Page 1

NT24k

Managed Industrial

Ethernet Switch

User Manual &

Installation

Guide

(Revised 8-5-2013)

Page 2

NT24k Industrial Ethernet Switch Installation Guide ...................................................................................... 4

NT24k Series Common Features ...................................................................................................................... 5

NT24k Rack Mount ................................................................................................................................................................... 8

NT24k-DR24........................................................................................................................................................................... 10

NT24k-DR16........................................................................................................................................................................... 12

NT24k Industrial Ethernet Switch Accessories .............................................................................................. 14

SAFETY WARNINGS .............................................................................................................................................. 16

Installation .................................................................................................................................................................. 18

Connecting the Unit ................................................................................................................................................... 22

Overview of Advanced Features ................................................................................................................................ 26

Mode of Operation .................................................................................................................................................................. 26

Port Mirroring ......................................................................................................................................................................... 26

Port Trunking .......................................................................................................................................................................... 26

Quality of Service (QoS) ......................................................................................................................................................... 27

Virtual LAN ............................................................................................................................................................................ 27

Rapid Spanning Tree Protocol ................................................................................................................................................ 28

SNMP Traps ............................................................................................................................................................................ 28

IGMP Snooping ...................................................................................................................................................................... 28

N-Ring ..................................................................................................................................................................................... 29

N-Link ..................................................................................................................................................................................... 29

CIP .......................................................................................................................................................................................... 29

PPP .......................................................................................................................................................................................... 29

Telnet ...................................................................................................................................................................................... 30

DHCP Client ........................................................................................................................................................................... 30

Web Software Configuration ..................................................................................................................................... 32

Web Management ................................................................................................................................................................... 32

Web Management – Product Information Page ...................................................................................................................... 33

Web Management – Menu Structure ....................................................................................................................................... 35

Configuration Page .................................................................................................................................................................. 36

Fault Page ................................ ................................................................ ................................................................ ................ 37

File Transfer Page ................................................................................................................................................................... 39

System Page ............................................................................................................................................................................ 42

User Management ................................................................................................................................................................... 44

Adding Users ...................................................................................................................................................................... 44

Bridging – Aging Time ........................................................................................................................................................... 46

Bridging – Multicast Addresses .............................................................................................................................................. 47

Bridging – Unicast Addresses ................................................................................................................................................. 49

CIP – Configuration ................................................................................................................................................................ 51

CIP – Status ............................................................................................................................................................................. 52

CIP – EIP Indicators ................................................................................................................................ ................................ 53

IGMP – Configuration ............................................................................................................................................................ 54

IGMP – Groups ....................................................................................................................................................................... 58

IGMP – RFilter Ports .............................................................................................................................................................. 59

IGMP – Routers ...................................................................................................................................................................... 61

N-Ring – Configuration – Basic .............................................................................................................................................. 62

N-Ring – Configuration – Port Sets ........................................................................................................................................ 64

N-Ring – Configuration – Advanced ...................................................................................................................................... 66

N-Ring – Status ....................................................................................................................................................................... 68

N-Link – Configuration – Basic .............................................................................................................................................. 71

N-Link – Configuration – Advanced ....................................................................................................................................... 75

N-Link – Status ....................................................................................................................................................................... 76

N-View – Configuration .......................................................................................................................................................... 81

N-View – Ports ................................................................................................ ................................ ........................................ 82

Ports – Configuration .............................................................................................................................................................. 84

Ports – Mirroring ..................................................................................................................................................................... 86

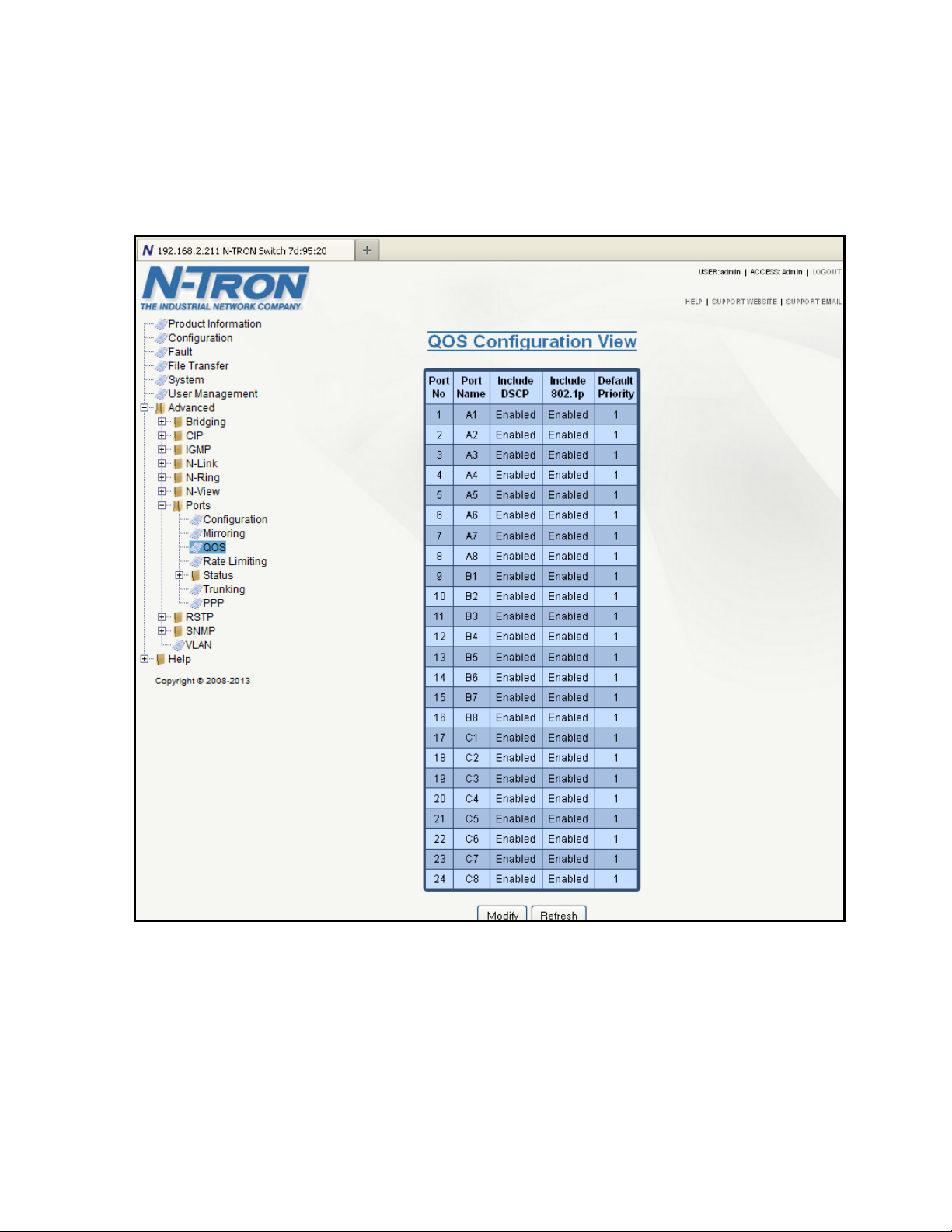

Ports – QOS............................................................................................................................................................................. 87

Ports – Rate Limiting .............................................................................................................................................................. 89

Ports – Status – Statistics ........................................................................................................................................................ 91

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 2 of 140

Page 3

Ports – Status – Utilization ...................................................................................................................................................... 92

Ports – Trunking ...................................................................................................................................................................... 93

Ports – PPP .............................................................................................................................................................................. 96

RSTP – Bridge ........................................................................................................................................................................ 97

RSTP – Ports ......................................................................................................................................................................... 101

SNMP – Configuration.......................................................................................................................................................... 103

SNMP – Trap Stations........................................................................................................................................................... 104

VLAN .................................................................................................................................................................................... 106

Help – Overview ........................................................................................................................................... 111

Help – Other .......................................................................................................................................................................... 113

Appendix A – XML Configuration File – Factory Defaults......................................................................... 117

N-TRON Limited Warranty .......................................................................................................................... 140

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 3 of 140

Page 4

NT24k Industrial Ethernet Switch Installation Guide

The NT24k is available in three configurations and this document addresses all three:

NT24k Rack Mount:

NT24k-DR24:

NT24k-DR16:

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 4 of 140

Page 5

NT24k Series Common Features

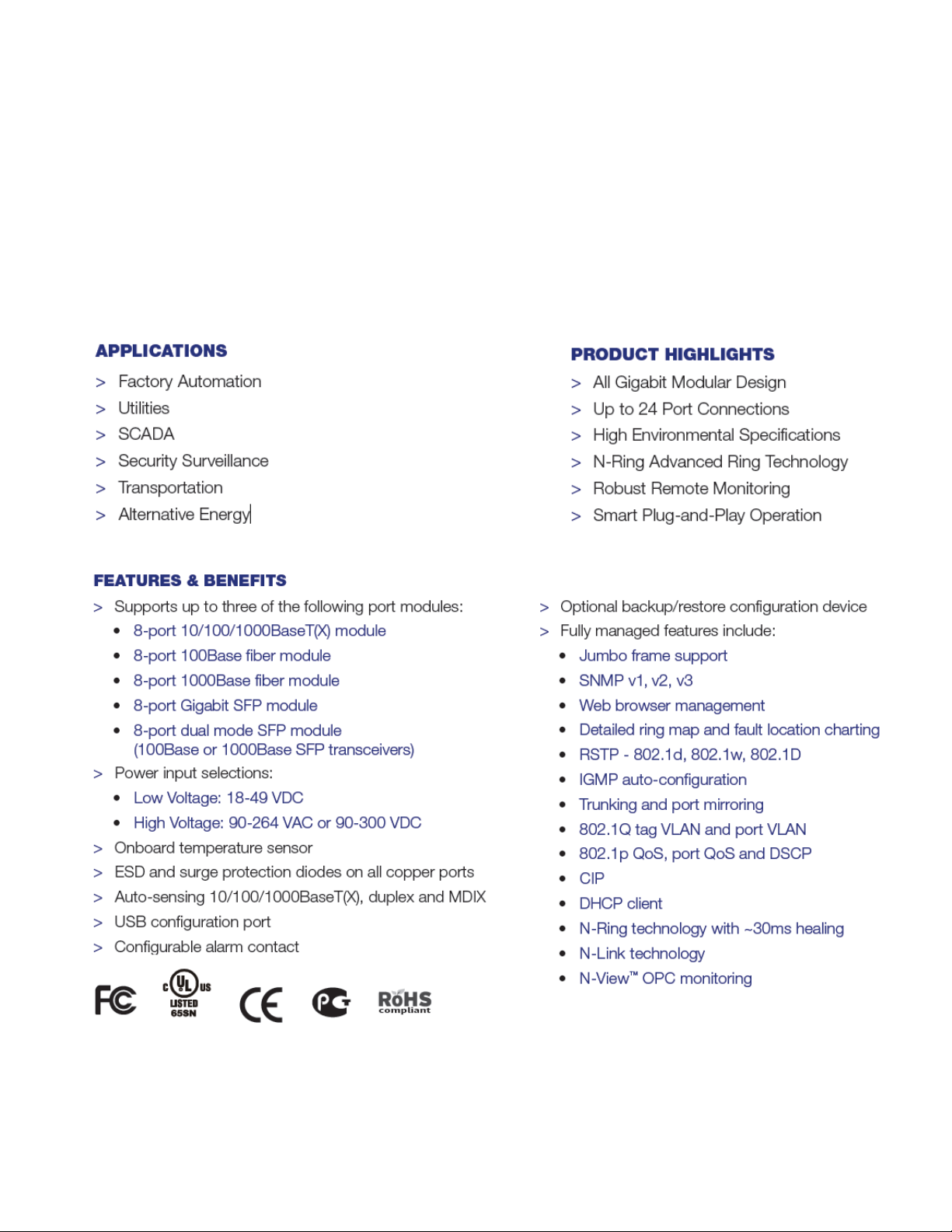

The NT24k are modular managed switches designed for factory automation, utilities, security surveillance,

SCADA and other industrial applications.

The versatile N-Tron® NT24k Managed Industrial Ethernet Switches feature connectivity for up to 24

Gigabit (16 for the NT24k-DR16) ports and offer a wide range of connectivity options—including 100Base,

Gigabit, fiber optic and copper options—in rugged Rack Mount or DIN-rail enclosures. Designed to handle

the most demanding environments, the NT24k Switches deliver wire-speed throughput and include

expanded shock and vibration tolerances, extreme operating temperature range and two or three slots to

accommodate mix-and-match port modules. N-Ring™ technology restores network communication within

~30ms of fault detection. Robust remote monitoring capabilities make management easy.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 5 of 140

Page 6

NT24k Series Common Features, Continued …

\

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 6 of 140

Page 7

NT24k Series Common Features, Continued …

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 7 of 140

Page 8

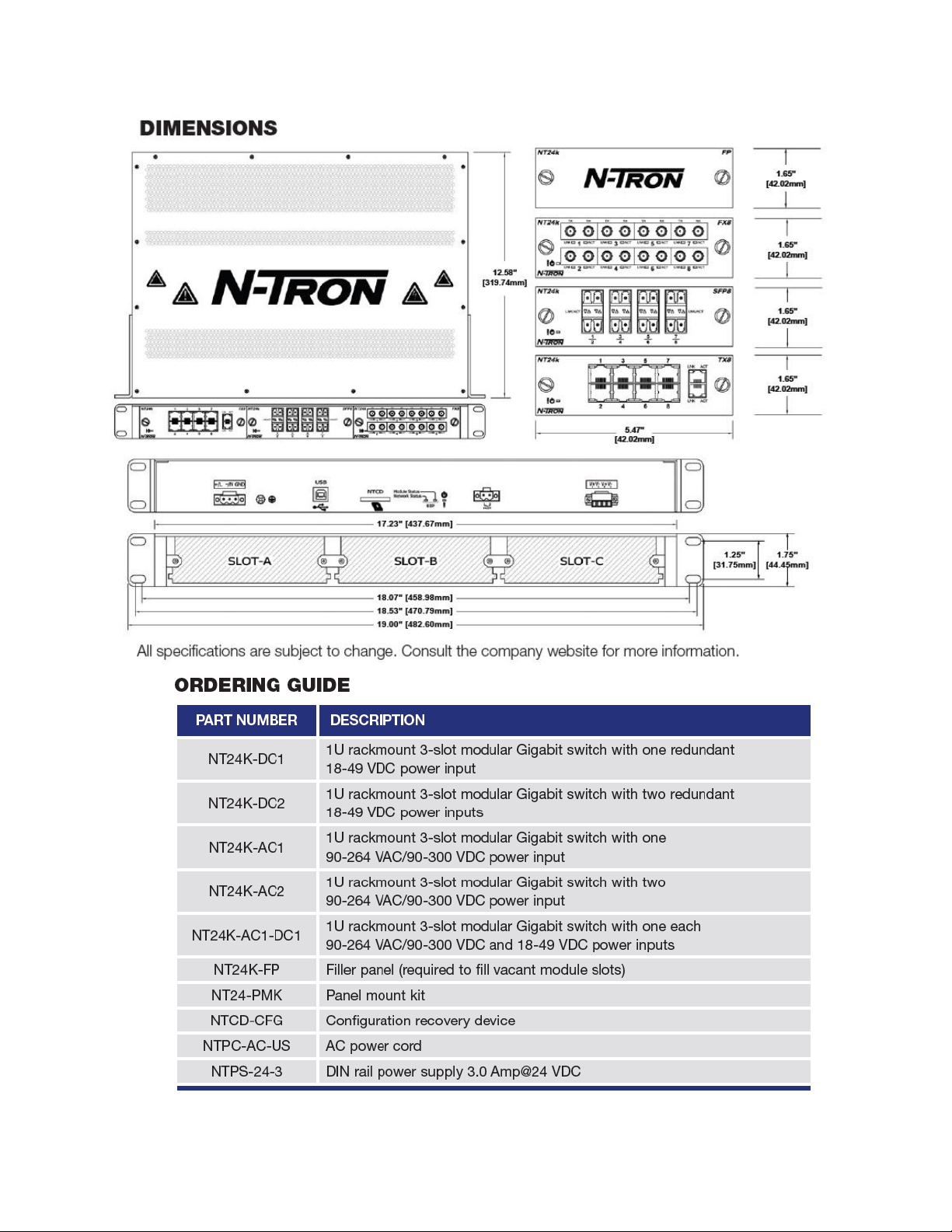

NT24k Rack Mount

The N-Tron® NT24k Rack Mounted Managed Industrial Ethernet Switch features connectivity for up to 24

