Page 1

NXP Semiconductors

Application Note

Document Number: AN5251

Rev. 1, 04/2018

S32R27/37 Hardware Design Guide

by: NXP Semiconductors

Contents

1 Introduction

The S32R is a 32-bit heterogeneous multi-core microcontroller

family primarily intended for use in computationally intensive

automotive RADAR applications. The device family

incorporates Power Architecture® cores arranged as two

independent e200z7260 for general computation and the

S32R274 device also features an e200z420 core with an

e200z419 checker core running in delayed lockstep

configuration for safety-critical and housekeeping tasks. The

family integrates high-performance signal processing features

designed to support sophisticated automotive RADAR

applications, and the S32R274 also integrates high accuracy

analog features to further enhance it's ability to interface with

a wide range of RADAR RF devices.

This application note illustrates the S32R family power supply

options and details the external circuitry required for power

supplies, oscillator connections, and supply decoupling pins. It

also discusses configuration options for clock, reset, ADC

modules and the RADAR analog front-end, as well as

recommended debug and peripheral communication

connections (including MIPI-CSI2) and other major external

hardware required for the device.

The S32R family requires multiple external power supplies to

operate. The main cores internal logic requires a 1.25 V power

supply. This can be supplied from an external source or on

some devices this can alternatively be provided by an internal

DC-DC regulator that requires a dedicated supply. 3.3 V is

1 Introduction.............................. .............................. 1

2 S32R family package options

overview.................................................................. 2

3 Power supply...........................................................3

4 Clock configuration...............................................15

5 Device reset configuration............... .....................17

6 Recommended debug connectors and

connector pin-out definitions.................... ............ 18

7 ADC overview........................... ........................... 22

8 RADAR analog front end..................................... 23

9 Example communication peripheral

connections.......................................... ................. 29

10 High speed layout considerations..........................48

A Revision History................................................... 49

Page 2

S32R family package options overview

required for the general purpose I/O, flash memory, analog front-end, external communications interfaces, and on-chip SAR

analog to digital converter.

2 S32R family package options overview

The S32R family is available in multiple device and package options that are suited to development, debug and commercial

production.

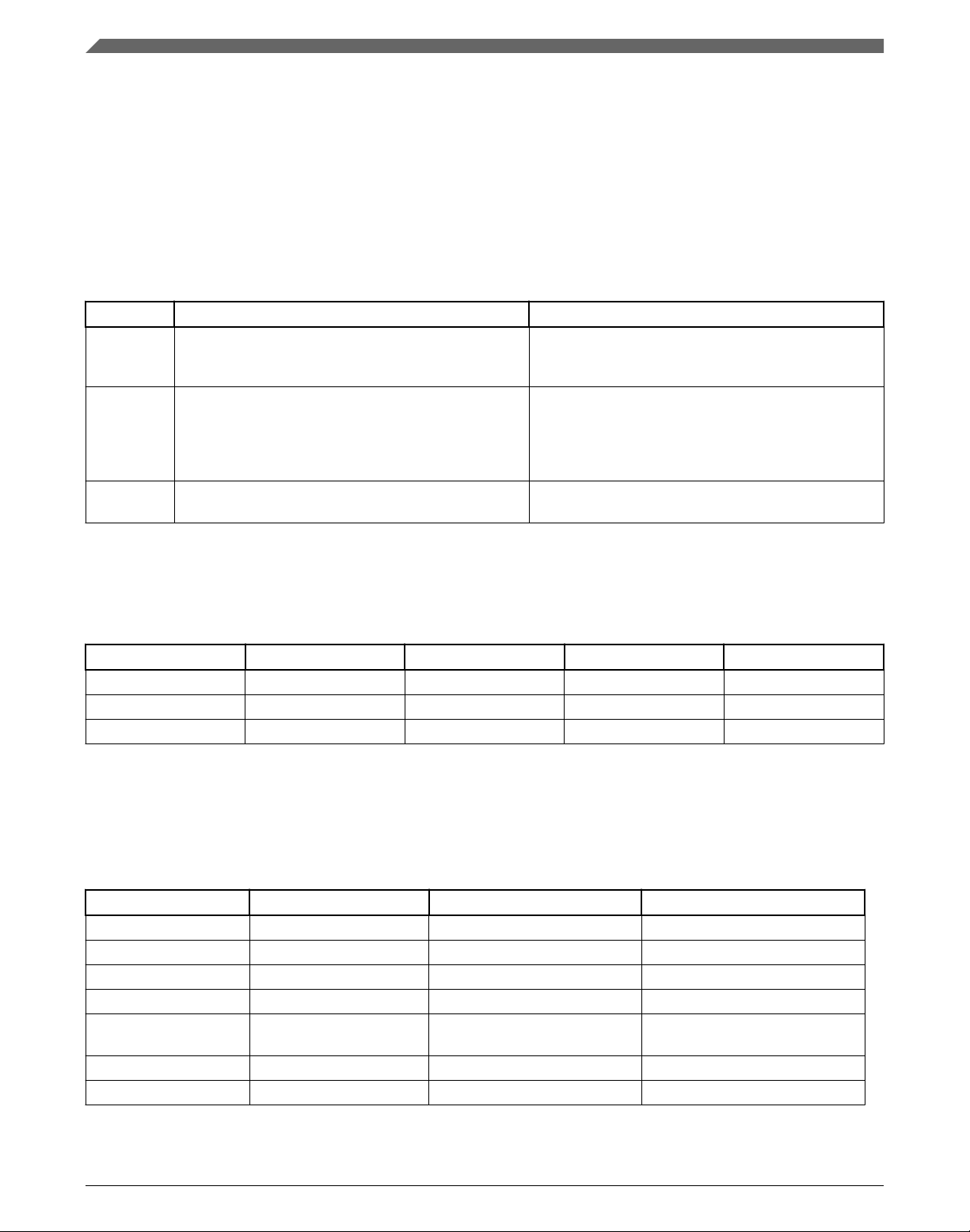

Table 1. S32R package description

Device Package Description

S32R274 257 Map ball grid array (MAPBGA) Full support for all device modules and features

including JTAG and Nexus High Speed Aurora Trace

debug interfaces.

S32R372 257 Map ball grid array (MAPBGA) Full support for all device modules and features

including JTAG and Nexus High Speed Aurora Trace

debug interfaces. Pin compatible with S32R274,

although with reduced feature set. See Table 3 below

for details.

S32R372 141 Map ball grid array (MAPBGA) Reduced support for some device modules and

features. See Table 3 for details of reduced features

The table below shows the physical dimensions of the packages. See the device data sheet for complete package dimensions

and ball placement. Drawings are also available on nxp.com, search for the case outline number shown in Table 2.

Table 2. Package sizes

Device Package Physical Size Case Outline Number Pitch

S32R274 257 MAPBGA 14 x 14 mm 98ASA00081D 0.8 mm

S32R372 257 MAPBGA 14 x 14 mm 98ASA00081D 0.8 mm

S32R372 141 MAPBGA 10 x 10 mm 84ASA00768D 0.65 mm

The table below shows the main differences between the S32R family, including the different available packages. This list

only references the differences that have a hardware impact. For full details of all differences between the various devices

please see the relevant device reference manuals.

Table 3. Feature Differences Between Packages

Feature S32R274 S32R372 257 MAPBGA S32R372 141 MAPBGA

SD-ADC 4x SD-ADC None None

DAC Yes None None

MIPI CSI2 4 Lanes + Clock 2 Lanes + Clock 2 Lanes + Clock

Ethernet Yes, up to RGMII interface. None None

Wave Generator Module

(WGM)

LINFlexD Yes, 1 module Yes, 1 module None

FlexPWM 1 module, 12 channels 1 module, 12 channels 1 module, 11 channels

Yes None None

Table continues on the next page...

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

2 NXP Semiconductors

Page 3

Power supply

Table 3. Feature Differences Between Packages (continued)

Feature S32R274 S32R372 257 MAPBGA S32R372 141 MAPBGA

SPI 2 modules 2 modules 2 modules, some chip selects not

available. See device muxing

sheet for details.

IIC 2 modules 2 modules 1 module (IIC1 only).

Serial Inter-Processor

Interface (SIPI)

System Timer Module

(STM)

System Timer Module

(STM)

FlexRay 1 module None None

FlexCAN 1x FlexCAN, 2x FlexCAN-FD2x FlexCAN-FD 2x FlexCAN-FD

Yes None None

3 modules x 4 channels 2 modules x 4 channels 2 modules x 4 channels

eTimer_0: 6 channels,

eTimer_1: 6 channels

eTimer_1:6 channels eTimer_1:5 channels

Device Power Supply Internal or External

regulation modes

Internal or External regulation

modes

External regulation mode only

3 Power supply

The S32R family of microcontroller units have a robust power management infrastructure that enables applications to select

among various user modes and to monitor internal voltages for high- and low-voltage conditions. The monitoring capability

is also used to ensure supply voltages and internal voltages are within the required operating ranges before the

microcontroller can exit the reset state and enter operation.

The microcontroller offers a DC-DC voltage regulator function as part of the power management controller (PMC) module.

This regulator can be used to supply the digital low voltage required for the internal logic and other low voltage supplies. The

device can be configured to use either this internal regulation mode or an external 1.25 V regulated power supply to provide

the core voltage. The standard configuration utilizes the internal DC-DC voltage regulator, with the following external supply

voltages:

• 3.3 V for main general purpose I/O, SAR ADC supply and reference, JTAG debug interface, flash memory supply

voltage and external communication interfaces (Ethernet, FlexRay, etc.)

• 3.13 - 5.5 V (required) for the internal DC-DC voltage regulator which supplies 1.25 V for the internal logic, PLL

circuits and low voltage/Nexus Aurora I/O, and MIPI-CSI2.

Detailed information on the power management configurations can be found in the Power management controller section.

1

1. Not available on the S32R372 141BGA Package.

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

NXP Semiconductors 3

Page 4

Power supply

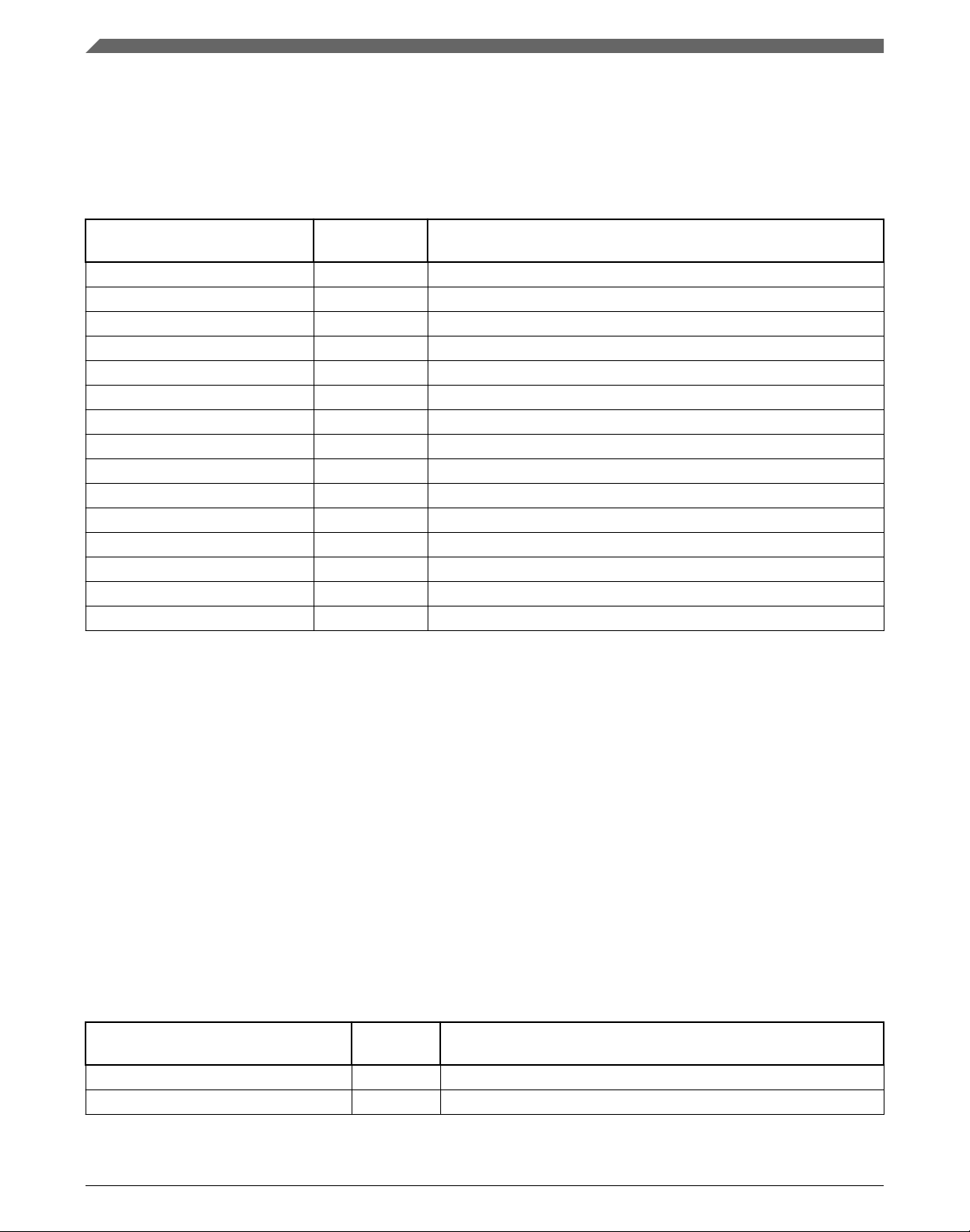

3.1 Power supply signals and decoupling

Table 4 lists all MCU power domains with corresponding pin names. Depending on the power management configuration,

some of the supplies below may not require an external power source. The power management configuration is detailed in

Power management controller.

