Ohlins FG 9700 User Manual

Racing manual

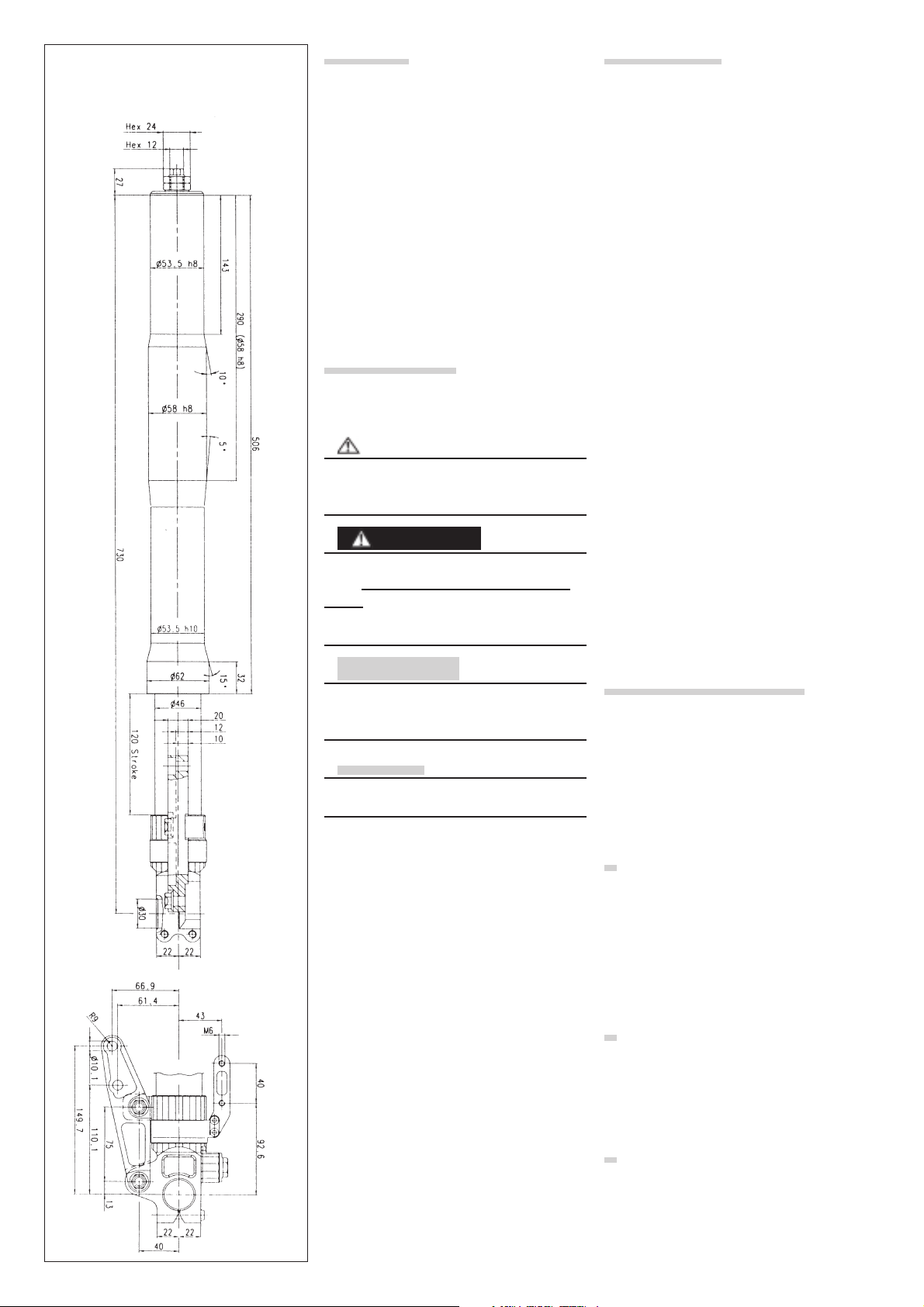

Öhlins super bike front fork FG 9700

Including:

Setting up

your fork

Changing

springs

and seals

Service

the fork

Trouble

shooting

Technical

info

Spare parts

& tools

Traction, handling,

comfort and safety

1

Öhlins super bike

front fork FG 9700

Contents

Introduction __________________ 2

Setting up your forks

Spring preload adjustment ______ 3

Rebound adjustment

Compression adjustment

Changing springs

Changing seals

Dismantling the forks __________ 4

Assembly of the forks

Troubleshooting

Oil level adjustment ___________ 5

Technical information

Spare parts __________________ 6

Tools

Safety signals

Particularly important information is

distinguished in this manual by the

following notations:

The Safety Alert Symbol means:

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

WARNING

Failure to follow WARNING instructions could result in severe injury or

death to the shock absorber operator,

a bystander or a person inspecting or

repairing the shock absorber.

Introduction

The Öhlins front forks use a Cartridge

system for damping. This gives a damping force which depends on the speed

of the piston in the cartridge system.

The combination of spring and airgap (oil level) gives a possibility to adjust the characteristic of the fork to suit

different tracks and riders.

For example a soft spring in combination with a small air-gap (high oil

level) gives a progressive action of the

front forks.

For better understanding, please refer to our oil level chart.

A telescopic front fork is depending

on a smooth friction-free action.

Make sure your front forks are serviced regularly and don’t use strong solvents such as brake cleaner to clean

the front forks. This will dry out the seals

and steel tubes and cause friction.

