

Image drum

Transferring roller

5. Drum cleaning

1 Cleaning

After the completion of transferring, the remaining toner on the image drum is temporarily

attracted by the electrostatic and the image drum surface is cleaned.

Fig 2.1.6

2 Roller cleaning

In the following case, there is a need of cleaning the charged roller, transfer roller, and

cleaning roller.

•

Warming up as switching on the power supply

•

Warming up after open-close of the cover

•

In case of termination of printing operation

•

By periodically change the bias voltage that is implied to each roller during continuous

printing, transfer the attached toner from roller to image drum and then return it to

developing device.

44306601TH Rev. 2

22 /

Page 23

Oki Data CONFIDENTIAL

Separating clutch

Feeding paper

Heater

Heat roller

Thermistor

Backup roller

Pressuring spring

Thermostat

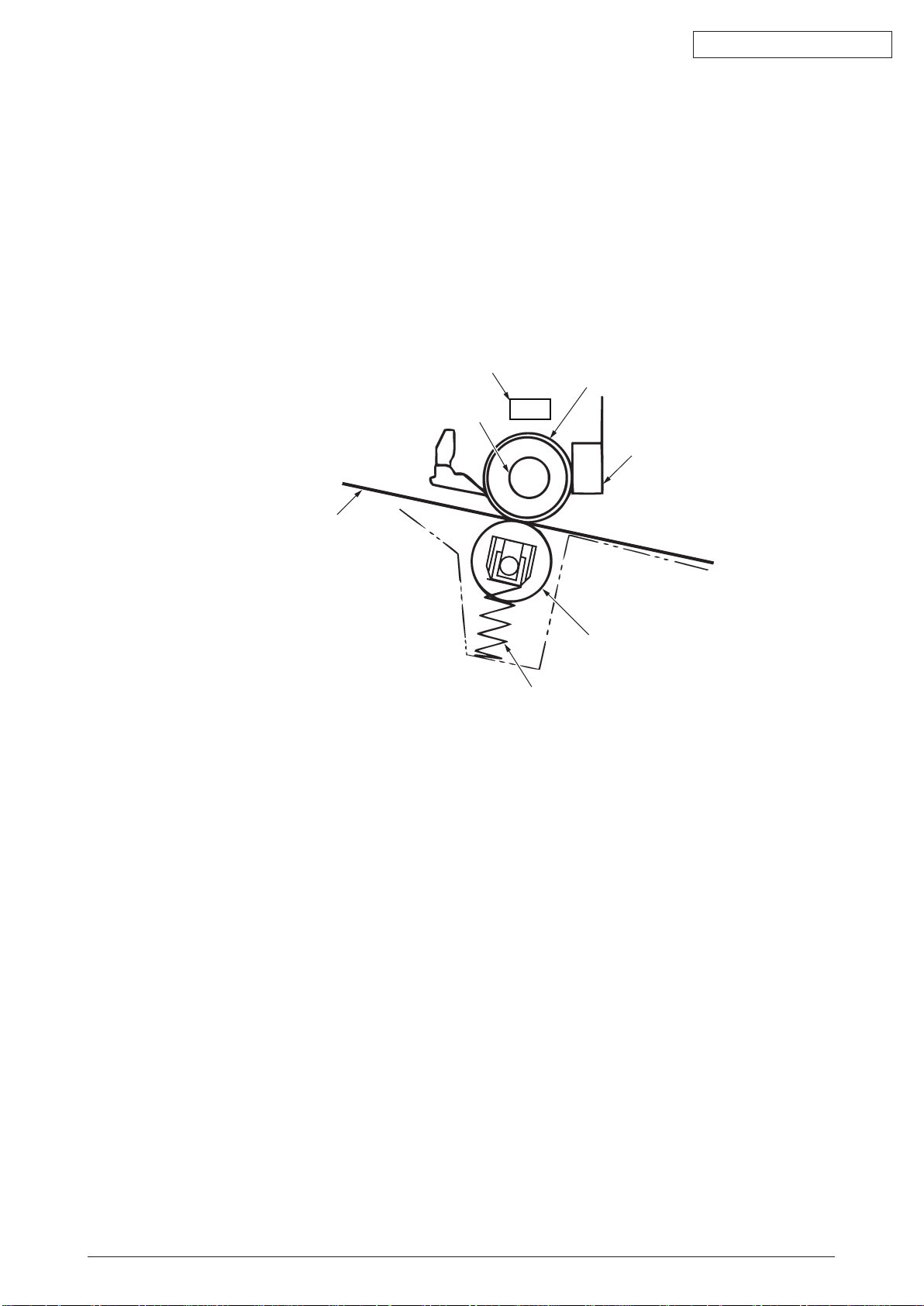

6. Fusing

After the termination of transfer the unsettled toner image is settled to paper by heat and pressure

while passing between Heat roller and Back up roller. Heat roller is Teflon coated and is mounted

by heater that can generate heat (Halogen lamp).

The thermistor that contacts the Heat roller adjusts the Heat roller temperature to the temperature

specified by the menu complying with the paper width. For safety the thermostat shuts off the

voltage supply to the Heater by opening the thermostat in the case of abnormally temperature

increasing.

The back up roller is held by the pressure springs on each terminal due to the pressure applied.

Fig 2.1.7

44306601TH Rev. 2

23 /

Page 24

Oki Data CONFIDENTIAL

:

:

:

:

:

:

:

:

:

Face down stacker

Face up stacker

The 2nd ejecting roller

The 1st ejecting roller

Backup roller

Duplex unit

Ejecting

sensor lever

Resist roller

MPT feeding roller

Multipurpose tray

Conveying roller

Conveying roller

Transferring roller

Pulse motor

Paper conveying route

Driving roller (Continuous rotation)

Driving roller (Control rotation)

Driving roller

Paper level indicator lever

Indicating lever

Photo sensor

Micro switch

Magnetic clutch

Solenoid

DC motor

Heat roller

Conveying roller

Pick up roller

Pick up roller

Feeding roller

Feeding roller

Tray 1

Tray 2

2nd tray unit (option)

Entrance

sensor lever

Image drum

Writing out

sensor lever

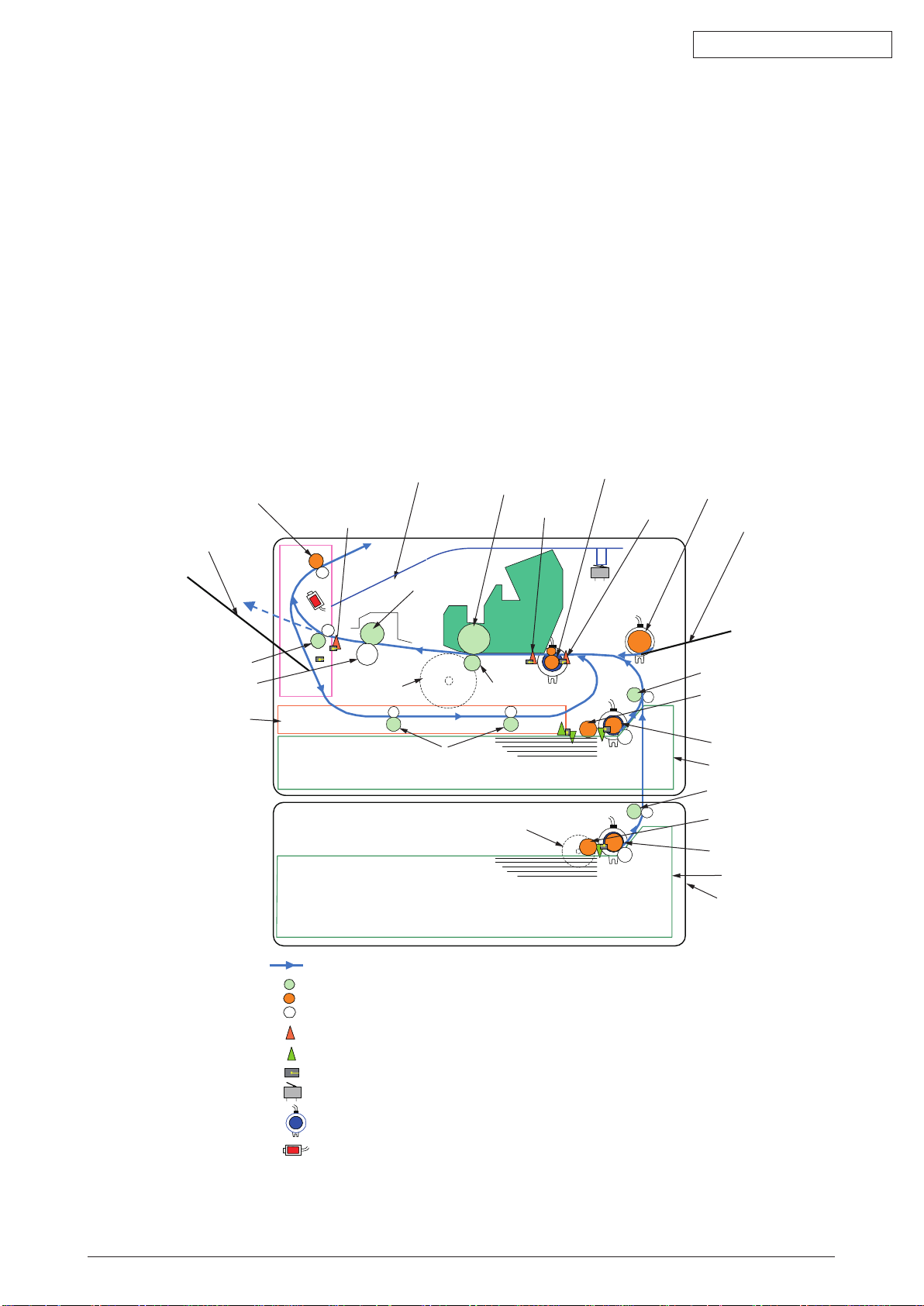

2.2 Printing process

The paper fed from Tray 1 and Tray 2 is conveyed by feeding roller, conveying roller, and resist

