Page 1

AN13215

Introduction to Boundary Scan of i.MX8/i.MX8X

Rev. 0 — 04/2021

by: NXP Semiconductors

Contents

1 Introduction

The i.MX 8/i.MX 8X families provide the boundary scan feature according to the

IEEE1149.1 specification via the JTAG controller.

The boundary scan is a method for checking the interconnections on PCBs and

internal IC sub-blocks. The mechanism is defined in the IEEE1149.1 standard.

2 Purpose

This application note shows how to use a Boundary Scan Description Language (BSDL) file associated with a Lauterbach

debugger to set all i.MX8 IOs into a known state through the boundary scan. When this is achieved, the proper IO state can be

checked using a multimeter to ensure there is no issue with the board.

This document focuses on entering the boundary scan mode for the board-level test. It provides the setup sequence and script

examples to ensure first-pass success.

1 Introduction......................................1

2 Purpose...........................................1

3 Overview......................................... 1

4 Software setup................................ 2

5 Hardware setup...............................3

6 Boundary scan using i.MX 8/i.MX 8

BSDL file and Lauterbach JTAG

debugger......................................... 6

7 Revision history.............................10

Application Note

The engineers should be familiar with the standard for the test access port and boundary scan architecture from the IEEE

1149.1 specification.

3 Overview

3.1 Boundary scan

The boundary scan technique allows the signals at component boundaries to be controlled and observed through the shift-register

stage associated with each pad. Each stage is a part of a larger boundary scan register cell, and cells for each pad are

interconnected serially to form a shift-register chain around the border of the design. This register can be used to read and write

port states.

In the normal mode, these cells are transparent and the core is connected to the ports. In the boundary scan mode, the core is

isolated from the ports and the port signals are controlled by the JTAG interface.

Figure 1 shows the JTAG controller block with the associated signals and exported registers. For more details, see the IEEE

1149.1 specification and the i.MX 8/i/MX 8X reference manuals.

Page 2

NXP Semiconductors

Figure 1. JTAG (IEEE 1149.1) block diagram

Software setup

3.2 Test Access Port (TAP) JTAG

The TAP is a general-purpose port and it can provide access to many test support functions built into the component. The JTAG

controller uses the TAP to access registers and it can be shared with other TAP controllers on the MCU. It has four or five signals,

as described in Table 1.

Table 1. TAP JTAG

Signal name I/O type Description

TCK Input The test clock input provides the clock

for the test logic.

TMS Input The value of the signal present at the

TMS during a rising edge at the TCK

determines the next state of the TAP

controller.

TDI Input Serial test instructions and data are

received by the test logic.

TDO Output This serial output is used for test

instructions and data from the test logic.

TRST_N Input This is an optional active-low signal to

reset the TAP controller.

4 Software setup

The TRACE32 installation package is available on the Lauterbach webpage. Download the proper version of TRACE32 for

your host operating system and get support for the used target by navigating to the "Download" menu option and then into the

"TRACE32 Software" menu option.

