Work Shop Manual

General Manual for Öhlins shock absorbers

© Öhlins Racing AB. All rights reserved. Any reprinting or unauthorized use without the

written permission of Öhlins Racing AB is prohibited. Printed in Sweden.

1

Introduction

All of Öhlins advanced suspension products are adapted

to the make and model. This means that length, travel,

and spring-action and damping characteristics, are tested

individually just for the vehicle fitted with Öhlins suspension. When servicing be sure to use the correct spare

parts.

The information, illustrations and specifications contained

in this manual are the latest product information available

at the time of publication. This manual is presented to make

the service of the Öhlins shock absorbers as easy and as

safe as possible with maximum performance out of the

serviced shock absorber as possible.

Safety signals

Important information concerning safety is distinguished in this manual by the following notations:

The Safety alert symbol means:

Caution! Your safety is involved.

WARNING!

Failure to follow warning instructions could result in

severe or fatal injury to anyone working with,

inspecting or using the suspension, or to bystanders.

CAUTION!

Caution indicates that special precautions must be

taken to avoid damage to the suspension.

NOTE!

This indicates information that is of importance with

regard to procedures.

Before you start

Öhlins Racing AB can not be held responsible for any

damage whatsoever to spare parts, suspension or vehicle,

or injury to persons, if the instructions for fitting and

maintenance are not followed exactly. Similarly, the

warranty will become null and void if the instructions are

not adhered to.

Make sure you have all the necessary tools before you

start working on the Öhlins shock absorber.

WARNING!

Please study and make certain that you fully understand the

work shop manual before handling the shock absorber. If

you have any questions regarding proper service procedures,

contact an Öhlins dealer or other qualified person.

NOTE!

Öhlins products are subject to continual improvement and

development. Consequently, although these instructions

include the most up-to-date information available at the

time of printing, there may be minor differences between

your suspension and this manual. Please consult your

Öhlins dealer if you have any questions with regard to the

contents of the manual.

WARNING!

The shock absorber is provided with a separate type reservoir filled with high-pressure nitrogen gas. To prevent

danger of explosion, study and make certain that you fully

understand the following information before handling the

shock absorber.

The manufacturer cannot be held responsible for damage to property or personal injury that may result from

improper handling.

1. Never tamper with or attempt to disassemble the cylinder or the reservoir.

Contents

Introduction ................................................................ 2

Safety instructions ...................................................... 2

McPherson 36 and 46 ............................................... 3

Shock absorber 46 .................................................. 15

Shock absorber 36 .................................................. 27

General .................................................................... 43

Drawings ................................................................. 55

2. Never expose the shock absorber to an open flame or

other excessive heat. The shock absorber may otherwise

explode due to too high pressure.

3. Be careful not to damage any part of the gas reservoir.

A damaged gas reservoir will impair the damping performance or cause malfunction.

4. Take care not to scratch the contact surface of the piston rod of the cylinder; oil could otherwise leak out.

5. Never attempt to remove the plug at the bottom of the

nitrogen gas reservoir. Any attempt to remove the plug

implies serious danger.

