Page 1

951X/XD AND 952X/XD

GPS C

HART NAVIGATORS

INSTALLATION MANUAL

Northstar Technologies

30 Sudbury Road

Acton, Massachusetts 01720

Revision C

Part Number GM1505C

www.northstarcmc.com

Service: 978/897-0770

Sales: 978/897-6600

Page 2

Page 3

Limited warranty policy

Northstar Technologies, a division of BSC, Inc., warrants the Northstar

951/952 to be free from defects in materials and workmanship for a

period of two (2) years. This warranty applies to the original purchaser

and to any subsequent owner during the warranty period, which begins

on the date of shipment of the unit, F.O.B. Acton, Massachusetts, to an

authorized Northstar dealer.

Systems may not be returned to Northstar without a Returned Materials

Authorization (RMA) number. Call the Northstar dealer or Northstar for

instructions.

During the unit’s warranty period, Northstar will repair or replace, at its

option, any part of the unit it finds to be defective due to faulty material(s) or workmanship. All such repairs and/or replacements will be

promptly performed by Northstar free-of-charge to the owner, excluding

freight costs incurred in shipping to the factory. Return shipments from

Northstar to points within the United States are made via ground transportation, freight prepaid. Special shipping charges (overnight, two-day,

and so on) are the responsibility of the owner.

To be covered by this warranty, the Northstar equipment must have been

in normal use. This warranty does not apply to units with defects caused

by improper installation, physical damage, abuse, tampering, lightning or

other abnormal electrical discharge, or to units with defaced or altered

serial numbers, or to units repaired by unauthorized persons or repaired

in a manner that violates Northstar’s recommended service procedures.

All repairs and/or replacements made under this warranty must be performed at Northstar’s facilities in Acton, Massachusetts. Performance of

warranty work elsewhere will not be authorized, and Northstar will not

pay for any charges for such work. Northstar will not be responsible for

payment of any charges imposed by a Northstar dealer or other party for

services requested by and/or performed for a unit’s owner in connection

with this warranty. Such services might include removal of the unit from

a vessel, inspection, packaging, handling, reinstallation, and the like.

Northstar Technologies assumes no responsibility for any consequential

losses of any nature with respect to any of its products or services sold,

rendered, or delivered. The foregoing is the only warranty expressed or

implied. No other warranty exists.

Page 4

Page 5

Contents

SECTION ONE - Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Who should read this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Scope of this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Getting technical support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Servicing the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Returning a unit for service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SECTION TWO - Installing the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Choosing a system location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Wiring the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Installing the antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Turning the unit on and off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Testing and troubleshooting the 951/952 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

SECTION THREE - Interfacing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Interfacing the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Configuring the NMEA output ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Connecting to other equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Setting the anchor-watch alarm honk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Configuring the RS-232 port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Ordering 951/952 software updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

APPENDIX A - Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

951/952 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

IEC compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Internal DGPS receiver specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

AN150 Active GPS Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

8410 Antenna Coupling Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Combination GPS/DGPS antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

951/952 INSTALLATION MANUAL Revision C Page i

Page 6

Page ii 951/952 INSTALLATION MANUAL Revision C

Page 7

Figures

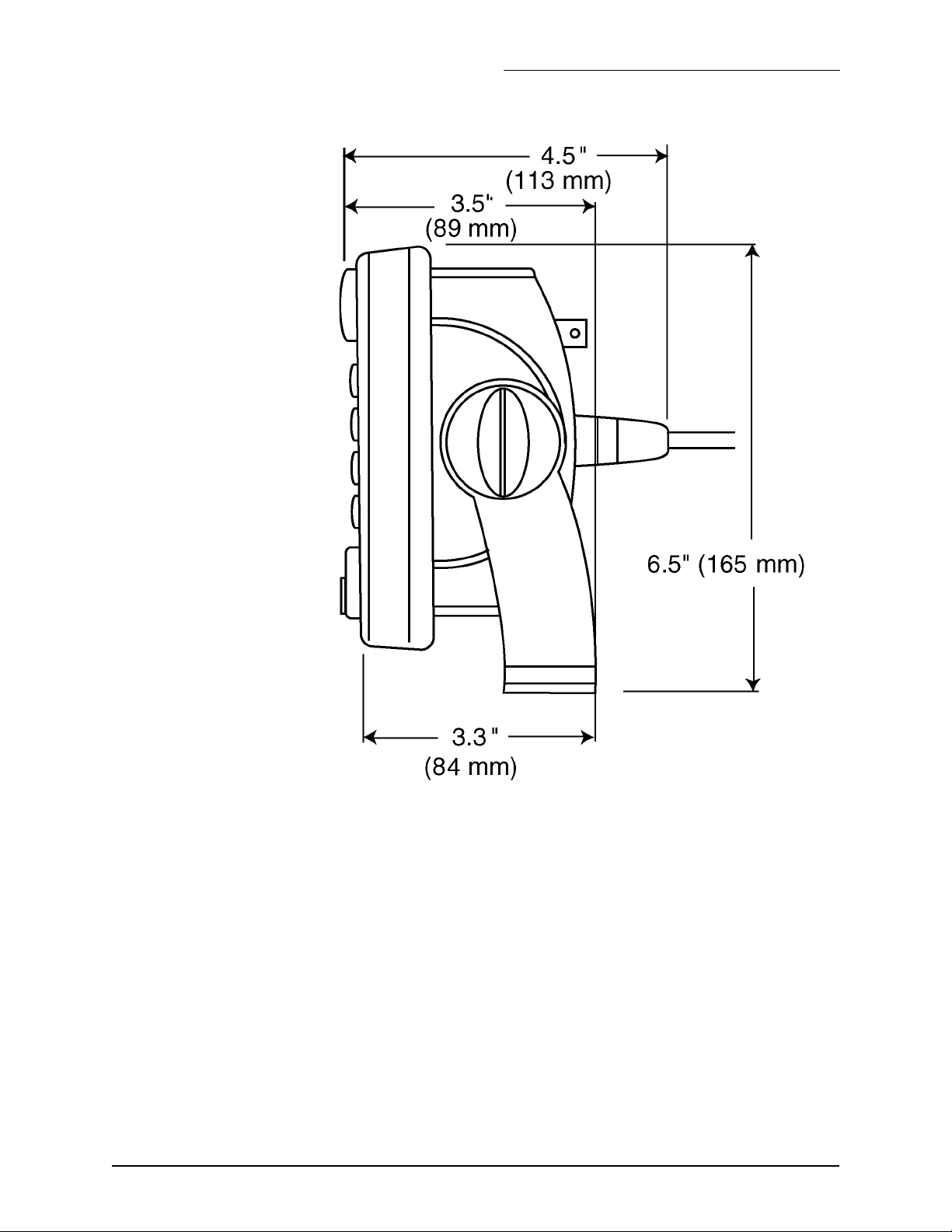

Figure 1: 951/952 dimensions (side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

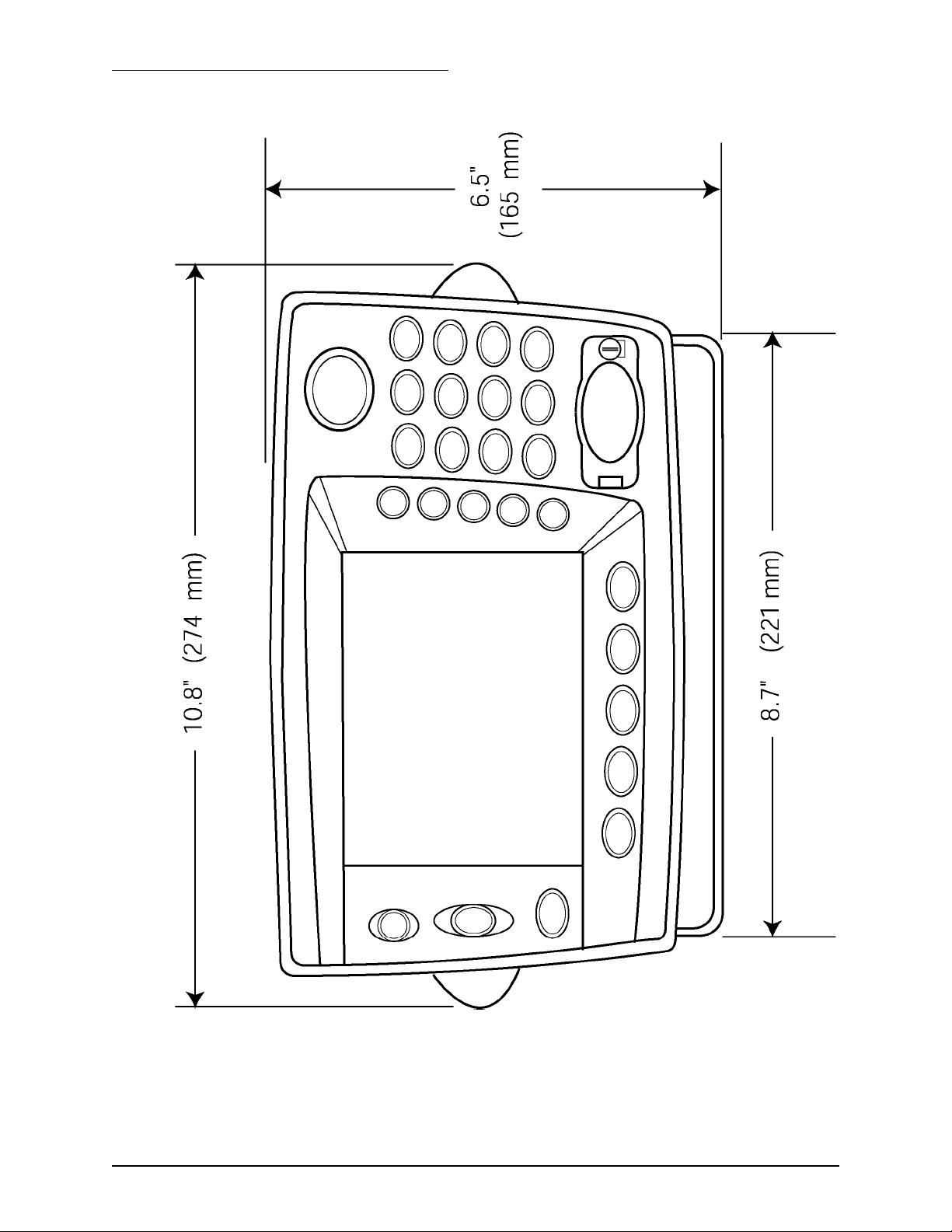

Figure 2: 951/952 dimensions (front) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

