Page 1

MMS Raman Spectrometer

A Product

Installation and Operation Manual

Document Number 000-40000-02-0906

Offices:

E-mail: Info@OceanOptics.com (General sales inquiries)

Ocean Optics™, Inc.

830 Douglas Ave., Dunedin, FL, USA 34698

Phone 727.733.2447

Fax 727.733.3962

8 a.m.– 8 p.m. (Mon-Thu), 8 a.m.– 6 p.m. (Fri) EST

Ocean Optics B.V. (Europe)

Geograaf 24, 6921 EW DUIVEN, The Netherlands

Phone 31-(0)26-3190500

F ax 31-(0)26-3190505

Info@OceanOpticsBV.com (European sales inquiries)

Orders@OceanOptics.com (Questions about orders)

TechSupport@OceanOptics.com (Technical support)

A

Page 2

Ocean Optics offers the most comprehensive, innovative and high-quality line of modular spectroscopy

tools in the world. Centice is an essential and valuable partner in this enterprise. We have partnered with

Centice because they are committed to the same goals of innovation and quality that inspire us here at

Ocean Optics. As always, Ocean Optics conducts its business in an open, honest and technically available

fashion. We invite you to contact us at Ocean Optics, Inc. (see front cover for contact information) or

Centice with any technical questions, comments, or applications inquiries. Centice can be contacted at the

following location:

Centice Corporation

4020 Stirrup Creek Dr, Suite 115

Durham, NC 27703

Phone: 919 405 4264

Fax: 919 405 4268

Web: http://www.centice.com

Copyright © 2001-2006 Ocean Optics, Inc.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, by any means, electronic,

mechanical, photocopying, recording, or otherwise, without written permission from Ocean Optics, Inc.

This manual is sold as part of an order and subject to the condition that it shall not, by way of trade or otherwise, be lent, re-sold, hired out or

otherwise circulated without the prior consent of Ocean Optics, Inc. in any form of binding or cover other than that in which it is published.

Trademarks

Microsoft, Windows, Windows 95, Windows 98, Windows Me, Windows NT, Windows 2000, Windows XP and Excel are either registered

trademarks or trademarks of Microsoft Corporation.

Limit of Liability

Every effort has been made to make this manual as complete and as accurate as possible, but no warranty or fitness is implied. The information

provided is on an “as is” basis. Ocean Optics, Inc. shall have neither liability nor responsibility to any person or entity with respect to any loss or

damages arising from the information contained in this manual.

Page 3

Table of Contents

About This Manual .......................................................................................................... iii

Document Purpose and Intended Audience.............................................................................. iii

What’s New in This Document .................................................................................................. iii

Document Summary.................................................................................................................. iii

Product-Related Documentation ............................................................................................... iv

Upgrades......................................................................................................................... iv

Laser Safety ....................................................................................................................iv

Chapter 1: Installation ........................................................................5

Introduction...................................................................................................................... 5

Applications ............................................................................................................................... 5

About SpectraSuite.................................................................................................................... 6

Features..................................................................................................................................... 6

Parts Included ................................................................................................................. 6

Other Equipment Needed..........................................................................................................6

Installation Procedure...................................................................................................... 7

Chapter 2: Operating the Spectrometer............................................9

Sample Placement .......................................................................................................... 9

Acquiring Spectra ............................................................................................................ 10

Appendix A: Specifications................................................................15

Appendix B: Introduction to Multimodal Multiplex Sampling.........17

Introduction...................................................................................................................... 17

Theory of Operation ........................................................................................................ 18

Coded Aperture ............................................................................................................... 18

Coded Aperture ............................................................................................................... 19

Multiplex (SNR) Advantage .......................................................................................................19

Multimodal (Etendue) Advantage .............................................................................................. 19

Imaging Aspect of MMS ............................................................................................................19

MMS and Conventional Multiplex Spectroscopy....................................................................... 20

Performance Comparison ............................................................................................... 20

Etendue ..................................................................................................................................... 20

000-40000-000-02-0906 i

Page 4

Table of Contents

Signal to Noise Ratio ................................................................................................................. 22

Measuring in Scattering Media.................................................................................................. 23

Conclusion....................................................................................................................... 23

Appendic C: Remote Interlock...........................................................25

Index .....................................................................................................................27

ii 000-40000-02-0906

Page 5

About This Manual

Document Purpose and Intended Audience

This document provides you with installation information to get your system up and running. It also

contains an in-depth discussion of Multimodal Sampling technology.

