Page 1

OK Industries. Connecting Technologies.

COPPER AND FIBRE OPTIC INTERCONNECT TOOLS

Page 2

PAGE 4-7

FIBRE OPTIC CABLE

STRIPPING TOOLS

PAGE 8

WIRE WRAPPING

OVERVIEW

PAGE 9

PTX SERIES

WRAP/UNWRAP TOOLS

PAGE 10

MANUAL WIRE WRAP/

UNWRAP TOOLS

PAGE 11

BIT & SLEEVE CHART

PAGE 12

SPECIALISED

BITS/SLEEVES

PAGE 13

DFB224 DUAL FUNCTION

WRAP/UNWRAP BIT & SLEEVE SET

PAGE 14

HAND WRAPPING &

UNWRAPPING TOOLS

PAGE 15

COPPER WIRE CUT &

STRIP TOOLS

2

Page 3

TELECOMMUNICATIONS INTERCONNECTION

3

E

NHANCING

NETWORK

RELIABILITY

WITH

OK I

NDUSTRIES

Founded in 1946, OK Industries is a major force in

the telecommunications and electronics

industries and is a division of a large diversified

multinational corporation. We are a global

supplier of hand tools for the interconnection of

communications networks. Our dependable

products employ precision technologies for the

preparation and connection of copper and Fibre

optic cables in applications including public and

enterprise voice and data communications. Ask

for OK Industries when you wish to build

reliability into your networks.

Page 4

FIBRE OPTIC CABLE

STRIPPING TOOLS

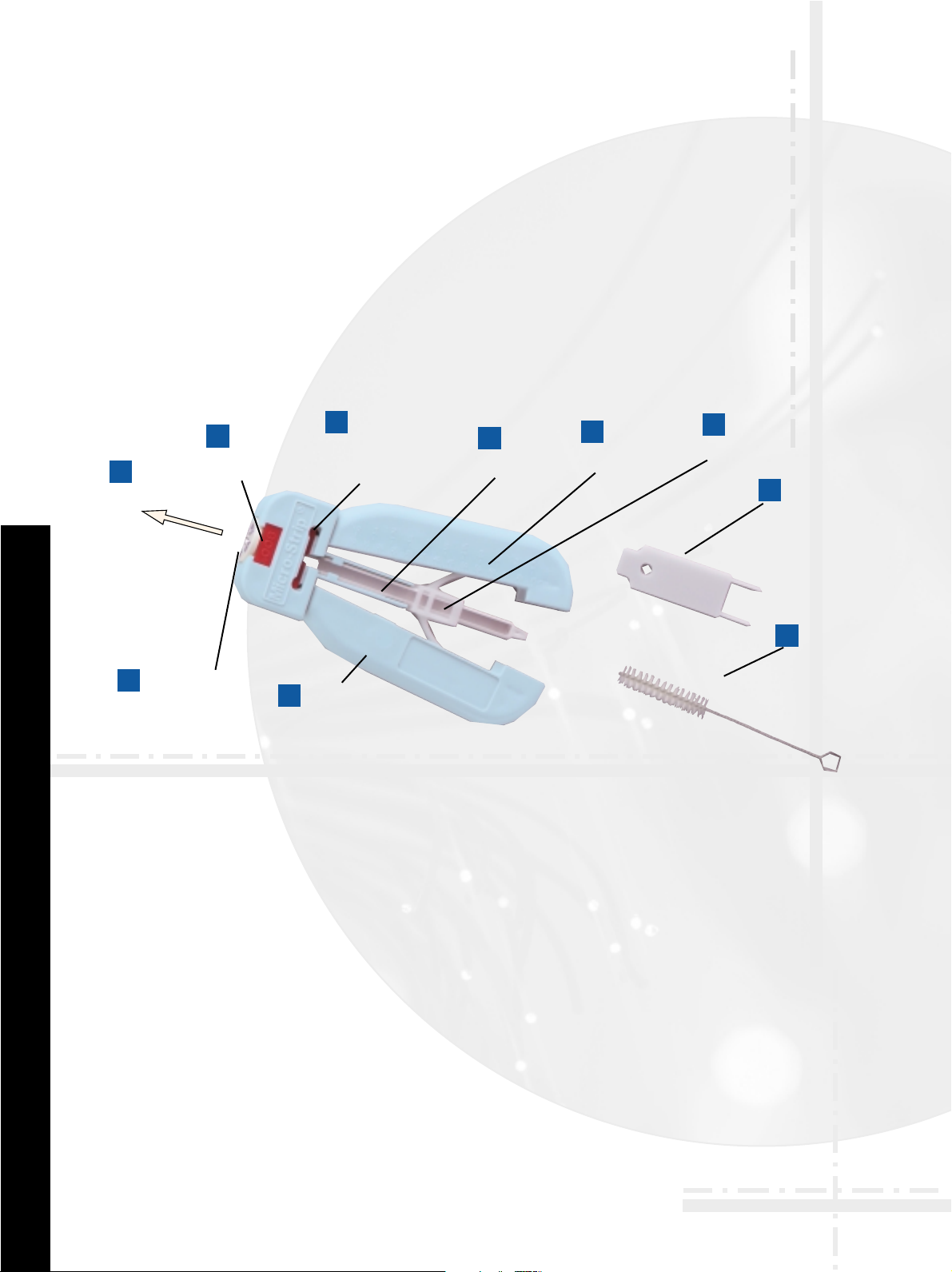

For installers and technicians working with fibre optic cable, OK Industries offers the patented Micro-Strip

®

Series

stripping tools. This innovative range of tools allows for quick, easy stripping of jackets, coatings and buffer materials,

yet is designed to preserve the integrity of the glass core. Opposing stripping blades self-align around the fibre to

assure concentric scoring and precision-stripped, nick-free fibre. The tools also include a fibre support channel, which

maintains perpendicularity between the fibre and the blades; this helps to prevent core damage from flexing and

bending. A thermal version is available to facilitate stripping of jackets, ribbon cables and other difficult applications.

A. Handle

Assembly

B. Fibre Guide

(interchangeable

and replaceable)

C. Stripping

Force

D. Fibre Guide

Lock

E. Cutter Blade Set

(interchangeable

and replaceable)

F. Fibre

Support

Channel

G. Strip

Length

Guide

H. Spring

Assembly

I. Push

Tool

J. Cleaning

Brush

A

B

C

D

E

F

G

H

I

J

NON-THERMAL AND THERMAL STRIPPING TOOL FEATURES

A HANDLE ASSEMBLY

Standard stripping handle

accepts interchangeable

parts quickly and easily.

B FIBRE GUIDE

Selected for each normal

diameter of unstripped

buffer or cable. Wrongsized fibre will not fit,

assuring that fibre is

precisely positioned,

properly stripped, and not

nicked or damaged.

C STRIPPING FORCE

is applied longitudinally

with the fibre. The chance

for harmful drag of

stripped fibre against the

blade is virtually

eliminated, even with

operator inattention or

fatigue.

D FIBRE GUIDE LOCK

holds the fibre guide

securely in position.

Colour-coded to match the

cutter blade set.

E CUTTER BLADE SET

Can be selected for each

FIBRE coating or cladding

diameter. Opposing blades

self-align around fibre

guide to assure concentric

scoring and precision-

stripped, nick-free fibre.

Blades travel in a straight

line to assure proper

alignment. Colour coded to

match the fibre lock.