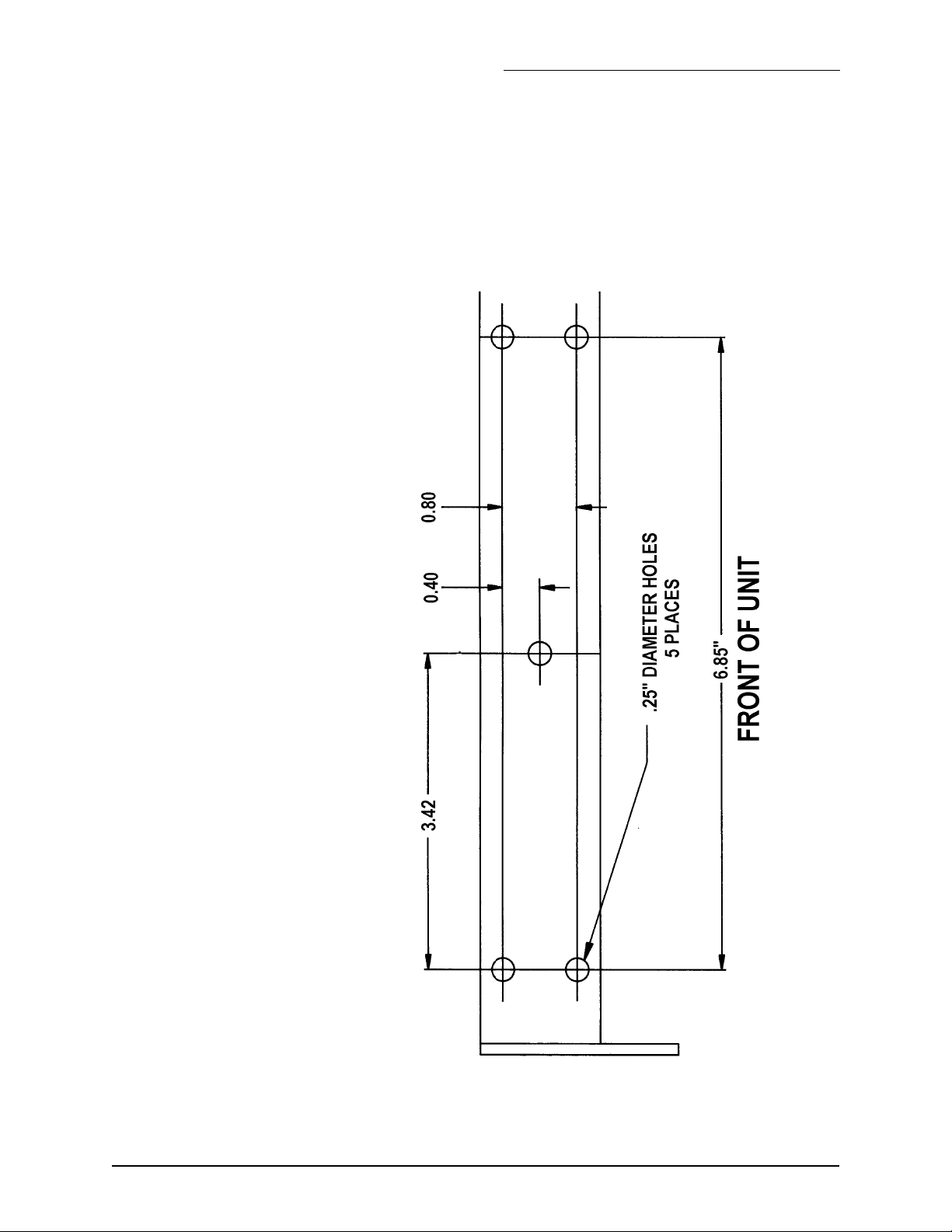

Figure 3: Yoke mount drilling dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

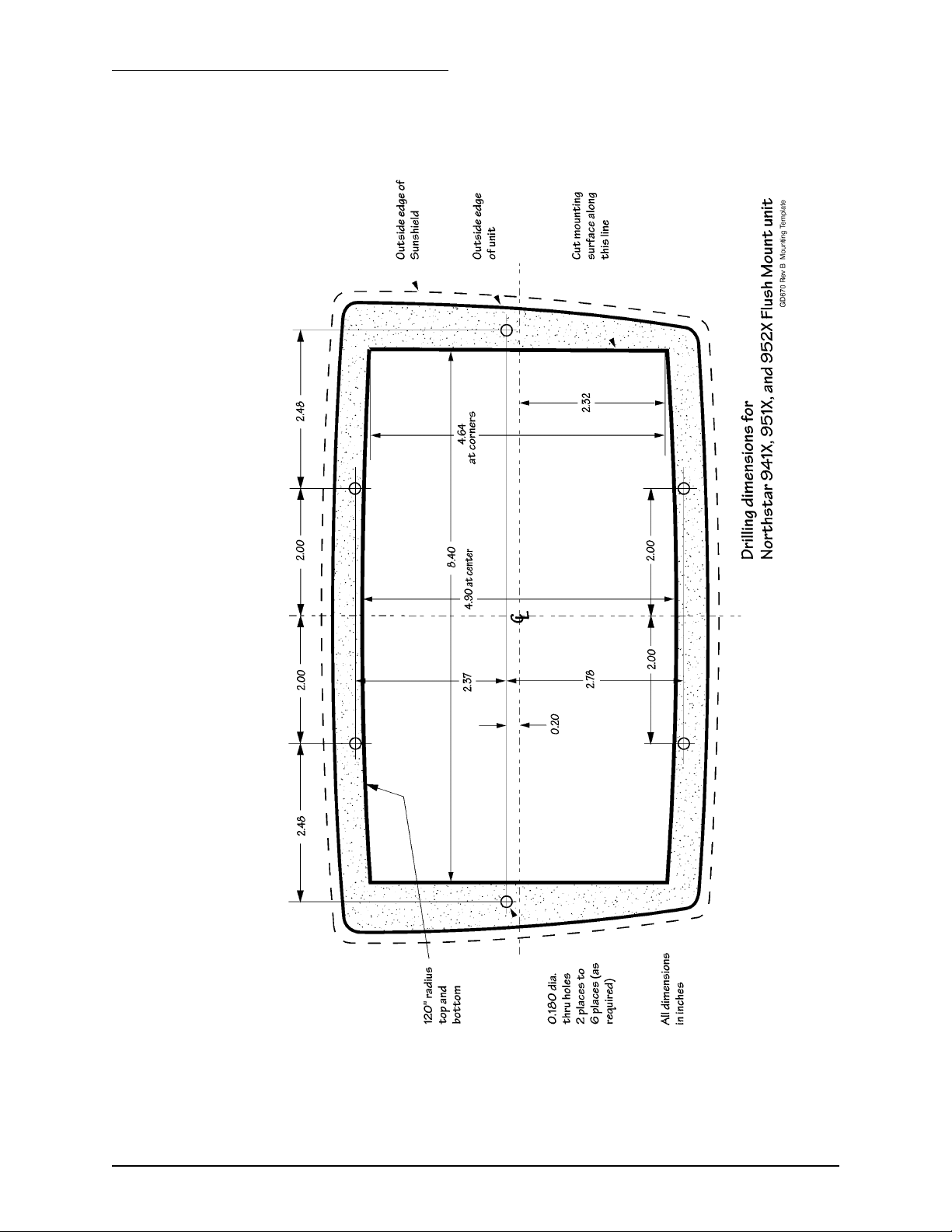

Figure 4: Flush mount drilling dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

