Page 1

UM10468

SSL2108X buck evaluation board

Rev. 1 — 30 August 2011 User manual

Document information

Info Content

Keywords SSL2108X, Buck, down converter, AC/DC conver te r, retrofit SSL, LED

driver, LED retrofit lamp, non-dimmable

Abstract The SSL2108X is a range of high-voltage Integrated Circuits (ICs),

intended to drive non-dimmable retrofit LED lamps in general lighting

applications. This document describes the evaluation board for mains

operated non-dimmable LED drivers using the SSL21081, SSL21082,

SSL21083 and SSL21084 controller ICs.

Refer to the SSL2108X data sheet for details on the SSL2108X device

and application note AN11041 for general application information.

Page 2

NXP Semiconductors

UM10468

SSL2108X buck evaluation board

Revision history

Rev Date Description

v.1 20110830 first issue

Contact information

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 2 of 27

Page 3

NXP Semiconductors

1. Introduction

WARNING

Lethal voltage and fire ignition hazard

The non-insulated high voltages that are present when operating this product, constitute a

risk of electric shock, personal injury, death and/or ignition of fire.

This product is intended for evaluation purposes only. It shall be operated in a designated test

area by personnel qualified according to local requirements and labor laws to work with

non-insulated mains voltages and high-voltage circuits. This product shall never be operated

unattended.

The SSL2108X is a family of high-voltage Integrated Circuits (IC), designed to drive

non-dimmable retrofit LED lamps in general lighting applications. The product family

consists of four ICs with different configurations which are shown in Table 1

Table 1. SSL2108X type number overview

Type Package V

SSL21081 SO8 100 to 120 300 V; 2 no

SSL21082 SO12

SSL21083 SO8 100 to 230 600 V; 5 no

SSL21084 SO12

[1]

[1]

mains

(V (AC))

range

SSL2108X buck evaluation board

Internal MOSFET

characteristics

UM10468

.

Adjustable brownout

protection

yes

yes

[1] SO12 package variants have more fused leads for lower thermal resistance and can be used when a higher

output power is needed.

Main benefits of the product family are:

• Small Printed-Circuit Board (PCB) footprint providing a compact solution

• High-efficiency (up to 95 %)

• Ease of integration

• Low electronic Bill Of Material (BOM)

The SSL2108X provides accurate output control with more than 5 % LED current

accuracy. The ICs can operate using Pulse-Width Modulation (PWM) dimming and have

many protection features including easy external temperature feedback.

The SSL2108X driver family is the high performance solution for the next generation of

retrofit LED lamps. These ICs provide a high efficiency, high-power factor solution in a

small form factor.

Remark: Unless otherwise stated all voltages are in V (DC).

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 3 of 27

Page 4

NXP Semiconductors

019aab173

019aab174

2. Safety warning

This reference board is connected to a high AC voltage (up to 250 V). Avoid touching the

demo board during operation. An isolated housing is obligatory when used in

uncontrolled, non-laboratory environments. Galvanic iso lation of the ma ins p hase using a

fixed or variable transformer (Variac) is always recommended. These devices are

recognized by the symbols shown in Figure 1

Fig 1. Variac isolation symbols

UM10468

SSL2108X buck evaluation board

a. Isolated b. Not isolated

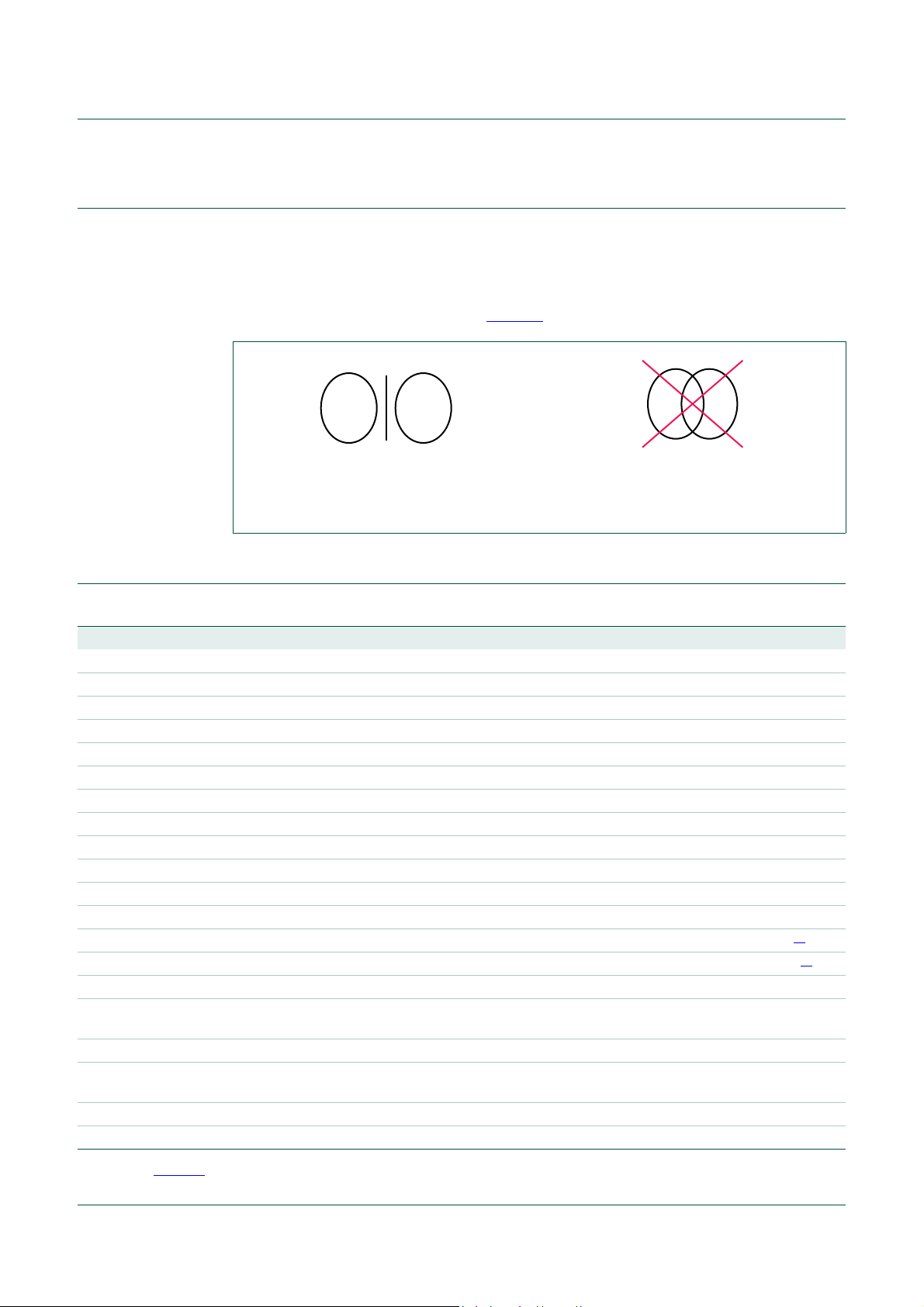

3. Specification

LED

LED

)

)

)

o(LED)

100 kHz -

70 mm 60 mm 23 mm maximum footprint

Table 2. Specifications for the reference board

Parameter Value Comment

AC line input voltage

SSL21081 and SSL21082 85 V (AC) to 138 V (AC) optimized for 100 V (AC)

