Ohaus CorporationOhaus Corporation

Ohaus Corporation

Ohaus CorporationOhaus Corporation

29 Hanover Road

Florham Park, NJ

07932-0900

INSTRUCTION MANUAL

Balances

1

Ohaus Corporation, 29 Hanover Road, Florham Park, New Jersey, 07932, USA

Declaration of Conformity

with the directives and standards mentioned.

Konformitätserkärung

genannten Richtlinien und Normen übereinstimmen.

Déclaration de conformité

«CE» - sont conformes aux directives et aux normes mentionnées ci-après.

Declaración de Conformidad

con el distintivo ,CE’ - están conformes con las directivas y normas citadas.

Dichiarazione di conformità

contrassegnati con la marcatura “CE” - sono conformi alle direttive e norme citate.

Balance Type/Waagentyp/Type de balance/Modelo de balanza/Tipo di biliancia Explorer and Voyager

Marked with: Directive Standard

Gekennzeichnet mit: Richtlinie Norm

Munis de la mention: Directive Norme

Con el distintivo: Directiva Norma

Contrassegnati con la Direttiva Norma

Marcatura:

Year of attachment of Electromagnetic compatibility EN45501:1992, EN50082-1:1992 Immunity

the CE mark EU 89/336, 92/31, 93/68 EN55022:1987 Funkstörungen

Jahr der ersten Elektromagnetische Verträglichkeit EN45501:1992, EN50082-1:1992 Immunität

Eichung EU 89/336, 92/31, 93/68 EN55022:1987 Emissions parasites

Année de la premère Compatibilité électromagnétique EN45501:1992, EN50082-1:1992 Immunité

vérification EU 89/336, 92/31, 93/68 EN55022:1987 Radiointerferencias

Año de la primera Compatibilidad electromagnética EN45501:1992, EN50082-1:1992 Inmunidad

verificación EU 89/336, 92/31, 93/68 EN55022:Verträglichkeit 1987 Radiointerferenze

annodella prima Compatibilità elettromagnetica EN45501:1992, EN50082-1:1992 Immunità

verifica

We, Ohaus Corporation, declare under our sole responsibility that the balance models listed below marked with “CE” - are in conformity

Wir , die Ohaus Corporation, erklären in alleiniger Verantw ortung, dass die untenstehenden W aagentypen, gekennzeichnet mit “CE” - mit den

Nous, Ohaus Corporation, déclarons sous notre seule responsabilité, que les types de balance ci-dessous cité - munis de la mention

Nostras, Ohaus Corporation, declaramos bajo responsabilidad exclusiva que los modelos de balanzas indicados a continuación -

Noi, Ohaus Corporation, U.S.A, dichiariamo sotto nostra unica responsabilità, che i tipi di bilance specificati di seguito -

EU 73/23 Low Voltage IEC1010-1 & EN60950:1992 Safety Regulations

EU 73/23 Niederspannung IEC1010-1 & EN60950:1992 Sicherheitsbestimmungen

EU 73/23 Basse tension IEC1010-1 & EN60950:1992 Consignes de sécurité

EU 73/23 Baja tensión IEC1010-1 & EN60950:1992 Disposiciones sobre seguridad

EU 73/23 Bassa tensione IEC1010-1 & EN60950:1992 Prescrizioni . di sicurezza

EU 89/336, 92/31, 93/68 EN55022:1987 Emissions

EU 90/384 NAWI EN45501:1992 Non Automatic Weighing Instruments

EU 90/384 FNSW EN45501:1992 Für nicht selbsttätige Waagen

EU 90/384 BFNA EN45501:1992 Balances à fonctionnement non automatique

EU 90/384 PBNA EN45501:1992 Para balanzas no automátäcas

EU 90.384 BFNA EN45501:1992 Per bilance a funzionamento non automatics

ISO 9001 Certificate for Ohaus Corporation.

and was awarded the ISO 9001 certificate. This certifies that Ohaus Corporation, USA, has a quality system that conforms with the international standards for quality

management and quality assurance (ISO 9000 series). Repeat audits are carried out by BVQI at intervals to check that the quality system is operated in the proper manner.

ISO 9001-Zertifikat für Ohaus Corporation.

erhielt das ISO 9001 Zertifikat. Dieses bescheinigt, dass Ohaus Corporation, USA über ein Qualitätssystem verfügt, welches den internationalen Normen für Qualitätsmanagement

und Qualitätssicherung (ISO 9000er-Reihe) entspricht. Anlässlich von Wiederhol-Audits durch das BVQI wird periodisch überprüft, ob das Qualitätssystem zweckmässig

gehandhabt wird.

Certificat ISO 9000 pour Ohaus Corporation.

obtenu le certificat, degré ISO 9001. Celui-ci atteste que Ohaus Corporation, USA, dispose d’un système qualité correspondant aux normes internationales pour la gestion de

la qualité et pour I’assurance qualité (degré ISO 9000). Des audits réguliers effectués par la BVQI vérifient si le système qualité est appliqué de facon appropriée.

Certificado ISO 9001 para Ohaus Corporation.

obtenido el certificado ISO 9001. Esto acredita que Ohaus Corporation, USA, dispone de un sistema de calidad que cumple las normas internacionales para gestión y garantfa

de calidad (ISO serie 9000). Con ocasión de las inspecciones de repetibilidad por parte de la BVQI, se comprueba periódicamente si el sistema de calidad se manipula de forma

correcta.

Certificato ISO 9001 per la Ohaus Corporation.

Bureau V eritas Quality International BVQI, e così fomice la dimostrazione che il suo sistema die Garanzia Qualità soddisfa i ma ssimi requisite. ll sistema della garanzia della

qualità Ohaus Corporation viene verificato periodicamente dall BVQI, dando cosi evidenza di.

Ohaus Corporation, USA, was examined and ev aluated in 1994 by the Bureau V eritas Quality International, BVQI,

Die Firma Ohaus Corporation, USA, wurde 1994 durch das Bureau V eritas Quality International BVQI geprüft, und

La société Ohaus Corporation, USA, a été contrôlée en 1994 par Bureau V eritas Quality International BVQI et a

La firma Ohaus Corporation, USA, ha sido inspeccionada por la Bureau V eritas Quality International (BVQI) y ha

ll sistema di garanzia della qualità della Società Ohaus Corporation, USA è certificato ISO 9001 sin dal 1994 dall

2

Notice

Certified scales,scales used for legal applications have the gener al type designation E...5 / V ...5 and EU type Approval (T2914). The year

of the initial verification is shown next to the CE mark. Such scales are verified in the factory and carry the "M" mark on the actual scale and the packaging. The year

of the initial verification is shown next to the CE mark. If the letter M is shown against a solid background, the scale may b e put into operation immediately . Should the

background be partitioned and hatched, the scale must be verified at its place of use by the certified Ohaus service. If national regulations limit the duration of the validity

of the verification certificate in individual countries, the end user of such a scale is personally responsible for arranging the repeat verification in good time.

Hinweise

Geeichte/eichpflichtige Waagen tr agen die allgemeine T ypenbezeichnung E... 5 / V ...5. Für sie liegt eine EU Bauartzulassung vor (T2914). Das Jahr der ersten Eichung

ist neben dem CE Zeichen aufgeführt. Solche Waagen sind ab Werk geeicht und tragen die Kennz eichnung "M" auf dem Gerät selbst und auf der Verpackung. Erscheint

der Buchstabe M auf vollem Grund, darf die W aage sofort in Betrieb genommen werden. Ist der Grund geteilt und schraffiert, muss die Waage am Verwendungsort durch

den zertifizierten Ohaus Service ortsgeeicht werden. Sof ern gemäss den nationalen Vorschriften in den einzelnen Staaten die Gültigk eitsdauer der Eichung beschränkt

ist, ist der Betreiber einer solchen Waage für die rechtzeitige Nacheichung selbst verantwortlich.

Remarques

Les balances vérifiées/admissibles à la vérification portent la désignation de modèle générale E...5 / V ... 5. Elles font l’objet d’une approbation de modèle UE (T2914).

L ’année de la vérification primitive est indiquée à côté de la marque CE. Ces balances sont vérifidées d’origine et portent la marque "M" sur I’appareil lui-même et sur

l’emballage, Si la lettre M apparaît sur un fond totalement vert, la balance peut être mise en service immédiatement. Si le fond est divisé et hachuré, la balance doit être

vérifiée sur le lieu d’ustilisation par le service après-vente Ohaus certifié. Dans les pays où la durée de validité de la vérification est limitée par des prescriptions

nationales, l’utilisateur est lui-même responsable de la vérification ultérieure d’une telle balance en temps voulu.

Notas

Las balanzas verificadas/verificables llevan la designatión general E...5 / V ...5 y cuentan con una aprobación de modelo UE (T2914). EL año de la primera verficación

está indicado al lado del distintivo CE. Estas balanzas están verificadas en fábrica y Ilevan la designatión "M" sobre el propio aparato y sobre el embalaje. Cuando la

letra M aparece sobre fondo sólido, la balanza se puede poner inmediatamente en funcionamiento. Si el fondo está dividido y rayado, la balanza ha de ser verificada en

el lugar de uso por el sevicio técnico Ohaus certificado. Si la duración de la validez de la verificación está limitada de acuerdo con las normas de los distintos países,

el propio usuario de tal balanza es responsable de la verificación posterior a su debido tiempo.

Avvertenza

Le bilance approvate hanno la denominazione del modello E... 5 / V ...5. Per esse esiste un’appprovazione CE del tipo . L ’anno delia prima verifica è indicato a fianco della

marcatura CE. I tipi marcati con un contrassegno "M" su sfondo verde pieno possono essere impiegati da subito. I tipi marcati con ii contrassegno "M" su sfondo nero/

barrato diagonalmente dovranno essere verificati sul luogo d’installazione da parte d’un tecnico autorizzato dal Servizio Assistenza Ohaus o ispettore dell’Ufficio Metrico.

Queste bilance sono state verificate in fabbrica

e recano il contrassegno "M" sull’apparecchio stesso, e sull’imballo. É obbligo dell’untente denunciare la detenzione dello strumento all’ufficio metrico competente per

territorio e sottoporio alia prescritta verifica periodica come da disposizioni ministeriali.

3

NOTE: THIS EQUIPMENT HAS BEEN TESTED AND FOUND T O COMPL Y WITH THE LIMITS FOR A CLASS A DIGITAL

DEVICE, PURSUANT TO PART 15 OF THE FCC R ULES.

THESE LIMITS ARE DESIGNED T O PRO VIDE REASONABLE PRO TECTION AGAINST HARMFUL INTERFERENCE

WHEN THE EQUIPMENT IS OPERATED IN A COMMERCIAL ENVIRONMENT. THIS EQUIPMENT GENERATES,

USES, AND CAN RADIATE RADIO FREQUENCY ENERGY AND, IF NO T INSTALLED AND USED IN ACCORDANCE

WITH THE INSTR UCTION MANUAL, MAY CAUSE HARMFUL INTERFERENCE TO RADIO COMMUNICATIONS. OPERATION OF THIS EQUIPMENT IN A RESIDENTIAL AREA IS LIKELY TO CAUSE HARMFUL INTERFERENCE IN

WHICH CASE THE USER WILL BE REQUIRED TO CORRECT THE INTERFERENCE AT HIS OWN EXPENSE.