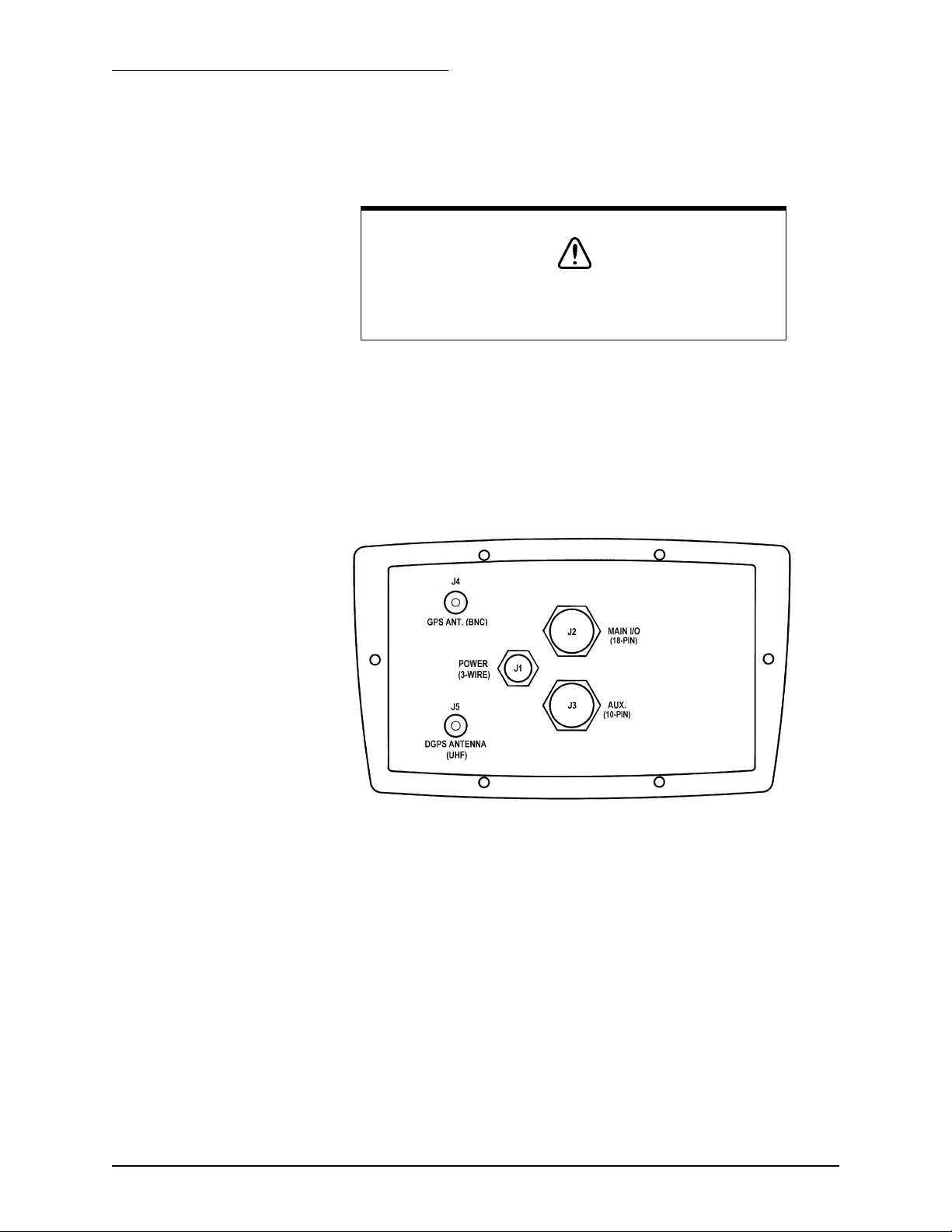

Figure 5: Rear connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Figure 6: Separation distances between antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Figure 7: GPS-only antenna (AN150) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 8: Stripping the coax cable jacket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Figure 9: Flared cable braid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Figure 10: Completed BNC connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Figure 11: Combo GPS/DGPS antenna (AN205-P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Figure 12: Correct AN205-P (combo antenna) splitter wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 13: Stripping the coax cable jacket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Figure 14: Flared cable braid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Figure 15: Completed TNC connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Figure 16: ACU assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Figure 17: Correct AN150 and 8410 wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Figure 18: PL 259 (UHF) connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Figure 19: Proper insertion of a chart cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Figure 20: Interface connector (as viewed from back of unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Figure 21: 200 PPNM output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Figure 22: Aux port interface diagram (wiring side view, solder cup) . . . . . . . . . . . . . . . . . . . . . . . . . .51

Figure 23: Pin 14 honk alarm interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

951/952 INSTALLATION MANUAL Revision C Page iii

Page 8

Page iv 951/952 INSTALLATION MANUAL Revision C

Page 9

Tables

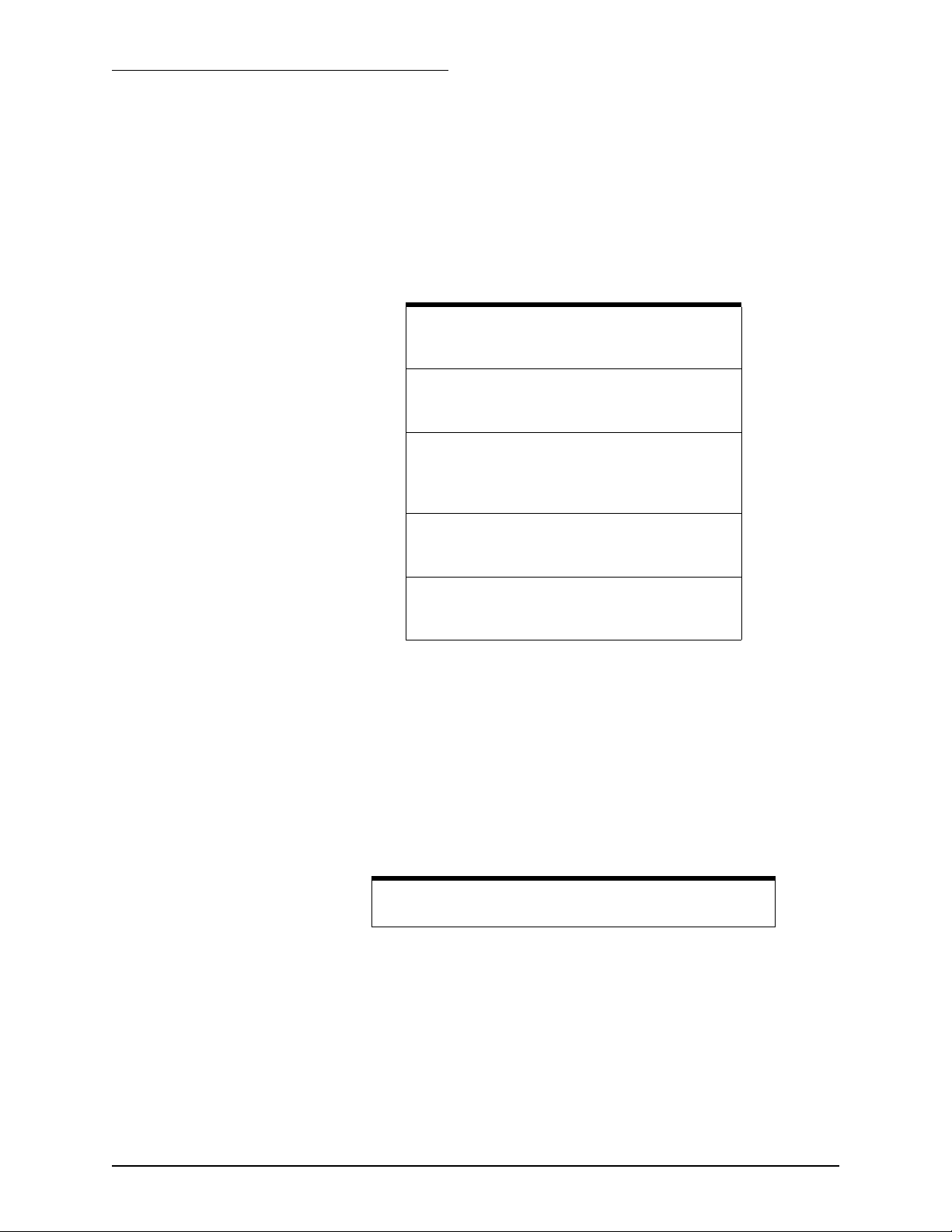

Table 1: Contacting Northstar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 2: Troubleshooting the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 3: Troubleshooting the GPS/DGPS antenna installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 4: Interface connector pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 5: Port setup options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 6: 0183 sentence identifiers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 7: Connecting to an external Northstar beacon receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 8: Connection to Northstar 800 port A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 9: Connection to Northstar 800 port B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 10: Northstar 800 series output port setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 11: Yeoman plotter setup with the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 12: Beep and honk settings for all alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 13: Standards for IEC compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

951/952 INSTALLATION MANUAL Revision C Page v

Page 10

Page vi 951/952 INSTALLATION MANUAL Revision C

Page 11

Welcome

SECTION ONE - Introduction

SECTION ONE - Introduction

The Northstar 951/952 Installation Manual describes how to install,

interface, and troubleshoot the Northstar 951 and 952 GPS chart navigators. Also described are the physical, mechanical, and electrical characteristics of each unit.

For complete details about operating the unit, see the Northstar 951/952

Operator’s Manual (part number GM1500C).

The terms “unit” and “951/952” are used throughout this manual to refer

to both the 951 and 952 GPS chart navigators. The 952 features a color

display, but is otherwise identical to the 951, except where noted. The

951X and 952X are both differential-ready so you can interface them to

an external differential receiver. The 951XD and 952XD have built-in differential receivers. Unless specifically indicated, all information in this

manual refers to both the X (non-differential) and XD (differential) versions of the unit.

Who should read this manual

The Northstar 951/952 Installation Manual is intended for marine techni-

cians who are configuring and installing either 951 or 952 GPS chart navigators.

Scope of this manual

In this manual, you’ll find information about the following:

• mounting and wiring the unit

• installing the antenna

• testing and troubleshooting the unit

• configuring the NMEA output ports

• configuring the RS-232 port

• connecting two units to share waypoints and routes

• technical specifications

The rest of this particular chapter explains how to obtain technical support and how to return a unit for factory service.

Getting technical support

After you’ve followed the instructions in this installation guide, if you

need additional technical support or have any other service-related questions, you can contact either your dealer or the Northstar Service Department. Northstar’s Service Department can be reached by email, fax, U.S.

951/952 INSTALLATION MANUAL Revision C Page 1

Page 12

SECTION ONE - Introduction

You can email the Northstar Service Department

directly from Northstar’s

website. The address is

www.northstarcmc.com.

Here, you also can

access additional technical information under

either the Manuals or

Support links.

mail, or phone as described in the table below. Whether you send an

email or fax, or write or phone, please have the unit’s serial number available, and be as complete and accurate as possible when describing the

problem so that a service technician can research the problem and provide the quickest possible response.

Northstar’s Service Department is available between 9:00 AM and 5:00

PM Eastern Time, Monday through Friday, excluding major holidays.

Table 1: Contacting Northstar

Email:

Service: service@northstarcmc.com

Sales: sales@northstarcmc.com

Fax:

Service: 978/897-1595

Sales: 978/897-7241

Telephone:

Main number: 978/897-6600 or 800/628-4487

Sales: 978/897-0770

Service: 978/897-6600

Hearing from you

Your feedback is important and helps Northstar ensure that this manual

is a valuable resource for all marine technicians. Send your questions,

comments, or suggestions about this manual to:

Servicing the unit

Repair of the unit is performed only at the Northstar factory. Service

includes a complete hardware and software check-out.

For a system under warranty, shipping charges to the factory are the only

cost for factory repair. Repaired units will be returned via prepaid economy ground freight (units returned overseas are chargeable).

U.S. mail:

30 Sudbury Road

Acton, MA 01720

Website:

www.northstarcmc.com (you can send email to

Northstar directly from this site)

service@northstarcmc.com

NOTE:

Field repairs are not authorized and will void the warranty!

Units and accessories returned for warranty repair that are determined to

be without fault are subject to a handling charge.

