NSC LM12CLK Datasheet

LM12CL

80W Operational Amplifier

General Description

The LM12 is a power op amp capable of driving±25V at

±

10Awhile operating from±30V supplies. The monolithic IC

can deliver 80W of sine wave power into a 4Ω load with

0.01%distortion. Power bandwidth is 60 kHz. Further, a

peak dissipation capability of 800W allows it to handle reactive loads such as transducers, actuators or small motors

without derating. Important features include:

input protection

•

controlled turn on

•

thermal limiting

•

overvoltage shutdown

•

output-current limiting

•

dynamic safe-area protection

•

±

The IC delivers

yet is completely protected against overloads, including

shorts to the supplies. The dynamic safe-area protection is

provided by instantaneous peak-temperature limiting within

the power transistor array.

The turn-on characteristics are controlled by keeping the

output open-circuited until the total supply voltage reaches

14V.The output is also opened as the case temperature ex-

10A output current at any output voltage

May 1999

ceeds 150˚C or as the supply voltage approaches the

BV

of the output transistors. The IC withstands overvolt-

CEO

ages to 80V.

This monolithic op amp is compensated for unity-gain feed-

back, with a small-signal bandwidth of 700 kHz. Slew rate is

9V/µs, even as a follower. Distortion and capacitive-load stability rival that of the best designs using complementary output transistors. Further, the IC withstands large differential

input voltages and is well behaved should the

common-mode range be exceeded.

The LM12 establishes that monolithic ICs can deliver considerable output power without resorting to complex switching

schemes. Devices can be paralleled or bridged for even

greater output capability. Applications include operational

power supplies, high-voltage regulators, high-quality audio

amplifiers, tape-head positioners, x-y plotters or other

servo-control systems.

The LM12 is supplied in a four-lead, TO-3 package with V−

on the case. A gold-eutectic die-attach to a molybdenum interface is used to avoid thermal fatigue problems. The LM12

is specified for either military or commercial temperature

range.