Introduction to Boundary Scan of i.MX8/i.MX8X, Rev. 0, 04/2021

Application Note 2 / 11

Page 3

NXP Semiconductors

Hardware setup

5 Hardware setup

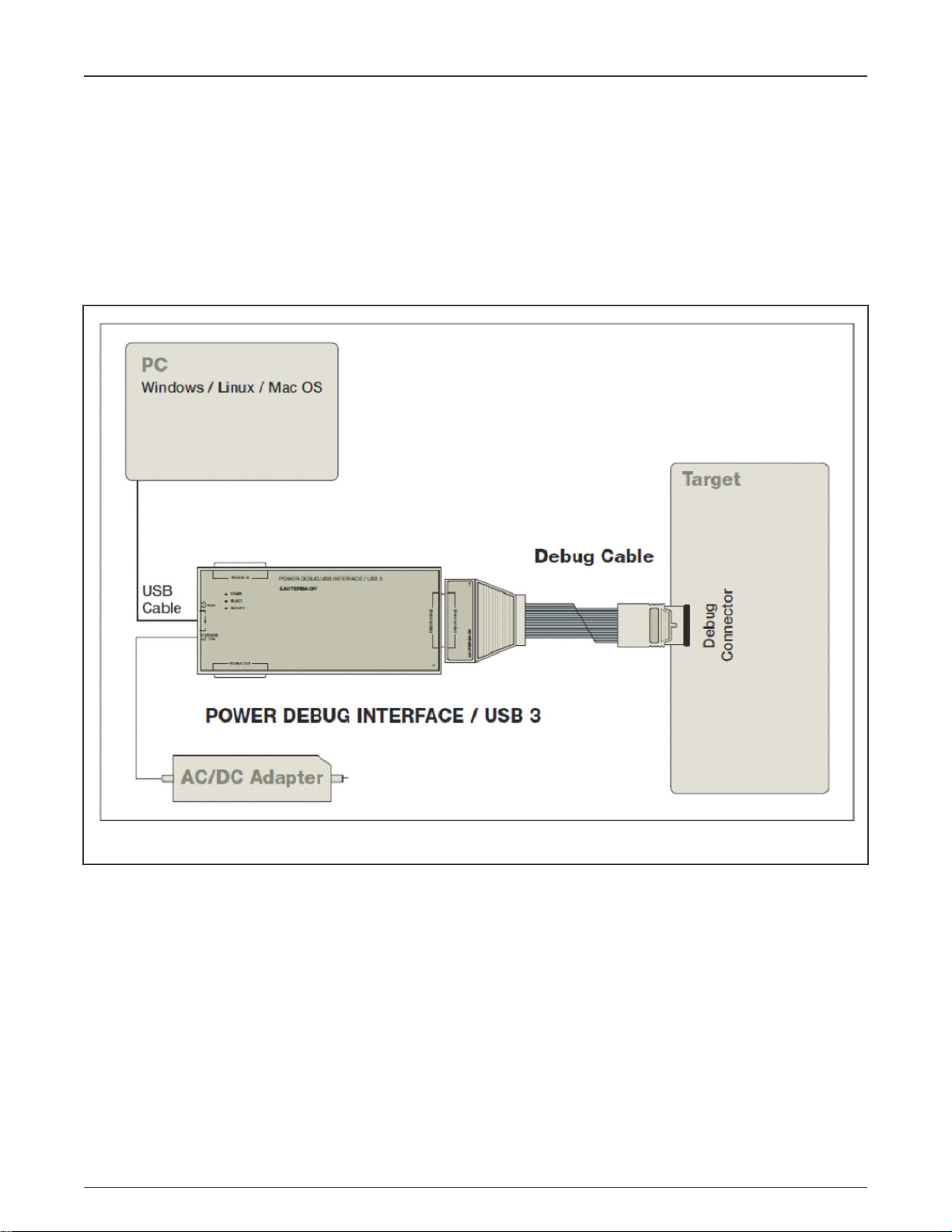

The TRACE32 debugger hardware always consists of the following:

• Universal debugger hardware

• Debug cable specific to the processor architecture

To connect to the i.MX 8QM/i.MX 8QXP processor, LA3500 DEBUG USB 3.0 with LA-3743 cable with ARMv8 and ARMv7

licenses is used.

Figure 2 shows a generic JTAG setup using the Lauterbach probe.

Figure 2. JTAG Lauterbach setup diagram

The following is recommended:

• To prevent damage to the debuggers or target, do not plug or unplug the debugger while the target is powered on.

The recommended sequence for powering the debugger and target on or off is as follows:

• Power on: debugger > target

• Power off: target > debugger

— Make sure that the debugger connector orientation is correct when plugging it to the board to prevent damage to the

i.MX part.

For example, see how the Lauterbach probe is connected to the i.MX8QXP MEK board in Figure 3.

1. Connect the Lauterbach JTAG debugger to the EVK board through the 10-pin JTAG interface.

Introduction to Boundary Scan of i.MX8/i.MX8X, Rev. 0, 04/2021

Application Note 3 / 11

Page 4

NXP Semiconductors

Hardware setup

2. Connect the Lauterbach JTAG debugger to the PC through the USB cable and then power on the debugger using a 5-V

power adapter.

