Page 1

1

NXP TDA9351/53/61/63 XXX SERIES

S

S

S

E

E

E

R

R

R

V

V

V

I

I

I

C

C

C

E

E

E

M

M

M

A

A

A

N

N

N

U

U

U

A

A

A

L

L

L

COLOUR TELEVISION

Page 2

.

2

CONTENTS

1. safety precautions ………………………………………………………………………………………3

2. block diagram ……………………………………………………………………………………………4

3. Replacement of memory IC ……………………………………………………………………………6

4. Service adjustment ……………………………………………………………………………………...6

5. ICs functional description ……………………………………………………………………………15

6. Test point waveform………………………………………………………………………………….…18

7. All ICs/transistors voltages…………………………………………………………………………….19

8. Purity / convergence adjustment……………………………………………………………………..20

9. KLX-PH22Z VER3.0 circuit diagram ………………………………………………………………22

10. KLX-PH22Z VER3.0 PCB ………………………………………………………………………….. 23

11. KLX-PH22Z .BOM ………………………………………………………………………………….. 24

Page 3

.

3

SAFETY PRECAUTIONS

1. The design of this product contains special hardware, many

circuits and components specially for safety purposes. For

continued protection, no changes should be made to the

original design unless authorized in writing by the

manufacturer. Replacement parts must be identical to those

used in the original circuits. Service should be performed by

qualified personnel only.

2. Alterations of the design or circuitry of the products should

not be made. Any design alterations or additions will void

the manufacturer’s warranty and will further relieve the

manufacturer of responsibility for personal injury or property

damage resulting therefrom.

3. Many electrical and mechanical parts in the products have

special safety-related characteristics. These characteristics

are often not evident from visual inspection nor can the

protection afforded by them necessarily be obtained by

using replacement components rated for higher voltage,

wattage, etc. Replacement parts which have these special

safety characteristics are identified in the parts list of

Service manual. Electrical components having such

features are identified by shading on the schematics

and by ( ! ) on the parts list in Service manual. The use

of a substitute replacement which does not have the same

safety characteristics as the recommended replacement

part shown in the parts list of Service manual may cause

shock, fire, or other hazards

4. Don’t short between the LIVE side ground and

ISOLATED (NEUTRAL) side ground or EARTH side

ground when repairing. Some model’s power circuit is

partly different in the GND. The difference of the GND is

shown by the LIVE: ( ) side GND, ISOLATED (NEUTRAL) :

( ) side GND and EARTH : ( ) side GND. Don’t short

between the LIVE side GND and ISOLATED (NEUTRAL)

side GND or EARTH side GND and never measure with a

measuring apparatus (oscilloscope etc.) the LIVE side GND

and ISOLATED (NEUTRAL) side GND or EARTH side GND

at the same time. If above note will not be kept, a fuse or

any parts will be broken.

5. If any repair has been made to the chassis, it is

recommended that the +B setting should be checked or

adjusted (See ADJUSTMENT OF +B POWER SUPPLY).

6. The high voltage applied to the picture tube must conform

with that specified in Service manual. Excessive high

voltage can cause an increase in X-Ray emission, arcing

and possible component damage, therefore operation under

excessive high voltage conditions should be kept to a

minimum, or should be prevented. If severe arcing occurs,

remove the AC power immediately and determine the cause

by visual inspection (incorrect installation, cracked or melted

high voltage harness, poor soldering, etc.). To maintain the

proper minimum level of soft X-Ray emission, components

in the high voltage circuitry including the picture tube must

be the exact replacements or alternatives approved by the

manufacturer of the complete product.

7. Do not check high voltage by drawing an arc. Use a high

voltage meter or a high voltage probe with a VTVM.

Discharge the picture tube before attempting meter

connection, by connecting a clip lead to the ground frame

and connecting the other end of the lead through a 10kΩ

2W resitor to the anode button.

8. When service is required, observe the original lead dress.

Extra precaution should be given to assure correct lead

dress in the high voltage circuit area. Where a short circuit

has occurred, those components that indicate evidence of

overheating should be replaced. Always use the

9. manufacturer’s replacement components.

10. Isolation Check

(Safety for Electrical Shock Hazard)

After re-assembling the product, always perform an isolation

check on the exposed metal parts of the cabinet (antenna

terminals, video/audio input and output terminals, Control

knobs, metal cabinet, screwheads, earphone jack, control

shafts, etc.) to be sure the product is safe to operate without

danger of electrical shock.

11. The surface of the TV screen is coated with a thin film which

can easily be damaged. Be very careful with it when handle

the TV. Should the TV screen become soiled, wipe it with a

soft dry cloth. Never rub it forcefully. Never use any cleaner

or detergent on it.

(1) Dielectric Strength Test

The isolation between the AC primary circuit and all metal

parts exposed to the user, particularly any exposed metal

part having a return path to the chassis should withstand a

voltage of 3000V AC (r.m.s.) for a period of one second.

(…Withstand a voltage of 1100V AC (r.m.s.) to an appliance

rated up to 120V, and 3000V AC (r.m.s.) to an appliance

rated 200V or more, for a periode of one second.)

This method of test requires a test equipment not generally

found in the service trade.

(2) Leakage Current Check

Plug the AC line cord directly into the AC outlet (do not use

a line isolation transformer during this check.). Using a

“Leakage Current Tester”, measure the leakage current

from each exposed metal part of the cabinet, particularly

any exposed metal part having a return path to the chassis,

to a known good earth ground (water pipe, etc.). Any

leakage current must not exceed 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.2mA AC

(r.m.s.).

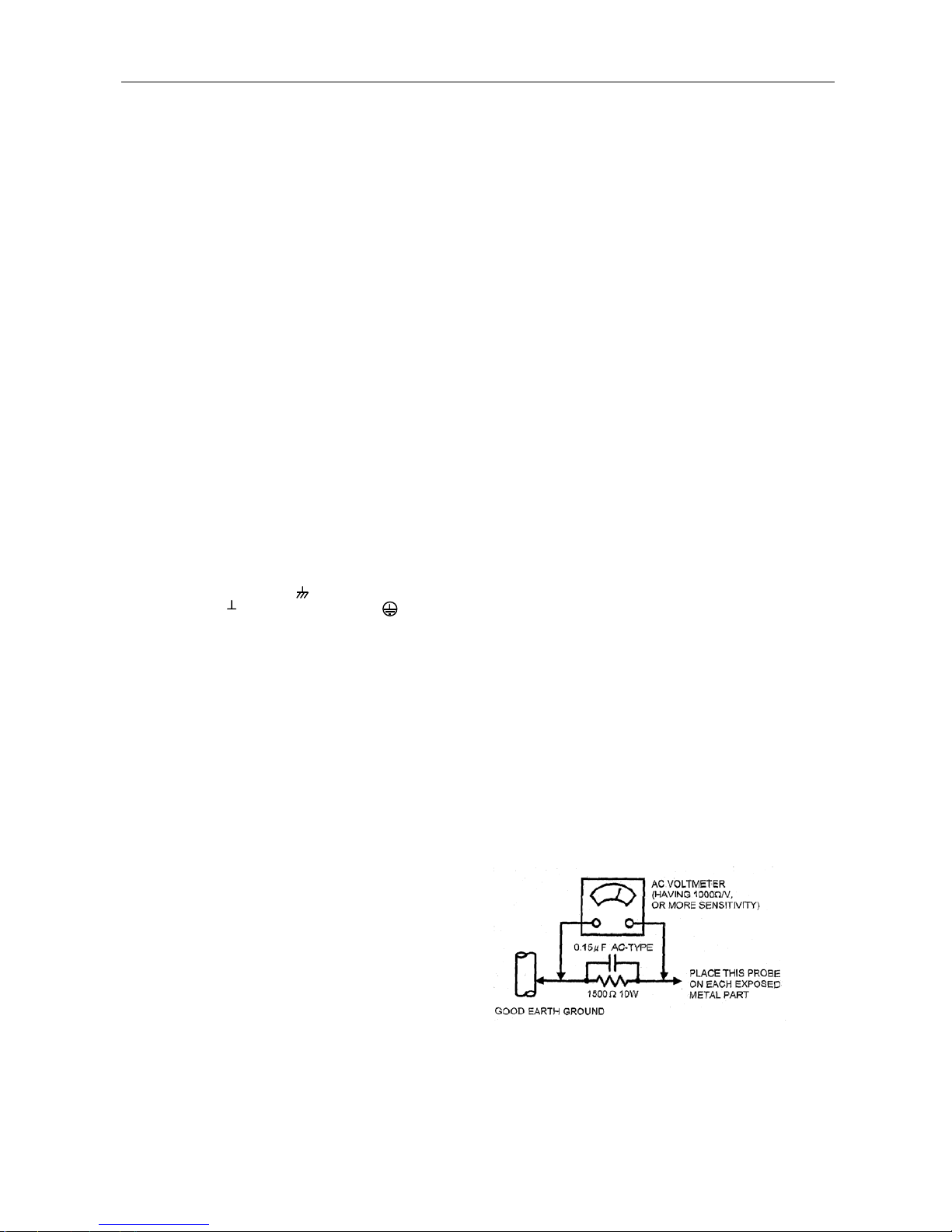

●Alternate Check Method

Plug the AC line cord directly into the AC outlet ( do not use

a line isolation transformer during this check.). Use an AC

voltmeter having 1000 ohms per volt or more sensitivity in

the following manner. Connect a 1500 Ω 10W resistor

paralleled by a 0.15 μ F AC-type capacitor between an

exposed metal part and a known good earth ground (water

pipe, etc.). Measure the AC voltage across the resistor with

the AC voltmeter. Move the resistor connection to each

exposed metal part, particularly any exposed metal part

having a return path to the chassis, and measure the AC

voltage across the resistor. Now, reverse the plug in the AC

outlet and repeat each measurement. Any voltage

measured must not exceed 0.75V AC (r.m.s.). This

corresponds to 0.5mA AC (r.m.s.).

However, in tropical area, this must not exceed 0.3V AC

(r.m.s.).

This corresponds to 0.2mA AC (r.m.s.)

Page 4

.

4

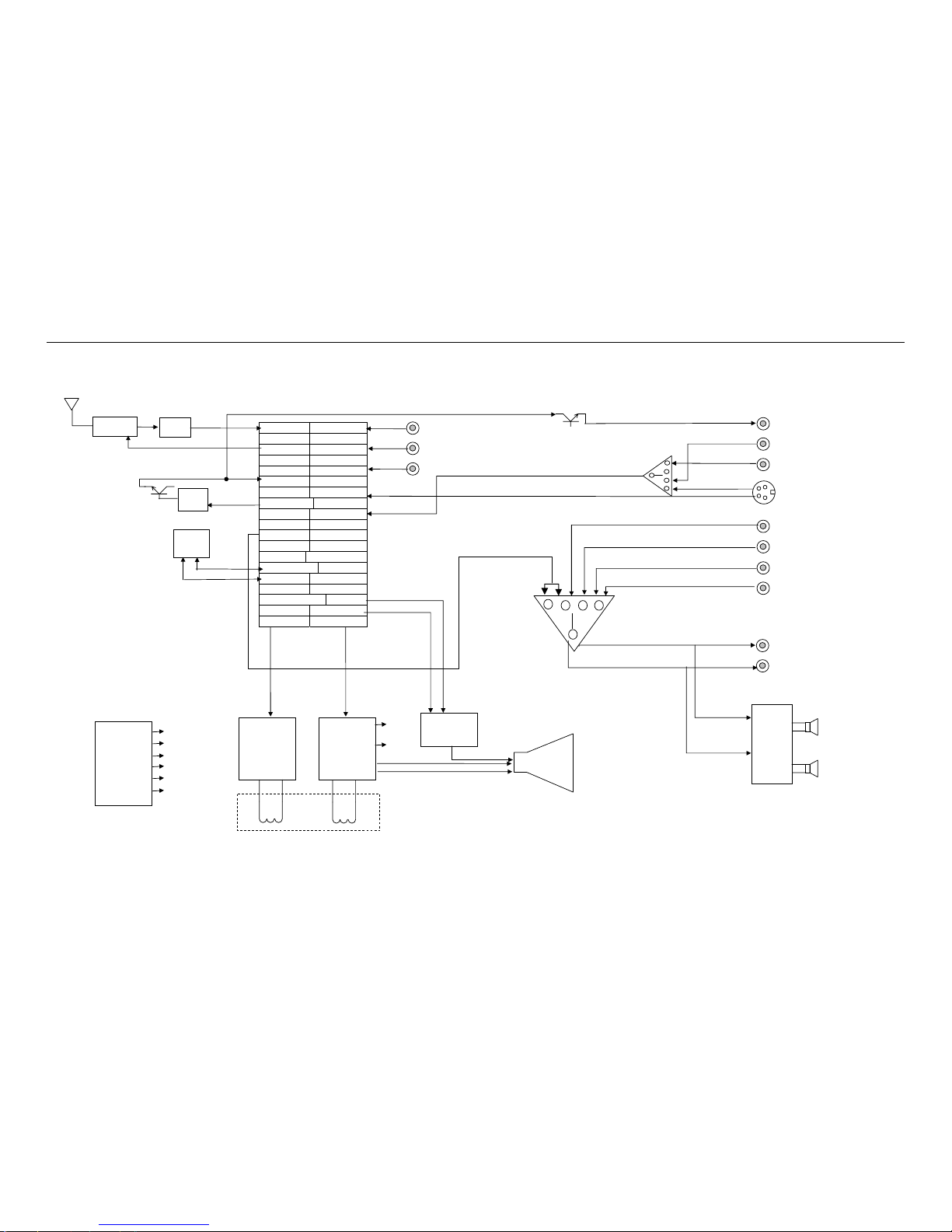

2 TV Block diagram

z

z

TUNER

SAW

IF IN R/Y IN

RF AGC G/U IN

B/V IN

CVBSINT

CHROMA

IFVO OUT

CVBS/Y IN

SDA

SCL

AUDIO OUT IK

RGB OUT

V OUT H OUT

S

TRAP

VoV2iV1iY

Cr

Cb

A

Ri2

A

Ri1

ALoA

Ro

S-VHS

24C08

POWER

UNIT

110

V26V14V

-14

V8V

3.3

V

CRT PCB

V IN

LA78040/41/

TDA8174A

V OUT

H IN

H OUT

H OUT

D

Y

heat

SCREE

N

FOCU

S

TDAXXXX

Vi1

OUT1-

OUT1+

Vi2

OUT2-

OUT2+

A

N752

2

CRT

A

Li1

A

Li2

C

Y

405

2

audio

audio

audio

audio

video

video

bus

video

video

video

180

V

405

2

Page 5

.