F FIBRE SUPPORT

CHANNEL

Guides fibre being stripped

(up to 900µm) in straight

line to prevent core

damage from flexing or

bending. For jacket

stripping, cable support

channel performs a similar

function.

G STRIP LENGTH GUIDE

calibrated in 1/16" for

desired strip lengths.

H SPRING ASSEMBLY

keeps handles apart, ready

for next fibre or cable

I PUSH TOOL

(supplied with handle)

makes installation and

removal of cutter blade

sets and fibre locks quick

and easy.

J CLEANING BRUSH

(supplied with handle)

effectively clears small

pieces of residue from the

tool.

FIBRE OPTIC CABLE STRIPPING TOOLS

4

Page 5

5

Use these two standard handles to strip

buffered fibre up to 900µm, or jacketed fibre

up to 3.1mm, quickly and easily. Simply select

and install the proper cutter blade sets, fibre

guides and fibre guide locks. Or if you prefer,

purchase Micro-Strip

®

and Soft-Strip®tools

individually fitted for the fibre or jacket

diameter you specify. Cutter blade sets, fibre

guides and fibre guide locks come already

installed.

THERMAL STRIPPING TOOL

COATING/BUFFER STRIPPING TOOL

Cutter Blade set

Fibre Guide

Fibre-Guide Lock

Cutter Blade set

Fibre Guide

Fibre-Guide Lock

◊ For best results use .0063 inch blade when removing a 250µm coating

◊◊ For best results use .0080 inch blade when removing a 900µm buffer.

*Catalogue numbers are for two cutter blade sets packaged together with a

matching Colour-coded fibre lock. Each cutter blade set consists of a pair of joined,

matched blades which must be snapped apart prior to use. Matched cutter blade

sets are NOT interchangeable, and must be used with their matching half.

Catalogue numbers are for a single, individually packaged fibre guide with

integral size indicator disk.

†Includes tool individually boxed with cleaning brush, push tool and instructions.

††Catalogue numbers are for single individually packaged fibre Guide (with

integral size indicator disk).

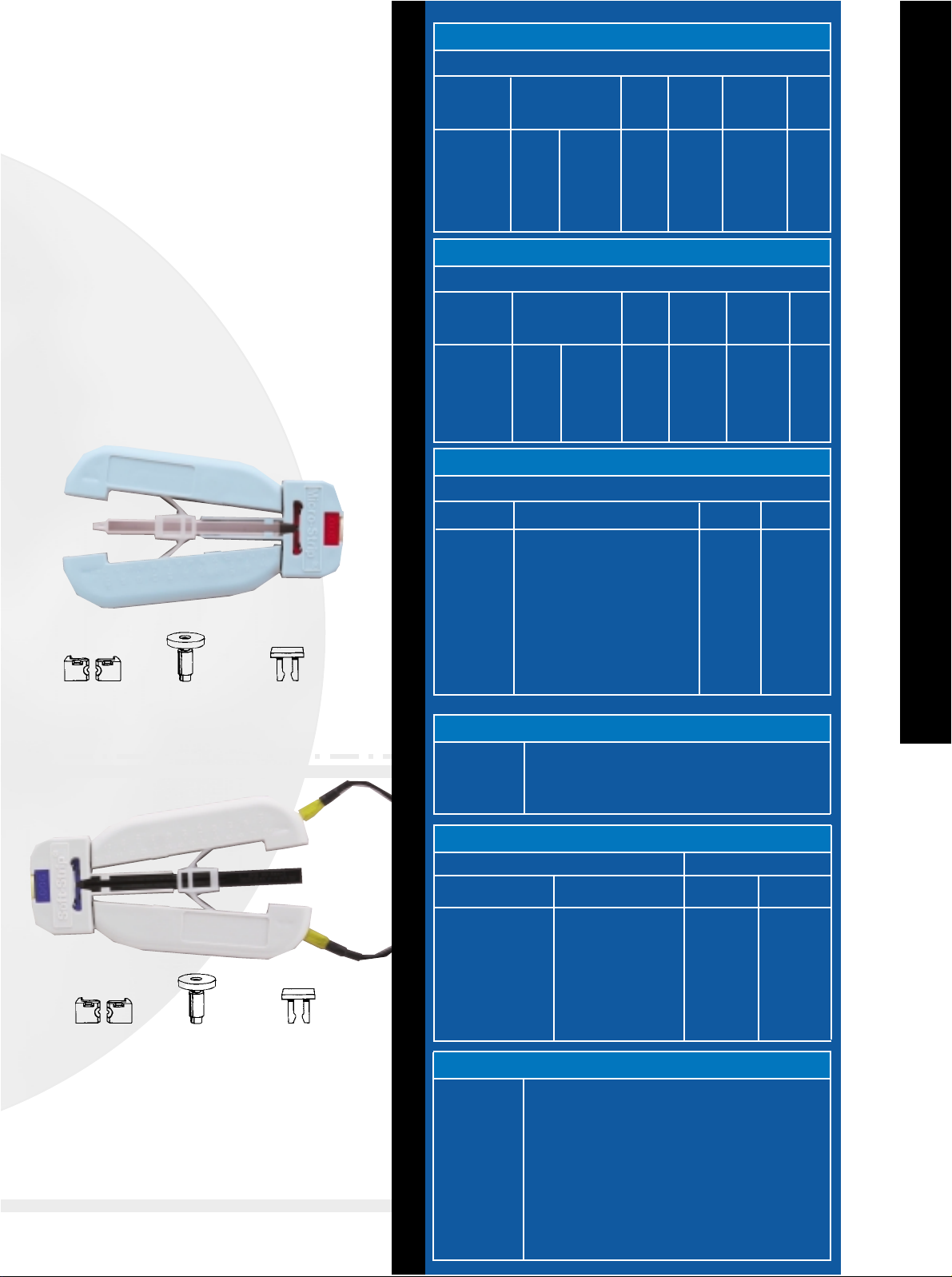

NON-THERMAL TOOLS

250µm Coating◊

900µm Buffer◊◊

2.5mm Jacket/

900µm Buffer

2.5mm Jacket

3mm Jacket

125-135

125-175

125-140

2.5

3.0

.0049-.0053

.0049-.0068

.0049-.0068

.098

.118

.0063

.008

.054

.054

FS-Ø6S-13

FS-Ø8S-40

FS-Ø8S-B5

FS-54S-D1

FS-54S-D2

FS-B-06S

FS-B-08S

FS-B-08S

FS-B-J54

FS-B-J54

COMPLETE TOOLS AND REPLACEMENT BLADE SETS

Fibre Cladding

Diameter to Expose or

Jacket Dia.

(µm) (in.)

Material

to be

Stripped

Proper

Blade

Diameter

(in.)