THIS DIGITAL APPARATUS DOES NOT EXCEED THE CLASS A LIMITS FOR RADIO NOISE EMISSIONS FROM

DIGIT AL APPARA TUS AS SET OUT IN THE INTERFERENCE-CA USING EQUIPMENT STANDARD ENTITLED “DIGIT AL APPARA TUS”, ICES-003 OF THE DEPARTMENT OF COMMUNICATIONS.

CET APPAREIL NUMERIQUE RESPECTE LES LIMITES DE BRUITS RADIOELECTRIQUES APPLICABLES AUX

APPAREILS NUMERIQUES DE CLASSE A PRESCRITES DANS LA NORME SUR LE MATERIEL BROUILLEUR :

“APP AREILS NUMERIQUES”, NMB-003 EDICTEE PAR LE MINISTRE DES COMMUNICA TIONS.

Unauthorized changes or modifications to this equipment are not permitted.

4

TABLE OF CONTENTS

OVER VIEW OF CONTR OLS ........................................................................................................................ 7

OVER VIEW OF DISPLA Y INDICATORS ...................................................................................................... 8

1. GETTING TO KNOW YOUR BALANCE .............................................................................................................. 9

1.1 Introduction ....................................................................................................................................................... 9

2. INST ALLA TION ................................................................................................................................................... 9

2.1 Unpacking and Checking the Standard Equipment ............................................................................................. 9

2.2 Selecting the Location ...................................................................................................................................... 1 0

2.3 Setting Up and Leveling the Balance ................................................................................................................ 10

2.4 Installing Cover Plate and P an.......................................................................................................................... 1 1

2.5 Installing Wind Shield........................................................................................................................................ 11

2.6 Connecting Power............................................................................................................................................. 11

3. OPERA TING YOUR BALANCE ......................................................................................................................... 1 2

3.1 The Menu (Basic Settings of the Instrument) ................................................................................................... 1 2

3.2 Turning On the Balance..................................................................................................................................... 13

3.3 Cal ibrat ion ..................................................................................................................................................... 1 3

3.3.1 Internal Calibration (InCALTM) .................................................................................................................. 15

3.3.2 Calibration Message ............................................................................................................................... 1 6

3.3.3 Calibration Adjust ................................................................................................................................... 1 7

3.3.4 Span Calibration ..................................................................................................................................... 1 8

3.3.5 User Calibration ...................................................................................................................................... 1 9

3.3.6 Linearity Calibration ................................................................................................................................ 2 0

3.3.7 Calibration Test ....................................................................................................................................... 2 1

3.3.8 Calibration GLP Printout ......................................................................................................................... 22

3.4 Weighing ..................................................................................................................................................... 2 3

3.5 Percent Weighing.............................................................................................................................................. 24

3.6 Parts Counting.................................................................................................................................................. 2 5

3.7 Animal Weighing ............................................................................................................................................... 2 6

3.8 Weigh Below..................................................................................................................................................... 27

3.9 Printing Data..................................................................................................................................................... 2 7

4. SETTING UP Y OUR BALANCE........................................................................................................................ 2 8

4.1 Setting Date and Time ...................................................................................................................................... 28

4.2 Readout ..................................................................................................................................................... 29

5

TABLE OF CONTENTS (Cont.)

4.3 Good Laboratory Practices (GLP) Data............................................................................................................. 3 0

4.4 Good Laboratory Practices (GLP) Set .............................................................................................................. 30

4.5 Print ..................................................................................................................................................... 3 1

4.6 RS232 ..................................................................................................................................................... 32

4.7 Legal for Trade (LFT) ......................................................................................................................................... 3 4

4.8 Mode ..................................................................................................................................................... 3 5

4.9 Units ..................................................................................................................................................... 3 6

4.10 Global ..................................................................................................................................................... 36

4.11 Custom Unit ............................................................................................................................................... 38

4.12 Menu Lock-Out Protection .......................................................................................................................... 4 0

5. CARE AND MAINTENANCE ............................................................................................................................ 4 1

5.1 T roubleshooting................................................................................................................................................. 41

5.2 RS232 Interface................................................................................................................................................ 4 2

5.3 Error Codes List................................................................................................................................................ 45

5.4 Information Messages ...................................................................................................................................... 45

5.5 Service Information........................................................................................................................................... 4 6

5.6 Replacement Parts ........................................................................................................................................... 4 6

5.7 Accessories ..................................................................................................................................................... 46

5.8 Specifications................................................................................................................................................... 47

6

OVERVIEW OF CONTROLS

1

2

3

4

5

No. Designation Function

1 I Po wer on off b utton.

2 Mode button Selects standard weighing, percent, parts counting and animal weighing modes.

3 Units button Selects weighing units.

6

8

9

7

10

11

12

4 Setup button Selects various submenus: calibration, date, time , readout, GLP data, GLP set, print,

RS232, LFT, function, units, global, custom.

5 >O/T< button When pressed, performs tare function and a center of zero function.

6 button When pressed, tra v els up through submenus.

7 button When pressed, tra v els down through submenus.

8 button When pressed, tr a v els to the left through men us.

9 button When pressed, tr a v els to the right through menus.

10 Enter/Print button When in menus, selects item on display, otherwise prints data.

11 Leveling feet Used to le v el the balance .

12 Leveling indicator Indicates le veling position of the balance.

7

OVERVIEW OF DISPLAY INDICATORS

6

5

4

3

2

1

No. Function

1 Use (Pointer Group) key to change - used to

prompt the user while navigating through the menu

system.

2 Standard (7) segment numeric characters. Seven

characters are availab le and are used f or display

ing weight values.

3 Center of Zero - Indicates Center of Zero in

Legal For Trade (LFT) has been selected in menu.

4 P - This symbol is not used.

5 T - This symbol is not used.

6 Stable - Indicates that the measured value has

become stable.

7 B/G - This symbol is not used.

8 Change - Is displayed together with Mode, Units

or Setup signifying that a change to balance

settings is being performed.

9 Mode - Is displayed when the Mode button is

pressed. Allo ws the user to know what area of the

balance menu is being addressed.

10 Units - Is displayed when the Units button is

pressed. Allows the user to know what area of the

balance menu is being addressed.

11 Setup - Is displayed when the Setup button is

pressed. Allows the user to know what area of the

balance menu is being addressed.

8

7

9

1718

No. Function

12 (British Flag) - Are (14) segment alpha numeric

13 Custom - The user can input a factor to meet

14 Symbols for weighing modes, include:

15 press >O/T< -This symbol is not used.

16 - Differentiated digit f or LFT.

17 press Enter - Used as a prompt to the user to

18 NET - Not Used

10

16

characters. Seven characters are used to present

features and functions.

unique unit measure applications.

% - Percent weighing.

PC - Parts counting.

GN - Grain.

N - Newtons.

m - Mommes.

mg - Milligrams.

g - Grams.

kg - Kilograms.

dwt - Penn yweight.

lb - Pounds.

oz - Ounces.

ct - Carats.

t - Taels. Taels are available in three types;

Hong Kong, Singapore, and Taiwan.

ti - Tical.

oz t - Ounces troy.

press the Enter button. The menu item display ed

is accepted/selected.

11

12

13

14

15

8

1. GETTING TO KNOW YOUR BALANCE

Please read through this section carefully, as it contains important information for safe and economical operation of

your Explorer Balance.

1.1 Introduction

Thank you for deciding to purchase an Explorer Balance from Ohaus. Thanks to a new modular design, your

Explorer Balance lets you adapt the balance to your changing needs. Remote displays , upgr aded displays which

can be table, wall or tow er mounted are a vailable as accessories. It off ers a high level of operating convenience and

useful functions to make accurate measurements. A unique LCD panel has a large 7 digit, 7 segment display which

indicates the weight value of an item being measured and a 7 digit British Flag display (14 segments) which spells

out items selected in the submenus. In addition, the display contains English words to indicate the status of the

balance. Arro w indicators in the display prompt the user as to what panel keys are to be pressed to initiate a change .

Panel controls are clearly marked as to their function with large Tare buttons on either side of the front panel. Operation and setup of the balance is straightforward and easy. The Explorer Balance is a v ailable in a variety of full scale

capacities ranging from 62 grams to 8,100 grams with FineRangeTM range models available . Legal for Trade versions

are availab le.

Behind your instrument stands OHAUS , a leading manufacturer of precision scales and balances. An Aftermarket

Department with trained instrument technicians is dedicated to provide you with the fastest service possible in the

event y our instrument requires servicing. OHAUS also has a Customer Service Department to answer any inquiries

regarding applications and accessories.

To ensure you mak e full use of the possibilities off ered b y your Explorer balance, we advise you to read through

these operating instructions very carefully .

2. INSTALLATION

2.1 Unpacking and Checking the Standard Equipment

Open the package and remove the instrument and the accessories. Check the completeness of the delivery. The

following accessories are part of the standard equipment of your new Explorer balance.

Analytical Top Loader

Equipment 62g, 110g, 162, 210, 410, 610g, 1550g, 2100g, 6100g, 4100g,

210g, 210/100g 410/100g 4100g, 4100/1000g 8100g

••

• Pan 3.5

••

••

• Pan 4.75"

••

••

• Pan 6" (0.01g units)

••

••

• Pan 8" (0.1g units)

••

••

• Draft Shield

••

••

• Wind Shield (6" Pan Units, 0.01g)

••

••

• AC Power Adapter

••

••

• Instruction Manual

••

••

• Warranty Card

••

* 4100g, 6100g and 8100g balances with internal calibration are equipped with a 6" Pan and Windshield.

• Remove packing material from the instrument.

• Check the instrument for transport damage. Immediately inform your Ohaus dealer if you have complaints or

parts are missing.

✓✓

✓

✓✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

·

✓ ✓

✓

✓ ✓

✓✓

✓

✓✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓*

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓*

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓

✓ ✓

• Store all parts of the packaging. This packaging guarantees the best possible protection for the tranport of your

instrument.

9

2.2 Selecting the Location

The balance should always be used in an en vironment which is free from e xcessive air currents, corrosives, vibration,

and temperature or humidity extremes. These factors will affect display ed w eight readings.

DO NOT install the balance:

• Next to open windows or doors causing drafts or

rapid temperature changes.

• Near air conditioning or heat vents.

• Near vibrating, rotating or reciprocating equipment.

• Near magnetic fields or equipment that generates

magnetic fields.

• On an unlevel work surface.

• Allow sufficient space around the instrument for

ease of operation and keep awa y from radiating heat

sources.

2.3 Setting Up and Leveling the Balance

Exact horizontal positioning and stable installation are prerequisites for repeatab le results . To compensate small

irregularites or inclinations at the location, the instrument can be leveled.

For exact horizontal positioning, the balance is equipped

with a level indicator located at the front on the control

panel and two leveling f eet located at the rear of the

balance.

Position the balance in the intended operating location.

Adjust the leveling f eet at the rear of the balance until the

Leveling

Indicator

Leveling

Foot

air bubble in the indicator is centered.

NOTE: The instrument should be leveled each time its

location is changed.

