Page 1

AN5426

Hardware Design Guidelines for S32K1xx Microcontrollers

Rev. 3 — December 2018

Contents

1 Introduction

The S32K series further extends the highly scalable portfolio of ARM

Cortex® MCUs in the automotive industry. It builds on the legacy of the KEA

series, whilst introducing higher memory options alongside a richer peripheral

set extending capability into a variety of automotive applications.

With a 2.70–5.5 V supply and focus on automotive environment robustness,

the S32K series devices are well suited to a wide range of applications in

electrical harsh environments. These devices are optimized for cost-sensitive

applications offering low pin-count options.

The S32K series offers a broad range of memory, peripherals, and package

options. They share common peripherals and pin counts allowing developers

to migrate easily within the MCU family or among the MCU families to take

advantage of more memory or feature integration. This scalability allows

developers to standardize on the S32K series for their end product platforms,

maximizing hardware and software reuse and reducing timeto-market.

Following are the general features of the S32K series MCUs:

• 32-bit ARM Cortex-M4 core with IEEE-754 compliant FPU, executing up

to 112 MHz

• Scalable memory footprints up to 2 MB flash and up to 256 KB SRAM

• Precision mixed-signal capability with on chip analog comparators and

multiple 12-bit ADCs

• Powerful timers for a broad range of applications including motor control,

lighting control and body applications

• Serial communication interfaces such as LPUART, LPSPI, LPI2C,

FlexCAN, CAN-FD, FlexIO and so on.

• SHE specification compliant security module

• Single power supply (2.70–5.5 V) with full functional flash program/

erase/read operations

• Functional safety compliance with ISO26262, with internal watchdog,

voltage monitors, clock monitors, memory protection and ECC

®

1 Introduction..........................................1

2 S32K family comparison..................... 1

3 Power supplies.................................... 2

3.1 Bulk and decoupling

capacitors ...............................3

4 Clock circuitry......................................3

4.1 EXTAL and XTAL pins.............3

4.2 Suggestions for the PCB

layout of oscillator circuit......... 4

5 Debug and programing interface....... 5

5.1 Debug connector pinouts........6

5.2 RESET system......................11

6 Analog comparator interface............ 11

7 Communication modules.................. 13

7.1 LIN interface for LPUART

module...................................13

7.2 CAN interface for FlexCAN

module...................................17

7.3 Inter-Integrated Circuit IIC......20

7.4 Ethernet MAC Interface......... 22

8 Quad Serial Peripheral Interface...... 23

9 Unused pins....................................... 26

10 General board layout guidelines.... 27

10.1 Traces recommendations.... 27

10.2 Grounding .......................... 27

10.3 EMI/EMC and ESD

considerations for layout....... 28

11 PCB layer stacking...........................30

12 Injection current...............................31

13 References........................................31

14 Revision history...............................31

Application Note

• Ambient operation temperature range: –40 °C to 125°C

• Software enablement: S32 Software Development Kit (SDK), S32 Design Studio (S32DS)

S32K family comparison

2

Please refer to the latest version of the Reference Manual for details.

Page 2

NXP Semiconductors

3 Power supplies

The power and ground pins are described in subsequent sections.

