Page 1

Freescale Semiconductor

Doc Number: TWRK64F120MUG

User’s Guide

TWR-K64F120M Tower Module

User’s Guide

by Freescale Semiconductor, Inc.

Rev. B, 03/2014

1 TWR-K64F120M

The TWR-K64F120M microcontroller module is designed

to work in either a standalone mode or as part of the

Freescale Tower System, a modular development platform

that enables rapid prototyping and tool reuse through

reconfigurable hardware. Take your design to the next level

and begin constructing your Tower System today by visiting

www.freescale.com/tower for additional Tower System

microcontroller modules and compatible peripherals. For

TWR-K64F120M-specific information and updates visit

www.freescale.com/TWR-K64F120M.

Contents

1. TWR-K64F120M . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. TWR-K64F120M Features . . . . . . . . . . . . . . . . . . . . . 2

4. Get to Know the TWR-K64F120M . . . . . . . . . . . . . . 3

5. Reference Documents . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . 4

7. Useful links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

© 2014 Freescale Semiconductor, Inc. All rights reserved.

Page 2

Contents

2Contents

The TWR-K64F120M includes:

• TWR-K64F120M for board assembly

• Quick Start Guide

• USB A to mini-B cable for debug interface and power

• CR2032 coin cell battery for VBAT power supply

• USB A to micro-B cable for MK64FN1M0VMD12 USB interface

3 TWR-K64F120M Features

• Τower-compatible microcontroller module

• MK64FN1M0VMD12 MCU (120 MHz, 1024 KB Flash, 256 KB RAM, low power, 144

MAPBGA package)