SSL21083 and SSL21084 230 V (AC) optimized for 100 V (AC)

Output voltage (V

SSL21081 and SSL21082 20 V to 70 V optimized for 60 V

SSL21083 and SSL21084 20 V to 140 V optimized for 120 V

Output current (I

SSL21081 95 mA, 70 mA, 38 mA adjust using jumpers J7A, J8A, J9A

SSL21082 160 mA, 125 mA, 105 mA adjust using jumpers J7A, J8A, J9A

SSL21083 55 mA, 35 mA, 18 mA adjust using jumpers J7A, J8A, J9A

SSL21084 80 mA, 69 mA, 53 mA adjust using jumpers J7A, J8A, J9A

Maximum LED output power (P

SSL21081 and SSL21083 6 W optimized for 6 W using dedicated loads

SSL21082 and SSL21084 15 W optimized for 10 W using dedicated loads

Switching frequency

Nominal switching frequency

sw(nom)

)

(f

Board dimension (L W H)

SSL21081, SSL21082, SSL21083

and SSL21084

Temperature

Operating temperature 40 Cto +100C-

[1]

[1]

[1] Refer to Section 5 for more detailed information.

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 4 of 27

Page 5

NXP Semiconductors

4. Performance data

4.1 Output load

UM10468

SSL2108X buck evaluation board

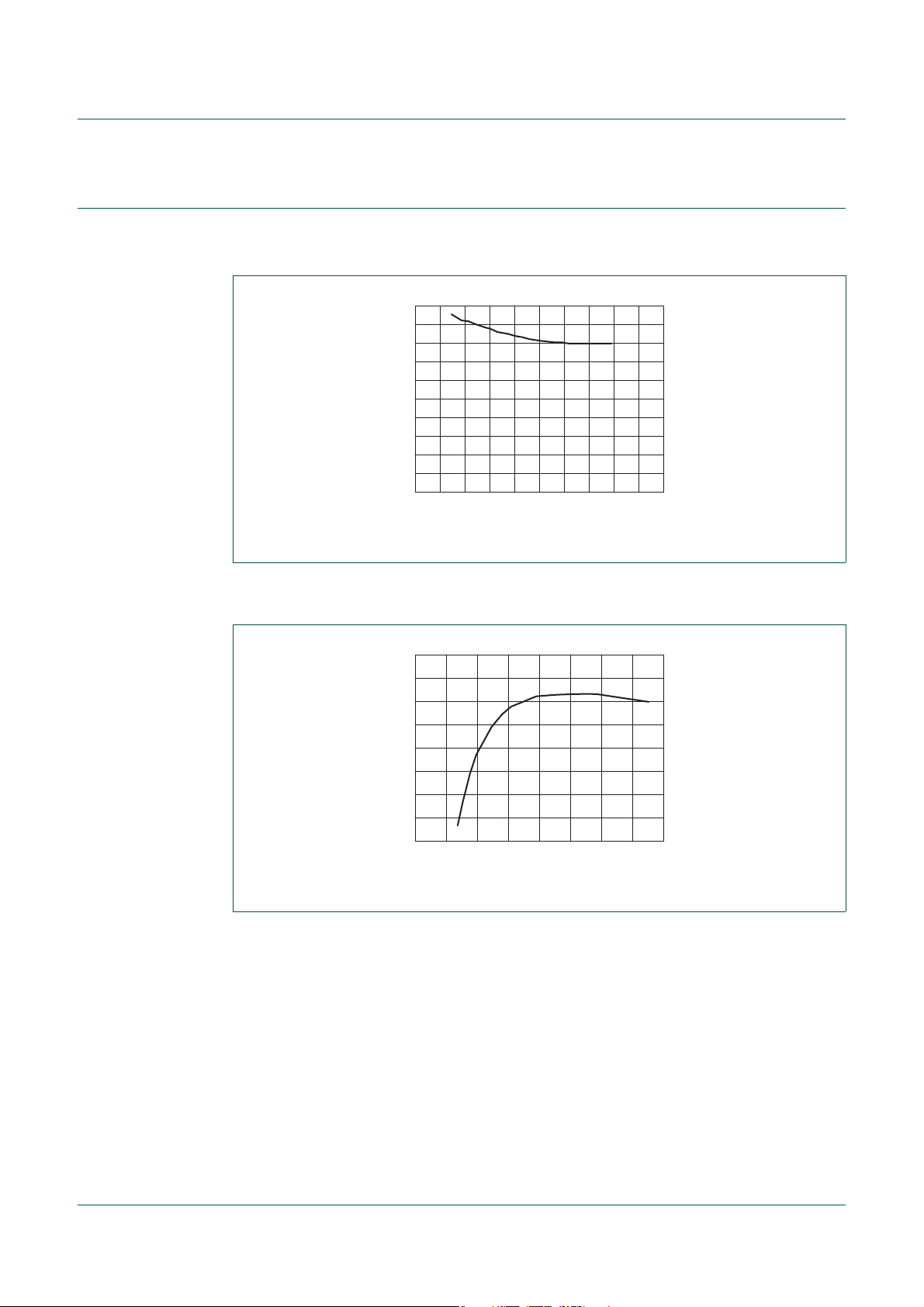

Fig 2. SSL21081 load curve: Io as a function of V

4.2 Efficiency Curve

l

o

(mA)

120

100

80

60

40

20

92

η

(%)

90

88

0 1008040 6020

019aac361

(V)

V

o

o

019aac362

86

84

08624

(W)

P

o

Fig 3. SSL21081: Efficiency () as a function of output power (Po)

