North Star M157206S, M157206R Maintenance Manual

Quick Facts

Engine Oil

Engine is shipped without oil. Fill before starting.

Use SAE 10W-30 motor oil.

Pump Oil

Pump is shipped with oil. Remove the red shipping plug and install vented dipstick.

Use SAE 30 Non-Detergent oil (item# 4043) for oil changes.

Water

Make sure your water flow is 20% higher than the pressure washer’s flow rate.

Make sure your water is clean and particle free.

Storage

Do not allow water to freeze in the pump, hose, or spray gun.

Add fuel stabilizer to the fuel tank before long term storage.

Spraying

Chemicals

Use any North Star brand or equivalent pressure washer chemicals.

Use black nozzle.

Maintenance

Schedule

Engine:

Oil: change after first 20 hours, then annually or every 100 hours.

Spark Plug: clean every 100 hrs, replace annually or every 300 hrs.

Air Filter: clean every 100 hours, replace annually or every 300 hrs.

Pump:

Oil: change after first 40 hours, then every 3 months or 500 hours.

Read and understand all manuals before operating.

M157206S

ITEM NUMBER:157205, 157207

SERIAL NUMBER:

Engine Model:

Pump Model:

Flow: Pressure:

Hose Length: Lance Length:

Nozzle Size:

®

Installation, Operation, and Maintenance Manual

PRESSURE WASHER: Cleans dirty surfaces with high pressure water.

To the Owner:

Thank you for purchasing a NorthStar pressure washer. Your machine is designed for long life, dependability,

and the top performance you demand! Take time now to read through this manual so you better understand the

machine’s operation, maintenance and safety precautions. Everyone who operates this machine must read and

understand this manual. The time you take now will prolong your machine’s life and prepare you for its safe

operation. Enjoy the exceptional performance of your NorthStar pressure washer, the industry leader!

The manufacturer reserves the right to make improvements in design and/or changes in specifications at any

time without incurring any obligation to install them on units previously sold.

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar Product Support 1-800-270-0810