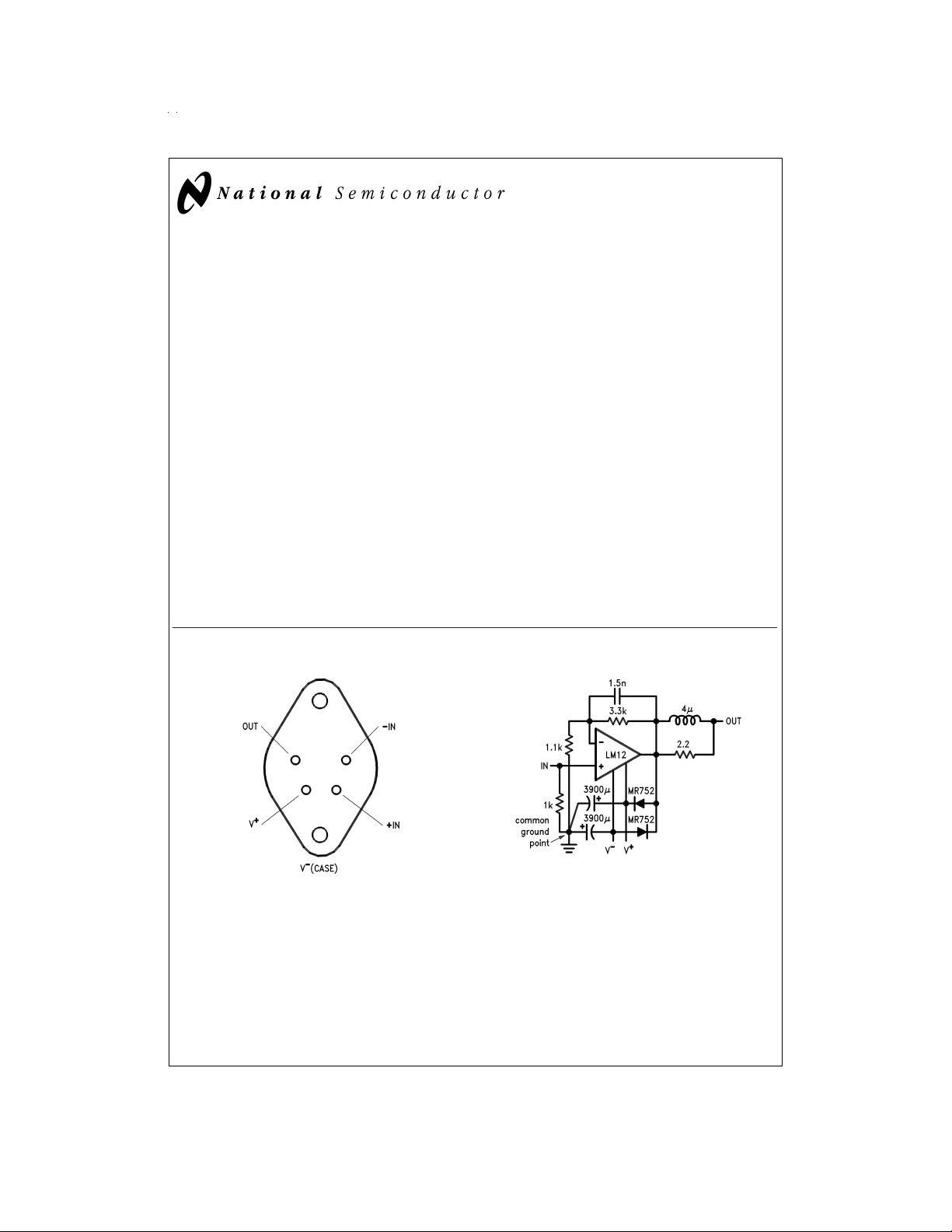

LM12CL 80W Operational Amplifier

Connection Diagram Typical Application

4-pin glass epoxy TO-3

socket is available from

AUGAT INC.

Part number 8112-AG7

Bottom View

Order Number LM12CLK

See NS Package Number K04A

© 1999 National Semiconductor Corporation DS008704 www.national.com

DS008704-1

*Low distortion (0.01%) audio amplifier

*

DS008704-2

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Storage Temperature Range −65˚C to 150˚C

Lead Temperature

(Soldering, 10 seconds) 300˚C

Distributors for availability and specifications.

Total Supply Voltage (Note 1) 80V

Input Voltage (Note 2)

Output Current Internally Limited

Operating Ratings

Total Supply Voltage 15V to 60V

Case Temperature (Note 4) 0˚C to 70˚C

Junction Temperature (Note 3)

Electrical Characteristics (Note 4)

Parameter Conditions Typ

25˚C

Input Offset Voltage

±

10V ≤ VS≤±0.5 V

Input Bias Current V− + 4V ≤ V

Input Offset Current V− +4V ≤ V

Common Mode V− +4V ≤ V

MAX,VCM

≤ V+ −2V 0.15 0.7/1.0 µA (max)

CM

≤ V+ −2V 0.03 0.2/0.3 µA (max)

CM

≤ V+ −2V 86 70/65 dB (min)

CM

=

0 2 15/20 mV (max)

Rejection

Power Supply V+=0.5 V

Rejection −6V ≥ V− ≥ −0.5 V

V−=−0.5 V

6V ≤ V+ ≤ 0.5 V

Output Saturation t

Threshold ∆V

=

ON

IN

=

I

OUT

, 90 70/65 dB (min)

MAX

MAX

, 110 75/70 dB (min)

MAX

MAX

1 ms,

=

5(10 ) mV,

1A 1.8 2.2/2.5 V (max)

8A 4 5/7 V (max)

10A 5 V (max)

Large Signal Voltage t

Gain V

Thermal Gradient P

=

2 ms,

ON

=

SAT

=

V

SAT

=

DISS

2V, I

8V, R

50W, t

=

0 100 30/20 V/mV (min)

OUT

=

4Ω 50 15/10 V/mV (min)

L

=

65 ms 30 100 µV/W (max)

ON

Feedback

Output-Current Limit t

ON

t

ON

=

10 ms, V

=

100 ms, V

=

10V 13 16 A (max)

DISS

=

58V 1.5 0.9/0.6 A (min)

DISS

1.5 1.7 A (max)