Page 2 951/952 INSTALLATION MANUAL Revision C

Page 13

Returning a unit for service

Before returning the

unit to the Northstar

factory, to prevent

delays it is critical

that you first obtain

a Return Materials

Authorization (RMA)

number from the

Northstar Service

Department. If you

purchased your unit

through a dealer, call

the dealer with your

serial number so

they can give you an

RMA number.

Shipments without a

proper RMA number

will not be accepted!

The unit is covered by a two-year hardware-only warranty, which, in

summary, states that if the unit is returned to the factory by the owner or

dealer during the warranty period, Northstar will repair or replace, free of

charge, any part found to be defective due to faulty materials or workmanship if the system has been properly installed and hasn’t been

abused. See the Limited Warranty Policy at the front of this manual for

further details. The only cost to the owner will be the one-way shipping

charges and any associated charges that may be imposed by the dealer. If

you have overnight or second-day shipping requirements, before shipping the unit, please call the factory for turnaround time, freight charges,

and payment arrangements.

You may want to back-up any user-defined waypoints and

routes before returning the unit for repair; see the Northstar

951/952 Operator’s Manual for information on customizing the

unit.

SECTION ONE - Introduction

CAUTION!

The unit should be shipped only in a properly designed carton with packing material. Shipments to the Northstar factory should be made to the

following address:

Northstar Technologies

Service Department

30 Sudbury Road

Acton, MA 01720 USA

951/952 INSTALLATION MANUAL Revision C Page 3

Page 14

SECTION ONE - Introduction

Page 4 951/952 INSTALLATION MANUAL Revision C

Page 15

SECTION TWO - Installing the unit

This chapter includes all the information needed to install the unit. It

begins with a review of the system components and then provides information on basic installation and powering on the unit. The rest of this

chapter describes how to wire the unit, install the antenna, and troubleshoot. Proper installation of the Northstar 951/952 is of utmost importance to accurately receive and effectively use GPS signals under a wide

variety of weather conditions.

Safety considerations

SECTION TWO - Installing the unit

WARNING!

Be sure to turn the power off at the main switchboard before starting the

installation. Further, it is highly recommended that you post a notice by this

switch telling others to keep power off while you’re performing the installation. If power is left on or turned on during the installation, then fire, electrical shock, or other serious injury may occur.

Ordering information

To order spare parts or replacement/missing parts, call the Northstar Sales

Department at 978-897-0770.

CAUTION!

Be sure to ground the equipment in order to prevent electrical shock and

mutual interference.

Be sure that the voltage of the power supply is compatible with the unit’s

voltage rating, which can be found on the label at the rear of the unit. Connecting to the wrong power supply can result in fire or damage to the

equipment.

Be sure to use the proper fuse. Using the incorrect fuse can result in fire or

damage to the unit.

Keep the following safe compass distance from the unit: 1.0m standard,

0.8m steering.

Be sure that the 951/952 doesn’t interfere with any of the on-board systems. Check all other systems to ensure that their performance doesn’t

degrade when the unit is turned on.

951/952 INSTALLATION MANUAL Revision C Page 5

Page 16

SECTION TWO - Installing the unit

System overview

The unit is shipped ready to install and operate (however, you’ll need special tools for assembling the coaxial cable connectors; see “Mounting the

AN150 antenna” on page 18.)

It is recommended that you follow the steps below:

1. Check the shipping carton for any damage, and immediately report

any damage to the carrier. Save all packing material in case you have

to return the unit to the factory for repair or evaluation.

2. Unpack the carton, and compare its contents with those on the packing list and what you ordered.

The shipping carton contains:

• the Northstar 951X/XD or 952X/XD

• yoke-mount kit

• flush-mount gasket

• GPS antenna

• 50-foot coaxial antenna cable

• for units with an internal differential beacon receiver: an 8410

Antenna Coupling Unit (ACU); or, an AN205-P combination GPS/

DGPS antenna

• 10-foot interface cable

• 10-foot power cable

• flush-mount drilling template

• connectors and parts kit

• sunshield

• Northstar 951XD/952XD Installation Manual

• Northstar 951XD/952XD Operator’s Manual

3. After reviewing the components, next, review the components of a

proper installation. For details, see “Ensuring a proper installation”

below.

4. Select the desired unit mounting location. For details, see ”Choosing

a system location” beginning on page 8.

5. Select the desired antenna mounting location. For details, see

”Installing the antenna” beginning on page 15.

6. Make the appropriate power wiring connections. For details, see

”Wiring the unit” beginning on page 13.

7. Turn on the unit. For details, see ”Turning the unit on and off” beginning on page 28.

8. To ensure that the system is running properly, perform a functional

test. For details, see ”Testing and troubleshooting the 951/952”

beginning on page 31.

9. If desired, interface the NMEA output ports; for details, see ”Configuring the NMEA output ports” beginning on page 41. If desired,

interface the RS-232 port; for details, see ”Configuring the RS-232

port” beginning on page 58.

Page 6 951/952 INSTALLATION MANUAL Revision C

Page 17

Installation considerations

The following basic setup information isn’t a substitute for all

the details in SECTION TWO. To ensure that you meet all critical installation parameters, be sure to read and follow all of

the requirements.

SECTION TWO - Installing the unit

CAUTION!

Ensuring a proper

installation

Bench-testing the

unit

To ensure a proper installation, it is highly recommended that you perform all of the following activities before starting the installation:

• preview/survey the vessel’s layout and existing equipment

• review all the installation materials

• review all the installation requirements, including:

- the physical requirements (spacing, location with regard to other

equipment, etc.)

- the electrical and electronic requirements (interference between

other pieces of equipment, power requirements, etc.)

Although the unit itself is very straightforward and easy to understand, it

has a few basic requirements that must be met before safe and proper

operation can be assured. The major parts of the rest of this section

address several topics regarding the minimum installation requirements

for the unit, in order to:

• minimize electrical wiring hazards

• accurately receive GPS signals

• navigate safely

Northstar recommends that you bench-test the unit before installing it on

the vessel. Bench-testing ensures that the equipment is fully operational,

and allows the GPS receiver to collect its almanac and ephemeris data for

the installed location, which results in less on-board installation time.

Using the AN150

GPS antenna

951/952 INSTALLATION MANUAL Revision C Page 7

The GPS antenna is best mounted in the clear, and low on the vessel to

avoid extra motion from pitching and rolling. It should be mounted lower

than directional high-power transmitting antennas such as radar or satcom. The length of coaxial cable to the “active” AN150 antenna (supplied

with the unit) must be a minimum of 20 feet, but not more than 100 feet.

Coil up any unused length of cable; do not cut it to less than 20 feet! Be

sure that all cable connectors are securely fastened, and that the cable

itself is not subject to any tight bends.

For complete details on the AN150, see ”Choosing an antenna location”

starting on page 15.

Page 18

SECTION TWO - Installing the unit

Using DGPS with an

AN150 and 8410

ACU

Using the AN205-P

DGPS antenna

If the unit is equipped with a differential receiver (and you’re using the

AN150 GPS antenna, not the AN205-P GPS/DGPS combo antenna), this

receiver must be connected to a Northstar 8410 differential Antenna

Coupling Unit (ACU). The ACU’s four-foot whip antenna should be

mounted as high as conveniently possible—but not at the highest

point—and as far away as possible from other antennas. The ACU can be

mounted on a standard marine antenna mount (1" diameter, 14 threads

per inch).

For complete details on the AN150/8410 ACU mounting requirements,

see ”Installing an 8410 ACU (for use with the AN150 only)” starting on

page 23.

For details on the DGPS antenna’s mounting requirements, see ”Choosing

an antenna location” starting on page 15.

Choosing a system location

The 951/952 unit houses the GPS receiver, optional differential receiver,

computer, power supply, lights, controls and the specially-coated display

screen. The mounting location should be chosen carefully before any

drilling or cutting takes place: Choose a mounting location that allows

good visibility of the unit’s screen, is within comfortable reach, and provides a reasonably direct path for running the required electrical cabling.

Be sure you have easy access to the control panel’s keys and that the display can be clearly seen from the normal vantage point when the user is

navigating. Even though the display screen contains an effective

anti-reflective coating, choose a location that will minimize glare from

windows or other bright objects. Although the 952 is direct-sunlight

viewable, for optimal viewing it is recommended that you install the 952

in a location that’s out of direct sunlight.

Although the unit itself is waterproof, the connectors at the back of the

unit aren’t immune to corrosion from saltwater spray. Protect the unit

from prolonged exposure to the elements by mounting it in a relatively

dry area, if possible. At the end of the day, the unit can be wiped off with

a damp cloth. When not in use, the unit should be covered with the sunshield to protect it from excessive heat.

To help plan the installation, see Figure 1: ”951/952 dimensions (side),”

below and Figure 2: ”951/952 dimensions (front),” below.

Page 8 951/952 INSTALLATION MANUAL Revision C

Page 19

SECTION TWO - Installing the unit

Figure 1: 951/952 dimensions (side)

951/952 INSTALLATION MANUAL Revision C Page 9

Page 20

SECTION TWO - Installing the unit

Figure 2: 951/952 dimensions (front)

Page 10 951/952 INSTALLATION MANUAL Revision C

Page 21

SECTION TWO - Installing the unit

Flush and

yoke-mounting

Whether you’re flush- or yoke-mounting the unit, allow at least 2½-inch

clearance at the rear for cables and connectors. For yoke mounting, leave

ample room (usually two inches) all around the sides and top to avoid

crowding the unit. For the recommended drilling dimensions, see

Figure 3 below. Before drilling holes, rotate the unit to the desired angle

to ensure proper clearance for cables and operation of the unit.

Figure 3: Yoke mount drilling dimensions

951/952 INSTALLATION MANUAL Revision C Page 11

Page 22

SECTION TWO - Installing the unit

For the recommended flush mounting drilling dimensions, see Figure 4

below.

Figure 4: Flush mount drilling dimensions

Page 12 951/952 INSTALLATION MANUAL Revision C

Page 23

Wiring the unit

SECTION TWO - Installing the unit

CAUTION!

When flush-mounting, be sure to mount the unit on a flat surface. Mounting on a curved surface can distort or break the

plastic and cause a breech in the waterproof seal. Do not overtighten as case damage may occur and waterproof integrity

may be compromised. This will void the warranty due to physical damage.