2

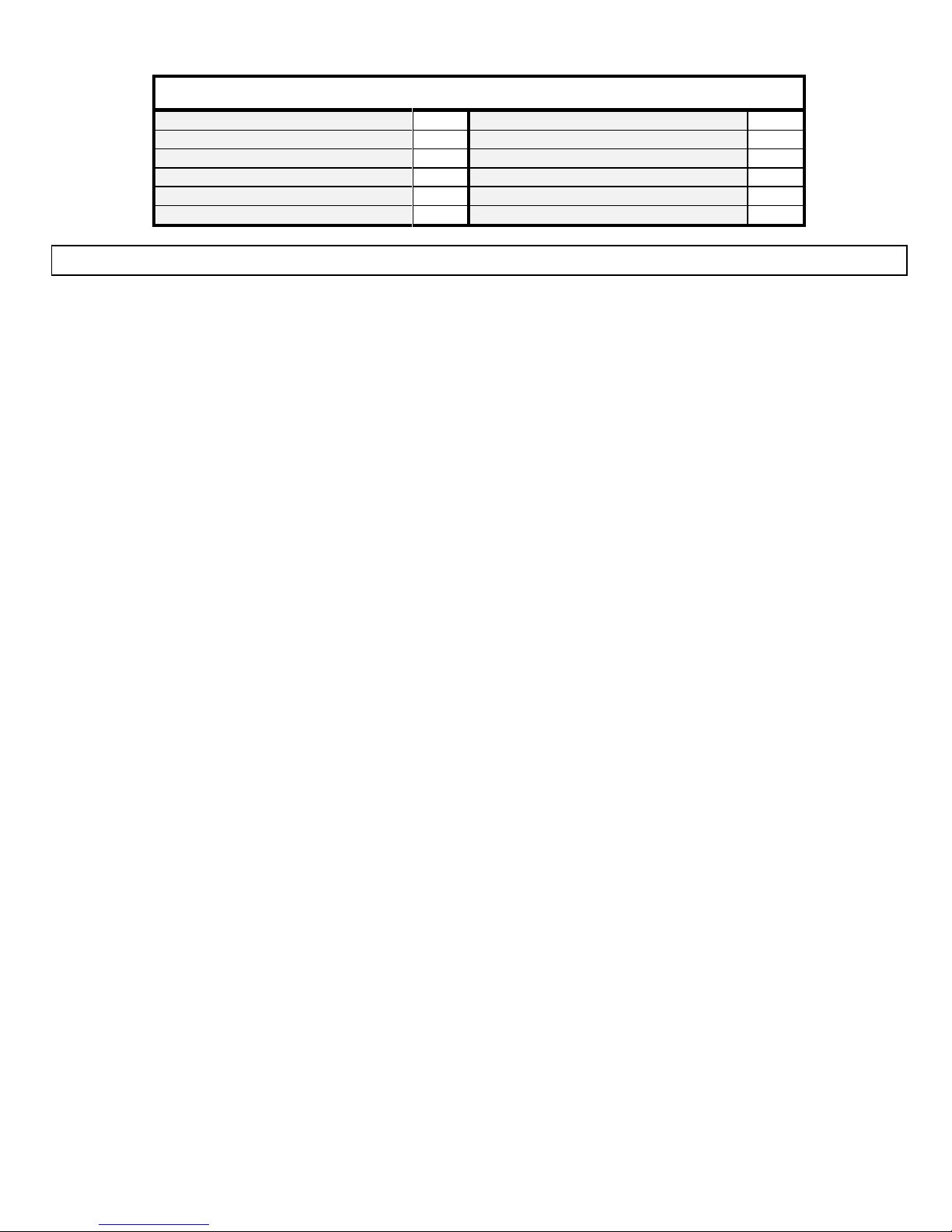

Table of Contents

Important Safety Instructions

2

Maintenance Instructions

10-11

Machine Component Identification

3

Moving and Handling Instructions

12

Installation Instructions

4-6

Long Term Storage

12

Operation Instructions

7-9

Troubleshooting

13

Safety Features

9

Parts Explosions

14-15

Limited Warranty

17

Important Safety Instructions

WARNING -Risk of Injection or Injury to Persons - Do Not Direct Discharge Stream at Persons. - Do not

use a hose if exterior damage is evident.

-Risk of explosion. - Do not spray flammable liquids. - Do not operate in a flammable

environment.

CAUTION -Risk of Asphyxiation - Exhaust fumes are deadly. For outdoor use only. Avoid inhaling exhaust

fumes.

-Risk of fire. Do not add fuel when the product is operating or hot.

-Gun kicks back. Hold with both hands.

-To reduce the risk of injury, read operating instructions carefully before use.

WARNING - When using this product basic precautions should always be followed, including the following:

1.) Read all the instructions before using the product.

2.) To reduce the risk of injury, close supervision is necessary when the product is used near children. Do

not allow irresponsible use by children. Always stop the product and bleed pressures before leaving

unattended, disconnecting hoses, or servicing the pump.

3.) Know how to stop the product and bleed pressures quickly. Be thoroughly familiar with the controls.

4.) Stay alert - watch what you are doing.

5.) Do not operate the product when fatigued or under the influence of alcohol or drugs. Never smoke

while operating or fueling this machine.

6.) Keep operating area clear of all persons.

7.) Do not overreach or stand on unstable support. Keep good footing and balance at all times. Wear

footwear capable of maintaining a good grip on wet surfaces - Do not place the machine on soft or

unstable ground.

8.) Follow the maintenance instructions specified in all manuals. Do not run machine without sufficient

lubrication or sufficient water to cool the pump.

9.) Wear safety glasses, gloves, face protection and appropriate clothing when operating the machine.

10.) Do not operate this machine with broken or missing parts. - Never alter the manufacturer’s original

design or deactivate any safety device on the machine.

11.) Risk of exposure to dangerous chemicals. Wear protective gloves when handling and cleaning with

chemicals. Follow the chemical manufacturer’s directions. Understand all safety hazards and first aid

for all chemicals being used. Check whether dangerous chemicals have been used and take any

precautions that may have been recommended by the supplier of these chemicals when cleaning

filters. Do not pump highly abrasive fluids or use with incompatible chemicals or solvents.

12.) Know the pressure and temperature limits of your machine. Be sure all high pressure accessories

meet or exceed your machine’s limits. Do not set the pressure relief valve above the machine’s limit.

13.) Do not move this machine by pulling on the hose. Do not use the pump to support other items of

equipment that impose unacceptable loads on the pump. Do not attempt to use this machine as a prop.

14.)To reduce risk of injury, do not secure the spray gun open. Your spray gun is equipped with a built-in

trigger safety latch to guard against accidental trigger release and potentially dangerous high pressure

spray. Rotate the safety latch to the locked position when not spraying.

