NorthStar MPPWE Maintenance Manual

MPPWE

ITEM NUMBER:

SERIAL NUMBER:

Engine Model:

Pump Model:

Proven Performance

K-BAR Industries, Faribault, MN, 55021

Flow:

Hose Length:

Nozzle Size:

Pressure:

Lance Length:

Installation, Operation, and Maintenance Manual

PRESSURE WASHER: Cleans dirty surfaces with high pressure water.

To the Owner:

Thank you for purchasing a Northstar pressure washer. Your machine is designed for long life, dependability,

and the top performance you demand! Take time now to read through this manual so you better understand the

machine’s operation, maintenance and safety precautions. Everyone who operates this machine must read and

understand this manual. The time you take now will prolong your machine’s life and prepare you for its safe

operation. Enjoy the exceptional performance of your Northstar pressure washer, the industry leader!

The manufacturer reserves the right to make improvements in design and/or changes in specifications at any

time without incurring any obligation to install them on units previously sold.

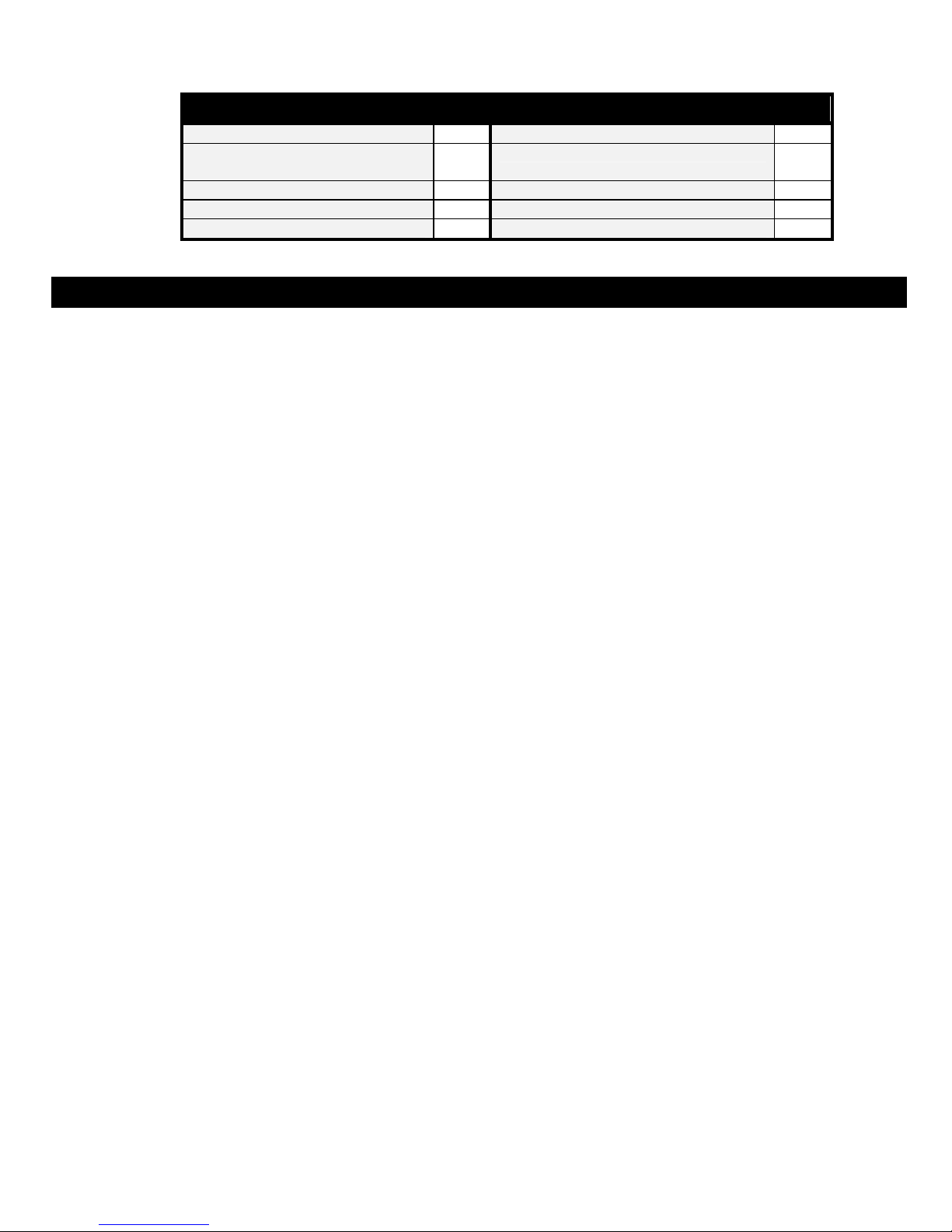

Quick Facts

Engine Oil Engine is shipped without oil. Fill before starting.

Use SAE 10W-30 motor oil.

Pump Oil Pump is shipped with oil. Change oil plug and check pump oil level before starting.

Use SAE 30 Non-detergent pump oil (item# 4043) or Cat Pump oil (item# 22158) for oil

changes.

Water Make sure your water flow is 20% higher than the pressure washer’s flow rate.

Make sure your water is clean and particle free.

Storage Do not allow water to freeze in the pump, hose, or spray gun.

Add fuel stabilizer to the fuel tank before long term storage.

Spraying

Chemicals

Maintenance

Schedule

Cat Pump: Oil: change after first 50 hours, then every 3 months or 500 hours.

General Pump: Oil: change after first 40 hours, then every 3 months or 500 hours.

Use any North Star brand or equivalent pressure washer chemicals.

Couple the chemical injector to the pump outlet. Use black nozzle.

Engine: Oil: change after first 20 hours, then annually or every 100 hours.

Spark Plug: clean every 100 hrs., replace annually or every 300 hrs.

Air Filter: clean every 100 hours, replace annually or every 300 hrs.

