N1020 Temperature Controller

INSTRUCTIONS MANUAL – V1.1x B

The USB interface IS NOT SEPARATE from the

signal input (PV) or the controller’s digital inputs and

outputs. It is intended for temporary use during

CONFIGURATION and MONITORING periods. For

the safety of people and equipment, it must only be

used when the piece of equipment is completely

disconnected from the input/output signals. Using the

USB in any other type of connection is possible but

requires a careful analysis by the person responsible

for installing it. When MONITORING for long periods

of time and with connected inputs and outputs, we

recommend using the RS485 interface, which is

available or optional in most of our products.

INTRODUCTION

The N1020 is a small and yet powerful temperature controller. It

accepts most of the temperature sensors used in industry and its 2

outputs can be configured independently as control or alarm output.

It also embeds an auto-adaptative PID control algorithm for best

system performance.

The configuration can be performed directly on the controller or through

the USB interface. The NConfig software (free) is the configuration

management tool. Connected to the USB of a Windows computer, the

controller is recognized as a serial communications port (COM) running

with a Modbus RTU protocol.

Through the USB interface, even if disconnected from the power

supply, the configuration performed in a piece of equipment can be can

be saved in a file and repeated in other pieces of equipment that

require the same configuration.

It is important that the users read carefully this manual before using

the controller. Verify if the release of this manual matches the

instrument version (the firmware version is shown when the controller

is energized). The N1020 main characteristics are:

Multi-sensor universal input;

Self-tuning PID parameters;

2 outputs: 1 relay and 1 logical pulse for SSR;

Output functions: Control, Alarm1 and Alarm 2;

8 distinct alarm functions;

Programmable timer;

Function key for enabling/disabling outputs, resetting the timer or

turning the timer ON/OFF;

Programmable soft-start;

Rate function

Password for parameters protection;

Capability of restoring factory calibration;

Universal power supply.

USB INTERFACE

The USB interface is used for CONFIGURING or MONITORING the

controller. The NConfig software must be used for the configuration.

It makes it possible to create, view, save and open configurations

from the equipment or files in your computer. The tool for saving and

opening configurations in files makes it possible to transfer

configurations between pieces of equipment and to make backup

copies. For specific models, the NConfig software also makes it

possible to update the firmware (internal software) of the controller

through the USB.

For MONITORING purposes you can use any supervisory software

(SCADA) or laboratory software that supports the MODBUS RTU

communication on a serial communications port. When connected to

the USB of a computer, the controller is recognized as a conventional

serial port (COM x). Use the NConfig software or consult the

DEVICE MANAGER in the Windows CONTROL PANEL to identify

the COM port that was assigned to the controller. Consult the

mapping of the MODBUS memory in the controller’s communications

manual and the documentation of your supervisory software to

conduct the MONITORING process.

NOVUS AUTOMATION 1/8

Follow the procedure below to use the USB communication of the

equipment:

1. Download the NConfig software from our website and install it on

your computer. The USB drivers necessary for operating the

communication will be installed together with the software.

2. Connect the USB cable between the equipment and the

computer. The controller does not have to be connected to a

power supply. The USB will provide enough power to operate the

communication (other equipment functions cannot operate).

3. Open the NConfig software, configure the communication and

start recognition of the device.

4. Consult the NConfig help desk for detailed instructions about

how to use it and solve problems.

INSTALLATION / CONNECTIONS

The controller must be fastened on a panel, following the sequence

of steps described below:

Prepare a panel cut-out 23 x 46 mm;

Remove the mounting clamps from the controller;

Insert the controller into the panel cut-out;

Slide the mounting clamp from the rear to a firm grip at the panel.