5

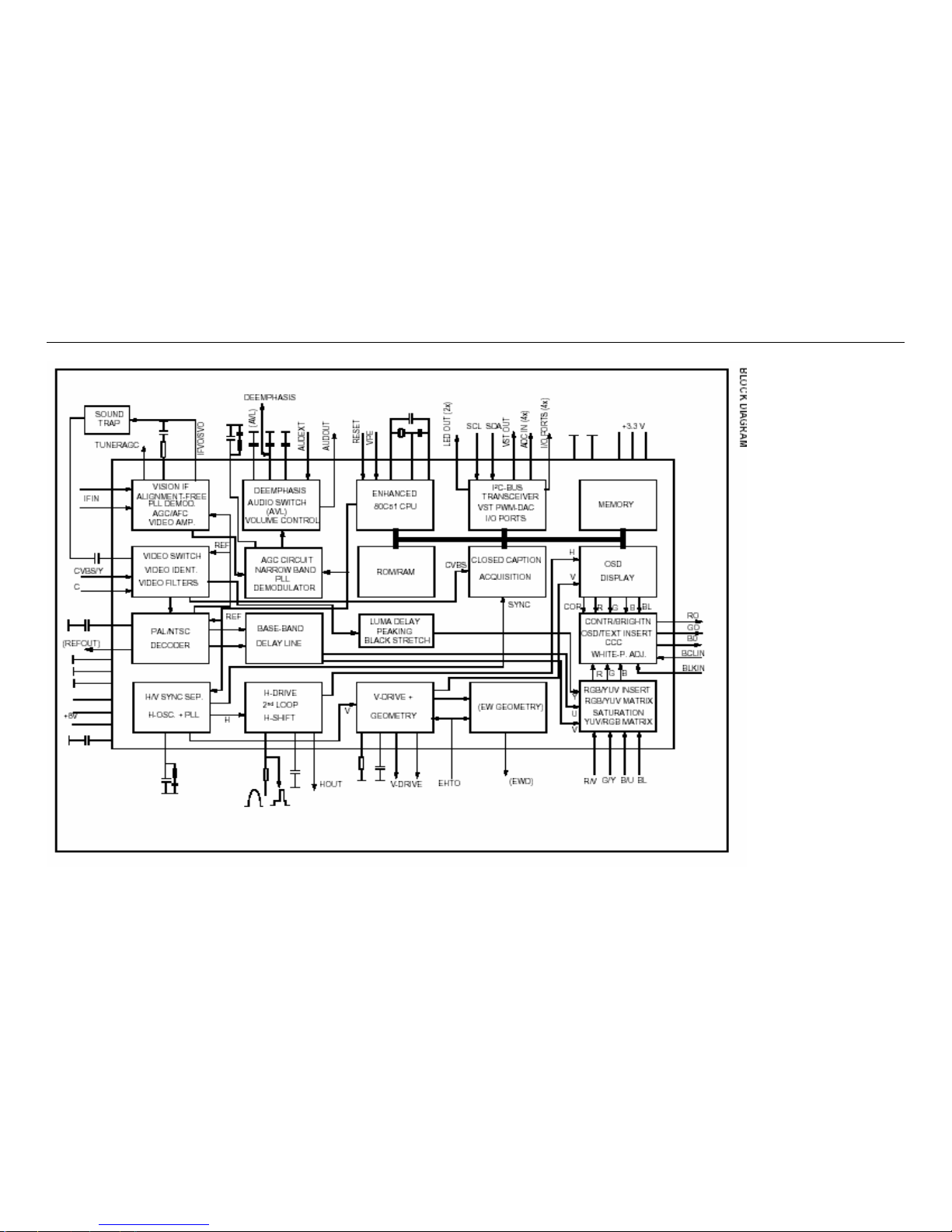

Block diagram TDA93xx/83xx series with mono intercarrier sound demodulator

Page 6

6

3.REPLACEMENT OF MEMORY IC

1. MEMORY IC.

This TV uses memory IC. In the memory IC are memorized data for correctly operating the video and

deflection circuits.

When replacing memory IC, be sure to use IC written with the initial value of data.

2. PROCEDURE FOR REPLACING MEMORY IC

(1) Power off

Switch the power off and unplug the power cord from AC outlet.

(2) Replace IC

Be sure to use memory IC written with the initial data values.

(3) Power On

Plug the power cord into the AC outlet and switch the power On.

(4) Check and set system default value:

1) Press “MENU” key followed by digits '6''4''8' and '3'. then Press “TEST” key on the Remote

control unit for factory used.

2) The red “M”or”factory” will be displayed on the screen, repeat this and it will changed as follow:

normal-M(factory)-BUS open-normal..

3) Press digital key, (Mkey) and corresponding on-screen display will be appeared.

4) Check the setting value of the SYSTEM default value of Table below. If the value is different,

select items by [CH+]/[CH-] keys and set value by [VOL+]/[VOL-] keys.

5) Press “STANDBY” key again and return to the normal screen.

4.SERVICE ADJUSTMENT

B1 POWER SUPPLY

1. Receive normal colour bar signal.

2. Connect DC voltmeter to VD524- and isolated ground.

3. Adjust potentiometer in power unit to get the voltage as 110V ±1.0V for 21 inch hereinafter,

FOCUS ADJUSTMENT

1. Receive a crosshatch signal.

2. While watching the screen, adjust the FOCUS VR to make the vertical and horizontal lines as fine and

sharp as possible.

BUS CONTROL ADJUSTMENT

TDA9351/9353:to enter BUS control mode, Press “MENU” key followed by digits '6''4''8' and '3'. then

press digit Press “0” to “9“ key, (Mkey) and corresponding on-screen display will be appeared.

TDA8370:to enter BUS control mode, Press “MENU” key followed by digits '6''4''8' and '3'. then Press

“TEST” key on the Remote control unit twice for factory used(or press digits '6''4''8' and '3' twice.). and then

press digit Press “0” to “9“ key, (Mkey) and corresponding on-screen display will be appeared.

On TV screen “TEST” will be indicated, this means entered bus control mode.

And press following key, each function will be available.

Page 7

7

Remote Hand Unit keys

[M1] [M2] [M3]

[M4] [M5] [M6]

[M7] [M8] [M9]

[M0]

Geometrical adjustment

MENU8 (9351)/servise 1(8370)

Receive PAL standard Complete pattern signal.

Adjustment steps:

a) Adjust V. SLOPE, to the center horizontal line just appeare from half bottom shadow.

b) Adjust V. SIZE, to get 90% of vertical picture contents would be displayed on CRT.

c) Adjust V. SHIFT, the center horizontal line correspond to CRT vertical center.

d) Adjust H.SHIFT, to get the picture horizontal center correspond to CRT horizontal center.

Receive NTSC signal and repeat above

AGC Adjustment.

MENU7 (9351)/servise 2(8370)

Receive 60dBμ(1mV)V

H

colour bar pattern signal,adjust AGC value(voltage from high to low),to noise

reduce gradually and just disappeared point.

CRTcut off and white balance adjustment.

MENU9 (9351)/B W BALANCE(8370)

Receive white signal.

a) CRT cut off adjustment.

1. Select “SC”, then automatically vertical scan will be stopped.

2. Adjust SCREEN control on Flyback transformer to get the darkest single horizontal line (red,

green, or blue, sometimes shows more yellow, more purple or more white).

b) White balance adjustment.

1. Select RD/BD menu.

2. Adjust RD/BD to get colour temperature as x=281, y=311

c) Sub-Brightness adjustment. (Use stair case signal)

