Ohlins TTX40, TTX46MT Owners Guide

MkI/MkII Automotive

TTX40/ TTX46MT

Owner’s Manual

2

Safety Precautions

Note!

The shock absorber is a very important part of the vehicle and

will therefore affect the stability of the vehicle.

Read and make sure that you understand the information in

this manual and the mounting instructions before you use this

product. If you have any questions regarding installation or

maintenance please contact your nearest Öhlins dealer.

Öhlins Racing AB can not be held responsible for any

damage to the shock absorber, vehicle, other property or injury

to persons, if the instructions for installing and maintenance are

not followed exactly.

Warning!

This product was developed and designed exclusively for a

specific vehicle model and should only be installed on the

intended vehicle model in its original condition as delivered from

the vehicle manufacturer.

The specifications for the particular shock absorber are results

from tests run on a factory equipped vehicle. If wheel

dimensions, springs and/or other chassis parts have been

changed or modified, the clearances and vehicle stability can be

affected.

This product contains pressurized nitrogen gas (N2). Do not

open, service or modify this product without proper education

(authorized Öhlins dealer/distributor) and proper tools.

After installing this product, take a test drive at low speed to

make sure that your vehicle has maintained its stability.

If the suspension makes an abnormal noise, or the function is

irregular, or if you notice any leakage from the product, please

stop the vehicle immediately and return the product to an Öhlins

Service Centre.

Safety Symbols

In this manual, mounting instructions and

other technical documents, important

information concerning safety is

distinguished by the following symbols:

The Safety Alert Symbol means: Warning!

Your safety is involved.

Warning!

The Warning Symbol means: Failure to

follow warning instructions can result in

severe or fatal injury to anyone working with,

inspecting or using the shock absorber, or

to bystanders.

Caution!

The Caution Symbol means: Special

precautions must be taken to avoid damage

to the shock absorber.

Note!

The Note Symbol indicates information that

is important regarding procedures.

© Öhlins Racing AB. All rights reserved. Any

reprinting or unauthorized use without the written

permission of Öhlins Racing AB is prohibited.

Printed in Sweden.

Note!

When working on this product, always read your Vehicle Service

Manual.

This Manual should be considered a part of the product and

should therefore accompany the product throughout its life cycle.

1

Page

Safety Precautions 1

1 - Introduction 3

2 - General description 4

3 - Damping force measurement 13

4 - Damping curve terminology 16

5 - External adjusters 17

6 - Limits in force and velocity 21

7 - Matching of damping force 21

8 - Hysteresis 22

9 - Cavitation 24

10 - Friction level 26

11 - Temperature stability 27

12 - Damper functions 28

13 - Damping guidelines 30

14 - Gas pressure 31

15 - Temperature range 31

Contents

16 - Routine maintenance 32

17 - Actions after a crash or re 33

18 - Valving reference program 34

19 - Damper conguration 35

20 - Damper dimensions 39

21 - Damper identication 54

22 - Technical data 54

23 - Optional parts 55

2

4

1 - Introduction

Congratulations on choosing the Öhlins TTX40/ TTX46 MT damper,

the latest generation of twin tube dampers from Öhlins.

Get to know your TTX40/ TTX46 MT, and be sure to read this

manual thoroughly before using the dampers. We recommend that

you keep this manual handy.

The TTX40/ TTX46 MT damper is the culmination of three

decades of Öhlins’ successful participation in world championship

events winning more than 200 World Championships. Many

years of work together with some of the world’s most successful

racing teams together with advanced dynamic analysis methods

developed at Öhlins Racing headquarter in Sweden has given

Öhlins the unique knowledge needed to design the TTX40/ TTX46

MT damper.

The Öhlins TTX40/ TTX46 MT damper, originally developed for

formula racing, is designed to handle the demanding damping

characteristics needed for all types of tracks, from street courses to

super speedways. The TTX40/ TTX46 MT damper is fully adjustable

with maximised damper response together with qualities you’ve

never seen before when it comes to ”settings”.

Low and high speed compression and rebound damping are

externally adjustable and fully independent. The adjustment range

is huge with equal increments of force throughout the adjustment

range. Even the shape of the damping curve can easily be changed.

All adjusters affect the ow from the main piston, not the piston rod

displacement volume.

The compression damping forces of the TTX40/ TTX46 MT

damper are not, as in a conventional damper, caused by a pressure

drop on the rebound side, but by increased pressure on the

compression side. This reduces the risk of cavitation and makes

any reservoir valve or high gas pressure unnecessary. So, no

balancing of reservoir damping to main piston damping is needed

to avoid cavitation and improve damping response.

Maximum response and minimum risk of cavitation will always

occur. With no reservoir valve, the internal pressure of the damper

unit will be kept to a minimum.

The low amount of hysteresis results in excellent short stroke/high

force performance. Also, a very low gas pressure can be used

without any loss of damping performance.

Along with the damper comes a unique Valving Reference

Program (available for download free of charge at www.ohlins.com).

Make sure to choose the correct one for your damper (MkI/MkII).

This computer model of the damper will allow you to nd

damping curves without a dynamometer. It will reduce building time

tremendously and allow exact damper adjustments in pit lane. The

TTX40/ TTX46 MT product will revolutionise the work for mechanics

and engineers in the racing business.

This manual text is based on TTX40/ TTX46 MT dampers. These

are through rod type dampers loaded with several new concepts.

As always, all dampers are tested before they are delivered to the

customer. In keeping with Öhlins long tradition of perfection, quality

is outstanding and long life is to be expected.

Welcome to the World of Öhlins.

Figure 1.1

Complete TTX40 and TTX46 MT MkII dampers without

springs.