Gigabit ports in a rugged 1U 19” rackmount enclosure. Designed to handle the most demanding

environments, the NT24k includes dual power inputs, extreme operating temperature range and three slots

to accommodate mix-and-match port modules.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 8 of 140

Page 9

NT24k Rack Mount, Continued …

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 9 of 140

Page 10

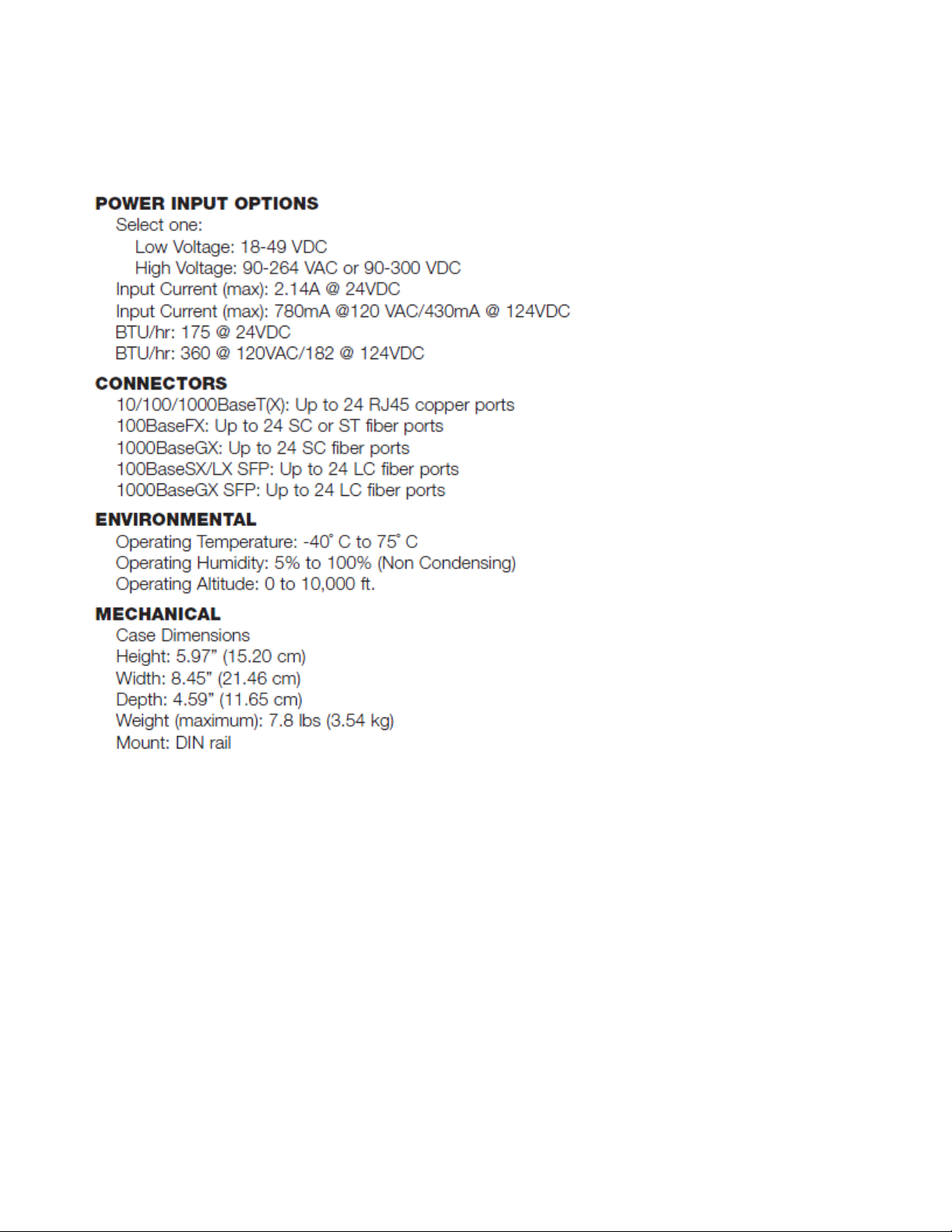

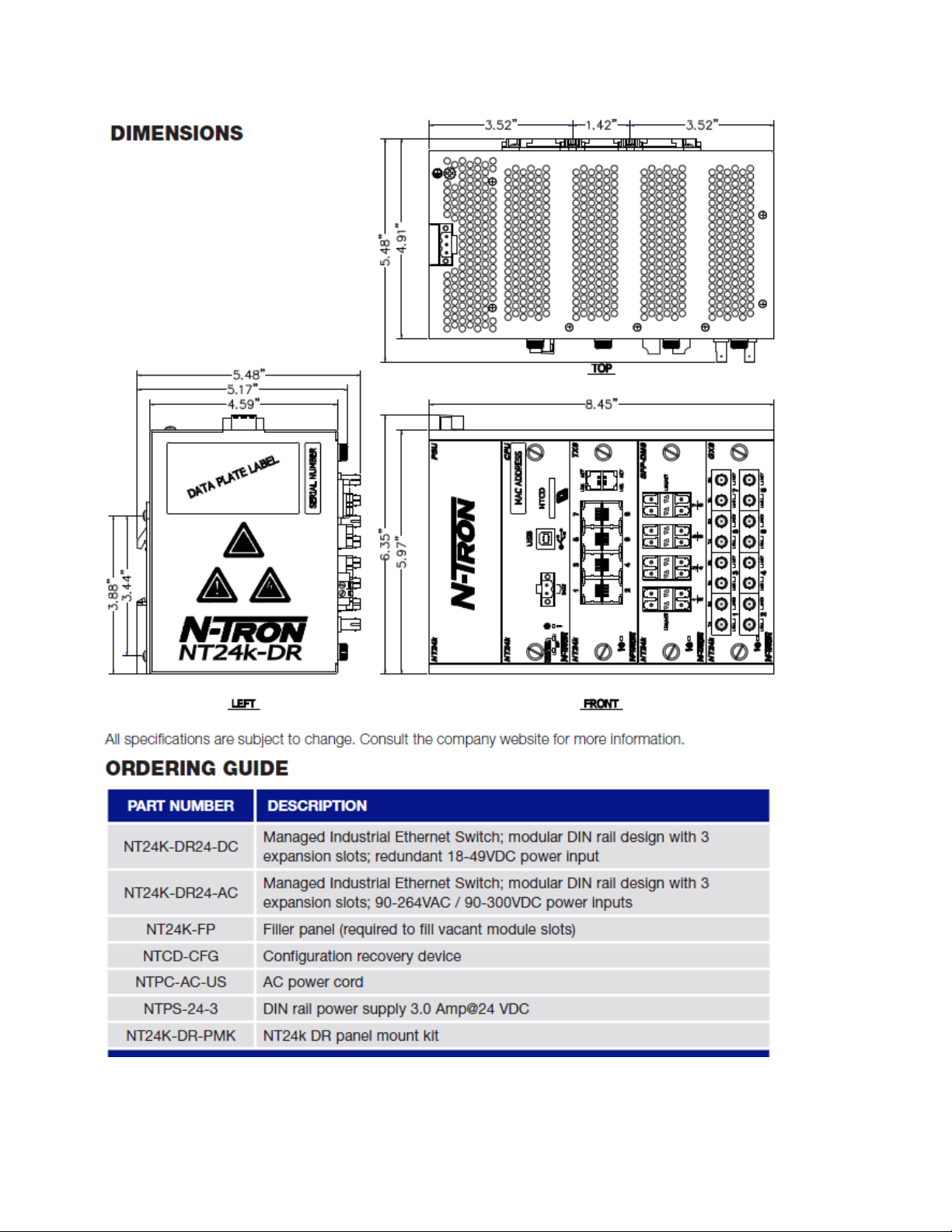

NT24k-DR24

The NT24k-DR24 Managed Industrial Ethernet Switch features connectivity for up to 24 Gigabit ports in a

rugged DIN-rail enclosure.

\

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 10 of 140

Page 11

NT24k-DR24,Continued…

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 11 of 140

Page 12

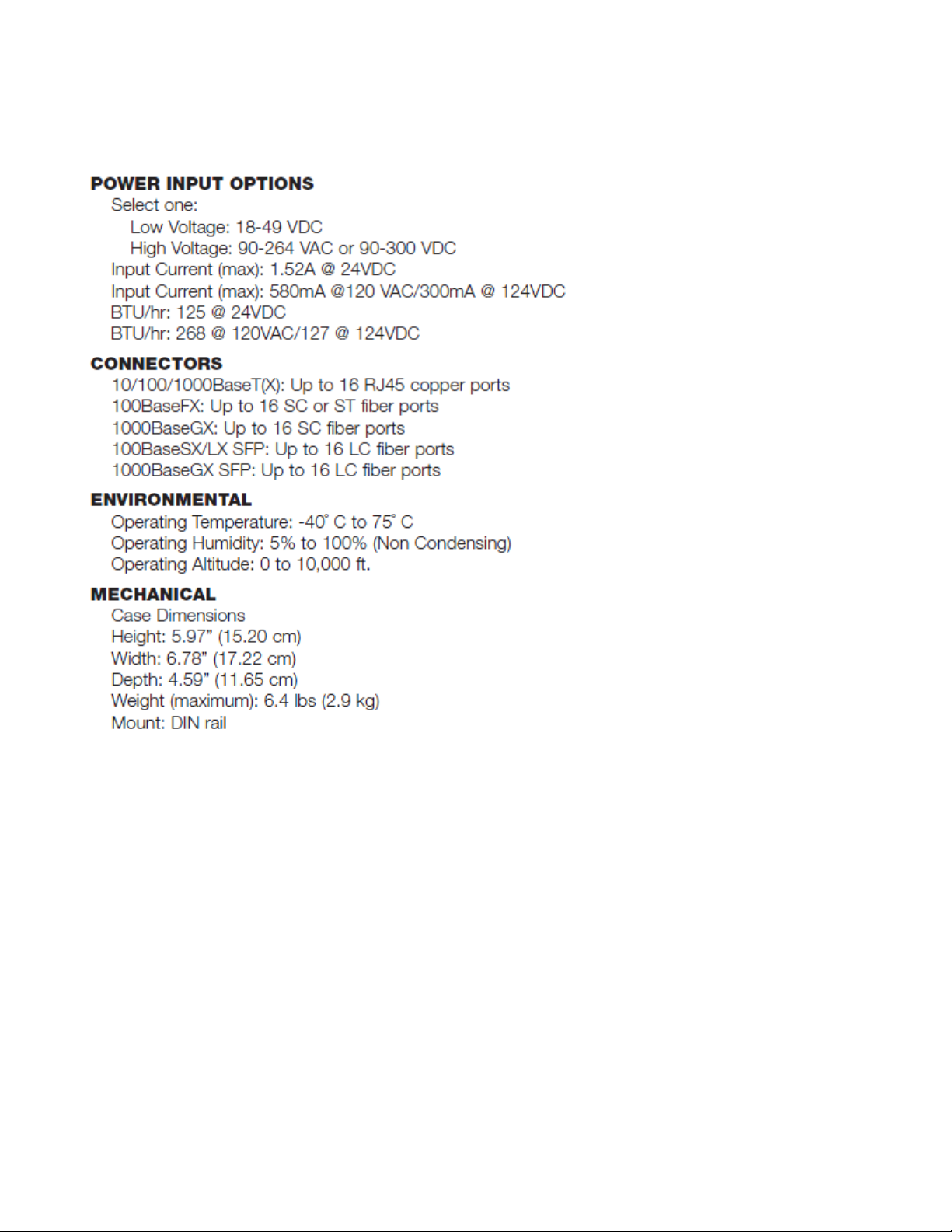

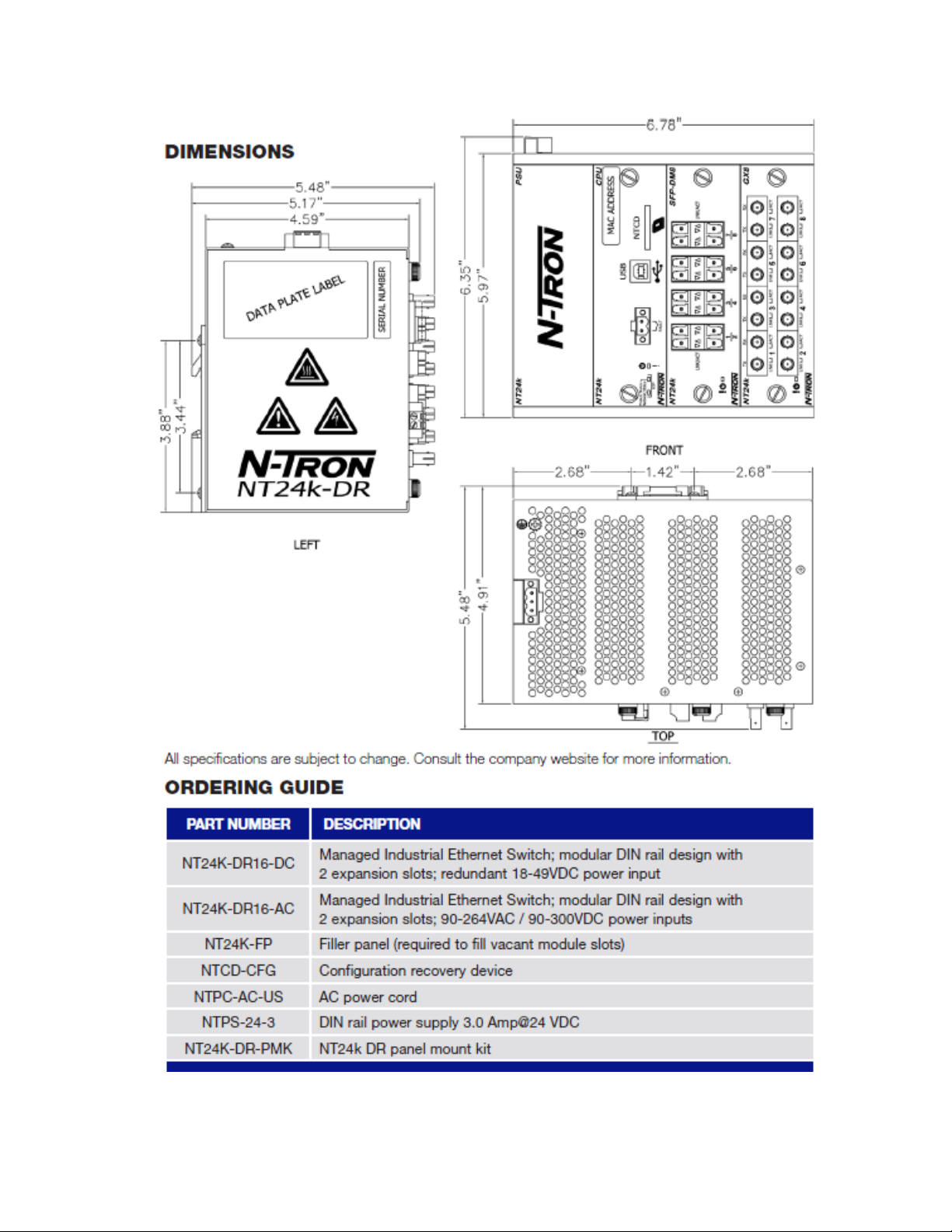

NT24k-DR16

The N-Tron® NT24k-DR16 Managed Industrial Ethernet Switch features connectivity for up to 16 Gigabit

ports in a rugged DIN rail enclosure.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 12 of 140

Page 13

NT24k-DR16, Continued …

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 13 of 140

Page 14

NTCD-CFG

Configuration Device

Ideal for saving, or restoring switch

configuration parameters quickly without

the need for a computer or software. One

configuration device per switch is

recommended.