1. Select SB menu.

2. Adjust SB to get the darkest step being cutoff.

MENU8

V SLOPE 31

V SHIFT 31

V AMP 31

V SCOR 31

H SHIFT 31

b

c d e

i

j k

f g h

Page 8

8

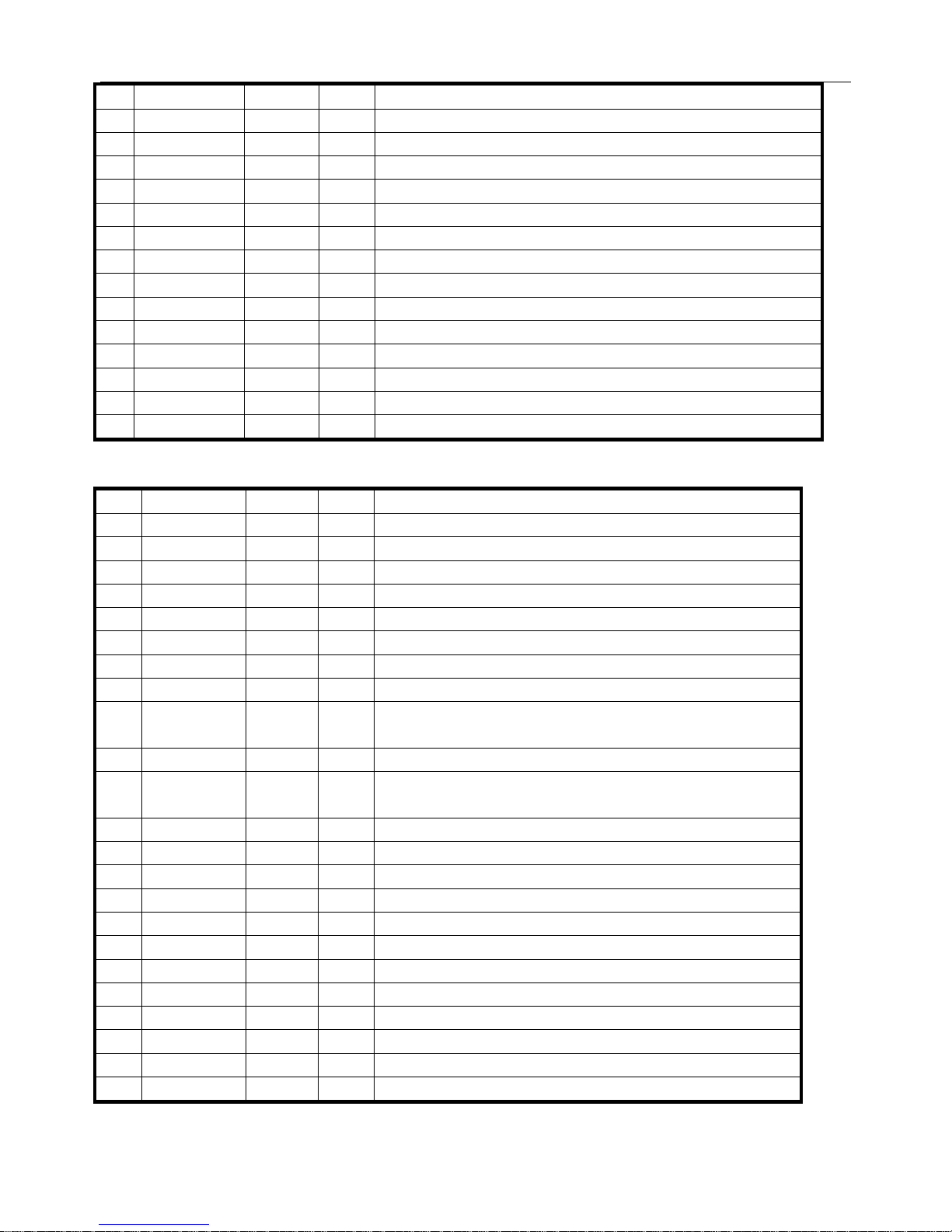

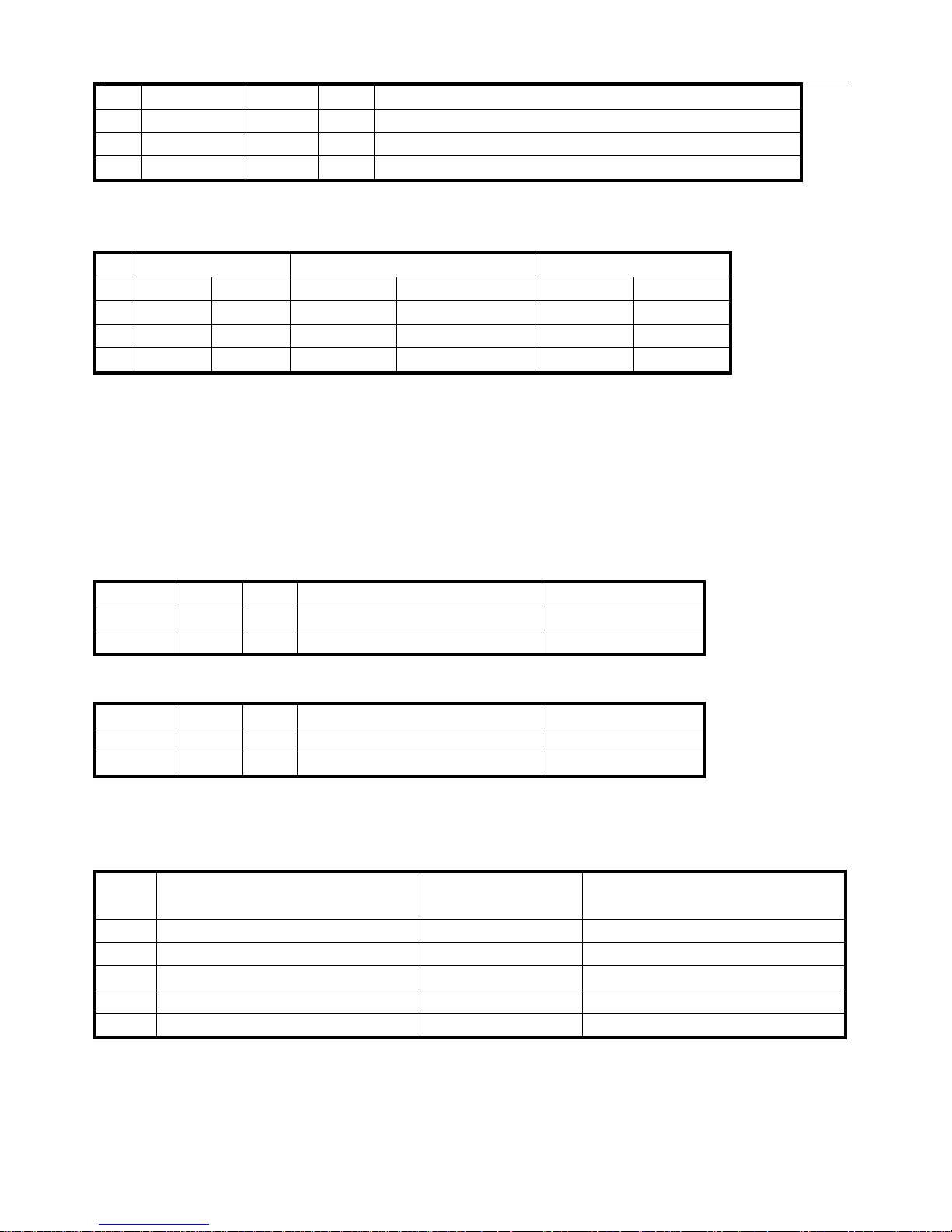

ICs Default Settings

1. TDA9351/9353

MI Items Vari

able

Prese

t

discription

M0 AVL ON/OFF ON Auto volume control select on menu.on:open;off:close.

FSL ON/OFF ON Vertical sync slice level select.off:auto;on: 60% of complex sync

FMWS 0-2 0 FM demodulation band width.0:standard(225khz);1: for over FM

modulation(450KHz);2:for over FM modulation(600KHz)

FFI ON/OFF OFF

IF PLL filter.on:short

time constant;off:normal

OSO ON/OFF ON Decreasing bright spot when switch off stay at the vertical over scan

period .ON:open;OFF:close.

FCO ON/OFF OFF Forced color system. On:only for single color system(for example

VCR); off:normal

WOOFER ON/OFF OFF Woofer select on menu.on:open;off:close.

DVD DELAY 0-8 2 Delay of turning to TV from DVD

DVD/VCD ON/OFF OFF Display on screen.on:DVD;OFF:VCD.

M1 BAND 0~2 2 Tuner band mode select,see attached table 1

AV OPT ON/OFF OFF AV control logic option,see table 2

AV CFG* 0~8 3 AV input stuts select, see table 2

NTSC MX USA/JAP USA NTSC matrix select(USA or JAPAN)

VIDEO OUT IF/CVBS CVBS AV output mode select:TV /display on screen

PRO 0-3 0 Sharp the boardline

PIN5 NTSC Compatible with other hardware, see table3

PIN7 VOL1 Compatible with other hardware, see table3

PIN8 MUTE Compatible with other hardware, see table3

START TIME 6-15 S 8 Delay time after power on

M2 VISION IF 38/38.9/4

5.75/58.7

5

38.9M IF select

DK ON/OFF OFF Sound system select

BG ON/OFF ON Sound system select

I ON/OFF OFF Sound system select

M ON/OFF OFF Sound system select

SIF PREFER DK/I/BG/M BG Sound system priority select when Auto scan

AUTO SOUND ON/OFF ON Sound system auto identify when auo scan

POWER OPT 0-2 2 Switch on mode,0:standby,1:power on;2:remember last time.

TXT DEF 0-3 0 Text language selset

TXT BRI 0-63 63 Text brightness set

SPANISH BIT ON/OFF OFF Spanish text bit

MI

M3 ENGLISH ON/OFF ON Language option

ARABIC ON/OFF OFF Language option

Page 9

9

PERSIAN ON/OFF OFF Language option

TURKISH ON/OFF OFF Language option

FRANCE ON/OFF OFF Language option

RUSSIA ON/OFF OFF Language option

HUNGARY ON/OFF ON Language option

SPANISH ON/OFF ON Language option

CROATIA ON/OFF ON Language option

GREECE ON/OFF ON Language option

PORTUGUESE ON/OFF ON Language option

BUGIARIA ON/OFF ON Language option

SERBIA ON/OFF ON Language option

ITALY ON/OFF ON Language option

ROMANIAN ON/OFF ON Language option

POLISH ON/OFF ON Language option

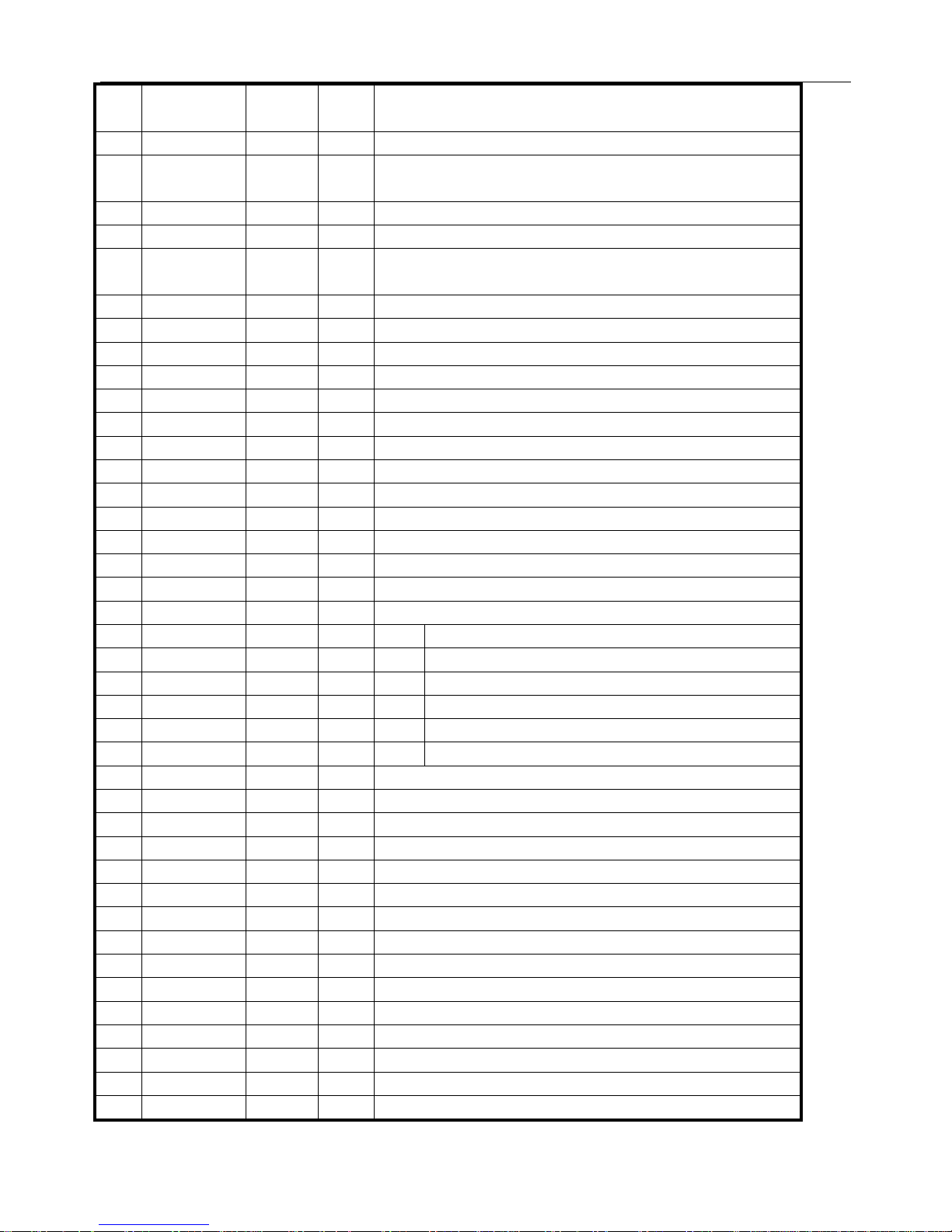

Items Variable Preset

M4 SUBCON 0~63 63 Subsidiary contrast setting

SUBCOL 0~63 63 Subsidiary color setting

SUBSHP 0~63 63 Subsidiary sharp setting

SUBTINT 0~15 15 Subsidiary tint setting

YDLY PAL 0~15 12 Y delay time setting of PAL

YDLY NTSC 0~15 12 Y delay time setting of NTSC

YDLY SEC 0~15 12 Y delay time setting of SECAM

YDLY AV 0~15 12 Y delay time setting of AV

UOC VOL SW ON/OFF OFF Audio output mode option.on:output controlled by volume;off:not

controlled.

UOC VOL 0-63 63 Audio output range setting of pin44

TDA9874

GAIN

0-30 5 Output range adjusting of TDA9874

CATHODE 0~15 15 Cathode voltage setting

SC BRI 0~63 32 The single horizontal line brightness setting

TINT RANGE 0-63 31 Tint adjust range setting

M5 OSD VPOS 0~63 53 OSD position setting of vertical

OSD HPOS 0~59 15 OSD position setting of horizontal

WIDE 0~63 15 Vertical range setting of wide screen mode

ZOOM 0~63 59 Vertical range setting of zoom mode

NENU TITLE 0~6 3 Color setting of menu title

MI HALFTONE 0-2 1 Halftone setting of menu

M6 SHIPMODE Ship mode setting option

Page 10

10

SEARCH

SPEED

0-3 1 Search speed setting.o:slow;3:fast

PWL 0-15 15 White peak limit

OSD

CONTRAST

0-3 0 OSD contrast setting.0:bitght;3:dark

BLUE STR. ON/OFF ON Blue level stretch option

BSD ON/OFF ON Black level stretch range.ON:30 IRE;OFF:20IRE.

AAS ON/OFF ON Black level actived area.ON:no more than 10%of black

background;OFF:no more than 20% of black background.

CORING 0-3 0 Coring and decrease nosie.0:off.

M7 AGC-TOP 0-63 24 RF AGC adjusting

AGC-SPEED 0-3 1 AGC delay time adjusting

LOGO OPT ON/OFF OFF LOGO option

VOL6 0-63 17 Volume setting of 10%

VOL16 0-63 32 Volume setting of 25%

VOL32 0-63 48 Volume setting of 50%

VOL63 0-63 63 Volume setting of 100%

7KEYS ON/OFF OFF “POWER”key option of key board

X RAY ON/OFF OFF X RAY protect function option

OSVE ON/OFF OFF AKB detect line hide option(supported by TDA9353/63)

HCO ON/OFF O FF Auto horizenal range revise option(supported by TDA9353/63)

M8 FREQUENCY 50HZ 60HZ Display vertical frequency automaticly

VSLOPE 0~63 31 31 Vertical slope adjusting

VSHIFT 0~63 31 31 Vertical shift adjusting

VAMP 0~63 31 31 Vertical size adjusting

VSCOR 0~63 31 31 Vertical correct adjusting

HSHIFT 0~63 31 31 Horizontal shift adjusting

RGBHS 0~63 31 Vertical shift adjusting of RBG/YUV

RGB HPOS 0~63 31 OSD horizontal shift adjusting of RBG/YUV

EW WIDTH 0~63 31 Horizontal range adjusting

EW PARA 0~63 31 East-west curve adjusting

UP CORNER 0~63 31 Up conner adjusting

LO CORNER 0~63 31 Low conner adjusting

H-PARA 0~63 31 Paralleloqram adjusting

H-BOW 0~63 31 Bow adjusting

EW-TRAPE 0~63 31

Trapezoid adjusting

M9 BT 0~63 48 Brightness adjusting of white balance

CT 0~63 48 Contrast adjusting of white balance

SC OFF Single horizontal line.open by “V+”;closed by “V-”

RB 0~63 32 Red cut adjusting

GB 0~63 32 Green cut adjusting

Page 11

11

RD 0~63 32 Red drive adjusting

GD 0~63 32 Green drive adjusting

BD 0~63 32 Blue drive adjusting

SB 0~63 40 Sub-brightness adjusting

ATTACHED TABLE1

BAND=0 BAND=1 BAND=2

PIN10(B2) PIN11(B1) PIN10(B2) PIN11(B1) PIN10(B2) PIN11(B1)

VL 0 0 0 1 1 0

VH 1 0 1 0 0 1

U 0 1 1 1 1 1

TABLE2

AV OPTION:MENU1→AV CFG;

O=TV→AV;1=TV→AV1→AV2;2=TV→AV1→AV2→S-VIDEO;3=TV→AV1→AV2→S-VIDEO→YUV;

5= TV→AV→S-VIDEO;6= TV→AV→S-VIDEO→YUV;7= TV→AV→YUV;8=TV→EURO;

9=TV→AV→EURO

When“AV OPT”is setting “OFF”,the logic table of AV control

MODE TV AV2 AV/AV1/YUV/EURO(RGB) SVHS

Pin62 L L H H

Pin63 L H L H

When“AV OPT”is setting “ON”,the logic table of AV control

MODE TV AV2 AV/AV1/YUV/EURO(RGB) SVHS

Pin62 H L L L

Pin63 H H L L

TABLE3

Pin5,pin7,pin8 is variable for c

ompating with other hardware

NTSC Control SAW filter ,switch between M

and N

VOL2 PWM control output for left AMP.

