Page 1

TWR-56F8400

User Manual

Rev. O.01

Freescale Semiconductor Inc.

Microcontroller Solutions Group

Page 2

Contents

Overview .......................................................................................................................................................... 4

1.1 Block Diagram ...................................................................................................................................................................... 5

1.2 Reference Documents ....................................................................................................................................................... 5

2 Hardware Features ................................................................................................................................... 6

2.1 Tower MCU Module ........................................................................................................................................................... 6

2.2 System Power ....................................................................................................................................................................... 6

2.2.1 P5V_USB ................................................................................................................................................................................................. 6

2.2.2 P3_3V ....................................................................................................................................................................................................... 6

2.2.3 P3_3V/5V ............................................................................................................................................................................................... 7

2.2.4 Default Power Configuration ........................................................................................................................................................ 7

2.3 MC56F84789 DSC ............................................................................................................................................................... 7

2.3.1 Clock Sources for the MC56F84789 DSC ................................................................................................................................. 7

2.3.2 Serial I/O Source Select Headers ................................................................................................................................................. 8

2.3.3 LEDs Controlled by the MC56F84789 DSC ............................................................................................................................. 9

2.3.4 Motor Control Connector ............................................................................................................................................................. 10

2.3.5 Auxiliary Connectors ..................................................................................................................................................................... 11

2.3.6 Tower Elevator Connectors ........................................................................................................................................................ 14

2.3.7 Thermistors as Analog Inputs ................................................................................................................................................... 14

2.3.8 CAN Transceiver .............................................................................................................................................................................. 14

2.3.9 IRQ or Input Pushbuttons ............................................................................................................................................................ 15

2.3.10 RESET ................................................................................................................................................................................................ 15

2.3.11 JTAG Header and OSBDM/OSJTAG Disconnect Header ............................................................................................... 15

2.4 OSBDM/OSJTAG ............................................................................................................................................................... 16

2.4.1 Debug Interface ................................................................................................................................................................................ 16

2.4.2 USB Serial Bridge Interface ......................................................................................................................................................... 16

2.4.3 Clocking the OSBDM/OSJTAG MCU (MC9S08JM60) ........................................................................................................ 16

2.4.4 OSBDM/OSJTAG/UART Function Select Header ............................................................................................................... 16

2.4.5 Bootloader Enable .......................................................................................................................................................................... 17

2.4.6 BDM Header ....................................................................................................................................................................................... 17

2.4.7 OSBDM/OSJTAG Status LEDs ..................................................................................................................................................... 17

2.4.8 OSBDM/OSJTAG Voltage Translation ..................................................................................................................................... 17

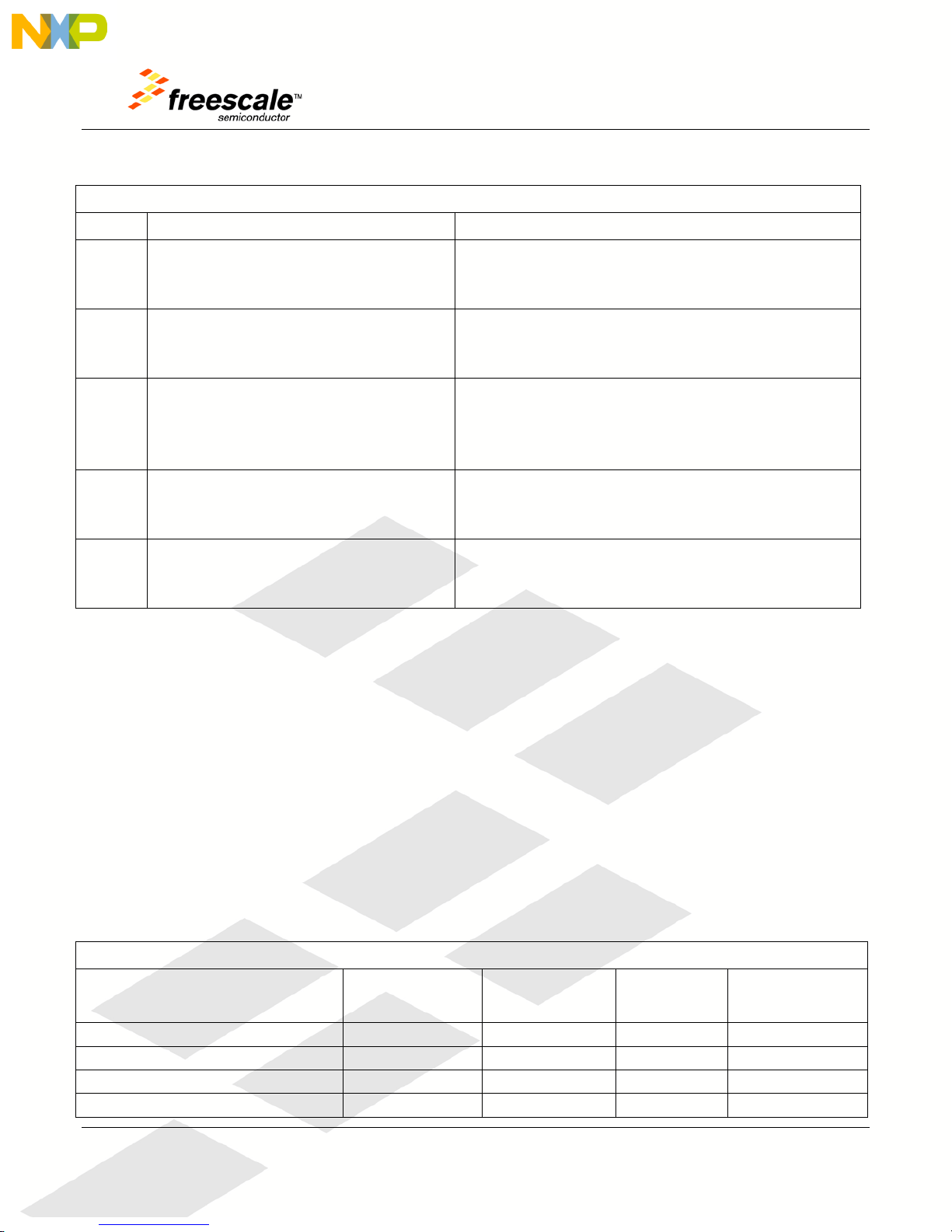

3 Jumper Table ........................................................................................................................................... 18

Appendix A – Tower Elevator Connector Pin Functions .............................................................. 20

Appendix B – TWR-56F8400 Board Schematic ............................................................................... 23

Appendix C – TWR-56F8400 Board BOM .......................................................................................... 24

Appendix D – TWR-56F8400 Board Jack Layout Top View ............................................................ 1

TWR-56F8400 User’s Manual Page 2 of 35

Page 3

JLW Ported from MC56F8257 to the 32-bit MC56F84789

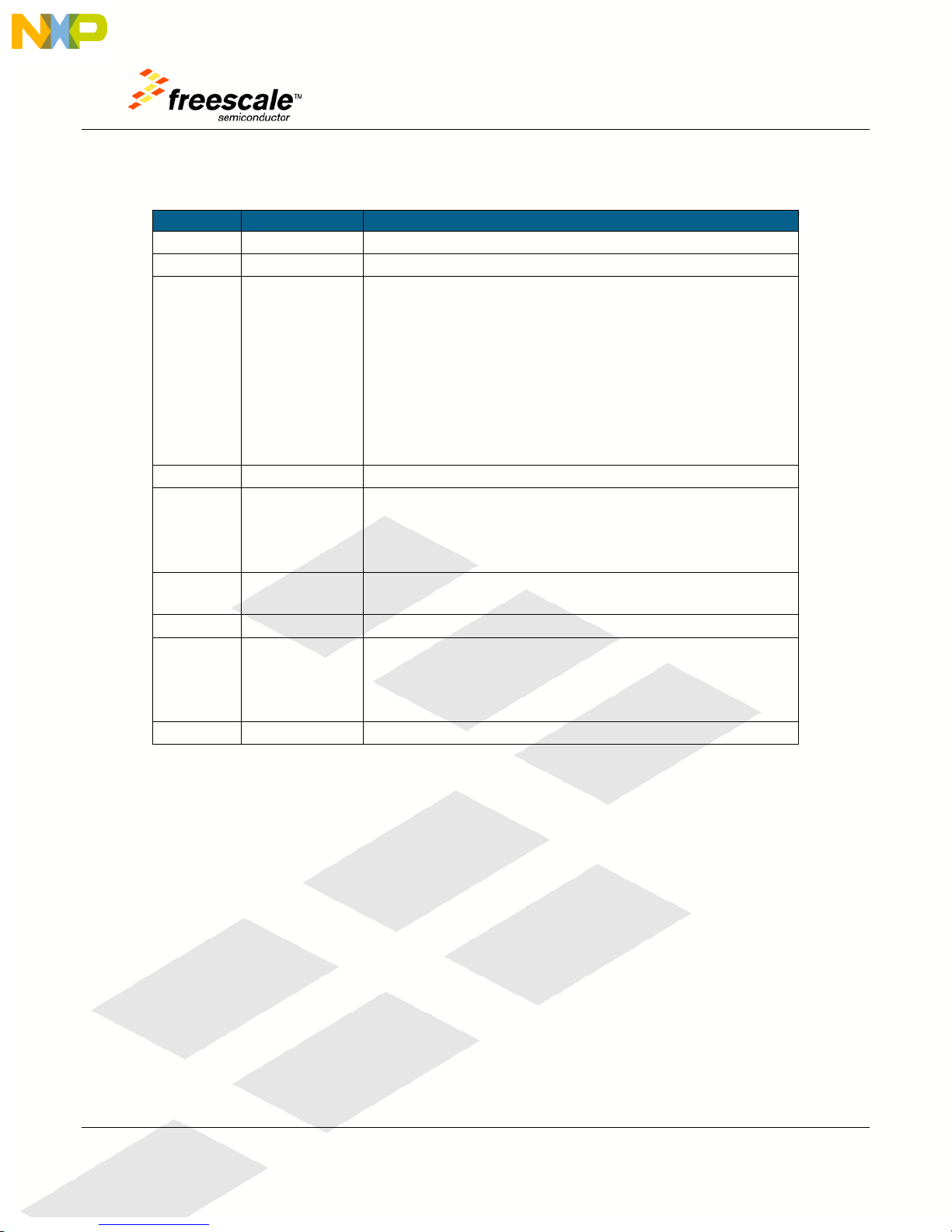

Revision History

Revision Date Changes

O 12 Dec 2009 Input from Jay Hartvigsen

O.01 4 Jan 2010 Update from Jay Hartvigsen

Reordered list of features in overview to match the table of

contents order. Correction to Table 2. Added LED Label

column in table 3. Added requested comment on CAN TXD

and RXD nets – that they also go to the elevator connector.

O.02 21 Jan 2010

O.03 29 Jan 2010 Updated document list in section 1.2 by Petr Stekl

Improved description of USB Serial Bridge Interface and

moved the circuit description of this interface from section

2.3.2 to section 2.4.2. Added Tower Elevator Connector

table. Added an appendix to put the schematic in. Added

BOM.

0.00

0.01

0.02 6 March 2012 JLW corrections to composite signal names

0.03 6 March 2012

0.04 7 March 2012 JLW added back schematic as rev B

25 February

2012

27 February

2012

Note: OSBDM implies “also OSJTAG” below.

Due to the tight layout, added appendix for layout of

headers used for jumpers to aid in their identification.

JLW responded to customer feedback as well as Ankar

feedback.

JLW removed schematic. Editor to embed schematic as

object. Corrected TOWER signal names per latest. Included

new functionality of S08 firmware for CDC serial port.

Released to publications.

TWR-56F8400 User’s Manual Page 3 of 35

Page 4

Overview

The MC56F8400 Tower 32-bit MCU Module (TWR-56F8400) is an evaluation, demonstration and

development board. The TWR-56F8400 can operate stand-alone or as the main control board in a

Tower system with peripheral modules. It can also be used as the main control board with an

APMOTOR56F8000E motor control board.

The following list summarizes the features of the TWR-56F8400:

• 32 bit Digital Signal Controller module featuring MC56F84789

• Tower compatible

• Selectable Power sources:

o USB on 56F8400 card

o Barrel connector on 56F8400 card

o Motor control board plug direct to 56F8400 card, no Tower connection, plug Motor

control to nine volts

o Tower elevator board (USB or Barrel on Primary side)

• Filtered power for VDDA and VSSA on the 32-bit MC56F84789DSC

• MC56F84789 DSC (Digital Signal Controller) in an 100 LQFP package

• Optional 8 MHz crystal circuit for the MC56F84789 DSC

• 9 LEDs controlled by the MC56F84789 DSC

• Motor Control Board connector for the APMOTOR56F8000E motor control board

• Auxiliary Signal connector

• Four Thermistors for single ended or differential analog inputs to the MC56F84789 DSC

• CAN transceiver, header, and termination

• Two push buttons for user input or interrupts to the MC56F84789 DSC

• Reset push button for the MC56F84789 DSC

• JTAG header for the MC56F84789 DSC with header to disconnect from OSBDM/OSJTAG

• Headers to connect SCI signals to either USB bridge with CDC(one channel) or elevator board

(two channels) or connect one to each

• Expansion via Primary Elevator connector

• MC9S08JM60 (‘JM60) MCU with a 4 MHz crystal provides:

o Open Source Debug (OSBDM/OSJTAG) circuit

o USB to SCI bridge with CDC and other techniques supported by third parties

o Simultaneious OSBDM/OSJTAG and USB to SCI bridge functions with no header required

to select

o Bootloader enable header allows easy upgrade to latest S08 firmware pushed down by

CodeWarrior

o BDM header for the MC9S08JM60 MCU

o Status and Target Power indicator LEDs

o Control of semiconductor switch to enable power to board from USB

TWR-56F8400 User’s Manual Page 4 of 35

Page 5

Motor Control&

Aux Connectors

(SPI, I2C, ADC, FEC, TPM, SCI, KB, etc.)

