Page 1

Freescale Semiconductor

User’s Guide

Document Number: RDAIRBAGPSI5UG

Rev. 2.0, 10/2014

RDAIRBAGPSI5 Airbag Reference Platform

© Freescale Semiconductor, Inc., 2014. All rights reserved.

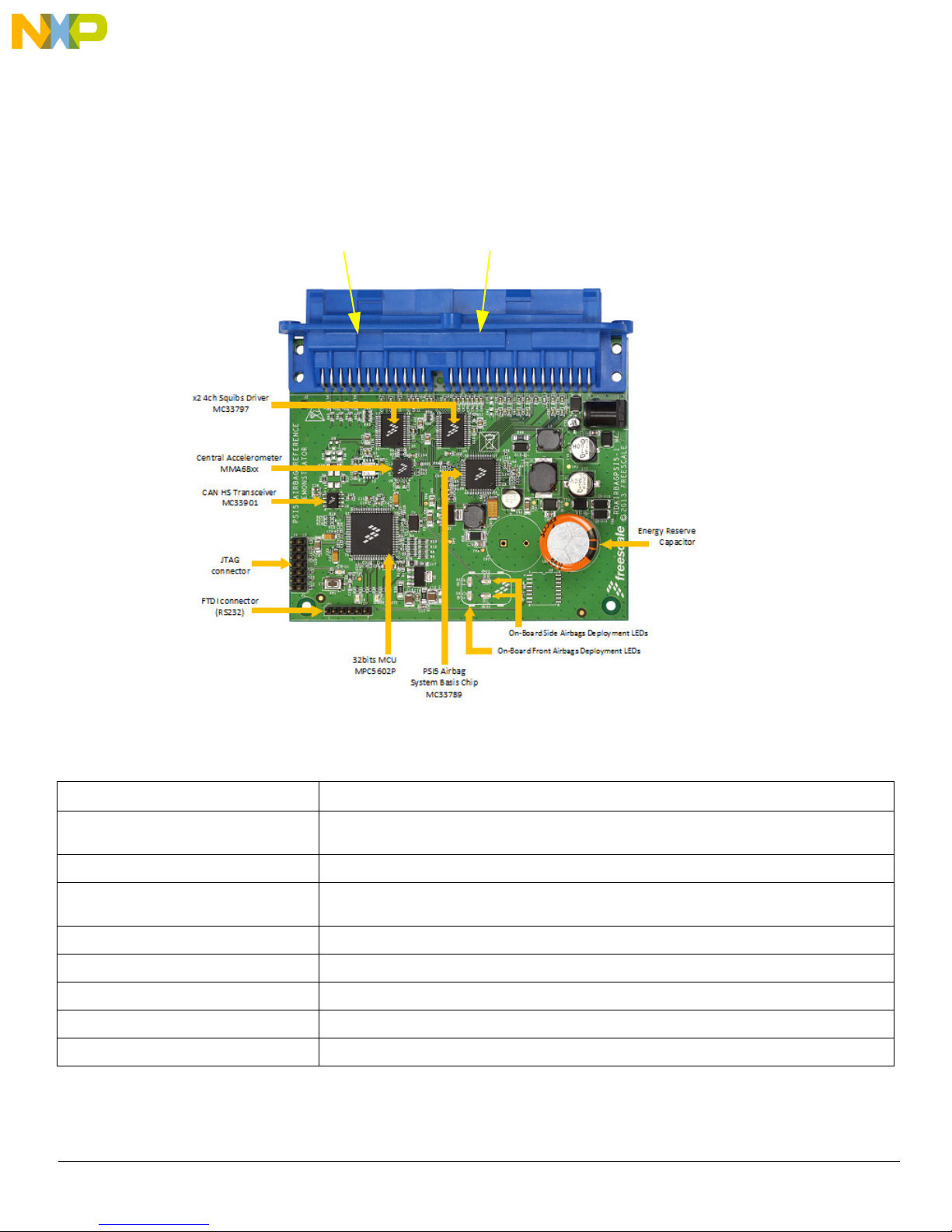

Figure 1. RDAIRBAGPSI5

Page 2

Table of Contents

1 Important Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Understanding the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Getting to know the Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Describing the Device Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Installing the Software and Setting up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8 Board Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9 Bill of Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

11 Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 3

1 Important Notice

Freescale provides the enclosed product(s) under the following conditions:

This reference design is intended for use of ENGINEERING DEVELOPMENT OR EVALUATION PURPOSES

ONLY. It is provided as a sample IC pre-soldered to a printed circuit board to make it easier to access inputs,

outputs, and supply terminals. This reference design may be used with any development system or other

source of I/O signals by simply connecting it to the host MCU or computer board via off-the-shelf cables. Final

device in an application will be heavily dependent on proper printed circuit board layout and heat sinking design

as well as attention to supply filtering, transient suppression, and I/O signal quality.

The goods provided may not be complete in terms of required design, marketing, and or manufacturing related

protective considerations, including product safety measures typically found in the end product incorporating

the goods. Due to the open construction of the product, it is the user's responsibility to take any and all

appropriate precautions with regard to electrostatic discharge. In order to minimize risks associated with the

customers applications, adequate design and operating safeguards must be provided by the customer to

minimize inherent or procedural hazards. For any safety concerns, contact Freescale sales and technical

support services.

Should this reference design not meet the specifications indicated in the kit, it may be returned within 30 days

from the date of delivery and will be replaced by a new kit.

Freescale reserves the right to make changes without further notice to any products herein. Freescale makes

no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor

does Freescale assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages.

“Typical” parameters can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typical”, must be validated for each customer application by customer’s

technical experts.

Freescale does not convey any license under its patent rights nor the rights of others. Freescale products are

not designed, intended, or authorized for use as components in systems intended for surgical implant into the

body, or other applications intended to support or sustain life, or for any other application in which the failure

of the Freescale product could create a situation where personal injury or death may occur.

Should the Buyer purchase or use Freescale products for any such unintended or unauthorized application,

the Buyer shall indemnify and hold Freescale and its officers, employees, subsidiaries, affiliates, and

distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising

out of, directly or indirectly, any claim of personal injury or death associated with such unintended or

unauthorized use, even if such claim alleges that Freescale was negligent regarding the design or manufacture

of the part.Freescale™ and the Freescale logo are trademarks of Freescale Semiconductor, Inc. All other

product or service names are the property of their respective owners.

© Freescale Semiconductor, Inc. 2014

Important Notice

Freescale Semiconductor 3

RDAIRPABPSI5UG , Rev. 2.0

Page 4

Getting Started

2 Getting Started

The RDAIRBAGPSI5 contents include:

• RDAIRBAGPSI5 Airbag Evaluation Platform board

•FTDI Cable

• Warranty card

The RDAIRBAGPSI5-1 contents include:

• RDAIRBAGPSI5-1 Airbag Evaluation Platform board

• PSI5 Satellites modules

• ECU Wiring Harness

•FTDI Cable

• Warranty card

2.1 Jump Start

Freescale’s analog product development boards help to easily evaluate Freescale products. These tools support analog mixed signal and

power solutions that include monolithic ICs using proven high-volume SMARTMOS mixed signal technology, and system-in-package

devices utilizing power, SMARTMOS and MCU dies. Freescale products enable longer battery life, smaller form factor, component count

reduction, ease of design, lower system cost and improved performance in powering state of the art systems.

•Go to www.freescale.com/analogtools

• Locate your kit

• Review your Tool Summary Page

• Look for

• Download documents, software, and other information

Once the files are downloaded, review the user guide in the bundle. The user guide includes setup instructions, BOM and schematics.

Jump start bundles are available on each tool summary page with the most relevant and current information. The information includes

everything needed for design.

4 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 5

Getting Started

2.2 Required Equipment

Minimum equipment required:

• Power supply (Power Plug or Laboratory Power Supply), with 12 V/2 Amp min current capability

• Oscilloscope (preferably 4-channel) with current probe(s)

• ECU Wiring Harness (included in the RDAIRBAGPSI5-1 kit)

• PSI5 Satellites Sensors (included in the RDAIRBAGPSI5-1 kit)

• Typical loads: 1.2 Ohm/2 Ohm for squibs, switch to ground for DC Sensors, LEDs for GPOs

Recommended equipment for ARP evaluation (GUI):

• FreeMASTER Software installed: http://www.freescale.com/arp

• Airbag Reference Platform FreeMASTER GUI Application: http://www.freescale.com/arp

• USB FTDI cable (Reference: TTL-232R-5V)

All software tools can be downloaded under Software & Tools tab of the RDAIRBAGPSI5 webpage. Registration might be required in order

to get access to the relevant files.

Recommended equipment for software development:

• Freescale CodeWarrior 10.5 or greater for Qorivva MCUs (Eclipse IDE) family installed: http://www.freescale.com/arp

• Airbag System Evaluation Software (source code): http://www.freescale.com/arp

• USB A-B cable

• P&E USB Multilink Debugger for Power Architecture:

http://www.freescale.com/webapp/sps/site/prod_summary.jsp?code=USBMLPPCNEXUS

2.3 System Requirements

• USB-enabled PC with Windows XP or greater

• FTDI Drivers installed for serial communication: http://www.ftdichip.com/Drivers/VCP.htm

Freescale Semiconductor 5

RDAIRPABPSI5UG , Rev. 2.0

Page 6

Understanding the System

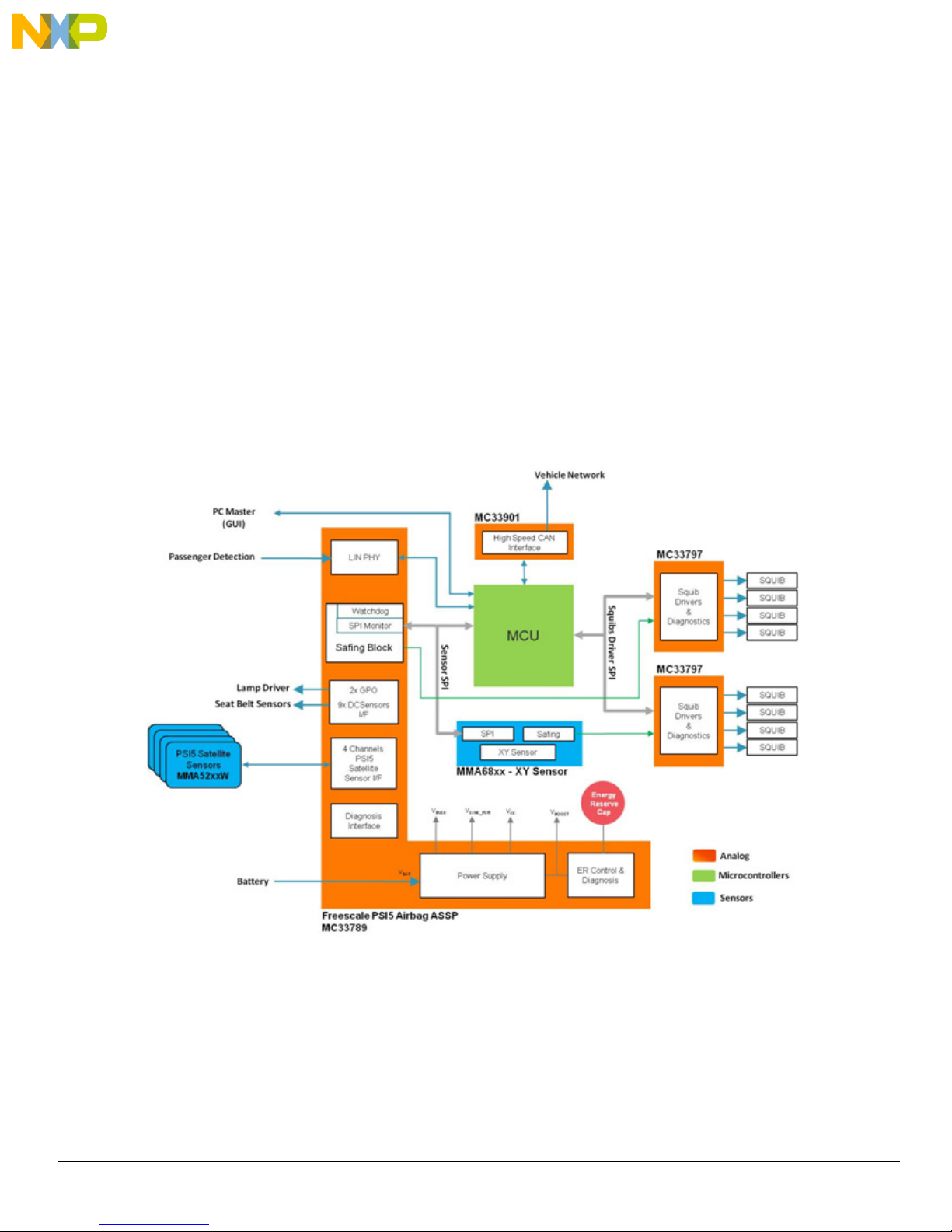

3 Understanding the System

The Freescale Airbag Reference Platform (ARP) is an application demonstrator system which provides an airbag Electronic Control Unit

(ECU) implementation example using complete Freescale standard products for the growing automotive safety segment. The GUI

firmware does not constitute a true airbag application but is intended to demonstrate features and capabilities of Freescale's standard

products aimed at the airbag market.