Power supplies

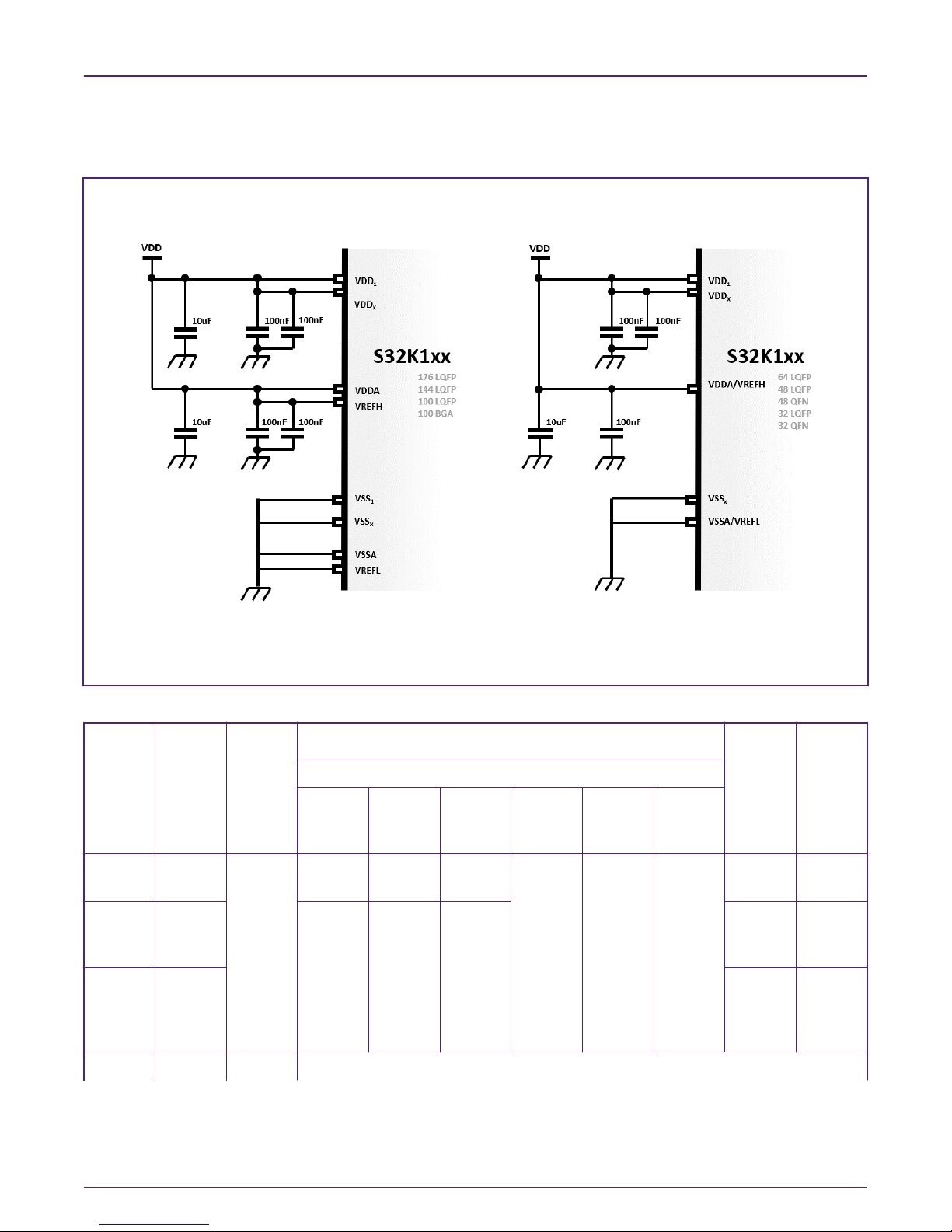

Figure 1. Power supply pins

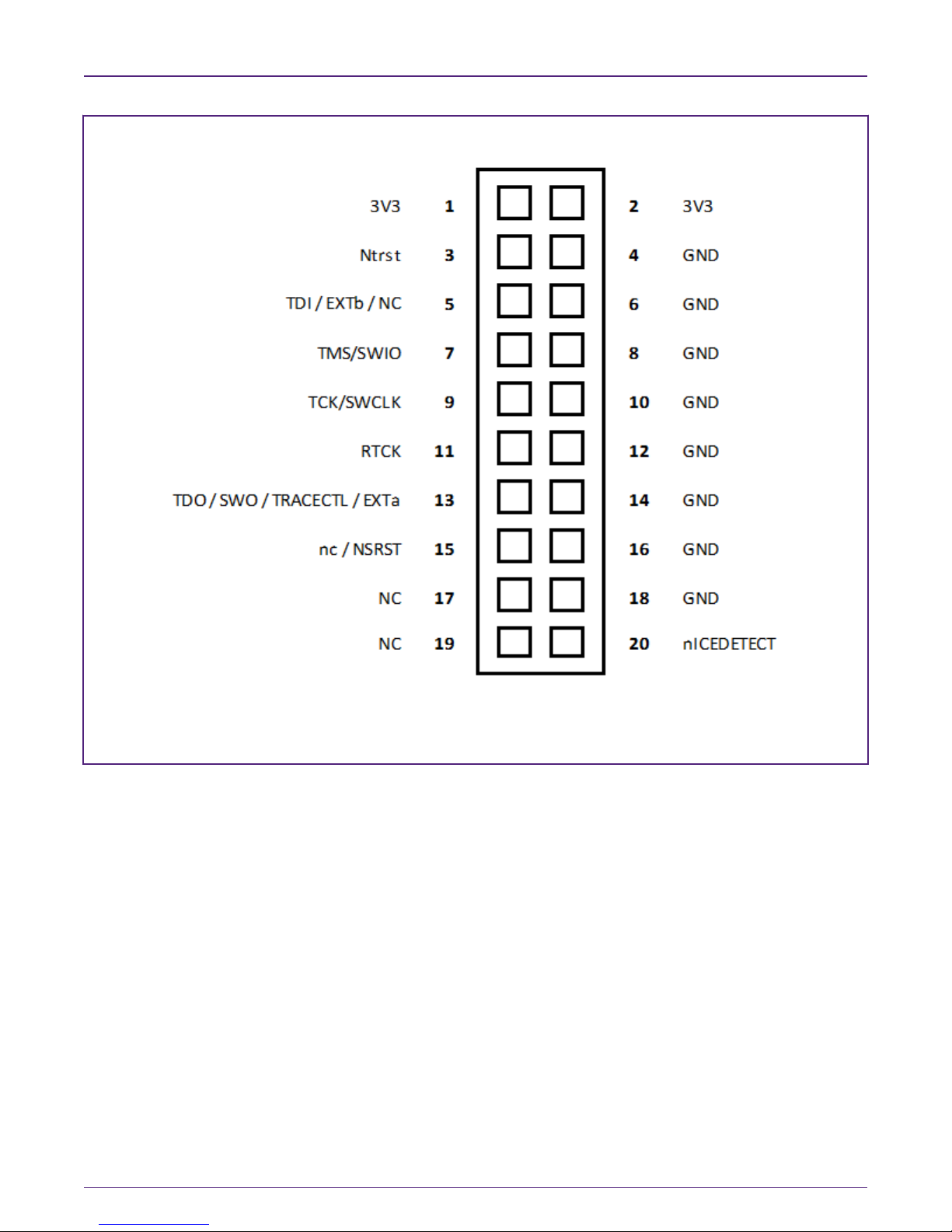

Table 1. Power domains and decoupling capacitors

Power

DescriptionVoltage

Bulk/Bypass Capacitor for domain Decoupli

Domain

VDDX

176

LQFP

1

Supply

5 V/3.3 V 10uF 10uF 10uF 10uF 10uF 10uF 0.1uF X7R

144

LQFP

voltage

1

VDDA

Analog

10uF 10uF 10uF 0.1uF X7R

supply

voltage

VREFH1ADC

reference

voltage

high

VSS

Ground GND VSS, VSSA and VREFL must be shorted to GND at package level.

Table continues on the next page...

100

LQFP/

BGA

Package

64 LQFP 48 LQFP/

QFN

32 LQFP/

QFN

Characte

ng

ristics

Capacito

r

per pin

Ceramic

Ceramic

0.1uF X7R

Ceramic

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

2 / 33

Page 3

NXP Semiconductors

Table 1. Power domains and decoupling capacitors (continued)

Clock circuitry

VSSA

VREFL

1. VDD and VDDA must be shorted to a common reference on PCB. Appropriate decoupling capacitors to be used to filter

noise on the supplies

Analog

Ground

ADC

reference

voltage

low

3.1 Bulk and decoupling capacitors

The bulk capacitor acts as a local power supply to the power pin, near the decoupling capacitors. Minimize the trace length

between the bulk capacitor and the decoupling capacitors.

Decoupling capacitors make the current loop between supply, MCU, and ground reference as short as possible for high frequency

transients and noise. Therefore, all decoupling capacitors should be placed as close as possible to each of their respective power

supply pin; the ground side of the decoupling capacitor should have a via to the pad which goes directly down to the ground plane.

The capacitor should not route to the power plane through a long trace.

4 Clock circuitry

The S32K1xx has the following clock sources:

• Fast internal reference clock (FIRC): 48 MHz.

• Slow internal reference clock (SIRC): 8 MHz.

• PLL: External oscillator as input source.

• External square wave input clock: up to 50 MHz.

• External oscillator clock (OSC): 4–40 MHz.

FIRC, SIRC are internal and does not have to be considered from the hardware design perspective. The external oscillator works

with a range from 4–40 MHz. It provides an output clock that can be provided to the PLL or used as clock source for some

peripherals. When using the external oscillator as input source for the PLL, the frequency range of the external oscillator should

be 8–40 MHz.

EXTAL and XTAL pins

4.1

These pins provide the interface for a crystal to control the internal clock generator circuitry. EXTAL is the input to the crystal

oscillator amplifier. XTAL is the output of the crystal oscillator amplifier. The pierce oscillator provides a robust, low-noise and lowpower external clock source. It is designed for optimal start-up margin with typical crystal oscillators. S32K1xx supports crystals

or resonators from 4 MHz to 40 MHz. The Input Capacitance of the EXTAL, XTAL pins is 7 pF.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

3 / 33

Page 4

NXP Semiconductors

Clock circuitry

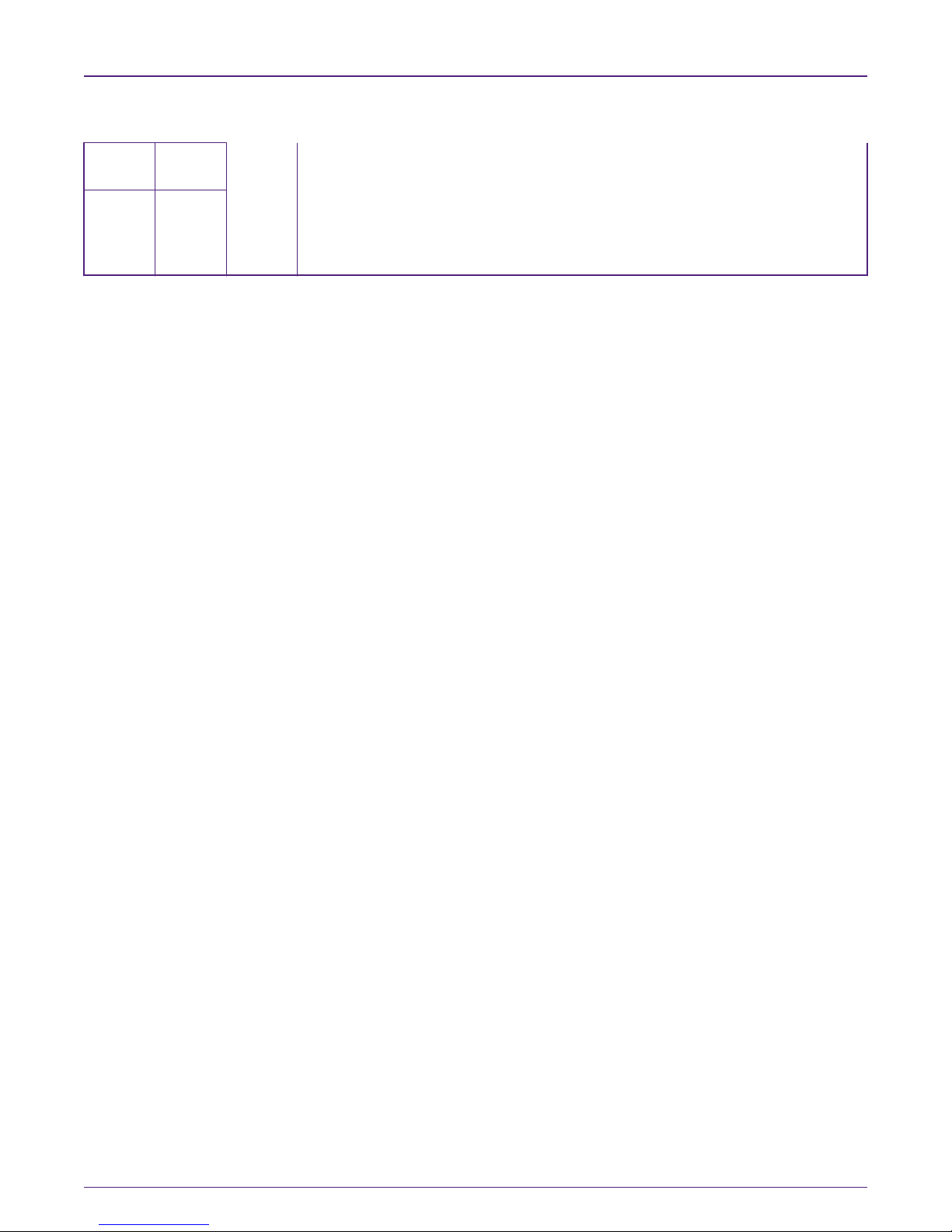

Figure 2. Reference oscillator circuit

Table 2. Components of the oscillator circuit

Symbol Description

RS Bias Resistor

RF

Feedback Resistor

• When Low-gain is selected, internal RF will be selected,

and external RF is not required.

• When High-gain is selected, external RF(1M Ohm) need

to be connected for proper operation of crystal. For

external resistor, up to 5% tolerance is allowed.

X1 Quartz Crystal / Ceramic Resonator

C

C

XTAL

EXTAL

Stabilizing Capacitor

Stabilizing Capacitor

The load capacitors are dependent on the specifications of the crystal and on the board capacitance. It is recommended to have

the crystal manufacturer evaluate the crystal on the PCB.