NT24k Industrial Ethernet Switch Accessories

The SD and USB connectors are for temporary connection only. Do not use, connect, or disconnect unless

the area is known to be non-hazardous. Connection or disconnection in an explosive atmosphere could result

in an explosion.

The configuration device is inserted in the back of the NT24k:

The unit could be configured with multiple power supply configuration.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 14 of 140

Page 15

Copyright, © N-Tron Corporation, 2010-2013

3101 International Dr. Bldg. 6

Mobile, AL 36606-3010

All rights reserved. Reproduction, adaptation, or translation without prior written permission from N-Tron

Corporation is prohibited, except as allowed under copyright laws.

Ethernet is a registered trademark of Xerox Corporation. All other product names, company names, logos

or other designations mentioned herein are trademarks of their respective owners.

The information contained in this document is subject to change without notice. N-Tron Corporation makes

no warranty of any kind with regard to this material, including, but not limited to, the implied warranties of

merchantability or fitness for a particular purpose. In no event shall N-Tron Corporation be liable for any

incidental, special, indirect or consequential damages whatsoever included but not limited to lost profits

arising out of errors or omissions in this manual or the information contained herein.

Warning

Do not perform any services on the unit unless qualified to do so. Do not substitute unauthorized parts or

make unauthorized modifications to the unit.

Do not operate the unit with the top cover removed, as this could create a shock or fire hazard.

Do not block the air vents on the sides or the top of the unit.

Do not operate the equipment in the presence of flammable gasses or fumes. Operating electrical equipment

in such an environment constitutes a definite safety hazard.

Do not operate the equipment in a manner not specified by this manual.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 15 of 140

Page 16

SAFETY WARNINGS

GENERAL SAFETY WARNINGS

WARNING: If the equipment is used in the manner not specified by N-Tron Corp., the protection

provided by the equipment may be impaired.

LASER SAFETY (Options - NTSFP-FX, NTSFP-FXE, NTSFP-SX, NTSFP-LX)

CAUTION: CLASS 1 LASER PRODUCT. Do not stare into the laser!

Contact Information

N-Tron Corporation

3101 International Dr. Bldg. 6

Mobile, AL 36606-3010

TEL: (251) 342-2164

FAX: (251) 342-6353

WEBSITE: www.n-tron.com

E-MAIL: N-TRON_Support@n-tron.com

ENVIRONMENTAL SAFETY

WARNING: The unit may become very hot to the touch in high temperature environments, so extreme

caution should be exercised in handling when energized. The unit should be disconnected from power and

allowed to cool for approximately 5 minutes before touching in high temperature applications.

ELECTRICAL SAFETY

WARNING: Do not remove the top cover.

WARNING: Do not operate the unit with the any cover removed.

WARNING: Properly ground the unit before connecting anything else to the unit. Units not properly

grounded may result in a safety risk and could be hazardous and may void the warranty. See the grounding

technique section of this user manual for proper ways to ground the unit.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 16 of 140

Page 17

WARNING: Do not work on equipment or cables during periods of lightning activity.

WARNING: Do not perform any services on the unit unless qualified to do so.

WARNING: Do not block the air vents.

WARNING: Observe proper DC Voltage polarity when installing power input cables. Reversing voltage

polarity can cause permanent damage to the unit and void the warranty.

Hazardous Location Installation Requirements

1. This equipment is suitable for use in Class I, Division 2, Groups A, B, C, and D or non-hazardous

locations only.

2. WARNING: Explosion Hazard – Substitution of components may impair suitability for Class I,

Div. 2.

3. WARNING: Explosion Hazard - do not disconnect while circuit is live, unless area is known to be

non-hazardous.

4. WARNING: Explosion Hazard – do not replace the device unless power has been switched off or

the area is known to be non-hazardous.

5. Surrounding Air Temperature: Rack Mount: -40˚C - 85˚C

Surrounding Air Temperature: DIN Rail 24 and 16: -40˚C - 75˚C

6. NT24k must be powered by a Class 2 source evaluated to UL1310 only.

7. Use 105°C or higher rated Copper wire, (0.22Nm) 2lb/in Tightening torque for field installed

conductors.

8. WARNING: Exposure to some chemicals may degrade the sealing properties of materials used in

the following devices and should be periodically inspected for any degradation and replaced as

necessary; Relay by Panasonic, Part No. TX2SS-3V, or Omron, part G6S2FDC3.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 17 of 140

Page 18

Please make sure the NT24k Ethernet Switch package contains the following items:

1. NT24k Switch

2. Product CD

Contact your carrier if any items are damaged.

Installation

Read the following warning before beginning the installation:

WARNING

Never install or work on electrical equipment or cabling during periods of lightning activity. Never connect

or disconnect power when hazardous gasses are present.

Disconnect the power cable before removing any enclosure panel.

UNPACKING

Remove all the equipment from the packaging, and store the packaging in a safe place. File any damage

claims with the carrier.

CLEANING

Clean only with a damp cloth.

RACK AND PANEL MOUNTING

The NT24k comes configured with standard rack mount brackets which may be used to mount our

products to standard 19" racks. As an alternative we offer our NT24k Panel Mount Assembly (P/N:

NT24k-PM) which may be used to securely mount the NT24k products to a panel or other flat surface.

A clearance of 1 inch should be observed on the sides, back, top and bottom to allow proper ventilation.

Also a cable bend radius of 4 inches should be observed for the front and back side of the unit.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 18 of 140

Page 19

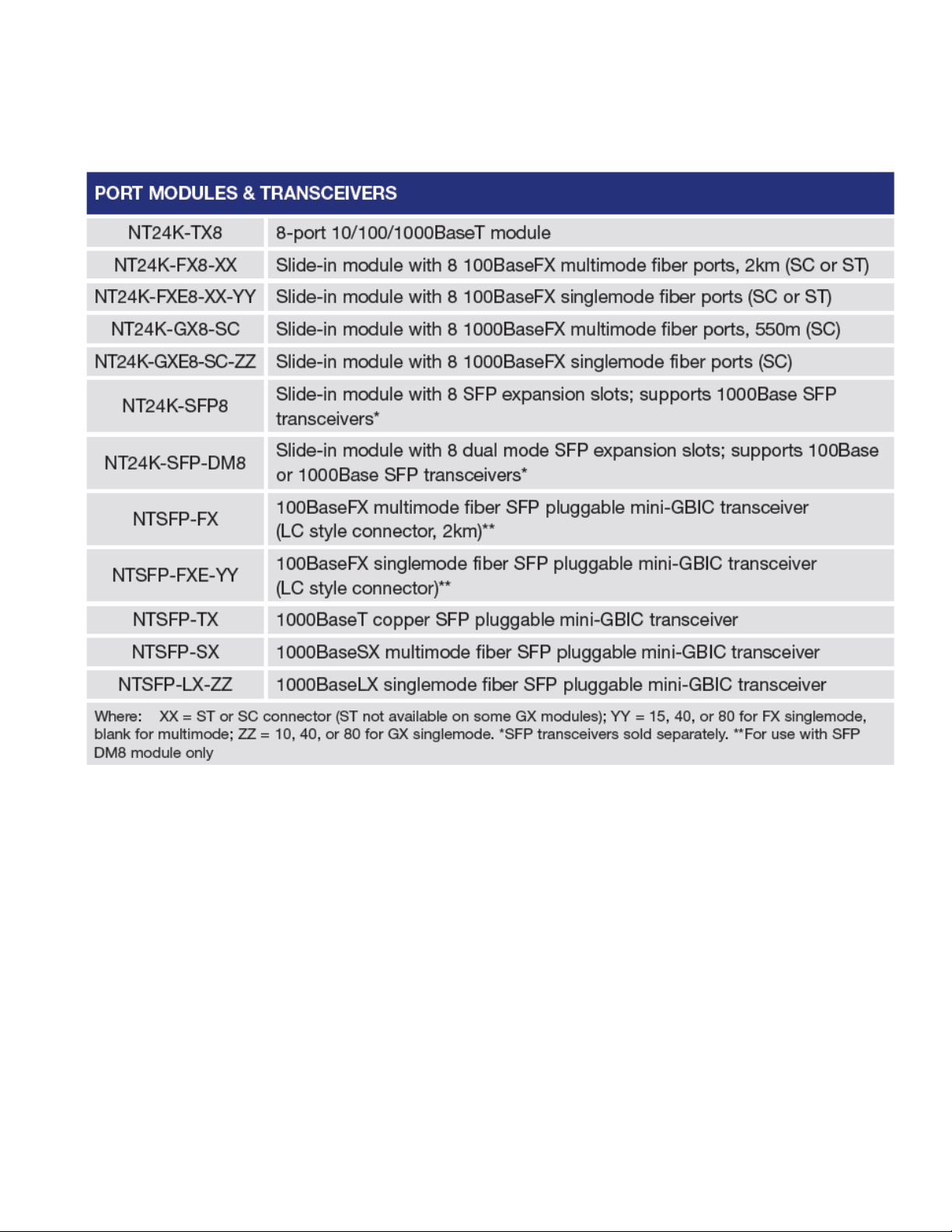

SFP

Transceiver

Maximum

Capacity per

switch

Module Required

NTSFP-TX

Up to 16

NT24k-SFP8 or NT24k-DM8

NTSFP-FX

Up to 24

NT24k-DM8

NTSFP-SX

Up to 24

NT24k-SFP8 or NT24k-DM8

NTSFP-LX

Up to 24

NT24k-SFP8 or NT24k-DM8

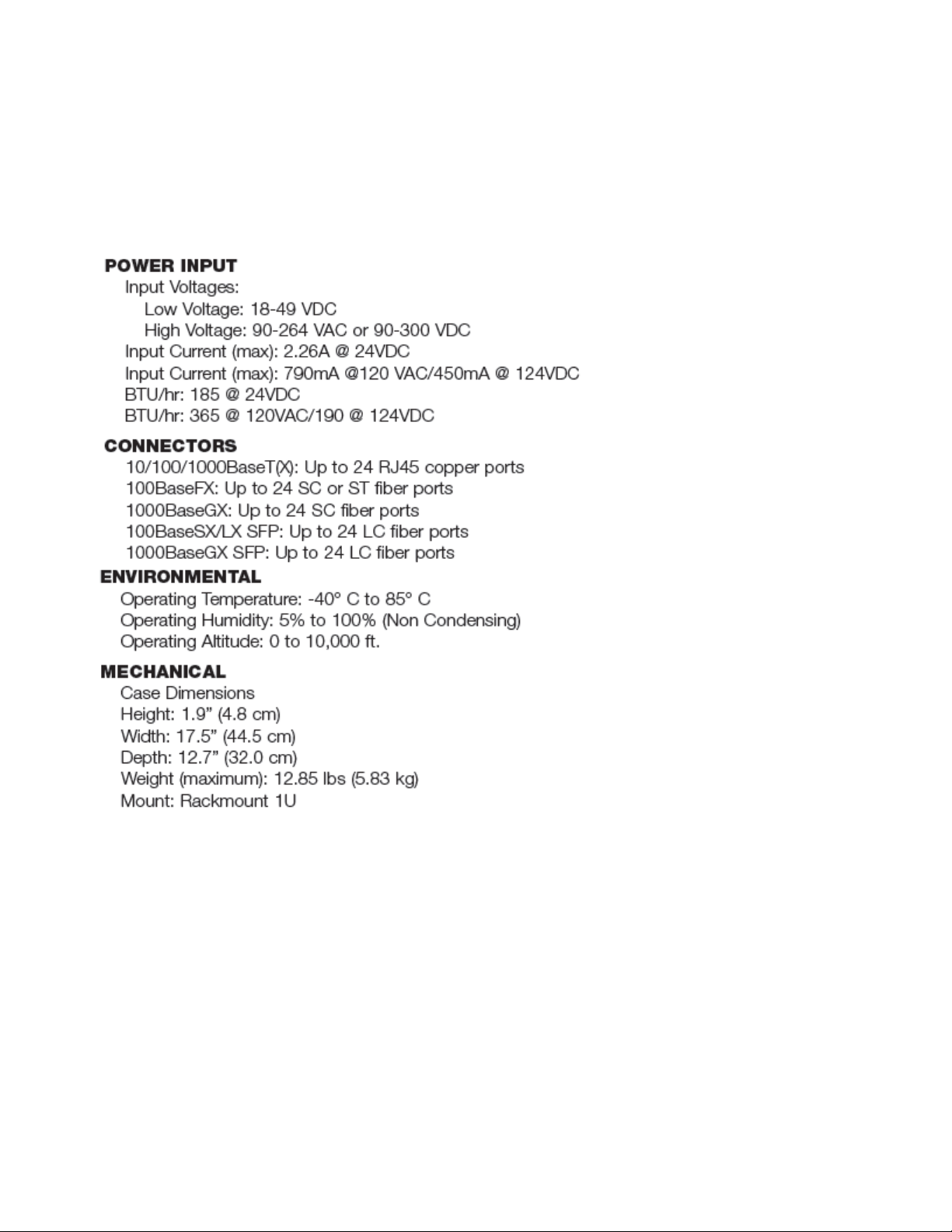

LED

Color

Description

GREEN

Power is ON

RED

Power is ON and a fault condition exists

OFF

Power is OFF

LNK

GREEN

10/100/1000Mb Link between ports

OFF

No Link between ports

ACT

GREEN

Data is active between ports. Activity light blink rate indicates activity, not

necessarily the volume of activity.

OFF

Data is inactive between ports

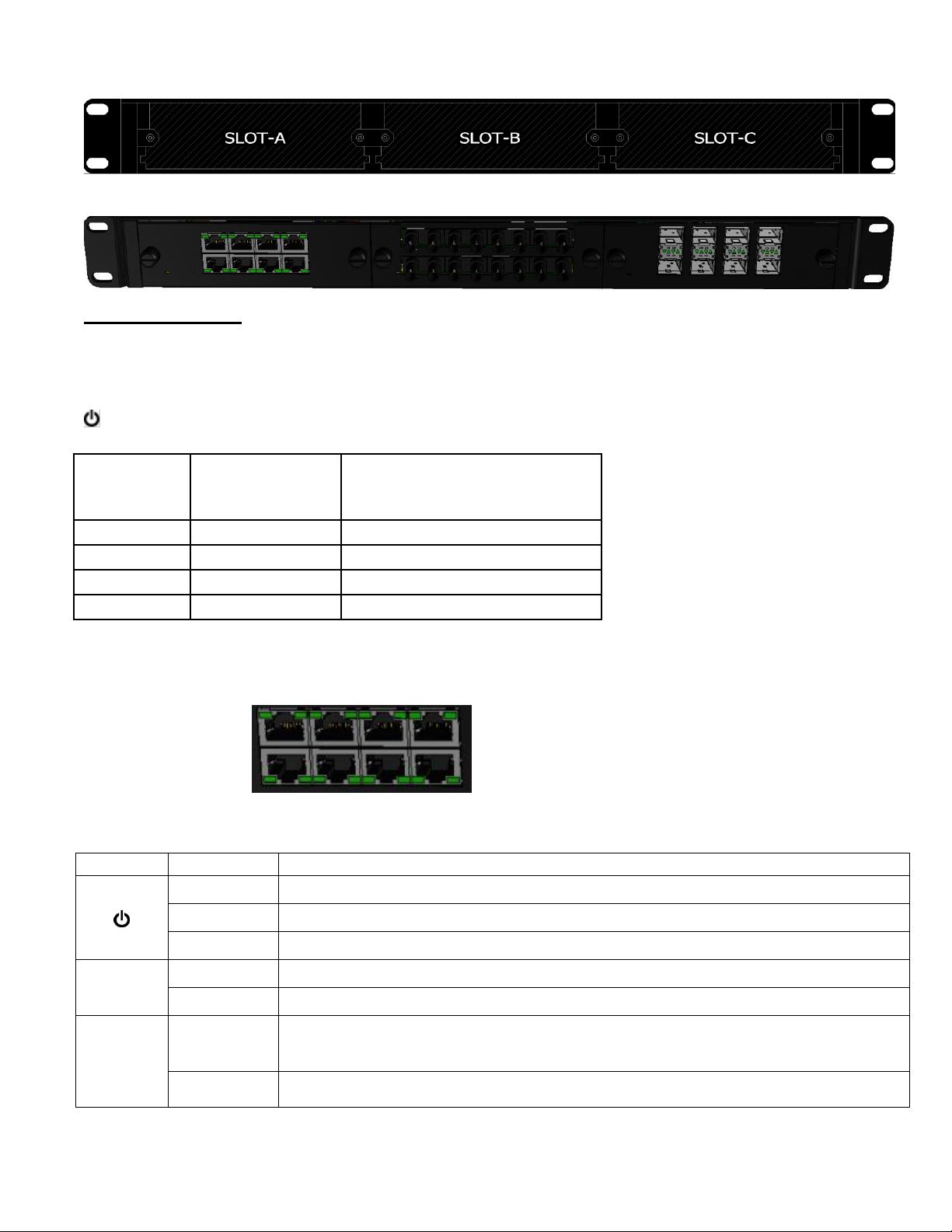

The front of an NT24k with the module slots identified:

The front of an NT24k populated with modules:

From Left to Right:

RJ45 Ports TX8 Module in slot A: Auto Sensing 10/100/1000 Base-TX Connections

Fiber Ports FX8 ST Module in Slot B: Eight of 100 based fiber ports

SFP8 Eight of SFP ports

Lower Left LED lights when Power is supplied to unit.