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 5 of 27

Page 6

NXP Semiconductors

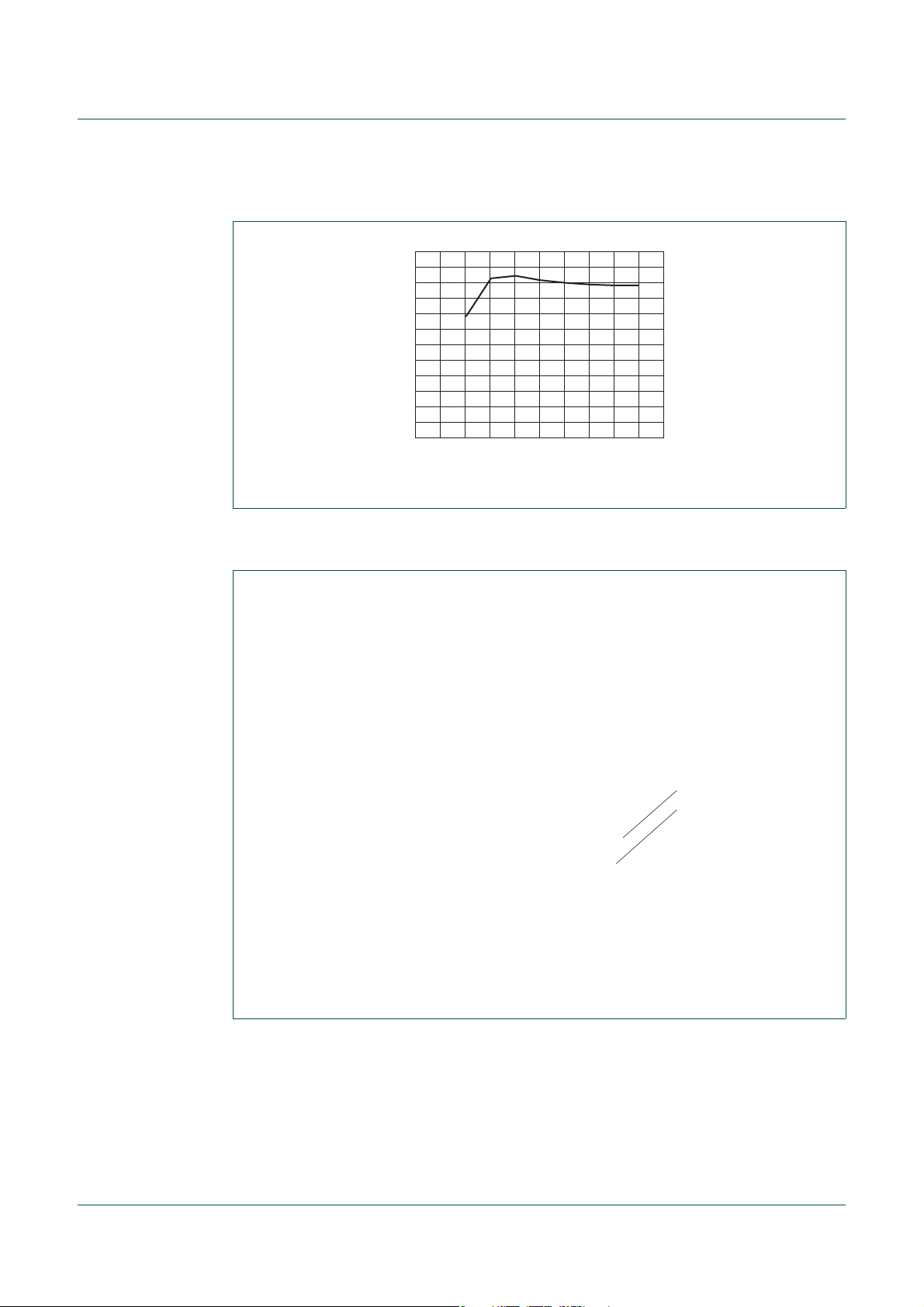

40

80

120

l

o

(mA)

0

V

mains

(V)

40 14012080 10060

019aac363

4.3 Input voltage dependency

UM10468

SSL2108X buck evaluation board

Fig 4. SSL21081 input voltage dependency: Io as a function of V

4.4 ElectroMagnetic Compatibility data

= V

mains

(1)

(2)

019aac364

IN

(1) Peak values.

(2) Average values.

Fig 5. SSL21081 EMC measurement L-phase according to FCC15 norm

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 6 of 27

Page 7

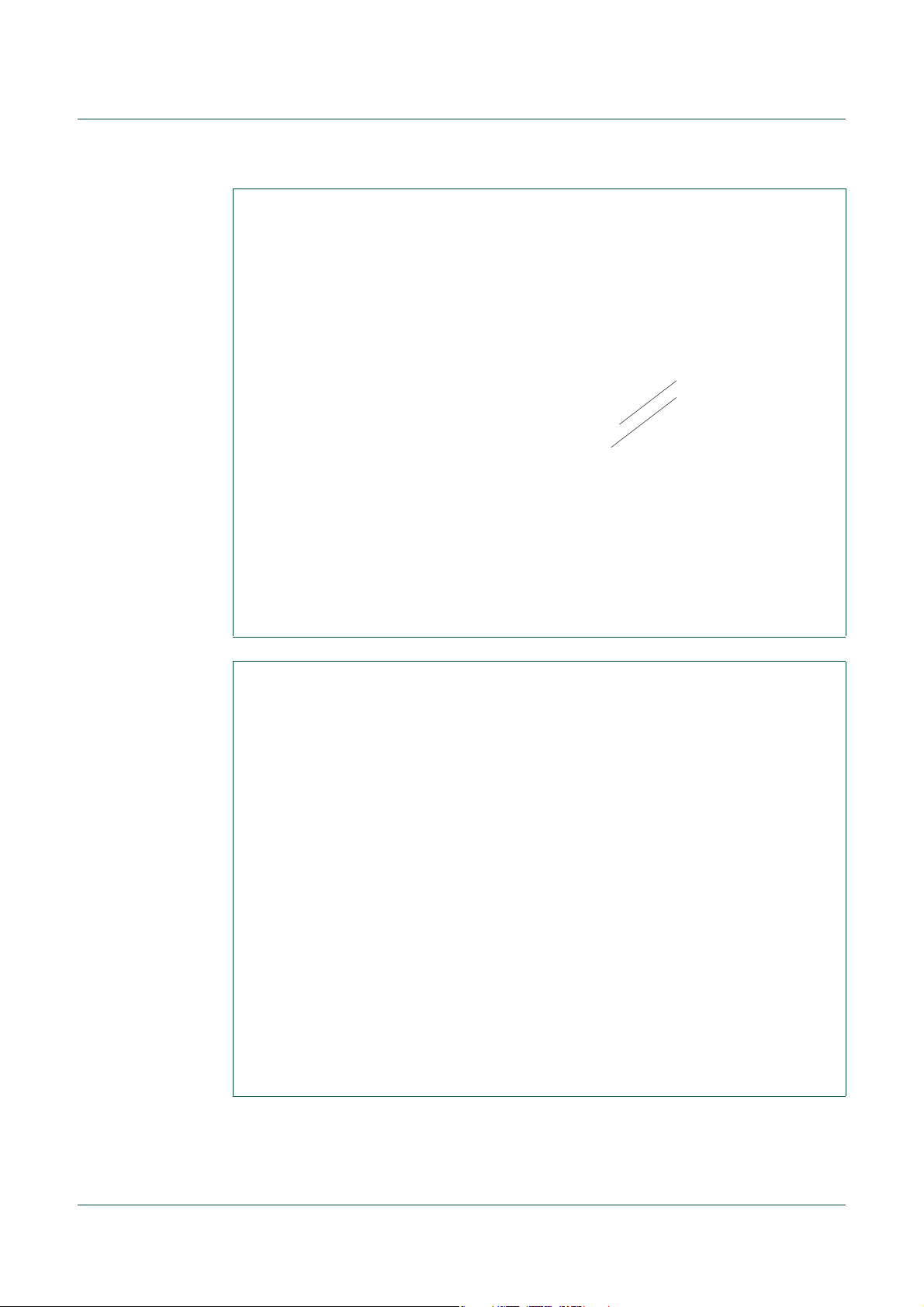

NXP Semiconductors

019aac365

(1)

(2)

UM10468

SSL2108X buck evaluation board

(1) Peak values.

(2) Average values.

Fig 6. SSL21081 EMC measurement N-phase according to FCC15 norm

(1) Peak values.

(2) Average values.

Fig 7. SSL21083 EMC measurement L-phase according to EN55015 norm

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 7 of 27

Page 8

NXP Semiconductors

UM10468

SSL2108X buck evaluation board

(1) Peak values.

(2) Average values.

