NSC COP87L88RWV-XE Datasheet

PRELIMINARY

September 1996

COP87L88RW

8-Bit One-Time Programmable (OTP) Microcontroller

with Pulse Train Generators and Capture Modules

Y

General Description

The COP87L88RW is a member of the COP8TM8-bit OTP

microcontroller family. It is pin and software compatible to

the mask ROM COP888GW product family. (Continued)

Key Features

Y

Multiply/divide functions

Y

Full duplex UART

Y

Four pulse train generators with 16-bit prescalers

Y

Two 16-bit input capture modules with 8-bit prescalers

Y

Two 16-bit timers, each with two 16-bit registers

supporting

Ð Processor independent PWM mode

Ð External event counter mode

Ð Input capture mode

Y

32 kbytes on-board OTP EPROM with security feature

Note: Mask ROMed devices with equivalent on-chip features and program

memory sizes of 16k is available.

Y

512 bytes on-board RAM

Additional Peripheral Features

Y

Idle Timer

Y

Multi-Input Wake-Up (MIWU) with optional interrupts (8)

Y

WATCHDOGTMand clock monitor logic

Y

MICROWIRE/PLUSTMserial I/O

I/O Features

Y

Memory mapped I/O

Y

Software selectable I/O options

Ð TRI-STATE

Ð Push-pull output

Ð Weak pull-up input

Ð High impedance input

É

output

Schmitt trigger inputs on ports G and L

Y

Package: 68 PLCC with I/O pins

CPU/Instruction Set Features

Y

1 ms instruction cycle time

Y

Fourteen multi-source vectored interrupts servicing

Ð External interrupt

Ð Idle timer T0

Ð Two timers (each with 2 interrupts)

Ð MICROWIRE/PLUS

Ð Multi-Input Wake-Up

Ð Software trap

Ð UART (2)

Ð Default VIS

Ð Capture timers

Ð Counters (one vector for all four counters)

Y

Versatile and easy to use instruction set

Y

8-bit Stack Pointer (SP)Ðstack in RAM

Y

Two 8-bit register indirect data memory pointers

(B and X)

Fully Static CMOS

Y

Two power saving modes: HALT and IDLE

Y

Single supply operation: 2.7V to 5.5V

Y

Temperature range:b40

Ctoa85§C

§

Development Support

Y

Emulation device for the COP888GW

Y

Real time emulation and full program debug offered by

MetaLink’s Development System

COP87L88RW 8-Bit One-Time Programmable (OTP) Microcontroller

with Pulse Train Generators and Capture Modules

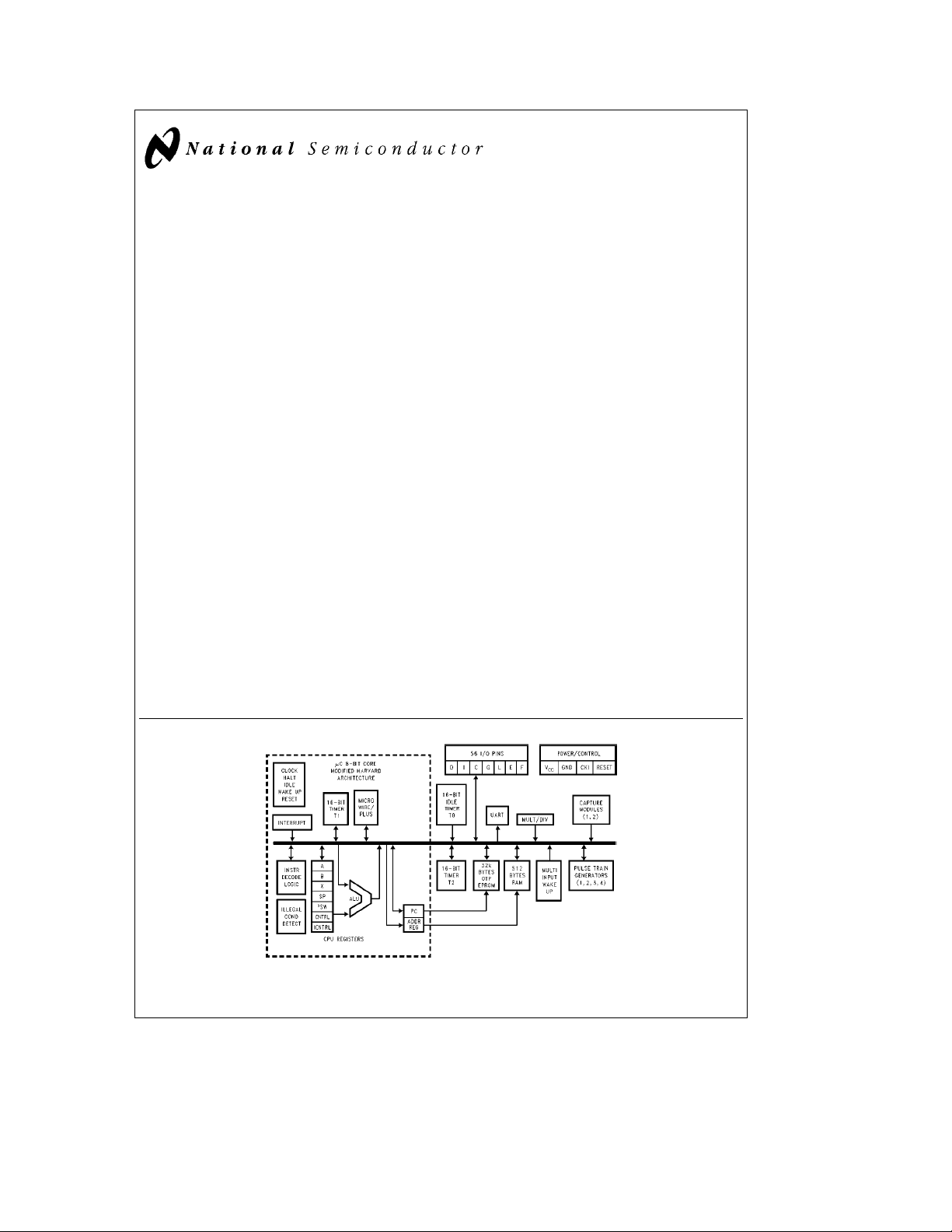

Block Diagram

FIGURE 1. COP87L88RW Block Diagram

TRI-STATEÉis a registered trademark of National Semiconductor Corporation.

MICROWIRE/PLUS

iceMASTER

C

1996 National Semiconductor Corporation RRD-B30M106/Printed in U. S. A.

TM

, COPSTMmicrocontrollers, MICROWIRETM, WATCHDOGTMand COP8TMare trademarks of National Semiconductor Corporation.

TM

is a trademark of MetaLink Corporation.

TL/DD12855

TL/DD/12855– 1

http://www.national.com

General Description (Continued)

It is a fully static part, fabricated using double-metal silicon

gate microCMOS technology. Features include an 8-bit

memory mapped architecture, MICROWIRE/PLUS serial

I/O, two 16-bit timer/counters supporting three modes

(Processor Independent PWM generation, External Event

counter and Input Capture mode capabilities), four independent 16-bit pulse train generators with 16-bit prescalers, two

independent 16-bit input capture modules with 8-bit prescalers, multiply and divide functions, full duplex UART, and two

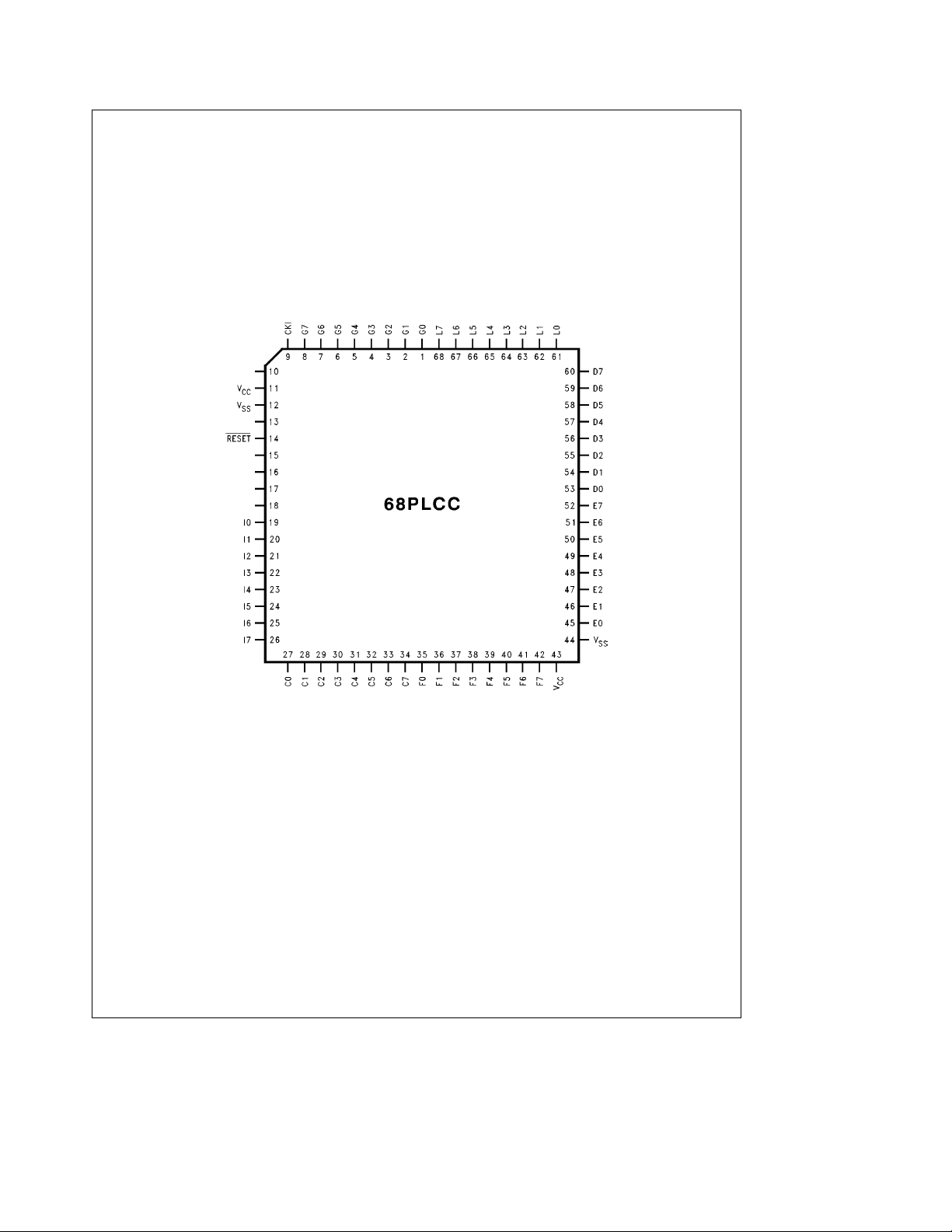

Connection Diagram

power savings modes (HALT and IDLE), both with a multi-sourced wake up/interrupt capability. This multi-sourced

interrupt capability may also be used independent of the

HALT or IDLE modes. Each I/O pin has software selectable

configurations. The devices operate over a voltage range of

2.7V--5.5V. High throughput is achieved with an efficient,

regular instruction set operating at a maximum of 1 ms per

instruction rate.