RECOMMENDATIONS FOR THE INSTALLATION

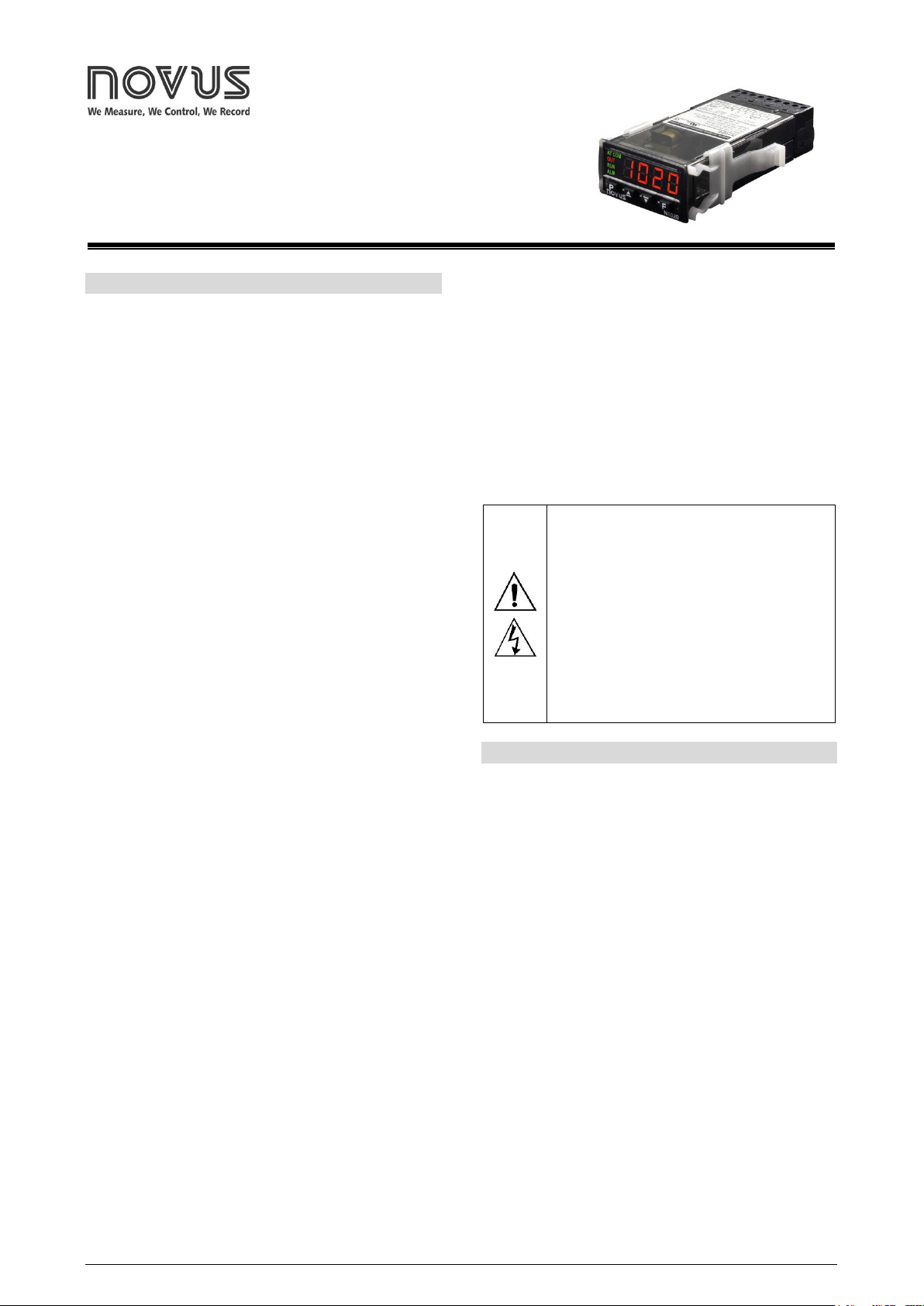

All electrical connections are made to the screw terminals at the

rear of the controller. They accept wire sizes from 0.5 to 1.5 mm2

(16 to 22 AWG). The terminals should be tightened to a torque of

0.4 Nm (3.5 lb in).

To minimize the pick-up of electrical noise, the low voltage DC

connections and the sensor input wiring should be routed away

from high-current power conductors. If this is impractical, use

shielded cables. In general, keep cable lengths to a minimum.

All electronic instruments must be powered by a clean mains

supply, proper for instrumentation.

It is strongly recommended to apply RC'S FILTERS (noise

suppressor) to contactor coils, solenoids, etc.

In any application it is essential to consider what can happen when

any part of the system fails. The controller features by themselves

can not assure total protection.