6. When scrapping the shock absorber follow the instructions for disposal.

2

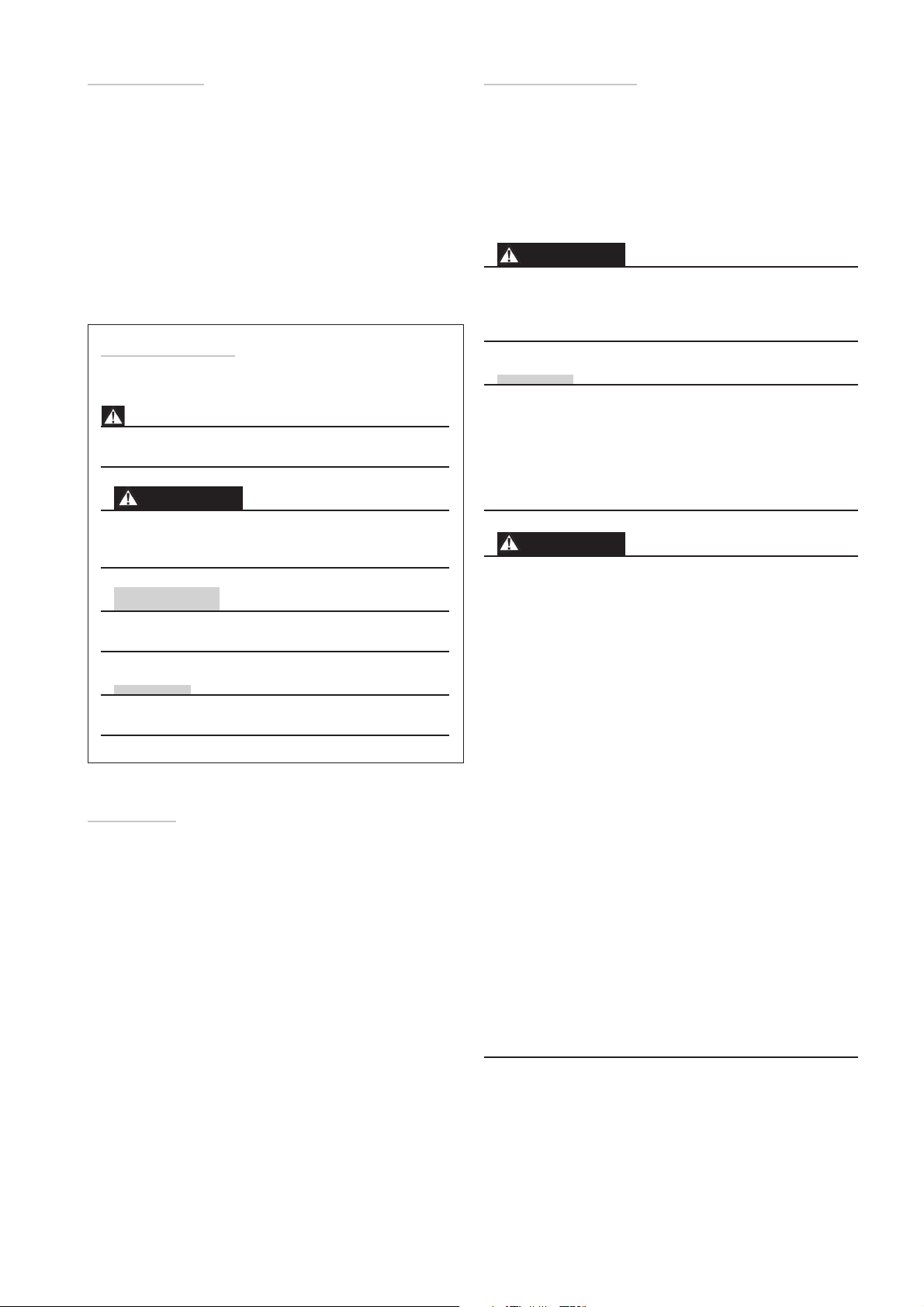

McPherson

36 and 46

Contents

McPherson 36 and 46 ............................................... 3

Dismantling the shock absorber .................................. 4

Dismantling the piston shaft ........................................ 6

Reassembling the piston shaft .................................... 7

Changings of bushing ................................................. 9

Assembling of McPherson shock absorber ............... 11

Shock absorber 46 .................................................. 15

Shock absorber 36 .................................................. 27

General .................................................................... 43

Drawings ................................................................. 55

3

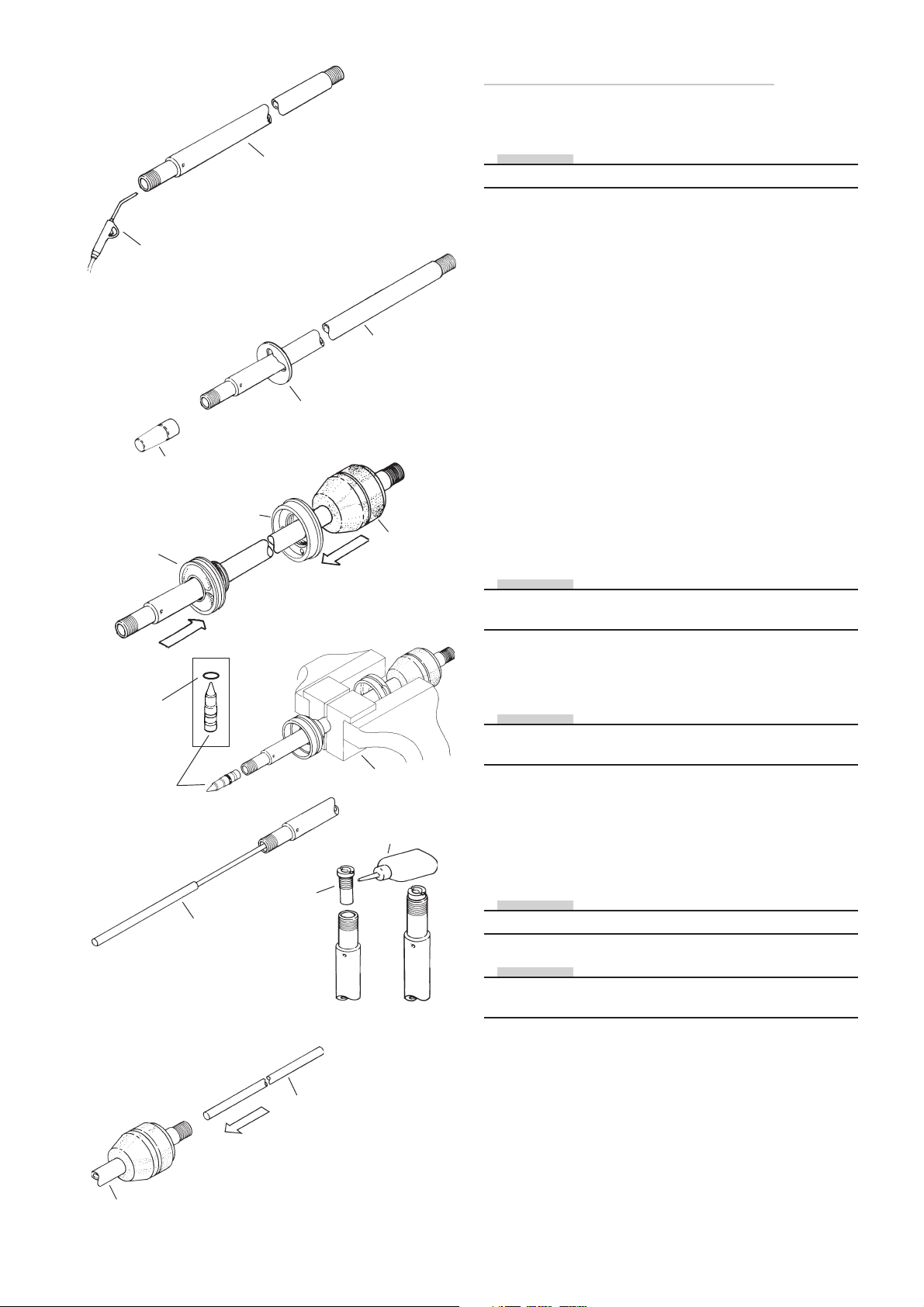

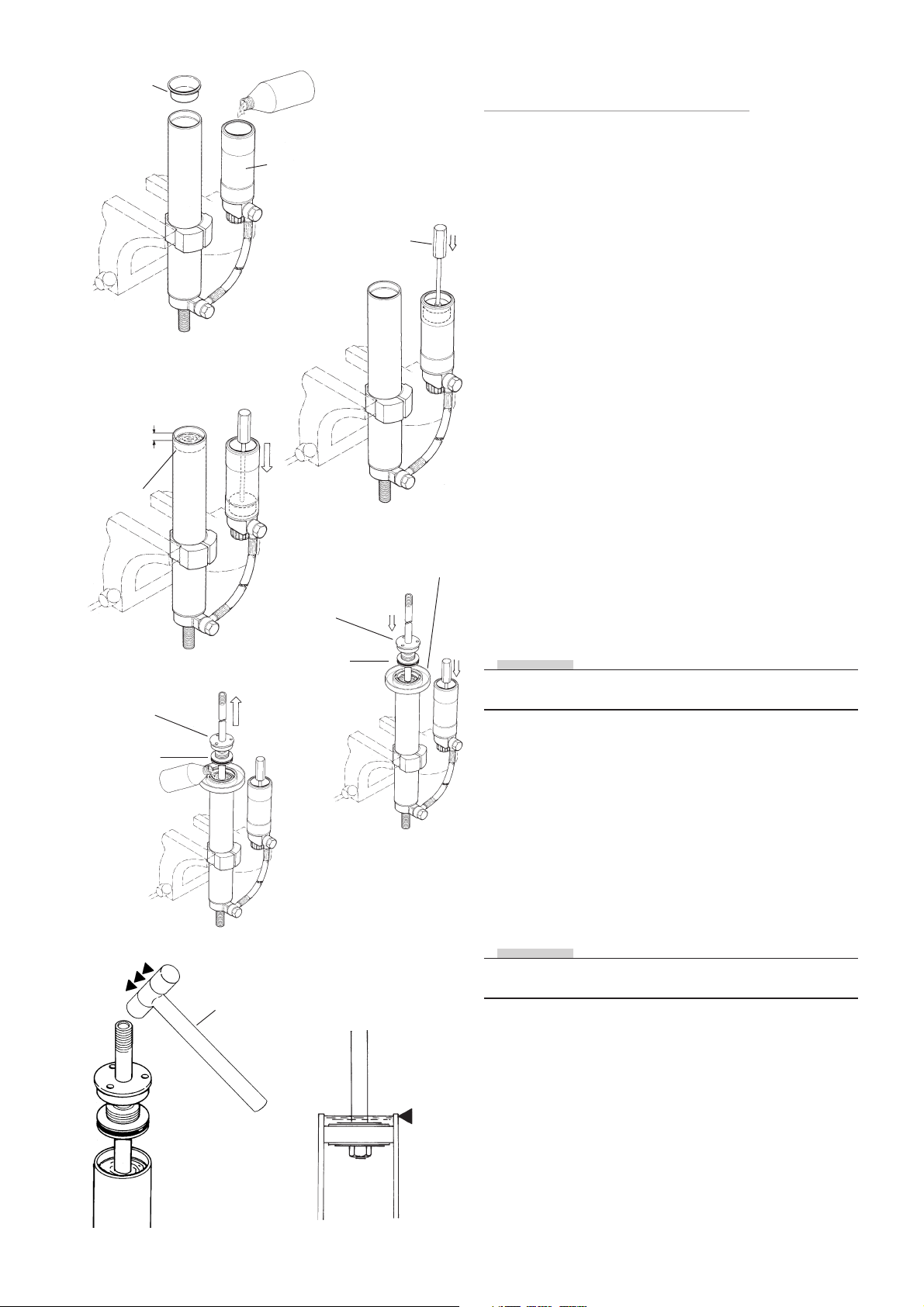

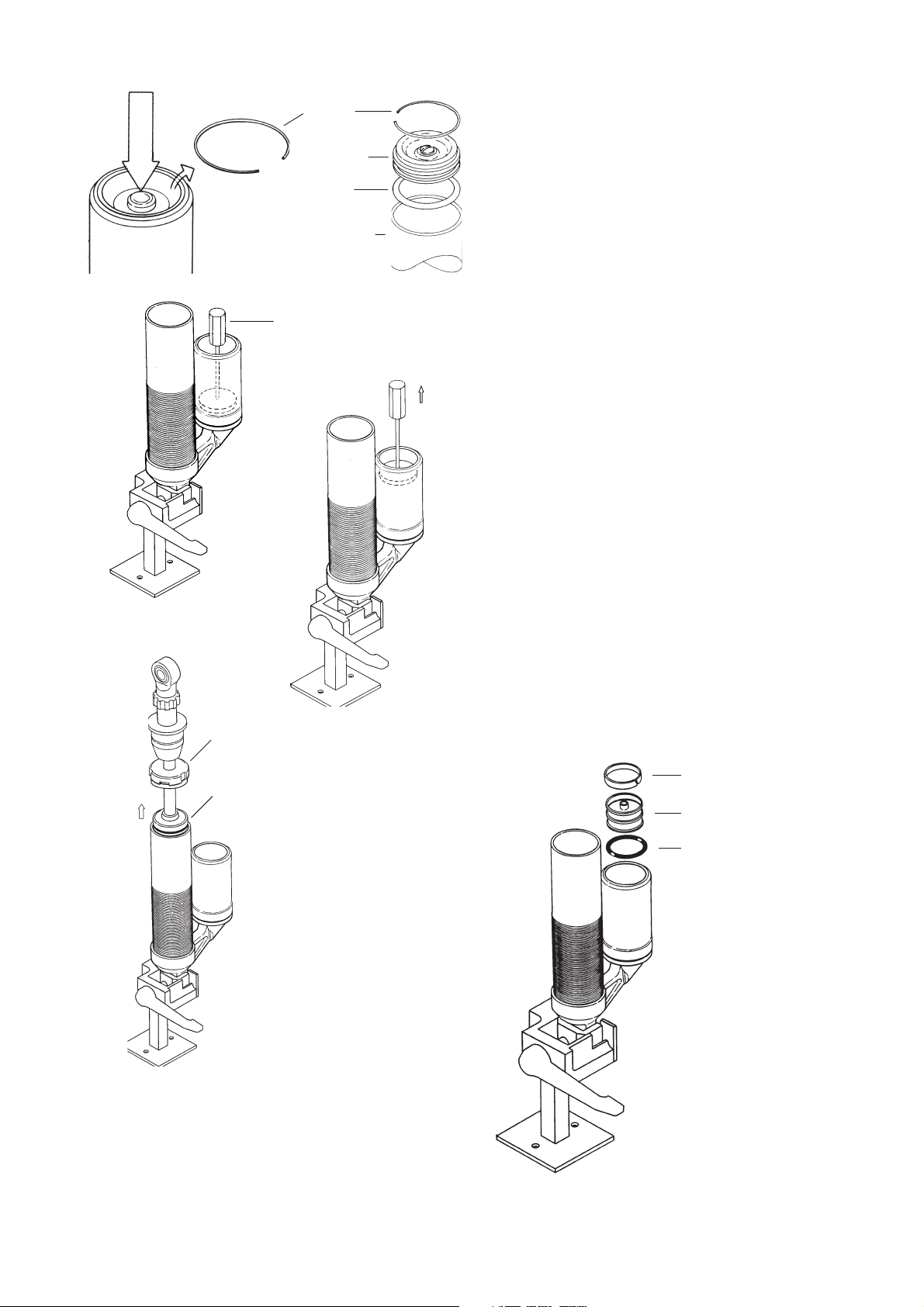

1:1

Dismantling the McPherson suspension

1:1

Remove the shock absorber from the vehicle by loosening first the top mount and then the lower bracket. Remove the strut from the vehicle.

NOTE!

To remove and service the shock absorber in McPherson

struts it is not necessary to remove the spring seats on

the strut, the top mount or the hose connected reservoir.

1:2

Fasten the strut in a vice. Loosen the lock nut at the lower

end of the strut.

Insert

NOTE!

Rebound

adjuster

1:2

Maximum

allen key

grip

Strut

Piston

shaft

Nut

CAUTION!

On struts without wheel bracket, use soft jaws.

NOTE!

To obtain maximal grip for the allen key, it is advisable to

close the rebound adjuster before the insert is removed.

Close by turning the adjuster wheel/screw clockwise.

Count the steps (clicks) when the wheel is turned.

1:3

Insert an allen key into the piston shaft and thread the

shaft out from the strut bottom. Free the insert by pulling

it out from the strut.

1:4

Remove the spring, clean the shock absorber and strut

carefully externally and inspect for damages.

1:5

Fasten the insert in a vice by use of soft jaws 1808-01

(50 mm) or 1808-02 (54 mm).

