Page 1

Optical Multiplexer

MPM-2000

Installation and Operation Manual

Document Number 000-10000-120-02-1209

Offices:

E-mail: Info@OceanOptics.com (General sales inquiries)

Ocean Optics, Inc. World Headquarters

830 Douglas Ave., Dunedin, FL, USA 34698

Phone 727.733.2447

Fax 727.733.3962

8 a.m.– 8 p.m. (Mon-Thu), 8 a.m.– 6 p.m. (Fri) EST

Ocean Optics Mikropack

Maybachstraße 11, D-73760, Ostfildern, Germany

Phone +49 (0)711 34 16 96-0

Fax +49 (0)711 34 16 96-85

Info@Mikropack.de (Mikropack sales inquiries)

Orders@OceanOptics.com (Questions about orders)

TechSupport@OceanOptics.com (Technical support)

Page 2

Copyright © 2009 Ocean Optics, Inc.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, by any means, electronic, mechanical, photocopying,

recording, or otherwise, without written permission from Ocean Optics, Inc.

This manual is sold as part of an order and subject to the condition that it shall not, by way of trade or otherwise, be lent, re-sold, hired out or otherwise circulated without

the prior consent of Ocean Optics, Inc. in any form of binding or cover other than that in which it is published.

Trademarks

Microsoft, Windows, Windows 95, Windows 98, Windows Me, Windows NT, Windows 2000, Windows XP and Excel are either registered trademarks or trademarks of

Microsoft Corporation.

Limit of Liability

Every effort has been made to make this manual as complete and as accurate as possible, but no warranty or fitness is implied. The information provided is on an “as is”

basis. Ocean Optics, Inc. shall have neither liability nor responsibility to any person or entity with respect to any loss or damages arising from the information contained in

this manual

Page 3

Important Safety Notices

1. Read all safety notices and operating instructions before operating this unit.

2. Inspect the item for transport damage before using the 24VDC power supply for the first time.

3. Adhere to all warning stickers on the unit and all warnings contained in this manual.

Warranty

Mikropack GmbH warrants to the original user of this instrument that it shall be free of any defects

resulting from faulty manufacture of this instrument for a period of 12 months from the original data of

shipment.

This instrument should not be used for any Clinical or Diagnostic purposes. Data generated in these

areas is not warranted in any way by Mikropack GmbH. Any defects covered by this Warranty shall be

corrected either by repair or by replacement, as determined by Mikropack GmbH.

There are no warranties that extend beyond the description herein.

This Warranty is in lieu of, and excludes, any and all other warranties or representations expressed,

implied, or statutory, including merchantability and fitness, as well as any and all other obligations or

liabilities of Mikropack GmbH including, but not limited to, special or consequential damages. No

person, firm, or corporation is authorized to assume for Mikropack GmbH. Any additional obligation or

liability not expressed provided for herein except in writing duly executed by an officer of Mikropack

GmbH:

MIKROPACK GmbH

Maybachstraße 11

D-73760 Ostfildern

Tel.: +49 (0)711 3428088 • Fax.: +49 (0)711 3428085

info@mikropack.de

e-mail:

Warranty Handling

► Procedure

Follow the procedure below to process a warranty claim:

1. Determine the problem or fault with your local distributor.

2. If a problem is evident, obtain an RMA number from your local distributor.

000-10000-120-02-1209 A

Page 4

Important Safety Notices

3. Send the equipment to the local distributor for repair. If the item is under warranty, shipping will

be free-of-charge both ways.

4. Contact your distributor for repair and delivery time. If the item is out of warranty, your

distributor will provide a repair cost to you. In this situation, the distributor will not proceed with

the repair until you order it.

Your system will be shipped back to you free of charge with insurance (if under warranty).

