LM1253A

Monolithic Triple 180 MHz I

2

C CRT Pre-amp With

Integrated Analog On Screen Display (OSD) Generator

General Description

The LM1253A pre-amp is an integrated high voltage triple

CRT pre-amp and Analog On Screen Display (OSD) generator. The IC is I

2

C controlled, and allows control of all the parameters necessary to setup and adjust the brightness and

contrast in the CRT display. In addition, it provides a programmable period vertical blanking pulse which is used to

blank the G1.

The LM1253A pre-amp is designed to work in cooperation

with the LM2453 driver, and provides a multiplexed video

signal (VideoPlex) interface to enable the DC clamp levels at

the cathode to be varied in order to set up the CRT bias and

to allow individual adjustment for brightness.

TheAnalogOSDhas a selectable palette allowing a wide selection of colors. The preset level of the OSD can be controlled by I

2

C to suit different CRT displays. The OSD signal

is internally mixed with the video signal, before the gain section, and thus gives excellent white tracking of the OSD with

the white color point setting of the video.

The Brightness settings are also mixed into the video signal

before the gain matching controls and consequently give excellent white color point tracking with variations in the Brightness control. An active horizontal blanking signal is added to

the video at the output, giving excellent smear performance,

and preventing video content dependent DC bias offsets as

a result of high frequency over shoot.

The OSD horizontal sync and blanking signal is derived from

a positive going flyback pulse. The digital section provides

easy interfacing of this signal with the deflection circuits.

The vertical blanking signal is taken from the vertical sync

signal, and the blanking duration is programmable. This system is highly integrated and requires a minimal number of

external components.

Black level clamping of the signal is carried out directly on

the AC coupled input signal into the high impedance preamplifier input, thus eliminating the need for additional black

level clamp capacitors.

The outputs are referenced to a DC level produced by the

LM1253A Pre-amp, and so are guaranteed to provide stable

DC operating levels within the system without the need for

additional external feedback components.

The IC is packaged in an industry standard wide body 28lead DIL molded plastic package.

Features

n 190 two-color ROM based Character Fonts

n 64 four-color ROM based Character Fonts

n Supports a programmable page size with up to 512

characters and line definition codes

n Support for 2 Display Windows (size of each window is

configurable)

n Programmable start position for each Display Window

n Programmable Resolutions: from 512 to 960 pixels per

line in 64 pixel increments

n Programmable Character Height, with automatic height

control with mode change

n Programmable Row Spacing between each display

character row

n Maximum Pixel clock of 92.2 MHz

n I

2

C compatible interface to controlling micro-controller

n Button boxes

n 180 MHz preamplifier with full video signal parametric

control

n VideoPlex

™

interface to the LM2453 driver

n OSD mixing with 64 out of 512 color mask

programmable selection

Intended Applications

n 1280 x 1024 Displays up to 75 Hz requiring OSD

capability

May 2000

LM1253A Monolithic Triple 180 MHz I

2

C CRT Pre-amp With Integrated Analog On Screen Display

(OSD) Generator

© 2000 National Semiconductor Corporation DS101265 www.national.com

Table of Contents

Block and Connection Diagrams 3

Absolute Maximum Ratings 5

Operating Ratings 5

Electrical Characteristics 5

Test Circuit 7

Test Settings 8

Pin Descriptions 8

Input/Output Schematics 13

National VideoPlex Video System 15

ESD and Arc-Over Protection 16

Pre-Amp Functional Description 17

Horizontal Phase Locked Loop 19

Fault Operation 19

Power Save Mode 19

Schematics 20

PCB Layout 22

OSD Generator Operation 23

Micro-Controller Interface 27

LM1253A Address Map 29

Pre-Amp Interface Registers 30

Two-Color Attribute Table 31

Four-Color Attribute Table 31

Display Page RAM 32

Controller Register Definitions 40

Character Font 51

List of Tables

Table 1 Control Test Settings 7

Table 2 Registers Controlling the Output

Video and Clamp Signal 18

Table 3 Character ROM Address Map 29

Table 4 Display Page RAM Address Map 29

Table 5 OSD Interface Registers 30

Table 6 Pre-Amp Interface Registers 31

Table 7 Two-Color Attribute Registers 31

Table 8 Four-Color Attribute Registers 31

Table 9 Example 1 I

2

C Transmission 35

Table 10 Example 2 I

2

C Transmissions 36

Table 11 Example 3 I

2

C Transmissions 39

Table 12 PLL Setting (Register 843Eh) 46

Table 13 Attribute Tables to I

2

C Address 48

LM1253A

www.national.com 2

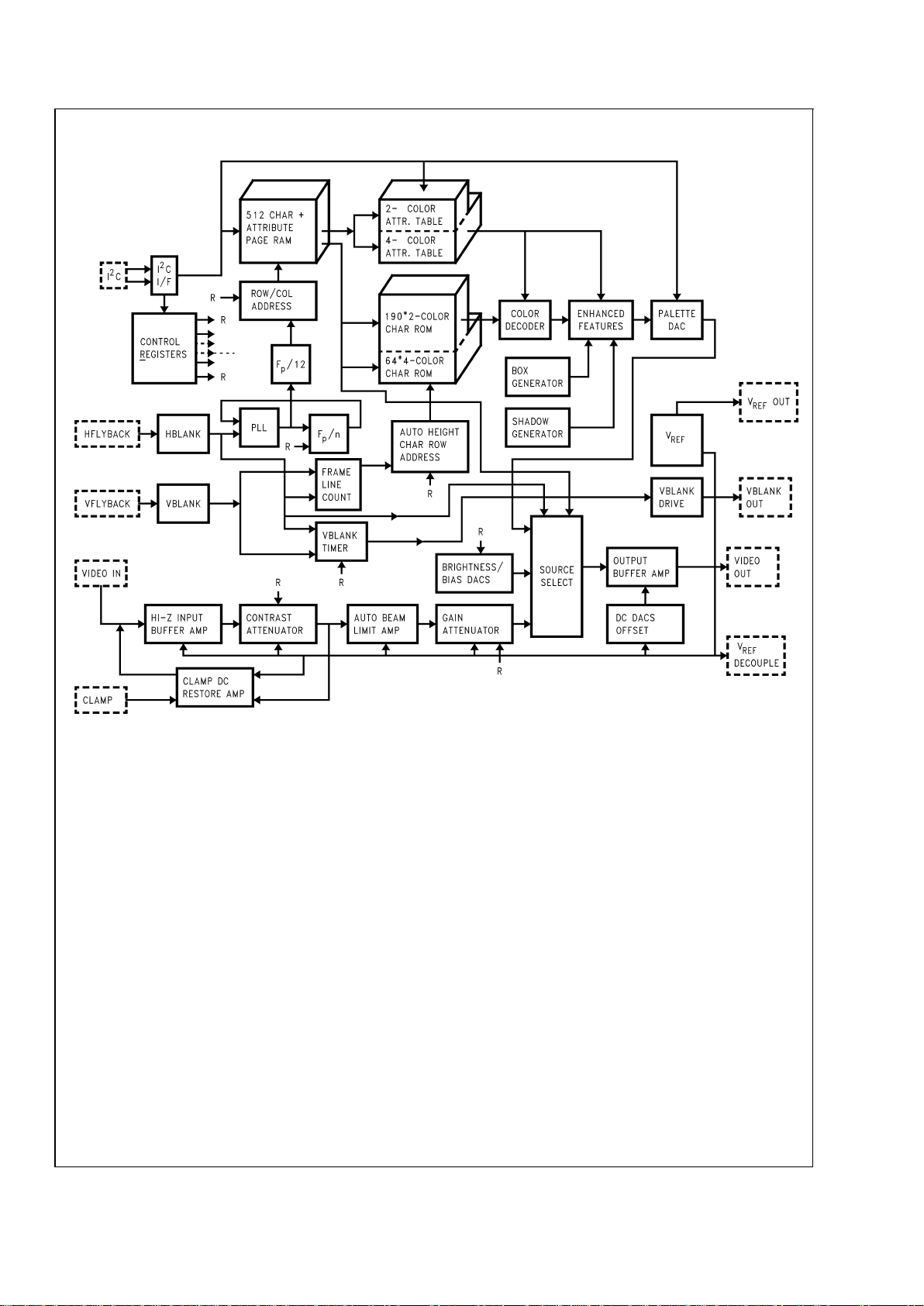

Block and Connection Diagrams

DS101265-1

FIGURE 1. Block Diagram

LM1253A

www.national.com3

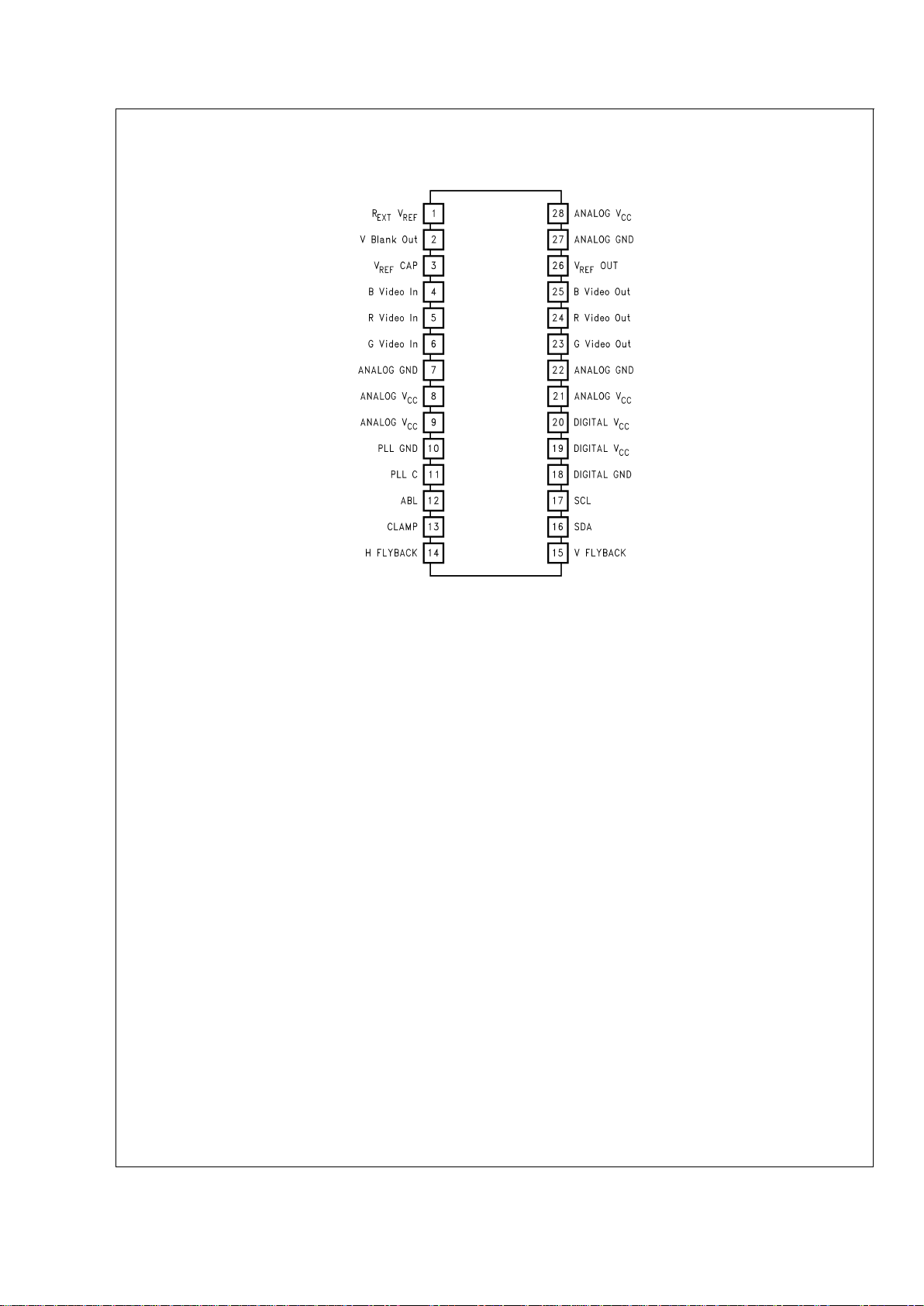

Block and Connection Diagrams (Continued)

28-Lead (0.600’’ wide) Molded Dual-In-Line Package

DS101265-2

Order Number LM1253AN

See NS Package Number N28B

FIGURE 2. Connection Diagram

LM1253A

www.national.com 4

Absolute Maximum Ratings (Notes 1, 3)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage, (V

CC

)6V

Input Voltage, (V

IN

)6V

Storage Temperature Range, (T

STG

) −65˚C to +150˚C

T

JMAX

150˚C

Lead Temperature (Soldering,

<

10 sec.) 300˚C

ESD Tolerance, Human Body Model 3 kV

Machine Model 300V

Operating Ranges (Note 2)

Temperature Range 0˚C to +70˚C

V

CC

+4.75V to +5.25V

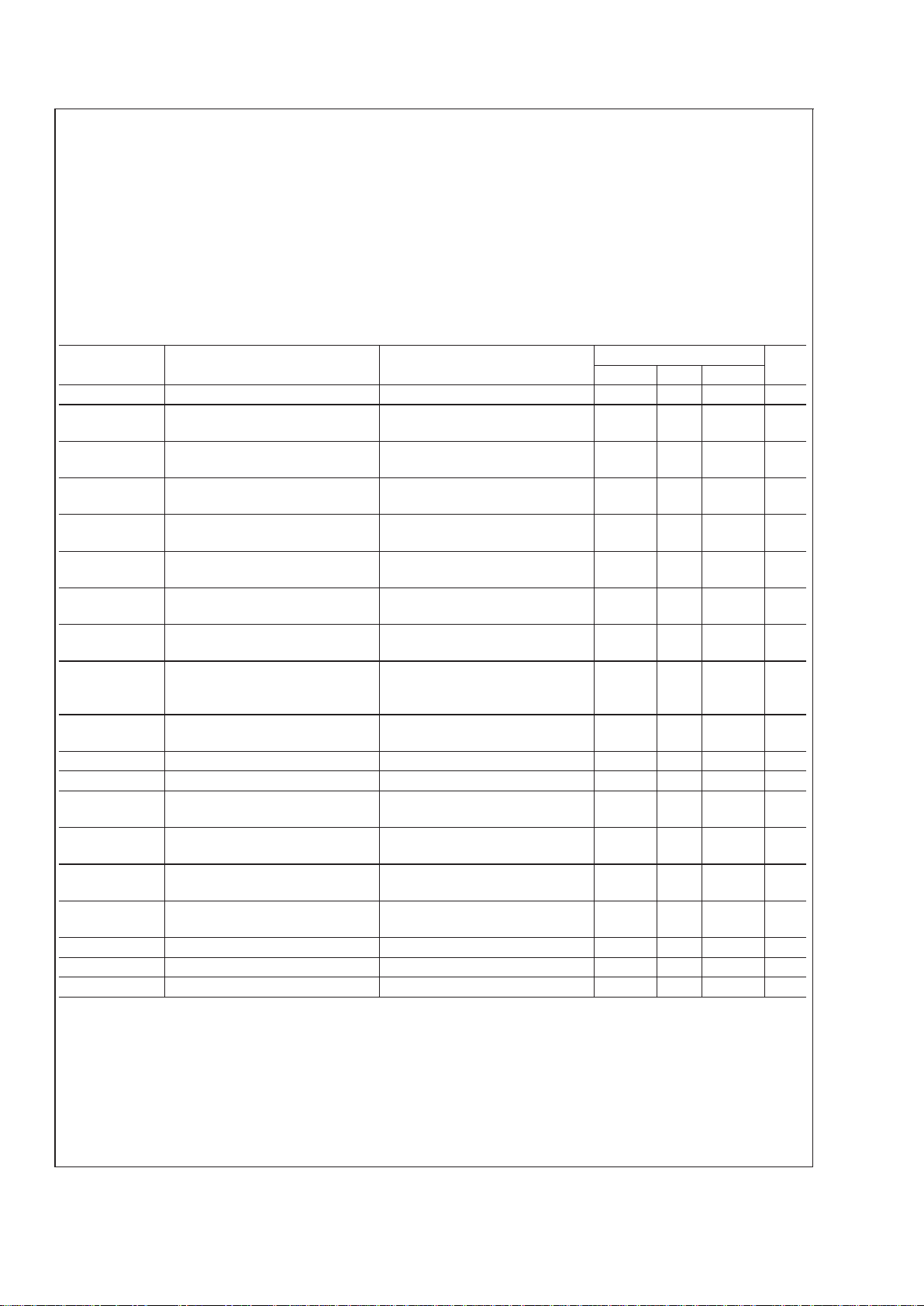

Active Video Signal Electrical Characteristics

(See

Figure 3

for Test Circuit, and

Table 1

for Control Test Settings Chart)

Unless otherwise noted: V

CC

= +5V, VIN= 0.7V, CL= 8 pF, Video Signal Output = 1 VPP,TA= 25˚C, V

ABL=VCC

.