Regularly, put a little Öhlins grease

(148-01) on the steel tube and work it

in by pushing the forks up and down.

Öhlins Racing AB can not be held

responsible for any damage to spare

parts or person if the mounting-, maintaining- and servicing instructions are

not followed exactly.

Also no guarantee can be given for

the performance and reliability if these

instructions are not followed.

CAUTION!

A CAUTION indicates special precautions that must be taken to avoid

damage to the shock absorber.

NOTE!

A NOTE provides key information to

make procedures easier or clear.

Setting up your forks

We would like to give you some basic

guidelines, how to set up your Öhlins

front forks. However you must remember that the front forks are just one part

of your motorcycle and to get it to work

properly, the whole motorcycle has to

be set up according to your bikes

manual.

1

Put your bike on a front stand so you

can fit the front forks.

Maximum torque on the bottom triple

clamp and steering damper bracket (if

it is located on the diameter on the outer

tube) is 15-18 Nm.

Fit the front wheel and brakes.

2

Unscrew the adjustment housing on top

of the fork (use tool 797-01) on both

upper tubes and slide the fork up and

down gentle to make sure everything

works correctly.

3

© Öhlins Racing AB.

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Öhlins Racing AB is prohibited.

Printed in Sweden.

2

Assemble the adjustment housing

again and set your initial preload of the

spring by using a 12 mm socket until

you get a ”static sag” of 25-30 mm.

Each turn gives 1 mm in preload, maximum preload is 18 mm.

4

The best way to check the ”static sag”

is to put the bike on the ground in running condition.

Measure the distance between the bottom of the outer tube to the fork bottom.

Then lift the front end of the bike, so

the fork is fully extended.

Take the measurement again. The difference between those two figures is

”static sag”.

5

The ”clickers” are a ”bleed function”

separate for rebound and compression

damping.

Rebound is on the top centre of the fork

and compression at the bottom part of

the fork.

You start to count from fully closed

(clockwise) and set it to the recommended ”click” (use tool 794-01).

For recommended start setting please

refer to the specification card.

Spring preload adjustment

Using a 12 mm wrench, turn the upper

adjustment screw.

Maximum adjustment range is 18 mm.

One turn on the adjustment screw will

cause 1 mm change in spring preload.

Adjust so the front forks lowers 25-30

mm from the top, unloaded position.

Rebound adjustment

Adjust the rebound rate on the adjustment screws positioned at the top centre of the front forks.

Use a hex key with a spherical head

(use tool 794-01).

Adjustment range from closed valve

(clockwise) until maximum open valve

(anticlockwise) is 20 ”clicks”.

Recommended adjustment ”click”, from

closed position (see specification card).

Compression adjustment

Adjust the compression rate on the

lower part of the front forks (compression valve). Use a hex key with spherical head (use tool 794-01).

Adjustment range from closed valve

(clockwise) to maximum open valve

(anticlockwise) is 20 ”clicks”.

Recommended adjustment ”clicks”,

from closed position (see specification

card).

Changing springs

1

Loosen the screws that hold the fork

legs in the upper triple clamps.

2

Loosen the adjustment housings (pos

7, page 7) about two turns (use tool

797-01).

3

Remove the fork legs from the motorcycle.

4

Fasten a fork leg in a vice. Use soft

jaws.

5

Unload the spring completely by turning the adjustment screw completely

anticlockwise. Use a 12 mm wrench.

Remove the blue locking nuts.

6

CAUTION!

Do not damage the o-ring and do not

drop the flat key into the fork leg.

Carefully remove the adjustment housing.

7

Remove the preload tube and spring.

(The free spring length see page 5).

8

Install the new spring and check the

oil level.

Install the tool 1765-01 on top of the

preload adjustment screw.

Pull out the piston rod as far as possible and turn the compression adjustment screw fully clockwise.

This will keep the piston rod in top position, which will make the continued

assembly easier.

9

Install the preload tube.

Install the tool 1766-01 on top of the

preload tube and fasten it below the

edge of the preload adjustment screw

(pos 18, page 7).

Remove the tool and continue the assembling.

10

Install the adjustment housing.

CAUTION!

The flat key must be guided in the slot

of the adjustment housing.

The o-ring must be greased, or it

might be damaged.

11

Install the two blue nuts.

12

Loosen the preload tube, and bring it

to its correct position in the adjustment

housing.

Tighten the lower lock nut gently, and

then unscrew it 1/4 of a turn.

Tighten the upper gently against the

lower nut.

Fasten the adjustment housing in the

fork leg.

Make sure that the fork leg is fully ex-

tended when tighten the adjustment

housing.

13

Install the fork legs on the motorcycle

and adjust the preload, compression

and rebound according to the above

instructions.

Changing seals

Put the fork legs upright for 15 minutes.

1

Fasten the fork leg in a vice. Use soft

jaws.

2

Unload the spring preload completely by

turning the adjustment screw completely

anticlockwise. Use a 12 mm wrench.

Make a note of the number of turns.

Remove the two blue lock nuts.

3

Carefully remove the adjustment hous-

ing.

CAUTION!

Do not damage the o-ring and do not

drop the flat key into the fork leg.

4

Remove the preload tube.

5

Slide the outer fork leg up until the top

bushing is just above the inner leg.

(Approx. 140 mm from complete bot-

tom position.

This is to make sure there is no oil

above the top bushing).

6

Slide the outer tube completely down.

(Fork seal touching fork bottom).

7

Push the piston rod down so that it is

in level with the top of the outer tube.

3

Loading...

Loading...