Complete

Tool

Catalogue

Number †

Replacement

Cutter Blade

Set Catalogue

Number *

Blade

Colour

Code

Purple

Red

Red

Natural

Natural

THERMAL TOOLS-SINGLE FIBRE

NON-THERMAL KITS

FSK-1

FSK-2

FSK-2A

Kit for 125/140 Cladding; 250/900 Coating; 2.5 & 3.0 mm Jackets

Kit for 125/250 Stripper; 125/900 Stripper; 2.5 or 3.0 mm Jacket

Stripper; Kevlar Scissor

Kit for 125/900 Buffer, 2.5MM jacket, scissors

OTHER ACCESSORIES

FSH

FSKS

FS-CB-1

FS-PT-1

FSCR-60-SW

FST-A-T3

FST-A-T4

FST-A-T5

FST-A-T6

FST-RHM-1

FST-RHM-2

Coating/Buffer Stripper Handle

Kevlar Scissors

Blade Cleaning Brush

Blade & Guide Assembly Tool

FIBRE Optic Sapphire Wedge Scribe

U.S. AC Adapter (Thermal Stripper only)

U.K. AC Adapter (Thermal Stripper only)

Euro AC Adapter (Thermal Stripper only)

Australian AC Adapter (Thermal Stripper only)

Heater Cartridge (FST-4B only)

Heater Cartridge (FST-4T only)

FIBRE GUIDES

≤250

250-343

407-457

457-533

533-635

635-787

787-889

889-1016

2.5

3.0

FS-G-26MM

FS-G-31MM

FS-G-10

FS-G-13

FS-G-18

FS-G-21

FS-G-25

FS-G-31

FS-G-35

FS-G-40

Jacket

Diameter (µm)

Catalogue

Number ††

Fibre Coating or Buffer

Dia. to Strip (µm)

Replacement Fibre

Guide Cat. No ††

THERMAL TOOLS-RIBBON FIBRE*

FSTR-3B-06-G1

FSTR-3B-06-G2

FSTR-3E-06-G3

FSTR-3E-06-G4

FSTR-3B-06-G5

FSTR-3B-06-G6

FSTR-3B-06-G8

FSTR-3B-06-G10

FSTR-3E-06-G15

12- Fibre AT&T ASR Thermal Ribbon Stripper

12- Fibre Bonded/Ribbonised Stripper

4 Fibre Encapsulated Thermal Stripper

8 Fibre Encapsulated Thermal Stripper

4 Fibre Bonded Thermal Stripper

8 Fibre Bonded Thermal Stripper

10 Fibre Bonded Thermal Stripper

6 Fibre Bonded Thermal Stripper

12 Fibre Encapsulated Thermal Stripper

FS-RB-06

FS-RB-06

FS-RB-06

FS-RB-06

FS-RB-06

FS-RB-06

FS-RB-06

FS-RB-06

FS-RB-06

FS-G-RG1

FS-G-RG2

FS-G-RG3

FS-G-RG4

FS-G-RG5

FS-G-RG6

FS-G-RG8

FS-G-RG10

FS-G-RG15

COMPLETE TOOLS AND REPLACEMENT BLADE SETS

Description

Catalogue Number

Replacement

Blade Set

Replacement

Ribbon Guide

COATING OR BUFFER

JACKET

AA BATTERIES

250µm Coating◊

900µm Buffer◊◊

AC ADAPTER

250µm Coating◊

900µm Buffer◊◊

125-135

125-175

125-135

125-175

.0049-.0053

.0049-.0068

.0049-.0053

.0049-.0068

.0063

.008

.0063

.008

FST-4B-06S-13

FST-4B-08S-40

FST-4T-06S-13

FST-4T-08S-40

FS-B-06S

FS-B-08S

FS-B-06S

FS-B-08S

COMPLETE TOOLS AND REPLACEMENT BLADE SETS

Fibre Cladding

Diameter to Expose or

Jacket Dia.

(µm) (in.)

Material

to be

Stripped

Proper

Blade

Diameter

(in.)

Complete

Too l

Catalogue

Number †

Replacement

Cutter Blade

Set Catalogue

Number *

Blade

Colour

Code

Purple

Red

Purple

Red

MICRO-STRIP ORDERING INFORMATION

* The Ribbon Fibre tools are all Electric Powered

Page 6

NON THERMAL STRIPPING TOOL

6

STRIPPING PROCEDURE

(BUFFERED OPTICAL FIBRE TOOL)

Hold tool in one hand, fibre in the other. Keep handles in fully expandable

position. Insert fibre through fibre guide until end aligns with rule markings

to match desired strip length (1).

Squeeze handles closed. Cutter blades are now scoring the buffer or

coating (2).

While maintaining a slight pressure to keep cutter closed, withdraw fibre

from tool, completing the stripping process (3).

STRIPPING PROCEDURE

(JACKETED FIBRE TOOL WITH LATCH BAR)

Insert cable through fibre guide. Align end of cable with rule marking

at desired strip length (1).

Close handles together so blades cut into jacket (2).

While holding handles closed, flip latch bar down around pin. Release

handles to latched, semi-open position. Do not reclose handles. Move hand

up to grasp head of tool. While other hand is holding cable firmly, pull with

a quick, smooth motion. Flip latch off pin. Stripped jacket will fall out

through rear of channel when handles are fully opened.Note: Never leave

tool with latch bar in locked position. This can cause Delrin spring to take a

set, preventing handles from opening fully. When stripping hard, tough or

thick jackets, it is not necessary to use latch bar. Lock bar out of the way by

tightening the screw.

Close handles. Blade sets cut almost

through the buffer or jacket without

ever touching the fibre.

With handles closed, pull fibre or cable

from tool. Always a precision strip

length. fibre is never nicked or damaged.

NON-THERMAL STRIPPING

JACKET AND COATING

2

3

PROPER TOOL SELECTION

Select the proper tool and components for either fibre stripping or jacket stripping by referring to the tables on the

back page. If necessary, install proper fibre guide, fibre guide lock and cutter blade set.

Insert correct fibre through guide and

into support channel to desired strip

length.

1

P ATENTED, SELF- CENTERING MICRO-STRIP

®

STRIPPING SYSTEM ASSURES

PRECISE, CONCENTRIC SCORING, WITHOUT CLADDING OR CORE DAMAGE.

SNAP-APART PRECISION-MACHINED BLADE HALVES

MOLDED INTO THERMOPLASTIC BODIES.

C

Fibre is withdrawn,

assuring a perfect

strip every time.

Only the coating or

buffer is scored.

fibre is never nicked

or damaged.

Fibre enters guide

through opening

dimensioned for a

particular diameter

range. Fibre that is

too large won’t

enter the guide;

fibre that’s too

small won’t be

stripped.

B As gripping handles close,

each blade half moves in a

straight line to self-align

around the fibre guide. This

places the blades in perfect

concentric relationship.

End of fibre

guide supports

blades during

stripping to

prevent blade

flexing

and

fatigue.

A

C

B

CAUTION

Always wear approved eye

protection when working

with any type of fibre optic

cable or wire.

A

Page 7

THERMAL STRIPPING TOOL

7

NOTE: Blades are Colour coded and matched to diameter and Colour of fibre guide lock. Replace

or install fibre guide and guide lock as needed. Always test-strip fibre or cable after installing new

blade set. Remove blades periodically and clean with brush provided and alcohol.

CAUTION: Heater units continuously when handles are closed. Do not hold handles closed for

longer than 20 seconds for AA and D-Size battery units, 10 seconds for 6-Volt battery/

AC adapter units, or overheating can damage tool. Do not touch heater oven while in operation.

Allow oven to cool before removal and cleaning.

Insert fibre through fibre guide and into

heater oven to desired length. Be sure

buffered fibre is flat in the oven channel.

Always allow at least 1/8" gap from fibre

tip to end of oven channel. Otherwise

heater oven movement will cause fibre

to buckle up and out of heating zone.

Close handles all the way. Blades are

precisely aligned for concentric scoring

without cladding, core or conductor

damage. Heater oven is automatically

activated to start the softening process.

Keep handles closed (AA or D-size 10-20

sec., 6V or AC adapter 4-8 sec.) for

optimum softening. Then begin to pull

the fibre, slowly increasing pull force

until coating releases from the fibre.