5.0V

3.3V

Freescale Device

External Connectors

Interface Circuits

Power

OSBDM (MC9S08JM60 MCU

Debug, Power, SCI Headers)

5.0V

USB

Mini-AB

Voltage

BDM

Header

Barrel Power Connector

5V-

MC56F84789

JTAG

Boot load HDR

o Voltage translators between 5V MC9S08JM60 MCU chip and 3.3V MC56F84789 DSC

chip

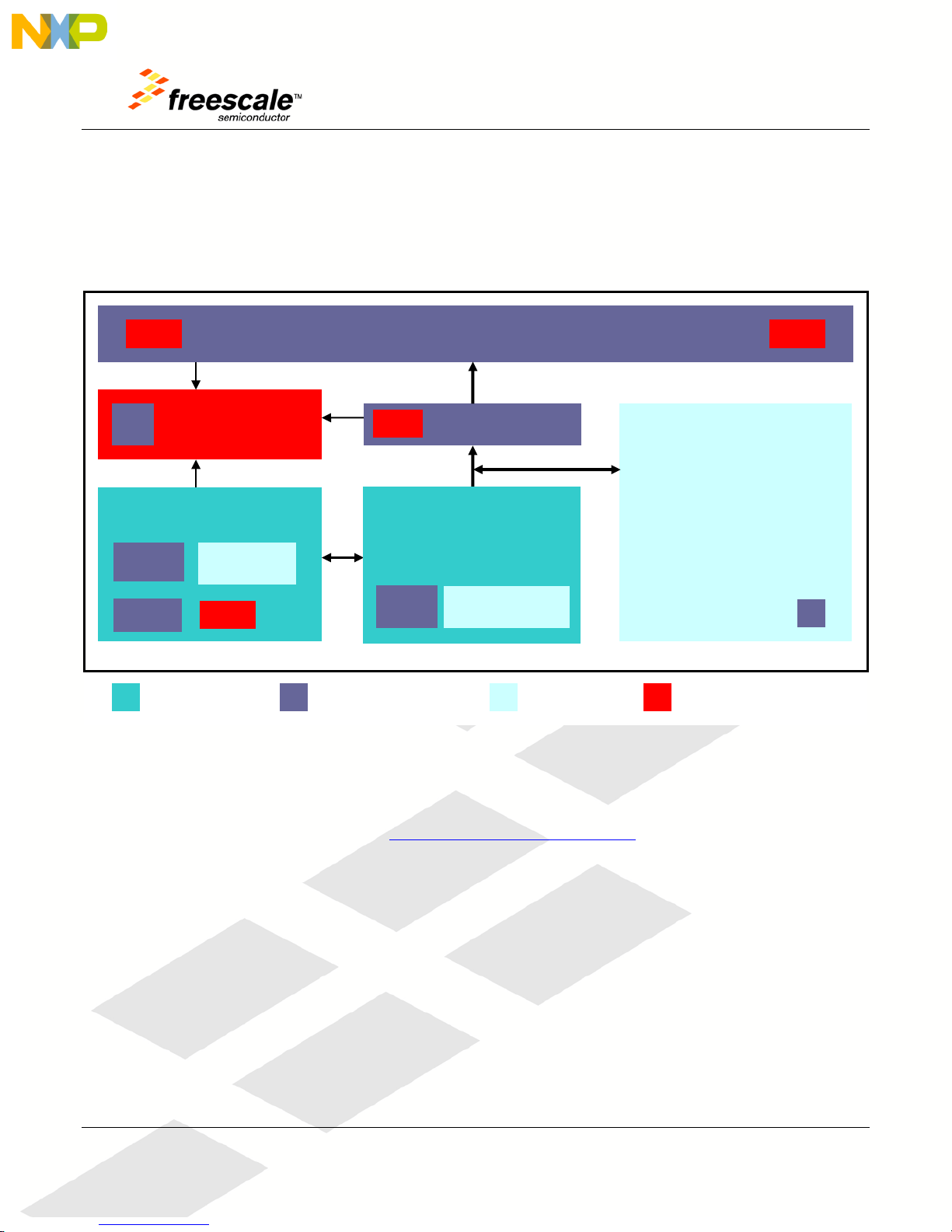

1.1 Block Diagram

A block diagram for the TWR-56F8400 is shown in Figure 1 below.

Tower Elevator Expansion Connectors

Power Selection HDRs

9V

Voltage Regulator

3.3V

• LEDs & Buffers (9)

• IRQ PB & HDRs (2)

• RESET PB

Digital Signal Controller

Translators

• Thermistors & HDRs (4)

• Analog Filters

• Microphone (optional)

Header

• CAN XCVR & HDR

Figure 1. TWR-56F8400 Block Diagram

1.2 Reference Documents

The documents listed below should be referenced for more information on the Freescale Tower

system and the TWR-56F8400. Refer to http://www.freesale.com/tower for the latest revision of all

Tower documentation.

• Freescale Tower Electromechanical Specification

• TWR-56F8400 Quick Start Guide

• TWR-56F8400 Lab Tutorials

• MC56F84XXX Reference Manual

• MC56F84XXX Data Sheet

• MC56F84XXX Chip Errata [if exists]

• AN3561, USB Bootloader for the MC9S08JM60

• Serial Bootloader for MC56F84XXX User Guide

• APMOTOR56F8000e Motor Control Demonstration System User Manual

TWR-56F8400 User’s Manual Page 5 of 35

Page 6

2 Hardware Features

This section provides more details about the features and functionality of the TWR-56F8400.

A drawing of the TWR-56F8400 showing the jack locations is shown in Appendix D. Features are

discussed below.

2.1 Tower MCU Module

The TWR-56F8400 board is an MCU Module designed for standalone use (or with a Freescale Tower

system) and complies with the electrical and mechanical specification as described in Freescale Tower

Electromechanical Specification. Connection to the Tower system is through two expansion card-edge

connectors that interface to the Elevator boards in a Tower system: the Primary and Secondary

Elevator connectors. The Primary Elevator connector, comprised of sides A and B, is utilized by the

TWR-56F8400, while the Secondary Elevator connector only makes connections to ground (GND). On

sheet 8 of the schematic the J500A and J500B symbols have names assigned to the card edge fingers

that correspond with the normal Tower pin assignments.

2.2 System Power

The TWR-56F8400 board has three power rails. They are P5V_USB, P3_3V and P3_3V/5V. They are

sourced and used as follows:

2.2.1 P5V_USB

The P5V_USB power rail is derived from the Mini-B USB connector at J18 and the inductor at L2. It is

used to power the on board OSBDM/OSJTAG/Serial Bridge circuit. This consists of the OSBDM/OSJTAG

MCU at U6, several pull-up resistors at R13, R14, R15, R527, and R528, the USB power switch at U501,

and the STATUS and TPWR LEDs at D12 and D13. If there is no USB cable connected to J18 there is no

power on this rail and these circuits are all powered down.

2.2.2 P3_3V

The P3_3V power rail is derived from a) the P3_3V_MOTOR power net from the motor control board

connector at J501, b) the P3_3V_ELEV power net from the tower connector at J500, or c) the on board

3.3V regulator at U1. The selection of which source is made with a shunt from J7-2 to another pin of J7

or to J6. Table 6 shows the operation of the different shunt positions. The selection of power into the

regulator is made with a shunt from J11-2 to another pin of J11 or to J10 which selects from a) the

P5V_TRG_USB power net out of the USB switch at U501, b) the P5V_ELEV power net from the elevator

connection at J500 pins A1 and B1, or c) the PWR_IN power net from the 2mm barrel jack at J3 through

resettable fuse F1. Table 6 shows the operation of the different shunt positions. The barrel jack input is

protected from reverse voltage inputs by diode D11. The input to the barrel jack may be from a 5V to

9V source and needs to be center positive.

TWR-56F8400 User’s Manual Page 6 of 35

Page 7

The P3_3V power rail provides power to the majority of the circuits on the board including the

MC56F84789 (including the analog power pins through L500 and L501), inverters at U500 and U502, a

buffer at U505, the on board LEDs at D1-D9, the thermistor divider circuits at RT1-RT4, and the pull-up

resistors at R2, R3, R11, R565, R570, and R562.

2.2.3 P3_3V/5V

The P3_3V/5V power rail is derived from the diode OR (using D500 and D501) of a) the P5V_ELEV

power net from the elevator connection (J500 pins A1 and B1), b) the P5V output of the USB power

switch at U501, or c) the P3_3V power rail from J7. When there is a USB cable connected or when the

tower elevator boards are connected this power rail will be a Schottky diode drop (about 0.3V) below

the 5V power nets. When there is no 5V source this power rail will be a Schottky diode drop below the

P3.3V power rail. This allows the inputs of the ICs powered by this rail to stay in a high impedance state

instead of loading down the inputs through the input protection diodes as would happen if there were

no power supplied to the buffers.

2.2.4 Default Power Configuration

The TWR-56F8400 board default power configuration uses the OSBDM/OSJTAG USB port for all power.

As soon as the OSBDM/OSJTAG firmware has started it negotiates with the Host PC USB port for full

USB power. Once approved it enables the 5V USB power switch (U501) which provides 5V to the

P3_3V/5V power rail and to the 3.3V regulator (U1) through headers J10 and J11. Likewise, the on

board voltage regulator provides 3.3V to the P3_3V power rail through headers J6 and J7. The 3.3V

regulator is able to provide up to 700 mA subject to the power dissipation and temperature limits of

the device.

2.3 MC56F84789 DSC

The primary circuits on the board are related to the MC56F84789 DSC. This part is supplied in a surface

mounted 100pin LQFP package at U2. Although the board was laid out to allow a ZIF socket at U3 in

parallel to the chip at U2 the TWR-56F8400 is only available for purchase with the surface mounted

chip.

2.3.1 Clock Sources for the MC56F84789 DSC

Three options are provided for clocking the MC56F84789 device:

1. Oscillator internal to the MC56F84789 chip – approximately 8 MHz.

2. 8 MHz crystal

3. External clock input from Primary Tower Connector or the AUX Connector.

The internal oscillator is used to clock the MC56F84789 immediately following reset. This is the default

operation. In this mode the zero ohm resistors at R4 and R10 allow the GPIOC0 and GPIOC1 pins of the

MC56F84789 to be used as inputs or outputs.

TWR-56F8400 User’s Manual Page 7 of 35

Page 8

2

GPIOF8/RXD0/TB1 from the 56F84789

To use an external crystal with the MC56F84789, zero ohm resistors R4 and R10 must be removed and

placed in the R5 and R7 positions. The desired crystal, load capacitors, and parallel resistor (if needed)

must be soldered to the board at Y1, C5, C6, and R6. (These components are not provided with the

TWR-56F8400 kit.) Following reset, reconfigure the GPIOC0 and GPIOC1 pins to the XTAL and EXTAL

functions to allow the use of an external crystal.

To use an external clock for the MC56F84789 make sure the zero ohm resistors are installed at R4 and

R10 and removed from R5 and R7. Provide a clock signal on either the Primary Tower Connector J500A

- pin B24 (the pin designated as CLOCKIN0) or on the AUX connector J502 - pin 8. Following reset,

configure the GPIOC0 pin to the CLKIN input function. In this mode the zero ohm resistor at R10 allows

the GPIOC1 pin of the MC56F84789 (pin 10) to be used as an input or output.

2.3.2 Serial I/O Source Select Headers

The TWR-56F8400 board allows the UART functions of the MC56F84789 DSC to be connected to a

serial interface at the primary Tower Connector J500A or through a USB bridge to the Host PC using the

OSBDM/OSJTAG MCU (U6). The selection of the RXD connections is done with the header at J8 as

shown in Table 1. The selection of the TXD connections is done with the header at J9 as shown in Table

2.

Table 1. J8 – RXD Source Select Header

J8 – RXD Source Select Header

Pin # Connected Signal Description

1 ELEV_RXD0 at J500A pin A41 Shunt pins 1 and 2 together to connect the DSC

RXDO pin to the primary Tower Connector RXD0

pin. (This is a default position.)

DSC – pin 6 (RXD0 function)

3 RXD_SEL from the USB bridge

function on the OSBDM/OSJTAG

MCU.