1:4

1:3

1:5

Insert

Strut

Tool

1808-01, 02

Spring

4

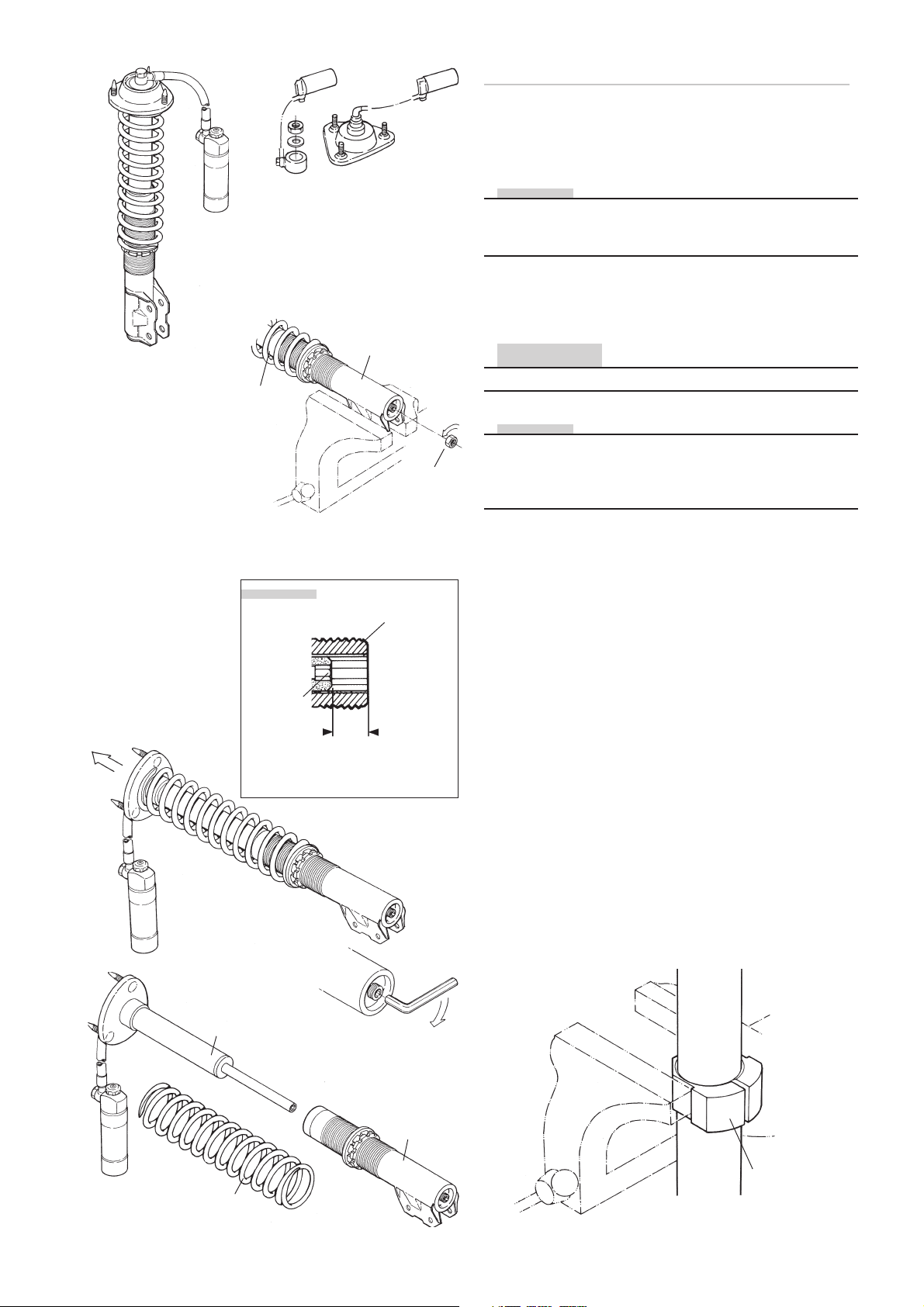

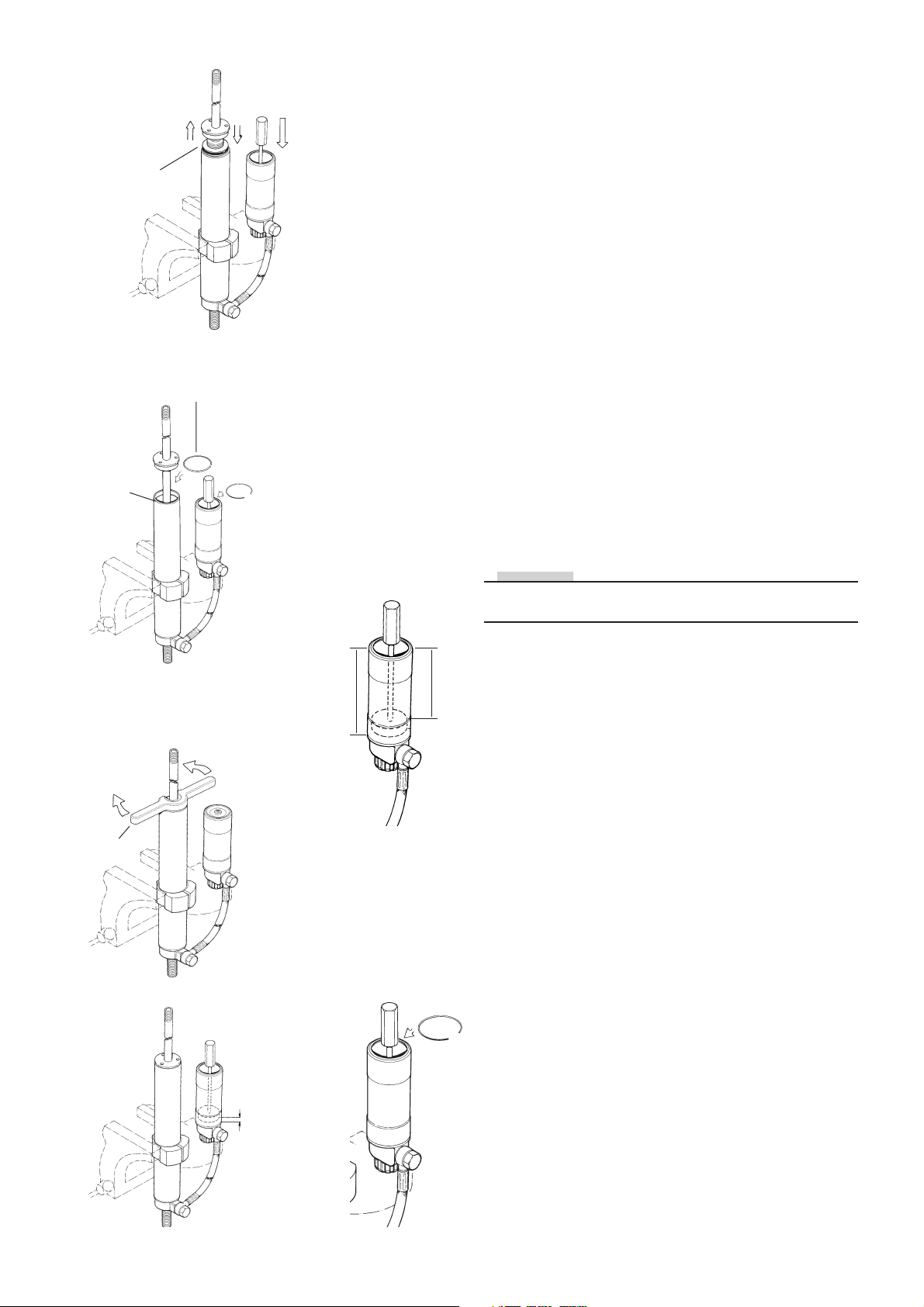

1:6 1:7

Injection

needle

1:6

Remove the screw and o-ring from the reservoir end cap

(Shock absorber head on shock absorber models without

external reservoir.)

NOTE!

Before the gas pressure is relieved the adjuster settings

must be counted and noted. Even check that the gas

pressure is correct. Following that, the adjusters should

be set in a fully open position.

1:7

Relieve the nitrogen gas pressure by inserting an injection

needle into the shaft through the rubber valve.

1:9

Tool

720-03

Tool

1858-01

Circlip

End cap

1:8

1:10

WARNING

Releasing high pressure gas from the shock absorber can

be hazardous. Do not perform any kind of service until

gas pressure is completely released.

1:8

Use tool 1858-01 to loosen and remove the cylinder end

cap. Push the seal head down and remove the circlip.

1:9

Push the end cap of the reservoir down into the reservoir,

use tool 720-03.

1:10

Remove the circlip. Remove the end cap.

1:11

Pull the shaft assembly up carefully and remove it from

the cylinder tube.

1:12

Drain the shock absorber from oil.

1:13

Remove the dividing piston with tool 720-02 and drain

the oil again.

End cap

Seal head

assembly

1:11

Reservoir

1:13

1:14

Remove all o-rings and seals.

1:15

Clean all parts carefully.