Remove the fibre from the tool with a

smooth, even motion.

1

2

3

Recess

marks

this

side

Replacement

Blades

Fibre

Guide

Lock

Blade

Removal

End

PUSH OUT

BACK SIDE

Fibre

Guide

Fibre

Guide

Lock

Removal

End

PUSH

TOOL

GENERAL

Strip outer jacket (if any), using Soft-Strip®non-thermal tool. Install and

connect battery(s), or install and connect AC adapter. Install proper cutter

blade set, fibre guide and fibre guide lock.

HEATER OVEN

Unit is activated when handles are closed. Close handles only when stripping.

Check heater operation by closing handles firmly for no longer than 10

seconds. Nose end of heater should be warm to the touch.

After stripping operation, remove heater oven from tool and clean with the

brush provided (spring assembly in later models includes automatic scrap

ejector.) Reinsert, making sure that heater oven is pushed completely

forward toward the blade area and snaps into place. 2" heater oven area

should be visible at front of tool so operator can monitor positioning and

preheating of coating.

CUTTER BLADE REPLACEMENT INSTRUCTION PROCEDURE FOR

NON-THERMAL AND THERMAL SOFT-STRIP

®

STRIPPING TOOLS

TO REMOVE INSTALLED BLADES:

1. Using flat end of push tool, remove fibre guide lock by pushing out from

back side of tool head.

2. Remove fibre guide from tool.

3. Using prong end of push tool in small holes on back side of tool head,

eject blade set.

IMPORTANT Do not remove cutter blades while fibre guide is still in tool.

TO INSTALL NEW BLADES:

(Furnished in a matched set for blade position.

Snap apar

t before installation.)

1. Install with “ears” pointing toward top of tool and recess marks visible.

Push firmly with flat end of push tool until both blades are seated.

2. Insert fibre guide through hole in top of tool until it stops.

3. Insert fibre guide lock through slot in front of tool head.

THERMAL

STRIPPING

Page 8

WIRE WRAPPING OVERVIEW

8

By bending the wire around the sharp corner

of the terminal, the oxide layer on both wire

and terminal is crushed or sheared, and a clean,

oxide-free metal-to-metal contact is obtained.

A “Regular” bit wraps the bare wirearound the terminal.

A “Modified” bit wraps a portion of insulation around

the terminal in addition to the bare wire.This

greatly increases the ability to withstand vibration.

Regular

Modified

In. .010 .015 .020 .025 .030 .035 .040 .045 .050 .055 .060 .065 .070 .075 .080 .085 .090 .095 .100

mm 0.25 0.38 0.51 0.64 0.76 0.89 1.02 1.14 1.27 1.40 1.52 1.65 1.78 1.91 2.03 2.16 2.29 2.41 2.54

.010 .014 .018 .022 .027 .032 .036 .041 .046 .051 .056 .061 .066 .071 .076 .081 .086 .091 .096 .101

0.25 0.36 0.46 0.56 0.69 0.81 0.91 1.04 1.17 1.30 1.42 1.55 1.68 1.80 1.93 2.06 2.18 2.31 2.44 2.57

.015 .018 .021 .025 .029 .033 .038 .043 .047 .052 .057 .062 .067 .072 .077 .082 .087 .092 .097 .102

0.38 0.46 0.53 0.64 0.74 0.84 0.97 1.09 1.19 1.32 1.45 1.58 1.70 1.83 1.96 2.08 2.21 2.34 2.46 2.59

.020 .022 .025 .028 .032 .036 .040 .045 .049 .053 .058 .063 .068 .073 .078 .083 .088 .093 .098 .103

0.51 0.56 0.64 0.71 0.81 0.91 1.02 1.14 1.25 1.35 1.47 1.60 1.73 1.85 1.98 2.11 2.24 2.36 2.49 2.62

.025 .027 .029 .032 .035 .039 .043 .047 .050 .056 .060 .065 .069 .074 .079 .084 .089 .094 .099 .104

0.64 0.69 0.74 0.81 0.89 0.99 1.09 1.19 1.27 1.42 1.52 1.65 1.75 1.88 2.01 2.13 2.26 2.39 2.52 2.64

.030 .032 .033 .036 .039 .042 .046 .050 .054 .058 .062 .067 .071 .076 .080 .085 .090 .095 .100 .105

0.76 0.81 0.84 0.91 0.99 1.07 1.17 1.27 1.37 1.47 1.58 1.70 1.80 1.93 2.03 2.16 2.29 2.41 2.54 2.67

.035 .036 .038 .040 .043 .046 .049 .052 .056 .060 .064 .069 .073 .078 .082 .087 .091 .096 .101 .106

0.89 0.91 0.97 1.02 1.09 1.17 1.25 1.32 1.42 1.52 1.63 1.75 1.85 1.98 2.08 2.21 2.31 2.44 2.57 2.69

.040 .041 .043 .045 .047 .050 .052 .056 .060 .064 .068 .072 .076 .080 .084 .089 .092 .097 .102 .107

1.02 1.04 1.09 1.14 1.19 1.27 1.32 1.42 1.52 1.63 1.73 1.83 1.93 2.03 2.13 2.26 2.34 2.46 2.59 2.72

.045 .046 .047 .049 .050 .054 .056 .060 .063 .067 .071 .074 .078 .083 .087 .091 .096 .101 .105 .109

1.14 1.17 1.19 1.25 1.27 1.37 1.42 1.52 1.60 1.70 1.80 1.88 1.98 2.11 2.21 2.31 2.44 2.57 2.67 2.77

.050 .051 .052 .053 .056 .058 .060 .064 .067 .071 .074 .078 .082 .086 .090 .094 .098 .103 .107 .111

1.27 1.30 1.32 1.35 1.42 1.47 1.52 1.63 1.70 1.80 1.88 1.98 2.08 2.18 2.29 2.39 2.49 2.62 2.72 2.82

Example: If “E”=.020”. “F”=.060”. The terminal diagonal is .063" as shown on chart.

Step 1: Bit, Sleeve and

Pre-Stripped Wire

Step 2: Wire Insertion

Step 3: Wire Anchoring

Step 4: Terminal

Insertion

Step 5: Finished

Connection

METAL- TO- METAL CONTACT

TYPES OF WRAP

TERMINAL DIAGONAL CHART

HOW TO MAKE WIRE

WRAPPED CONNECTIONS

Wire Size Min. number Min. strip

AWG Dia. Dia. of turns force

inches mm (Bare Wire) lbs. gms

16 .051 1.30 4 15 6800

18 .0403 1.00 4 15 6800

20 .032 0.80 5 8 3600

22 .0253 0.65 5 8 3600

24 .0201 0.50 6 7 3200

26 .0159 0.40 7 6 2700

28 .0126 0.32 7 5 2200

30 .0100 0.25 7 3.3 1500

*Conforms to MIL-STD-1130B

STRIP FORCE CHART

SOME HINTS ON MAKING WRAPPED CONNECTIONS

OPEN WRAP & SPIRAL WRAP

Just keep the OK tool on the

terminal until the wrap is

complete. Early removal can

result in spiral and open wraps.

PIGTAIL

Wire wrapping is a precision

technique and the wrong bit

and sleeve just cannot do the

job. Improper selection can

cause problems ranging from

“Pigtails” to loose wraps.