• Dual-role USB interface with Micro-AB USB connector

• General purpose Tower Plugin (TWRPI) socket

TWR-K64F120M Tower Module, Rev. B

2 Freescale Semiconductor

Page 3

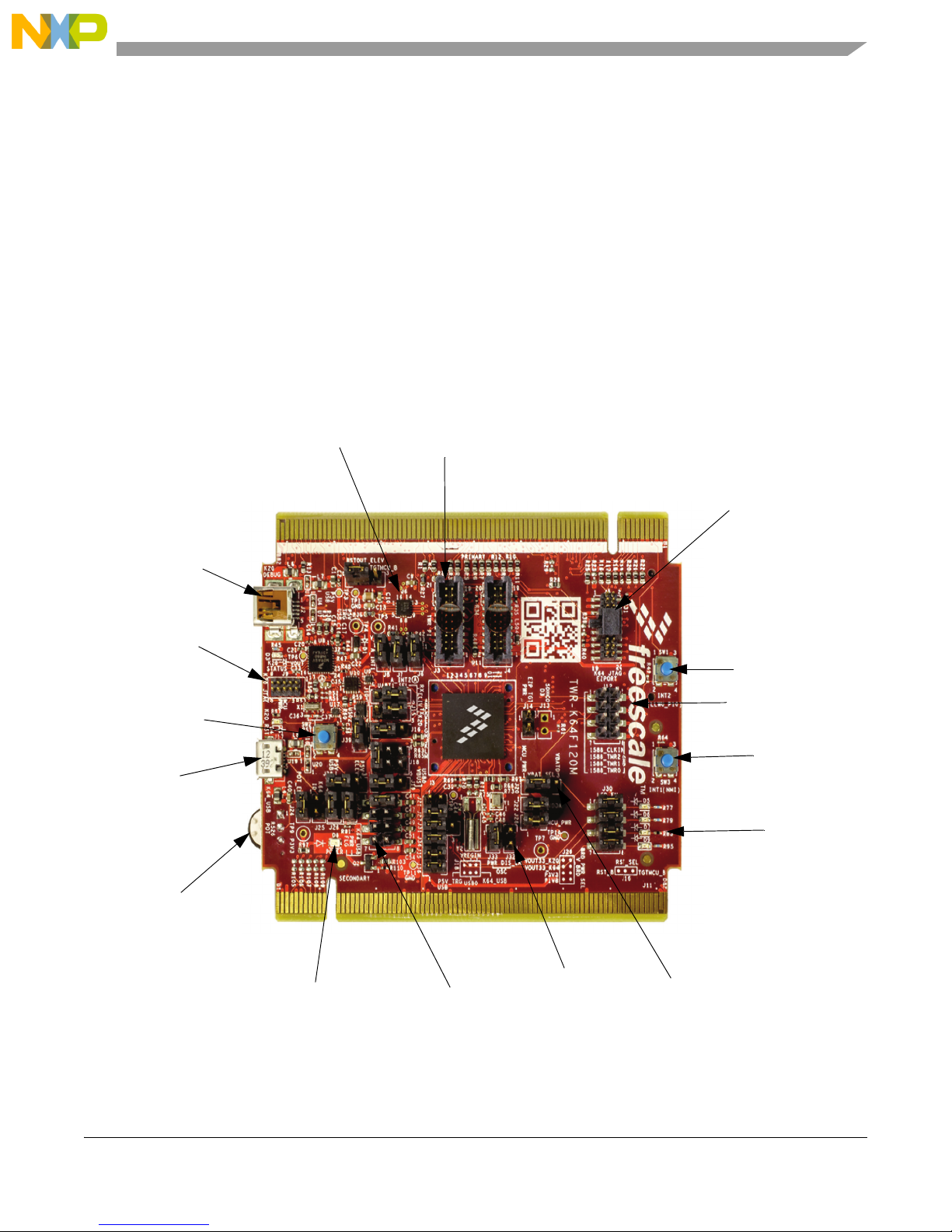

Get to know the TWR-K64F120M

VBAT Options

50 MHz OSC

Enable/Disable

Regulator

Option

Selector

General-purpose

TWRPI Plug-in

Accelerometer

K64 JTAG

SW1

1588

SW3

LEDs

VBAT Options

50 MHz OSC

Enable/Disable

Regulator Option

Selector

Board Power

Indicator

Potentiometer

K64 Micro-USB

RESET

OpenSDA

Debug

Power/OpenSDA

Mini-USB

• On-board debug circuit: MK20DX128VM5 open (OpenSDA) with virtual serial port

• Three axis accelerometer (MMA8451Q)

• Four user controllable LEDs

• Two user pushbutton switches for GPIO interrupts

• One user pushbutton switch for MK64FN1M0VMD12 or MK20DX128VFM5 reset

• One Potentiometer

• Independent, battery-operated power supply for Real Time Clock (RTC) and tamper detection

modules

• SD card slot

4 Get to know the TWR-K64F120M

Figure 1. Front side of TWR-K64F120M module (TWRPI devices not shown)

Freescale Semiconductor 3

TWR-K64F120M Tower Module, Rev. B

Page 4

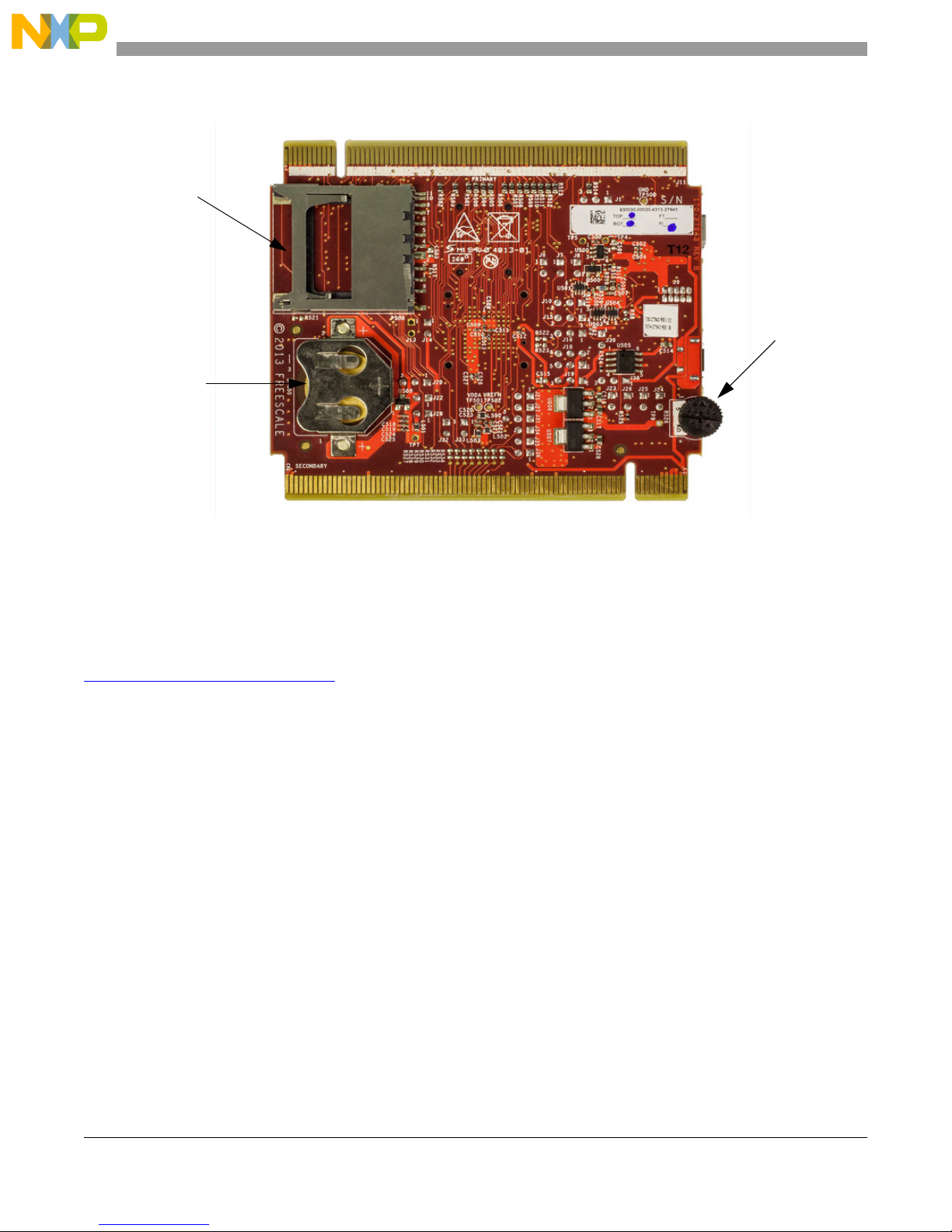

Reference Documents

SD Card

Receptacle

Potentiometer

Battery Receptacle

Figure 2. Back side of TWR-K64F120M

5 Reference Documents

The documents listed below should be referenced for more information on the Kinetis family, Tower