Power Dissipation t

Rating V

ON

DISS

=

100 ms, V

=

DC Thermal Resistance (Note 5) V

=

V

DISS

58V 80 52/35 W (min)

DISS

58V 2.7 4.5 ˚C/W (max)

=

20V 100 80/55 W (min)

DISS

=

20V 2.3 2.9 ˚C/W (max)

AC Thermal Resistance (Note 5) 1.6 2.1 ˚C/W (max)

Supply Current V

Note 1: Absolute maximum ratings indicate limits beyondwhichdamagetothedevicemay occur. The maximum voltage forwhichtheLM12isguaranteedto operate

is given in the operating ratings and in Note 4. With inductive loads or output shorts, other restrictions described in applications section apply.

Note 2: Neither input should exceed the supply voltage by more than 50 volts nor should the voltage between one input and any other terminal exceed 60 volts.

Note 3: Operating junction temperature is internally limited near 225˚C within the power transistor and 160˚C for the control circuitry.

Note 4: The supply voltage is

internal power dissipation is P

face type refers to limits or special conditions over full temperature range. With no heat sink, the package will heat at a rate of 35˚C/sec per 100W of internal

dissipation.

Note 5: This thermal resistance is based upon a peak temperature of 200˚C in the center of the power transistor and a case temperature of 25˚C measured at the

center of the package bottom. The maximum junction temperature of the control circuitry can be estimated based upon a dc thermal resistance of 0.9˚C/W or an ac

thermal resistance of 0.6˚C/W for any operating voltage.

±

30V (V

. Temperaturerange is 0˚C ≤ TC≤ 70˚C where TCis the case temperature. Standard typeface indicates limits at 25˚C while bold-

DISS

=

OUT

=

60V), unless otherwise specified. The voltage across the conducting output transistor (supply to output) is V

MAX

0, I

=

0 60 120/140 mA (max)

OUT

LM12CL Units

Limits

DISS

and

Although the output and supply leads are resistant to electrostatic discharges from handling, the input leads are not.

The part should be treated accordingly.