Note: -X Crystal Oscillator

-E Halt Enable

http://www.national.com 2

Order Number COP87L88RWV-XE

See NS Plastic Chip Package Number V68A

FIGURE 2. Connection Diagram

Top View

TL/DD/12855– 2

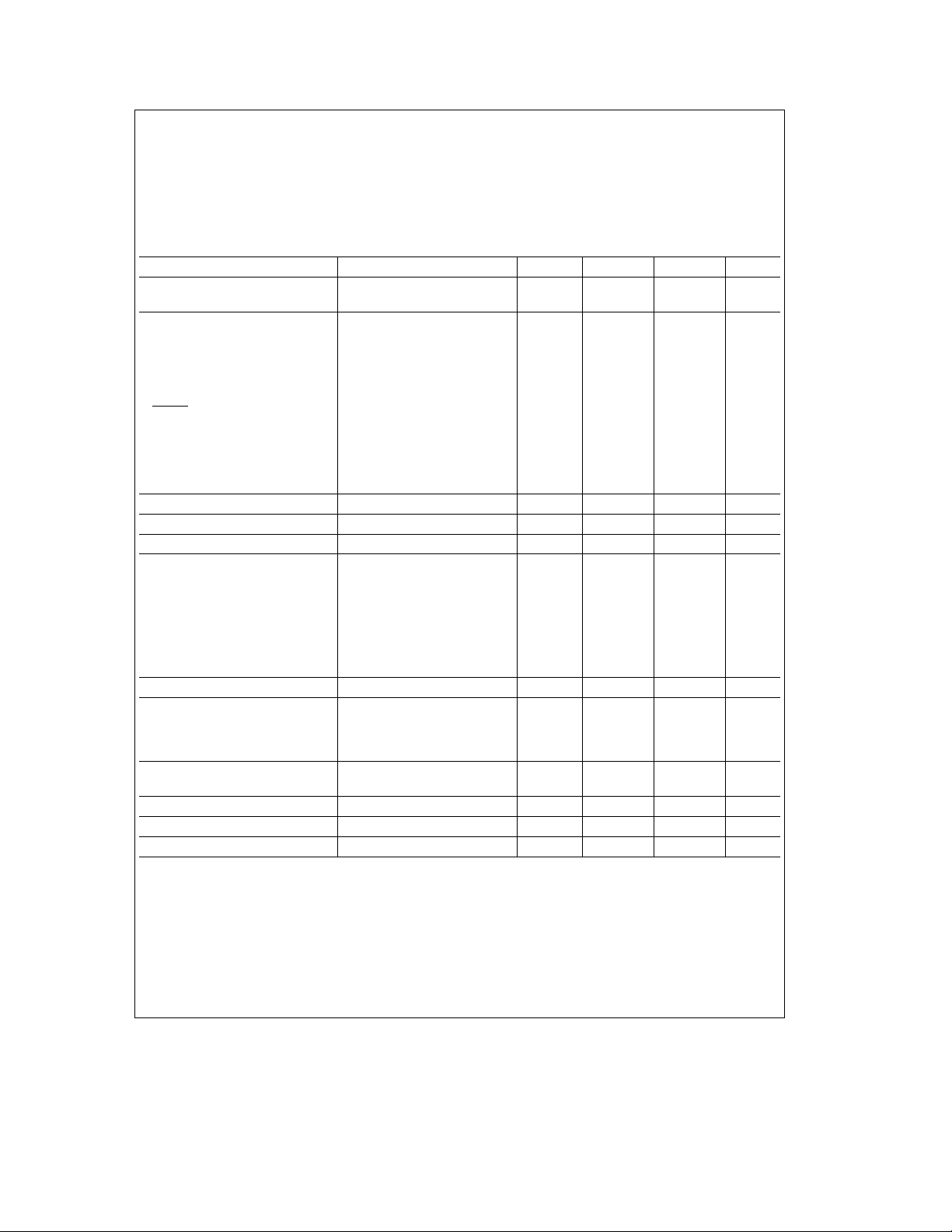

Absolute Maximum Ratings (Note)

SuppIy Voltage (V

Voltage at Any Pin

Total Current into VCCPin (Source) 100 mA

Total Current out of GND Pin (Sink) 110 mA

Storage Temperature Range

)7V

CC

b

0.3V to V

b

65§Ctoa150§C

CC

a

0.3V

Note:

Absolute maximum ratings indicate limits beyond

which damage to the device may occur. DC and AC electrical specifications are not ensured when operating the device at absolute maximum ratings.

DC Electrical Characteristics

b

40§CsT

s

a

85§C unless otherwise specified

A

Parameter ConditIons Min Typ Max UnIts

Operating Voltage 2.7 5.5 V

Power Supply Ripple (Note 1) Peak-to-Peak 0.1 V

CC

V

Supply Current (Note 2)

e

CKI

10 MHz V

HALT Current (Note 3) V

IDLE Current

e

CKI

10 MHz V

Input Levels (V

RESET

, CKI

IH,VIL

)

Logic High 0.8 V

Logic Low 0.2 V

All Other Inputs

Logic High 0.7 V

Logic Low 0.2 V

Hi-Z Input Leakage V

Input Pullup Current V

G Port Input Hysteresis (Note 6) 0.05 V

CC

CC

CC

CC

CC

e

e

e

e

e

e

5.5V, t

5.5V, CKIe0 MHz 12 mA

1 ms14mA

c

5.5V 1.7 mA

CC

CC

5.5V

5.5V, V

e

0V 40

IN

b

2

CC

a

b

250 mA

0.35 V

CC

CC

2 mA

CC

V

V

V

V

V

Output Current Levels

D Outputs

Source V

Sink (Note 4) V

All Others

Source (Weak Pull-Up Mode) V

Source (Push-Pull Mode) V

Sink (Push-Pull Mode) V

TRI-STATE Leakage V

CC

CC

CC

CC

CC

CC

e

e

e

e

e

e

4.5V, V

4.5V, V

4.5V, V

4.5V, V

4.5V, V

5.5V

e

3.3V

OH

e

1V 10 mA

OL

e

2.7V

OH

e

3.3V

OH

e

0.4V 1.6 mA

OL

b

0.4 mA

b

10

b

0.4 mA

b

2

b

100 mA

a

2 mA

Allowable Sink/Source

Current per Pin

D Outputs (Sink) 15 mA

All others 3mA

Maximum Input Current Room Temp

without Latchup (Note 5, 7)

g

200 mA

RAM Retention Voltage, Vr(Note 6) 500 ns Rise and Fall Time (min) 2 V

Input Capacitance (Note 7) 7 pF

Load Capacitance on D2 (Note 7) 1000 pF

http://www.national.com3

AC Electrical Characteristics

b

40§CsT

s

a

85§C unless otherwise specified

A

Parameter Conditions Min Typ Max Units

Instruction Cycle Time (tc)