3

2 - General Description

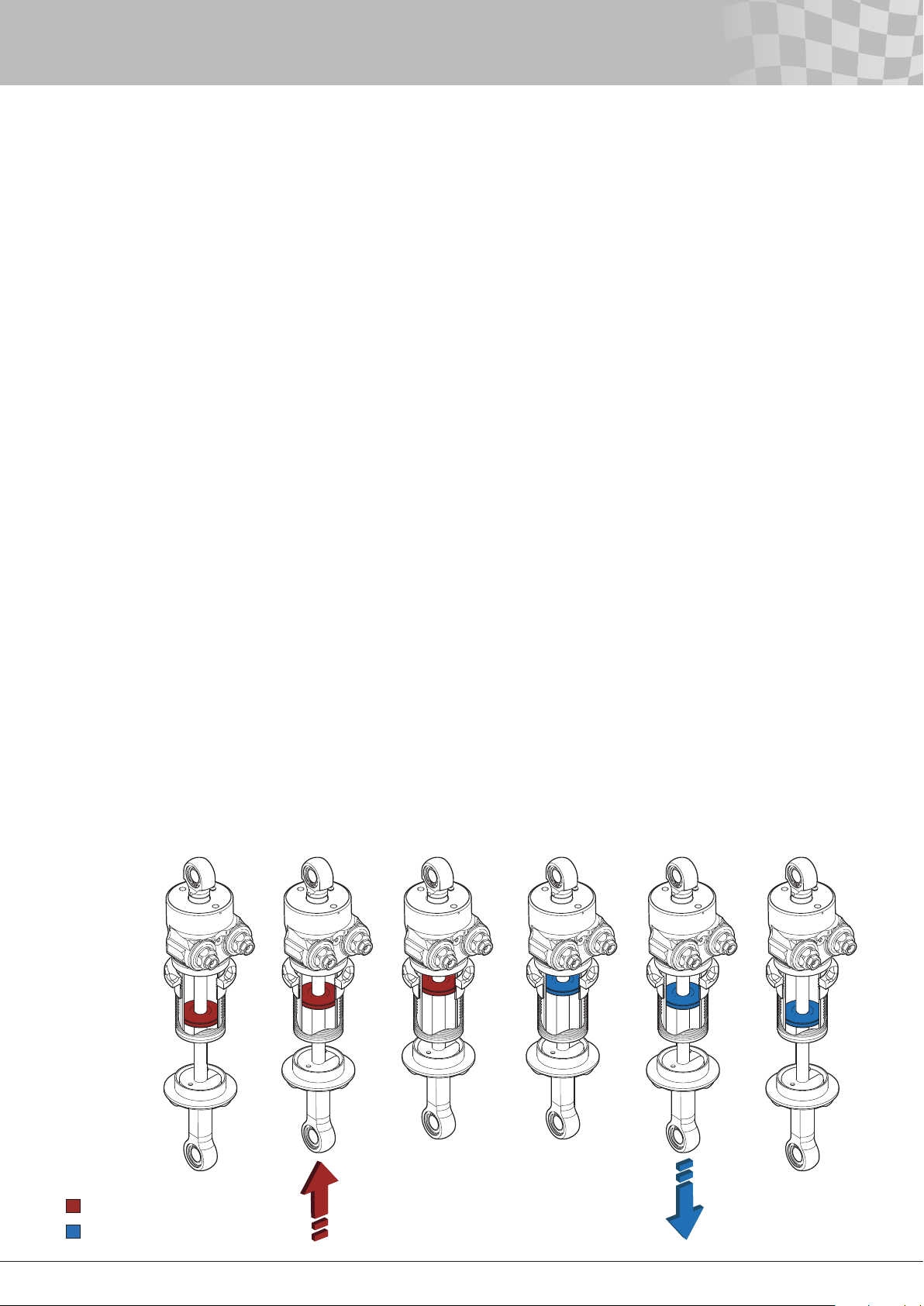

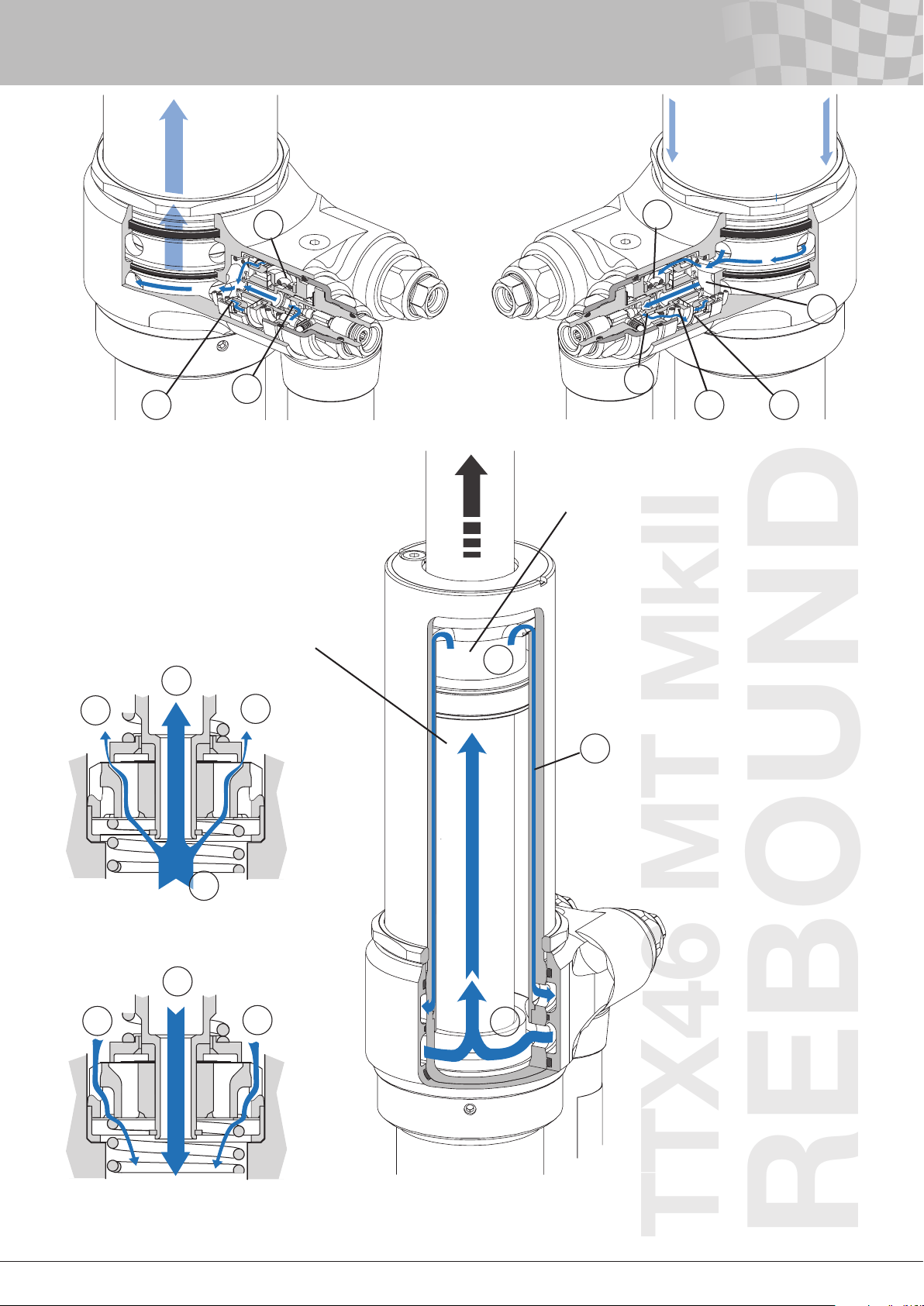

Compression damping cycle Rebound damping cycle

The compression damping cycle describes the situation when the

rod and piston unit moves into the damper body shortening the

length of the damper. While the rebound damping cycle describes

the situation when the rod and piston unit moves out from the

damper body extending the length of the damper.

The terminology ”compression side” of the piston here refers to

the oil volume in front of the piston when the external piston rod is

moving into the damper body (compression cycle). The ”rebound

side ” of the piston refers to the oil volume in front of the piston

when the external piston rod is moving out of the damper body

(rebound cycle).

When the rod and piston unit doesn’t move, the internal

pressure in the whole damper unit is equal with the set gas

pressure. When track conditions cause the vehicle suspension

to move, the damper piston will attempt to move through the

damper oil. In order for the piston to move, oil must ow from

one side of the main piston to the other. The restriction of the

valves causes a pressure difference between the two sides of

the piston, resulting in damping forces. In the TTX40/TTX46MT,

this pressure difference comes from increased pressure on the

forward side of the piston and not reduced pressure on the

backside, as in conventional dampers.

Unless a different valve conguration is used compression

to rebound, the compression and rebound valves are identical

(exceptions are model specic dampers like the BMF and POF

dampers). On both sides in the MkI there are three types and

in the MkII there are two types of valves used for adjusting the

damping characteristics.

• Bleed valve (MkI/MkII)

• Shim valve (MkI/MkII)

• Poppet valve (MkI)

Valve description - TTX40/TTX46MT MkI

The compression bleed valve (low speed) is in parallel with the

compression poppet valve (high speed) and the rebound bleed

valve (low speed) is in parallel with the rebound poppet valve

(high speed). The poppet valves are pushed against their seats by

preloaded coil springs.

The preload is externally adjustable. The amount of preload of

the poppet valves determines the pressure differentials across the

main piston necessary to make the poppet valves open. For more

information about the bleed valves and the poppet valves, see

chapter External adjusters.

The shim valves are placed on the nose of the poppet valves.

These shim stacks affect the opening characteristic of the poppet

valves. The shim conguration can be changed to achieve different

opening characteristics of the poppet valve. Also, there are two

check valves installed in the damper, making the compression and

rebound valves fully independent.

Valve description - TTX40/TTX46MT MkII

The compression bleed valve (low speed) is in parallel with the

compression shim valve (high speed) and the rebound bleed valve

(low speed) is in parallel with the rebound shim valve. The shim

stacks are pushed against their valves by preloaded coil springs.

The preload is externally adjustable. The amount of preload of

the shim stacks determines the pressure differentials across the

main piston necessary to make the shim valves open. For more

information about the bleed valves and the shim valves, see chapter

External adjusters.

The combination of shims on the valve affect the opening

characteristic of the valves. Also, there are two check valves

installed in the damper, making the compression and rebound

valves fully independent.