4 GPIOF5/RXD1/XB_OUT5 from the

56F84789 DSC – pin 42 (RXD1

function)

5 ELEV_RXD1 at J500 pin A43 Shunt pins 4 and 5 together to connect the DSC

Shunt pins 2 and 3 together to connect the DSC

RXD0 pin to the USB serial bridge function.

Shunt pin 3 and 4 together to connect the DSC

RXD1 pin to the USB serial bridge function.

RXD1 pin to the primary Tower Connector RXD1

pin. (This is a default position.)

TWR-56F8400 User’s Manual Page 8 of 35

Page 9

Table 2. J9 – TXD Source Select Header

J9 – TXD Source Select Header

Pin # Connected Signal Description

1 ELEV_TXD0 at J500A pin A42 Shunt pins 1 and 2 together to connect the DSC

TXDO pin to the primary Tower Connector TXD0

pin. (This is a default position.)

2 GPIOC2/TXD0/TB0/XB_IN2/CLKO

from the 56F84789 DSC – pin 5 (TXD0

function)

3 TXD_SEL to the USB bridge function

on the OSBDM/OSJTAG MCU.

4 GPIOF4/TXD1/XB_OUT4 from the

56F84789 DSC – pin 41 (TXD1

function)

5 ELEV_TXD1 at J500 pin A44 Shunt pins 4 and 5 together to connect the DSC

As can be seen in the tables the 56F84789 DSC serial signals may be connected to either the Tower

serial signals or to the USB bridge chip; however, only one channel may be connected to the USB

bridge chip. If the associated 56F84789 DSC serial pins are not being used for the serial functions the

shunts should be removed from those pins. For more information on the USB Serial Bridge function see

section 2.4.2 USB Serial Bridge Interface.

Shunt pins 2 and 3 together to connect the DSC

TXD0 pin to the USB serial bridge function.

Shunt pin 3 and 4 together to connect the DSC

TXD1 pin to the USB serial bridge function.

TXD1 pin to the primary Tower Connector TXD1

pin. (This is a default position.)

2.3.3 LEDs Controlled by the MC56F84789 DSC

There are nine LEDs with buffers connected to the MC56F84789 DSC. Inverting buffers (U500A-F and

U502D-F) isolate the LEDs from the DSC pins by providing high impedance inputs. The LEDs are

powered by the P3_3V rail and draw about 5mA each. Table 3 shows the DSC pin names associated

with each LED.

Table 3. LEDs Controlled by the MC56F84789 DSC

LEDs Controlled by the MC56F84789 DSC

MC56F84789 DSC

Pin Name

GPIOE0/PWMA_0B 68 D1 E0 Green

GPIOE1/PWMA_0A 69 D2 E1 Yellow

GPIOE2/PWMA_1B 74 D3 E2 Green

GPIOE3/PWMA_1A 75 D4 E3 Yellow

TWR-56F8400 User’s Manual Page 9 of 35

MC56F84789

Pin Number

LED

Reference

LED

Label

LED

Color

Page 10

GPIOE4/PWMA_2B/XB_IN2 82 D5 E4 Green

GPIOE5/PWMA_2A/XB_IN3 83 D6 E5 Yellow

GPIOE6/PWMA_3B/XB_IN4/PW

MB_2B

GPIOE7/PWMA_3A/XB_IN5/PW

MB_2A

GPIOF6/TB2/PWMA_3X/PWMB_

3X/XB_IN2

84 D7 E6 Green

85 D8 E7 Yellow

94 D9 F6 Amber

2.3.4 Motor Control Connector

The TWR-56F8400 board may be connected to a motor control board such as the APMOTOR56F8000E.

The motor control connector (J501) is on the bottom of the board to provide a convenient connection

to the motor control board.

Some of the MC56F84789 DSC pins are connected to the motor control connector. Those pins

associated with analog inputs have 100 ohm resistors in series to provide some ESD protection for the

analog inputs of the DSC. Those pins providing analog signals from the motor control board have 2200

pf caps with the resistors to provide a low pass filter. The connector pin out is shown in Table 4.

Table 4. Motor Control Connector Pin Out

Motor Control Connector J501 Pin Out

Pin

#

1 P3_3V_MOTOR 2 GPIOB7/ANB7&ANC15&CMPB_IN2

3 GND 4 RESETB/ GPIOD4

5 GPIOF4/TXD1/XB_OUT8 6 GPIOA3/ANA3&VREFLA&CMPA_IN2

7 GPIOF3/SDA1/XB_OUT7 8 GND

9 GPIOE1/PWMA_0A 10 GPIOA0/ANA0&CMPA_IN3/CMPC_O

11 GPIOE0/PWMA_0B 12 GPIOA1/ANA1&CMPA_IN0

13 GPIOC3/TA0/CMPA_O/RXD0/CLKIN1 14 GPIOA2/ANA2&VREFHA&CMPA_IN1

15 GPIOC13/TA3/XB_IN6/EWM_OUT_B 16 GND

MC56F84789 DSC Signal Pin

#

MC56F84789 DSC Signal

(With 100 ohms in series)

(With 0 ohms in series – remove to

isolate)

(With 100 ohms in series)

(With 100 ohm, 2200 pf low pass filter)

(With 100 ohm, 2200 pf low pass filter)

(With 100 ohm, 2200 pf low pass filter)

TWR-56F8400 User’s Manual Page 10 of 35

Page 11

Motor Control Connector J501 Pin Out

Pin

#

17 GPIOC4/TA1/CMPB_O/XB_IN8/EWM_OUT_B 18 GPIOB0/ANB0&CMPB_IN3

19 GPIOC6/TA2/XB_IN3/CMP_REF 20 GPIOB1/ANB1&CMPB_IN0

21 GPIOC15/SCL0/XB_OUT5 22 GPIOB2/ANB2&VREFHB&CMPC_IN3

23 GPIOC14/SDA0/XB_OUT4 24 GND

25 TDI /GPIOD0 26 GPIOE7/PWMA_3A/XB_IN5/PWMB_2A

27 TDO/ GPIOD1 28 GPIOE6/PWMA_3B/XB_IN4/PWMB_2B

29 TCK/GPIOD2 30 GPIOE3/PWMA_1A

31 TMS /GPIOD3 32 GPIOE2/PWMA_1B

33 GPIOB3/ANB3&VREFLB&CMPC_IN0

35 GPIOB4/ANB4&ANC12&CMPC_IN1

37 GPIOB5/ANB5&ANC13&CMPC_IN2

39 GPIOB6/ANB6&ANC14&CMPB_IN1

MC56F84789 DSC Signal Pin

#

34 GPIOE5/PWMA_2A/XB_IN3

(With 100 ohms in series)

36 GPIOE4/PWMA_2B/XB_IN2

(With 100 ohms in series)

38 GPIOA4/ANA4&ANC8&CMPD_IN0

(With 100 ohms in series)

40 GPIOA5/ANA5&ANC9

(With 100 ohms in series)

MC56F84789 DSC Signal

(With 100 ohm, 2200 pf low pass filter)

(With 100 ohm, 2200 pf low pass filter)

(With 100 ohm, 2200 pf low pass filter)

(With 100 ohms in series)

(With 100 ohms in series)

2.3.5 Auxiliary Connectors

In addition to the motor control connector the TWR-56F8400 board also provides two auxiliary

connectors (J502 and J503) on the bottom of the board. These connectors provide access to the

MC56F84789 DSC signals that are not covered by the motor control connector. Those pins associated

with analog inputs have 100 ohm resistors in series to provide some ESD protection for the analog

inputs of the DSC. The connector pin out is shown in Table 5.

Table 5. Auxiliary Connector J502 Pin Out

Auxiliary Connectors J502 and J503 Pin Out

Pin

#

J50

2-1

J50

2-3

TWR-56F8400 User’s Manual Page 11 of 35

MC56F84789 DSC Signal Pin

#

GPIOF0/XB_IN6/TB2/SCK1 J50

2-2

GPIOF1/CLKO1/XB_IN7/CMPD_O J50

2-4

MC56F84789 DSC Signal

GPIOA6/ANA6&ANC10

(With 100 ohms in series)

GPIOA7/ANA7&ANC11

(With 100 ohms in series)

Page 12

Auxiliary Connectors J502 and J503 Pin Out

Pin

#

J50

2-5

J50

2-7

J50

2-9

J50

2-

11

J50

2-

13

J50

2-

15

J50

2-

17

J50

2-

19

J50

2-

21

J50

2-

23

J50

2-

25

J50

3-1

J50

3-3

J50

3-5

MC56F84789 DSC Signal Pin

GPIOF2/SCL1/XB_OUT6 J50

GPIOF5/RXD1/XB_OUT9 J50

GPIOF6/TB2/PWMA_3X/PWMB_3X/XB_I

N2

GPIOF7/TB3/CMPC_O/SS1_B/XB_IN3 J50

GPIOF8/RXD0/TB1/CMPD_O J50

GPIOC11/CANTX/SCL1/TXD1 J50

GPIOC12/CANRX/SDA1/RXD1 J50

GND J50

No Connection J50

No Connection J50

No Connection J50

GPIOA8/ANC16&CMPD_IN1 J50

GPIOA9/ANC17&CMPD_IN2 J50

GPIOA10/ANC18&CMPD_IN3 J50

#

2-6

2-8

J50

2-

10

2-

12

2-

14

2-

16

2-

18

2-

20

2-

22

2-

24

2-

26

3-2

3-4

3-6

MC56F84789 DSC Signal

GND

GPIOC0/EXTAL/CLKIN0

GPIOC1/XTAL

GPIOC2/TXD0/TB0/XB_IN2/CLKO0

GPIOC5/DACO/XB_IN7

GPIOC7/SS0_B/TXD0

GPIOC8/MISO0/RXD0/XB_IN9

GPIOC9/SCK0/XB_IN4

GPIOC10/MOSI0/XB_IN5/MISO0

No Connection

No Connection

GPIOF12/MISO1/PWMB_FAULT2

GPIOF13/MOSI1/PWMB_FAULT1

GPIOF14/SCK1/PWMB_FAULT0

TWR-56F8400 User’s Manual Page 12 of 35

Page 13

Auxiliary Connectors J502 and J503 Pin Out

Pin

#

J50

3-7

J50

3-9

J50

3-

11

J50

3-

13

J50

3-

15

J50

3-

17

J50

3-

19

J50

3-

21

J50

3-

23

J50

3-

25

J50

3-

27

J50

3-

29

J50

3-

31

MC56F84789 DSC Signal Pin

GPIOA11/ANC19&VREFHC J50

GPIOB8/ANC20&VREFLC J50

GPIOB9/ANC21/XB_IN9/MISO2 J50

GPIOB10/ANC22/XB_IN8/MOSI2 J50

GPIOB11/ANC23/XB_IN7/SCK2 J50

GPIOD5/RXD2/XB_IN5/XB_OUT9 J50

GPIOD6/TXD2/XB_IN4/XB_OUT8 J50

GPIOD7/XB_OUT11/XB_IN7/MISO1 J50

GPIOE8/PWMB_2B/PWMA_FAULT0 J50

GPIOE9/PWMB_2A/PWMA_FAULT1 J50

GPIOF9/

RXD2/PWMA_FAULT7/PWMB_FAULT7/X

B_OUT11

GPIOF10/TXD2

/PWMA_FAULT6/PWMB_FAULT6/XB_OU

T10

GPIOF11/TXD0/XB_IN11 J50

MC56F84789 DSC Signal

#

GPIOF15/RXD0/XB_IN10

3-8

GPIOG0/PWMB_1B/XB_OUT6

3-

10

GPIOG1/PWMB_1A/XB_OUT7

3-

12

GPIOG2/PWMB_0B/XB_OUT4

3-

14

GPIOG3/PWMB_0A/XB_OUT5

3-

16

GPIOG4/PWMB_3B/PWMA_FAULT2

3-

18

GPIOG5/PWMB_3A/PWMA_FAULT3

3-

20

GPIOG6/PWMA_FAULT4/PWMB_FAULT4/TB2

3-

22

GPIOG7/PWMA_FAULT5/PWMB_FAULT5/XB_

3-

24

GPIOG8/PWMB_0X/PWMA_0X/TA2/XB_OUT1

3-

26

J50

GPIOG9/PWMB_1X/PWMA_1X/TA3/XB_OUT1

3-

28

J50

GPIOG10/PWMB_2X/PWMA_2X/XB_IN8/SS_B

3-

30

GPIOG11/TB3/CLKO0/MOSI1

3-

32

/XB_OUT8

OUT9

0

1

2

TWR-56F8400 User’s Manual Page 13 of 35

Page 14

2.3.6 Tower Elevator Connectors

The TWR-56F8400 board features two expansion card-edge connectors that interface to Elevator

boards in a Tower System: the Primary and Secondary Elevator connectors. The Primary Elevator

connector, comprised of sides A and B, is utilized by the TWR-56F8400 board, while the Secondary

Elevator connector only makes connections to ground (GND). Table 7 in Appendix A – Tower Elevator

Connector Pin Functions lists the pin functions for the Primary Elevator Connector.