B 000-10000-120-02-1209

Page 5

Table of Contents

About This Manual .............................................................................................................iii

Document Purpose and Intended Audience..............................................................................iii

What’s New in this Document ................................................................................................... iii

Document Summary..................................................................................................................iii

Product-Related Documentation ............................................................................................... iii

Upgrades ............................................................................................................................iv

Chapter 1: Setup...................................................................................1

Overview.............................................................................................................................1

Unpacking the MPM-2000..................................................................................................2

Contents .............................................................................................................................2

Typical System Configuration ............................................................................................3

Chapter 2: MPM-2000 Specifications .................................................5

Operating Environment ......................................................................................................5

MPM-2000 Components ....................................................................................................6

Front Panel ................................................................................................................................ 6

Rear Panel................................................................................................................................. 7

Chapter 3: Operating Instructions......................................................9

Operating Software ............................................................................................................9

Channel Mode ...........................................................................................................................10

Program Mode ...........................................................................................................................11

Small Mode................................................................................................................................ 12

Main Toolbar.............................................................................................................................. 13

Menu Options ............................................................................................................................13

Options Dialog Box....................................................................................................................14

MPM-2000.drv ....................................................................................................................15

Appendix A: RS232 ASCII Commands...............................................17

Program File .......................................................................................................................17

New Data Format ...................................................................................................................... 19

000-10000-120-02-1209 i

Page 6

Table of Contents

Syntax.................................................................................................................................20

Operating/Interfacing with the Optical Multiplexer.............................................................21

Calibrating the MPM-2000 .................................................................................................22

Index ......................................................................................................23

ii 000-10000-120-02-1209

Page 7

About This Manual

Document Purpose and Intended Audience

This document provides you with an installation section to get your system up and running.

What’s New in this Document

This version of the Optical Multiplexer MPM-2000 Installation and Operation Manual removes

calibration information.

Document Summary

Chapter Description

Chapter 1: Setup

Chapter 2: MPM-2000 Specifications

Chapter 3: Operating Instructions

Appendix A: RS232 ASCII Commands

Contains a list of package contents and unpacking

instructions.

Contains operating environment specifications, as

well as other physical details of the product.

Provides instructions for operating Windows-based

software that comes with the MPM-2000.

Provides the RS232 ASCII command information for

the multiplexer.

Product-Related Documentation

You can access documentation for Ocean Optics products by visiting our website at

http://www.oceanoptics.com. Select Technical → Operating Instructions, then choose the appropriate

document from the available drop-down lists. Or, use the

of the web page.

You can also access operating instructions for Ocean Optics products on the

Resources

Engineering-level documentation is located on our website at Technical → Engineering Docs.

CD included with the system.

Search by Model Number field at the bottom

Software and Technical

000-10000-120-02-1209 iii

Page 8

About This Manual

Upgrades

Occasionally, you may find that you need Ocean Optics to make a change or an upgrade to your system.

To facilitate these changes, you must first contact Customer Support and obtain a Return Merchandise

Authorization (RMA) number. Please contact an Ocean Optics Application Scientist for specific

instructions when returning a product.

iv 000-10000-120-02-1209

Page 9

Chapter 1

Setup

Overview

The MPM-2000 Fiber Optic Multiplexer is a compact instrument that can optically couple one input

channel to 16 different output channels. The MPM-2000 consists of a precisely controlled DC-motor with

encoder and end switch on a rotator block. The optical path couples via UV collimating lenses.

The Multiplexer features a CNC controller working in positioning mode, which eliminates step loss. The

MPM-2000 is software controlled and interfaces to a PC through the RS-232 protocol. It automatically

saves all calibrated positions in the memory of the controlling unit, and easy-to-use software facilitates

calibration. The software enables full control of the switching order and delay time.

The MPM-2000 is ideal for applications in process industry, where you need to measure multiple

locations with multiple probes but with a single spectrometer channel and/or light source. The MPM-2000

operates as a stand-alone unit and includes a sample program to guide you in setting up your application.

The CD contains a driver for Windows, and you can configure the MPM-2000 in Ocean Optics

OOIbase32 Platinum software.

The following sections provide instructions on unpacking and setting up your MPM-2000 Optical

Multiplexer.

000-10000-120-02-1209 1

Page 10

1: Setup

Unpacking the MPM-2000

► Procedure

1. Unpack the Optical Multiplexer carefully. Dropping this instrument can cause permanent

damage.

2. Inspect the outside of the instrument and make sure that there is no damage. Do not use the

instrument if damage is present. Contact your dealer for repair or replacement information, if

necessary.

3. Use this instrument in a clean laboratory environment.

4. Submit the Registration Card to for warranty and support purposes.

Contents

Your MPM-2000 Optical Multiplexer package should contain the following:

MPM-2000 Main System

MPM-2000 24VDC Power Supply

Caution

Before using the power supply of the MPM-2000 for the first time, inspect the item for

transport damage. Be sure to adhere to all warnings on the unit and in this operational

manual.