Symbol Parameter Conditions

LM1253A

Units

Min Typ Max

I

CC1MAX

Maximum Supply Current Test Setting 1, No Output Load 245 mA

V

OUT BLK

Active Video Black Level Minimum

Output Voltage

Test Setting 1, No AC Input Signal

V

REF

V

DC

LE Linearity Error Test Setting 3, (Note 4), Triangular

Step Signal Input

1%

V

OUT WHITE

Active Video White Level Max

Output Voltage

Test Setting 3, AC Input Signal

2.7 V

t

r

Rise Time Test Setting 3, (Note 5), 10% to

90%, AC Input Signal

3.0 ns

t

f

Fall Time Test Setting 3, (Note 5), 90% to

10%, AC Input Signal

3.0 ns

OS

R

Rising Edge Overshoot Test Setting 3, (Note 5), AC Input

Signal

5%

OS

F

Falling Edge Overshoot Test Setting 3, (Note 5), AC Input

Signal

5%

f(−3dB) Video Amplifier Bandwidth Measured in AC2DC002 Demo

Board. LM1253A set for 40 V

PP

swing at LM2453 output

180 MHz

A

CONTRAST

Contrast Max-Min Adjustment

Range

Test Setting 2, AC Input Signal

20 dB

A

GAIN

Gain Max-Min Adjustment Range Test Setting 2, AC Input Signal 10 dB

A

MAX

Max Signal Voltage Gain Test Setting 2, AC Input Signal 1.8 V/V

V

ABL TH

Auto Beam Limit Control Upper

Limit

Test Setting 3, (Note 6), AC Input

Signal

4.5 V

V

ABL RANGE

Auto Beam Limit Control Voltage

Range

Test Setting 3, (Note 6), AC Input

Signal

3V

∆A

ABL

Auto Beam Limit Control Range Test Setting 3, (Note 6), AC Input

Signal

−10 dB

I

ABL MAX

Auto Beam Limit Input Current

Sink Capability

Test Setting 3, (Note 6), AC Input

Signal

1mA

C

IP

Input AC Coupling Capacitor Test Setting 3 4.7 nF

V

REF

Typical V

REF

Output Voltage 1.55 1.65 1.75 V

XT Channel to Channel Crosstalk 10 MHz 40 dB

LM1253A

www.national.com5

Brightness/Bias Signal Electrical Characteristics

(See

Figure 3

for Test Circuit, and

Table 1

for Control Test Settings Chart)

Unless otherwise noted: VCC= +5V, VIN= 0.7V, CL= 8 pF, Video Signal Output = 1 VPP,TA= 25˚C, V

ABL=VCC

.

Symbol Parameter Conditions

LM1253A

Units

Min Typ Max

V

BLANK MAX

Maximum Blanking Level Test Setting 1 V

REF

−

0.90

V

V

BLANK MIN

Minimum Blanking Level Test Setting 4 V

REF

V

t

BLK r

Blanking Rise Time Test Setting 1, 10% to 90%, 10 ns

t

BLK f

Blanking Fall Time Test Setting 1, 90% to 10%, 10 ns

OS

BLK MAX

Maximum Rise or Fall Edge

Overshoot

Test Setting 1, 10% to 90% or

90% to 10%, Settling Time Must

be Less Than 50 ns

20 %

OSD Electrical Characteristics

(See

Figure 3

for Test Circuit)

Unless otherwise noted: VCC= +5V, VIN= 0.7V, CL= 8 pF, Video Signal Output = 1 VPP,TA= 25˚C, V

ABL=VCC

.

Symbol Parameter Conditions

LM1253A

Units

Min Typ Max

V

OSDHIGH MAX

Maximum OSD Level with OSD

Contrast 11

Palette Set at 111. OSD Contrast

Level 11, Test Setting 3

V

REF

+

0.95

V

V

OSDHIGH 10

Maximum OSD Level with OSD

Contrast 10

Palette Set at 111. OSD Contrast

Level 10, Test Setting 3

V

REF

+

0.77

V

V

OSDHIGH 01

Maximum OSD Level with OSD

Contrast 01

Palette Set at 111. OSD Contrast

Level 01, Test Setting 3

V

REF

+

0.59

V

V

OSDHIGH 00

Maximum OSD Level with OSD

Contrast 00

Palette Set at 111. OSD Contrast

Level 00, Test Setting 3

V

REF

+

0.41

V

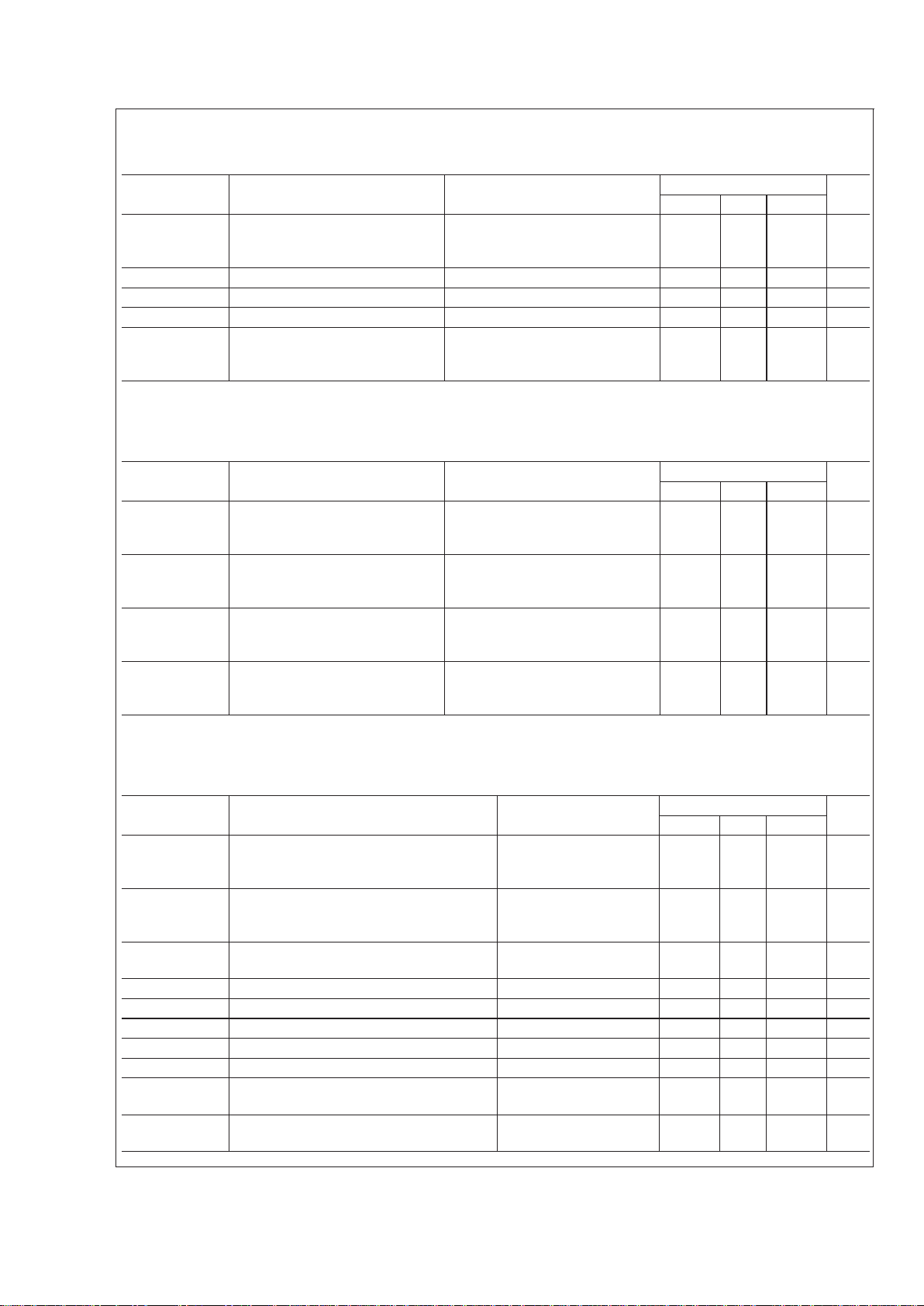

External Interface Signals Electrical Characteristics

(See

Figure 3

for Test Circuit)

Unless otherwise noted: VCC= +5V, VIN= 0.7V, CL= 8 pF, Video Signal Output = 1 VPP,TA= 25˚C, V

ABL=VCC

.

Symbol Parameter Conditions

LM1253A

Units

Min Typ Max

I

IN−MAX

Maximum normal forward scan current at

lowest horizontal frequency that input can

withstand

−150 µA

V

HBLANK TRIG

Voltage on H Flyback (Pin 14) which will

Trigger an HBLANK Signal

100V H Flyback Signal

through a 100 kΩ

Resistor

0.8 V

I

IN+MAX

Maximum flyback scan current at 125 kHz

that input can withstand

1.5 mA

t

min hflb

Minimum Flyback Width 1 µs

t

H

Horizontal Period 20 125 kHz

t

PW CLAMP

Minimum Clamp Pulse Width 200 ns

V

CLAMP L MAX

Maximum Low Level Clamp Pulse Voltage 1 V

V

CLAMP H MIN

Minimum High Level Clamp Pulse Voltage 3 V

V

VBLANK HIGH

Minimum High Level of Vertical Blank

Output

V

VREF BLANK

<

0.75V V

REF

+1

V

V

VBLANK LOW

Maximum Low Level of Vertical Blank

Output

I

VBLANK OUT

= 100 µA V

REF

−1

V

LM1253A

www.national.com 6

External Interface Signals Electrical Characteristics (Continued)

(See

Figure 3

for Test Circuit)

Unless otherwise noted: VCC= +5V, VIN= 0.7V, CL= 8 pF, Video Signal Output = 1 VPP,TA= 25˚C, V

ABL=VCC

.

Symbol Parameter Conditions

LM1253A

Units

Min Typ Max

V

CCDET

VCCUndervoltage Detection Threshold 3.9 V

F

FREE_RUN

Free Run HBLANK Frequency 30 60 kHz

V

IL

Low Level Input Voltage for SDA and SCL

Pins

1.5 V

V

IH

High Level Input Voltage for SDA and SCL

Pins

3V

V

OL

Low Level Output Voltage for SDA and SCL

Pins

3 mA Sink Current

0 0.4 V

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.

Note 2: Operating Ranges indicate conditions forwhichthedevice is functional, but do not guarantee specific performance limits. For guaranteed specifications and

test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions listed. Some performance characteristics may

change when the device is not operated under the listed test conditions.

Note 3: All voltages are measured with respect to GND, unless otherwise specified.

Note 4: Linearity Error = 100

*

(step

max

–step

min

)/step

ave

Where: The input signal is a 16 step staircase signal waveform with 0.7 V

P-P

level, subdivided into 16 equal steps, with each step approximately 100 ns in width

step

max

is the maximum voltage step at the output

step

min

is the minimum voltage step at the output

step

ave

is the average voltage of the 16 steps at the output.

Note 5: Input from signal generator: t

r,tf

<

1 ns.

Note 6: ABL should provide smooth decrease in gain over the operational range of 0 dB to −5 dB

∆A

ABL

= A(V

ABL=VABL MAX GAIN

)–A (V

ABL=VABL MIN GAIN

)

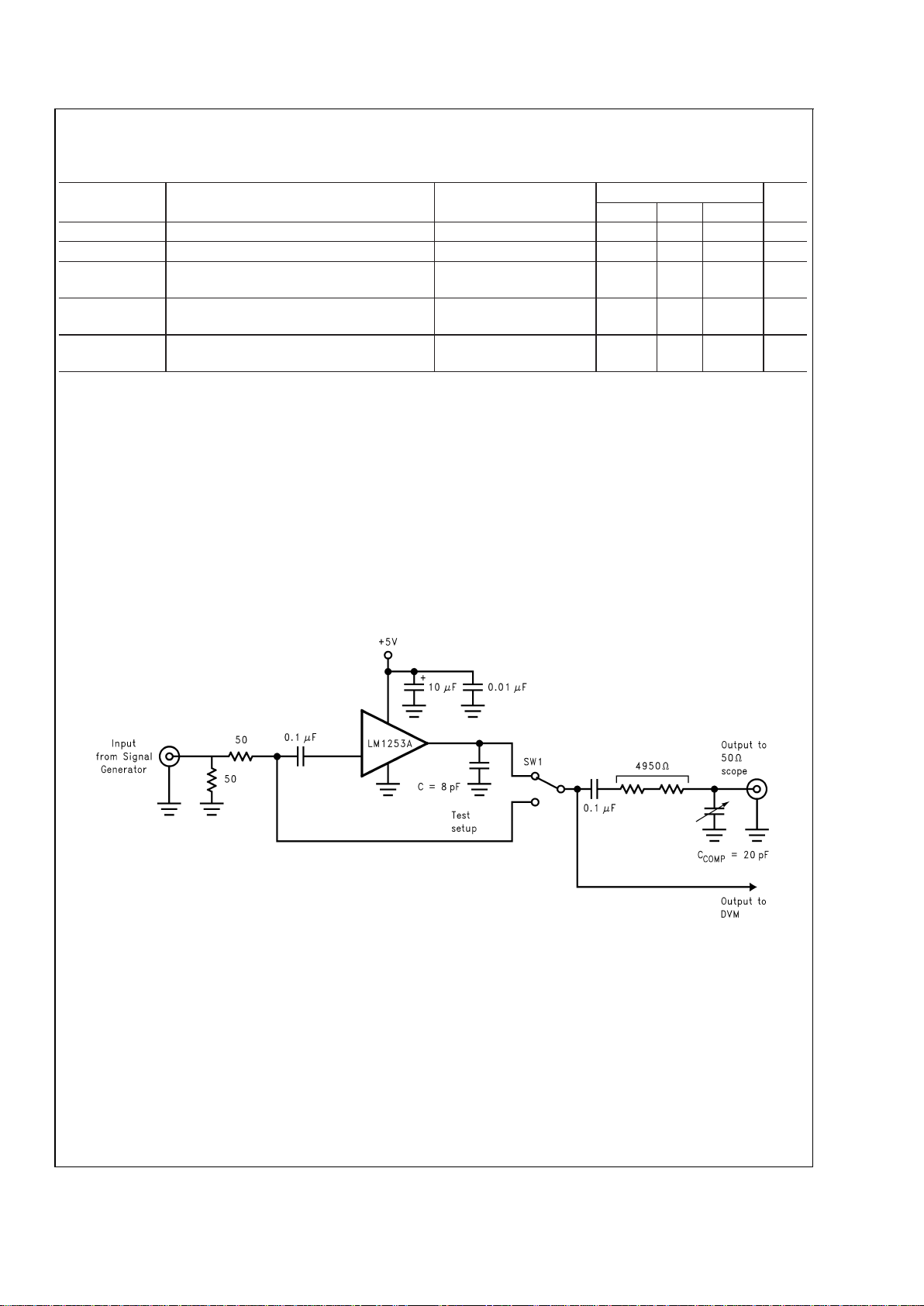

Test Circuit

DS101265-3

Note: 8 pF load includes parasitic capacitance

FIGURE 3. Test Circuit

LM1253A

www.national.com7

Test Settings

TABLE 1. Control Test Settings

Control

No.

of

Bits

Basic

Test

Setting 1

Basic

Test

Setting 2

Basic

Test

Setting 3

Basic

Test

Setting 4

Contrast 7 Max

(Hex 7F)

Max

(Hex 7F)

Max

(Hex 7F)

Max

(Hex 7F)

R,G,B Gain 7 Max

(Hex 7F)

Max

(Hex 7F)

Set for 1 V

P-P

on all Channels

Max

(Hex 7F)

Brightness 8 Max

(Hex FF)

Max

(Hex FF)

Min

(Hex 00)

Min

(Hex 00)

R,G,B Bias 8 Max

(Hex FF)

Max

(Hex FF)

Min

(Hex 00)

Min

(Hex 00)

DC Offset 3 Min

(Hex 07)

Max

(Hex 00)

Min

(Hex 07)

Min

(Hex 07)

Pedestal Offset 3 Max

(Hex 07)

Max

(Hex 07)

Min

(Hex 00)

Min

(Hex 00)

Pin Descriptions

Pin 1 —R

EXTVREF

A10kΩ1% resistor is connected to this

pin to set up the internal current sources. The LM1253A is

optimized for this value of resistor. A DC voltage only will be

on this pin. Decreasing the value of this resistor will increase

supply current while degrading performance; increasing the

value of the resistor will decrease supply current and also

degrade the performance. Do not place the resistor close to

sources of heat such as the CRT driver.