NOTE: The RJ45 data ports have two LEDs located on each connector. The left LED indicates LINK

status, and the right LED indicates ACTIVITY.

LEDs: The table below describes the operating modes:

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 19 of 140

Page 20

Input AC 115/230V

Output DC 24-28V

Output Current 1.5A @ 24V

1.0A @ 28V

Power 36W

35 mm DIN-Rail Mountable

Dimensions: 45X75X91 mm

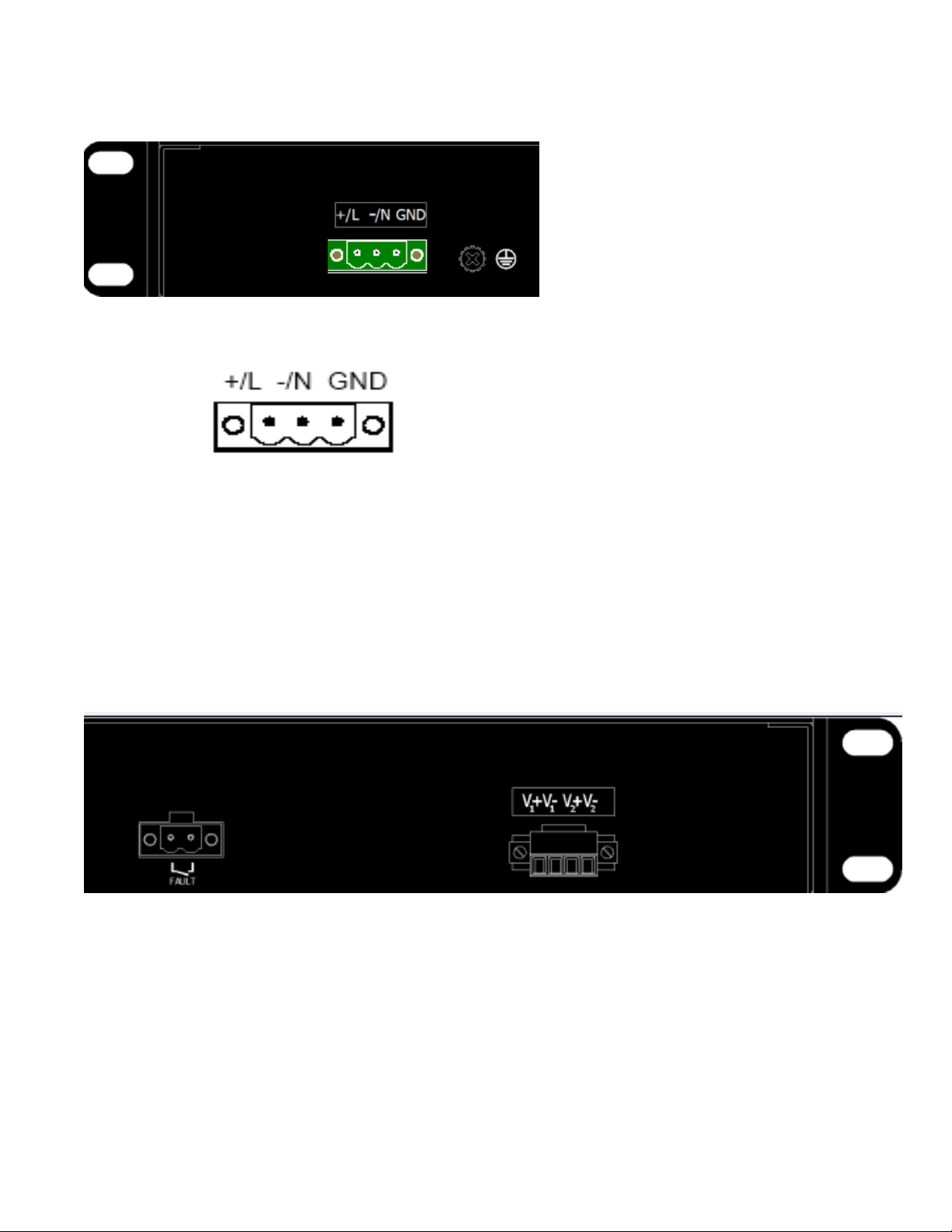

APPLYING POWER AND FAULT CONNECTIONS (Back View)

All NT24k can operate with one power supply, either AC or DC. The Rack Mount NT24k can accept up to

two power supply units. Each power supply can be AC or DC. Each low voltage DC Power supply includes

redundancy (two DC supplies).

The example below is shown from the back and includes a AC Power supply on the left and a DC

power supply on the right, looking from the back:

NT24k with DC Power Supply Installed:

Unscrew & Remove the DC Voltage Input

Plug from the Power Input Header

Install the DC Power Cables into the Plug

(observing polarity).

Plug the Voltage Input Plug back into the

Power Input Header.

Tightening torque for the terminal block

power plug is 0.5 Nm/0.368 Pound Foot.

Verify the Power LED stays ON.

Notes:

When a DC Power supply is installed, only one power supply must be connected to power for

minimal operation. For redundant power operation, V1 and V2 inputs must be connected to separate

DC Voltage sources. This device will draw current from both sources simultaneously. Use 16-28

gauge wire when connecting to the power supply.

Recommended 24V DC Power Supplies, similar to: N-Tron’s P/N NTPS-24-1.5

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 20 of 140

Page 21

NT24k with AC Power Supply Installed:

Unscrew & Remove the AC Voltage Input

Plug from the Power Input Header

Install the AC Power Cables into the Plug

(observing polarity).

Plug the Voltage Input Plug back into the

Power Input Header.

Tightening torque for the terminal block

power plug is 0.5 Nm/0.368 Pound Foot.

Verify the Power LED stays ON.

When an AC Power supply is installed (i.e., the –AC option), Use 12-24 gauge wire when

connecting to the power supply.

NT24k Fault Pins

The Fault pins on the back of the NT24k can be used for an alarm contact. The current carrying capacity is

1A at 24VDC. It is normally open and the relay closes when a fault condition occurs, though this can be

reversed via configuration. These pins can be used to connect an external warning device such as a light in

order to provide an external alarm. The conditions for generating a fault condition (closing the relay) can be

configured through software.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 21 of 140

Page 22

Connecting the Unit

For FX/FXE units, remove the dust cap from the fiber optic connectors and connect the fiber optic cables.

The TX port on the FX/FXE models should be connected to the RX port of the far end station. The RX port

on the FX/FXE versions should be connected to the TX port of the far end station.

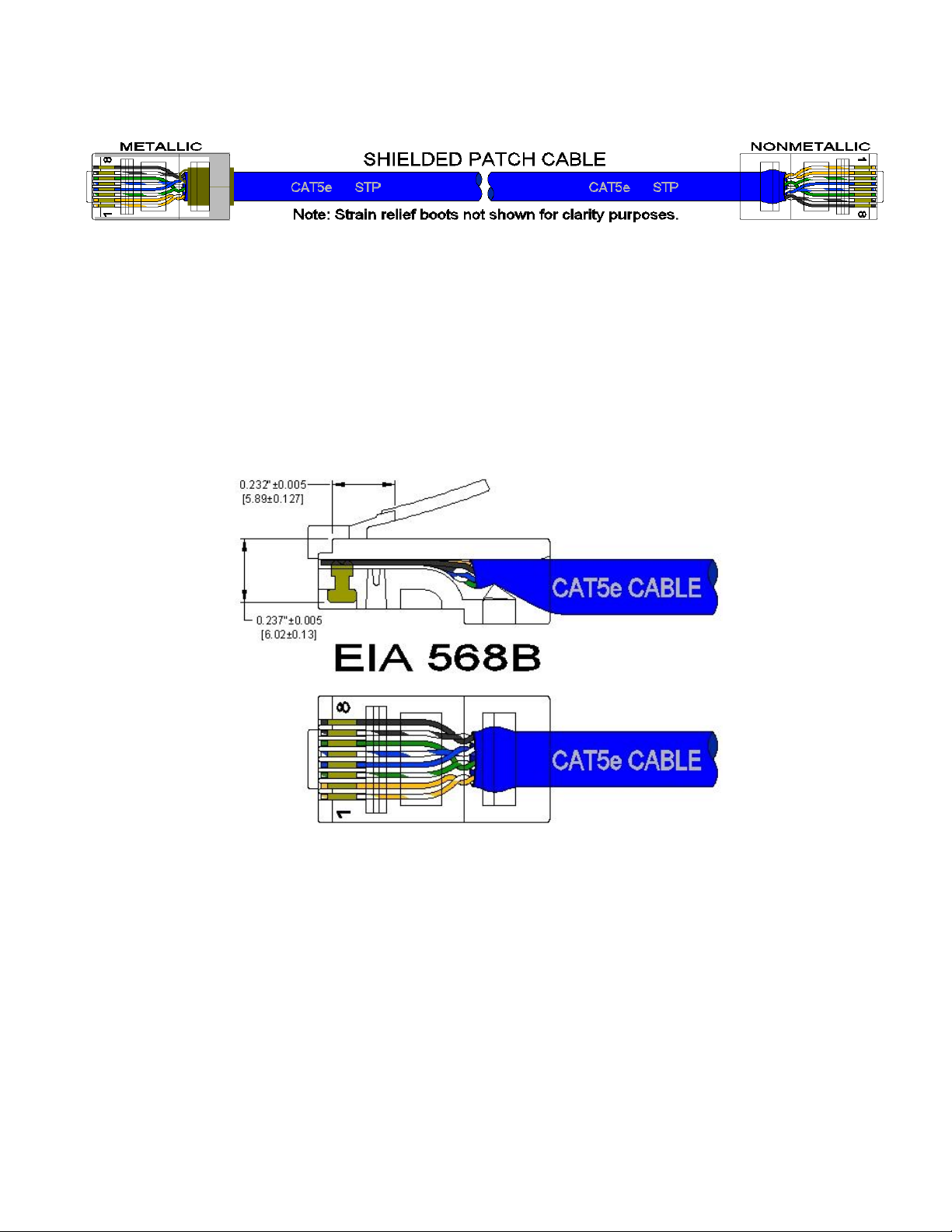

For 10/100/1000/T(x) ports, plug a Category 5E twisted pair cable into the RJ45 connector. Connect the

other end to the far end station. Verify that the LNK LEDs are ON once the connection has been completed.

To connect any port to another device (end node, Switch or Repeater), use a standard Category 5E straight

through or crossover cable with a

minimum length of one meter and a

maximum length of 100 meters.

N-Tron recommends the use of premanufactured Cat5E cables to ensure the

best performance. If this is not an option

and users must terminate their own ends

on the Cat5E cables; one of the two color

coded standards shown to the right should

be utilized. If a user does not follow one

of these two color code standards then the

performance and maximum cable distance

will be reduced significantly, and may

prevent the switch from establishing a

link.

Warning: Creating a port to port connection on the same switch (i.e. loop) is an illegal operation and

will create a broadcast storm which will crash the network!

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 22 of 140

Page 23

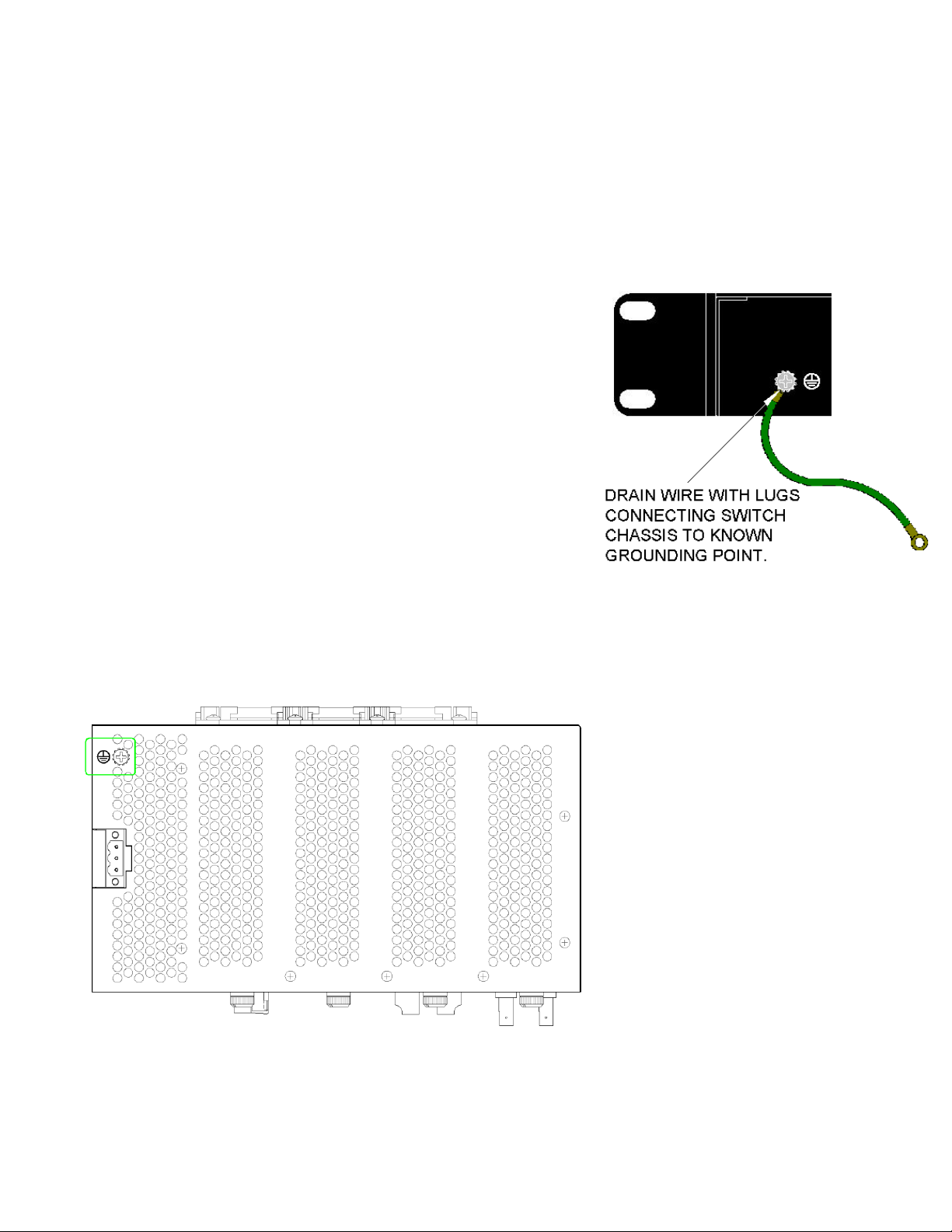

N-TRON SWITCH GROUNDING TECHNIQUES

The grounding philosophy of any control system is an integral part of the design. N-Tron switches are

designed to be grounded, but the user has been given the flexibility to float the switch when required. The

best noise immunity and emissions (i.e. CE) are obtained when the N-Tron switch chassis is connected to

earth ground via a drain wire. In the case of both the DC and AC Power supply options for the

NT24k/NT24k-AC the power supply is isolated from chassis ground. Therefore the user must not attempt

to ground the switch to earth ground via the power supply. In other N-Tron switches it is common to use

the V- for the purpose of grounding. This must NOT be attempted in the NT24k or NT24k-AC.

