Page 1

TDA8932B

Class-D audio amplifier

Rev. 03 — 21 June 2007 Product data sheet

1. General description

The TDA8932B is a high efficiency class-D amplifier with low power dissipation.

The continuous time output power is 2 × 15 W in stereo half-bridge application (RL=4Ω)

or 1 × 30 W in mono full-bridge application (RL=8Ω). Due to the low power dissipation

the device can be used without any external heat sink when playing music. Due to the

implementation of thermal foldback, even for high supply voltages and/or lower load

impedances, the device remains operating with considerable music output power without

the need for an external heat sink.

The device has two full-differential inputs driving two independent outputs. It can be used

as mono full-bridge configuration (BTL) or as stereo half-bridge configuration (SE).

2. Features

n Operating voltage from 10 V to 36 V asymmetrical or ±5 V to ±18 V symmetrical

n Mono-bridged tied load (full-bridge) or stereo single-ended (half-bridge) application

n Application without heatsink using thermally enhanced small outline package

n High efficiency and low-power dissipation

n Thermally protected and thermal foldback

n Current limiting to avoid audio holes

n Full short-circuit proof across load and to supply lines (using advanced current

n Switchable internal or external oscillator (master-slave setting)

n No pop noise

n Full-differential inputs

3. Applications

n Flat panel television sets

n Flat panel monitor sets

n Multimedia systems

n Wireless speakers

n Mini and micro systems

n Home sound sets

protection)

Page 2

NXP Semiconductors

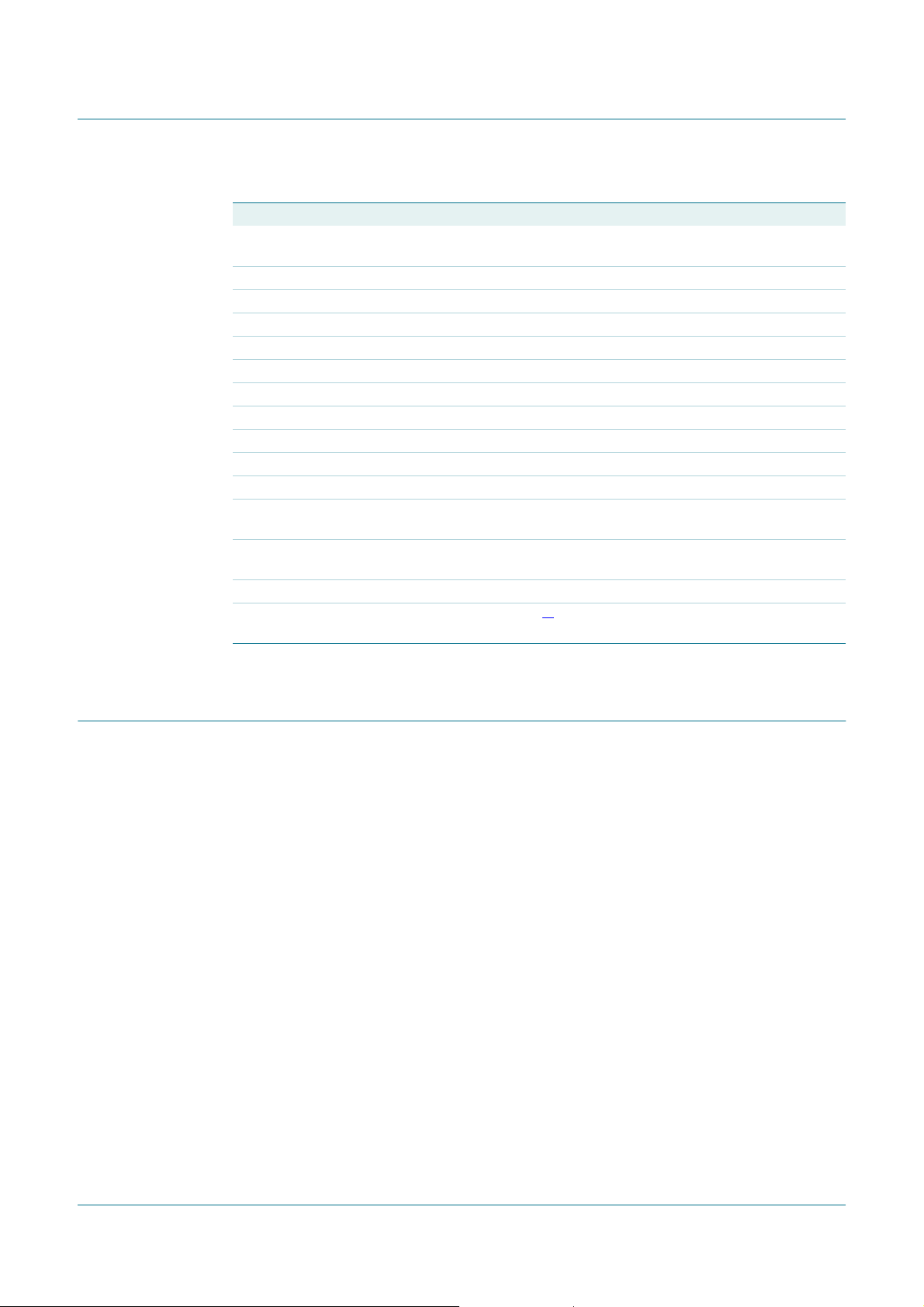

4. Quick reference data

Table 1. Quick reference data

VP= 22 V; f

Symbol Parameter Conditions Min Typ Max Unit

Supplies

V

P

I

P

I

q(tot)

Stereo SE channel; R

P

o(RMS)

Mono BTL; R

P

o(RMS)

osc

supply voltage asymmetrical supply 10 22 36 V

supply current Sleep mode - 0.6 1.0 mA

total quiescent

current

RMS output power continuous time output power

RMS output power continuous time output power;

= 320 kHz; T

< 0.1 Ω

s

[1]

< 0.1 Ω

s

TDA8932B

Class-D audio amplifier

=25°C; unless otherwise specified.

amb

Operating mode; no load, no

snubbers and no filter

connected

[1]

per channel;

THD+N = 10 %; f

=4Ω; VP= 22 V 13.8 15.3 - W

R

L

=8Ω; VP= 30 V 14.0 15.5 - W

R

L

= 1 kHz

i

short time output power per

channel; THD+N = 10 %;

f

= 1 kHz

i

RL=4Ω; VP= 29 V 23.8 26.5 - W

THD+N = 10 %; f

=4Ω; VP= 12 V 15.5 17.2 - W

R

L

=8Ω; VP= 22 V 28.9 32.1 - W

R

L

= 1 kHz

i

short time output power;

THD+N = 10 %; f

= 1 kHz

i

RL=8Ω; VP= 29 V 49.5 55.0 - W

- 4050mA

[2]

[2]

[1] Output power is measured indirectly; based on R

[2] Two layer application board (55 mm × 45 mm), 35 µm copper, FR4 base material in free air with natural

convection.

measurement.

DSon

5. Ordering information

Table 2. Ordering information

Type number Package

Name Description Version

TDA8932BT SO32 plastic small outline package; 32 leads;

body width 7.5 mm

TDA8932BTW HTSSOP32 plastic thermal enhanced thin shrink small outline

package; 32 leads; body width 6.1 mm; lead pitch

0.65 mm; exposed die pad

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 2 of 48

SOT287-1

SOT549-1

Page 3

NXP Semiconductors

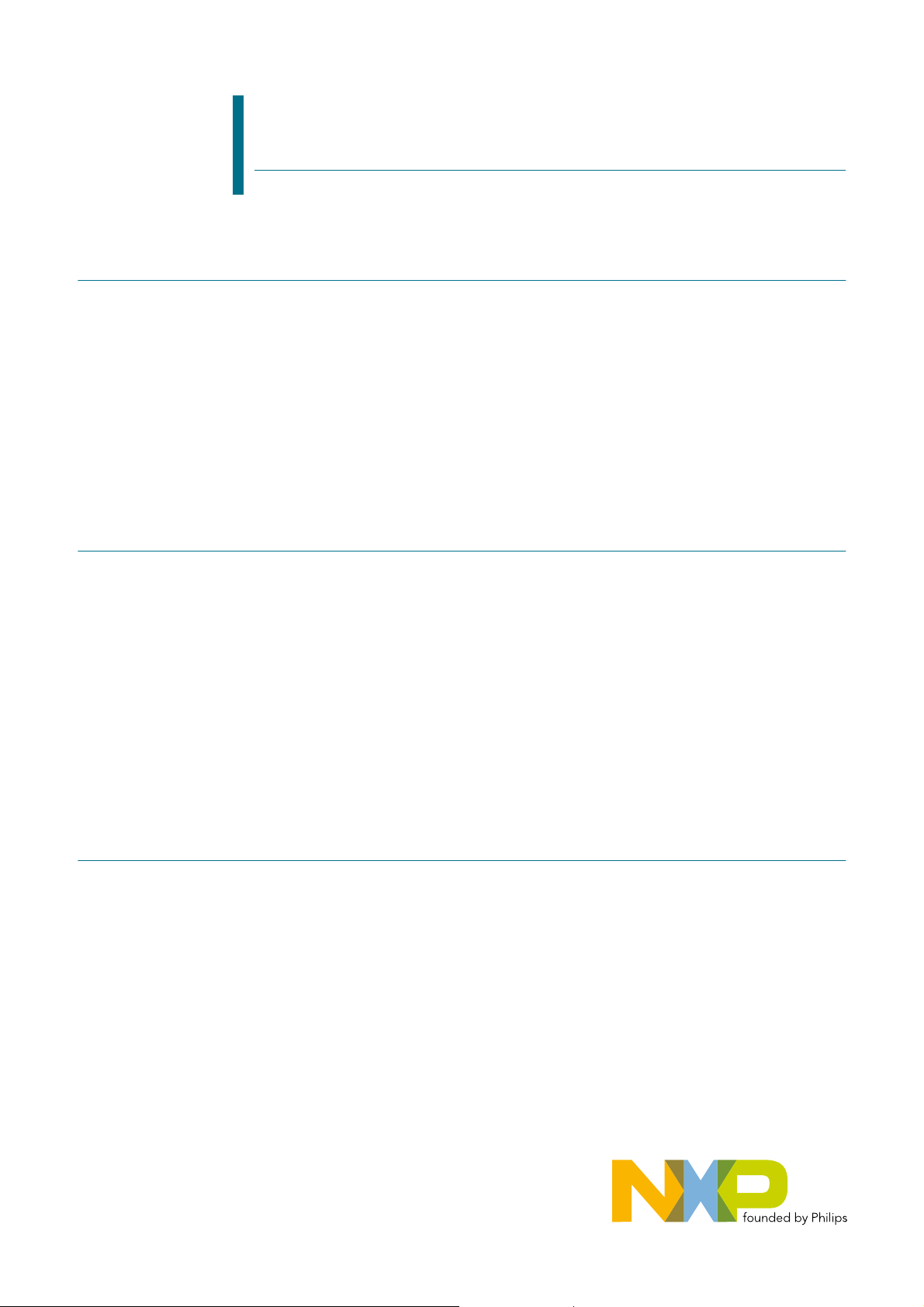

6. Block diagram

TDA8932B

Class-D audio amplifier

IN1P

IN1N

INREF

IN2P

IN2N

DIAG

CGND

OSCREF OSCIO V

10 31 8

2

3

12

15

14

4

7

OSCILLATOR

V

SSD

PROTECTIONS:

OVP, OCP, OTP,

UVP, TF, WP

PWM

MODULATOR

MANAGER

PWM

MODULATOR

DDA

CTRL

CTRL

DRIVER

HIGH

DRIVER

LOW

DRIVER

HIGH

DRIVER

LOW

V

DDA

STABILIZER 11 V

V

SSP1

V

DDA

STABILIZER 11 V

V

SSP2

28

BOOT1

29

V

DDP1

27

OUT1

26

V

SSP1

21

BOOT2

20

V

DDP2

22

OUT2

23

V

SSP2

25

STAB1

24

STAB2

POWERUP

ENGAGE

TEST

6

5

13

Fig 1. Block diagram

MODE

V

SSA

9

TDA8932B

V

SSD(HW)

1, 16, 17, 32

REGULATOR 5 V

V

SSD

V

DDA

V

SSA

HALF SUPPLY VOLTAGE

18

11

30

19

001aaf597

DREF

HVPREF

HVP1

HVP2

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 3 of 48

Page 4

NXP Semiconductors

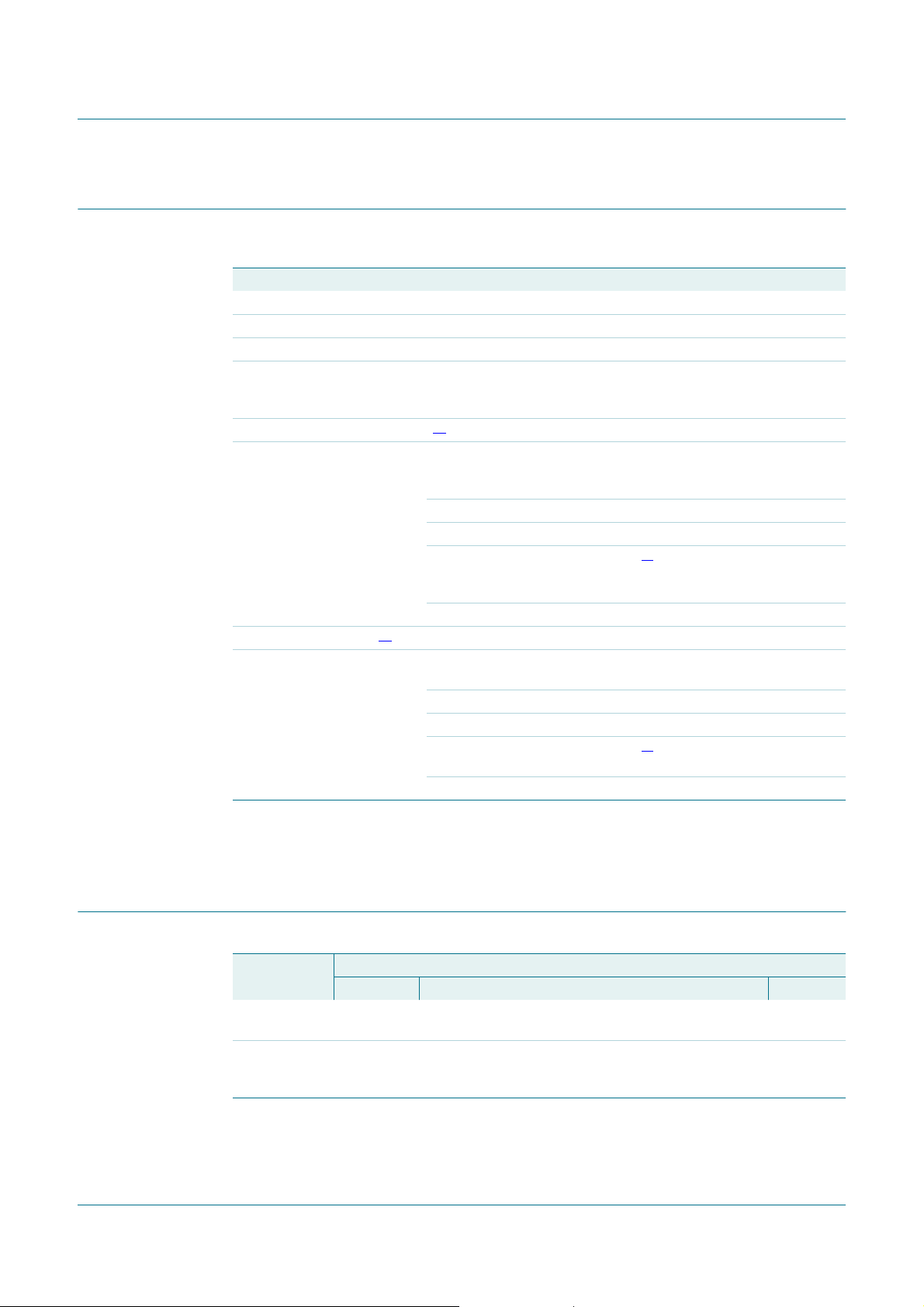

7. Pinning information

7.1 Pinning

TDA8932B

Class-D audio amplifier

V

SSD(HW)

ENGAGE BOOT1

POWERUP OUT1

OSCREF

HVPREF OUT2

V

SSD(HW)

1

2

IN1P OSCIO

3

IN1N HVP1

4

DIAG V

5

6

7

CGND V

8

V

DDA

V

SSA

INREF BOOT2

TEST V

IN2N HVP2

IN2P DREF

9

10

11

12

13

14

15

16

TDA8932BT

001aaf598

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

V

SSD(HW)

DDP1

SSP1

STAB1

STAB2

V

SSP2

DDP2

V

SSD(HW)

V

SSD(HW)

ENGAGE BOOT1

POWERUP OUT1

OSCREF V

HVPREF OUT2

V

SSD(HW)

1

2

IN1P OSCIO

3

IN1N HVP1

4

DIAG V

5

6

7

CGND V

8

V

DDA

9

V

SSA

10

11

12

INREF BOOT2

13

TEST V

14

IN2N HVP2

15

IN2P DREF

16

TDA8932BTW

Fig 2. Pin configuration SO32 Fig 3. Pin configuration HTSSOP32

7.2 Pin description

Table 3. Pin description

Symbol Pin Description

V

SSD(HW)