Figure 29

shows the

components connected to pin 1,

Figure 11

shows the internal

schematic of pin 1.

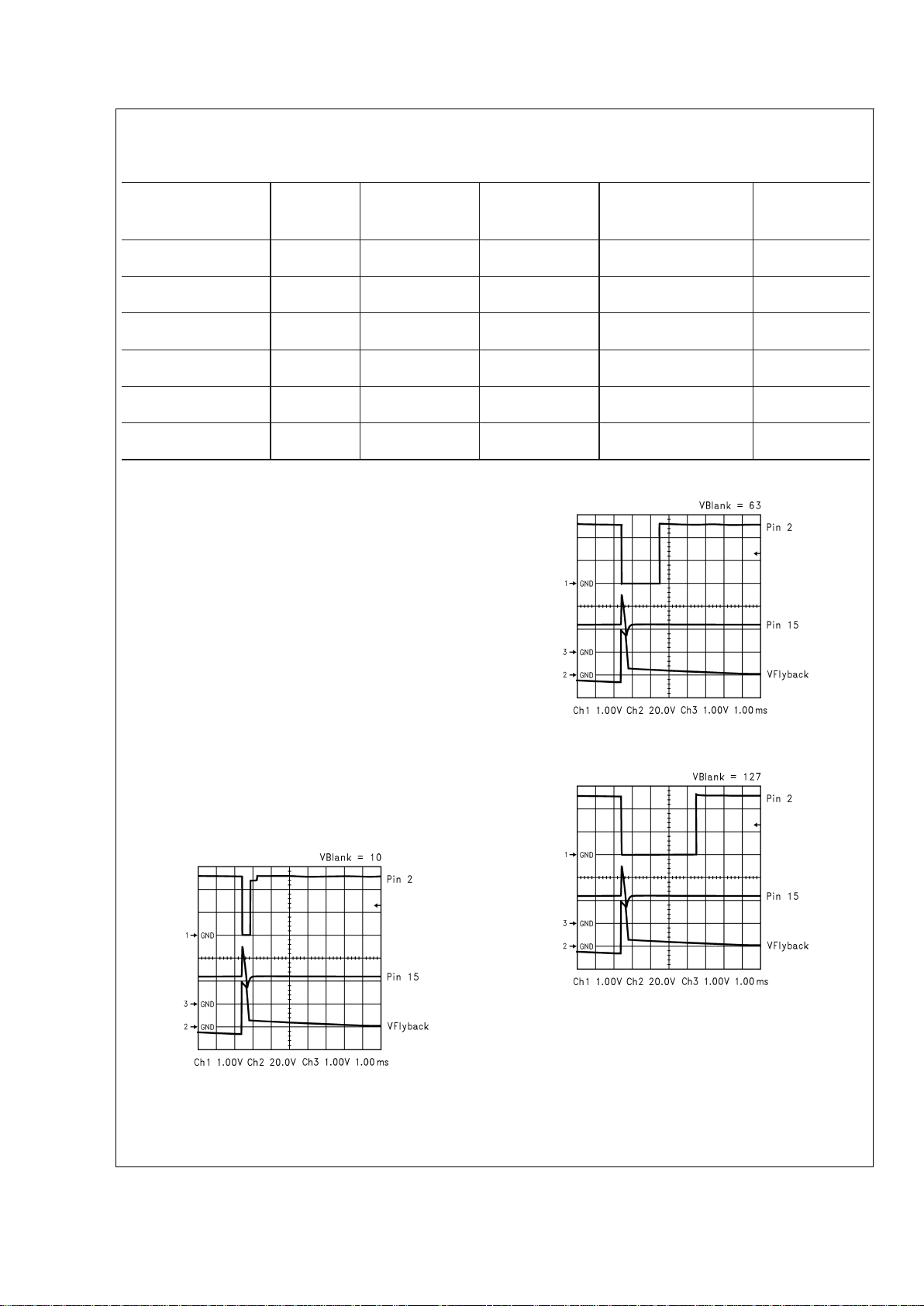

Pin 2—V Blank Out This pin supplies a variable width,

negative going pulse at the vertical rate to the CRT Driver. V

Blank is triggered from the signal on pin 15, which comes

from the vertical flyback. The CRT Driver supplies the pull up

for this pin. The width of this pulse is set by the value in the

VBLANKDUR register (8403h).

Figures 4, 5, 6

show the resulting V Blank Out pulse with various values in register

8403h. The trace connecting pin 2 of the LM1253A to the

LM2453 must be kept away from the output circuitry of the

LM2453.

Figure 29

shows the external schematic of pin 2,

Figure 12

shows the internal schematic of pin 2.

Pin 3—V

REF

Cap A 0.1 µF capacitor is placed close to this

pin to decouple V

REF.VREF

is used by the three video chan-

nel circuits to make the VideoPlex signal.

Figure 29

shows

the external schematic of pin 3,

Figure 13

shows the internal

schematic of pin 3.

Pin 4, 5, 6 —Blue, Red, and Green Video In The red, blue,

and green video signal is AC coupled into these pins. The

value of the capacitors is very important as they also serve

DS101265-7

FIGURE 4. V Blank = 10

DS101265-8

FIGURE 5. V Blank = 63

DS101265-9

FIGURE 6. V Blank = 127

LM1253A

www.national.com 8

Pin Descriptions (Continued)

as the DC clamp control capacitors. A value of 0.0047 µF is

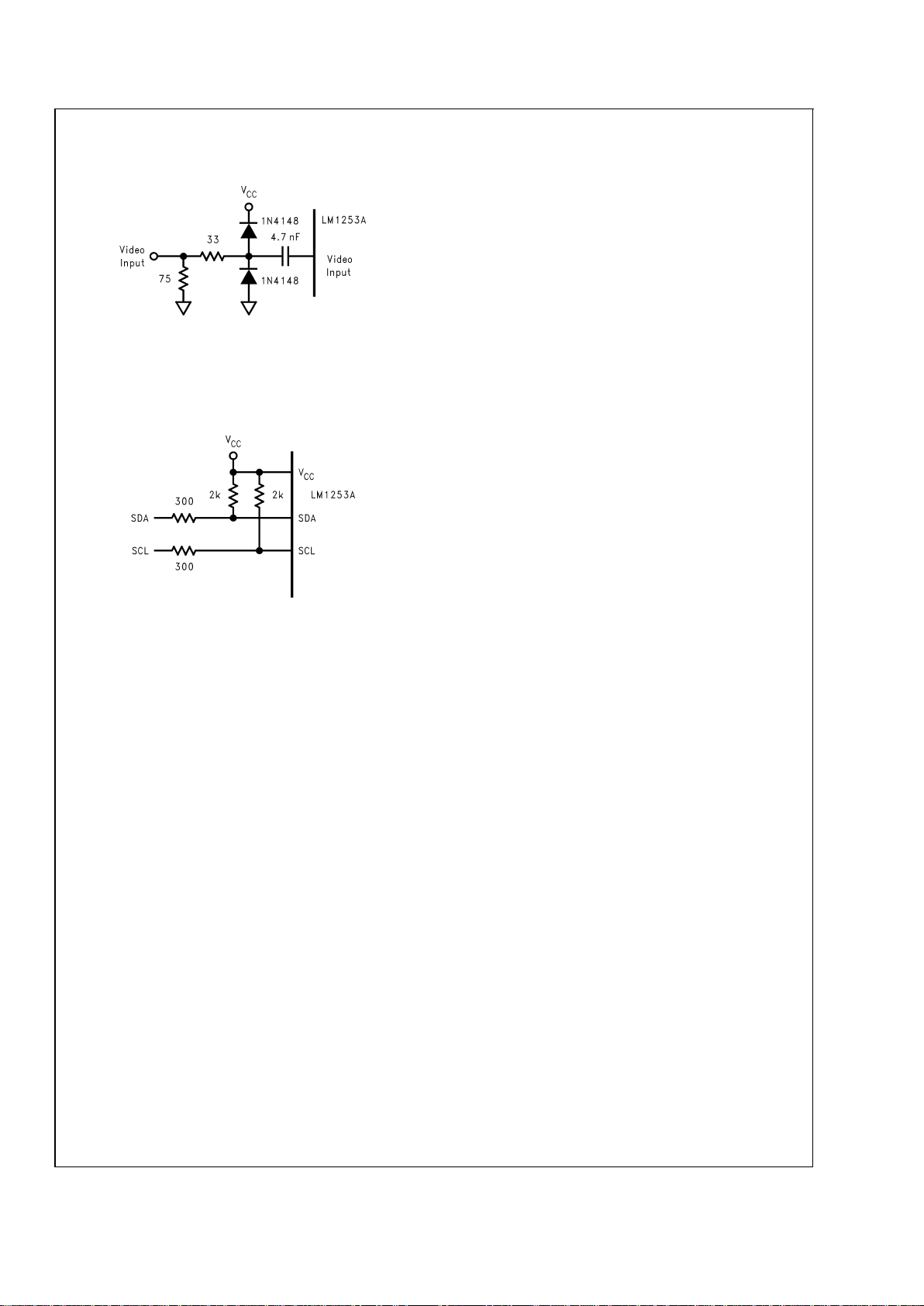

used in the demo boards. The schematic shown in

Figure 29

which has a series resistance of 33Ω and clamp diodes to

V

CC

and ground should be used to protect the LM1253A

from ESD. A good ground should be between the input connector and the LM1253A. The video traces should be kept

short.

Figure 29

shows the external schematic of pins 4, 5,

and 6,

Figure 14

shows the internal schematic of pins 4, 5,

and 6.

Pin 7 — Analog Ground Ground for the video section of the

LM1253A. All ground pins of the LM1253A should be connected together by a ground plane under the LM1253A. See

Figure 31

, which shows a sample layout.

Pin 8 — Analog Supply 5V supply for the video section of

the preamp. A 0.1 µF capacitor should be connected between pin 7 and pin 8, as close as possible to the LM1253A.

A 100 µF capacitor should also be connected between pin 7

and pin 8.

Pin 9— Analog Supply 5V supply for the PLL section of the

LM1253A. A 0.1 µF capacitor should be connected between

pin 9 and pin 7, as close as possible to the LM1253A.

Pin 10—PLL Ground Ground for the PLL section of the

LM1253A. Only the PLL components connected to pin 11

should be connected to this ground pin. Pin 10 should also

be connected to the ground plane under the LM1253A. All

ground pins of the LM1253A should be connected together

by a ground plane under the LM1253A. See

Figure 31

, which

shows a sample layout.

Pin 11—PLL C A resistor capacitor network is connected to

this pin. It is used to convert the charge current of the charge

pump of the PLL into a voltage that is used to control the

variable oscillator. These components should be located

very close to the LM1253A with a short ground trace to pin

10.

The recommended values are R28 = 6.2 kΩ, C23 = 0.1 µF,

and C33 = 2.2 nF. When these component values are used

the range and gain values in

Table 12

can be loaded into

register 843Eh.

An example layout is shown in

Figure 31,Figure 29

shows

the external schematic of pin 11,

Figure 15

shows the inter-

nal schematic.