Software CD (contains MPM-2000 software and Calibration software)

PC-MPM-2000 Serial Cable

2 000-10000-120-02-1209

Page 11

Typical System Configuration

1: Setup

000-10000-120-1209 3

Page 12

1: Setup

4 000-10000-120-02-1209

Page 13

Chapter 2

MPM-2000 Specifications

This section provides information on the operating environment and physical controls of the MPM-2000.

Operating Environment

The following table provides information on optimizing the operating environment of your MPM-2000.

Operating Environment The MPM-2000 Unit . . .

Moisture Is designed for operation in dry rooms only.

Ventilation Should be situated so that its location or position does not interfere

with proper ventilation.

Heat Should be situated away from any device that emits excessive heat.

Object and Liquid Entry Should be positioned so that objects do not fall on top of the unit.

Additionally, ensure that no liquids are spilled into the enclosure

through openings.

Power Sources The unit should be connected to a power supply only of the type

described in the operating instructions or as marked on the unit.

000-10000-120-02-1209 5

Page 14

2: MPM-2000 Specifications

Error LED

Connectors

MPM-2000 Components

The following sections describe the components located on the front and rear of the MPM-2000 unit.

Front Panel

SMA 905

Note

The front panel of both the 1 x 16 and 2 x 8 versions of the MPM-2000 are identical.

Only the rear panel will differ (two inputs on the 2 x 8 version).

Power LED

6 000-10000-120-02-1209

Page 15

Rear Panel

(connects to PC)

SMA 905

Connector

(connects to

spectrometer)

2: MPM-2000 Specifications

Type Sign

RS232 Port

Connection

24 VDC Power Input

000-10000-120-1209 7

Page 16

2: MPM-2000 Specifications

8 000-10000-120-02-1209

Page 17

Chapter 3

Operating Instructions

Operating Software

The MPM-2000 comes with easy-to-use Windows-based software that allows you to control the MPM2000 Optical Multiplexer manually or create sequence programs (scripts) with preconfigured channel

settings and delay times. The graphical software interface allows you to choose from three modes of

operation:

Channel Mode

Program Mode

Small Mode

000-10000-120-02-1209 9

Page 18

3: Operating Instructions

Channel Mode

Channel Mode allows you to change the active channel on the MPM-2000. You can click on any of the

blue buttons associated with the SMA 905 Connectors on the front of the MPM-2000 to activate that

channel.

Once you activate a channel, the button for that channel turns red until you activate another channel.

10 000-10000-120-02-1209

Page 19

Program Mode

3: Operating Instructions

Program Mode allows you to create or change sequence programs used by the MPM-2000. The Program

Mode interface contains the following items:

Item Description

Step Column Identifies the individual step number in the sequence program

Channel Identifies the channel that the MPM-2000 will switch to in this step

Time to wait Identifies the delay time before the MPM-2000 proceeds to the next step

Time unit Defines the unit of time for the Time to wait column

Continuous

No of runs

000-10000-120-1209 11

When checked, instructs the software to run the sequence program a

specified number of times (specified in the

Specifies the number of times the software will execute the sequence program

(a value of –1 instructs the software to run the program until manually

stopped)

no of runs box)