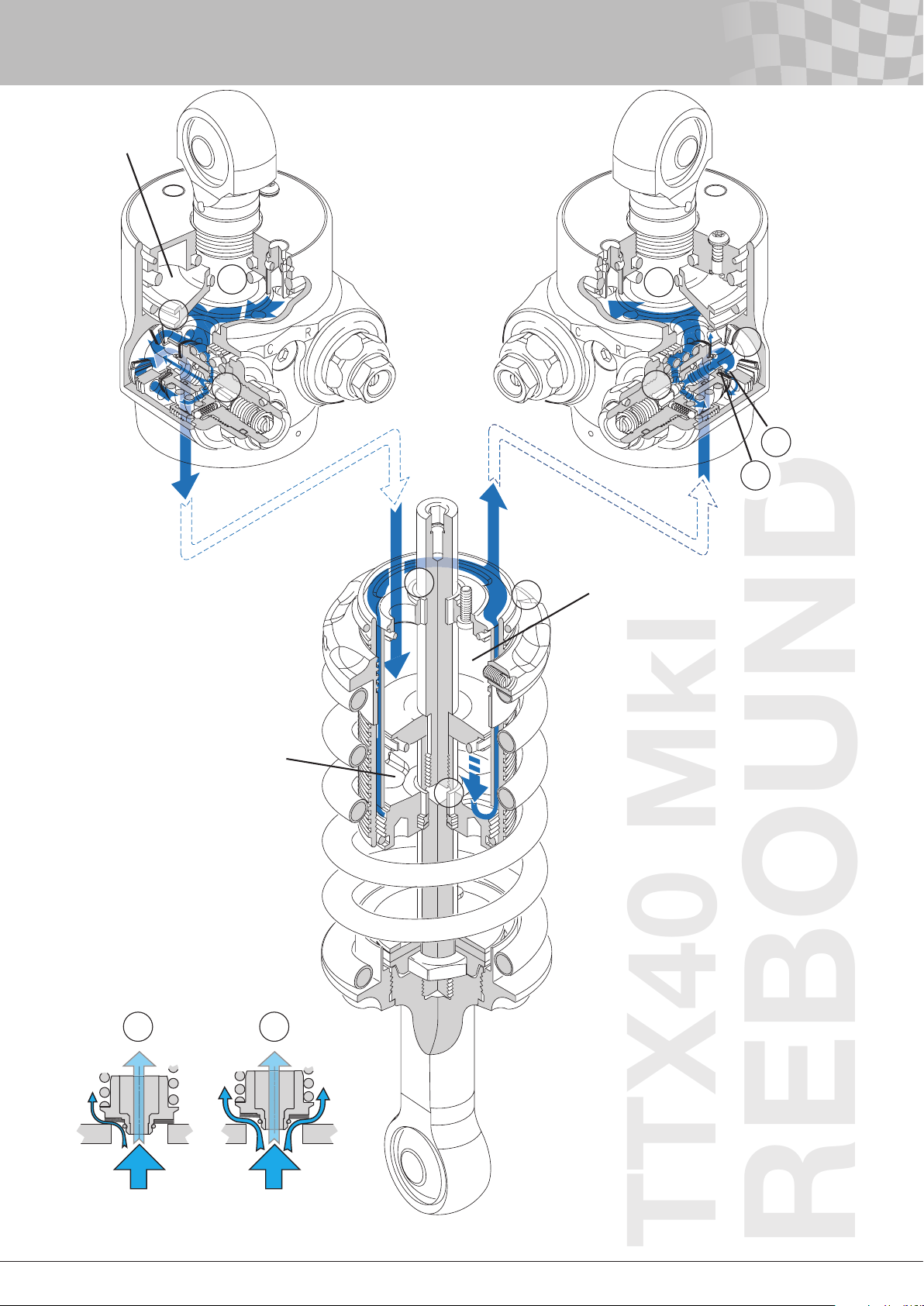

Figure 2.1

Compression and Rebound damping cycle TTX40

Compression damping cycle

Rebound damping cycle

4

6

2 - General Description

Flow circuit at compression cycle

How the oil flows from the compression side to the rebound side of

the piston will be described here. This is caused by increased pressure

on the compression side of the main piston, while the pressure on the

rebound side is almost constant at the set gas pressure.

1a. TTX40

The oil will reach the compression valves by passing through the

port of the separating plate (fig. 2.3-A and 2.7-A) extending into

the cylinder head and leading the oil into a chamber below the

compression valves (fig. 2.3-B, 2.7-B and 2.8a-B). Because of

the small restriction of this port, the pressure in this camber will

be very much the same as the compression side of the cylinder

tube. The piston velocity and how the valves are set determine

the pressure in the camber. The pressure will help to close the

check valve in this camber.

1b. TTX46MT

The oil will reach the compression valves by passing through

the holes in the outer tube (fig. 2.11-A) extending into the

valve housing and leading the oil into a chamber below the

compression valves (fig. 2.11-B). Because of the small restriction

of this port, the pressure in this camber will be very much the

same as the compression side of the cylinder tube. The piston

velocity and how the valves are set determine the pressure in

the camber. The pressure will help close the check valve in this

camber.

2. TTX40/ TTX46 MT

Depending on the pressure, different things will occur. As the

velocity increases, the pressure will rise.

2a. TTX40/ TTX46 MT

In the initial part of a compression stroke, when the velocity

of the piston is low, the oil will pass through the adjustable

low speed compression bleed valve. In this bleed valve, the

restriction takes place in the passage (fig. 2.3-C, 2.6a-C, 2.7-C,

2.10a-C and 2.11-C) between the needle seat (integrated to the

needle housing) and the needle. As long as the piston is moving

and the bleed valve is not fully closed, some oil will always ow

through the bleed valve. If the bleed valve is fully closed, this

passage will be blocked.

2b.1 TTX40/ TTX46 MT MkI

As the velocity increases, the shim stack on the nose of the

poppet valve will start to open and oil can pass between the shim

stack and the poppet valve seat (fig. 2.2-D and 2.3-D). The stack

conguration will decide the opening pressure. An increased

stiffness of the stack will raise the opening pressure and thus

raise the damping force. The shape of the nose on the poppet

valve gives the shims freedom to bend and lift from the seat,

no matter how much preload from spring there is on the poppet

valve. This will allow the shim stack to always open gradually and

therefore a small amount of oil will pass through the shim stack

even with a very low pressure drop over the piston.

2b.2 TTX40/ TTX46 MT MkII

As the velocity increases, the shim on the valve will start to bend

and the valve will start to open and oil can pass between the

shim stack and the valve (fig. 2.6a-D, 2.7-D, 2.10a-D and 2.11-

D). The stack conguration will decide the opening pressure.

All shims with a lager diameter then 20 mm will affect the initial

opening of the stack. An increased stiffness of the stack will raise

the opening pressure and thus raise the damping force. This will

allow the shim stack to always open gradually and therefore a

small amount of oil will pass through the shim stack even with a

very low pressure drop over the piston.

2c.1 TTX40/ TTX46 MT MkI

As the piston velocity increases further, the internal pressure

rises. At a certain velocity the movement of the piston creates

a pressure difference across the main piston that is equal to the

predetermined pressure required to open the poppet valve. The

oil is now free to ow between the poppet valve and the seat (fig.

2.2-E and 2.3-E). Due to the oil ow, the nose shims will follow

the poppet valve up from the seat.

Note!

In practice, the piston often does not reach a velocity high enough to

cause a sufficient pressure drop and open the poppet valve.

By using a very stiff shim stack in combination with little preload on

the poppet valve, the oil ow through the shim stack will be very

limited before the poppet valve opens. This will make the opening

of the poppet valve more abrupt and the shim stack will open at a

higher velocity. This will change the characteristics of the damping

curve.

Note!

The opening characteristic of the poppet valve is always abrupt, unlike

the gradual opening characteristic of the shim stack.

2c.2 TTX40/ TTX46 MT MkII

As the piston velocity increases further, the internal pressure

rises. At a certain velocity the movement of the piston creates

a pressure difference across the main piston that is equal to

the predetermined pressure required to compress the spring

(fig. 2.7-E and 2.11-E) and allow the shims to bend more. The

preload of the spring and the shim stack will determine how

much the shims will bend. The more the shims bend the greater

are the cavities that allows the oil to ow through the valve.

Note!

Usually, the piston does not reach a velocity high enough to cause a

sufficient pressure drop and open the shim valve totally.

5

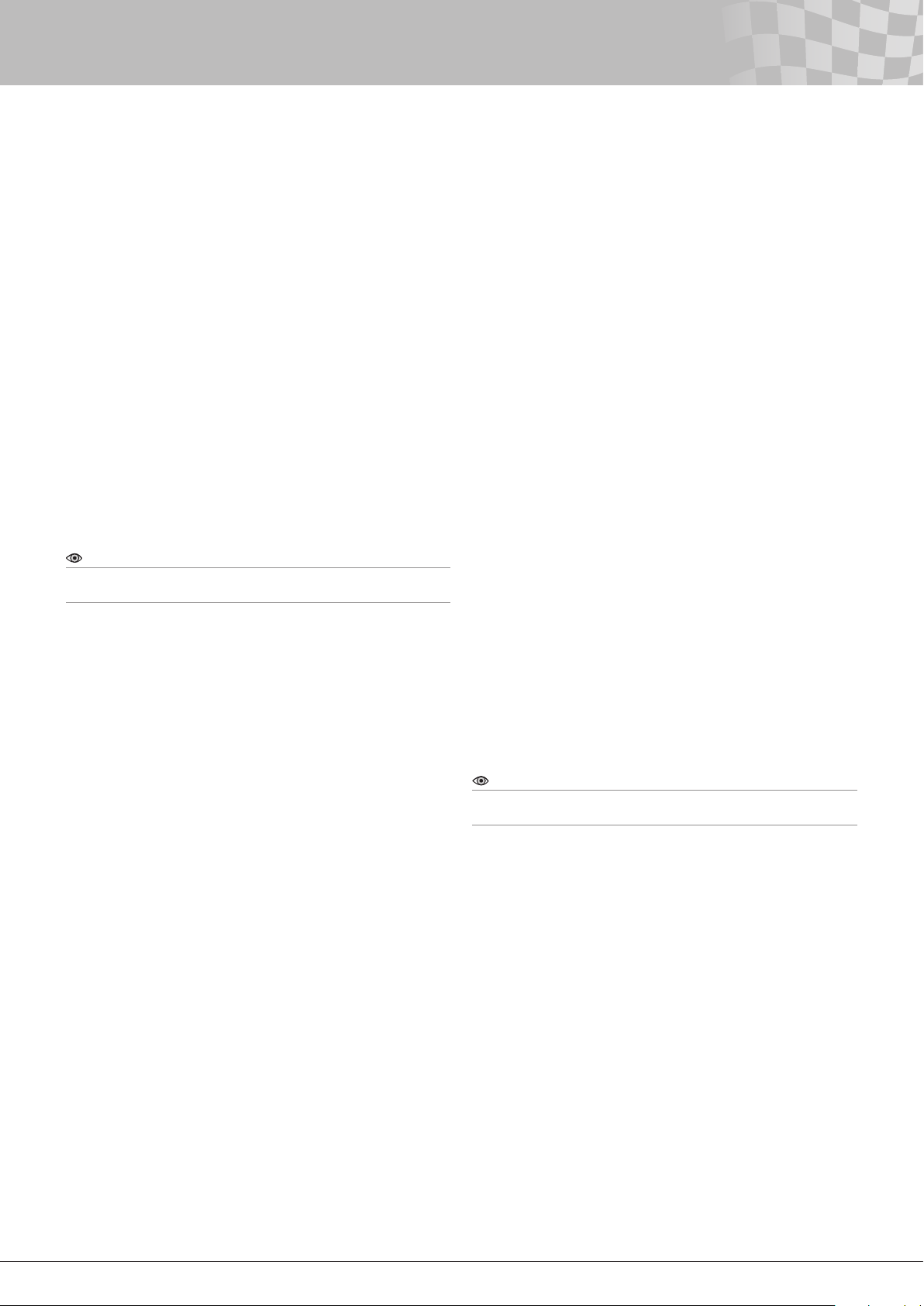

2 - General Description

3. TTX40/ TTX46 MT

The oil has now reached the low-pressure zone at the gas

reservoir (g. 2.3-F, 2.7-F and 2.11-F). This volume is in direct

contact with the separating piston on the TTX40 and connected

to the separating piston by a small hole on the TTX46MT. The

separating piston separates the oil from the nitrogen gas. Here

the pressure is always equal to the set gas pressure. As the

TTX40/TTX46MT is a through rod damper, there will be no uid

displacement by the piston rod. However, a gas volume is still

needed to reduce changes of the static internal pressure due to

volume changes caused by temperature variations. The rising

temperature of the damper will increase the volume of the oil.

