North Star 1572081, 1572082, 1572091, 1572092, M1572081J Owner's Manual

M1572081I.1

ITEM NUMBER: 1572081, 1572082,

1572091, 1572092

SERIAL NUMBER: _____________

Owner’s Manual

Cold Water, Belt Drive Pressure Washer

Instructions for Installation/Set-up, Operation, Maintenance, & Storage

This pressure washer produces cold water high pressure spray. Cleaning chemicals may be incorporated into the

spray if desired. The pressure pump for this equipment is powered by a gasoline internal combustion engine.

WARNING: SPECIAL HAZARDS

CO Poisoning: Exhaust from engine contains carbon monoxide, a poisonous gas that can cause carbon monoxide

poisoning and possible death if inhaled. ONLY run pressure washer OUTDOORS and at least 20 feet from the home, away

from windows, vents and air intakes, to allow proper ventilation. If you start to feel sick, dizzy, or weak while using the

pressure washer, shut off the engine and get to fresh air RIGHT AWAY.

Injection Injury: High-pressure spray can pierce skin and underlying tissues, leading to serious injury and possible

amputation. Such an injection injury can result in blood poisoning and/or severe tissue damage.

Flying Debris: High-pressure spray can cause flying debris and possible surface damage.

Slips/Falls: Spray discharge can cause puddles and slippery surfaces. Spray-gun kickback can cause operator loss of

balance and falls.

Electric shock: Operating equipment in wet conditions or near water can cause electric shock.

Chemical Exposure: Cleaning chemical vapors or contact with skin may be hazardous.

Fire/Explosion: Engine sparking can ignite fuel or other flammable liquids or vapors in the vicinity. Hot exhaust from engine

can ignite combustible materials.

Burns: Pressure Washer pump and engine are hot surfaces that can cause burn injuries.

Detailed safety information about these hazards appears throughout this manual.

Inspect Upon Delivery: FIRST! Inspect for missing or damaged components. See “Initial Set-Up” section for where

to report missing or damaged parts.

Add Engine Oil: Engine is shipped without oil. See engine manual for instructions on capacity and viscosity

recommendations.

Replace Temporary Pump Oil Plug: Pump is shipped with oil but with a temporary shipping plug. Check pump oil

level before starting and replace temporary shipping plug with permanent oil fill plug provided within plastic bag

containing this Owner’s Manual.

Battery Required: A battery is not included. A battery must be installed before starting the engine or damage to the

engine voltage regulator will result. Purchase a standard 12 VDC, 18 Ah lawn and garden battery (Group U1-7).

Water Flow Requirements: Make sure your supply water flow rate is 20% higher than the pressure washer's flow

rate (see "Specifications" section for detail), and that your water is clean and particle free.

Chemical Spraying: Use only approved pressure washer chemicals designed for high-pressure use. Use chemical

adjustment knob to regulate cleaning power (on select units).

Storage: Do not allow water to freeze in the pump, hose, or spray gun(s). See “Storage” for more information.

Maintenance Schedule: Engine, pump, and belts require periodic inspection and servicing to keep pressure washer

functioning efficiently. See “Maintenance Schedule Summary” for frequency of servicing.

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar Product Support 1-800-270-0810

Equipment Protection Quick Facts

2

Table of Contents

Equipment Protection Quick Facts ........................................................................................................................................ 1

TABLE OF CONTENTS ................................................................................................................................................ 2

ABOUT YOUR PRESSURE WASHER ......................................................................................................................... 4

SPECIFICATIONS ........................................................................................................................................................ 5

COMPONENT IDENTIFICATION .................................................................................................................................. 6

SAFETY ........................................................................................................................................................................ 7

Hazard Signal Word Definitions ............................................................................................................................................ 7

SAFETY LABELING ..................................................................................................................................................... 8

Safety Decal Locations ......................................................................................................................................................... 8

Safety Decals ........................................................................................................................................................................ 9

INITIAL SET-UP .......................................................................................................................................................... 10

Step 1. Inspect & Unpack ...................................................................................................................................................... 10

Components: ....................................................................................................................................................................... 10

Hardware Bag: .................................................................................................................................................................... 11

Step 2. Assembly ................................................................................................................................................................... 12

Prepare Water Pump: ......................................................................................................................................................... 13

Battery Installation................................................................................................................................................................. 13

Step 3. Select Suitable Location ........................................................................................................................................... 14

Elevating or lowering your pressure washer ....................................................................................................................... 14

Outdoor Use Only ............................................................................................................................................................... 14

Install Spark Arrestor (if Required) ...................................................................................................................................... 15

OPERATION ............................................................................................................................................................... 16

Follow Safety Rules for Operation ....................................................................................................................................... 16

Preparing for Operation ........................................................................................................................................................ 17

Check/Add Oil to Pump ....................................................................................................................................................... 17

Check/Add Engine Oil ......................................................................................................................................................... 17

Inspect Fuel System/Check for Leaks ................................................................................................................................. 18

Connect Hoses, Water Supply, and Spray Nozzle .............................................................................................................. 19

Attach High Pressure Hose to Water Outlet ........................................................................................................................ 20

Prime the Water Supply ...................................................................................................................................................... 21

Start-Up Procedures .............................................................................................................................................................. 22

Start the Engine to Power the Pump. .................................................................................................................................. 22

Apply Cleaning Chemical (If Desired) ................................................................................................................................. 23

Begin High Pressure Spray ................................................................................................................................................. 23

Shutdown ............................................................................................................................................................................... 24

STORAGE ................................................................................................................................................................... 25

Between-Use Storage ............................................................................................................................................................ 25

Prepare Pressure Washer for Freezing Conditions ............................................................................................................ 25

Prepare Engine for Long Term Storage ............................................................................................................................... 26

Prepare Pressure Washer for Storage ................................................................................................................................. 26

MAINTENANCE & REPAIR ........................................................................................................................................ 27

MAINTENANCE SCHEDULE SUMMARY .................................................................................................................. 27

DETAILED INSTRUCTIONS – MAINTENANCE & REPAIR ...................................................................................... 27

Follow Safety Rules ............................................................................................................................................................ 27

Keep Pressure Washer Clean ............................................................................................................................................. 27

Inspect Spray System ......................................................................................................................................................... 28

3

Clean Inlet Filter .................................................................................................................................................................. 28

Check Tire Pressure ........................................................................................................................................................... 28

Change Pump Oil ................................................................................................................................................................ 28

............................................................................................................................................................................................ 28

Drive Belt Maintenance ....................................................................................................................................................... 29

TROUBLESHOOTING ................................................................................................................................................ 30

PARTS EXPLOSION- MODEL #1572081, 1572082, 1572091, 1572092-REV I.1 ..................................................... 31

PARTS EXPLOSION- MODEL #1572081, 1572082, 1572091, 1572092-REV I.1 ..................................................... 32

PUMP ASSEMBLIES .................................................................................................................................................. 33

PUMP EXPLODED VIEW- NSB4540 (A1572081) ...................................................................................................... 34

PUMP EXPLODED VIEW- NSSHFB6030 (A1572082) ............................................................................................... 36

PUMP EXPLODED VIEW- NSB5050 (A1572091) ...................................................................................................... 38

PUMP EXPLODED VIEW- NSSHFB7035 (A1572092) ............................................................................................... 40

LIMITED WARRANTY ................................................................................................................................................ 42

4

About Your Pressure Washer

WARNING: Read this Manual

Carefully read and follow all instructions and safety

information for using this pressure washer. Improper

use or maintenance of the pressure washer can result

in serious injury or death to the operator or

bystanders.