3. Connect the MEK board to the power supply.

Figure 3. Lauterbach connected to i.MX8QXP MEK

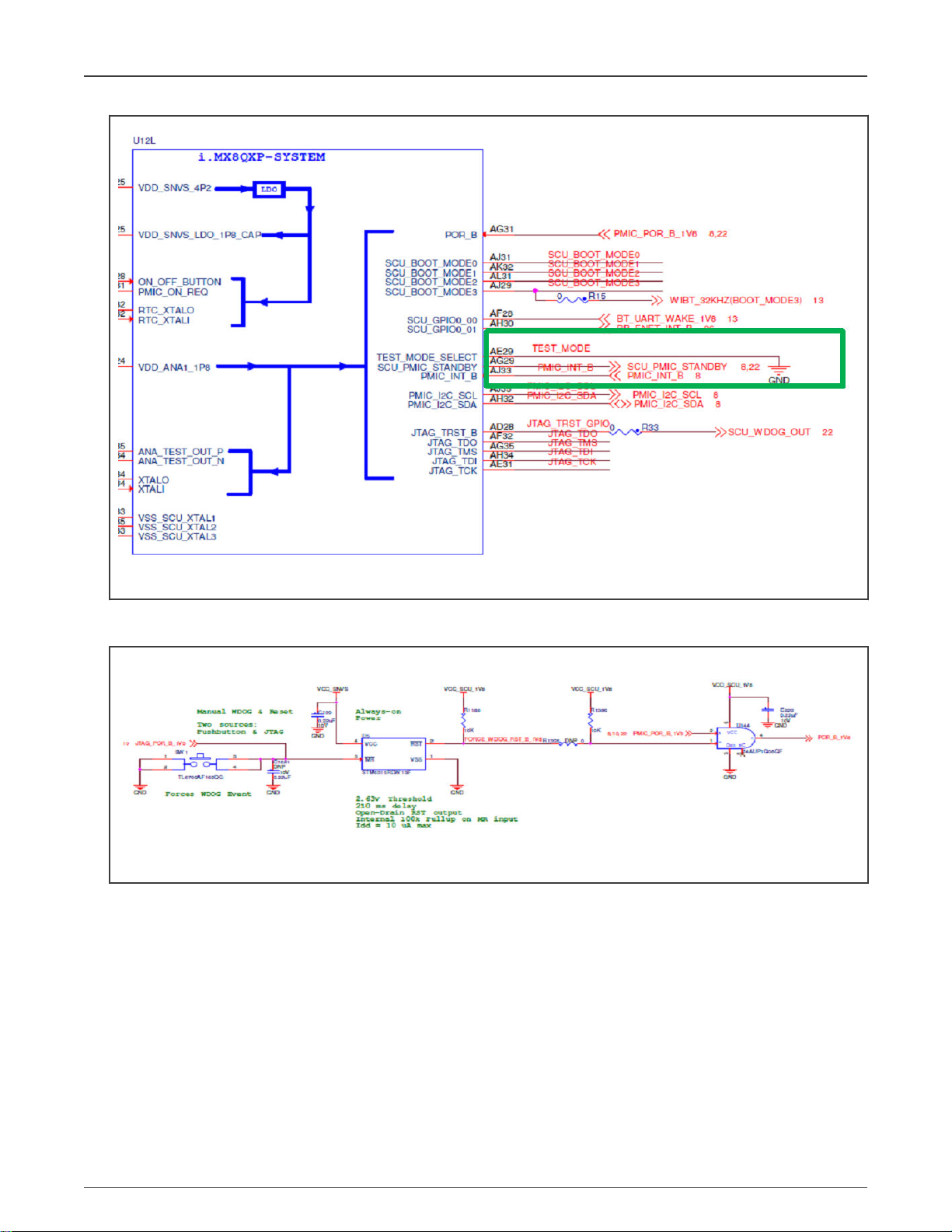

5.1 Board setup for boundary scan

Each NXP SoC has the boundary scan conditions detailed in the hardware developer's guide document. The dedicated SoC BSDL

files describe the conditions to determine the SoC to enter the boundary scan mode.

For example, the i.MX8QXP BSDL file shows that the COMPLIANCE_PATTERNS needed for the boundary scan conditions are

as follows:

• Attribute COMPLIANCE_PATTERNS of MX8QXP: entity is "(TEST_MODE_SELECT, POR_B) (01)";

Under these conditions, the TEST_MODE signal must be set to low and the POR_B must be set to high. The boot selecting DIP

switches must be set to the "Serial Download Mode".