1:14

Teflon band

Dividing piston

O-ring

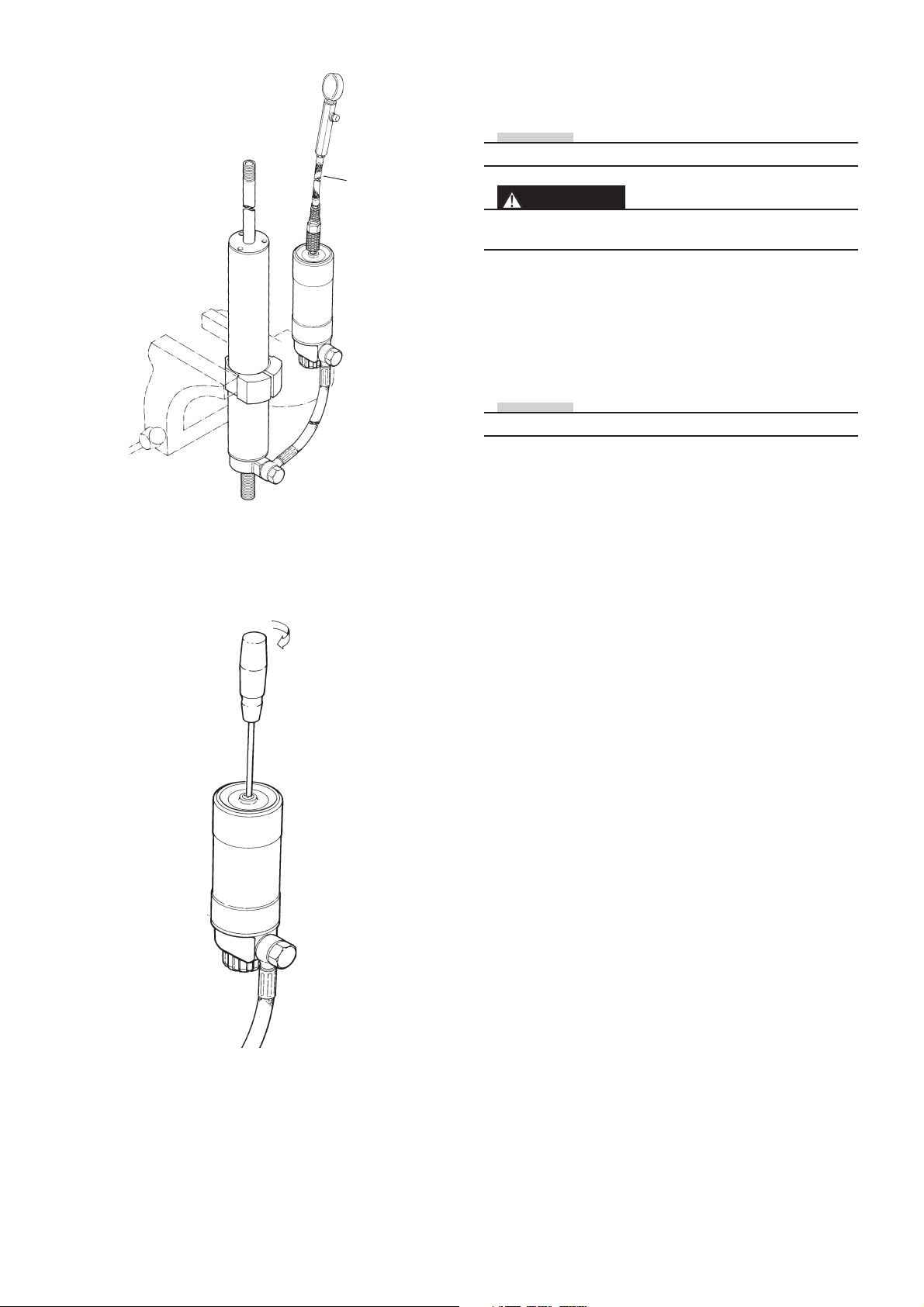

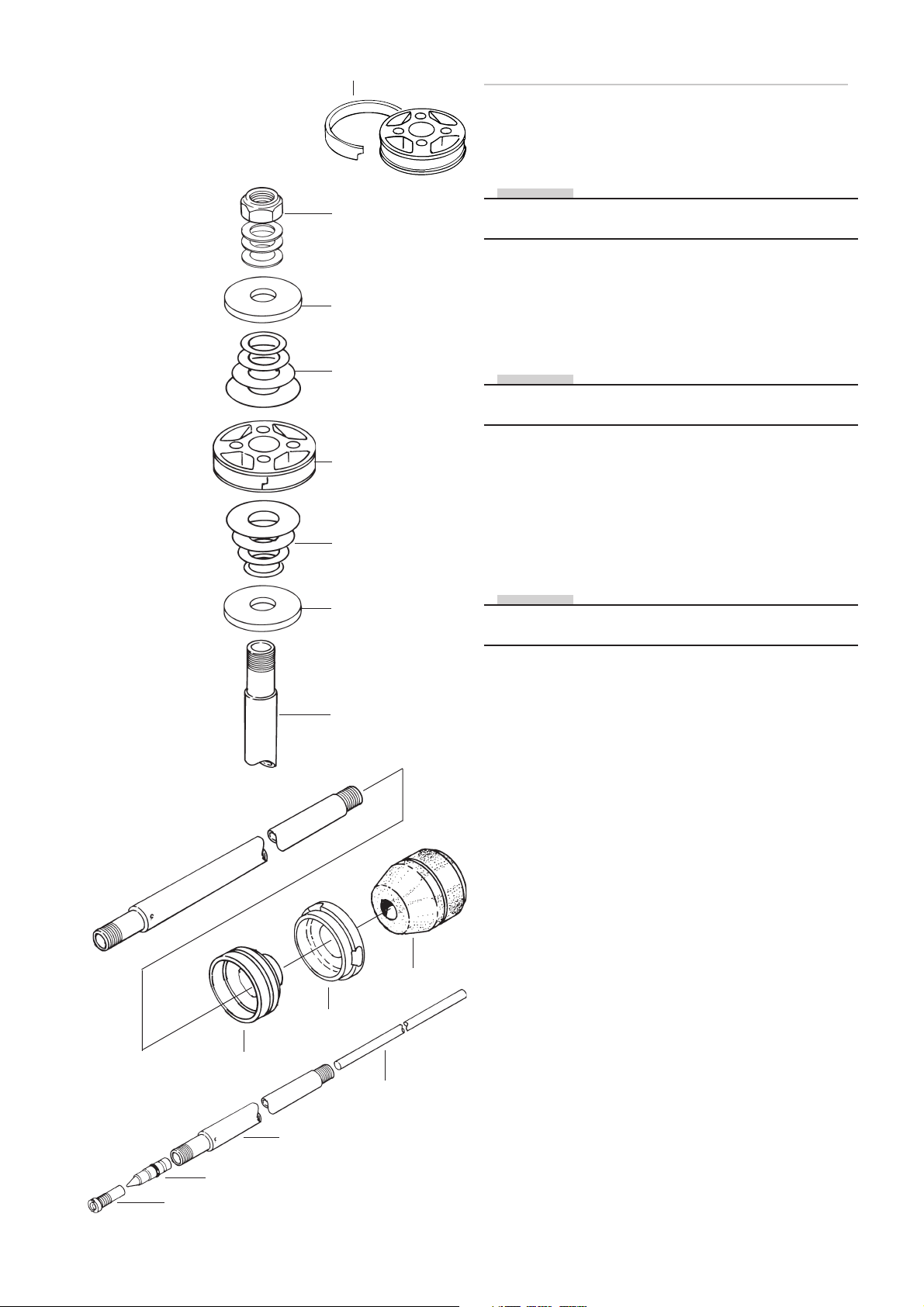

5

O-ring

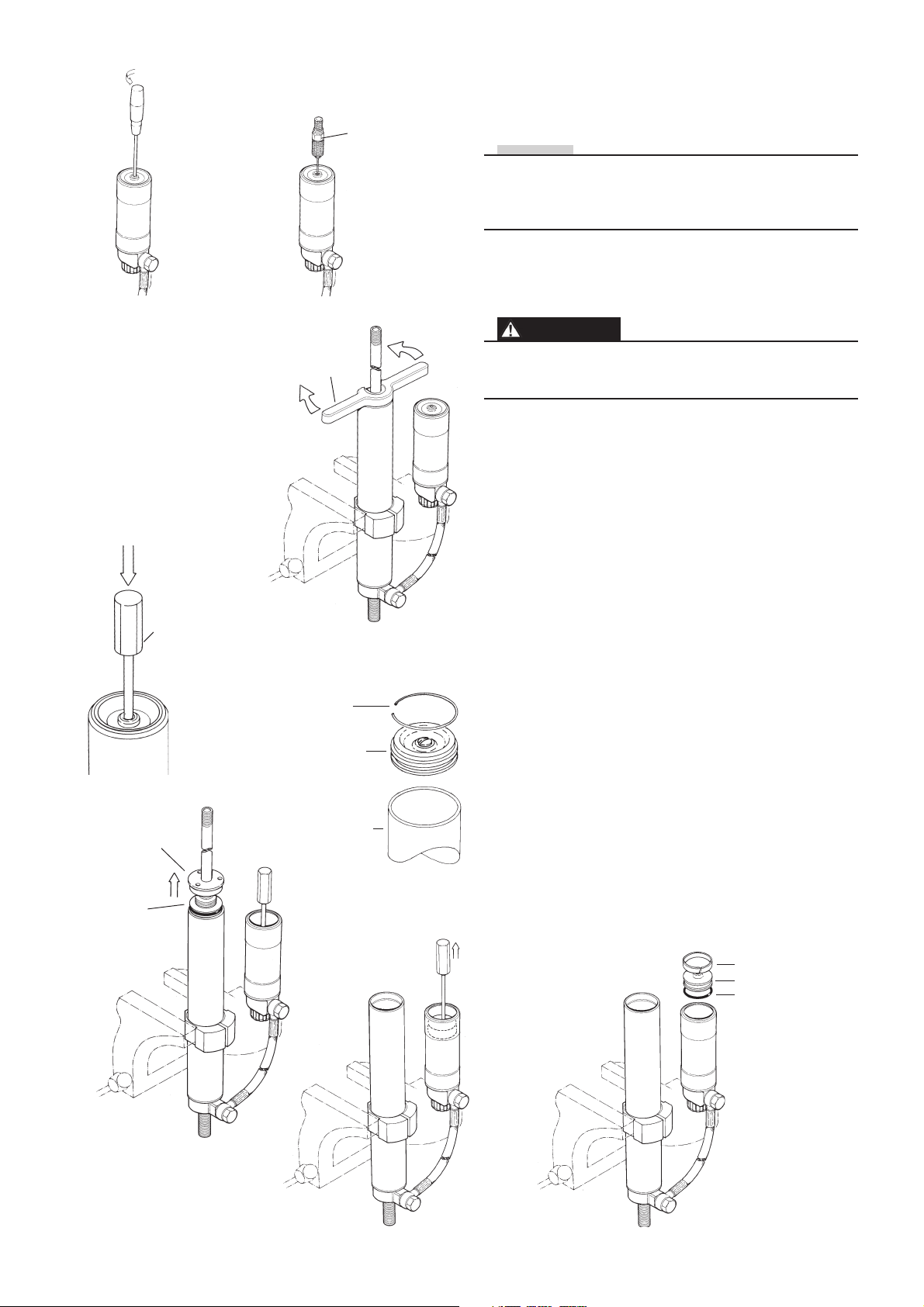

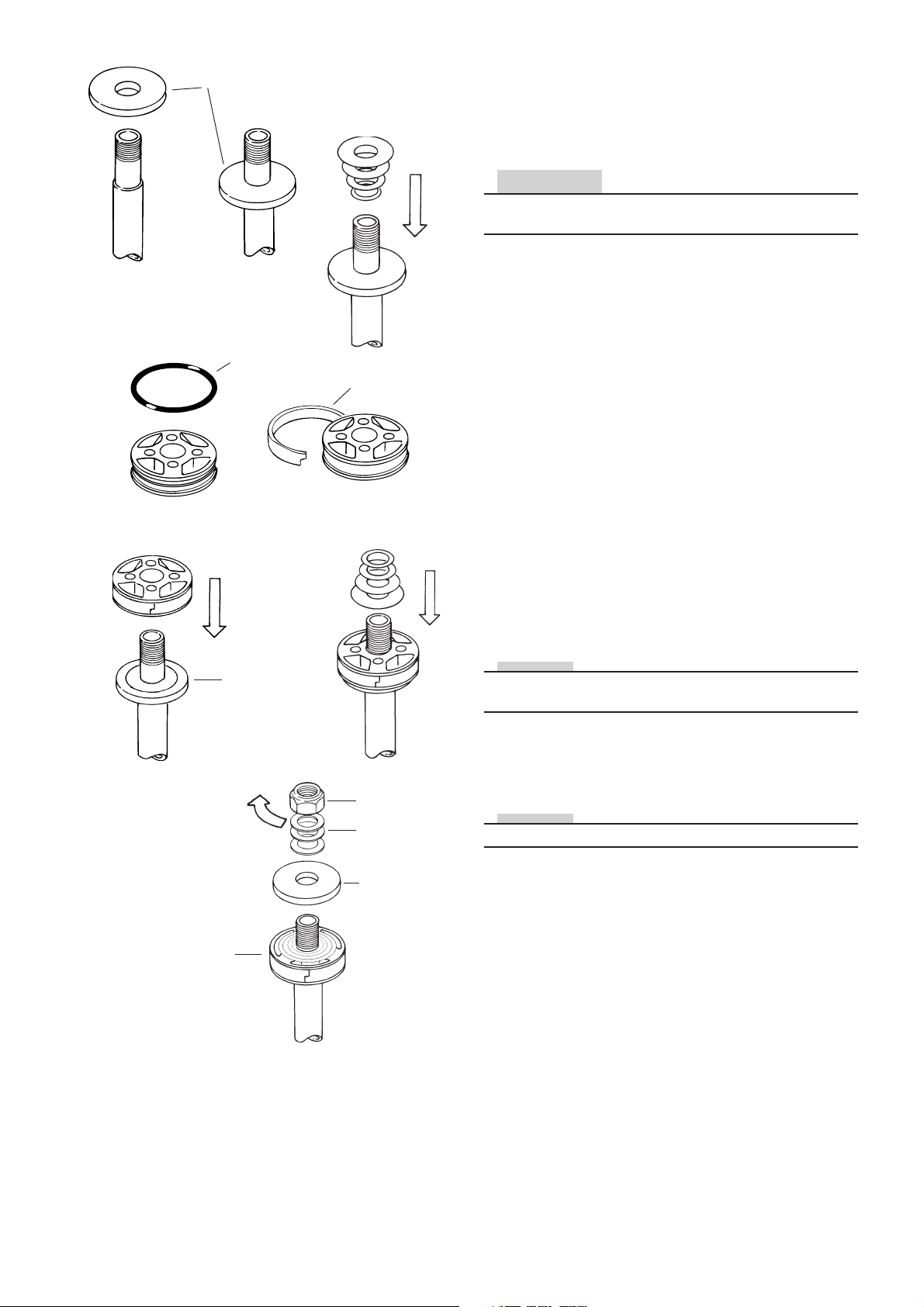

2:2

Piston band

Dismantling the piston shaft assembly

2:1

Fasten the shaft assembly in a vice with soft jaws. Use

clamping tool (727-xx)