2.3.7 Thermistors as Analog Inputs

The TWR-56F8400 board provides four thermistors (RT1-4) near the corners of the board that can be

used as single ended or differential analog inputs to the MC56F84789 DSC as can be seen on sheet 6 of

the schematic. In addition to each thermistor there is a resistor between the thermistor and P3_3V and

another resistor between the thermistor and ground. The thermistors are all 10K ohm parts but the

associated divider chain uses different resistors. This makes the voltage across the thermistor larger or

smaller and provides the ability to try the different gain settings on the analog channels. All four

thermistor circuits are designed to provide useable differential inputs over the temperature range of

90˚C to -20˚C. RT2 and RT4 both give a differential voltage of ~1.65V at 25˚C. RT1 gives a differential

voltage of 0.10V and RT3 gives a differential voltage of 0.28V at 25 ˚C.

In addition to the thermistor voltage divider chain each thermistor has a 0.1 uF capacitor in parallel.

Each thermistor circuit also has a header that allows the thermistor to be disconnected from the

analog inputs to the DSC. If a user wishes to apply an external analog value these headers may be

removed and the external analog signal attached to the DSC side of the headers. Finally, each analog

input to the DSC has a 100 ohm series resistor and a 2200 pF capacitor as a low pass filter. This helps

protect the DSC from electrostatic discharges and lowers the impedance of the analog signal so that it

can be sampled with less noise.

2.3.8 CAN Transceiver

The TWR-56F8400 board has a CAN transceiver circuit that may be connected to the CAN pins of the

DSC. The CAN transceiver (U503) can be connected to the GPIOC11/CANTX/SCL1/TXD1 and

GPIOC12/CANRX/SDA1/RXD1 pins of the DSC through the header at J16. Installing a shunt from pin 1 to

pin 2 connects the TXD nets and installing a shunt from pin 3 to pin 4 connects the RXD nets. Note that

the GPIOC11/CANTX/SCL1/TXD1 and GPIOC12/CANRX/SDA1/RXD1 nets also go to the primary elevator

edge connector (J500A) pins B41 and B42 and to the Auxiliary connector (J502) pins 15 and 17. When

using these nets for CAN communications care must be taken that these nets are not driven from these

other connectors.

The transceiver is capable of running from 3.3V and is powered by the P3_3V/5V power rail. The

transceiver output is connected to header J13 with CANH connected to pin 4 and CANL connected to

TWR-56F8400 User’s Manual Page 14 of 35

Page 15

pin 3. A 120 ohm parallel termination resistor,R560, may be connected between these nets by

installing a shunt on header J15.

2.3.9 IRQ or Input Pushbuttons

The TWR-56F8400 board has two pushbuttons (SW1 and SW2) that can be used to provide inputs or

interrupts to the DSC. Each has a 10K ohm pull up resistor to P3_3V and a 0.1 uF capacitor to ground to

minimize bounce on the output.

Pushbutton SW1 is connected to header J4 where the switch output can be connected to either DSC

pin GPIOC2/TXD0/TB0/XB_IN2/CLKO0 (default) or GPIOF6/TB2/PWMA_3X/PWMB_3X/XB_IN2

depending on the position of the shunt on the header (pin 1 to pin 2 is the default). Similarly,

pushbutton SW2 is connected to header J5 where the switch output can be connected to either DSC

pin GPIOF8/RXD0/TB1/CMPD_O (default) or GPIOF7/TB3/CMPC_O/SS1_B/XB_IN3 depending on the

position of the shunt on the header (pin 1 to pin 2 is the default).

If the pushbutton switches are not being used as an interrupt, or other purpose, it is best to remove

the shunt to the DSC so that the 0.1 uF capacitor is not loading down the DSC pins.

2.3.10 RESET

The GPIOD4/RESET_B pin of the DSC is connected to the motor control connector and the tower

connector but also to a pushbutton (SW3) and through buffers to the OSBDM/OSJTAG chip. It is pulled

to P3_3V by a 10K ohm resistor. It may be pulled low by the pushbutton or by Q1 in response to a high

output from the OSBDM/OSJTAG chip (pin 1) on the TRESET_OUT net. The state of the

GPIOD4/RESET_B signal is provided to the OSBDM/OSJTAG chip through a voltage translator (U504B).

This buffer is powered by the P3_3V/5V power rail so that its input will remain high impedance when

there is no USB cable connected. The buffered RESET signal is provided to pin 33 of the

OSBDM/OSJTAG chip and is used by the OSBDM/OSJTAG program in that chip.

2.3.11 JTAG Header and OSBDM/OSJTAG Disconnect Header

The TWR-56F8400 board includes an OSBDM/OSJTAG circuit as a debug interface to the MC56F84789

DSC for normal purposes. If the user desires to use a different debugger connection, header J14

provides a connection point for an external JTAG aware debugger. If an external debugger is connected

to the JTAG header the shunts at J21 (pins 1 to 2, 3 to 4, 5 to 6, and 7 to 8) which connect the

OSBDM/OSJTAG circuit to the JTAG signals should be removed, allowing the external debugger to

control the JTAG port, rather than the ‘JM60.

The TWR-56F8400 board provides a 2.2K ohm pull up resistor to 3.3V on the TMS line. If an external

JTAG aware debugger also has a pull up on this line, the external debugger may not be able to pull the

TMS line low. If this happens, remove one of the pull up resistors on the TMS line.

TWR-56F8400 User’s Manual Page 15 of 35

Page 16

2.4 OSBDM/OSJTAG

2.4.1 Debug Interface

An on-board MC9S08JM60 based Open Source BDM (OSBDM/OSJTAG) circuit provides a debug

interface to the MC56F84789. A standard USB A male to Mini-B male cable (supplied) can be used for

debugging via the USB connector, J18.

2.4.2 USB Serial Bridge Interface

The on-board MC9S08JM60 can also be used as a USB to Serial bridge interface for the UART signals

from the MC56F84789 DSC. This bridge circuit is described in detail in section 2.3.2 Serial I/O Source

Select Headers.

The RXD_SEL signal goes to the MC56F84789 DSC. The USB bridge chip is powered by 5V so its output

is a 5V output. The buffer (U505) is able to accept the 5V signal from the USB bridge chip (T_TXD1) and

converts it to the 3.3V signal (RXD_SEL) for the DSC. The buffer output is enabled by an inverted RTS

signal (TXD_RXD_EN_B) from the USB bridge chip. If there is no USB connection to the TWR board the

RTS signal is not driven and the 3.3V powered inverter (U502C) input is biased low disabling the output

of the buffer.

In a similar way TXD_SEL is a 3.3V signal from the MC56F84789 DSC. The USB bridge chip is expecting a

5V input on T_RXD1. The buffer between these two signals (U504C) is powered by P3_3V/5V. It will

accept the 3.3V input from the DSC and convert it to the 5V signal needed by the USB bridge chip. The

buffer output is enabled by the same inverted RTS signal (TXD_RXD_EN_B) discussed above. If there is

no USB connection to the TWR board, the RTS signal is not driven and the 5V powered buffer disabled

so nothing is driving the powered down USB bridge chip.

The serial interface signals from the MC56F84789 DSC may be routed to the MC9S08JM60 serial

interface via header and Berg straps. Using the USB serial bridge the MC9S08JM60 will convert the

serial interface data into USB packets and send them to the host PC where they may be handled by a

PC application normally conversant with a serial port.

2.4.3 Clocking the OSBDM/OSJTAG MCU (MC9S08JM60)

The MC9S08JM60 MCU uses an on board 4 MHz external crystal circuit (Y2, R16, C7, and C9) for its

clock. There are no user options for clocking the MC9S08JM60.

2.4.4 Reserved Function Select Header

Header J20 selects whether the on-board MC9S08JM60 MCU operates as an OSBDM/OSJTAG debug

interface or as a USB Serial Bridge interface on older versions of S08 firmware such as may have existed

TWR-56F8400 User’s Manual Page 16 of 35

Page 17

on prototypes of the TWR56F8400. Leaving the shunt on the header enables the OSBDM/OSJTAG

debug interface. Removing the shunt on header J20 enables the USB Serial Bridge interface. The

header, J20, is subsequently reserved for future use.

2.4.5 Bootloader Enable

In addition to the OSBDM/OSJTAG Debug interface and the USB Serial Bridge interface the

MC9S08JM60 device used in the OSBDM/OSJTAG circuit is preprogrammed with a USB Bootloader.

The USB Bootloader will run following a power-on reset if a shunt is installed on header J17. This

allows in-circuit reprogramming of the JM60 flash memory via USB. This enables the OSBDM/OSJTAG

firmware to be upgraded by the user when upgrades become available. In normal OSBDM/OSJTAG /

USB Serial Bridge operation this shunt must be left off. For details on the USB Bootloader, refer

to Application Note AN3561 on the Freescale website (http://www.freescale.com

The USB Bootloader communicates with a GUI application running on a host PC. The GUI application

can be found on the Freescale website; search keyword “JM60 GUI”. Refer to section 2.5 and 3.3 of

AN3561 for details on installing and running the application.

2.4.6 BDM Header

The BDM header at J22 is used for initial programming of the MC9S08JM60 MCU or if reprogramming

when the bootloader fails. An external 9S08 BDM debugger would be connected to J22 and used to

program the MCU. This is not expected to be a normal user interface, however it is useful if the ‘JM60

device is inadvertently reprogrammed with firmware that is not functional.

2.4.7 OSBDM/OSJTAG Status LEDs

The MC9S08JM60 OSBDM/OSJTAG MCU controls two status LEDs at D12 and D13. Refer to the

OSBDM/OSJTAG instructions for the meaning of the LEDs.

2.4.8 OSBDM/OSJTAG Voltage Translation

Since the OSBDM/OSJTAG MCU runs from 5V and the 56F84789 DSC runs from 3.3V there needs to be

voltage translation between the two circuits. This is done through U505, U504A and U502B. U505 has

5V tolerant inputs and provides 3.3V signals (TCK, TDI, and TMS) to the DSC’s JTAG pins through the

shunts on header J21. U504A is powered by the P3_3V/5V rail and translates the 3.3V TDO signal from

the DSC to a 5V signal for the OSBDM/OSJTAG MCU. The outputs of both of these translators are high

impedance if the signal OUT_EN_B goes high. This happens if the OSBDM/OSJTAG circuit looses power

(no power to the USB connector). In that case the OUT_EN signal from the OSBDM/OSJTAG MCU (pin

15) is biased low by R12. The inverter at U502B then drives OUT_EN_B high in response. Additional

information is included in section 2.4.2.

TWR-56F8400 User’s Manual Page 17 of 35

Page 18

Jumper

Function

Shunts

Description

1-2, 3-4

Connect RT1 circuit to the MC56F827 DSC

none

Disconnect RT1 circuit from the MC56F84789 DSC

1-2, 3-4

Connect RT2 circuit to the MC56F827 DSC

none

Disconnect RT2 circuit from the MC56F84789 DSC

1-2

Connect SW1 to MC56F84789 DSC pin

GPIOC2/TXD0/TB0/XB_IN2/CLKO0

3-4

Connect SW1 to MC56F84789 DSC pin

GPIOF6/TB2/PWMA_3X/PWMB_3X/XB_IN2

none

Disconnect SW1 from the MC56F84789 DSC

1-2

Connect SW2 to MC56F84789 DSC pin

GPIOF8/RXD0/TB1/CMPD_O

3-4

Connect SW2 to MC56F84789 DSC pin

GPIOF7/TB3/CMPC_O/SS1_B/XB_IN3

none

Disconnect SW2 from the MC56F84789 DSC

J6-1 to

J7-2

Connect the on-board voltage regulator to the

P3_3V power rail

J7-1 to

J7-2

Connect P3_3V_MOTOR to the P3_3V power rail

(power the 3.3V rail from the motor control connector)