IN1P 2 positive audio input for channel 1

IN1N 3 negative audio input for channel 1

DIAG 4 diagnostic output; open-drain

ENGAGE 5 engage input to switch between Mute mode and Operating mode

POWERUP 6 power-up input to switch between Sleep mode and Mute mode

CGND 7 control ground; reference for POWERUP, ENGAGE and DIAG

V

DDA

V

SSA

OSCREF 10 input internal oscillator setting (only master setting)

HVPREF 11 decoupling of internal half supply voltage reference

INREF 12 decoupling for input reference voltage

TEST 13 test signal input; for testing purpose only

IN2N 14 negative audio input for channel 2

IN2P 15 positive audio input for channel 2

V

SSD(HW)

V

SSD(HW)

DREF 18 decoupling of internal (reference) 5 V regulator for logic supply

1 negative digital supply voltage and handle wafer connection

8 positive analog supply voltage

9 negative analog supply voltage

16 negative digital supply voltage and handle wafer connection

17 negative digital supply voltage and handle wafer connection

001aaf599

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

V

SSD(HW)

DDP1

SSP1

STAB1

STAB2

SSP2

DDP2

V

SSD(HW)

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 4 of 48

Page 5

NXP Semiconductors

Table 3. Pin description (Continued)

Symbol Pin Description

HVP2 19 half supply output voltage 2 for charging single-ended capacitor for

V

DDP2

BOOT2 21 bootstrap high-side driver channel 2

OUT2 22 PWM output channel 2

V

SSP2

STAB2 24 decoupling of internal 11 V regulator for channel 2 drivers

STAB1 25 decoupling of internal 11 V regulator for channel 1 drivers

V

SSP1

OUT1 27 PWM output channel 1

BOOT1 28 bootstrap high-side driver channel 1

V

DDP1

HVP1 30 half supply output voltage 1 for charging single-ended capacitor for

OSCIO 31 oscillator input in slave configuration or oscillator output in master

V

SSD(HW)

Exposed die

pad

TDA8932B

Class-D audio amplifier

channel 2

20 positive power supply voltage for channel 2

23 negative power supply voltage for channel 2

26 negative power supply voltage for channel 1

29 positive power supply voltage for channel 1

channel 1

configuration

32 negative digital supply voltage and handle wafer connection

- HTSSOP32 package only

[1]

[1] The exposed die pad has to be connected to V

8. Functional description

8.1 General

The TDA8932B is a mono full-bridge or stereo half-bridge audio power amplifier using

class-D technology. The audio input signal is converted into a Pulse Width Modulated

(PWM) signal via an analog input stage and PWM modulator. To enable the output power

Diffusion Metal Oxide Semiconductor (DMOS) transistors to be driven, this digital PWM

signal is applied to a control and handshake block and driver circuits forboth the high side

and low side. A 2nd-order low-pass filter converts the PWM signal to an analog audio

signal across the loudspeakers.

The TDA8932B contains two independent half-bridges with full differential input stages.

The loudspeakers can be connected in the following configurations:

• Mono full-bridge: Bridge Tied Load (BTL)

• Stereo half-bridge: Single-Ended (SE)

The TDA8932B contains common circuits to both channels such as the oscillator, all

reference sources, the mode functionality and a digital timing manager. The following

protections are built-in: thermal foldback, temperature, current and voltage protections.

SSD(HW)

.

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 5 of 48

Page 6

NXP Semiconductors

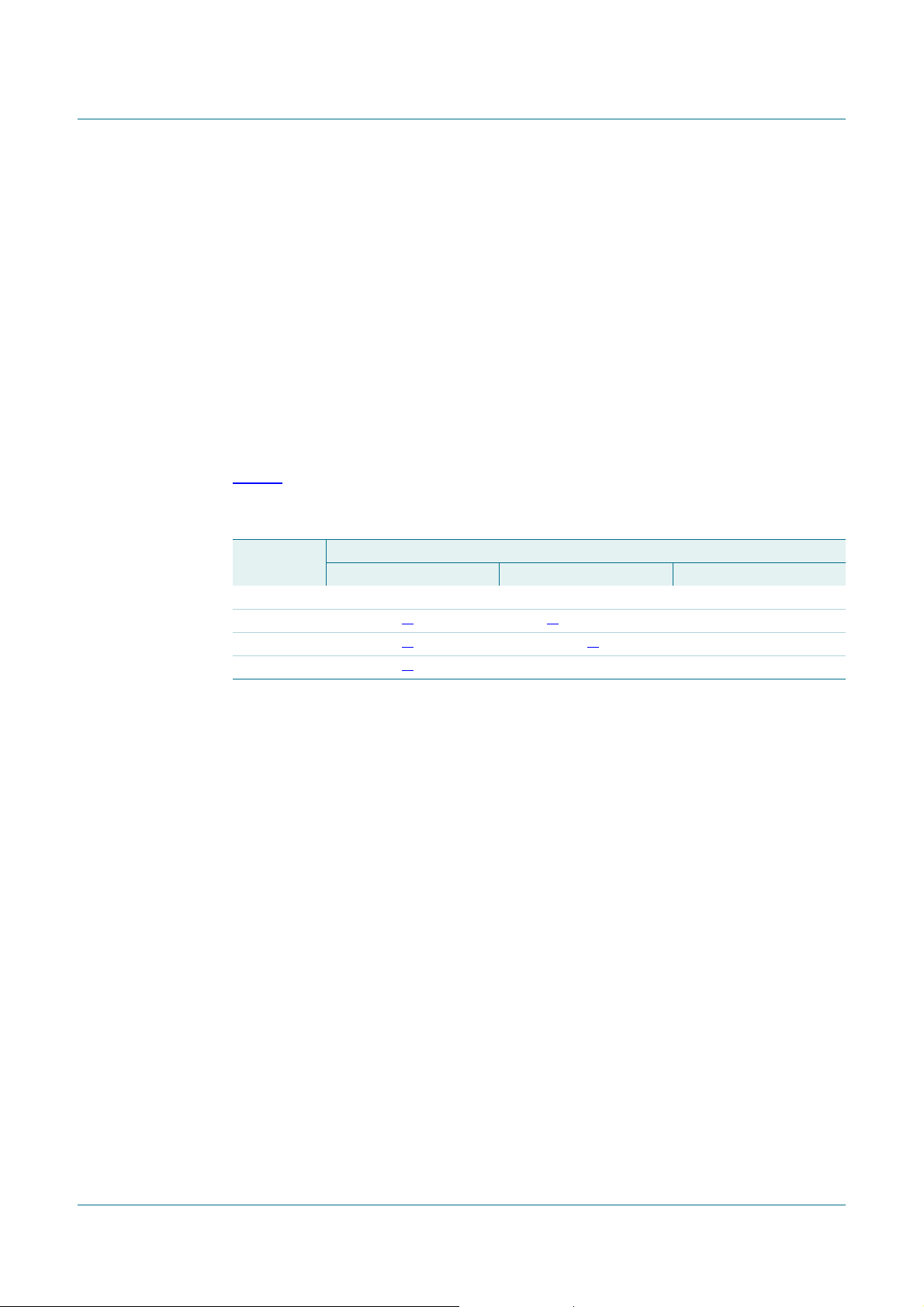

8.2 Mode selection and interfacing

The TDA8932B can be switched in three operating modes using pins POWERUP and

ENGAGE:

• Sleep mode: with low supply current.

• Mutemode: the amplifiers are switching idle (50 % duty cycle), but the audio signal at

• Operating mode: the amplifiers are fully operational with output signal.

• Fault mode.

Both pins POWERUP and ENGAGE refer to pin CGND.

Table 4 shows the different modes as a function of the voltages on the POWERUP and

ENGAGE pins.

Table 4. Mode selection

Mode Pin

Sleep < 0.8 V < 0.8 V don’t care

Mute 2 V to 6.0 V

Operating 2 V to 6.0 V

Fault 2 V to 6.0 V

TDA8932B

Class-D audio amplifier

the output is suppressed bydisabling the Vl-converter input stages. The capacitors on

pins HVP1 and HVP2 have been charged to half the supply voltage (asymmetrical

supply only).

POWERUP ENGAGE DIAG

[1]

[1]

[1]

[1]

< 0.8 V

2.4 V to 6.0 V

don’t care < 0.8 V

[1]

> 2 V

>2V

[1] In case of symmetrical supply conditions the voltage applied to pins POWERUP and ENGAGE must never

exceed the supply voltage (V

DDA

, V

DDP1

or V

DDP2

).

If the transition between Mute mode and Operatingmode is controlled via a time constant,

the start-up will be pop free since the DC output offset voltage is applied gradually to the

output between Mute mode and Operating mode. The bias current setting of the

VI-converters is related to the voltage on pin ENGAGE:

• Mute mode: the bias current setting of the VI-converters is zero (VI-converters

disabled)

• Operating mode: the bias current is at maximum

The time constant required to apply the DC output offset voltage gradually between Mute

mode and Operating mode can be generated by applying a decoupling capacitor on pin

ENGAGE. The value of the capacitor on pin ENGAGE should be 470 nF.

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 6 of 48

Page 7

NXP Semiconductors

V

P

POWERUP

DREF

HVPREF

HVP1, HVP2

2.0 V (typical)

ENGAGE

1.2 V (typical)

TDA8932B

Class-D audio amplifier

≤ 0.8 V

audio

OUT1, OUT2

PWM

DIAG

OSCIO

Fig 4. Start-up sequence

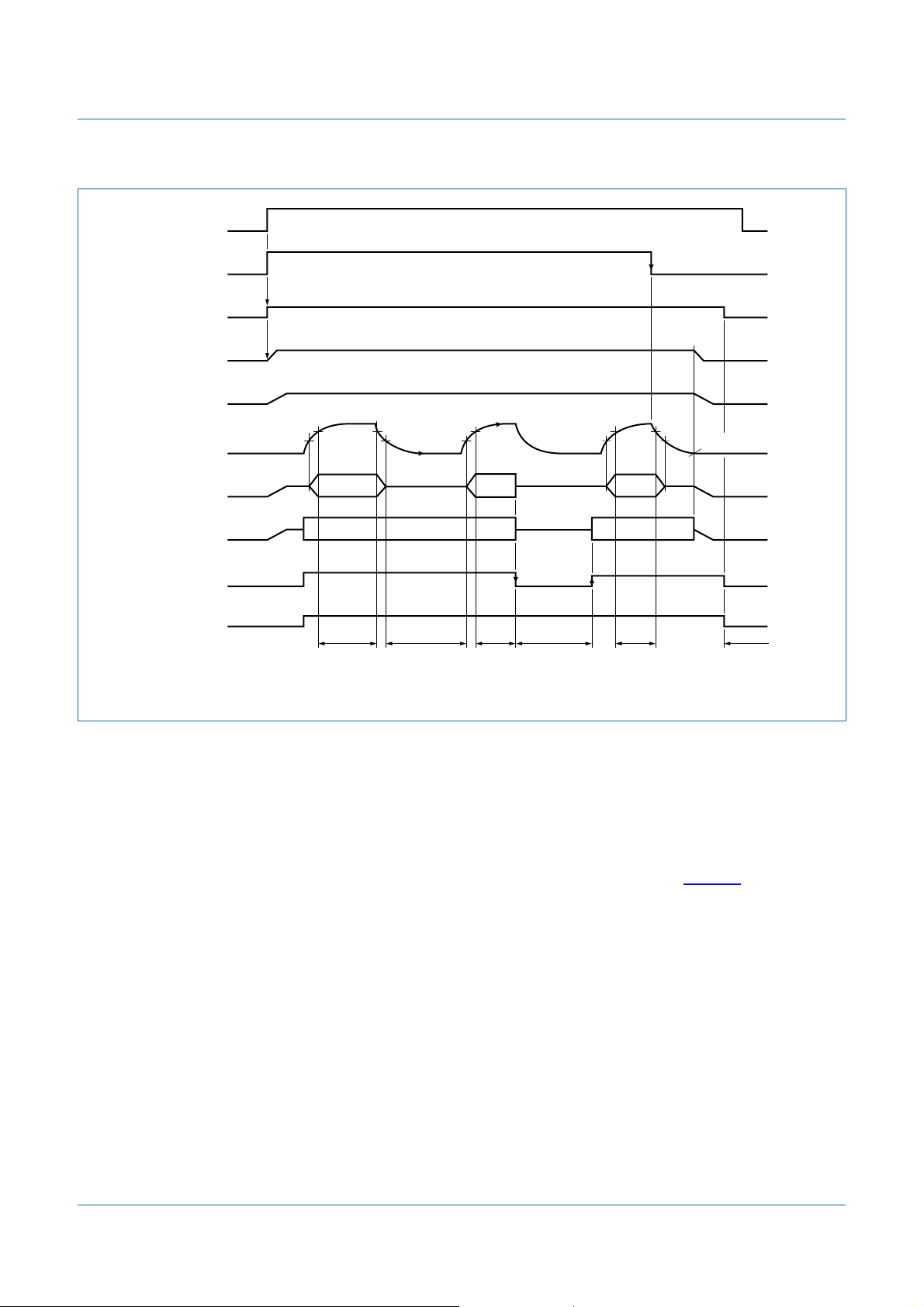

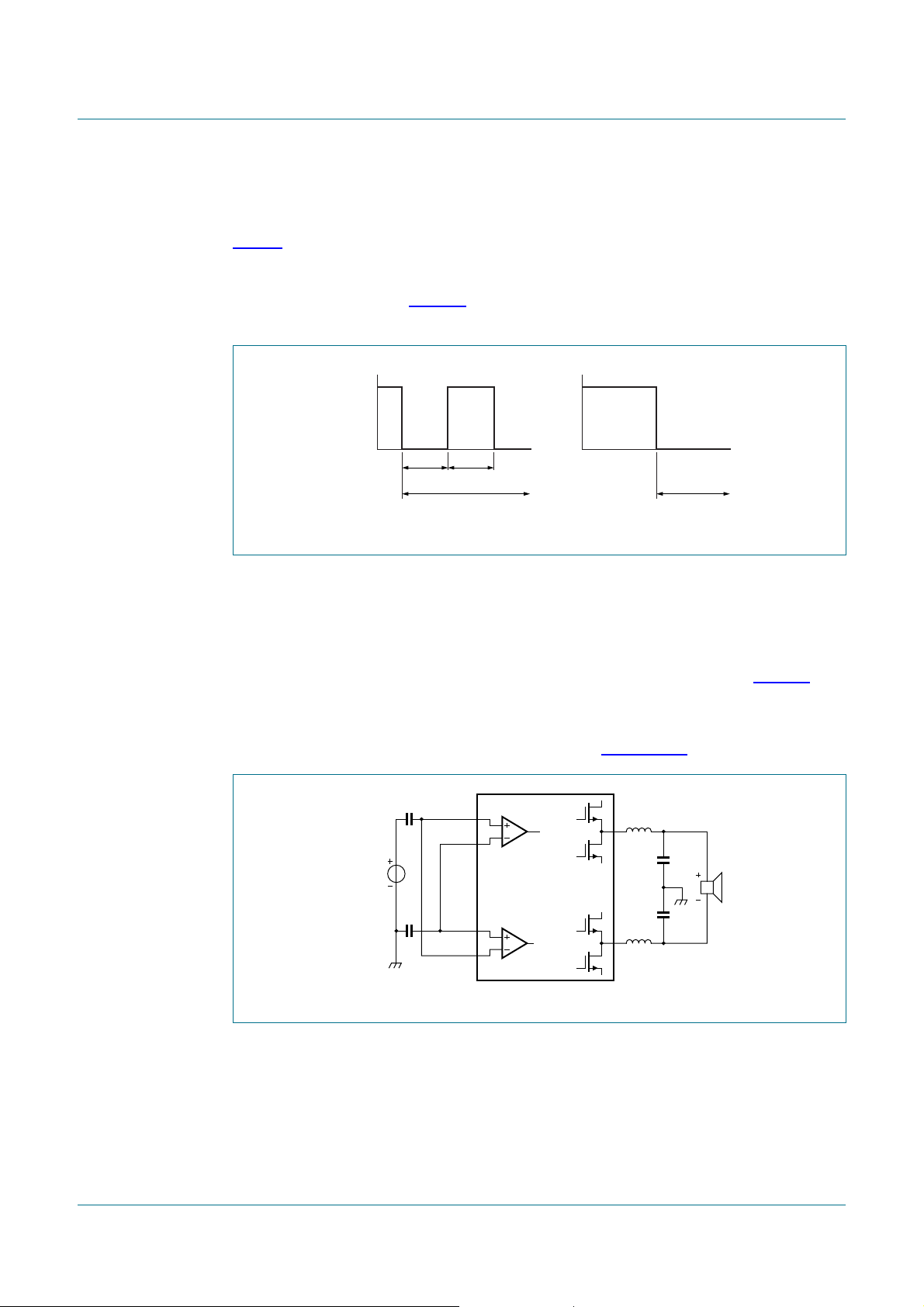

8.3 Pulse width modulation frequency

The output signal of the amplifier is a PWM signal with a carrier frequency of

approximately 320 kHz. Using a 2nd-order low-pass filter in the application results in an

analog audio signal across the loudspeaker. The PWM switching frequency can be set by

an external resistor Rosc connected between pins OSCREF and V

frequency can be set between 300 kHz and 500 kHz. Using an external resistor of 39 kΩ,

the carrier frequency is set to an optimized value of 320 kHz (see Figure 5).