Wire Wrapping is a method of making a wire connection by coiling the bare wire around the sharp corners of a

terminal under mechanical tension. The technology was developed as an alternative to soldering, which presents

various safety and reliability problems in many applications. A principal advantage of wire wrapping is that it

provides a high-reliability connection that is also easily removed to correct or modify a wiring layout. Wire wrapping

subjects the wire to tremendous tension and compression forces, causing the oxide layer on both wire and terminal

to be crushed or sheared, resulting in a clean, oxide-free metal-to-metal contact. A standard wrap is generally used

for 24 AWG and larger diameter wires; a modified wrap is typically used for 24 AWG and smaller wires, and is used

almost exclusively for 28 to 30 AWG wires. In either case, the wrap style affects only the connection’s mechanical

stability; both styles provide suitable electrical connections.

WIRE WRAPPING OVERVIEW

INSUFFICIENT TURNS

It’s easy to feed wire into the

slot in the OK bit correctly. Be

sure the stripped end of the

wire is “pushed-in” all the way.

OVERWRAP

Do not press too hard. Let the

OK tools do the work. Excessive

pressure can lead to

overwrapping. Backforce "BF"

to prevent overwrapping is

available on most power tools

and is recommended for use

with 26 through 30 AWG wire.

Page 9

PTX SERIES ERGONOMIC WIRE WRAPPING TOOLS

PTX SERIES

ERGONOMIC WIRE WRAPPING TOOLS

Part No. Description Weight Voltage RPM

PTX Battery Wrap/Unwrap Tool (Battery not included) 1.2 lb. 3.6V* 3700

PTX-1 Electric Wrap/Unwrap Tool - 115V 0.86 lb. 115V 3700

PTX-1BF Electric Wrap/Unwrap Tool w/Backforce - 115V 0.86 lb. 115V 3700

PTX-2 Electric Wrap/Unwrap Tool - 230V 1.0 lb. 230V 4200

PTX-2-UK Electric Wrap/Unwrap Tool - UK Plug - 230V 1.0 lb. 230V 4200

PTX-2BF Electric Wrap/Unwrap Tool w/Backforce - 230V 1.0 lb. 230V 4200

PTX-2BF-UK Electric Wrap/Unwrap Tool w/Backforce - UK Plug - 230V 1.0 lb. 230V 4200

PTX-KIT1 115V battery tool kit (tool, charger, (2) batteries)

PTX-KIT2 230V battery tool kit (tool, charger, (2) batteries)

PTX-KIT2-UK 230V battery tool kit w/ UK Plug (tool, charger, (2) batteries)

* Powered by long-life NiMH battery

The PTX Series Wire Wrapping Tools from OK Industries

bring revolutionary new benefits to installers, telecom

technicians and other users. With worker safety in

mind, we consulted a certified ergonomist and

created an ergonomic tool, which includes a

lightweight, well-balanced construction, dual-finger

short-throw trigger, and a long handle to mitigate

pressure on the palm. These features help to prevent

repetitive stresses and result in an industry-leading design

from a comfort and safety standpoint. Ask for the PTX Series

Wire Wrapping Tools from OK Industries — and arm your

workers with the tools that offer efficiency and worker

safety in your interconnect activity.

PTX-BC1

PTX-B

KEY FEATURES

ACCESSORIES

■ PTX-B PTX Battery, 3.6V

■ PTX-BC1 115V Charger for

PTX-B battery

■ PTX-BC2 230V Charger for

PTX-B battery

■ PTX-BC2-UK 230V Charger with

UK Plug for

PTX-B battery

9

Low Battery Indicator

High Power Motor

Reverses for

Unwrapping

Permanently

Attached

Collet Nut

Ergonomic,

Rugged

Tool Design

■ Ergonomic Design — Minimises Repetitive Stress

■ Rugged Construction for Field Usage

■ Battery and Electric Powered Versions Available

■ Wraps and Unwraps 20 to 30 AWG Wire

■ Rated Maximum Usage: 2,500 cycles/day

■ For Bits & Sleeves: see Page 11

Page 10

MANUAL WIRE WRAPPING TOOLS & KITS

10

The G100/R3278 and G200/R3278 tools are designed

with a chuck nose piece to make use of the full line of

bits and sleeves made for power tools. The

G100/R3278INS is coated with an insulative material,

providing 1000V of dielectric strength across most of

the housing, to help ensure worker and system safety.

These tools accommodate wire sizes from 22 AWG

(0.65mm) thru 32 AWG (0.20mm).

The combination of the G100/R3394 unwrap tool

and the SU unwrap bits gives you the best tool for

high speed wire unwrapping. High production, long

life, low maintenance. Use Unwrap Set SU2026 for

wire AWG 20 thru 26 (0.80 thru 0.40mm) and Set

SU2832 for wire AWG 26 thru 32 (0.40 thru 0.20mm).

Unwrap Bit Unwrap Sleeve Bit and Sleeve Wire Size Terminal Hole Diameter

Part No. Part No. Set No. AWG mm Inches mm

2026UB 2032 SU2026 22-26 0.65-0.40 .070 1.77

2832UB 2032 SU2832 26-32 0.40-0.20 .036 0.96

G100/R3394

G100/R3278 Aluminum

This is a complete kit for technicians working at a Main

Distributing Frame. The G200/R3278 Manual Gun

produces wire wrapped connections merely by

squeezing the trigger, and works with any bit and

sleeve. The versatile HW-UW-224 Hand Wrap-Unwrap

Tool (22-24 AWG) does the work of two tools in one wrapping and unwrapping - just by changing the cap

from one end to the other. The ST-100 22-24 AWG wire

Cut-and-Strip Tool offers easy, clean stripping of up to

four wires with 15/16" - 19/16" adjustable strip off

length. This kit comes complete with KB224 22-24 AWG

bit, P2224 22-24 AWG sleeve and H-1000 cordura tool

pouch.

WWK-1

G100/R3394 Bits & Sleeves:

MANUAL WIRE WRAPPING

TOOLS & KITS

■

G200/R3278 :

Lexan™

■

G200/R3278-K :

Speed Wrap Tool kit

■

G100/R3278 :

Aluminum

■ G100/R3278INS :

Aluminum (insulated)

■

For Bits & Sleeves :

see page 11

■

WWK-1 : Telecom Wire Wrap Kit

■

G100/R3394 :

Manual Wire Unwrapping Tool

MANUAL WIRE WRAPPING TOOLS

MANUAL WIRE UNWRAPPING TOOL

G200/R3278 Lexan™

G100/R3278INS

(Shown with Bit/Sleeve)