System, and MCU Modules. These can be found in the documentation section of

http://www.freescale.com/kinetis

• TWR-K64F120M-SCH: Schematics

• TWR-K64F120M-PWA: Design Package

• K64P144M120SF5RM: Reference Manual

• Tower Configuration Tool

• Tower Mechanical Drawing

6 Hardware description

The TWR-K64F120M is a Tower MCU Module featuring the MK64FN1M0VMD12—a Kinetis

microcontroller in a 144 MAPBGA featuring a USB 2.0 full speed on-the-go (OTG) controller, a 10/100

Ethernet MAC with IEEE1588, hardware encryption, and tamper detection coupled with a secure real-time

clock on an independent battery supply. It is intended for use in the Freescale Tower System but can also

operate alone. The on-board OpenSDA debug circuit provides a Serial Debug interface and a power supply

input through a single mini-USB connector.

4 Freescale Semiconductor

TWR-K64F120M Tower Module, Rev. B

Page 5

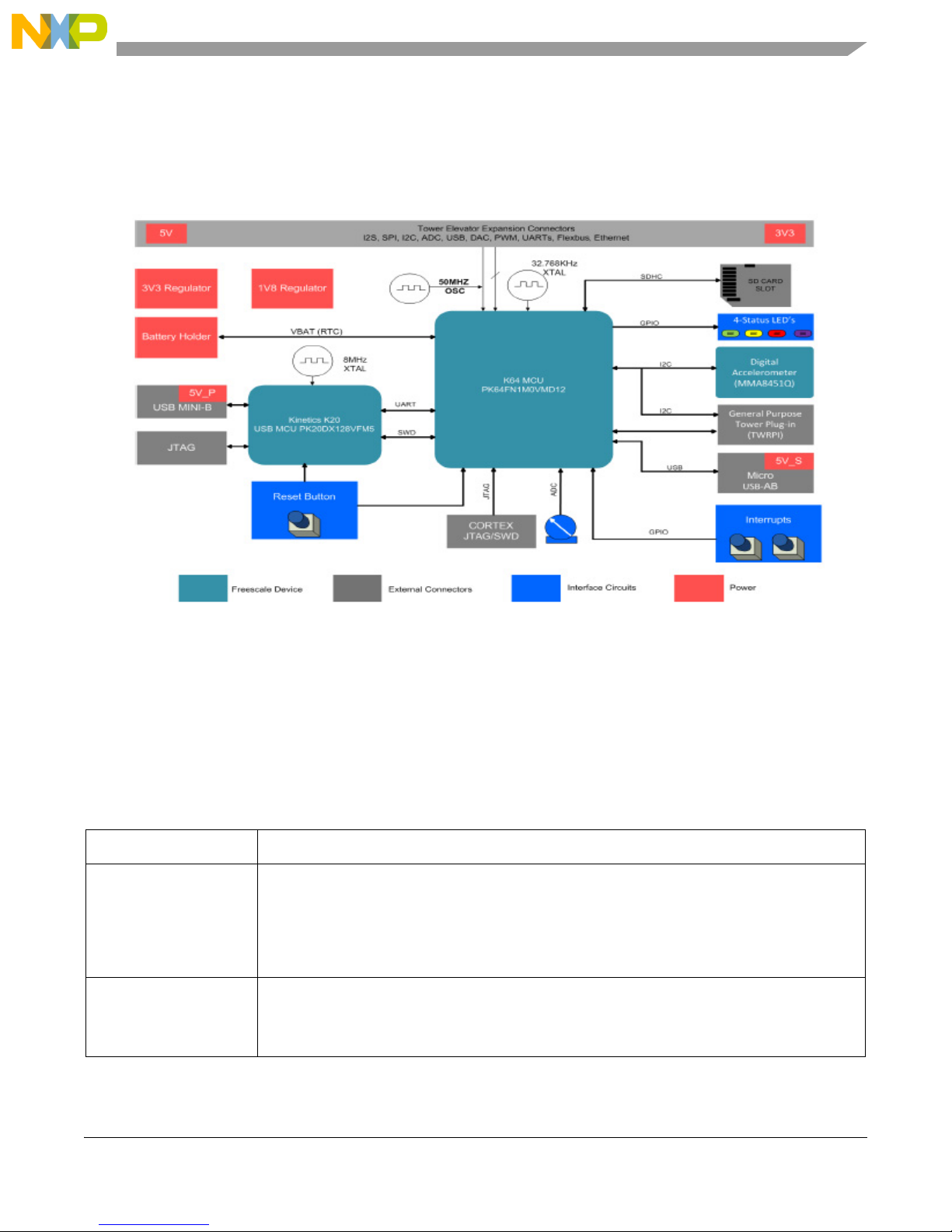

6.1 Block Diagram

The block diagram of the TWR-K64F120M board is presented in Figure 3:

Hardware description

Figure 3. Block diagram

6.2 Microntroller

The TWR-K64F120M features the MK64FN1M0VMD12 MCU. This 120 MHz microcontroller is part of

the Kinetis K6x family and is implemented in a 144 MAPBGA package. The following table notes some

of the features of the MK64FN1M0VMD12 MCU.