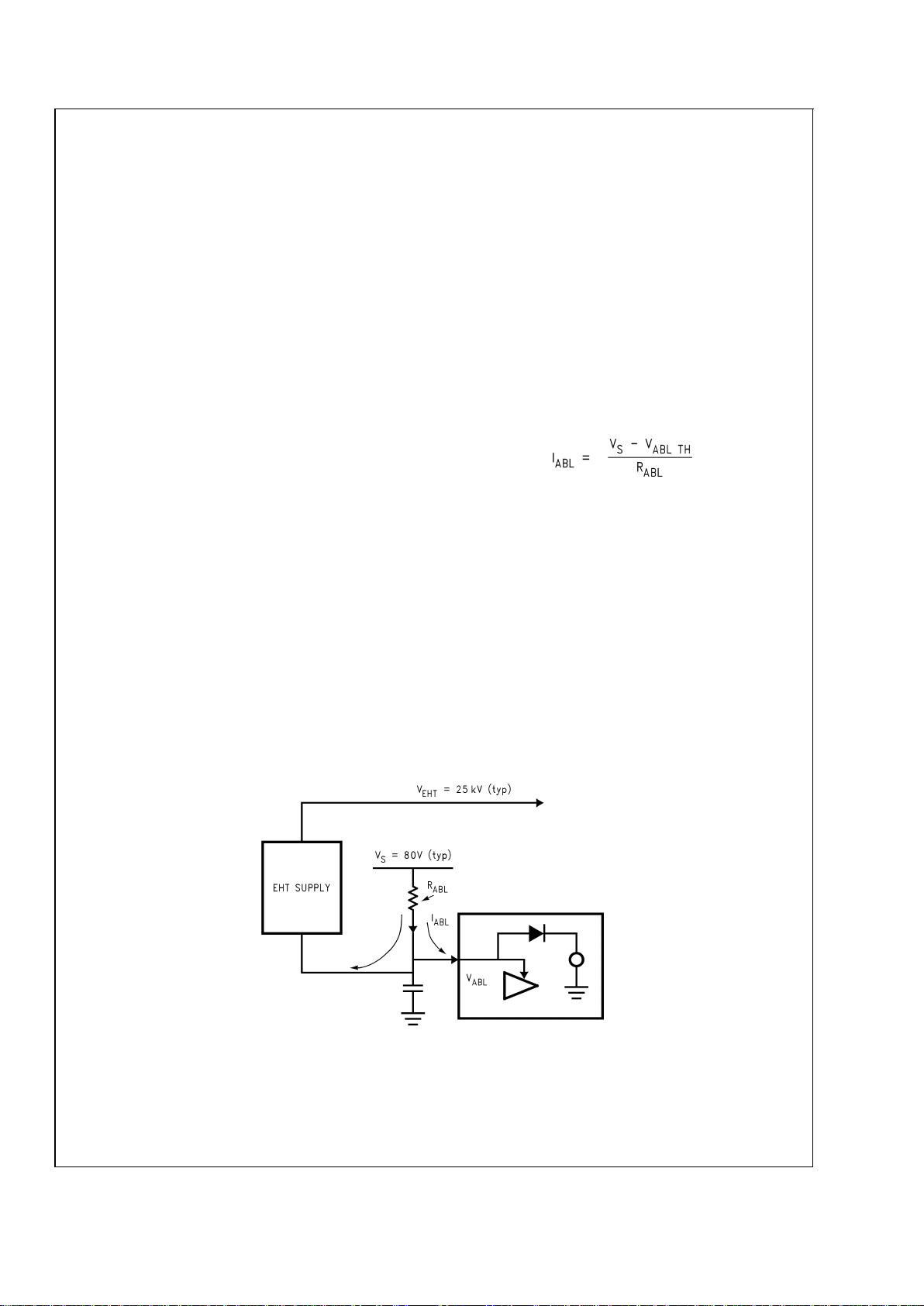

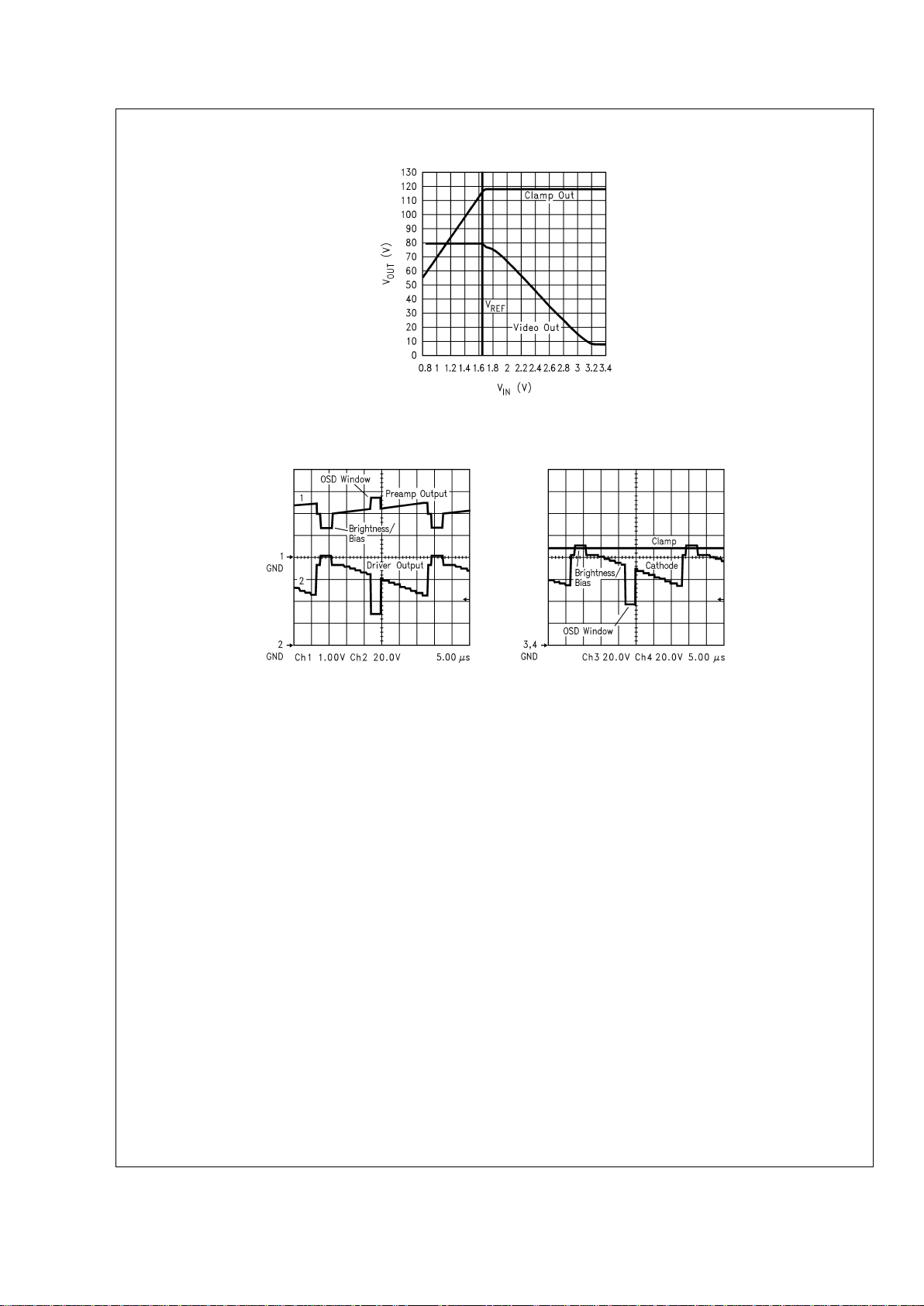

Pin 12—ABL The Auto Beam Limit control reduces the gain

of the video amplifiers in response to a control voltage proportional to the CRT beam current. The ABL acts on all three

channels in an identical manner.This is required for CRT life

and X-ray protection. The beam current limit circuit application is as shown in

Figure 7

: when no current is being drawn

by the EHT supply, current flows from the supply rail through

the ABL resistor and into the ABL input of the IC. The IC

clamps the input voltage to a low impedance voltage source

(the 5V supply rail).

When current is drawn from the EHT supply, the current

passes through the ABL resistor, and reduces the current

flowing into the ABL input of the IC.

When the EHT current is high enough, the current flowing

into the ABL input of the IC drops to zero. This current level

determines the ABL threshold and is given by:

Where:

V

S

is the external supply (usually the CRT driver supply rail,

about 80V)

V

ABL TH

is the threshold ABL voltage of the IC

R

ABL

is the ABL resistor value

I

ABL

is the ABL limit

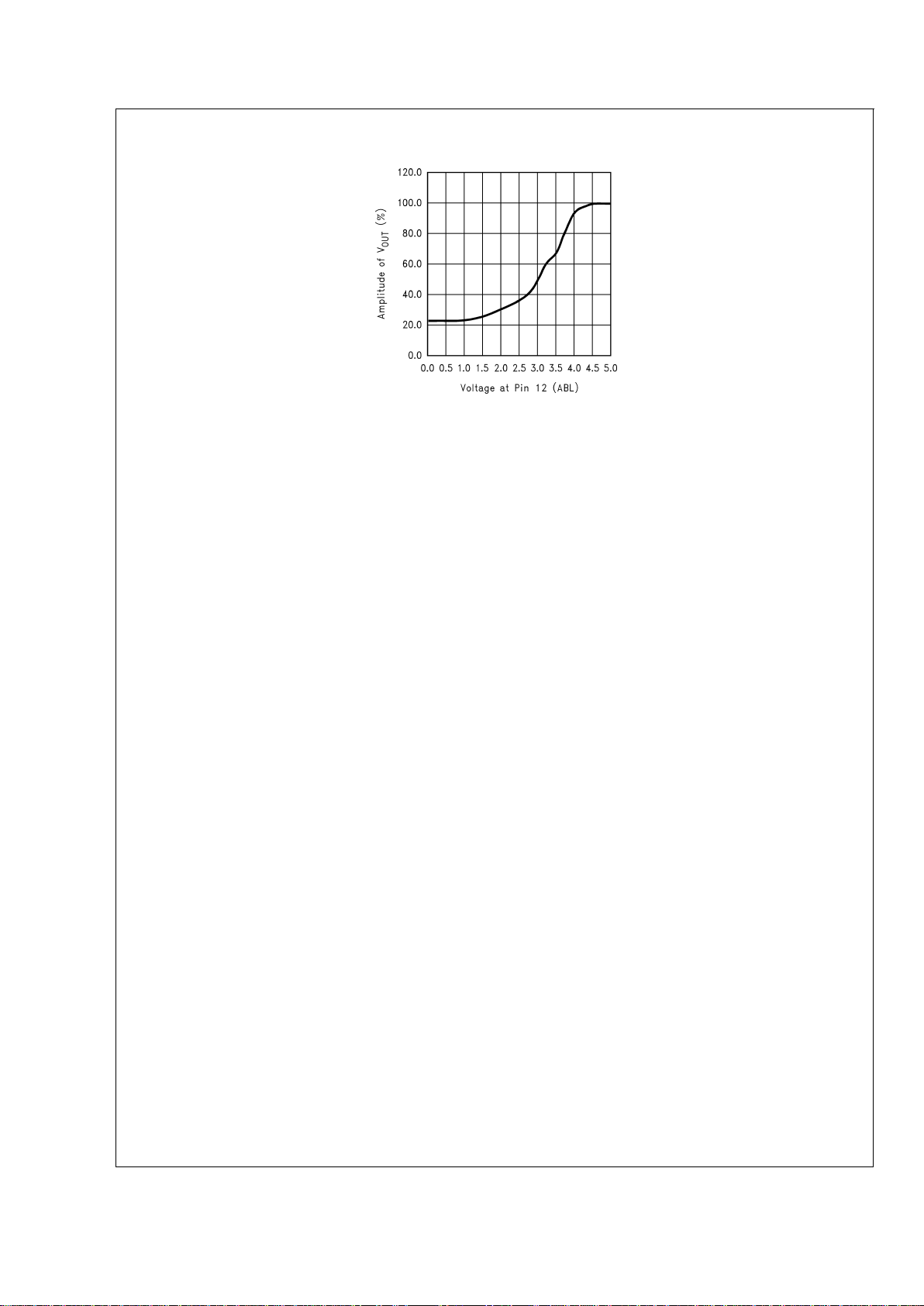

When the voltage on the ABL input drops below the ABL

threshold of the pre-amp, the gain of the pre-amp decreases,

which is shown in

Figure 8

, which reduces the beam current.

Afeedback loop is thus established which acts to prevent the

average beam current exceeding I

ABL

.

Figure 29

shows the external schematic of pin 12,

Figure 16

shows the internal schematic.

DS101265-12

FIGURE 7. ABL

LM1253A

www.national.com9

Pin Descriptions (Continued)

Pin 13—Clamp A positive going clamp signal is input on

this pin. Using this signal black level clamping of the video is

carried out directly on the input video that is AC coupled into

the high impedance preamplifier input, thus eliminating the

need for additional black level clamp capacitors.

Figure 29

shows the external schematic of pin 13,

Figure 17

shows the

internal schematic. An optional capacitor to ground may be

needed if noise interferes with the clamp signal.

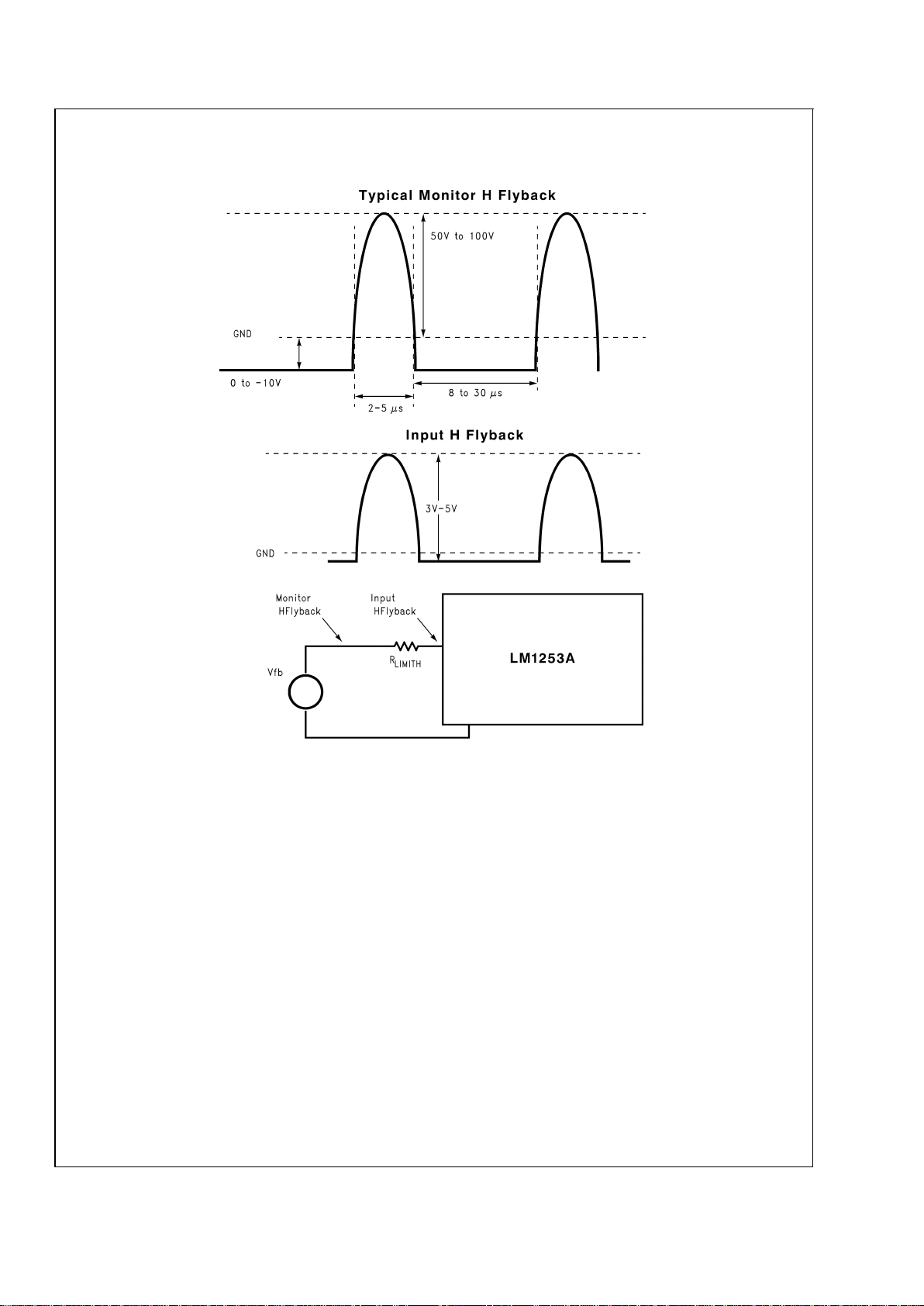

Pin 14—H Flyback H Flyback is an analog signal input from

the monitor horizontal scan. HBLANK is a digital signal derived from the horizontal flyback pulse as shown in

Figure 9

.

An optional capacitor and/or resistor to ground may be

needed if noise interferes with the H Flyback signal.

The horizontal flyback from the monitor must be a clean signal. There should be no ringing or other noise on the flyback.

DS101265-70

FIGURE 8. Effect of ABL Voltage on V

OUT

LM1253A

www.national.com 10

Pin Descriptions (Continued)

R

LIMITH

is set to limit the input current into the IC to a maximum value of +1 mA during flyback and −150 µA during normal forward scan. For example if an h flyback with a peak of

100V is used, R

LIMITH

= 100 kΩ.The internal input impedance of pin 14 is low to limit the maximum voltage swing at

the input to within the supply rail and ground. The IC interface circuit creates a digital signal from this waveform, which

is used as the blanking signal, and termed HBLANK. This

signal is used by the video amplifier for blanking the video

and by the OSD generator as the horizontal sync reference

for the PLL.

Loss of the horizontal flyback pulse implies that the monitor

is not scanning, and therefore no image is being displayed.

The HBLANK pulse is still required by the LM2453 CRT

driver in order to maintain correct bias conditions in the CRT

until the power supplies are switched off, but video will be set

at black level to prevent front of screen problems, using the

NO_VID line. See also the

Loss of Horizontal Flyback

sec-

tion.

Figure 29

shows the external schematic of pin 14,

Figure 18

shows the internal schematic.