The ARP addresses a mid-range airbag market segment, with up to eight squib drivers (for squibs and seatbelt pre-tensioners) and four

satellite sensor interfaces supporting four or more high g collision sensors positioned around the vehicle. All other vehicle infrastructure

(including seat belt sensors and vehicle communications networks) and ECU functions (including full power supply architecture and a local

mid g X/Y safing sensor) are also supported.

The new ARP hardware is implemented using a standard Freescale Qorivva 32-bit microcontroller (MPC560xP), Analog (MC33789 and

MC33797). In the case of sensors, the families include both local ECU and PSI5 satellite sensors. The ARP implements a system safety

architecture based on the features in the standard products supported by appropriate firmware.

The example ECU is implemented on a single Printed Circuit Board (PCB). Vehicle functions - in principal, satellite sensors, seat belt

switches and warning lamps - can be accessed thanks to the ECU cables.

This User Manual is intended to detail the available hardware functionality and related software drivers (firmware) offered in the Freescale

ARP.

The high level system block diagram here outlines the way the Freescale standard products are used to implement an example airbag

ECU.

6 Freescale Semiconductor, Inc.

Figure 2. RDAIRBAGPSI5 Block Diagram

RDAIRPABPSI5UG , Rev. 2.0

Page 7

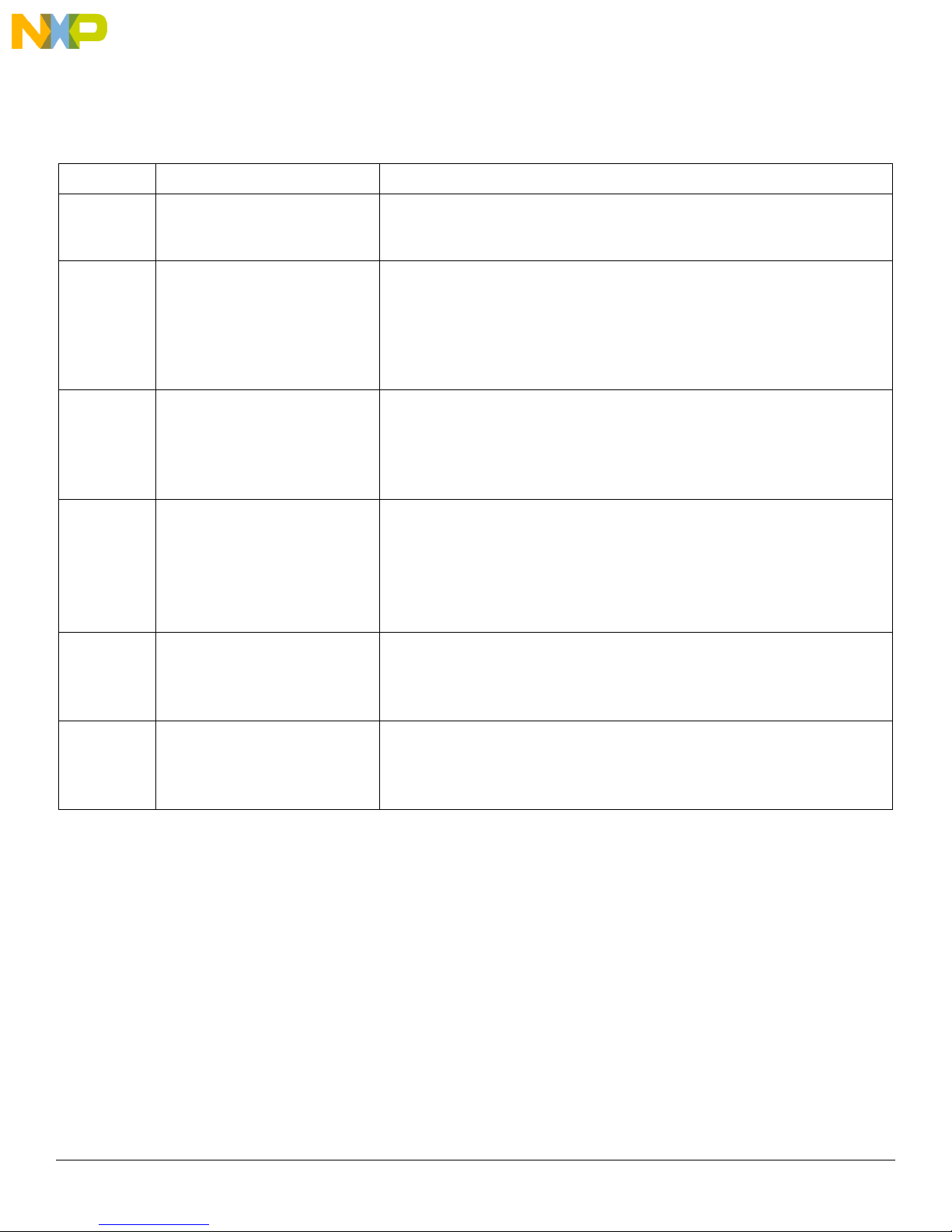

3.1 Device Features and Functional Description

This reference design features the following Freescale products:

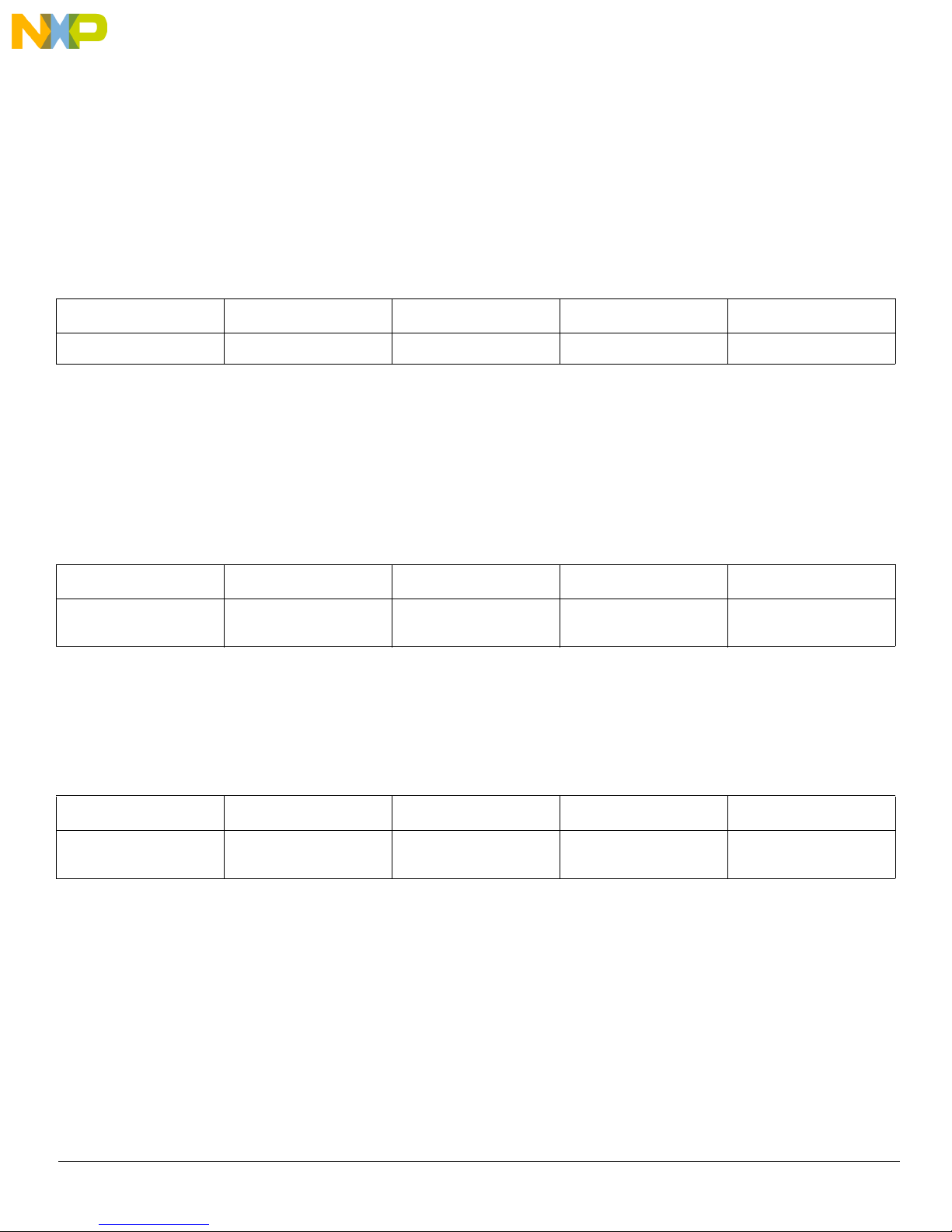

Table 1. Airbag Reference Platform Device Features

Device Description Features

Understanding the System

MPC560xP

MC33789

MMA68xx

MC33797

MC33901

MMA52xx

MMA51xx

Qorivva 32-bit Microcontroller

Airbag System Basis Chip (PSI5)

ECU Local X/Y Accelerometer

Four Channel Squib Driver

High Speed CAN Physical Layer

High G Collision Satellite Sensor

• Scalable MCU family for safety applications

• e200z0 Power Architecture 32-bit core up to 64 MHz

• Scalable memory, up to 512 KB flash

• Power supply for complete ECU

• Up to four Satellite Sensor interfaces (PSI5)

• Up to nine configurable switch input monitors for simple switch, resistive and

Hall-effect sensor interface

• Safing block and watchdog

• LIN 2.1 physical layer interface

• ±20 g to ±120 g full-scale range, independently specified for each axis

• SPI-compatible serial interface

• 10-bit digital signed or unsigned SPI data output

• Independent programmable arming functions for each axis

• 12 low-pass filter options, ranging from 50 Hz to 1000 Hz

• Four channel high-side and low-side 2.0 A FET switches

• Externally adjustable FET current limiting

• Adjustable current limit range: 0.8 to 2.0 A

• Diagnostics for high-side safing sensor status

• Resistance and voltage diagnostics for squibs

• 8-bit SPI for diagnostics and FET switch activation

• ISO11898-2 and -5 compatible

• Standby mode with remote CAN wake-up on some versions

• Very low current consumption in standby mode, typ. 8 µA

• Excellent EMC performance supports CAN FD up to 2 Mbps

• ±60 g to ±480 g full-scale range

• PSI5 Version 1.3 Compatible (PSI5-P10P-500/3L)

• Selectable 400 Hz, 3 pole, or 4 pole low-pass Filter

• X-axis (MMA52xx) and Z-axis (MMA51xx) available

3.1.1 MPC5602P - Microcontroller

This microcontroller is a member of the highly successful Qorivva MPC560xP family of automotive microcontrollers.

It belongs to an expanding range of automotive-focused products designed to address chassis applications as well as airbag applications.

The advanced and cost-efficient host processor core of this automotive controller family complies with the Power Architecture® embedded

category. It operates at speeds of up to 64 MHz and offers high performance processing optimized for low power consumption. It

capitalizes on the available development infrastructure of current Power Architecture® devices and is supported with software drivers,

operating systems and configuration code to assist with users implementations.