roller. When feeding paper is from MPT, it is conveyed by MPT, feeding roller, and resist roller.

After that the feeding paper that is conveyed by image drum and the nip part of transfer roller

forms toner image on the paper through electrophotographic process. And then, the toner on the

paper is fused by the heat and pressure as the fuser unit passing through. The paper that fused

the toner image is ejected from the face down stacker of the ejecting roller. In the case of face

up ejecting, it needs to open the backside cover and install face up stacker. (It is unavailable for

duplex printing while it is face up ejecting.)

The above is about the operations at simplex printing, yet the below explains the operations at

duplex printing. While duplex printing, the paper, which firstly passed through the fuser unit after

the backside printing, is conveyed to the inward of Duplex Unit, by the reverse operation of the

second ejecting roller that is a certain time after removing the first ejecting roller of the paper rear

side. Paper, is conveyed by conveying roller of Duplex Unit, and then merges to the same route

with the feeding paper that is from the tray. Onwards, it is the same with the simplex printing

operation by the feeding paper from tray.

44306601TH Rev. 2

Fig 2.2.1

24 /

Page 25

Oki Data CONFIDENTIAL

Resist roller

Resist clutch

Entrance sensor lever

Conveying roller

Paper feeding roller

Pick up roller

DC motor

(Counterclockwise rotation)

Paper feeding clutch

Paper

Writing out sensor lever

Resist clutch

Writing out sensor lever

Resist roller

Entrance sensor lever

Paper feeding clutch

MPT paper feeding roller

Paper

DV motor

(Counterclockwise rotation)

(1) Paper feeding from Tray 1

1. As DC motor rotating (Counterclockwise rotation), if set the paper feeding clutch as ON,

as the paper feeding roller and pick up roller rotating, the paper that is inside the tray is

conveyed.

2. T

he paper is conveyed by the conveying roller. After the entrance sensor level set to be ON,

it bumps into the stopping resist roller, a certain more amount of paper is conveyed. (This

corrects the paper skew.)

f set the resist clutch as ON, the paper is conveyed by resist roller.

3. I

Fig 2.2.2

(2) Paper feeding from Multipurpose tray (MPT)(MB470,MB480)

1. As DC motor rotating (Counterclockwise rotation), if set paper feeding clutch as ON the MPT

paper feeding roller starts to rotate, the paper in the tray is conveyed.

fter setting the entrance sensor lever as ON, the paper bumps into the stopping resist roller, a

2. A

certain more amount of paper is conveyed. (This corrects the skew of paper.)

f set the resist clutch as ON, the paper is conveyed by resist roller.

3. I

44306601TH Rev. 2

Fig 2.2.3

25 /

Page 26

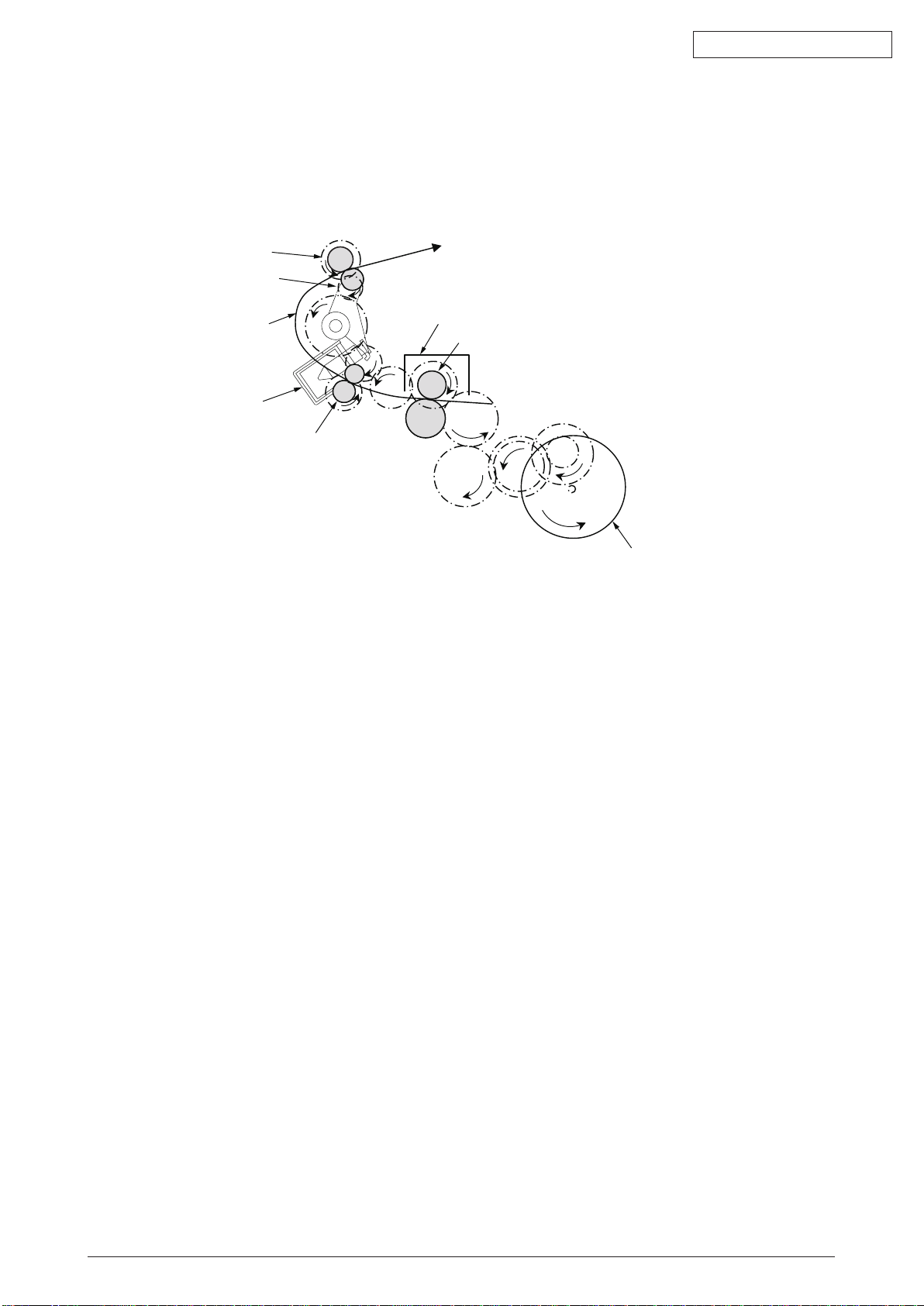

(3) Fuser unit and paper ejecting

Eject roller

Eject roller

Planet gear

Paper route

Solenoid

Fuser unit

Heat roller

DC motor

(Counterclockwise rotation)

1. The fuser unit and eject roller is

2. Si

multaneously the eject roller rotates, and then the paper is ejected.

Oki Data CONFIDENTIAL

Fig 2.2.4

44306601TH Rev. 2

26 /

Page 27

Oki Data CONFIDENTIAL

Fuser unit

Fuser unit

Heat roller

Heat roller

DC motor

(Counterclockwise rotation)

DC motor

(Counterclockwise rotation)

Resist roller

Resist roller

Resist clutch

Resist clutch

Resist Entrance

sensor lever

Resist Entrance

sensor lever

Duplex conveying roller

Writing out

sensor lever

Writing out

sensor lever

Duplex conveying roller

The 1st ejecting roller

The 1st ejecting roller

The 2nd ejecting

roller

The 2nd ejecting

roller

Planet gear

Planet gear

Solenoid

(OFF)

Solenoid

(ON)

[ Normal rotation ]

[ Inverse rotation ]

Belt

Duplex conveying rollerDuplex conveying roller

Belt

(4) Paper reversing and paper multi-feeding

1. TRemoving the first eject roller at the rear part of paper and set the solenoid as ON for a

while, then the planet gear starts to move, the second eject roller starts inverse rotating

(Counterclockwise rotation).

