Ntron Senz-Tx Specifications

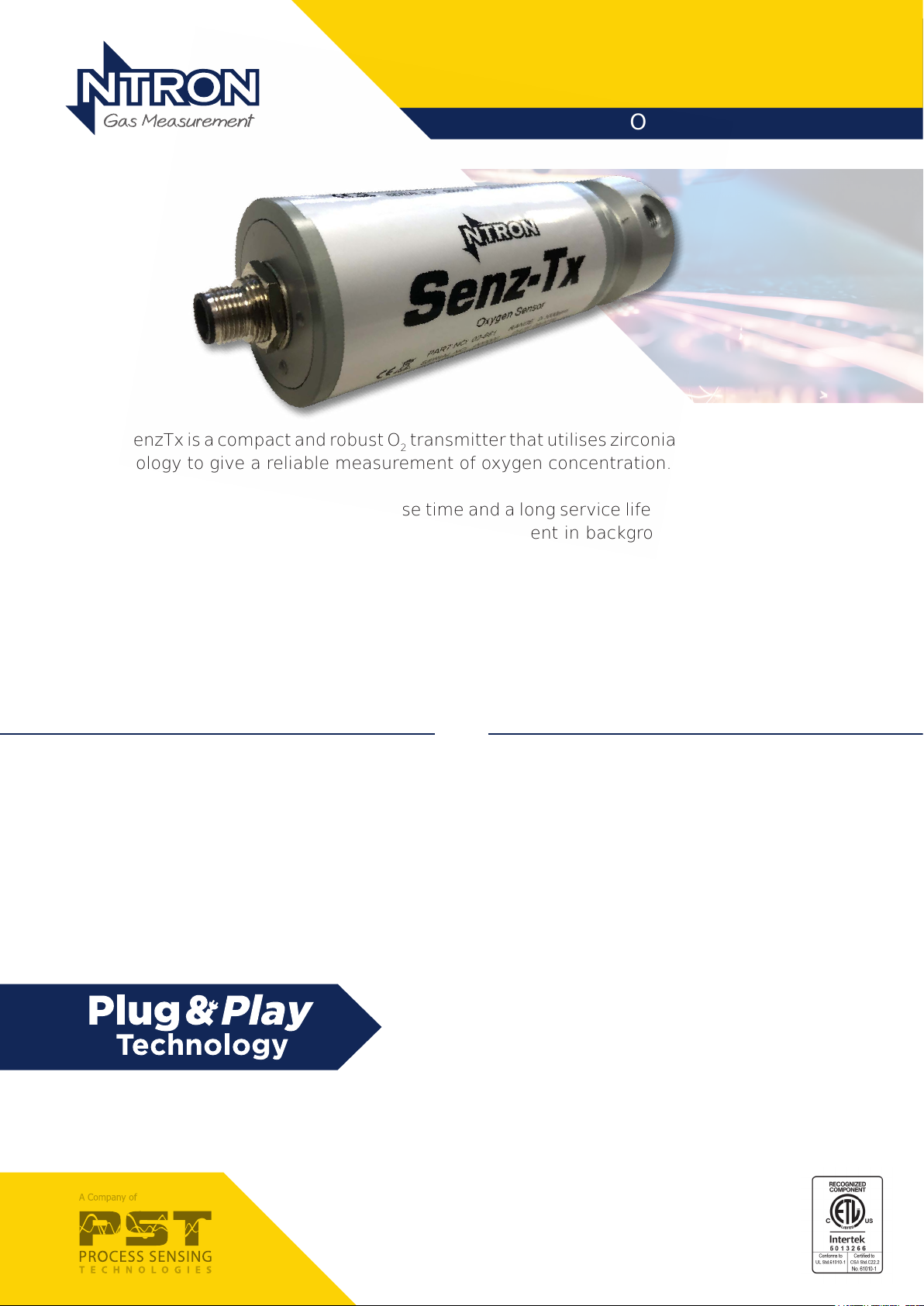

SenzTx

Oxygen Transmitter

The SenzTx is a compact and robust O2 transmitter that utilises zirconia or electrochemical

technology to give a reliable measurement of oxygen concentration.