Thank you for purchasing a NorthStar Pressure Washer!

It is designed for long life, dependability, and top

performance.

Intended Use. Produce a high-pressure water spray.

Incorporate cleaning chemicals into a low-pressure

water spray.

Note: Do not use for other purposes, as unforeseen

hazards or equipment damage may result.

Gasoline powered pressure washers are for

OUTDOOR USE ONLY. Be sure to read about site

selection for running this pressure washer in the "Initial

Set-up" section of this manual.

Water Supply. The pump requires a clean, standard tap

water supply provided through a garden hose at a flow

rate of at least 6 gallons per minute. The use of a

backflow preventer on the water supply hose is

recommended and may be required by local code. Any

cleaning chemicals that are used must be specifically

approved for use in pressure washers.

Power Source. The pressure washer is powered by a

gasoline engine.

Supplies Required. Normal operation will require you

to supply:

Pressure Washer pump oil

Gasoline

Engine oil

12-Volt standard lawn and garden battery

Personal Protection Equipment

See “Specifications” section of this manual for more

detail.

Site Location. Intended for outdoor use only.

Personal Protection. Wear safety apparel during

operation, including safety glasses with side and top

protection. Ear protection is also recommended if

working near any operating engine. Other safety apparel

includes waterproof insulated gloves, safety glasses

with side and top protection, and non-slip protective

footwear. Cleaning chemicals may require the use of

respiration mask; refer to chemical label for further

instruction.

Adult control only. Only trained adults should set up

and operate the pressure washer. Do not let children

operate.

Under The Influence. Never operate, or let anyone else

operate, the pressure washer while fatigued or under

the influence of alcohol, drugs, or medication.

ATTENTION: Rental Companies and Private

Owners who loan this equipment to others!

All persons to whom you rent/loan this pressure washer

to must have access to and read this manual. Keep this

owner’s manual with the pressure washer at all times

and advise all persons who will operate the machine to

read it. You must also provide personal instruction on

how to safely set-up and operate the pressure washer

and remain available to answer any questions a

renter/borrower might have. Owner’s Manuals are

available from NorthStar at 1-800-270-0810.

5

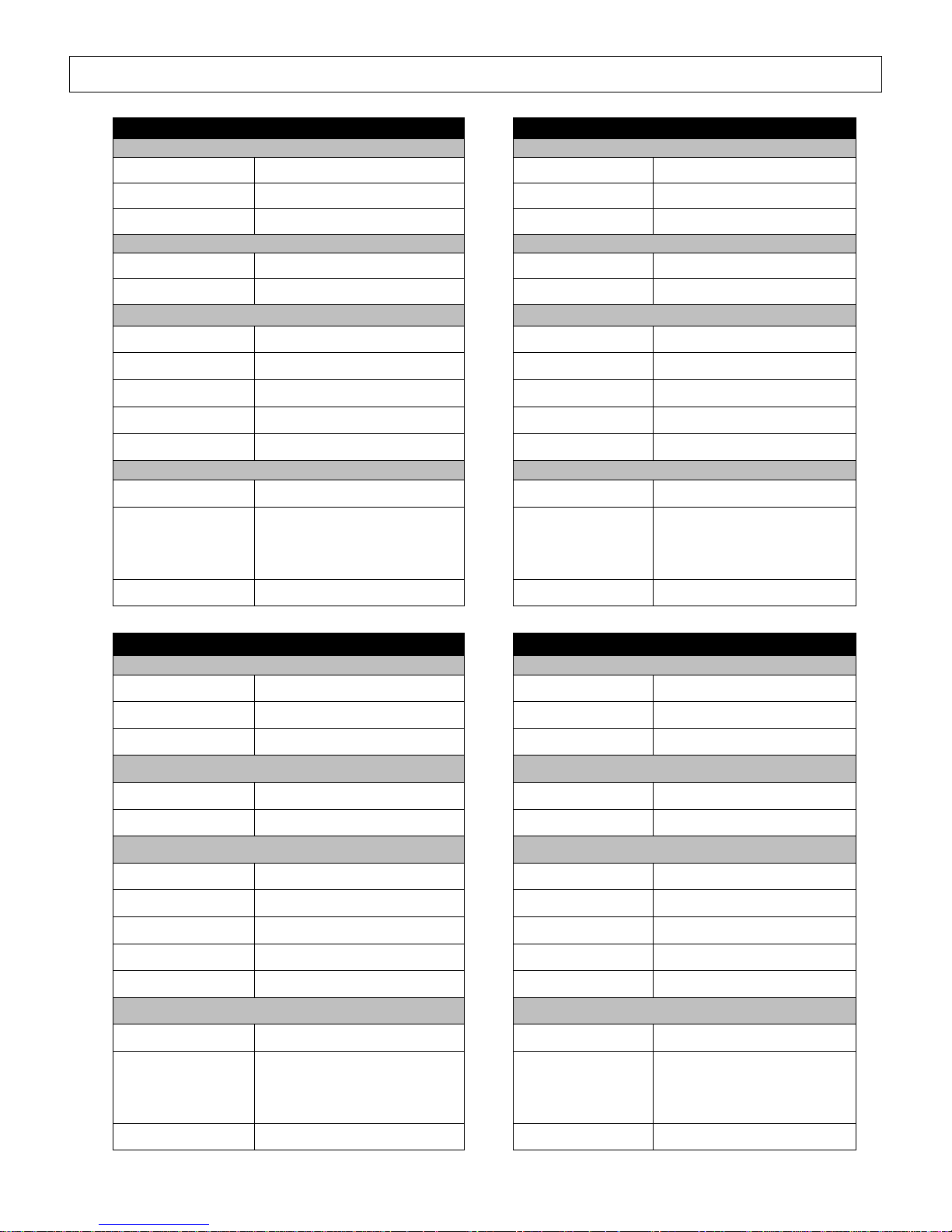

Specifications

1572081

1572082

FLOW OUTPUT

FLOW OUTPUT

PSI (bar)

4000 (276)

PSI (bar)

3000 (207)

GPM (l/min)

4.5 (17)

GPM (l/min)

6 (22.7)

Max Water Temp

140° F (60°C)

Max Water Temp

140° F (60°C)

ENGINE

ENGINE

Engine

Briggs Vanguard

Engine

Briggs Vanguard

Displacement (cc)

479 cc

Displacement (cc)

479 cc

DIMENSIONS/COMPONENTS

DIMENSIONS/COMPONENTS

Length

34”

Length

34”

Width

32.75”

Width

32.75”

Height

30”

Height

30”

Pump Model

NorthStar B4540

Pump Model

NorthStar SHFB5030

Pump Oil Capacity

26.88 oz.

