NorthStar Rim Tach 6200 Instruction Manual

r

TM

NorthSta

brand

Instruction Manual

Rim Tach® 6200

Digital Tachometer

Designed for use in

4.5” 56C-Face, Coupled, Foot Mounted,

or Pulley Driven Applications

1 791-1003-00 Rev.D 17 November 2008

NorthStar RIM Tach® 6200 Instruction Manual

2 17 November 2008

NorthStar RIM Tach® 6200 Instruction Manual

Table of Contents

Chapter/Paragraph/Illustration Page

1 Introduction .......................................................................................................................................

m

1.0 Safety Sum

1.1 General

1.2 Description

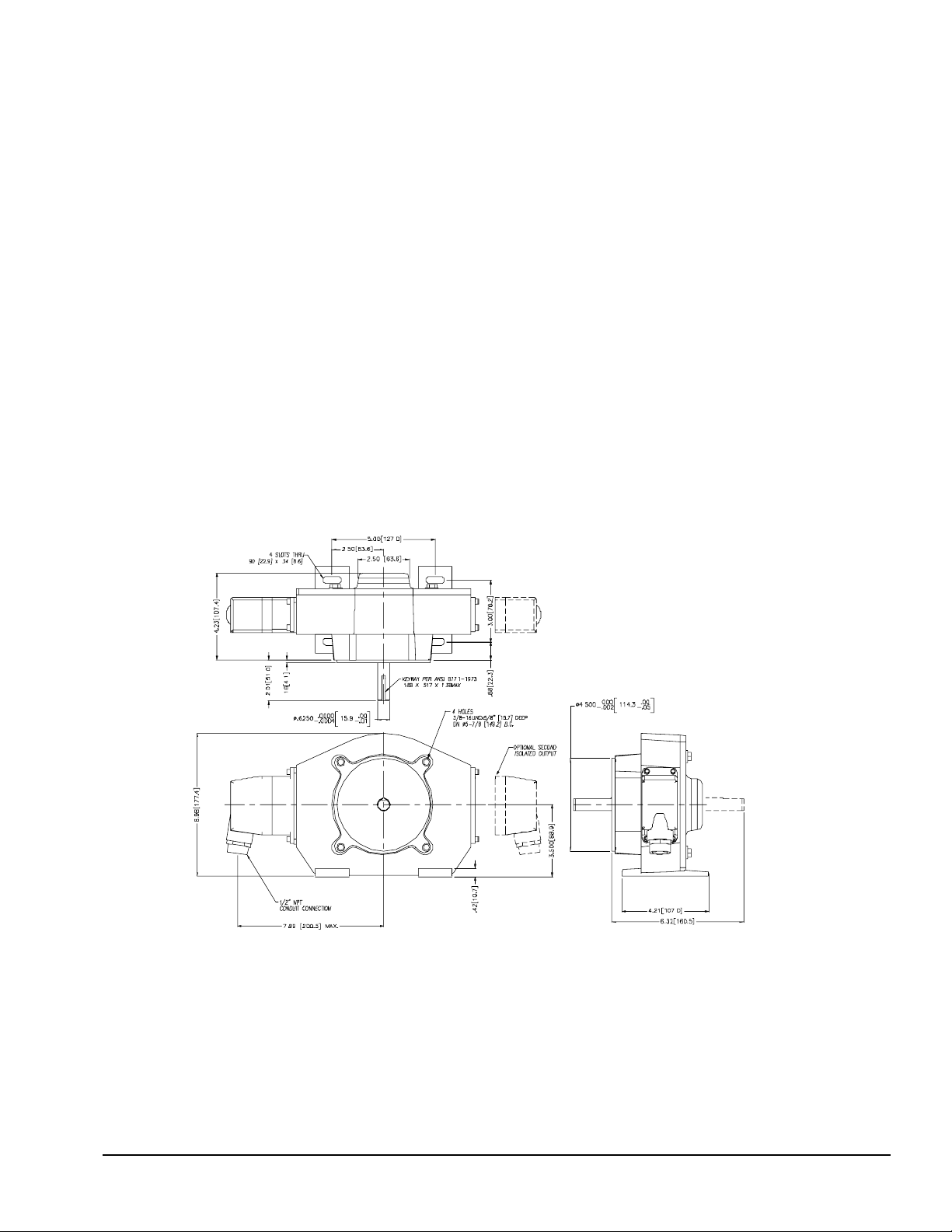

Figure 1: 6200 Dimensional Drawing

1.3 Safety Sum

ary.......................................................................................................................................... 4

........................................................................................................................

..................................................................................................................................................

......................................................................................... 5

m

ary.......................................................................................................................................... 6

................................ 5

2 Installation ......................................................................................................................................... 7

2.0 Inspection and Unpacking………………………………………………………………………………….7

Figure 2: 6200 Spare Parts .......................................................................................................... 7

2.1 Painting

2.2 56 C-Face Bracket Mounting

Figure 3: Model 6200 56 C Bracket Mounting ............................................................................ 8

2.3 Foot Mounting

Figure 4: Model 6200 Foot Mounting.......................................................................................... 9

2.4 Pulley Mounting................................................................................................................