What’s New in This Document

This version of the MMS Raman Spectrometer Installation and Operation Manual adds clarification to

the Acquiring Spectra

Document Summary

Chapter Description

procedure.

Chapter 1: Installation Provides a list of system components, and

operating requirements. Also contains instructions

for installing the MMS Raman spectrometer.

Chapter 2: Operating the Spectrometer Contains instructions for using the MMS Raman

spectrometer.

Appendix A: Specifications Provides product specifications for the MMS

Raman spectrometer.

Appendix B: Introduction to Multimodal

Multiplex Sampling

Appendix C: Remote Interlock Contains information on the Remote Interlock

Contains a whitepaper with technical information

describing the operation of the MMS Raman

spectrometer.

feature.

000-40000-000-02-0906 iii

Page 6

About This Manual

Product-Related Documentation

You can access documentation for Ocean Optics products by visiting our website at

http://www.oceanoptics.com. Select Technical → Operating Instructions, then choose the appropriate

document from the available drop-down lists. Or, use the Search by Model Number field at the bottom

of the web page.

• Detailed instructions for SpectraSuite Spectrometer Operating Software are located at:

http://www.oceanoptics.com/technical/spectrasuite.pdf

You can also access operating instructions for Ocean Optics products on the Software and Technical

Resources CD included with the system.

Engineering-level documentation is located on our website at Technical → Engineering Docs.

.

Upgrades

Occasionally, you may find that you need Ocean Optics to make a change or an upgrade to your system.

To facilitate these changes, you must first contact Customer Support and obtain a Return Merchandise

Authorization (RMA) number. Please contact Ocean Optics for specific instructions when returning a

product.

Laser Safety

Although the MMS Raman Spectrometer is laser-safe, we advise that laser safety eyewear must be worn

while operating the system. The MMS Raman uses a Class 3b laser that can cause serious eye injury. The

unit contains a remote interlock feature that deactivates the laser when a plug is inserted (see Remote

Interlock

Optics

for more information). Safety goggles are available for use with the system. Contact an Ocean

Applications Scientist for details.

iv 000-40000-000-02-0906

Page 7

Chapter 1

Installation

Introduction

The Centice Multimodal Multiplex Sampling (MMS) Raman spectrometer provides significantly higher

measurement sensitivity than a conventional grating based slit entrance spectrometer due to its unique

multimodal multiplex sampling (MMS) technology. An MMS-based spectrometer samples nearly 1,000

optical channels simultaneously through a large area coded aperture – instead of a slit – then applies

proprietary algorithms to precisely construct the spectral content of a source. With MMS technology, both

high resolution and high light throughput can be achieved simultaneously in a single shot measurement.

SpectraSuite software is available with this spectrometer to aid you with your spectral analysis.

The Centice Raman spectrometer is designed to be easy to use and operate with minimal set-up. Follow

the detailed step by step instructions described in this chapter to install the spectrometer.

Applications

MMS-based instruments are ideal for measuring weak, scattering and diffuse sources and samples

because the spectrometer can collect and process far more light through its wide area aperture, without

affecting spectral resolution.

Key applications include material inspection, identification of unknown materials, and quantitative

analysis of both intermediates and final products in the chemical and pharmaceutical industries. Any

material that is Raman-active and fits within the sample chamber of the instrument can be measured.

Typical samples include powders, liquids and polymers. The system is also ideal for teaching and

research applications in colleges and universities.

The MMS system uses a wide-area aperture that cannot be illuminated effectively with a fiber input. The

aperture should be slightly overfilled to obtain the best spectrum. The wide-area aperture and grating

cannot be changed. The MMS aperture and grating are designed specifically for the detector. For fiberbased Raman analysis, consider our

000-40000-000-02-0906 5

QE65000 Spectrometer or the Raman Systems R-3000.

Page 8

1: Installation

About SpectraSuite

SpectraSuite is a completely modular, Java-based spectroscopy software platform that operates on

Windows, Macintosh and Linux operating systems. The software can control any Ocean Optics USB

spectrometer and device, as well as any other manufacturer’s USB instrumentation using the appropriate

drivers. SpectraSuite is a user-customizable, advanced acquisition and display program that provides a

real-time interface to a variety of signal-processing functions. With SpectraSuite, you have the ability to

perform spectroscopic measurements (such as absorbance, reflectance, and emission), control all system

parameters, collect and display data in real time, and perform reference monitoring and time acquisition

experiments.