The majority of installation problems are caused by shortcuts taken with

system cables. When installing the unit, be sure that you:

• assemble connectors carefully

• don’t make sharp bends

• leave service and drip loops

• tie-wrap all cables to keep them secure

• if cables are shortened, lengthened, or re-terminated, seal all wiring

splices

Electrical power

requirements

The unit should be connected to a source of 10- to 40-volt electrical

power, using at least 16-gauge wire. A 10-foot fused power cable is supplied with the unit, and should be long enough for most installations. If it

is necessary to lengthen the power cable, however, you may extend it to a

maximum of 25 feet (using at least 14-gauge wire for runs over 15 feet)

without adversely affecting the operation of the unit.

CAUTION!

Ensure that fuse or circuit-breaker protection is provided at the

power source.

The unit is a negative-ground system that is reverse-polarity protected;

an external fuse prevents damage to sensitive components.

The wires in the 10-foot power cable must be connected as follows (black

and white can be connected together at the power source):

NOTE:

If a noise-free earth grounding point isn’t available, the white

wire should be capped and insulated. It shouldn’t be used

when an earth ground isn’t available.

• Red → Positive(+) (fused lead)

• Black → Negative(–)

• White → Ground (earth)

951/952 INSTALLATION MANUAL Revision C Page 13

Page 24

SECTION TWO - Installing the unit

Northstar strongly recommends as a good safety practice that the unit be

connected to an external circuit breaker or 3-amp fuse located near the

battery or breaker box. The internal fuse is designed to protect the unit

itself; the external fuse or breaker is intended to protect the vessel wiring

and prevent electrical fires. The power wiring should be connected

directly to the battery when possible for optimum noise immunity.

• 14-gauge connecting wire (recommended for runs of 15 feet or

more)

• 16-gauge minimum allowed for runs up to 15 feet

CAUTION!

The unit requires the following DC power:

• 10–40VDC

• negative ground only

Figure 5: Rear connectors

• J1 - Power Connector (3-wire)

• J2 - Main I/O Interface Connector (18-wire)

• J3 - Auxiliary (10-wire)

• J4 - GPS Antenna Connector (BNC)

• J5 - DGPS Antenna Connector (UHF)

Internal fuse

Page 14 951/952 INSTALLATION MANUAL Revision C

The unit is designed with an internal fusible link to protect against faulty

power wiring. The link consists of a short length of 30 AWG wire located

on the I/O circuit board.

Page 25

Replacement of the fusible link should be performed only by a qualified

electronics technician. If this link becomes open-circuited between the

white and black wires, carefully check all power wiring on the vessel,

especially the white and black wires on the power cable, before removing

the link. You access the link by removing the 10 outer case screws to

open the unit, then removing the four computer-board screws and lifting

the computer board out to expose the I/O board below. The link should

be replaced with another short length of 30-gauge wire.

Installing the antenna

SECTION TWO - Installing the unit

Choosing an

antenna

Choosing an

antenna location

Three antenna choices are available for the 951X/952X or 951XD/952XD:

• one for reception of GPS-only signals (the standard one-piece

“active” AN150 antenna)

• one for reception of both GPS and DGPS signals (a two-piece

antenna system comprising the standard AN150 GPS antenna and

the 8410 DGPS coupler)

• one for reception of both GPS and DGPS signals (optional one-piece

AN205-P “combination” antenna)

Choosing the AN150 antenna location

The GPS receiving antenna is a vital link between the unit’s receiver and

the outside world. Aesthetics and easy access should be secondary to providing strong and reliable GPS signals to the unit’s receiver. You should

select a location for the antenna that meets the following requirements:

• The antenna should have a reasonably clear view of the horizon, but

be no higher than necessary (side-to-side motion of the antenna

caused by rolling of the vessel may degrade the SOG and COG readings); however, the antenna should be 12 to 18 inches above the surrounding surfaces to avoid interference.

• The antenna must be out of the radiation path of any on-board radar

sets or strong magnetic fields.

• The antenna must be lower than any INMARSAT communications

antenna.

• The antenna should be as far as possible from other high-power

transmitting antennas.

• Watch out for electromagnetic “shading” of antennas from rigging,

other vessels, shoreline buildings, and so on. Secure the cable well.

To avoid mutual interferences among different antennas on the vessel,

refer to the recommended separation distances illustrated in Figure 6:

”Separation distances between antennas,” below. This figure shows the

minimum recommended distances for the separation of the GPS antenna

from other antennas and physical mounting surfaces. Under normal circumstances, following these guidelines usually results in a relatively trou-

951/952 INSTALLATION MANUAL Revision C Page 15

Page 26

SECTION TWO - Installing the unit

ble-free installation; however, the installer may want to adjust these

distances, depending on the particular equipment and how it’s configured. Because each installation is unique—according to the wishes of the

customer—this information should be used only as a guideline. It isn’t

absolute in determining the best location for every possible equipment

configuration.

Figure 6: Separation distances between antennas

NOTE:

Be especially careful about the distance between the combo

antenna and any sources of magnetic interference (for example, the INMARSAT antenna).

Choosing the AN205-P combination antenna location

For applications where optimum portability is required, or when you

want only a single antenna, a combination GPS/DGPS antenna is available. The “combo” antenna should be located where it has a clear view of

the horizon, but where it isn’t the highest point on the vessel. Keep the

combo antenna at least six feet away from objects that can “shade” GPS or

differential signals.

If poor GPS Signal-to-Noise Ratio (SNR) readings are obtained after the

unit has been running for several minutes, check that you have the

proper length of cable, and verify the quality of the antenna location and

the quality and proper termination of the connectors. SNR should be as

Page 16 951/952 INSTALLATION MANUAL Revision C

Page 27

SECTION TWO - Installing the unit

high as possible: Values of 15 and higher are preferable, and anything

below 10 could indicate poor reception.

NOTE:

Concerns for the AN205-P that aren’t explained in Table 3,

“Troubleshooting the GPS/DGPS antenna installation,” on

page 35, include the fact that mounting a loop-type antenna in

close proximity to a radome (radar-set antenna) can degrade

signals or cause a complete loss of the beacon signal. The

klystron or magnetron contained in the radar antenna produces a very dense magnetic field, whether or not the radar

set is turned on. These magnetic field effects are also present

during the operation of the servo motors located on gyro-stabilized TV or INMARSAT communications dish platforms. Signal-degradation checks should be performed before finalizing

the installation.

Installing the

AN150 antenna

Whereas a loran or differential antenna should be mounted high on the

vessel for best performance, the GPS antenna should be mounted as low

as possible and out in the open to avoid “shading” (placement of the

antenna where it’s partially obscured, by another object, from the signals

it must receive). If you’re mounting the GPS antenna on top of a tower or

mast, understand that the unit will be affected by the pitch and roll of the

vessel. Often, the bow or stern can provide a location where shading is

minimized while serving to keep the antenna low. Be sure that any directional L-band transmitting antennas (such as radar or satellite communication antennas) can never point at the GPS antenna, since its internal

preamplifier is quickly destroyed by such radiation.

3.00

ANTENNA

.91

O-RING

ADAPTER

1.82

CAPTIVE SCREW

Figure 7: GPS-only antenna (AN150)

951/952 INSTALLATION MANUAL Revision C Page 17

Page 28

SECTION TWO - Installing the unit

Wiring the AN150 antenna

Supplied with the antenna is a 50-foot length of RG-59 coaxial cable to

use with the GPS-only AN150 “active” antenna (as well as the GPS/DGPS

AN205-P “combo” antenna).

Mounting the AN150 antenna

Too ls nee de d:

One TNC connector is pre-attached to the antenna-end of the RG-59

coaxial cable. Connection to the antenna itself involves the following

steps:

CAUTION!

The GPS-only antenna must be used with a minimum of 20

feet of cable, and no more than 100 feet. Any unused length

must be coiled up; do not cut it to less than 20 feet!

• flat-bladed screwdriver

• knife blade

• Amphenol crimp tools

1. Remove the antenna base by loosening the four captive screws in the

base.

2. Screw the base onto the top of the antenna mount (standard 1"-14

marine thread).

3. Feed the open end of the supplied coax cable down through the

antenna base and through the hollow core of the antenna mount.

4. Affix the TNC connector-end of the coax to the mating connector

inside the upper half of the GPS antenna. Be sure to tighten it

securely, as vibration can loosen the connection over time. In addition, protect the coax-to-antenna connection with liquid electrical

tape or self-vulcanizing electrical tape.

5. Align the upper half of the antenna with the bottom half and tighten

the four screws. Be careful not to over-tighten the screws, as this may

deform the watertight seal between the two antenna halves.

6. Make a termination for a male BNC connection—as described in the

following steps—then connect the antenna to the female BNC connection at the back of the unit.

1. Strip cable jacket to the following dimensions (in

inches), as illustrated in Figure 8: ”Stripping the coax

cable jacket,” below: a=0.57, b=0.34, c=0.14, d=0.43. Do

not nick the center conductor.

Page 18 951/952 INSTALLATION MANUAL Revision C

Page 29

SECTION TWO - Installing the unit

Figure 8: Stripping the coax cable jacket

2. See Figure 9: ”Flared cable braid,” below: Slide outer ferrule on as shown. Slightly flare the end of cable braid,

as shown, to facilitate insertion into inner ferrule.

Installing the

AN205-P antenna

Figure 9: Flared cable braid

3. Place center contact onto center conductor so that it

butts against the cable dielectric. Crimp the contact in

place using Amphenol tool handle #227-944 and Cavity

B of Die Set 227-980-3.

4. Install cable assembly into body assembly so inner ferrule slides over dielectric and under braid. Push cable

assembly forward until contact seats in insulator. Slide

outer ferrule over braid and up against connector body.

Crimp outer ferrule using Cavity A of tools specified

above. The connector ferrule-to-cable junction can be

sealed and protected using adhesive-lined heat shrink.

Figure 10: Completed BNC connector

The AN205-P combo antenna provides for an easier, more compact, and

more attractive installation, and in many cases, the loop antenna’s design

improves the noise rejection of signals interfering with differential signals.