4.2

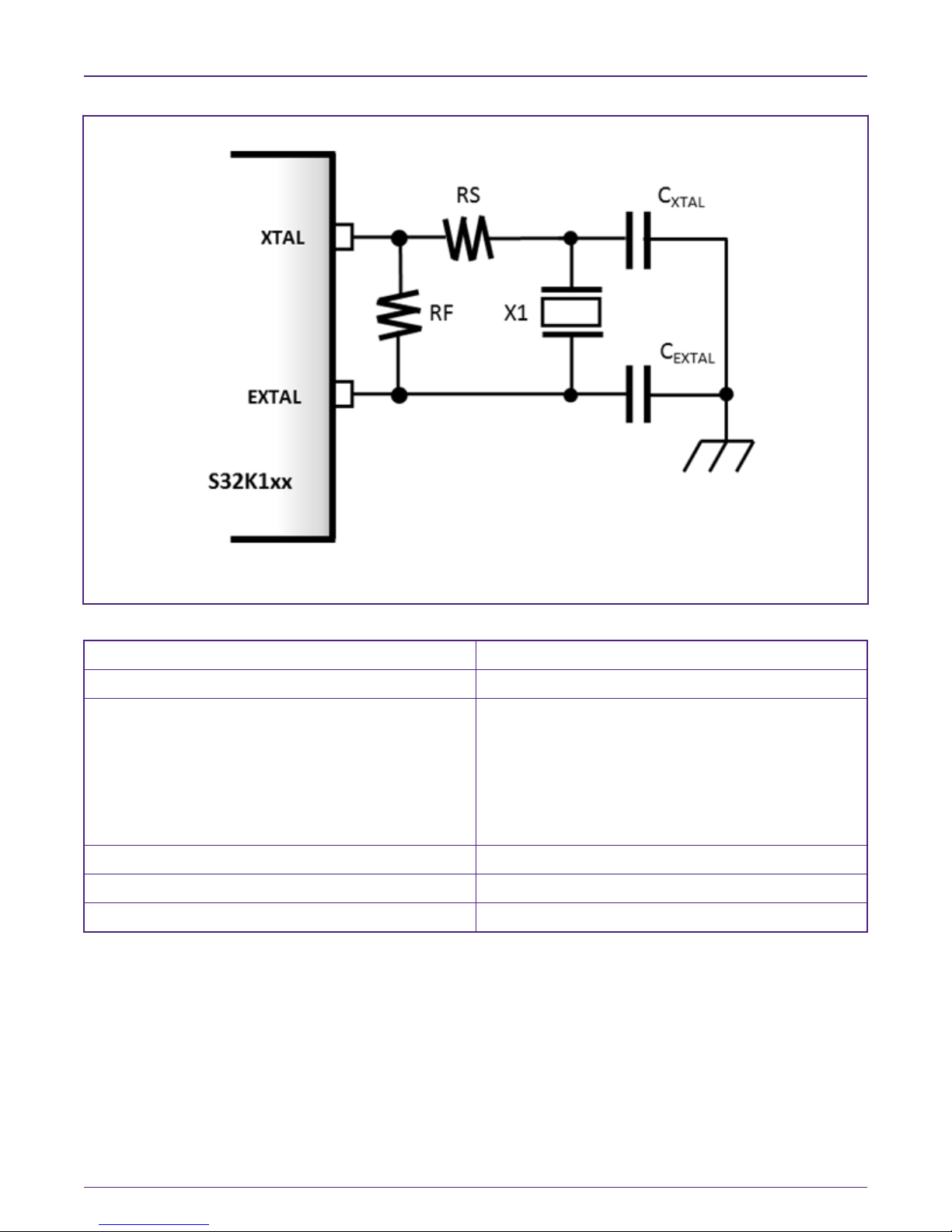

Suggestions for the PCB layout of oscillator circuit

The crystal oscillator is an analog circuit and must be designed carefully and according to the analog-board layout rules:

• External feedback resistor [Rf] is not needed because it’s already integrated.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

4 / 33

Page 5

NXP Semiconductors

Debug and programing interface

• It is recommended to send the PCB to the crystal manufacturer to determine the negative oscillation margin as well as the

optimum regarding C

and C

. These values together with the expected PCB, pin, etc. stray capacity values should be used as a starting

EXTAL

XTAL

and C

capacitors. The data sheet includes recommendations for the tank capacitors C

EXTAL

point.

• Signal traces between the XTAL/EXTAL pins, the crystal and the external capacitors must be as short as possible, without

using any via. This minimizes parasitic capacitance and sensitivity to crosstalk and EMI. The capacitance of the signal

traces must be considered when dimensioning the load capacitors.

• In case there is only 1-2 PCB layers, it is recommended to place a guard ring around the oscillator components and to

connect it to the a solid ground plane. A ground area should be placed under the crystal oscillator area. This ground guard

ring must be clean ground. This means that no current from and to other devices should be flowing through the guard ring.

This guard ring should be connected to VSS x of the S32K1xx with a short trace. Never connect the ground guard ring to

any other ground signal on the board. Also avoid implementing ground loops.

XTAL

• The main oscillation loop current is flowing between the crystal and the load capacitors. This signal path (crystal to C

to

to crystal) should be kept as short as possible and should have a symmetric layout. Hence, both capacitor’s

CXTAL

ground connections should always be as close together as possible.

• The EXTAL and XTAL pins should only be connected to required oscillator components and must not be connected to any

other devices.

The following figure 3, shows the recommended placement and routing for the oscillator layout.

EXTAL

Figure 3. Suggested crystal oscillator layout

5 Debug and programing interface

A number of commonly used debug connectors are shown here. Most of the ARM development tools uses one of these pin out’s.

When developing your ARM circuit board, it is recommended to use a standard debug signal arrangement to make connection

to debugger easier.

The SWD/SWV pins are overlaid on top of the JTAG pins as follows:

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

5 / 33

Page 6

NXP Semiconductors

Debug and programing interface

Table 3. JTAG signal description

JTAG Mode SWD Mode Signal

TCK SWCLK Clock into the core

TDI - JTAG Test Data Input

TDO SWV JTAG Test Data Output / SWV trace data output

(SWO)

TMS SWDIO JTAG Test Mode Select / SWD data in/out

GND GND -

The pull up/down resitors for the JTAG signals are included internally by the default pad configuration. See the device reference

manual and datasheet.

5.1

Debug connector pinouts

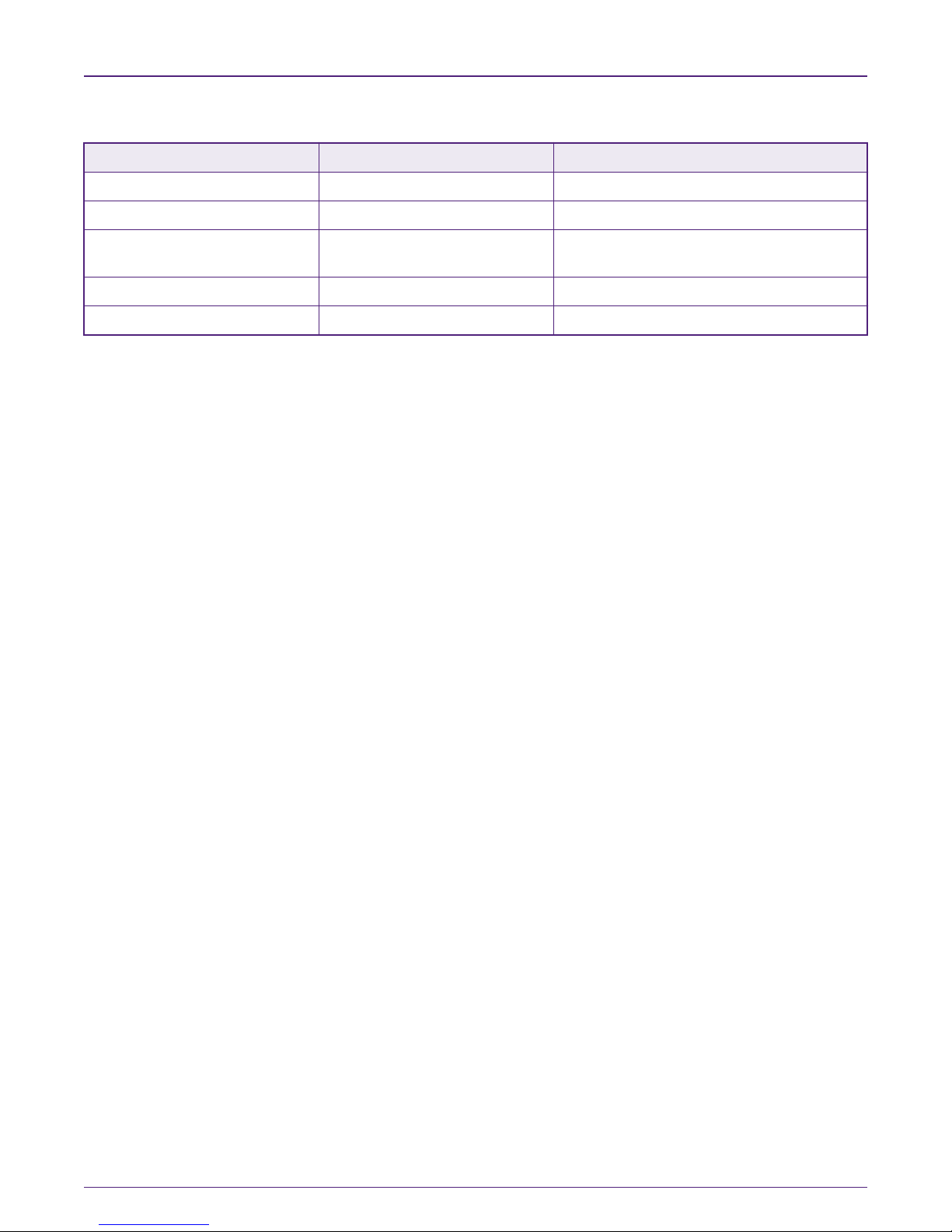

5.1.1 20-pin Cortex Debug D ETM connector

Some newer ARM microcontroller board use a 0.05” 20-pin header (Samtec FTSH-110) for both debug and trace. (The signals

greyed out are not available on the Cortex-M3 or Cortex-M4.) The 20-pin Cortex Debug D ETM connector support both JTAG and

Serial Wire debug protocols. When the Serial debug protocol is used, the TDO signal can be used for Serial Wire Viewer output

for trace capture. The connector also provides a 4-bit wide trace port for capturing of trace that require a higher trace bandwidth

(example, when ETM trace is enabled).