Fig 8. SSL21083 EMC measurement N-phase according to EN55015 norm

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 8 of 27

Page 9

NXP Semiconductors

019aac366

(1)

(2)

4.5 SSL21081 mains harmonics

Table 3. SSL21081 mains conducted harmonics

Line Percent (%) Class-C Except Line Percent (%) Class-C Except

1 100 100 100 21 5.9 3 undefined

2 0 2 undefined 22 0 2 undefined

3 84.7 30 86 23 4.4 3 undefined

4 0 2 undefined 24 0.4 2 undefined

5 59.8 10 61 25 3.8 3 undefined

6 0 2 undefined 26 0.4 2 undefined

7 34.1 7 undefined 27 3.6 3 undefined

8 0 2 undefined 28 0 2 undefined

9 17.9 5 undefined 29 3.2 3 undefined

10 0 2 undefined 30 0 2 undefined

11 15.4 3 undefined 31 2.2 3 undefined

12 0 2 undefined 32 0.2 2 undefined

13 13.9 3 undefined 33 2.2 3 undefined

14 0 2 undefined 34 0.2 2 undefined

15 9.7 3 undefined 35 2 3 undefined

16 4.5 2 undefined 36 0.4 2 undefined

17 7 3 undefined 37 1.9 3 undefined

18 0.6 2 undefined 38 0 2 undefined

19 6.8 3 undefined 39 1.4 3 undefined

20 0.3 2 undefined 40 0 2 undefined

UM10468

SSL2108X buck evaluation board

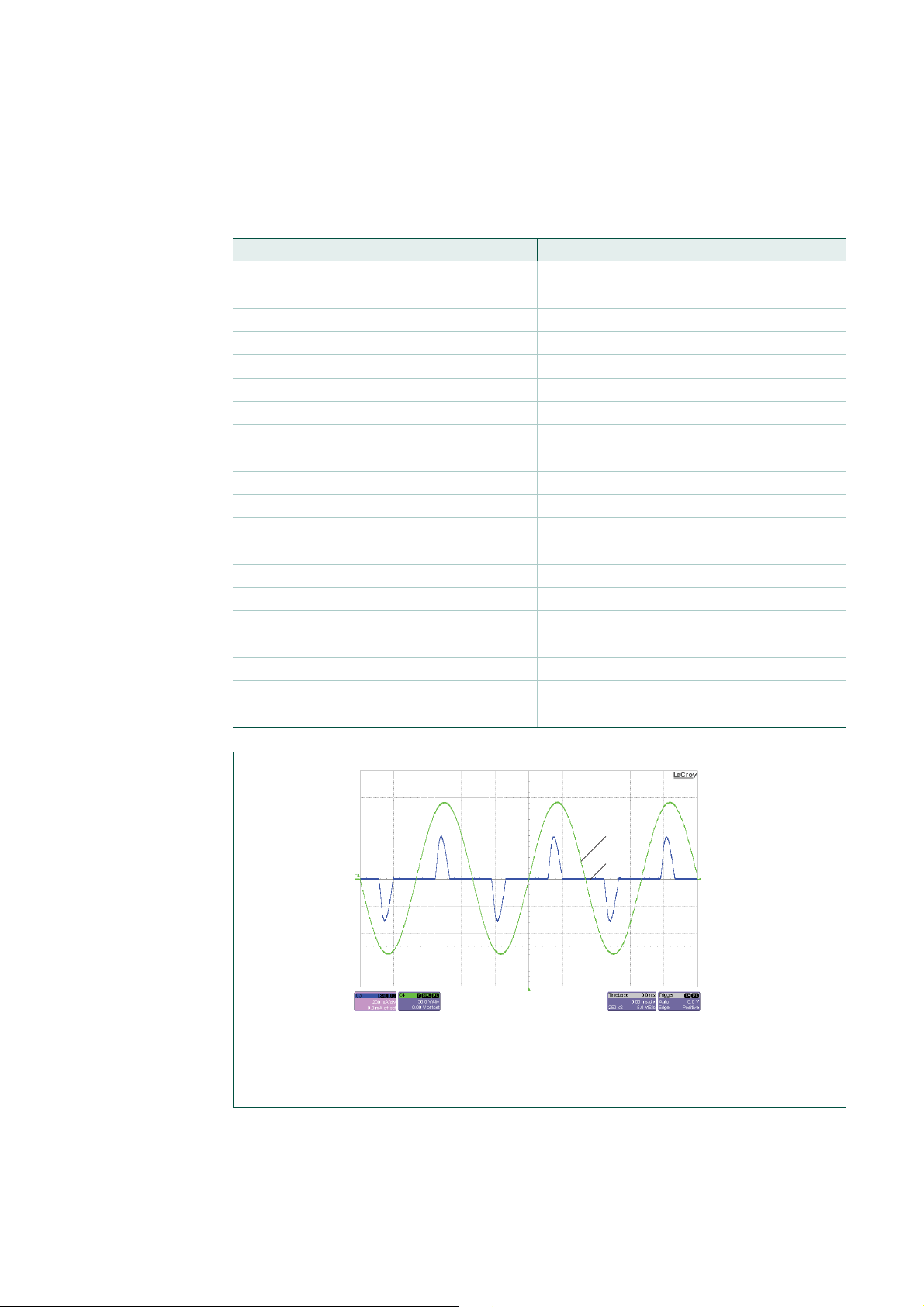

(1) Input voltage VIN.

(2) Input current I

.

I

Fig 9. VIN and II for a 100 V; 60 Hz AC mains supply

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 9 of 27

Page 10

NXP Semiconductors

019aac367

(1)

(2)

UM10468

SSL2108X buck evaluation board

(1) Drain voltage V

(2) Source voltage V

Fig 10. V

DRAIN

and V

.

DRAIN

SOURCE

SOURCE

.

typical waveforms

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 10 of 27

Page 11

NXP Semiconductors

5. Connection data

The evaluation board operates from either:

• SSL21081 and SSL21082: 100 V (AC) to 120 V (AC) mains supply voltage

• SSL21083 and SSL21084: 230 V (AC) mains supply voltage

The evaluation board is designed to work with an LED module with an operating voltage

of:

• SSL21081 and SSL21082: 60 V

• SSL21083 and SSL21084: 120 V

Loads consisting of multiple high-power LEDs in series with similar operating voltages can

also be used. A dedicated SHARP GW5BDQ27KK3 LED load for connecting to conn ector

K2A is available on request. Other loads can be connected to either connector K2A or K3.

When attaching an LED load to a board under power (hot plugging), an inrush peak

current occurs due to discharge of capacitor C3. After several discharges, the LEDs will

deteriorate or become damaged.

UM10468

SSL2108X buck evaluation board

Jumper settings J1A to J6A shown in Table 4

each device to function correctly.

Table 4. SSL2108X jumper settings overview

IC Package Jumper settings

J1A J2A J3A J4A J5A J6A

SSL21081 SO8 no yes no yes no yes

SSL21083

SSL21082 SO12 yes no yes no yes no

SSL21084

set the package-specific circuitry to enable

5.1 The board connections

When connecting the evaluation board consider the following:

• Place a galvanic isolated transformer between the AC source and the evaluation

board connector K1A, if used.

• Connect a user-defined LED module to connector K2A or K3. Ensure that the anode

of the LED module is connected to one of the positive LED terminals.