15.) Do not clean this machine with its own spray. Cleaning should be done with a damp sponge with the

engine OFF.

SAVE THESE INSTRUCTIONS

3

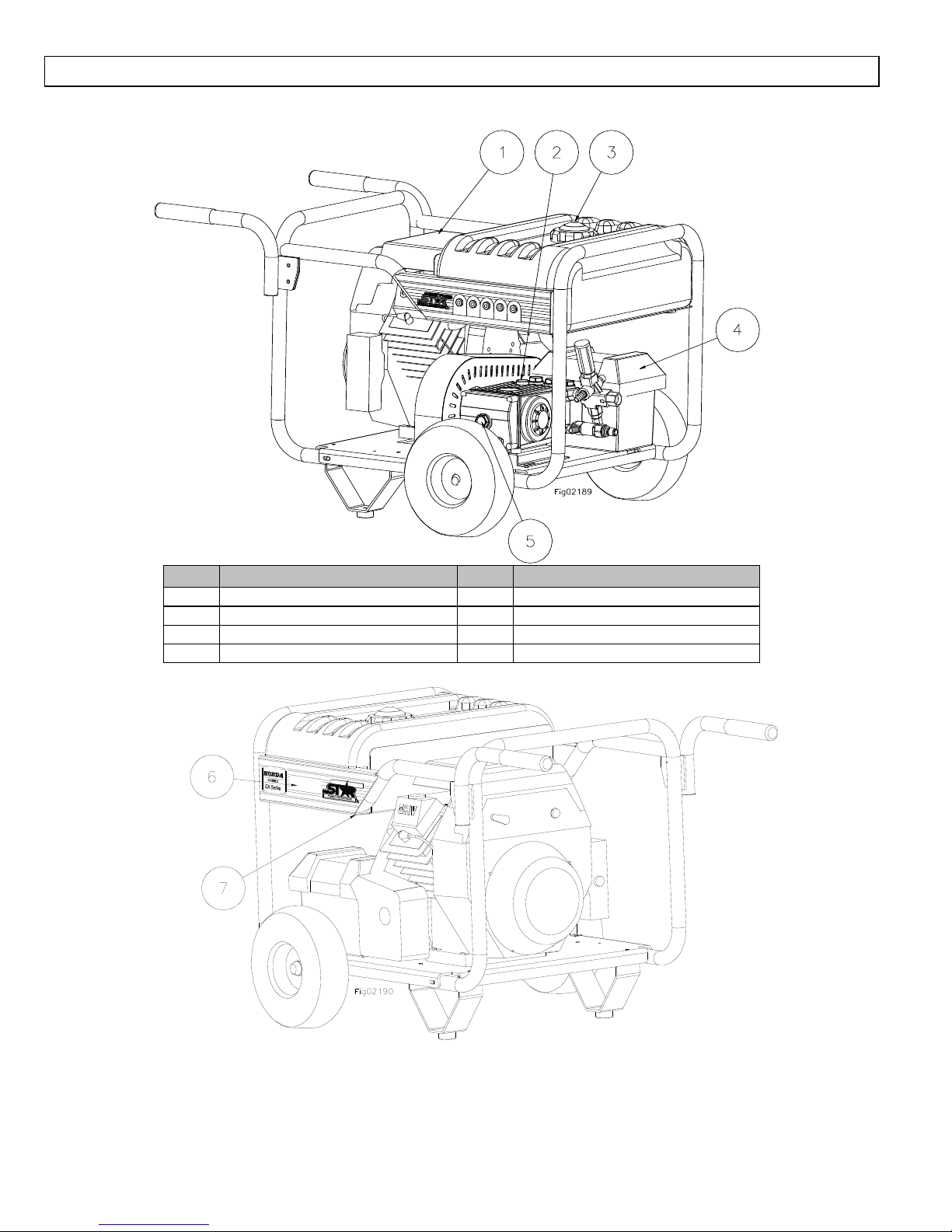

Machine Component Identification

Ref

Description

Ref

Description

1

Engine

5

Pump Oil Sight Glass

2

Pump Oil Fill/Dipstick

6

Startup/Shutdown Instructions

3

Gas Cap with Gauge

7

Fuel Shutoff Valve

4

Battery Box

T

2.) Attach pressure hose

4.) Turn water supply ON.

3.) Attach gun and lance

COMMERCIAL

purge air from pump.

5.) Squeeze trigger to

7.) Start engine

6.) Insert nozzle

POWERED BY

Start

1.) Attach garden hose

1.) Turn engine OFF.