2:3

Lock nut

Washer

Rebound

shims stack

Piston

Compression

shims stack

Washer

2:2

Remove teflon band from the damper piston

2:3

Remove the lock nut, the rebound shims stack, the

damper piston and the compression shim stack.

NOTE!

Put the shim stack aside and place the shims in the same

order as they were fitted on shaft.

2:4

Remove all the other parts from the shaft and put them

aside in correct order.

2:5

Remove the adjustment valve jet, the adjustment needle

and the adjustment pin.

2:6

Clean all parts carefully and inspect for wear or damage.

Check the o-ring of the needle and replace if necessary.

2:7

Inspect the shaft for bends and scratches.

2:8

Replace teflon ring, o-rings and lock nut.

2:4

Seal head

End cap

Piston shaft

Bump rubber

Adjustment pin

2:9

If necessary replace bump rubber, scraper ring and cap,

seal head assembly and eventual other defect parts.

2:5

Piston shaft

Needle

Valve jet

6

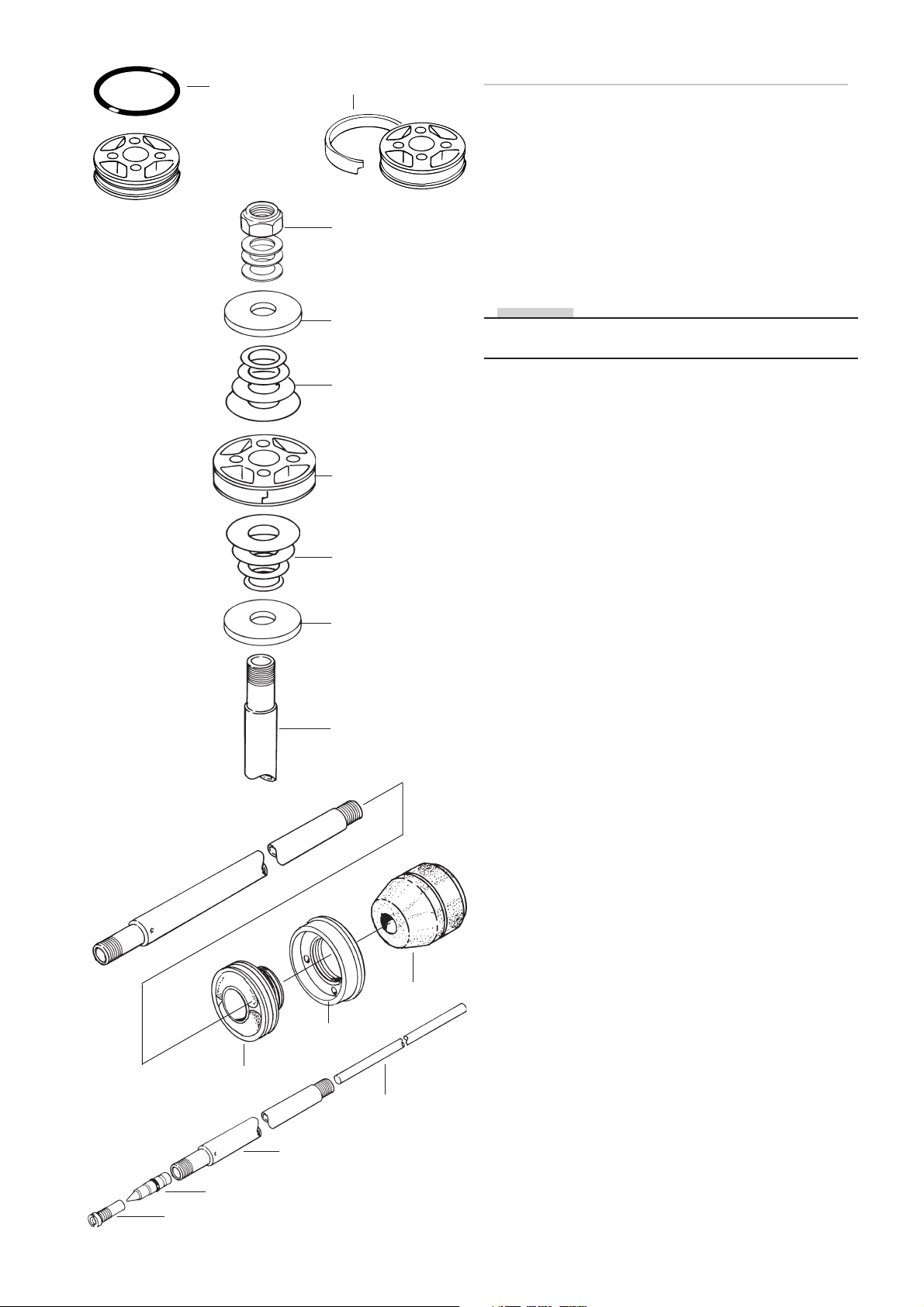

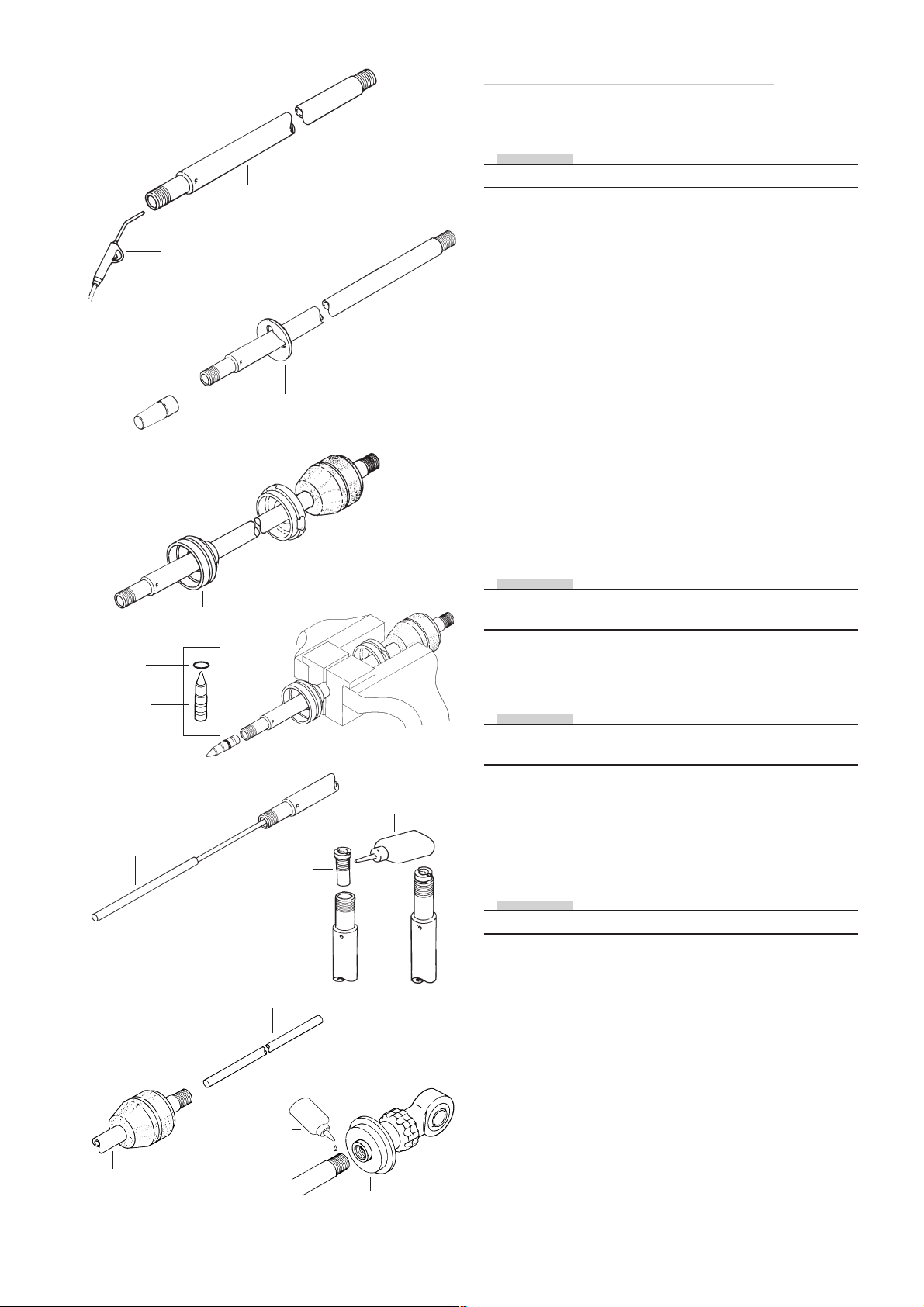

Reassembling the piston shaft

3:3

Seal head

O-ring

Adjuster

needle

3:1

Pressure

air gun

Fitting sleeve

1785-xx

3:7

Tool 1748-01

3:4

End

cap

Piston shaft

3:4

Spacer

3:6

Nozzle

Piston shaft

Bump rubber

Soft jaws

727-xx

Loctite 222

3:8

3:5

3:1

Blow the piston shaft clean with compressed air.

NOTE!

Apply Öhlins red grease (146-01) to all o-rings and seals.

3:2

Check the spec.card to see whether spacers are to be

used on the piston shaft. If so, mount these before fitting

the seal head assembly.