Figure 5: Model 5200 Pulley Mounting ....................................................................................... 10

2.5 Sensor M

Figure 6: Sensor Module Installation........................................................................................... 11

Figure 7: Sensor Module Installation (

2.6 Electrical Installation

2.6.1 Quick Release Connector Hood W

Figure 8: Quick Release Connector Installation

Methods and apparatus disclosed and described herein have been developed solely on company funds of Dynapar No government or other contractual

support or relationship whatsoever has existed which in any way affects or mitigates proprietary rights of Dynapar in these developments. Methods and

apparatus disclosed herein may be subject to U.S. Patents existing or applied for. Dynapar reserves the right to add, improve, modify, or withdraw functions,

design modifications, or products at any time without notice. Dynapar shall not be liable for errors contained herein or for incidental or consequential

damages in connection with furnishing, performance, or use of this material.

Considerations

............................................................................................................................................

odule Installation

.............................................................................................................................. 8

......................................................................................................................

..........................

......................................................................................................................... 11

ontinued........................................................................ 12

C

..................................................................................................................................

i

ring.................................................................................................... 13

.......................................................................... 14

4

5

8

9

10

13

3 17 November 2008

NorthStar RIM Tach® 6200 Instruction Manual

CHAPTER 1

INTRODUCTION

1.0 Safety Summary

High current, voltage, and rotating parts can cause serious or fatal injury. The use of electric machinery, like all other uses of

concentrated power and rotating equipm

maintain electric machinery in accordance with applicable provisions of the National Electrical Code and sound local

practices. Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety

standards of design, manufacture, and intended use of the instrument. Dynapar assumes no liability for the customer's failure

to comply with these requirements.

Rotating Machinery

Avoid contact with rotating parts. Avoid by-passing or renderi

extended exposure in close proximity to machinery with high noise levels. Use proper care and procedures in handling,

lifting, installing, operating and maintaining the equipment.

Before Installation

Safe maintenance practice with qualified personnel is imperative. Before starting m

(1) equipment connected to the shaft will not cause mechanical rotation, (2) main machine windings have been disconnected

and secured from all electrical power sources, and (3) all accessory devices associates with the work area have been deenergized. If high potential insulation test is required, follow procedures and precautions outlined in NEMA standards MG-1.

ent, may be hazardous. Only qualified personnel should install, operate, and

noperative any safety guards or protection devices. Avoid

ng i

intenance procedures, be positive that,

a

Grounding

Improperly grounding the frame of the machine can cause serious or fatal injury to personnel. Grounding of the machine

and structure should comply with the National Electrical Code and with sound local practices. Check wiring diagram

e

fram

before connecting power.

Do Not Operate In An Explosive Atmosphere

s. Operating any electrical instrument in such an

Do not operate the instrument in the presence of flammable gases or fum

environment constitutes a definite safety hazard.

Keep Away From Live Circuits

i

Operating personnel must not remove instrument covers. Qual

replacement and internal adjustments. Do not replace components with power cable connected. To avoid injuries, always

disconnect power and discharge circuits before touching them.

Do Not Substitute Parts Or Modify Instrument

Do not install substitute parts or perform any unauthorized m

dangerous. Return the instrument to an authorized Dynapar representative for service and repair to ensure that safety features

are maintained.

Dangerous Procedure Cautions

A CAUTION heading precedes potentially dangerous procedures throughout this m

be followed.

fied maintenance personnel must make component

odification to the instrum

e

ent. Introducing additional hazards is

nual. Instructions in the warnings must

a

4 17 November 2008

1.1 General

These instructions do not claim to cover all details of variation in equipment or to provide for every possible contingency or

hazard met in connection with installation, operation, and service. If further information is desired or should particular

problems arise which are not covered sufficiently for the purchaser’s purposes, please contact Dynapar, or one of its

designated representatives.

1.2 Description

The RIM Tach

feedback from both AC and DC electric motors with pulse counts ranging from 60 through 2048 pulses per revolution. The

RIM Tach

magneto-resistive technology capable of withstanding the harshest industrial environments. This ensures precise and

consistent digital motor speed feedback.

The NorthStar RIM Tach

resistance sensor module with encapsulated surface mount electronics. The encapsulation provides resistance to water, oil

mist, dirt, high temperatures, and other harsh environments. The sensor module includes a 10-pin quick connector requiring

only a screwdriver for final electrical installation. The non-contact magneto-resistive sensor and rugged magnetized pulse

wheel are designed and machined to function properly without any adjustments. The RIM Tach

reliable speed signals for many monitoring and control applications, and is a standard feedback device for AC and DC

variable speed drives. The unit is bi-directional providing square wave outputs.

®

6200 is a high performance and reliable Digital Tachometer, designed to provide position and velocity

6200 utilizes rugged ductile iron casting construction and provides interchangeable sensor modules and a

®

6200 is mounted in a variety of ways and utilizes a patented, heavy-duty, one piece, magneto-

6200 provides precise,

Figure 1: 6200 Dimensional Drawing

5 791-1003-00 Rev.D 17 November 2008

Loading...

Loading...