• Connector K4 can be used:

– to connect an external NTC resistance. Remove the pre-soldered NTC RT1 (see

)

Ref. 1

– to use a PWM dimming signal to the converter (see Ref. 1

)

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 11 of 27

Page 12

NXP Semiconductors

UM10468

SSL2108X buck evaluation board

external NTC/

PWM input

NTC -

NTC +

mains

input

Fig 11. Board connection diagram

6. Functional description

The SSL2108X IC (Ref. 1) uses Boundary Conduction Mode (BCM) with peak current

control. The SSL2108X controls and drives the converter. In addition, the SSL2108X

offers a low component count LED buck converter solution . Valley switching and PWM

dimming are implemented into the SSL2108X together with several protection features:

J10

C3

K3

LED +

J5

J6

D2

K2

C1D1C8

L1

019aac358

LED -

LED +

LED -

LED load

LED load

X55

IC1

L3

D3

C2

J9

J8

J7

RT1

K4

K1

L

N

J3

J2

J1

J4

FUSE 1

L2

• UnderVoltage LockOut (UVLO)

• Leading-Edge Blanking (LEB)

• OverCurrent Protection (OCP)

• Internal OverTemperature Protection (OTP)

• Brownout protection

• Short-Winding Protection (SWP)

• Output Short Protection (OSP)

• NTC over temperature control and protection

Both the SWP and the OSP are latched protections circuits. These protective features

cause the IC to halt until a reset is executed. If V

resets the latched protection mode. Restarting the evaluation board is done by removing

AC mains supply voltage. All other protective features cause a safe restart of the

converter. Refer to the SSL2108X data sheet for detailed information on all protective

features.

Depending on the selected SSL2108X version, the evaluation board is optimized for an

LED voltage, LED current and resulting output power. See Table 2

J7A is set to apply the full output power to the LED load. Setting jumper J8A or J9A

instead reduces the output power to either 66 % or 33 % of the original output power.

Remark: Do not remove or set jumpers when the board is connected to the AC mains

supply voltage because LED damage can occur.

drops below its restart level, the IC

CC

. As a default, jumper

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 12 of 27

Page 13

NXP Semiconductors

Jumper J10A is connected in series with the brownout capacitor C8. Removing this

jumper sets the brownout protection trigger values to be reset to default value.

Remark: Brownout protection is only available in the SSL21082 and SSL21084.

TVS Diode D2 is present to protect the DC circuit against overvoltage.

7. Board optimization

The EMC filter calculations for components C1, C2, L1 are described in AN11041 (see

Ref. 2

). On the evaluation board, L2 and C8 have been added to provide extra filtering to

meet EMC norms.

Power factor of the evaluation board depends mainly on the input resistance of the input

fused resistor FUS1. A higher resistance proportionally increases the power factor but

reduces the overall efficiency of the evaluation board.

Another way to get higher power factor is to add a valley fill circuit. The valley fill circuit

improves power factor with reduced efficiency losses. The disadvantage is the higher

component count needed. Figure 12

resistance as a function of power factor and efficiency.

UM10468

SSL2108X buck evaluation board

gives an overview for the SSL21081 of input

019aac359

R

(Ω)

in

PF

0.8

0.6

0.4

0.2

0.0

η

(%)

(1) Efficiency curve.

(2) Power factor curve.

94

90

86

82

78

0 1208040

(1)

(2)

Fig 12. Input resistance (RIN) as a function of Power Factor (PF) and Efficiency ()

Remark: Calculations for other components on the SSL2108X evaluation board can be

found in AN11041 (see Ref. 2

).

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 13 of 27

Page 14

NXP Semiconductors

019aac538

56 Ω

1 MΩ

MCR22-6

22 nF

7.1 Active bypass

An increased value for the inrush current resistor causes the board to operate with the

most phase cut dimmers, but also lowers the efficiency. If a higher power factor is not

required, but leading-edge dimmer compatibility and high efficiency are important, the

active bypass option is available. In this circuit, the inrush current resistor is bypassed

using an SCR (see Figure 13

Fig 13. Active bypass

UM10468

SSL2108X buck evaluation board

).

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 14 of 27

Page 15

NXP Semiconductors

SSL2108X buck evaluation board

8. Negative Temperature Coefficient (NTC) function

The NTC pin can act as a control for thermal protection, an input for disabling/enabling the

light output using PWM dimming and a soft-start function.

When using the NTC pin as a control for thermal protection, the pre-soldered NTC RT1

can be used. Alternatively, a user-defined NTC resistor can be directly connected to this

pin through connector K4. Remove the pre-soldered NTC RT 1 in this case. If necessar y, a

resistor R6 can be mounted to fine-tune the NTC protection. As the default, a 0

resistance is mounted.

In addition, a PWM signal can be connected to connector K4, making PWM dimming

possible. Capacitor C7 is used as the soft-start capacitor. When using the soft-start

capacitor, the NTC protection function changes from auto-restart protection to a latched

protection.

Remark: Detailed information on the NTC function can be found in the SSL2108X

data sheet (see Ref. 1

).

UM10468

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 15 of 27

Page 16

NXP Semiconductors

9. Schematic

K1 K2

FUS 1

L1

UM10468

SSL2108X buck evaluation board

K3

LED+

LED-

L1

LED+

to mains

RGND

TP2

test point

R5

earth

N

D1

C8

RGND

L2

D2

C1

TP3

test point

D3

C3C2

LED-

to LED’s

L3

R1R2R3R4

J7J8J9

C6

C7

test point

J1

J2

J3

J4

test point

RT1

NTC

R6

TP1

TP2

NTC+

NTC-

n.c.

GND

VCC

NTC

GND

S

K4

IC1

1

2

3

4

5

6

7

(SOURCE)

(VCC)

(NTC)

SSL21081/

SSL21083

SSL21082/

SSL21084

TP4

test point

(GND)

(DVDT)

test point

TP2

14

13

12

11

10

9

8

DRAINHV

n.c.

GND

GND

DVDT

TONMAX

GND

TP7

test point

J5

J6

C4

TP6

test point

J10

TP5

test point

C6

019aac360

Fig 14. Schematic

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 16 of 27

Page 17

NXP Semiconductors

UM10468

SSL2108X buck evaluation board

10. Bill of materials (BOM)

10.1 BOM for SSL21081 evaluation board

Table 5. SSL21081 Bill of materials

Ref. Description and value Manufacturer and part no. Remark

A1 SSL21081 controller IC NXP Semiconductors A1A IC socket Wells-cti; 652B0142211-002 not mounted

C1 filter capacitor; 10 F; 200 V Nichicon; UVZ2D100MPD1TD C2 filter capacitor; 10 F; 200 V Nichicon; UVZ2D100MPD1TD C3 ripple capacitor; 2.2 F; 450 V Panasonic; ECA2WHG2R2 C4 dV/dt capacitor; 2 kV; 150 pF Multicomp; MCCA000740 C5 VCC supply; capacitor; 10 F; 25 V Murata; GRM21BR61E106KA73L C6 t

C7 soft-start/ripple filter; 22 F; 10 V Kemet; C1206C226M8PACTU C8 filter capacitor - not mounted

D1 bridge rectifier; 1 A; 600 V Multicomp; DBLS105G D2 TVS; 200 V; 1.5 KW ST Microelectronics; 1.5KE 200A D3 ES1J; 1 A; 600 V Multicomp; ES1J Fus 1 fused resistor; 2 W; 10 R Welwyn; EMC2-10RK J1 to J9 headers Fischer Elektronik; MK 05/50G J10 header Fischer Elektronik; MK 05/50G not mounted