J7-2 to

Connect P3_3V_ELEV to the P3_3V power rail

J7-2

open

Disconnect the P3_3V power rail – no power

1-2

Connect ELEV_RXD0 from the Tower connector

2-3

Connect RXD_SEL from the USB Serial Bridge to

GPIOF8/RXD0/TB1/CMPD_O

open

Disconnect MC56F84789 DSC pin

GPIOF8/RXD0/TB1/CMPD_O

3-4

Connect RXD_SEL from the USB Serial Bridge to

MC56F84789 DSC pin GPIOF5/RXD1/XB_OUT9

4-5

Connect ELEV_RXD1 from the Tower connector

to MC56F84789 DSC pin GPIOF5/RXD1/XB_OUT9

open

Disconnect MC56F84789 DSC pin

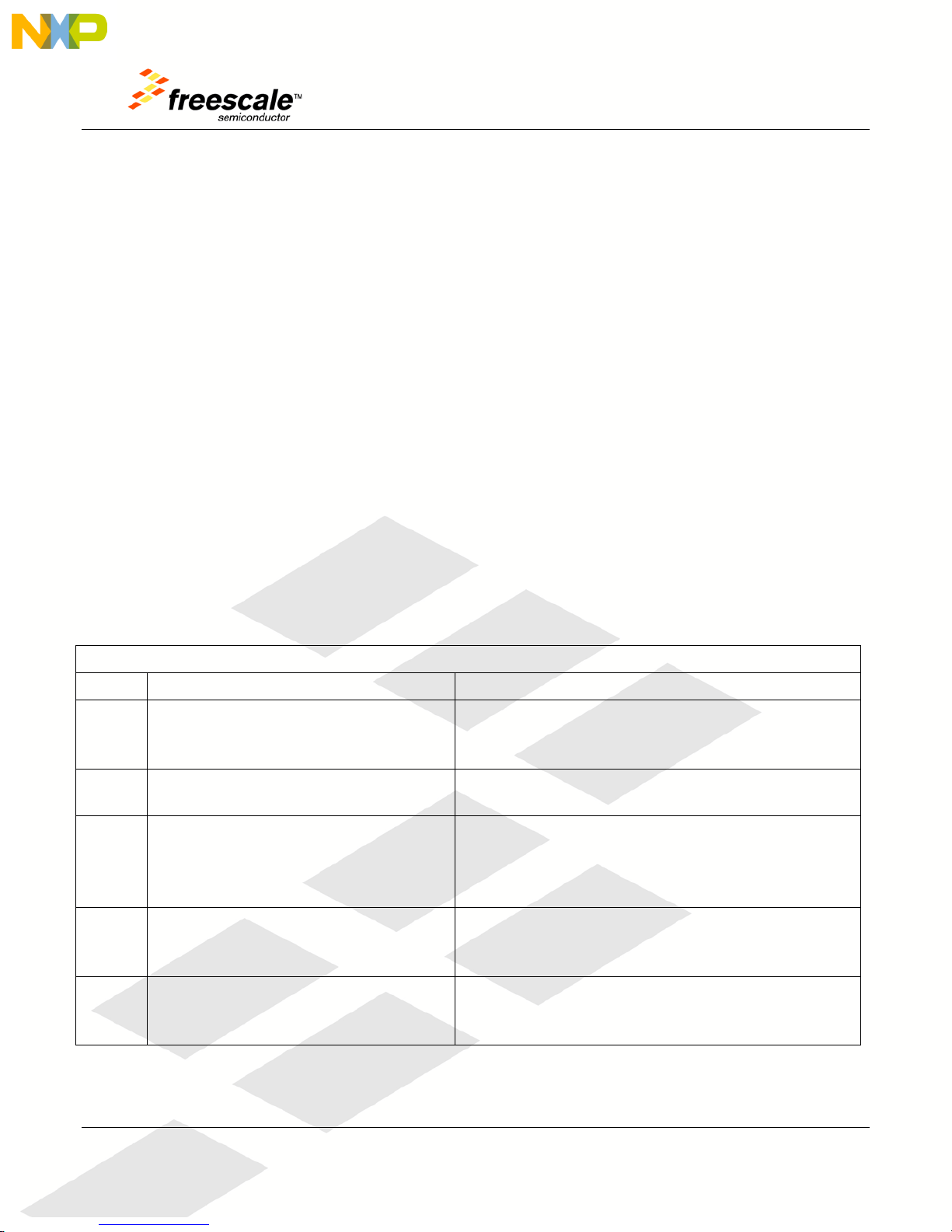

3 Jumper Table

There are several headers provided for isolation, configuration, and feature selection. Refer to Table 6

for details. The default shunt positions are shown in bold.

Table 6. TWR-56F8400 Jumper Table

J1 Thermistor RT1 Connect

J2 Thermistor RT2 Connect

J4 IRQ1 Select

J5 IRQ0 Select

J6 and

J7

J8

3.3V Source Select

RXD Source Select (note that

only one connection can be

made to pin 3 at a time)

J7-3

Pin 2

(power the 3.3V rail from the tower connector)

to MC56F84789 DSC pin

GPIOF8/RXD0/TB1/CMPD_O

MC56F84789 DSC pin

TWR-56F8400 User’s Manual Page 18 of 35

Pin 4

GPIOF5/RXD1/XB_OUT9

Page 19

Jumper

Function

Shunts

Description

1-2

Connect ELEV_TXD0 from the Tower connector

GPIOC2/TXD0/TB0/XB_IN2/CLKO0

2-3

Connect TXD_SEL from the USB Serial Bridge to

open

Disconnect MC56F84789 DSC pin

3-4

Connect TXD_SEL from the USB Serial Bridge to

4-5

Connect ELEV_TXD1 from the Tower connector

to MC56F84789 DSC pin GPIOF4/TXD1/XB_OUT8

open

Disconnect MC56F84789 DSC pin

J10-1 to

J11-2

Connect the power in barrel connector (through fuse

F1) to the input of the 3.3V voltage regulator

J11-1 to

J11-2

Connect P5V_TRG_USB (the switched USB 5V) to

the input of the 3.3V voltage regulator

J11-2 to

J11-3

Connect P5V_ELEV to the input of the 3.3V voltage

regulator

open

Disconnect the input of the 3.3V voltage regulator

open

Unused

1-2

Connect the 120 ohm CAN termination resistor

open

No CAN termination

1-2, 3-4

Connect the CAN transceiver TXD and RXD to

GPIOC12/CANRX/SDA1/RXD1

open

Disconnect the CAN transceiver

1-2

Enable USB bootloading of the MCU Flash memory

open

Disable bootloading

1-2, 3-4

Connect RT3 circuit to the MC56F827 DSC

none

Disconnect RT3 circuit from the MC56F84789 DSC

1-2

Reserved-deprecated

none

Reserved-deprecated

1-2, 3-4,

5-6, 7-8

Connect the OSBDM/OSJTAG debug signals

(JTAG) to the MC56F84789 DSC JTAG pins

none

Disconnect OSBDM/OSJTAG from the MC56F84789

DSC

1-2, 3-4

Connect RT4 circuit to the MC56F827 DSC

none

Disconnect RT4 circuit from the MC56F84789 DSC

to MC56F84789 DSC pin

MC56F84789 DSC pin

GPIOC2/TXD0/TB0/XB_IN2/CLKO0

J9

TXD Source Select (note that

only one connection can be

made to pin 3 at a time)

Pin 2

GPIOC2/TXD0/TB0/XB_IN2/CLKO0

MC56F84789 DSC pin GPIOF4/TXD1/XB_OUT8

Pin 4

GPIOF4/TXD1/XB_OUT8

J10 and

J11

J12 Unused

J15 CAN Termination Enable

J16 CAN Enable

J17 MC9S08JM60 Bootload Enabl e

J19 Thermistor RT3 Connect

J20

J21

5V Source Select

RESERVEC /

OSBDM/OSJTAG Enable

OSBDM/OSJTAG Connect to

JTAG

J11-2

MC56F84789 DSC pins

GPIOC11/CANTX/SCL1/TXD1

J23 Thermistor RT4 Connect

TWR-56F8400 User’s Manual Page 19 of 35

Page 20

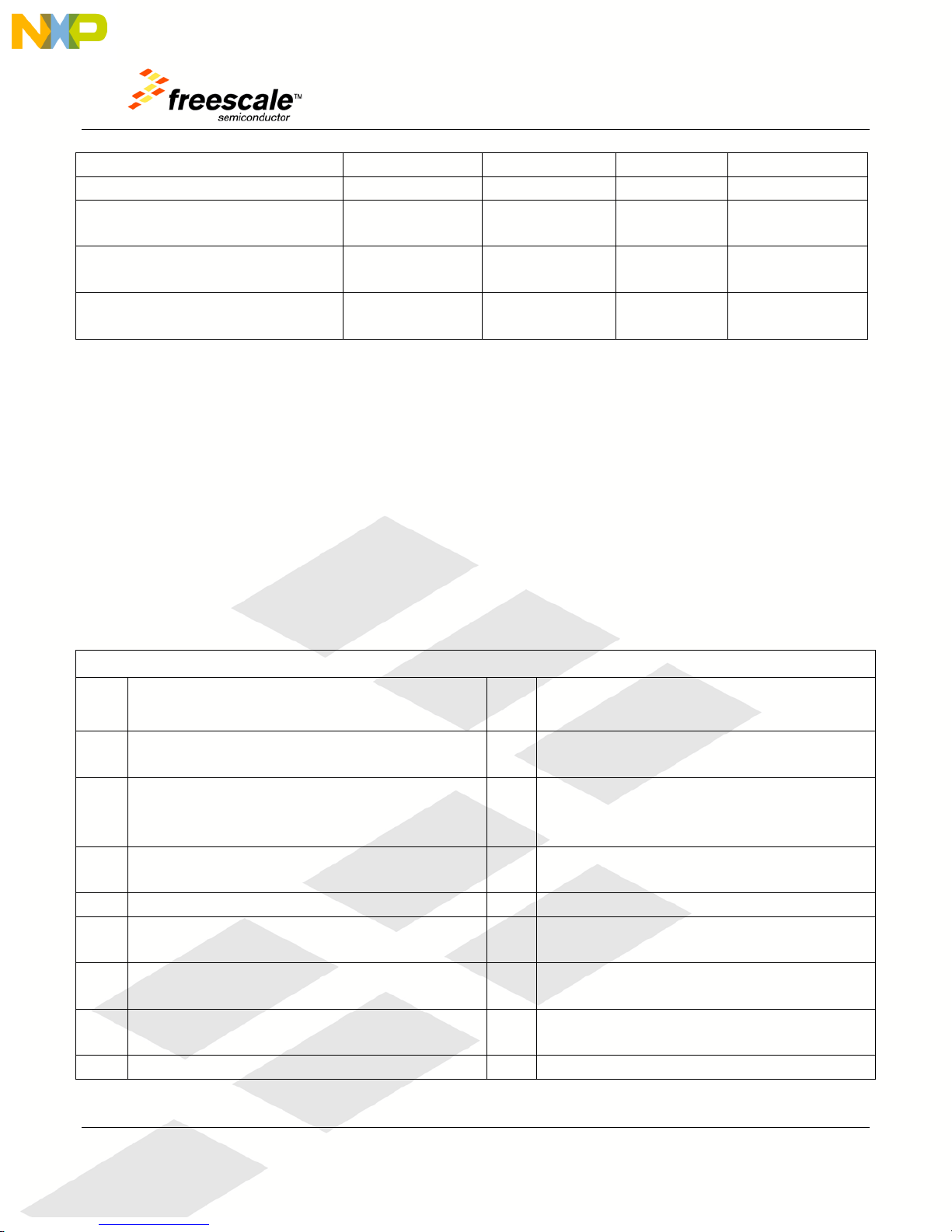

Appendix A – Tower Elevator Connector Pin Functions

Table 7 provides the pin out for the Primary Elevator Connector. An “X” in the “Used” column

indicates that there is a connection from the TWR-56F8400 board to that pin on the Elevator

connector. An “X” in the “Jmp” column indicates that a jumper is available that can isolate the

onboard circuitry from the Elevator connector. An “X” in the “Jmp” column indicates that a jumper is

available that can isolate part of the onboard circuitry from the Elevator connector.

The function listed in the “Usage” column is the function(s) that the pin is expected to be programmed

to provide when used with the Tower system. All of the MC56F84789 pins (except power) have

multiple functions. Not all of the possible functions are shown.

Note that all analog pins (ANAn or ANBn) have a low pass filter to ground consisting of a 100 ohm

resistor and a 2200 pf capacitor. This is to protect the analog inputs of the DSC from a static discharge

at one of the connectors. See schematic sheets 6 and 7 in Appendix B – TWR-56F8400 Board

Schematic.