Freescale Semiconductor 7

RDAIRPABPSI5UG , Rev. 2.0

Page 8

Understanding the System

3.1.2 MC33789 - Airbag System Basis Chip

This device implements all vehicle sensor interfaces and the airbag system support functions:

3.1.2.1 Power Supply Block

• A switched-mode power supply DC-DC converter in a boost configuration to generate the high voltage level (33 V), in

which energy is stored in the autarky capacitor, and used to allow continued operation of the airbag system for a defined

time following a collision, which leads to disconnection of the battery

• A switched-mode power supply DC-DC converter in a buck configuration, to efficiently step down the boost supply to a

level suitable for supplying the satellite sensors interfaces (9.0 V) and further regulators, for the local ECU supplies

• A switched capacitor charge pump to double the output of the buck converter, for use in supplying the necessary voltage

for the PSI5 sync pulse generation (18 V)

• A linear regulator to provide the local logic supply (5.0 V) for ECU devices i.e. microcontroller, local sensor, squib driver

3.1.2.2 Safing Block

This block includes a SPI monitor which inputs all inertial sensors (PSI5 satellites and onboard sensors) read by the microcontroller over

the sensor SPI interface, and compares it to pre-defined threshold acceleration values for each local and vehicle collision sensor. Based

on this comparison, where the threshold is exceeded in three consecutive acquisition cycles, the system is armed by enabling the safing

outputs, which in turn enables the squib drivers, so that the application can fire the necessary squibs based on the airbag algorithm results.

3.1.2.3 DC Sensors Interface

A low speed (DC) interface which connects to resistive, simple switch and hall effect sensors which are used to check whether seat belts

are being worn through seat belt switches and seat position through seat track sensors.

3.1.2.4 PSI5 Satellite Sensors Interface

Four Satellite sensors interfaces, which connect to collision sensors distributed around the vehicle. The interfaces are implemented based

on the PSI5 V1.3 specification, and can operate in synchronous modes. It detects current drawn by the satellite and translates the

current-modulated satellite messages into digital data, which the MCU retrieves via the SPI interface.

3.1.2.5 LIN Physical Layer

For connection to vehicle diagnostic interface (K-line) or Occupant Classification System.

3.1.2.6 Lamp Driver

A flexible high or low-side driver which can be configured in hardware which supports PWM driven LED or warning lamp driver.

3.1.2.7 Diagnostics

A number of measures which allow diagnosis of implemented functions on the system basis chip, e.g. all voltage supplies including power

transistor temperature monitors, autarky capacitor ESR, etc.

3.1.2.8 Additional Communication Line

MC33789 is designed to support the Additional Communication Line (ACL) aspect of the ISO-26021 standard, which requires an

independent hardwired signal (ACL) to implement the scrapping feature.

8 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 9

Understanding the System

3.2 MMA6813KW - ECU Local Sensor

The ECU local sensor acceleration data is used by the airbag application to cross check the acceleration data received from the satellite

collision sensors, to confirm that a collision is really happening, and that airbags need to be deployed.

The local sensor used in the ARP is dual channel, and confirms both frontal and side impacts. In addition, the MMA68xx includes its own

safing block, which will compare the measured acceleration to configurable thresholds and set safing outputs accordingly. This function is

used in the ARP to enable the squib drivers, and therefore be an independent part of the system safing architecture - both the safing blocks

in the system basis chip and in the local sensor must enable the squib drivers before the application is able to fire the appropriate squibs.

3.3 MC33797 - Four Channel Squib Driver

Each channel consists of a high-side and a low-side switch. The ARP uses two MC33797 devices connected in cross-coupled mode, i.e.

high-side switch from one device and low-side switch from the other, connected to each squib or seat belt pre-tensioner. This ensures no

single point of failure in the squib output stage.

The MC33797 implements a comprehensive set of diagnostic features that allows the application to ensure that the squib driver stage is

operating correctly.

3.4 MMA5xxx - High G Satellite Collision Sensor

A single channel acceleration sensor operating in the range of 60 - 480g (depending on G-cell fitted), which includes a PSI5 V1.3 interface

for direct connection to the system basis chip. The device can operate in either asynchronous (point-to-point single sensor connection) or

synchronous (bus mode with multiple sensors connected to each interface) mode. The device can be used either for frontal collisions or

side impacts. For more information about PSI5, please refer to the PSI5 standard specification for airbag systems:

http://psi5.org/

Freescale Semiconductor 9

RDAIRPABPSI5UG , Rev. 2.0

Page 10

Getting to know the Hardware

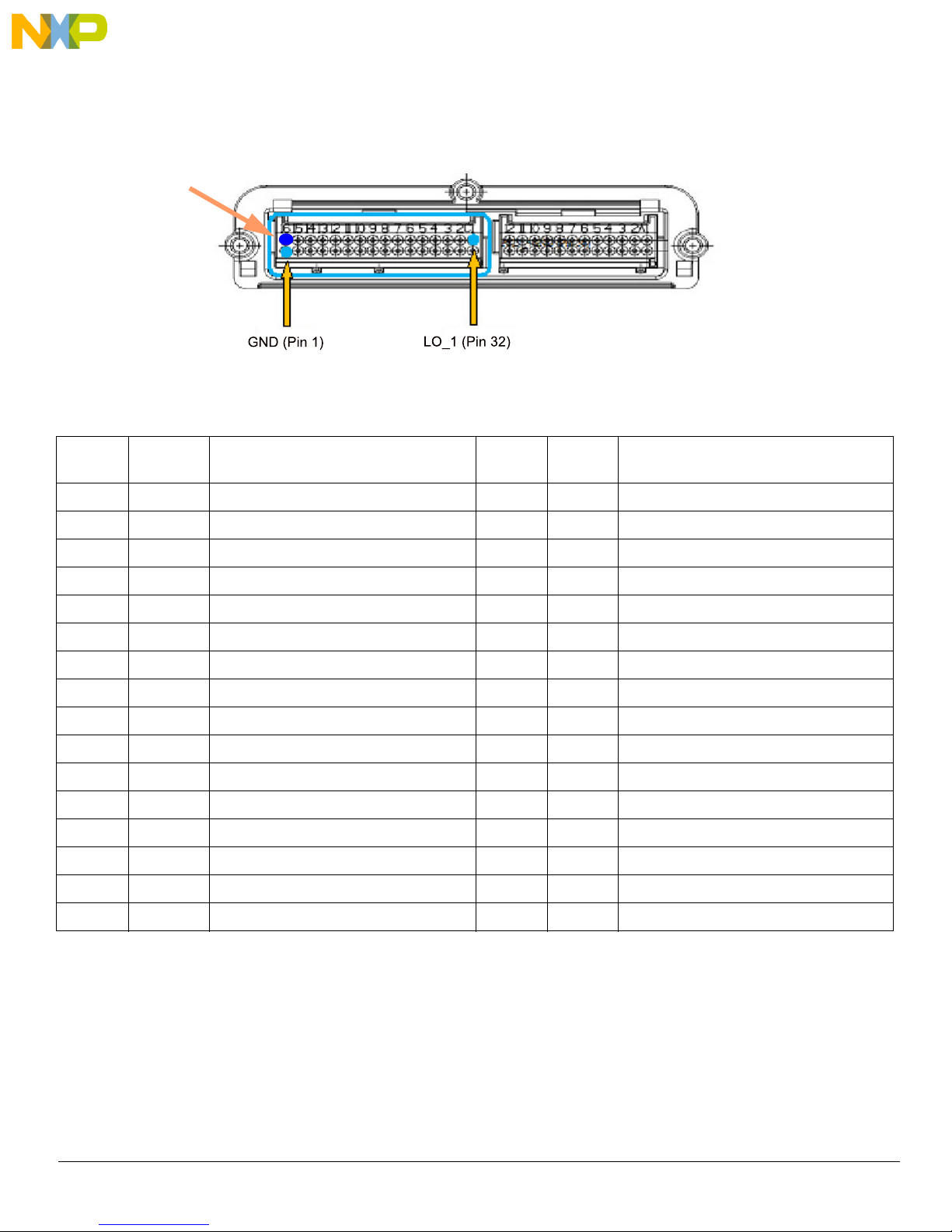

24-pin connector 32-pin connector

4 Getting to know the Hardware

4.1 Overview

RDAIRBAGPSI5 is an eight loops airbag system ECU. Figure 3 shows all the main components of an airbag ECU hardware. Table 2 lists

all the functions performed by each component.

Figure 3. Board Description

Table 2. Board Description

Name Definition

x2 4ch Squibs Driver MC33797 x2 Four channels Squibs Driver configured in cross-coupled mode to make an eight firing loops airbag

system

Central Accelerometer MMA68xx Central Accelerometer, also called Local Safing Sensor, designed for use in automotive airbag systems

CAN HS Transceiver MC33901 Physical interface between the CAN protocol controller of an MCU and the physical dual wires of the

CAN bus

JTAG Connector P&E USB Multilink Debugger

FTDI Connector (RS232) USB to serial communication connector for GUI application

32-bit MCU MPC5602P Qorivva Power Architecture MCU for Chassis and Safety Application

PSI5 Airbag System Basis Chip MC33789 Airbag System Basis Chip (SBC) with Power Supply and PSI5 Sensor Interface

On-Board Front Airbags Deployment LEDs 2x LEDs used to indicate a front impact Deployment event: Front Driver and/or Front Passenger

10 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 11

Getting to know the Hardware

REDD2,3,4,5

OrangeD6

GreenD7

YellowD1

Table 2. Board Description (continued)

Name Definition

On-Board Side Airbags Deployment LEDs 2x LEDs used to indicate a side impact Deployment event: Rear Right and/or Rear Left

Energy Reserve Capacitor Autarky Capacitor used as Energy Reserve in case of Battery disconnection

4.2 LED Display

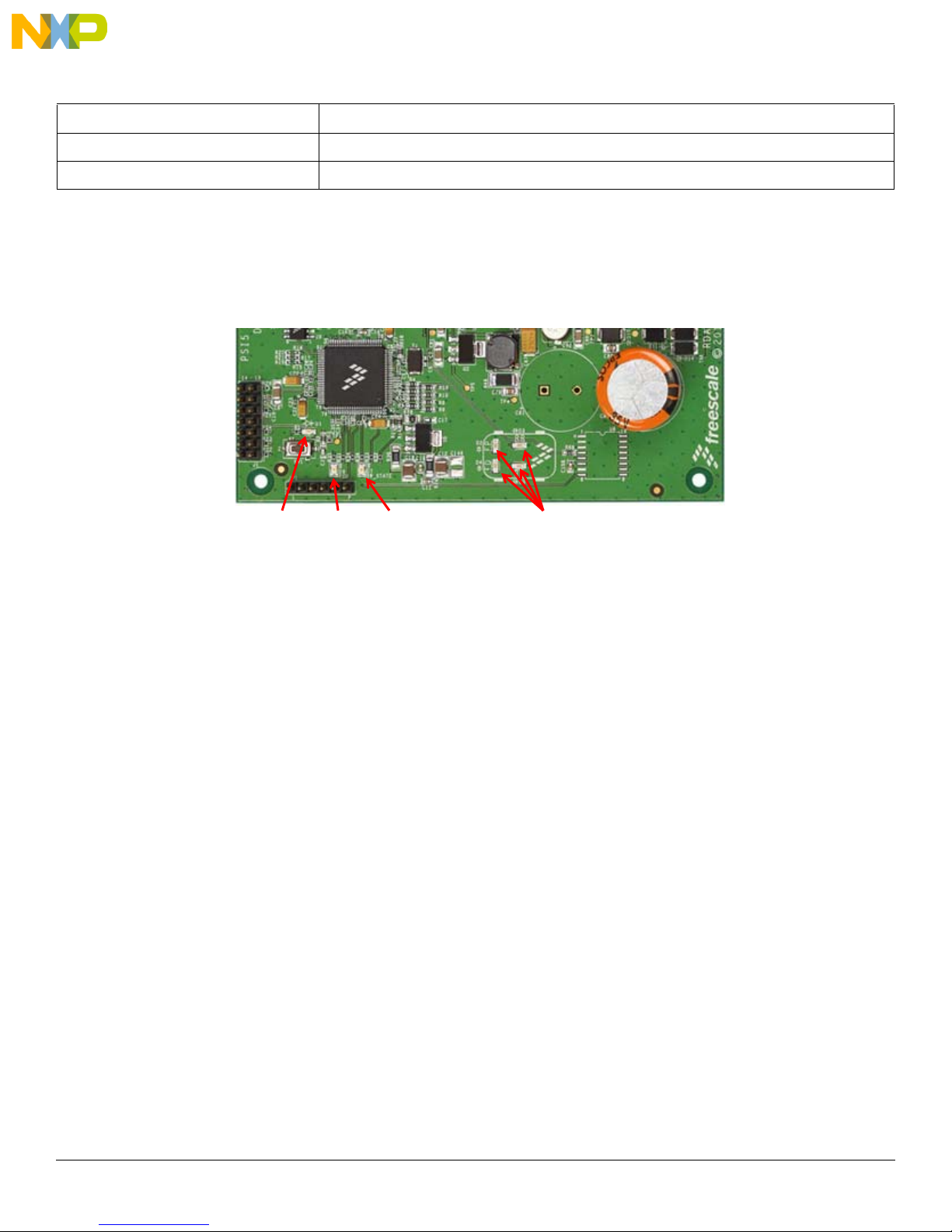

This section describes the LEDs on the lower portion of the RDAIRBAGPSI5 board.