Table 4. MCU power supply pins

Domain name Supply

Voltage

VDD_LV_CORE 1.25 V Low-voltage supply for core logic

VDD_HV_IOx 3.3 V High-voltage supply for general purpose I/O

VDD_HV_RAW 3.3 V High-voltage, high fidelity supply for analog front-end block

VDD_HV_DAC

VDD_HV_ADC 3.3 V Voltage supply for SAR ADC module

VDD_HV_ADCREF0/2

VDD_HV_FLA 3.3 V Voltage supply for flash memory

VDD_HV_PMU 3.3 V Voltage supply for power management unit

VDD_HV_IO_PWM

VDD_HV_REG3V8

VDD_LV_LFASTPLL

VDD_LV_IO_AURORA

VDD_LV_PLL0 1.25 V Voltage supply for system PLL

VDD_LV_IO 1.25 V Low voltage supply for general purpose I/O

VDD_LV_DPHY

1. Not present on S32R372 141MAPBGA Package

2. To ensure optimum SAR ADC performance it is recommended to have a ground plane below the VDD_HV_ADCREF0/2

traces.

3. Internal regulation mode. When using external regulation mode, this domain can be tied to VDD_HV_PMU

4. The naming convention VDD_LV_LFASTPLL is equal to VDD_LV_DRFPLL. Not present on S32R372 141MAPBGA

Package

5. VDD_LV_IO_AURORA must be connected to the same voltage supply as VDD_LV_CORE. The supplies must be brought

up simultaneously.

6. Can be supplied from VDD_LV_CORE supply with filtering as recommended below.

1

2

1

1

4

5

6

3.3 V High-voltage supply for DAC module in analog front-end

3.3 V Voltage reference for SAR ADC 0/2

3.3 V Voltage supply for PWM IO

3.13 V - 5.5 V

1.25 V Voltage supply for DigiRF (SIPI/LFAST) PLL

1.25 V Voltage supply for Nexus Aurora I/O

1.25 V Low voltage supply for MIPI-CSI2 DHPY

3

Voltage supply for internal DC-DC voltage regulator

Description

Some of the supplies can be powered with different supply voltages. The internal voltage regulator supply,

VDD_HV_REG3V8, can be supplied with a voltage between 3.13 V and 5.5 V. See the device data sheet for specific

information and to learn what voltage ranges can be safely connected to the power pins.

Table 5 shows all power domains and the suggested decoupling and/or filter capacitors for their corresponding pins. These

values are provided as a guideline and will vary depending on the application and capability of the power supplies used.

The decoupling capacitors must be placed as close as possible to the MCU supply pins, with priority given to those with the

smallest capacitance value.

Table 5. Supply pin decoupling capacitors

Domain name Supply

Voltage

VDD _LV_CORE 1.25 V 0.1 μF x 16, 4.7 μF x 4, 10 μF x 2 (40 μF total)

VDD_HV_IOx 3.3 V 2 x 0.1 μF for each VDD_HV_IO supply

Table continues on the next page...

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

4 NXP Semiconductors

Minimum Decoupling Capacitors

1

2

Page 5

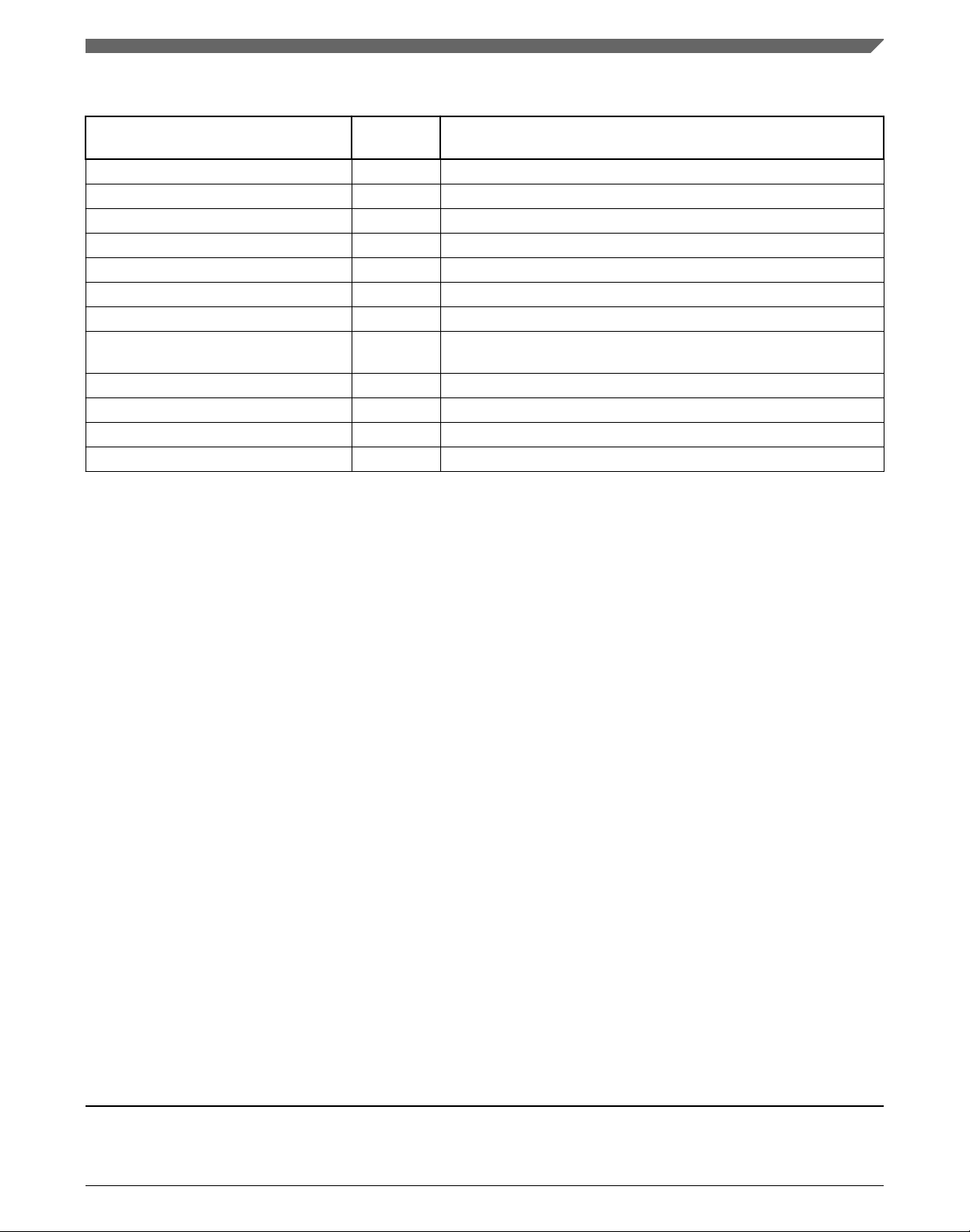

Table 5. Supply pin decoupling capacitors (continued)

Power supply

Domain name Supply

Voltage

VDD_HV_RAW 3.3 V 0.1 μF, 1 μF

VDD_HV_DAC

VDD_HV_ADC 3.3 V 0.1 μF, 1 μF

VDD_HV_ADCREF0/2 3.3 V 0.01 μF, 1 μF

VDD_HV_IO_PWM

VDD_HV_FLA 3.3 V 0.1 μF, 1000 pF

VDD_HV_PMU 3.3 V 100 nF, 4.7 μF

VDD_HV_REG3V8

VDD_LV_DRFPLL

VDD_LV_IO_AURORA 1.25 V 0.1 μF, 1 μF

VDD_LV_PLL0 1.25 V 1000 pF, 0.1 μF, 1μF, 0.01 μF

VDD_LV_DPHY 1.25 V Ferrite bead, >5 μF, 100 nF, 1000 pF

1. When using internal regulation mode, assure that the total capacitance (accounting for temperature variations) never falls

below 40 μF

2. External capacitors for the IO pins are dependent on the application.

3. Not present on S32R372 141BGA Package

4. When device is configured in external regulation mode and supply is connected to VDD_HV_PMU. For internal regulation

mode see SMPS external component configuration

3

3

3

3

3.3 V 1000 pF, 0.1 μF, 1 μF

3.3 V 2x 0.1 μF for each supply

3.13 V - 5.5

V

1.25 V 1000 pF, 0.1 μF, 1 μF, 0.01 μF

Minimum Decoupling Capacitors

1 μF Ceramic

4

The device has several pins for the connection to external decoupling capacitors for the analog front-end. Details of these can

be found in RADAR analog front end

3.2

Decoupling capacitors layout priority

When trade-offs must be made in the schematic layout, it is important to ensure that the highest priority supplies have

decoupling capacitors placed as closely as possible to the MCU. The list below outlines the recommended order of the

supplies from highest to lowest priority in terms of their importance for decoupling.

1. VDD_HV_RAW & VDD_HV_DAC

2. VDD_HV_ADCREF0/2

3. VDD_HV_ADC

4. VDD_LV_PLL0

5. VDD_LV_DPHY

6. VDD_LV_CORE

7. VDD_LV_AURORA

8. VDD_HV_PMU

9. VDD_HV_FLA

10. VDD_LV_LFASTPLL

2

11. VDD_LV_IO

12. VDD_HV_PWM

3

13. VDD_HV_IO

2. Not present on S32R372 141MAPBGA Package

3. Not present on S32R372 141MAPBGA Package

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

NXP Semiconductors 5

Page 6

Power supply

Highest priority is given to the high-fidelity analog front end supplies VDD_HV_RAW and VDD_HV_DAC, as their

decoupling must be prioritized to maintain analog signal integrity. VDD_HV_ADRREF0, VDD_HV_ADREF1, and

VDD_HV_ADC is the SAR analog-to-digital converters reference and power supply decoupling. Clean supplies are vital to

ensure that the highest accuracy is achieved with the ADCs. The supply for the system PLL is prioritized as this helps to

ensure reliable and stable operation from the internal PLL circuit.

Medium priority is given to VDD_LV_CORE, VDD_LV_DRFPLL, VDD_LV_AURORA, VDD_HV_PMU,

VDD_LV_DPHY and VDD_HV_FLA. VDD_LV_CORE is the main supply for the on-chip digital logic and this is

prioritized as it affects the largest amount of logic on the device. VDD_LV_AURORA powers the high speed Nexus Aurora

pins and noise on this domain would affect the quality of the output. VDD_HV_PMU is the power management unit supply

and VDD_LV_DPHY is the MIPI-CSI2 DPHY supply. The MIPI-CSI2 DPHY is a high speed module which requires

minimal noise in order to acheive the specified performance levels. VDD_HV_FLA is the input supply for the flash memory.

A good supply to the flash memory ensures reliable flash programming and erasing.

VDD_LV_LFASTPLL powers the PLL for the LFAST/SIPI communication interface. 4 VDD_HV_IO, VDD_HV_PWM,

and VDD_LV_IO drive GPIO and other external communication interfaces. Although it is still important that these supplies

have a clean power signal, the hardware they power is less affected by noise and they are considered of lower priority.

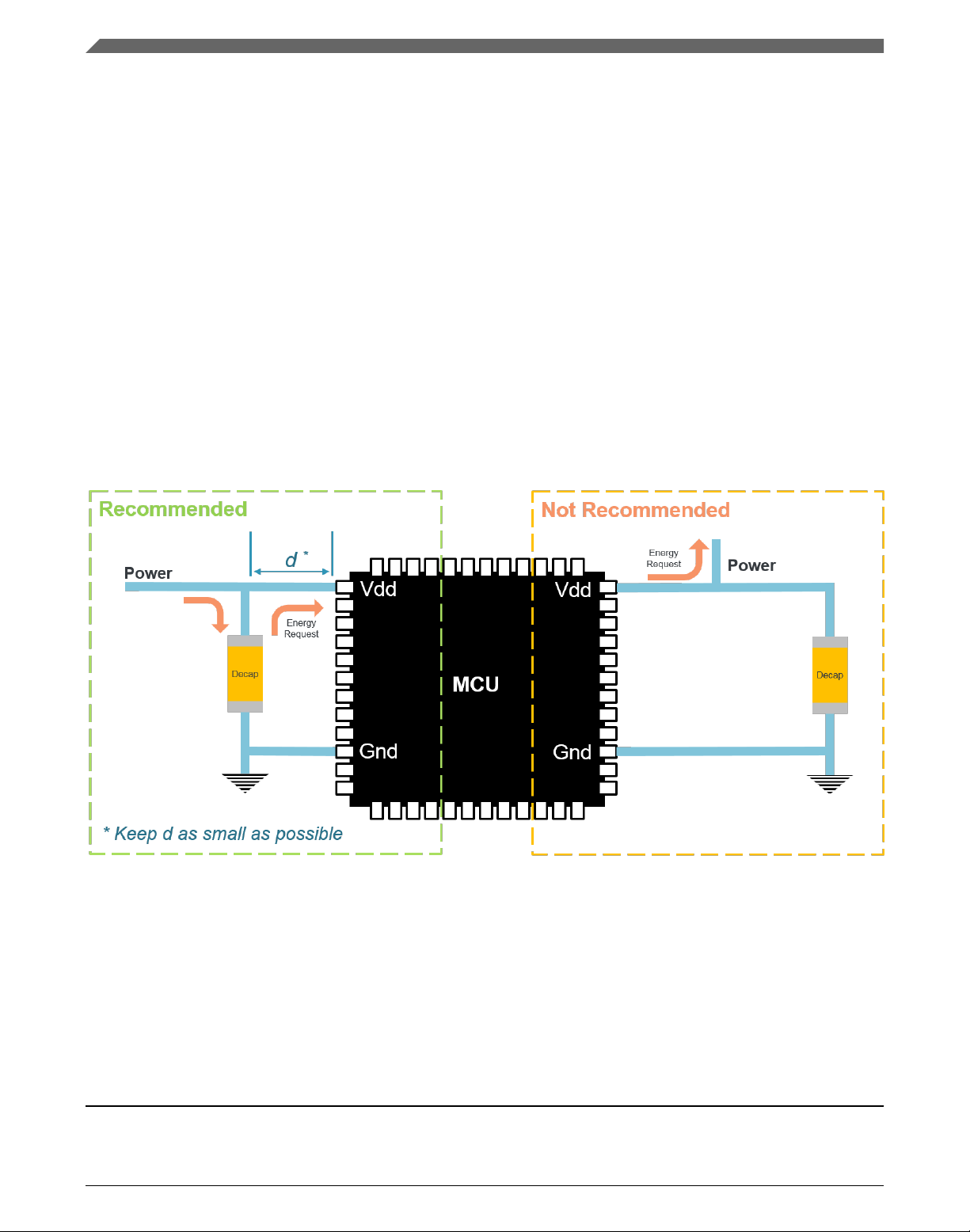

When completing the layout of decoupling capacitors care should be taken to reduce the volume of the space in the

transmission line between the device and the capacitor, which results in faster response to energy requests from the device.