If two or more TDA8932B devices are used in the same audio application, it is

recommended to synchronize the switching frequency of all devices. This can be realized

by connecting all pins OSCIO together and configure one of the TDA8932B in the

application as clock master, while the other TDA8932B devices are configured in slave

mode.

AUDIO AUDIO AUDIO

PWMPWM

operating operating

001aaf885

SSD(HW)

sleepmute operating fault

. The carrier

Pin OSCIO is a 3-state input or output buffer.Pin OSCIO is configured in master mode as

oscillator output and in slave modeas oscillator input. Master mode is enabled byapplying

a resistor while slave mode is entered by connecting pin OSCREF directly to pin V

SSD(HW)

(without any resistor).

The value of the resistor also sets the frequency of the carrier which can be estimated by

the following formula:

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 7 of 48

Page 8

NXP Semiconductors

TDA8932B

Class-D audio amplifier

osc

12.45 109×

=

--------------------------- -

Rosc

f

Where:

f

= oscillator frequency (Hz)

osc

Rosc = oscillator resistor (on pin OSCREF) (Ω)

550

f

osc

(kHz)

450

350

250

25 454030 35

Fig 5. Oscillation frequency as a function of resistor Rosc

(1)

001aad758

Rosc (kΩ)

Table 5 summarizes how to configure the TDA8932B in master or slave configuration.

For device synchronization see Section 14.6 “Device synchronization”.

Table 5. Master or slave configuration

Configuration Pin

OSCREF OSCIO

Master Rosc > 25 kΩ to V

Slave Rosc = 0 Ω; shorted to V

SSD(HW)

SSD(HW)

output

input

8.4 Protection

The following protection is included in the TDA8932B:

• Thermal Foldback (TF)

• OverTemperature Protection (OTP)

• OverCurrent Protection (OCP)

• Window Protection (WP)

• Supply voltage protection:

– UnderVoltage Protection (UVP)

– OverVoltage Protection (OVP)

– UnBalance Protection (UBP)

• ElectroStatic Discharge (ESD)

The reaction of the device to the different fault conditions differs per protection.

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 8 of 48

Page 9

NXP Semiconductors

8.4.1 Thermal Foldback (TF)

If the junction temperature of the TDA8932B exceeds the threshold level (Tj> 140 °C) the

gain of the amplifier is decreased graduallyto a level where the combination of dissipation

(P) and the thermal resistance from junction to ambient [R

temperature around the threshold level.

This means that the device will not completely switch off, but remains operational at lower

output power levels. Especially with music output signals this feature enables high peak

output power while still operating without any external heat sink other than the

printed-circuit board area.

If the junction temperature still increases due to external causes, the OTP shuts down the

amplifier completely.

8.4.2 OverTemperature Protection (OTP)

If the junction temperature Tj> 155 °C, then the power stage will shut down immediately.

8.4.3 OverCurrent Protection (OCP)

When the loudspeaker terminals are short-circuited or if one of the demodulated outputs

of the amplifier is short-circuited to one of the supply lines, this will be detected by the

OCP.

TDA8932B

Class-D audio amplifier

] results in a junction

th(j-a)

If the output current exceeds the maximum output current (I

be limitedby the amplifier to 4 A while the amplifier outputs remain switching (the amplifier

is NOT shutdown completely). This is called current limiting.

The amplifier can distinguish between an impedance drop of the loudspeaker and a

low-ohmic short-circuit across the load or to one of the supply lines. This impedance

threshold depends on the supply voltage used:

• Incase of a short-circuit across the load, the audio amplifier is switchedoff completely

and after approximately 100 ms it will try to restart again. If the short-circuit condition

is still present after this time, this cycle will be repeated. The average dissipation will

be low because of this low duty cycle.

• In case of a short to one of the supply lines, this will trigger the OCP and the amplifier

will be shut down. During restart the window protection will be activated. As a result

the amplifier will not start until 100 ms after the short to the supply lines is removed.

• In case of impedance drop (e.g. due to dynamic behavior of the loudspeaker) the

same protection will be activated. The maximum output current is again limited to 4 A,

but the amplifier will NOT switch off completely (thus preventing audio holes from

occurring). The result will be a clipping output signal without any artifacts.

8.4.4 Window Protection (WP)

The WP checks the PWM output voltage before switchingfrom Sleep mode to Mute mode

(outputs switching) and is activated:

> 4 A), this current will

O(ocp)

• During the start-up sequence, when pin POWERUP is switched from Sleep mode to

Mute mode. In the event of a short-circuit at one of the output terminals to V

V

, V

SSP1

for open-circuit outputs. Because the check is done before enablingthe power stages,

no large currents will flow in the event of a short-circuit.

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 9 of 48

DDP2

or V

the start-up procedure is interrupted and the TDA8932B waits

SSP2

DDP1

,

Page 10

NXP Semiconductors

• When the amplifier is completely shut down due to activation of the OCP because a

8.4.5 Supply voltage protection

If the supply voltage drops below 10 V, the UnderVoltage Protection (UVP) circuit is

activated and the system will shut down directly. This switch-off will be silent and without

pop noise. When the supply voltage rises above the threshold level, the system is

restarted again after 100 ms.

If the supply voltage exceeds 36 V the OverVoltage Protection (OVP) circuit is activated

and the power stages will shut down. It is re-enabled as soon as the supply voltage drops

below the threshold level. The system is restarted again after 100 ms.

It should be noted that supply voltages > 40 V may damage the TDA8932B. Two

conditions should be distinguished:

1. If the supply voltage is pumped to higher values by the TDA8932B application itself

2. If a supply voltage > 40 V is caused by other or external causes, then the TDA8932B

TDA8932B

Class-D audio amplifier

short-circuit to one of the supply lines is made, then during restart (after 100 ms) the

window protection will be activated. As a result the amplifier will not start until the

short-circuit to the supply lines is removed.

(see also Section 14.3), the OVP is triggered and the TDA8932B is shut down. The

supply voltage will decrease and the TDA8932B is protected against any overstress.

will shut down, but the device can still be damaged since the supply voltage will

remain > 40 V in this case. The OVP protection is not a supply voltage clamp.

An additional UnBalance Protection (UBP) circuit compares the positive analog supply

voltage (V

) and the negative analog supply voltage (V

DDA

) and is triggered if the

SSA

voltage difference between them exceeds a certain level. This level depends on the sum

of both supply voltages. The unbalance threshold levels can be defined as follows:

• LOW-level threshold: V

• HIGH-level threshold: V

P(th)(ubp)l

P(th)(ubp)h

<8⁄5× V

>8⁄3× V

HVPREF

HVPREF

In a symmetrical supply the UBP is released when the unbalance of the supply voltage is

within 6 % of its starting value.

Table 6 shows an overview of all protection and the effect on the output signal.

Table 6. Protection overview

Protection Restart

When fault is removed Every 100 ms

OTP no yes

OCP yes no

WP yes no

UVP no yes

OVP no yes

UBP no yes

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 10 of 48

Page 11

NXP Semiconductors

8.5 Diagnostic input and output

Whenevera protection is triggered, except for TF, pin DIAG is activated to LOWlevel (see

Table 6). An internal reference supply will pull-up the open-drain DIAG output to

approximately 2.4 V. This internal reference supply can deliver approximately 50 µA.

Pin DIAG refers to pin CGND. The diagnostic output signal during different short

conditions is illustrated in Figure 6. Using pin DIAG as input, a voltage < 0.8 V will put the

device into Fault mode.

TDA8932B

Class-D audio amplifier

V

2.4 V

0 V

o

amplifier

restart no restart

≈ 50 ms

≈ 50 ms

shorted load

2.4 V

0 V

V

o

short to

supply line

001aad759

Fig 6. Diagnostic output for different short-circuit conditions

8.6 Differential inputs

For a high common-mode rejection ratio and a maximum of flexibility in the application,

the audio inputs are fully differential. By connecting the inputs anti-parallel, the phase of

one of the two channels can be inverted, so that the amplifier can operate as a mono BTL

amplifier. The input configuration for a mono BTL application is illustrated in Figure 7.

In SE configuration it is also recommended to connect the two differential inputs in

anti-phase. This has advantages forthe current handling of the power supply at low signal

frequencies and minimizes supply pumping (see also Section 14.8).

IN1P

IN1N

OUT1

audio

input

IN2P

IN2N

OUT2

001aad760

Fig 7. Input configuration for mono BTL application

8.7 Output voltage buffers

When pin POWERUP is set HIGH, the half supply output voltage buffers are switched on

in asymmetrical supply configuration. The start-up will be pop free since the device starts

switching when the capacitor on pin HVPREF and the SE capacitors are completely

charged.

Output voltage buffers:

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 11 of 48

Page 12

NXP Semiconductors

• PinsHVP1 and HVP2: The time requiredfor charging the SE capacitor depends on its

value. The half supply voltage output is disabled when the TDA8932B is used in a

symmetrical supply application.

• Pin HVPREF: This output voltage reference buffer charges the capacitor on pin

HVPREF.

• PinINREF: This output voltage reference buffercharges the input referencecapacitor

on pin INREF. Pin INREF applies the bias voltage for the inputs.

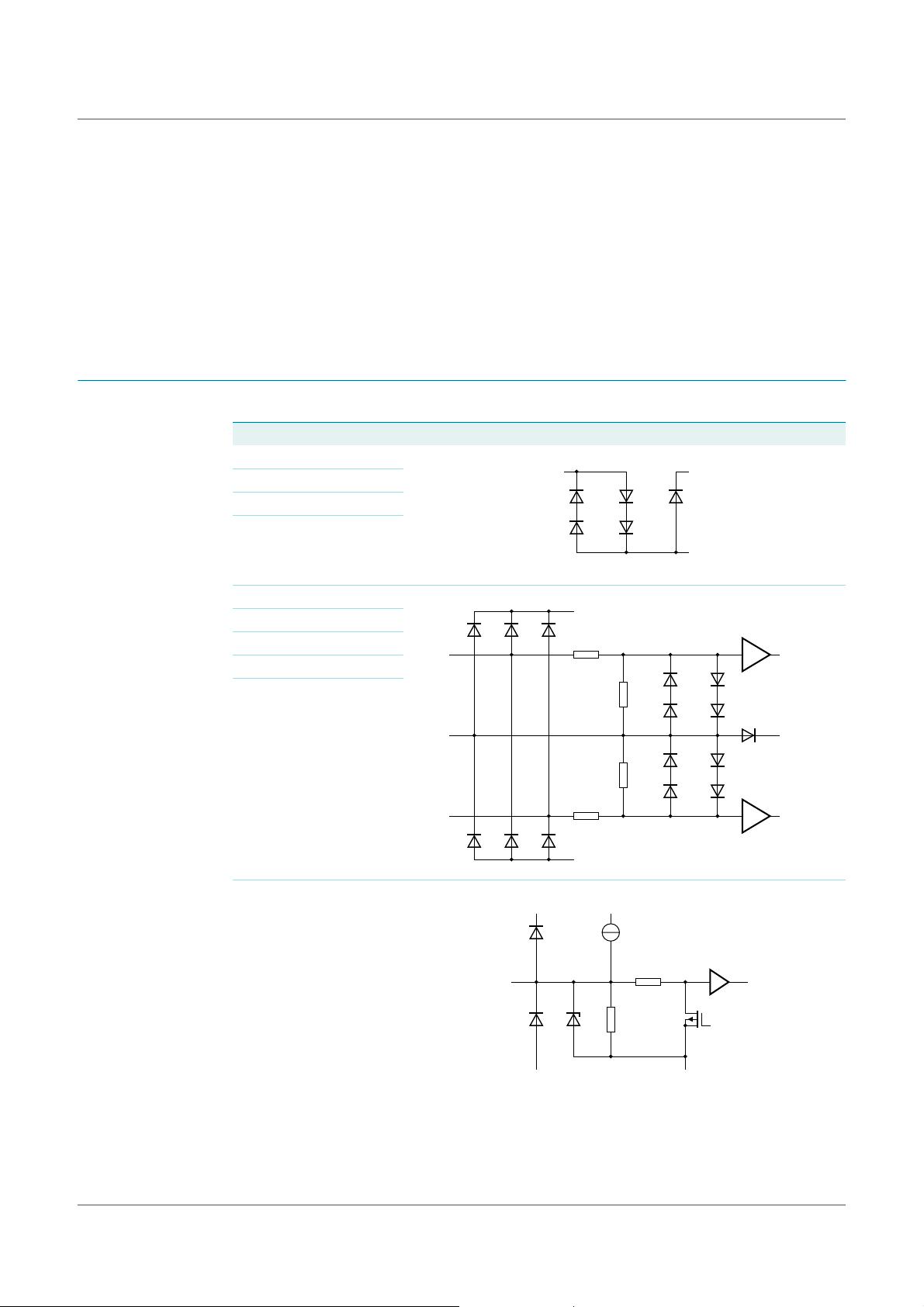

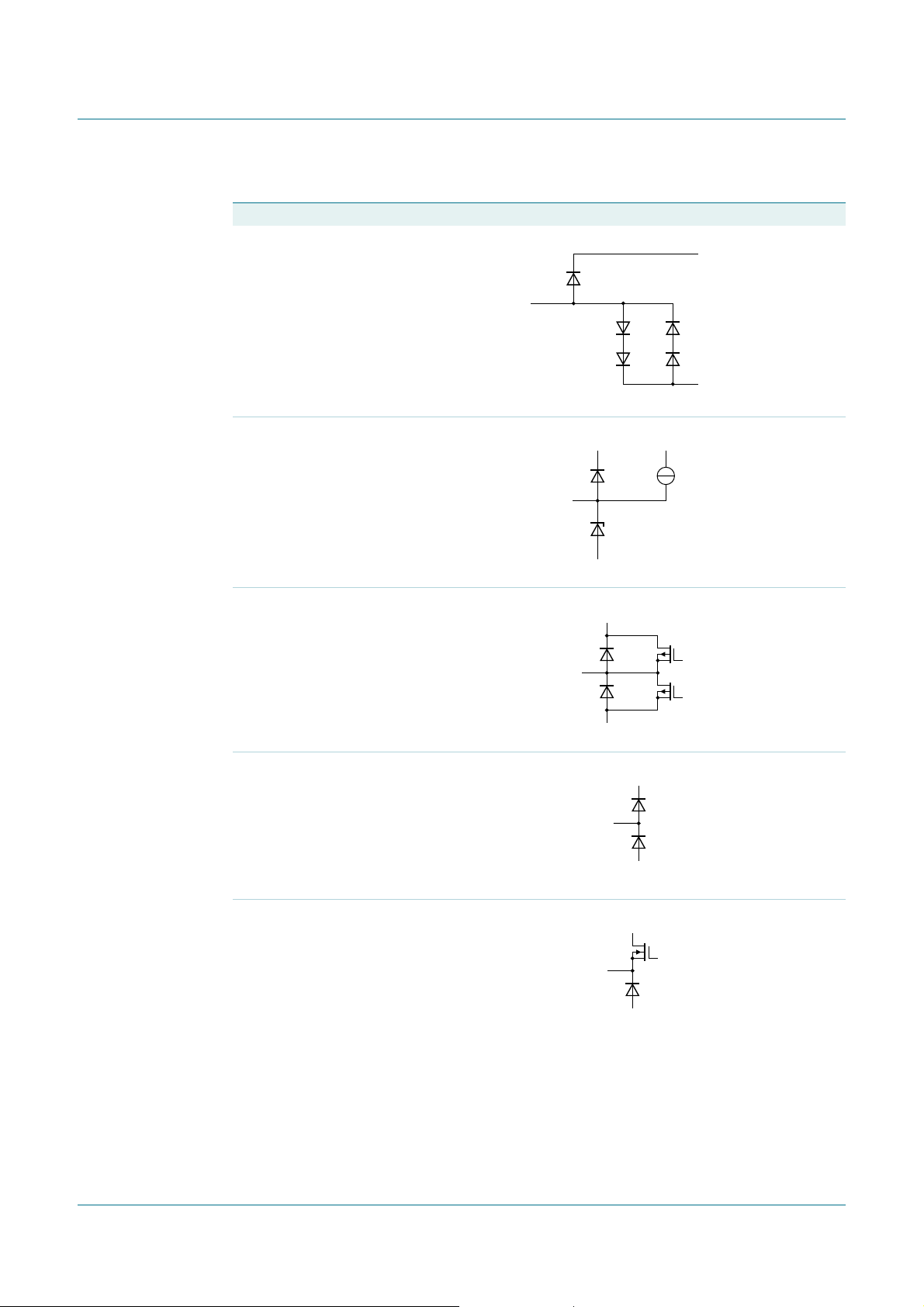

9. Internal circuitry

Table 7. Internal circuitry

Pin Symbol Equivalent circuit

1V

16 V

17 V

32 V

SSD(HW)

SSD(HW)

SSD(HW)

SSD(HW)