Introduction to Boundary Scan of i.MX8/i.MX8X, Rev. 0, 04/2021

Application Note 4 / 11

Page 5

NXP Semiconductors

Hardware setup

Figure 4. BOOT selection switches

In the i.MX8QXP MEK board schematics, notice the following:

• The TEST_MODE signal is always low.

Introduction to Boundary Scan of i.MX8/i.MX8X, Rev. 0, 04/2021

Application Note 5 / 11

Page 6

NXP Semiconductors

Boundary scan using i.MX 8/i.MX 8 BSDL file and Lauterbach JTAG debugger

Figure 5. TEST_MODE signal always low

• The POR_B signal can be driven by the JTAG debugger/reset button to determine the BOOT ROM to enter the boundary

scan.

Figure 6. POR_B signal

6 Boundary scan using i.MX 8/i.MX 8 BSDL file and Lauterbach JTAG debugger

The recommendations before starting the boundary scan procedure are as follows:

• Using BSDL to check the board with an inappropriate multimeter can damage the board. Before performing

measurements, check what pins can be manipulated in the boundary scan safely without damaging the components

on your board.

• I/O pin power considerations: The boundary scan operation uses each of the available device pins to drive or read values

within a given system. Therefore, the power supply pin for each specific module must be powered for the IO buffers to

operate. This is straightforward for the digital pins within the system.

The boundary scan is as follows:

Introduction to Boundary Scan of i.MX8/i.MX8X, Rev. 0, 04/2021

Application Note 6 / 11

Page 7

NXP Semiconductors

Boundary scan using i.MX 8/i.MX 8 BSDL file and Lauterbach JTAG debugger

• Perform the software and hardware setups described in the previous sections. If the Lauterbach installation is properly

done, a “Trace32 Devices” entry appears in the Device Manager:

Figure 7. Trace32 Devices

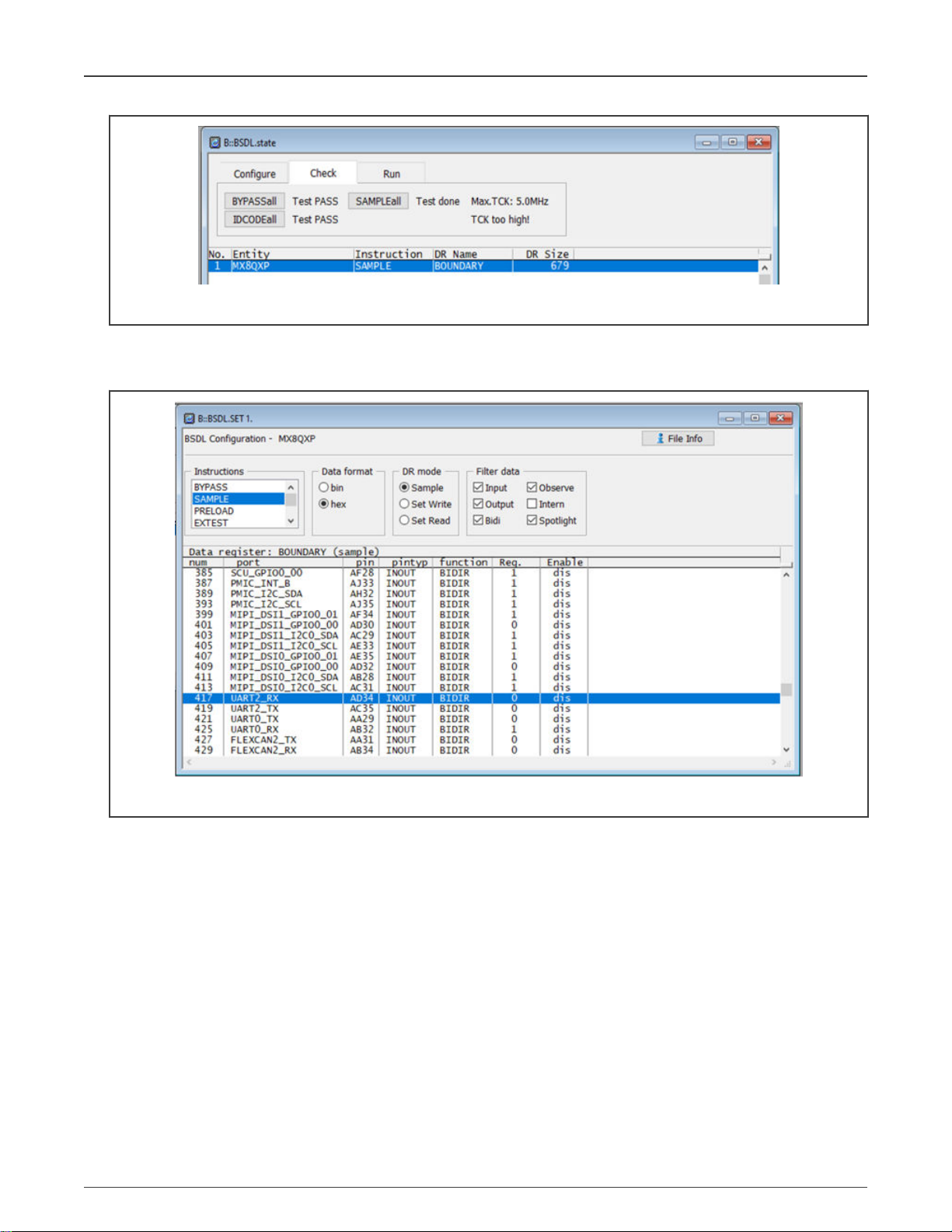

• Open the TRACE32 software, type in the following commands with each command followed by the "Enter" key or create a

CMM script with the following commands:

— SYStem.Down

— BSDL.RESet

— BSDL.ParkState Select-DR-Scan

— BSDL.state

Figure 8. TRACE32 software

• The "BSDL.state" command opens a new window. Click the “FILE” button and load the BSDL file you want to validate.

Introduction to Boundary Scan of i.MX8/i.MX8X, Rev. 0, 04/2021

Application Note 7 / 11

Page 8

NXP Semiconductors

Figure 9. BSDL file

For the i.MX 8 SoC, four BSDL files are provided. Select the one that is compatible with the used i.MX 8QXP SOC

and has the power domain for ENET set according to the board schematics.

Boundary scan using i.MX 8/i.MX 8 BSDL file and Lauterbach JTAG debugger

NOTE

Figure 10. Board schematics

• After loading the file, type in the "BSDL.SOFTRESET" command followed by the "Enter" key.

• Switch to the “Check” tab of the "BSDL.state" window. Click the “BYPASSall” and “IDCODEall” buttons to see if both

results can pass. The BYPASS/CLAMP/HIGHZ check passes.

Figure 11. BSDL.state window

• Click the “SAMPLEall” button and the “No result” entry changes to “Test done”. Then double-click the entity name and the

"BSDL.SET" window appears.

Introduction to Boundary Scan of i.MX8/i.MX8X, Rev. 0, 04/2021

Application Note 8 / 11

Page 9

NXP Semiconductors

Boundary scan using i.MX 8/i.MX 8 BSDL file and Lauterbach JTAG debugger

Figure 12. BSDL.SET window

• In the "BSDL.SET" window, uncheck the “Intern” checkbox to filter out the internal registers. The remaining contents is the

sampled value on each signal pin. Use a multimeter to measure the voltage of at least three signal pins and see if the

logic state matches the sampled value.

Figure 13. “Intern” checkbox

• Click the “EXTEST” entry in the “Instructions” list and choose the “Set Write” option in the “DR mode” field. Make sure

that the states of UART2_RX and UART2_TX are set to UART2_RX = output 1, UART2_TX = output 1 (if it exists). Then

switch to the "BSDL.state" window and check the “SetAndRun” and “TwoStepDR” checkboxes.

Introduction to Boundary Scan of i.MX8/i.MX8X, Rev. 0, 04/2021

Application Note 9 / 11

Page 10

NXP Semiconductors

Revision history

Figure 14. “SetAndRun” and “TwoStepDR” checkboxes

7 Revision history

Table 2. Revision history

Revision number Date Substantive changes

0 04/2021 Initial release

Introduction to Boundary Scan of i.MX8/i.MX8X, Rev. 0, 04/2021

Application Note 10 / 11

Page 11

How To Reach Us

Home Page:

nxp.com

Web Support:

nxp.com/support

Information in this document is provided solely to enable system and software implementers to use NXP products. There

are no express or implied copyright licenses granted hereunder to design or fabricate any integrated circuits based on the

information in this document. NXP reserves the right to make changes without further notice to any products herein.