The capacitor should always be the closest to the device so that the energy comes from the capacitor and not from the power

trace, as illustrated in the figure below.

Figure 1. Decoupling capacitor placement recommendation

3.3

The S32R family has a dedicated module for configuration and monitoring of power supplies, enable signals, internal

component trimming, and power-on reset generation. The Power Management Controller (PMC) consists of an analog block

and a supporting digital interface that provides control over the analog components. The PMC chapter in the device reference

manual explores the digital block in depth.

4. This interface is not present on the S32R372 device, but the supply name remains the same for the 257MAPBGA

6 NXP Semiconductors

Power management controller

package to avoid confusion, and is not present on the 141MAPBGA package.

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

Page 7

Power supply

NOTE

This document will focus on the external hardware and connections concerned with the

PMC analog block.

3.3.1 Core supply options

The S32R family offers two options for supplying the 1.25 V used by the core and other low-voltage digital power domains.

• Internal voltage regulation mode, using the integrated DC-DC voltage regulator (VREG)

• External voltage regulation mode using an externally regulated 1.25 V supply

5

The input pin VREG_SEL allows selection between internal and external regulation modes, the function of this input is

described in the table below.

6

Table 6. VREG_SEL input signal

Input Level Core Supply Mode

High (3.3 V) Internal regulation mode

Low (GND) External regulation mode

The PMC has an internal voltage regulator function that uses a switched-mode power supply (SMPS) circuit to supply the

1.25 V required by the internal core logic, VDD_LV_CORE and the other low-voltage digital supplies

(VDD_LV_AURORA, VDD_LV_PLL0, VDD_LV_DPHY and VDD_LV_IO). The regulator requires the support of

external circuitry detailed in SMPS external component configuration. This configuration is an asynchronous buck regulator

with nominal switching frequency of 1 MHz. The switching frequency may be modulated to improve the EMI performance

of the device, further information on this feature can be found in the PMC chapter in the device reference manual.

VREG_SEL is part of a collection of I/O signals that relate to the VREG operation mode. The other pins are mentioned in the

table below.

Table 7. PMC Voltage regulator signals

Signal Name Direction VREG Enabled (Internal Mode) VREG Disabled (External Mode)

VREG_POR_B Input External power-on reset. If not used it is

recommended to be externally pulled up

to 3.3 V, but can be left floating.

Internally pulled up to 3.3 V.

VREG_ISENS

VREG_SWP

1

1

Input Current sense input to internal regulator Not used. Connect to VDD_LV_CORE

Output Output from internal VREG. Controls the

gate of the external switching PMOS

transistor

2

Power-on reset (POR) input. Used by

external circuitry to trigger a POR or hold

device in reset state. Should be used to

hold device in reset until supplies are

within the ranges described in the device

data sheet.

Not used, can be left floating. Internally

pulled up, do not connect to GND.

1. Not present on S32R372 141MAPBGA package.

2. If the connection between VREG_SWP and the PMOS gate is broken, the switch may fully turn on. For added protection

against this risk, a 100 Kilo Ohm resistor can be connected between VDD_HV_REG3V8 and the PMOS gate.

5. Not supported on S32R372 141MAPBGA package.

6. VREG_SEL pad is internally bonded to GND on S32R372 141MAPBGA package.

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

NXP Semiconductors 7

Page 8

DC-DC

VReg

Board supply 5V -12V

DC-DC

VReg

SWP

SAR ADC

3.3V

low noise

POR

Lin.

VReg

3.3V

low noise

Lin.

VReg

Lin.

VReg

POR_B

DC-DC

VReg

AFE

Internal Lin. VRegs

3.3V

low noise

HV_PMU

3.3V

HV_REG_3V8

3.13V - 5.5V

LV_DRFPLL

LV_PLL0

LFAST

PLL

System

PLL

HV_ADCREF0/2

HV_ADC

1.25V

HV_DAC

HV_RAW

LV_IO_AURORA

NEXUS

AURORA

See "SMPS

External

Component

Configuration"

LV_DPHY

MIPI

CSI2

HV_FLA

HV_IOx

ISENS

LV_CORE

1.25V, 1.8A

HV_IO_PWM

Power supply

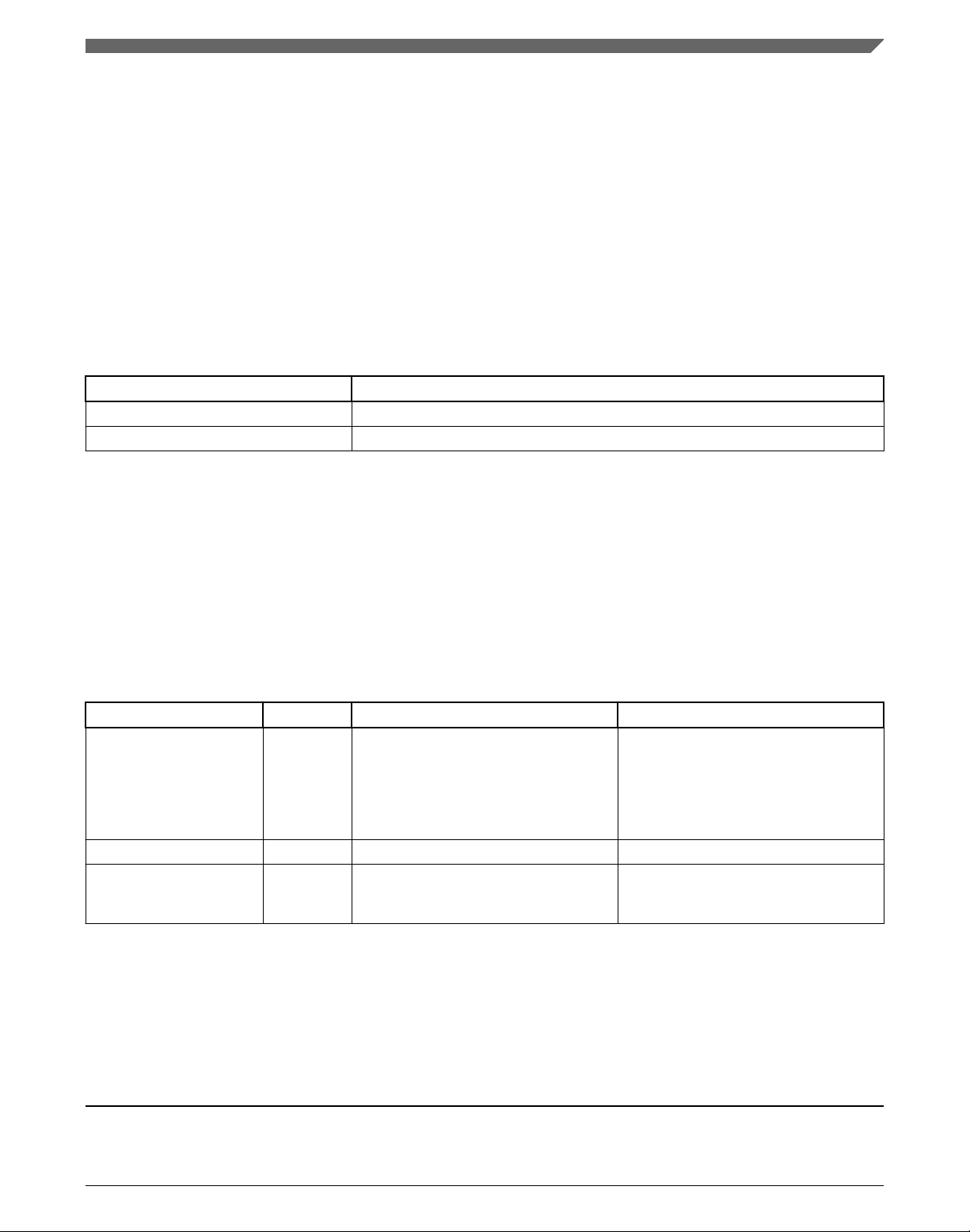

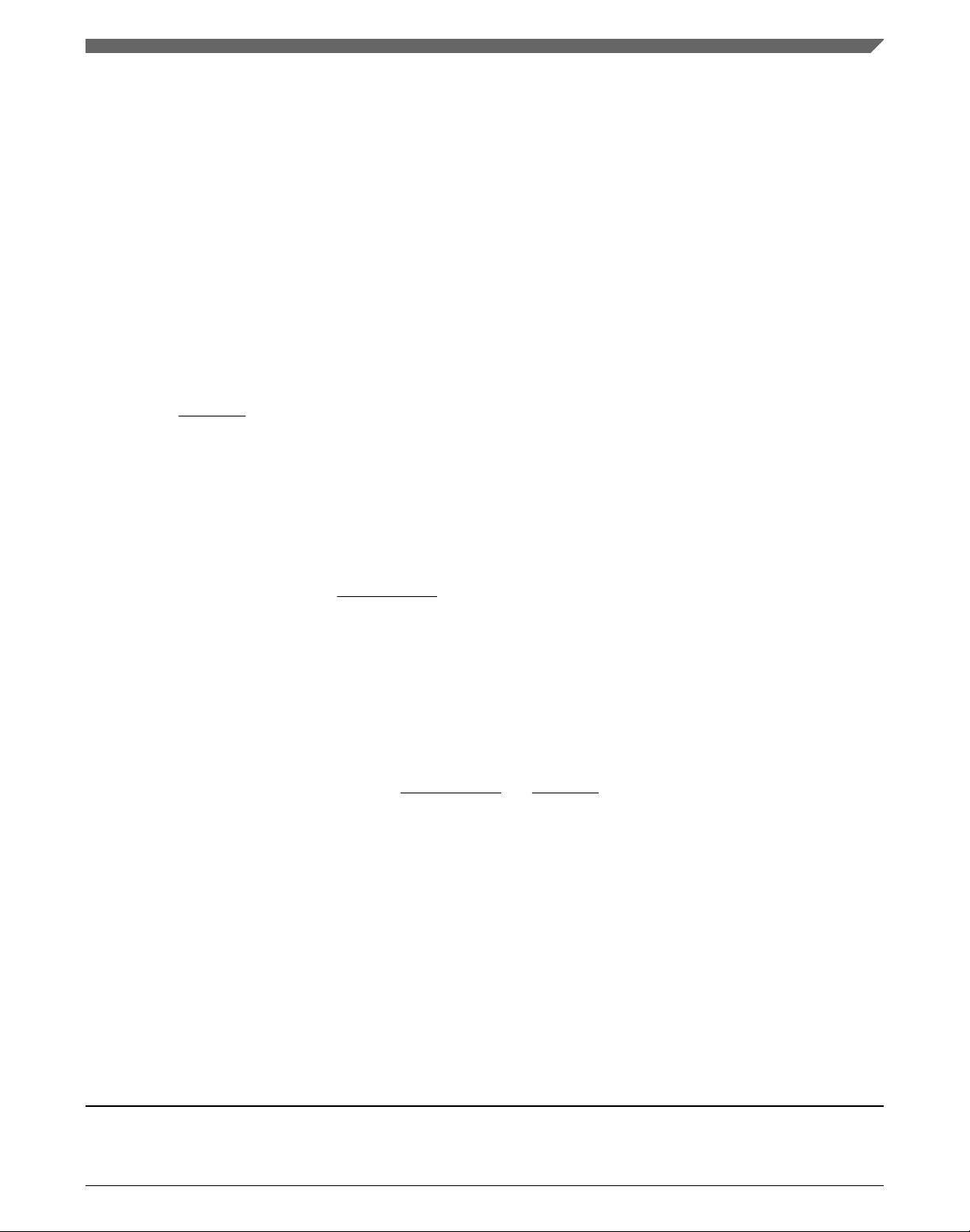

3.3.2 Internal voltage regulator supply mode

The standard device configuration for the S32R family 257 MAPBGA packages uses the internal DC-DC voltage regulator to

supply the core voltage and other low-voltage digital supplies. Figure 2 shows all the power supply connections required

when operating in internal voltage regulation mode and also provides guidelines on how to structure the power nets. Values

for the decoupling capacitors shown in the figure are listed in Table 5.

Figure 2. Supply connections

The internal regulator requires a dedicated 3.13 V - 5.5 V supply alongside the 3.3 V PMC supply to generate the 1.25 V

digital low voltage. The support of an external PMOS switch circuit is also required, details are given in SMPS external

component configuration. The analog front-end (AFE) requires high-fidelity supplies and careful decoupling to support its

sensitive analog functionality, covered in RADAR analog front end.

Internal regulation mode is enabled by driving the VREG_SEL input high and has the following attributes.