In the case of the AC power supply option (i.e., NT24k-AC) the

chassis may be connected to earth ground using the safety input of

the input power plug labeled “GND” (refer to the drawing above

which shows the pin out of the AC power plug) or using the

ground lug located at the rear of the chassis (see adjacent

illustration).

In the case of the NT24k, the only viable safety ground option is

using the ground lug at the rear of the chassis (see adjacent

illustration).

For the Din-Rail models see the illustration below for grounding:

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 23 of 140

Page 24

If the use of shielded cables is required, it is generally recommended to only connect the shield at one end to

prevent ground loops and interference with low level signals (i.e. thermocouples, RTD, etc.). Cat5e cables

manufactured to EIA-568A or 568B specifications are required for use with N-Tron Switches.

In the event all Cat5e patch cable distances are small (i.e. All Ethernet devices are located in the same local

cabinet and/or referenced to the same earth ground), it is permissible to use fully shielded cables terminated

to chassis ground at both ends in systems void of low level analog signals.

RJ45 CONNECTOR CRIMP SPECIFICATIONS

Please reference the illustration below for your Cat5 cable specifications:

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 24 of 140

Page 25

USB INTERFACE

The NT24k switches provide a USB interface accessed via the USB connector labeled as “USB” on the

back of the unit near the center. This is used to access the Command Line Interpreter (CLI) or PPP (Point-

to-Point Protocol). PPP allows any configuration and status that the browser does.

USB Cable

Connect the USB port of your PC and the Switch using a standard USB cable. You will require a cable with

a Type A connector for the PC end, and a Type B connector for the Switch end.

Standard USB cables are readily available from a variety of computer stores.

HyperTerminal

The following configuration should be used in HyperTerminal:

Port Settings: 115200

Data Bits: 8

Parity: NONE

Stop bits: 1

Flow Control: NONE

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 25 of 140

Page 26

Overview of Advanced Features

Mode of Operation

Each port on the switch can be configured into different modes of operation as shown below:

Copper Ports: 1000Base Copper or any Fiber Ports:

- Half Duplex - Full Duplex

- Full Duplex

- Auto Negotiation

Half Duplex

In half duplex mode, the CSMA/CD media access method is the means by which two or more stations share

a common transmission medium. To transmit, a station waits (defers) for a quiet period on the medium (that

is, no other station is transmitting) and then sends the intended message in bit-serial form. If, after initiating

a transmission, the message collides with that of another station, then each transmitting station intentionally

transmits for an additional predefined period to ensure propagation of the collision throughout the system.

The station remains silent for a random amount of time (back-off) before attempting to transmit again.

Full Duplex

Full duplex operation allows simultaneous communication between a pair of stations using point-to-point

media (dedicated channel). Full duplex operation does not require that transmitters defer, nor do they

monitor or react to receive activity, as there is no contention for a shared medium in this mode.

Auto Negotiation

In Auto Negotiation mode, the port / hardware detects the mode of operation of the station that is connected

to this port and sets its mode to match the mode of the station.

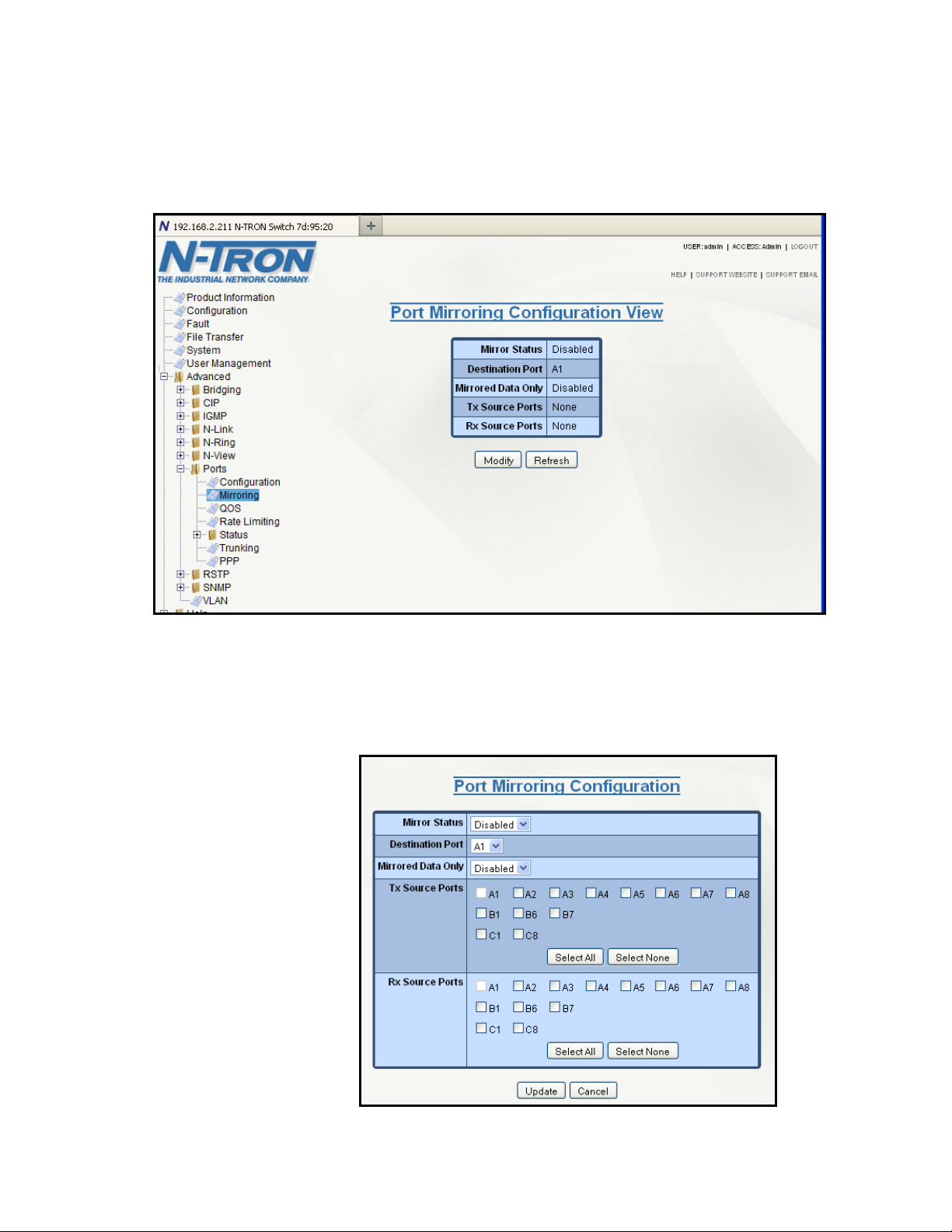

Port Mirroring

A Mirroring Port is a dedicated port that is configured to receive the copies of Ethernet frames that are being

transmitted out and also being received in from any other port that is being monitored.

Port Trunking

Port Trunking is the ability to group network ports to increase the bandwidth between two machines (switch

or any work station). This feature allows grouping of high-speed connectivity and provides redundant

connection between switches, so that a trunk can act as a single link between the switches.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 26 of 140

Page 27

Quality of Service (QoS)

Quality of service (QoS) refers to resource reservation control mechanisms. Quality of service is the ability

to provide different priority to different applications, users, or data flows. Quality of service guarantees are

important if the network capacity is insufficient, especially for real-time streaming multimedia applications

such as voice over IP, online games and IP-TV, since these often require fixed bit rate and are delay

sensitive, and in networks where the capacity is a limited resource, for example in cellular data

communication. In the absence of network congestion, QoS mechanisms are not required.

Each of the three QOS methods below may be included based on the settings on the relevant browser page:

1) IEEE802.1p (Tagged QOS), or

2) DSCP (differentiated services code points) (RFC 2474).

3) Port (‘Default Priority’) (if not one or4 both of the two above)

Virtual LAN

The switch provides support for setting up tagged Virtual LANs (Local Area Networks). A port may belong

to any number of Virtual LANs. The VLAN membership of a device is determined by the VLAN(s) that

have been defined for the port to which the device is connected. If a device should move from one port to

another, it loses its current VLAN membership and inherits that of the new port it is connected to.

VLANs facilitate easy administration of logical groups of devices that can communicate as if they

were on the same LAN. Traffic between VLANs is restricted, unless the ports are explicitly configured

as overlapping VLANs. Switches forward unicast, multicast, and broadcast traffic only on LAN segments

that serve the VLAN to which the traffic belongs.

A Default Virtual LAN (VID=1) exists to which a port, which is not a member of any other Virtual LAN,

will belong. This allows the switch to operate as a ‘normal’ switch when it is used in a network. A port may

be automatically removed (or not) from the Default VLAN when it is reconfigured to belong to another

Virtual LAN, because that is the most common operation.

If switch ports are configured to transmit and receive untagged frames, end devices are able to communicate

throughout the LAN. Using Tagged VLANs, the switch has the ability to take non-tagged packets in some

ports, add a VLAN tag to the packet and send it out tagged ports on the switch. The VLANs can also be

configured to accept tagged packets in tagged ports, strip the tags off the packets, and send the packets back

out other untagged ports. This allows a network administrator to set up the switch to support devices on the

network that do not support VLAN Tagged packets. The administrator can also set up the ports to discard

any packets that are tagged or to discard any packets that are untagged based on a hybrid VLAN of both

tagged and untagged ports, and using the VLAN Ingress Filter on the switch.

For each switch port there is one and only one PVID (port VLAN ID) setting. If an incoming frame is

untagged and untagged frames are being accepted, then that frame will inherit the tag of the PVID value for

that port. Subsequent switch routing and treatment will be in accordance with that VLAN switch map. By

configuring PVIDs properly and configuring for all frames to exit untagged, the switch can achieve a ‘port

VLAN’ configuration in which all frames in and out can be untagged, thus not requiring external devices to

be VLAN cognizant.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 27 of 140

Page 28

To understand how a VLAN configuration will perform, first look at the port on which the frame enters the

switch, then the VLAN ID (if the frame is tagged) or the PVID (if the frame is untagged). The VLAN

defined by the VID or PVID defines a VLAN group with a membership of ports. This membership

determines whether a port is included or excluded as to frame egress from the switch.

The NT24k switch also has the ability to allow overlapping VLANs. Overlapping VLANs give the user the

ability to have one or more ports share two or more VLAN groups. For more information and examples on

how this could be implemented, please see the ‘VLAN Configuration Examples’ in this document, and/or

our website’s technical documents. Note that RSTP is supported on a single VLAN.

Rapid Spanning Tree Protocol

The Rapid Spanning Tree Protocol as specified in IEEE 802.1D-2004 is supported. One Spanning Tree on

one VLAN is supported. The Rapid Spanning Tree Protocol (RSTP) supersedes the Spanning Tree Protocol

(STP) which was described in IEEE 802.1D-1998. The RSTP establishes a simply connected active

network topology from the arbitrarily connected bridges of a bridged network. Bridges effectively connect

just the LANs to which their forwarding ports are attached. Ports that are in a blocking state do not forward

frames. The bridges in the network exchange sufficient information to automatically derive a spanning tree.

RSTP allows for much quicker learning of network topology changes than the older STP. RSTP supports

new and improved features such as rapid transition to forwarding state. Rather than forwarding them from

the root bridge, RSTP also sends out new BPDUs every hello time. RSTP interoperates with older STP

switches by falling back to STP when the older BPDUs are detected on bridge ports. The user can also

manually configure bridge ports to use STP when desired.

SNMP Traps

The NT24k switch supports SNMP Trap Stations to which SNMP Traps will be sent. The switch supports

four standard traps; Link Status (Link Up / Link Down), Cold Start, Warm Start, and Authentication Errors.

SNMP Traps will be sent to all the trap stations configured on the switch when the corresponding trap is

enabled.

IGMP Snooping

IGMP Snooping is enabled by default, and the switch is Plug and Play for IGMP. IGMP snooping provides

intelligent network support for multicast applications. In particular, unneeded traffic is reduced. IGMP

Snooping is configured via the web console and if enabled, operates dynamically upon each power up.

Also, there can be manual only or manual and dynamic operation. Note that “static multicast group

address” can be used whether IGMP Snooping is enabled or not.

IGMP Snooping will function dynamically without user intervention. If some of the devices in the LAN do

not understand IGMP, then manual settings are provided to accommodate them. The Internet Group

Management Protocol (IGMP) is a protocol that provides a way for a computer to report its multicast group

membership to adjacent ‘routers’. In this case N-Tron NT24k switches provide router-like functionality.

Multicasting allows one computer to send content to multiple other computers that have identified

themselves as interested in receiving the originating computer's content. Multicasting can be used to

transmit only to an audience that has joined (and not left) a multicast group membership. IGMP version 2 is

formally described in the Internet Engineering Task Force (IETF) Request for Comments (RFC) 2236.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 28 of 140

Page 29

IGMP version 1 is formally described in the Internet Engineering Task Force (IETF) Request for Comments

(RFC) 1112. The NT24k supports v1 and v2.

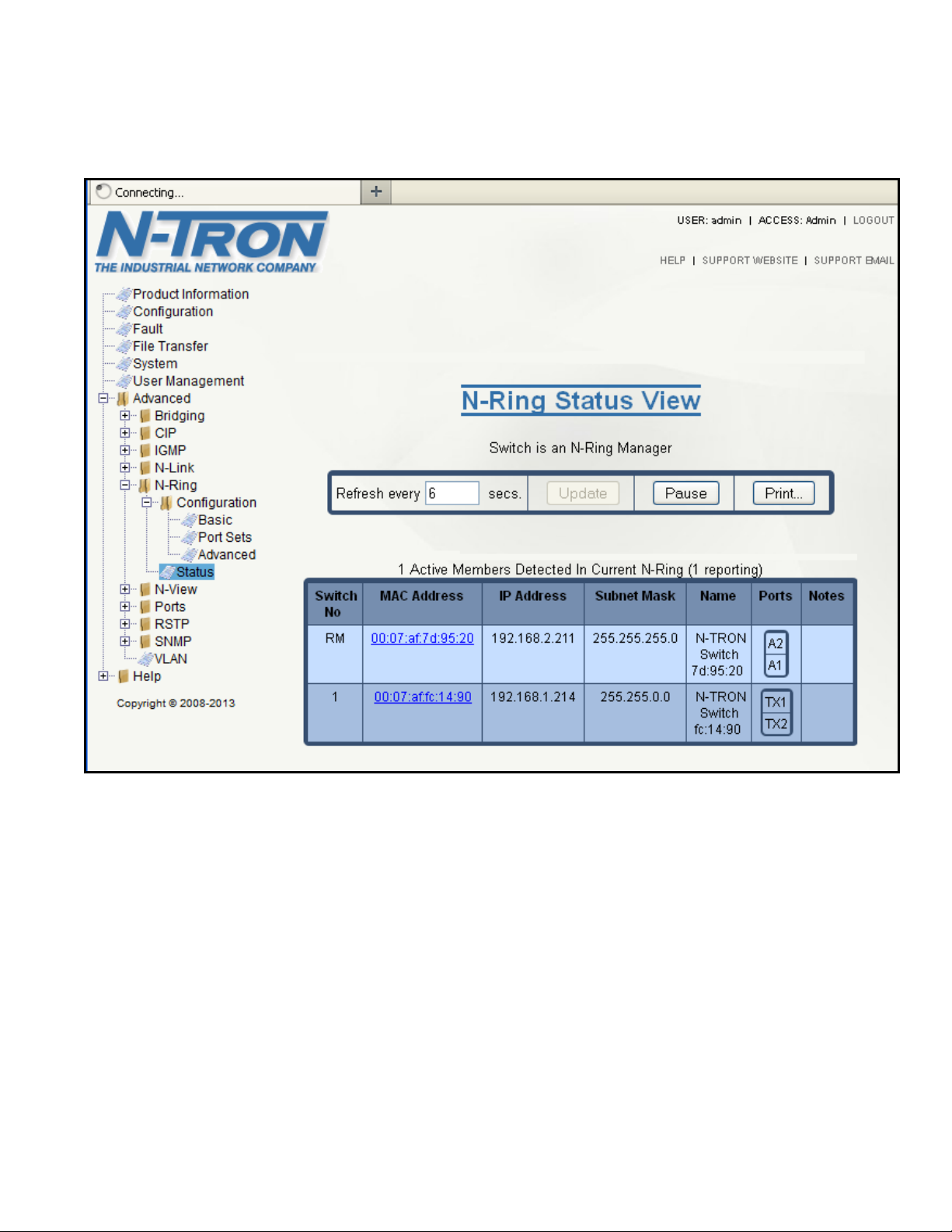

N-Ring

N-Ring is enabled by default, and the switch is Plug and Play for N-Ring except that initially one must

enable an N-Ring enabled device to be the N-Ring Manager for a given N-Ring. Subsequently, N-Ring

operates dynamically upon each power up. Using N-Tron's proprietary N-Ring technology offers expanded

ring size capacity, detailed fault diagnostics, and a standard healing time of 30ms. The N-Ring Manager

periodically checks the health of the N-Ring via health check packets. If the N-Ring Manager stops

receiving the health check packets, it times out and converts the N-Ring to a backbone within 30ms. When

using all N-Ring enabled switches in the ring, a detailed ring map and fault location chart is also provided

on the N-Ring Manager’s web browser. N-Ring status is also sent from the N-Ring Manager to the N-View

OPC Server to identify the health status of the ring. Up to 250 N-Ring enabled switches can participate in

one N-Ring topology. Switches that do not have N-Ring capability may be used in an N-Ring, however the

ring map and fault location chart cannot be as detailed at these locations.