Table 1. Features of MK64FN1M0VMD12

Feature Description

Ultra low power – 11 low-power modes with power and clock gating for optimal peripheral activity and recovery

times.

– Full memory and analog operation down to 1.71 V for extended battery life

– Low-leakage wake-up unit with up to six internal modules and sixteen pins as wake-up sources

in low-leakage stop (LLS)/very low-leakage stop (VLLS) modes

– Low-power timer for continual system operation in reduced power states

Flash and SRAM – 1024KB flash featuring fast access times, high reliability, and four levels of security protection

– 256 KB of SRAM

– No user or system intervention to complete programming and erase functions and full operation

down to 1.71 V

Freescale Semiconductor 5

TWR-K64F120M Tower Module, Rev. B

Page 6

Hardware description

Table 1. Features of MK64FN1M0VMD12

Mixed signal capability – High-speed 16-bit ADC with configurable resolution

– Single or differential output modes for improved noise rejection

– 500-ns conversion time achievable with programmable delay block

triggering

– Three high-speed comparators providing fast and accurate motor overcurrent

protection by driving PWMs to a safe state

– Optional analog voltage reference provides an accurate reference to

analog blocks

– Two 12-bit DACs

Performance – 120MHz ARM CortexM4 core with DSP instruction set, single cycle MAC, and single instruction

multiple data (SIMD) extensions

– Up to four channel DMA for peripheral and memory servicing with reduced CPU loading and

faster system throughput

– Cross bar switch enables concurrent multi-master bus accesses, increasing bus bandwidth

– Independent flash banks allowing concurrent code execution and firmware updating with no

performance degradation or complex coding routines

Timing and Control – Four FlexTimers with a total of 12 channels

– Hardware dead-time insertion and quadrature decoding for motor control

– Carrier modulator timer for infrared waveform generation in remote control applications

– Four-channel 32-bit periodic interrupt timer provides time base for RTOS task scheduler or

trigger source for ADC conversion and programmable delay block

– One low power timer

– One independent real time clock

Connectivity and

Communications

Reliability, Safety and

Security

– Full-Speed USB Device/Host/On-The-Go with device charge detect capability

– Optimized charging current/time for portable USB devices, enabling longer battery life

– USB low-voltage regulator supplies up to 120 mA off chip at 3.3 volts to power external

components from 5volt input

– Six UARTs:

One UART supports RS232 with flow control, RS485, and ISO7816

Five UARTs support RS232 with flow control and RS485

– One Inter-IC Sound (I2S) serial interface for audio system interfacing

– Three DSPI modules and two I2C modules

– One Ethernet module with 1588

– A multi-function external bus interface (FlexBUS) controller capable of interfacing to slave-only

devices.

– A secured digital host controller (SDHC)

– One FlexCAN module

– Hardware Encryption co-processor for secure data transfer and storage. Faster than software

implementations and with minimal CPU loading. Supports a wide variety of algorithms - DES,

3DES, AES, MD5, SHA-1, SHA-256

– System security and tamper detection with secure real-time clock (RTC) and independent battery

supply. Secure key storage with internal/external tamper detection for unsecured flash,

temperature, clock, and supply voltage variations and physical attack detection

– Memory protection unit provides memory protection for all masters on the cross bar switch,

increasing software reliability

– Cyclic redundancy check (CRC) engine validates memory contents and communication data,

increasing system reliability

– Independently-clocked COP guards against clock skew or code runaway for fail-safe

applications such as the IEC 60730 safety standard for household appliances

– External watchdog monitor drives output pin to safe state for external components in the event

that a watchdog timeout occurs

– Included in Freescale’s product longevity

6 Freescale Semiconductor

TWR-K64F120M Tower Module, Rev. B

Page 7

Hardware description

6.3 Clocking

The Kinetis MCUs start up from an internal digitally-controlled oscillator (DCO). Software can enable the

main external oscillator (EXTAL0/XTAL0) if desired. The external oscillator/resonator can range from

32.768 KHz up to a 50 MHz. A 50 MHz Oscillator is the default external source for the MCG oscillator

inputs (XTAL/EXTAL).

A 32.768 KHz crystal is connected to the RTC oscillator inputs by default.

By populating isolation resistors, other external clock sources for the MK64FN1M0VMD12 can be used,

including the CLKIN0 signal that can be provided by either pin B24 on primary TWR-ELEV or pin 20 of

TWRPI connector J3.