1, 16,

17, 32

TDA8932B

Class-D audio amplifier

V

DDA

V

SSA

001aad784

2 IN1P

3 IN1N

12 INREF

14 IN2N

15 IN2P

4 DIAG

2, 15

12

3, 14

V

DDA

2 kΩ

± 20 %

48 kΩ

± 20 %

48 kΩ

± 20 %

2 kΩ

± 20 %

V

SSA

V

DDA

4

2.5 V

50 µA

500 Ω

± 20 %

100 kΩ

± 20 %

V/I

HVPREF

V/I

001aad785

V

SSA

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

CGND

001aaf607

Product data sheet Rev. 03— 21 June 2007 12 of 48

Page 13

NXP Semiconductors

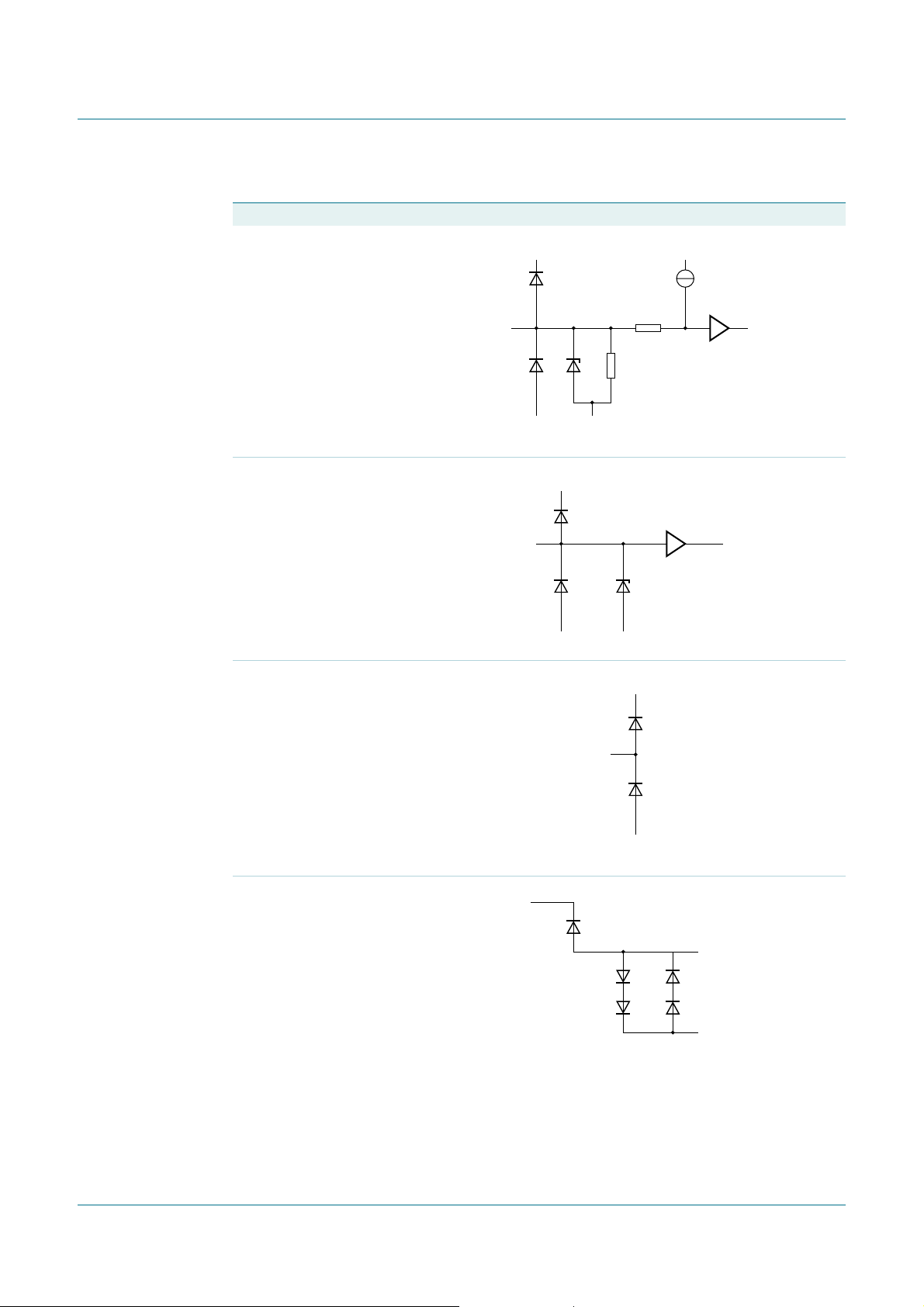

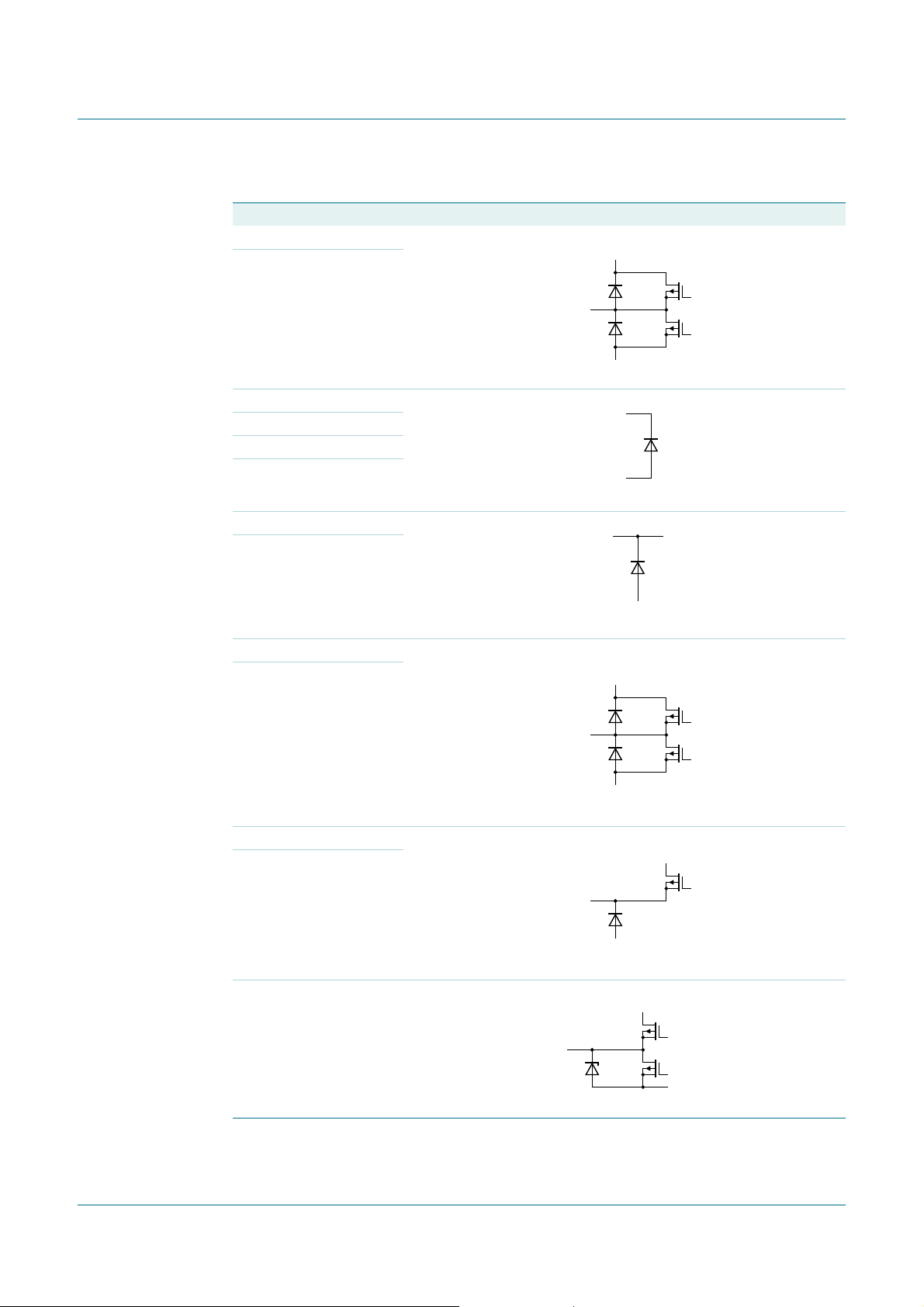

Table 7. Internal circuitry (Continued)

Pin Symbol Equivalent circuit

5 ENGAGE

TDA8932B

Class-D audio amplifier

2 kΩ

± 20 %

2.8 V

I

ref

= 50 µA

V

DDA

5

100 kΩ

± 20 %

6 POWERUP

7 CGND

SSA

CGND

V

DDA

V

SSA

CGND

V

DDA

7

V

SSA

001aad789

001aaf608

001aad788

V

6

8V

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

DDA

8

V

SSA

V

SSD

001aad790

Product data sheet Rev. 03— 21 June 2007 13 of 48

Page 14

NXP Semiconductors

Table 7. Internal circuitry (Continued)

Pin Symbol Equivalent circuit

9V

SSA

TDA8932B

Class-D audio amplifier

V

DDA

9

V

SSD

001aad791

10 OSCREF

11 HVPREF

13 TEST

V

DDA

I

ref

10

V

SSA

V

11

V

13

DDA

SSA

V

V

001aad795

001aad792

001aaf604

DDA

SSA

18 DREF

V

DD

18

V

SSD

001aag025

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 14 of 48

Page 15

NXP Semiconductors

Table 7. Internal circuitry (Continued)

Pin Symbol Equivalent circuit

19 HVP2

30 HVP1

19, 30

V

V

DDA

SSA

TDA8932B

Class-D audio amplifier

001aag026

20 V

23 V

26 V

29 V

DDP2

SSP2

SSP1

DDP1

21 BOOT2

28 BOOT1

22 OUT2

27 OUT1

24 STAB2

25 STAB1

22, 27

20, 29

23, 26

21, 28

V

V

V

V

001aad798

OUT1, OUT2

001aad799

DDP1,

DDP2

SSP1,

SSP2

001aag027

V

DDA

24, 25

V

SSP1,

V

SSP2

001aag028

31 OSCIO

DREF

31

V

SSD

001aag029

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 15 of 48

Page 16

NXP Semiconductors

10. Limiting values

Table 8. Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

P

V

x

I

ORM

T

j

T

stg

T

amb

P power dissipation - 5 W

V

esd

TDA8932B

Class-D audio amplifier

supply voltage asymmetrical supply

voltage on pin x

IN1P, IN1N, IN2P, IN2N

OSCREF, OSCIO, TEST

POWERUP, ENGAGE,

DIAG

all other pins

repetitive peak output

current

maximum output

current limiting

junction temperature - 150 °C

storage temperature −55 +150 °C

ambient temperature −40 +85 °C

electrostatic discharge

voltage

HBM

MM

[1]

−0.3 +40 V

[2]

−5+5V

[3]

V

SSD(HW)

[4]

V

CGND

[5]

VSS− 0.3 VDD + 0.3 V

[6]

4-A

[7]

−2000 +2000 V

[8]

−200 +200 V

− 0.3 5 V

− 0.3 6 V

[1] VP = V

[2] Measured with respect to pin INREF; Vx < VDD + 0.3 V.

[3] Measured with respect to pin V

[4] Measured with respect to pin CGND; Vx < VDD + 0.3 V.

[5] VSS = V

[6] Current limiting concept.

[7] Human Body Model (HBM); Rs= 1500 Ω; C = 100 pF

For pins 2, 3, 11, 14 and 15 V

[8] Machine Model (MM); Rs=0Ω; C = 200 pF; L = 0.75 µH.

DDP1

SSP1

− V

= V

SSP1

SSP2

= V

DDP2

; VDD = V

− V

SSD(HW)

DDP1

esd

SSP2

.

; Vx < VDD + 0.3 V.

= V

= ±1800 V.

DDP2

.

11. Thermal characteristics

Table 9. Thermal characteristics

Symbol Parameter Conditions Min Typ Max Unit

SO32 package

R

Ψ

Ψ

th(j-a)

j-lead

j-top

thermal resistance from junction

to ambient

thermal characterization

parameter from junction to lead

thermal characterization

parameter from junction to top

free air natural convection

JEDEC test board

2 layer application board

[1]

- 41 44 K/W

[2]

- 44 - K/W

- - 30 K/W

[3]

- - 8 K/W

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 16 of 48

Page 17

NXP Semiconductors

TDA8932B

Class-D audio amplifier

Table 9. Thermal characteristics (Continued)

Symbol Parameter Conditions Min Typ Max Unit

HTSSOP32 package

R

th(j-a)

thermal resistance from junction

to ambient

Ψ

j-lead

thermal characterization

parameter from junction to lead

Ψ

j-top

thermal characterization

parameter from junction to top

R

th(j-c)

thermal resistance from junction

to case

[1] Measured on a JEDEC high K-factor test board (standard EIA/JESD 51-7) in free air with natural convection.

[2] Two layer application board (55 mm × 45 mm), 35 µm copper, FR4 base material in free air with natural convection.

[3] Strongly depends on where the measurement is taken on the package.

[4] Two layer application board (55 mm × 40 mm), 35 µm copper, FR4 base material in free air with natural convection.

free air natural convection

[1]

JEDEC test board

2 layer application board

- 47 50 K/W

[4]

- 48 - K/W

- - 30 K/W

[3]

- - 2 K/W

free air natural convection - 4.0 - K/W

12. Static characteristics

Table 10. Static characteristics

VP= 22 V; f

Symbol Parameter Conditions Min Typ Max Unit

Supply

V

P

I

P

I

q(tot)

Series resistance output power switches

R

DSon

Power-up input: pin POWERUP

V

I

I

I

V

IL

V

IH

Engage input: pin ENGAGE

V

O

V

I

I

O

V

IL

V

IH

= 320 kHz; T

osc

=25°C; unless otherwise specified.

amb

supply voltage asymmetrical supply 10 22 36 V

symmetrical supply ±5 ±11 ±18 V

supply current Sleep mode; no load - 0.6 1.0 mA

total quiescent current Operating mode; no load, no

- 4050mA

snubbers and no filter connected

drain-source on-state

resistance

[1]

Tj=25°C - 150 - mΩ

= 125 °C - 234 - mΩ

T

j

input voltage 0 - 6.0 V

input current VI=3V - 1 20 µA

LOW-level input voltage 0 - 0.8 V

HIGH-level input voltage 2 - 6.0 V

[1]

output voltage open pin 2.4 2.8 3.1 V

input voltage 0 - 6.0 V

output current VI= 0 V - 50 60 µA

LOW-level input voltage 0 - 0.8 V

HIGH-level input voltage 2.4 - 6.0 V

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 17 of 48

Page 18

NXP Semiconductors

TDA8932B

Class-D audio amplifier

Table 10. Static characteristics (Continued)

VP= 22 V; f

Symbol Parameter Conditions Min Typ Max Unit

Diagnostic output: pin DIAG

V

O

Bias voltage for inputs: pin INREF

V

O(bias)

Half supply voltage

Pins HVP1 and HVP2

V

O

I

O

Pin HVPREF

V

O

Reference voltage for internal logic: pin DREF

V

O

Amplifier outputs: pins OUT1 and OUT2

|V

O(offset)

Stabilizer output: pins STAB1 and STAB2

V

O

Voltage protection

V

P(uvp)

V

P(ovp)

V

P(th)(ubp)l

V

P(th)(ubp)h

Current protection

I

O(ocp)

Temperature protection

T

act(th_prot)

= 320 kHz; T

osc

=25°C; unless otherwise specified.

amb

[1]

output voltage protection activated; see Table 6 - - 0.8 V

Operating mode 2 2.5 3.3 V

bias output voltage with respect to pin V

SSA

output voltage half supply voltage to charge SE

capacitor

output current V

= VO− 1V;

HVP1

V

HVP2=VO

− 1V

output voltage half supply reference voltage in

Mute mode

- 2.1 - V

0.5VP−

0.5V

P

0.2

-50-mA

0.5VP−

0.5V

P

0.2

output voltage 4.5 4.8 5.1 V

| output offset voltage SE; with respect to pin HVPREF

Mute mode - - 15 mV

Operating mode - - 100 mV

BTL

Mute mode - - 20 mV

Operating mode - - 150 mV

output voltage Mute mode and Operating mode;

with respect to pins V

V

SSP2

SSP1

and

undervoltage protection

10 11 12 V

8.0 9.2 9.9 V

supply voltage

overvoltage protection

36.1 37.4 40 V

supply voltage

low unbalance protection

V

HVPREF

= 11 V - - 18 V

threshold supply voltage

high unbalance protection

V

HVPREF

= 11 V 29 - - V

threshold supply voltage

overcurrent protection

current limiting 4 5 - A

output current

thermal protectionactivation

155 - 160 °C

temperature

0.5VP +

0.2

0.5VP +

0.2

V

V

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 18 of 48

Page 19

NXP Semiconductors

TDA8932B

Class-D audio amplifier

Table 10. Static characteristics (Continued)

VP= 22 V; f

= 320 kHz; T

osc

=25°C; unless otherwise specified.

amb

Symbol Parameter Conditions Min Typ Max Unit

T

act(th_fold)

thermal foldback activation

140 - 150 °C

temperature

Oscillator reference; pin OSCIO

V

IH

V

IL

V

OH

V

OL

N

slave(max)

[1] Measured with respect to pin CGND.

[2] Measured with respect to pin V

HIGH-level input voltage 4.0 - 5 V

LOW-level input voltage 0 - 0.8 V

HIGH-level output voltage 4.0 - 5 V

LOW-level output voltage 0 - 0.8 V

maximum number of slaves driven by one master 12 - - -

[2]

SSD(HW)

.