Pump Oil Capacity

26.88 oz.

SUPPLIES REQUIRED (not included)

SUPPLIES REQUIRED (not included)

Engine Oil

Refer to engine owner’s manual

Engine Oil

Refer to engine owner’s manual

Pump Oil (Shipped

with Oil, but refills

required)

Universal Tractor Transmission

Oil

(part # COCP2101) or

Mobil 1 Synthetic Oil 15W50

Pump Oil (Shipped

with Oil, but refills

required)

Universal Tractor Transmission

Oil

(part # COCP2101) or

Mobil 1 Synthetic Oil 15W50

Battery

12 Volt, 18 amp (Group U1-7)

Battery

12 Volt, 18 amp (Group U1-7)

1572091

1572092

FLOW OUTPUT

FLOW OUTPUT

PSI (bar)

5000 (345)

PSI (bar)

3500 (241)

GPM (l/min)

5 (18.9)

GPM (l/min)

7 (26.5)

Max Water Temp

140° F (60°C)

Max Water Temp

140° F (60°C)

ENGINE

ENGINE

Engine

Honda GX660

Engine

Honda GX660

Displacement (cc)

660 cc

Displacement (cc)

660 cc

DIMENSIONS/COMPONENTS

DIMENSIONS/COMPONENTS

Length

33.75”

Length

33.75”

Width

34”

Width

34”

Height

32.25”

Height

32.25”

Pump Model

NorthStar B5050

Pump Model

NorthStar SHF7035

Pump Oil Capacity

35.84 oz

Pump Oil Capacity

35.84 oz

SUPPLIES REQUIRED (not included)

SUPPLIES REQUIRED (not included)

Engine Oil

Refer to engine owner’s manual

Engine Oil

Refer to engine owner’s manual

Pump Oil (Shipped

with Oil, but refills

required)

Universal Tractor Transmission

Oil

(part # COCP2101) or

Mobil 1 Synthetic Oil 15W50

Pump Oil (Shipped

with Oil, but refills

required)