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

6 / 33

Page 7

NXP Semiconductors

Debug and programing interface

Figure 4. 20-pin Cortex Debug D ETM connector pin layout

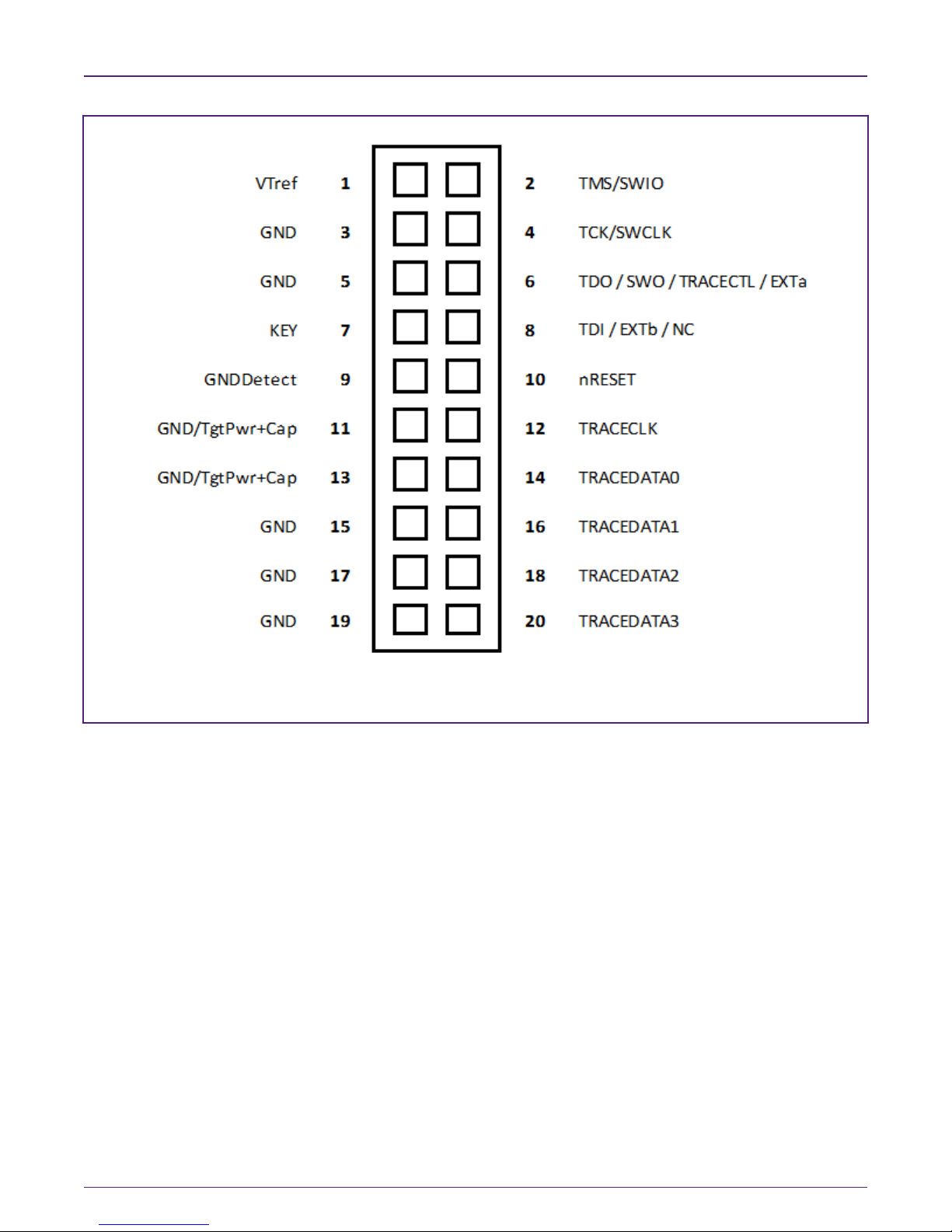

5.1.2 10-pin Cortex Debug connector

For device without ETM, you can use an even smaller 0.05” 10-pin connector (Samtec FTSH-105) for debug. Similar to the 20pin Cortex Debug D ETM connector, both JTAG and Serial-Wire debug protocols are supported in the 10-pin version.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

7 / 33

Page 8

NXP Semiconductors

Figure 5. 10-pin Cortex Debug connector pin layout

Debug and programing interface

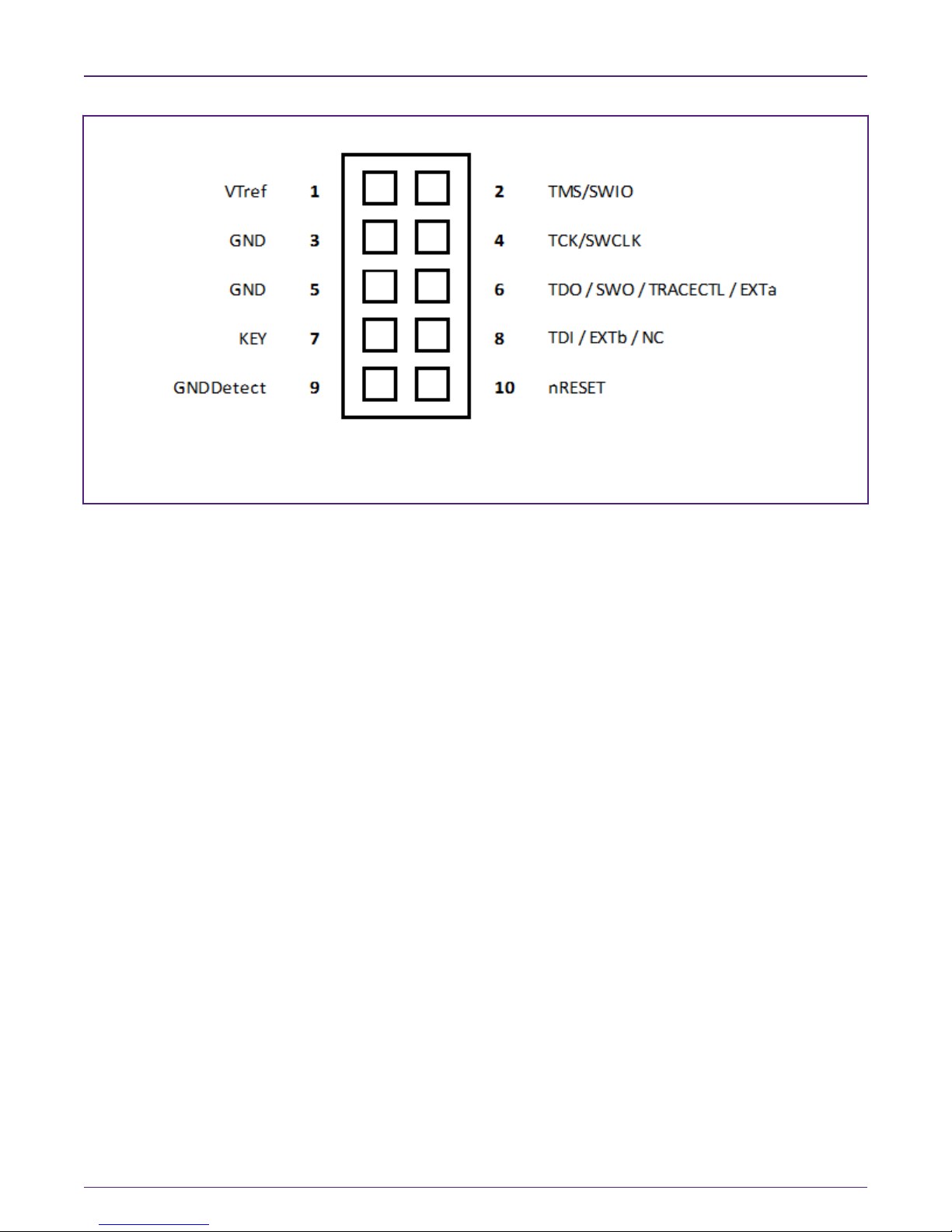

5.1.3 Legacy 20-pin IDC connector

A common debug connector used in ARM development boards is the 20-pin IDC connector. The 20-pin IDC connector arrange

support JTAG debug, Serial Wire debug (SWIO and SWCLK), Serial Wire Output (SWO). The nICEDETECT pin allows the target

system to detect if a debugger is connected. When no debugger is attached, this pin is pulled high. A debugger connection

connects this pin to ground. This is used in some development boards that support multiple JTAG con- figurations. The nSRST

connection is optional; debugger can reset a Cortex-M system via the System Control Block (SCB) so this connection is often

omitted from the top level of microcontroller designs.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