Read and understand all manuals before operating.

Any Questions, Comments, Problems or Parts Orders

In the United States In the United Kingdom

Northstar Customer Service

Call 1-800-270-0810 Northern Tool and Equipment Co. (UK) Ltd.

Hours: Monday - Friday 7:00 AM to 5:30 PM Unit 2, Keel Close,

Saturday 7:30 AM-11:30 AM Central Time Portsmouth, Hants PO3 5QD, England

Call 02392639752

Table of Contents

Important Safety Instructions 2 Maintenance Instructions 11-12

Machine Component

Identification

Installation Instructions 4-7 Long Term Storage 13

Operation Instructions 8-10 Troubleshooting 14

Safety Features 10-11 Parts Breakdowns 15-20

3 Moving and Handling Instructions 13

Important Safety Instructions

WARNING -Risk of injection or injury to persons - Do not direct discharge stream at persons or animals. Do

not use a hose if exterior damage is evident.

-Risk of explosion. Do not spray flammable liquids. Do not operate in a flammable environment.

CAUTION -Risk of asphyxiation - Exhaust fumes are deadly. For outdoor use only. Avoid inhaling exhaust

fumes.

-Risk of fire. Do not add fuel when the product is operating or hot.

-Gun kicks back. Hold with both hands.

-To reduce the risk of injury, read operating instructions carefully before use.

WARNING - When using this pressure washer, basic precautions should always be followed, including the following:

1.) Read all the instructions before using this product.

2.) To reduce the risk of injury, close supervision is necessary when the pressure washer is used near

children. Do not allow irresponsible use by children. Always stop the unit and bleed or relieve pressures

before leaving unattended, disconnecting hoses, or servicing the pump.

3.) Know how to stop the unit and bleed pressures quickly. Be thoroughly familiar with the controls.

4.) Stay alert - watch what you are doing.

5.) Do not operate when fatigued or under the influence of alcohol or drugs. Never smoke while operating

or fueling this machine.

6.) Keep operating area clear of all persons.

7.) Do not overreach or stand on unstable support. Keep good footing and balance at all times. Wear

footwear capable of maintaining a good grip on wet surfaces. Do not place the machine on soft or

unstable ground.