Figure 4. LED Locations

The following LEDs are provided as visual output devices for the RDAIRBAGPSI5 board:

1. LED D1 indicates when a System Reset occurred (LED color: Yellow).

2. LED D2 first indicates MC33789 is correctly initialized only during INIT phase. Then, it is used to display Front

Passenger deployment during GUI Application mode (LED color: Red).

3. LED D3 first indicates MMA68xx is correctly initialized only during INIT phase. Then, it is used to display Rear Right

Side deployment during GUI Application mode (LED color: Red).

4. LED D4 first indicates MC33797 are correctly initialized only during INIT phase. Then, it is used to display Front Driver

deployment during GUI Application mode (LED color: Red).

5. LED D5 first indicates MCU is correctly initialized only during INIT phase. Then, it is used to display Rear Left Side

deployment during GUI Application mode (LED color: Red).

6. LED D6 indicates when a FCU fault is detected by MCU (LED color: Orange).

Note: If no FCU faults are detected, LED is turned ON.

7. LED D7 indicates MCU Software is running (LED color: Green).

Freescale Semiconductor 11

RDAIRPABPSI5UG , Rev. 2.0

Page 12

Getting to know the Hardware

Pin 2

4.3 Connectors

This section discusses the ARP 32-pin and 24-pin positions and their descriptions.

Figure 5. J1 32-pin Connector Location

Table 3: 32-pin Connector Pin List

Position

1 GND Ground Signal 17 IN6 Port 6 of input monitor for DC sensor

2 VBAT Battery Voltage 18 IN5 Port 5 of input monitor for DC sensor

3 GND Ground Signal 19 IN4 Port 4 of input monitor for DC sensor

4 VBAT Battery Voltage 20 IN3 Port 3 of input monitor for DC sensor

5 NC Not connected 21 IN2 Port 2 of input monitor for DC sensor

6 NC Not connected 22 IN1 Port 1 of input monitor for DC sensor

7 OUT2_S Source pin of configurable output FET 2 23 CANH CAN Bus High Signal

8 OUT2_D Drain pin of configurable output FET 2 24 CANL CAN Bus Low Signal

9 OUT1_D Drain pin of configurable output FET 1 25 HI_4 Source of the Squib Driver High-side switch 4

10 OUT1_S Source pin of configurable output FET 1 26 LO_4 Drain of the Squib Driver Low-side switch 4

11 LIN_GND LIN Ground 27 HI_3 Source of the Squib Driver High-side switch 3

12 LIN LIN Signal 28 LO_3 Drain of the Squib Driver Low-side switch 3

13 NC Not connected 29 HI_2 Source of the Squib Driver High-side switch 2

14 IN9 Port 9 of input monitor for DC sensor 30 LO_2 Drain of the Squib Driver Low-side switch 2

15 IN8 Port 8 of input monitor for DC sensor 31 HI_1 Source of the Squib Driver High-side switch 1

Signal

name

Description Position

Signal

name

Description

16 IN7 Port 7 of input monitor for DC sensor 32 LO_1 Drain of the Squib Driver Low-side switch 1

12 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 13

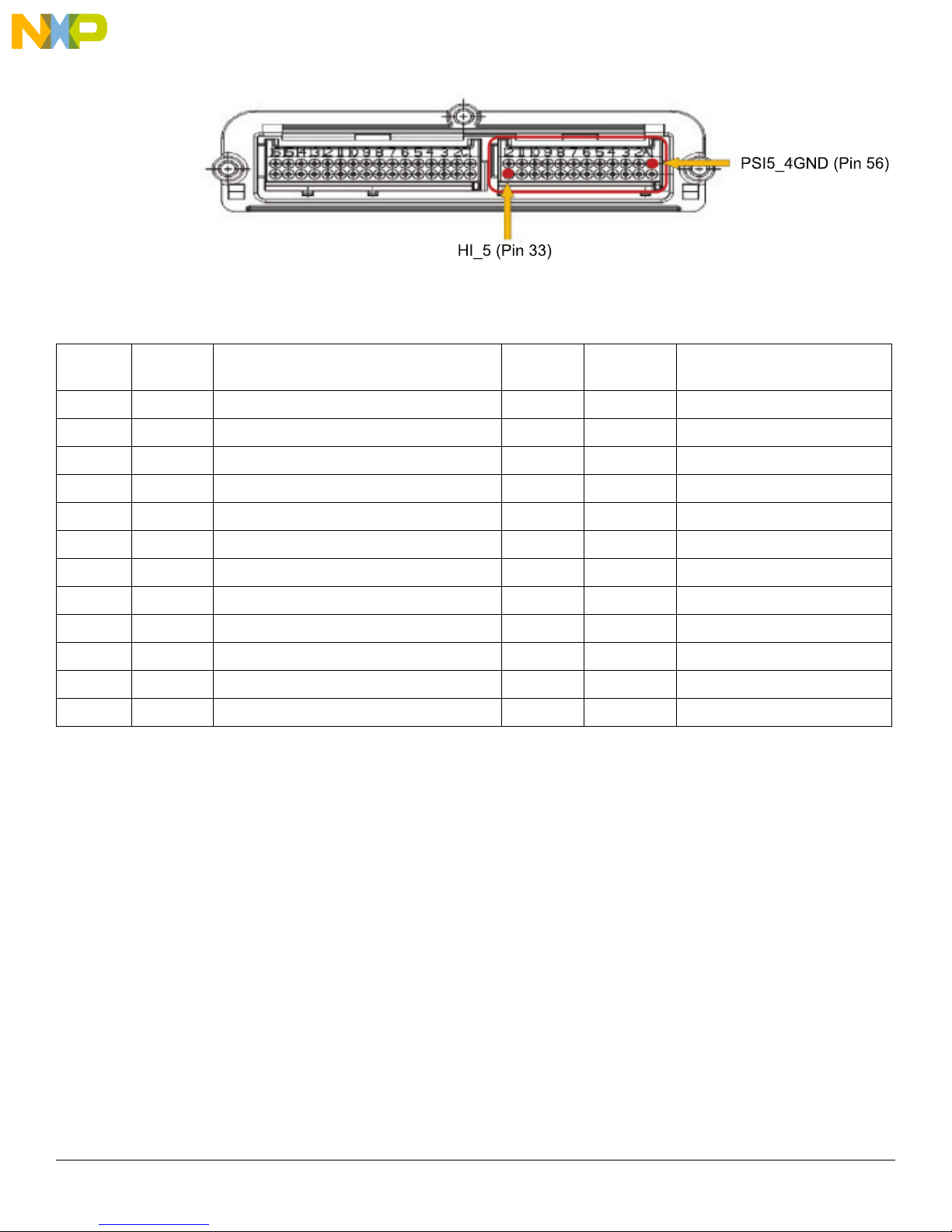

Table 4: 24-pin Connector List

Getting to know the Hardware

Figure 6. J2 24-pin Connector Location

Position

33 HI_5 Source of the Squib Driver High-side switch 5 45 NC Not Connected

34 LO_5 Drain of the Squib Driver Low-side switch 5 46 NC Not Connected

35 HI_6 Source of the Squib Driver High-side switch 6 47 NC Not Connected

36 LO_6 Drain of the Squib Driver Low-side switch 6 48 NC Not Connected

37 HI_7 Source of the Squib Driver High-side switch 7 49 PSI5_1OUT PSI5 Channel1 Signal line

38 LO_7 Drain of the Squib Driver Low-side switch 7 50 PSI5_1GND PSI5 Channel1 Ground line

39 HI_8 Source of the Squib Driver High-side switch 8 51 PSI5_2OUT PSI5 Signal Channel2 line

40 LO_8 Drain of the Squib Driver Low-side switch 8 52 PSI5_2GND PSI5 Channel2 Ground line

41 GND Ground signal 53 PSI5_3OUT PSI5 Channel3 Signal line

42 GND Ground signal 54 PSI5_3GND PSI5 Channel3 Ground line

43 NC Not Connected 55 PSI5_4OUT PSI5 Channel4 Signal line

44 NC Not Connected 56 PSI5_4GND PSI5 Channel4 Ground line

Signal

name

Description Position Signal name Description

Freescale Semiconductor 13

RDAIRPABPSI5UG , Rev. 2.0

Page 14

Describing the Device Functions

5 Describing the Device Functions

The RDAIRBAGPSI5UG Airbag Reference Platform is aimed to cover all major functions of a true airbag system application.

The following section describes individual functions and available view using the GUI:

5.1 MC33789 - Airbag System Basis Chip

5.1.1 Power Supply - Boost Converter and Energy Reserve

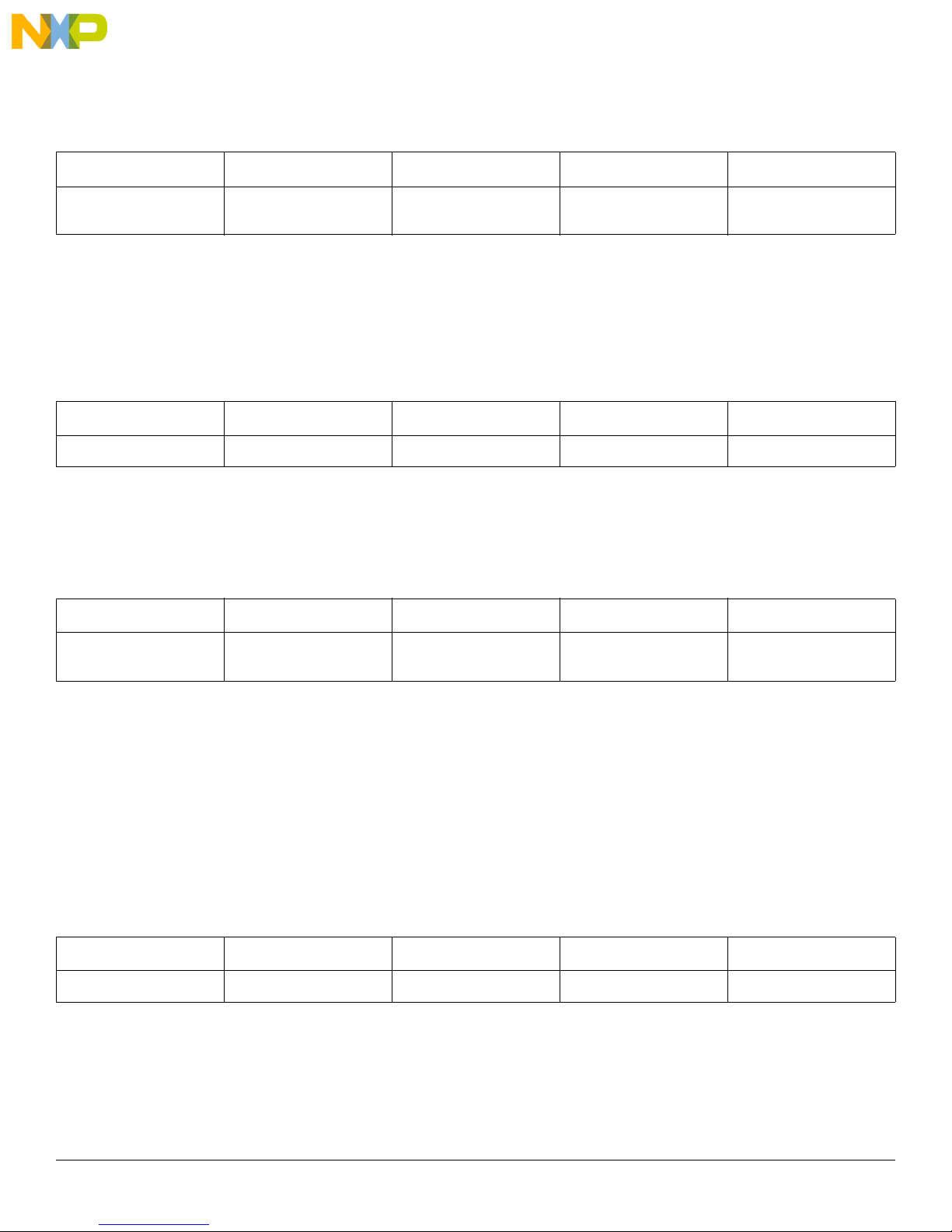

Table 5. Power Supply - Boost Converter and Energy Reserve

Define Function Config Register Diagnosis Comment

MC33789 Energy Reserve Supply PS_CONTROL AI_CONTROL

Default setting for the boost converter is ON and will start up when VBATT exceeds a predefined limit. Initially, the boost converter will

charge a small capacitor. Default setting for the energy reserve is OFF to prevent excessive inrush current at key on. The firmware must

turn the energy reserve on through the PS_CONTROL register once VBOOST is stable. Firmware can monitor VBOOST through the

analog output pin selected through AI_CONTROL register. After the energy reserve is turned on, the large energy reserve capacitor (min

2200 µF) will be charged.