Crystal, Resonator 1.0 DC ms

Ceramic

Inputs

t

SETUP

t

HOLD

Output Propagation Delay (Note 9) R

t

PD1,tPD0

SO, SK V

All Others V

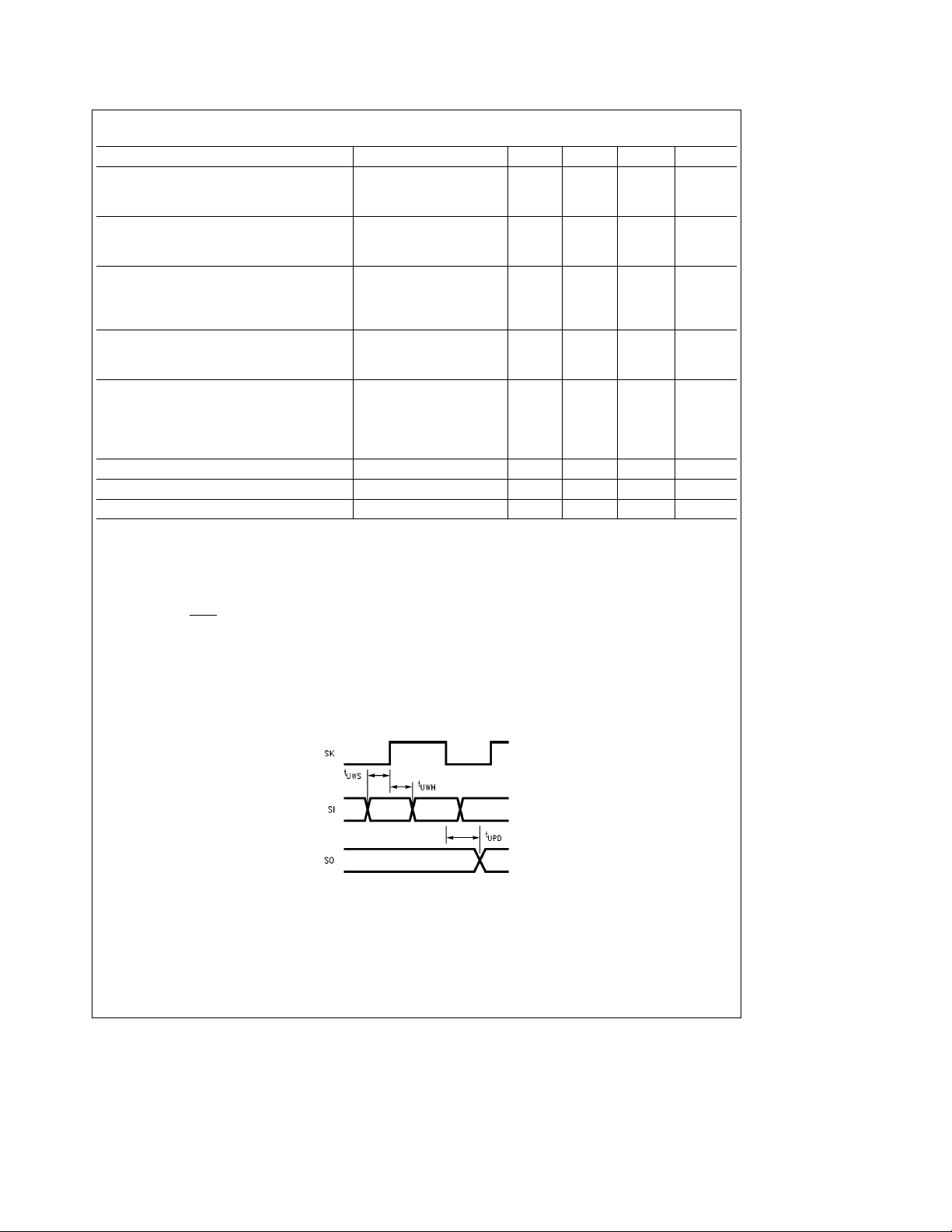

MICROWIRETMSetup Time (t

MICROWIRE Hold Time (t

MICROWIRE Output Propagation Delay (t

) (Note 7) V

UWS

) (Note 7) V

UWH

UPD

)V

t

V

4.5V 200 ns

CC

t

V

4.5V 60 ns

CC

L

CC

CC

CC

CC

CC

e

t

t

t

t

t

e

2.2k, C

100 pF

L

4.5V 0.7 ms

4.5V 1 ms

4.5V 20

4.5V 56 ns

4.5V 220

Input Pulse Width (Note 8)

Interrupt Input High Time 1

Interrupt Input Low Time 1 t

Timer 1, 2 Input High Time 1

c

Timer 1, 2 Input Low Time 1

Capture Timer High Time 1 CKI

Capture Timer Low Time 1 CKI

Reset Pause Width 1 ms

Note 1: Maximum rate of voltage change to be defined.

Note 2: Supply current is measured after running 2000 cydes with a square wave CKI input, CKO open, inputs at rails and outputs open.

Note 3: The HALT mode will stop CKI from oscillatng. Test conditions: All inputs tied to V

low and not driving a load; D outputs programmed low and not driving a load. Parameter refers to HALT mode entered via setting bit 7 of the G Port data register.

Part will pull up CKI during HALT in crystal clock mode.

Note 4: The user must guarantee that D2 pin does not source more than 10 mA during RESET. If D2 sources more than 10 mA during reset, the device will go into

programming mode.

Note 5: Pins G6 and RESET

when biased at voltages greater than VCC(the pins do not have source current when biased at a voltage below VCC.) The effective resistance to VCCis 750X

V

CC

(typical). These two pins will not latch up. The voltage at the pins must be limited to less than 14V. WARNING: Voltages in excess of 14V will cause damage to the

pins. This warning excludes ESD transients.

Note 6: Condition and parameter valid only for part in HALT mode.

Note 7: Parameter characterized but not tested.

e

Note 8: t

Note 9: The output propagation delay is referenced to the end of the instruction cycle where the output change occurs.

Instruction Cycle Time

c

are designed with a high voltage input network. These pins allow input voltages greater than VCCand the pins will have sink current to

, L, C, E, F, and G port I/O’s configured as outputs and programmed

CC

FIGURE 3. MICROWIRE/PLUS Timing

http://www.national.com 4

TL/DD/12855– 3

Pin Descriptions

VCCand GND are the power supply pins. All VCCand GND

pins must be connected.

CKI is the clock input. This comes from a crystal oscillator

(in conjunction with CKO). See Oscillator Description section.

RESET

is the master reset input. See Reset description

section.

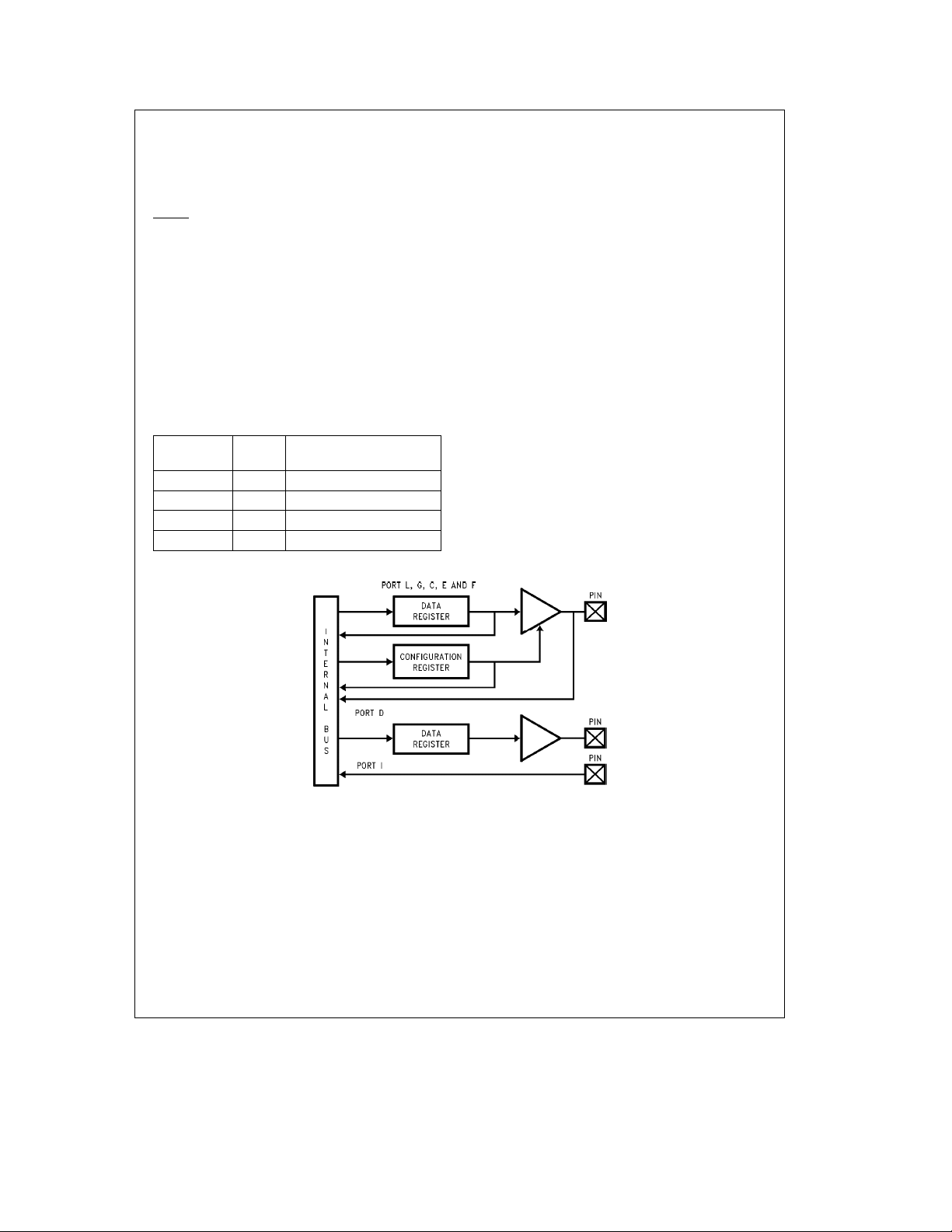

The device contains five bidirectional 8-bit I/O ports (C, E,

F, G and L), where each individual bit may be independently

configured as an input (Schmitt trigger inputs on ports L and

G), output or TRI-STATE under program control. Three data

memory address locations are allocated for each of these

I/O ports. Each I/O port has two associated 8-bit memory

mapped registers, the CONFIGURATION register and the

output DATA register. A memory mapped address is also

reserved for the input pins of each I/O port. (See the memory map for the various addresses associated with the I/O

ports.)

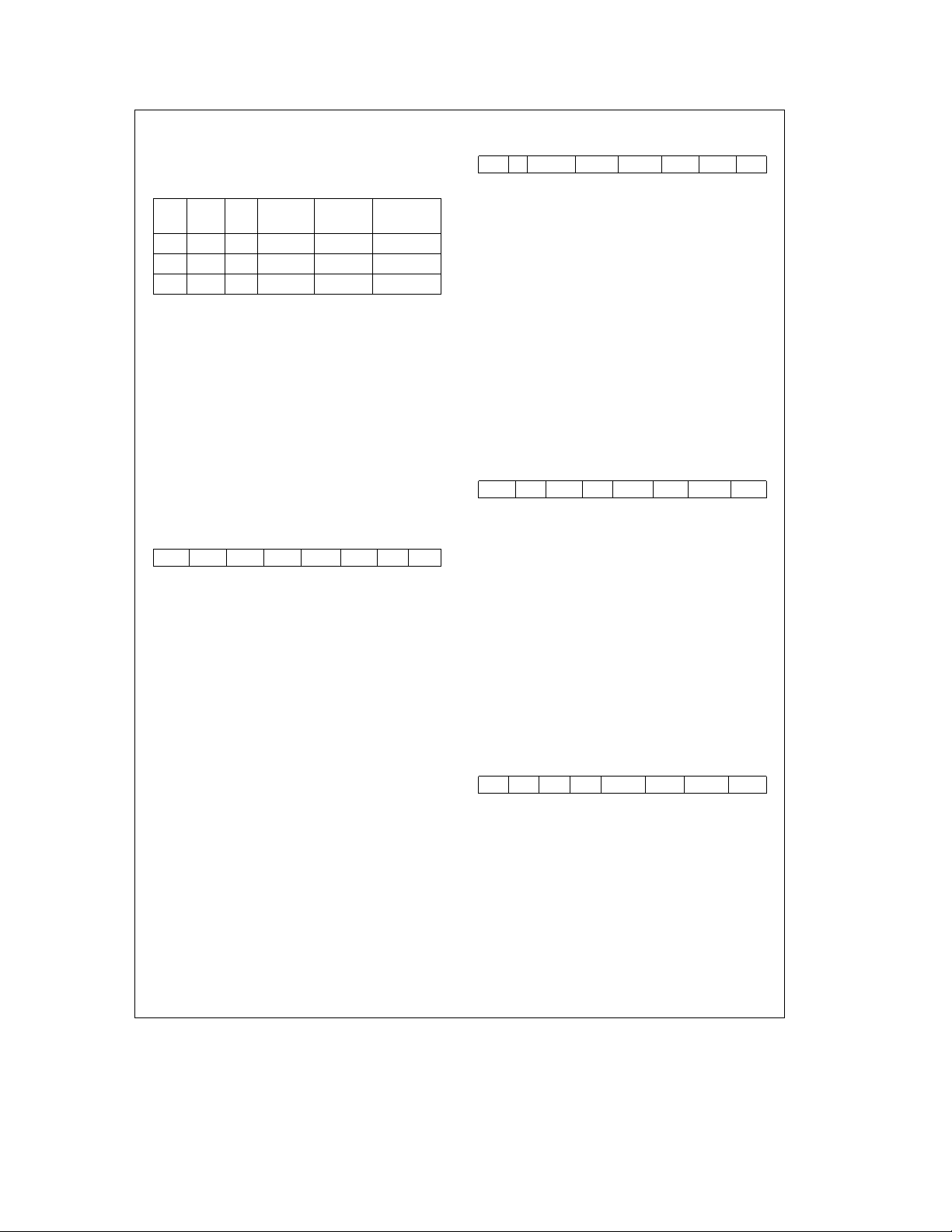

Figure 4

DATA and CONFIGURATION registers allow for each port

bit to be individually configured under software control as

shown below:

Configuration Data

Register Register

0 0 Hi-Z Input (TRI-STATE Output)

0 1 Input with Weak Pull-Up

1 0 Push-Pull Zero Output

1 1 Push-Pull One Output

shows the I/O port configurations. The

Port Set-Up

PORT L is an 8-bit I/O port. All L-pins have Schmitt triggers

on the inputs.

The Port L supports Multi-Input Wake Up on all eight pins.

L1 is used for the UART external clock. L2 and L3 are used

for the UART transmit and receive. L4 and L5 are used for

the timer input functions T2A and T2B. L6 and L7 are used

for the capture timer input functions CAP1 and CAP2.

The Port L has the following alternate features:

L0 MIWU

L1 MIWU or CKX

L2 MIWU or TDX

L3 MIWU or RDX

L4 MIWU or T2A

L5 MIWU or T2B

L6 MIWU or CAP1

L7 MIWU or CAP2

Port G is an 8-bit port with 6 I/O pins (G0 –G5), an input pin

(G6), and a dedicated output pin (G7). Pins G0 –G6 all have

Schmitt Triggers on their inputs. Pin G7 serves as the dedicated output pin for the CKO clock output. There are two

registers associated with the G Port, a data register and a

configuration register. Therefore, each of the 6 I/O bits

(G0–G5) can be individually configured under software control.

FIGURE 4. I/O Port Configurations

TL/DD/12855– 4

http://www.national.com5

Pin Descriptions (Continued)

Since G6 is an input only pin and G7 is dedicated CKO clock

output pin, the associated bits in the data and configuration

registers for G6 and G7 are used for special purpose functions as outlined below. Reading the G6 and G7 data bits

will return zeros.

Note that the chip will be placed in the HALT mode by writing a ‘‘1’’ to bit 7 of the Port G Data Register. Similarly the

chip will be placed in the IDLE mode by writing a ‘‘1’’ to bit 6

of the Port G Data Register.

Writing a ‘‘1’’ to bit 6 of the Port G Configuration Register

enables the MICROWIRE/PLUS to operate with the alternate phase of the SK clock.

Config Reg. Data Reg.

G7 Not Used HALT

G6 Alternate SK IDLE

Port G has the following alternate features:

G0 INTR (ExternaI Interrupt Input)

G2 T1B (Timer T1 Capture Input)

G3 T1A (Timer T1 I/O)

G4 SO (MICROWIRE Serial Data Output)

G5 SK (MICROWIRE SeriaI Clock)

G6 SI (MICROWIRE Serial Data Input)

Port G has the following dedicated functions:

G7 CKO OsciIlator dedicated output

Ports C and F are 8-bit I/O ports.

Port E is an 8-bit I/O port. It has the following alternate

features:

E0 CT1 (Output for counter1, PuIse Train Generator)

E1 CT2 (Output for counter2, Pulse Train Generator)

E2 CT3 (Output for counter3, PuIse Train Generator)

E3 CT4 (Output for counter4, Pulse Train Generator)

Port I is an eight-bit Hi-Z input port.

Port D is an 8-bit output port that is preset high when

RESET

goes Iow. The user can tie two or more D port out-

puts (except D2) together in order to get a higher drive.

Note: Care must be exercised with the D2 pin operation. At RESET, the

external loads on this pin must ensure that the output voltages stay

above 0.8 V

keep the external loading on D2 to

to prevent the chip from entering special modes. Also

CC

k

1000 pF.

Functional Description

The architecture of the device is modified Harvard architecture. With the Harvard architecture, the control store program memory (ROM) is separated from the data store memory (RAM). Both ROM and RAM have their own separate

addressing space with separate address buses. The architecture, though based on Harvard architecture, permits

transfer of data from ROM to RAM.

CPU REGISTERS

The CPU can do an 8-bit addition, subtraction, logical or

shift operation in one instruction (t

There are six CPU registers:

A is the 8-bit Accumulator Register

PC is the 15-bit Program Counter Register

PU is the upper 7 bits of the program counter (PC)

PL is the lower 8 bits of the program counter (PC)

B is an 8-bit RAM address pointer, which can be optionally

post auto incremented or decremented.

http://www.national.com 6

) cycle time.

c

X is an 8-bit alternate RAM address pointer, which can be

optionally post auto incremented or decremented.

SP is the 8-bit stack pointer, which points to the subroutine/

interrupt stack (in RAM). The SP is initialized to RAM address 06F with reset.

S is the 8-bit Data Segment Address Register used to extend the Iower haIf of the address range (00 to 7F) into 256

data segments of 128 bytes each.

All the CPU registers are memory mapped with the exception of the AccumuIator (A) and the Program Counter (PC).

PROGRAM MEMORY

The program memory consists of 32 kbytes of OTP

EPROM. These bytes may hoId program instructions or constant data (data tables for the LAID instruction, jump vectors

for the JID instruction, and interrupt vectors for the VIS instruction). The program memory is addressed by the 15-bit

program counter (PC). All interrupts in the devices Vector to

program memory location 0FF Hex.

The device can be configured to inhibit external reads of the

program memory. This is done by programming the Security

Byte.

Note: Mask ROMed devices with equivalent on-chip features and program

memory sizes of 16k is available.

SECURITY FEATURE

The program memory array has an associate Security Byte

that is located outside of the program address range. This

byte can be addressed only from programming mode by a

programmer tool.

Security is an optional feature and can only be asserted

after the memory array has been programmed and verified.

A secured part will read all 00(hex) by a programmer. The

part will fail Blank Check and will fail Verify operations. A

Read operation will fill the programmer’s memory with

00(hex). The Security Byte itself is always readable with value of 00(hex) if unsecure and FF(hex) if secure.

DATA MEMORY

The data memory address space includes the on-chip RAM

and data registers, the I/O registers (Configuration, Data

and Pin), the control registers, the MICROWIRE/PLUS SIO

shift register, and the various registers, and counters associated with the timers (with the exception of the IDLE timer).

Data memory is addressed directly by the instruction or indirectly by the B, X, SP pointers and S register.

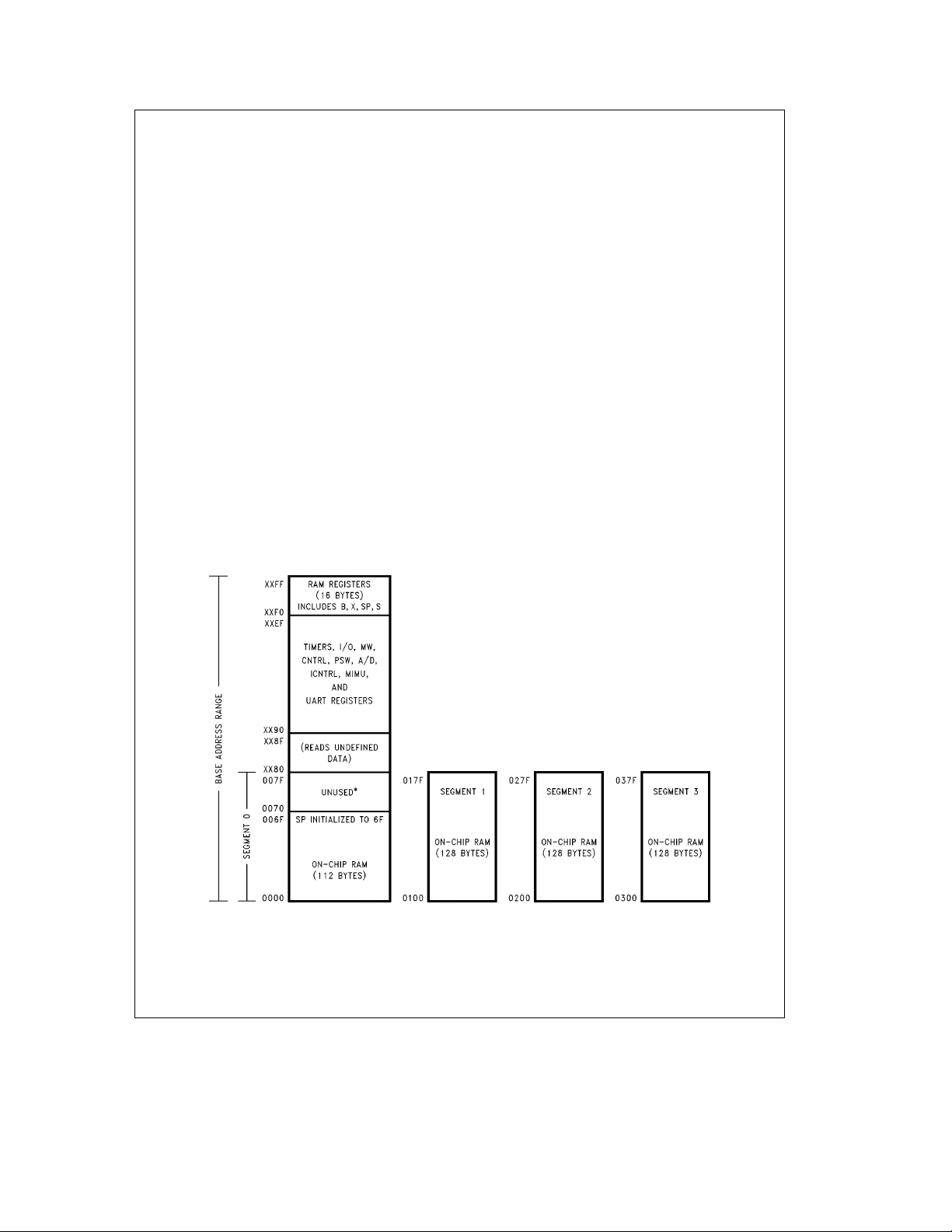

The data memory consists of 512 bytes of RAM. Sixteen

bytes of RAM are mapped as ‘‘registers’’ at addresses 0F0

to 0FF Hex. These registers can be loaded immediately,

and also decremented and tested with the DRSZ (decrement register and skip if zero) instruction. The memory

pointer registers X, SP, B and S are memory mapped into

this space at address locations 0FC to 0FF Hex respectively, with the other registers being available for general usage.