• The PMC internal power-on-reset (POR) and low-voltage/high-voltage detect (LVD/HVD) circuits are enabled by

default.

• The internal POR will keep the device in reset until all the monitored supplies have reached their minimum operation

threshold.

• The internal POR function means that the external POR pin VREG_POR_B is not needed. As such, it is internally

pulled up to the PMC supply voltage. It can be left floating or alternatively connected to 3.3 V.

• VREG_POR_B remains active in internal regulation mode, even though POR is managed internally. If pulled low it

will cause a power-on reset regardless of voltage regulation mode.

• The internal LVD/HVD circuits are by default enabled to ensure the expected boot-up sequence occurs. More

information on the LVDs/HVDs is available in Low-Voltage (LVD) and High-Voltage Detection (HVD).

• Use a single Linear VREG to supply both VDD_HV_RAW and VDD_HV_DAC. Both supply pins must have the

recommended filtering as described in Table 5 and have separate routes (star route) of roughly equal length to the

Linear VREG.

• Either ramp VDD_HV_IO and VDD_HV_PMC together or ramp VDD_HV_IO before VDD_HV_PMC such that the

two supplies always maintain 100 mV or less difference when using internal regulation mode.

• VDD_HV_IO, VDD_HV_IO_RGMII, VDD_HV_IO_PWM and VDD_HV_IO_LFAST supplies should be treated as a

single supply from a board perspective.

7

8 NXP Semiconductors

7. VREG_POR_B can be used in internal regulation mode to ensure that the POR sequence is only started when main

power supply reaches a stable regulation point. This can assist in cases where the power supply reaches the

minimum LVD threshold but then drops below the threshold again when loaded, before reaching a stable regulation

point.

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

Page 9

Power supply

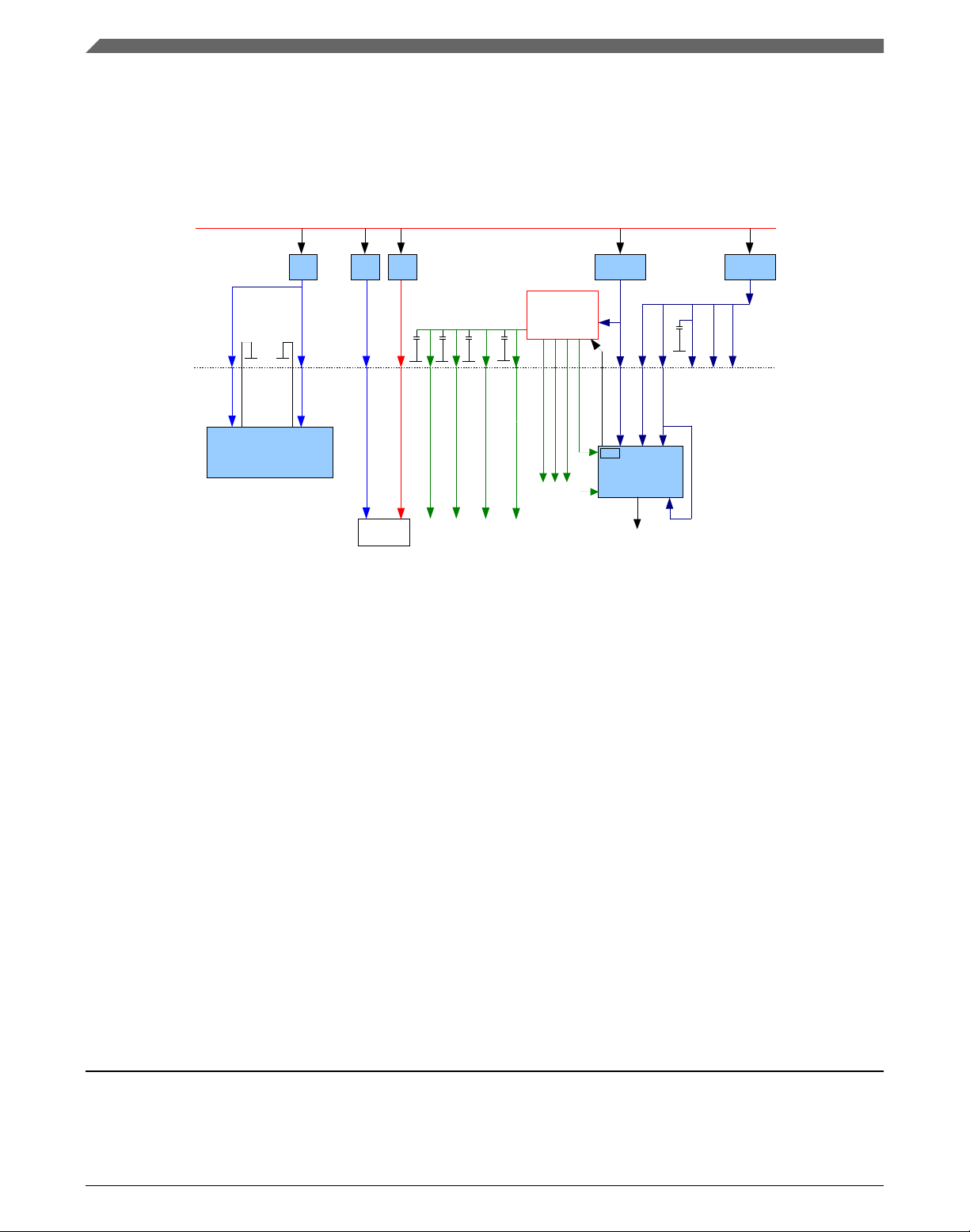

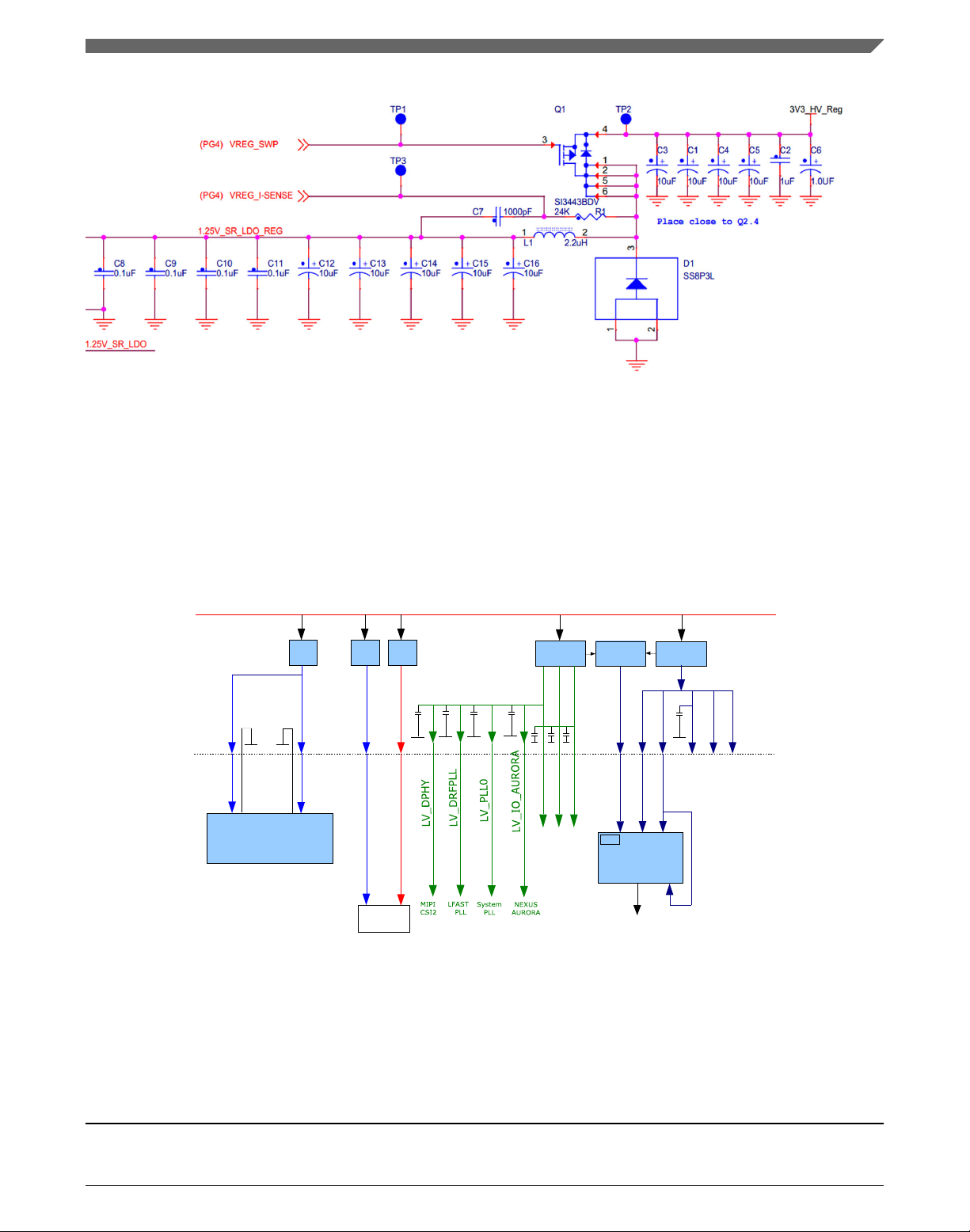

3.3.3 SMPS external component configuration

When operating in internal voltage regulation mode, an SMPS circuit is required along with the support of external

components in order to minimize noise and maintain a stable supply to guarantee device performance. Special care must be

taken so that the switched regulator does not introduce noise into high-fidelity analog components. The external component

layout is shown in Figure 3.

Figure 3. SMPS external components layout

Table 8 provides recommended values for the external components.

Table 8. External component values

Component Label Recommended Value

M1 SI3443, 2SQ2315

L1 2.2 μH 3A <100 mΩ series resistance (E.g. Bourns SRU8043-2R2Y)

D1 SS8P3L 8A Schottcky diode

R1 24 kΩ

C1 10 μF ceramic

Table continues on the next page...

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

NXP Semiconductors 9

Page 10

Power supply

Table 8. External component values (continued)

Component Label Recommended Value

C2 100 nF ceramic

C3 100 nF ceramic (place close to inductor)

C4 10 μF ceramic (place close to inductor)

C5 1 nF ceramic

C6 4x 100 nF + 4x 10 nF ceramic (place close to MCU supply pins)

C7 4x 10 μF ceramic (place close to MCU supply pins)

C8 100 nF ceramic (place close to MCU supply pins)

C9 1 μF ceramic (place close to MCU supply pins)

1. These are the same capacitors as those listed for VDD_LV_CORE in Table 2

For optimum electro-magnetic interference (EMI) performance, it is critical that the inner and outer loops shown in Figure 3

overlap on the PCB and are made as short as possible. It is highly recommended to have a section of the PCB ground plane

dedicated to making a good connection between the grounds of C1/C2 and C3/C4. This measure will help to ensure that the

loops are made as short as possible.

The role of C1/C2 is to guarantee a low input impedance to the buck converter. In a similar manner, C3/C4 make the

impedance low at the buck converter output. This measure helps reduce the high frequency content of the current passing

through the highlighted branch 'Iload', making it less critical that the buck converter components be placed close to the

VDD/VSS pins of the MCU. However, it is important that capacitors C6 and C7 are placed as closely as possible to the

VDD/VSS pins of the MCU, as they guarantee the low impedance of the core MCU supply and also help to reduce the high

frequency content of the 'Iload' path.

1

The gate-driver circuitry also forms important current loops that must be minimized (not shown in Figure 3). For that

purpose, C8/C9 must be placed as close as possible to the gate-driver supply pins. The ground connections for C8/C9 must be

made as short as possible to C1/C2. When the PMOS switch is turned on, the high-frequency current that charges the gate

comes from C1/C2, passing through the PMOS gate into the gate-driver pin. That current is carried to the gate-driver VSS pin

returning to C1/C2. This current loop must be made as small as possible.

Conversely, when the PMOS switch is turned off, high-frequency currents enter in the PMOS gate coming from the gatedriver pin and flows into C1/C2, returning through the ground into C8/C9 and then into the gate-driver supply pin.

Minimizing this second loop area is as critical as the first.

To shield nearby nets from the gate-driver generated noise, it is also recommended that the gate-driver supply pins are used

to shield the VREG_SWP net until it reaches the PMOS switch. Nets on other PCB layer should avoid running parallel to this

net.

The figure below is a circuit schematic showing an example SMPS circuit derived from the above guidelines. For best

performance, use the component values recommended in Table 8.

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

10 NXP Semiconductors

Page 11

DC-DC

VReg

Board supply 5V -12V

SAR ADC

3.3V

low noise

POR

Lin.

VReg

3.3V

low noise

Lin.

VReg

Lin.