5.1.2 Power Supply - Energy Reserve Capacitor ESR Diagnostic

Table 6. Power Supply - Energy Reserve Capacitor ESR Diagnostic

Define Function Config Register Diagnosis Comment

MC33789 Energy Reserve

Capacitor Diagnostic

During ESR diagnostic, the energy reserve capacitor is slightly discharged and the firmware can calculate, based on the discharge rate,

the value of the capacitor's equivalent series resistance (ESR) - this is a measure of the condition of the capacitor.

ESR_DIAG ESR_DIAG

5.1.3 Power Supply - Buck Converter

Table 7. Power Supply - Buck Converter

Define Function Config Register Diagnosis Comment

MC33789 Vcc5, DC Sensor and

Satellite Sensor Supply

Buck converter is internally enabled when the VBOOST voltage is above the under-voltage lockout threshold. The firmware cannot disable

the Buck converter in the RDAIRBAGPSI5 application.

PS_CONTROL AI_CONTROL

14 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 15

5.1.4 Power Supply - SYNC Pulse Supply

Table 8. Power Supply – SYNC Pulse Supply

Define Function Config Register Diagnosis Comment

Describing the Device Functions

MC33789 Satellite Sensor SYNC

Pulse Supply

Default setting for the SYNC supply is OFF. Firmware needs to turn the SYNC supply on through PS_CONTROL register only if the satellite

sensors are operating in synchronous mode. Firmware can monitor VSYNC voltage through the analog output pin selected through the

AI_CONTROL register.

PS_CONTROL AI_CONTROL

5.1.5 Power Supply - ECU Logic Supply

Table 9. Power Supply - ECU Logic Supply

Define Function Config Register Diagnosis Comment

MC33789 Linear Regulator – –

The internal ECU logic supply is always on and firmware has no configuration to perform.

5.1.6 Safing Block - Sensor Data Thresholds

Table 10. Safing Block - Sensor Data Thresholds

Define Function Config Register Diagnosis Comment

MC33789 Threshold T_UNLOCK,

SAFE_TH_n

–

In order to be able to change the sensor data threshold value or values at which the ARM/DISARM pins are set to their active states (i.e.

the system is armed when a sensor value exceeds the defined threshold), a secure firmware sequence must be carried out to unlock the

threshold register using T_UNLOCK. Once that is done, the threshold can be changed by firmware through the SAFE_TH_n register.

Notes: There is no special firmware required to input sensor data into the safing block. The SPI protocol on the sensor SPI interface is

the same to both the local sensor and the satellite sensor interfaces on the system basis chip, and whenever the microcontroller reads a

sensor value, the response from the sensor or system basis chip is recognized as being sensor data, and is automatically read into the

safing block. The only requirement the application has to meet is that the sensor data is read in the correct sequence, starting with the

local sensor X-axis data followed by the Y-axis, and then the satellite sensor interfaces on the system basis chip.

5.1.7 Safing Block - Diagnostics

Table 11. Safing Block - Diagnostics

Define Function Config Register Diagnosis Comment

MC33789 Linear Regulator – SAFE_CTL

The firmware has the capability to change the mode in which the safing block is operating, so that diagnosis of the ARM/DISARM pins can

be diagnosed or the scrapping mode (i.e. the system is armed when no sensor data exceeds any threshold, used to fire all squibs when

a vehicle is being scrapped) can be entered. Either of these changes is only possible at startup prior to the safing block entering normal

operation.

Freescale Semiconductor 15

RDAIRPABPSI5UG , Rev. 2.0

Page 16

Describing the Device Functions

5.1.8 DC Sensors

Table 12. DC Sensors

Define Function Config Register Diagnosis Comment

MC33789 Seat belt/Seat track

sensor interface

The firmware must select which DC sensor is active and which supply voltage is used on that sensor through the DCS_CONTROL register.

The firmware must also select the correct sensor to be read through the analog output pin using the AI_CONTROL register. Note that both

registers can be returned to their default state by a correct write to the DIAG_CLR register.

DCS_CONTROL,

AI_CONTROL

–

5.1.9 PSI5 Satellite Sensor Interface

Table 13. PSI5 Satellite Sensor Interface

Define Function Config Register Diagnosis Comment

MC33789 Satellite Sensor LINE_MODE,

LINE_ENABLE

The firmware must select the correct mode of operation of the satellite sensor interface and enable each interface individually. The

interfaces should be enabled one at a time to reduce current inrush.

When the interface is enabled, the satellite sensor will automatically send its initialization data, and the firmware must handle this data to

ensure the sensor is operating correctly.

5.1.9.1 LIN Physical Layer

Table 14. LIN Physical Layer

–

Define Function Config Register Diagnosis Comment

MC33789 LIN physical layer LIN_CONFIG –

The firmware has the potential to change the configuration of the LIN physical layer, but the default setting is the most common

configuration.

A special mode exists which allows the Manchester encoded data from a satellite sensor to be monitored on the LIN RXD output pin, for

example in case MCU has a PSI5 peripheral module embedded.

5.1.9.2 Lamp Driver

Table 15. Lamp Driver

Define Function Config Register Diagnosis Comment

MC33789 Lamp driver GPOn_CTL GPOn_CTL

The firmware must configure whether the driver is a high or low-side switch, and the PWM output duty cycle. In the response to the

command, the firmware can check that high or low thresholds on the pins have been exceeded, and whether an over-temperature

shutdown has occurred.

As part of the application, the warning lamp should be turned on at key on, kept illuminated until the startup diagnostic procedure has

completed, and the system is ready to start operating.

16 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 17

Describing the Device Functions

5.1.9.3 Diagnostics

Table 16. Diagnostics

Define Function Config Register Diagnosis Comment

MC33789 Diagnostics – STATUS, AI_CONTROL

The firmware can monitor the operation of the main ASSP through the STATUS and AI_CONTROL registers.

5.2 MMA6813KW - Local ECU Acceleration Sensor

The local ECU acceleration sensor is a dual channel device which also includes a safing block. At start up, the configuration, offset

cancellation, and self test of the device, occur before the configuration is complete ('ENDINIT' set) and the device goes into normal

operation.

5.2.1 Configuration - General

Table 17. Configuration - General

Define Function Config Register Diagnosis Comment

MMA6813KW Configuration DEVCFG –

The general configuration sets up the data format, whether offset monitoring is enabled, and the functionality of the ARM_X and ARM_Y

output pins. When configuration is complete, the ENDINIT bit is set and this locks out access to the configuration registers.

5.2.2 Configuration - Axis Operation

Table 18. Configuration - Axis Operation

Define Function Config Register Diagnosis Comment

MMA6813KW Configuration DEVCFG_X,

DEVCFG_Y

The axis operation configuration triggers self-test and selects one of the low pass filter options for each axis.

–

5.2.3 Configuration - Arming Operation

Table 19. Configuration - Arming Operation

Define Function Config Register Diagnosis Comment

MMA6813KW Configuration ARMCFG_X,

ARMCFG_Y

–

The arming operation configuration defines the arming pulse stretch period and the arming window, which has different meanings,

depending on which arming mode is configured.

Freescale Semiconductor 17

RDAIRPABPSI5UG , Rev. 2.0

Page 18

Describing the Device Functions

5.2.4 Configuration - Arming Threshold

Table 20. Configuration - Arming Threshold

Define Function Config Register Diagnosis Comment

MMA6813KW Configuration ARMT_XP, ARMT_XN

ARMT_YP, ARMT_YN

For each axis, both the positive and negative threshold can be set above which and when the arming window requirements are met, the

arm outputs will be set to active as defined in the arming operations register.

In the startup phase, the threshold can be set to such a level that when the self test deflection is triggered, the arming outputs will become

active. This can be used as part of the self-test at startup. After completion of the self test, thresholds should be set back to the correct

application values, and before the configuration is complete, by setting the 'ENDINIT' bit, after which no further configuration changes can

be made.

The complete startup and self-test procedure is described in the ARP specification (Airbag Reference Platform).

Note that after the configuration is complete and the 'ENDINIT' bit is set, a CRC check of the configuration is carried out in the background,

which will lead to an error in the status register if a configuration bit flips.

–

5.2.5 Status

Table 21. Status

Define Function Config Register Diagnosis Comment

MMA6813KW Status – DEVSTAT

Internal errors are flagged in the DEVSTAT register.

5.3 MC33797 - Four Channel Squib Driver (FCS)

The ARP uses two Four Channel Squib Drivers (FCS) configured in cross-coupled mode to safely implement eight squib drivers.

The four channel squib driver is addressed using an 8-bit SPI interface over which commands and data are sent.

The only configuration possible is the time the device remains enabled after the fire enable (FEN1, FEN2) pins have been activated. This

is equivalent to the arming pulse stretch time applied to the safing output on both the system basis chip and the local ECU sensor. Two

commands are required to change this time - first is an unlock command and second is the programmed time between 0 and 255

Default is 0

Firing the squibs also requires two commands - the first arms one of the banks of drivers, the second turns on the required switches. More

than one switch can be turned on by a single command.

The majority of the commands relate to diagnostics of the four channel squib driver and the connected squibs. A full list of diagnostic

commands is available in the ARP specification (Airbag Reference Platform).

ms.

ms.

5.4 MMA5xxx High G Satellite Collision PSI5 Sensor

Configuration of the device is done off line prior to assembly in the system.

As soon as the device is switched on, it will begin an internal configuration and self test, and also sends initialization data, which is received

in the system basis chip and checked by the application. Once the device has completed sending the initialization data, which concludes

with an OK or NOK message, it enters normal operation and starts sending sensor data, either autonomously if in asynchronous mode,

or in response to SYNC pulses on the satellite sensor interface if in synchronous mode.

18 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 19

Installing the Software and Setting up the Hardware

6 Installing the Software and Setting up the Hardware

ARP software is built on basic low level MCU drivers (MCAL), which provide access to the modules ADC, GPIO, EEPROM, SPI, LINFlex,

etc. in the microcontroller, thus providing all necessary MCU functions. The upper software layer contains Complex Drivers for all main

ARP devices - Main Airbag ASIC MC33789 (Analog system Basis Chip (ASBC) Driver), Central Accelerometer MMA6813KW (ACC

Driver), and Four Channel Squib Driver MC33797 (SQUIB Driver). These drivers have an MCU independent API, which means no

modification of ASBC, SQUIB or ACC drivers is needed for all MCU derivatives (8/16/32-bit).

Figure 7. SW Design Concept

6.1 Hardware Abstraction Layer (HAL)

The software architecture for this Airbag Reference Platform uses a Hardware Abstraction Layer that removes details of working with a

MPC560xP 32-bit microcontroller. This will allow a developer to focus attention on the application tasks instead of focusing on the very

specific functionality of the MCU used. Software applications can then be created based on a higher level of understanding.

6.2 GUI - FreeMASTER Software

FreeMASTER software was designed to provide a debugging, diagnostic, and demonstration tool for the development of algorithms and

applications. Moreover, it's very useful for tuning the application for different power stages and motors, because almost all the application

parameters can be changed via the FreeMASTER interface. This consists of a component running on a PC and another part of the

component running on the target controller, connected via an RS-232 serial port or USB. A small program is resident in the controller that

communicates with the FreeMASTER software to parse commands, return status information to the PC, and process control information

from the PC. FreeMASTER software, executed on the PC, uses Microsoft Internet Explorer as the user interface.