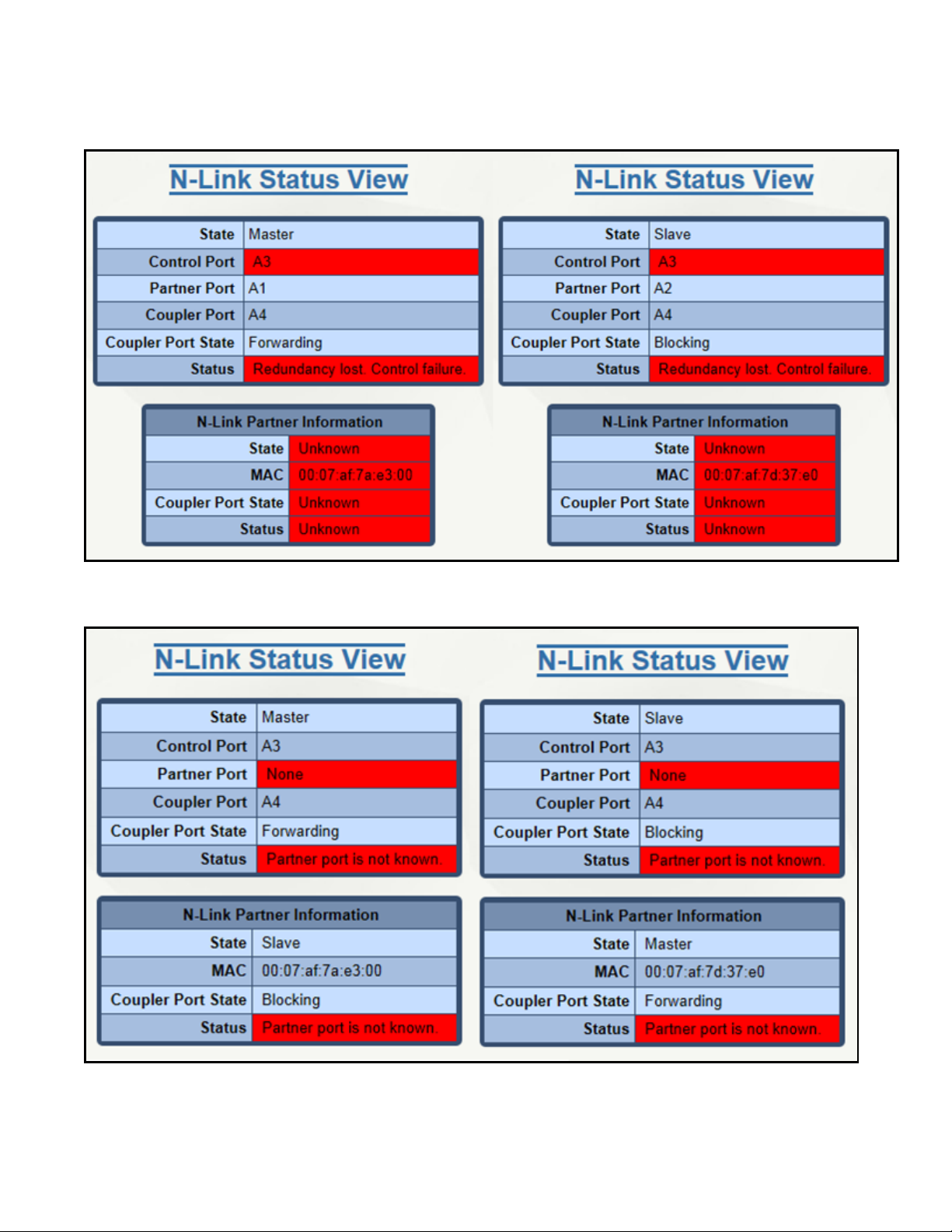

N-Link

The purpose of N-Link is to provide a way to redundantly couple an N-Ring topology to one or more other

topologies, usually other N-Ring topologies. Each N-Link configuration requires 4 switches: N-Link

Master, N-Link Slave, N-Link Primary Coupler, and N-Link Standby Coupler. N-Link will monitor the link

status of the Primary and Standby Coupler links. While the Primary Coupler link is healthy, it will forward

network traffic and the Standby Coupler link will block network traffic. When a problem is detected on the

Primary Coupler link, the Primary Coupler link will block network traffic and the Standby Coupler link will

forward network traffic. While the N-Link Master and Slave are in communication via the Control link,

only one Coupler link (Primary or Standby) will forward network traffic while the other Coupler link will

block network traffic.

CIP

The CIP (Common Industrial Protocol) feature allows N-Tron switches to directly provide switch

information and configuration access to Programmable Logic Controller (PLC) and Human Machine

Interface (HMI) applications via a standardized communication protocol. For example, a PLC may be

programmed to monitor port links or N-Ring status and cause a status indicator to turn red on an HMI if a

port goes link down or if N-Ring has a fault. CIP is formally described in ODVA Publication Number

PUB00001 (Volume 1: Common Industrial Protocol (CIP™)), and Publication Number: PUB00002

(Volume 2: Ethernet/IP Adaptation of CIP). N-Tron provides EDS and ICO files. N-TRON_CIP_Tags.pdf

is for a particular environment, but reveals the tags available.

Note: Information about using CIP with the NT24k can be found in the CIP User Manual & Installation

Guide and the CIP Installation Kit for the NT24k switch family.

PPP

Point to Point Protocol (PPP) allows a browser like interface over the CLI port.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 29 of 140

Page 30

Telnet

Telnet allows a CLI like interface over the internet. The NT24k supports up to two concurrent Telnet users.

DHCP Client

The switch will automatically obtain an IP assignment from a DHCP Server, or optionally Fallback to a

configured IP assignment if unable to get an IP assignment from a DHCP server. Communication between

the client and server can optionally go through a DHCP Relay Agent. The DHCP Client is enabled in

factory defaults, with 192.168.1.210 as the faillback address.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 30 of 140

Page 31

TROUBLESHOOTING

1. Make sure the (Power LED) is ON.

2. Make sure you are supplying sufficient current for the version chosen. Note: The Inrush

current will exceed the steady state current by ~ 2X.

3. Verify that Link LEDs are ON for connected ports.

4. Verify cabling used between stations.

5. Verify that cabling is Category 5E or greater for 100Mbit and Gigabit operation.

SUPPORT

Contact N-Tron Corporation at:

TEL: 251-342-2164

FAX: 251-342-6353

E-MAIL: N-TRON_Support@n-tron.com

WEB: www.n-tron.com

FCC STATEMENT

This product complies with Part 15 of the FCC-A Rules.

Operation is subject to the following conditions:

(1) This device may not cause harmful Interference

(2) This device must accept any interference received, including interference that may cause

undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. Operation of this device in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his/her own

expense.

INDUSTRY CANADA

This Class A digital apparatus meets all requirements of the Canadian Interference Causing Equipment

Regulations. Operation is subject to the following two conditions; (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

Cet appareillage numérique de la classe A répond à toutes les exigences de l'interférence canadienne

causant des règlements d'équipement. L'opération est sujette aux deux conditions suivantes: (1) ce

dispositif peut ne pas causer l'interférence nocive, et (2) ce dispositif doit accepter n'importe quelle

interférence reçue, y compris l'interférence qui peut causer l'opération peu désirée.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 31 of 140

Page 32

Web Software Configuration

Web Management

Enter the switch’s IP address in any web browser and login to the web management feature of the NT24k.

The DHCP Client is enabled in factory defaults, with 192.168.1.210 as the fallback address.

Default:

User Name: admin

Password: admin

Up to 5 concurrent web users are allowed.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 32 of 140

Page 33

Web Management – Product Information Page

Product

Name:

The full name of this switch model, including any factory configured options.

The Product Name says -AC1 if there is one AC in either location and -AC2 if there

are two of AC power units. Also, Product Name says -DC1 if there is one DC in

either location and -DC2 if there are two of DC power units.This matches the Part

Number on the Data Sheet.

Switch

Model:

The base model of this switch.

Switch

Family:

The family of switches in which this model, and similar models, belong.

Software

The firmware's software version.

When the administrator either first logs onto a NT24k switch or selects the page on the left, the Product

Information page will be displayed. On the left hand side of the screen there is a list of configurable settings

that the NT24k switch will support. This section of the manual will go through each and every choice listed

on the left hand side of the screen and explain how to configure those settings. In the center of the main

home page the administrator can see some basic information like what firmware revision the switch is

running. The firmware can be upgraded at a later time in the field using http.

The Product Information page lists various information about the switch:

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 33 of 140

Page 34

Version:

Build Date:

The firmware's build date.

Boot

Loader:

The boot loader's software version.

Copyright:

The copyright.

URL:

The company's home page on the internet.

Switch Modules: The presently installed modules, including SFP transceivers.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 34 of 140

Page 35

Web Management – Menu Structure

To the left, there is a menu which is shown fully opened below, in three parts). The pages opened by each

of the individual selections are described in the rest of this section. The use of each of these pages is also

described in this section.

On the left is the basic navigation. Below that the ‘Advanced’ folder can be opened to see what is presented

in the middle below. Help text can be accessed from this left hand navigation as below on the right, or by

pressing ‘Help’ in the upper right hand corner of each browser page to get context dependent help.

Standard Menu: Advanced menu: Help Menu:

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 35 of 140

Page 36

Configuration Page

The Configuration section of web management gives an administrator the ability to save a running

configuration into the NVRAM. This step is needed in order for the switch to remember any changes after a

power cycle.

The “Save” button will save all current changes to the configuration for use after the next power cycle. If a

configuration device is installed, the configuration will also be saved to the device.

Selecting the “Restore” button will discard all unsaved changes, and load the most recently saved

configuration settings.

Selecting the “Reboot” button reboots the switch and reloads the most recently saved configuration. If a

configuration device is installed, the configuration stored on the device will be loaded and used.

The “Factory” button resets the switch's configuration to factory defaults except for any of the user

selectable items below. If a configuration device is installed, Save Configuration is then necessary to update

the configuration stored on the configuration device.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 36 of 140

Page 37

Fault Page

The page provides configurable selections indicating the ways to notify when a Power, N-Ring Manager,

Port Usage, Temperature, or Configuration Device fault occurs. In each case, the notification may consist of

any combination of the options: Show Web, Show LED, and Contact.

Fault Contact: Determines if the fault relay is normally open (Close on Fault) or normally

closed (Open on Fault).

Show Web: The fault is displayed on the browser pages.

Show LED: The fault is indicated on the Power LED as red.

Contact: The fault is indicated by opening or closing the contact switch.

Power AC (Left): Indicates low voltage on the left AC power supply.

Power AC (Right): Indicates low voltage on the right AC power supply.

The location of a power supply is based on the left or right hand side when viewing

from the front of the switch. Looking from the front of the unit: AC1 is on the right

side, and/or AC2 is on left side.

Port Usage Fault: Indicates that the port usage, for one or more ports, is below the Usage Alarm Low

setting, or above the Usage Alarm High setting (see Port Configuration View and

Port Utilization View).

Temperature: Indicates that the temperature of the switch is outside of the configured limits.

Configuration Device: Indicates that the configuration on an installed configuration device is invalid.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 37 of 140

Page 38

Fault Page, continued …

Power DC V1 (Left):

Indicates a low voltage on the left power supply DC V1.

Power DC V2 (Left):

Indicates a low voltage on the left power supply DC V2.

Power DC V3 (Right):

Indicates a low voltage on the right power supply DC V3.

Power DC V4 (Right):

Indicates a low voltage on the right power supply DC V4.

N-Ring Manager signal faults consist of: Broken, Partial Break (Low), Partial Break (High), and Multiple

Managers. N-Link Faults are reported by the N-Link Master.

The location of a power supply is based on the left or right hand side of a person viewing the front of the

switch. Looking from the front of the unit: DC V1 and V2 are on the right side, and DC V3 and V4 are on

the left side. If a low voltage DC power supply is installed, these additional choices appear:

Note: V1 and V2 Power Faults are disabled in factory defaults on a low voltage DC power supply.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 38 of 140

Page 39

File Transfer Page

Type of transfer to be performed: Choices are: Upload image to switch, Upload bootloader to switch,

Import Configuration to switch, or Export Saved Configuration from switch.

File Transfer gives the administrator the ability to Upgrade Image or Bootloader Firmware, or to import an

XML configuration file to the switch or to export a saved XML configuration file from the NT24k switch.

This allows administrators to backup their configurations to a server offsite in case they need to reload their

custom configurations at a later time. Administrators can, for example, update the firmware in the field

without losing their current configurations. It is important not to cycle power on the switch or interrupt the

data connection between the server and the switch while you are transferring a file.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 39 of 140

Page 40

File Transfer, continued …

When “Upgrade Image Firmware”, “Upgrade BootLoader Firmware", or “Import Configuration to switch”

is selected, you can browse and select an image or configuration file to upgrade with.

Reference Appendix A – XML Configuration File – Factory Defaults.

NOTE THAT YOU MUST REBOOT THE SWITCH TO BEGIN RUNNING THE NEWLY

UPGRADED IMAGE.

On “Import Configuration to switch” the existing Internet Address, Gateway, and Subnet Mask can be

retained. Also, you can retain the current user names and passwords, and/or the currently stored SNMP

settings:

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 40 of 140

Page 41

File Transfer, continued …

On “Export Saved Configuration from switch” pressing the “Configuration Settings” hyperlink brings up

the Windows utilities to specify to just open it or where to save it and the filename.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 41 of 140

Page 42

System Page

The factory default is DHCP. Setting the IP Configuration to DHCP will use the Primary Management

VLAN ports to receive an IP address from the DHCP Server. Changes to the Primary Management VLAN

are made in the VLAN section. If no changes are made, the default VLAN will be used as the default

Primary Management VLAN. The factory default fallback IP address is 192.168.1.201 if no DHCP is

received.

Static mode System Configuration View:

When the IP Configuration is in either DHCP or Static Mode:

IP Configuration: Method used to obtain an IP Address, Subnet Mask and Gateway Address

IP Address: Contains the current IP Address of the device.

Subnet Mask: Contains the current Subnet Mask of the device.