VReg

POR_B

DC-DC

VReg

AFE

Internal Lin. VRegs

3.3V

low noise

HV_PMU

3.3V

HV_REG_3V8

HV_ADCREF0/2

HV_ADC

1.25V

HV_DAC

HV_RAW

DC-DC

VReg

HV_FLA

HV_IOx

LV_CORE

1.25V, 1.8A

HV_IO_PWM

External

Monitor

Power supply

Figure 4. Example schematic of SMPS external components

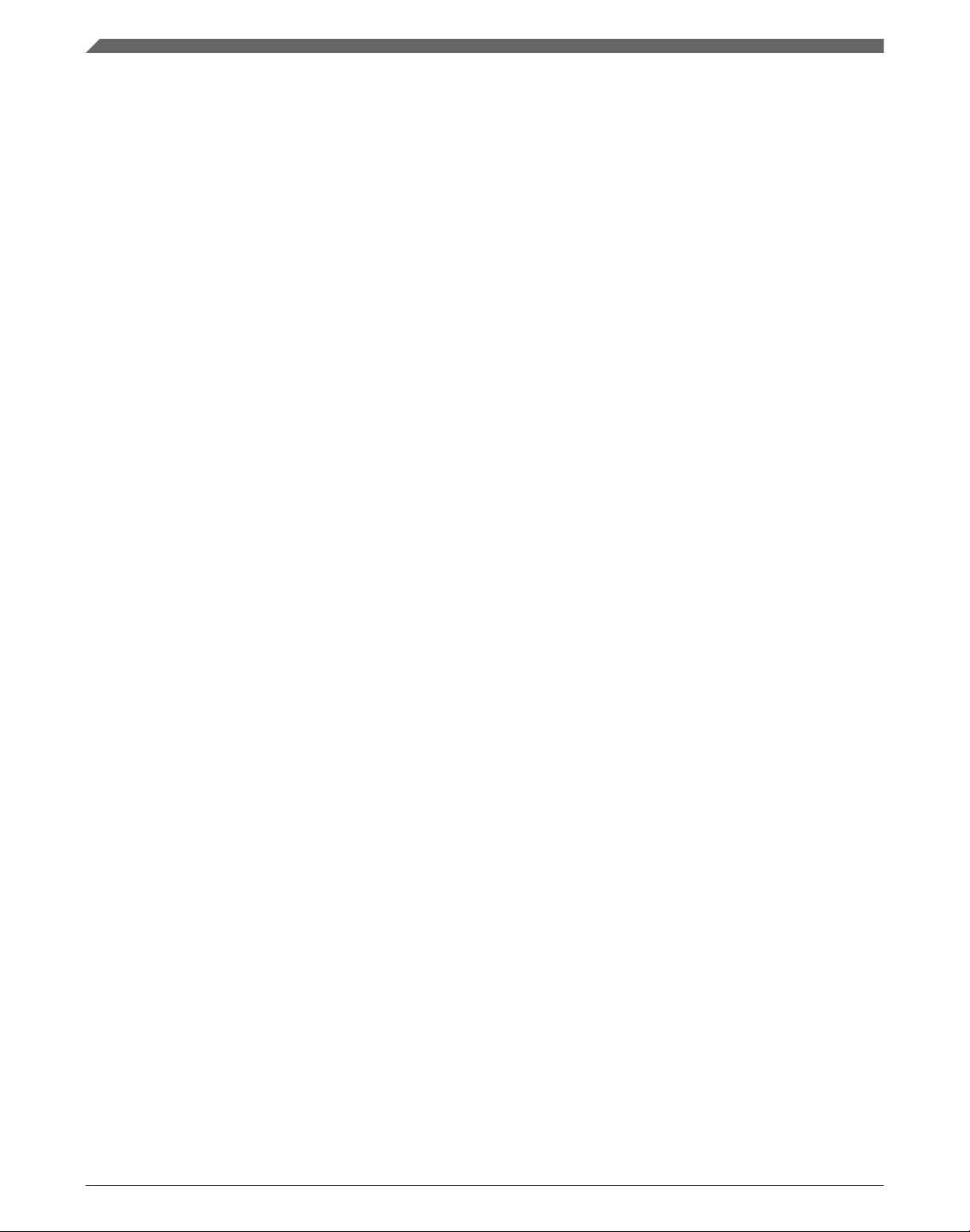

3.3.4 External supply mode

If there is a stable 1.25 V regulated supply available to provide the digital low voltage, the internal voltage regulator can be

disabled. This also negates the need for the external SMPS circuit. An overview of the power connections required for such a

configuration is shown in Figure 5. This is the default and only configuration for the S32R372 141MAPBGA packaged

device, due to the reduced pin count.

This mode of operation can be selected by driving the VREG_SEL pin low.8 This disables the internal:

• Voltage regulator (VREG)

• VDD_LV POR function (can be enabled by software)

• VDD_LV LVD/HVD circuits (can be enabled by software)

8. Not required on S32R372 141MAPBGA package as VREG_SEL is internally bonded to GND

NXP Semiconductors 11

Figure 5. Supply connections

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

Page 12

Power supply

When internal regulation is disabled, the signals VREG_ISENS and VREG_SWP are not needed as they are for feedback and

control of the SMPS circuitry. VREG_ISENS should be connected to VDD_LV_CORE and VREG_SWP is internally pulled

up, so should be left floating.

In external regulation mode, the supply for the internal voltage regulator, VDD_HV_REG3V8, can be connected to the same

supply voltage as VDD_HV_PMU.

Use a single Linear VREG to supply both VDD_HV_RAW and VDD_HV_DAC. Both supply pins must have the

recommended filtering as described in Table 5 and have separate routes (star route) of roughly equal length to the Linear

VREG.

VDD_HV_IO, VDD_HV_IO_RGMII, VDD_HV_IO_PWM and VDD_HV_IO_LFAST supplies should be treated as a

single supply from a board perspective.

VDD_LV POR and LVD/HVD is the responsibility of the external regulation circuit. The device must be kept in reset

(VREG_POR_B driven low) during power-up until all supplies have reached their minimum operating threshold and also

during operation if any of the supplies move outside the specified range, as defined in the device data sheet. To achieve this,

external LVD/HVD circuits are needed to monitor the supplies. After power-up, the internal LVDs/HVDs can be enabled by

software to act as a second tier of detection and provide power supply information to the software.

9

3.4

The S32R family has the capability to monitor selected supply voltages internally. This section concerns only with the

internal monitoring functions for POR and LVD/HVD. The external POR and LVD/HVD circuit behavior will vary and

should be designed using the device data sheet as reference. From this point, it is assumed that internal regulation mode is

being used unless where explicitly stated. In external regulation mode, the internal POR and LVD/HVD are disabled by

default but can be enabled by software after power-up.

The function of the POR and LVD circuits is to hold the device in reset as long as the supply voltages to the LVD circuits are

below the minimum operating voltage. The device is held in reset until the point at which the supplies cross the lower

threshold and the POR and LVDs are released.

3.4.1

The internal LVD and HVD circuits monitor whether the voltage on the corresponding supply is below or above defined

values and either assert a reset or an interrupt. The LVDs/HVDs also support hysteresis for the falling and rising trip points.

Although there is an option to disable the LVDs and HVDs following reset, they are capable of being used in a ‘monitor’

only mode and are also capable of generating a safe/interrupt event. The LVDs/HVDs can also be configured after device

initialization to prevent reset when a supply crosses the LVD threshold, providing a higher voltage range. An application then

must verify the device remains in the functional range.

Supply monitoring

Behavior of LVD / HVD

NOTE

The LVDs that form the power-on reset functionality, monitoring VDD_LV_CORE and

VDD_HV_PMU, cannot be disabled. These modules are used during power-up phase and

must ensure that an absolute lowest threshold of operation is never crossed. This is not a

guarantee that the device will function down to this level. It is rather a guarantee that the

device will recover if this level is crossed.

9. Not required on S32R372 141MAPBGA package as these signals are internally bonded.

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

12 NXP Semiconductors

Page 13

Power supply

3.4.2 Low-Voltage (LVD) and High-Voltage Detection (HVD)

The internal LVD circuits monitor whether the voltage on the corresponding supply is below defined values and either assert

a reset or an interrupt, while the HVD circuits monitor to ensure a supply does not exceed an upper voltage limit. The LVDs/

HVDs also support hysteresis in the falling and rising trip points.

• All LVDs and HVDs are capable of generating either a reset or an interrupt based on configuration, with the exception

of two POR threshold monitors

• LVD monitoring the internal core voltage (VDD_LV_CORE) always generates a reset when triggered.

• LVD monitoring the PMC voltage supply input (VDD_HV_PMU) always generates a reset when triggered.

• All LVDs and HVDs configured for reset generation cause functional or destructive reset. Reset is not exited until all

destructive reset conditions are cleared.

• The appropriate bits in the PMC status registers are set by LVD and HVD events.

• LVD and HVD control is protected by the SoC-wide register protection scheme. Therefore, it is configurable as long as

the scheme is followed.

• There are user option bits available to allow degrading of “configurable” LVDs/HVDs from destructive down to

functional reset. This is a write once mechanism managed by SSCM during device initialization.

• When the LVD or the HVD is enabled for destructive reset generation, then when a trigger event is detected, the

external RESET_B pin is driven low.

Please refer to the device data sheet for LVD and HVD characteristics.

10

:

3.4.3 Power-on reset

The power management controller (PMC) controls the internal power-on reset (POR) signal for the MCU. POR is the

combination of all internal POR signals from the analog PMC block. When the critical power supplies are below minimum

levels (internal regulation mode) or the VREG_POR_B pin is driven low, the MCU is held in the POWERUP phase of the

reset state machine, POR asserted, until the power supplies have reached specified levels. When the required voltage levels

are reached, POR is deasserted and is input to the reset generation module (MC_RGM) which propagates the device through

the next steps of the boot process.

The PMC has internal POR low voltage detect (LVD) circuits to detect the minimum critical power supply voltages required

to operate the internal voltage regulator, including hysteresis. It monitors:

• The voltage on the 1.25 V supply input, VDD_LV_CORE

• The 3.3 V signal used internally by the PMC, VDD_HV_PMU

Once both these supply voltages are above the threshold the internal POR signal will deassert. See Device reset configuration

and the Reset chapter in the reference manual for VREG_POR_B and RESET_B pin functionality.

3.5

The device is considered to be in a power sequence (POWER-UP state) when the device is either not supplied or is partially

supplied. An internal power-on reset (POR) signal is used to identify POWER-UP state. This signal is released on exit of the

power sequence. The power-on reset signal is a combination of LVD monitoring of the VDD_LV_CORE and

VDD_HV_PMU supplies. The exit from the next phase, PHASE0, depends on the release of the secondary LVD/HVD

circuits, which monitor:

Power sequence

• VDD_LV_PLL0

• VDD_HV_IO

• VDD_HV_FLA

• VDD_HV_ADC

10. As mentioned previously, the internal POR management is disabled by default when external regulation mode is

selected. They cannot be disabled when operating in internal VREG mode.

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

NXP Semiconductors 13

Page 14

Power supply

Once they have reached the minimum operating threshold the device will exit reset. For more information on phases of the

reset process, please refer to the Reset chapter in the device reference manual.

The actual threshold use for each internal LVD depends on the configuration of the device. This is configurable by hardware

(flash option bits content) or by software (LVD event configuration through PMC register interface). Once the power-on

signal has been asserted, the device configuration is reset to default power-up configuration. During the initialization phase,

the device defaults to a pre-determined state for each of the LVDs, HVDs, and the internal regulators. As the flash memory

becomes available, the differential read process allows the trimmed data to be available for trimming the internal LVDs,

HVDs, and regulators.

3.5.1 Power-up sequence

In this section, the assumption is made that all supplies are low when entering the power-up sequence. Brown-out and power

down sequences are specified in further sections below.

There are simple power sequencing rules to follow in order to correctly power-up the device:

• The system PLL supply (VDD_LV_PLL0) and the core supply (VDD_LV_CORE) must be powered simultaneously. It

is recommended to connect them to the same voltage supply.

• The high-voltage I/O supply (VDD_HV_IO) and the Power Management Unit supply (VDD_HV_PMU) must be

powered simultaneously or VDD_HV_IO ramped before VDD_HV_PMU such that the two supplies always maintain

less than 100 mV difference during the power ramp. They can be connected to the same voltage supply.

• If VDD_HV_DAC and VDD_HV_RAW are supplied by 2 separate regulators, the following must be met:

• For RAW or DAC ramp rates less than 1ms, VDD_HV_DAC comes on no earlier than 500 us before

VDD_HV_RAW.

• for RAW or DAC ramp rates greater than 1ms, VDD_HV_DAC is below 2.0V at the time VDD_HV_RAW

reaches 1.0 V.

• Alternatively VDD_HV_DAC and VDD_HV_RAW can be supplied from the same regulator, providing adequate

decoupling is provided as described in Power supply signals and decoupling

• For the S32R274 device the SD ADCs must be powered before a signal is applied to their inputs, to ensure protection

of the input channels from overdrive signal levels. To do this, ramp VDD_HV_RAW supply before applying input to

the SD ADCs.

All power supplies should ramp at slew rates within the ranges recommended in the device data sheet. For recommended

supply groupings for the S32R372 devices please see the device data sheet power sequencing requirements section.

3.5.2

If the threshold of the configurable monitor LVDs is crossed and they are configured to generate a destructive reset, the

device re-enters the PHASE0 phase. The power-down sequence is started and the device enters the POWER-UP state as soon

as the threshold of one of the POR LVDs (monitoring VDD_LV_CORE and VDD_HV_PMU) is crossed. The device

supplies may then proceed to drop down to ground either through device leakage or external pull-down.

3.5.3

During brown-out, the device re-enters the POWER-UP phase as soon as the threshold of either POR VDD 1.2 V or APOR is

crossed.