13. Dynamic characteristics

Table 11. Switching characteristics

VP= 22 V; T

Symbol Parameter Conditions Min Typ Max Unit

Internal oscillator

f

osc

Timing PWM output: pins OUT1 and OUT2

t

r

t

f

t

w(min)

=25°C; unless otherwise specified.

amb

oscillator frequency Rosc = 39 kΩ - 320 - kHz

range 300 - 500 kHz

rise time IO=0A - 10 - ns

fall time IO=0A - 10 - ns

minimum pulse width IO=0A - 80 - ns

Table 12. SE characteristics

VP= 22 V; RL=2×4Ω; fi= 1 kHz; f

= 320 kHz; Rs< 0.1

osc

[1]

Ω

; T

=25°C; unless otherwise specified.

amb

Symbol Parameter Conditions Min Typ Max Unit

THD+N total harmonic

distortion-plus-noise

G

|∆G

α

cs

v(cl)

v

closed-loop voltage gain Vi= 100 mV; no load 29 30 31 dB

| voltage gain difference - 0.5 1 dB

channel separation Po= 1 W; fi= 1 kHz 70 80 - dB

=1W

P

o

fi= 1 kHz - 0.015 0.05 %

= 6 kHz - 0.08 0.10 %

f

i

SVRR supply voltage ripple rejection Operating mode

[2]

[3]

fi= 100 Hz - 60 - dB

= 1 kHz 40 50 - dB

f

i

| input impedance differential 70 100 - kΩ

|Z

i

V

n(o)

noise output voltage Operating mode; Rs=0Ω

Mute mode

V

O(mute)

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 19 of 48

mute output voltage Mute mode; Vi= 1 V (RMS) and

f

= 1 kHz

i

[4]

- 100 150 µV

[4]

- 70 100 µV

- 100 - µV

Page 20

NXP Semiconductors

TDA8932B

Class-D audio amplifier

Table 12. SE characteristics (Continued)

VP= 22 V; RL=2×4Ω; fi= 1 kHz; f

= 320 kHz; Rs< 0.1

osc

[1]

Ω

; T

=25°C; unless otherwise specified.

amb

Symbol Parameter Conditions Min Typ Max Unit

CMRR common mode rejection ratio V

η

po

P

o(RMS)

output power efficiency Po=15W

RMS output power continuous time output power per

= 1 V (RMS) - 75 - dB

i(cm)

=22V; RL=4Ω 90 92 - %

V

P

=30V; RL=8Ω 91 93 - %

V

P

[5]

channel

RL=4Ω; VP=22V

THD+N = 0.5 %; f

THD+N = 0.5 %; f

THD+N = 10 %; f

THD+N = 10 %; f

=8Ω; VP=30V

R

L

THD+N = 0.5 %; f

THD+N = 0.5 %; f

THD+N = 10 %; f

THD+N = 10 %; f

short time output power per channel

= 1 kHz 10.9 12.1 - W

i

= 100 Hz - 12.1 - W

i

= 1 kHz 13.8 15.3 - W

i

= 100 Hz - 15.3 - W

i

= 1 kHz 11.1 12.3 - W

i

= 100 Hz - 12.3 - W

i

= 1 kHz 14.0 15.5 - W

i

= 100 Hz - 15.5 - W

i

[5]

RL=4Ω; VP=29V

THD+N = 0.5 % 19.0 21.1 - W

THD+N = 10 % 23.8 26.5 - W

[1] Rs is the series resistance of inductor and capacitor of low-pass LC filter in the application.

[2] THD+N is measured in a bandwidth of 20 Hz to 20 kHz, AES17 brick wall.

[3] Maximum V

[4] B = 20 Hz to 20 kHz, AES17 brick wall.

[5] Output power is measured indirectly; based on R

Two layer application board (55 mm × 45 mm), 35 µm copper, FR4 base material in free air with natural convection.

= 2 V (p-p); Rs=0Ω.

ripple

measurement.

DSon

Table 13. BTL characteristics

VP= 22 V; RL=8Ω; fi= 1 kHz; f

= 320 kHz; Rs< 0.1

osc

[1]

Ω

; T

=25°C; unless otherwise specified.

amb

Symbol Parameter Conditions Min Typ Max Unit

THD+N total harmonic

distortion-plus-noise

G

v(cl)

closed-loop voltage gain 35 36 37 dB

=1W

P

o

fi= 1 kHz - 0.007 0.1 %

= 6 kHz - 0.05 0.1 %

f

i

SVRR supply voltage ripple rejection Operating mode

[2]

[3]

fi= 100 Hz - 75 - dB

= 1000 Hz 70 75 - dB

f

i

sleep; f

| input impedance differential 35 50 kΩ

|Z

i

= 100 Hz

i

[3]

-80-dB

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 20 of 48

Page 21

NXP Semiconductors

TDA8932B

Class-D audio amplifier

Table 13. BTL characteristics (Continued)

VP= 22 V; RL=8Ω; fi= 1 kHz; f

= 320 kHz; Rs< 0.1

osc

[1]

Ω

; T

=25°C; unless otherwise specified.

amb

Symbol Parameter Conditions Min Typ Max Unit

V

n(o)

V

O(mute)

CMRR common mode rejection ratio V

η

po

P

o(RMS)

noise output voltage Rs=0Ω

[4]

Operating mode

Mute mode

mute output voltage Mute mode; Vi= 1 V (RMS) and

f

= 1 kHz

i

= 1 V (RMS) - 75 - dB

i(cm)

- 100 150 µV

[4]

- 70 100 µV

- 100 - µV

output power efficiency Po= 15 W; VP= 12 V and RL=4Ω 88 90 - %

= 30 W; VP= 22 V and RL=8Ω 90 92 - %

P

o

RMS output power continuous time output power

[5]

RL=4Ω; VP=12V

THD+N = 0.5 %; f

THD+N = 0.5 %; f

THD+N = 10 %; f

THD+N = 10 %; f

=8Ω; VP=22V

R

L

THD+N = 0.5 %; f

THD+N = 0.5 %; f

THD+N = 10 %; f

THD+N = 10 %; f

short time output power

= 1 kHz 11.8 13.2 - W

i

= 100 Hz - 13.2 - W

i

= 1 kHz 15.5 17.2 - W

i

= 100 Hz - 17.2 - W

i

= 1 kHz 23.1 25.7 - W

i

= 100 Hz - 25.7 - W

i

= 1 kHz 28.9 32.1 - W

i

= 100 Hz - 32.1 - W

i

[5]

RL=4Ω; VP=15V

THD+N = 0.5 % 18.5 20.6 - W

THD+N = 10 % 23.9 26.6 - W

=8Ω; VP=29V

R

L

THD+N = 0.5 % 36.0 40.0 - W

THD+N = 10 % 49.5 55.0 - W

[1] Rs is the series resistance of inductor and capacitor of low-pass LC filter in the application.

[2] THD+N is measured in a bandwidth of 20 Hz to 20 kHz, AES17 brick wall.

[3] Maximum V

[4] B = 20 Hz to 20 kHz, AES17 brick wall.

[5] Output power is measured indirectly; based on R

Two layer application board (55 mm × 45 mm), 35 µm copper, FR4 base material in free air with natural convection.

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 21 of 48

= 2 V (p-p); Rs=0Ω.

ripple

measurement.

DSon

Page 22

NXP Semiconductors

14. Application information

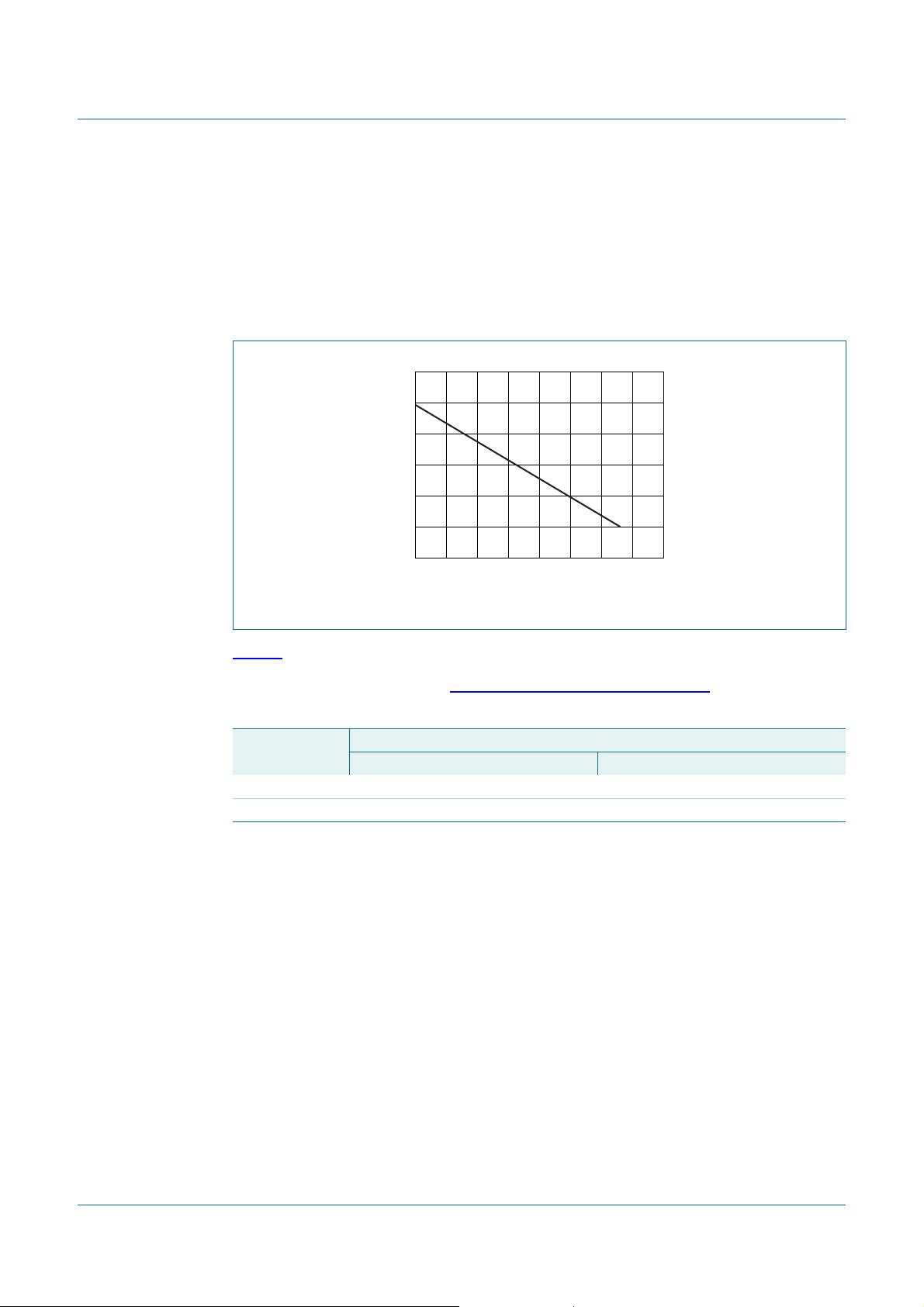

14.1 Output power estimation

The output power Po at THD+N = 0.5 %, just before clipping, for the SE and BTL

configuration can be estimated using Equation 2 and Equation 3.

SE configuration:

TDA8932B

Class-D audio amplifier

R

L

DSonRsRESR

1t

8R

×

L

– f

×()× VP×

wmin()

osc

P

o 0.5%()

----------------------------------------------------------

RLR

=

+++

-------------------------------------------------------------------------------------------------------------------------------------------

BTL configuration:

R

L

+()×

DSonRs

1t

2R

×

L

– f

×()× VP×

wmin()

osc

P

o 0.5%()

------------------------------------------------------

RL2+ R

=

--------------------------------------------------------------------------------------------------------------------------------------

Where:

VP= supply voltage V

DDP1

− V

SSP1

(V) or V

DDP2

− V

SSP2

(V)

RL= load impedance (Ω)

R

= on-resistance power switch (Ω)

DSon

Rs= series resistance output inductor (Ω)

R

= equivalent series resistance SE capacitor (Ω)

ESR

t

= minimum pulse width (s); 80 ns typical

w(min)

f

= oscillator frequency (Hz); 320 kHz typical with Rosc = 39 kΩ

osc

The output power Po at THD+N = 10 % can be estimated by:

2

(2)

2

(3)

P

o10%()

1.25 P

×=

o 0.5%()

(4)

Figure 8 and Figure 9 show the estimated output power at THD+N = 0.5 % and

THD+N = 10 % as a function of the supply voltage for SE and BTL configurations at

different load impedances. The output power is calculated with: R

Tj=25°C), Rs= 0.05 Ω, R

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 22 of 48

= 0.05 Ω and I

ESR

= 4 A (minimum).

O(ocp)

= 0.15 Ω (at

DSon

Page 23

NXP Semiconductors

TDA8932B

Class-D audio amplifier

RL = 4 Ω

6 Ω

8 Ω

VP (V)

001aad768

40

P

o

(W)

30

20

10

0

10 403020

40

P

o

(W)

30

20

10

0

10 403020

a. THD+N = 0.5 % b. THD+N = 10 %

Fig 8. SE output power as a function of supply voltage

RL = 8 Ω

001aad770

P

(W)

80

o

60

P

(W)

80

o

60

001aad769

RL = 4 Ω

6 Ω

8 Ω

VP (V)

001aad771

RL = 8 Ω

6 Ω

6 Ω

40

20

0

10 403020

4 Ω

VP (V)

40

20

0

10 403020

a. THD+N = 0.5 % b. THD+N = 10 %

Fig 9. BTL output power as a function of supply voltage

4 Ω

VP (V)

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 23 of 48

Page 24

NXP Semiconductors

14.2 Output current limiting

TDA8932B

Class-D audio amplifier

The peak output current I

is internally limited above a level of 4 A (minimum). During

O(max)

normal operation the output current should not exceed this threshold level of 4 A

otherwise the output signal is distorted. The peak output current in SE or BTL

configurations can be estimated using Equation 5 and Equation 6.

SE configuration:

0.5 VP×

I

O max()

----------------------------------------------------------

RLR

+++

DSonRsRESR

4A≤≤

BTL configuration:

V

I

O max()

------------------------------------------------------

RL2+ R

P

+()×

DSonRs

4A≤≤

Where:

VP= supply voltage V

DDP1

− V

SSP1

(V) or V

DDP2

− V

SSP2

(V)

RL= load impedance (Ω)

R

= on-resistance power switch (Ω)

DSon

Rs= series resistance output inductor (Ω)

R

= equivalent series resistance SE capacitor (Ω)

ESR

(5)

(6)

Example:

A4Ω speaker in the BTL configuration can be used up to a supply voltage of 18 V without

running into current limiting. Current limiting (clipping) will avoid audio holes but it causes

a comparable distortion like voltage clipping.

14.3 Speaker configuration and impedance

For a flat frequency response (second-order Butterworth filter) it is necessary to change

the low-pass filter components Llc and Clc according to the speaker configuration and

impedance. Table 14 shows the practical required values.

Table 14. Filter component values

Configuration RL (Ω) Llc (µH) Clc (nF)

SE 4 22 680

6 33 470

8 47 330

BTL 4 10 1500

6 15 1000

8 22 680

14.4 Single-ended capacitor

The SE capacitor forms a high-pass filter with the speaker impedance. So the frequency

response will roll-off with 20 dB per decade below f

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 24 of 48

(3 dB cut-off frequency).

-3dB

Page 25

NXP Semiconductors

The 3 dB cut-off frequency is equal to:

TDA8932B

Class-D audio amplifier

f

=

3dB–

1

-----------------------------------

2π RL× Cse×

Where:

f

= 3 dB cut-off frequency (Hz)

-3dB

RL= load impedance (Ω)

Cse = single-ended capacitance (F); see Figure 36

Table 15 shows an overview of the required SE capacitor values in case of 60 Hz, 40 Hz

or 20 Hz 3 dB cut-off frequency.

Table 15. SE capacitor values

Impedance (Ω) Cse (µF)

4 680 1000 2200

6 470 680 1500

8 330 470 1000

14.5 Gain reduction

The gain of the TDA8932B is internally fixed at 30 dB for SE (or 36 dB for BTL). The gain

can be reduced by a resistive voltage divider at the input (see Figure 10).

f

=60Hz f

-3dB

=40Hz f

-3dB

-3dB

(7)

=20Hz

470 nF

R1

audio in

Fig 10. Input configuration for reducing gain

R2

R3

470 nF

100

kΩ

001aad762

When applying a resistive divider, the total closed-loop gain G

Equation 8 and Equation 9:

R

G

vtot()Gvcl()

20

log+=

----------------------------------------- -

R

EQ

EQ

R1 R2+()+

Where:

G

= total closed-loop voltage gain (dB)

v(tot)

G

= closed-loop voltage gain, fixed at 30 dB for SE (dB)

v(cl)

REQ= equivalent resistance, R3 and Zi (Ω)

R1 = series resistor (Ω)

R2 = series resistor (Ω)

can be calculated by

v(tot)

(8)

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 25 of 48

Page 26

NXP Semiconductors

TDA8932B

Class-D audio amplifier

EQ

=

R3 Zi×

------------------

R3 Zi+

R

Where:

REQ= equivalent resistance (Ω)

R3 = parallel resistor (Ω)

Zi = internal input impedance (Ω)

Example:

Substituting R1 = R2 = 4.7 kΩ,Zi= 100 kΩ andR3=22kΩ in Equation 8 and Equation 9

results in a gain of G

v(tot)

= 26.3 dB.