10

2.4 Installing Cover Plate and Pan

Pan

Cover Plate

2.5 Installing Wind Shield

Wind Shield

Balances in the range of 62g to 410g are shipped with

the pan and the protective cov er plate not installed. On

balances equipped with a draft shield, slide open the side

door and place the cover plate into position. Then, insert

the pan into the center hole which is the measuring

transducer. Higher capacity balances with 6" or 8" pans

do not have a cover plate.

On 610g to 4100g balances with 0.01g resolution, a wind

shield is required to reduce the possibility of air currents

from disturbing the pan. When the wind shield is in

place, air currents are deflected up over the pan.

Make sure the wind shield is firmly snapped into place.

2.6 Connecting Power

AC Adapter Connection

Rear of Balance

NOTE: 4100g, 6100g and 8100g balances with internal

calibration are equipped with a 6" Pan and Windshield.

Connect the AC Adapter supplied to the three pin connector located at the rear of the balance.

The balance is now ready for operation.

11

3 OPERA TING Y OUR BALANCE

3.1 The Menu (Basic Settings of the Instrument)

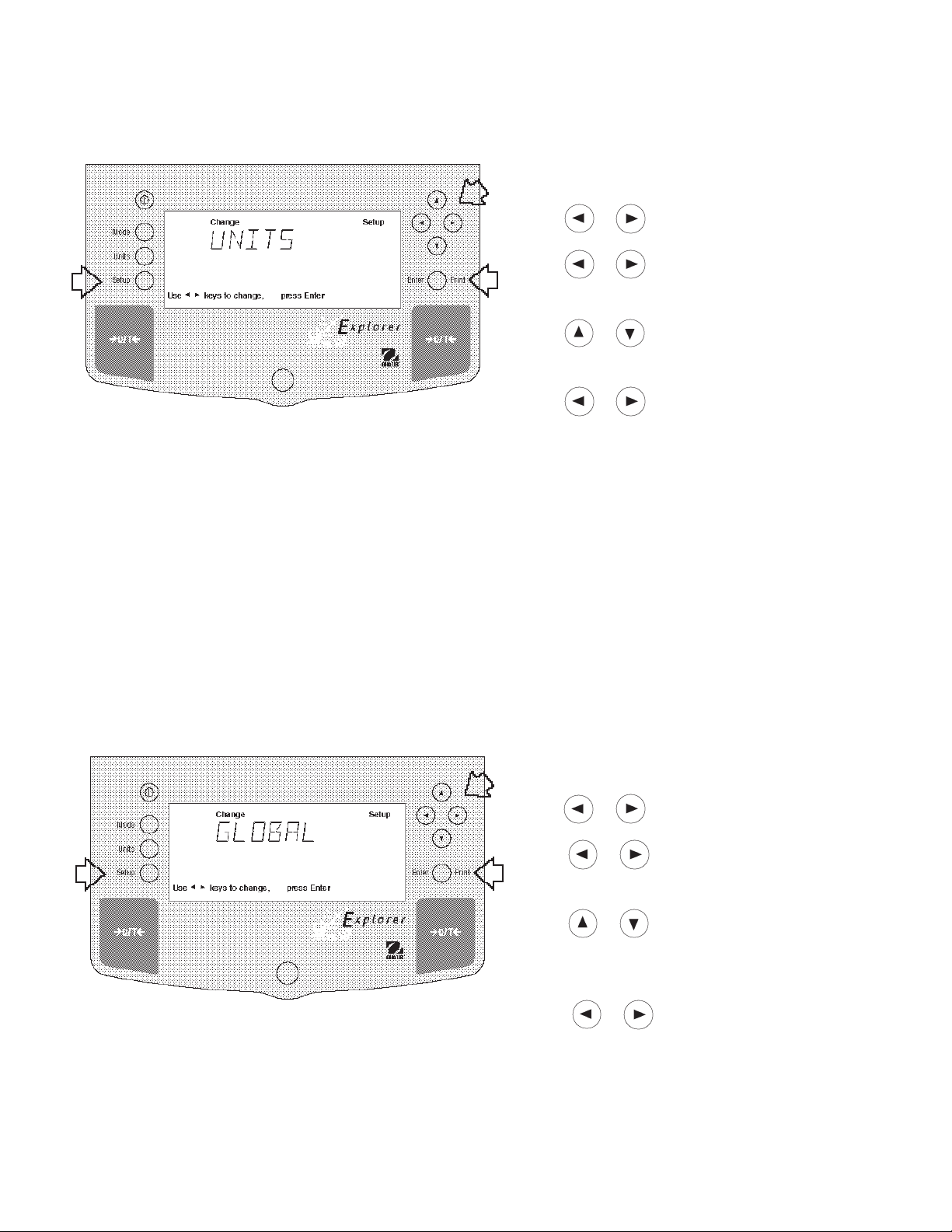

The Explorer balance has three basic menus; each is selected b y front panel b uttons marked Mode, Units and Setup.

Mode Button

The Mode button, when pressed, permits the selection of four weighing modes which are: weigh, percent, count and

animal weighing. These modes are controlled by an on or off selection made in the Setup menu under the submenu

Mode as displayed.

Units Button

The Units button, when pressed, allows the balance to display v alues in selected measuring unit.

Setup Button

The Setup button, when pressed, allows entry into thirteen submenus which allows you to set the balance for specific

operating parameters. Each of the thirteen submenus contain settings which are user selectable. The table below

illustrates the various submenus and the functions which are selectable . The items shown on the men u, which are

bolded, are the factory default settings. In other words, if you did not enter the Setup men u, the balance would function in the basic manner shown by the various settings which are bolded. The setup submenus shown below are

arranged in the order as displayed in the balance .

START

CALIBRATION

InCALTM Calibration (No Lock)*

Span Calibration

User Calibration

Linearity Calibration

Calibration Test (No Lock)

Calibration Msg ON/OFF

Calibration Adj

Lock ON/OFF

Exit

* (If option is installed.)

+ 100 (0)

READOUT

Filter -0-, -1-, -2-, -3Stable .5d, 1d, 2d, 5d

Auto 0 OFF, .5d, 1d, 5d

Lock ON/OFF

Exit

PRINT

Auto Print OFF, Cont, Inter, On Stb

Interval Enter 1 seconds

Stable ON/OFF

Numeric ON/OFF

GLP Cont ON/OFF

GLP Tare ON/OFF

Reference ON /OFF

Lock ON/OFF

Exit

SETUP SUBMENUS

DATE

Type m/d/y

Set Date

Exit

GLP DATA

User Number Enter 7 digits

Project Number Enter 7 digits

Lock ON/OFF

Exit

RS232

Baud 300, 1200, 2400, 4800, 9600

Parity None, -E-, -Odd-, -0-, -1Data 7,8

Stop 1, 2

Lock ON/OFF

Exit

TIME

Type 12 Hour/24 Hour

Set Time

Adjust Enter xx seconds

Exit

GLP SET

Time ON/OFF

Balance ID ON/OFF

User Number ON/OFF

Project Number ON/OFF

Difference ON/OFF

Name ON/OFF

Lock ON/OFF

Exit

LEGAL FOR TRADE

LFT LOCK ON/OFF

(Locked using switch)

GLOBAL

List NO/YES

Reset NO/YES

Version Software No.

Lock ON/OFF

MODE

Weigh ON/OFF

Percent ON/OFF

Count ON/OFF

Animal ON/OFF

Lock ON/OFF

Exit

UNITS

Units ON/OFF

Lock ON/OFF

Exit

12

CUSTOM

Factor Enter 7 digits

Exponent Enter +3 to -3

LSD Enter .5 to 100

Lock ON/OFF

Exit

3.2 Turning On the Balance

The Explorer balance is ready to operate after the installation procedures are performed. When the balance is first

turned on and it completes its checks, it can be used to weigh or tare materials without setting the menus.

It is recommended that you read this manual carefully and set the balance to operate for y our specific applications

using the procedures in Chapter 4 Setting up Your Balance and calibrate the balance before using.

The balance is a high precision instrument and will give you years of service if kept clean and handled carefully. If

you have an y prob lems oper ating the instrument or require additional information, please feel free to contact our

Product Service Department at (800) 526-0659.

In this section, you will enter the menu for the first time. Do not worry if you are unfamiliar with the function of the

buttons on the panel, the display pro vides the necessary coaching as you go along.

Power On/Off

To turn the balance ON, press the ON/OFF button

(circled button with an I inside) located at the upper lefthand corner of the panel once. To turn OFF, press button

again.

Stabilization

Before initially using the balance, allow time for it to

adjust to its new environment. The balance only requires to be plugged in to warm up. Recommended

warm up period is twenty (20) minutes. Analytical Class I

balances require at least 2 hours. The internal circuits of

the balance are powered whenever it is plugged into a

power source.

Calibration

Refer to paragraph 3.3 and calibrate the balance bef ore

3.3 Calibration

Explorer balances offer a choice of five calibration methods: Internal Calibration (InCALTM), Span Calibration, User

Calibration, Linearity Calibration, and CalTestTM.

•

•

• User

• Linearity

• Cal Test

TM

InCal

Span

- Span calibration ensures that the balance reads correctly within specifications using two

- User calibration is a method where the balance can be calibr ated using a mass of kno wn

- Calibration test allows the stored calibration data to be tested against the current mass being

Internal calibration (InCALTM) of the balance is accomplished by an internal mass (If option is

installed). When CAL MSG is selected and set ON, CAL NOW is displayed when the

balance requires calibration. When CAL MSG is set OFF, the message CAL NOW is not

displayed.

weight values: zero and a weight value at incremental values of full capacity and or 100% of

the balance’s full capacity.

value and by entering that numeric value into the balance.

- Linearity calibration minimizes deviation between actual and display ed weights within the

balance’s weighing range . Three w eight v alues are used: zero, a weight value at midpoint of

the balance's weighing range, and a weight value at or near the balance’s specified capacity.

used for the test.

proceeding.

•

Lock

- Can be set on or off. When set on, Span, User and Linearity are locked out and cannot be

used.

13

3.3 Calibration (Cont.)

Calibration Menu Protection

NOTES:

• Calibration may be lock ed out to prevent unauthorized

personnel from changing calibration. If calibration has

been locked out, y ou can only access Cal Test and when

installed, Internal Calibration (InCALTM) .

• To lock out calibration menu, after calibration, refer to the

section titled Menu Lock-Out Protection.

Calibration Masses

Before beginning calibration, make sure masses are

availab le. If you begin calibration and realize calibration

masses are not availab le, exit the menu. The balance will

retain previously stored calibration data. Calibration

should be performed as necessary to ensure accurate

weighing. Masses required to perform the procedures are

listed in the adjacent table.

NOTE:

Any of the calibration modes can be terminated

time

by pressing either the Mode, Units or Setup buttons .

at any

CALIBRA TION MASSES

LINEARITY SPAN ONLY CAPACITY MASSES MASSES

62g 20g/50g 50g

162g 50g/150g 150g

110g 50g/100g 100g

210g 100g/200g 200g

410g 200g/400g 400g

610g 200g/500g 500g

1550g 500g/1500g 1500g

2100g 1000g/2000g 2000g

4100g 2000g/4000g 4000g

6100g 2000g/5000g 5000g

8100g 4000g/8000g 8000g

It is recommended that masses must meet or exceed

ASTM Class 1 Tolerance. Calibration masses are

available as accessories.