Universal Tractor Transmission

Oil

(part # COCP2101) or

Mobil 1 Synthetic Oil 15W50

Battery

12 Volt, 18 amp (Group U1-7)

Battery

12 Volt, 18 amp (Group U1-7)

6

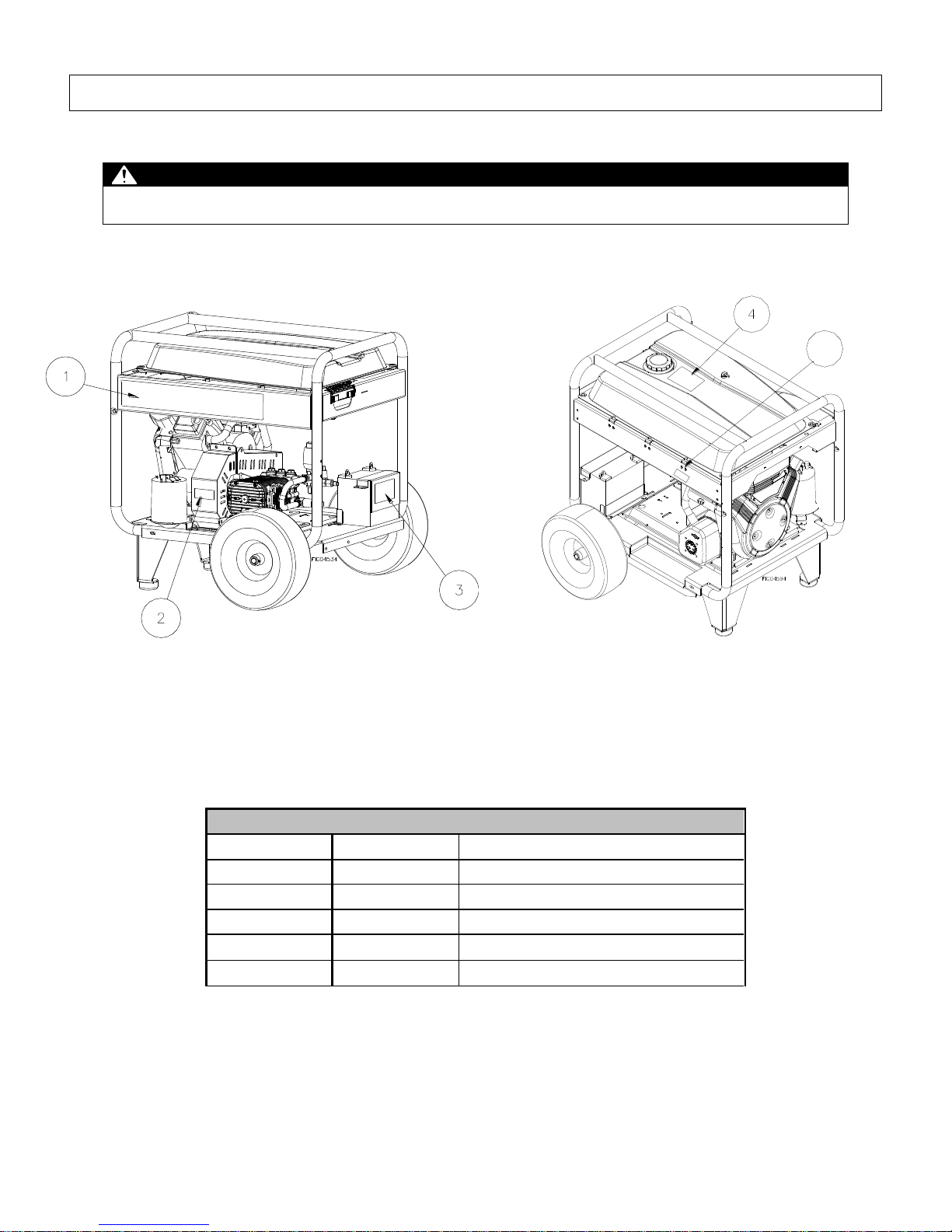

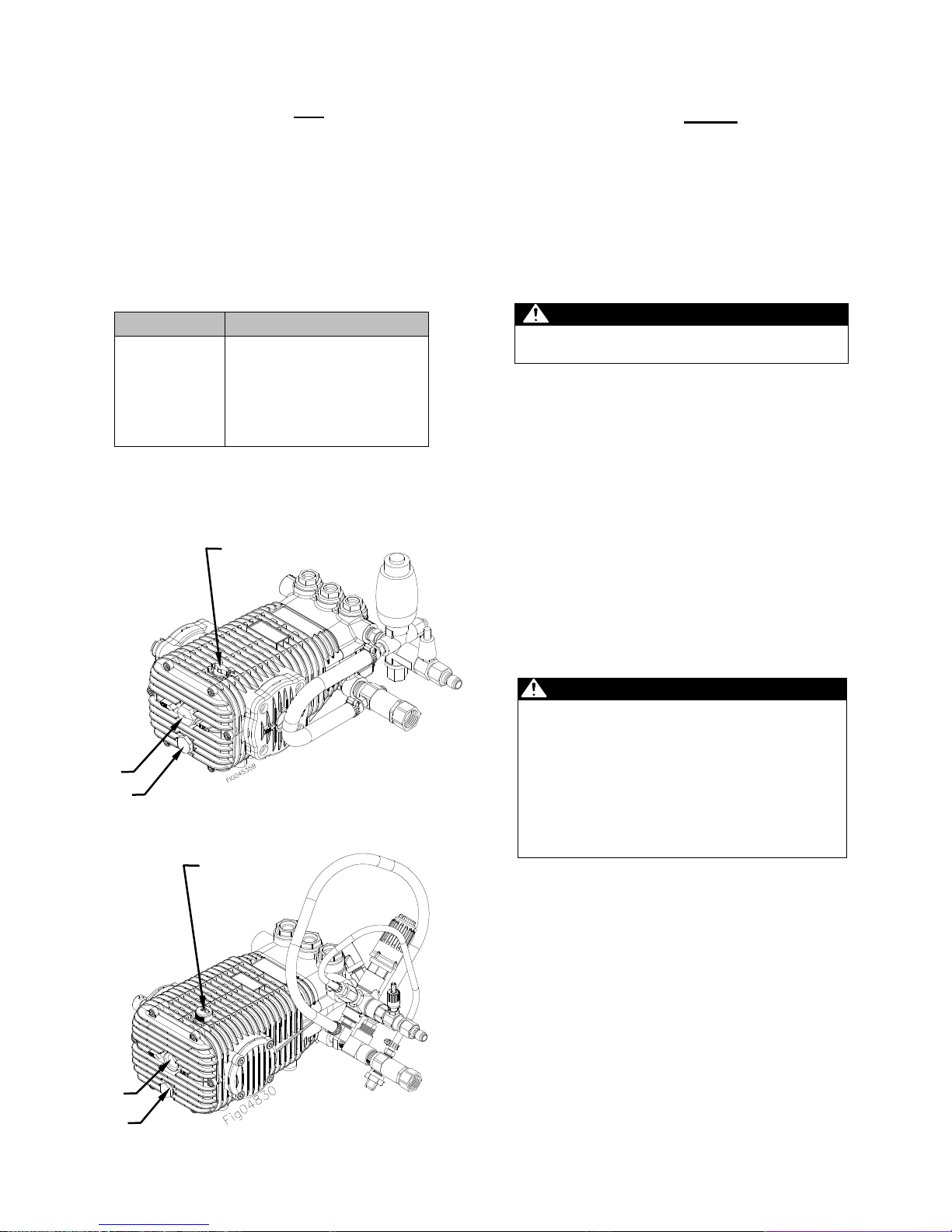

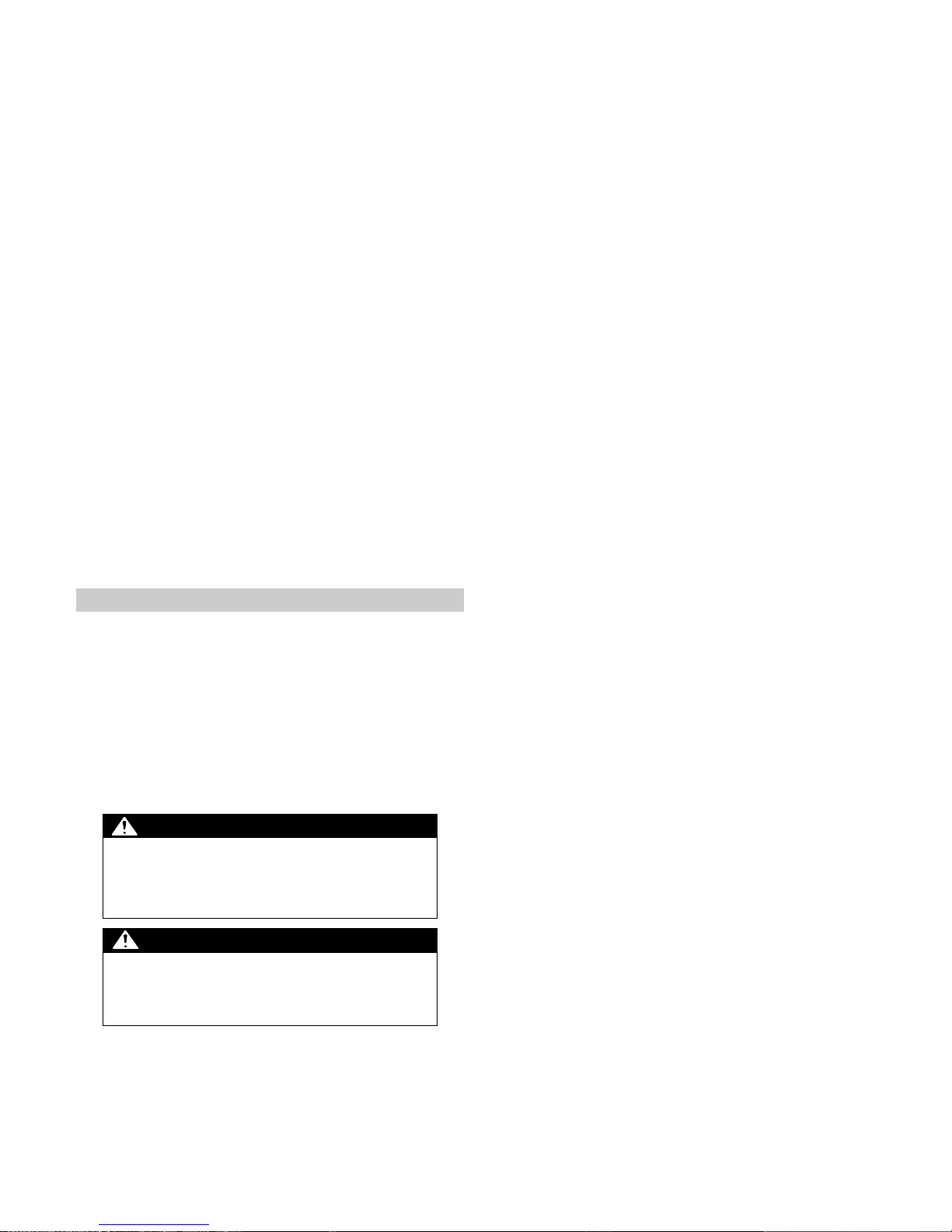

Component Identification

1. Engine Oil Fill. Use included funnel to add engine

oil to unit.