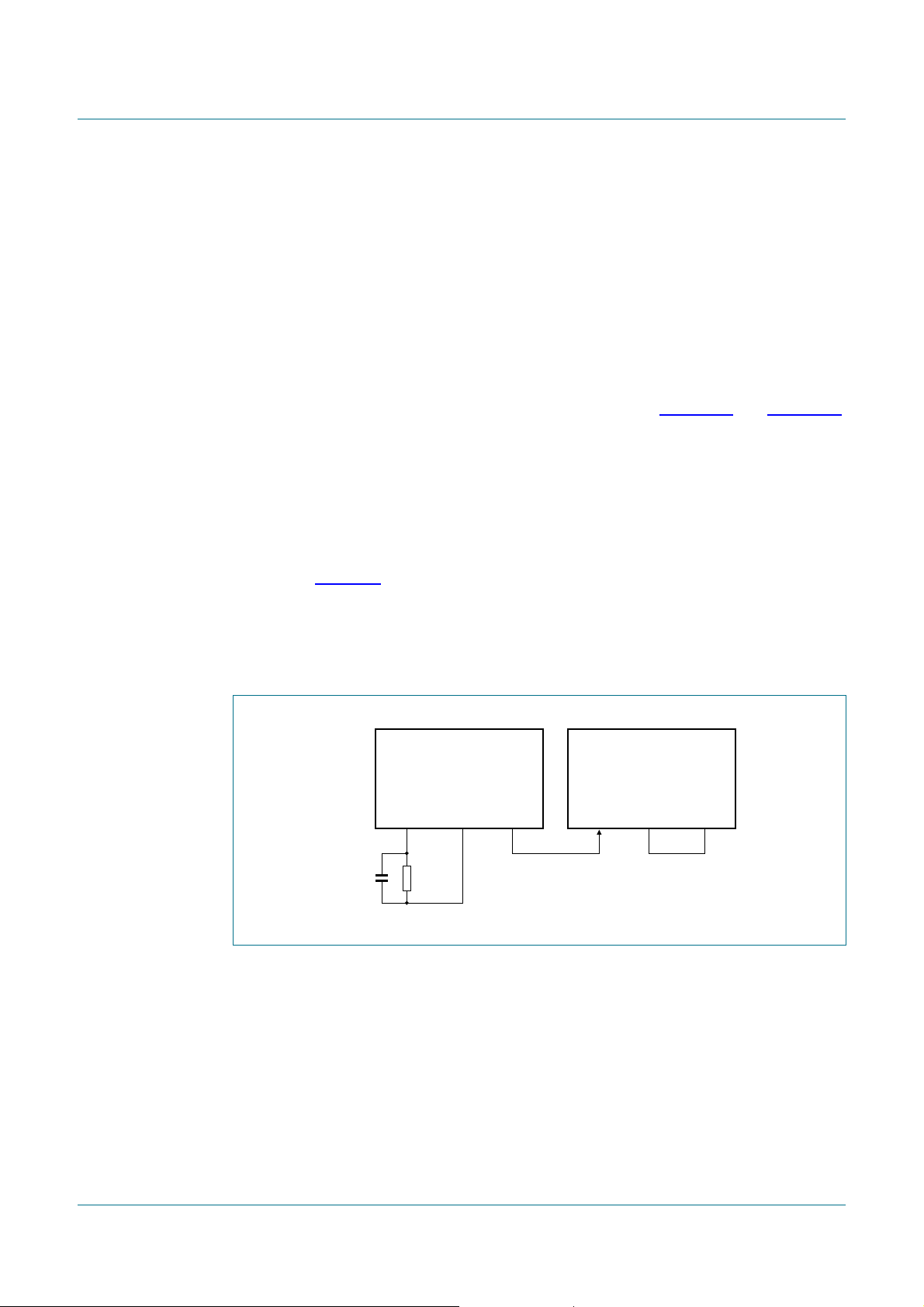

14.6 Device synchronization

If two or more TDA8932B devices are used in one application it is recommended that all

devices are synchronized running at the same switching frequency to avoid beat tones.

Synchronization canbe realized byconnecting all OSCIO pins together andconfigure one

of the TDA8932B devicesas master,while the other TDA8932B devices are configured as

slaves (see Figure 11).

A device is configured as master when connecting a resistor between pins OSCREF and

V

SSD(HW)

oscillator output for synchronization. The OSCREF pins of the slave devices should be

shorted to V

setting the carrier frequency. Pin OSCIO of the master is then configured as an

SSD(HW)

configuring pin OSCIO as an input.

(9)

master slave

C

osc

100 nF

TDA8932B

OSCREF V

R

osc

39 kΩ

IC1

SSD(HW)

OSCIO

OSCIO OSCREF

IC2

TDA8932B

V

SSD(HW)

001aaf600

Fig 11. Master slave concept in two chip application

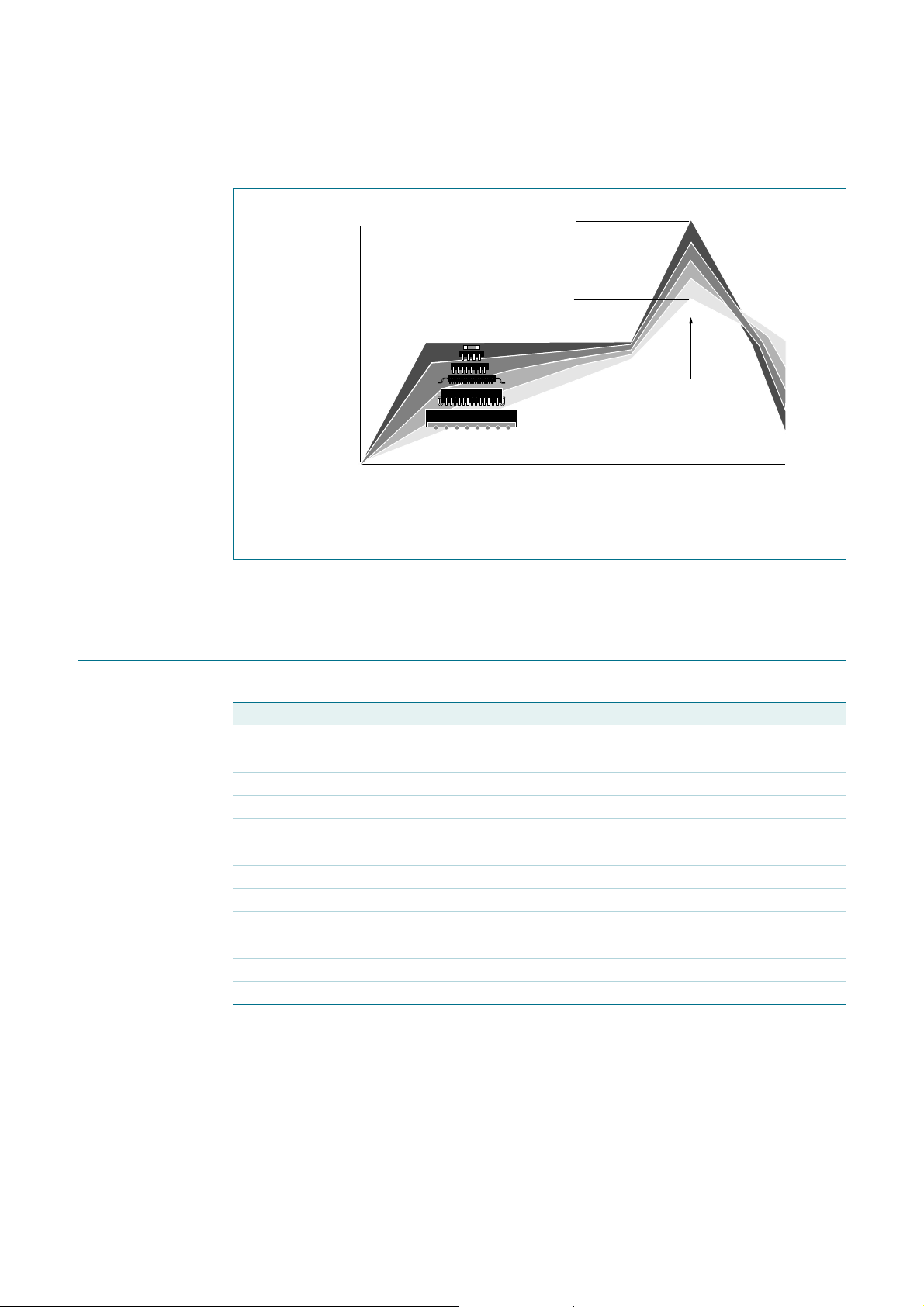

14.7 Thermal behavior (printed-circuit board considerations)

The TDA8932B is available in two different thermally enhanced packages:

TDA8932BT in a SO32 (SOT287-1) package for reflow and wave solder process

TDA8932BTW in an HTSSOP32 (SOT549-1) package for reflow solder process only

The SO32 package has special thermal corner-leads, increasing the power capability

(reducing the overall R

and 32) should be attached to a copper plane. The SO package is very suitable for

applications with limited space for a thermal plane (in a single layer PCB design).

. To benefit from the corner leads pins V

th(j-a)

SSD(HW)

(pins 1, 16, 17

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 26 of 48

Page 27

NXP Semiconductors

The HTSSOP32 package has an exposed die-pad that reduces significantly the overall

R

th(j-a)

plane forcooling. The HTSSOP package will havea low thermal resistance when used on

a multi-layer PCB with sufficient space for one or two thermal planes.

Increasing the area of the thermal plane, the number of planes or the copper thickness

can reduce further the thermal resistance R

. Therefore it is required to solder the exposed die-pad (at V

of both packages.

th(j-a)

TDA8932B

Class-D audio amplifier

level) to a copper

SSD

Typical thermal resistance R

application board (55 mm × 45 mm), 35 µm copper, FR4 base material is 44 K/W.

Typical thermal resistance R

application board (55 mm × 40 mm), 35 µm copper, FR4 base material is 48 K/W.

Equation 10 shows the relation between the maximum allowable power dissipation P and

the thermal resistance from junction to ambient.

R

th j a–()

T

=

------------------------------------

–

j max()Tamb

P

Where:

R

= thermal resistance from junction to ambient

th(j-a)

T

= maximum junction temperature

j(max)

T

= ambient temperature

amb

P = power dissipation which is determined by the efficiency of the TDA8932B

The power dissipation is shown in Figure 22 (SE) and Figure 34 (BTL).

The thermal foldback will limit the maximum junction temperature to 140 °C.

14.8 Pumping effects

of the SO32 package soldered at a small 2-layer

th(j-a)

of the HTSSOP32 package soldered at a small 2-layer

th(j-a)

(10)

When the amplifier is used in a SE configuration, a so-called 'pumping effect' can occur.

During one switching interval, energy is taken from one supply (e.g. V

that energy is delivered back to the other supply line (e.g. V

) and visa versa. When

SSP1

), whilea part of

DDP1

the power supply cannot sink energy, the voltage across the output capacitors of that

power supply will increase.

The voltage increase caused by the pumping effect depends on:

• Speaker impedance

• Supply voltage

• Audio signal frequency

• Value of decoupling capacitors on supply lines

• Source and sink currents of other channels

The pumping effect should not cause a malfunction of either the audio amplifier and/or the

power supply. For instance, this malfunction can be caused by triggering of the

undervoltage or overvoltage protection of the amplifier.

Pumping effects in a SE configuration can be minimized by connecting audio inputs in

anti-phase and change the polarity of one speaker. This is illustrated in Figure 12.

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 27 of 48

Page 28

NXP Semiconductors

TDA8932B

Class-D audio amplifier

IN1P

audio

in1

audio

in2

IN1N

IN2N

IN2P

Fig 12. SE application for reducing pumping effects

OUT1

OUT2

001aad763

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 28 of 48

Page 29

NXP Semiconductors

14.9 SE curves measured in reference design

TDA8932B

Class-D audio amplifier

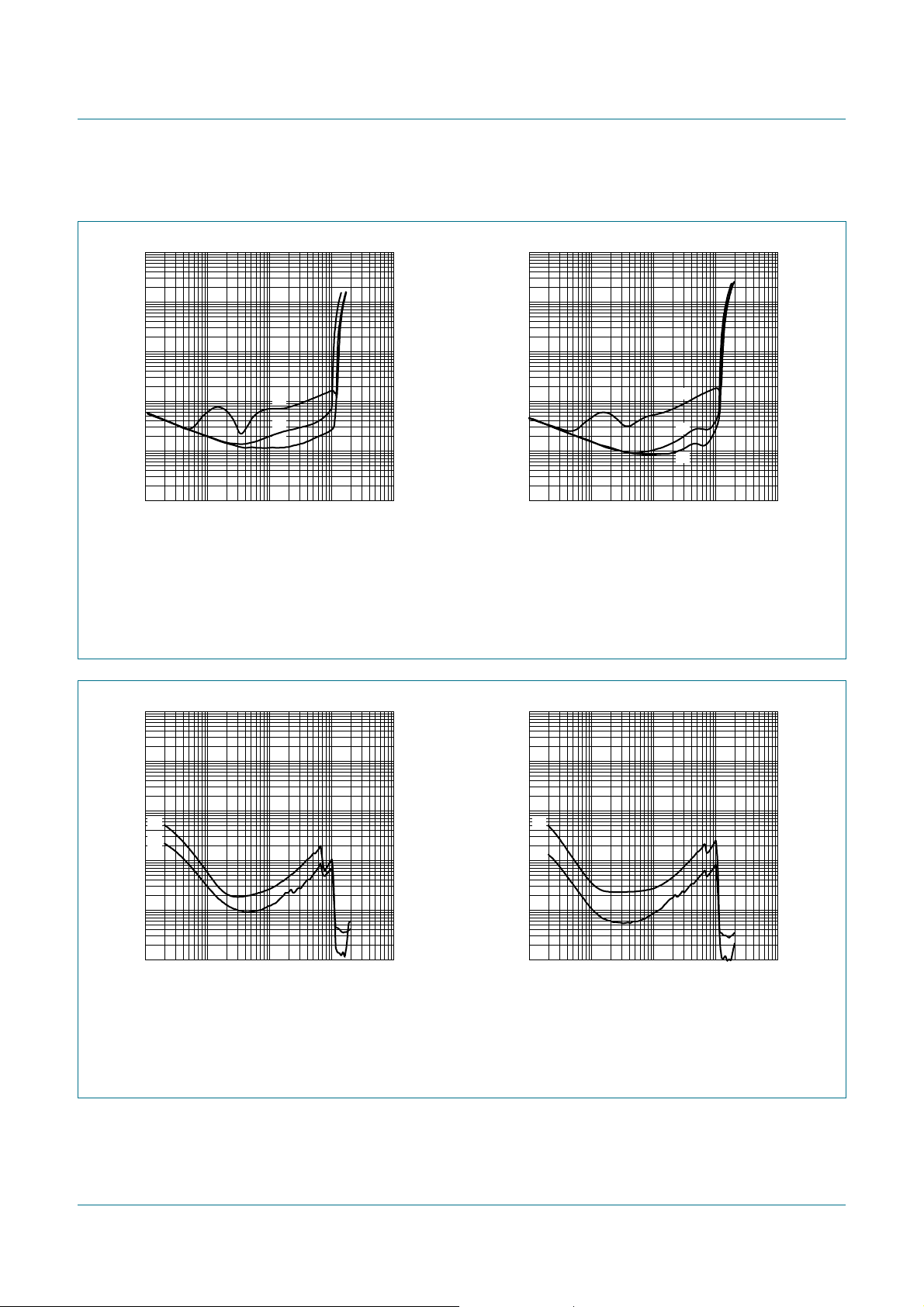

1010

001aad772

2

10

THD+N

(%)

10

1

−1

10

−2

10

−3

2

10

10

−2

10

−1

10

THD+N

(%)

10

10

10

2

10

1

−1

−2

−3

−2

10

−1

(1)

(2)

(3)

1

Po (W/channel)

a. VP=22V; RL=2× 4 Ω b. VP=30V; RL=2× 8 Ω

(1) fi= 6 kHz

(2) fi= 100 Hz

(3) fi= 1 kHz

Fig 13. Total harmonic distortion-plus-noise as a function of output power per channel

001aad773

(1)

(2)

(3)

2

1

1010

Po (W/channel)

10

10

001aad774

4

fi (Hz)

2

10

THD+N

(%)

10

1

(1)

(2)

−1

10

−2

10

−3

5

10

10 10

2

10

2

10

THD+N

(%)

10

1

(1)

(2)

−1

10

−2

10

−3

10

10 10

2

10

3

10

a. VP=22V; RL=2× 4 Ω b. VP=30V; RL=2× 8 Ω

(1) Po=10W

(2) Po=1W

Fig 14. Total harmonic distortion-plus-noise as a function of frequency

001aad775

3

10

4

10

fi (Hz)