Freescale Semiconductor 19

RDAIRPABPSI5UG , Rev. 2.0

Page 20

Installing the Software and Setting up the Hardware

6.2.1 Installing FreeMASTER on your Computer

To set up the GUI on your PC, you have to install the FreeMASTER software if not already installed.

Notes: If FreeMASTER is already on your system, the steps in this section can be skipped.

1. Start the FMASTERSW.exe install shield wizard. The file can be downloaded from http://www.freescale.com. The License

Agreement box is displayed and you are prompted for further actions.

2. Clicking the Next button starts the installation program. The Installation Wizard prompts you for further actions.

3. Follow the instructions given by the Installation Wizard.

6.2.2 FreeMASTER Serial Communication Driver

The presented application includes the FreeMASTER Serial Communication Driver.

The main advantage of this driver is a unification across all supported Freescale processor products, as well as several new features that

were added. One of the key features implemented in the new driver is Target-Side Addressing (TSA), which enables an embedded

application to describe the memory objects it grants the host access to. By enabling the so-called "TSA-Safety" option, the application

memory can be protected from illegal or invalid memory accesses.

To include the FreeMASTER Serial Communication Driver in the application, the user has to manually include the driver files in the

CodeWarrior project. For the presented application, the driver files have already been included.

The FreeMASTER driver files are located in the following folder:

• {Project_Loc}\Sources\GUI

This folder contains platform-dependent driver C-source and header files, including a master header file freemaster.h.

For instance, in the current ARP, user will find freemaster_MPC56xx.c and freemaster_MPC56xx.h for Qorivva MPC56xxP family.

This folder also contains common driver source files, shared by the driver for all supported platforms.

All C files included in the FreeMASTER folder are added to the project for compilation and linking.

The master header file freemaster.h declares the common data types, macros, and prototypes of the FreeMASTER driver API functions.

This should be included in the application (using #include directive), wherever there is need to call any of the FreeMASTER driver API

functions.

The FreeMASTER driver does NOT perform any initialization or configuration of the SCI module it uses to communicate. This is the user's

responsibility to configure the communication module before the FreeMASTER driver is initialized by the FMSTR_Init() call. The default

baud rate of the SCI communication is set to 9600 Bd.

FreeMASTER uses a poll-driven communication mode. It does not require the setting of interrupts for SCI. Both communication and

protocol decoding are handled in the application background loop. The polling-mode requires a periodic call of the FMSTR_Poll() function

in the application main.

The driver is configured using the freemaster_cfg.h header file. The user has to modify this file to configure the FreeMASTER driver. The

FreeMASTER driver C-source files include the configuration file, and use the macros defined there for conditional and parameter

compilation.

For more information, a detailed description of the FreeMASTER Serial Communication Driver is provided in the FreeMASTER Serial

Communication Driver User's Manual.

6.2.3 Airbag Reference Platform - GUI

FreeMASTER GUI application can work in two modes:

• Debug mode - GUI firmware together with GUI applications allow debug of the main ARP devices - MC33789 (Airbag

System Basis Chip), MC33797 (Four Channel Squib Driver), and MMA6813KW (Central Accelerometer). The device

registers are readable and configurable. At all times, the registers remain visible and can be monitored. This is intended

to aid engineers understand both the hardware and software routines.

• Application mode - Application mode allows ARP users to view acceleration data from central and satellite

accelerometers. These numerical values are also plotted on a graph, which allows informative outlook to the

acceleration levels of all sensors. Deployment of squibs is simulated in this mode on a simple car model picture, using

pictures of both front and side deployments. The same simulation is performed at MCU level, indicated using the four

onboard red LEDs.

Notes: The GUI firmware is already loaded into Airbag Reference Platform after delivery and immediately ready for using with the

FreeMASTER GUI application.

20 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 21

Installing the Software and Setting up the Hardware

6.2.4 FreeMASTER Debug Mode

Parameters of the devices MC33789, MC33797, or MMA6813KW, can be arbitrarily changed. Parameters are sent to the selected device

after the button press "Send Parameters To Reference Board". All meaningful device registers are shown in the registry table "Command

Responses Table" at the bottom of the each device page. For each cell in this table, a tool-tip help is available. View these tips, hover over

the cell to see descriptions of the selected register (For an example page see

Figure 8).

Figure 8. FreeMASTER Debug Page for the MC33789 Device

After starting the watchdog refresh (Watchdog -> Enable), parameters "Safing Thresholds" and "Dwell Extensions" in MC33789 cannot

be changed.

6.2.5 FreeMASTER Application Mode

ARP Application mode permits the user to (see Figure 9):

• View acceleration data from central and satellite accelerometers. These numerical values are displayed in points where

sensors should be placed inside the car.

• View acceleration data plotted on a graph, which allows informative outlook to the acceleration levels of all sensors and

a simple car model simulation of the both front and side collisions. Plotted data is only informative, since transferred

data from sensors is averaged for illustration of ARP functionality only.

• Simulate deployment of an airbag when the acceleration data reaches the threshold values. These thresholds are set

to very low limits, so even a soft hit of the satellite sensor to the ARP board will cause relevant airbags’ "deployment".

Airbags deployment is illustrated in the GUI thanks to front and side airbags pictures. (Any "collision" at the driver or

passenger location causes inflation of two front airbags. Impact from left side causes inflation of the left side airbags,

and impact from right side causes deployment of the right side airbags. Anytime after deployment, simulation is possible

to reset an inflated bag or bags by pressing button "Reset Deployed Airbags".

Freescale Semiconductor 21

RDAIRPABPSI5UG , Rev. 2.0

Page 22

Installing the Software and Setting up the Hardware

Figure 9. FreeMASTER Application Mode

Notes: In this GUI mode during simulated airbags’ "deployment", the relevant squibs drivers are not activated. In order to deploy front

airbags, a combination of acceleration values (Front Satellites & Central Accel) above the threshold is required to simulate front

deployment.

Other deployment indicators can be found on the actual ARP Hardware. Four red color LEDs are implemented onboard in order to provide

the same information as displayed on FreeMASTER GUI. User can also take advantage of this onboard LEDs in case a real application

firmware is developed based on Freescale ARP to indicate which car airbags have been deployed.

Figure 10. On-Board and Side Airbags Red Color LEDs

22 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 23

Installing the Software and Setting up the Hardware

OR

FTDI

cable

FTDI

cable

OR

6.2.6 Configuring the Hardware using FreeMASTER

Figure 11. RDAIRBAGPSI5 Configured for ARP Evaluation Using FreeMASTER GUI

Figure 12. RDAIRBAGPSI5-1 Configured for ARP Evaluation Using FreeMASTER GUI

Freescale Semiconductor 23

RDAIRPABPSI5UG , Rev. 2.0

Page 24

Installing the Software and Setting up the Hardware

In order to perform the demonstration examples, set up the reference platform hardware and software as follows. All software tools can

be downloaded under Software & Tools tab of the RDAIRBAGPSI5 webpage. Registration might be required in order to get access to the

relevant files.

1. Install FreeMASTER Software (can be downloaded from freescale.com/freemaster).

2. Connect ECU wiring harness to the ARP blue connector.

3. Connect the power supply, either using a power plug or lab power supply.

CAUTION

Please pay attention to the power supply's polarity.

(DO NOT connect both power supply’s inputs).

4. Switch on the power supply at 5.2 - 20 V. (Nominal value: 12 V)

5. Initialization Phase:

• On the ARP Hardware, four red LEDs should turn on one after another, then they all turn off

• This firmware sequence is intended to provide visual information to the user that all four main devices (MC33789,

MMA68xx, MC33797 and MCU) are correctly initialized

• The Green and Orange LEDs should remain ON

6. Connect the Airbag Reference Platform to the PC using an FTDI cable. Upon connection of FTDI cable, autoinstallation begins. If

not, visit http://www.ftdichip.com/Drivers/VCP.htm and select the driver compatible with the OS being used.

7. Wait until FTDI drivers installation is completed (during first connection, drivers for the device have to be installed. This can take

several minutes). When finished, a status message is displayed in the Windows taskbar and confirms the appropriate drivers were

installed correctly.

8. Launch the ARP Graphical User Interface by double clicking on the RDAIRBAGPSI5_FreeMASTER application file.The ARP GUI

should appear as in

Figure 13.

Figure 13. ARP Graphical User Interface

24 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 25

Installing the Software and Setting up the Hardware

9. Open "File/Start communication" to establish the connection. See Figure 14.

Figure 14. ARP Graphical User Interface File/Start

At the bottom of the GUI screen, a message "Communication With Reference Board Works Properly" should appear. Once the steps

above are all accomplished, proceed to using the GUI for evaluation. Refer to the

Troubleshooting Section for assistance in using the

GUI.

Freescale Semiconductor 25

RDAIRPABPSI5UG , Rev. 2.0

Page 26

Installing the Software and Setting up the Hardware

6.2.7 Troubleshooting

If this message box appears immediately after launching the ARP GUI, select OK and proceed to the following steps:

Figure 15. Unspecified Error Window

1. In Project menu, under Options -> Comm tab, select correct COM port associated with the FTDI cable now connected to the host

computer. Speed used for this GUI is 256000.

2. Open "File\Start communication" to establish the connection.

Incomplete and/or inaccurate execution of the above steps results in the message depicted in Figure 15.

The error sources could be:

• The ARP demo has no power. Check the power supply setup.

• COM ports are not assigned correctly.

• On the PC desktop, right click on "My computer" and select "Properties". The "System Properties" window will open.

• Select the "Hardware" tab, then select the "Device Manager" button. In a new window, expand the "Ports (COM & LPT)".

• If the USB drivers are installed properly, the virtual COM ports will be listed, e.g. "USB Serial Port (COMx)". The PC

assigns COMx port number. Note the port number used for FreeMASTER control pages configuration described in

Step 1 above.

COM ports are now assigned correctly, and the previous message box no longer appears. Instead, at the bottom of the GUI, a message

“Communication With Reference Board Works Properly” is seen. See Figure 16.

Figure 16. Communication With Reference Board Works Properly Window

26 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 27

Installing the Software and Setting up the Hardware

6.3 MicroController Abstraction Layer (MCAL)

A Microcontroller Abstraction Layer (MCAL) is defined in order to provide basic MCU drivers to the SW Reference Platform upper Layers.

The primarily intent is to allow the software developer to easily modify source code or replace the microcontroller - for example , use of

S12X 16-bit MCU - with no modification of the Complex drivers (i.e. ASBC, SQUIB or ACC). Thanks to the MCAL, a software developer

can maximize re-use of the SW Reference Platform APIs in order to build their own SW application.

RDAIRBAGPSI5 can be configured to modify the MCU Software code using CodeWarrior to download a customized firmware. The

following sections describe all steps required to configure RDAIRBAGPSI5 for MCU Software development.

6.3.1 Installing CodeWarrior 10.5 or Greater

This procedure explains how to obtain and install the latest version of CodeWarrior 10.5 or greater.

Notes: The sample software in this kit requires CodeWarrior 10.5 or greater. If CodeWarrior 10.5 or greater is already on your system,

the steps in this section can be skipped.

1. Obtain the latest CodeWarrior 10.5 (or greater) installer file from freescale.com/codewarrior.

2. Run the executable file and follow the instructions.

During the installation, there is a request to select components to install. User must install at least the Qorivva component. Select the

Qorivva component and click on "Next" to complete the installation.

Freescale Semiconductor 27

Figure 17. CodeWarrior Choose Components

RDAIRPABPSI5UG , Rev. 2.0

Page 28

Installing the Software and Setting up the Hardware

6.3.2 Interface

The Airbag Reference Platform (ARP) may be used with the P&E's USB BDM Multilink which provides an easy-to-use debug and

programming interface for Freescale’s Power Architecture® MPC5xx line of microprocessors. This accessory will be needed to flash the

MCU using Freescale CodeWarrior 10.5 or greater. See

Figure 18.

Figure 18. P&E USB Multilink Debugger

6.3.3 Configuring the Hardware using CodeWarrior

Figure 19. RDAIRBAGPSI5 Configured for MCU Software Development

28 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 29

Installing the Software and Setting up the Hardware

In order to perform the demonstration examples, first setup the evaluation board hardware and software as follows:

1. Connect the P&E USB Multilink Debugger between the reference design board and the computer.

2. Wait until P&E USB Multilink Debugger drivers installation is completed (during first connection, drivers for the device have to be

installed. This can take several minutes). When finished, a status message is displayed in the Windows taskbar and confirms the

appropriate drivers were installed correctly.