J1A jumper Lumberg; 2,54MKB not mounted

J2A jumper Lumberg; 2,54MKB J3A jumper Lumberg; 2,54MKB not mounted

J4A jumper Lumberg; 2,54MKB J5A jumper Lumberg; 2,54MKB not mounted

J6A jumper Lumberg; 2,54MKB J7A jumper Lumberg; 2,54MKB J8A jumper Lumberg; 2,54MKB not mounted

J9A jumper Lumberg; 2,54MKB not mounted

J10A jumper Lumberg; 2,54MKB not mounted

K1 header Weidmuller; SL 5.08/3/90 K1A socket Weidmuller; BL 5.08/3 K2 header Weidmuller; SL 5.08/2/90 K2A socket Weidmuller; BL 5.08/2 K3 header Fischer Elektronik; BL3.36Z K4 header Fischer Elektronik; BL3.36Z L1 filter inductor; 1 mH; 170 mA Murata power solutions; 22R105C L2 filter inductor; Short - L3 buck inductor; 1 mH; 0.5 A Wurth elektronik; 768772102 R1 R

R2 R

on(max)

sense

sense

capacitor - not mounted

; 6.8 ; 0.33 W; 1 % Panasonic; ERJ8BQF6R8V ; 3.3 ; 0.33 W; 1 % Panasonic; ERJ8BQF3R3V -

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 17 of 27

Page 18

NXP Semiconductors

UM10468

SSL2108X buck evaluation board

Table 5. SSL21081 Bill of materials

…continued

Ref. Description and value Manufacturer and part no. Remark

R3 R

R4 R

; 5.1 0.25 W; 1 % Vishay dale; CRCW12065R10FKEA -

sense

; 16 ; 0.25 W; 1 % VIshay dale; CRCW120616R0FKEA -

sense

R5 inrush resistor; 0 Multicomp; MC 0.1W 0805 0R R6 resistor; 0 Multicomp; MC 0.1W 0805 0R RT1 NTC; 100 k EPCOS; B57164K104J TP1 to TP8 test pins Vero; 20-313138 X56 jumper link Fischer Elektronik; 2412 015 30123 X57 jumper link; Fischer Elektronik; 2412 015 30123 -

10.2 BOM for SSL21082 evaluation board

Table 6. SSL21082 Bill of materials

Ref. Description and value Manufacturer and part no. Remark

A1 SSL21082 Controller IC NXP Semiconductors; SSL21082T A1A IC Socket; n.m. Wells-cti; 652B0142211-002 not mounted

C1 filter capacitor; 10 F; 200 V Nichicon; UVZ2D100MPD1TD C2 filter capacitor; 10 F; 200 V Nichicon; UVZ2D100MPD1TD C3 ripple capacitor; 2.2 F; 450 V Panasonic; ECA2WHG2R2 C4 dV/dt capacitor; 150 pF; 2000 V Multicomp; MCCA000740 C5 VCC supply capacitor; 10 µF; 25 V MURATA; GRM21BR61E106KA73L C6 t

on(max)

C7 soft-start/ripple filter; 22 F; 10 V KEMET; C1206C226M8PACTU C8 filter capacitor; n.m. - not mounted

D1 bridge rectifier; 1 A; 600 V Multicomp; DBLS105G D2 TVS; 200 V; 1.5 kW ST Microelectronics; 1.5KE200A D3 ES1J; 1 A; 600 V Multicomp; ES1J Fus 1 fused resistor; 2 W; 10 Welwyn; EMC2-10RK J1 to J9 headers Fischer Elektronik; MK 05/50G J10 header Fischer Elektronik; MK 05/50G J1A jumper Lumberg; 2,54MKB J2A jumper; n.m. Lumberg; 2,54MKB not mounted

J3A jumper Lumberg; 2,54MKB J4A jumper; n.m. Lumberg; 2,54MKB not mounted

J5A jumper Lumberg; 2,54MKB J6' jumper; n.m. Lumberg; 2,54MKB not mounted

J7A jumper Lumberg; 2,54MKB J8A jumper; n.m. Lumberg; 2,54MKB not mounted

J9A jumper; n.m. Lumberg; 2,54MKB not mounted

J10A jumper Lumberg; 2,54MKB K1 header Weidmuller; SL 5.08/3/90 K1A socket Weidmuller; BL 5.08/3 K2 header Weidmuller; SL 5.08/2/90 -

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 18 of 27

capacitor; 100 pF; 100 V AVX; 08051A101JAT2A -

Page 19

NXP Semiconductors

UM10468

SSL2108X buck evaluation board

Table 6. SSL21082 Bill of materials

…continued

Ref. Description and value Manufacturer and part no. Remark

K2A socket Weidmuller; BL 5.08/2 K3 header Fischer Elektronik; BL3.36Z K4 header Fischer Elektronik; BL3.36Z L1 filter inductor; 1 mH; 170 mA Murata power solutions; 22R105C L2 filter inductor; short - L3 buck inductor; 680 H; 0.35 A Panasonic; ELC09D681F R1 R

R2 R

R3 R

R4 R

; 0.33 W; 1 %; 6.8 Panasonic; ERJ8BQF6R8V -

sense

; 0.3 3 W; 1 %; 1.6 Panasonic; ERJ8BQF1R6V -

sense

; 0.25 W; 1 %; 2.2 Panasonic; ERJ8BQF2R2V -

sense

; 0.25 W; 1 %; 2.7 Panasonic; ERJ8BQF2R7V -

sense

R5 inrush resistor; 0 Multicomp; MC 0.1 W 0805 0 R R6 resistor; 0 Multicomp; MC 0.1 W 0805 0 R RT1 NTC; 100 k EPCOS; B57164K104J TP1 to TP8 test pins Vero; 20-313138 X56 jumper link Fischer Elektronik; 2412 015 30123 X57 jumper link Fischer Elektronik; 2412 015 30123 -

10.3 BOM for SSL21083 evaluation board

Table 7. SSL21083 Bill of materials

Ref. Description and value Manufacturer and part no. Remark

A1 SSL21083 Controller IC NXP Semiconductors; SSL21083 A1A IC Socket; n.m. Wells-cti; 652B0142211-002 not mounted

C1 filter capacitor; 4.7 F; 400 V Panasonic; ECA2GHG4R7 C2 filter capacitor; 4.7 F; 400 V Panasonic; ECA2GHG4R7 C3 ripple capacitor; 3.3 F; 400 V Panasonic; ECA2GHG3R3 C4 dV/dt capacitor; 100 pF; 1000 V Johanson Dielectrics;

C5 VCC supply capacitor; 10 F; 25 V Murata; GRM21BR61E106KA73L C6 t

on(max)

C7 soft-start/ripple filter; 22 F 10 V KEMET; C1206C226M8PACTU C8 filter capacitor; n.m. - not mounted

D1 bridge rectifier; 1 A; 600 V Multicomp; DBLS105G D2 TVS; 400 V; 1.5 kW ST Microelectronics; 1.5KE400A D3 ES1J; 1 A; 600 V Multicomp; ES1J Fus 1 fused resistor; 2 W; 22 Welwyn; EMC2-22RKI J1-J9 headers Fischer elektronik; MK 05/50G J10 header; n.m. Fischer Elektronik; MK 05/50G not mounted