5

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 29 of 48

Page 30

NXP Semiconductors

TDA8932B

Class-D audio amplifier

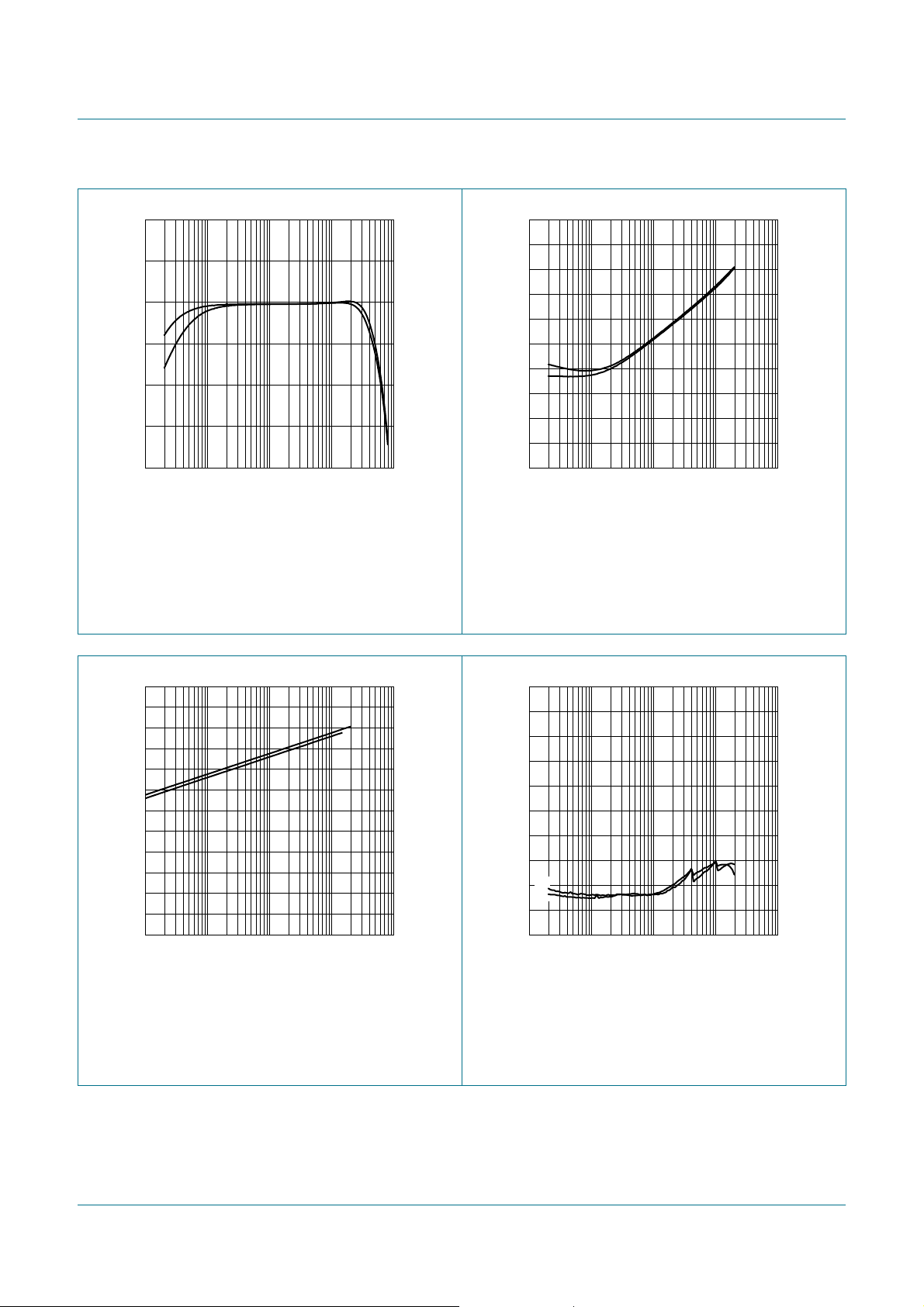

10

001aad777

4

(Hz)

f

i

5

40

G

v

(dB)

30

(1)

(2)

20

10

10 10

2

10

3

10

10

Vi= 100 mV (RMS); Ri=0Ω; Cse = 1000 µF

(1) VP= 30 V; RL=2× 8 Ω

(2) VP= 22 V; RL=2× 4 Ω

001aad776

4

f

(Hz)

i

0

SVRR

(dB)

−20

−40

(1)

−60

(2)

−80

5

−100

10 10

V

ripple

2

10

3

10

= 500 mV (RMS) referenced to ground;

Ri=0Ω (shorted input)

(1) VP=30V; RL=2× 8 Ω

(2) VP=22V; RL=2× 4 Ω

Fig 15. Gain as a function of frequency Fig 16. Supply voltage ripple rejection as a function of

frequency

001aad778

(2)

(1)

1010

Po (W/channel)

10

2

S/N

(dB)

120

80

40

0

−2

10

−1

1

Ri=0Ω; 20 kHz brick-wall filter AES17

(1) VP= 22 V; RL=2× 4 Ω

(2) VP= 30 V; RL=2× 8 Ω

Fig 17. Signal-to-noise ratio as a function of output

power per channel

10

001aad779

4

f

(Hz)

i

5

0

α

cs

(dB)

−20

−40

−60

(1)

−80

(2)

−100

10 10

Po= 1 W; C

2

10

HVPREF

3

10

=47µF

(1) VP=22V; RL=2× 4 Ω

(2) VP=30V; RL=2× 8 Ω

Fig 18. Channel separation as a function of frequency

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 30 of 48

Page 31

NXP Semiconductors

TDA8932B

Class-D audio amplifier

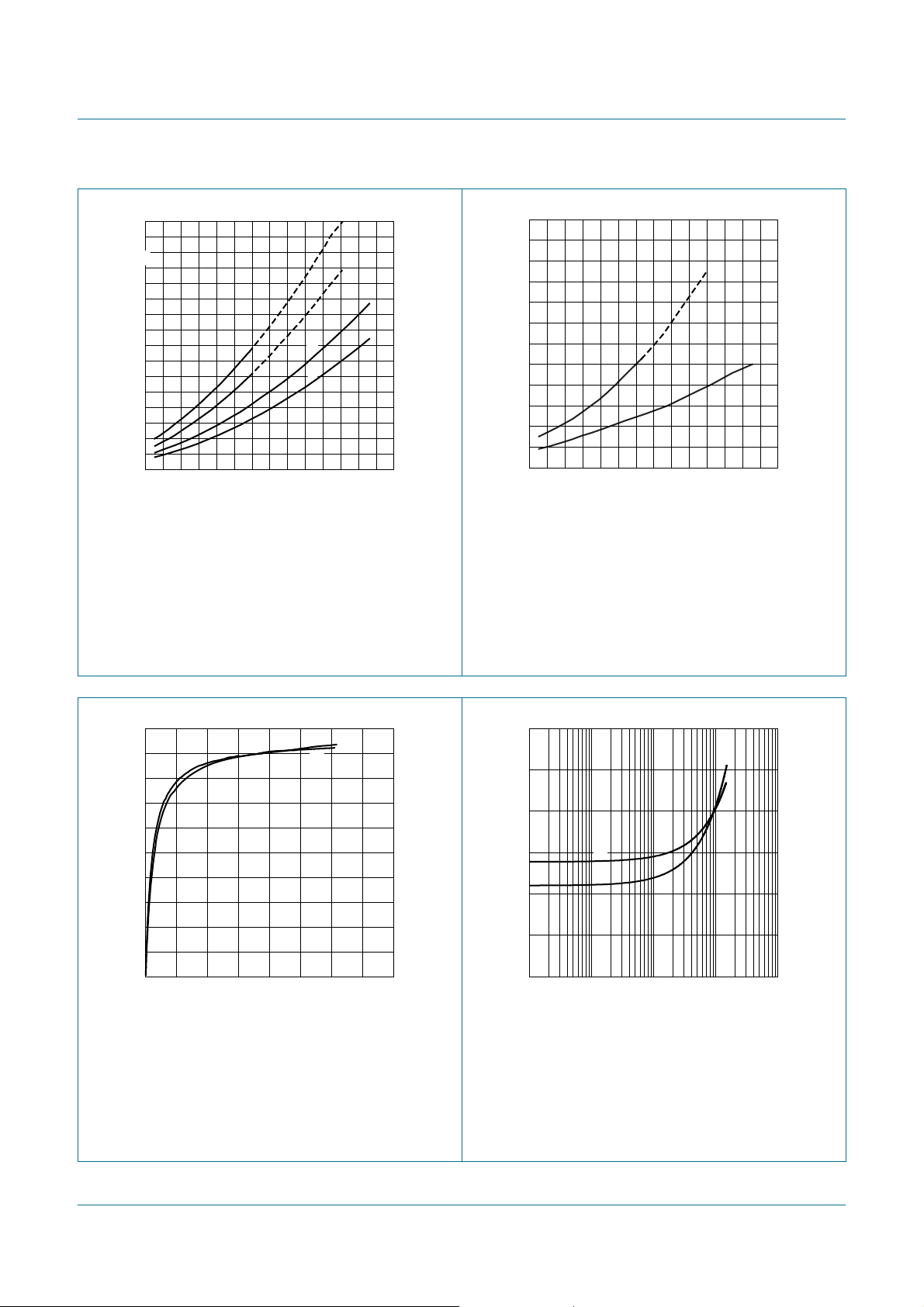

32

P

o

(W/channel)

24

16

8

0

10 3830 3414 18 22 26

001aaf886

(1)

(2)

(3)

(4)

VP (V)

fi= 1 kHz (short time PO); dashed line will require

heat sink for continuous time output power

(1) RL=2× 4 Ω; THD+N = 10 %

(2) RL=2× 4 Ω; THD+N = 0.5 %

(3) RL=2× 8 Ω; THD+N = 10 %

(4) RL=2× 8 Ω; THD+N = 0.5 %

Fig 19. Output power per channel as a function of

supply voltage

6

P

(W)

4

2

0

10 383414 18 22 26 30

(1)

(2)

001aaf889

VP (V)

fi= 1 kHz; power dissipation in junction only; short

time Po at THD+N = 10 %; dashed line will require

heat sink for continuous time output power

(1) RL=2× 4 Ω

(2) RL=2× 8 Ω

Fig 20. Power dissipation as a function of supply

voltage

100

η

po

(%)

80

60

40

20

0

02015510

(1) V

fi= 1 kHz;

P

η

=

------------------------ -

PO

2P

= 22 V; RL=2× 4 Ω

2P

×

o

o

p+×

001aad780

(2)

(1)

Po (W/channel)

(2) VP= 30 V; RL=2× 8 Ω

Fig 21. Output power efficiency as a function of output

power per channel

001aad781

1010

P

(W/channel)

o

2

10

P

(W)

3.0

2.0

1.0

(2)

(1)

0

−2

10

−1

1

fi= 1 kHz; power dissipation in junction only

(1) VP=22V; RL=2× 4 Ω

(2) VP=30V; RL=2× 8 Ω

Fig 22. Powerdissipation as a function of output power

per channel (two channels driven)

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 31 of 48

Page 32

NXP Semiconductors

TDA8932B

Class-D audio amplifier

32

P

o

(W/channel)

24

16

8

0

(3)

(2)

(1)

0 600480240 360120

001aaf887

t (s)

a. RL=2× 4 Ω; fi= 1 kHz; 2 layer SO32 application

board (55 mm × 45 mm) without heat sink

(1) VP=22V

(2) VP=26V

(3) VP=29V

Fig 23. Output power per channel as a function of time

32

P

o

(W/channel)

24

16

8

0

(2)

(1)

0 600480240 360120

001aaf888

t (s)

b. RL=2× 8 Ω; fi= 1 kHz; 2 layer SO32 application

board (55 mm × 45 mm) without heat sink

(1) VP=30V

(2) VP=34V

4

V

o

(V)

3

2

1

0

sleep

03210.5 2.51.5

Vi= 100 mV (RMS value); fi= 1 kHz; V

operating

001aaf890

V

POWERUP

ENGAGE

(V)

>3V Vi= 100 mV (RMS value); fi= 1 kHz;

Fig 24. Output voltage as a function of voltage on pin

POWERUP

4

V

o

(V)

3

2

1

0

V

mute

03210.5 2.51.5

POWERUP

>2V

001aaf891

operating

V

ENGAGE

(V)

Fig 25. Output voltage as a function of voltage on pin

ENGAGE

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 32 of 48

Page 33

NXP Semiconductors

14.10 BTL curves measured in reference design

TDA8932B

Class-D audio amplifier

1010

001aad782

Po (W)

2

10

THD+N

(%)

10

1

−1

10

−2

10

−3

2

10

10

−2

10

10

THD+N

(%)

10

10

10

10

2

1

−1

−2

−3

−2

10

−1

(1)

(2)

(3)

1

a. VP=12V; RL=4Ω b. VP=22V; RL=8Ω

(1) fi= 6 kHz

(2) fi= 1 kHz

(3) fi= 100 Hz

Fig 26. Total harmonic distortion-plus-noise as a function of output power

001aad783

(1)

(2)

(3)

−1

1

1010

Po (W)

2

10

10

001aae114

4

fi (Hz)

2

10

THD+N

(%)

10

1

−1

10

−2

10

−3

5

10

10 10

2

10

THD+N

(%)

10

1

−1

10

(1)

−2

10

−3

10

10 10

(2)

2

10

3

10

a. VP=12V; RL=4Ω b. VP=22V; RL=8Ω

(1) Po=10W

(2) Po=1W

Fig 27. Total harmonic distortion-plus-noise as a function of frequency

001aae115

(1)

(2)

2

10

3

10

4

10

fi (Hz)

5

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 33 of 48

Page 34

NXP Semiconductors

TDA8932B

Class-D audio amplifier

40

G

v

(dB)

30

20

10

10 10

2

10

3

10

10

Vi= 100 mV (RMS); Ri=0Ω

(1) VP= 12 V; RL=4Ω

(2) VP= 22 V; RL=8Ω

001aae116

4

f

(Hz)

i

0

SVRR

(dB)

(1)(2)

5

−20

−40

−60

−80

−100

10 10

V

ripple

2

10

3

10

= 500 mV (RMS) referenced to ground;

Ri=0Ω (shorted input)

(1) VP=22V; RL=8Ω

001aae117

(1)

(2)

(Hz)

i

5

4

10

f

(2) VP=12V; RL=4Ω

Fig 28. Gain as a function of frequency Fig 29. Supply voltage ripple rejection as a function of

frequency

1010

001aae118

Po (W)

2

10

S/N

(dB)

120

80

40

(2)

(1)

0

−2

10

−1

1

Ri=0Ω; 20 kHz brick-wall filter AES17

(1) RL=4Ω; VP=12V

(2) RL=8Ω; VP=22V

Fig 30. Signal-to-noise ratio as a function of output

power

70

P

o

(W)

60

50

40

30

20

10

0

10 34261814 3022

(3)

(1)

(2)

(4)

001aaf893

VP (V)

fi= 1 kHz (short time PO); dashed line will require

heat sink for continuous time output power

(1) RL=4Ω; THD+N = 10 %

(2) RL=4Ω; THD+N = 0.5 %

(3) RL=8Ω; THD+N = 10 %

(4) RL=8Ω; THD+N = 0.5 %

Fig 31. Output power as a function of supply voltage

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 34 of 48

Page 35

NXP Semiconductors

TDA8932B

Class-D audio amplifier

001aaf896

P

(W)

32

o

24

16

8

0

0 600480240 360120

(3)

(2)

(1)

a. RL=4Ω; fi= 1 kHz; 2 layer SO32 application

board (55 mm × 45 mm) without heat sink

(1) VP=12V

(2) VP= 13.5 V

(3) VP=15V

Fig 32. Output power as a function of time

t (s)

001aaf899

t (s)

P

(W)

60

o

50

40

30

20

10

(3)

0

0 600480240 360120

(2)

(1)

b. RL=8Ω; fi= 1 kHz; 2 layer SO32 application

board (55 mm × 45 mm) without heat sink

(1) VP=22V

(2) VP=26V

(3) VP=29V

100

η

po

(%)

80

60

40

20

0

0302010

fi= 1 kHz;

(1) V

= 12 V; RL=4Ω

P

(1)

(2)

P

η

PO

o

=

--------------------

Pop+()

001aae119

Po (W)

(2) VP= 22 V; RL=8Ω

Fig 33. Output power efficiency as a function of output

power

1010

001aae120

P

(W)

o

2

10

P

(W)

3.0

2.0

1.0

(2)

(1)

0

−2

10

−1

1

fi= 1 kHz; power dissipation in junction only

(1) VP=12V; RL=4Ω

(2) VP=22V; RL=8Ω

Fig 34. Power dissipation as a function of output power

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 35 of 48

Page 36

NXP Semiconductors

TDA8932B

Class-D audio amplifier

6

P

(W)

4

2

0

10 34261814 3022

fi= 1 kHz; power dissipation in junction only; short time Po at THD+N = 10 %; dashed line will require heat sink for

continuous time output power

(1) RL=4Ω

(2) RL= 8 Ω

(1)

Fig 35. Power dissipation as a function of supply voltage

001aaf904

(2)

VP (V)