8.) Follow the maintenance instructions specified in all manuals. Do not run machine without sufficient

lubrication or sufficient water to cool the pump.

9.) Wear safety glasses, gloves, face protection and appropriate clothing when operating the machine.

10.) Do not operate this machine with broken or missing parts. Never alter the manufacturer’s original design

or deactivate any safety device on the machine.

11.) Risk of exposure to dangerous chemicals. Wear protective gloves when handling and cleaning with

chemicals. Follow the chemical manufacturer’s directions. Understand all safety hazards and first aid for

all chemicals being used. Check whether dangerous chemicals have been used and take any

precautions that may have been recommended by the supplier of these chemicals when cleaning filters.

Do not pump highly abrasive fluids or use with incompatible chemicals or solvents.

12.) Know the pressure and temperature limits of your machine. Be sure all high pressure accessories meet

or exceed your machine’s limits. Do not set the pressure relief valve above the machine’s limit.

13.) Do not move this machine by pulling on the hose. Do not use the pump to support other items of

equipment that impose unacceptable loads on the pump. Do not attempt to use this machine as a prop.

14.)To reduce risk of injury, do not secure the spray gun open. Your spray gun is equipped with a built-in

trigger safety latch to guard against accidental trigger release and potentially dangerous high pressure

spray. Rotate the safety latch to the locked position when not spraying.

15.) Do not clean this machine with its own spray. Cleaning should be done with a damp sponge with the

engine OFF.