J1A jumper; n.m. Lumberg; 2,54MKB not mounted

J2A jumper Lumberg; 2,54MKB J3A jumper; n.m. Lumberg; 2,54MKB not mounted

J4A jumper Lumberg; 2,54MKB -

-

102R18W101KV4E

capacitor; n.m. - -

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 19 of 27

Page 20

NXP Semiconductors

UM10468

SSL2108X buck evaluation board

Table 7. SSL21083 Bill of materials

…continued

Ref. Description and value Manufacturer and part no. Remark

J5A jumper; n.m. Lumberg; 2,54MKB not mounted

J6A jumper Lumberg; 2,54MKB J7A jumper Lumberg; 2,54MKB J8A jumper; n.m. Lumberg; 2,54MKB not mounted

J9A jumper; n.m. Lumberg; 2,54MKB not mounted

J10A jumper; n.m. Lumberg; 2,54MKB not mounted

K1 header Weidmuller; SL 5.08/3/90 K1A socket Weidmuller; BL 5.08/3 K2 header Weidmuller; SL 5.08/2/90 K2A socket Weidmuller; BL 5.08/2 K3 header Fischer Elektronik; BL3.36Z K4 header Fischer Elektronik; BL3.36Z L1 filter inductor; 1 mH; 170 mA Murata power solutions; 22R105C L2 filter inductor; wire - L3 buck inductor; 3.3 mH; 100 mA Murata power solutions; 22R335C R1 R

R2 R

R3 R

R4 R

; 0.125 W; 1 %; 20 Multicomp; MC 0.125W 1206 1% 20R -

sense

; 0.33 W; 5 %; 4.3 Panasonic; ERJ8BQF4R3V -

sense

; 0.33 W; 1 %,6.8 Panasonic; ERJ8BQF6R8V -

sense

; 0.33 W; 5 %; 18 Panasonic; ERJT08J180V -

sense

R5 inrush resistor; 0 Multicomp; MC 0.1W 0805 0R R6 resistor; 0 Multicomp; MC 0.1W 0805 0R RT1 NTC; 100 k EPCOS; B57164K104J TP1-TP8 test pins Vero; 20-313138 X56 jumper link Fischer Elektronik; 2412 015 30123 X57 jumper link Fischer Elektronik; 2412 015 30123 -

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 20 of 27

Page 21

NXP Semiconductors

UM10468

SSL2108X buck evaluation board

10.4 BOM for SSL21084 evaluation board

Table 8. SSL21084 Bill of materials

Ref. Description and value Manufacturer and part no. Remark

A1 SSL21084 Controller IC

A1A IC Socket; n.m. Wells-cti; 652B0142211-002 not mounted

C1 filter capacitor; 4.7 F; 400 V Panasonic; ECA2GHG4R7 C2 filter capacitor; 4.7 F; 400 V Panasonic; ECA2GHG4R7 C3 ripple capacitor; 3.3 F; 400 V Panasonic; ECA2GHG3R3 C4 dV/dt capacitor; 100 pF; 1000 V Johanson Dielectrics;

C5 VCC supply capacitor; 10 F; 25 V Murata; GRM21BR61E106KA73L C6 t

on(max)

C7 soft-start/ripple filter; 22 F; 10 V KEMET; C1206C226M8PACTU C8 filter capacitor; n.m. - not mounted

D1 bridge rectifier; 1 A; 600 V Multicomp; DBLS105G D2 TVS; 400 V; 1.5 kW ST Microelectronics; 1.5KE400A D3 ES1J; 1 A; 600 V Multicomp; ES1J Fus 1 fused resistor; 2 W; 22 Welwyn; EMC2-22RKI J1-J9 headers Fischer Elektronik; MK 05/50G J10 header; n.m. Fischer Elektronik; MK 05/50G not mounted

J1A jumper; n.m. Lumberg; 2,54MKB not mounted

J2A jumper Lumberg; 2,54MKB J3A jumper; n.m. Lumberg; 2,54MKB not mounted

J4A jumper Lumberg; 2,54MKB J5A jumper; n.m. Lumberg; 2,54MKB not mounted

J6A jumper Lumberg; 2,54MKB J7A jumper Lumberg; 2,54MKB J8A jumper; n.m. Lumberg; 2,54MKB not mounted

J9A jumper; n.m. Lumberg; 2,54MKB not mounted

J10A jumper; n.m. Lumberg; 2,54MKB not mounted

K1 header Weidmuller; SL 5.08/3/90 K1A socket Weidmuller; BL 5.08/3 K2 header Weidmuller; SL 5.08/2/90 K2A socket Weidmuller; BL 5.08/2 K3 header Fischer Elektronik; BL3.36Z K4 header Fischer Elektronik; BL3.36Z L1 filter inductor; 1 mH; 170 mA Murata power solutions; 22R105C L2 filter inductor; wire - L3 buck inductor; 3.3 mH; 100 mA Murata power solutions; 22R335C R1 R

R2 R

R3 R

R4 R

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 21 of 27

sense

sense

sense

sense

NXPSemiconductors;SSL21084T -

-

102R18W101KV4E

capacitor; 100 pF; 100 V AVX; 08051A101JAT2A -

; 0.33 W; 1 %,6.2 Panasonic; ERJ8RQF6R2V ; 0.25 W; 1 %; 3.6 Panasonic; ERJ8RQF3R6V ; 0.33 W; 1 %; 5.1 Panasonic; ERJ8BQF5R1V ; 0.33 W; 1 %; 8.2 Panasonic; ERJ8BQF8R2V -

Page 22

NXP Semiconductors

UM10468

SSL2108X buck evaluation board

Table 8. SSL21084 Bill of materials

Ref. Description and value Manufacturer and part no. Remark

R5 inrush resistor; 0 Multicomp; MC 0.1W 0805 0R R6 resistor; 0 Multicomp; MC 0.1W 0805 0R RT1 NTC; 100 k EPCOS; B57164K104J TP1-TP8 test pins Vero; 20-313138 X56 jumper link Fischer Elektronik; 2412 015 30123 X57 jumper link Fischer Elektronik; 2412 015 30123 -

…continued

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 22 of 27

Page 23

NXP Semiconductors

019aac354

019aac353

11. Printed-Circuit Board (PCB) data

1 1.1 Evaluation board photographs

Remark: The configuration of the SSL21083 is similar to the SSL21081 although BOM is

different. The same is true of the SSL21084 when compared to the SSL21082.

UM10468

SSL2108X buck evaluation board

The evaluation board shown in Figure 15

is a large format footprint. Its size enables the

full functionality of the SSL2108X IC family to be highlighted. The measurement pins,

connectors and other components are used to allow any one of the SSL2108 X ICs to be

dropped in to place.

Figure 16

shows the SSL21081 reference board which can be used in retrofit lamp

designs. It is clear that the total form factor is reduced using the SSL2108X ICs in a

real-world application. A PCB size reduction and thus an ef ficiency of more than 92 % can

be reached.

019aac355

a. Top view: SSL21081 (SO8). b. Top view: SSL21082 (SO12).

c. Bottom view.

Fig 15. SSL21081 and SSL21082 evaluation board photographs

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 23 of 27

Page 24

NXP Semiconductors

019aac357

019aac356

UM10468

SSL2108X buck evaluation board

a. Top view: SSL21081 (SO8) reference board.

b. Top view: SSL21082 (SO12) reference board.