TELECOM WIRE WRAP KIT

Page 11

WIRE WRAPPING BITS AND SLEEVES

11

BITS AND SLEEVES CHART ( AWG) INCHES

BITS AND SLEEVES CHART MILLIMETRES

Maximum Minimum Maximum Terminal Terminal

Wire Bit Sleeve Insulation Terminal Terminal Hole Effective Hole

Gauge Regular Modified Part No. Part No. Diameter Diagonal Diagonal Depth Radius Diameter

mm mm mm mm mm mm mm

1.00

●

KB18 P194 – 1.52 1.85 25.40 3.81 1.90

0.80

●

WB20M P194LN 1.50 1.07 1.85 25.40 3.81 1.90

0.65-0.80

●

KB2075 P2224 – 1.07 1.85 25.40 3.12 1.90

0.65

●

KB22LT P2224 – 1.54 2.15 25.40 3.17 2.18

0.65

●

KB22 P2224 – 1.37 1.85 19.05 2.97 1.90

0.65

●

WB2275M P2224 1.32 1.24 1.87 25.40 3.35 1.90

0.50-0.65

●

KB224LH P2224 – 1.54 2.15 25.40 2.97 2.18

0.50-0.65

●

KB224-1 P2224 – 1.37 1.85 25.40 2.82 1.90

0.50-0.65

●

KB224 P2224 – 1.37 1.85 20.50 2.82 1.90

0.50-0.65

●

WB224M P2224 1.27 1.24 1.87 31.75 3.07 1.90

0.50

●

*KB2444 P3032LN – 0.60 1.09 25.40 2.10 1.11

0.50

●

WB24DH P2224 1.17 1.37 1.85 44.50 2.97 1.90

0.50

●

KB24 P2426 – 1.39 1.87 19.05 2.54 1.90

0.50

●

*WB24SM P3032LN 1.11 0.60 1.09 19.05 2.48 1.11

0.50

●

WB24DHM P2224 1.27 1.24 1.72 28.50 2.99 1.75

0.40-0.50

●

WB2426M P2224 1.17 1.37 1.85 19.05 2.99 1.90

0.40-0.50

●

KB2466 OK8519 – 1.37 1.65 25.40 2.48 1.67

0.40

●

*KB2639 P26LN – 0.58 0.96 19.05 1.72 1.02

0.40

●

KB26 P2426 – 1.47 1.85 25.40 2.54 1.90

0.40

●

*WB26SM P26LN 0.79 0.58 0.96 19.05 1.90 1.02

0.40

●

WB26M P2224 1.17 1.37 1.85 25.40 2.99 1.90

0.40

●

*WB2644M P3032LN 1.17 0.60 1.09 19.05 2.48 1.11

0.40

●

WB2669M P2426 1.04 1.34 1.72 25.40 2.77 1.75

0.32

●

*WB28SHM P3032 0.76 0.79 0.89 19.05 1.67 0.91

0.29-0.32

●

*WB2829M P3032L 0.91 0.83 0.96 19.05 2.31 1.02

0.25

●

*SB30MSH-B P3032 0.69 0.79 0.89 19.05 1.62 0.91

0.25

●

*SB30MMK P3032 0.58 0.79 0.89 19.05 1.62 0.91

0.20-0.25

●

*WB3032M P3032 0.69 0.86 0.96 19.05 1.62 1.02

* These tools are recommended for 0.63mm terminals on 2.54mm centres

WIRE WRAPPING BITS & SLEEVES

Maximum Minimum Maximum Terminal Terminal

Wire Bit Sleeve Insulation Terminal Terminal Hole Effective Hole

Gauge Regular Modified Part No. Part No. Diameter Diagonal Diagonal Depth Radius Diameter

(AWG) Inches Inches Inches Inches Inches Inches

18

●

KB18 P194 – .060 .073 1.00 .150 .075

20

●

WB20M P194LN .059 .042 .073 1.000 .150 .075

20-22

●

KB2075 P2224 – .042 .073 1.000 .123 .075

22

●

KB22LT P2224 – .061 .085 1.000 .125 .086

22

●

KB22 P2224 – .054 .073 .750 .117 .075

22

●

WB2275M P2224 .052 .049 .074 1.000 .132 .075

22-24

●

KB224LH P2224 – .061 .085 1.000 .117 .086

22-24

●

KB224-1 P2224 – .054 .073 1.000 .111 .075

22-24

●

KB224 P2224 – .054 .073 .807 .111 .075

22-24

●

WB224M P2224 .050 .049 .074 1.250 .121 .075

24

●

*KB2444 P3032LN – .024 .043 1.000 .083 .044

24

●

WB24DH P2224 .046 .054 .073 1.750 .117 .075

24

●

KB24 P2426 – .055 .074 .750 .100 .075

24

●

*WB24SM P3032LN .044 .024 .043 .750 .098 .044

24

●

WB24DHM P2224 .050 .049 .068 1.125 .118 .069

24-26

●

WB2426M P2224 .046 .054 .073 .750 .118 .075

24-26

●

KB2466 OK8519 – .054 .065 1.000 .098 .066

26

●

*KB2639 P26LN – .023 .038 .750 .068 .040

26

●

KB26 P2426 – .058 .073 1.000 .100 .075

26

●

*WB26SM P26LN .031 .023 .038 .750 .075 .040

26

●

WB26M P2224 .046 .054 .073 1.000 .118 .075

26

●

*WB2644M P3032LN .046 .024 .043 .750 .098 .044

26

●

WB2669M P2426 .041 .053 .068 1.000 .109 .069

28

●

WB2870M P2426 .034 .053 .068 1.000 .103 .070

28-29

●

*WB2829M P3032L .036 .033 .038 .750 .091 .040

30

●

*SB30MSH-B P3032 .027 .031 .035 .750 .064 .036

30

●

*SB30MMK P3032 .023 .031 .035 .750 .064 .036

30-32

●

*WB3032M P3032 .027 .034 .038 .750 .064 .040

*These tools are recommended for .025" square terminals on .100 centres

Fully compatible with any make or model wire wrapping tool,

except G100 and G200 manual tools, which are obsolete and

require special bits and sleeves.

Page 12

specialised BITS AND SLEEVES

12

Precision devices which attach easily to your wire wrapping

tool for applications requiring extra “reach”. Simply install

the extension into the tool, then install the bit and sleeve

into the extension. Fits all Electric and Manual wire

wrapping tools. Compatible with all bits and sleeves made

for Power Wire Wrapping Tools.

The insulated sleeves are covered with a material which

provides 1000V dielectric strength which helps to prevent

shorting between pins and enhances worker safety.

P2426-5

KB24-5

Maximum Minimum Maximum Terminal Terminal

Bit Sleeve Wire Size Regular Modified Insulation Terminal Terminal Hole Effective Hole

Part No. Part No. Diameter Diagonal Diagonal Depth Radius Diameter

AWG mm In. mm In. mm In. mm In. mm In. mm In. mm

KB22-5 P2224-5 22 0.65

●

– – .054 1.37 .073 1.85 .750 19.05 .117 2.97 .075 1.90

KB24-5 P2426-5 24 0.50

●

– – .055 1.39 .073 1.85 .750 19.05 .100 2.54 .075 1.90

KB26-5 P2426-5 26 0.40

●

– – .058 1.47 .073 1.85 .750 19.05 .100 2.54 .075 1.90

SPECIALISED BITS & SLEEVES

POWER UNWRAPPING BITS & SLEEVES

WIRE WRAPPING EXTENSION ATTACHMENTS

BITS AND INSULATED SLEEVES

2” (5CM)

LONGER THAN STANDARD BITS& SLEEVES

Unwrap Unwrap Bit and Wire Size Terminal

Bit Sleeve Sleeve Hole Dia.