6.4 System Power

When installed into a Tower System, the TWR-K64F120M can be powered from either an on-board source

or from another source in the assembled Tower System.

In standalone operation, the main power source (5.0 V) for the TWR-K64F120M module is derived from

either the OpenSDA USB mini-B connector (J2) or the MK64FN1M0VMD12 USB micro-AB connector

(J17). Two low dropout regulators provide 3.3 V and 1.8 V supplies from the 5.0 V input voltage.

Additionally, the 3.3 V regulator built into the MK64FN1M0VMD12 MCU can be selected to power the

3.3 V bus. All the user selectable options can be configured using two headers, J18, J19, and J29. Refer to

sheet 4 and 5 of the TWR-K64F120M schematics for more details.

6.5 DryIce and RTC VBAT

The DryIce tamper detection module and the Real Time Clock (RTC) module on the

MK64FN1M0VMD12 have two modes of operation: system powerup and system powerdown. During

system powerdown, the tamper detection module and the RTC are powered from the backup power supply

(VBAT) and electrically isolated from the rest of the MCU. The TWR-K64F120M provides a battery

receptacle for a coin cell battery that can be used as the VBAT supply. The receptacle can accept common

20mm diameter 3 V lithium coin cell batteries.

6.6 Debug Interface

There are two debug interface options available: the on-board OpenSDA circuit and an external ARM

JTAG connector. The ARM JTAG connector (J5) is a standard 2x10pin connector, with one pin keyed, to

allow an external debugger access to the JTAG interface of the MK64FN1M0VMD12. Alternatively, the

on-board OpenSDA debug interface can be used to access the debug interface of the

MK64FN1M0VMD12.

6.7 OpenSDA

An on-board MK20DX128VFM5 based Open-Standard serial and debug adapter (OpenSDA) circuit

provides a JTAG debug interface to the MK64FN1M0VMD12. A standard USB A male to mini-B male

cable (provided) can be used for debugging via the USB connector (J2). The OpenSDA interface also

provides a USB to serial bridge. Drivers for the OpenSDA interface are provided in the P&E Micro

Freescale Semiconductor 7

TWR-K64F120M Tower Module, Rev. B

Page 8

Hardware description

OpenSDA Tower Toolkit. These drivers and more utilities can be found online at

http://www.pemicro.com/opensda.

6.8 Cortex Debug Connector

The Cortex Debug connector is a 20pin (0.05") connector providing access to the SWD, JTAG, EzPort

signals available on the K64 device. The pinout and K64 pin connections to the debug connector (J5) are

shown in the following table.

Table 2. Cortex Debug Connector

Pin Function TWR-K64F120M Connection

1 VTref 3.3 V MCU supply (MCU_PWR)

2TMS / SWDIO PTA3/JTAG_TMS/SWD_DIO/UART0_RTS/FTM0_CH0

3 GND Ground

4 TCK / SWCLK PTA0/JTAG_TCLK/SWD_CLK/EZP_CLK/UART0_CTS/UART0_COL/FTM0_CH5

5 GND Ground

6TDO / SWO PTA2/JTAG_TDO/TRACE_SWO/EZP_DO/UART0_TX/FTM0_CH7

7Key —

8TDI PTA1/JTAG_TDI/EZP_DI/UART0_RX/FTM0_CH6

9 GND Detect PTA4/LLWU_P3/NMI/EZP_CS/FTM0_CH1

10 nRESET RESET_b

11 Target Power 5 V supply (via J14)

12 TRACECLK PTA6/FTM0_CH3/CLKOUTB/TRACE_CLKOUT

13 Target Power 5 V supply (via J14)

14 TRACEDATA[0] PTA10/FTM2_CH0/MII0_RXD2/FTM2_QD_PHA/TRACE_D0

15 GND Ground

16 TRACEDATA[1] PTA9/FTM1_CH1/MII0_RXD3/FTM1_QD_PHB/TRACE_D1

17 GND Ground

18 TRACEDATA[2] PTA8/ADC0_SE11/FTM1_CH0/FTM1_QD_PHA/TRACE_D2

19 GND Ground

20 TRACEDATA[3] PTA7/ADC0_SE10/FTM0_CH4/TRACE_D3

6.9 Accelerometer

An MMA8451Q digital accelerometer is connected to the MK64FN1M0VMD12 MCU through an I2C

interface (I2C1) and GPIO/IRQ signals (PTA6 and PTA8).

8 Freescale Semiconductor

TWR-K64F120M Tower Module, Rev. B

Page 9

Hardware description

6.10 Potentiometer, Pushbuttons, LEDs

The TWR-K64F120M also features:

• A potentiometer connected to an ADC input signal (ADC1_SE18).