Page 20

3: Operating Instructions

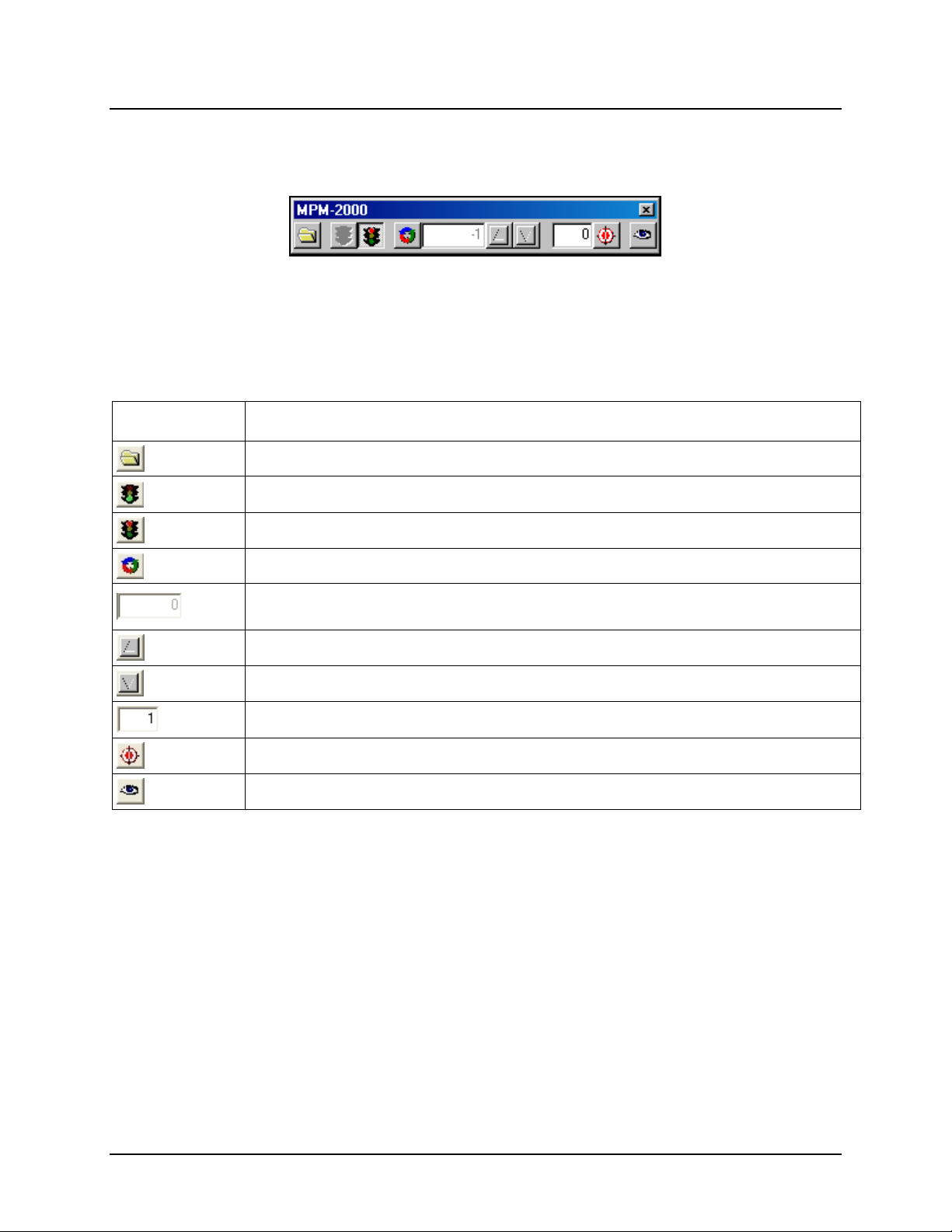

Small Mode

Small Mode provides all functionality of the software in a condensed menu bar. When using another

software package, the Always on Top feature of Small Mode eliminates the need to consistently switch

back and forth between applications. This mode is only accessible via the

The Small Mode screen contains the following options:

Item Function

Load an existing program sequence

Activate the loaded program sequence

Stop the currently running program sequence

View Menu.

Enable continuous mode

Specifies the number of times the program sequence will execute (if continuous mode

is active)

Increase the active channel on the MPM-2000 by one (+ 1 channel)

Decrease the active channel on the MPM-2000 by one (- 1 channel)

Specify a channel on the MPM-2000

Switch to the channel specified in the text box to the left of this button

Exit Small Mode and return to Channel Mode

12 000-10000-120-02-1209

Page 21

3: Operating Instructions

Main Toolbar

The Main Toolbar is only visible in Channel Mode and Program Mode. It contains the following buttons

and features:

Button Function

Switch to Channel Mode

Switch to Program Mode

Open new program sequence

Open an existing program sequence

Save the current program sequence

Start the currently loaded program sequence

Stop the currently running program sequence

Menu Options

The MPM-2000 software menu bar has four options:

File Menu

View Menu

Tools Menu

? (help)

The sections that follow detail each of these options.