2. B

y the inverse rotation of the second eject roller the paper is inversely rotated and conveyed to

Duplex.

aper is conveyed by Duplex conveying roller.

3. P

fter setting the entrance sensor lever as ON, paper bumps into the stopped resist roller, still a

4. A

certain more amount of paper is conveyed. (This corrects the skew of paper.).

f set the Resist clutch as ON, paper is conveyed by Resist roller.

5. I

Fig 2.2.5

44306601TH Rev. 2

Fig 2.2.6

27 /

Page 28

Oki Data CONFIDENTIAL

Magnet

Agitating bar Agitating gear

Crack part

Agitating bar

Agitating bar

Agitating gear

Sensor plate

Sensor plate

Toner sensor

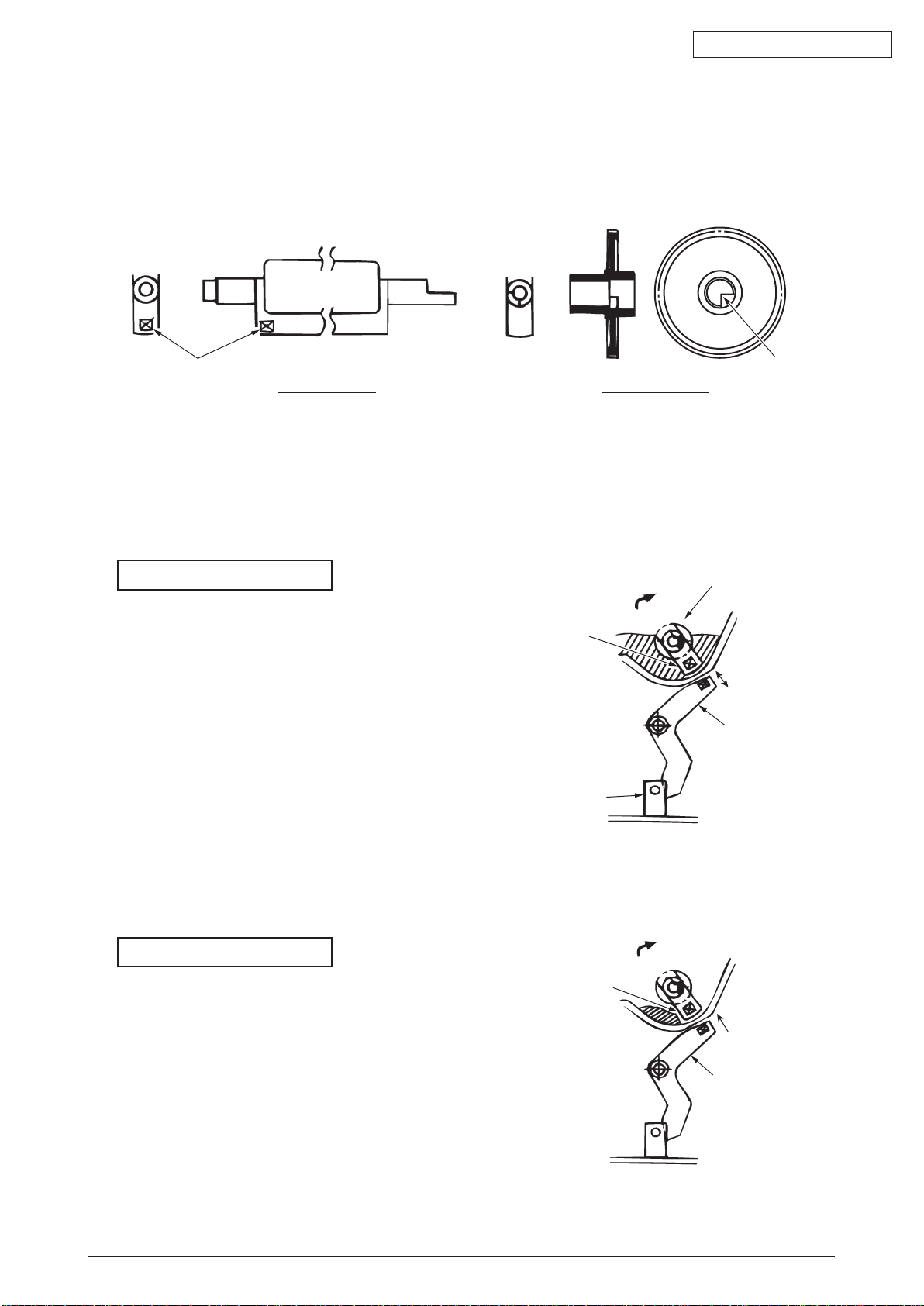

2.3 Toner entrance detection

• Equipment

Toner entrance detecting equipment consists the agitating gear that agitating the agitating bar at

a certain speed and magnet that is on the agitating bar.

Fig 2.3.1

•

Operation

Detecting the toner low by monitoring the congruous time intervals between the magnet that is

set on the sensor plate and the magnet attached on the agitating bar,

Operation in toner full status

•

The crack part of agitating gear meshing with

the projection portion of agitating bar, the

agitating bar rotates in accordance with the

rotating of gear.

•

Even after the magnet part of the agitating

Bar reaches the highest position, it still

rotates at the same speed by the pressure of

the agitating gear due to the toner resistance.

Fig 2.3.2

Operation in toner low status

•

When the magnet part of the agitating bar

reaches the highest position, because

there is no resistance from toner, the

agitating bar drops earlier than the gear

by the gravity itself, and stops by that

status.

For this reason, the time that the magnet

of agitating Bar magnetic attracts the

magnet of sensor plate becomes longer.

The toner low status can be inspected by

Fig 2.3.3

monitoring this time.

44306601TH Rev. 2

28 /

Page 29

Toner full status

Oki Data CONFIDENTIAL

Fig 2.3.4

Toner low status t1

ner sensor alarm actuates if there is not any change on toner sensor.

• To

• Toner sensor is not monitored while main (drum) motor is stopping.

t2 t1,t2: Magnet attracting time

Fig 2.3.5

44306601TH Rev. 2

29 /

Page 30

Oki Data CONFIDENTIAL

3. MfP insTallaTion

3.1 Precautions and Prohibition

Table 3.1.1

• Do not install the MFP in the vicinity of high temperature or fire.

• Do not install the MFP at the place where a chemical reaction may take place (laboratory,

etc.).

• Do not install the MFP near flammable solution like alcohol, thinner, etc.

• Do not install the MFP at the place where a small child can reach.

• Do not install the MFP at an unstable place (unsteady frame, tilted place, etc.).

• Do not install the MFP at a highly humid or dusty place or under the direct sunshine.

• Do not install the MFP under the environment of sea breeze or caustic gas.

• Do not install the MFP at a highly vibrating place.

• When you drop the MFP or damage the cover, remove the power plug from the outlet and

contact the Customers’ Service Center.

Electric shock, fire or injury may occur.

• Do not connect the power cord, printer cable and earth wire as otherwise directed by the

Manual. A fire may break out.

• Do not insert a thing in the vent hole.

Electric shock, fire or injury may occur.

• Do not place a cup with water on the MFP.

Electric shock or fire may occur.

• Do not touch the fuser unit when you open the printer cover.

Burn may occur.

• Do not throw the toner cartridge or image drum cartridge into fire.

Burn may occur by the dust explosion.

• Do not use a highly flammable spray near the MFP.

Fire may break out as there are high temperature parts inside the printer.

• When the cover becomes abnormally hot, a smoke arises or a strange odor comes out,

remove the power plug from the outlet and contact the Customers’ Service Center.

Fire may break out.

• When liquid like water drops inside the MFP, remove the power plug from the outlet and

contact the Customers’ Service Center.

Fire may break out.

• When a thing like a clip drops inside the MFP, remove the power plug from the outlet and

take out that thing.

• Do not operate or disassemble the MFP as otherwise directed in the Manual.

Electric shock, fire or injury may occur.

44306601TH Rev. 2

30 /

Page 31

Oki Data CONFIDENTIAL

Table 3.1.2

• Do not install the MFP at the place where the vent hole is blocked.

• Do not install the MFP on the shaggy carpet.

• Do not install the MFP at the place with little draught or without ventilation like a room with

no window.

• Install the MFP away from the monitor TV.

• When the MFP is to be moved, hold both ends of the printer.

• This MFP weighs about 19kg (MB480).

• When to switch the power on or while printing, do not come near the paper exit of the MFP.

Injury may occur.

As regards the items of caution, explain to the customer showing the items of caution of the

User’s Manual. Particularly, explain fully about the power supply cord and earth cable.