• Two pushbutton switches (SW1 and SW3 connected to PTC6 and PTA4, respectively)

• Four user controllable LEDs connected to GPIO signals (optionally isolated using jumpers):

— Yellow/Green LED (D5) to PTE6

— Yellow LED (D6) to PTE7

— Orange LED (D7) to PTE8

— Blue LED (D9) to PTE9

6.11 General Purpose Tower Plug-in (TWRPI) Socket

The TWR-K64F120M features a socket (J3 and J4) that can accept a variety of different Tower Plugin

modules featuring sensors, RF transceivers, and other peripherals. The General Purpose TWRPI socket

provides access to I2C, SPI, IRQs, GPIOs, timers, analog conversion signals, TWRPI ID signals, reset,

and voltage supplies. The pinout for the TWRPI Socket is defined in Tab le 3.

Table 3. General Purpose TWRPI Socket Pinout

J4 J3

Pin Description Pin Description

1 5 V VCC 1 GND

2 3.3 V VCC 2 GND

3GND 3I2C: SCL

4 3.3 V VDDA 4 I2C: SDA

5 VSS (Analog GND) 5 GND

6 VSS (Analog GND) 6 GND

7 VSS (Analog GND) 7 GND

8 ADC: Analog 0 8 GND

9 ADC: Analog 1 9 SPI: MISO

10 VSS (Analog GND) 10 SPI: MOSI

11 VSS (Analog GND) 11 SPI: SS

12 ADC: Analog 2 12 SPI: CLK

13 VSS (Analog GND) 13 GND

14 VSS (Analog GND) 14 GND

15 GND 15 GPIO: GPIO0/IRQ

16 GND 16 GPIO:GPIO1/IRQ

17 ADC: TWRPI ID 0 17 UART: UART_RX or GPIO: GPIO2

Freescale Semiconductor 9

TWR-K64F120M Tower Module, Rev. B

Page 10

Hardware description

Table 3. General Purpose TWRPI Socket Pinout

18 ADC: TWRPI ID 1 18 UART: UART_TX or GPIO: GPIO3

19 GND 19 UART: UART_CTS or GPIO: GPIO4/Timer

20 Reset 20 UART: UART_RTS or GPIO: GPIO5/Timer

6.12 USB

The MK64FN1M0VMD12 features a fullspeed/lowspeed USB module with OTG/Host/Device capability

and built-in transceiver. The TWR K64F120M routes the USB D+ and D signals from the

MK64FN1M0VMD12 MCU directly to the on-board microUSB connector (J17).

A power supply switch with an enable input signal and overcurrent flag output signal is used to supply

power to the USB connector when the MK64FN1M0VMD12 is operating in host mode. Port pin PTC8 is

connected to the flag output signal and port pin PTC9 is used to drive the enable signal. Both PTC8 and

PTC9 port pins can be isolated with jumpers (J23 and J26, respectively) if needed.

6.13 Secure Digital Card Slot

A Secure Digital (SD) card slot is available on the TWR-K64F120M connected to the SD Host Controller

(SDHC) signals of the MCU. This slot will accept standard format SD memory cards. See the following

table for the SDHC signal connection details.

Table 4. SD Card Socket Connection

Pin Function TWR-K64F120M Connection

1 SDHC0_D3 PTE4/LLWU_P2/SPI1_PCS0/UART3_TX/SDHC0_D3/TRACE_D0

2 SDHC0_CMD PTE3/ADC0_DM2/ADC1_SE7A/SPI1_SIN/UART1_RTS/SDHC0_CMD/TRACE_D1/SPI1_S

OUT

3 VSS1 GND

4 VDD 3.3 V Board supply (V_BRD)

5 SDHC0_DCLK PTE2/LLWU_P1/ADC0_DP2/ADC1_SE6A/SPI1_SCK/UART1_CTS/SDHC0_DCLK/TRACE

_D2

6 VSS2 GND

7 SDHC0_D0 PTE1/LLWU_P0/ADC1_SE5A/SPI1_SOUT/UART1_RX/SDHC0_D0/TRACE_D3/I2C1_SCL/

SPI1_SIN

8 SDHC0_D1 PTE0/ADC1_SE4A/SPI1_PCS1/UART1_TX/SDHC0_D1/TRACE_CLKOUT/I2C1_SDA/RTC

_CLKOUT

9 SDHC0_D2 PTE5/SPI1_PCS2/UART3_RX/SDHC0_D2/FTM3_CH0

10 SD_CARD_DETECT PTB20/SPI2_PCS0/FB_AD31/CMP0_OUT

11 CD_WP_COMMON GND

12 SD_CARD_WP PTB21/SPI2_SCK/FB_AD30/CMP1_OUT

10 Freescale Semiconductor

TWR-K64F120M Tower Module, Rev. B

Page 11

Hardware description

6.14 External Bus Interface – FlexBus

The device features a multi-function external bus interface called Flexbus, which is capable of interfacing

to slave-only devices.. The FlexBus interface is not used directly on the TWR-K64F120M. Instead, a

subset of the FlexBus signals are connected to the Primary Connector on the TWR-ELEV so that the

external bus can access devices on Tower peripheral modules. Refer to sheet 8 of the TWR-K64F120M

schematic for more detail.