Features

• Novel Multimodal Multiplex Spectroscopy (MMS)

-1

• Spectral resolution of ~4 cm

• Spectral range of 220-2000 cm

• Integration times ranging from 50 ms-100 seconds

• Sample holder for cuvettes and test tubes

• Rapid analysis, with no sample preparation

-1

Parts Included

• Digital Raman Spectrometer with integrated sample holder (holds up to 10-mm cuvettes and test

tubes)

• Power supply for the Spectrometer CCD Camera

• Key for turning the laser on/off

• Removable Remote Interlock plug to automatically disable the laser (see Remote Interlock

more information)

• USB cable to interface to the PC

• Ocean Optics Software and Technical Resources CD with this user manual

Caution

You must first install the software before you power up the spectrometer.

Other Equipment Needed

In addition to the parts you received with your spectrometer, you will need the following equipment to

run your experiments:

• Ocean Optics’ SpectraSuite Spectrometer Operating Software

• A computer to run the software. See the SpectraSuite Spectrometer Operating Software

Installation and Operation Manual for SpectraSuite system requirements.

• Safety goggles (such as the R-2001-GL goggles from Ocean Optics)

for

6 000-40000-000-02-0906

Page 9

1: Installation

Installation Procedure

Before you power up your Raman spectrometer, you must install the software. See the SpectraSuite

Spectrometer Operating Software Installation and Operation Manual for software installation

instructions. See Product-Related Documentation

for more information on accessing this document.

Procedure

►

1. Install SpectraSuite on the destination computer. See the SpectraSuite Spectrometer Operating

Software Installation and Operation Manual for information on SpectraSuite.