3:3

Use fitting sleeve (1785-xx) to protect the seal in the seal

head assembly.

3:4

Lubricate the piston shaft with shock absorber fluid so

that the seal head assembly slides on easily.

3:5

Put on the end cap and the bump rubber.

3:6

Grip the piston shaft with soft jaws 727-xx.

Fit the O-ring on the adjustment needle. Apply plenty of

red grease on the O-ring so that the needle slides easily

into the piston shaft.

NOTE!

Always ensure that the correct needle is used in relation

to the nozzle.

3:7

Press the needle down, using the tool 1748-01, until it

comes to a stop.

NOTE!

If the seating in the nozzle is chamfered, the nozzle must

be replaced with one without chamfer.

3:8

Carefully tighten the nozzle. Use Loctite 222.

3:9

Apply a little red grease to the adjustment rod and insert

it into the piston shaft from the top.

NOTE!

Ensure that the thread on the piston shaft is free from oil.

Piston shaft

NOTE!

Regardings 12 mm shaft, see page 27, chapter shock

absorber 36.

3:9

Adjustment rod

7

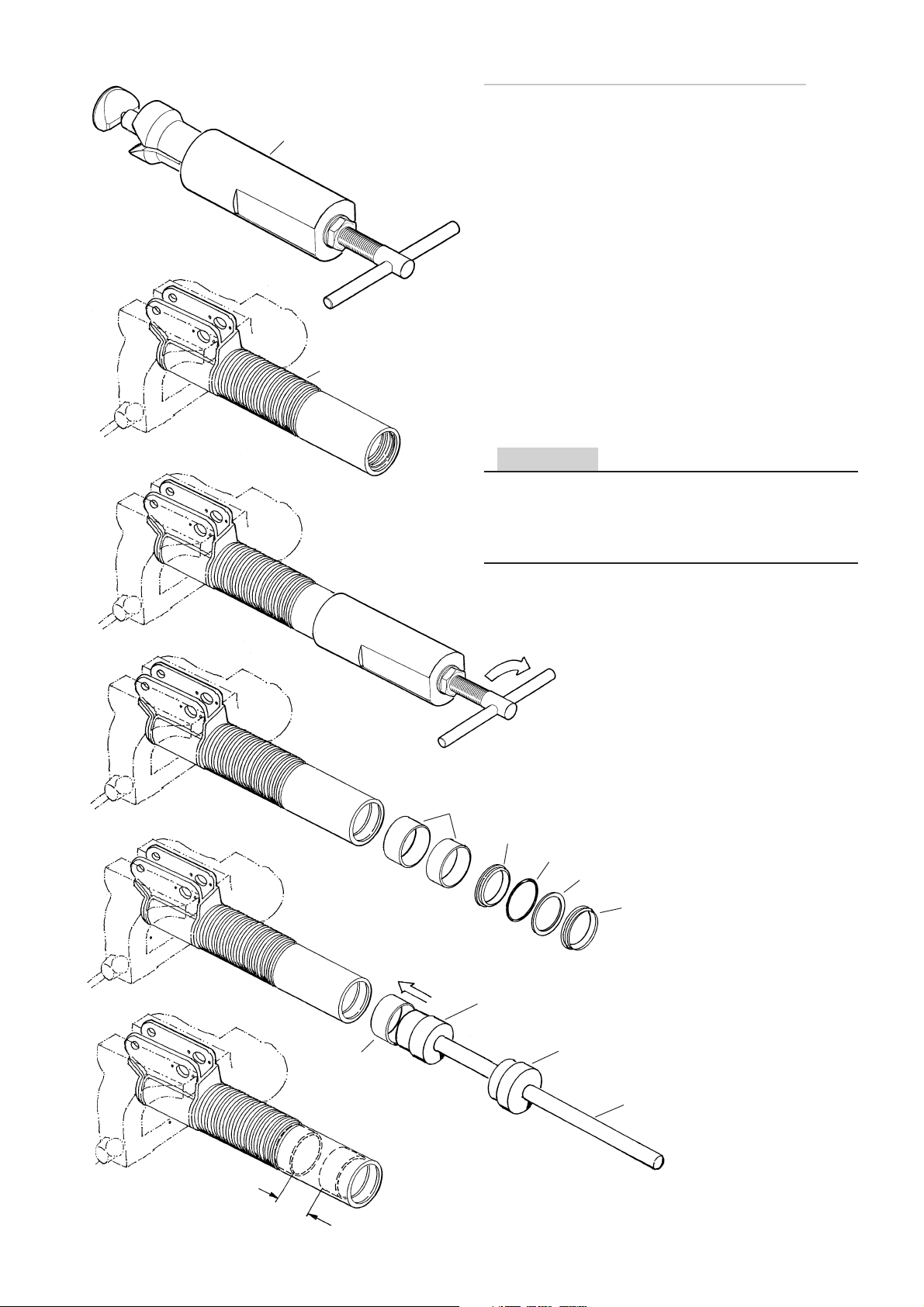

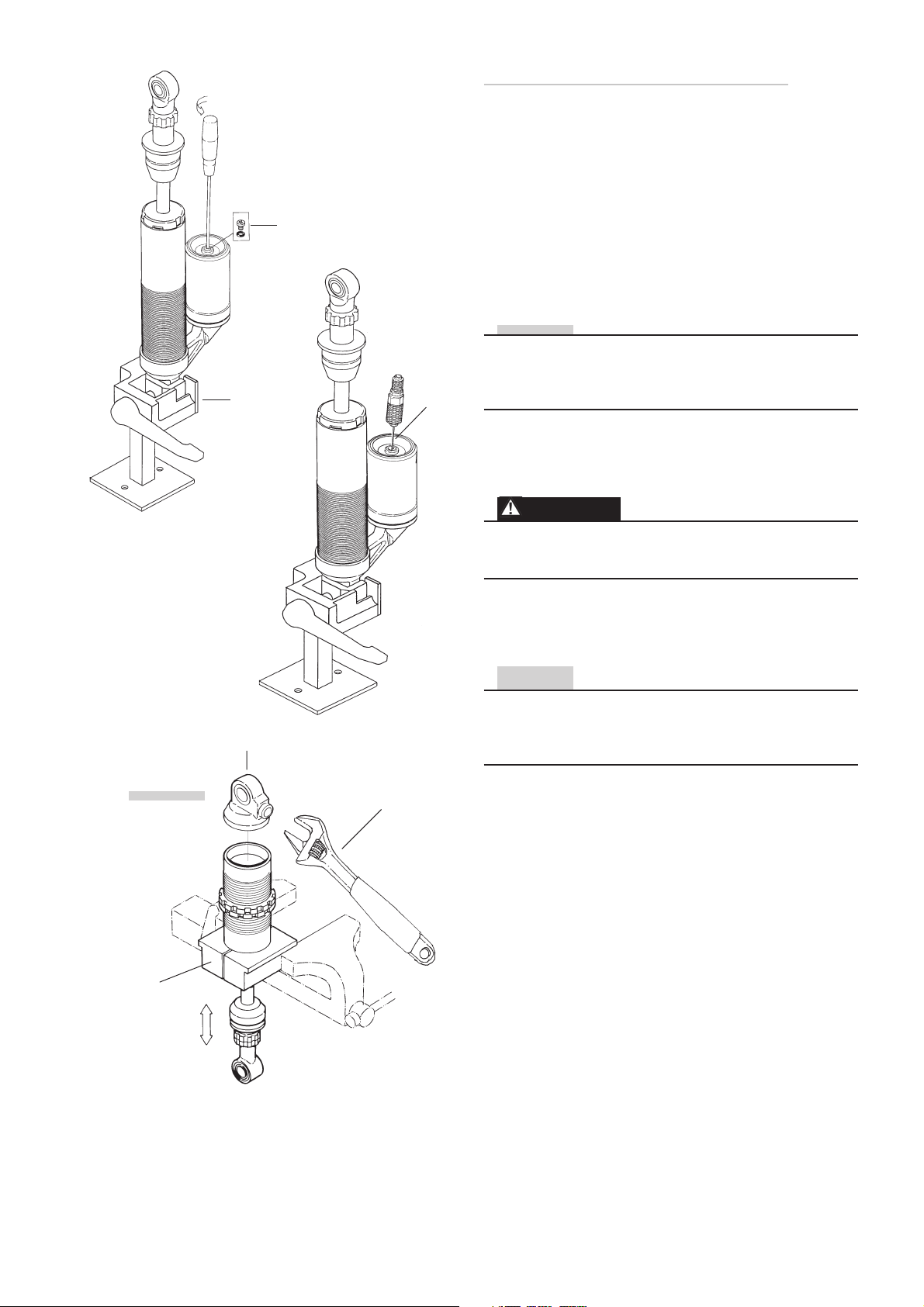

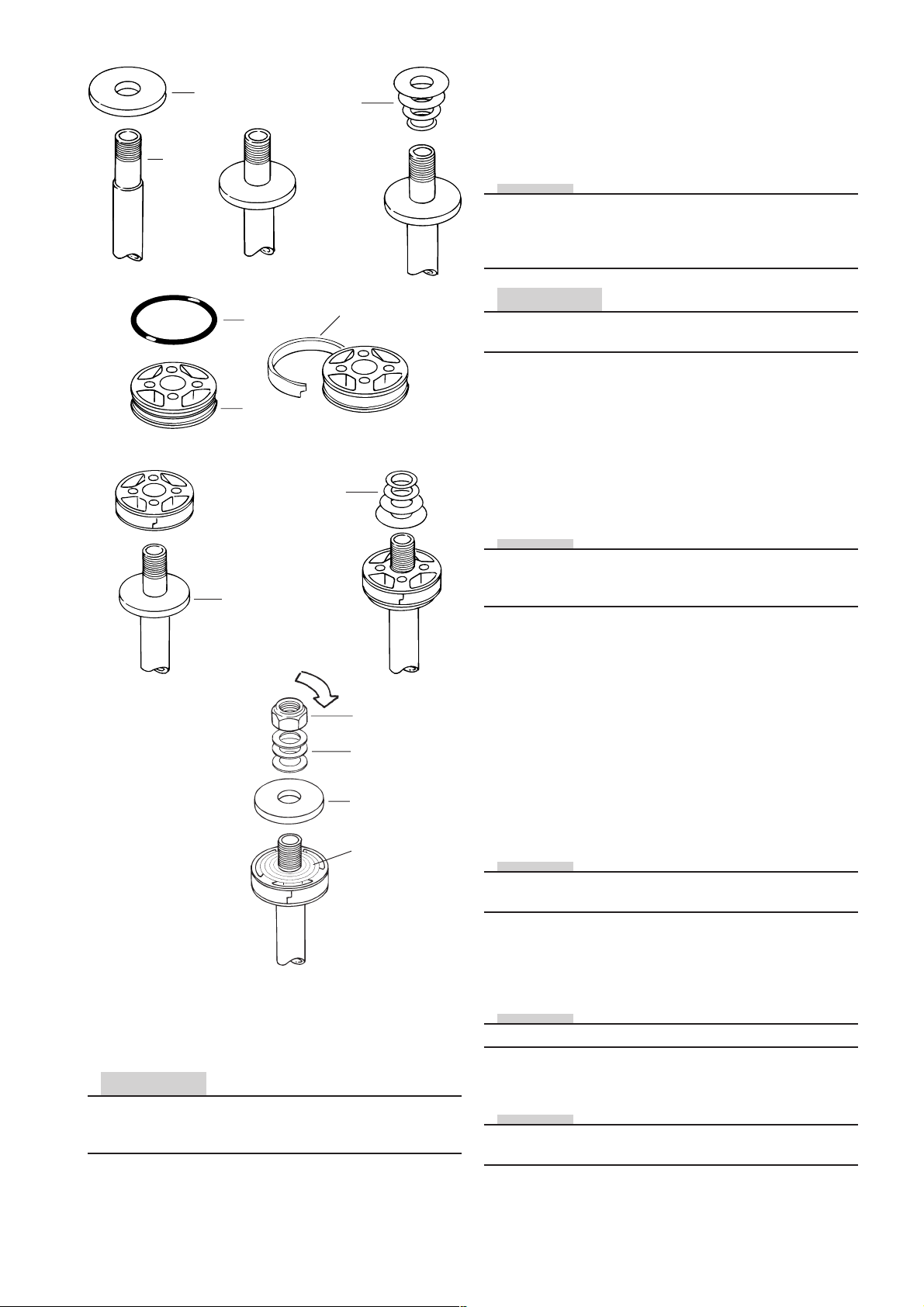

3:11

Stop washer

3:13

Compression

side shims

Mounting of piston on piston shaft

and fitting shims

3:10

Grip the end eye in a vice. Use soft jaws.

CAUTION!

The chamfered side of the stop washer must face away

from the lock nut.

3:11

Put the stop washer in position.

3:12

Check shims and replace if necessary.

3:16

Piston

30 Nm

O-ring

3:15

519-xx

3:17

Teflon band

Rebound

side shims

Lock nut

Washer

3:13

Place shims on the compression side according to the

spec. card.

3:14

Ensure that the correct piston is beeing used. If a flat

piston is used face the piston using 1200 abrasive paper

to ensure a completely even and flat surface. Ensure that

there are no burrs or particels on the piston or in the fluid

ducts.

3:15

Where applicable, fit the O-ring underneath the Teflon

band on the piston. Mount the piston ring.

3:16

Put the piston on the piston shaft.

NOTE!

Ensure that the piston faces the correct way. The grooved

side of the piston must face the nut.

3:17

Fit the shims on the rebound side. Carefully check the

spec.card to see which washer (519- xx) is to lie on the

top shim.

NOTE!

There are several different types of 519-xx washers.

519-xx

3:18

Stop

washer

3:18

Refit the stop washer, the washers and the lock nut, torque

tighten to 30 Nm.

8

Changing of bushings in the strut.

4:1

4:2

Tool

1828-01

Strut

4:1

Fasten the strut in a vice horizontally. Use Bushing removal

tool 1828-01 ( ø50-ø54 only).

4:2

Push the tool into the lower bushing, fix it and pull the

bushing out together with the upper bushing, the scrapers and the support ring. (and o-rings when frequent)

4:3

Clean the strut carefully and reinstall the bushings. Use

attachment bar 1757-01, installing sleeve 1759-xx and

guide ring 1758-xx. Start with the lower bushing and push

it down all the way to the seat.

4:4

The upper bushing should be pushed down so it is 100

mm above the lower bushing. Apply some locking fluid

Loctite 601 or similar before installing them.