The instruction set permits any bit in memory to be set,

reset or tested. All I/O and registers (except A and PC) are

memory mapped; therefore, I/O bits and register bits can be

directly and individually set, reset and tested. The accumulator (A) bits can also be directly and individually tested.

Note: RAM contents are undefined upon power-up.

Data Memory Segment RAM

Extension

Data memory address 0FF is used as a memory mapped

location for the Data Segment Address Register (S).

Data Memory Segment RAM Extension (Continued)

The data store memory is either addressed directly by a

single-byte address within the instruction, or indirectly relative to the reference of the B, X, or SP pointers (each contains a single-byte address). This single-byte address allows

an addressing range of 256 locations from 00 to FF hex.

The upper bit of this single-byte address divides the data

store memory into two separate sections as outlined previously. With the exception of the RAM register memory from

address locations 00F0 to 00FF, all RAM memory is memory mapped with the upper bit of the single-byte address being equal to zero. This allows the upper bit of the single-byte

address to determine whether or not the base address

range (from 0000 to 00FF) is extended. If this upper bit

equals one (representing address range 0080 to 00FF),

then address extension does not take place. Alternatively, if

this upper bit equals zero, then the data segment extension

register S is used to extend the base address range (from

0000 to 007F) from XX00 to XX7F, where XX represents the

8 bits from the S register. Thus the 128-byte data segment

extensions are located from addresses 0100 to 017F for

data segment 1, 0200 to 027F for data segment 2, etc., up

to FF00 to FF7F for data segment 255. The base address

range from 0000 to 007F represents data segment 0.

Figure 5

illustrates how the S register data memory extension is used in extending the lower half of the base address

range (00 to 7F hex) into 256 data segments of 128 bytes

each, with a total addressing range of 32 kbytes from XX00

to XX7F. This organization allows a total of 256 data segments of 128-bytes each with an additional upper base segment of 128 bytes. Furthermore, all addressing modes are

available for all data segments. The S register must be

changed under program control to move from one data segment (128 bytes) to another. However, the upper base segment (containing the 16 memory registers, I/O registers,

controI registers, etc.) is always available regardless of the

contents of the S register, since the upper base segment

(address range 0080 to 00FF) is independent of data segment extension.

The instructions that utilize the stack pointer (SP) always

reference the stack as part of the base segment (Segment

0), regardless of the contents of the S register. The S register is not changed by these instructions. Consequently, the

stack (used with subroutine linkage and interrupts) is always

located in the base segment. The stack pointer will be initialized to point at data memory location 006F as a result of

reset.

The 128 bytes of RAM contained in the base segment are

split between the Iower and upper base segments. The first

112 bytes of RAM are resident from address 0000 to 006F

in the Iower base segment, while the remaining 16 bytes of

RAM represent the 16 data memory registers located at addresses 00F0 to 00FF of the upper base segment. No RAM

is located at the upper sixteen addresses (0070 to 007F) of

the lower base segment.

Additional RAM beyond these initial 128 bytes, however, will

always be memory mapped in groups of 128 bytes (or less)

at the data segment address extensions (XX00 to XX7F) of

the lower base segment. The additional 384 bytes of RAM

in this device are memory mapped at address locations

0100 to 017F

0200 to 027F, and 0300 to 037F hex.

§

*Reads as all ones.

TL/DD/12855– 5

FIGURE 5. RAM Organization

http://www.national.com7

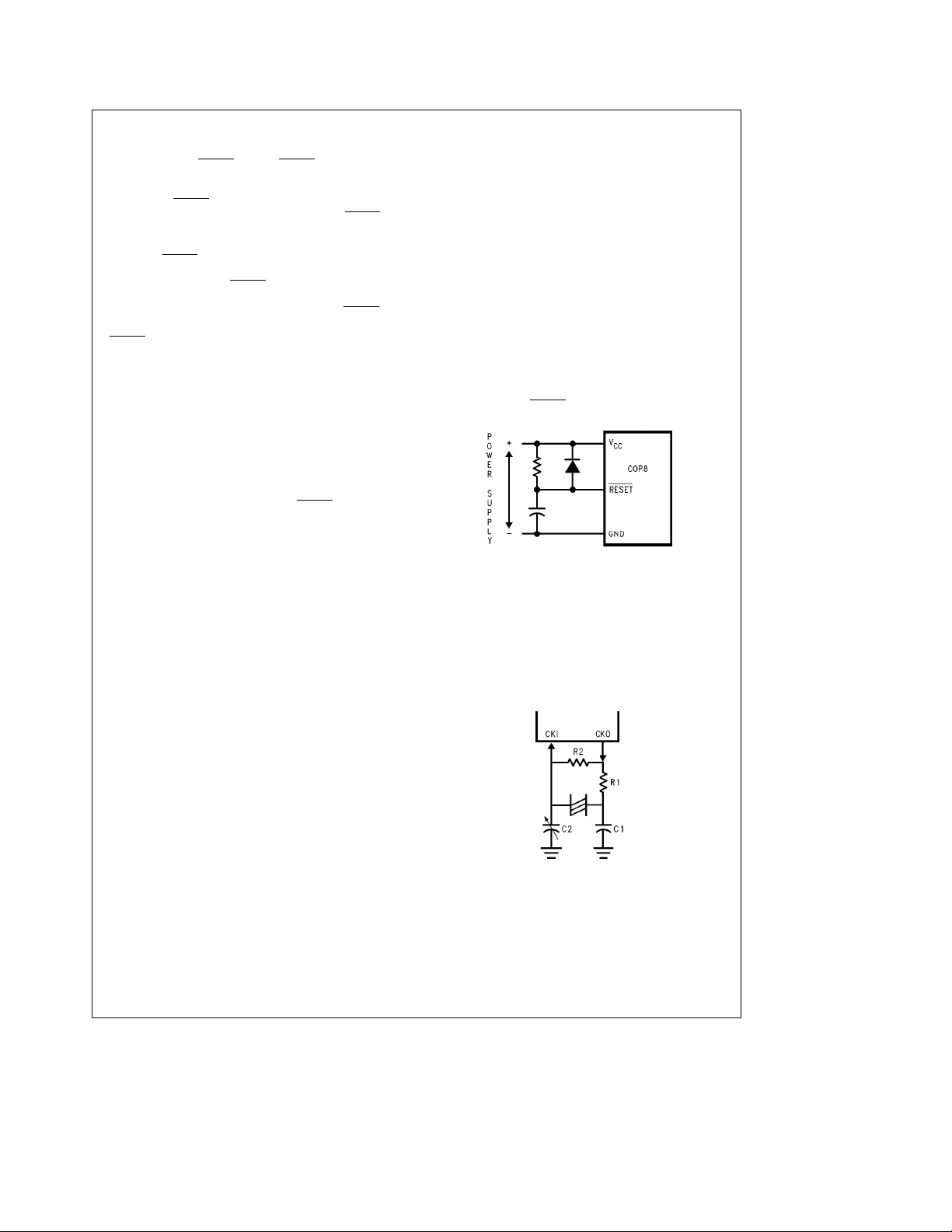

Reset

This device enters a reset state immediately upon detecting

a logic low on the RESET

low for a minimum of one instruction cycle to guarantee a

valid reset. During power-up initialization, the user must insure that the RESET

the specified V

with a delay 5 times (5x) greater than the power supply rise

CC

time is recommended.

When the RESET

ized immediately, with any observed delay being only propagation delay. When the RESET

comes out of the reset state synchronously. This device will

be running within two instruction cycles of the RESET

going high.

RESET

may also be used to exit this device from the HALT

mode.

Some registers are reset to a known state, whereas other

registers and RAM are ‘‘unchanged’’ by reset. When the

controller goes into reset state while it is performing a write

operation to one of these registers or RAM that are ‘‘unchanged’’ by reset, the register or RAM value will become

unknown (i.e. not unchanged). This is because the write operation is terminated prematurely by reset and the results

become uncertain. These registers and RAM locations are

unchanged by reset only if they are not written to when the

controller resets.

The following initializations occur with RESET

Port L: TRI-STATE

Port C: TRI-STATE

Port G: TRI-STATE

Port E: TRI-STATE

Port F: TRI-STATE

Port D: HIGH

PC: CLEARED

PSW, CNTRL and ICNTRL registers: CLEARED

SIOR:

UNAFFECTED after RESET with power already applied

RANDOM after RESET at power-on

T1CNTRL: CLEARED

T2CNTRL: CLEARED

TxRA, TxRB: RANDOM

CCMR1, CCMR2: CLEARED

CM1PSC, CM1CRL, CM1CRH, CM2PSC, CM2CRL, and

CM2CRH:

UNAFFECTED after RESET with power already applied

RANDOM after RESET at power-on

CCR1 and CCR2: CLEARED

CxPRH, CxPRL, CxCTH, and CxCTL:

RANDOM after RESET at power-on

PSR, ENUR and ENUI: CLEARED

ENU: CLEARED except Bit 1 (TBMT)

Accumulator, Timer 1 and Timer 2:

RANDOM after RESET with crystal clock option (power already applied)

pin. The RESET pin must be held

pin is held low until this device is within

voltage. An R/C circuit on the RESET pin

input goes low, the I/O ports are initial-

pin goes high, this device

pin

:

e

1

UNAFFECTED after RESET with RC clock option (power

already applied)

RANDOM after RESET at power-on

MDCR: CLEARED

MDR1, MDR2, MDR3, MDR4, MDR5: RANDOM

WKEN, WKEDG: CLEARED

WKPND: RANDOM

S Register: CLEARED

SP (Stack Pointer): Loaded with 6F Hex

B and X Pointers:

UNAFFECTED after RESET with power already applied

RANDOM after RESET at power-on

RAM:

UNAFFECTED after RESET with power already applied

RANDOM after RESET at power-on

The external RC network shown in

to ensure that the RESET

Figure 6

should be used

pin is held low until the power

supply to the chip stabilizes.