Table 7. TWR-56F8400 Primary Elevator Connector Pin Out

TWR-56F8400 Primary Connector

Pin Name Usage Used Jmp Pin Name Usage Used Jmp

B1 5V_1 5V Power X X A1 5V_2 5V Power X X

B2 GND Ground X A2 GND_9 Ground X

B3 3.3V_1 3.3V Power X X A3 3.3V_4 3.3V Power X X

B4 ELE_PS_SENSE_1 3.3V Power X X A4 3.3V_5 3.3V Power X X

B5 GND_2 Ground X A5 GND_10 Ground X

B6 GND_3 Ground X A6 GND_11 Ground X

SDHC_CLK / SPI1_CLK SCK (see also pin B48)

B7

SDHC_D3 / SPI1_CS1_b

B8

SDHC_D3 / SPI1_CS0_b SS_B (see also pin B46)

B9

SDHC_CMD / SPI1_MOSI MOSI (see also pin B45)

B10

SDHC_D0 / SPI1_MISO MISO (see also pin B44)

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21 GPIO1 / UART1_RTS1 GPIOB4/ANB4&CMPC_M1 X

B22 GPIO2 / SDHC_D1 GPIOB5/ANB5&CMPC_M2 X

ETH_COL_1

ETH_RXER_1

ETH_TXCLK_1

ETH_TXEN_1

ETH_TXER

ETH_TXD3

ETH_TXD2

ETH_TXD1_1

ETH_TXD0_1

X

A8

X A9 GPIO9/UART1_CTS1

X

X

A7

A10 GPIO8/SDHC_D2

A11 GPIO7 / SD_WP_DET

A12

A13

A14

A15

A16

A17

A18

A19

A20

X

A21

X

A22

I2C0_SCL SCL0

I2C0_SDA SDA0

ETH_CRS

ETH_MDC_1

ETH_MDIO_1

ETH_RXCLK_1

ETH_RXDV_1

ETH_RXD3

ETH_RXD2

ETH_RXD1_1

ETH_RXD0_1

I2S0_MCLK

I2S0_DOUT_SCLK

GPIOA4/ANA4

GPIOA5/ANA5

GPIOA6/ANA6

X

X

X

X

X

X

X

X

TWR-56F8400 User’s Manual Page 20 of 35

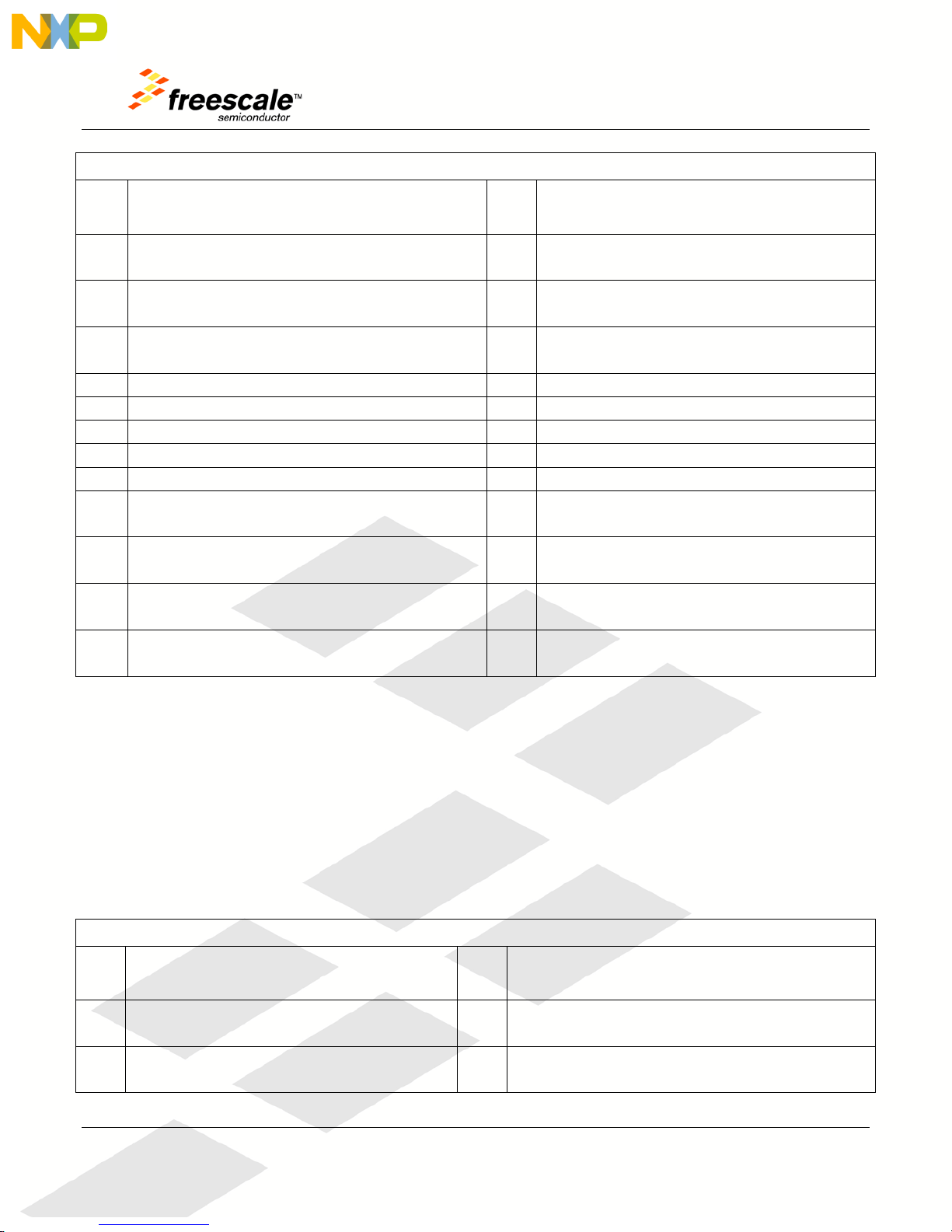

Page 21

TWR-56F8400 Primary Connector

Pin Name Usage Used Jmp Pin Name Usage Used Jmp

B23 GPIO3 GPIOB6/ANB6&CMPB_M1 X

B24 CLKIN0 XTAL&CLKIN X

B25 CLKOUT1 A25

B26 GND_4 Ground X A26 GND_12 Ground X

B27

B28

B29

B30

B31 GND_5 Ground X A31 GND_13 Ground X

B32

B33

B34

B35 GPIO4 GPIOB7/ANB7&CMPB_M2 X

B36 3.3V_2 3.3V Power X X A36 3.3V_6 3.3V Power X

B37

B38

B39

B40

B41

B42

B43

B44

B45

B46

B47

B48

B49 GND_6 Ground X A49 GND_14 Ground X

B50

B51

B52 GPIO5/SPI0_HOLD/IO3 GPIOF0 X A52 GPIO16/SPI0_WP/IO2

B53 RSRV_B53 A53 GPIO17

B54 RSRV_B54 A54

B55

B56

B57

B58

B59

B60

B61

B62

EBI_ALE / EBI_CS1_b

B63

B64

B65 GND_7 Ground X A65 GND_15 Ground X

B66 EBI_AD15

AN7 ANB3&CMPC_M0

AN6 ANB2&CMPC_P2

AN5 ANB1&VERFLB&CMPB_M0

AN4 ANB0&VERFHB&CMPB_P2

DAC1

TMR3 TA3

TMR2 TA2

PWM7 PWM3B

PWM6 PWM2B

PWM5 PWM1B

PWM4 PWM0B

CAN0_RX0 CANRX

CAN0_TX0 CANTX

1WIRE

SPI0_MISO/IO1 MISO (see also pin B11)

SPI0_MOSI/IO0 MOSI (see also pin B10)

SPI0_CS0_b SS_B (see also pin B9)

SPI0_CS1_b

SPI0_CLK SCK (see also pin B7)

I1C1_SCL1 SCL1

I2C1_SDA1 SDA1

IRQ_H

IRQ_G

IRQ_F

IRQ_E

IRQ_D

IRQ_C

IRQ_B TB1 (see also pin A41)

IRQ_A

EBI_CS0_b

TB0 (see also pin A42) X X A62

X

A23

X

A24

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X X A61

A27

A28

A29

A30

A32

A33

A34

X

A35 GPIO6 GPIOA7/ANA7 X

A37

A38

A39

A40

X

A41

X

A42

A43

A44

A45 VSSA

A46 VDDA

A47 CAN1_RX

A48 CAN1_TX

A50 GPIO14

A51 GPIO15

A55

A56

A57

A58

A59

A60

A63

A64 CLKOUT0 CLKO X

A66 EBI_AD14

I2S0_DOUT_WS

I2S0_DOUT_DIN0

I2S0_DOUT_DOUT0

AN3 ANA3&CMPA_M2

AN2 ANA2&CMPA_M1

AN1 ANA1&VREFLA&CMPA_M0

AN0 ANA0&VREFHA&CMPA_P2/CMPC_O

DAC0 DAC0

TMR1 TA1

TMR0 TA0

PWM3 PWM3A

PWM2 PWM2A

PWM1 PWM1A

PWM0 PWM0A

UART0_RX ELEV_RXD0 (see also pin B61)

UART0_TX ELEV_TXD0 (see also pin B62)

UART1_RX ELEV_RXD1

UART1_TX ELEV_TXD1

USB0_DM

USB0_DP

USB0_ID

USB0_VBUS

I2S0_DIN_SCK TB3

I2S0_DIN_WS TB2

I2S0_DIN1

I2S0_DOUT1

RSTIN_b RESET_B

RSTOUT_b RESET_B

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

TWR-56F8400 User’s Manual Page 21 of 35

Page 22

TWR-56F8400 Primary Connector

Pin Name Usage Used Jmp Pin Name Usage Used Jmp

B67 EBI_AD16

B68 EBI_AD17

B69 EBI_AD18

B70

B71

B72

B73

B74

B75

B76

B77

B78

B79

B80

B81 GND_8 Ground X A81 GND_16 Ground X

B82 3.3V_3 3.3V Power X X A82 3.3V_7 3.3V Power X

EBI_AD19

EBI_R/ W_b

EBI_OE_b

EBI_D7

EBI_D6

EBI_D5

EBI_D4

EBI_D3

EBI_D2

EBI_D1

EBI_D0

A67 EBI_AD13

A68 EBI_AD12

A69 EBI_AD11

A70 EBI_AD10

A71 EBI_AD9

A72 EBI_AD8

A73 EBI_AD7

A74 EBI_AD6

A75 EBI_AD5

A76 EBI_AD4

A77 EBI_AD3

A78 EBI_AD2

A79 EBI_AD1

A80 EBI_AD0

X

TWR-56F8400 User’s Manual Page 22 of 35

Page 23

Appendix B – TWR-56F8400 Board Schematic

The Schematic supplied a standalone PDF file. Please go to www.freescale.com/TWR-56F8400 to

download.

TWR-56F8400 User’s Manual Page 23 of 35

Page 24

Qty

Ref.

Mfr. Name

Mfr. Part Number

Mfr. Part Description

3

C508,C511,C

TDK

C1608X5R1A225K

CAP CER 2.2UF 10V 10% X5R 0603

VENKEL

C0603X5R100-225KNE

CAP CER 2.2UF 10V 10% X5R 0603

MURATA

GRM188R61A225KE34D

CAP CER 2.2UF 10V 10% X5R 0603

25

C3,C4,C8,C50

Yageo

CC0603KRX7R8BB104

CAP CER 0.10UF 25V 10% X7R 0603

MURATA

GRM188R71E104KA01

CAP CER 0.10UF 25V 10% X7R 0603

AVX

06033C104KAT2A

CAP CER 0.10UF 25V 10% X7R 0603

KEMET

C0603C104K3RAC

CAP CER 0.10UF 25V 10% X7R 0603

2

C7,C9

SKYMOS

0603CG180J500NT

CAP CER 18PF 50V 5% C0G 0603

VENKEL

C0603C0G500-180JNE

CAP CER 18PF 50V 5% C0G 0603

WALSIN

0603N180J500LT

CAP CER 18PF 50V 5% C0G 0603

KEMET

C0603C180J5GAC

CAP CER 18PF 50V 5% C0G 0603

AVX

06035A180JAT2A

CAP CER 18PF 50V 5% C0G 0603

MURATA

GRM1885C1H180JA01J

CAP CER 18PF 50V 5% C0G 0603

YAGEO

CC0603JRNPO9BN180

CAP CER 18PF 50V 5% C0G 0603

7

C1,C2,C506,C

WALSIN

0805X106K160CT

CAP CER 10UF 16V 10% X5R 0805

KYOCERA

CM21X5R106K16AT

CAP CER 10UF 16V 10% X5R 0805

Appendix C – TWR-56F8400 Board BOM

The BOM is supplied as an embedded worksheet object, just below. Right click on the object below

and select “Worksheet Object”, then “Open” to read the BOM or work with it as a spreadsheet.

545

COMPANY

0,C501,C503,

C505,C509,C

510,C513,C51

4,C515,C530,

C532,C533,C

535,C536,C53

7,C538,C539,

C542,C543,C

544,C546,C54

7

516,C520,C54

0,C541

WALSIN

TECHNOLOGY

CORP.

VENKEL

COMPANY

COMPANY

TECHNOLOGY

CORP.

AMERICA

TECHNOLOGY

CORP.

0603B104K250CT CAP CER 0.10UF 25V 10% X7R 0603

C0603X7R250-104KNE CAP CER 0.10UF 25V 10% X7R 0603

TWR-56F8400 User’s Manual Page 24 of 35

Page 25

AVX

0805YD106KAT2A

CAP CER 10UF 16V 10% X5R 0805

KEMET

C0805C106K4PAC

CAP CER 10UF 16V 10% X5R 0805

MURATA

GRM21BR61C106KE15L

CAP CER 10UF 16V 10% X5R 0805

15

C502,C504,C

SMEC

MCCE222K0NRTF

CAP CER 2200PF 50V 10% X7R 0402

1

C534

MURATA

GRM1885C1H102JA01D

CAP CER 1000PF 50V 5% C0G 0603

2

L1,L2

TDK

MPZ2012S331A

IND FER BEAD 330OHM@100MHZ 2.5A --

2

L500,L501

MURATA

BLM18BD601SN1D

IND 600 OHM@100MHZ 0.2A 25% 0603 SMT

3

J15,J17,J20

SAMTEC

HTSW-102-07-G-S

HDR 1X2 TH 100MIL SP 335H AU 95L

ANYTRONIC

090021S02015-2LF

HDR 1X2 TH 100MIL SP 339H AU 98L

SAMTEC

HTSW-102-07-SM-S

HDR 1X2 TH 100MIL SP 330H AU 100L

SAMTEC

TSW-102-07-G-S

HDR 1X2 TH 100MIL SP 330H AU 100L

3M

929647-01-02-EU

HDR 1X2 TH 100MIL SP 330H AU 100L

KEYSTONE

5001

TEST POINT BLACK 40 MIL DRILL 180 MIL

YAGEO

AMERICA

507,C512,C51

7,C518,C519,

C521,C522,C

523,C524,C52

5,C526,C527,

C528

CC0805KKX5R7BB106 CAP CER 10UF 16V 10% X5R 0805

WALSIN

TECHNOLOGY

CORP.