Power-down sequence

Brown-out management

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

14 NXP Semiconductors

Page 15

XOSC

40MHz

1-2ps Jitter

Bypass:

40MHz

FMPLL_1

VCO:600-

1250MHz

IRCOSC

16MHz

Cryst

40MHz

SDPLL

320MHz

IRC_CLK

PLL_CLK0

PLL_CLK1

PLL_0

VCO: 600-

1250MHz

OSC

40MHz

XOSC_CLK

SDPLL_CLK

AFE

XTAL

EXTAL

Clock configuration

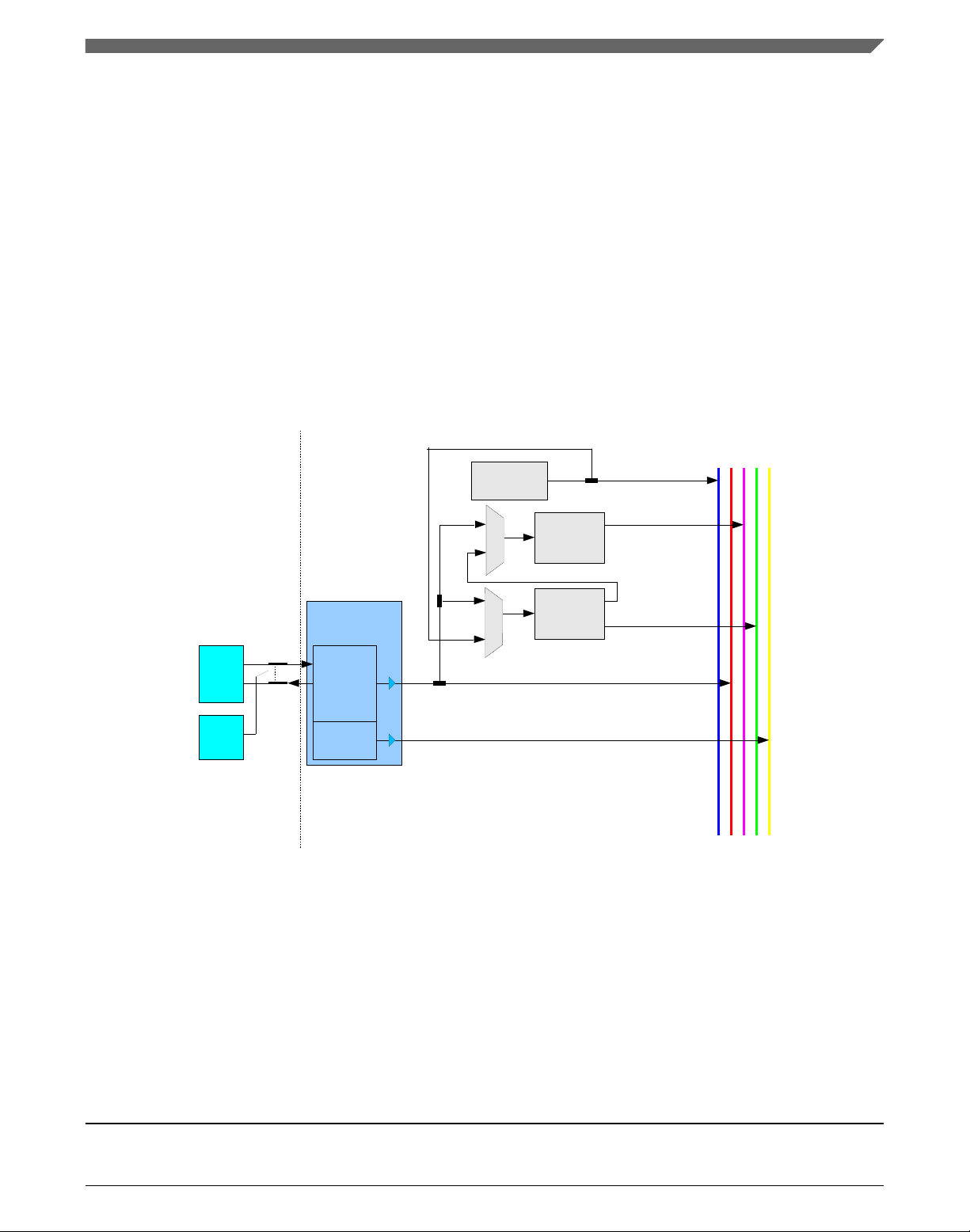

4 Clock configuration

The S32R family system reference clock can be sourced in three ways: using the internal RC oscillator (IRCOSC),

connecting an external crystal or connecting an external oscillator (XOSC). To use XOSC, an external 40 MHz crystal or

oscillator must be connected through the XTAL and EXTAL pins. XTAL and EXTAL pins also support differential LVDS

clock inputs. Information on how to do this can be found in Connecting external clock sources. IRCOSC or XOSC is used as

the clock source for the internal phase-locked loops (PLL) to generate the high frequency clocks for the cores and

peripherals.

This structure provides five different clock domains that are available as the source for system and peripheral clocks:

• IRCOSC - 16 MHz internal reliable RC oscillator

• XOSC - 40 MHz oscillator (using external crystal (XTAL) or external oscillator in bypass (EXTAL))

• PLL0 - up to 240 MHz PLL

• PLL1 - up to 240 MHz frequency-modulated (FM) PLL

• SDPLL- 320 MHz11 PLL for the Sigma-Delta ADC

Figure 6. S32R family clock sources

During power up, the IRCOSC is the default clock for the system. In normal operation, software can then configure each of

the system components to use one of the clock domains as the clock source. The dual PLL must be enabled by software and

can provide separate system and peripheral clocks. PLL0 is the primary PLL driven by the reference clock and used to

provide a clock to the device modules. PLL1 is a frequency-modulated PLL (FMPLL) driven by PLL0 and is used to provide

the system clock. Alternatively, XOSC can be used to drive PLL1.

The most important aspects of an accurate clock source require that some care be taken in the layout and design of the

circuitry around the crystal and PLL power supplies. Any noise in these circuits can affect the accuracy of the clock source to

the PLL. The power supply for the PLL is taken from VDD_LV_PLL0. Noise on this supply can affect the accuracy and

jitter performance of the PLLs. In order to minimize any potential noise, it is recommended that the additional capacitors

recommended in Table 5 are fitted to the VDD_LV_PLL0 supply.

11. Divided by 2 (160 MHz), and 4 (80 MHz) if used for system and peripheral clocks

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

NXP Semiconductors 15

Page 16

XTAL EXTAL

Crystal

S32R27X / S32R37X

XTAL EXTAL

S32R27X / S32R37X

40MHz

Clock

Clock configuration

4.1 Connecting external clock sources

The S32R family features internal load capacitance on the XTAL and EXTAL pins for connecting external clock sources.

This feature is intended to simplify the design and reduce the overall system cost by eliminating external components and

reducing the PCB footprint. See the device data sheet for details on the internal capacitance values. PCB designers must take

into account the parasitic capacitance levels on the signal lines connecting an external oscillator to the XTAL and EXTAL

pins in order to avoid frequency deviation. Generally, for a crystal with load capacitance of 8 pF, a capacitance figure of 12

pF on the signal lines connected to both XTAL and EXTAL will result in good oscillator performance. Choose a crystal with

a Q factor of > 25,000.

A diagram for the connection of an external 40 MHz crystal oscillator is shown in the figure below.

Figure 7. External oscillator connection

The oscillator should be placed as close as possible to the MCU. In order to minimize signal degradation, the circuitry should

be placed entirely on only one PCB layer, avoiding unnecessary vias where possible. Do not allow any signals to cross the

crystal connections to the device. Absolutely no high current or high speed signals should be run near any of the crystal

components.

Other than the connections shown in the above schematics, no other connections should be made to the crystal or EXTAL

and XTAL device pins. Do not use XTAL to drive any other circuitry than shown.

If an external single clock source is being used as clock reference to the MCU, then the XTAL pin should be left floating and

the clock should be provided to EXTAL as shown in the figure below. Note that the clock source should be a low voltage

signal, please ensure any source meets the specifications detailed in the device data sheet for the input signal to avoid

potential damage to the device.

Figure 8. External clock connection (Single Ended Bypass Mode)

In order to use a differential LVDS clock input for the device, the device offers 100 Ω internal termination resistance between

EXTAL and XTAL pins. For differential operation positive clock should be connected to XTAL and negative to EXTAL

pins, and if the clock is a differential voltage source then AC coupling capacitors of 0.01 uF should be used, as shown in the

figure below. Care should be taken during PCB design to avoid vias, and ensure that all differential pairs are trace and

impedance matched, and also follow differential pair best practices as detailed later in the document.

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

16 NXP Semiconductors

Page 17

S32R27X / S32R37X

S32R27X / S32R37X

Device reset configuration

Figure 9. External clock connection (Differential LVDS AC Coupled Mode)

Figure 10. External clock connection (Differential LVDS DC Coupled Mode)

Using either of these methods to connect an external clock makes it available as the XOSC internal clock source.

5

Device reset configuration

The S32R family of MCU's require only very basic external reset circuitry. External circuitry for device configuration is not

required. The device is configured during reset based on data in stored flash memory.

5.1

The S32R family of devices feature two active-low external reset signals:

RESET_B is a bidirectional reset input/output that indicates if the device is active (high signal) or in reset. It is thus weak

pull-up after the reset sequence has completed, but an external pull up resistor to VDD_HV_IO should also be used. A falling

edge on this pin will trigger a functional reset to the Reset Generation Module (RGM). Forcing this pin low will keep the

device in the last phase of the reset sequence (Phase3[Functional]).

In external voltage regulation mode, VREG_POR_B allows external supply circuits to signal to the MCU when power is

available, so the power-up sequence can begin. It should be forced high when the critical power supplies cross the LVD

threshold.

External reset signals

• Functional reset (RESET_B)

• Power-on reset (VREG_POR_B)

In internal regulation mode, VREG_POR_B is not needed as the POR is managed within the PMC. It is internally pulled up

to the PMC voltage, so it can be left floating. Alternatively, it can be connected to VDD_HV_PMU through a 4.7 Kilo Ohm

pull-up resistor.

Both of these pins operate on the 3.3 V power domain.

12. Note that

reset in the device.

NXP Semiconductors 17

, 12

VREG_POR_B remains active in internal regulation mode. As such, if it is pulled low it will cause a power-on

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

Page 18

Recommended debug connectors and connector pin-out definitions

6 Recommended debug connectors and connector pin-out

definitions

The S32R microcontroller family implements the newly added (in the IEEE-ISTO 5001™-2011 version of the standard) high

speed serial Nexus trace Auxiliary Port that uses the Xilinx™ Aurora physical interface. The Aurora interface allows the

Nexus protocol information to be transmitted serially at a high date rate over one or more Aurora lanes. The Aurora protocol

handles the encoding of the data and stripes the information across the number of lanes available on the device.

Table 9 shows the recommended connectors for different applications for the S32Rxxx Family.

Table 9. Recommended connectors

Connector style Target system part number Connector type

14-pin BERG JTAG only 3M 2514-6002UB JTAG-only configuration

17-position (2 × 17, 34-pin) Samtec Samtec ASP-137973-01 Serial Nexus configuration (supports up

to 8 simplex lanes, less lanes are

available if duplex support or High

Speed Calibration LFAST interface

support is required)

NOTE

Whichever connector is chosen, "keep-out" areas may be required by some tools. Consult

the preferred tool vendor to determine any area that must remain clear around the debug

connector. Some tool vendors may include an extension cable to minimize "keep-out"

areas, but use of an extension will degrade the signal. In many cases, this degradation will

be insignificant, but it depends on many factors including clock frequency and target

board layout.

6.1

Table 10 shows the pinout of the recommended JTAG connector to support the S32R device family.

The recommended connector for the target system is Tyco part number 2514-6002UB.

S32R Family JTAG connector

Table 10. Recommended JTAG connector pinout

Description Pin Pin Description

TDI 1 2 GND/VSS

TDO 3 4 GND/VSS

TCK 5

EVTI0 7 8 VREG_POR_B

RESET_B 9 10 TMS

VREF/VDD 11 12 GND/VSS

EVTO0 13 14 JCOMP

1

6 GND/VSS

1. If LBIST is enabled, an external pull resistor between 1 Kilo and 100 Kilo Ohm must be connected between TCK and either

VDD/VSS to avoid LBIST failures

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

18 NXP Semiconductors

Page 19

Recommended debug connectors and connector pin-out definitions

Figure 11. Diagram of the JTAG connector pinout

6.2

For high speed Nexus Aurora trace applications, the Samtec™ ERF8 Series connector is recommended in the IEEE-ISTO

5001™-2011 standard. For the S32R family, the 17 position (34 pins) connector is recommended. The part number of the

Samtec connectors are shown in Table 11.

S32R family high-speed Nexus serial trace connector

Table 11. Recommended high-speed serial trace connector part numbers

Connector Part number (Samtec) Style Description

HS34 ASP-137973-01 Samtec ERF8 Series, 17

position by 2 row

HS34 ASP-177706-02 Samtec ERF8 Series, 17

position by 2 row

The Samtec ERF8 series of connectors is intended for high speed applications requiring a minimum footprint size with a

reliable, latching connection. The recommended connector has two rows of seventeen contacts each with a spacing of 0.8

mm. The connector provides isolation between the high-speed trace signals and the low-speed JTAG and control signals. It

also provides ample ground connections to ensure signal integrity. If at all possible, the connector should be placed onto the

target system with the even numbered pins nearest the edge of the printed circuit board. It is also recommended that the

"even" side of the connector be mounted closer to the edge of the printed circuit board to facilitate a direct connection to the

tool.

Figure 12 is courtesy of Samtec U.S.A.

Vertical mount for MCU

module

Right Angle mount for MCU

module

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

NXP Semiconductors 19

Page 20

Recommended debug connectors and connector pin-out definitions

Figure 12. Recommended Nexus connector

Table 12 shows the recommended pinout for the Samtec connector.

Table 12. S32R family high-speed serial trace connector

Function Pin No Pin No Function

TX0+ 1 2 VREF

TX0- 3 4 TCK/TCKC/DRCLK

VSS 5 6 TMS/TMSC/TxDataP

TX1+ 7 8 TDI/TxDataN

TX1- 9 10 TDO/RxDataP

VSS 11 12 JCOMP/RxDataN

TX2+ 13 14 EVTI1

TX2- 15 16 EVTI0

VSS 17 18 EVTO0

TX3+ 19 20 VREG_POR_B

TX3- 21 22 RESET_B

VSS 23 24 VSS

1

(TX4+)

1

(TX4-)

VSS 29 30 VSS

1

(TX5+)

1

(TX5-)

VSS GND GND VSS

25 26 CLK+

27 28 CLK-

31 32 EVTO1/RDY

33 34 N/C

1. Reserved for TXn signals, not currently used.

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

20 NXP Semiconductors

Page 21

+

–

+

–

Clock

transmitter

100 Ω

On-chip

receiver

In target

system

+

–

+

–

Tool

+

–

+

–

Aurora

receiver

Aurora

transmitter

Two to four Aurora

lanes are supported.