2.) Turn water supply OFF.

3.) Squeeze trigger to

relieve system pressure

4.) Remove garden hose

5.) Remove pressure hose.

6.) Turn fuel valve OFF.

Stop

4

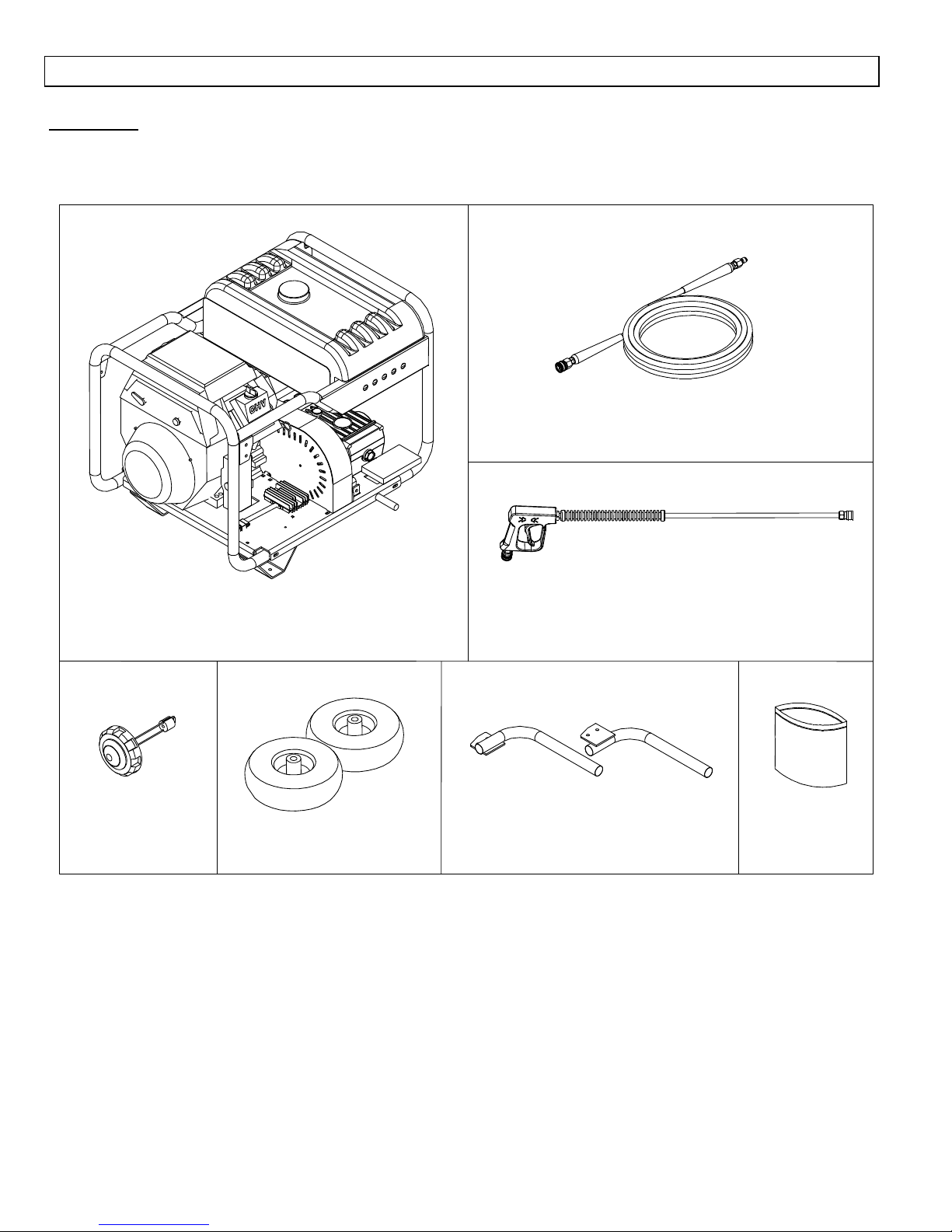

Installation Instructions

FIG02225

MAIN UNIT

HOSE

SPRAY GUN, LANCE, NOZZLE HOLDER

FUEL TANK CAP

(MAY ALREADY

BE INSTALLED)

WHEELS

HANDLES

HARDWARE

BAG

I.) Unpack

Separate and identify the components. Use the assembly instructions in this manual for assembly.