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 36 of 48

Page 37

NXP Semiconductors

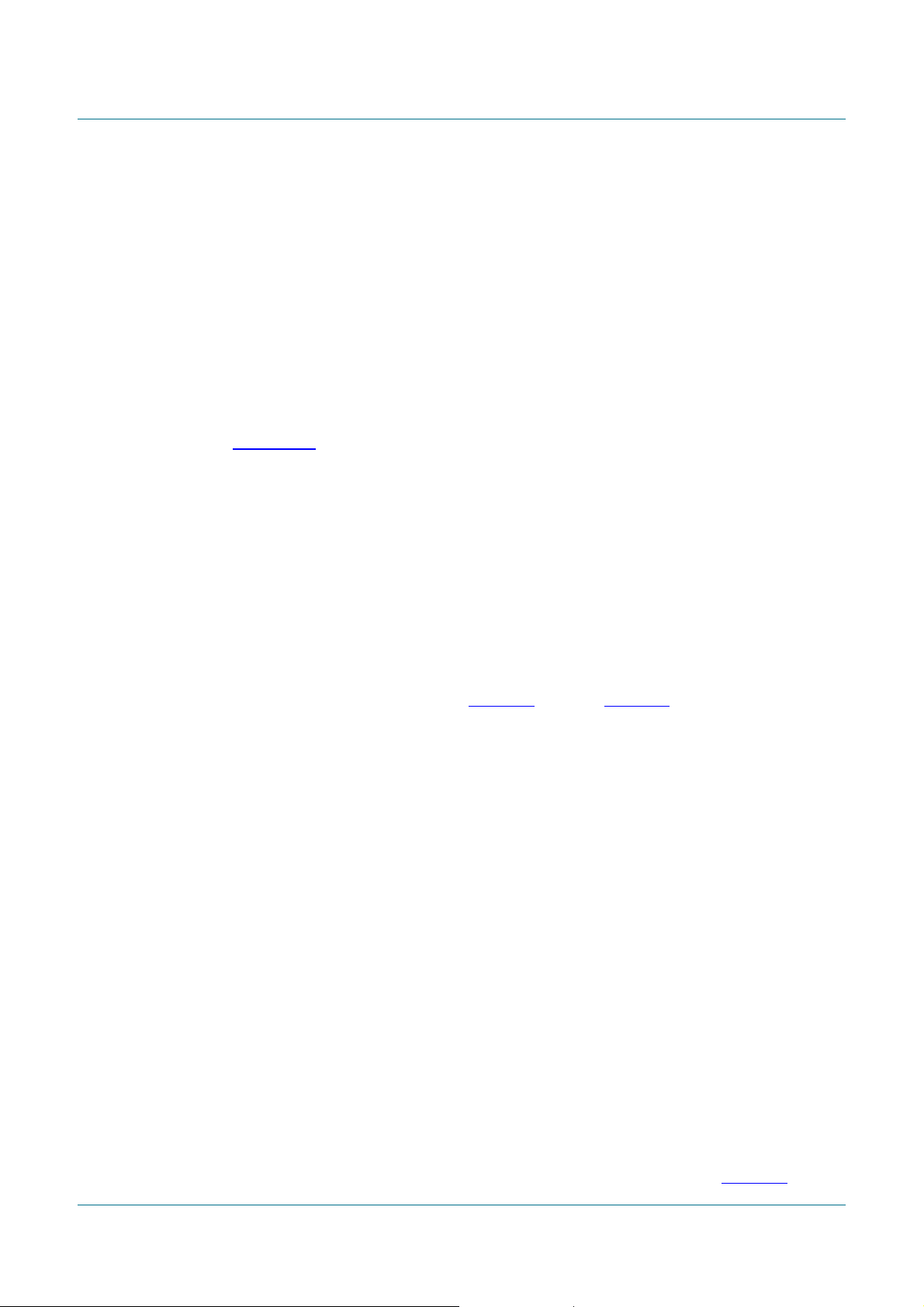

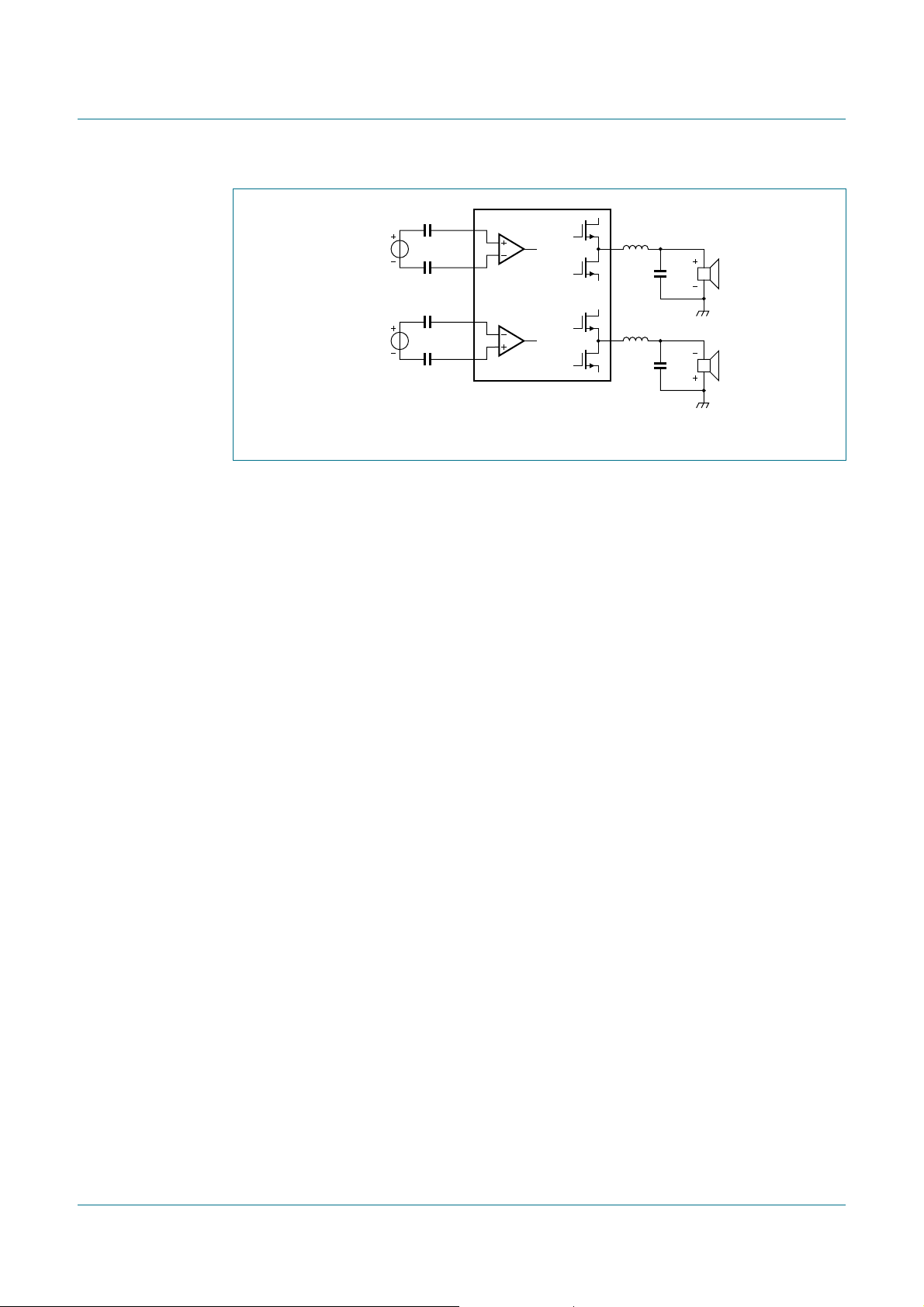

14.11 Typical application schematics (simplified)

VP VPA

GND

Rvdda

10 Ω

Cvdda

100 nF

Cvddp

220 µF

(35 V)

TDA8932B

Class-D audio amplifier

VP

MUTE control

SLEEP control

Chvpref

47 µF (25 V)

Cin

470 nF

Cosc

100 nF

Rosc

39 kΩ

Cin

470 nF

Cen

470 nF

Chvp

100 nF

V

SSD(HW)

Cin

470 nF

ENGAGE BOOT1

POWERUP OUT1

VPA

OSCREF

HVPREF OUT2

Cinref

100 nF

Cin

470 nF

V

SSD(HW)

1

IN1P

2

IN1N HVP1

3

DIAG

4

5

6

CGND

7

V

DDA

8

V

SSA

TDA8932B

9

U1

10

11

INREF

12

TEST

13

IN2N HVP2

14

IN2P DREF

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

V

SSD(HW)

OSCIO

V

DDP1

V

SSP1

STAB1

STAB2

V

SSP2

BOOT2

V

DDP2

V

SSD(HW)

Cbo

15

nF

Cbo

15

nF

Fig 36. Typical simplified application diagram for 2 × SE (asymmetrical supply)

Cstab

100 nF

VP

Cvddp

100 nF

Cdref

100 nF

VP

Cvddp

100 nF

Llc

Rsn

10 Ω

Csn

470 pF

Llc

Rsn

10 Ω

Csn

470 pF

Chvp

100 nF

Chvp

100 nF

Clc

Clc

Cse

Cse

001aaf601

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 37 of 48

Page 38

NXP Semiconductors

VP VPA

GND

Rvdda

10 Ω

Cvdda

100 nF

Cvddp

220 µF

(35 V)

TDA8932B

Class-D audio amplifier

VP

Cin

1 µF

Cin

1 µF

MUTE

control

SLEEP

control

Cosc

100 nF

Rosc

39 kΩ

Cen

470 nF

Chvp

100 nF

V

SSD(HW)

ENGAGE BOOT1

POWERUP OUT1

VPA

OSCREF

HVPREF OUT2

Cinref

100 nF

V

SSD(HW)

1

IN1P

2

IN1N HVP1

3

DIAG

4

5

6

CGND

7

V

DDA

8

V

SSA

TDA8932B

9

U1

10

11

INREF

12

TEST

13

IN2N HVP2

14

IN2P DREF

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

V

SSD(HW)

OSCIO

V

DDP1

V

SSP1

STAB1

STAB2

V

SSP2

BOOT2

V

DDP2

V

SSD(HW)

Cbo

15 nF

Cbo

15 nF

Fig 37. Typical simplified application diagram for 1 × BTL (asymmetrical supply)

Rhvp

470 Ω

Cstab

100 nF

VP

Cvddp

100 nF

Cdref

100 nF

Rhvp

470 Ω

VP

Cvddp

100 nF

Rsn

10 Ω

Csn

470 pF

Rsn

10 Ω

Csn

470 pF

Chvp

100 nF

Chvp

100 nF

Llc

Clc

Clc

Llc

001aaf602

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 38 of 48

Page 39

NXP Semiconductors

VDD VDDA

GND

VSS VSSA

Rvdda

10 Ω

Rvssa

10 Ω

Cvdda

100 nF

Cvssa

100 nF

Cvddp

220 µF

(25 V)

Cvssp

220 µF

(25 V)

TDA8932B

Class-D audio amplifier

VDD

VSS

MUTE control

SLEEP control

VSSA

Cin

470 nF

Cosc

100 nF

Rosc

39 kΩ

Cin

470 nF

Cen

470 nF

V

SSD(HW)

VSSA

Cin

470 nF

ENGAGE BOOT1

POWERUP OUT1

VDDA

VSSA

OSCREF

HVPREF OUT2

Cinref

100 nF

Cin

470 nF

V

SSD(HW)

VSSA

1

IN1P

2

IN1N HVP1

3

DIAG

4

5

6

CGND

7

V

DDA

8

V

SSA

TDA8932B

9

U1

10

11

INREF

12

TEST

13

IN2N HVP2

14

IN2P DREF

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

V

SSD(HW)

OSCIO

V

DDP1

V

SSP1

STAB1

STAB2

V

SSP2

BOOT2

V

DDP2

V

SSD(HW)

Cbo

15 nF

Cstab

100 nF

Cbo

15 nF

Cdref

100 nF

VSS

Cvssp

100 nF

VSS

VDD

Cvddp

100 nF

Cvssp

100 nF

VSSA

VDD

VSSA

Cvddp

100 nF

Llc

Rsn

10 Ω

Csn

470 pF

Llc

Rsn

10 Ω

Csn

470 pF

Clc

Clc

001aaf603

Fig 38. Typical simplified application diagram for 2 × SE (symmetrical supply)

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 39 of 48

Page 40

NXP Semiconductors

VDD VDDA

GND

VSS

Rvdda

10 Ω

Rvssa

10 Ω

Cvdda

100 nF

Cvssa

100 nF

VSSA

Cvddp

220 µF

(25 V)

Cvssp

220 µF

(25 V)

TDA8932B

Class-D audio amplifier

VDD

VSS

Cin

1 µF

Cin

1 µF

VSSA

MUTE

control

SLEEP

control

Cosc

100 nF

Rosc

39 kΩ

Cen

470 nF

V

SSD(HW)

VSSA

ENGAGE BOOT1

POWERUP OUT1

VDDA

VSSA

OSCREF

HVPREF OUT2

Cinref

100 nF

V

SSD(HW)

VSSA

1

IN1P

2

IN1N HVP1

3

DIAG

4

5

6

CGND

7

V

DDA

8

V

SSA

TDA8932B

9

U1

10

11

INREF

12

TEST

13

IN2N HVP2

14

IN2P DREF

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

V

SSD(HW)

OSCIO

V

DDP1

V

SSP1

STAB1

STAB2

V

SSP2

BOOT2

V

DDP2

V

SSD(HW)

Cbo

15 nF

Cstab

100 nF

Cbo

15 nF

Cdref

100 nF

VSS

Cvssp

100 nF

VSS

VDD

Cvddp

100 nF

Cvssp

100 nF

VDD

VSSA

Cvddp

100 nF

Llc

Rsn

10 Ω

Csn

470 pF

Llc

Rsn

10 Ω

Csn

470 pF

VSSA

Clc

Clc

001aaf606

Fig 39. Typical simplified application diagram for 1 × BTL (symmetrical supply)

15. Test information

15.1 Quality information

The

General Quality Specification for Integrated Circuits, SNW-FQ-611

TDA8932B_3 © NXP B.V. 21 June 2007. All rights reserved.

Product data sheet Rev. 03— 21 June 2007 40 of 48

is applicable.

Page 41

NXP Semiconductors

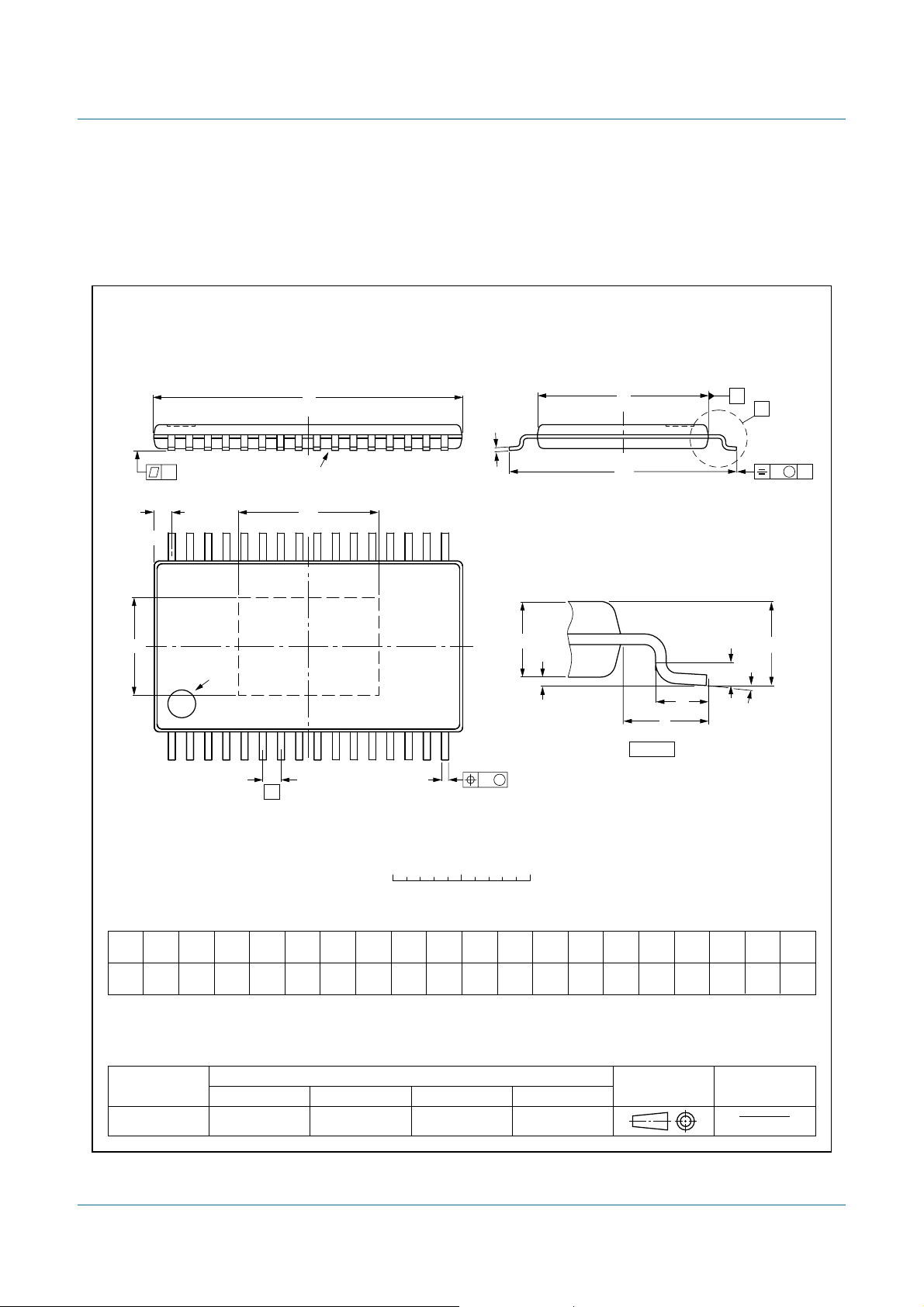

16. Package outline

TDA8932B

Class-D audio amplifier

SO32: plastic small outline package; 32 leads; body width 7.5 mm

D

c

y

Z

32

pin 1 index

1

e

17

16

w M

b

p

SOT287-1

E

H

E

A

2

A

1

detail X

A

X

v M

A

Q

(A )

L

p

L

A

3

θ

0 5 10 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

UNIT

inches

Note

1. Plastic or metal protrusions of 0.15 mm (0.006 inch) maximum per side are not included.

A

A1A2A3b

max.

0.3

mm

2.65

0.1

OUTLINE

VERSION

SOT287-1 MO-119

0.1

0.012

0.004

2.45

0.25

2.25