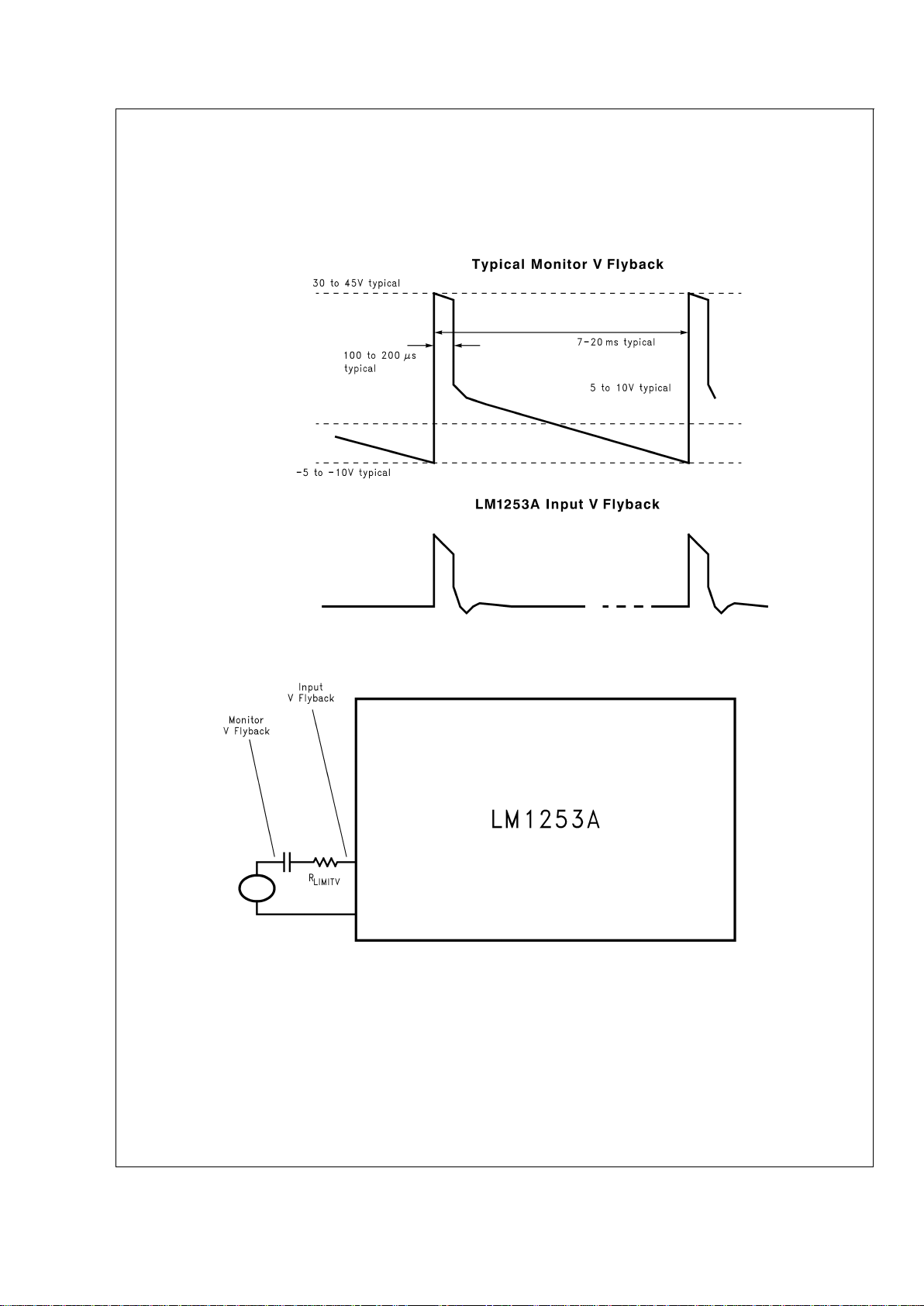

Pin 15—V Flyback This is an analog signal from the moni-

tor vertical scan. The analog waveform is AC coupled and

fed to the input of the IC via a current limiting resistor to pre-

vent the positive and negative excursions of the signal causing excessive current or voltage swing at the input to the IC.

See

Figure 10

.

R

LIMITV

is set to limit the maximum input voltage swing into

the IC to less than the supply rails. The input to the IC is

positive edge triggered, and ignores the falling edge. Because of horizontal rate noise on the waveform, the input

buffer incorporates hysteresis, triggering at a positive going

threshold of V

VTH+

and a negative going threshold of V

VTH

.

The input buffer produces a digital signal VSTART which is

used to start the VBLANK timer. The positive rising edge of

VSTART sets a counter timer, which counts horizontal periods using the HBLANK signal. The timer resets VBLANK

when it reaches the value preset in the register VCOUNT

(set by the micro-controller over I

2

C). While the output

VBLANK is active, an AND function prevents any further

transitions on the VSTART waveform from retriggering the

counter.

The positive edge of the VSTART signal is initially transmitted through to VBLANK through an OR function, as the timer

may take up to one horizontal line period to begin timing the

duration of the pulse. The application must ensure that the

DS101265-13

FIGURE 9. H Flyback Input Pulse

LM1253A

www.national.com11

Pin Descriptions (Continued)

VFLYBACKvertical flyback pulse is kept high during that initial period to prevent the output VBLANK from switching between high and low states.

Loss of vertical flyback pulse implies that the monitor is not

scanning, and therefore no image is being displayed. The

VBLANK pulses are still required by the LM2453 CRT driver

in order to maintain correct bias conditions in the CRT until

the power supplies are switched off, but video will be set at

black level to prevent front of screen problems, using the

NO_VID line. See also the

Loss of Vertical Flyback Pulse

section.

Figure 29

shows the external schematic of pin 15,

Figure 19

shows the internal schematic.

Pin 16—SDA The I

2

C data line. A pull up resistor of about

2kΩshould be connected between this pin and +5V.A300Ω

resistor should be connected in series with the data line to

protect the IC against arcing.

Figure 29

shows the external

schematic of pin 16,

Figure 20

shows the internal schematic.

Pin 17—SCL The I

2

C clock line. A pull up resistor of about

2kΩshould be connected between this pin and +5V.A300Ω

resistor should be connected in series with the clock line to

protect the IC against arcing.

Figure 29

shows the external

schematic of pin 17,

Figure 20

shows the internal schematic.

Pin 18 — Digital Ground Ground for the OSD section of the

LM1253A. All ground pins of the LM1253A should be connected together by a ground plane under the LM1253A. See

Figure 31

, which shows a sample layout.

Pin 19 — Digital Supply 5V supply for the OSD section of

the LM1253A. A 0.1 µF capacitor should be connected between pin 18 and pin 19, as close as possible to the

LM1253A.

DS101265-5

FIGURE 10. Vertical Flyback Input Pulse

LM1253A

www.national.com 12

Pin Descriptions (Continued)

Pin 20 — Digital Supply 5V supply for the OSD section of

the LM1253A. Pins 19 and 20 should be tied together under

normal operating conditions.

Pin 21—Analog Supply 5V supply for the video section of

the preamp. A 0.1 µF capacitor should be connected between pin 21 and pin 22, as close as possible to the

LM1253A.

Pin 22—Analog Ground Ground for the video section of

the LM1253A. All ground pins of the LM1253A should be

connected together by a ground plane under the LM1253A.

See

Figure 31

, which shows a sample layout.

Pin 23, 24, and 25— Green, Red, and Blue Video Out

These pins output the red, green, and blue video information

in the VideoPlex format. These pins are connected to the

LM2453 using as short of traces as possible. An inductor

should be in series with the trace between the preamp and

CRT driver. The value of this inductor depends on the board

layout.

Figures 29, 30

show the external schematic of pins

23, 24, and 25,

Figure 21

shows the internal schematic.

Pin 26—V

REF

Out The voltage that the VideoPlex signal is

referenced to is output on this pin. A 0.1 µF capacitor should

be connected between this pin and ground and be located

close to the LM1253A. This pin is connected to the V

REF

pin

of the LM2453. A 0.1 µF capacitor also needs to be connected very close to the LM2453. A 100 µF capacitor should

also be connected to this trace.

Figures 29, 30

show the ex-

ternal schematic of pin 26,

Figure 22

shows the internal

schematic.

Pin 27—Analog Ground Ground for the band gap refer-

ence section of the LM1253A. All ground pins of the

LM1253A should be connected together by a ground plane

under the LM1253A. See

Figure 31

, which shows a sample

layout.

Pin 28 — Analog Supply 5V supply for the band gap refer-

ence section of the preamp. A 0.1 µF capacitor should be

connected between pin 27 and pin 28, as close as possible

to the LM1253A. See

Figure 31

, which shows a sample lay-

out.

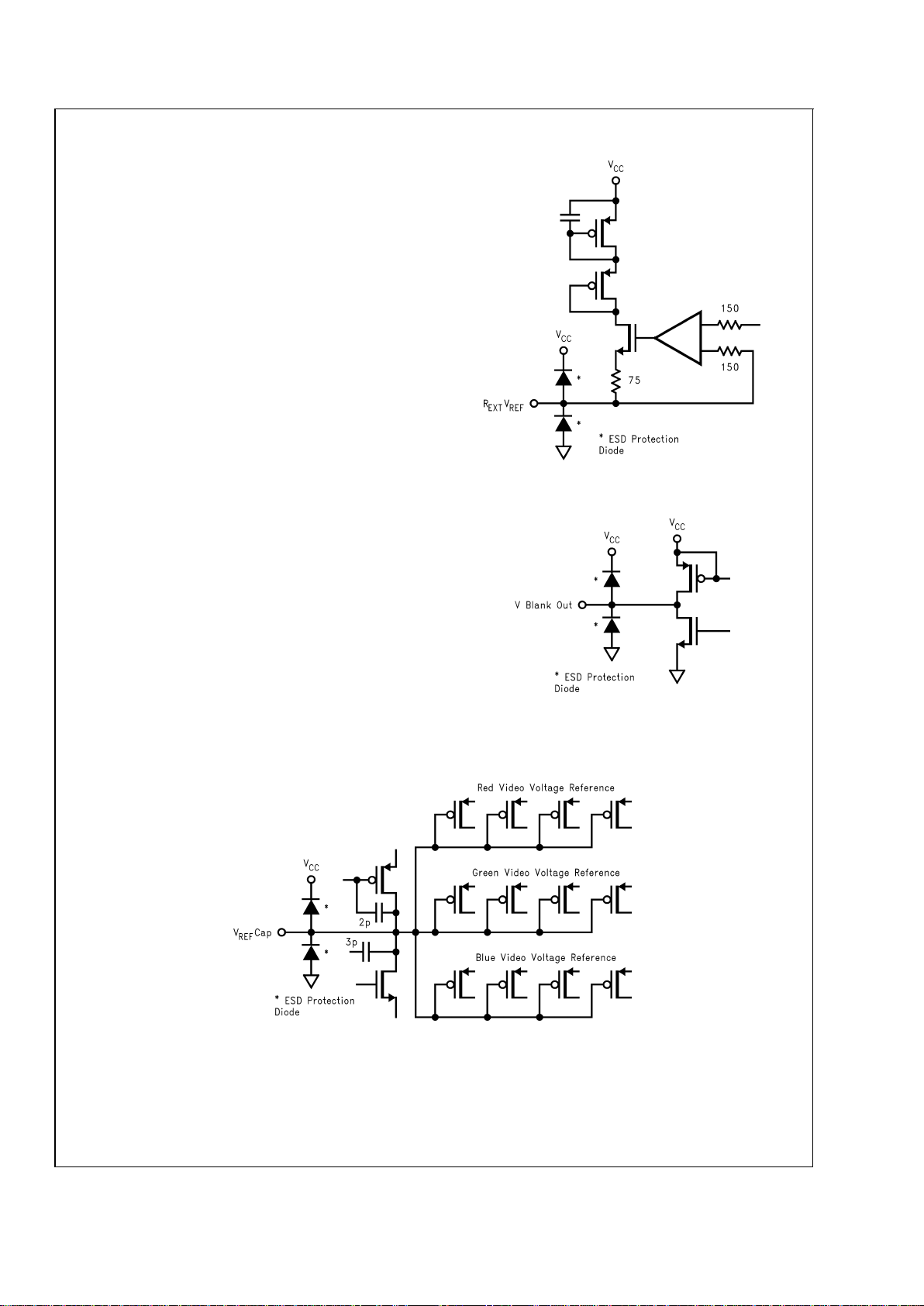

Input/Output Schematics

DS101265-14

FIGURE 11. Pin 1 (R

EXTVREF

)

DS101265-15

FIGURE 12. Pin 2 (V Blank Out)

DS101265-16

FIGURE 13. Pin 3 (V

REF

Cap)

LM1253A

www.national.com13

Input/Output Schematics (Continued)

DS101265-17

FIGURE 14. Pins 4, 5, and 6 (Video In)

DS101265-18

FIGURE 15. Pin 11 (PLL C)

DS101265-19

FIGURE 16. Pin 12 (ABL)

DS101265-20

FIGURE 17. Pin 13 (Clamp)

DS101265-21

FIGURE 18. Pin 14 (H Flyback)

DS101265-22

FIGURE 19. Pin 15 (V Flyback)

DS101265-23

FIGURE 20. Pins 16 and 17 (SDA and SCL)

LM1253A

www.national.com 14

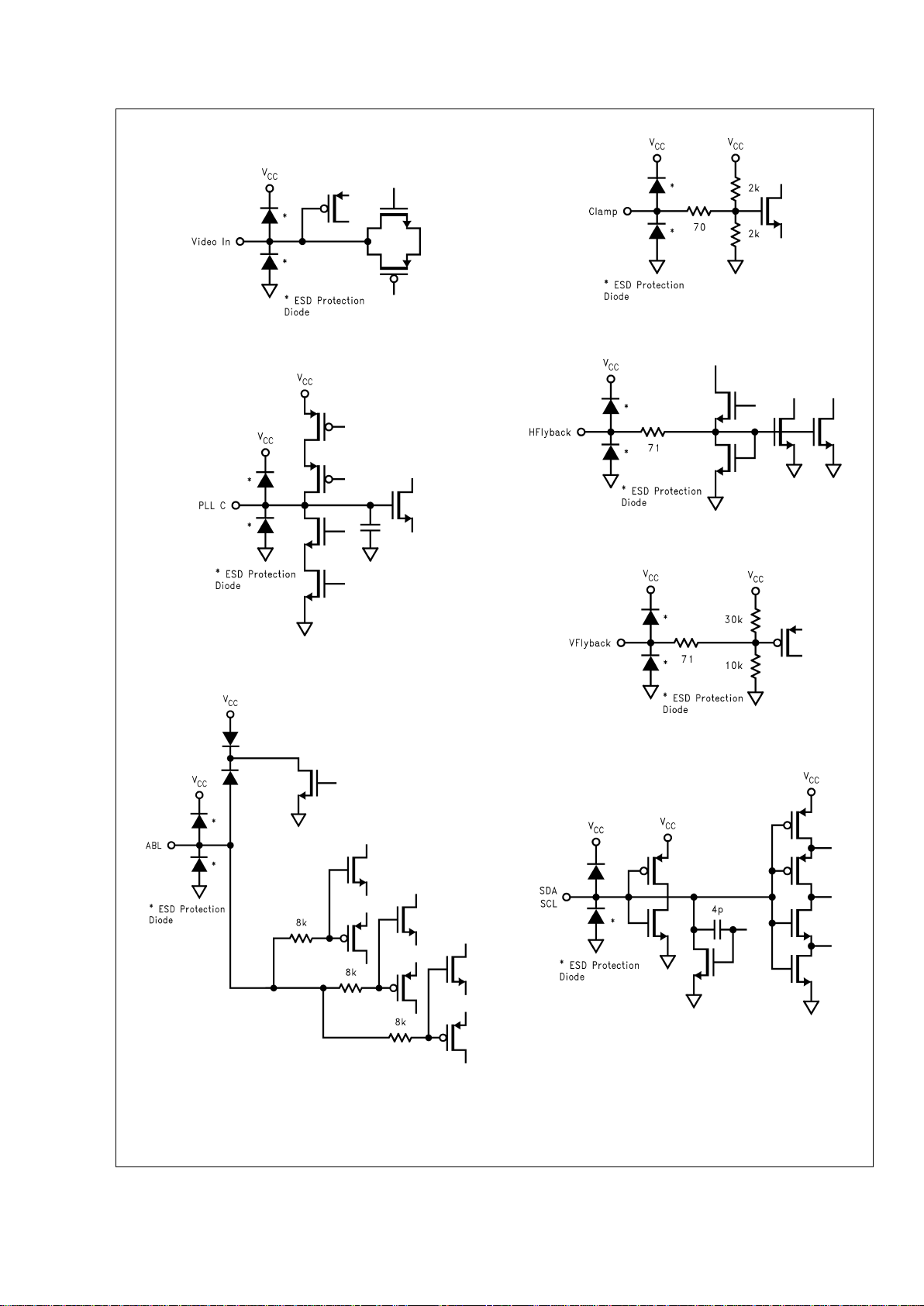

Input/Output Schematics (Continued)

National VideoPlex Video System

The LM1253A CRT Pre-Amp in conjunction with the LM2453

CRT driver uses the National VideoPlex multiplexed video

signal to send the video signal and DC clamp level from the

pre-amp to the CRT driver. The basic signal scheme is

shown in

Figure 23

.