CAUTION

Heat the strut up with a heat air gun, before the installation is made. Be careful to get the bushings straight. Put

the shock absorber cylinder into the strut and check the

function to make sure that the bushings are installed in a

correct way.

4:4

4:3

4:3

4:5

Refit the scrapers and the support ring.

Pull the bushings out

by turning clockwise

Bushings

Seal

Circlip

Support ring

Scraper

Installing sleeve

100 mm

Bushing

Guide ring

Attachment bar

9

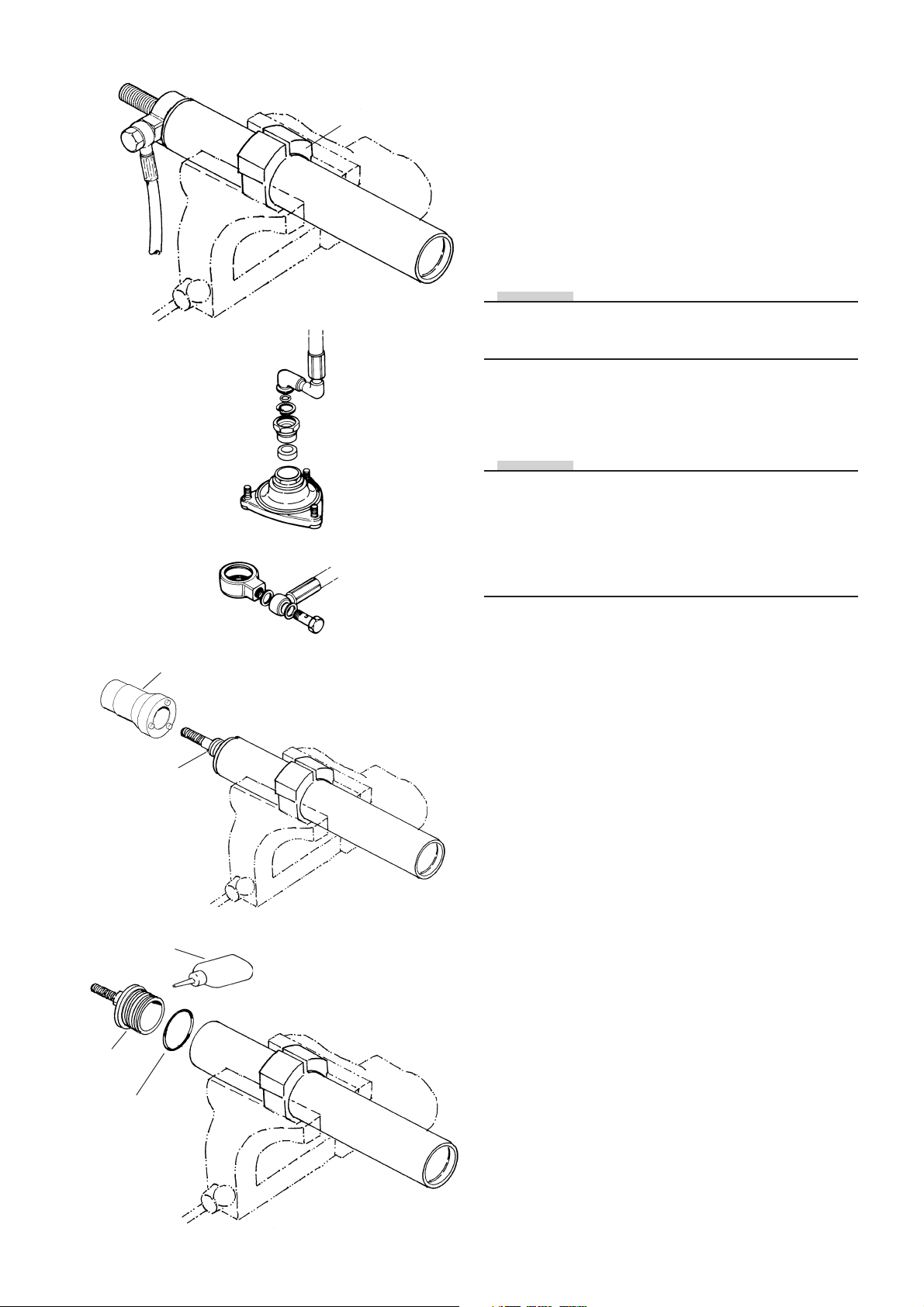

4:6

Hose connections

Tool 1808-01, 02

4:7

Removal and refitting of the cylinder head

4:6

Fasten the cylinder body in a vice horizontally. Again use

tools 1808-01 or 1808-02.

4:7

Remove the hose connection.

4:8

Loosen and remove the Cylinder head. Use tool 1807-01

and a breaker bar.

NOTE!

The thread on the cylinder head is fixed with Loctite 648.

This makes it necessary to use a heat air gun to heat the

cylinder head before it is unthreaded.

4:9

When refitting the cylinder head it is of vital importance

to use Loctite again.

NOTE!

1807-01 for cylinder head 5188 and 5594.

1857-01 for cylinder head Mc Pherson ø40 together with

sleeve 5991-01 for cylinder head 5911-03 and 5911-04.

1857-01 for cylinder head Mc Pherson ø40 together with

sleeve 5991-02 for cylinder head 5911-01 and 5911-02

Cylinder head

Loctite

Cylinder

head

O-ring

Tool 1807-01

4:8

4:9

10

5:1

Plastic

plug

Reservoir

Tool 0720-02

Assembling of

McPherson shock absorber

5:1

Insert a plastic plug (764-01) in the cylinder tube. Fill up

with Öhlins fluid all the way to the edge of the reservoir.

5:2

Push the dividing piston, with teflon band and O-ring fitted,

down in to the reservoir without allowing it to be pressed

back over the circlip groove, make sure that there is no air

between the piston and the oil.

10 mm

Circlip

groove

End cap

Seal head

assembly

5:3

5:5

5:2

End cap

Seal head

assembly

5:4

Retainer

fluid cap

5:3

Push the dividing piston to the bottom, using tool 720-02.

Close the compression adjuster.

Measure the distance from the edge of the reservoir to

the upper edge of the dividing piston and make a note of

the lenght. Fill the cylinder tube with Öhlins fluid to about

10 mm below the circlip groove.

5:4

Install an fluid retainer cup. Insert the piston shaft into the

cylinder tube. Take care, that fluid does not squirt up.

When the piston is submerged in the fluid the piston shaft

should be pressed down hard, to force out air between

the shims and piston.

5:5

Wait a while to allow air bubbles to rise to the surface.

Pull the piston shaft up a bit, without allowing the bleed

holes to come above the surface. Top up with more fluid

if required.

NOTE!

This labour forces fluid through the apertures of the main

piston and helps to bleed out all air.

5:6

Repeat this procedure until all air is expelled. If the shims

are very hard, a check can be made by pushing down the

piston rod very hard. If there is still air remaining the fluid

level will move. If so, strike the piston shaft end firmly

with a plastic hammer to make the shims open.