WALSIN

TECHNOLOGY

CORP.

CORPORATIO

N LIMITED

SAMTEC TSW-102-07-S-S HDR 1X2 TH 100MIL SP 330H AU 100L

FCI 77311-801-02LF HDR 1X2 TH 100MIL SP 330H AU 100L

ANYTRONIC

CORPORATIO

N LIMITED

1 TP4 COMPONENTS

CORPORATIO

N

0402B222K500CT CAP CER 2200PF 50V 10% X7R 0402

0603N102J500LT CAP CER 1000PF 50V 5% C0G 0603

SMT

090021S02018-2LF HDR 1X2 TH 100MIL SP 339H AU 98L

TP-105-01-00 TEST POINT PIN .100 x .45 BLACK TH

ELECTRONICS

KOBICONN 151-203-RC TEST POINT PIN .100 x .45 BLACK TH

4 J4,J5,J7,J11 Pinrex

Enterprise Co.,

Ltd

FCI 77311-801-03LF HDR 1X3 TH 100MIL SP 339H AU 118L

SAMTEC TSW-103-07-S-S HDR 1X3 TH 100MIL SP 339H AU 118L

TWR-56F8400 User’s Manual Page 25 of 35

TH

210-91-03GB01 HDR 1X3 TH 100MIL SP 339H AU 118L

Page 26

1

J3

WIN WIN

DC0005E-2.0

CON 1 PWR PLUG RA TH 1A -- 430H NI

SWITCHCRAFT

RAPC722X

CON 1 PWR PLUG RA TH 5A -- 430H NI

ANYTRONIC

4004201N0-16LF

CON 1 PWR PLUG RA TH 1A -- 433H NI

2

J6,J10

SAMTEC

TSW-101-07-L-S

HDR 1X1 TH -- 350H AU 100L

ANYTRONIC

090021S01015-2LF

HDR 1X1 TH -- 350H AU 100L

FRAMATOME

68000-201HLF

HDR 1X1 TH -- 350H AU 100L

ANYTRONIC

08026M34015#6T-10LF-T

CON 2X20 SMT SKT 100MIL CTR 307H AU

ANYTRONIC

08026M32615#6T-10LF-T

CON 2X13 SKT SMT 100MIL CTR 307H AU

1

J18

WIN WIN

MUBF-5S-TSROBTC

CON 1X5 USB MINI-B RA SHLD SKT SMT

1

J500

1

J21

SAMTEC

TSM-104-01-L-DV-A-P-TR

HDR 2X4 SMT 100MIL CTR 400H AU

FCI

98401-801A08LF

HDR 2X4 SMT 100MIL CTR 393H AU

ANYTRONIC

090092H04015N6T-2LF

HDR 2X4 SMT 100MIL CTR 409H AU

FCI

98401-101A08LF

HDR 2X4 SMT 100MIL CTR 393H AU

1

J13

ANYTRONIC

090092H05015N6T-2LF

HDR 2X5 SMT 100MIL CTR 414H AU

FCI

98401-801A10LF

HDR 2X5 SMT 100MIL CTR 400H AU

SAMTEC TSW-103-07-G-S HDR 1X3 TH 100MIL SP 339H AU 118L

ANYTRONIC

CORPORATIO

N LIMITED

PRECISION

INDUSTRIAL

CO. LTD

CORPORATIO

N LIMITED

CORPORATIO

N LIMITED

CONNECTORS

INTERNATION

AL

090021S03015-2LF HDR 1X3 TH 100MIL SP 339H AU 100L

1 J503 SAMTEC TSM-116-01-S-DV-P-TR HDR 2X16 SMT 100mil CTR 380H Au

1 J501 SAMTEC SSM-120-L-DV-BE CON 2X20 SMT SKT 100MIL CTR 307H AU

FCI 89898-320ALF CON 2X20 SMT SKT 100MIL CTR 284H AU

CORPORATIO

N LIMITED

1 J502 SAMTEC SSM-113-L-DV-TR CON 2X13 SKT SMT 100MIL CTR 300H AU

CORPORATIO

N LIMITED

FCI 89898-313ALF CON 2X13 SKT SMT 100MIL CTR 284H AU

PRECISION

INDUSTRIAL

CO. LTD

CORPORATIO

N LIMITED

0.8MM SP 159H AU

CORPORATIO

N LIMITED

TWR-56F8400 User’s Manual Page 26 of 35

Page 27

5

J1,J2,J16,J19,

FCI

95278-101A04LF

HDR 2X2 SMT 100MIL CTR 402H AU

SAMTEC

TSM-102-01-L-DV-P-TR

HDR 2X2 SMT 100MIL CTR 400H AU

ANYTRONIC

090092M02015N6T-2LF

HDR 2X2 SMT 100MIL CTR 414H AU

FCI

95278-801A04LF

HDR 2X2 SMT 100MIL CTR 402H AU

1

J22

FCI

95278-801A06LF

HDR 2X3 SMT 100MIL CTR 402H AU

FCI

95278-101A06LF

HDR 2X3 SMT 100MIL CTR 402H AU

ANYTRONIC

090092M03015N6T-2LF

HDR 2X3 SMT 100MIL CTR 414H AU

SAMTEC

TSM-103-01-L-DV-P-TR

HDR 2X3 SMT 100MIL CTR 380H AU

2

J8,J9

FCI

54201-G0805ALF

HDR 1X5 SMT 100MIL SP 380H AU

ANYTRONIC

090092M07015N6T-2LF

HDR 2X7 SMT 2.54MM SP 397H AU

SAMTEC

TSM-107-01-L-DV-P-TR

HDR 2X7 SMT 2.54MM SP 380H AU

1

Y2

ECS INC.

ECS-40-20-5PX-TR

XTAL 4MHZ -- SMT

2

U500,U502

TEXAS

SN74LVC04APWE4_

IC GATE HEX INV -- TSSOP14

1

U6

FREESCALE

MC9S08JM60CLD

IC MCU 8BIT 60K FLASH 48MHZ 2.7-5.5V

1

U505

NXP

74LVC125APW

IC BUF QUAD TS 1.65-3.6V TSSOP14

TEXAS

SN74LVC125APWG4

IC BUF QUAD TS 1.65-3.6V TSSOP14

1

U503

PHILIPS

PCA82C250T/N4

IC XCVR CAN 1MBAUD 5V S08

FCI 98401-101A10LF HDR 2X5 SMT 100MIL CTR 400H AU

SAMTEC TSM-105-01-L-DV-A-P-TR HDR 2X5 SMT 100MIL CTR 400H AU

J23

CORPORATIO

N LIMITED

CORPORATIO

N LIMITED

SAMTEC TSM-105-01-L-SV-P-TR HDR 1X5 SMT 100MIL S P 380H AU

FCI 54201-S0805ALF HDR 1X5 SMT 100MIL SP 380H AU

1 J14 FCI 95278-801A14LF HDR 2X7 SMT 2.54MM SP 382H AU

CORPORATIO

N LIMITED

FCI 95278-101A14LF HDR 2X7 SMT 2.54MM SP 382H AU

INTERNATION

AL

INSTRUMENTS

1 U501 MICREL MIC2026-1YM IC LIN SW PWR ACTIVE HIGH DUAL 2.7V-

5.5V 0.5A SOIC8

SEMICONDUC

TOR

SEMICONDUC

TORS

INSTRUMENTS

1 U504 TEXAS

INSTRUMENTS

SN74HCT125D IC BUF QUAD TS 4.5-5.5V SOIC14

LQFP44

SEMICONDUC

TOR

TWR-56F8400 User’s Manual Page 27 of 35

Page 28

PHILIPS

PCA82C250TD-G

IC CAN TS 5.5V SO 8

1

U1

LINEAR

LT1129CST-3.3#PBF

IC VREG LDO 3.3V 0.7A 4.3-20V SOT-223

1

D9

Bright Led

BL-HJF36D-TRB

LED AMB SGL 30MA 0603

5

D2,D4,D6,D8,

Bright Led

BL-HKC36D-TRB

LED YEL SGL 30MA 0603

6

D1,D3,D5,D7,

Bright Led

BL-HGE36D-TRB

LED YEL GRN SGL 30MA 0603

1

R560

WALSIN

WR04X1200FTL

RES MF 120 OHM 1/16W 1% 0402

VISHAY

CRCW0402120RFKED

RES MF 120 OHM 1/16W 1% 0402

THYE MING

CR02FL6-120R

RES MF 120 OHM 1/16W 1% 0402

40

R510,R511,R

VISHAY

CRCW0402100RFKED

RES MF 100 OHM 1/16W 1% 0402

PHILIPS

SEMICONDUC

TOR

SEMICONDUC

TOR

TECHNOLOGY

Electronics Corp

PCA82C250TD IC CTLR CAN 1MBAUD 4.5-5.5V SO 8

D13

D10,D12

512,R513,R51

4,R515,R516,

R517,R518,R

519,R520,R52

1,R522,R523,

R524,R525,R

526,R529,R53

0,R531,R532,

R533,R534,R

535,R537,R53

8,R540,R541,

R542,R543,R

544,R545,R54

6,R547,R548,

R549,R550,R

551,R552,R55

3

Bright Led

Electronics Corp

Electronics Corp

Electronics Corp

TECHNOLOGY

CORP.

INTERTECHNO

LOGY

TECH CO LTD

INTERTECHNO

LOGY

BL-HJF36D-AV-TRB LED AMB SGL 30MA 0603

VENKEL

COMPANY

TWR-56F8400 User’s Manual Page 28 of 35

CR0402-16W-1000FT RES MF 100 OHM 1/16W 1% 0402

Page 29

WALSIN

WR04X1000FTL

RES MF 100 OHM 1/16W 1% 0402

1

R1

WALSIN

WR04X2700FTL

RES MF 270 OHM 1/16W 1% 0402

KOA SPEER

RK73H1ETTP2700F

RES MF 270 OHM 1/16W 1% 0402

6

R508,R509,R

KOA SPEER

RK73H1ETTP4991F

RES MF 4.99K 1/16W 1% 0402

KOA SPEER

RK73H1ETTP1583F

RES MF 158K 1/16W 1% 0402

15

R2,R3,R8,R9,

WALSIN

WR04X1002FTL

RES MF 10.0K 1/16W 1% 0402

VISHAY

CRCW040210K0FKED

RES MF 10.0K 1/16W 1% 0402

KOA SPEER

RK73H1ETTP1002F

RES MF 10.0K 1/16W 1% 0402

SKYMOS

SCR-0402-K-103-F-T

RES MF 10.0K 1/16W 1% 0402

VIKING

CR-02FL6---10K

RES MF 10.0K 1/16W 1% 0402

SMEC

RC73A2Z1002FTF

RES MF 10.0K 1/16W 1% 0402

YAGEO

9C04021A1002FLPF3

RES MF 10.0K 1/16W 1% 0402

VENKEL

CR0402-16W-1002FT

RES MF 10.0K 1/16W 1% 0402

BOURNS

CR0402-FX-1002GLF

RES MF 10.0K 1/16W 1% 0402

VENKEL

CR0402-16W-1002FSNT

RES MF 10.0K 1/16W 1% 0402

3

R4,R10,R568

SMEC

RC73JP2DTF

RES MF ZERO OHM 1/8W -- 0805

VENKEL

CR0805-8W-000T

RES MF ZERO OHM 1/8W -- 0805

VISHAY

CRCW0805000RJNEA

RES MF ZERO OHM 1/8W -- 0805

KOA SPEER

RK73Z2ATTD

RES MF ZERO OHM 1/8W -- 0805

THYE MING

TECH CO LTD

TECHNOLOGY

CORP.

TECHNOLOGY

CORP.

562,R569,R57

1,R576

WALSIN

TECHNOLOGY

CORP.

2 R505,R506 WALSIN

TECHNOLOGY

CORP.

CR-02FL6--100R RES MF 100 OHM 1/16W 1% 0402

WR04X4991FTL RES MF 4.99K 1/16W 1% 0402.

WR04X1583FTL RES MF 158K 1/16W 1% 0402

R11,R12,R13,

R14,R15,R55

4,R555,R561,

R570,R574,R

575

TECHNOLOGY

CORP.