The response of the LM2453 CRT driver to the VideoPlex

signal from the LM1253A Pre-Amp is shown in

Figure 24

.

Note that there are two sections in the video signal; the video

information is above V

REF

and the clamp information is be-

low V

REF

. The signals on the video out and clamp pins of the

LM2453 for an arbitrary video waveform from the LM1253A

is shown in

Figure 25

.

DS101265-24

FIGURE 21. Pins 23, 24, and 25 (Video Out)

DS101265-25

FIGURE 22. Pin 26 V

REF

Out

DS101265-26

FIGURE 23. National VideoPlex Video Signal (Pre-Amp Output)

LM1253A

www.national.com15

National VideoPlex Video System (Continued)

ESD and Arc-Over Protection

The LM1253A incorporates full ESD protection with special

consideration given to maximizing arc-over robustness. The

monitor designer must still use good circuit design and PCB

layout techniques. The human body model ESD susceptibility of the LM1253A is 2 kV,however many monitor manufacturers are now testing their monitors to the level 4 of the IEC

801-2 specification which requires the monitor to survive an

8 kV discharge. External ESD protection is needed to survive this level of ESD. The LM1253A provides excellent protection against both ESD and arc-over, but this is not a substitute for good PCB layout.

Figure 26

show the recommended input protection for the

LM1253A. This provides the best protection against ESD.

When this protection is combined with good PCB layout the

LM1253A will easily survive the IEC 801-2 level 4 testing

(8 kV ESD). It is strongly recommended that the protection

diodes be added as shown in

Figure 26

. The 1N4148 diode

has a maximum capacitance of 4 pF which will have little effect on the response of the video system due to the low impedance of the input video.

The ESD cells of the LM1253A also provide good protection

against arc-over, however good PCB layout is necessary.

The LM1253A should not be exposed directly to the voltages

that may occur during arc-over. The main vulnerability of the

LM1253A to arc-over is though the ground traces on the

PCB. For proper protection all ground connections associated with the LM1253A, including the grounds to the bypass

capacitors, must have short returns to the ground pins. Asignificant ground plane should be used to connect all the

LM1253A grounds.

Figure 31

, which shows the demo board

layout, is an excellent example of an effective ground plane.

The list below should be followed to ensure a PCB with good

grounding:

•

All grounds associated with the LM1253A should be connected together through a large ground plane.

•

CRT driver ground is connected to the video pre-amp

ground at one point.

•

CRTand arc protection grounds are connected directly to

the chassis or main ground. There is no arc-over current

flow from these grounds through the LM1253A grounds.

•

Input signal traces for SDA, SCL, H Flyback, V Flyback,

Clamp should be kept away from the LM2453 and all

traces that an arc can travel on.

•

Output signal traces of the LM1253A (video, V

BLANK

,

V

REF

) should be kept away from traces that carry the out-

put signals of the LM2453.

If any one of the above suggestions is not followed the

LM1253A may become more vulnerable to arc-over. Improper grounding is by far the most common cause of a

video pre-amp failure during arc-over.

DS101265-27

FIGURE 24. DC I/O Transfer Characteristics for the LM2453 CRT Driver

(Test Conditions: V

REF

= 1.65V, V

CC1

= 80V, VBB= 8V)

DS101265-28

FIGURE 25. LM2453 Input and Output Waveforms

LM1253A

www.national.com 16

ESD and Arc-Over Protection

(Continued)

The I

2

C specification recommends that the SDA and SCL

pins should be protected from arc-over.This is done by adding a resistor in series with each pin.

Figure 27

shows how

the resistors are connected to the SDA and SCL lines.

Pre-Amp Functional Description

Figure 1

shows the block diagram of the LM1253A. The

video signal is input to the LM1253A through the circuit

shown in

Figure 26

. Black level clamping is carried out directly on the AC coupled input signal at the input of the high

impedance buffer amplifier, thus eliminating the need for

black level clamp capacitors. The following sections then

modify the input video signal:

•

Contrast Attenuator—Sets the contrast level of the video

signal for all three channels.

•

Auto Beam Limit—Reduces the gain of all three video

amplifiers in response to a control voltage proportional to

the CRT beam current.

•

Gain Attenuator —Separately sets the gain for each

video channel.

•

Brightness—Sets the brightness for all three channels.

•

Bias—Adds an offset to the brightness controls for all

three video channels.

•

Pedestal—Adds a dc voltage offset to the brightness

control, in order that bi-directional control of the brightness control is always possible at all bias voltage settings.

•

Source Select—Switches between the input video signal

and the analog OSD signal generated by the 3 bit pallet

DAC control block.

•

DC Offset—Adds a dc voltage offset to all three video

outputs.

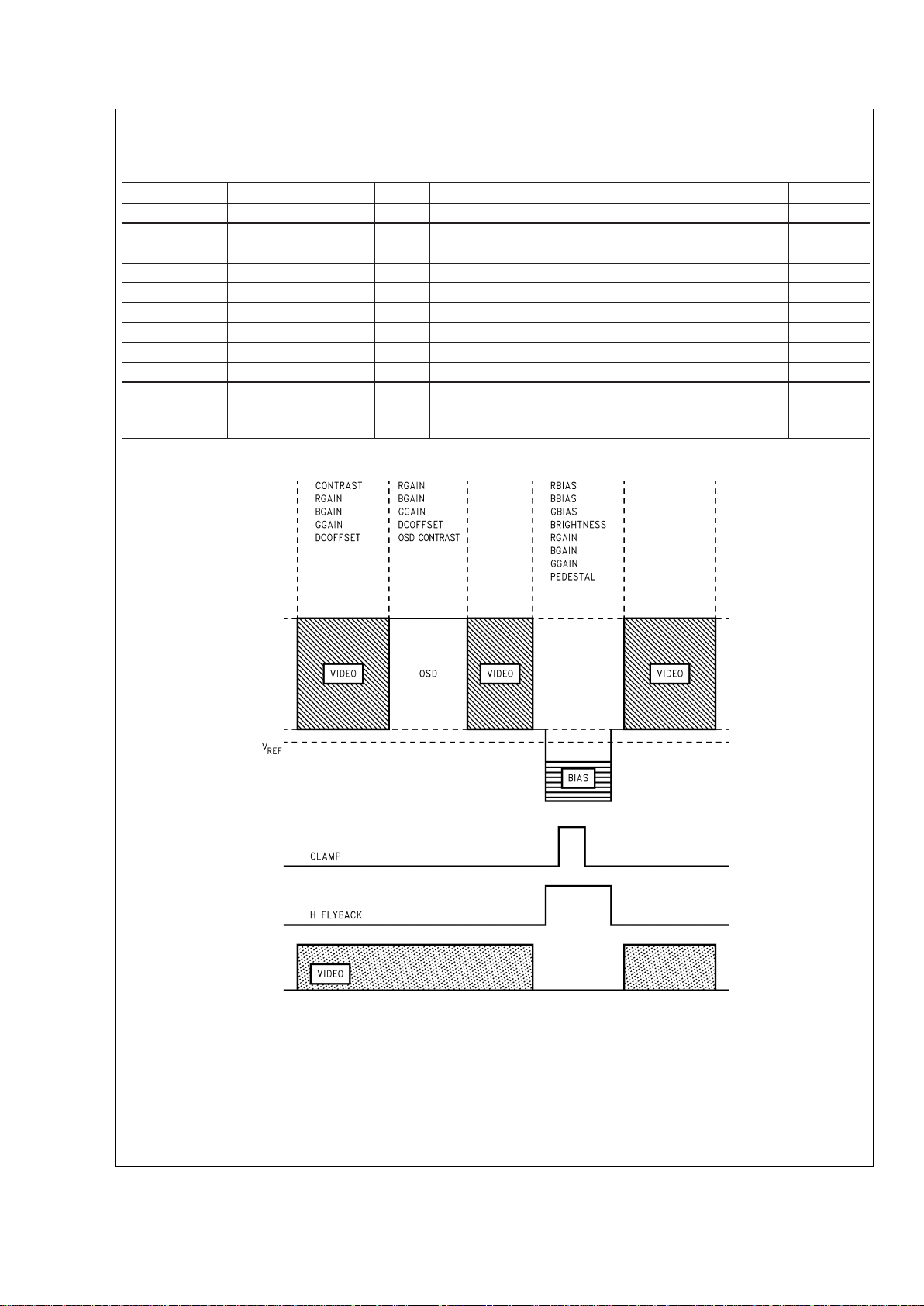

The above sections use the registers shown in

Table 2.Fig-

ure 28

shows which section of the output video and clamp

signal each register controls.

DS101265-29

FIGURE 26. Recommended Video Input ESD Protection

DS101265-30

FIGURE 27. Recommended Arc-Over Protection for

SDA and SCL Pins

LM1253A

www.national.com17

Pre-Amp Functional Description (Continued)

TABLE 2. Registers Controlling the Output Video and Clamp Signal

Parameter Address Size Description Default

BGAIN 8430h 7 Bit Blue Channel Gain 60h

GGAIN 8431h 7 Bit Green Channel Gain 60h

RGAIN 8432h 7 Bit Red Channel Gain 60h

CONTRAST 8433h 7 Bit Overall Gain of All Three Channels 60h

BBIAS 8434h 8 Bit Blue Bias Clamp Pulse Amplitude 80h

GBIAS 8435h 8 Bit Green Bias Clamp Pulse Amplitude 80h

RBIAS 8436h 8 Bit Red Bias Clamp Pulse Amplitude 80h

BRIGHTNESS 8437h 8 Bit Amplitude of Brightness Clamp Pulse of All 3 Channels 80h

PEDESTAL 8438h Bits 7–5 3 Bit Offset to the Brightness Control 4h

OSD

CONTRAST

8438h Bits 4–3 2 Bit OSD Gain 2h

DC OFFSET 8438h Bits 2–0 3 Bit Active Video DC Offset of All 3 Channels 4h

An active horizontal blanking signal is added to the video at

the output, giving excellent smear performance, and preventing video content dependent DC bias offsets as a result

of high frequency over shoot.

The outputs are referenced to a DC level (V

REF

) produced by

the LM1253A preamp, and so are guaranteed to provide

stable DC operating levels within the system without the

need for additional external feedback components.

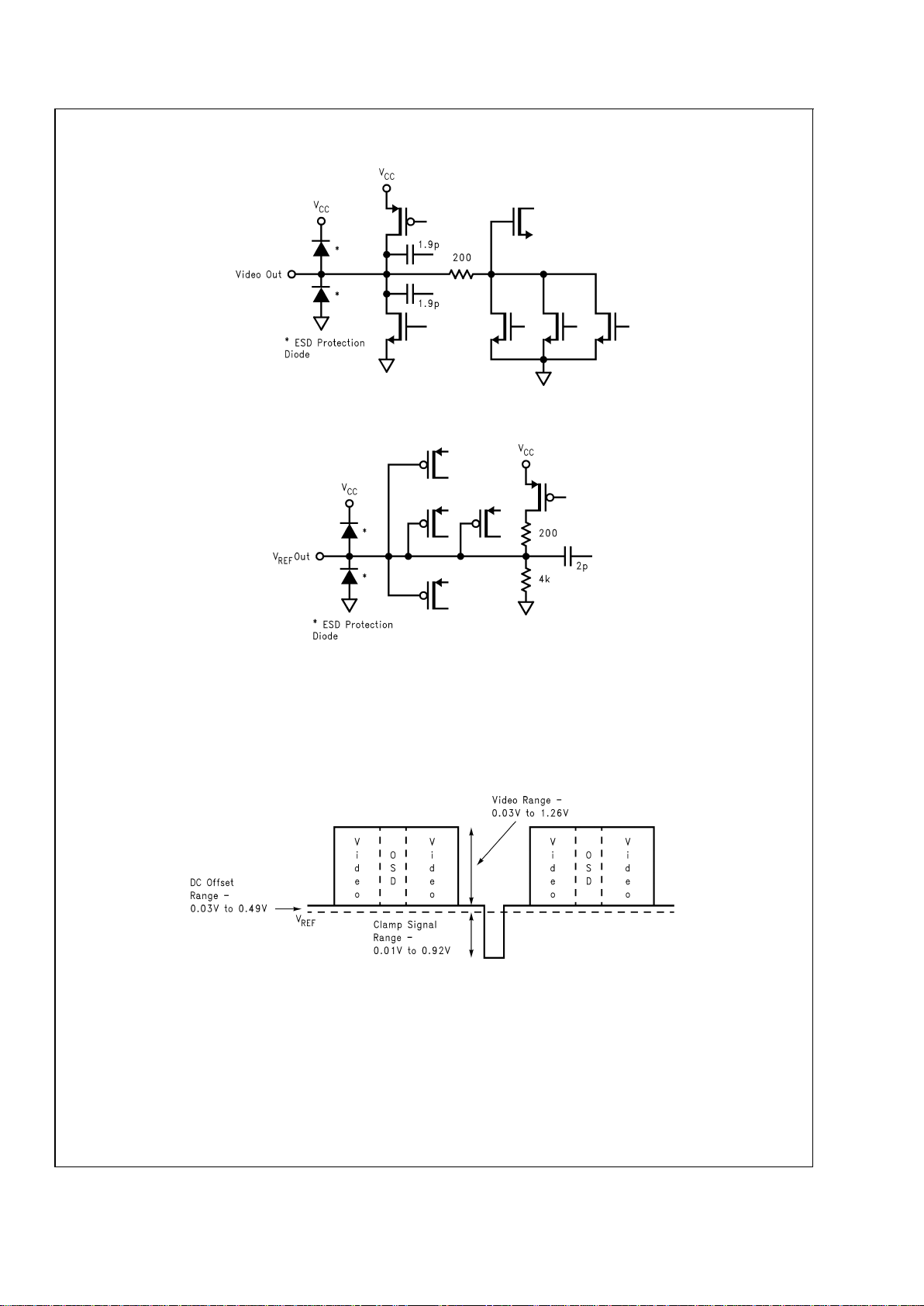

DS101265-31

FIGURE 28. Register Control of the Output Video and Clamp Signal

LM1253A

www.national.com 18

Pre-Amp Functional Description

(Continued)

Active Video Transfer Characteristic

Gain, contrast, and DC Offset control the amplitude of the

active video. The Contrast Control range is 20 dB (10X) and

the Gain Control range is 10 dB (3.2X). The DC offset can

vary the active video output level by about 470 mV in total,

allowing a total range of adjustment of about 24V in seven

3.4V steps at the output of a typical LM2453 CRT driver.

OSD Transfer Characteristic

Gain, DC Offset, and OSD Contrast control the amplitude of

the OSD signal. The OSD is not affected by the Brightness

control, but is proportional to the Gain control, with a gain

control range of 10 dB (3.2X). The DC offset will affect the

OSD output level by 470 mV in total. The OSD Contrast will

change the amplitude of the OSD output level by 610 mV in

total.

Brightness/Bias Transfer Characteristic

Bias, Brightness, Gain, and Pedestal control the amplitude

of the brightness/bias (clamp) portion of the signal. The bias

control range sets the brightness/bias pulse between 0.12V

and 0.55V below the value of V

REF

during blanking. The bias

voltage is unaffected by changes in the other controls. The

brightness control is bi-directional and adds or subtracts an

additional amount of between –0.2V and +0.2V to the

brightness/bias pulse during blanking, when gain is set to

maximum. If gain is reduced, the brightness output voltage is

reduced in proportion to allow gain tracking of the brightness

control. The Pedestal controls the offset to the brightness

control, in order that bi-directional operation of the brightness control is always possible at all bias voltage settings.