RCl5cPOWER SUPPLY RISE TIME

TL/DD/12855– 6

FIGURE 6. Recommended Reset Circuit

Oscillator Circuits

The chip can be driven by a clock input on the CKI input pin

which can be between DC and 10 MHz. The CKO output

clock is on pin G7 (crystal configuration), The CKI input frequency is divided down by 10 to produce the instruction

cycle clock (t

Figure 7

CRYSTAL OSCILLATOR

CKI and CKO can be connected to make a closed loop

crystal (or resonator) controlled oscillator.

).

c

shows the Crystal diagram

FIGURE 7. Crystal Diagram

TL/DD/12855– 7

http://www.national.com 8

Oscillator Circuits (Continued)

Table I shows the component values required for various

standard crystal values.

TABLE I. CrystaI Oscillator Configuration, T

R1 R2 C1 C2 CKI Freq

(kX)(MX) (pF) (pF) (MHz)

0 1 30 30 – 36 10 V

0 1 30 30 – 36 4 V

0 1 200 100 – 150 0.455 V

e

25§C

A

Conditions

e

5V

CC

e

5V

CC

e

5V

CC

Control Registers

CNTRL Register (Address X’00EE)

The Timer1 (T1) and MICROWIRE/PLUS control register

contains the following bits:

SL1 & Select the MICROWIRE/PLUS clock divide by (00

SL0 2, 01e4, 1xe8)

IEDG External interrupt edge polarity select (0eRising

MSEL Selects G5 and G4 as MICROWIRE/PLUS signals

T1C0 Timer T1 Start/Stop control in timer modes 1 and 2

T1C1 Timer T1 mode control bit

T1C2 Timer T1 mode control bit

T1C3 Timer T1 mode control bit

T1C3 T1C2 T1C1 T1C0 MSEL IEDG SL1 SL0

Bit 7 Bit 0

PSW Register (Address X’00EF)

The PSW register contains the following select bits:

GIE GIobaI interrupt enable (enables interrupts)

EXEN EnabIe externaI interrupt

BUSY MICROWIRE/PLUS busy shifting flag

EXPND ExternaI interrupt pending

T1ENA Timer T1 Interrupt Enable for Timer Underflow or

T1PNDA Timer T1 Interrupt Pending Flag (Autoreload RA

e

edge, 1

Falling edge)

SK and SO respectively

T1 Underflow Interrupt Pending Flag in timer mode 3

T1A Input capture edge

in mode 1, T1 Underflow in Mode 2, T1A capture

edge in mode 3)

C Carry FIag

HC Half Carry Flag

HC C T1PNDA T1ENA EXPND BUSY EXEN GIE

Bit 7 Bit 0

The Half-Carry fIag is aIso affected by aII the instructions

that affect the Carry fIag. The SC (Set Carry) and RC (Reset

Carry) instructions wilI respectiveIy set or clear both the carry flags. In addition to the SC and RC instructions, ADC,

SUBC, RRC and RLC instructions affect the Carry and Half

Carry fIags.

ICNTRL Register (Address X’00E8)

The ICNTRL register contains the foIlowing bits:

T1ENB Timer T1 Interrupt Enable for T1B Input capture

edge

T1PNDB Timer T1 Interrupt Pending Flag for T1B capture

edge

e

mWEN EnabIe MICROWIRE/PLUS interrupt

mWPND MICROWIRE/PLUS interrupt pending

T0EN Timer T0 Interrupt Enable (Bit 12 toggle)

T0PND Timer T0 Interrupt pending

LPEN L Port Interrupt Enable (Multi-Input Wake up/In-

terrupt)

Bit 7 couId be used as a flag

Unused LPEN T0PND T0EN m WPND mWEN T1PNDB T1ENB

Bit 7 Bit 0

T2CNTRL Register (Address X’00C6)

The T2CNTRL register contains the following bits:

T2ENB Timer T2 Interrupt Enable for T2B Input capture

edge

T2PNDB Timer T2 Interrupt Pending Flag for T2B capture

edge

T2ENA Timer T2 Interrupt Enable for Timer Underflow or

T2A Input capture edge

T2PNDA Timer T2 Interrupt Pending Flag (Auto reload RA

in mode 1, T2 Underflow in mode 2, T2A capture

edge in mode 3)

T2C0 Timer T2 Start/Stop control in timer modes 1 and

2 Timer T2 Underflow Interrupt Pending Flag in

timer mode 3

T2C1 Timer T2 mode control bit

T2C2 Timer T2 mode control bit

T2C3 Timer T2 mode control bit

T2C3 T2C2 T2C1 T2C0 T2PNDA T2ENA T2PNDB T2ENB

Bit 7 Bit 0

http://www.national.com9

Timers

The device contains a very versatile set of timers (T0, T1,

T2). All timers and associated autoreload/capture registers

power up containing random data.

TIMER T0 (IDLE TIMER)

The device supports applications that require maintaining

reaI time and Iow power with the IDLE mode. This IDLE

mode support is furnished by the IDLE timer T0, which is a

16-bit timer. The Timer T0 runs continuously at the fixed

rate of the instruction cycle cIock, t

or write to the IDLE Timer T0, which is a count down timer.

The Timer T0 supports the following functions:

Exit out of the Idle Mode (See Idle Mode description)

#

Start up delay out of the HALT mode

#

The IDLE Timer T0 can generate an interrupt when the thirteenth bit toggIes. This toggle is Iatched into the T0PND

pending flag, and wiIl occur every 4 ms at the maximum

clock frequency (t

interrupt from the thirteenth bit of Timer T0 to be enabled or

disabIed. Setting T0EN will enable the interrupt, while resetting it will disable the interrupt.

TIMER T1 AND TIMER T2

The device has a set of two powerful timer/counter blocks,

T1 and T2. The associated features and functioning of a

timer block are described by referring to the timer block Tx.

Since the two timer blocks, T1 and T2 are identical, all comments are equally applicable to either of the two timer

blocks.

Each timer block consists of a 16-bit timer, Tx, and two

supporting 16-bit autoreload/capture registers, RxA and

RxB. Each timer block has two pins associated with it, TxA

and TxB. The pin TxA supports I/O required by the timer

block, while the pin TxB is an input to the timer block. The

powerful and flexible timer block allows the device to easily

perform all timer functions with minimal software overhead.

The timer block has three operating modes: Processor Independent PWM mode, External Event Counter mode, and

Input Capture mode.

The control bits TxC3, TxC2, and TxC1 allow selection of

the different modes of operation.

Mode 1. Processor Independent PWM Mode

As the name suggests, this mode allows the device to generate a PWM signal with very minimal user intervention. The

e

1 ms). A control flag T0EN allows the

c

. The user cannot read

c

user only has to define the parameters of the PWM signal

(ON time and OFF time). Once begun, the timer block will

continuously generate the PWM signal completely independent of the microcontroller. The user software services the

timer block only when the PWM parameters require updating.

In this mode the timer Tx counts down at a fixed rate of tc.

Upon every underflow the timer is alternately reloaded with

the contents of supporting registers, RxA and RxB. The very

first underflow of the timer causes the timer to reload from

the register RxA. Subsequent underflows cause the timer to

be reloaded from the registers alternately beginning with the

register RxB.

The Tx Timer control bits, TxC3, TxC2 and TxC1 set up the

timer for PWM mode operation.

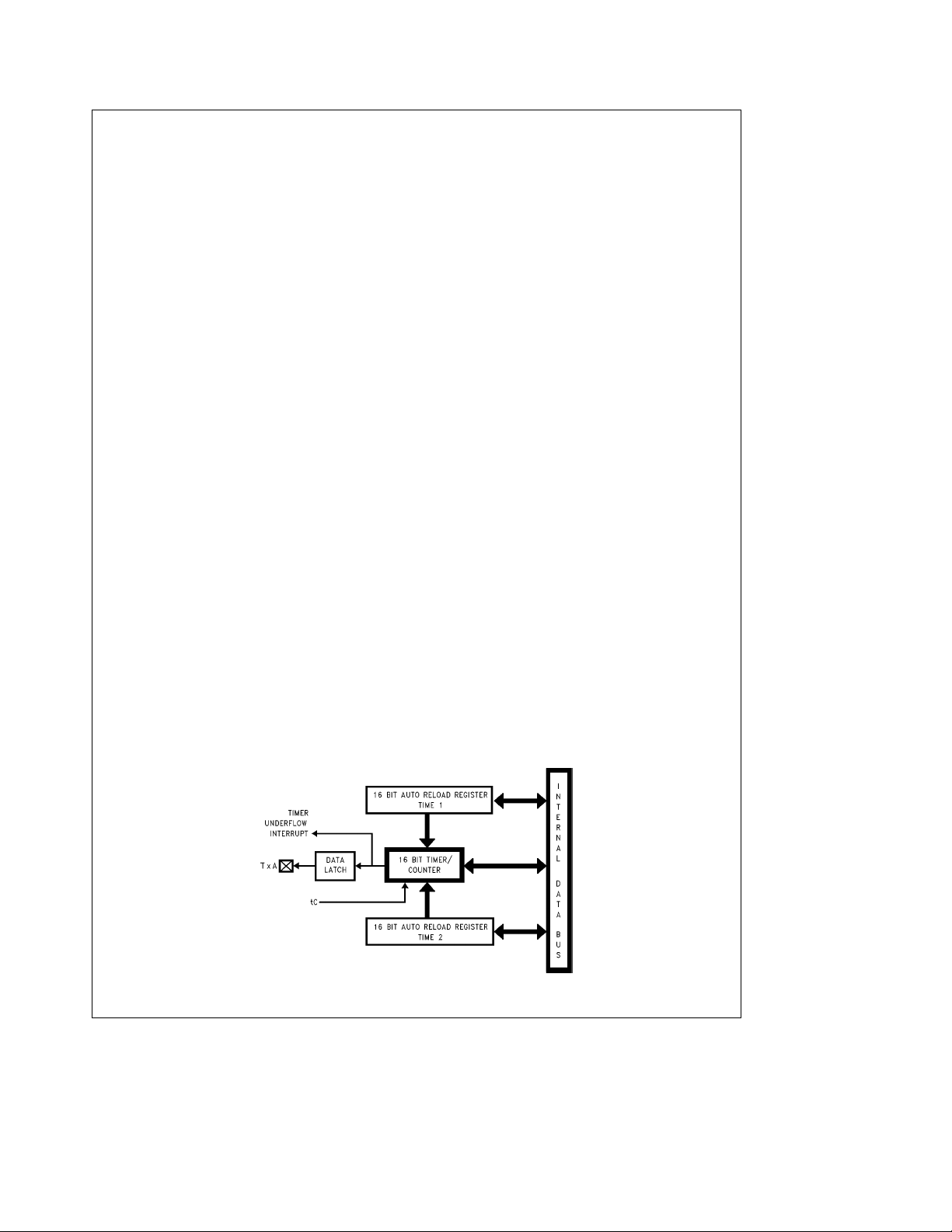

Figure 8

shows a block diagram of the timer in PWM mode.