SAVE THESE INSTRUCTIONS

2

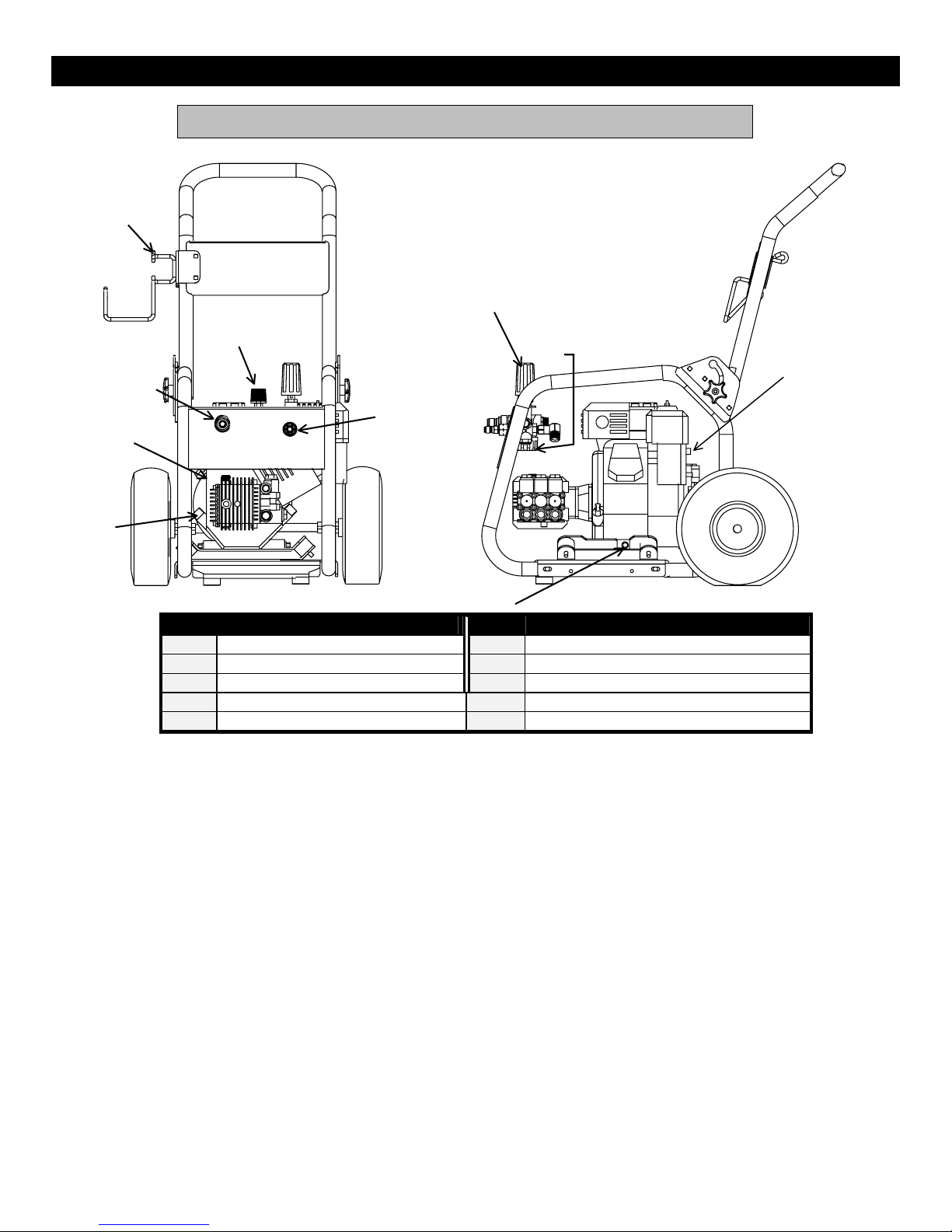

Machine Component Identification

157816, 157817, 157818, 157819, 157820

1

7

3

8

2

6

4

10

5

Ref # Description Ref # Description

1 Hose/Gun Holder 6 Water Outlet (Pressure Hose)

2 Water Inlet (Garden Hose) 7 Pressure Adjustment (unloader)

3 Easy Start Knob 8 Inlet Filter

4 Engine Start/Stop Switch 9 Engine Oil Drain

5 Engine Oil Fill 10 Engine Controls (see engine manual)

9

00477

3

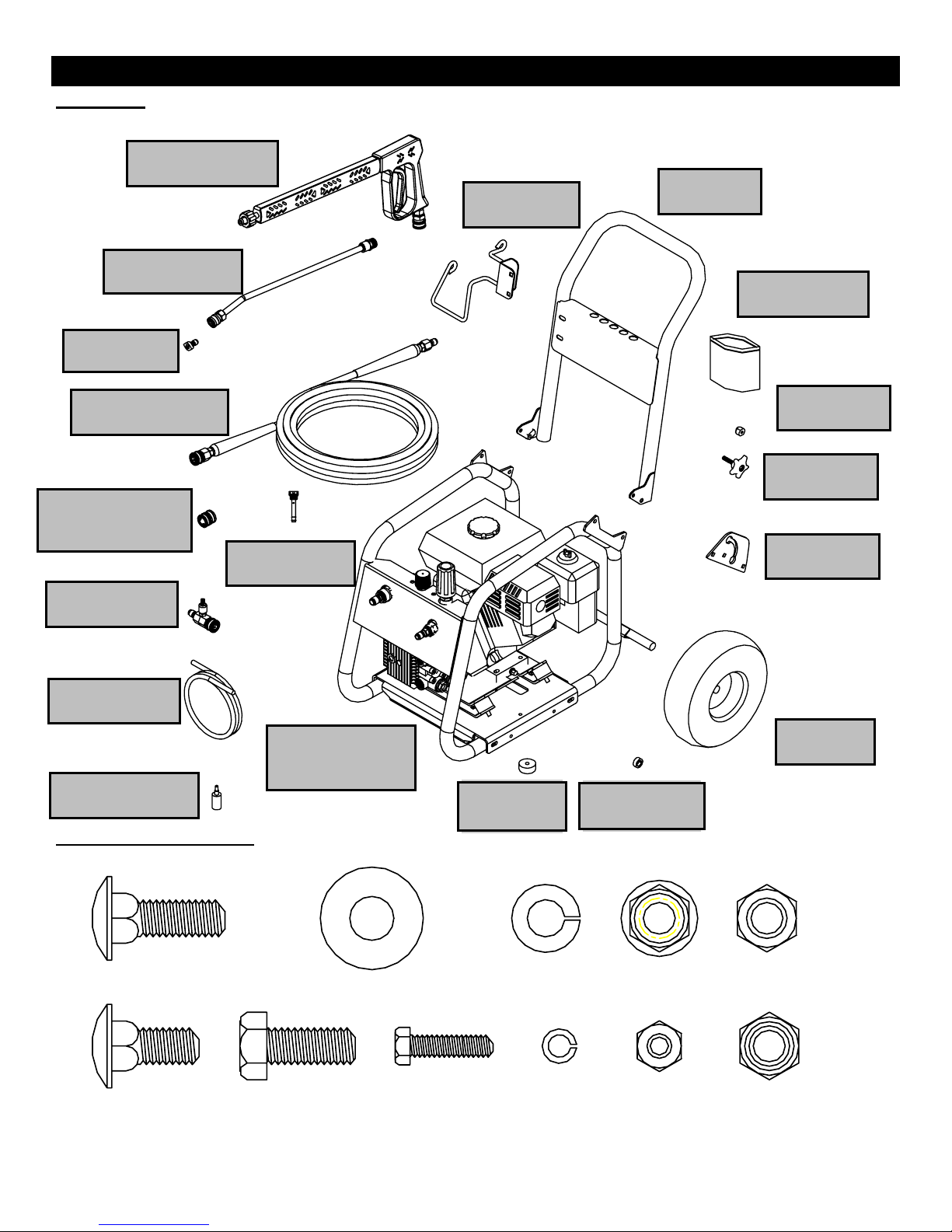

Installation Instructions

I.) Unpack

Separate and identify the components found in the box(es). Use the assembly instructions in this manual for assembly.

Spray Gun & Grip

Qty-1

Hose Hook

Qty-1

Lance Extension

Qty-1

Nozzle

Qty-5

Handle

Qty-1

Fastener Bag

Qty-1

High Pressure Hose

Qty-1

Garden Hose Quick

Couple Socket

Qty-1

Vented Dipstick*

Qty-1

Chemical Injector

Qty-1

Clear Hose

Qty-1

Engine/Pump/Base

Assembly

Chemical Strainer

Qty-1

Qty-1

II.) Open Fastener Bag

A. Open fastener bag and separate the fasteners.

Rubber Foot

Qty-2

Wheel Retainer

Qty 2

Spacers

Qty-2

Handle Knob

Qty-2

Handle Ear

Qty-2

Wheel

Qty-2

5/16-18 x 1”

Carriage Bolt

Qty.- 2

5/16-18 x 3/4”

Carriage Bolt

Qty.- 6

5/16

Flat Washer

Qty.- 2

#5/16 x 3/4”

Hex Bolt

Qty.- 2

#10 x 3/4”

Hex Bolt

Qty.- 1

Lock Washer

Qty.- 6

#10 Lock

Washer

5/16

Qty.- 1

5/16”