Auto Beam Limit Control

The Auto Beam Limit control reduces the gain of the video

amplifier in response to a control voltage proportional to the

CRT beam current. It is not recommended that this input be

used as an analog contrast control.

Horizontal Phase Locked Loop

A phase locked oscillator produces a pixel clock for the OSD

generator. This oscillator takes the HBLANK signal as the

sync signal. Aprogrammable divider sets the divide ratio and

thus the number of pixels on a horizontal line.

Fault Operation

Loss of Vertical Flyback Pulse

Loss of vertical flyback pulse implies that the monitor is not

scanning, and therefore no image is being displayed. The

VBLANK pulses are still required by the LM2453 CRT driver

in order to maintain correct bias conditions in the CRT until

the power supplies are switched off, but video is set at black

level.

Note also that interlace mode is supported by the LM1253A.

In interlace mode, a frame is composed of two sequential

fields. In the first field, the odd lines are displayed. In the second field the even lines are displayed. Acomplete frame consists of an odd number of horizontal lines, so that each field

contains a half line. This will result in an alternate half line

phase difference between each field of the VFLYBACK pulse

with respect to the HBLANK pulse.

Loss of Horizontal Flyback

Loss of horizontal flyback pulse implies that the monitor is

not scanning, and therefore no image is being displayed.

The HBLANK pulse is still required by the LM2453 CRT

driver in order to maintain correct bias conditions in the CRT

until the power supplies are switched off, but video is set at

black level.

In the absence of an externally supplied horizontal flyback

pulse, the PLL will free run and generate its own HBLANK

pulse. The PLL free run pulse will be gated into the HBLANK

line to the pre-amp to allow normal operation of the pre-amp

and driver biasing.

V

CC

Detect

The V

CC

power supply will be continuously monitored by the

LM1253A. Should the V

CC

supply drop to less than V

CCDET

then the video signal will be set to V

REF

.

The device will continue to operate down to V

CCDET

, although some parameters may fall outside of specification

when the supply drops below V

CCMIN

.

Power Save Mode

Procedure To Put The LM1253A Into Power Save Mode

or Power Off Blanking

If the monitor has a power save mode the following procedure should be used to put the LM1253A into power save

mode. This should be used for both power save modes initiated from the video card and power save modes initiated by

a user on the front panel of the monitor.

1. Set Bias and Brightness registers (8434h – 8437h) to 0.

2. Set the LM1253A to blank video by setting register

8439h to 01h.

3. Turn off the 8V and 80V supply to the LM2453.

4. Set the LM1253A to power save by setting register

8439h to 02h.

LM1253A

www.national.com19

Schematics

DS101265-34

FIGURE 29. LM1253A/LM2453 Demo Board Schematic

LM1253A

www.national.com 20

Schematics (Continued)

DS101265-69

FIGURE 30. LM1253A/LM2453 Demo Board Schematic (continued)

LM1253A

www.national.com21

PCB Layout

DS101265-35

FIGURE 31. LM1253A/LM2453 Demo Board Layout

LM1253A

www.national.com 22

OSD Generator Operation

Page Operation

The block diagram of the OSD generator is shown

Figure 32

.

Video information is created using any of the 256 predefined characters stored in the mask programmed ROM.

Each character has a unique 8 bit code that is used as its address. Consecutive rows of characters make up the displayed window. These characters can be stored in the page

RAM, written under I

2

C controlled commands by the monitor

micro-controller. Each row can contain any number of characters up to the limit of the displayable line length, although

some restrictions concerning the enhanced features apply

on character rows longer than 32 characters

The number of characters across the width and height of the

page can be varied under I

2

C control, but the total number of

characters that can be stored and displayed on the screen is

limited to 512 including any row end, skip line, and window

end control characters. The horizontal and vertical start position can also be programmed under I

2

C control.

OSD Video DAC

The OSD DAC is controlled by the 9 bit (3x9 bits) OSD video

information coming from the pixel serializer look-up table.

The OSD DAC is shown in the

Figure 33

, where the gain is

programmable by the 2 bit OSD CONTRAST register, in 4

stages to give the required OSD signal.

The analog signal created by the OSD DACs is biased with

respect to V

REF

.

DS101265-36

FIGURE 32. Block Diagram of the OSD Generator

DS101265-37

FIGURE 33. Block Diagram of OSD DACs

LM1253A

www.national.com23

OSD Generator Operation (Continued)

OSD Video Timing

The OSD SELECT signal switches the source of video information within the preamplifier from external video to the internally generated OSD video.

Windows

Two separate windows can be opened, utilizing the data

stored in the page RAM. Each window has its own horizontal

and vertical start position, although the second window

should be horizontally spaced at least two character spaces

away from the first window, and should never overlap the

first window when both windows are on. The OSD window

must be placed within the active video.

Character Cell

Each character is defined as a 12 wide by 18 high matrix of

picture elements, or ‘pixels’. The character font is shown in

Figures 45, 46, 47, 48, 49, 50

. There are two types of char-

acters defined in the character ROM:

1. Two-color: There are 190 two-color characters. Each

pixel of these characters is defined by a single bit value.

If the bit value is 0, then the color is defined as ‘Color 1’

or the ‘background’ color. If the bit value is 1, then the

color is defined as ‘Color 2’, or the ‘foreground’ color.An

example of a character is shown in

Figure 34

.

2. Four-color: There are 64 four-color characters stored in

the character ROM. Each pixel of the four-color character is defined by two bits of information, and thus can define four different colors, Color 1, Color 2, Color 3, and

Color 4. Color 1 is defined as the ‘background’ color.All

other colors are considered ‘foreground’ colors, although

for most purposes, any of the four colors may be used in

any way. Because each four-color character has two

bits, the LM1253A internally has a matrix of two planes

of ROM as shown in

Figure 35

.

12 columns

18 rows

COLOR 1

COLOR 2

DS101265-38

FIGURE 34. A Two-Color Character

Plane 1 + Plane 2 = Composite

DS101265-39

FIGURE 35. A Four-Color Character

LM1253A

www.national.com 24

OSD Generator Operation (Continued)

Attribute Tables

Each character has an attribute value assigned to it in the

page RAM. The attribute value is 4 bits wide, making each

character entry in the page RAM 12 bits wide in total. The attribute value acts as an address which points to one of 16

entries in either the two-color attribute table RAM or the fourcolor attribute table RAM. The attribute word in the table contains the coding information which defines which color is represented by Color 1 and Color 2 in the two color attribute

table and Color 1, Color 2, Color 3, Color 4 in the four-color

attribute table. Each color is defined by a 9 bit value, with 3

bits assigned to each channel of RGB. A dynamic look up

table defines each of the 16 different color combination selections or ‘palettes’. As the look up table can be dynamically

coded by the micro-controller over the I

2

C interface, each

color can be assigned to any one of 2

9

(i.e. 512) choices.

This allows a maximum of 64 different colors to be used

within one page using the 4-color characters, with up to 4 different colors within any one character and 32 different colors

using the 2-color characters, with 2 different colors within

any one character.

Transparent Disable

In addition to the 9 lines of video data, a tenth data line is

generated by the transparent disable bit. When this line is

activated, the black color code will be translated as ‘transparent’ or invisible. This allows the video information from

the PC system to be visible on the screen when this is

present. Note that this feature is enabled on all black of the

first 8 attribute table entries.

Enhanced Features

In addition to the wide selection of colors for each character,

additional character features can be selected on a character

by character basis.

1. Button Boxes— The OSD generator examines the character string being displayed and if the ‘button box’ attributes have been set in the Enhanced feature byte,

then a box creator selectively substitutes the character

pixels in either or both the top and right most pixel line or

column with a button box pixel. The shade of the button

box pixel depends upon whether a ‘depressed’ or

‘raised’ box is required, and can be programmed by

I

2

C.The raised pixel color (‘highlight’) is defined by the

value in the color palette register, EF1 (normally white).

The depressed pixel (‘lowlight’) color by the value in the

color palette register EF2 (normally gray). See

Figure

36

.

2. Heavy Button Boxes—When heavy button boxes are

selected, the color palette value stored in register EF3 is

used for the depressed (‘lowlight’) pixel color instead of

the value in register EF2.

3. Shadowing—Shadowing can be added to two-color

characters by choosing the appropriate attribute value

for the character. When a character is shadowed, a

shadow pixel is added to the lower right edges of the

color 2 image, as shown in

Figure 37

. The color of the

shadow is determined by the value in the color palette

register EF3 (normally black).

4. Bordering—A border can be added to the two-color

characters. When a character is bordered, a border pixel

is added at every horizontal, vertical or diagonal transition between Color 1 and Color 2. See

Figure 38

. The

color of the border is determined by the value in the color

palette register EF3 (normally black).

5. Blinking—If blinking is enabled as an attribute, all colors

within the character except the button box pixels which

have been over-written will alternately switch to Color 1

and then back to Color 2 at a rate determined by the

micro-controller under I

2

C control.

LM1253A

www.national.com25

OSD Generator Operation (Continued)

RAISED

CHAR1

CHAR1

Bit 0

(of Previous

Character)

Line 0

(of Character

Below)

Bit 11

Bit 0

Line 0

Line 17

DS101265-40

DEPRESSED

CHAR1

CHAR1

Bit 0

(of Previous

Character)

Line 0

(of Character

Below)

Bit 11

Bit 0

Line 0

Line 17

DS101265-41

Effect on the screen:

DS101265-42

FIGURE 36. Button Boxes

DS101265-43

FIGURE 37. Shadowing

DS101265-44

FIGURE 38. Bordering

LM1253A

www.national.com 26

Micro-Controller Interface

The micro-controller interfaces to the LM1253A pre-amp via

an I

2

C interface. The protocol of the interface begins with a

Start Pulse followed by a byte comprised of a seven bit Slave

Device Address and a Read/Write bit. Since the first byte is

composed of both the address and the read/write bit the address of the LM1253A for writing is BAh (1011 1010) and the

address for reading is BBh (1011 1011). The development

software provided by National Semiconductor will automatically take care of the difference between the read and write

addresses if the target address under the communications

tab is set to BAh.

Figures 39, 40

show a write and read se-

quence across the I

2

C interface.

Write Sequence

The write sequence begins with a start condition which consists of the master pulling SDA low while SCL is held high.

The slave device address is next sent. The address byte is

made up of an address of seven bits (7-1) and the read/write

bit (0). Bit 0 is low to indicate a write operation. Each byte

that is sent is followed by an acknowledge. When SCL is

high the master will release the SDAline. The slave must pull

SDAlow to acknowledge. The register to be written to is next

sent in two bytes, the least significant byte being sent first.

The master can then send the data, which consists of one or

more bytes. Each data byte is followed by an acknowledge

bit. If more than one data byte is sent the data will increment

to the next address location. See

Figure 39

.

Read Sequence

Read sequences are comprised of two I

2

C transfer sequences: The first is a write sequence that only transfers the

two byte address to be accessed. The second is a read sequence that starts at the address transferred in the previous

address only write access and increments to the next address upon every data byte read. This is shown in

Figure 40

.

DS101265-45

FIGURE 39. I2C Write Sequence

LM1253A

www.national.com27

Micro-Controller Interface (Continued)

The write sequence consists of the Start Pulse, the Slave

Device Address, the Read/Write bit (a zero, indicating a

write) and the Acknowledge bit; the next byte is the least significant byte of the address to be accessed, followed by its

Acknowledge bit. This is then followed by a byte containing

the most significant address byte, followed by its Acknowledge bit. Then a Stop bit indicates the end of the address

only write access.

Next the read data access will be performed beginning with

the Start Pulse, the Slave Device Address, the Read/Write

bit (a one, indicating a read) and the Acknowledge bit. The

next 8 bits will be the read data driven out by the LM1253A

pre-amp associated with the address indicated by the two

address bytes. Subsequent read data bytes will correspond

to the next increment address locations.

Read data from the LM1253A only when both OSD windows

are disabled.

DS101265-46

FIGURE 40. I2C Read Sequence

LM1253A

www.national.com 28

LM1253A Address Map

TABLE 3. Character ROM Address Map

Address

Range

R/W Description

CHARACTER ROM

0000h–2FFFh R ROM Character Fonts, 190 two-color Character Fonts that are read-only.

The format of the address is as follows:

A15–A14: Always zeros.

A13–A6: Character value (00h–BFh are valid values)

A5–A1: Row of the character (00h–11h are valid values)

A0: Low byte of line when a zero. High byte of line when a one.

The low byte will contain the first eight pixels of the line with data Bit 0 corresponding to the left

most bit in the Character Font line. The high byte will contain the last four pixels and data Bits

7–4 are “don’t cares”. Data Bit 3 of the high byte corresponds to the right most pixel in the

Character Font line.

3000h–3FFFh R ROM Character Fonts, 64 four-color Character Fonts that are read-only.

The format of the address is as follows:

A15–A14: Always zeros.

A13–A6: Character value (C0h–FFh are valid values)

A5–A1: Row of the character (00h–11h are valid values)

A0: Low byte of line when a zero. High byte of line when a one.

The low byte will contain the first eight pixels of the line with data Bit 0 corresponding to the left

most bit in the Character Font line. The high byte will contain the last four pixels and data Bits

7–4 are “don’t cares”. Data Bit 3 of the high byte corresponds to the right most pixel in the

Character Font line.

NOTE: The value of Bit 0 of the Character Font Access Control Register (I

2

C Address 8402h) is a

zero, it indicates that the Bit 0 data value of the four-color pixels is being accessed via these

addresses. When the value of Bit 0 of the Access Control Register is a one, it indicates that the

Bit 1 data value of the four-color pixel is being accessed via these addresses.

4000h–7FFFh RESERVED.

TABLE 4. Display Page RAM Address Map

Address

Range

R/W Description

DISPLAY PAGE RAM

8000h–81FF R/W Display Page RAM Characters. A total of 512 display characters, skipped line, end-of-row and

end-of-window character codes may be supported via this range.

To support skipped lines and character attributes a number of special case rules are used when

writing to this range. (Refer to the

Display Page RAM

section of this document for more details.)

LM1253A

www.national.com29

Pre-Amp Interface Registers

TABLE 5. OSD Interface Registers

LM1253A OSD Interface Registers

Register Address Default D7 D6 D5 D4 D3 D2 D1 D0

Fonts-2 Color 0000–2FFE PIXEL[7:0]

+1 XXXX PIXEL[11:8]

Fonts-4 Color 3000–3FFE PIXEL[7:0]

+1 XXXX PIXEL[11:8]

Display Page 8000–83FF CHAR_CODE[7:4] or reserved CHAR_CODE[3:0] or ATTR_CODE

FRMCTRL1 8400 10h X X X TD CDPR D2E D1E OSE

FRMCTRL2 8401 80h PIXELS_PER_LINE[2:0] BLINK_PERIOD[4:0]

CHARFONTACC 8402 00h XXXXXXATTR FONT4

VBLANKDUR 8403 10h X VBLANK_DURATION[6:0]

CHARHTCTRL 8404 51h CHAR_HEIGHT[7:0]

BBHLCTRLB0 8405 FFh B[1:0] G[2:0] R[2:0]

BBHLCTRLB1 8406 01h XXXXXXXB[2]

BBLLCTRLB0 8407 00h B[1:0] G[2:0] R[2:0]

BBLLCTRLB1 8408 00h XXXXXXXB[2]

CHSDWCTRLB0 8409 00h B[1:0] G[2:0] R[2:0]

CHSDWCTRLB1 840A 00h XXXXXXXB[2]

ROMSIGCTRL 840D 00h XXXXXXXCRS

ROMSIGDATAB0 840E 00h CRC[7:0]

ROMSIGDATAB1 840F 00h CRC[15:8]

HSTRT1 8410 13h HPOS[7:0]

VSTRT1 8411 14h VPOS[7:0]

COLWIDTH1B0 8414 00h COL[7:0]

COLWIDTH1B1 8415 00h COL[15:8]

COLWIDTH1B2 8416 00h COL[23:16]

COLWIDTH1B3 8417 00h COL[31:24]

HSTRT2 8418 56h HPOS[7:0]

VSTRT2 8419 5Bh VPOS[7:0]

W2STRTADRL 841A 00h ADDR[7:0]

W2STRTADRH 841B 01h XXXXXXXADDR[8]

COLWIDTH2B0 841C 00h COL[7:0]

COLWIDTH2B1 841D 00h COL[15:8]

COLWIDTH2B2 841E 00h COL[23:16]

COLWIDTH2B3 841F 00h COL[31:24]

Note: Set Reserved bits to 0.