On-chip

circuitry

100 pF

100 pF

100 Ω

100 Ω

Recommended debug connectors and connector pin-out definitions

6.3 Nexus Aurora target system requirements

The Nexus Aurora interface requires termination and AC coupling of the signals between the target system and the tool. The

termination resistor for the Aurora clock is located inside the MCU. An external termination resistor is required. The transmit

termination resistor must be implemented in the target system; however, it may be implemented internal to the FPGA of the

tool.

Figure 13. Nexus Aurora termination and coupling circuits

6.4

Next to the connector, additional circuitry is required for the Nexus/JTAG debug circuitry. The S32Rxxx devices include

internal pull devices that ensure the pins remain in a safe state. However, if there is additional circuitry connected to the

Nexus/JTAG pins, or long traces that could be affected by other signals (due to crosstalk from high-current or high-speed

signals), a minimum number of external pull resistors can be added to ensure proper operation under all conditions.

Minimum external circuitry

Table 13. Optional external pullups/downs

Nexus/JTAG signal Resistor/capacitor direction and

value

JCOMP 4.7 kΩ pulldown Holds debug port in reset and prevents

VREG_POR_B 4.7 kΩ pullup See External reset signals for details

RESET_B 4.7 kΩ pullup See External reset signals for details

Nexus CLKP & CLKN 10 pF on the signal lines The LVDS Nexus clock signals require a

any debug commands from interfering

with the normal operation of the MCU

capacitor for high speed functionality

EVTI 4.7 kΩ pullup A pullup resistor prevents debug mode

from being forced after reset if debug

mode is enabled (JCOMP = high). It also

prevents breakpoints from being forced if

debug mode is enabled.

Description

NXP Semiconductors 21

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

Page 22

ADC overview

Table 13. Optional external pullups/downs

Nexus/JTAG signal Resistor/capacitor direction and

value

NOTE:

In addition to the pullup and pulldown resistors, some systems may want to use buffers between the JTAG connector inputs

(JCOMP, TDI, TDO, TMS, EVTI, EVTO, VREG_POR_B, and RESET_B) and the MCU. This will prevent over-voltage

conditions from causing damage to the MCU signals. Normal systems should not require this circuitry, but it is helpful in

systems that can be exposed to improper connections that provide voltages that are outside the operating conditions of the

MCU. A common circuit to use is the Texas Instruments™ SN74CBTLV38615. This device is a bus switch that implements

a bidirectional interface between two terminals with less than 5 Ω of resistance. It should be powered by the same supply that

powers the debug port. The device enable should be connected to ground for the interface to be enabled whenever the debug

port on the MCU is powered. This circuit provides a high impedance to the tool when the debug port is powered off.

7

ADC overview

The S32R274 has two types of analog-to-digital converters (ADCs) that are designed for different applications:

• Two 12-bit Successive-Approximation-Register (SAR) ADCs with a configurable number of channels (up to 16 each)

for voltage and temperature monitoring among other general applications

• Four 12-bit Sigma-Delta (SD) ADC instances for rapid RADAR signal conversions

Description

In almost all situations, a

resistor is not required on this

signal.

The S32R372 device also has two 12-bit SAR ADCs with a configurable number of channels (up to 16 each), but does not

have any SDADC instances.

The SDADC (where applicable) is part of the RADAR analog front-end and is detailed in Sigma-Delta ADC. This chapter

will focus on the SAR ADCs.

The SAR ADCs receive input from 16 multiplexed pins. Please refer to the Power supply section for information on how to

connect the ADC power and reference pins.

Each ADC instance receives input from a number of pins (channels), some of which are multiplexed to share with other ADC

instances. This multiplexing, along with many other attributes of the ADCs, is controlled by configuration registers. Each

ADC instance has an interface to the DMA controller for retrieval of converted data, the FCCU for error handling and the

interrupt controller. Conversions can be triggered by hardware, software or externally:

• A Cross triggering unit (CTU) connected to each ADC allows automatic generation of ADC conversion requests on

user selected conditions without CPU involvement.

• eTimer module provides the capability for external trigger injection to request a conversion.

• The CPU can request a conversion through software

7.1

On the S32R family 257MAPBGA packages there are 16 external analog pins and on the S32R372 141MAPBGA package

there are 6 external analog pins, that act as input channels for the SAR ADCs. They are multiplexed in order to facilitate

sharing of the pins among the ADC instances.

SAR analog input pin multiplexing

There is an analog bypass bit "APC" in the Multiplexed Signal Configuration Register (MCSR) registers of the System

Integration Unit (SIUL2) for the pins to disable the digital circuitry from the analog pins.

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

22 NXP Semiconductors

Page 23

Table 14 gives the analog input pin assignment for the S32R family packages.

Table 14. ADC pin muxing

RADAR analog front end

Channel Number ADC_0 S32R274

and

S32R372

257MAPB

GA PAD

Channel 0 PB[7](GPIO_23) M3 - PB[13]

Channel 1 PB[8]

(GPIO_24)

Channel 2 PC[1]

(GPIO_33)

Channel 3 PC[2]

(GPIO_34)

Channel 4 PE[6]

(GPIO_70)

Channel 5 PE[2]

(GPIO_66)

Channel 6 PE[7]

(GPIO_71)

Channel 7 PE[4]

(GPIO_68)

Channel 8 PE[5]

(GPIO_69)

Channel 9 PMC_to_ADC - - - - - Internal

Channel 10 Bandgap

Reference PMC

Channel 11 PB[9]

(GPIO_25)

Channel 12 PB[10]

(GPIO_26)

Channel 13 PB[11]

(GPIO_27)

Channel 14 PB[12]

(GPIO_28)

Channel 15 TSENS0 - - TSENS1 - - Internal

N1 - PB[14]

N3 - PB[15]

P1 - PC[0]

M4 K2 - - - External

R1 L2 - - - External

T1 - - - - External

P3 L1 - - - External

R2 - - - - External

- - Bandgap

T3 - PB[9]

R3 - PB[10]

T2 - PB[11]

U2 - PB[12]

S32R372

141MAPB

GA PAD

ADC_1 S32R274

(GPIO_29)

(GPIO_30)

(GPIO_31)

(GPIO_32)

Reference PMC

(GPIO_25)

(GPIO_26)

(GPIO_27)

(GPIO_28)

S32R372

and

S32R372

257MAPB

GA PAD

J4 H3 External

L1 - External

K4 H2 External

L2 J3 External

- - Internal

T3 - External

R3 - External

T2 - External

U2 - External

141MAPB

GA PAD

Channel Type

8 RADAR analog front end

The S32R microcontroller family integrates a number of high-performance digital and analog subsystems to support the

implementation of next-generation RADAR-based advanced driver assistance systems. The analog front-end (AFE) module

acts as an interface to the control registers for use with the integrated analog hard block, which includes:

• Sigma-delta PLL (SDPLL) producing 320 MHz/160 MHz/80 MHz clocks for AFE components

• Low phase noise, low (1-2ps) jitter 40 MHz oscillator (XOSC)

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

NXP Semiconductors 23

Page 24

Filtered Output

Bus Interface

Decimation

Filters x4

Modulator

Output

x4

14 bits x4

Conversion

Complete x4

Control

Registers

Interrupts

A/D Input

Pairs x4

Crystal

Interface

DAC

Output

Pair

Powers,

Grounds,

Tank

Capacitors

Filter Enables

DAC Data

Clock

Generation

AFE Analog Block

SDPLL Output

320 MHz, 160 MHz,

80 MHz clocks

IPS

RADAR analog front end

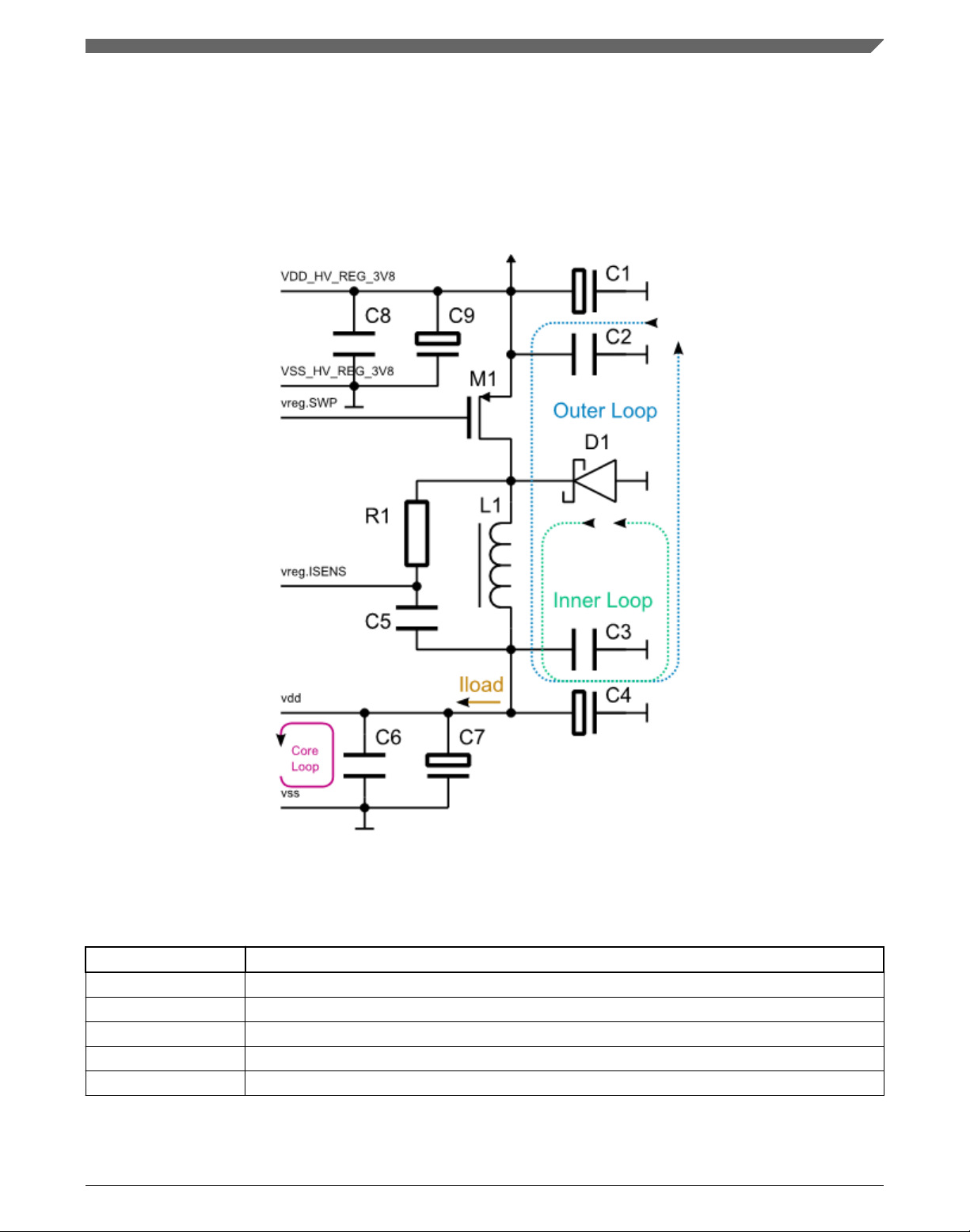

The S32R27X AFE also contains:

• Four continuous time sigma-delta ADCs (SDADC)

• 12-bit high accuracy digital-to-analog converter (DAC)

A diagram of the AFE structure is shown in Figure 14. To support the high accuracy, high dynamic range analog

functionality of the above features, careful configuration of power supplies and external circuitry is required to preserve

signal integrity.

24 NXP Semiconductors

Figure 14. AFE Wrapper block diagram

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

Page 25

RADAR analog front end

8.1 AFE power supplies and external connections

The AFE module requires multiple external connections. These are a mixture of high-fidelity analog power supplies, digital

power supplies, ground connections, external capacitor connections and output signals for the various functions.

Table 15. AFE power supply connections

Name Voltage

Range

VDD_HV_RAW 3.13 V - 3.6 V 3.3 V Connects to 1.4 V regulators for: XOSC, SD PLL and SD

VDD_HV_DAC 3.13 V - 3.6 V 3.3 V Connects to DAC regulator

Domain Function

ADC analog and digital.

The table below shows the pins that the AFE exposes for the connection of external components. The components should be

connected between the pin and ground.

Table 16. AFE external component connections

Pin Name Function Recommended

SD_R External 0.1% trimming resistor for

tuning the ADC resistor array.

VDD_LV_SDCLK External bypass capacitor for LVDS

analog 1.4 V VREG.

VDD_LV_OSC External bypass capacitor for XOSC

analog 1.4 V VREG

VDD_LV_SDPLL External bypass capacitor for SD PLL

analog 1.4 V VREG.

VDD_LV_RADARREF External bypass capacitor for 1.2 V from

the VREF.

DAC_C DAC connection to external cap for

noise filtering.

SD_CM ADC common mode external bypass

capacitor

VDD_LV_SDADC External bypass capacitor for ADC

analog 1.4 V Vreg.

VDD_LV_RADARDIG External bypass capacitor for ADC

digital 1.4 V Vreg.