File Menu

The File Menu contains the following options:

Menu Option Description

New Clear the program grid and open a new program sequence

Open Open an existing program sequence

Save Save the program sequence that you are currently editing

Save As Save the program sequence that you are currently editing with a new filename

Options Opens the Options dialog box

Exit Exits the MPM-2000 software

000-10000-120-1209 13

Page 22

3: Operating Instructions

View Menu

The View Menu allows you to toggle between the three different application modes. You can only access

Small Mode using this option.

Tools Menu

The Tools Menu contains the following options:

Menu Option Description

Connect Connects to the MPM-2000

Disconnect Disconnects from the MPM-2000

Options Opens the Options dialog box

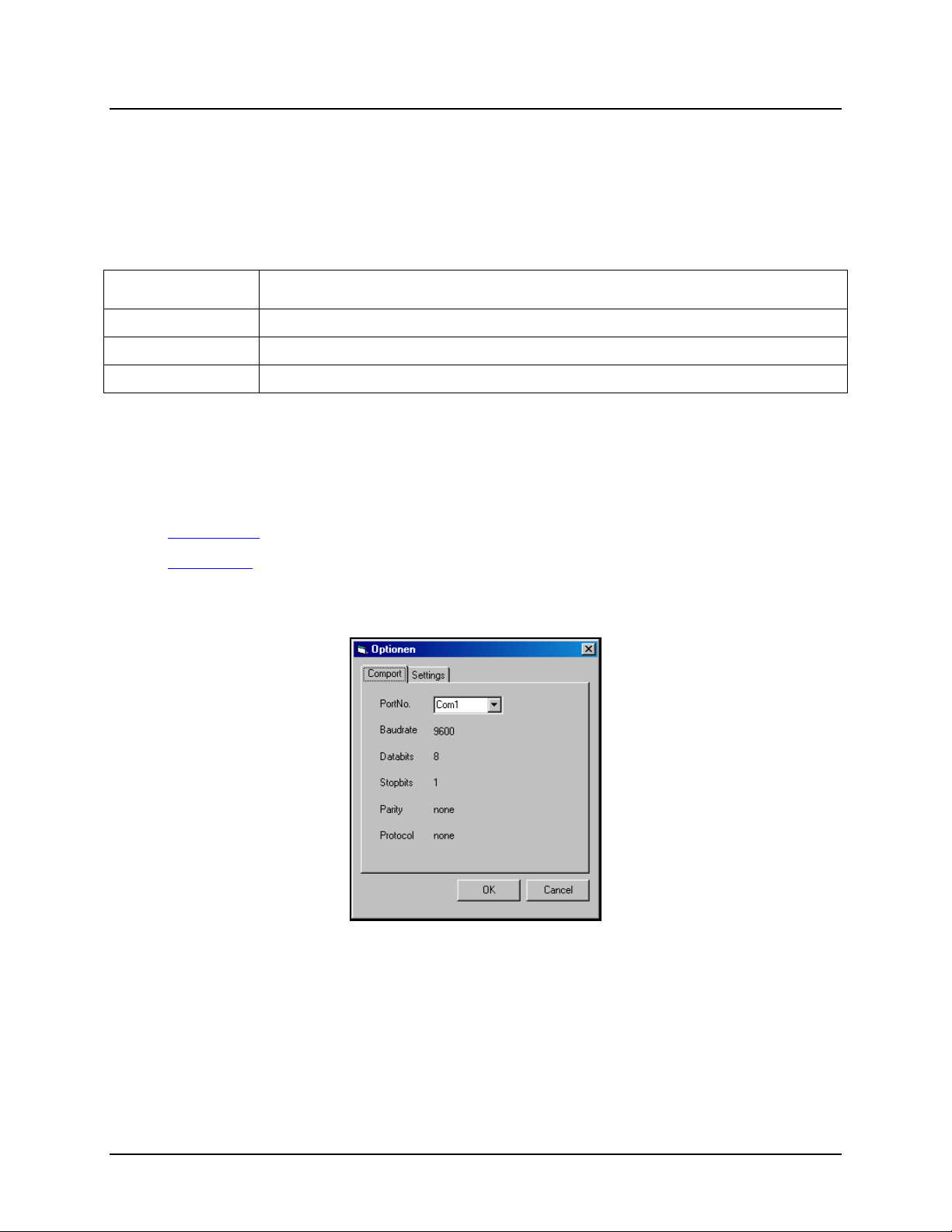

Options Dialog Box

The Options dialog box is accessible from the File Menu or Tools Menu. It contains the following two

tabs:

Comport Tab

Settings Tab

Comport Tab

Select the COM port on the PC that you will use to communicate to the MPM-2000, and then click the

OK button.