LM1253A

www.national.com 30

Pre-Amp Interface Registers (Continued)

TABLE 6. Pre-Amp Interface Registers

LM1253A Pre-Amp Interface Registers

Register Address Default D7 D6 D5 D4 D3 D2 D1 D0

BGAINCTRL 8430 60h X BGAIN[6:0]

GGAINCTRL 8431 60h X GGAIN[6:0]

RGAINCTRL 8432 60h X RGAIN[6:0]

CONTRCTRL 8433 60h X CONTRAST[6:0]

BBIASCTRL 8434 80h BBIAS[7:0]

GBIASCTRL 8435 80h GBIAS[7:0]

RBIASCTRL 8436 80h RBIAS[7:0]

BRIGHTCTRL 8437 80h BRIGHTNESS[7:0]

DCOFFSET 8438 94h PEDESTAL[2:0] OSD CONT[1:0] DC OFFSET[2:0]

GLOBALCTRL 8439 00h XXXXXXPSBV

PLLFREQRNG 843E 16h X X IVIGAIN[1:0] X X PFR[1:0]

SRTSTCTRL 843F 00h X AID XXXXXSRST

Note: Set Reserved bits to 0.

Two-Color Attribute Table

TABLE 7. Two-Color Attribute Registers

LM1253A Two-Color Attribute Registers

Register Address D7 D6 D5 D4 D3 D2 D1 D0

ATT2C0n 8440 +

(n*4)

C1B[1:0] C1G[2:0] C1R[2:0]

ATT2C1n +1 C2B[0] C2G[2:0] C2R[2:0] C1B[2]

ATT2C2n +2 X X EF[3:0] C2B[2:1]

ATT2C3n +3 XXXXXXXX

Note: Set Reserved bits to 0.

Two-colordisplay characterAttribute Table.The attributes for two-color display characters may be written or read via the following

address format:

A15–A6: Always 1000_0100_01b.

A5–A2: Attribute code (0h-Fh are valid values), n

A1–A0: Determines which of the 3 bytes is to be accessed.

NOTE: In the table, n indicates the attribute number 0

<=n<

=15

NOTE: When writing, bytes 0 through 2 must be written, in that order. Bytes 0 through 2 will take effect after byte 2 is written.

Since byte 3 contains all reserved bits, this byte may be written, but no effect will result.

When reading, it is OK to read only one, two, or all three bytes.

If writing more than one 2-color attributes using the auto increment feature, all four bytes must be written.

Four-Color Attribute Table

TABLE 8. Four-Color Attribute Registers

LM1253A Four-Color Attribute Registers

Register Address D7 D6 D5 D4 D3 D2 D1 D0

ATT4C0n 8500 +

(n*8)

C1B[1:0] C1G[2:0] C1R[2:0]

ATT4C1n +1 C2B[0] C2G[2:0] C2R[2:0] C1B[2]

ATT4C2n +2 X X EF[3:0] C2B[2:1]

LM1253A

www.national.com31

Four-Color Attribute Table (Continued)

TABLE 8. Four-Color Attribute Registers (Continued)

LM1253A Four-Color Attribute Registers

Register Address D7 D6 D5 D4 D3 D2 D1 D0

ATT4C3n +3 XXXXXXXX

ATT4C4n +4 C3B[1:0] C3G[2:0] C3R[2:0]

ATT4C5n +5 C4B[0] C4G[2:0] C4R[2:0] C3B[2]

ATT4C6n +6 XXXXXX C4B[2:1]

ATT4C7n +7 XXXXXXXX

Note: Set Reserved bits to 0.

Four-color display character Attribute Table. The attributes for four-color display characters may be written or read via the following address format:

A15–A7: Always 1000_0101_0b

A6–A3: Attribute value (0h–Fh are valid values), n

A2–A0: Determine which of the six bytes of the attribute is to be accessed.

NOTE: In the table, n indicates the attribute number, 0

<=n<

=15

NOTE: When writing, bytes 0 to 2 must be written, in that order and bytes 4 to 6 must be written, in that order.

Bytes 0 through 2 will take effect after byte 2 is written. Bytes 4 through 6 will take effect after byte 6 is written.

Since bytes 5 and 7 contain all reserved bits, these bytes may be written, but no effect will result. When reading, it is OK to read

only one, two, or all three bytes.

If writing more than one 4-color attributes using the auto increment feature, all eight bytes must be written.

Display Page RAM

The OSD Window

The Display Page RAM contains all of the 8 bit display character codes and their associated 4 bit attribute codes, and the special

12 bit page control codes—the row-end, skip-line parameters and window-end characters.

The LM1253A has a distinct advantage over many OSD generators that it allows variable size and format windows. The window

size is not dictated by a fixed geometry area of RAM. Instead, 512 locations of 12 bit words are allocated in RAM for the definition

of the windows, with special control codes to define the window size and shape.

Window width can be any length supported by the number of pixels per line that is selected divided by the number of pixels in a

character line. It must be remembered that OSD characters displayed during the monitor blanking time will not be displayed on

the screen, so the practical limit to the number of horizontal characters on a line is reduced by the number of characters within

the horizontal blanking period.

Character Code And Attribute Code

Each of the 512 x 12 bit locations in the page RAM is comprised of an 8 bit character or control code, and a 4 bit attribute code:

Bits 11–4 Character Code: These 8 bits define which of the 254 characters is to be called from the character ROM. Valid char-

acter codes are 02h–FFh.

Bits 3–0: Attribute code. These 4 bits address the attribute table used to specify which of the 16 locations in RAM specify the

colors and enhanced features to be used for this particular character. Two separate attribute tables are used, one for

2-color characters, the other for 4-color characters.

Each of the characters are stored in sequence in the page RAM. Special codes are used between lines to show where one line

ends and the next begins, and also to allow blank (or ‘skipped’) lines to be added between character rows.

DS101265-47

LM1253A

www.national.com 32

Display Page RAM (Continued)

Row End Code

To signify the end of a row of characters, a special ‘Row-End’ (RE) code is used in place of a character code.

Bits 11–4 Row-End Code: A special character code of 01h

Bits 3–0: Don’t care

The RE character tells the OSD generator that the character codes following must be placed on a new row in the displayed win-

dow.

Skipped Line Parameters

Each displayed row of characters may have up to 15 skipped (i.e., blank) lines beneath it in order to allow finer control of the vertical spacing of character rows. (Each skipped line is treated as a single auto-height character pixel line, so multiple scan lines

may actually be displayed in order to maintain accurate size relative to the character cell— see section

Constant Character

Height Mechanism

).

To specify the number of skipped lines, the first character in each new row of characters to be displayed is interpreted differently

than the other characters in the row. Instead of interpreting the data in the location as a character code, the information of the

12 bit word is defined as follows:

Bits 11–8 Reserved.

Bits 7–4: Skipped Lines. These four bits determine how many blank pixel lines will be inserted between the present row of dis-

play characters and the next row of display characters. A range of 0–15 may be selected.

Bits 3–0: Attribute code. The pixels in the skipped lines will normally be Color 1 of the addressed 2-Color Attribute Table entry.

Note that the pixels in the first line immediately below the character may be overwritten by the pixel override system

that creates the button box. (Refer to the

Button Box Formation

Section for more information.)

Each new line MUST start with an SL code, even if the number of skipped lines to follow is zero. An SL code MUST always follow

an RE control code.

An RE code may follow an SL code if several ‘transparent’ lines are required between sections of the window (see example 3 below). In this case, skipped lines of zero characters are displayed, causing a break in the window.

Window-End Code

To signify the end of the window, a special ‘Window-End’ (WE) code is used in place of a Row-End code.

Bits 11–4 Window-End Code: A special character code of 00h

Bits 3–0: Don’t care

The WE control code tells the OSD generator that the character codes following belong to another displayed window at the next

window location. A WE control code may follow normal characters or an SL parameter, but never an RE control code.

Writing To The Page RAM

The Display Page RAM can contain up to 512 of the above listed characters and control codes. Each character, or control code

will consume one of the possible 512 locations. For convenience, a single write instruction to bit 3 of the Frame Control Register

(8400h) can reset the page RAM value to all zero.

Display Window 1 will also start at the first location (corresponding to the I

2

C address 8000h). This location must always contain

the Skip-Line (SL) parameters associated with the first row of Display Window 1. Subsequent locations should contain the characters to be displayed on row 1 of Display Window 1, until the RE character code or WE character code is written into the Display

Page-RAM.

DS101265-48

DS101265-49

DS101265-50

LM1253A

www.national.com33

Display Page RAM (Continued)

The skip-line parameters associated with the next row must always be written to the location immediately after the preceding

row’s row-end character. The only exception to this rule is when a window-end character (value 00h) is encountered. It is important to note that a row-end character should not precede a window-end character (otherwise the window-end character will be interpreted as the next row’s skip-line parameters). Instead, the window-end character will both end the row and the window making

it unnecessary to precede it with a row-end character.

The I

2

C Format for writing a sequence of display characters is minimized by allowing sequential characters with the same at-

tribute code to be sent in a string as follows:

Byte

#

1—I2C Slave Address

Byte

#

2—LSB Address

Byte

#

3—MSB Address

Byte

#

4—Attribute Table Entry to use for the following characters

Byte

#

5—First display character, SL parameter, RE or WE control code.

Byte

#

6—Second display character, SL parameter, RE or WE control code.

Byte

#

7—Third display character, SL parameter, RE or WE control code.

.

.

Byte

#

n—Last display character in this color sequence, SL parameter, RE or WE control code to use the associated Attribute

Table Entry.

The Attribute Table Entry (Byte #4, of the above) is automatically associated with each subsequent display character or SL code

written. The following are examples of how the Display Page RAM associates to the actual On-Screen Display Window #1.

EXAMPLE #1:

A 3 X 3 character matrix of white characters on a black background is to be displayed using 2-color character codes:

The actual On-Screen Display of Window #1 is shown in

Figure 41

. Note the dotted white lines are not shown on the monitor.

They are shown here to show where the character ends.

Notes:

•

Every row must begin with an attribute and a SL. Display

Page RAM memory location 8000h will always be associated with the SL of row 0 of Display Window #1.

•

Every row except the last row of a Display Window must

end with an RE character. The character immediately after an RE character is always the SL value for the next

row.

•

The last row in a Display Window must be a WE character. The WE character must NOT be preceded by an RE

character.

•

The entire Display Window may be written in a single I2C

write sequence because the Attribute Table entry (i.e., the

color palette) does not change for the entire Display Window.

•

The Attribute Table Entry that is associated with RE and

WE characters are “don’t cares”. In general it is most efficient just to allow them to be the same value as the Attribute Table Entry associated with the previous display

character.

•

The colors of the characters and background can be

stored in a single location in the 2-color attribute table, in

location ATT0.

•

The data shown in

Table 9

is sent to the LM1253A in one

I

2

C transmission.

DS101265-51

FIGURE 41. Example 1 OSD

LM1253A

www.national.com 34

Display Page RAM (Continued)

TABLE 9. Example 1 I

2

C Transmission

Command

Sent

(hex)

Description

RAM Address

of the Character

or Command

I

2

C start condition (See the

Micro-Controller Interface

Section)

BA Chip address (See the

Micro-Controller Interface

Section)

00 Address LSB

80 Address MSB

00 Use Attribute table 00 for the following characters

00 Skip 0 lines 8000

02 Character “A” 8001

03 Character “B” 8002

04 Character “C” 8003

01 Row end 8004

00 Skip 0 lines 8005

05 Character “D” 8006

06 Character “E” 8007

07 Character “F” 8008

01 Row end 8009

00 Skip 0 lines 800A

08 Character “G” 800B

09 Character “H” 800C

0A Character “I” 800D

00 Window end 800E

I

2

C stop condition (See the

Micro-Controller Interface

Section)

EXAMPLE

#

2:

A 3X3 character matrix of characters on a black background is to be displayed on the screen, using 2-color character codes.

2 skipped lines are required below the first line of characters, 3 skipped lines are required below the second line of characters,

and 4 skipped lines are required below the third line of characters. The first line of characters will use color attribute 0, the second

line will use color attribute 1, the third line will use color attribute 0 for the first character, color attribute 1 for the second character,

and color attribute 2 for the third character. This is shown in

Figure 42

.

LM1253A

www.national.com35

Display Page RAM (Continued)

Notes:

•

Every row must begin with an attribute and a SL value.

Display Page RAM memory location 8000h will always be

associated with the SL of row 0 of Display Window #1.

•

If an I2C transmission finishes without an RE (in the

middle of a row) the first byte sent in the next I

2

C trans-

mission is the attribute.

•

Every row except the last row of a Display Window must

end with an RE character. The character immediately after an RE character is always the SL value for the next

row.

•

The last row in a Display Window must be a WE character. The WE character must NOT be preceded by an RE

character.

•

The data shown in

Table 10

is sent to the LM1253A in five

I

2

C transmissions.

TABLE 10. Example 2 I

2

C Transmissions

Command

Sent

(hex)

Description

RAM Address of

the Character

or Command

I

2

C start condition (See the

Micro-Controller Interface

Section)

BA Chip address (See the

Micro-Controller Interface

Section)

00 Address LSB

80 Address MSB

00 Use Attribute table 00 for the following characters

02 Skip 2 lines 8000

02 Character “A” 8001

03 Character “B” 8002

04 Character “C” 8003

01 Row end 8004

I

2

C stop condition (See the

Micro-Controller Interface

Section)

I

2

C start condition (See the

Micro-Controller Interface

Section)

BA Chip address (See the

Micro-Controller Interface

Section)

05 Address LSB

80 Address MSB

DS101265-52

FIGURE 42. Example 2 OSD

LM1253A

www.national.com 36

Display Page RAM (Continued)

TABLE 10. Example 2 I

2

C Transmissions (Continued)

Command

Sent

(hex)

Description

RAM Address of

the Character

or Command

01 Use Attribute table 01 for the following characters

03 Skip 3 lines 8005

05 Character “D” 8006

06 Character “E” 8007

07 Character “F” 8008

01 Row end 8009

I

2

C stop condition (See the

Micro-Controller Interface

Section)

I

2

C start condition (See the

Micro-Controller Interface

Section)

BA Chip address (See the

Micro-Controller Interface

Section)

0A Address LSB

80 Address MSB

00 Use Attribute table 00 for the following characters

04 Skip 4 lines 800A

08 Character “G” 800B

I

2

C stop condition (See the

Micro-Controller Interface

Section)

I

2

C start condition (See the

Micro-Controller Interface

Section)

BA Chip Address

0C Address LSB

80 Address MSB

01 Use Attribute table 01 for the following characters

09 Character “H” 800C

I

2

C stop condition (See the

Micro-Controller Interface

Section)

I

2

C start condition (See the

Micro-Controller Interface

Section)

BA Chip address (See the

Micro-Controller Interface

Section)

0D Address LSB

80 Address MSB

02 Use Attribute table 02 for the following characters

0A Character “I” 800D

00 Window end 800E

I

2

C stop condition (See the

Micro-Controller Interface

Section)

EXAMPLE #3:

Twodifferent length rows of characters with a black background are to be displayed on the screen, using 2-color character codes.

3 transparent skipped lines are required between the character rows. This is shown in

Figure 43

.

LM1253A

www.national.com37

Display Page RAM (Continued)

Notes:

•

In order to centralize the three characters above the five