ELECTRICAL CONNECTIONS

TYPE

CODE

RANGE OF MEASUREMENT

J

Tc j

Range: -110 to 950 ºC (-166 to 1742 ºF)

K

Tc k

Range: -150 to 1370 ºC (-238 to 2498 ºF)

T

Tc t

Range: -160 to 400 ºC (-256 to 752 ºF)

N

Tc n

Range: -270 to 1300 ºC (-454 to 2372 ºF)

R

Tc r

Range: -50 to 1760 ºC (-58 to 3200 ºF)

S

Tc s

Range: -50 to 1760 ºC (-58 to 3200 ºF)

B

Tc b

Range: 400 to 1800 ºC (752 to 3272 ºF)

E

Tc e

Range:-90 to 730 ºC (-130 to 1346 ºF)

Pt100

Pt

Range: -200 to 850 ºC (-328 to 1562 ºF)

0 to 50 mV

L0.50

Linear. Programmable indication -1999 to 9999

off

Alarms turned Off.

lo

Alarm of Absolute Minimum Value. Triggers when the value of

measured PV is below the value defined for alarm Setpoint

(SPA1 or SPA2).

SPA1

PV

ki

Alarm of Valor Absolute Maximum Value. Triggers when the

value of measured PV is above the value defined for alarm

Setpoint.

SPA1

PV

dif

Alarm of Differential Value. In this function the parameters

SPA1 and SPA2 represent the deviation of PV in relation to

the SP of CONTROL.

SP

PV

SP + SPA1

SP – SPA1

SP

PV

SV – SPA1

SV + SPA1

SPA1 positive

SPA1 negative

difl

Alarm of Minimum Differential Value. It triggers when the value

of PV is below the defined point by (using the Alarm 1 as

example):

SP

PV

SP – SPA1

SP

PV

SP – SPA1

SPA1 positive

SPA1 negative

difk

Alarm of Valor Maximum Differential Value. Triggers when the

value of PV is above the defined point by (using Alarm 1 as

example):

SP

PV

SP + SPA1

SP

PV

SP + SPA1

SPA1 positive

SPA1 negative

t.0n

Timer ON alarm. Sets alarm output ON when timer is runing.

t.end

Timer end. Configures the alarm to actuate when the timer

expires.

ierr

Sensor Break Alarm. Activated when the input signal of PV is

interrupted, out of the range or when Pt100 in short-circuit.

MODE

A1t1

a2t1

A1t2

A2t2

ACTION

Normal

Operation

0

0

Alarm Event

Alarm

Output

Activation for

a defined time

1 to 6500 s

0

Alarm Event

Alarm

Output

T1

Activation with

delay

0

1 to 6500 s

Alarm Event

Alarm

Output

T2

Intermittent

Activation

1 to 6500 s

1 to 6500 s

Alarm Event

Alarm

Output

T1

T2

T1

The controller complete set of features is drawn in Fig. 01. The

features loaded in a particular unit are shown on its label:

Fig. 01 - Connections of the back panel

FEATURES

INPUT TYPE SELECTION

Select the input type (in parameter “tYPE”) from Table 01 below.

N1020 Temperature Controller

Table 01 - Input Types

OUTPUTS

The N1020 offers two output channels, user configurable as Control

output, Alarm 1 output or Alarm 2 output.

OUT1 - Logical pulse, 5 Vdc / 25 mA, available at terminals 4 and 5.

OUT2 - Relay SPST-NA, 1.5 A / 240 Vac, available at terminals 6

and 7.

Note: The outputs can be configured independently from each other,

for example, both can be control outputs at the same time.

CONTROL OUTPUT

The control strategy can be configured as ON / OFF or PID.

ALARM OUTPUT

There two alarms available in the N1020. The alarms can be

assigned to either output, logical or relay. The alarm functions are

described below.

ALARM FUNCTIONS

The alarms can be configured to operate with nine different functions,

as shown in Table 02.

NOVUS AUTOMATION 2/8

Table 02 – Alarm functions

Alarms Timer Modes (Temporization)

The controller alarms can be configured to perform 4 timer modes:

Table 03 - Temporization Functions for the Alarms

The signs associated to the alarms will light when the alarm condition

is recognized, not following the actual state of the output, which may

be temporarily OFF because of the temporization.