44306601TH Rev. 2

31 /

Page 32

3.2 MFP Unpacking Procedure

This MFP weighs about 19kg (MB480).

•

Open the upper lid.

•

Take out the accessor

•

Remove the upper buffer material.

•

Take out the equipment

Oki Data CONFIDENTIAL

Personal injuries may occur.

y box.

44306601TH Rev. 2

Fig 3.2.1

32 /

Page 33

30cm

20cm

20cm

100cm

50cm

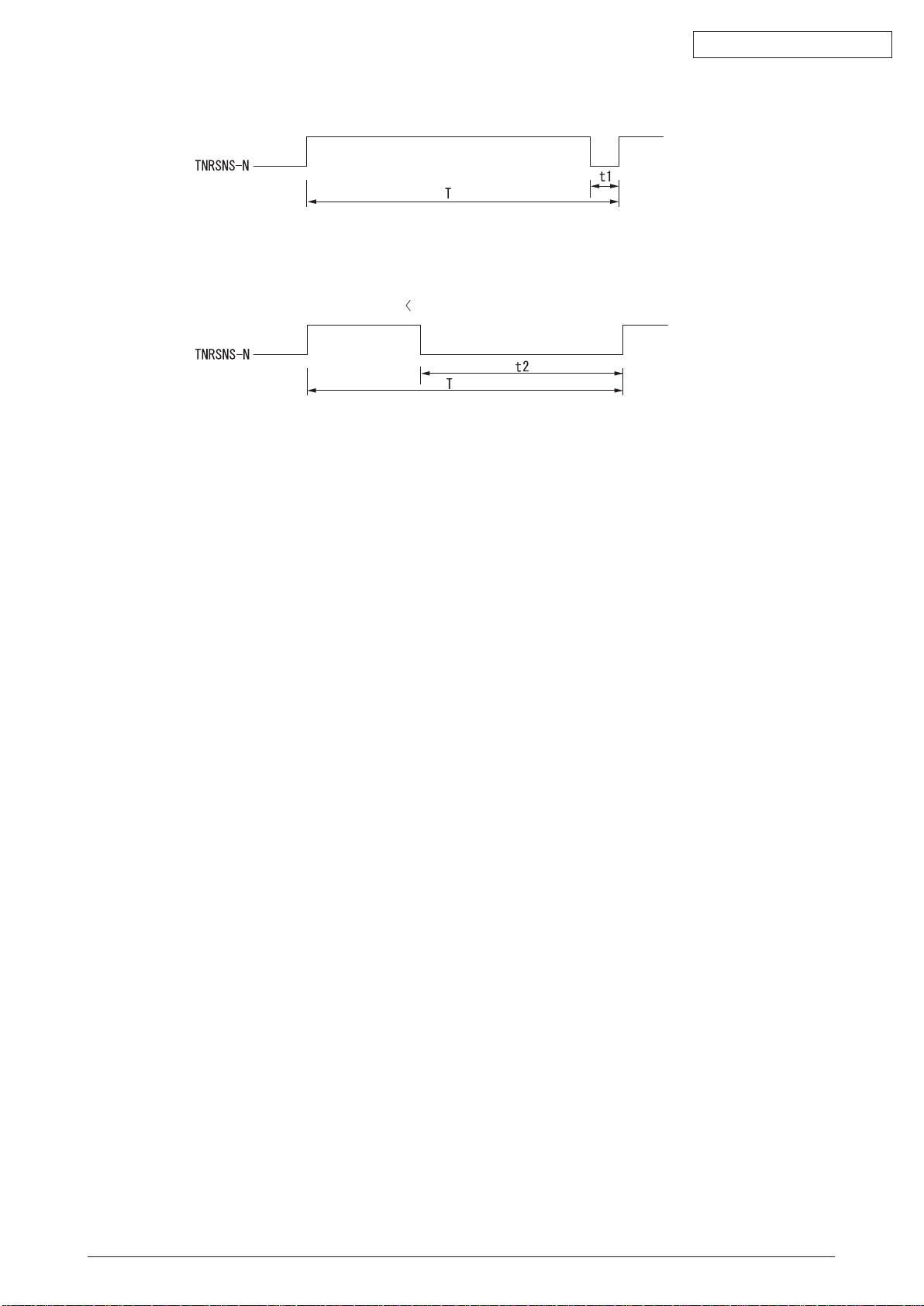

3.3 MFP Installation Instructions

•

Install the MFP at a place under the following temperature and humidity:

Amb

Ambient Humidity : 20 to 80% relative humidity

Maximum Wet-Bulb Temperature : 25°C

•

Be careful not to be bedewed.

•

When the MFP is to be installed at a place where the humidity is less than 30%, use a

humidifier or a static electricity prevention mat.

ient Temperature : 10 to 32°C

Installation Space

•

Place the MFP on a flat desk with enough space for the legs of the MFP.

•

Secure enough space around the MFP.

Top View

Oki Data CONFIDENTIAL

Side View

Fig 3.3.1

Fig 3.3.2

44306601TH Rev. 2

33 /

Page 34

3.4 Packed Units and Attachments

•

Confirm whether there are scratches, stains, etc. on the exterior of the machine.

•

Confirm whether there are lacking items, damages, etc. among the accessories.

•

If anything unusual is found, contact the user’s section in charge and follow its

instruction.

Personal injuries may occur.

This MFP weighs about 19kg (MB480).

MFP (main body)

Oki Data CONFIDENTIAL

Fig 3.4.1

Starter Toner Cartridges

Fig 3.4.2

Explain to customers that the toner cartridge and the image drum cartridge are separable.

MFP Software CD-ROM

Power Cord

Warranty and Registration Card

Users Manuals

Note! The printer cable is not included in the accessories.

44306601TH Rev. 2

34 /

Page 35

Pad-Middle

Film

Silica-Gel pac

k

protection pad

protection pad

3.5 Assembly Procedure

3.5.1 MFP Main Body

Remove Protective Equipment

(1) Lift the scanner.

(2) Remove the Pad-Middle.

(3) Remove the Film with two Silica-Gel packs.

Oki Data CONFIDENTIAL

Fig 3.5.1

(4) Remove the eight adhesive tapes on the outside of MFP.

Fig 3.5.2

(5) Open the document cover.

Then remove the four adhesive tapes and two protection pads.

44306601TH Rev. 2

Fig 3.5.3

35 /

Page 36

Paper Cassette

Open Button

A6 size paper

Retainer

MB480

(6) Pull out the paper cassete.

A6 paper

(7) Remove the Retainer and the A6 size paper. (In case of MB480 )

Oki Data CONFIDENTIAL

Fig 3.5.4

(8) Open Multi-purpose Tray. Remove the A6 size paper. (In case of MB470/MB480 )

44306601TH Rev. 2

Fig 3.5.5

36 /

Page 37

Install Image Drum Cartridges

Image Drum Cartridge

Protection sheet

A

B

C

(1) Pull out the image drum cartridge gently.

Note! • Handle the image drum very carefully as it is quite easily

injured.

• Do not expose the image drum cartridge to direct sunshine or bright light

(approximately 1,500 lux or more) . Do not leave it more than 5 minutes under the

room light.

Oki Data CONFIDENTIAL

Fig 3.5.6

(2) Place the image drum cartridge on a flat desk, remove the tape which fastens the protection

sheet and pull it out in the direction of the arrow.

Note! Do not work on the image drum off the desk top.

Fig 3.5.7

(3) Holding the image drum by its top center , lower it into place in the printer locating the pegs (A

& B) at each end into their slots in the sides of the printer cavity (C) .

44306601TH Rev. 2

Fig 3.5.8

37 /

Page 38

Oki Data CONFIDENTIAL

(4) Release the lock by pushing the knob of the toner cover in the direction of the arrow and

remove the toner cover.

Fig 3.5.9

(5) Gently shake the cartridge from end to end several times to loosen and distribute the toner

evenly inside the cartridge.

(6) Remove the wrapping material and peel off the adhesive tape from the underside of the

cartridge.

Fig 3.5.10

44306601TH Rev. 2

38 /

Page 39

Oki Data CONFIDENTIAL

(7) Holding the cartridge by its top center with the coloured lever to the right , lower it into the

printer over the image drum unit from which the toner cover was removed.

Insert the left end of the cartridge into the top of the image drum unit first , push it against

the pins on the drum unit then lower the right end of the cartridge down onto the image

drum unit.

Fig 3.5.11

(8) Pressing gentry down on the cartridge to ensure that it is firmly seated , push the coloured

lever towards the rear of the printer.

This will lock the cartridge into place and release toner into the image drum unit.

Fig 3.5.12

Note! • The starter toner (the toner cartridge attached to the product at the time of(purchase)

• Confirm whether the lever of the toner cartridge is turned fully in the direction of the

44306601TH Rev. 2

c

an print approximately 1,000 sheets of A4 paper in case of 5% coverage.