8 / 33

Page 9

NXP Semiconductors

Debug and programing interface

Figure 6. 20-pin IDC connector

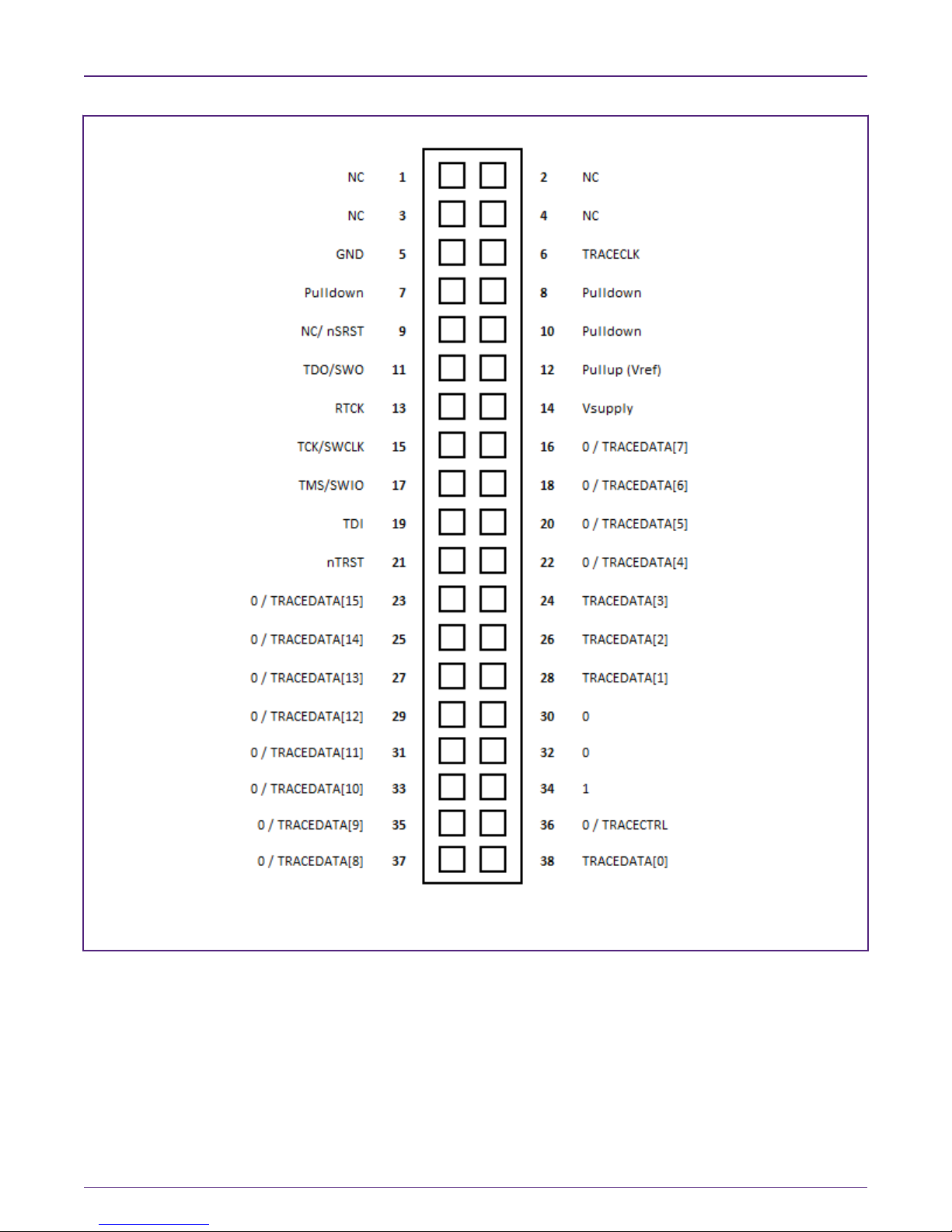

5.1.4 38-pin Mictor connector

In some ARM system designs, Mictor connector is used when trace port is required (example, for instruction trace with ETM). It

can also be used for JTAG/SWD connection. The 20-pin IDC connector can be connected in parallel with the Mictor connector

(only one is use at a time).

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

9 / 33

Page 10

NXP Semiconductors

Debug and programing interface

Figure 7. 38-pin Mictor connector

Typically a Cortex-M3 or Cortex-M4 microcontroller only has 4-bit of trace data signals, so most of the trace data pins on the Mictor

connectors are not used. The Mictor connector is used mostly in other ARM Cortex processors (CortexA8/A9, Cortex-R4) or in

some multiprocessor systems the trace system might require a wider trace port. In such cases, some of the other unused pins

on the connector will also be used. For a typical Cortex-M3 or Cortex-M4 system, the Cortex Debug D ETM connector is

recommended.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

10 / 33

Page 11

NXP Semiconductors

Analog comparator interface

5.2 RESET system

Resetting the MCU provides a way to start processing from a known set of initial conditions. System reset begins with the on-chip

regulator in full regulation and system clocking generation from an internal reference.

5.2.1 External pin RESET

For all reset sources, the RESET_B pin is driven low by the MCU for at least 128 bus clock cycles and until flash memory

initialization has completed.

After flash memory initialization has completed, the RESET_B pin is released and the internal chip reset desserts. Keeping the

RESET_B pin asserted externally delays the negation of the internal chip reset.

On this device, RESET is a dedicated pin. This pin is open drain and has an internal pull/up device. Asserting RESET wakes the

device from any mode. During a pin reset, the RCM's SRS[PIN] bit is set. Hence, application software can detect an external pin

RESET by reading this register.

In case RESET_PIN_CFG within Flash Option Register (FTFC_FOPT) is cleared, RESET_B pin is disabled following a POR and

cannot be enabled as reset function. When this option is selected, there could be a short period of contention during a POR ramp

where the device drives the pin low prior to establishing the setting of this option and releasing the reset function on the pin. The

RESET pin is the same as the standard GPIO. It can operate as a pseudo open-drain output because there is also a PMOS

device in the output stage.

This bit is preserved through system resets and low-power modes. When RESET_B pin function is disabled, it cannot be used

as a source for low-power mode wake-up.

NOTE

When the reset pin has been disabled and security has been enabled by means of the FSEC register, a mass

erase can be performed only by setting both the Mass Erase and System Reset Request fields in the MDM-AP

register.

The reset line has an internal pull-up resistor. If the environment and the customer application is noisy, an external pull up resistor

(between 10KOhmshms-100KOhms) can be added and to avoid a sporadic or unintended reset occurs. Refer to the device

datasheet for the value of the internal pull-up resistor value.

Despite a capacitor in the reset line is not directly required for the MCU. In some cases, in order to add a further ESD protection,

an external capacitor is added between the RESET pin to ground. The values of the pull up resistor and the capacitor must be

selected according to the design requirements of the application. Refer to the device datasheet for the minimum RESET pulse

value that can be detected for the MCU.

Analog comparator interface

6

The comparator (CMP) module provides a circuit for comparing two analog input voltages in the S32K1xx Microcontrollers. The

comparator circuit is designed to operate across the full range of the supply voltage, known as rail-to-rail operation. CMPO is high

when the non-inverting input is greater than the inverting input, and is low when the non-inverting input is less than the inverting

input.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

11 / 33

Page 12

NXP Semiconductors

Analog comparator interface

Figure 8. General windowed timing diagram

Figure 9. CMP high level diagram

The switching of the high-speed interfaces or any GPIO may introduce some noise to the analog or comparator inputs due to

inductance/capacitive coupling between the MCU pins. The cross-talk may be introduced by PCB tracks that run close to each

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

12 / 33

Page 13

NXP Semiconductors

Communication modules

other or that cross each other. In order to avoid and mitigate the high-frequency noise and any coupling. Please ensure that the

analog comparator input signal impedance is 50K or less.(see Figure 9. on page 12)

Figure 10. Shielding of analog signals

Placing ground planes and shapes alongside sensitive analog signals provides shielding on the PCB. Care should be taken to

minimize the length of the paths of these types of signal on the PCB. This prevents interference and I/O cross-talk affecting the

signal. The large amount of metal has the lowest possible resistance and lowest possible inductance because of the large, flattened

conductor pattern. The ground plane acts as a low-impedance return path for decoupling high-frequency currents caused by fast

digital logic. It also minimizes emissions from electromagnetic interference/radio-frequency interference (EMI/RFI). In other hand,

the ground planes also permit high-speed digital or analog signals to be transmitted via transmission-line (microstrip or stripline)

techniques, where controlled impedances are required.

Communication modules

7

7.1 LIN interface for LPUART module

The Local Interconnect Network (LIN) is a serial communication protocol, designed to support automotive networks. As the lowest

level of a hierarchical network, LIN enables cost-effective communication with sensors and actuators when all the features of CAN

are not required.