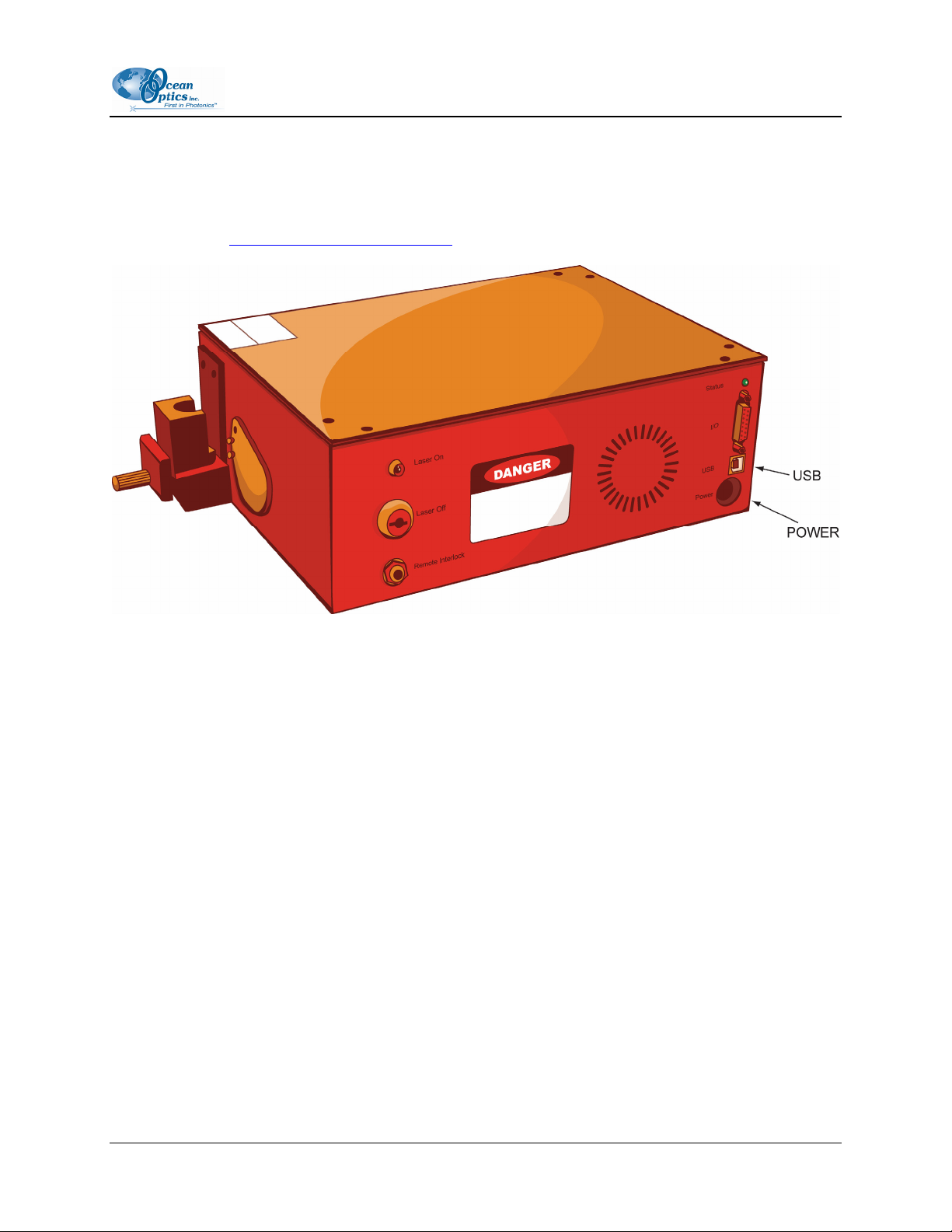

2. Connect the camera power supply to the power interface of the device, and plug the power supply

into an AC outlet. All functions of the spectrometer are operational when it is powered on except

for the laser.

3. Locate the USB cable provided with the spectrometer. Connect one end of the USB cable to the

USB interface of the spectrometer camera and the other end into the computer. Your computer

system should detect the new hardware. Follow the instructions for your computer system for it to

recognize the new hardware device.

000-40000-000-02-0906 7

Page 10

1: Installation

8 000-40000-000-02-0906

Page 11

CHAPTER 2

Operating the Spectrometer

This chapter describes the procedure to operate your MMS Raman spectrometer. Follow these

instructions carefully for optimum results.

A schematic layout of the MMS Raman spectrometer is shown below:

Sample Placement

The MMS Raman spectrometer contains an attached sample holder. Remove the sample holder cover and

place the cuvette with your sample into the sample holder. You can adjust its distance from the lens using

the z-axis knob. In general, liquid samples should be placed as close to the lens as possible; solid samples

should be placed as far from the lens as possible.

000-40000-000-02-0906 9

Page 12

3: Operating the Spectrometer

Acquiring Spectra

► Procedure

1. Remove the sample holder cover.

2. Place the sample cuvette in the sample holder and adjust its distance from the lens using the Zaxis knob. Then, replace the cover.

3. Turn the laser safety key to the On position (vertical) to activate the laser. The laser is not active

at this point. A signal is sent to the spectrometer’s processor requesting activation of the laser.

The LED on the spectrometer lights. Two seconds after the processor receives the laser activation

request, the processor sends the activation signal to the laser controller. The laser is now

operating.

Note

If you attempt to take a scan with the laser off, a warning appears in SpectraSuite:

4. If you have not already done so, start the SpectraSuite software application.

SpectraSuite should now recognize the spectrometer (a picture of the spectrometer appears in the

Data Sources pane of the SpectraSuite window).

10 000-40000-000-02-0906

Page 13

3: Operating the Spectrometer

5. Click on the line under the MMS Raman Spectrometer’s Acquisition node (expand the node if

necessary) in the Data Sources pane, then click on the spectrum graph to activate the acquisition

controls at the top of the screen.

6. Click

(single shot) to start a scan after installing the MMS Raman Spectrometer. Unlike

other Ocean Optics spectrometers, you must first click an acquisition control to start a scan after

installing the MMS Raman Spectrometer. This precaution is taken since the MMS Raman

Spectrometer uses an internal laser.

7. The spectrum graph appears in wavelength units. Select either Processing | Processing Mode |

Raman Shifts or Processing | x-axis Units | Raman Shifts. The next acquisition appears in

Raman Shifts. Click

(single shot) or (continuous) acquisition control on the

SpectraSuite screen to take your Raman spectrum.

000-40000-000-02-0906 11

Page 14

3: Operating the Spectrometer

Note

SpectraSuite automatically takes a dark reading for you.

8. You can display the CCD image, if desired. Either right-click on the spectrometer in the Data

Sources pane and select Spectrometer Features or select Spectrometer | Spectrometer

Features from the menu. Use Auto Equalize to adjust the contrast and brightness.