www.national.com 2

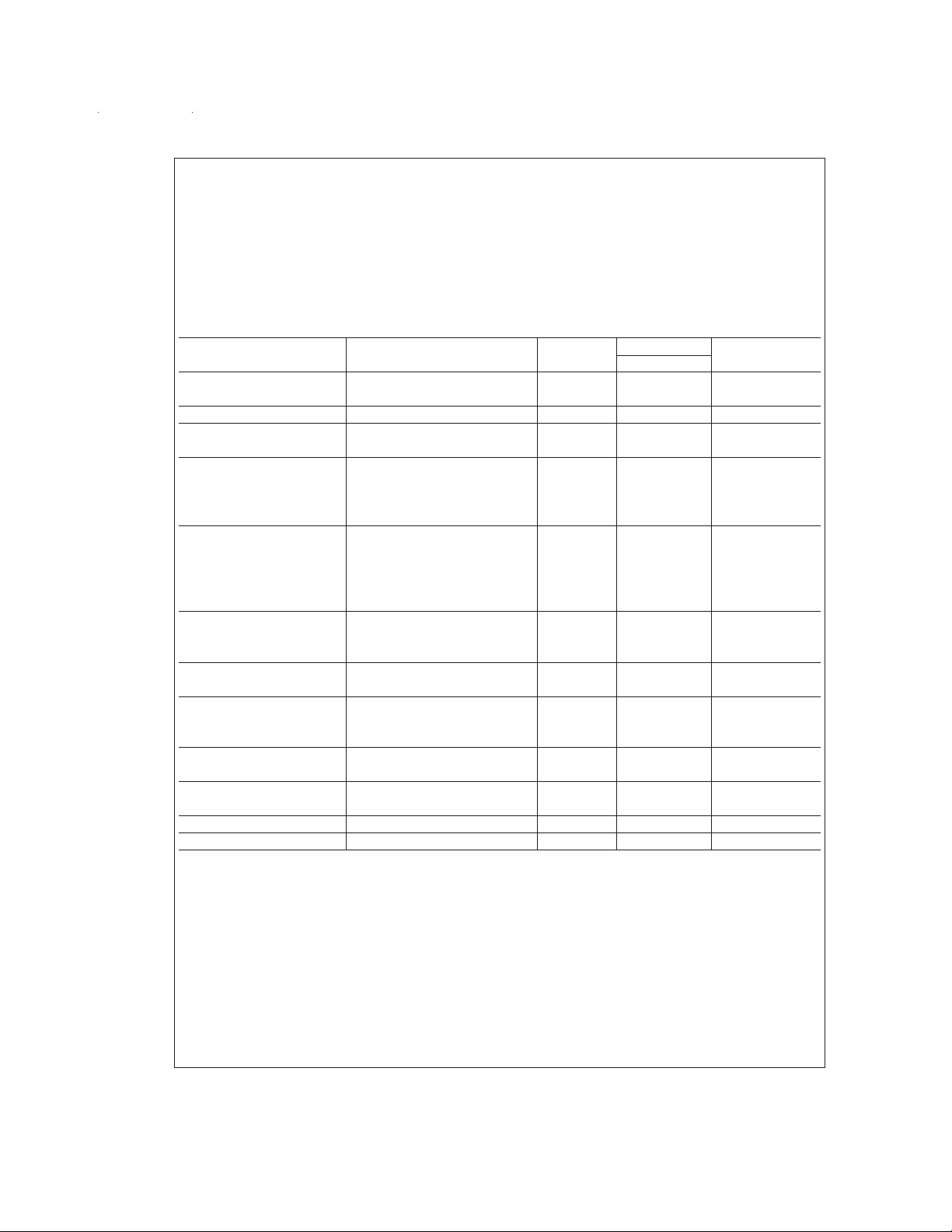

Output-Transistor Ratings (guaranteed)