Features of the LPUART module supports and include:

• LIN master and slave operation

• Full-duplex, standard non-return-to-zero (NRZ) format

• Programmable baud rates (13-bit modulo divider) with configurable oversampling ratio from 4x to 32x

• Transmit and receive baud rate can operate asynchronous to the bus clock:

— Baud rate can be configured independently of the bus clock frequency

— Supports operation in Stop modes

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

13 / 33

Page 14

NXP Semiconductors

• Interrupt, DMA or polled operation:

— Transmit data register empty and transmission complete

— Receive data register full

— Receive overrun, parity error, framing error, and noise error

— Idle receiver detect

— Active edge on receive pin

— Break detect supporting LIN

— Receive data match

• Hardware parity generation and checking

• Programmable 7-bit, 8-bit, 9-bit or 10-bit character length

• Programmable 1-bit or 2-bit stop bits

• Three receiver wakeup methods:

— Idle line wakeup

— Address mark wakeup

— Receive data match

Communication modules

• Automatic address matching to reduce ISR overhead:

— Address mark matching

— Idle line address matching

— Address match start, address match end

• Optional 13-bit break character generation / 11-bit break character detection

• Configurable idle length detection supporting 1, 2, 4, 8, 16, 32, 64 or 128 idle characters

• Selectable transmitter output and receiver input polarity

• Hardware flow control support for request to send (RTS) and clear to send (CTS) signals

• Selectable IrDA 1.4 return-to-zero-inverted (RZI) format with programmable pulse width

• Independent FIFO structure for transmit and receive

— Separate configurable watermark for receive and transmit requests

Option for receiver to assert request after a configurable number of idle characters if receive FIFO is not empty.

Table 4. LPUART signal description

Signal Description I/O

TXD Transmit data. This pin is normally an

I/O

output, but is an input (tristated) in

single wire mode whenever the

transmitter is disabled or transmit

direction is configured for receive data.

RXD Receive data. I

CTS_B Clear to send. I

RTS_B Request to send. O

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

14 / 33

Page 15

NXP Semiconductors

Communication modules

The LIN bus topology utilizes a single master and multiple nodes, as shown below. Connecting application modules to the vehicle

network makes them accessible for diagnostics and service.

Figure 11. LIN bus topology

The LIN transmitter is a low-side MOSFET with current limitation and overcurrent transmitter shutdown. A selectable internal pullup resistor with a serial diode structure is integrated, so no external pull-up components are required for the application in a slave

node. To be used as a master node, an external resistor of 1 kΩ in series with a diode must be placed in parallel between VBAT

[Battery Voltage] and the LIN Bus line. The fall time from recessive to dominant and the rise time from dominant to recessive is

selectable and controlled to guarantee communication quality and reduce EMC emissions.

Figure 12. Circuit diagram for LIN interface

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

15 / 33

Page 16

NXP Semiconductors

7.1.1 LIN components data

Table 5. LIN components

Reference Part Mounting Remark

Communication modules

DMLIN

RML1 and RML2

C1

Diode Mandatory only for master

ECU

Resistor: 2 kΩ

Power Loss: 250 mW

Mandatory only for Master

ECU

Tolerance: 1%

Package Size: 1206

Requirement:

Min Power rating of the

complete master termination

has to be ≥ 500 mW

Capacitor:

Mandatory

Slave ECU: typically 220 pF

Master ECU: from 560 pF up

to approximately ten times that

value in the slave node

[CSLAVE], so that the total line

capacitance is less dependent

on the number of slave nodes.

Reverse Polarity protection

from LIN to VSUP.

For Master ECU

If more than 2 resistors are

used in parallel, the values

have to be chosen in a way

that the overall resistance RM

of 1 kΩ and the minimum

power loss of the complete

master termination has to be

fulfilled.

For Slave ECU

RMLIN1 and RMLIN2 are not

needed on the PCB layout

The value of the master node

has to be chosen in a way that

the LIN specification is fulfilled.

C2

ESD1

Tolerance: 10%

Package Size: 0805

Voltage: ≥50 V

Capacitor:

Package Size: 0805

ESD Protection

Package Size: 0603-0805

Optional Mounting of the optional part

only allowed if there is an

explicit written permission of

the respective OEM available.

Place close to the connector.

Optional

Layout pad for an additional

ESD protection part.

Mounting of the optional part

only allowed if there is an

explicit written permission of

the respective OEM available.

Place close to the connector.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

16 / 33

Page 17

NXP Semiconductors

Communication modules

7.2 CAN interface for FlexCAN module

The physical layer characteristics for CAN are specified in ISO-11898-2. This standard specifies the use of cable comprising

parallel wires with an impedance of nominally 120 Ω (95 Ω as minimum and 140 Ω as maximum). The use of shielded twisted

pair cables is generally necessary for electromagnetic compatibility (EMC) reasons, although ISO-11898-2 also allows for

unshielded cable. A maximum line length of 40 meters is specified for CAN at a data rate of 1 Mb. However, at lower data rates,

potentially much longer lines are possible. ISO-11898-2 specifies a line topology, with individual nodes connected using short

stubs.

Though not exclusively intended for automotive applications, CAN protocol is designed to meet the specific requirements of a

vehicle serial data bus: real-time processing, reliable operation in the EMI environment of a vehicle, cost-effectiveness, and

required bandwidth.

Each CAN station is connected physically to the CAN bus lines through a transceiver device. The transceiver is capable of driving

the large current needed for the CAN bus and has current protection against defective CAN or defective stations. A typical CAN

system with an S32K1xx microcontroller is shown in Figure 13. on page 17

Figure 13. CAN system

The FlexCAN module is a full implementation of the CAN protocol specification, the CAN with Flexible Data rate (CAN FD) protocol

and the CAN 2.0 version B protocol, which supports both standard and extended message frames and long payloads up to 64

bytes transferred at faster rates up to 8 Mbps. The message buffers are stored in an embedded RAM dedicated to the FlexCAN

module. See the chip configuration details in the Reference Manual for the number of message buffers configured in the chip.

Like most others CAN physical transceivers, the CANH, CANL and SPLIT pins are available for the designer to terminate bus

depending on the application. The Figure 14. on page 18 and Figure 15. on page 18 show examples of the CAN node

terminations.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

17 / 33

Page 18

NXP Semiconductors

Communication modules

Figure 14. CAN physical transceiver circuit

Figure 15. CAN physical transceiver circuit with common mode choke

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

18 / 33

Page 19

NXP Semiconductors

7.2.1 CAN components data

Table 6. CAN components

Reference Description

Denotes a guard track next to a high/medium speed track.

Guard tracks are connected such that each end of the track is

connected to ground. A guard track should be connected to

the ground plane at least every 500 mils. Spacing from any

protected conductor and the guard track must not exceed 20

mils.

Communication modules

CBUS1 and CBUS2

Z1 and Z2

RTERM1,

RTERM2 and CCOM1

LBUS1–Common mode choke

The Capacitors CBUS1 and CBUS2 are not specifically

required. They may be added for EMC reasons, in which

case the maximum capacitance from either bus wire to

ground must not exceed 300 pF total. If zener stacks are also

needed, the parasitic capacitance of the zener stacks must

also be included in the total capacitance budget.

The zener stacks Z1 and Z2 could be required to satisfy

Automotive EMC requirements (ESD in particular). These

devices should be placed close to the connector.

Depending on the position of the node within the CAN network

it might need a specific termination. RTERM1, RTERM2 and

CCOM1 must be that they assist in having an overall cable

impedance. On a bus implementation of a CAN network only

the two nodes on the two ends of the bus have terminator

resistors. The nodes not placed on the end of the CAN bus do

not have termination. A thorough analysis is required to

maintain this requirement of the CAN networks.

The SPLIT pin on the transceiver is optional and the designer

might choose not to use it. This pin helps stabilize the recessive

state of the CAN bus and can be enabled or disabled by

software when required.

A common mode choke on the CANH and CANL lines can

help reduce coupled electromagnetic interference and

needed to satisfy Automotive EMC requirements. This choke,

together with transient suppressors on the transceiver pins

can greatly reduce coupled electromagnetic noise, and highfrequency transients. LBUS1 is not specifically required.

7.2.2 CAN termination

In a transmission line, there are two current paths, one to carry the currents from the driver to the receiver and another to provide

the return path back to the driver. In the CAN transmission lines is more complex because there are two signals that are sharing

a common termination as well as a ground return path. For reliable CAN communications, it is essential that the reflections in the

transmission line be kept as small as possible. This can only be done by proper cable termination. Figure 16. on page 20 and

Figure 17. on page 20 demonstrates two CAN termination schemes.

Reflections happen very quickly during and just after signal transitions. On a long line, the reflections are more likely to continue

long enough to cause the receiver to misread logic levels. On short lines, the reflections occur much sooner and have no effect

on the received logic levels.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

19 / 33

Page 20

NXP Semiconductors

Communication modules

7.2.2.1 Parallel termination

In CAN applications, both ends of the bus must be terminated because any node on the bus may transmit/receive data. Each end

of the link has a termination resistor equal to the characteristic impedance of the cable, although the recommended value for the

termination resistors is nominally 120 Ω (100 Ω as minimum and 130 Ω as maximum).