(1,500 sheets of A4 paper in case of ISO-pattern.)

arrow when Toner Empty Messages are displayed in the LCD.

39 /

Page 40

Oki Data CONFIDENTIAL

Lock

Unlock

Scanning head

OK

Lamp

Scanning head

NG

Unlocking Scanning head

The scan unit is locked during transport to protect the scanning mechanism from

being damaged. Be sure to unlock the scan unit before using the machine.

(1) Open the ADF Doc Lid.

(2) Move the lock switch to the “Unlocked position”.

(The lock switch is located on the left corner on the flat bed.)

(3) Close the ADF Doc Lid.

Fig 3.5.13

Note: If you need to move your MFP or Scanner unit for repair or any other reason, be sure

ock your Scanner before moving. To lock your Scanner, please do the following,

to l

1. Turn off your MFP.

2. If the scanning head is not located at the left end, turn the MFP on to return the

scanning head to the left end. After the scanning head is returned to the left end,

turn the power supply off.

3. Move the lock switch to the “Locked Position”.

44306601TH Rev. 2

Fig 3.5.14

40 /

Page 41

Plate

Cork

Paper Guide

Load Paper in Paper Cassette

Printing face down

Paper Stopper

Paper life display

(1) Pull out the paper cassette.

Note! Do not remove the cork on the plate.

(2

) Conform the paper guide to the paper size and fix it firmly.

Oki Data CONFIDENTIAL

Fig 3.5.15

(3) Shuffle the sheets of paper and arrange up, down, left and right properly.

Fig 3.5.16

(4) Make the printable side down and set the paper.

•

Plac

Note!

Fix the paper by the paper stopper.

(5)

e the paper in front of the paper cartridge.

•

S

et the paper not to exceed “

”mark of the paper guide. (250 sheets weighing 70kg)

▼

(6) Return the paper cassette to the MFP.

44306601TH Rev. 2

Fig 3.5.17

41 /

Page 42

Load Paper in the Manual Feed Opening

Manual Feed Opening

Manual Feeding Guide

Manual feeding

opening

Manual Feeding Guide

Manual Feeding Guide

Manual feeding

opening

Manual Feeding Guide

(1) Put a finger in the dent at the center of the manual feed opening and pull forward.

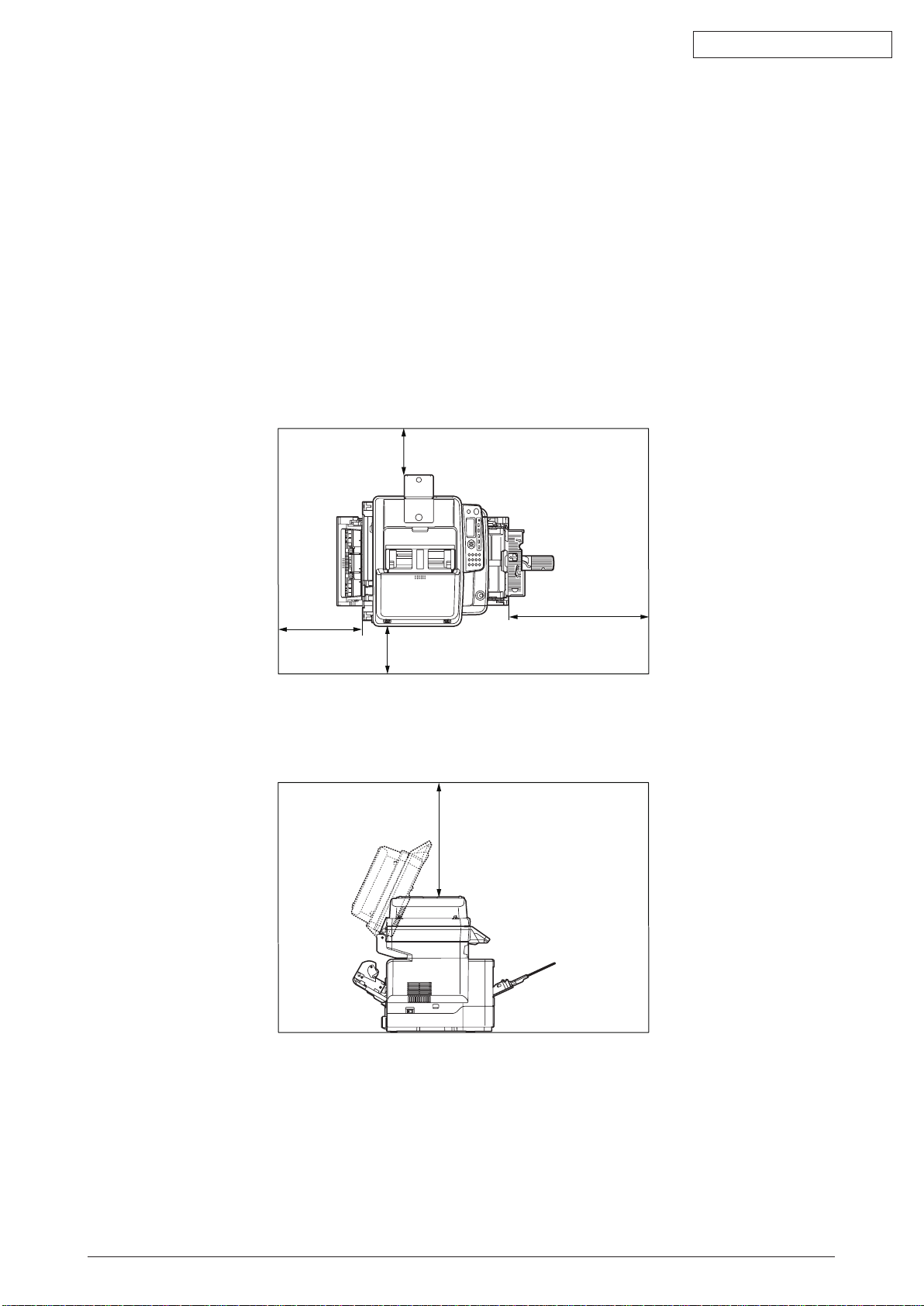

Fig 3.5.18

(2) Conform the manual feeding guide to the size of the paper.

Oki Data CONFIDENTIAL

(3) Arrange the left and right of the paper.

(MB460) (MB470/MB480)

Fig 3.5.19

(4) Make the printing side up and insert the paper straight to the rear end along the manual

feed guide.

(MB460) (MB470/MB480)

44306601TH Rev. 2

Fig 3.5.20

42 /

Page 43

Oki Data CONFIDENTIAL

Paper Guide

Setup orientation of papers

Face Up

ABC

Setup orientation of papers

Face Down

Align in the upper-left corner

Placing the Original

In the Auto Document Feeder

(1) Make sure your document is free of staples, paper clips and is not tore out.

(2) If you have multiple pages, fan your document(s) to avoid occasional paper jam. The ADF

holds up to 50 pages at one time.

Fig 3.5.21

Place your document(s) with the text FACE UP in the ADF.

(3)

(4) Adjust the Paper Guides to center the document(s) in the ADF.

On the Document Glass

(1) Place your original with the text face down on the document glass.