Also the damper body will expand as the temperature increases,

but not to the same extent.

4. TTX40/ TTX46 MT

Now the oil will ow through the compression check valve (g.

2.3-G, 2.6b-G, 2.7-G, 2.10b-G and 2.11-G) positioned at the

rebound valves. However, as long as the low speed rebound

bleed valve isn’t fully closed, some oil will ow the through this

valve backwards (g. 2.3-H, 2.6b-H, 2.7-H, 2.10b-H and 2.11-H).

Note!

The compression check valve is placed together with the rebound

valves.

5. TTX40/ TTX46 MT

From here the oil ows between the two tubes (fig. 2.3-I, 2.7-I

and 2.11-I). The oil re-enters the main tube on the rebound side

through ports placed between the end cap and the inner tube

(fig. 2.3-J, 2.7-J and 2.11-J).

The compression ow circuit is completed.

Flow circuit at rebound cycle

Below is a description of how the oil flows from the rebound side to the

compression side of the piston. The rebound cycle is very similar to the

compression cycle, but the flow will be in the opposite direction and

the oil will move through different valves. During the rebound stroke, the

pressure of the rebound side of the main piston is increased, while the

pressure of the compression side is kept almost constant.

1a. TTX40

First of all, the oil has to get to the rebound valves. The ports

between the end cap and the inner tube (fig. 2.5-A and 2.9-A) will

lead the oil to the volume between the tubes (fig. 2.5-B and 2.9-

B) from where the oil will reach the chamber below the rebound

valves (fig. 2.5-C and 2.9-C). The pressure here will be roughly

the same as in the rebound side of the cylinder tube due to small

restrictions of the oil ow. The pressure will help to close the

check valve in this camber.

1b. TTX46MT

First the oil has to get to the rebound valves. The ports between

the upper seal head and the inner tube (fig. 2.13-A) will lead the

oil to the volume between the tubes (fig. 2.13-B) from where the

oil will reach the chamber below the rebound valves (fig. 2.13-C).

The pressure here will be roughly the same as in the rebound side

of the cylinder tube due to small restrictions of the oil ow. This

pressure will help to close the check valve in this camber.

2. TTX40/ TTX46 MT

See section 2. TTX40/ TTX46 MT under Flow circuit at

compression cycle in this chapter for more detailed information

as the rebound valves are identical to the compression valves.

2a. TTX40/ TTX46 MT

Unless the low speed rebound valve is fully closed, the oil will

rst pass through this valve

(fig.2.5-D, 2.8a-D, 2.9-D, 2.12a-D and 2.13-D).

2b.1 TTX40/ TTX46 MT MkI

The second valve to open is normally the nose shim stack (fig.

2.4-E and 2.5-E).

2b.2 MkII

The second valve to open is the shim stack on the valve (fig.

2.8a-E, 2.9-E, 2.12a-E and 2.13-E). It starts with the largest

shims, diameter more than 20 mm, starts to bend and in this way

lets the oil ow through the vavle.

2c.1 MkI

If the pressure level reaches the opening pressure of the poppet

valve, the poppet valve will open (fig. 2.4-F and 2.5-F).

2c.2 MkII

If the pressure level reaches the opening pressure of the spring

valve, the spring will let the preload ring to lift and the shim stack

will let more oil through the valve (g. 2.9-F and 2.13-F).

3. Now the oil has reached the low-pressure zone at the gas

reservoir (fig. 2.5-G, 2.9-G and 2.13-G), where the pressure is

equal to the gas pressure.

4. The oil will now ow through the rebound check valve (fig.

2.5-H, 2.8b-H, 2.9-H, 2.12b-H and 2.13-H) positioned at the

compression valves. Some oil can, in the same way as described

above in Flow circuit at compression cycle, ow backwards

through the low speed compression valve (fig. 2.5-I, 2.8b-I, 2.9-I,

2.12b-I and 2.13-I) unless it is set to the fully closed position.

Note!

The compression check valve is located together with the rebound

valves.

5. Finally the oil re-enters the main tube on the compression

side through a port in the separating plate (fig. 2.5-J, 2.9-J and

2.13-J).

The rebound circuit is completed.

6

8

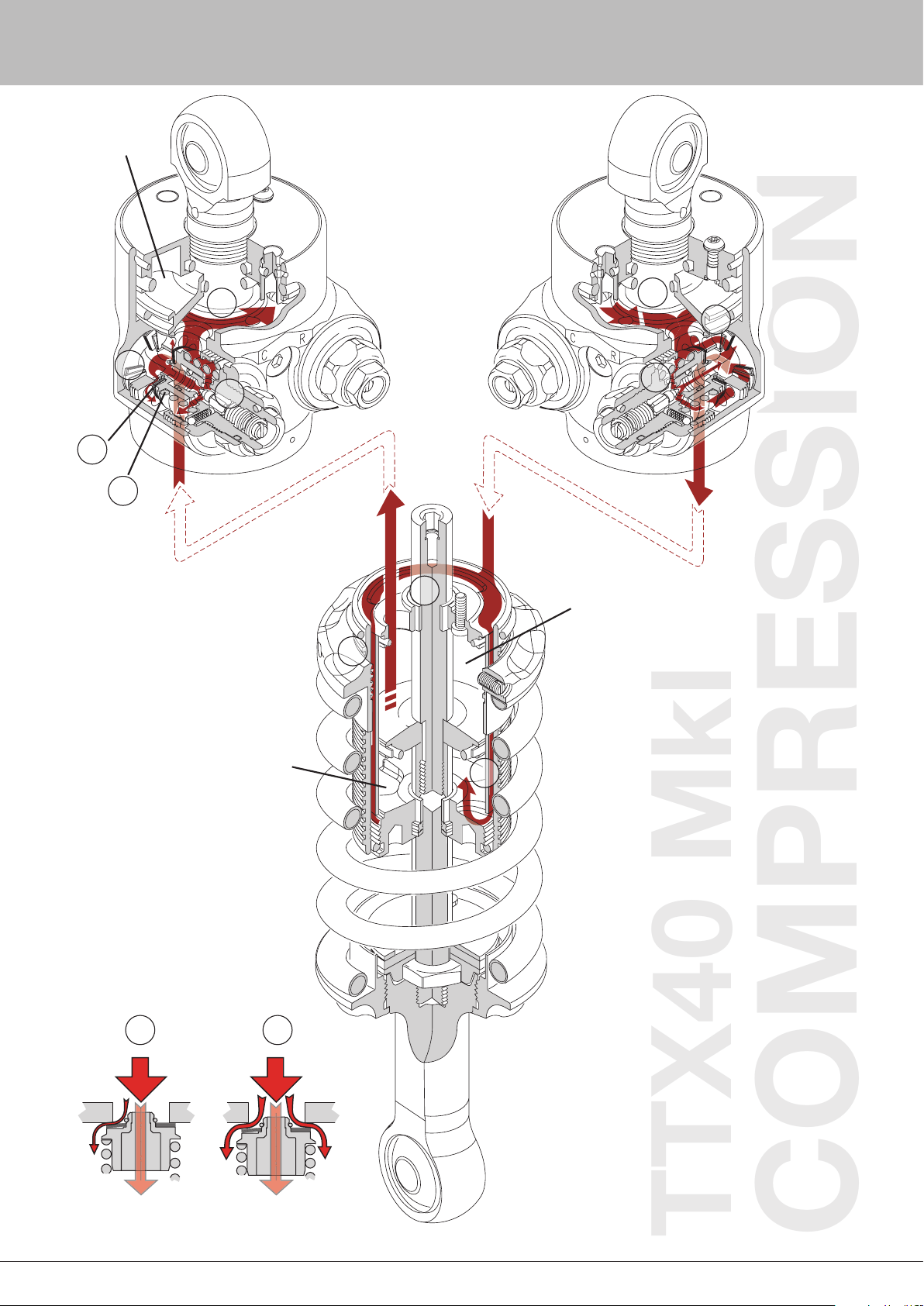

2 - General Description

TTX40 MkI

COMPRESSION

Gas volume

F

B

C

D

E

A

I

Compression side

F

G

H

Rebound side

D E

Figure 2.2

Poppet valve for compression TTX40 MkI.