3. Launch the CodeWarrior Suite.

4. Connect the power supply, either using a power plug or lab power supply.

CAUTION

Please pay attention to the power supply's polarity.

(DO NOT connect both power supply’s inputs).

5. Switch on the power supply at 5.2 to 20 V.

6. Connect ECU wiring harness to the ARP blue connector.

7. Start development of your application using CodeWarrior.

6.4 Complex Drivers

6.4.1 Airbag System Basis Chip (ASBC) SW Driver

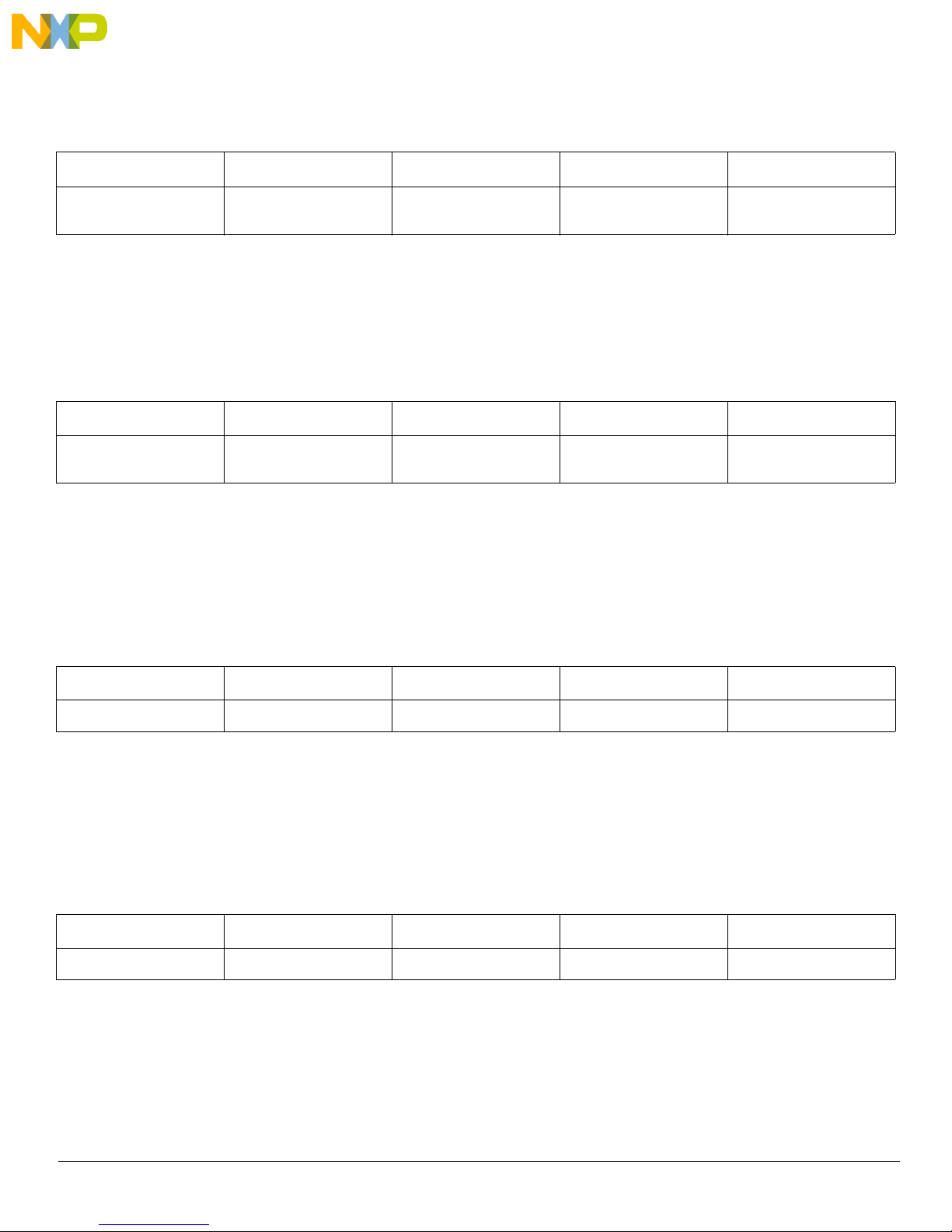

Table 22: Airbag System Basis Chip SW Driver API

Function Name Function Parameters Return Type Function

Asbc_Init

Asbc_GetStatus

Asbc_SetAnlMuxSource

Asbc_SetDcsMuxSource

Asbc_SetVregMode

Asbc_GetVregStatus

Asbc_SetPsi5Mode

Asbc_GetPsi5Status

Asbc_SetLinMode

Asbc_GetLinStatus

Asbc_SetGpo

Asbc_GetGpoStatus

Spi_Channel [in]

*Config [in]

Spi_Channel [in]

*Status [out]

Spi_Channel [in]

Source [in]

Spi_Channel [in]

Source [in]

Voltage [in]

Spi_Channel [in]

*Config [in]

Spi_Channel [in]

*Status [out]

Spi_Channel [in]

*Config [in]

Spi_Channel [in]

*Status [out]

Spi_Channel [in]

*Config [in]

Spi_Channel [in]

*Status [out]

Spi_Channel [in]

GpoChannel [in]

GpoPwmDutyCycle [in]

GpoDriverConfig [in]

Spi_Channel [in]

GpoChannel [in]

*Status [out]

Asbc_ReturnType

Asbc_ReturnType

Asbc_ReturnType

Asbc_ReturnType

Asbc_ReturnType

Asbc_ReturnType

Asbc_ReturnType

Asbc_ReturnType Return the status of the ASBC PSI5 interface.

Asbc_ReturnType

Asbc_ReturnType Return the ASBC LIN transceiver status.

Asbc_ReturnType

Asbc_ReturnType

Initialize the Airbag System Basis Chip and returns the

confirmation of initialization. Multiple initialization configuration is

supported via the Config parameter.

Return the status of the ASBC. Only the general statuses are

reported via this service.

Allow to change the analog parameter which is connected to the

AOUT output.

Determines which DC sensor input channel shell be connected for

diagnostic output.

Set the ASBC Voltage regulator. Various configurations of voltage

regulators are supported via the Asbc_VregConfig container.

Return the status of the ASBC Voltage regulators. This also

contains the Boost and Buck statuses.

Set the ASBC PSI5 four satellite sensor interface. Various

configurations of PSI5 interface are supported via the

Asbc_Psi5Config container.

Set the ASBC LIN transceiver mode. Via the Asbc_LinConfig

configuration container various configurations are supported.

Set the ASBC output channel mode. Various configuration for each

output channel are supported via the Asbc_GpoDriverConfig

configuration container.

Return the ASBC output channel status. This includes the

high/low-side selection, thermal shutdown and the voltage level.

Description

Freescale Semiconductor 29

RDAIRPABPSI5UG , Rev. 2.0

Page 30

Installing the Software and Setting up the Hardware

Table 22: Airbag System Basis Chip SW Driver API (continued)

Asbc_ReadSensor

Asbc_FeedWatchdog

Asbc_ProgramCmd

Spi_Channel [in]

SequenceIdentifier [in]

LogicalChannel [in]

Spi_Channel [in]

WD_Polarity [in]

Spi_Channel [in]

Command [in]

Data [in]

SpiResponse [out]

Asbc_ReturnType

Asbc_ReturnType

Asbc_ReturnType Send any ASBC command to the device and read its response.

This function provides sensor request/response to retrieve sensor

data from satellite interface block.

Update the ASBC Watchdog. A successful watchdog refresh is an

SPI command (high), following another SPI command (low).

6.4.2 ASBC API Parameters Detail

Brief description of input and output API parameters is in the following paragraphs. Descriptions contain only a verbal description of the

parameter. Values which can variable acquired are described in the header file MC33789.h.

Parameters of the Asbc_Init API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• Config (Asbc_ConfigType) - input configuration structure:

• Asbc_SafingThreshold0 - 8 bits safing 0 threshold value

• Asbc_SafingDwellExt0 - extension of the arming pulse width (either 255 ms or 2.0 s) for threshold0

• Asbc_SafingThreshold1 - 8 bits safing 1 threshold value

• Asbc_SafingDwellExt1 - extension of the arming pulse width (either 255 ms or 2.0 s) for threshold1

• Asbc_SafingThreshold2 - 8 bits safing 2 threshold value

• Asbc_SafingDwellExt2 - extension of the arming pulse width (either 255 ms or 2.0 s) for threshold2

• Asbc_SafingThreshold3 - 8 bits safing 3 threshold value

• Asbc_SafingDwellExt3 - extension of the arming pulse width (either 255 ms or 2.0 s) for threshold3

• Asbc_SafingThreshold4 - 8 bits safing 4 threshold value

• Asbc_SafingDwellExt4 - extension of the arming pulse width (either 255 ms or 2.0 s) for threshold4

• Asbc_SafingThreshold5 - 8 bits safing 5 threshold value

• Asbc_SafingDwellExt5 - extension of the arming pulse width (either 255 ms or 2.0 s) for threshold5

• Asbc_SafingThreshold6 - 8 bits safing 6 threshold value

• Asbc_SafingDwellExt6 - extension of the arming pulse width (either 255 ms or 2.0 s) for threshold6

• Asbc_SafingThreshold7 - 8 bits safing 7 threshold value

• Asbc_SafingDwellExt7 - extension of the arming pulse width (either 255 ms or 2.0 s) for threshold7

Parameters of the Asbc_GetStatus API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• Status (Asbc_StatusType) output status structure containing the common status of the ASBC device:

• Asbc_VregSyncSuppOverTemp - Sync supply over-temperature error

• Asbc_VregSensRegulOverTemp - DC sensor regulator over-temperature error

• Asbc_VregBoostOverTemp - Boost supply over-temperature error

• Asbc_VregIgnState

• Asbc_WakeupPinState - wake-up pin state

• Asbc_WdogState - watchdog state

• Asbc_WdogErrStatus - watchdog error status

• Asbc_SafingSequenceErr - safing sequence error

30 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 31

Installing the Software and Setting up the Hardware

• Asbc_SafingOffsetErr - safing offset error

• Asbc_SafingMode - safing mode status

• Asbc_SafingDataCount - number of digital sensor messages received with valid sensor data

• Safing threshold settings - these parameters are returned the same values as described in the initialization function

• ASBC_Init

Parameters of the Asbc_SetAnlMuxSource API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• Source (Asbc_AnlMuxSourceType) input parameter - analog source which will be connected to the MUX input

Parameters of the Asbc_SetDcsMuxSource API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• Source (Asbc_DcsMuxSourceType) input parameter - sensor channel selection determines which DC sensor input shall

be connected for diagnostics output

• Voltage (Asbc_DcsMuxSourceType) input parameter - bias voltage selection determines which regulated voltage shall

be used as a bias supply on the DC sensor output stage for diagnostics

Parameters of the Asbc_SetSafingMode API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• SafingMode (Asbc_SafingModeRequestType) input parameter - safing mode request

• SafingTestEnable (Asbc_SafingTestEnableType) input parameter - safing test enable

• SafingLevel (Asbc_SafingLevelType) input parameter - arming output level

Parameters of the Asbc_SetVregMode API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• Config (Asbc_VregConfigType) input configuration parameter - configuration of the ASBC voltage regulator:

• Asbc_VregSyncSupply (Asbc_VregConfigType) input parameter - Sync supply control

• Asbc_VregBoost (Asbc_VregBoostType) input parameter - Boost regulator control

• Asbc_VregBuck (Asbc_VregBuckType) input parameter - Buck regulator control

• Asbc_VregEnergyReserve (Asbc_VregEnergyReserveType) input parameter - energy reserve control

Parameters of the Asbc_GetVregStatus API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• VregEnergyReserveTest (Asbc_VregEnergyReserveTestType) input parameter - energy reserve test diagnostic control

• Status (Asbc_VregStatusType) output structure containing the status of the ASBC voltage regulators:

• Asbc_VregBoost (Asbc_VregStatBoostType) - report boost voltage less/greater than threshold (~80% of target)