2. Oil Dipstick. Check engine oil level.

3. Carbon Canister. Prevents gasoline vapors from

exiting the fuel system.

4. Belt Guard. Guards against accidental contact

with moving parts.

5. Pump Oil Sight Glass. Fill pump oil to middle of

the sight glass.

6. Pump Oil Fill. Add pump oil here. Replace

shipping plug with vented dipstick.

7. Battery. Storage place to house the battery. (Not

included, customer to purchase separately)

8. Nozzle Holder. Removable device that will clip on

your belt and stores nozzles.

9. Nozzles. Change nozzles for different spray

patterns.

10. Water Outlet. Connect high pressure hose

here.

11. Fuel Shutoff Valve. Turn fuel shut-off valve to

OFF position before transporting or servicing the

pressure washer.

12. Gas Tank and cap. Fuel storage container and

cap.

13. Muffler. An acoustic device installed onto the

exhaust system that is designed to reduce noise.

14. Engine. The air-cooled engine powers the pump.

See “Parts Explosion” for more details

7

Safety

DANGER

WARNING

CAUTION

CAUTION

NOTICE

Hazard Signal Word Definitions

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury

or death.

DANGER (red) indicates a hazardous situation, which if

not avoided, will result in death or serious injury.

WARNING (orange) indicates a hazardous situation,

which if not avoided, could result in death or serious

injury.

CAUTION (yellow), used with the safety alert symbol,

indicates a hazardous situation, which if not avoided,

could result in minor or moderate injury.

CAUTION (yellow), without the safety alert symbol, is

used to address practices not related to personal injury.

NOTICE is used to address practices not related to

personal injury.

8

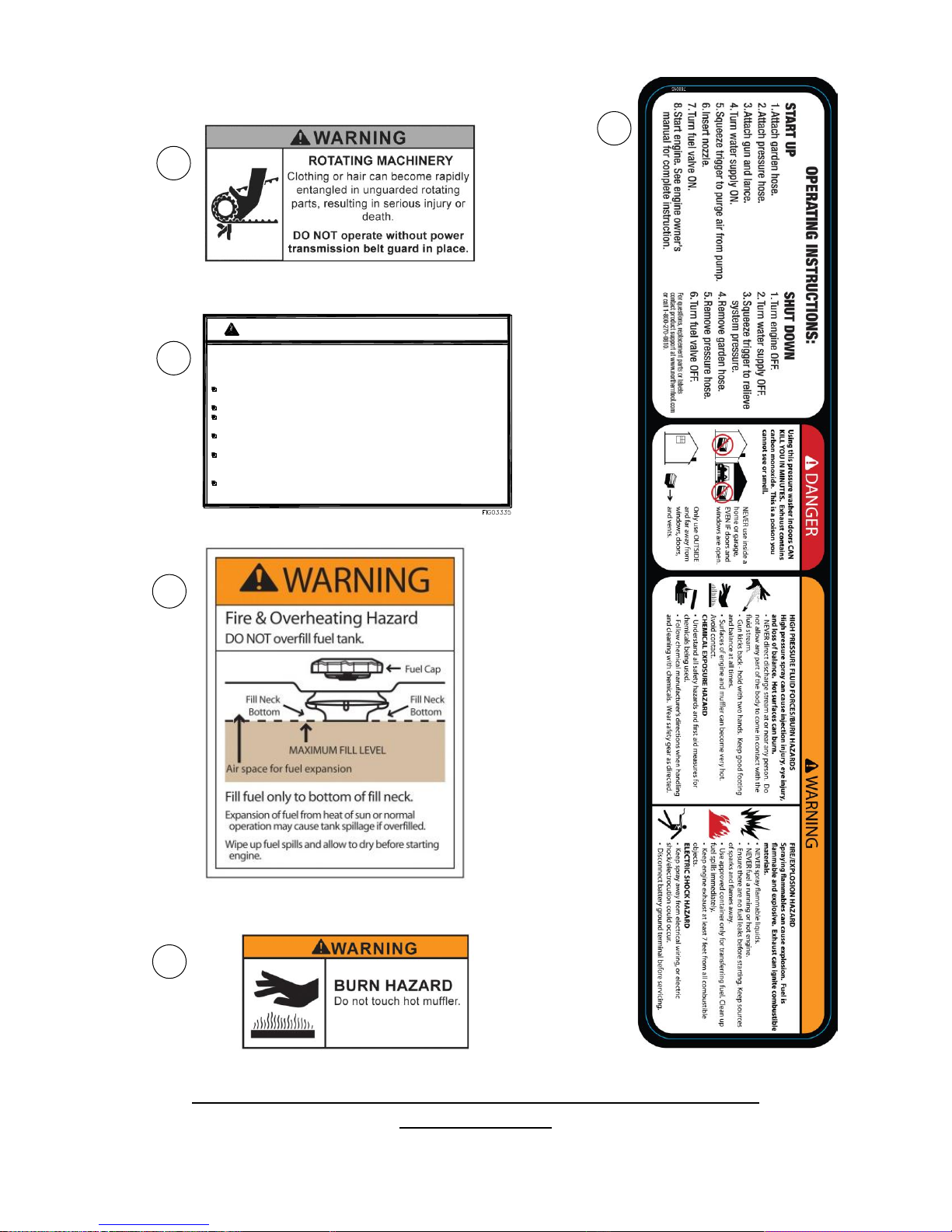

Safety Labeling

On-Product Warning Labels

Location

Part numbers

Description

1

788915

Operating Instructions with Warnings

2

786632

Rotating Machinery

3

782397

Battery Hazard

4

786837

Fire/Overheating/Overfill

5

786635

Burn Hazard

5

Safety Decal Locations

WARNING:

ALWAYS make sure safety labels are in place and in good condition. If a safety label is missing or not legible, order new labels

from NorthStar Product Support at 1-800-270-0810.

9

Safety Decals

ALWAYS use eye protection. Caustic acid and explosive

gases can cause blindness or severe burns.

NO smoking, sparks, or flames.