J

Figure 2.3

Flow circuit during compression cycle for TTX40 MkI.

7

TTX40 MkI

REBOUND

Gas volume

2 - General Description

G

H

I

J

B

Compression side

G

C

D

E

F

Rebound Side

E F

A

Figure 2.4

Poppet valve for rebound TTX40 MkI.

Figure 2.5

Flow circuit during rebound cycle for TTX40 MkI.

8

10

2 - General Description

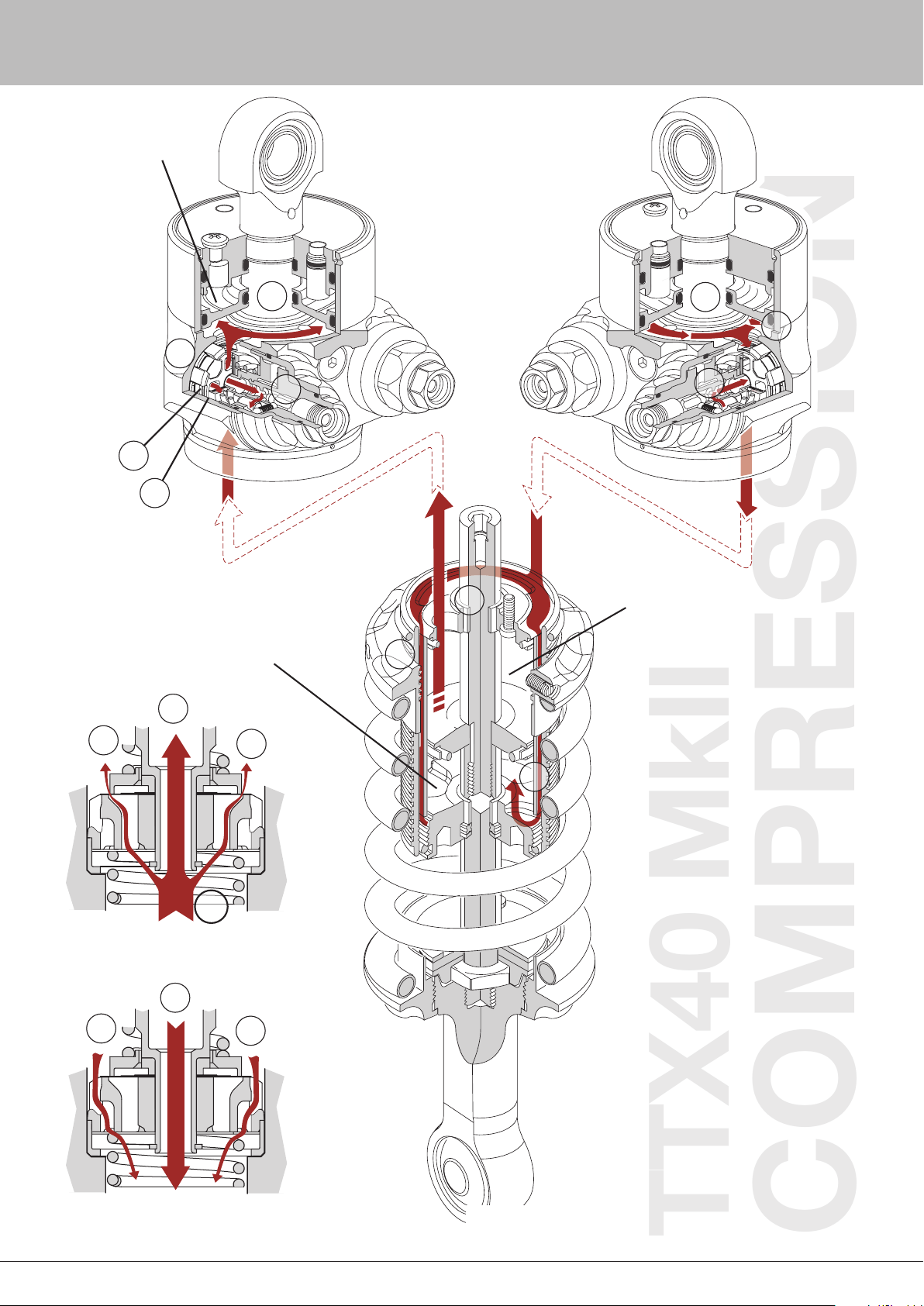

TTX40 MkII

COMPRESSION

Gas volume

F

B

C

D

E

A

Rebound Side

C

D

D

I

Compression side

F

G

H

B

Figure 2.6a

Flow through the main valve TTX40 MkII.

H

G

Figure 2.6b

Flow through the check valve TTX40 MkII.

G

J

Figure 2.7

Flow circuit during compression cycle for TTX40 MkII.

9

TTX40 MkII

REBOUND

Gas volume

2 - General Description

G

H

I

J

Rebound Side

D

E

E

Compression side

B

G

C

D

E

F

Figure 2.8a

C

Flow through the main valve TTX40 MkII.

I

HH

Figure 2.8b

Flow through the check valve TTX40 MkII.

A

Figure 2.9

Flow circuit during rebound cycle for TTX40 MkII.