951/952 INSTALLATION MANUAL Revision C Page 19

Page 30

SECTION TWO - Installing the unit

7.00

2.5

TNC

3.5

Figure 11: Combo GPS/DGPS antenna (AN205-P)

CAUTION!

The combo antenna must be used with a minimum of 20 feet

of cable, and no more than 100 feet. Any unused length must

be coiled up; do not cut it to less than 20 feet!

Wiring the AN205-P antenna

When you use the AN205-P antenna, a cable “splitter” is required to separate the signal path of the single cable connected at the antenna into two

cables for connection to the 951/952. For the proper installation of the

splitter, refer to Figure 12: ”Correct AN205-P (combo antenna) splitter

wiring,” below. The splitter should be located near the unit for convenience, but may be situated virtually anywhere along the length of the

maximum 100 feet of RG-59 GPS cable, without appreciable signal loss.

Note, however, that the splitter isn’t weatherproof and should be placed

in a protected area where it won’t be subjected to direct water splash or

spray.

Page 20 951/952 INSTALLATION MANUAL Revision C

Page 31

SECTION TWO - Installing the unit

Figure 12: Correct AN205-P (combo antenna) splitter wiring

Avoid tight bends when installing any antenna cable. Be sure to fasten

the cable along its length to avoid chafing or whipping of any kind.

After you’ve mounted the antenna and cut the cable to length—not less

than 50 feet—install the supplied TNC connector at the other (952X) end.

See Figure 13, Figure 14, and Figure 15 below. A satisfactory crimp for

this connector may be made with a commonly available, high-quality

crimping tool designed for use with TNC connectors.

NOTE:

Be sure that you properly install the TNC connector: Most system failures—whether continuous or intermittent—can be

traced to poor connector installation.

951/952 INSTALLATION MANUAL Revision C Page 21

Page 32

SECTION TWO - Installing the unit

Mounting the AN205-P antenna

1. Strip cable jacket to the following dimensions (in inches), as illustrated in Figure 13: ”Stripping the coax cable jacket,” below: a=0.57,

b=0.34, c=0.14, d=0.43. Do not nick the center conductor.

Figure 13: Stripping the coax cable jacket

2. Figure 14: ”Flared cable braid,” below: Slide outer ferrule on as

shown. Slightly flare the end of cable braid, as shown, to facilitate

insertion into inner ferrule.

Figure 14: Flared cable braid

3. Place center contact onto center conductor so that it butts against

the cable dielectric. Crimp the contact in place using Amphenol tool

handle #227-944 and Cavity B of Die Set 227-980-3.

4. Install cable assembly into body assembly so inner ferrule slides over

dielectric and under braid. Push cable assembly forward until contact seats in insulator. Slide outer ferrule over braid and up against

connector body. Crimp outer ferrule using Cavity A of tools specified

above. The connector ferrule-to-cable junction can be sealed and

protected using adhesive-lined heat shrink.

Figure 15: Completed TNC connector

Page 22 951/952 INSTALLATION MANUAL Revision C

Page 33

SECTION TWO - Installing the unit

Installing an 8410

ACU (for use with

the AN150 only)

The Northstar 8410 Antenna Coupling Unit (ACU—supplied with a unit

that’s equipped with a DG PS receiver) is used when you don’t want to use

the combo AN205-P antenna. Although similar in appearance to Northstar loran ACUs, only the unit labeled “8410” will work with the internal

DGPS receiver. The ACU also serves as a sturdy mounting base for the

whip antenna.

The ACU consists of two pieces. The circuitry is sealed in a rugged, waterproof, fiberglass polycarbonate body, the upper end of which is threaded

to accept a standard 4-foot whip antenna. A large female thread is molded

into the lower portion, or base, of the ACU body into which the upper

half is secured (see Figure 16, “ACU assembly”). A gasket and rubber

O-ring on the upper half provide weathertight sealing when the two

halves are secured. The bottom of the base is threaded (1"–14) to mount

onto an antenna mast or onto a standard deck mount.

Figure 16: ACU assembly

951/952 INSTALLATION MANUAL Revision C Page 23

Page 34

SECTION TWO - Installing the unit

The ACU connects to the 951X or 952X with RG-58U coaxial cable, which

carries signals to the differential receiver and DC power to the ACU

amplifier. See Figure 17 below for the correct AN150/8410 wiring. A

25-foot length of this cable is supplied with the unit. This cable may be

extended up to a length of 300 feet. The cable passes up through the hollow ACU base and connects to the PL-259 (UHF) connector at the bottom

of the ACU. For UHF connector preparation, see“Differential GPS antenna

cable connectors” beginning on page 25.

CAUTION!

Maintaining the ACU’s weathertight seal between its upper and

lower halves requires only hand-tightening the two together.

Using a wrench or other tool may distort the gasket or housing/

rubber O-ring inside, or break the coupler base.

NOTE:

This connection must be made before the ACU is screwed into

its base.

Figure 17: Correct AN150 and 8410 wiring

Page 24 951/952 INSTALLATION MANUAL Revision C

Page 35

SECTION TWO - Installing the unit

RF grounding

The grounding system is an equal partner with the antenna in producing

quality differential beacon signals for the 951/952 differential receiver.

Essentially, the ground system provides a secure connection to a large

electrical mass; ideally, the earth itself. On a vessel, this means establishing electrical contact with “seawater” ground. On a steel vessel, a good

connection to the hull or steel pilothouse is sufficient. Wood or fiberglass

vessels require a metal ground plate or a thru-hull fitting. If the metal

ground plate is impractical, the engine block or the negative (–) battery

terminal can sometimes be used, but only as a last choice due to stray

electrical noise that may be present at these locations.

Lack of proper grounding can adversely affect differential signal strength,

as well as SNRs, and is the most common source of problems with differential antenna installations. The same grounding techniques that have

worked well for loran systems will work equally well for differential

antenna systems. The 8410 ACU has a separate black ground wire inside

the coupler base. This wire is the AC signal ground connection from the

antenna input circuit. The purpose of bringing it out is to make available

a separate signal ground path. Use #16 AWG minimum for grounding. If

possible, use a grounding “strap” that is designed for this purpose.

Other electrical equipment onboard can cause large amounts of electrical

noise, even at points that appear well-grounded. Try several ground

points (ground plate, vessel ground, engine block, and so on) to determine which works best under different conditions.

WARNING!

Whenever any antenna is disconnected from on-board equipment, be sure to ground the antenna shield in order to discharge extremely large static voltages that can quickly build up

on an ungrounded antenna system. These voltages are hazardous to personnel and equipment!

Differential GPS antenna cable connectors

Both ends of the differential beacon receiver antenna cable terminate in

UHF connectors. To prepare UHF connectors, follow the assembly

instructions in Figure 18. For best results, coat these connectors with silicone dielectric grease (DC 4 or equivalent) to protect the connector junction against water intrusion and surface corrosion of the contacts. In

addition, protect the connector area, including the shield-to-connector

junction and jacket-to-crimp ferrule area, with liquid electrical tape (Starbright Liquid Tape comes in color-coordinating black or white) or

self-vulcanizing electrical tape (Tommy Tape).

951/952 INSTALLATION MANUAL Revision C Page 25

Page 36

SECTION TWO - Installing the unit

Figure 18: PL 259 (UHF) connector

Mounting the 8410

The Northstar 8410 differential receiver antenna should be mounted as

high as conveniently possible (but not at the highest point) and as far

away as possible from other antennas. If you have several possible

antenna locations, you may evaluate each by operating the unit with the

DGPS antenna temporarily mounted in each location.

The best location is one providing the lowest “noise” count (atmospheric

impulse noise generated by thunderstorms and other conditions, including vessel-generated noise and any on-board interference) and highest

Signal-to-Noise Ratio (SNR). You can view both of these values after you

turn the unit’s power on; see ”Turning the unit on” starting on page 29.

Page 26 951/952 INSTALLATION MANUAL Revision C

Page 37

SECTION TWO - Installing the unit

Another major concern, precipitation static (called “P-static”), must be

addressed when installing the differential antenna. P-static generally

appears only during rain or snow; consequently, it can easily be overlooked during installation. Much like a loran antenna, the effects of

P-static are minimized if the differential antenna is mounted so that it

isn’t the highest metallic object on the vessel. The highest metal object

acts much like a lightning rod, attracting tiny static discharges in the

atmosphere. If the differential receiver antenna is the highest object,

these discharges can totally override the differential signals and cause

poor operation in bad weather. The optimum antenna location is high

and clear for fair-weather operation, but below the top of a metal mast or

other antenna for best foul-weather operation. On sailing vessels, the

ACU could be mounted on top of a low mast, or on the stern rail if no

other suitable location is available.

The 8410 differential receiver ACU can be mounted on a standard marine

antenna mount (one inch diameter, 14 threads per inch).

For special applications involving serious grounding problems, or where

optimum portability is required, you can use the AN205-P combination

GPS/DGPS antenna; for details, see ”Installing the AN205-P antenna”

starting on page 19.

951/952 INSTALLATION MANUAL Revision C Page 27

Page 38

SECTION TWO - Installing the unit

Turning the unit on and off

Inserting a chart

cartridge

If using a chart cartridge, you should insert the cartridge before turning the

unit on (to avoid any possibility of a system lock-up). The cartridge slot is

located at the lower right-hand corner of the unit. If the unit is off, you

can verify whether a cartridge has already been installed by opening the

cartridge access door (turn its handle ¼-turn counter-clockwise) and

looking inside the slot. If the unit is on, you can verify whether a cartridge has already been installed by pressing the

key to the right of the CHART screen (the cartridge access door must be

fully closed and latched to display this information). One of two possible

screens will be displayed:

• If a cartridge is present, the cartridge name and date are displayed at

the bottom of the CHART SETUP/STATUS

• If a cartridge is either not installed or incorrectly installed, the words

NONE INSERTED are displayed (at right below).

CHART SETUP menu

screen (at left below).

The cartridge name is derived from its Navionics catalog number. The

date may not be present for all cartridges, especially older ones; in these

cases, the word PRESENT is displayed in place of the cartridge name and

date.