Gateway: Contains the current Gateway of the device.

MAC Address: MAC Address of the device.

System Up Time: This parameter represents the total time count. This time has elapsed since the switch was

turned ON or RESET.

Name: It shows the name of the product, which allows alphanumeric and special characters (#, _, -) only.

Contact: The person to contact for system issues, which should be someone within your organization.

Location: The physical location of the switch.

Temperature:: The calculated ambient temperature near the switch. This calculation is only valid after a

warm-up period.

Upper Threshold: The highest temperature for the switch without causing a fault to occur. The threshold is specified

as an integer in C degrees. The range is from -60°C to 100°C, and the default is product dependent.

Lower Threshold: The lowest temperature for the switch without causing a fault to occur. The threshold is specified as

an integer in C degrees. The range is from -60°C to 100°C, and the default is product dependent.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 42 of 140

Page 43

DHCP mode System Configuration View:

When the IP Configuration is in DHCP Mode the following information is added:

Client ID: Option used by DHCP clients to specify their unique identifier. The identifier may be the

MAC address, switch name, or entered as a text string or hex characters.

Fallback IP Address: Contains the configured Fallback IP Address of the device. The default is 192.168.1.201.

Fallback Subnet Mask: Contains the configured Fallback Subnet Mask of the device.

Fallback Gateway: Contains the configured Fallback Gateway of the device.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 43 of 140

Page 44

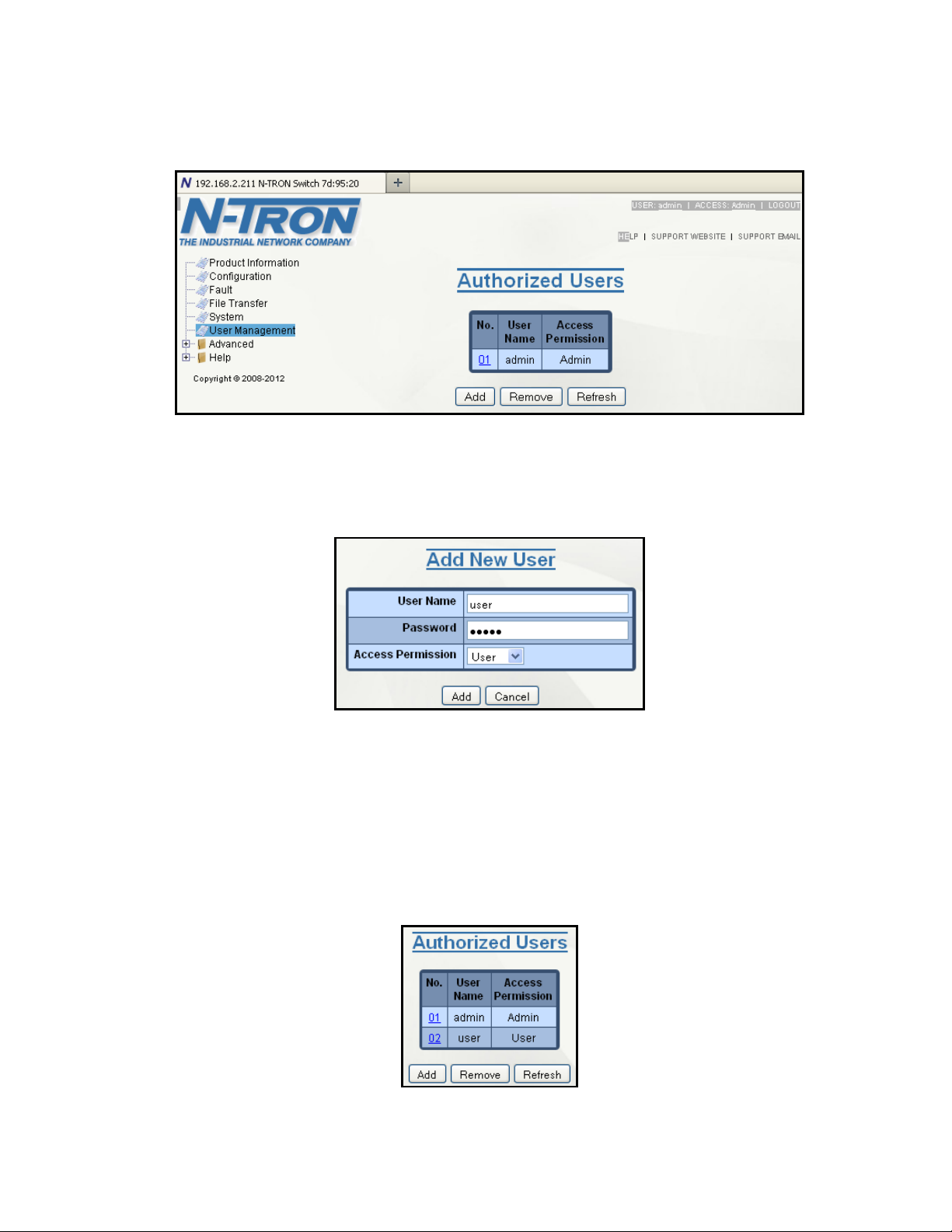

User Management

The User Management screen allows users to view, add, modify and remove system user accounts. The

display includes a list of all the users who have access to the management features of the switch and their

access permissions.

Adding Users

Following the Add button on the above example, the administrator can add another user and assign the user

a username, a password, and the user’s permissions (user/administrator).

User names may include all alphanumerical characters, "_" and "-" and must be 3 to 15 characters long.

Passwords may include all printable characters except ":" and spaces and must be 3 to 15 characters long.

Admin permission gives the right to change and view any switch configuration and to change and view any

current port settings.User level access permission gives the right to view switch configurations and to view

current port settings, but cannot make any changes to these settings.

A page should display after the administrator clicks the Add button indicating that the user was successfully

added.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 44 of 140

Page 45

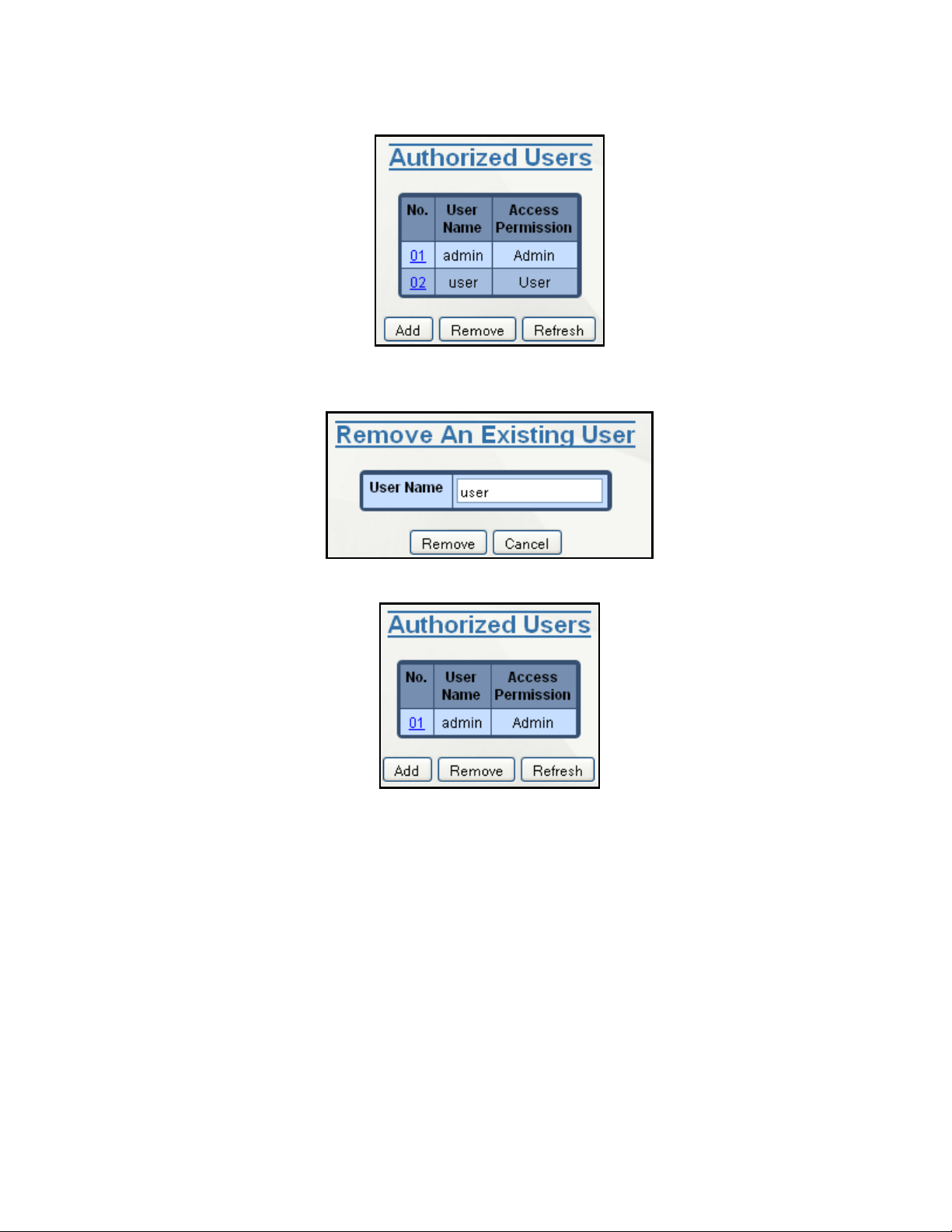

Adding Users, Continued …

In order to remove a user, simply click on the Remove button at the bottom of the page.

Following the Remove button on the above example, the administrator can remove a user by entering in the

user’s name and clicking the Remove button.

A page should follow indicating that the user was successfully removed from the list.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 45 of 140

Page 46

Bridging – Aging Time

The Aging Time tab under the Bridging category will display the currently configured Aging Time. This

page allows users to modify this variable to meet their needs. This configurable field displays the desired

aging time for dynamically learned MAC addresses. Inactive MAC addresses will be removed from the

Hardware Address Entry Table after the aging time period has expired. The internal aging time period will

be between 1 and 2 times the selected aging time value. The selected aging time value range is 10-630

seconds. The default aging time is 300 seconds.

After selecting the Modify button, the user will be presented with a page that allows the number to be

entered and updated.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 46 of 140

Page 47

Bridging – Multicast Addresses

The Multicast Addresses tab under the Bridging category will display a list of Multicast Group Addresses

that are associated with respective port numbers. This may be used to statically assign a Multicast Group

Address access to a group of ports on the switch.

Following the Add button on the page above, the administrator must enter a valid Multicast Group Address

and associate it with a port number or list on the switch. Once the administrator clicks on the Add button,

the changes will take effect instantly.

Note: If there are multiple ports on different VLANs, the NT24k will apply the static multicast address to

the lowest VLAN-ID that is associated with one of the ports assigned to the static multicast address.

So if the lowest VLAN-ID contains all the ports assigned to the static multicast address (an umbrella

VLAN), it will function for all those ports with no problems. This can be achieved with overlapping

VLANs.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 47 of 140

Page 48

Bridging – Multicast Addresses Continued…

After adding a Multicast Group Address, it will appear on the main list and will show the associated ports

that go along with that address.

Following the Remove button on the example above, the administrator will be presented with a list of

Multicast Group Addresses that are configured on the switch. Using the pull-down menu, the administrator

should select the desired address to be removed. Then click on the Remove button at the bottom of the

page.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 48 of 140

Page 49

Bridging – Unicast Addresses

The Unicast Addresses tab under the Bridging category will display a list of MAC addresses that are

associated with each respective port number. This can be used to statically assign a MAC address access to

a single port on the switch.

Following the Add button on the page above, the administrator must enter a valid MAC address and

associate it with a port number on the switch. Once the administrator hits the Add button, the changes will

take effect instantly.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 49 of 140

Page 50

Bridging – Unicast Addresses, Continued…

Once a static MAC address has been added, it will be displayed in a list on the main page under the Unicast

Addresses tab.

Following the Remove button on the example above, an administrator can delete a static MAC address from

the list by pressing the Delete button on the page to remove the entry

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 50 of 140

Page 51

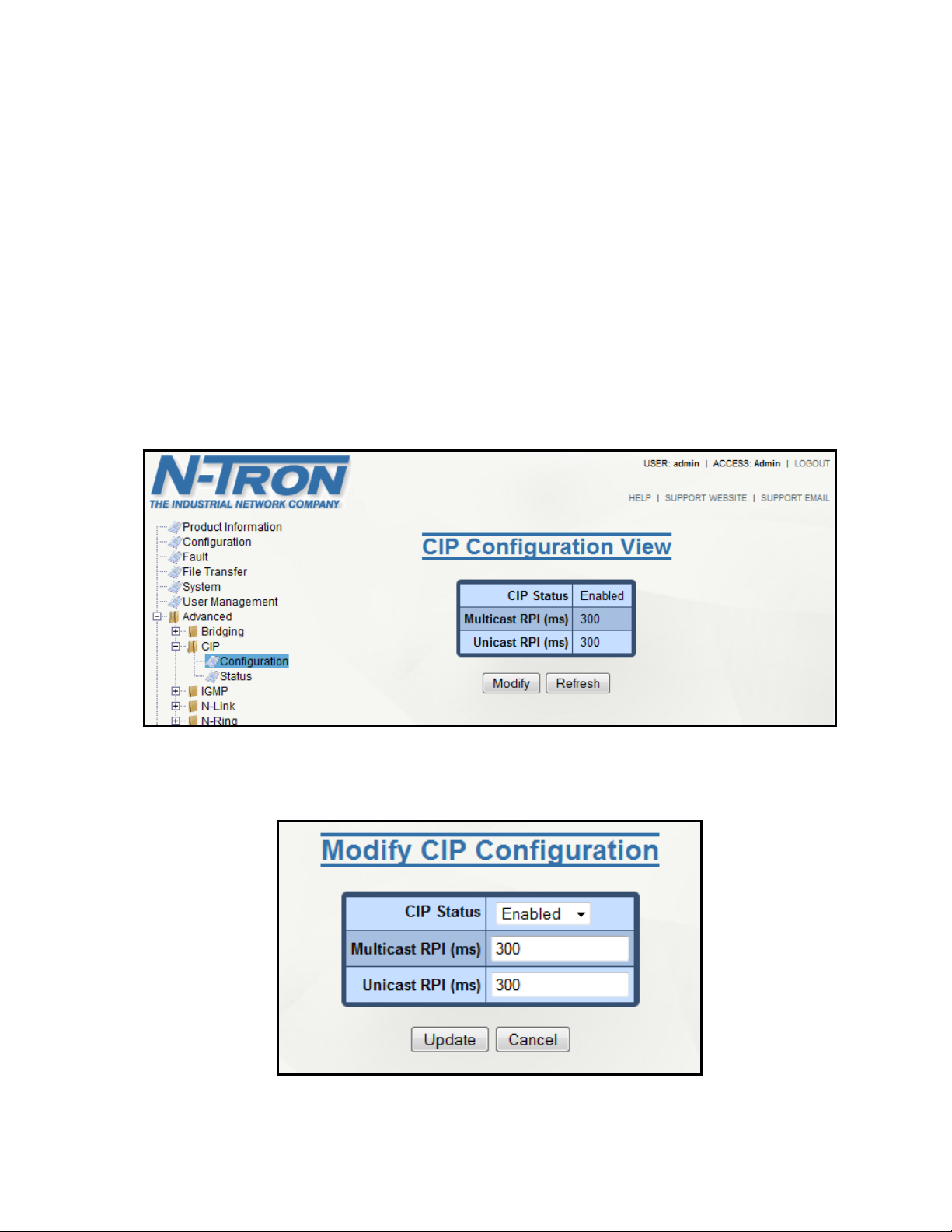

CIP – Configuration

Note: Information about using CIP with the NT24k can be found in the CIP User Manual & Installation

Guide and the CIP Installation Kit for the NT24k switch family.

The Configuration tab under the CIP category will display basic variables for CIP, and the status:

Cip Status:

Enables or Disables CIP on the Switch. Default: Enabled.