DVD Output for DVD&TV cabine control VOL1 PWM control output for right AMP.

SCART Scart detect level input WOOFER For woofer controlling

MUTE For audio mute mode MUTE2 For mute mode 2

LED For LED controlling SV-DT S-VIDEO detect level input

BAND3 For band3 controlling 5060 Output for 50/60Hz alternate

Page 12

12

2. OM8370

B/W BALANCE

MI Items Vari

able

Prese

t

discription

DRI R 0~63 32 RED DRIVE

DRI G 0~63 32 GREEN DRIVE

DRI B 0~63 32 BLUE DRIVE

CUT R 0~63 32 RED CUT

CUT G 0~63 32 GREEN CUT

BT 0~63 32 Brightness adjust of white balance

CT 0~63 32 cont rast adjust of white balance

Note: press "MUTE" To enter the single horizontal line mode,and press again exit.

S0 POW 0-2 1 Switch on mode,0:standby,1:power on;2:remember last time.

LOGO ON/OFF OFF LOGO option

DRCS LOAD ON/OFF OFF Speicel letter load for logo(supportted by 24C16,set OFF normally)

SAVER ON/OFF OFF Option of screen saver

MENU BG 0~2 2 Background of menu(0:no;1:blue;2:half tone)

AV control logic level option ON

TV AV1 AV2 SVHS OTHER

PIN62 0 1 0 1 1 OFF

PIN63 0 0 1 1 0

PIN62 1 0 0 0 0

AV OPT ON/OFF

ON

PIN63 1 0 1 0 0

AV2 ON/OFF ON Option of AV2

SVHS ON/OFF OFF Option of SVHS

YUV ON/OFF OFF Option of YUV

SCART ON/OFF OFF Option of SCART

DVD ON/OFF OFF Option of DVD

DVD SRC V/S/YUV V Select of DVD input mode

DVD LOGIC 0-3 3 DVD logic output level select(pin62 63)

S1 FREQUENCY 50HZ Display vertical frequency automaticly

H PH 0~63 31 Horizontal shift adjusting

V SL 0~ 63 24 Vertical slope adjusting

V SH 0~63 21 Vertical shift adjusting

V SI 0~63 33 Vertical size adjusting

V SC 0~63 27 Vertical correct adjusting

H PH YUV 0~63 31 Horizontal shift adjusting of YUV/RGB

S2 AGC 0~63 24 Adjusting of RF AGC

COOL R 0~63 30 Cool color temperature adjusting of red

COOL G 0~63 32 Cool color temperature adjusting of green

COOL B 0~63 42 Cool color temperature adjusting of blue

WARM R 0~63 42 Warm color temperature adjusting of red

WARM G 0~63 32 Warm color temperature a djusting of green

Page 13

13

WARM B 0~63 30 Warm color temperature adjusting of blue

BR-YUV 0~63 32 Bias voltage of red for YUV

BG-YUV 0~63 32 Bias voltage of green for YUV

WIDE 0~63 17 Vertical size adjusting of wide mode

ZOOM 0~63 50 Vertical size adjusting of zoom mode

S3 VP 7~63 38 Vertical shift of OSD

HP 0~63 30 Horizonol shift of OSD

HP-YUV 0~30 30 Horizonol shift of YUV

OSD BRI 0~3 0 Brightness of OSD

S4 AGC-SPEED 0-3 1 AGC delay time adjusting

POW ON TIM 6-15 8 Powe on delay on time setting

VIDEO OUT IF/CVBS CVBS AV out mode option(IF:TV;CVBS:screen)

PIN5 NTSC Compatible with other hardware, see table*

PIN7 VOL1 Compatible with other hardware, see table*

PIN8 MUTE Compatible with other hardware, see table*

AKB ON/OFF ON Auto black level adjusting

NBL ON/OFF OFF Auto detect of black current

RC FORMAT NEC/RC5 NEC Code select of Renote Control

Note:wrong select may cause useless of RC

KEYBOARD SANYO/

PHILIPH

S

SANY

O

Keyboard select

MONO

* For compatible of other hardware, there are different functions of pin 5,7,8.

woofer For woofer control

Vol2 Volume PWM control of right AMP.

Vol1 Volume PWM control of left AMP.

Band3 For band control for the third pin of tuner

NTSC For SAW filter control

SCART Detect signal input of SCART

DVD Output control level for DVD

MUTE Control signal for MUTE

5060 Control signal for 50/60 switch

MUTE2 Control signal for MUTE2

SV-DT Detect signal For S-Video

S5 ENGLISH ON/OFF ON Language option

FRENCE ON/OFF ON Language option

RUSSIAN ON/OFF ON Language option

TURKISH ON/OFF ON Language option

FARSI ON/OFF ON Language option

ARABIC ON/OFF ON Language option

BULGARIAN ON/OFF ON Language option

RUMANNIAM ON/OFF ON Language option

SPANISH ON/OFF ON Language option

Page 14

14

PORTUGUESE ON/OFF ON Language option

ITALIAN ON/OFF ON Language option

GERMAN ON/OFF ON Language option

DUTCH ON/OFF ON Language option

SWEDISH ON/OFF ON Language option

NORWEGIAN ON/OFF ON Language option

HUNGARIAN ON/OFF ON Language option

POLISH ON/OFF ON Language option

CZECH ON/OFF ON Language option

SLOVENE ON/OFF ON Language option

CROATIAN ON/OFF ON Language option

MACEDONIAN ON/OFF ON Language option

SERBIAN ON/OFF ON Language option

GREEK ON/OFF ON Language option

Items Variable Preset

S6 UOC VOL SW 0~63 63 Subsidiary contrast setting

UOC/PWM

VOL

0~63 63 Subsidiary color setting

VOL10 0~100 25 Volmule of diagram 25%

VOL25 0~100 50 Volmule of diagram 50%

VOL50 0~100 75 Volmule of diagram 75%

VOL100 0~100 100 Volmule of diagram 1 00%

WOOFER ON/OFF OFF Woofer option on menu

TDA9860

WOOF

ON/OFF OFF Woofer output mode select (from TDA9860 or PWM)

OFF:PWM;on:TDA9860.

TDA9874

GAIN

ON/OFF OFF Gain of TDA9874 output

AGN ON/OFF OFF Gain of FM output .OFF:normal;no:+6dB

S7 IF 38/38.9/

45.75/

58.75

38.9M IF setting

FMWS 0~2 0 Band width of FM demodulation.0:standard(225kHz) ;1:fo r FM

over modulation (450kHz);2:over modulation (600kHz)

VST 0~2 0 VST band control option

BAND3

VHFL 0 0

VHFH 1 0

Band

opt=0

UHF 0 1

VHFL 0 1

VHFH 1 0

Band

opt=1

UHF 1 1

Page 15

15

VHFL 1 0 0

VHFH 0 1 0

Band

opt=2/

band

3

UHF 1 1 1

FST BAND ON/OFF OFF OFF:TABLE1;ON:TABLE2. NOTE*

FST LH Frequency of H band setting*

FST HU Frequency of U band setting*

SECAM ON/OFF ON SECAM system option

DK ON/OFF ON Sound system option

I ON/OFF ON Sound system option

M ON/OFF OFF Sound system option

BG ON/OFF ON Sound system option

AUTO

SOUND

ON/OFF ON Sound system auto indefine for auto search

SIFPREFER DK/I/BG/M BG Perfer sound system for auto search

S8 SUB CON 0~63 32 Subsidiary contrast setting

SUB BRI 0~63 32 Subsidiary brightness setting

SUB COL 0~63 32 Subsidiary color setting

SUB SHA 0~63 32 Subsidiary sharp setting

SUB TINT 0~31 16 Subsidiary tint setting

YDLY PAL 0~15 2 Y delay time setting of PAL

YDLY NTSC 0~ 15 2 Y delay time setting of NTSC

YDLY AV 0~15 2 Y delay time setting of AV

CATHE 0~15 8 Cathode drive level of CRT

SC.BRI 0~63 8 Brightness of the single horizontal line mode

PWL 0~15 15 Limit of peak of white level

5. ICs functional description

UOC TDA93XX/83XX

SYMBOL PIN DESCRIPTION

STAND BY output. 1 In STAND BY mode, high level (Power OFF).

For Power ON this pin will be reduced to low.

SCL 2 I2C-bus clock line

SDA 3 I2C-bus data line

TUNING 4 tuning Voltage (Vt) PWM output

P3.0/NTSC SW 5 Port 3.0 or NTSC output/SCART SW input, Forced NTSC selection,

Low-level output, otherwise High output.

KEY 6 Control keys input *3

VOL 7 Sound Volume control PWM output

MUTE 8 Sound mute output

VSSC/P 9 Digit ground for μ-controller core and periphery

BAND1 10 Tuner Band selection output

BAND2 11 Tuner Band selection output

VSSA 12 Analog ground of teletext decoder and digital ground of TV-processor

Page 16

16

SECPLL 13 SECAM PLL decoupling

VP2 14 2nd supply voltage TV-processor(+8V)

DECDIG 15 decoupling digital supply of TV-processor

PH2LF 16 Phase-2 filter

PH1LF 17 Phase-1 filter

GND3 18 Ground 3 for TV-processor

DECBG 19 Band gap decoupling

AVL/EWD 20 Automatic volume leveling /EAST-WEST drive output

VDRB 21 Vertical drive B output

VDRA 22 Vertical drive A output

IFIN1 23 IF input 1

IFIN2 24 IF input 2

IREF 25 Reference current input

VSC 26 Vertical sawtooth capacitor

TUNER AGC 27 Tuner AGC output

AUDEEM/SIFIN1 *1 28 Audio deemphasis or SIF input

DECSDEM/SIFIN2 29

decoupling sound demodulator or SIF input 2

GND2 30

ground 2 for TV processor

SNDPLL/SIFAGC *1 31

narrow band PLL filter or AGC sound IF

AVL/SNDIF/REF0/

AMOUT *1

32

Automatic Volume Levelling / sound IF input / subcarrier reference output / audio

deemphasis

HOUT 33

horizontal output

FBISO 34

flyback input/sandcastle output

AUDEXT/QSSO/

AMOUT *1

35

external audio output / QSS intercarrier out

EHTO 36

EHT/overvoltage protection input

PLL IF 37

IF-PLL loop filter

IFVO/SVO 38

IF video output / selected CVBS output

VP1 39

supply voltage TV processor

CVBS INT 40

internal CVBS input

GND1 41

ground for TV processor

CVBS/Y 42

CVBS/Y input

CHROMA 43

C input

AUDOUT/AMOUT *1 44

audio output /AM audio output (volume controlled)

INSSW2 45

2nd RGB / YUV insertion input

R2/VIN 46

2nd R input / V (R-Y) input / PR input

G2/YIN 47

2nd G input / Y input

B2/UIN 48

2nd B input / U (B-Y) input / PB input

BCLIN 49

beam current limiter input

BLKIN 50

black current input / V-guard input

RO 51

Red output

GO 52

Green output

BO 53

Blue output

VDDA 54

analog supply of Closed Caption decoder and digital supply of TV-processor (3.3

Page 17

17

V)

VPE 55

OTP Programming Voltage

VDDC 56

digital supply to core (3.3 V)

OSCGND 57

oscillator ground supply

XTALIN 58

crystal oscillator input

XTALOUT 59

crystal oscillator output

RESET 60

reset

VDDP 61

digital supply to periphery (+3.3 V)

P1.0/INT1 62

TV/AV (AV1) / AV2 /S-VHS mode Output.

P1.1/T0 63

TV/AV (AV1) / AV2 /S-VHS mode Output.

P1.2/INT0 64

Remote control signal input.

Note

1. The function of pin 20, 28, 29, 31, 32, 35 and 44 is dependent on the IC version (mono intercarrier FM demodulator

/QSS IF amplifier and East-West output or not) and on some software control bits. The valid combinations are given in

table 1.

2. the vertical guard function can be controlled via pin 49 or pin 50. the selection is made by means of the

IVG bit in subaddress 2BH.

TABLE 1

IC version FM-PLL version QSS version

East-West

Y/N

N Y N Y

CMB1/CMB0

bits

00 01/10/11 00 01/10/11 00 01/10/11 00 01/10/11

AM bits

- - - - - 0 1 - 0 1

Pin 20

AVL EWD AVL EWD

Pin 28 AUDEEM SIFIN1

Pin 29 DECSDEM SIFIN2

Pin 31 SNDPLL SIFAGC

Pin 32

SNDIF(1) REFO(2) AVL/SNDIF(1) REFO(2) AMOUT REFO(2) AMOUT REFO(2)

Pin 35

AUDEXT AUDEXT QSSO AMOUT AUDEXT QSSO AMOUT

Pin 44 AUDOUT Controlled AM or audio out

Note

1. When additional (external) selectivity is required for FM-PLL system pin 32 can be used as sound IF input.

This function is selected by means of SIF bit in subaddress 28H.

2. the reference output signal is only available for the CMB1/CMB0 setting of 0/1. for the other settings this pin is

a switch output(see also 5 table 67).