14

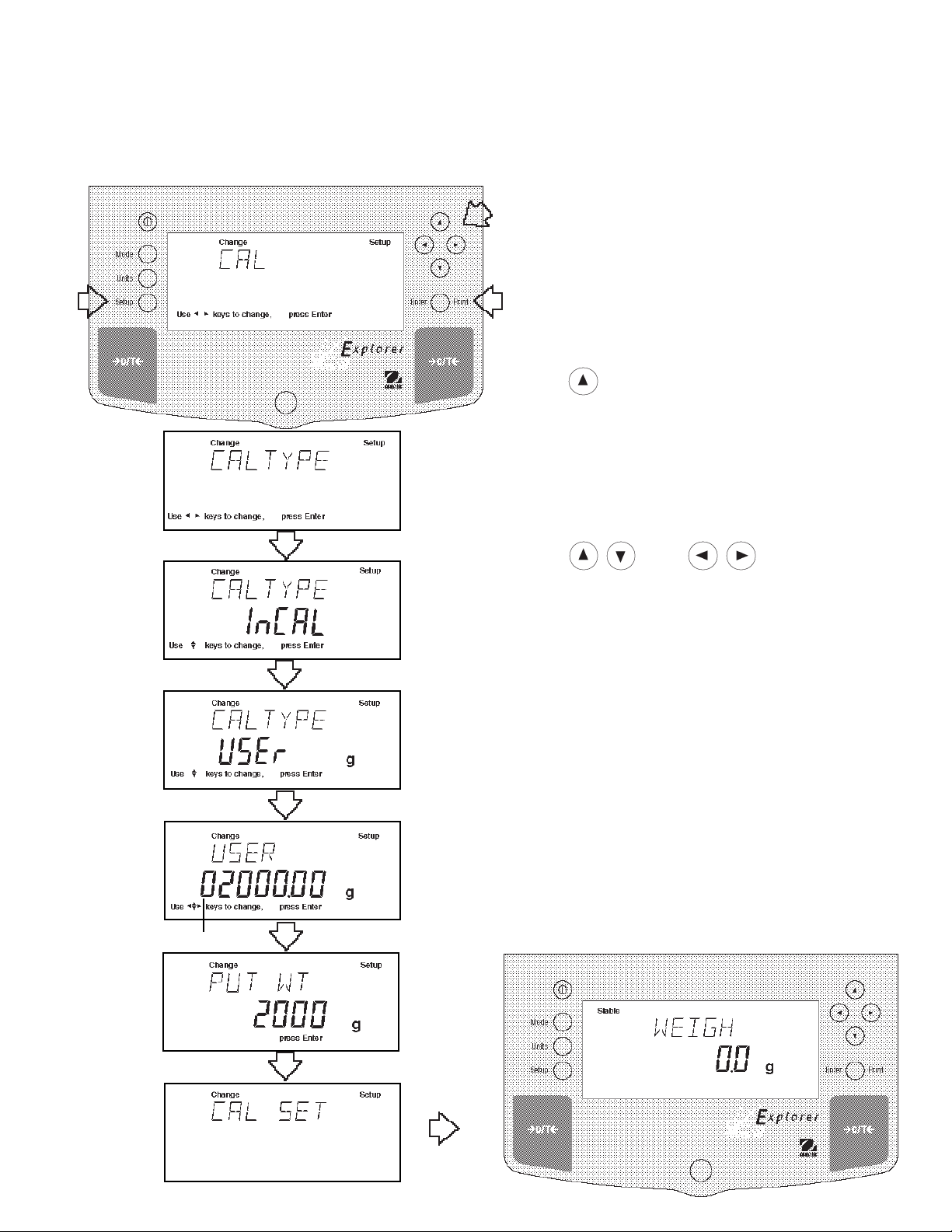

3.3.1 Internal Calibration (InCALTM)

On Explorer balances equipped with the InCalTM feature, calibration can be accomplished using the internal calibration

mass. When the balance requires calibration, a screen prompt of CAL NOW appears. This display can be turned off

as described in paragraph 3.3.2. Also, a software adjust feature is incorporated which permits the internal calibration

mass to be adjusted to +100 counts. The adjust feature is described in paragraph 3.3.3. Internal calibration can be

performed at any time providing the balance has warmed up to operating temperature.

Procedure

• Press the Setup button, CAL is displayed.

• Press Enter button, CAL TYPE is displayed.

• Press Enter button, CAL TYPE InCAL is displa yed.

• Press Enter button, INCAL is displayed.

IMPORTANT !

DO NOT DISTURB THE BALANCE DURING

CALIBRA TION. IF THE MESSAGE UNSTBLE

IS DISPLA YED , THE BALANCE W AS UNABLE

TO ACQUIRE STABLE DATA DURING INTERNAL CALIBRATION. THE BALANCE WILL

CONTINUE TO PERFORM INTERNAL CALIBRA TION UNTIL READINGS ST ABILIZE. THE

BALANCE WILL THEN COMPLETE THE INTERNAL CALIBRATION FUNCTION.

TO EXIT INTERNAL CALIBRATION MODE

BEFORE COMPLETION, PRESS ENTER OR

SETUP BUTTONS.

STABILITY CAN BE AFFECTED BY TEMPERATURE, AIR CURRENTS, VIBRATION,

ETC...

NOTE: If a weight is left on the pan, the balance will

display CLR PAN (remov e the w eight from the pan).

The balance automatically resumes calibration.

The internal mass is positioned sev eral times during

calibration and then removed, then after a few seconds, CAL SET is displayed indicating a successful

calibration. The display then returns to WEIGH mode.

15

3.3.2 Calibration Message

On Explorer balances equipped with the InCalTM feature, a screen prompt of CAL NOW appears when the balance

requires calibration. This displa y can be turned off if it is desired not to hav e the balance indicate that calibration is

required. Turning the display off has no effect on the basic balance oper ation.

Procedure

• Press the Setup button, CAL is displayed.

• Press Enter button, CAL TYPE is displayed.

• Press button, CAL MSG is displayed.

• Press Enter button, CAL MSG ON is displayed.

• Press or button and select either ON or

OFF. When OFF is selected, the CAL NOW message

will not appear in the display.

NOTE: When the balance is in a legal for trade mode,

this option is locked ON. In this condition, the balance

will display the CAL NOW message when recalibration

is required.

• Press Enter button, SAVED is momentarily displayed,

then the display indicates CAL ADJ.

NOTE: At this point you ma y continue with the calibr a tion adjust procedure on the next page or exit.

The calibration adjust procedure is only used when it is

desired to calibrate the internal calibration mass to a

known external Class I mass if a difference exits .

• Press button until EXIT is displayed.

• Press Enter button, display returns to WEIGH

mode.

16

3.3.3 Calibration Adjust

Balances with InCalTM contain software which allows the

internal calibration mass to be adjusted + 100 divisions at

full scale capacity. This permits calibrating the balance

using an external Class I mass which is traceable to a

certified standard.

Procedure

• Perform the internal calibration procedure of paragraph 3.3.1.

• Press >O/T< button to zero the balance.

• Place a Class I mass equal to the

value

of the balance. Note the reading on the balance and see if the balance indicates the exact

weight or indicates a higher or lower reading. If the

reading is higher or lower , proceed.

• Press the Setup button, CAL is displayed.

• Press Enter button, CAL TYPE is displayed.

• Press button until , CAL ADJ is display ed.

• Press Enter button, CAL ADJ 0 should be displayed (0 is factory setting).

NOTE: Balance will retain last CAL ADJ setting.

• Press or button until desired number is

displayed.

• Press Enter button, SA VED is momentarily displa y ed,

then display indicates LOCK.

• Press Enter button, LOCK ON or LOCK OFF is

displayed.

• Press or button and select either LOCK ON

or LOCK OFF. LOCK ON is normally used in legal

for trade applications. When set ON, and legal for

trade is enabled in the balance, the calibration adjust

is disabled and whatev er setting w as entered will

remain in the balance.

• Press Enter button, SAVED is momentarily displa y ed,

then EXIT is displayed.

• Press Enter button, display returns to WEIGH

mode.

• Perform the internal calibration procedure of paragraph 3.3.1. The v alue entered as an adjustment is

now stored. Place the calibration mass on the pan

and check. Repeat procedure if further correction is

required. The display must agree with the mass used

for calibration.

• To return to factory setting, follow procedure abov e

and set CAL ADJ to 0.

span calibration

17

3.3.4 Span Calibration

Span calibration utilizes two calibration points, one at zero and the other at full span or incremental v alues starting at

25% of full capacity. As an example, an 8.1kg balance will accept either 2kg, 4kg, 6kg or 8kg for span calibration.

V alues which are belo w or in between will not be accepted and the balance will display its maximum capacity. When

LFT is set on, only full span calibration value can be used. Sample display illustrates an 8.1 kg balance

Procedure

• Press the Setup button, CAL is displayed.

• Press Enter button, CAL TYPE is displayed.

• Press Enter button, CAL TYPE InCAL is displayed.

• Press button to select SPAN calibration, CAL

TYPE SPAN is display ed.

• Press Enter button, W ORKING is displa y ed.

NOTE: If a weight is left on the pan, the balance will

display CLR PAN (remov e the w eight from the pan).

The balance automatically resumes calibration.

• Display changes to PUT WT 8000 g. The displayed

weight is the full capacity of the balance.

• Place specified calibration mass on pan.

NOTE: For an 8.1kg balance, either 2kg, 4kg, 6kg or

8kg can be used for span calibration. The PUT

WEIGHT message indicates the calibration mass that

is on the pan.

• Press Enter button, WORKING is displayed. After a

few seconds CAL SET is displayed, the display then

returns to WEIGH mode.

• Span calibration is completed.

• Remove calibration mass from the pan.

18

3.3.5 User Calibration

User calibration is used when it is desired to calibrate the balance using a mass of known value . When LFT is set on,

the balance will only accept full span calibration, 25%, 50% and 75% values are disabled. To use this calibration

feature, proceed as f ollows:

Procedure

• Press the Setup button, CAL is displayed.

• Press Enter button, CAL TYPE is displayed.

• Press Enter button, CAL TYPE InCAL is dis played.

• Press button twice to select USER calibration,

CAL TYPE USer is displa y ed.

• Press Enter button, the display indicates the last

calibration mass value which was entered with the

first digit flashing. (Sampleillustrates 2000g).

• Press and or and enter the

desired mass value. This number must be at least

25% of the full span value.

(FLASHING)

• Press Enter button, WORKING is displayed.

NOTE: If a weight is left on the pan, the balance will

display CLR PAN (remov e the w eight from the pan).

The balance automatically resumes calibration.

• Display changes to PUT WT 2000 g.

• Place specified calibration mass on pan.

• Press Enter button, WORKING is displayed. After a

few seconds CAL SET is displayed, the display then

returns to WEIGH mode.

• User calibration is completed.

• Remove calibration mass from the pan.

19

3.3.6 Linearity Calibration

Linearity calibration utilizes three calibration points, one at zero , center span and full span. This method minimizes

deviation between actual and displa yed weights within the balance's w eighing range . Three weight values are used;

zero, a weight v alue at midpoint of the balance's weighing range and a w eight v alue at or near the specified capacity.