Safe Area

DS008704-31

DC Thermal Resistance

Typical Performance Characteristics

Pulse Power Limit

DS008704-34

Output Saturation Voltage

Pulse Power Limit

Large Signal Response

DS008704-32

DS008704-35

Pulse Thermal Resistance

DS008704-33

Peak Output Current

DS008704-36

Follower Pulse Response

Large Signal Gain

DS008704-37

DS008704-40

Thermal Response

DS008704-38

DS008704-41

DS008704-39

Total Harmonic Distortion

DS008704-42

www.national.com3

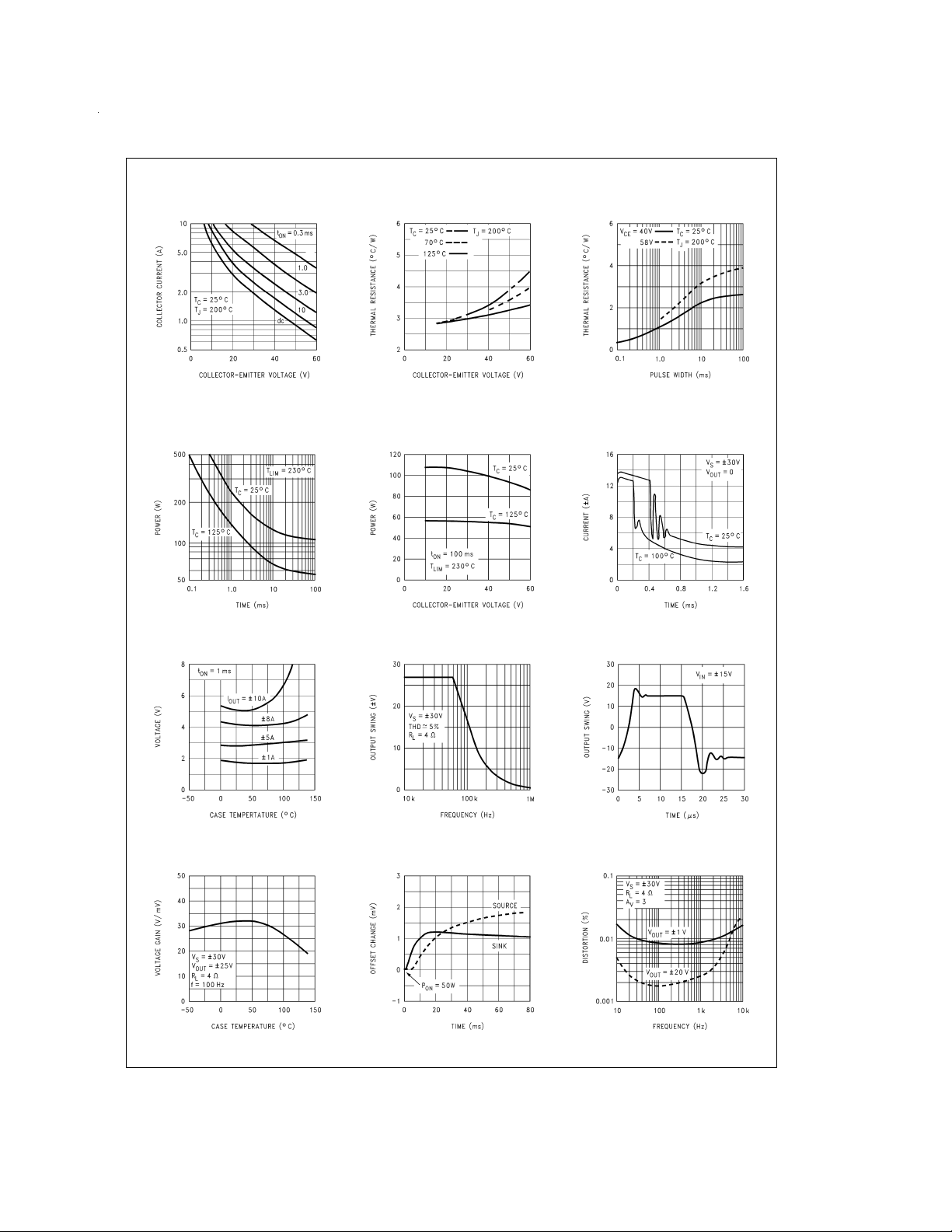

Typical Performance Characteristics (Continued)

Frequency Response

Input Bias Current

Supply Current

DS008704-43

DS008704-46

Output Impedance

Input Noise Voltage

Supply Current

DS008704-44

DS008704-47

Power Supply Rejection

DS008704-45

Common Mode Rejection

DS008704-48

Cross-Supply Current

DS008704-49

Application Information

GENERAL

Twenty five years ago the operational amplifier was a specialized design tool used primarily for analog computation.

However, the availability of low cost IC op amps in the late

1960’s prompted their use in rather mundane applications,

replacing a few discrete components. Once a few basic principles are mastered, op amps can be used to give exceptionally good results in a wide range of applications while minimizing both cost and design effort.

The availability of a monolithic power op amp now promises

to extend these advantages to high-power designs. Some

conventional applications are given here to illustrate op amp

design principles as they relate to power circuitry. The inevitable fall in prices, as the economies of volume production

www.national.com 4

DS008704-50

DS008704-51

are realized, will prompt their use in applications that might

now seem trivial. Replacing single power transistors with an

op amp will become economical because of improved performance, simplification of attendant circuitry, vastly improved fault protection, greater reliability and the reduction of

design time.

Power op amps introduce new factors into the design equation. With current transients above 10A, both the inductance

and resistance of wire interconnects become important in a

number of ways. Further, power ratings are a crucial factor in

determining performance. But the power capability of the IC

cannot be realized unless it is properly mounted to an adequate heat sink. Thus, thermal design is of major importance with power op amps.

This application summary starts off by identifying the origin

of strange problems observed while using the LM12 in a

Application Information (Continued)

wide variety of designs with all sorts of fault conditions.A few

simple precautions will eliminate these problems. One

would do well to read the section on supply bypassing,

lead inductance, output clamp diodes, ground loops and

reactive loading before doing any experimentation.

Should there be problems with erratic operation,

blow-outs, excessive distortion or oscillation, another

look at these sections is in order.