Flange Nut

Qty.- 2

#10 Hex Nut

Qty.- 1

5/16-18

Hex Nut

Qty.- 6

5/16-18

Nyloc Nut

Qty.- 2

4

III.) Assembly Instructions

r

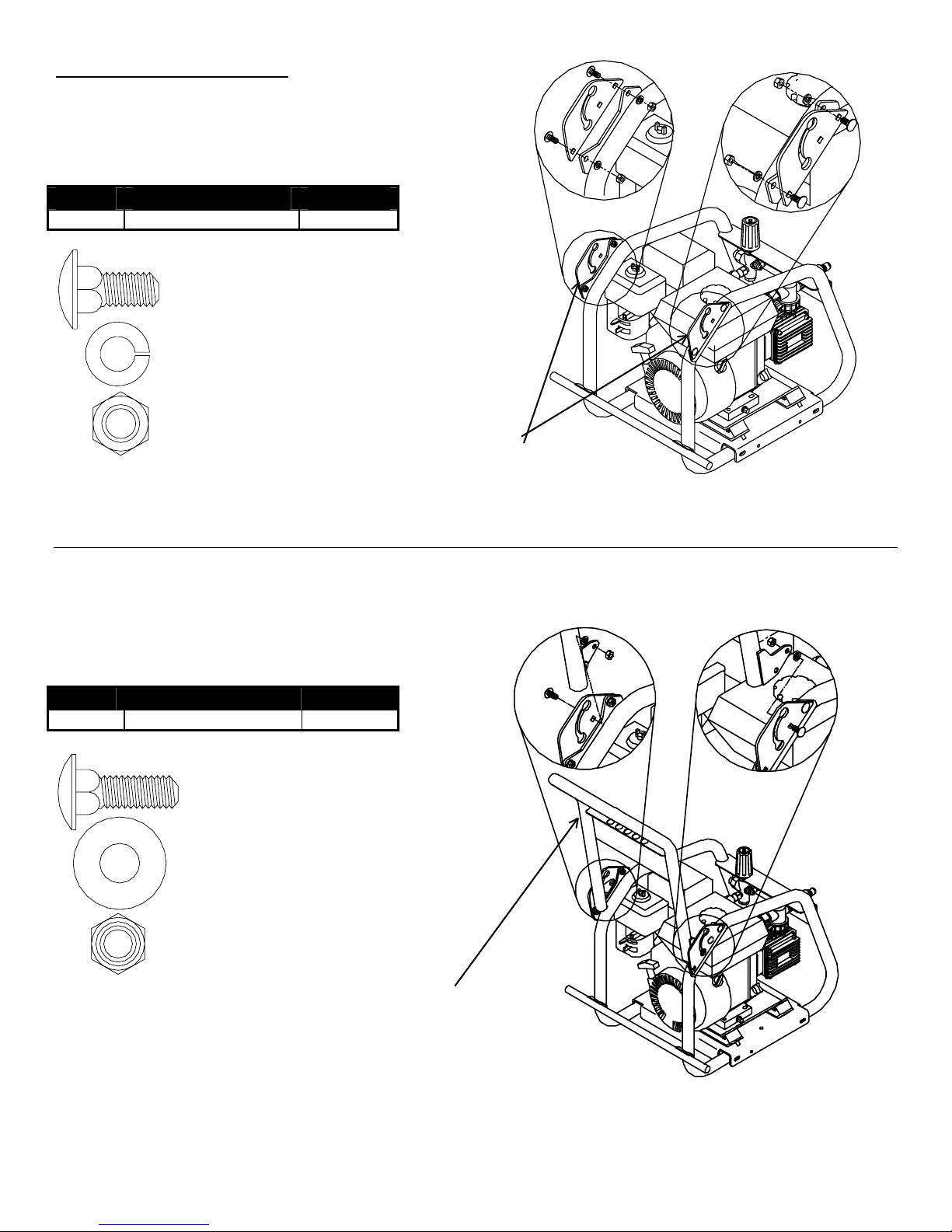

A. Assemble Hinge Ears to pressure washer with

carriage bolts, lock washers, and hex nuts. Thread nut

on to bolt hand tight.

Item # Description Qty.

32525 Hinge Ear 2

5/16-18 x 3/4” Carriage Bolt

Qty. 4

5/16 Lock Washer

Qty. 4

5/16-18 Hex Nut

Qty. 4

00489

B. Attach Handle to Hinge Ears with carriage bolts, flat

washers and nyloc nuts. Tighten nyloc nuts then loosen

1/4 turn so handle hinges freely.

Item # Description Qty.