NXP makes no warranty, representation, or guarantee regarding the suitability of its products for any particular purpose, nor

does NXP assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any

and all liability, including without limitation consequential or incidental damages. “Typical” parameters that may be provided

in NXP data sheets and/or specifications can and do vary in different applications, and actual performance may vary over

time. All operating parameters, including “typicals,” must be validated for each customer application by customer's technical

experts. NXP does not convey any license under its patent rights nor the rights of others. NXP sells products pursuant to

standard terms and conditions of sale, which can be found at the following address: nxp.com/SalesTermsandConditions.

Right to make changes - NXP Semiconductors reserves the right to make changes to information published in this

document, including without limitation specifications and product descriptions, at any time and without notice. This

document supersedes and replaces all information supplied prior to the publication hereof.

Security — Customer understands that all NXP products may be subject to unidentified or documented vulnerabilities.

Customer is responsible for the design and operation of its applications and products throughout their lifecycles to reduce

the effect of these vulnerabilities on customer’s applications and products. Customer’s responsibility also extends to other

open and/or proprietary technologies supported by NXP products for use in customer’s applications. NXP accepts no

liability for any vulnerability. Customer should regularly check security updates from NXP and follow up appropriately.

Customer shall select products with security features that best meet rules, regulations, and standards of the intended

application and make the ultimate design decisions regarding its products and is solely responsible for compliance with all

legal, regulatory, and security related requirements concerning its products, regardless of any information or support that

may be provided by NXP. NXP has a Product Security Incident Response Team (PSIRT) (reachable at PSIRT@nxp.com)

that manages the investigation, reporting, and solution release to security vulnerabilities of NXP products.

NXP, the NXP logo, NXP SECURE CONNECTIONS FOR A SMARTER WORLD, COOLFLUX,EMBRACE, GREENCHIP,

HITAG, ICODE, JCOP, LIFE, VIBES, MIFARE, MIFARE CLASSIC, MIFARE DESFire, MIFARE PLUS, MIFARE FLEX,

MANTIS, MIFARE ULTRALIGHT, MIFARE4MOBILE, MIGLO, NTAG, ROADLINK, SMARTLX, SMARTMX, STARPLUG,

TOPFET, TRENCHMOS, UCODE, Freescale, the Freescale logo, AltiVec, CodeWarrior, ColdFire, ColdFire+, the Energy

Efficient Solutions logo, Kinetis, Layerscape, MagniV, mobileGT, PEG, PowerQUICC, Processor Expert, QorIQ, QorIQ

Qonverge, SafeAssure, the SafeAssure logo, StarCore, Symphony, VortiQa, Vybrid, Airfast, BeeKit, BeeStack, CoreNet,

Flexis, MXC, Platform in a Package, QUICC Engine, Tower, TurboLink, EdgeScale, EdgeLock, eIQ, and Immersive3D are

trademarks of NXP B.V. All other product or service names are the property of their respective owners. AMBA, Arm, Arm7,

Arm7TDMI, Arm9, Arm11, Artisan, big.LITTLE, Cordio, CoreLink, CoreSight, Cortex, DesignStart, DynamIQ, Jazelle,

Keil, Mali, Mbed, Mbed Enabled, NEON, POP, RealView, SecurCore, Socrates, Thumb, TrustZone, ULINK, ULINK2,

ULINK-ME, ULINK-PLUS, ULINKpro, μVision, Versatile are trademarks or registered trademarks of Arm Limited (or its

subsidiaries) in the US and/or elsewhere. The related technology may be protected by any or all of patents, copyrights,

designs and trade secrets. All rights reserved. Oracle and Java are registered trademarks of Oracle and/or its affiliates. The

Power Architecture and Power.org word marks and the Power and Power.org logos and related marks are trademarks and

service marks licensed by Power.org.

©

NXP B.V. 2021. All rights reserved.

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

Date of release: 04/2021

Document identifier: AN13215

Loading...

Loading...