Pin No. 6: Control keys input voltage

AN17821A/17823A Function : audio output

Function POWER MENU TV/AV V- V+ P- P+

Voltage 11/16-

13/16VDD

9/16-

11/16VDD

7/16-

9/16VDD

5/16-

7/16VDD

3/16-

5/16VDD

1/16-

3/16VDD 0-1/16VDD

Page 18

18

Symbol PIN Function Symbol PIN Function

Vcc 1 Power supply GND 7 ground

Out 1 (+) 2 Ch 1 output (+) In 2 8 Ch 2 input

GND(out 1) 3 Ch 1Ground VOL 9 Volume Control

Out 1 (-) 4 Ch 1 output (-) Out 2 (-) 10 Ch 2 output (-)

Standby 5 Mute input GND(out 2) 11 Ch 2 Ground

In 1 6 Ch 1 input Out 2 (+) 12 Ch 2 output (+)

Note: AN17823A is pin 1 to 9, AN17821A is pin 1 to 12.

LA78040/78041/TDA8172A Function : vertical output

Symbol PIN Function Symbol PIN Function

INV IN 1 Input V OUT 5 Vertical output

VCC1 2 Power VCC2 6 Output power supply

PUMP UP 3 Pump up power NON INV IN 7 Negative feedback

GND 4 Ground

6. Test point Waveforms

V451 C

5Vpp

0.9Vpp

1000Vpp

1.3Vpp

1Vpp

CRT KB

CRT KG CRT KR

95Vpp

95Vpp

95Vpp

T511 PIN7 HEATER

300Vpp 22Vpp

V451 B

2.7Vpp

TDA93XX PIN53

2.5Vpp

2.5Vpp

3.8Vpp

TDA93XX PIN52 TDA93XX PIN51

TDA93XX PIN33

TDA93XX PIN34

0.8Vpp

TDA93XX PIN21

TDA93XX PIN22

TDA93XX PIN59

1.2Vpp

2.6Vpp

TDA93XX PIN40

TDA93XX PIN38

Page 19

19

7. IC voltages

TDA93XX

PIN 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

V 2.8 3.8 3.6 3.3 3.5 3.5 0.1 0.1 0 5.4 0.1 0 2.3 8 5 3

PIN 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

V 4 0 4 0.9 0.7 0.8 1.9 1.9 3.9 3.8 1.6 3.2 3.4 0 2.4 0.1

PIN 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

V 0.6 0.5 3.7 1.7 2.4 3.1 8 3.8 0 3.4 1.5 3.6 2.3 2.6 2.6 2.6

PIN 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

V 2.3 7.2 2.7 2.7 2.7 3.5 0 3.5 0.1 1.7 1.8 0 3.5 0.1 0.1 5

LA76040

PIN 1 2 3 4 5 6 7

V 0.7 15 -12 -15 0.3 15.9 -0.07

AN 17821A

PIN 1 2 3 4 5 6 7 8 9 10 11 12

V 12 7 0 7 3.3 1.4 0 1.4 0 7 0 7

TDA9859

PIN 1 2 3 4 5 6 7 8 9 10 11 12 13 14

V 4.0 0 4.0 8.0 4.0 8.0 4.0 0 4.0 4.0 4.0 4.0 4.0 4.0

PIN 15 16 17 18 19 20 21 22 23 24 25 26 27 28

V 4.0 4.5 4.6 4.0 4.0 4.0 4.0 4.0 4.0 4.0 0 4.0 4.0 4.0

PIN 29 30 31 32

V 4.0 4.0 0 4.0

Page 20

20

8. PURITY / CONVERGENCE ADJUSTMENT

PURITY ADJUSTMENT

1. Demagnetize CRT with the demagnetizer.

2. Loosen the retainer screw of the deflection yoke.

3.

Remove the wedges.

4.

Input a green raster signal from the signal generator,

and turn the screen to green raster.

5.

Move the deflection yoke backward.

6.

Bring the long lug of the purity magnets on the short

lug and position them horizontally. (Fig2)

7.

Adjust the gap between two lugs so that the GREEN

RASTER will come into the center of the screen. (Fig.

3)

8.

Move the deflection yoke forward, and fix the position

of the deflection yoke so that the whole screen will

become green.

9.

Insert the wedge to the top side of the deflection yoke

so that it will not move.

10.

Imput a crosshatch signal.

11.

Verify that the screen is horizontal.

12.

Input red and blue raster signals, and make sure that

purity is properly adjusted.

CRT

WEDGE

DEFLECTION YOKE

P

4 6

P: PURITY MAGNET

4: 4-POLES

(convergence magnets)

6: 6-POLES (convergence magnets)

P/C MAGNETS

Fig. 1

PURITY MAGNETS

Long lug

Short lug

Bring the long lug over the short lug

and position them horizontally.

Fig. 2

(FRONT VIEW)

GREEN RASTER

CENTER

Fig. 3

Page 21

21

STATIC CONVERGENCE ADJUSTMENT

1. Input a crosshatch signal.

2. Using 4-pole convergence magnets, overlap the red

and blue lines in the center of the screen (Fig. 1) and

turn them to magenta (red/blue).

3. Using 6-pole convergence magnets, overlap the

magenta (red/blue) and green lines in the center of the

screen and turn them to white.

4. Repeat 2 and 3 above, and make the best

convergence.

DYNAMIC CONVERGENCE ADJUSTMENT

1. Move the deflection yoke up and down and overlap

lines in the periphery. (Fig. 2)

2. Move the deflection yoke left to right and overlap the

lines in the periphery. (Fig. 3)

3. Repeat 1 and 2 above, and make the best

convergence.

After adjustment, fix the wedge at the original position.

Fasten the retainer screw of the deflection yoke.

Fix the 6 magnets with glue.

(FRONT VIEW)

Fig. 1

(FRONT VIEW)

RED GREEN BLUE

BLUE

RED

GREEN GREEN

RED BLUE

BLUE GREEN RED

Fig.2

(FRONT VIEW)

RED GREEN BLUE BLUE GREEN RED

RED

GREEN

BLUE

BLUE

GREEN

RED

Fig. 3

Page 22

1 2 3 4 5 6 7 8

A

B

C

D

E

F

G

H

8

7654321

H

G

F

E

D

C

B

A

CRT BOARD

234

R918

1/2W/2.7K

R915 2WSJ12K

R928

1/2W/2.7K

R925

2WSJ12K

R932 47

C939

2KV102

R938

1/2W/2.7K

R935

2WSJ12K

C456

1.6KV9100p

C451

500V/1000pF

C401

35V47uF

R454

2W270

R403

1/4W1K

C452

500V/3900pF

V401

2SC2383

ABL

R451

2W 1.5

R487

1/2W22K

C303

2A104

R305

1W 2180

C3047

50V100uF

D301

1N4004

Flyback Transformer

C449

160V/4.7uF

C460

250V0.39uF

L441

LF-044-2-37uH

2

3

4

1

2

3

4

XS401

XS402

1234567

N451 LA78040

D442

FR157

R561

3WSJ1

MAIN BOARD

XS601

XS601A

C610

470uF

3W/16OHM

3W/16OHM

D551

HER207

D553

FR154

D555

FR154

D556

FR154

C518

AC400V/2200p

R514

1/2WRI12M

D554

FR154

C305

25V/470u

C552

1KV/470p

C601

25V1000UF

C553

25V1000uF

R572

2W 27

C561

160V/47uF

RP551

B-2K

R555

1/2WDJ100K

R574

7.5K

V552

2SC1815

D562

HZ6C3/6.2V(

日立)

R557

1/2WDJ150k

R570

1/2WDJ47K

R571

22K

V562

2SA1015

C558

470uF

C306

25V/470u

R564

2WDJ2.2

B+

110V

B4

+15V

B5

5V

B6

8V

N501

PC817(SHARP)

B4

+15V

V451

D1651/TT2190

T451

UU10.5

C437A

TXP-5

B8

27V

C403

160V/47uF

B+

110V

TJC3-4A

TJC2-5A

B10

180V

ATTENTION:

(1)2SC:2SC536-E/F/G,2SC1815-O/Y/GR;

(2)D:1S1555;1N4148;1S2473;1S2076;D5442;

(3)2SA:2SA608;-E/F;2SA1015-O/Y/GR;

(4)0.01:CT1-08B-2F4-63V-0.01uF-Z

(5)KK470:CT1-06B-2B4-63V-470p-K

(6)FFXXX:CL11-63V-XXXuF-K

(7)200NJXXX:CBB22-200V-XXXuF-J

(8)1500MJXXX:CBB12-1600V-XXXuF-J

SAFETY NOTE:

ALL parts with symbol are important safety parts

please do dot use substitutes to repiace them

DESIGN&SPECIFICATIONS ARE SUBJECT TO CHANGE

WITHOUT PRIOR NOTICE

TJC3-5A

SCN-5Y

TJC3-2A

TJC3-2A

SCN-2Y

SCN-2Y

XP402

TJC2-5Y

11

6

8

9

10

571

XX-XX-XX

U901

CRT

D931

1N4148

K9N

TJC2-1A

XS901

!

!