Before inserting the cartridge, make sure that its label is facing up and

that the cartridge is oriented as shown in Figure 19 below. Insert the cartridge gently but firmly into position with one straight, smooth motion. If

you partially insert the cartridge, then move the cartridge again after

stopping, it may become stuck in an awkward position.

Page 28 951/952 INSTALLATION MANUAL Revision C

Page 39

The Navionics chart cartridge must remain free

from debris and moisture

at all times. To ensure that

you do not expose the cartridge to any environmental damage, please use

caution when changing

the cartridge. Exercise

care when inserting the

cartridge into the Northstar unit (see description

and illustration at right).

When not in use, store the

cartridge in a clean, dry

place away from heat,

humidity, and dust.

Improper handling and

storage of the cartridge

may result in damage to

the Northstar unit. Such

damage is not covered

under manufacturer warranty.

SECTION TWO - Installing the unit

Figure 19: Proper insertion of a chart cartridge

Turning the unit on

To activate the unit, briefly press the PWR key. You’ll be greeted with a

map of the Earth with the words “NORTHSTAR” (at left below) or

“NORTHSTAR 952X” (at right below), then the owner identification message. Next, the unit performs a series of self-tests (the 951 and 952

self-test screens vary slightly) in which critical components and functions

are checked for any errors.

951/952 INSTALLATION MANUAL Revision C Page 29

Page 40

SECTION TWO - Installing the unit

NOTE:

If the unit’s power has been off and its display screen is “cold,”

a brief warm-up period may be required for the display screen

to achieve its full intensity.

Advisory message

When the unit is powered up, a special advisory message is displayed as a

precautionary reminder that the unit’s chart cartography must not be

relied upon as the sole means of safe navigation. Although every effort

has been made to ensure that the data used by the unit is as close to

paper charts as possible, errors and omissions are inevitable. Therefore,

extreme care must be used when navigating by means of electronic

charts. It is the captain’s responsibility to cross-check the 951/952 against

other sources of navigation data.

To proceed, you must first acknowledge your acceptance of the advisory

message by pressing any one of the five function keys located beneath

the display screen.

GPS signals

Page 30 951/952 INSTALLATION MANUAL Revision C

Once the unit is turned on and has acquired satellite data, you can check

the quality of the GPS signals being received by viewing the various satellites’ SNR (Signal-to-Noise Ratio) readings: Press the

view the GPS POSITION screen (as shown at left below), then press the

POSITION key to

Page 41

SECTION TWO - Installing the unit

DGPS INFO menu key to view the DGPS STATUS screen (as shown at

right below).

Turning the unit off

To shut off the unit, press and hold the PWR key for approximately four

seconds until the screen goes dark.

Testing and troubleshooting the 951/952

Installation-test

checklist

Troubleshooting

common

installation

problems

Problem Area Symptom Possible Solutions/Reasons

POWER Pressing the PWR key doesn’t start the

To test the system after installation, first apply power to the unit and confirm power is on with no errors. Next, check for the presence of GPS and

DGPS signals. Review the chart-plotter function: With the chart cartridge

inserted, confirm that the chart map is displayed.

Typical problems you may encounter either during or after the installation process are outlined in the following tables: Table 2, “Troubleshooting the installation,” on page 31 below, and Table 3, “Troubleshooting the

GPS/DGPS antenna installation,” on page 35.

Table 2: Troubleshooting the installation

• Check the fuse and the power to the

unit.

unit.

DISPLAY The unit powers up, beeps, and the back-

light can be operated up and down, but

there isn’t any video.

951/952 INSTALLATION MANUAL Revision C Page 31

• If a 951, try adjusting the contrast by

pressing the

the display may have failed (the 952’s

ARROW key adjusts only brightness,

not contrast). Call your Northstar

dealer or the Northstar Service

Department.

ARROW key. If a 952,

Page 42

SECTION TWO - Installing the unit

Table 2: Troubleshooting the installation (continued)

Problem Area Symptom Possible Solutions/Reasons

DISPLAY (cont’d) The display screen dims, either slightly or

more, after the unit has been on for a certain time.

SYSTEM

System lock-ups

SYSTEM

System lock-ups

Software-related:

System locks up under certain conditions,

such as when configuring screens, routes,

waypoints, or tide data.

Displays error message

System always freezes at one particular

screen.

Hardware-related:

The system locks up on a random basis with

no apparent pattern.

ROM NO GOOD.

• The unit may be implementing its

auto-dimming mode. Auto-dimming

helps maintain the integrity of the display and reduce power consumption

when the unit is on and running too

hot for its current environment. In this

case the display screen may dim to

half its intensity.

• Install the latest software version; to

order, call the Northstar Service

Department.

• Install the latest software version; to

order, call the Northstar Service

Department.

• Internal software failure; call your

Northstar dealer or the Northstar Service Department.

• Internal hardware failure; call your

Northstar dealer or the Northstar Service Department.

SYSTEM

Configuration

The system locks up when using a chart

card.

System fails any initial self-tests other than

ROM NO GOOD.

No GPS or DGPS

• Possible bad chart card. Remove the

card, and inspect the pin area of the

card and the unit for damage. If the

pins in the unit are bent or damaged,

to prevent further damage, don’t

insert another card. If you’re sure that

the card pins aren’t bent, try inserting

a new card.

• Internal hardware failure; call your

Northstar dealer or the Northstar Service Department.

• Possible incorrect installation of the

AS110/AS105 splitter cables; they

may be reversed at the splitter for the

GPS and differential output ports.

• For verification and troubleshooting of

the antenna system, see Table 3,

“Troubleshooting the GPS/DGPS

antenna installation,” on page 35.

Page 32 951/952 INSTALLATION MANUAL Revision C

Page 43

SECTION TWO - Installing the unit

Table 2: Troubleshooting the installation (continued)

Problem Area Symptom Possible Solutions/Reasons

DGPS

(DIFFERENTIAL)

There’s no DGPS indicator on the display

screen, and:

The BEACON RX SELF-TEST message

says

FAI L E D (press the STAR key to

access the USER CUSTOMIZATION

screen, then press the

MATION

VICE INFORMATION screen).

There’s no DGPS indicator on the screen,

and:

The BEACON RX SELF-TEST message

reads

access the USER CUSTOMIZATION

screen, then press the SERVICE INFOR-

MATION

VICE INFORMATION screen),

menu key to display the SER-

PASSED (press the STAR key to

menu key to display the SER-

DGPS STATUS

(press the POSITION key to access

ING

GPS POSITION screen, then press the

the

SERVICE INFOR-

and the

message reads SEARCH-

DGPS INFO key to display the DGPS

STATUS

screen).

• Wait 30 minutes after start-up (only if

a new unit).

• Check for an open or shorted bea-

con-antenna cable connector.

• Check for proper ground (8410 only).

• The Northstar 8410 ACU or the differ-

ential circuit board may be defective;

call your Northstar dealer or the

Northstar Service Department.

• Wait 30 minutes after start-up (only if

a new unit) so the receiver can find a

differential transmitter within range)

check local knowledge or transmitters).

• Check for high noise level, possibly

due to a storm front, or for local interference at the marina or on the vessel. For details about noise-level

meanings, see the Northstar 951/952

Operator’s Manual (GM1500C).

• Turn off power to each and all of the

vessel’s other instruments, one at a

time, to isolate the source of the interference.

• Try manually selecting and setting a

DGPS beacon station to be used to

see if the signal can be received.

• Consult the Coast Guard's Local

Notice to Mariners to determine if

there’s a scheduled maintenance outage for the station you’re trying to

use.

• For additional guidance, call your

Northstar dealer or the Northstar Service Department.

DGPS (cont’d) There’s no DGPS indicator on the screen,

and:

The BEACON RX SELF-TEST AND SOFTWARE reads PASSED, and the DGPS

STATUS message reads OLD CORRECTIONS

.

951/952 INSTALLATION MANUAL Revision C Page 33

• No DGPS corrections have been

received, and the system has

returned to non-differential operation.

You may be out of range of a transmitter, or if you’re experiencing bad

weather, noise may be interfering. In

either case, you must wait.

Page 44

SECTION TWO - Installing the unit

Table 2: Troubleshooting the installation (continued)

Problem Area Symptom Possible Solutions/Reasons

There’s no DGPS indicator on the CHART

screen, and:

The BEACON RX SELF-TEST AND SOFTWARE reads PASSED, and the DGPS

STATUS

There’s no DGPS indicator on the CHART

screen, and:

BCN UNHEALTHY is displayed.

GPS The unit powers up, but poor GPS SNR

readings are obtained even after running

the unit for several minutes.

message reads POOR DOPS.

• Wait for the satellite configuration to

automatically update, which should

only take a few minutes.

• Wait—the transmitter is switching to

another beacon. You can try manually

switching to another transmitter.

• Check that you have the proper

length and type of cable, and that all

connections are clean and secure.

• Verify the quality of the antenna loca-

tion (the antenna should have a clear

view of the sky). For the correct

antenna placement, see Figure 6.

• See Table 3, “Troubleshooting the

GPS/DGPS antenna installation,” on

page 35.

Page 34 951/952 INSTALLATION MANUAL Revision C

Page 45

SECTION TWO - Installing the unit

Troubleshooting

common GPS/DGPS

antenna installation

problems

Whenever possible, the best and most efficient way to troubleshoot is to

use a known-good set of cables, a splitter for combo antennas (when

applicable), and working antennas as spares for swapping.

In Table 3, “Troubleshooting the GPS/DGPS antenna installation,” on

page 35, the Northstar AN150 refers to the 12-dB GPS antenna; the

Northstar 8410 coupler with whip antenna refers to the beacon receiver

whip-type (E-field) antenna; and the Northstar AN205-P refers to the

combination (combo) GPS/DGPS loop antenna with splitter.

Table 3: Troubleshooting the GPS/DGPS antenna installation

Antenna Symptom Possible Solutions/Reasons

GPS ANTENNA Poor or no GPS signal while using the

AN150 antenna.

If 5.5 VDC low or missing with load connected:

• Turn off any onboard transmitting

devices.

• Check for 5.5 VDC at antenna with

and without antenna load connected.

• Check for 5.5 VDC at 951/952 BNC

connector.