12 000-40000-000-02-0906

Page 15

3: Operating the Spectrometer

9. Save the spectrum or export it to an ASCII text file.

000-40000-000-02-0906 13

Page 16

3: Operating the Spectrometer

14 000-40000-000-02-0906

Page 17

Appendix A

Specifications

Specification Value

Spectral Range 220-2200 cm-1

Spectral Resolution ~4 cm-1

Grating (*) 1200 lines/mm Transmissive Volume phase grating

CCD specifications:

Chip Hamamatsu CCD

Pixel Array 512 x 122 Active pixels

Pixel Size 24 x 24 microns

Well Capacity 300,000 electrons

Quantum Efficiency 85% at 250 nm

Dark Noise 200 e-/pixel/sec @ 0o C

A/D resolution 16 bits

Exposure Time 50ms to 100 s

Detector readout noise 8 e- RMS

Gain 4.7 e-/ADC count

Cooling to 20o C below ambient temperature

Laser Source Requirements:

Lasing Wavelength: 785 nm

Power Output: > 70 mW

Spectral Line-width: < 0.2 nm

000-40000-000-02-0906 15

Page 18

A: Specifications

Specification Value

General Specs:

Operating temperature range -10o to 35o C

Operating Voltage 120 VAC, 50-60Hz

Power Consumption (Maximum) 25 W

Computer Interface USB 2

16

000-40000-000-02-0906

Page 19

Appendix B

Introduction to Multimodal

Multiplex Sampling

Introduction

This appendix describes a new generation of spectrometer technology that employs multimodal multiplex

sampling (MMS). The performance of a spectrometer based on MMS is then compared to conventional

slit and fiber input spectrometers.

Dispersive spectrometers come in two basic designs: scanned-grating monochromators and static grating

designs with detector arrays. With the availability of inexpensive linear detectors and charge coupled

devices (CCDs) in the UV/Visible/NIR region, dispersive spectrometers are moving away from scannedgrating designs to static implementations. Static implementations are preferred for their single shot

measurements, fast data acquisition times and

high mechanical reliability. A typical static

grating design is shown in Figure 1.

Figure 1: A traditional static grating spectrometer

Most dispersive designs use a fiber based input

while some implement a vertical slit which is

binned on the detector to increase sensitivity. In

such traditional designs, there is an inherent

tradeoff between resolution and light throughput.

While spectral resolution increases as slit width

decreases, a narrow input slit greatly limits

photon throughput and likewise, measurement

sensitivity.

Centice is introducing a new patent pending

spectrometer design based on an optical sensing

technology originally developed at

Duke University called Multimodal Multiplex

Sampling (MMS).

000-40000-000-02-0906 17

Page 20

B: Introduction to Multimodal Sampling

An MMS-based spectrometer samples nearly 1,000 optical channels simultaneously through a coded

aperture – instead of a slit – then applies proprietary algorithms to precisely construct the spectral content

of a source. With MMS technology, both resolution and throughput (aka etendue) can be maintained and

optimized in a single-shot measurement. Interestingly, while the exact performance advantages of MMS

vary with the particular circumstances, in no case can a fiber or slit input spectrometer outperform an

identically configured MMS system.

The most dramatic MMS performance advantage is realized when making difficult measurements such as

measuring weak, scattering and/or diffuse sources commonly occurring in life science applications as well

as field or portable use. Diffuse and scattering samples are particularly challenging for conventional

sensors to measure because light collection is extremely low and thus, spectral features of interest are

flattened or are not detected at all. MMS systems inherently alleviate this problem. Furthermore, MMS

technology can be used for UV-Visible, NIR, Fluorescence and Raman spectroscopy. In this whitepaper,

we will provide an overview of MMS and compare its performance to slit/fiber based spectrometers.

Theory of Operation

The layout of a typical MMS spectrometer is shown in Figure 2. This particular design uses a dispersive

grating geometry with a coded aperture in place of a traditional slit/fiber. Light enters the system through

the coded aperture and is collimated onto the grating by a collimating lens. The grating spectrally

disperses the light which is then mapped

to a 2-D detector array such as a CCD.

The dispersive element could be a

transmissive volume phase hologram or a

reflective holographic grating depending

on the spectral range and other system

design parameters. It is important to note

that the MMS technology platform can b

implemented using a wide variety of

optical designs and be applied to any

spectral range.