There should be no more than two terminating resistors in the network, regardless of how many nodes are connected, because

additional terminations place extra load on the drivers. ISO-11898-2 recommends not integrating a terminating resistor into a

node, but rather attaching standalone termination resistors at the furthest ends of the bus. This is to avoid a loss of a termination

resistor if a node containing that resistor is disconnected. The concept also applies to avoiding the connection of more than two

termination resistors to the bus, or locating termination resistors at other points in the bus rather than at the two ends.

Figure 16. d CAN Bus - parallel termination

7.2.2.2 Parallel termination with common-mode filtering

To further enhance signal quality, split the terminating resistors at each end in two and place a filter capacitor, CSPLIT, between

the two resistors. This filters unwanted high frequency noise from the bus lines and reduces common-mode emissions.

Figure 17. CAN Bus – parallel transmission with common-mode filtering

7.3 Inter-Integrated Circuit IIC

The Inter-Intergrated Circuit (IIC) bus is a two-wire, bidirectional serial bus that provides a simple, efficient method of data exchange

between devices. Being a two-wire device, the IIC bus minimizes the need for large numbers of connections between devices,

and eliminates the need for an address decoder. This bus is suitable for applications requiring occasional communications over

a short distance between a number of devices. It also provides flexibility, allowing additional devices to be connected to the bus

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

20 / 33

Page 21

NXP Semiconductors

Communication modules

for further expansion and system development. Both SDA and SCL are bidirectional lines, connected to a positive supply voltage

via a pull-up resistor (see Figure 18. on page 21. When the bus is free, both lines are high. The output stages of devices

connected to the bus must have an open-drain or open collector in order to perform the wired-AND function. The interface is

designed to operate up to 100 kbps with maximum bus loading and timing. The device is capable of operating at higher baud

rates, up to a maximum of clock/20, with reduced bus loading. The maximum communication length and the number of devices

that can be connected are limited by a maximum bus capacitance of 400 pF.

Figure 18. Connection of I2C-bus devices to the I2C-bus

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

21 / 33

Page 22

NXP Semiconductors

Communication modules

Figure 19. Maximum value of RP as a function of bus capacitance for a standard-mode I2C-bus

7.4 Ethernet MAC Interface

MII/RMII Interface signal can be directly routed to the MAC-NET interface, however series termination resistors may be considerate

on RXCLK, TXCLK and all RX/TX signals for EMI suppression. MII/RMII series termination should be placed within 100 of the

Ethernet Physical Interface and routed to an uninterrupted reference plane. 33-50 Ohms series termination resistors have been

to be good recommended value for improving EMI.

Although RMII and MII are synchronous bus architectures, there are a number of factors limiting signal trace lengths. With a longer

trace, the signal becomes more attenuated at the destination and thus more susceptible to noise interference. Longer traces also

act as antennas, and if run on the surface layer, can increase EMI radiation. If a long trace is running near and adjacent to a noisy

signal, the unwanted signals could be coupled in as cross talk. It is recommended to keep the signal trace lengths as short as

possible. Ideally, keep the traces under 6 inches. Trace length matching, to within 2.0 inches on the MII or RMII bus is also

recommended. Significant differences in the trace lengths can cause data timing issues. Minimize the use of vias throughout the

design. Vias add capacitance to signal traces. As with any high-speed data signal, good design practices dictate that impedance

should be maintained and stubs should be avoided throughout the entire data path.

MII signaling: Figure 20. on page 23 shows the PHY-MAC and MAC-MAC connections in an MII interface. Data is exchanged

via 4-bit wide data nibbles TXD[3:0] and RXD[3:0]. Data transmission is synchronous with the transmit (TX_CLK) and receive

(RX_CLK) clocks. For the PHY-MAC interface, both clock signals are provided by the PHY and are typically derived from an

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

22 / 33

Page 23

NXP Semiconductors

Quad Serial Peripheral Interface

external crystal running at a nominal 25 MHz or from the CLK_OUT signal on the switch. When the Ethernet Switch is configured

for MAC-MAC communication, the switch provides the clocks and acts like a PHY.

Figure 20. MII interface connections

RMII signaling: RMII data is exchanged via 2-bit data signals TXD[1:0] and RXD[1:0] as shown in Figure 21. on page 23.

Transmit and receive signals are synchronous with the shared reference clock, REF_CLK.

Figure 21. RMII interface connections

8 Quad Serial Peripheral Interface

S32K1xx has one instance of QuadSPI. The Quad Serial Peripheral Interface (QuadSPI) block acts as an interface to external

serial flash device. It supports SDR and HyperRAM modes upto 4 and 8 bidirectional data lines respectively. The QuadSPI

supports an A-side and a B-side. The A-side of the QuadSPI is connected to the fast pads (80 mA) while the B-side connects to

the 20 mA pads. See datasheet for operating values.

Only one external memory will be supported in any given application and it will not be permitted to run the A-side and the B-side

of the QuadSPI simultaneously. As such the following external memory options can be supported:

• Single Quad Flash on the A-side

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

23 / 33

Page 24

NXP Semiconductors

Figure 22. External memory option - Single Quad Flash on the A-side

Quad Serial Peripheral Interface

• Single HyperRAM on the B-side

Figure 23. External memory option - Single HyperRAM on the B-side

• Single Quad Flash on the B-side.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

24 / 33

Page 25

NXP Semiconductors

Figure 24. External memory option - Single Quad Flash on the B-side

Quad Serial Peripheral Interface

Data and Clock Signal Termination: Clock generation and distribution becomes more difficult as the speed and performance

of microprocessors increase to higher limits. Controlled and precise clocking distribution techniques are needed to maintain a

synchronous system. Clock signal quality and skew are the two major problems with distributing clock signals. With higher

frequencies, and the associated fast edge rates, long traces behave like transmission lines. Ring back, overshoot, and undershoot

occur as a result of poor termination of transmission lines. They contribute to bad signal quality, false switching, and they can

cause damage in extreme cases.

Given the effective output driver strength of 25-33 Ohms and the transmission line characteristic impedance of 50 Ohms, one

should add the termination resistor close to the output driver, to minimize the reflection as shown below.

Figure 25. Point-To-Point transmission line

Data Signal Routing: In order to keep the correct timing for the data transfer from the Microcontroller to the IC Memory, the PCB

data traces should be the same length and time delay as the clock trace from Microcontroller to the IC Memory. Data signals

should be routed with controlled impedance traces to reduce signal reflections. Avoid routing traces with 90 ° angle corners. The

recommendation is to cut the corner and smooth the trace when a trace route needs to change direction. To further improve the

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

25 / 33

Page 26

NXP Semiconductors

Unused pins

signal integrity, avoid using multiple signal layers for data signal routing. All signal traces should have a continuous and solid

reference plane, either GND or VDD.

Clock Signal Routing: In high speed synchronous data transfer, good signal integrity in a PCB design is of critical importance,

especially for the clock signals, SCLK and DQS. When routing the clock signal, special cares should be taken. The following

practices are recommended.

• Run the clock signal at least -w3w of the trace width away from all other signal traces. This helps keep the clock signal clean

from crosstalk noise.

• Use as few via(s) as possible for the whole clock signal path. Vias cause impedance change and signal reflection.

• All signal traces should go with a solid reference plane, either GND or VCC.

• Run the clock trace as straight as possible and avoid using serpentine routing.

• Keep a continuous ground in the next layer as reference plane.

• Route the clock trace with controlled impedance.

• Keep the clock signal from disturbance or crosstalk by separating it from other signals by using wider spacing. Data bus

should be routed with matching length to the reference of the clock. The matching length is recommended to be within ± 50

mils.

Figure 26. Recommended clock signal routing

9 Unused pins

The unused digital and analog pins must be left floating. In software, the application should ensure that the ports function of the

MCU is 'DISABLED'. The DISABLED function is default state for all pins not initialized.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

26 / 33

Page 27

NXP Semiconductors

General board layout guidelines

10 General board layout guidelines

10.1 Traces recommendations

A right angle in a trace can cause more radiation. The capacitance increases in the region of the corner and the characteristic

impedance changes. This impedance change causes reflections. Avoid right-angle bends in a trace and try to route them with at

least two 45° corners. To minimize any impedance change, the best routing would be a round bend, as shown in Figure 27. on

page 27.

Figure 27. Poor and correct way of bending traces in right angles

To minimize crosstalk, not only between two signals on one layer but also between adjacent layers, route them 90° to each other.

Complex boards need to use vias while routing; you have to be careful when using them. These add additional capacitance and

inductance, and reflections occur due to the change in the characteristic impedance. Vias also increase the trace length. While

using differential signals, use vias in both traces or compensate the delay in the other trace.

10.2

Grounding techniques apply to both multi-layer and single-layer PCBs. The objective of grounding techniques is to minimize the

ground impedance and thus to reduce the potential of the ground loop from circuit back to the supply.

Grounding

• Route high-speed signals above a solid and unbroken ground plane.

• Do not split the ground plane into separate planes for analog, digital, and power pins. A single and continuous ground

plane is recommended.

• There should be no floating metal/shape of any kind near any area close to the microcontroller pins. Fill copper in the

unused area of signal planes and connect these coppers to the ground plane through vias.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

27 / 33

Page 28

NXP Semiconductors

General board layout guidelines

Figure 28. Eliminating floating metal/shape

10.3 EMI/EMC and ESD considerations for layout

These considerations are important for all system and board designs. Though the theory behind this is well explained, each board

and system experiences this in its own way. There are many PCB and component related variables involved.