5:6

Plastic

hammer

5:7

When all air has been expelled, pull the piston shaft up as

far as possible without the bleed holes in the piston shaft

coming above the surface of the fluid. Top up with fluid

all the way up to the edge of the cylinder tube.

NOTE!

Rotate the piston shaft lightly to seat the teflon band properly against the body tube bore.

5:7

Fluid

level

11

Seal head

assembly

5:8

Retainer ring

Dividing piston

completely down

5:8

Push the seal head down against the fluid and carefully

down to the O-ring groove make sure that the bleedhole

is facing away from you. Then push the piston shaft down

halfway. Make sure that the dividing piston is completely

down to the bottom of the reservoir.

5:9

Open the compression valve and, using a blunt screwdriver, push the seal head assembly down until the circlip

groove is visible.

5:10

Fit the circlip and pull up the piston shaft up, make sure

that the circlip is fixed in its groove and in the seal head

assembly groove.

5:11

Fit the end cap with tool 1858-01. Apply red grease 146-01.

Tighten to 50 Nm.

5:9

Circlip

groove

Tool

1858-01

5:10

5:12

5:12

With the piston shaft fully out measure again from the

edge of the reservoir to the upper edge of the dividing

piston. If the value between the first and the second

measurement is more than 7 mm or less than 4 mm, open

the filling screw and adjust the position of the dividing

piston carefully, if the piston is too far in top up with fluid

in filling hole. Then screw in the filling screw.

5:13

NOTE!

Put the dividing piston in correct position according to

table.

5:13

Reservoir Position

L

P

length (L) of dividing piston (P)

80 47

90 57

110 77

120 87

133 100

150 117

180 147

220 187

5:11

7-10 mm

5:14

5:14

Fit the O-ring on the reservoir cap assy, apply some red

grease on the O-ring and push it into the chamber using

tool 720-03. Fit the circlip make certain that it enters its

groove properly.

12

Pressurising and assembling protective

cover on the cylinder

5:15

Gas filling tool

1781-01

NOTE!

Nitrogen (N2) gas . Use pressure gauge (1781-01).

WARNING!

Use of inflammable gas for pressurising the shock

absorber can be hazardous. Use nitrogen gas (N2) only.

5:15

Check the gas pressure stipulated in the spec.card. Dip

the needle of the gas tool (1781-01) in red grease and

insert the needle through the gas filler valve.

Charge with gas to the correct pressure, according to the

spec.card.

NOTE!

Ensure that there is no leakage of gas or fluid.

5:16

Screw in the gas filler screw with O-ring.

5:16

13

Shock absorber 46

Contents

Shock absorber 46 .................................................. 15

Dismantling the shock absorber ................................ 16

Dismantling the piston shaft ...................................... 18

Reassembling the piston shaft .................................. 19

Cylinder head............................................................ 21

Assembling the shock absorber ................................ 22

External reservoir ...................................................... 23

End piece on reservoir .............................................. 24

Seal head assembly .................................................. 24

Spring assembly ....................................................... 26

Shock absorber 36 .................................................. 27

General .................................................................... 43

Drawings ................................................................. 55

14

1:3

Tool

773-01

Screw and

O-ring

1:4

Injection

needle

Dismantling the shock absorber

1:1

Remove the spring, use tool 747-01.

Use correct tool to avoid damages.

1:2

Clean the shock absorber carefully externally and inspect

for damages.

1:3

Fasten the shock absorber use tool 773-01. Remove the

screw and o-ring from the reservoir end cap

(Shock absorber head on shock absorber models without

external reservoir.)

NOTE!

Before the gas pressure is relieved the adjuster settings

must be counted and noted. Even check that the gas

pressure is correct. Following that, the adjusters should

be set in a fully open position.

1:4

Relieve the nitrogen gas pressure by inserting an injection

needle into the shaft through the valve rubber.

WARNING

Releasing high pressure gas from the shock absorber can

be hazardous. Do not perform any kind of service until

gas pressure is completely released.

Tool 765-01

NOTE!

Cylinder head

Adjustable

wrench

1:5

Remove the end cap from the shock absorber body. Use

a chisel and a hammer.

NOTE!

Shock absorbers type D ( Internal dividing piston) must

have their cylinder head removed. The cylinder tube is

fitted in a vice with tool (765-01). Heat the head with a

heatgun and use a adjustable wrench to remove it.

1:6

Depress the seal head approximately 15 mm.

1:7

Release and remove the circlip from the cylinder tube

with tool 715-01 or a similar tool. If necessary remove

burrs from the circlip groove with a riffer.

15

1:8

Circlip

1:8

Push the end cap of the reservoir down into the reservoir,

use tool 720-03, remove the circlip. Remove the end cap.

1:9

End cap

O-ring

Reservoir

Measure pin

1:10

1:9

Fit a measure pin to the dividing piston.

1.10

Lower the oil level by pulling the reservoir dividing piston

outwards by help of the measure pin and by pulling the

shaft outwards.

1:11

Pull the shaft assembly up carefully and remove it from

the cylinder tube.

1:12

Remove the dividing piston and drain the shock absorber

from oil.

1:13

Remove all o-rings and seals.

1:14

Clean all parts carefully.

1:11

End cap

Seal head

assembly

Teflon band

1:12

Dividing piston

O-ring

16

2:3

Piston band

Dismantling the piston shaft assembly

2:1

Fasten the shaft assembly in a vice with soft jaws. Use

clamping tool (727-xx)

2:4

Lock nut

Washer

Rebound

shims stack

Piston

Compression

shims stack

Washer

NOTE!

The following text (2:2 and 2:3) is related to shock

absorbers of PDS type only.

2:2

Remove the lock nut (13 mm key)of the PDS piston and

remove the washer. Remove the upper shims stack, the

piston and the lower shim stack. Remove the stop washer

and loosen the PDS piston holder (13 mm key).

NOTE!

Put the shim stack aside and place the shims in the same

order as they were fitted on piston holder.

2:3

Remove teflon band of the damper piston

2:4

Remove the lock nut (already done on PDS model), the

rebound shims stack, the damper piston and the

compression shim stack.

NOTE!

Put the shim stack aside and place the shims in the same

order as they were fitted on shaft.

2:5

Seal head

End cap

Piston shaft

Bump rubber

Adjustment pin

2:5

Remove all the other parts from the shaft and put them

aside in correct order.

2:6.

Remove the end eye, use a heatgun.

Remove the adjustment valve jet, the adjustment needle

and the adjustment pin.

2:7

Clean all parts carefully and inspect for wear or damage.

Check the o-ring of the needle and replace if necessary.

2:8

Inspect the shaft for bends and scratches.

2:9

Replace piston ring, o-rings and lock nut.

2:10

If necessary replace bump rubber, scraper ring and cap,

seal head assembly and eventual other defect parts.

2:6

Piston shaft

Needle

Valve jet

17

LOCTITE

3:3

3:1

Pressure

air gun

Piston shaft

Spacer

3:2

Reassembling the piston shaft

3:1

Blow the piston shaft clean with compressed air.

NOTE!

Apply Öhlins red grease (146-01) to all o-rings and seals.

3:2

Check the spec.card to see whether spacers are to be

used on the piston shaft. If so, mount these before fitting

the seal head assembly.

3:3

Use fitting sleeve (1785-02) to protect the seal in the seal

head assembly.

3:4

Lubricate the piston shaft with shock absorber fluid so

that the seal head assembly slides on easily.

Fitting sleeve

1785-01

O-ring

Adjustable

needle

Tool 1748-01

3:4

Seal head

3:7

End cap

Nozzle

3:5

Bump rubber

3:6

loctite 222

3:8

3:5

Put on the end cap and the bump rubber.

3:6

Grip the piston shaft with soft jaws 727-xx.

Fit the O-ring on the adjustment needle. Apply plenty of

red grease on the O-ring so that the needle slides easily

into the piston shaft.

NOTE!

Always ensure that the correct needle is used in relation

to the nozzle.

3:7

Press the needle down, using the tool 1748-01, until it

comes to a stop.

NOTE!

If the seating in the nozzle is chamfered, the nozzle must

be replaced with one without chamfer.

3:8

Carefully tighten the nozzle. Use Loctite 222.

3:9

Apply a little red grease to the adjustment rod and insert

it into the piston shaft from the top.

NOTE!

Ensure that the thread on the piston shaft is free from oil.

Piston shaft

Adjustment rod

3:9

Loctite 270

3:10

End eye

Mounting the end eye.

3:10

Use Loctite 270 on the piston shaft thread, screw the end

eye on and tighten using an adjustable wrench.

Tightening torque: See page drawings for correct torque.

18

Piston

shaft

3:12

Stop washer

Compression

shims

3:14

Mounting of piston on piston shaft

and fitting shims

3:11

Grip the end eye in a vice. Use soft jaws.

Put the “top out” spring in position, if one is beeing used.

NOTE!

Always ensure that the correct spring is used. Check also

that the spring does not protrude too far above the sleeve.

There is a risk that the sleeve will slide down when tightening the shims nut.

3:17

3:16

3:19

O-ring

Piston

519-xx

30 Nm

Teflon band

Rebound

shims

3:18

Lock nut

Washer

Stop washer

519-xx

Shim stack

CAUTION!

The chamfered side of the stop washer must face away

from the lock nut.

3:12

Put the stop washer in position.

3:13

Check shims and replace if necessary.

3:14

Place shims on the compression side according to the

spec. card.

NOTE!

Make sure to put the shims in right order and that the

shims are in correct position to the piston. (See spec.

card)

3:15

Ensure that the correct piston is beeing used. If a flat

piston is used face the piston using 1200 abrasive paper

to ensure a completely even and flat surface. Ensure that

there are no burrs or particels on the piston or in the fluid

ducts.

3:16

Where applicable, fit the O-ring underneath the Teflon

band on the piston. Mount the piston ring.

3:17

Put the piston on the piston shaft.

NOTE!

Ensure that the piston faces the correct way. The grooved

side of the piston must face the nut.

3:20

Fit the PDS piston holder and tighten it to 30 Nm. Fit the

stop washer, the lower shim stack, the piston and the

upper shim stack. Use cleaner to make the shims dry, so

they do not rotate during assembly work.

CAUTION!

It is of great importance that the triangular shims are in

correct position when the PDS piston assembly is

mounted. Check from both sides.

3:21

Put the washer and lock nut back to the PDS holder and

tighten to 18 Nm.

3:18

Fit the shims on the rebound side. Carefully check the

spec.card to see which washer (519- xx) is to lie on the

top shim.

NOTE!

There are several different types of 519-xx washers.

3:19

Refit the lock nut, torque tighten to 30 Nm.

NOTE!

The following text (4.10-4.11) is related to shock absorbers of PDS type only .

19

Loading...

Loading...