Initial Blocking of Alarm

The initial blocking option inhibits the alarm from being recognized if

an alarm condition is present when the controller is first energized (or

after a transition from run YES NO). The alarm will be enabled

only after the occurrence of a non alarm condition followed by a new

occurrence for the alarm.

N1020 Temperature Controller

Soak

Temperature

PV

Ramp

Time

SP

The initial blocking is useful, for instance, when one of the alarms is

configured as a minimum value alarm, causing the activation of the

alarm soon upon the process start-up, an occurrence that may be

undesirable.

The initial blocking is disabled for the sensor break alarm function.

RAMP AND SOAK FUNCTION

When the parameter Rate is configured, the N1020 performs a

gradual SV increase from the current PV value to the temperature

value set in SV. The user defines the rate of rise in degrees per

minute at the Rate prompt. When SV is reached, the temperature

is leveled at this point for 1 to 9999 minutes as programmed in the

T1me prompt. Setting 0 (zero) at T1me defines an infinite length soak

profile.

Fig. 02 - Ramp to Soak Function

The Ramp function will work whenever the controller is powered on,

the rvn parameter is set to YES or the SP variable is changed.

To disable the ramp function, set Rate = 0.0

After a power failure the controller will resume ramp generation at the

current value of PV.

OFFSET

Allows fine trimming the PV indication to compensate for sensor

errors. Default value: zero.