This application note does not go into the electromagnetic theory or explain the whys of different techniques used to combat the

effects, but it considers the effects and solutions most recommended as applied to CMOS circuits. EMI is radio frequency energy

that interferes with the operation of an electronic device. This radio frequency energy can be produced by the device itself or by

other devices nearby. Studying EMC for your system allows testing the ability of your system to operate successfully counteracting

the effects of unplanned electromagnetic disturbances coming from the devices and systems around it. The electromagnetic noise

or disturbances travels via two media: Conduction and Radiation.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

28 / 33

Page 29

NXP Semiconductors

Figure 29. Electromagnetic noise propagation

General board layout guidelines

The design considerations narrow down to:

• The radiated & conducted EMI from the board should be lower than the allowed levels by the standards you are following.

• The ability of the board to operate successfully counteracting the radiated & conducted electromagnetic energy (EMC)

from other systems around it.

The EMI sources for a system consists of several components such as PCB, connectors, cables and so on. The PCB plays a

major role in radiating the high frequency noise. At higher frequencies and fast-switching currents and voltages, the PCB traces

become effective antennas radiating electromagnetic energy; e.g., a large loop of signal and corresponding ground. The five main

sources of radiation are: digital signals propagating on traces, current return loop areas, inadequate power supply filtering or

decoupling, transmission line effects, and lack of power and ground planes. Fast switching clocks, external buses and PWM

signals are used as control outputs and in switching power supplies. The power supply is another major contributor to EMI. RF

signals can propagate from one section of the board to another building up EMI. Switching power supplies radiate the energy

which can fail the EMI test. This is a huge subject and there are many books, articles and white papers detailing the theory behind

it and the design criteria to combat its effects.

Every board or system is different as far as EMI/EMC and ESD issues are concerned, requiring its own solution.

However, the common guidelines to reduce an unwanted generation of electromagnetic energy are as shown below:

• Ensure that the power supply is rated for the application and optimized with decoupling capacitors.

• Provide adequate filter capacitors on the power supply source. The bulk/bypass and decoupling capacitors should have

low equivalent series inductance (ESL).

• Create ground planes if there are spaces available on the routing layers. Connect these ground areas to the ground plane

with vias.

• Keep the current loops as small as possible. Add as many decoupling capacitors as possible. Always apply current return

rules to reduce loop areas.

• Keep high-speed signals away from other signals and especially away from input and output ports or connectors.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

29 / 33

Page 30

NXP Semiconductors

PCB layer stacking

11 PCB layer stacking

To reach signal integrity and performance requirements, at minimum a four-layer PCB is recommended for implementing Ethernet

applications and systems. The following layer stack-ups are recommended for four, six, and eight-layer boards, although other

options are possible.

Figure 30. Recommended PCB layer stack-up

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

30 / 33

Page 31

NXP Semiconductors

Injection current

12 Injection current

All pins implement protection diodes that protect against electrostatic discharge (ESD). In many cases, both digital and analog

pins need to be connected to voltages that are higher than the operating voltage of the device pin. In addition to providing protection

from ESD, these diode structures will also clamp the voltage to a diode drop above the supply of that pin segment. This is

permissible, as long as the current injection is limited as defined in the device specification. Current can be limited by adding a

series resistor on the signal. The input protection diodes will keep the voltage at the pin to a safe level (per the absolute maximum

ratings of the device) as long as it is less than the maximum injection current specification.

For more reference see AN4731.

Figure 31. Input protection circuit for I/O port

13 References

• Crystal Oscillator Troubleshooting Guide - NXP Semiconductors

• AN2049 Some Characteristics and Design Notes for Crystal Feedback ...

• AN10853 ESD and EMC sensitivity of IC - NXP Semiconductors

• AN2321: Designing for Board Level Electromagnetic Compatibility - NXP Semiconductors

• AN10897 A guide to designing for ESD and EMC

Revision history

14

Table 7. Sample revision history

Revision number Date Substantive changes

0 03/2017 Initial release

Table continues on the next page...

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

31 / 33

Page 32

NXP Semiconductors

Table 7. Sample revision history (continued)

Revision number Date Substantive changes

Revision history

1 06/2017

2

02/2018

1. In Table 1. Power domains and decoupling

capacitors on page 2 Footnote is added in the table

2. In Clock circuitry on page 3 the value of Fast

internal reference clock is changed to 48MHz from

48-60MHz and value of External square wave input

clock changed to 50 MHz from 60 MHz

3. In #unique_8/

unique_8_Connect_42_TABLE_WGL_5ZD_CZ

deleted the line (if not .........by MCU)

4. External pin RESET on page 11 changed from

When the RESET................. drain output to The

RESET pin....................output stage

5. In Power supplies on page 2 Figure 1. on page 2

updated.

6. In Clock circuitry on page 3 When using the

external oscillator....the frequency range of the

external oscillator should be 4–40 MHz changed to

8–40 MHz

7. New chapter Analog comparator interface on page

11 added

1. Updated the table Table 1. Power domains and

decoupling capacitors on page 2.

3 12/2018

2. Added the following sections Quad Serial

Peripheral Interface on page 23, Injection current

on page 31, PCB layer stacking on page 30,

Ethernet MAC Interface on page 22

1. Updated Figure 1. on page 2

2. In Debug and programing interface on page 5

removed the text "

Usually, MCUs do not include pull-up or pull-down

resistors on JTAG/SWD pins".

3. In External pin RESET on page 11 removed the

paragraph "In prototype designs.......330 pF are

recommended" and added "The reset line has

an ......pull-up resistor value" and "Despite a

capacitor in.....detected for the MCU".

4. Removed the column "Required pull-up / pulldown"

from Table 3. JTAG signal description on page 6.

5. In External pin RESET on page 11 removed the

figure "RESET circuit".

6. Updated Unused pins on page 26 and added a

note.

Hardware Design Guidelines for S32K1xx Microcontrollers , Rev. 3, December 2018

Application Note

32 / 33

Page 33

How To Reach Us

Home Page:

nxp.com

Web Support:

nxp.com/support

Information in this document is provided solely to enable system and software implementers to

use NXP products. There are no express or implied copyright licenses granted hereunder to

design or fabricate any integrated circuits based on the information in this document. NXP

reserves the right to make changes without further notice to any products herein.

NXP makes no warranty, representation, or guarantee regarding the suitability of its products for

any particular purpose, nor does NXP assume any liability arising out of the application or use

of any product or circuit, and specifically disclaims any and all liability, including without limitation

consequential or incidental damages. “Typical” parameters that may be provided in NXP data

sheets and/or specifications can and do vary in different applications, and actual performance

may vary over time. All operating parameters, including “typicals,” must be validated for each

customer application by customer's technical experts. NXP does not convey any license under

its patent rights nor the rights of others. NXP sells products pursuant to standard terms and

conditions of sale, which can be found at the following address: nxp.com/

SalesTermsandConditions.

NXP, the NXP logo, NXP SECURE CONNECTIONS FOR A SMARTER WORLD, COOLFLUX,

EMBRACE, GREENCHIP, HITAG, I2C BUS, ICODE, JCOP, LIFE VIBES, MIFARE, MIFARE

CLASSIC, MIFARE DESFire, MIFARE PLUS, MIFARE FLEX, MANTIS, MIFARE ULTRALIGHT,

MIFARE4MOBILE, MIGLO, NTAG, ROADLINK, SMARTLX, SMARTMX, STARPLUG, TOPFET,

TRENCHMOS, UCODE, Freescale, the Freescale logo, AltiVec, C‑5, CodeTEST, CodeWarrior,

ColdFire, ColdFire+, C‑Ware, the Energy Efficient Solutions logo, Kinetis, Layerscape, MagniV,

mobileGT, PEG, PowerQUICC, Processor Expert, QorIQ, QorIQ Qonverge, Ready Play,

SafeAssure, the SafeAssure logo, StarCore, Symphony, VortiQa, Vybrid, Airfast, BeeKit,

BeeStack, CoreNet, Flexis, MXC, Platform in a Package, QUICC Engine, SMARTMOS, Tower,

TurboLink, and UMEMS are trademarks of NXP B.V. All other product or service names are the

property of their respective owners. ARM, AMBA, ARM Powered, Artisan, Cortex, Jazelle, Keil,

SecurCore, Thumb, TrustZone, and μVision are registered trademarks of ARM Limited (or its

subsidiaries) in the EU and/or elsewhere. ARM7, ARM9, ARM11, big.LITTLE, CoreLink,

CoreSight, DesignStart, Mali, mbed, NEON, POP, Sensinode, Socrates, ULINK and Versatile are

trademarks of ARM Limited (or its subsidiaries) in the EU and/or elsewhere. All rights reserved.

Oracle and Java are registered trademarks of Oracle and/or its affiliates. The Power Architecture

and Power.org word marks and the Power and Power.org logos and related marks are trademarks

and service marks licensed by Power.org.

©

NXP B.V. 2018. All rights reserved.

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

Date of release: December 2018

Document identifier: AN5426

Loading...

Loading...