INTERTECHNO

LOGY

COMPONENTS

AMERICA

COMPANY

COMPANY

COMPANY

INTERTECHNO

LOGY

TWR-56F8400 User’s Manual Page 29 of 35

Page 30

ROHM

MCR10EZPJ000

RES MF ZERO OHM 1/8W -- 0805

TMTEC

CR-05JL7----0R

RES MF ZERO OHM 1/8W 5% 0805

BOURNS

CR0805-J/-000ELF

RES MF ZERO OHM 1/8W -- 0805

YAGEO

RC0805JR-070RL

RES MF ZERO OHM 1/8W -- 0805

2

R572,R573

BOURNS

CR0402FX33R0GLF

RES MF 33.0 OHM 1/16W 1% 0402

THYE MING

CR-02FL6---33R

RES MF 33.0 OHM 1/16W 1% 0402

WALSIN

WR04X33R0FTL

RES MF 33.0 OHM 1/16W 1% 0402

YAGEO

RC0402FR-0733RL

RES MF 33.0 OHM 1/16W 1% 0402

BOURNS

CR0402-FX-1001GLF

RES MF 1.0K 1/16W 1% 0402

VISHAY

CRCW-0402-1K00-FK-E3

RES MF 1.0K 1/16W 1% 0402

KOA SPEER

RK73H1ETTP1001F

RES MF 1.0K 1/16W 1% 0402

THYE MING

CR-02FL6----1K

RES MF 1.0K 1/16W 1% 0402

PANASONIC

ERJ-2RKF1001X

RES MF 1.0K 1/16W 1% 0402

2

R566,R567

SMEC

RC73A2Z5362FTF

RES MF 53.6K 1/16W 1% RC0402

KOA SPEER

RK73H1ETTP5362F

RES MF 53.6K 1/16W 1% 0402

WALSIN

WR04X5362FTL

RES MF 53.6K 1/16W 1% 0402.

9

R500,R501,R

VISHAY

CRCW0402330RFK

RES MF 330 OHM 1/16W 1% 0402

WALSIN

WR04X3300FTL

RES MF 330 OHM 1/16W 1% 0402

THYE MING

CR-02FL6--330R

RES MF 330ohm 1/16W 1% 0402

3 R557,R563,R

564

PANASONIC ERJ6GEY0R00V RES TF 0 ZERO OHM 1/8W 5% RC0805

ROHS COMPLIANT

AMERICA

TECH CO LTD

TECHNOLOGY

CORP.

AMERICA

YAGEO

AMERICA

RC0402FR-071KL RES MF 1.0K 1/16W 1% 0402

502,R503,R50

4,R507,R556,

R558,R559

INTERTECHNO

LOGY

TECH CO LTD

WALSIN

TECHNOLOGY

CORP.

KOA SPEER RK73H1ETTPL1001F RES MF 1.0K 1/16W 1% 0402

Rohm

Semiconductor

TECHNOLOGY

CORP.

INTERTECHNO

LOGY

TECHNOLOGY

CORP.

WR04X1001FTL RES MF 1.0K 1/16W 1% 0402

MCR01MZPF1001 RES MF 1.0K 1/16W 1% 0402

TECH CO LTD

1 R16 T HYE MING

TECH CO LTD

TWR-56F8400 User’s Manual Page 30 of 35

CR02FL6--10M RES MF 10M 1/16w 1% 0402

Page 31

1

R565

WALSIN

WR04X2201FTL

RES MF 2.2K 1/16W 1% 0402

VISHAY

CRCW04022K20FKED

RES MF 2.2K 1/16W 1% 0402

KOA SPEER

RK73H1ETTP2201F

RES MF 2.2K 1/16W 1% 0402

4

RT1,RT2,RT3,

MURATA

NCP18XH103F03RB

THERMISTOR 10K 1/10W 1% 0603

MICRO

MMBT3904-TP

TRAN NPN GEN 200MA 40V SOT23

1

D501

FAIRCHILD

BAT54C

DIODE SCH DUAL CC 200MA 30V SOT23

1

D11

ON

SMF12AT1G

DIODE ZNR 200W 12V SOD-123

3

SW1,SW2,SW

BOURNS

7914J-1-000E

SW SMT 4.0MM FMS 0.1A MAX 16V MAX

1

F1

TYCO

SMD100F-2

FUSE PLYSW 40A 30V SMT

1

U3

1 YAMAICHI

IC500-1004-004P

SKT 100 LQFP TH 0.5MM 846H -- 89L

1 FREESCALE

PC56F84789VLL

IC CTLER DSP 32BIT LQFP100

0

C5,C6

KEMET

C0805C220J5GAC

CAP CER 22PF 50V 5% C0G CC0805

AVX

08055A220JAT2A

CAP CER 22PF 50V 5% C0G 0805

WALSIN

TECHNOLOGY

CORP.

TECHNOLOGY

CORP.

INTERTECHNO

LOGY

RT4

1 D500 ROHM RSX101M-30TR DIODE SCH PWR RECT 1A 30V SOD-123

ON

SEMICONDUC

TOR

1 Q1 PHILIPS

SEMICONDUC

TOR

WR04X1005FTL RES MF 10M 1/16W 1% 0402

MBR130LSFT1G DIODE SCH PWR RECT 1A 30V SOD-123

MMBT3904 TRAN NPN SW 40VCE 200mA SOT23

COMMERCIAL

COMPONENTS

CORP

ON

SEMICONDUC

TOR

1 U5 LITTELFUSE SP0503BAHTG DIODE TVS ARRAY 3CH -- 5V 0.225W

SEMICONDUC

TOR

3

ELECTRONICS

ELECTRONICS

SEMICONDUC

TOR

MMBT3904LT1G TRAN NPN GEN 200MA 40V SOT-23

SOT143

ROHS COMPLIANT

TWR-56F8400 User’s Manual Page 31 of 35

Page 32

KOA SPEER

NPO0805HTTD220J

CAP CER 22PF 50V 5% C0G 0805

VENKEL

C0805C0G500-220JNE

CAP CER 22PF 50V 5% C0G 0805

0

C529,C531

TDK

C2012X7R1E474K

CAP CER 0.47UF 25V 10% X7R 0805

VENKEL

C0805X7R250-474KNE

CAP CER 0.47UF 25V 10% X7R 0805

WALSIN

0805B474K250CT

CAP CER 0.47UF 25V 10% X7R 0805

SAMTEC

TSW-102-07-S-S

HDR 1X2 TH 100MIL SP 330H AU 100L

FCI

77311-801-02LF

HDR 1X2 TH 100MIL SP 330H AU 100L

ANYTRONIC

090021S02018-2LF

HDR 1X2 TH 100MIL SP 339H AU 98L

0

TP1,TP2,TP3,

COMPONENTS

TP-105-01-00

TEST POINT PIN .100 x .45 BLACK TH

KEYSTONE

5001

TEST POINT BLACK 40 MIL DRILL 180 MIL

KOBICONN

151-203-RC

TEST POINT PIN .100 x .45 BLACK TH

0

Y1

CITIZEN

HCM49-8.000MABJ-UT

XTAL 8.000MHZ SER SMT

CTS

ATS08ASM-T

XTAL 8.000MHZ SER SMT

ECS INC.

ECS-80-18-5PX

XTAL 8MHZ SER SMT

0

U2

FREESCALE

PC56F84789VLL

IC CTLER DSP 32BIT LQFP100

0

R536

VISHAY

CRCW0402100RFKED

RES MF 100 OHM 1/16W 1% 0402

VENKEL

CR0402-16W-1000FT

RES MF 100 OHM 1/16W 1% 0402

WALSIN

TECHNOLOGY

CORP.

COMPANY

COMPANY

AVX 08053C474KAT2A CAP CER 0.47UF 25V 10% X7R 0805

KEMET C0805C474K3RAC CAP CER 0.47UF 25V 10% X7R 0805

TECHNOLOGY

CORP.

0 J12 SAMTEC HTSW-102-07-G-S HDR 1X2 TH 100MIL SP 335H AU 95L

ANYTRONIC

CORPORATIO

N LIMITED

SAMTEC HTSW-102-07-SM-S HDR 1X2 TH 100MIL SP 330H AU 100L

SAMTEC TSW-102-07-G-S HDR 1X2 TH 100MIL SP 330H AU 100L

3M 929647-01-02-EU HDR 1X2 TH 100MIL SP 330H AU 100L

0805N220J500LT CAP CER 22PF 50V 5% C0G 0805

090021S02015-2LF HDR 1X2 TH 100MIL SP 339H AU 98L

TP5,TP6,TP7,

TP8

CORPORATIO

N LIMITED

CORPORATIO

N

ELECTRONICS

INTERNATION

AL

SEMICONDUC

TOR

INTERTECHNO

LOGY

COMPANY

TH

TWR-56F8400 User’s Manual Page 32 of 35

Page 33

WALSIN

WR04X1000FTL

RES MF 100 OHM 1/16W 1% 0402

0

R5,R7

SMEC

RC73JP2DTF

RES MF ZERO OHM 1/8W -- 0805

VENKEL

CR0805-8W-000T

RES MF ZERO OHM 1/8W -- 0805

VISHAY

CRCW0805000RJNEA

RES MF ZERO OHM 1/8W -- 0805

KOA SPEER

RK73Z2ATTD

RES MF ZERO OHM 1/8W -- 0805

PANASONIC

ERJ6GEY0R00V

RES TF 0 ZERO OHM 1/8W 5% RC0805

ROHM

MCR10EZPJ000

RES MF ZERO OHM 1/8W -- 0805

TMTEC

CR-05JL7----0R

RES MF ZERO OHM 1/8W 5% 0805

BOURNS

CR0805-J/-000ELF

RES MF ZERO OHM 1/8W -- 0805

YAGEO

RC0805JR-070RL

RES MF ZERO OHM 1/8W -- 0805

ROHM

MCR10EZPF1000

RES MF 100OHM 1/8W 1% 0805

KOA SPEER

RK73H2ATTD1000F

RES MF 100OHM 1/8W 1% 0805

VENKEL

CR0805-8W-1000FT

RES MF 100OHM 1/8W 1% 0805

VISHAY

CRCW0805100RFKEA

RES MF 100 OHM 1/8W 1% 0805

0

R6

BOURNS

CR0805-FX-1004ELF

RES MF 1.00M 1/8W 1% 0805

KOA SPEER

RK73H2ATTD1004F

RES MF 1.00M 1/8W 1% 0805

VENKEL

CR0805-8W-1004FSNT

RES MF 1.00M 1/8W 1% 0805

ROHM

MCR10EZPF1004

RES MF 1.0M 1/8W 1% 0805

PANASONIC

ERJ6ENF1004V

RES MF 1.00M 1/8W 1% 0805

0

R527,R528

YAGEO

RC0402FR-071KL

RES MF 1.0K 1/16W 1% 0402

BOURNS

CR0402-FX-1001GLF

RES MF 1.0K 1/16W 1% 0402

VISHAY

CRCW-0402-1K00-FK-E3

RES MF 1.0K 1/16W 1% 0402

KOA SPEER

RK73H1ETTP1001F

RES MF 1.0K 1/16W 1% 0402

THYE MING

CR-02FL6----1K

RES MF 1.0K 1/16W 1% 0402

THYE MING

TECH CO LTD

TECHNOLOGY

CORP.

COMPANY

INTERTECHNO

LOGY

AMERICA

0 R539 PANASONIC ERJ6ENF1000V RES MF 100OHM 1/8W 1% 0805

YAGEO

AMERICA

CR-02FL6--100R RES MF 100 OHM 1/16W 1% 0402

ROHS COMPLIANT

RC0805FR-07100RL RES MF 100OHM 1/8W 1% 0805

COMPANY

INTERTECHNO

LOGY

BOURNS CR0805-FX-1000ELF RES MF 100OHM 1/8W 1% 0805

COMPANY

VISHAY

INTERTECHNO

LOGY

AMERICA

INTERTECHNO

LOGY

TECH CO LTD

CRCW08051M00FKEA RES MF 1.00M 1/8W 1% 0805

TWR-56F8400 User’s Manual Page 33 of 35

Page 34

PANASONIC

ERJ-2RKF1001X

RES MF 1.0K 1/16W 1% 0402

KOA SPEER

RK73H1ETTPL1001F

RES MF 1.0K 1/16W 1% 0402

0

U4

KNOWLES

SPM0408HE5H-SB

MICROPHONE MINI SISONIC 300 OHM

WALSIN

TECHNOLOGY

CORP.

WR04X1001FTL RES MF 1.0K 1/16W 1% 0402

Rohm

Semiconductor

ACOUSTICS

MCR01MZPF1001 RES MF 1.0K 1/16W 1% 0402

59DB 1.5-3.6V SMT

TWR-56F8400 User’s Manual Page 34 of 35

Page 35

Freescale Semiconductor Inc.

Microcontroller Solutions Group

Appendix D – TWR-56F8400 Board Jack Layout Top View

DSC

JM60

USB

PWR

503-1

503-31

1

100

FUSE

17-1

2-1

2-3

14-1

14-2

1-1

1-2

1-3

1-4

8-1

8-5

9-1

9-5

5-1

4-1

5-3

4-3

6

10

7

11

7-3

11-3

13-1

13-2

13-9

19-1

19-3

21-1

21-8

21-1

21-6

23-1

23-4

16-1

16-4

15-2

15-1

20-1

20-2

TWR56F8400 T OP

All numbers Jack or Pin designati on

Loading...

Loading...