You must ensure that this option is correct before the MPM-2000 will communicate with the PC.

14 000-10000-120-02-1209

Page 23

3: Operating Instructions

Settings Tab

Click the Always On Top check box to position the software window above any other running

applications, and then click the

To specify the default mode that the MPM-2000 software will enter upon startup, select one of the three

radio button options under the

OK button to save your changes.

Startup View section of the Settings tab, and then click the OK button.

MPM-2000.drv

The MPM-2000.DRV is an interface DLL for use with Visual Basic or C/C++. It allows you to integrate

the MPM-2000 in your own custom application.

The MPM-2000.DRV package contains a sample program written in Visual Basic® and a sample

program written in Visual C++®.

For further details on how to use the MPM-2000.drv, consult the online documentation included with the

MPM-2000.DRV.

000-10000-120-1209 15

Page 24

3: Operating Instructions

16 000-10000-120-02-1209

Page 25

RS232 ASCII Commands

Program File

The MPM-2000 Optical Multiplexer is interfaced via the RS232 protocol.

The settings for the serial communications are:

Baudrate: 9600

Databits: 8

Parity: None

Stop bits: 1

Handshaking: None

Appendix A

A program file stored in the MPM-2000’s EEPROM contains all necessary data:

Serial Number

Software Version Number (only for the windows software)

Calibration data (positions of all 16 channels)

Startup / Reference-sequence

The program file looks like the following sample code except for the position data.

Note

For new devices with serial numbers of 039180029 and above or 050460021 and above,

see

New Data Format.

000-10000-120-02-1209 17

Page 26

A: RS232 ASCII Commands

Line Command

1 answ0 // asynchronous answers deactivated

2 jmp1

3 SWVersion100 // version of the windows-software

4 SN03918XXXX // serialnumber of the multiplexer

5 Ch01-400 // absolute position of channel 1: -400

6 Ch02-100 // absolute position of channel 2: -100

7 Ch03200 // ...

8 Ch04500

9 Ch05800

10 Ch061100

11 Ch071400

12 Ch081700

13 Ch092000

14 Ch102300

15 Ch112700

16 Ch123000

17 Ch133300

18 Ch143600

19 Ch153900

20 Ch164200 // absolute position of channel 16: 4200

21 A1

22 v-60 //--------------23 delay800 // get reference position

24 gohix //

25 delay50 //--------------26 la-400 // goto channel 1

27 m // execute movement

28 delay10

18 000-10000-120-02-1209

Page 27

New Data Format

Line Command

1 answ 0

2 jmp 1

3 la 200

4 la 39180030

5 la -1095

6 la -188

7 la 711

8 la 1611

9 la 2516

10 la 3412

11 la 4312

12 la 5209

13 la 6104

14 la 6996

15 la 7887

16 la 8799

17 la 9700

18 la 10600

19 la 11508

20 la 12404

21 a 1

22 v -70

23 delay 600

24 gohix

25 delay 50

26 la -1095

27 m

28 delay 50

A: RS232 ASCII Commands

000-10000-120-1209 19

Page 28

A: RS232 ASCII Commands

Syntax

Every command sent via RS232 to the MPM-2000 consists of the following parts:

Command sequence, Parameter (if needed), Carriage Return [CR]

To set an absolute position you need to send:

LA1000[CR] // Load absolute position 1000

M[CR] // initiate motion

Command Description Example

M Initiate Motion (Move) M[CR]

LA Load absolute target position

Allows programming of the desired target position relative to the

present zero or "home" position.

POS Get actual position

This command returns the actual position

GST

Get Status

This command returns motion controller status.