The management and protection circuitry can also affect operation. Should the total supply voltage exceed ratings or

drop below 15–20V, the op amp shuts off completely. Case

temperatures above 150˚C also cause shut down until the

temperature drops to 145˚C. This may take several seconds,

depending on the thermal system. Activation of the dynamic

safe-area protection causes both the main feedback loop to

lose control and a reduction in output power, with possible

oscillations. In ac applications, the dynamic protection will

cause waveform distortion. Since the LM12 is well protected

against thermal overloads, the suggestions for determining

power dissipation and heat sink requirements are presented

last.

SUPPLY BYPASSING

All op amps should have their supply leads bypassed with

low-inductance capacitors having short leads and located

close to the package terminals to avoid spurious oscillation

problems. Power op amps require larger bypass capacitors.

The LM12 is stable with good-quality electrolytic bypass capacitors greater than 20 µF. Other considerations may require larger capacitors.

The current in the supply leads is a rectified component of

the load current. If adequate bypassing is not provided, this

distorted signal can be fed back into internal circuitry. Low

distortion at high frequencies requires that the supplies be

bypassed with 470 µF or more, at the package terminals.

LEAD INDUCTANCE

With ordinary op amps, lead-inductance problems are usually restricted to supply bypassing. Power op amps are also

sensitive to inductance in the output lead, particularly with

heavy capacitive loading. Feedback to the input should be

taken directly from the output terminal, minimizing common

inductance with the load. Sensing to a remote load must be

accompanied by a high-frequency feedback path directly

from the output terminal. Lead inductance can also cause

voltage surges on the supplies. With long leads to the power

source, energy stored in the lead inductance when the output is shorted can be dumped back into the supply bypass

capacitors when the short is removed. The magnitude of this

transient is reduced by increasing the size of the bypass capacitor near the IC. With 20 µF local bypass, these voltage

surges are important only if the lead length exceeds a couple

>

feet (

1 µH lead inductance). Twisting together the supply

and ground leads minimizes the effect.

GROUND LOOPS

With fast, high-current circuitry, all sorts of problems can

arise from improper grounding. In general, difficulties can be

avoided by returning all grounds separately to a common

point. Sometimes this is impractical. When compromising,

special attention should be paid to the ground returns for the

supply bypasses, load and input signal. Ground planes also

help to provide proper grounding.

Many problems unrelated to system performance can be

traced to the grounding of line-operated test equipment used

for system checkout. Hidden paths are particularly difficult to

sort out when several pieces of test equipment are used but

can be minimized by using current probes or the new isolated oscilloscope pre-amplifiers. Eliminating any direct

ground connection between the signal generator and the oscilloscope synchronization input solves one common problem.