R916 47

R911 47

L901

22uH

R

G

B

FOUSE

R458

1/2W4.7K

C112

0.01u

W711

10K

D484

HZ9A2

ABL

D559

HZ9B2/8.7V

C437A

2W2.2

D452

FR305*

D451

FR309*

D401

FR157

C402

250V/10u

B10

180V

C566

16V47uF

R318

220

R445

1W 10*

C326

35V/47u*

L311

410uH*

B8

27V

B6

8V

C455

1.6KV3300p*

R1111

3.3K

LED

TRL-R

V561

2SC1815

C1101

16V/47u

1

2

3

4

XS003

XS702

R1112

47

R706

2.2K

R705

2.7K

R704

3.9K

R703

4.7K

R702

8.2K

R701

27K

R700

150K

MUNE

V- AV/TVV+CH-CH+

B5

5V

R567

1/2W1K

\B2

\B1

IF

MB

VL

VH

UB

TU

AGC

A101

TDQ

R714

10K

R723

27K

R715

10K

R105

10K

V701

2SC1815Y

C718

220p

N705

KA33V

C708

50V4.7u

R718

2WSJ12K

R716

12K

B+

110V

C103

50V4.7u

C104

50V4.7u

C107

50V0.47u

C105

50V0.47u

C102

2A104

C101

10uF

R108

27K

R116

10K

R131

15K

C131

100uF

B7

5V

C109

50V4.7u

C132

0.01uF

C110

0.01u

R107

100

R110

390

R109

1K

C111

0.01u

R108

5.6K

R111

56

R100

100

B6

12V

R459

1WSJ1.2

R404

1WSJ1K

14''/21'' COLOR TV BASIC SCHEMATIC DIAGRAM

C602

2A104

R608

1

R609

4.7

C607

16V/100u

R607

220

12345

N601 TDA2003

B2

16V

V602

2SC1815Y

C608

50V4.7u

1

2

3

4

5

XS201

XP902

C615

10uF

L110

1.2uH

V101

2SC1674

C823

16V/10u

R825

100

R829

1K

C821

220uF

B7

5V

V801

2SA1015

R315

1W 10*

C307

50v4.7u*

CDS

R731

10K

V603

2SC1815*

RP311

50K*

RP312

10K*

R313

100k*

R312

10k*

R314

270k*

V311

2SC1815*

V303

2SD2012*

C311

0.1u*

C312

0.1u*

C315

35V/47u*

C314

35V/470uF*

R319

18k*

R320

39k*

R321

2.7k*

R318

5.6k*

R323

2.7k*

R322

4.7k*

V312

2SA1015*

D311

1N4148*

R316

8.2k*

R938

1/4W 33

GZS10-2-108P

GND

IR OUT

VCC

REM

BRM1030

BSC24-01N4014K

BSC25-N0832

XP901

SCN-4Y

R933

330

C931

330p

V931

2SC2482

8

7

10

1

2

4

6

5

3

9

T471

BSC25-T1010A

R203

680

R610

5.6K

R613

1K

C604

0.01uF

XS102

SCN-2YV

R

L

AV BOARD

V in

L in

R in

V out

R out

L out

C209

0.01uF

R802

47K

R801

4.7K

C801

10uF

R455

27K

R481

10K

R

G

B

R219

100

R303

1.8K

R218

100

R301

1.8K

R213

10K

C805

10uF

R810

4.7K

R809

47K

C802

10uF

R803

4.7K

R804

47K

C213

10uF

C803

50V/1uF

R805

82

R806

100

R811

47K

R812

4.7K

C806

10uF

B7

5V

R202 RJ1/4W39K

C705

220pF

1 2 3 4

5678

N701

AT24C08

B5

5V

R7113.3K

C486

220pF

C605

10uF

1000pF

XS804

SZ-3W

Y-in

Cb-in

Cr-in R821

100

C204 0.1uF

C219 10uF

R459

100

R216100

C612

10uF*

C210 3300pF

Z101

LBN3828H

V822

2SC1815

R823

27K

R824

27K

V823

2SC1815

R827

2.2K

R826

2.2K

C823

10uF

C822

10uF

R829

100

R828

100

XS602

TJC3-2A

3W/8OHM

V921

2SC2482

V911

2SC2482

R916A

330

R936

330

R926

330

CON&IR BOARD

TJC3-5A

SCN-5Y

Ver: B01 Model: KLX-PH22Z

1 2 3 4 5 6 7 8 9 101112 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

64

63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33

IR IN

AV2

AV1

VDDP

RESET

XTAL OUT

XTAL IN

OSC GND

VDDC

VPE

VDDA

B OUT

G OUT

R OUT

BLANKING

BCLIN

B2/UIN

G2/YIN

R2/VIN

INSSW2

AUDOUT/AMOUT

CHROMA

CVBS/Y

GND1

CVBSINT

VP1

IFVO/SVO

PLL IF

EHTO

AUDEXT

FBISO

HOUTAVL/REF

SNDPLL/SIFAGC

IF IN1

DECSDEM/SIFIN2

AUDEEM/SIFIN1

TUNER AGC

VSC

GND2

IF IN2

IREF

VDRA

VDRB

AVL/EWD

DECBG

GND3

PH1LF

PH2LF

DECDIG

VP2

SEC PLL

VSSA

BAND2

BAND1

VSS C/P

MUTE

VOL1

KEY

NTSC SW

TUNING

SDA

SCL

STAND BY

TDA9341

N201

T501

21":YBC40-28/1950A

B3

-15V

9

10

4

7

2

3

11

12

13

14

15

16

D558

1N4148

D557

15K

C591

47u

D552

FR154

C562

35V/470uF

C567

220uF

1 2 3 4 5 6 7 8 9 10 11 12

Vcc

Ch1 out

GND

Ch1 out

Standby

Ch1 in

GND

Ch2 in

Volume

Ch2 out

GND

Ch2 out

AN7522N601

D701

1N4148

1 2 3 4 5 6 7 8

910111213141516

y1 in

y3 in

y out

y4 in

y2 in

INH

V

x3 in

x2 in

x out

x1 in

x4 in

ab

V

Vss

EE

DD

N801

CD4052

Y in

C in

C807

10uF

C808 10uF

C825

10uF

C824

10uF

R70610K

R7093.3K

R7083. 3K

R721

100

R719

100

B1

3.6V

C216

50V/4.7uF

R807

100

R808

82

B6

8V

C820

47uF

R822

270

B3

-15V

R304A

1/4W 2.2

B6

8V

R226 2.2K

C712 0.01uF

G701

12.0M

C481

16V/47uF

D461

1N4148

R465

560K

TUNING

IR IN

AV1

VL

ABL

TV A

VH

AV2

VIF

VIF

MUTE

IR

S DE

S DE

VDRB

VDRA

AGC

VIDEO OUT

OFF/ON

OFF/ON

H out

AGC

AV/TV

Y U V

LSR

C iN

AR in

V1 Y in

AL in

TUNING

AV1/2

KEY

FBP

W602

7.5mm*

B6

8V

R612

18K

R604

270K

R614

68K

C603

10uF

R606

18K

R605

56K

C613

10uF

R616

47K

R615

1K

C604

0.01uF

C607

10uF

R609

47K

C606

0.01uF

LSR

R617

100

LSL

V601

2SA1015

D601

1N4148

R611

10K

C611

100uF

R601

1K

B9

11V

V301

2SC1815

C301

47uF

R301

8.2K

R303

1K

R302

47K

R304

4.7K

R305

15K

V302

2SC1815

R306

4.7K

C302

10uF

R307

1.8K

V303

2SC1815

R309

22K

R308

6.8K

R331

10K

V304

2SC1815

R3321KR310

6.8K

RP303

50K

V305

2SC1815

R334

1K

R335

47K

PPC-PHASE

HORIZ-SIZEPPC-AMP

C437

630V0.047uF*

L422

240uH*

R405

1W2K*

C422

400V0.1uF*

EW

R460

82K

B6

8V

R322A

1/4W82K

V2 in

D563

10K

B9

11V

R560

10K

R591

15K*

V564

C1815

R592

10K

C563

50V/1uF

VD591

HZ6C3

V553

A1015

R594

R22K

FU501

T3.15A

R505

5.6K

V501

2SA1015

R516

3.3k

VD515

HZ9C1

D511

1N4148

D512

1N4148

D506

FR154

D501

RL207

D502

RL207

D503

RL207

D504

RL207

C503/C506 1KV/1000p

R502

8D-11

R515

1K

R517

22K

R506

2.7K

R511

1/6W22

R503

1/2W 120K

R504

1/2W 120k

R513

3W 68

V513

21":2SC5287

V502

29":2SC3807(

三洋)

C518A

2A153

R512

2W 68

C521

2KV/680p

C514

FK0.1u

C509

CL21 2A153

L501

ET24

C501

AC280V/0.1uF

C502

AC280V/0.1uF

O

O

0

0

RT501

MZ73-14RM

1

2

LIVE AREA

C507

400V/220uF

Degauss Coil

AC input

L909

LM-01

XP502

XS502

SW501

KDC-A04

AC220V/50zH

XS501

21":2SC2655

C511

1KV/1000p

C513

2KV/470p

C522

2A472

R509 15k

D508

1N4148

TJC1-2A

TJC1-2A

KDC-A11

L502

UF16*

29":2SC5297

29":YBC43-28/1969

B2

16V

B8

27V

B9

11V

R317

1k*

R311

39k*

D5017(华微)

C565

2A102

29":BSC26-01N4010E

BSC26-N2148

樱发

29"短管:BSC26 -01N40 10F

BSC26-N2143

樱发

三菱

29":BSC26-01N4004F

BSC26-01N

樱发

R501

1/2W 120K

C505

X

C504

X

R552

1W 0.47

R551

1W 0.47

R563

2WDJ0.47

R569

10K

R568

1K

D550

1N4148

V563

2SD882

C554

16V470uF

C556

0.01

78L05

OUTIN

GND

V565

78L05

B1

3.6V

D704

1N4148

D703

1N4148

C701

47uF

C716

47uF

C112

0.01uF

R701

1/4W27

29"待机电路

R729

3.3K

W554

1.5K

B9

11V

KEY

C704 0.01uF

C709

0.01uF

VOL1

R712 3.3K

MUTE

R7163. 3K

R7043. 3K

SW/NTSC

VH

VL

C224

0.22uF

L201

10UH

B6

8V

C205 16V/47uF

C202

0.22uF

C223 2200PF

R808

100

R807

100

R806

100

C206 2A472

R201

1.5K

C20350V/1UF

C205

50V/2.2UF

C211 50V/2.2UF

C207 1000pF

C208

1000pF

VDRB

VDRA

C211

CL21 2A104

C2142A472

R205

2.7K

C215 820pF

C483

1000pF

R402 100

R453

2.2K

HOUT

FBP

C80110UF R8011K

AUDOEXT

EHTO

R206 390C217

2A104

Z201

5.5M

Z202

6.0M

Z203

6.5M

L202 6. 8uH

V202

C1815

R222100

R223

180

B6

8V

V201

C1815

R221 390

R224 56

R225

390

C218

10UF

VOUT

CVBS/Y

CHROMA

AOUT

R208 1K

R214 5.6K

SW

C809

0.01uF

C808

0.01uF

C807

0.01uF

R/VIN

G/YIN

B/UIN

ABL

R212

100

R211

100

R210

100

D203

HZ9A2

D202

HZ9A2

D201

HZ9A2

BLANKING

R OUT

B OUT

G OUT

C715 10uF

C717 0.01uF

L701

10uH

L702

10uH

L703

10uH

C712

0.01uF

C712

0.01uF

C713 10uF

C718 0.01uF

R OUT

G OUT

B OUT

BIANKING

BIANKING

V932

2SC2482

V933

BF421

R912 10K

R932A

10K

R922 10K

R937

220

D921

1N4148

R923

330

C921

330p

V922

2SC2482

V923

BF421

R927

220

D911

1N4148

R913

330

C911

330p

V912

2SC2482

V913

BF421

R917 330

D932

1N4007

D922 1N4007

D9121N4007

C301

2200p

C302

2A104

R302

1/4W 1

R401

1/2W220K

C231 1KV471

R483

27K

C482

500V/4700pF

R486

1K

C458

50V/1uF(CD73)

R482

10K

D481

1N4148

C484

1000pF

R456

100K

EHTO

EHTO

V303

IRF630

Page 23

Page 24

NO. PART NO. NAME SPECIFICATION

UNIT

QT

Y

BOARD

PLACE

1 10-00PC817-000 IC

PC817B

PCS

1 MAIN

2 10-0078L05-000 IC 78L05

PCS

1 MAIN

3 10-0078040-000 IC LA78040/STV8172A

PCS

1 MAIN

4 10-0024C06-000 IC AT24C08

PCS

1 MAIN

5 10-0000574-000 IC

UPC574J/W574/KA33V

PCS

1 MAIN

6 10-0009351-000 IC TDA9351/61/53/63

PCS

1 MAIN

7 10-000821A-000 IC AN17823A/AN7523

PCS

1 MAIN

8 11-2SA1015-P00 TRANSISTOR

2SA1015-O/Y

PCS

2 MAIN

9 11-2SC1815-P00 TRANSISTOR

2SC1815Y

PCS

7 MAIN

10 11-2SD2012-P00 TRANSISTOR

2SD2012

PCS

1 MAIN

11 11-2SC3807-000 TRANSISTOR

2SC3807-CTV-YA/2SC2655

PCS

1 MAIN

12 11-2SC2383-P00 TRANSISTOR

2SC2383Y

PCS

1 MAIN

13 11-00BF423-P00 TRANSISTOR BF423/BF421

PCS

3 CRT

14 11-00BF422-P00 TRANSISTOR BF422/BF420

PCS

6 CRT

15 11-0PH2369-000 TRANSISTOR

PH2369

PCS

1 MAIN

16 11-2SC5287-000 TRANSISTOR

2SC5287

PCS

1 MAIN

17 11-2SC1674-000 TRANSISTOR

2SC1674

PCS

1 MAIN

18 11-2SD1651-C00 TRANSISTOR 2SD1651C

PCS

1 MAIN

19 12-0IN4148-P52 SWITCHING DIODE 1N4148

PCS

11 MAIN

CRT

20 12-01N4007-P52 SWITCHING DIODE 1N4007

PCS

4 MAIN

CRT

21 12-00FR154-L15 SWITCHING DIODE FR154(L15/H10)

PCS

7 MAIN

22 12-00FR157-P52 SWITCHING DIODE FR157

PCS

4 MAIN

23 12-0HER207-L15 SWITCHING DIODE HER207(L15/H10)

PCS

1 MAIN

24 12-00RL207-P52 SWITCHING DIODE RL207

PCS

4 MAIN

25 12-03V43C3-P52 ZENER DIODE 3C3/3.4V

PCS

1 MAIN

26 12-05V15C2-P52 ZENER DIODE 5C2/5.1V

PCS

2 MAIN

27 12-06V26C3-P52 ZENER DIODE 6C3/6.2V

PCS

1 MAIN

28 12-08V29A2-P52 ZENER DIODE 9A2/8.2V

PCS

2 MAIN

29 12-08V79B2-P52 ZENER DIODE 9B2/8.7V

PCS

1 MAIN

D562.

D201.D202.D203.D484.D941.

D559.

D551.

D501.D502.D503.D504.

D701

D101.

D301.

D912.D922.D932.

D506.D552.D553.D554.D555.D556

D401.D462.

V101

V451

D461.D481.D508.D511.D512.D550.D702.D558

D911.D921.D931

V913.V923.V933.

V911.V912.V921.V922.V931.V932.

V701A

V513

V201.V202.V552.V561.V601.

V563

V502

V401

N552

N201

N601

V501.V562.

KLX-PH22 VER 3.0 main bom list(for 14 and 21 inch)

PAL/SECAM BG/DK/I , MONO AUDIO , AV port(front three and back TWO)