Sample display illustrates an 8.1 kg balance.

Procedure

• Press the Setup button, CAL is displayed.

• Press Enter button, CAL TYPE is displayed.

• Press Enter button, CAL TYPE InCAL is displayed.

• Press button three times to select LIN calibration, CAL TYPE Lin is displa y ed.

• Press Enter button, WORKING is displayed.

NOTE: If a weight is left on the pan, the balance will

display CLR PAN (remo v e the weight from the pan).

The balance automatically resumes calibration.

• Display changes to PUT WT 4000 g. The displayed

weight is half the capacity of the balance.

• Place specified calibration mass on pan.

• Press Enter button, WORKING is displayed. After a

few seconds displa y changes to PUT WT 8000 g.

The display ed weight is the full capacity of the

balance.

• Place specified calibration mass on pan.

• Press Enter button, WORKING is displayed. After a

few seconds CAL SET is displayed, the display then

returns to WEIGH mode.

• Linearity calibration is completed.

• Remove calibration mass from the pan.

20

3.3.7 Calibration T est

Calibration test feature allows a check of a kno wn calibr ation mass against the last stored calibration information in

the balance. Sample displa y illustr ates an 8.1 kg balance.

Procedure

• Press the Setup button, CAL is displayed.

• Press Enter button, CAL TYPE is displayed.

• Press Enter button, CAL TYPE InCAL is displayed.

• Press button to select CALTEST calibration,

CALtESt is displayed.

• Press Enter button, W ORKING is displa y ed.

NOTE: If a weight is left on the pan, the balance will

display CLR PAN (remo v e the weight from the pan).

The balance automatically resumes calibration.

• Display changes to PUT WT 8000 g. The displayed

weight is the full capacity of the balance.

• Place specified calibration mass on pan.

• Press Enter button, WORKING is displayed. After a

few seconds, DIFF is displayed. The display nowindi

cates the actual difference in weight between what

value was just placed on the pan and the pre vious

weight value which was stored in the balance . After

approximately 8 seconds, the displa y returns to the

WEIGH mode.

• Remove calibration test mass from the pan.

21

3.3.8 Calibration GLP Printout

If any option in the GLP Set Menu is turned On, GLP automatically prints data after calibration is completed.

Span Calibration Printout

When performing Span calibration with all GLP options

turned on, a printout is automatically made after the

calibration is completed.

InCAL

When performing InCALTMcalibration with all GLP options

turned on, a printout is automatically made after the

calibration is completed.

TM

Calibration Printout

- - - - - SPAN CAL - - - - - -

12/01/97 1:00:00 PM

Bal Id 1234

Cal: 8000.00g

Old: 8000.00g

Dif: 0.00g

Wt. Ref ......................................

USER NO 2056853

PROJ NO 100012

Name........................................

- - - - - END - - - - -

- - - - - INCAL - - - - - 12/01/97 1:00:00 PM

Bal Id 1234

Cal: 8000.00g

Old: 8000.00g

Dif: 0.00g

Wt. Ref ......................................

USER NO 2056853

PROJ NO 100012

Name........................................

Linearity Calibration Printout

When performing a Linearity calibration with all GLP

options turned on, a printout is automatically made after

the calibration is completed.

Calibration T est Printout

When performing a Calibration Test with all GLP options

turned on, a printout is automatically made after the

calibration is completed.

- - - - - END - - - - -

- - - - - LIN CAL - - - - - 12/01/97 1:00:00 PM

Bal Id 1234

Cal: 8000.00g

Old: 7999.08g

Dif: 0.02g

Wt. Ref ......................................

USER NO 2056853

PROJ NO 100012

Name........................................

- - - - - END - - - - -

- - - - - CAL TEST - - - - - 12/01/97 1:00:00 PM

Bal Id 1234

Cal: 8000.00g

Act: 8000.02g

Dif: 0.02g

Wt. Ref ......................................

USER NO 2056853

PROJ NO 100012

Name........................................

22

- - - - - END - - - - -

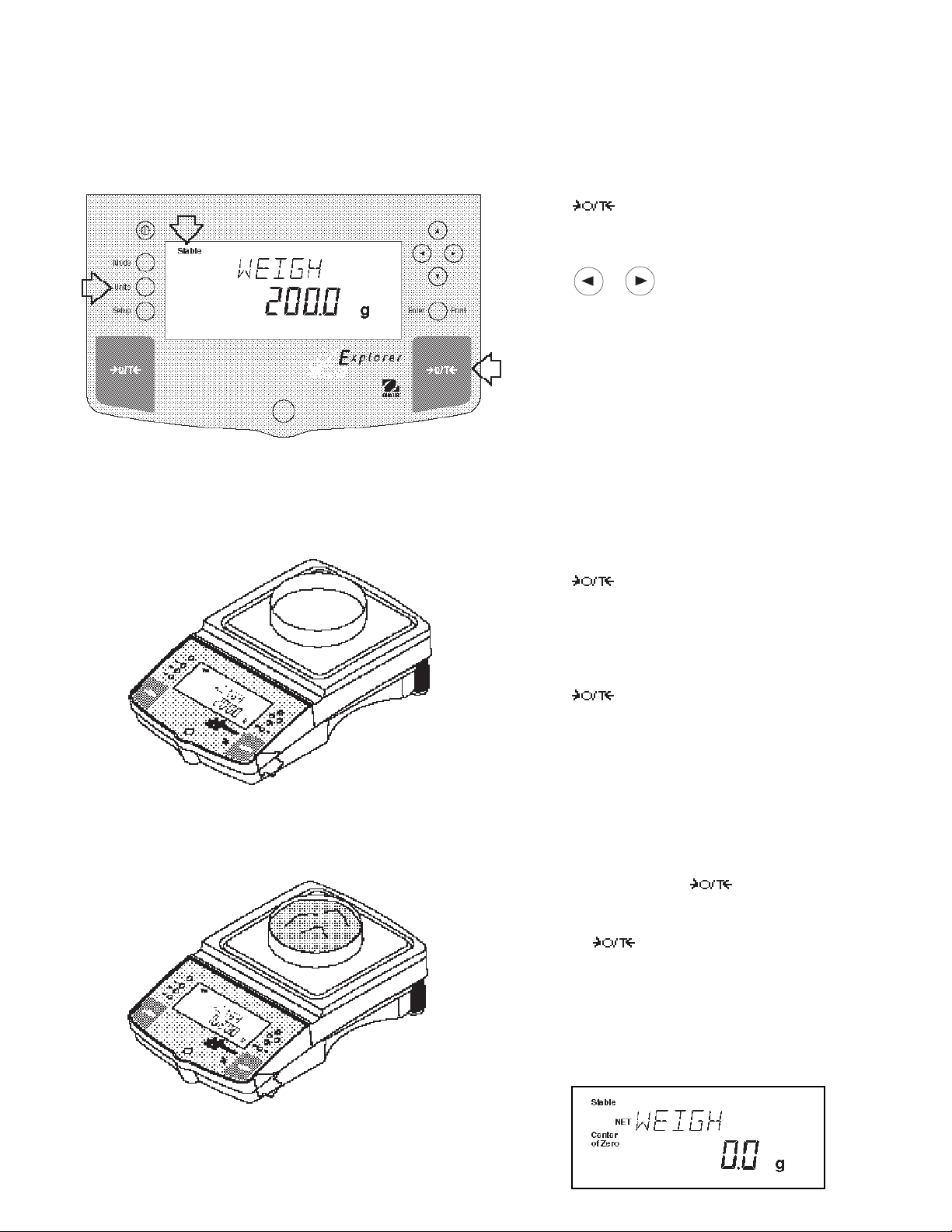

3.4 Weighing

NOTE: The Explorer balances are shipped with grams only enabled. When the balance is to be used with other

Type Approv ed/Legal for Trade units of measure, the desired unit must be enabled. Ref er to paragr aph 4.9 to

enable other measuring units.

Procedure

• Press to rezero the display.

• Press Units button to select measuring unit.

• Press or button for desired measuring unit.

•Press Enter button, balance is now ready for weigh

ing.

• Place the object(s) or material to be weighed on the

pan. Example illustrates a 200 gram weight.

• Wait for the stability indicator to appear bef ore reading the weight.

Zero/Tare

When weighing material or objects that must be held in a container, taring stores the container weight in the balance’s memory, separate from the weight of the material in the container .

Procedure

• Press with no load on the pan to set the

balance to zero.

(

Example

• Place an empty container on the pan. Its weight is

displayed.

• Press the display blanks until stab le w eight

readings are received, then indicates zero . The

container’s weight is stored in memory.

• Add material to the container. As material is added,

its net weight is displayed.

Container 200g)

• Removing the container and material from the plat-

form will cause the balance to display the container’s

weight as a negative number. The tared weight will

remain in memory until is pressed again or

the balance is turned off.

• Pressing resets the balance to zero .

NOTE: When Legal for Trade software option LFT NET

and LFT LOCK are both set ON, the balance indicates

NET WEIGH.

(

Example

Material 1620g)

23

3.5 Per cent Weighing

Percent W eighing is

permits you to place a reference load on the balance, then view other loads as a percentage of the reference. The

load you place on the pan as a reference ma y be displayed as any percentage you select from 5% to 100% (in 1%

increments). One hundred percent does not necessarily have to represent the reference load. Subsequent loads,

displayed as a percentage of the reference are limited only by the capacity of the balance. The default setting is

Reference 100%. Refer to paragraph 4.8 to enable percent w eighing.

enabled only

when Percent is turned ON in the Mode submenu under Setup . Percent weighing

Procedure

• Press the Mode button.

• Press or button until PERCENT is displayed.

• Press Enter button, PUT>PAN 100% is displa y ed. If

a container is used, the balance can be tared at this

point. The % display momentarily blanks while the

balance is taring out.

• Put the reference load on the pan.

• Press or button and select reference

weight percentage (P ercent Range 5 to 100). Hold

button down f or f ast change .

• Press Enter button to save setting, WORKING is

displayed ... calculating reference w eight.

Balance displays reference weight for five seconds in

selected measuring unit, then displays the percentage.

• Remove the reference weight from the pan and replace it with another load. The second load is displayed as a percentage of the ref erence .

NOTE: The PERCENT display (n umber of digits) is a

function of the accuracy of the balance and the size of

the reference weight. The displa y examples were with a

300g mass used with an 8.1 kilogram balance.

24

3.6 Parts Counting

Parts Counting is

Mode button. In the parts counting mode, the balance displa ys the quantity of parts you place on the pan. Since the

balance determines the quantity based on the average weight of a single part, all parts must be reasonably uniform in

weight.

enabled only

when Count is turned ON in the Mode submenu under Setup and selected with the

Procedure

• Press the Mode button.

• Press or button until COUNT is displayed.

• Press Enter button to sav e setting, PUT>PAN 10 PC

is displayed (def ault setting), balance will retain last

sample size sav ed.

• Press >O/T< if taring is required.

• Press or button and select sample size.

Sample size is 5 to 1000 pieces.

• Place sample size on the pan.

• Press Enter button to continue, display indicates

WORKING.

Balance displays the reference w eight of an individual

piece part for five seconds and then displays the total

number pieces on the pan.

• Remove the sample and place parts to be counted on

the pan. Balance displays number of pieces.