Fig 3.5.22

44306601TH Rev. 2

Fig 3.5.23

43 /

Page 44

Oki Data CONFIDENTIAL

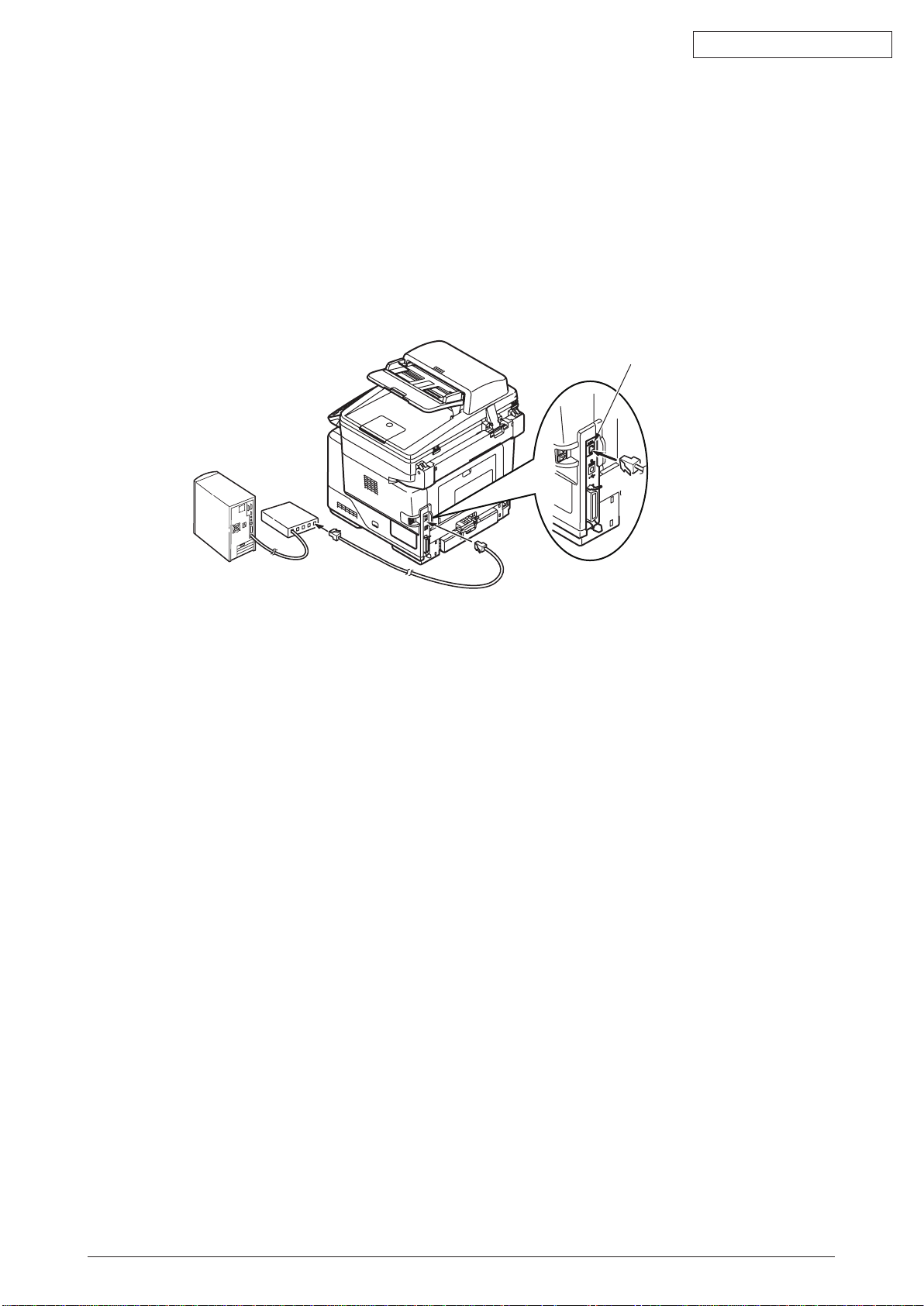

3.5.2 Power Cable Connection

Conditions for Power Supplies

•

Observe the following conditions:

ernate Current (AC) : 110 ~127VAC(Range 99~140VAC)/220 ~240VAC(Range

Alt

198~264VAC)

Power Supply Frequency : 50Hz or 60Hz±2%

•

Use a voltage regulator when the power supply is not stable.

•

The maximum power consumption of this MFP is 800W. Confirm that the power supply has

sufficient extra capacity.

Table 3.5.1

It may expose you to electric shocks or cause a fire.

• Never fail to switch off the power supply at the time of connection or removal of the electric

cord and earth cable.

• Always connect the earth cable to the earth terminal equipped only for that purpose. Never

connect the earth cable with water pipe, gas pipe, telephone cable earth terminal, lightening

rod, etc.

ways grasp the power plug at the time of connection and removal of the electric cord.

• Al

• Always make sure that the electric plug is inserted fully into the outlet.

• Do not connect or disconnect the electric plug with the wet hand.

• Do not install the electric cord at the place liable to be stepped on and do not put things on

the electric cord.

• Do not bundle up or tie up the electric cord

• Do not use the damaged electric cord.

• Do not put many loads on one electric outlet.

• Do not connect this MFP to the same outlet with other electric machines. Particularly,

erroneous operation may occur by electric noise when the same outlet is shared by the air

conditioner, duplicator, shredder, etc. at the same time. When the same outlet had to be used,

use a noise filter or noise cut transformer on the market.

• Use the attached electric cord only.

• Do not use an extension cord. Use the cord of over rating 15A if you had to use one.

• When you use the extension cord, the MFP may not operate normally due to the drop of AC

voltage.

• Do not shut down the power supply or remove the power plug while printing.

• Disconnect the power cord when the MFP would not be used for some long while due to

consecutive holidays or journey.

As to the connection of the electric cord and earth cable, explain fully to the customer showing

the User’s Manual.

44306601TH Rev. 2

44 /

Page 45

Connect Power Supply Cord

Earth Terminal

Earth Cable

Note! Be certain the power switch is placed in the OFF (O) position.

(1) Insert the electric cord in the MFP.

(2) Connect the earth wire to the earth terminal of the AC power source outlet.

(3) Connect the AC power cord insertion plug to the AC power source outlet.

Oki Data CONFIDENTIAL

Press ON (I) of Power Switch

Fig 3.5.24

Fig 3.5.25

44306601TH Rev. 2

45 /

Page 46

Memory Cover

Knob

3.5.3 Installation of Optional Components

OI

(1) Extension Memory Installation

Fig 3.5.26

Table 3.5.2

Type On-board Memory slot Total

N/A (Standard) 64MB - 64MB

64MB option

DIMM

MEM64D

256MB option

DIMM

MEM256D

64MB 64MB 128MB

64MB 256MB 320MB

Oki Data CONFIDENTIAL

Note! • You m

•

A 64MB memory is installed as standard in the memory slot. If you use a 256MB

ust use genuine Oki Original. Otherwise, the memory will not work.

memory, remove the 64MB memory before use.

Switch the power supply of the MFP off and pull out the electric cord.

Note! If installed with the switch on, an electric shock or a trouble to the MFP may occur.

Fig 3.5.27

Open the memory cover.

1) Release the lock by pushing the knob of the memory cover in the direction of the arrow and

open the memory cover.

44306601TH Rev. 2

Fig 3.5.28

46 /

Page 47

Oki Data CONFIDENTIAL

Memory Cover

Install the memory.

Note! Do not touch electronic parts and connector terminal.

1) Neutralize static electricity by letting the bag touch the metal part before taking out the

memory from the bag.

ay attention to the direction of the memory. There is a cut on the terminal part of the

2) P

memory to fit it into the connector of the slot.

3) Insert the memory in the empty slot and bring it down to the circuit board side.

Fig 3.5.29

Close the memory cover.

1) Close the memory cover. Confirm that it is firmly locked.

44306601TH Rev. 2

Fig 3.5.30

47 /

Page 48

(2) Installation of second tray unit

O I

Holes in the

printer bottom

Protrusions

This tray is intended to increase the amount of paper that can be loaded in the MFP. It holds

530 sheets of 70kg ream weight paper, allowing to print 1110(MB480) sheets continuously

when combined with the standard paper cassette and multi-purpose tray.

Turning OFF the MFP power and disconnecting the power cord

Note! If an expansion memory is installed with the power switched ON, the MFP may be

oken.

br

Oki Data CONFIDENTIAL

Fig 3.5.31

Fig 3.5.32

Placing the MFP on the second tray unit.

Note! The MFP weighs Approx. 19kg (MB480).

1) Align the holes in the bottom of the MFP to the protr

2) Place the MFP gently on the second tray unit.

usions of the second tray unit.

44306601TH Rev. 2

Fig 3.5.33

48 /

Page 49

Oki Data CONFIDENTIAL

Cover-piece

Cover-piece

B460/B470 B480

2nd-piece

2nd-piece

3) Remove the four Cover-pieces in the direction of the arrow. Do not put or drop the

Cover-pieces inside the MFP.

Fig 3.5.34

4) Attach the two 2nd-pieces as shown in Fig. 3.5.35.

To detach the second tray unit, follow the same procedure inversely.

Fig 3.5.35

44306601TH Rev. 2

49 /

Page 50

Oki Data CONFIDENTIAL

3.5.4 Confirm the Recognition of Option

In order to confirm that the items of option are correctly installed, conduct the menu map

printing referring to “3.6 Configuration Page Print”.

(1) Confirm Recognition of Additional Memory

Confirm the contents of the configuration pages.

Confirm the total memory size displayed as “TOTAL MEMORY SIZE” in the header portion.

Fig 3.5.36

(2) Confirm Recognition of second tray

Confirm the contents of the configuration pages.

Confirm the displayed as "Tray 2" in the header portion.

Fig 3.5.37

44306601TH Rev. 2

50 /

Page 51

3.6 Configuration Page Print

Make sure that the MFP operates normally.

(1) Set sheets of A4 paper in the tray.

(2) From the panel menu, select "Menu".

(Press the down button to go to "Menu" and then press the enter button.)

(3) Select "Print Information".

(Press the down button to go to "Print Information" and then press the enter button.)

(4) Select "Configuration".

(5) Select "Execute".