Part No. Part No. Set AWG mm In. mm

2026UB SOK-2230 PUW-2226 20-26 0.80-0.40 .070 1.77

2832UB SOK-2230 PUW2830 26-32 0.40-0.20 .038 0.96

Maximum Minimum Maximum Terminal Terminal

Bit Sleeve Wire Size Regular Modified Insulation Terminal Terminal Hole Effective Hole

Part No. Part No. Diameter Diagonal Diagonal Depth Radius Diameter

AWG mm In. mm In. mm In. mm In. mm In. mm In. mm

KB22 P2224INS 22 0.65

●

– – .054 1.37 .073 1.85 .750 19.05 .117 2.97 .075 1.90

KB224 P2224INS 22-24 0.50-0.65

●

– – .054 1.37 .073 1.85 .807 20.50 .111 2.82 .075 1.90

KB24 P2426INS 26 0.50

●

– – .055 1.39 .074 1.87 .750 19.05 .100 2.54 .075 1.90

KB26 P2426INS 26 0.40

●

– – .058 1.47 .073 1.85 1.0 25.40 .100 2.54 .075 1.90

Maximum Minimum Maximum Terminal Terminal

Bit Sleeve Wire Size Regular Modified Insulation Terminal Terminal Hole Effective Hole

Part No. Part No. Diameter Diagonal Diagonal Depth Radius Diameter

AWG mm In. mm In. mm In. mm In. mm In. mm In. mm

KB22-5 P2224-5INS 22 0.65

●

– – .054 1.37 .073 1.85 .750 19.05 .117 2.97 .075 1.90

KB24-5 P2426-5INS 24 0.50

●

– – .055 1.39 .073 1.85 .750 19.05 .100 2.54 .075 1.90

KB26-5 P2426-5INS 26 0.40

●

– – .058 1.47 .073 1.85 .750 19.05 .100 2.54 .075 1.90

■

EXT-400 :

4.0’’ (100mm) extension

These bits and sleeves are designed for wire wrapping in

areas requiring deep penetration. Their 5" (127mm)

length ensures “true” connections in hard-to-get-at

locations.

P2426-5INS

KB24-5

EXTENDED LENGTH (5”) BITS AND INSULATED SLEEVES

For PTX Series battery or electric wrap/unwrap tool.

Page 13

Min. Terminal Max. Terminal Terminal Terminal Hole Effective

Part # Description Wire Size Diagonal Diagonal Hole Depth Diameter Radius

mm AWG mm in. mm in. mm in. mm in. mm in.

DFB224 Dual Function Wrap/Unwrap .50/.65 22/24 1.37 .054 1.85 .073 25.04 1.00 1.90 .075 2.82 .111

Bit/Sleeve Set, 22/24 AWG

DFB2426 Dual Wrap/Unwrap bit & .40/.50 24/26 1.37 .054 1.85 .073 25.04 1.00 1.67 .066 2.48 .098

sleeve set, 24-26 AWG

The Wrap/Unwrap bit is shipped with the sleeve set in the wrap position.

To change to the unwrap simply pull the sleeve out

approximately 1/4” (the sleeve is spring loaded and you should feel some tension while pulling forward), rotate the sleeve in either

direction 180

0

and release. The sleeve should now be seated approximately 1/4” lower than in the wrap position. This will expose

the unwrap feature on the bit.

To change back to the wrap position pull the sleeve out approximately 1/2” and rotate the sleeve in either direction 180

0

and release

The spout should be in the 12:00 position and the sleeve should be locked in position.

Note: If you cannot rotate the sleeve, you need to pull the sleeve out further before trying to rotate the sleeve.

OK INDUSTRIES INTRODUCES THE DFB224 DUAL FUNCTION BIT

HOW TO USE THE DFB224

DFB224 DUAL FUNCTION

WRAP/UNWRAP BIT

& SLEEVE SET

This innovative product represents a truly revolutionary approach to wire wrapping, by combining both the wrap and the

unwrap functions into one bit/sleeve set. The bit is precision machined for high quality wrapping in the clockwise direction,

but also includes the removal mechanism that is used to unwrap when operated counterclockwise. The user can quickly and

easily switch back and forth between wrap and unwrap mode by retracting or extending the retractable sleeve, and flipping

the switch on a wrap/unwrap power tool (i.e., a power wire wrapping tool with reversible motor). This product, which can

wrap or unwrap 22 and 24 AWG wire, enables the user to maximize operating efficiency while eliminating the need to

purchase and carry extra tools or bits for unwrapping. Also, to prevent pin-to-pin shorting, the retractable sleeve is coated

with a durable 1000V dielectric material.

13

DFB224 DUAL FUNCTION WRAP/UNWRAP BIT & SLEEVE SET

KB-DF224 (wrap/unwrap bit)

P-DF2224 (wrap/unwrap sleeve assembly)

KB-DF2426 (replacement bit for DFB2426)

P-DF2426 (replacementSleeve Assy, DFB2426)

Page 14

HAND WRAPPING AND UNWRAPPING TOOL

14

Wire Size Max. Insulation Terminal Hole Terminal Hole Outside

Part No. Reg. Mod. Type Diameter Diameter Depth Diameter

AWG mm Inches mm Inches mm Inches mm Inches mm

HW-224

●

A 22-24 0.65-0.50 – – .075 1.90 .807 20.50 .218 5.53

HW-224LH

●

A 22-24 0.65-0.50 – – .086 2.18 1.000 25.40 .218 5.53

HW-24DHM

●

A 24 0.50 .050 1.27 .069 1.75 1.125 28.50 .218 5.53

HW-2426

●

A 24-26 0.50-0.40 – – .075 1.90 .750 19.05 .218 5.53

HW-26

●

A 26 0.40 – – .075 1.90 1.000 25.40 .218 5.53

*HW-26SM

●

A 26 0.40 .031 0.79 .040 1.02 .750 19.05 .125 3.17

*HW-30

●

B 30 0.25 .027 0.69 .036 0.91 .750 19.05 .125 3.17

*These tools are recommended for .025" (0.63mm) square terminals on .100" (2.54mm) centres

Note: HW-22 and HW-24 have been replaced by HW-224.

These tools are used to remove wire connections

using 18 thru 32 gauge wire.

Type of Terminal Terminal Outside

Part No. Type Wire Size Unwrap Hole Diameter Hole Depth Diameter

AWG mm Inches mm Inches mm Inches mm

UW1 A 20-26 0.80-0.40 Left Hand .070 1.77 1.000 25.40 .156 3.96

UW2 E 20-26 0.80-0.40 Left and Right Hand .070 1.77 1.000 25.40 .156 3.96

UW4 D 20-26 0.80-0.40 Left Hand .070 1.77 2.360 60.00 .187 4.74

UW5 D 20-26 0.80-0.40 Left and Right Hand .070 1.77 2.360 60.00 .187 4.74

UWD93-93 E 24-32 0.50-0.20 Left and Right Hand .038 0.96 1.000 25.40 .093 2.36

UW2832C D 28-32 0.32-0.20 Left and Right Hand .038 0.96 .750 19.05 .156 3.96

Type “A”

Type “E”

Max. Terminal Terminal

Part Wire Size Insulation Hole Hole Outside Wire Size

Number Reg Mod Diameter Diameter Depth Diameter

AWG mm In. mm In. mm In. mm In. mm AWG mm

HW-UW-224

●

22-24

0.50

– – .075 1.90 .807 20.50 .218 5.53 20-26

0.80

0.65 0.40

HW-UW-224-1

●

22-24

0.50

– – .075 1.90 1.000 25.40 .218 5.53 20-26

0.80

0.65 0.40

HW-UW-224LH

●

22-24

0.50

– – .086 2.18 1.000 25.40 .218 5.53 20-26

0.80

0.65 0.40

HW-UW-24DHM

●

24 0.50 .050 1.27 .069 1.75 1.125 28.50 .218 5.53 20-26

0.80

0.40

*HW-UW-24SM

●

24 0.50 .044 1.11 .044 1.11 .750 19.05 .156 3.96 20-26

0.80

0.40

HW-UW-2426

●

24-26

0.40

– – .075 1.90 .750 19.05 .218 5.53 20-26

0.80

0.50 0.40

HW-UW-26

●

26 0.40 – – .075 1.90 1.000 25.40 .218 5.53 20-26

0.80

0.40

*HW-UW-26SM

●

26 0.40 .031 0.79 .040 1.02 .750 19.05 .125 3.17 24-32

0.50

0.20

*These tools are recommended for .025" (0.63mm) square terminals on .100" (2.54mm) centres.