Update

Update is a function which permits placing additional

samples which are greater than the value of the original

sample but less than three times the value. This action

increases the accuracy of the measurement.

• Place sample on the pan which is at least one but not

more than three times the original sample size.

• Press Mode button, COUNT is displayed.

• Press Enter button, UPDATE is displayed.

• Press Enter button, WORKING is displa y ed then the

reference weight f ollow ed b y the new sample siz e .

25

3.7 Animal Weighing

Animal Weighing is

enabled only

when Animal is turned ON in the Mode submenu under Setup.

Procedure

• Press the Mode button.

• Press or button until ANIMAL is displayed.

• Press Enter button to continue, LEVEL is display ed.

• Press or button to change animal weighing

level, 0, 1, 2 or 3. 0 level represents an inactive

subject, 3 is used for a very active subject.

• Press Enter button to continue, AUTO is displa y ed.

• Press or button to select AUT O ON or OFF.

• Press Enter button to continue.

When the AUTO function is set ON, different subjects can

be weighed one after another without pressing any

buttons. When the balance displays READY, simply

place subject on pan.

Starting Animal Cycle

• Place animal container if used on pan.

• Press to tare the container.

• Place subject on pan.

• The animal cycle will automatically start if AUTO was

set to ON.

• Press Enter button to start animal cycle if AUTO was

set to OFF.

During Animal Cycle

• Display shows countdown to A W0.

Completed Animal Cycle

• Balance displays weight until subject is removed from

the pan.

26

3.8 Weigh Below

The Explorer balance is equipped with a weigh below

hook at the bottom of the balance. To use this feature,

remove power from the balance and remo ve the protective cover underneath the balance. See illustration for

location. The balance can be supported using lab jacks

or any other convienent method. Make sure the balance is level and secure . Apply power and operate the

balance. Attach items to be weighed to the hook

underneath the balance.

3.9 Printing Data

Printing data to an external computer or printer requires that the communications parameters in the Setup menu,

Print options and communication parameters be set first. Refer to page 25 Print menu settings and page 27 for

RS232 communication settings.

Procedure

• Press the Print button. Printing to an e xternal printer

or computer will occur each time the Print button is

pressed unless autoprint feature is turned on in which

case printing can occur in a continuous fashion, at

specified intervals or each time a stable reading is

achieved.

Sample printout is shown below with time turned on.

SAMPLE PRINTOUT

12/01/97 12:01:37 AM

429.5 g

For a review of of printing samples, refer to Section 4

Setting Up Your Balance . What is printed is controlled

by the GLP Set Menu and the selection of GLP Cont.

or GLP Tare in the Print Menu.

27

4. SETTING UP YOUR BALANCE

4.1 Setting Date and Time

Your Explorer balance provides date and time data which can be viewed on a computer or printed out on an external

printer. When y ou put y our ne w instrument into operation f or the first time , y ou should enter the current date and the

time. These settings are retained as long as the balance remains connected to a power source.

Date

Date is a feature which enables the balance to be set to a

U.S.A. date standard or European date standard. U.S.

standard has the month, date, followed b y the y ear, each

separated by (/) in the printout. The European date

standard has the day first, followed b y the month and

then the year; each separated by a period. The def ault

setting is U.S.A. Standard.

Procedure

• Press the Setup button, CAL is displayed.

• Press or button and select Date from the

menu.

• Press Enter button, TYPE is displa y ed.

• Press Enter button, SET M d y, d M y, y M d, M y d,

y d M, or d y M is displayed.

• Press or button and select type of date.

• Press Enter button, SAVED is displayed, then SET is

displayed.

• Press Enter button, first digit of date is flashing.

• Using arrow buttons, enter the correct date.

• When the correct date is entered, press Enter button,

SA VED displa ys momentarily and EXIT appears.

• Press Enter button, balance returns to a weighing

mode.

Time

Time is a feature which enables the balance to be set to

the current time in either U.S.A. standards (12 hour

periods) or European/Military standards (24 hour periods).

The default setting is U .S.A. Standard.

Procedure

• Press the Setup button, CAL is displayed.

• Press or button and select Time from the

menu.

• Press Enter button, TYPE is displa y ed.

• Press Enter button, TYPE 12 hr is displa y ed.

• Press or button and select 12 hr or 24 hr.

• Press Enter button, SA VED is displa y ed momentarily

then SET is displayed.

• Press Enter button,SET with time is flashing.

• Using arrow buttons, enter the correct time.

• When the correct time is entered, press Enter button,

SA VED displa ys momentarily and EXIT appears.

• Press Enter button, balance returns to a weighing

mode.

Adjustments up to +60 seconds a month can be made

to the balance internal clock. Repeat the first seven

steps, ADJUST is display ed. Using arrow buttons,

enter time correction and press Enter button.

28

4.2 Readout

The Readout menu is used to adapt the balance to environmental conditions. It contains four submenus: Stable,

Auto 0, Filter, Loc k and Exit. Lock enables you to program balance parameters and to loc k the settings .

Procedure

To select any of the items in the Readout menu, proceed

as follows:

• Press the Setup button, CAL is displayed.

• Press or button until READOUT is dis-

played.

• Press Enter button to sav e setting.

• Press or button until either STABLE, A U TO

0, FILTER, LOCK or EXIT is displayed.

• Press Enter button to save setting.

• Press or button and select the desired menu

setting.

• Press Enter button SA VED is displayed.

• Press or button to continue or EXIT.

• Press Enter button to sav e setting.

Stability

The stability range specifies the weighing results and must be within a preset tolerance limit for a certain time to turn

the stability indicator ON. When a displayed w eight changes be y ond the allowable range, the stability indicator turns

OFF, indicating an unstable condition. Factory default setting is sho wn in bold type .

.5 d Smallest range: stability indicator is ON only

when displayed weight is stable within .5 divisions.

1 d Reduced range .

2 d Normal range.

5 d Largest range, stability indicator is ON e v en though displa y ed w eight

changes slightly .

When the RS232 interface is configured to print stable data only, the stability range also gov erns data output. Displayed data will only be output if it is within the selected stability r ange .

Auto-Zer o

Auto-Zero minimizes the eff ects of temperature changes and shift on the z ero reading. The balance maintains the

zero display until the threshold is e xceeded. F actory default setting is sho wn in bold type.

OFFT urns Auto-Zero OFF.

.5 d Sets threshold to .5 divisions.

1 d Sets threshold to 1 division.

3 d Sets threshold to 3 divisions.

Filter

Filter compensates for vibration or excessiv e air currents. Def ault settings are shown bold.

-0- reduced stability, fastest stabilization time

-1- normal stability , normal stabilization time

-2- more stability, slow stabilization time.

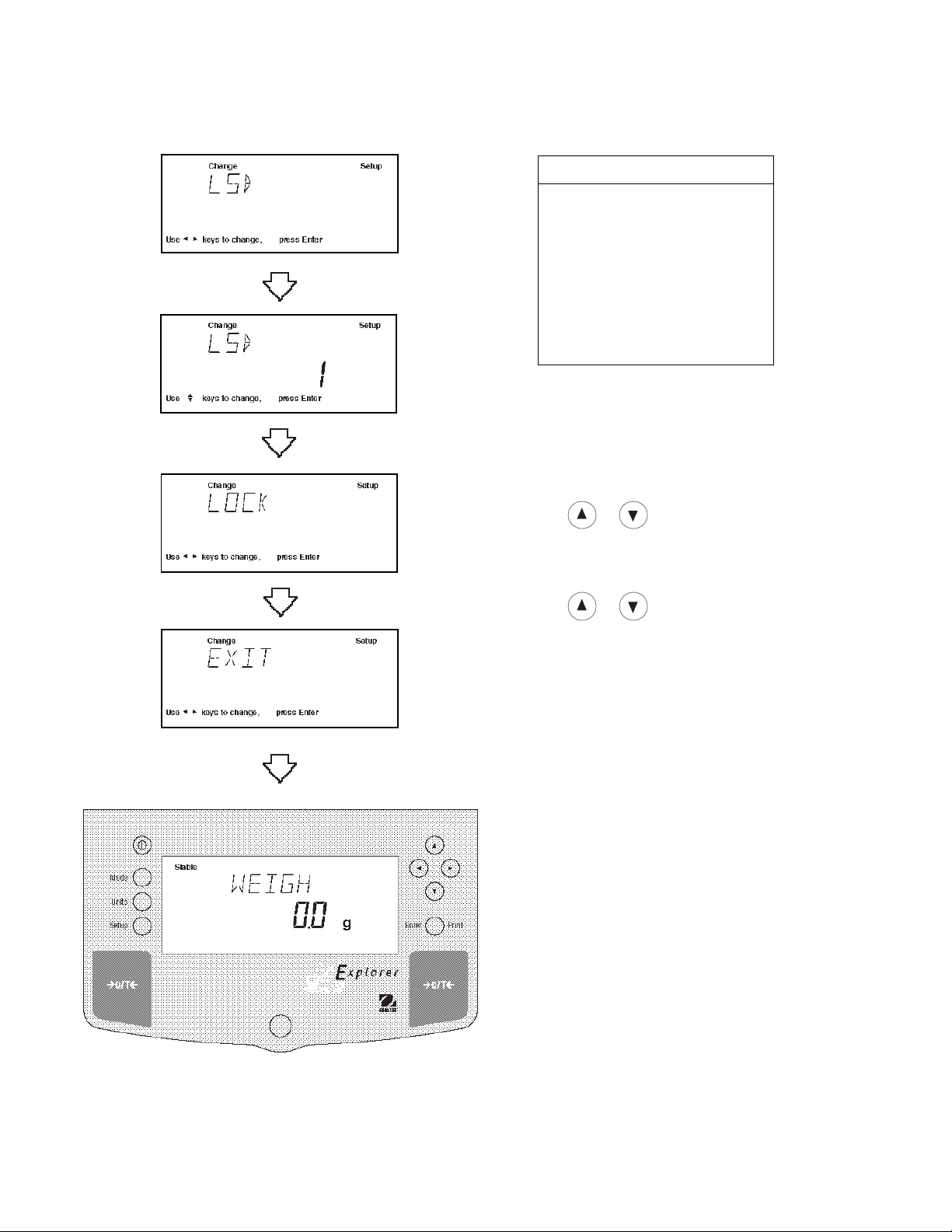

Lock

Lock ON/OFF can only be changed when the hardware Lock Switch is set OFF/disabled. A menu is locked when the

menu lock is set ON and the Lock switch is ON. Loc k when selected and turned on, locks all of the entries made

under the Readout menu. In the locked condition, items may be look ed at b ut not changed in the menu. When set

off, entries may be changed. OFF is the default setting.

-3- maximum stability, slowest stabilization time.