(Sample) MB460

Oki Data CONFIDENTIAL

44306601TH Rev. 2

Fig 3.6.1

51 /

Page 52

(Sample) MB470

Oki Data CONFIDENTIAL

44306601TH Rev. 2

Fig 3.6.2

52 /

Page 53

(Sample) MB480

Oki Data CONFIDENTIAL

44306601TH Rev. 2

Fig 3.6.3

53 /

Page 54

Oki Data CONFIDENTIAL

3.7 Network Information Print

Confirm the network information print.

(1) Push the TEST switch beside the network connector on the back of the MFP for 5 seconds

and release. Then the network information will be printed.

(Sample) In case of MB460

44306601TH Rev. 2

Fig 3.7.1

54 /

Page 55

UBS Interface

Connector

3.8 Connection Procedures

<USB Connection>

Prepare a USB Cable.

Note! • The cable of the MFP is not attached. Users should buy seperately.

•

•

Obtain the cable of USB specification by yourself.

Use the USB cable of Hi-Speed specification in case the connection is to be made

sing “HI-Speed” mode of USB2.0.

u

Oki Data CONFIDENTIAL

Fig 3.8.1

Switch off the power of the

Memo Although the USB cable can be connected or removed with the switch of the

computer and printer on, switch off the power of the MFP at this step in order to

ensure installation of the MFP driver and USB driver later.

Connect the

(1) Plug the USB cable into the USB interface connector of the MFP.

(2) Plug the USB cable into the USB interface connector of the computer.

Note! Be careful not to insert the USB cable into the network interface connector.

Or e

MFP

with the computer.

lse it may cause troubles.

MFP

and computer.

44306601TH Rev. 2

Fig 3.8.2

55 /

Page 56

<LAN Cable Connection>

Network Interface Connector

Prepare the LAN cable.

Switch off the power of the MFP and computer.

Connect the computer and MFP.

(1) Plug the Ethernet cable into the network interface connector of the MFP.

(2) Plug the Ethernet cable into the hub.

Oki Data CONFIDENTIAL

Fig 3.8.3

44306601TH Rev. 2

56 /

Page 57

TEL Connector

LINE Connector

TEL

LINE

<TEL cable. Line Cable Connection>Note! only MB470/MB480

Prepare the TEL cable and Line cable.

Preparing cores

Memo Use two longer ones of two kinds cores packed with MFP.

How to attach a cores

Memo Wind the TEL cable and Line cable on each core 1 time and then close the core

cases to fix them. The cores must be about 80~100mm away from the each connector.

Oki Data CONFIDENTIAL

The places for connecting each cables

Fig 3.8.4

Fig 3.8.5

44306601TH Rev. 2

57 /

Page 58

The state after connecting

Use for Fax.

(Only MB470/MB480)

for TEL

for LINE

for USB

for LAN

Oki Data CONFIDENTIAL

Fig 3.8.6

Table 3.8.1

Cable Core Name Part No. Core shape Winding count

for TEL SFT-59SN 1051007C0001 Long Type 1

for LINE SFT-59SN 1051007C0001 Long Type 1

Do not also connect to switchboard directly or exclusive use line without any conversion

※

MB460 MB470 MB480

X

X

equipment.

44306601TH Rev. 2

58 /

Page 59

3.9 Checking of User Paper

Set the medium the user uses, set up media type/weight, conduct menu map/demo print and

confirm that the toner does not peel off.

Oki Data CONFIDENTIAL

Table 3.9.1

Types Weight

55kg(64g/m2) Light

Regular

paper*3

Postcard*4 - - - -

Envelope*4 - - - -

Label paper - Heavy Labels Labels

*1

*2

55-64kg(64-74g/m2) Medium Light Medium Light

65-75kg(75-87g/m2) Medium Medium

76-89kg(88-104g/m2) Medium Heavy Medium Heavy

90-105kg(105-120g/m2) Heavy Heavy

: The set-up of the media type at the time of shipment from the factory is “Plain”.

: Thickness and type of paper can be set up by the printer driver. When they are set up

Setting values of the MFP Setting*2 for [Media weight]

Media weight Media type*1

Plain

of the printer driver

Light

by the printer driver, the printer driver set-up has priority. When “Automatic Selection” is

selected by “Paper Feed Method” of the printer driver or when “Printer Set-up” is selected

by “Paper Thickness”, printing is made by the set-up of the MFP.

*3

: Thickness of paper for both side printing is 55~90kg in weight (64~105g/m2).

*4

: Set-up of media weight and media type is not necessary for postcards and envelopes.

44306601TH Rev. 2

59 /

Page 60

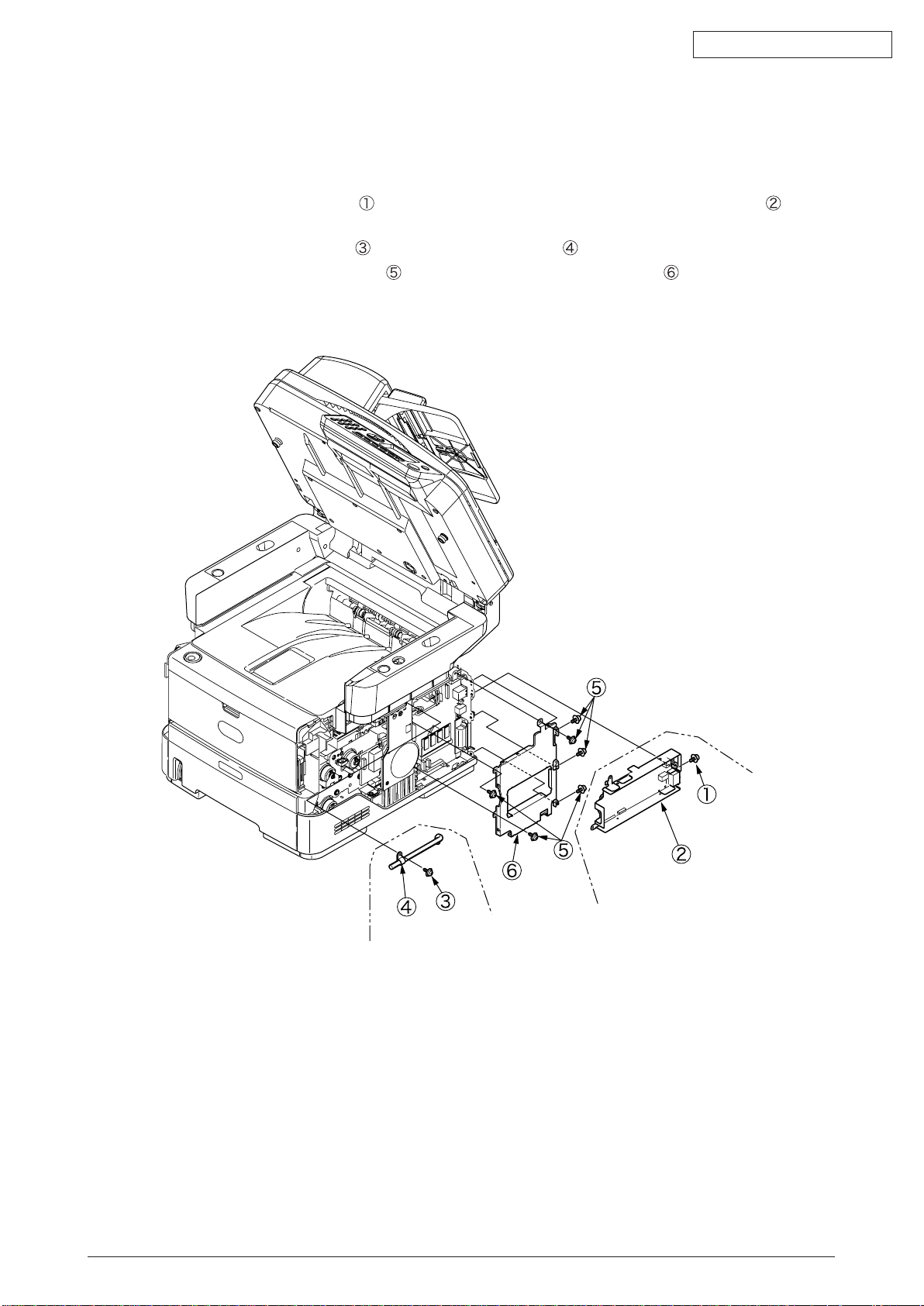

4. RePlaCeMenT of PaRTs

OFF

ON

Shutting

off

Reconnecting

Earth cable

Earth terminal

Warning

This section explains the field replacement procedures for parts, assemblies and component

units. While those replacement procedures refer to the disassembling of parts, follow the same

procedures inversely for reassembling them.

The part numbers (1, 2, etc.) employed in this manual are different from those assigned in the

corresponding configuration diagrams of Disassembly for Maintenance (44306601TL) and

RSPL (44306601TR/44306621TR/44306641TR).