e

Figure 2: Schematic of a MMS spectrometer

18 000-40000-000-02-0906

Page 21

B: Introduction to Multimodal Sampling

Coded Aperture

The coded aperture is fabricated in such a manner that it has

transmissive and blocking apertures. MMS allows for the

flexible use of these aperture codes and custom codes can be

implemented to optimize the performance for any specific

application. To estimate a spectrum, place the source at the

input to illuminate the whole aperture. For ease and

convenience, a fiber bundle can also be attached to the aperture

if the sample is physically remote from the spectrometer. By

the use of collimating and focusing lenses, the input aperture is

spectrally imaged onto the CCD. The CCD measures

multiplexed patterns of the aperture depending on the spectral

content of the source. The CCD measurements are then inverted

by the use of appropriate algorithms and the source spectrum is

reconstructed. It is important to know the particular aperture code that is implemented in the system for

the inversion algorithms. Figure 3 illustrates the spectrum from an Argon lamp obtained with a MMS

spectrometer. Some key differentiators for this technique include the following:

Multiplex (SNR) Advantage

Figure 3: Spectrum of Argon lamp

obtained with an MMS

spectrometer

A slit/fiber spectrometer measures each spectral channel separately onto a pixel in the detector. However

in MMS, each pixel in the detector measures several spectral channels of the source in tandem. This is the

multiplex advantage of MMS; resulting in a substantial improvement in signal-to-noise ratio (SNR) (see

Signal to Noise Ratio

).

Multimodal (Etendue) Advantage

MMS spectrometers offer an etendue advantage (see Etendue). Every spectral source radiates into

numerous spatial modes. For fiber or slit based systems, only a few modes can be coupled into the

system. Since the aperture area of the MMS input is comparatively large, many modes of the source can

be simultaneously coupled into the optical system.

Imaging Aspect of MMS

Inherently, MMS is an imaging spectrometer design. So this technique can be easily adapted to

simultaneously measuring many spectral inputs using a single detector array.

000-40000-000-02-0906 19

Page 22

B: Introduction to Multimodal Sampling

MMS and Conventional Multiplex Spectroscopy

Multiplex design has been applied to spectroscopy for over 50 years, including both Fourier and

Hadamard transform designs. In general, these designs have been applied to infrared spectroscopy and

have emphasized minimizing the number of electronic detectors used. For example, dynamic mask

Hadamard transform spectrometers employ spatial light modulators (SLM) such as MEMS based devices

or electro-optic elements to temporally multiplex spectral channels. SLM is a device that controls the

transmission or reflection of light electronically and is placed between the grating and the detector. The

SLM spectrally encodes the dispersed light from the grating and combines them in coded fashion (like a

Hadamard transform) onto the detector, one row at a time. Since the coding is done between the grating

and the detector, there is no real etendue advantage in such spectrometers. Furthermore, data acquisition

is performed serially.

In contrast, MMS is a true 2-dimensional parallel acquisition and processing system that captures both

spatial and spectral information simultaneously throughout the entire aperture. This leads to a number of

performance advantages (not the least of which is higher etendue and SNR) as well as unique features

such as multi-input and hyperspectral imaging. These important differences enable MMS designs to

outperform conventional multiplex as well as fiber and slit entrance spectrometer designs. In addition to

its performance advantages, MMS can be implemented using commonly available low cost components.

Performance Comparison

In this section, the performance of MMS spectrometer is compared with that of a conventional slit and

fiber input spectrometers. System components for each system (f number, grating, lenses, filters, detector

etc.) are identical. For these experiments, a Raman spectrometer with an excitation wavelength of 663 nm

is used as the test-bed.

This system implements an f/2 optical design and a Kodak CCD detector, cooled to -18oC. The system

was set up to accommodate each of three entrance designs: 1) pin hole, 2) vertically binned slit, and 3)

coded aperture. To provide a fair performance comparison of the three sampling methods, the width of the

pin hole, slit width and feature size of coded aperture are equivalent. Thus the optical resolution of each

configuration is equal. Additionally, the height of the slit and aperture are equal.

Etendue

Etendue is a well accepted measure for optical throughput as it specifies the geometric capability of an

optical system to transmit radiation. The numeric value of the etendue is a constant of the system and is

calculated as the product of the entrance aperture (or slit area) and the solid angle through which light is

accepted.

Assume that the input aperture implements an order N matrix. Such an aperture typically has 2N x N

aperture elements, with each element proportional to the pixel size. The etendue of such a spectrometer is

given by:

Etendue (MMS) = 0.5 x 2N x N x Ω

where Ω is the input solid angle and the factor of 0.5 takes into account the fact that only 50% of the

aperture elements are transparent.