29

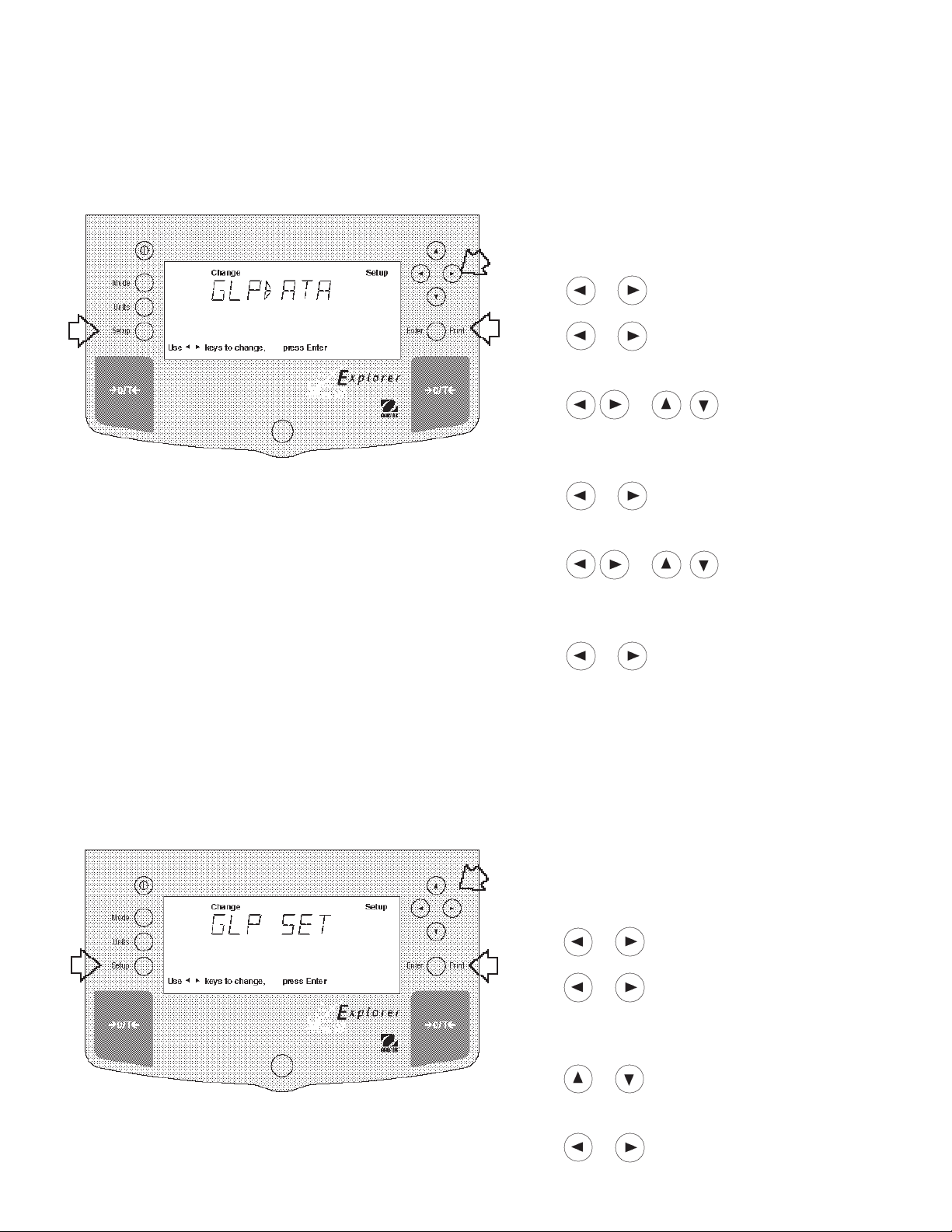

4.3 Good Laboratory Practices (GLP) Data

The GLP Data submenu enables the storage of a user identification number (7 digits) and/or a project number

(digits). When entered into the balance, the identification number and project number are a v ailab le when printing

providing they are turned on in the GLP Set submenu. A lock setting is also available which locks in the user identification and project number .

Procedure

To select any of the items in the GLP Data menu, proceed as follows:

• Press the Setup button, CAL is displayed.

• Press or button until GLP DAT A is displa yed.

• Press Enter button to continue.

• Press or button until either USER NO,

PROJ NO, LOCK or EXIT is displayed.

• Press Enter button to continue.

• Press or buttons as directed by

the display and enter a 7 digit number for the user ID

number.

• Press Enter button to sav e setting.

• Press or button until either USER NO,

PROJ NO, LOCK or EXIT is displayed.

• Press Enter button to continue.

• Press or buttons as directed by

the display and enter a 7 digit number for the project

number.

• Press Enter button to save setting.

• Press or button to select next item or EXIT.

• Press Enter button to continue.

4.4 Good Laboratory Practices (GLP) Set

Good Laboratory Practices (GLP) Set submenu allows the selection and will permit printing of Time, Balance Identification Number, User Identification Number, Project Number , Difference and Name data to be printed. When the

selected items are set to ON, these items are not displayed. The default setting is OFF. When an external printer is

used, and all items are set ON and the balance is calibrated, the printer will print out calibration data for audit trail

purposes and will indicate date, and time. (It should be noted that the User ID n umber and Project number must be

entered in the GLP Data submenu before printed data is availab le).

Procedure

To select any of the items in the GLP Set menu, proceed

as follows:

• Press the Setup button, CAL is displayed.

• Press or button until GLP SET is displayed.

• Press Enter button to sav e setting.

• Press or button until either TIME, BAL ID ,

USER NO, PROJ NO, DIFF, NAME, LOCK or EXIT is

displayed.

• Press Enter button to sav e setting.

• Press or button and select either ON or

OFF.

• Press Enter button to sav e setting.

• Press or button to continue or EXIT.

• Press Enter button to sav e setting.

30

4.5 Print

The Print menu provides a number of options which can be turned ON or OFF. It contains eight submenus: Auto

Print, feature which includes selection of Off, Continuous , Interval and on Stability, Inter , specifies time interval f or

automatic output of displayed data, Stable data-only feature, Numeric only or full display data f or output, GLPCont,

GLPT are, Reference which prints ref erence w eight v alue and Loc k which enab le y ou to prog ram balance param-

eters and to lock the settings.

Procedure

• Press the Setup button, CAL is displayed.

• Press or button until PRINT is displayed.

• Press Enter button to continue.

• Press or button until either AUTOPRT,

INTER, STABLE, NUMERIC , GLPCONT, GLPTARE,

REFEREN, LOCK or EXIT is displayed.

• Press Enter button to continue.

• Press or button and select either menu

setting or ON or OFF.

• Press Enter button to sav e setting.

• Press or button to select next item or EXIT.

• Press Enter button to continue.

Auto Print Feature

When enabled, the Auto Print feature causes the balance to automatically output display data in one of three ways:

continuously, at user specified time intervals, or upon stability. Default settings are shown bold.

OFF when set on turns off the auto print feature

Cont when set on, outputs printed data continuously

Inter provides a user specified printing interval

On Stb pro vides printed data only when a stab le reading is achie v ed

Interval

Can be set to provide a specified printing interval between 1 and 3600 seconds.

Print Stable Data Only

When set On , this feature permits only stable display data to be output. OFF is the default setting.

Print Numeric Data Only

When Numeric Data Only function is turned ON, this allows the balance to output numeric data only for RS232

output. OFF is the default setting.

31

4.5 Print (Cont.)

GLP Continuously

When the GLP Continuously function is set ON, allows the balance to output the GLP selections each time a weight

value is printed to the printer. OFF is the default setting. The following example is with GLP Cont On.

Sample Printout

GLP Set Menu

Options Turned On

12/01/97 12:01:37 AM

429.5 g

12/01/97 12:01:52 AM

Bal Id

429.8 g

12/01/97 12:02:17 AM

Bal Id

USER NO 1000001

429.8 g

12/01/97 12:02:43 AM

Bal Id

USER NO 1000001

PROJ NO 2000002

429.5 g

12/01/97 12:02:43 AM

Bal Id

USER NO 1000001

PROJ NO 2000002

Name . . . . . . . . .. . . . . .

429.5 g

Time = On

Time = On

Balance ID = On

Time = On

Bal ID = On

User No. = On

Time = On

Bal ID = On

User No = On

Proj No = On

Time = On

Bal ID = On

User No = On

Proj No =

Name = On

GLP Once After Tare

When the GLP Tare function is set ON, allows the balance to output the GLP selections once after tare when the

weight value is printed to the printer. OFF is the def ault setting. The following e xample is with GLP Once After Tare.

GLP Set Menu

Options Turned On

12/01/97 12:01:37 AM

429.5 g

429.6 g

429.7 g

429.7 g

429.7 g

Time = On

Reference

When the Reference function is set ON, prints the value of weight used as a ref erence in either Percent and Parts

Counting modes. OFF is the def ault setting.

Lock

Lock ON/OFF can only be changed when the hardware Lock Switch is set OFF/unlocked. A menu is locked when the

menu lock is set ON and the Lock Switch is ON. Lock when selected and turned on, locks all of the entries made

under the Print menu. In the locked condition, items may be look ed at but not changed in the menu. When set off,

entries may be changed. OFF is the default setting.