MAIN BOM:BOM-KLX-PH22 VER 3.0

PART PLACE

Ⅰ、Electron component

N501

V565

N451

N701

Page 25

NO. PART NO. NAME SPECIFICATION

UNIT

QT

Y

BOARD

PLACE

30 12-09V19C1-P52 ZENER DIODE 9C1/9.1V

PCS

1 MAIN

31 16-RMF393J-P52 CARBON FILM RESISTOR RM-1/6W-39KΩ-G

PCS

1 MAIN

32 16-RTF390J-P52 CARBON FILM RESISTOR RT14-1/6W-39Ω-J

PCS

1 MAIN

33 16-RTF470J-P52 CARBON FILM RESISTOR RT14-1/6W-47Ω-J

PCS

3 CRT

34 16-RTF560J-P52 CARBON FILM RESISTOR RT14-1/6W-56Ω-J

PCS

1 MAIN

35 16-RTF101J-P52 CARBON FILM RESISTOR RT14-1/6W-100Ω-J

PCS

13 MAIN

MAIN

36 16-RTF181J-P52 CARBON FILM RESISTOR RT14-1/6W-180Ω-J

PCS

1 MAIN

37 16-RTF221J-P52 CARBON FILM RESISTOR RT14-1/6W-220Ω-J

PCS

4 MAIN

CRT

38 16-RTF331J-P52 CARBON FILM RESISTOR RT14-1/6W-330Ω-J

PCS

3 CRT

39 16-RTF391J-P52 CARBON FILM RESISTOR RT14-1/6W-390Ω-J

PCS

6 MAIN

CRT

40 16-RTF471J-P52 CARBON FILM RESISTOR RT14-1/6W-470Ω-J

PCS

1 MAIN

41 16-RTF681J-P52 CARBON FILM RESISTOR RT14-1/6W-680Ω-J

PCS

2 MAIN

42 16-RTF102J-P52 CARBON FILM RESISTOR RT14-1/6W-1KΩ-J

PCS

8 MAIN

43 16-RTF122J-P52 CARBON FILM RESISTOR RT14-1/6W-1.2KΩ-J

PCS

1 MAIN

44 16-RTF182J-P52 CARBON FILM RESISTOR RT14-1/6W-1.8KΩ-J

PCS

3 MAIN

45 16-RTF222J-P52 CARBON FILM RESISTOR RT14-1/6W-2.2KΩ-J

PCS

2 MAIN

46 16-RTF272J-P52 CARBON FILM RESISTOR RT14-1/6W-2.7KΩ-J

PCS

2 MAIN

47 16-RTF332J-P52 CARBON FILM RESISTOR RT14-1/6W-3.3KΩ-J

PCS

9 MAIN

48 16-RTF392J-P52 CARBON FILM RESISTOR RT14-1/6W-3.9KΩ-J

PCS

2 MAIN

49 16-RTF472J-P52 CARBON FILM RESISTOR RT14-1/6W-4.7KΩ-J

PCS

2 MAIN

50 16-RTF562J-P52 CARBON FILM RESISTOR RT14-1/6W-5.6KΩ-J

PCS

3 MAIN

51 16-RTF752J-P52 CARBON FILM RESISTOR RT14-1/6W-7.5KΩ-J

PCS

2 MAIN

52 16-RTF103J-P52 CARBON FILM RESISTOR RT14-1/6W-10KΩ-J

PCS

16 MAIN

MAIN

CRT

53 16-RTF153J-P52 CARBON FILM RESISTOR RT14-1/6W-15KΩ-J

PCS

3 MAIN

54 16-RTF183J-P52 CARBON FILM RESISTOR RT14-1/6W-18KΩ-J

PCS

1 MAIN

55 16-RTF223J-P52 CARBON FILM RESISTOR RT14-1/6W-22KΩ-J

PCS

3 MAIN

56 16-RTF273J-P52 CARBON FILM RESISTOR RT14-1/6W-27KΩ-J

PCS

2 MAIN

57 16-RTF333J-P52 CARBON FILM RESISTOR RT14-1/6W-33KΩ-J

PCS

3 MAIN

58 16-RTF683J-P52 CARBON FILM RESISTOR RT14-1/6W-68KΩ-J

PCS

1 MAIN

59 16-RTF104J-P52 CARBON FILM RESISTOR RT14-1/6W-100KΩ-J

PCS

2 MAIN

60 16-RTF154J-P52 CARBON FILM RESISTOR RT14-1/6W-150KΩ-J

PCS

1 MAIN

61 16-RTF274J-P52 CARBON FILM RESISTOR RT14-1/6W-270KΩ-J

PCS

1 MAIN

62 16-RTF564J-P52 CARBON FILM RESISTOR RT14-1/6W-560KΩ-J

PCS

1 MAIN

PART PLACE

R465.

R603.

R456.

R108.

R604.

D557

R209.R517.R571.

R455.R483.

R102.R452.

R213.R481.R482.R569.R610.R614.R705.

R706.R707.W711.R725.R726.R811.

R922.R932A.R912.

R201.R509.R724.

R457.R606.

R105.R613.

R214.R505.R710.

R574

R215.R301.R303.

R226.R453.

R205.R506.

R516.R704.R708.R709.R711.R712.R715.

R107

R203.R731

R207.R208.R486.R515.R568.R801.R802.R812

R104.

R917.R927.R937.

R916A.R926.R936.

R206.R221.R225.

R913.R923.R933.

R210.R211.R212.R216.R218.R219.R222.

R402.R459.R719.R721.R722.R809.

R223.

R106.

R202.

R103.

R911.R916.R932.

R224.

D515

Page 26

NO. PART NO. NAME SPECIFICATION

UNIT

QT

Y

BOARD

PLACE

63 16-RTG10AJ-P52 CARBON FILM RESISTOR RT14-1/4W-1Ω-J

PCS

1 MAIN

64 16-RTG22AJ-P52 CARBON FILM RESISTOR RT14-1/4W-2.2Ω-J

PCS

1 MAIN

65 16-RTG220J-P52 CARBON FILM RESISTOR RT14-1/4W-22Ω-J

PCS

1 MAIN

66 16-RTG270J-P52 CARBON FILM RESISTOR RT14-1/4W-27Ω-J

PCS

1 MAIN

67 16-RTG330J-P52 CARBON FILM RESISTOR RT14-1/4W-33Ω-J

PCS

1 CRT

68 16-RTG102J-P52 CARBON FILM RESISTOR RT14-1/4W-1KΩ-J

PCS

1 MAIN

69 16-RTG225J-P52 CARBON FILM RESISTOR RT14-1/4W-2.2MΩ-J

PCS

1 MAIN

70 16-RTH102J-P52 CARBON FILM RESISTOR RT15-1/2W-1KΩ-J

PCS

1 MAIN

71 16-RTH272J-P52 CARBON FILM RESISTOR RT15-1/2W-2.7KΩ-J

PCS

3 CRT

72 16-RTH472J-P52 CARBON FILM RESISTOR RT15-1/2W-4.7KΩ-J

PCS

1 MAIN

73 16-RTH103J-P52 CARBON FILM RESISTOR RT15-1/2W-22KΩ-J

PCS

1 MAIN

74 16-RTH224J-P52 CARBON FILM RESISTOR RT15-1/2W-220KΩ-J

PCS

2 MAIN

75 16-RYH124J-P52 METAL OXIDE FILM RESISTOR RY15-1/2W-120KΩ-J

PCS

2 MAIN

76 16-RYG154J-P52 METAL OXIDE FILM RESISTOR RY14-1/4W-150KΩ-J

PCS

1 MAIN

77 16-RYH473J-P52 METAL OXIDE FILM RESISTOR RY15-1/2W-47KΩ-J

PCS

1 MAIN

78 16-RYH104J-P52 METAL OXIDE FILM RESISTOR RY15-1/2W-100KΩ-J

PCS

1 MAIN

79 16-RYI47BJ-P52 METAL OXIDE FILM RESISTOR RY16-1W-0.47Ω-J

PCS

1 MAIN

80 16-RYI12AJ-L15 METAL OXIDE FILM RESISTOR RY16-1W-1.2Ω-J(L15/H10)

PCS

2 MAIN

81 16-RYI220J-L15 METAL OXIDE FILM RESISTOR RY16-1W-22Ω-J

PCS

1 MAIN

82 16-RYI181J-P52 METAL OXIDE FILM RESISTOR RY16-1W-180Ω-J

PCS

1 MAIN

83 16-RYI102J-P52 METAL OXIDE FILM RESISTOR RY16-1W-1KΩ-J

PCS

1 MAIN

84 16-RYJ68BJ-L20 METAL OXIDE FILM RESISTOR RY21-2W-0.68Ω-J

PCS

1 MAIN

85 16-RYJ10AJ-L20 METAL OXIDE FILM RESISTOR RY21-2W-1Ω-J

PCS

2 MAIN

86 16-RYJ15AJ-L20 METAL OXIDE FILM RESISTOR RY21-2W-1.5Ω-J

PCS

1 MAIN

87 16-RYJ270J-L20 METAL OXIDE FILM RESISTOR RY21-2W-27Ω-J

PCS

1 MAIN

88 16-RYJ271J-L15 METAL OXIDE FILM RESISTOR RY21-2W-270Ω-J(L17.5/H10)

PCS

1 MAIN

89 16-RYJ103J-L20 METAL OXIDE FILM RESISTOR RY17-2W-10KΩ-J

PCS

1 MAIN

90 16-RYJ123J-L15 METAL OXIDE FILM RESISTOR RY21-2W-12KΩ-J(L17.5/H10)

PCS

3 MAIN

91 16-RYK680J-L20 METAL OXIDE FILM RESISTOR RY18-3W-68Ω-J

PCS

2 MAIN

92 16-RIH126K-P52 HIGH VOLTAGE INSULATED RESIS. RI40-1/2W-12MΩ-K

PCS

1 MAIN

93 16-MF8D11J-000 ORGANIC SOLID RESISTOR MF72-8D11

PCS

1 MAIN

94 16-RW02K2J-000 TRIMMER POTENTIOMETER

W206-2AL2KΩ

PCS

1 MAIN

95 16-RM7214J-000 DEGAUSSING THERMISTOR MZ72A-14RM(three pin)

PCS

1 MAIN

96 17-00E100M-PO0 MINI ELEC.CAPACITOR CD110-16V-10μF-M

PCS

15 MAIN

MAIN

MAIN

97 17-00E470M-PO0 MINI ELEC.CAPACITOR CD110-16V-47μF-M

PCS

8 MAIN

MAIN

PART PLACE

C813

C201.C222.C481.C566.C701.C708.C716

C591

RP551.

RAJ501.

C101.C102.C103.C108.C213.C219.C603.

C604.C605.C623.C713.C715.C801.C802.

R915.R925.R935.

R512.R513.

R514.

R502.

R451.

R572

R454.

R558.

R305.

R404.

R563.

R561.R564.

R555.

R551.R552

R304.

R101.

R401.R501.

R503.R504

R557.

R570.

R567

R918.R928.R938.

R458.

R487.

R701.

R940.

R403

R576.

R302.

R304A.

R511

Page 27

NO. PART NO. NAME SPECIFICATION

UNIT

QT

Y

BOARD

PLACE

98 17-00E221M-PO0 MINI ELEC.CAPACITOR CD110-16V-220μF-M

PCS

1 MAIN

99 17-00E471M-PO0 MINI ELEC.CAPACITOR CD110-16V-470μF-M

PCS

2 MAIN

100 17-00F471M-PO0 MINI ELEC.CAPACITOR CD110-25V-470μF-M

PCS

2 MAIN

101 17-00F102M-PO0 MINI ELEC.CAPACITOR CD110-25V-1000μF-M

PCS

2 MAIN

102 17-00G470M-PO0 MINI ELEC.CAPACITOR CD110-35V-47μF-M

PCS

1 MAIN

103 17-00G101M-PO0 MINI ELEC.CAPACITOR CD110-35V-100μF-M

PCS

1 MAIN

104 17-00G471M-PO0 MINI ELEC.CAPACITOR CD110-35V-470μF-M

PCS

1 MAIN

105 17-00I47BM-PO0 MINI ELEC.CAPACITOR CD110-50V-0.47μF-M

PCS

2 MAIN

106 17-00I10AM-PO0 MINI ELEC.CAPACITOR CD110-50V-1μF-M

PCS

2 MAIN

107 17-00I22AM-PO0 MINI ELEC.CAPACITOR CD110-50V-2.2μF-M

PCS

2 MAIN

108 17-00I47AM-PO0 MINI ELEC.CAPACITOR CD110-50V-4.7μF-M

PCS

2 MAIN

109 17-00Q100M-PO0 MINI ELEC.CAPACITOR CD288H-250V-10μF-M

PCS

1 MAIN

110 17-00N47AM-PO0 MINI ELEC.CAPACITOR CD288H-160V-4.7μF-M

PCS

1 MAIN

111 17-00N470M-PO0 MINI ELEC.CAPACITOR CD288H-160V-47μF-M

PCS

2 MAIN

112 17-00P101M-000 MINI ELEC.CAPACITOR CD293-400V-100µF-M

PCS

1 MAIN

113 17-00I10AM-730 MINI ELEC.CAPACITOR CD73-BP-50V-1uF-M

PCS

1 MAIN

114 18-00K102K-PO0 INDUCTVE POLY.CAPACITOR

CL11-100V-102K(PEI)

PCS

2 MAIN

115 18-00K222K-PO0 INDUCTVE POLY.CAPACITOR

CL11-100V-222K(PEI)

PCS

1 MAIN

116 18-00K472K-PO0 INDUCTVE POLY.CAPACITOR

CL11-100V-472K(PEI)

PCS

1 MAIN

117 18-00K153K-PO0 INDUCTVE POLY.CAPACITOR

CL11-100V-153K(PEI)

PCS

1 MAIN

118 18-00K104K-PO0 INDUCTVE POLY.CAPACITOR

CL11-100V-104K(PEI)

PCS

7 MAIN

119 18-00K224K-PO0 INDUCTVE POLY.CAPACITOR

CL11-100V-224K(PEI)

PCS

2 MAIN

120 18-21X153K-7L5 METALIZED POLY.CAPACITOR

CL21X-100V-153K(MPE)

PCS

1 MAIN

121 18-21X104K-PO0 METALIZED POLY.CAPACITOR

CL21X-100V-104K(MPE)

PCS

1 MAIN

122 18-21X394K-7L5 METALIZED POLY.CAPACITOR CBB21-400V-0.39µF-K

PCS

1 MAIN

123 18-81U912J-L20 METALIZED POLY.CAPACITOR

CBB81-1.6KV-912J(PPS)

PCS

1 MAIN

124 18-0AN104M-L15 METALIZED POLY.CAPACITOR

CBB23A/CIS-275VAC-104K(X2)

PCS

1 MAIN

125 19-RHJ330J-P00 CERAMIC CAPACITOR CC1-RH-63V-33pF-J

PCS

2 MAIN

126 19-2B4561J-P00 CERAMIC CAPACITOR CC1-2B4-63V-220pF-K

PCS

3 MAIN

127 19-2B4561J-P00 CERAMIC CAPACITOR CC1-2B4-63V-330pF-K

PCS

3 MAIN

128 19-2B4561J-P00 CERAMIC CAPACITOR CC1-2B4-63V-560pF-K

PCS

1 MAIN

129 19-2B4821J-P00 CERAMIC CAPACITOR CC1-2B4-63V-820pF-K

PCS

1 MAIN

130 19-2BJ102K-P00 CERAMIC CAPACITOR CC1-2B4-63V-1000pF-K

PCS

5 MAIN

131 19-2BJ222K-P00 CERAMIC CAPACITOR CC1-2B4-63V-2200pF-K

PCS

1 MAIN

132 19-2BJ332K-P00 CERAMIC CAPACITOR CC1-2B4-63V-3300pF-K

PCS

1 MAIN

133 19-2BJ103Z-P00 CERAMIC CAPACITOR CC1-2B4-63V-0.01μF-Z

PCS

13 MAIN

MAIN

134 19-2BJ104Z-P00 CERAMIC CAPACITOR CC1-2B4-63V-0.1μF-Z

PCS

1 MAIN

PART PLACE

C712

C223.

C210.