• Asbc_VregChargDischarFault (Asbc_VregStatChargDischarFaultType) - CER charge/discharge switch failure

status

• Asbc_VregSyncSupply (Asbc_VregSyncSupplyType) - Sync supply status

• Asbc_VregBoostEnable (Asbc_VregBoostType) - Boost regulator status

• Asbc_VregBuckEnable (Asbc_VregBuckType) - Buck regulator status

• Asbc_VregEnergyReserve (Asbc_VregEnergyReserveType) - energy reserve status

• Asbc_VregEnergyReserveValue (unit8) - energy reserve test diagnostic status

Freescale Semiconductor 31

RDAIRPABPSI5UG , Rev. 2.0

Page 32

Installing the Software and Setting up the Hardware

Parameters of the Asbc_SetPsi5Mode API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• Config (Asbc_Psi5ConfigType) input configuration structure of the ASBC PSI5 interface:

• Asbc_PSI5Chann1Mode (Asbc_PSI5Chann1ModeType) - PSI5 channel 1 mode - Synchronous SATSYNC

(Steered Mode) or Synchronous TDM Mode

• Asbc_PSI5Chann1Enable (Asbc_PSI5Chann1EnableType) - PSI5 channel 1 enable/disable

• Asbc_PSI5Chann1SynPuls (Asbc_PSI5Chann1SynPulsType) - PSI5 channel 1 sync pulse enable/disable

• Asbc_PSI5Chann2Mode (Asbc_PSI5Chann2ModeType) - PSI5 channel 2 mode - Synchronous SATSYNC

(Steered Mode) or Synchronous TDM Mode

• Asbc_PSI5Chann2Enable (Asbc_PSI5Chann2EnableType) - PSI5 channel 2 enable/disable

• Asbc_PSI5Chann2SynPuls (Asbc_PSI5Chann2SynPulsType) - PSI5 channel 2 sync pulse enable/disable

• Asbc_PSI5Chann3Mode (Asbc_PSI5Chann3ModeType) - PSI5 channel 3 mode - Synchronous SATSYNC

(Steered Mode) or Synchronous TDM Mode

• Asbc_PSI5Chann3Enable (Asbc_PSI5Chann3EnableType) - PSI5 channel 3 enable/disable

• Asbc_PSI5Chann3SynPuls (Asbc_PSI5Chann3SynPulsType) - PSI5 channel 3 sync pulse enable/disable

• Asbc_PSI5Chann4Mode (Asbc_PSI5Chann4ModeType) - PSI5 channel 4 mode - Synchronous SATSYNC

(Steered Mode) or Synchronous TDM Mode

• Asbc_PSI5Chann4Enable (Asbc_PSI5Chann4EnableType) - PSI5 channel 4 enable/disable

• Asbc_PSI5Chann4SynPuls (Asbc_PSI5Chann4SynPulsType) - PSI5 channel 4 sync pulse enable/disable

Parameters of the Asbc_GetPsi5Status API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• Status (Asbc_Psi5StatusType) output structure containing the status of the ASBC PSI5 interface: - returned parameters

are the same as are described in Asbc_SetPsi5Mode function above

Parameters of the Asbc_SetLinMode API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• Config (Asbc_LinConfigType) input configuration structure of the ASBC LIN bus interface:

• Asbc_LinSlewRate (Asbc_LinSlewRateType) - LIN slew rate selection

• Asbc_LinRXDMode (Asbc_LinRXDModeType) - RxD output function

• Asbc_LinRXOut (Asbc_LinRXOutType) - Rx output selection (for RxD satellite function)

Parameters of the Asbc_GetLinStatus API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• Status (Asbc_LinStatusType) output structure containing the status of the ASBC LIN bus interface:

• Asbc_LinSlewRate (Asbc_LinSlewRateType) - LIN slew rate selection

• Asbc_LinRXDMode (Asbc_LinRXDModeType) - RxD output function

• Asbc_LinRXOut (Asbc_LinRXOutType) - Rx output selection (for RxD satellite function)

Parameters of the Asbc_SetGpo API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• GpoChannel (Asbc_GpoChannelType) - selected GPO pin

• GpoPwmDutyCycle (Asbc_GpoPwmDutyCycleType) - output PWM duty cycle

• GpoDriverConfig (Asbc_GpoDriverConfigType) - HS/LS driver configuration selection

32 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 33

Installing the Software and Setting up the Hardware

Parameters of the Asbc_GetGpoStatus API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• GpoChannel (Asbc_GpoChannelType) - selected GPO pin

• Status (Asbc_GpoStatusType) output structure containing the status of the selected output:

• Asbc_GpoDriverConfig - HS/LS driver configuration selection

• Asbc_GpoDriverOn13 - driver ON 1/3 VPWR comparator result

• Asbc_GpoDriverOn23 - driver ON 2/3 VPWR comparator result

• Asbc_GpoDriverOff13 - driver OFF 1/3 VPWR comparator result

• Asbc_GpoDriverOff23 - driver OFF 2/3 VPWR comparator result

Parameters of the Asbc_ReadSensor API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• SequenceIdentifier (Asbc_PSI5SequenceIdentifierType) - PSI5 sequence identifier (used for synchronizing samples)

• LogicalChannel (Asbc_PSI5LogicalChannelType) - PSI5 logical channel selection

• SensorData (unit16) - data from selected satellite sensor

• SensorStatus (Asbc_SensorStatusType) - satellite sensor response status

Parameters of the Asbc_FeedWatchdog API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• WD_Polarity (Asbc_WdLevelType) - watchdog polarity value

Parameters of the Asbc_ProgramCmd API function:

• Spi_Channel (Asbc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• Command (Asbc_SpiChannelType) - non sensor command

• Data (unit16) - data

• SpiResponse (unit16) - response to the sent command

6.5 Central Accelerometer Driver

The Central Accelerometer Driver (ACC) is created as a separate software module. The main advantage is full HW abstraction and API

independence used in the MCU family. The driver API covers the entire functionality of the main accelerometer, which means all

accelerometer functionality can be controlled using API functions.

The ACC Driver is dependent on the BSD layer (basic SPI driver), and on the GPIO driver (General Purpose Input/Output), which provides

basic functions for controlling input/output MCU pins.

Table 23: Central Accelerometer SW Driver API

Function Name Function Parameters Return Type Function Description

Initialize the central accelerometer device and returns the

confirmation of initialization. Multiple initialization configuration is

supported via the Config parameter.

Acc_Init

Spi_Channel [in]

*Config [in]

Acc_ReturnType

Acc_GetStatus

Acc_GetAccelData

Freescale Semiconductor 33

Spi_Channel [in]

*Status [out]

Spi_Channel [in]

AccelCmdX [in]

AccelCmdY [in]

*Status [out]

Acc_ReturnType Return the whole status of the Mesquite accelerometer device.

Acc_ReturnType

RDAIRPABPSI5UG , Rev. 2.0

Read the X and Y axis accelerometer moving values and other

necessary statuses.

Page 34

Installing the Software and Setting up the Hardware

Table 23: Central Accelerometer SW Driver API (continued)

Acc_ProgramCmd

Spi_Channel [in]

RegAddress [in] Data [in]

SpiResponse [out]

Acc_ReturnType Read/write independently any IC register.

6.5.1 ACC API Parameters Detail Descriptions

A brief description of input and output API parameters is in the following paragraphs. Descriptions contain only a verbal description of the

parameter. Values which each variable acquires are described in the header file MMA68xx.h.

Parameters of the Acc_Init API function:

• Spi_Channel (Acc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• Config (Acc_ConfigType) - input configuration structure:

• Acc_ConfSignData - this variable determines the format of acceleration data results

• Acc_OffsetMoni - offset monitor circuit enable/disable

• Acc_ArmOutput - mode of operation for the ARM_X/PCM_X and ARM_Y/PCM_Y pins

• Acc_XAxisSelfTest - enable or disable the self-test circuitry for X axis

• Acc_YAxisSelfTest - enable or disable the self-test circuitry for Y axis

• Acc_XLowPassFilter - the low pass filter selection bits independently select a low-pass filter for X axis

• Acc_YLowPassFilter - the low pass filter selection bits independently select a low-pass filter for Y axis

• Acc_XArmPulseStretch - pulse stretch time for X arming outputs

• Acc_YArmPulseStretch - pulse stretch time for Y arming outputs

• Acc_XArm_PosWin_CountLimit - X axis positive arming window size definitions or arming count limit definitions

function (depending on the state of the Acc_ArmOutput variable)

• Acc_YArm_PosWin_CountLimit - Y axis positive arming window size definitions or arming count limit definitions

function (depending on the state of the Acc_ArmOutput variable)

• Acc_XArm_NegWinSize - X axis negative arming window size definitions (meaning depend on the state of the

Acc_ArmOutput variable)

• Acc_YArm_NegWinSize - Y axis negative arming window size definitions (meaning depend on the state of the

Acc_ArmOutput variable)

• Acc_XArmPositiveThreshold - this value contain the X axis positive threshold to be used by the arming function

• Acc_YArmPositiveThreshold - this value contain the Y axis positive threshold to be used by the arming function

• Acc_XArmNegativeThreshold - this value contain the X axis negative thresholds to be used by the arming function

• Acc_YArmNegativeThreshold - this value contain the Y axis negative thresholds to be used by the arming function

Parameters of the Acc_GetStatus API function:

• Spi_Channel (Acc_SpiChannelType) - logical SPI channel number (not physical SPI channel)

• Status (Acc_StatusType) output status structure containing the complete status of the ACC device:

• Acc_SerialNumber - device serial number

• Acc_LotNumberHigh - device high lot number value

• Acc_LotNumberMidd - device midd lot number value

• Acc_LotNumberLow - device low lot number value

• Acc_PartNumber - device part number

• Acc_XPositiveTestDeflection - device self test positive deflection values for X axis

• Acc_YPositiveTestDeflection - self test positive deflection values for Y axis

• Acc_XFullScaleAccelerationRange - X self test magnitude selection

• Acc_YFullScaleAccelerationRange - Y self test magnitude selection

• Acc_DeviceReset - this device reset flag is set during device initialization following a device reset

• Acc_X_OffsetOverRange - the offset monitor over range flag is set if the acceleration signal of the X axis reaches

the specified offset limit

34 Freescale Semiconductor, Inc.

RDAIRPABPSI5UG , Rev. 2.0

Page 35

Installing the Software and Setting up the Hardware

• Acc_Y_OffsetOverRange - the offset monitor over range flag is set if the acceleration signal of the Y axis reaches

the specified offset limit

• Acc_SpiMisoError - the MISO data mismatch flag is set when a MISO Data mismatch fault occurs

• Acc_DeviceInitFlag - the device initialization flag is set during the interval between negation of internal reset and

completion of internal device initialization

• Acc_SigmaDeltaOverRange - the sigma delta modulator over range flag is set if the sigma delta modulator for either

axis becomes saturated

• Acc_InterDataError - the internal data error flag is set if a customer or OTP register data CRC fault or other internal

fault is detected

• Acc_FuseWarning - the fuse warn bit is set if a marginally programmed fuse is detected

• Acc_InitEnd - the ENDINIT bit is a control bit use to indicate that the user has completed all device and system level

initialization tests, and that Mesquite will operate in normal mode

• Acc_SignData - this parameter determines the format of acceleration data results

• Acc_OffsetMoni - offset monitor circuit is enable/disable

• Acc_ArmOutput - the ARM Configuration type select the mode of operation for the ARM_X/PCM_X,

ARM_Y/PCM_Y pins

• Acc_XAxisSelfTest - enable or disable the self-test circuitry for X axis

• Acc_YAxisSelfTest - enable or disable the self-test circuitry for Y axis

• Acc_XLowPassFilter - the low pass filter selection bits independently select a low-pass filter for X axis

• Acc_YLowPassFilter - the low pass filter selection bits independently select a low-pass filter for Y axis

• Acc_XArmPulseStretch - pulse stretch time for X arming outputs

• Acc_YArmPulseStretch - pulse stretch time for Y arming outputs

• Acc_XArm_PosWin_CountLimit - X axis positive arming window size definitions or arming count limit definitions

function (depending on the state of the Acc_ArmOutput variable)

• Acc_YArm_PosWin_CountLimit - Y axis positive arming window size definitions or arming count limit definitions

function (depending on the state of the Acc_ArmOutput variable)

• Acc_Arm_XNegWinSize - X axis negative arming window size definitions (meaning depend on the state of the

Acc_ArmOutput variable)

• Acc_Arm_YNegWinSize - Y axis negative arming window size definitions (meaning depend on the state of the

Acc_ArmOutput variable)