32

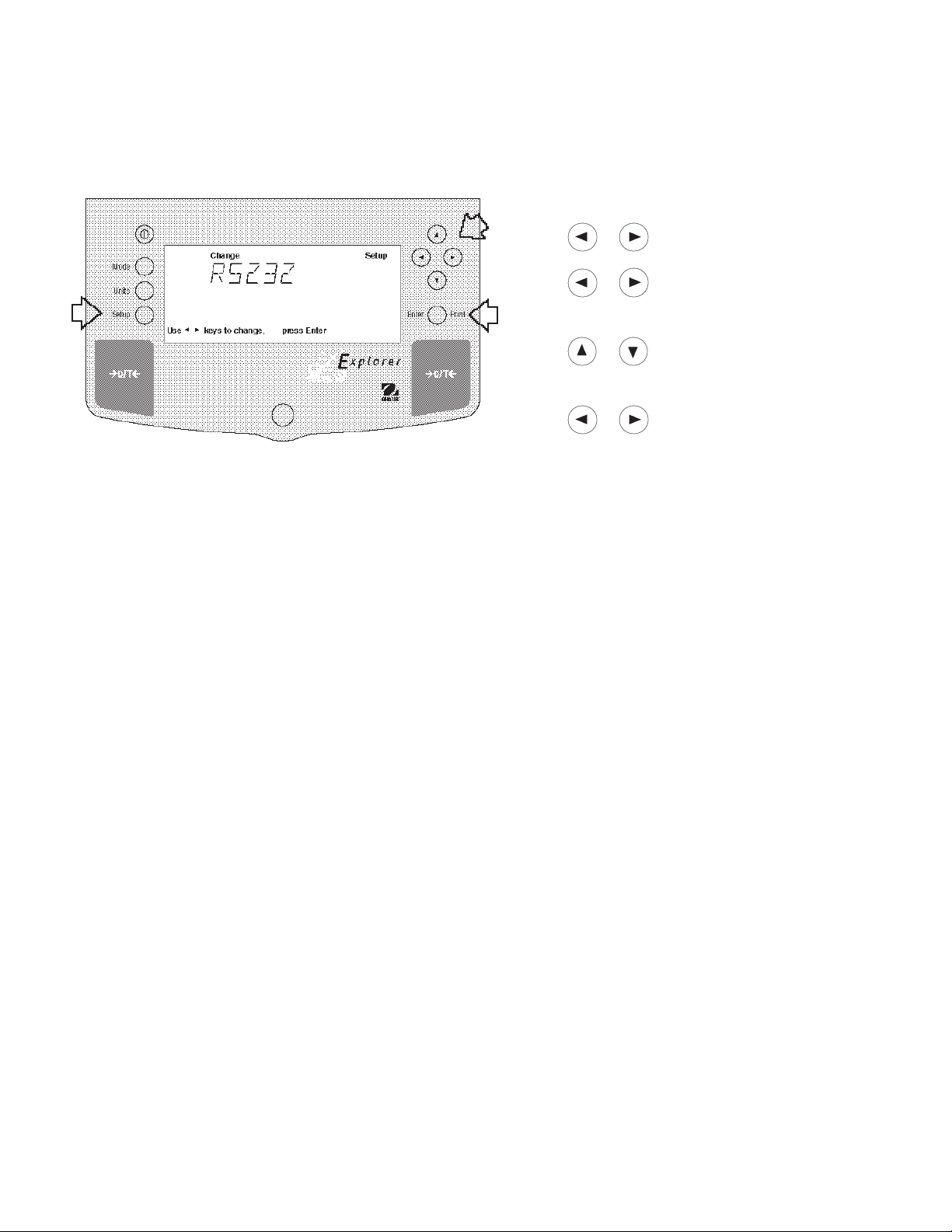

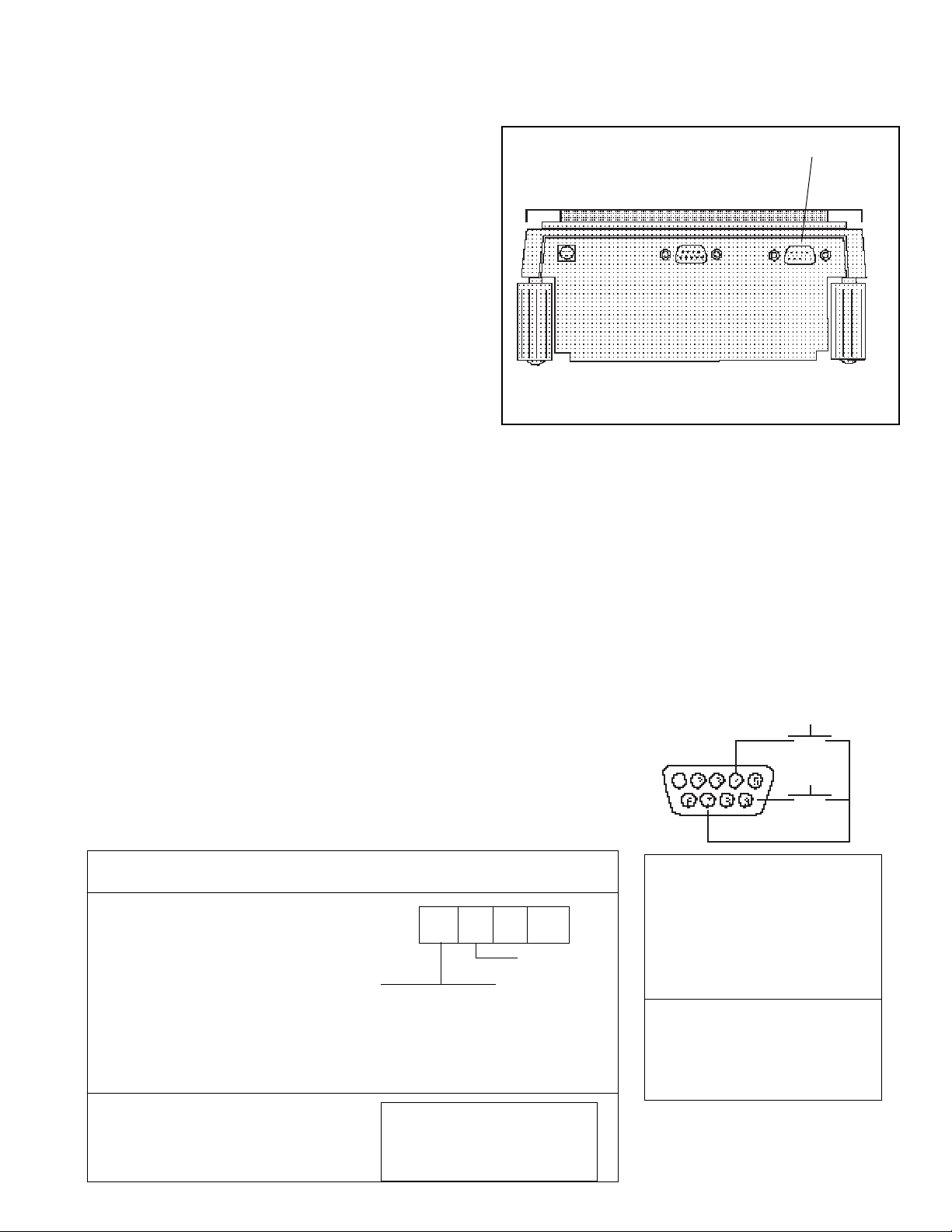

4.6 RS232

The RS232 menu provides communication parameters which can be set to accommodate e xternal printers or computers. It contains five submenus: Baud rate, Parity, Data, Stop bit and Lock ON or OFF which enable you to

program balance parameters and to lock the settings .

Procedure

• Press the Setup button, CAL is displayed.

• Press or button until RS232 is displayed.

• Press Enter button to sav e setting.

• Press or button until either BA UD, PARITY ,

DAT A, ST OP, LOCK or EXIT is display ed.

• Press Enter button to save setting.

• Press or button and select the desired

menu setting.

• Press Enter button to save setting.

• Press or button to continue or EXIT.

• Press Enter button to sav e setting.

Baud Rate

This submenu is used to select the desired baud rate. There are fiv e available baud rates to choose from: 300, 1200,

2400, 4800 and 9600. The default setting is 2400.

Parity

Parity can be set to Odd, Even or None . The default setting is None.

Data Bits

To set the number of data bits to 7 or 8. The default setting is 7.

Stop Bits

The number of stop bits can be set to 1 or 2. The default setting is 2.

Lock

Lock ON/OFF can only be changed when the hardware Lock Switch is set OFF/disabled. A menu is locked when the

menu lock is set ON and the Lock Switch is ON. Lock when selected and turned on, locks all of the entries made

under the RS232 menu. In the locked condition, items may be look ed at but not changed in the menu. When set off,

entries may be changed. OFF is the default setting.

33

4.7 Legal for Trade (LFT)

Legal for Trade (LFT) is a software controlled option which can be set to LFT LOCK. When LFT LOCK is set ON,

certain items in the Calibration, Readout, Print, Mode and Units menus are automatically preset and locked to permit

the balance to operate in a legal for trade application and works in conjunction with a Lock Switch. Default setting is

UNLOCKED . See default tab le.

Procedure

• Press the Setup button, CAL is displayed.

• Press button repeately until LFT is displayed.

• Press Enter button, LFT LOCK is displayed.

• Press Enter button, LFT LOCK OFF is displayed.

• Press or button and select either ON or OFF.

• Press Enter button, SA VED is momentarily display ed

followed by EXIT.

• Press Enter button, balance returns to weigh mode.

DEF AUL T T ABLE

LFT and Lock Switch Menu lock Default Value

Date Menu Unlocked

Time Menu Unlocked

NOTE: For legal for trade applications, the balance must

be physically sealed. Refer to section on LFT Sealing.

Calibration Menu

Span, Linearity, User Locked

CalTest Unlocked

Internal Calibration Unlocked

Cal Adj Locked

Cal Msg Locked ON

Readout Menu

Stability Unlocked .5d (limited to .5d and 1d)

Auto zero Unlocked .5d (limited to OFF and .5d)

Filter Level Unlocked -1GLP Data Menu Unlocked

GLP Selections Unlocked

Print Options Unlocked

RS232 Menu Unlocked

LFT Menu Lockswitch Locked

Function menu Locked Weigh

Units Menu Locked Grams*

Global Menu Locked

Custom Menu Unlocked

* Units oz and oz t cannot be simultaneously enabled.

If Print Numeric Data is turned ON, then Print Stable Data Only is

locked ON.

The display check countdown appears during the first

120 seconds after plugging in the balance and only when

the balance has been previously set with Type Approved/

Legal for Trade ON.

When the balance is first turned ON and LFT has been

previously set ON, the following display will appear if LFT

is set in the menu and the Lock Switch is set ON.

When the balance is first turned ON and LFT has been

previously set ON, the following display will appear if LFT

is set in the menu and Calibration menu is locked, and

the Lock Switch is set ON.

When LFT LOCK is turned ON, the weigh mode display

appears as shown below .

• • •

34

4.8 Mode

The Mode submenu permits the selection of five modes which can be turned ON or OFF. These modes are: Weigh,

Percent, Count, Animal and Lock. Weigh is turned ON and all others have a default setting of OFF. When any of

the modes are turned ON, they can be selected for operation from the Mode button.

Procedure

• Press the Setup button, CAL is displayed.

• Press or button until MODE is displayed.

• Press Enter button to sav e setting.

• Press or button until either WEIGH, PERCENT, COUNT, ANIMAL, LOCK or EXIT is displayed.

• Press Enter button to save setting.

• Press or button and select either ON or

OFF.

• Press Enter button to sav e setting.

• Press or button to continue or EXIT.

• Press Enter button to save setting.

Weigh

The Weigh submen u is always set to ON as a default.

Percent

Percent weighing permits you to place a reference load on the balance, then view other loads as a percentage of the

reference. Selection is made using the Mode button. The def ault setting is OFF.

Count

Counting is used when counting quanties of parts. Selection is made using the Mode button. The default setting is

OFF.

Animal

Animal weighing provides special settings to accommodate animal mov ements . Selection is made using the Mode

button. The def ault setting is OFF.

Lock

Lock ON/OFF can only be changed when the hardware Lock Switch is set OFF/disabled. A menu is locked when the

menu lock is set ON and the Lock Switch is ON. Lock when selected and turned on, locks all of the entries made

under the Mode menu. In the locked condition, items may be look ed at but not changed in the menu. When set off,

entries may be changed. OFF is the default setting.

35

4.9 Units

The Units submenu permits the selection of the measuring units which can be turned ON or OFF and locked.

Procedure

• Press the Setup button, CAL is displayed.

• Press or button until UNITS is displayed.

• Press Enter button to continue.

• Press or button until desired measuring unit

is displayed.

• Press Enter button to continue.

• Press or button and select either ON or

OFF.

• Press Enter button to sav e setting.

• Press or button to select next item or EXIT.

• Press Enter button to continue.

Units

Measuring units settings are made using the Units button. This menu permits the measuring units to be turned ON or

OFF. The default setting is OFF.

Lock

Lock when selected and turned on, locks all of the entries made under the Units button. The default setting is OFF.

4.10 Global

This menu contains two functions which can be set to either a yes or no type of operation. These functions are: List,

and Reset. The default settings are NO. Global List is a con vienent method of examining which parameters are set

up in the balance. The parameters do not show up on the display b ut print out when selected. The Global menu

contains the List function. When Version is selected, the software re vision of the balance is displayed.

Procedure

• Press the Setup button.

• Press or button until GLOBAL is displayed.

• Press Enter button to continue.

• Press or button until either LIST, RESET,

VERSION, LOCK or EXIT is displayed.

• Press Enter button to continue.