Note: HW-UW-22 and HW-UW-24 have been replaced by HW-UW-224.

Terminal Terminal

Hole Hole Outside

Diameter Depth Diameter

In. mm In. mm In. mm

.

.070 1.77 1.000 25.40 .156 3.96

.070 1.77 1.000 25.40 .156 3.96

.086 2.18 .750 19.05 .156 3.96

.070 1.77 1.000 25.40 .156 3.96

.038 0.96 1.000 25.40 .093 2.36

.070 1.77 1.000 25.40 .156 3.96

.070 1.77 1.000 25.40 .156 3.96

.038 0.96 1.000 25.40 .093 2.36

.

To switch from wire wrapping to unwrapping takes

only seconds - just a quick change of the cap from

one end to the other.

HAND UNWRAPPING TOOLS

HAND WRAPPING AND UNWRAPPING TOOLS

WRAPPING SIDE UNWRAPPING SIDE

HAND WRAPPING AND UNWRAPPING

TOOLS

HAND WRAPPING TOOLS

These Hand Wrapping Tools are carefully designed to

produce perfect wire wrapped connections.

Precision, long-lasting tools for use where occasional

wraps are required or where power wire-wrapping

tools are not practical. Compact and convenient.

Type “D”

Page 15

COPPER WIRE CUT AND STRIP TOOLS

15

A revolutionary concept for easy and clean stripping of wires for wire wrapping, electronic and appliance

applications. Biomechanically designed for maximum efficiency.

Easy to operate... place wire (up to 4) in stripping slot with ends extending beyond cutter blades... press tool and

pull... wire is cut and stripped to proper “wire wrapping” length. The hardened steel cutting blades and sturdy

construction of the tool ensure long life. Strip length easily adjustable for your application.

Replacement blades are interchangeable between ST-100 series and OK-3907 wire-stripping tools. These fine blades

are made from specially tempered spring steel. The stripping slot is carefully centered within the blade to ensure

clean, no nick stripping. The replacement blade support sections are made of heat treated plated steel. They are

designed to accurately centre the slots of the stripping blade, making possible clean, nick-free wire stripping. Easy

replacement.

Replacement Blade Replacement Blade Support For use with:

OK-3907-B 3907-BS-224 OK-3907 ST-100

OK-3907-24B 3907-BS-2030 OK-3907-24 ST-100-24

OK-3907-26B 3907-BS-2030 OK-3907-26 ST-100-26

OK-3907-26B 3907-BS-2030 OK-3907-26SP ST-100-26SP & 875

OK-3907-28B 3907-BS-2030 OK-3907-28 ST-100-28

OK-3907-30B 3907-BS-2030 OK-3907-30 ST-100-30

Part No. Wire Size Adjustable Strip-Off Length

AWG mm Inches mm

ST-100 22-24 0.65-0.50 1-5⁄16" to 1-9⁄16" 33.33 to 39.68

ST-100-24 24 0.50 1-5⁄16" to 1-5⁄16" 33.33 to 39.68

ST-100-24-875 24 0.50 7⁄8" to 1-2⁄8" 22.22 to 28.57

ST-100-26 26 0.40 1-5⁄16" to 1-11⁄16" 33.33 to 42.86

ST-100-26SP 26 0.40 1-1⁄2" to 2” 38.10 to 50.80

ST-100-26-875 26 0.40 7⁄8" to 1-1⁄8" 22.22 to 28.57

ST-100-28 28 0.32 7⁄8" to 1-1⁄8" 22.22 to 28.57

ST-100-30 30 0.25 7⁄8" to 1-1⁄8" 22.22 to 28.57

ST-100-30

The OK-3907 Series from OK Industries is the industry’s

leading cut-and-strip tool for cooper interconnect

applications. Installers and telecom technicians enjoy its

rugged construction, comfortable rubber grips, and

high-leverage handle design, which allows time savings

through the simultaneous cutting of multiple wires. The

OK-3907-26 applies to 26-gauge wire. Replacement

cutting blades and blade supports are also available.

COPPER WIRE CUT

& STRIP TOOLS

WIRE CUT- AND- STRIP TOOLS - ST-100 SERIES

ADJUSTABLE PRECISION WIRE STRIPPERS

OK-3907 SERIES

BLADE AND BLADE SUPPORT REPLACEMENTS

: ST-100 SERIES AND OK-3907 SERIES

■

Replacement Blade/Blade Supports

- Weight: 5.1 o.z (144.6 gms)

- Length: 6.75” (171.5 mm)

Part No. Wire Size Adjustable Strip-Off Length

AWG mm Inches mm

OK-3907 22-24 0.65 1-1⁄2" to 1-3⁄4" 38.10 to 44.45

OK-3907-26 26 0.40 1-1⁄2" to 1-3⁄4" 38.10 to 44.45

OK-3907

Page 16

OK International Ltd.

Eagle Close, Chandlers Ford

Hampshire, SO50 4NF, U.K.

Tel: +44 (0)23 8048 9100

Fax: +44 (0)23 8048 9109

OK Industries is an OK International Company

OK Industries. Connecting Technologies.

OK Industries Inc.

500 Nuber Avenue

Mount Vernon, NY 10550 USA

Tel: +1 (914) 663 0684

Fax: +1 (914) 663 0573

OK International Inc.

1530 O‘Brien Drive,

Menlo Park, CA 94025 USA

Tel: +1 (650) 325 3291

Fax: +1 (650) 325 5932

OK International GmbH

Postfach 14 30,

D-64504 Groß-Gerau, Germany

Tel: +49 (0)61 52-71 12-0

Fax: +49 (0)61 52-71 12-22

OK International S.A.

Rue Ampere, Z.I. Lyon Nord

69730 Genay, France

Tel: +33 (0)4 72 08 75 75

Fax: +33 (0)4 72 08 75 70

OK International SPA

Strada Statale 11 - No 28

20010 Vittuone (Milano), Italy

Tel: +39 02 90 25 161

Fax: +39 02 90 11 11 47

OK International (Japan)

1-10-6 Ebisu

,

Shibuya-ku,Tokyo,

150-0013, Japan

Tel: +81 3 3449-7451

Fax: +81 3 3440-2010

OK International (Taiwan)

5th Floor, No. 79, Sec 1

Hsin Tai Wu Road, Hsi-Chih

Taipei Hsien,Taiwan, R.O.C.

Tel: +886 (2) 2698-4013

Fax: +886 (2) 2698-4021

OK International (China)

Hua Pu International Plaza,

No. 19 Chao Yang Men Wai Avenue,

Beijing 100020, China

Tel: +86 10-6599-2304

Fax: +86 10-6599-2342

OK Korea (Representative) Co.

5 Fl, Yang Chun Bldg,

330-11 Shin Jung-Dong,

Yang Chun-Ku, Seoul, Korea

Tel: +82 (2) 643-8833

Fax: +82 (2) 643-5539

OK Australia (Representative) PTY Ltd.

Unit 1, 8 Grex Avenue,

Minchinbury 2770, NSW, Australia

Tel: +61 (2) 9832 8052

Fax: +61 (2) 9832 8045

www.okindustries.com

TEL- UK - 01

Loading...

Loading...