AFE_FILTER Bypass capacitor for filtered analog

supply

VDD_LV_DAC2V5 Bypass capacitor rampDAC 2.5 V VREG 1.0 μF & 0.1 μF grounded to

40.2 Kilo Ohm +/-0.1%

1.0 μF & 0.1 μF grounded to

VSS_LV_SDCLK

1.0 μF & 0.1 μF grounded to

VSS_LV_OSC

1.0 μF & 0.1 μF grounded to

VSS_LV_SDPLL

1.0 μF grounded to VSS_LV_SDADC

10 μF connected to VDD_HV_DAC

1.0 μF & 0.1 μF grounded to

VSS_LV_SDADC

0.47 μF & 0.1 μF grounded to

VSS_LV_SDADC

1.0 μF & 0.1 μF grounded to

VSS_LV_RADARDIG

1.0 μF & 0.1 μF grounded to

VSS_LV_SDADC

VSS_HV_REGDAC

8.2 Sigma-Delta ADC

The four time-continuous SD ADCs receive input as a differential pair. Each instance has two dedicated input pins.

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

NXP Semiconductors 25

Page 26

RADAR analog front end

Table 17. Sigma-Delta ADC external connections

Name Pin

(257MBGA)

SD_0_ADCN A1 I ADC0 negative input

SD_1_ADCN A2 I ADC1 negative input

SD_2_ADCN A3 I ADC2 negative input

SD_3_ADCN A4 I ADC3 negative input

SD_0_ADCP B1 I ADC0 positive input

SD_1_ADCP B2 I ADC1 positive input

SD_2_ADCP B3 I ADC2 positive input

SD_3_ADCP B4 I ADC3 positive input

AC coupling capacitors should be used at the SD ADC inputs in order to remove any DC bias present and allow the AC

signal to pass through. This ensures that the ADC's operate within their input range. The recommended value for these

capacitors is 0.22μF, as shown in Figure 15.

Direction Function

Figure 15. SD ADC AC coupling capacitors

8.3

The DAC is used to produce analog ramp signals for generation of RADAR waveforms.

Digital-to-Analog Converter

Table 18. DAC signal description

Name Pin (257MBGA) Direction Function

DAC_AN C8 O DAC negative output (current)

Connected to external 300

Ohm resistor

Table continues on the next page...

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

26 NXP Semiconductors

Page 27

S32R274

DAC_AP

DAC_AN

300 Ohm

300 Ohm

RADAR analog front end

Table 18. DAC signal description (continued)

Name Pin (257MBGA) Direction Function

DAC_AP C7 O DAC positive output (current)

Connected to external 300

Ohm resistor

The resistors are required because the DAC output is a current source. Figure 16 shows how to connect the external resistors

to the DAC output pins.

8.4

There are no external connections required for the Sigma-Delta PLL. Information on configuration can be found in the

Analog Front End chapter in the device reference manual.

8.5

Instructions on how to connect an external source to drive the XOSC clock can be found in Connecting external clock

sources.

XOSC_EXTAL F1 C1 I EXTAL analog input

XOSC_XTAL E1 D1 O XTAL analog output

Figure 16. DAC Output Pin Connections

Sigma-Delta PLL

XOSC

Table 19. XOSC external connections

Name Pin (257MBGA) Pin (141BGA) Direction Function

signal

signal

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

NXP Semiconductors 27

Page 28

RADAR analog front end

8.6 AFE pin configuration when not using on-board ADC's and DAC

For an application which utilizes the MIPI-CSI2 interface to provide raw ADC data to the S32R274 device the unused pads

for the on board SD-ADC's and DAC, along with associated supplies must be configured as shown in Table 20 to ensure safe

operation of the device. These connections also apply to the S32R372 257 MAPBGA package since this is pin compatible

and does not contain the on-board ADC's.

Table 20. AFE Pin Requirements when using off-chip ADC/DAC

Pin Number Pin Name Requirement

A1 SD_0_ADCN Connect to SD_0_ADCP and leave floating (or N.C for S32R372)

A2 SD_1_ADCN Connect to SD_1_ADCP and leave floating (or N.C for S32R372)

A3 SD_2_ADCN Connect to SD_2_ADCP and leave floating (or N.C for S32R372)

A4 SD_3_ADCN Connect to SD_3_ADCP and leave floating (or N.C for S32R372)

B1 SD_0_ADCP Connect to SD_0_ADCN and leave floating (or N.C for S32R372)

B2 SD_1_ADCP Connect to SD_1_ADCN and leave floating (or N.C for S32R372)

B3 SD_2_ADCP Connect to SD_2_ADCN and leave floating (or N.C for S32R372)

B4 SD_3_ADCP Connect to SD_3_ADCN and leave floating (or N.C for S32R372)

C1 SD_CM 1 μF Capacitor to Ground

C2 SD_R Can be relaxed to 40k-47k Ohm +/- 10%

C5 DAC_C Not used, leave floating

C7 DAC_AP Not used, leave floating

C8 DAC_AN Not used, leave floating

D4 AFE_FILTER 0.1 & 1 μF Capacitor to Ground

C3 VDD_LV_RADARREF 1uF Capacitor to Ground

D1 VDD_HV_RAW 3.3 V

D2 VSS_HV_RAW Tied to Ground

D8 VDD_HV_DAC 3.3 V

D7 VSS_HV_DAC Tied to Ground

E4 VDD_LV_SDADC 0.47 μF Capacitor to Ground

C4 VSS_LV_SDADC Tied to Ground

D3 VDD_LV_RADARDIG 1 μF Capacitor to Ground

E3 VSS_LV_RADARDIG Tied to Ground

F3 VDD_LV_OSC 0.1 & 1 μF Capacitor to Ground

F2 VSS_LV_OSC Tied to Ground

E1 XOSC_XTAL Differential clock supplied from external differential source + or F1 XOSC_EXTAL Differential clock supplied from external differential source - or +

E2 VDD_LV_SDPLL 0.1 & 1 μF Capacitor to Ground

F4 VSS_LV_SDPLL Tied to Ground

G3 VDD_LV_SDCLK 0.1 & 1 μF Capacitor to Ground

G4 VSS_LV_SDCLK Tied to Ground

Table continues on the next page...

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

28 NXP Semiconductors

Page 29

+

0.47uF

+

0.1uF

3.3V or 5V

1

6

2

7

3

8

4

9

5

DB9F

FB

1

V+

C1-

C2+

C2-

V-

DOUT2

8

Vcc

16

GND

15

DOUT1

RIN1 ROUT1

DIN1

DIN2

ROUT2

0.1uF

SCI_TXDA

SCI_RXDA

MAX3232

SCI_RXDA2

HOST-R2

SCI_TXDA2

HOST-T2

9

HOST-R1

HOST-T1

+

0.47uF

+

0.47uF

+

10

11

12

7

RIN2

14

13

2

4

C1+

3

6

5

Example communication peripheral connections

Table 20. AFE Pin Requirements when using off-chip ADC/DAC (continued)

C6 VDD_HV_DAC_2V5 1 μF Capacitor to Ground

D5 VSS_HV_REGDAC Tied to Ground

H3 VSS_SUB_INPWB0 Tied to Ground

D6 VSS_SUB_INPWB1 Tied to Ground

H4 VSS_SUB_OUTPWB Tied to Ground

9 Example communication peripheral connections

There are a wide range of peripheral pins available on the MCU. Many of these have fairly standard definitions for their use.

This section provides example connections for some of the most commonly used communications peripherals, such as LIN,

FlexCAN, FlexRay, and RS-232 communication interfaces.

9.1

Example RS232 interface

The RS-232 (TIA/EIA-232-F) standard is a fairly common interface that is available on all computers. While this interface is

disappearing, adapters are available to allow the use of RS-232 peripherals through other interfaces, such as USB. RS-232

was intended to be a very low-cost and low-performance interface. This interface was originally specified with signal

voltages of +12 V and –12 V, typically. However, this has been lowered to a typical minimum voltage of +5 V and –5 V in

recent years.

Figure 17 and Table 21 show the typical connections between the serial port of an MCU and the MAX3232-EP RS-232D

transceiver from Texas Instruments http://www.ti.com/. The transceiver operates from either a 3.3 V or a 5 V supply and

includes two charge pumps to generate the output voltages that are required. This device contains two transmit drivers and

two receivers. The charge pumps require four external capacitors.

NXP Semiconductors 29

Figure 17. Typical SCI to RS232 circuit

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

Page 30

Example communication peripheral connections

The commercial grade MAX3232 device is not rated for the full automotive temperature

of -40 to +125° C and is not intended for automotive applications. This circuit should not

be used or populated in a production module intended for automotive use. However, in

many cases, the RS-232 interface is intended only as a development interface; therefore,

the commercial device can be used for prototyping purposes. Texas Instruments does

offer a device option with an operating temperature range of -40 to +85° C. Texas

Instruments has an enhanced version of the device, MAX3232-EP, that is intended for

aerospace, medical, and defense applications. This version is available with an operating

temperature range of –55 to +125° C.

Table 21. Typical RS-232D connector definition

Pin number Description

1 Connect to pin 4 and 6

2 RS-232 TX (Transmit)

3 RS-232 RX (Receive)

4 Connect to pin 1 and 6

5 GND

6 Connect to pin 1 and 4

7 N/C

8 N/C

9 N/C

NOTE

NOTE

N/C pins are not connected. The shell of the connector should be connected through a

ferrite bead to ground.

9.2

Local Interconnect Network (LIN) is a commonly used low-speed network interface that consists of a master node

communicating with multiple remote slave nodes. Only a single wire is required for communication and is commonly

included in the vehicle wiring harness. Figure 18 shows a typical interface implemented using the NXP MC33661 LIN

transceiver.

Example LIN interface

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

30 NXP Semiconductors

Page 31

Control

Receiver

INH

Control

5

GND

7 VSUP

MC33661

LIN Bus

Master Node

Pullup

RXDx

TXDx

VPWR

33K Ω

+5V

10K Ω

GPIO

+5V

Slave Node

12

34

WAKE

WAKE

Master

3

WAKE

2

EN

1

RXD

4

TXD

6

LIN

8

INH

30kΩ

Slope

Control

20 μA

10 μF

1kΩ

Example communication peripheral connections

Figure 18. Typical LIN connections

Table 22 below shows the pins of the MC33661 and their typical connections to an MCU.

Table 22. MC33661 pin definitions and example system connections

Pin number Pin name Pin direction Full pin name MCU or system

1 RXD Output Receive Data

Output

2 EN Input Enable Control MCU GPIO Enables operation

3 Wake Input Wake Input LIN Bus Wake

4 TXD Input Transmit Data Input MCU LIN TXD LIN Transmit Data

5 GND Input Ground System Ground

6 LIN Input/Output LIN Bus LIN bus Bidirectional pin

7 VSUP Input Power Supply Protected battery

Table continues on the next page...

Description

connection

MCU LIN RXD LIN Receive Data

Output to the MCU

of the device

1

Wake enables the

devices out of

sleep mode

Input from the MCU

Device ground

Reference

reference

that represents the

single-wire transmit

and receiver

voltage

This is the power

supply for the

device and is

typically connected

to a nominal 12 V

NXP Semiconductors 31

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

Page 32

Example communication peripheral connections

Table 22. MC33661 pin definitions and example system connections (continued)

Pin number Pin name Pin direction Full pin name MCU or system

connection

8 INH Output Inhibit Output LIN Bus (if master) The Inhibit pin

1. Wake is an optional signal on the LIN connector, but may come directly from a switch.

Description

controls either an

external regulator

to turn on a slave

node or is

connected through

a resistor to the LIN

bus on master

nodes

There is no standard industry-defined LIN connector. NXP uses a 4-pin Molex® connector that allows for the LIN bus pin, a

power supply source (VPWR), a wakeup signal, and a ground reference. Slave nodes will often implement two connectors to

allow a daisy-chain of multiple nodes to be easily implemented. Table 23 shows the NXP pinout.

Table 23. LIN connector pinout recommendation

Function Pin number Pin number Function

LIN Bus 4 3 VPWR

Wake 2 1 Ground

In a typical system, these pins would be used as follows:

• LIN bus—This is the single-wire LIN bus that connects between the master LIN node and the slave LIN nodes.

• VPWR—This connector input can be used as the power input to a slave node. Care should be taken that sufficient

current is available for the total number of LIN slaves that are powered through this connection. In some systems, this

may come from the master LIN node.

• Wake—The Wake signal is typically used for each individual slave node to enable the LIN physical interface of that

node and to consequently enable the power supply (using the INH output) to power up the MCU to perform some

action. For example, when the handle on a car door is lifted, to turn on the MCU that controls a function inside the

vehicle, such as powering a smart dome light or enabling the controls of a smart seat.

• Ground—Ground reference for the module.

Part numbers for the 4-pin Molex Mini-Fit Jr.™ connector are shown in Table 24.

Table 24. Recommended connector part numbers

Description Manufacturer part number

(Molex)

4-pin right-angle connector with flange for target system, tin contacts, with latch 39-29-1048

4-pin right-angle connector with pegs for target system, tin contacts, with latch 39-30-1040

4-pin vertical connector with pegs for target system, tin contacts, with latch 39-29-9042

4-pin right-angle connector with flange for target system, gold contacts, latch 39-29-5043

Mating connector with latch for cable assemblies 39-01-2040

Socket terminal for mating cable assembly 39-00-0077

S32R27/37 Hardware Design Guide, Rev. 1, 04/2018

32 NXP Semiconductors

Page 33

MCU FR_x_TX

MCU FR_x_TXEN

MCU FR_x_RX

MCU GPIO

MCU_GPIO

BP

BM

Vbatt

+5V

+3.3V

+3.3V

+

10 μF

+

10K

47R

47nF

4700 pF

10K

C21

33pF

C21

33pF

+

10 μF

+

4700pF

47R

++

10 μF

47pF

TJA1080ATS/1

TRXD0

11

TRXD1

10

TXD

5