20 000-40000-000-02-0906

Page 23

B: Introduction to Multimodal Sampling

The etendue for a slit based spectrometer achieving the same resolution is:

Etendue (Slit) = 2N x 1 x Ω

and for a fiber input-based spectrometer, the etendue is:

Etendue (Fiber) = 1 x 1 x Ω

Therefore,

E

MMS

NE=

/2

Slit

and

E

MMS

Fiber

2

NE=

Typical MMS implementations use proprietary coding schemes that range in order from N=16-48. That

translates to an etendue advantage of 8-24X compared to slit based spectrometers or 256-2304X

compared to fiber based spectrometers. This is illustrated in Figures 4 and 5.

Figure 4: Etendue advantage of

MMS compared to a binned slit.

Figure 5: Etendue advantage of

MMS compared to a pin hole.

000-40000-000-02-0906 21

Page 24

B: Introduction to Multimodal Sampling

Signal to Noise Ratio

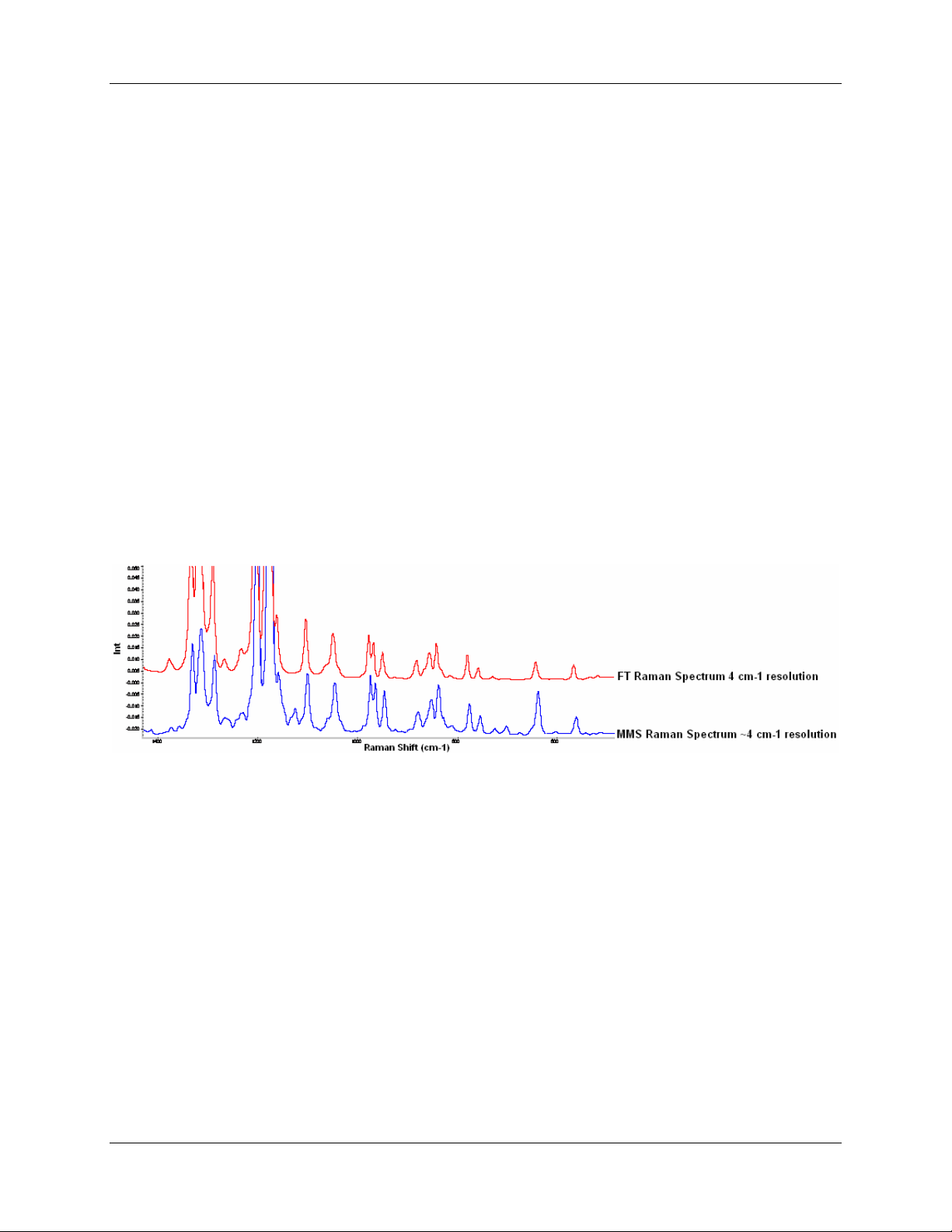

A better understanding of the performance advantage of MMS spectroscopy can be obtained by

comparing spectra from real samples. Raman spectra of Toluene are measured with three different

configurations and an integration time of 2 seconds: fiber-input (Figure 6), vertically binned slit (Figure

7), and MMS (Figure 8), where all other system parameters are equivalent. These data show a noticeable

signal to noise ratio advantage of MMS. The specific advantage depends on the source noise

characteristics, detector noise characteristics and the spectral content of the source, and therefore cannot

be generalized for all cases. However, MMS spectrometers always offer superior signal to noise

performance versus these conventional designs.