Bit Description

1 Position mode

0

0 velocity mode

1 Speed command is analog input

1

0 Speed command comes via RS232

1 Speed command is PWM (SOR2)

2

0 Speed command is analog voltage (SOR1)

3

1 amplifier enabled

0 amplifier disabled

4

1 in position

LA1000[CR]

M[CR]

POS[CR]

GST[CR]

0 not in position

5

1 rising edge on external switch is valid

0 falling edge on external switch is valid

6

1 external switch now high level

0 external switch now low level

20 000-10000-120-02-1209

Page 29

A: RS232 ASCII Commands

Command Description Example

GFS

ANSW Asynchronous answer ON / OFF

GPROGSEQ This command returns the complete program sequence stored in

Get Fault Status

This command returns the fault status

Bit Description

0

Over-temperature condition

1

Over-current condition

2

Under-voltage (<10VDC)

3

Over-voltage (>32VDC)

ANSW1 activated

ANSW0 deactivated

the EEPROM

GFS[CR]

ANSW0[CR]

GPROGSEQ[CR]

Operating/Interfacing with the Optical Multiplexer

The software needs to execute the following steps:

1. Read the complete program out of the EEPROM in the multiplexer

2. Extract the Serial number of the MPM-2000

3. Extract the position for each channel out of the file and save them for example in an array

4. Set the position for any of the channels

The program can be read with the GPROGSEQ command. It will look like the sample program. Only the

software version, the serial number and the positions will change with each device.

Check for an MPM-2000 by looking for the serial number as follows:

MPM-2000 1x16: 03918XXXX

MPM-2000 2x8: 05046XXXX

Where XXXX = a running serial number

The positions are stored in the file as follows:

CH01-500 Channel 1, absolute position –500

CH133000 Channel 13, absolute position 3000

Once the positions are extracted and stored you can set the position of the motor with the command

sequence:

LAPosition[CR]

M[CR]

000-10000-120-1209 21

Page 30

A: RS232 ASCII Commands

To check if the MPM-2000 has reached the given position you can poll the actual position (POS[CR]) and

compare it with desired position.

Note: A difference of +/-1 between the desired position and the real position can occur. This is not a

functional error.

Calibrating the MPM-2000

To calibrate the MPM-2000 Optical Multiplexer, you must write the complete program file to the

EEPROM in the MPM-2000. This means that every line included in the original file must again be

written to and stored in the EEPROM.

Caution

Do NOT change anything other than the numbers representing the channel

positions! Any other change can lead to a system malfunction.

Commands to Save a File to the EEPROM

Command Description Example

PROGSEQ Defines the beginning of a Sequence program. All commands

given after PROGSEQ will be sent directly to the EEPROM until

the END command

(

Caution: Do NOT cut the supply power to the motor during

programming).

END Defines the end of the program. All commands given after the END

will be immediately carried out by the motor.

GPROGSEQ Gets program sequence

This function returns the complete program stored in the EEPROM

ENPROG Starts the program

This Program command can also be saved with the EEPSAV

command. The program will then run directly after turning on the

power to the motor.

DIPROG Deactivates the program DIPROG[CR]

LR Loads relative position

Loads new relative position

PROGSEQ[CR]

END[CR]

GPROGSEQ[CR]

ENPROG[CR]

LA1000[CR]

M[CR]

22 000-10000-120-02-1209

Page 31

Index

A

Acquisition Parameter Options, 17

ASCII commands, 21

C

Channel Mode, 10

components, 6

front panel, 6

rear panel, 7

Comport Options, 18

Comport Tab, 14

configuration

typical system, 3

D

document

audience, iii

purpose, iii

summary, iii

F

File Menu, 13

I

O

operating environment, 5

operating instructions, 9

options

Acquisition Parameter, 17

Comport, 18

Options Dialog Box, 14

P

package contents, 2

product-related documentation, iii

program file, 21

syntax, 24

Program Mode, 11

R

RS232, 21

S

Settings Tab, 15

setup, 1

Small Mode, 12

software, 9

specifications, 5

interfacing

with multiplexer, 25

tab

M

Main Toolbar, 13

menu

File, 13

Tools, 14

View, 14

Menu Options, 13

mode

Channel, 10

Program, 11

Small, 12

MPM-2000.drv, 19

000-10000-120-02-1209 23

Comport, 14

Settings, 15

Tools Menu, 14

unpacking procedure, 2

upgrades, iv

View Menu, 14

T

U

V

Page 32

Index

W

warranty, A

what's new, iii

24 000-10000-120-02-1209

Loading...

Loading...