Fig 16. SSL21081 and SSL21082 reference board photographs

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 24 of 27

Page 25

NXP Semiconductors

12. Abbreviations

Table 9. Abbreviations

Acronym Description

BCM Boundary Conduction Mode

CCM Continuous Conducti on Mode

DCM Discontinuous Cond uction Mode

EMC ElectroMagnetic Compatibility

EMI ElectroMagnetic Interference

LED Light Emitting Diode

MOSFET Metal-Oxide Semiconductor Field-Effect Transistor

OCP O verCurrent Protection

OSP Output Short Protection

OTP OverTemperature Protection

PCB Printed-Circuit Board

PWM Pulse-Width Modulation

SSL Solid-State Lighting

SWP Short-Winding Protection

UVLO UnderVoltage LockOut

UM10468

SSL2108X buck evaluation board

13. References

[1] SSL2108X — SSL2108X driver data sheet.

[2] AN11041 — SSL2108X driver for SSL applications.

[3] AN10876 — Buck converter for SSL applications.

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 25 of 27

Page 26

NXP Semiconductors

14. Legal information

UM10468

SSL2108X buck evaluation board

14.1 Definitions

Draft — The document is a draft version only. The content is still under

internal review and subject to formal approval, which may result in

modifications or additions. NXP Semiconductors does not give any

representations or warranties as to the accuracy or completeness of

information included herein and shall have no liability for the consequences of

use of such information.

14.2 Disclaimers

Limited warranty and liability — Information in this document is believed to

be accurate and reliable. However, NXP Semiconductors does not give any

representations or warranties, expressed or implied, as to the accuracy or

completeness of such information and shall have no liability for the

consequences of use of such information.

In no event shall NXP Semiconductors be liable for any indirect, incidental,

punitive, special or consequential damages (including - without limitation - lost

profits, lost savings, business interruption, costs related to the removal or

replacement of any products or rework charges) whether or not such

damages are based on tort (including negligence), warranty, breach of

contract or any other legal theory.

Notwithstanding any damages that customer might incur for any reason

whatsoever, NXP Semi conductors’ aggregat e and cumulative liabil ity towards

customer for the products described herein shall be limited in accordance

with the Terms and conditions of commercial sale of NXP Semiconductors.

Right to make changes — NXP Semiconductors reserves the right to make

changes to information published in this document, including without

limitation specifications and product descriptions, at any time and without

notice. This document supersedes and replaces all information supplied prior

to the publication hereof.

Suitability for use — NXP Semiconductors products are not designed,

authorized or warranted to be suitable for use in life support, life-critical or

safety-critical systems or equipment, nor in applications where failure or

malfunction of an NXP Semiconductors product can reasonably be expected

to result in personal injury, death or severe property or environmental

damage. NXP Semiconductors accepts no liability for inclusion and/or use of

NXP Semiconductors products in such equipment or applica tions and

therefore such inclusion and/or use is at the customer’s own risk.

Applications — Applications that are described herein for any of these

products are for illustrative purposes only. NXP Semiconduct ors makes no

representation or warranty that such applications will be suitable for the

specified use without further testing or modification.

Customers are responsible for the design and operation of their applications

and products using NXP Semiconductors product s, and NXP Semiconductors

accepts no liability for any assistance with applications or customer product

design. It is customer’s sole responsibility to determine whether the NXP

Semiconductors product is suitable and fit for the customer’s applications and

products planned, as well as for the planned application and use of

customer’s third party customer(s). Customers should provide appropriate

design and operating safeguards to minimize the risks associated with their

applications and products.

NXP Semiconductors does not accept any liability related to any default ,

damage, costs or problem which is based on any weakness or default in the

customer’s applications or products, or the application or use by customer’s

third party customer(s). Customer is responsible for doing all necessary

testing for the customer’s applications and products using NXP

Semiconductors products in order to avoid a default of the applications and

the products or of the application or use by customer’s third part y

customer(s). NXP does not accept any liability in this respect.

Export control — This document as well as the item(s) described herein

may be subject to export control regulations. Export might require a prior

authorization from national authorities.

Evaluation products — This product is provided on an “as is” and “with all

faults” basis for evaluation purposes only. NXP Semiconductors, its affiliates

and their suppliers expressly disclaim all warranties, whet her express, implied

or statutory, including but not limited to the implied warranties of

non-infringement, merchantability and fitness for a particular purpose. The

entire risk as to the quality, or arising out of the use or performance, of this

product remains with customer.

In no event shall NXP Semiconductors, its affiliates or their su ppliers be liable

to customer for any special, indirect, consequential, punitive or incidental

damages (including without limitation damages for l oss of bu siness, busi ness

interruption, loss of use, loss of data or information, and the like) arising out

the use of or inability to use the product, whether or not based on tort

(including negligence), strict liability, breach of contract, breach of warranty or

any other theory , even if advised of the possibility of such damages.

Notwithstanding any damages that customer might incur for any reason

whatsoever (including without limitation, all damages referenced above and

all direct or general damages), the entire liability of NXP Semiconductors, its

affiliates and their suppliers and customer’s exclusive remedy for all of the

foregoing shall be limited to actual damages incurred by customer based on

reasonable reliance up to the greater of the amount actually paid by customer

for the product or five dollars (US$5.00). The foregoin g limita tions, exclusions

and disclaimers shall apply to the maximum extent permitted by applicable

law, even if any remedy fails of its essential purpose.

14.3 Trademarks

Notice: All referenced brands, prod uct names, service names and trademarks

are the property of their respective owners.

UM10468 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

User manual Rev. 1 — 30 August 2011 26 of 27

Page 27

NXP Semiconductors

15. Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Safety warning . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 Performance data. . . . . . . . . . . . . . . . . . . . . . . . 5

4.1 Output load. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.2 Efficiency Curve . . . . . . . . . . . . . . . . . . . . . . . . 5

4.3 Input voltage dependency. . . . . . . . . . . . . . . . . 6

4.4 ElectroMagnetic Compatibility data . . . . . . . . . 6

4.5 SSL21081 mains harmonics. . . . . . . . . . . . . . . 9

5 Connection data. . . . . . . . . . . . . . . . . . . . . . . . 11

5.1 The board connections. . . . . . . . . . . . . . . . . . 11

6 Functional description . . . . . . . . . . . . . . . . . . 12

7 Board optimization . . . . . . . . . . . . . . . . . . . . . 13

7.1 Active bypass . . . . . . . . . . . . . . . . . . . . . . . . . 14

8 Neg ative Temperature Coefficient (NTC)

function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9 Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10 Bill of materials (BOM) . . . . . . . . . . . . . . . . . . 17

10.1 BOM for SSL21081 evaluation bo ard. . . . . . . 17

10.2 BOM for SSL21082 evaluation bo ard. . . . . . . 18

10.3 BOM for SSL21083 evaluation bo ard. . . . . . . 19

10.4 BOM for SSL21084 evaluation bo ard. . . . . . . 21

11 Printed-Circuit Board (PCB) data. . . . . . . . . . 23

11.1 Evaluation board photographs . . . . . . . . . . . . 23

12 Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . 25

13 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

14 Legal information. . . . . . . . . . . . . . . . . . . . . . . 26

14.1 Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

14.2 Disclaimers. . . . . . . . . . . . . . . . . . . . . . . . . . . 26

14.3 Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . 26

15 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

UM10468

SSL2108X buck evaluation board

Please be aware that important notices concerning this document and the product(s)

described herein, have been included in section ‘Legal information’.

© NXP B.V. 2011. All rights reserved.

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

Date of release: 30 August 2011

Document identifier: UM10468

Loading...

Loading...