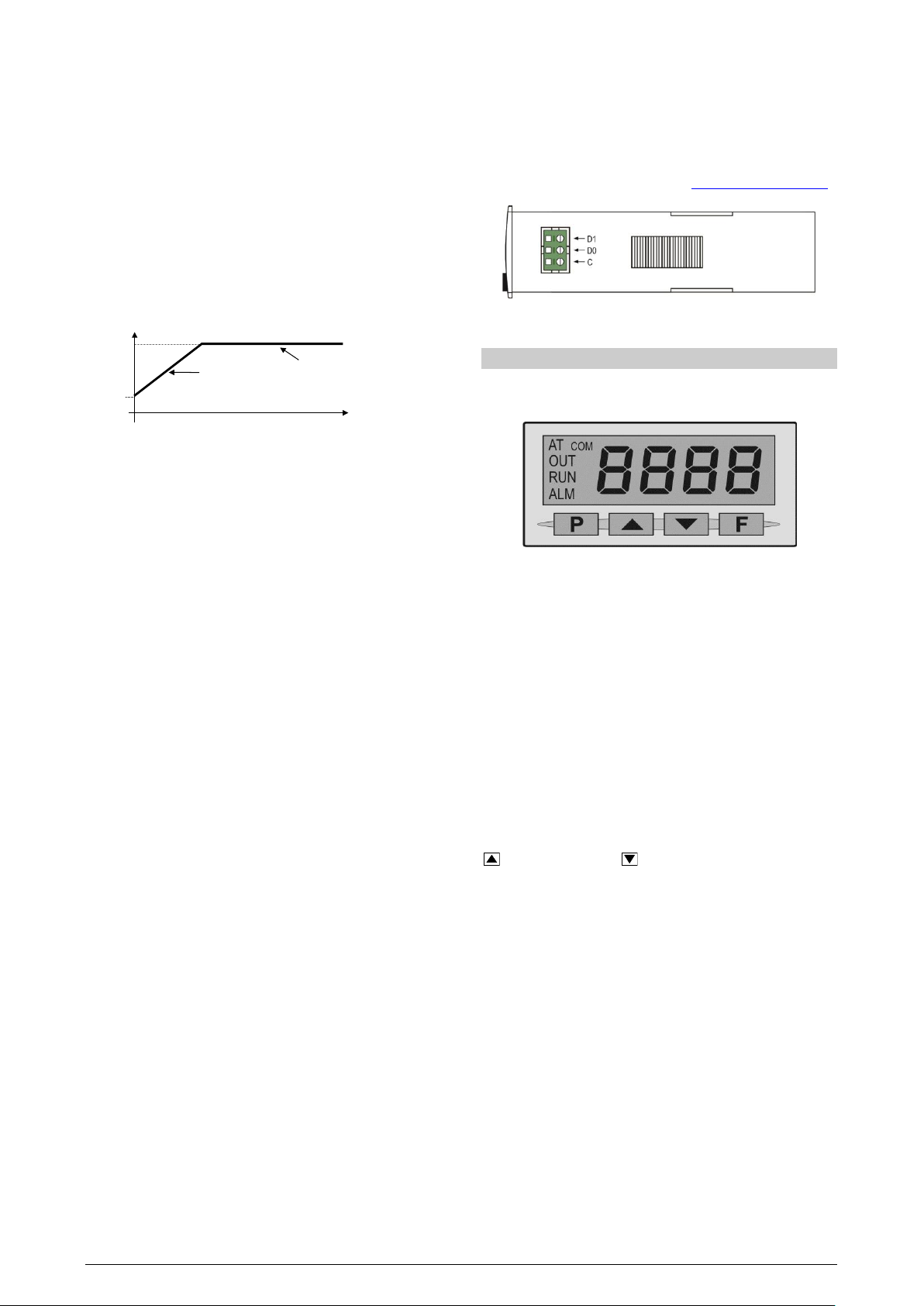

SERIAL COMMUNICATION

For full documentation download the Registers Table N1020 for

Serial Communication on our web site – www.novusautomation.com.

Fig. 02-a – Serial Communications Conections

OPERATION

The controller’s front panel, with its parts, can be seen in the Fig. 03:

TIMER FUNCTION

The N1020 embeds a timer function (decreasing) for applications that

require particular process duration.

Once defined the time interval in the T1me parameter, the timer will

START when:

When PV reaches the temperature programmed in the SP

parameter.

When enabling the control (RUN = YES).

By pressing the F key when configured to Timer reset mode (the

timer is reloaded with the T1me parameter and restarts counting).

By pressing the F key in ON/OFF mode stops the timer counting;

pressing it again, resumes the counting.

When the timer expires, the two possible actions can be:

Disables de control (RUN→ NO) or

Activate the alarm.

FUNCTIONS FOR THE F KEY

The F key on the frontal keypad is meant for special commands, as

follows:

Enable outputs (identically to the RUN parameter).

Timer reset: - reloads the timer and initiates a new time

counting.

Timer ON/OFF. Timer holds or resumes counting each time

the F key is pressed.

Keeping the F key pressed for 3 seconds resets the timer

(reloads the timer to the value set in T1me), initiating a new

time counting.

Note: when the F key is configured as RUN = YES/NO (RUN =

f.key), the controller outputs are born disabled after powers up.

SOFT-START

The Soft-start function is generally used in processes that require

slow start-up, where the instantaneous application of 100% of the

available power to the load may cause damages to parts of the

system.

In order to disable this function, the soft-start parameter must be

configured with 0 (zero).

NOVUS AUTOMATION 3/8

Fig. 03 - Identification of the parts referring to the front panel

Display: Displays the current value of PV. When configuring a

parameter, the display alternates between the parameter prompt and

its value (the parameter value is shown with a light blinking to

differentiate it from the parameter prompt).

The display contains also the signs AT, OUT, RUN ALM and COM:

AT Indicator: Stays ON while the controller is in tuning process.

OUT Indicator: For relay or pulse control output; it reflects the

actual state of the output.

RUN Indicator: Indicates that the controller is active, with the

control output and alarms enabled. (RUN=YES).

ALM Indicator: Signalize the occurrence of alarm condition. It

lights when either alarm is active.

COM Indicator: Flashes when there is RS485 activity.

P Key: Used to walk through the menu parameters.

Increment key and Decrement key: allow altering the

values of the parameters.

F Key: accesses special functions: RUN (toggles YES/NO) and the

two modes of timer control.

STARTUP

When the controller is powered up, it displays its firmware version for

3 seconds, after which the controller starts normal operation. The

value of PV is then displayed and the outputs are enabled.

In order for the controller to operate properly in a process, its

parameters need to be configured first, such that it can perform

accordingly to the system requirements. The user must be aware of

the importance of each parameter and for each one determine a valid

condition.

The parameters are grouped in levels according to their functionality

and operation easiness. The 5 levels of parameters are:

1 – Operation

2 – Tuning

3 – Alarms

4 – Configuration

5 – Calibration

The P key is used for accessing the parameters within a level.

Loading...

Loading...