10

12

2 - General Description

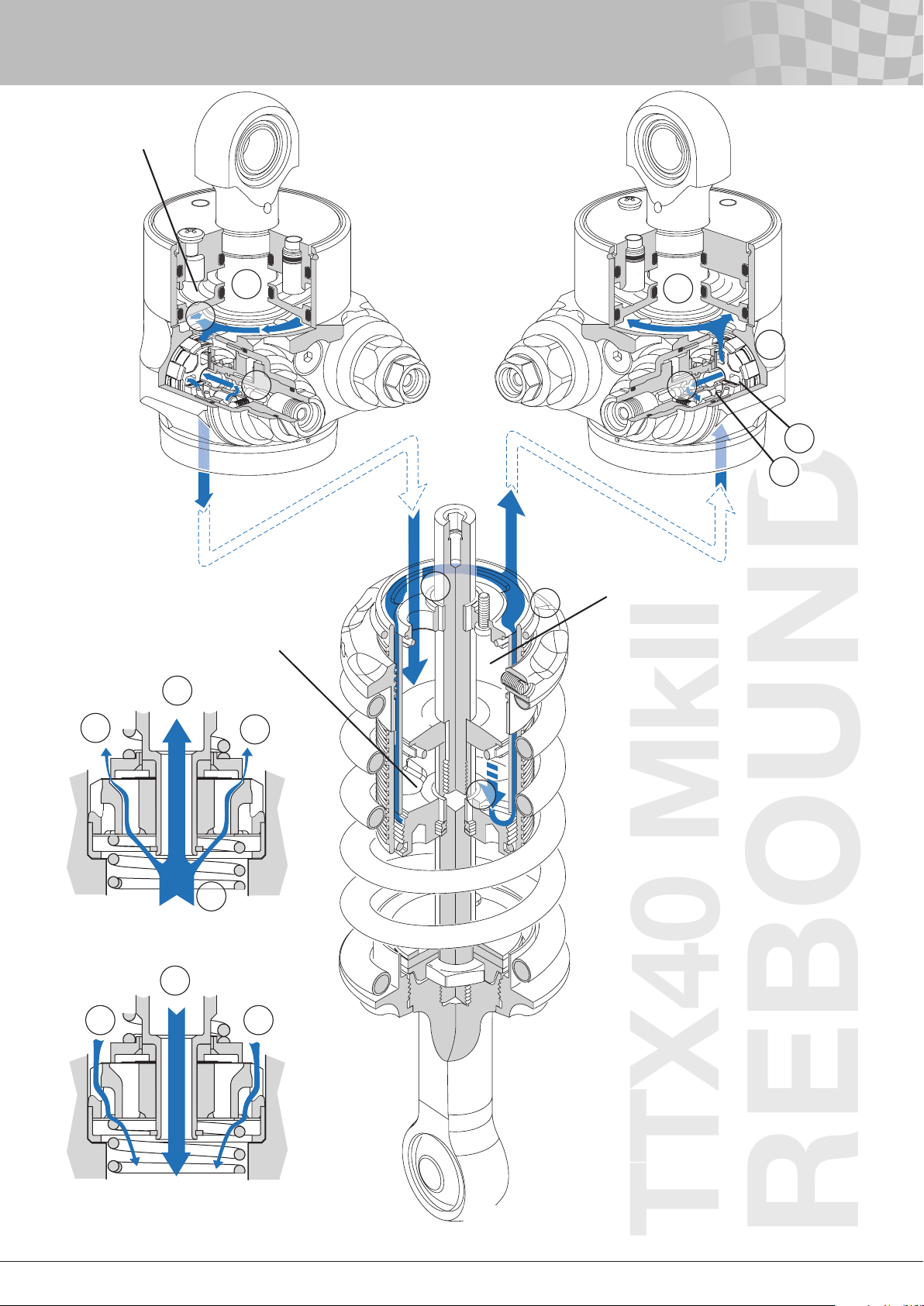

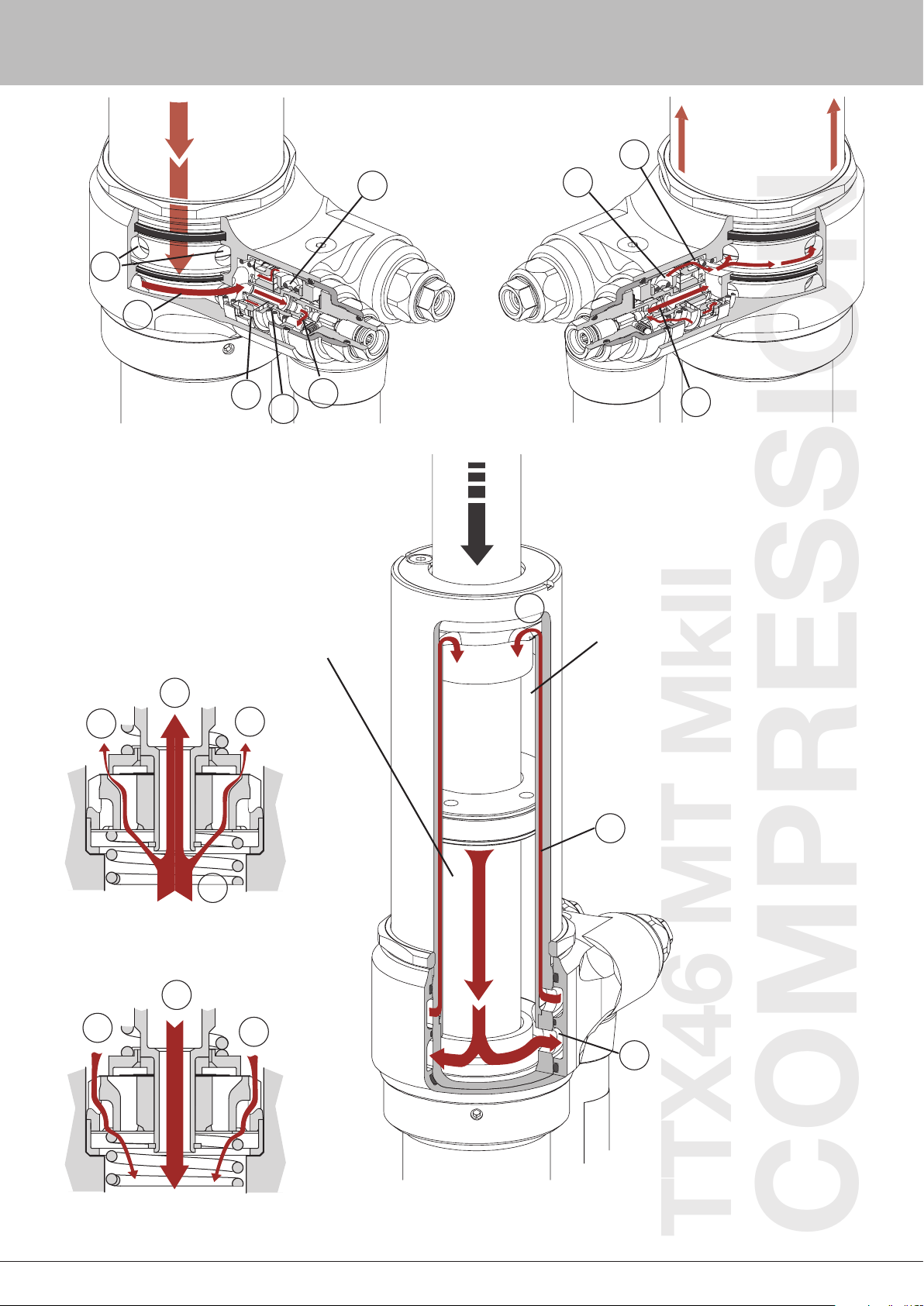

TTX46 MT MkII

COMPRESSION

G

F

A

B

D

Compression side

C

E

J

F

H

Rebound side

C

D

Figure 2.10a

Flow through the main valve TTX46 MT MkII.

H

G

D

B

G

I

A

Figure 2.10b

Flow through the check valve TTX46 MT MkII.

Figure 2.11

Flow circuit during compression cycle for TTX46 MT MkII.

11

2 - General Description

TTX46 MT MkII

REBOUND

G

I

H

Rebound Side

Compression side

A

D

G

C

D

EF

E

Figure 2.12a

Flow through the main valve TTX46 MT MkII.

H

C

I

E

H

B

J

Figure 2.12b

Flow through the check valve TTX46 MT MkII.

Figure 2.13

Flow circuit during rebound cycle for TTX46 MT MkII.

12

14

3 - Damping Force Measurement

Damping forces is a frequent subject of discussions at race

weekends. It is important to understand that depending on how the

damping forces are measured, the force values can turn out very

differently.

Within a race team, where the values normally always come from

the same source this is normally not a problem. A team mainly

needs a damper dynamometer to ensure their dampers produce the

damping forces that are expected. This means that no “heavy duty”

dynamometer is needed. For formula racing applications and many

other types of asphalt racing a dynamometer that can reach 5 inch/

second (0.127 m/s) is enough. The type of dynamometers mainly

used are of the “crank type”. The price tag, size and simplicity are

the main advantages of these machines. A crank dynamometer

can be used for “continuous measurement” or “peak velocity

measurement”. A hydraulic dynamometer can be used for any type

of measurement.

The requirements for a damper manufacturer, doing research and

development, are very different and other types of machines are

needed.

There is not one perfect way of measuring damping forces, as

different situations ask for different needs.

See chapter Damping curve terminology for information about

how to read damping graphs.

For a race team a continuous measurement of the damping force

is very good: the measurement is quick, makes it very easy to tune

the damping curve to a desired shape, hysteresis and cavitation is

easy to detect and “dynamic problems” can be found. An example

of a dynamic problem that can be detected this way is sticking

check valves.

With continuous measurement of the damping force, the damper

movement mimics a “sine wave”, often in the region of 1.6 Hz.

As both the acceleration and the deceleration part can be seen,

there will be two force values for any given velocity except for the

maximum velocity. Sometimes the terminology “dynamic testing”

is used for this type of damper testing, including other types of

movements than just sine wave movements, but with the common

factor that the measurements are done during variations in velocity.

As can be seen in the gure, the acceleration force values are lower

than the deceleration force values when passing zero velocity. This

separation at low velocities is called “hysteresis”. See chapter

Hysteresis for more information. When ”matching” dampers, the

teams often pick half of the cycle to keep the overlay of curves

from different dampers as clean as possible. It is common to use

compression opening (measurement during acceleration) and

rebound closing (measurement during deceleration).

Many times the result of continuous damping force measurement

can be presented in a force-displacement graph. These types of

curves are sometimes named “egg curves”.

If continuous measurement is used, the forces given are

dependent on the stroke and frequency being used. By changing

the crank length and the frequency of the dynamometer machine

so to maintain the same peak velocity, let say 5 inch/second, the

damping force curves will change. From the formula below, you nd

that, for example, a reduction of the amplitude to half will give the

same peak speed if the frequency is doubled.

v

= A • 2π • f [ m/s ]

max

v

= peak velocity [ m/s ]

max

A = amplitude [ m ]

f = frequency [ Hz ]

The less travel required to reach a specic velocity, the more

pronounced the hysteresis will be in the graph. As hysteresis is

found when the movement change direction, in other words at zero

velocity, tests where different strokes have been used to produce

the same peak velocity will differ at low velocities due to hysteresis.

See chapter Hysteresis for more information.