5

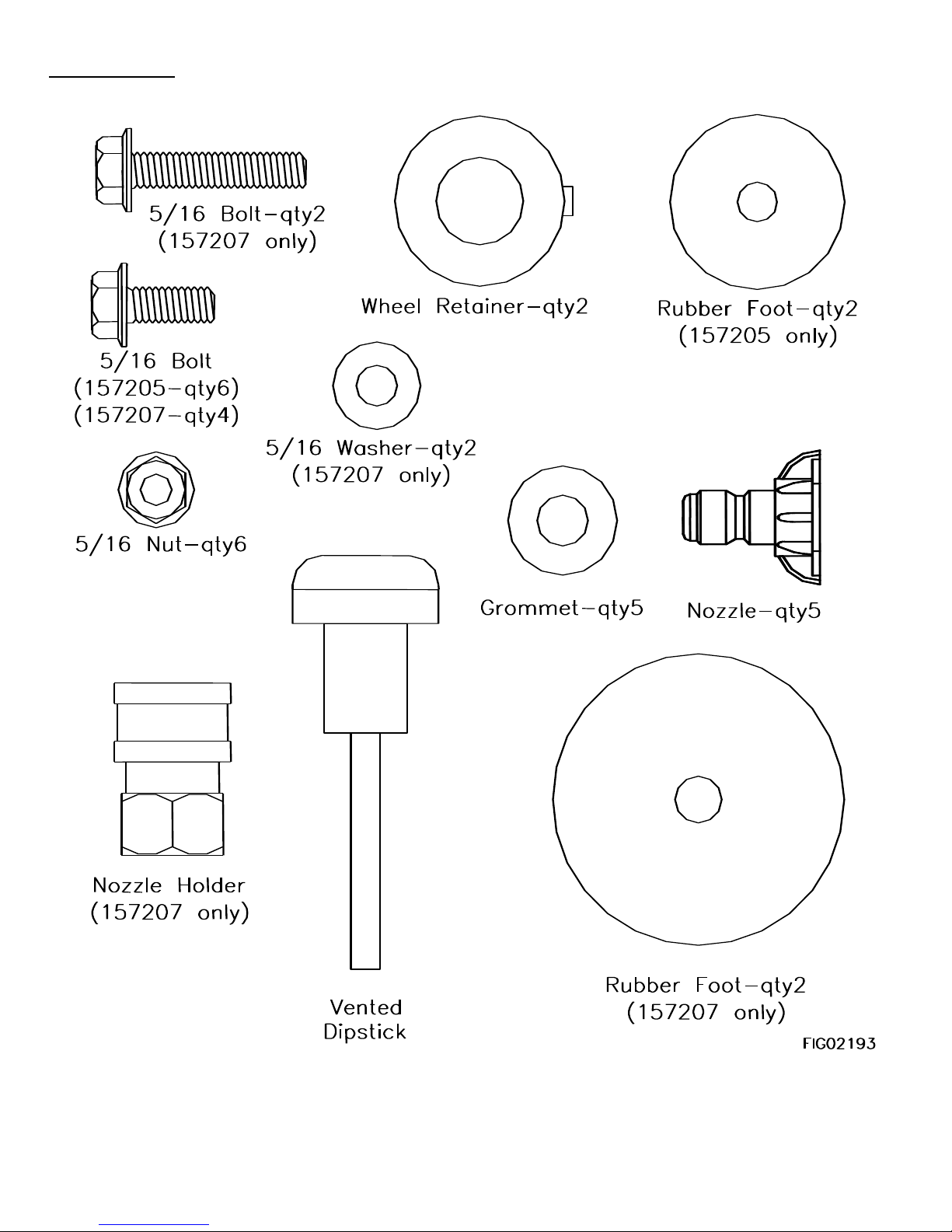

Hardware Bag

6

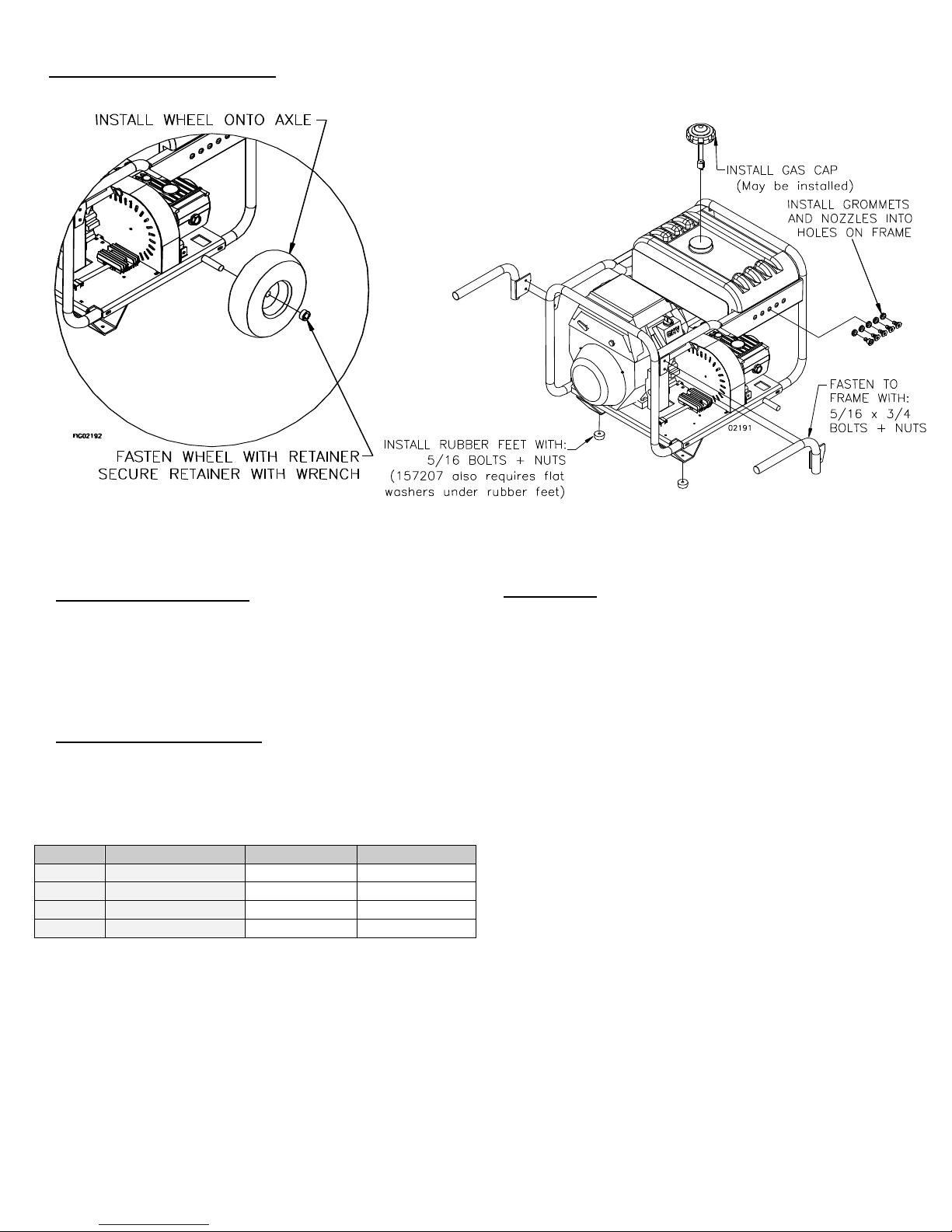

II.) Assembly Instructions

Item #

Engine/Pump

Type of Fluid

QTY

157205

Briggs Vanguard

SAE 10W30

1.75qt (1.7L)

157207

Honda GX670

SAE 10W30

1.48qt (1.4L)

157205

AR RKA 45G40

SAE 30**

15.0oz (.44L)

157207

General T9281

SAE 30**

40.60oz (1.2L)

III.) Pump Preparation

A.) Remove red shipping plug from oil fill hole.

B.) Install vented dipstick into oil fill hole.

C.) Make sure the oil is 1/2 way up oil sight glass.

IV.) Engine Preparation

A.) Fill engine with SAE 10W30 oil.

B.) Fill fuel tank with unleaded gasoline, 86 octane min.

Quantities Of Fluid

**SAE Non-Detergent (Item# 4043)

V.) Battery

Warning: Sulfuric acid is a corrosive poison.

Avoid contact with skin, eyes or clothing. Always

wear safety glasses when working on or near the

battery.

The battery box provides protection for the battery and

will accept a standard lawn tractor size battery (Group

U1-7). The engine requires a 12 volts dc battery, with a

minimum rating of 18 Amp-Hours. When installing a

battery, always connect the red colored (“positive” or “+”)

cable first. When disconnecting a battery, always

remove the black colored (“negative” or “-”) cable first.

Loading...

Loading...