6.15 Ethernet and 1588

The MK64FN10MVDC12 features a 10/100 Mbps Ethernet MAC with MII and RMII interfaces. The

TWR-K64F120M routes MII/RMII interface signals from the K64 MCU to the Primary Connector which

allows a connection to an external Etherent PHY that can be found on some Tower peripheral modules.

When the K64 Ethernet MAC is operating in RMII mode, synchronization of the MCU clock and the 50

MHz RMII transfer clock is important. The MCU input clock must be kept in phase with the 50 MHz clock

supplied to the external PHY. Therefore, the TWR-K64F120M provides the option (see Table 5, Ethernet

operation jumper settings) to clock the MCU from an external clock from CLKIN0 pin on the Primary

Connector. The Tower peripheral module implementing the RMII PHY device should drive a 50 MHz

clock on the CLKIN0 pin that is kept in phase with the clock supplied to the RMII PHY.

The TWR-SER1 module that comes as part of the TWR-K64F120M-KIT provides a 10/100 Ethernet PHY

that can operate in either MII or RMII mode. By default, the PHY is boot strapped to operate in MII mode;

therefore, jumper configuration changes may be required. Table shows the settings for proper

interoperability between the Ethernet interface on the TWR-SER and the TWR-K64F120M.

Table 5. Ethernet operation jumper settings

Tower Module Jumper Setting

TWR-K64F120M J32 ON

—J33OFF

TWR-SER J2 3-4

—J32-3

— J11 9-10

6.16 TWR-K64F120M Jumper Options and Headers

The following is a list of all the jumper options on the TWR-K64F120M. The default installed jumper

settings are indicated by white text on a black background.

Option Jumper Setting Description

Freescale Semiconductor 11

Table 6. Jumper options and headers

TWR-K64F120M Tower Module, Rev. B

Page 12

Hardware description

Table 6. Jumper options and headers

50MHz Clock OSC power J33 1-2 Enable V_BRD power supply to 50MHz OSC

J32 1-2 Disable V_BRD power supply to 50MHz OSC

JTAG Board Power Selection J14 ON Connect 5V output (P5V_TRG_USB)

to JTAG port (supports powering board from

JTAG pod supporting 5V supply output)

OFF Disconnect OSJTAG 5V output

(P5V_TRG_USB) from JTAG port

UART4_TX J36 ON Connect PTE24 as UART4_TX to Secondary TWR_ELEV

OFF Disconnect PTE24 as UART4_TX to Secondary TWR_ELEV

UART4_RX J27 ON Connect PTE25 as UART4_RX to Secondary TWR_ELEV

OFF Disconnect PTE25 as UART4_RX to Secondary TWR_ELEV

SDHC_WP / UART4_RTS_B J34 ON Connect PTE27 as UART4_RTS_B to Secondary TWR_ELEV

or as SDHC_WP to SD card slot as write protect signal

OFF Disconnect PTE27 as UART4_RTS_B to Secondary

TWR_ELEV or as SDHC_WP to SD card slot as write protect

signal

GPIO3_ELEV J35

ON Connect PTE28 as General Purpose IO to TWR_ELEV

OFF Disconnect PTE28 as General Purpose IO to TWR_ELEV

UART_CTS / RTC_CLKOUT/

1588_CLKIN

J31 ON Connect PTE26 as UART_CTS to Secondary TWR_ELEV or

as RTC_CLKOUT to primary TWR_ELEV or as Clock input for

1588

OFF Disconnect PTE26 as UART_CTS to Secondary TWR_ELEV

or as RTC_CLKOUT to primary TWR_ELEV or as Clock input

for 1588

TAMPER0 J21

ON Connect Tamper0 signal to test point

OFF

K64 VREG IN Selector J19 1-2 VBUS Signal on micro_USB connector J17 connects to

K64_VREGIN to allow standalone USB operation

2-3 VBUS signal from TWR ELEV connector connects to

K64_VREGIN to allow USB operation with complete Tower

System

3.3 V Voltage Regulator Input

Selector

J18

1-2 Output of USB power switch controlled by the VTRG_EN

signal from the K20 MCU. Provides input to 3.3V regulator.

2-3 Output of USB power from primary elevator Pin A57 to 3.3V

regulator.

5-6 Output of USB power from K64 VREGIN to 3.3 regulator

12 Freescale Semiconductor

TWR-K64F120M Tower Module, Rev. B

Page 13

Hardware description

Table 6. Jumper options and headers

Board Power Selector J29 1-2 Connect K20 USB regulator output (VOUT_3V3) to on-board

supply (V_BRD)

3-4 Connect K64 USB regulator output (VOUT_3V3) to on-board

supply (V_BRD)

5-6 Connect 3.3V on-board regulator output (P3V3) to on-board

supply (V_BRD)

7-8 Connect 1.8 V on-board regulator output (P1V8) to on-board

supply (V_BRD)

MCU Power connection J28 ON Connect on-board 3.3V or 1.8V supply (V_BRD) to MCU VDD