C105.C107.C209.C110.C112.C221.C556.

C568.C616.C709.C717.C718.C714.C703

C911.C921.C931.

C225.

C215.

C207.C208.C483.C484.R216

C456.

C501.

C710.C711.

C486.C702.C111

C202.C224.

C509.

C212

C460.

C301.

C206.C214.C522.

C518A.

C204.C217.C302.C303.C514.C707.C806

C403.C561.

C507.

C458

C565.C565A

C205.C211.

C216.C559.

C402.

C459.

C304.

C562

C705.C706

C203.C811.

C554.C558.

C305.C306.

C553.C601.

C401.

C567

Page 28

NO. PART NO. NAME SPECIFICATION

UNIT

QT

Y

BOARD

PLACE

135 19-2BR102K-P00 CERAMIC CAPACITOR CT81-2B-500V-1000pF-K

PCS

1 MAIN

136 19-2BR392K-7L5 CERAMIC CAPACITOR CT81-2B-500V-3900pF-K

PCS

1 MAIN

137 19-2BR392K-7L5 CERAMIC CAPACITOR CT81-2B-500V-4700pF-K

PCS

1 MAIN

138 19-2BV471K-7L5 CERAMIC CAPACITOR CT81-2B-1KV-470pF-K

PCS

2 MAIN

139 19-2BV102K-7L5 CERAMIC CAPACITOR CT81-2B-1KV-1000pF-K

PCS

2 MAIN

140 19-2BV471K-7L5 CERAMIC CAPACITOR CT81-2B-2KV-470pF-K

PCS

1 MAIN

141 19-2BV681K-7L5 CERAMIC CAPACITOR CT81-2B-2KV-680pF-K

PCS

2 MAIN

142 19-2BV102K-7L5 CERAMIC CAPACITOR CT81-2B-2KV-1000pF-K

PCS

1 CRT

143 19-ACP222M-L10

CERAMIC CAPACITOR CT7-2E4-400VAC-2200PF-M

PCS

1 MAIN

144 20-30712AK-P52 INDUCTOR WITH COLOR CIDES

LGA0307-1.2µH-K

PCS

1 MAIN

145 20-307100K-P52 INDUCTOR WITH COLOR CIDES

LGA0307-10µH-K

PCS

4 MAIN

146 20-307330K-P52 INDUCTOR WITH COLOR CIDES

LGA0307-22µH-K

PCS

1 CRT

147 20-41068AK-P53 INDUCTOR WITH COLOR CIDES

LGA0307-6.8µH-K

PCS

1 MAIN

148 20-000T55M-P00 FILTER X5.5B

PCS

1 MAIN

149 20-000T65M-P00 FILTER X6.5B

PCS

1 MAIN

150 21-YDD37UH-000 HORIZONTAL LINEARITY COIL

YDD-37µH

PCS

1 MAIN

151 21-YDDUF16-000 POWER FILTER TRANSFORMER

JLF-98-UF16/YDDUF16

PCS

1 MAIN

152 21-DDUU105-000 HORIZONTAL DRIVE TRANSFORMER YDD-UU10.5

PCS

1 MAIN

153 21-YBC1950-A00 SWITCHING POWER TRANSFORMER YBC40-28/1950A

PCS

1 MAIN

154 22-000012M-000 QUARTZ

12MHz

PCS

1 MAIN

155 22-LBN389H-000 IF FILTER KDV-F38.9H/LBN38.9H

PCS

1 MAIN

156 23-1N4014K-000 FLYBACK TRANSFORMER BSC24-01N4014K

PCS

1 MAIN

157 24-05053V8-000 TUNER EWE-5053-V8/EWE-1053-V3

PCS

1 MAIN

158 25-00V2141-000 AV TIP JACK AV2-14-1

PCS

1 MAIN

159 25-GZS2108-000 SOCKET GZ10-2-108

PCS

1 CRT

160 25-H7100D1-000 ERTH CONNECTOR CH7-10-1DY

PCS

1 CRT

161 25-H7100D2-000 ERTH CONNECTOR CH7-10-2DY

PCS

2 MAIN

162 25-CH655D0-000 ERTH CONNECTOR CH6-5-5DY

PCS

1 MAIN

163 25-CH655D0-000 ERTH CONNECTOR CH6-5-5DY

PCS

1 MAIN

164 25-5B025D2-000 CONNECTOR CH5B-2.5-2DY

PCS

4 MAIN

165 25-5B025D3-000 CONNECTOR CH5B-2.5-3DY

PCS

1 MAIN

166 25-5B025D4-000 CONNECTOR CH5B-2.5-4DY

PCS

3 MAIN

167 25-5B025D5-000 CONNECTOR CH5B-2.5-5DY

PCS

1 MAIN

168 25-00BXGJ1-000 FUSE BRACKET BXGJ-1

PCS

2 MAIN

169 26-94DY450-000 4PIN CONNECTOR CH9-2.5-4DY-450-CH5B

PCS

1 CRT

170 26-95DY500-000 5PIN CONNECTOR CH9-2.5-5DY-500-CH5B

PCS

1 CRT

171 28-250V315-000 FUSE

250V-3.15A

PCS

1 MAIN

172 29-PH22V10-000 MAIN PCB KLX-PH22Z VER:1.0

PCS

1 MAIN

PART PLACE

XP901.

FU501.

XS403.XS701.XS703

XS201

FU501

XP902.

XS402.

XS404.

XS602.XS603.XS702.XS803

XS804

XS801.

XS902.

K9N.

XS501.XS502.

G701.

Z101

T401.

A101

L441.

L501.

T451.

T501.

L901.

L202.

Z202.

Z203.

C943.

C518.

L101.

L201.L203.L701.L702.L703.

C404.C552.

C511

C513

C521.

C451.C504.C506.

C452.

C482.

Page 29

NO. PART NO. NAME SPECIFICATION

UNIT

QT

Y

BOARD

PLACE

173 JUMPER 2.5mm

PCS

3 MAIN

174 JUMPER 5mm

PCS

3 MAIN

175 JUMPER 7.5mm

PCS

30 MAIN

MAIN

MAIN

MAIN

MAIN

CRT

176 JUMPER 10mm

PCS

17 MAIN

MAIN

MAIN

177 JUMPER 12.5mm

PCS

9 MAIN

MAIN

178 JUMPER 15mm

PCS

3 MAIN

179 JUMPER 20mm

PCS

2 MAIN

1 32-0021MF3-000 HEAT SINK(POWER) 21MF3(1.35mm)

PCS

1 MAIN

2 32-0021HV3-000 HEAT SINK(IC.VERTICAL) 21HV3(1.5mm)

PCS

1 MAIN

3 32-21MMB1-100

HEAT SINK(17823)

21MMB1-1

PCS

1 MAIN

4 32-0007210-000

HEAT SINK(2012)

H=30mm

PCS

1 MAIN

1 43-1103060-000 SCREW(POINTED)

TR 3×6 (acutilingual)

PCS

1 MAIN

2 43-1103080-000 SCREW(POINTED)

TR 3×8 (acutilingual)

PCS

1 MAIN

3 43-1103080-TAP TAPPING SCREW

ST3×8

PCS

1

4 43-1103102-000 SCREW FOR HEAT SINK

M3×10

PCS

2 MAIN

5 43-7130000-000 NUT FOR HEAT SINK M3

PCS

4 MAIN

1 77-00FL001-000 HEAT CONDUCTION SILICON GREASE

PCS

5 MAIN

2 77-00FL002-000 RED GLUE

PCS

6 MAIN

3 77-00FL003-000 ANODE SILICON GREASE

PCS

1 MAIN

PART PLACE

CRT

V432.N451.V513.N601.

Ⅳ、Assistant material

V432.N451.V513.N601.V563.

V432.N451.V513.N601.V563. RP551.

N601.

N451.

V563.

V432.V513.

V451+N451

N601.

V563.

Ⅲ、SCREW

W602.D452.L403.

W207

Ⅱ、Frame

V513.

W707.W807.W809.W810.W812.W904.R826

R511A.W513.W709

W201.L301.W303.L505.W551.W702.W703.

W705.W706

R723. W813.W814.W815.R914.R924. R934.

N801(3-15)

W902.

W206.W504.W505.W509.W510.W553.W556.

W501.W811.C803

W101.W102.W103.W202.W203.W204.W209

W301.W302.W503A.W508.W555.W601.W604.

W608.W701.W706.W708.W712.W713.W714.

N801(12-13).N802(2-3).XS403

Page 30

NO. PART NO. NAME SPECIFICATION

UNIT

QTY

ADD PART PLACE DELETE PART PLACE

BOARD

PLACE

1 JUMPER 2.5mm -2 N801

(12-13).N802(2-3) MAIN

2 JUMPER 5mm -1 W811 MAIN

3 JUMPER 7.5mm +1 R713.R714 N801(3-15). MAIN

4 JUMPER 10mm +1 W802. MAIN

5 JUMPER 5mm -1 C803 MAIN

6 JUMPER 20mm +1 W803 MAIN

7 16-RTF101J-P52 CARBON FILM RESISTOR RT14-1/6W-100Ω-J +3 R217.R825.R810 MAIN

8 16-RTF102J-P52 CARBON FILM RESISTOR RT14-1/6W-1KΩ-J +3 R816.R822.R824. MAIN

9 16-RTF222J-P52 CARBON FILM RESISTOR RT14-1/6W-2.2KΩ-J +1 R819. MAIN

10 16-RTF332J-P52 CARBON FILM RESISTOR RT14-1/6W-3.3KΩ-J +2 R803.R804 MAIN

11 16-RTF103J-P52 CARBON FILM RESISTOR RT14-1/6W-10KΩ-J +1 R815 MAIN

12 16-RTF104J-P52 CARBON FILM RESISTOR RT14-1/6W-100KΩ-J +1 R821. MAIN

13 19-2BJ103Z-P00 CERAMIC CAPACITOR CC1-2B4-63V-0.01μF-Z +1 R822 MAIN

14 17-00E100M-PO0 MINI ELEC.CAPACITOR CD110-16V-10μF-M +5 C218.C803.C815.C818. MAIN

C819 MAIN

15 17-00E470M-PO0 MINI ELEC.CAPACITOR CD110-16V-47μF-M +1 C805. MAIN

16 17-00E471M-PO0 MINI ELEC.CAPACITOR CD110-16V-470μF-M +1 C821. MAIN

17 17-00I10AM-PO0 MINI ELEC.CAPACITOR CD110-50V-1μF-M +1 C812 MAIN

18 11-2SC1815-P00 TRANSISTOR

2SC1815Y

+2 V802.V803. MAIN

19 25-5B025D2-000 CONNECTOR CH5B-2.5-2DY -1 XS803 MAIN

20 25-5B025D3-000 CONNECTOR CH5B-2.5-3DY 0 XS803 XS804 short

L1.R1 MAIN

21 25-00V2141-000 AV TIP JACK AV2-14-1 -1 XS801 MAIN

22 25-000V614-000 AV TIP JACK AV6-14 +1 XS801 MAIN

23 10-04052BE-000 IC HCF4052BE +2 N801.N802 MAIN

Additive BOM list

F01: Add double channel AV (AV port front three and back six) NO.:BOM-KLX-PH22 VER 3.0-F01

Page 31

NO. PART NO. NAME SPECIFICATION

UNIT

QTY

ADD PART PLACE DELETE PART PLACE

BOARD

PLACE

1 JUMPER 7.5mm

PCS

+2 W805.W804. MAIN

2 16-RTF101J-P52 CARBON FILM RESISTOR RT13-1/6W-100Ω-J

PCS

+3 R806.R807.R808 MAIN

3 16-RTF823J-P52 CARBON FILM RESISTOR RT14-1/6W-82KΩ-J

PCS

+2 R702.R703 MAIN

4 19-2BJ103Z-P00 CERAMIC CAPACITOR CC1-2B4-63V-0.01μF-Z

PCS

+3 C807.C808.C809 MAIN

5 25-5B025D3-000 CONNECTOR CH5B-2.5-3DY

PCS

+1 XS804 MAIN

6 25-5B025D4-000 CONNECTOR CH5B-2.5-4DY

PCS

+1 XS805 MAIN

7 25-5B025D6-000 CONNECTOR CH5B-2.5-6DY

PCS

+1 XS802 MAIN

9 43-1103102-000 SCREW FOR SCART BOARD M3×10(Ni)

PCS

+2 SCART

10 SCART BOARD KLX-PH.SCART

PCS

+1 SCART

NO. PART NO. NAME SPECIFICATION

UNIT

QTY

ADD PART PLACE DELETE PART PLACE

BOARD

PLACE

1 JUMPER 15mm -1 D452 MAIN

2 16-RTF102J-P52 CARBON FILM RESISTOR RT14-1/6W-1KΩ-J +1 R317 MAIN

3 16-RTF272J-P52 CARBON FILM RESISTOR RT14-1/6W-2.7KΩ-J +2 R321.R323. MAIN

4 16-RTF472J-P52 CARBON FILM RESISTOR RT14-1/6W-4.7KΩ-J +1 R322 MAIN

5 16-RTF562J-P52 CARBON FILM RESISTOR RT14-1/6W-5.6KΩ-J +1 R318 MAIN

6 16-RTF822J-P52 CARBON FILM RESISTOR RT14-1/6W-8.2KΩ-J +1 R316 MAIN

7 16-RTF103J-P52 CARBON FILM RESISTOR RT14-1/6W-10KΩ-J +1 R312 MAIN

8 16-RTF183J-P52 CARBON FILM RESISTOR RT14-1/6W-18KΩ-J +1 R319 MAIN

9 16-RTF393J-P52 CARBON FILM RESISTOR RT14-1/6W-39KΩ-J +2 R311.R320 MAIN