The underfIows can be programmed to toggle the TxA output pin. The underfIows can also be programmed to generate interrupts.

UnderfIows from the timer are alternately latched into two

pending flags, TxPNDA and TxPNDB. The user must reset

these pending fIags under software control. Two control enabIe fIags, TxENA and TxENB, alIow the interrupts from the

timer underflow to be enabled or disabled. Setting the timer

enable flag TxENA wilI cause an interrupt when a timer underflow causes the RxA register to be reloaded into the timer. Setting the timer enable flag TxENB will cause an interrupt when a timer underflow causes the RxB register to be

reloaded into the timer. Resetting the timer enable flags will

disable the associated interrupts.

Either or both of the timer underflow interrupts may be enabled. This gives the user the flexibility of interrupting once

per PWM period on either the rising or falling edge of the

PWM output. Alternatively, the user may choose to interrupt

on both edges of the PWM output.

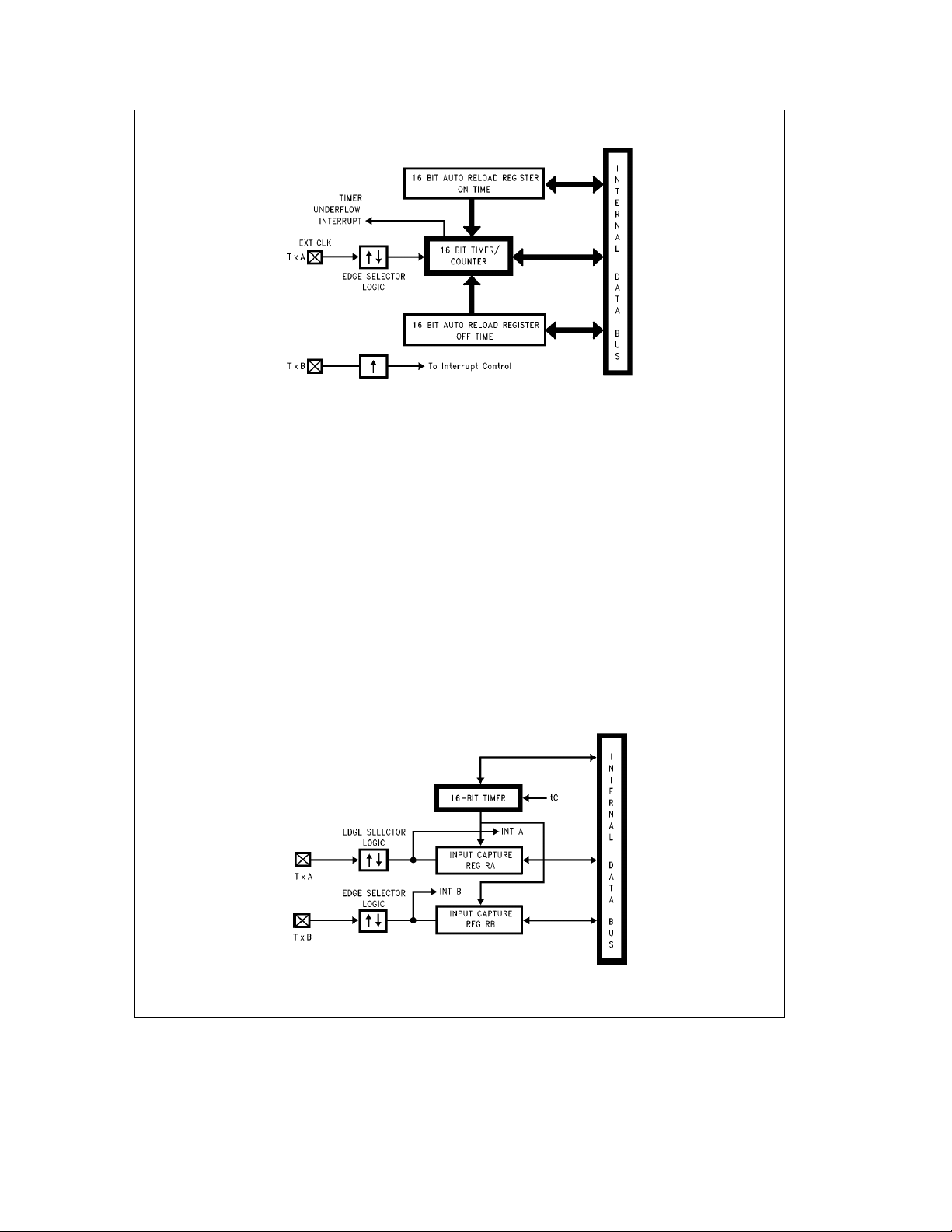

Mode 2. ExternaI Event Counter Mode

This mode is quite similar to the processor independent

PWM mode described above. The main difference is that

the timer, Tx, is cIocked by the input signal from the TxA pin.

The Tx timer control bits, TxC3, TxC2 and TxC1 allow the

timer to be clocked either on a positive or negative edge

from the TxA pin. Underflows from the timer are Iatched into

the TxPNDA pending flag. Setting the TxENA control flag

will cause an interrupt when the timer underflows.

FIGURE 8. Timer in PWM Mode

http://www.national.com 10

TL/DD/12855– 8

Timers (Continued)

FIGURE 9. Timer in External Event Counter Mode

In this mode the input pin TxB can be used as an independent positive edge sensitive interrupt input if the TxENB

control flag is set. The occurrence of a positive edge on the

TxB input pin is latched into the TxPNDB flag.

Figure 9

shows a block diagram of the timer in External

Event Counter mode.

Note: The PWM output is not available in this mode since the TxA pin is

being used as the counter input clock.

Mode 3. Input Capture Mode

The device can precisely measure external frequencies or

time external events by placing the timer block, Tx, in the

input capture mode.

In this mode, the timer Tx is constantly running at the fixed

t

rate. The two registers, RxA and RxB, act as capture

c

registers. Each register acts in conjunction with a pin. The

register RxA acts in conjunction with the TxA pin and the

register RxB acts in conjunction with the TxB pin.

The timer value gets copied over into the register when a

trigger event occurs on its corresponding pin. Control bits,

TxC3, TxC2 and TxC1, allow the trigger events to be specified either as a positive or a negative edge. The trigger condition for each input pin can be specified independently.

TL/DD/12855– 9

The trigger conditions can also be programmed to generate

interrupts. The occurrence of the specified trigger condition

on the TxA and TxB pins will be respectively Iatched into the

pending flags, TxPNDA and TxPNDB.

The control flag TxENA allows the interrupt on TxA to be

either enabled or disabled. Setting the TxENA flag enables

interrupts to be generated when the selected trigger condition occurs on the TxA pin. Similarly, the flag TxENB controls the interrupts from the TxB pin.

Underflows from the timer can also be programmed to generate interrupts. Underflows are latched into the timer TxC0

pending flag (the TxC0 control bit serves as the timer underflow interrupt pending flag in the Input Capture mode). Consequently, the TxC0 control bit should be reset when entering the Input Capture mode. The timer underflow interrupt is

enabled with the TxENA control flag. When a TxA interrupt

occurs in the Input Capture mode, the user must check both

the TxPNDA and TxC0 pending flags in order to determine

whether a TxA input capture or a timer underflow (or both)

caused the interrupt.

Figure 10

shows a block diagram of the timer in Input Cap-

ture mode.

FIGURE 10. Timer in Input Capture Mode

TL/DD/12855– 10

http://www.national.com11

Timers (Continued)