32459 Handle 1

Hinge Ea

00488

5/16-18 x 1” Carriage Bolt

Qty. 2

5/16 Flat Washer

Qty. 2

5/16-18 Nyloc Nut

Qty. 2

00490

Handle

00491

5

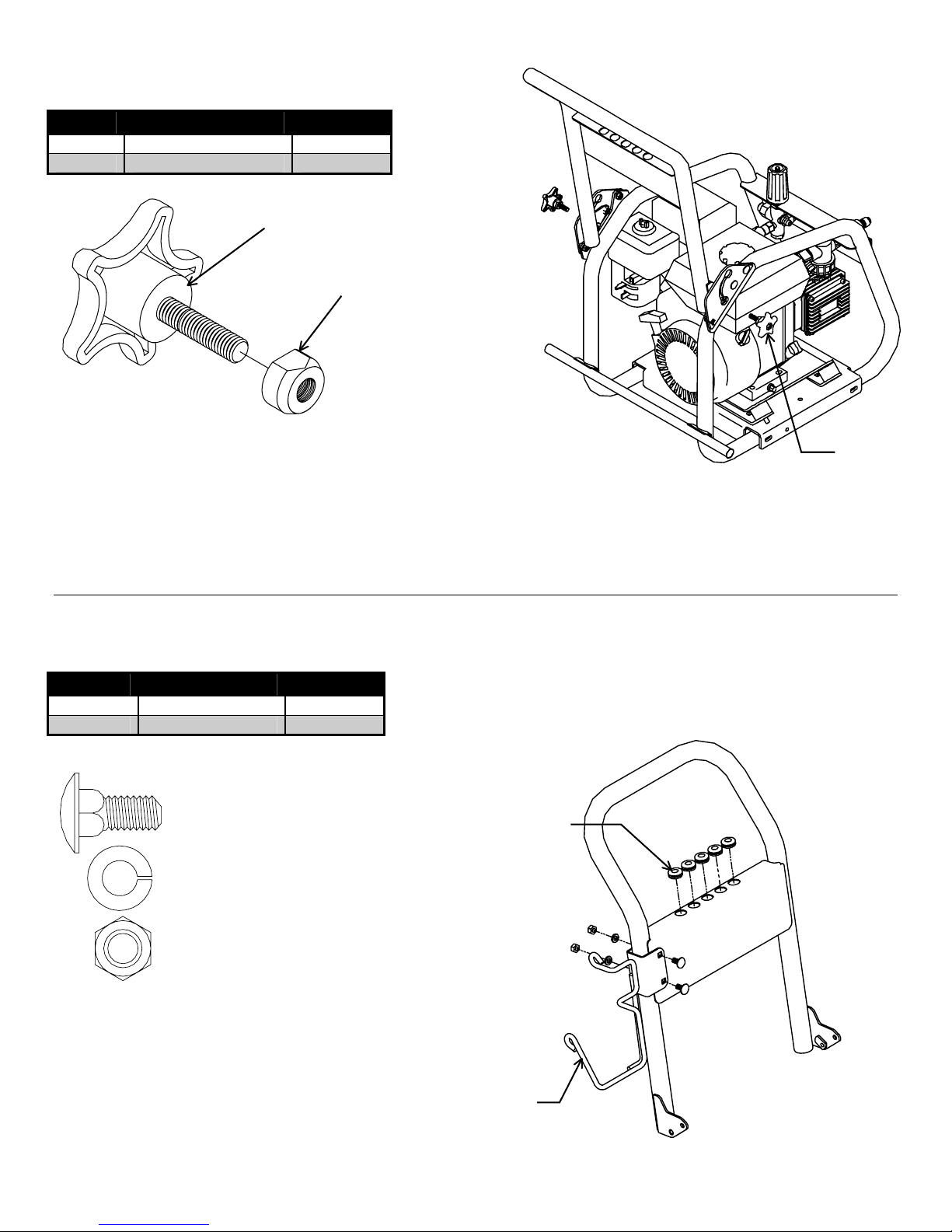

C. Tighten all nuts from step A. Assemble Spacers on to

Knobs. Thread Knob and Spacer to secure Handle.

Item # Description Qty.

32463 Knob 2

32738 Spacer 2

Knob

Spacer

00493

D. Attach Hose Hook to Handle with bolts, lock washer

and hex nuts. Insert Grommets as shown.

Item # Description Qty.

32612 Hose Hook 1

17156 Grommet 5

5/16-18 x 3/4” Carriage Bolt

Qty. 2

Knob

Grommet

5/16 Lock Washer

Qty. 2

5/16-18 Hex Nut

Qty. 2

00489

Hose Hook

00494

6

Loading...

Loading...