OFF Disconnect on-board 3.3V or 1.8V supply (V_BRD) to MCU

VDD

MCU Power VDDA for current

measurement

J22

ON Connect MCU_PWR (3.3V or 1.8V) to VDDA and VREFH

OFF Disconnect MCU_PWR (3.3V or 1.8V) to VDDA and VREFH

VBAT Power Source J20 1-2 Connect VBAT to on-board 3.3 V or 1.8 V supply

2-3 Connect VBAT to the higher voltage between MCU supply

(MCU_PWR) or coin cell supply (VBATD)

Accelerometer IRQ Connection J7 ON Connect PTA8 to INT2 pin of accelerometer

J8 ON Connect PTA6 to INT1 pin of accelerometer

OFF Disconnect PTA6 and/or PTA8 from INT1 and/or INT2 of

accelerometer

External Pull down on SDHC D3 J13 ON External 10K ohm Pull down on SDHC_D3

OFF No pull down on SDHC_D3

LED connections J30 1-2 Connect PTE6 to Yellow/Green LED (D5)

3-4 Connect PTE7 to Yellow LED (D6)

5-6 Connect PTE8 to Orange LED (D7)

7-8 Connect PTE9 to Blue LED (D8)

5V power selection J38 1-2 Connect 5V power from OpenSDA (mini USB) to power switch

MIC2026

2-3 Connect 5V power from Elevator to power switch MIC2016

Micro USB power enable J26

Micro USB overcurrent flag J23

Micro USB ID selection J25

Freescale Semiconductor 13

ON Connect PTC9 to USB power enable on power switch

MIC2026

OFF Disconnect PTC9 from USB power enable on power switch

MIC2026

ON Connect PTC8 to overcurrent flag on power switch MIC2026

OFF Disconnect PTC8 from overcurrent flag on power switch

MIC2026

ON USB Host / Device ID selection is controlled by PTE12

OFF No ID selection USB Host / Device

TWR-K64F120M Tower Module, Rev. B

Page 14

Useful links

Table 6. Jumper options and headers

Potentiometer connection J24 ON Connect potentiometer to ADC1_SE18

OFF Disconnect potentiometer from ADC1_SE18

General Purpose TWRPI

V_BRD power enable

GPIO RESET_OUT_B connection J1

Target MCU UART1_RX output

selection

Target MCU UART1_TX output

selection

SWD_CLK_TGTMCU output

selection

Reset selection for SW2 Reset button J16

J6 ON Connect on-board 1.8 V or 3.3 V supply (V_BRD) to TWRPI

J10 1-2 Connect MCU’s UART1_RX to OpenSDA virtual COM RX port

J15 1-2 Connect MCU’s UART1_TX to OpenSDA virtual COM TX port

J39 ON Enable the SWD_CLK_TGTMCU connection between the

3V power (GPT_VBRD)

OFF Disconnect fromboard 1.8 V or 3.3 V supply (V_BRD) to

TWRPI 3V power (GPT_VBRD)

1-2 Connect PTB7 to RESET_OUT_B signal

2-3 RESET_OUT_B signal resets the target MCU

2-3 Connect MCU’s UART1_RX to primary Elevator (A41)

UART0_RX

2-3 Connect MCU’s UART1_RX to primary Elevator (A42)

UART0_RX

OpenSDA and target MCU

OFF Isolate the SWD_CLK_TGTMCU connection between the

OpenSDA and target MCU

1-2 Connect the reset button to target MCU before level shifter

2-3 Connect the reset button to target MCU without passing

through level shifter

7 Useful links

www.freescale.com/twr-k64f120m

www.iar.com/freescale

www.pemicro.com

www.pemicro.com/opensda

www.freescale.com/codewarrior

www.segger.com

www.segger.com/jlinkflashdownload.html

TWR-K64F120M Tower Module, Rev. B

14 Freescale Semiconductor

Page 15

Useful links

Freescale Semiconductor 15

TWR-K64F120M Tower Module, Rev. B

Page 16

How to Reach Us:

Home Page:

freescale.com

Web Support:

freescale.com/support

Information in this document is provided solely to enable system and software

implementers to use Freescale products. There are no express or implied copyright

licenses granted hereunder to design or fabricate any integrated circuits based on the

information in this document.

Freescale reserves the right to make changes without further notice to any products

herein. Freescale makes no warranty, representation, or guarantee regarding the

suitability of its products for any particular purpose, nor does Freescale assume any

liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation consequential or incidental

damages. “Typical” parameters that may be provided in Freescale data sheets and/or

specifications can and do vary in different applications, and actual performance may

vary over time. All operating parameters, including “typicals,” must be validated for

each customer application by customer’s technical experts. Freescale does not convey

any license under its patent rights nor the rights of others. Freescale sells products

pursuant to standard terms and conditions of sale, which can be found at the following

address: freescale.com/SalesTermsandConditions.

Freescale and the Freescale logo are trademarks of Freescale Semiconductor, Inc.,

Reg. U.S. Pat. & Tm. Off. Tower is a trademark of Freescale Semiconductor, Inc. All

other product or service names are the property of their respective owners.

© 2014 Freescale Semiconductor, Inc.

Document Number: TWRK64F120MUG

Rev. B

03/2014

Loading...

Loading...