13

3 - Damping Force Measurement

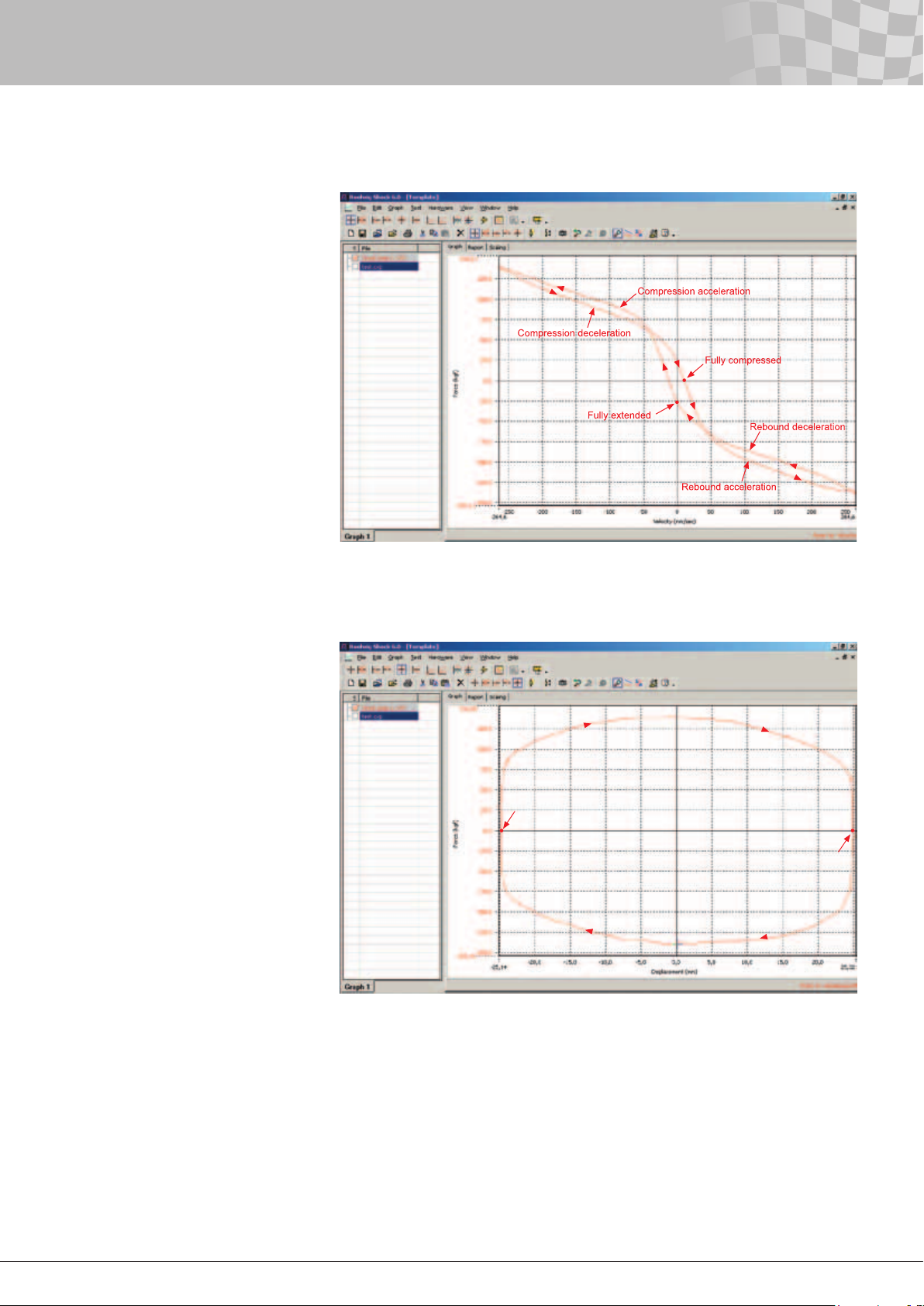

Figure 3.1

Damping force measured continuously in a

Roehrig dynamometer.

The bleeds are fully closed.

Figure 3.2

Damping force measured continuously in

a Roehrig dynamometer.

Here the result is presented in a

force‑displacement graph.

The data comes from the same run as in

the previous figure.

Fully extended

Fully compressed

14

16

3 - Damping Force Measurement

Note!

Comparing the forces figures 3.2 with the force of 3.3, there is a huge

difference in force at low speed. When the damping force is measured

continuously the hysteresis give the impression that the bleeds are

quite open and a small bleed change can be hard to notice in the

graph.

Sometimes the software uses a lter to reduce the level of noise in

the graphs. Some race teams do damping force measurement at

constant velocity.

Sometimes the terminology “static testing” is used for this type

of testing. For matching dampers this method is excellent. For

a damper manufacturer, working with different race teams using

different methods of measuring damping forces, measuring at

a constant velocity is preferred. Otherwise as explained above,

when using continuous measurement, there is always a risk that

the values discussed comes from different methods of measuring.

When the damping force is given at a constant velocity, there is

only one value of the damping force at each specic velocity.

A crank dynamometer can’t be used for constant velocity

measurement, but by measuring the damping force at different

peak velocities, the result is normally very close.

When a crank dynamometer is used, the machine always

produces sine wave movement. By changing the frequency of the

dynamometer, different peak velocities are reached.

The number of runs varies depending on the needs. Of course

small steps extend the test time. In a hydraulic dynamometer,

the piston rod is accelerating to the desired velocity in a short

distance, and the ow of oil through the valves in the damper

is kept “static” during a large part of the stroke. This makes

it possible to take hundreds of measurement before the

dynamometer decelerates the piston rod.

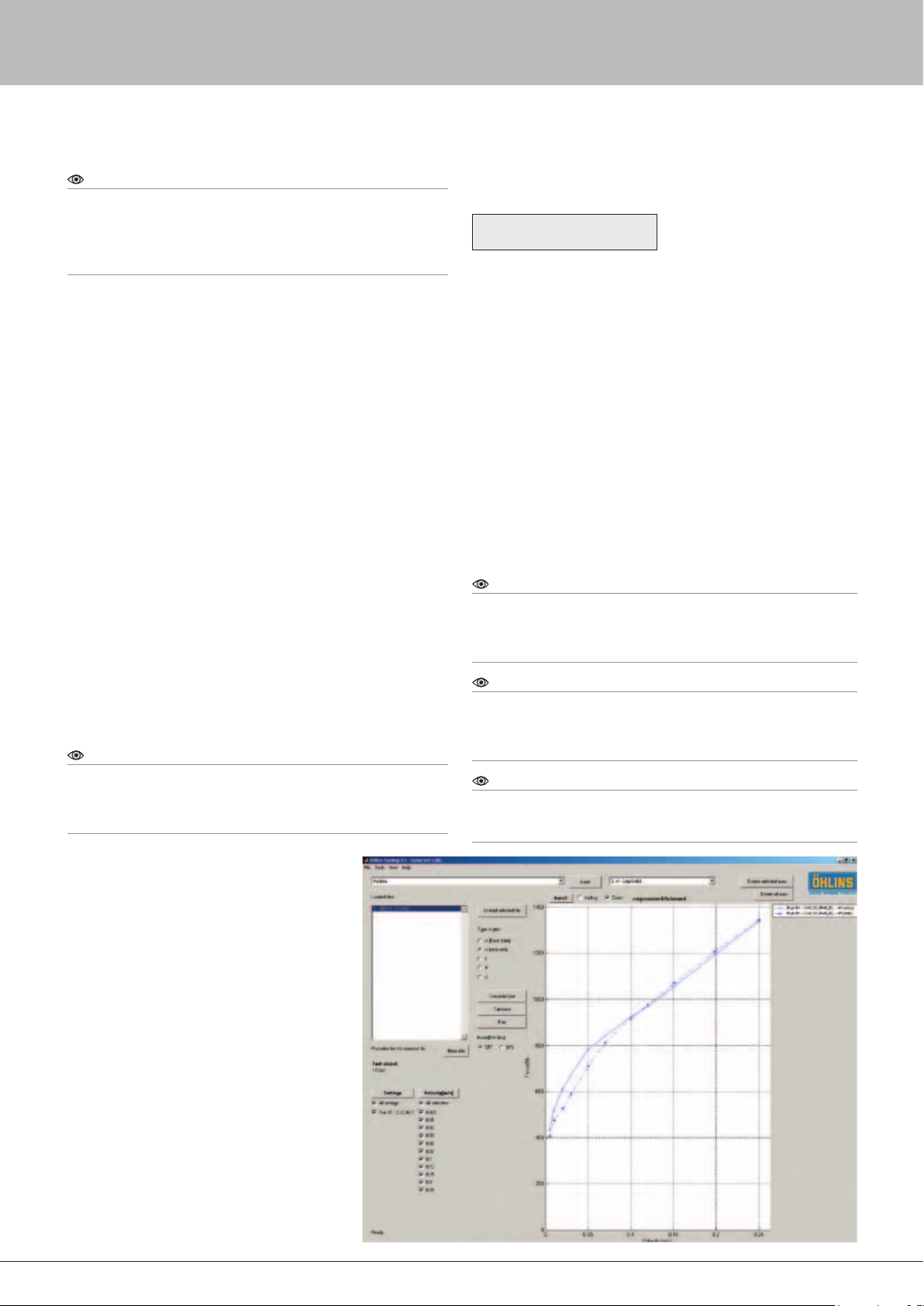

Note!

In this manual, if there is no other information, all graphs illustrated

come from Öhlins TTX VRP. The data used in the TTX VRP are

produced by an Instron hydraulic dynamometer at Öhlins Laboratory.

The forces are measured at constant velocity.

It is very important to know when dynamometer

testing dampers if the forces measured are

compensated for gas force or not.

Most racing dampers (pressurised, and not

through rod type) add a gas force to the damping

force. The gas force should be seen as an extra

spring force from a spring with very low rate. This

force is position dependant (close to constant)

and not velocity dependant and should therefore

be removed when damping force is plotted.

An idea of the amount of gas force a damper

produces at a specic piston position (normally

small variations at piston positions) can be found

by compressing the damper by hand and keeping

it at a static position. The gas force will now try to

push the piston rod out of the damper body.

This force is calculated as

F

= p

• A

rod

p

= gas pressure above atmosphere pressure

gas

(the value read on the pressure gauge when

pressurizing the damper) [N/m2, 1 bar=105 N/m2 = 15 psi]

A

= piston rod area

rod

For example, at 10 bar (15 psi) gas pressure in the TT44/40 (∅16

mm piston rod), the gas force is approximately 200 N (45 lbs).

When you look at a dynamometer curve that has been gas force

compensated, you are looking at the actual damping forces

produced by the damper.

For non gas compensated dynamometer curves, the actual

damping forces are calculated from the formulas below.