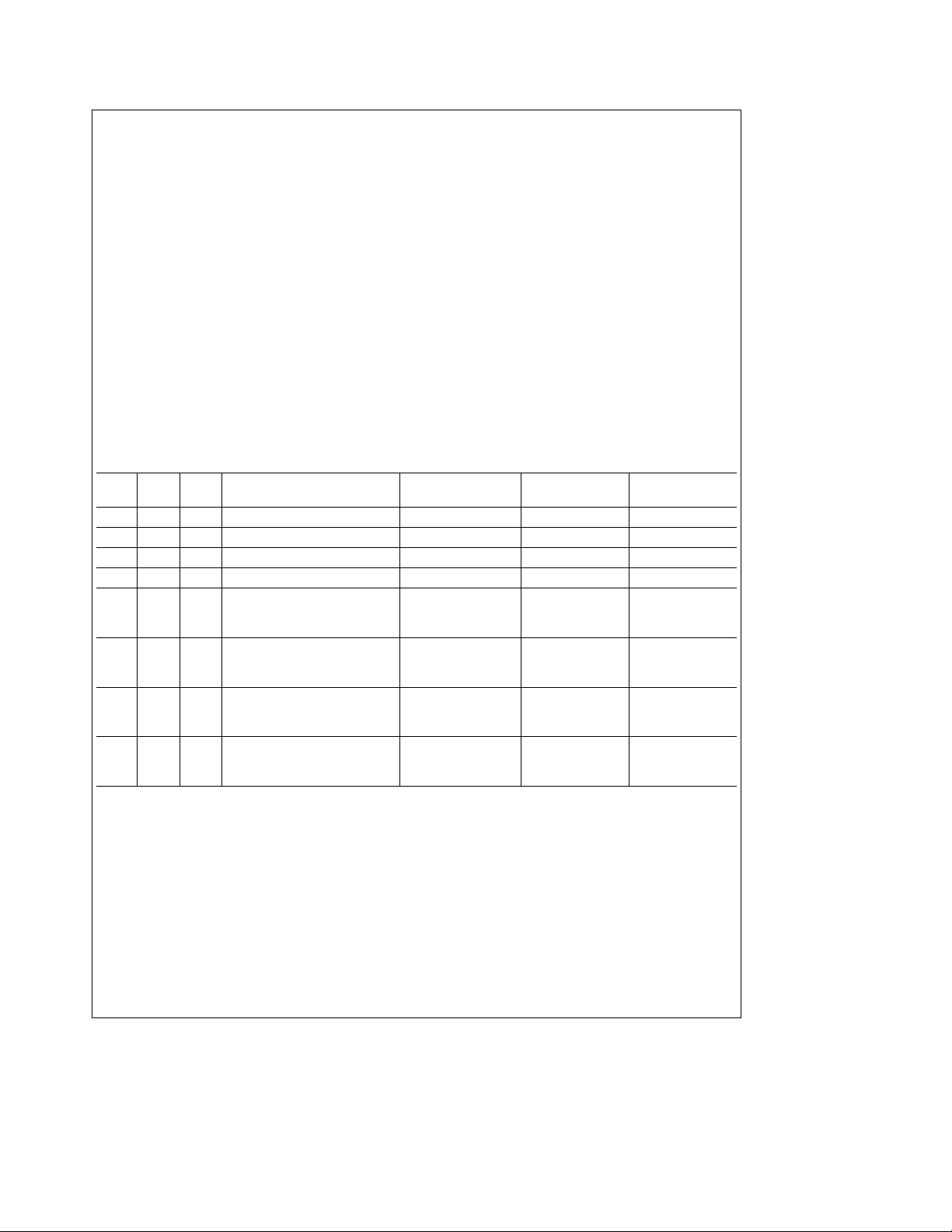

TIMER CONTROL FLAGS

The timers T1 and T2 have identical control structures. The

control bits and their functions are summarized below.

TxC0 Timer Start/Stop control in Modes 1 and 2 (Proc-

TxPNDA Timer Interrupt Pending Flag

TxPNDB Timer Interrupt Pending Flag

TxENA Timer Interrupt Enable Flag

TxENB Timer Interrupt Enable Flag

TxC3 Timer Mode Control

TxC2 Timer Mode Control

TxC1 Timer Mode Control

The timer mode control bits (TxC3, TxC2 and TxC1) are detailed below:

TxC3 TxC2 TxC1 Timer Mode

essor Independent PWM and External Event

Counter), where 1

derfIow Interrupt Pending Flag in Mode 3 (Input

Capture)

e

1

Timer Interrupt Enabled

0eTimer Interrupt Disabled

0 0 0 MODE 2 (External Event Counter) Timer Underflow Positive TxB Edge TxA Positive Edge

0 0 1 MODE 2 (External Event Counter) Timer Underflow Positive TxB Edge TxA Negative Edge

1 0 1 MODE 1 (PWM) TxA Toggle Autoreload RA Autoreload RB t

1 0 0 MODE 1 (PWM) No TxA Toggle Autoreload RA Autoreload RB t

0 1 0 MODE 3 (Capture) Captures: Positive TxA Edge or Positive TxB Edge t

1 1 0 MODE 3 (Capture) Captures: Positive TxA Edge or Negative TxB Edge t

0 1 1 MODE 3 (Capture) Captures: Negative TxA Edge or Positive TxB Edge t

1 1 1 MODE 3 (Capture) Captures: Negative TxA Edge or Negative TxB Edge t

e

Start, 0eStop Timer Un-

TABLE II. Timer Mode Control

TxA Positive Edge Timer Underflow

TxB Positive Edge

TxA Positive Edge Timer Underflow

TxB Negative Edge

TxA Negative Edge Timer Underflow

TxB Positive Edge

TxA Negative Edge Timer Underflow

TxB Negative Edge

Capture Timer

This device contains two independent capture timers, Capture Timer 1 and Capture Timer 2. Each capture timer contains an 8-bit programmable prescaler register, a 16-bit

down counter, a 16-bit input capture register, and capture

edge select logic. The 16-bit down counter is clocked at a

specific frequency determined by the value loaded into the

prescaler register. A selected positive or negative edge

transition on the capture input causes the contents of the

down counter to be latched into the capture register. The

values captured in the registers reflect the elapsed time between two positive or two negative transitions on the capture input. The time between a positive and negative edge

(a pulse width) may be measured if the selected capture

edge is switched after the first edge is captured. Each capture timer may be stopped/started under software control,

and each capture timer may be configured to interrupt the

microcontroller on an underflow or input capture.

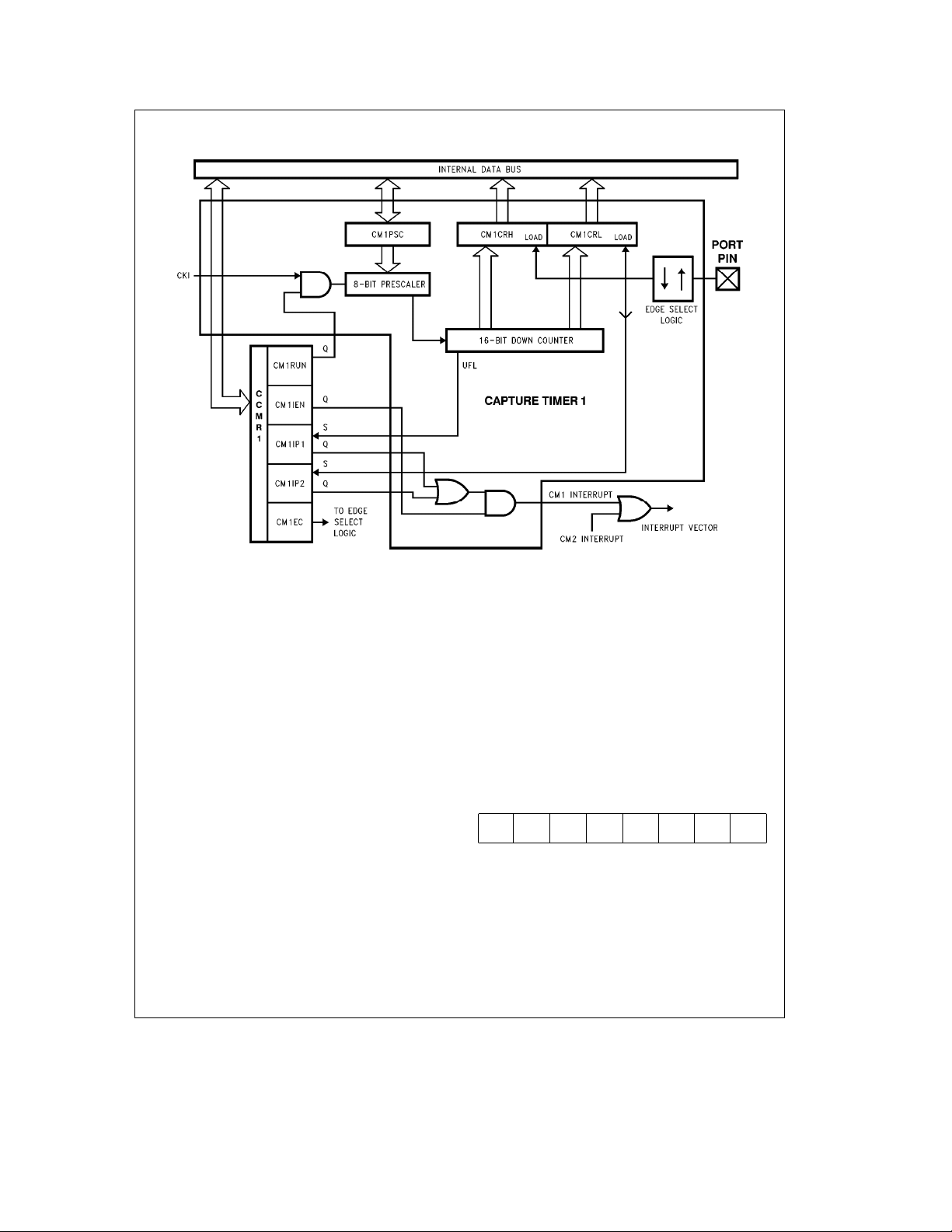

Figure 11

Interrupt A Interrupt B Timer

shows the capture timer 1 block diagram.

Source Source Counts On

c

c

c

c

c

c

http://www.national.com 12

Timers (Continued)

FIGURE 11. Capture Timer 1 Block Diagram

The registers shown in the block diagram include those for

Capture Timer 1 (CM1), as well as, the capture timer 1 control register. These registers are read/writable (with the exception of the capture registers, which are read-only) and

may be accessed through the data memory address/data

bus. The registers are designated as:

CM1PSC Capture Timer 1 Prescaler (8-bit)

CM1CRL Capture Timer 1 Capture Register (Low-byte),

read-only

CM1CRH Capture Timer 1 Capture Register (High-byte),

read-only

CM2PSC Capture Timer 2 Prescaler (8-bit)

CM2CRL Capture Timer 2 Capture Register (Low-byte),

read-only

CM2CRH Capture Timer 2 Capture Register (High-byte),

read-only

CCMR1 Control Register for Capture Timer 1

CCMR2 Control Register for Capture Timer 2

TL/DD/12855– 11

CONTROL REGISTER BITS

The control bits for Capture Timer 1 (CM1) and Capture

Timer 2 (CM2) are contained in CCMR1 and CCMR2.

The CCMR1 Register Bits are:

CM1RUN CM1 start/stop control bit (1

e

start; 0estop)

CM1IEN CM1 interrupt enable control bit (1eenable

IRQ)

CM1IP1 CM1 interrupt pending bit 1 (1

e

CM1 under-

flowed)

CM1IP2 CM1 interrupt pending bit 2 (1

e

CM1 captured)

CM1EC Select the active edge for capture on CM1 (0

rising, 1efalling)

CM1TM CM1 test mode control bit (1especial test path

in test mode. This bit is reserved during normal

operation, and must never be set to one.)

CM1 un- un- CM1 CM1 CM1 CM1 CM1

TM used used EC IP2 IP1 IEN RUN

Bit 7 Bit 0

All interrupt pending bits must be reset by software.

e

http://www.national.com13

Loading...

Loading...