NEVER touch both battery terminals at the same time with your

hand or any non-insulated tools.

FLUSH immediately with water if battery acid contacts eyes,

skin, or clothing.

CONNECT cables in correct sequence: FIRST RED to POSITIVE

terminal, then BLACK to NEGATIVE terminal. When disconnecting,

DISCONNECT BLACK cable first, then RED.

NEVER charge a visibly damaged or frozen battery. ALWAYS

read and follow charger instructions.

BATTERIES:

1) contain caustic acid, 2) emit explosive gases,

3) can cause electric shock

WARNING - BATTERY HAZARDS

782397

5

4 3 2

1

To order replacement safety labels, call NorthStar Product Support

at 1-800-270-0810.

10

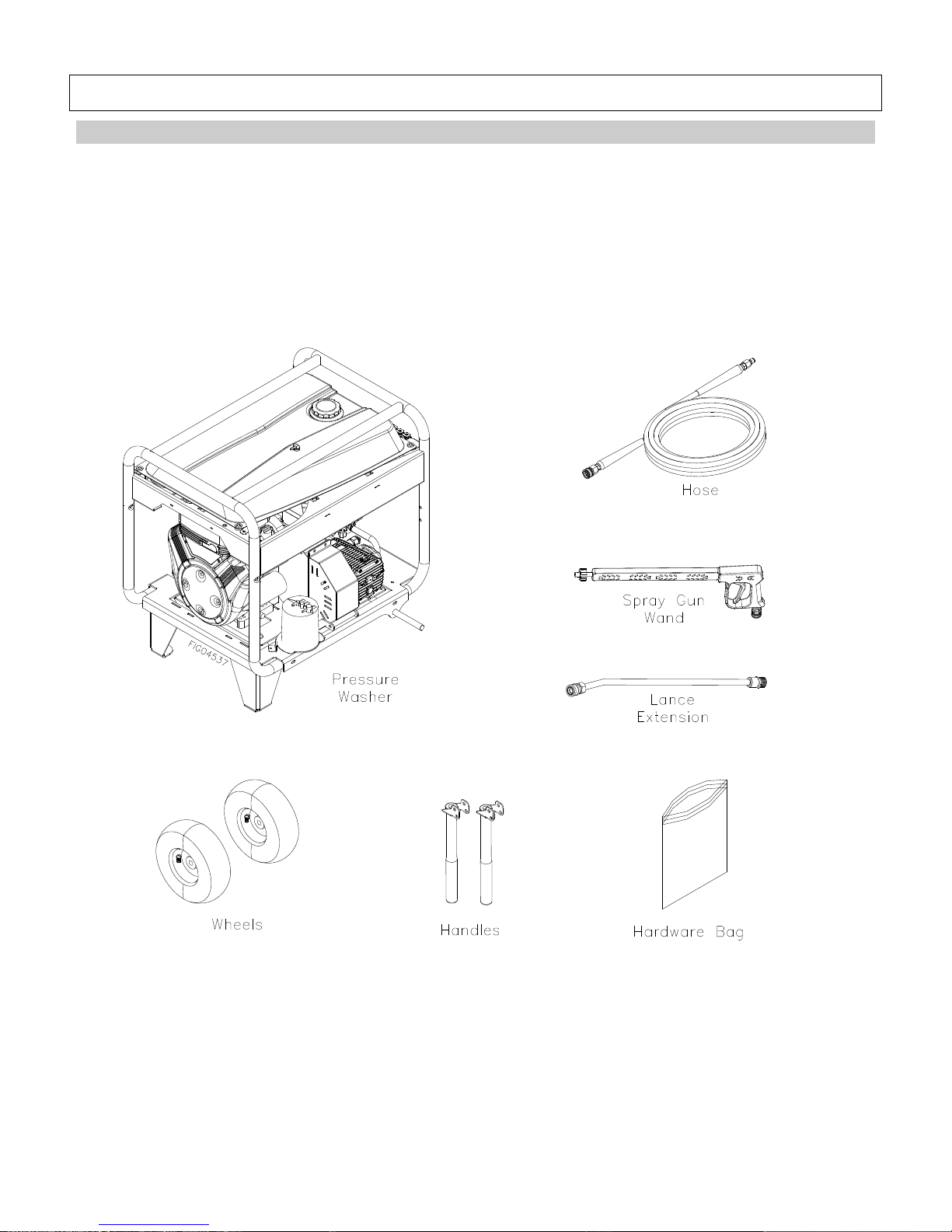

Initial Set-Up

Step 1. Inspect & Unpack

Upon receipt for missing or damaged parts. Verify that it is the pressure washer you ordered.

See “Component Identification” section of this manual for a diagram of the pressure washer and its components.

For missing or damaged components, contact Product Support at 1-800-270-0810.

If complete, fill out product serial number information. See “Limited Warranty” section of this manual.

Components:

11

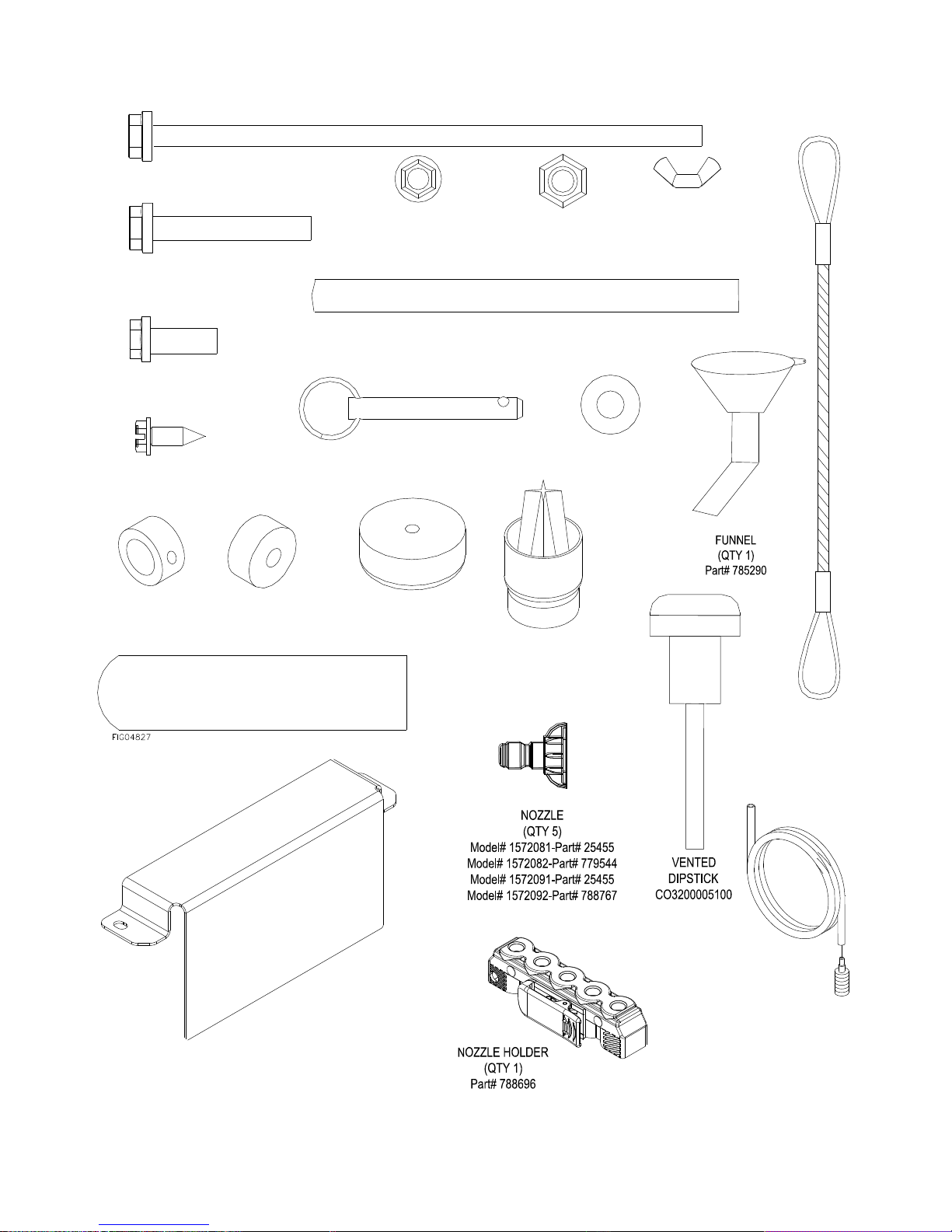

Hardware Bag:

GRIP

(QTY 2)

Part# 30747

5/16" FLAT WASHER

(QTY 10)

Part# 82021

BUMPER

(QTY 2)

Part# 2215

5/16" X 1" BOLT

(QTY 2)

Part# 82016

WHEEL RETAINER

(QTY 2)

Part# 305200

3/8" X 2-1/2" BOLT

(QTY 2)

Part# 82106

LARGE BUMPER

(QTY 2)

Part# 15431

6" LANYARD

(QTY 2)

Part# 786756

5/16" FLANGE NUT

(QTY 2)

Part# 82019

3/8" COTTERLESS PIN

(QTY 2)

Part# 38070

1/4" X 3/4" SELF TAPPER

(QTY 2)

Part# 82232

3/8" NYLOC NUT

(QTY 2)

Part# 82027

BATTERY TIE PLATE

(QTY 1)

Part# 787620

1/4" X 7" BOLT

(QTY 2)

Part# 82377

1/4" WINGNUT

(QTY2)

Part# 82083

CHEMICAL INJECTOR HOSE AND

STRAINER

(QTY 1)

Part#777165

1/2" X 6" REINFORCED PVC HOSE

(QTY 1)

Part# 30160

SPARK ARRESTOR

(QTY 1)

Part# 781341

1572091/1572092

12

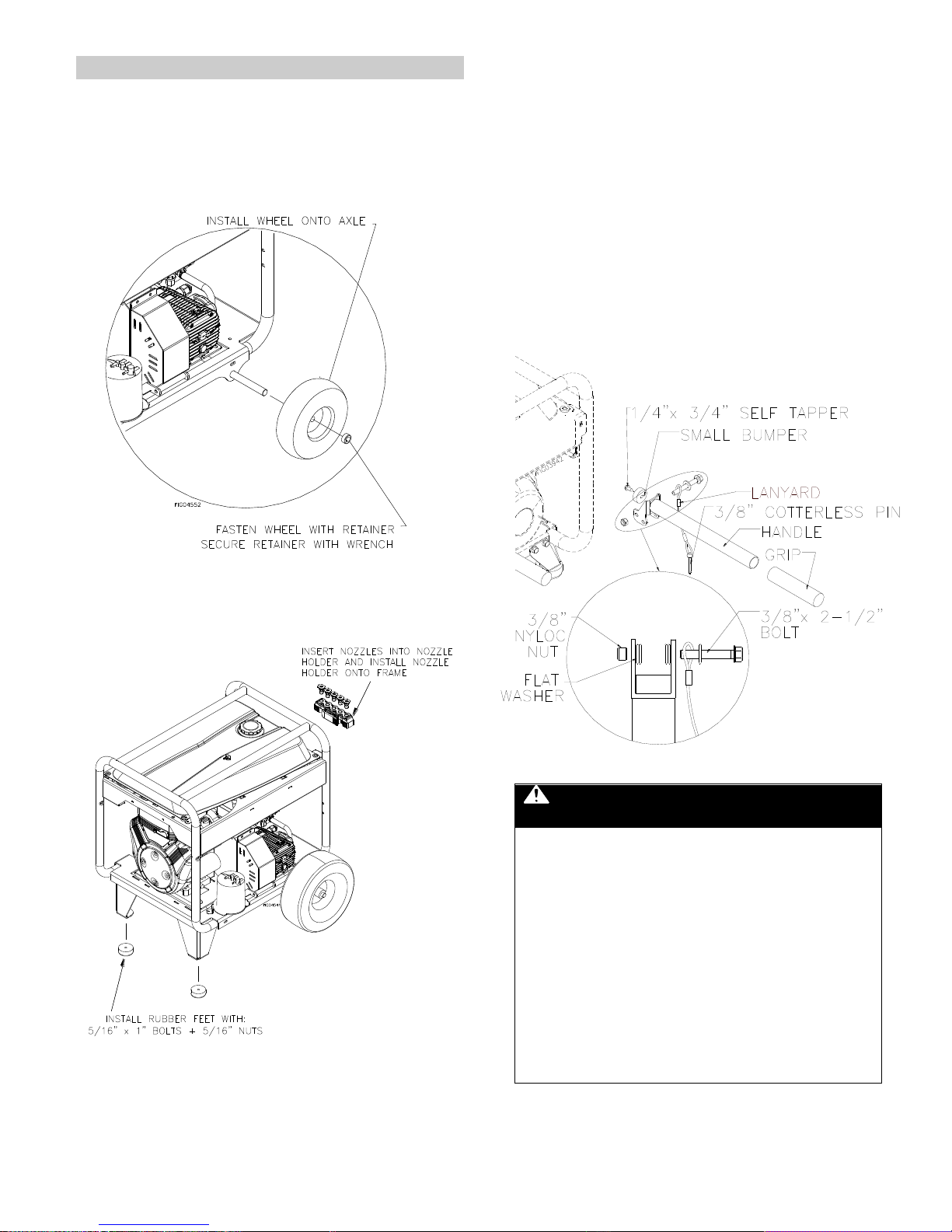

Step 2. Assembly

Hazard

High-pressure fluid discharge from leaks (even pinsized) or ruptured components can pierce skin and

inject fluid into the body. Injection injury can result in

blood poisoning and/or severe tissue damage leading

to infection, gangrene, and possibly amputation.