Compression damping = measured compression force – Frod

Rebound damping = measured rebound force + Frod

The TTX damper has no resulting force from the gas pressure (Frod

= 0), so it always gives the same forces no matter if the testing is

gas compensated or not.

[ N ]

gas

rod

Note!

If matching the forces from a TTX damper with the forces from a

conventional damper tested without gas compensation, the forces of

the conventional damper has to be gas force compensated with the

formulas above to get the same amount of damping.

Note!

Keep in mind that even if the method for measuring the damping

forces is identical there can be some small variations in the result from

different damper dynamometers, due to individual variations between

the machines.

Note!

All damping curves will change with temperature, so always keep

track of the temperature. See chapter Temperature stability for more

information.

Figure 5.3

Damping force measured at constant velocity.

The lined curve is compression, the dotted

curve is rebound. The setting is the same as in

the two previous figures.

15

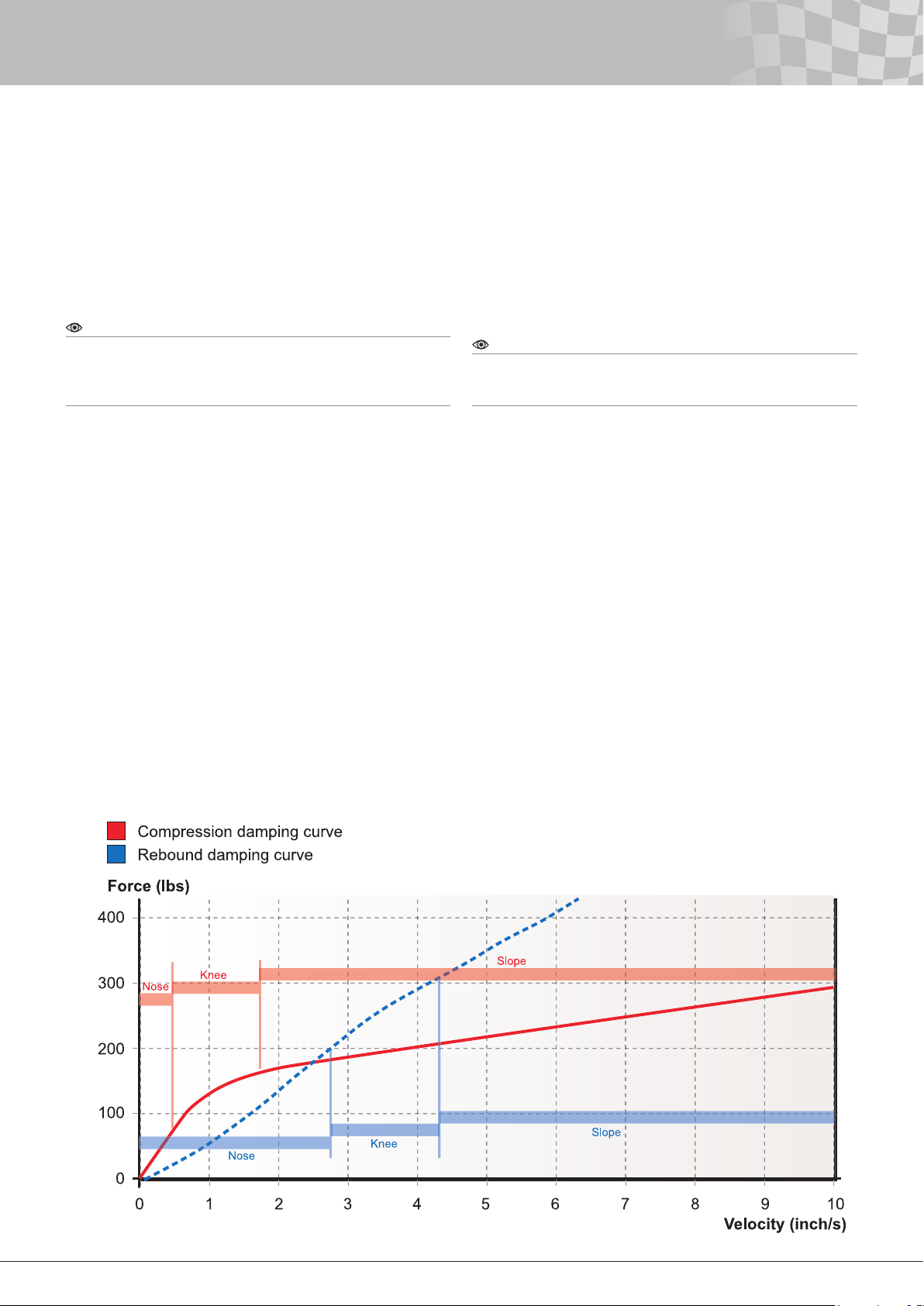

4 - Damping Curve Terminology

In order to understand the next part of this manual we must all

speak the same language. In the damper industry there are terms

used to help describe different parts of a dynamometer graph.

The three key words are nose (low speed), knee and slope

(high speed). Careful study of this section will yield a complete

understanding of these terms and allow you to read damper curves.

The horizontal axis in the gure gives damper velocity and the

vertical axis shows damping force.

Note!

The velocity of the damper refers to the velocity of the piston rod

movements, not to the speed of the car. Most of the piston rod

movements on a race car reach only low velocities and the percentage

number of strokes going though all zones described below is low.

Take a look at the gure above and notice the rst portion of the

damping curves – starting at 0 inch/second and ending at about 0.4

inch/second on the compression curve and about 2.7 inch/second

on the rebound curve. This part of the curve is called the nose and

is also referred to as low speed. The valve affecting this part of the

curve is the low speed adjuster. It is always of a xed orice type

(the size of the orice is not variable by pressure, but by clicker

adjustments) and is often called bleed. The design and size of the

bleed determines the characteristics and shape of the nose.

The nish of the nose zone coincides with the beginning of the knee

zone. Its location in the curve can be found by identifying where the

upwards curve rst begins to level off into a radius. Locating where

the knee radius stops and blends into the straight line identies the

end of the knee zone and the beginning of the slope zone.

The shape of the knee is determined by the opening characteristic,

gradual or abrupt. The more abrupt the opening phase is, the

sharper the knee will be. The converse is also true. Normally the

shape of the curve in the knee zone comes from the transition

of the shims bending and when the force is big enough to start

compress the high speed spring. At 1.2 inch/second the valve

has totally gone from the shims bending to the spring opening.

Due to the more open bleed on the rebound. The knees are not so

pronounced.

Note!

Wide open bleeds in combination with a stiff shim stack and a lot of

preload can allow the low speed zone to extend into relatively high

velocities.

The shim stack and the preload of the coil spring normally

determine the slope, also referred to as high speed. In most cases

the slope will continue to rise in a straight line to damper speeds

well beyond those found in most racing dynamometer charts.

Eventually the slope will increase at an exponential rate. This

happens when the size of the channels transporting the oil begin to

restrict the oil ow (channels are also xed orices).

The slope angle relative to the horizontal plane denes the

magnitude of the slope and can be quantied as Pound/(Inch/

Sec.) or N/(m/s). The nose, knee and slope are key words to

understanding the following concepts.

Figure 4.1

Terminology

16

18

5 - External Adjusters

General description

Most dampers that are external adjustable have some type of low

speed adjuster. Low speed adjusters are almost always externally

adjustable orices that become xed after adjustment. Fixed in the

sense that the orice area is not dependent on the pressure drop

over the orice.

In the damper industry, these adjustable orices are often

referred to as bleeds or low speed adjusters. Unlike shim stacks,

bleed orices do not change size in response to changes in

pressure. Because oil will always travel the path of least resistance,

it will rst ow through the open bleeds until there is enough

pressure to open any other valves. Oil ows through the bleeds any

time the piston rod is moving, and continues to ow in parallel with

the ow through the piston shim stack after the stack has opened.

The most common type of external high speed adjuster is an

adjuster that moves the knee up or down without changing the

slope, or just marginally changing it. To achieve this, the amount

of force pushing the valve, shim or poppet valve, against its seat is

varied. That is done by changing the preload of the spring element,

shim stack, coil spring, cup spring etc.

The oil ow that is controlled by the external adjusters varies

between different type of dampers. The larger the ow is, the better

the conditions will be for a powerful adjuster. There are two reasons

for that.

• A larger ow is easier to control. The tolerances for the

dimensions on the valve parts have to be tightened if the ow is

reduced.

External adjusters summarised

The TTX40/TTX46MT damper from Öhlins comes as a 4-way

externally adjustable damper. As some racing classes have

rules about the maximum number of external adjusters there is

a possibility to change the vales to a valve that is only one way

adjustable.

By changing just one valve you can make the damper 3-way

adjustable and by changing both valves you can make it 2-way

adjustable. This valve has the high speed adjuster lock or only a low

speed (bleed) adjuster. To adjust the high speed in this valve you

need to take the valve out of the damper and re-shim it. The text

below describes the valves that the dampers are delivered with.

• A larger pressure area, the pressure area is proportional to the oil

ow, will keep the internal pressure of the damper at a lower level.

This increases the damper response and the damper will build up

damping force quicker.

Figure 5.1

External adjusters

17

Loading...

Loading...