The zirconia sensor oers fast response time and a long service life with virtually no drift,

whilst the electrochemical sensor allows measurement in background gases containing

hydrocarbons.

The minimum output range of 0 to 10ppm is ideal for nitrogen generation or glove box

monitoring. The SenzTx transmitter can also be supplied with measuring ranges up to 0

to 96% O

The exibility is further enhanced by process connection multiple output options.

for oxygen concentrators.

2

FeaturesApplications

» Gas generation (oxygen / nitrogen)

» Additive manufacturing

» Glove box purge and leak detection

» Industrial gas applications

» Zirconia or electrochemical sensor

technology options

» Measurement range:

0 to 10ppm up to 0 to 96% O

» RS 485 modbus protocol

» 24VDC power supply

» M12 electrical connection

» KF40 Flange, Flowthrough and Flow

Orice process connection options

available

2

» Combined Sensor & Electronics

allows for ease of integration.

» Lightweight and robust (< 0.3Kgs)

Issue No. STX01_V1_EN_0819

SenzTx

Oxygen Transmitter

Proven sensor technology

With a choice of either zirconia or

electrochemical sensor technology the

SenzTx oers reliability, accuracy and

exibility. Both technologies have a broad

measurement capability allowing the user

to measure from selected ranges from 1ppm

to 96% oxygen.

Zirconia sensor

The Ntron zirconia oxygen sensor is a nondepleting zirconia solid electrolyte sensor.

A small capillary on the sensor controls

the diusion of oxygen into the sensor.

When heated to over 400°C oxygen is

electronically reduced causing current ow

through the zirconia electrolyte. Zirconium-

oxide allows the movement of oxygen

ions through the substrate from a high to

a low concentration. The measurement of

oxygen is determined by the current owing

through the electrodes. The zirconia sensor

has an unlimited shelf life without the loss

of calibration and has an expected life in

excess of 5 years. The zirconia sensor is

not position sensitive and has low cross

sensitivity to other gases and does not dry

out.

Low maintenance and cost of ownership

Due to the highly stable nature of the

sensor, a calibration interval of once per

year is required, allowing for signicant cost

savings. The construction of our zirconia

oxygen sensor means that only 100 mL/

min of sample gas is required, providing

application exibility and further potential

cost savings.

Fast response time

Zirconia oxygen sensors respond very

quickly to oxygen concentrations in both

directions with a T90 of less than 10 seconds

within a set range.

Electrochemical sensor

The key elements of the electrochemical

sensors are a membrane, cathode, anode,

electrolyte and measurement circuit. The

sensing membrane (covering the cathode)

is made of PTFE and is mounted over a

metal perforated electrode. The space

between the membrane and the electrode

is lled either with an aqueous alkaline or

an acid electrolyte. In normal operation,

all portions of the anode and cathode are

immersed in the electrolyte. As oxygen

diuses through the membrane into the

electrolyte it causes a reaction between

the cathode and anode generating an EMF.

This current is proportional to the amount

of oxygen present in the sample gas. In the

absence of oxygen there is no output from

the electrochemical sensor, meaning only

one calibration is required.

Sensor contruction

The main body of the sensor is fabricated

from high density PVDF. The supporting ring

at the face of the sensor is constructed of

stainless steel. This results in an oxygen

sensor that is chemically resistant to most

sampling atmospheres and can be used with

trace solvents and hydrocarbons present in

the sample gas, unlike zirconia (due to the

high temperature of the sensor).

Installation exibility

The compact SenzTx oxygen transmitter

with its inbuilt microprocessor, is designed

for OEM applications with minimal use input.

With the ow through sensor with orice

option, the sensor can handle up to 2 bar

g and provide the correct ow through the

sensor. This eliminates the need for external

ow control.

TXi Communication &

Diagnostics terminal

The TXi calibration makes set-up, calibration

and diagnostics easy. Simply connect this

unit in series with the SenzTx with the cable

provided and perform the desired task

without the need to look at the control panel

which may be far away.

Loading...

Loading...