Never use a finger or skin to check for

leaks.

Never operate machine with damaged or

missing hoses/parts.

Never attempt to repair a high-pressure

hose or component – Always replace it with

a part that is rated at or above the pressure

rating of this machine.

Note: Remove contents from pallet and assembly can

occur at this time.

1. Install wheel onto axle using a 5/32” allen

wrench.

2. Install Nozzles into Nozzle Holder, Install Nozzle

Holder onto Frame and Install Rubber Feet.

3. Install grip onto handle

4. Attach small bumper to handle with ¼” x ¾” self-

tapper.

5. Insert (1) 3/8” x 2-1/2” bolt through (1) flat

washer and through one end of lanyard as

shown below. Attach 3/8” cotterless pin to other

end of lanyard.

6. Install handle to pressure washer using 3/8” x

21/2” bolt, (4) flat washers and (1) 3/8” nyloc nut

until washers press against tube walls. Repeat

to for both sides.

7. Insert cotterless pin through bottom hole of arm

so handle doesn’t fold up while in use.

13

Prepare Water Pump:

Pump

Oil Type

NorthStar

Universal Tractor

Transmission Oil

(part # COCP2101)

Mobil 1 Synthetic oil

15W-50

WARNING: Battery Hazards

Batteries are hazardous because they contain

caustic acid, can emit explosive gases, and can

cause electric shock. Caution must be exercised

when making connections to a battery to avoid

shock and contact with the acid, and to prevent

any sparking that could lead to an explosion.

ALWAYS follow the general battery safety rules

and instructions.

Oil drain plug

Sight glass

Oil fill cap

1572081 & 1572082

1572091 & 1572092

Oil drain plug

Sight glass

Oil fill cap

1. Verify pump oil level.

Note: The pump is shipped with oil.

a. Remove shipping plug and install vented

dipstick.

b. Verify that oil level is half way up the

sight glass (or at the indicator line on the

dip stick).

2. If oil level is low, fill using the type of pump oil

specified below. See the “Specifications” section

of this manual to determine the type of pump that

came equipped with this pressure washer.

3. Replace oil fill cap.

Prepare Engine

1. Fill engine with oil.

Note: Engine is shipped without oil. You must add

oil before first use.

a. Refer to Engine Manual to locate oil-fill

port and for instructions on filling. Use

the oil grade and quantity specified in the

Engine Manual.

b. Low oil shutdown feature on 1572081 &

1572082 prevents the engine from

Never open oil port while engine is running. Hot oil can

spray over face and body.

starting without sufficient oil.

WARNING: Burn Hazard

Battery Installation

1. Install a 12-volt standard lawn and garden

battery (Group U1-7) with a minimum of 18 amp

hour rating. The engine will NOT run unless a

battery is installed.

The battery is to be supplied by the

customer and should be installed in the

protective battery compartment located near

the engine.

2. Following the steps below for connecting and

disconnecting the battery:

General Battery Safety Rules

ALWAYS use eye protection and protective

clothing when handling batteries.

NEVER smoke or work near sparks or other

sources of ignition.

NEVER touch both battery terminals at the same

time with your hand or any non-insulated tools.

If battery acid contacts skin or clothing, flush

immediately with water and neutralize with baking

soda.

14

Connecting the Battery

Always connect the cables in the following sequence to

avoid possible shock:

a. Find the battery cables located inside the battery

compartment.

b. Connect the red cable to the positive (+)

terminal of the battery.

c. Then connect the black cable to the negative (-)

terminal of the battery.

d. Reinstall the battery strap before using the

pressure washer.

Disconnecting the Battery

Always disconnect cables in the following sequence to

avoid possible shock.

a. First, disconnect the black cable from the

negative (-) terminal of the battery.

b. Next, disconnect the red cable from the positive

(+) terminal of the battery.

c. Remove the battery from the battery

compartment.

d. Reinstall the battery strap.

Step 3. Select Suitable Location

Moving and Handling

Moving your pressure washer around

Use the handles to manually move the pressure

washer.

Pull the pressure washer behind you has you

walk.

To turn, lift slightly on the handles and pivot the

pressure washer on the back wheels.

WARNING: Lifting hazard

The pressure washer is heavy. It can crush and

cause serious injury if it rolls out of control or tips

over. Follow the instructions below for safely

moving the pressure washer.

WARNING: Location hazards

Choose a suitable site for operating your pressure

washer to prevent possible death from carbon

monoxide poisoning or injury from fire/explosion, hot

surfaces or equipment tip-over.

Elevating or lowering your pressure washer

To reduce risk of injury, it is recommended that

two adults lift the pressure washer.

Only lift the pressure washer by the bumper and

handle. Do not use the pump or engine as a lifting

point.

Outdoor Use Only

Select a suitable outdoor location:

Away from all building windows and air intakes.

Where no flammable vapors, dusts, and gases

are present.

Where there is adequate, unobstructed ventilation

airflow.

Away from dusty/dirty conditions.

With adequate clearance from combustible

materials.

On a firm, level, heat-resistant surface with good

drainage.

1. Never run the pressure washer in an enclosed or

partially enclosed location such as a building,

garage, barn, shed, or house. These spaces can

trap poisonous gases. Running a fan or opening

windows will not provide adequate ventilation to

prevent dangerous CO build-up.

2. Only use the pressure washer outdoors and at

least 20 feet from the home, away from windows,

vents and air intakes, to allow proper ventilation. If

you start to feel sick, dizzy, or weak while using

the pressure washer, shut off the engine and get

to fresh air RIGHT AWAY.

3. Place the pressure

4. washer so that the exhaust fumes will not be

directed towards people or building air intakes.

5. Do not locate and use the pressure washer in the

presence of flammable vapors, dust, gases, or

other potentially combustible materials.

6. Ensure that working, battery-operated or battery

back-up carbon monoxide alarms are used in any

dwelling/structure that is in close proximity to the

running pressure washer.

7. Note that this pressure washer is NOT designed

or approved for use in vehicles or marine

applications. Never run the pressure washer

inside RVs or other vehicles, on boats, or on pickup truck beds.

Positioning:

1. The pressure washer should be positioned on a

firm, level (less that 3 degree slope), heatresistant surface with good drainage and a nearby

water supply.

2. The pressure washer should be placed within

garden hose distance of a continuous water

supply. Ensure that the pressure washer sits level

and will not slide or shift during operation. If

Loading...

Loading...