• It indicates a bad connector installa-

tion, bad GPS board, or bad AN150

antenna.

a

If 5.5 VDC is missing with load disconnected:

If 5.5 VDC is present:

DGPS ANTENNA No GPS or DGPS

Poor or no GPS signal while using the

AN205-P antenna with splitter:

If 7.75 VDC is low or missing with load connected:

If 7.75 VDC is low or missing with load disconnected:

• It indicates a bad GPS board.

• It indicates a bad AN150. Replace the

AN150.

• Bad splitter configuration.

b

• Splitter cables may be reversed for

GPS and DGPS output.

• Check installation for correct cabling.

• Check for 7.75 VDC at antenna with

and without antenna load (cables and

splitter) connected.c (Use “T” connectors to measure VDC under load.)

• Check for 7.75 VDC at 951/952 UHF/

DGPS connector.

• It indicates a bad connector installa-

tion, bad differential 8500-A board,

bad AN2xx. The load is too great or

the 8500-A board is defective.

• It indicates a bad 8500-A board, or

other internal fault.

If 7.75 VDC is present at processor UHF

connector but not at antenna:

951/952 INSTALLATION MANUAL Revision C Page 35

• It indicates bad cabling, bad connec-

tors, or a bad splitter.

Page 46

SECTION TWO - Installing the unit

Table 3: Troubleshooting the GPS/DGPS antenna installation (continued)

Antenna Symptom Possible Solutions/Reasons

DGPS ANTENNA

(cont’d)

No beacon signal (applies to all DGPS

antennas):

If the

BEACON RX SELF-TEST reads

FAILED:”

“

If the coax and antenna are okay and there

is 7.75 VDC:

• Press the STAR key to display the

USER CUSTOMIZATION screen,

then press the

OPTIONS

RECEIVER

menu key to display the

RECEIVER OPTIONS screen: Here,

check that the

option is set to “ENABLED” and the

DGPS OPERATION

BEACON FREQ option is set to

AUTO,” and that the BEACON

“

BAUD RATE

“

AUTO.”

option is set to

• Press the STAR key to access the

USER CUSTOMIZATION screen,

then press the SERVICE INFOR-

MATION

SERVICE INFORMATION screen:

Here, check that the BEACON RX

SELF-TEST

menu key to display the

reads “PASSED.”

• Check the coax and antenna for open/

short, and check for 7.75 VDC at the

UHF connector, under load.

• The 8500-A board may be bad.

Page 36 951/952 INSTALLATION MANUAL Revision C

Page 47

SECTION TWO - Installing the unit

Table 3: Troubleshooting the GPS/DGPS antenna installation (continued)

Antenna Symptom Possible Solutions/Reasons

DGPS ANTENNA

(cont’d)

High beacon SNR or low signal.

When vessel interference is still present:

When the source of the interference is

found:

• Turn off all electrical devices and

equipment on the vessel, then check

for improvement. Check fluorescent

lights, gauges, and so forth. Be creative! Check for power-line interference by moving away from the dock

and/or the marina. Verify that the

antenna is mounted in accordance

with the recommendations shown in

Figure 6.

• Isolate to the interfering device, with

breaker panel if necessary, or by

physical disconnection, if required.

• Experiment with different grounding

locations (the best ground is the

ocean). Drop a temporary wire

attached to 8410 black wire over the

side of the vessel to see if the interference source can be fixed by grounding techniques.

• Disconnect shore power and move

away from the dock and/or marina

(power lines and lights can cause

interference).

• Temporarily relocate the 8410 or

combo antenna as far away from the

interfering source as possible, and

monitor the effect on reception. If it

improves, consider relocating the

antenna or try to determine if the interference can be eliminated at its

source.

• Normally, noise that affects an 8410

DGPS coupler won’t affect a combo

antenna and vice versa. Consider

temporarily changing antenna types

to determine the effects on signal

reception.

Poor, intermittent, or no beacon signal using

a known-good loop or combo antenna.

a. The GPS receiver AA180 supplies the 5.5 VDC to the AN150 active GPS antenna.

951/952 INSTALLATION MANUAL Revision C Page 37

• Check the proximity of the antenna to

radar antennas or other transmitting

devices, such as INMARSAT. A

radome can affect H-field antennas

even when power is off. Hint: To test

for the best location, move the

antenna and coax to temporary locations using an over-the-deck length of

coax, then relocate as necessary.

Page 48

SECTION TWO - Installing the unit

b. Testing the GPS portion of the splitter and a combo antenna: When using a combo antenna and split-

ter, the splitter gets 7.75 VDC from the beacon receiver, and then feeds the combo pre-amp with that

same voltage level. The splitter must have this 7.75 VDC supplied to the differential port in order for

the GPS and the differential signal to be passed through the splitter. To test the GPS portion of the

combo antenna, disconnect the splitter and plug the combo antenna directly into the GPS BNC connector (provided that the 5.5 VDC is present). This troubleshooting technique effectively eliminates

the splitter from the equation. If the splitter is bad, GPS may not work when connected normally

(provided that the 7.75 VDC from the beacon receiver is present). Note that the combo antenna

should never be plugged directly into the GPS port under normal circumstances because the voltage

feeding the amplifier is too low and this will result in low GPS signal levels being sent to the GPS

receiver.

c. The beacon receiver (8500) supplies the 7.75 VDC to the 8410 (in the case of a whip-type antenna

installation), or the splitter (in the case of a combo antenna installation), which in turn feeds the

combo antenna.

Page 38 951/952 INSTALLATION MANUAL Revision C

Page 49

SECTION THREE - Interfacing

This chapter includes the information needed to interface the 951/952 to

other equipment on the vessel. Major topics include:

• interfacing the unit

• connecting the unit to other equipment

• connecting the unit to other 951s, 952s, and 941s in order to transfer

• configuring the NMEA output ports

• configuring the RS-232 port

• uploading software

Interfacing the unit

The unit is easily interfaced to other equipment as described below. The

most common interface data format used with installations today is

NMEA 0183, which is a widely accepted standard of data transfer

between almost all types of marine electronics, enabling completely different instruments to “speak” a common language.

SECTION THREE - Interfacing

all waypoints and routes

Connector pin

wiring

The unit has the following ports:

• two programmable NMEA input/output ports

• one RS-232 input/output port that you can customize for communi-

cating data to or from other instruments

A list of wire designations for the interface connector is displayed on the

unit’s PORT SETUP OPTIONS screen, accessed from the USER CUSTOMI-

ZATION screen by pressing the

WIRING INFO menu key:

951/952 INSTALLATION MANUAL Revision C Page 39

Page 50

SECTION THREE - Interfacing

Figure 20: Interface connector (as viewed from back of unit)

Table 4: Interface connector pins

Description Wire color Pin

NMEA PORT 1 INPUT A BROWN 3

NMEA PORT 1 INPUT B BLUE 1

NMEA PORT 1 INPUT

GROUND

NMEA PORT 1 OUTPUT A VIOLET 12

NMEA PORT 1 OUTPUT B GRAY 7

NMEA PORT 1 OUTPUT

GND

NMEA PORT 2 INPUT A WHITE w/BROWN STRIPE 6

NMEA PORT 2 INPUT B BROWN w/WHITE STRIPE 2

NMEA PORT 2 INPUT

GROUND

NMEA PORT 2 OUTPUT A YELLOW 15

NMEA PORT 2 OUTPUT B ORANGE 11

NMEA PORT 2 OUTPUT

GND

RS-232 GROUND TAN 17

RS-232 RX GREEN 16

RS-232 TX RED 18

WHITE w/BLUE STRIPE 4

BLUE w/WHITE STRIPE 8

WHITE 5

BLACK 10

EXT. GND / FOIL DRAIN WHITE/ORANGE & SHIELD 9

RESERVED ORANGE w/WHITE STRIPE 13

200 PPNM/HONK OUT

(Pulses Per Nautical Mile)

Page 40 951/952 INSTALLATION MANUAL Revision C

PINK 14

Page 51

SECTION THREE - Interfacing

200 ppnm output

The unit provides an open-collector transistor output (on pin 14) that’s

programmed to produce 200 pulses per nautical mile for those devices

requiring this output.

The emitter of the NPN transistor is connected to ground, and the collector connects to the output pin side (see Figure 21: ”200 PPNM output,”

below). The output can sink 100mA, and can withstand a maximum positive voltage of 50 volts.

If the output connects to a highly inductive device (for example, a relay),

a spike suppression diode such as a 1N4001 should be connected across

the load. Cathode connects to the power side of the device and anode

connects to the output pin side.

The output produces a negative pulse 80ms wide and supports speeds

from zero to 100 knots (clamps at 100kt).

Figure 21: 200 PPNM output

Configuring the NMEA output ports

Each output port can be programmed to meet most any special requirements of devices that conform to the NMEA 0183—and other—data format specifications. The

selection of the specific 0183 sentences that the 951/952 will transmit.

1. Press the

2. Press the PORT SETUP OPTIONS menu key to display the PORT

SETUP OPTIONS screen.

951/952 INSTALLATION MANUAL Revision C Page 41

STAR key until you see the USER CUSTOMIZATION screen.

SETUP function described below allows the

Page 52

SECTION THREE - Interfacing

3. Press the PORT 1 SETUP or PORT 2 SETUP menu key. On either

screen, the unit displays a list of data format control options, as

shown below.

Check the installation instructions of the equipment to which you’re

interfacing for any special requirements. The Northstar factory settings

are adequate for most peripheral equipment, but the following options

are available, if needed:

Table 5: Port setup options

Parameter Options

OUTPUT FORMAT

(see below)

NMEA 0183 TALKER ID

(see page 45)

NMEA 0183 LL PRECISION

(see page 46)

Page 42 951/952 INSTALLATION MANUAL Revision C

choose NMEA 0180, NMEA

0183 V2.0, 0183 V1.5, RAY

0183, DATAM CDX, or NONE

choose GP, LC, or II, to make

the unit look like a GPS receiver,

Loran-C receiver, or an “integrated instrument”

choose hundredths of minutes,

thousandths of minutes, or

ten-thousandths of minutes

Page 53

Table 5: Port setup options (continued)

Parameter Options

SECTION THREE - Interfacing

Setting the output