Multicast RPI:

The minimum Requested Packet Interval for Class 1 (multicast) connections, in milliseconds.

Requests for less than this value will be rejected. Range: 300-300000. Default = 300 ms.

Unicast RPI:

The minimum Requested Packet Interval for Class 3 (unicast) connections, in milliseconds.

Requests for less than this value will be rejected. Range: 300-300000. Default = 300 ms.

Following the Modify button on the above example, the administrator can modify the variables.

Additionally, you may Disable or Enable CIP altogether.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 51 of 140

Page 52

CIP – Status

Product Name:

Switch Model Number.

Vendor:

This is N-Tron's ODVA EtherNet/IP Vendor ID (1006).

Device Type:

The ODVA Device Type is Communications Adapter (= 0x0C hex).

Major Revision:

The Major Revision of the CIP implementation.

Minor Revision:

The Minor Revision of the CIP implementation.

Serial Number (hex):

CIP Serial number, unique across all N-Tron CIP devices. This is the

last 4 octets of the base switch MAC.

Number of Multicast

Connections:

Current number of CIP Ethernet/IP class 1 (multicast) connections.

Number of Unicast

Connections:

Current number of CIP Ethernet/IP class 3 (unicast) connections.

The Status tab under the CIP category will display the CIP status.

The following switch status and partner status information will be shown:

Identity Information:

Connection Information:

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 52 of 140

Page 53

CIP – EIP Indicators

Indicator State

Summary

Description

Steady Off

No Power

The switch is not powered up.

Steady Green

Device operational

The switch is operating normally.

Flashing Green

Standby

The switch has not been configured for CIP operations.

Flashing Red

Minor fault

A recoverable minor fault has occurred.

Steady Red

Major fault

A non-recoverable major fault has occurred.

Indicator State

Summary

Description

Steady Off

Not powered, no IP

address

The switch is not powered up, or IP address has not

been configured.

Flashing Green

No connections

An IP address is configured, but no connections have

been established.

Steady Green

Connected

A connection has been established.

Flashing Red

Connection timeout

A connection has timed out.

These indicators are either located on the back of the Rack Mount version of the switch, or

on the front of the CPU module on the DIN rail versions of the switch.

The Module Status indicator shows the status of the switch.

The Network Status indicator shows the status of the EtherNet/IP network interface.

Module Status:

Network Status:

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 53 of 140

Page 54

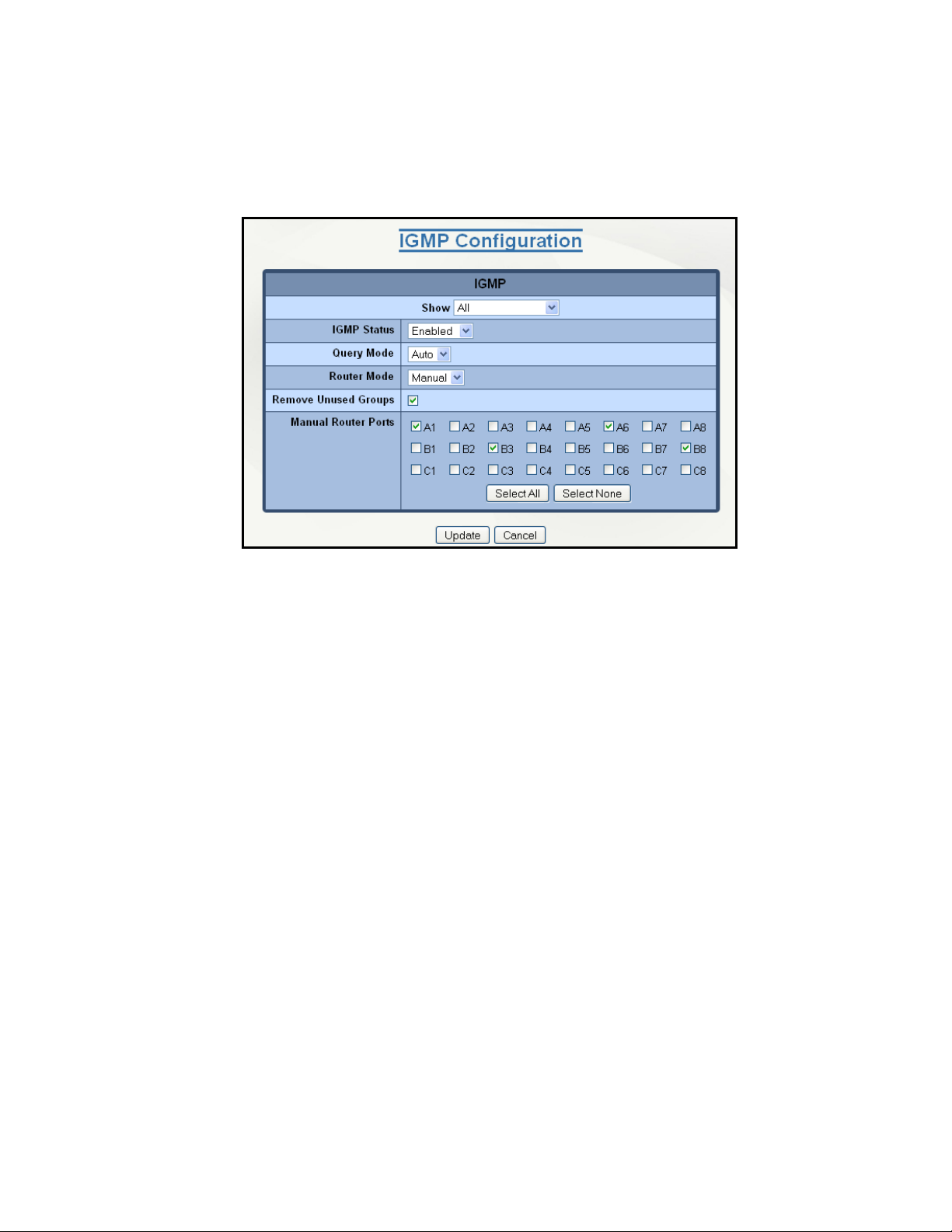

IGMP – Configuration

The Configuration tab under the IGMP category will display the IGMP basic configuration settings. By default,

IGMP is enabled.

Following the Modify button, the administrator will see a list of configurable fields for the IGMP configuration. Once

these fields are filled in to meet the needs of the administrator’s network, the changes may be updated by clicking the

Update button at the bottom of the page.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 54 of 140

Page 55

IGMP – Configuration, Continued…

The IGMP Status pull-down allows the user to enable or disable IGMP completely.

The Query Mode pull-down allows the user to set query mode for Automatic (the default), On (always), or

Off (never). In Automatic multiple switches will ensure that only one switch is the active querier.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 55 of 140

Page 56

IGMP – Configuration, Continued…

The Router Mode pull-down allows the user to choose router mode. ‘Auto’ allows for dynamically detected

and manually set router ports. ‘Manual’ allows only for manually set router ports. ‘None’ allows no router

ports. On an N-Ring Manager, the ring ports are informatively shown as router ports.

The user can specify the manual router ports:

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 56 of 140

Page 57

IGMP – Configuration, Continued…

If Remove Unused Groups is checked then unused IGMP Groups will be removed and traffic with those

multicast addresses will be treated as normal multicast. If unchecked, then unused IGMP Groups are not

removed and traffic with those multicast addresses will be limited. The default is checked. Note that IGMP

Groups are not retained through a power cycle.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 57 of 140

Page 58

Total Number of Active IP

Group Memberships:

Total Number of Active Group IP Memberships based on the dotted quad

(aaa.bbb.ccc.ddd) view and counting each joined port.

Group IP:

Dynamically created Multicast group IP address.

Port Name:

The descriptive name of the port.

VLAN ID:

VLAN in which the Group IP is assigned. The range is 1-4094.

IGMP – Groups

The Groups tab under the IGMP category will display a list of IGMP groups based on the Group IP and the

port that it is associated with.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 58 of 140

Page 59

IGMP – RFilter Ports

The ‘rfilter’ (Router Multicast Data Filter) function allows you to choose whether or not DATA frames

with KNOWN group multicast addresses are sent to the ‘router’ ports (links to other switches). Control

packets (Join, Leave) will be sent to the router(s) regardless of this setting. “KNOWN” is known from

dynamic IGMP Snooping operations. If IGMP is enabled and a port is a 'router port', then RFilter enabled

stops IGMP group data from egressing on the port unless a join to that specific IGMP group has come into

the port. IGMP controls (Join, Leave, Query) are still sent.

The factory default is that the Router Multicast Data Filter is enabled for all ports, so any router ports do

NOT get DATA frames with KNOWN multicast destination addresses unless a join to a specific multicast

address has been received on that port. Joins override an rfilter.

If rfilter is disabled, router ports do get DATA frames with KNOWN multicast destination addresses

Rfilter can be set for individual ports: any, all, or none. For each port, rfilter will have an impact only if that

port is manually or dynamically chosen as a router port.

Default configuration:

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 59 of 140

Page 60

IGMP – RFilter, Continued…

Modifying rfilter port settings:

After pressing ‘Modify’, the administrator can select which ports to identify as RFilter ports or choose all

ports.

The administrator can view all possible ports (‘Modules’), currently installed ports, or currently linked up

ports:

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 60 of 140

Page 61

IGMP – Routers

The Routers tab under the IGMP category will display a list of Auto-detected Router IPs and the port

numbers that they are associated with. The Router IP address is auto-detected.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 61 of 140

Page 62

N-Ring – Configuration – Basic

This page displays the N-Ring basic configuration settings. By default, N-Ring is in Auto Member mode.

If in N-Ring Manager Mode, the Basic Configuration View will be:

Notes:

1. Only tagged N-Ring is supported. That is best for frame priority reasons.

2. Do not create redundant links unless either RSTP or N-Ring is enabled.

3. The Default VLAN and any active N-Ring VLAN cannot be deleted.

4. N-Ring Manager cannot have RSTP enabled on the N_Ring ports. N-Ring Manager will disable

RSTP on the N-Ring ports if necessary. Other ports may have RSTP enabled.

5. RSTP & N-Ring are different modes and cannot share links or segments. If a port is both an RSTP

port and an active N-Ring port, then the port will be disabled for RSTP.

6. Do not connect the N-Ring to actively Trunking ports on an Auto Member.

7. Do not create redundant links unless either RSTP or N-Ring is enabled.

8. Any one NT24k can only participate in one N-Ring.

9. Since VLANs are implemented for security reasons as well as traffic flow, N-Ring only makes

minimal changes. It is up to the administrator to ensure that VLANs are configured correctly on the

N-Ring manager and all N-Ring members.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 62 of 140

Page 63

N-Ring – Configuration – Basic, Continued …

If N-Ring is disabled, the Basic Configuration View will be:

Following the Modify button on the above example, the administrator will see a pulldown of configurable

choices for the N-Ring configuration, as below.

If N-Ring Mode is “Manager”, then a pull-down allows selection of available ports (in this case A1/A2, and

A5/B3) as N-Ring ports.

If N-Ring Mode is “Manager”, then VLAN ID can be set to a unique VLAN id (1 ~ 4094). Default is 3333.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 63 of 140

Page 64

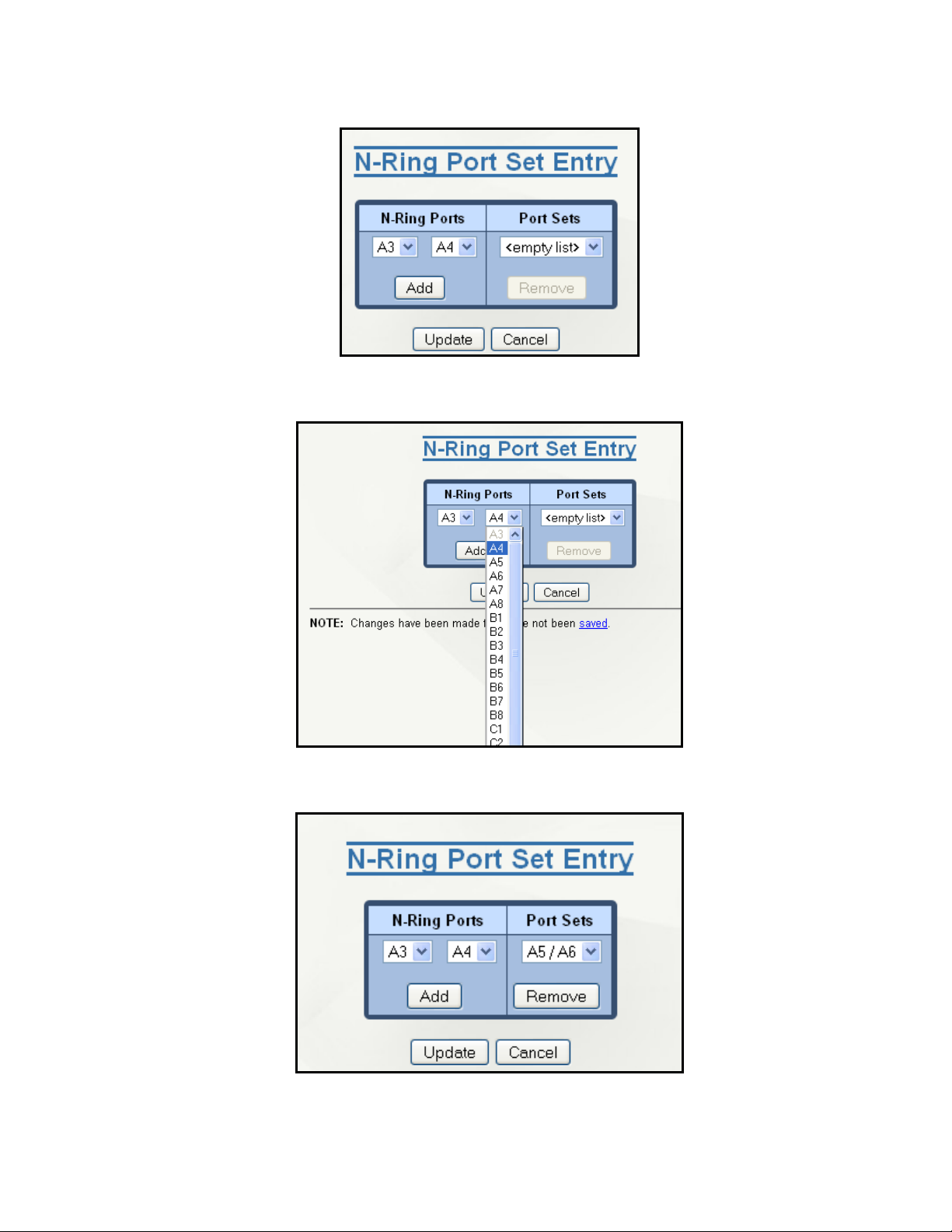

N-Ring – Configuration – Port Sets

Set:

Port set table index.

Ports:

Designated pair of N-Ring ports. To reassign different pairs, the port sets containing those ports, if

any, must first be deleted before the ports can be reassigned (a port can only belong to one port set).

A port set is a group of two ports that may be used for an N-Ring. The default N-Ring Port Set is as shown,

if available. In any event it is the lowest two installed ports.

Pressing ‘Modify’ on the page above yields this page:

To delete a port set, click the checkbox in the desired row and then click the Delete button.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 64 of 140

Page 65

N-Ring – Configuration – Port Sets, Continued …

Pressing ‘Add’ on the page above yields:

The N-Ring ports can be selected by pulldown.

In this mode port sets can be deleted from a pulldown.

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 65 of 140

Page 66

N-Ring – Configuration – Advanced

Keep-Alive

Timeout:

The amount of time to wait in seconds to receive a keep-alive request before switching

from active member back to auto member. The default is 31. The range is 15 to 300

seconds, with an entry of zero disabling the feature.

Auto Member

Detection

Timeout:

The amount of time to wait in seconds to receive N-Ring frames on any auto member

port (at boot up) before assuming the switch is not part of an N-Ring.

In factory defaults the N-Ring mode is Auto Member and the page looks like this:

(Revised 8-5-2013) NT24k Managed Industrial Ethernet Switch User Manual & Installation Guide Page 66 of 140

Page 67