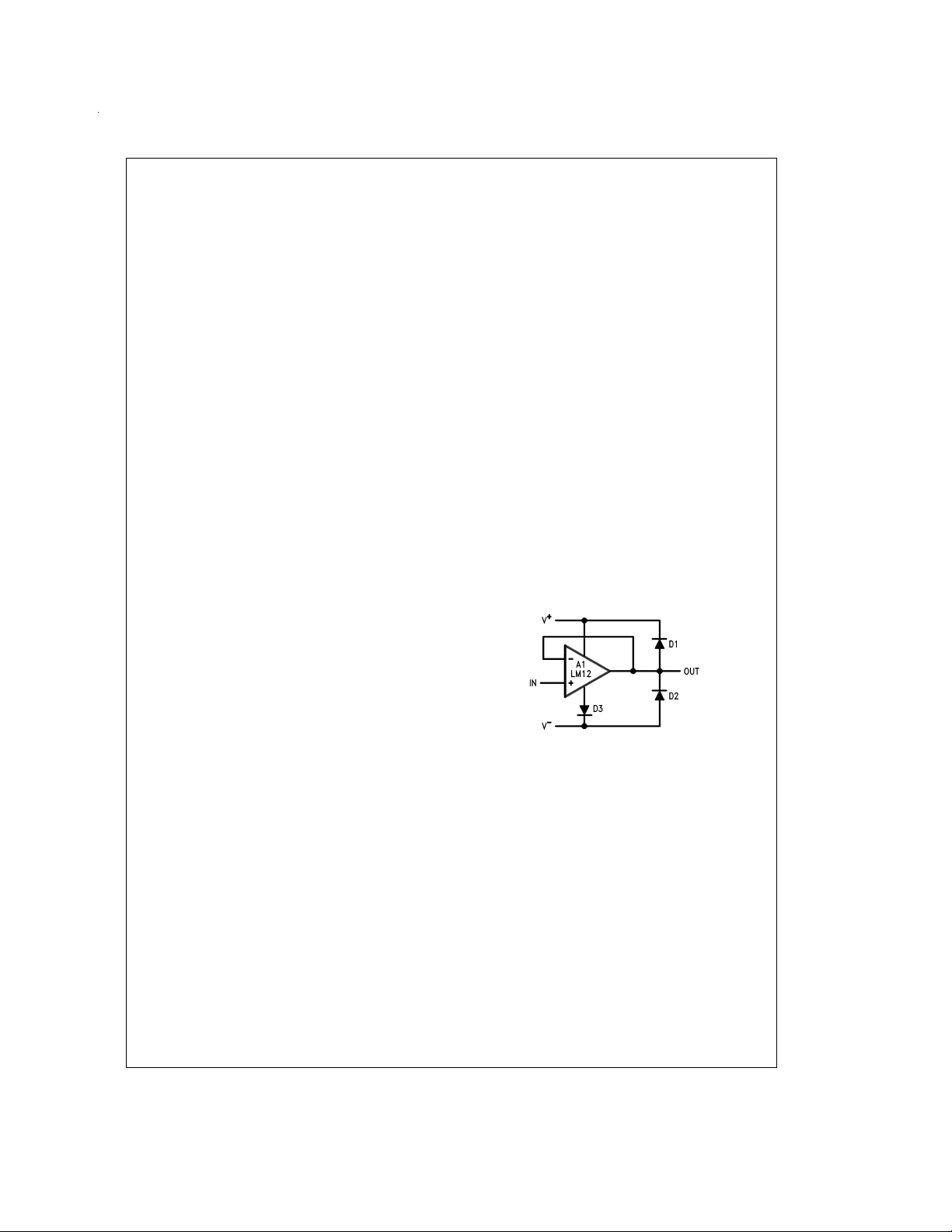

OUTPUT CLAMP DIODES

When a push-pull amplifier goes into power limit while driving an inductive load, the stored energy in the load inductance can drive the output outside the supplies.Although the

LM12 has internal clamp diodes that can handle several amperes for a few milliseconds, extreme conditions can cause

destruction of the IC. The internal clamp diodes are imperfect in that about half the clamp current flows into the supply

to which the output is clamped while the other half flows

across the supplies. Therefore, the use of external diodes to

clamp the output to the power supplies is strongly recommended. This is particularly important with higher supply

voltages.

Experience has demonstrated that hard-wire shorting the

output to the supplies can induce random failures if these external clamp diodes are not used and the supply voltages are

±

above

20V. Therefore it is prudent to use outputclamp diodes even when the load is not particularly inductive. This

also applies to experimental setups in that blowouts have

been observed when diodes were not used. In packaged

equipment, it may be possible to eliminate these diodes, providing that fault conditions can be controlled.

DS008704-6

Heat sinking of the clamp diodes is usually unimportant in

that they only clamp current transients. Forward drop with

15A fault transients is of greater concern. Usually, these

transients die out rapidly. The clamp to the negative supply

can have somewhat reduced effectiveness under worst case

conditions should the forward drop exceed 1.0V. Mounting

this diode to the power op amp heat sink improves the situation. Although the need has only been demonstrated with

some motor loads, including a third diode (D3 above) will

eliminate any concern about the clamp diodes. This diode,

however, must be capable of dissipating continuous power

as determined by the negative supply current of the op amp.

REACTIVE LOADING

The LM12 is normally stable with resistive, inductive or

smaller capacitive loads. Larger capacitive loads interact

with the open-loop output resistance (about 1Ω) to reduce

the phase margin of the feedback loop, ultimately causing

oscillation. The critical capacitance depends upon the feedback applied around the amplifier; a unity-gain follower can

handle about 0.01 µF, while more than 1 µF does not cause

problems if the loop gain is ten. With loop gains greater than

unity, a speedup capacitor across the feedback resistor will

www.national.com5

Loading...

Loading...