Figure 6: Raman spectrum of

toluene with a pinhole aperture

.

Figure 7: Raman spectrum of toluene

measured with a slit.

Figure 8: Raman spectra of toluene

measured with MMS.

Additional Raman spectra obtained with the MMS spectrometer are shown in Figures 9 and 10.

Figure 9: Raman spectrum of Tylenol with MMS

spectrometer (20s integration)

Figure 10: Raman spectrum of toluene with MMS

spectrometer (20s integration)

22 000-40000-000-02-0906

Page 25

B: Introduction to Multimodal Sampling

Measuring in Scattering Media

igh etendue MMS systems perform extremely well when measuring scattering samples such as blood or

H

ssue. For comparative purposes, we measure the Raman spectrum of ethanol in lipid. Lipid is a blood

ti

ulating medium which offers scattering properties similar to that of blood. The Raman spectra are

em

own in Figures 11, 12 and 13. A higher percentage of Raman scattered photons – the signal of interest –

sh

entering the wide area aperture of the MMS system as evidenced by the stronger primary ethanol peak

is

these figures. The spectra have been zoomed in to 800-1100 cm-1 range. Note that this is a 663 nm

in

excitation sy

stem, so some of the Raman ethanol peaks are lost in the background fluorescence.

Figure 11: Raman spectrum of

ethanol in lipid with pinhole

Figure 12: Raman spectrum of

ethanol in lipid with a binned slit.

Figure 13: Raman spectrum of

ethanol in lipid

with MMS

Conclusion

Multimodal multiplex spectroscopy is an example of how digital instruments can be adapted to specific

measurement tasks, in this case efficient signal collection from wide area sources. Of course, sensors are

evaluated in practice by how well they perform specific tasks. For MMS systems, attractive applications

focus on molecular recognition and imaging for life and chemical science applications. While we have

shown in this white paper that MMS systems offer performance advantages over conventional systems,

the use of MMS systems as embedded biological and chemical sensors will perhaps be more significant

than their application as general purpose bench top spectrometers.

000-40000-000-02-0906 23

Page 26

B: Introduction to Multimodal Sampling

24 000-40000-000-02-0906

Page 27

Appendix C

Remote Interlock

The laser activation request signal passes through the Remote Interlock, a 0.25” phone jack on the panel

of the spectrometer. The Remote Interlock feature has been designed to pass this signal with no plug

inserted into the jack. An unwired plug (0.25” phone plug, 3 conductor type: Tip, Ring, and Shield,

provided) inserted into the jack opens this signal path. The spectrometer processor will no longer receive

the activation request and will stop sending the activation signal to the laser controller, shutting off the

laser. This will also cause the Laser On LED to turn off.

Connecting the Tip and Ring conductors of the plug to the normally closed (NC) contacts of an external

user-specified switch maintains the laser activation request signal path when the plug is inserted into the

Remote Interlock jack. Opening the external switch contacts disables the laser.

000-40000-000-02-0906 25

Page 28

B: Introduction to Multimodal Sampling

26 000-40000-000-02-0906

Page 29

Index

theory of operation, 18

A

additional equipment, 6

applications, 5

C

coded aperature, 19

comparison to conventional spectrometer, 20

conventional multiplex spectroscopy, 20

D

document

audience, iii

purpose, iii

summary, iii

E

etendue, 18, 19, 20

P

parts included, 6

product-related documentation, iv

R

remote interlock, iv

S

scattering samples, 23

signal-to-noise ratio, 19, 22

specifications, 15

spectra

acquiring, 10

SpectraSuite, 6

spectrometer

operation, 9

placement, 9

specifications, 15

F

T

features, 6

theeory of operation, 18

I

U

imaging, 19

installation, 5, 7

upgrades, iv

M

MMS, 17

000-40000-000-02-0906 27

Page 30

000-40000-000-02-0906 28

Loading...

Loading...