4.1 Precautions on the replacement of parts

(1) Prior to replacing a part, be sure to disconnect the AC cord and interface cable.

(a) To disconnect the AC cord, always follow the procedure described below:

Switch the power switch of printer off “O”.

Disconnect the AC insertion plug of the AC power cord from the AC power source.

Disconnect the earth wire from the earth terminal of the AC power source outlet.

Disconnect the AC cord and the interface cable with the printer.

Risk of Electric Shock

Oki Data CONFIDENTIAL

There is a risk of electric shock during replacement of the low voltage power supply.

Use insulating gloves or avoid direct contact with any conducting part of the power supply,

and caution should be exercised during replacement.

The capacitor may take one minute to complete discharge after the AC cord is unplugged.

Also, there is a possibility that the capacitor doesn’t discharge because of a breakage of

the PCB, etc., so remember the possibility of electric shock to avoid electric shock.

(b) To reconnect the printer, always follow the procedure described below:

Connect the AC cord and the interface cable with the printer.

Connect the earth wire to the earth terminal of the AC power source outlet.

Connect the AC power cord insertion plug to the AC power source outlet.

Switch the power switch of printer on “I”.

Fig 4.1.1

(2) Do not disassemble the MFP as long as it is operating normally.

(3) Limit disassembly to a necessary minimum. Do not remove other parts than those specified in

the part replacement procedure.

(4)

Use the designated maintenance tools.

(5) Conduct disassembly by following the specified sequential order. Failure to observe this order

could damage the parts.

Screws, collars and other small parts should be attached provisionally to their original

(6)

positions, since they are liable to be lost.

(7)

When handling a microprocessor, ROM, RAM and other ICs and circuit boards, do not wear

gloves that tend to generate static electricity.

(8)

Printed-circuit boards should not be placed directly on an equipment or floor.

44306601TH Rev. 2

60 /

Page 61

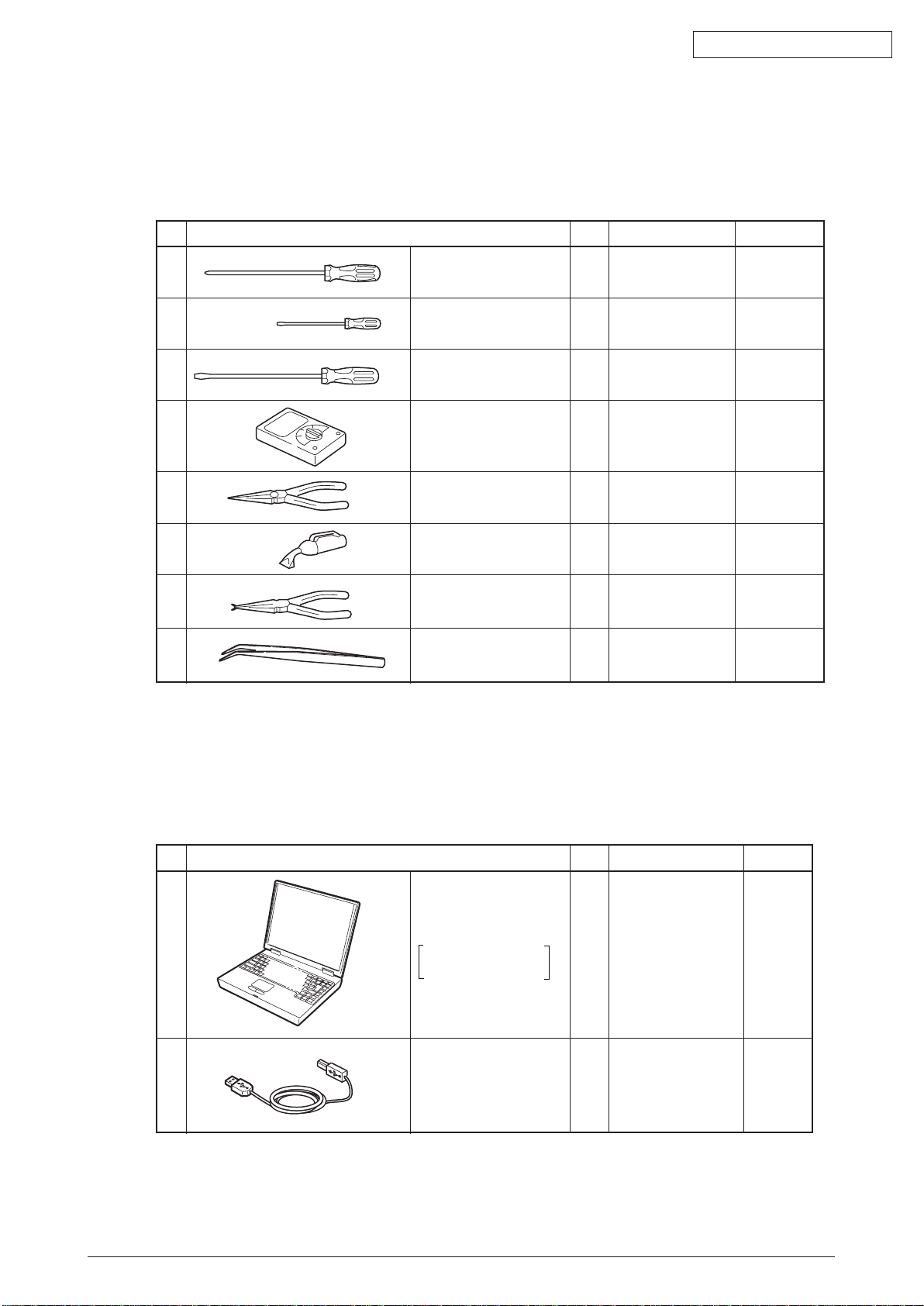

Oki Data CONFIDENTIAL

No. Q' ty Place of use RemarksService Tools

2 USB cable 1

1

Laptop computer

Must have maintenance

utilities installed

1

No. Q' ty Place of use

Remarks

Service Tools

1

2

3

4

5

6

No. 2-200 Philips

screwdriver, Magnetized

No. 3-100 screwdriver

No. 5-200 screwdriver

Digital multimeter

Pliers

E-ring pliers

Handy cleaner

1

1

1

1

1

1

Tweezers

Curved-tip

type

Refer to the

following note.

1

3~5 mm screws

7

8

1

[Maintenance Tools]

Table 4.1.1 indicates the tools necessary to replace printed-circuit boards and component units.

Table 4.1.1

Note:

Use a vacuum cleaner dealing with toner. Using a common vacuum cleaner may cause fire.

Table 4.1.2 indicates the tools necessary for using maintenance utilities.

Table 4.1.2

44306601TH Rev. 2

61 /

Page 62

4.2 Parts layout

A

A

A’

A’

Stacker-Cover-Assy

Cover-Side-R

Cover-Side-L

Plate-Base-PCB

Plate-Assy-Base

Motor-Fan

Duplex

Rear-Cover-Assy

Fuser-Assy

OPE

Cover-Assy

Guide-Paper-Duplex

GuidePaper-R

Manual-Assy

Front-Guide-Assy

CU board

Toner cartridge

Low voltage

power board

High voltage

power board

Paper cassette

Image drum cartridge

This section explains the main parts layout of the equipment.

MB460

Oki Data CONFIDENTIAL

44306601TH Rev. 2

Fig 4.2.1

62 /

Page 63

MB470

A

A

A’

A’

Stacker-Cover-Assy

Cover-Side-R

Cover-Side-L

Plate-Base-PCB

Plate-Assy-Base

Motor-Fan

Rear-Cover-Assy

Fuser-Assy

OPE

Cover-Assy

Guide-Paper-Duplex

GuidePaper-R

Manual-Assy

Front-Guide-Assy

CU board

Toner cartridge

Low voltage

power board

High voltage

power board

Paper cassette

Image drum cartridge

Oki Data CONFIDENTIAL

44306601TH Rev. 2

Fig 4.2.2

63 /

Page 64

MB480

A

A

A’

A’

Stacker-Cover-Assy

Cover-Side-R

Cover-Side-L

Plate-Base-PCB

Plate-Assy-Base

Motor-Fan

Duplex

Rear-Cover-Assy

Fuser-Assy

OPE

Cover-Assy

Guide-Paper-Duplex

GuidePaper-R

Manual-Assy

Front-Guide-Assy

CU board

Toner cartridge

Low voltage

power board

High voltage

power board

Paper cassette

Image drum cartridge

Oki Data CONFIDENTIAL

44306601TH Rev. 2

Fig 4.2.3

64 /

Page 65

[Base unit]

Photo Interrupter

Roller-Pick-Up

Roller-Feed-Now

Guide-Cassette-L

Guide-Cassette-R

Plate-Base

Gear-Assy-Clutch

MB460/MB470

Oki Data CONFIDENTIAL

44306601TH Rev. 2

Fig 4.2.4

65 /